Real-time forecasting method for hydrogenolysis degree in hydrofining and system thereof

A hydrorefining and real-time prediction technology, applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve problems such as insufficient desulfurization, excessive S content in hydrocracking end products, complex structures, etc., to achieve Reduce the probability of calculation non-convergence, ensure catalyst activity, and ensure the effect of qualified S content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

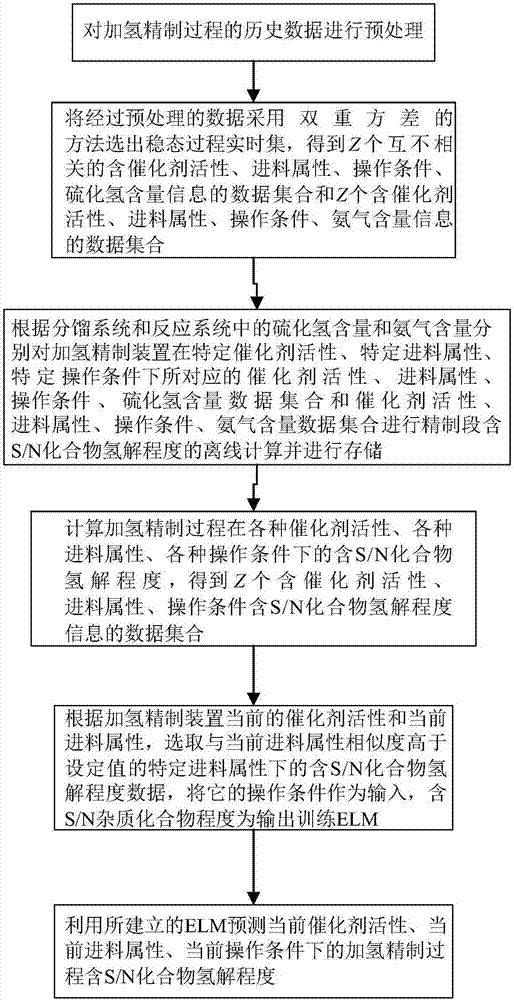

[0069] The method for real-time prediction of the degree of hydrogenolysis of sulfur and / or nitrogen-containing compounds in the hydrorefining process provided by this example, such as figure 1 shown, including:

[0070] 1) Preprocessing the historical data of the hydrorefining unit using a threshold denoising method;

[0071] 2) Screen the preprocessed process data using the double variance steady-state discriminant method, divide the selected steady-state data into several historical operating time domains according to the catalyst activity of the reaction system of the hydrocracking process, and obtain the uncorrelated Z A data set containing information on catalyst activity, feed properties, operating conditions, and hydrogen sulfide content and Z data sets containing information on catalyst activity, feed properties, operating conditions, and ammonia content;

[0072] 3) According to the hydrogen sulfide content and ammonia content of the whole hydrocracking process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com