Clean production process of lactic acid

A clean production and process technology, which is applied in the separation/purification of carboxylic acid compounds, microorganisms, and microorganism-based methods, etc., can solve the problems of high material consumption and excessive discharge of waste water and waste, and achieve low material consumption, extremely low discharge, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

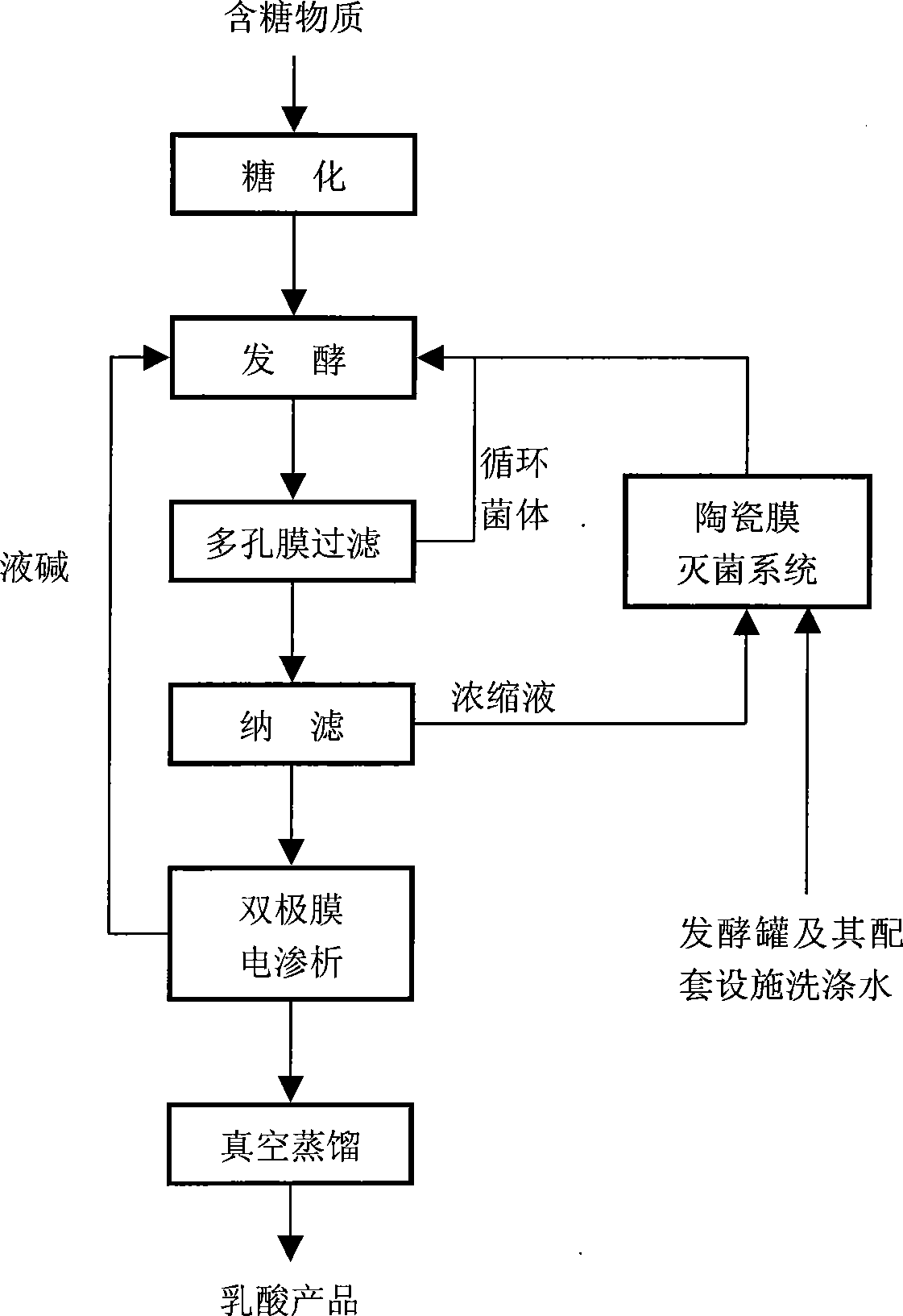

[0031] Attached figure 1 Shown, the realization steps of the present invention are as follows:

[0032] (1) Grinding corn and dissolving it in water by heating, removing solid particles with a drum filter, adding glucoamylase to the filtrate to prepare 10 L of saccharified solution with a glucose concentration of 15% by mass.

[0033] (2) Add the prepared saccharification solution into a fermenter, add 2% by mass percentage (dry weight) of soybean meal hydrolyzate and 7% of the volume of saccharification solution Lactobacillus delbrueckii, ferment at a temperature of 45°C, and adopt automatic control The mode of continuously adding the sodium hydroxide solution that mass percent concentration is 20% adjusts the pH value of the system, makes pH maintain at 6.8.

[0034] (3) When the mass percentage concentration of sugar content in the fermentation system is lower than 0.5%, the fermentation liquid is pumped into the ceramic membrane unit, the pore diameter of the ceramic memb...

Embodiment 2

[0039] Attached figure 1 Shown, the realization steps of the present invention are as follows:

[0040] (1) Grinding corn and dissolving it in water by heating, removing solid particles with a rotary drum filter, adding glucoamylase to the filtrate to prepare 10 L of saccharification solution with a concentration of 20% by mass.

[0041] (2) Add the prepared saccharified liquid into a fermenter, add 3% corn steep liquor by mass percentage (dry weight) and Lactobacillus delbrueckii with 8% saccharified liquid volume, ferment at a temperature of 50°C, and adopt self-controlled The method is to continuously add potassium hydroxide solution with a mass percent concentration of 30% to adjust the pH of the system, so that the pH is maintained at 6.8.

[0042] (3) When the sugar content mass percentage concentration in the fermentation system is lower than 1%, the fermentation liquid is pumped into the stainless steel membrane filtration unit, the aperture of the stainless steel mem...

Embodiment 3

[0047] Attached figure 1 Shown, the realization steps of the present invention are as follows:

[0048] (1) Grinding corn and dissolving it in water by heating, removing solid particles with a rotary drum filter, adding glucoamylase to the filtrate to prepare 10 L of saccharified solution with a concentration of 10% by mass.

[0049] (2) Add the prepared saccharification liquid into a fermenter, add corn steep liquor and bran of 5% by mass percentage (dry weight) and Lactobacillus delbrueckii with a volume of 12% of the saccharification liquid, ferment at a temperature of 48°C, and use The method of self-control control continuously adds sodium hydroxide solution with a mass percent concentration of 15% to adjust the pH of the system, so that the pH is maintained at 6.8.

[0050] (3) When the sugar content mass percentage concentration in the fermentation system is lower than 1%, the fermentation liquid is pumped into the PVC microfiltration membrane filtration unit, the pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com