Patents

Literature

253results about How to "Small rate of change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

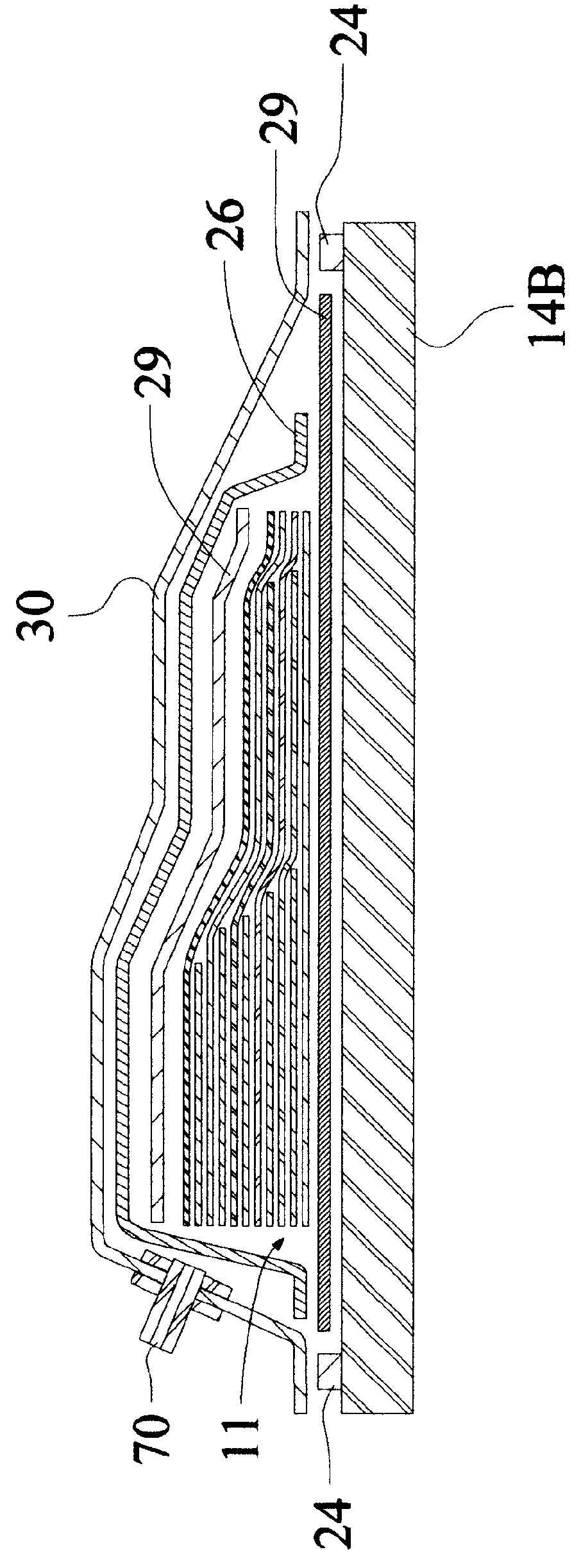

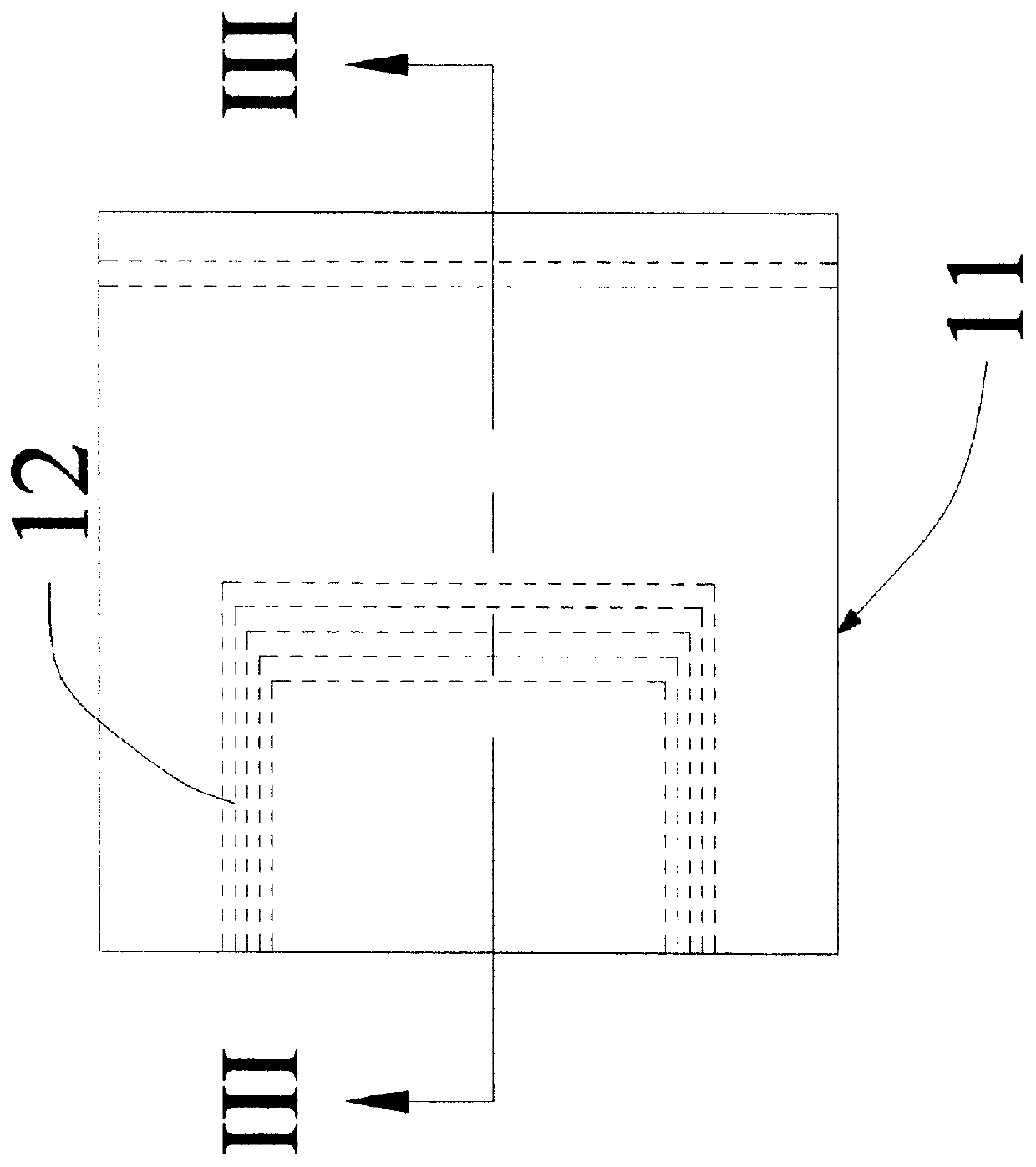

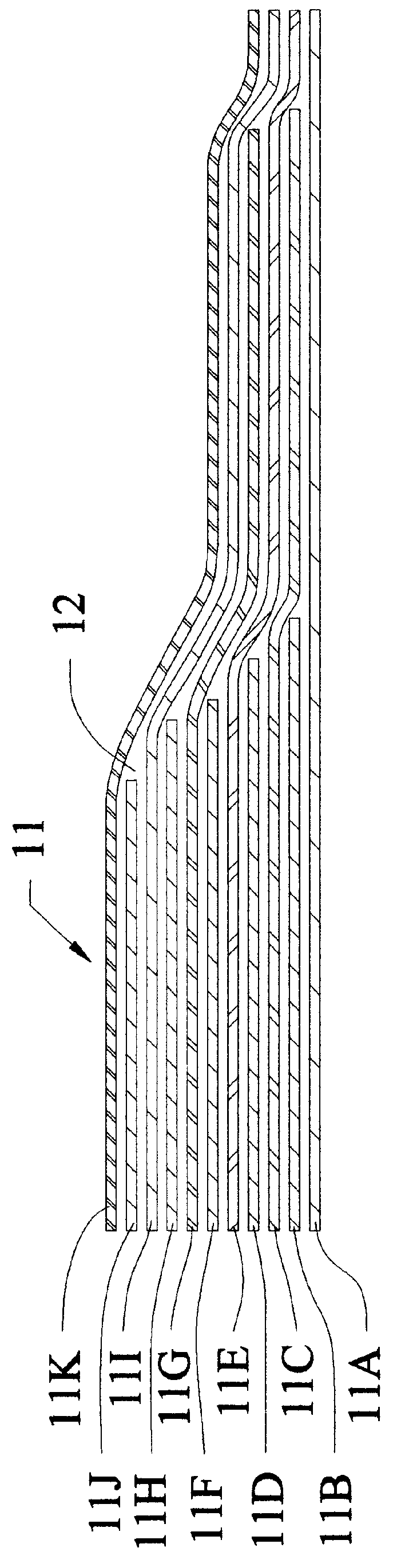

Method for manufacture of minimum porosity, wrinkle free composite parts

A process and associated apparatus used to prepare a thermoplastic composite from a plurality of plies of thermoplastic resin prepregs. The prepregs are formed into a composite structure under two chambers; a rigid outer chamber (of any convenient size or shape) and a second flexible inner chamber containing a prepreg lay-up. The absolute pressures are reduced concurrently in a stepwise method in both chambers. This concurrent, stepped pressure reduction is accomplished at a rate which prevents the vacuum bag from moving far from the prepregs, and prevents wrinkles from forming in the prepregs. Pinching off the diffusion paths required for the removal of unwanted gases is eliminated. The lay-up is then heated and the absolute pressure in the outer rigid chamber is increased. This pressure constrains the flexible inner chamber during out-gassing of the thermoplastic resin, preventing wrinkles from forming in the prepregs. The absolute pressure in the outer rigid chamber is increased to atmospheric pressure or greater causing the prepregs to consolidate. A low absolute pressure is maintained in the flexible inner chamber. The temperature is then increased to the cure temperature of the resin and held for a time sufficient for the resin to cure. The resulting consolidated thermoplastic resin is substantially void free and detectable wrinkles are absent.

Owner:HALE HAROLD P

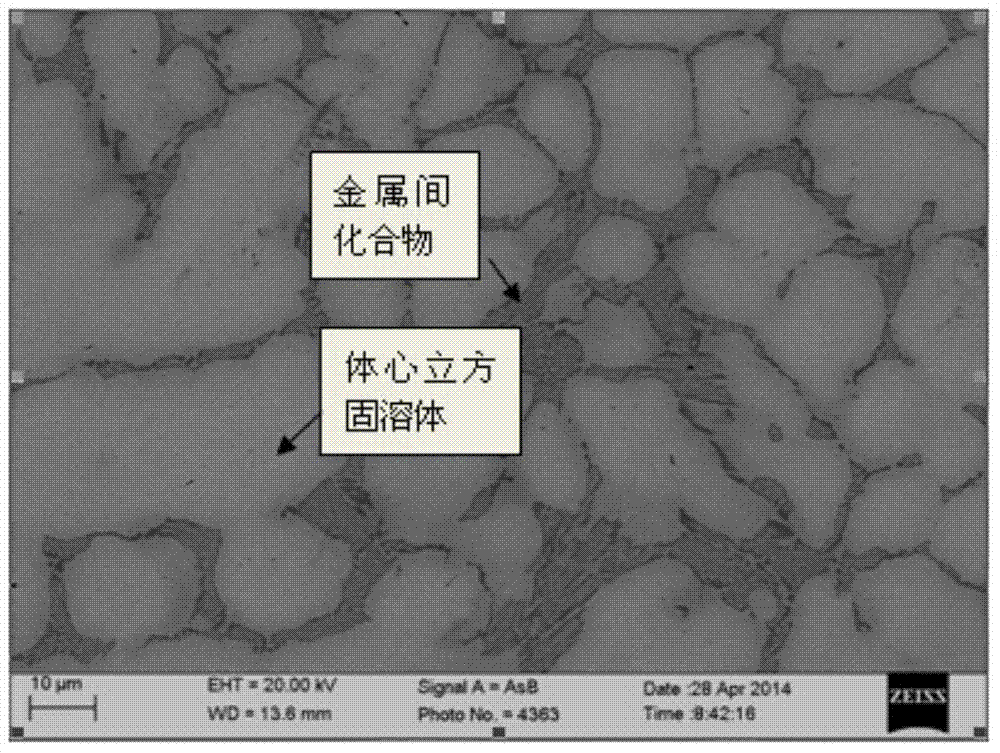

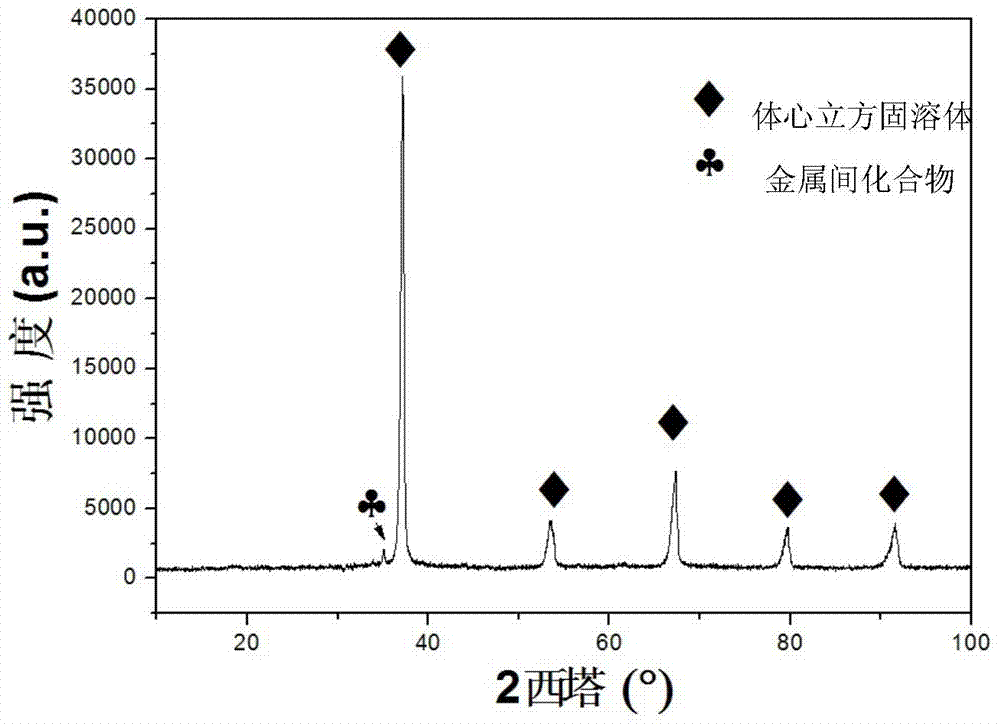

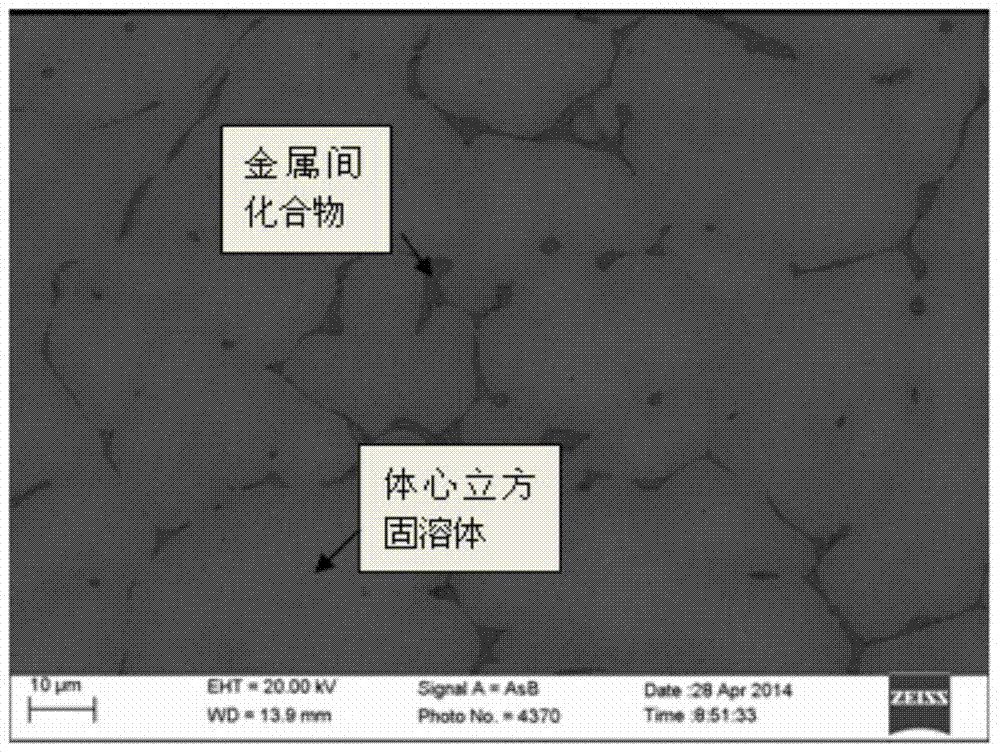

Low thermal expansion coefficient NaMxAlySiz high entropy alloy and preparation method thereof

The invention relates to a low thermal expansion coefficient NaMxAlySiz high entropy alloy and a preparation method thereof, the chemical components of the alloy are as follows: 75 <= a <= 100%, 0 <= x <= 10%, 0<= y<= 10%, 0<= z<= 5%, N is arbitrary three or more than three of Ta, Nb, Hf, Zr, Ti, Mo and W, and M is any one or more than one of V, Mn, Fe, Co, Ni and Cr. The alloy phase structure is as follows: a body centered cubic solid solution and an intermetallic compound. The alloy is prepared by arc melting method in three stages. The NaMxAlySiz high entropy alloy has a low thermal expansion coefficient at the temperature in the range of room temperature to 1000 DEG C, the change rate is less than 20%, and the alloy has a broad application prospect in the high temperature industrial field.

Owner:UNIV OF SCI & TECH BEIJING

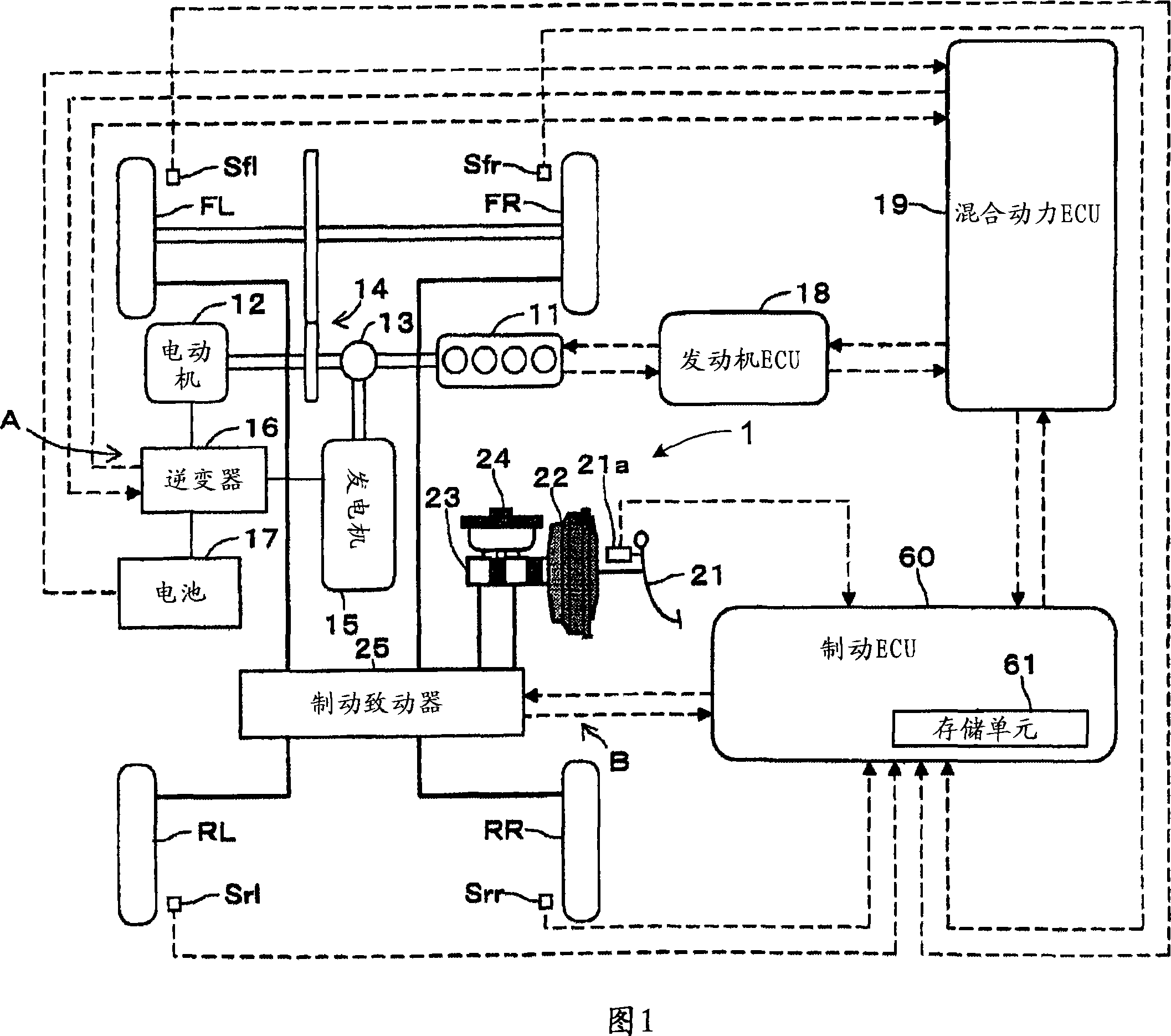

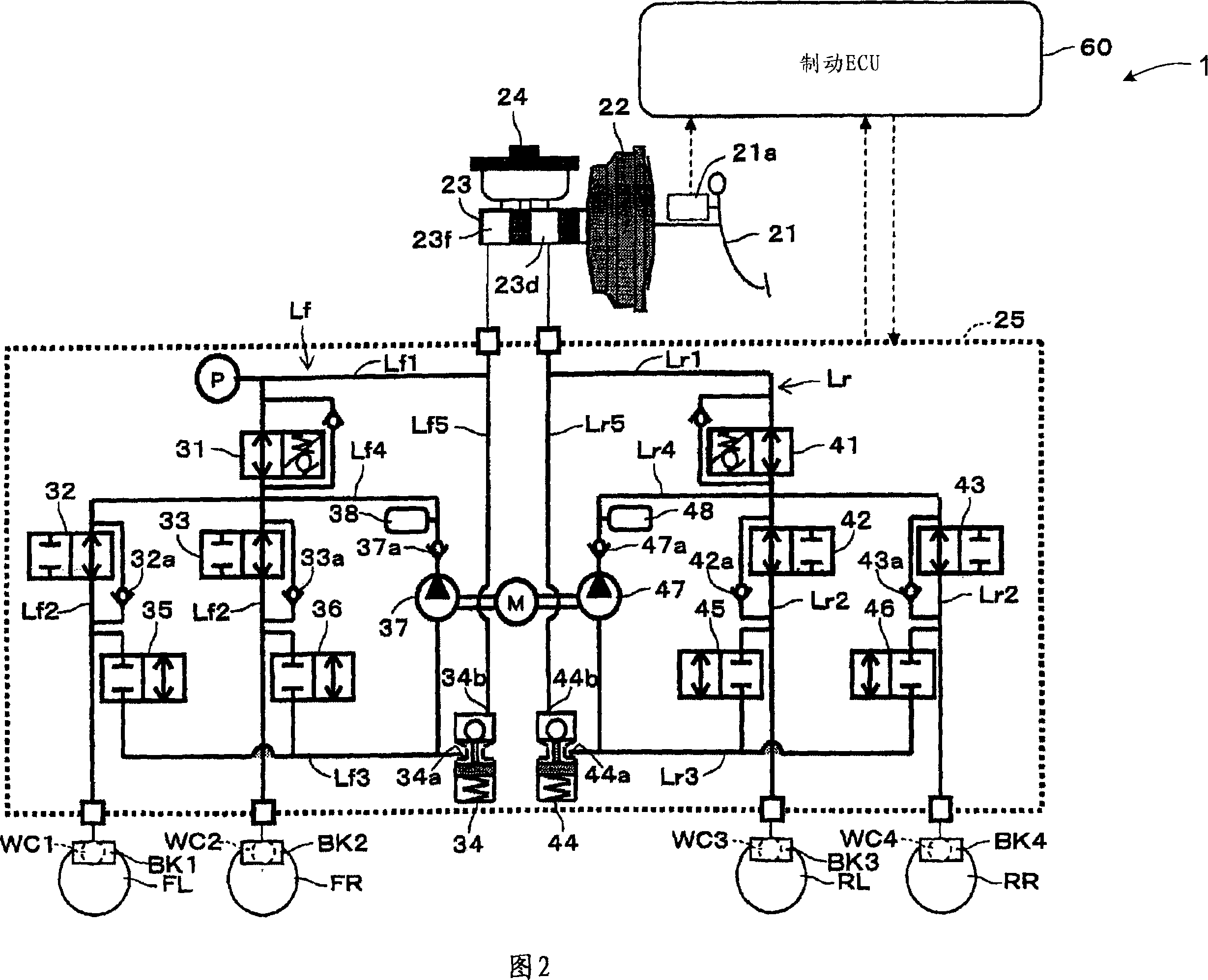

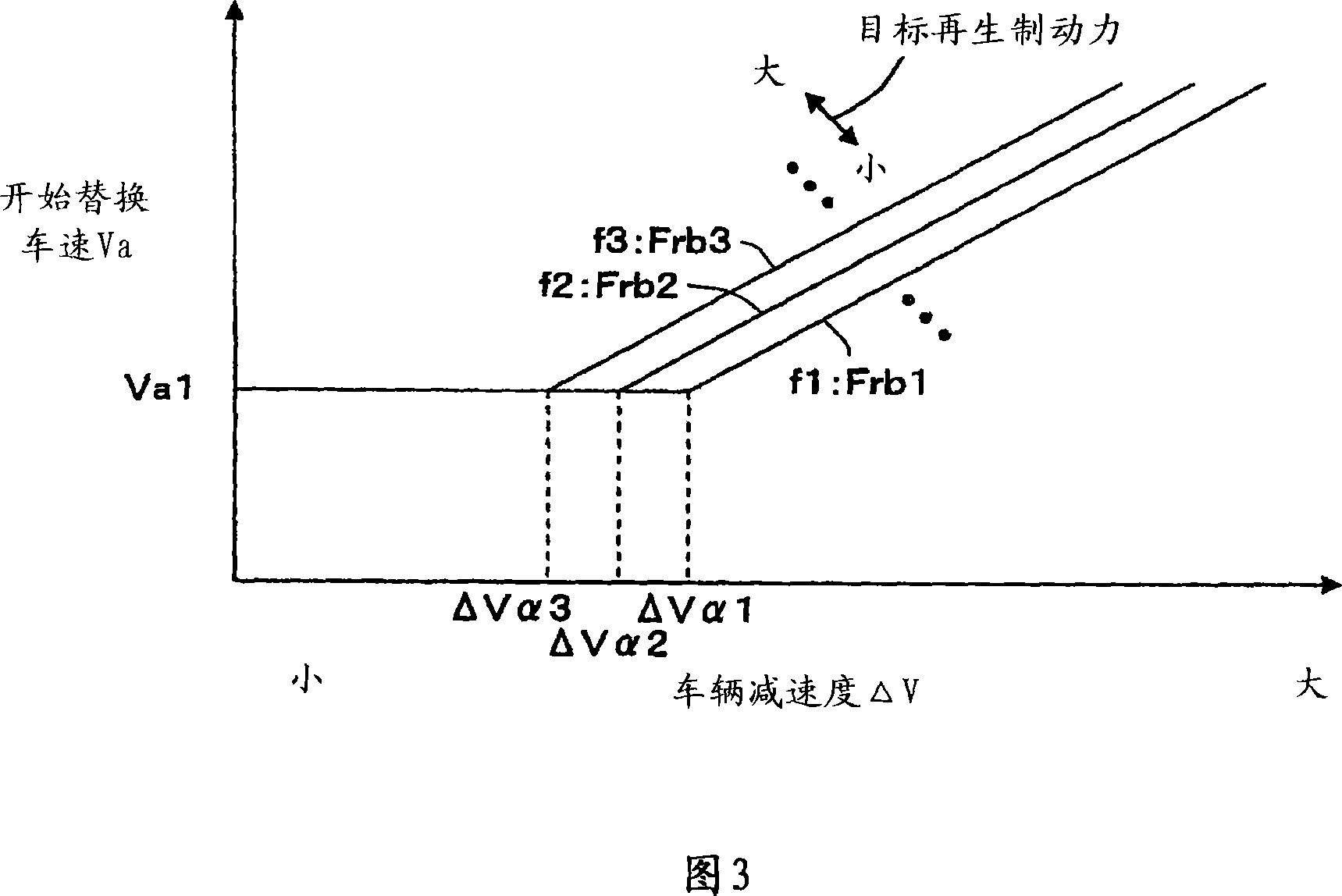

Braking apparatus for vehicle

ActiveCN101049825AReplacement control reductionReplacement control ensuresBraking action transmissionElectric energy vehiclesRegenerative brakeHydraulic brake

A braking apparatus for a vehicle includes a hydraulic brake apparatus generating a basic hydraulic pressure so that a basic hydraulic braking force is generated at wheels, the hydraulic brake apparatus generating a controlled hydraulic pressure so that a controlled hydraulic braking force is generated at the wheels, a regenerative brake apparatus causing a regenerative braking force to be generated at any of the wheels, and braking force replacement controlling means for gradually replacing the regenerative braking force with the controlled hydraulic braking force while braking during which at least the regenerative braking force is applied for a purpose of achieving a braking force replacement control to ensure a total braking force required for the wheels by decreasing the regenerativebraking force at a gradient within a predetermined range and by increasing the controlled hydraulic braking force in response to the decrease of the regenerative braking force.

Owner:ADVICS CO LTD

Preparation method of microporous kyanite-based lightweight insulating refractory material

The invention relates to a preparation method of a microporous kyanite-based lightweight insulating refractory material. The preparation method is realized by comprising the following steps: (1) by taking kyanite, auxiliary materials and a cementing material as raw materials, adding a certain amount of dispersing agent, thickening time control agent and foam stabilizer, premixing, adding a certain amount of water, and mixing to prepare uniform slurry; (2) adding a certain amount of foaming agent in the slurry, mechanically agitating and foaming to prepare uniform foam slurry; (3) injecting the foam slurry into a mould, standing under a room-temperature environment so as to be cued and formed; (4) demoulding a green body, and then drying and sintering to obtain the microporous kyanite-based lightweight insulating refractory material. The prepared microporous kyanite-based lightweight insulating refractory material has the advantages of microfine air bore aperture (20-200mum), low volume density, high porosity, high strength, small sintering line change rate, low thermal conductivity, high usage temperature and the like. The raw materials are mainly kyanite, and other raw materials are common materials in refractory material industry, and are non-toxic and low-cost. The preparation method is simple and is easily controlled for the technology, and is suitable for industrial production.

Owner:ZHENGZHOU UNIV

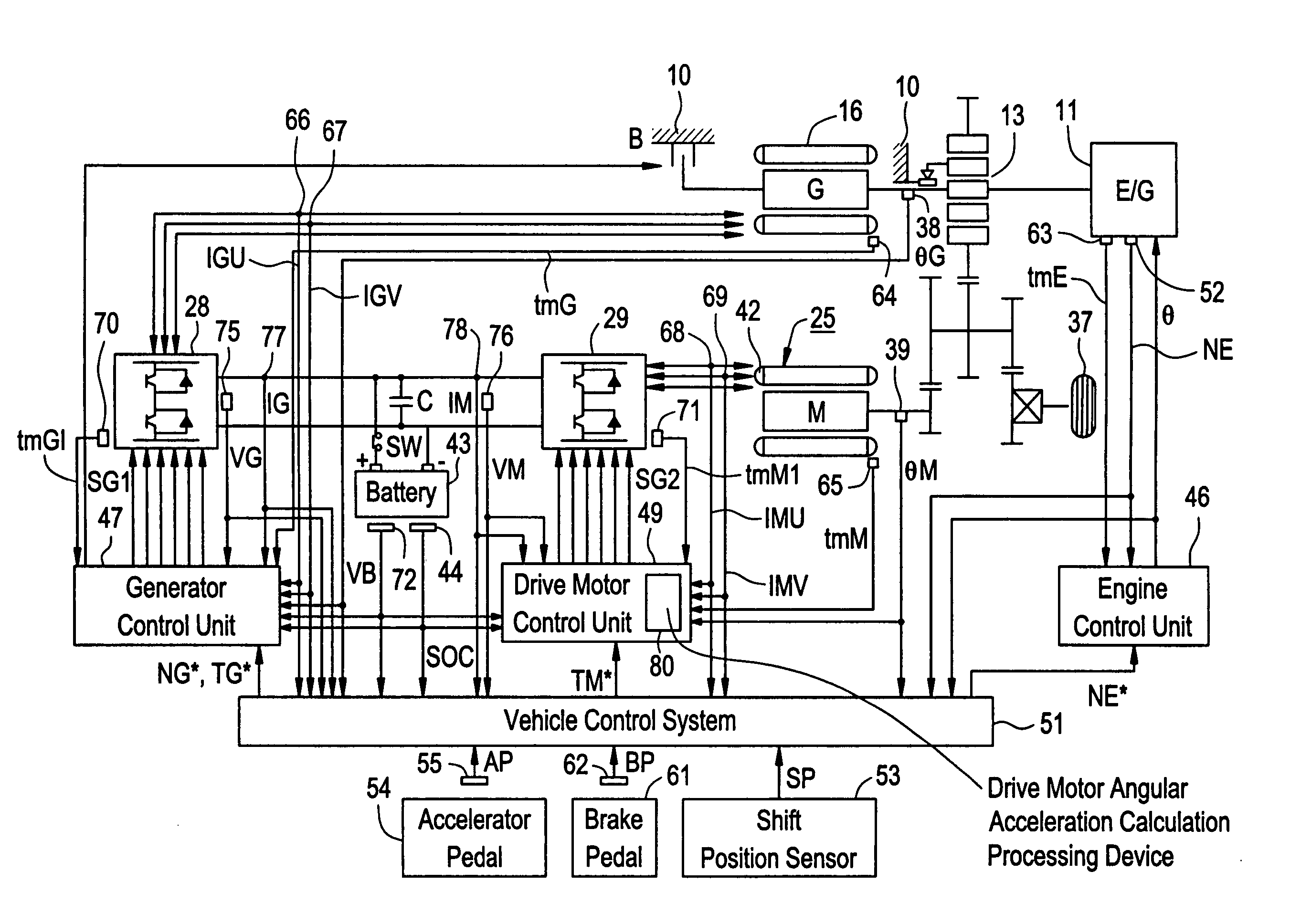

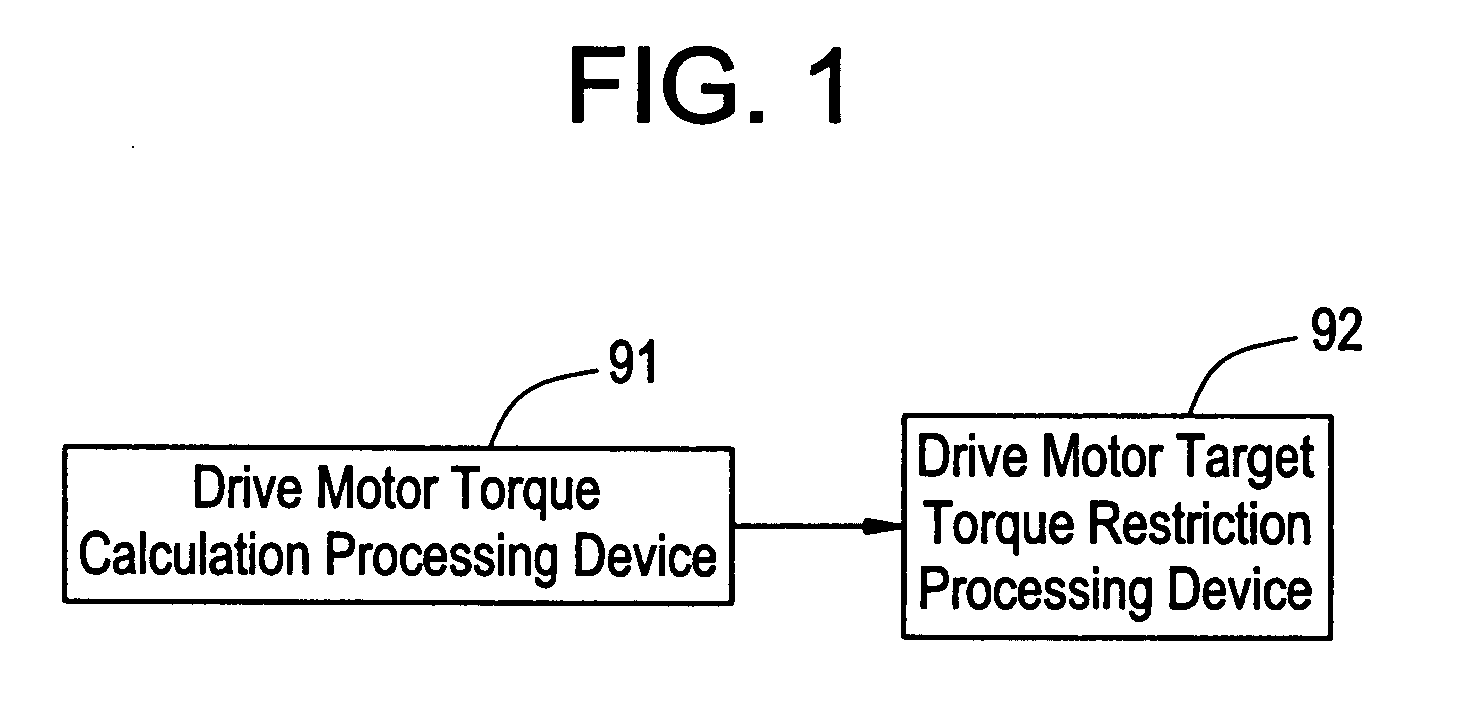

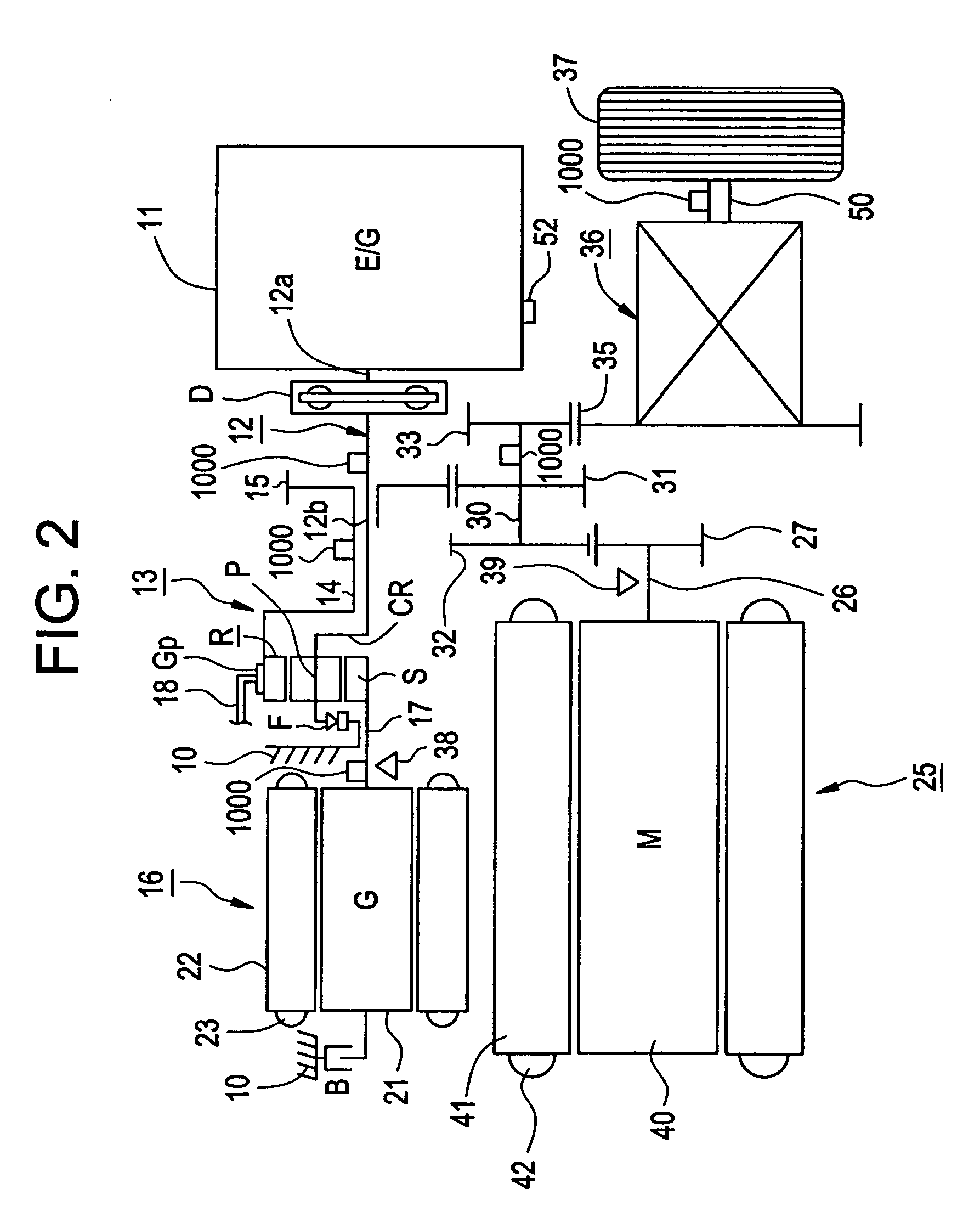

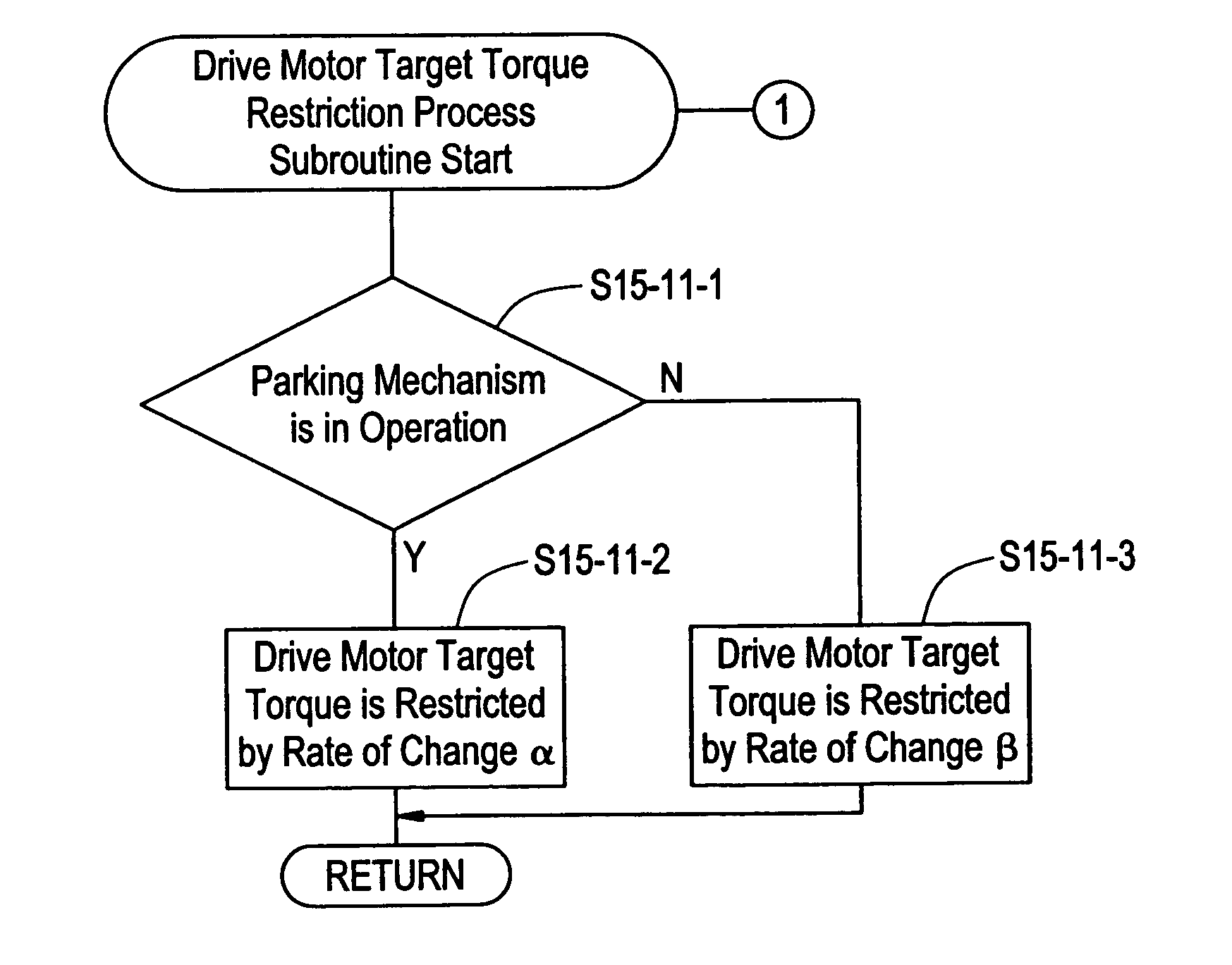

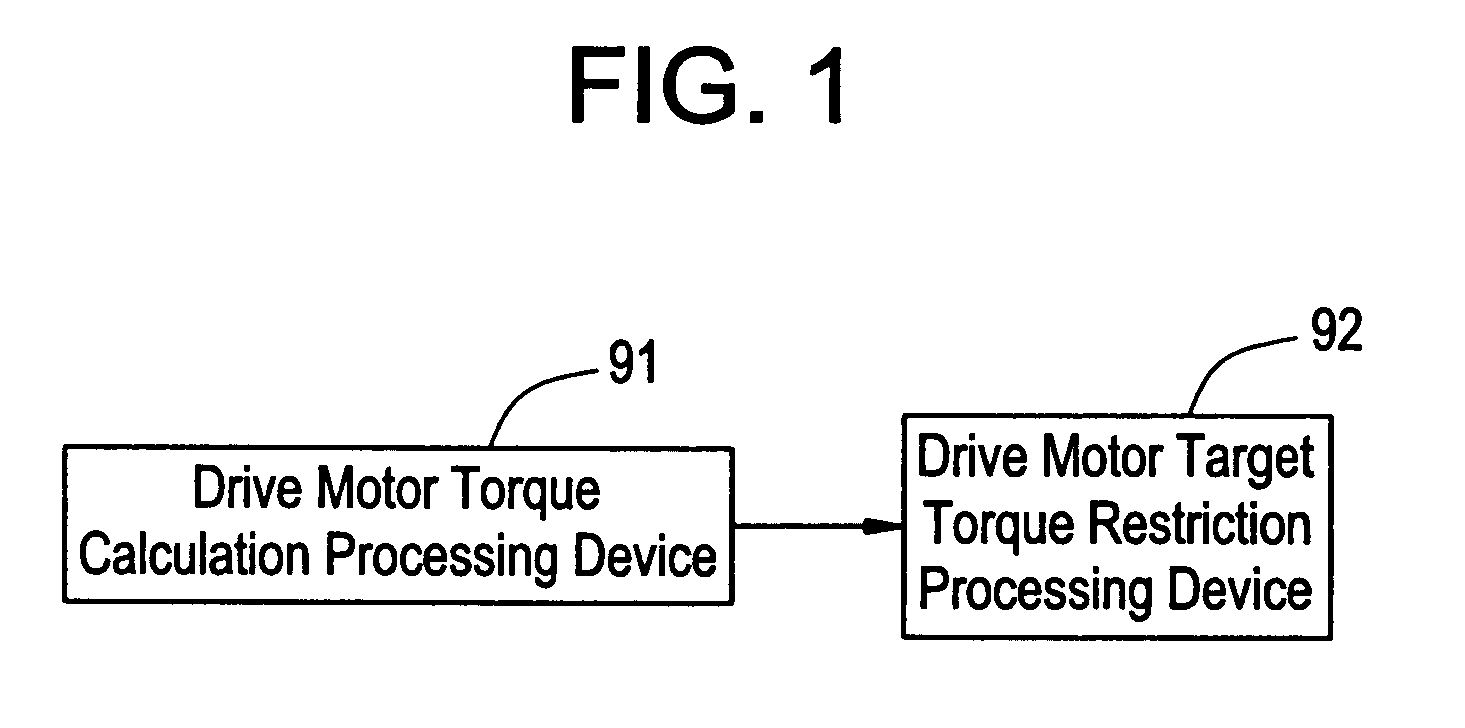

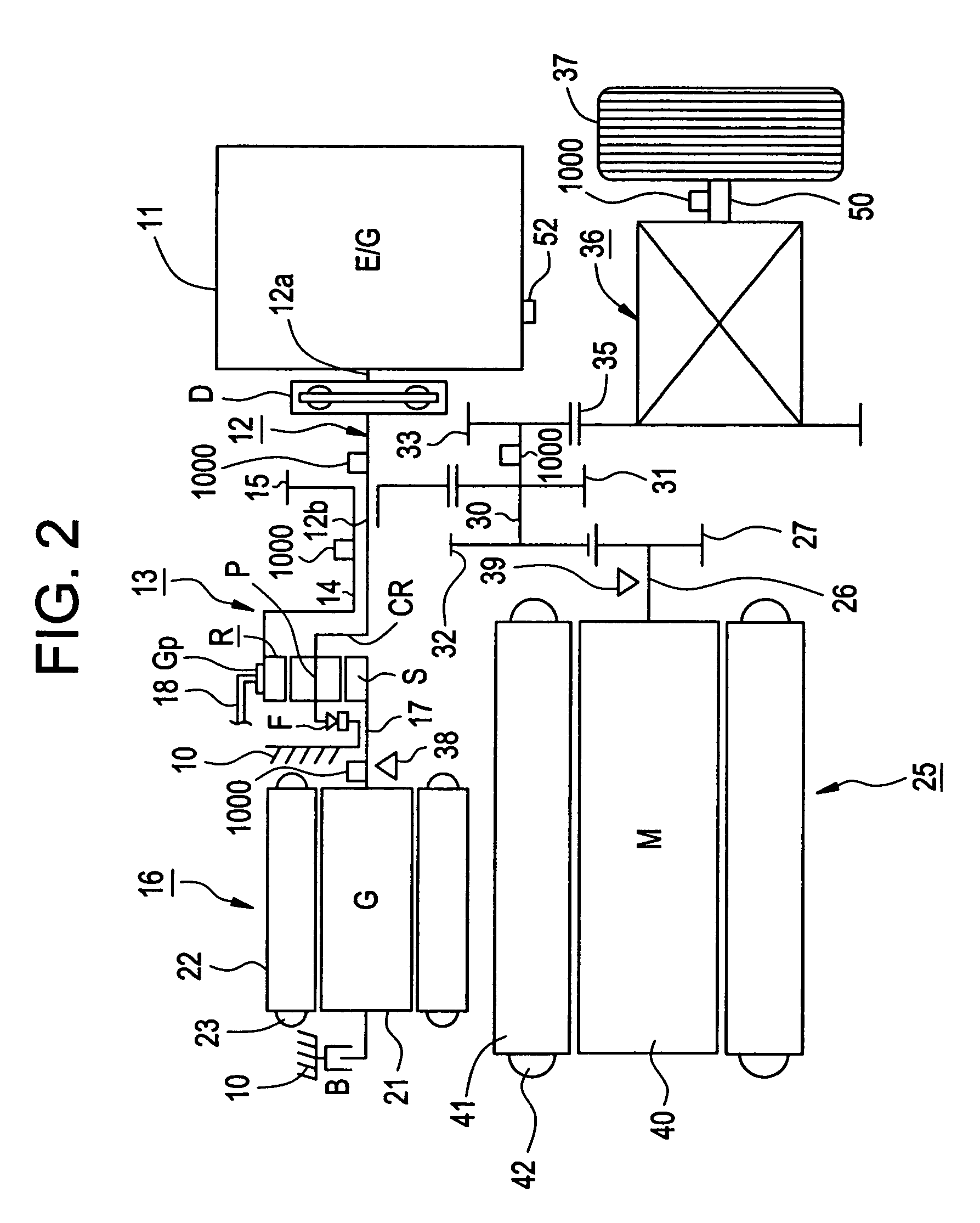

Drive control system for electric vehicle and method of drive control of electric vehicle

ActiveUS20050159861A1Mechanism is preventedSuppress mutationVehicle fittingsDigital data processing detailsElectric machineControl system

A drive control system for an electric vehicle and a method of drive control of the electric vehicle. The drive control system for the electric vehicle includes a drive motor target torque calculation processing device for calculating a drive motor target torque representing a target torque of a drive motor; and a drive motor target torque restriction processing device that judges whether or not a parking mechanism is in operation and, if the parking mechanism is in operation, restricts variations in the drive motor target torque.

Owner:AISIN AW CO LTD

Dielectric material for thermostable laminated ceramic capacitor with basic-metal inner electrode

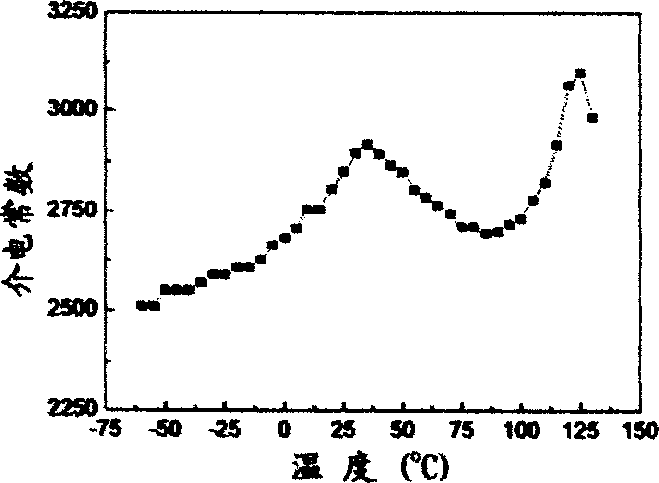

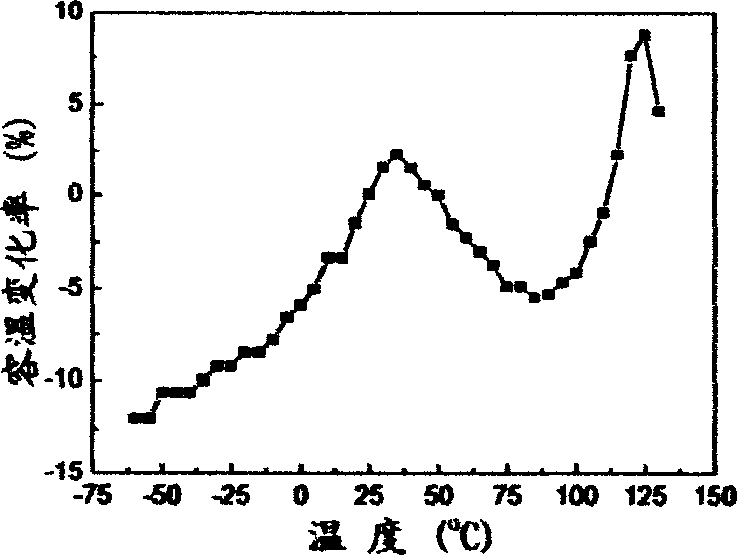

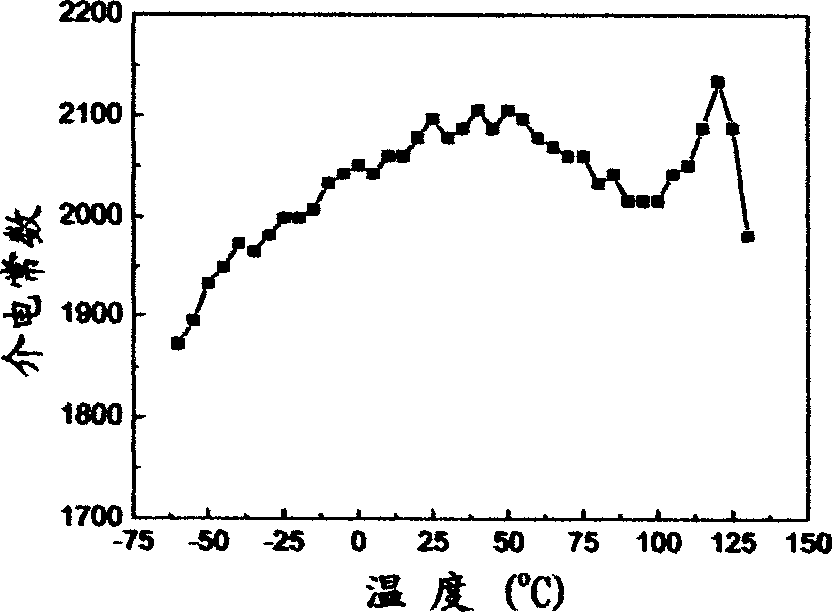

InactiveCN1404080AImprove uniformityImprove performanceFixed capacitor dielectricCeramicsDielectric lossCeramic capacitor

The present invention is material for laminated ceramic capacitor with high temperature stability and basic material inner electrodes. The inner electrode is made of low cost metal, such as Ni, Cu and their alloy. The dielectric material comprises BaTiO3 as main component, and additives in cludes CaO, CaTiO3, BaO, SiO2, SrO2, MnO2, MgO, Co2O3, Co3O4, Fe2O3 and Y2O3 as well as one or more RE oxide and salt in certain proportion and is prepared through mixing, sintering in reducing atmosphere of mixed nitrogen and hydrogen. The dielectric has excellent performance, including room temperature dielectric constant of 2000-3000, etc. The material of the present invention is suitable for producing great capacity superthin laminated ceramic capacity with high insulating resistivity and stable performance.

Owner:TSINGHUA UNIV

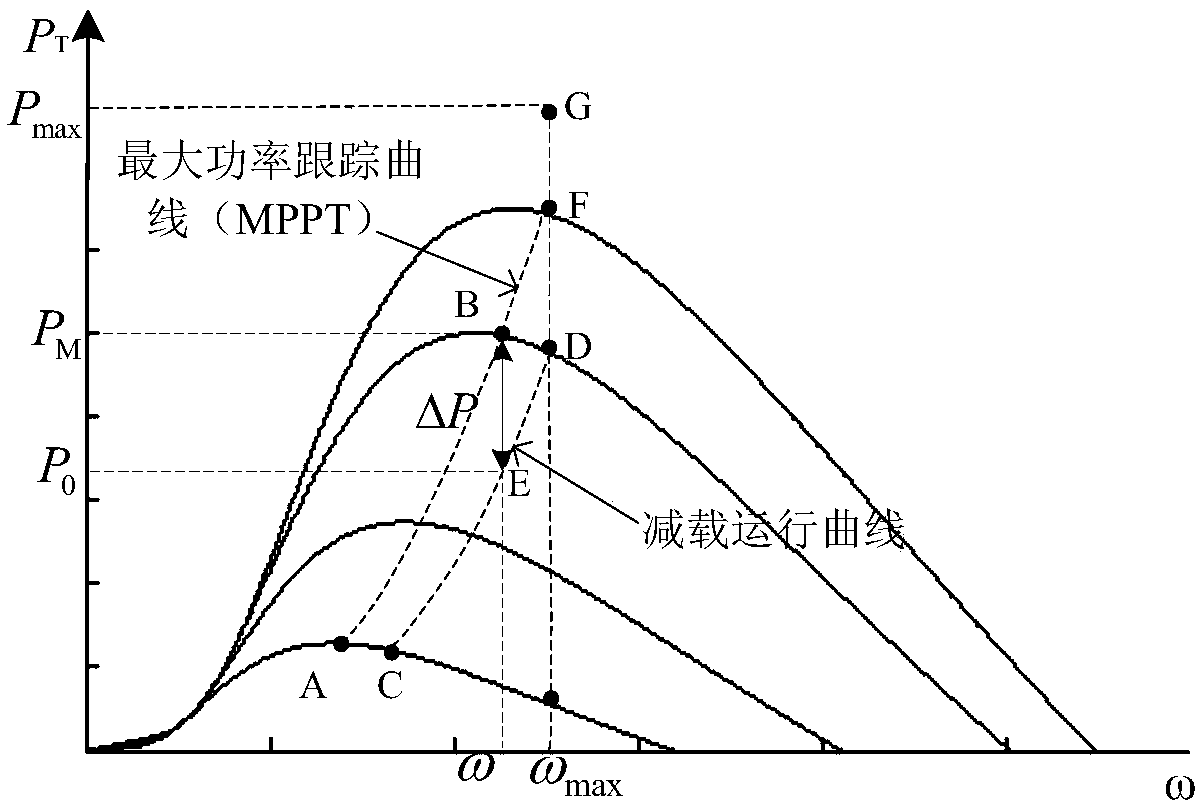

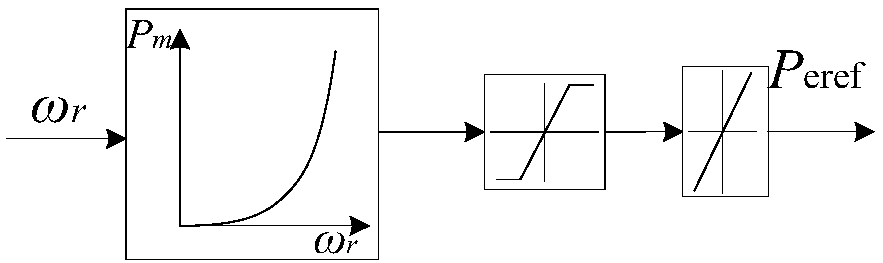

Comprehensive control system adopting doubly-fed wind generator participated in power grid primary frequency modulation

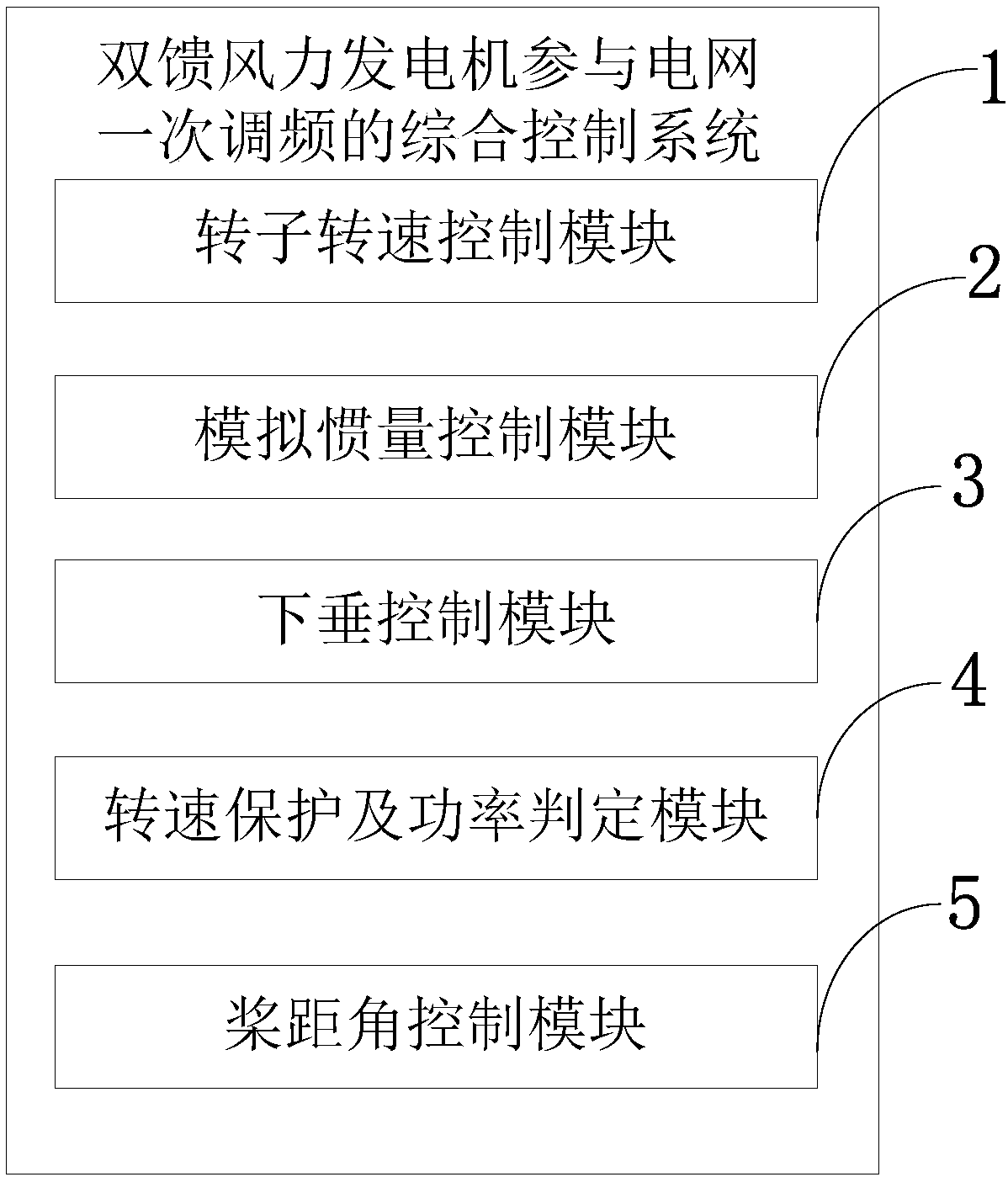

InactiveCN108448623AVerify availabilityReduce active powerSingle network parallel feeding arrangementsPower oscillations reduction/preventionControl systemFrequency modulation

The invention belongs to the technical field of wind power generation, and discloses a comprehensive control system adopting a doubly-fed wind generator participated in power grid primary frequency modulation. The control system comprises a rotor rotary speed control module, a simulation inertia control module, a droop control module, a rotary speed protection and power determination module and apitch angle control module. After the wind generator is participated in frequency modulation, the power grid inertia is equivalently enlarged, so that the doubly-fed asynchronous wind generator can have inertia response on the power grid frequent as the conventional synchronous generator, thereby lowering change rate of the power grid frequency; and by controlling the rotary speed and the pitch angle, the wind generator output is lowered, so that the wind generator has certain active backup capacity to be participated in primary frequency modulation, thereby lowering steady-state error of thefrequency.

Owner:SOUTHWEST JIAOTONG UNIV

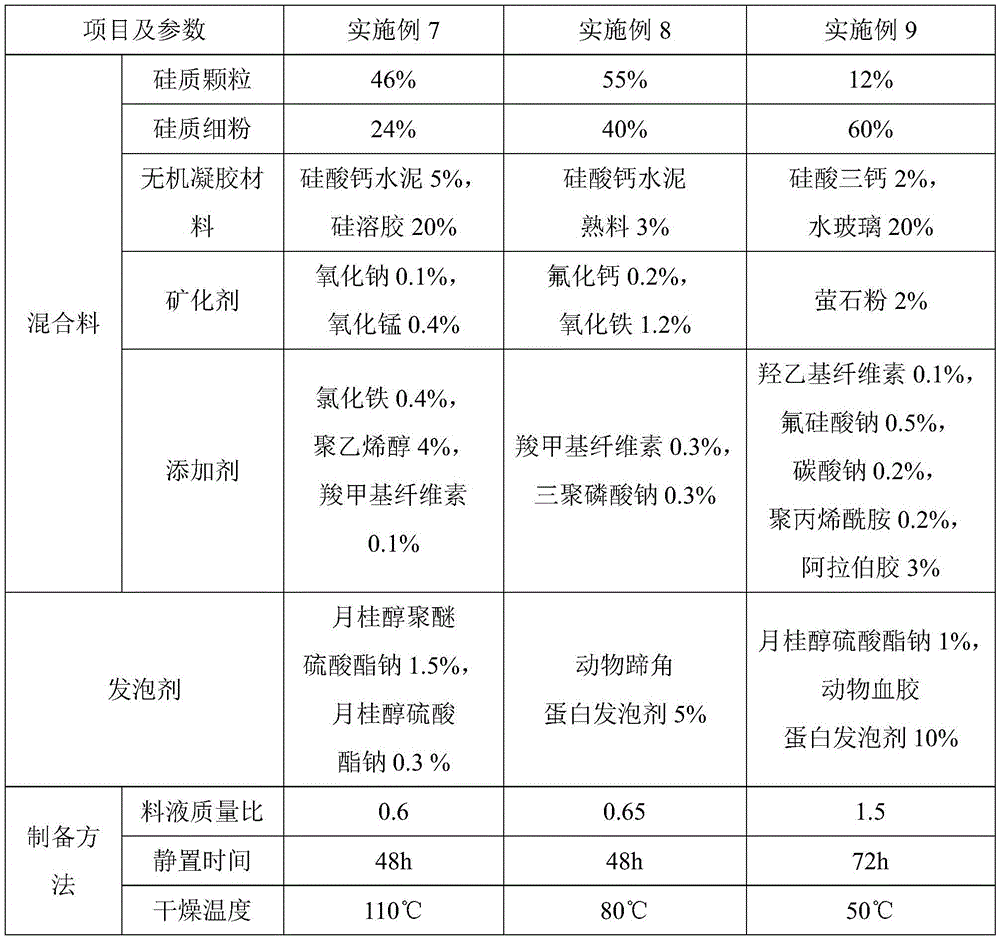

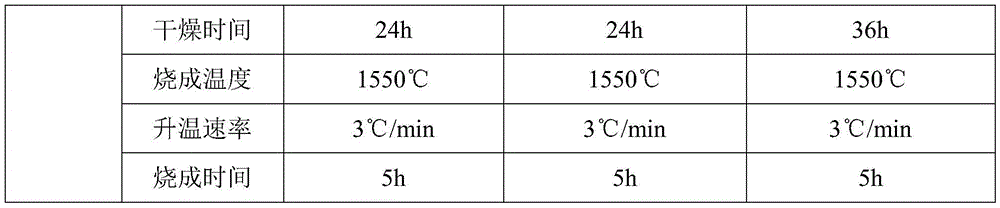

Micropore light weight silica brick and preparation method thereof

The invention discloses a micropore light weight silica brick and a preparation method thereof. The light weight silica brick is mainly prepared from a mixture and a foaming agent; a use quantity of the foaming agent is 0.1% to 10% of mass of the mixture; the mixture consists of the following components in percentage by mass: 70% to 95% of siliceous material, 1% to 25% of inorganic cementitious material, 0.1% to 15% of mineralizer, and 0.1% to 5% of additive, wherein the siliceous material consists of siliceous particles and siliceous fine powder, a particle size of the siliceous particles is 0.1 to 3mm, a particle size of the siliceous fine powder is smaller than or equal to 0.075mm, and a mass ratio of the siliceous particles to the siliceous fine powder is (1 to 65):(35 to 99). The obtained micropore light weight silica brick product has the advantages of fine aperture, small density, low thermal conductivity, high porosity, high mechanical intensity, high high-temperature volume stability, high resistance to the acid atmosphere, high slagging resistance and the like, is low in preparation cost and good in heat insulation effect, meets the harsh requirements of thermal equipment for a high-temperature environment and heat insulation, and is suitable for popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Drive control system for electric vehicle and method of drive control of electric vehicle

ActiveUS7496435B2Avoid it happening againSmall rate of changeVehicle fittingsDigital data processing detailsElectric machineControl system

A drive control system for an electric vehicle and a method of drive control of the electric vehicle. The drive control system for the electric vehicle includes a drive motor target torque calculation processing device for calculating a drive motor target torque representing a target torque of a drive motor; and a drive motor target torque restriction processing device that judges whether or not a parking mechanism is in operation and, if the parking mechanism is in operation, restricts variations in the drive motor target torque.

Owner:AISIN AW CO LTD

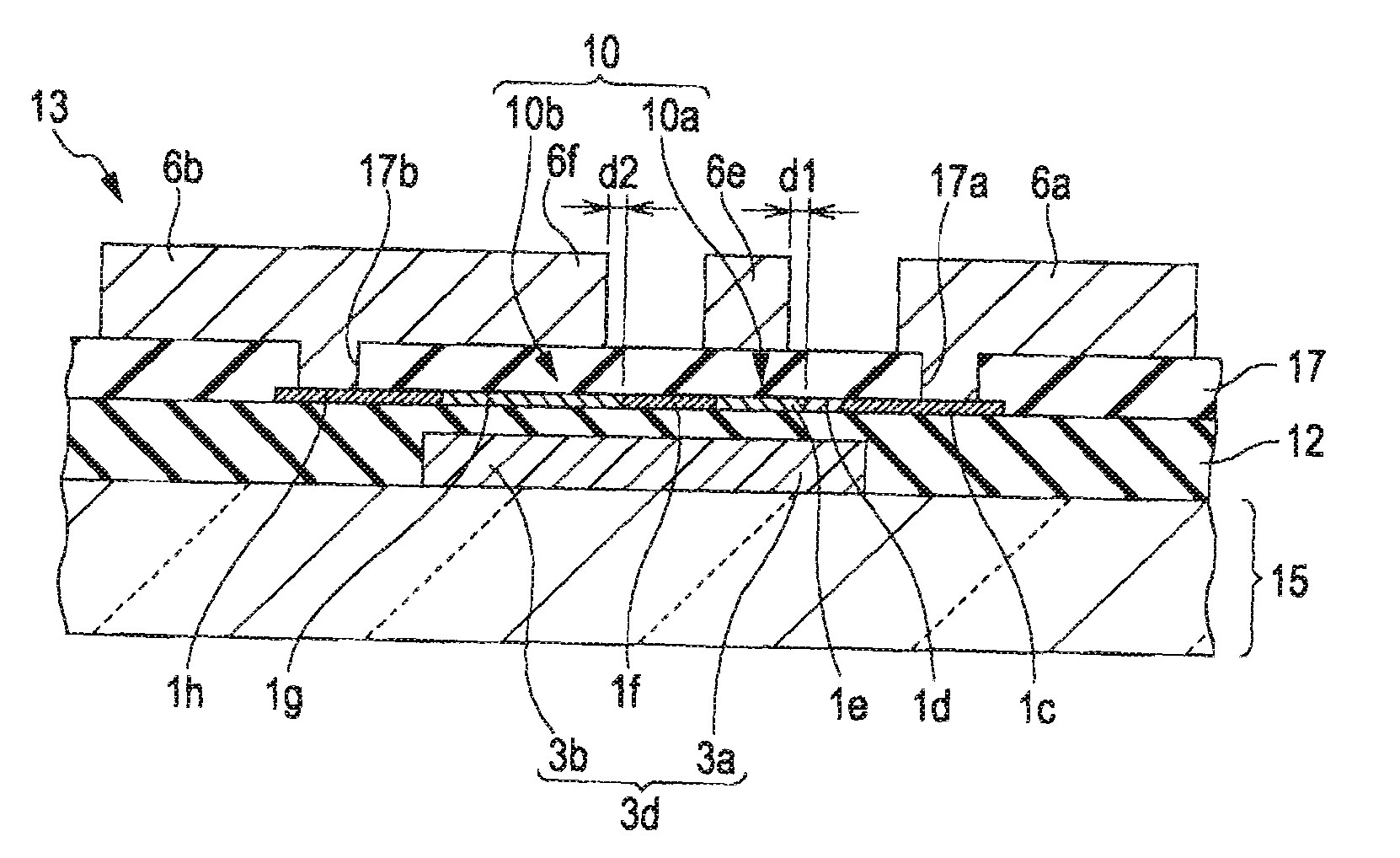

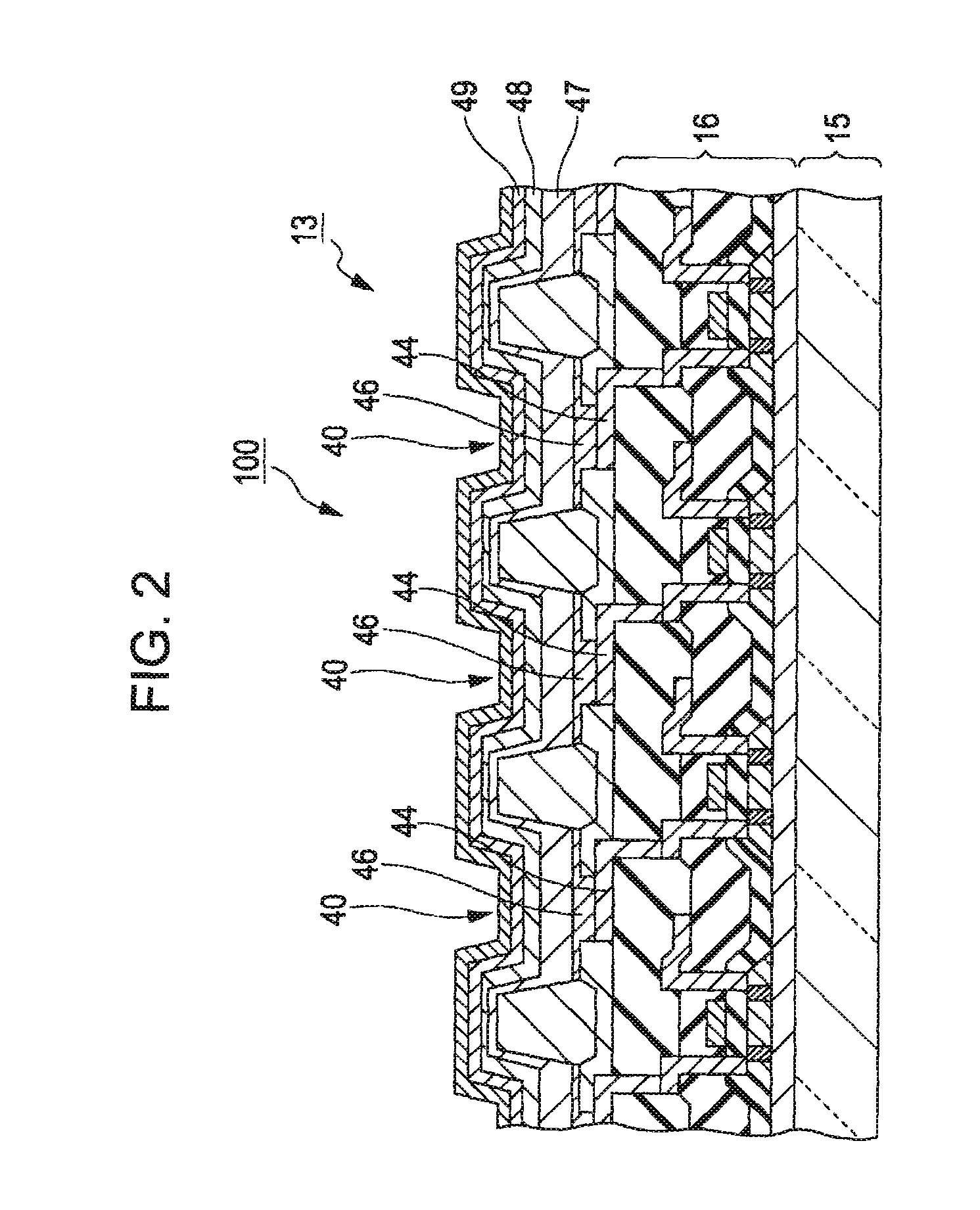

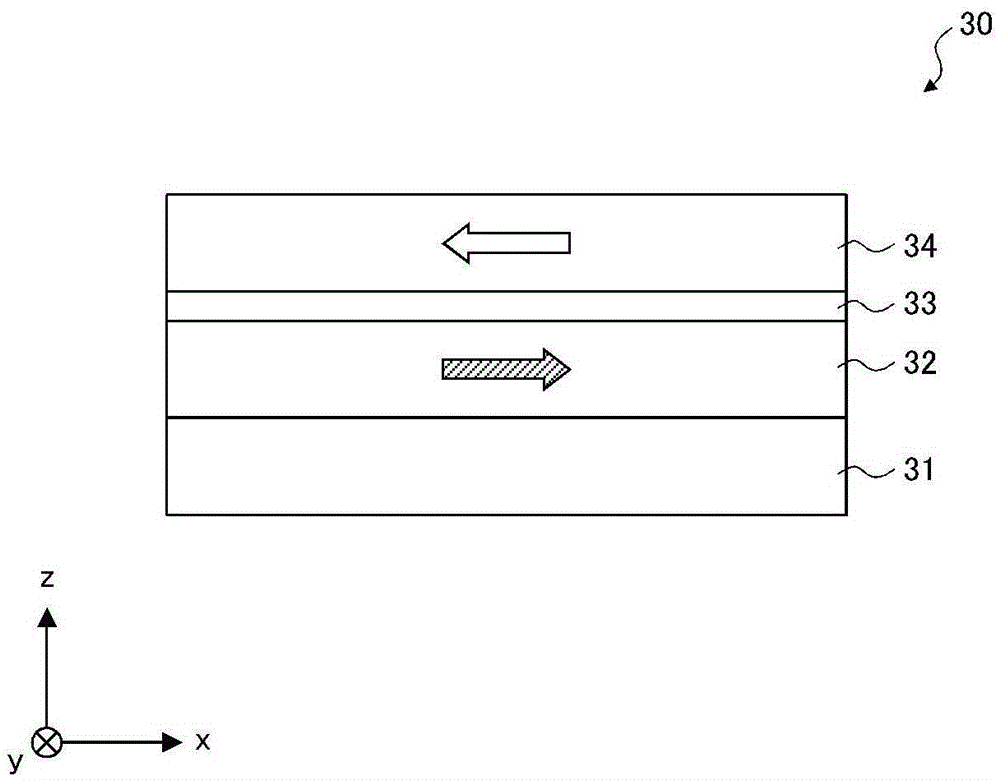

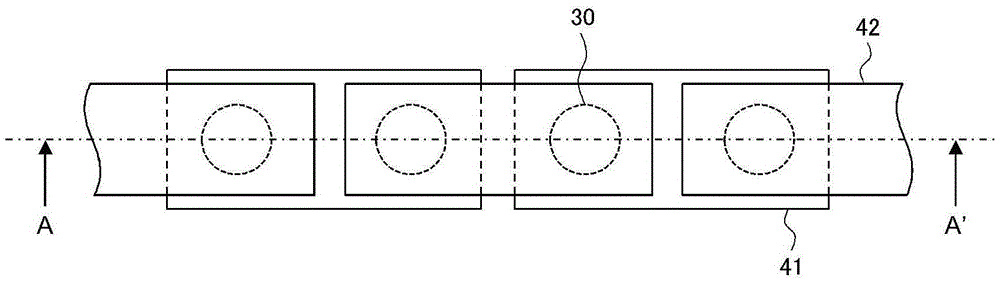

Semiconductor device and electro-optical device

ActiveUS20080128705A1Reduce leakage currentIncrease contrastLiquid crystal compositionsSemiconductor/solid-state device detailsDrain currentActive layer

A semiconductor device and an electro-optical device that ensures a stable output are provided even when there is a change in a source-drain current in a saturated operation region of a thin film transistor due to kink effects. The thin film transistor has a multi-gate structure with a polycrystalline silicon film as an active layer, and a source-side first thin film transistor portion and a drain-side second thin film transistor portion connected in series. The first thin film transistor portion has a drain-side back gate electrode that is connected with a first front gate electrode. The second thin film transistor portion has a source-side back gate electrode that is connected with a second front gate electrode.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

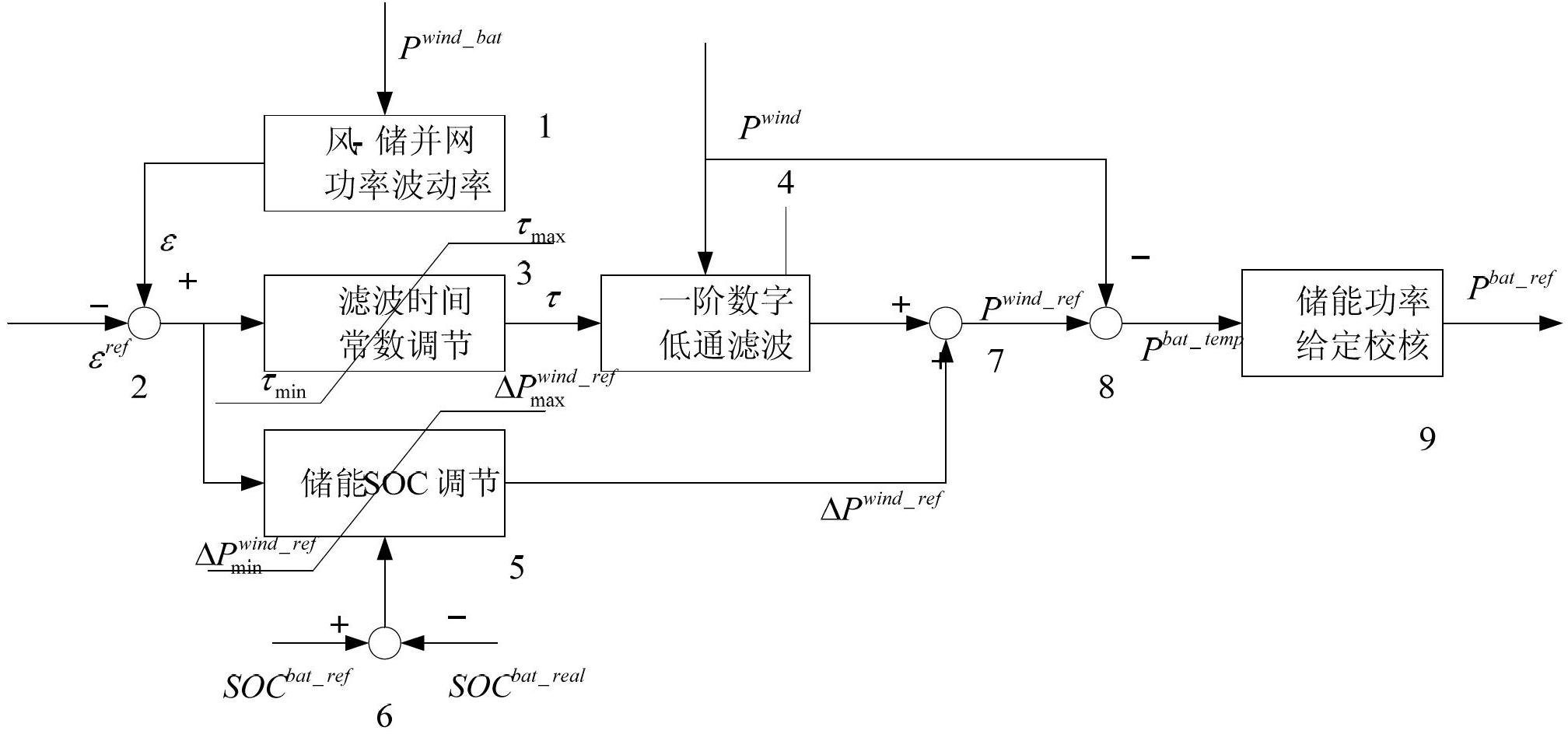

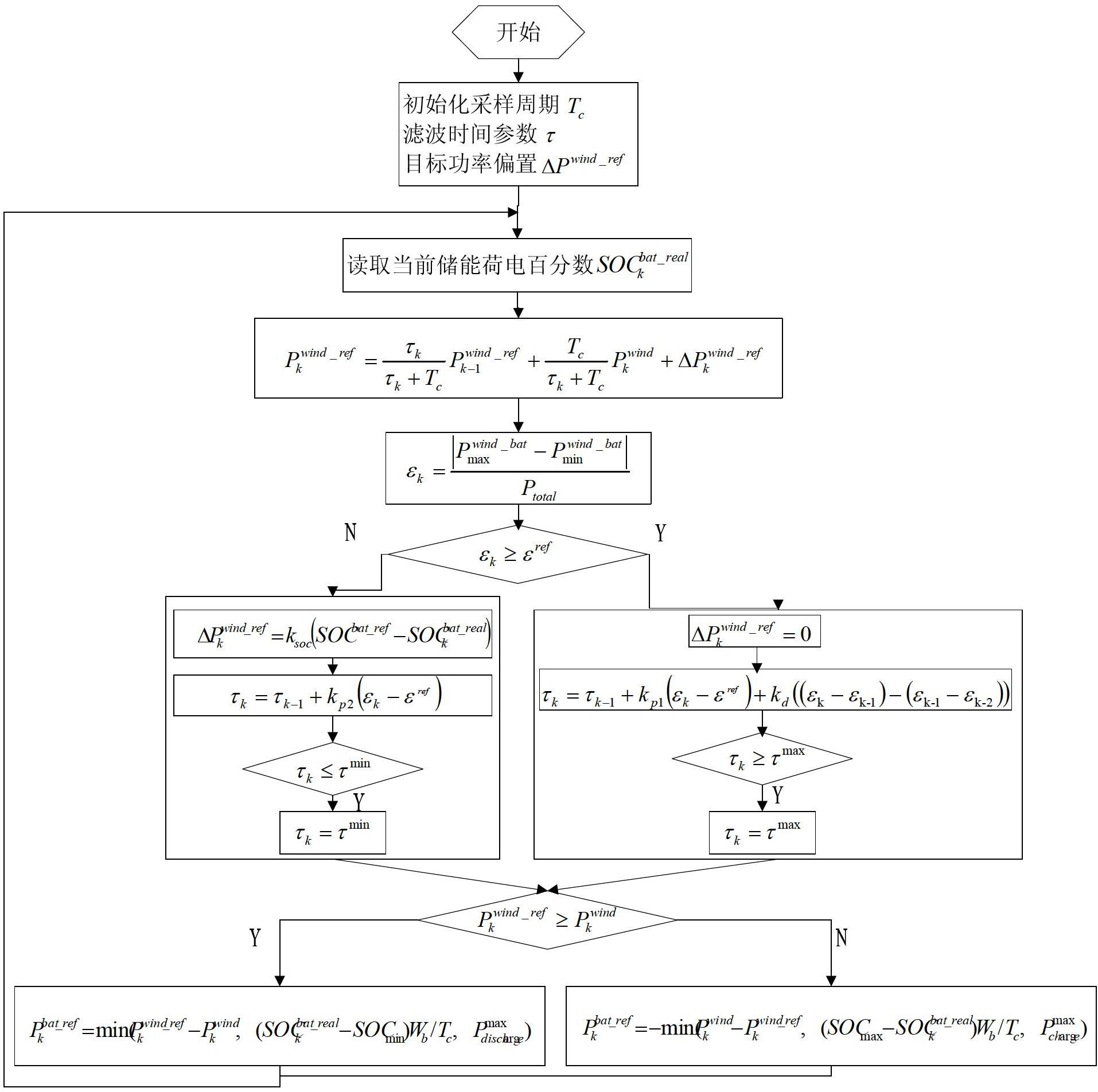

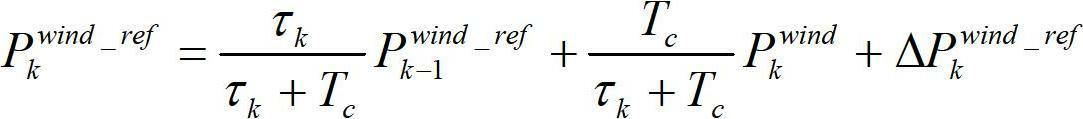

Energy storage battery system power giving method for stabilizing wind power grid connection power fluctuation

ActiveCN102664421AAdaptableImprove quick response abilityEnergy storageAc network load balancingElectricityBattery charge

The invention relates to an energy storage battery system power giving method for stabilizing wind power grid connection power fluctuation. The method comprises the following steps of: (1) determining a sampling control period, and initializing a filtering time constant and a wind power grid connection target power offset value; (2) reading current battery charge percent; (3) calculating a smoothened wind power grid connection power target value; and (4) calculating the output target value of an energy storage battery system. According to the method provided by the invention, the change rate of wind power output power fluctuation can be reduced, power smoothening standby of the energy storage battery system is considered simultaneously, and the wind power smoothening capability of an energy storage battery is brought into full play.

Owner:CHINA ELECTRIC POWER RES INST +1

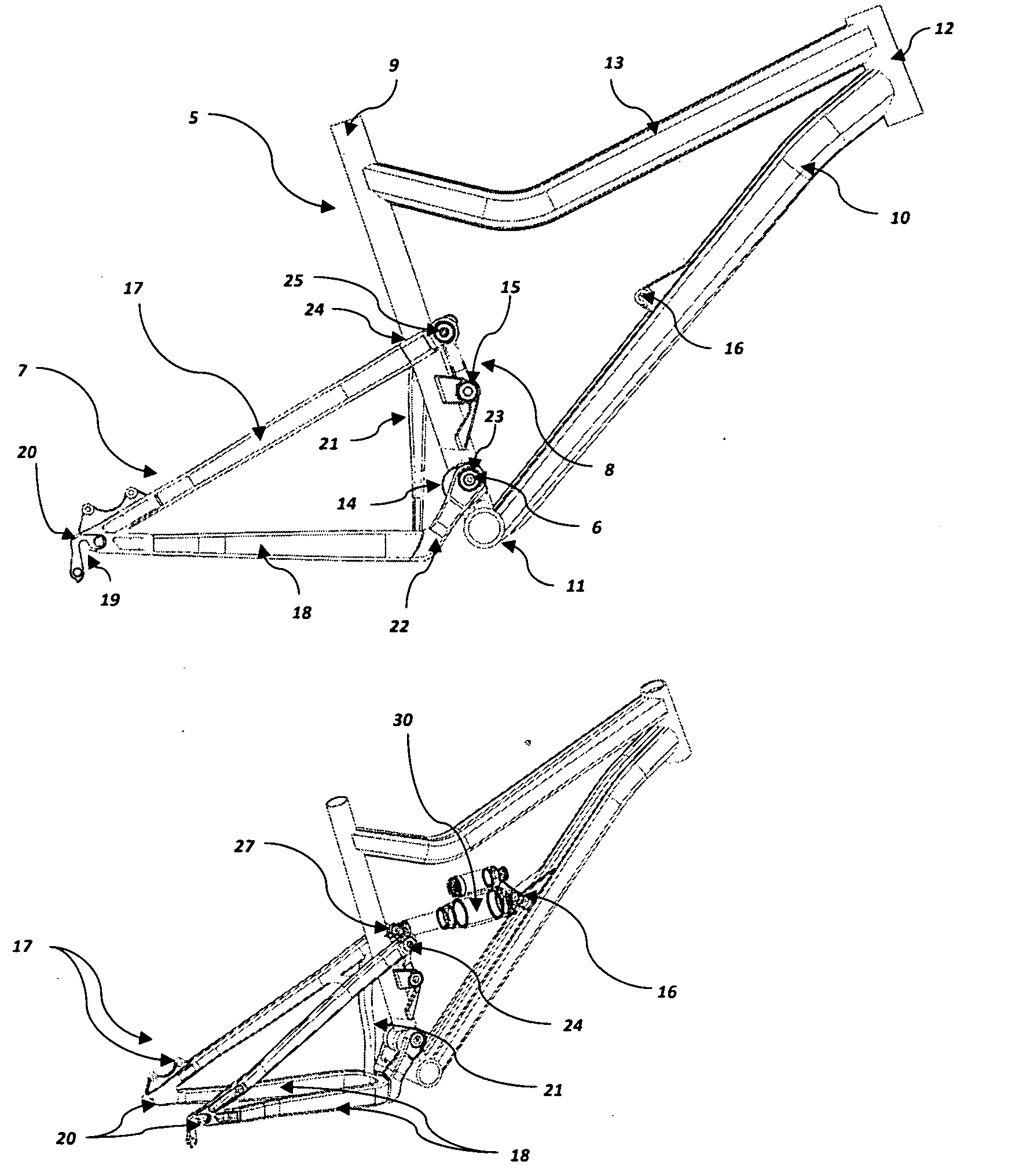

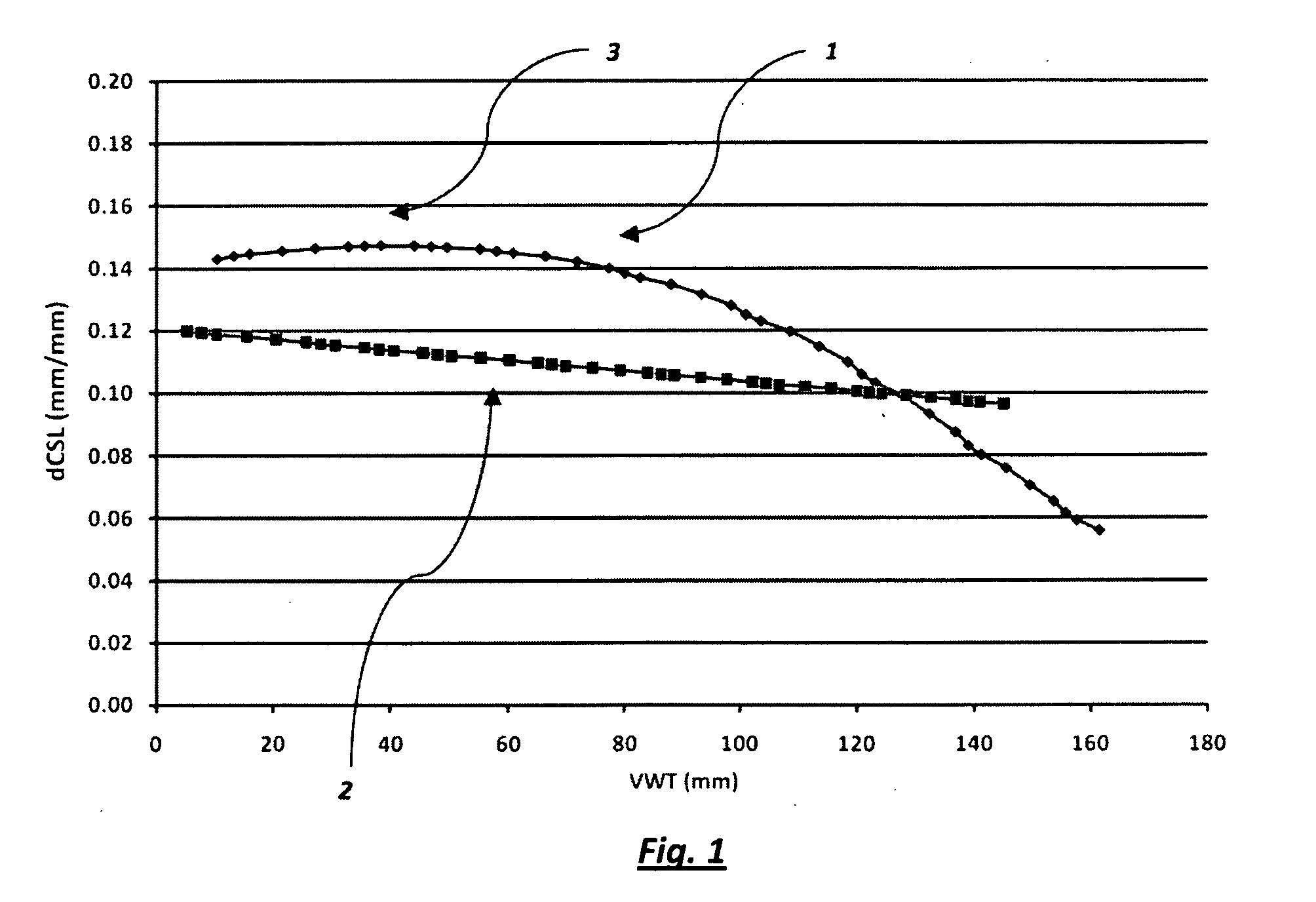

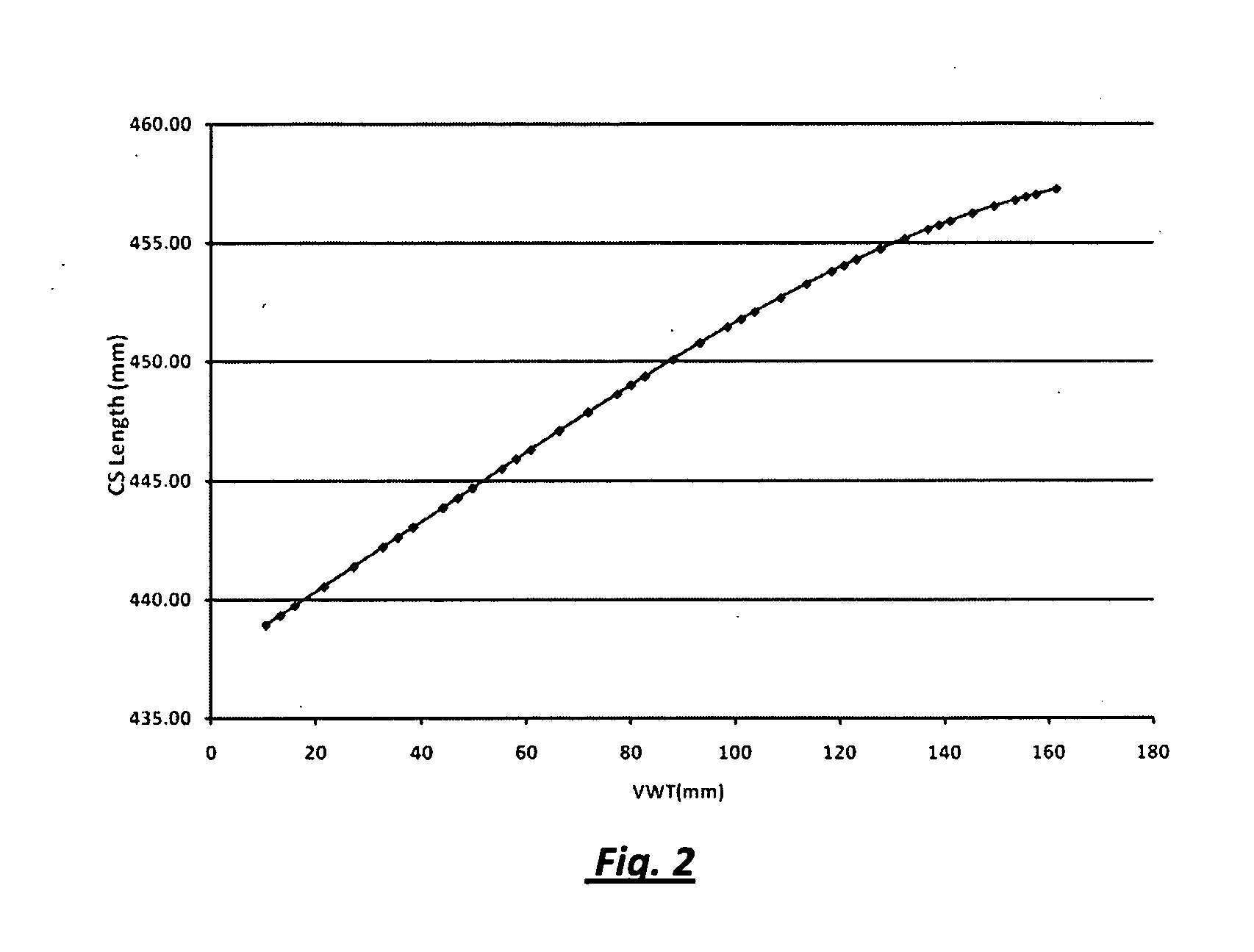

Bicycle Rear Suspension Linkage

ActiveUS20110018228A1Pedaling performanceOptimized shock ratePassenger cyclesChildren cyclesVertical planeMechanical engineering

A bicycle comprising a front triangle and a rear wheel having a rear wheel axis, a rear wheel suspension system further comprising a link further comprising a first pivotal axis for connection to said front triangle and a second pivotal axis for connection to a rear wheel swingarm, wherein the distance from said second pivotal axis to a first vertical plane decreases during a first portion of suspension compression and increases during a second portion of suspension compression; and wherein said first vertical plane is defined as a plane which is perpendicular to the ground and offset in the direction of the rear wheel with respect to the first and second pivotal axis. During the first portion of suspension compression and during the second portion of suspension compression the front triangle remains stationary with respect to the first vertical plane.

Owner:SINE SUSPENSION LLC

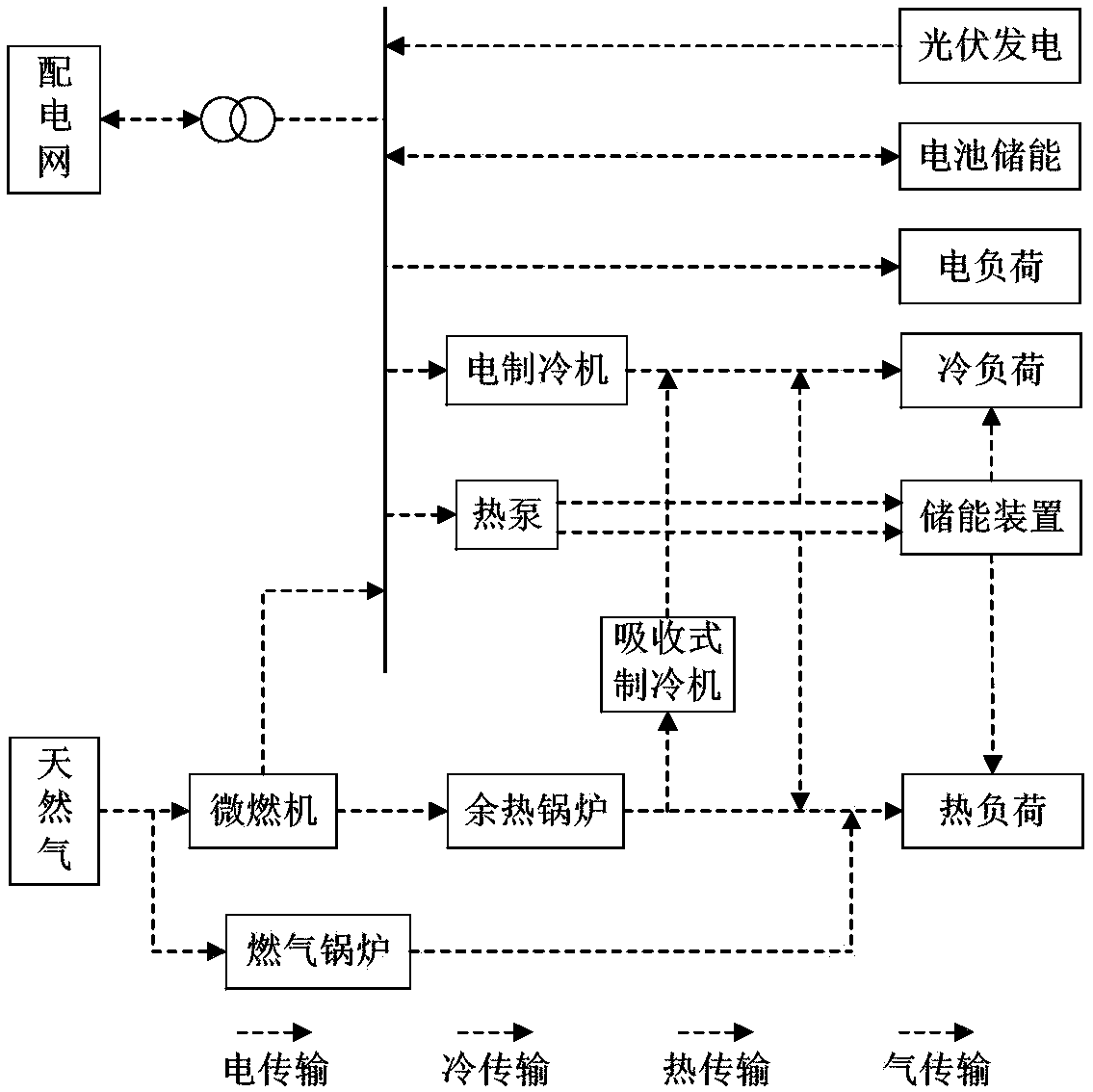

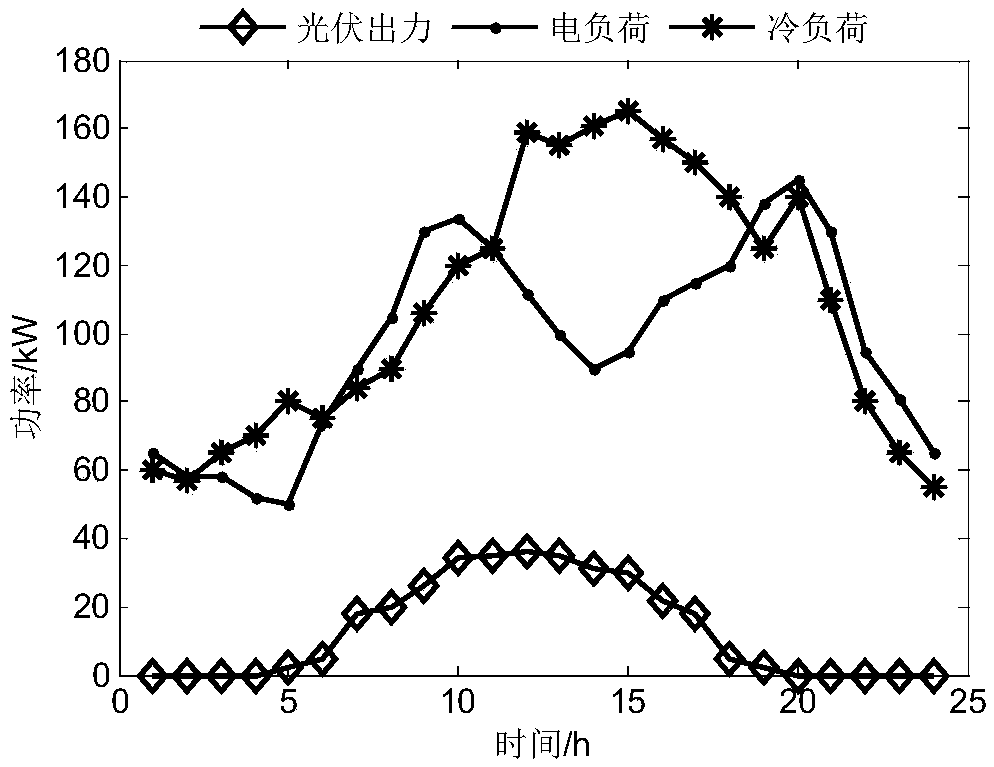

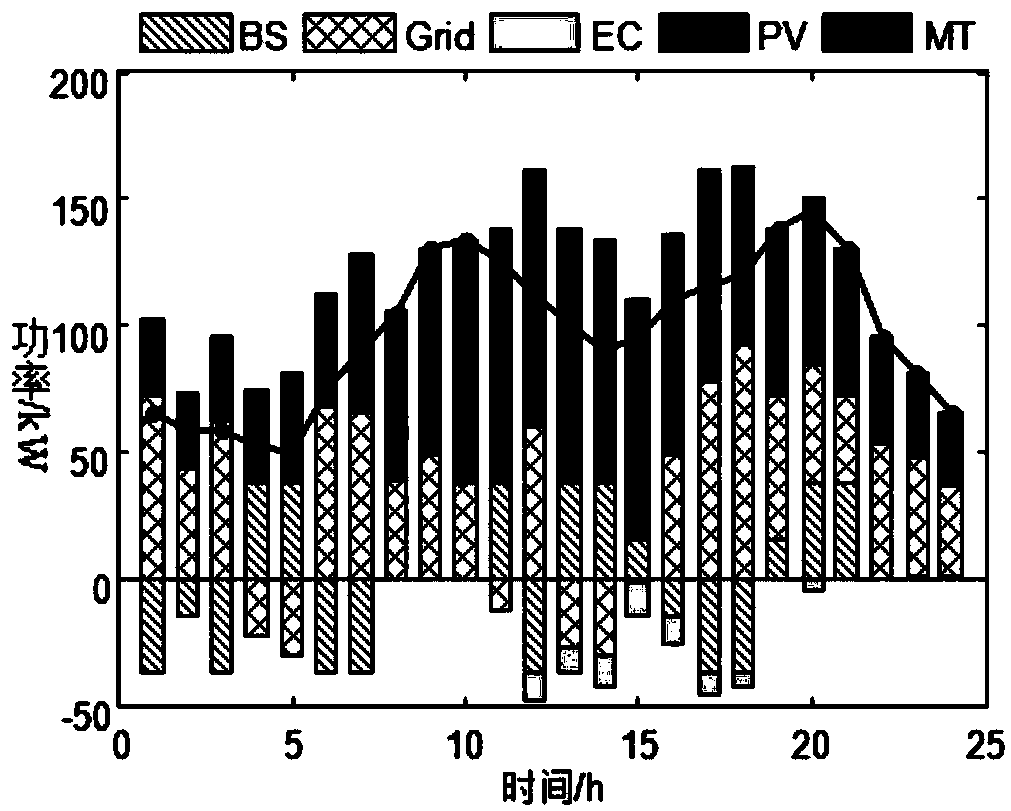

An economical dispatching method for distributed combined cooling, heating and power systems with multi-energy storage

InactiveCN109146182AEasy to decoupleImprove economyForecastingInformation technology support systemMicrogridEnergy coupling

The invention discloses an economic dispatching method of a distributed combined cooling, heating and power supply system considering multiple energy storage. Ground-source heat pump and cold, Heat and electricity energy storage are introduced into the dispatching of the cogeneration system, and a distributed combined cooling, heating and power system with photovoltaic, CCHP, ground source heat pump and various energy storage devices is established. The objective function is to minimize the total cost in the dispatching cycle. The model is modeled by yalmip and solved by cplex solver, so as toobtain the optimal output of each equipment. The invention can realize the coordinated dispatching and conversion among the three energies of cooling, heating and electricity in the CCHP type microgrid, reduces the adverse influence of the energy coupling action, enhances the flexible adjustment ability of the system, and has remarkable economic benefits.

Owner:NANJING UNIV OF SCI & TECH

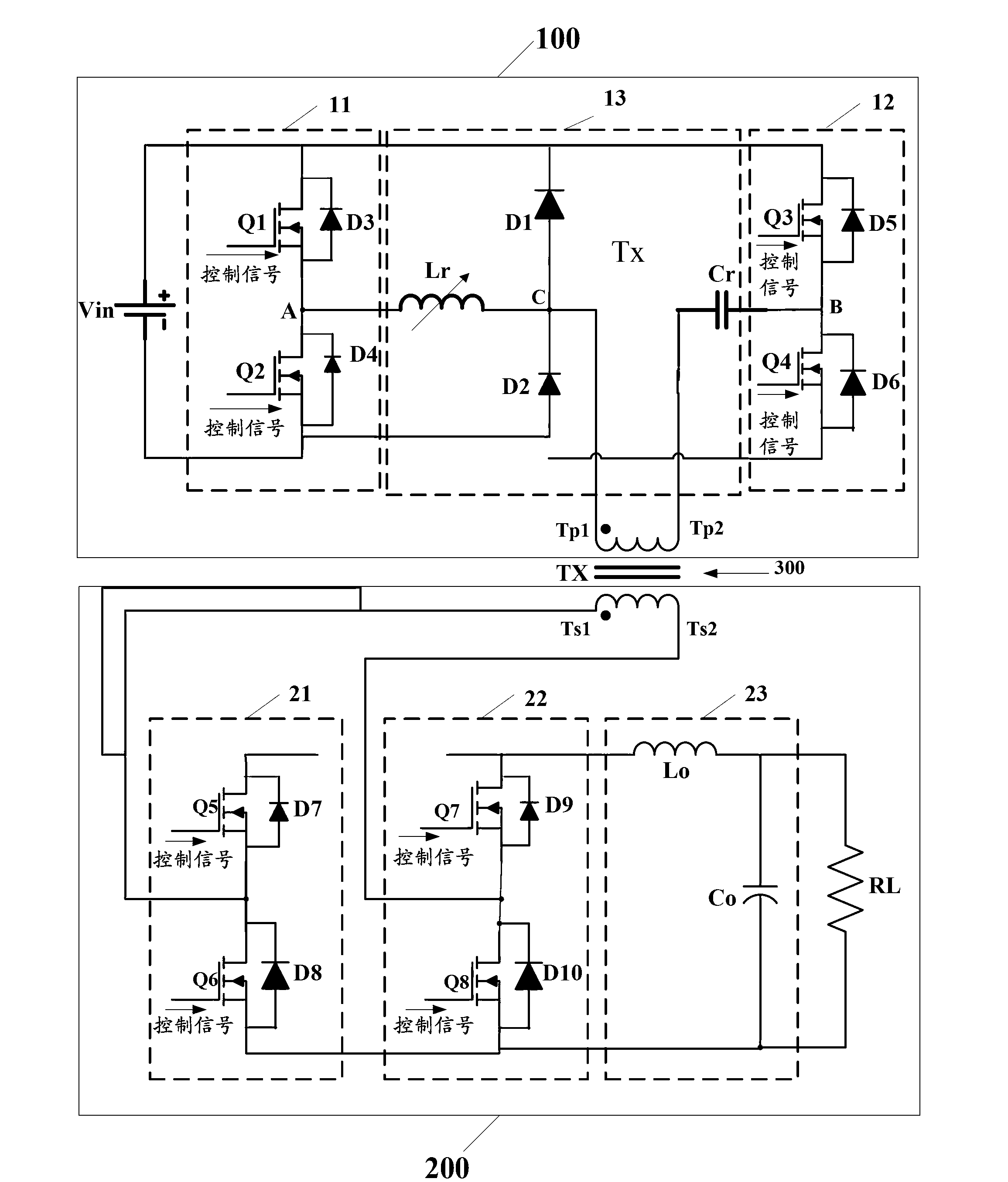

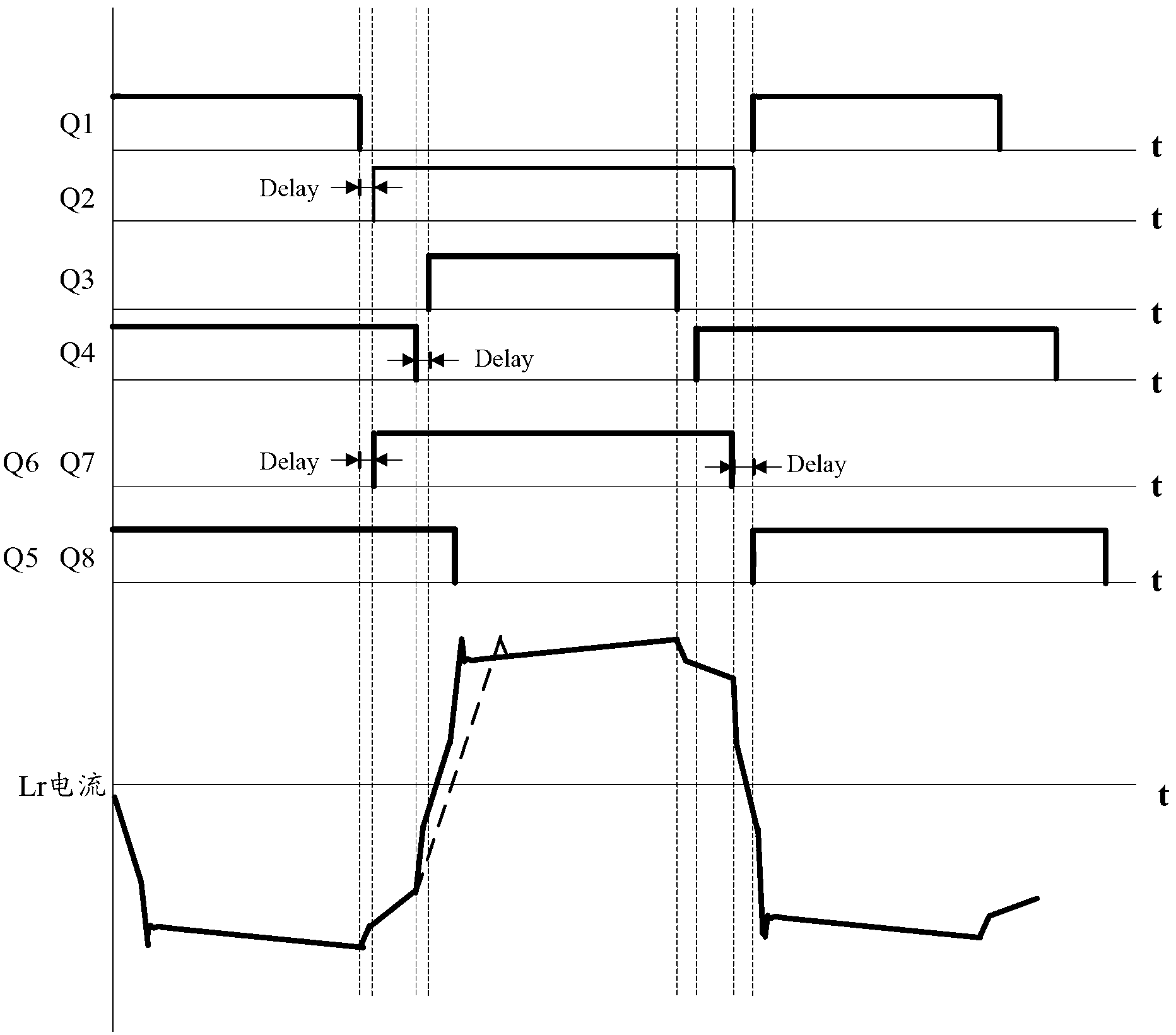

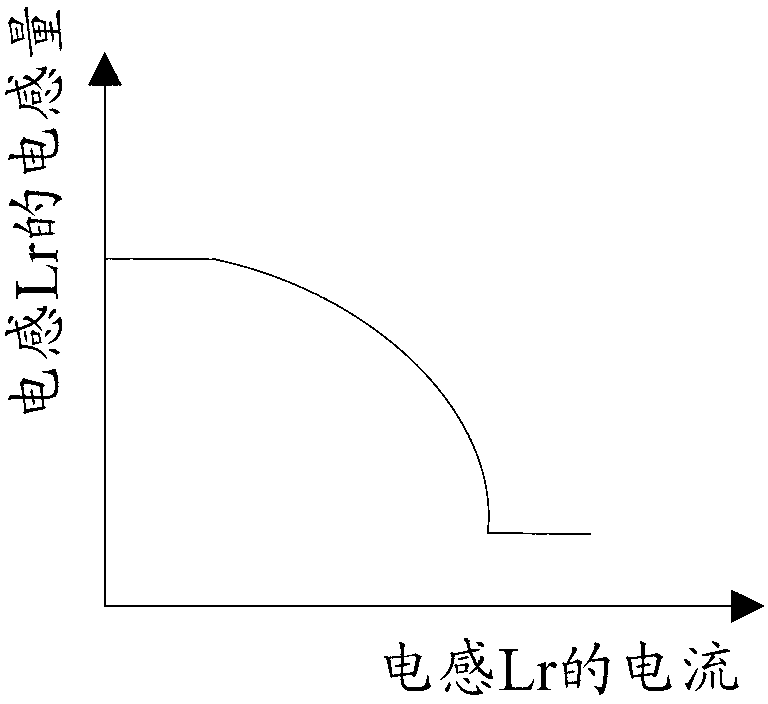

Full bridge topology power supply, control method and communication equipment

ActiveCN103066854AReduce lossesImprove performanceDc-dc conversionElectric variable regulationVoltage spikeFull bridge

The invention discloses a full bridge topology power supply, a control method and communication equipment. An inductance clamping circuit capable of self-adjusting resonance is arranged in a full bridge topology power supply device, inductance value features can be automatically adjusted with the utilization self-adjusted resonance inductance in the inductance clamping circuit and according to the size of passed current, a control circuit controls each switch tube of a full bridge topology, wide zero voltage switch load range, small circulation energy and small duty ratio loss are achieved, and therefore light loading vice side rectifying loss is reduced, light loading converting efficiency is enhanced, performance of flexible switches of a full bridge is improved, wide load range zero voltage opening up of primary side switch tubes of the full bridge is favorable for being achieved, switch loss is reduced, and efficiency of full load range is improved. Besides, the changing rate of primary side current is lowered by the self-adjusted resonance inductance, the vice side rectifier tube voltage spike is clamped through the self-adjusting resonance inductance clamping circuit, and therefore vice side rectifier tube source drain electrode voltage spike is lowered, and application reliability is improved.

Owner:HUAWEI TECH CO LTD

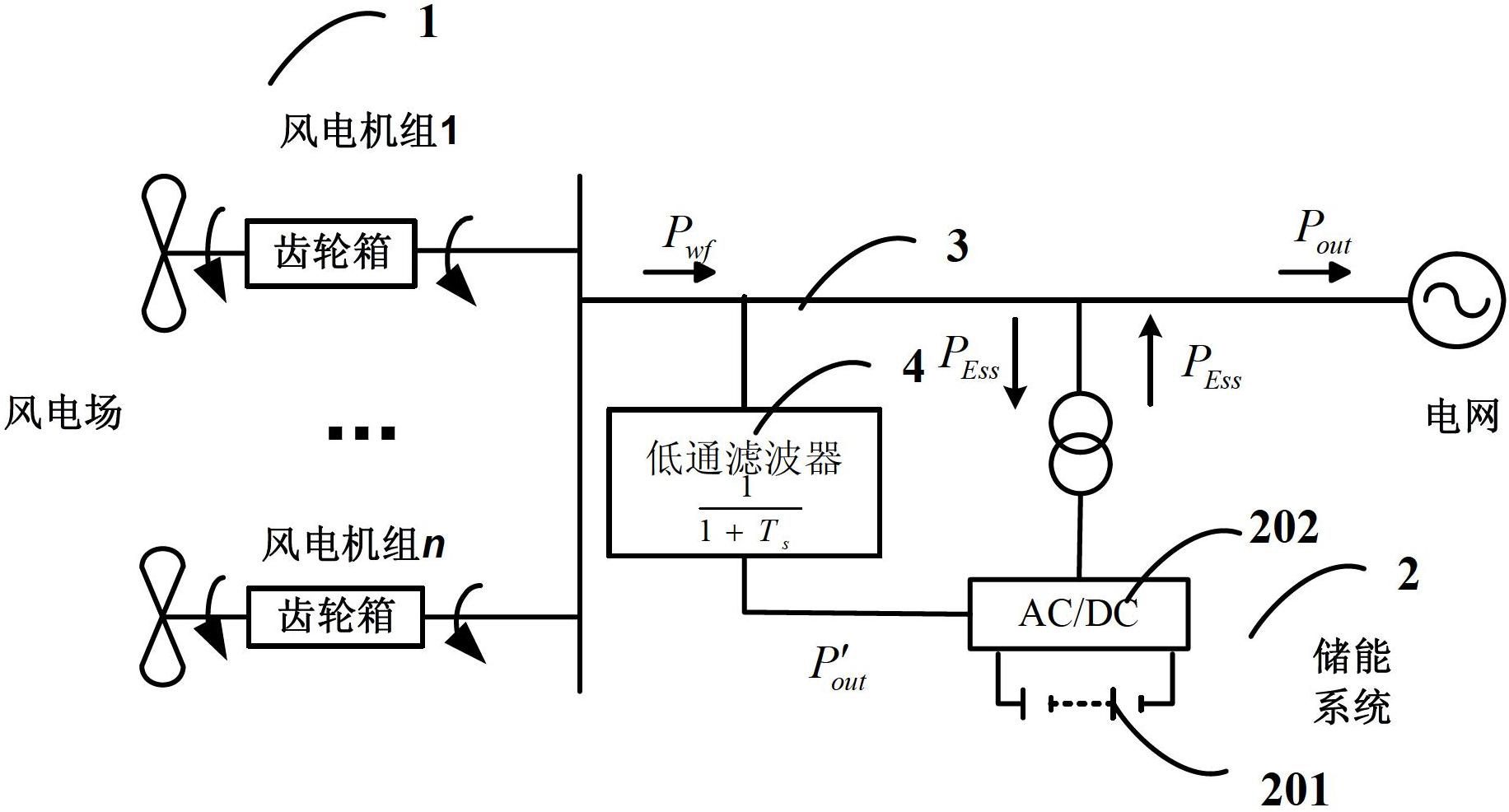

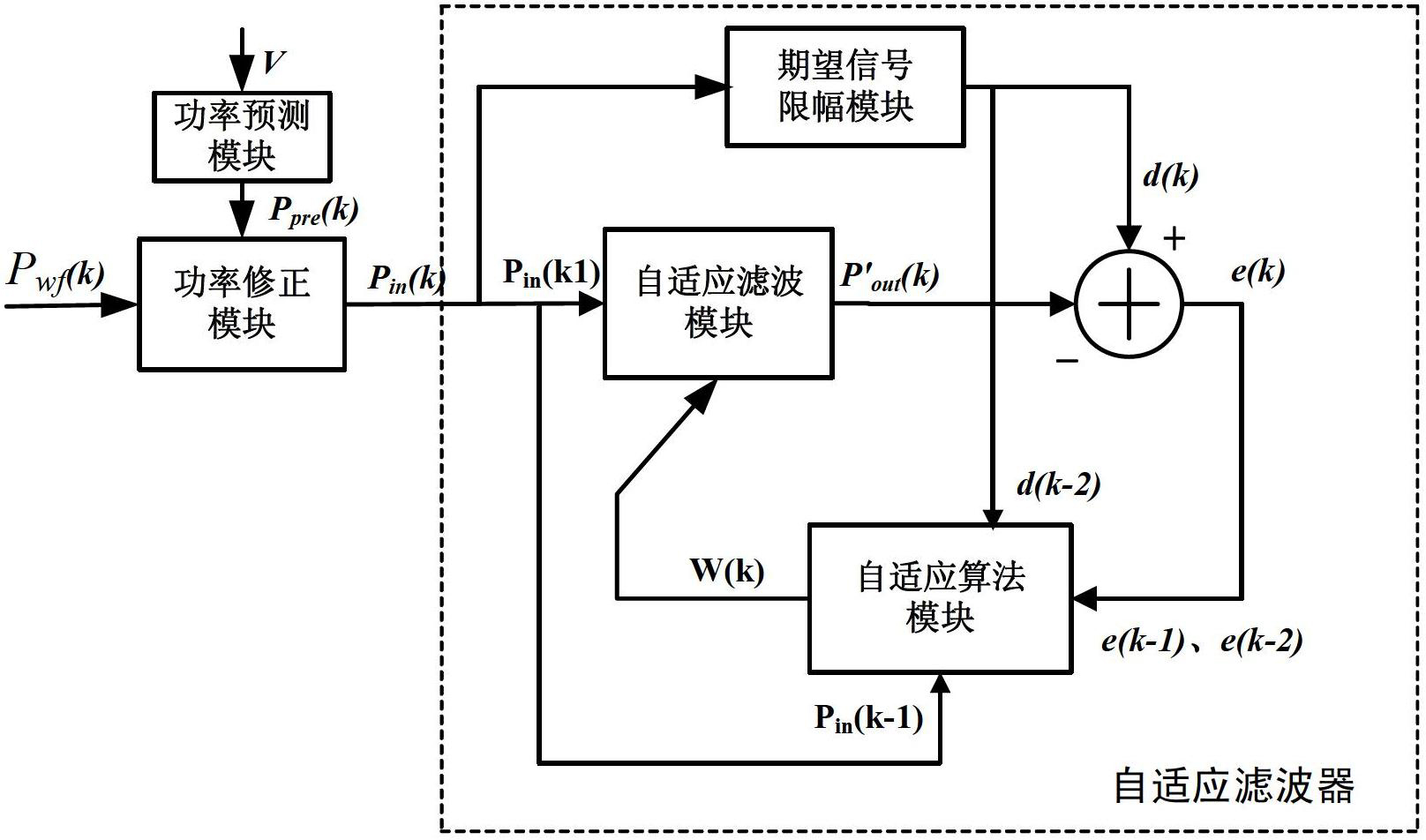

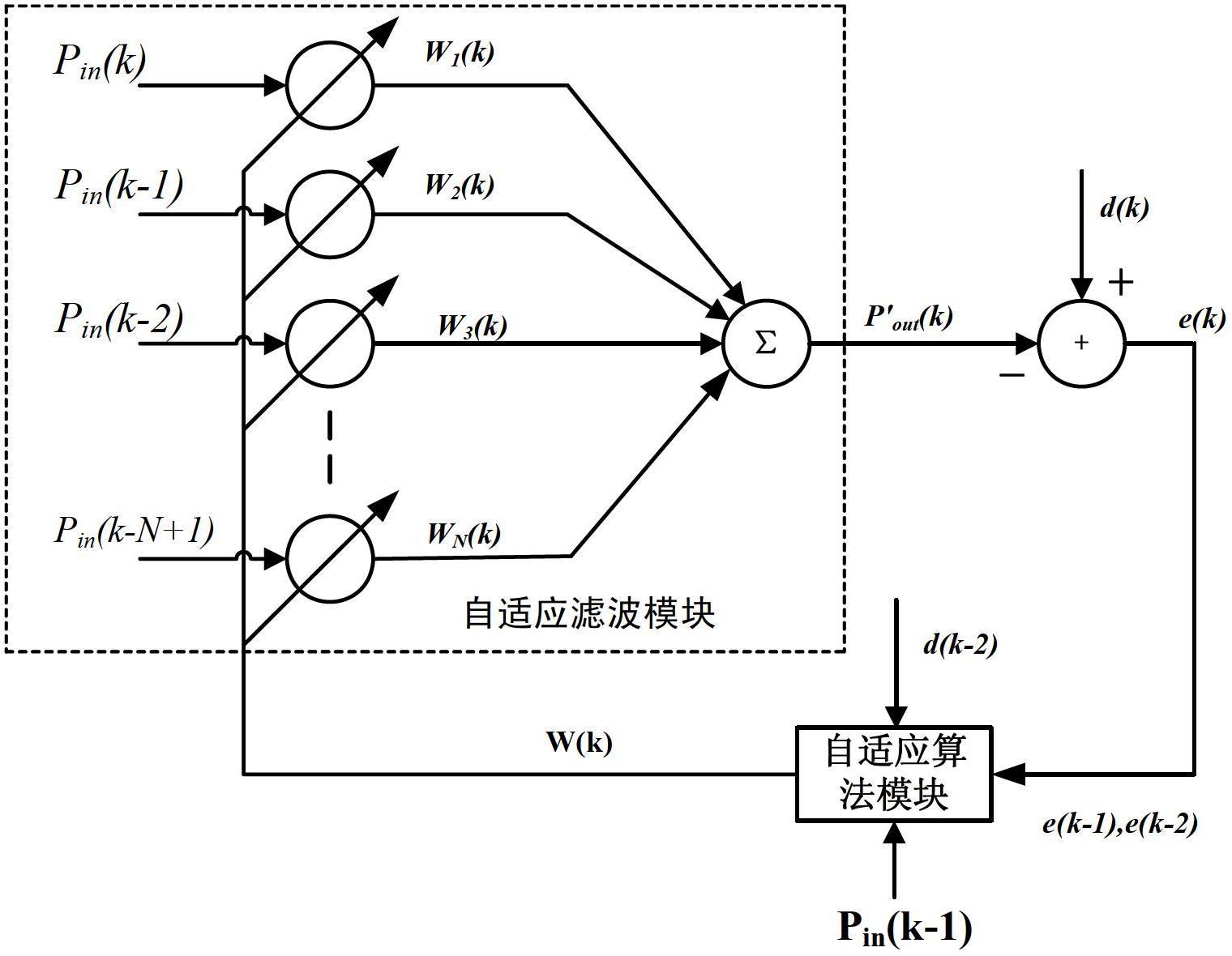

Method for smoothing output power of wind power station by utilizing energy storage system

InactiveCN102664422ASmall rate of changeFast convergenceEnergy storageAc network load balancingAdaptive filtering algorithmWeight coefficient

The invention discloses a method for smoothing output power of a wind power station by utilizing an energy storage system. In the method, not only wind power is introduced to predict or rectify the output power of the wind power station, but an improved self-adaptive filtering algorithm is applied. Since the output power of the wind power station is rectified by predicting the wind power, the change rate of the output power of the wind power station is decreased, and the output power of the wind power station can meet standards to inject into a power grid. By employing the self-adaptive filtering algorithm, regarding to the input power in different time, time weight coefficient in an adaptive filtering structure can be automatically calculated according to the input, so that the defect that different input cannot correspond to different filtering time constant by utilizing a low pass filter smoothing method in the past can be overcome. After the smoothing method is employed to smooth the output power of the wind power station, the output voltage of the wind power station is kept stable, fluctuation and flicker of the power grid voltage is reduced, harmonic pollution is reduced and accidents are reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

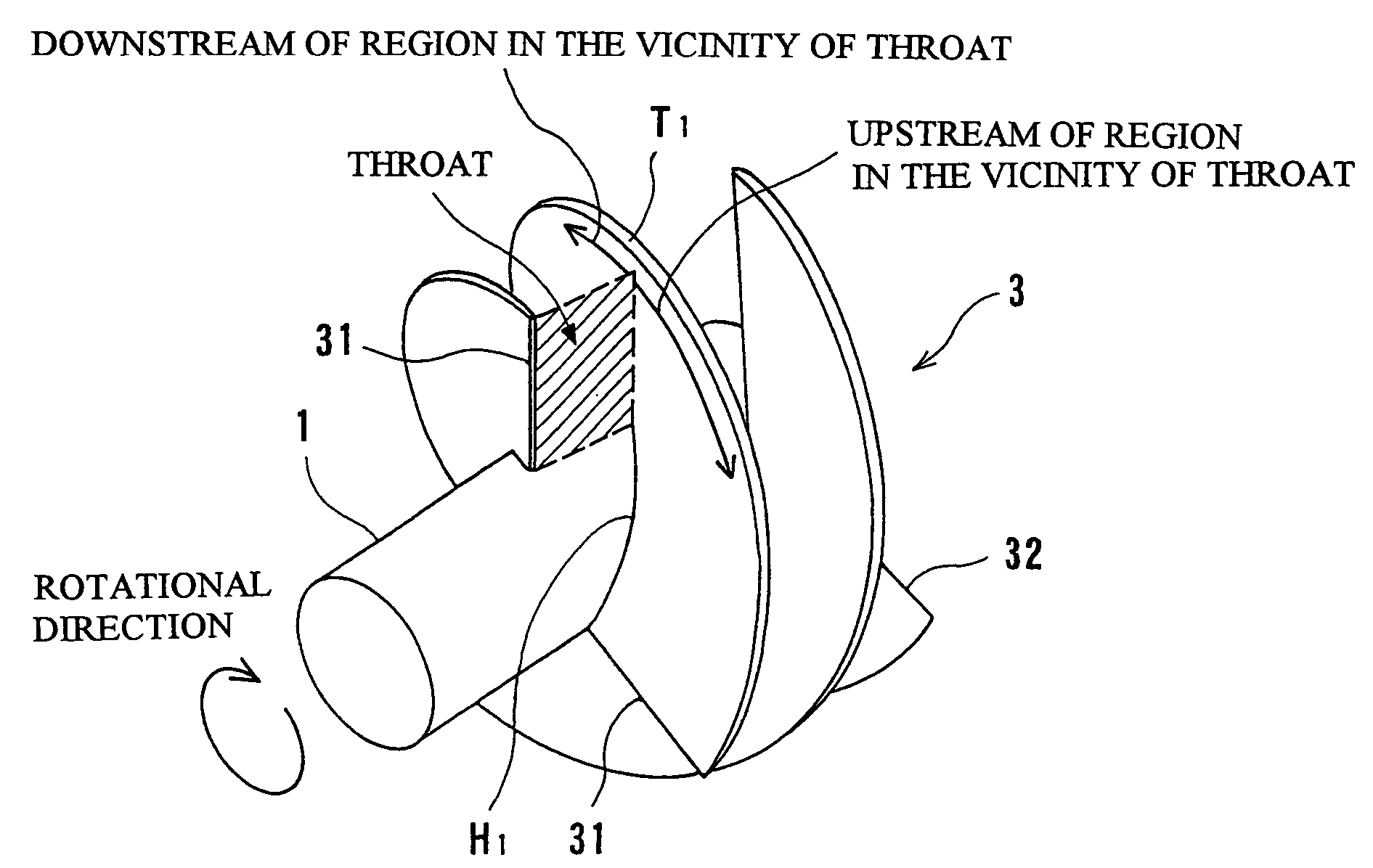

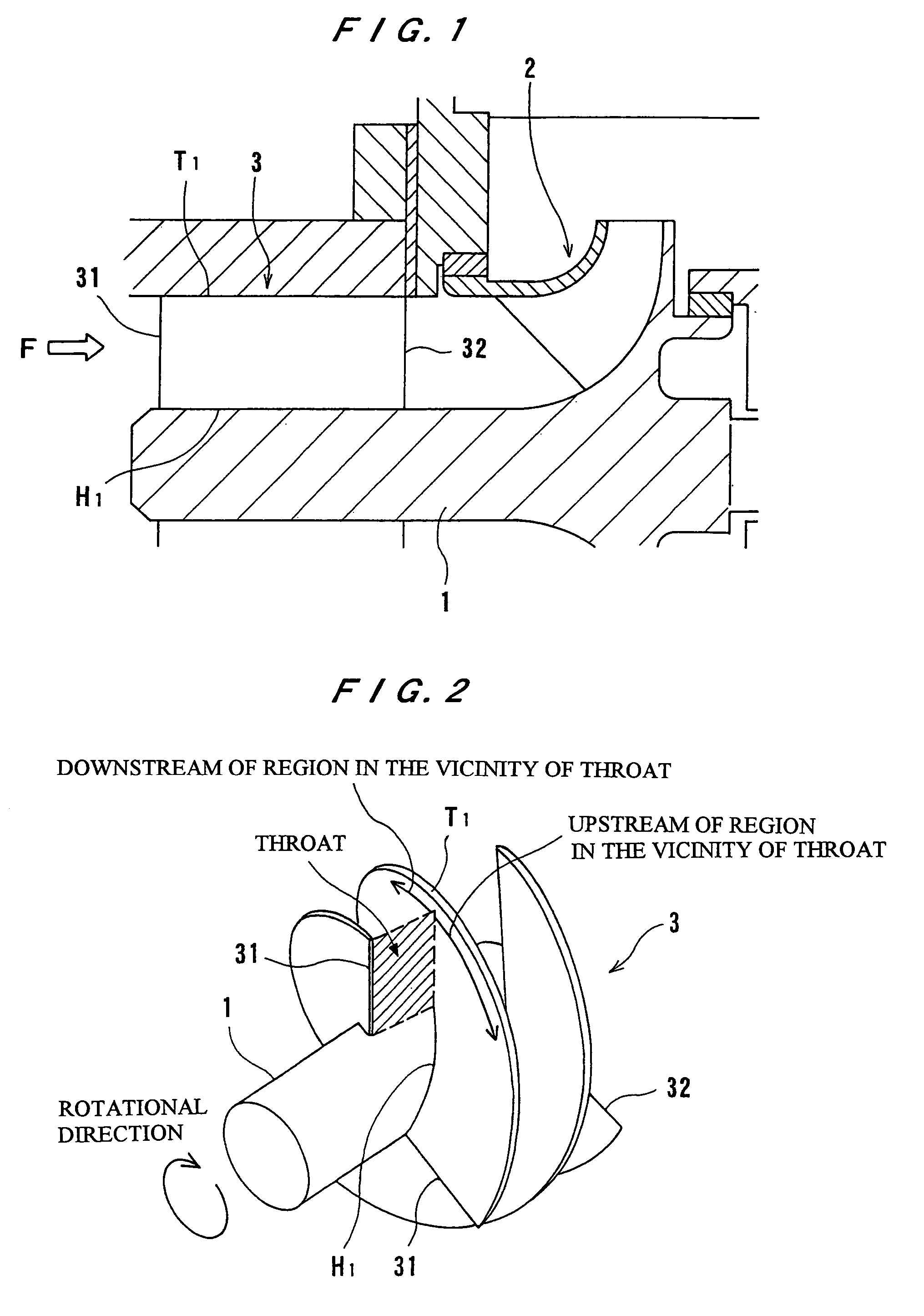

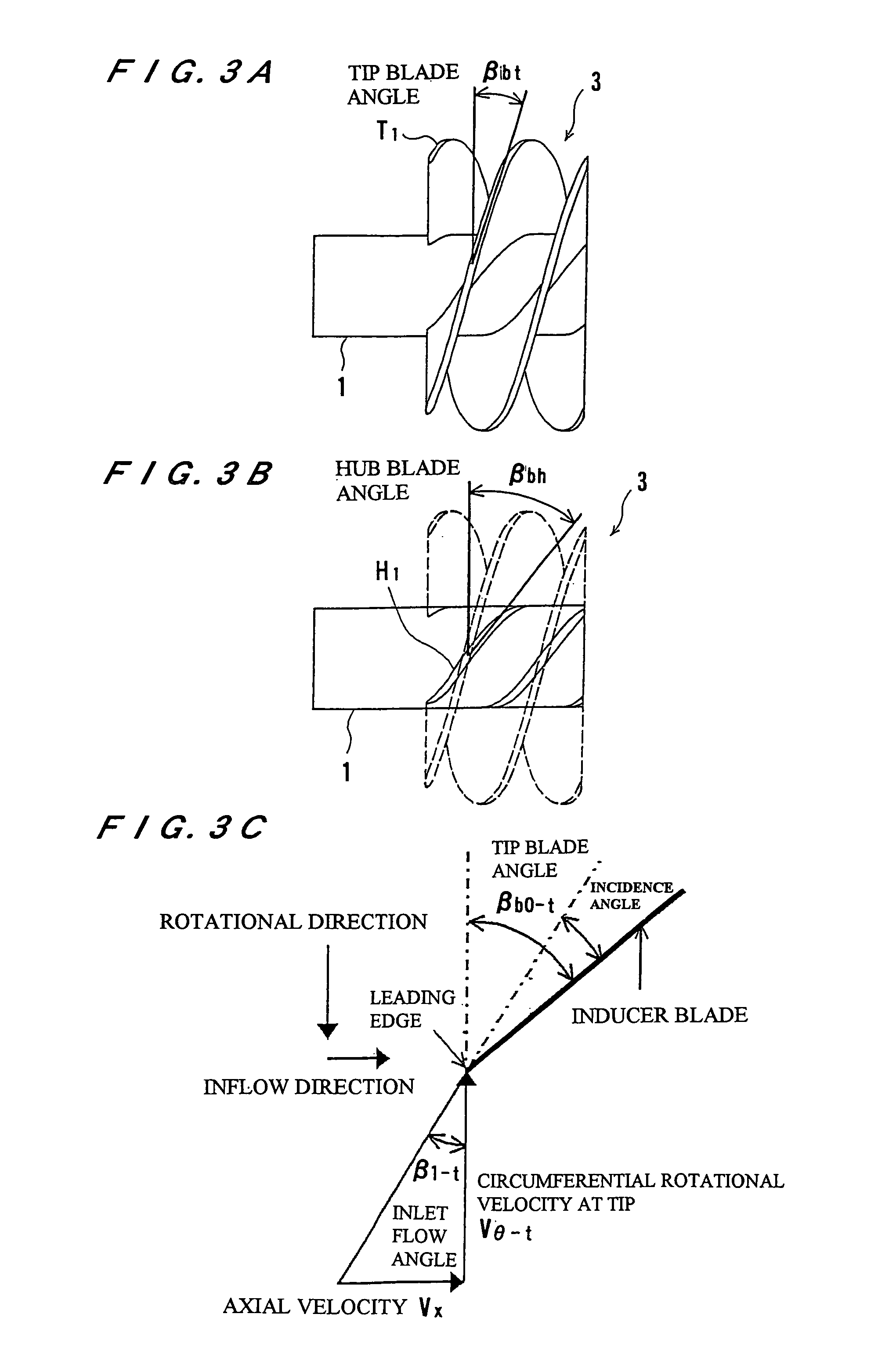

Inducer, and inducer-equipped pump

InactiveUS7207767B2Improve reliabilityInhibition of refluxPropellersPump componentsImpellerLeading edge

The present invention is concerned with an axial-flow or mixed-flow inducer (3) which is disposed upstream of a main impeller (2) for improving the suction capability of a pump such as a turbopump. In the inducer (3), a blade angle (βbt) from a tip (T1) to a hub (H1) at a blade leading edge (31) is substantially the same as an inlet flow angle (β1−t) at a designed flow rate.

Owner:EBARA CORP

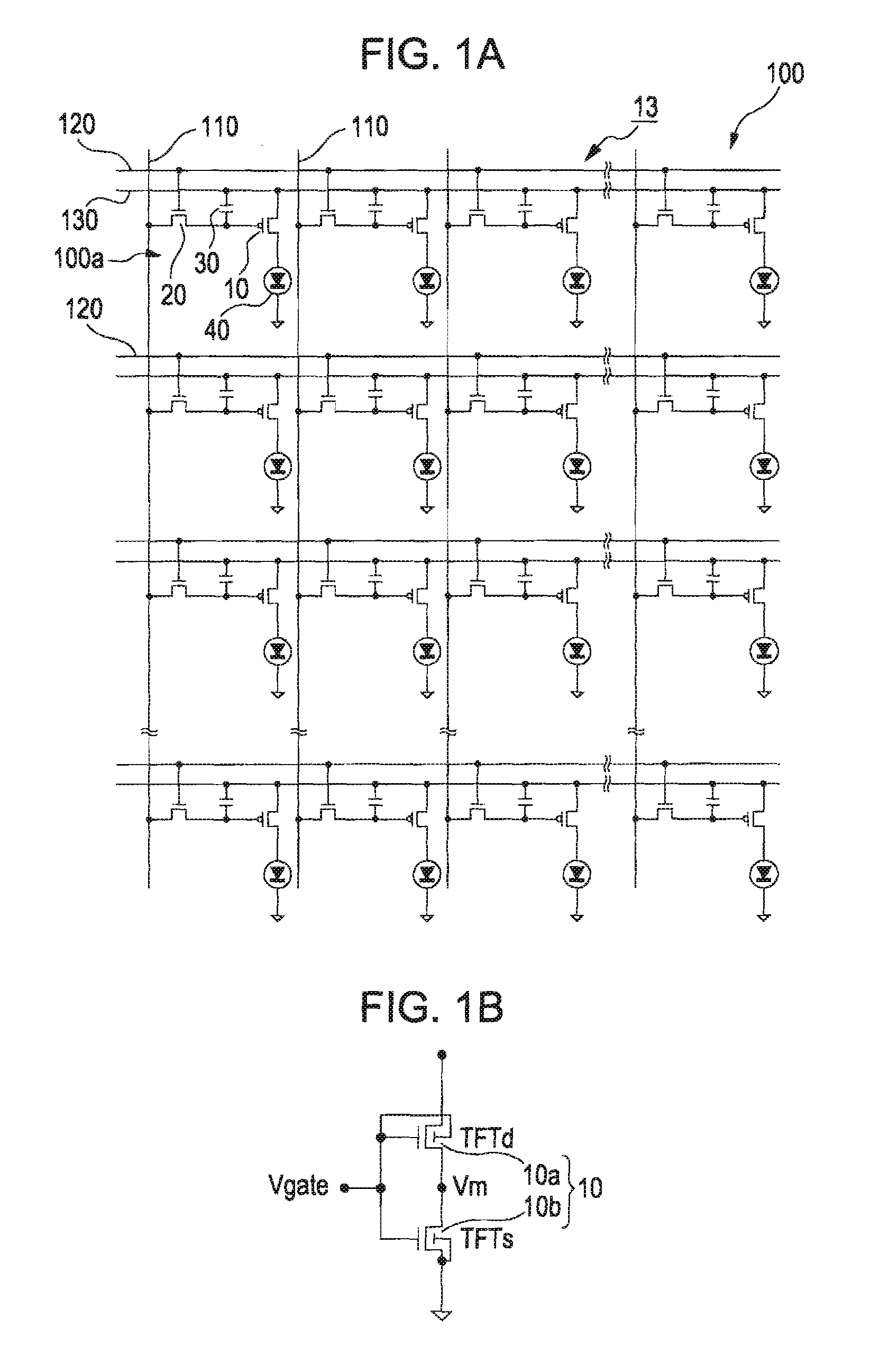

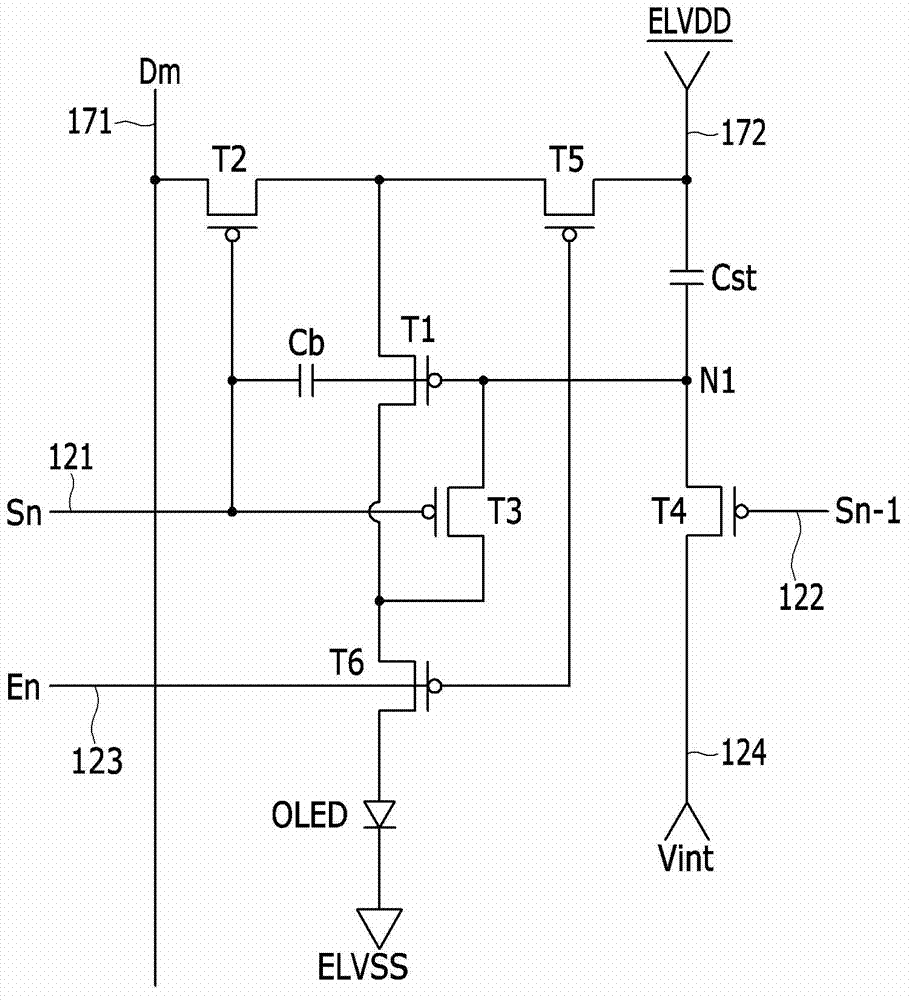

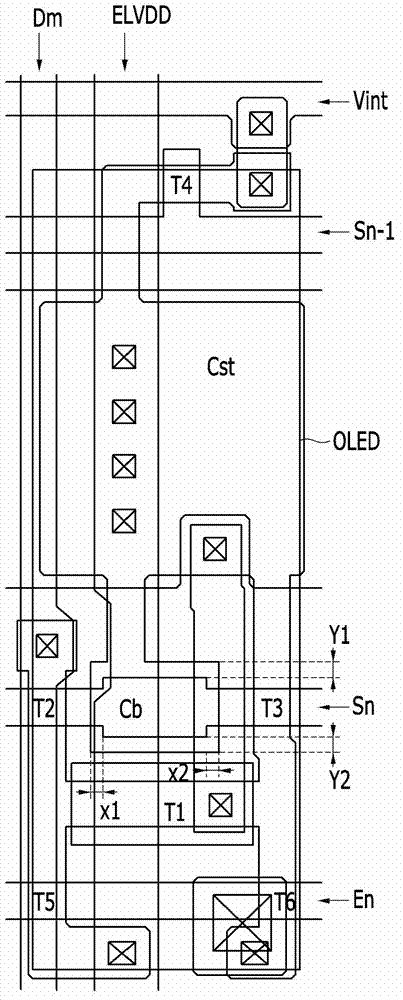

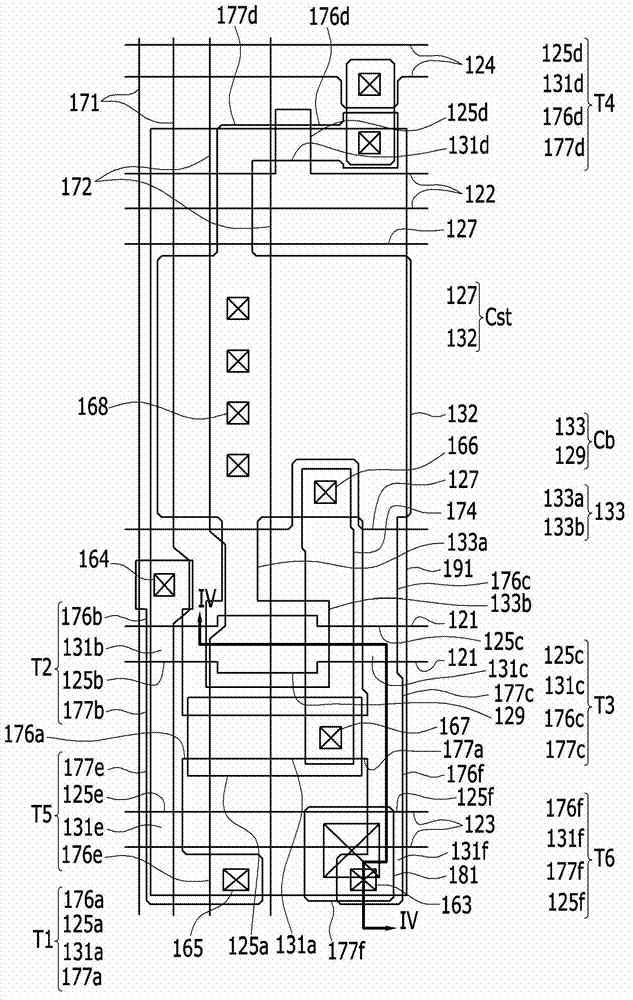

Organic light emitting diode display

ActiveCN103489889ASmall rate of changeImproved color bias artifactsStatic indicating devicesSolid-state devicesScan lineData signal

An organic light emitting diode (OLED) display includes a substrate; a scan line formed on the substrate and applying a scan signal; a data line and a driving voltage line intersecting the scan line and respectively applying a data signal and a driving voltage; a switching TFT connected to the scan line and data line; a driving TFT connected to a switching drain electrode of the switching TFT and the driving voltage line; an OLED connected to the driving drain electrode of the driving TFT; a storage capacitor connected between the driving voltage line and the driving gate electrode of the driving TFT; and a boosting capacitor including a first boosting capacitor plate connected to the driving gate electrode and a second boosting capacitor plate overlapping the first boosting capacitor plate and connected to the scan line, where an area of the first boosting capacitor plate of the boosting capacitor is larger than an area of the second boosting capacitor plate.

Owner:SAMSUNG DISPLAY CO LTD

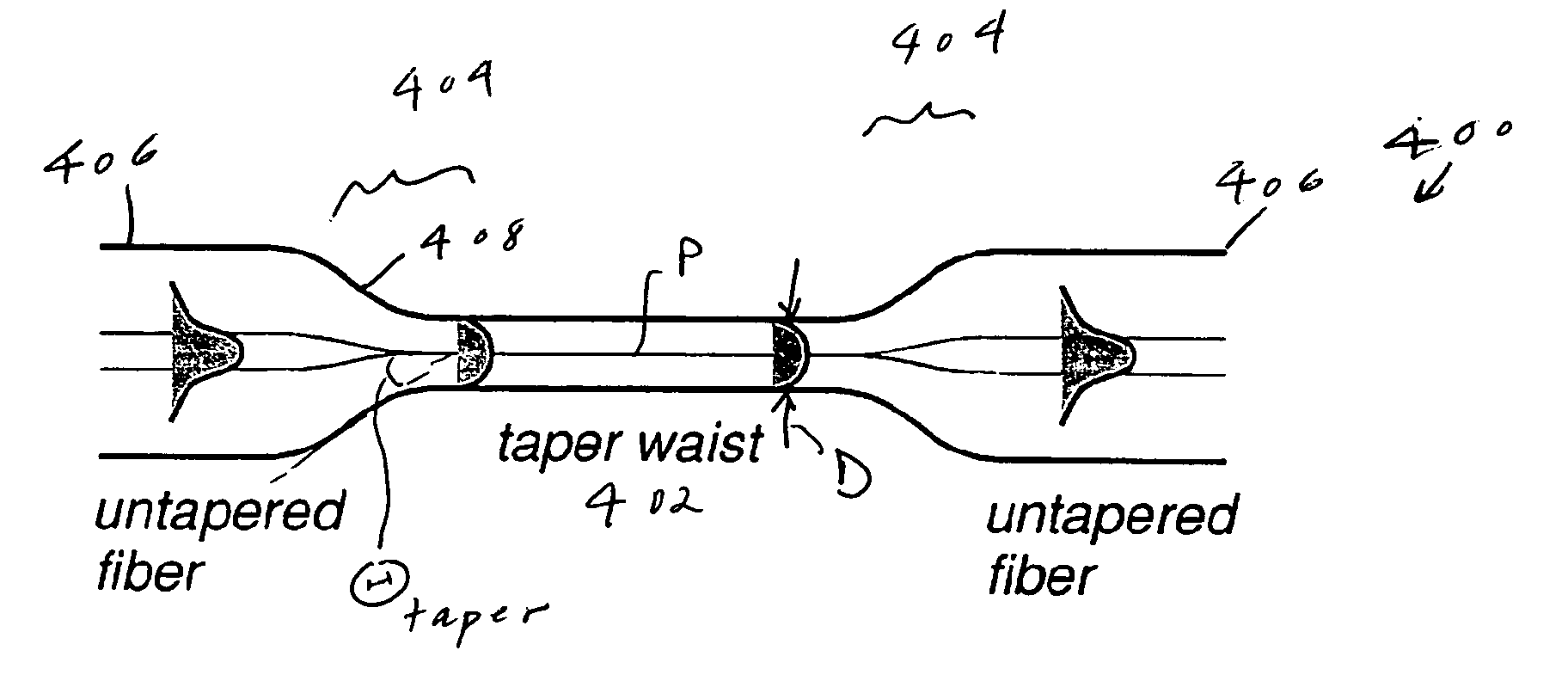

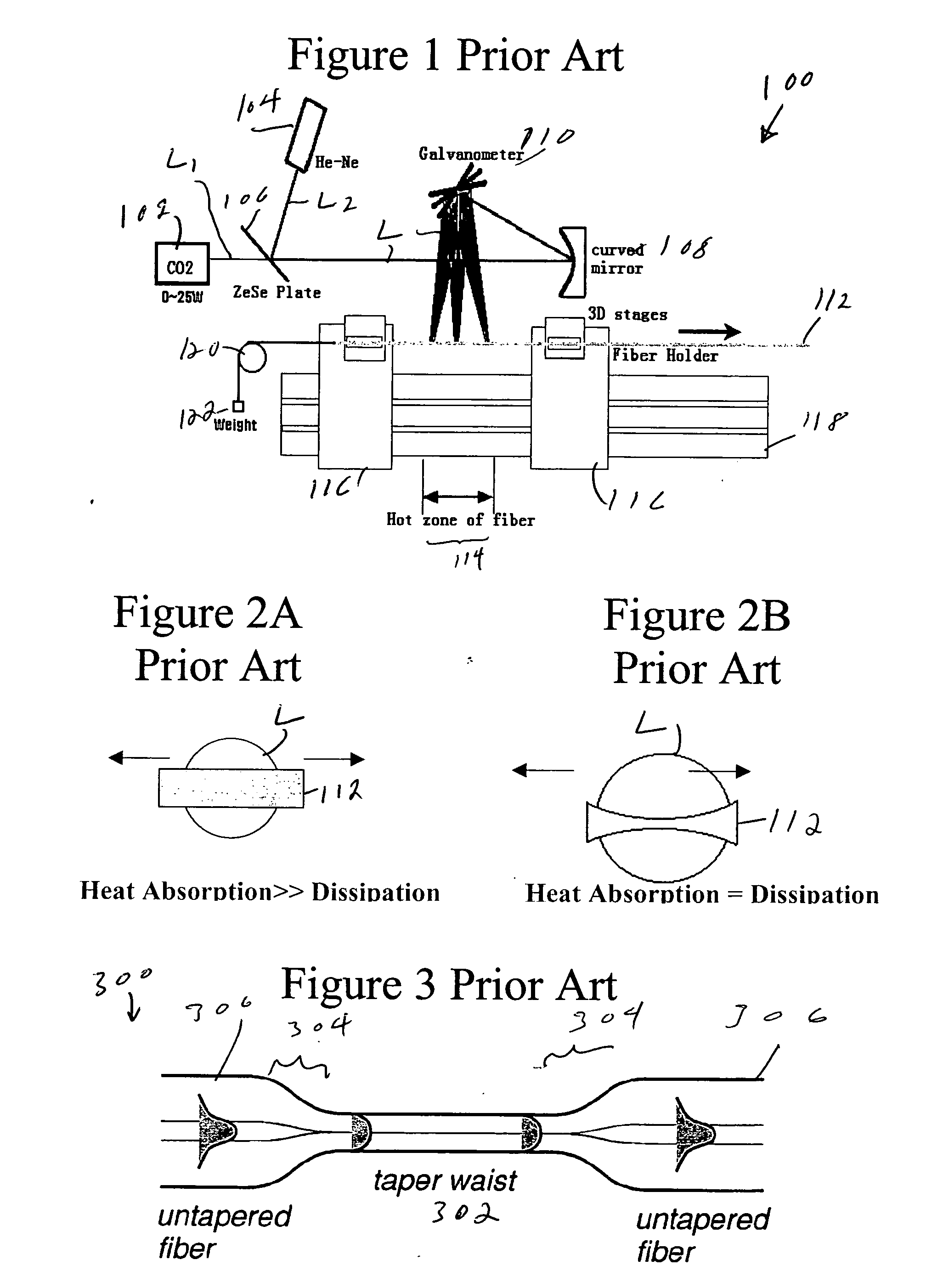

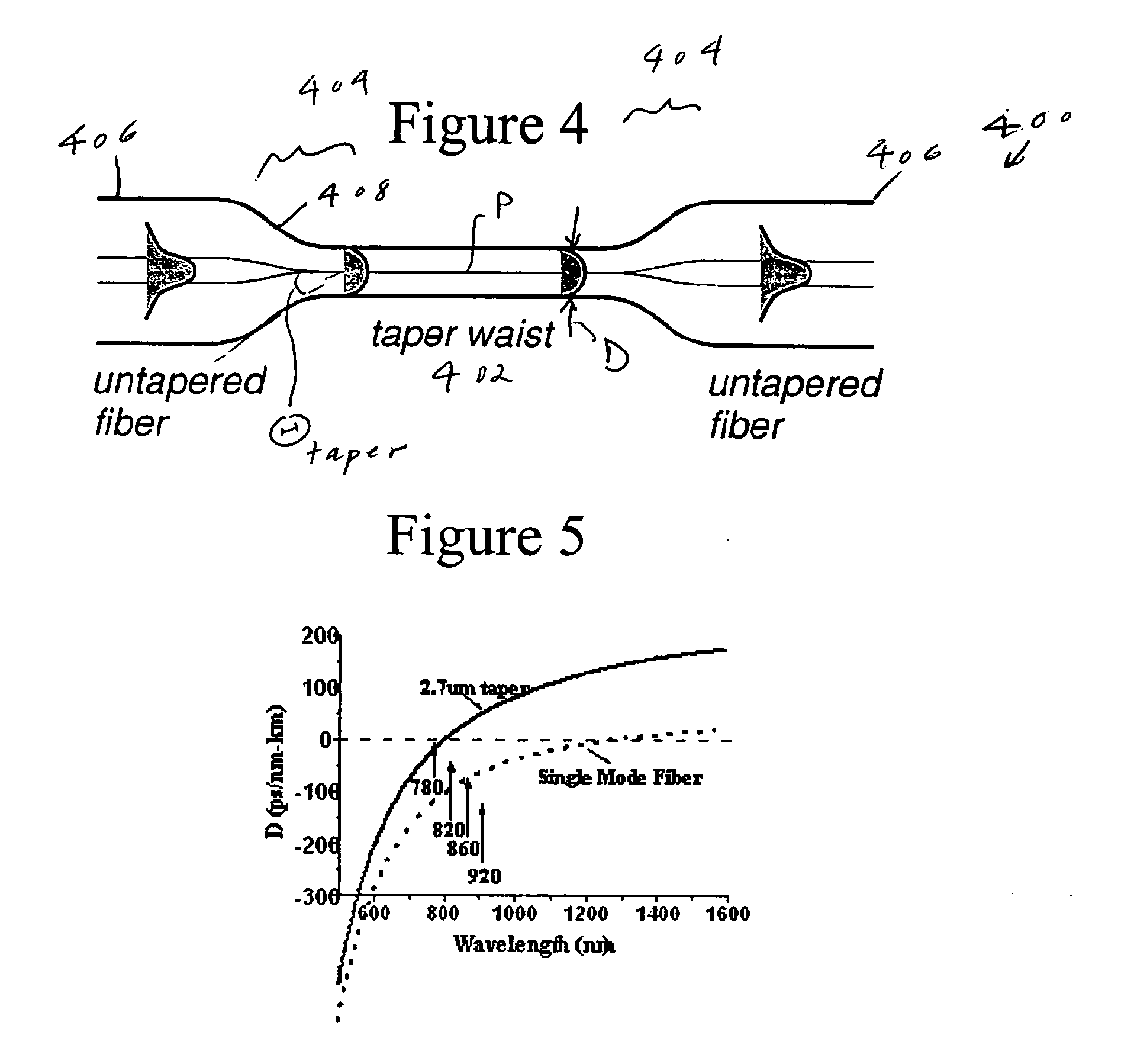

Fiber device with high nonlinearity, dispersion control and gain

InactiveUS20050094941A1Minimize coupling loss in transition zoneReduce lossesGlass making apparatusOptical fibre with polarisationEngineeringOptic system

An optical fiber is tapered, for example, by heating it with a CO2 laser. The tapering process is controlled such that the taper transition regions have taper angles selected to minimize loss. The taper waist has a diameter selected to introduce desired dispersion properties and desired nonlinearity. The optical fiber can be used as a dispersion compensator in a fiber laser or other fiber optic system. The nonlinearity in the tapered optical fiber allows the generation of ultrashort light pulses.

Owner:UNIVERSITY OF ROCHESTER

Aluminum oxide hollow sphere light insulating brick and preparation method thereof

The invention relates to an aluminum oxide hollow sphere light insulating brick and a preparation method thereof. The technical scheme of the method comprises the steps of mixing 45-55wt% of aluminum oxide hollow sphere, 30-45wt% of Al2O3 micro powder, 6-13wt% of Rho-Al2O3 micro powder with 3-6wt% of silicon micro powder, additionally adding 5-15wt% of organic polymer fine powder and 20-30wt% of water according to the weight percentage of the mixture, evenly stirring, and molding in a pouring way, maintaining for 24-48h under the condition of room temperature, demolding, drying for 20-36h under the condition of the temperature being 100-120DEG C, and keeping the temperature under the condition of 1600-1700DEG C. The method is simple in technology and low in cost. The aluminum oxide hollowsphere light insulating brick prepared by the method is characterized by being low in volume density, low in heat conductivity, high in compression strength, high in use temperature, good in insulating effect, high in load softening temperature, and low in heavy firing line change rate.

Owner:WUHAN UNIV OF SCI & TECH

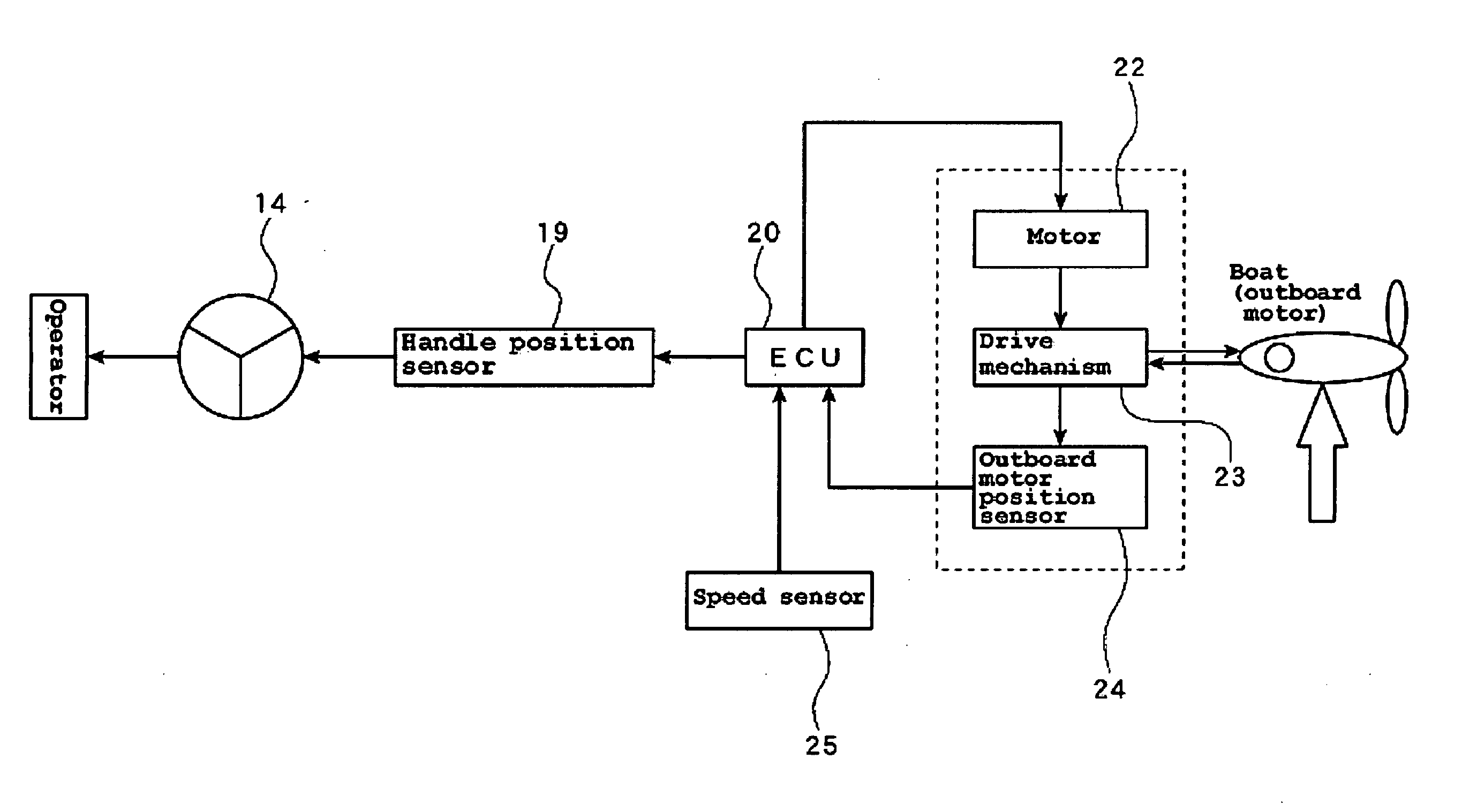

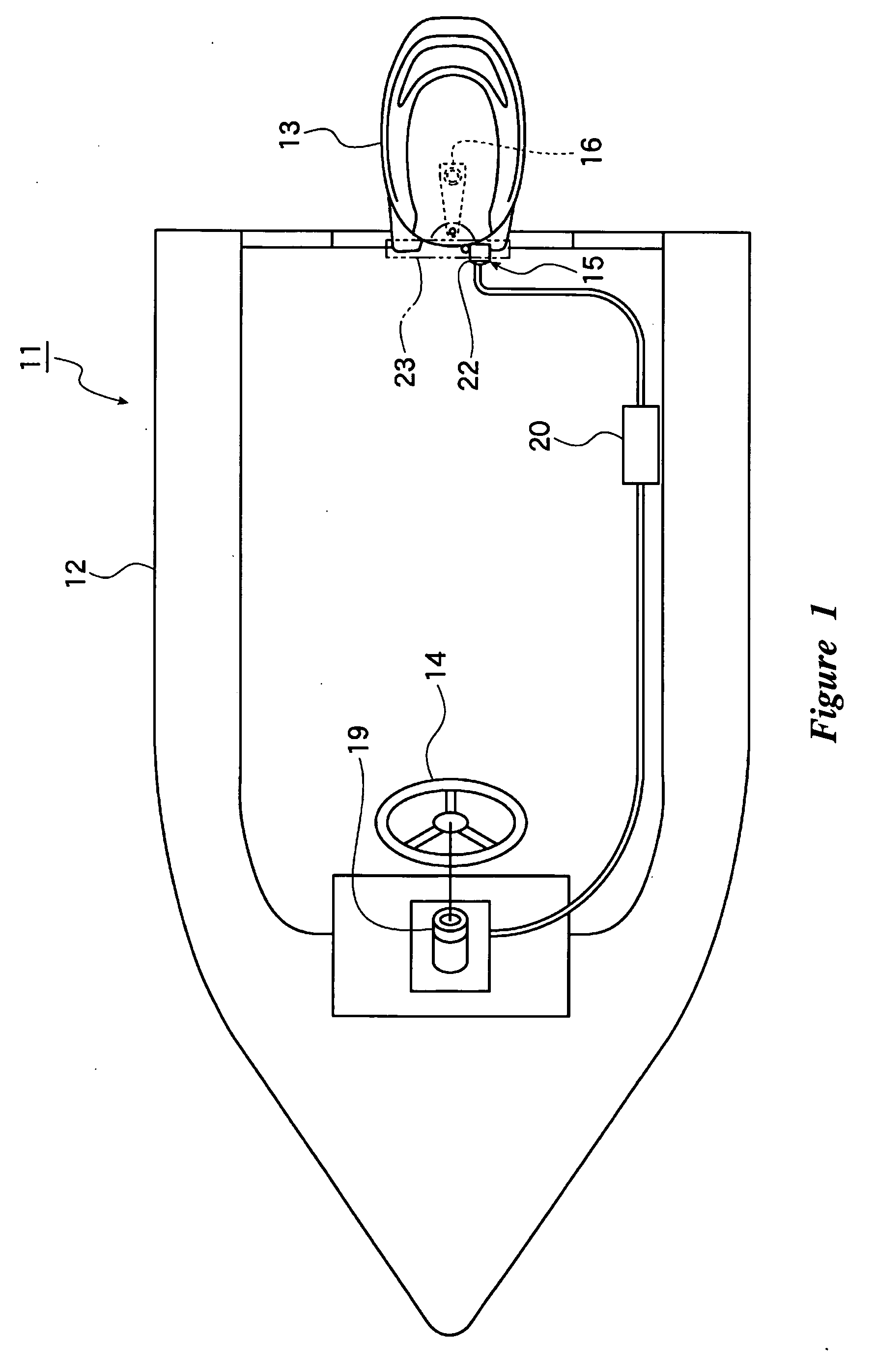

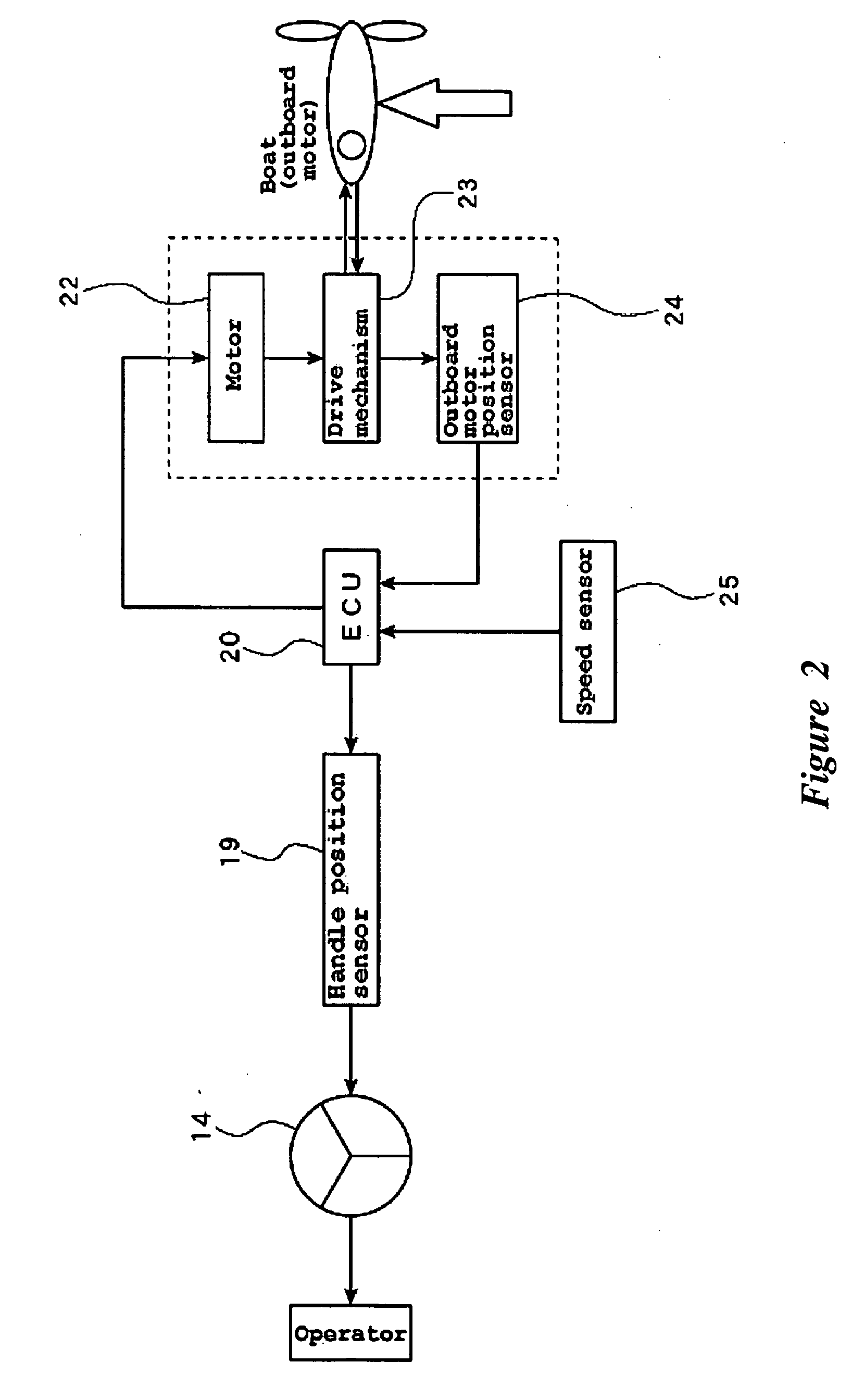

Steering control system for boat

ActiveUS20060180070A1Small rate of changePower plant using land vehicleSteering ruddersControl signalSteering control

A rudder control device for a boat can include a handle position sensor for detecting an operation angle of a handle. An engine control unit can be provided for receiving a detection signal from the handle position sensor. A motor can be provided for receiving a control signal from the engine control unit to drive a steering member to a predetermined rotation angle corresponding to the operation angle. The engine control unit can receive a signal from a speed sensor for detecting a boat speed to control an upper limit of the rotation angle to be smaller when the boat speed is higher than a predetermined value than when not.

Owner:YAMAHA MARINE KK

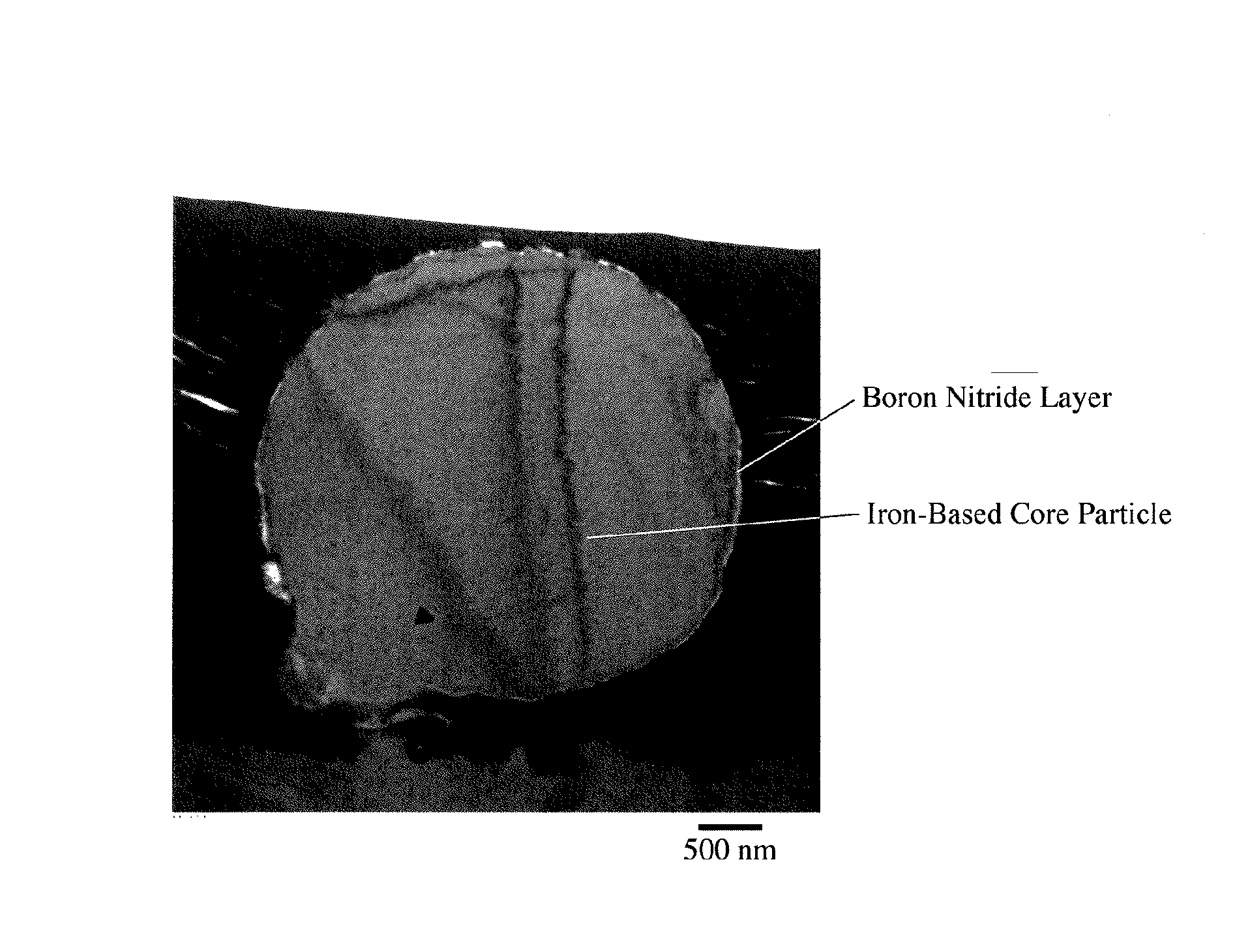

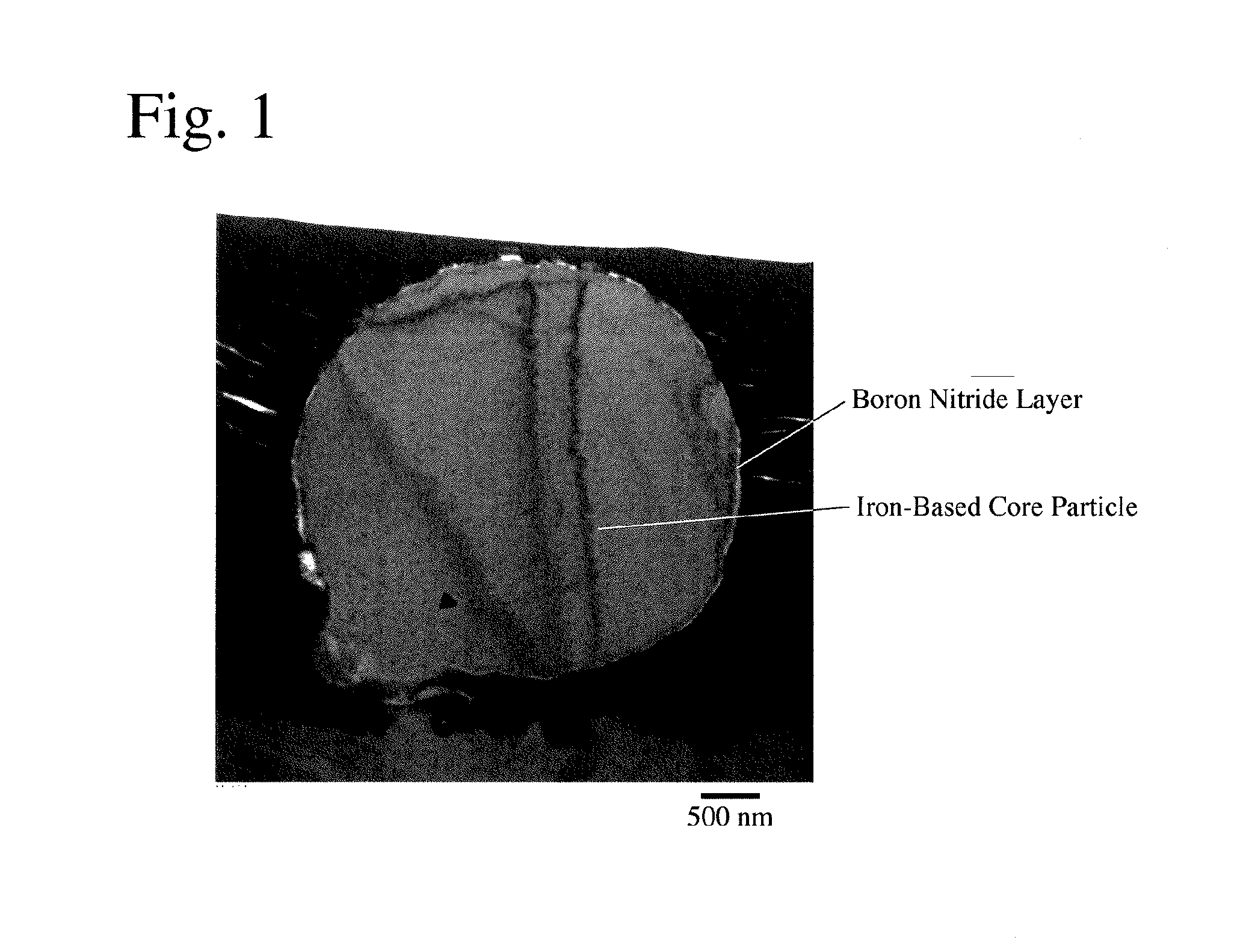

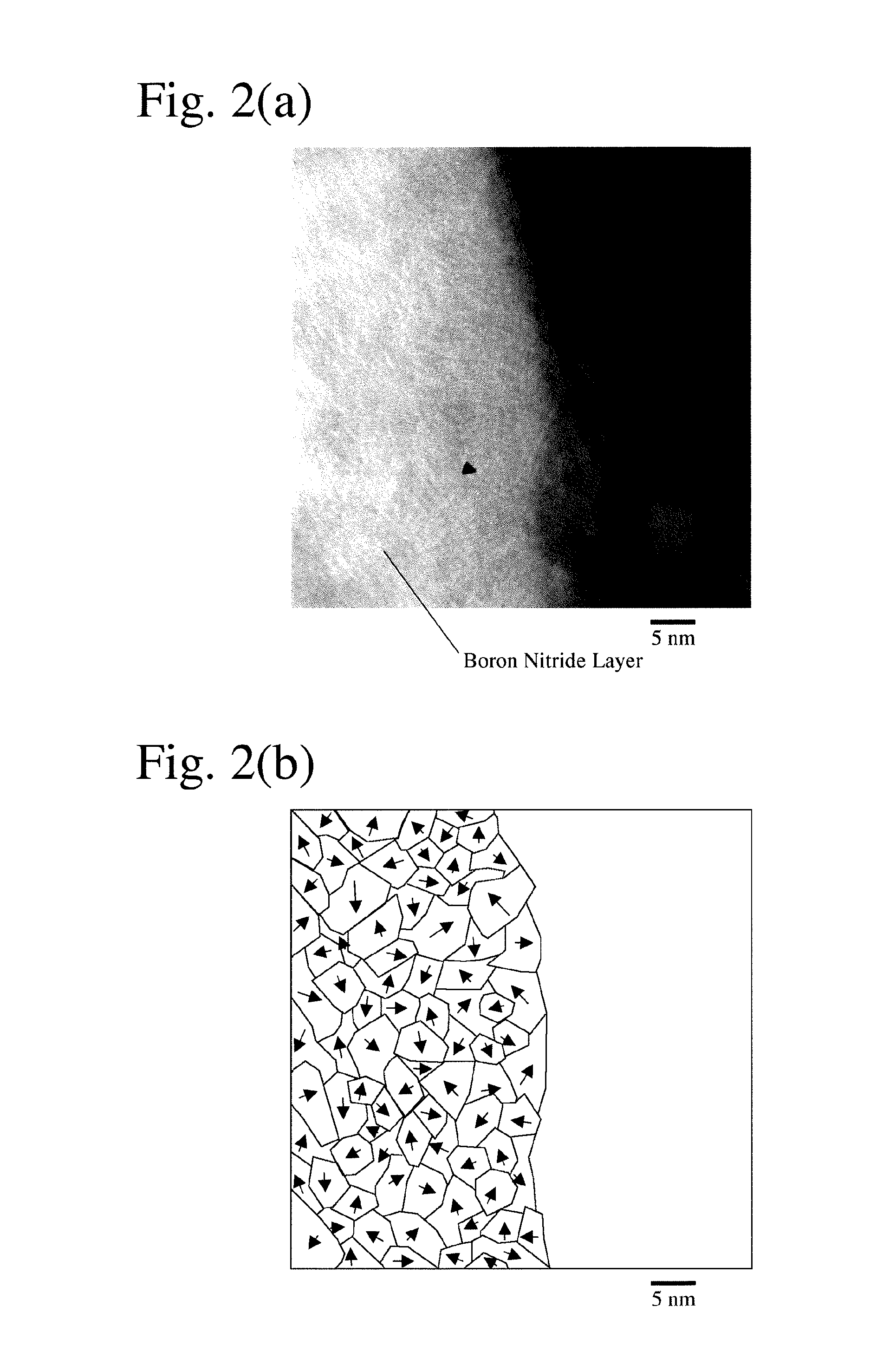

Composite, soft-magnetic powder and its production method, and dust core formed thereby

InactiveUS20130277601A1High densityImprove the lubrication effectLiquid surface applicatorsTransportation and packagingIron nitrideCrystal orientation

A composite, soft-magnetic powder comprising soft-magnetic, iron-based core particles having an average particle size of 2-100 μm, and boron nitride-based coating layers each covering at least part of each soft-magnetic, iron-based core particle, said coating layers being polycrystalline layers comprising fine boron nitride crystal grains having different crystal orientations and an average crystal grain size of 3-15 nm, the average thickness of said polycrystalline layers being 6.6% or less of the average particle size of said soft-magnetic, iron-based core particles, is produced by (1) mixing iron nitride powder having an average particle size of 2-100 μm with boron powder having an average particle size of 0.1-10 μm, (2) heat-treating the resultant mixed powder at a temperature of 600-850° C. in a nitrogen atmosphere, and (3) removing non-magnetic components.

Owner:HITACHI METALS LTD

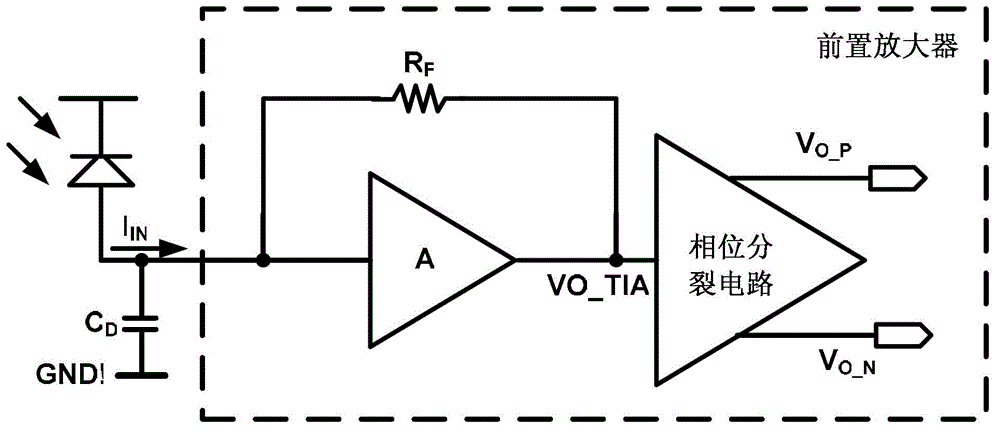

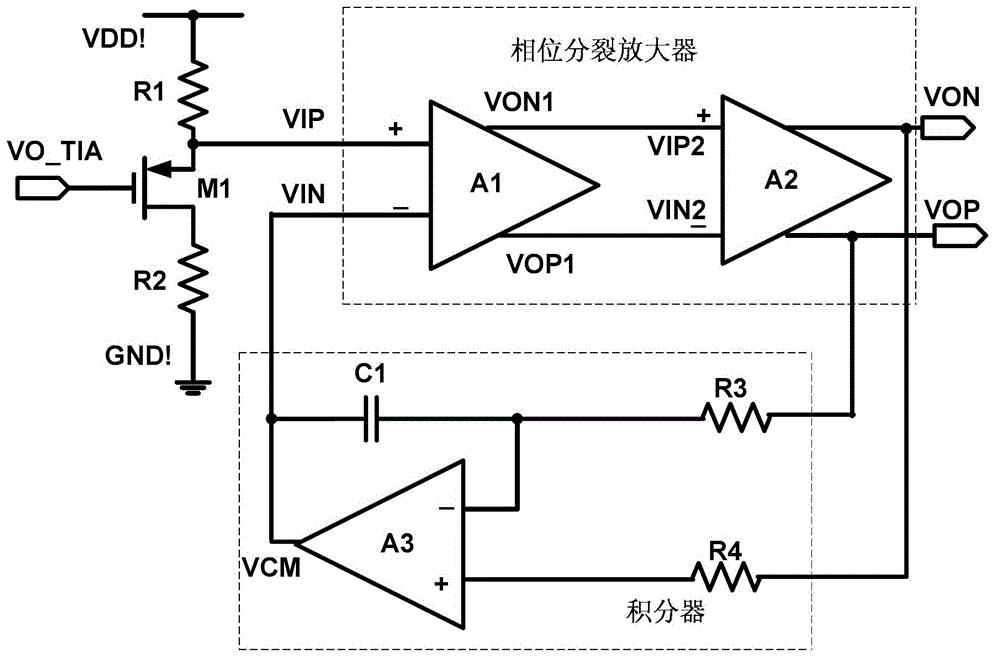

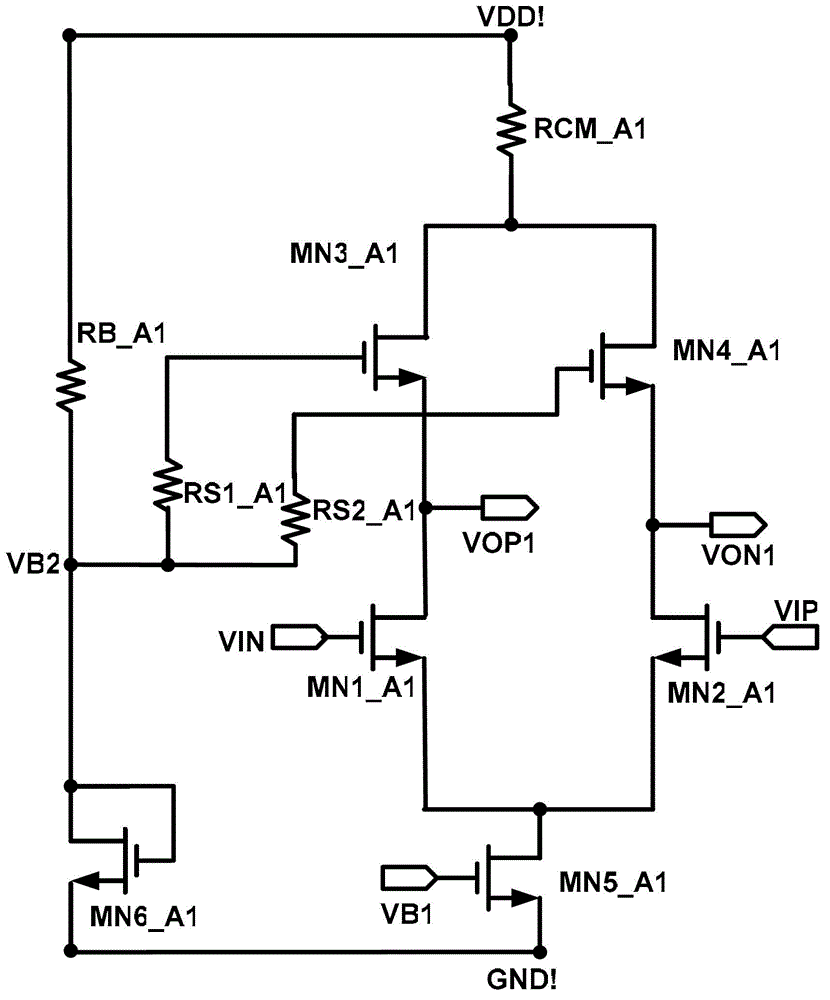

High-speed phase splitting circuit with band spreading function

InactiveCN102723916AWorking bandwidthIncrease working frequencyAmplifier modifications to extend bandwidthIntegratorPhase splitting

The invention discloses a high-speed phase splitting circuit with a band spreading function, belongs to the field of communication circuits, and aims to solve the problem of limitation of the bandwidth of a trans-impedance amplifier in the conventional phase splitting circuit on the working frequency of a pre-amplifier. The high-speed phase splitting circuit with the band spreading function comprises a first P-channel metal oxide semiconductor (PMOS) transistor M1, a resistor R1, a resistor R2, a phase splitting amplifier and an integrator, wherein the phase splitting amplifier is formed by cascading a first amplifier A1 and a second amplifier A2; the integrator consists of a third amplifier A3, a resistor R3, a resistor R4 and a capacitor C1; a source of the first PMOS transistor M1 is connected with a power supply through the resistor R1 and also connected with a non-inverting input end of the first amplifier A1, and a drain of the first PMOS transistor M1 is grounded through the resistor R2; two output ends of the second amplifier A2 are respectively connected with two input ends of the integrator; and the output end of the integrator is connected with an inverting input end of the first amplifier A1.

Owner:FUJIAN EOCHIP SEMICON CO LTD

Magnetic Sensor Including Resistor Array Including A Plurality Of Resistive Element Sections

ActiveCN105783684ASmall rate of changeMagnetic field detection sensitivity decreasesMagnetic measurementsElectric/magnetic position measurementsMagnetic reluctanceResistor

A magnetic sensor for detecting a component of an external magnetic field in a specific direction includes a resistor array including a plurality of resistive element sections each having a magnetoresistance element. Each of the plurality of resistive element sections has a different output characteristic curve with respect to the component of the external magnetic field in the specific direction.

Owner:TDK CORPARATION

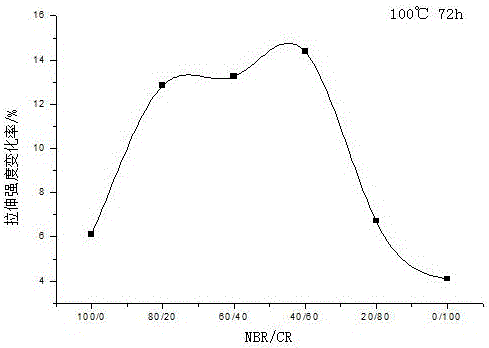

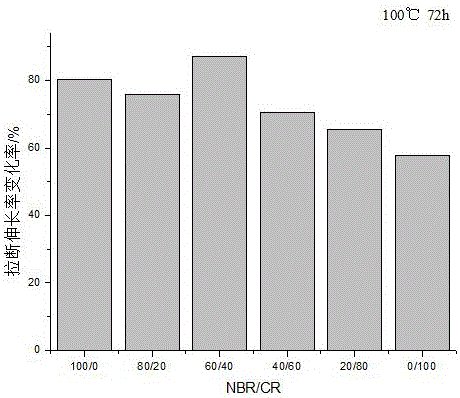

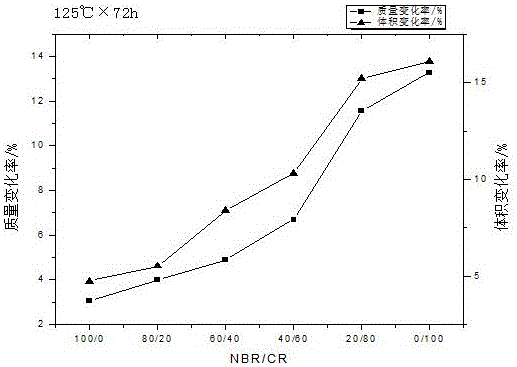

Insulated oil-resistant sealing rubber and preparation method thereof

InactiveCN105754162AGood oil resistanceGood resistance to non-polar solventsNitrile rubberPlasticizer

The invention discloses insulated oil-resistant sealing rubber. The insulated oil-resistant sealing rubber is prepared from the following raw materials in parts by mass: 40-80 parts of nitrile rubber, 20-60 parts of chloroprene rubber, 1-1.5 parts of an accelerant, 0.5-2 parts of sulfur, 0.8-3.2 parts of magnesium oxide, 4-5 parts of zinc oxide, 45-55 parts of carbon black, 2-4 parts of an anti-ageing agent, 2-3 parts of stearic acid and 10-15 parts of a plasticizer. The invention further discloses a preparation method for the rubber. The rubber has good processing performance, ageing resistance and oil resistance.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

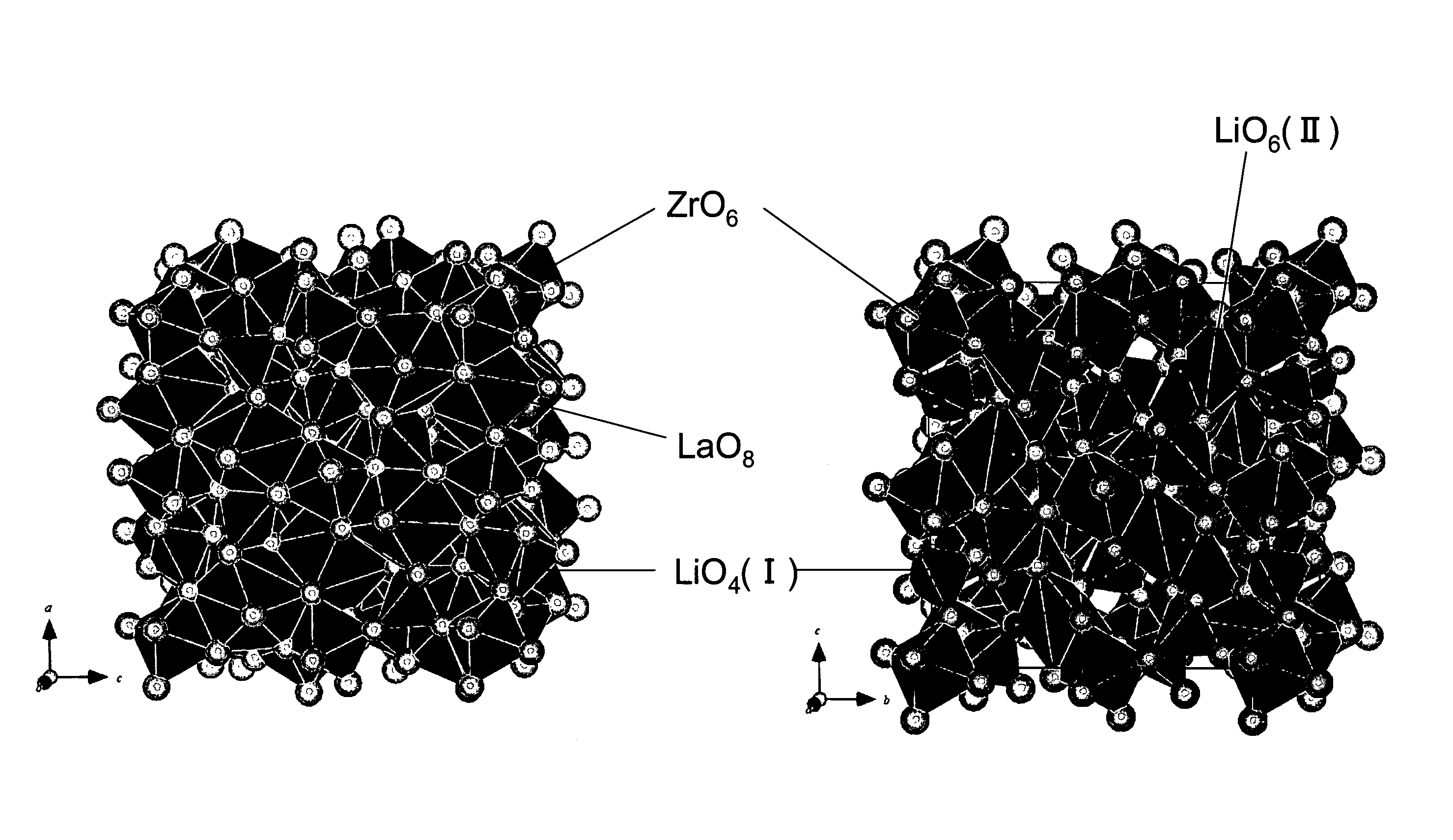

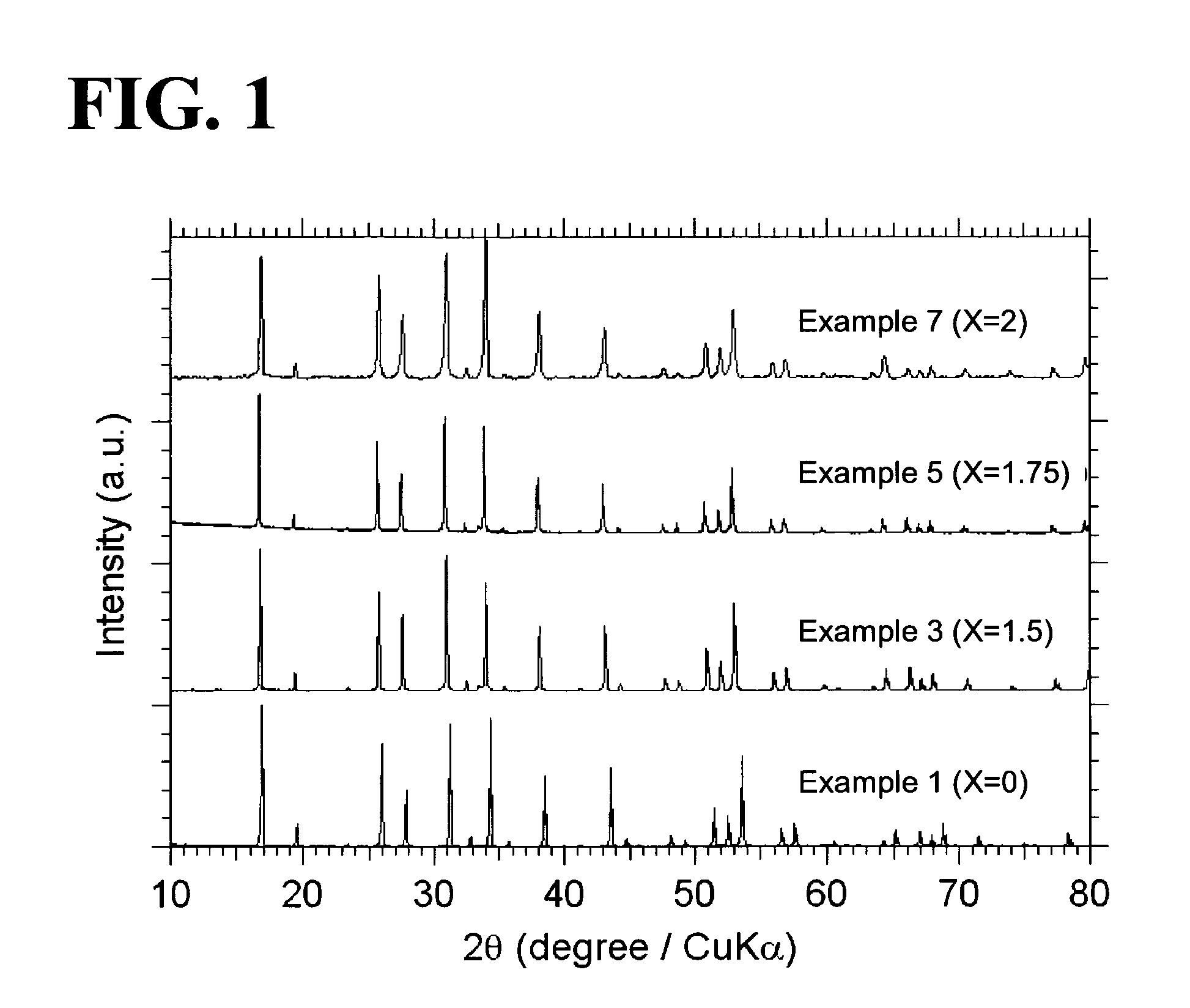

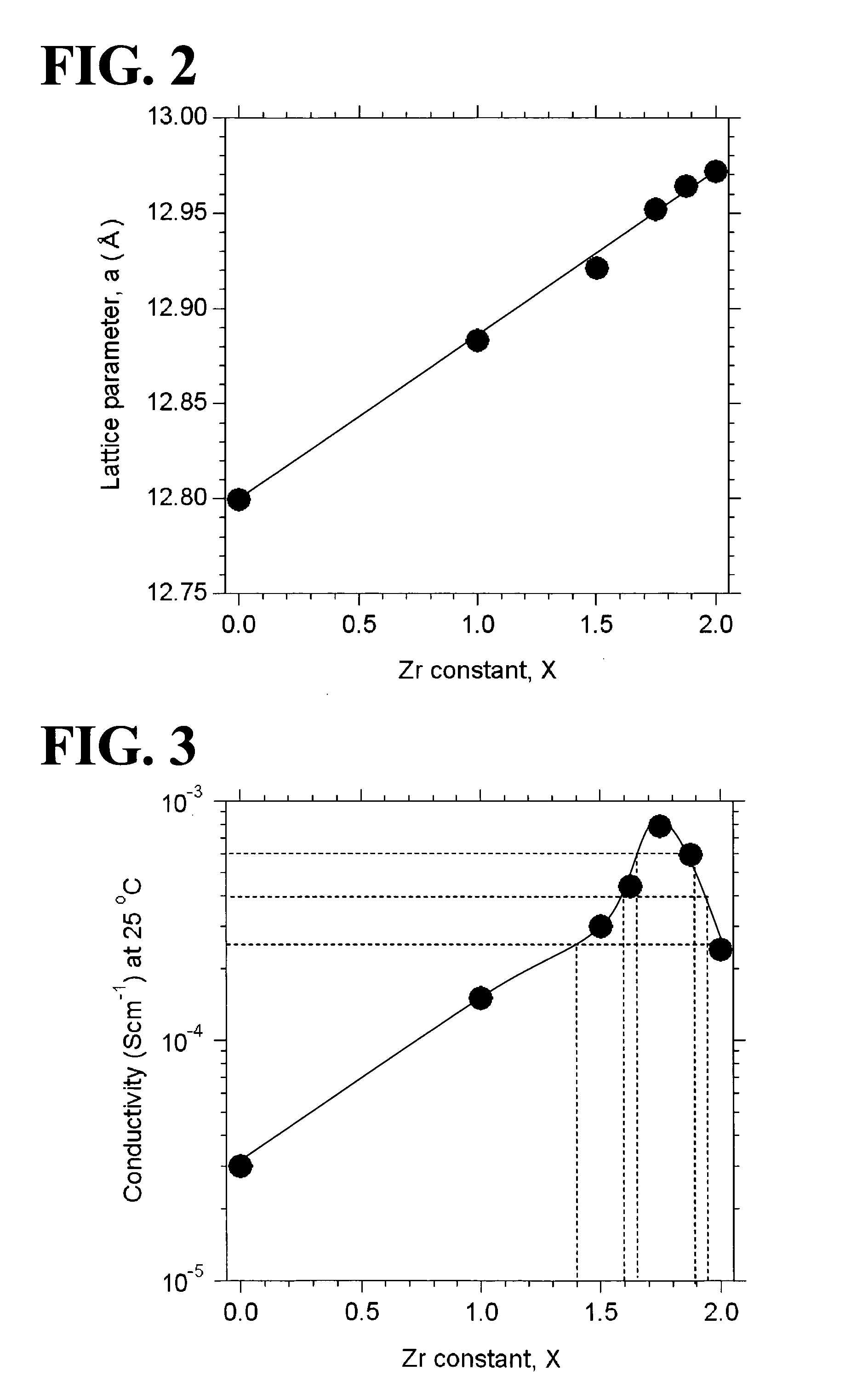

Garnet-type lithium ion-conducting oxide and all-solid-state lithium ion secondary battery containing the same

ActiveUS8986895B2Improve lithium ion conductivityWide potential windowOxygen/ozone/oxide/hydroxideIon-exchanger regenerationCrystallographyAll solid state

An all-solid-state lithium ion secondary battery containing a novel garnet-type oxide serving as a solid electrolyte. The garnet-type lithium ion-conducting oxide is one represented by the formula Li5+XLa3(ZrX, A2-X)O12, wherein A is at least one selected from the group consisting of Sc, Ti, V, Y, Nb, Hf, Ta, Al, Si, Ga, Ge, and Sn and X satisfies the inequality 1.4≦X<2, or is one obtained by substituting an element having an ionic radius different from that of Zr for Zr sites in an garnet-type lithium ion-conducting oxide represented by the formula Li7La3Zr2O12, wherein the normalized intensity of an X-ray diffraction (XRD) pattern with a diffraction peak, as normalized on the basis of the intensity of a diffraction peak, is 9.2 or more.

Owner:TOYOTA CENT RES & DEV LAB INC

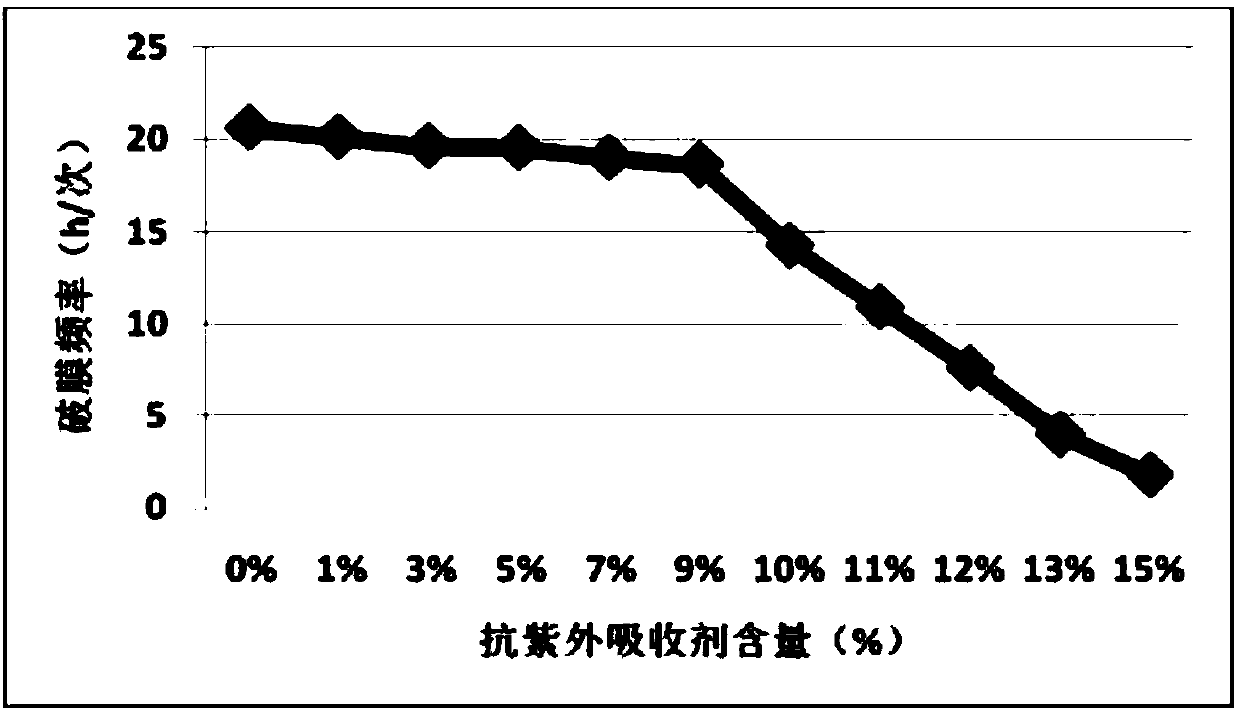

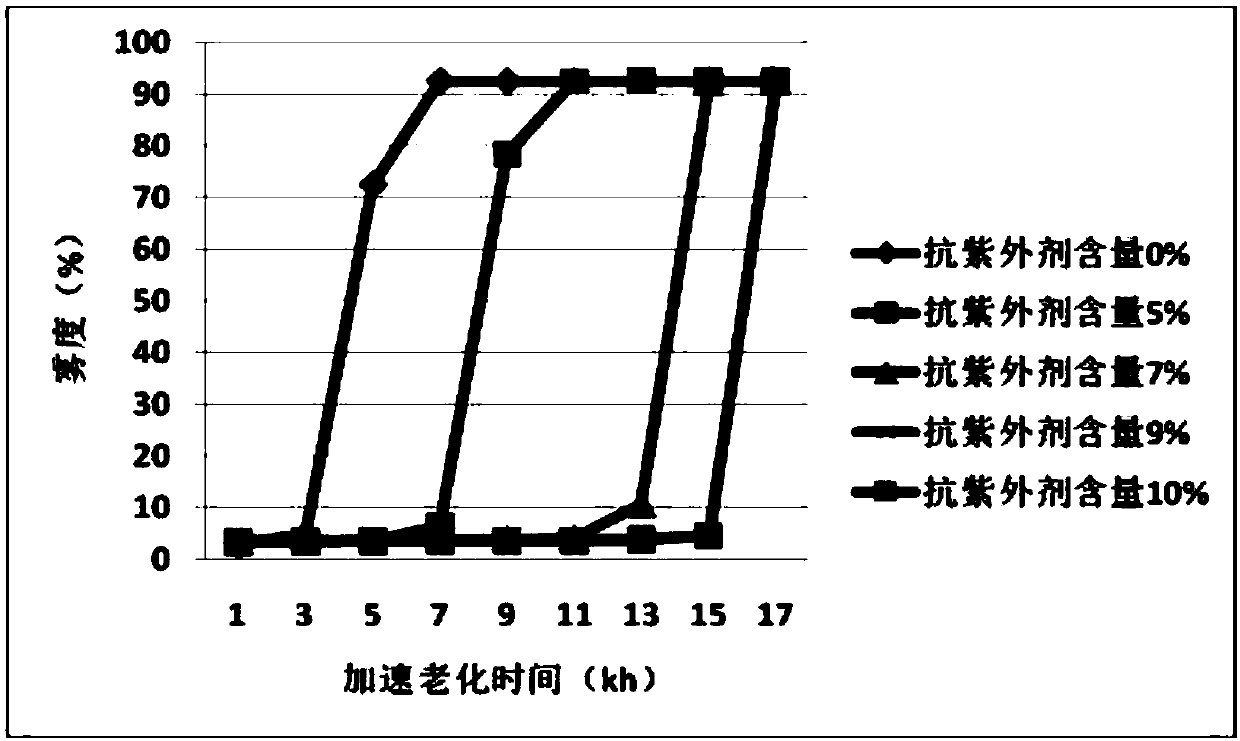

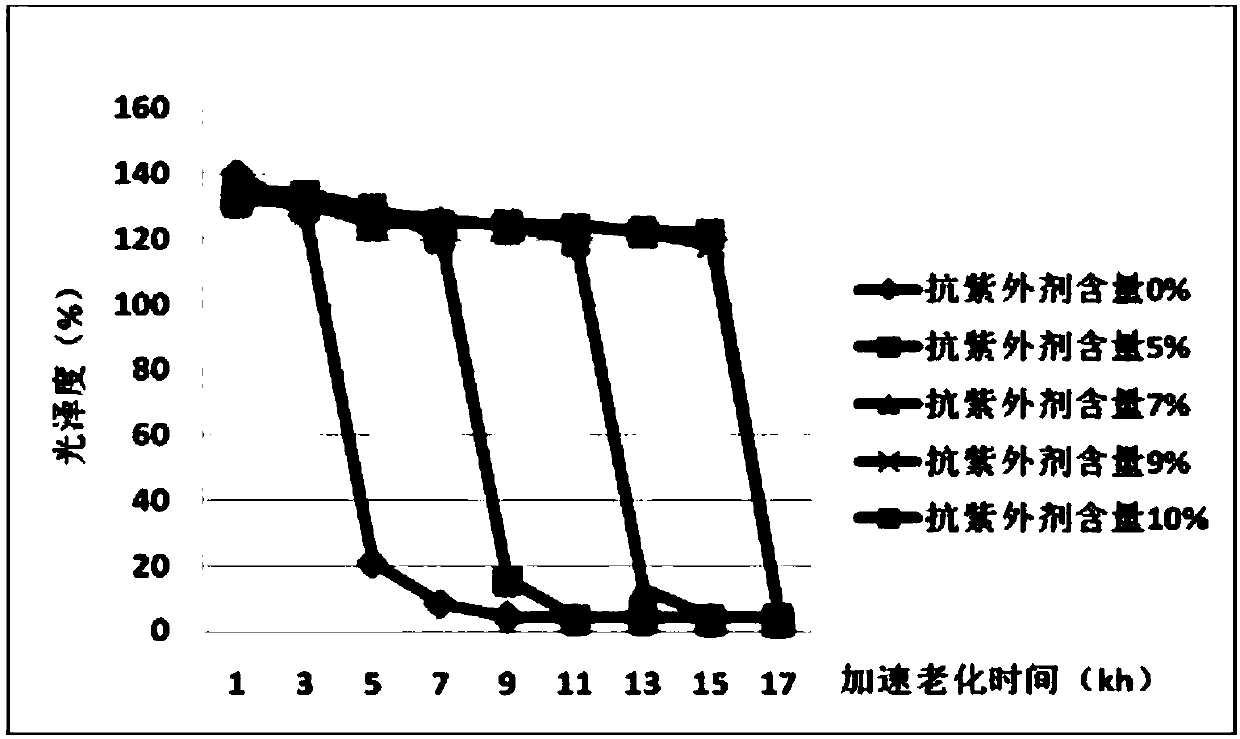

Anti-ultraviolet bidirectional stretching polyester film and preparation method thereof

InactiveCN107839323AImprove product performanceEnhanced anti-aging effectSynthetic resin layered productsFlat articlesPolyesterChemistry

The invention relates to an anti-ultraviolet bidirectional stretching polyester film and a preparation method thereof. The an anti-ultraviolet bidirectional stretching polyester film is composed of anupper surface layer, a core layer, and a lower surface layer. The core layer is composed of an anti-ultraviolet absorbent and polyethylene glycol terephthalate slice; the upper surface layer is composed of the anti-ultraviolet absorbent, an anti-adhesion agent, and the polyethylene glycol terephthalate slice; and the lower surface layer is composed of the anti-adhesion agent and the modified polyethylene glycol terephthalate slice. The product has the characteristics of UV resistance, heat sealing, high intensity, hydrolysis resistance, corrosion resistance, and high thermostability, can be widely used in the fields of outdoor product package and building, and belongs to the functional film, performance is outstanding, cost is low, and the method has a wide application prospect.

Owner:ANHUI GUOFENG PLASTIC

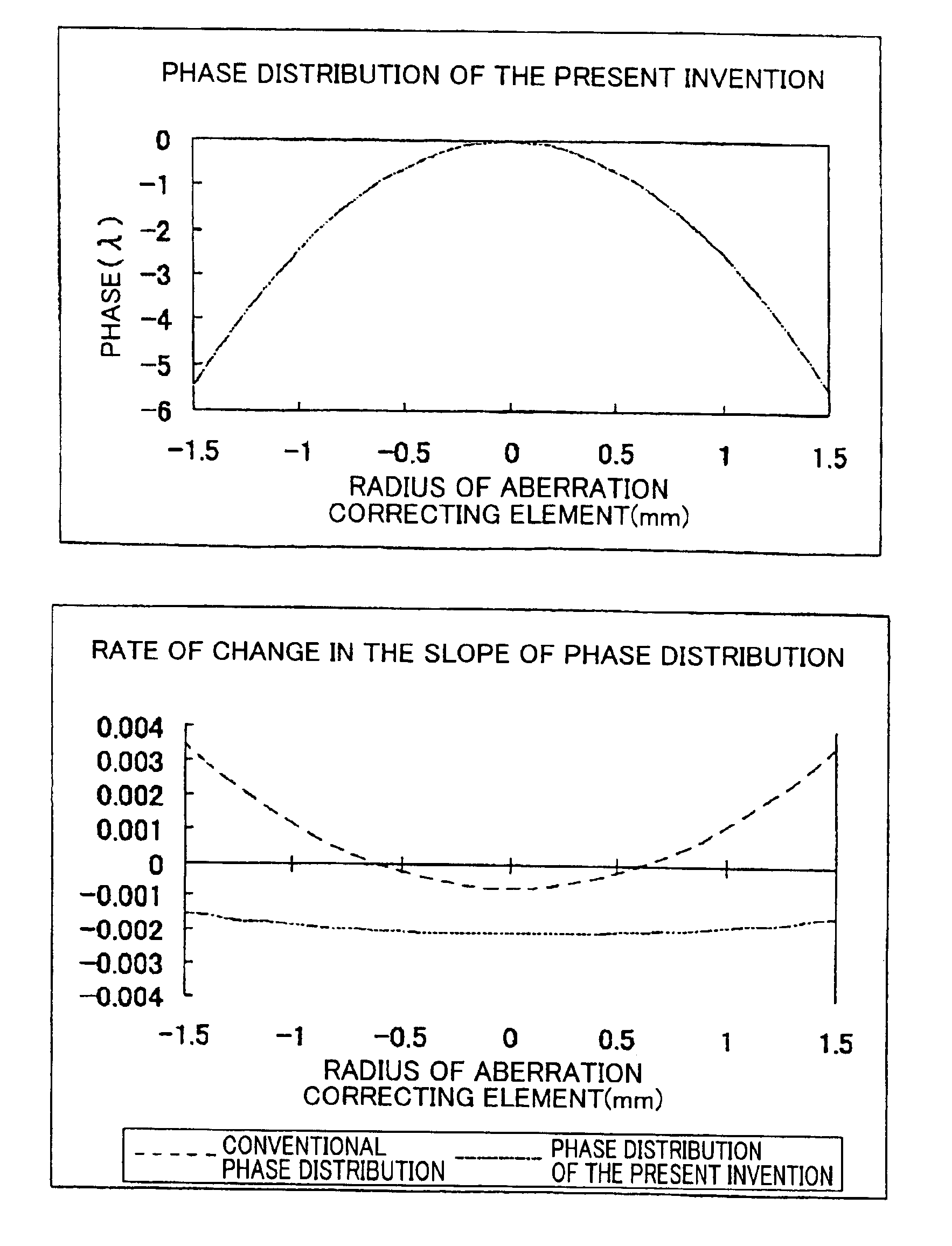

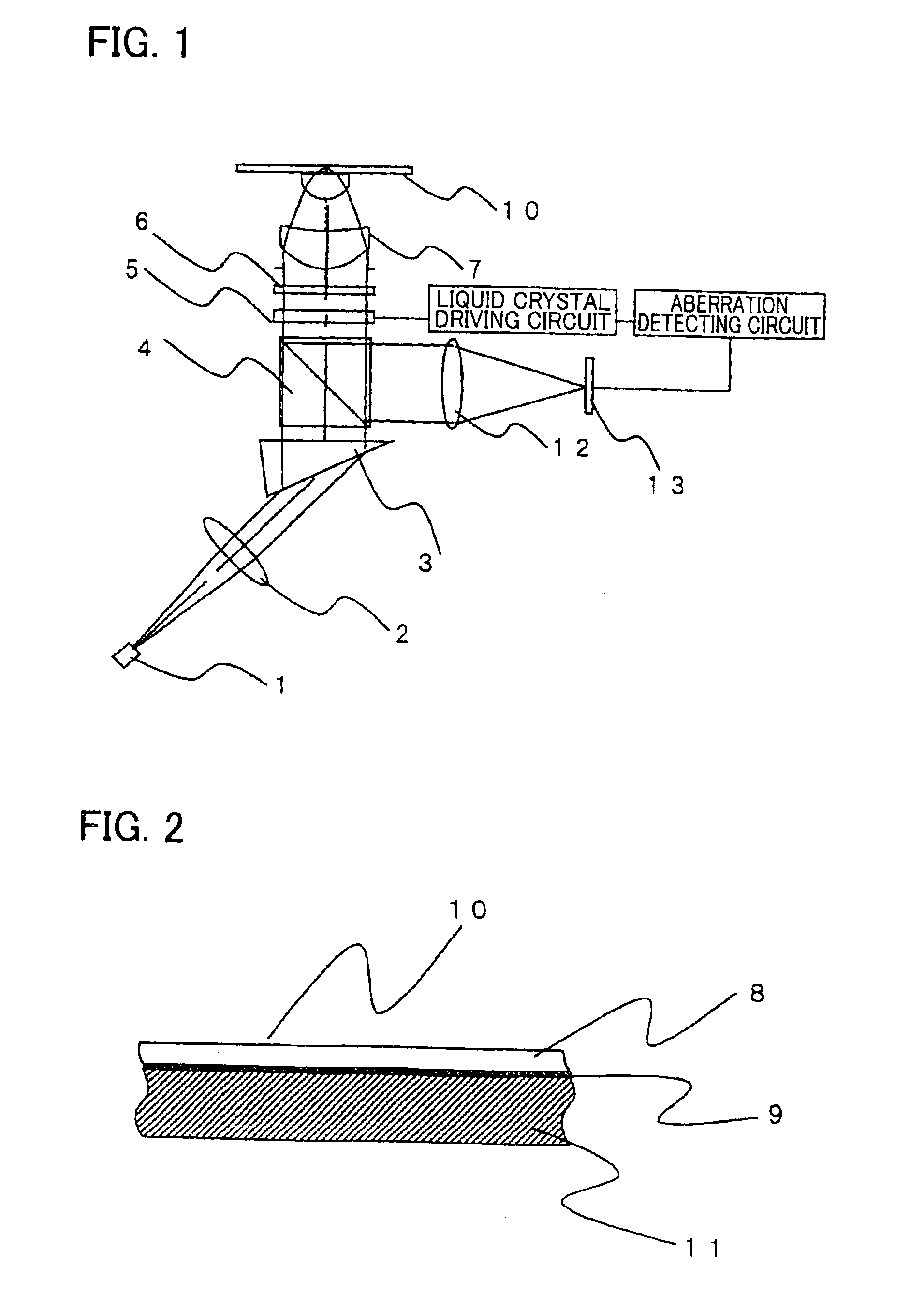

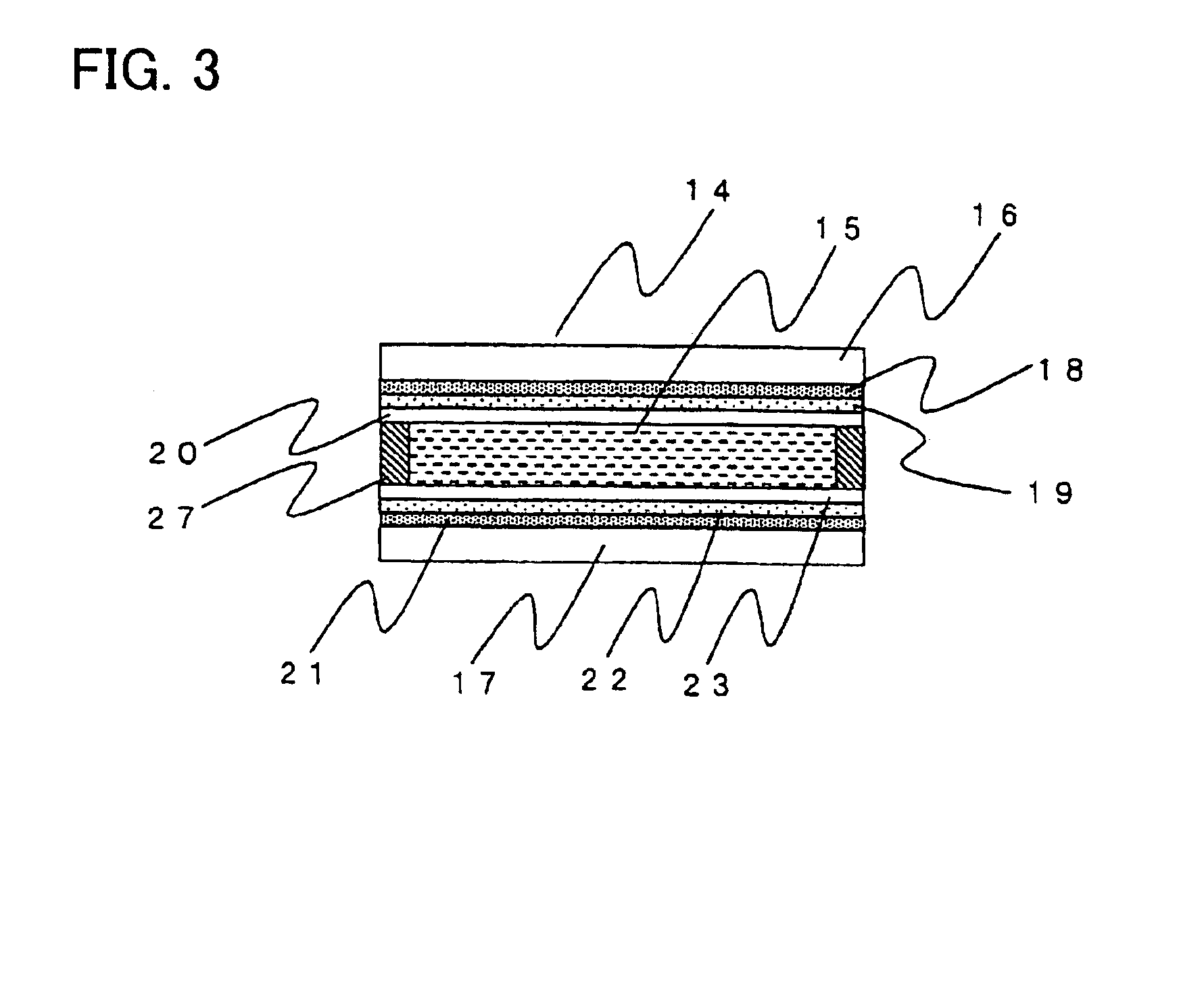

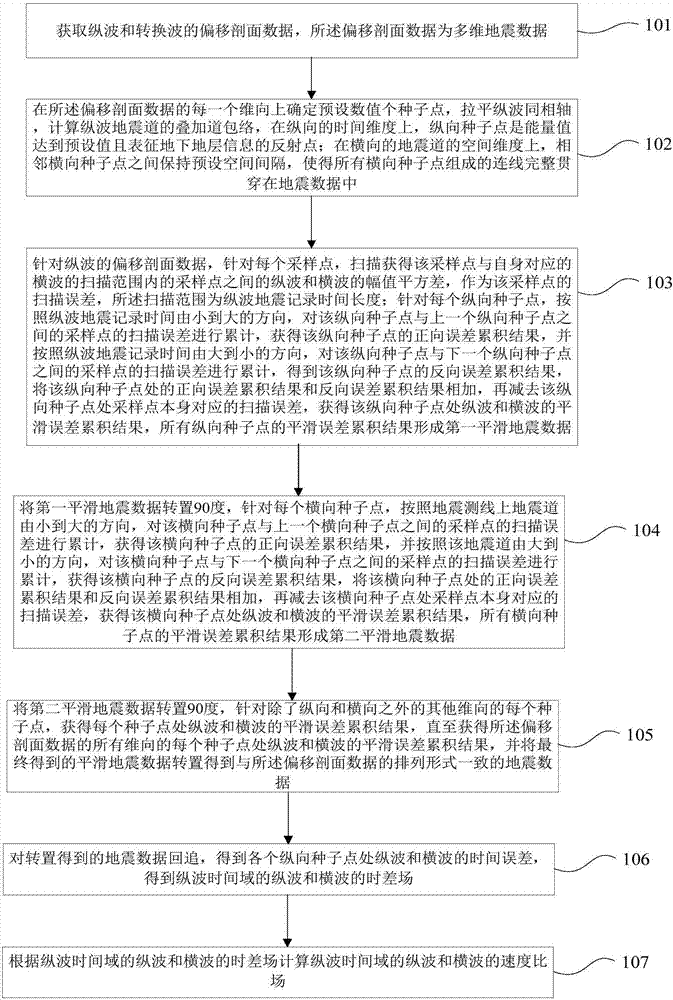

Optical pickup device

InactiveUS6937381B2Small rate of changeEasily realizedOptical beam sourcesRecord information storageOptical pickupOptical axis

An optical pickup device which includes (A) a light source, and (B) an objective lens and an aberration correcting optical system which are located in a light path from the light source to an optical recording medium is so arranged that the aberration correcting optical system imparts a phase distribution to luminous flux which transmits the aberration correcting optical system, so as to correct a predetermined aberration; and an amount of phase of the aberration correcting optical system when correcting the aberration is set in such a manner that the aberration correcting optical system imparts a larger amount of phase at a position farther from a point where the aberration correcting optical system crosses an optical axis of light emitted from the light source. With this, it is possible to increase a tolerance for the center misalignment of the objective lens so as to reduce aberration caused by the center misalignment.

Owner:SHARP KK

Clay light-weight brick and preparation method thereof

InactiveCN103435332ALarge reservesRealize comprehensive utilizationCeramic materials productionCeramicwareBrickPhysical chemistry

The invention relates to a clay light-weight brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps of: firstly applying 30-40wt% of kyanite or flint clay, 35-45wt% of coal ash and 15-35wt% of plastic clays as raw materials, additionally adding 35-55wt% of pore-forming agents of the raw materials or 2-4wt% of polystyrene spheres, then additionally adding 6-10wt% of bonding agents of the raw materials, uniformly mixing, granulating, drying, and baking at 120-300 DEG C to prepare clay light-weight aggregates; then applying 10-20wt% of first-stage aggregates, 20-30wt% of second-stage aggregates, 15-25wt% of three-stage aggregates, 15-25wt% of the coal ash, 10-20wt% of the kyanite or the flint clay and 10-20wt% of the plastic clays as mixed materials, additionally adding 40-60wt% of the pore-forming agents of the mixed materials or 2-4wt% of the polystyrene spheres, then additionally adding 5-15wt% of the bonding agents of the mixed materials, uniformly mixing, forming, drying, and keeping temperature at 1200-1400 DEG C for 3-10 hours. The preparation method disclosed by the invention has the advantages of low cost, energy conservation and environmental friendliness; the product prepared through the method disclosed by the invention has the advantages of low volume density, good compressive strength as well as small linear changing rate and low heat conduction coefficient after being burnt.

Owner:WUHAN UNIV OF SCI & TECH

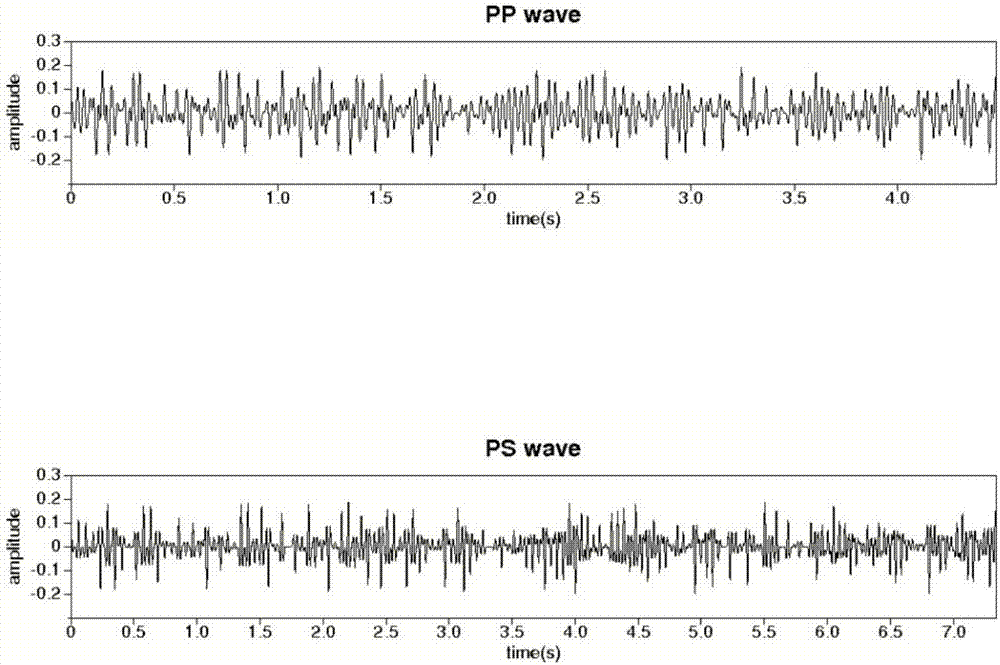

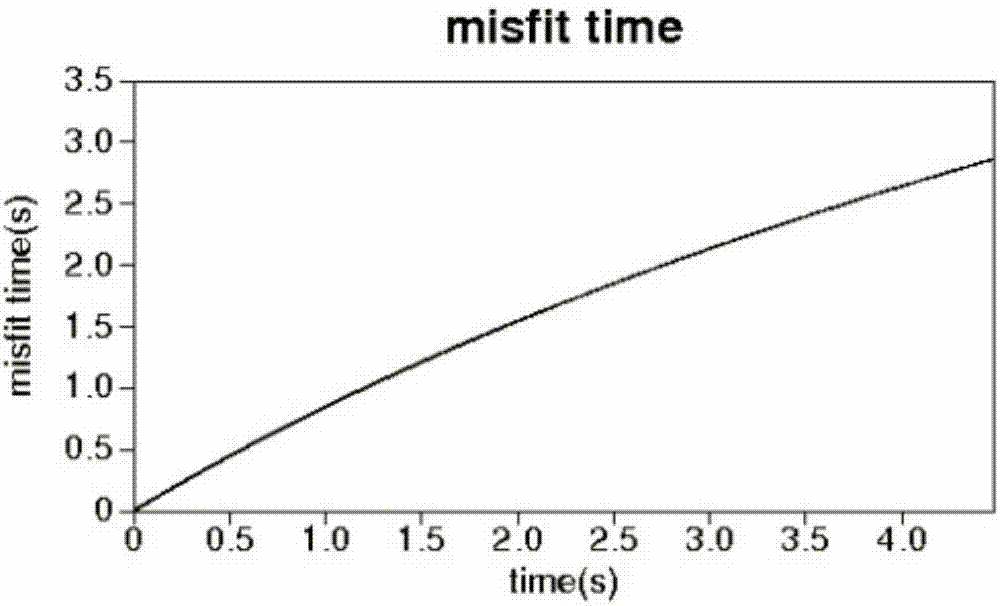

Multiwave time domain matching method and device

ActiveCN107167843AImprove stabilitySmall rate of changeSeismic signal processingTime domainLongitudinal wave

The embodiment of the invention provides a multiwave time domain matching method and device. The method comprises steps of determining preset numbers of seed points in each dimensional direction of deviation profile data; for the deviation profile data of longitudinal waves, acquiring smoothing error accumulation results of the longitudinal waves and the transverse waves at the seed points, wherein the smoothing error accumulation results of all longitudinal seed points form first smoothing earthquake data; transposing the first smoothing earthquake for 90 degrees to acquire smoothing error accumulation results of the longitudinal waves and transverse waves at the seed points, wherein the smoothing error accumulation results of all transverse seed points form second smoothing earthquake data; transposing the second smoothing earthquake for 90 degrees, and acquiring smoothing error accumulation results of the longitudinal waves and the transverse waves at each of seed points in other dimensional directions except for longitudinal and transverse directions; backtracking earthquake data obtained through the transposition to obtain time difference field of the longitudinal waves and the transverse waves of the longitudinal wave time domain; and according to the time difference field, calculating speed ratios of the longitudinal waves and the transverse waves of the longitudinal wave time domain.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

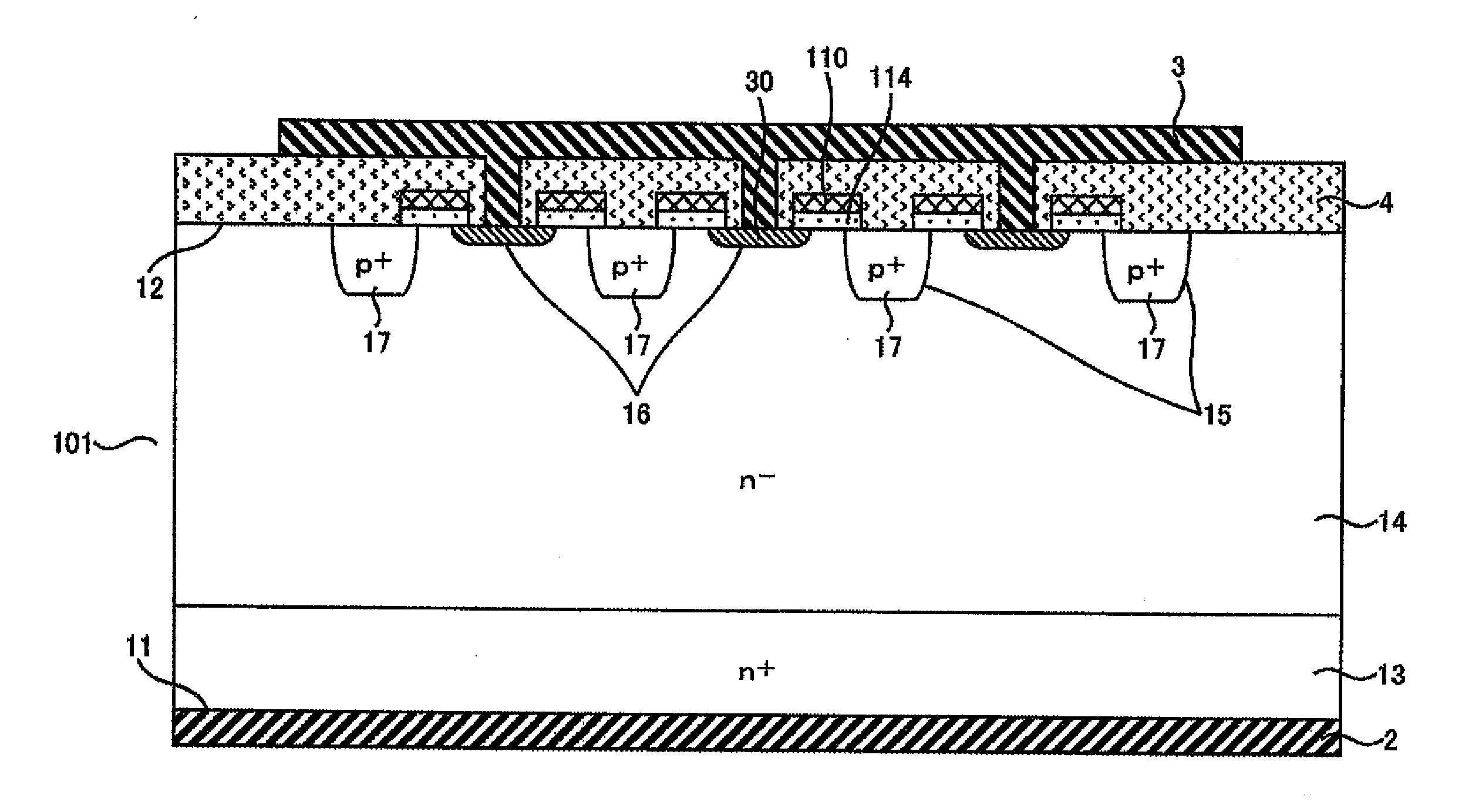

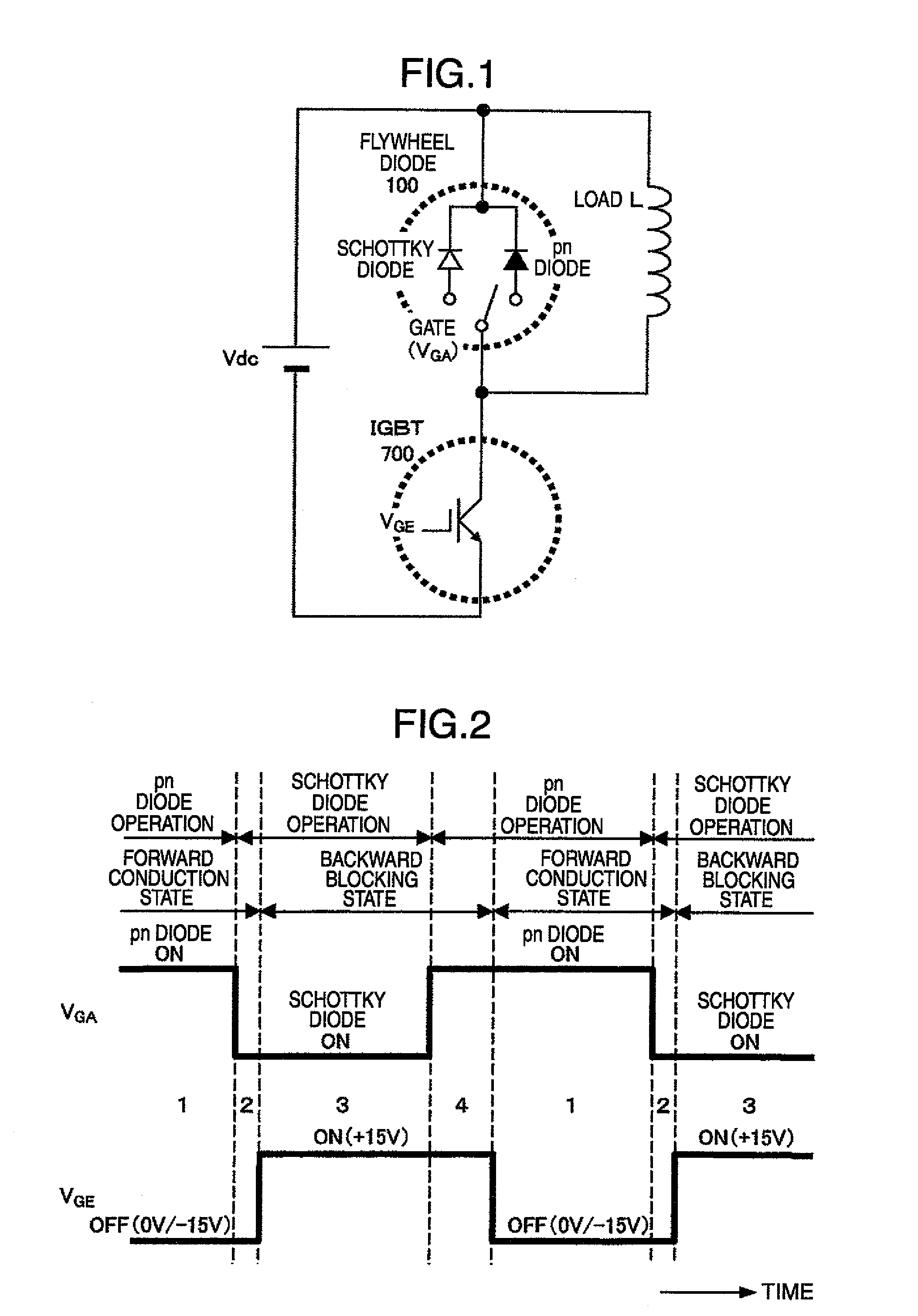

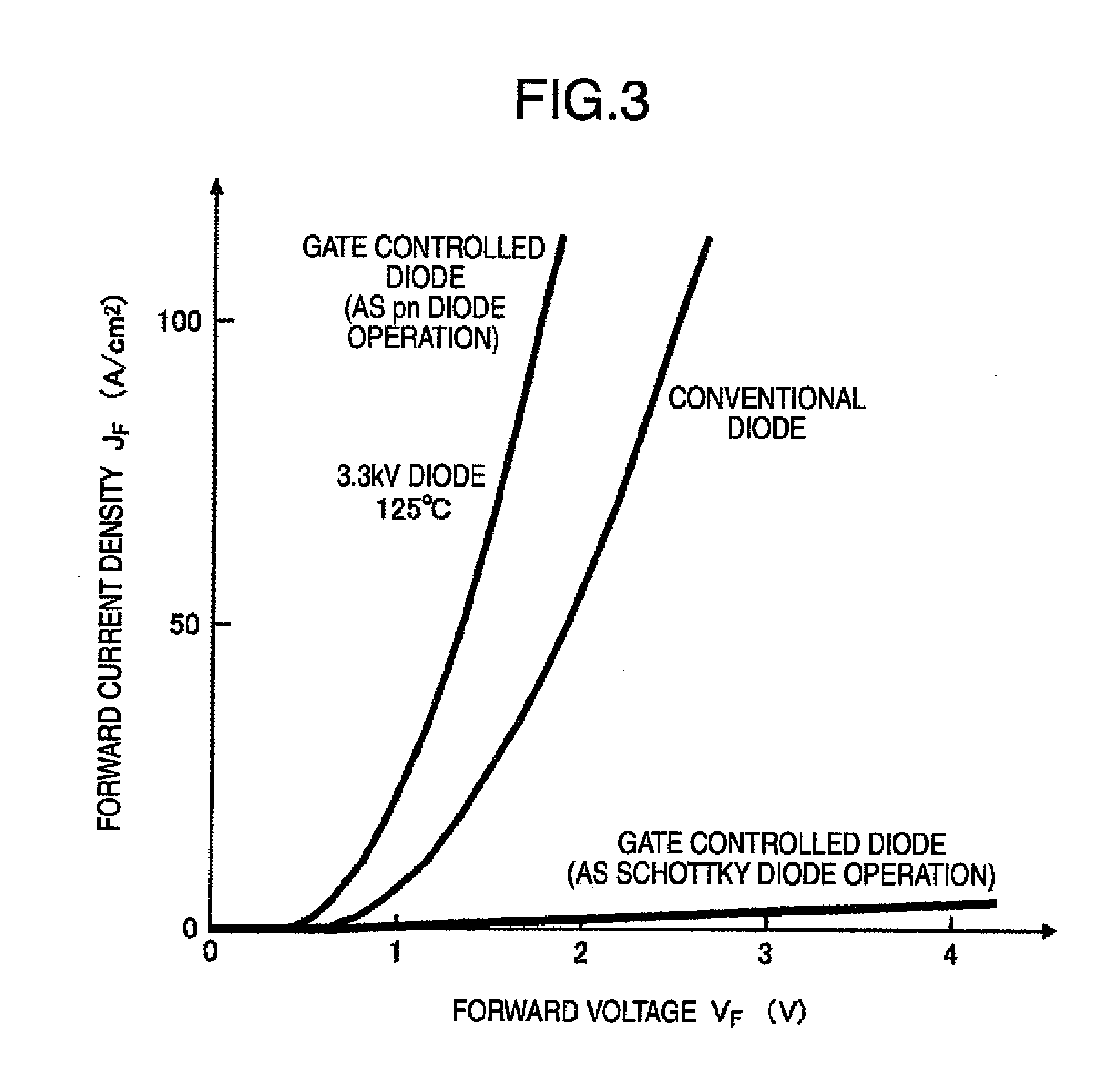

Semiconductor device and power converter using it

ActiveUS20110073905A1Lower forward voltage dropTotal current dropTransistorSolid-state devicesFlyback diodeSchottky diode

A semiconductor device and a power converter using it wherein a switching power device and a flywheel diode are connected in series, the flywheel diode includes a region having a Schottky junction to operate as a Schottky diode and a region having a pn junction to operate as a pn diode and control operation is performed such that when current flows forwardly through the flywheel diode, the pn diode operates and when the flywheel diode recovers backwardly, the Schottky diode operates mainly.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com