Patents

Literature

518 results about "Gaseous hydrocarbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gaseous Hydrocarbons. Definition - What does Gaseous Hydrocarbons mean? Gaseous hydrocarbons are organic compounds of hydrogen and carbon that are in a gaseous state. At room temperature, the hydrocarbons methane (CH 4) and ethane (C 2H 6) are gaseous.

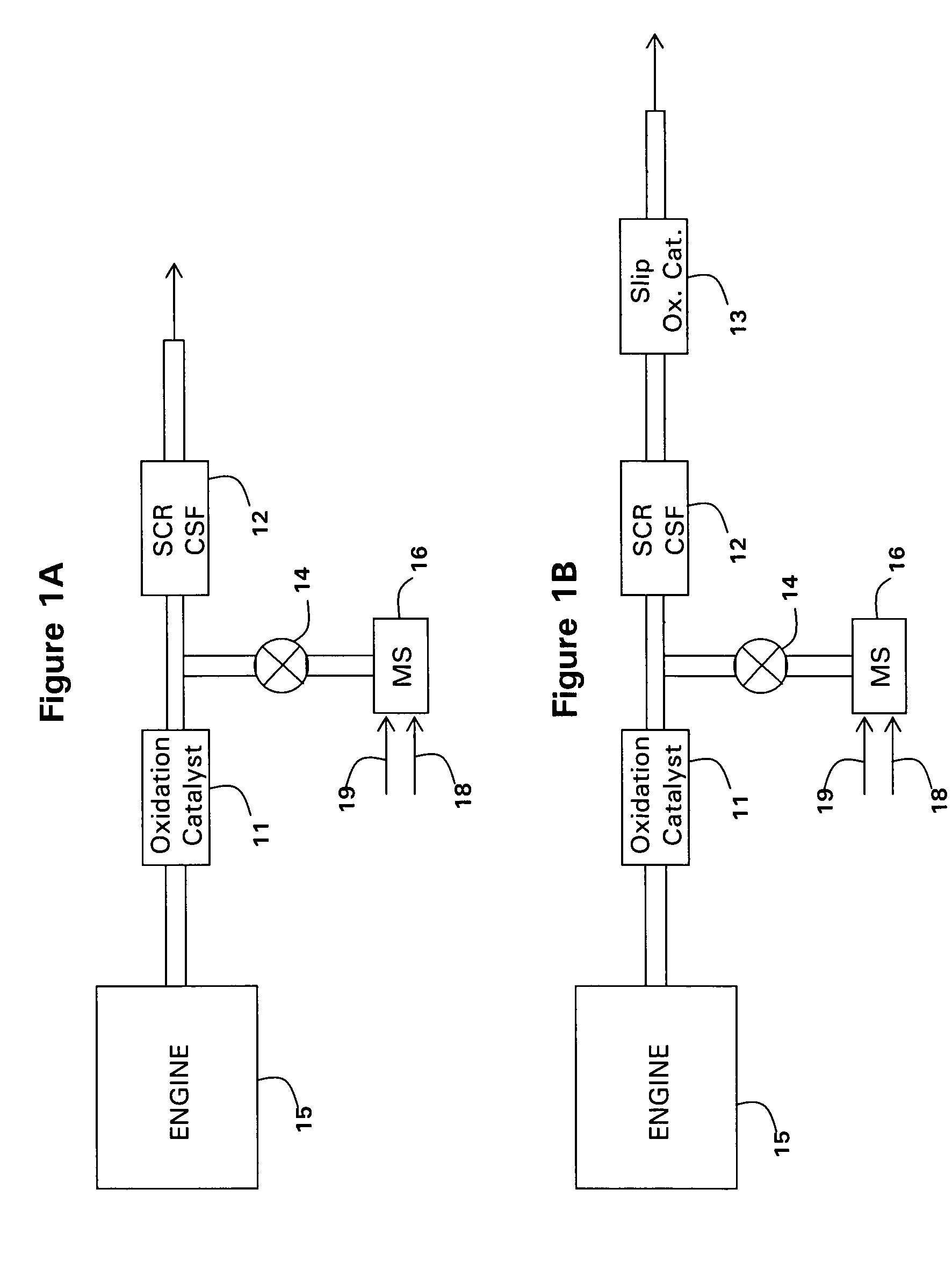

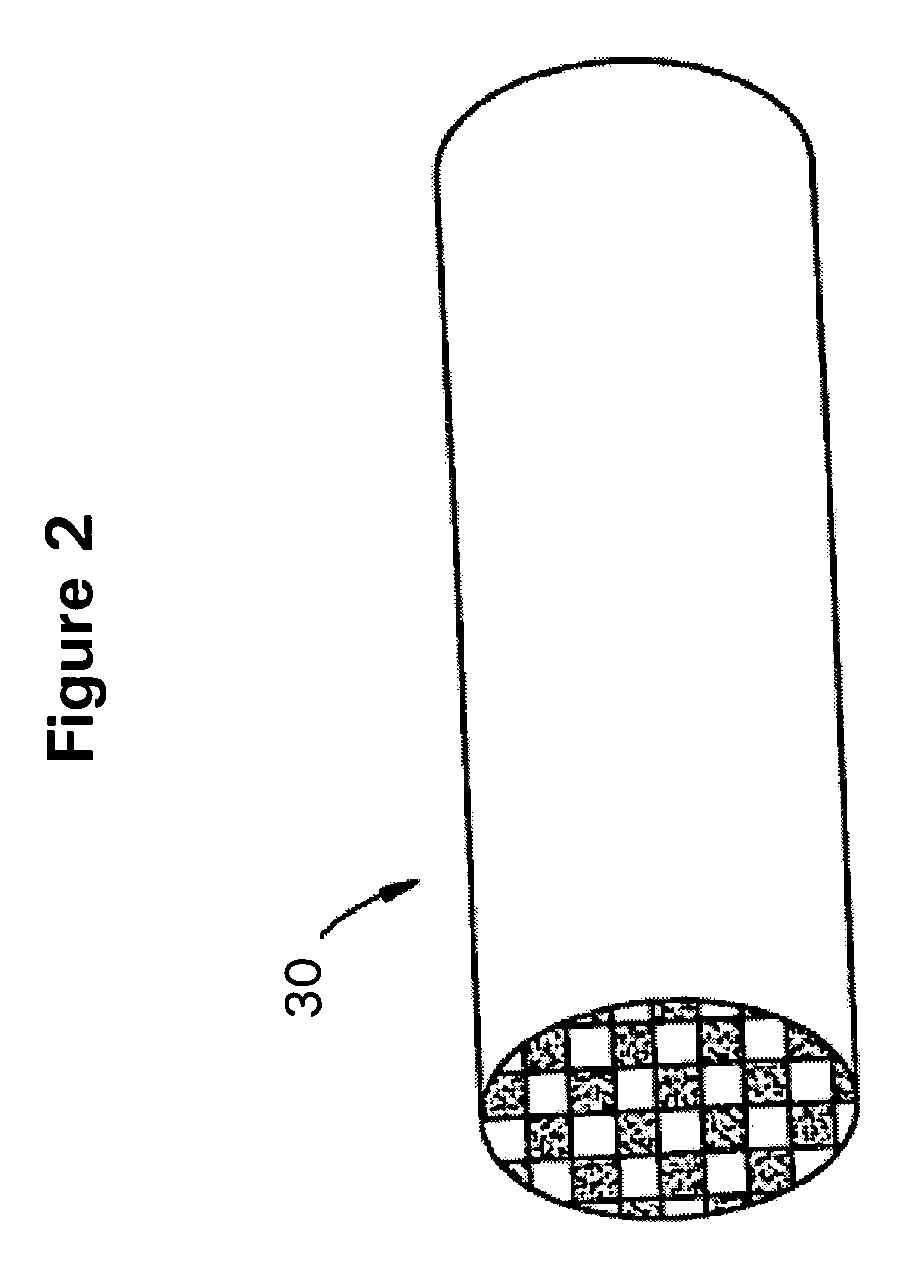

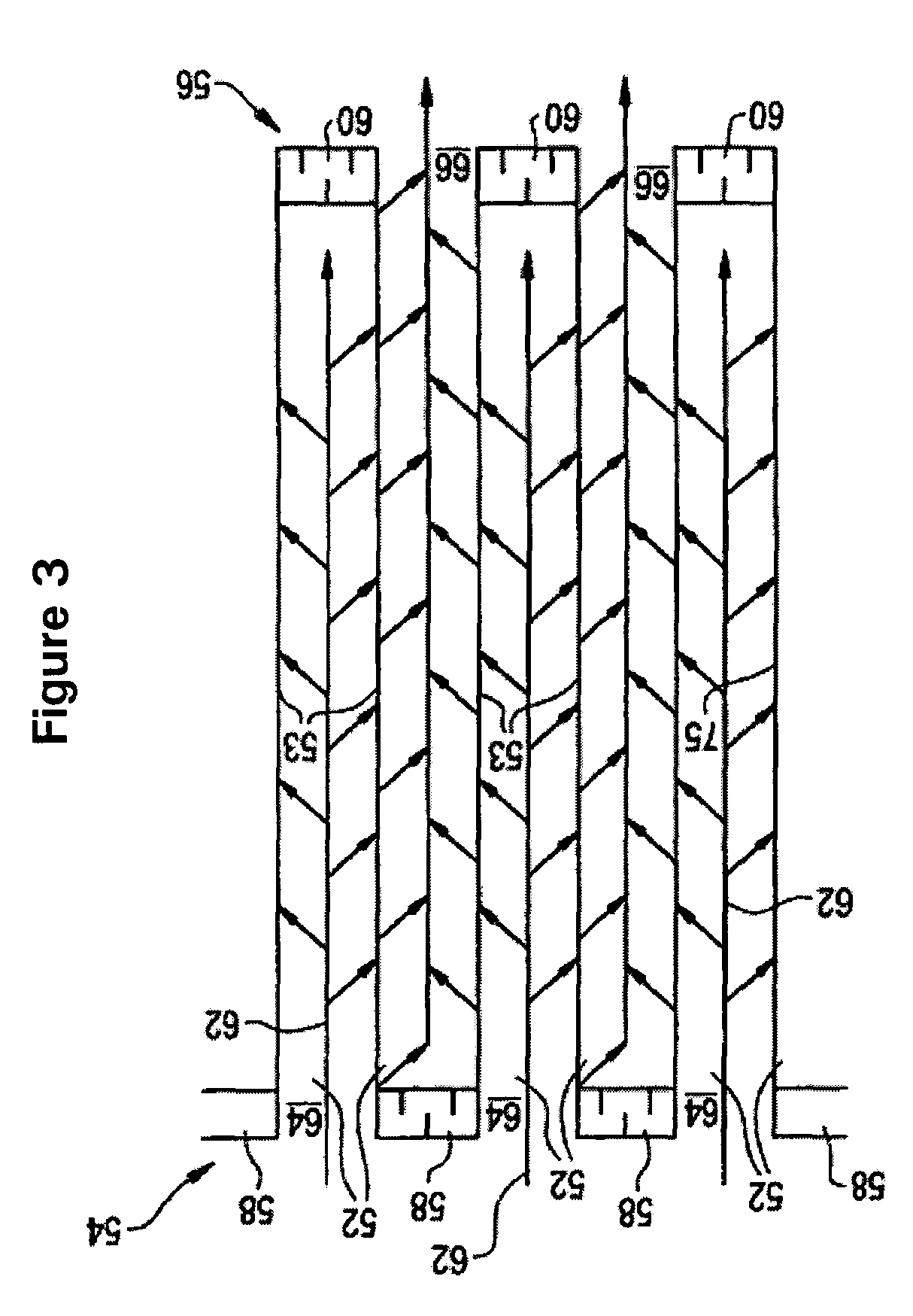

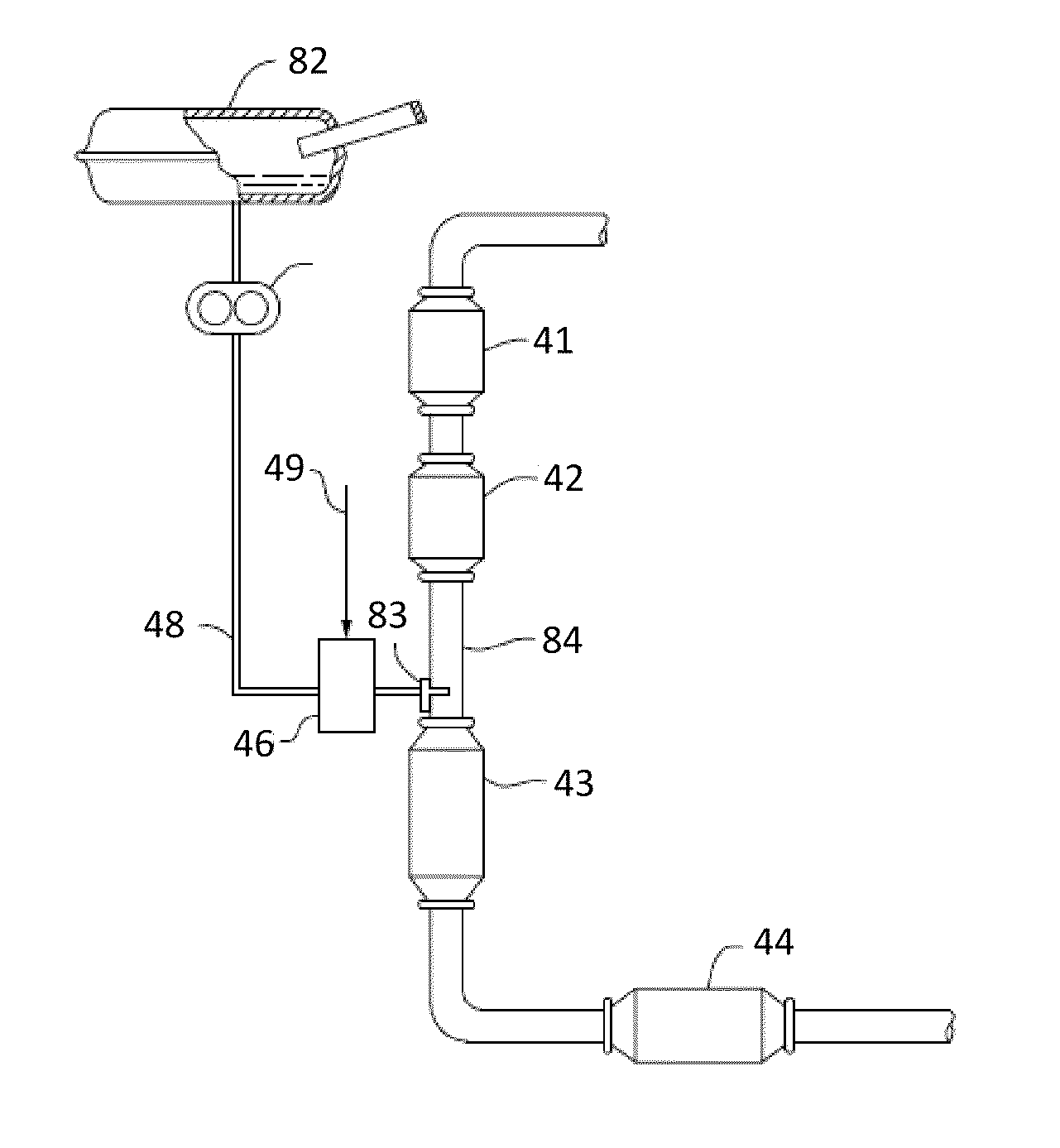

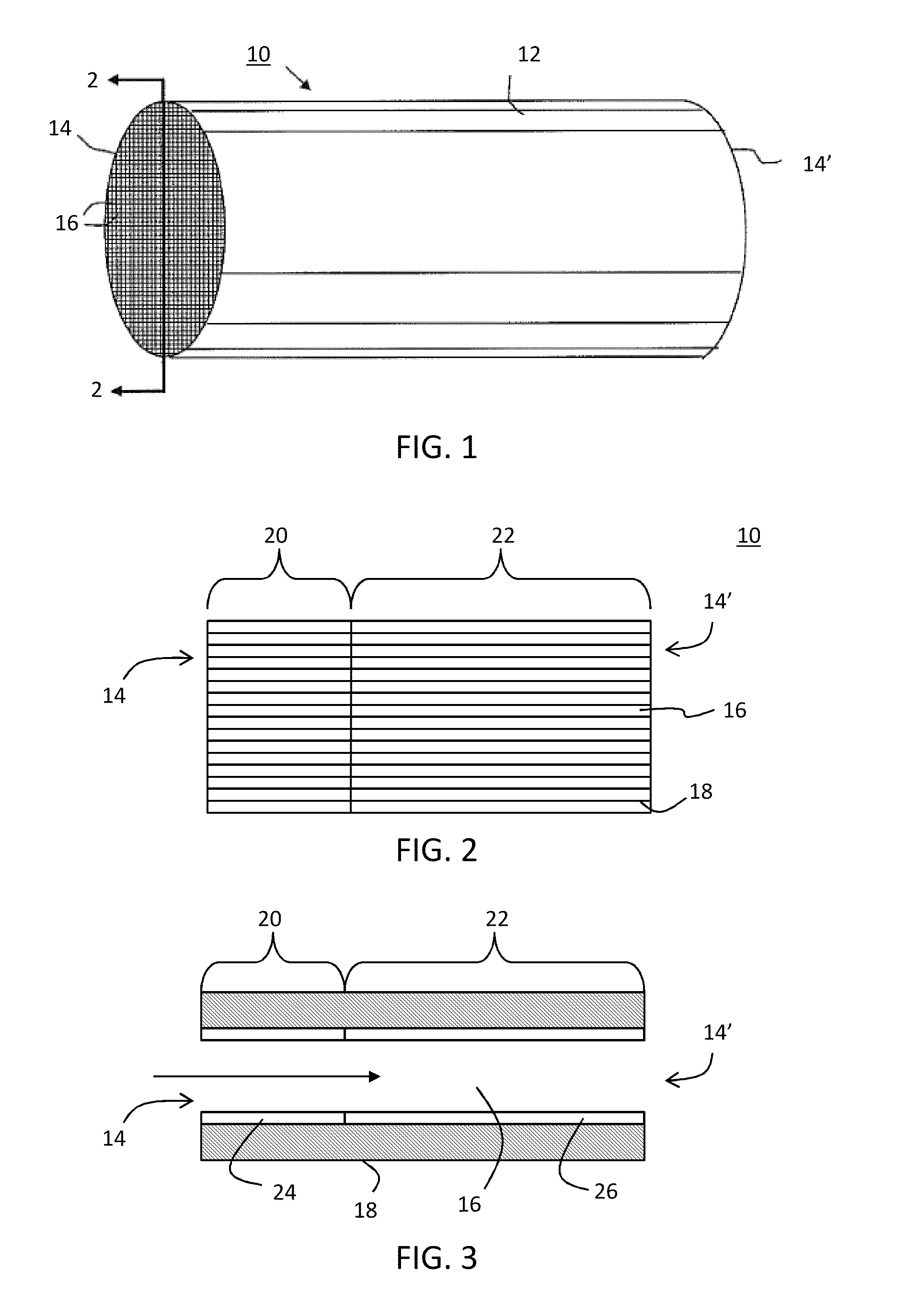

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

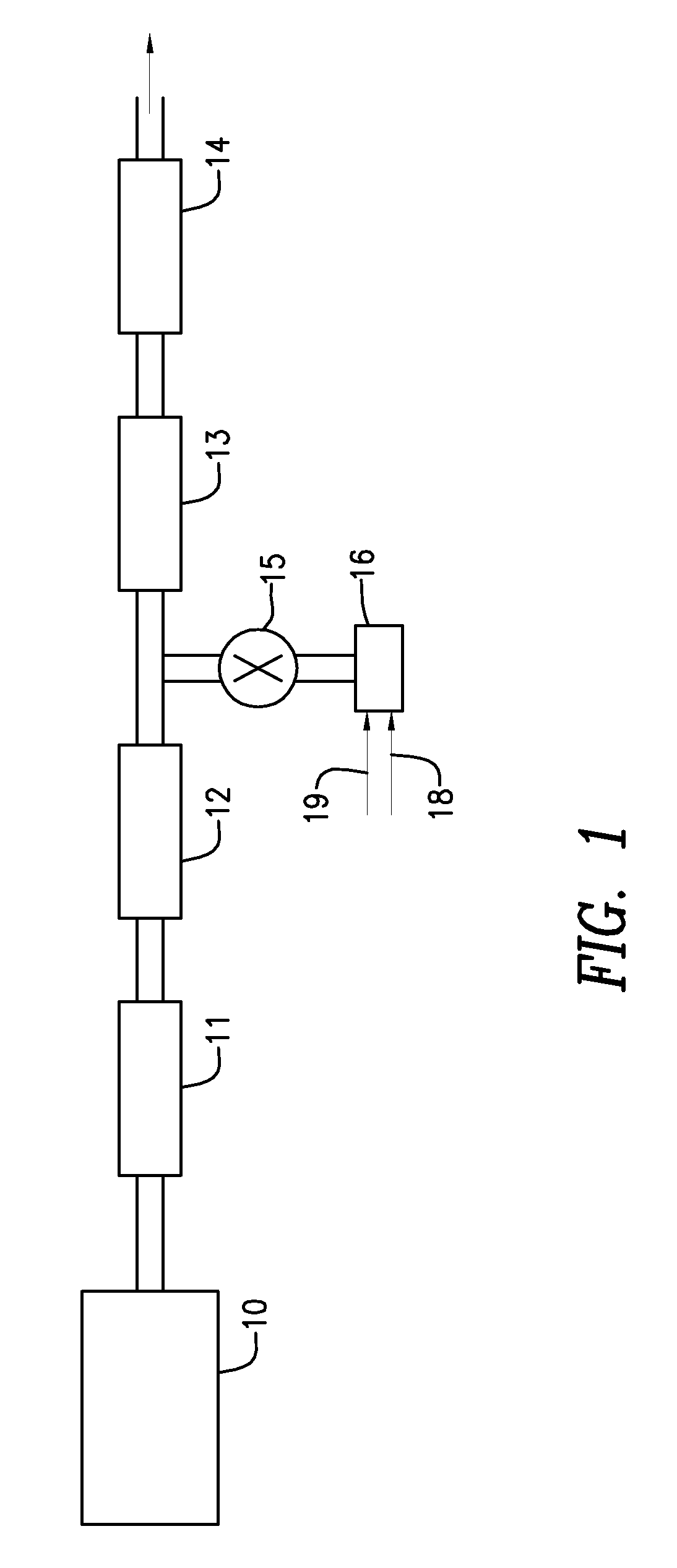

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

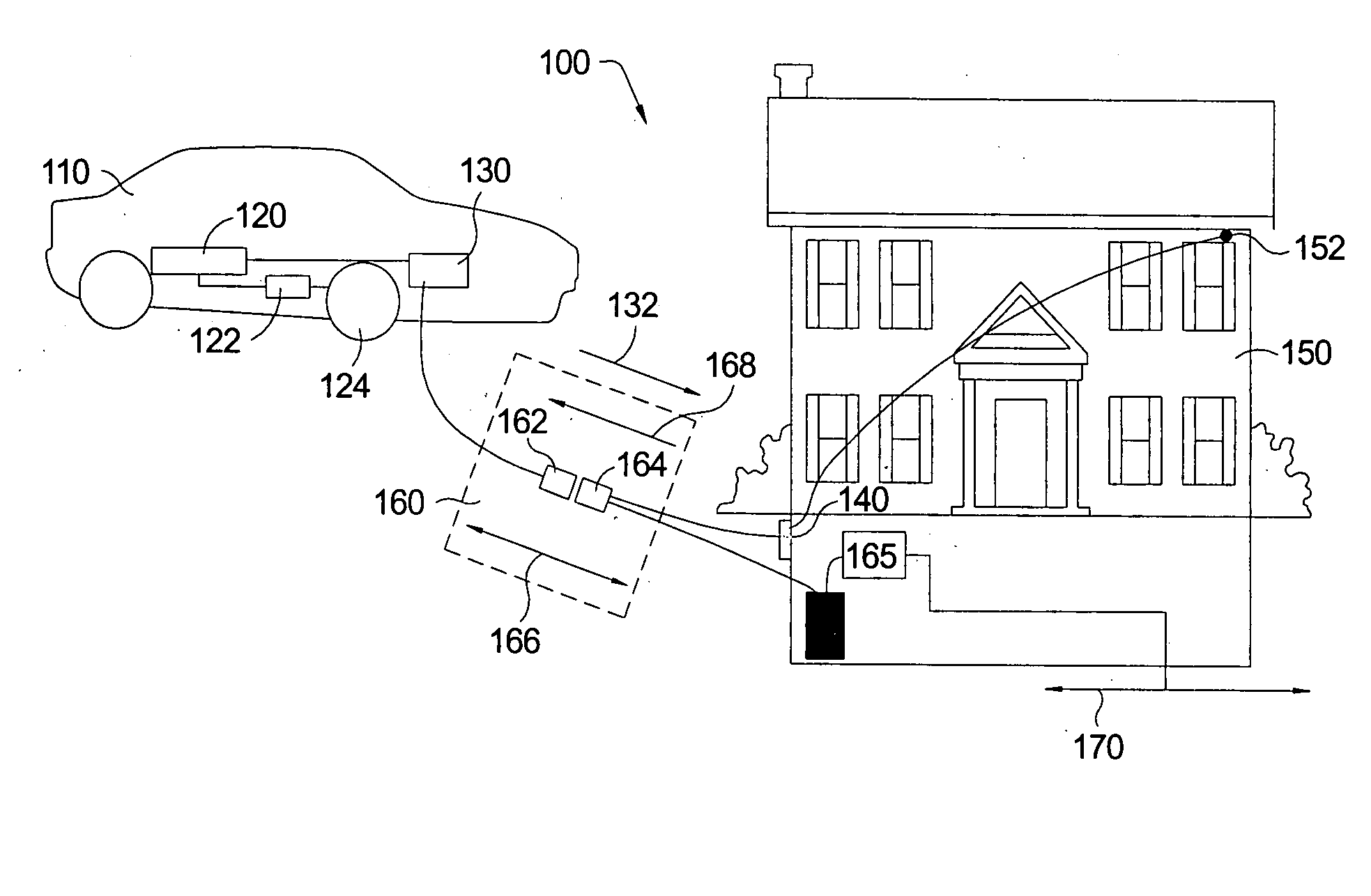

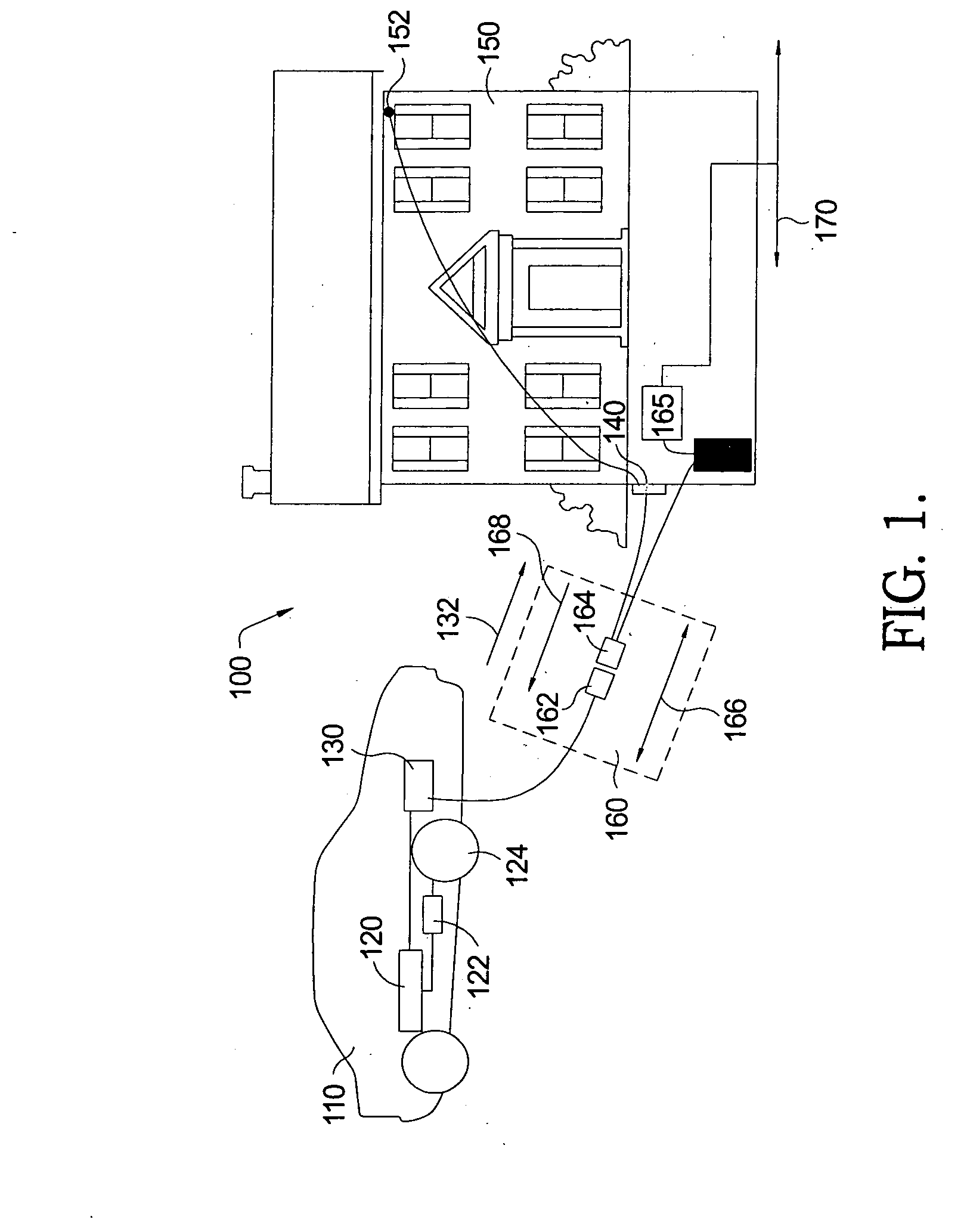

Electric vehicle having multiple-use APU system

ActiveUS20060219448A1Reducing net metered electricityIncrease powerAuxillary drivesBatteries circuit arrangementsElectricityFuel cells

During periods of vehicle inactivity, a vehicle-based APU electric generating system may be coupled into a regional electric grid to send electricity into the grid. A currently-preferred APU is a solid oxide fuel cell system. When a large number of vehicles are thus equipped and connected, substantial electric buffering can be effected to the grid load. A vehicle-based APU can also function as a back-up generator to a docking facility in the event of power failure of the grid. Gaseous hydrocarbon is readily supplied by pipe in many locations as a commercial and residential heating fuel source, and a hydrocarbon reformer on the vehicle can be attached to the fuel source, enabling an APU to operate as a stationary power source indefinitely. An optional storage tank on the vehicle may be refueled with gaseous fuel, for example, while the battery is being electrically recharged by the grid.

Owner:APTIV TECH LTD

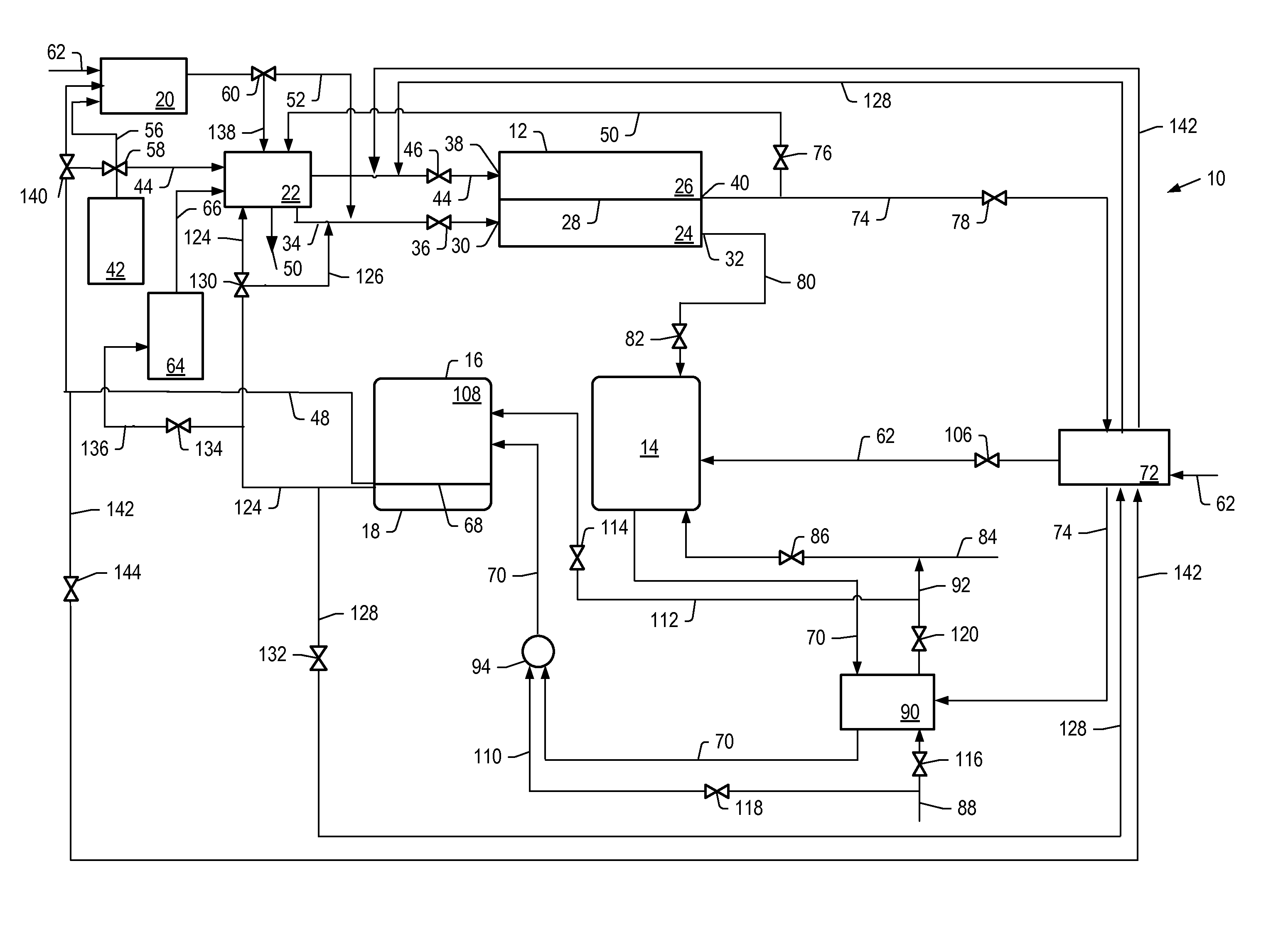

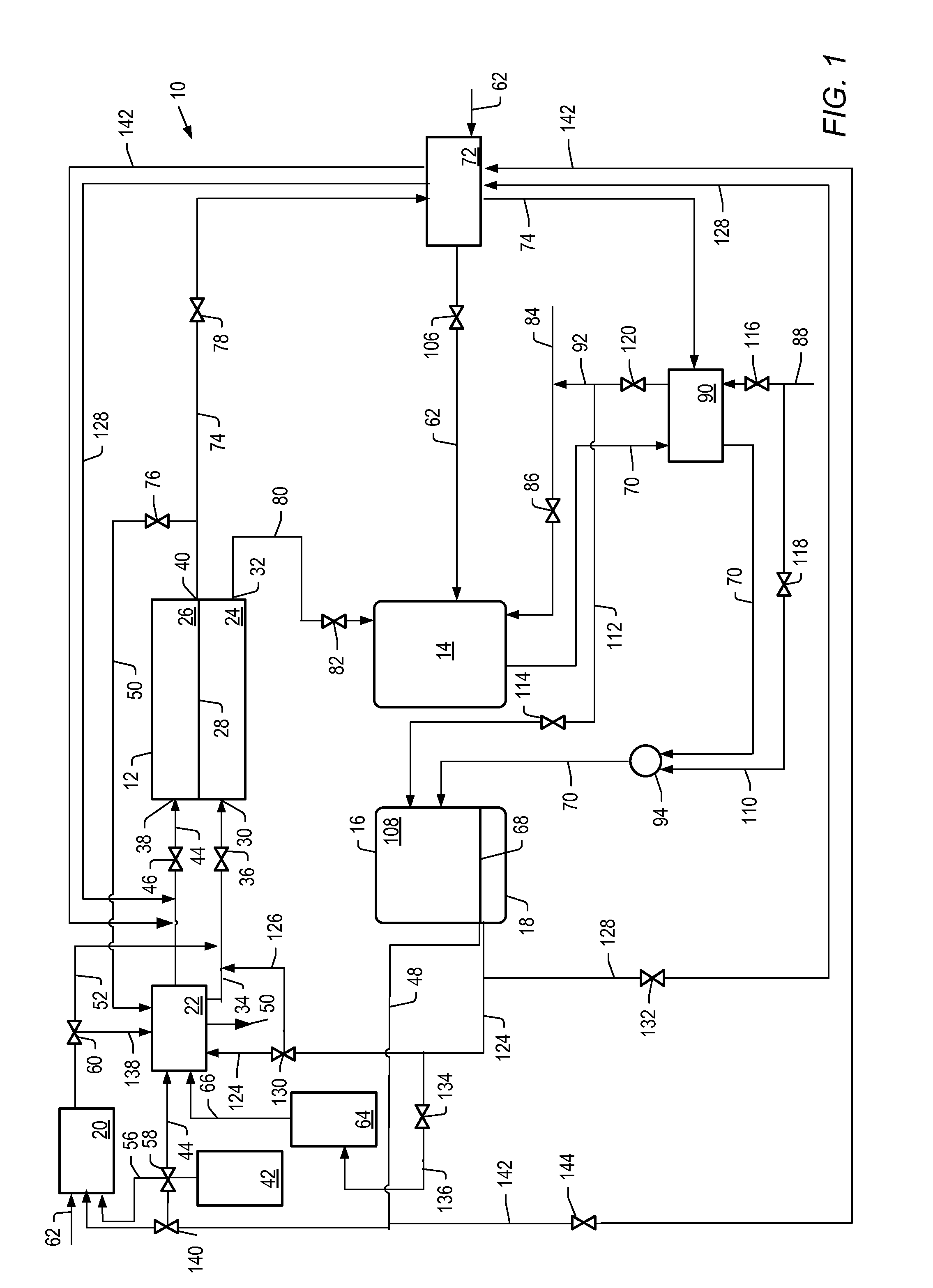

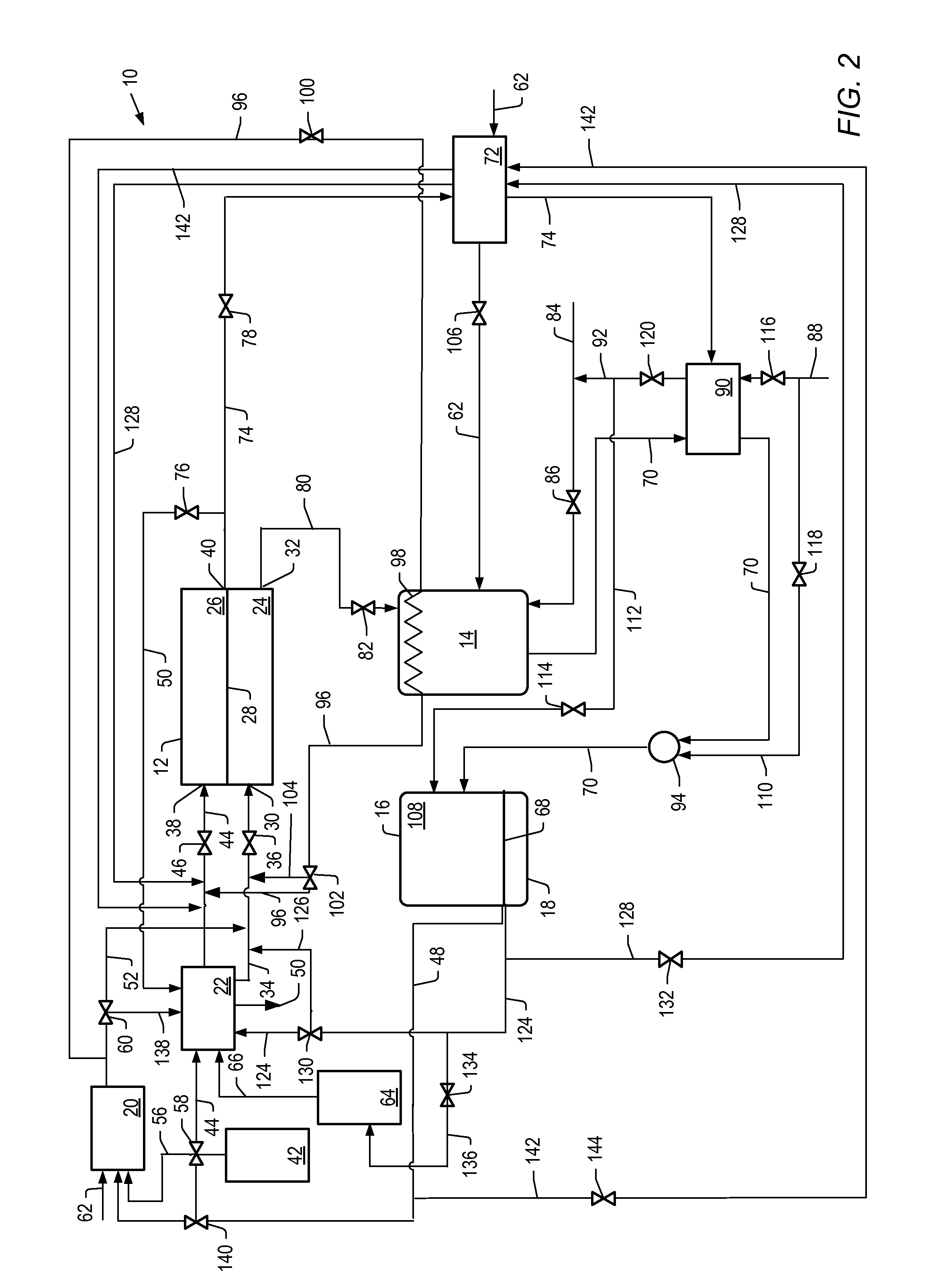

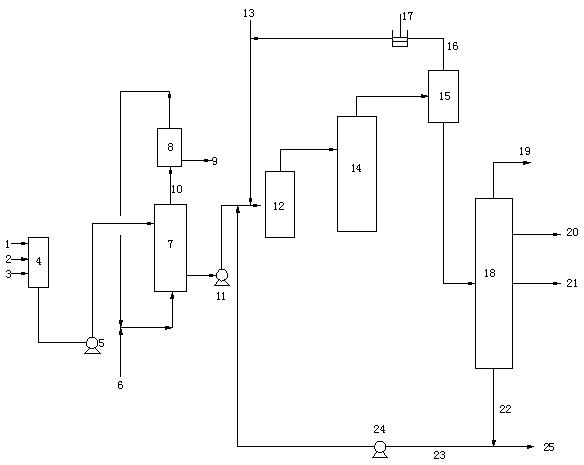

Cryogenic process utilizing high pressure absorber column

Owner:ABB LUMMUS GLOBAL INC

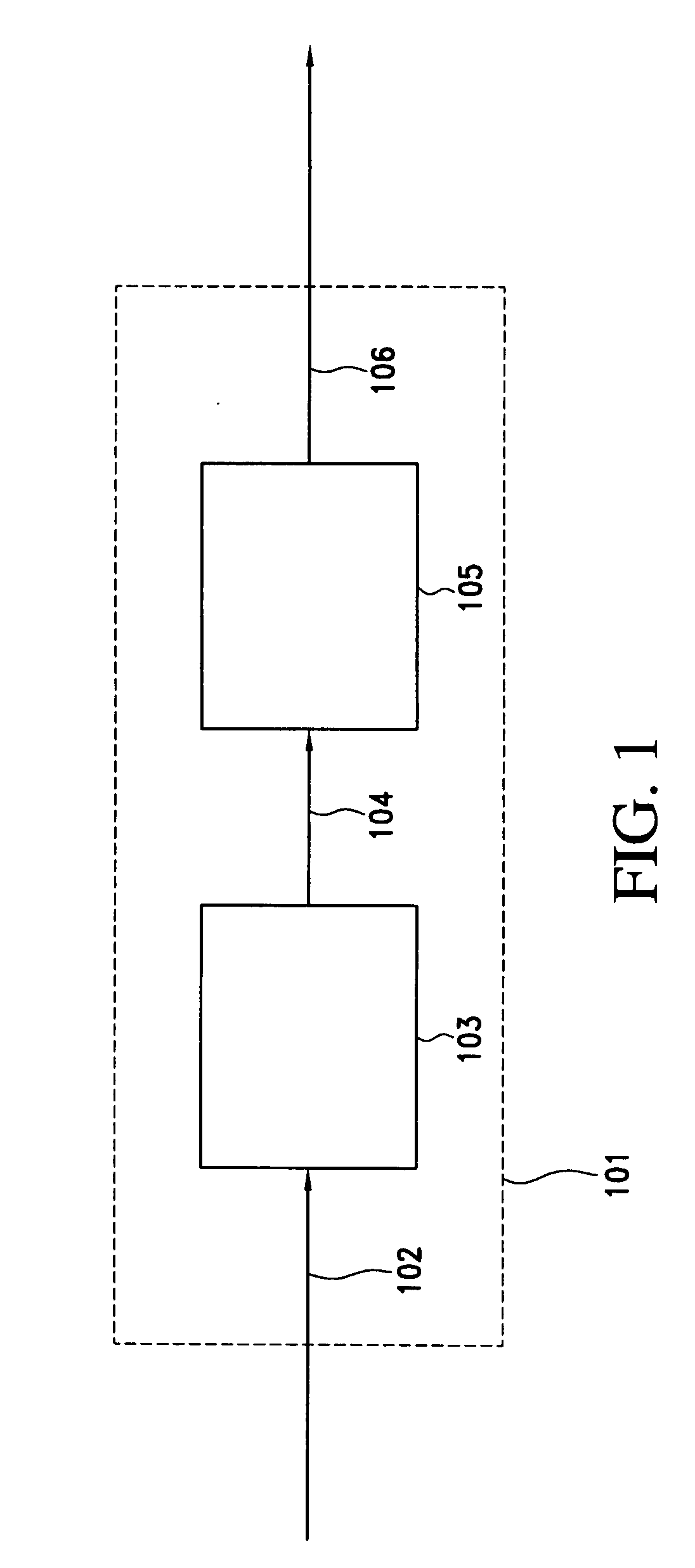

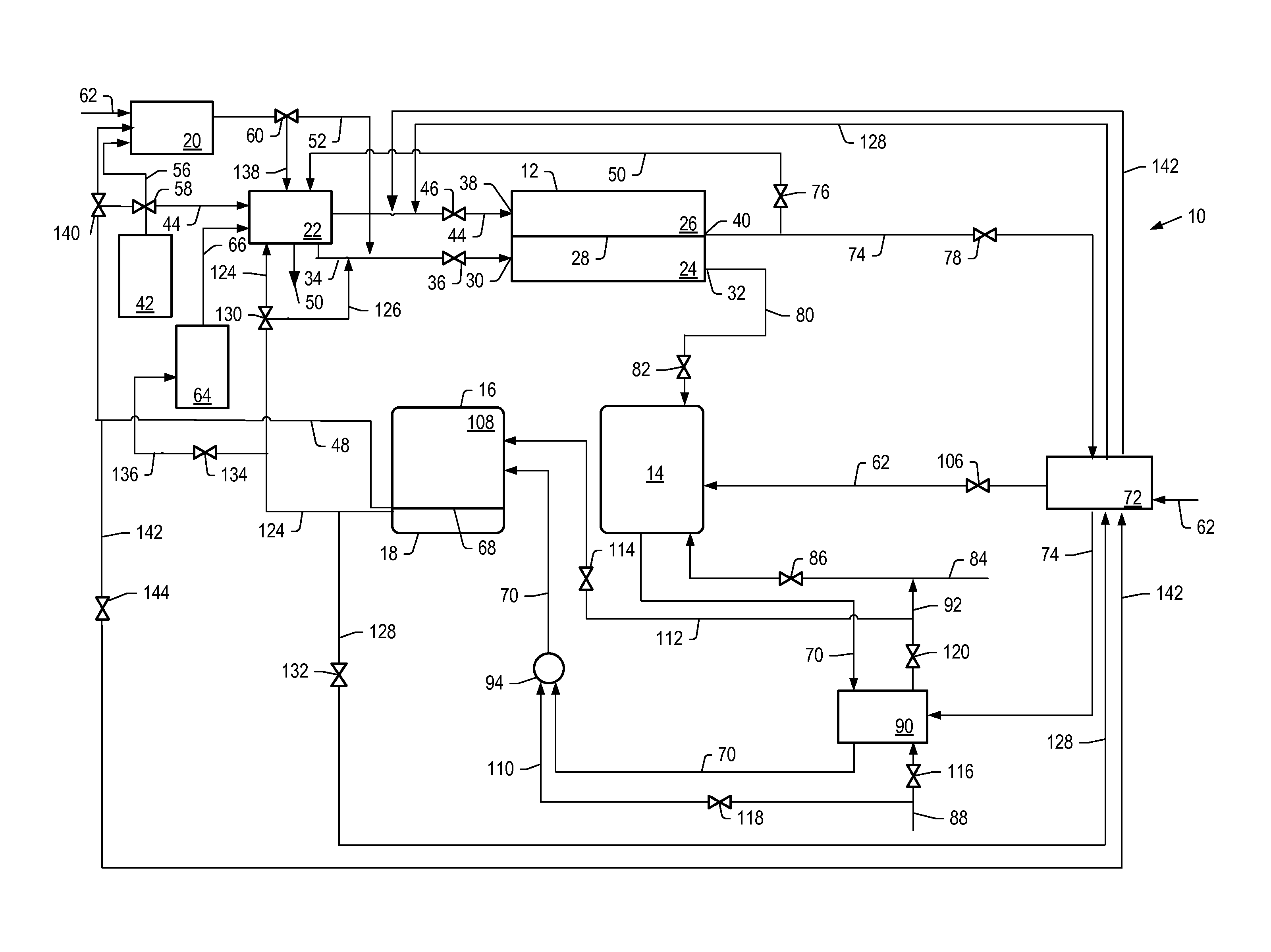

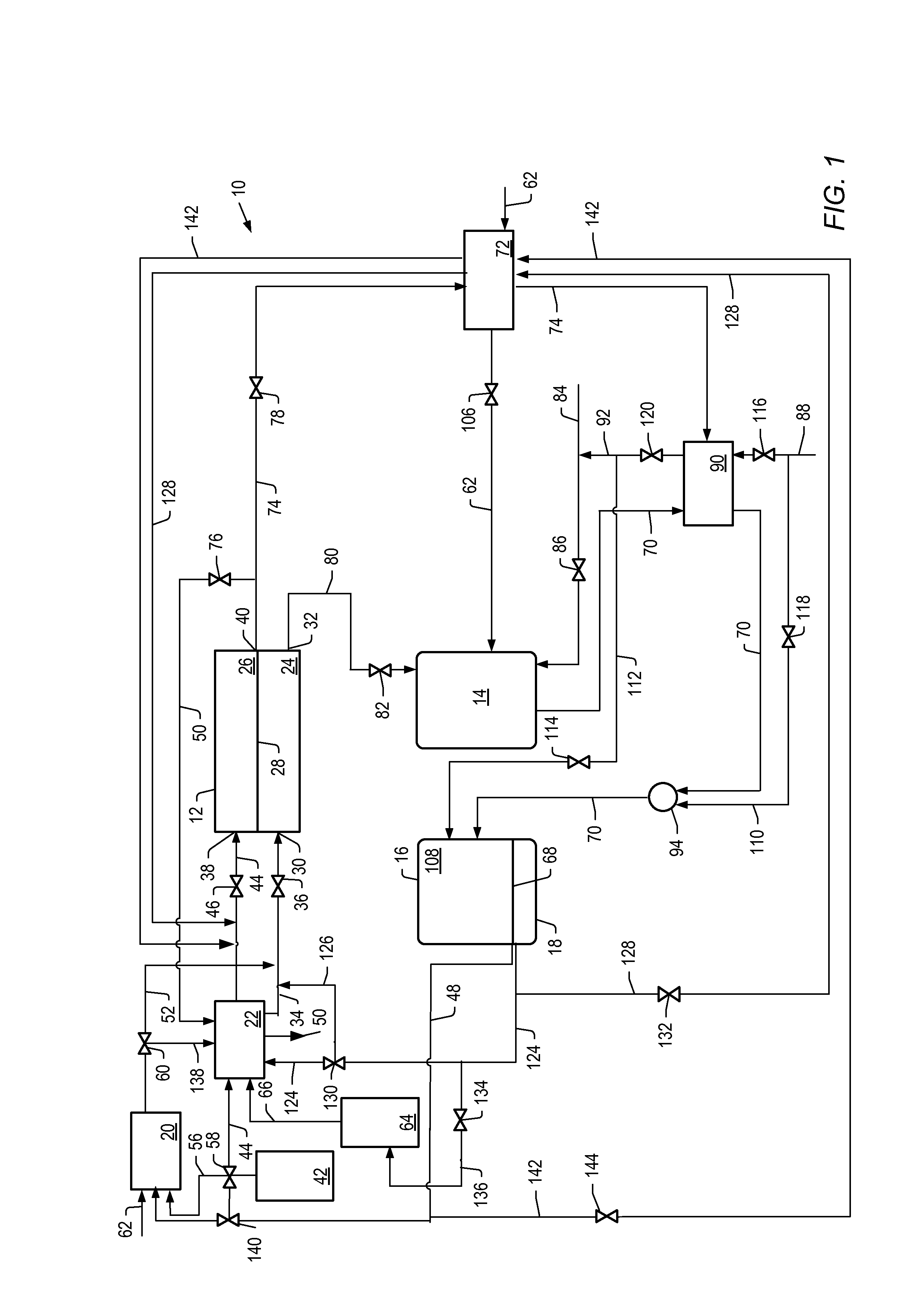

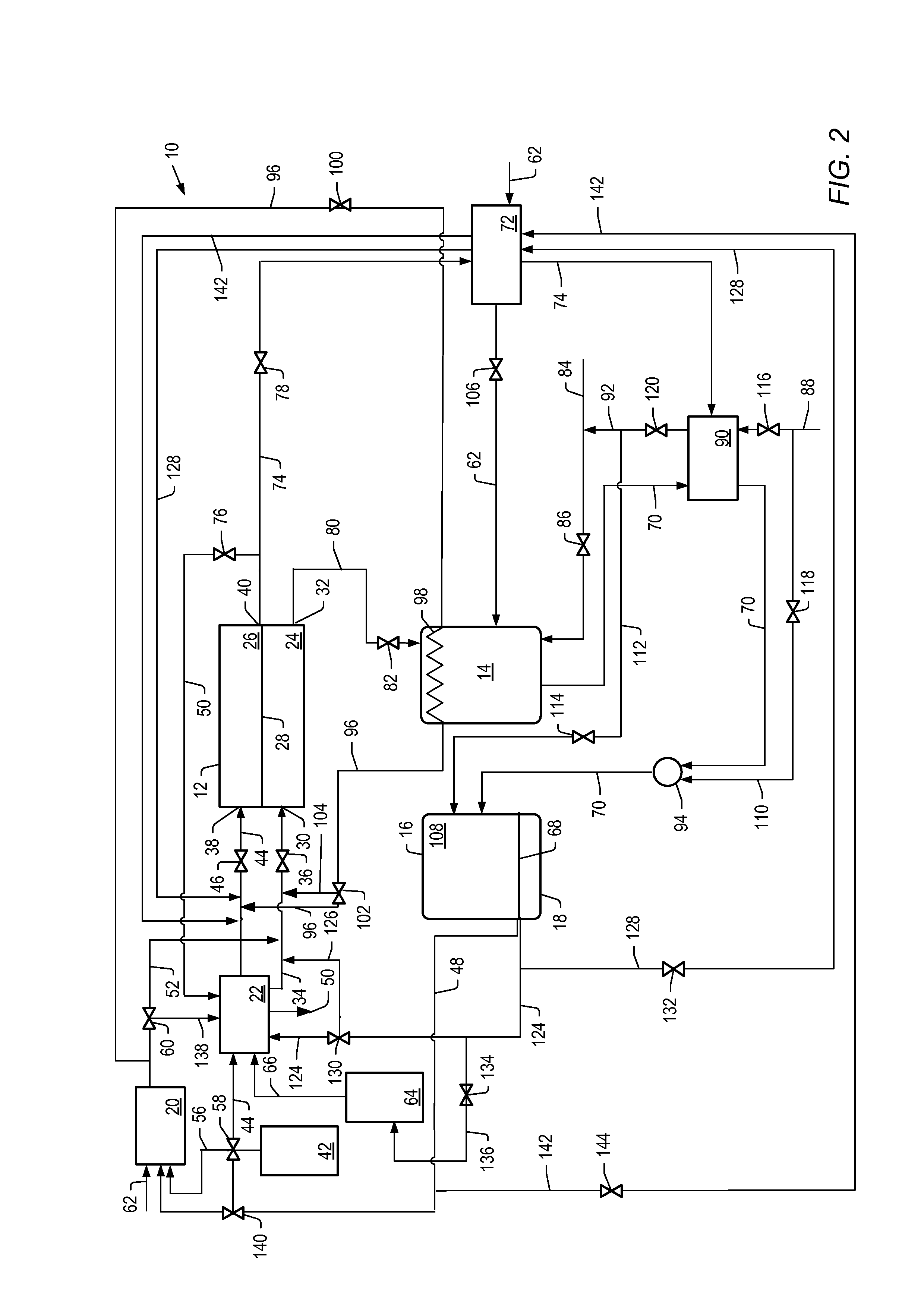

Systems and processes of operating fuel cell systems

InactiveUS20110111315A1Well mixedFuel cell auxillariesFused electrolyte fuel cellsSteam reformingFuel cells

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

Method and system for extraction of hydrocarbons from oil shale

Owner:ULTRA SAFE NUCLEAR CORP

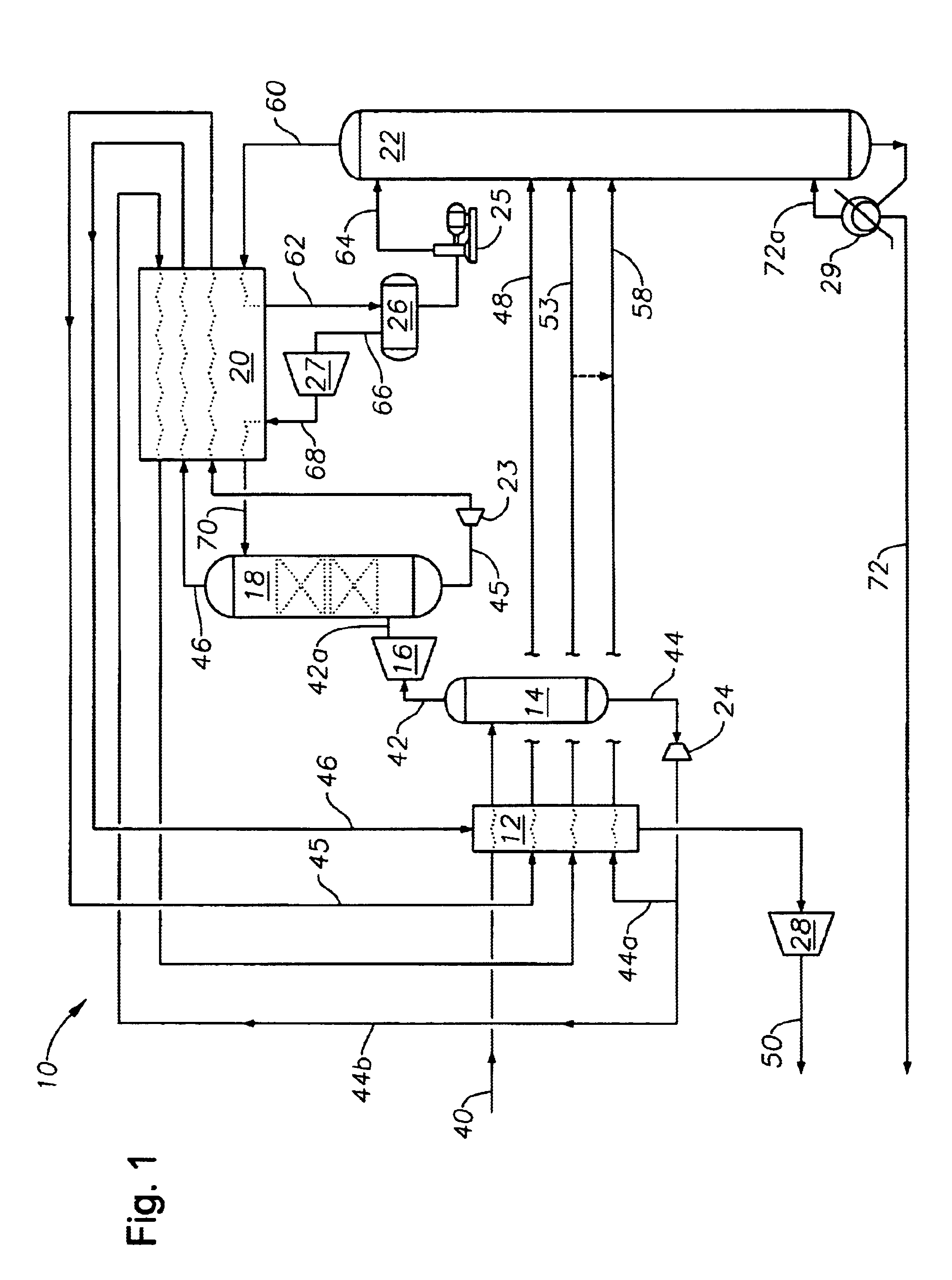

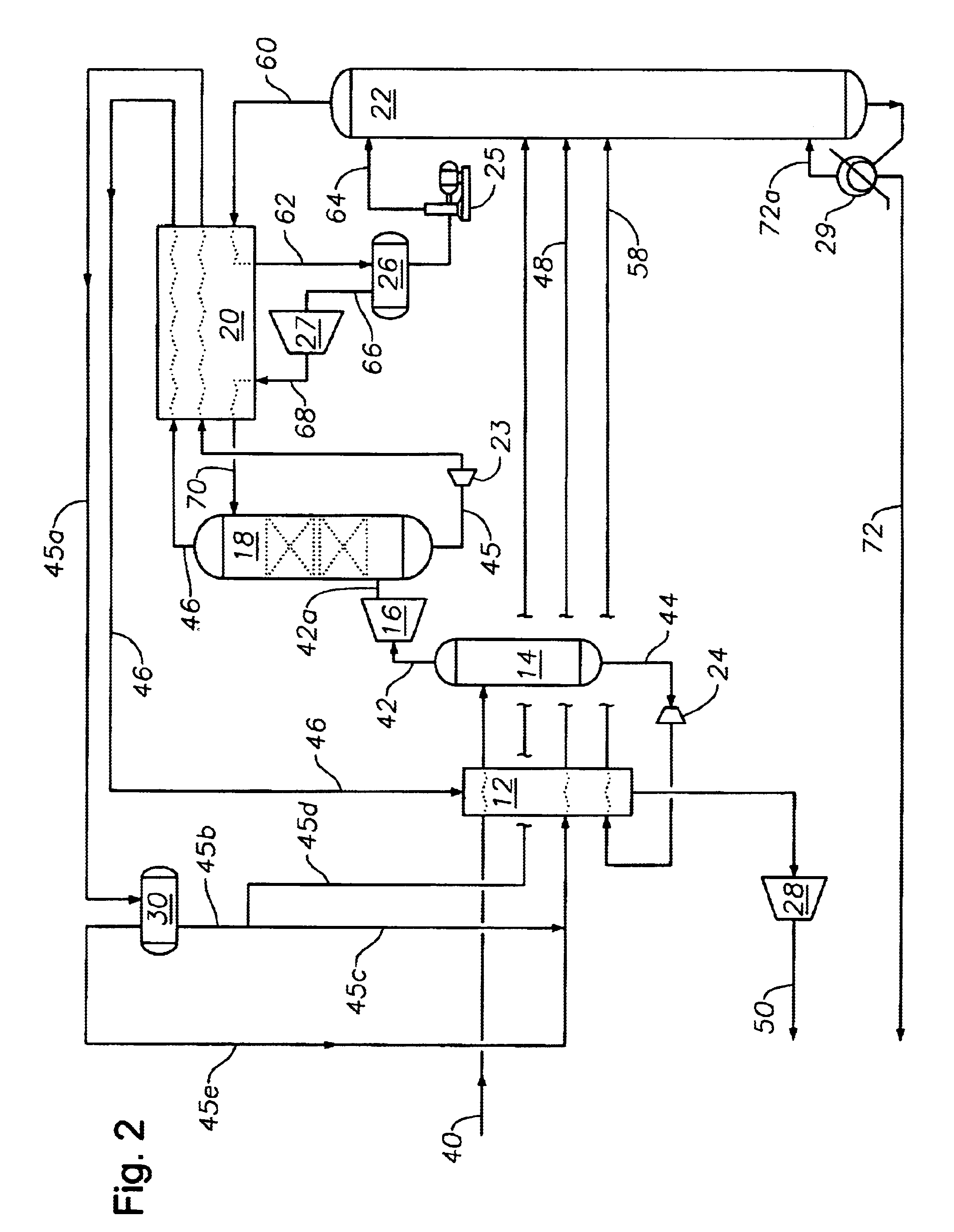

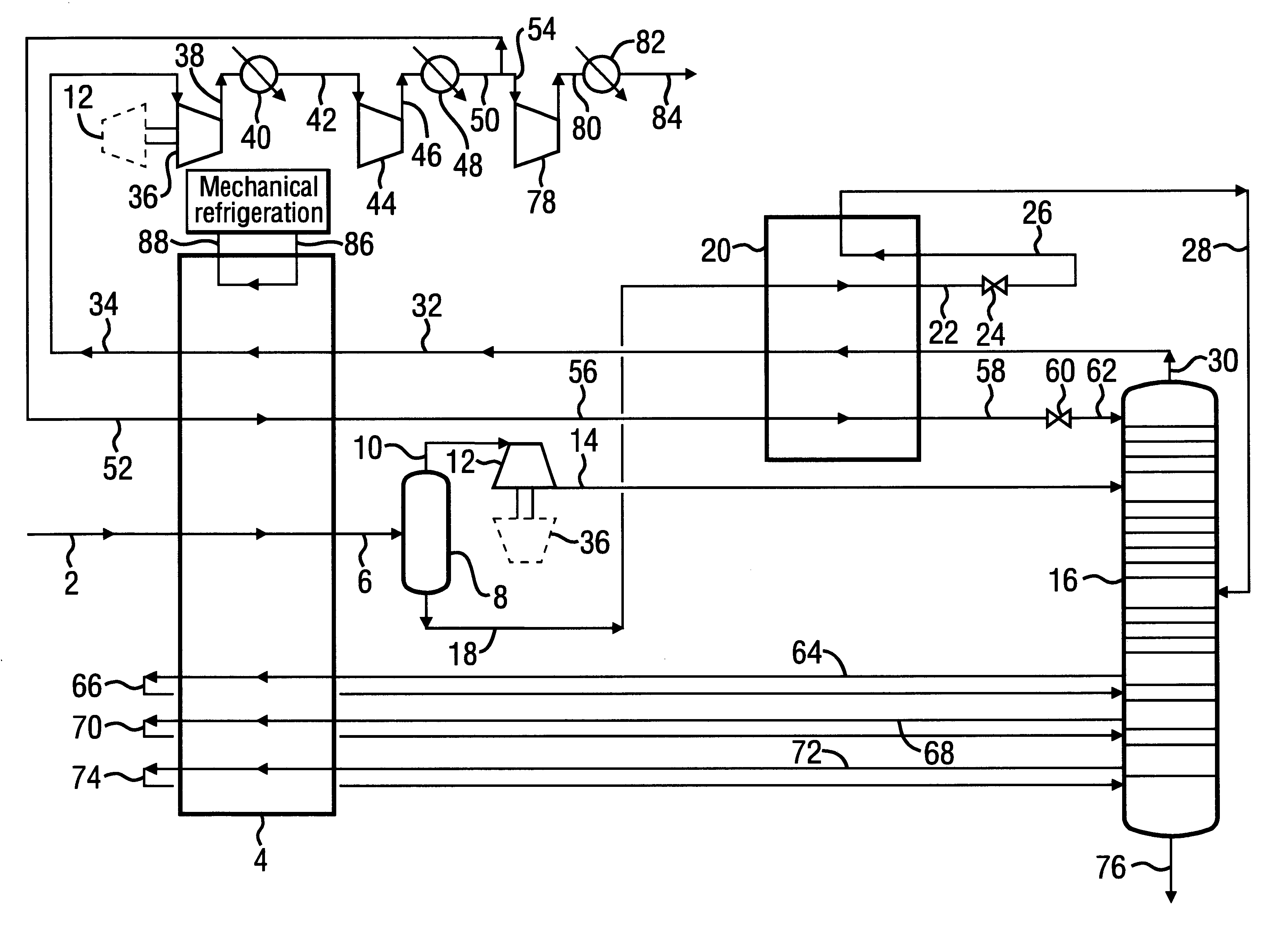

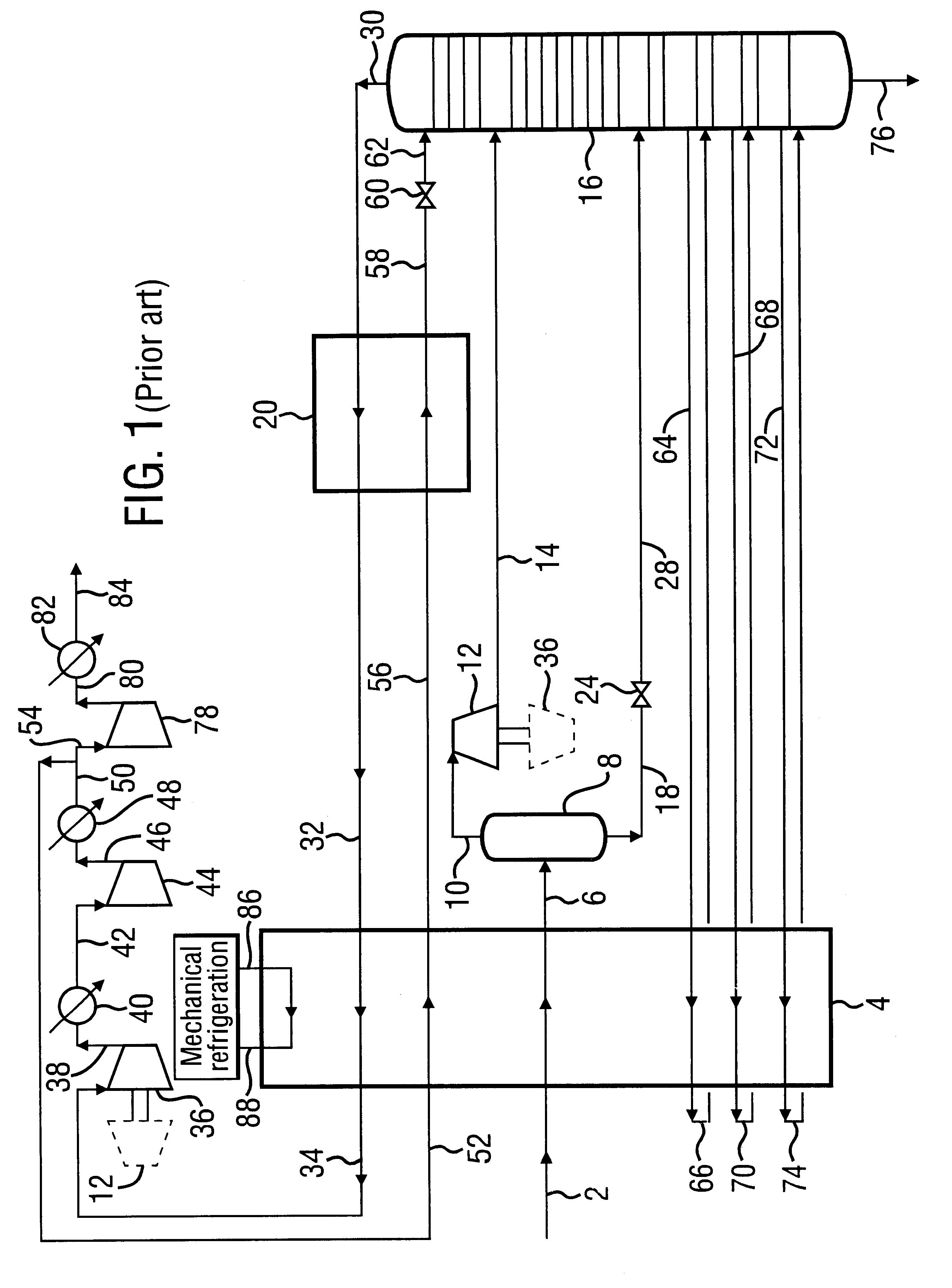

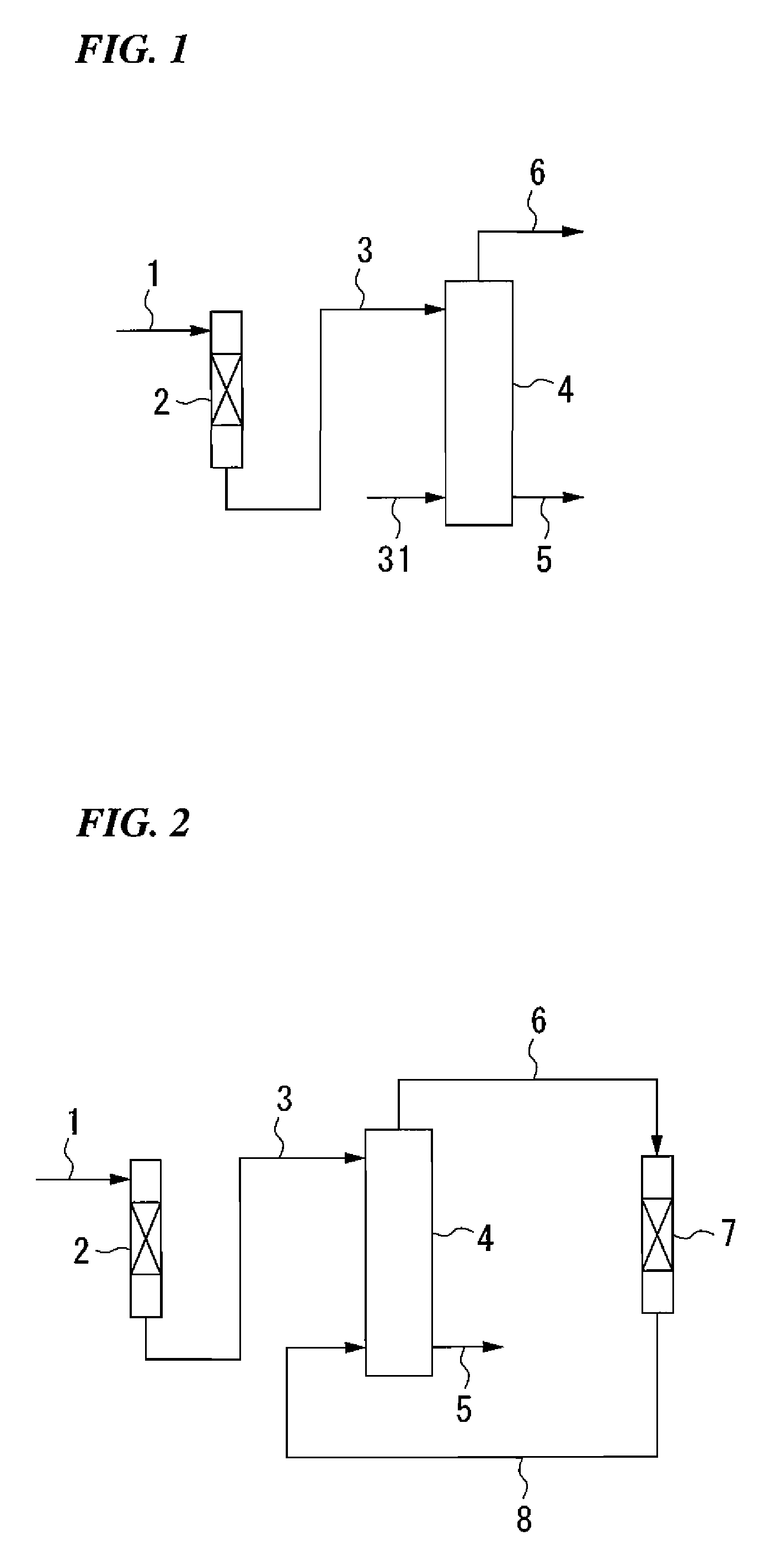

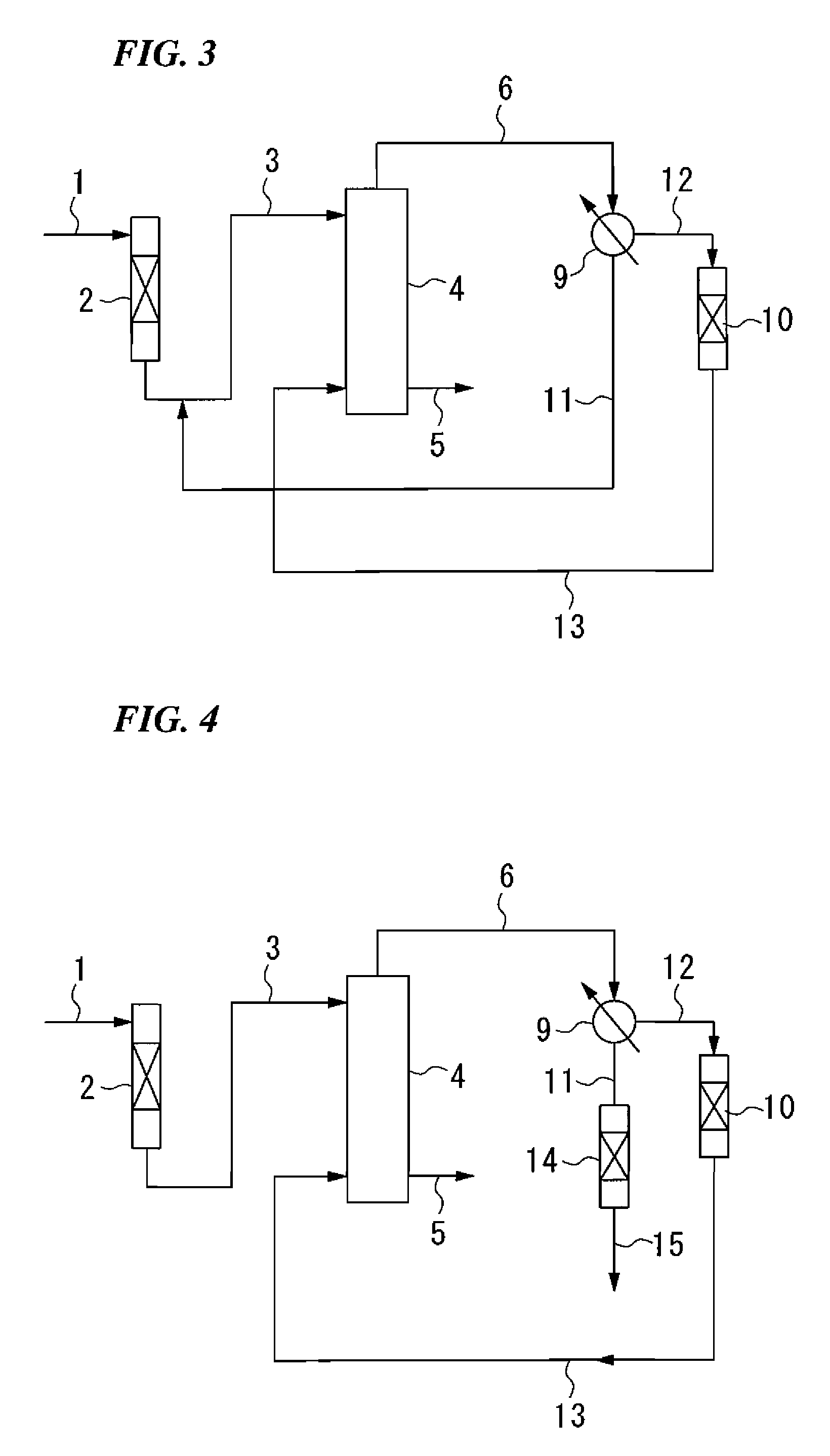

Hydrocarbon separation process and apparatus

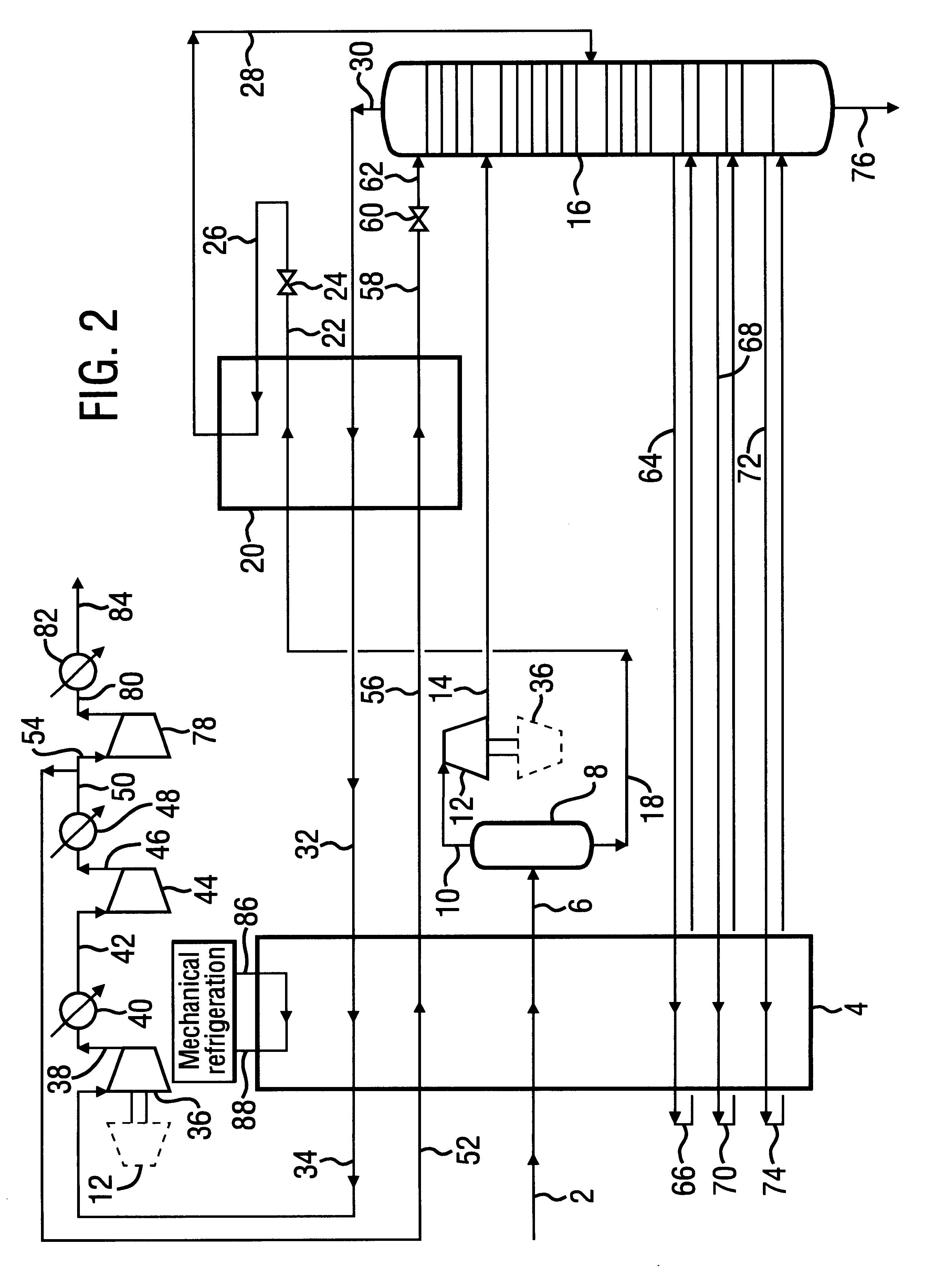

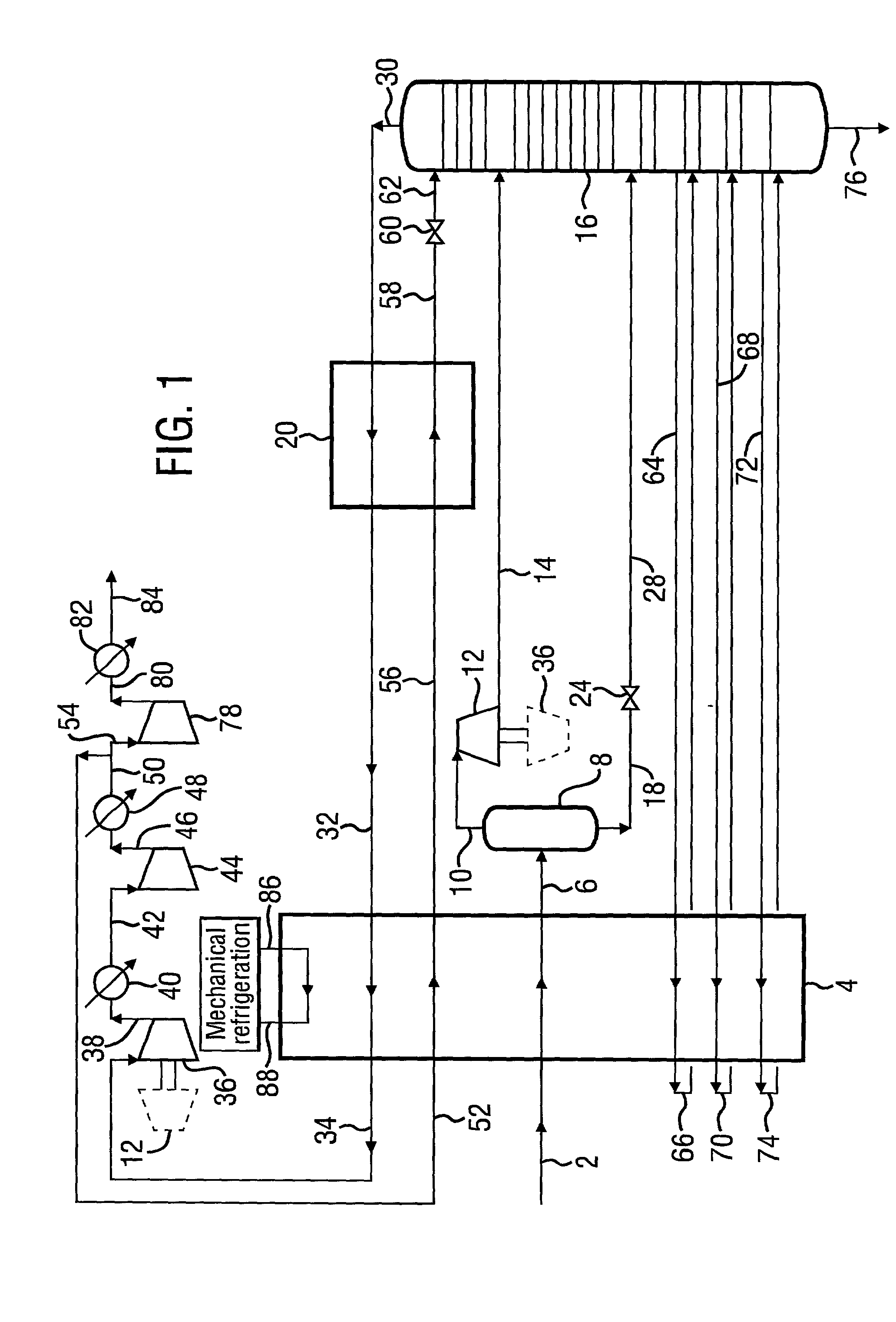

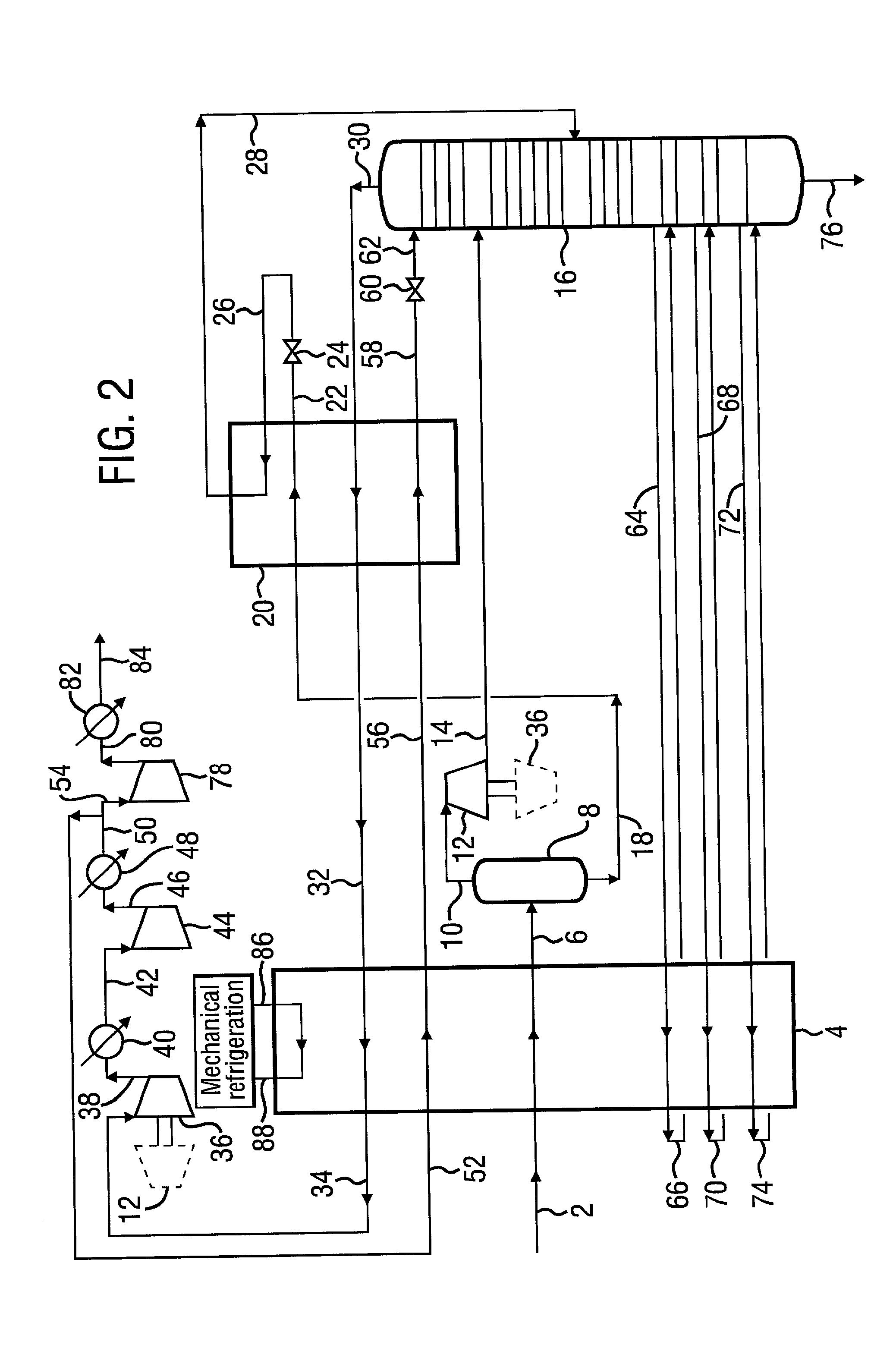

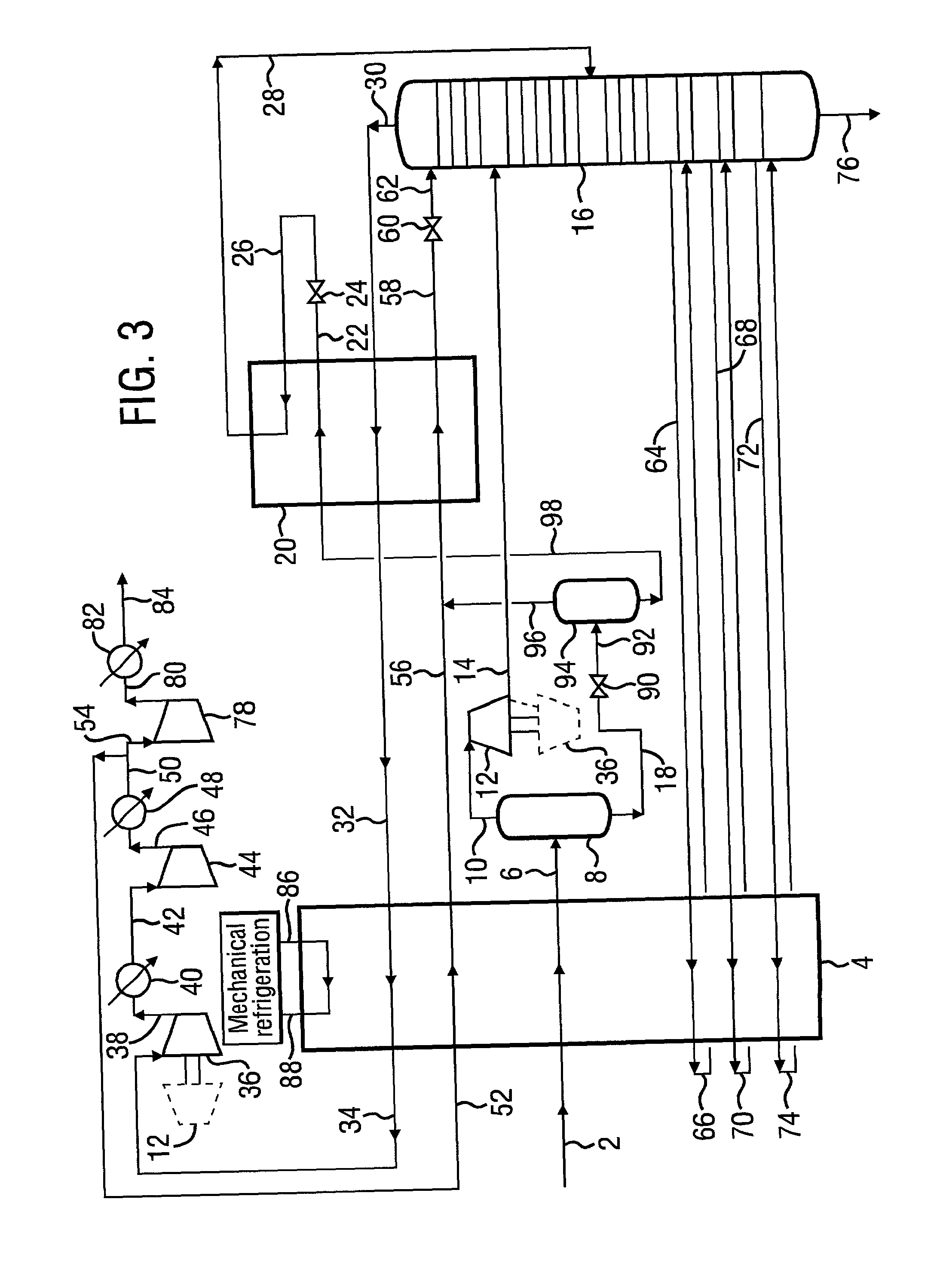

InactiveUS6363744B2Reduce the temperaturePromote recoverySolidificationLiquefactionPhysical chemistryRefrigeration

A process is described for separating the heavier hydrocarbons from a gaseous hydrocarbon feed wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a fractionation column. The liquid portion is subcooled in heat exchange with the overhead vapour from the fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. The rewarmed residual vapour is subsequently compressed to a pressure suitable for export, with a portion of the compressed gas being cooled, condensed and recycled back to reflux the top section of the fractionation column.Also described is a process wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a high pressure wash column. The liquid portion is expanded and fed to the base of the high pressure wash column. Bottoms liquid from the wash column is subcooled in heat exchange with the overhead vapour from a fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. Vapour from the high pressure wash column is partially condensed, with the liquid portion used to provide reflux to the high pressure wash column and the fractionation column.The processes are especially applicable to recovery of ethane and heavier components from natural gas. Overall process power requirements are reduced, recovery of the desired heavy hydrocarbons is increased or both of these effects are realised.

Owner:COSTAIN OIL GAS & PROCESS

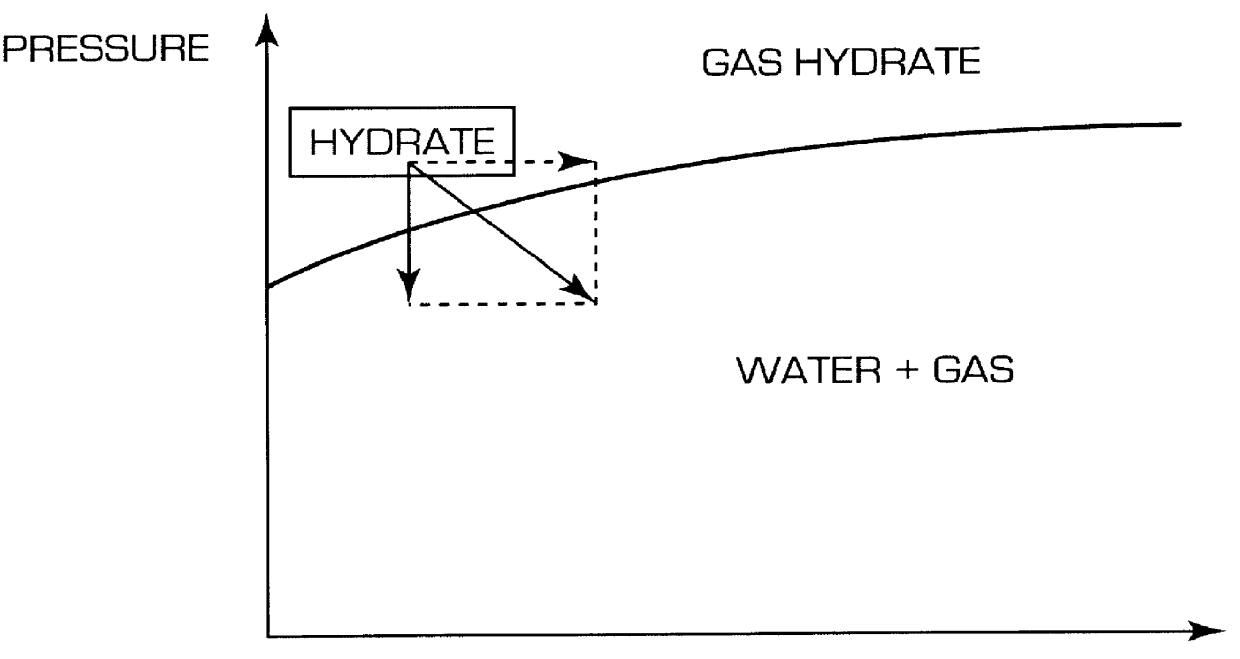

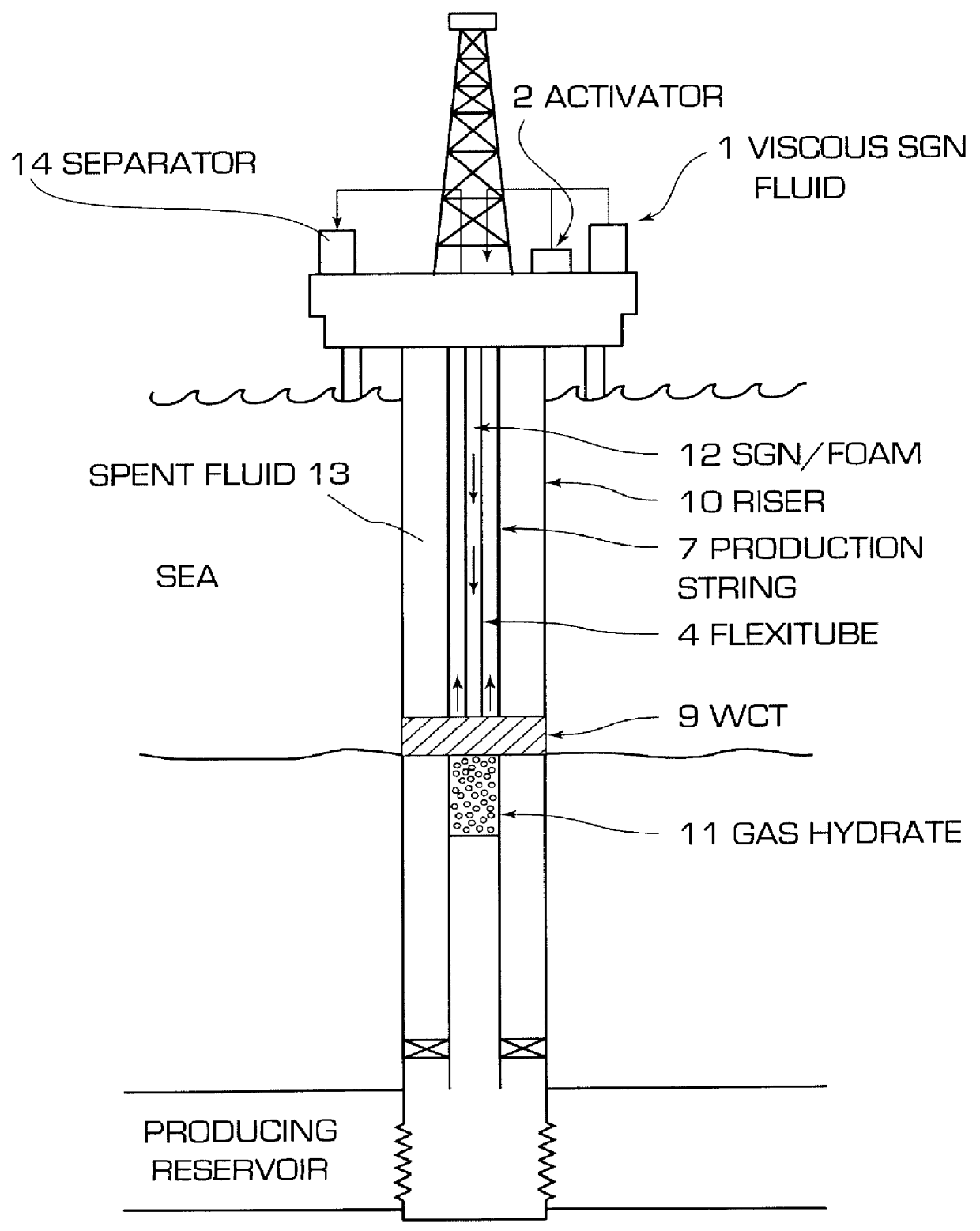

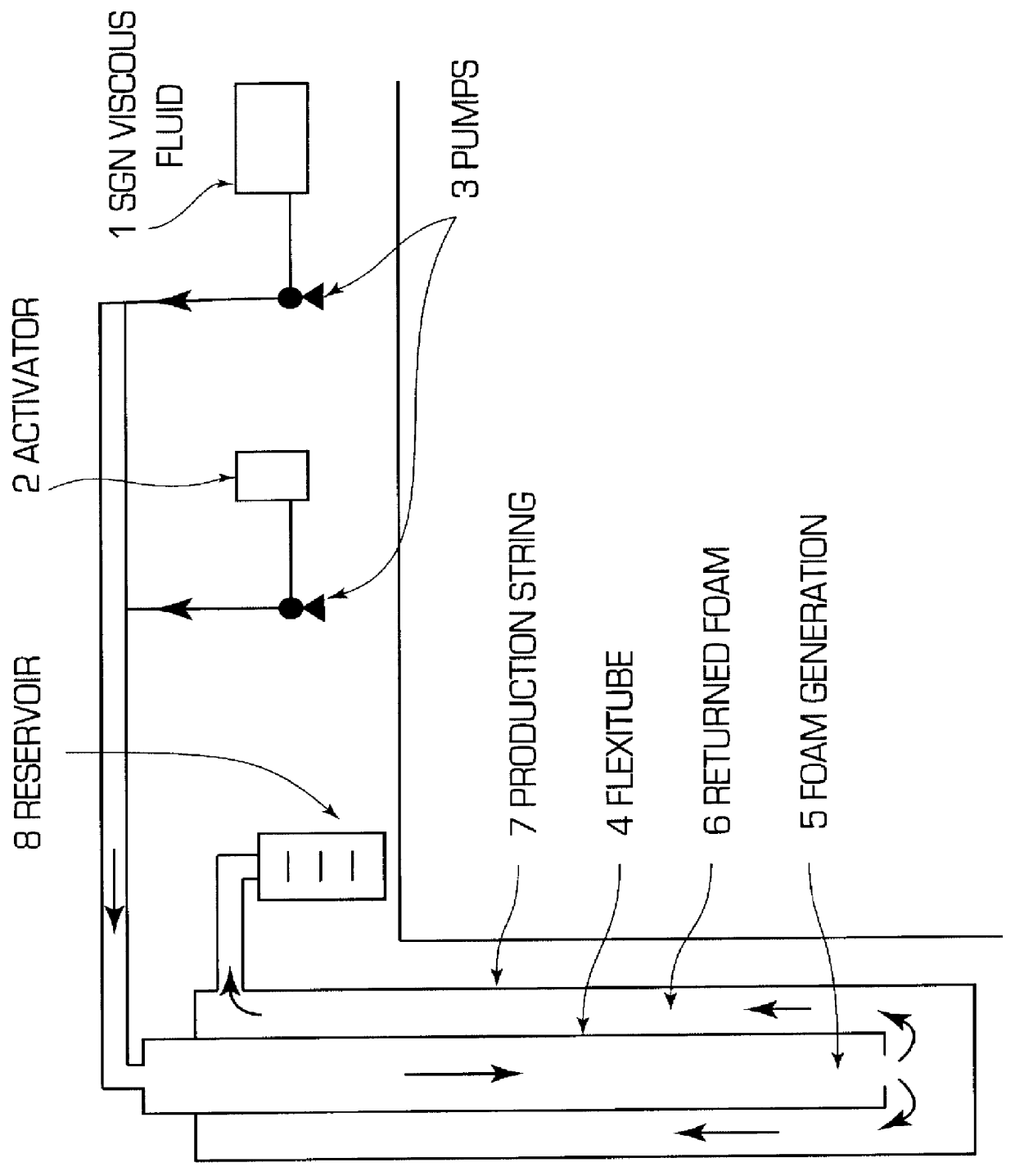

Process for the thermo-hydraulic control of gas hydrates

InactiveUS6035933AInhibition formationPipeline systemsDifferential sedimentationForming gasGas phase

A process for the thermo-hydraulic control of gas hydrates in subsea production and injection wells as well as pipelines which transport liquid or gaseous hydrocarbons is described, the process making use of a Nitrogen Generating System foamed or in solution. The control may signify the prevention of the formation of the gas hydrates or the dissolution of the gas hydrate plug already formed. Under conditions of use designed for the prevention of the formation of gas hydrates the SGN fluid prevents the thermal conditions leading to the gas hydrate plugs. Under conditions of use designed to dissolve the already formed gas hydrate plugs, the SGN fluid alters the thermo-hydraulic conditions which favor the gas hydrate plugs, so that they are dissolved and return to the water+gas phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

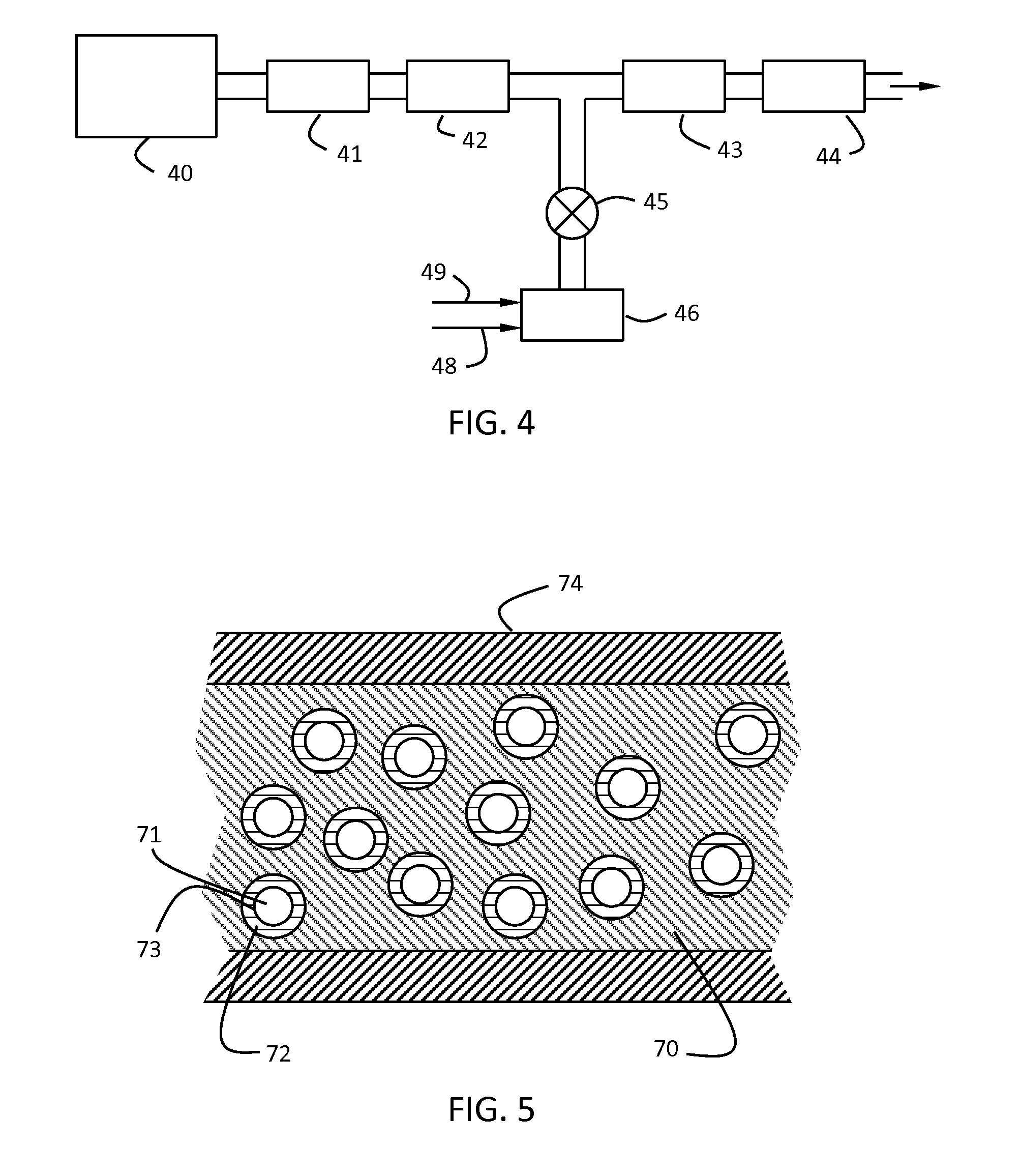

Process and device for sterilising ambient air

InactiveUS20070253860A1Lower the volumeEasy to useMechanical apparatusLighting and heating apparatusCompound (substance)Ionization

A process is disclosed for sterilising ambient air conducted in an air duct (401), as well as a use of a device for breaking down gaseous hydrocarbon emissions in order to sterilise ambient air conducted in an air duct (104), and a device for sterilising ambient air conducted in an air duct (401). Ambient air is supplied to the air duct (401) of an UV unit (403) for irradiation with UV radiation, and the thus pre-purified ambient air is supplied to a downstream ionization unit (407) arranged in the air duct and in which the ambient air is ionised.

Owner:SCHRODER WERNER

Emission Treatment Catalysts, Systems and Methods

ActiveUS20090288402A1Easy to controlNitrogen compoundsInternal combustion piston enginesNitrogen oxideTreatment system

Zoned diesel oxidation catalysts containing a higher precious metal loading in the inlet zone that the outlet zone and an equal or shorter length inlet zone are described. Emission treatment systems and methods of remediating nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons using zoned diesel oxidation catalysts are also described.

Owner:BASF CORP

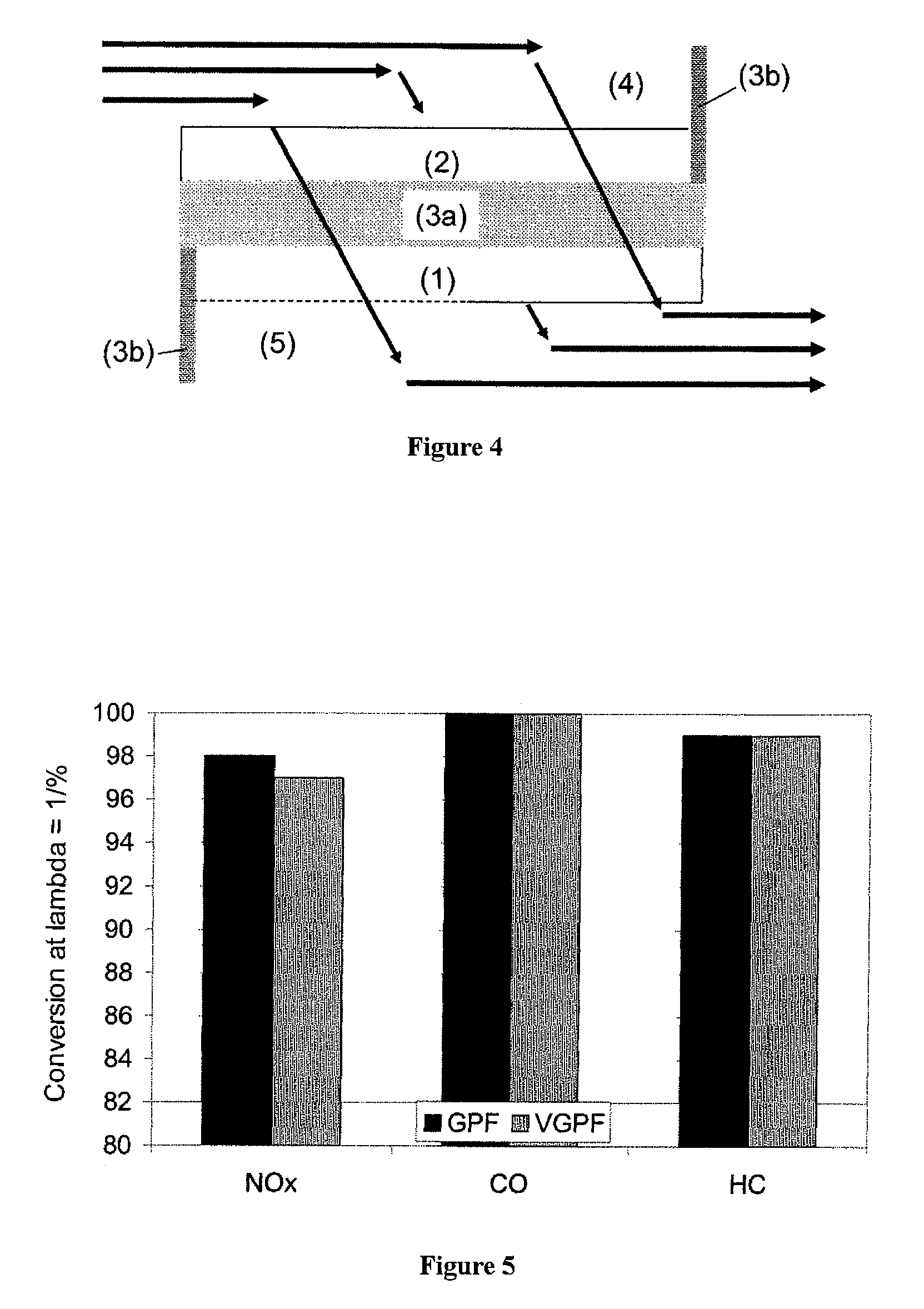

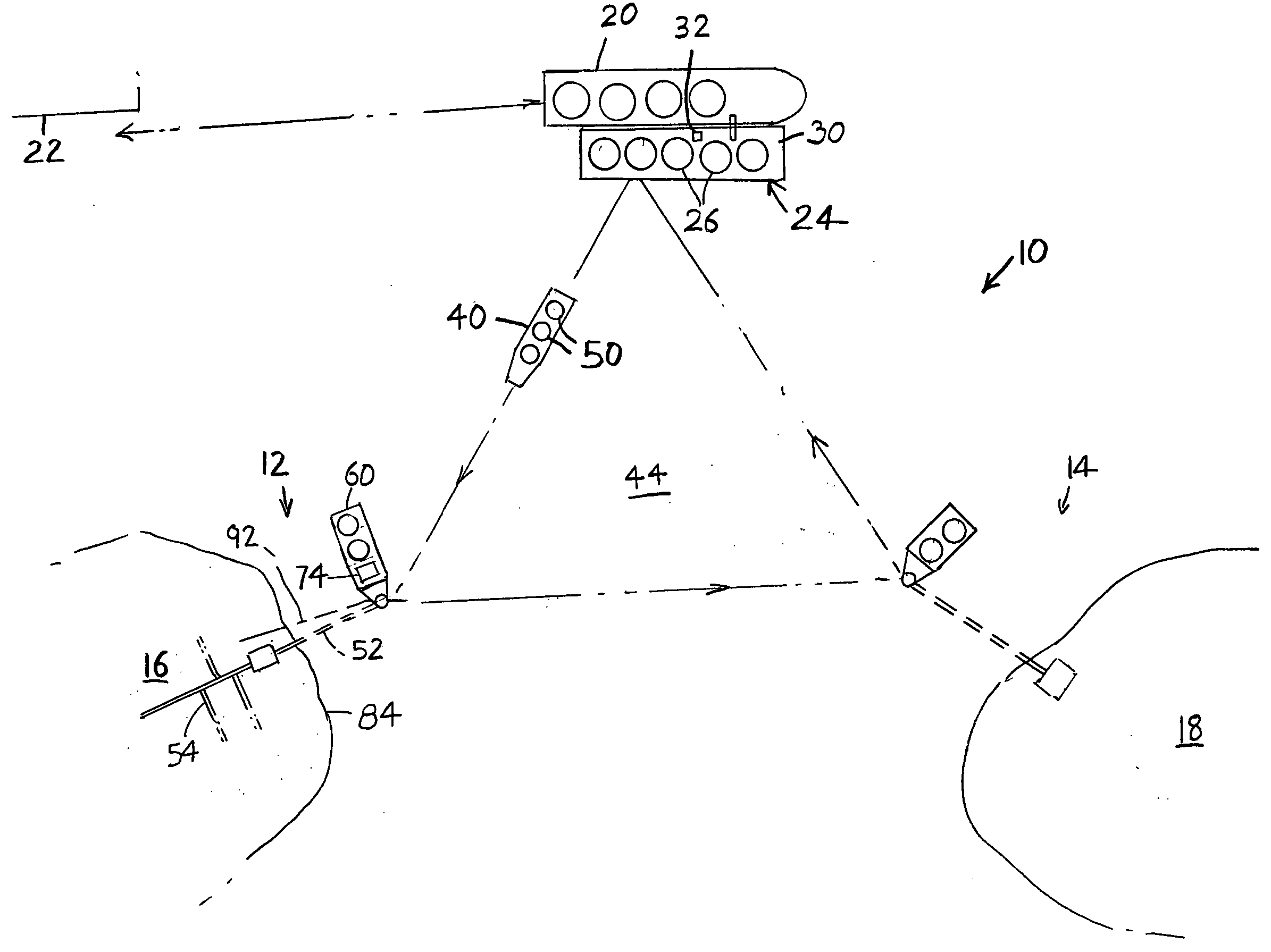

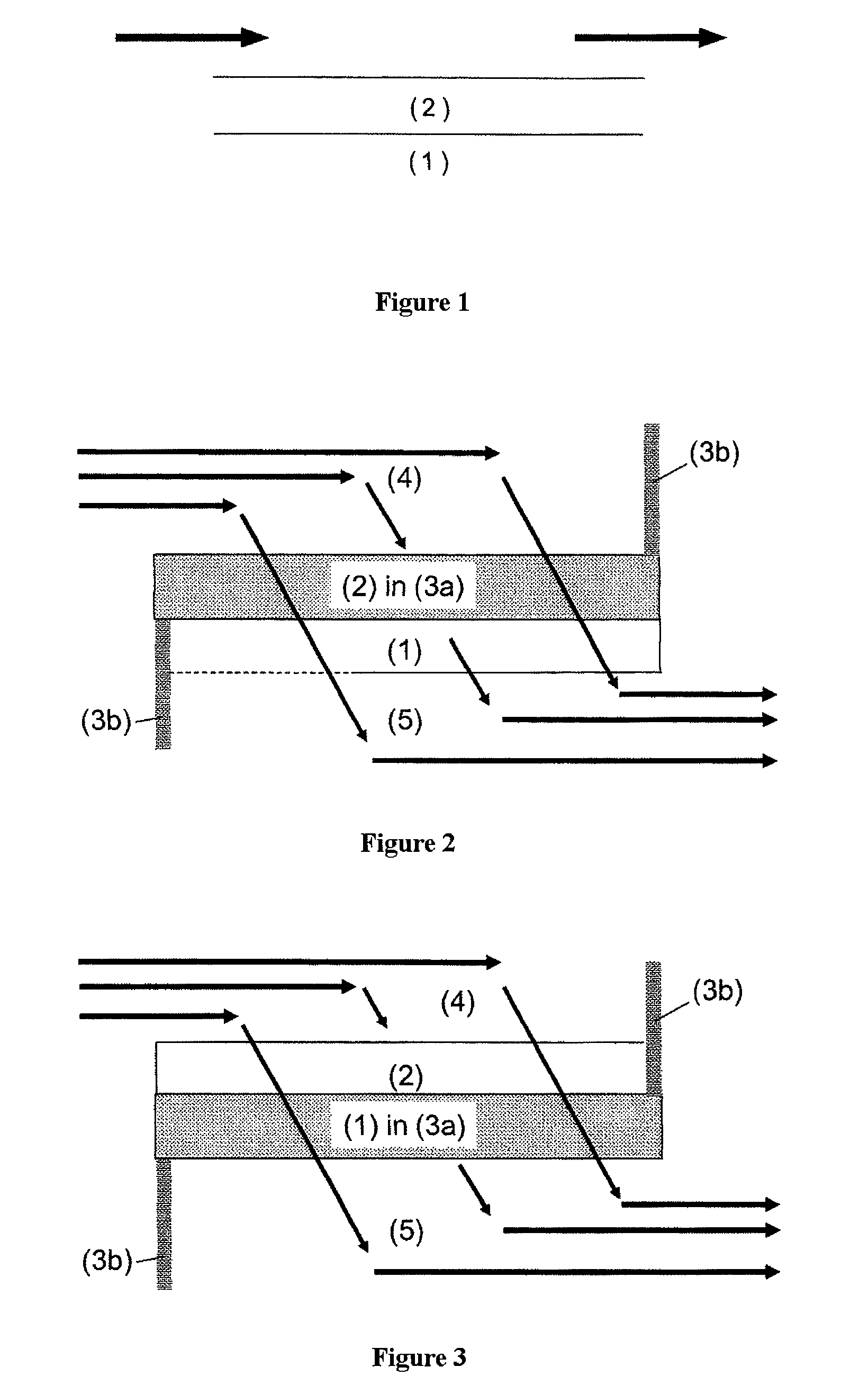

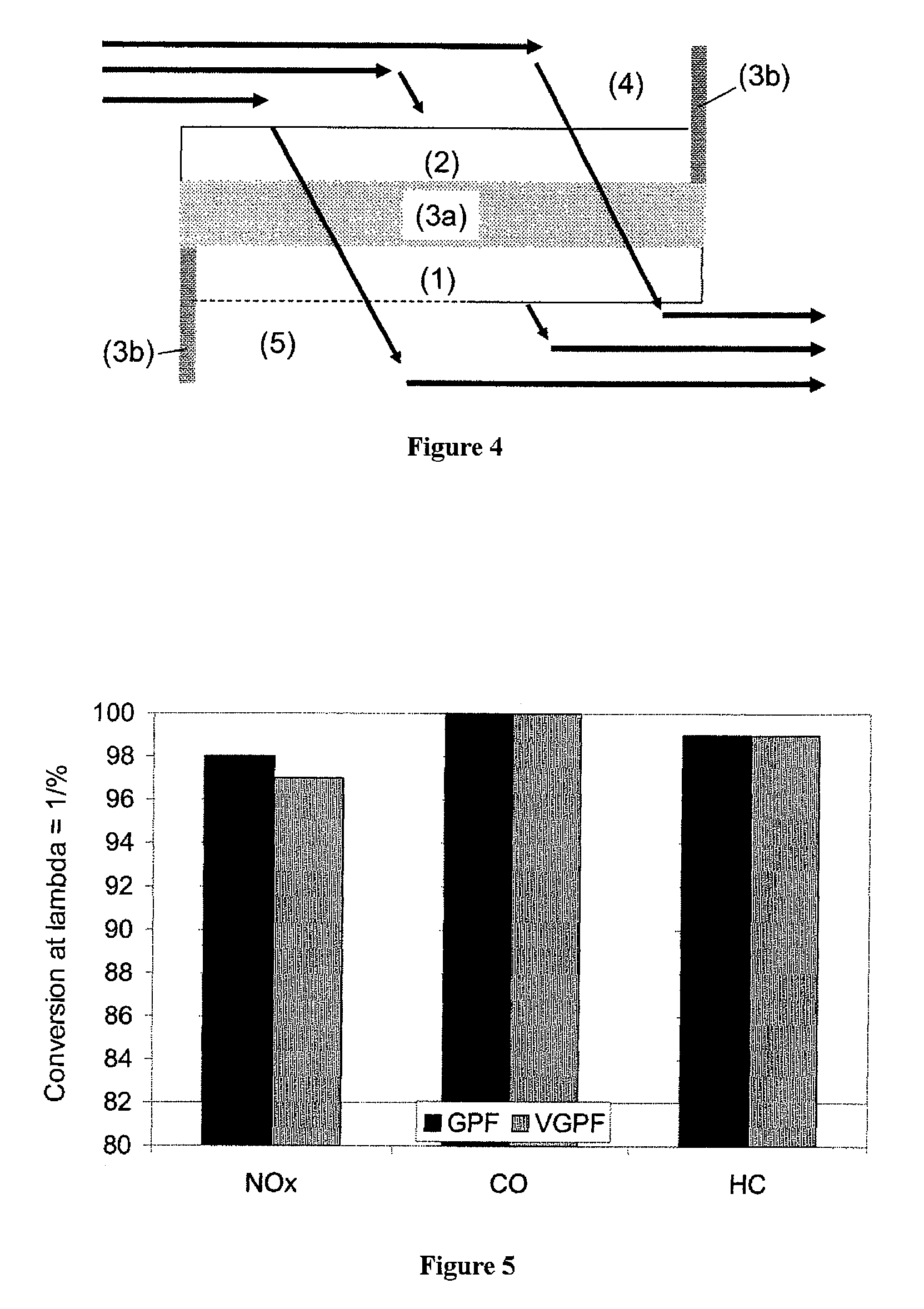

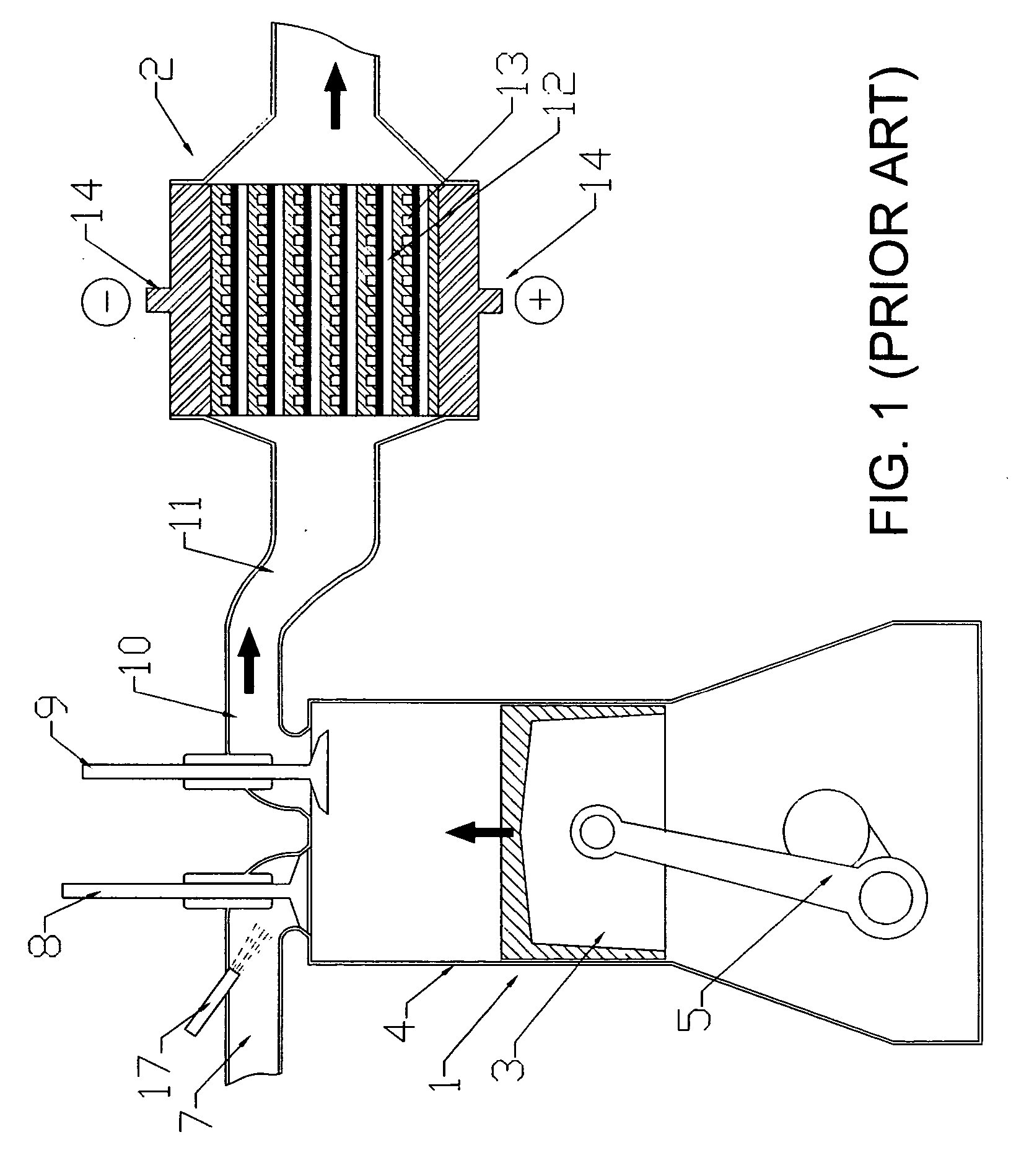

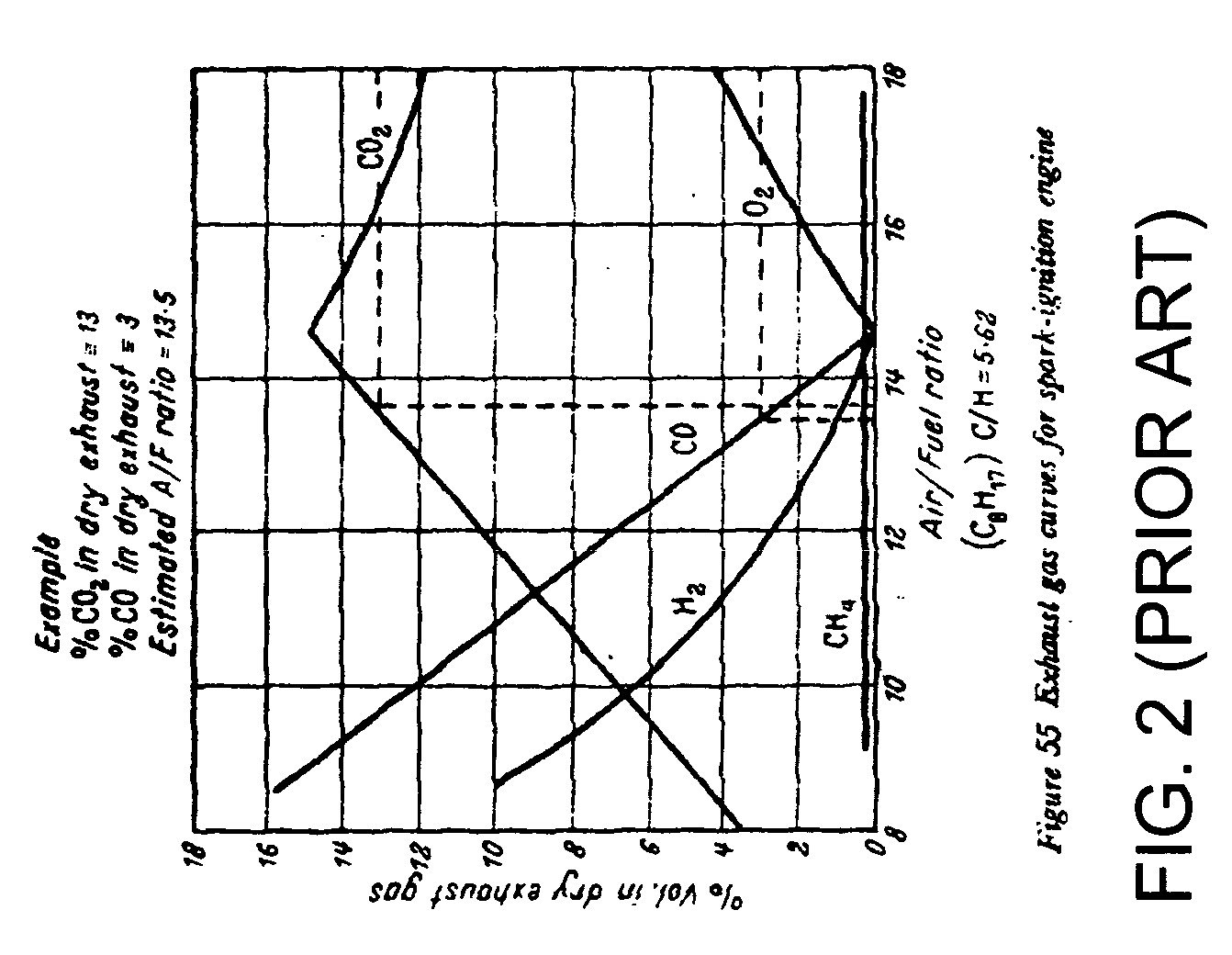

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS20090087365A1Sufficient thermal aging stabilityImproved thermal cycling stabilityCombination devicesOrganic chemistryExternal combustion engineEngineering

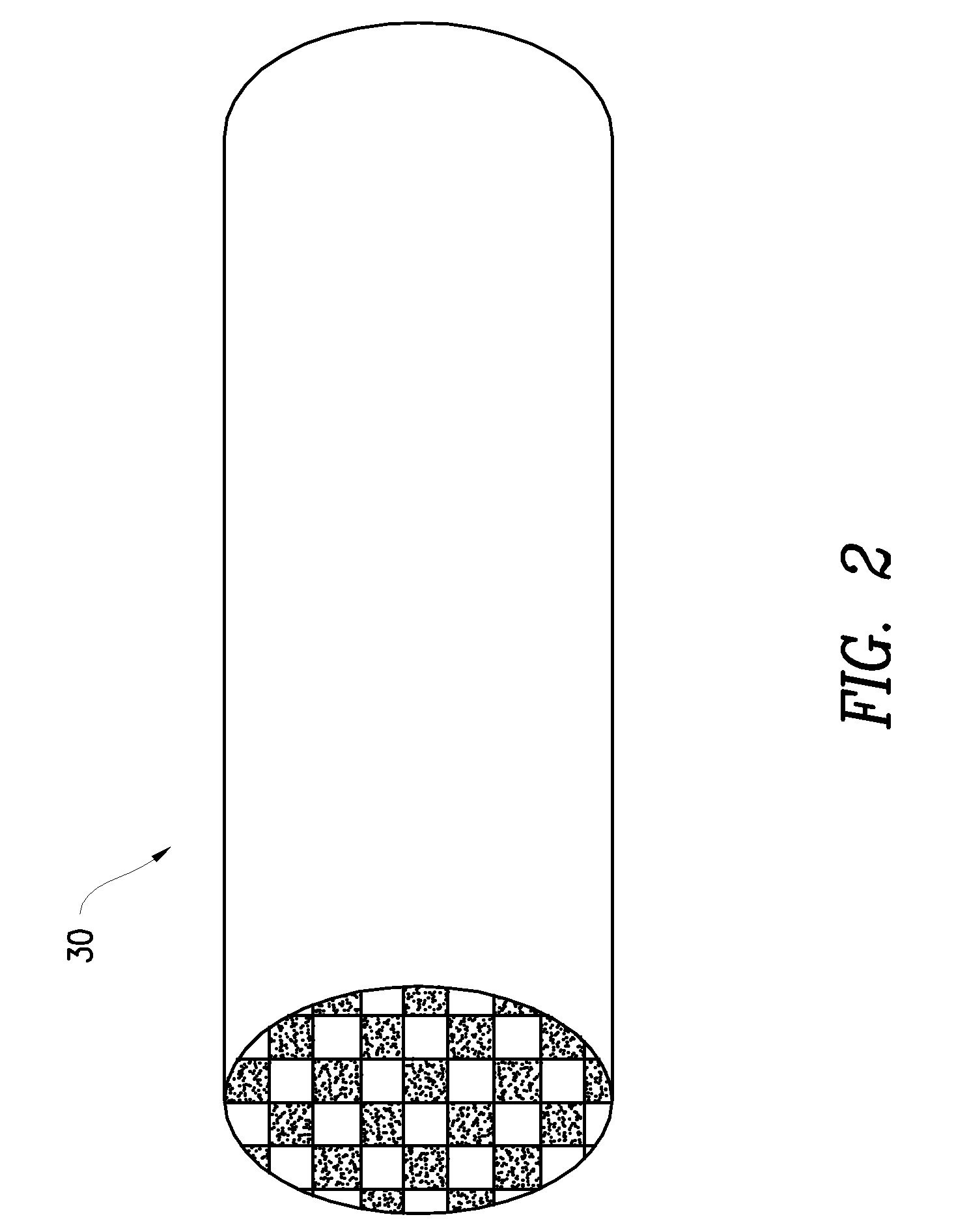

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. The introduction of the EU-5 exhaust gas standard in Europe in 2010 will for the first time impose a legal limit to these particulate emissions for gasoline vehicles. Future exhaust gas cleaning concepts for these vehicles must include devices for removing these particulates.A catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines are presented, which are suitable, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

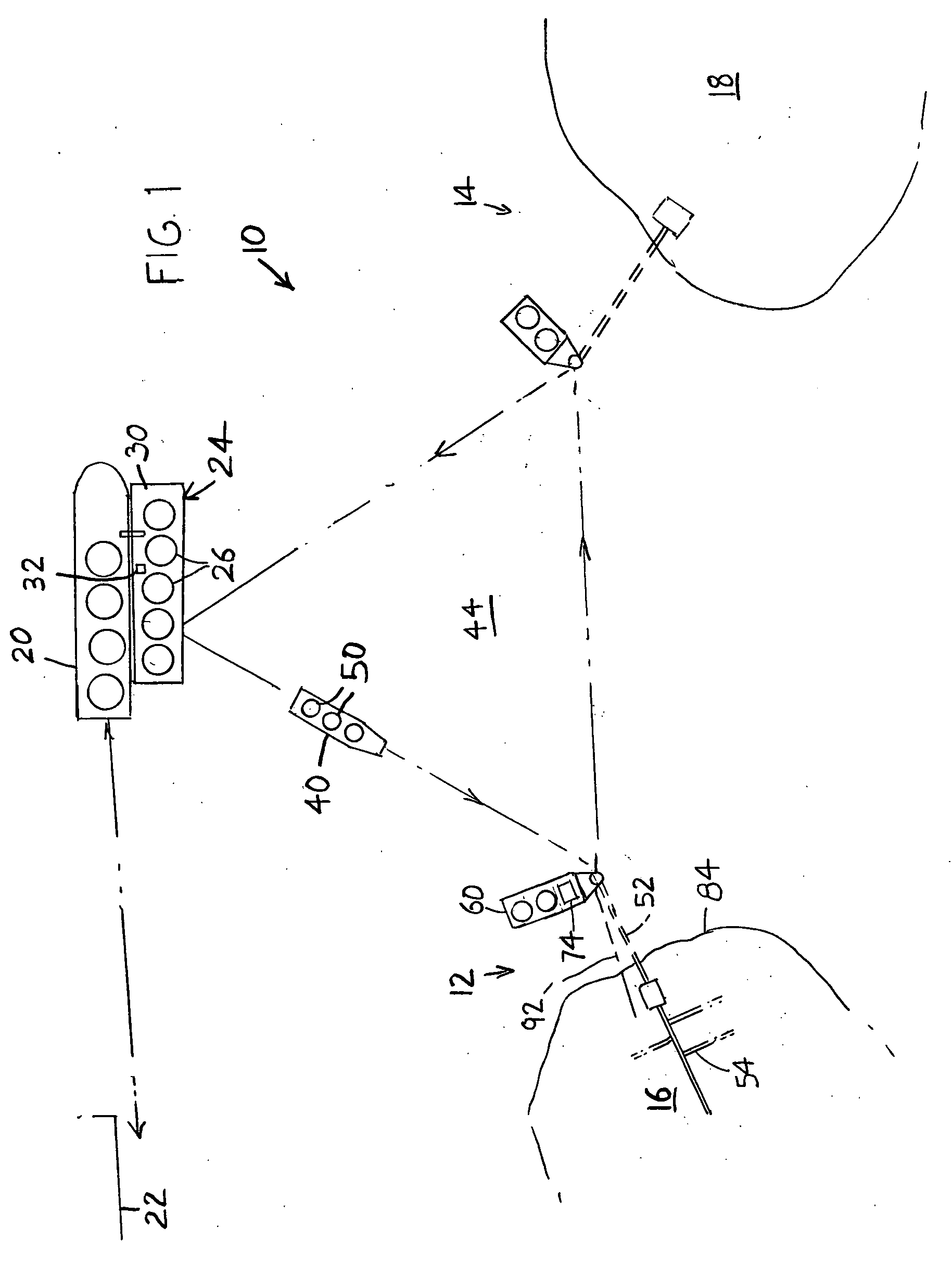

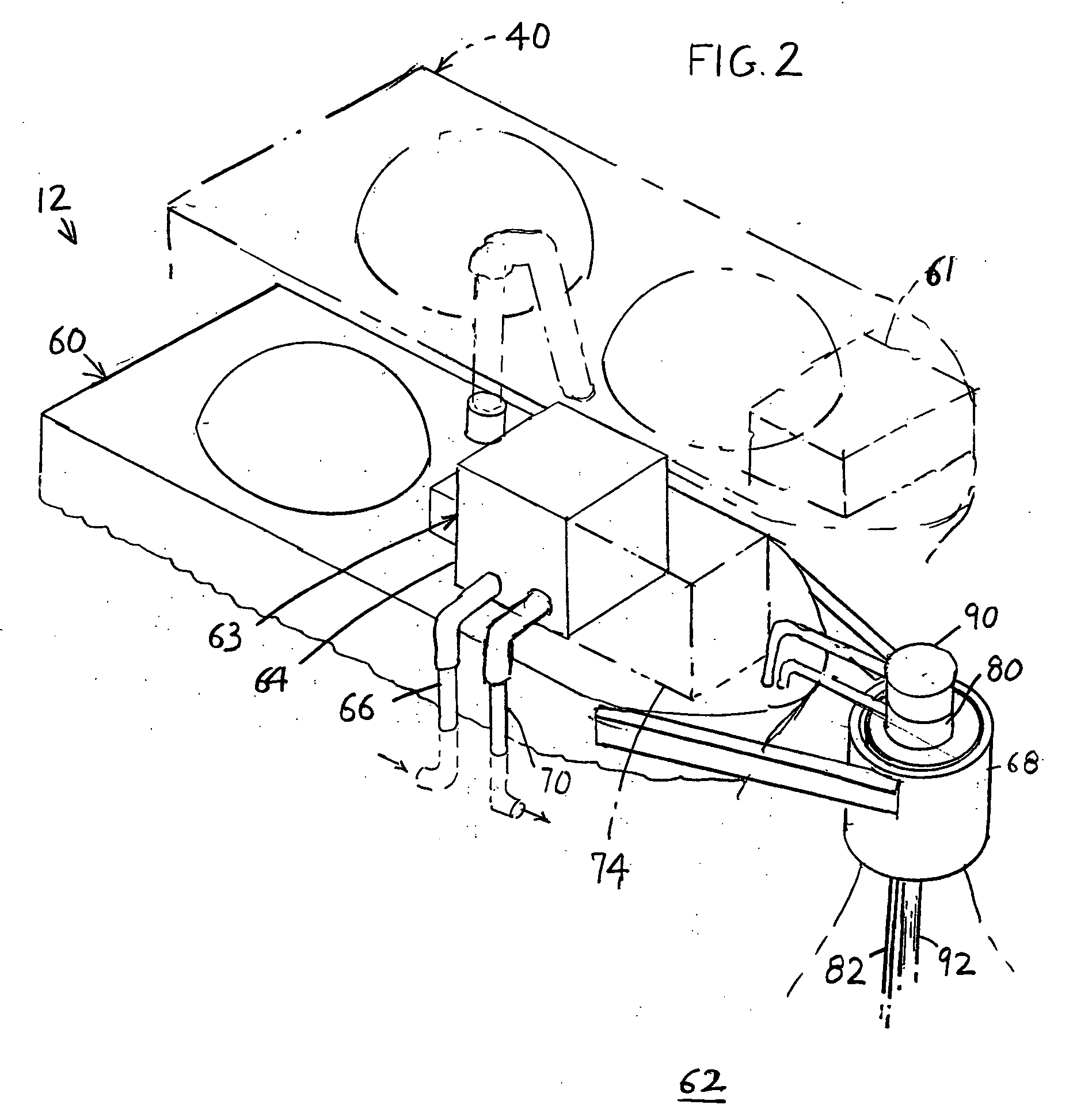

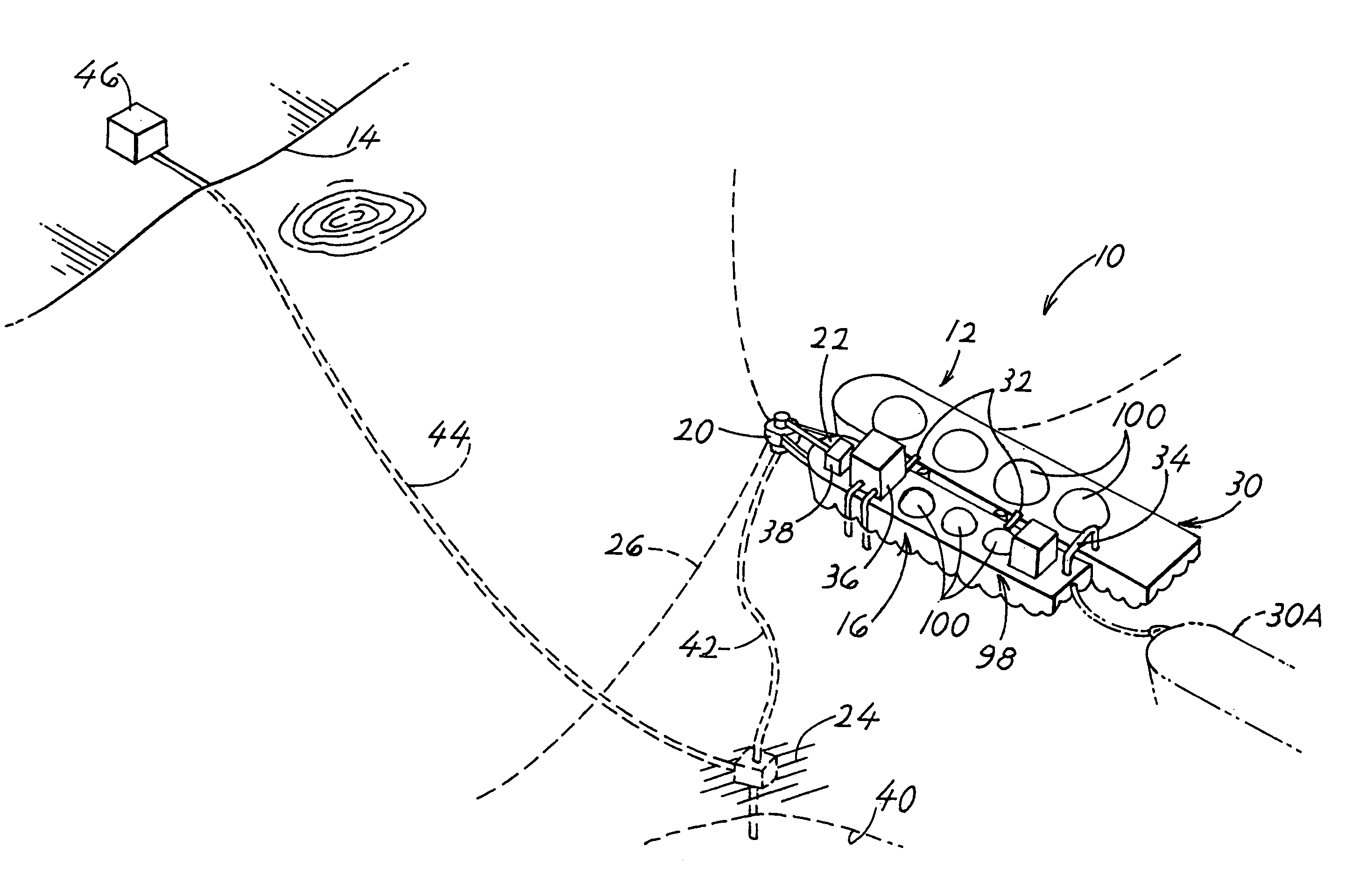

Gas distribution system

InactiveUS20060180231A1Reduce storage capacityLiquid fillingGas handling applicationsElectricityPower station

An economical system provides gaseous hydrocarbon to numerous locations (16, 18) that are each in the vicinity of an ocean coast, such as islands in a developing country, so the coastal inhabitants have access to low cost, easily supplied by pipeline and clean-burning natural gas. The system includes a local supply station (24), or hub, that stores natural gas, as by receiving LNG (liquefied natural gas) that has been liquefied by cooling it to −160° C., from a large tanker (20) having a storage capacity of over 50 million standard cubic feet of natural gas. Shuttle boats (40) that each has a much smaller LNG storage capacity than the tanker, load LNG from the local supply station, carry it to one of a plurality of local coastal stations (12, 14), heat the LNG to produce gaseous hydrocarbons, and transfer the gaseous hydrocarbons to an offshore receiving facility of the local coastal station. The gaseous hydrocarbons are then used by the local coastal station as to distribute gaseous hydrocarbons to residents of the island or to fuel an electricity generating plant.

Owner:SINGLE BUOY MOORINGS INC

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS8066963B2Eliminate emissionsSmall sizeCombination devicesOrganic chemistryExternal combustion engineChemical measurement

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. There is disclosed a catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

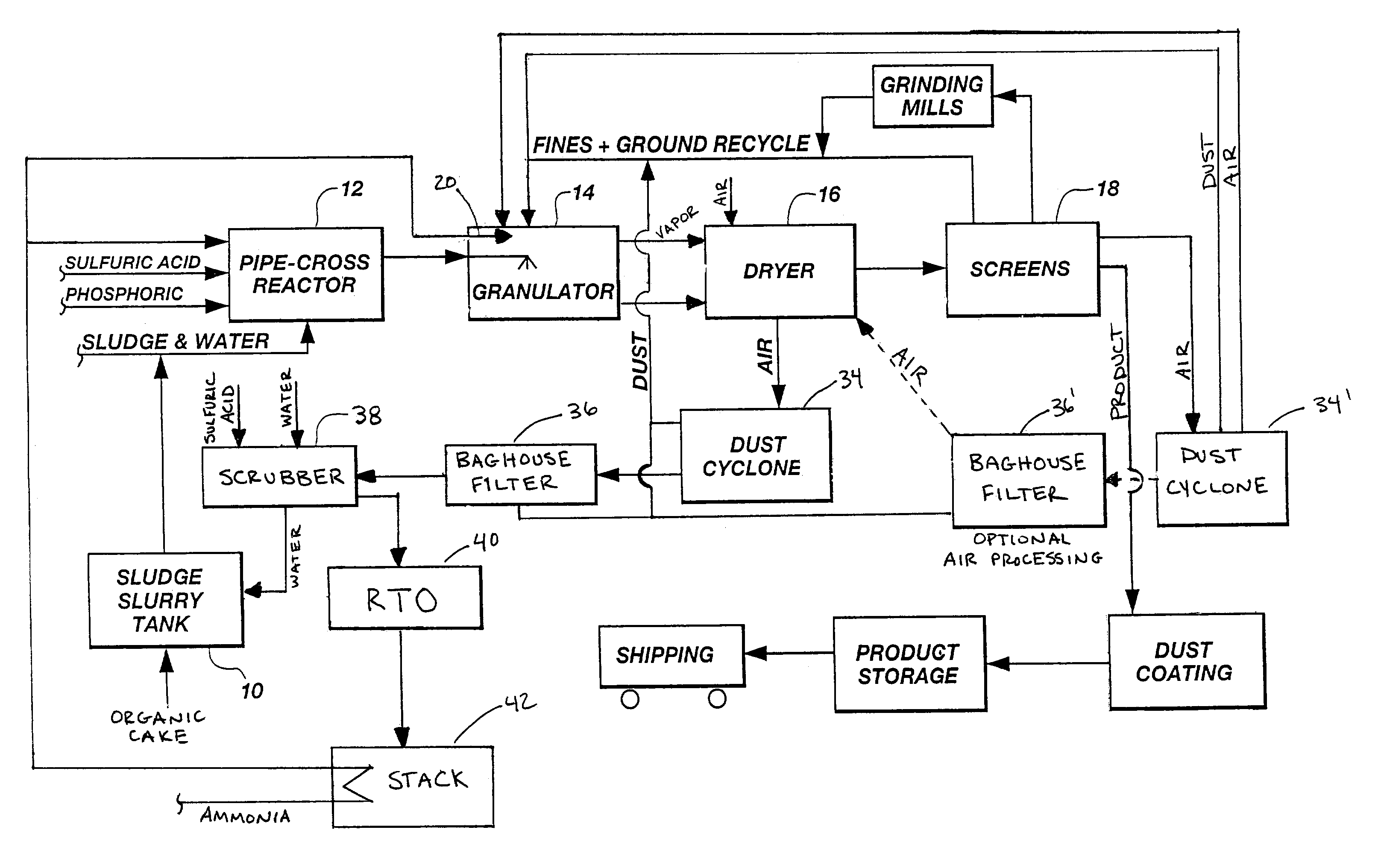

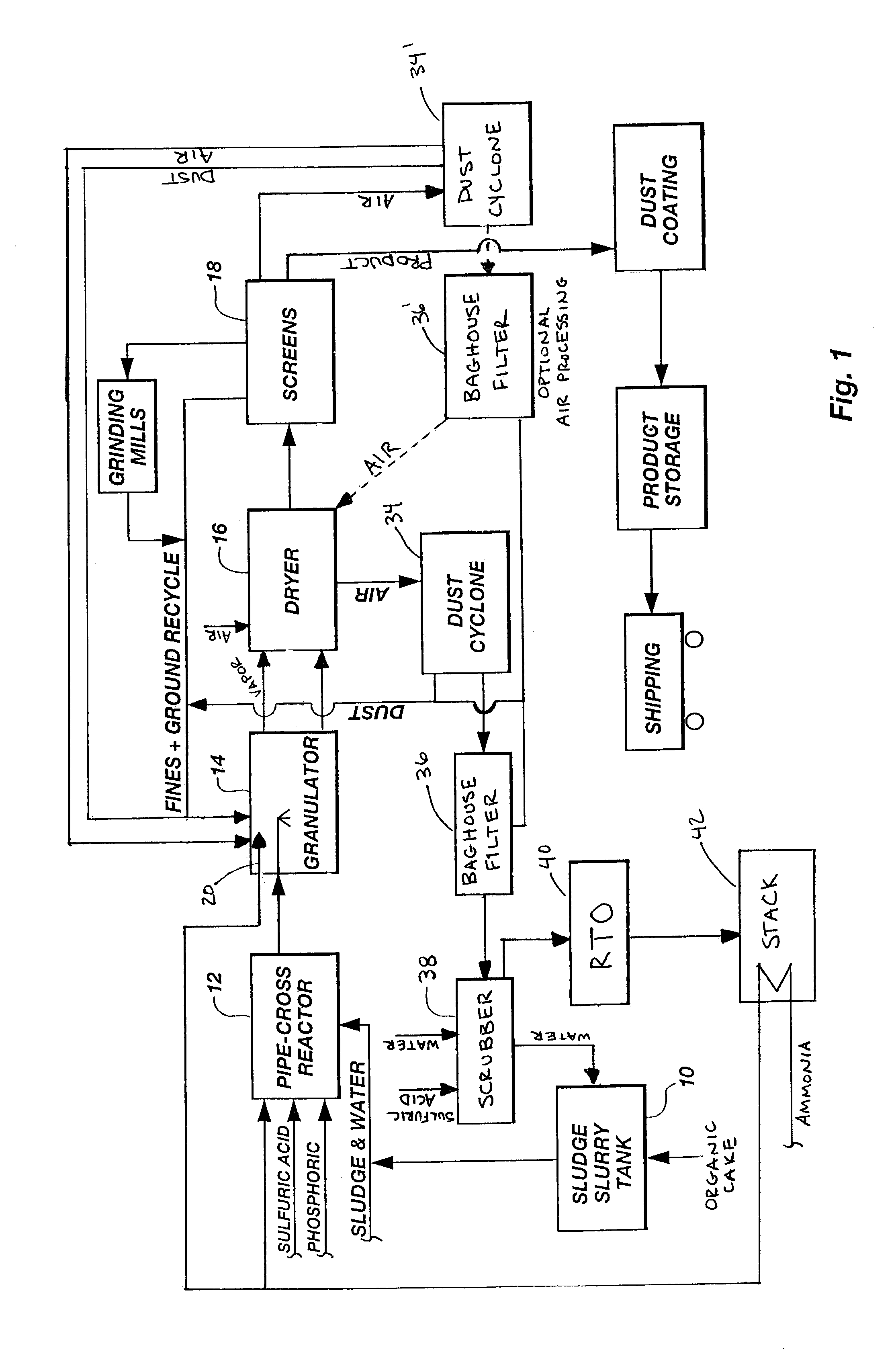

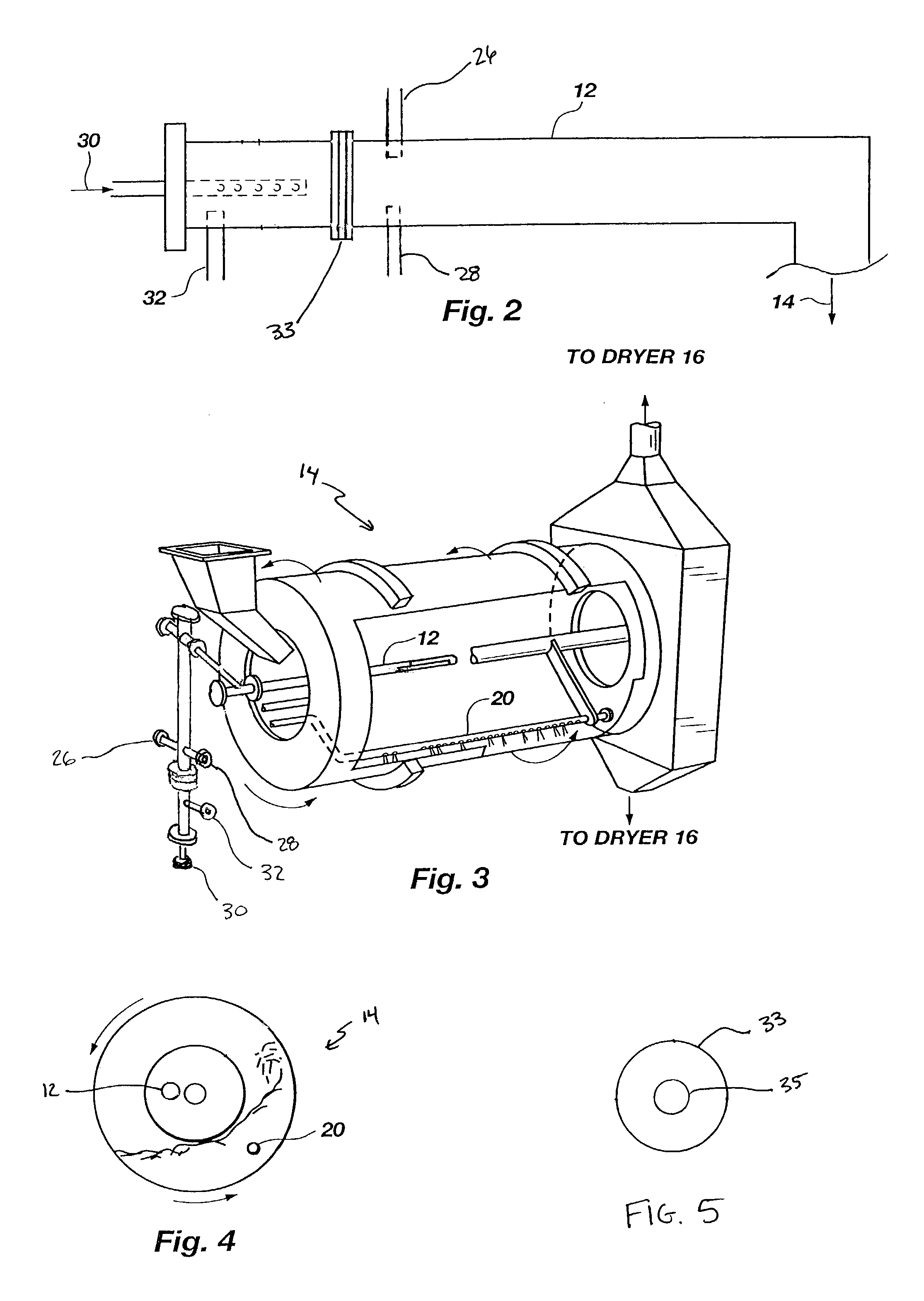

Organic recycling with a pipe-cross or tubular reactor

ActiveUS7128880B2Reduce moisture contentSimple compositionPhosphatesAnimal corpse fertilisersWater vaporSludge

The invention is directed to a process for enhancing the plant nutrient value of relatively low analysis organic waste material (e.g. sewage sludge) involves treating the waste material with an acid and base in a pipe-cross reactor or tubular to form a melt; spraying the melt onto a recycling bed of fines in a granulator and flashing off the water contained in the melt as steam; rolling the melt onto recycled fine particles in a granulator to form granulated particles; and drying these granulated particles to form an enhanced plant nutrient value composition (e.g. a fertilizer or soil conditioner having a greater NPK value than the original relatively low analysis organic waste material). The process further includes drawing off the fumes from the granulator, passing them through a dryer with the granulated particles, and subsequently oxidizing the fumes to eliminate volatile organic compounds and / or gaseous hydrocarbon pollutants be converting such into carbon dioxide and water vapor.

Owner:UNITY FERTILIZER LLC

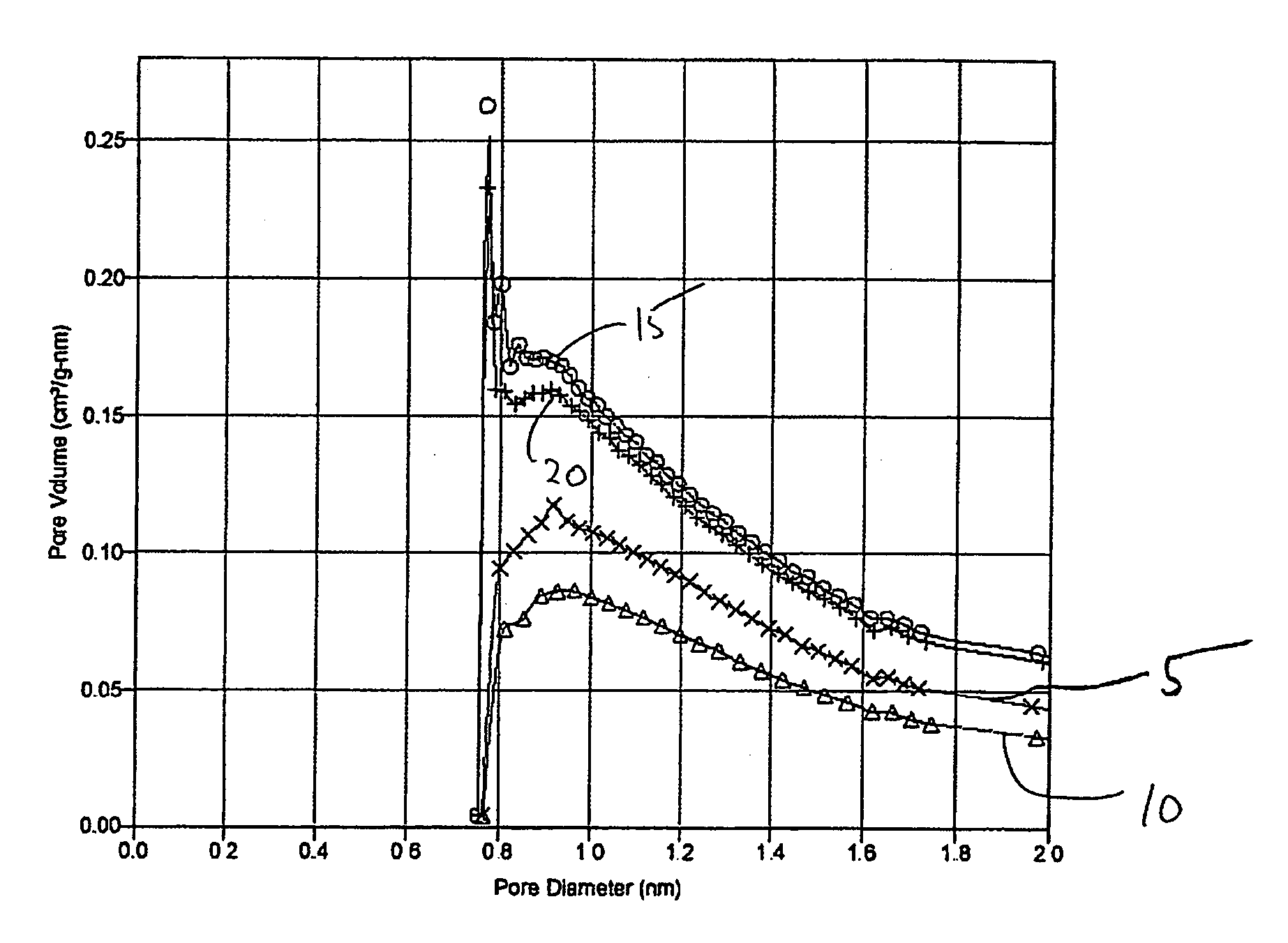

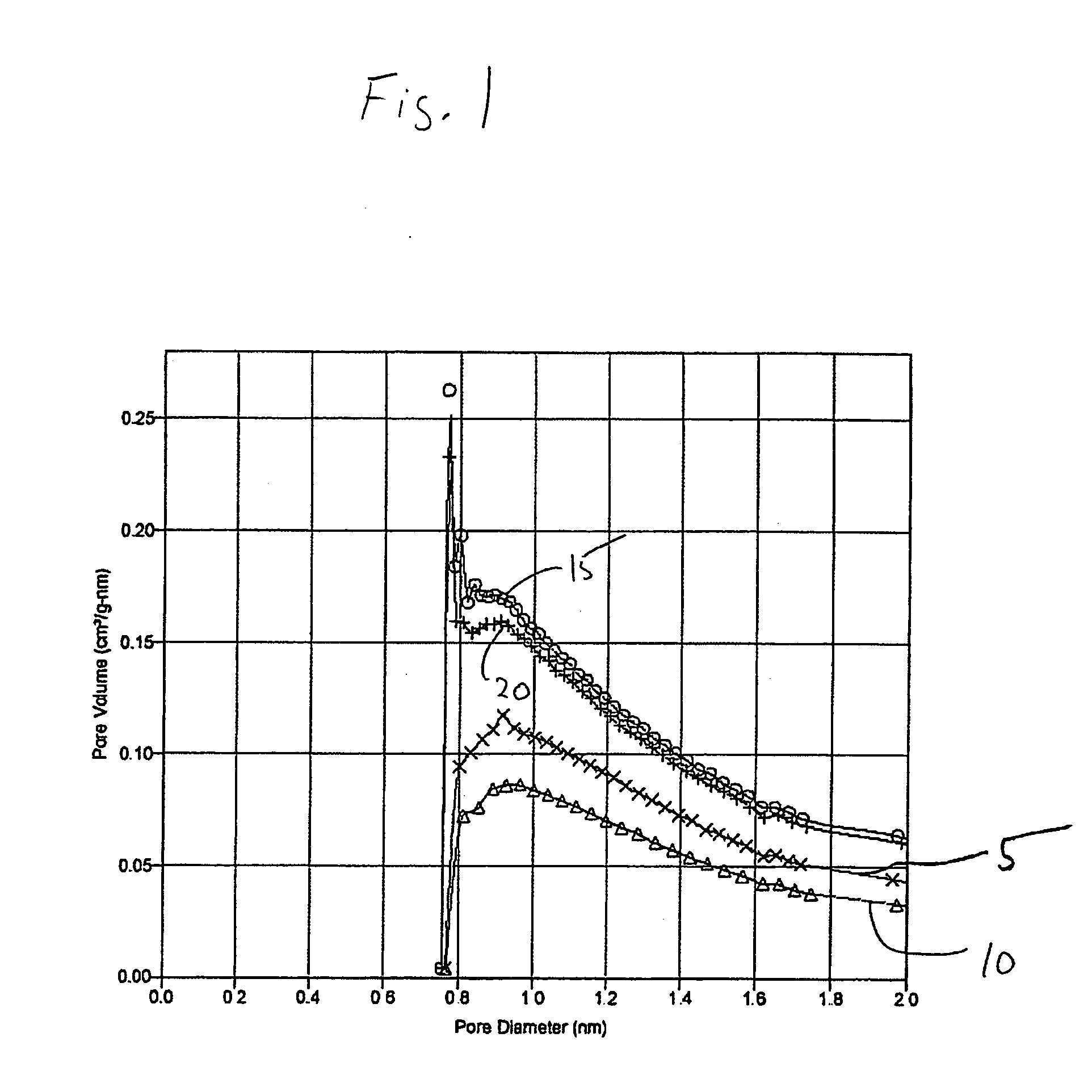

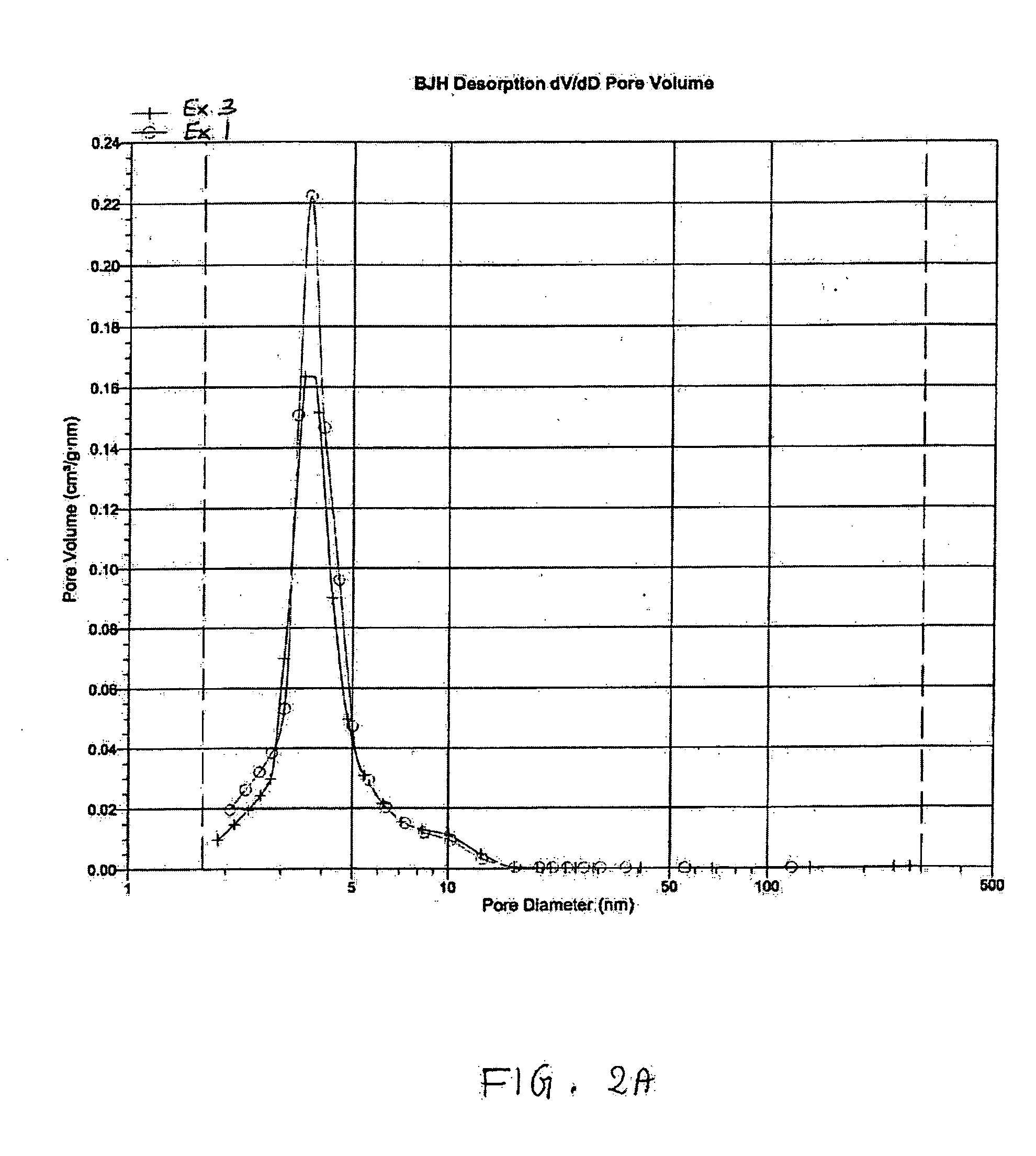

Catalyst for hydroprocessing of Fischer-Tropsch products

InactiveUS20050274646A1Lower the volumeLess economic valuePretreated surfacesCatalyst activation/preparationPore diameterSilicon dioxide

The invention generally relates to methods for modifying a porous amorphous material comprising micropores to reduce its micropore volume and to form a support for a hydroprocessing catalyst, to methods of making said catalyst, as well as to methods for hydrocracking employing said hydroprocessing catalyst characterized by a lower selectivity towards undesirable gaseous hydrocarbon products. In one embodiment, the method for modifying the amorphous material comprises depositing an inorganic oxide or inorganic oxide precursor to the amorphous material; and treating the deposited amorphous material so as to reduce its micropore volume by at least about 5 percent, while its mean pore diameter is substantially unchanged or changed by not more than about 10 percent. Further embodiments include the amorphous material comprising silica-alumina, and the deposited inorganic oxide or inorganic oxide precursor comprising silicon.

Owner:CONOCOPHILLIPS CO

Systems and processes of operating fuel cell systems

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

Hydrocarbon separation process and apparatus

InactiveUS20010008073A1Reduced overhead temperaturePromote recoverySolidificationLiquefactionRefluxFractionation

A process is described for separating the heavier hydrocarbons from a gaseous hydrocarbon feed wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a fractionation column. The liquid portion is subcooled in heat exchange with the overhead vapour from the fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. The rewarmed residual vapour is subsequently compressed to a pressure suitable for export, with a portion of the compressed gas being cooled, condensed and recycled back to reflux the top section of the fractionation column. Also described is a process wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a high pressure wash column. The liquid portion is expanded and fed to the base of the high pressure wash column. Bottoms liquid from the wash column is subcooled in heat exchange with the overhead vapour from a fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. Vapour from the high pressure wash column is partially condensed, with the liquid portion used to provide reflux to the high pressure wash column and the fractionation column. The processes are especially applicable to recovery of ethane and heavier components from natural gas. Overall process power requirements are reduced, recovery of the desired heavy hydrocarbons is increased or both of these effects are realised.

Owner:COSTAIN OIL GAS & PROCESS

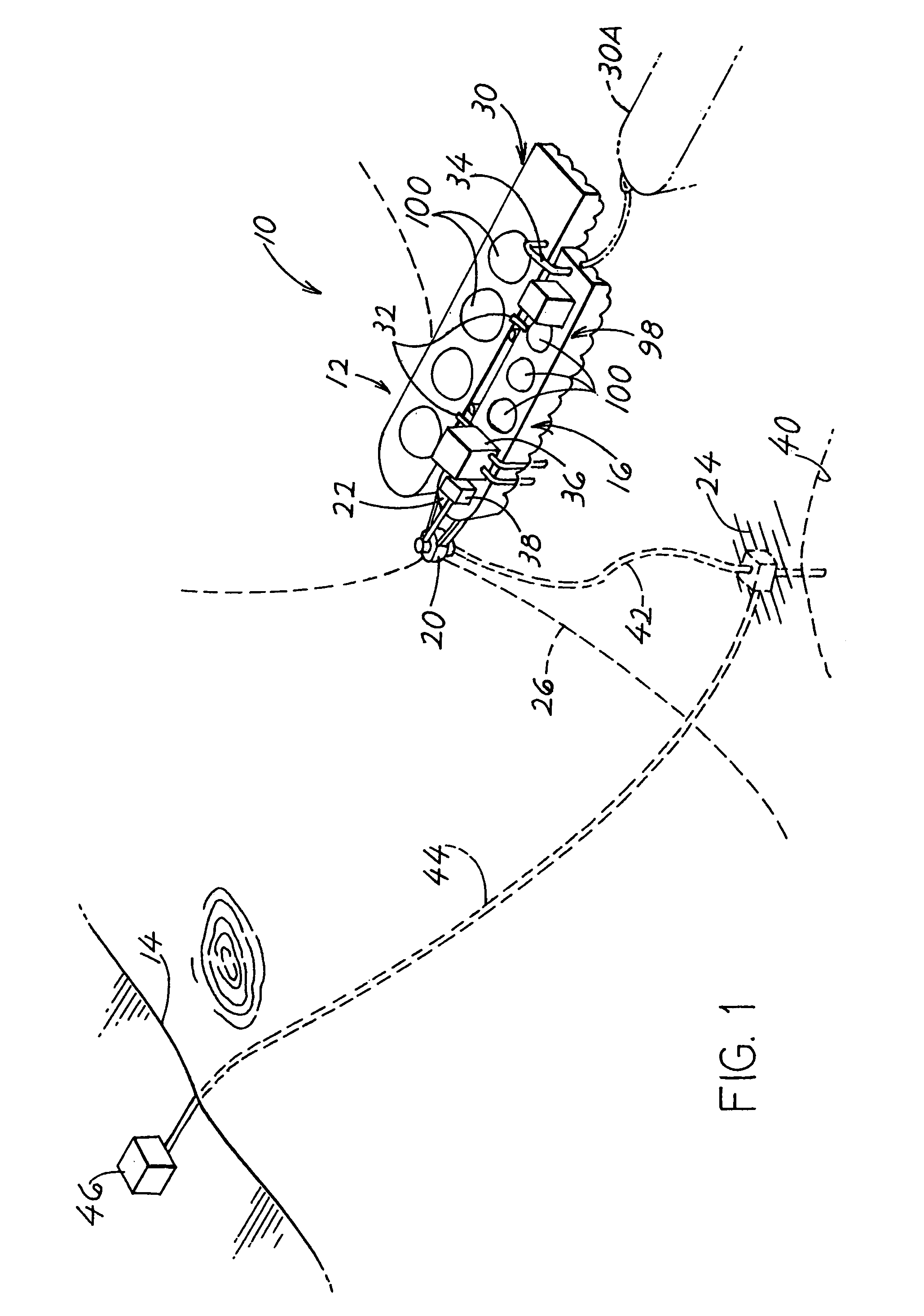

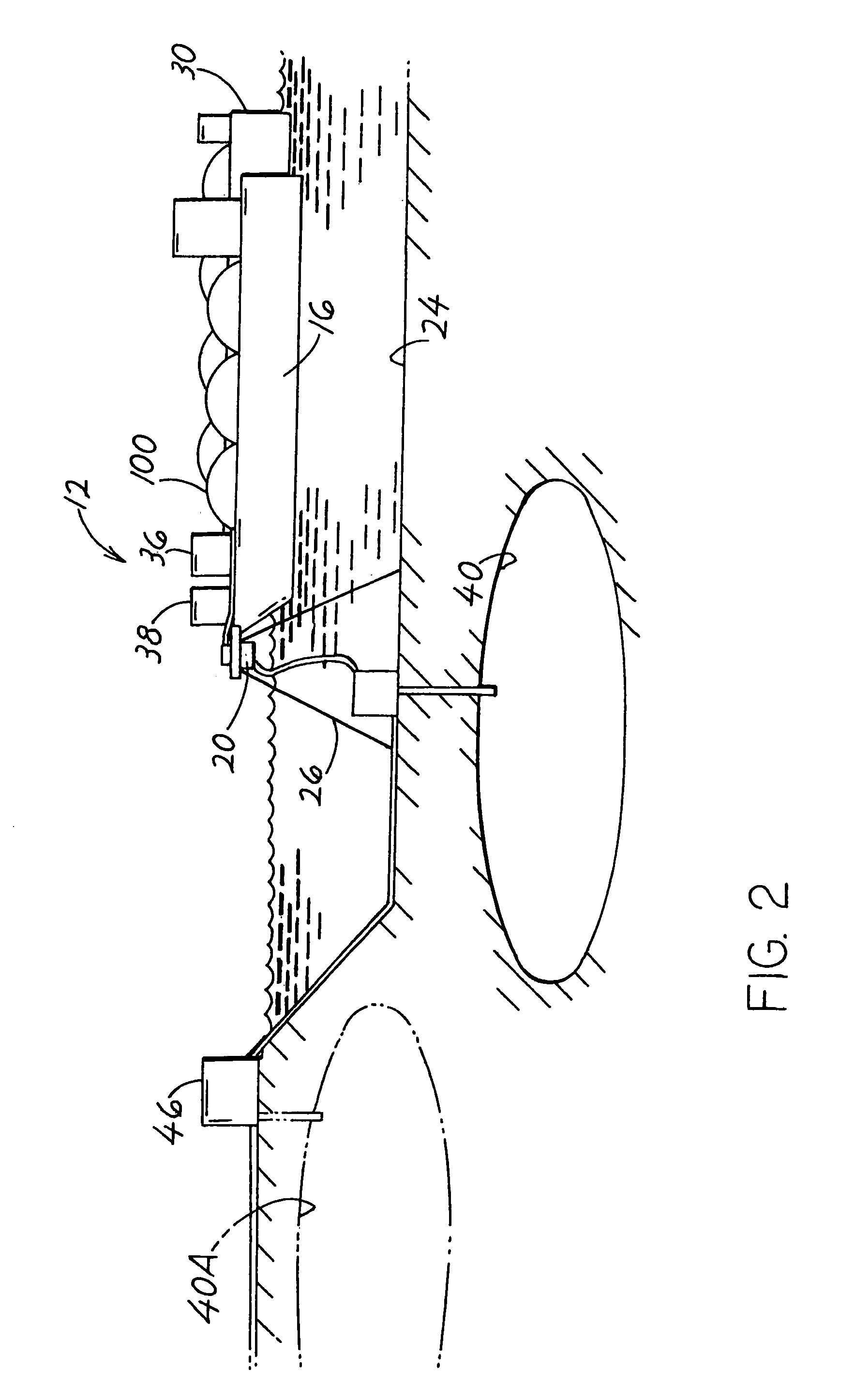

Quick LNG offloading

ActiveUS7080673B2Low costReceive quicklyGas handling applicationsGas handling/storage effectsProduct gasEngineering

A system of the type wherein LNG from a tanker (30) is offloaded to a moored vessel (16), which has a regas unit (36) which heats the LNG to transform it into gaseous hydrocarbons, and which has a pump unit (38) that pumps the gaseous hydrocarbons to a consumer (46) such as an onshore gas distribution facility. The system is constructed to enable more rapid tanker unloading so the tanker is released earlier to sail back to a pickup location. The moored vessel has a thermally insulated LNG storage facility such as LNG tanks (100), with a capacity to store all LNG not regassed during offloading of the tanker. The regas unit has sufficient capacity to regas all LNG received in one tanker load, before the tanker returns with another load of LNG.

Owner:SINGLE BUOY MOORINGS INC

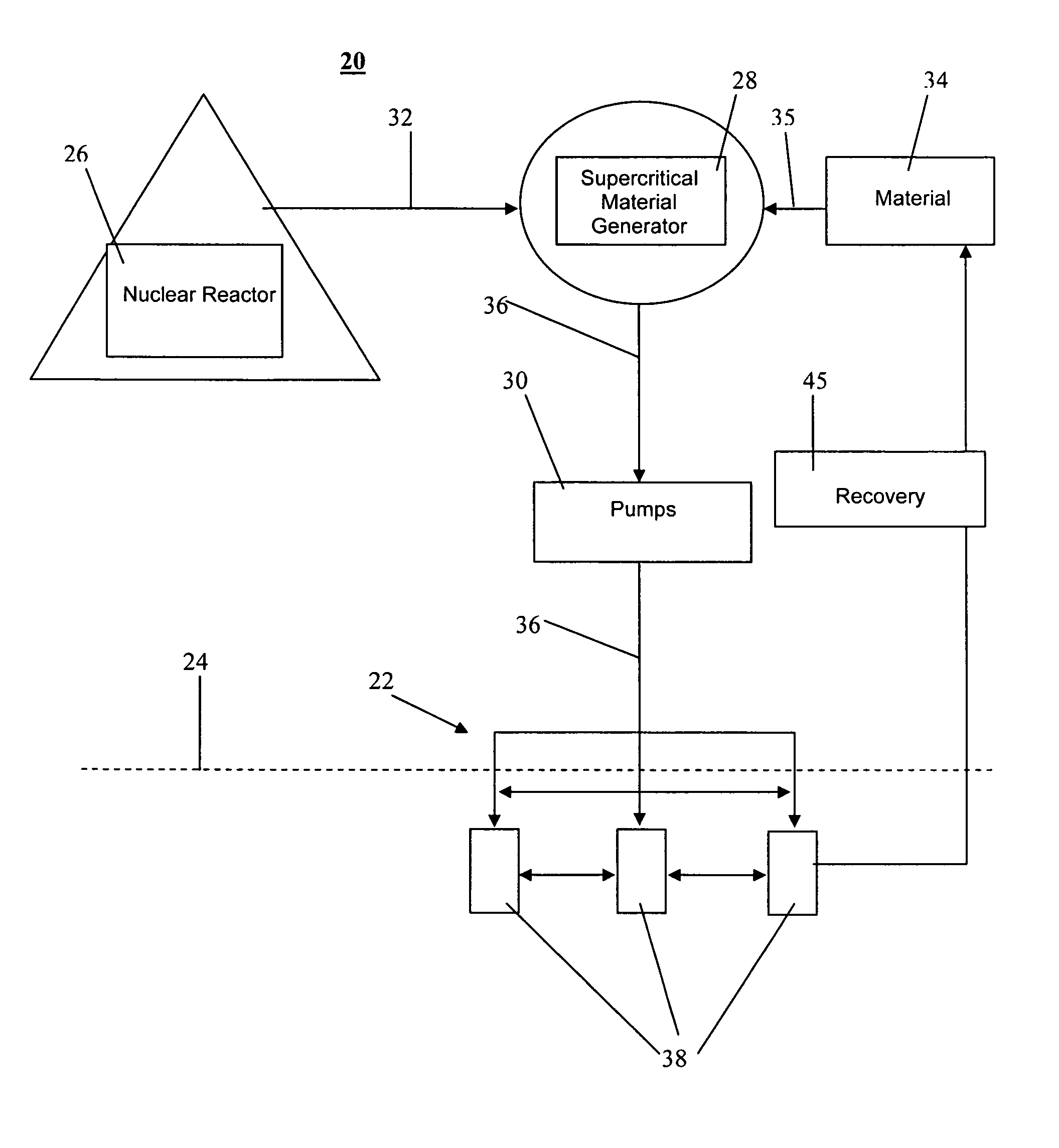

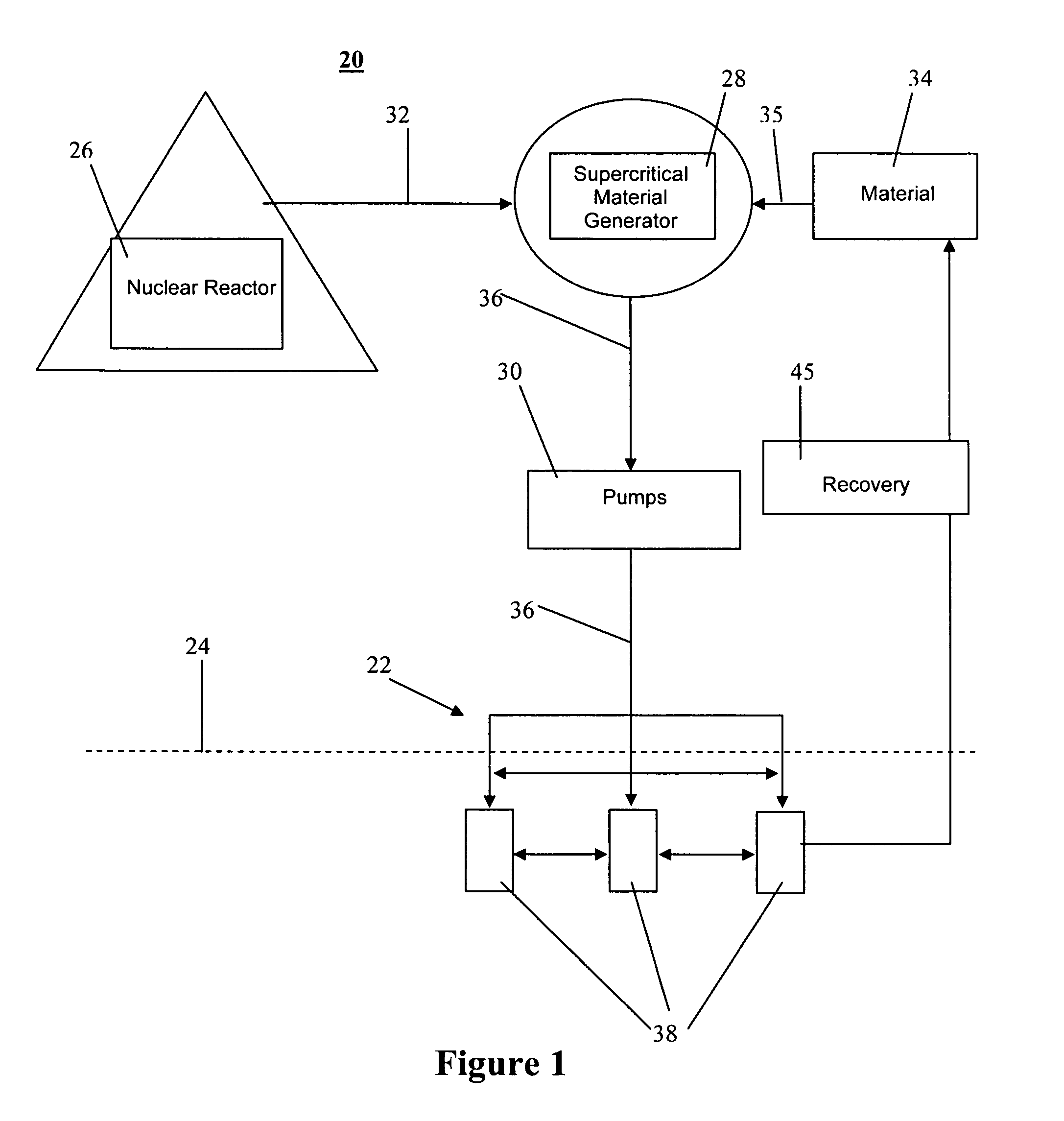

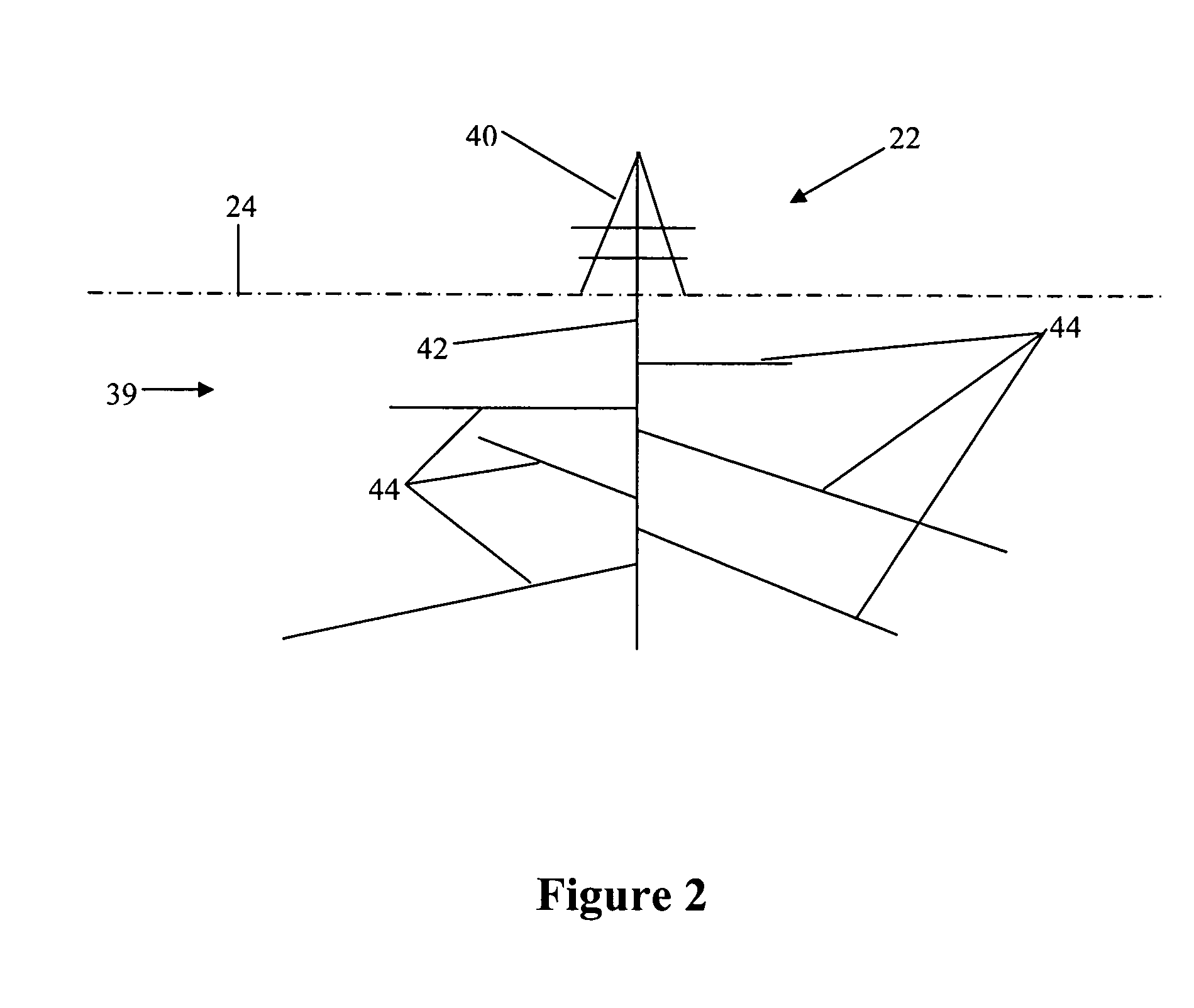

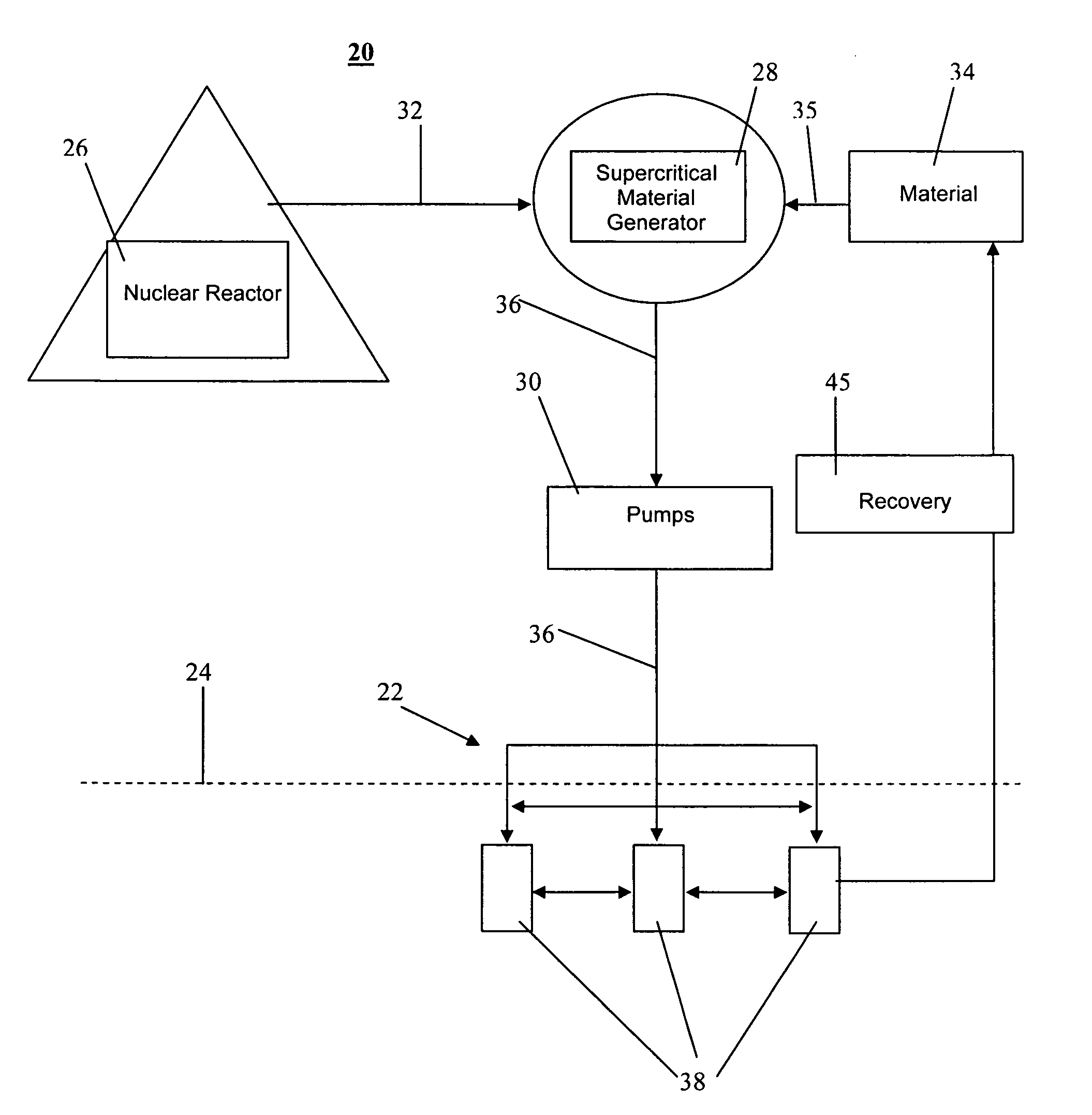

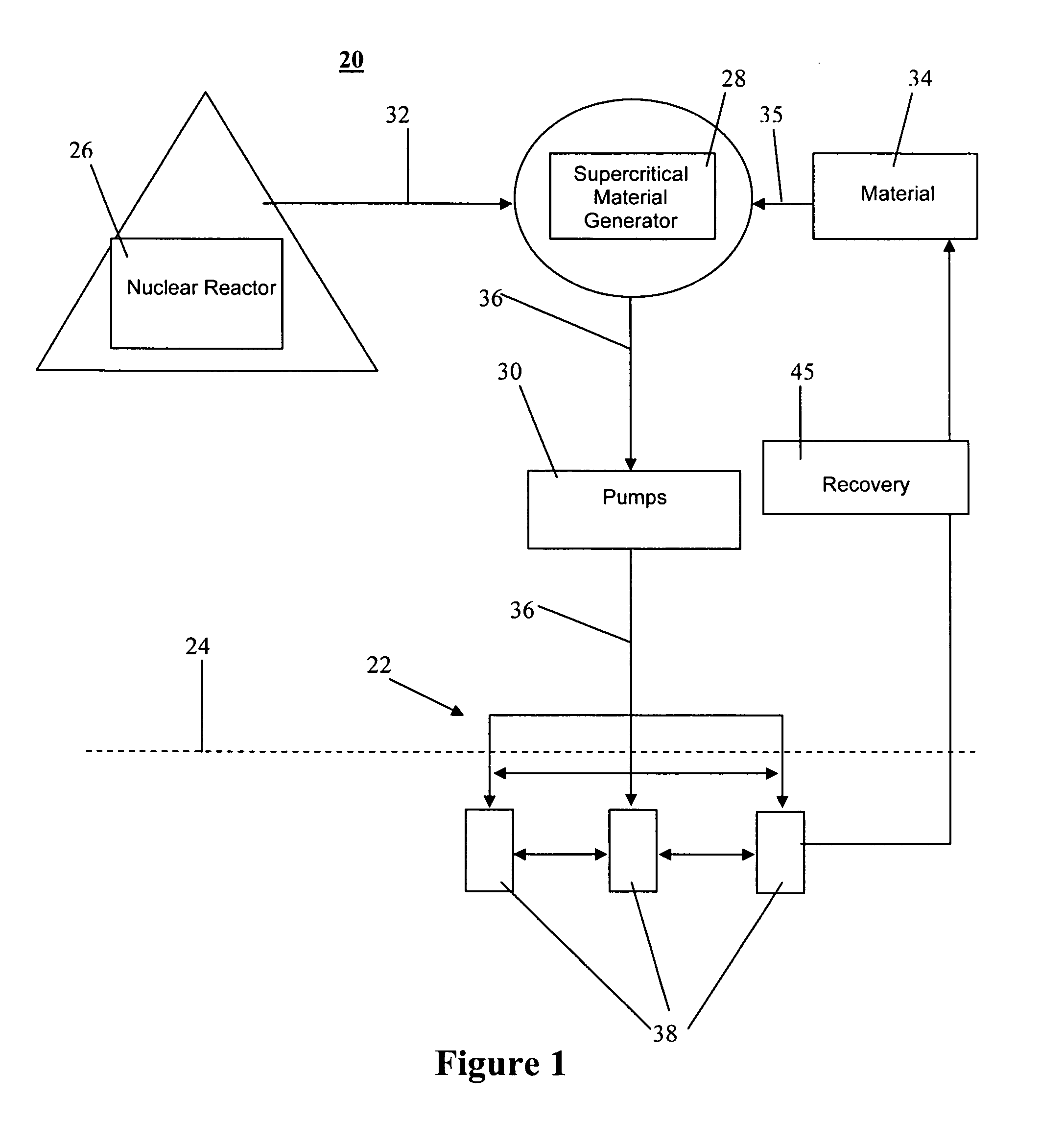

Method and system for extraction of hydrocarbons from oil shale

InactiveUS20070181301A1Improve permeabilityHigh porosityInsulationFluid removalOil shale gasEnergy source

A system and method for extracting hydrocarbon products from oil shale using nuclear energy sources for energy to fracture the oil shale formations and provide sufficient heat and pressure to produce liquid and gaseous hydrocarbon products. Embodiments of the present invention also disclose steps for extracting the hydrocarbon products from the oil shale formations.

Owner:ULTRA SAFE NUCLEAR CORP

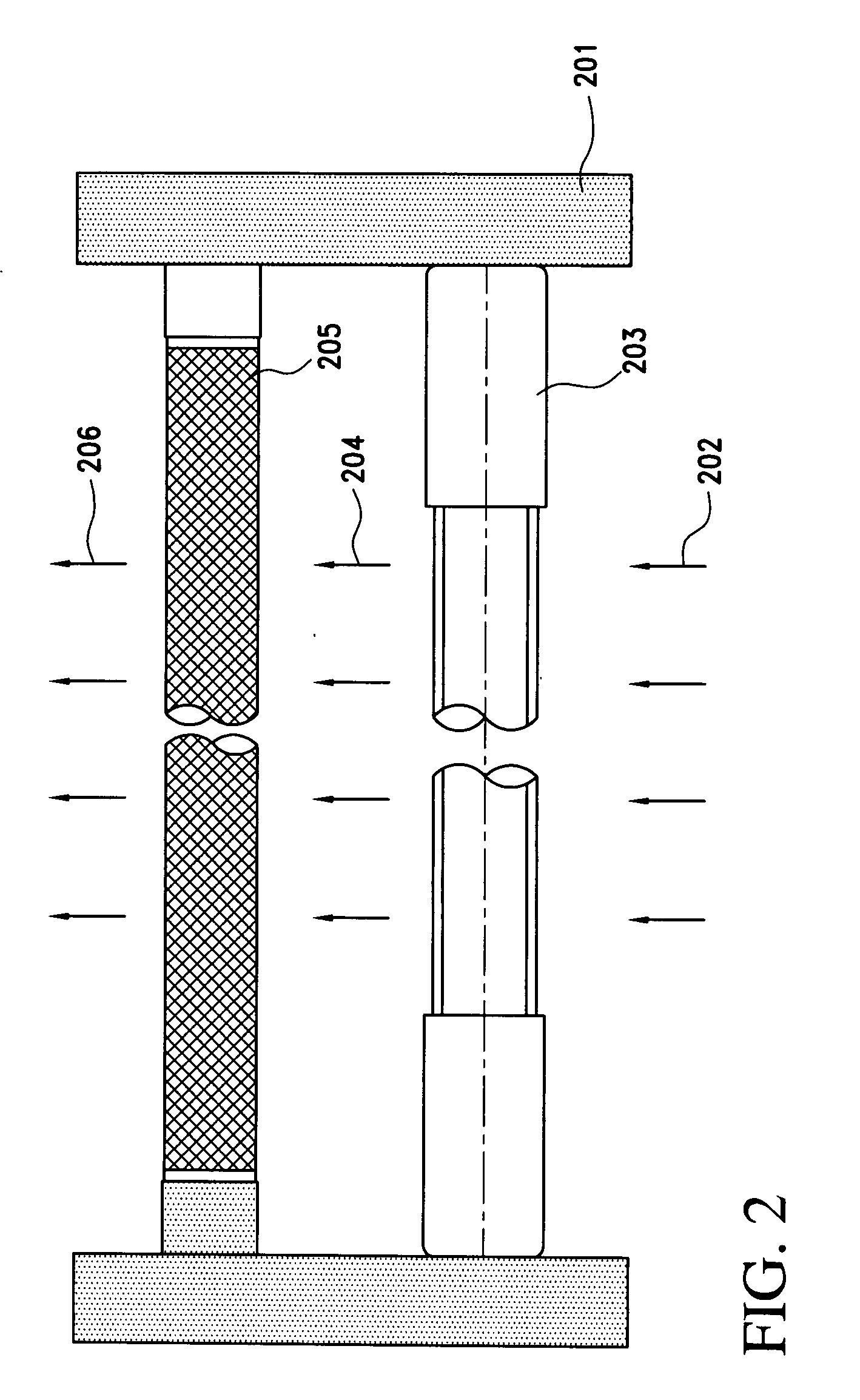

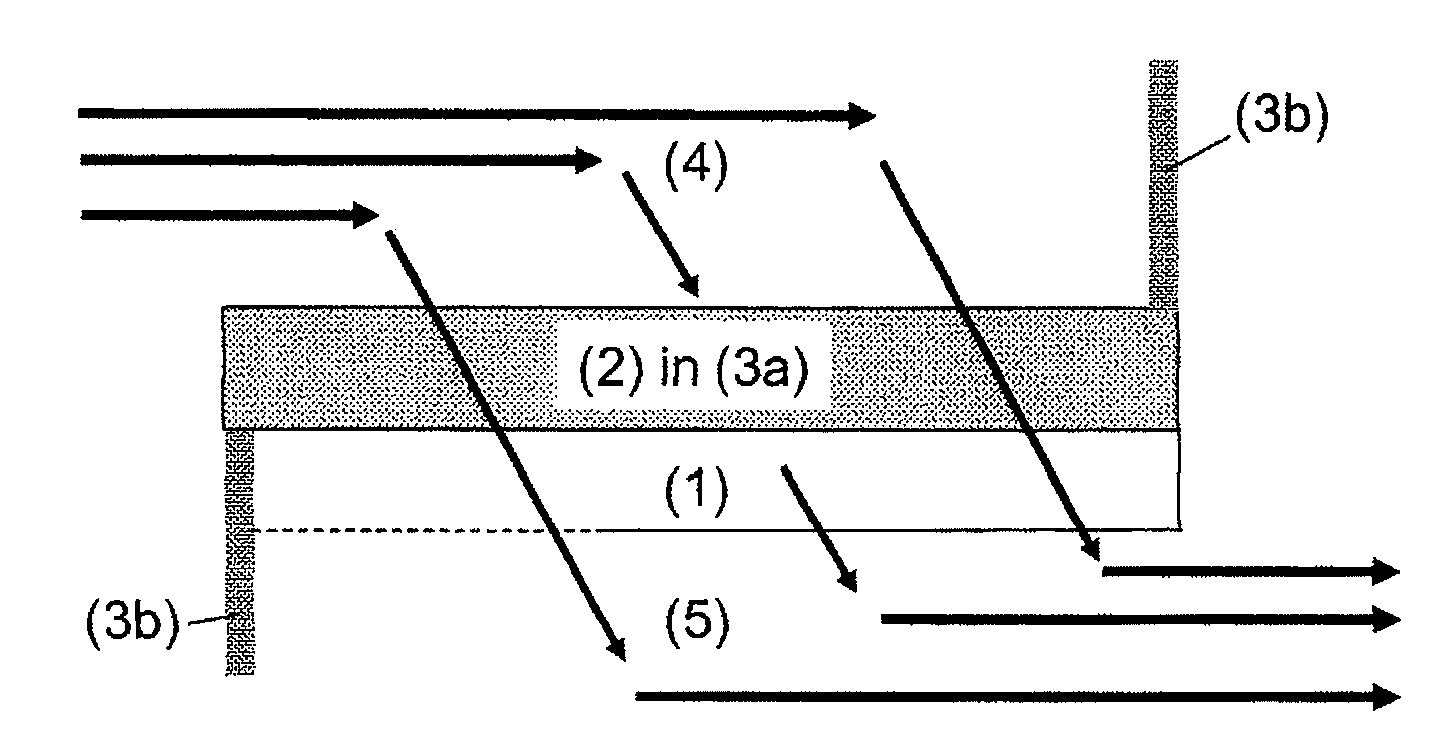

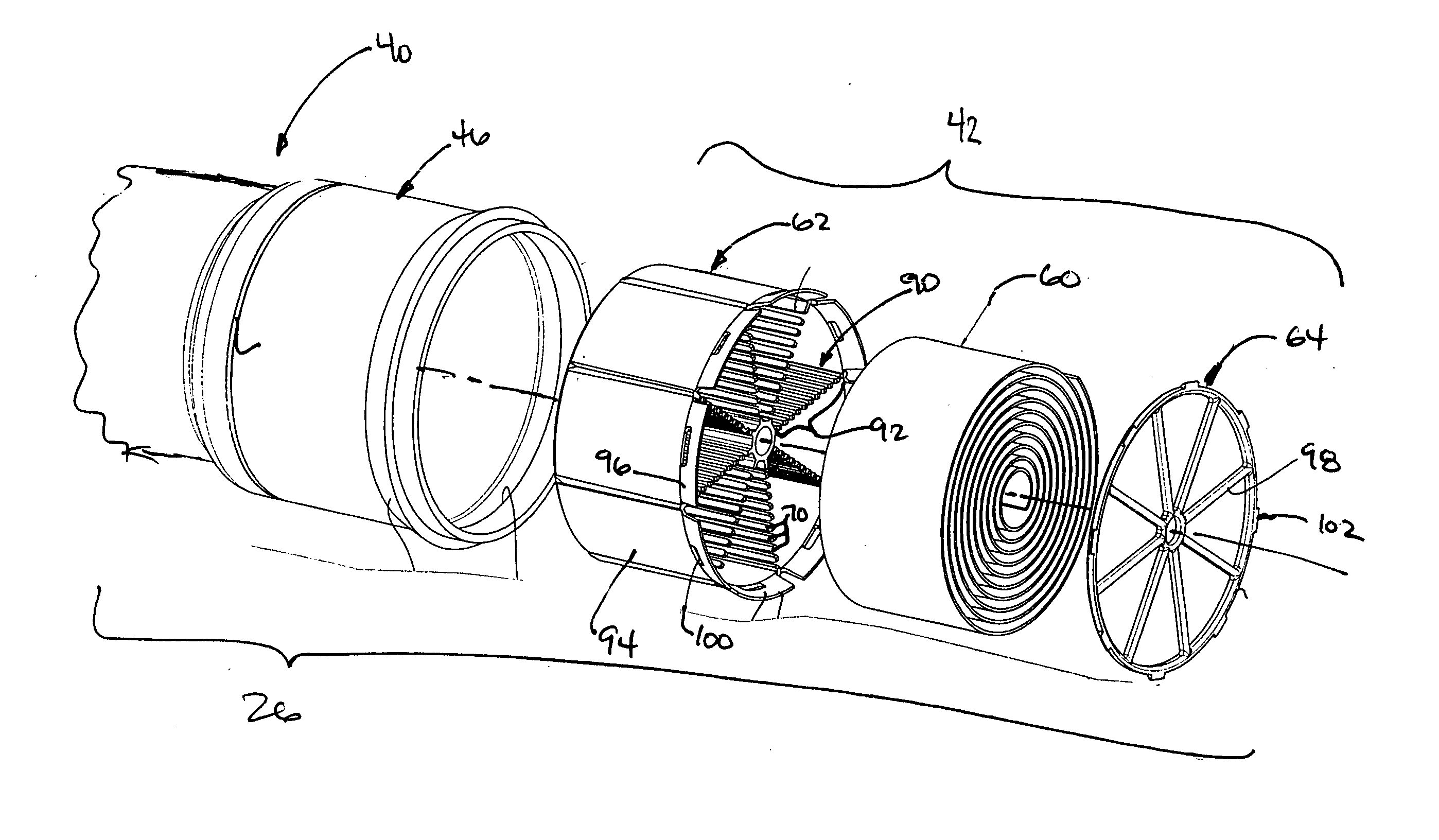

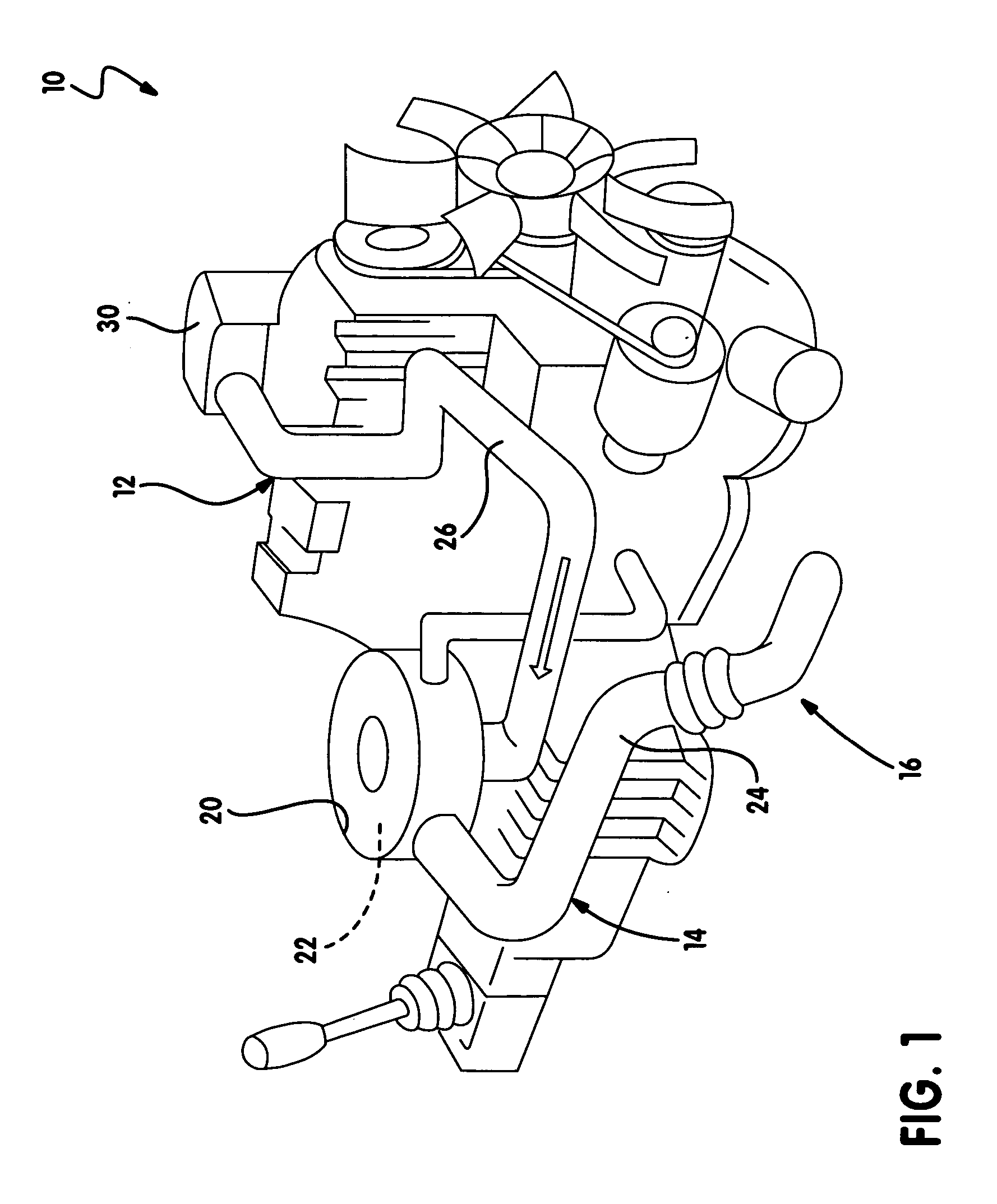

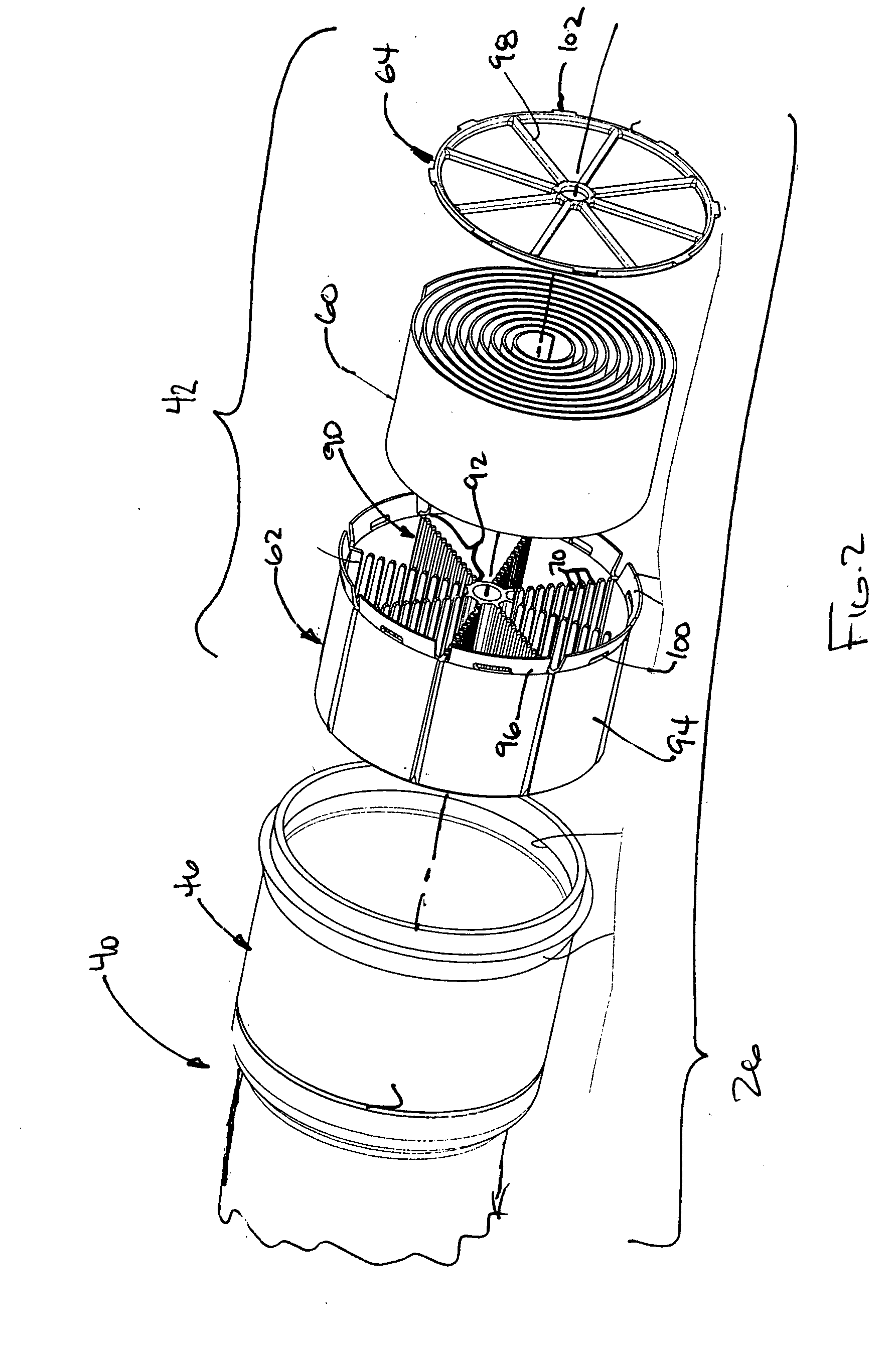

Air induction system with hydrocarbon trap assembly

InactiveUS20060150811A1Evaporative emission can be reducedCombination devicesGas treatmentHydrocotyle bowlesioidesPhysical chemistry

A hydrocarbon trap that includes a sheet paper element and a plurality of fingers. The paper element is at least partially formed of a material capable of adsorbing and desorbing gaseous hydrocarbons. The paper element is arranged into a plurality of adjacent sheet members. The fingers are disposed between and support adjacent pairs of the sheet members so that each adjacent pair of the sheet members forms a flow channel. A method for filtering gaseous hydrocarbons from an air flow is also provided.

Owner:NOVARES US ENGINE COMPONENTS INC

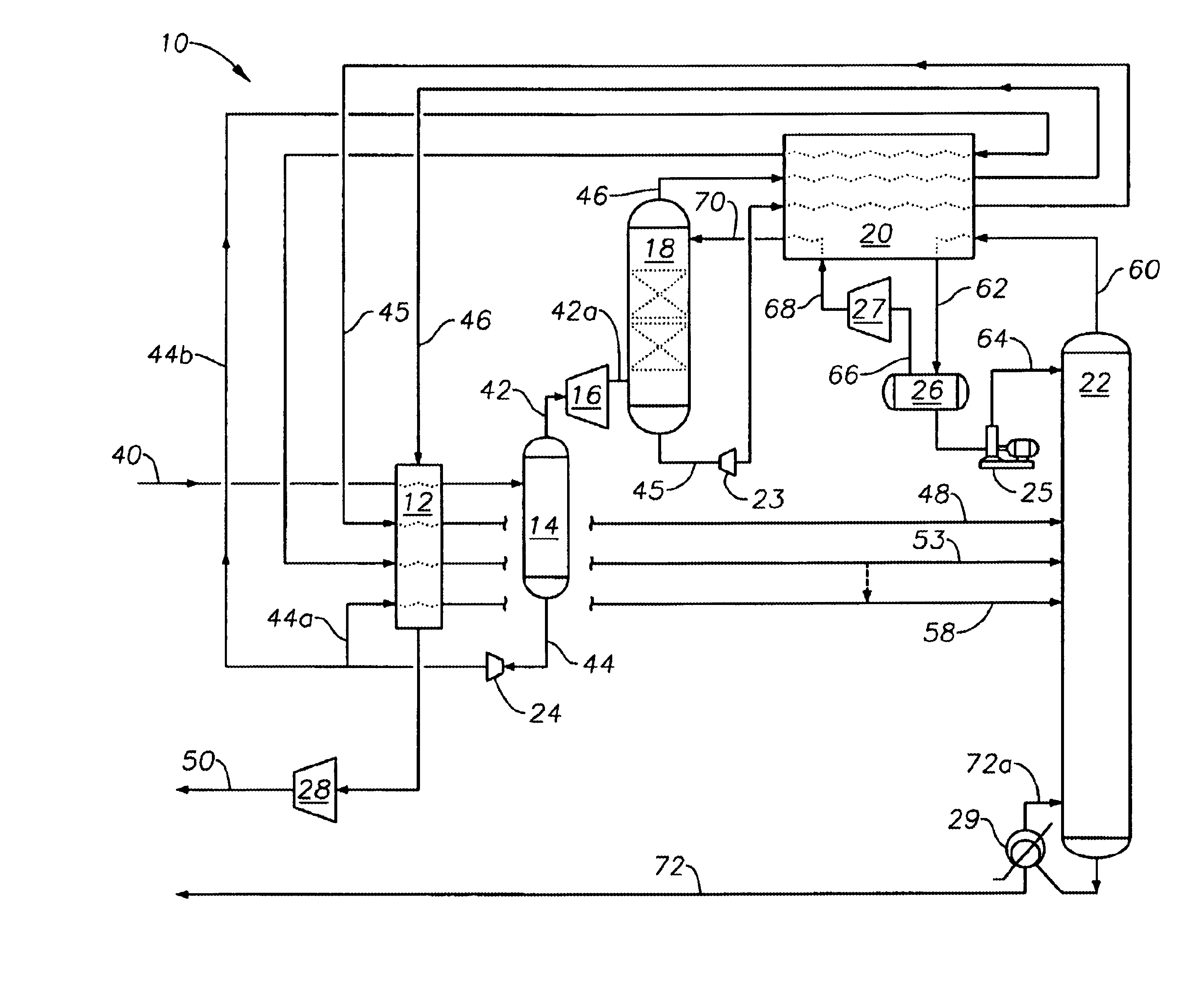

Cryogenic process utilizing high pressure absorber column

A cryogenic process and apparatus for separating multi-component gaseous hydrocarbon streams to recover both gaseous and liquid compounds. More particularly, the cryogenic processes and apparatus of this invention utilize a high pressure absorber to improve the energy efficiency of processing natural gas for pipeline gas sales and recovering natural gas liquids (NGL) gas from gaseous hydrocarbon streams.

Owner:ABB LUMMUS GLOBAL INC

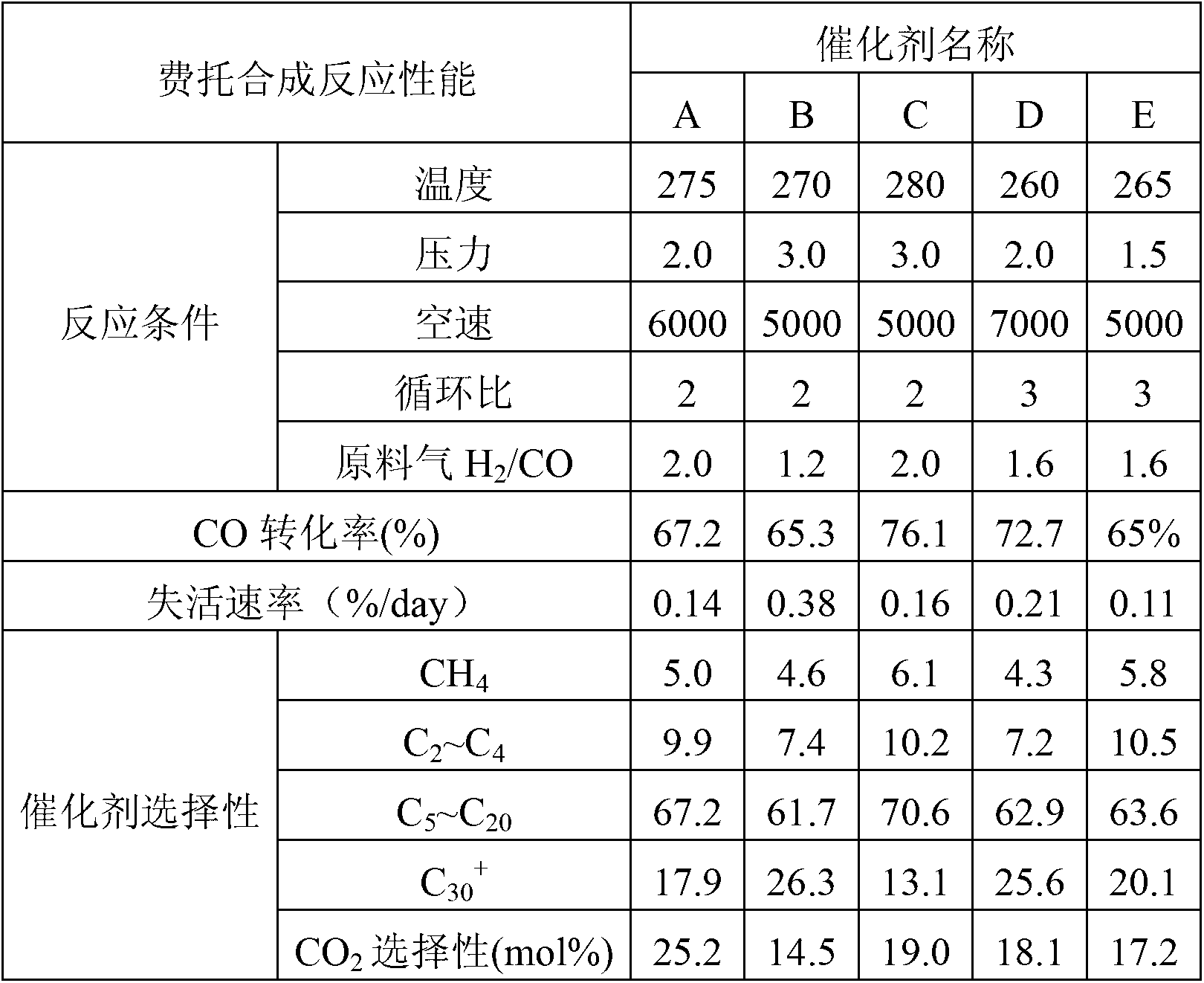

Reduction method for iron-based catalyst for Fischer-Tropsch synthesis in fixed bed

ActiveCN103071543AReduce carbon depositionHigh activityCatalyst activation/preparationLiquid hydrocarbon mixture productionHydrogenFixed bed

The invention discloses a reduction method for an iron-based catalyst for Fischer-Tropsch synthesis in a fixed bed. The method comprises the following steps: adding the iron-based catalyst into a fixed bed reactor; and introducing gaseous hydrocarbon or mixed gas of hydrogen and gaseous hydrocarbon into the fixed bed reactor for reduction reaction to reduce the iron-based catalyst. The reduction method has the advantages that (1) the reduced catalyst has a little carbon deposit, so the catalyst has high activity and stability; (2) the product selectivity of the catalyst can be effectively modulated, and the selectivity for C5-30 in products is high; and (3) the reduced catalyst has a little carburization, so the catalyst has high wear resistance.

Owner:SYNFUELS CHINA TECH CO LTD

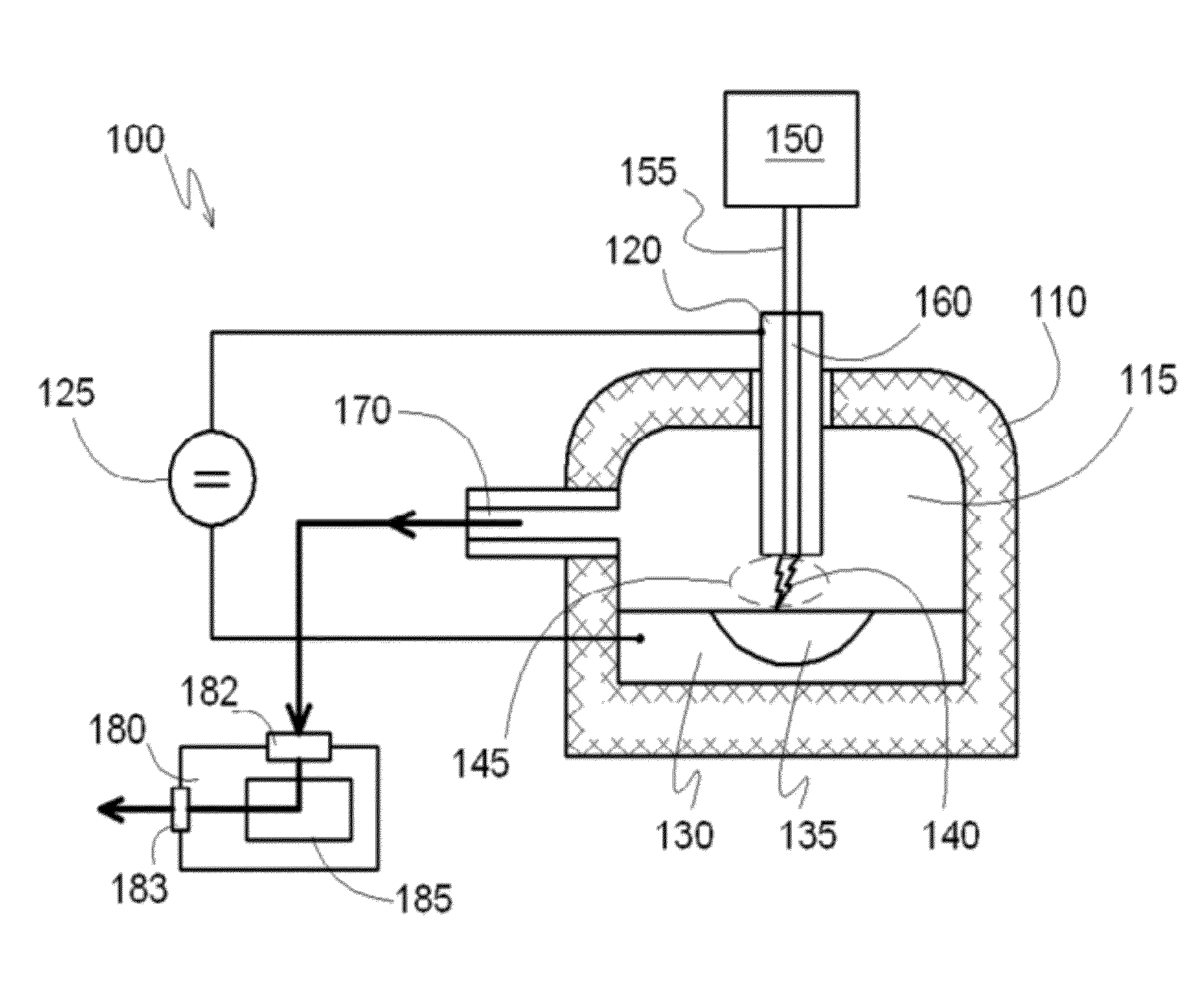

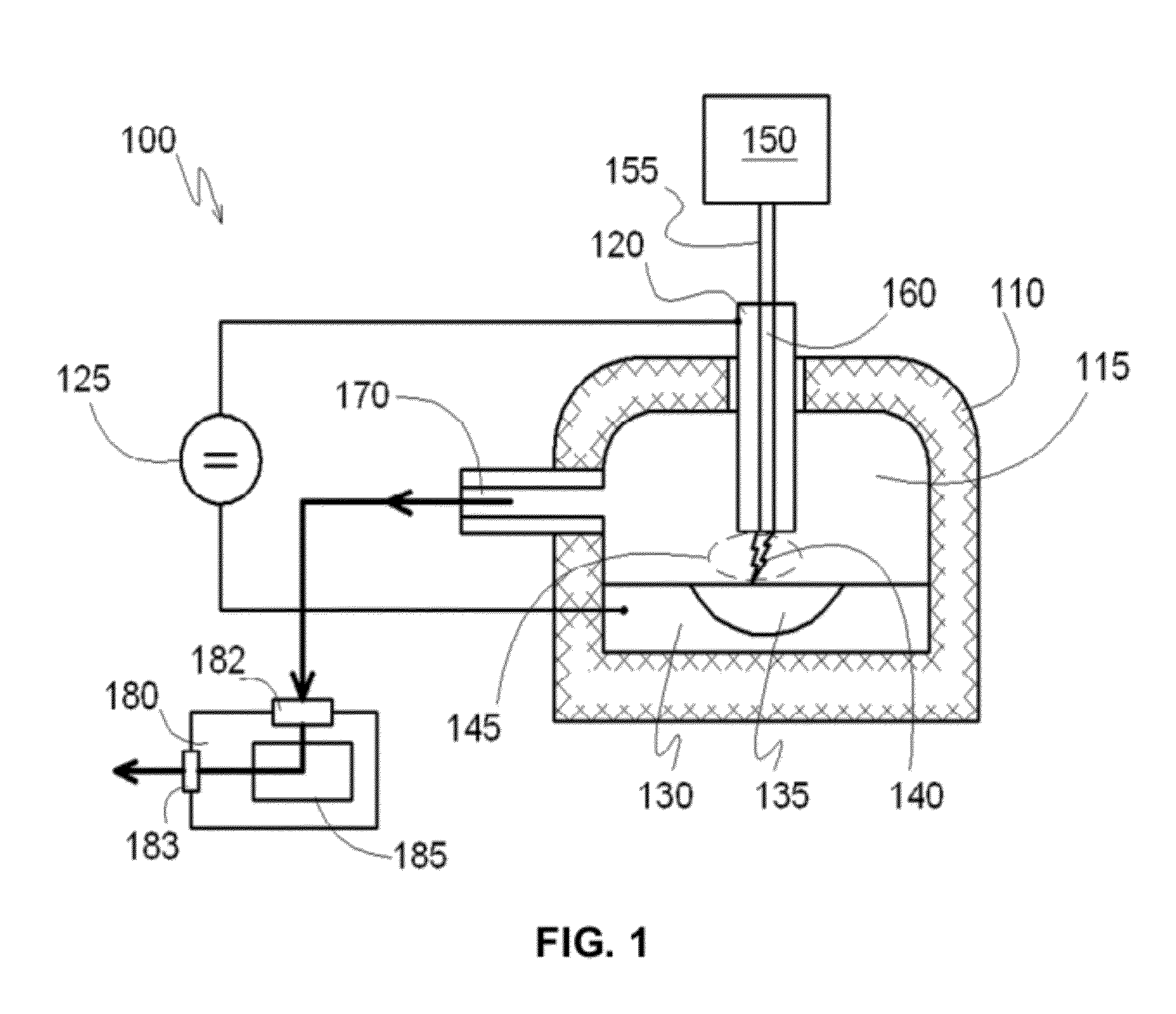

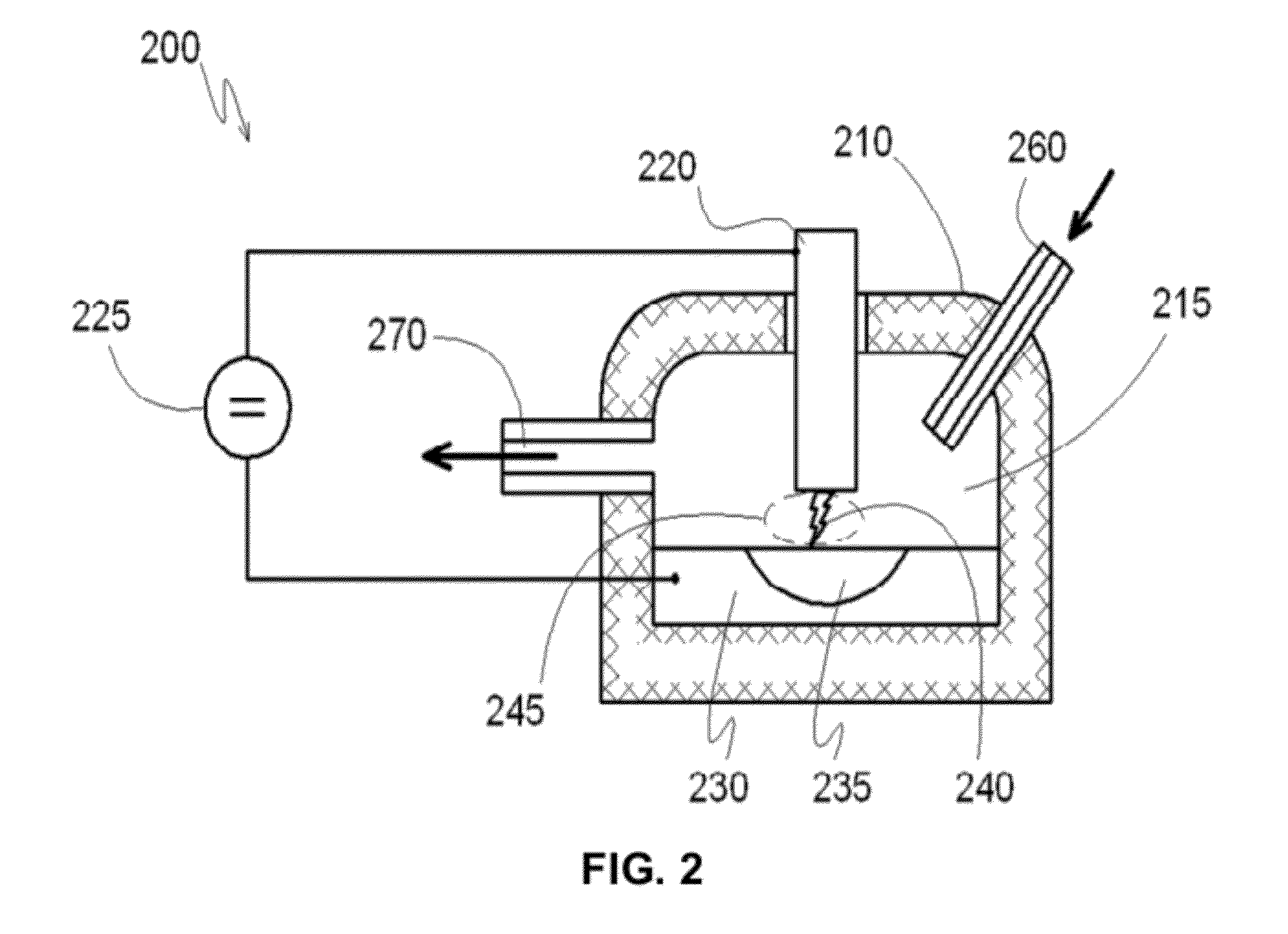

System and method for producing carbon nanotubes

A method of producing carbon nanotubes, comprising, in a reaction chamber: evaporating at least a partially melted electrode comprising a catalyst by an electrical arc discharge; condensing the evaporated catalyst vapors to form nanoparticles comprising the catalyst; and decomposing gaseous hydrocarbons in the presence of the nanoparticles to form carbon nanotubes on the surface of the nanoparticles. Also a system for producing carbon nanotubes, comprising: a reactor comprising two electrodes, wherein at least one of the electrodes is at least a partially melted electrode comprising a catalyst, the reactor adapted for evaporating the at least partially melted electrode by an electrical arc discharge and for condensing its vapors to form nanoparticles comprising the catalyst, wherein the electrodes are disposed in a reaction chamber for decomposing gaseous hydrocarbons in the presence of the nanoparticles to form carbon nanotubes on the surface of the nanoparticles.

Owner:MCD TECH SARL

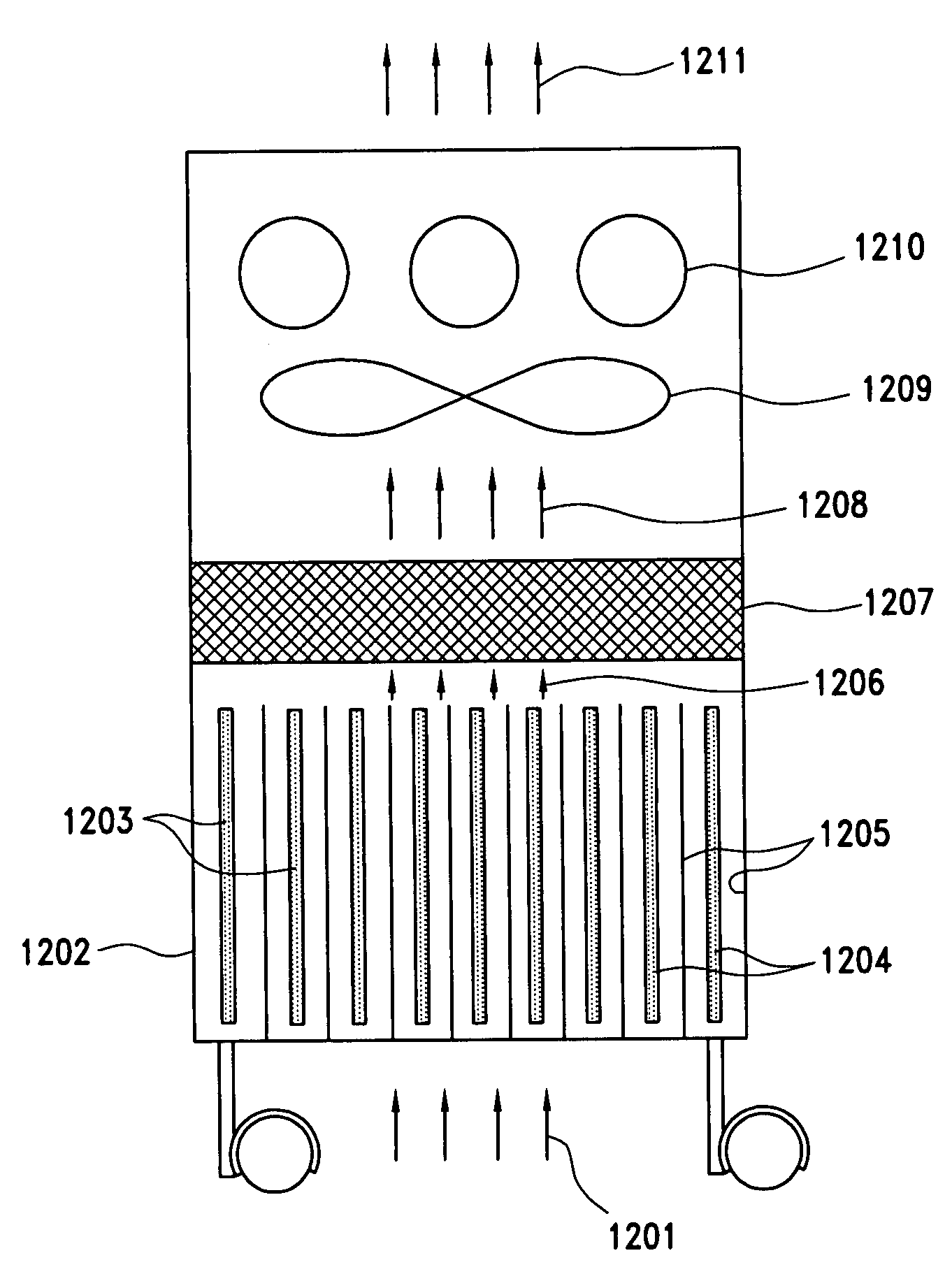

Emission Treatment System

ActiveUS20090158719A1Easy to controlRatio is limitedNitrous oxide captureGas treatmentNitrogen oxideSoot

An emission treatment system and method for remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams are described. The emission treatment system has an oxidation catalyst upstream of a soot filter upstream from a NOx reducing catalyst.

Owner:BASF CORP

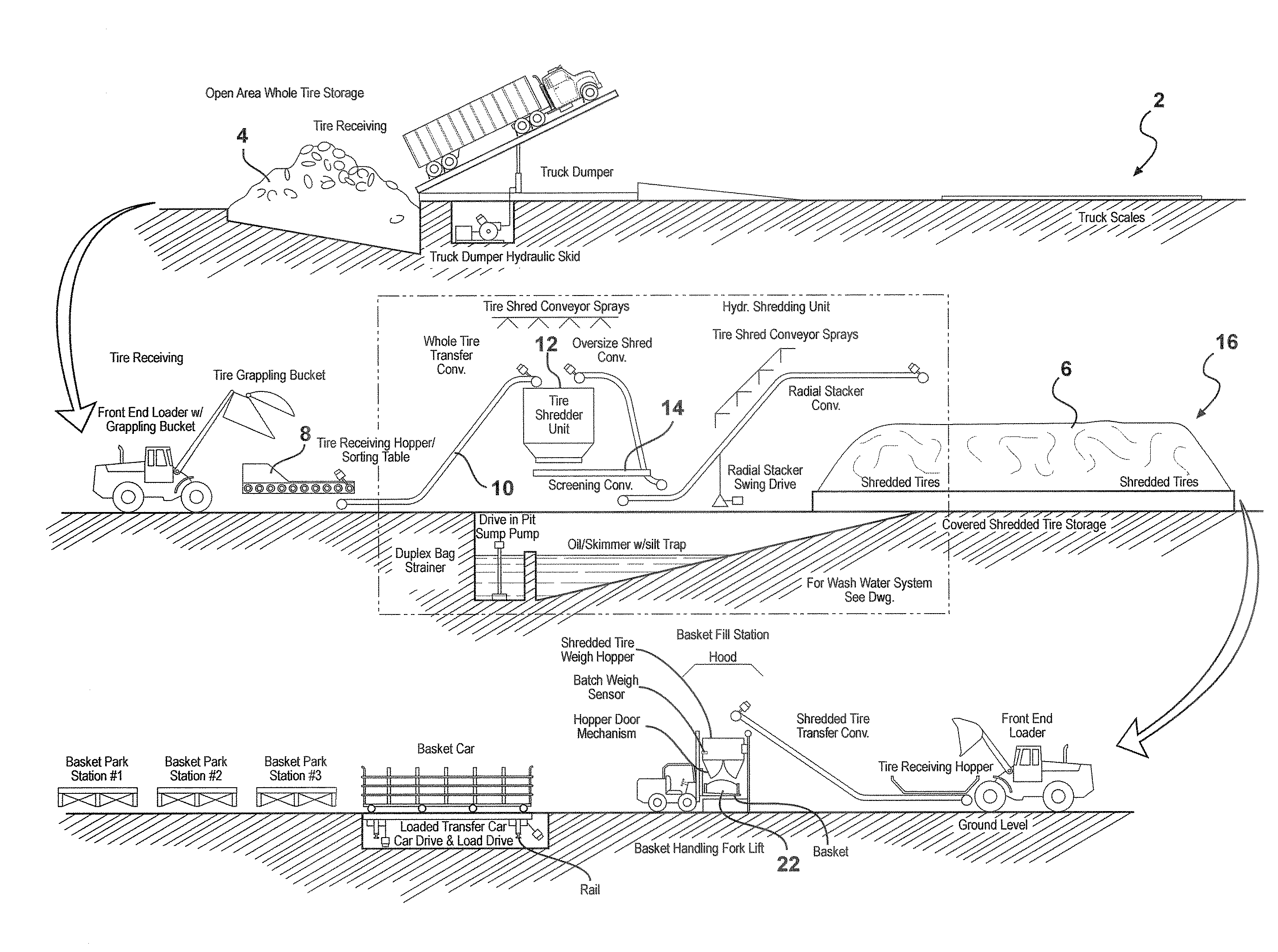

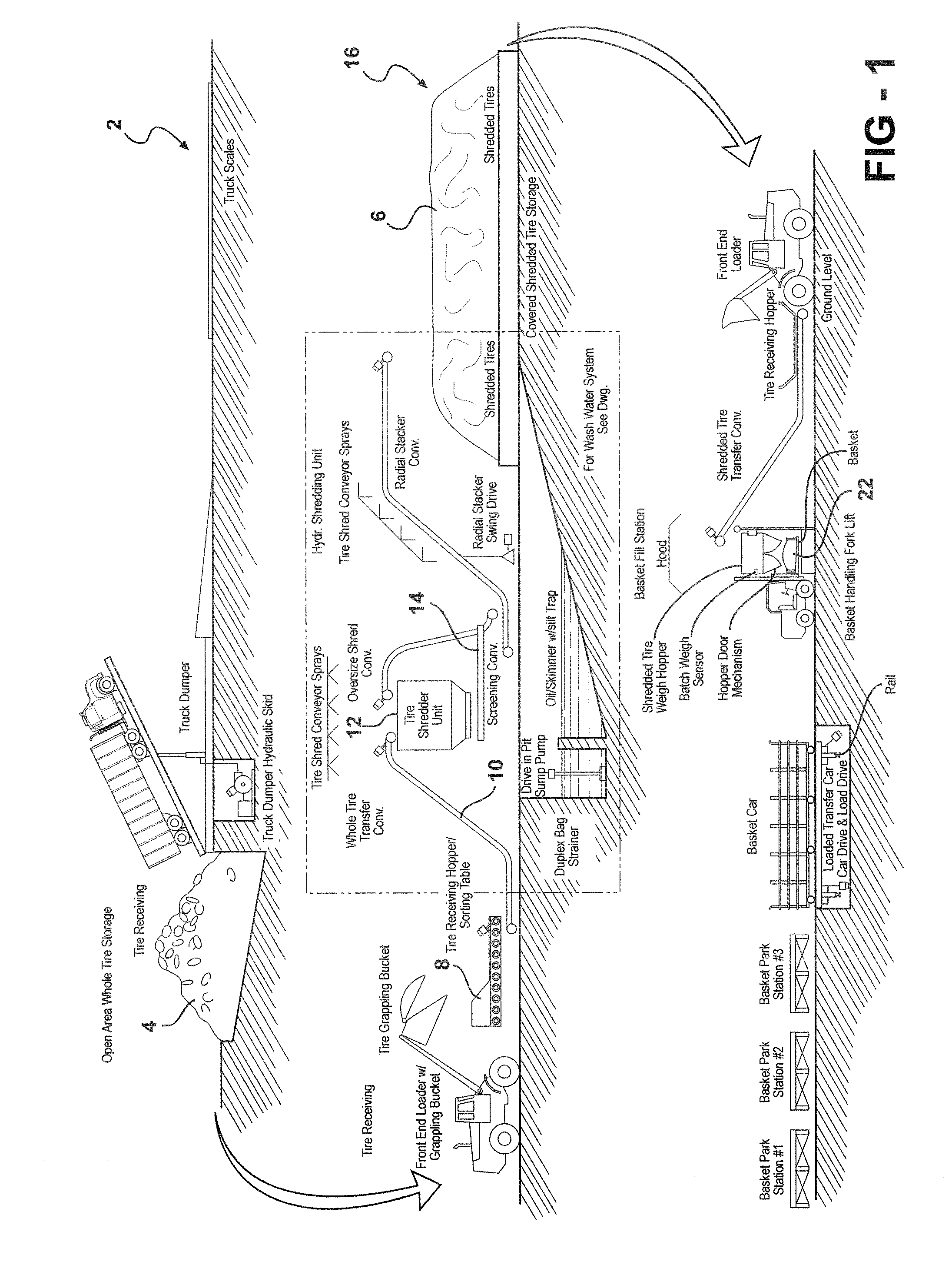

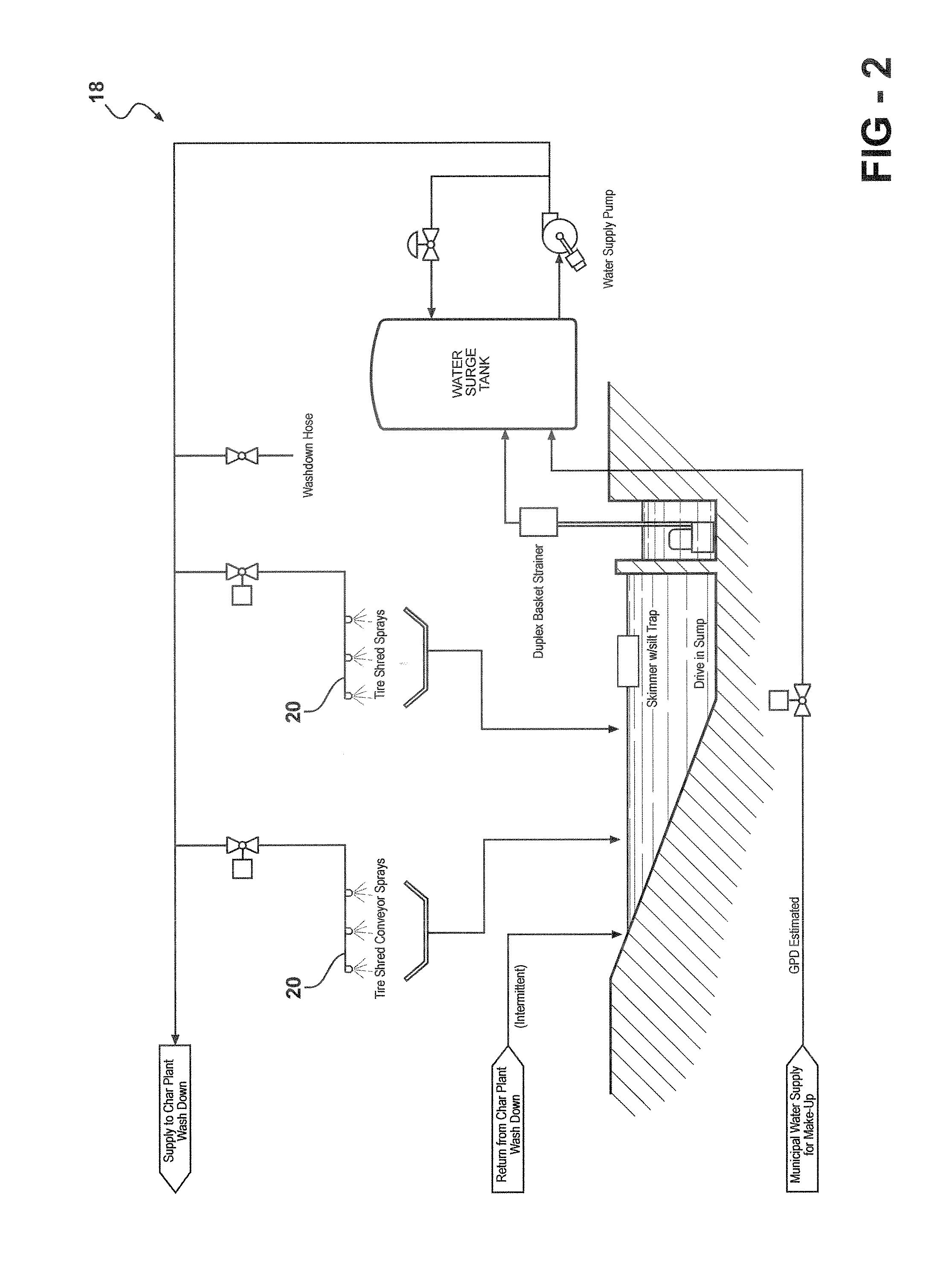

Pyrolyzed rubber products and processes

A pyrolysis process is provided. The process includes the steps of: depositing a quantity of waste into a porous container, the porous container adapted to allow a convective stream of substantially anaerobic gas to flow therethrough; inserting the porous container into a pyrolysis thermal processor; sealing the thermal processor; circulating the convective stream of gas through the pyrolysis thermal processor; heating the waste according to a first time-temperature profile to pyrolyze the waste and form a carbonaceous char; and cooling the carbonaceous char by circulating the convective stream of gas through a cooler. An oil product and a gaseous hydrocarbon product are produced during the pyrolysis. The carbonaceous char is further processed to form a carbon black product and a recyclable metal product.

Owner:TELLUS TECH

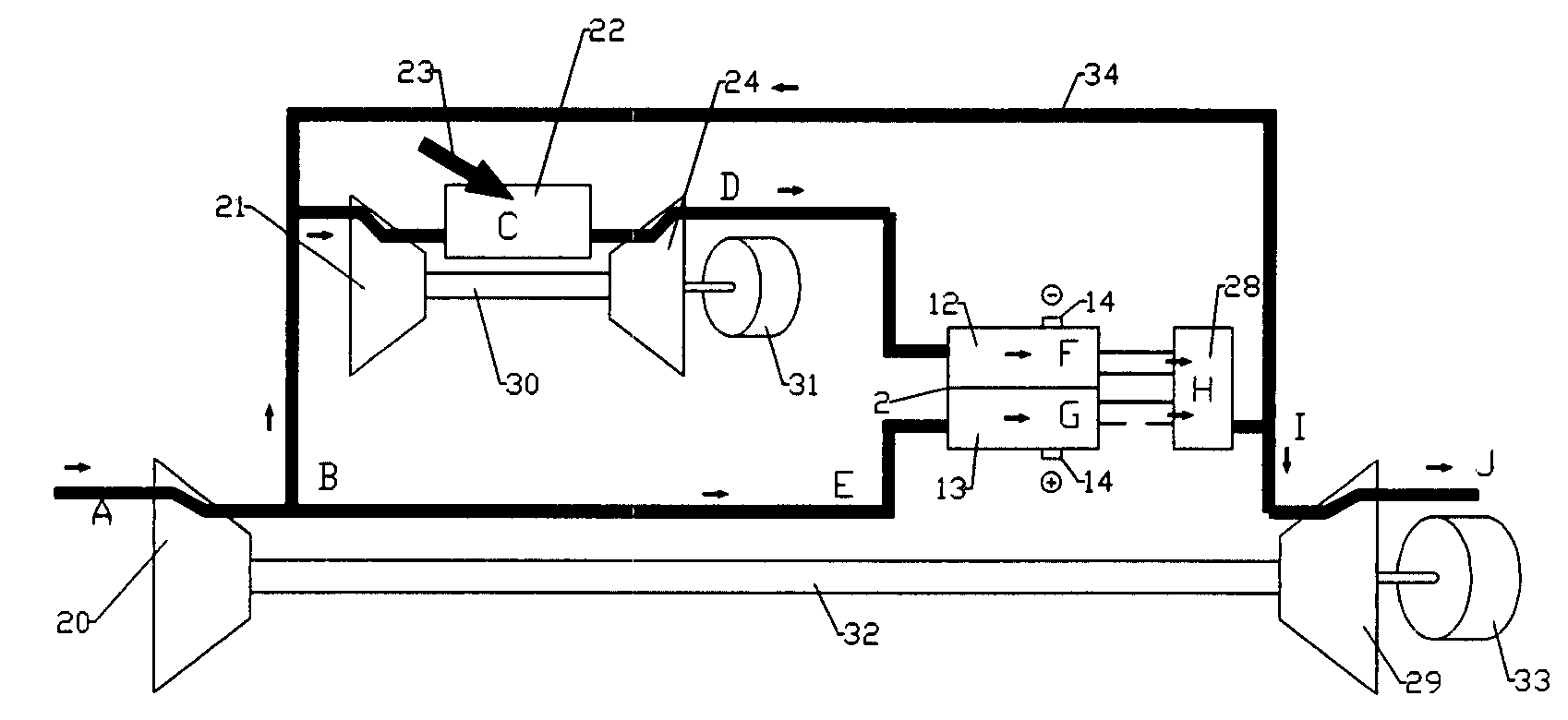

Hybrid fuel cell system with internal combustion reforming

InactiveUS20050048345A1Increased power plant efficiencyStart fastHydrogenFuel cell auxillariesPartial oxidationAlcohol fuel

The present invention is a hybrid system for generating power from hydrocarbon and alcohol fuels using a two-stage process to achieve high overall energy conversion efficiency. The first stage is a reformer and fuel cell subsystem that uses an internal combustion engine operated at an air / fuel ratio richer than stoichiometric as a partial oxidation reformer for commonly available liquid or gaseous hydrocarbon or alcohol fuels. The engine produces shaft power and a product gas mixture containing hydrogen, carbon monoxide, and traces of light hydrocarbons that is used as fuel in fuel cells to generate electric power. The second stage is a heat engine subsystem that captures heat from the reformer and fuel cell subsystem, and produces additional shaft power. In addition to efficiency, advantages include adaptability to a variety of fuels, quick system startup with immediate shaft power availability, and low emission of pollutantants.

Owner:MEACHAM G B KIRBY

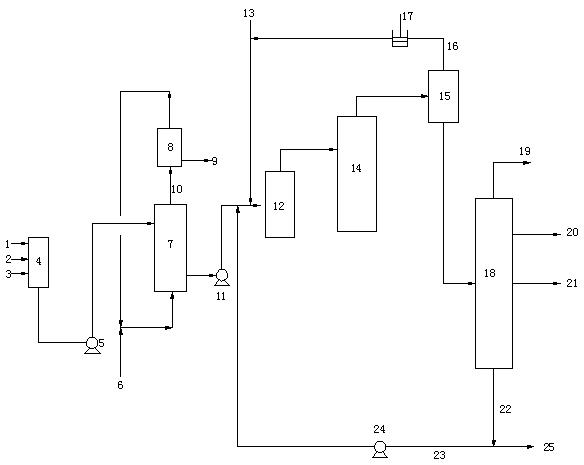

Coal tar heavy fraction suspension-bed hydrocracking method and system thereof

InactiveCN101962571AHigh yieldSimple structureTreatment with hydrotreatment processesHydrogenGasoline

The invention belongs to the technical field of coal chemical industry, and provides a coal tar heavy fraction suspension-bed hydrocracking method. The method comprises the following steps: mixing raw materials of coal tar heavy fractions with a catalyst and a vulcanizing agent to form a uniform mixed material; vulcanizing the catalyst in the mixed material under the action of hydrogen; preheating the vulcanized mixed material, and then allowing the preheated material to enter a suspension-bed reactor for hydrocracking reaction; and fractionating the product from the suspension-bed reactor to finally obtain gaseous hydrocarbon, gasoline fractions, diesel fractions and tail oil. In the invention, by directly adopting the hydrocracking method with a coal tar heavy fraction suspension bed and a system thereof, the coal tar heavy fractions can keep light weight, and the yield of the fuel oil product hydrogenated by coal tar can be effectively increased; and the suspension-bed hydrogenation reactor has simple structure without a bed layer, thus causing no phenomena such as blockage, increased pressure drop, overtemperature and the like occurred on the reaction bed layer, and the reactor further has the characteristics of great operation flexibility, long operation cycle, being safe and stable, easy control and the like.

Owner:DALIAN UNIV OF TECH

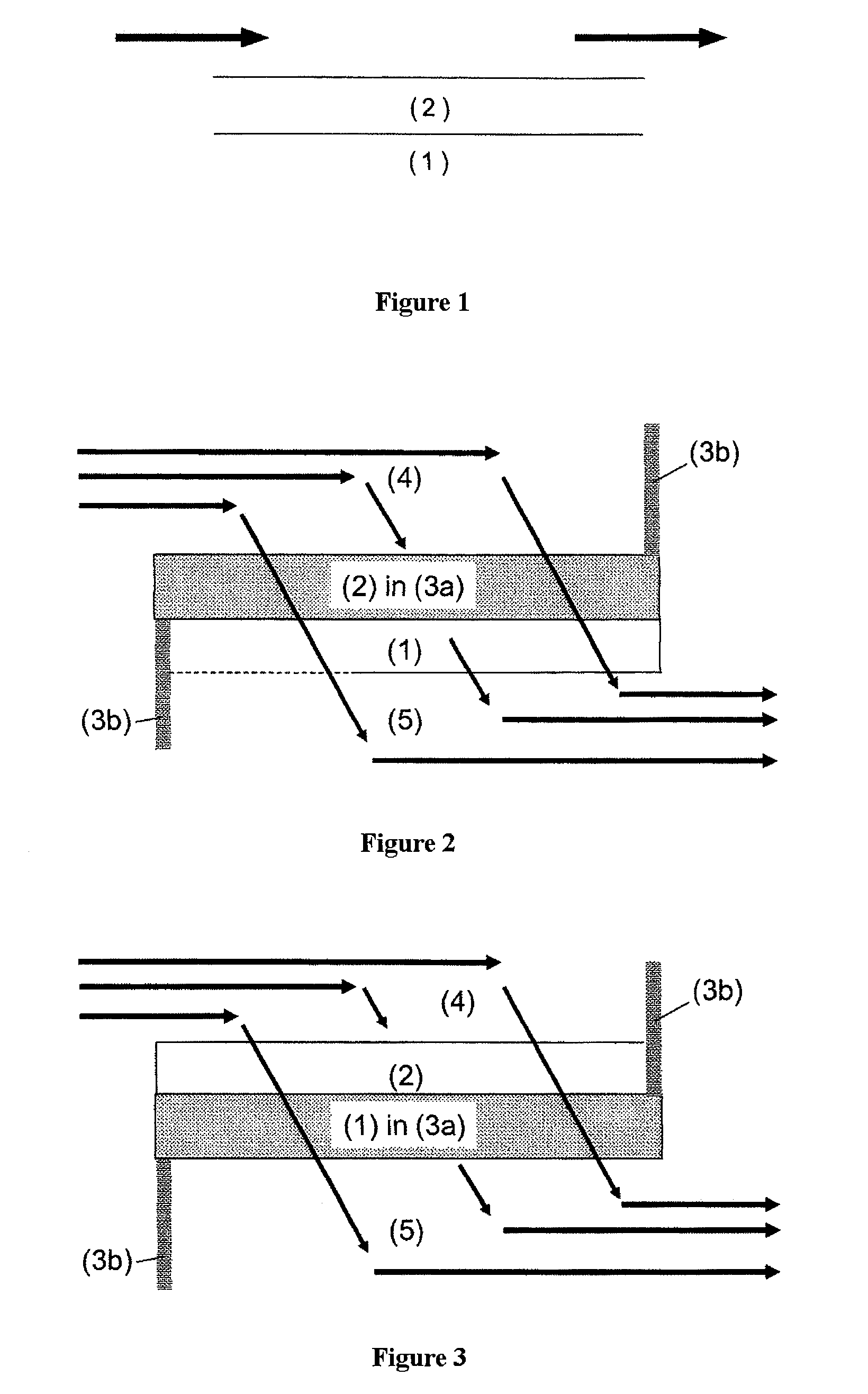

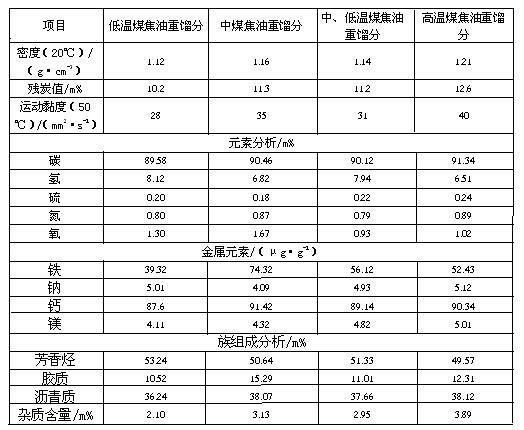

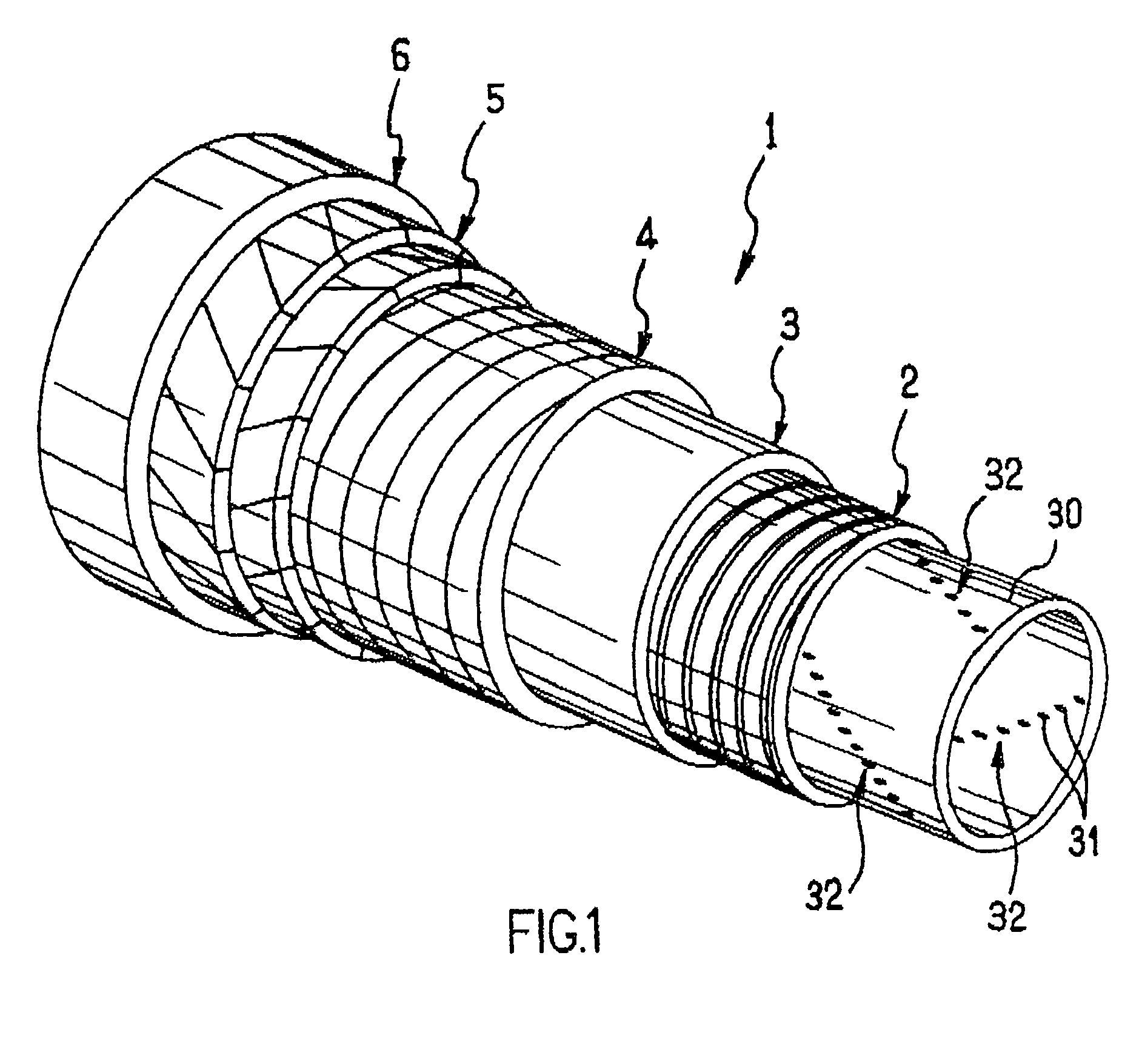

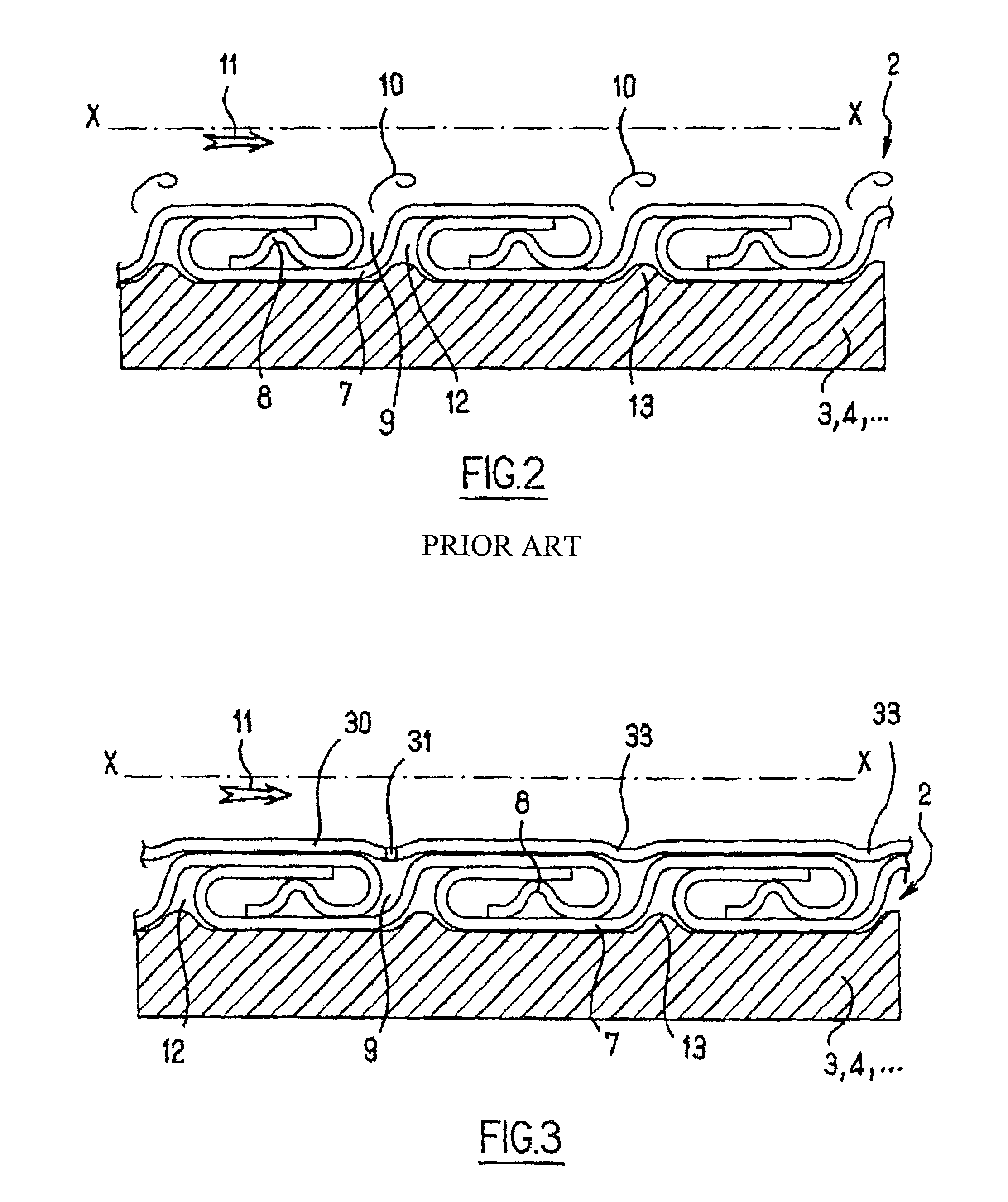

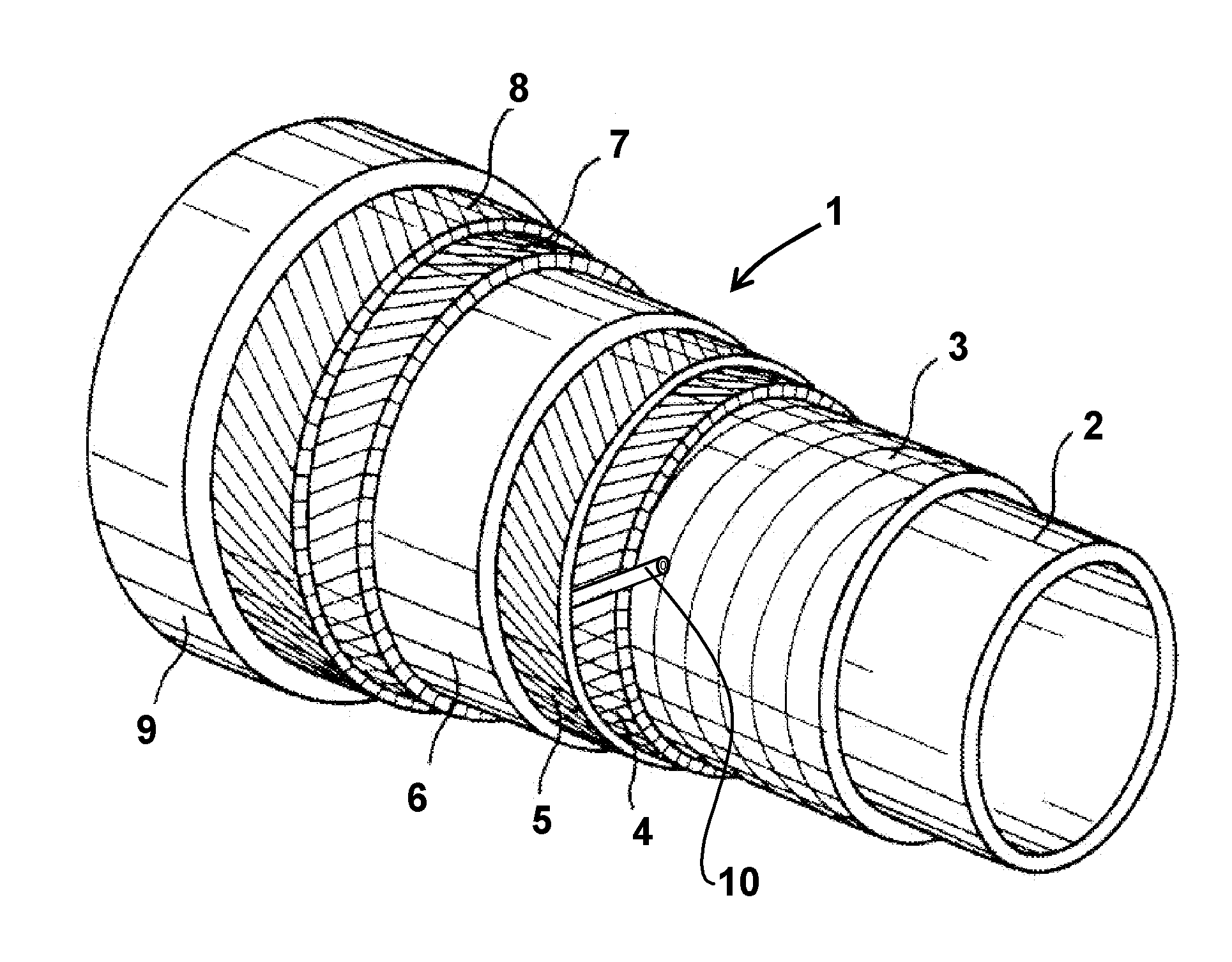

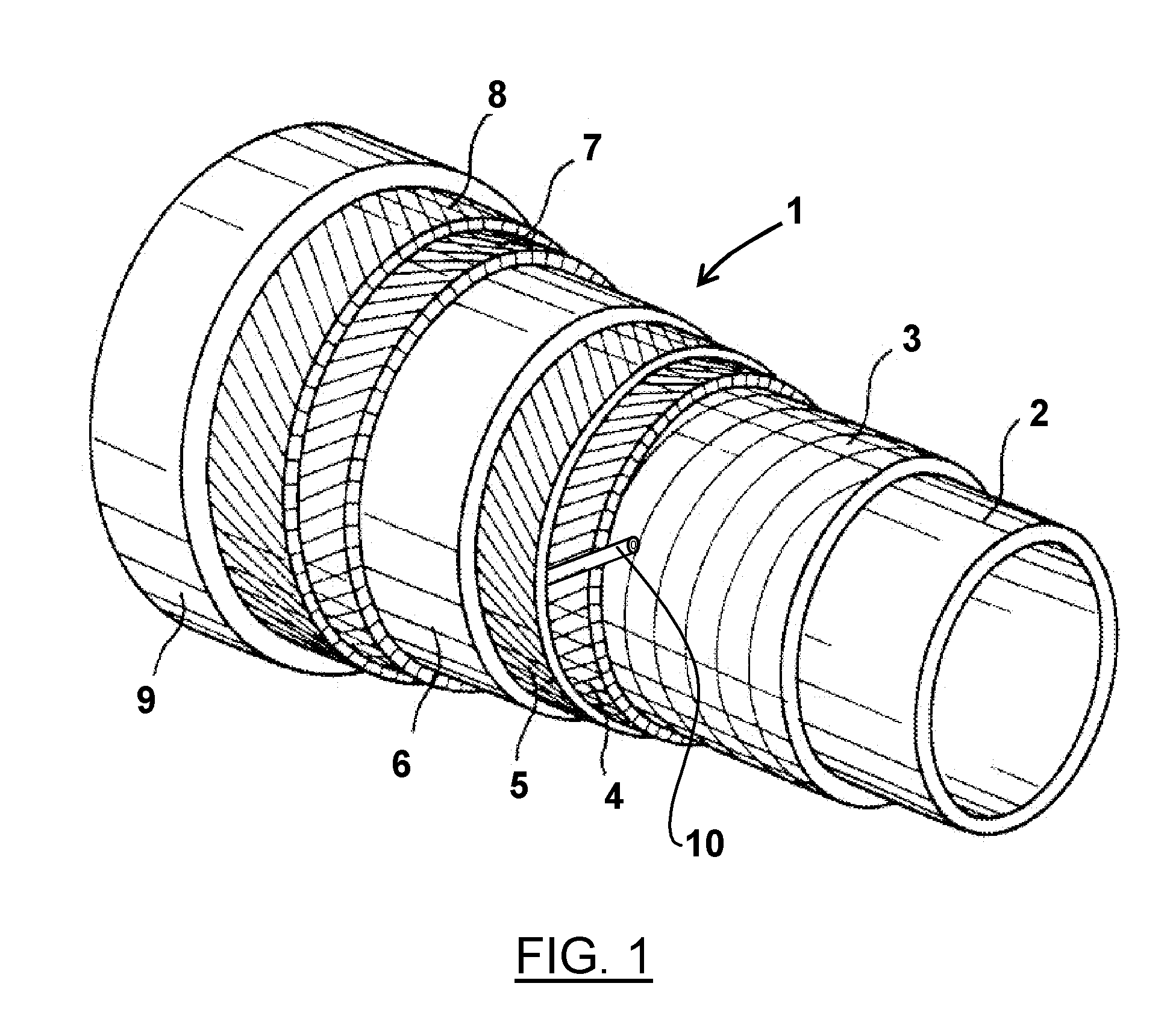

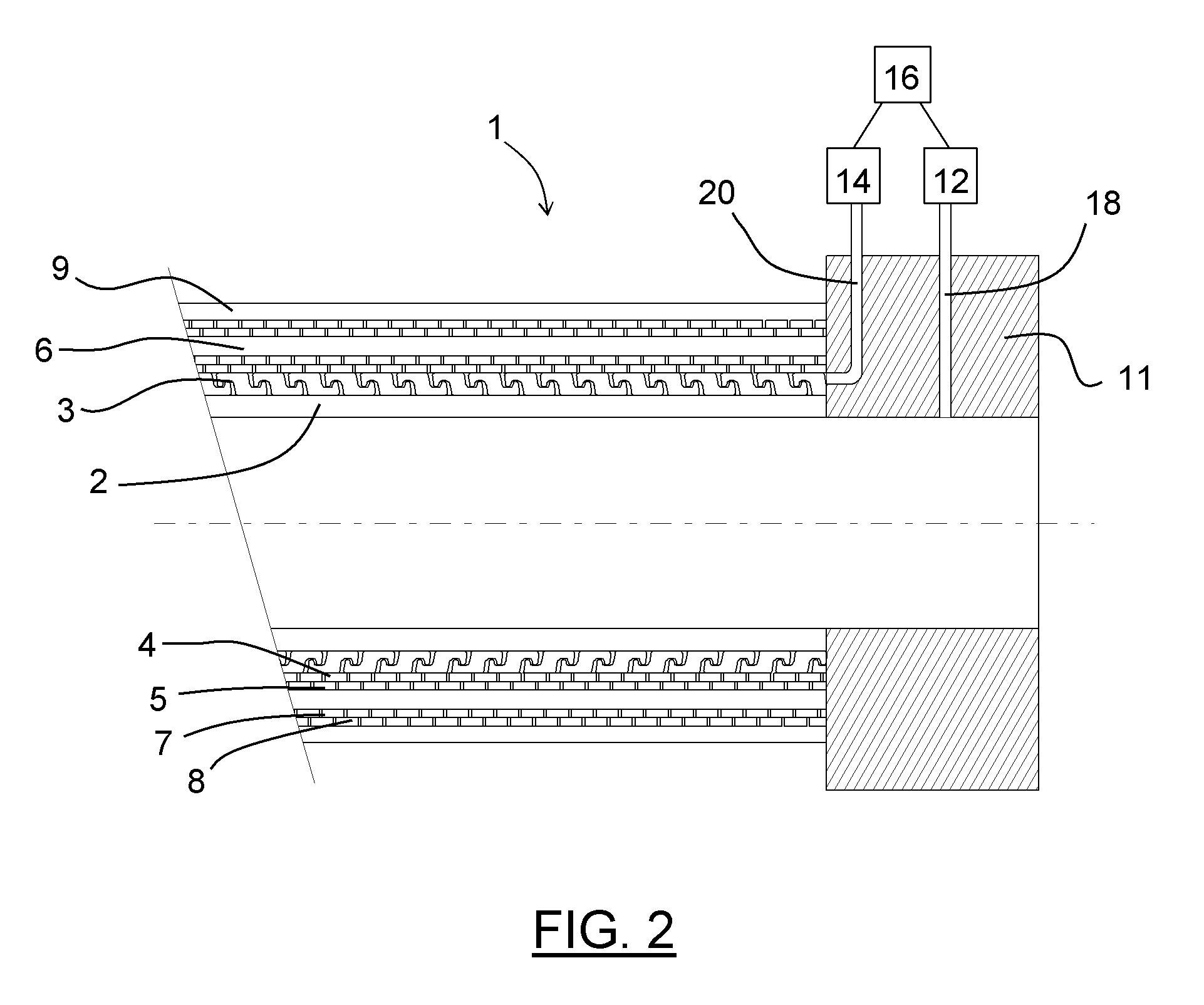

Flexible tubular duct for the transport of fluid and particularly gaseous hydrocarbons with an anti-turbulence carcass and internal lining

A flexible tubular pipe for transporting hydrocarbons, the pipe comprising at least one carcass, an internal pressure sheath and one or more armor layers. The carcass forms the innermost structural element of the pipe and consists of an interlocked spiral winding of a strip or wire with some shape. The turns of the carcass are internally covered with an anti-turbulence sheath pierced with holes which is intended to oppose turbulence of the hydrocarbon flowing through the pipe and prevent associated resonance phenomena.

Owner:TECH FRANCE SA

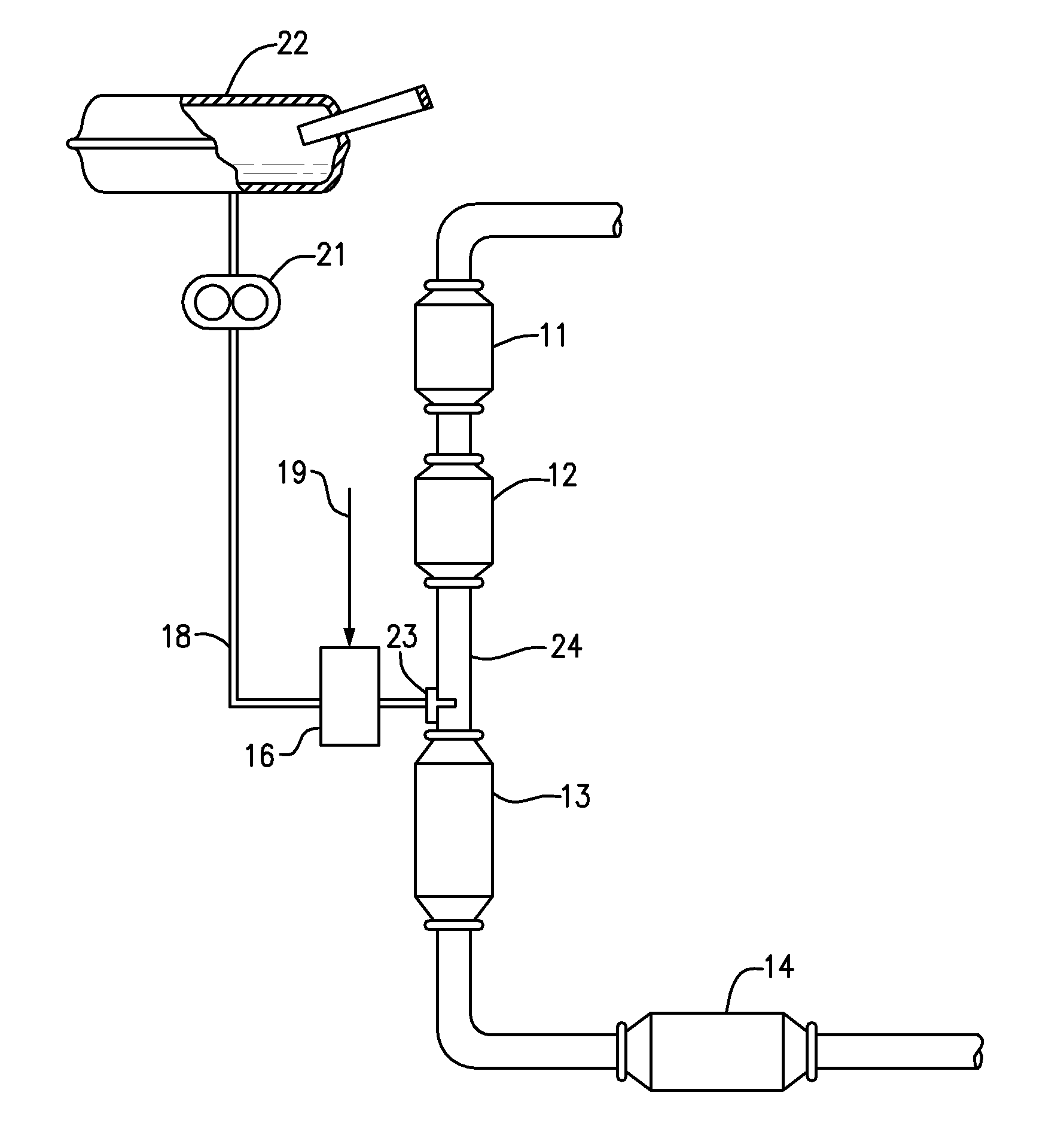

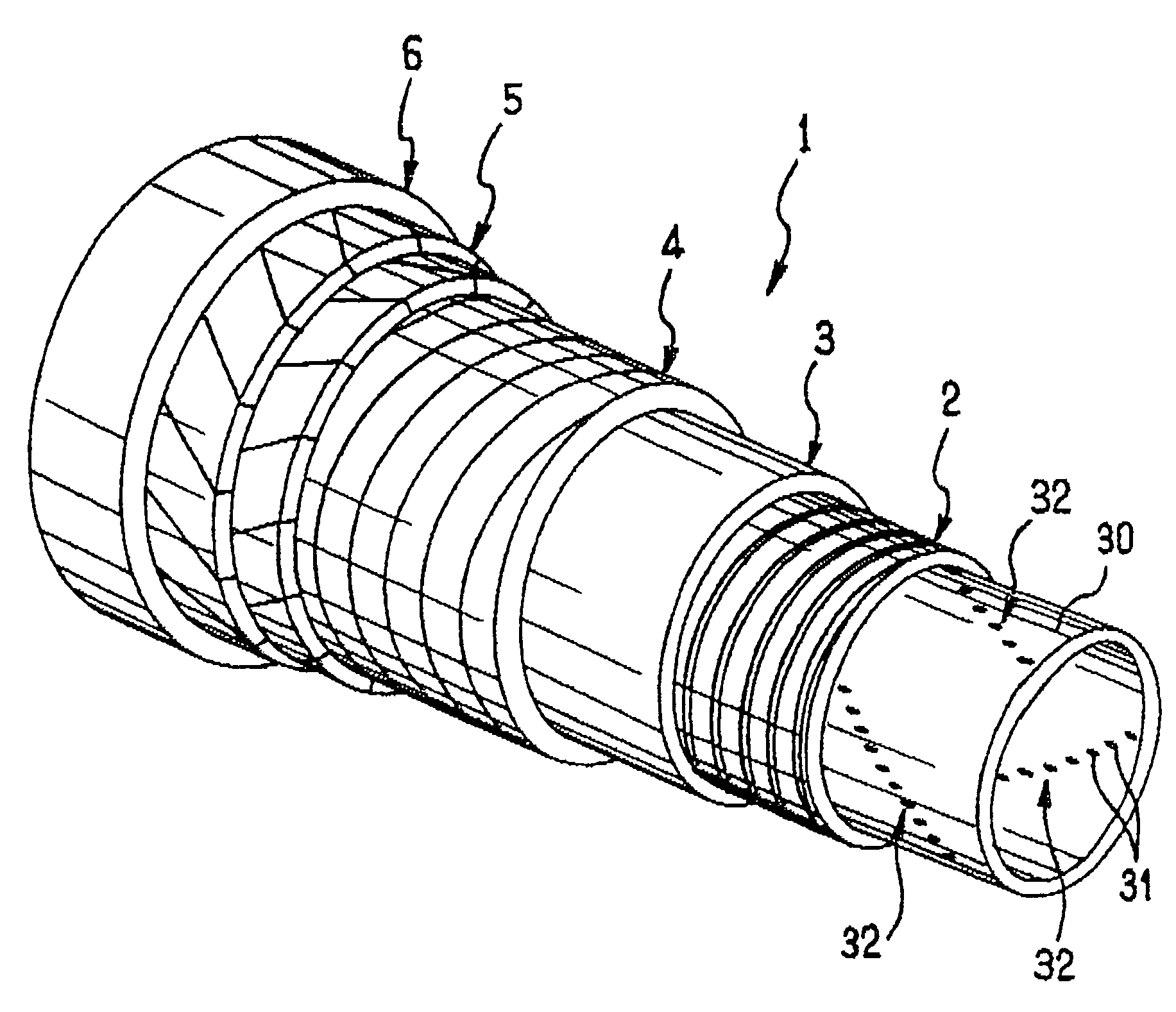

Mercury removal apparatus for liquid hydrocarbon

InactiveUS20100025184A1Easy to useComponent can be removedPhysical/chemical process catalystsUsing liquid separation agentLiquid stateLiquid hydrocarbons

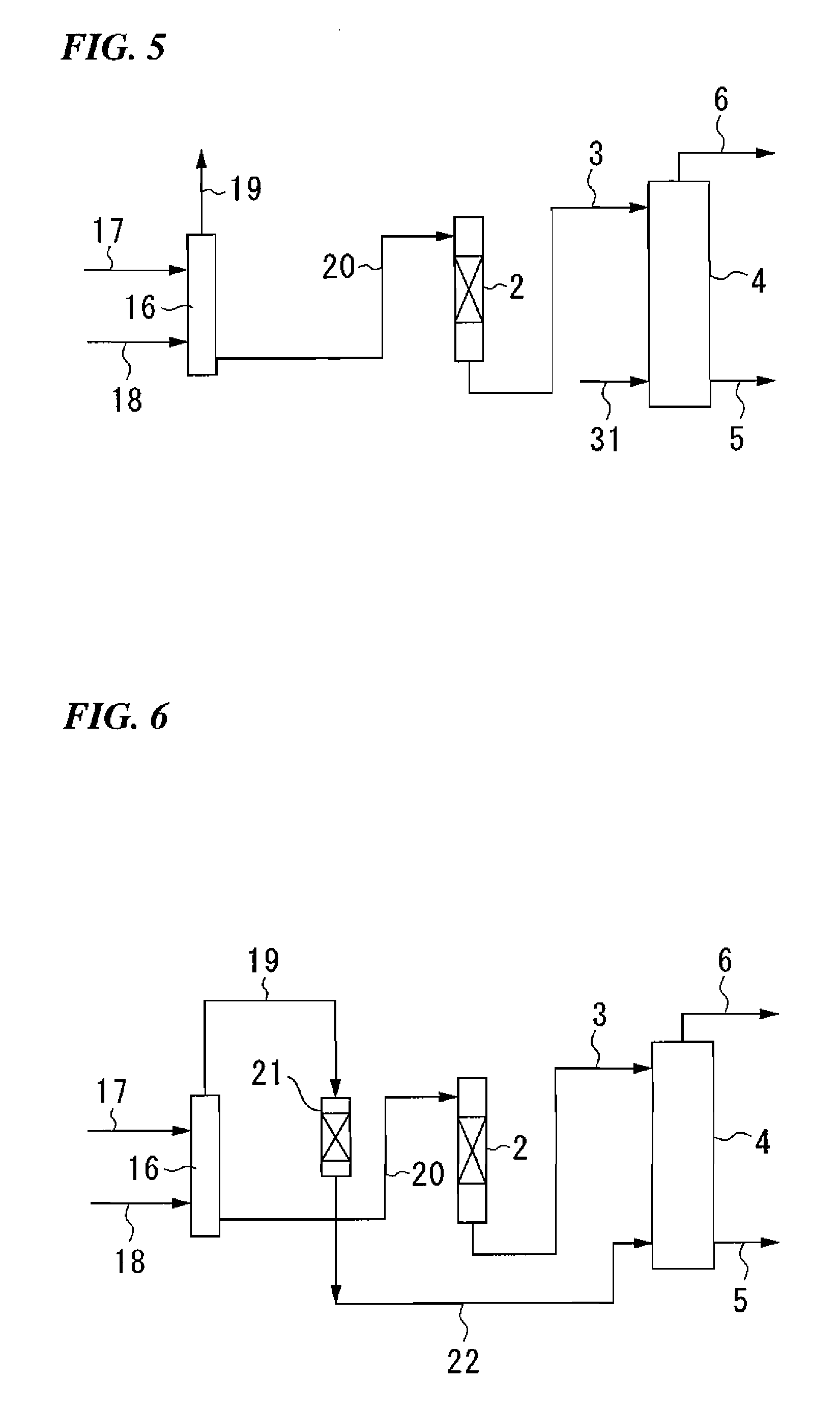

A mercury removal apparatus for a liquid hydrocarbon of the present invention includes a conversion device 2 which converts a mercury component in a raw liquid hydrocarbon into elemental mercury to obtain a first liquid hydrocarbon containing the elemental mercury; and a first stripping device 4 which brings the first liquid hydrocarbon into counter-current contact with a first stripping gas, thereby transferring the elemental mercury in the first liquid hydrocarbon to the first stripping gas to obtain a second liquid hydrocarbon in which the amount of the elemental mercury decreases and a first gaseous hydrocarbon containing the elemental mercury.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD +1

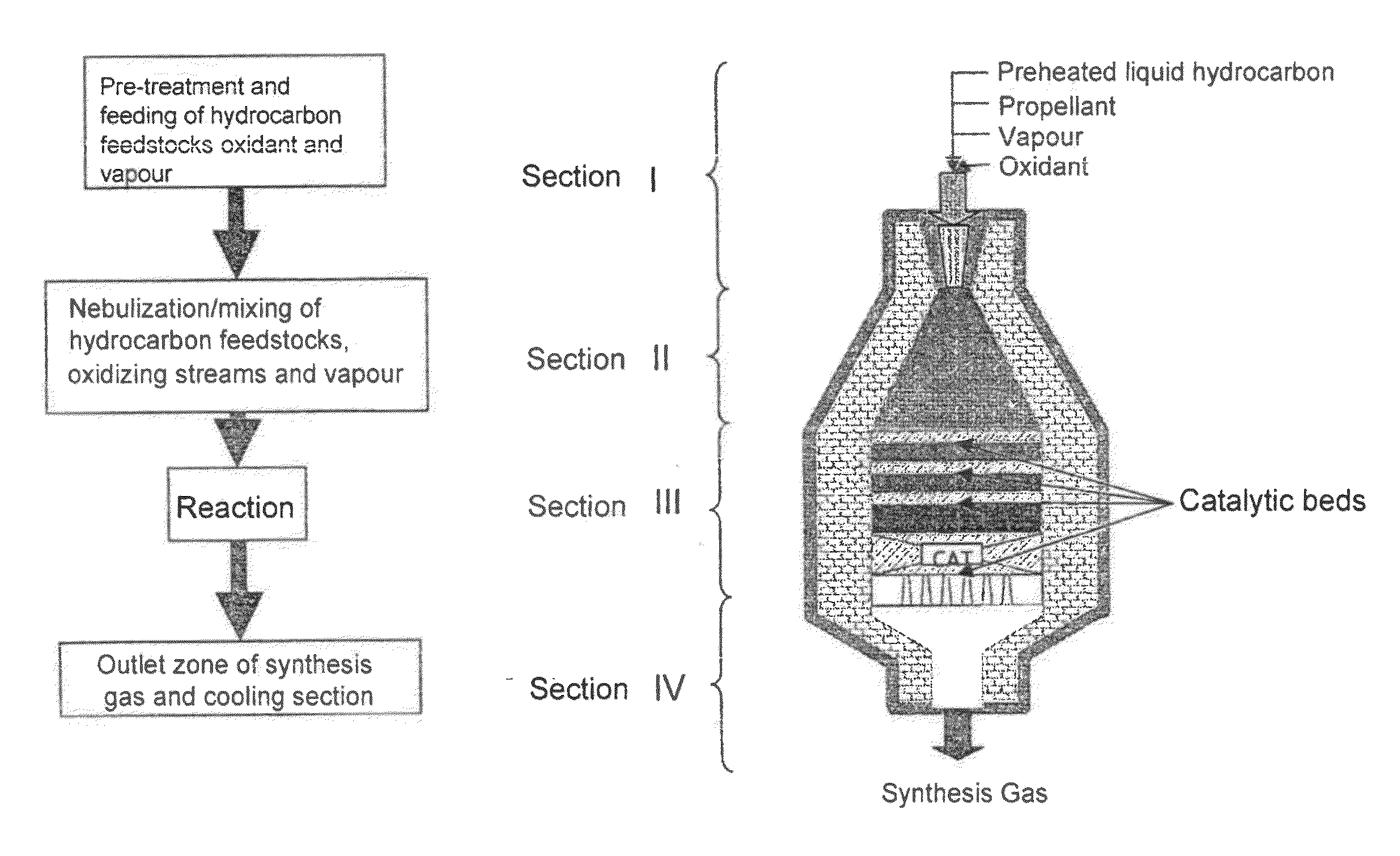

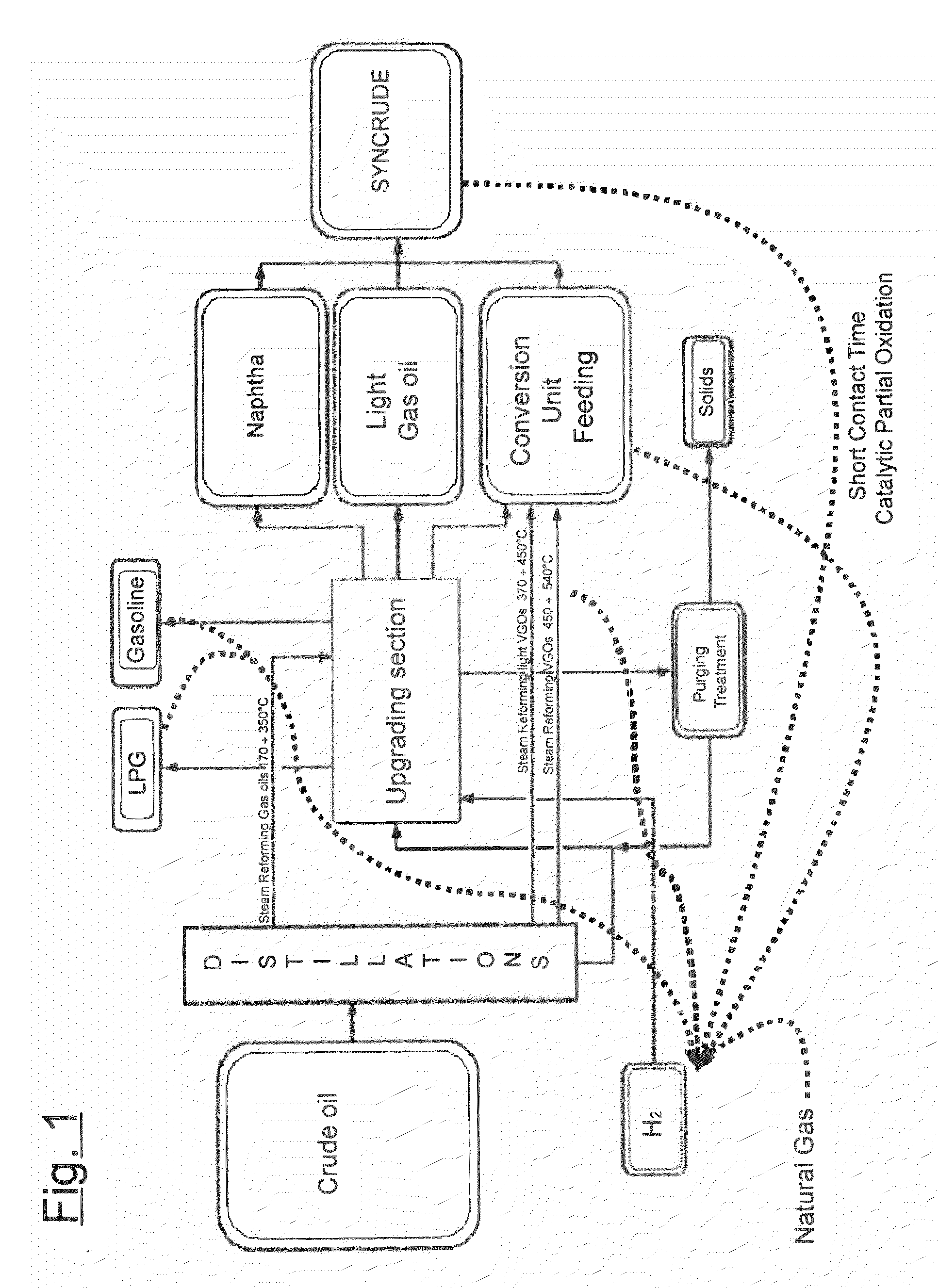

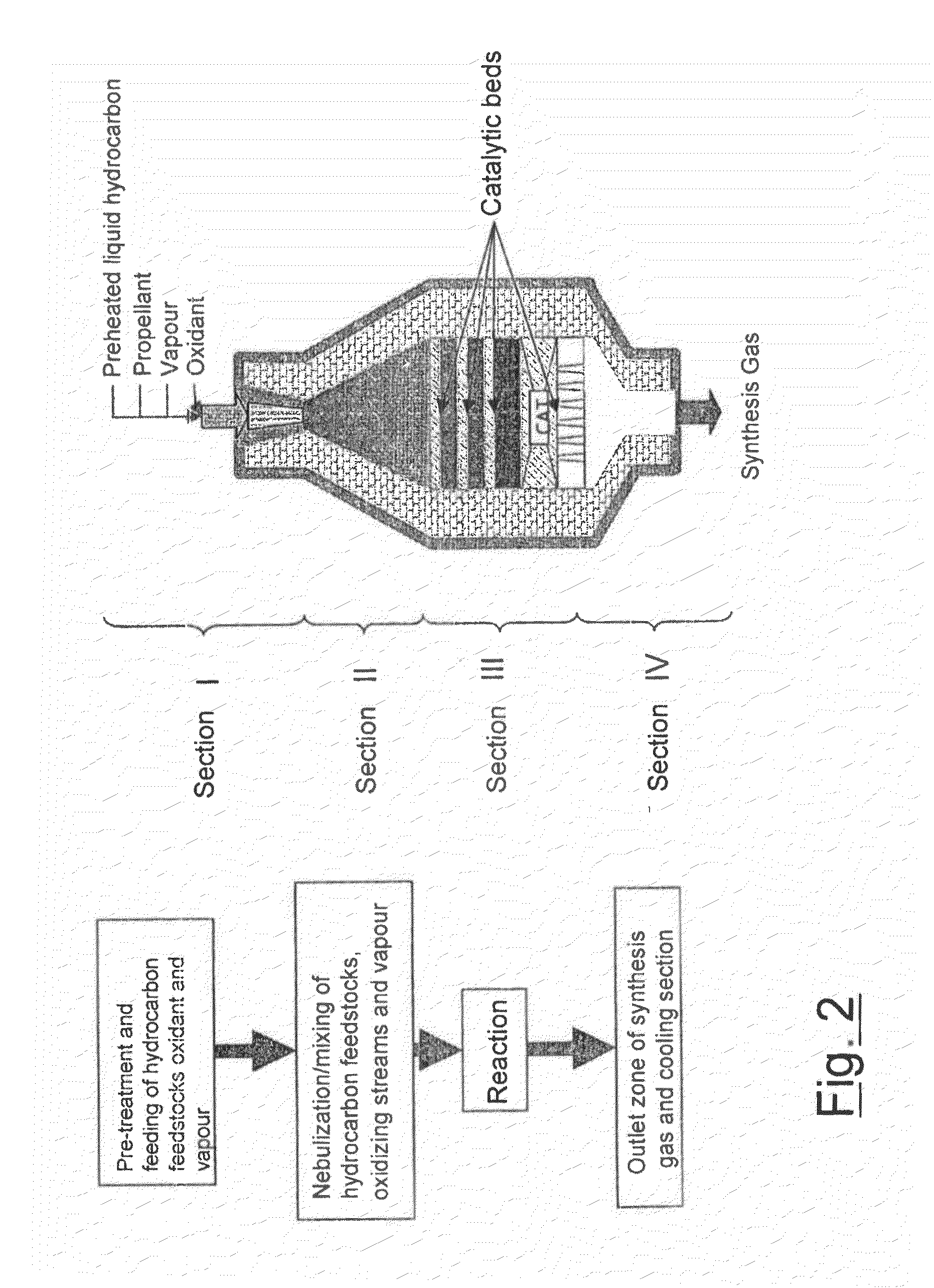

Process for the production of synthesis gas and hydrogen starting from liquid or gaseous hydrocarbons

An apparatus, containing: (I) an inlet section into which a liquid and optionally a gaseous reagent stream is fed, the inlet section containing a device, which nebulizes and / or vaporizes the liquid stream, the device optionally utilizing vapor and / or a gaseous hydrocarbon stream as propellant; (II) a mixing section containing a chamber having a cylindrical or truncated-conical geometry, which mixes the reagent stream exiting the inlet section (I), to form a reaction mixture; (III) a reaction section including i) a first structured catalytic bed a ii) a structured catalytic bed heating device, in which the reaction mixture exiting the mixing section (II) flows through each layer of the first structured catalytic bed with a contact time varying from 0.01 to 10 ms, to produce a mixture of reaction products; and IV) a cooling section of the mixture of reaction products leaving the reaction section (III).

Owner:ENI SPA

Flexible tubular pipe for transporting gaseous hydrocarbons

ActiveUS20100084035A1Avoid oversizingPressure resistance performance substantially lowPipe couplingsFluid-tightness measurementProduct gasEngineering

The invention relates to a flexible tubular duct for transporting gases under high pressure in the field of offshore oil exploitation. The duct is of the unlinked and smooth passageway type, and comprises from inside to outside an inner polymer tube, a pressure vault formed by the short-pitch rolling of at least one wire, a first inner pair of crossed traction armour plies, an intermediate polymer sleeve, a second outer pair of crossed traction armour plies and an outer polymer sleeve. The inner pair of traction armour plies is wound with a helical angle of less than 35° and the outer pair of traction armour plies is wound with a helical angle substantially equal to 55°.

Owner:TECH FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com