Patents

Literature

65results about How to "Fine aperture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

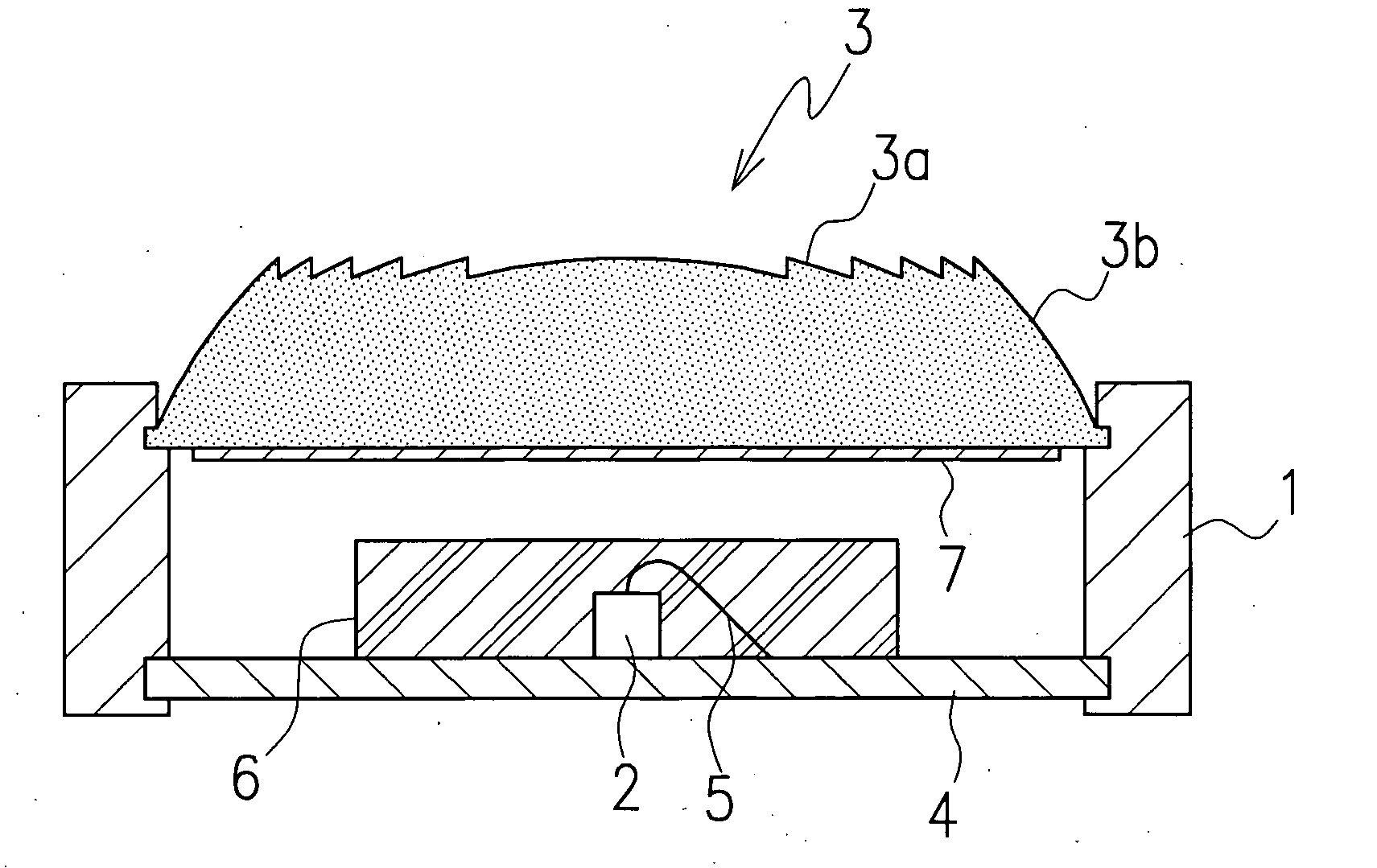

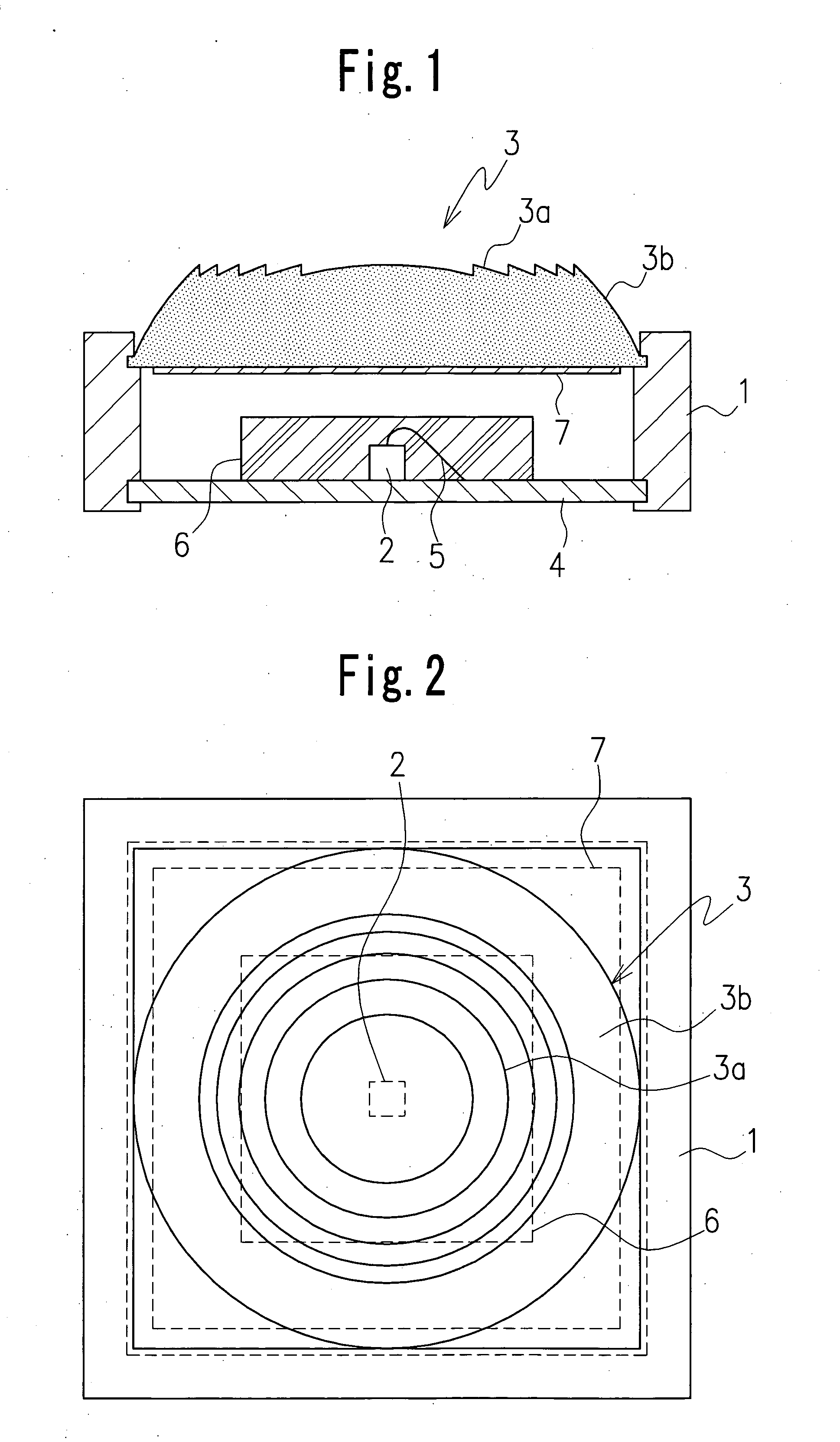

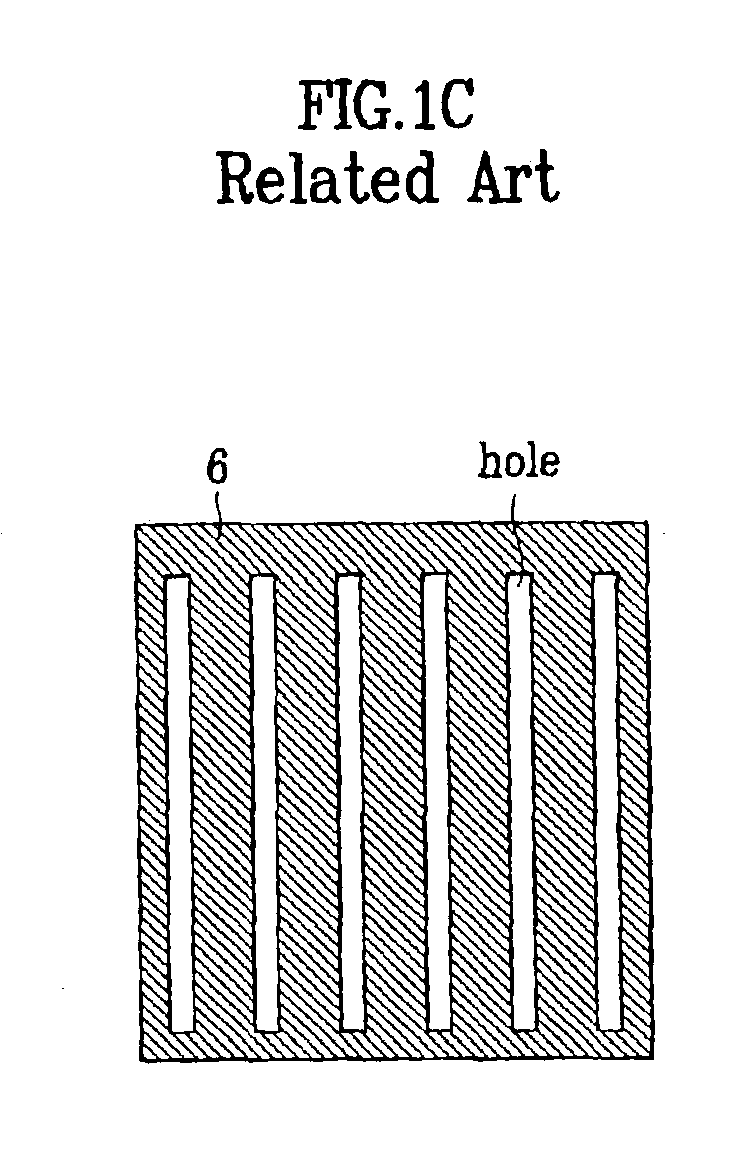

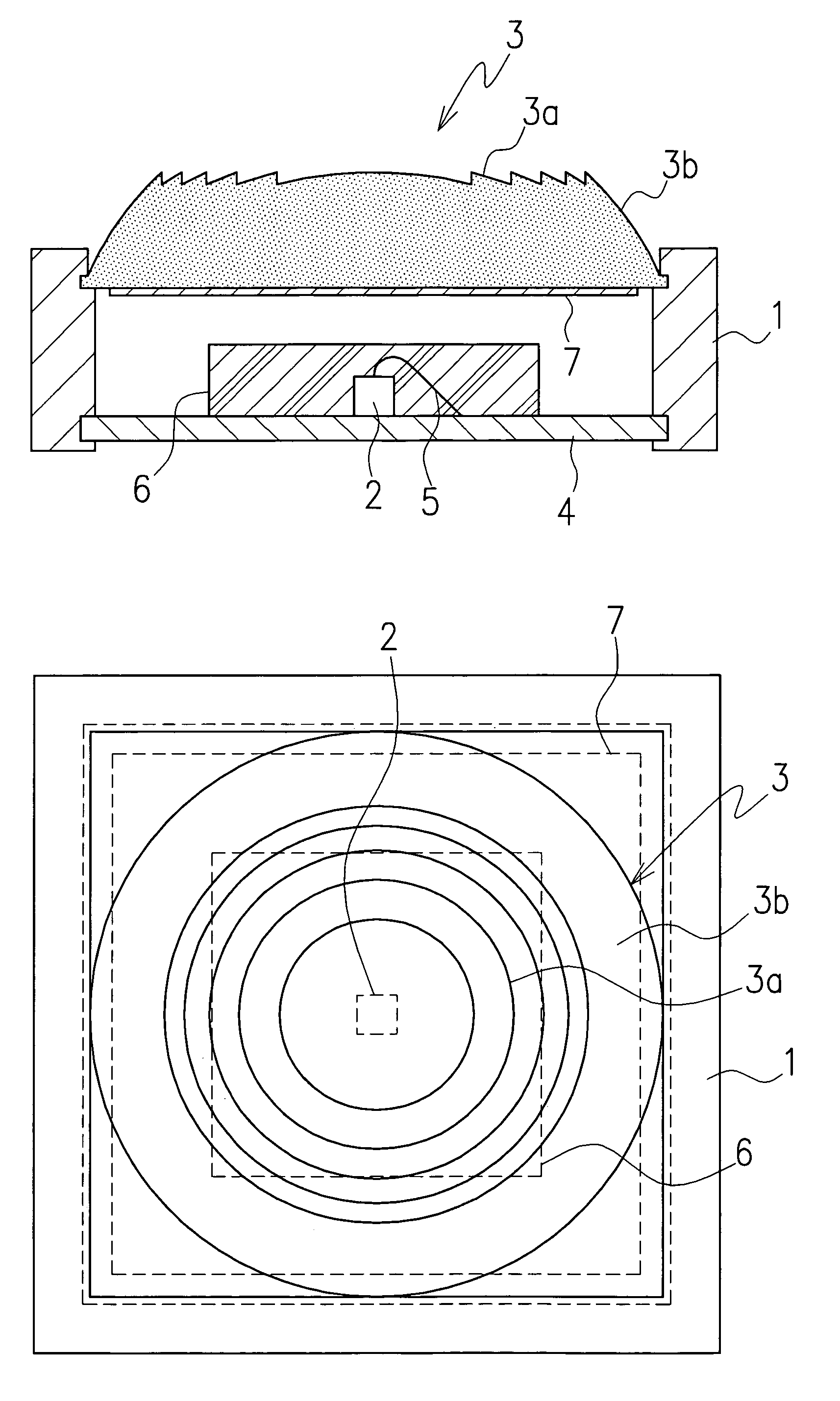

Lighting apparatus

ActiveUS20050201109A1Maintain qualityReduce thicknessLight source combinationsLighting support devicesFresnel lensOptoelectronics

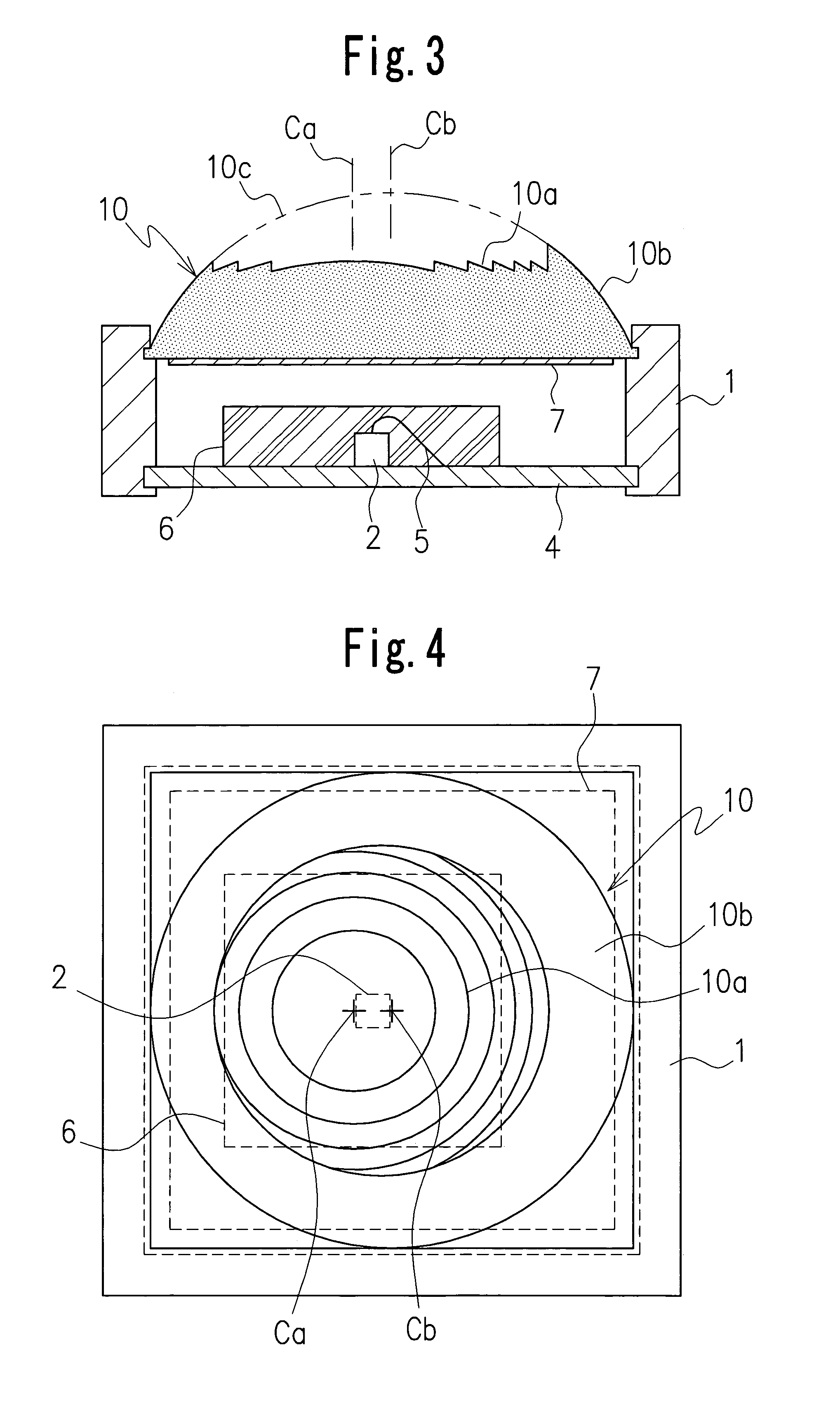

A lighting apparatus comprising a support, a light source having an emission surface and disposed in the support, a lens disposed to face the emission surface of the light source, and a half-mirror film provided on at least a surface of the lens, the half-mirror film being a thin film comprising a metallic material such as aluminum, the lens being a light-focusing lens, the lens having a peripheral part and a central part, the peripheral part including a lens surface comprising a smoothly curved surface, and the central part including a Fresnel lens surface.

Owner:CITIZEN ELECTRONICS CO LTD

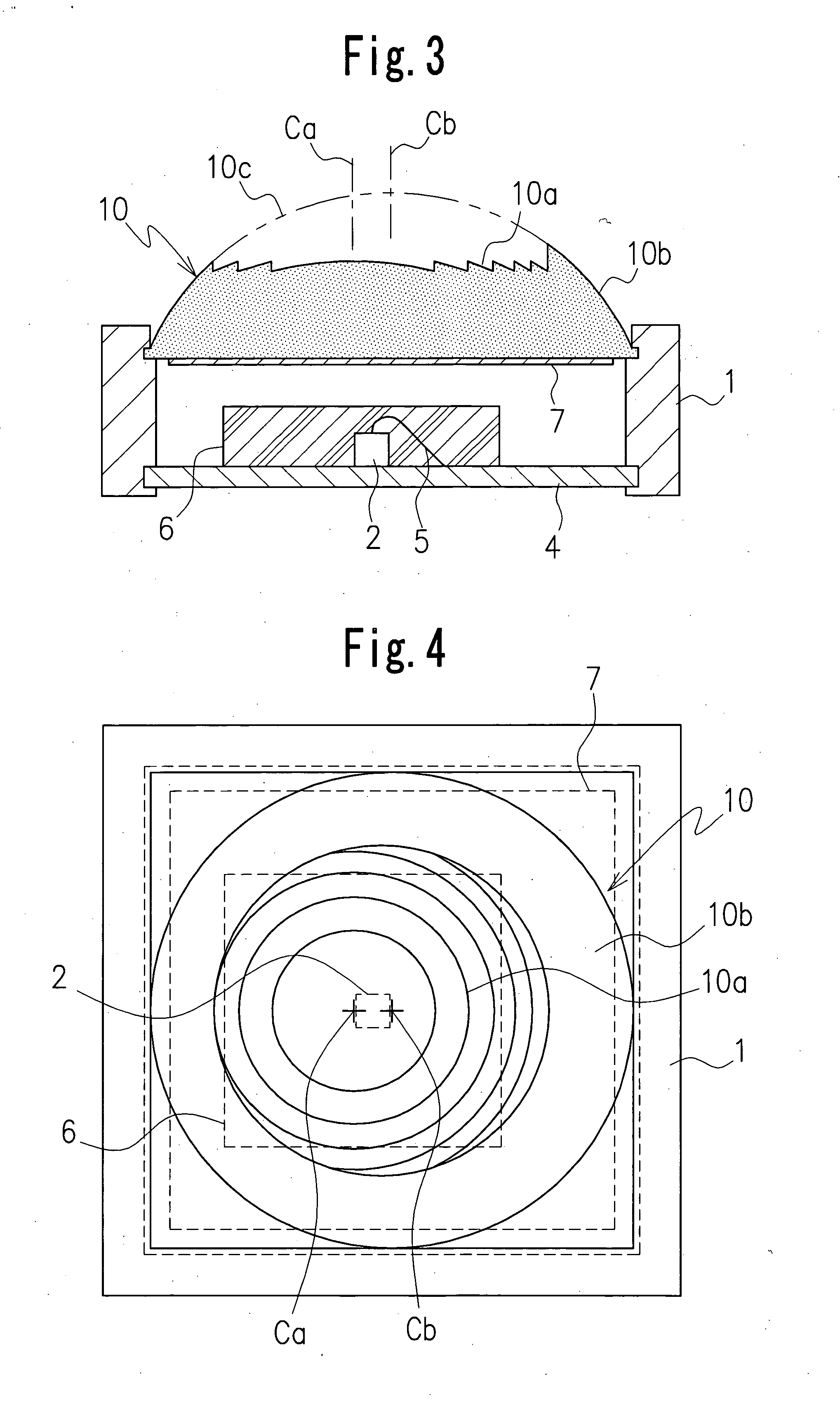

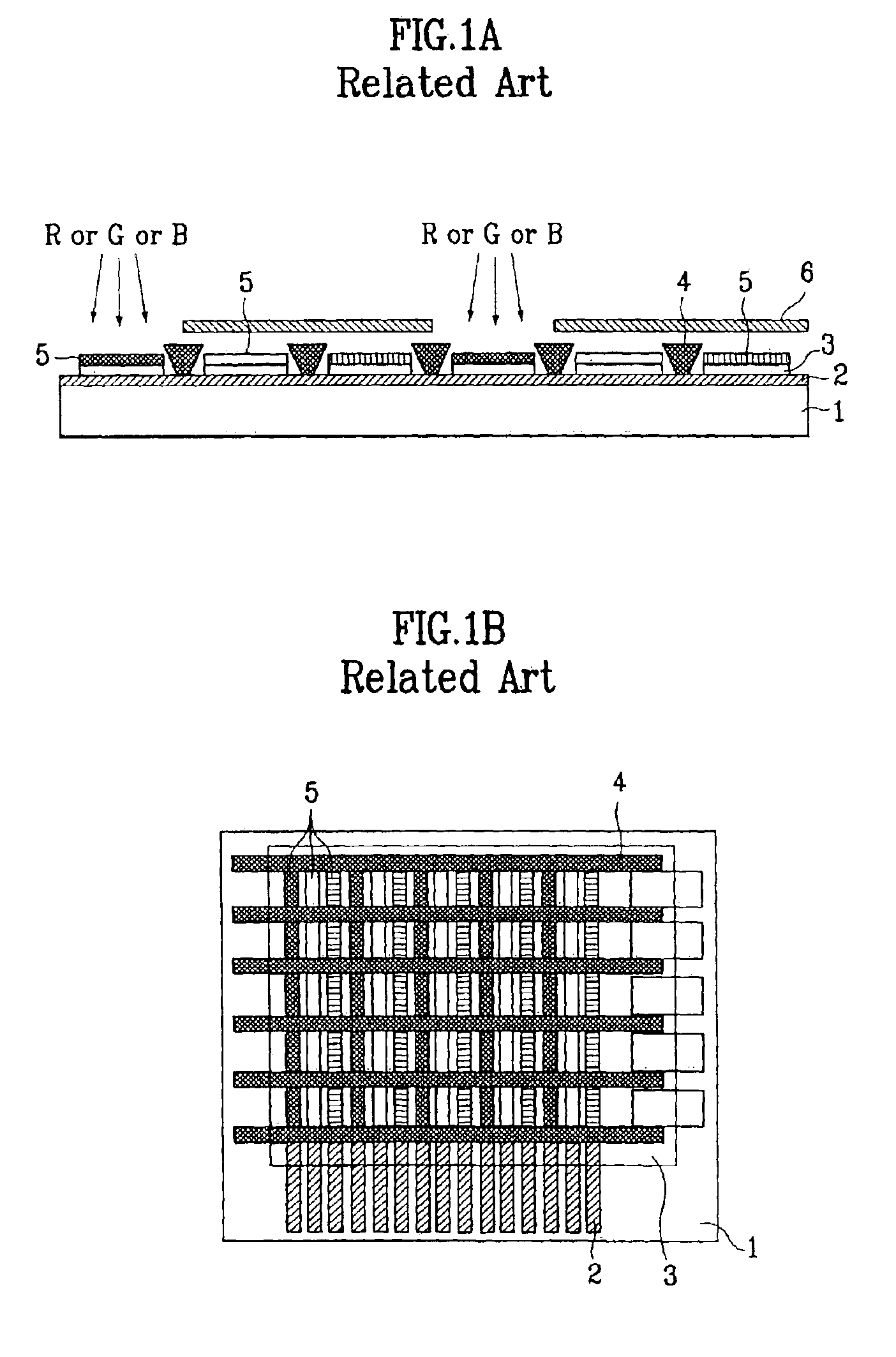

Shadow mask and flat display fabricated by using the same and method for fabricating the same

InactiveUS6946783B2Avoid deformationFine apertureElectroluminescent light sourcesElectrode and associated part arrangementsDisplay deviceFlat panel display

Shadow mask, flat display fabricated by using the same, and method for fabricating the flat display, the shadow mask including a substrate, a plurality of via holes formed in the substrate on a plurality of rows, inclusive of first via holes on odd numbered rows, and second via holes on even numbered rows, wherein the first via holes are arranged to straddle the second via holes, and bridges formed between the first via holes, and between the second via holes, thereby improving an aperture.

Owner:LG DISPLAY CO LTD

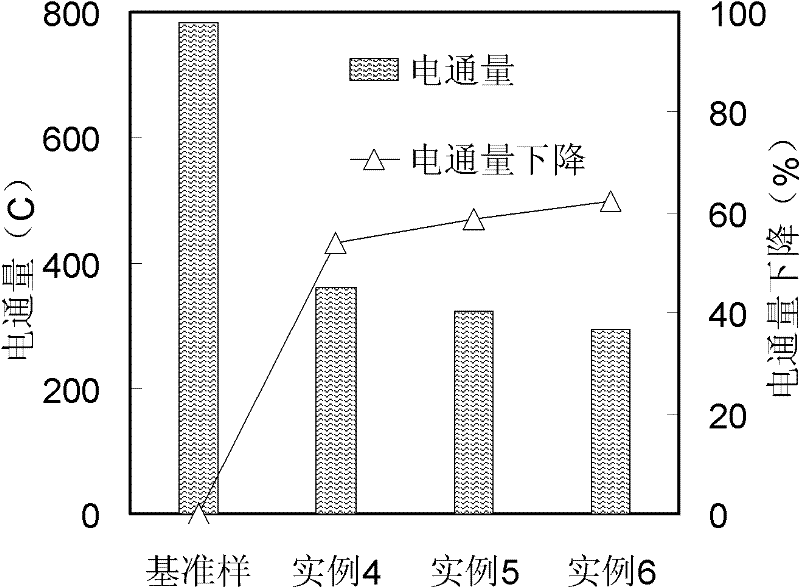

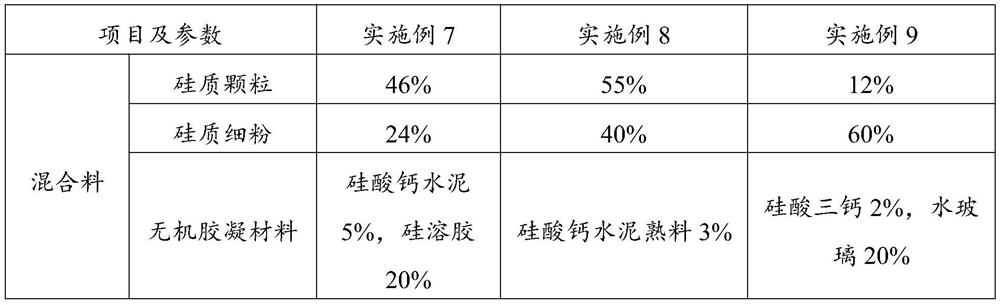

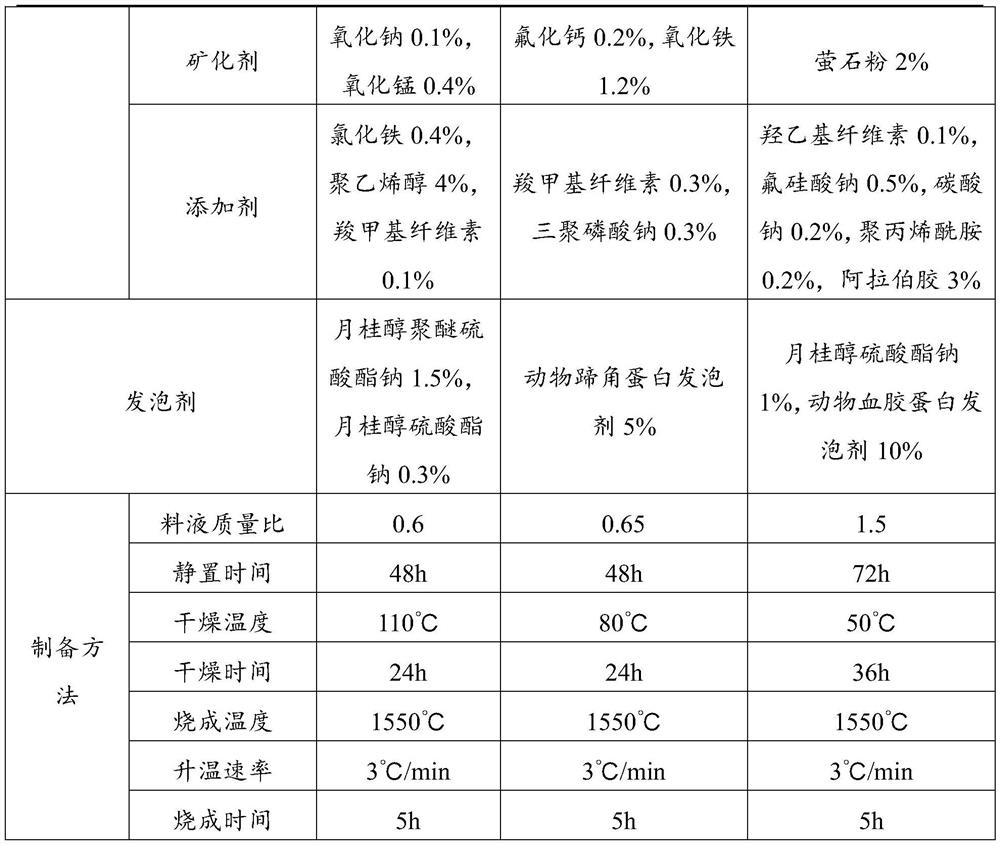

Preparation method of microporous kyanite-based lightweight insulating refractory material

The invention relates to a preparation method of a microporous kyanite-based lightweight insulating refractory material. The preparation method is realized by comprising the following steps: (1) by taking kyanite, auxiliary materials and a cementing material as raw materials, adding a certain amount of dispersing agent, thickening time control agent and foam stabilizer, premixing, adding a certain amount of water, and mixing to prepare uniform slurry; (2) adding a certain amount of foaming agent in the slurry, mechanically agitating and foaming to prepare uniform foam slurry; (3) injecting the foam slurry into a mould, standing under a room-temperature environment so as to be cued and formed; (4) demoulding a green body, and then drying and sintering to obtain the microporous kyanite-based lightweight insulating refractory material. The prepared microporous kyanite-based lightweight insulating refractory material has the advantages of microfine air bore aperture (20-200mum), low volume density, high porosity, high strength, small sintering line change rate, low thermal conductivity, high usage temperature and the like. The raw materials are mainly kyanite, and other raw materials are common materials in refractory material industry, and are non-toxic and low-cost. The preparation method is simple and is easily controlled for the technology, and is suitable for industrial production.

Owner:ZHENGZHOU UNIV

Lighting apparatus

ActiveUS7182481B2Maintain qualityReduce thicknessLight source combinationsLighting support devicesFresnel lensLight equipment

A lighting apparatus comprising a support, a light source having an emission surface and disposed in the support, a lens disposed to face the emission surface of the light source, and a half-mirror film provided on at least a surface of the lens, the half-mirror film being a thin film comprising a metallic material such as aluminum, the lens being a light-focusing lens, the lens having a peripheral part and a central part, the peripheral part including a lens surface comprising a smoothly curved surface, and the central part including a Fresnel lens surface.

Owner:CITIZEN ELECTRONICS CO LTD

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

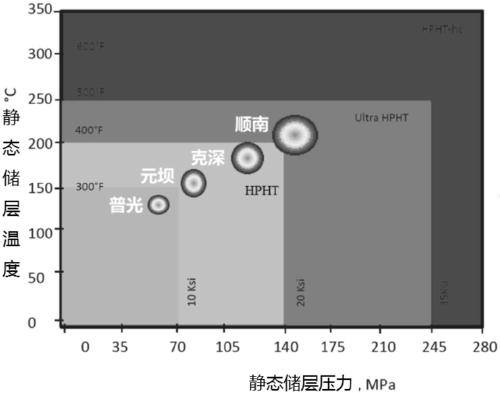

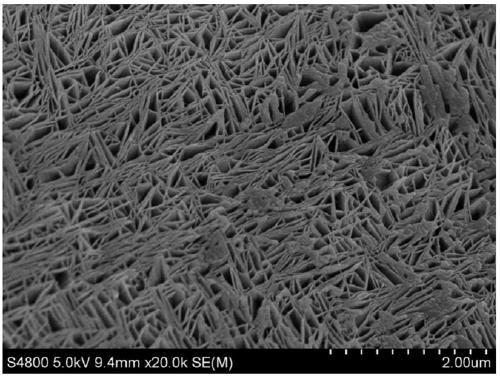

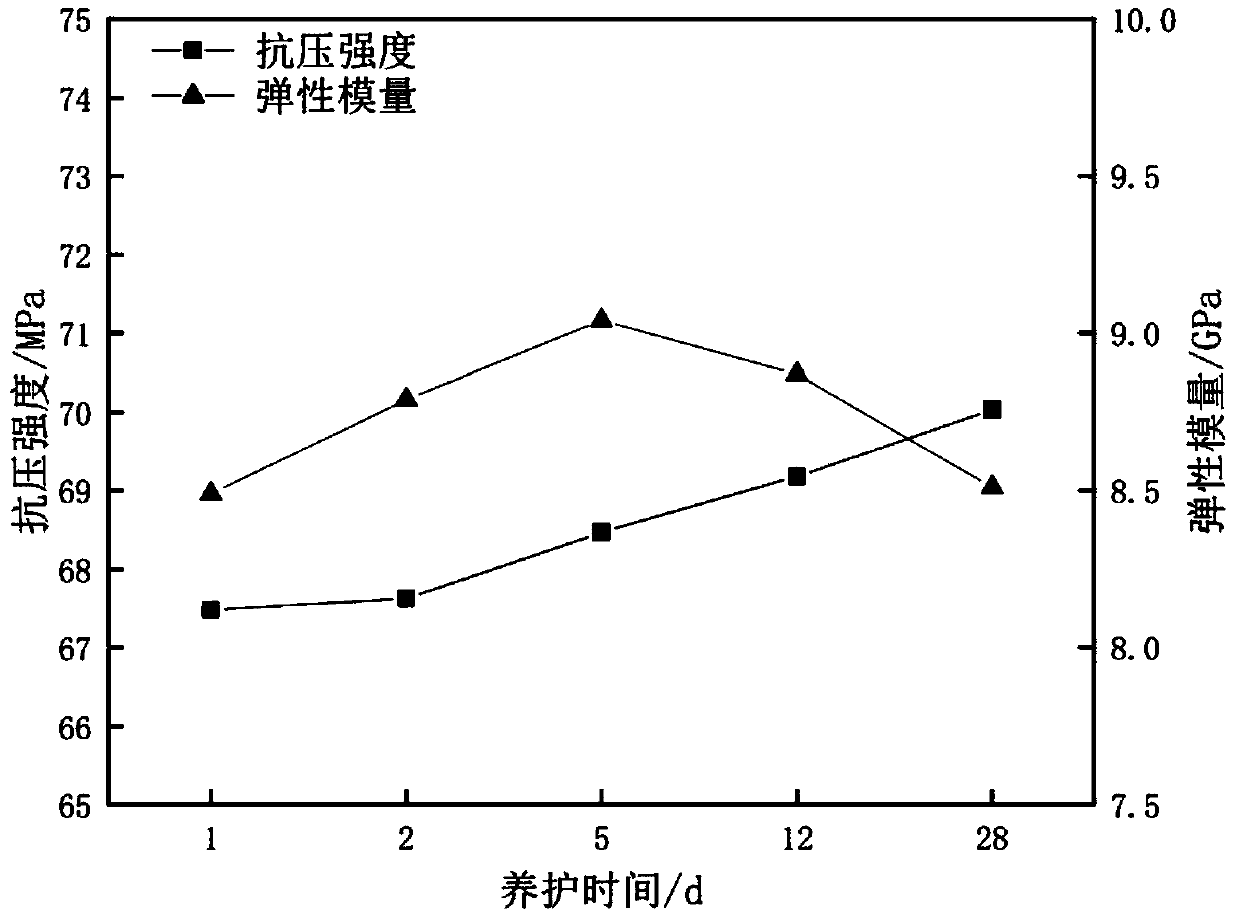

Nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and preparation method thereof

The invention relates to a nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and a preparation method thereof. The slurry system comprises the followingingredients in parts by weight: 100 parts of oil well cement, 15-25 parts of coarse silica sand, 15-20 parts of fine silica sand, 1-10 parts of nano-silicon dioxide, 1-10 parts of nano-calcium carbonate, 0.2-1 part of a defoaming agent, 4-10 parts of a fluid loss agent, 0-3 parts of a drag reduction agent, 0.5-4 parts of a retarder and 30-100 parts of water. In the slurry system, set cement has excellent compressive strength and toughness under superhigh temperature, and the compressive strength and the elasticity modulus cannot be obviously changed as the maintenance time is prolonged. The slurry system has good rheological property, lower water loss and proper thickening time, and the comprehensive properties of the slurry system can completely meet the related requirements of site wellcementing construction, so that the technical support is provided for well cementing under high temperature. A nano-material obtained by mixing the nano-silicon dioxide and the nano-calcium carbonateis added, and micropores of the set cement can be effectively filled, so that the system becomes denser. Therefore, the volume shrinkage of the set cement is relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Low-porosity chrome corundum brick and preparation method thereof

The invention discloses a low-porosity chrome corundum brick and a preparation method thereof. The low-porosity chrome corundum brick is prepared from the following raw materials in percentage by mass: 18-28 percent of corundum with the raw material granularity being 5-3mm, 30-40 percent of corundum with the raw material granularity being 3-1mm, 10-20 percent of corundum with the raw material granularity being 1-0mm, 10-20 percent of corundum with the raw material granularity being smaller than 0.088mm, 1-15 percent of high-content chromium ore or fused chrome oxide with the raw material granularity being 1-0mm and 2-15 percent of high-purity chromium oxide with the raw material granularity being smaller than 0.088mm; and in addition, a phosphate binder accounting 2-5 percent for the total mass of all the raw materials is added. According to the low-porosity chrome corundum brick and the preparation method, a product is prepared by material mixing, forming, sintering, impregnating with a nanometer oxide suspension and microwave drying according to burdening of the low-porosity chrome corundum brick, can lower the apparent porosity and the porosity aperture of a chrome corundum material, and reacts with permeated molten slag to form a high melting point substance, increases the viscosity of the molten slag, and slows down permeation of the molten slag.

Owner:河南瑞泰耐火材料科技有限公司

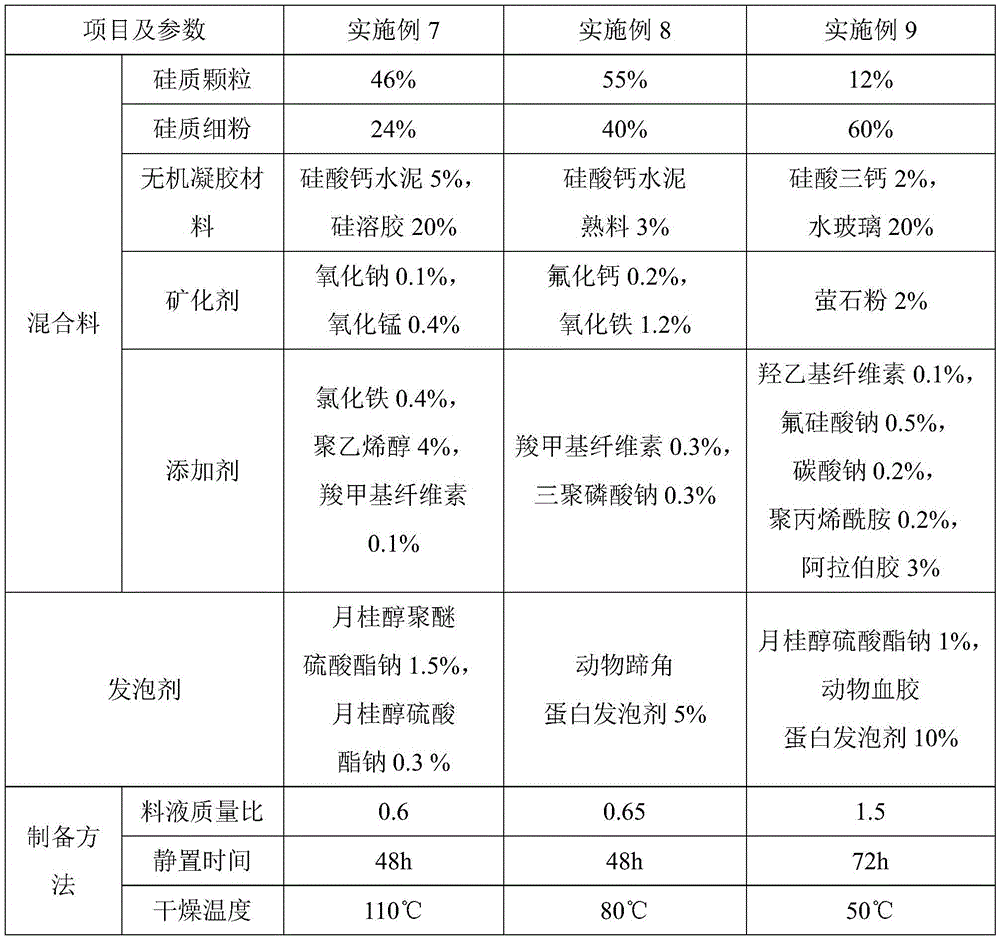

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

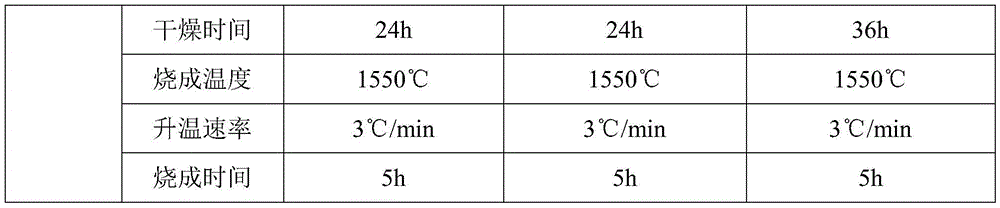

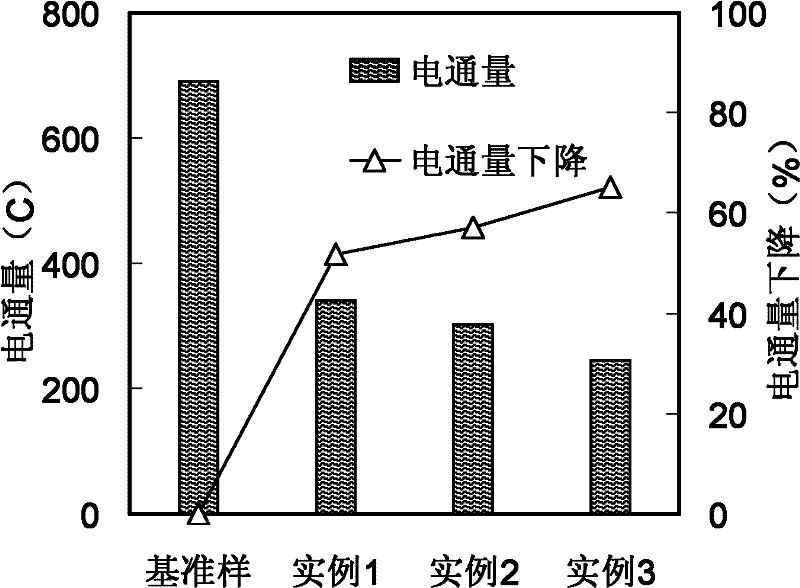

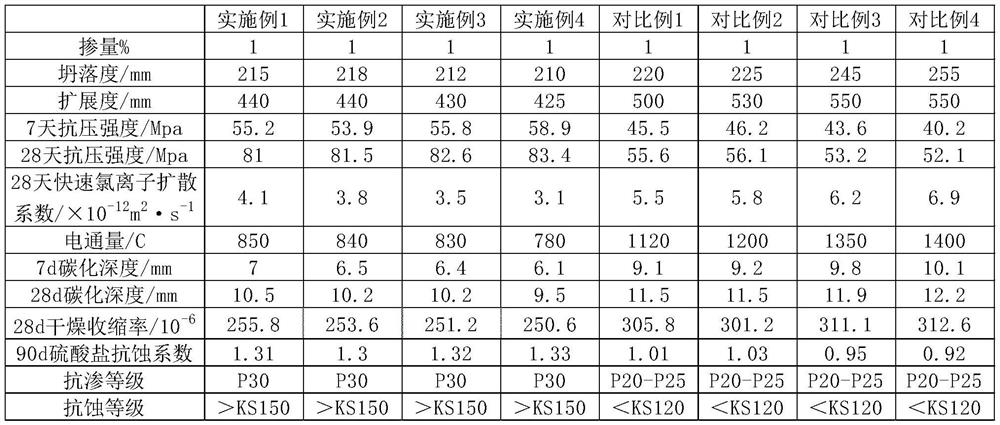

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

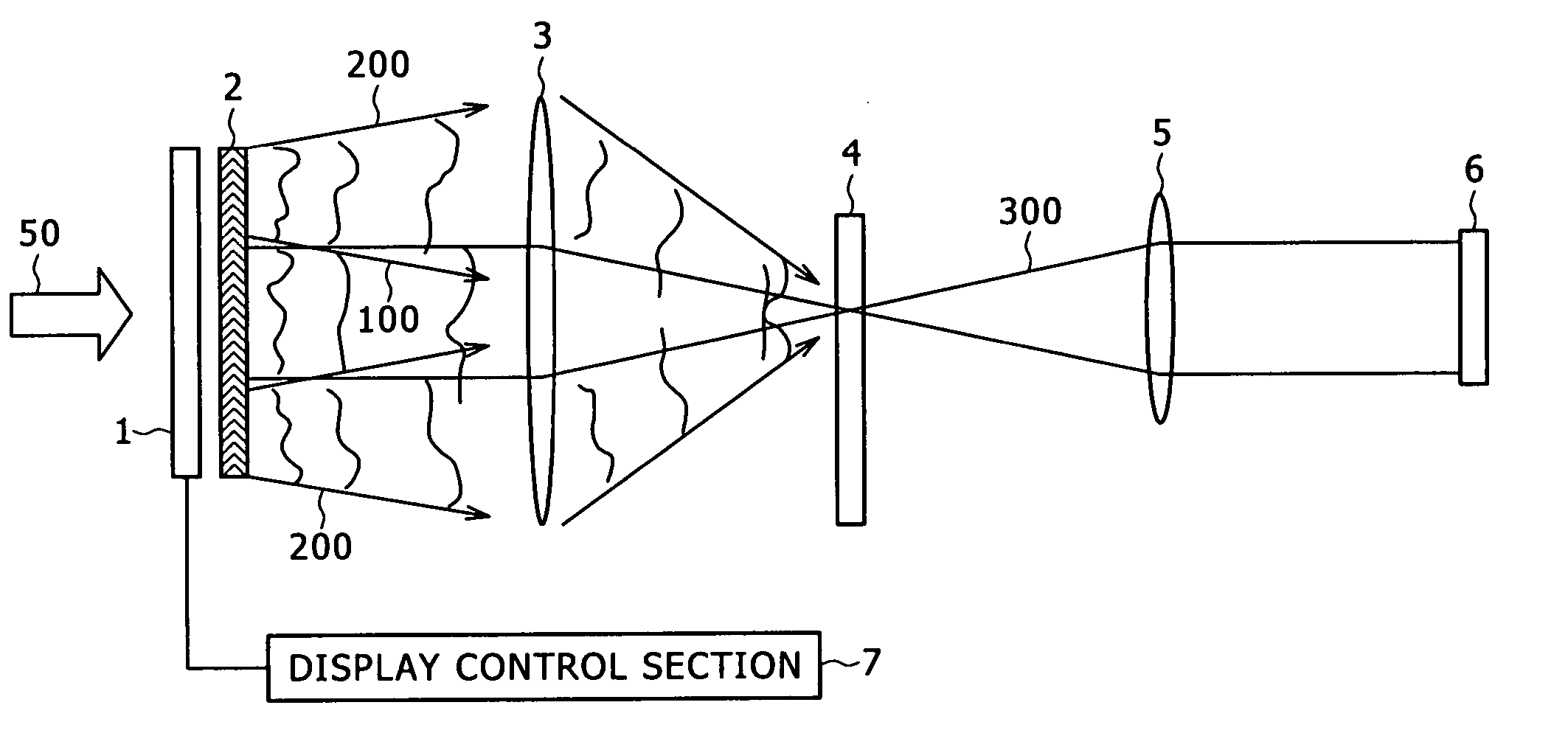

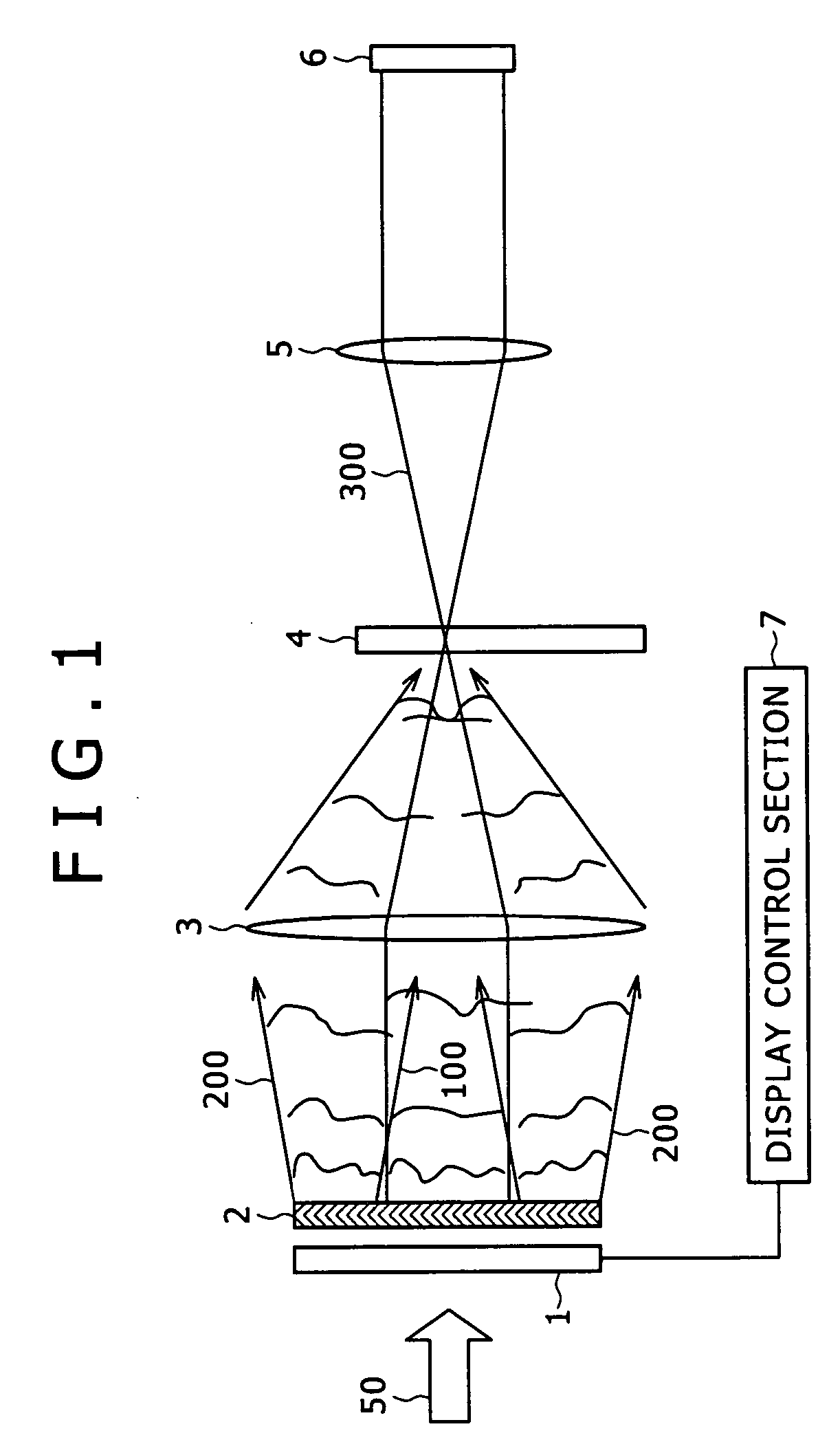

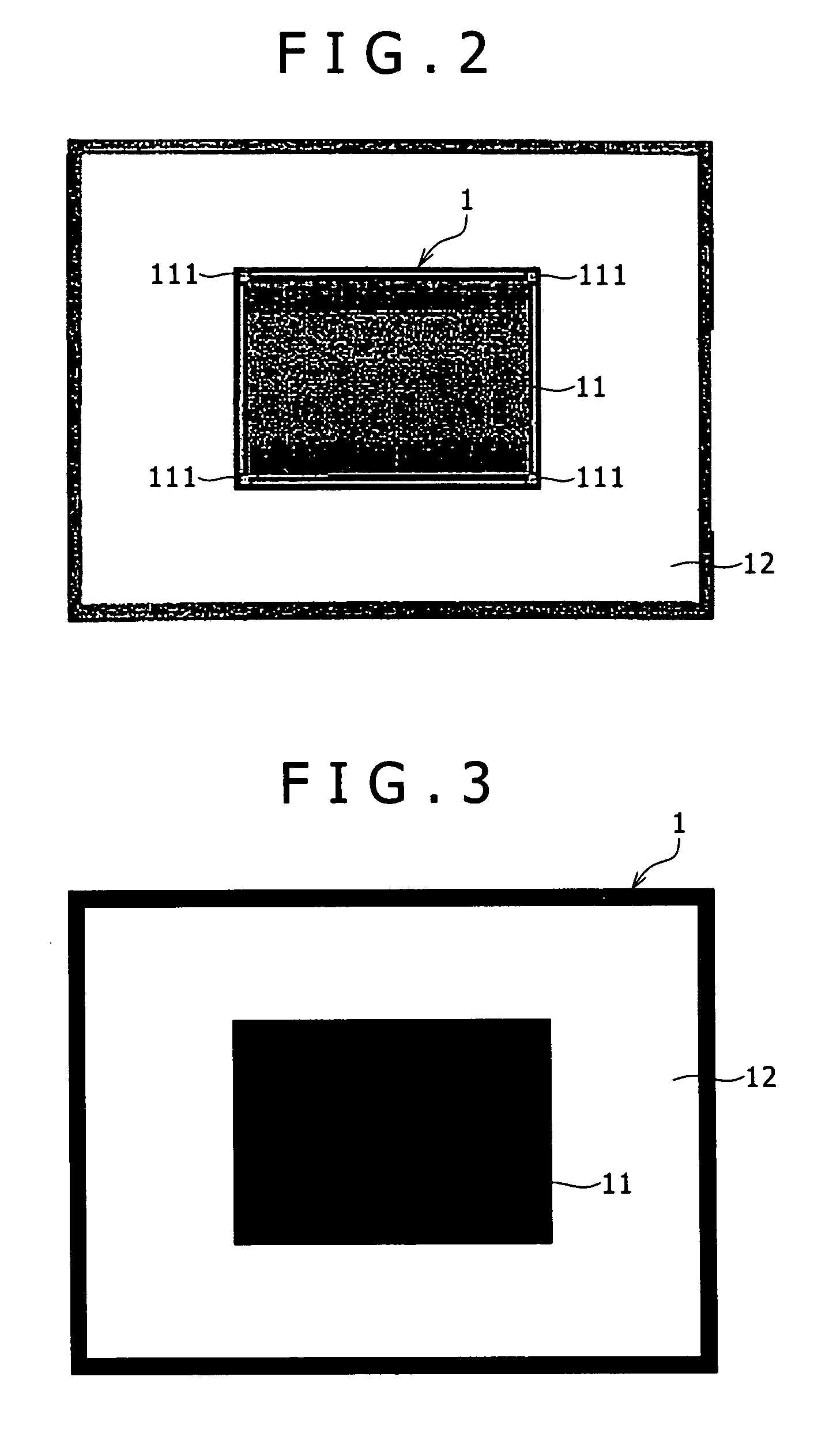

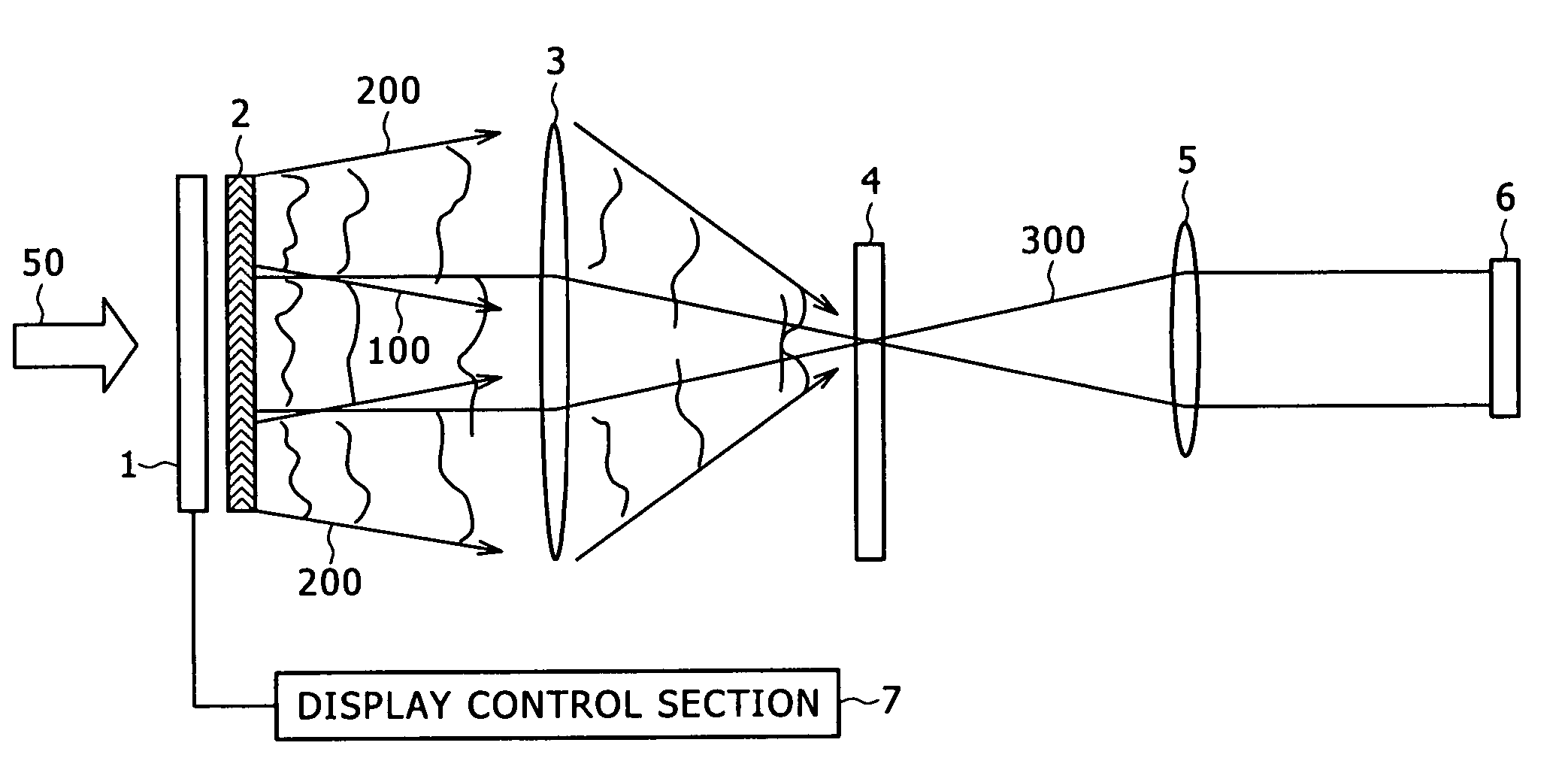

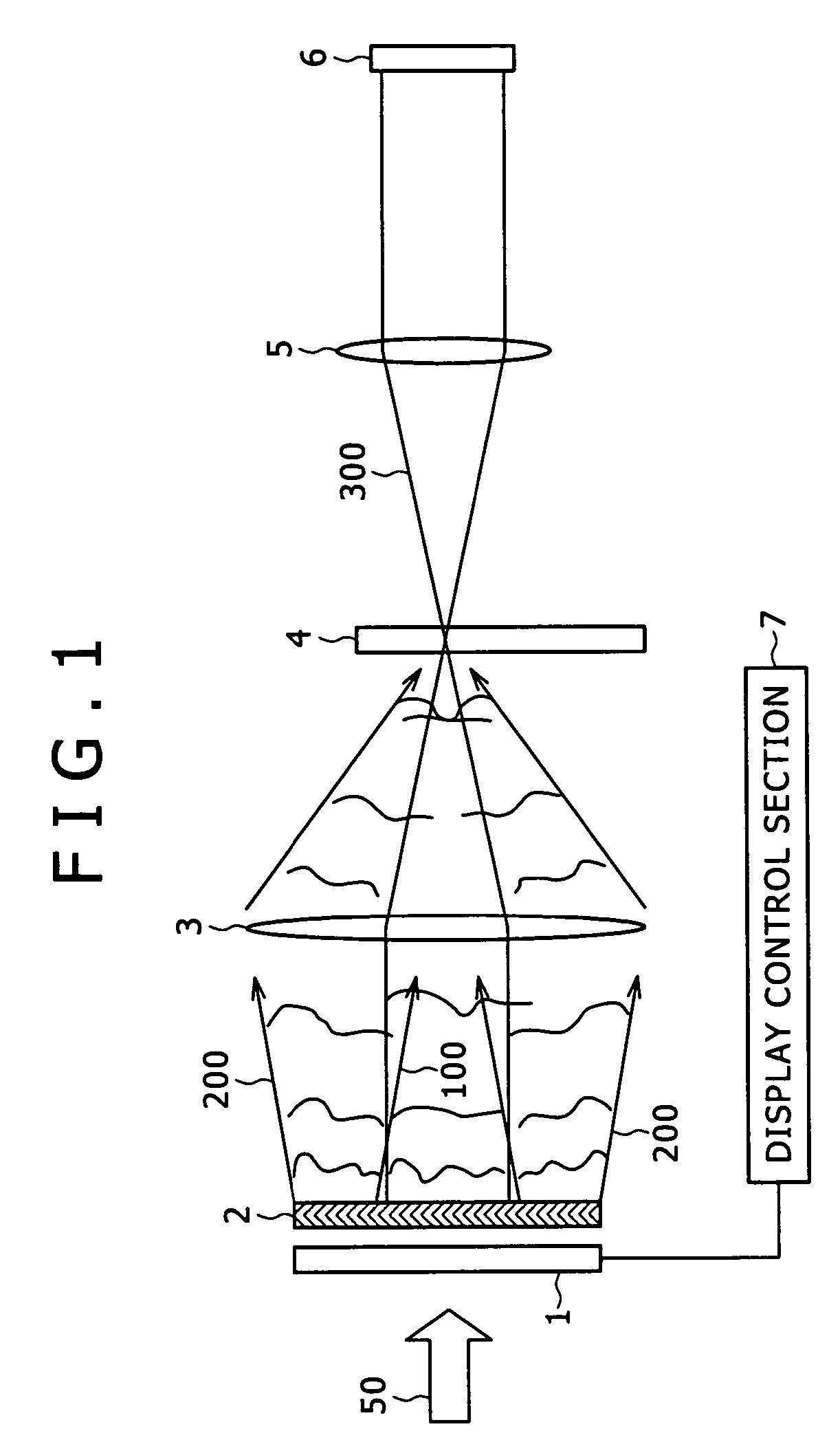

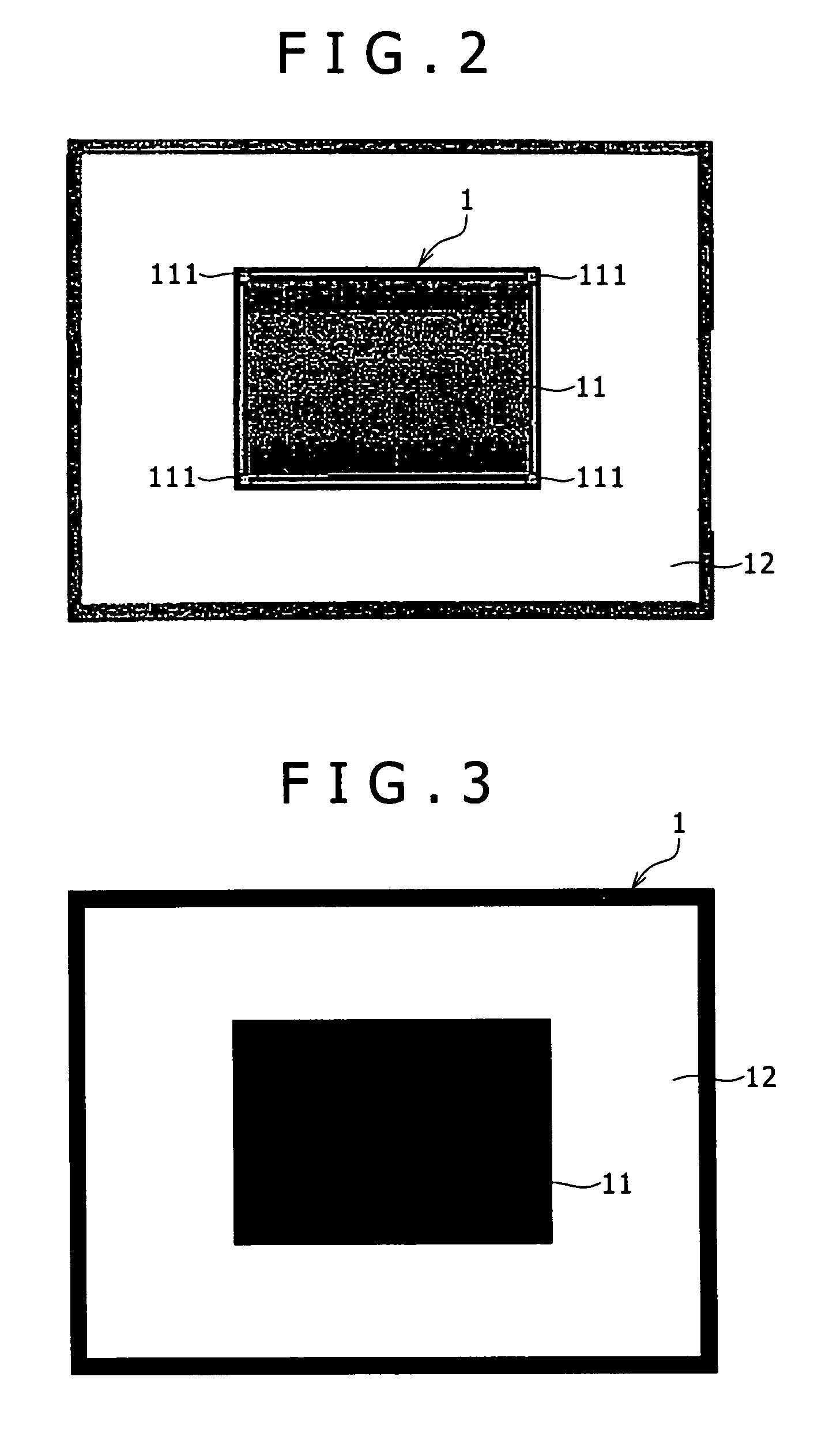

Inline type speckle multiplexed hologram recording apparatus and inline type speckle multiplexed hologram recording method

InactiveUS20050243389A1High picture qualityFine apertureOptical beam sourcesHolographic optical componentsLaser lightIntensity modulation

An inline type speckle multiplexed hologram recording apparatus and method is disclosed which can condense signal light and reference light in a sufficiently overlapping relationship with each other on a hologram recording medium without using a lens having a large aperture and a wide angle of view. A signal light region and a reference light region are displayed on a spatial light modulator, and laser light is intensity modulated with recording data displayed in the signal light region to produce signal light while the laser light having passed through the reference light region is used as reference light. The signal light and the reference light are diffused by a diffuser and then condensed in an overlapping relationship with each other on a hologram recording medium by a lens such that interference fringes produced thereby are recorded in the hologram recording medium.

Owner:SONY CORP

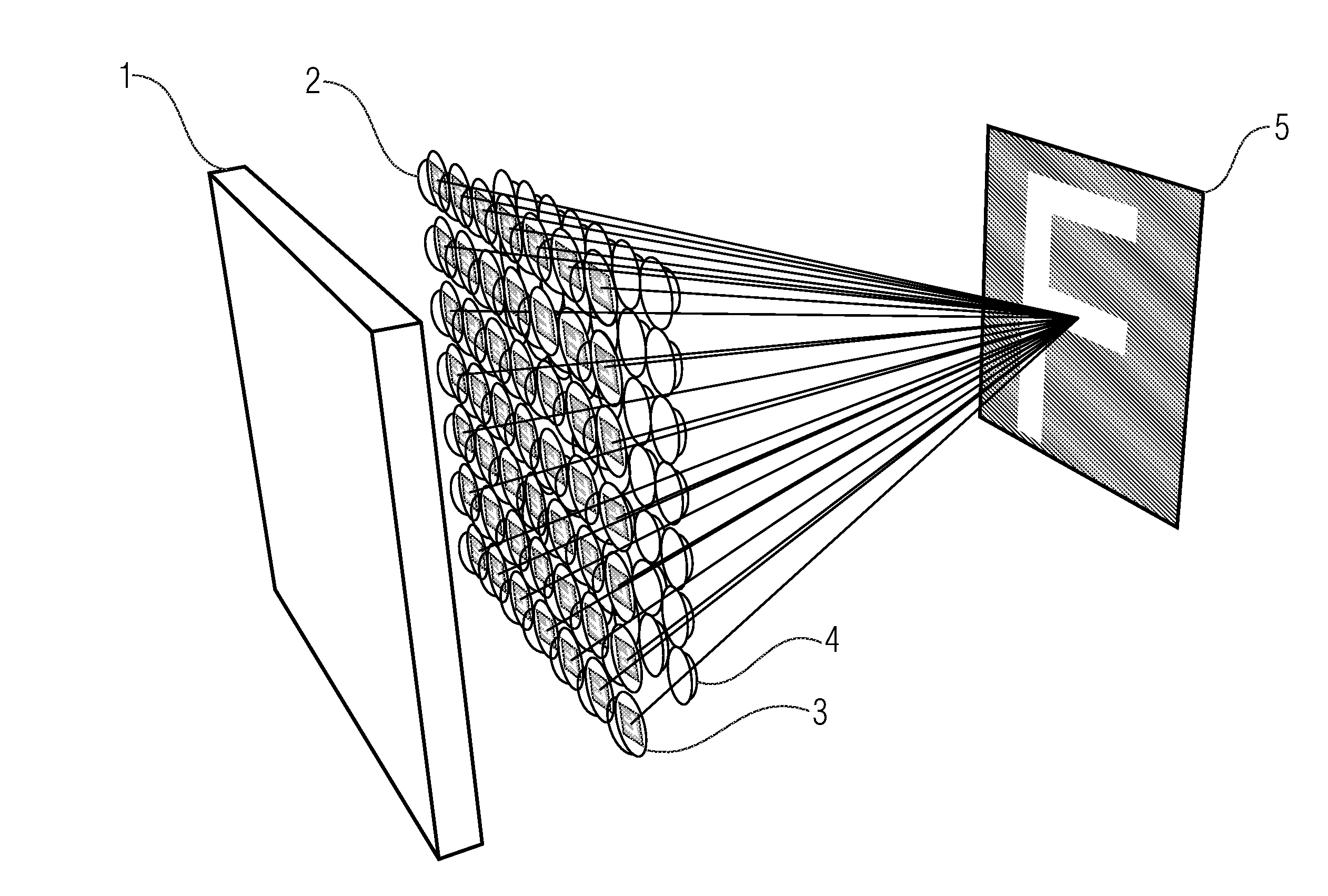

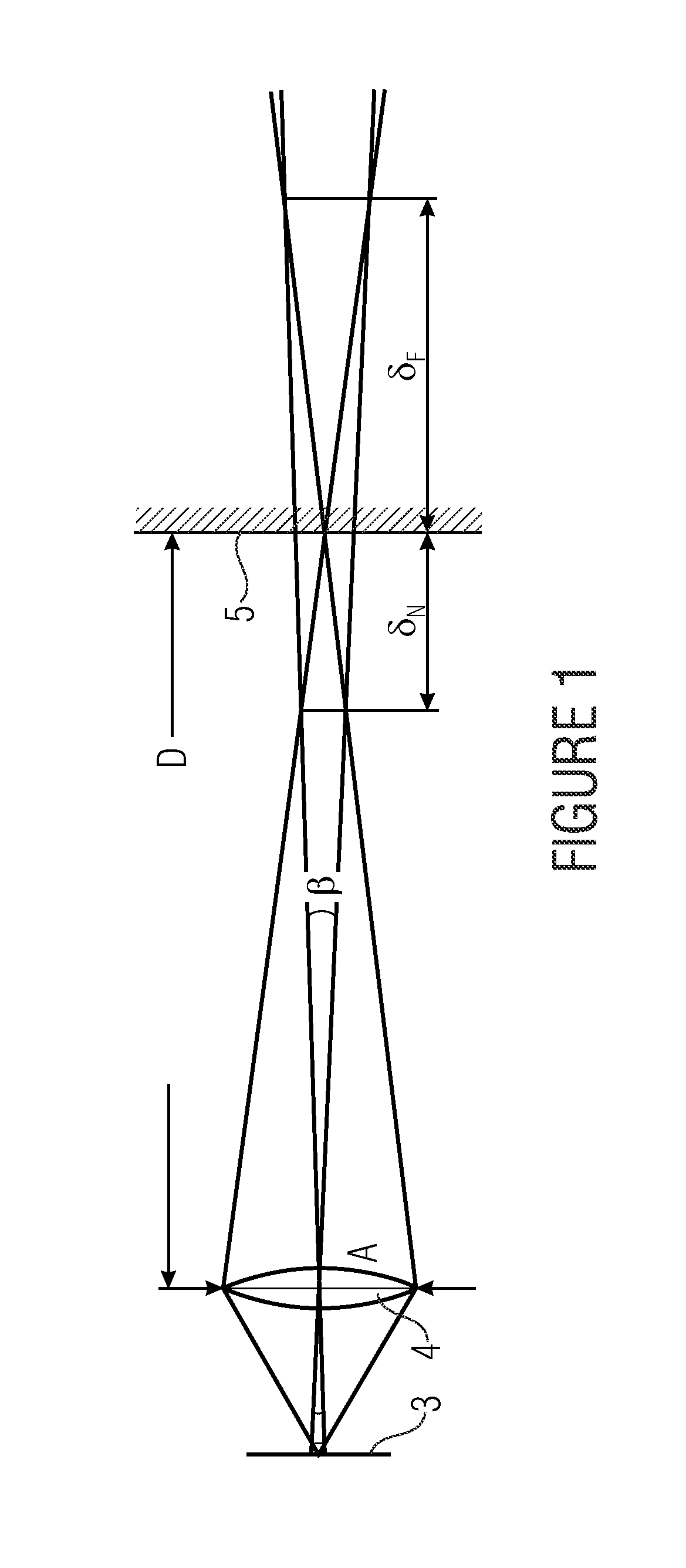

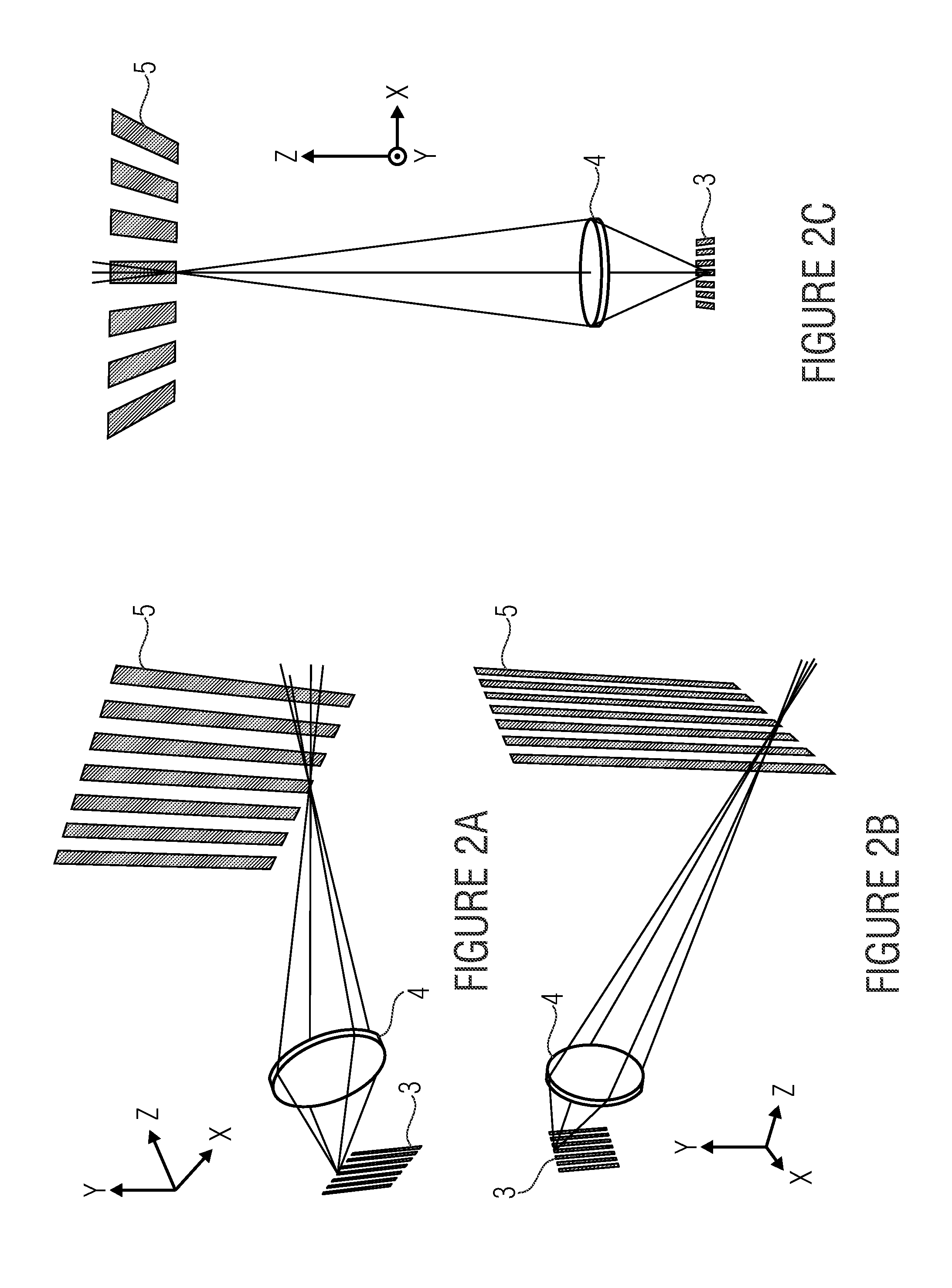

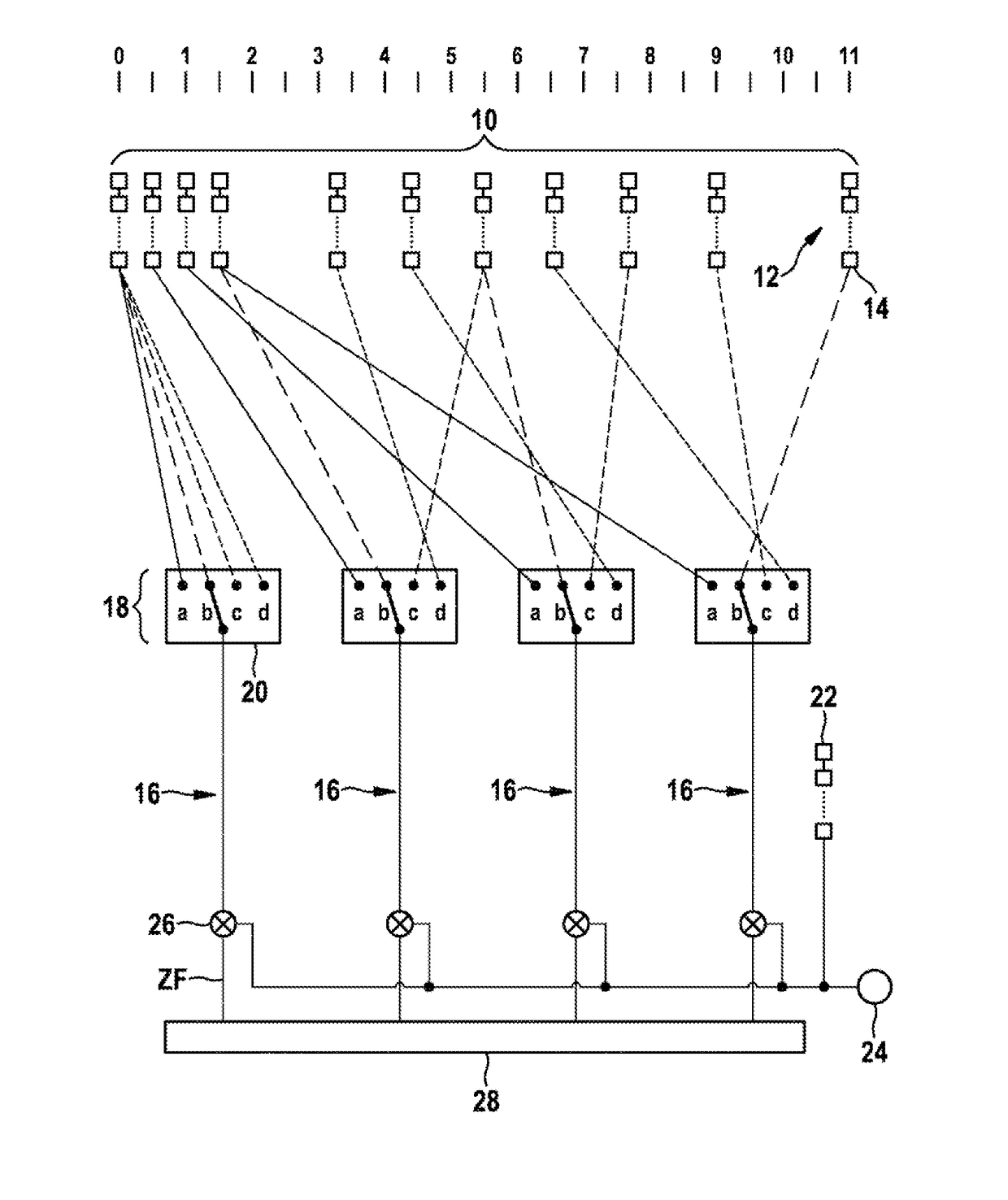

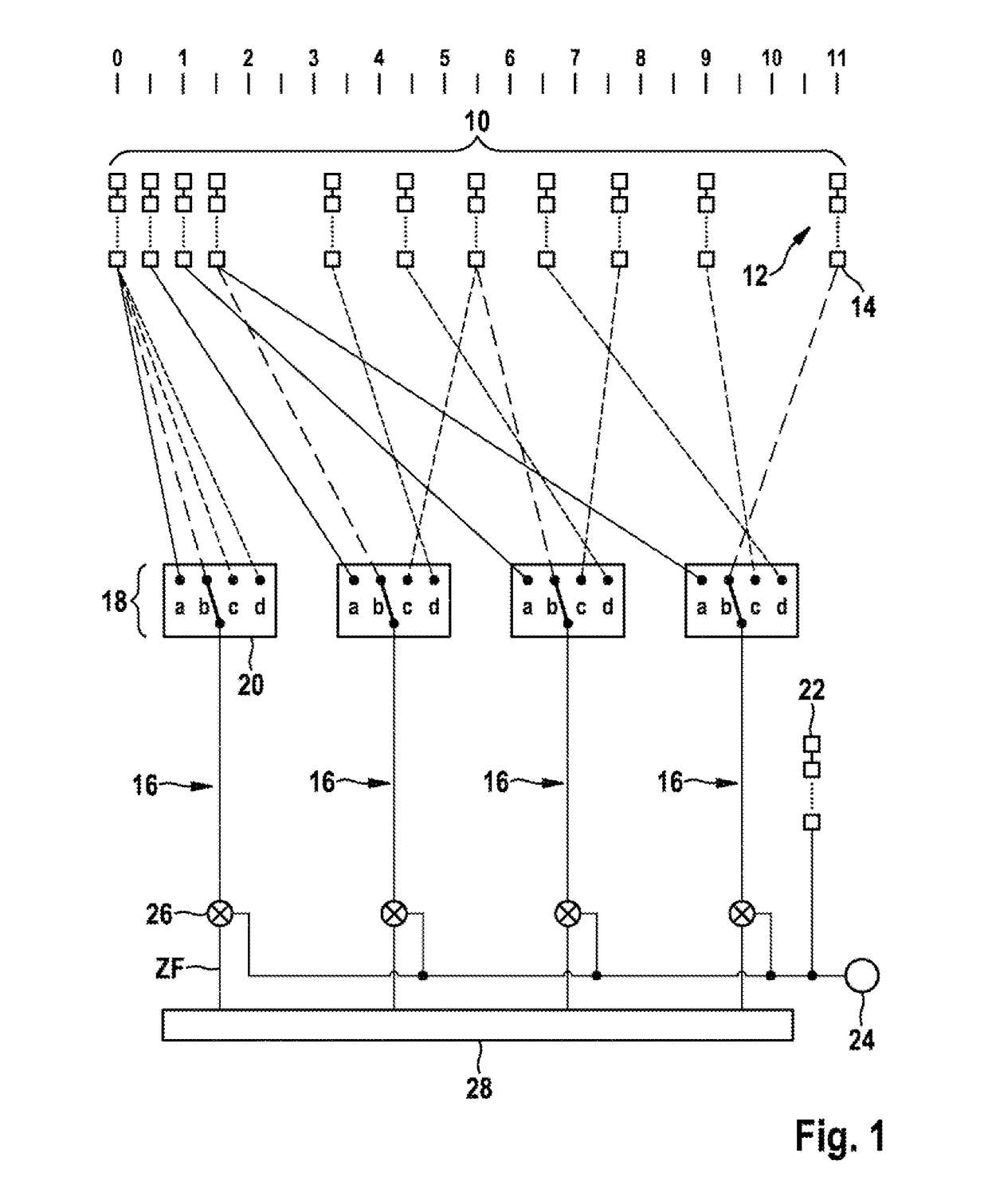

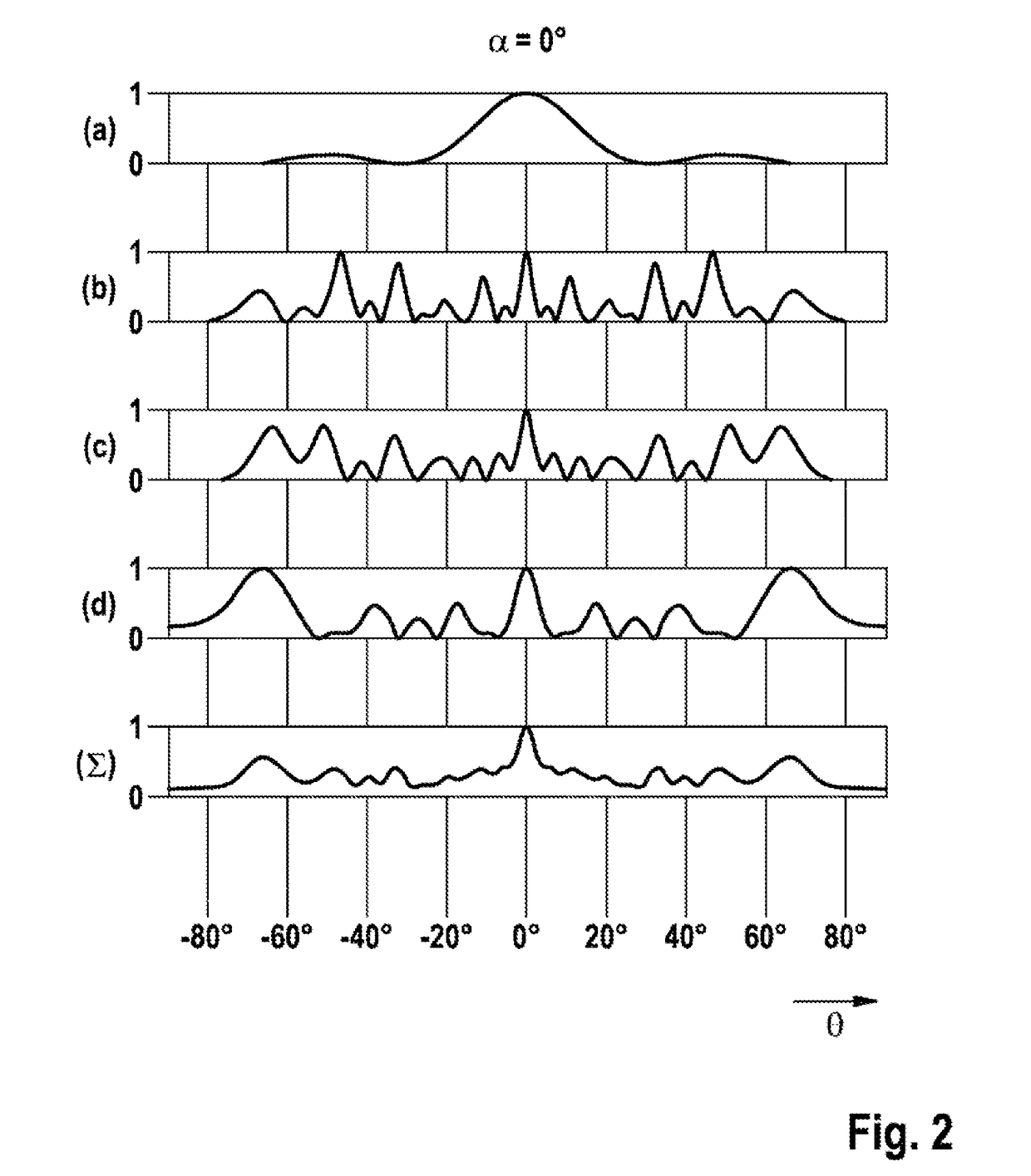

Projection display with multi-channel optics with non-circular overall aperture

ActiveUS20150062446A1Fine apertureIncrease the transmission areaTelevision system scanning detailsPulse generatorProjection imageDisplay device

A projection display is provided with an imager that is implemented to generate individual images in a distribution of sub-areas of an imaging plane of the imager. The projection display also includes a multi-channel optics, which is configured to map one allocated sub-area of the imager each per channel, such that the mappings of the individual images are combined to an overall image in a projection area. At least some channels of the multi-channel optics are arranged along at least one curve which is similar to at least one elongated image feature of the overall image, so that a two-dimension anisotropic out-of-focus behavior of each projected image point is obtained. In this way, a large depth of focus range can be combined with relatively high projection brightness without having to accept losses with respect to the focused illustration of image features that are to be projected with sufficient focus.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Compound concrete anti-corrosion and rust-resistant agent

The invention discloses a compound concrete anti-corrosion and rust-resistant agent which comprises the following components in parts by weight: 15-30 parts of a polycarboxylic acid water reducing agent, 3-12 parts of sodium dodecyl sulfate, 15.7-20.6 parts of N-dimethylethanolamine, 1-5 parts of sodium molybdate, and 50-60 parts of water. The compound concrete anti-corrosion and rust-resistant agent can block capillary holes in the concrete, improves the chloride ion permeability resistance of concrete, can significantly alleviate the damage of chloride ions on a reinforcing steel bar passivation film, enhances the sulfate corrosion resistant ability of the concrete, has excellent rust-resistant performance and good repair performance, can enhance durability of the concrete and the comprehensive anti-corrosion ability of the concrete, and significantly improves the durability of buildings.

Owner:HUNAN CONSTR ENG GRP COR +1

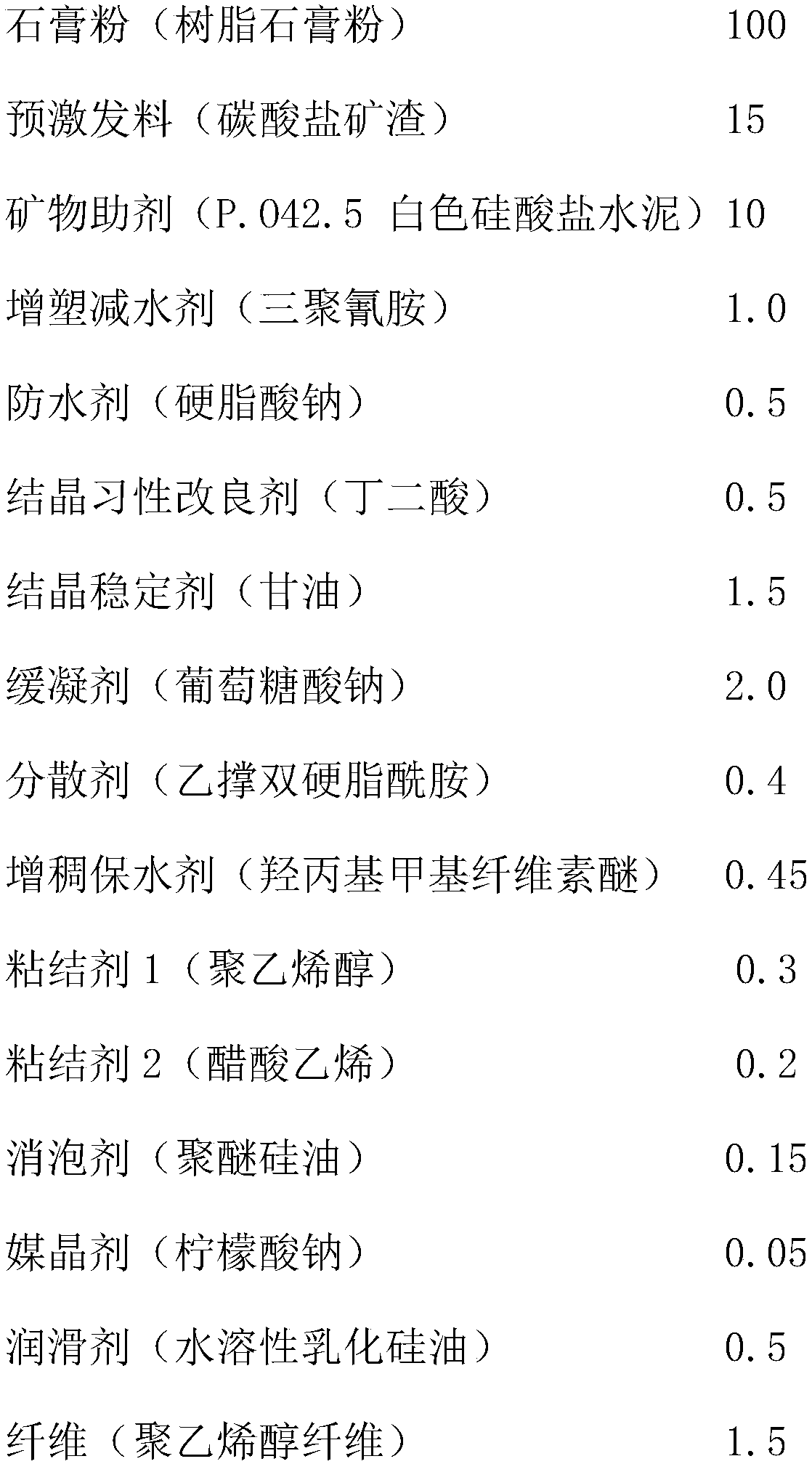

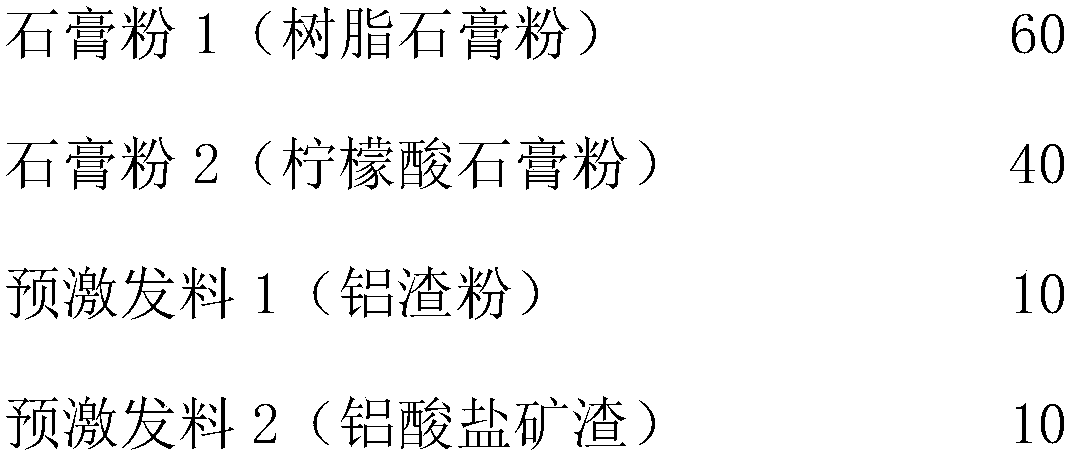

Gypsum-based composite binding material for extruded 3D printing and preparation method thereof

InactiveCN108383465AProlong clotting timeEasy to manufactureAdditive manufacturing apparatusCeramic shaping apparatusFiberCrack resistance

The invention discloses a gypsum-based composite binding material for extruded 3D printing and a preparation method thereof and relates to the field of civil engineering / 3D printing materials. Aimingat defects in the prior art, the invention provides the gypsum-based composite binding material for extruded 3D printing. The binding material is prepared from the following components: gypsum, pre-excited material, mineral additives, a plasticized water reducing agent, a waterproof agent, a crystal habit improver, a cystallizing stabilizer, a retarder, a dispersing agent, a water-retentive and thickening admixture, an adhesive, an antifoaming agent, a crystal modifier, a lubricating agent and fibers. The binding material disclosed by the invention has the beneficial effects that the preparedgypsum-based composite binding material for extruded 3D printing is wide in source, excellent in liquidity and environmentally friendly and has excellent extrusion continuity, constructability, mechanical property, water seepage resistance and cracking resistance.

Owner:深圳市明远建筑科技有限公司

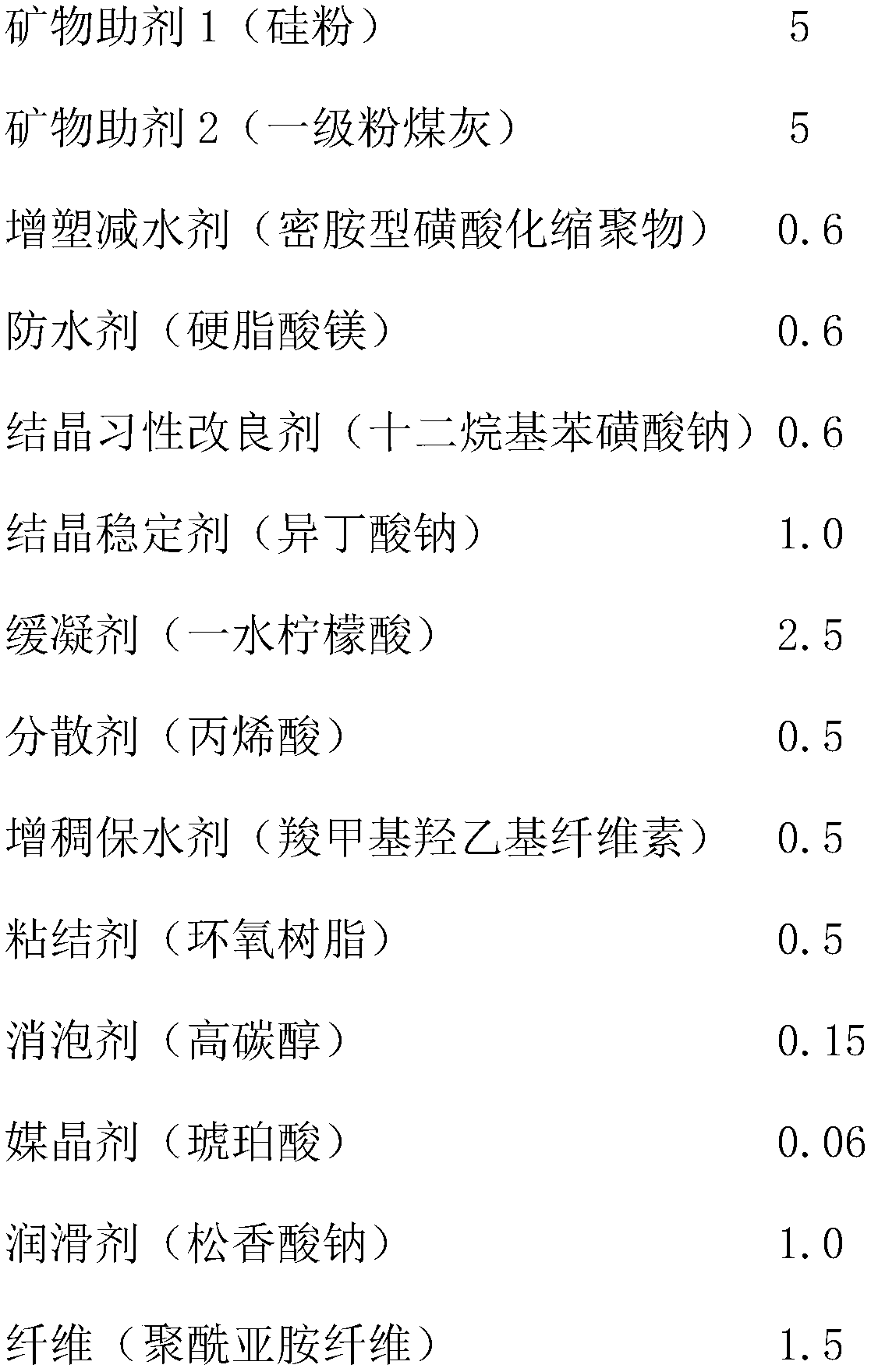

Magnesium-chromium-zirconium composite brick

The invention belongs to the field of refractory materials, and particularly relates to a magnesium-chromium-zirconium composite brick. The magnesium-chromium-zirconium composite brick is produced by adopting the following materials: 30-50% of electrically-fused magnesium-chromium sand with the granularity of 3-5mm, 10-20% of electrically-fused magnesium-chromium sand with the granularity of less than 3mm, 10-30% of South Africa chromium concentrate with the granularity of not greater than 2mm, 5-15% of sintered magnesium sand powder with the granularity of not greater than 0.088mm, and 2-5% of an organic-inorganic compound binding agent. The magnesium-chromium-zirconium composite brick is produced by the following steps: mixing the materials except the organic-inorganic compound binding agent, then adding the organic-inorganic compound binding agent, carrying out mulling, pressing, drying, sintering to obtain a sintered brick, carrying out pressurized permeation on the sintered brick in a zirconium oxychloride solution, and drying. The magnesium-chromium-zirconium composite brick has the slagging resistance and the permeation prevention property of conventional magnesium-chromium refractory materials, is applicable to the field of refining of steel metallurgy, can remarkably prolong the service life of refining equipment and has good economical and social benefits.

Owner:河南瑞泰耐火材料科技有限公司

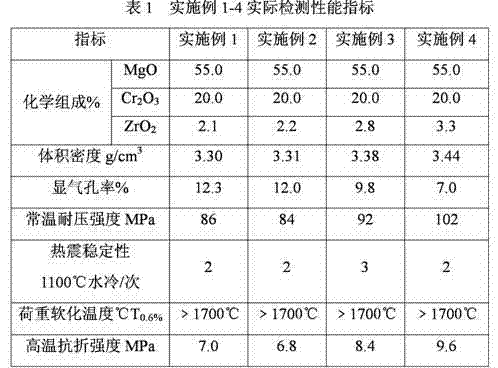

Interface agent and preparation method thereof and application of interface agent in fabricated building structure

The invention provides an interface agent, a preparation method thereof and an application of the interface agent in a fabricated building structure. The interface agent uses an ultrafine composition,and the low-temperature construction performance and the bonding strength of the interface agent are improved. The interface agent is prepared from a component A and a component B, wherein the component A is prepared from ordinary Portland cement, white Portland cement, a low-temperature reinforcing agent, a dispersing agent, fine aggregate, mineral powder and dense silica fume, and the componentB is prepared from emulsion, cellulose ether, a thickening time control agent, a defoaming agent and water. The interface agent has the excellent characteristics of high bonding strength, long hardening time, low temperature resistance and the like. The interface agent is applied to a fabricated building structure, and has remarkable economic and social benefits for improving the construction efficiency and engineering quality of the fabricated building structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

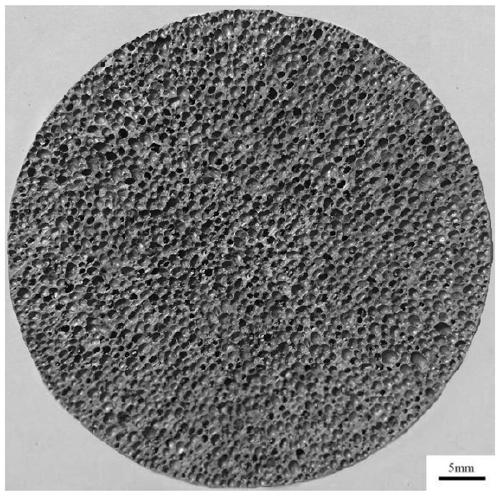

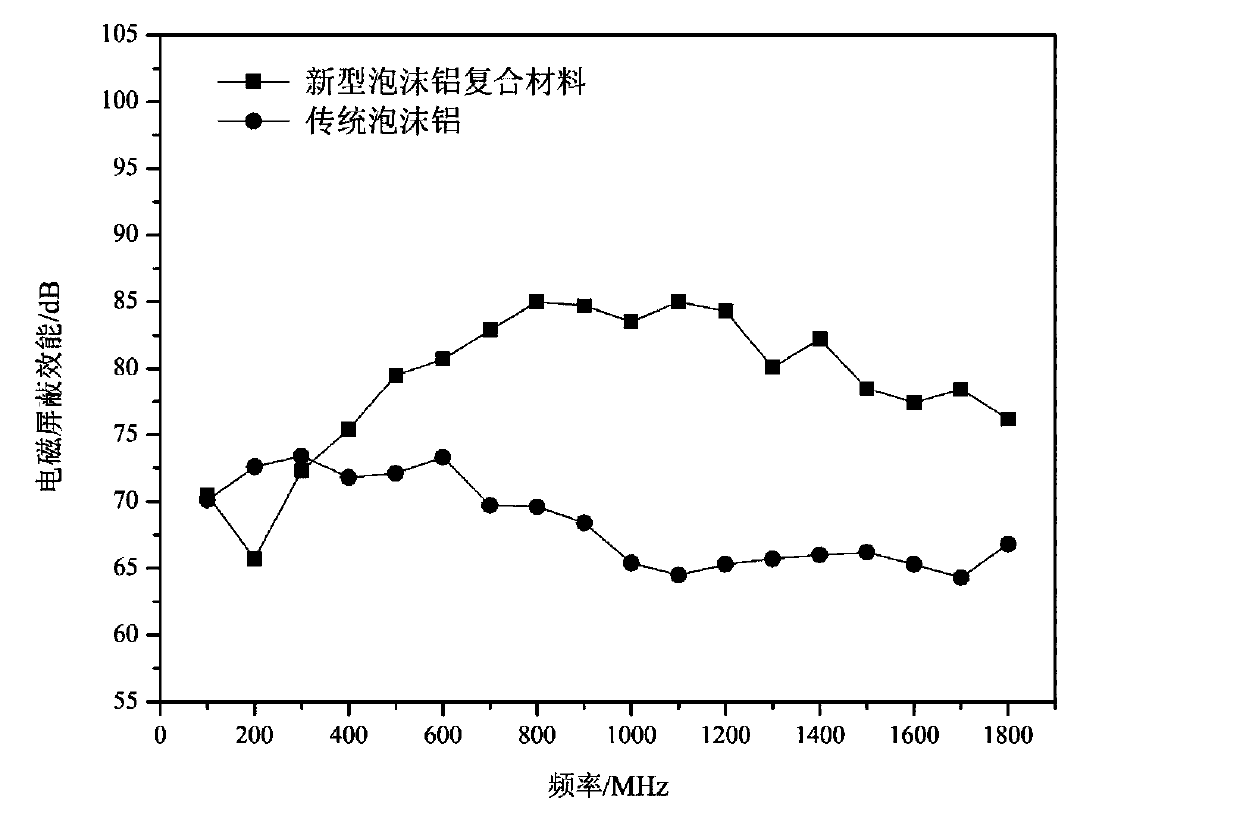

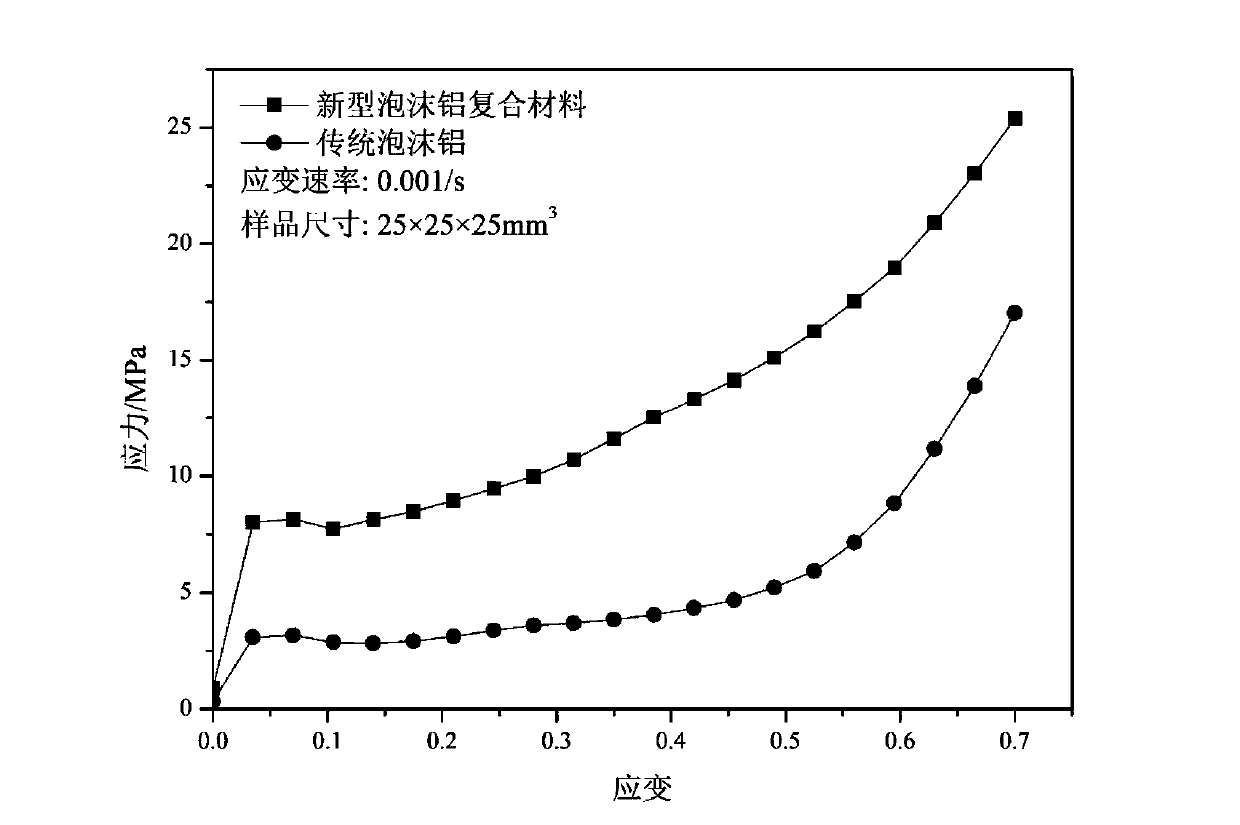

Method for preparing electromagnetic shielding foamed aluminum composite material

ActiveCN109881036AReduce burning lossReduce clumpingTransition element hydridesFoaming agentMicrosphere

The invention discloses a method for preparing an electromagnetic shielding foamed aluminum composite material. The method includes the steps that a magnesium block and a hollow ceramics microsphere are added by stepping composition, then, after a pre-treated titanium hydride foaming agent is added, the surface is provided with a layer of dense oxidation film, thus the mixture can be foamed intensively in a certain temperature range, the effect of aperture decreasing is realized, and finally, a novel closed-cell foamed aluminum composite material is obtained. According to the method for preparing the electromagnetic shielding foamed aluminum composite material, the obtained closed-cell foamed aluminum composite material has the characteristics of being low in cost, small in aperture, highin strength, excellent in electromagnetic shielding performance and the like.

Owner:HEBEI UNIV OF TECH

Concrete moisturizing curing and surface strengthening method

ActiveCN110273553AIncrease penetration depthImprove surface qualityBuilding material handlingHydration reactionPolymer science

The invention relates to a concrete moisturizing curing and surface strengthening method. By using a pre-saturated water-absorbing curing film, a concrete member coated with a permeable crystallization material is closely covered and cured, on the one hand, the condition for continuous permeation of the permeable crystallization material is provided, the penetration depth of the permeable crystallization material is increased, on the other hand, sufficient water is provided for the hydration reaction of the permeable crystallization material in pores of concrete, the pore diameter can be effectively refined, and a good dense filling effect is achieved. Meanwhile, good moisturizing curing further reduces the occurrence of cracks on the concrete surface and improves the quality of the concrete surface.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Inline type speckle multiplexed hologram recording apparatus and inline type speckle multiplexed hologram recording method

InactiveUS7362482B2Improve picture qualityFine apertureOptical beam sourcesHolographic optical componentsData displaySpatial light modulator

An inline type speckle multiplexed hologram recording apparatus and method is disclosed which can condense signal light and reference light in a sufficiently overlapping relationship with each other on a hologram recording medium without using a lens having a large aperture and a wide angle of view. A signal light region and a reference light region are displayed on a spatial light modulator, and laser light is intensity modulated with recording data displayed in the signal light region to produce signal light while the laser light having passed through the reference light region is used as reference light. The signal light and the reference light are diffused by a diffuser and then condensed in an overlapping relationship with each other on a hologram recording medium by a lens such that interference fringes produced thereby are recorded in the hologram recording medium.

Owner:SONY CORP

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

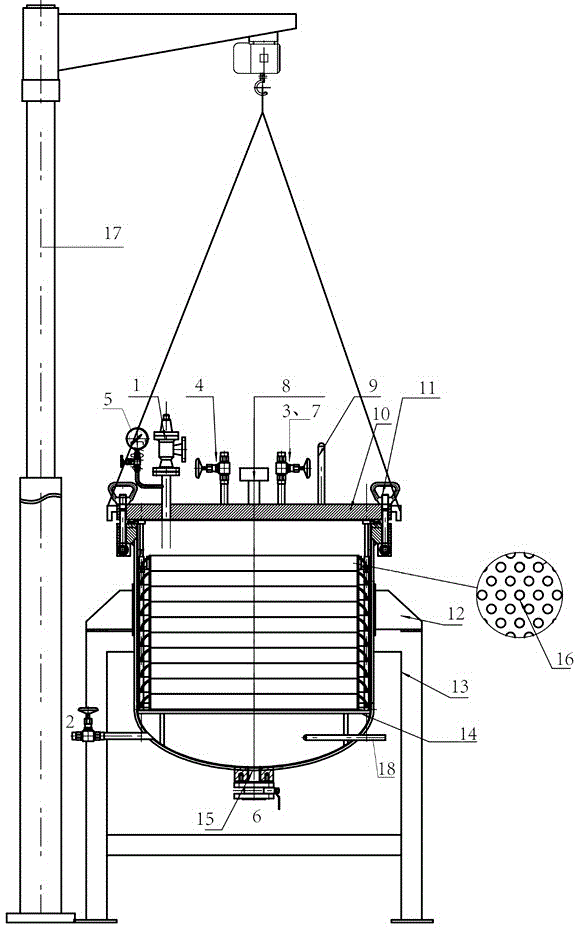

Device and method for strengthening recycled aggregate by means of CO2

ActiveCN106277885AEnhance basic propertiesLow water absorptionSolid waste managementPorosityCarbon dioxide cylinder

The invention relates to a device and method for strengthening recycled aggregate by means of CO2. The device comprises a reaction kettle with a kettle cover, a plurality of layers of stacked material frames are arranged in the reaction kettle, a gas inlet connected with a carbon dioxide steel cylinder is formed in the side of the reaction kettle, a pressurizing opening is formed in the kettle cover and connected with the carbon dioxide steel cylinder through a booster pump, and the kettle cover is further provided with an exhaust port and a vacuum opening connected with a vacuum pump. The device is simple in structure, convenient to install and maintain, convenient to clean and high in universality. By means of reaction of CO2 and recycled aggregate, the recycled aggregate is strengthened, basic properties of the recycled aggregate are improved, the water absorption rate and porosity of the recycled aggregate are reduced, the aperture is reduced, carbonization time is shortened, carbonization depth is increased, the treatment effect is improved, the yield is increased, and the equipment utilization rate is increased.

Owner:FUZHOU UNIV

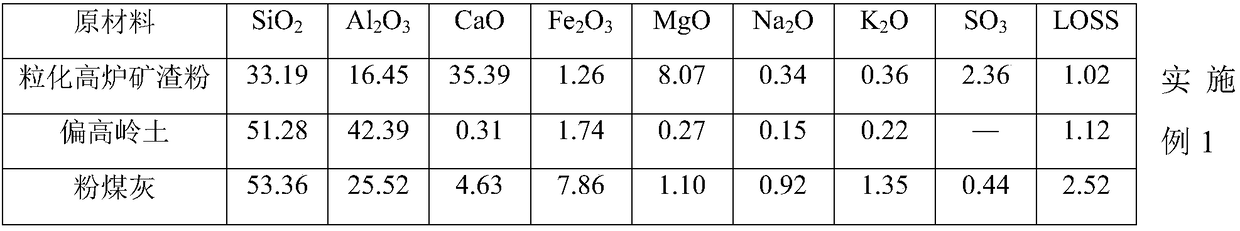

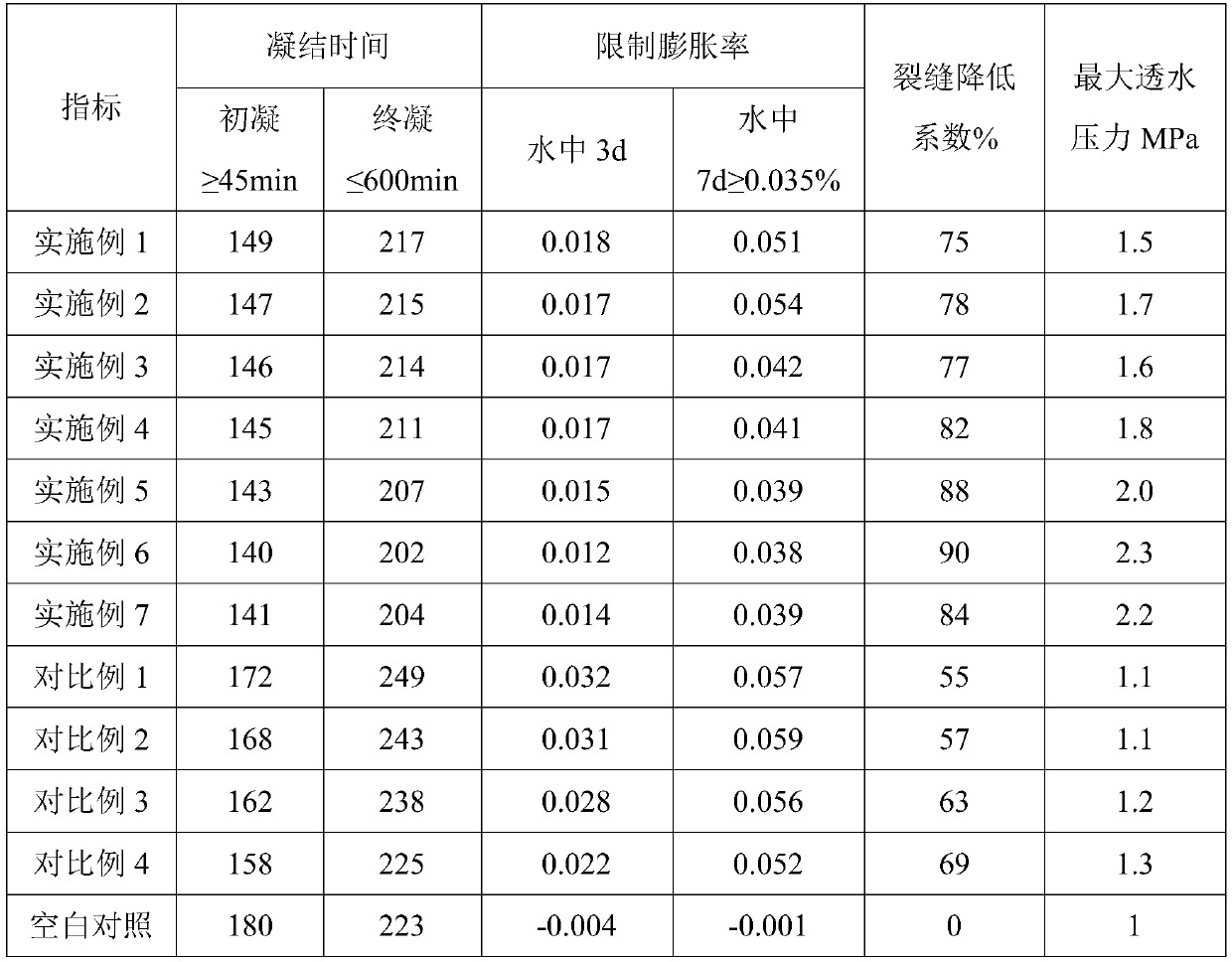

A method for optimizing performance of calcium-based geopolymer by multi-component composite powder

The invention discloses a method for optimizing performance of calcium-based geopolymer by multi-component composite powder. The method includes the following steps: an influence rule of NaOH on hardened slurry strength is analyzed by utilizing a single-component slag as a gelling material; the influence rule of Na2SiO3 with different forms on compressive strength of granulation blast furnace slagnet paste is analyzed, and Na2SiO3 in a liquid state is determined to be adopted as an exciting agent; through analyzing the rule of the Na2SiO3 with different moduli on the compressive strength of the granulation blast furnace slag net paste, the Na2SiO3 in the liquid state the modulus of which is 1 is determined to be adopted as the exciting agent; finally the influence rule of the Na2SiO3 in the liquid state with different mixing amounts on the compressive strength of granulation blast furnace slag net paste is analyzed; monomer activity of various gelling materials and the influence rulethereof on the hardened slurry strength are researched according to an obtained alkaline exciting agent experiment parameter; and 80% of slag powder, 10% of metakaolin and 10% of fly ash are selectedas the multi-component composite powder. The calcium-based geopolymer is prepared by the multi-component composite powder, an effect that a calcium-based geopolymer hydration product and a pore structure thereof are optimized is achieved, and the compressive strength of the prepared calcium-based geopolymer is higher.

Owner:盐城桂友科技有限公司

Expansoive fiber crack-resistant waterproofing agent for concrete and preparation method thereof

ActiveCN110240430AImprove compactnessImprove adhesionSolid waste managementPyrophylliteCellulose fiber

The invention discloses an expansive fiber crack-resistant waterproofing agent for concrete and a preparation method thereof, belonging to the technical field of concrete admixture production; and the expansive fiber crack-resistant waterproofing agent comprises the following components in%age by weight: 15-25% of wollastonite powder, 20-32% of coal gangue powder, 30-40% of pyrophyllite powder, 15-25% of desulfurized gypsum and 3-10% of cellulose fiber. According to the invention, through the synergistic effect of the desulfurizing gypsum, the coal gangue, the pyrophyllite, the cellulose fiber and the like, the compactness of the concrete is effectively enhanced, capillary pores are reduced, and the impermeability, corrosion resistance and bending resistance are greatly improved.

Owner:GUANGDONG YUESHENG SPECIAL BUILDING MATERIALS

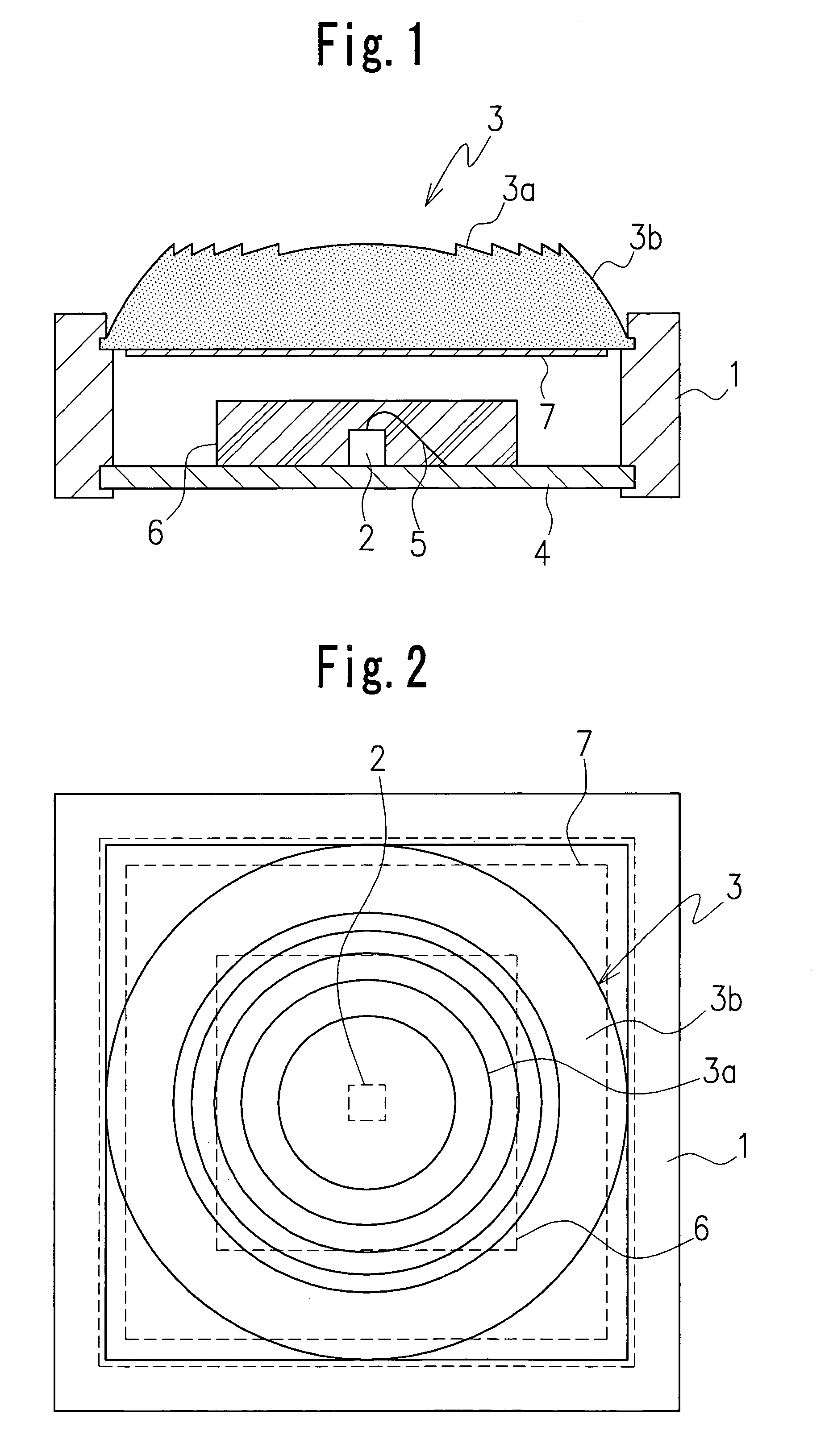

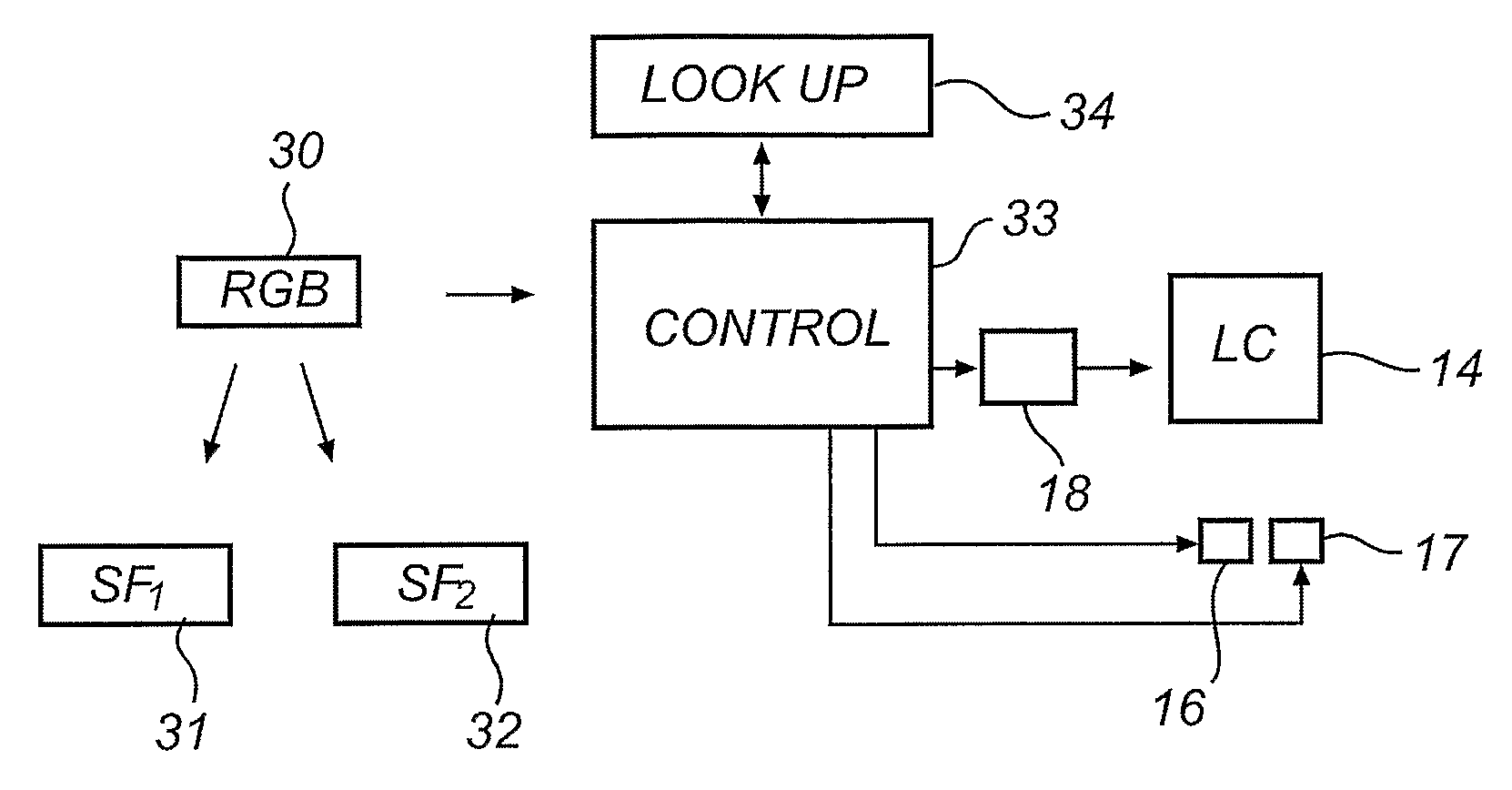

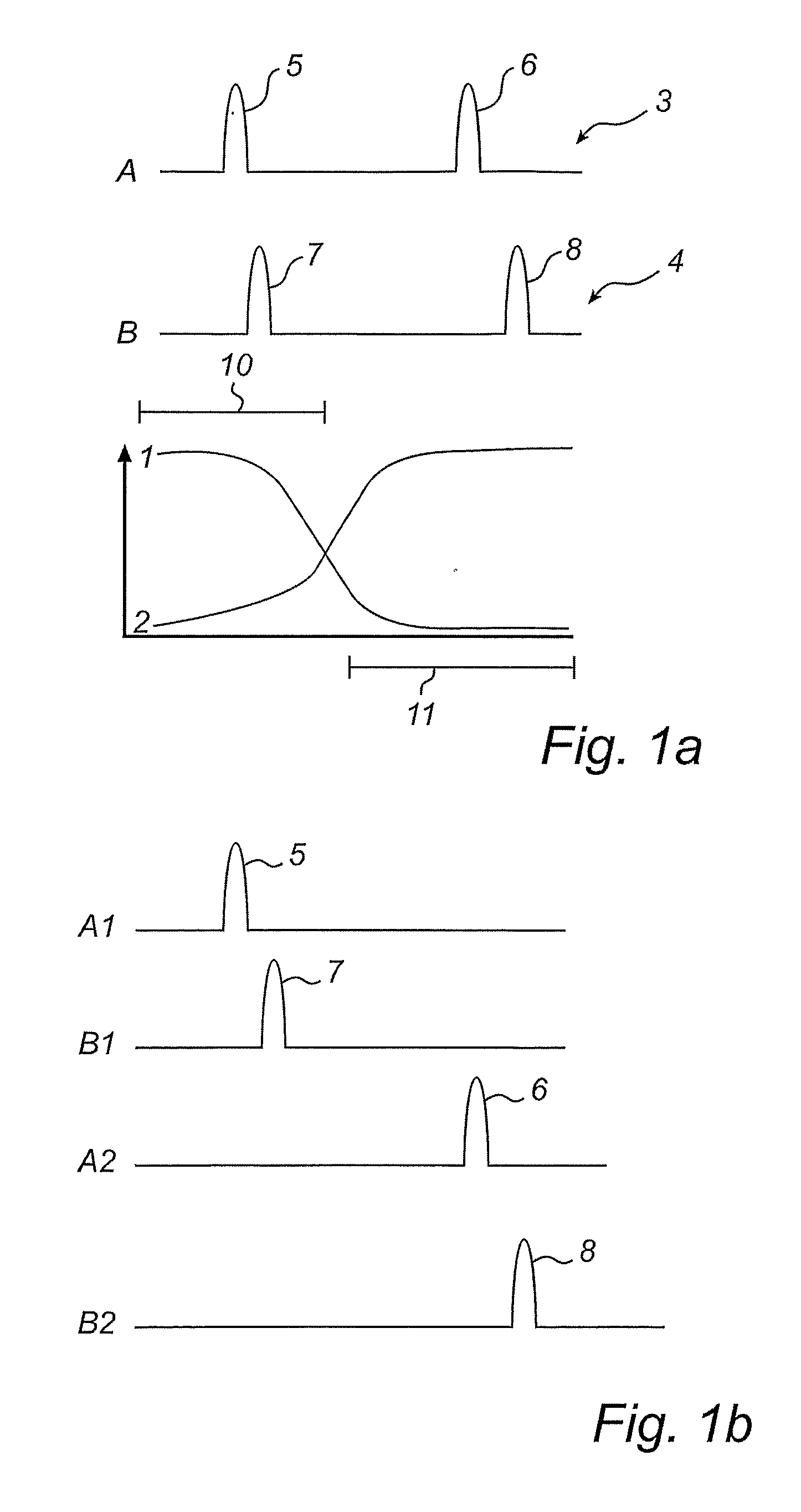

Color Display

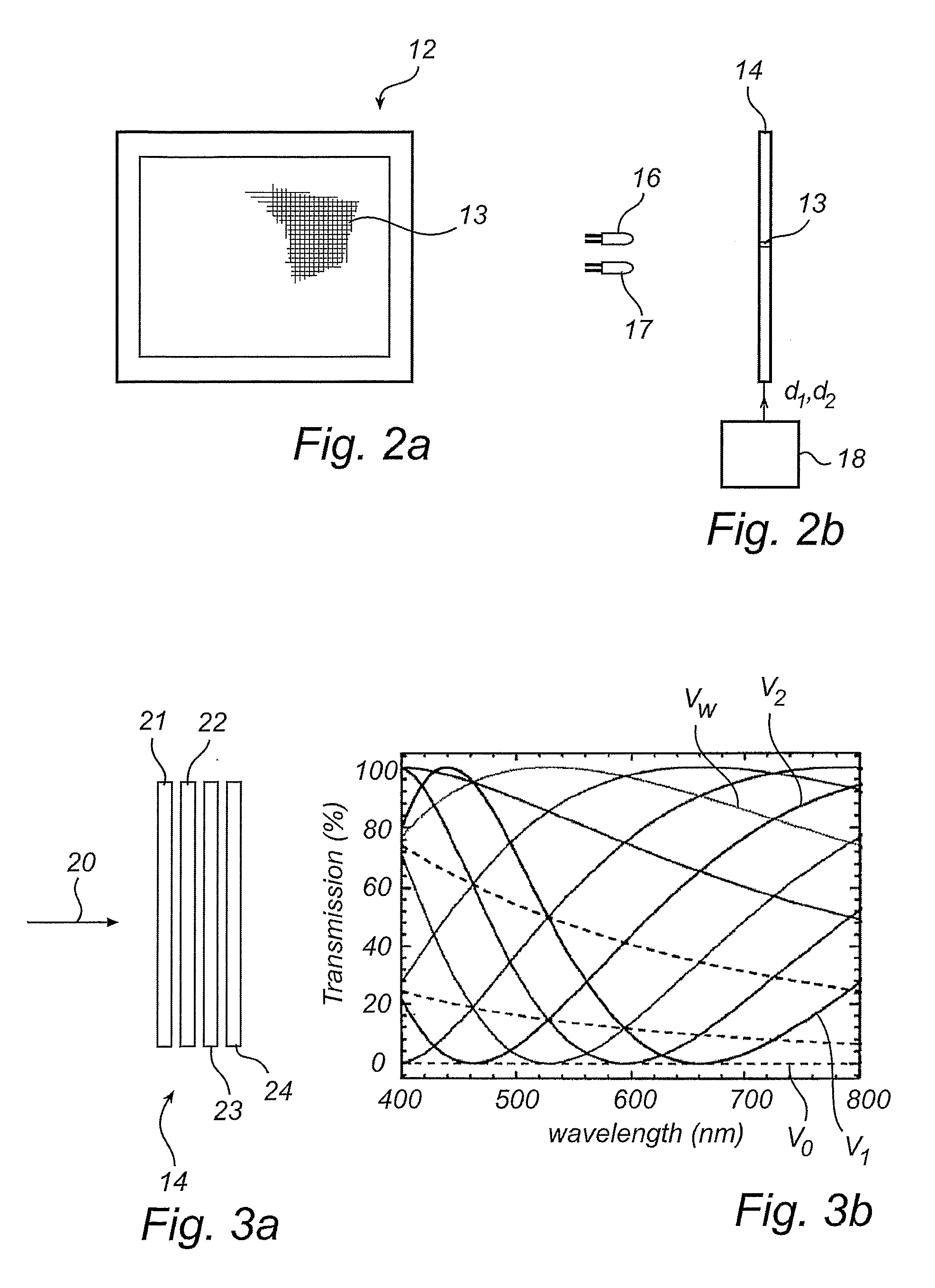

InactiveUS20080094329A1Reduce complexityFine apertureStatic indicating devicesPicture reproducersLiquid crystal light valveRadiance

The present invention relates to a color display device, comprising at least two light sources (16, 17), having different radiance spectra, and a liquid crystal light valve layer (14). The light sources (16, 17) are activated sequentially and the light valve layer is provided with driving signals (d1, d2) in such a way that it obtains a strong wavelength dependence. This allows the display device to produce primary colors without the provision of color filters. This provides a less complex display, which is suitable for mobile applications and provides high brightness.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

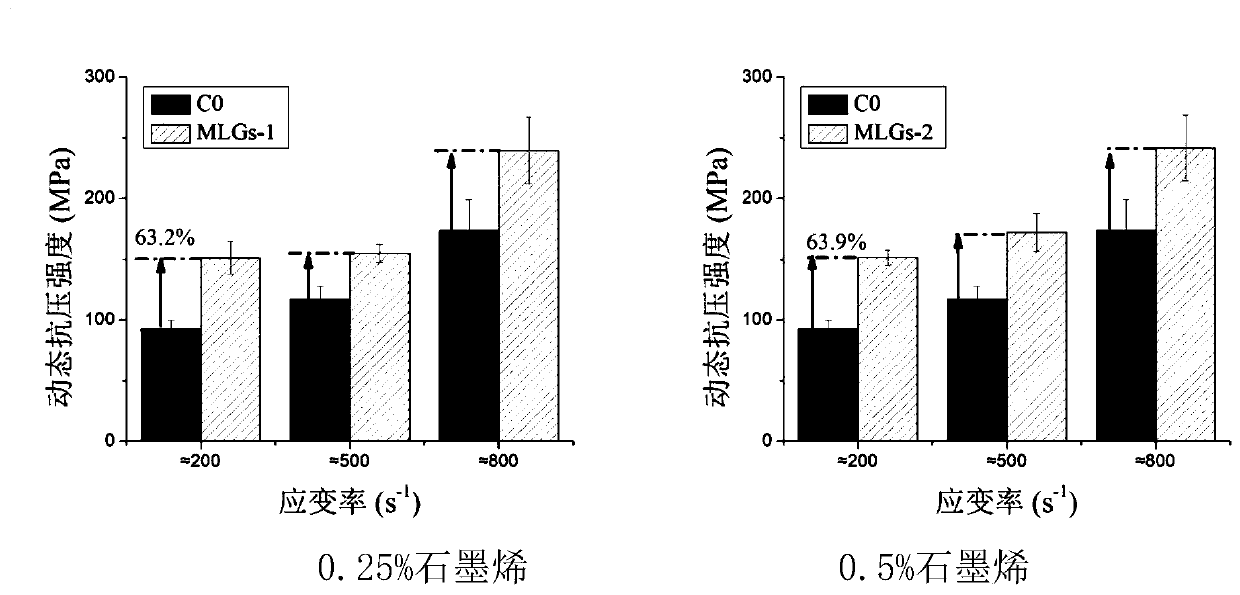

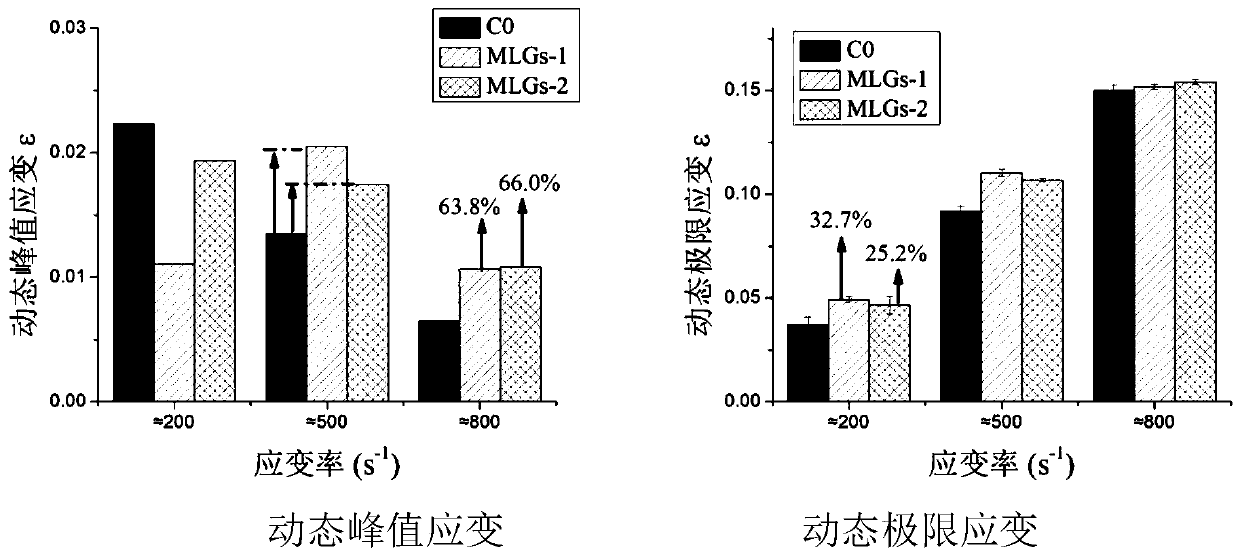

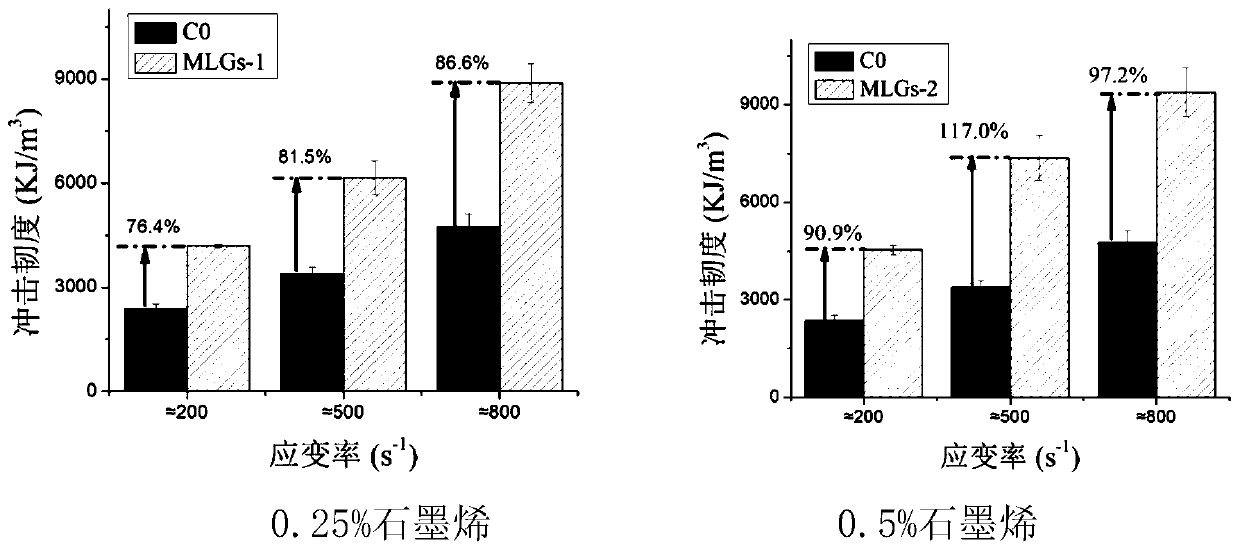

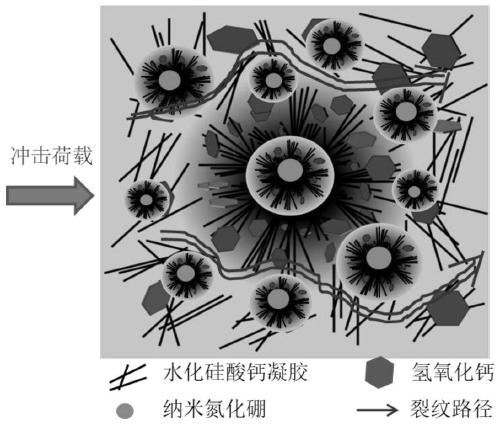

Impact-resistant graphene reinforced reactive powder concrete

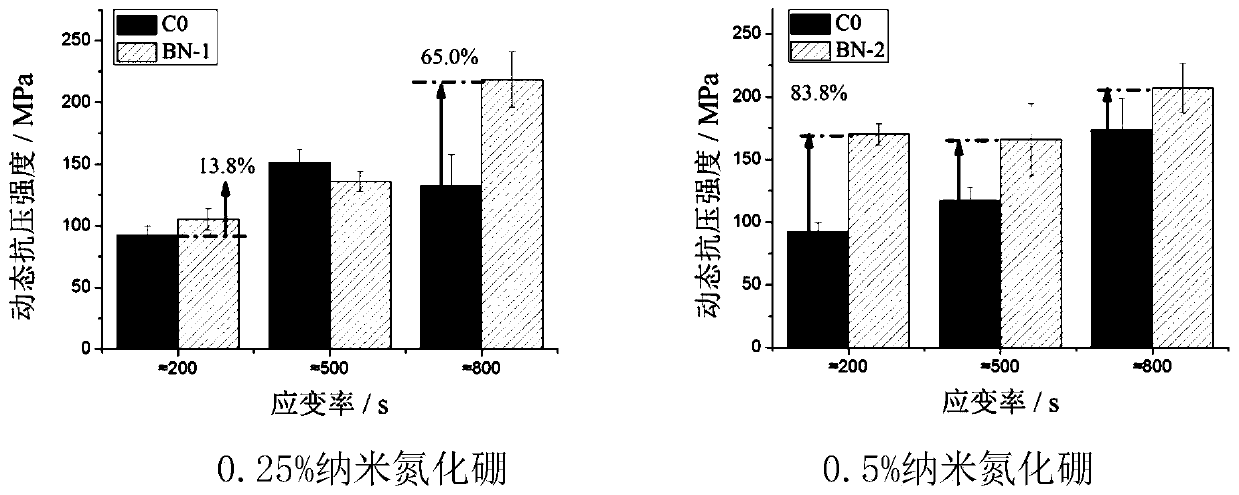

The invention discloses an impact-resistant graphene reinforced reactive powder concrete. Raw materials of the impact-resistant graphene-reinforced reactive powder concrete include cement, graphene, silica fume, fly ash, sands, a water reducer and water. The graphene can significantly enhance the dynamic compressive strength, the peak strain, the ultimate strain and the impact toughness of reactive powder concrete. When the strain rate is in a range of 200-800 / s and the dosage of the graphene is 0.25-0.5%, the dynamic compressive strength of concrete can be increased by 63.9%, the dynamic peakstrain can be increased by 66.0%, the dynamic ultimate strain can be increased by 32.7%, and the impact toughness can be increased by 117.0%.

Owner:DALIAN UNIV OF TECH

Microporous lightweight silica brick and preparation method thereof

The invention discloses a microporous lightweight silica brick and a preparation method thereof, the lightweight silica brick is mainly prepared from a mixture and a foaming agent, and the dosage of the foaming agent is 0.1-10% of the mass of the mixture; the mixture is prepared from the following components in percentage by mass: 70%-95% of a siliceous material, 1%-25% of an inorganic cementing material, 0.1%-15% of a mineralizing agent and 0.1%-5% of an additive; wherein the siliceous material is composed of siliceous particles and siliceous fine powder, the particle size of the siliceous particles is 0.1-3 mm, the particle size of the siliceous fine powder is smaller than or equal to 0.075 mm, and the mass ratio of the siliceous particles to the siliceous fine powder is (1-65): (35-99). The obtained microporous lightweight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical strength, good high-temperature volume stability, strong acid atmosphere and slag erosion resistance and the like, is low in preparation cost and good in heat insulation effect, meets harsh high-temperature environment and heat insulation requirements of thermal equipment, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Anti-corrosion anti-cracking permeability reducing agent for marine concrete and preparation method of anti-corrosion anti-cracking permeability reducing agent

ActiveCN114634325AImprove compactnessImprove corrosion resistanceSolid waste managementFiberPhosphate

The invention discloses an anti-corrosion anti-cracking permeability reducing agent for marine concrete and a preparation method of the anti-corrosion anti-cracking permeability reducing agent, and belongs to the technical field of concrete admixtures. The anti-seepage agent is prepared from the following raw materials in parts by weight: 5 to 10 parts of a water reducing agent, 4 to 10 parts of a micro-nano anti-seepage component, 1.5 to 3.5 parts of an air entraining agent, 3 to 9 parts of anti-crack fiber, 1 to 3 parts of inositol hexaphosphate, 1 to 5 parts of polypropylene glycol, 0.5 to 1 part of hydroxy propyl distarch phosphate, 0.5 to 1.5 parts of chitosan and 20 to 30 parts of water. According to the anti-seepage agent disclosed by the invention, nano silicon dioxide is modified in two steps and then is mixed with the anti-cracking fiber, two isolated strength enhancing substances are organically combined and jointly act with other raw materials, the anti-seepage and anti-cracking properties of a concrete material are remarkably improved, and the obtained admixture does not contain substances harmful to a human body, is chlorine-free, green and environment-friendly, and has a good application prospect. The durability of the concrete in the marine environment can be greatly improved, the service life is prolonged, and the safety is improved.

Owner:日照海工研新材料有限公司

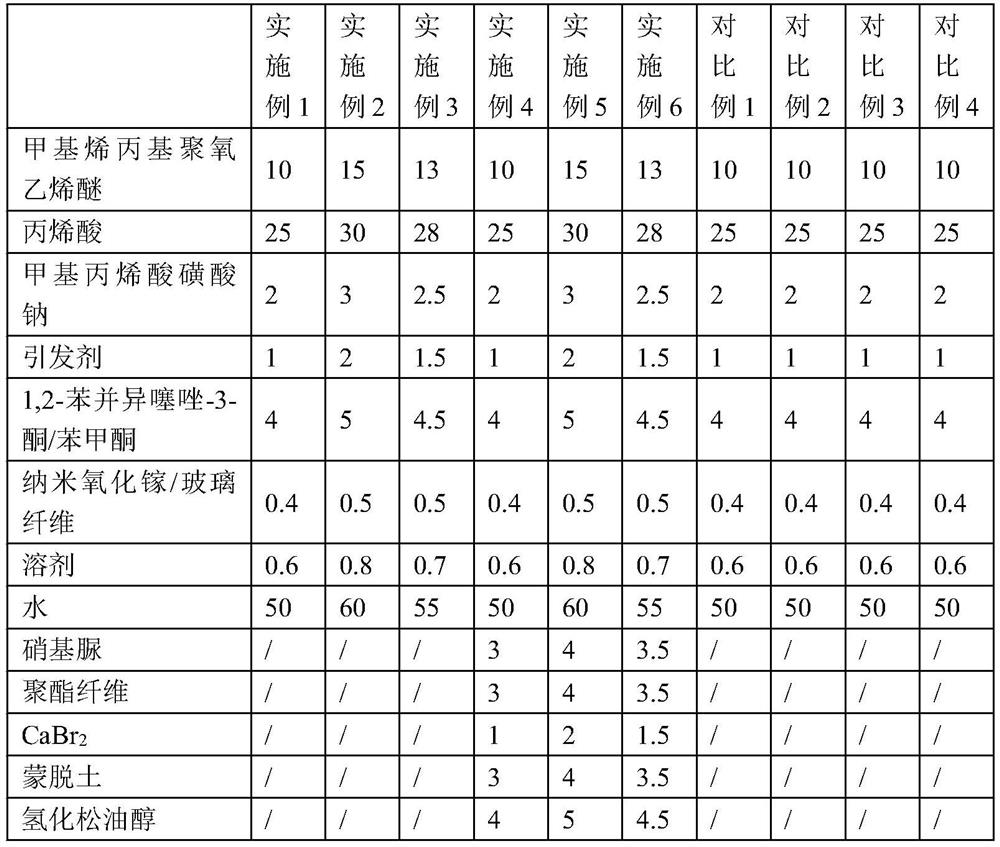

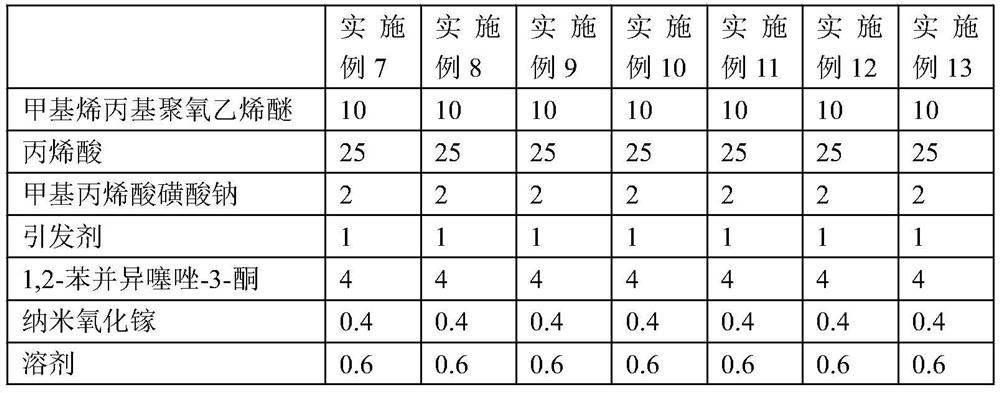

Early-strength polycarboxylate superplasticizer and preparation method thereof

The invention relates to the field of water reducing agents, and discloses an early-strength polycarboxylate superplasticizer and a preparation method thereof. The early-strength polycarboxylate superplasticizer is prepared from 10 to 15 parts of methylallylpolyoxyethylene ether, 25-30 parts of acrylic acid, 2-3 parts of sodium sulfonate methacrylate, 1-2 parts of an initiator, 4-5 parts of 1,2-benzisothiazole-3-one, 0.4-0.5 part of nanometer gallium oxide, 0.6-0.8 part of a solvent, and 50-60 parts of water. The preparation method comprises the following steps: mixing nanometer gallium oxide and a solvent, adding 1,2-benzisothiazole-3-one, and adding the mixture into a polycarboxylic acid polymer synthesized by other components to obtain the polycarboxylate superplasticizer. The preparation method has the advantages that the nanometer gallium oxide contains a microcosmic porous structure and can be better blended with 1,2-benzisothiazole-3-one after being mixed with a solvent, so a product adsorbing free carboxyl groups is obtained, the content of the free carboxyl groups capable of being complexed with calcium ions in a liquid phase is reduced, hydration is accelerated, coagulation time is shortened, water consumption is reduced, water film layers are decreased, and aggregate-cement interface structure is changed, so the early strength of concrete is better improved.

Owner:唐山冀东水泥外加剂有限责任公司 +1

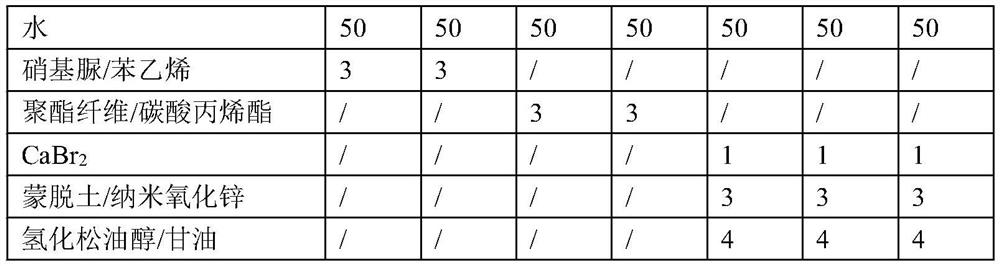

Impact-resistant nanometer boron nitride-modified concrete

The invention discloses an impact-resistant nanometer boron nitride-modified reactive powder concrete. Raw materials of the impact-resistant nanometer boron nitride-modified reactive powder concrete include cement, nanometer boron nitride, silica fume, fly ash, sands, a water reducer and water. The nanometer boron nitride can significantly enhance the dynamic compressive strength, dynamic peak strain and impact toughness of the reactive powder concrete. When the strain rate is in a range of 200-800 / s and the dosage of the nanometer boron nitride is 0.25-0.5%, the dynamic compressive strength of concrete can be increased by 83.8%, the dynamic peak strain can be increased by 30.5%, and the impact toughness can be increased by 94.6%.

Owner:DALIAN UNIV OF TECH

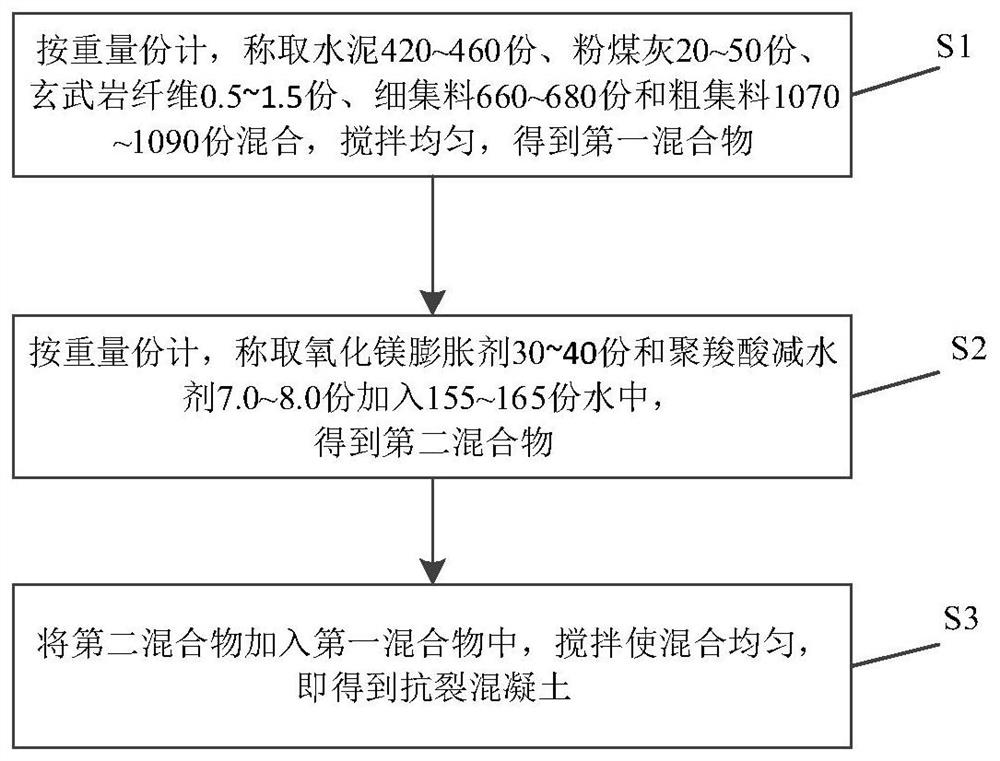

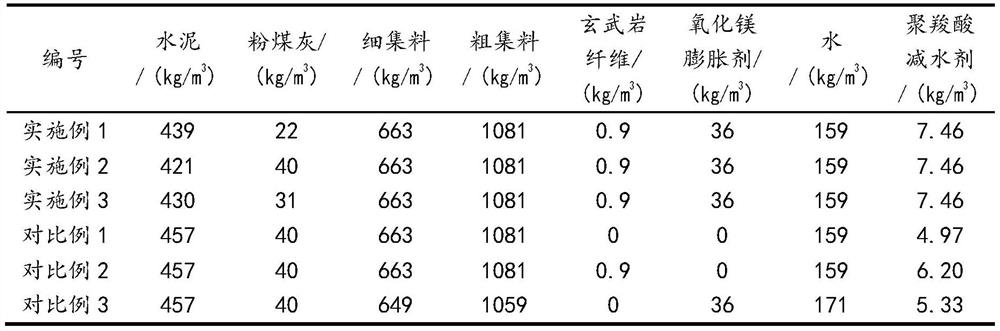

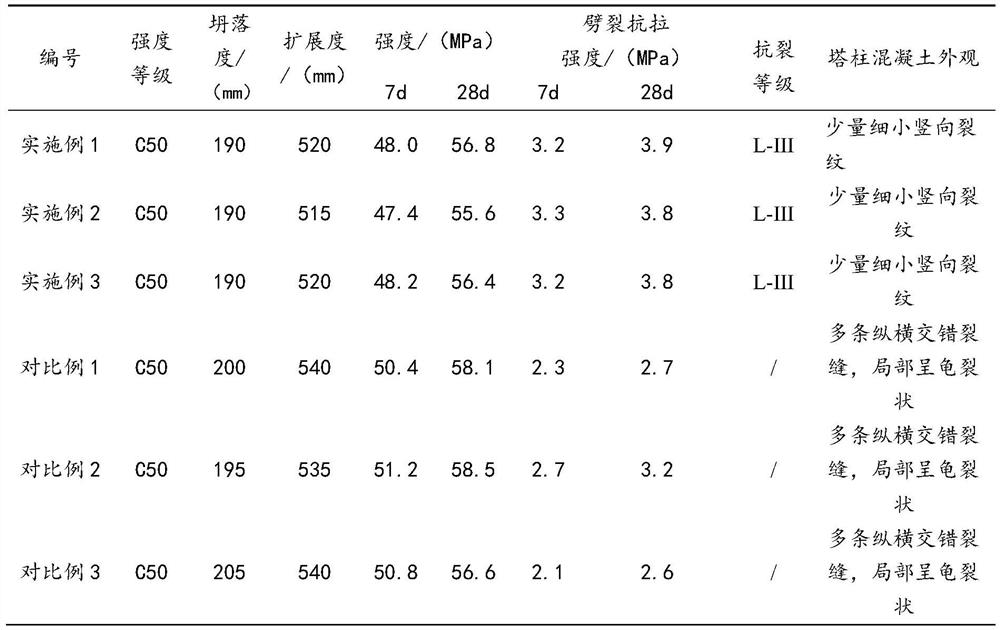

Anti-crack concrete for cable-stayed bridge tower column and preparation method of anti-crack concrete

The invention relates to the technical field of concrete materials, in particular to anti-crack concrete for a cable-stayed bridge tower column and a preparation method of the anti-crack concrete. The anti-crack concrete is prepared from the following components in parts by weight: 420 to 460 parts of cement, 20 to 50 parts of fly ash, 660 to 680 parts of fine aggregate, 1070 to 1090 parts of coarse aggregate, 0.5 to 1.5 parts of basalt fiber, 7.0 to 8.0 parts of polycarboxylate superplasticizer, 155 to 165 parts of water and 30 to 40 parts of magnesium oxide expanding agent. The 7d splitting tensile strength of the prepared anti-crack concrete is larger than or equal to 3.2 MPa, the 28d splitting tensile strength of the anti-crack concrete is larger than or equal to 3.8 MPa, and the anti-crack grade reaches the L-III grade.

Owner:中铁大桥局第七工程有限公司

Angle-resolving radar sensor

ActiveUS9810768B2High resolutionSmall apertureRadio wave direction/deviation determination systemsAntenna adaptation in movable bodiesAngle of incidenceRadar

An angle-resolving radar sensor, e.g., for motor vehicles, includes; an antenna having multiple antenna elements which are each switchable to one of multiple evaluation channels; and an evaluation device for determining the angle of incidence of a received signal based on the amplitudes measured in the evaluation channels. The number of antenna elements is greater than the number of evaluation channels and a switching device is provided to connect the evaluation channels alternatingly to different selections of antenna elements.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com