Deep dehydrating method for methylacrolein

A methacrolein and deep dehydration technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of reduced dehydration performance of molecular sieves, limitations of large-scale industrial production, large amount of molecular sieves, etc., to meet the needs of industrial production , Reduce energy consumption, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

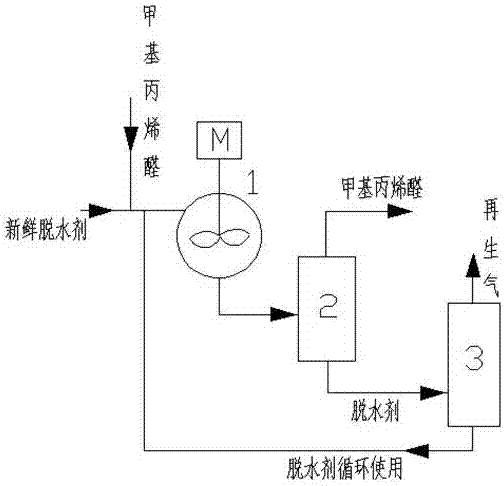

Image

Examples

Embodiment 1

[0031] Mix and stir methacrolein with a water content of 0.20% and fresh dehydrating agent at a mass ratio of 1:1, and then separate into layers after stirring evenly, and the water content in the aldehyde drops to 0.007%.

Embodiment 2

[0033] The methacrolein with a water content of 0.20% and the regenerated dehydrating agent are mixed and stirred at a mass ratio of 1:1, and the layers are separated after stirring evenly, and the water content in the aldehyde is reduced to 0.007%.

Embodiment 3

[0035] Mix and stir methacrolein with a water content of 0.20% and fresh dehydrating agent at a mass ratio of 1:0.75, and then separate into layers after stirring evenly, and the water content in the aldehyde drops to 0.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com