Patents

Literature

127results about How to "Extend the start cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation method for coal tar suspension bed of heterogeneous catalyst

ActiveCN101885982ATo achieve the purpose of recyclingImprove utilization efficiencyTreatment with hydrotreatment processesFuel oilBULK ACTIVE INGREDIENT

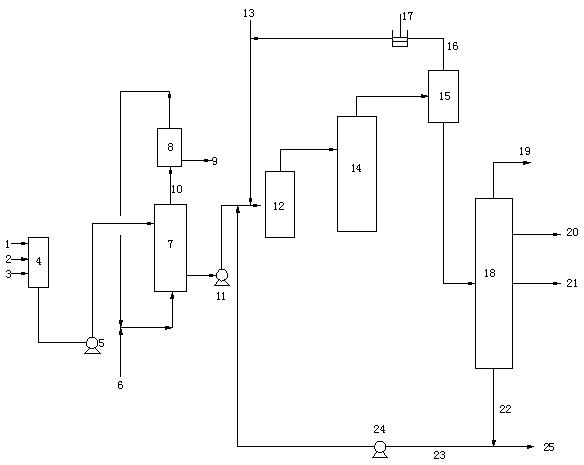

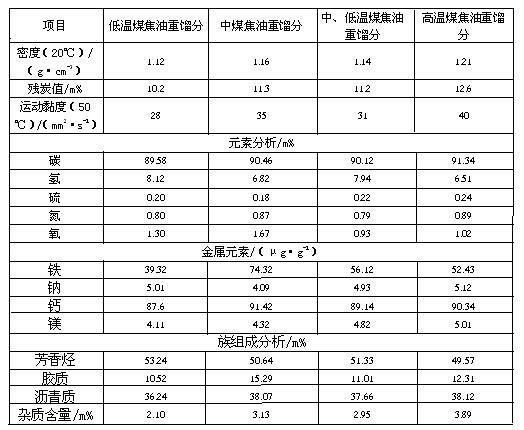

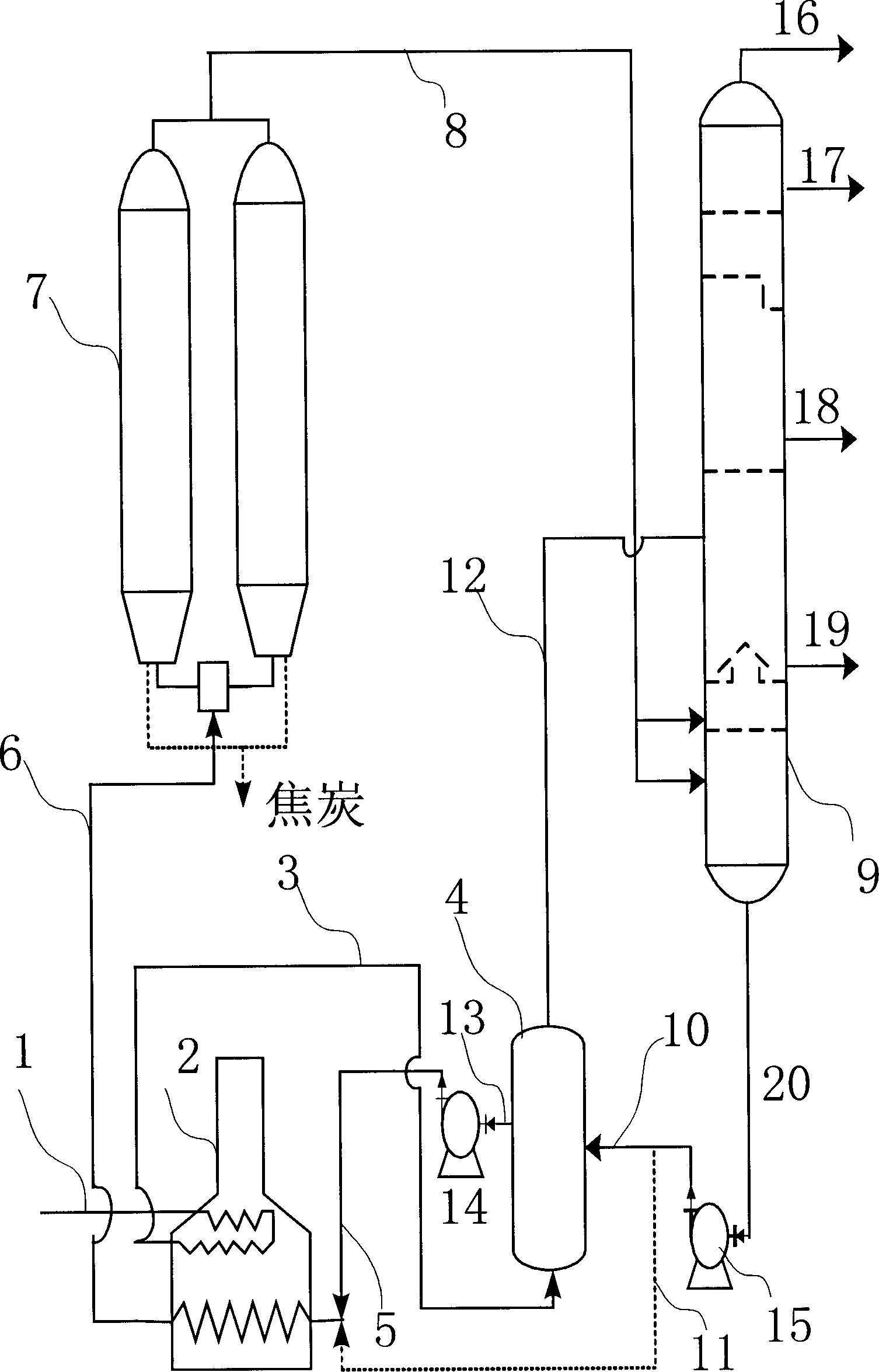

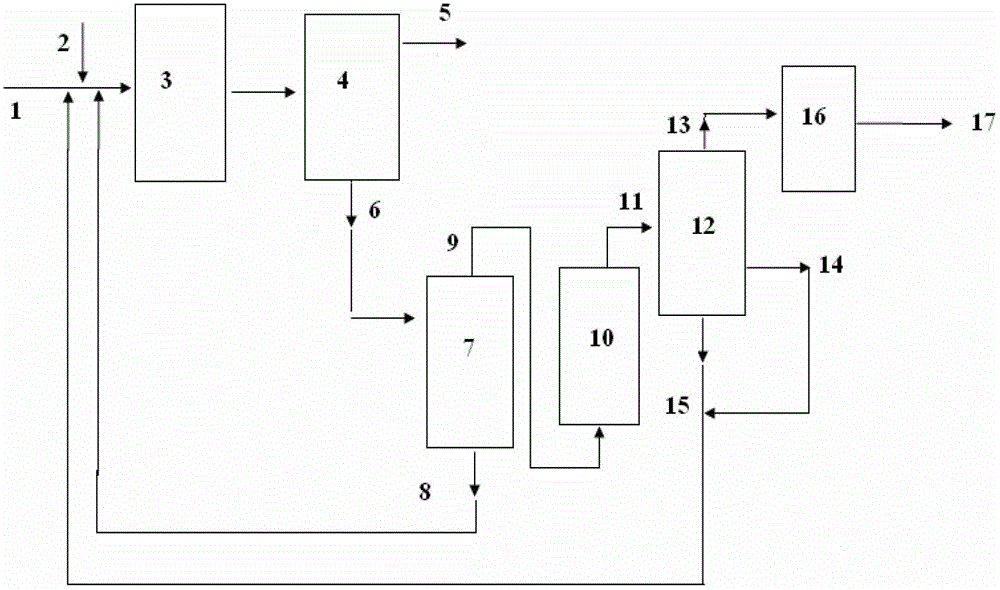

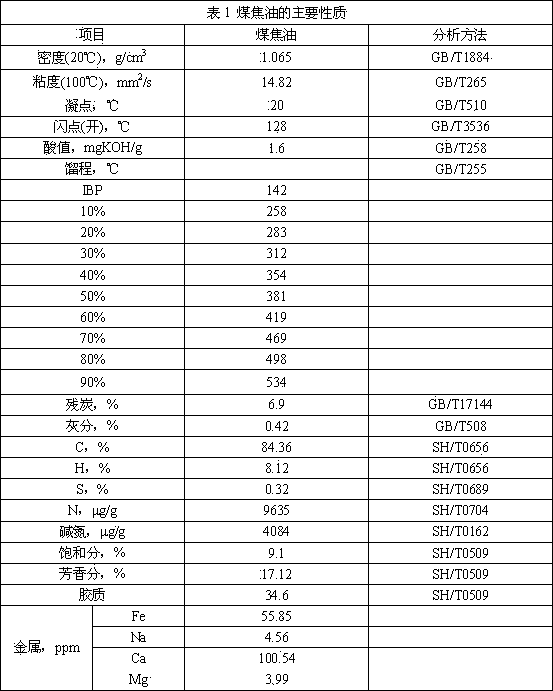

The invention relates to a hydrogenation method for a coal tar suspension bed of a heterogeneous catalyst. The method comprises processes of coal tar raw material pretreatment and distillatory separation, coal tar heavy fraction suspension bed hydrogenation cracking and conventional light fraction oil extraction, wherein the suspension bed hydrogenation reaction temperature is between 320 and 480DEG C, the reaction pressure is 8 to 19MPa, the volume air speed is 0.3 to 3.0h<-1>, the hydrogen oil volume ratio is 500 to 2,000, the catalyst is a powdery granular coal tar suspension bed hydrogenation catalyst of a single metal active ingredient containing molybdenum, nickel, cobalt, tungsten or iron or a composite multi-metal active ingredient, the adding amount of the catalyst is based on the ratio of the metal quantity of the active ingredient to the weight of the coal tar raw materials of 0.1: 100-4: 100, most of tail oil containing the catalyst after lightweight oil is separated froma hydrogenation reaction product is directly circulated to a hydrogenation bed reactor, a small part of tail oil is subjected to catalyst removal treatment and then circulated to the hydrogenation bed reactor to be subjected to further lightweight treatment, and the heavy oil is totally or furthest circulated. The method fulfills the purposes of maximum production of the lightweight oil in the coal tar and cyclic utilization of the catalyst, and greatly improves the utilization efficiency of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

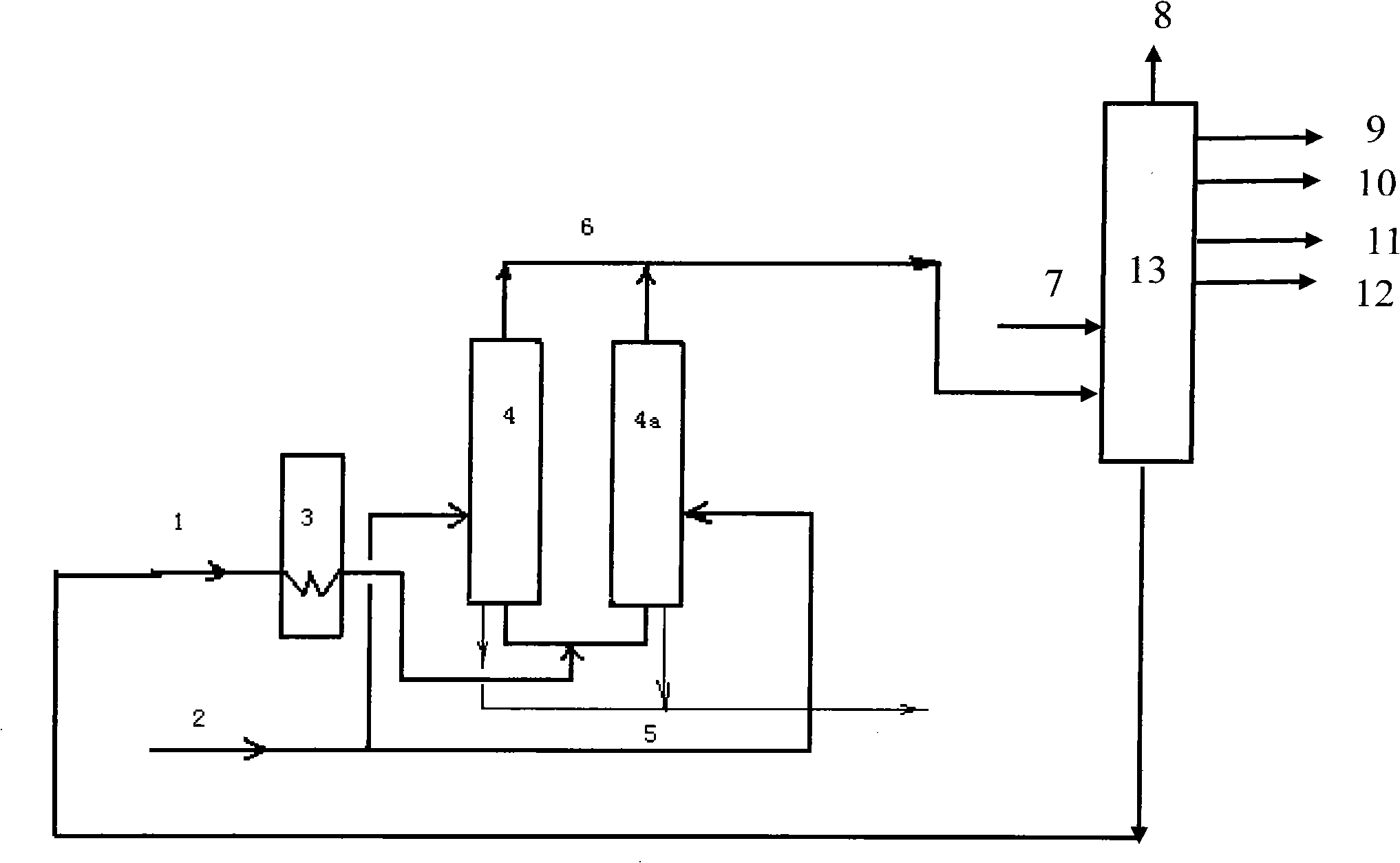

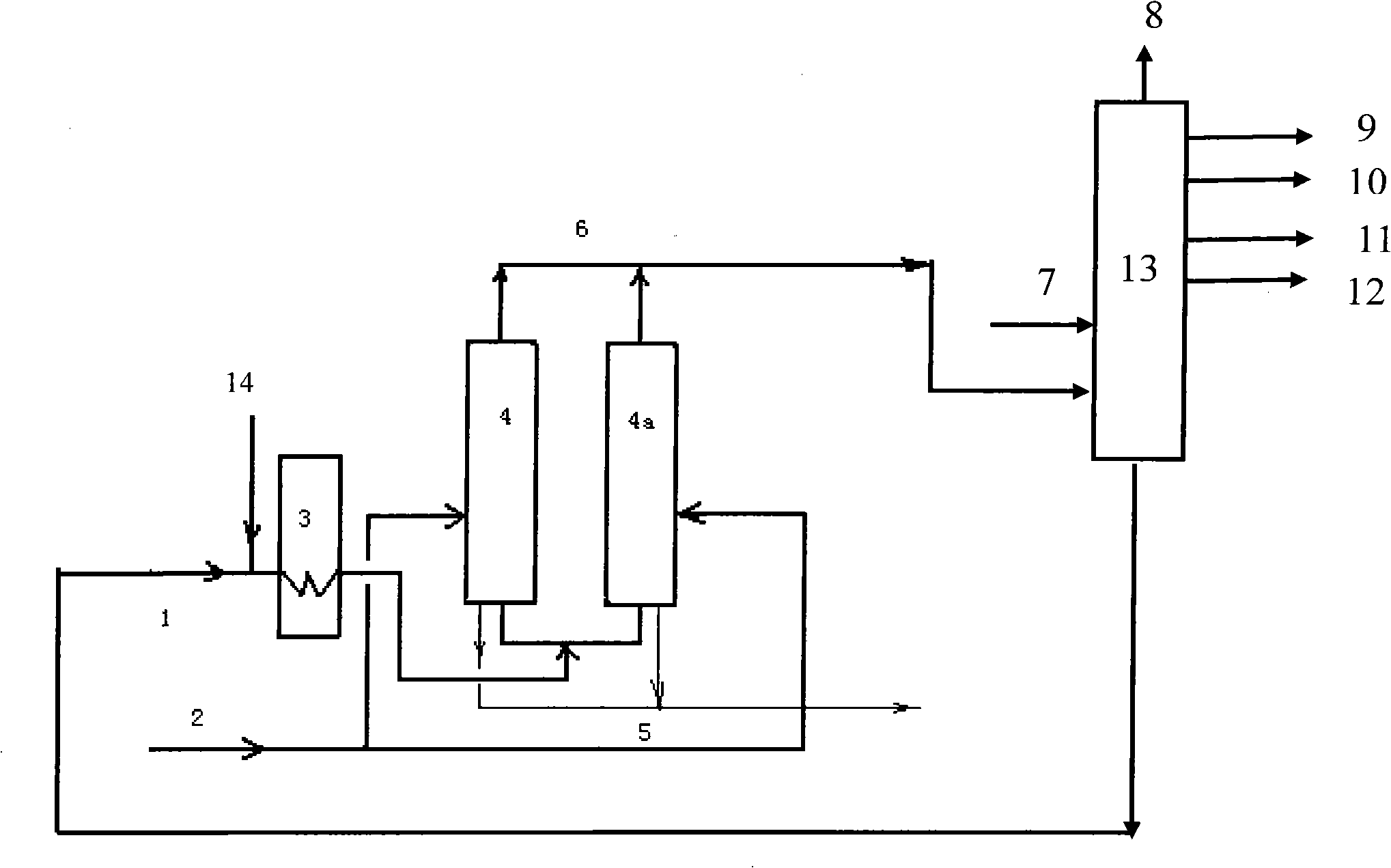

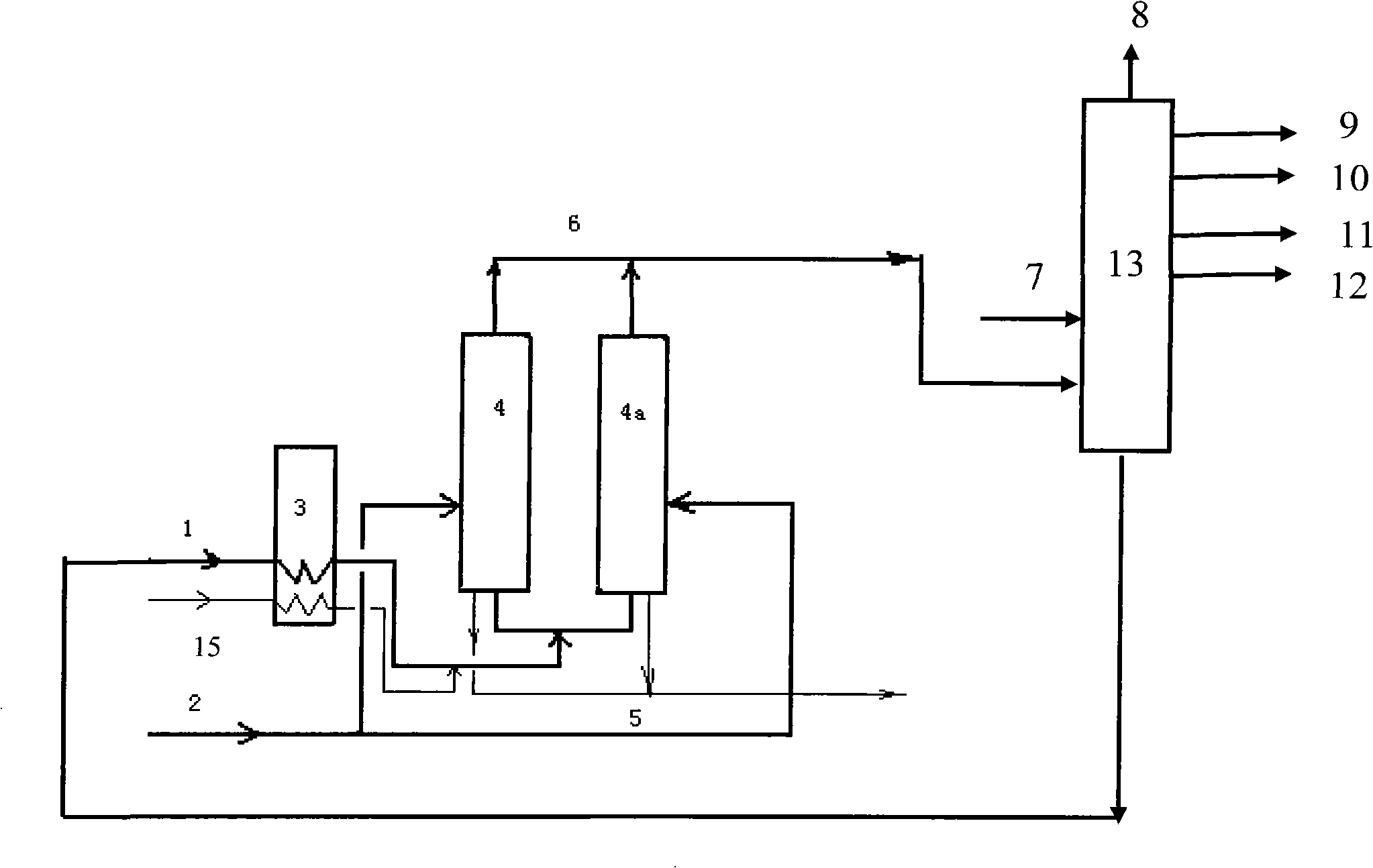

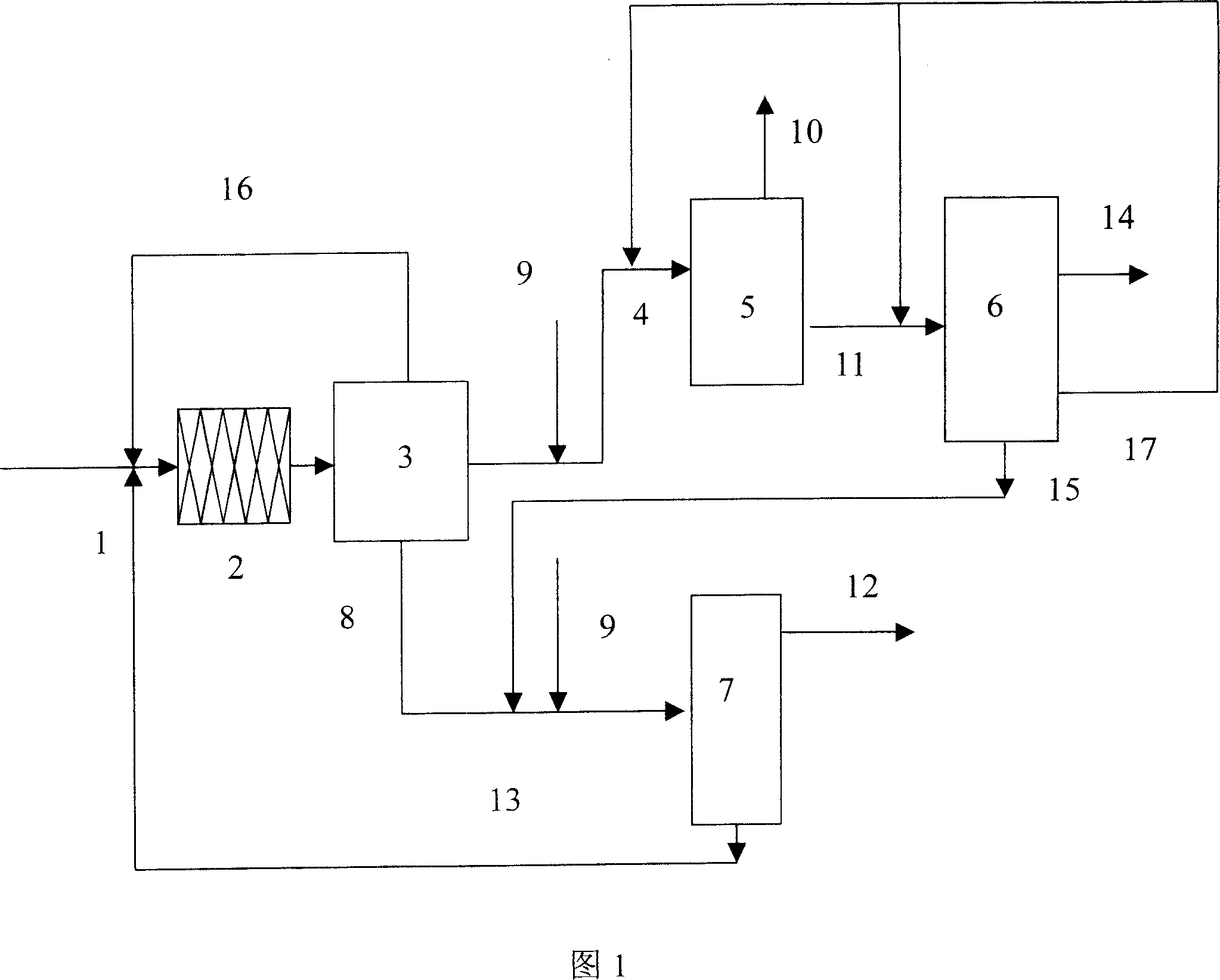

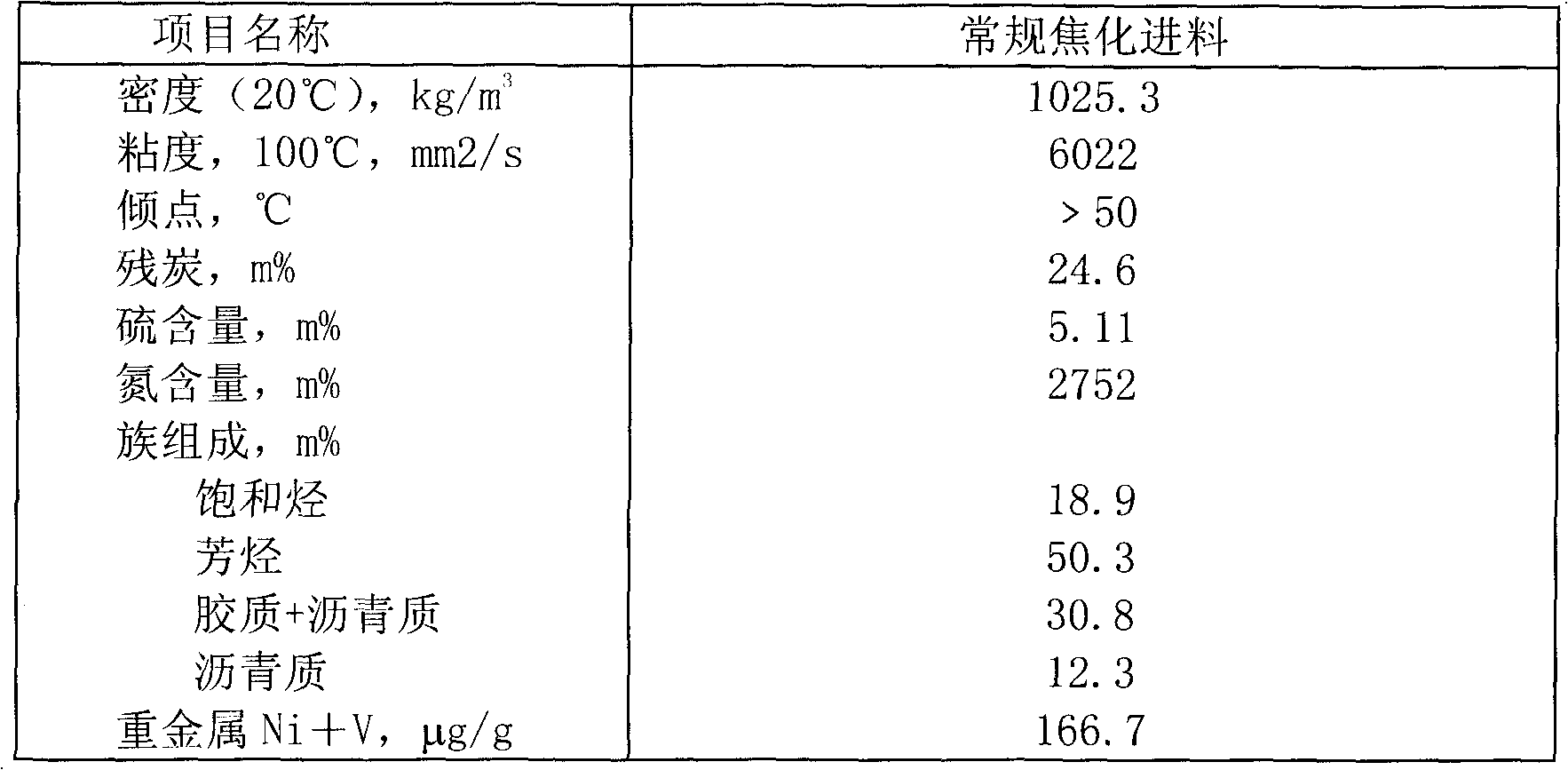

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

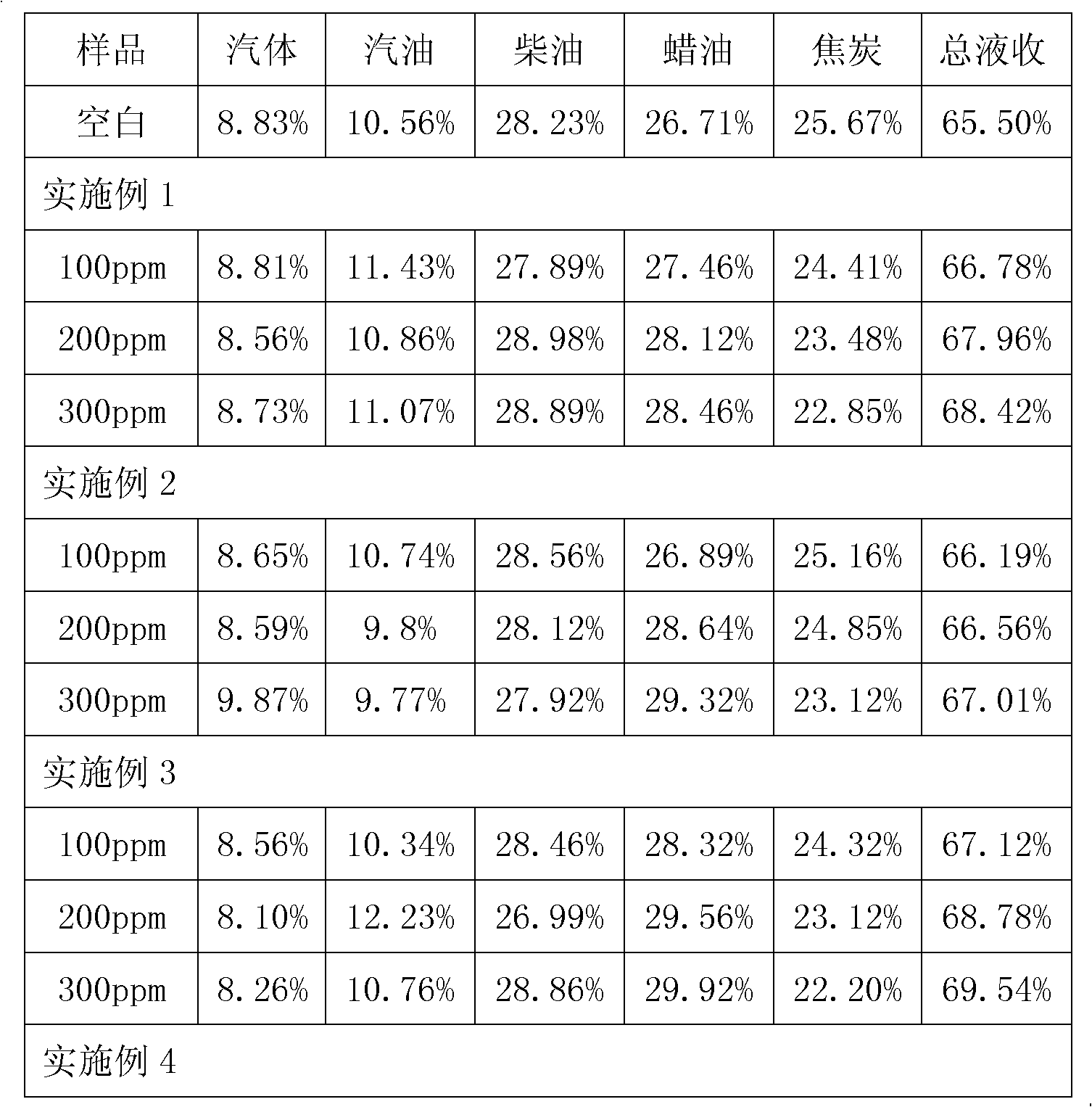

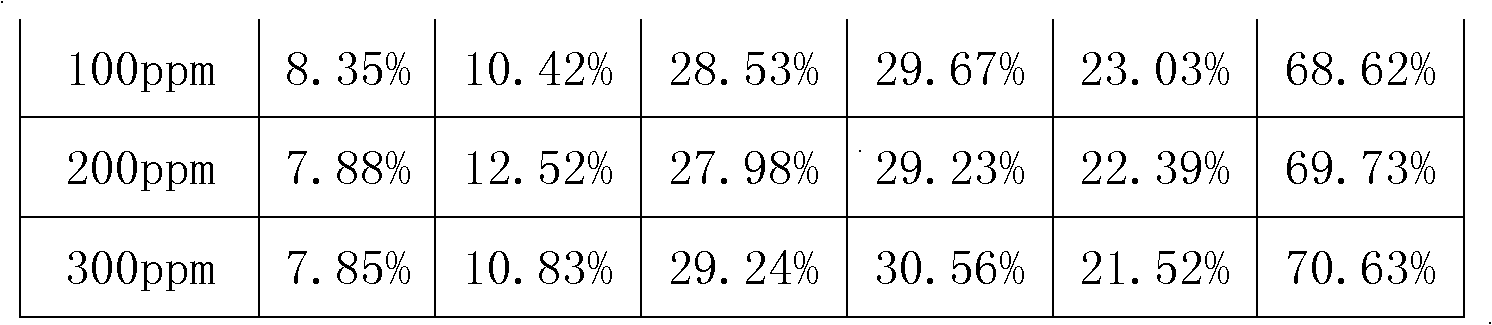

Compound coal tar hydrogenation catalyst and preparation method thereof

ActiveCN101927167AReduce manufacturing costReduce use costHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsLow activityIron sulfide

The invention relates to a compound coal tar hydrogenation catalyst and a preparation method thereof. The catalyst comprises a high-activity component of water-soluble salts of molybdenum, nickel, cobalt or tungsten and comprises a low-activity component of iron oxide ore or iron sulfide ore, wherein the mass ratio of the metals in the high-activity component to the metals in the low-activity component is 1:1,000 to 1:10; iron accounts for more than or equal to 40 weight percent of the ore; and water accounts for less than 2 weight percent of the catalyst. The catalyst is used for the coal tar hydrocracking technical process in a suspension bed, has higher hydrogenation activity and the lightweight oil yield of over 94 percent, and can be recycled; the preparation and use cost of the catalyst can be greatly reduced, the consumption of the catalyst is reduced in the process, the coke deposition of the reaction system is avoided simultaneously and the operation cycle is prolonged.

Owner:CCTEG CHINA COAL RES INST

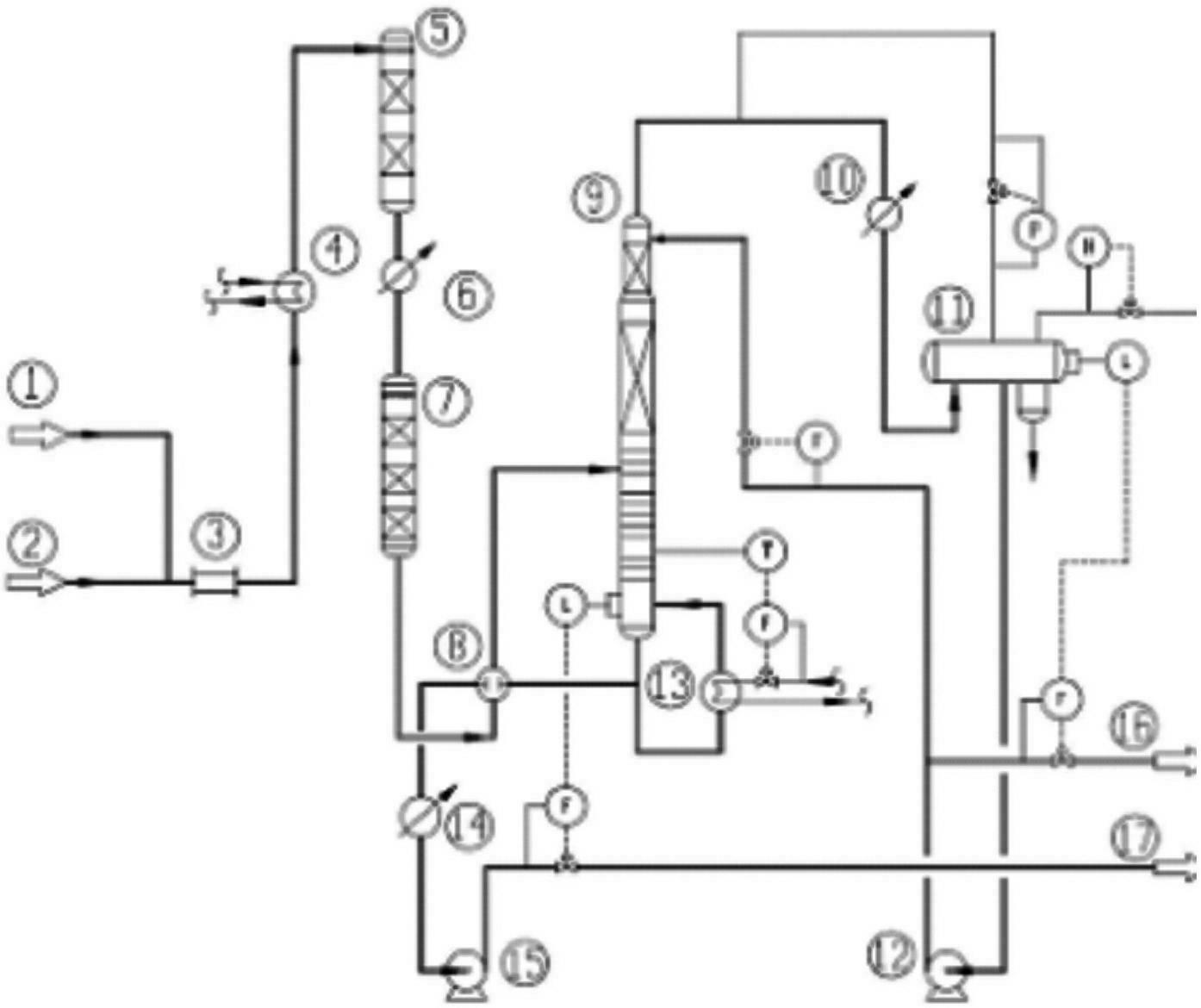

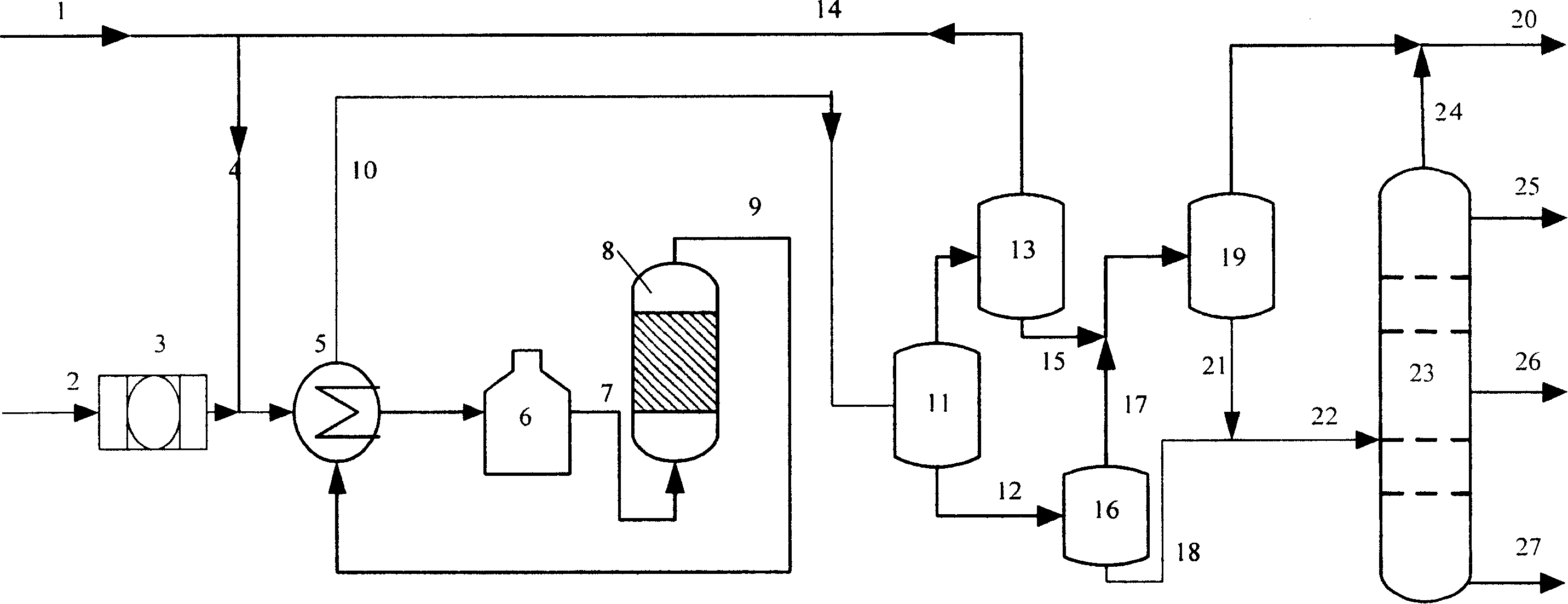

Coal tar heavy fraction suspension-bed hydrocracking method and system thereof

InactiveCN101962571AHigh yieldSimple structureTreatment with hydrotreatment processesHydrogenGasoline

The invention belongs to the technical field of coal chemical industry, and provides a coal tar heavy fraction suspension-bed hydrocracking method. The method comprises the following steps: mixing raw materials of coal tar heavy fractions with a catalyst and a vulcanizing agent to form a uniform mixed material; vulcanizing the catalyst in the mixed material under the action of hydrogen; preheating the vulcanized mixed material, and then allowing the preheated material to enter a suspension-bed reactor for hydrocracking reaction; and fractionating the product from the suspension-bed reactor to finally obtain gaseous hydrocarbon, gasoline fractions, diesel fractions and tail oil. In the invention, by directly adopting the hydrocracking method with a coal tar heavy fraction suspension bed and a system thereof, the coal tar heavy fractions can keep light weight, and the yield of the fuel oil product hydrogenated by coal tar can be effectively increased; and the suspension-bed hydrogenation reactor has simple structure without a bed layer, thus causing no phenomena such as blockage, increased pressure drop, overtemperature and the like occurred on the reaction bed layer, and the reactor further has the characteristics of great operation flexibility, long operation cycle, being safe and stable, easy control and the like.

Owner:DALIAN UNIV OF TECH

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

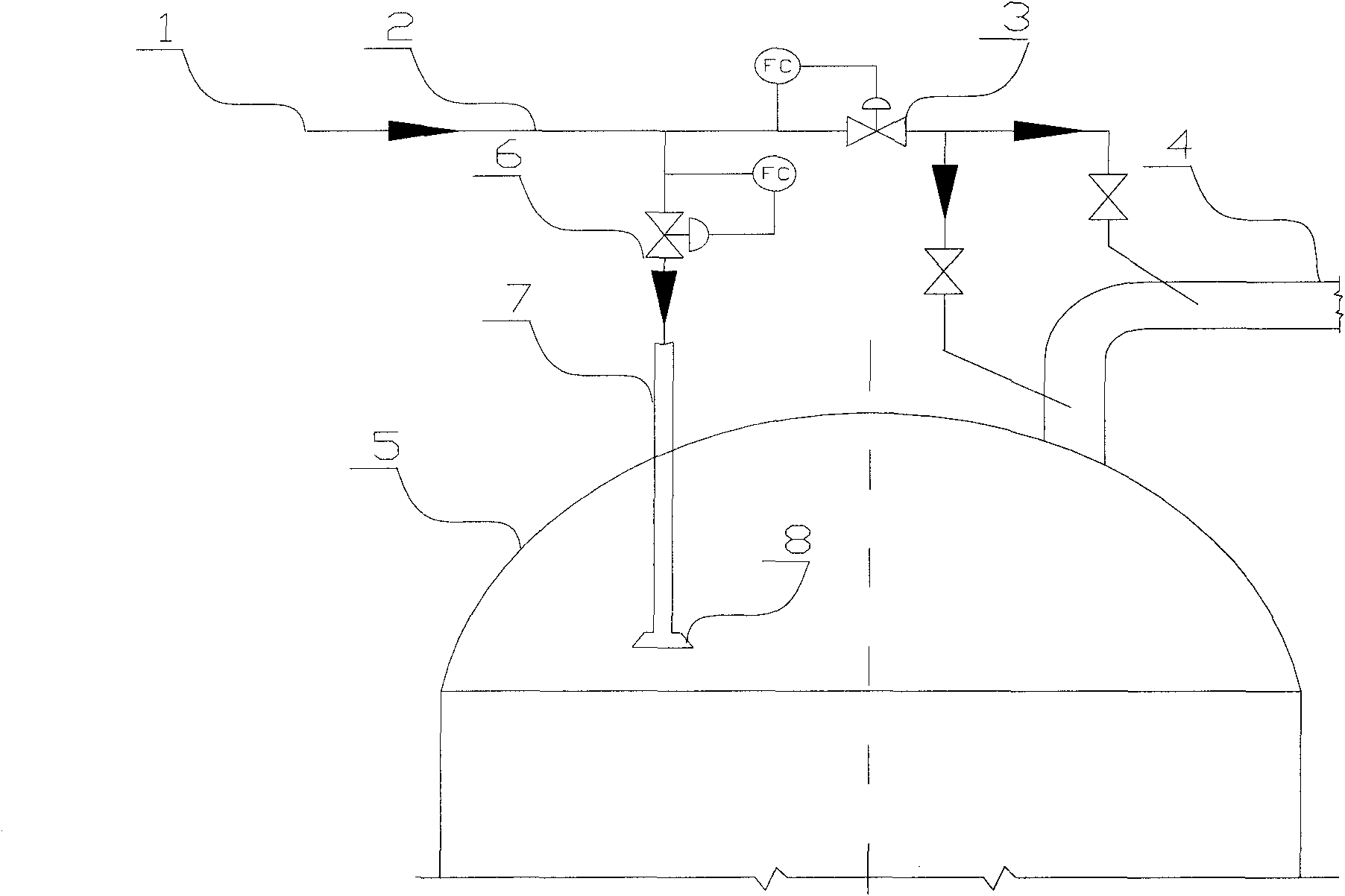

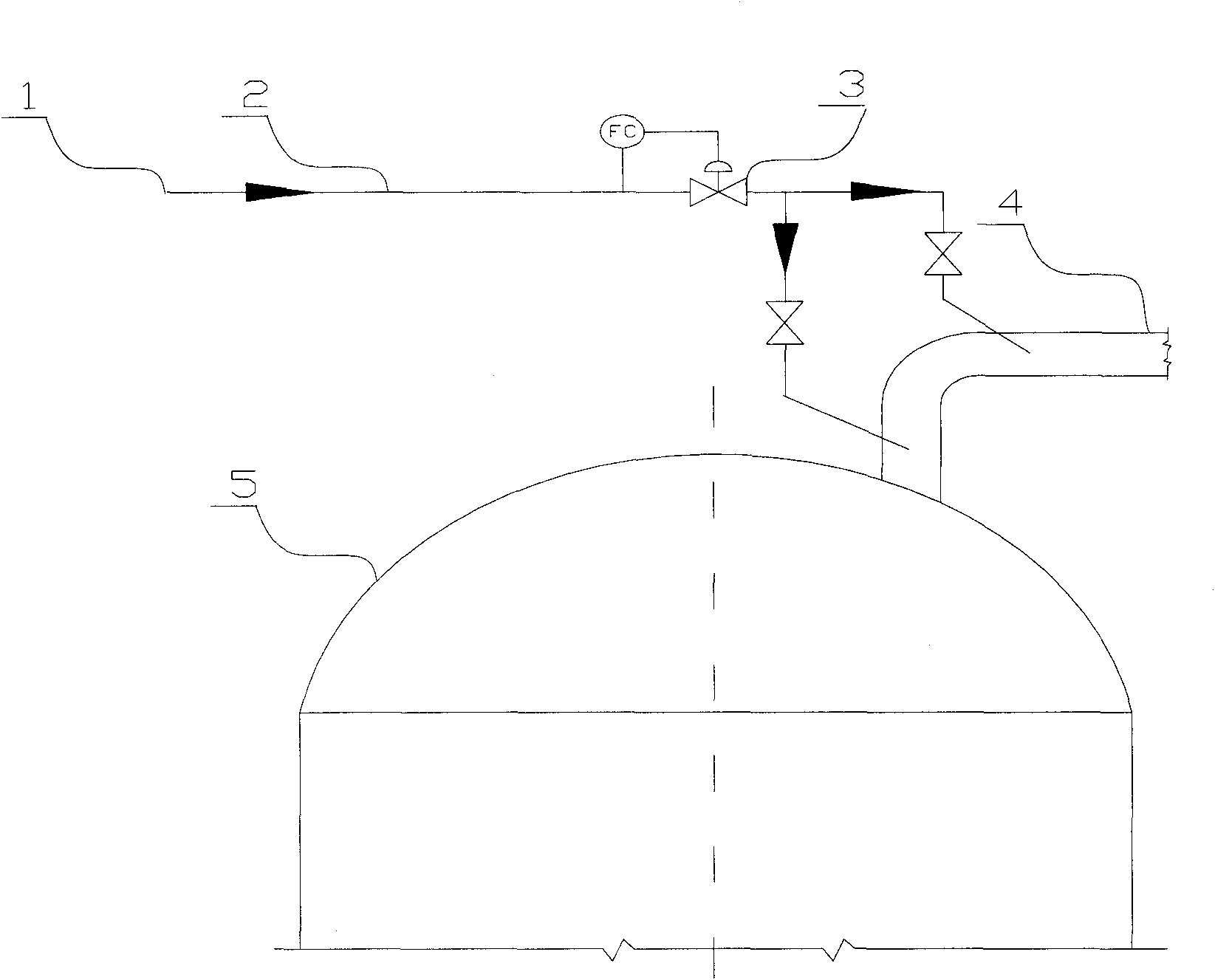

High acid value hydrocarbon oil delayed coking method

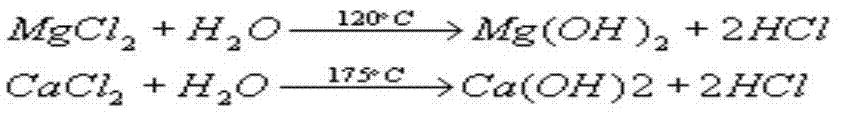

ActiveCN1580193AReduce corrosionExtend the coking start-up periodThermal non-catalytic crackingProduct gasComing out

The invention is a kind of method of delaying peracid hydrocarbon oil's burning. The process follows this. first, lead the raw material to coking heater to warm-up at the convection section, at upside of the beamy, heat up to temperature of 350 to 450 degree. Second, put outcome into cracking case and distill cymogene hydrocarbon and gas which come out from the top of reactor. Third, heat up the weight crackate, which comes out from the top of reactor, at radiant section of furnace to the temperature of 480-510 degree. Forth burn the outcome in coke chamber and then distill the burned gas to gain coking gas, gasoline, diesel, petrolatum oil and circulation oil. The advantages of the invention is that, first, it can produce peracid base oil by delayed coke equipment. Second, it can delay the coke's canker by peracid base oil and prolong the burning cycle length.

Owner:CHINA PETROLEUM & CHEM CORP +1

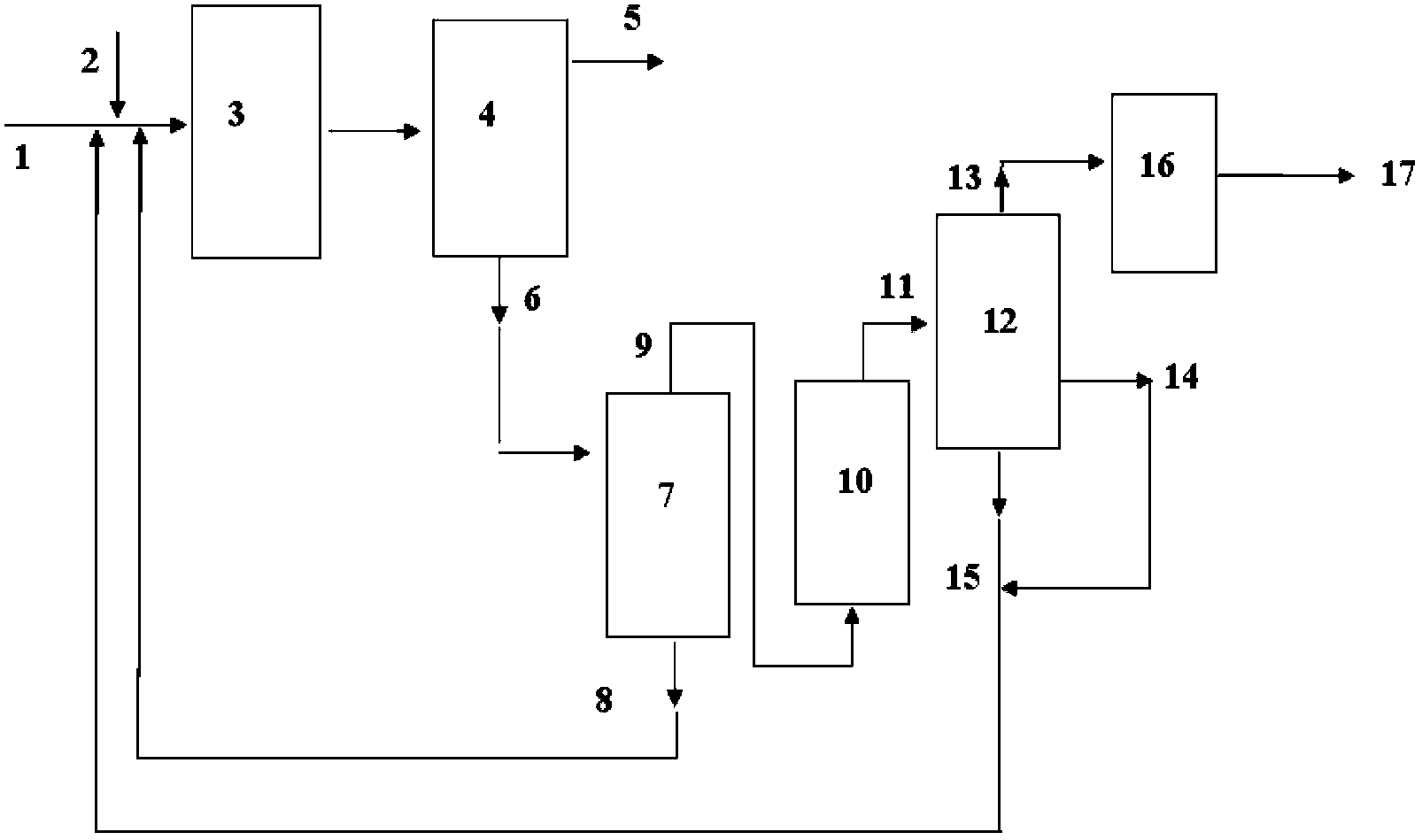

Combination processing method of inferior heavy oil

ActiveCN103789036AHigh yieldHigh residual carbon valueTreatment with hydrotreatment processesHydrogenGasoline

A combination processing method of inferior heavy oil comprises the following steps that: A, a heavy oil feedstock enters into a liquid flow bed reactor for hydrocracking in the effects of hydrogen and a dispersible hydrocracking catalyst; B, the obtained hydrogenation product is fractionally distilled to obtain light oil and heavy oil, the cutting point is 320-380 DEG C, and the light oil is led out of the device; C, the heavy oil obtained by fractional distillation is extracted by a solvent to obtain deasphalted oil and deoiled asphalt; D, the deoiled asphalt is contacted with a catalytic cracking catalyst for cracking reaction in catalytic cracking conditions, and light oil, heavy cycle oil and slurry oil are obtained by fractional distillation; E, the deoiled asphalt obtained by the step C is recycled into the liquid flow bed reactor in the step A. According to the combination processing method provided by the invention, a variety of processes are integrated for processing of the inferior heavy oil, full transformation of the heavy oil can be realized, and more gasoline and diesel oil which are excellent in performances can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for converting low-quality heavy oil into light clean fuel oil

ActiveCN101899323AImprove separation efficiencyEasy to separateTreatment with plural serial stages onlyVacuum distillationDistillationSolid particle

The invention discloses a catalytic conversion method for converting low-quality heavy oil into light clean fuel oil, which comprises: (1), introducing low-quality raw material oil into a catalytic cracking reactor having two reaction areas for performing a cracking reaction, wherein the reaction conditions in the catalytic cracking reactor ensure the catalytic wax oil obtained by the reaction is12 to 60 weight percent based on the weight of the low-quality raw material oil; (2) introducing the catalytic wax oil carrying catalyst particles into a reduced-pressure distillation tower, and separating a catalytic wax oil light fraction from the top of the tower; (3) hydrogenating the catalytic wax oil light fraction to obtain hydrogenated catalytic wax oil; and (4) circulating the hydrogenated catalytic wax oil to a catalytic conversion device for further reaction to obtain a light fuel oil target product. The method provided by the invention has the advantages that: due to the catalyticcracking of the low-quality heavy oil raw material, the catalytic wax oil yield is high, and the dry gas yield and cock yield are low; after solid particle removal and hydrogenation, the obtained catalytic wax oil can be introduced back to the catalytic cracking device for recycling, so the light oil yield of the whole process is increased by 5 to 15 percent and oil slurry yield is reduced; and thus, the high-efficiency use of oil resources is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

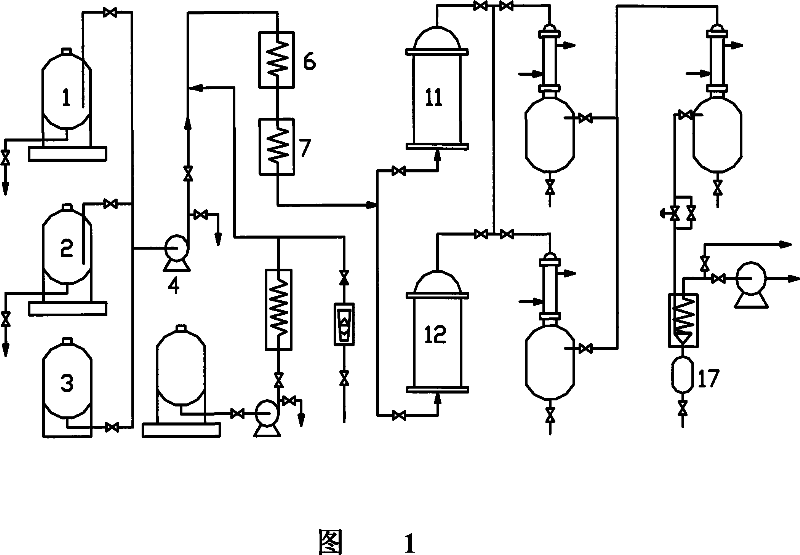

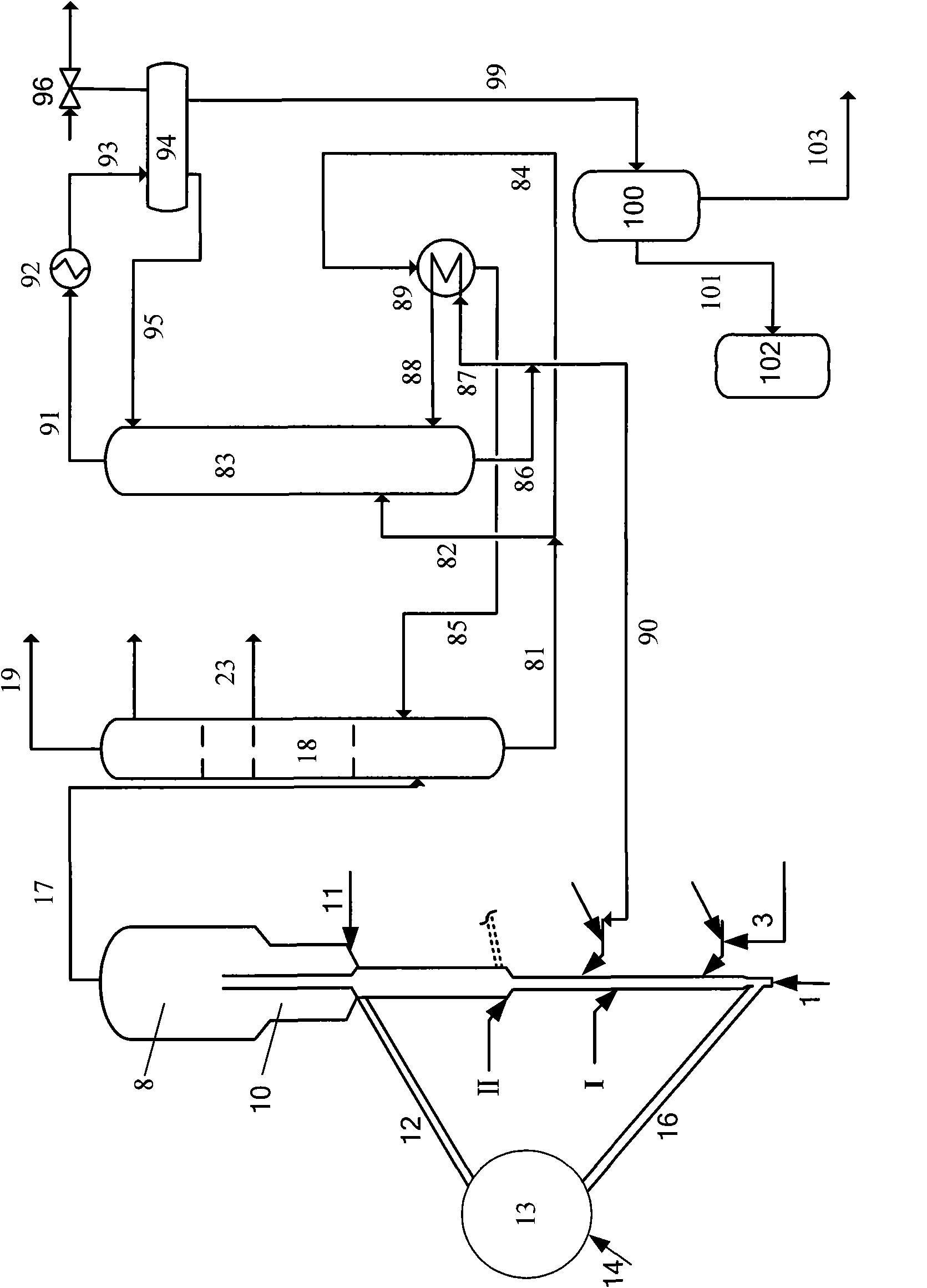

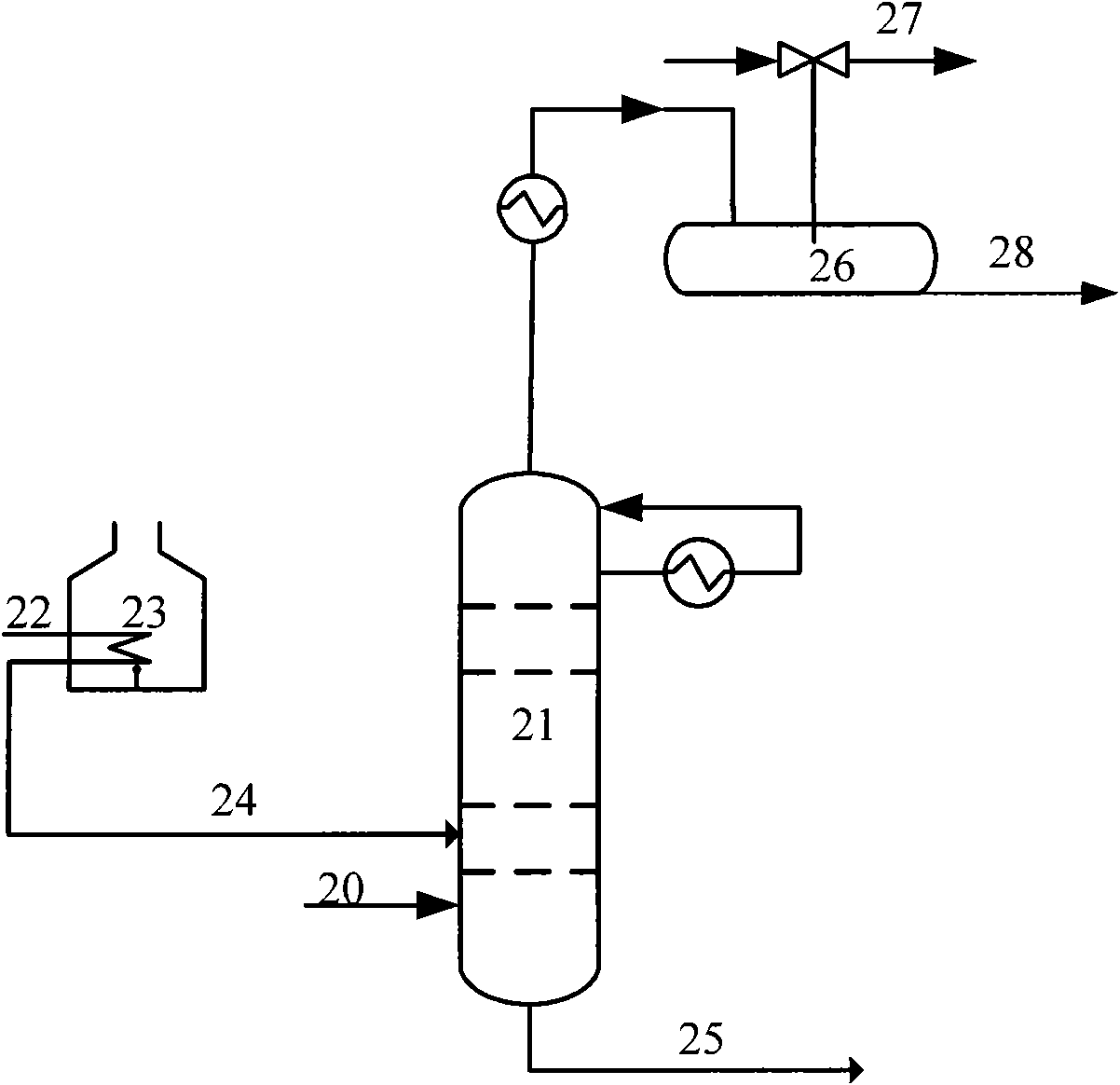

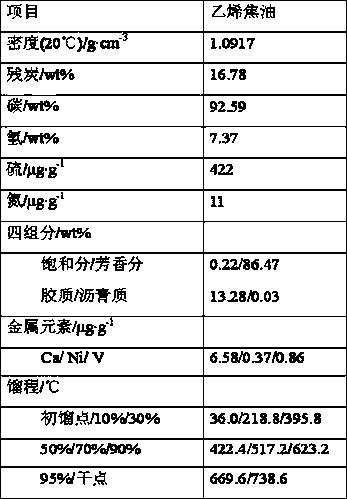

Process and system for treating ethylene tar

ActiveCN109929592APlay a role in strippingRestricted accessTreatment with hydrotreatment processesCracking reactionTreatment system

The invention discloses a process and a system for treating ethylene tar. According to the process, preheated ethylene tar contacts a coking reaction effluent from a delayed coking reaction system ina pretreatment reactor, and a light component and a heavy component are obtained after separation; the heavy component enters the delayed coking reaction system, and the generated coking reaction effluent enters the pretreatment reactor; the light component and hydrogen enter a hydrogenation reaction system, and the reaction effluent is separated to obtain gas, gasoline distillate, diesel oil distillate and heavy oil distillate; and the heavy oil distillate enters a catalytic cracking reaction system, and the catalytic diesel oil obtained after separation enters the pretreatment reaction. Thetreatment system comprises the pretreatment reactor, the coking reaction system, the hydrogenation reaction system, and the catalytic cracking reaction system. With the process and the system of the present invention, the stable long-cycle operation of the whole treatment system can be ensured, and the yield of the light oil product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst aid for residual oil suspended bed and its use

InactiveCN1632070AImprove coke suppression effect of hydrogenationReduce the amount of cokingLiquid hydrocarbon mixture productionRefining to eliminate hetero atomsCarboxylateActive agent

Disclosed is a suspended bed hydrogenation catalyst assistant belongs to the fields of oil procession and oil chemical technology. The assistant contains are or the combination of several ones willingly chosen from high molecule, synthesis organic high molecule, natural surface active agent, synthesis surface active agent, condensed aromatics, organic alcohol, organic carboxylate surfactant, organic carboxylic acid amide, organic carboxylic acid halogen, organic phosphide. It can be applied in the course of suspended bed hydrogenation, as well as that of hydrogenation mixing of hydrogenation and liquidifying coal. By adding the assistant, the hydrogenation effect of catalyst can be increased, as well as decreasing scale formation in reactor in the time of decreasing scale formation in fractional distillation part of the reacting pipe.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method and device for inhibiting coking of residue fluid catalytic disengager

ActiveCN102041096AEliminates the possibility of cokingFast drainageCatalytic crackingTreatment apparatus corrosion/fouling inhibitionDrainage tubesPetroleum

The invention provides a method and a device for preventing interior of a disengager from coking by quickly extracting oil gas from the fluidized catalytic cracking disengager of petroleum, wherein the device comprises a primary cyclone separator, a straight connection component which is arranged on the tail end of exit tube of the primary cyclone separator, a top cyclone separator, an oil gas drainage tube, an inertial separation component which is on the lower end of inlet of the drainage tube, a stripping section, an anti-coking steam ring and a disengager. The oil gas and the steam within the disengager are discharged out from the oil gas drainage tube only, the lower end of opening of the oil gas drainage tube is equipped with the inertial separation component so as to reduce the catalyst which is entered into the oil gas drainage tube by splashing while discharging from the dipleg of the primary cyclone separator and the dipleg of the top cyclone separator, the exit tube of the primary cyclone separator is tangentially connected to the oil gas drainage tube by means of the straight connection component, and a rotational flow is formed on the upper section of the oil gas drainage tube, so that a vortex low-pressure region is formed and the drainage draft of the oil gas is increased. The method and the device for inhibiting coking of residue fluid catalytic disengager provided by the invention have the advantages that the structure is simple and compact, the fast and efficient separation between the oil gas and the catalyst is ensured, the oil gas within the space of the disengager is extracted quickly, the retention period of the oil gas within the disengager is reduced greatly, the coking phenomenon within the disengager is inhibited effectively and therefore the operation cycle of the catalytic device is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

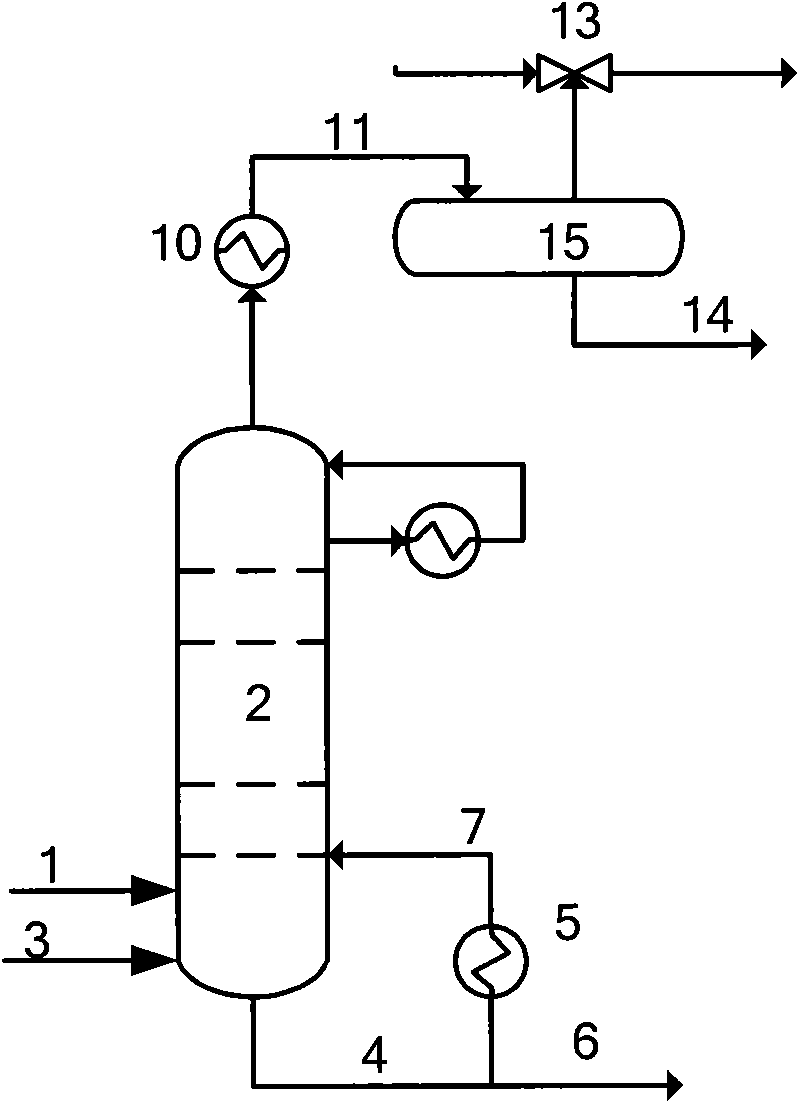

Method for synthesizing MTBE (methyl tert-butyl ether) by reaction of mixed C4 with low isobutene content and methanol

InactiveCN102701917AReduce loadMild responseChemical industryEther preparation by compound additionChemistryCatalytic distillation

The invention relates to a method for synthesizing MTBE (methyl tert-butyl ether) by the reaction of mixed C4 with a low isobutene content and methanol, which comprises the following steps: 1, pre-etherification reaction: the mixed C4 containing 10-15wt% of isobutene and the methanol are fully mixed by a static mixer according to the molecular ratio of isobutene to methanol of (1:1)-(1:1.1), and then the mixture enters a pre-etherification reactor provided with a fixed bed catalyst bed layer for pre-etherification; 2, etherification reaction: material coming out of the pre-etherification reactor enters an etherification reactor provided with a fixed bed catalyst bed layer for etherification, wherein the conversion rate of the isobutene at an outlet of the etherification reactor is larger than or equal to 90%; and 3, product separation and purification: material coming out of the etherification reactor enters a catalytic distillation tower for further reaction and separation, the upper part of the catalytic distillation tower is provided with a catalyst bed layer, and an MTBE product is produced at the lower part of the catalytic distillation tower. Compared with the prior art, the method disclosed by the invention has the characteristics that a weight separation tower is eliminated, the loss of the isobutene in weight separation is avoided, and the yield of the MTBE product is improved.

Owner:CHANGLING PETRO CHEM ENG DESIGN

Coking method for processing highly acid crude oil

ActiveCN101280213AReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerCorrosion

The invention discloses a method of processing highly-acidic crude oil through the delayed coking process; the method includes that the low temperature highly-acidic crude oil is fed from the middle-lower part and the high temperature low-acidic coking raw material is fed from the bottom; the high temperature oil gas generated by the high temperature cracking of the low-acidic coking raw material is mixed with the low temperature highly-acidic crude oil so that the highly-acidic crude oil is enabled to realize the purpose of the deacidification through the pyrolysis deacidification under high temperature; meanwhile, the cracking temperature of the low-acidic coking raw material is lowered; the high temperature cracking time of the conventional raw materials; thereby, the coking yield is reduced and the stable operation period of the single tower is prolonged; besides, the preheating temperature of the highly-acidic crude oil can avoid the strong corrosion stage of the acid; the corrosion on the heating device caused by the acid can be reduced or avoided when the temperature is even lower than the corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for inferior heavy oil and residual oil

ActiveCN100340643CExpand sourceQuality improvementTreatment with hydrotreatment processesFixed bedSlurry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for alleviating coking of coke tower top oil gas pipeline

The invention provides a method for alleviating coking of a coke tower top oil gas pipeline. The method comprises the following steps: 1, spraying parts of quenching oil into a coke tower from the upper part or the top of the coke tower, and pre-quenching a coke tower top oil gas; and 2, spraying the other parts of the quenching oil in a tower outlet oil gas pipeline into the pipeline, and quenching the high temperature oil gas in the tower outlet oil gas pipeline. The method allows the temperature of the coke tower top oil gas to be effectively reduced and a secondary reaction to be timely inhibited, so the coking of the coke tower top oil gas pipeline can be effectively alleviated, and the on-stream period of a coking delay apparatus is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

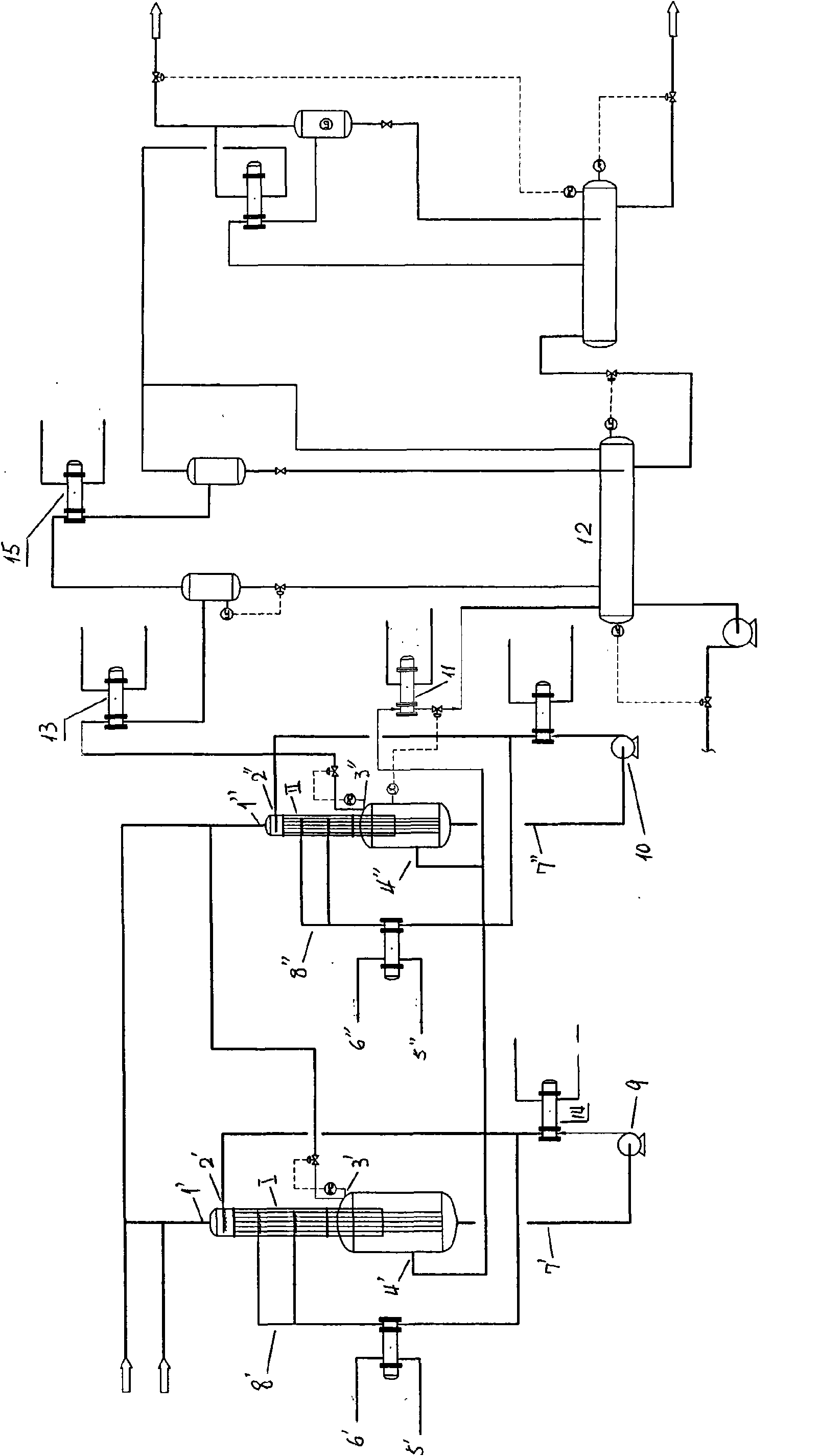

Process for continuously producing corresponding aldehyde by alkene hydroformylation reaction

ActiveCN101575272AFully playAdequate responsePreparation by carbon monoxide reactionFormylation reactionGas phase

The invention discloses a process for continuously producing corresponding aldehyde by alkene hydroformylation reaction. The process comprises the following steps: heating a water-soluble alkene hydroformylation catalyst water solution to between 80 and 95 DEG C and then making the water-soluble alkene hydroformylation catalyst water solution enter NO. 1 and NO.2 alkene hydroformylation continuous reactors (I and II) from liquid distributors (2' and 2'); when the catalyst water solution is cyclically stable, introducing mixed gas of alkene and synthesis gas of purified hydrogen and carbon monoxide to the NO.1 reactor, and carrying out hydroformylation reaction on the alkene on an interface of a cyclical catalyst liquid membrane; discharging unreacted mixed gas at the end of a separation section of the bottom of the NO.1 reactor and a gas-phase byproduct from the NO.1 reactor; automatically separating an aldehyde product from the catalyst water solution, discharging the aldehyde product and the catalyst water solution from liquid aldehyde outlet (4') of the NO.1 reactor, and making the aldehyde product and the catalyst water solution enter a coarse aldehyde tank (12); and supplementing the mixed gas of the alkene and the synthesis gas of the hydrogen and the carbon monoxide by the unreacted mixed gas which is discharged from a reaction residual gas outlet (3') of the NO.1 reactor and the gas-phase byproduct, and introducing the mixed gas into the NO.2 reactor (II) to further react.

Owner:南京荣欣化工有限公司 +3

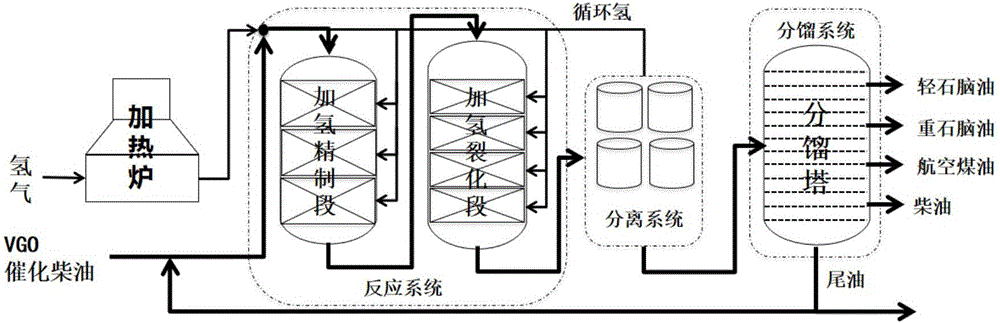

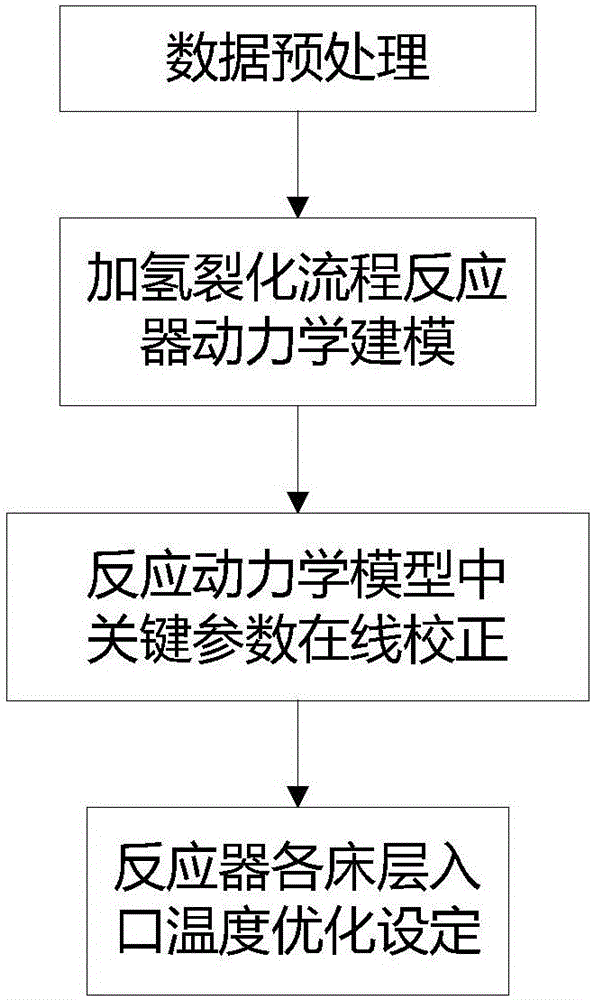

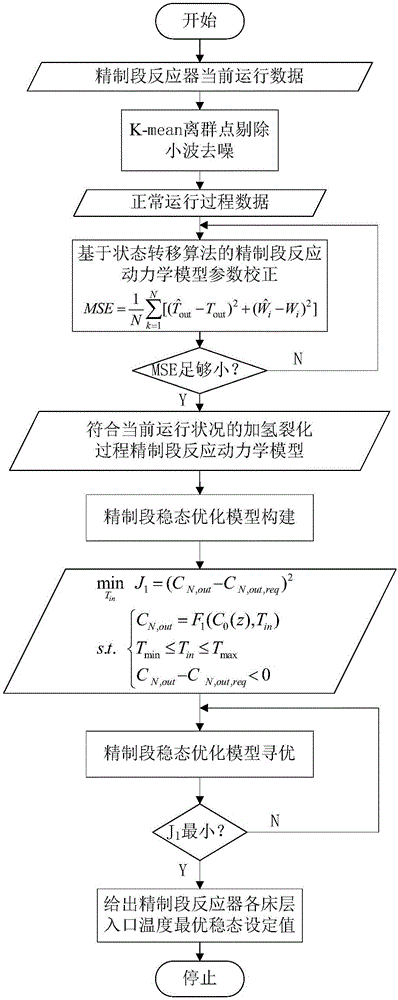

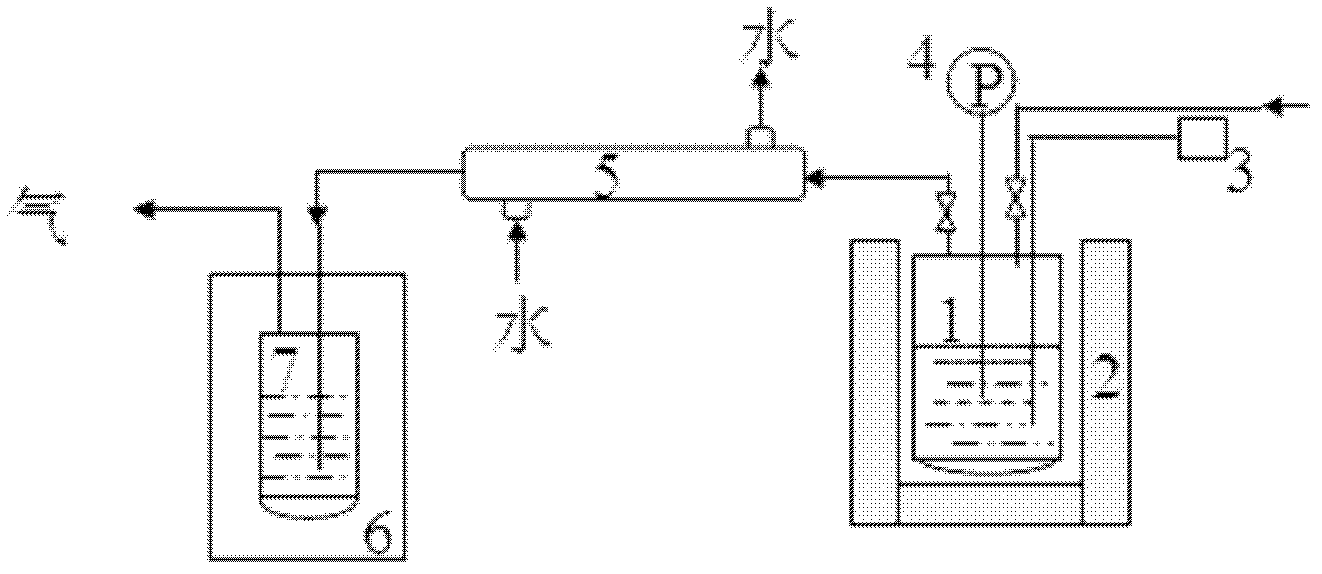

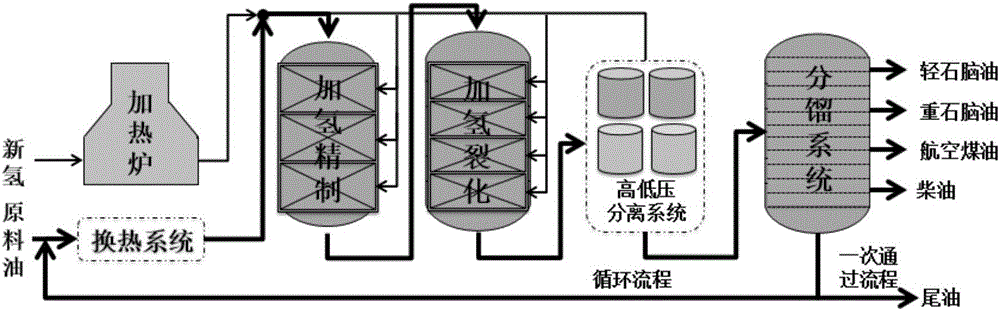

Method for optimizing reaction conditions of hydrocracking process

ActiveCN106778008AAvoid interferenceImprove accuracyChemical processes analysis/designSpecial data processing applicationsEnergy balancingMaterial balance

The invention provides a method for optimizing reaction conditions of the hydrocracking process. The method includes the steps that chemical reactions in the hydrocracking process are classified according to the lumping theory, and a kinetic model of a reactor is set up by combining material balance and energy balance principles; further, a state transition algorithm is adopted to correct parameters of the kinetic model, a steady optimizing model is set up based on the corrected reaction kinetic model to optimize inlet temperature of all bed layers of the hydrocracking process reactor on line, and then the purposes of prolonging the operation cycle of equipment and increasing economic benefits of an enterprise are achieved.

Owner:CENT SOUTH UNIV

Additive for promoting residual oil thermal cracking reaction and preparing method and application thereof

ActiveCN102585881APromote decompositionPromote decomposition and inhibit coke formationThermal non-catalytic crackingEmulsionAntioxidant

The invention belongs to the field of chemical engineering and relates to an additive for promoting residual oil thermal cracking reaction and a preparing method and application thereof. The additive for promoting residual oil thermal cracking reaction contains the following components by weight: 15-20 parts of ash-free dispersing agents, 2-5 parts of metal deactivator, 10-15 parts of antioxidant, 20-25 parts of antioxidant and corrosion inhibitor, 5-10 parts of polymerization inhibitor, 5-10 parts of emulsion wetting agents and 15-40 parts of solvents. The additive is used for delaying a coking unit, promoting residual oil thermal cracking reaction, improving liquid yield and simultaneously reducing furnace tube coking.

Owner:宜兴汉光高新石化有限公司

Residual oil hydrotreating method

InactiveCN106367113AImprove economic efficiencyImprove responsivenessTreatment with hydrotreatment processesKeroseneChemistry

The invention discloses a residual oil hydrotreating method. According to the method, on the basis of the material feeding of the original residual oil fixation bed hydrogenation device, a suitable proportion of an inferior quality light oil product is added, a hydrogenation protection agent, a hydrogenation demetallization catalyst, a hydrogenation desulfurization catalyst, a hydrogenation denitrogenation catalyst and a hydrogenation residue carbon removing catalyst are sequentially used, the product is fractionated to obtain gasoline, kerosene, diesel oil distillates and hydrogenated tail oil, and the hydrogenated tail oil can be used as the fed material for a catalytic cracking device. According to the present invention, with the method, the viscosity of the material feeding system of the residual oil fixation bed hydrogenation device can be reduced while the system reaction performance and the product quality can be improved.

Owner:SINOPEC YANGZI PETROCHEM +1

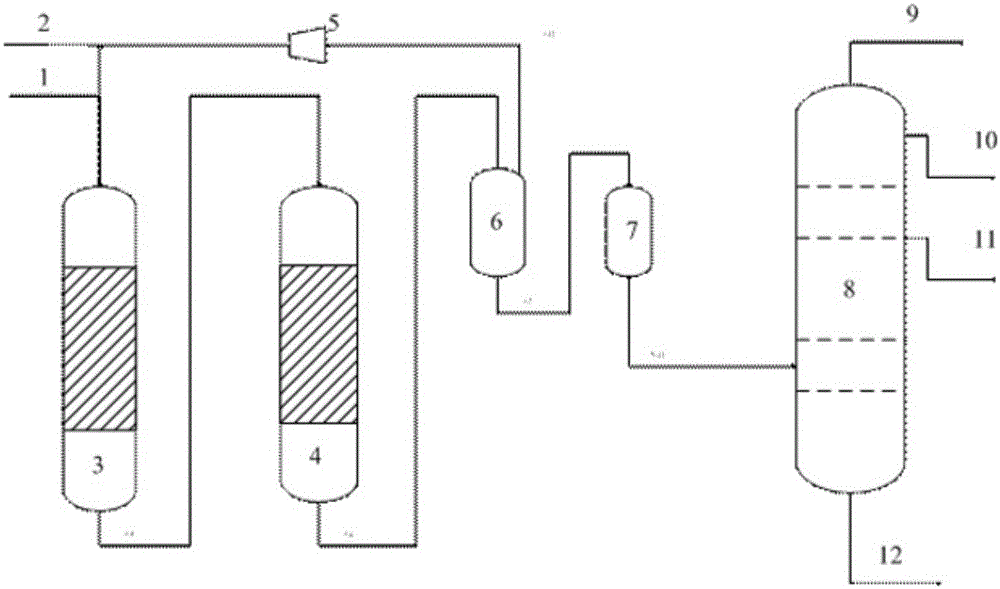

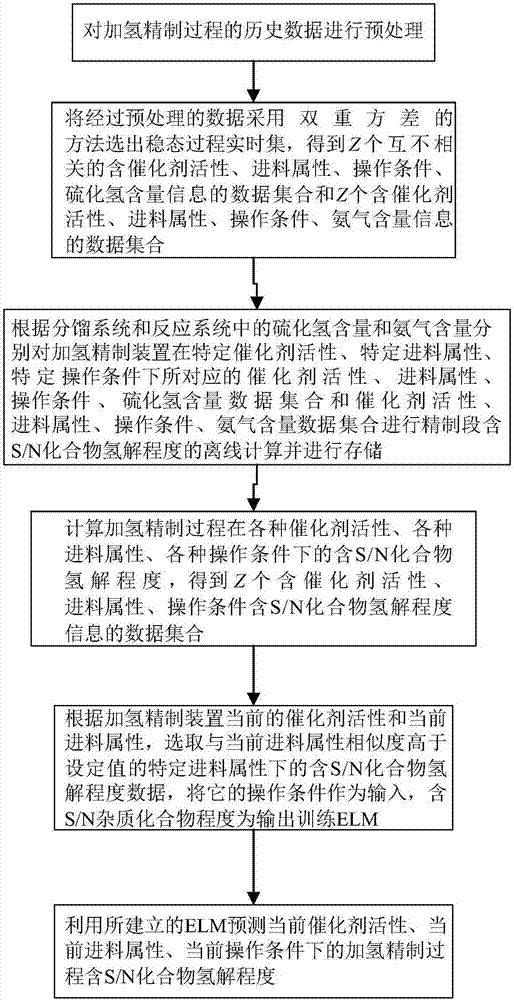

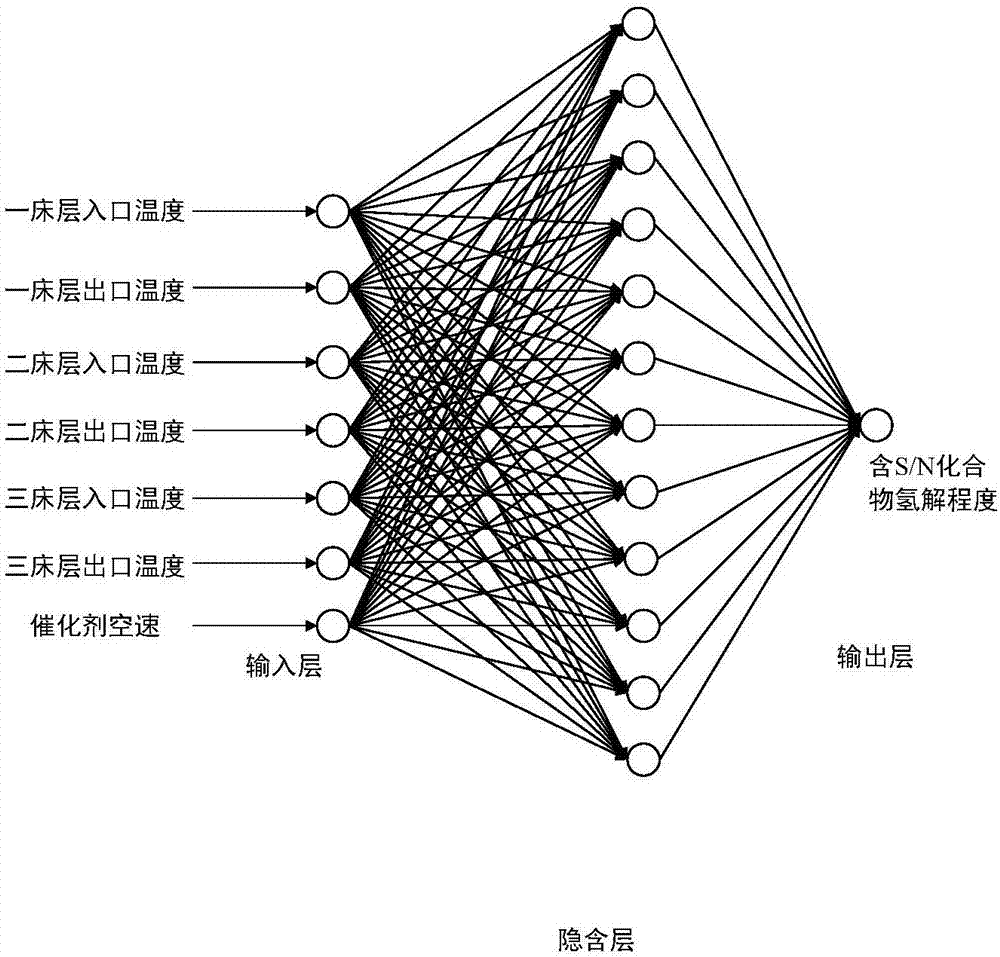

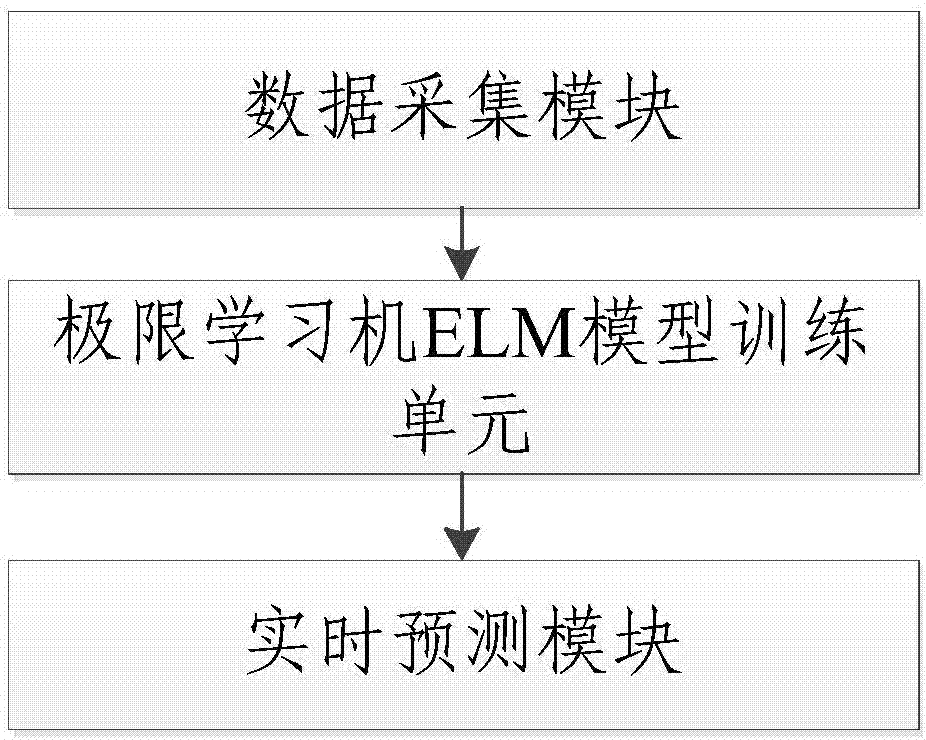

Real-time forecasting method for hydrogenolysis degree in hydrofining and system thereof

ActiveCN106874644ARun fastImprove learning abilityChemical property predictionElectric testing/monitoringLearning machineSulfur

The invention provides a real-time forecasting method for a hydrogenolysis degree of a sulfur and / or nitrogen-containing compound in a hydrofining process and a system thereof. The method comprises the step of utilizing an extreme learning machine ELM model to forecast the hydrogenolysis degree of the sulfur and / or nitrogen-containing compound in real time on the basis of the existing operation condition of the process. According to the method provided by the invention, the ELM is utilized to forecast the hydrogenolysis degree of the sulfur and / or nitrogen-containing compound in the hydrofining process in real time according to the online detectable process variable of a hydrocracking flow and the important state information is supplied for the running optimization of a refining reactor of the hydrocracking flow.

Owner:CENT SOUTH UNIV

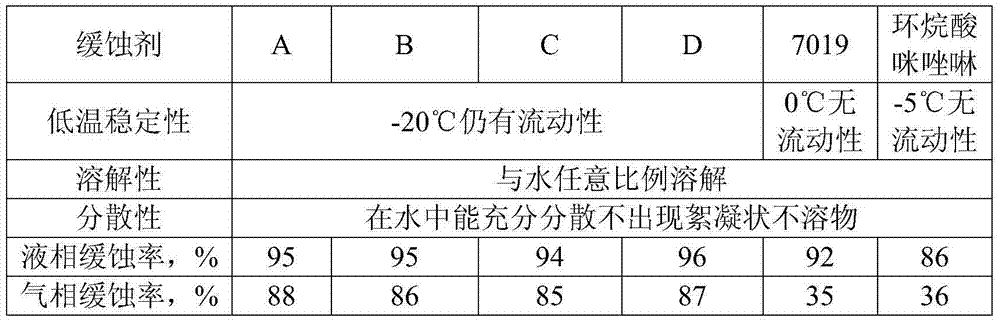

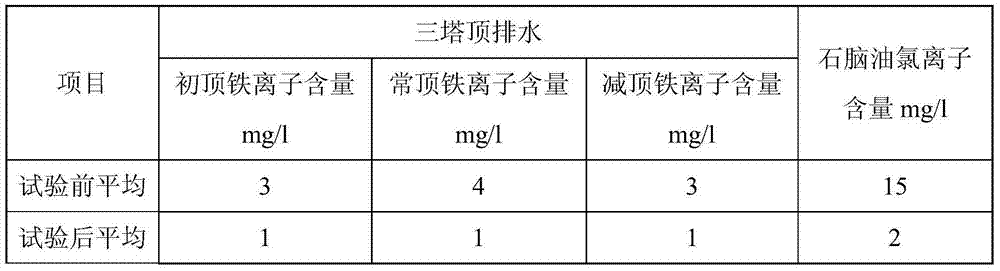

Water-soluble compound corrosion inhibitor

ActiveCN103937528AImprove performanceGood water solubilityDistillation corrosion inhibitionSolubilityBenzotriazole

The invention relates to a water-soluble compound corrosion inhibitor. The water-soluble compound corrosion inhibitor comprises 20-40wt% of pyridine derivatives, 5-20wt% of methyl benzotriazole, 15-40wt% of organic amine and 20-40% of solvent. The corrosion inhibitor product is stable in performance, good in water solubility, high in anticorrosion capacity, high in neutralizing capacity and good in film-forming property; when the corrosion inhibitor is applied to a tower top system, an extra neutralizer is not needed to be added again, and therefore, the corrosion inhibitor is especially applicable to the tower top system of a reduced pressure relief device in the petroleum industry and can be applied to tower top water injection of the reduced pressure relief device or the tower top water injection of other petroleum processing devices.

Owner:金浦新材料股份有限公司

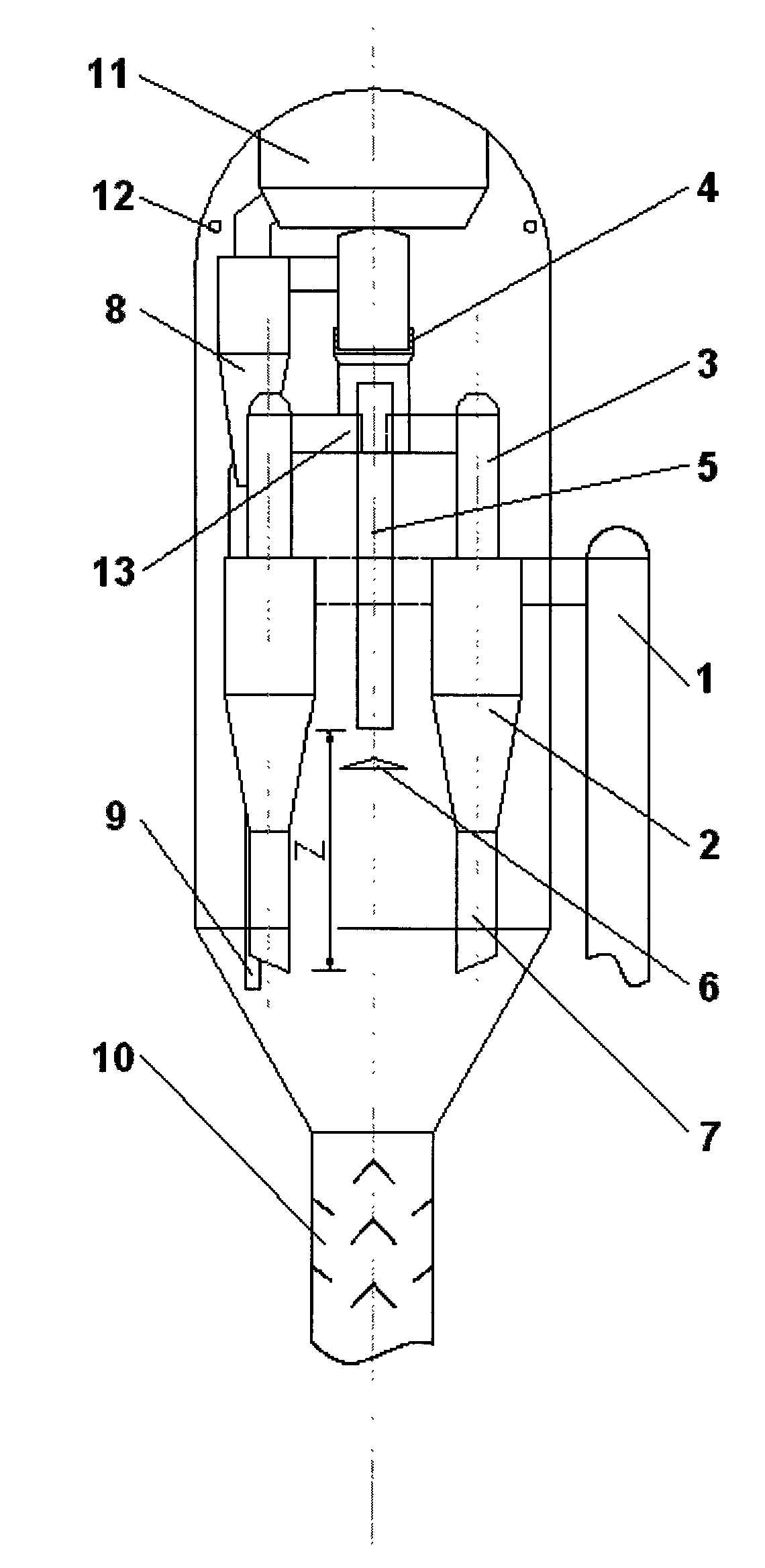

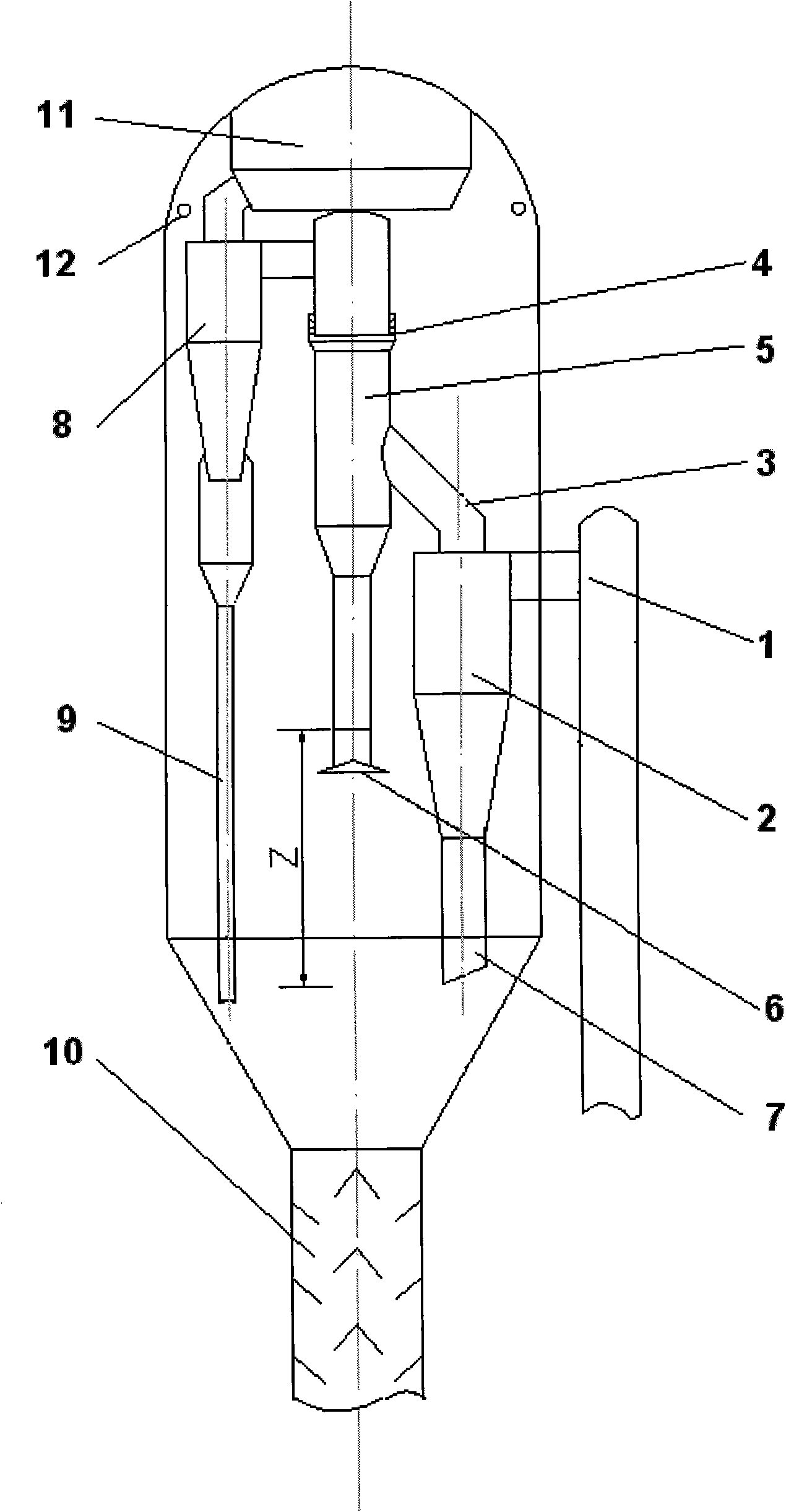

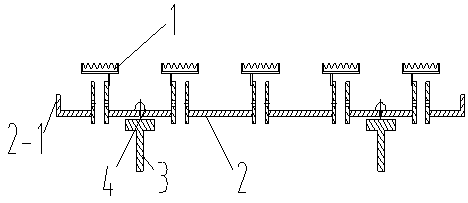

Fast lead-out device and method of oil gas for restraining coking in heavy oil catalytic cracking settler

ActiveCN102373087AEliminates the possibility of cokingShort stayCatalytic crackingTreatment apparatus corrosion/fouling inhibitionWork periodCyclone

The invention discloses a fast lead-out device and method of oil gas for restraining coking in a heavy oil catalytic cracking settler. The device comprises a rough cyclone separator (2) in the settler, a top cyclone separator (8), an oil gas drain tube (5) and a steam stripping section (10) arranged at the bottom of the settler, characterized in that: an opening at the bottom of the oil gas drain tube (5) is arranged more highly than a discharge port of a dip leg (2) of the rough cyclone separator (2) and simultaneously more highly than a discharge port of a dip leg (9) of the top cyclone separator (8), and the height difference of the latter is larger than the splashing height of the catalyst discharged from the dip leg (2) of the rough cyclone separator (2). The use of the invention can rapidly separate the oil gas from the catalyst, the oil gas enters in the space of the settler and is rapidly discharged, thus the diffusion of the oil gas to the all space of the settler can be avoided, the coking caused by long-time retention of the oil gas in the space of the settler can be eliminated, and the working period of the device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

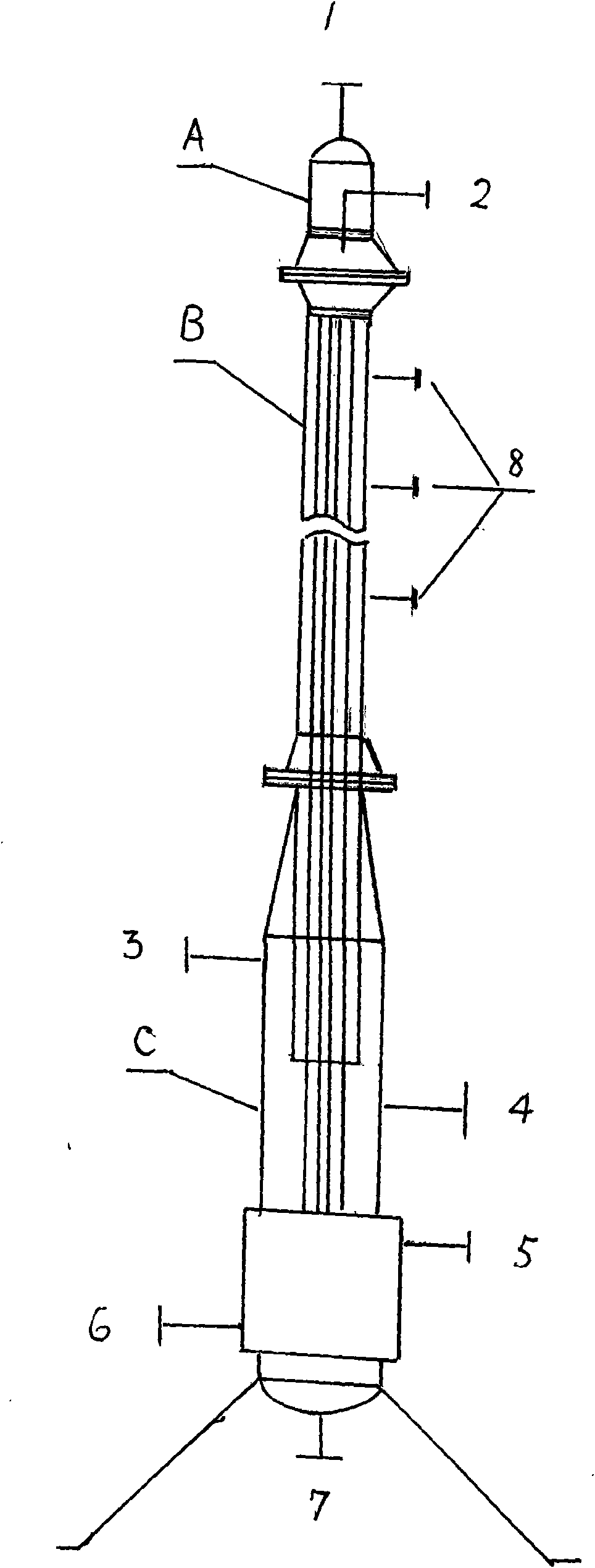

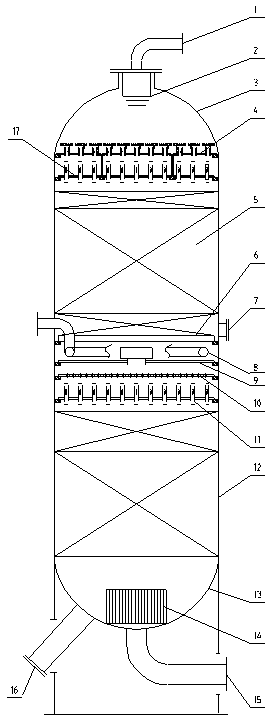

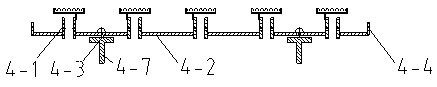

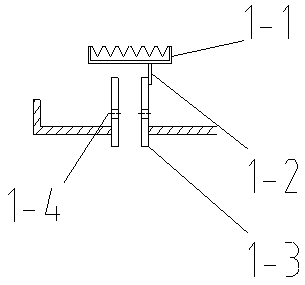

A hydrogenation reactor having an impact reducing element

ActiveCN109985570AIt has the function of reducing flushing and current sharingImprove distributionChemical/physical processesRefining to eliminate hetero atomsProcess engineeringDistributor

The invention discloses a hydrogenation reactor with an impact reducing element. The fixed bed hydrogenation reactor comprises a material inlet pipe, an inlet diffuser, a reactor upper head, an impactreducing flow equalizing disc, a catalyst bed layer, a catalyst support grid, a reactor cylinder, a reactor lower head, an outlet collector, a material outlet pipe and a catalyst discharge pipe. Theimpact reducing flow equalizing disc is arranged in an idle space of the reactor upper head or above the top end of the reactor cylinder and a top distribution disc; the impact reducing flow equalizing disc is provided with a plurality of distributors and each distributor comprises a flow equalizing disc, a downcomer and a connecting rod, and the flow equalizing discs are connected with the downcomers through the connecting rods. The hydrogenation reactor disclosed by the invention is suitable for hydrofining or hydrocracking treatment processes of oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

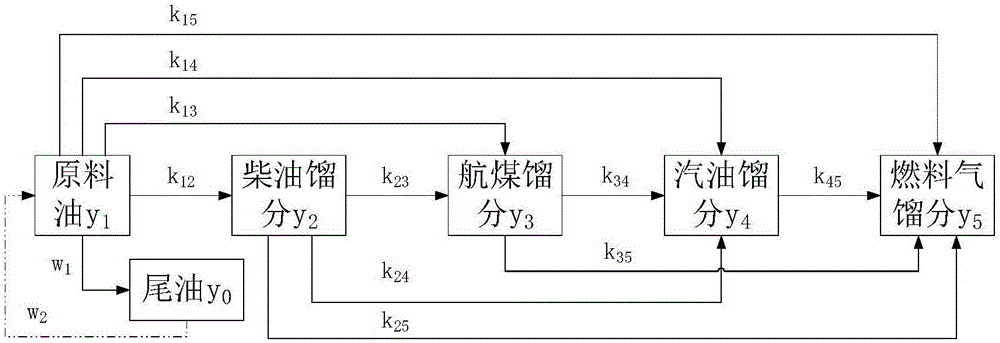

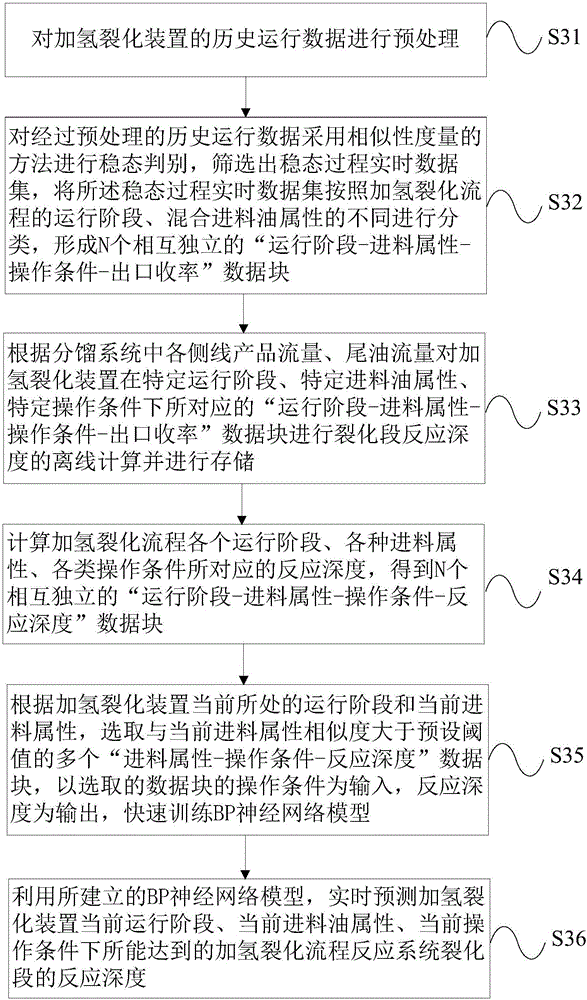

Method and device for real-time prediction of reaction depth of hydrocracker

ActiveCN106281431AKeep aliveLessen the training loadBiological neural network modelsHydrocarbon oil crackingInjection volumeHydrogen

The invention provides a method and device for real-time prediction of the reaction depth of a hydrocracker. The method comprises the steps of establishing steady-state datasets for different working conditions, wherein operation datasets corresponding to different steady-state working conditions are screened out from historical datasets with the similarity measurement method, and the operation datasets are stored in a classified mode according to device operation phases and mixed feeding oil properties; conducting neural network optimal training sample set optimization, wherein based on the feeding oil properties under the current working condition, an optimal training sample is selected from the steady-state working condition operation datasets of the hydrocracker according to the similarity of mixing indexes to achieve fast training of a neural network; conducting real-time prediction of the reaction depth. By the adoption of the method and device, the reaction depth of the hydrocracker is predicted under the current operation phase, the current feed properties and the current operation condition, real-time state information is provided for optimal control of the injection volume of quenching hydrogen in the process, and a basis is provided for protecting the activity of a catalyst, prolonging the on-stream time of the hydrocracker and realizing flexible adjustment of processing amount of a target product.

Owner:CENT SOUTH UNIV

Esterizing tower reaction separating flow new process for producing ethyl acetate

ActiveCN1616398AReduce contentReduce generationOrganic compound preparationCarboxylic acid esters preparationAcetic acidAlcohol

The present invention relates to ethyl acetate producing process in esterifying tower with high rectification effect. The technological scheme is that the acetic acid and ethanol solution after sulfuric acid catalyzed esterification is gasified under steam heating condition to form the azeotrope system of ester, water, alcohol and acid; and the azeotrope system is rectified and separated in an esterifying tower to obtain the coarse ester product in the top. The present invention features that inside the esterifying tower, there is regular ripple stainless steel sheet packing. The ripple stainless steel sheet packing has great specific surface area and high separation effect, consists of different sizes, and is optimized based on driving force mathematic model established according to material property and esterification and separation purity. The present invention has low esterifying tower resistance, and high esterification product purity with coarse ester content up to 95 %.

Owner:SHANGHAI HUAYI ENERGY CHEM

A combined processing method of inferior heavy oil

ActiveCN103789036BHigh yieldHigh residual carbon valueTreatment with hydrotreatment processesHydrogenLower grade

A combination processing method of inferior heavy oil comprises the following steps that: A, a heavy oil feedstock enters into a liquid flow bed reactor for hydrocracking in the effects of hydrogen and a dispersible hydrocracking catalyst; B, the obtained hydrogenation product is fractionally distilled to obtain light oil and heavy oil, the cutting point is 320-380 DEG C, and the light oil is led out of the device; C, the heavy oil obtained by fractional distillation is extracted by a solvent to obtain deasphalted oil and deoiled asphalt; D, the deoiled asphalt is contacted with a catalytic cracking catalyst for cracking reaction in catalytic cracking conditions, and light oil, heavy cycle oil and slurry oil are obtained by fractional distillation; E, the deoiled asphalt obtained by the step C is recycled into the liquid flow bed reactor in the step A. According to the combination processing method provided by the invention, a variety of processes are integrated for processing of the inferior heavy oil, full transformation of the heavy oil can be realized, and more gasoline and diesel oil which are excellent in performances can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

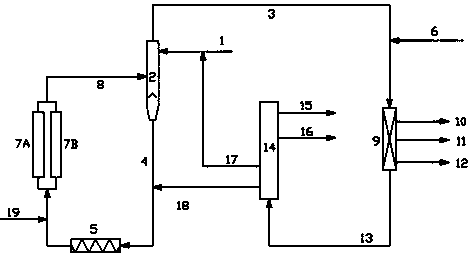

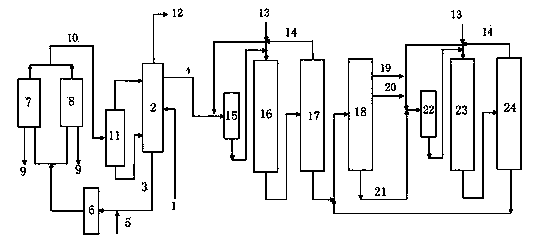

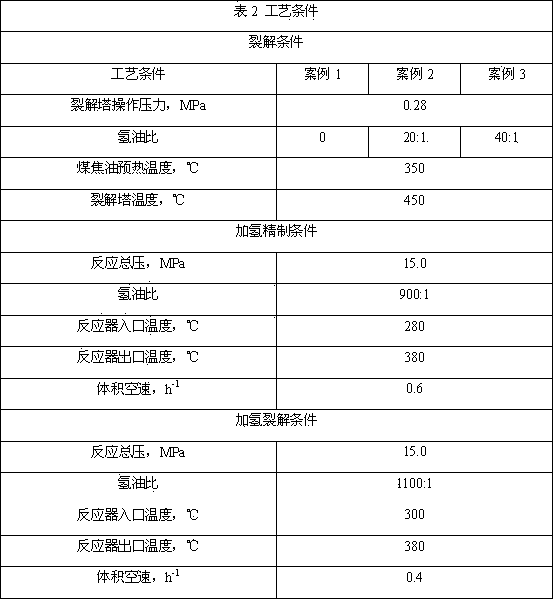

Combined process for preparing fuel oil by hydro-cracking and hydro-upgrading of coal tar

ActiveCN103627429AEffective processingLow yieldTreatment with hydrotreatment processesLiquid productFuel oil

The invention discloses a combined process for preparing fuel oil by hydro-cracking and hydro-upgrading of coal tar, and belongs to the field of coal chemical industries. The coal tar is fractionated through a fractionating tower, then heavy component oil whose boiling point is larger than 360 DEG C and light component oil whose boiling point is lower than 360 DEG C are obtained, the heavy component oil is subjected to a cracking reaction under a hydrogen condition, generated oil formed in the cracking reaction goes back to the fractionating tower, the light component oil whose boiling point is lower than 360 DEG C is subjected to hydro-refining and hydro-cracking systems, so that gasoline and diesel blended components of high quality can be obtained. According to the invention, coke generated is obviously reduced, polymerization and condensation of unsaturated hydrocarbons such as olefin, aromatic hydrocarbons and the like are inhibited, the incidence of coking is reduced, the yield of liquid products obtained through a delayed coking process is improved, working periods of devices are prolonged, and equipment investment is reduced. According to the invention, products of high quality can be produced, and the utilization rate of the coal tar is improved, thereby bringing substantial economic benefits and facilitating environment protection.

Owner:WUHAN KELIN FINE CHEM +1

Stabilized hydrogenation method of coal liquefied oil

ActiveCN100378201CRelieve the phenomenon that the pressure drop rises too fastQuality improvementLiquid hydrocarbon mixture productionRefining to eliminate hetero atomsWork periodHydrogen

A hydrogenation stabilizing method of coal liquefied oil is carried out by filtering coal liquefied oil, entering it and hydrogen into expanded bed reactor from reactor bottom, contacting with hydrogenation refined catalyst, gas-liquid separating, distilling, separating, circulating for hydrogen-enriched flow separated and returning it to expanded bed reactor. It has slower reactor pressure raising speed, longer working period, better catalyst activity and coal liquefied oil quality.

Owner:CHINA PETROLEUM & CHEM CORP

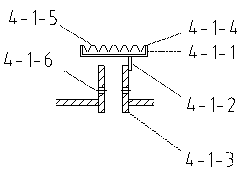

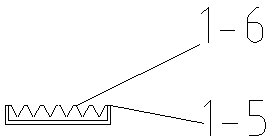

Toothed weir type impact reducing and uniform fluid distributing plate

ActiveCN108097178AReduce impactEliminate shockChemical/physical processesHydrocarbon oils treatmentEngineeringDistributor

The invention discloses a toothed weir type impact reducing and uniform fluid distributing plate and belongs to the field of chemical equipment. The toothed weir type impact reducing and uniform fluiddistributing plate comprises a tray and distributors arranged on the tray, wherein each distributor comprises a uniform fluid distributing plate, a material lowering pipe and connecting rods, and theuniform fluid distributing plate is arranged above the material lowering pipe and connected with the material lowering pipe through the connecting rods. The toothed weir type impact reducing and uniform fluid distributing plate has the characteristics of impact reducing and uniform fluid distributing functions, good distribution effect, small size, low mounting precision requirement and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

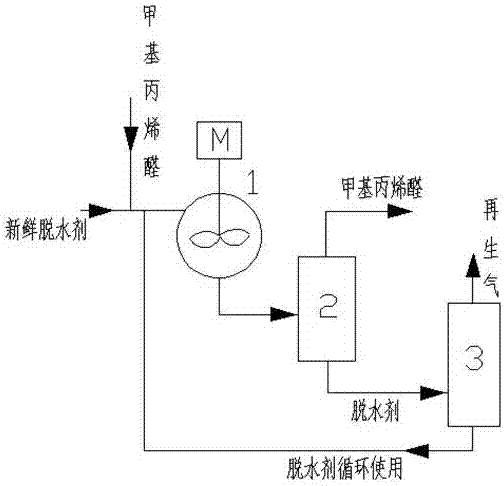

Deep dehydrating method for methylacrolein

ActiveCN106905130AInhibit aggregationEasy to operateCarbonyl compound separation/purificationAlcoholMaterial consumption

The invention relates to the technical field of the petrochemical industry and in particular to a deep dehydrating method for methylacrolein. The method comprises the following steps: using the methylacrolein as a raw material; using polyhydric alcohol as a dehydrating agent, and mixing and stirring the methylacrolein and the polyhydric alcohol according to the weight proportion of 1:0.5-20, conveying to a demixer after uniformly stirring, taking supernatant liquid after stewing and layering, to obtain the dehydrated methylacrolein. The operation process is simple, the energy and material consumption is effectively reduced, the polymerism of the methylacrolein caused by the high temperature can be avoided, the working period is prolonged, the industrial production requirements can be satisfied better, and the method is suitable for extensive popularization and application.

Owner:齐翔华利新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com