Coal tar heavy fraction suspension-bed hydrocracking method and system thereof

A technology for hydrocracking and heavy fractions, applied in the field of coal chemical industry, can solve the problems of reducing the service life of the catalyst, difficult to control the production operation, increasing the pressure of the bed layer, etc., and achieves the effects of easy control, long start-up period, and large operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

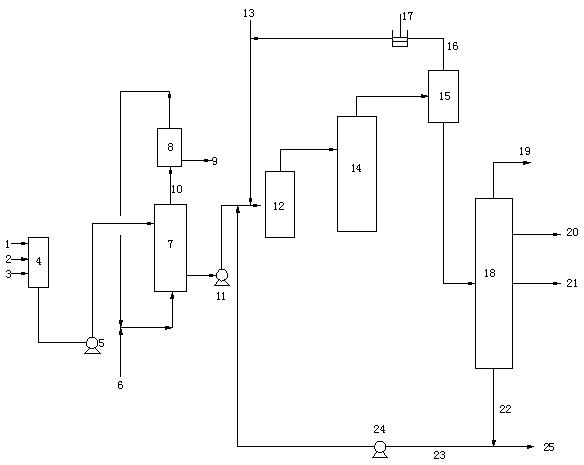

[0025] Using the above figure 1 In the coal tar heavy fraction suspended bed hydrocracking system shown, the coal tar heavy fraction 1, catalyst 2 and vulcanizing agent 3 are sent to the mixer 4 according to the required ratio, and the mixer is uniformly mixed with a strong stirrer, and the The mixed material is sent to the vulcanizer 7 by the high-pressure pump 5 for vulcanization, and the hydrogen-rich 10 in the vulcanization process is separated by the condensation separator 8 to separate the water 9 for recycling. Circulating rich hydrogen 10 is mixed with low-pressure hydrogen 6 and enters sulfurizer 7. The material from sulfurizer 7 is mixed with high-pressure hydrogen 13, circulating hydrogen 16 and circulating tail oil 23 through high-pressure pump 11 and then enters preheating furnace 12. The preheated The material is sent to the suspended bed reactor 14 for hydrocracking reaction, and the reaction product is sent to the high-pressure separator 15 for gas-liquid separ...

Embodiment 5~8

[0029] Using the above figure 1 The test method and process of the suspended bed hydrocracking system for the heavy fraction of coal tar shown are the same as those of the above-mentioned Examples 1-4.

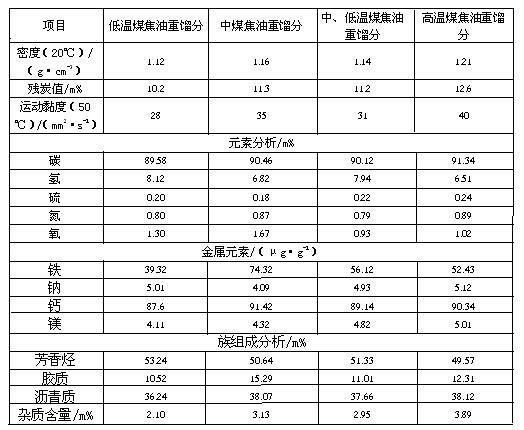

[0030] In the test, the addition amount of 4 kinds of heavy fractions of coal tar is 15kg / h, and the catalyst composition is Mo8%, Ni0.4%, Ce0.3%, P0.4%; Speed 0.4h -1 The first-stage vulcanization is carried out under the same conditions, and then the temperature is raised to 330°C, and the second-stage vulcanization is carried out under the same conditions as above. During the vulcanization process, the volume ratio of hydrogen to oil is 600, DMS is used as the vulcanizing agent, and the addition amount is 0.3% (calculated based on the mass of heavy fraction of coal tar). The preheating temperature of the material after vulcanization is 370°C. The reaction conditions and results of the suspension bed hydrocracking test are shown in Table 3.

[0031] Table 3 Reaction con...

Embodiment 9~12

[0034] Using the above figure 1 The test method and process of the suspended bed hydrocracking system for the heavy fraction of coal tar shown are the same as those of the above-mentioned Examples 1-4.

[0035] In the test, the addition amount of the heavy fraction of coal tar was 20kg / h, and the catalyst composition was Mo6%, Ni0.6%, Ce0.5%, P0.5%; the four mixed materials were all mixed at 0.4MPa, 200°C, and the space velocity was 0.2 h -1 The first-stage vulcanization is carried out under the same conditions, and then the temperature is raised to 340°C, and the second-stage vulcanization is carried out under the same conditions as above. During the vulcanization process, the volume ratio of hydrogen to oil is 700, DMDS is used as the vulcanizing agent, and the addition amount is 0.4% (calculated based on the mass of heavy fraction of coal tar). The preheating temperature of the material after vulcanization is 380°C. The reaction conditions and results of the suspension be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com