Patents

Literature

1418results about How to "Reduce material consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

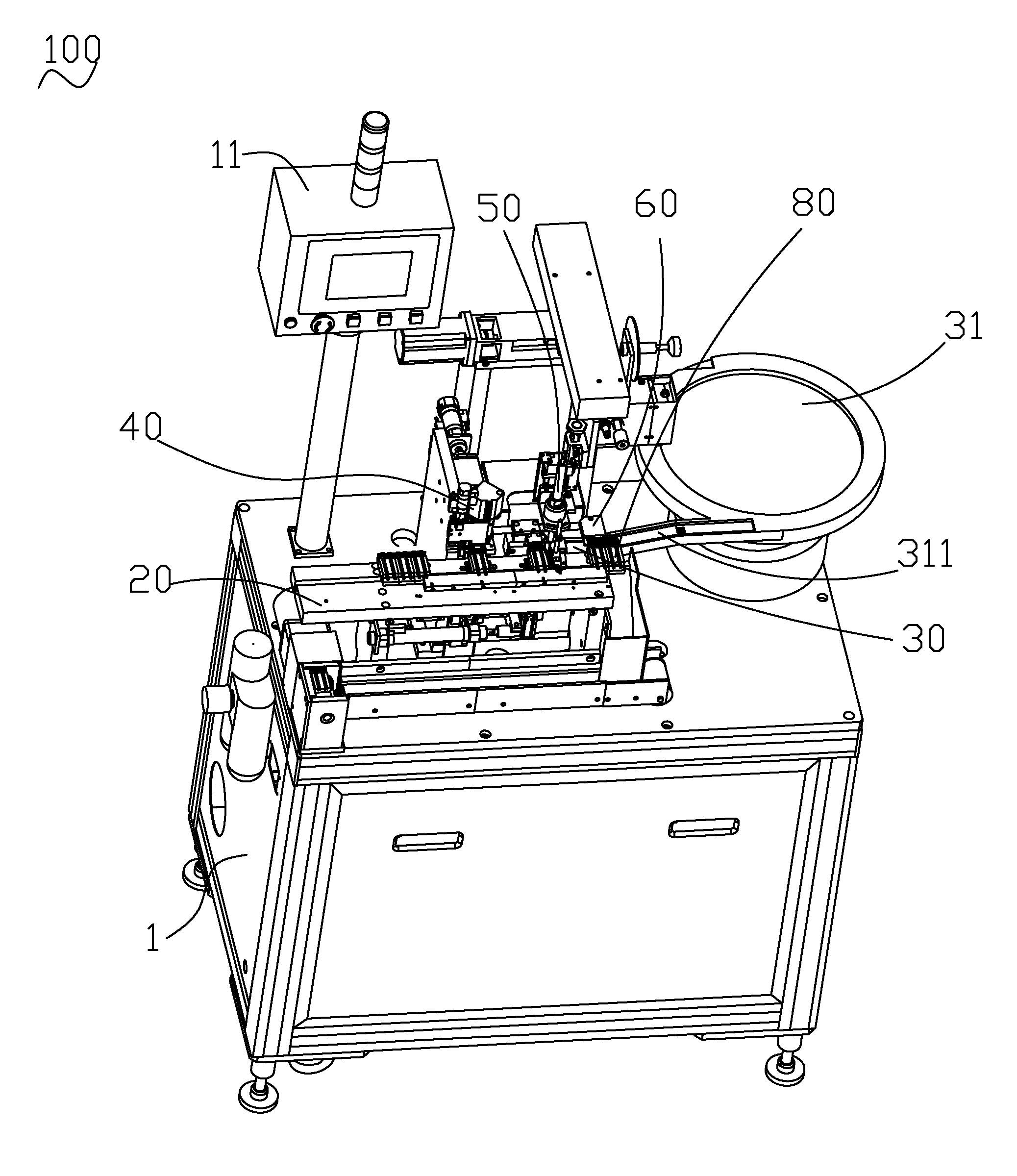

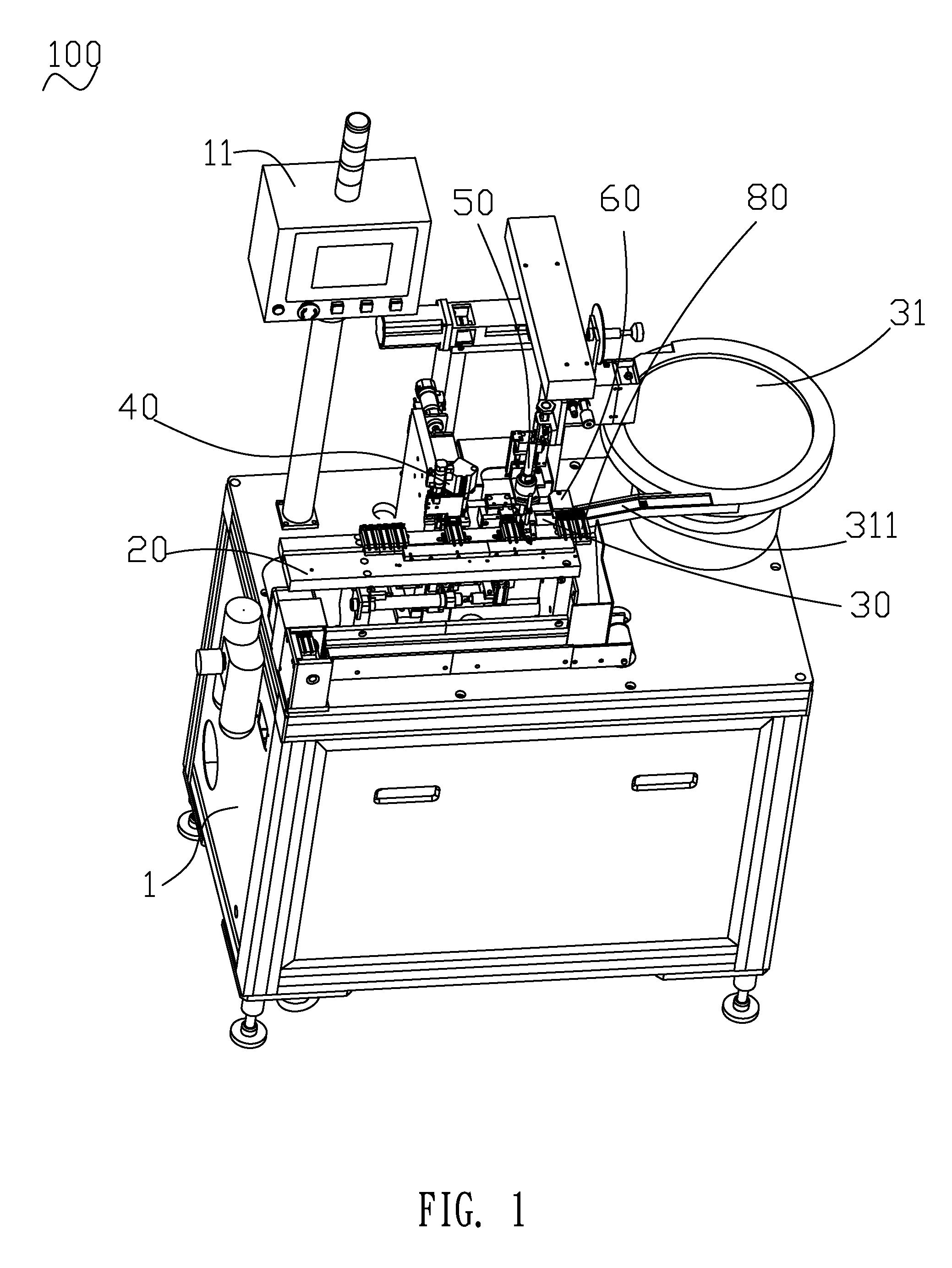

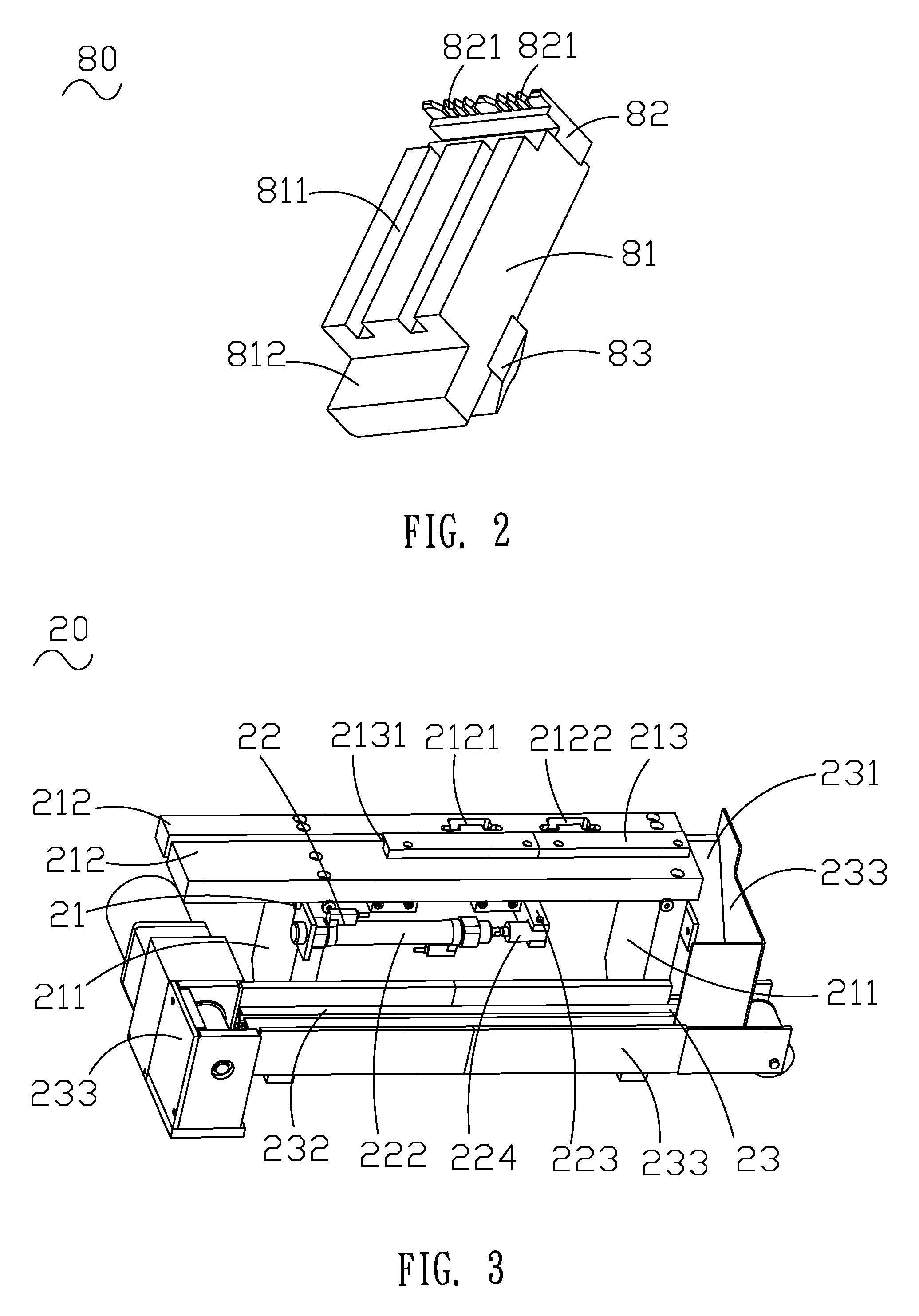

Automatic soldering machine

InactiveUS8011557B1High production efficacyImprove product qualityWelding/cutting auxillary devicesFeeding apparatusControl systemEngineering

An automatic soldering machine for soldering wires, each exposing at least one core wire and electronic components with at least one soldering portion respectively is disclosed. The automatic soldering machine comprises an equipment, a delivery mechanism, a plurality of clamps, a feeding mechanism, an insulation removing mechanism, a soldering mechanism, an unloading mechanism and a programmable control system. The delivery mechanism delivers the wires. The clamps locate the wires. The feeding mechanism conveys the electronic components. The insulation removing mechanism cuts the core wires and strips insulations at tops of the core wires. The soldering mechanism solders the core wires and the soldering portions of the electronic components. The unloading mechanism separates the soldered electronic components and core wires off from the clamps. The programmable control system is connect to the aforesaid mechanisms and controls thereof with high production efficacy and stable production quality.

Owner:CHENG UEI PRECISION IND CO LTD

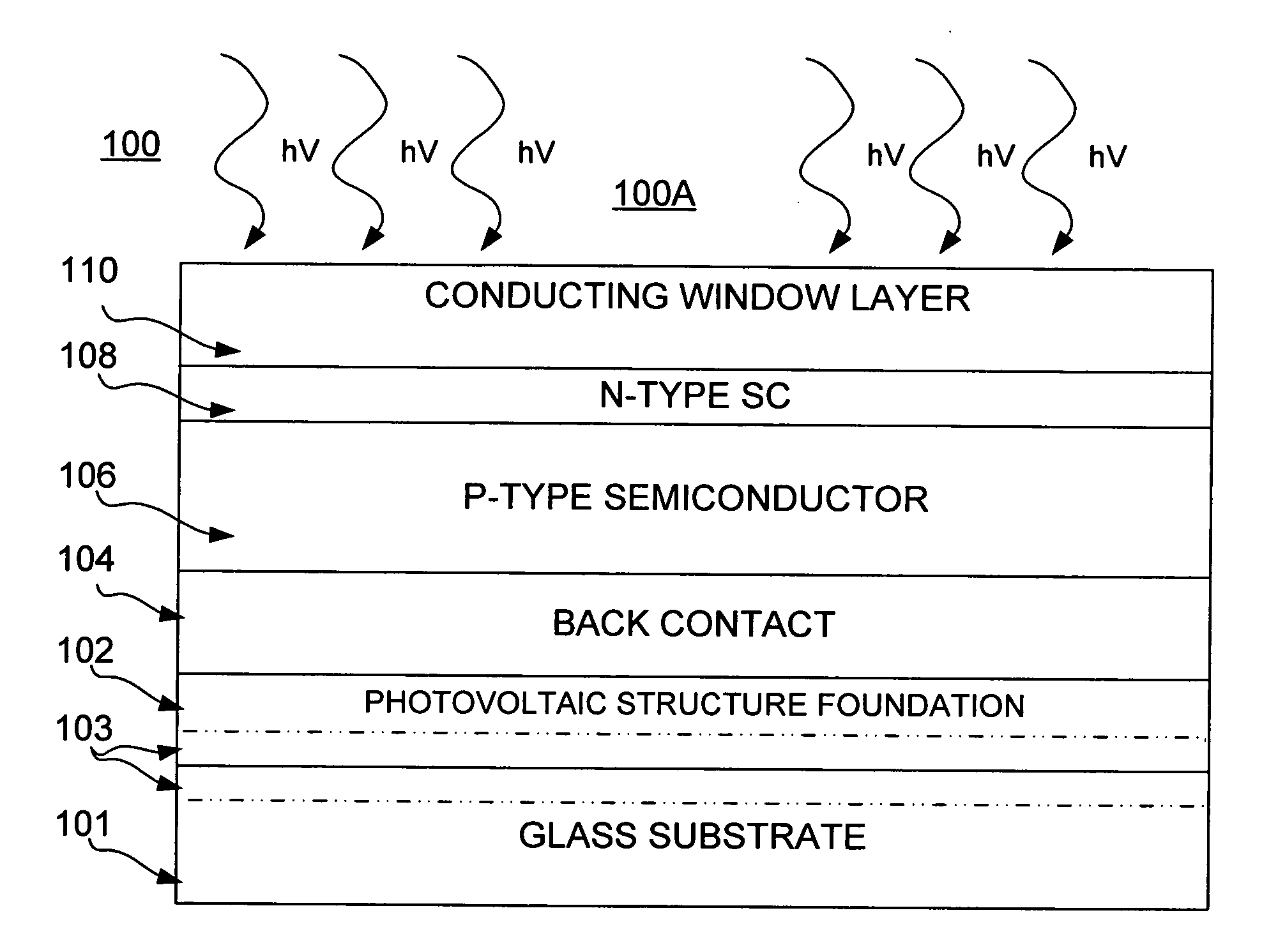

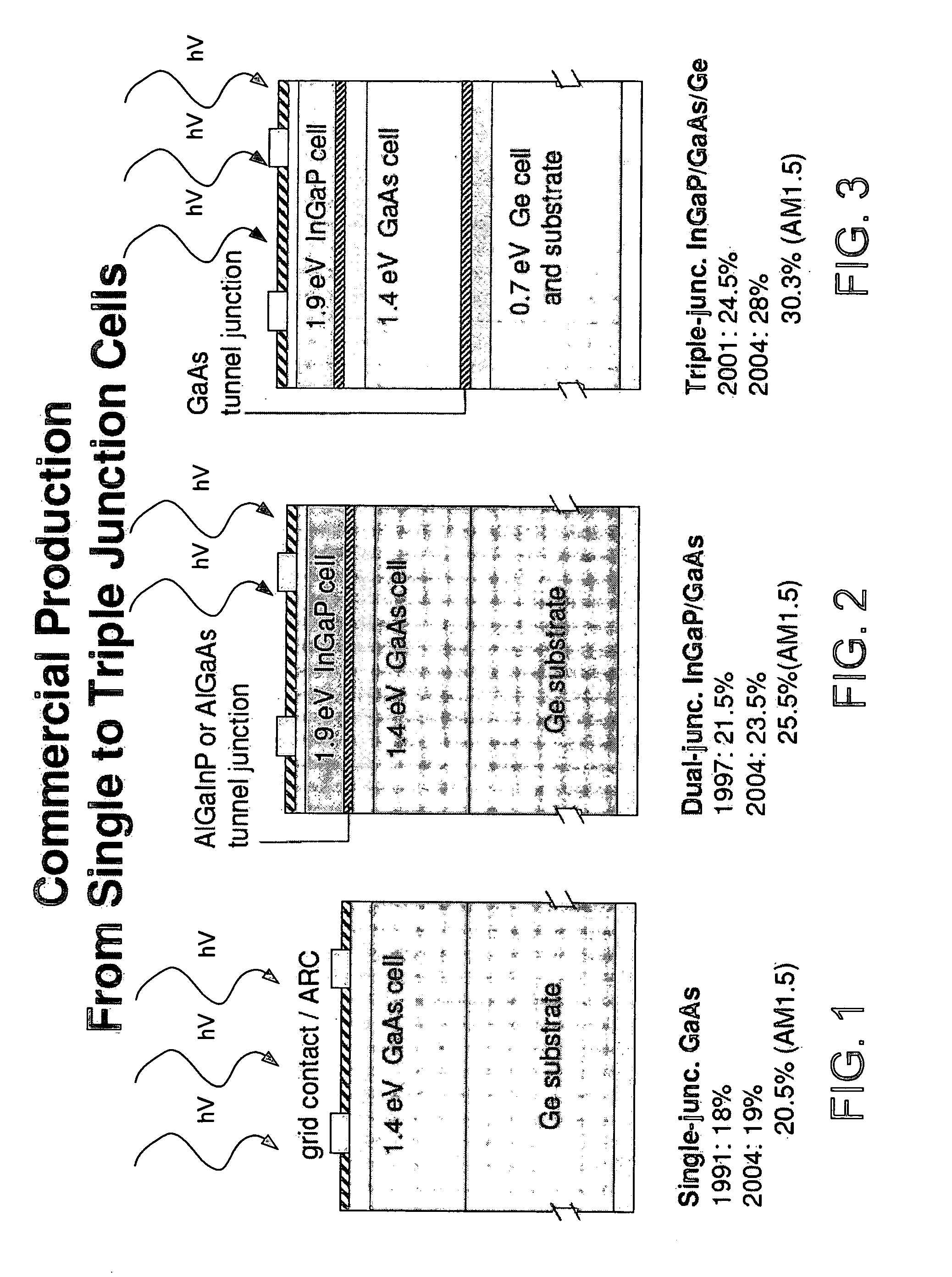

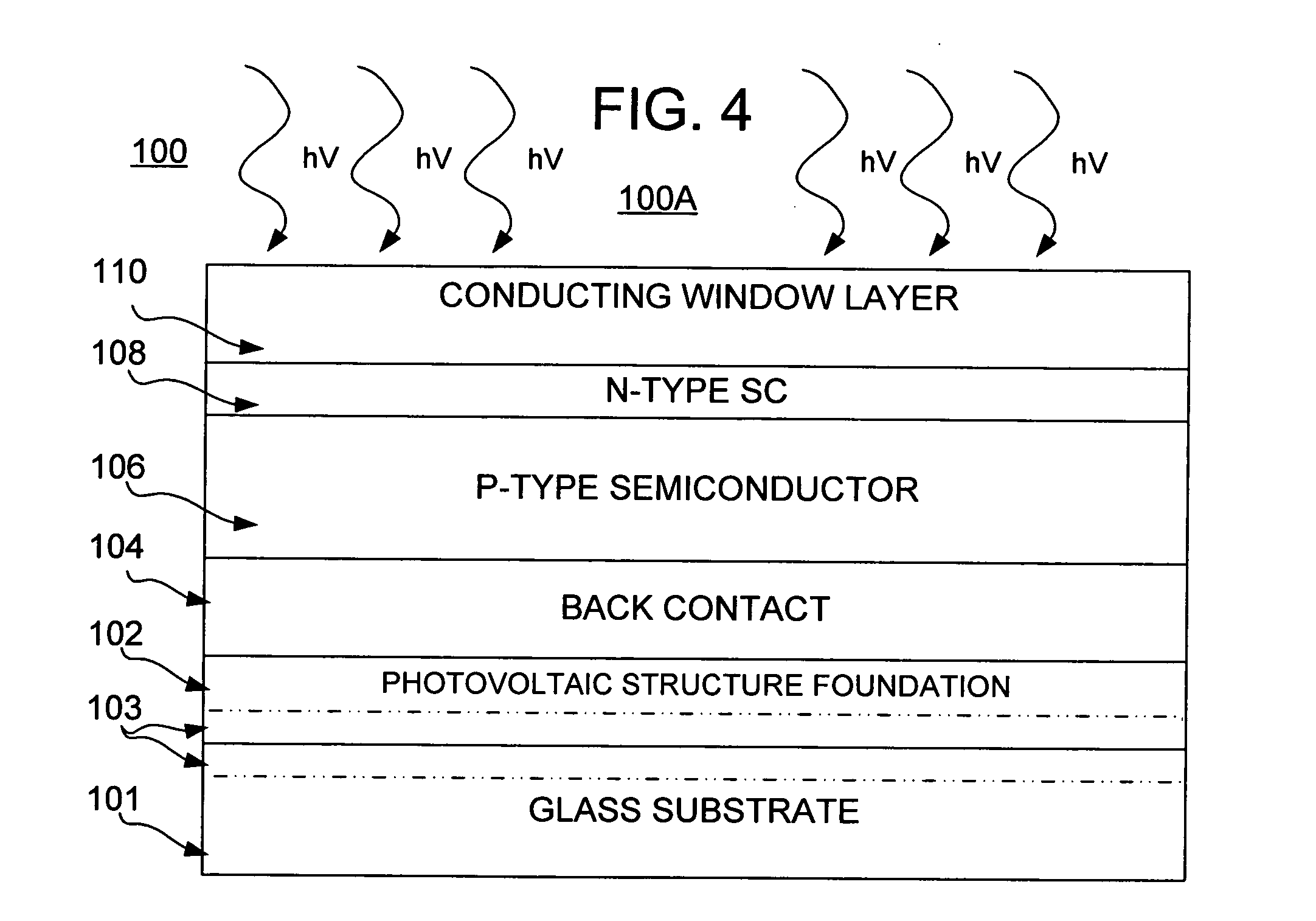

Thin film photovoltaic structure

InactiveUS20070277875A1Improve conversion efficiencyWide range of designsPhotovoltaic energy generationSemiconductor devicesSingle crystalEngineering

Photovoltaic devices include an insulator structure bonded to an exfoliation layer, preferably of a substantially single-crystal donor semiconductor wafer, and at least one photovoltaic device layer, such as a conductive layer. In a preferred embodiment, a device may include a conductive layer adjacent to the insulator substrate and integral to the exfoliation layer, near the side that faces the insulator substrate, such as between the insulator substrate and the exfoliation layer. In a further preferred embodiment, a device may include a plurality of photovoltaic device layers distal to the insulator substrate and in or on the exfoliation layer, preferably having been epitaxially grown on the exfoliation layer after the exfoliation layer has been anodically bonded to the insulator substrate by means of electrolysis.

Owner:CORNING INC

Big-broiler feedstuff and preparation method thereof

ActiveCN101455278AHigh nutritional valueIncrease profitAnimal feeding stuffAccessory food factorsBiotechnologyPhytase

The present invention belongs to the field of poultry feed technology, specifically to a meat large chicken feed and method for preparing the same. The meat large chicken feed is composed of the following components by weight parts: 30-80 parts of corn, 0-30 parts of wheat, 5-40 parts of bean pulp, 0-10 parts of peanut meal, 0-10 parts of cotton meal, 2-8 parts of corn protein powder, 0.5-5.0 parts of lipid, 1.0-6.0 parts of hypo-powder, 0.5-2.0 parts of mountain flour, 0.5-2.0 parts of calcium hydrogen orthophosphate, 0.2-0.4 parts of salt, 0.1-1.0 parts of complex vitamin; 0.1-1.0 parts of complex trace elements, 0.05-0.5 parts of micro-ecological formulation, 0.01-0.2 parts of Chinese herbal medicines additives, and 0.01-0.2 parts of phytase. The inventive meat large chicken feed has high digestibility, nutrient balance, low harmful components, and high security, so that the resistance of broiler chickens is increased and the pollution to the environment is significantly reduced.

Owner:SHANDONG NEW HOPE LIUHE GROUP

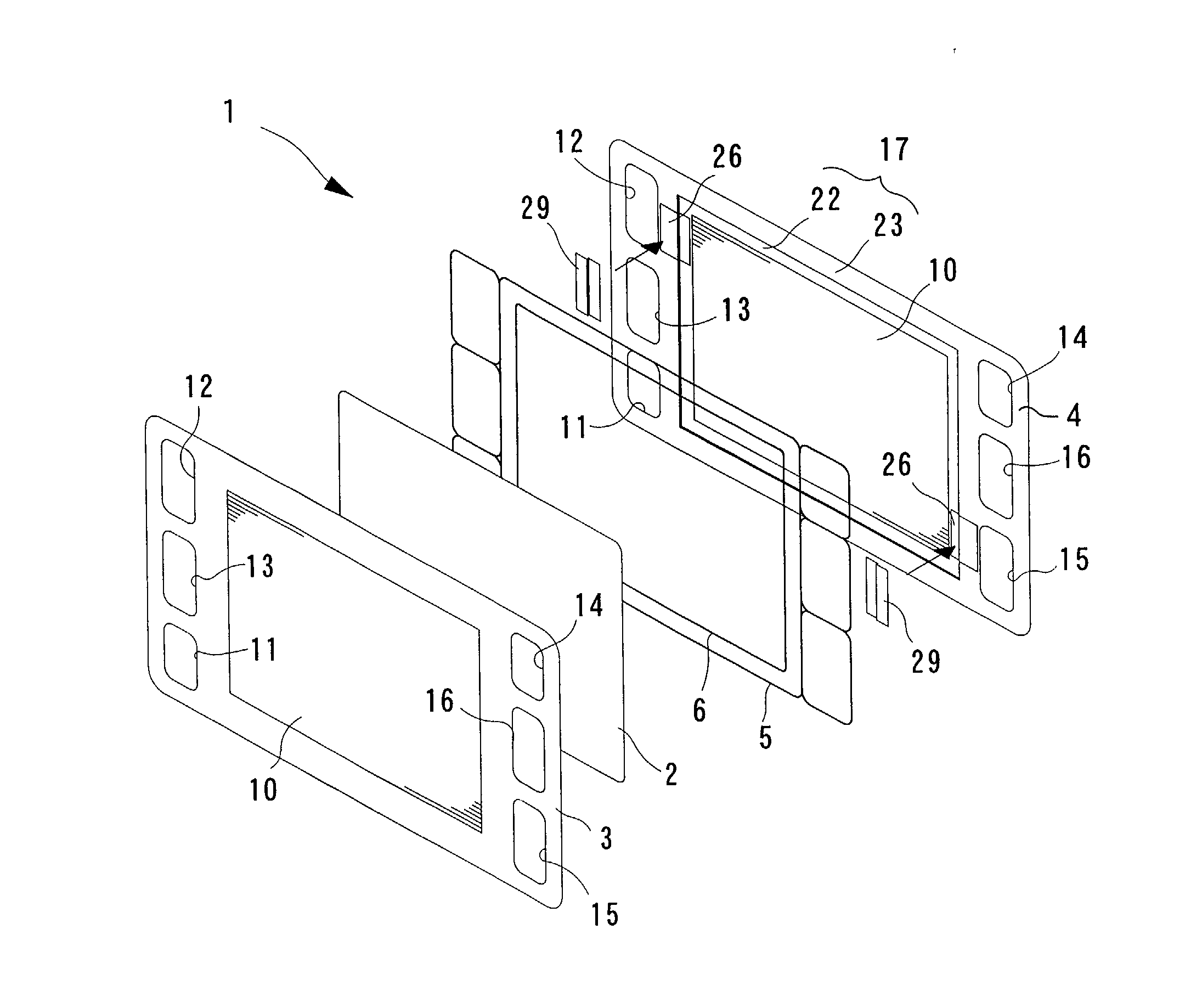

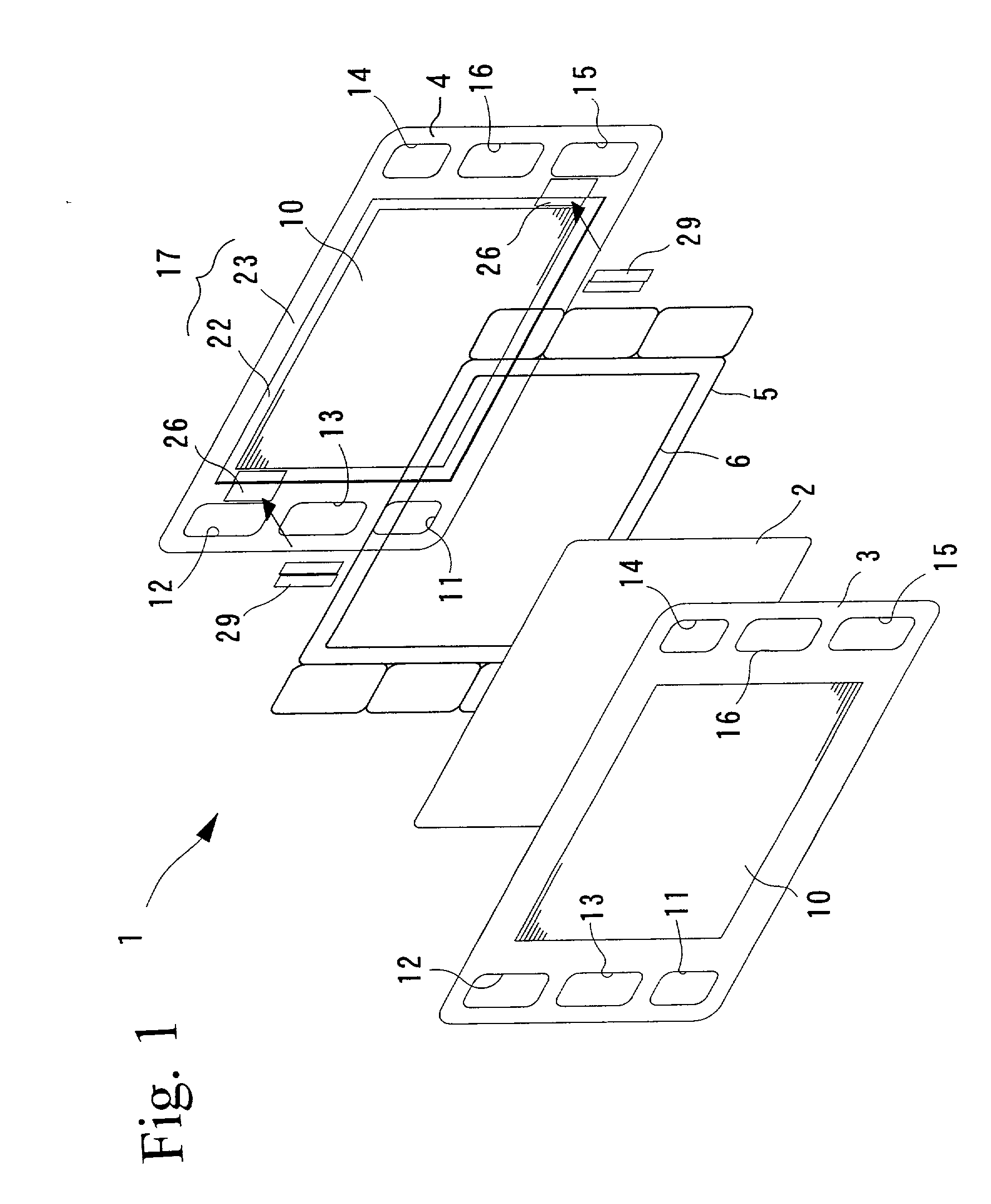

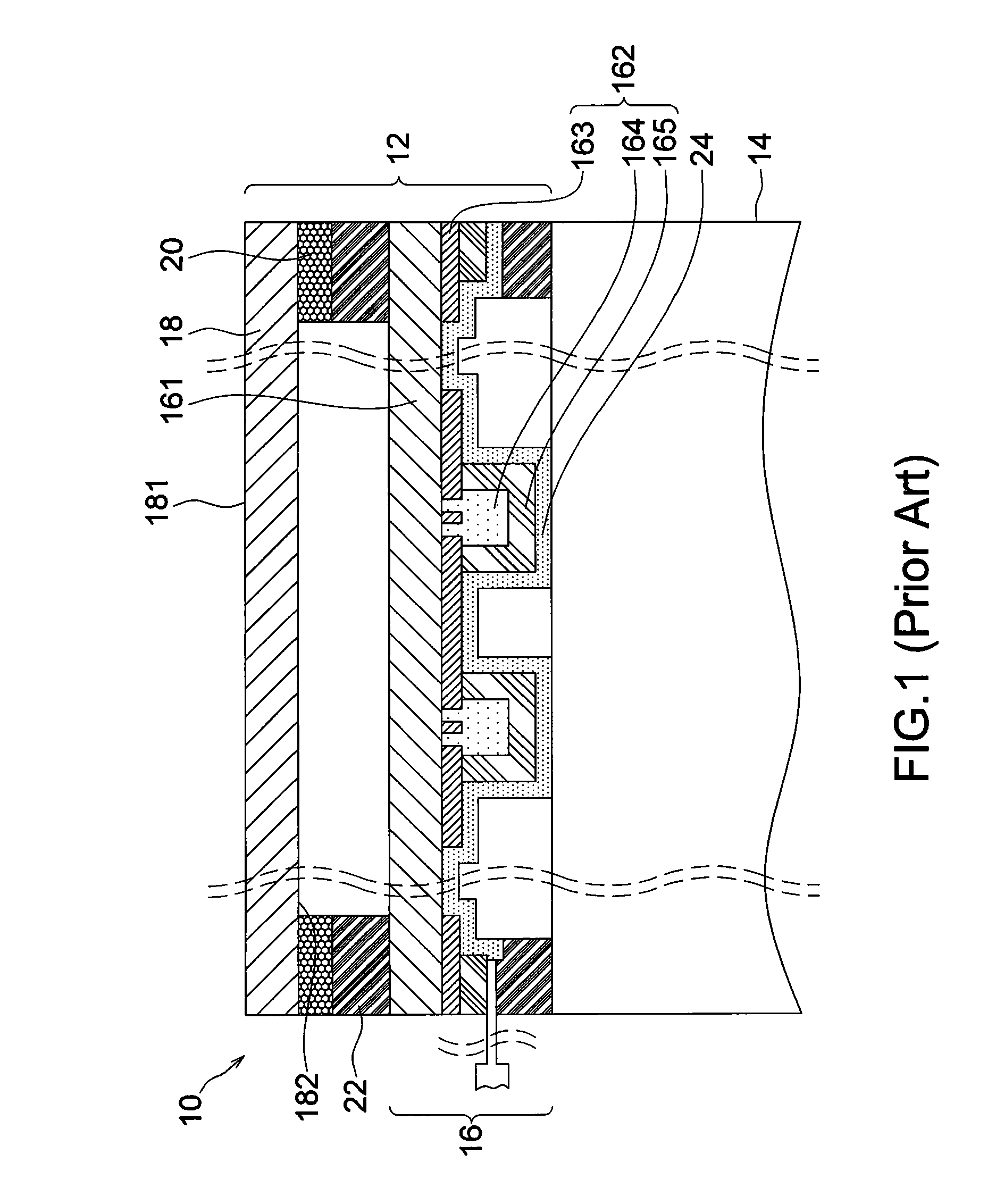

Fuel cell and fuel cell stack

InactiveUS20020127461A1Reduce thicknessImprove sealingSolid electrolytesFuel cells groupingPolymer electrolytesFuel cells

The present invention provides a fuel cell comprising a pair of separators sandwiching outsides of a membrane electrode assembly composed of a pair of electrodes provided on both sides of a solid polymer electrolyte membrane, an outer seal member sandwiched by a pair of separators at a position surrounding an outer periphery of the membrane electrode assembly, an inner seal member sandwiched by one of the pair of separators and an outer periphery of the electrolyte membrane, and a backing member opposing to the inner seal member interposing the electrolyte membrane, wherein steps are formed at contact surfaces of the inner seal member and the outer seal member on one of the pair of separators.

Owner:HONDA MOTOR CO LTD

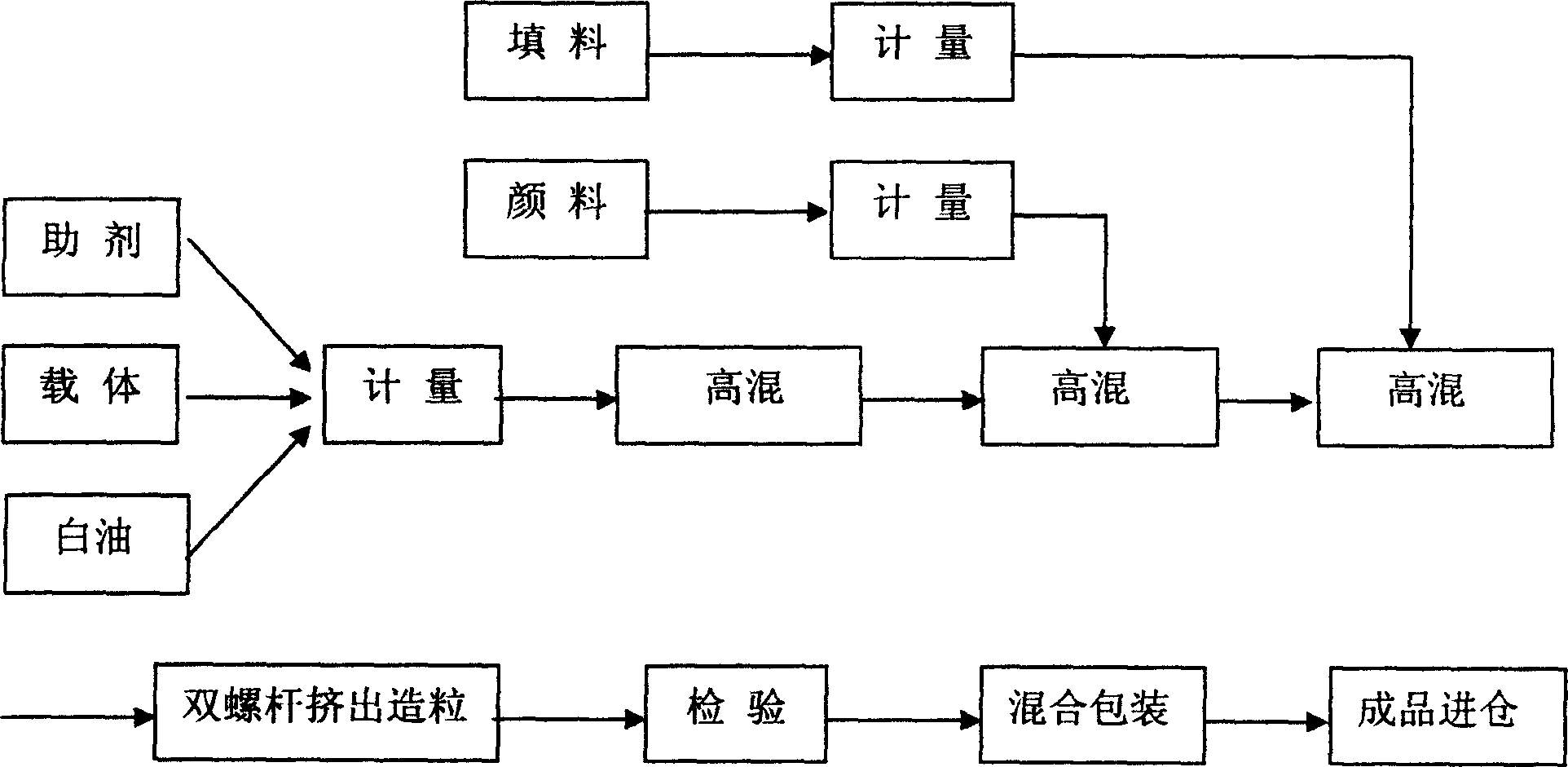

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

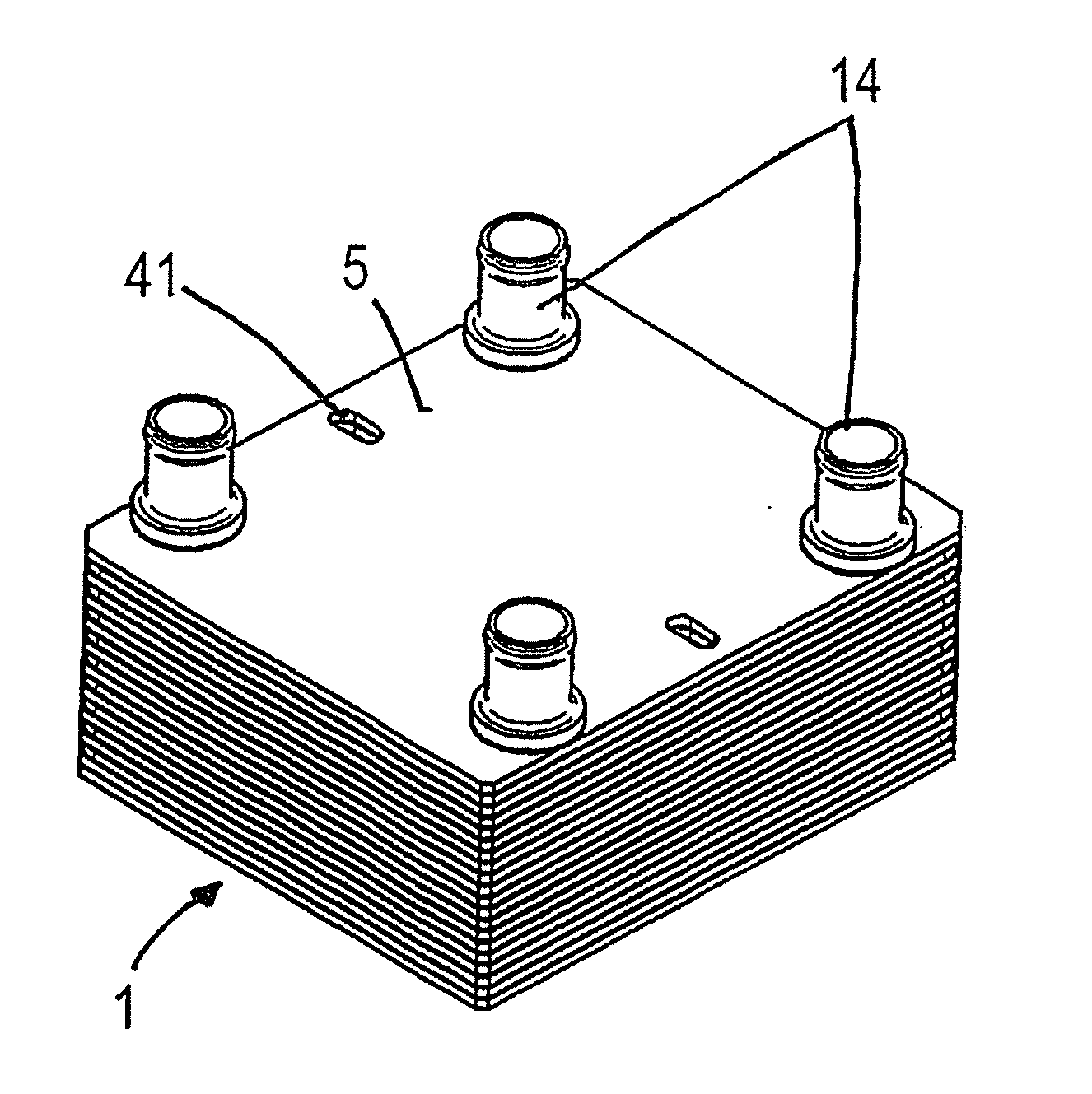

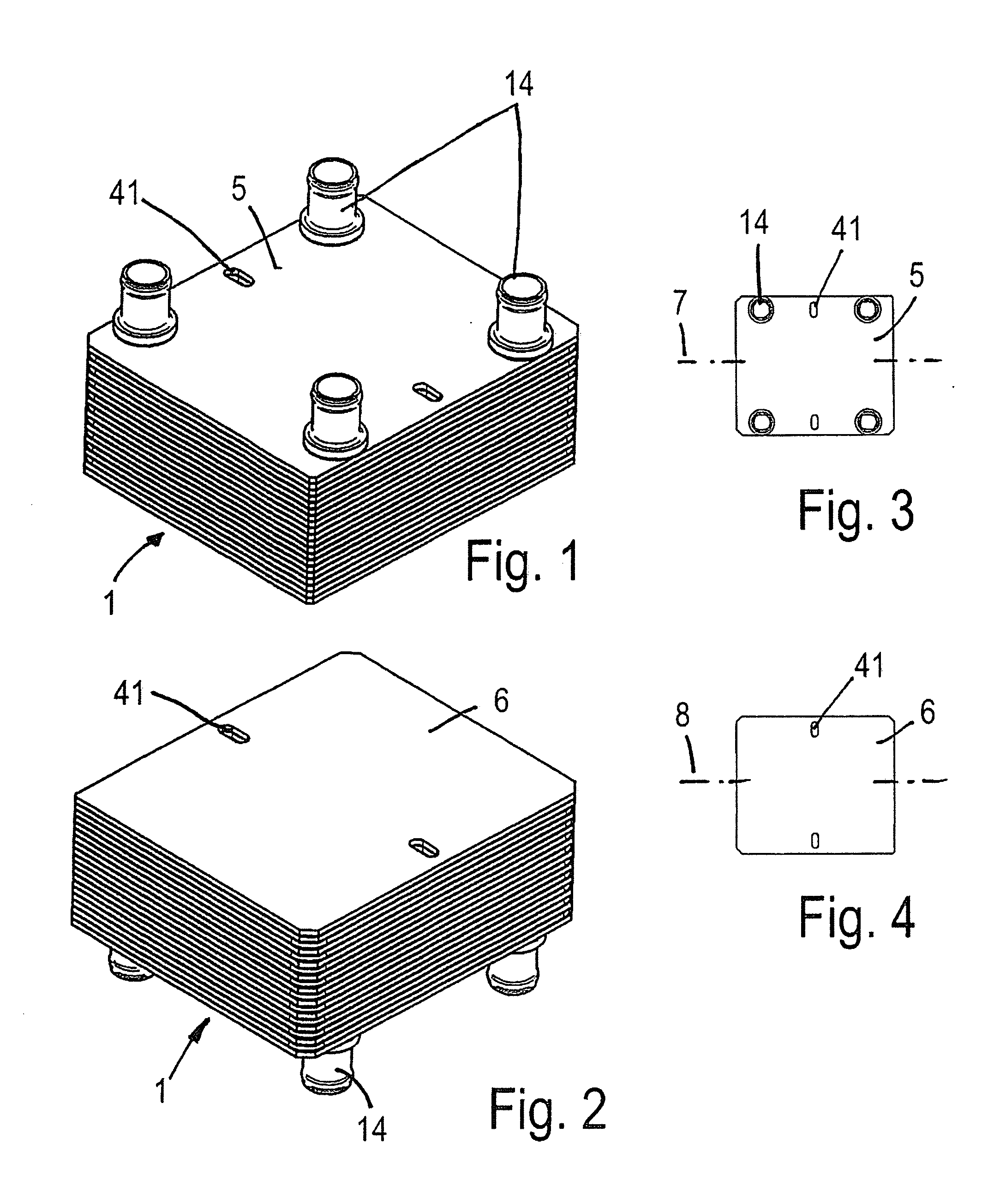

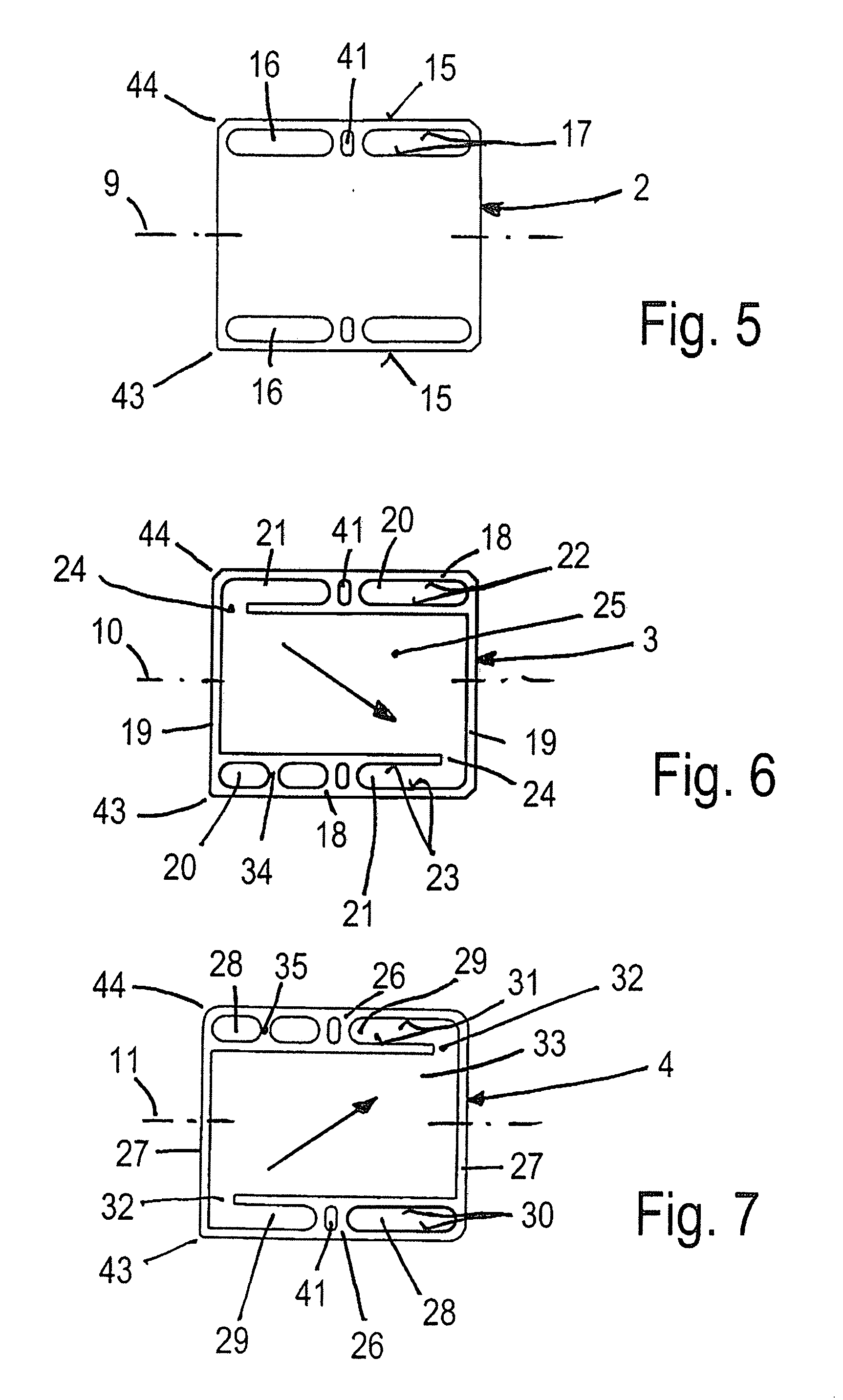

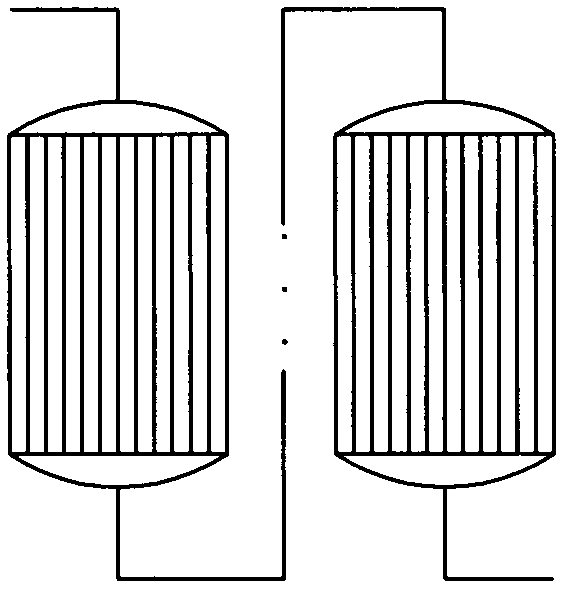

Heat exchanger network

InactiveUS20110120678A1Reduce material consumptionLess warpStationary tubular conduit assembliesHeat transfer modificationEngineeringMechanical engineering

A heat exchanger grid includes a stack including and arranged between end plates and further includes dividing plates and spacers arranged between the end plates to form sealed chambers for at least two heat exchange media. The end plates include one or both of inlet and outlet openings for the at least two media. The dividing plates including first passages aligned with the one or both of the inlet and outlet openings. The first passages are delimited by circumferentially enclosed edges and form collecting channels for the at least two media. The spacers include frames which are delimited circumferentially by rails and which spacers include second and third passages which are aligned at least partly with respect to the one or both of the inlet and outlet openings. The first, second, and third passages are arranged as slots with a part of the second and third passages being delimited by circumferentially enclosed edges and another part of the second and third passages including pass-through gaps facing toward the sealed chambers and except for the gaps, the second and third passages are enclosed.

Owner:AUTOKUHLER GMBH & CO KG

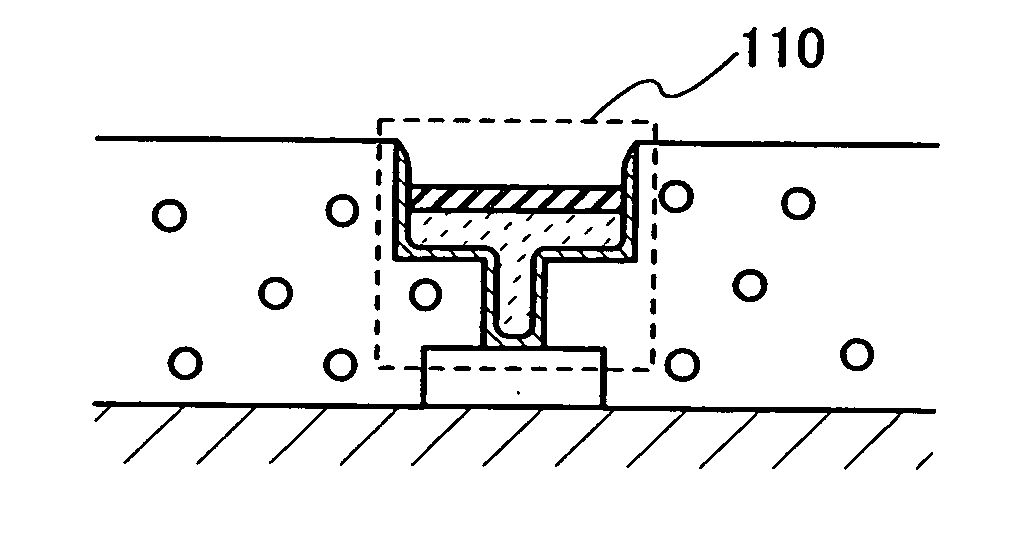

Semiconductor device and method for manufacturing the same

InactiveUS20060113671A1High aspect ratioReduce the number of processesSemiconductor/solid-state device detailsSolid-state devicesSputteringDevice material

In a manufacturing process of a semiconductor device, electroplating and CMP have had a problem of increase in manufacturing costs for forming a wiring. Correspondingly, an opening is formed in a porous insulating film after a mask is formed thereover, and a conductive material containing Ag is dropped into the opening. Further, a first conductive layer is formed by baking the conductive material dropped into the opening by selective irradiation with laser light. Subsequently, a metal film is formed over the entire surface by sputtering, and the mask is removed thereafter to have only the metal film remain over the first conductive layer, thereby forming an embedded wiring layer formed with a stack of the first conductive layer containing Ag and the second conductive layer (metal film).

Owner:SEMICON ENERGY LAB CO LTD

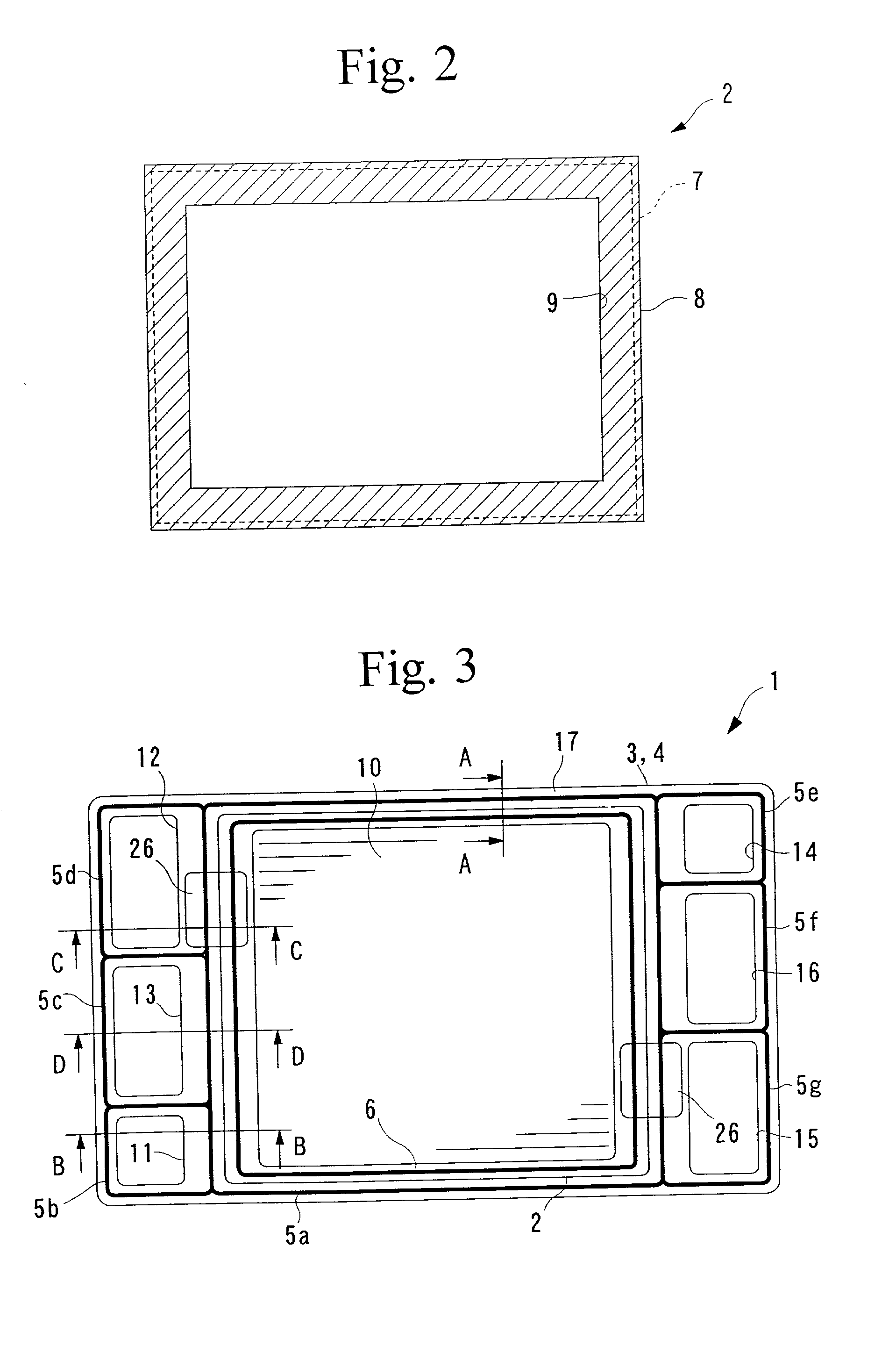

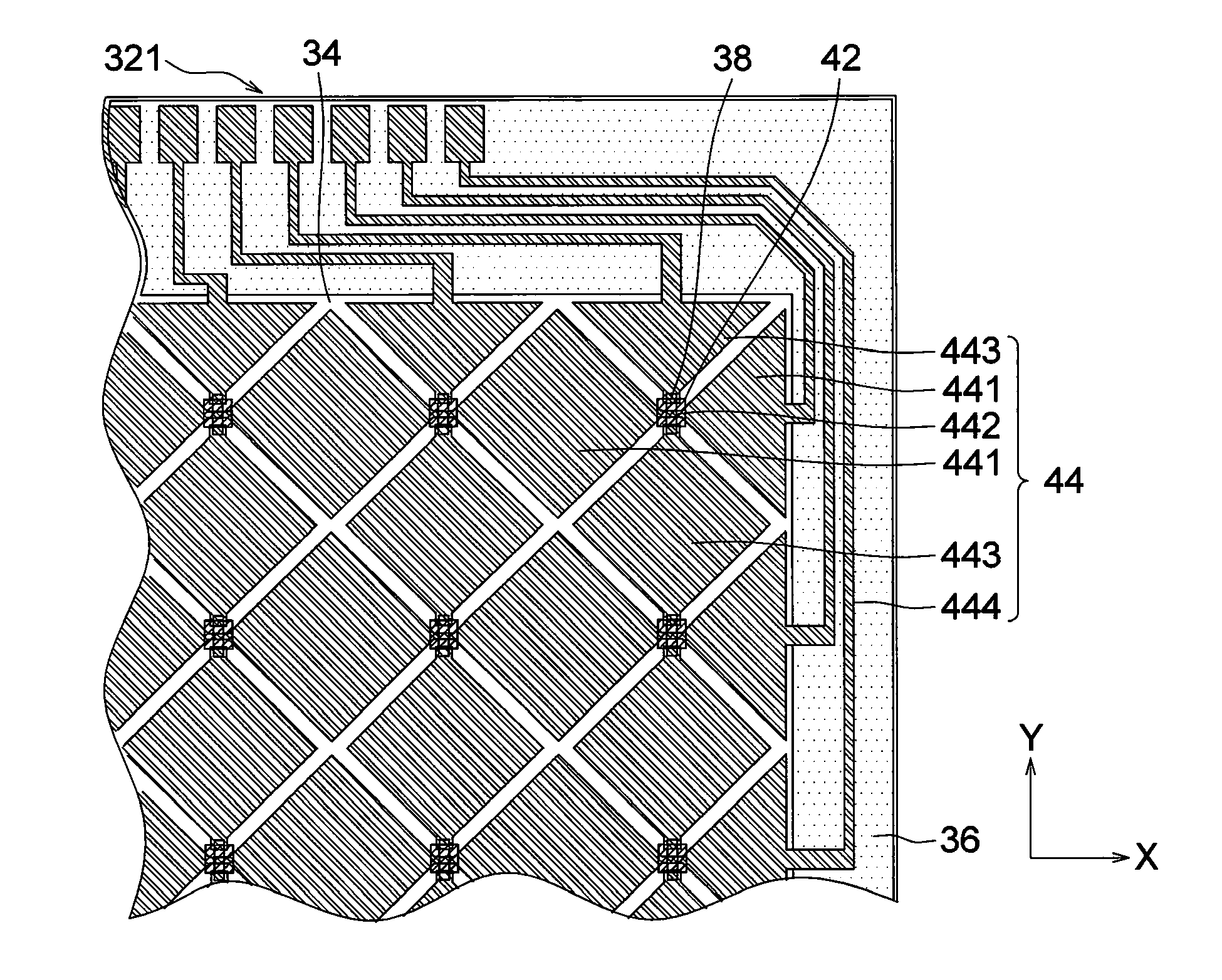

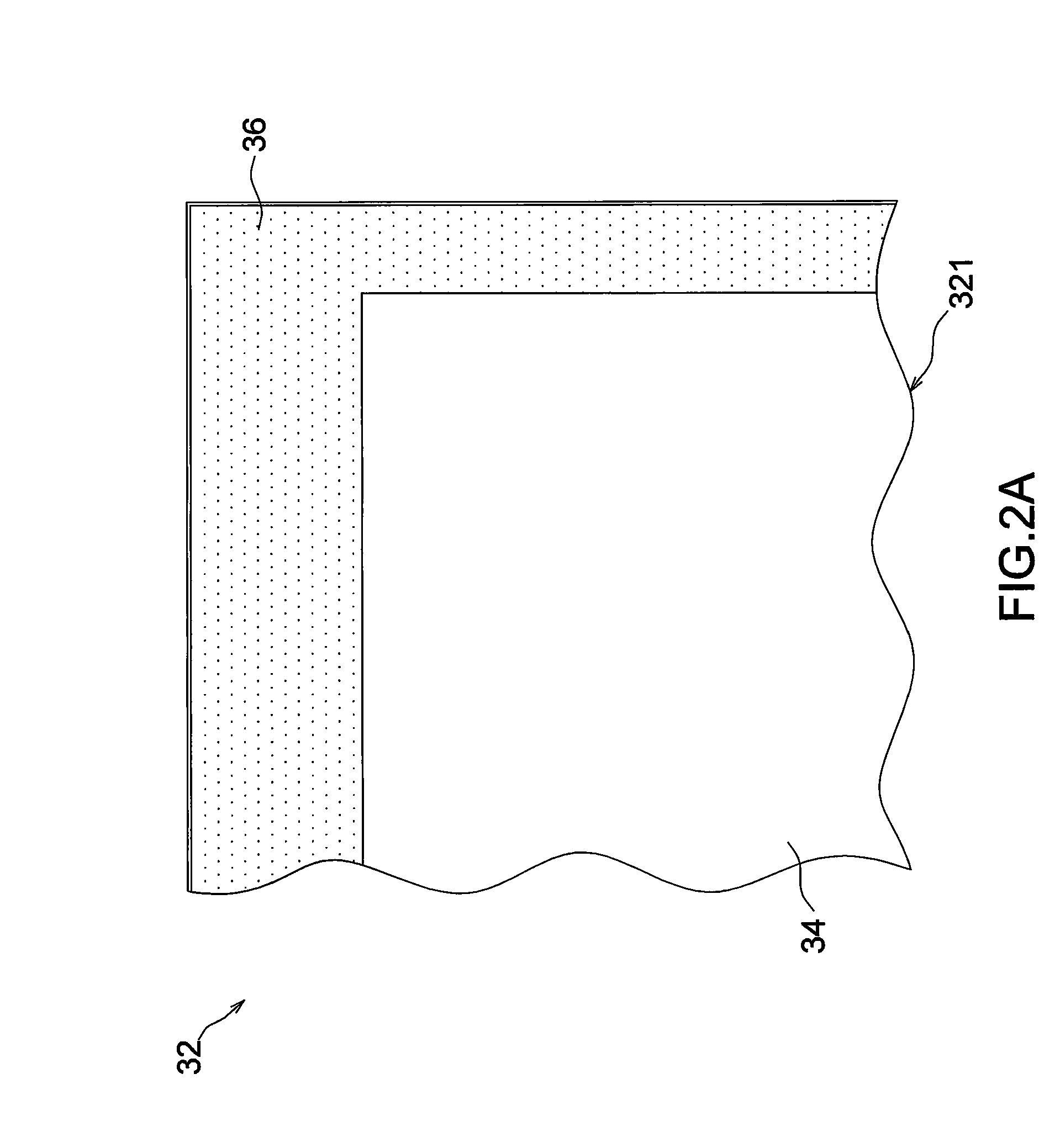

Thin touch panel

ActiveUS20110007005A1Reduce material consumptionHigh transparencyNon-linear opticsInput/output processes for data processingManufacturing cost reductionOptical bonding

A thin touch panel includes a transparent substrate with a black bordering around the inner surface of the transparent substrate. A plurality of metal connecting structures, metal guiding lines, transparent insulating structures and a transparent sensing layer are formed on the inner surface, so that the transparent substrate not only provides a touch surface, but also has the touch sensing ability, to decrease the manufacture material and increase the transmittance of the touch panel. Besides, the manufacture of the thin touch panel may not use any optical adhesive to decrease the manufacture cost and improve the yield. Further, the thin touch panel may satisfy the trend of thin design.

Owner:BUWON PRECISION SCI

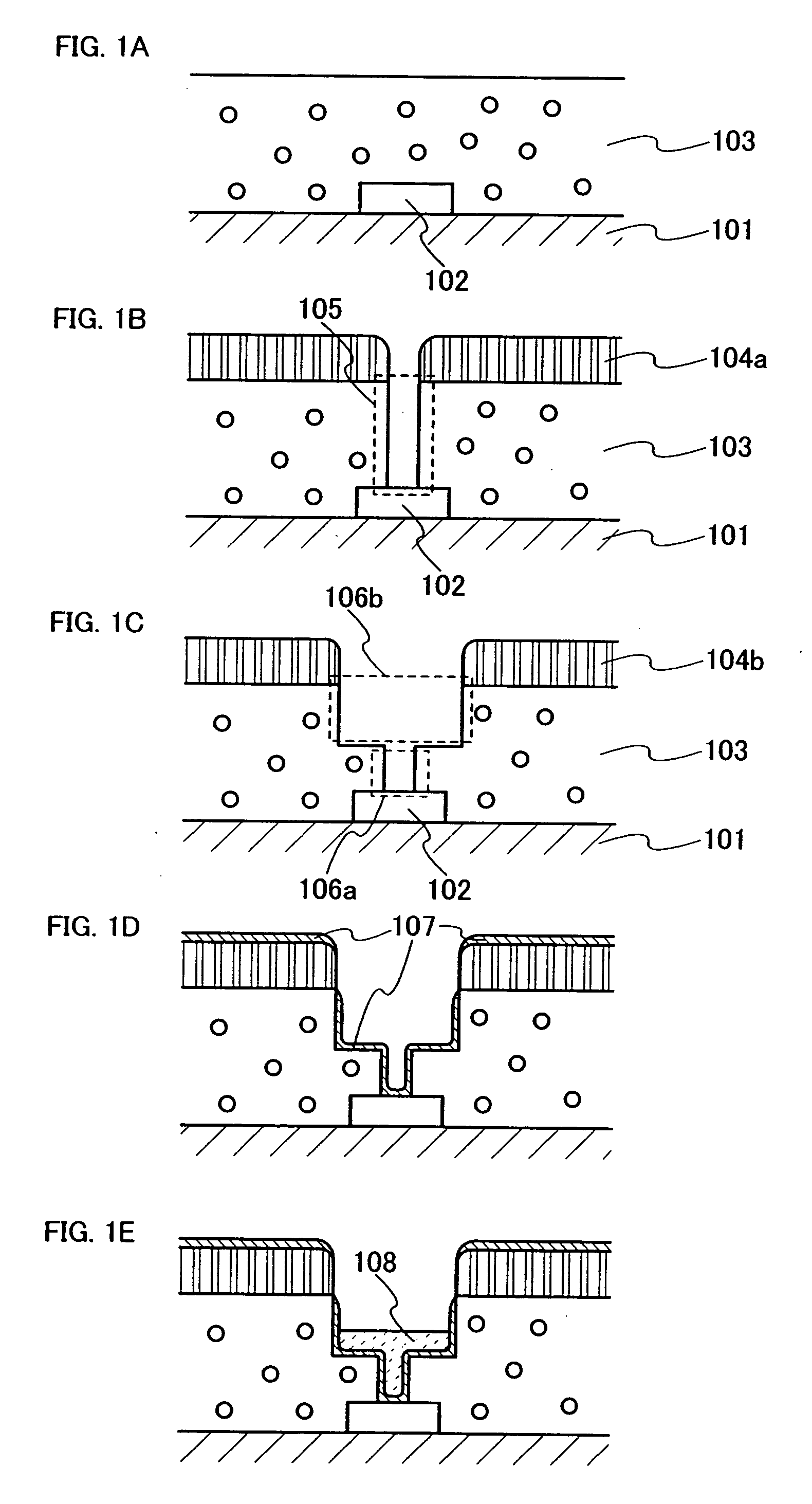

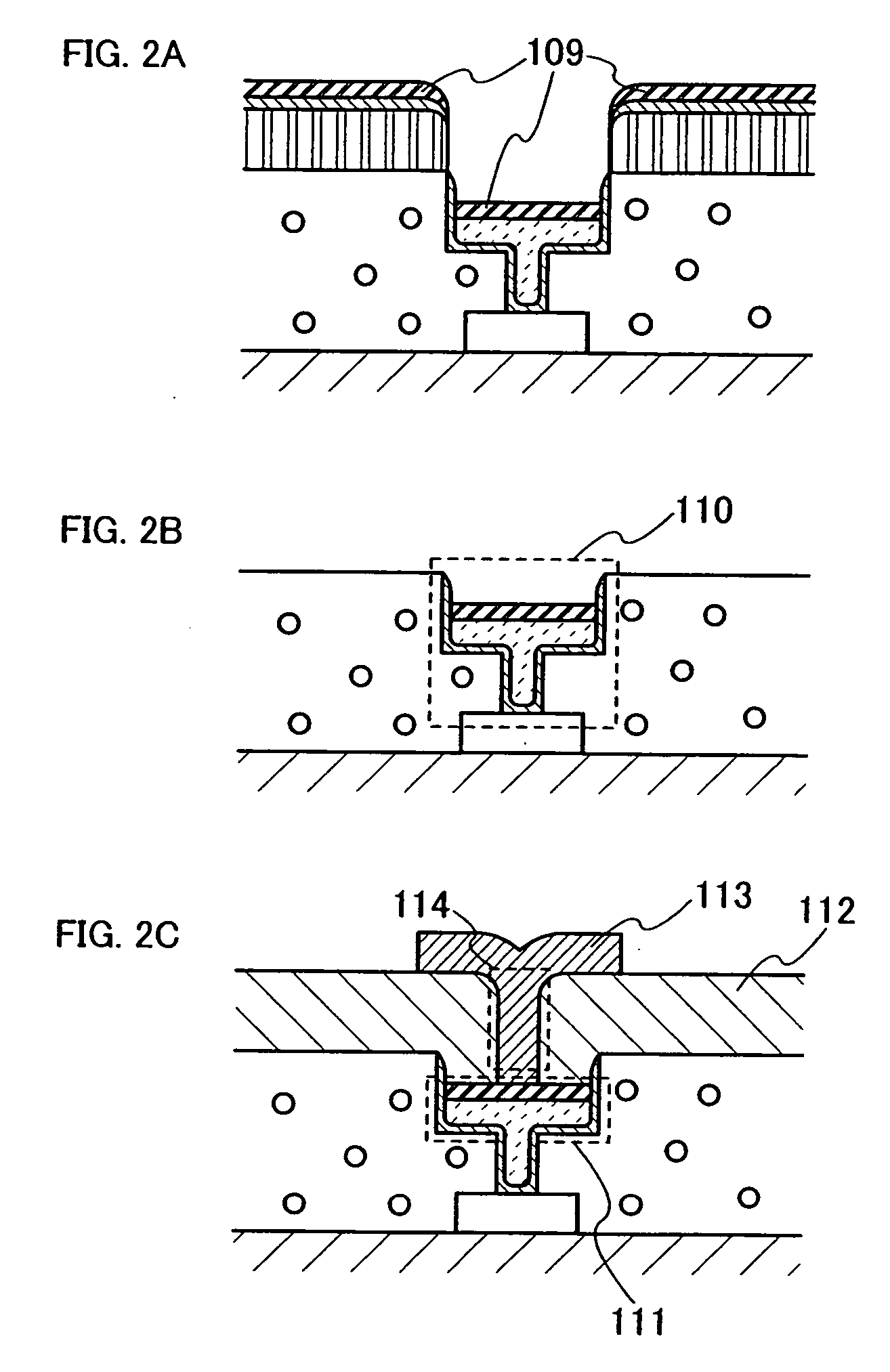

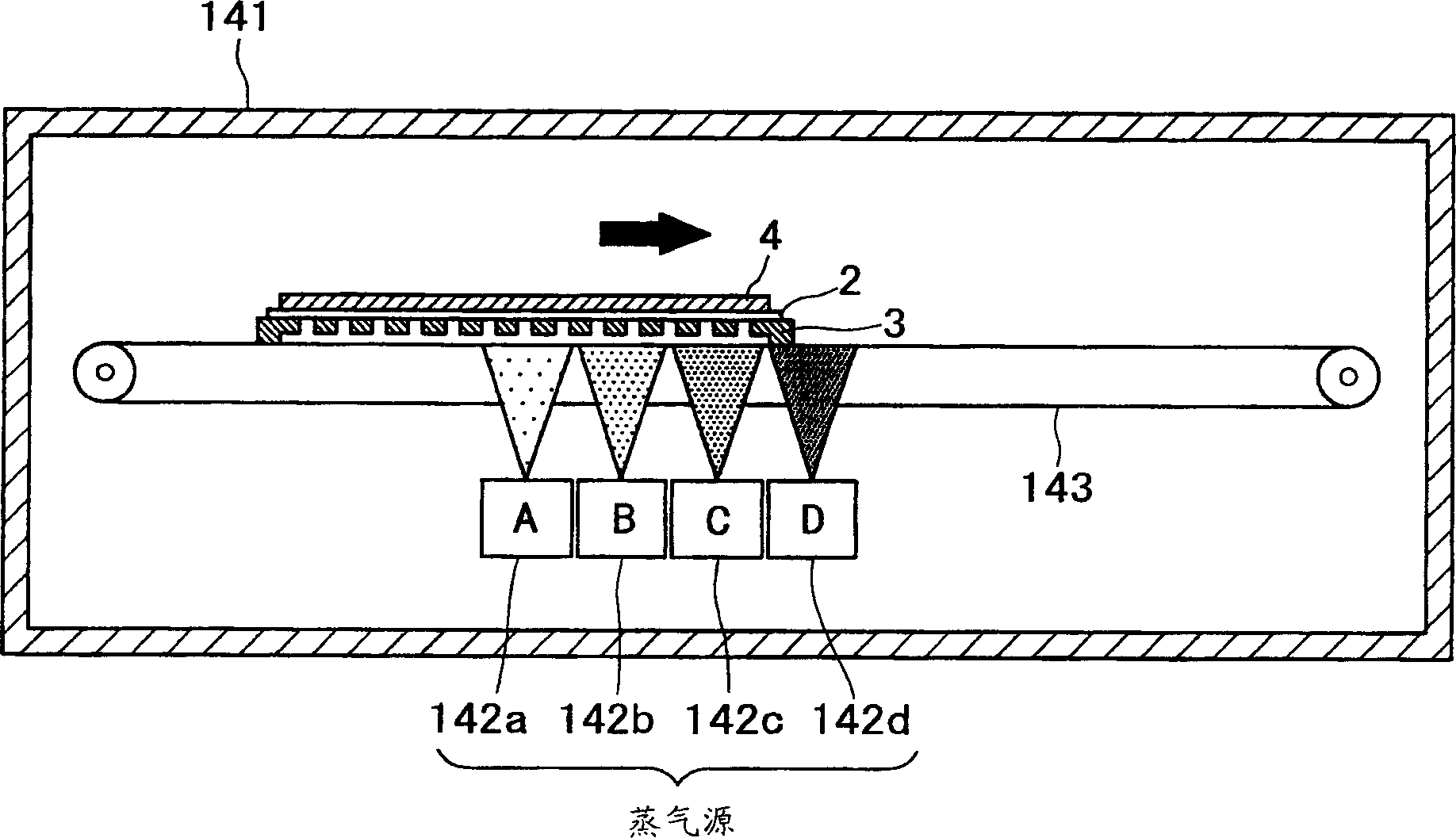

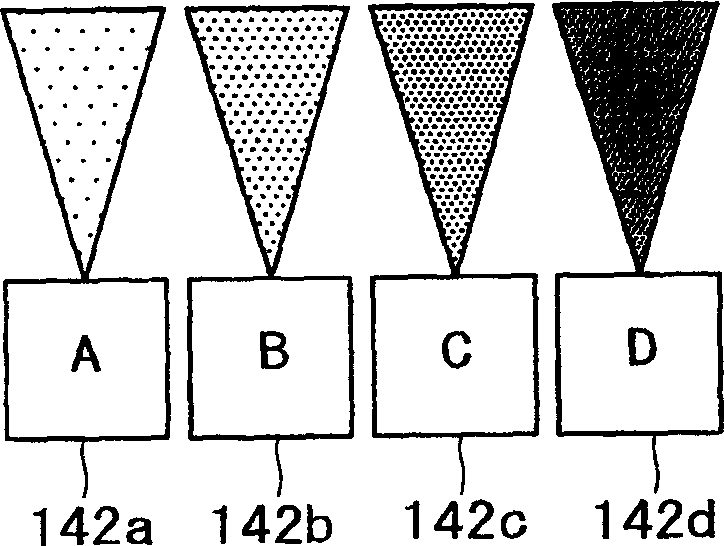

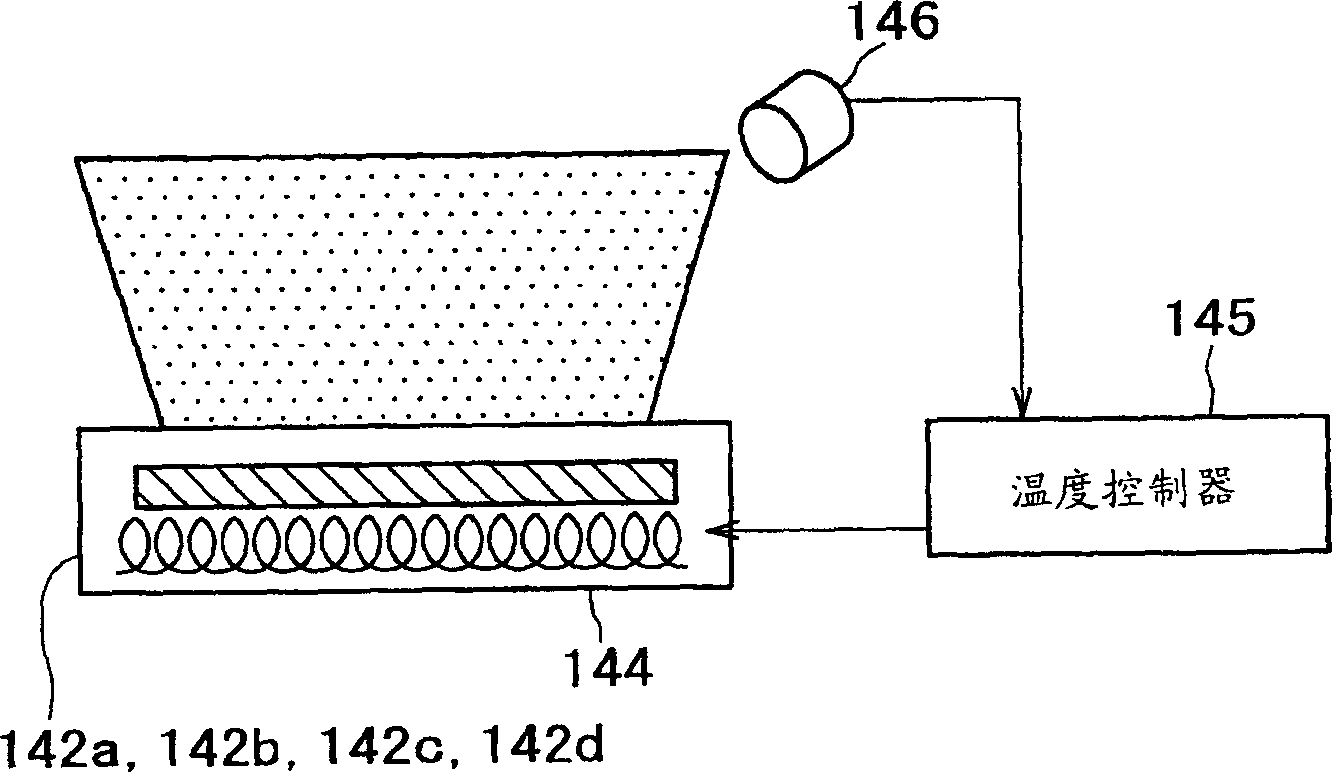

Method, system and apparatus for mfg. organic electroluminescence device and its display apparatus

InactiveCN1476279AImprove preprocessing efficiencyHigh costElectroluminescent light sourcesSolid-state devicesEngineeringOrganic electroluminescence

In manufacturing an organic electroluminescence device including a plurality of layers sequentially laminated on a substrate, the plurality of layers are laminated at a film formation portion on the substrate by varying the relative positions of the substrate on which to perform film formation and a plurality of vapor sources arranged side by side so that the substrate passes sequentially through positions corresponding to the plurality of vapor sources.

Owner:SONY CORP

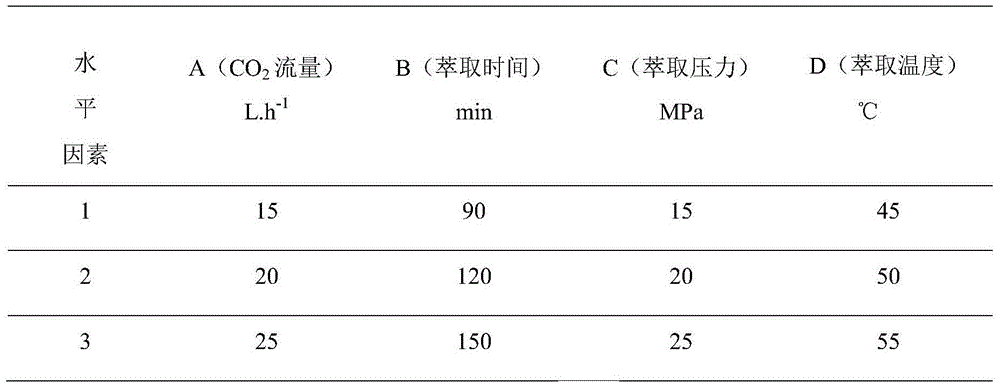

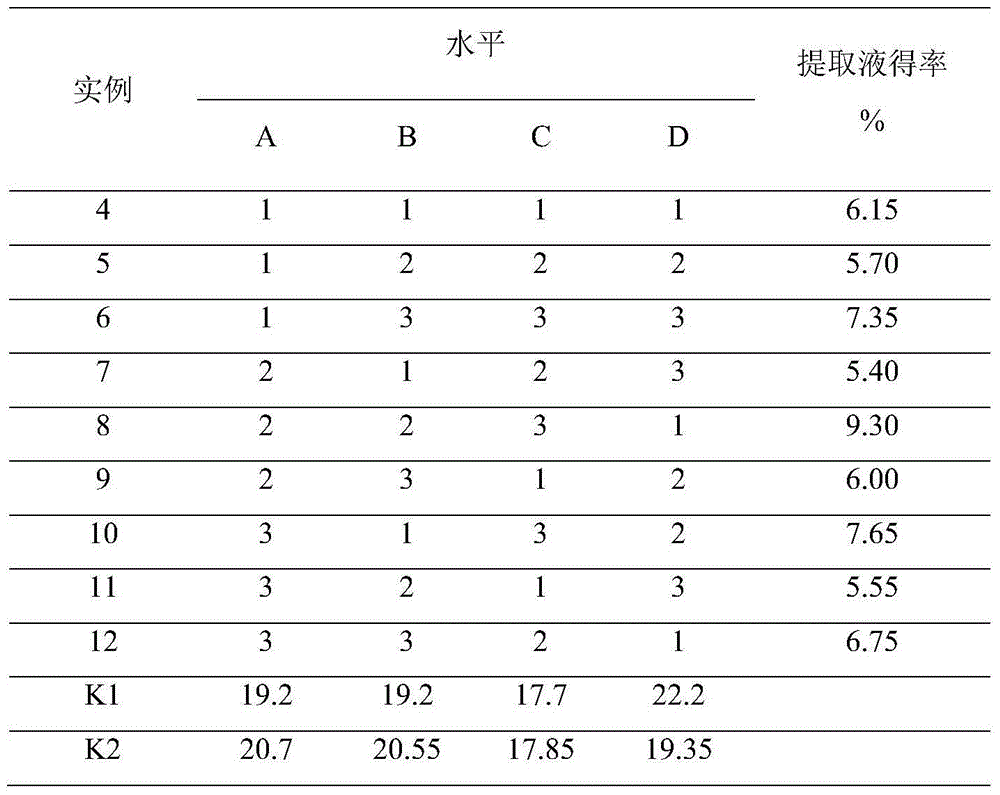

Method for preparing tobacco herbal fragrant substance for cigarette solution of electronic cigarette

ActiveCN104450186ANo pollution in the processHigh yieldTobacco treatmentEssential-oils/perfumesLiquid smokeSolvent

The invention discloses a method for preparing a tobacco herbal fragrant substance for cigarette solution of an electronic cigarette. The method comprises the steps that waste and inferior tobaccos are extracted in an ultrasound-enhanced supercritical extraction device for 1.5-2 hours at the temperature of 40-55 DEG C in the presence of an entrainer under the conditions that the ultrasonic frequency is 20KHz, the ultrasonic power is 100W, the flow rate of carbon dioxide of 10-20L / h and the extraction pressure is 15-25 MPa, so as to prepare a mixed solution of carbon dioxide and the tobacco herbal fragrant substance, wherein the entrainer is a mixed solvent of propylene glycol, ethanol and distilled water; the mixed solution is separated by virtue of a separation kettle at temperature of 45- 60 DEG C under the separation pressure of 7-12MPa to obtain the tobacco herbal fragrant substance. The tobacco herbal fragrant substance contains tobacco natural fragrant substance components, nicotine and the like and is applied to the cigarette solution of the electronic cigarette so that the cigarette solution of the electronic cigarette is endowed with the same sense organ characteristic and a satisfaction sense of smoking as common cigarettes. The extraction method is easy to carry out, low in cost, and stable and safe in product quality; the environment pollution is avoided; compared with the conventional supercritical extraction process, the method has the advantage that material consumption and energy consumption are reduced.

Owner:CHINA TOBACCO SHANDONG IND

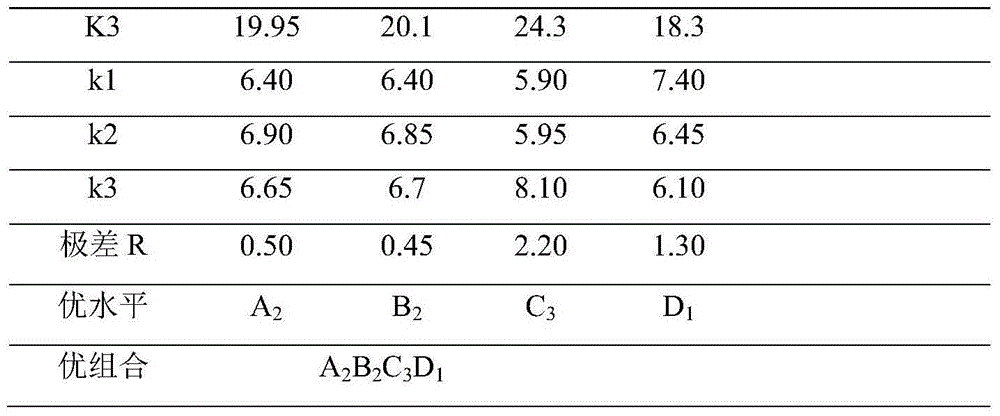

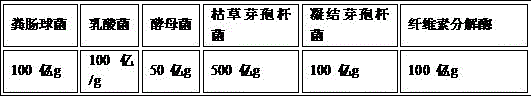

Compound biological strain for feed and preparation method of fermented feed

InactiveCN105483040AInhibition of reproductionEliminate odorFungiBacteriaBiotechnologyBacterial counts

The invention provides a compound biological strain for feed. The compound biological strain comprises enterococcus faecalis, lactobacilli, saccharomycetes, bacillus subtilis and bacillus coagulans, wherein the bacterial count ratio of the enterococcus faecalis to the lactobacilli to the saccharomycetes to the bacillus subtilis to the bacillus coagulans is (0.5 to 1.5):(0.5 to 1.5):(0.1 to 0.5):(4 to 6):(0.5 to 1.5). The compound biological strain for feed and a preparation method of fermented feed provided by the invention have the advantages that the release of crude protein and amino acid in coarse feed can be promoted, and the animal absorption is facilitated.

Owner:河南世纪天缘生态科技有限公司

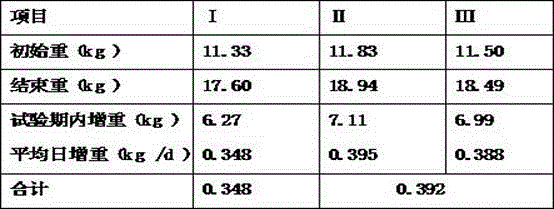

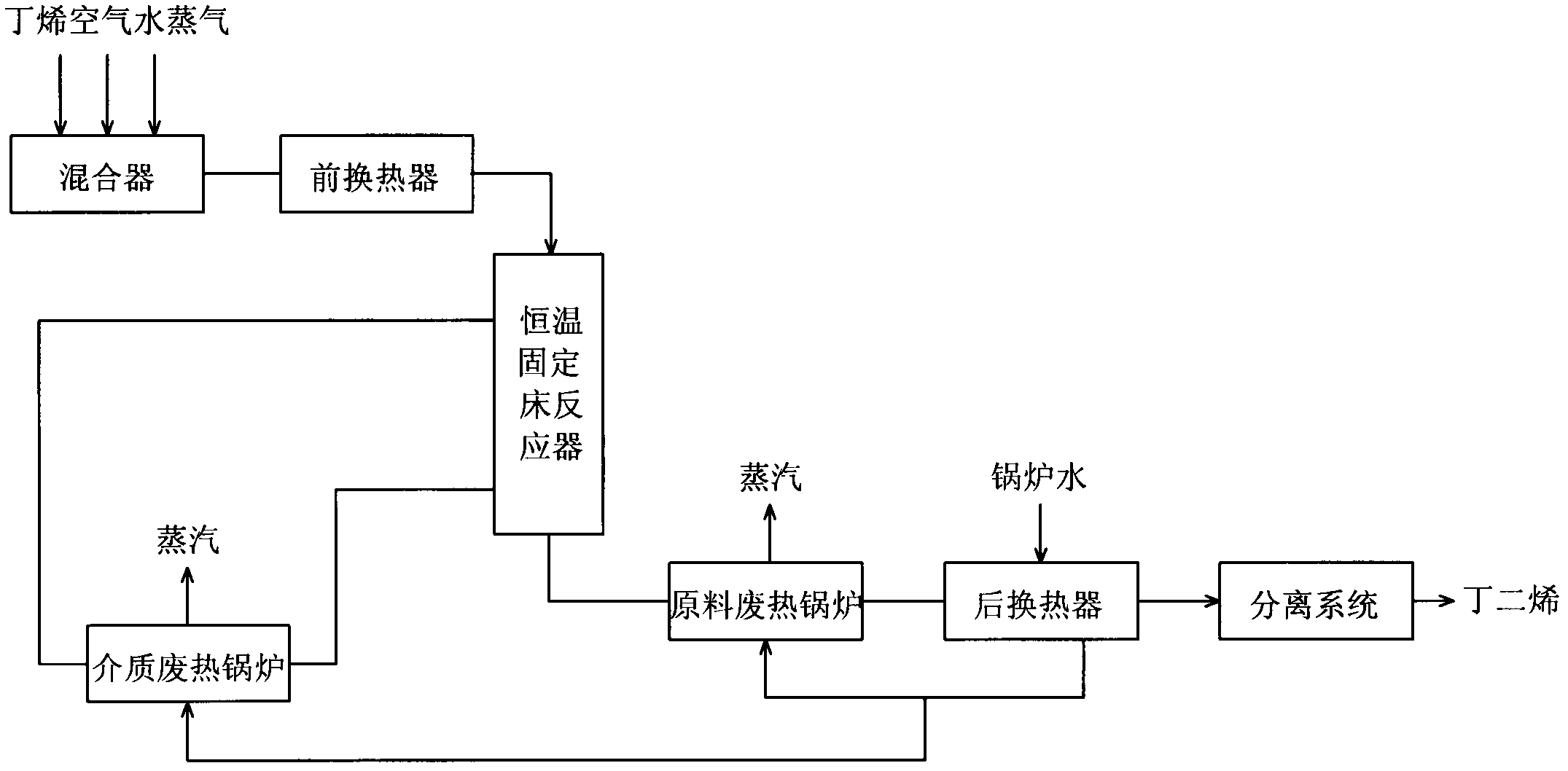

Method for preparing butadiene by oxidization and dehydrogenation of butane using constant-temperature static bed

InactiveCN102442874AHigh selectivityExtended service lifeHydrocarbonsHydrocarbon preparationButeneButadiene Dioxide

The invention provides a method for preparing butadiene by oxidization and dehydrogenation of butane using a constant-temperature static bed, which specifically comprises the steps that: the butane, air and water vapor are added into a static mixer according to proportions; mixed raw materials are heated to a certain temperature by a pre-heat exchanger, and then enter a constant-temperature static bed reactor for oxidization and dehydrogenation, wherein the static bed reactor is filled with catalyst, and the temperature of a catalyst bed layer of the reactor is controlled to be constant; after the mixed raw materials are oxidized and dehydrogenated, reaction products enter a post-heat exchanger for heat exchange through a raw material waste heat boiler, the products after heat exchange enter a separating system for separating the butadiene, so that butadiene product is obtained. In comparison with the prior art, the method for preparing butadiene by oxidization and dehydrogenation of butane using the constant-temperature static bed disclosed by the invention reaches a conversion per pass of the butadiene of 75%-85%, and the selectivity of the butadiene of at least 95%. The method can increase the conversion rate of the butane and the yield of the butadiene, reduce the butane and water consumed by the butadiene, greatly lower energy consumption, and decrease sewage discharge.

Owner:SHANDONG HUAMAO NEW MATERIALS

Method for producing aromatic carboxylic acid using nitrogen oxide as catalytic additive

InactiveCN1865214AReduce dosageImprove productivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsToxic gasCombustion

This invention provides a method for producing aromatic carboxylic acids with oxynitrides as catalytic additive, which is realized by adding a small amount of oxynitrides with specific structures to the current MC-type liquid catalytic system. Compared to the conventional MC type catalytic oxidation process, the adding of oxynitrides with specific structures significantly accelerates the oxidation reaction of the methyl aromatic hydrocarbons, stimulating the process of transforming methyl aromatic hydrocarbons to aromatic carboxylic acids. The adding of oxynitrides with specific structures can also improve the selectivity of the reaction process, and decrease combustion side reaction. Besides, it can moderately decrease the bromine concentration in the system, thus decrease the etching of the reaction system to the apparatus and the bromine-containing toxic gas discharging.

Owner:SINOPEC YANGZI PETROCHEM +1

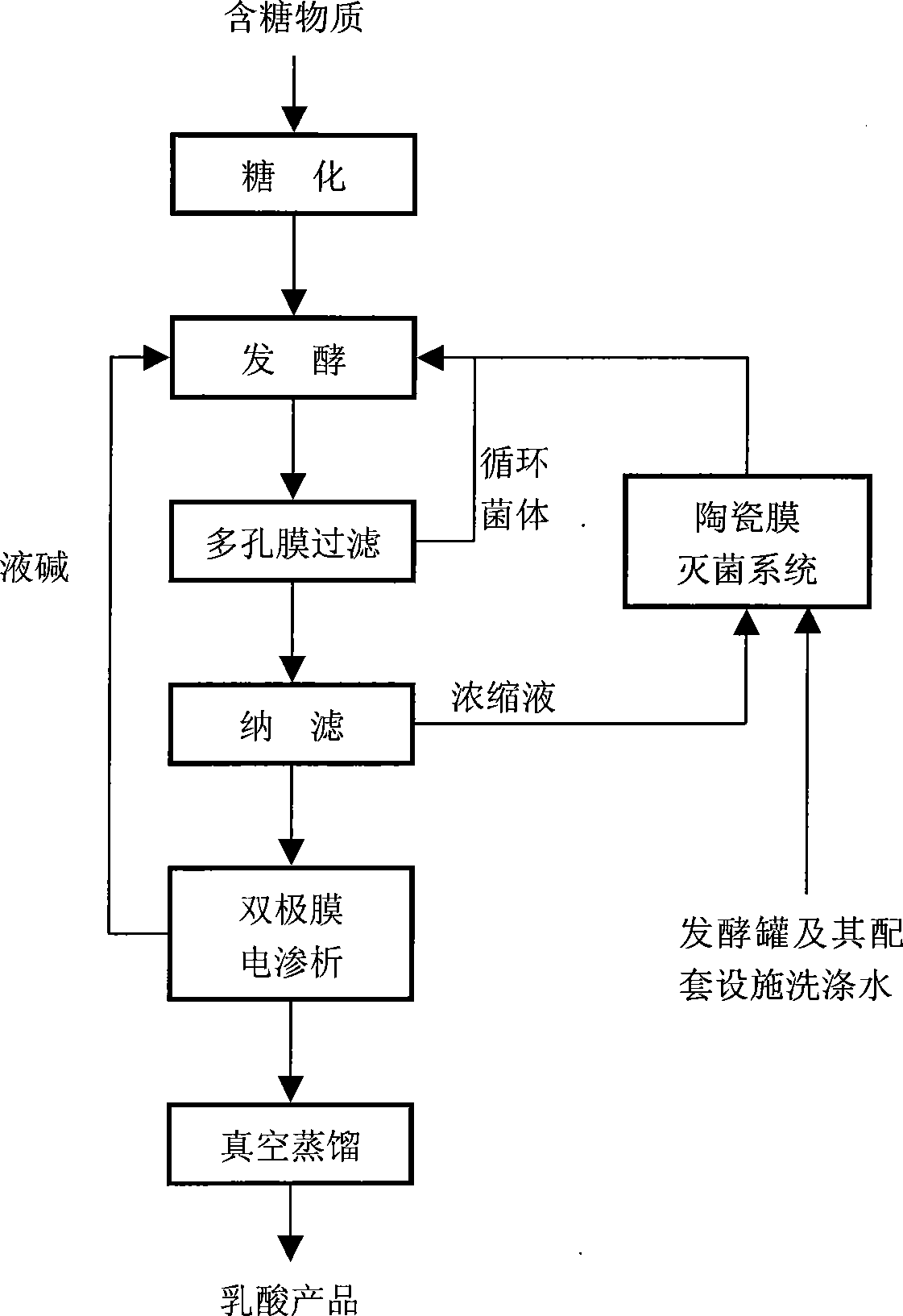

Clean production process of lactic acid

ActiveCN101392273AGreat advantageProduction to preventSemi-permeable membranesMicroorganism based processesPollutionElectrodialysis

Owner:NANJING TECH UNIV

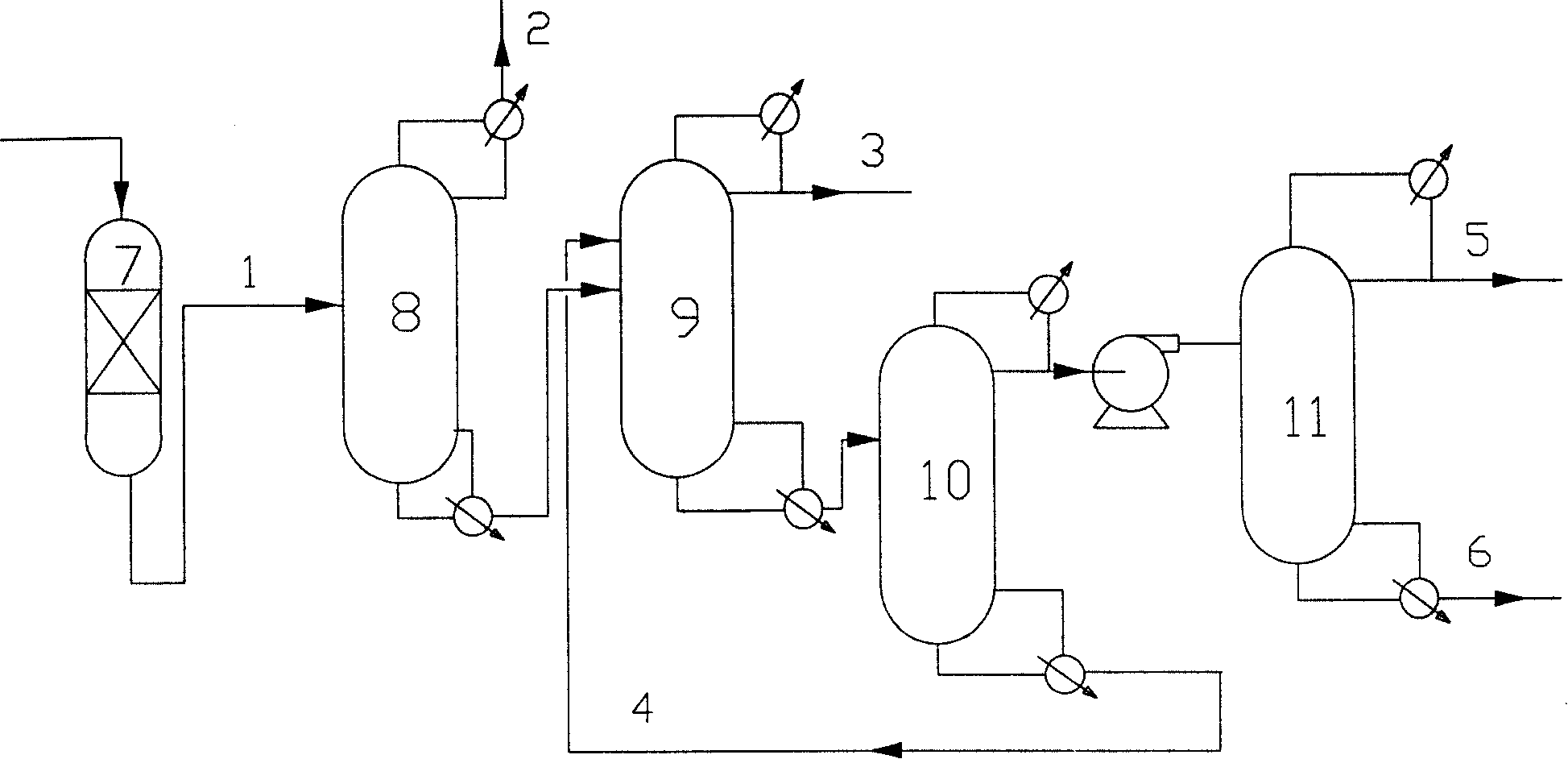

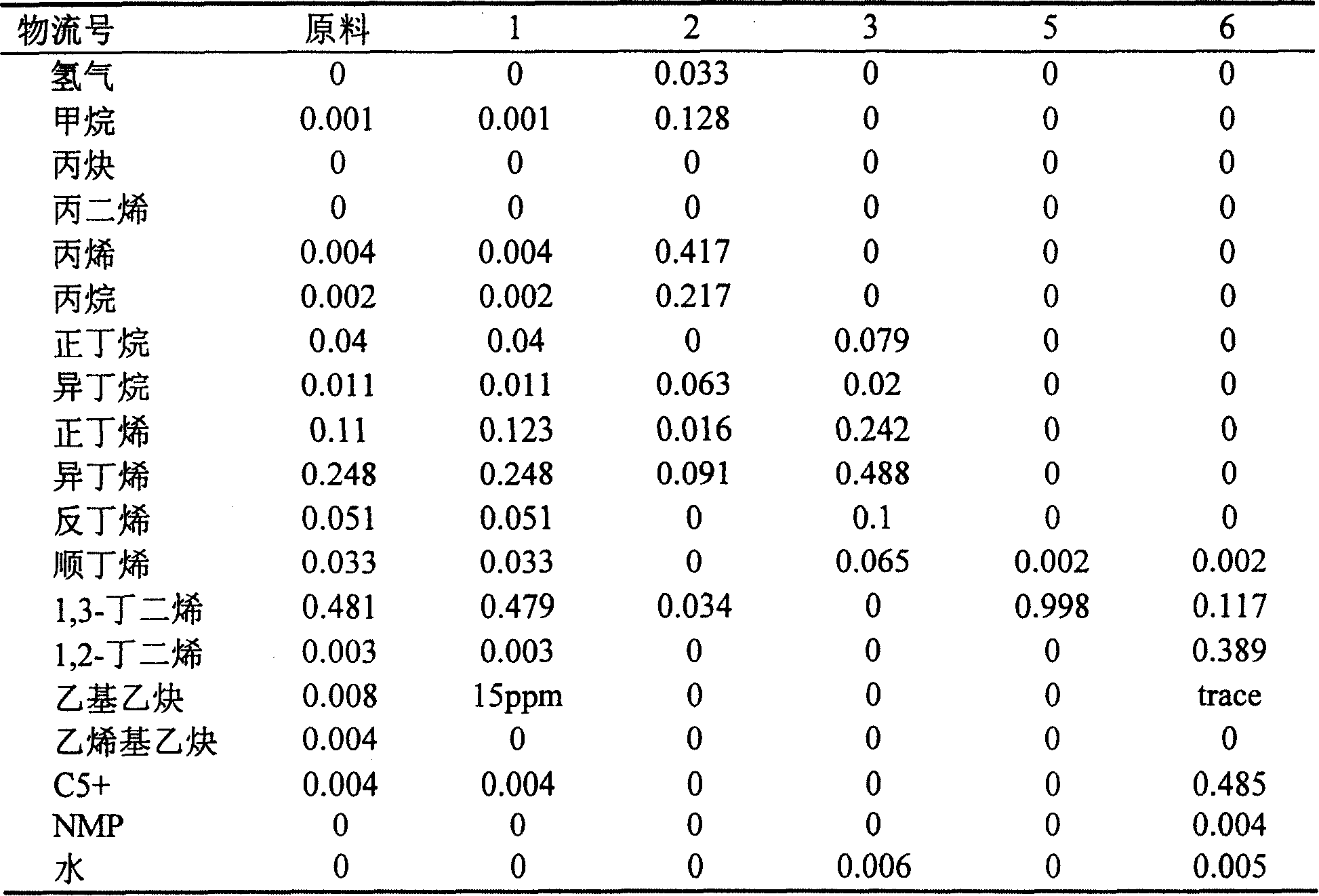

Extraction method for a segment of butadiene with NMP method

ActiveCN101172929ASimple processLess investmentDistillation purification/separationHydrocarbonsEngineeringTower

The invention discloses a NMP butadiene sectional extraction method with a forward hydrogenation technology. The invention solves the problems existed in the prior NMP butadiene sectional extraction method that the tower top of a leaching and rectifying tower has large load, needs a circulated pressure compressor and has high requirement on the grade of refrigerant. The invention provides a butadiene section extraction method of leading a slight tower and canceling the circulated pressure compressor in the sectional extraction technology, and the invention comprises the steps of hydrogenation,releasing the slight components, leaching and rectifying, adsorption stripping, refining and so on. The invention is characterized in that the forward hydrogenation technology is adopted so that theacetylene hydrocarbon is released before leaching and rectifying, thereby increasing the operational safety, and the slight components are released in advance before leaching and refining so that thematerial positioned on the tower top of the adsorption stripping tower can be condensed to liquid phase, thereby being able to be transported to a refining tower through a pump; the invention cancelsthe compressor, thereby saving the device investment, decreasing the energy consumption, simplifying the operation, and being high in safety. Besides, with strong adaptive capacity on raw material, the operation of the device is not influenced by the regeneration period of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

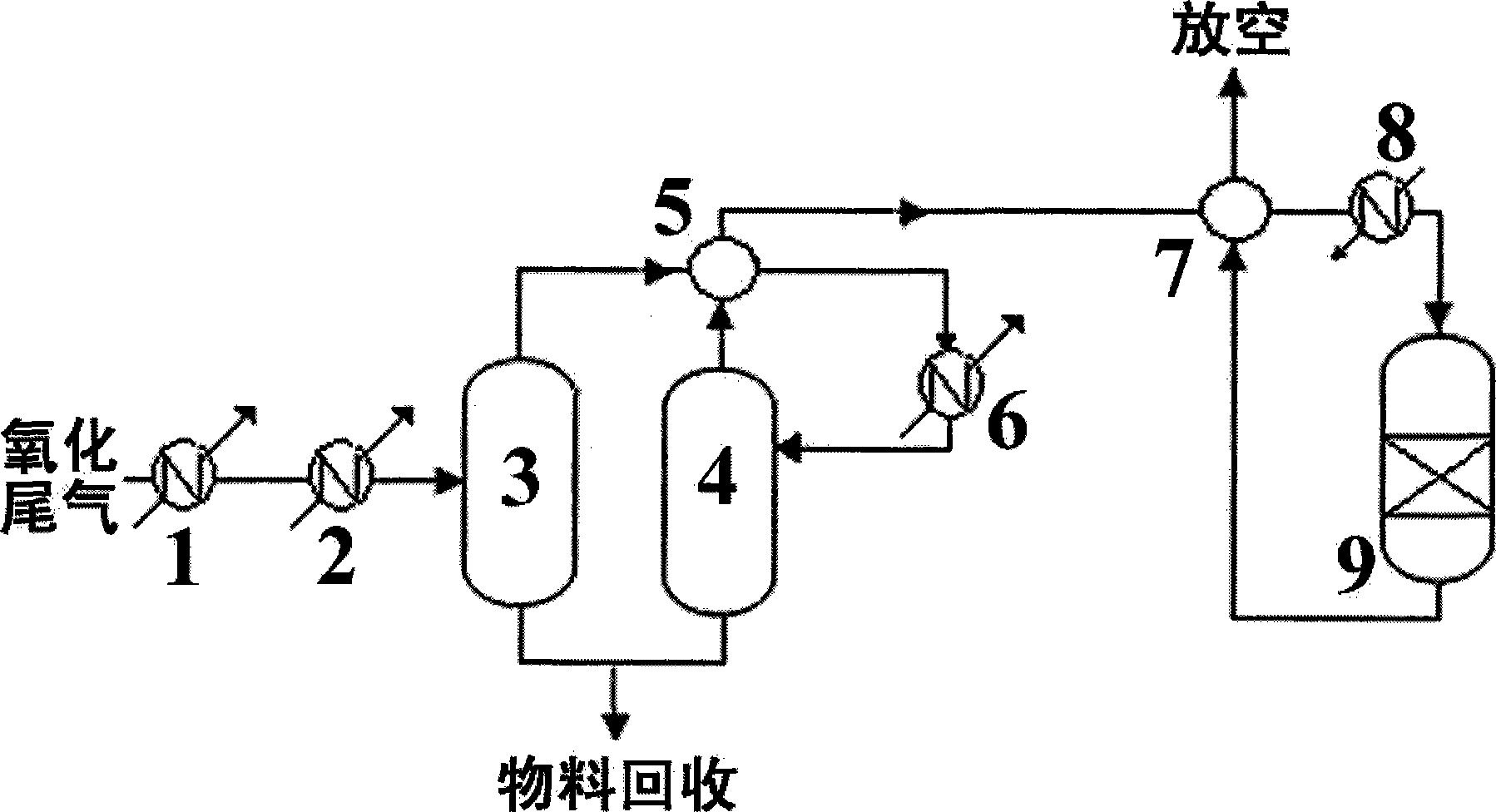

Process for treating oxidized exhaust gas

ActiveCN101543684AReduce the temperatureAchieve reuseOrganic compound preparationChemical industryLoss rateDevice material

The invention discloses a novel method for recovering and treating oxidized exhaust gas generated in phenol production, which comprises the following steps: adopting deep cooling to achieve liquefaction separation of organic matters by reducing the temperature of the exhaust gas to below 5 DEG C, wherein the material recovery rate reaches more than 95 percent; and adopting a Pt catalyst to decompose residual total hydrocarbons and cumene in the exhaust gas at a temperature of between 220 and 450 DEG C to achieve emission after reaching standards. The method can improve the exhaust emission quality, recover effective components in the exhaust gas, and reduce the device loss rate and the device material consumption on the basis of raw water cooling and activated carbon adsorption.

Owner:CHINA PETROLEUM & CHEM CORP

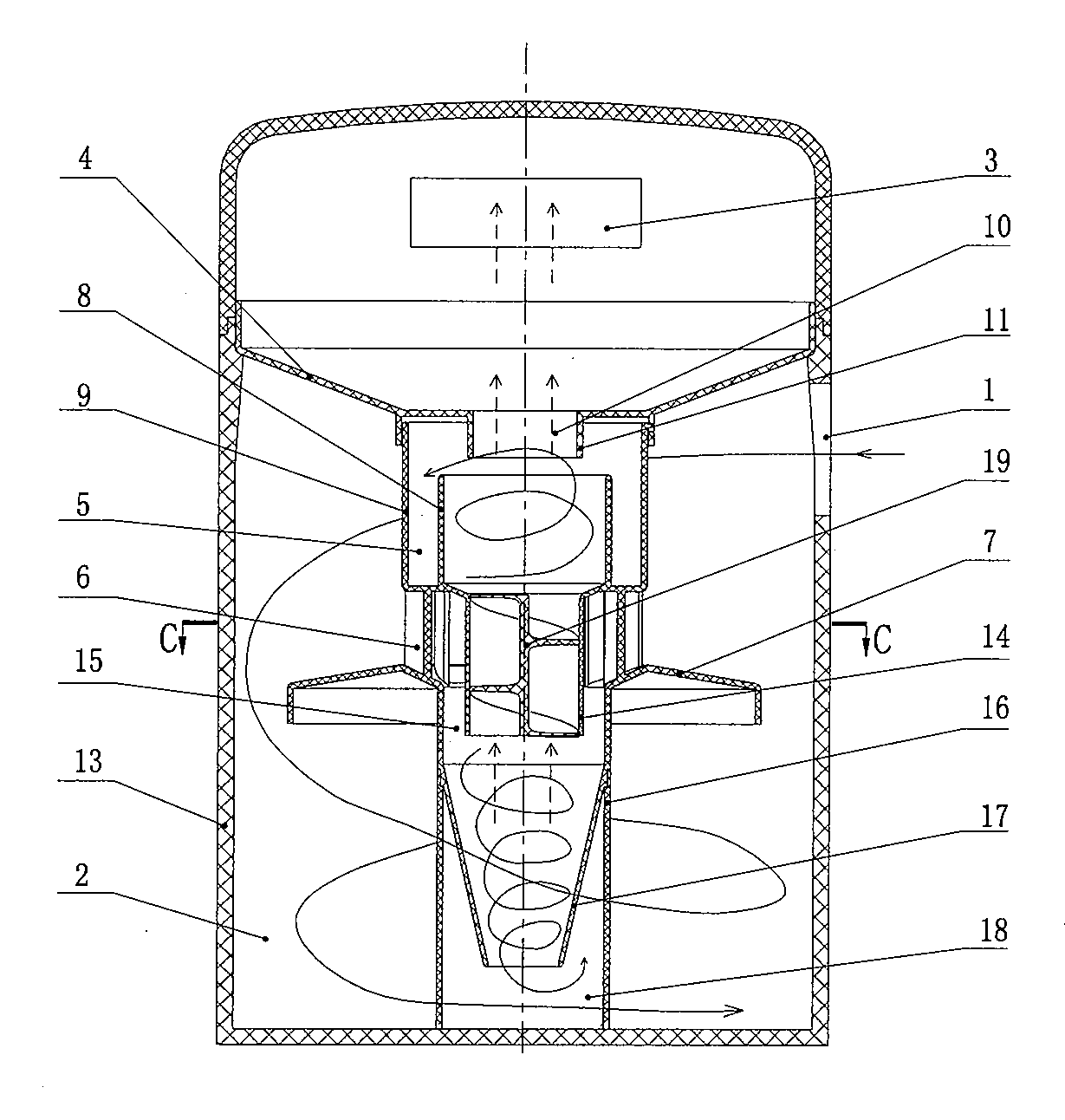

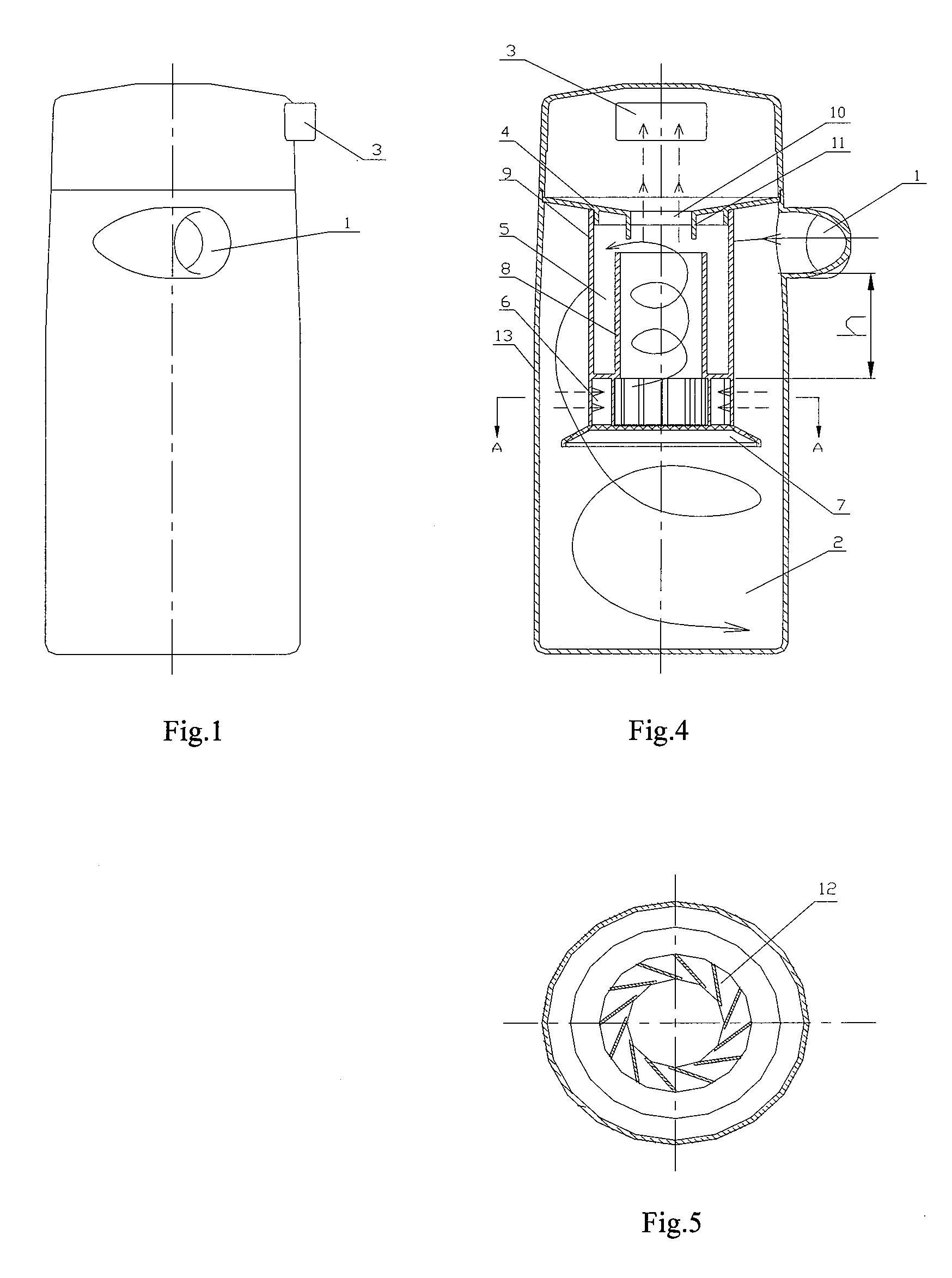

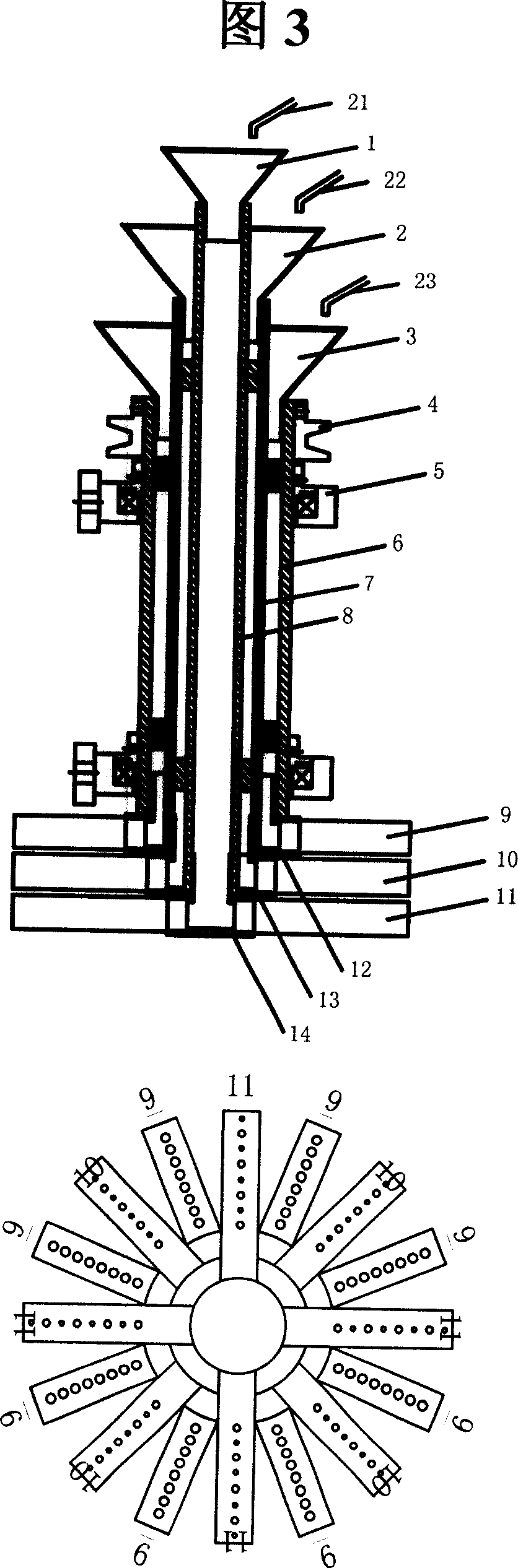

Dust Collector Cup of Fall Centrifugal Separation Type

InactiveUS20080104795A1Lower the volumeMore compact structureCleaning filter meansCombination devicesEngineeringDust collector

A dust collector cup working in the principle of fall centrifugal separation, consists of cup body (13), outlet (3) on the cup body (13), inlet (1) tangential to the circumferential wall of the cup body (13), and a separator settled in the cup body (13). The separator is composed of outlet tube (9), inlet (6) on the wall of the outlet tube (9), and the isolating shield (7) under the inlet (6) of the outlet tube (9), with the outlet tube (9) linked to the outlet (3) of the cup body (13). The fall between the horizontal positions of the lower end of inlet of the cup body (13) and the upper end of the inlet (6) of the outlet tube (9) is 0-140 mm.

Owner:WANG YUEDAN

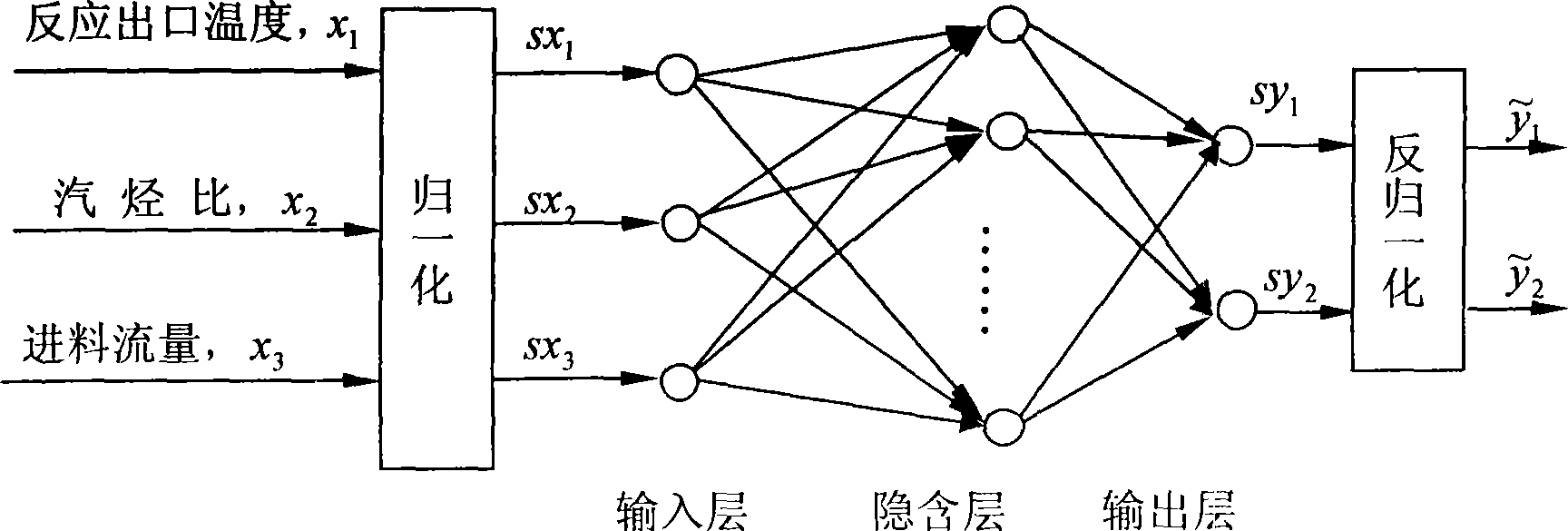

Method for optimizing cracking reaction operating condition of ethylene cracking furnace

InactiveCN101414158AHigh yieldReduce material consumptionThermal non-catalytic crackingOrganic chemistryProcess engineeringNetwork model

The invention relates to a method for optimizing operating conditions of a cracking reaction in an ethylene cracking furnace. The method comprises the following steps: selecting outlet temperature and cracking feed load of the cracking furnace, as well as a steam-hydrocarbon ratio (or dilution ratio) as input variables of a process model of the cracking reaction; selecting an ethylene yield and a propylene-ethylene ratio (or total triene yield) which reflect the cracking degree as dependent variables of the model; establishing a neural network model of the ethylene cracking reaction process by taking actual production data of the ethylene cracking furnace and experimental data of an experimental cracking model as training samples; and further performing optimization calculation on the operating conditions of the cracking reaction to obtain the optimum operating conditions of the cracking reaction, thus maximizing yield of the ethylene or the triene in the cracking products under a load constraint satisfying the production requirements.

Owner:EAST CHINA UNIV OF SCI & TECH

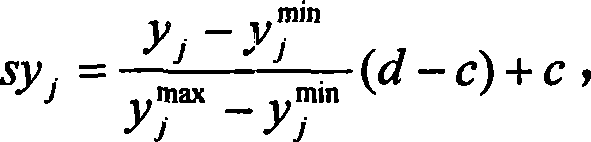

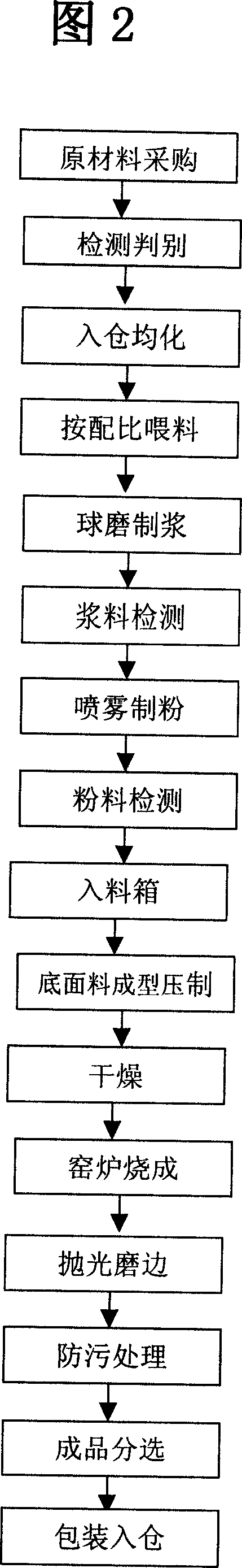

Production method of natural stone texture imitating ceramic wall ground tile

ActiveCN101096112AMeet performance requirementsGood environmental benefitsCeramic shaping plantsClaywaresMicrowaveBrick

The invention discloses a producing method for ceramic tile with like texture of natural stone. The purpose of invention is that a producing method for ceramic tile with natural stone texture layer, beautiful colored effect, circumstance protection benefit, low cost and satisfying national ceramic tile standard is provided. Ceramic slurry is adopted and is sprayed on the surface of dried tile in mixing or half mixing state or tile is prepared by full slurry. The tile is dried by microwave and is sent into stove to be calcined so as to fabricate ceramic tile with natural texture and similar effect to natural stone. The invention is characterized in that 10-25% of quartz, 10-25% of kaoline and 50-80% of mixed sand are mixed into ball mill for wet-ball milling; after the mixed is screened pulpiness over-glaze slurry is prepared; slurry mentioned above is set on dried ceramic tile in drenching glaze way; after ceramic tile after applying glaze slurry is dried by microwave it is sent into ceramic roller kiln; it is calcined for 60-100 minutes under the temperature of 1180- 1220deg.C; then it is polished or not polished; finally it is fabricated.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

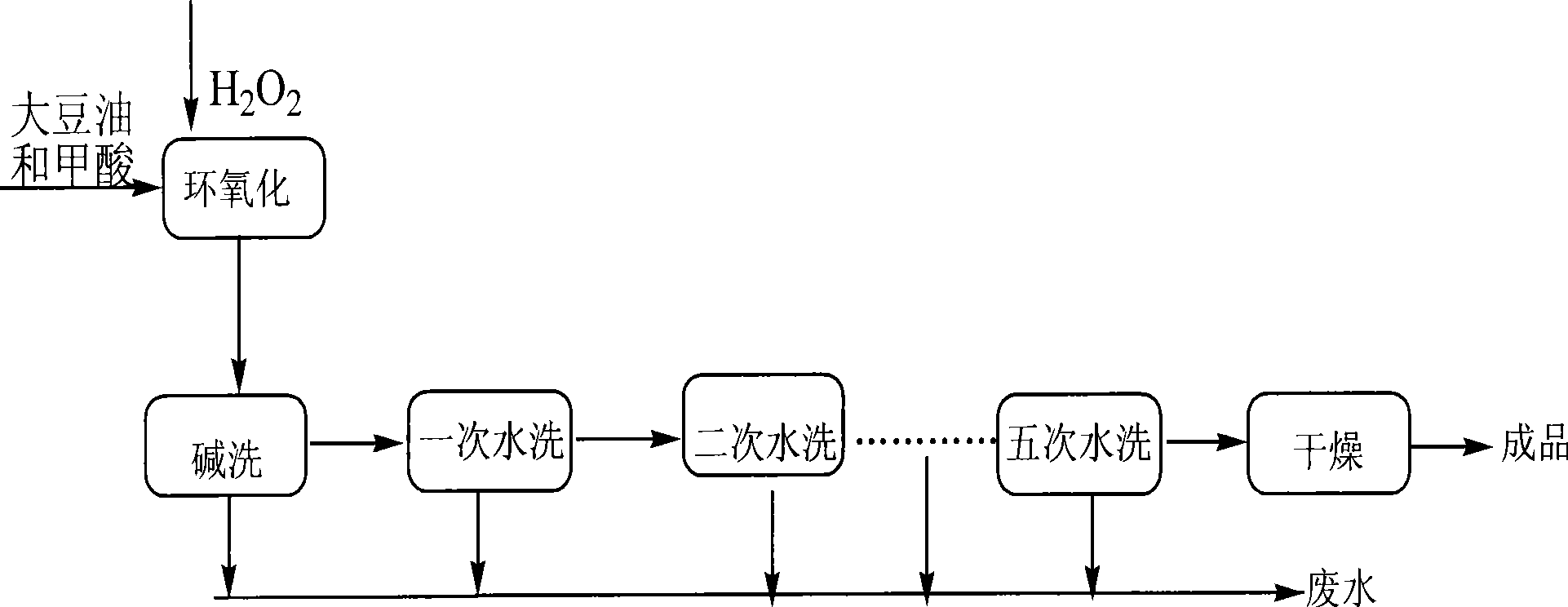

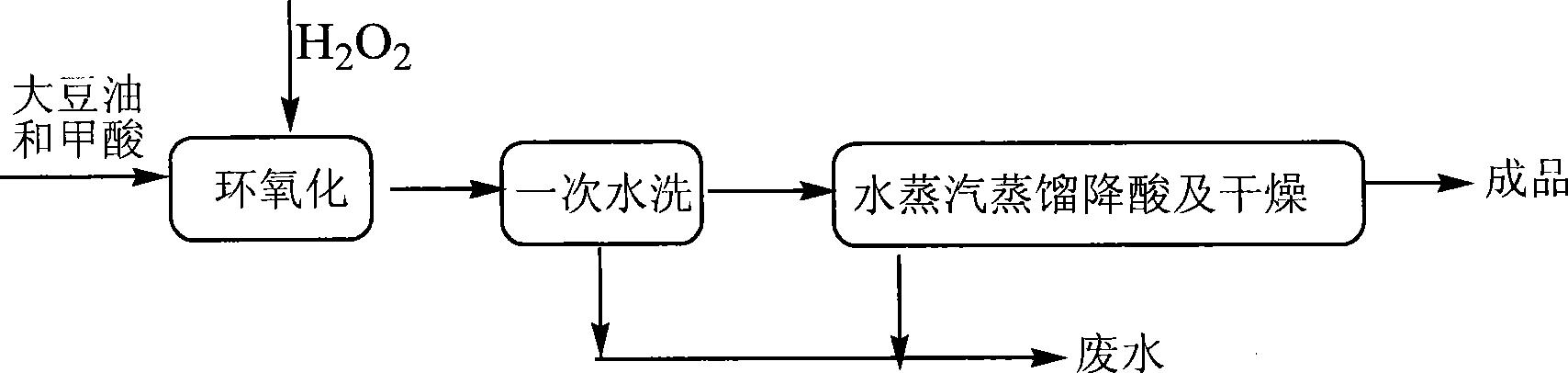

High-quality epoxy ester production method with low energy consumption and little wastewater

InactiveCN101445495AReduce the number of washesReduce material consumptionOrganic chemistrySOYBEAN SEED OILFormic acid

A high-quality epoxy oil and ester production method with low energy consumption and little wastewater belongs to the technical field of fine chemical industry, energy conservation and emission reduction. The method comprises the following steps: selecting soybean oil or unsaturated fatty acid methyl (ethyl) esters as raw materials; adding hydrogen peroxide as oxygen source and formic acid as oxygen carrier; epoxidizing; washing with water for one time; distilling with steam to reduce acid and dry the product; and refining to obtain epoxy soybean oil or epoxy fatty acid methyl (ethyl) esters. The method has the advantages of low energy consumption, reduced wastewater emission, greatly shortened entire production cycle, high quality of the epoxy product and low acid value.

Owner:JIANGNAN UNIV

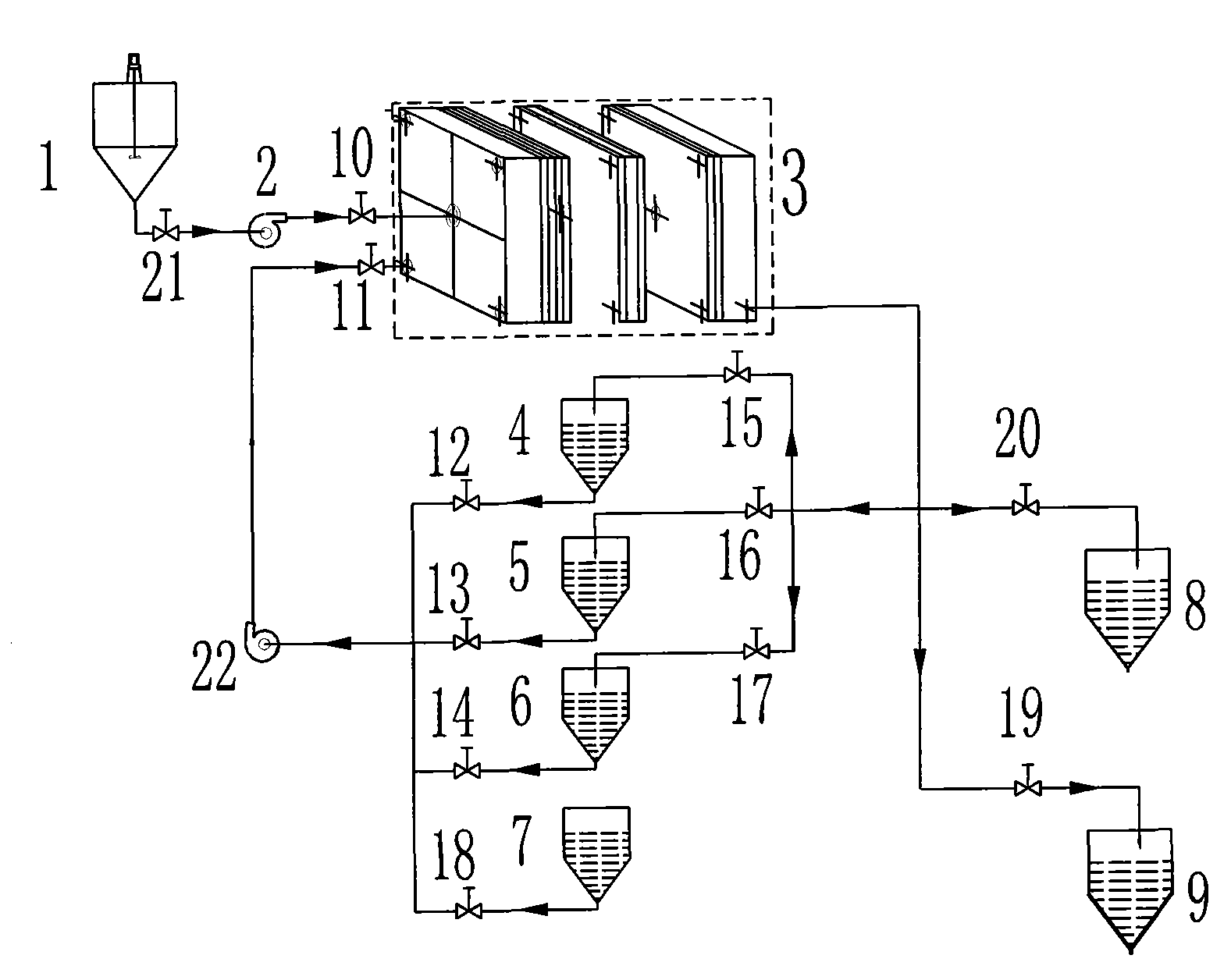

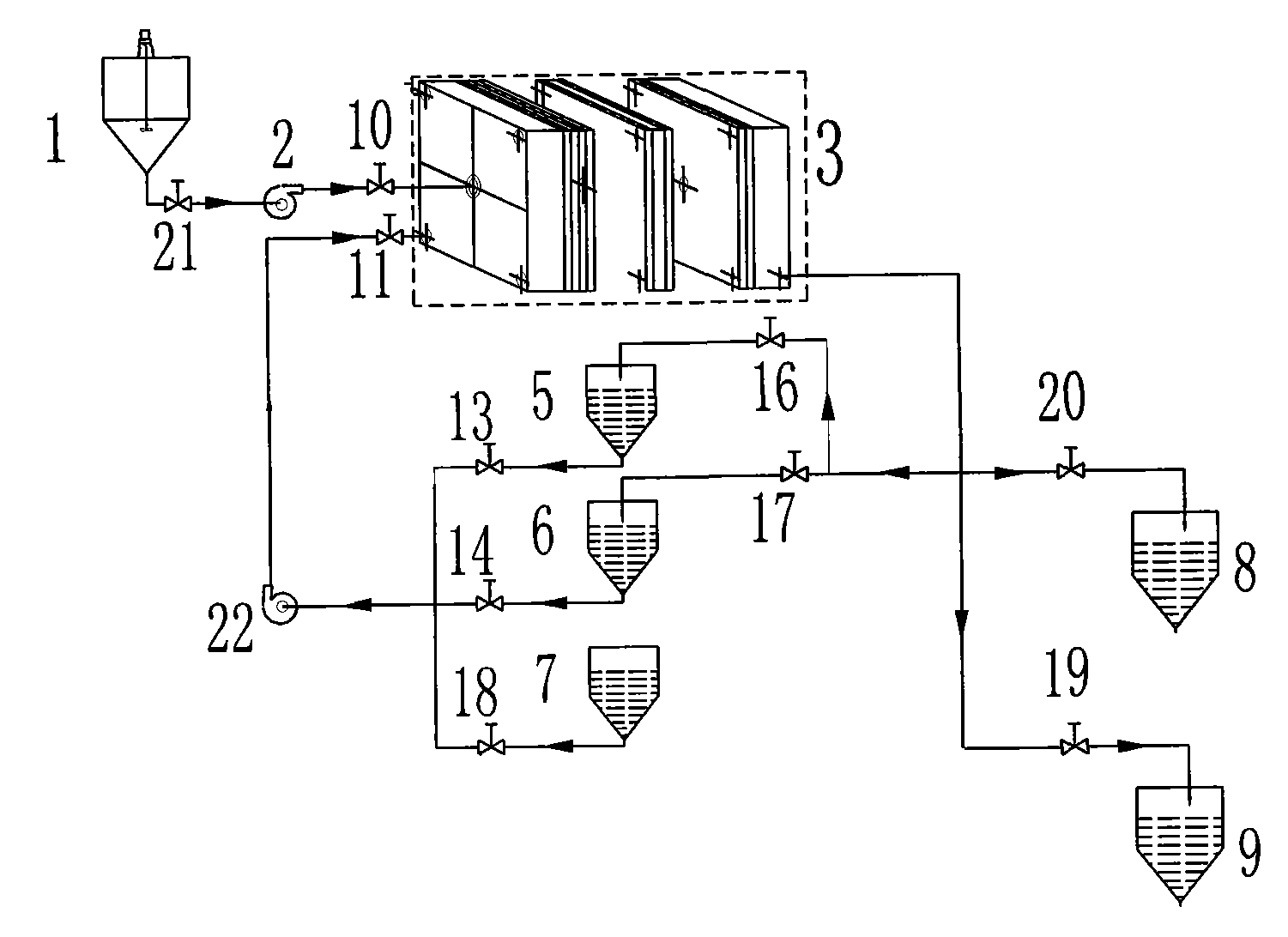

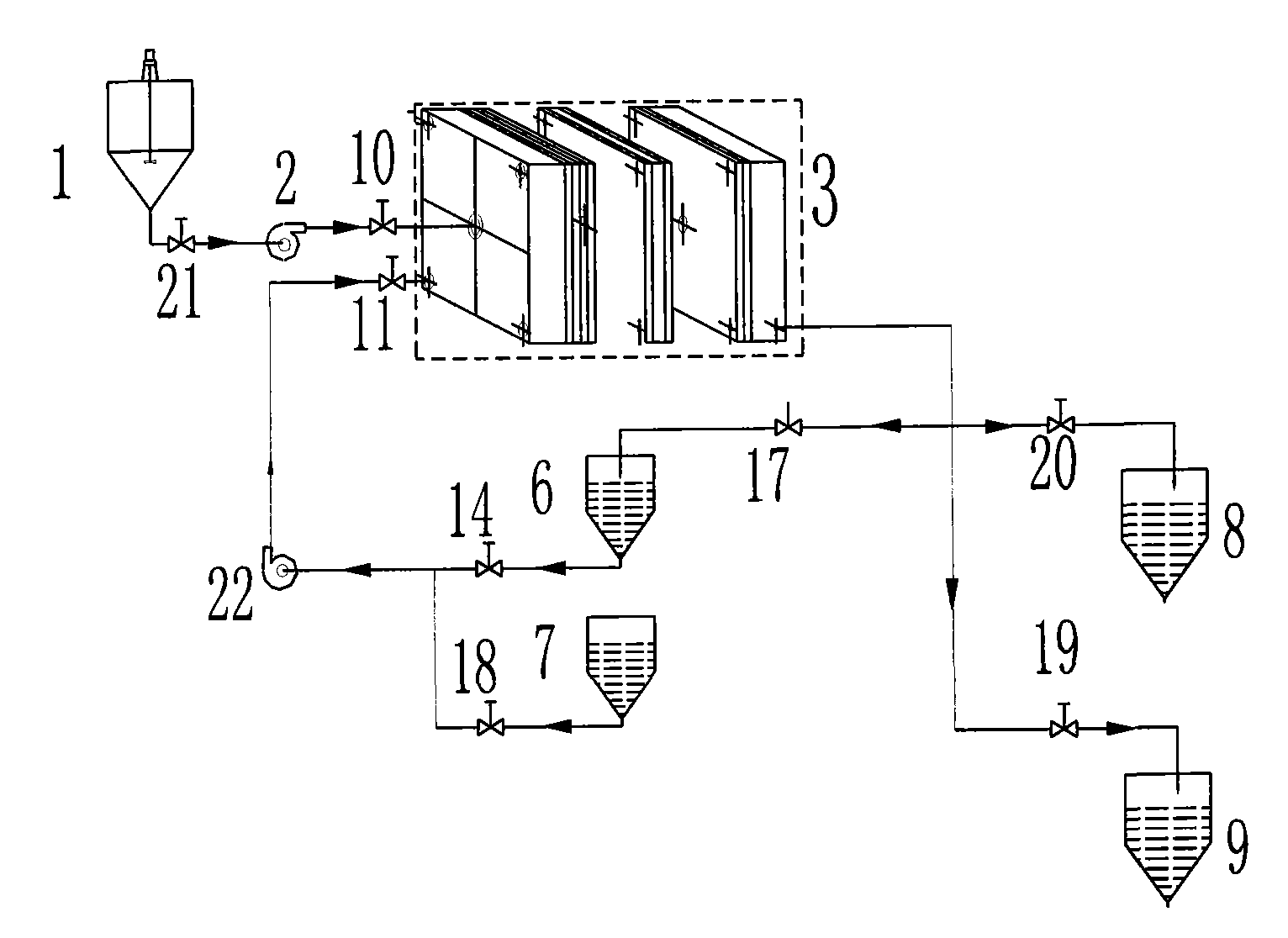

Multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method

InactiveCN102071311AWater-soluble zinc content is reducedReduce environmental risksFiltration separationProcess efficiency improvementElectrolysisSlag

The invention relates to a multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method which are applicable to industries such as the metallic zinc electrolysis industry, hydrometallurgy and the like. The system provided by the invention comprises a membrane filter press, wherein the feed port end of the membrane filter press is connected with a zinc calcine acid leaching liquor feed pool, and the discharge port end of the membrane filter press is respectively connected with a filtrate pool and a collection liquor pool; and a waste electrodeposit liquor circulation pool, a circulation washing pool and a clean washing water pool are connected in parallel between the feed port end and discharge port end of the membrane filter press. The method provided by the invention comprises the following steps: (1) feeding materials; (2) carrying out multisection acid leaching by using the waste electrodeposit liquor at different temperature gradients; (3) carrying out multistage countercurrent washing by using zinc-containing washing water of different concentrations; and (4) carrying out filter pressing on the filter cake. According to the invention, the content of water-soluble zinc (in terms of Zn) in zinc waste slag in the mainstream technique in metallic zinc electrolysis industry at present can be reduced from 3.5-6.0% to below 0.5%; and the acid leaching and washing efficiency are greatly enhanced, and the acid leaching recovery rate of zinc ore can be higher than 97%.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

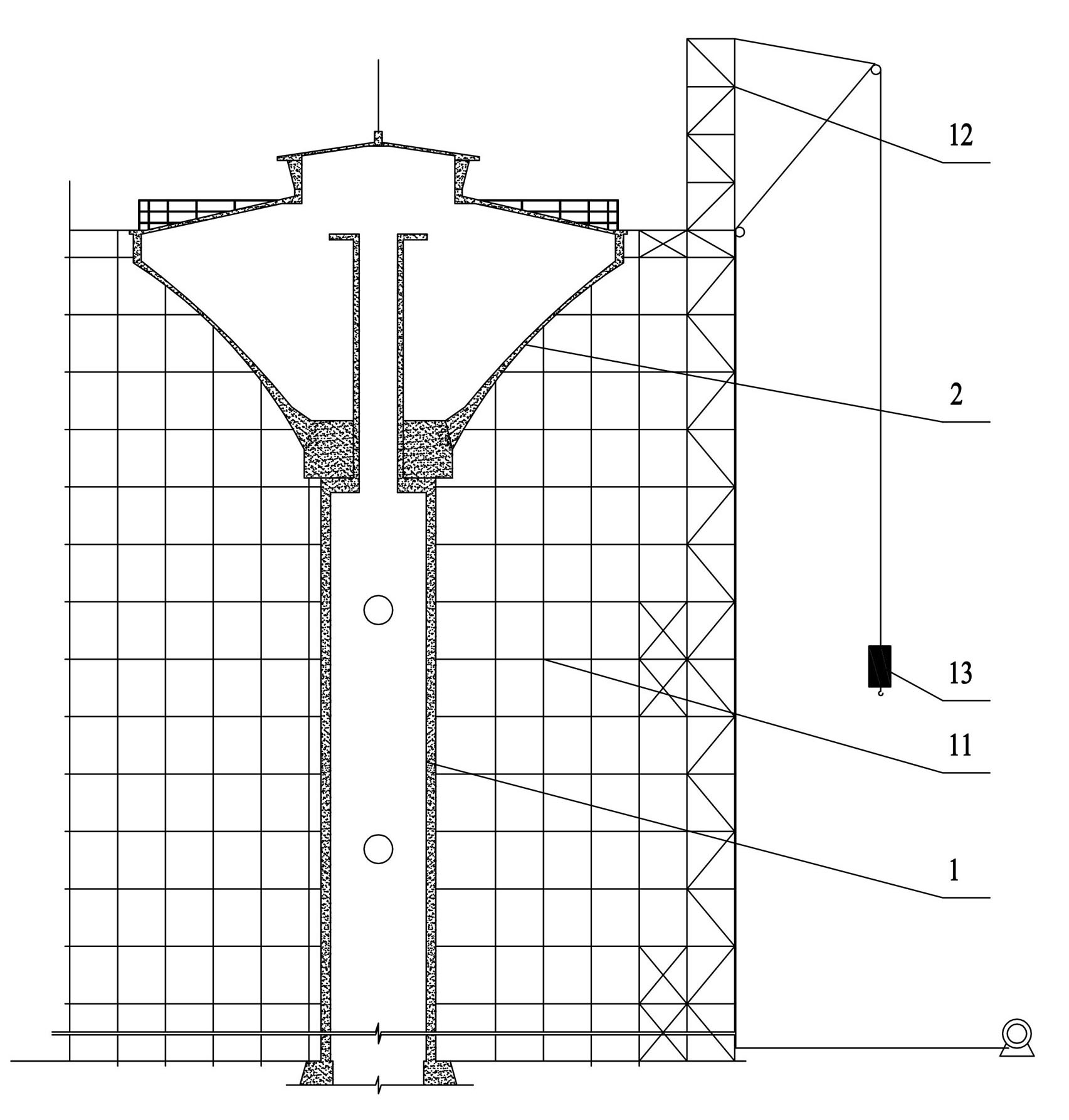

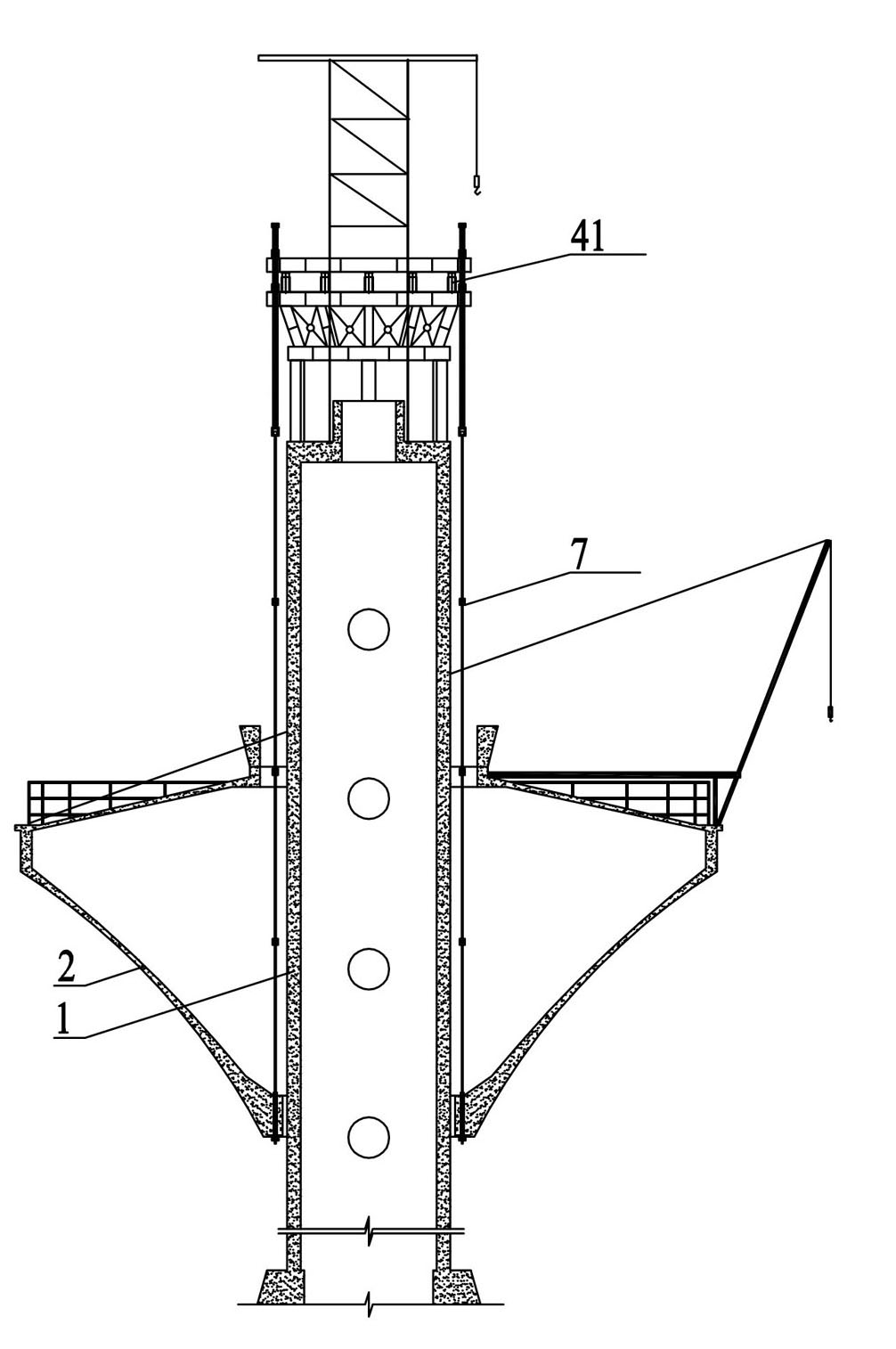

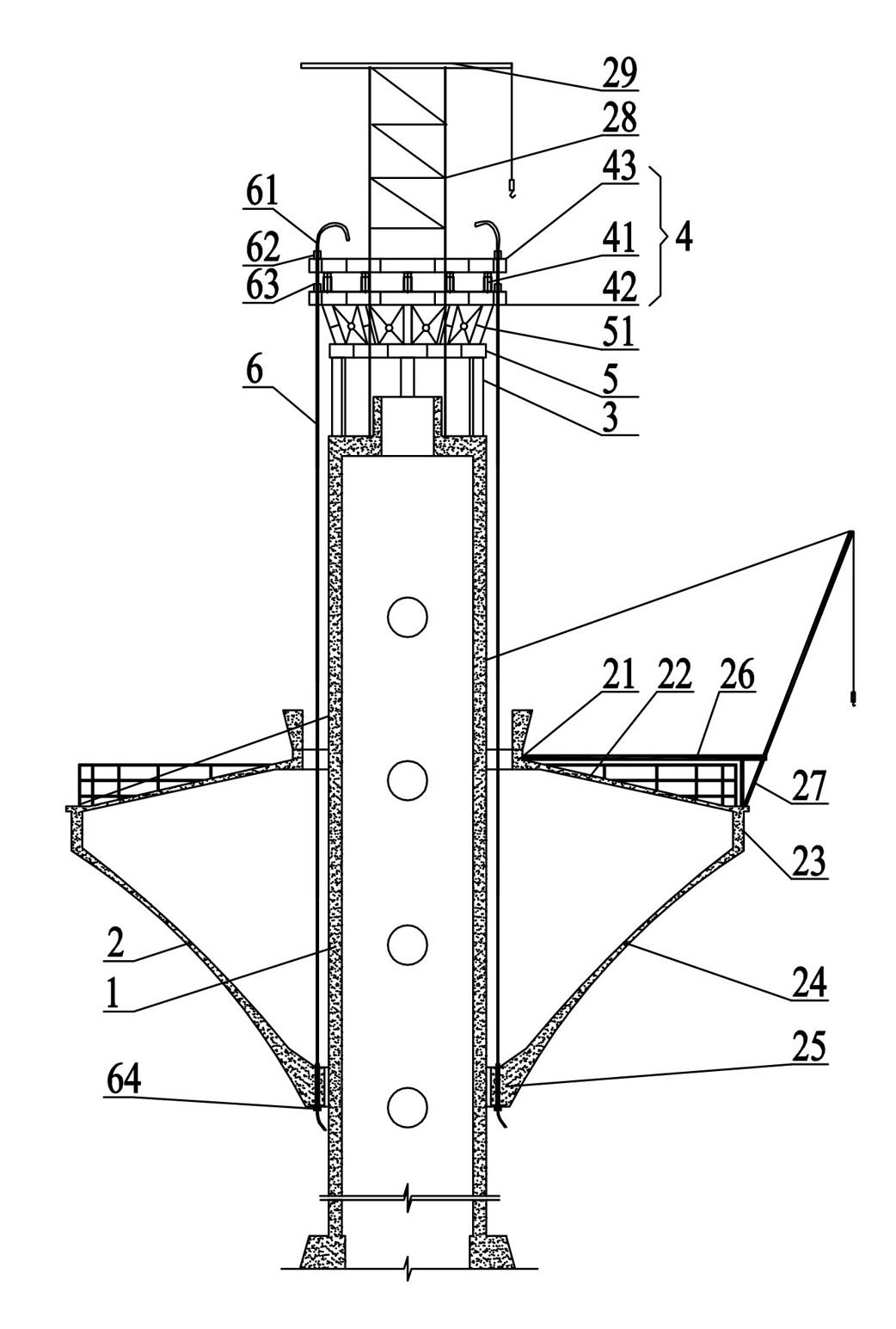

Hoisting method of hyperbolic water-tower water tank and hoisting device

The invention discloses a hoisting method of a hyperbolic water-tower water tank and a hoisting device. The hoisting method comprises the following steps of: firstly, prefabricating a water tank, installing lifting equipment, and starting to lift after a real-load pressure test is qualified; during lifting, firstly, jacking steel beams and driving a steel strand to lift; after a stroke is completed, utilizing a locking anchorage device to clamp the steel strand at a static steel beam, returning oil, then utilizing the locking anchorage device to clamp the steel strand onto a moving steel beam after falling back, thereby completing a hoisting cycle for one time; and repeatly lifting until the water tank is lifted to the position and then fixing. The hoisting device comprises a lifting part, a supporting part and a sling assembly, wherein the lifting part comprises a moving steel beam, a static steel beam and a hydraulic lifting device arranged between the moving steel beam and the static steel beam; and the sling assembly comprises a steel stand. The top of the steel stand penetrates through the moving steel beam and the static steel beam and is clamped on the steel beams through the locking anchorage device, and the bottom of the steel stand is connected with the water tank. The construction method and the device are simple in operation and have the advantages of low cost, low labor strength, low energy consumption, strong safety and reliability and good quality of construction.

Owner:五矿二十三冶建设集团有限公司

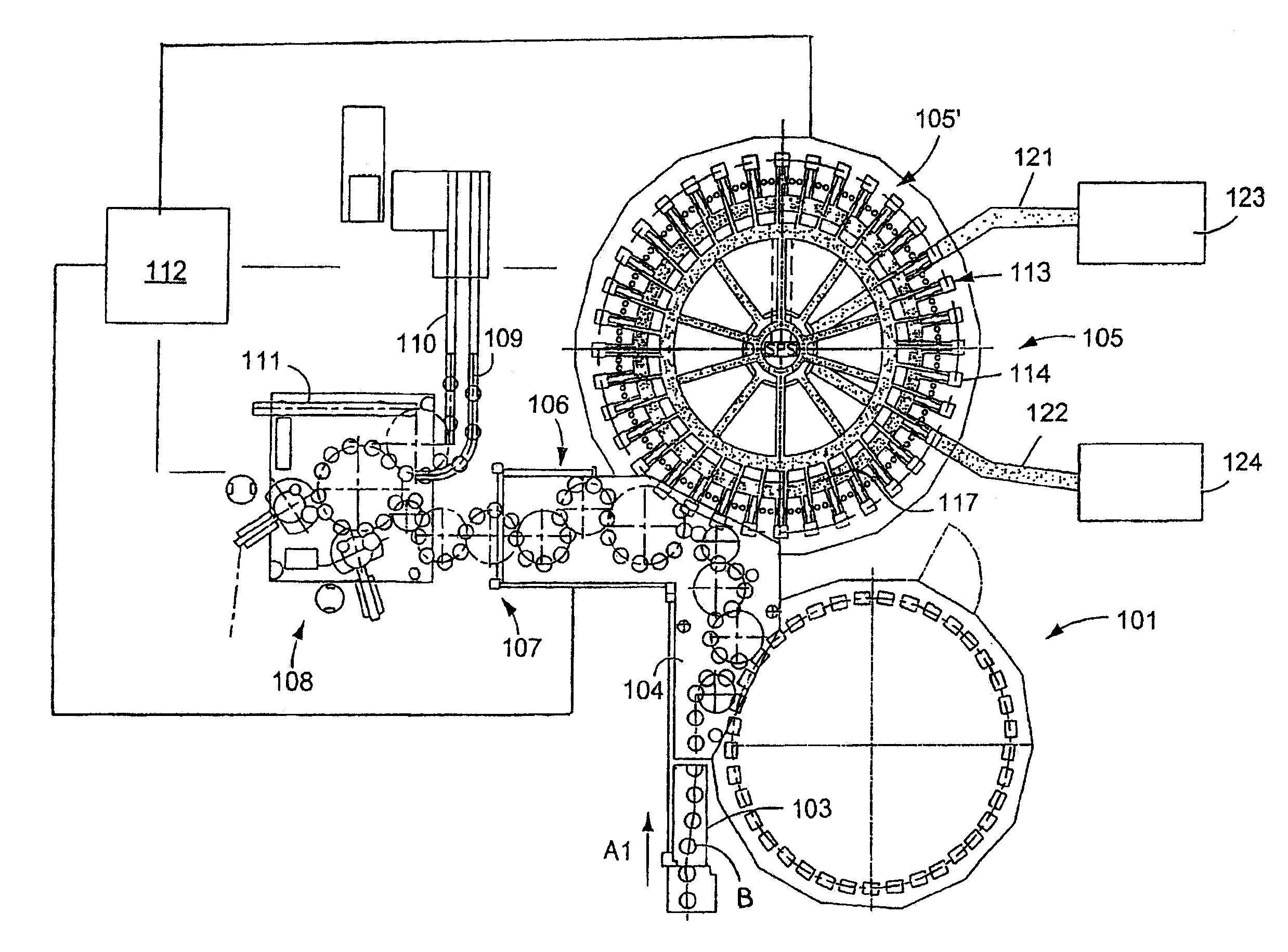

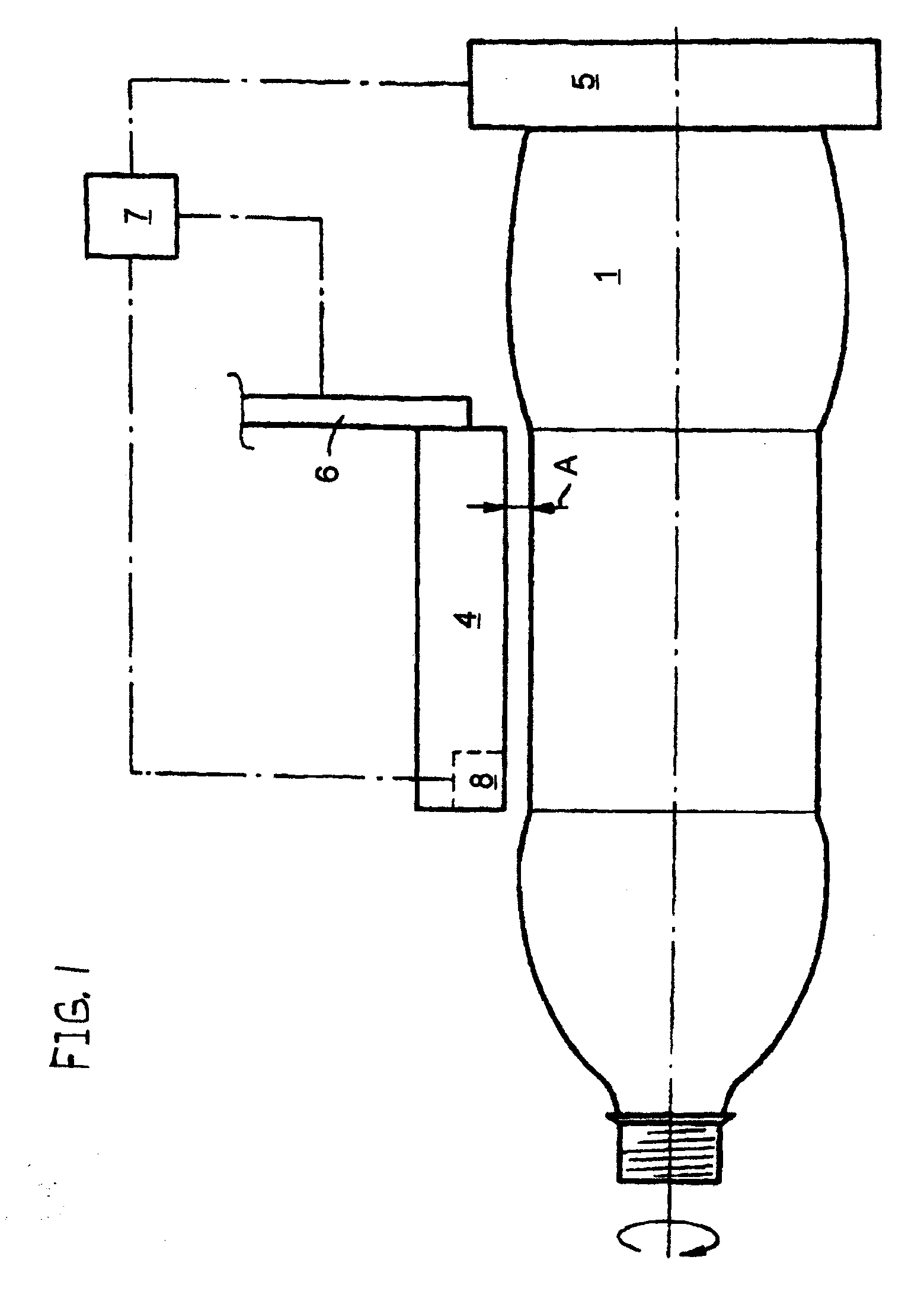

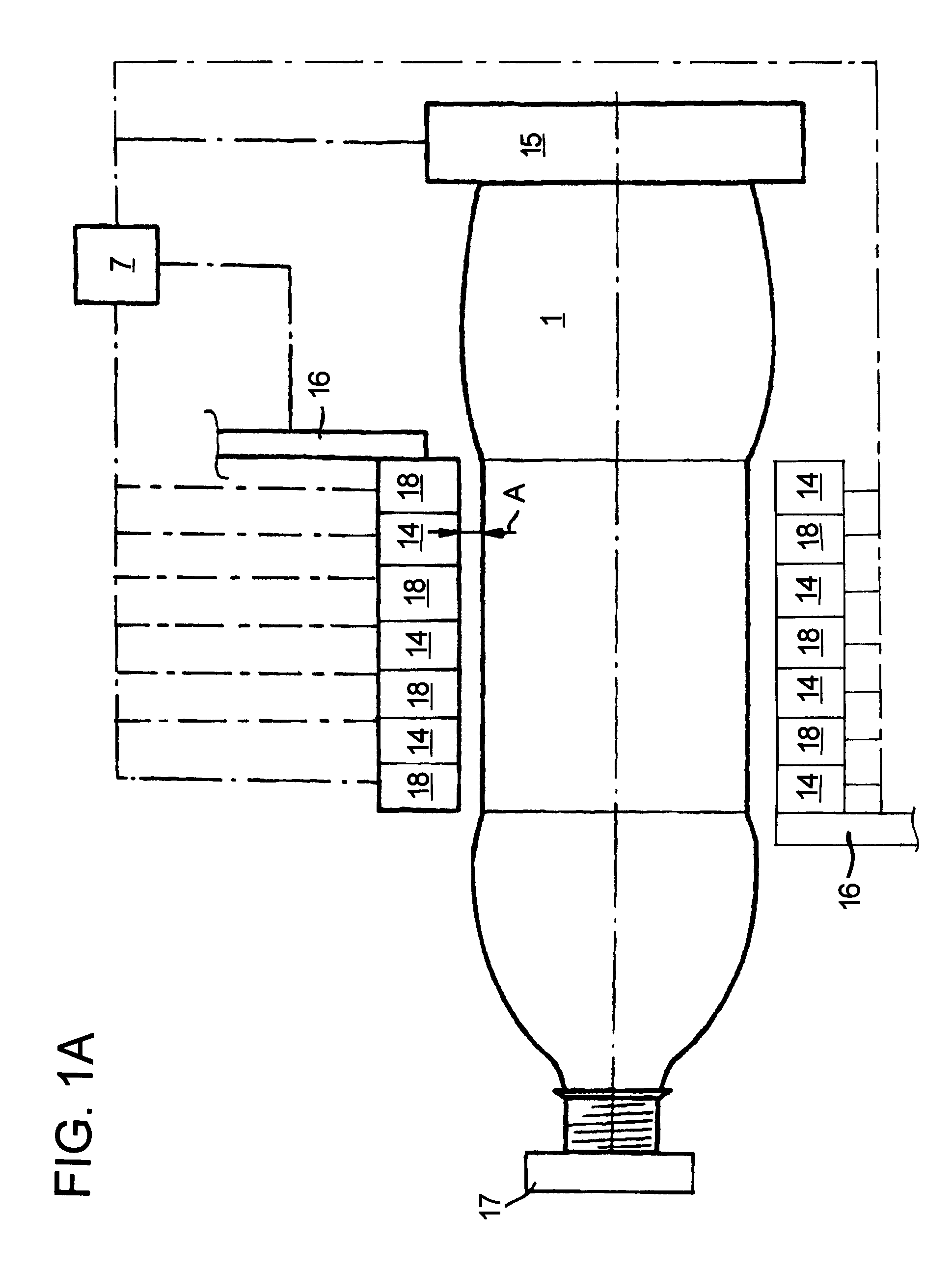

Method and apparatus for the circumferential printing onto individual bottles in a run of bottles where the individual bottles in the run have at least one varying dimension due to manufacturing tolerances, the method and apparatus providing more consistent artwork on individual containers in the run of containers

ActiveUS20090205516A1Reduce material consumptionLow costTypewritersPower drive mechanismsTrademarkEngineering

A method and apparatus for the circumferential printing onto individual bottles in a run of bottles where the individual bottles in the run have at least one varying dimension due to manufacturing tolerances, the method and apparatus providing more consistent artwork on individual containers in the run of containers. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

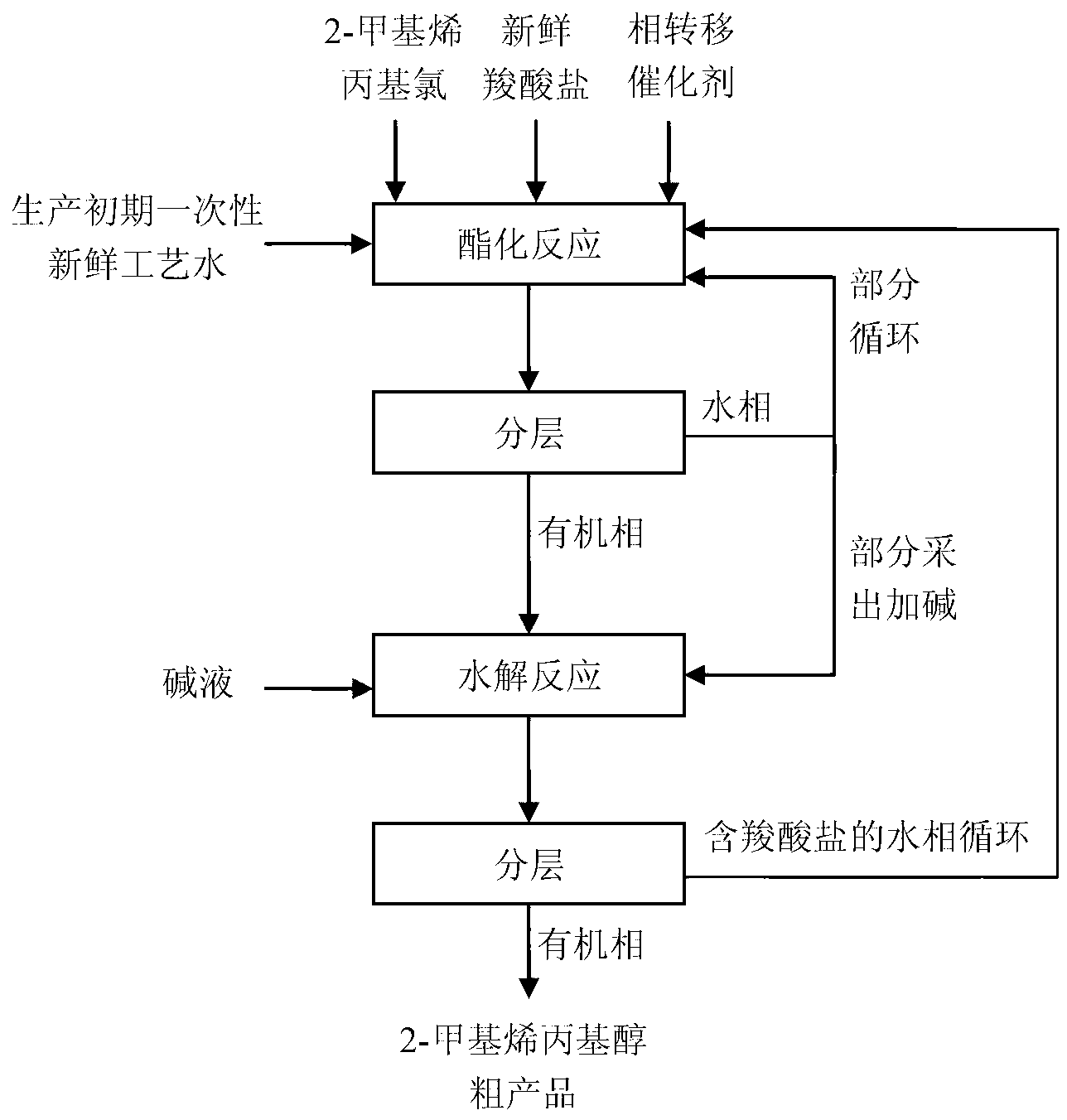

Method for preparing 2-methyl allyl alcohol by esterification and hydrolysis

ActiveCN103242139AImprove conversion rateHigh selectivityOxygen-containing compound preparationOrganic compound preparationChemical industryCarboxylic salt

The invention belongs to the field of chemical industry, and discloses a method for preparing 2-methyl allyl alcohol by esterification and hydrolysis. The method comprises the following steps of: first, performing esterification reaction of 2-methyl allyl chloride and carboxylate; and then, kalifying for hydrolysis reaction to synthesize 2-methyl allyl alcohol. The synthesizing steps are as follows: (1) esterification reaction: under the effect of a phase transfer catalyst, adding carboxylate, water and 2-methyl allyl chloride into a high pressure kettle for esterification reaction; after esterification reaction, cooling, standing and layering the reaction liquor to obtain an organic layer and a water layer, wherein the organic layer is a mixture which takes 2-methyl allyl carboxylate as a main product; (2) hydrolysis reaction: adding alkali liquor to the organic layer obtained in the esterification reaction stage for hydrolysis reaction; cooling, standing and layering the mixed liquor obtained by hydrolysis to obtain an organic layer and a water layer, wherein the organic layer is a target product, namely 2-methyl allyl alcohol. The method is high in material conversion ratio and product selectivity, the product yield is improved, and the separation energy consumption and material consumption are reduced.

Owner:NANJING UNIV OF TECH

Method for extraction and separation of xanthophyll and flavones in marigold

InactiveCN103936643AEfficient separationReduce dosageOrganic chemistryPlant ingredientsXanthonoidOrganic solvent

The invention relates to a method for extraction and separation of xanthophyll and flavones in marigold, and belongs to the technical field of extraction of the xanthophyll and flavonoids compounds. According to the method, marigold petal powder is added into an isopropanol-potassium hydroxide two-aqueous-phase system for one-step extraction to separate an upper phase and a lower phase, and a final product is prepared by dealkalization, filtration and evaporation. The method greatly simplifies the process of extraction and separation of the xanthophyll and the flavones, and overcomes the defects of large use amount of organic solvents, high material consumption and high energy consumption. The extraction rate of the xanthophyll in the upper phase reaches 86.73%, and the xanthophyll ester saponification rate reaches 93.98%, and the extraction rate of the flavonoids compounds in the lower phase reaches 78.31%. The method is easy to operate, and green, can realize simultaneous xanthophyll saponification and extraction, and can be used for effective separation of the flavonoids compounds.

Owner:JIANGSU UNIV

Ethylenediamine perchlorate.triethylene diamine perchlorate eutectic initiating explosive and preparation method thereof

InactiveCN101570459AReduce material consumption and energy consumptionObvious superiorityInorganic oxygen-halogen salt explosive compositionsDiamineEthylenediamine

The invention discloses an ethylenediamine perchlorate.triethylene diamine perchlorate eutectic initiating explosive and a preparation method thereof. The initiating explosive is a eutectic compound of ethylenediamine perchlorate and triethylene diamine perchlorate, can be initiated under the action of outside excitation energy and has better explosion output power. The preparation method is as follows: the eutectic compound of the ethylenediamine perchlorate and the triethylene diamine perchlorate is prepared by the neutralization reaction through using ethylene, triethylene diamine and perchloric acid as raw materials under the solution state, wherein the molecular ratio of the ethylenediamine perchlorate and the triethylene diamine perchlorate in the prepared eutectic compound is 1:1. The invention has the advantages of small moisture absorption, large explosion power, simple manufacture process, energy saving, consumption reduction, and no harm to environment.

Owner:NANJING UNIV OF SCI & TECH

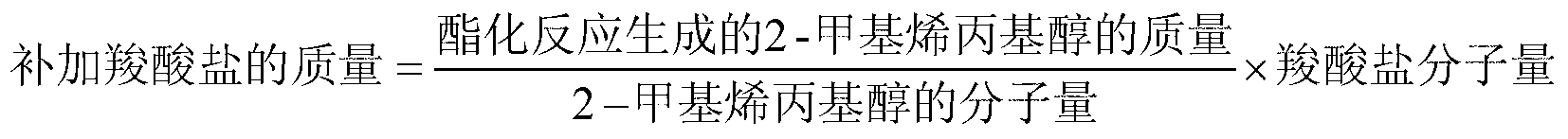

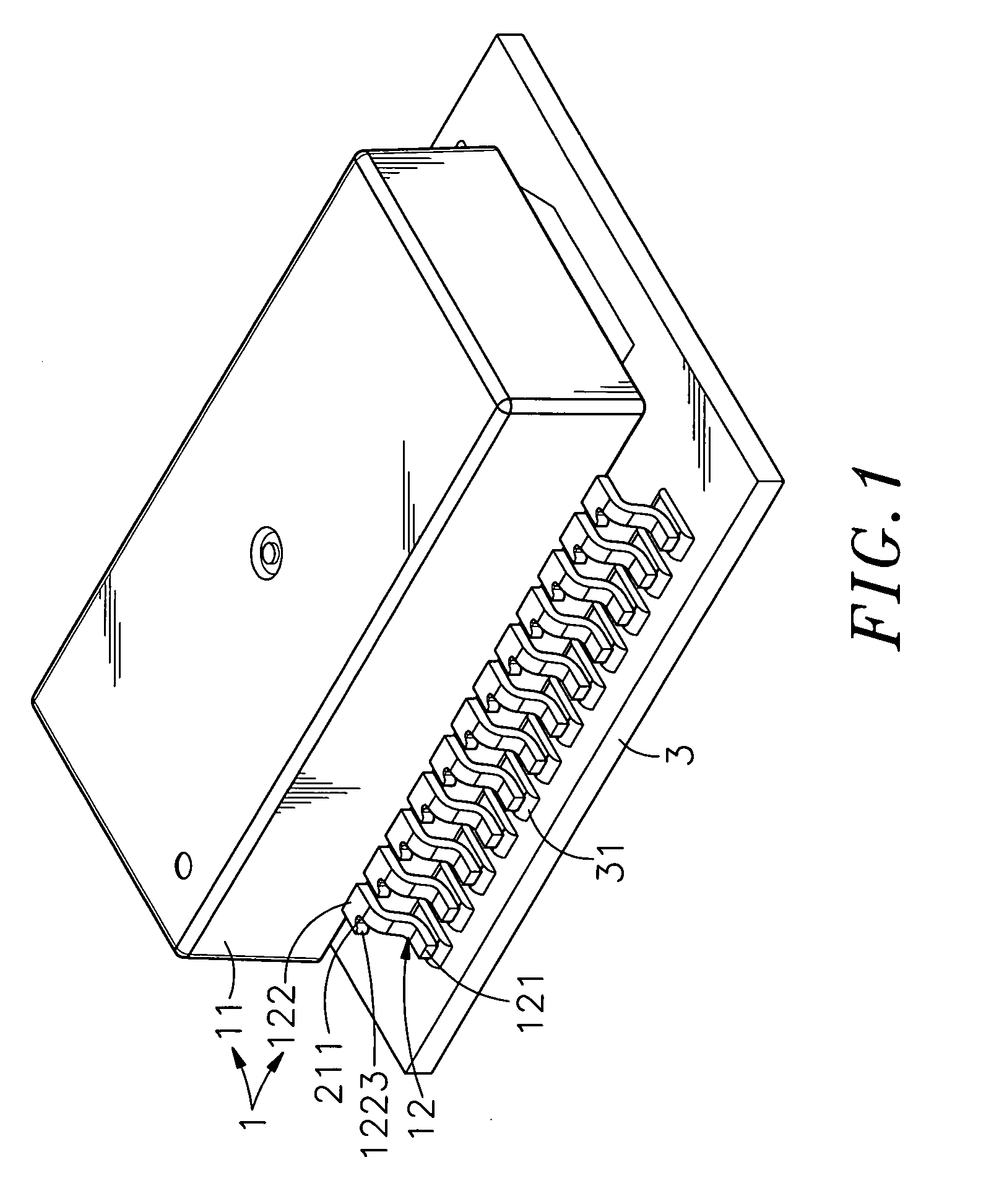

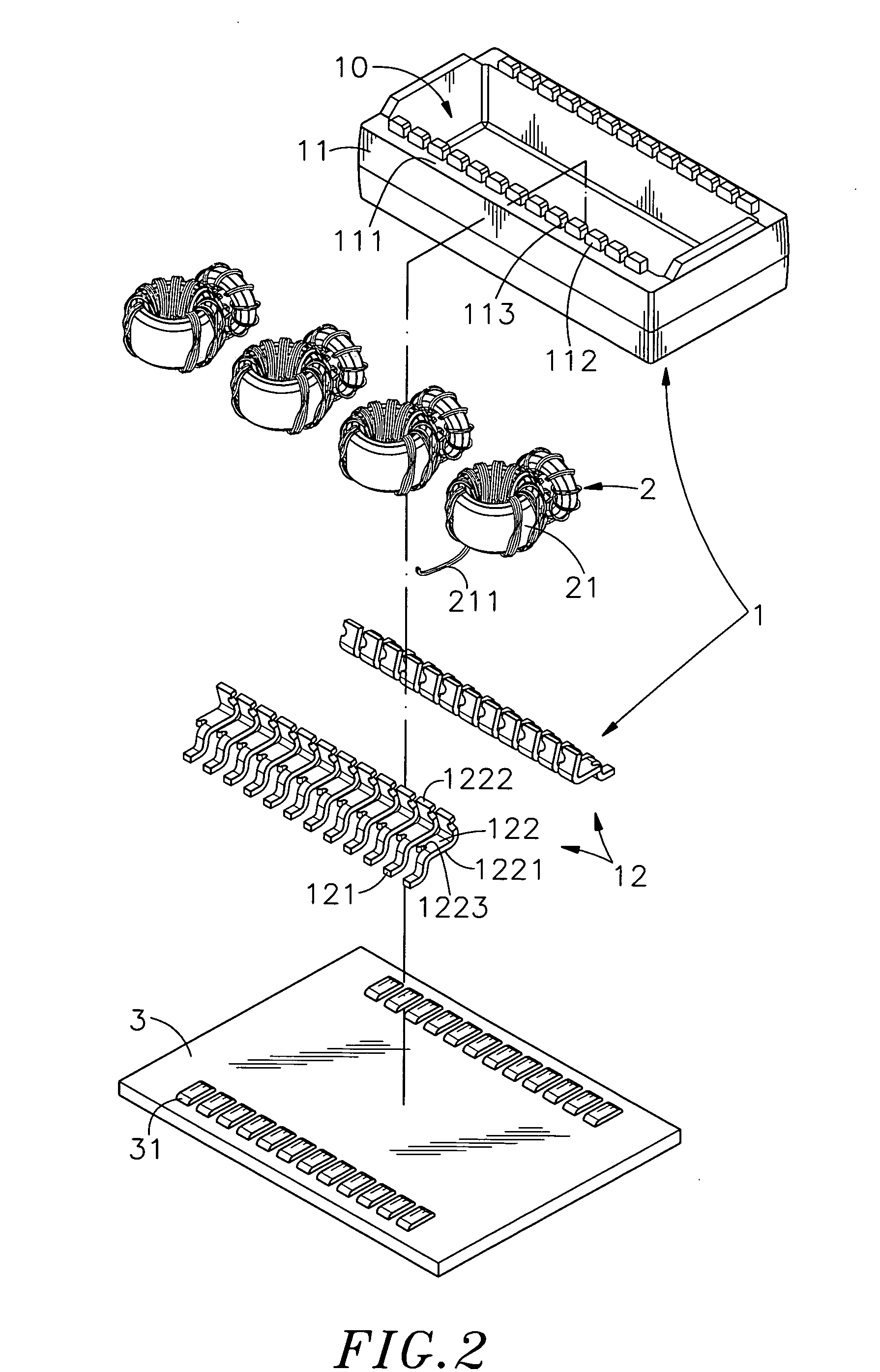

Signal filter module

InactiveUS20100142173A1Diminishes terminal material consumptionReduce manufacturing costImpedence networksCoupling for high frequencyExternal circuitMetal

A signal filter module includes an electrically insulative housing having protruding blocks respectively protruded from the bottom edge of each of two opposite vertical sidewalls thereof and a wire groove defined between each two adjacent protruding blocks, metal terminals each having a base partially embedded in one of the vertical sidewalls of the electrically insulative housing and partially exposed to the outside of the associating vertical sidewall to provide a bonding surface and a bonding tip extended from one end of the base and suspending outside the electrically insulative housing for bonding to an external circuit board, and filter elements each having coils wound thereon with lead ends of the coils respectively inserted through the wire grooves of the electrically insulative housing and bonded to the bonding surfaces of the bases of the metal terminals.

Owner:U D ELECTRONIC CORP

Efficient suspension liquid fertilizer containing fulvic acid for lettuce and preparation method thereof

InactiveCN106064983APromote absorptionImprove drought resistance and cold resistanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersTrace elementPotassium

The invention discloses a method applied to efficient suspension liquid fertilizer containing fulvic acid for lettuce. The suspension liquid fertilizer includes, by weight, 10-25 parts of fulvic acid, 35-50 parts of major element, 1-10 parts of medium element, 0.2-3 parts of trace element, 0-3 parts of functional substance, 3-5 parts of suspended aid, 2-12 parts of a composite chelating agent, 0-1 parts of a defoaming agent, 0-1 parts of solution stabilizer, and a thickener. The preparation method comprises the steps of: adding water, potassium humate, nitrogen fertilizer and potassium fertilizer into a reactor A, and conducting high-speed stirring to prepare a saturated mother liquor; adding water, phosphate fertilizer, trace element material, a dispersing agent, a filler and partial defoaming agent into a reactor B, conducting high-speed stirring and grinding for the formation of a solid-liquid mixture; mixing the saturated mother liquor and solid-liquid the mixture, adding a thickening agent, residual defoaming agent and an anti-freezer, and emulsifying to prepare a suspension liquid fertilizer. The invention has the advantages of high total nutrient content, no layering or deposition, and realization of long distance transportation.

Owner:GUANGDONG FENGKANG BIOTECH

Productive technology for magma fruit 1iquor

The production process of raw nectar fruit white liquor mainly includes the procedures of raw material preparation, fermentation and distillation, etc. and it is characterized by that it includes thefollowing steps: cleaning fruit, cutting the fruit into small blocks; saccharifying glutinous rice or rice and converting it into mixed pulp containing dextrine and glucose; adding double-functional distiller's yeast, adding clean water and making fermentation, then making distillation, filtering and removing impurities so as to obtain the invented product with palatable taste.

Owner:李松林

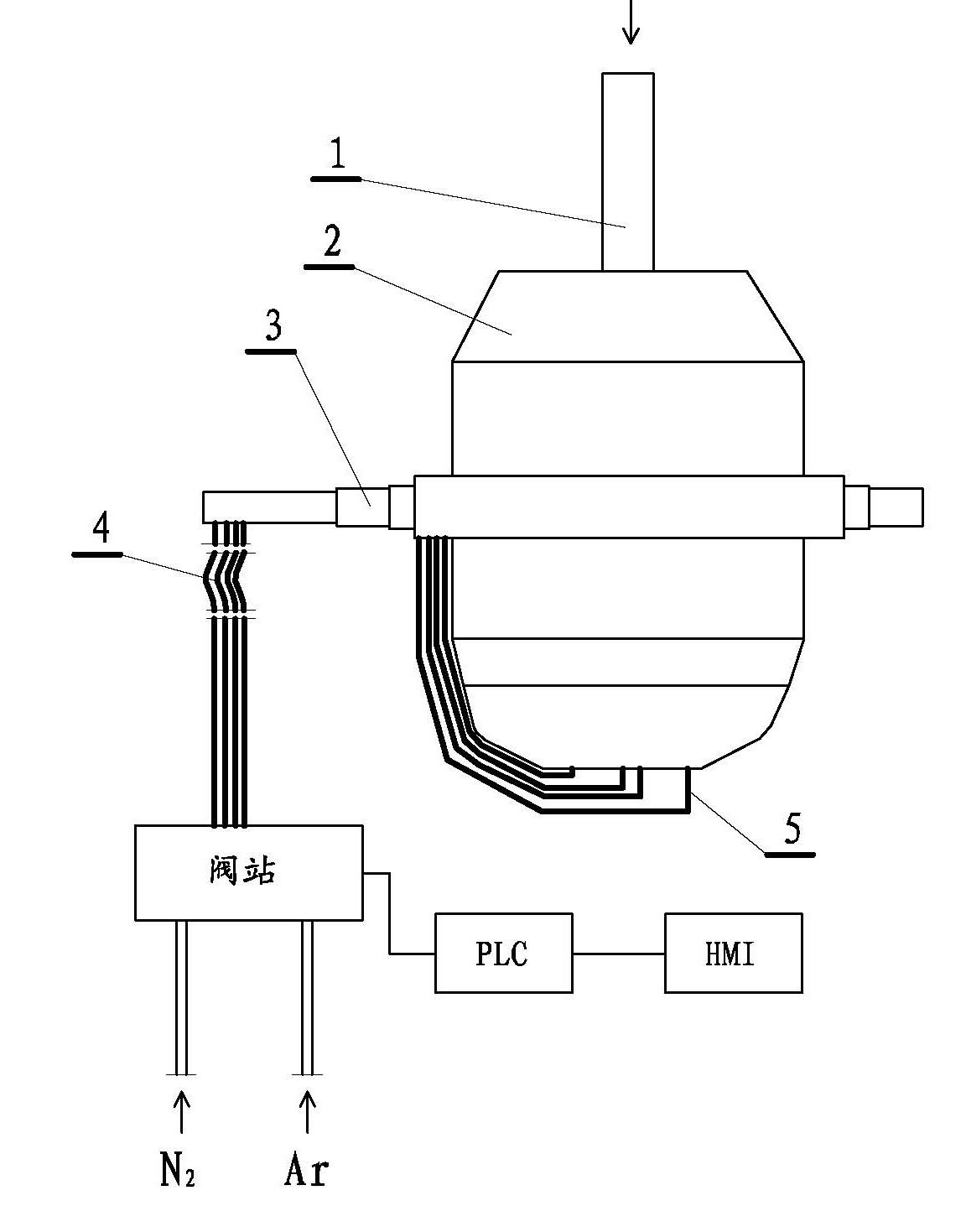

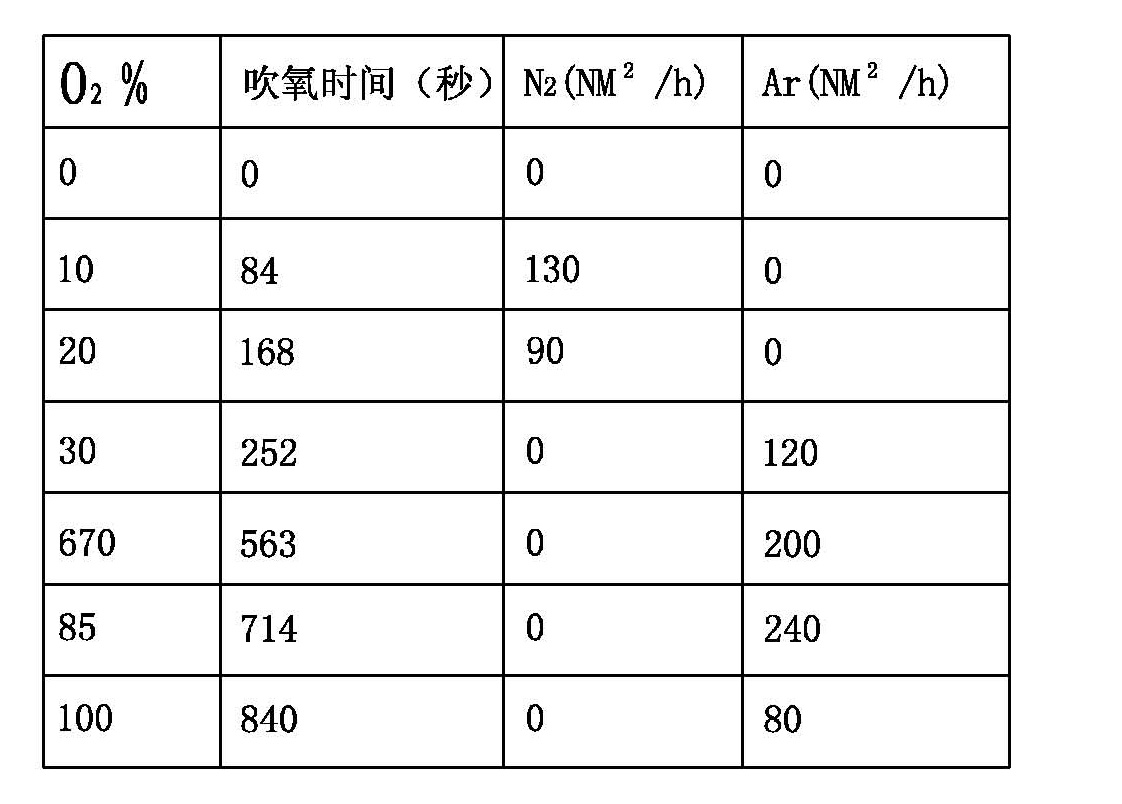

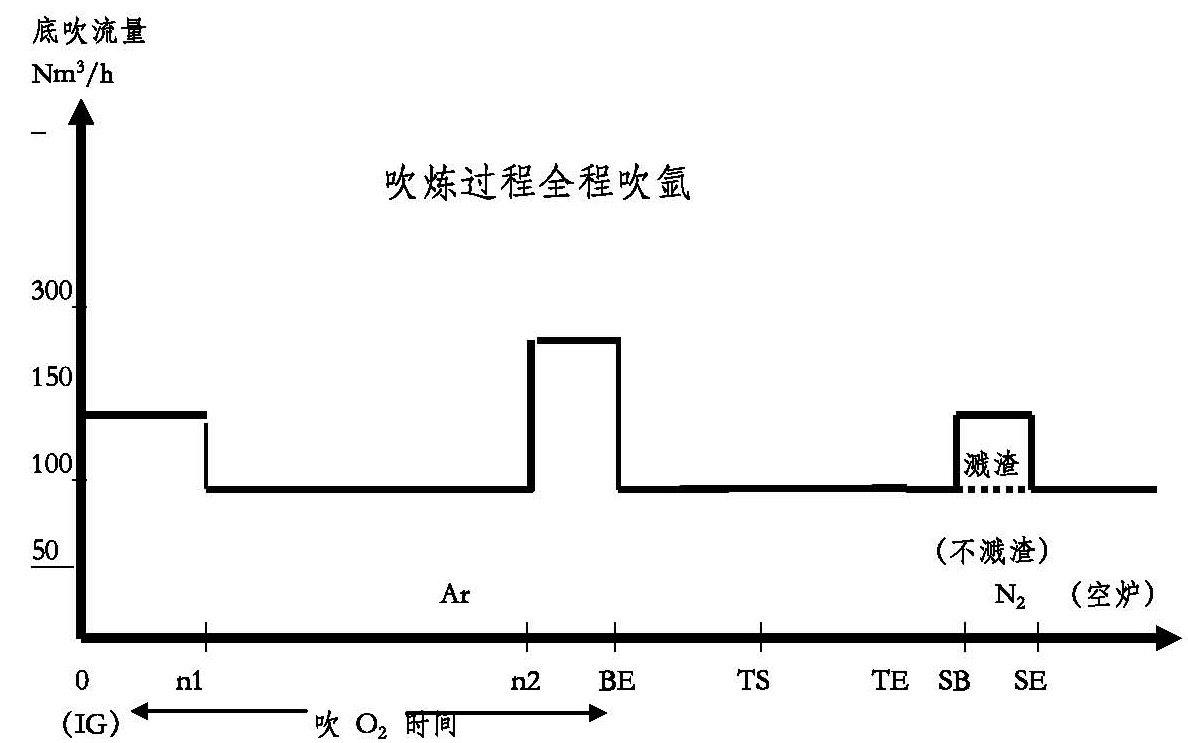

Method for automatic bottom blowing control of converter

InactiveCN102041346AQuality improvementShorten blowing timeManufacturing convertersHuman–machine interfaceSmelting process

The invention relates to a method for the automatic bottom blowing control of a converter. Hardware adopted by the method in the invention comprises a converter with a combined blowing function, a valve station for supplying argon and nitrogen and a PLC (programmable logic controller) with an HMI (human machine interface), wherein the PLC controls the valve station and stores a plurality of bottom blowing models. The method comprises the followings steps: selecting a bottom blowing model; confirming; loading a flow set value; transmitting the flow set value; and monitoring smelting process. According to different nitrogen contents and carbon contents of a target steel type, 9 models are combined in the invention, production operation personnel select a corresponding model code only according to a steel type to be smelted, and the parameter and the curve data of the model are automatically downloaded to the PLC. Thus, in the invention, the phenomenon that production operation personnel continuously and manually adjust valve opening in the conventional production step is reduced, thus the operation intensity is lightened. The PLC automatically switches nitrogen and argon, controls stable intake pressure and adjustable branch pipe flow, has high control precision and strong degree of automation and lowers production cost.

Owner:BEIJING JIANLONG HEAVY IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com