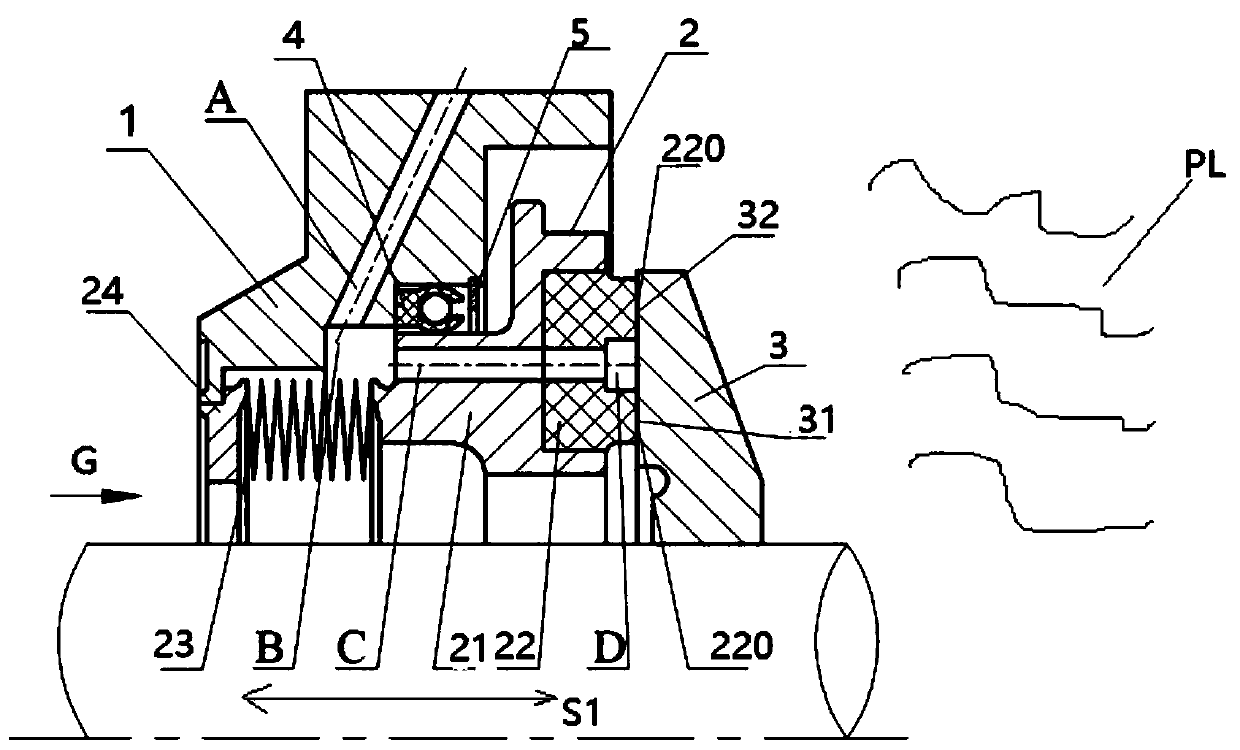

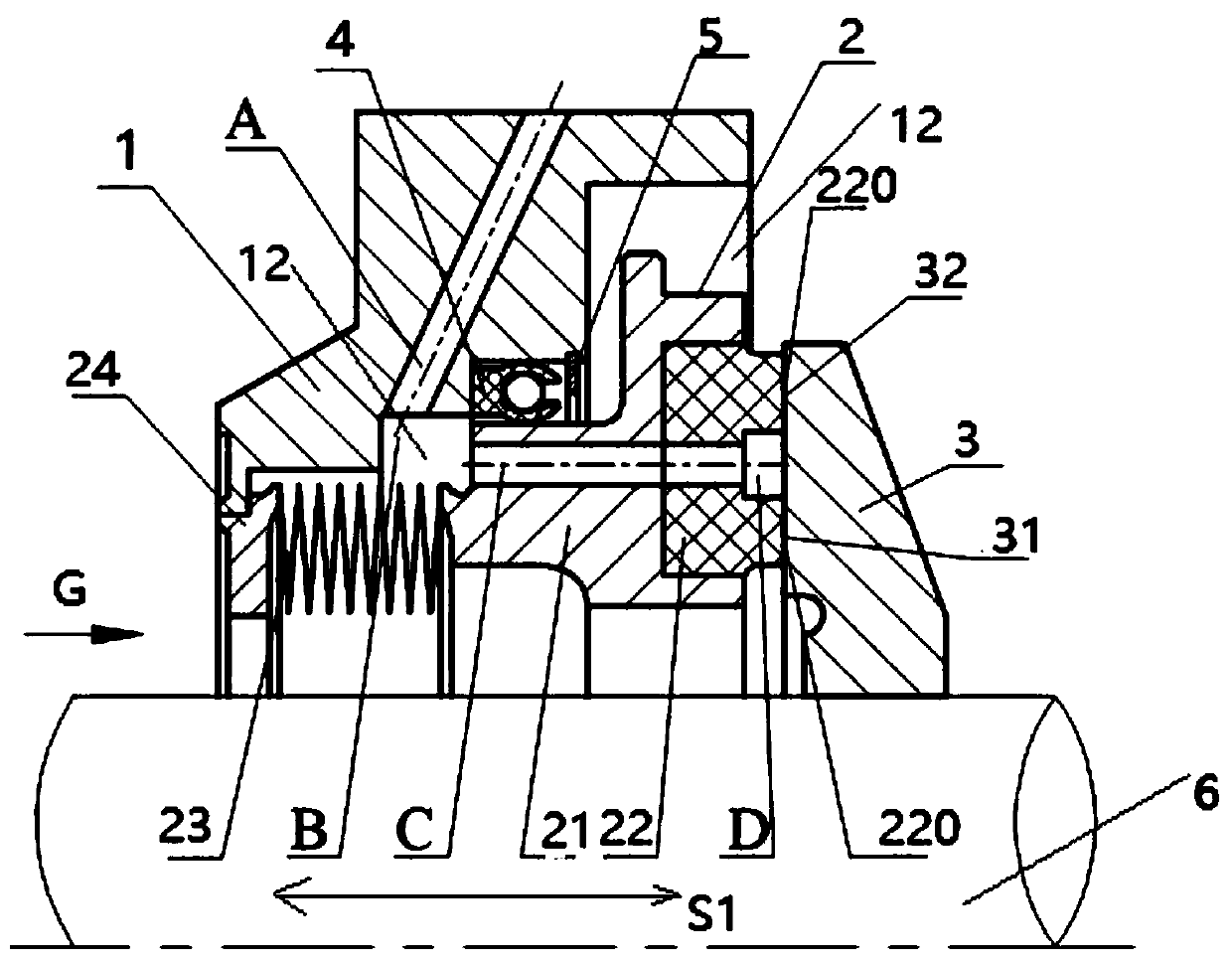

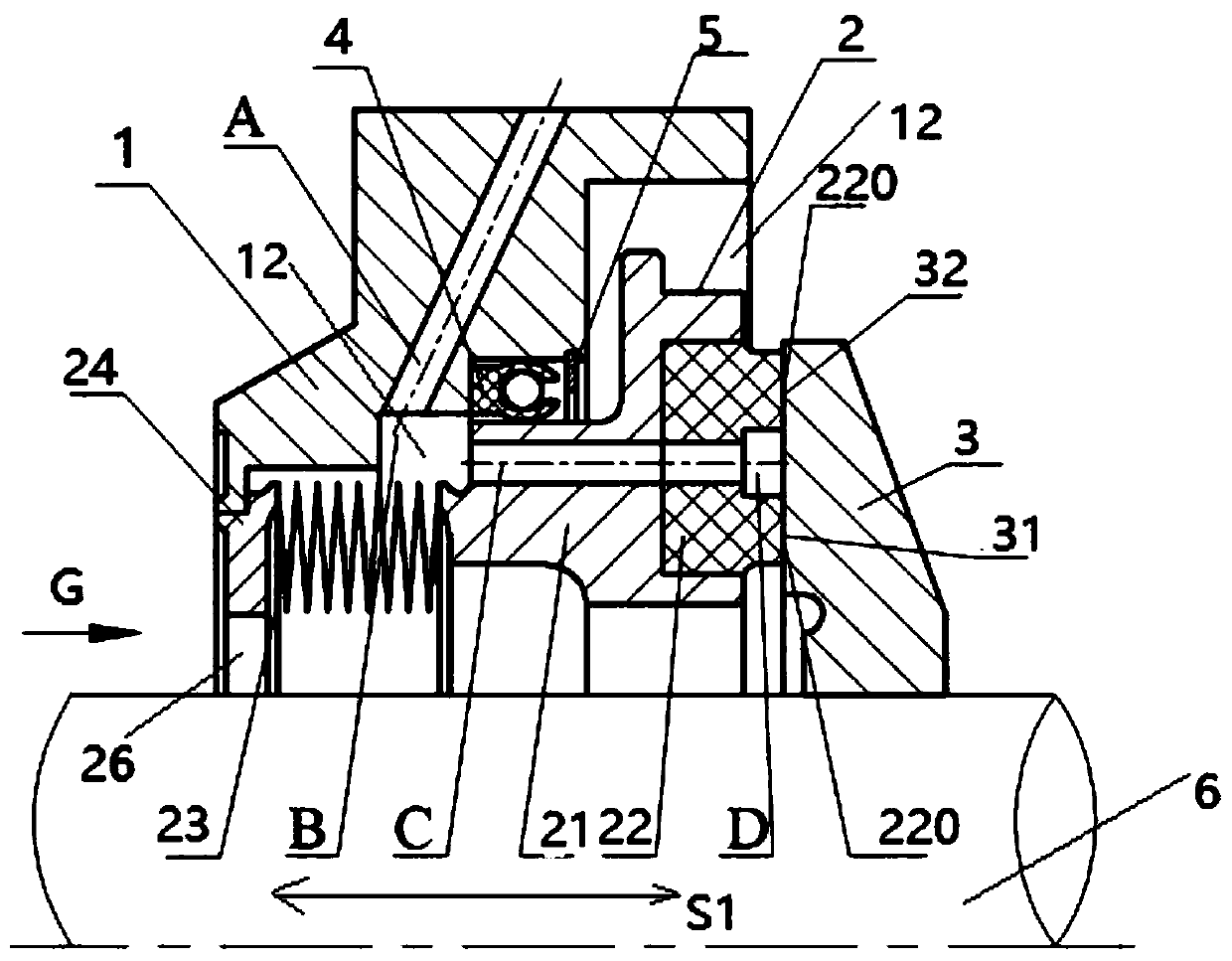

Dynamic sealing device for turbo pump and turbo pump set

A technology for dynamic sealing and turbo pumps, which is applied in the sealing field of turbo pumps. It can solve the problems of poor rigidity and stability of turbo pumps, low critical speed of turbo pump shafts, and complex structures, and achieve compact overall layout, shortened axial dimensions, and reduced The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Various exemplary embodiments of the present invention will now be described in detail. The detailed description should not be considered as a limitation of the present invention, but rather as a more detailed description of certain aspects, features and embodiments of the present invention.

[0029] It will be apparent to those skilled in the art that various modifications and changes can be made in the specific embodiments of the present invention described herein without departing from the scope or spirit of the present invention. Other embodiments will be apparent to the skilled person from the description of the present invention. The specification and examples in this application are exemplary only.

[0030] For example, the oxidant pump and the fuel pump in the turbopump group of the liquid engine can be arranged coaxially, and the dynamic sealing device can be arranged between the oxidizer pump and the fuel pump, so as to prevent the leaked oxidant and fuel from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com