Patents

Literature

398 results about "Turbopump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A turbopump is a propellant pump with two main components: a rotodynamic pump and a driving gas turbine, usually both mounted on the same shaft, or sometimes geared together. The purpose of a turbopump is to produce a high-pressure fluid for feeding a combustion chamber or other use.

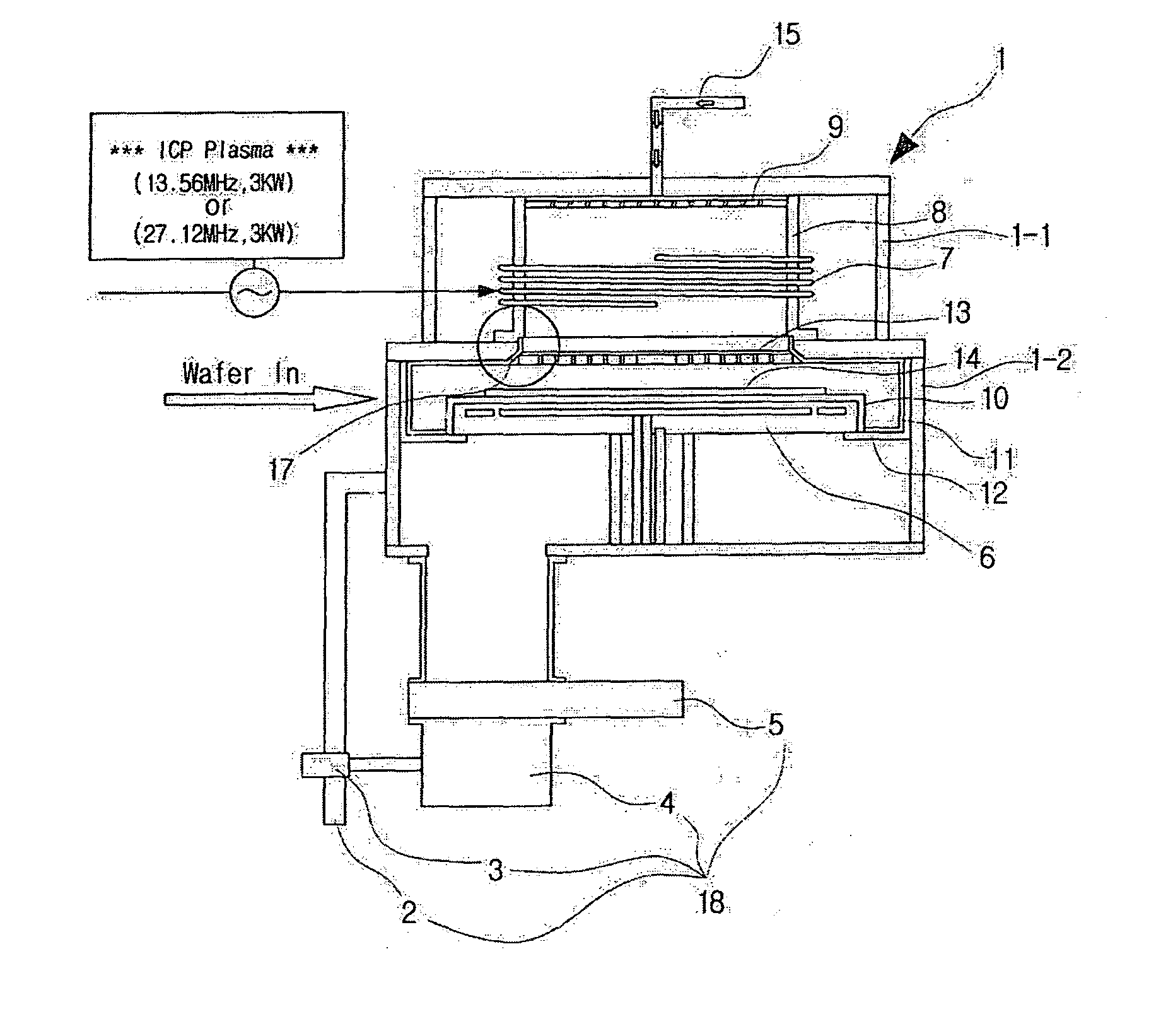

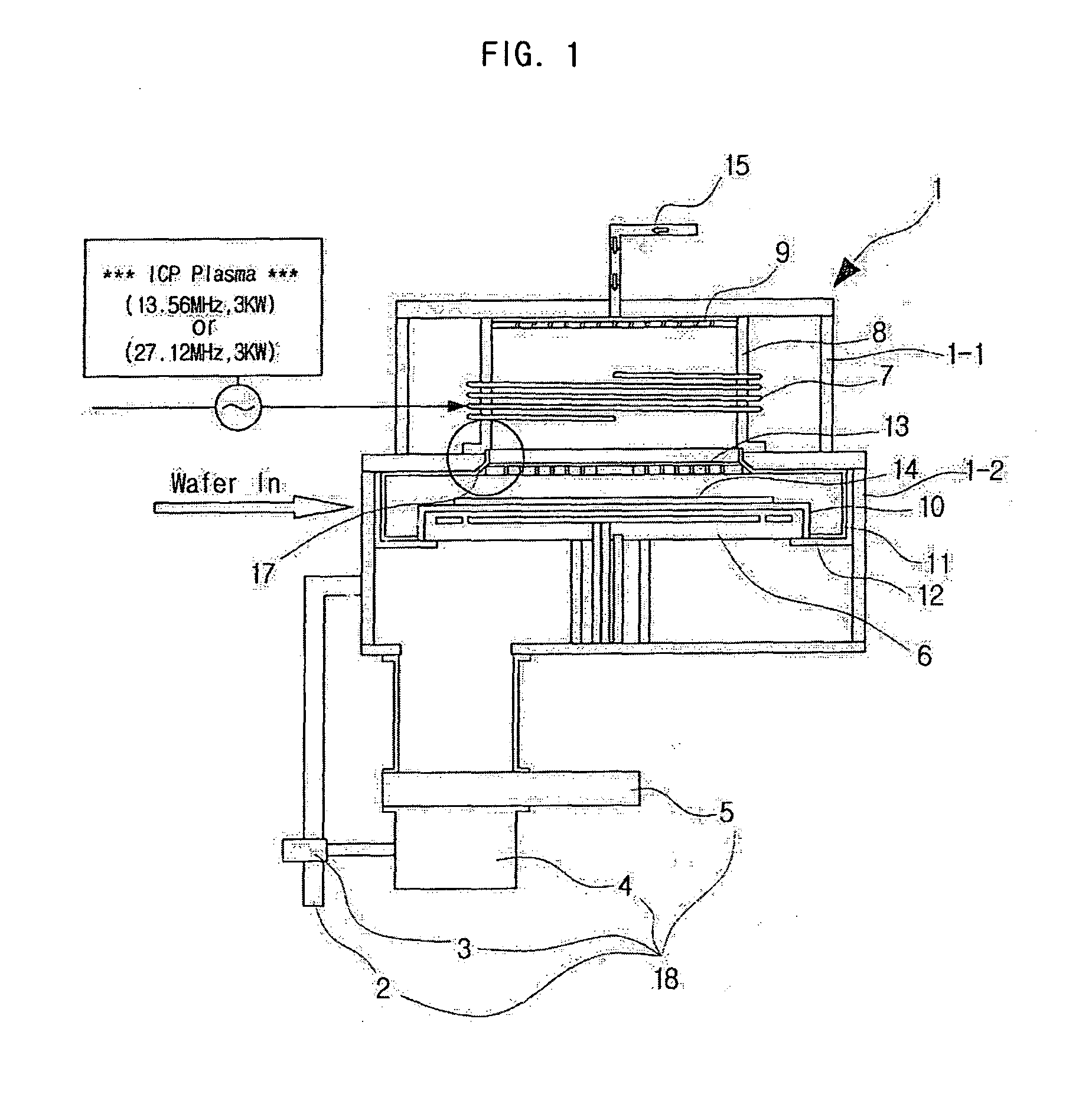

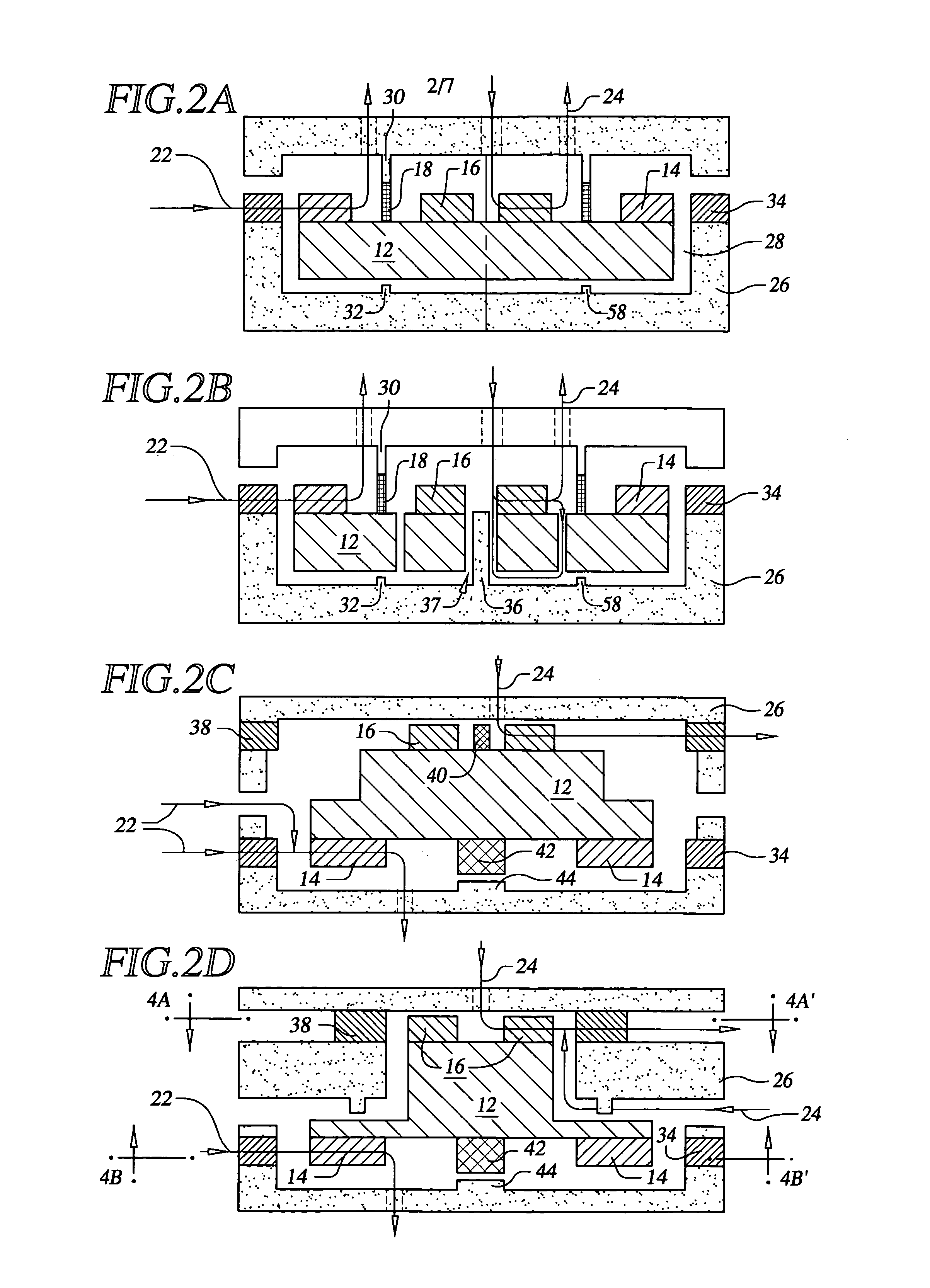

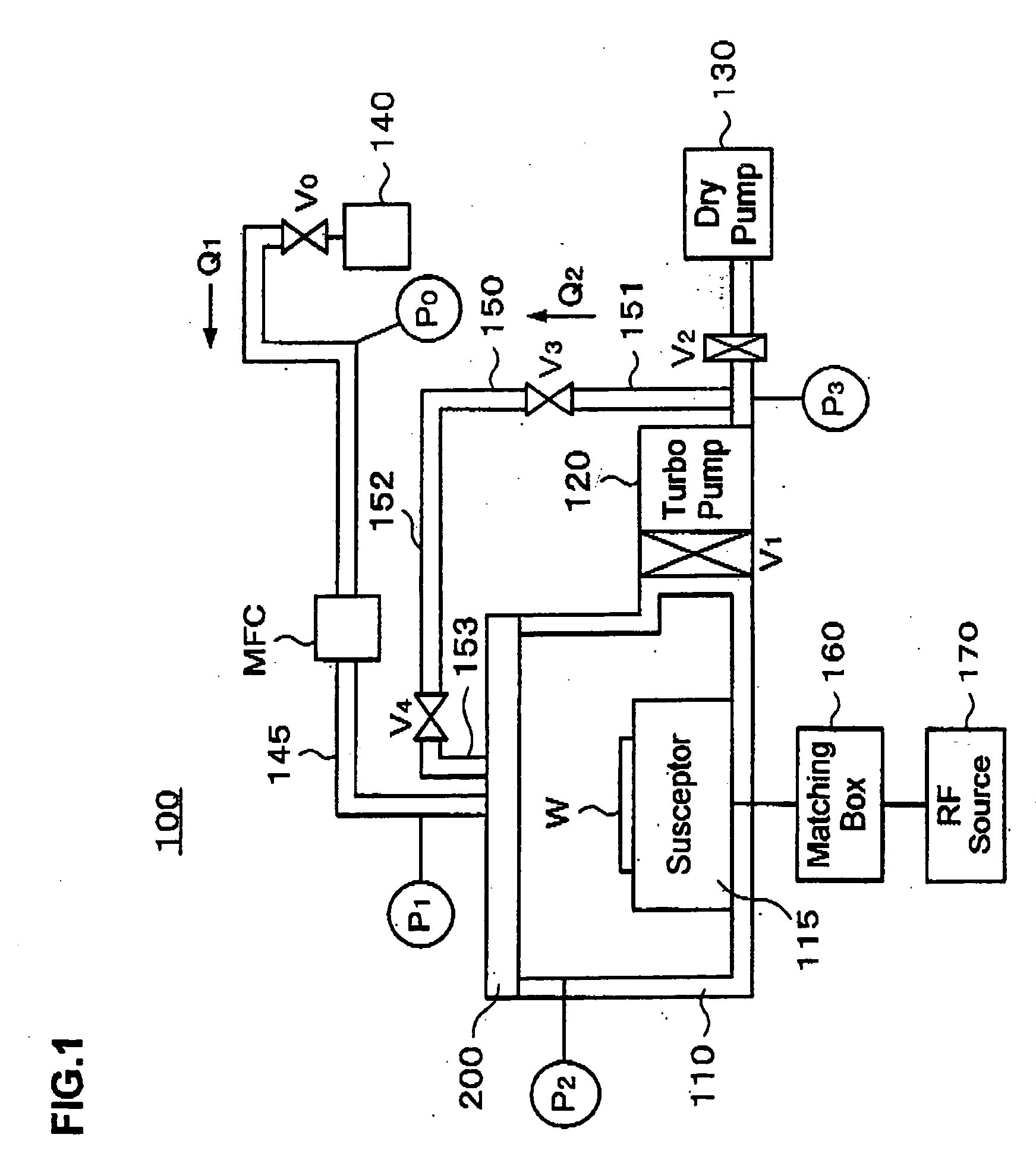

Apparatus for surface-treating wafer using high-frequency inductively-coupled plasma

InactiveUS20100243165A1Well formedPrevent characteristic deteriorationElectric discharge tubesSemiconductor/solid-state device manufacturingInductively coupled plasmaEngineering

Disclosed herein is an apparatus for surface-treating a wafer using high-frequency inductively-coupled plasma, including a process chamber including a plasma generation unit into which a reaction gas is introduced and which generates plasma, and a wafer treatment unit in which any one or more selected from among plasma treatment, thin film formation and etching is performed; and a pressure control unit including a vacuum plate, and a pumping port, a two-stage valve, a turbo pump and an APC valve which are organically connected with the vacuum plate, to control a pressure in the process chamber and a pumping rate.

Owner:EUGENE TECH CO LTD

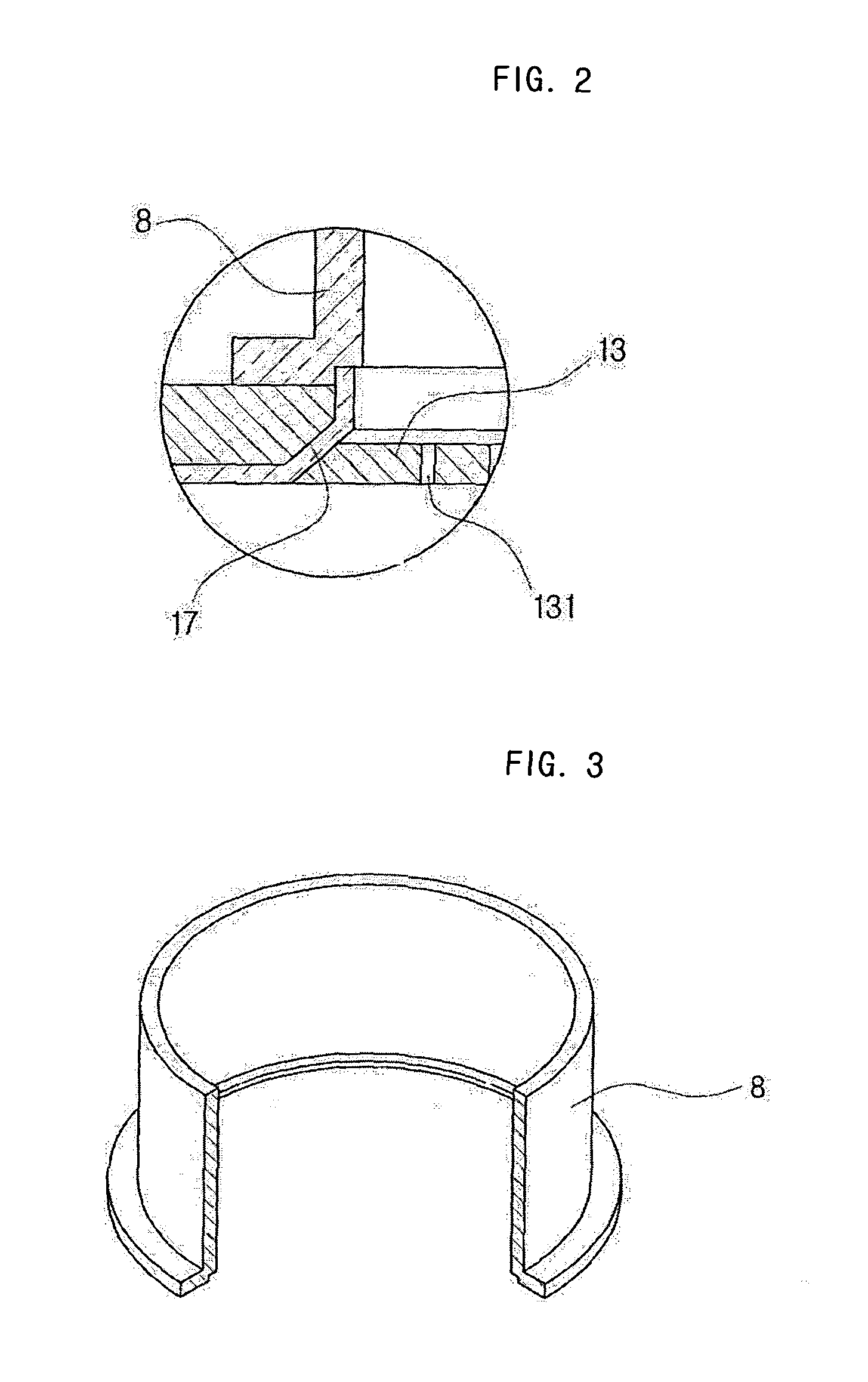

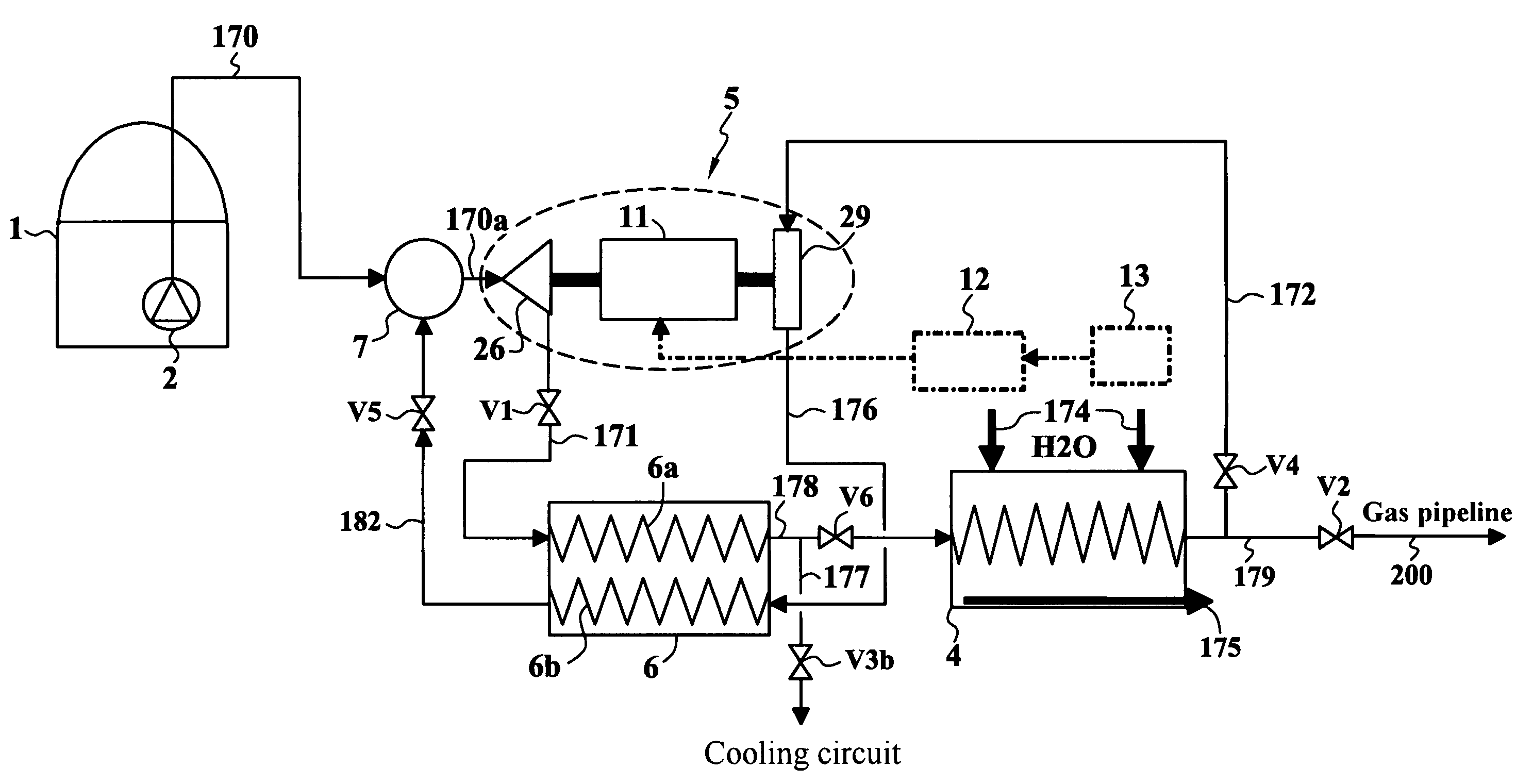

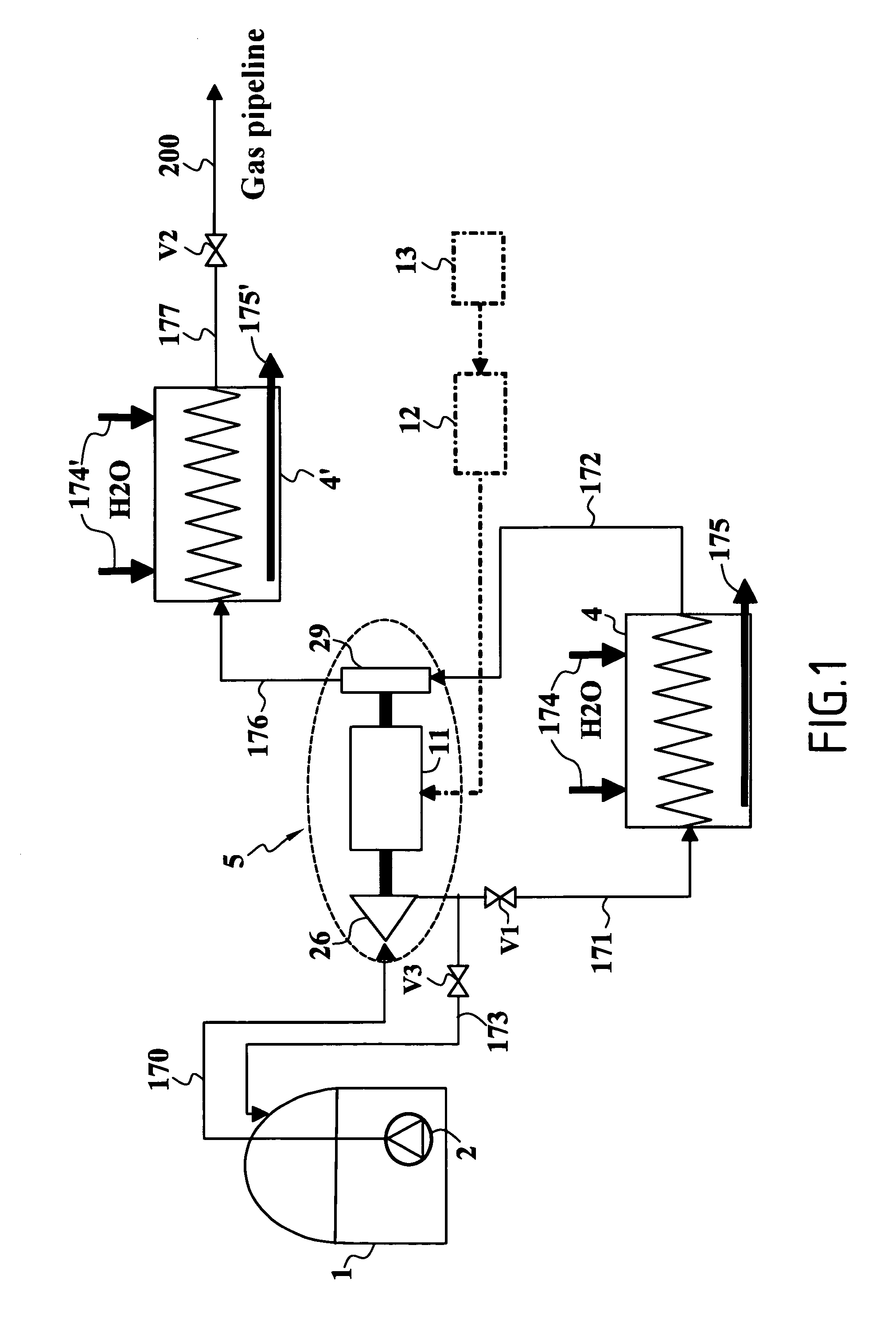

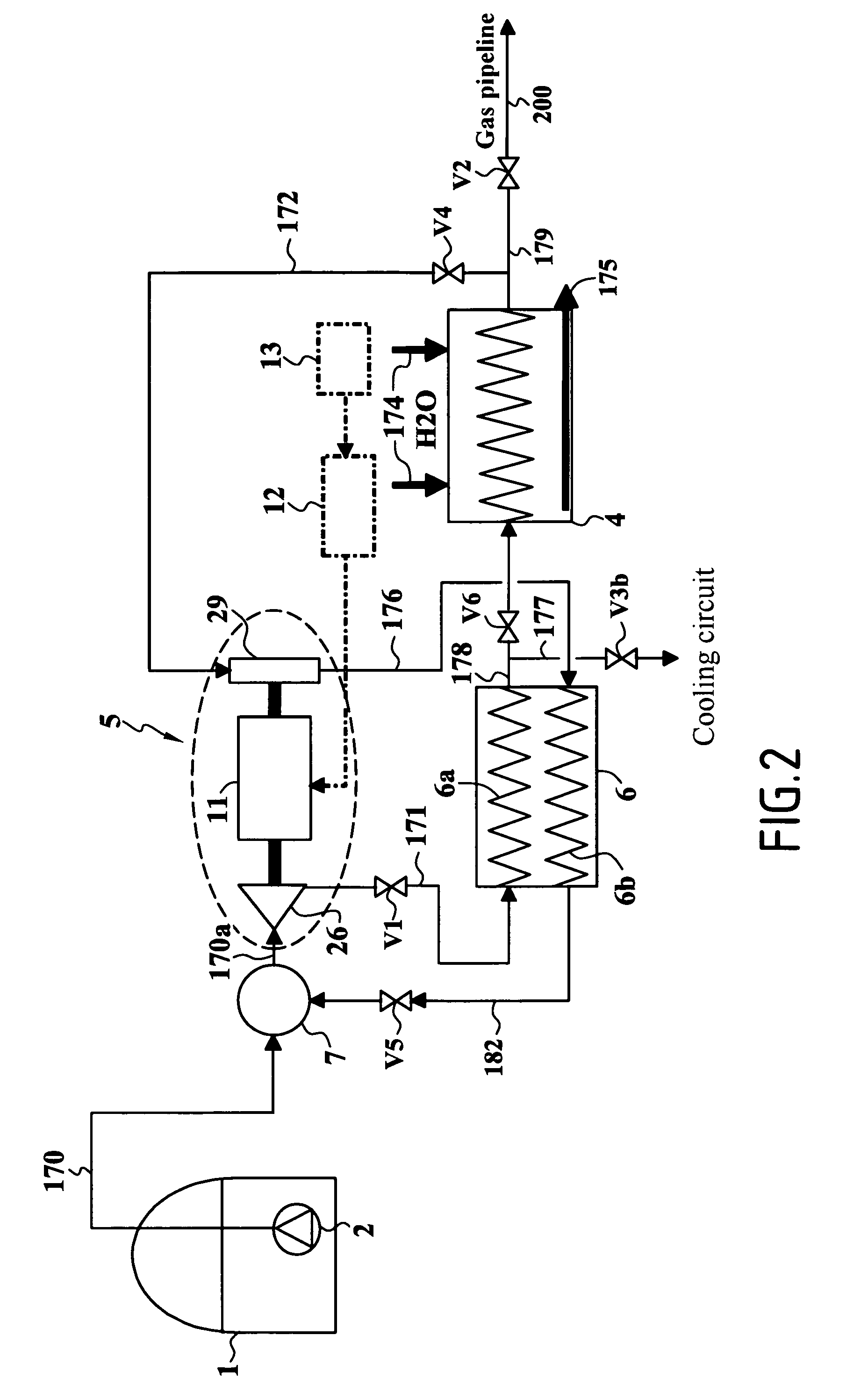

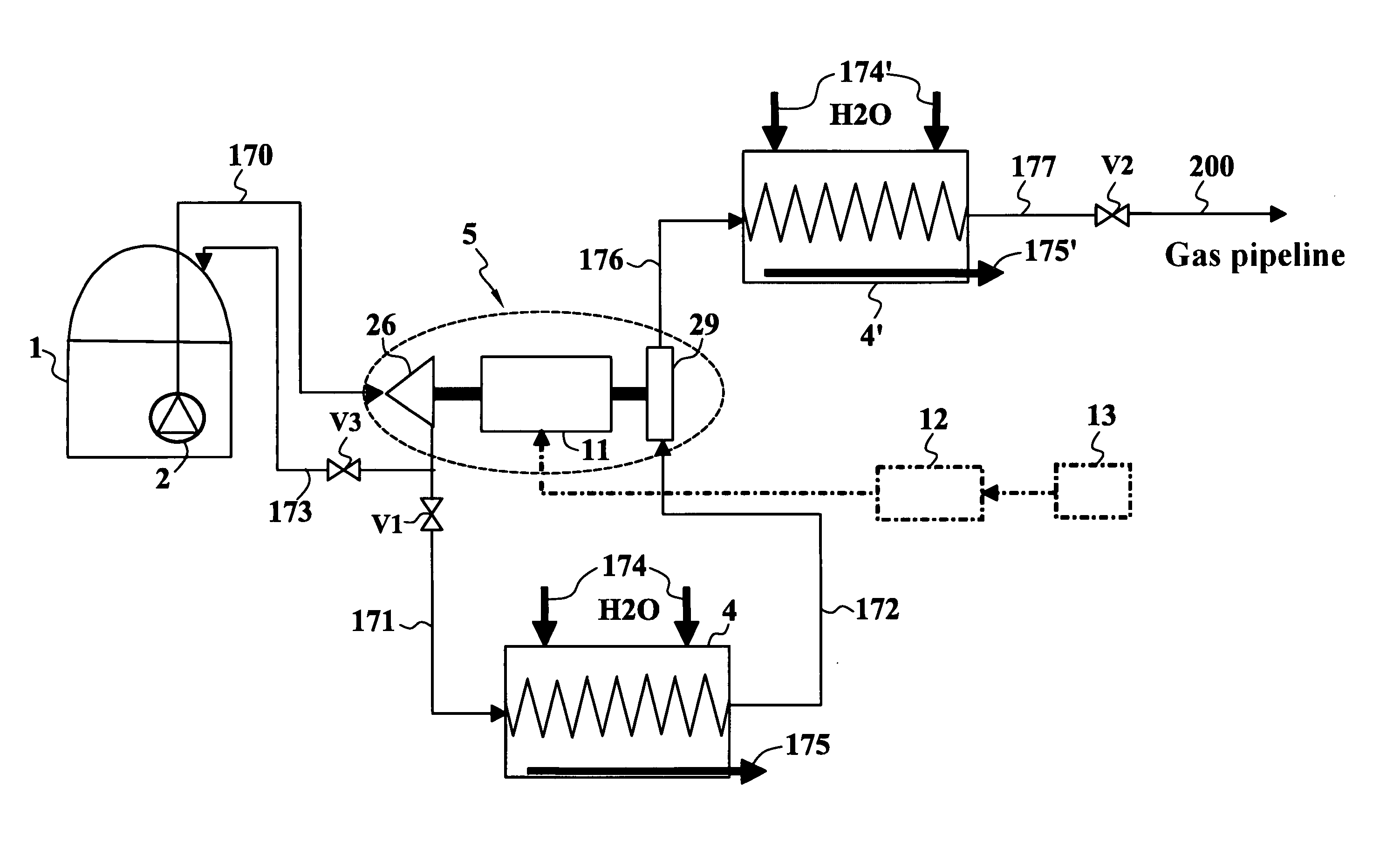

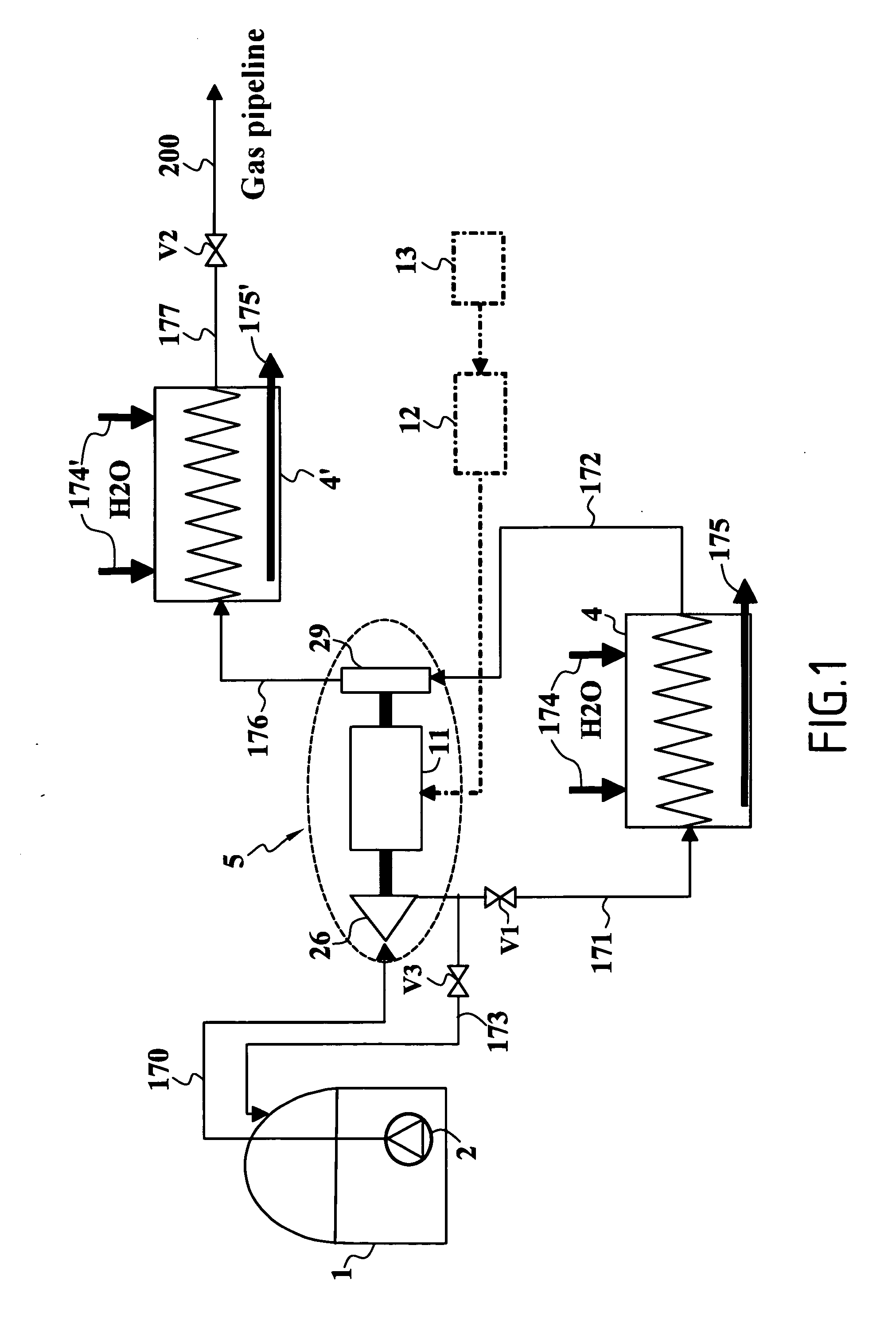

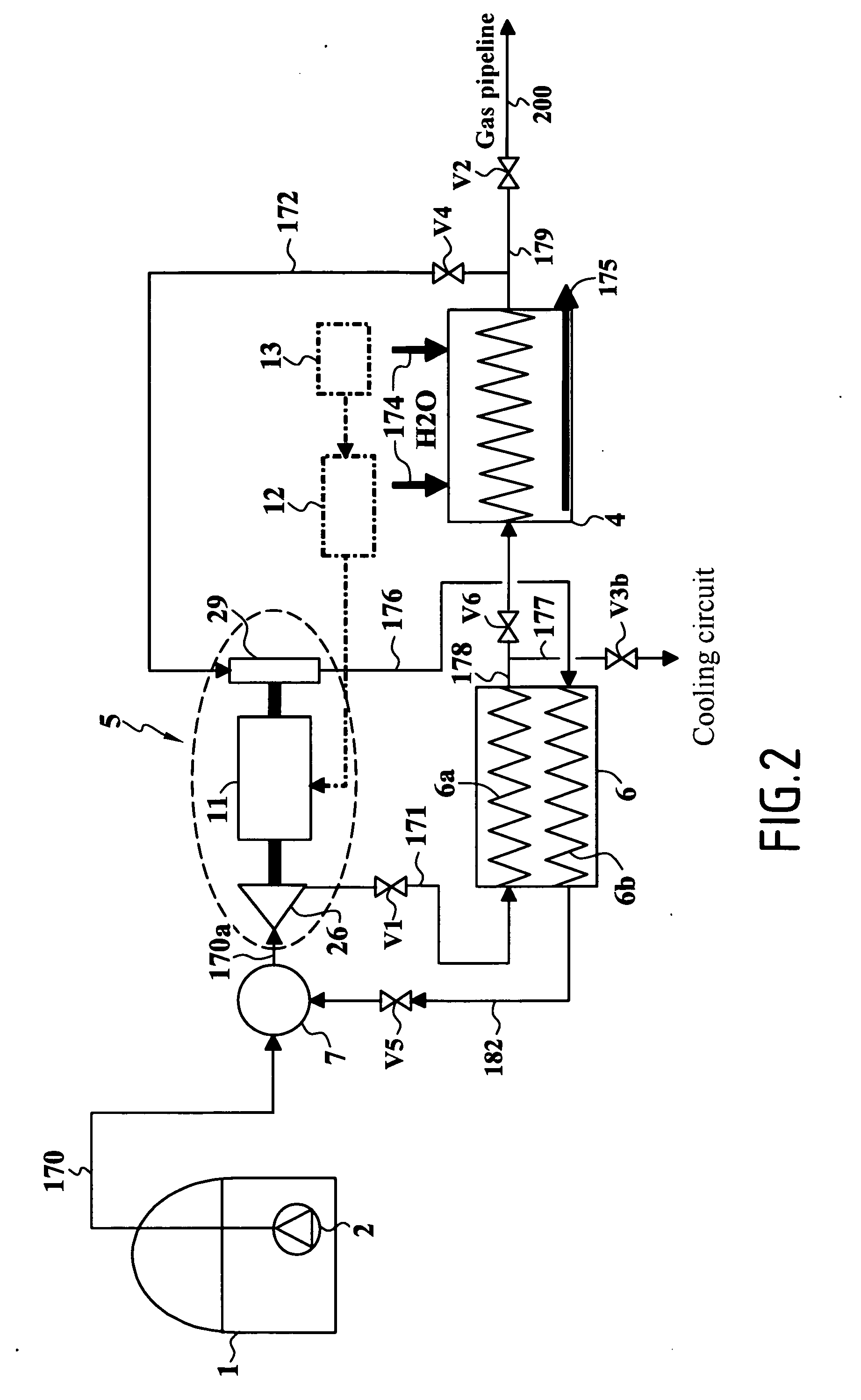

Compression-evaporation system for liquefied gas

InactiveUS7406830B2Reduce and even eliminate consumptionGas handling applicationsGas handling/storage effectsEvaporationEngineering

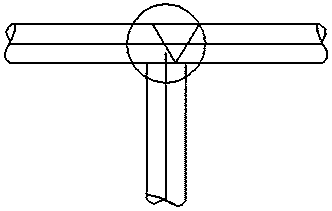

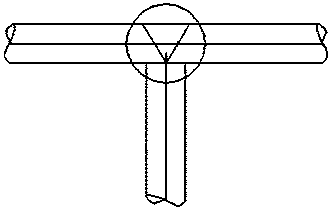

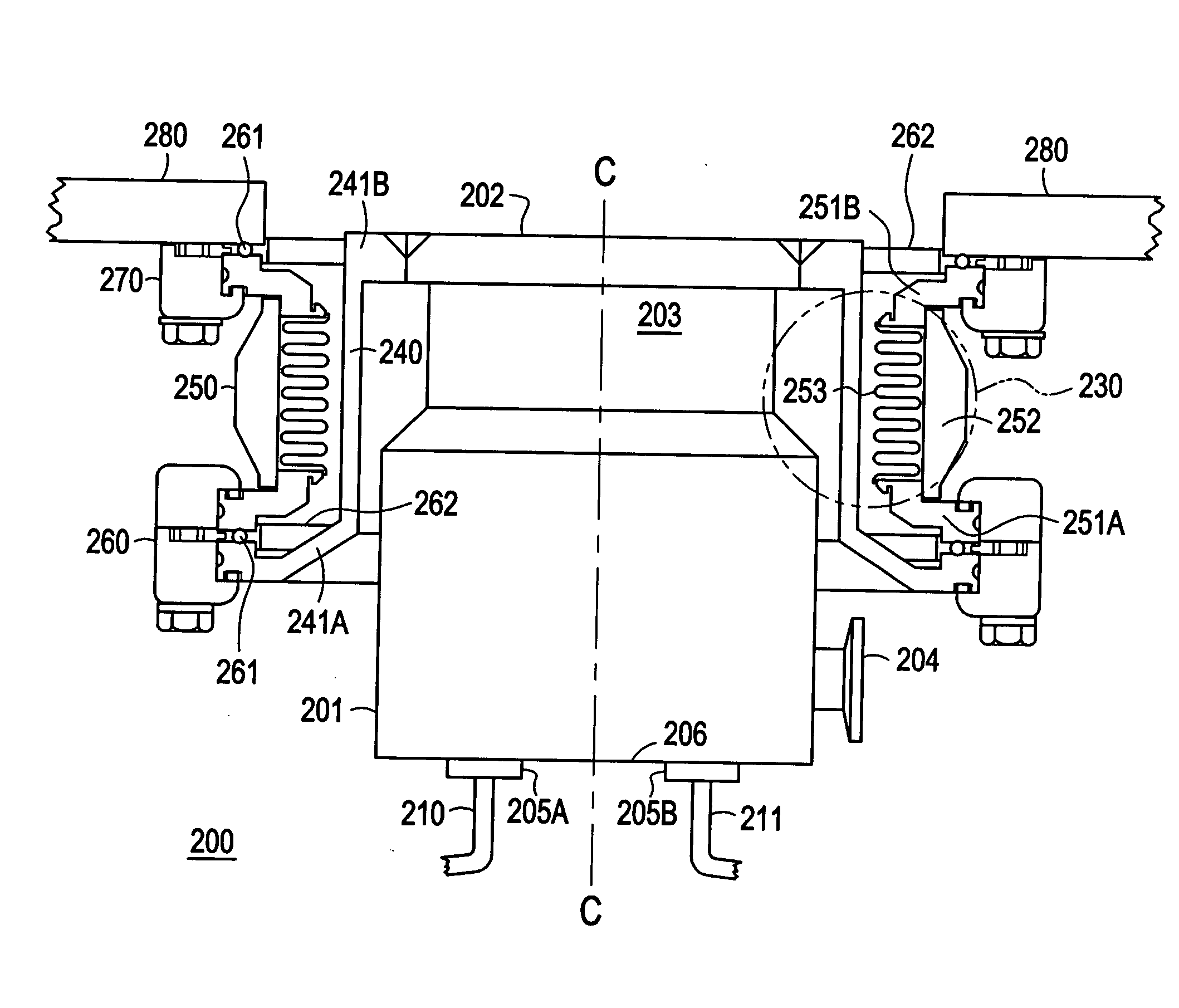

The compressor-evaporator system for liquefied gas contained in a tank comprises, in addition to a deice for evaporation by heat exchange with a liquid and devices for conditioning and transferring gas to a pipeline, a motor-driven turbopump comprising a rotary assembly of high bending stiffness on a common shaft line, with at least one high pressure pump, a turbine, and a central electrical machine capable of being used in motor mode or in generator mode. The rotary assembly of the motor-driven turbopump is adapted to present a high speed of rotation, greater than 12,000 rpm, while remaining outside ranges for exciting critical speeds in rotation. All of the internal portions of the motor-driven turbopump are immersed in a cryogenic fluid that is the same as the liquefied gas contained in the tank. The internal cavities of the motor-driven turbopump that are under different thermodynamic conditions are separated by contactless dynamic seals. Electronic power circuits connected to an electricity network control the central electrical machine in motor mode or generator mode.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Micro-channel type cooling method

InactiveCN103824826AHeat dissipation adjustableSemiconductor/solid-state device detailsSolid-state devicesEngineeringTurbopump

The invention discloses a micro-channel type cooling method which is mainly applied to the field of cooling of packaging boards integrating with multiple high-power chips. According to the micro-channel type cooling method, heat sources integrated on a substrate are respectively provided with a temperature sensor, the temperature sensors are connected with an external controller, a cooling plate with liquid flow channels is arranged above the substrate integrated with the multiple heat sources in a covering mode, and the controller controls the starting and stopping of a turbine pump and fans according to data collected by the temperature sensors; if the power of the heat sources is stable, the number of micro-channels is set properly according to the power of the heat sources, a main flow channel is provided with a regulating valve which is controlled by the controller, and thus the flow of liquid is regulated; if the power of the heat sources is changeable, the flow channels are evenly distributed, a flow electromagnetic valve controlled by the controller is arranged at the bifurcation between the main cooling flow channel and each heat source micro-flow-channel, flow distribution of each power device is regulated according to actual working conditions, and thus the multiple heat sources can be cooled stably and efficiently, and the cooling capacity can be adjusted.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

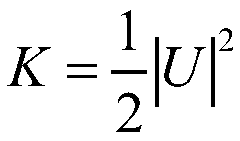

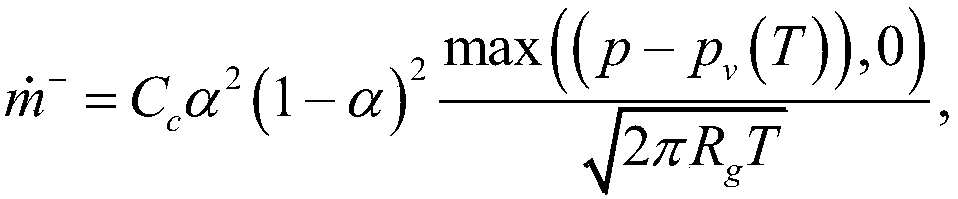

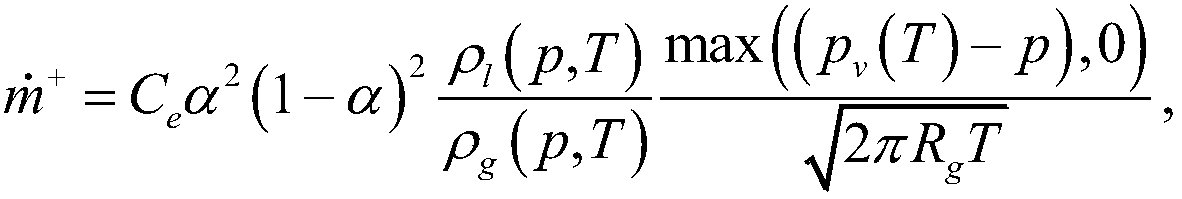

Numerical simulation method for cavitation compressible flow shock wave dynamics

ActiveCN108763800ARealize simulationHelp in in-depth researchSustainable transportationDesign optimisation/simulationShock waveAviation

The invention discloses a numerical simulation method for cavitation compressible flow shock wave dynamics and belongs to the field of numerical simulation of cavitation compressible flow and shock wave dynamics. A three-dimensional computing watershed based on three-dimensional geometric modeling software is established; a three-dimensional computing watershed mesh is divided based on mesh generation software; a cavitation compressible flow computational fluid dynamics model is established; an initial boundary condition is set to perform a three-dimensional computational domain flow field numerical computation; based on flow field post-processing software, the computational result is post-processed to obtain the unsteady evolution process of a multi-phase bubble structure. The numerical simulation method for cavitation compressible flow shock wave dynamics in the invention facilitates in-depth study of the cavitation physical mechanism, can be applied to the field of cavitation compressible flow and shock dynamics numerical simulation and solves related engineering problems. The cavitation compressible flow and shock dynamics numerical simulation engineering application area comprises hydraulic machinery, marine propellers, aviation turbo pump induction wheels, underwater supercavitation weapon applications.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Compression-evaporation system for liquefied gas

InactiveUS20060222523A1Reduce and even eliminate consumptionGas handling applicationsGas handling/storage effectsEvaporationEngineering

The compressor-evaporator system for liquefied gas contained in a tank comprises, in addition to a deice for evaporation by heat exchange with a liquid and devices for conditioning and transferring gas to a pipeline, a motor-driven turbopump comprising a rotary assembly of high bending stiffness on a common shaft line, with at least one high pressure pump, a turbine, and a central electrical machine capable of being used in motor mode or in generator mode. The rotary assembly of the motor-driven turbopump is adapted to present a high speed of rotation, greater than 12,000 rpm, while remaining outside ranges for exciting critical speeds in rotation. All of the internal portions of the motor-driven turbopump are immersed in a cryogenic fluid that is the same as the liquefied gas contained in the tank. The internal cavities of the motor-driven turbopump that are under different thermodynamic conditions are separated by contactless dynamic seals. Electronic power circuits connected to an electricity network control the central electrical machine in motor mode or generator mode.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

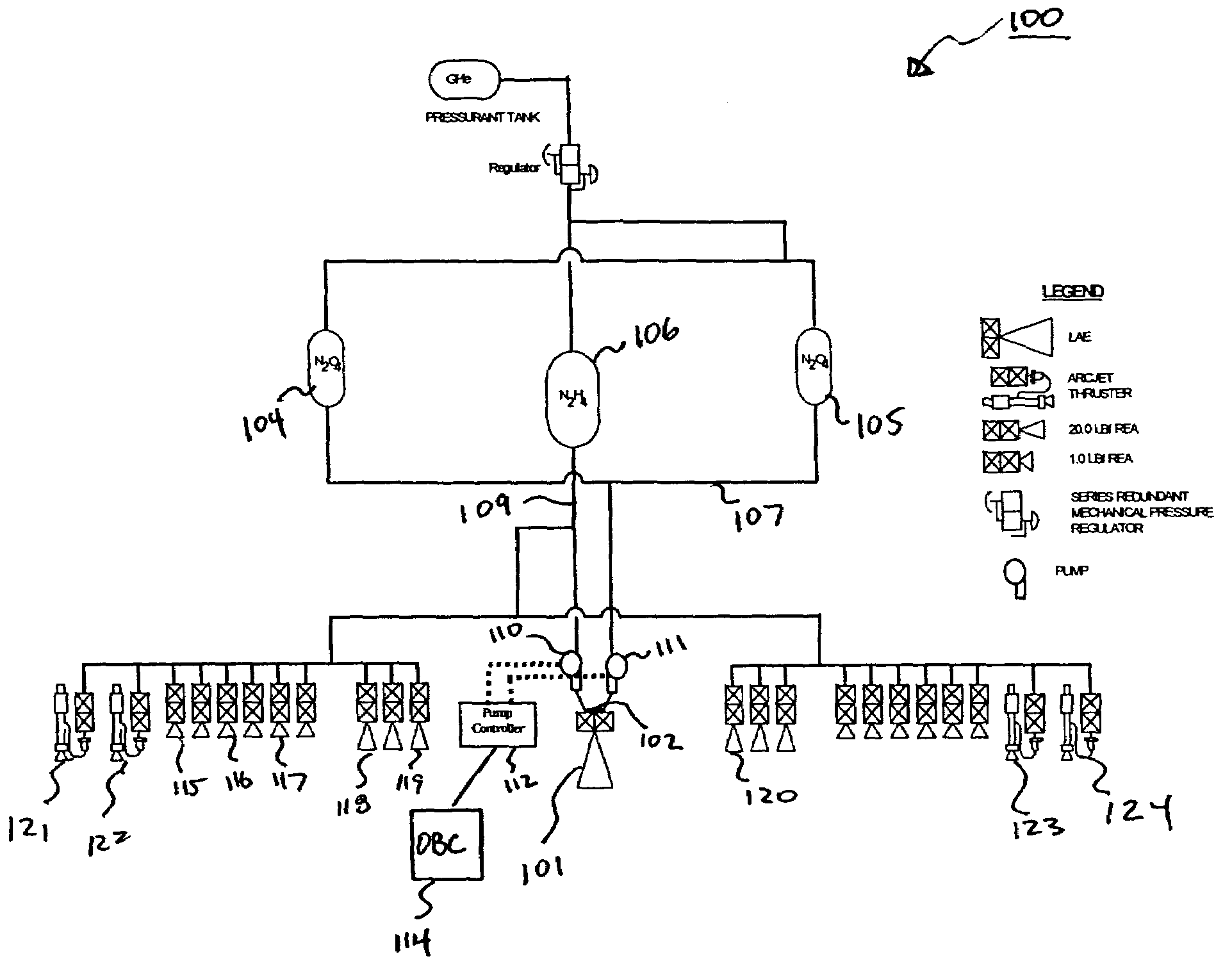

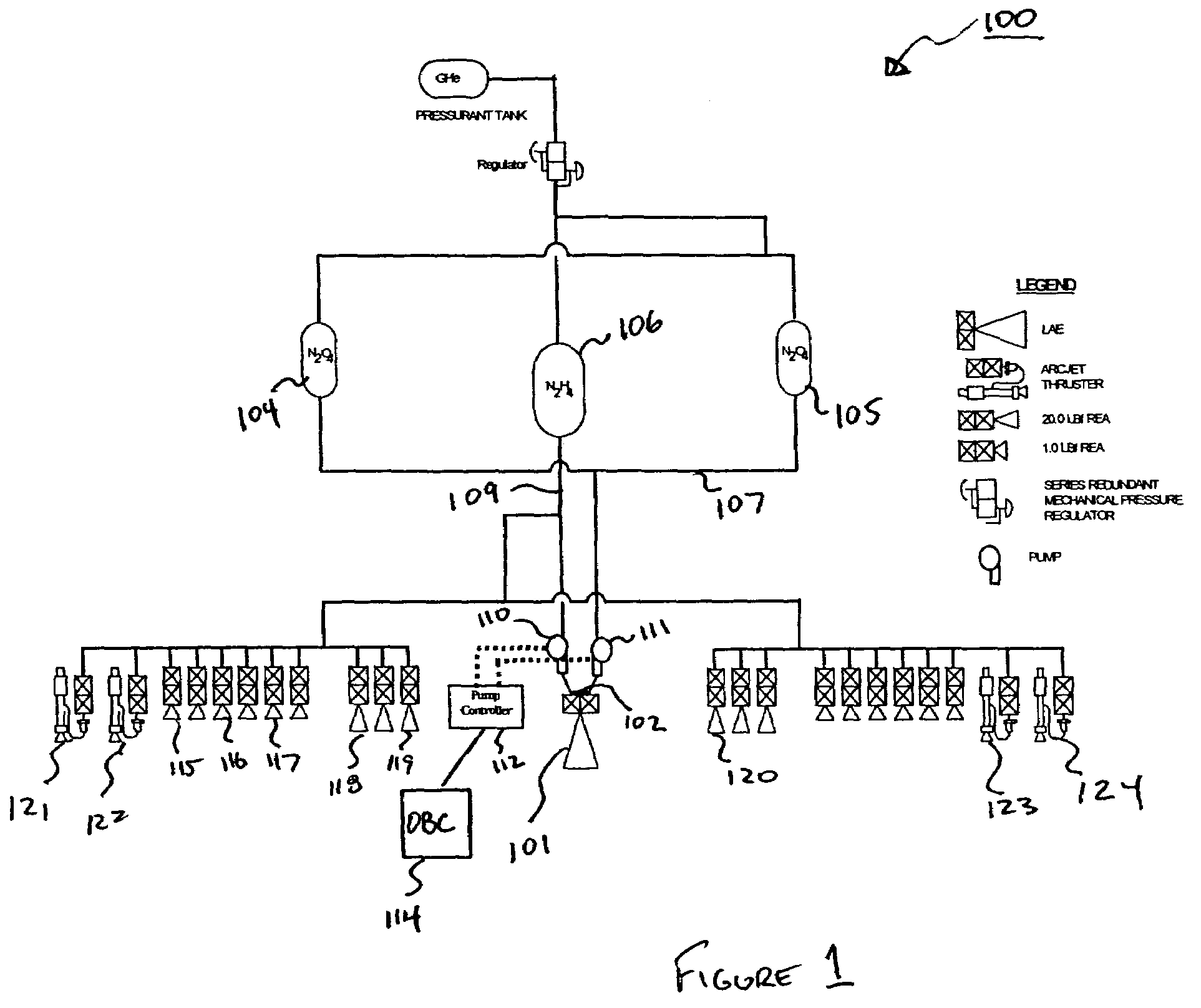

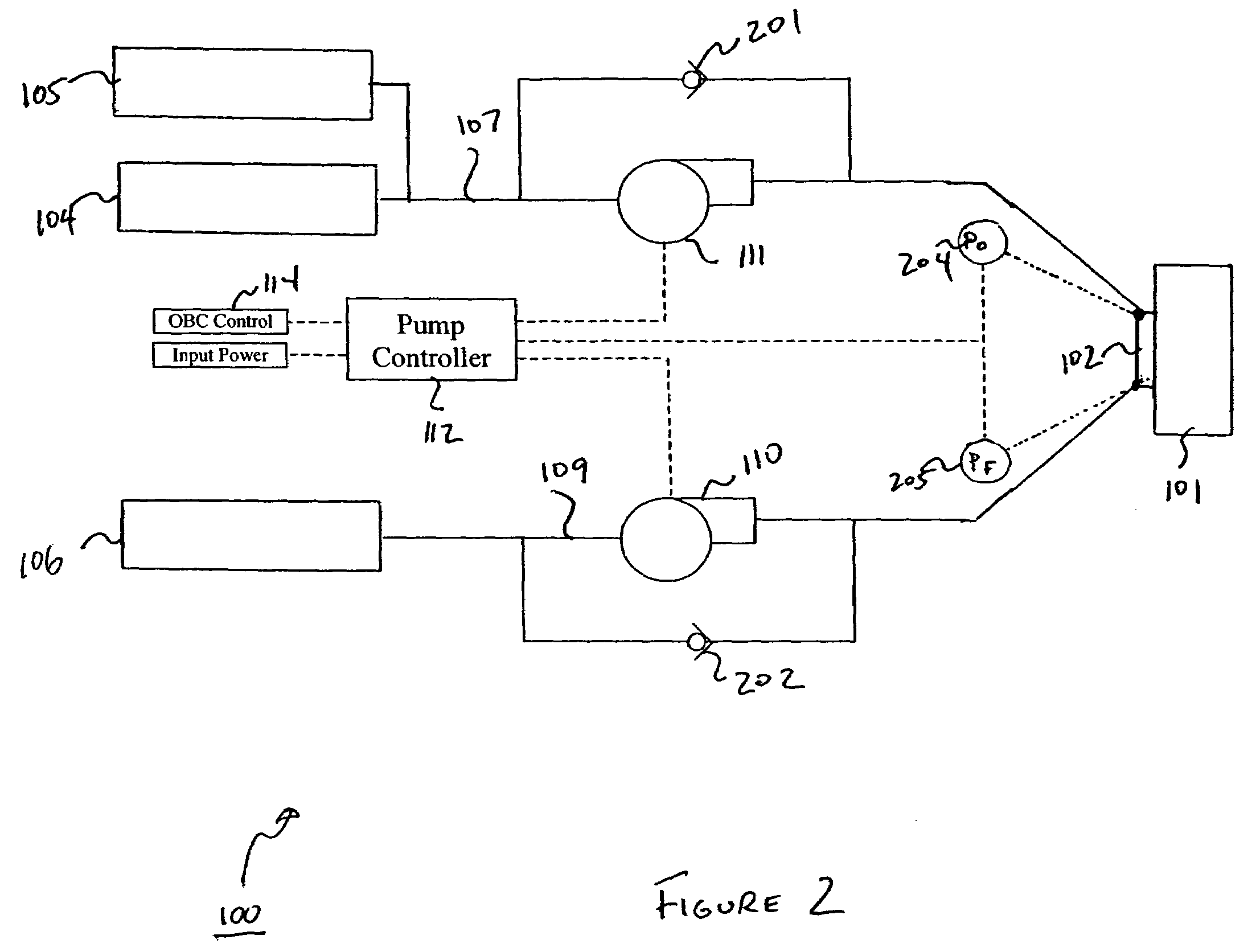

Enhanced high-efficiency spacecraft propulsion system

InactiveUS7762498B1Improving seal materialImproving geometry selectionLaunch systemsCosmonautic propulsion system apparatusSpacecraft propulsionOn board

A high-efficiency spacecraft propulsion system, including includes electric pumps inserted in the oxidizer and fuel lines that increase liquid apogee engine (“LAE”) operating pressure and reduce tank-operating pressure. An on-board computer generates pump drive signals, in response to measured oxidizer and fuel line pressures, that are input to the pump controller electronics. The controller electronics provides current drives to the pump motors. The system uses an LAE that can operate at higher thrust chamber pressures (e.g., 500 psia) than standard LAEs, where pump-fed rocket motors have integrated turbopumps that are fuel operated. The turbopump increases LAE complexity and cost, reduces fuel efficiency, and is not compatible with active thrust and mixture ratio control.

Owner:LOCKHEED MARTIN CORP

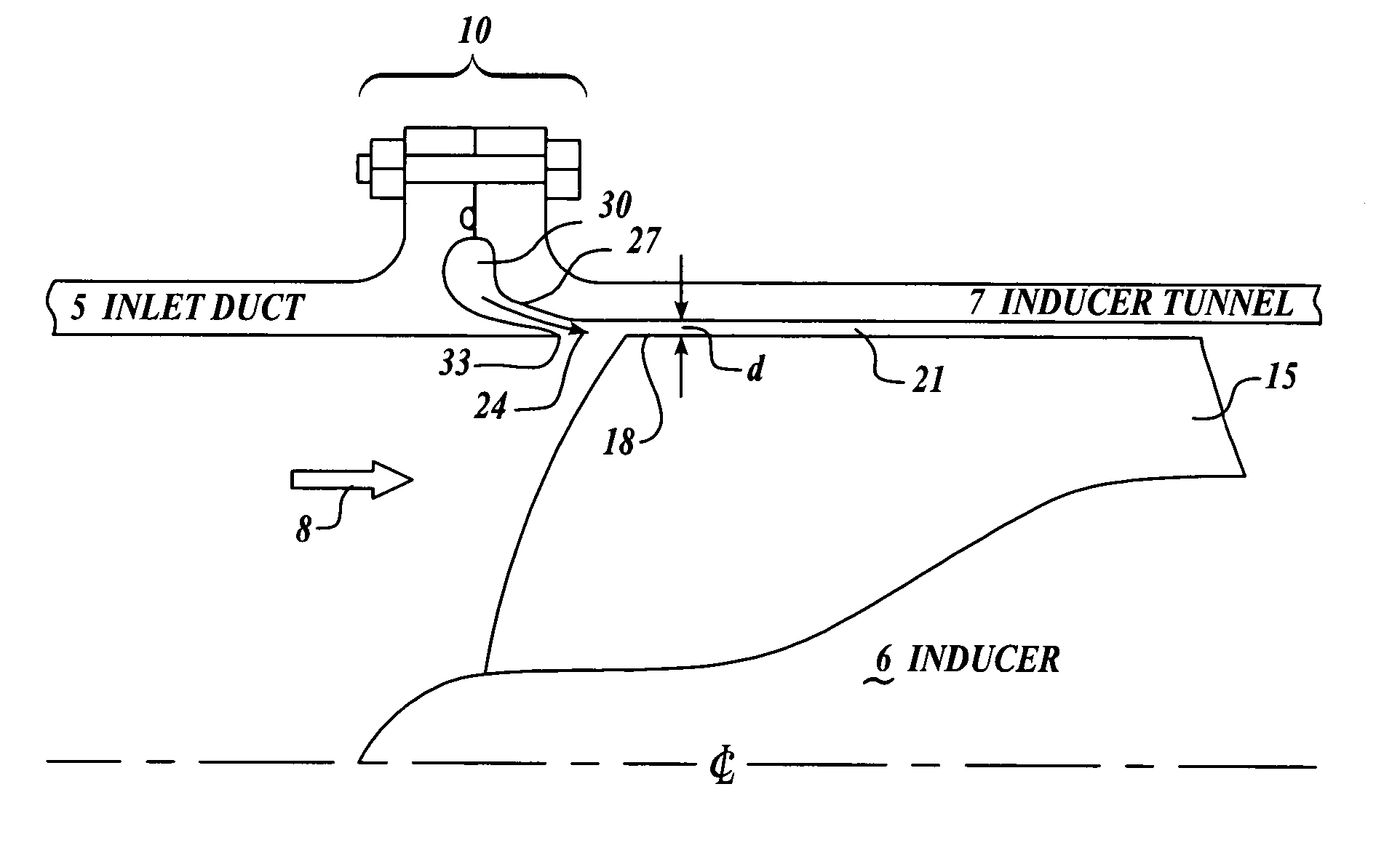

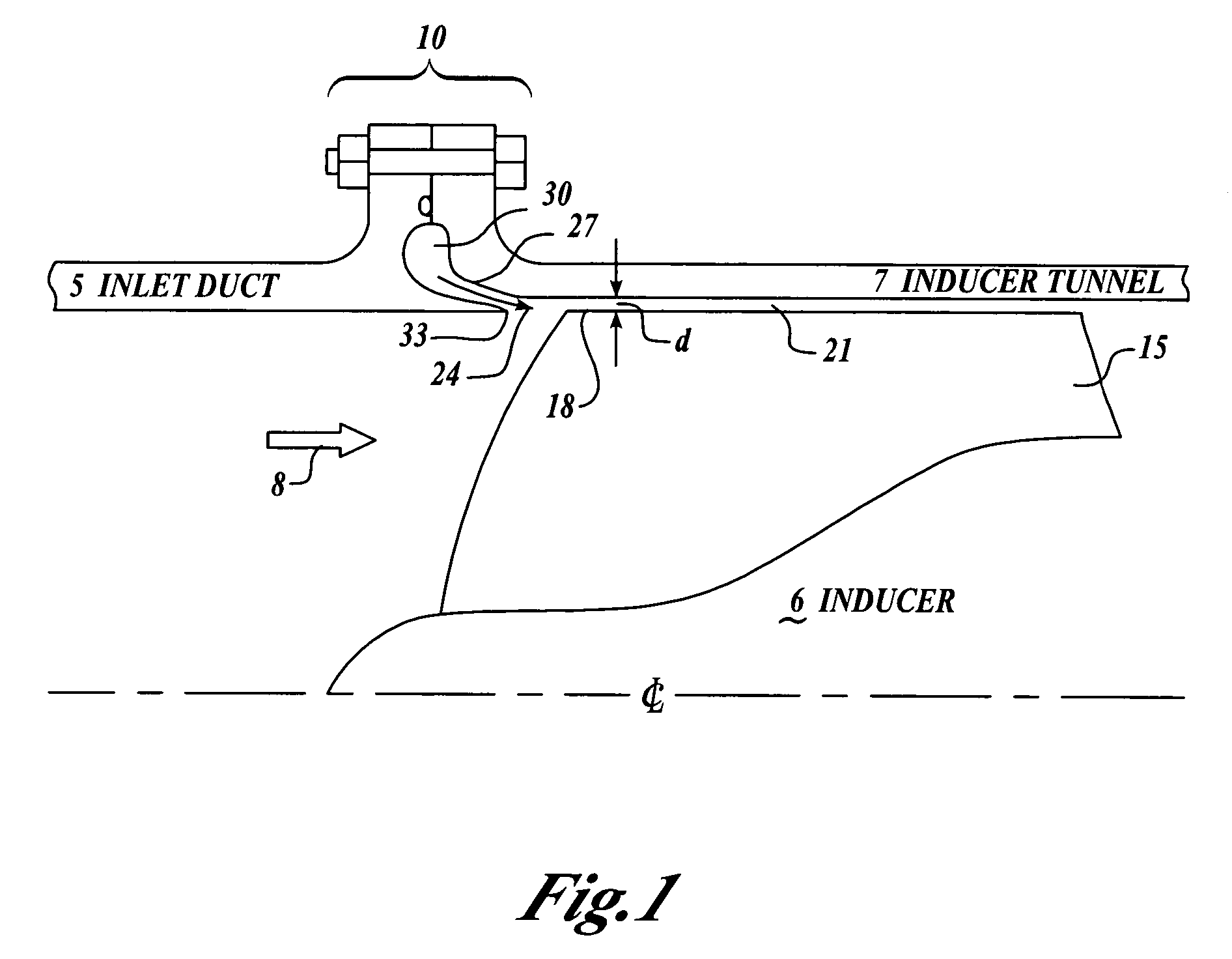

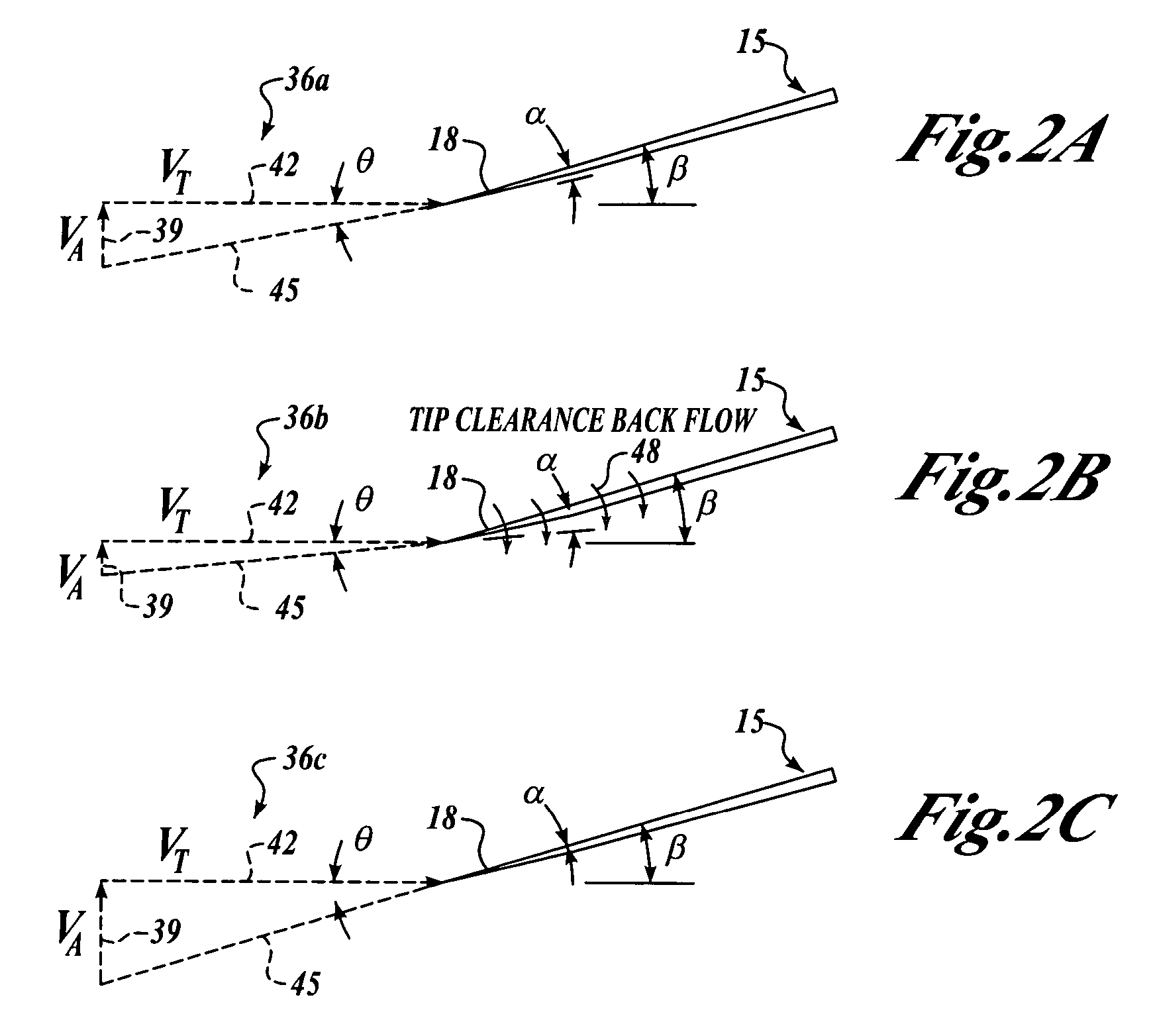

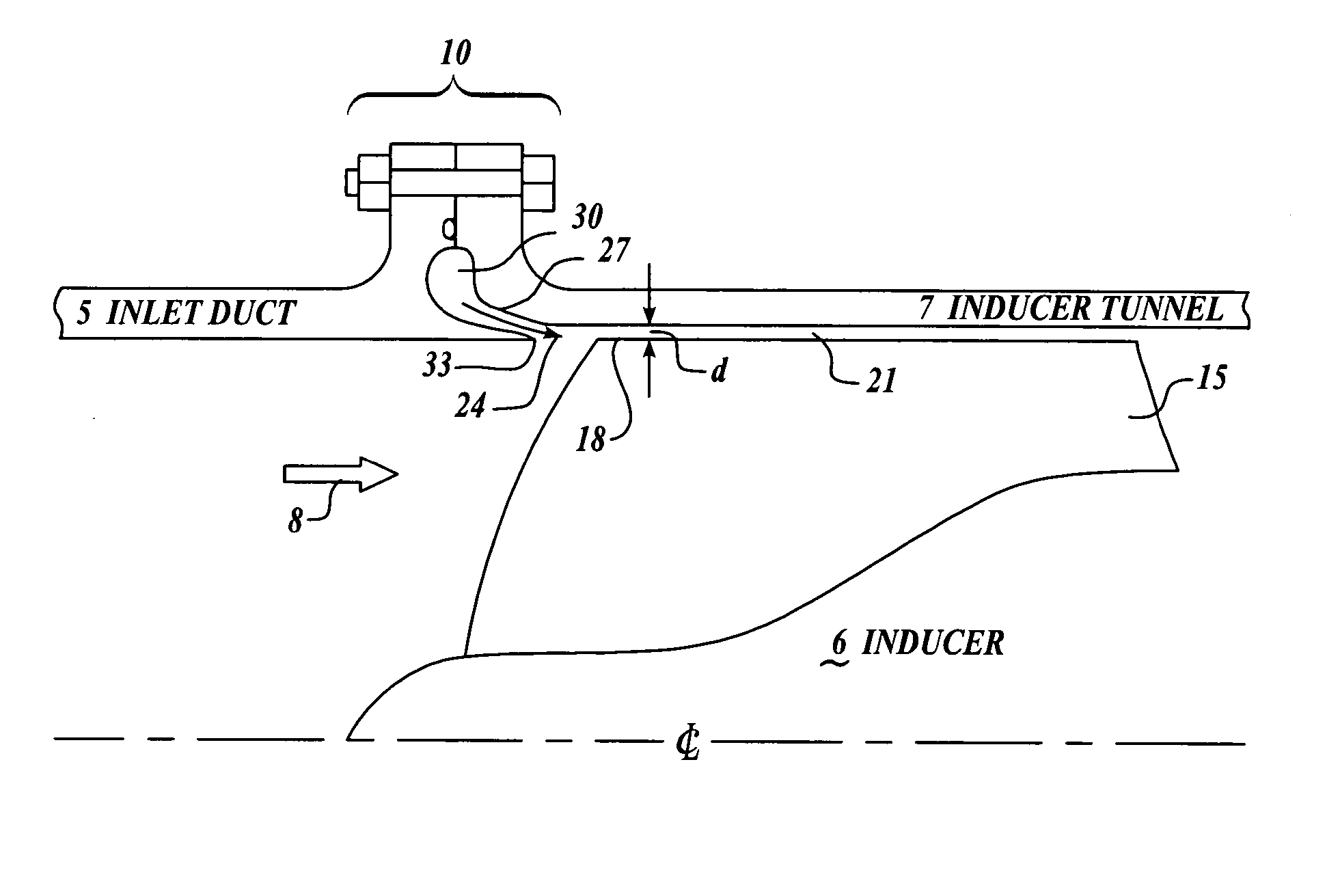

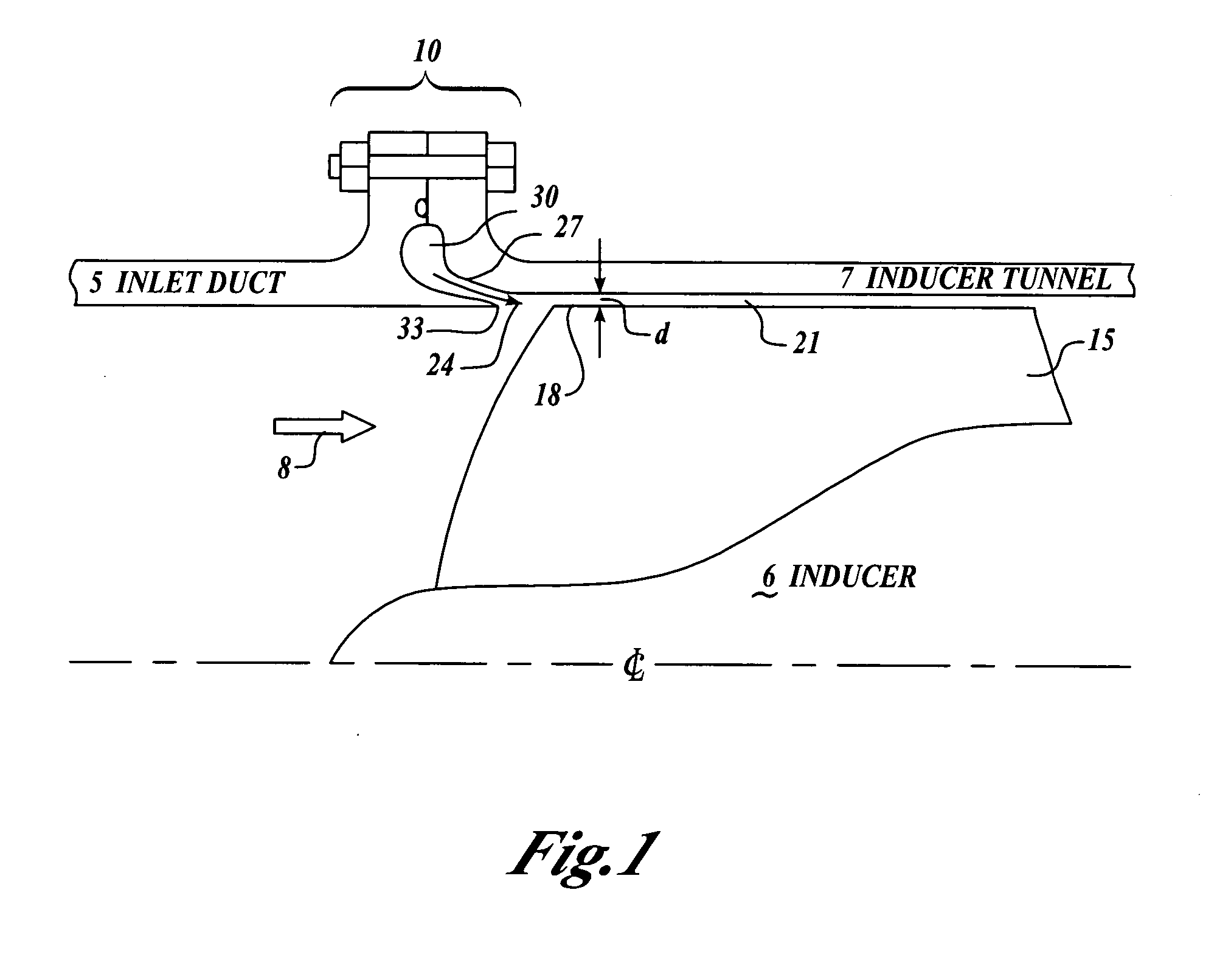

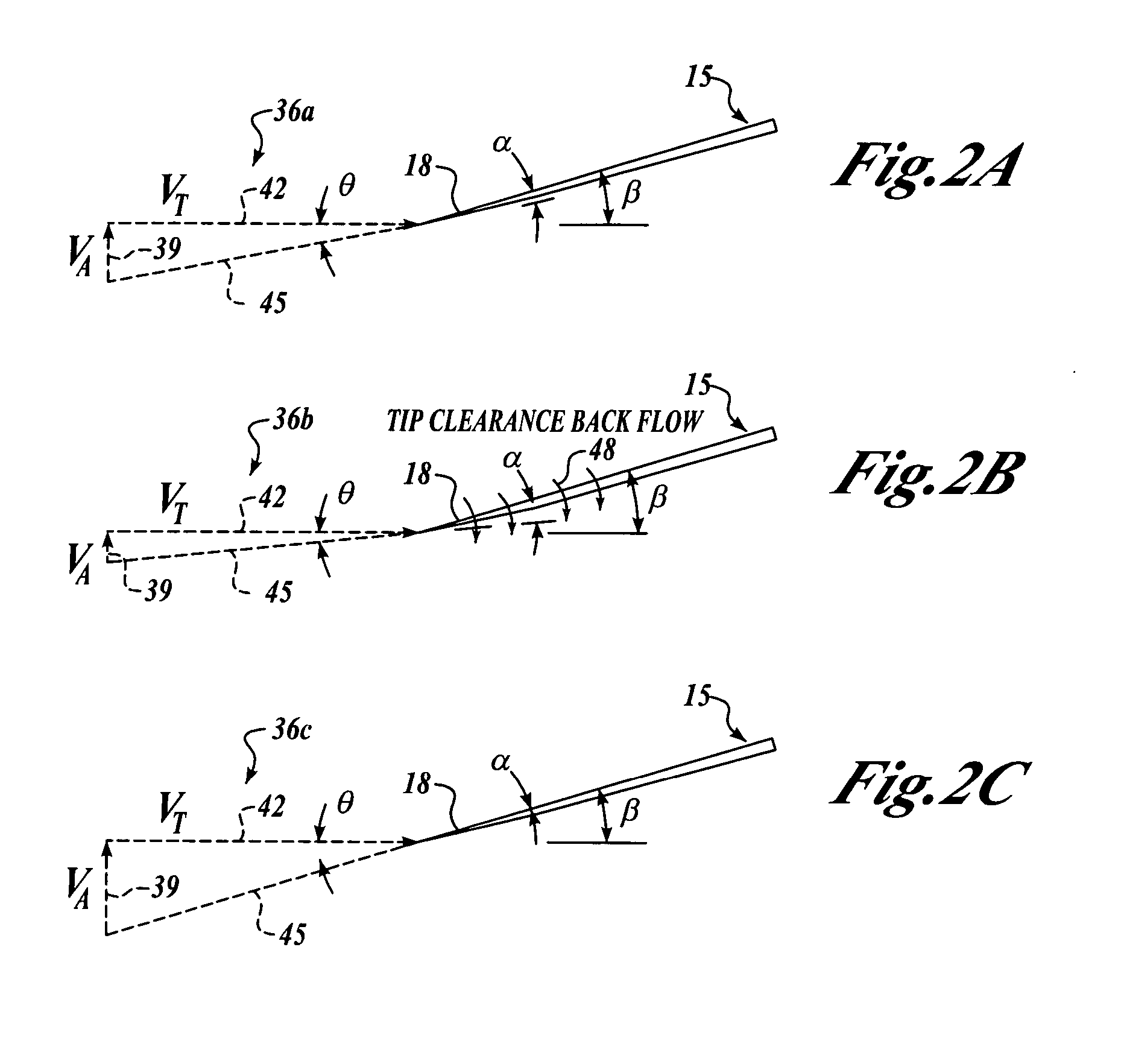

Inducer tip vortex suppressor

InactiveUS7097414B2Suppress higher order cavitationsReduce refluxPump componentsStatorsCavitationSuppressor

Embodiments of the invention provide a method, device, and turbopump configured to suppress higher order cavitations at an inducer tip in a turbopump. An inducer having a tip is rotated, and a first flow is induced axially through the inducer at a first velocity. A second fluid flow is introduced toward a tip of the inducer substantially parallel to the first fluid flow at a second velocity that is greater than the first velocity, such that back flow through the tip of the inducer is reduced.

Owner:THE BOEING CO +1

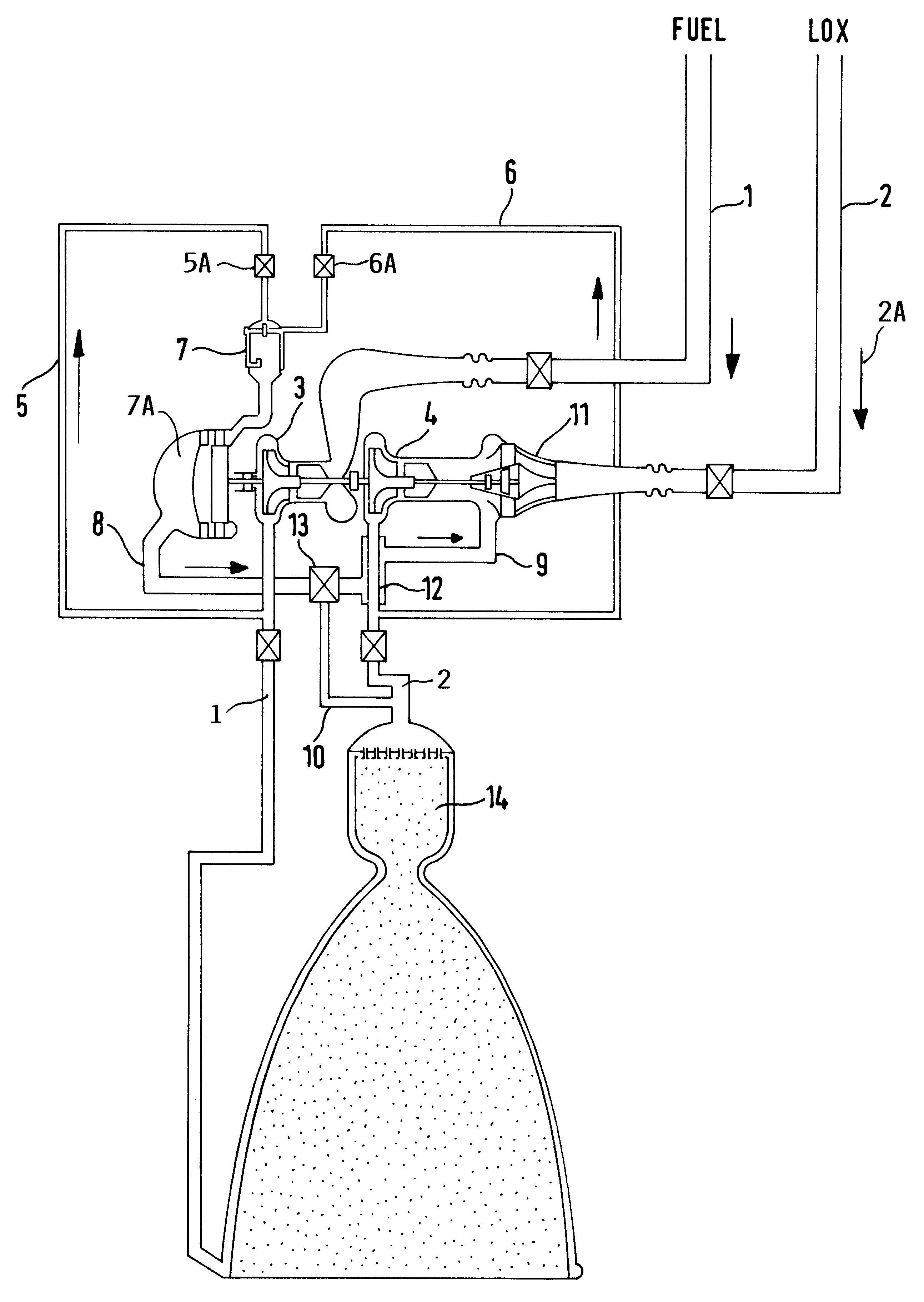

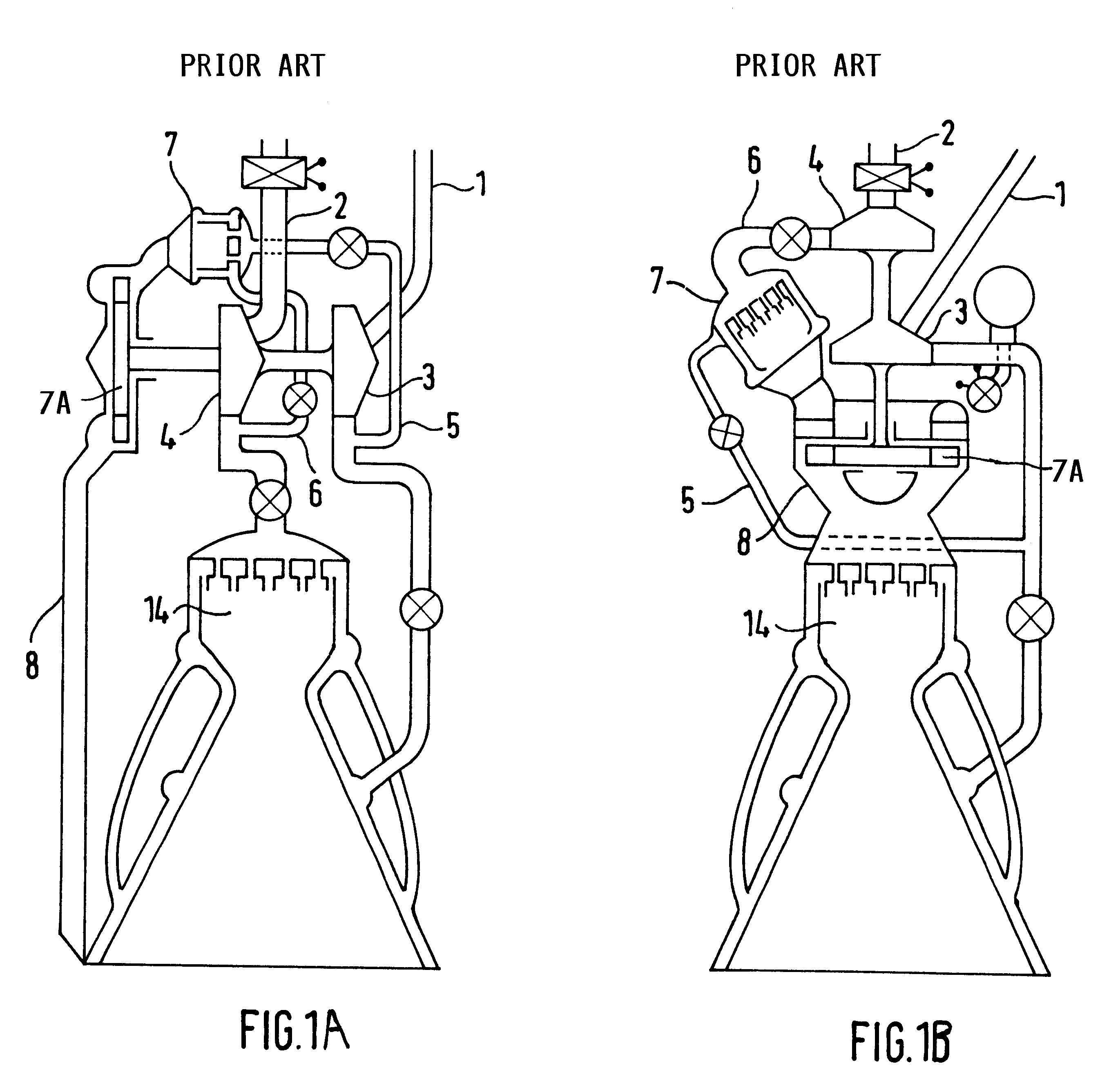

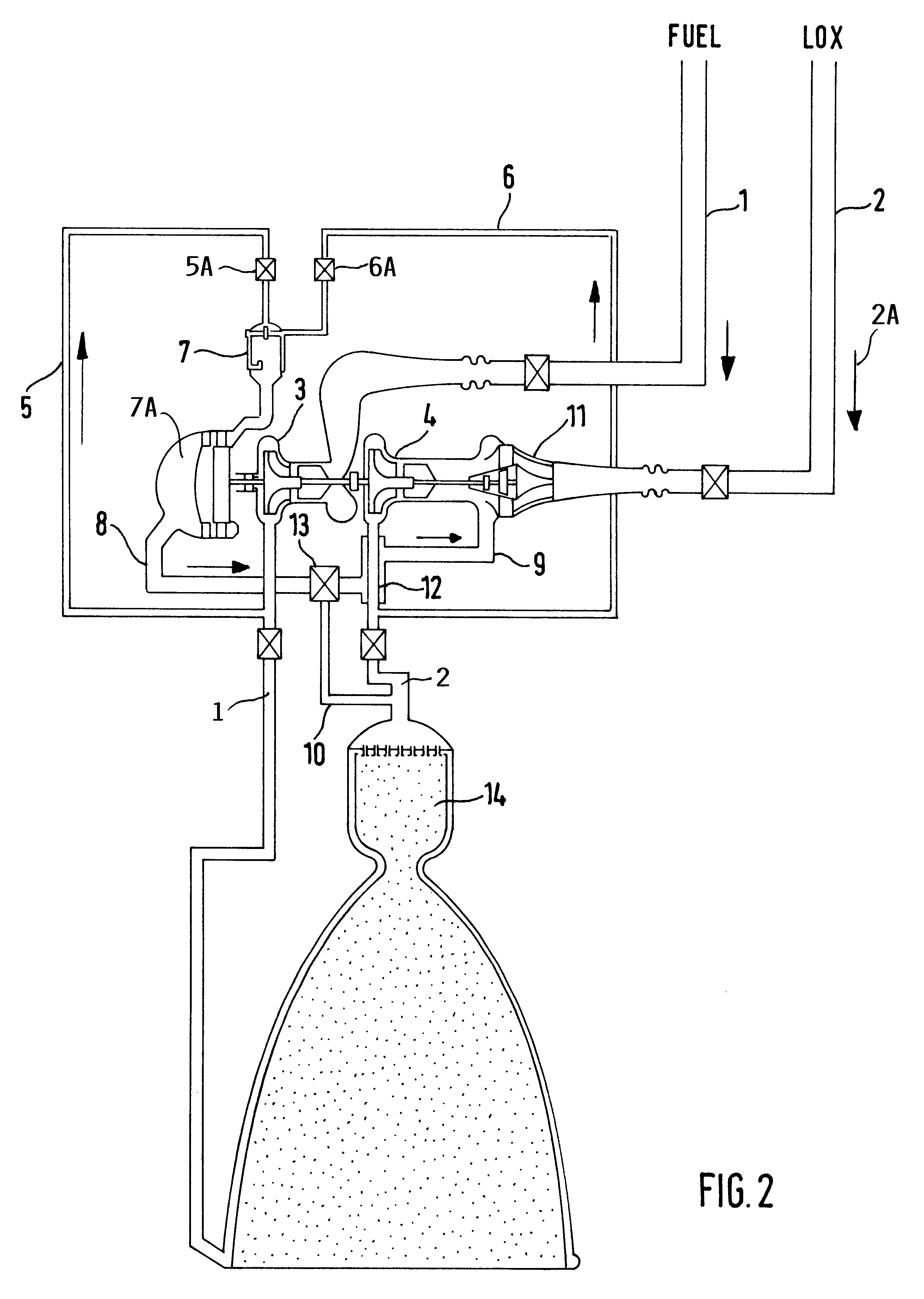

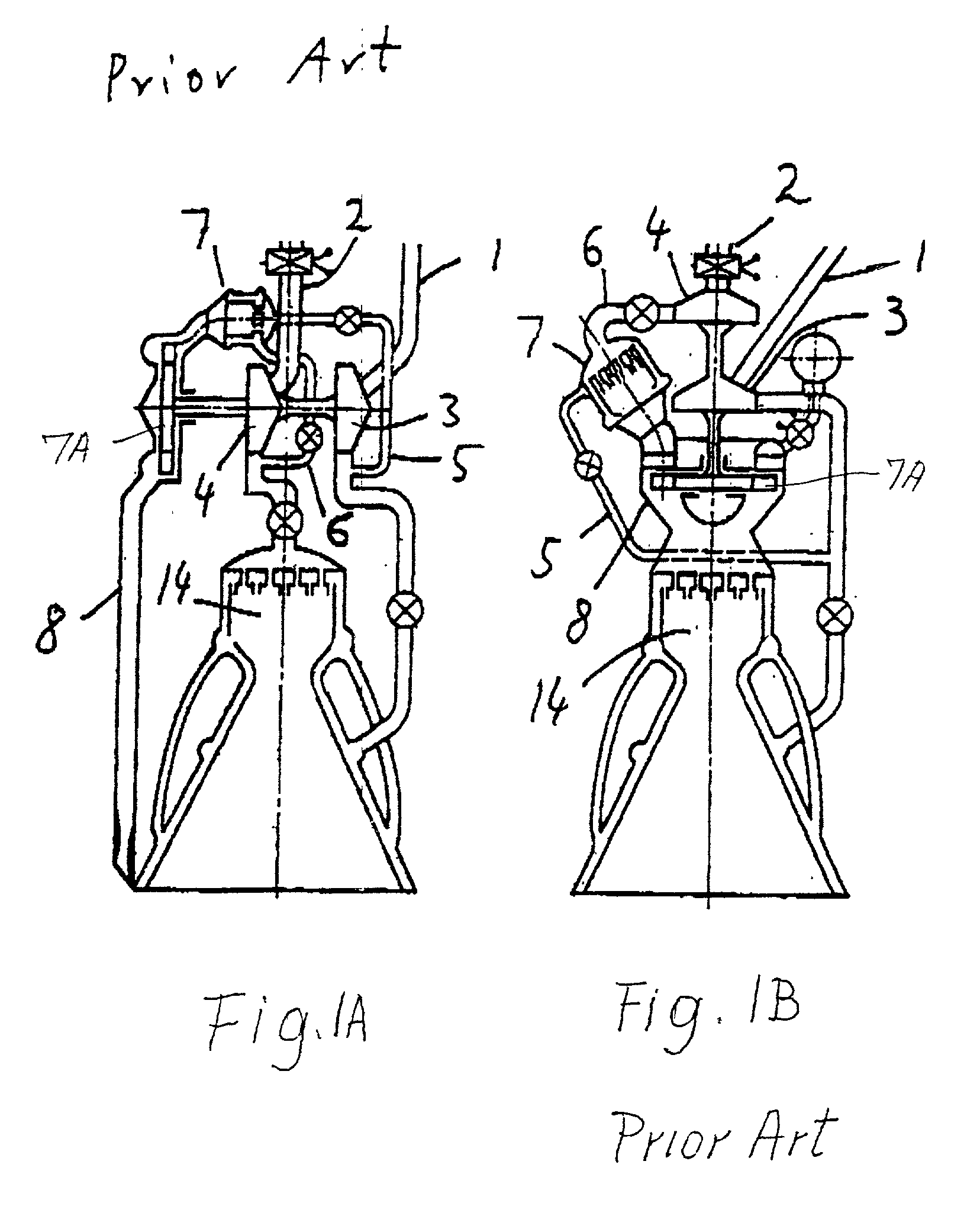

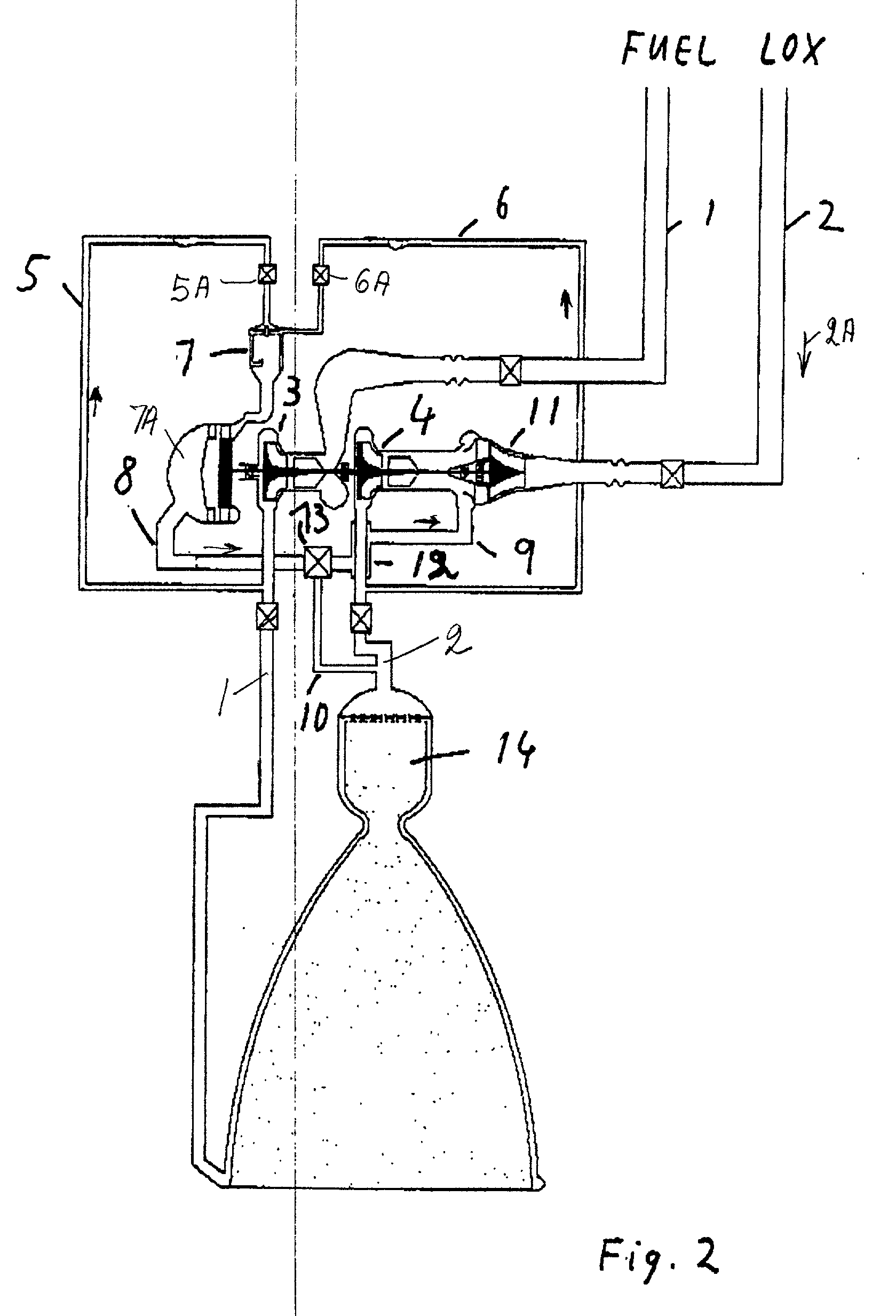

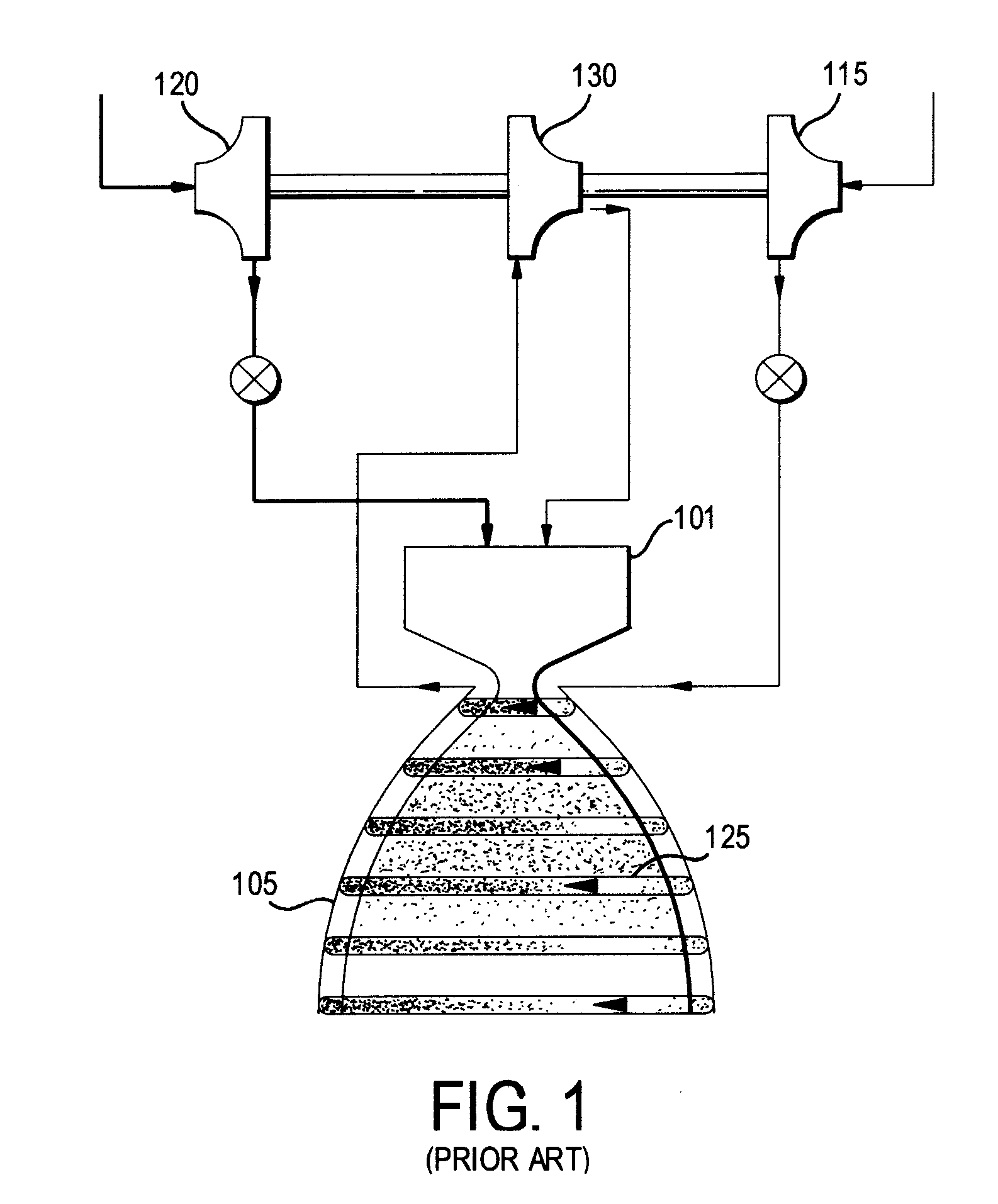

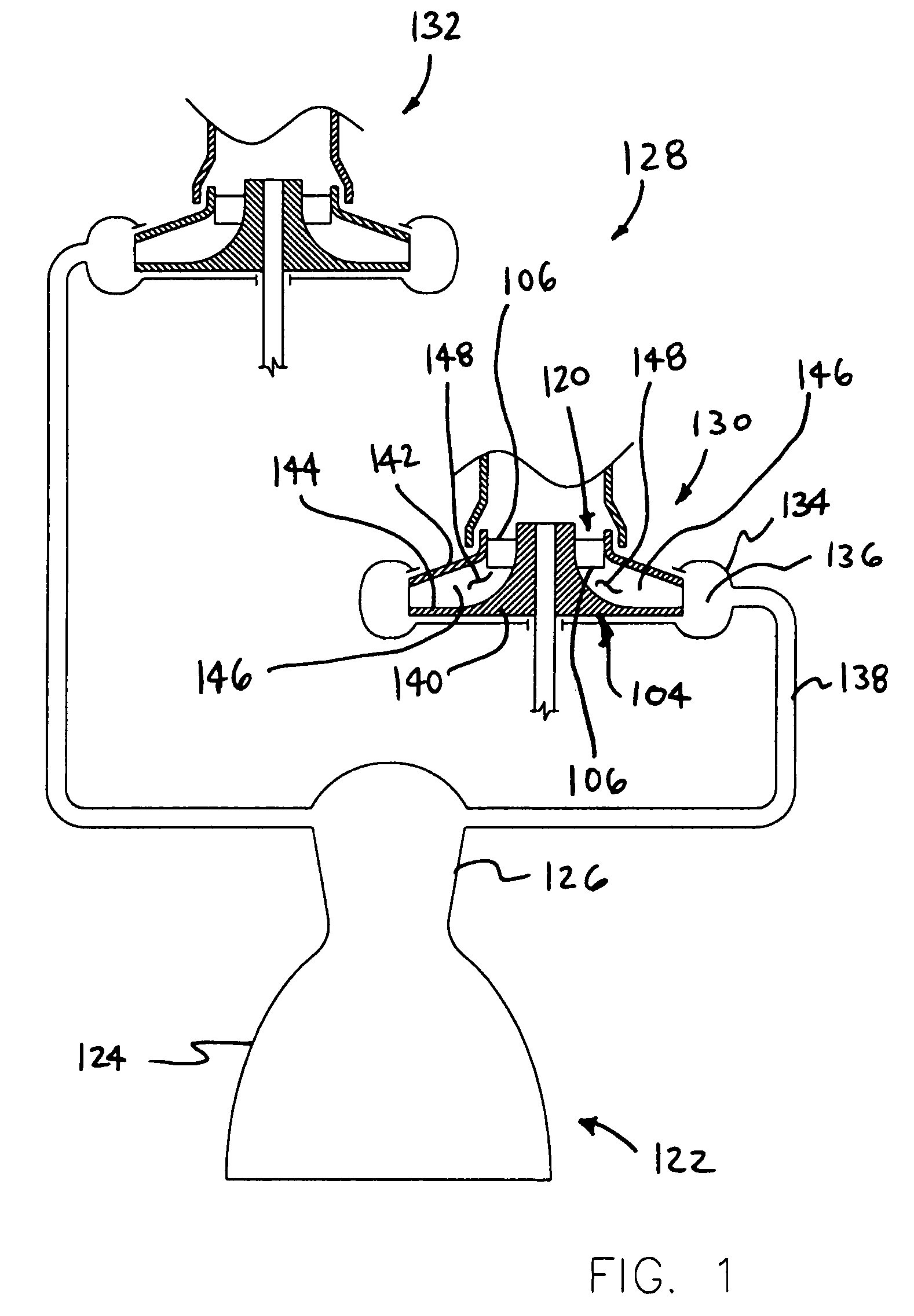

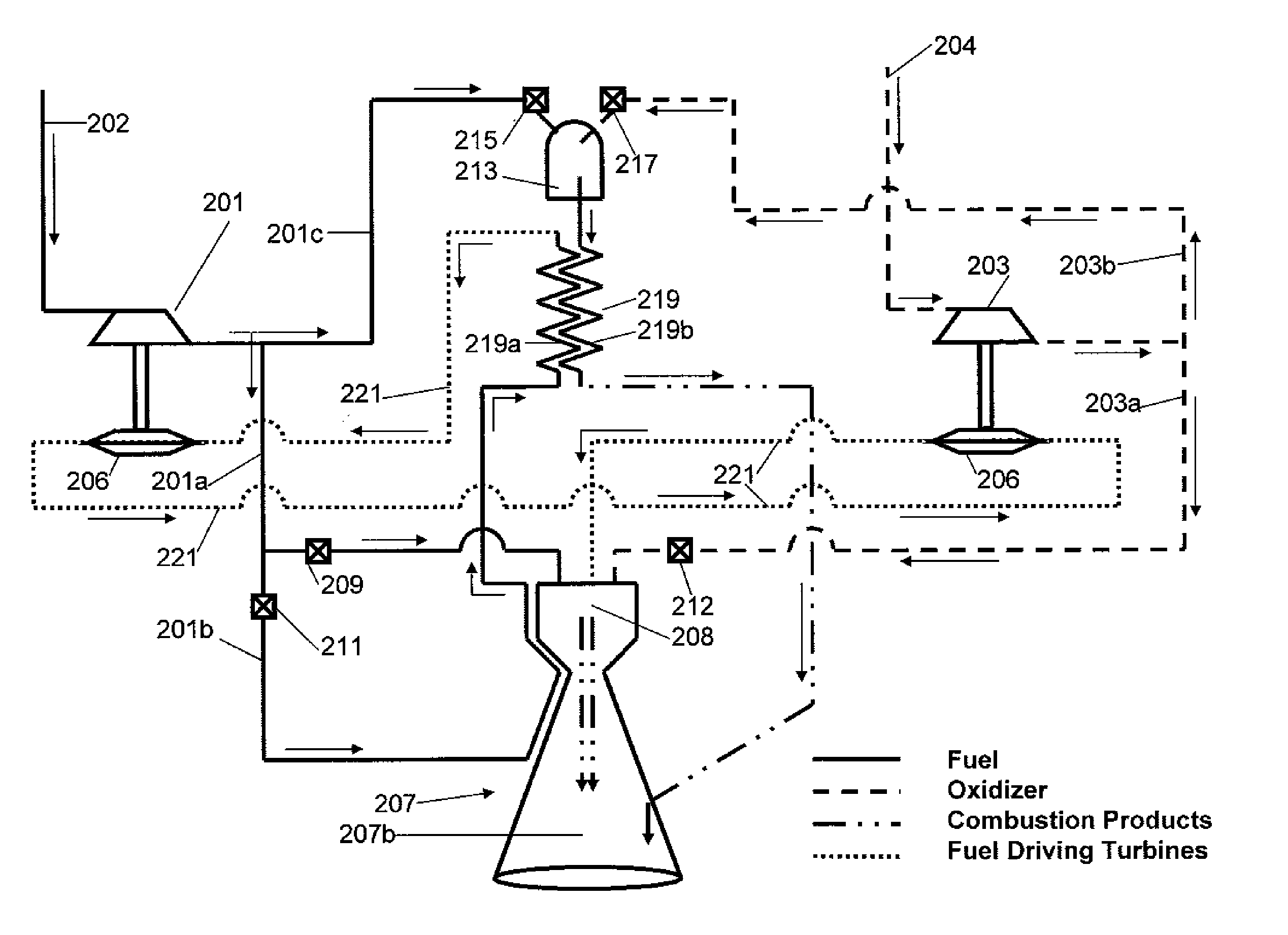

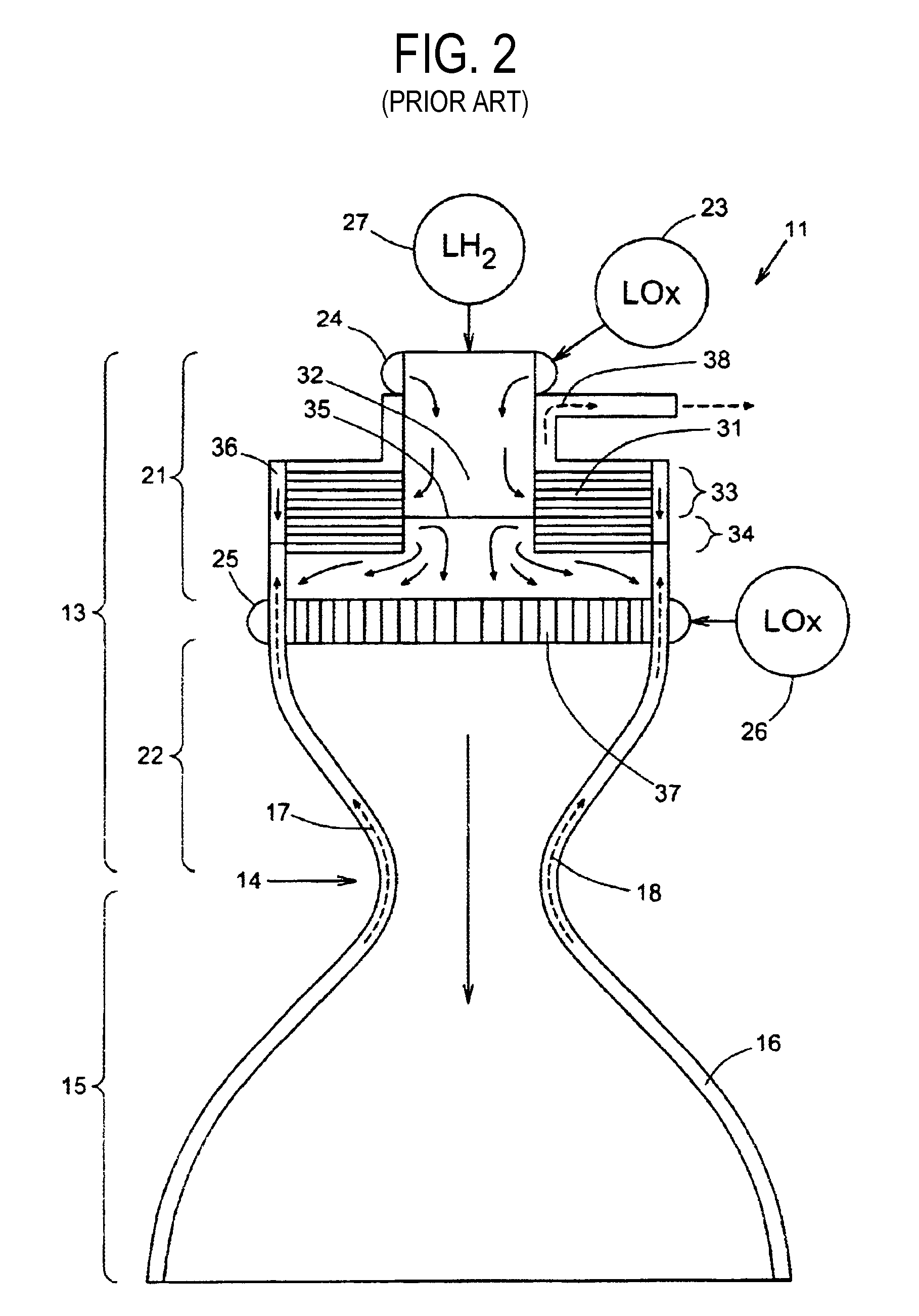

Liquid fuel rocket engine with a closed flow cycle

InactiveUS6470670B2Easy constructionReduce the temperatureRocket engine plantsCombustion chamberProduct gas

A liquid fuel rocket engine with a closed direct auxiliary flow cycle has a combustion chamber connected to each liquid fuel source through a respective main liquid fuel supply line. A turbo pump is provided in each main fuel supply line. The turbo pump is driven by a gas generator which is connected to a first bypass fuel supply line for supplying fuel to the gas generator. An exhaust gas duct (8, 9, 10) leads from the gas generator into at least one main fuel supply line for feeding gas generator exhaust gas into the main fuel supply line upstream of the turbo pump.

Owner:ASTRIUM GMBH

Liquid fuel rocket engine with a closed flow cycle

InactiveUS20010015063A1Easy constructionReduce the temperatureRocket engine plantsCombustion chamberProduct gas

A liquid fuel rocket engine with a closed direct auxiliary flow cycle has a combustion chamber connected to each liquid fuel source through a respective main liquid fuel supply line. A turbo pump is provided in each main fuel supply line. The turbo pump is driven by a gas generator which is connected to a first bypass fuel supply line for supplying fuel to the gas generator. An exhaust gas duct (8, 9, 10) leads from the gas generator into at least one main fuel supply line for feeding gas generator exhaust gas into the main fuel supply line upstream of the turbo pump.

Owner:ASTRIUM GMBH

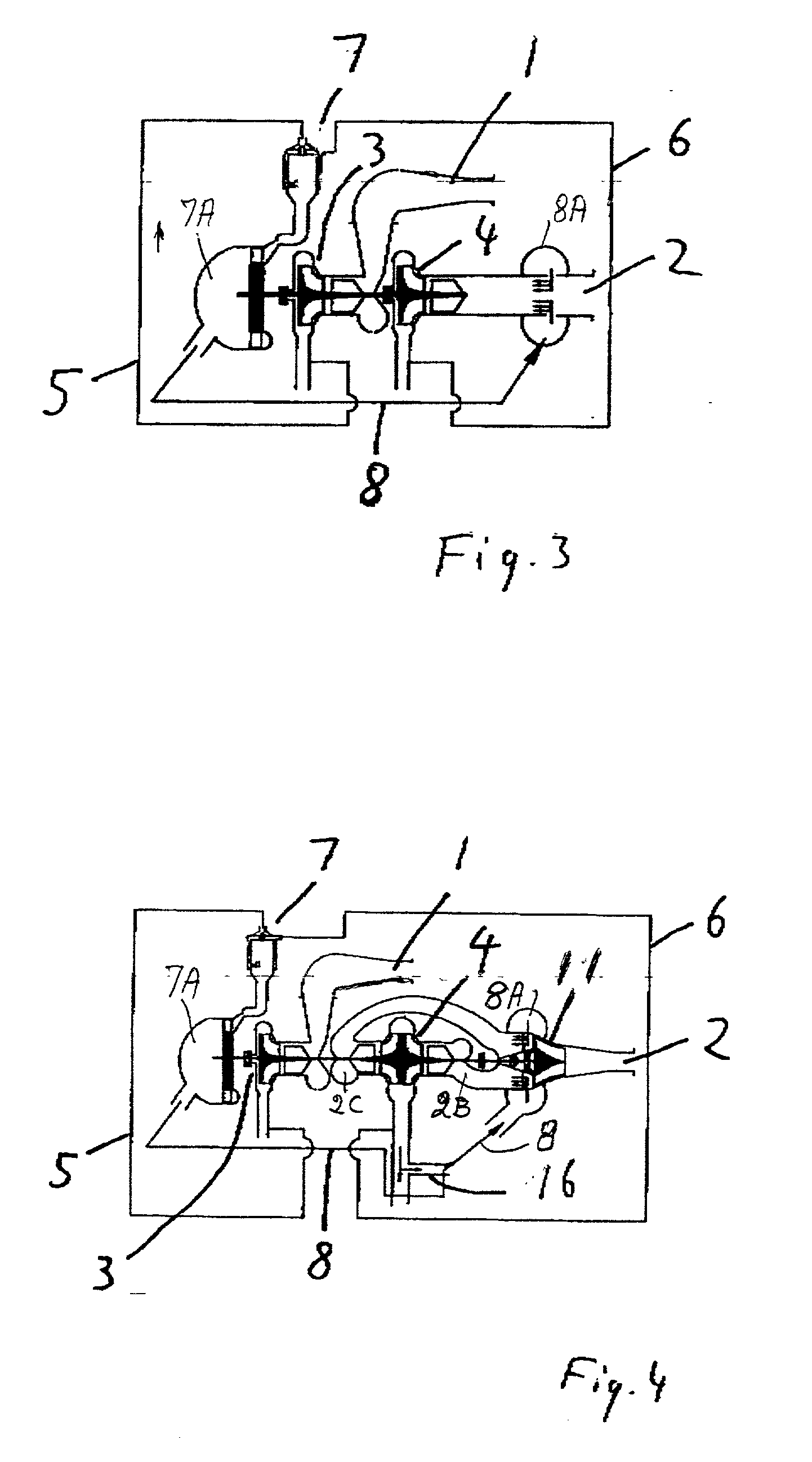

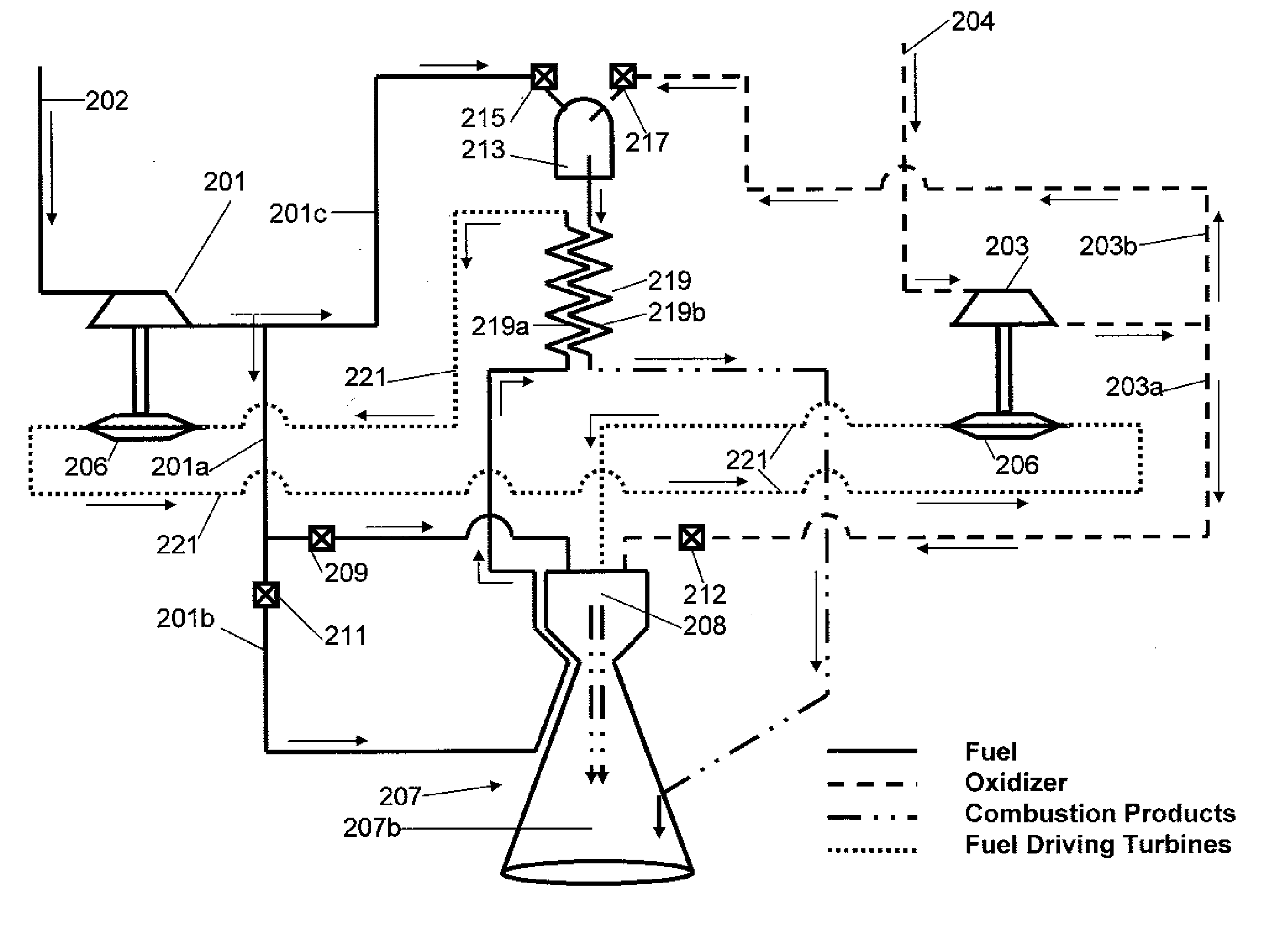

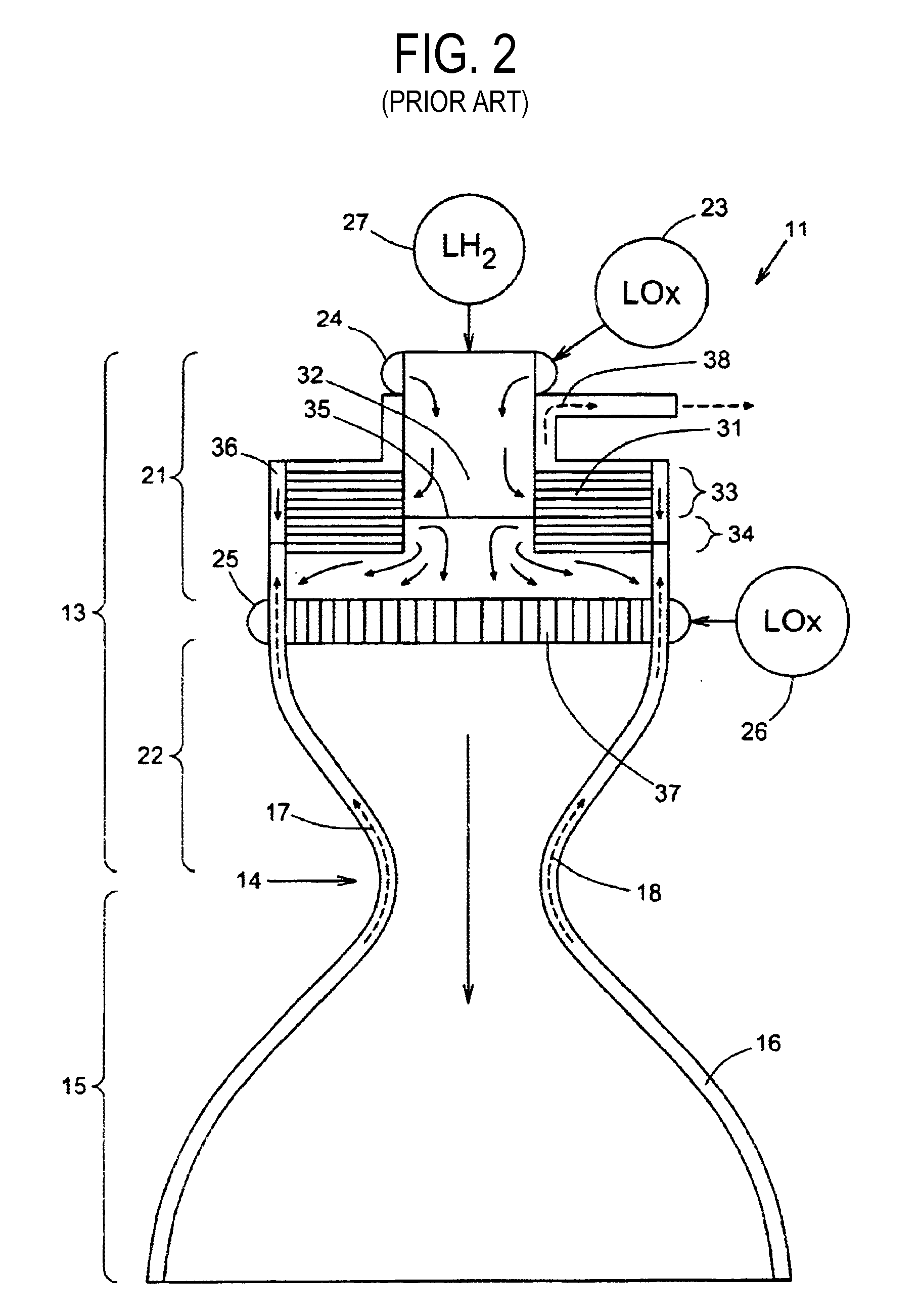

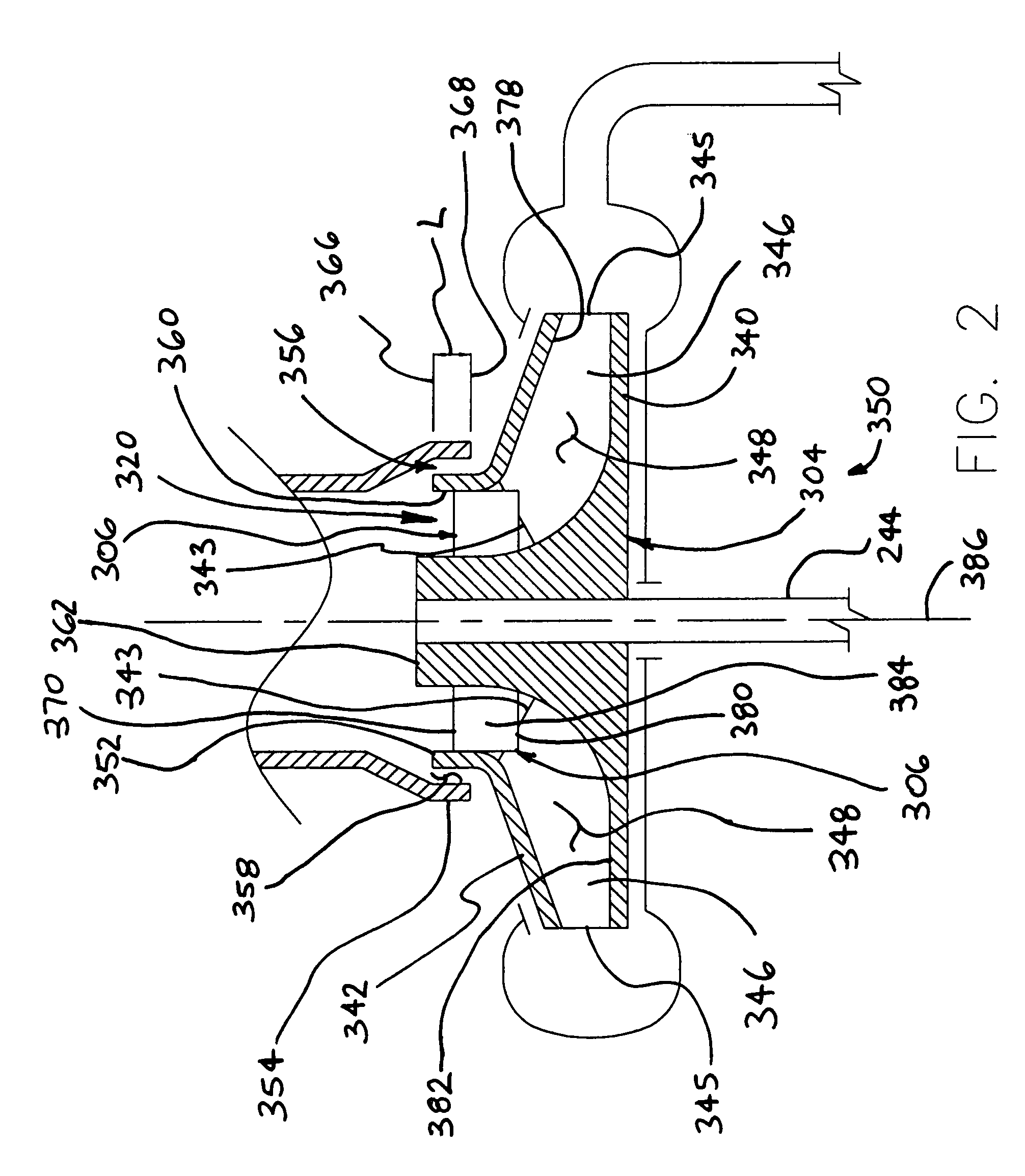

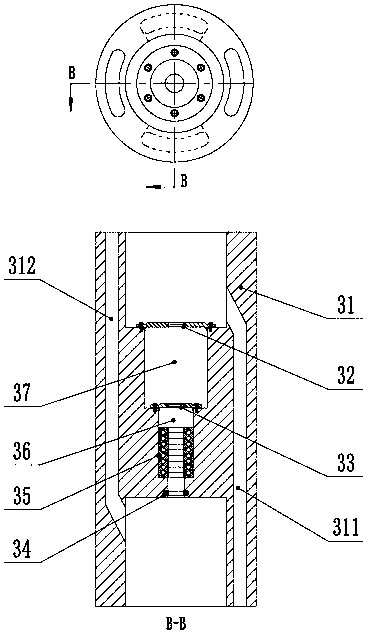

Gas-Generator Augmented Expander Cycle Rocket Engine

InactiveUS20100024386A1Delicate balance of performanceCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberNuclear engineering

An augmented expander cycle rocket engine includes first and second turbopumps for respectively pumping fuel and oxidizer. A gas-generator receives a first portion of fuel output from the first turbopump and a first portion of oxidizer output from the second turbopump to ignite and discharge heated gas. A heat exchanger close-coupled to the gas-generator receives in a first conduit the discharged heated gas, and transfers heat to an adjacent second conduit carrying fuel exiting the cooling passages of a primary combustion chamber. Heat is transferred to the fuel passing through the cooling passages. The heated fuel enters the second conduit of the heat exchanger to absorb more heat from the first conduit, and then flows to drive a turbine of one or both of the turbopumps. The arrangement prevents the turbopumps exposure to combusted gas that could freeze in the turbomachinery and cause catastrophic failure upon attempted engine restart.

Owner:NASA

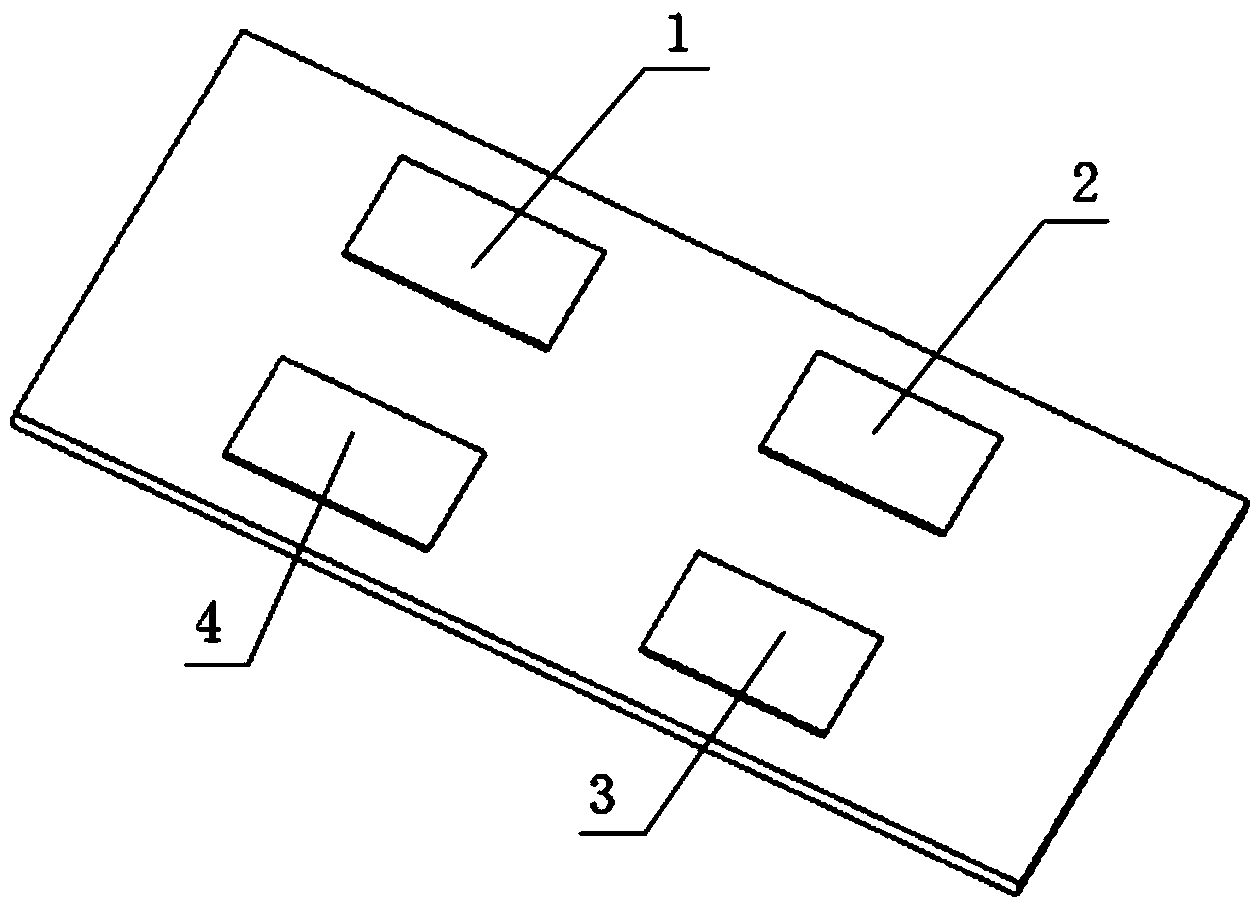

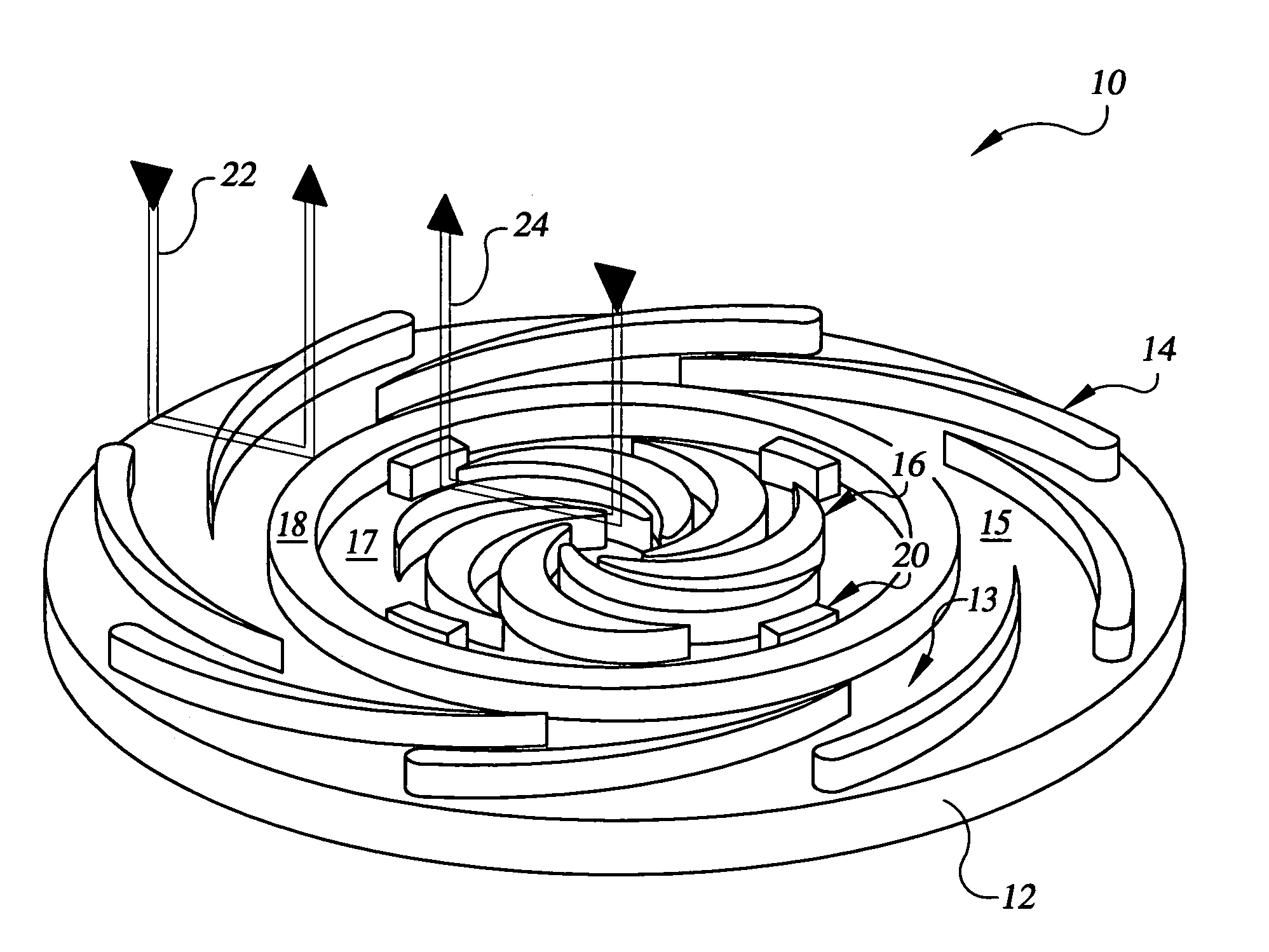

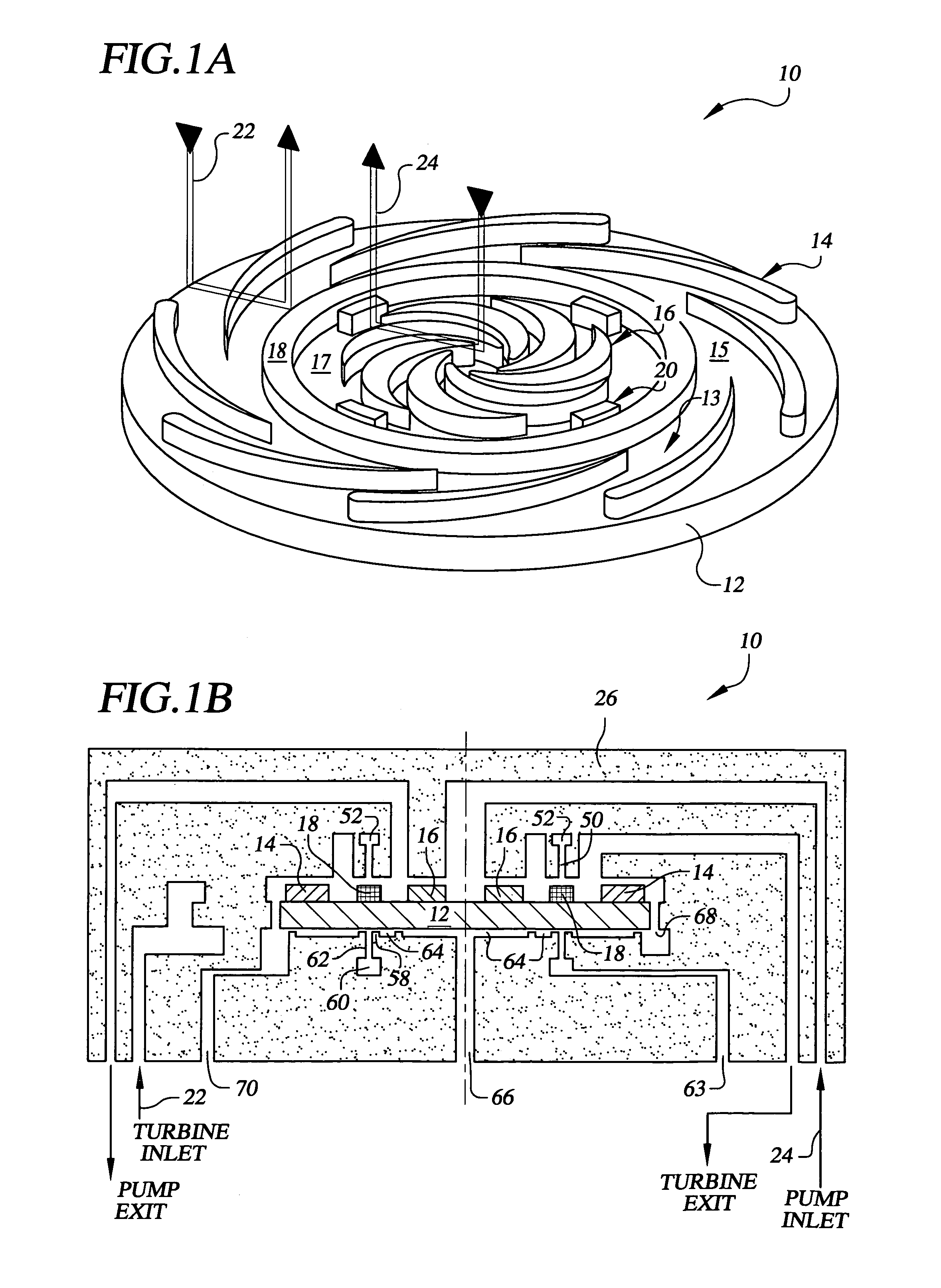

Planar turbopump assembly

InactiveUS7074016B1Simple designEnabling centrifugal operationEngine manufactureBlade accessoriesTurbine bladeTurbopump

A turbopump including a rotor having a first face and a second face and being characterized by a rotor axial height between the first and second rotor faces and by a rotor diameter. A rotor housing includes bearing surfaces for supporting rotation of the rotor, includes turbine inlet and turbine outlet ports and pump inlet and pump outlet ports, and includes pump and turbine fluid sealing surfaces. A plurality of turbine blades of a turbine blade axial height, and a plurality of pump blades of a pump blade axial height, are disposed on a face of the rotor. The turbine blades and pump blades can be together disposed on the rotor first face. Further or alternatively, a turbopump axial height including rotor bearings, turbine blade and pump blade axial height, and rotor axial height, can be less than rotor diameter.

Owner:MASSACHUSETTS INST OF TECH

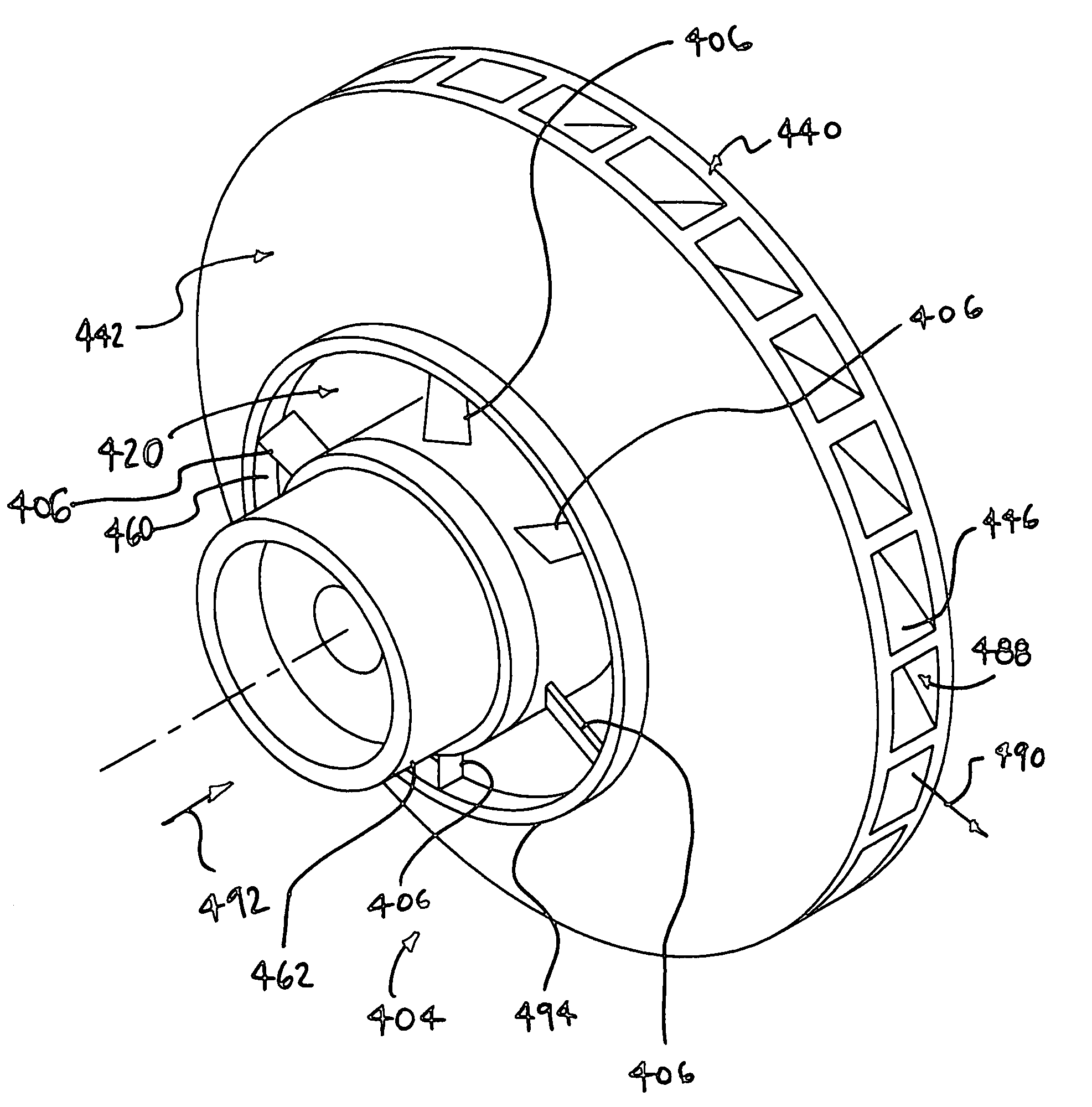

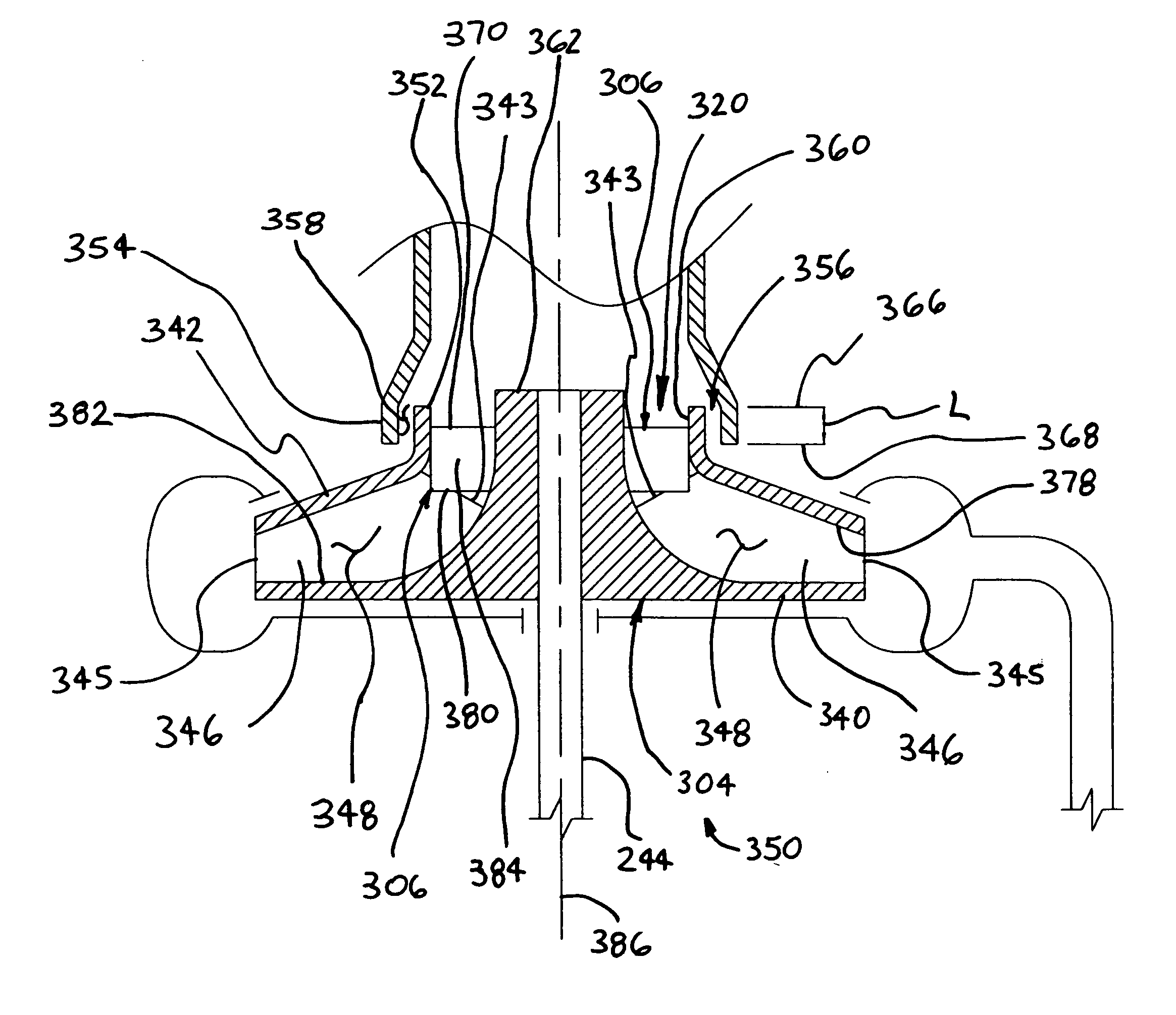

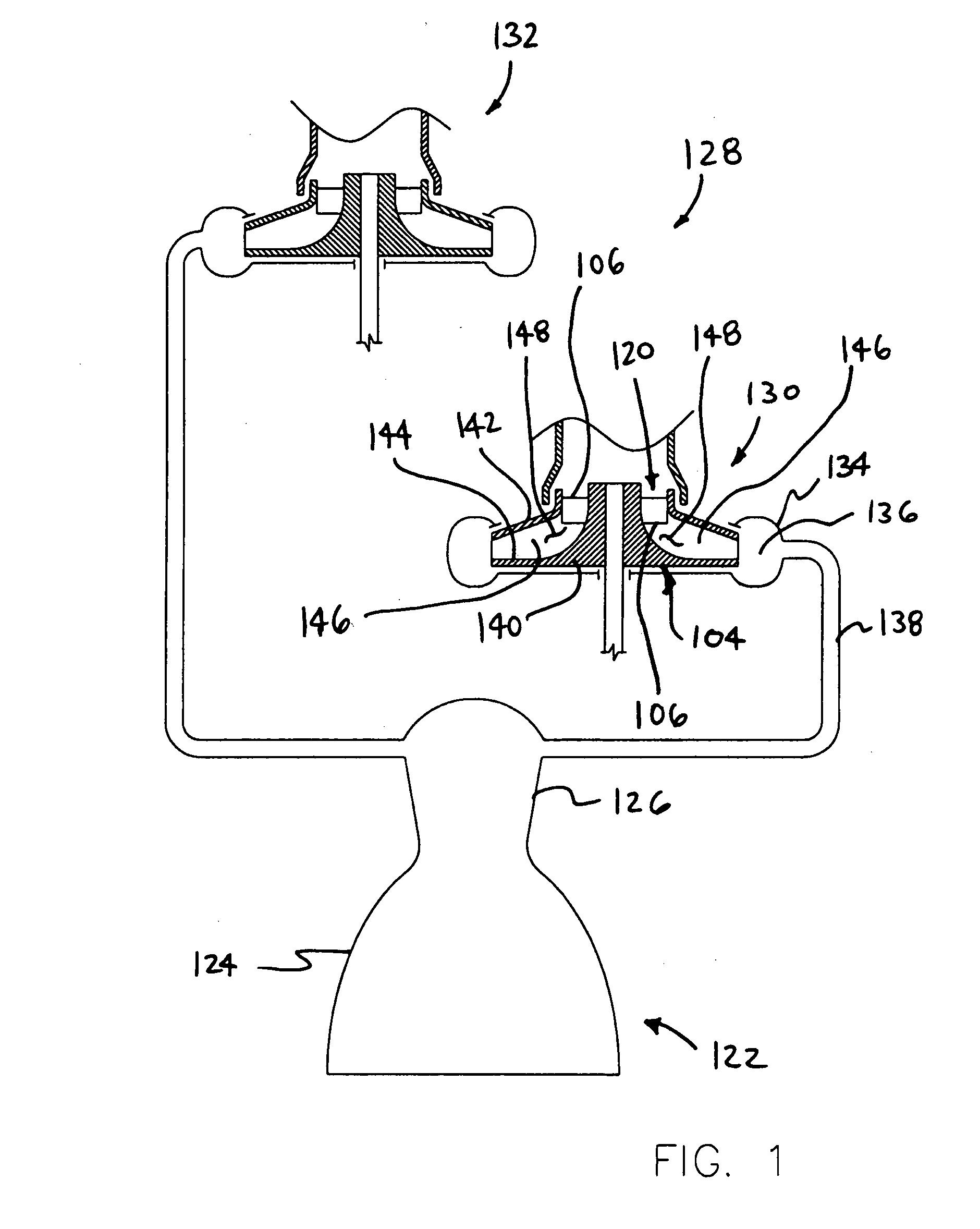

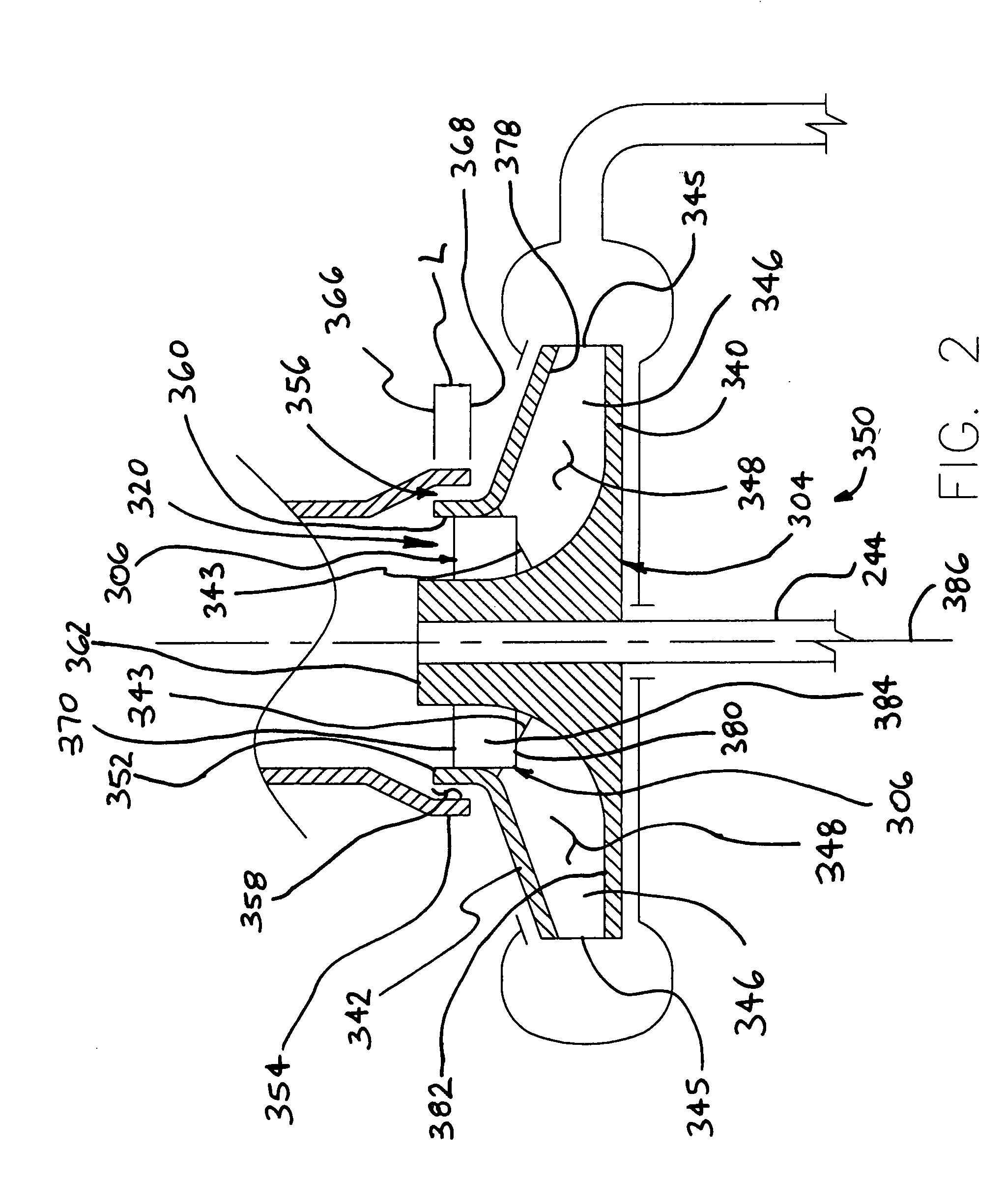

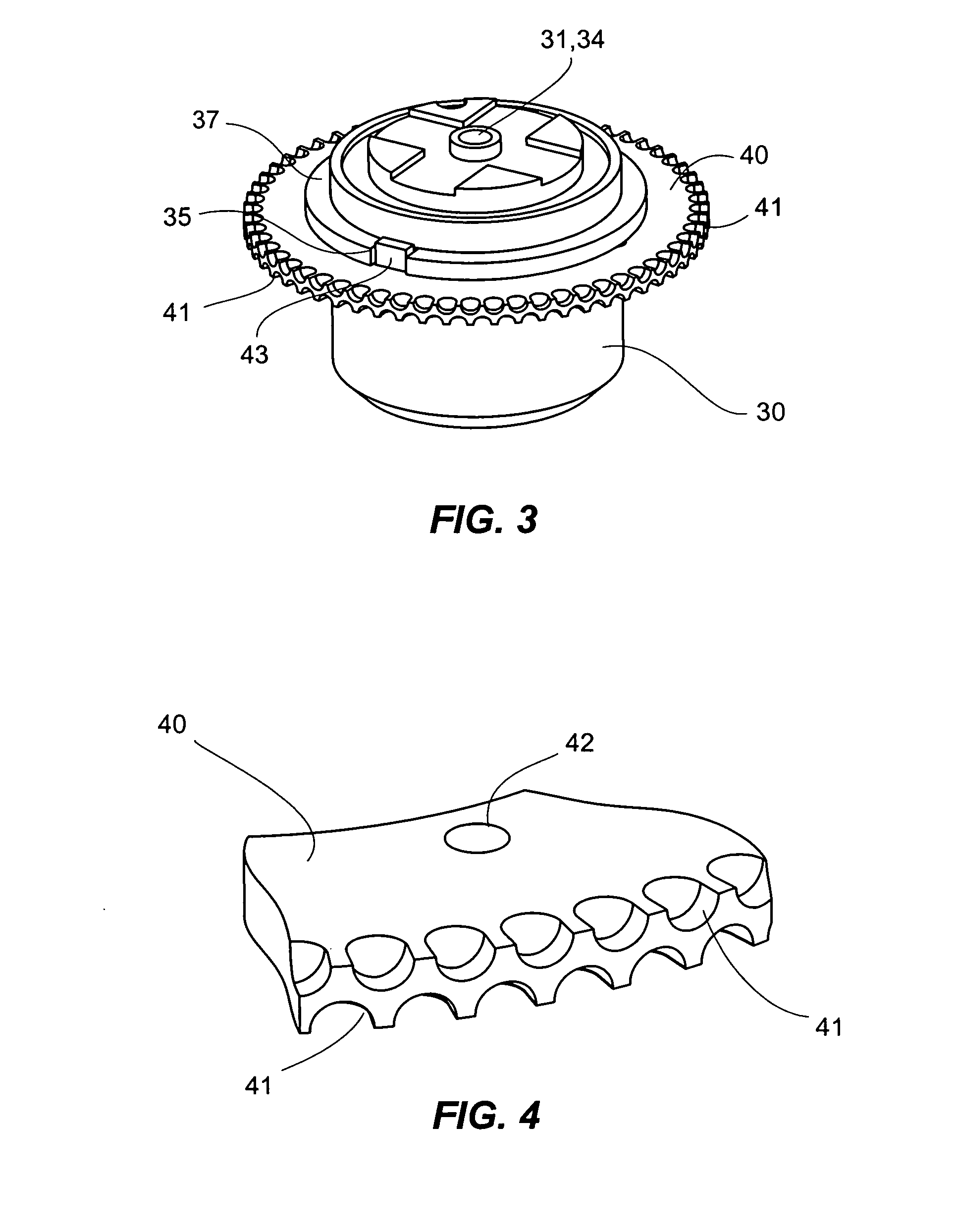

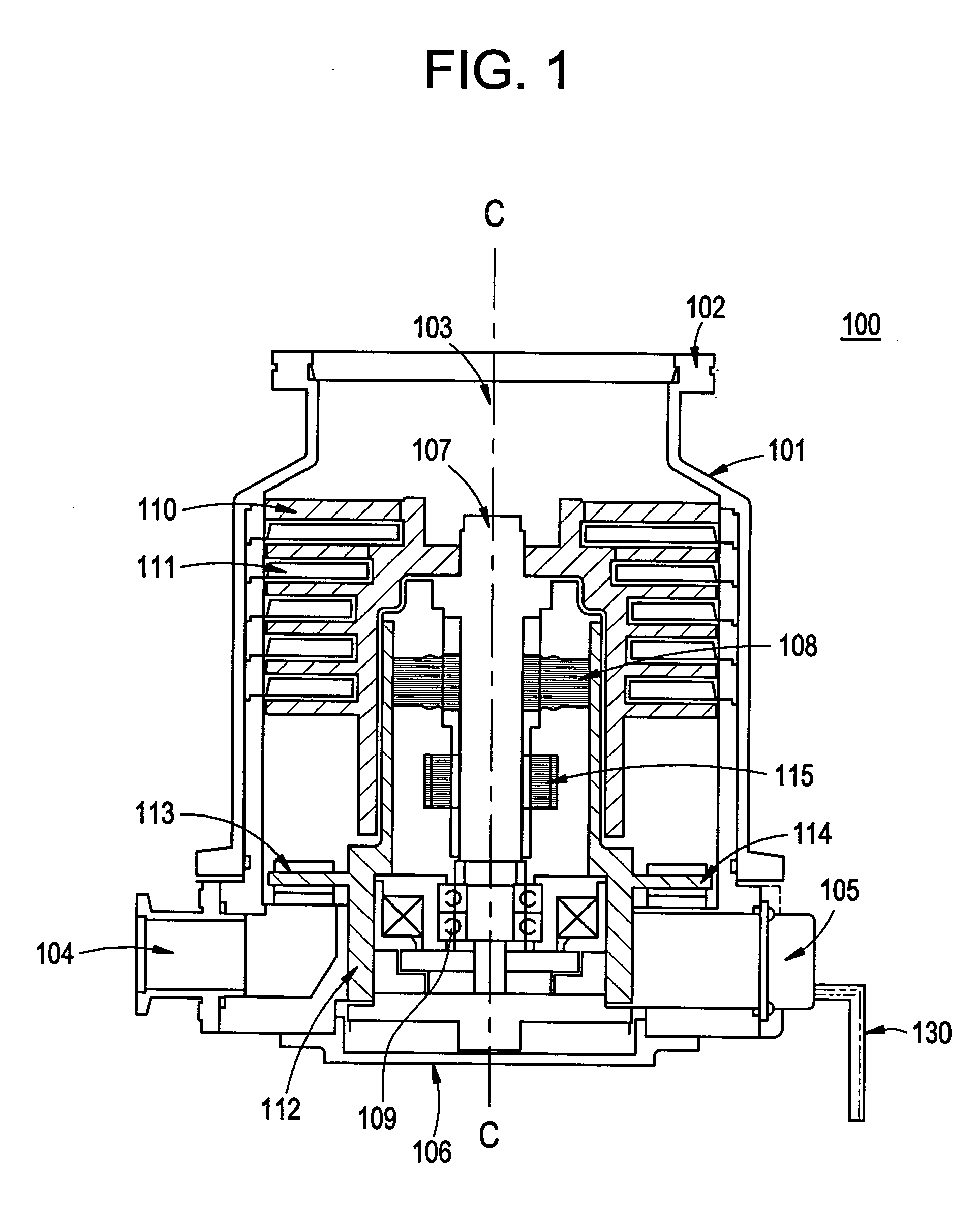

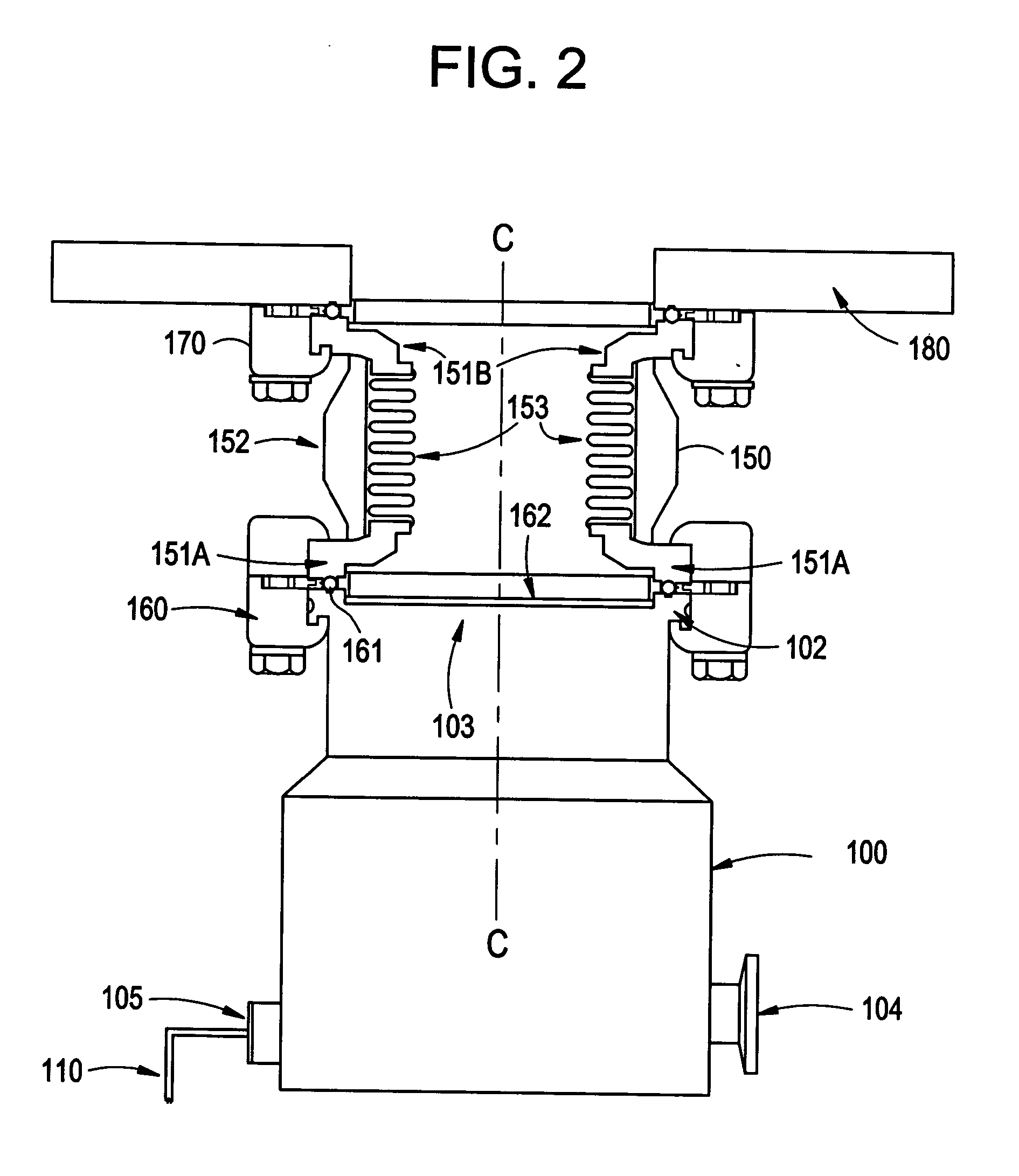

Inlet partial blades for structural integrity and performance

Methods and apparatus for conveying fluids (e.g., liquids, gases, and mixtures thereof) are disclosed. A turbopump in accordance with an exemplary implementation of the present invention comprises an impeller defining at least one flow channel and a shroud defining an opening communicating with the at least one flow channel. In certain advantageous implementations, at least one inlet partial of the impeller extends into the opening defined by the shroud. The at least one inlet partial may advantageously be capable of supporting the opening in the shroud. In some cases, the impeller may include a plurality of these inlet partials.

Owner:THE BOEING CO +1

Inlet partial blades for structural integrity and performance

ActiveUS20050152779A1Reduced scallopingImprove efficiencyPropellersPump componentsImpellerEngineering

Methods and apparatus for conveying fluids (e.g., liquids, gases, and mixtures thereof) are disclosed. A turbopump in accordance with an exemplary implementation of the present invention comprises an impeller defining at least one flow channel and a shroud defining an opening communicating with the at least one flow channel. In certain advantageous implementations, at least one inlet partial of the impeller extends into the opening defined by the shroud. The at least one inlet partial may advantageously be capable of supporting the opening in the shroud. In some cases, the impeller may include a plurality of these inlet partials.

Owner:THE BOEING CO +1

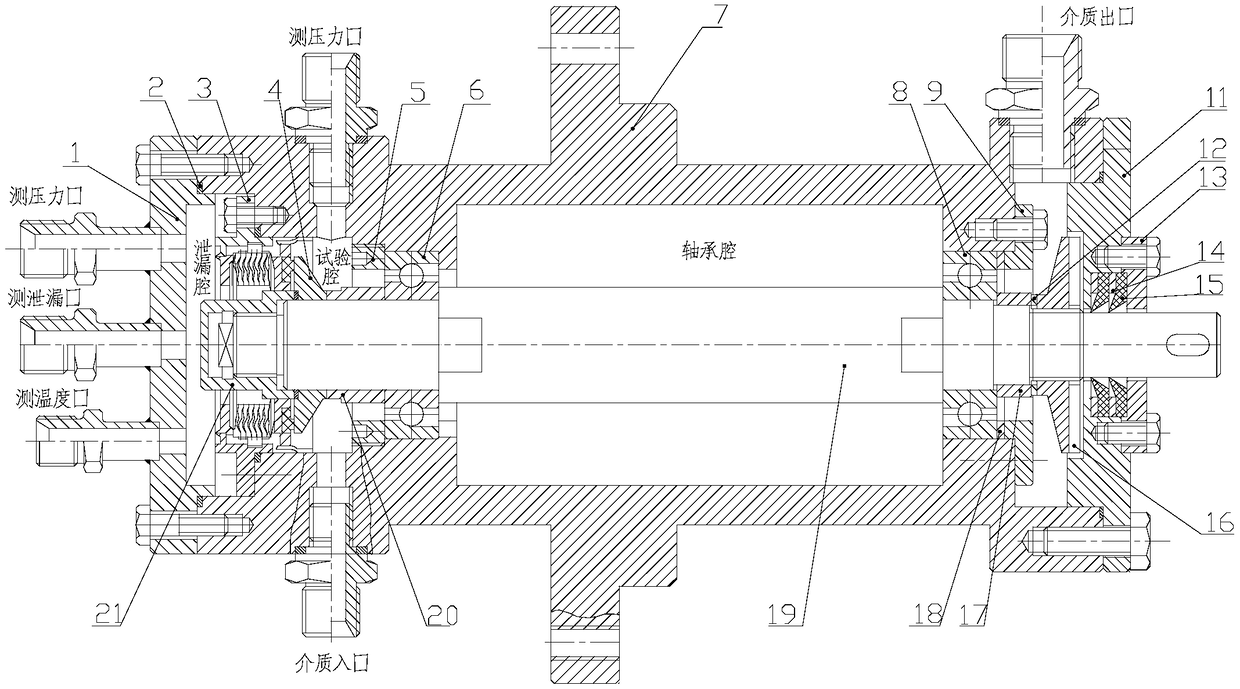

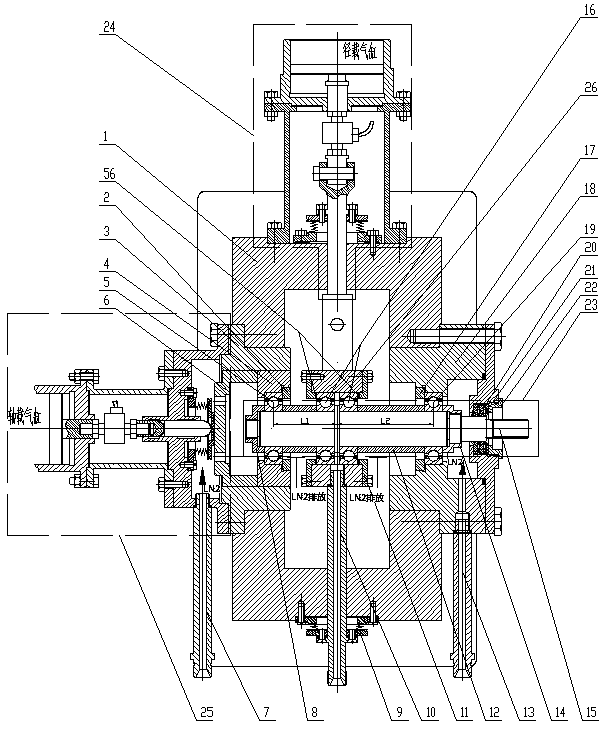

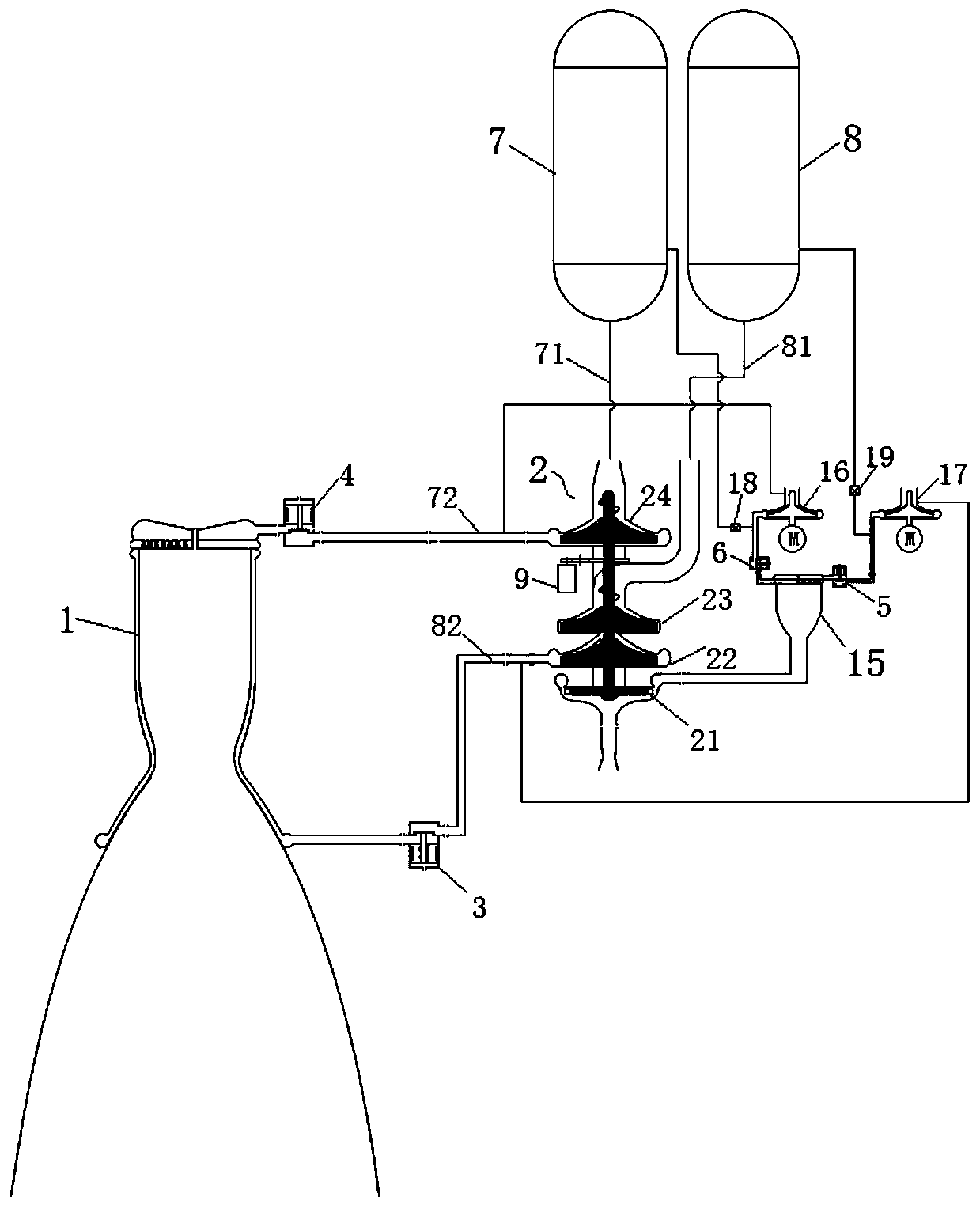

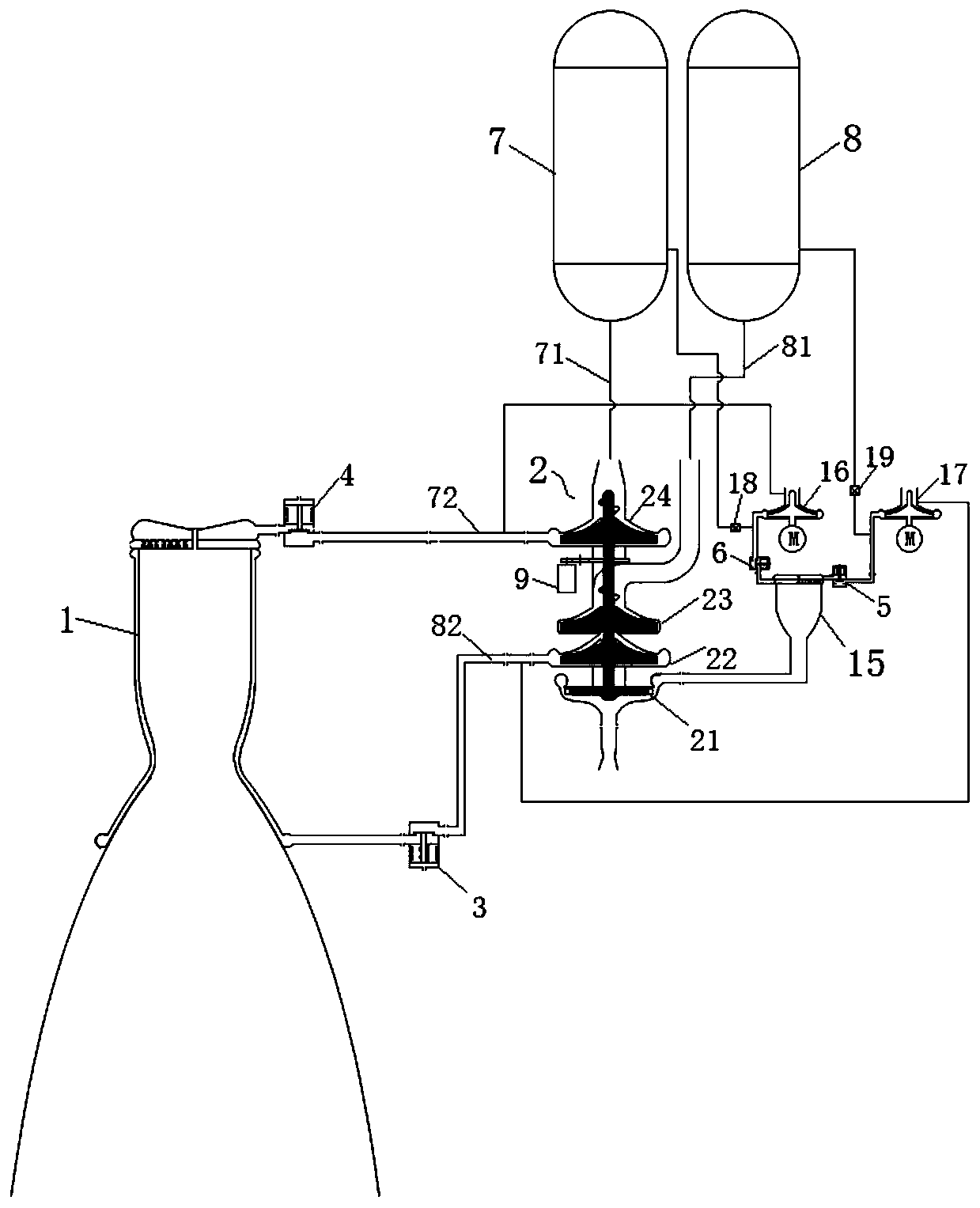

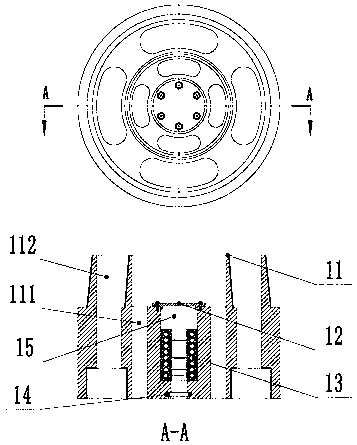

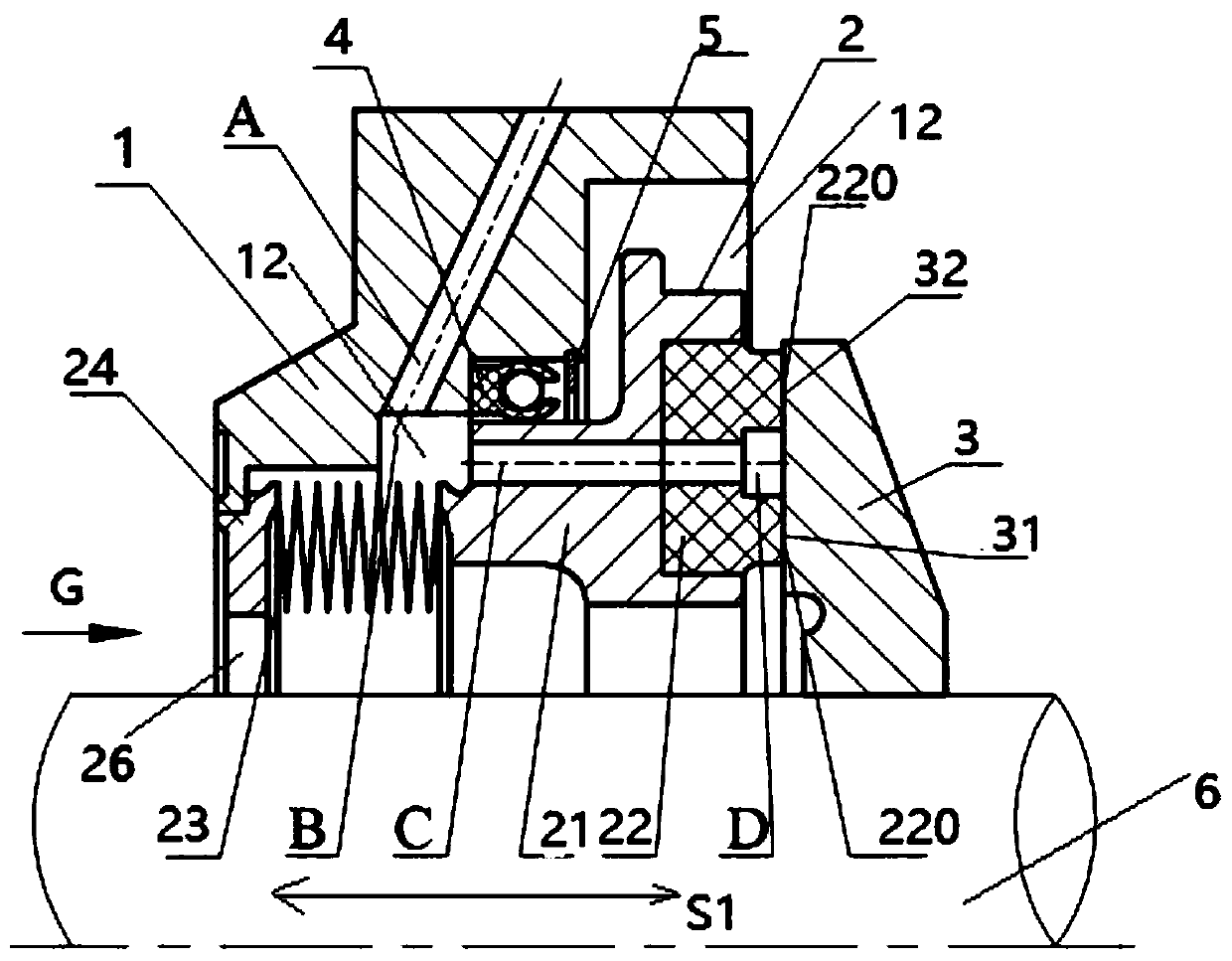

End face sealing test device for liquid rocket engine turbine pump under low-temperature and high-speed

The invention discloses an end face sealing test device for a liquid rocket engine turbine pump under a low-temperature and a high-speed. The device is applied to a sampling test of an end face sealing assembly of a rocket engine of a liquid hydrogen liquid oxygen propellant, in a running-in test and a research performance test, an end face sealing assembly product ( such as an engine static ringassembly and an engine moving ring ) is assembled in the test device of the invention, a working environment of the engine turbine pump is simulated, the sealing performance and the structural rationality of the sealing assembly product are checked, and the sealing performance of the sealing assembly product can be quantitatively detected. According to the device, the test device does not contractand deform under a low-temperature environment, and runs stably at a high speed, the device provides an important basis for improving various problems in the design of the end face sealing assembly product.

Owner:BEIJING AEROSPACE PROPULSION INST

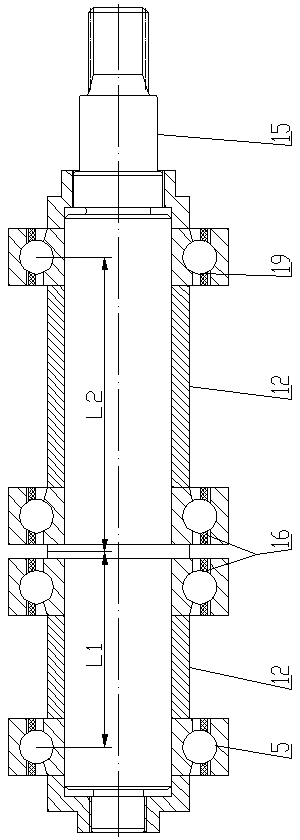

Test device and test method for fatigue life of bearing with ultra-low temperature and high DN value

PendingCN109975022AImprove cooling effectReduce vibrationMachine bearings testingRubber CupEngineering

The invention discloses a test device and a test method for fatigue life of a bearing with ultra-low temperature and a high DN value. The test device comprises a device housing, wherein the device housing is connected with an axial flexible loading device and a radial flexible loading device; the axial flexible loading device and the radial flexible loading device are connected with a test rotor respectively; the test rotor comprises a main shaft; a tested bearing, a supporting process bearing, two loading process bearings and a shaft sleeve are installed on the main shaft; the main shaft andend covers are sealed by means of rubber cup sealing pieces; a force transmission sleeve having a through hole is installed between the axial flexible loading device and the radial flexible loading device; and a tested bearing outer sleeve and a front pressing cover fix a tested bearing outer ring through threaded connection, the tested bearing outer sleeve is connected with a front intermediate sleeve, and the front intermediate sleeve is connected with a front positioning cover. The test device and the test method realize the simulation of actual operating conditions of a low-temperature bearing in a turbopump of a low-temperature liquid rocket engine, including the ambient temperature, load, rotational speed and cooling flow rate being consistent or approximated to the actual operatingconditions.

Owner:北京宇航推进科技有限公司

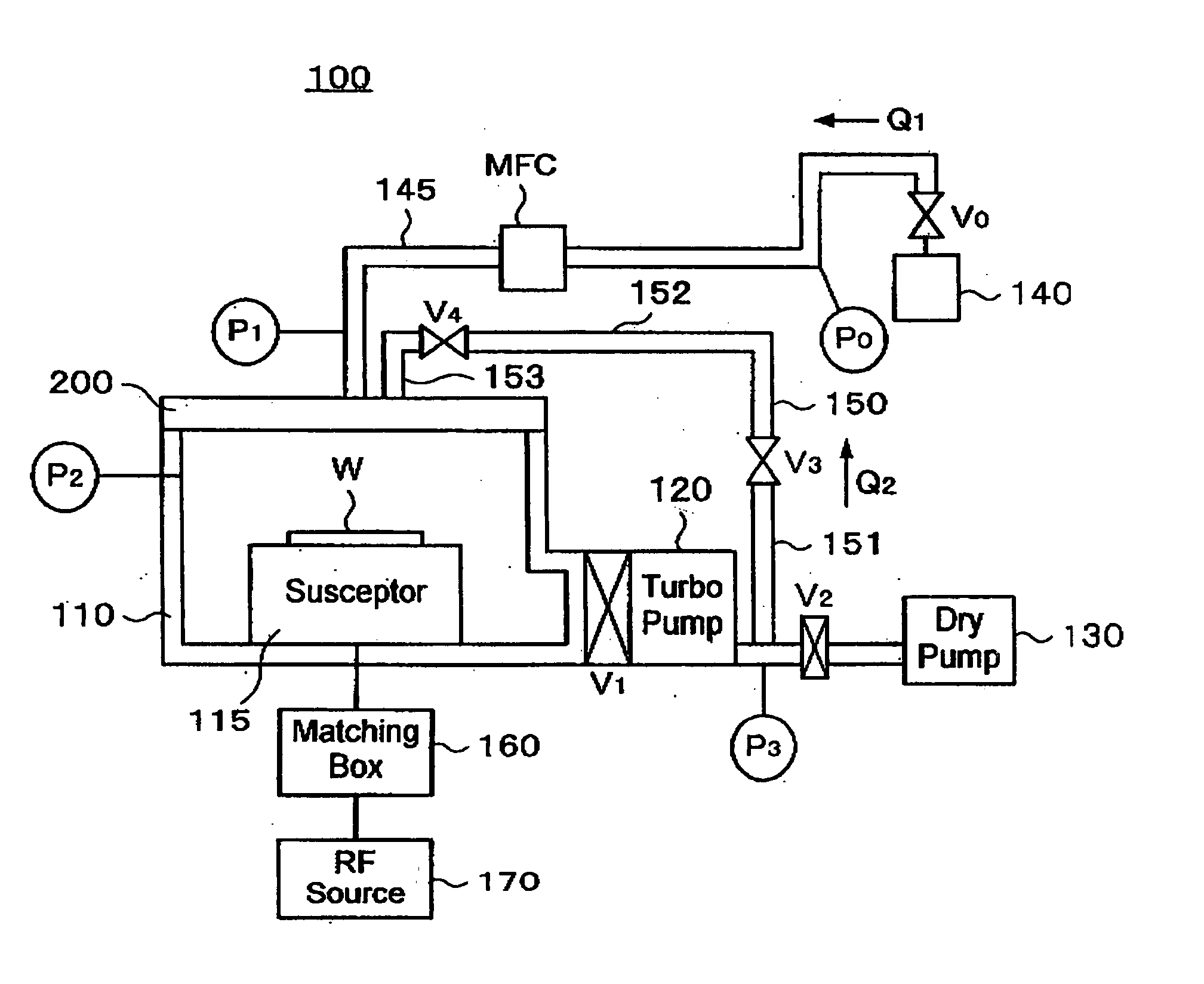

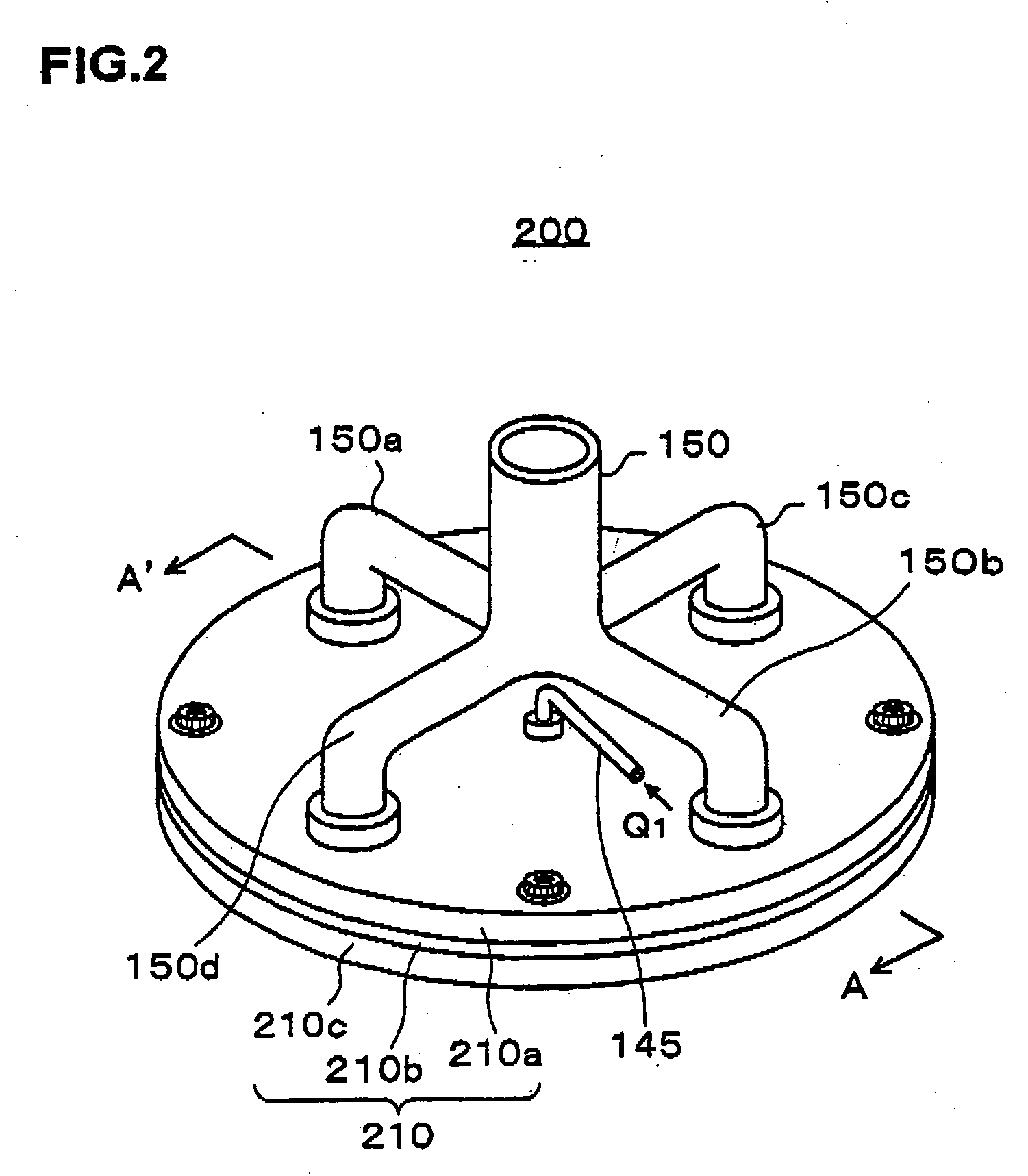

Processing method for conservation of processing gases

InactiveUS20050279731A1Easy to controlElectric discharge tubesDecorative surface effectsProcess engineeringTurbopump

In order to facilitate control of a circulating gas, in a processing apparatus 100 having a showerhead 200 for supplying a processing gas into a processing chamber via a plurality of gas supply holes, a turbo pump 120 for evacuating the processing gas from the processing chamber 110 and a circulating gas piping 150 for returning at least a portion (circulating gas Q2) of the exhaust gas evacuated from the processing chamber by the turbo pump to the showerhead, the showerhead is provided with a primary gas supply system that supplies a primary gas Q1 supplied from a gas source 140 into the processing chamber via a plurality of primary gas outlet holes h1 and a circulating gas supply system that supplies the circulating gas into the processing chamber via a plurality of circulating gas supply holes h2, with the primary gas supply system and the circulating gas supply system constituted as systems independent of each other. Since the primary gas and the circulating gas are allowed to become mixed only in the processing chamber, the circulating gas can be controlled with a greater degree of ease without having to implement pressure control.

Owner:TOSHIBA MEMORY CORP

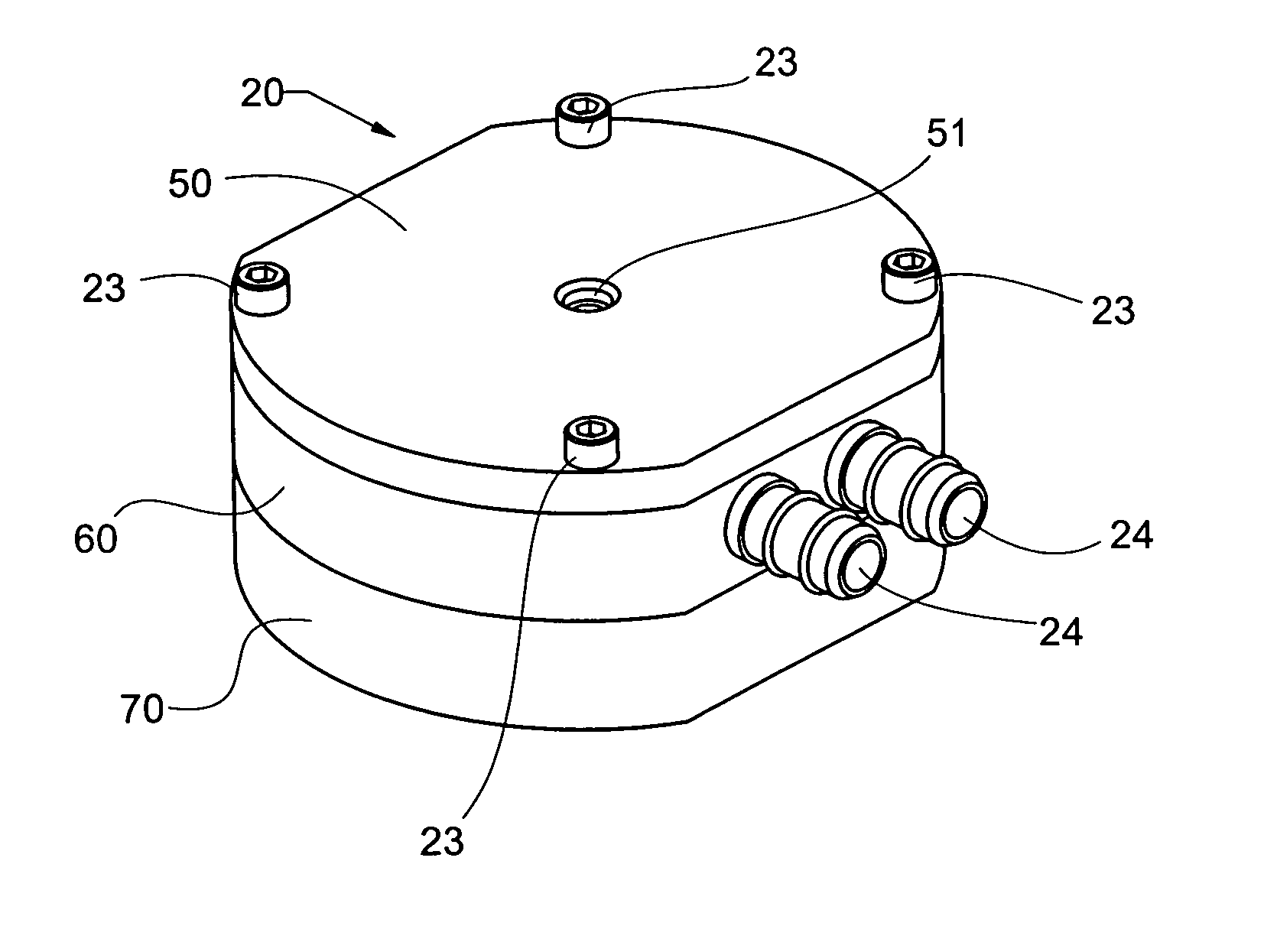

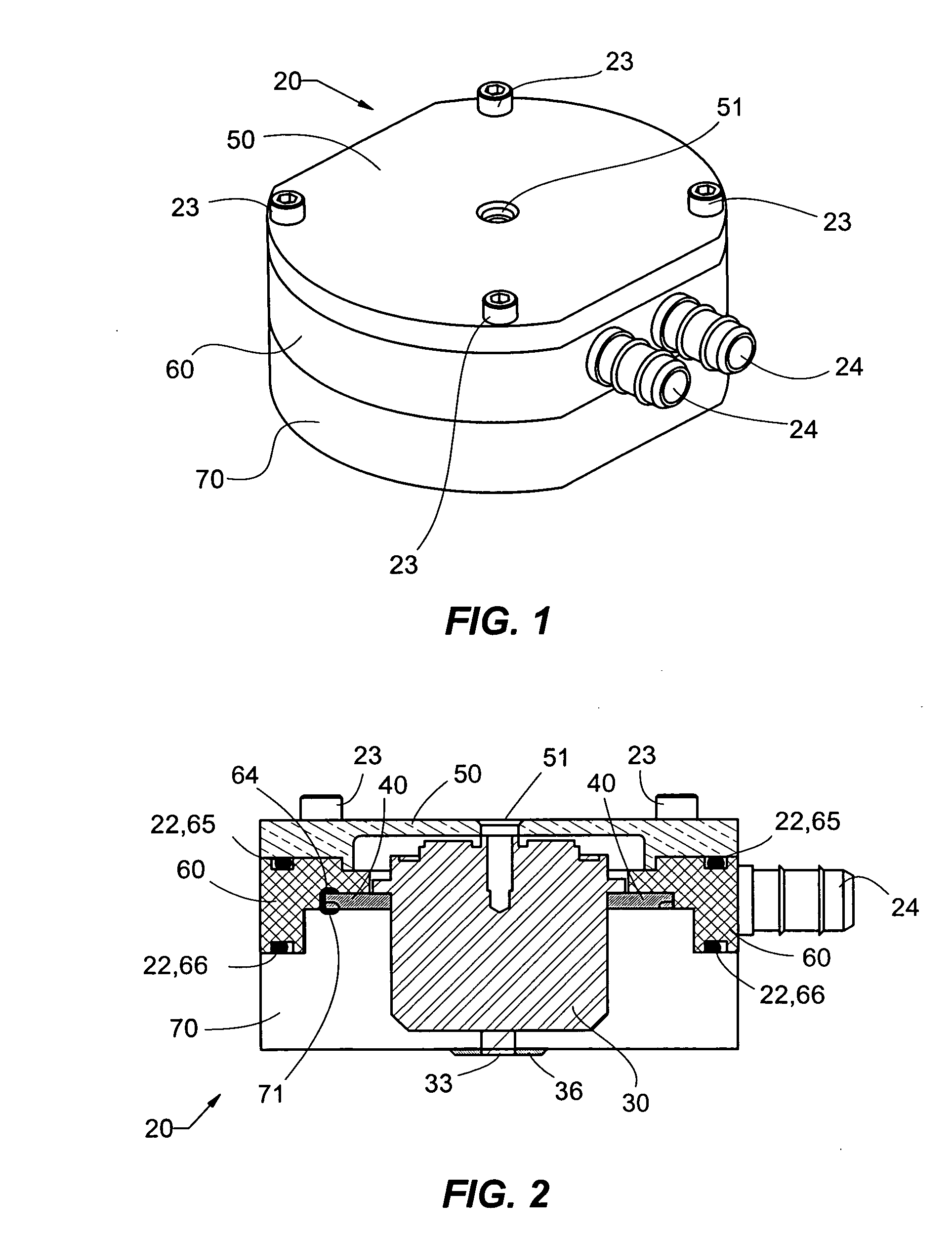

Spindle-motor driven pump system

ActiveUS20050168079A1Low costImprove reliabilityCircumferential flow pumpsTransverse flow pumpsImpellerHard disc drive

The present invention is a compact pump that is powered by a brushless DC spindle-motor, as used in disk drives and CD-ROM drives. A hard drive type spindle-motor is a brushless DC motor that is highly balanced, very reliable, available at low cost, and is capable of significant rotational speeds. According to the present invention, a spindle-motor is mounted to a pump housing and to an impeller within the housing. The spindle-motor rotates the impeller causing movement of a fluid. Preferably for spray cooling, the pump is a turbine pump.

Owner:PARKER INTANGIBLES LLC

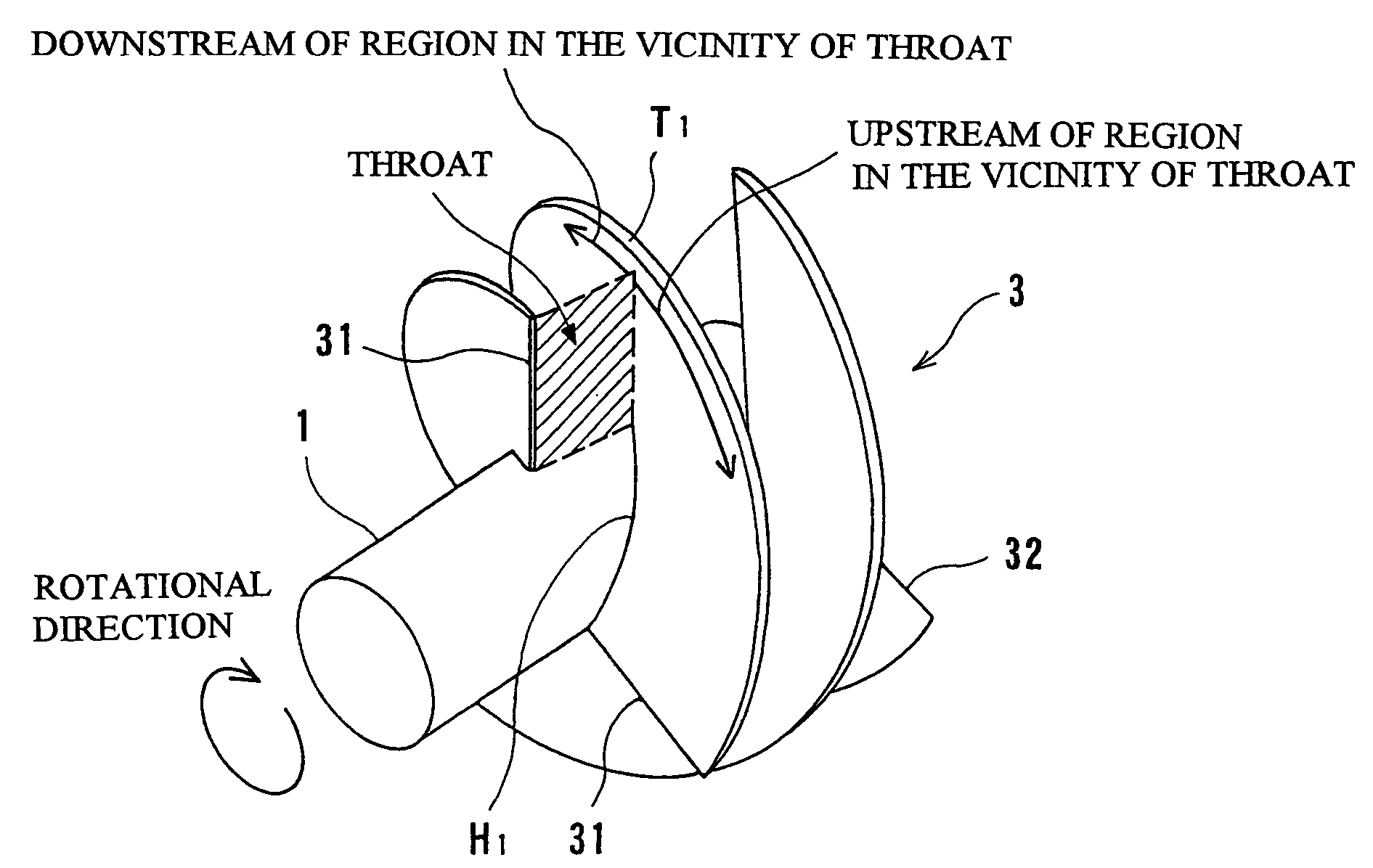

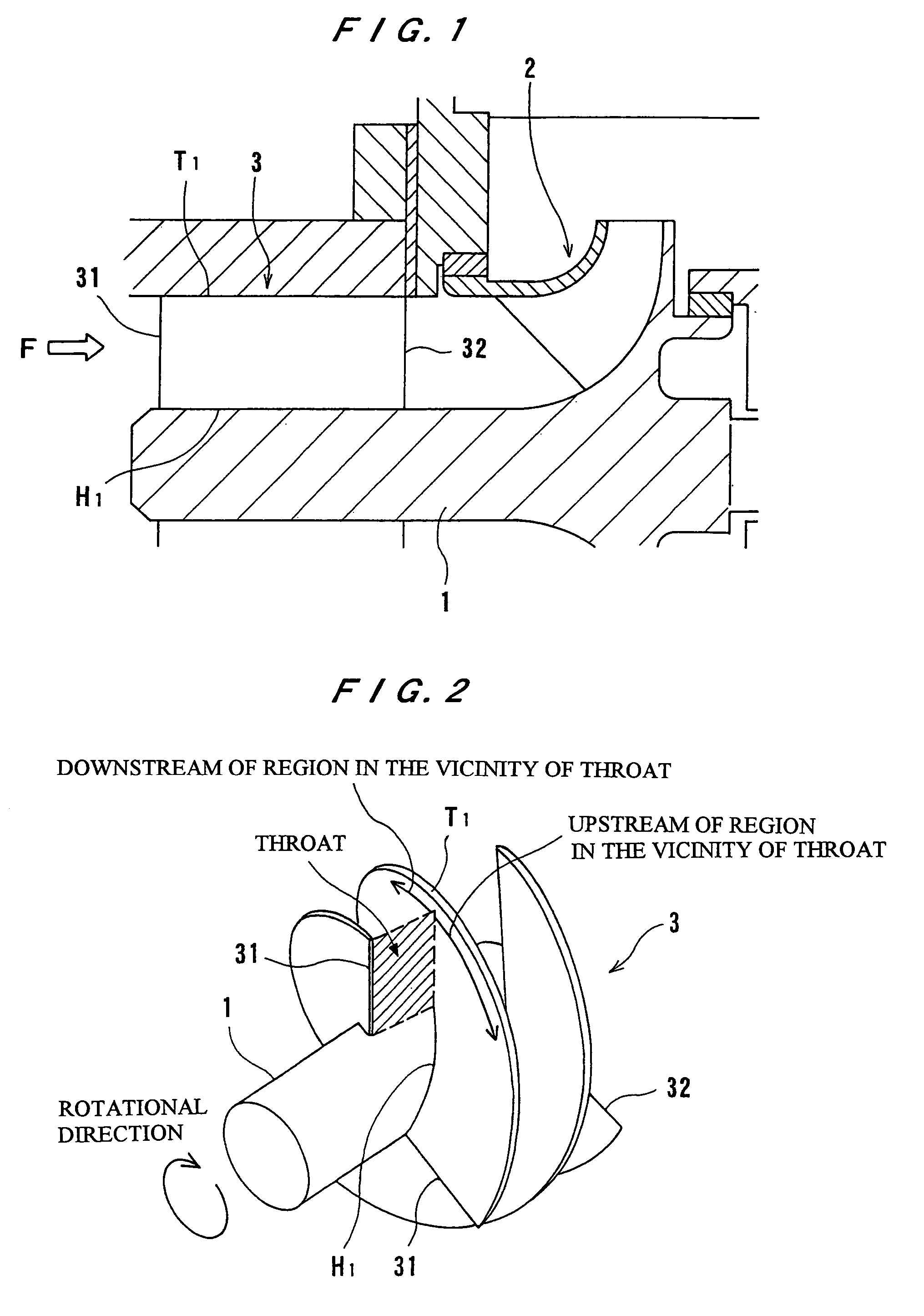

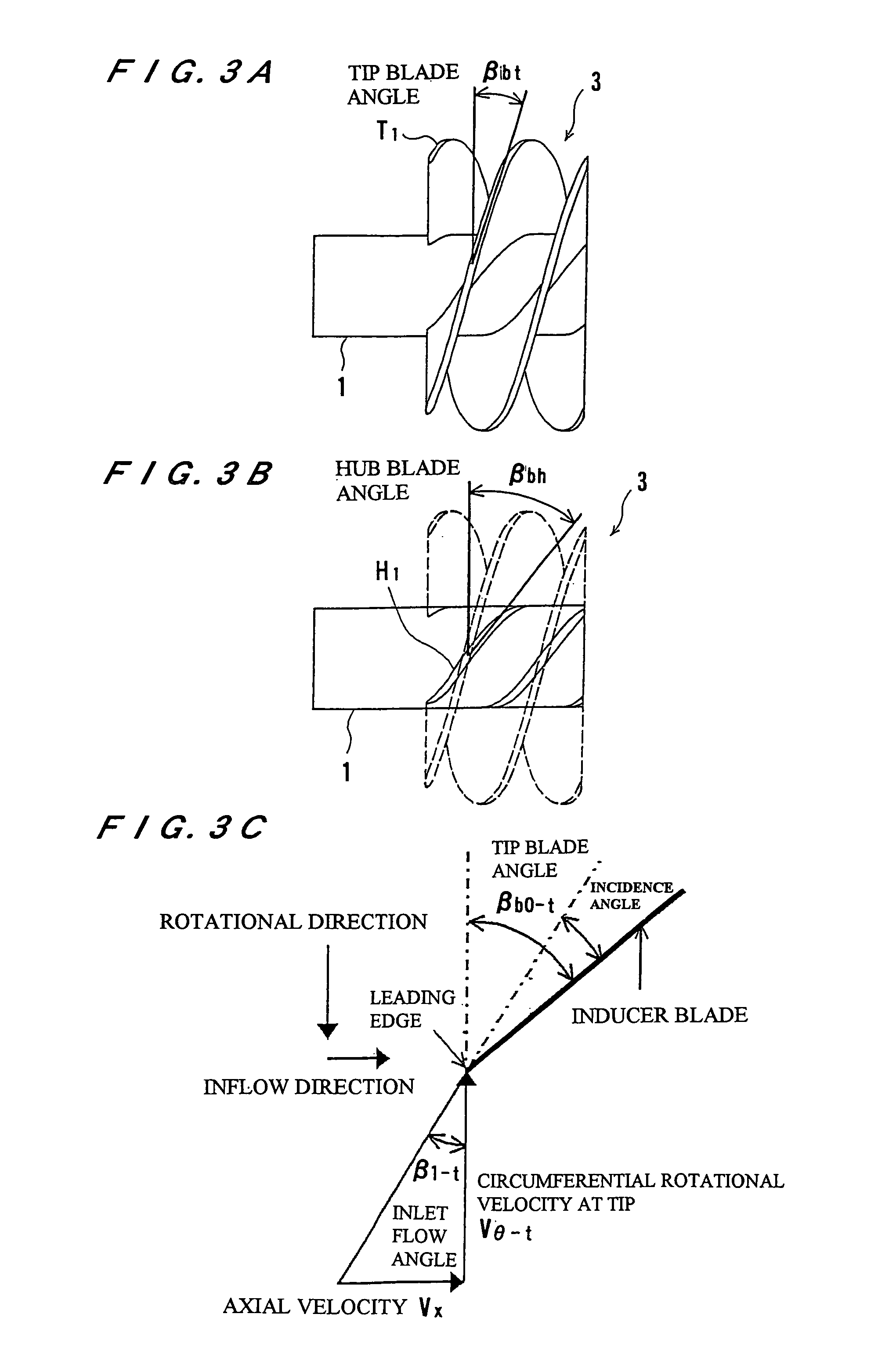

Inducer, and inducer-equipped pump

InactiveUS7207767B2Improve reliabilityInhibition of refluxPropellersPump componentsImpellerLeading edge

The present invention is concerned with an axial-flow or mixed-flow inducer (3) which is disposed upstream of a main impeller (2) for improving the suction capability of a pump such as a turbopump. In the inducer (3), a blade angle (βbt) from a tip (T1) to a hub (H1) at a blade leading edge (31) is substantially the same as an inlet flow angle (β1−t) at a designed flow rate.

Owner:EBARA CORP

Repeated starting rocket engine and starting method

The invention relates to the technical field of aerospace propulsion, in particular to a repeated starting rocket engine and a starting method. According to the repeated starting rocket engine, an oxidizing agent and fuel are led out of the rear end of a turbopump, a generator is ignited to generate flue gas at a certain pressure so as to drive the turbopump to rotate, and repeated starting of therocket engine is achieved. The turbopump can be started in the mode of pumping media to the fuel gas generator, repeated stable starting of the rocket engine can be realized and the starting structure is simplified.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Inducer tip vortex suppressor

InactiveUS20050129500A1Suppress higher order cavitationsReduce refluxPump componentsStatorsCavitationSuppressor

Embodiments of the invention provide a method, device, and turbopump configured to suppress higher order cavitations at an inducer tip in a turbopump. An inducer having a tip is rotated, and a first flow is induced axially through the inducer at a first velocity. A second fluid flow is introduced toward a tip of the inducer substantially parallel to the first fluid flow at a second velocity that is greater than the first velocity, such that back flow through the tip of the inducer is reduced.

Owner:THE BOEING CO +1

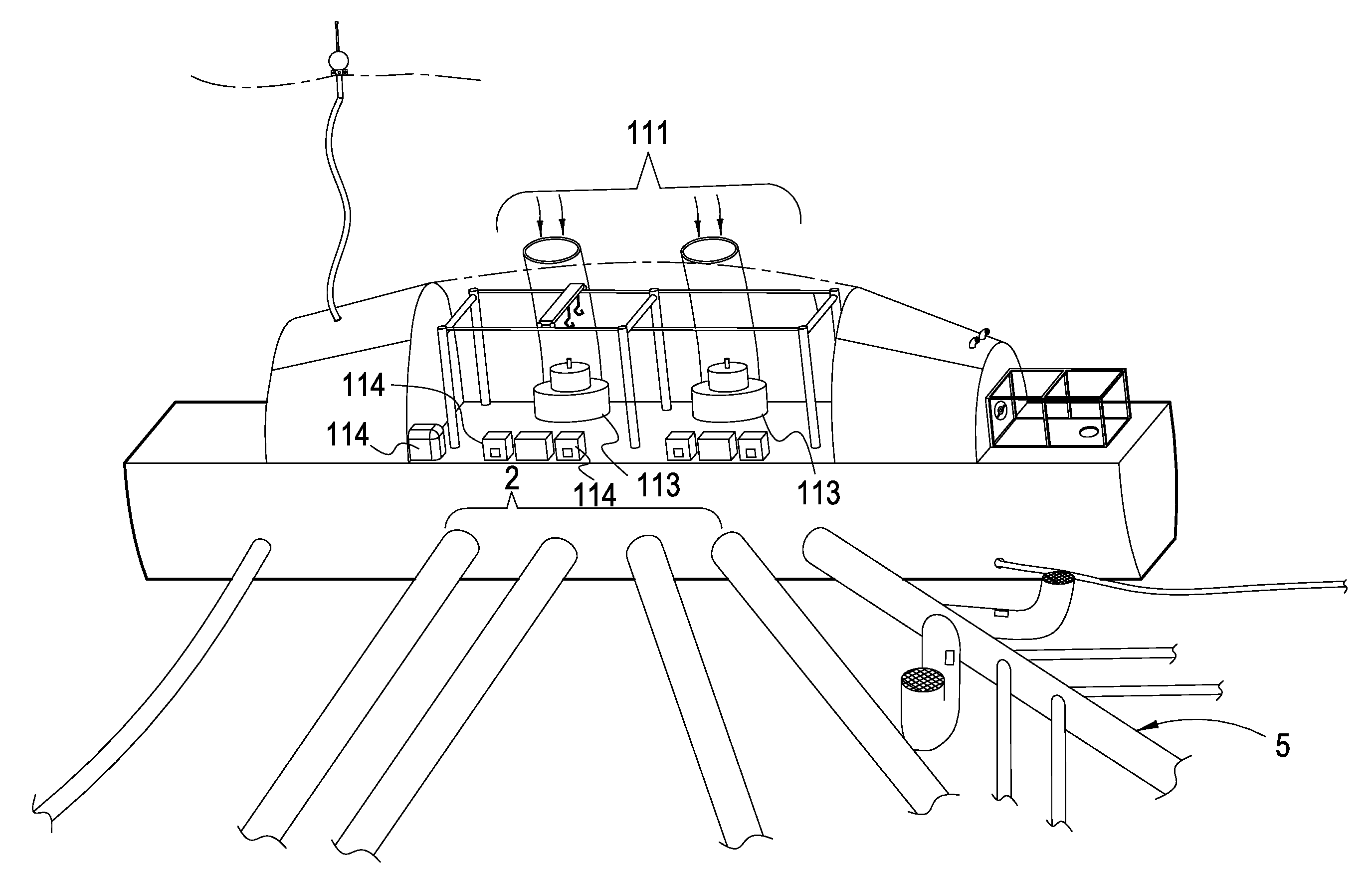

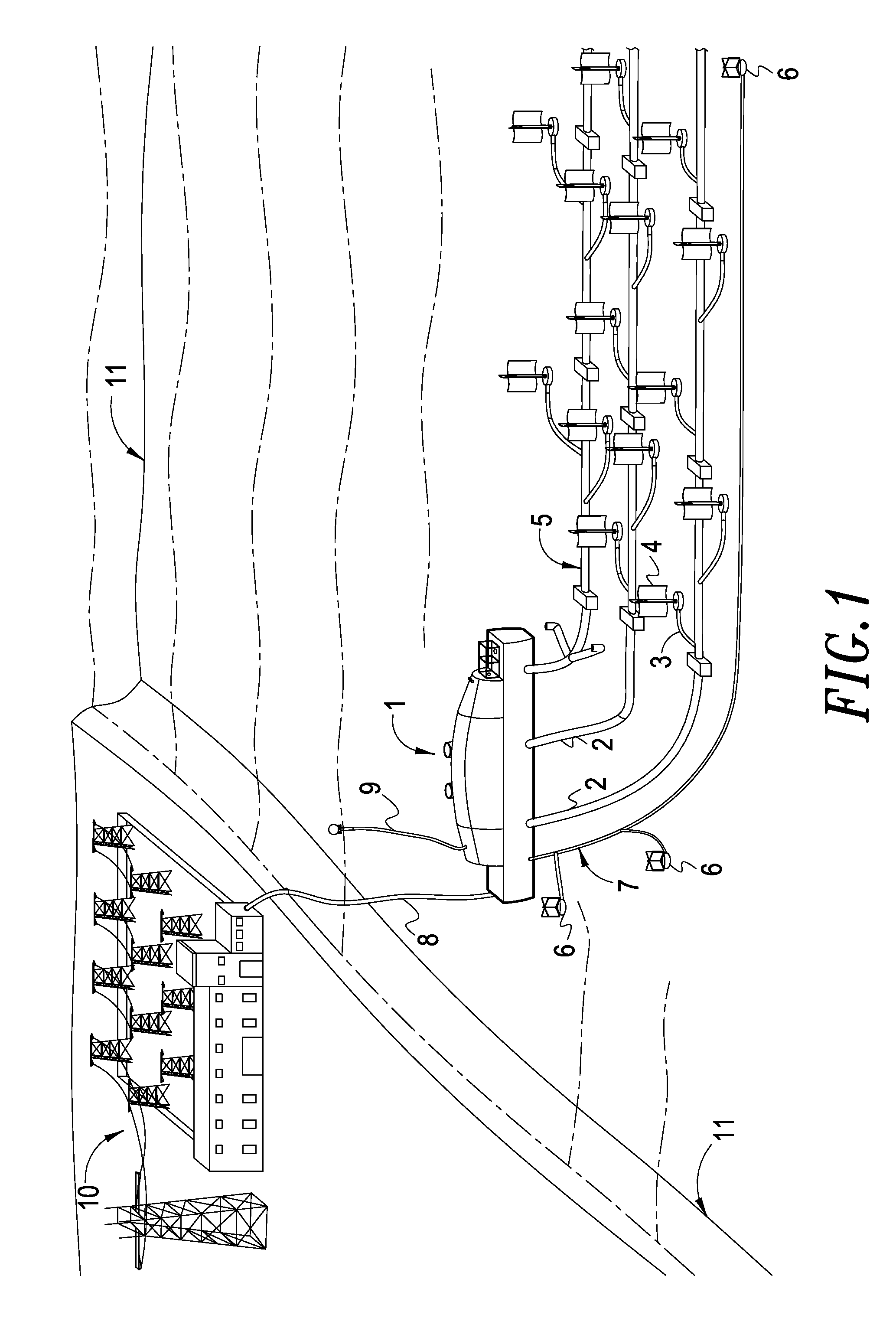

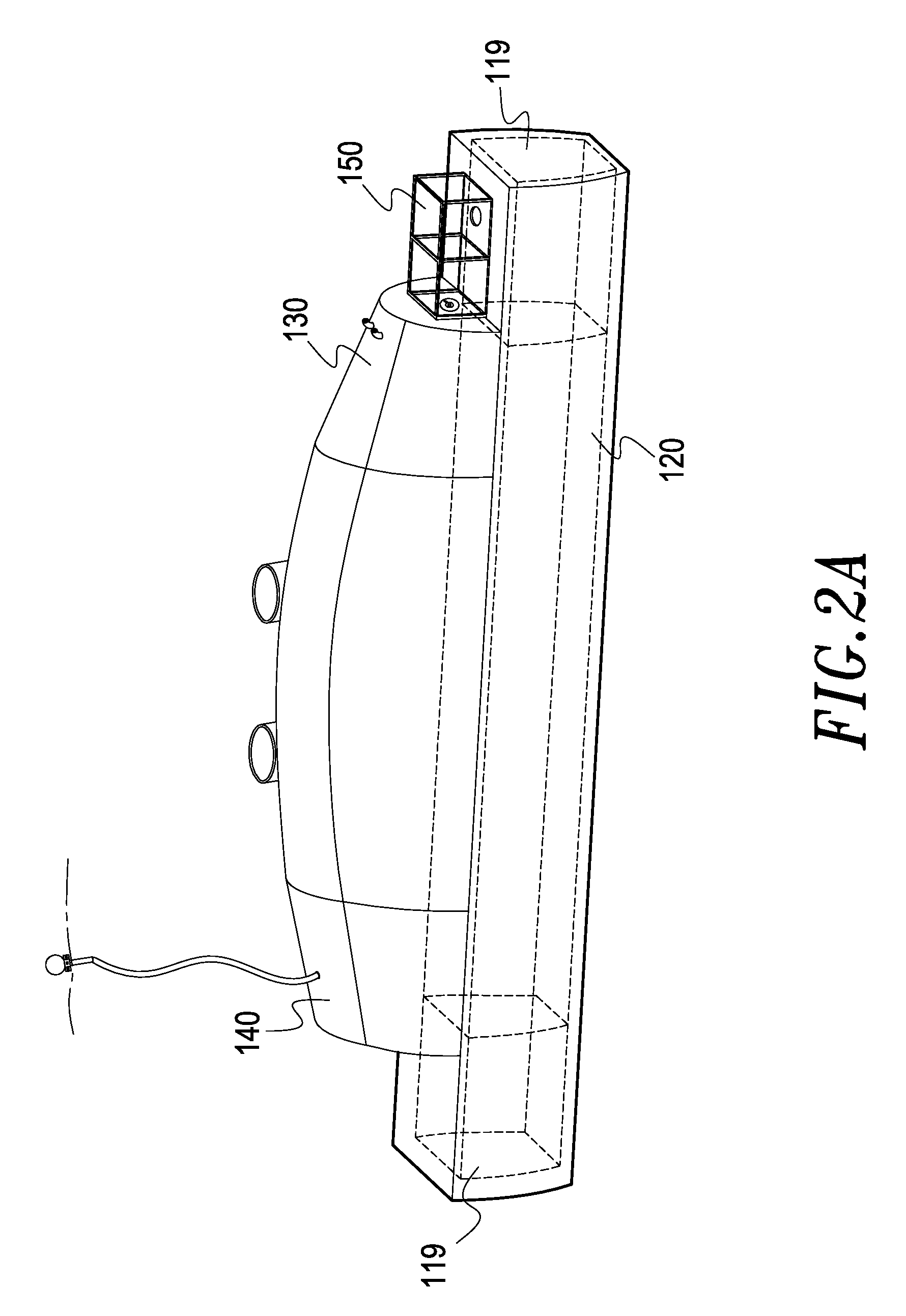

Sea Floor Pump Tailrace Hydraulic Generation System

A small or medium size hydraulic generation plant with a steel shell is placed on the sea floor of the stronger tidal / ocean current site. It is added an air hose to get the fresh air, and an entrance for the technician entering, at out side, the plant is connected with three tidal speed meters, a sea floor cable, an inland remote supervision and control center and a group of tailrace pipe of which the branch pipes of which the branch pipes are connected with a tidal / ocean turbine pump farm.In operation, the plant bring in the sea floor water to generate electricity on large scale. The electricity is transmitted to land by the sea floor cable, while the tailrace firstly drops to the tailrace pond and continually flows thru the tailrace pipes to the turbine pump farm, at last, it is pumped out to the sea floor by the tidal / ocean turbine pump farm.

Owner:TENG CHING SHIH

Turbo pump

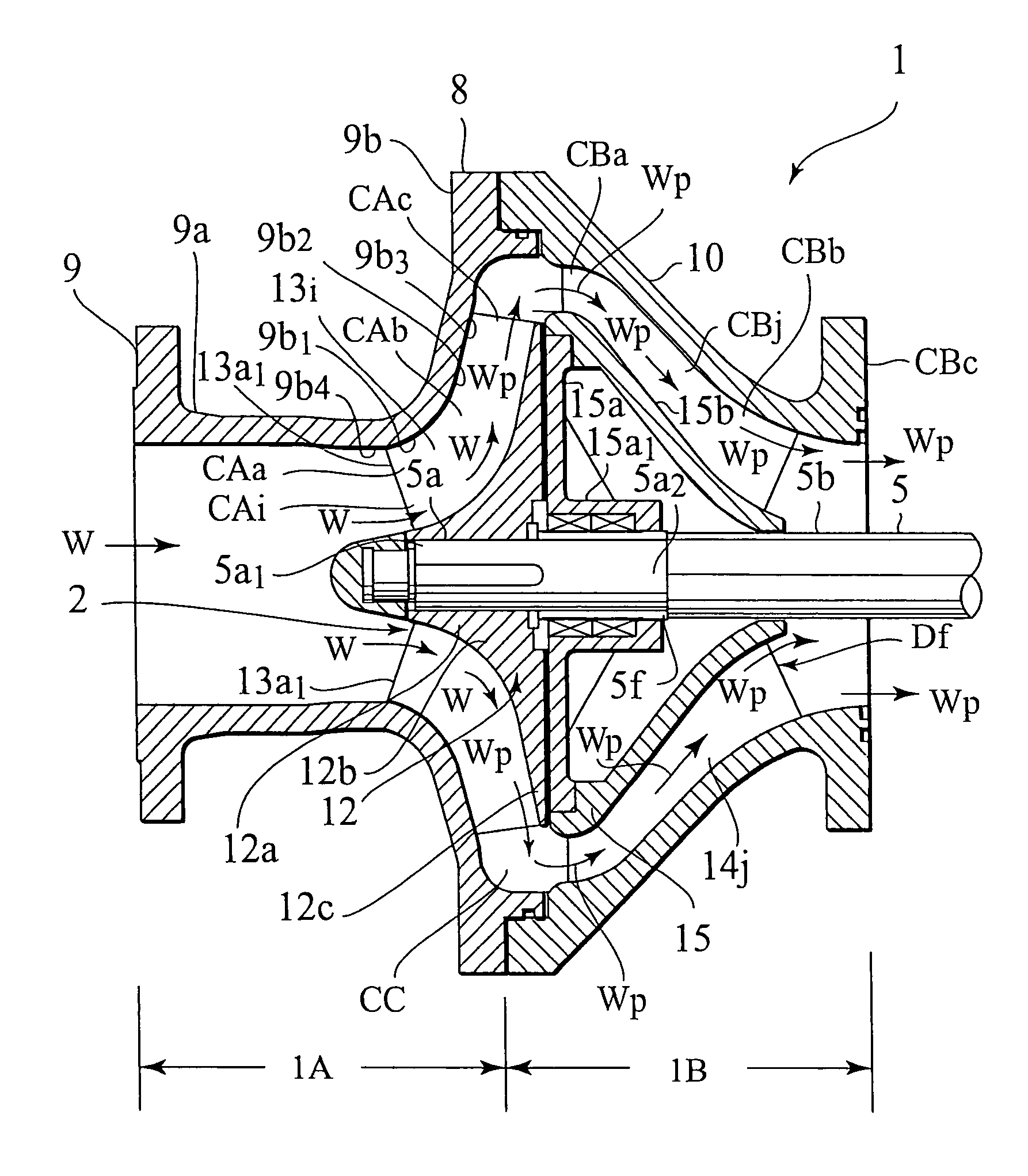

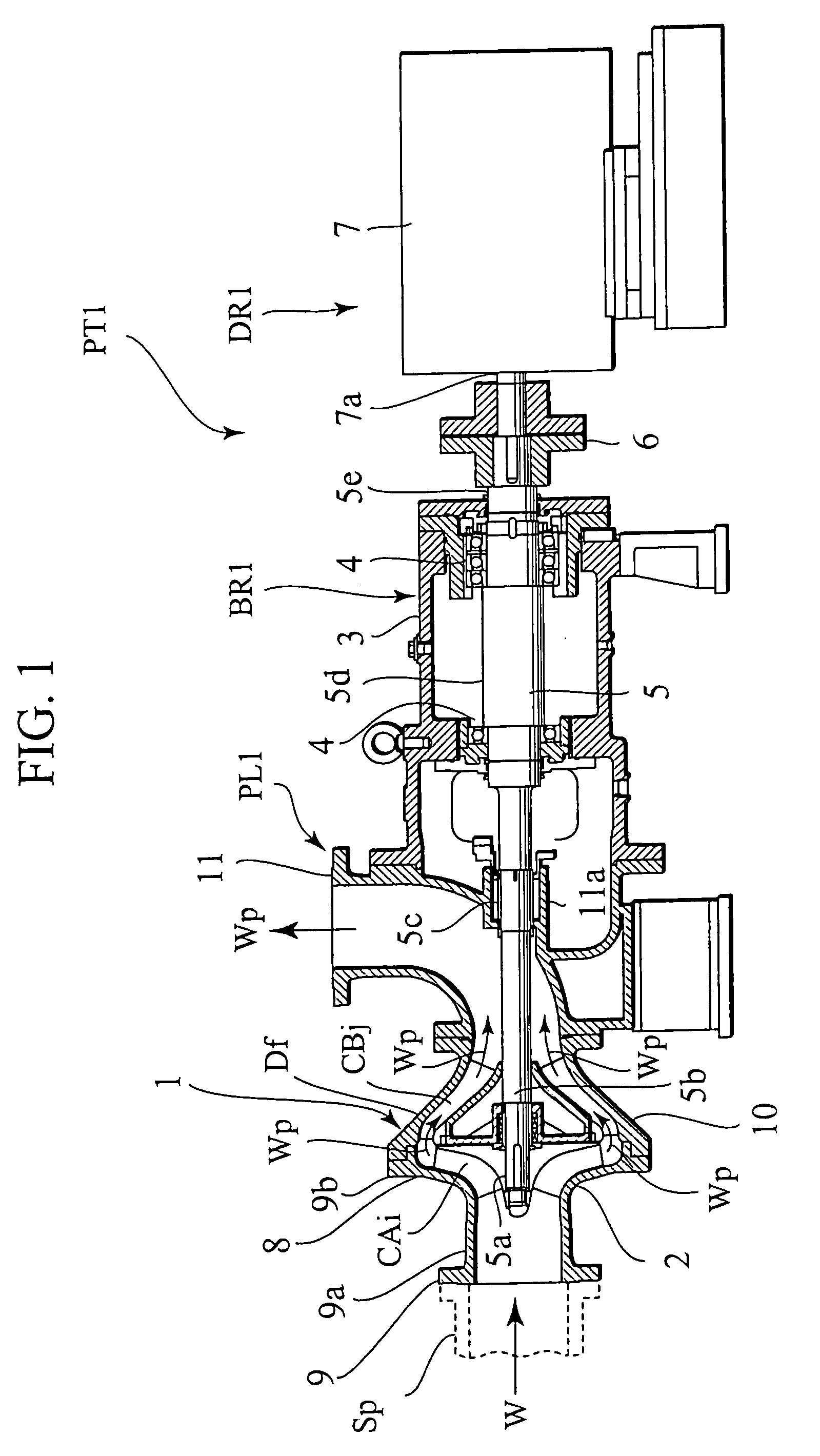

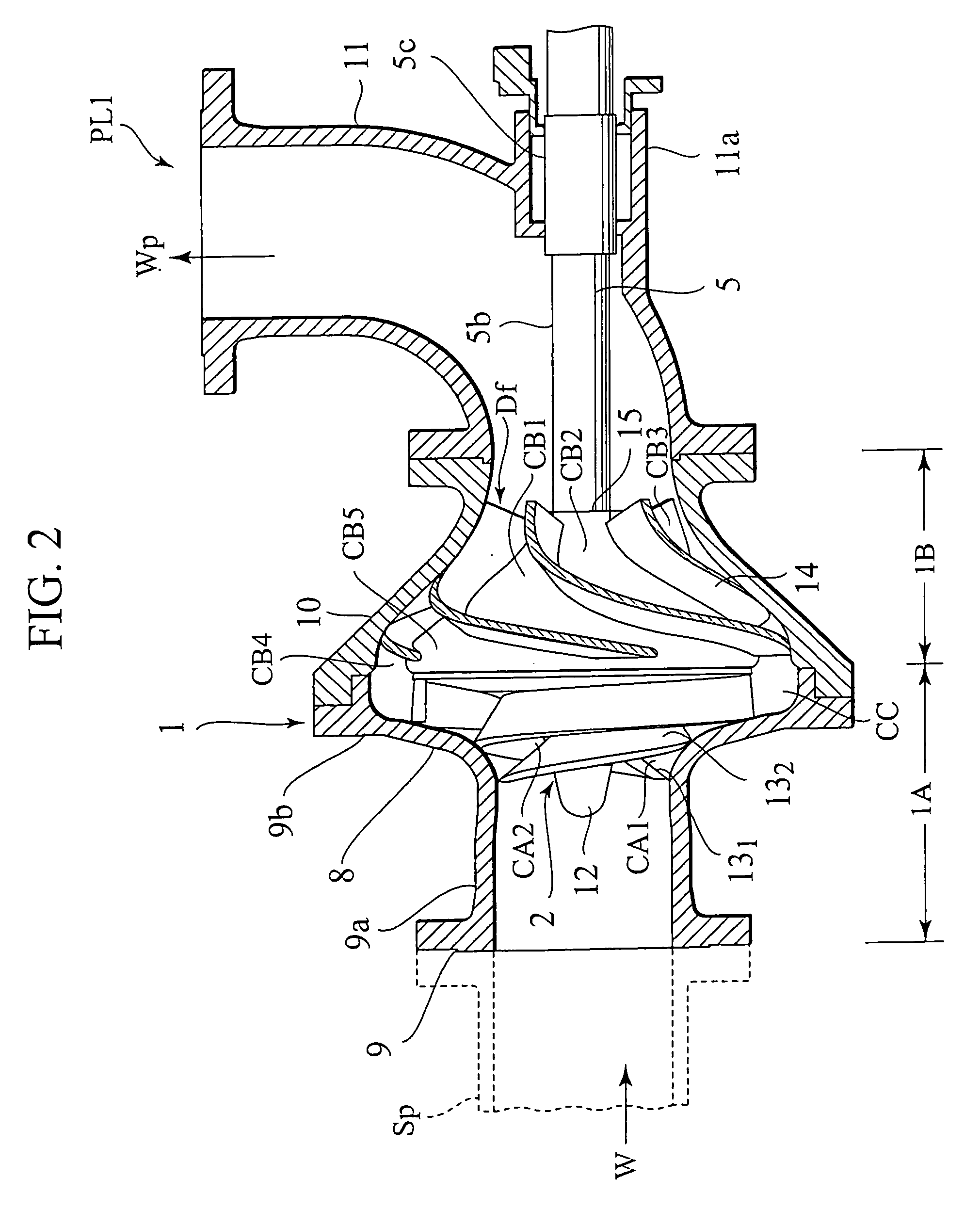

In order to provide a high-head, large-delivery turbopump adapted for excellent suction performance and foreign matter passability by having characteristics of an inducer, axial flow vanes, and mixed flow vanes imparted together to centrifugal vanes, a progressively diameter-increased suction casing rear part (9b) has arranged therein an impeller (2) configured with two to four rotary vanes (13) wound around a hub (12), to define rotary channels (CA) having a vane outlet channel width (b2) of 26% in proportion to a vane inlet outer circumference diameter (d10), the rotary vanes being each respectively configured as a collision-less connection of an upstream axial-flow screw part (13a) provided with an inducer part (13a1) extending into a suction fluid path of a suction casing front part (9a) at a vane inlet angle (beta1) of 14°, an intermediate mixed-flow screw part (13b), and a downstream centrifugal screw part (13c).

Owner:ISHIGAKI CO LTD

Turbine lifting device for fluidized exploitation of natural-gas hydrate

ActiveCN108374650AShorten the timeCost savingsConstructionsFluid removalMechanical crushingUpper joint

The invention discloses a turbine lifting device for fluidized exploitation of natural-gas hydrate. The turbine lifting device comprises an upper joint, a turbine pump, a bridge-type channel, a universal-shaft assembly, a turbine motor and a lower joint, wherein the upper joint is connected with the turbine pump and a sleeve; the bridge-type channel is connected with the turbine pump and the turbine motor; the upper part of the universal-shaft assembly is connected with a central shaft of the turbine motor, and the lower part of the universal-shaft assembly is connected with a central shaft ofthe turbine pump; the universal-shaft assembly is positioned in a sealing cavity of the bridge-type channel; the lower joint is connected with the turbine motor and a sleeve. The turbine lifting device disclosed by the invention has the beneficial effects that power can be provided for jet crushing and mechanical crushing of the hydrate and lifting of hydrate slurry simultaneously, so that the drilling-down time and the cost can be saved and the development period can be shortened; the turbine motor and the turbine pump are used as power and lifting equipment, so that the operation of the turbine lifting device is smooth; the gas lift effect can be achieved by utilizing the phase-stage change of the hydrate, and the energy utilization efficiency and the lifting efficiency can be improved.

Owner:SOUTHWEST PETROLEUM UNIV

Gas-generator augmented expander cycle rocket engine

InactiveUS7900436B2Delicate balance of performanceCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberNuclear engineering

An augmented expander cycle rocket engine includes first and second turbopumps for respectively pumping fuel and oxidizer. A gas-generator receives a first portion of fuel output from the first turbopump and a first portion of oxidizer output from the second turbopump to ignite and discharge heated gas. A heat exchanger close-coupled to the gas-generator receives in a first conduit the discharged heated gas, and transfers heat to an adjacent second conduit carrying fuel exiting the cooling passages of a primary combustion chamber. Heat is transferred to the fuel passing through the cooling passages. The heated fuel enters the second conduit of the heat exchanger to absorb more heat from the first conduit, and then flows to drive a turbine of one or both of the turbopumps. The arrangement prevents the turbopumps exposure to combusted gas that could freeze in the turbomachinery and cause catastrophic failure upon attempted engine restart.

Owner:NASA

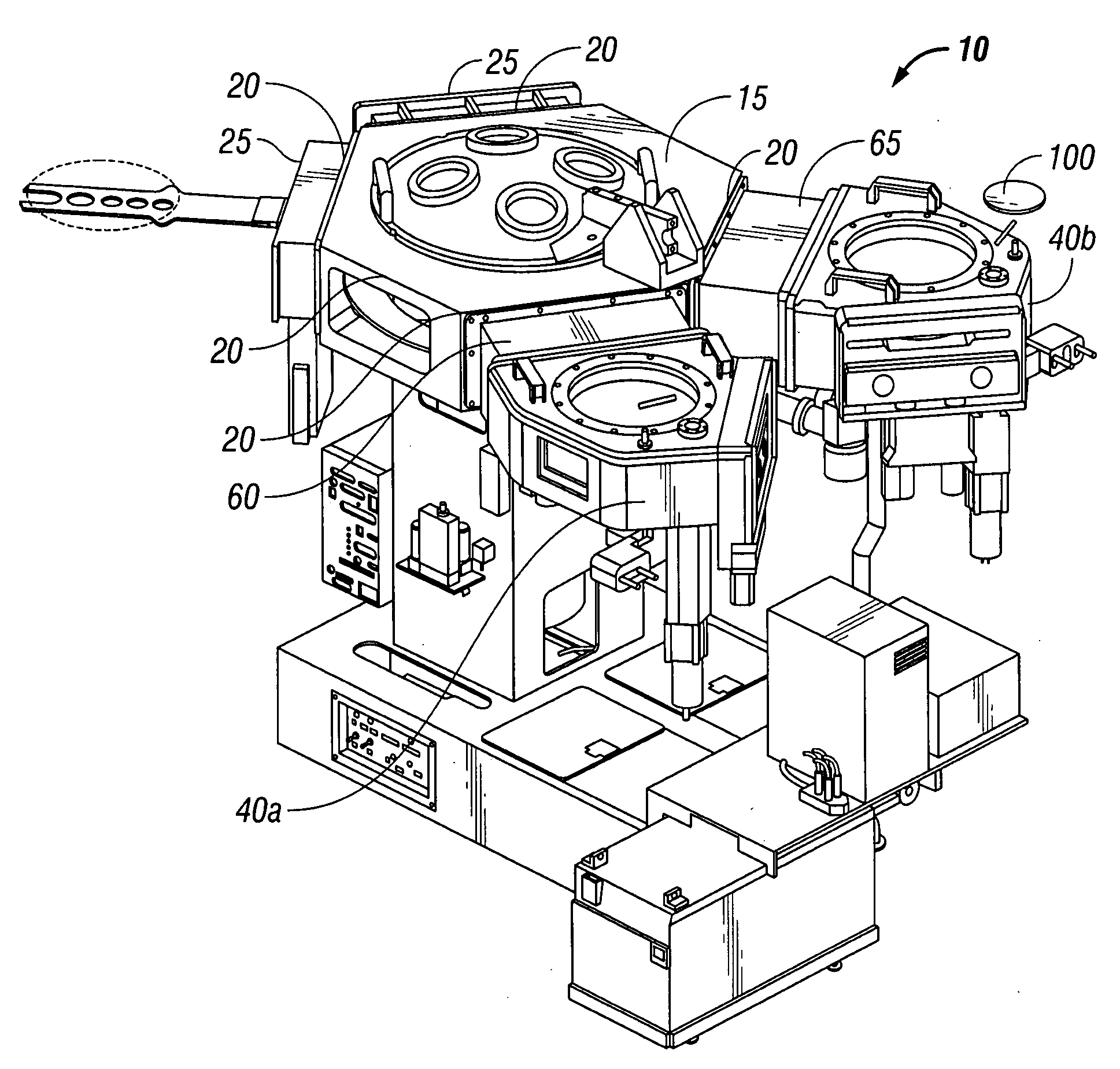

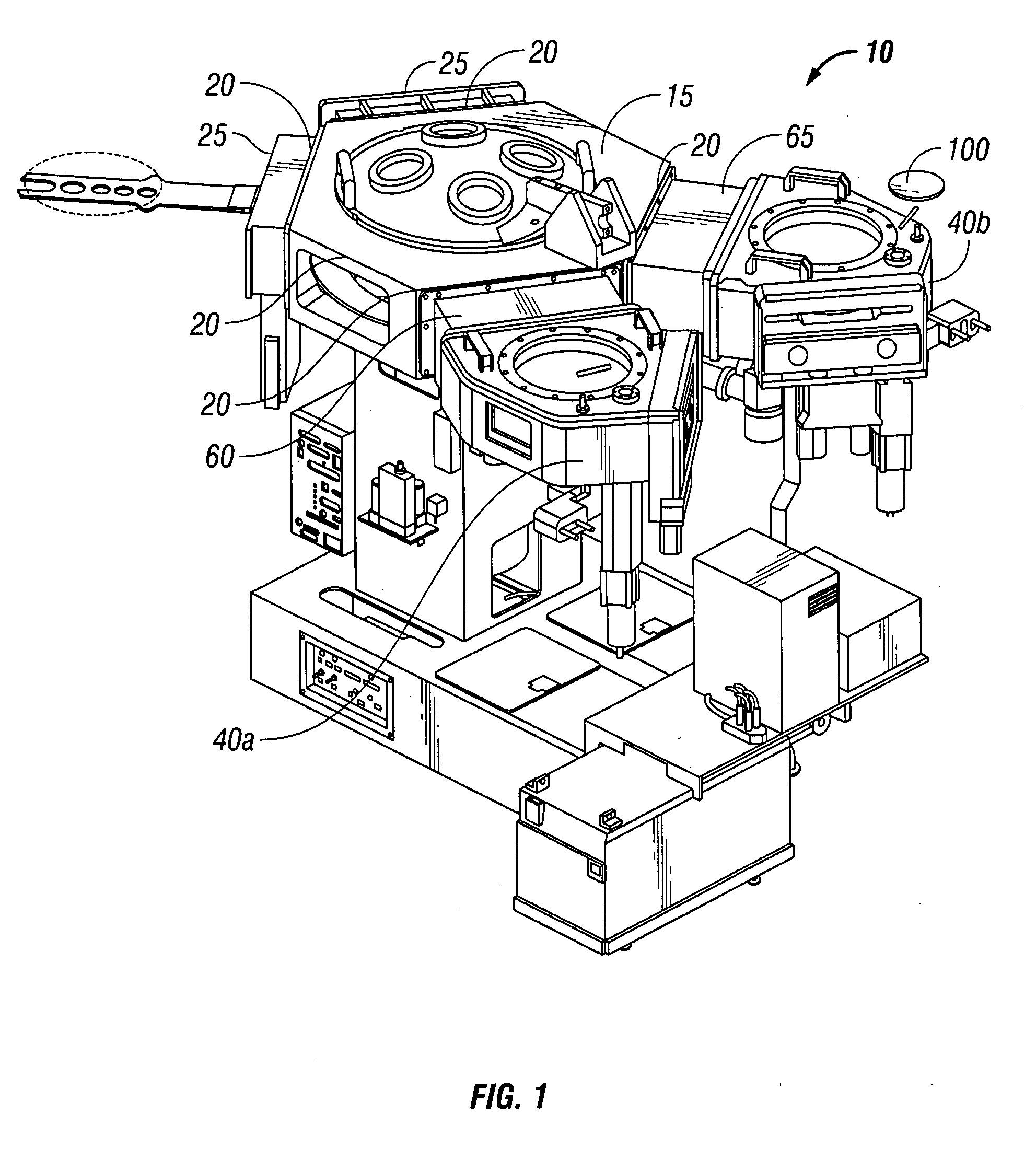

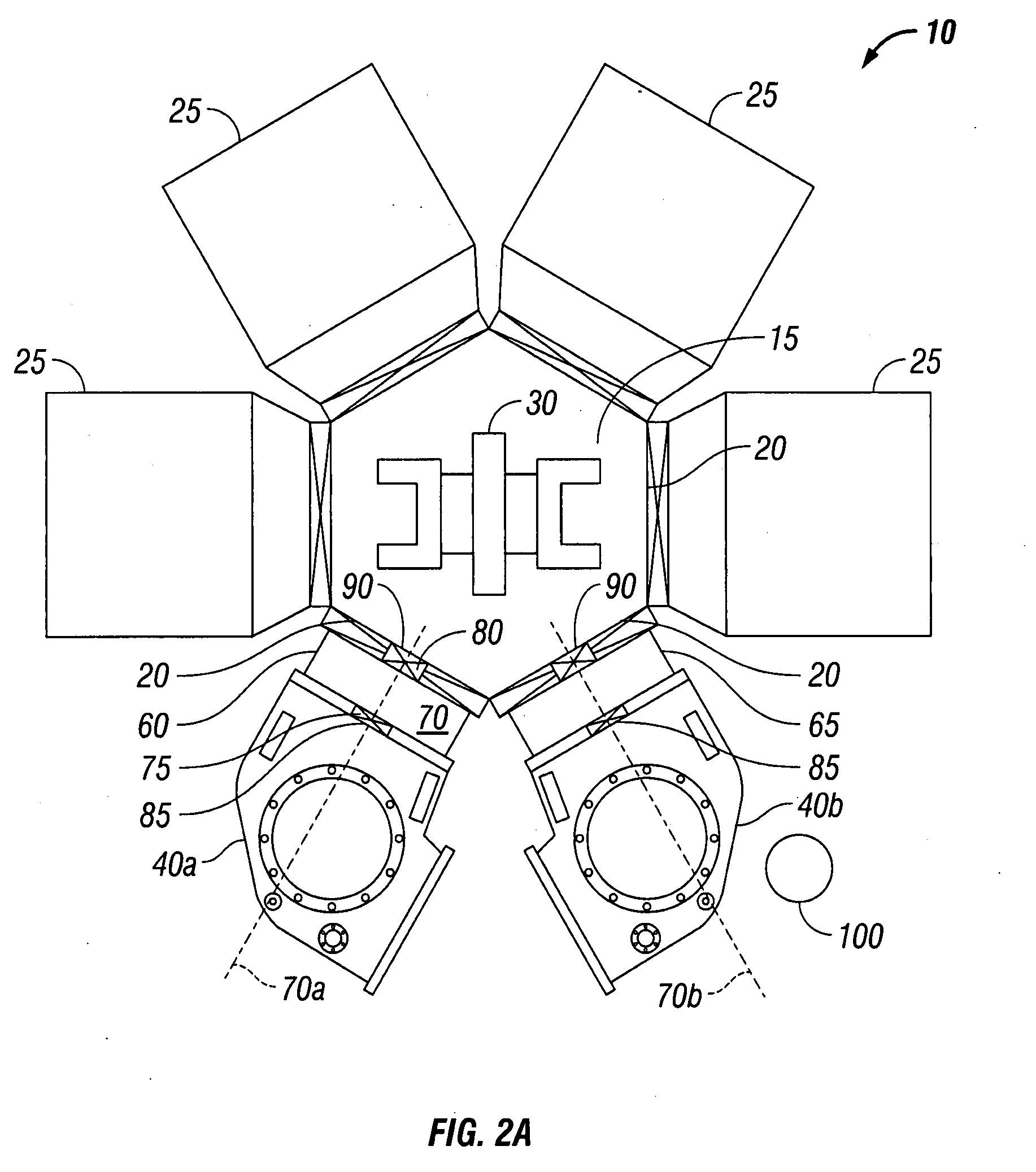

Integral facet cryopump, water vapor pump, or high vacuum pump

A cluster tool has a transfer chamber, and a load lock chamber. An adaptor is configured to be coupled between the transfer chamber and the load lock chamber. The adaptor has an adaptor housing with an interior space including an entrance with a first valve and an exit with a second valve. The adaptor housing forms a substrate path through the interior space. The first valve connects the interior space and the load lock chamber. The second valve connects the interior space and the transfer chamber. A cryogenic surface is associated with the adaptor. Other pumps can be associated with the adaptor, such as, for example, a turbo pump, or water vapor pump. The cryogenic surface is configured to selectively evacuate the interior space. A wafer is adapted to be moved through the first valve and through the adaptor housing along the path. The wafer is moved through the exit and into the transfer chamber once the second valve is opened. This adaptor can be applied to the process chamber as well as the load lock.

Owner:EDWARDS VACUUM LLC

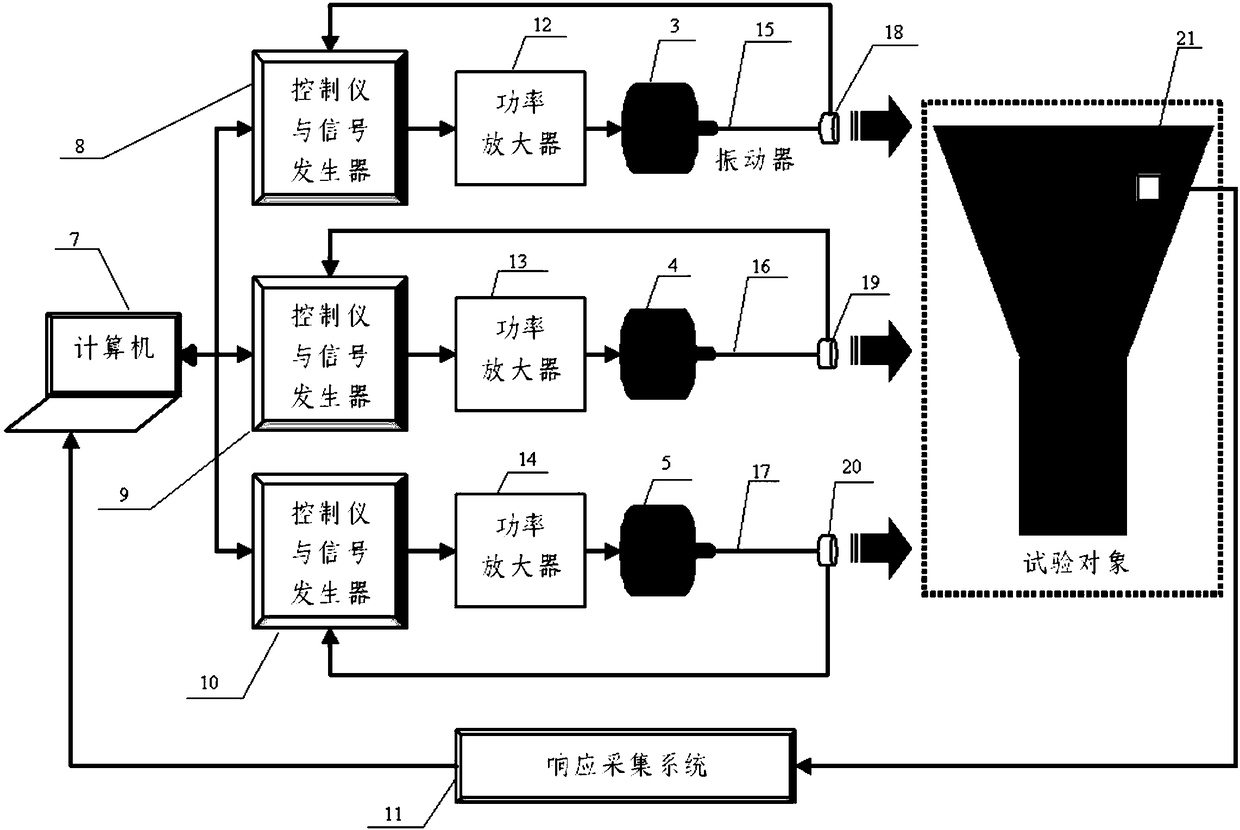

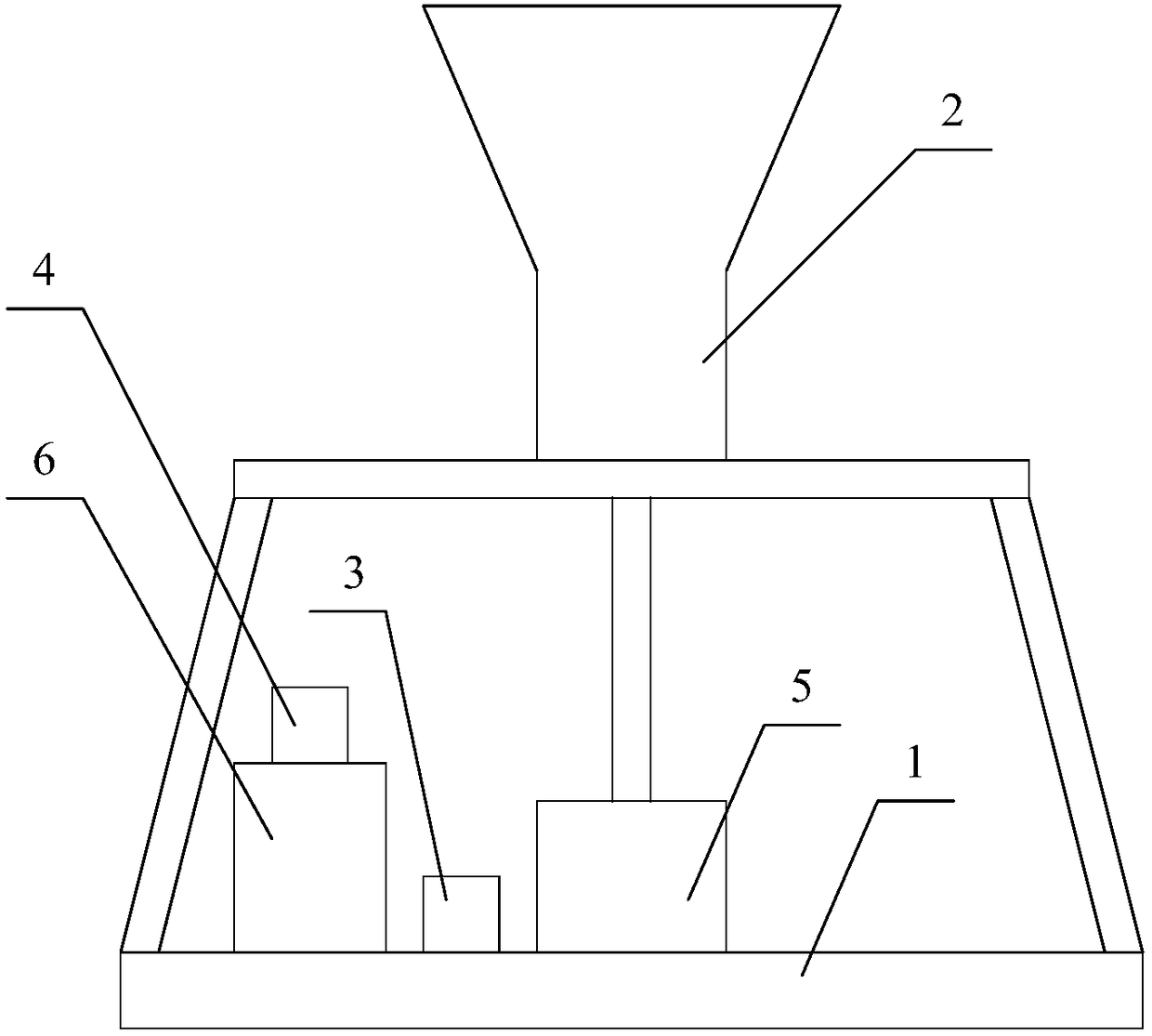

Composite vibration component test system of turbopump-feed liquid rocket engine structure

ActiveCN108519206AImplement Spectral FeaturesLow costEngine testingVibration testingCombustion chamberFrequency spectrum

The invention provides a composite vibration component test system of a turbopump-feed liquid rocket engine structure, and relates to the field of a structural composite vibration component test method. The system comprises three vibration exciters, an excitation support device, a computer, three control instrument and signal generators, a response acquisition system, three power amplifiers, threeexcitation rods, three force transducers and an acceleration sensor. According to the system, a vibration response which is difficult to realize by one single vibration excitation source is excited for the engine structure by employing excitation of multiple groups of vibration exciters, vibration response frequency spectrum components simultaneously comprise frequency spectrum characteristics ofa plurality of excitation sources including an engine combustion chamber, a turbine pump, and a combustion gas generating device etc., an amplification rule or an attenuation rule of each vibration excitation load spectrum can also be reflected, the sensitive degrees of the engine structural vibration response to different excitation sources are obtained through a relation analysis of the structural vibration response frequency spectrum synthesis components and the excitation sources, the cost is low, the technical difficulty is moderate, and the system is applicable to the turbopump-feed liquid rocket engine structure.

Owner:XIAN AEROSPACE PROPULSION INST

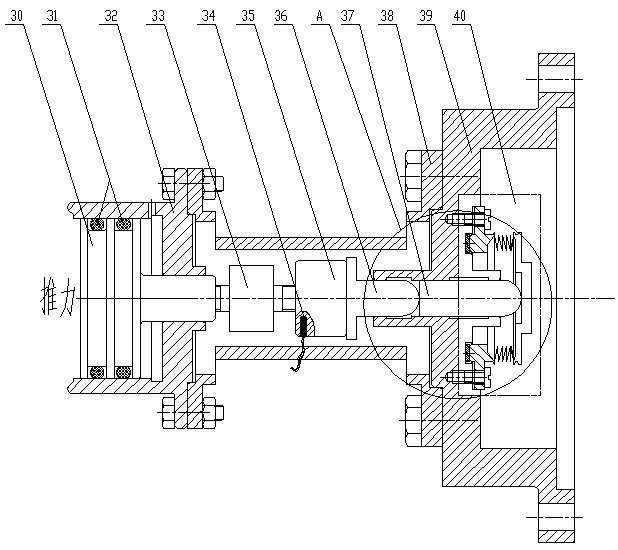

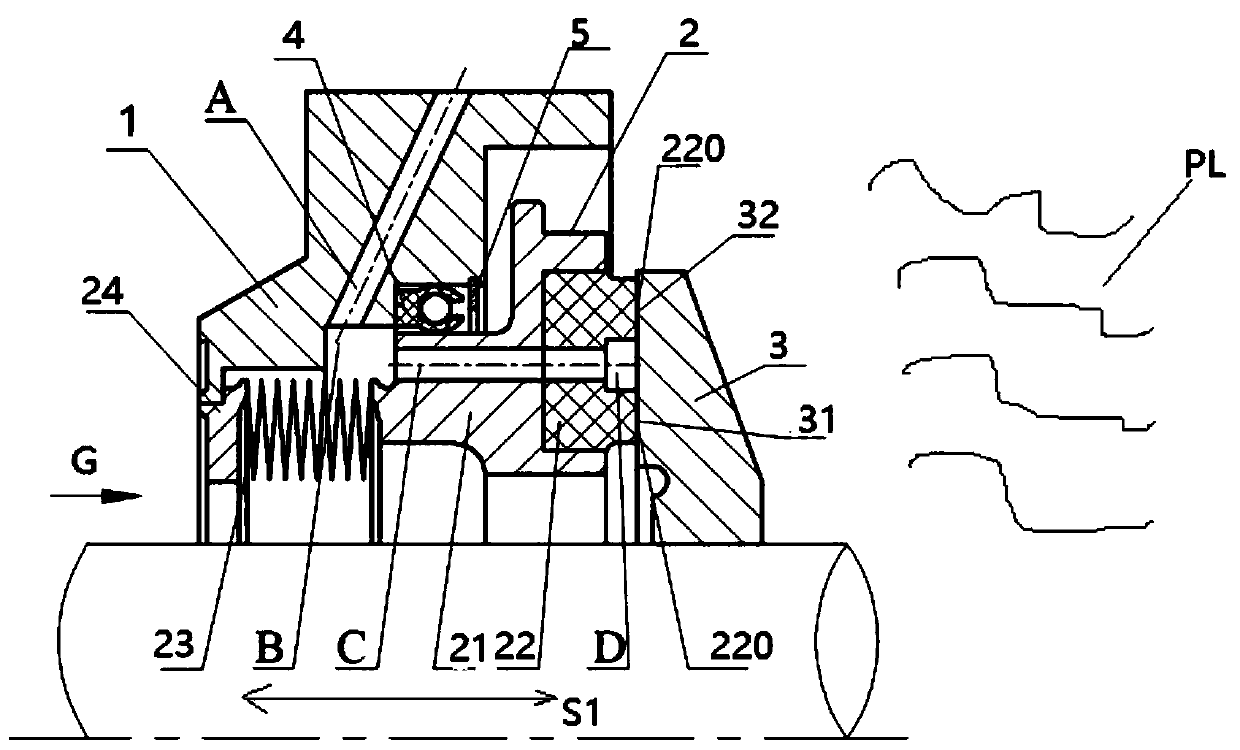

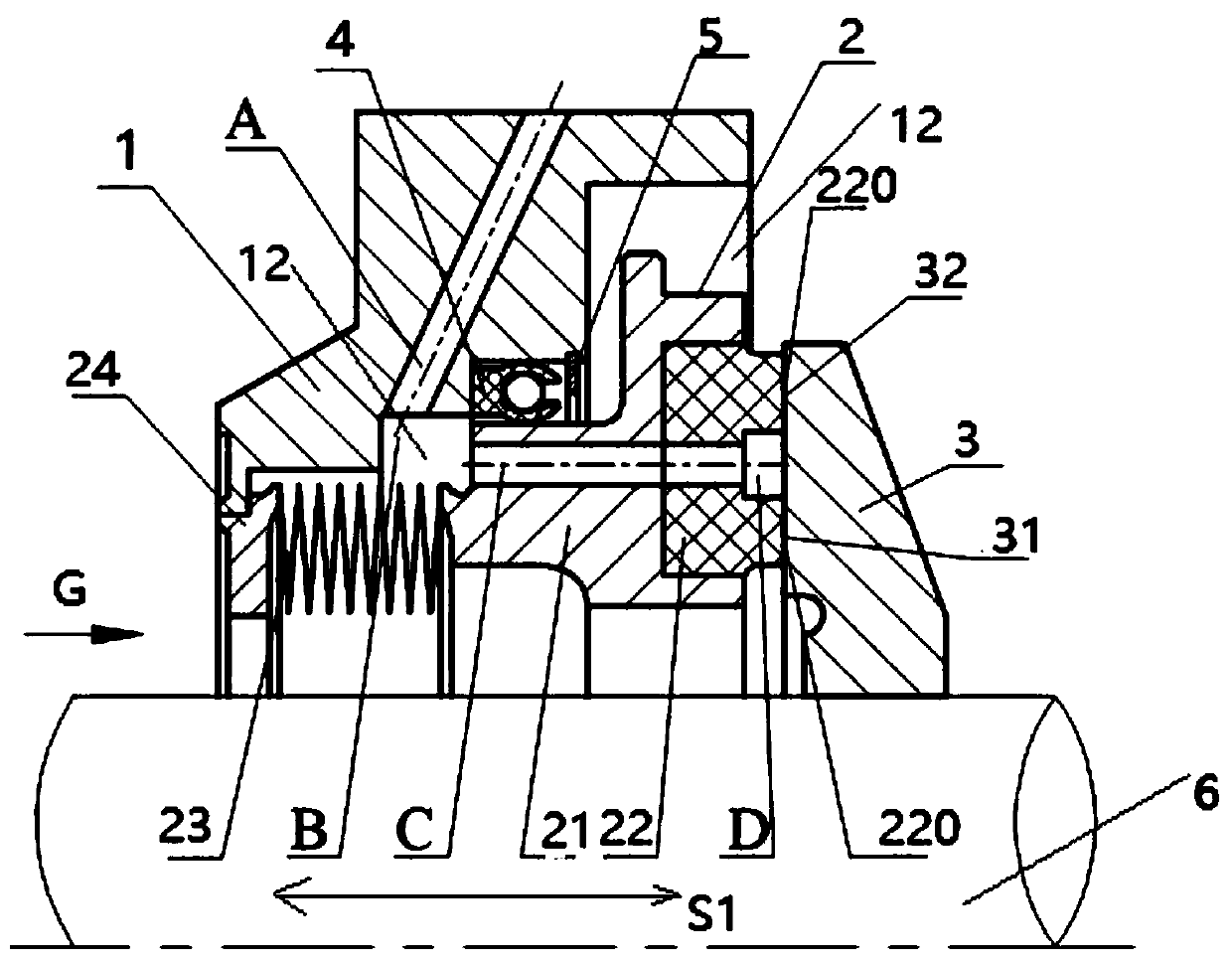

Dynamic sealing device for turbo pump and turbo pump set

The invention provides a dynamic sealing device for a turbo pump and a turbo pump set. The dynamic sealing device comprises a shell, a static ring assembly and a moving ring, wherein the static ring assembly is arranged in the shell, the end, in the first direction, of the static ring assembly is connected with the shell, the other end of the static ring assembly is used for abutting against the moving ring, the inner side of the shell and the static ring assembly define a discharge cavity, one end of the shell communicates with the discharge cavity, the other end of the shell is provided witha discharge channel communicating with the external environment, a groove is formed in the other end of the static ring assembly, the moving ring seals the groove by abutting against a sealing end surface of the other end, the static ring assembly comprises a drainage hole in the first direction, one end of the drainage hole communicates with the groove, and the other end of the drainage hole communicates with the discharge cavity. According to the dynamic sealing device, the structure of the turbo pump set can be simplified, the size of the axial direction of the turbo pump set is shortened,so that the performance of the turbo pump set is improved.

Owner:SHAANXI LANDSPACE TECH CO LTD

Vibration damper with nested turbo molecular pump

ActiveUS20050013703A1Improve throughputReduce vibrationSolidificationLiquefactionEngineeringTurbopump

A gas turbo pump assembly for connection to a port of a vacuum chamber and having high throughput with low vibration. The assembly comprises a turbo pump and a vibration damper. The pump has a pump body with an external surface and a center axis defining a first axial end and a second axial end of the pump. The pump also has a pump inlet port, the inlet port being coupled to the vacuum chamber port disposed at the first axial end of the pump, and an exit port disposed proximate the second axial end of the pump. The assembly vibration damper is structured to enclose a substantial portion of the pump in a nested arrangement.

Owner:APPLIED MATERIALS INC

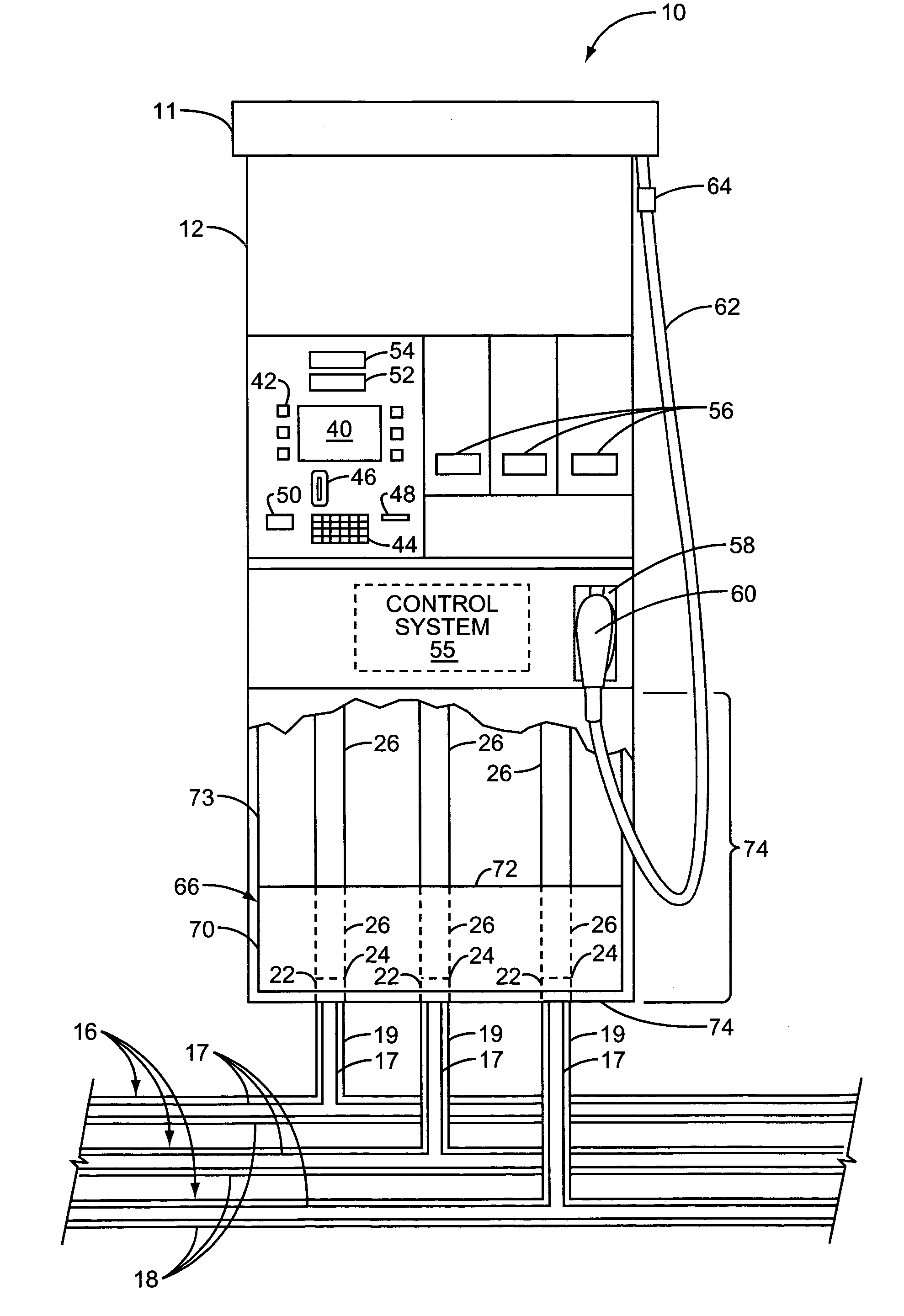

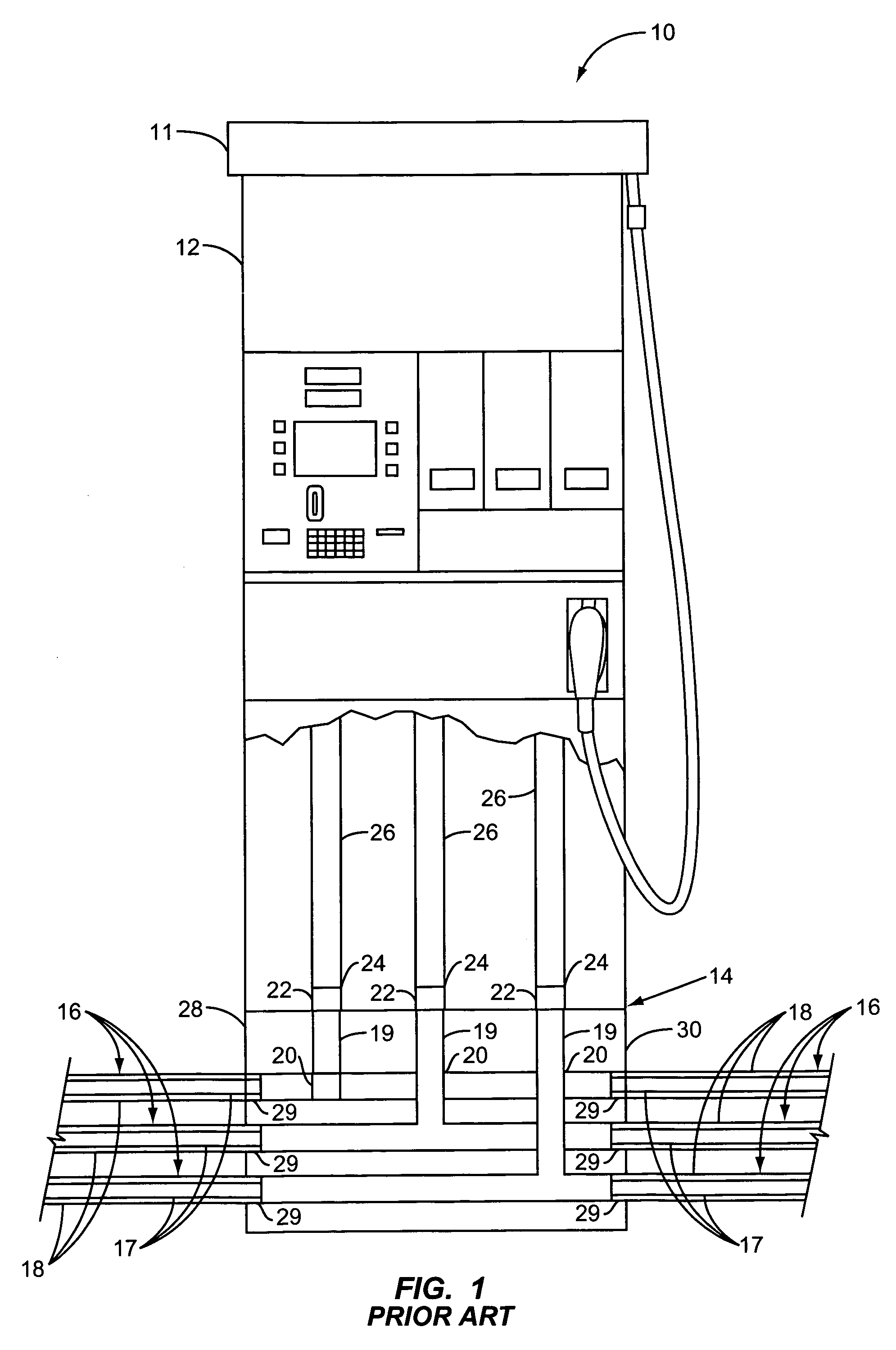

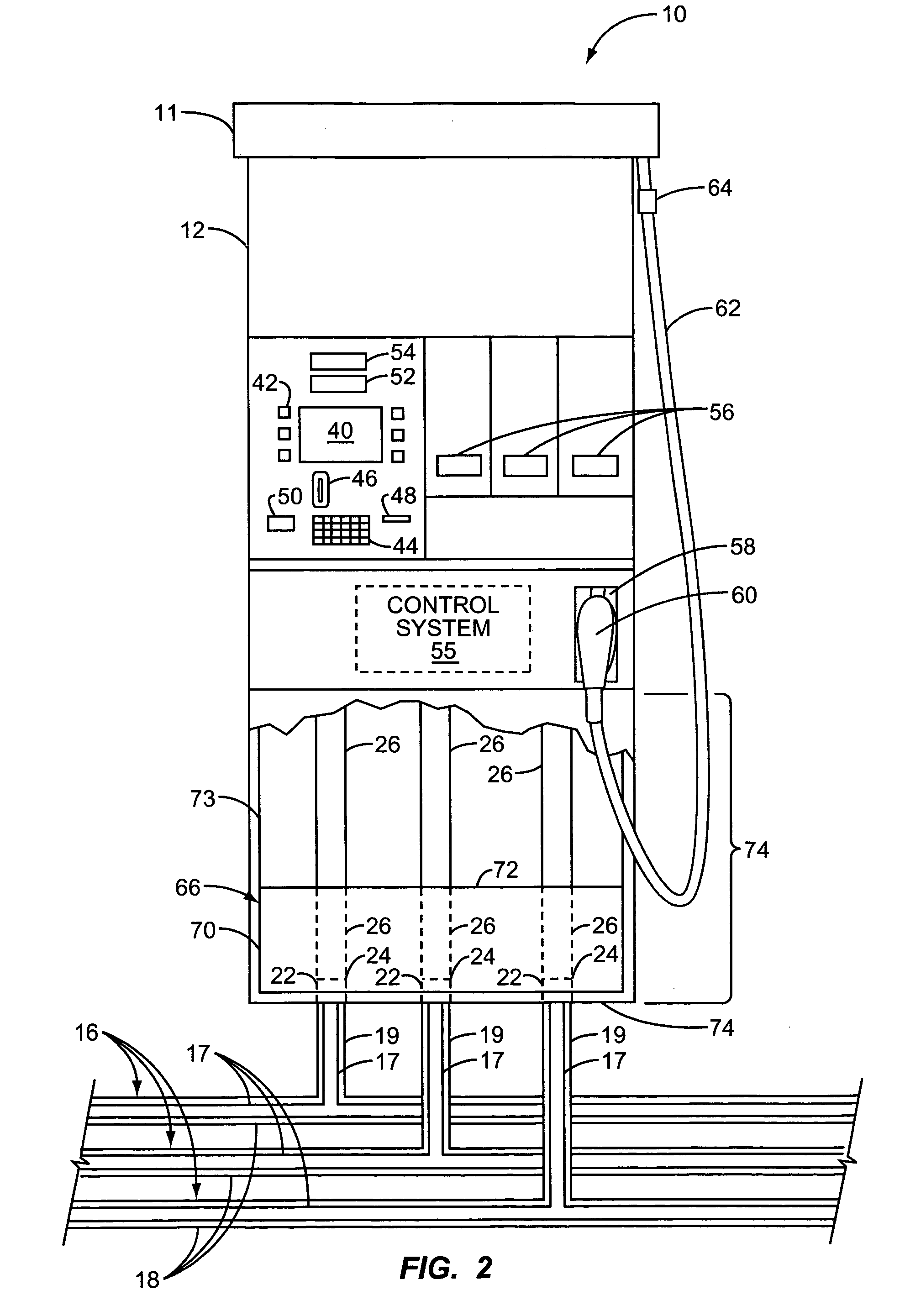

Leak container for fuel dispenser

ActiveUS20050236045A1Avoid environmentLiquid fillingPipeline systemsNuclear engineeringControl system

A leak collection chamber is provided inside the housing of a fuel dispenser. The leak collection chamber collects any leaked fuel from fuel handling components inside the fuel dispenser so that the fuel does not leak to the environment. The leak collection chamber can be removed form the fuel dispenser for evacuation. The control system inside the fuel dispenser can determine the liquid level inside the leak containment chamber and generate signals and alarms if the liquid level exceeds a threshold liquid level value and / or the rate of increase in liquid level exceeds a threshold liquid level increase value. The control system can alert service personnel and / or other systems of the leak collection chamber liquid level. Further, the control system and / or other systems shut down the submersible turbine pump that services the fuel dispenser with fuel in response to catastrophic leak condition.

Owner:GILBARCO

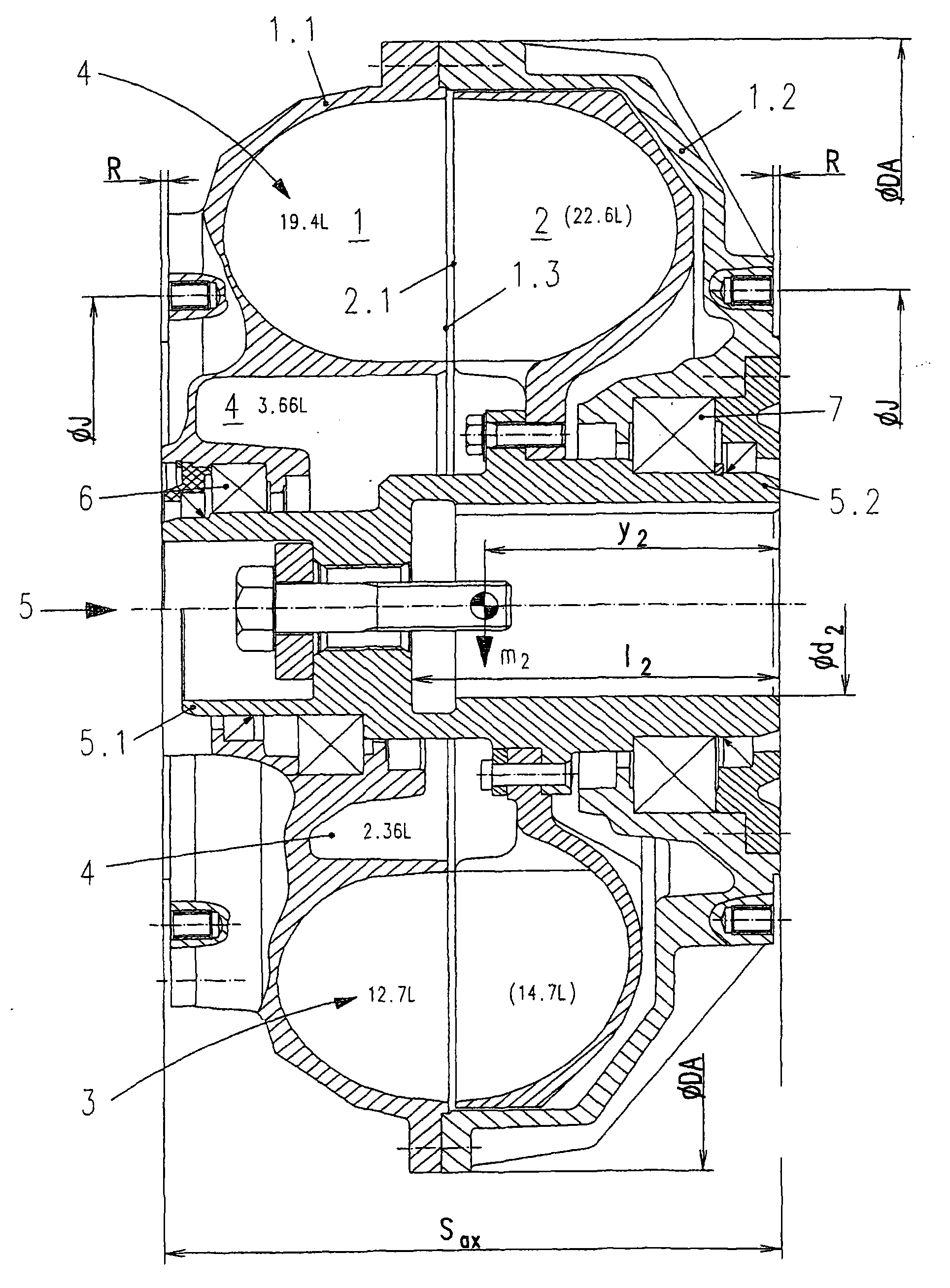

Hydrodynamic clutch

ActiveCN101688570ALarge working chamber volumeIncreased power transfer capabilityRotary clutchesRotary couplingImpellerTurbine wheel

The invention relates to a hydrodynamic clutch with a constant or variable filling of working medium, - having a pump wheel comprising a pump wheel blade arrangement, and - having a turbine wheel comprising a turbine wheel blade arrangement; - the pump wheel and turbine wheel together form a toroidal working chamber which, for torque transmission, can be filled with the working medium; - having anaccumulating chamber for receiving working medium from the working chamber, wherein the accumulating chamber is connected in a working-medium-conducting fashion to the working chamber; - the workingmedium can be conducted from the accumulating chamber into the working chamber in order to increase the transmissible torque, and from the working chamber into the accumulating chamber in order to reduce the transmissible torque. The hydrodynamic clutch is characterized in that the ratio of the volume of the working space to the installation volume of the hydrodynamic clutch is greater than 0.26,wherein the installation volume of the hydrodynamic clutch is defined by a cylinder volume which has a constant diameter and whose outer diameter corresponds to the maximum outer diameter of the hydrodynamic clutch and whose axial length corresponds to the maximum axial extent of the hydrodynamic clutch.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com