Patents

Literature

41 results about "Bone clamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unilateral fixator

ActiveUS20070282338A1Great advantageDiagnosticsComputer-aided planning/modellingBone clampSacroiliac joint

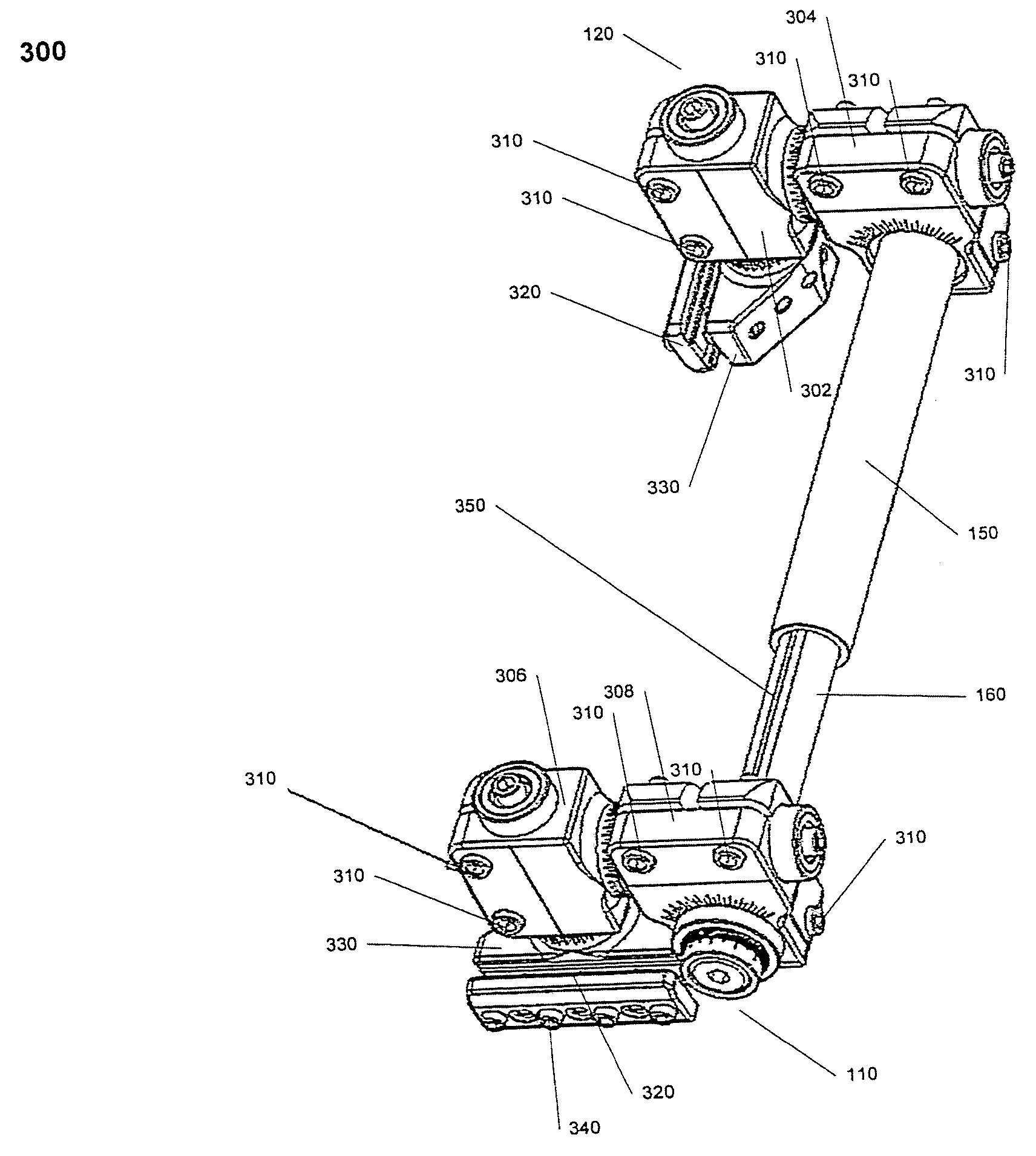

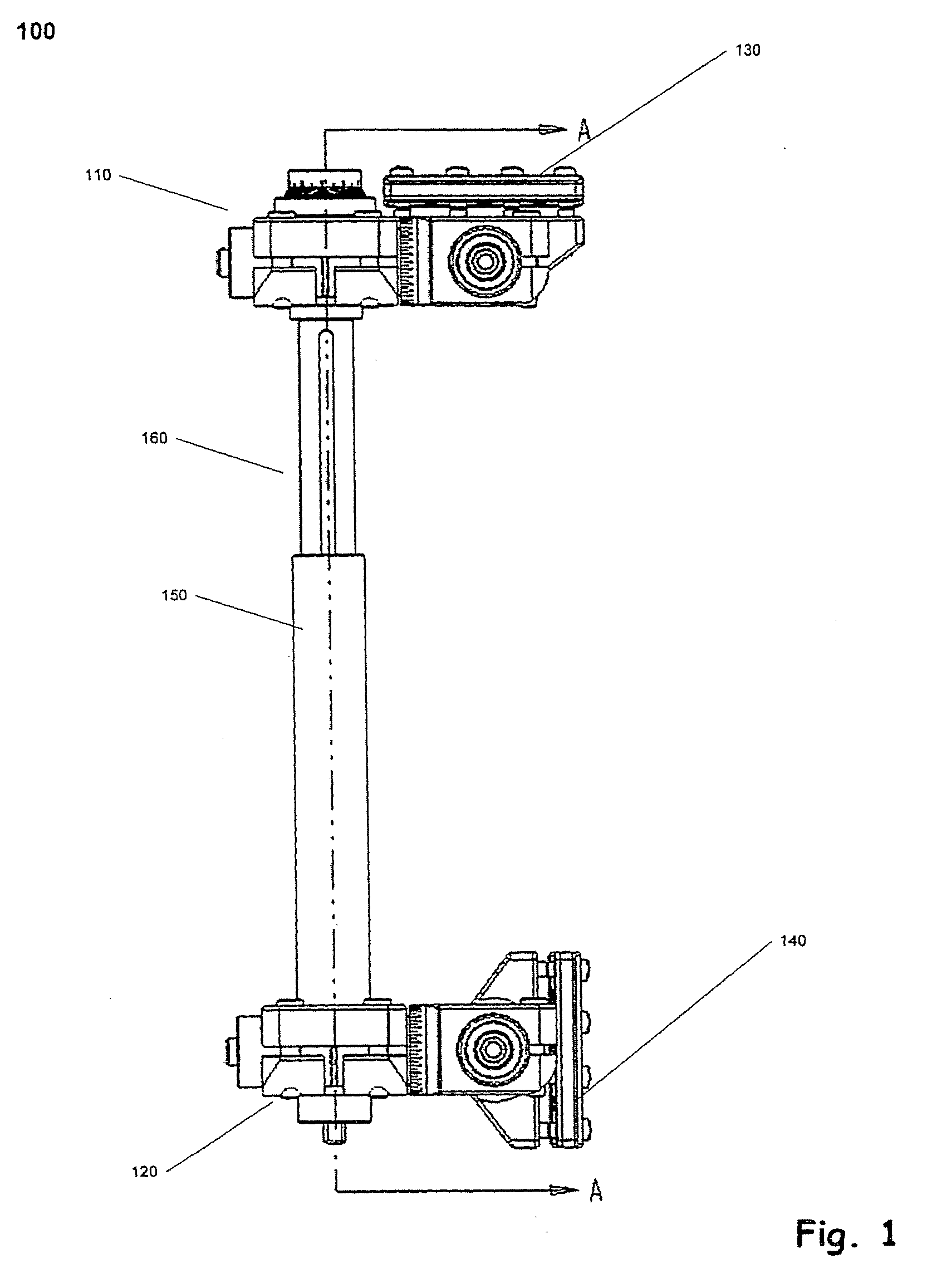

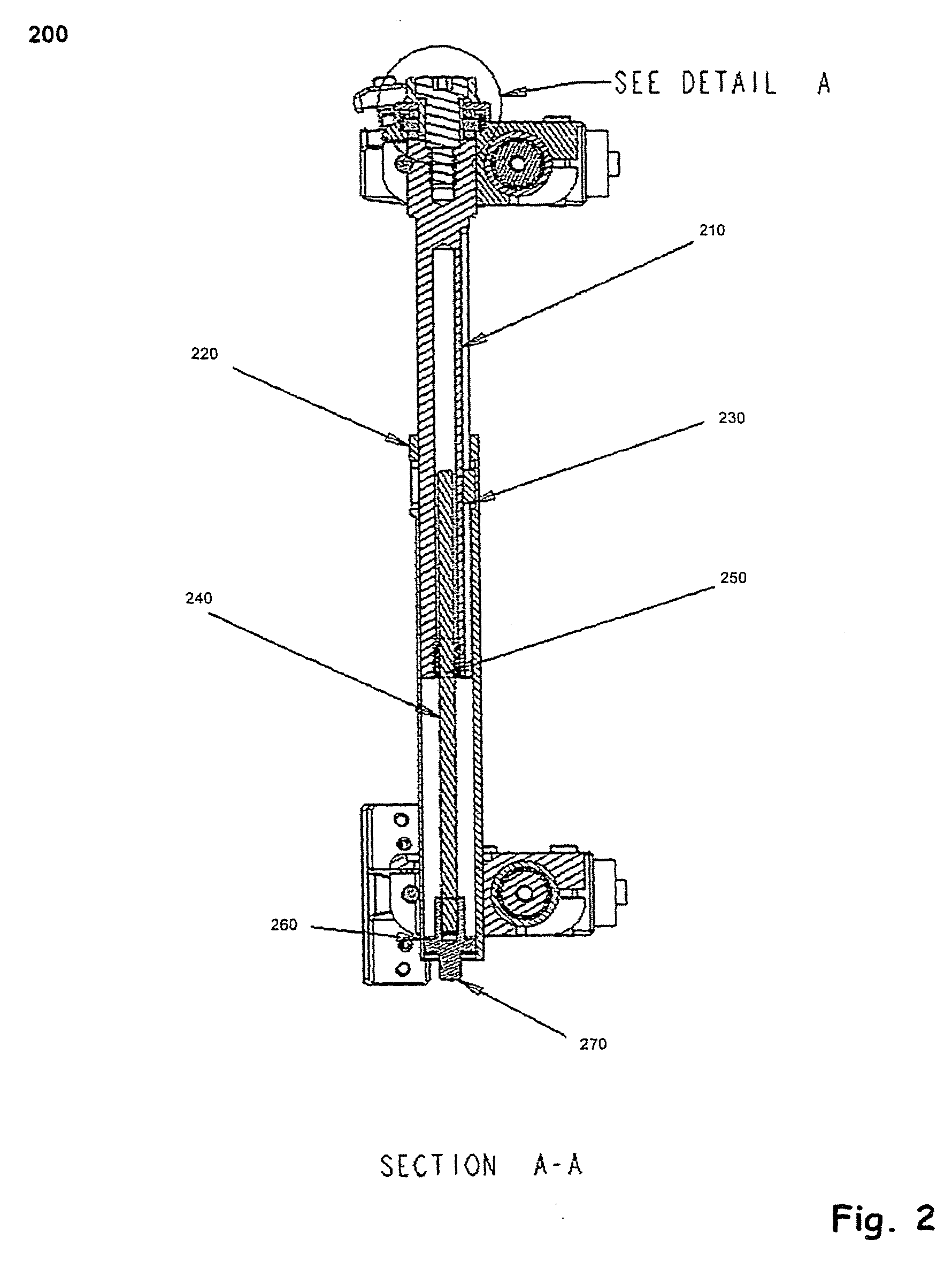

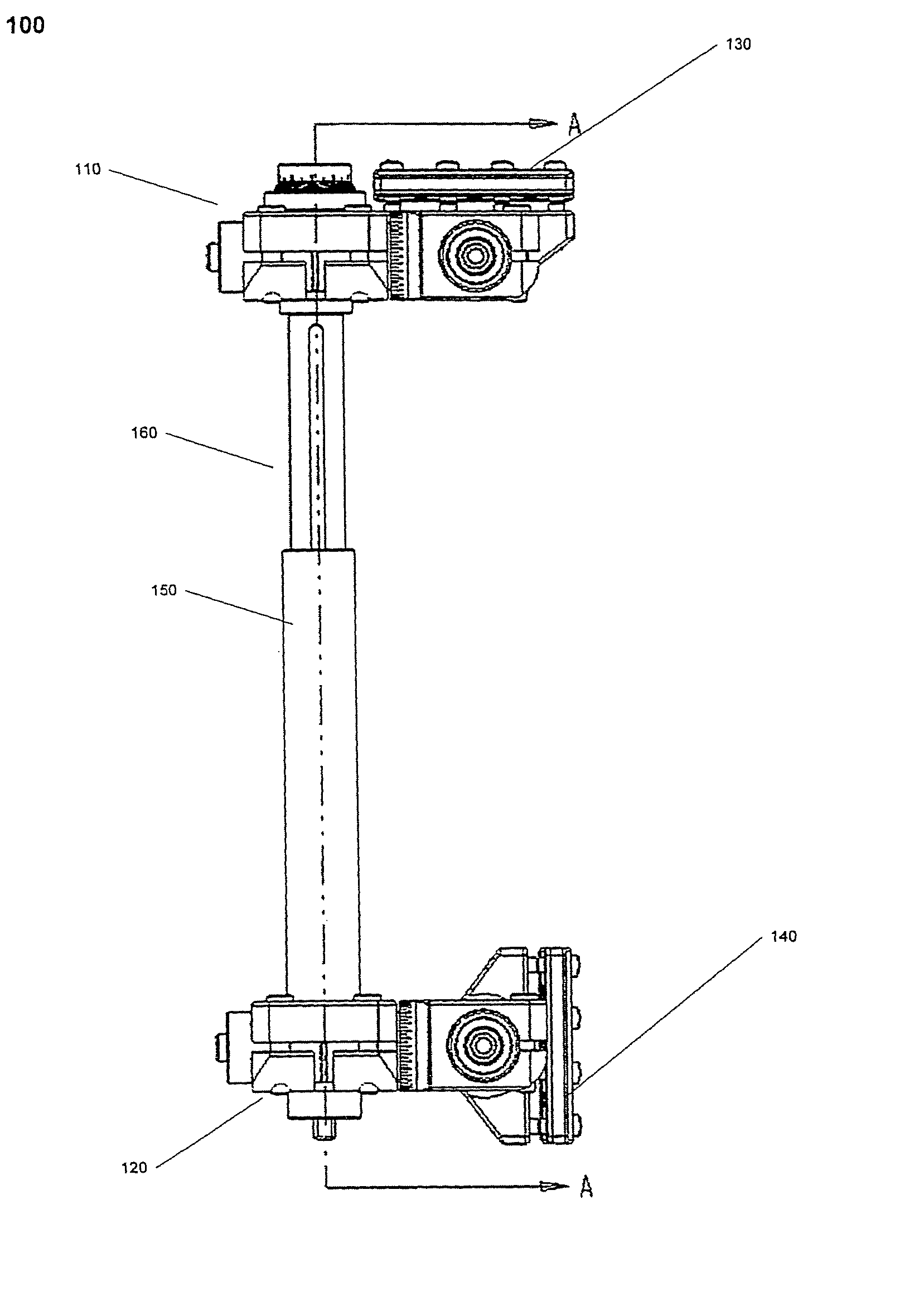

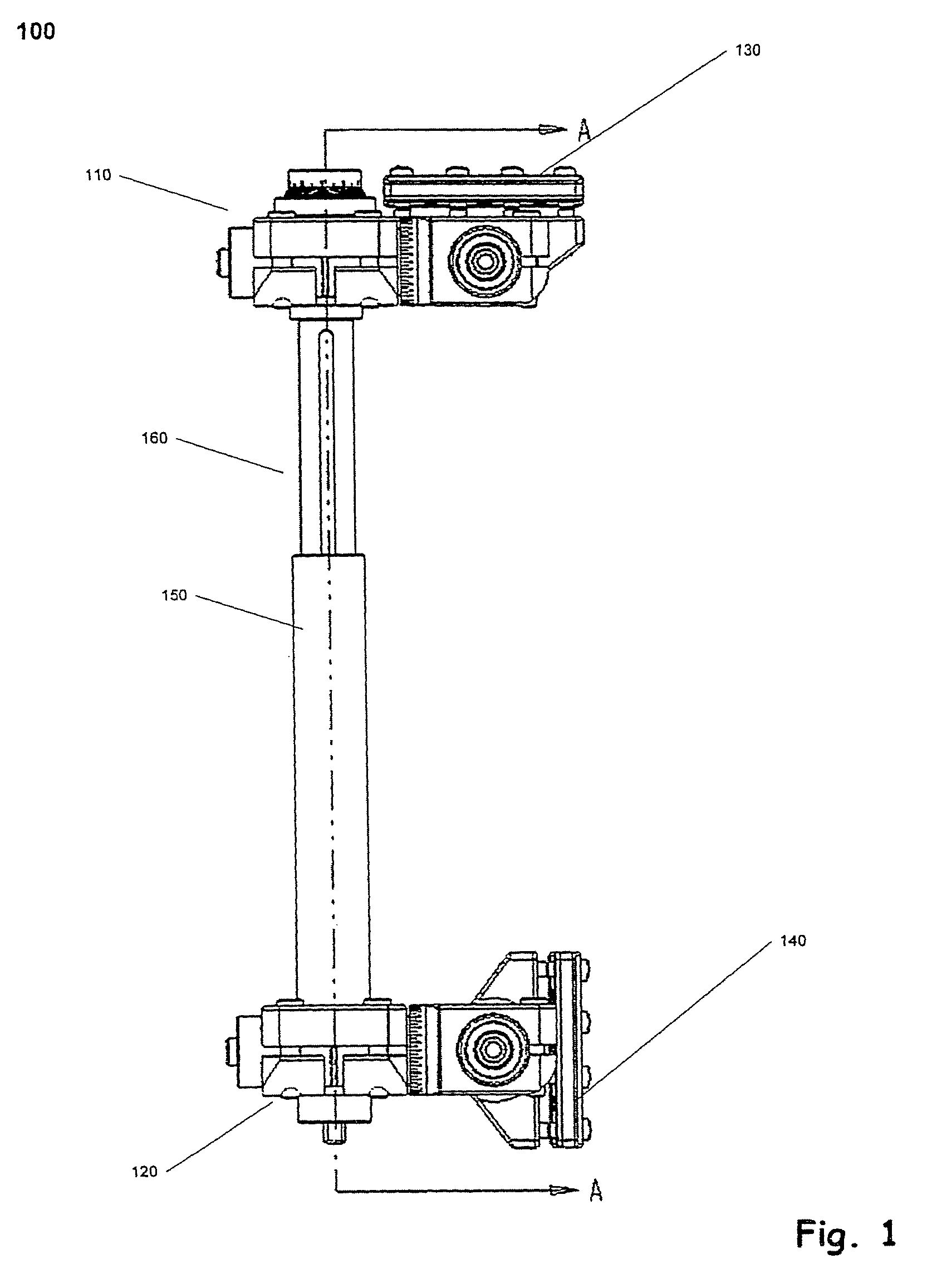

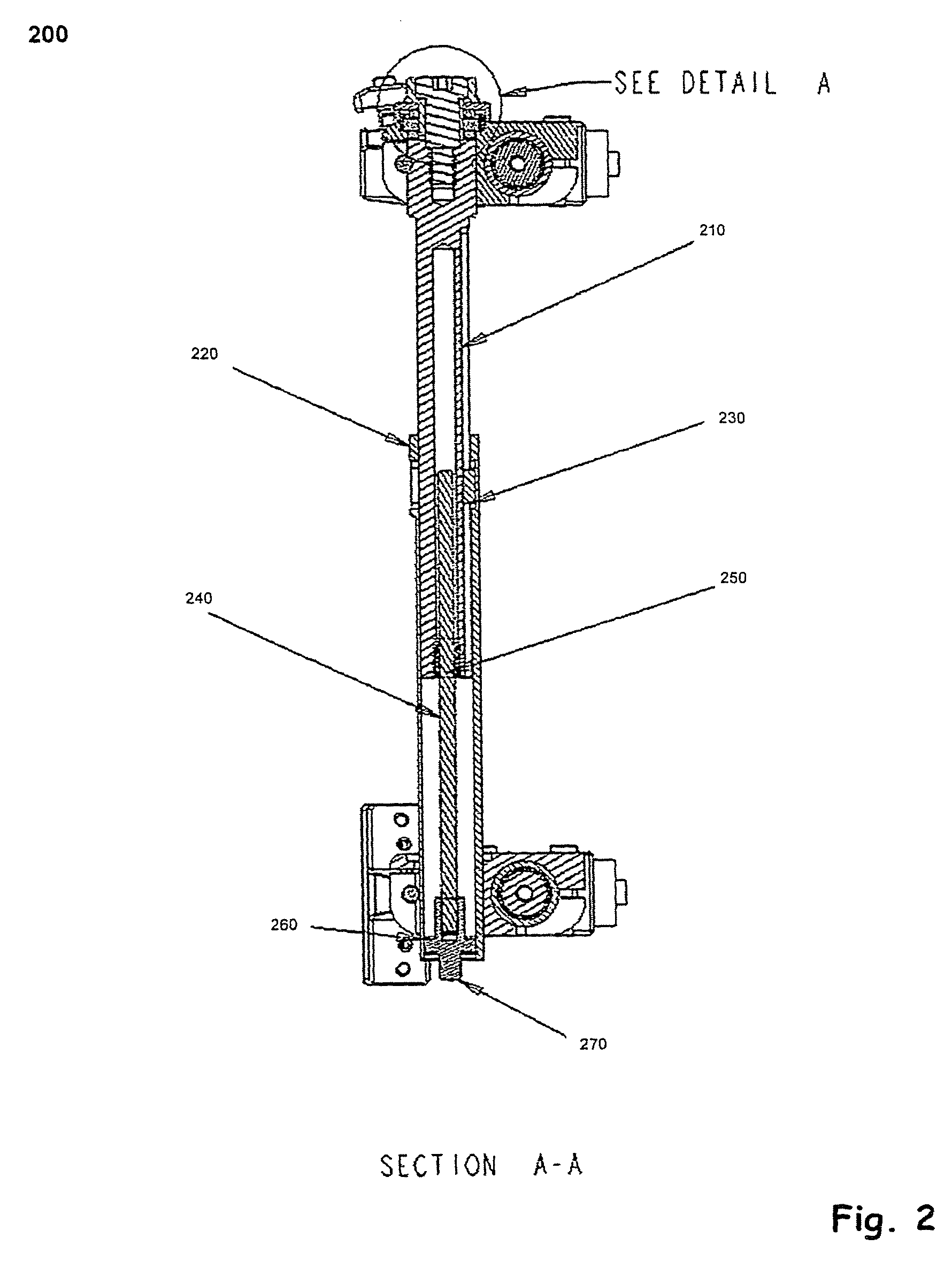

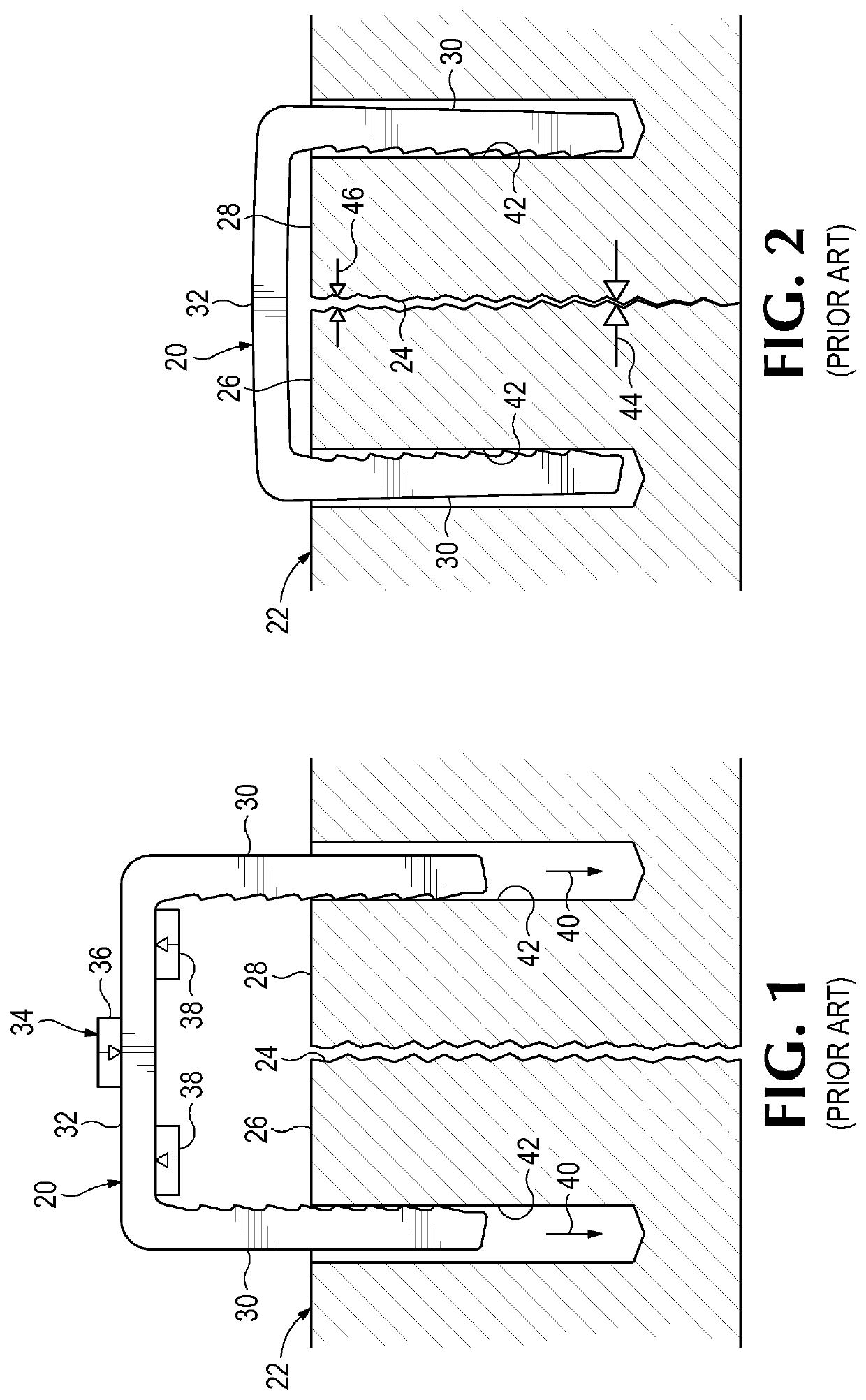

A unilateral fixator for adjustment of a first bone portion relative to a second bone portion. The fixator includes a telescopically adjustable strut having first and second ends and a strut axis, and first and second compound joints. The first compound joint is coupled to the first end of the strut and to a first bone clamp, and includes a first gear mechanism controlling linear and rotational motion of the first bone clamp relative to first and second axes while the first bone clamp is engaged with the first bone portion. The first and second axes are generally orthogonal to one another and to the strut axis. The second compound joint is coupled to the second end of the strut and to a second bone clamp and includes a second gear mechanism controlling linear and rotational adjustment of the second bone clamp. The first compound movable joints can rotate about the strut axis.

Owner:AMDT HLDG INC

Unilateral fixator

ActiveUS8388619B2Great advantageDiagnosticsComputer-aided planning/modellingBone clampFirst tarsal bone

A unilateral fixator for adjustment of a first bone portion relative to a second bone portion. The fixator includes a telescopically adjustable strut having first and second ends and a strut axis, and first and second compound joints. The first compound joint is coupled to the first end of the strut and to a first bone clamp, and includes a first gear mechanism controlling linear and rotational motion of the first bone clamp relative to first and second axes while the first bone clamp is engaged with the first bone portion. The first and second axes are generally orthogonal to one another and to the strut axis. The second compound joint is coupled to the second end of the strut and to a second bone clamp and includes a second gear mechanism controlling linear and rotational adjustment of the second bone clamp. The first compound movable joints can rotate about the strut axis.

Owner:ARTHREX INC

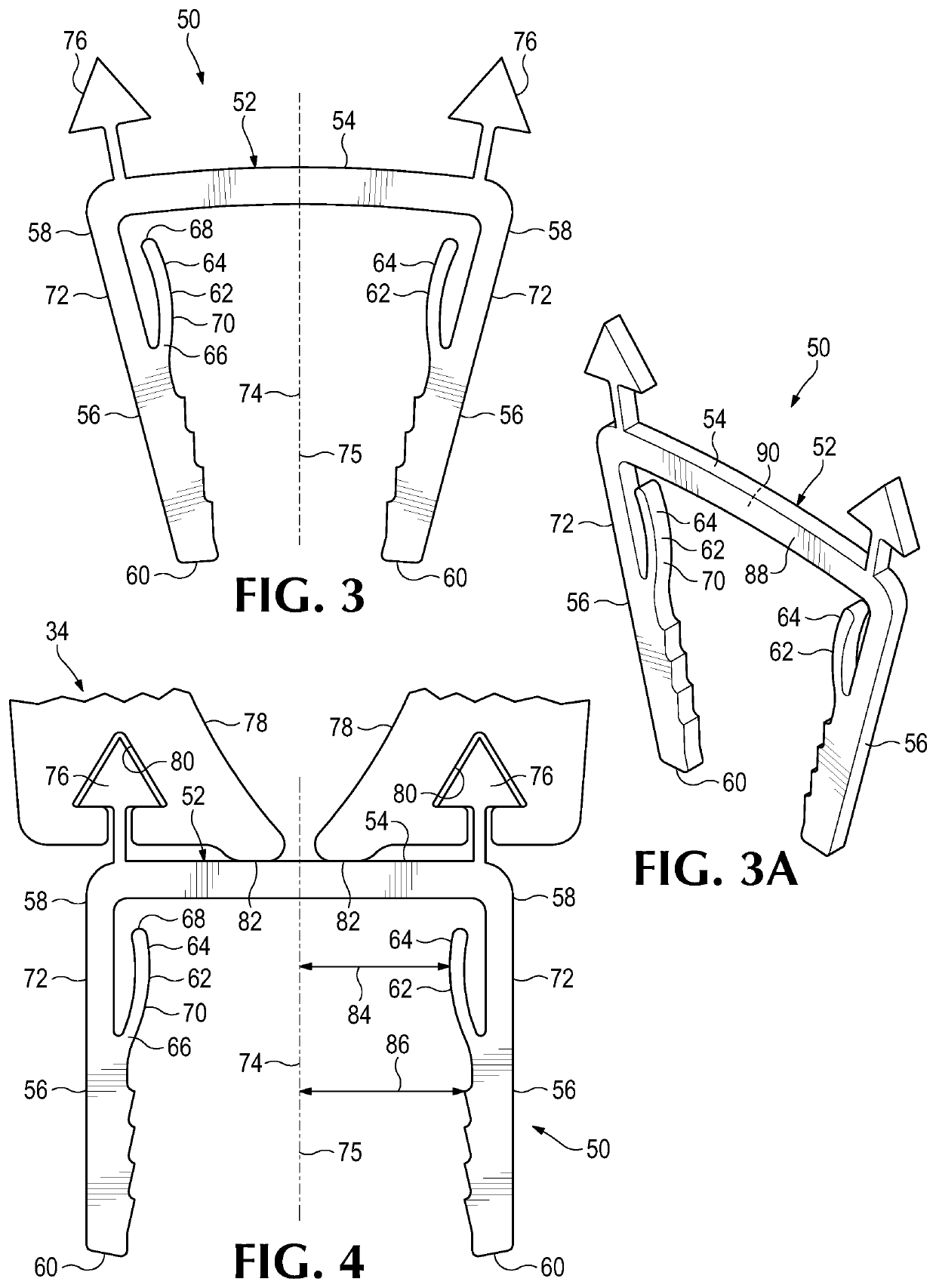

Bone clamp

A bone clamp moving bone segments relative to each other. The clamp comprises a first and second branch and a bridge connecting the first and second branch. Each branch may have a free end and a rear end. The bone clamp may have a first, undeformed state, where the branches may be angled or substantially parallel with respect to each other. The bone clamp may have a second, deformed state, where the braches may be moved from the first state. The bone clamp may be deformed using an instrument such as pliers. When the bone clamp is in the deformed state, the branches may be inserted into bone segments. Thereafter, the instrument may be disengage from the bone clamp and the clamp may return to its undeformed state. While returning to the first, undeformed, state the bone clamp may apply compressive or distraction forces on the bone segments, thereby moving the bone segments relative to each other.

Owner:SYNTHES GMBH

Bone clamp

A bone clamp moving bone segments relative to each other. The clamp comprises a first and second branch and a bridge connecting the first and second branch. The bone clamp may have a first, undeformed state, where the branches may be angled or substantially parallel with respect to each other. The bone clamp may have a second, deformed state, where the branches may be moved from the first state. The bone clamp may be deformed using an instrument such as pliers. When the bone clamp is in the deformed state, the branches may be inserted into bone segments. Thereafter, the instrument may be disengage from the bone clamp and the clamp may return to its undeformed state. While returning to the first, undeformed, state the bone clamp may apply compressive or distraction forces on the bone segments, thereby moving the bone segments relative to each other.

Owner:SYNTHES GMBH

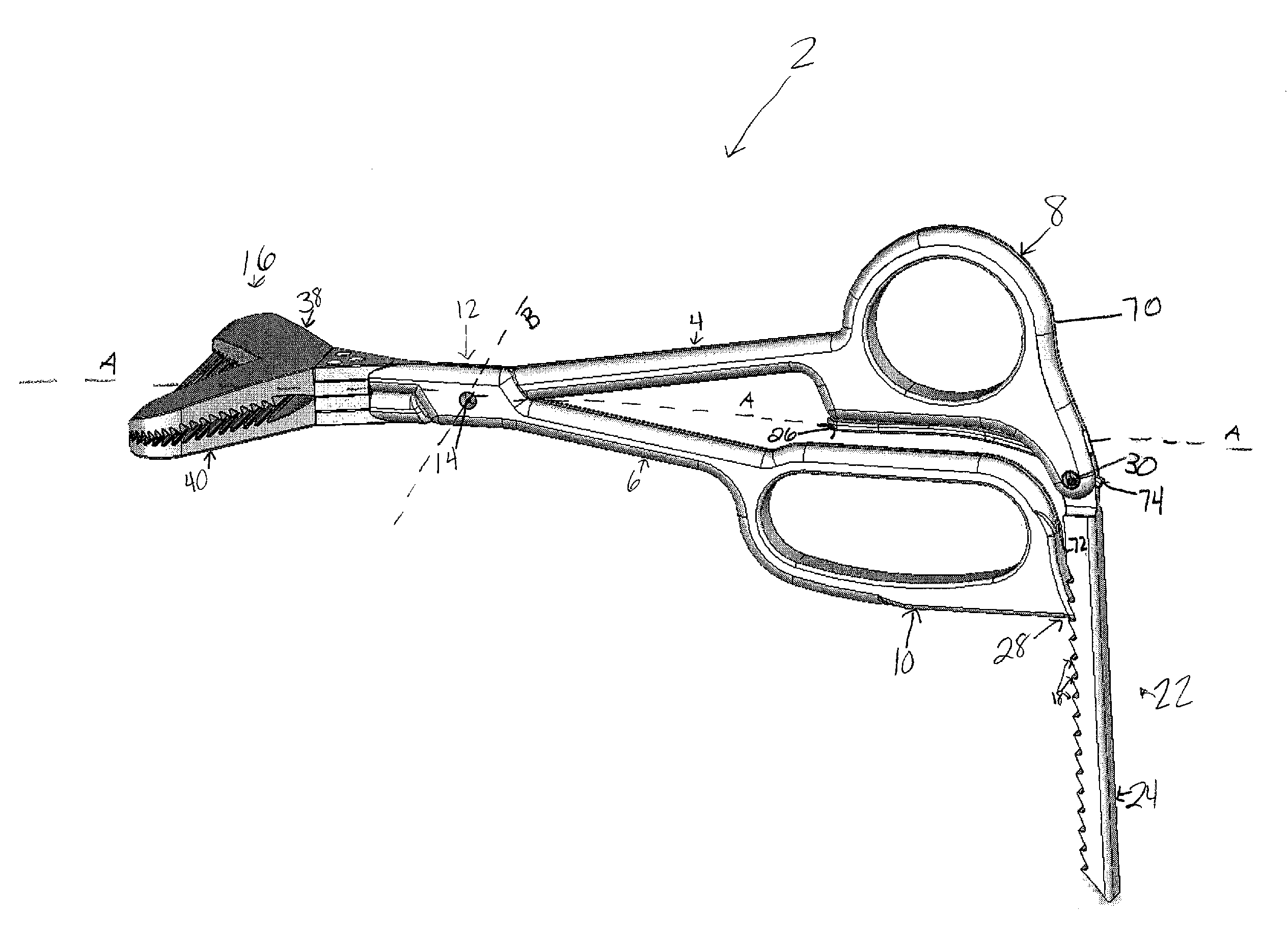

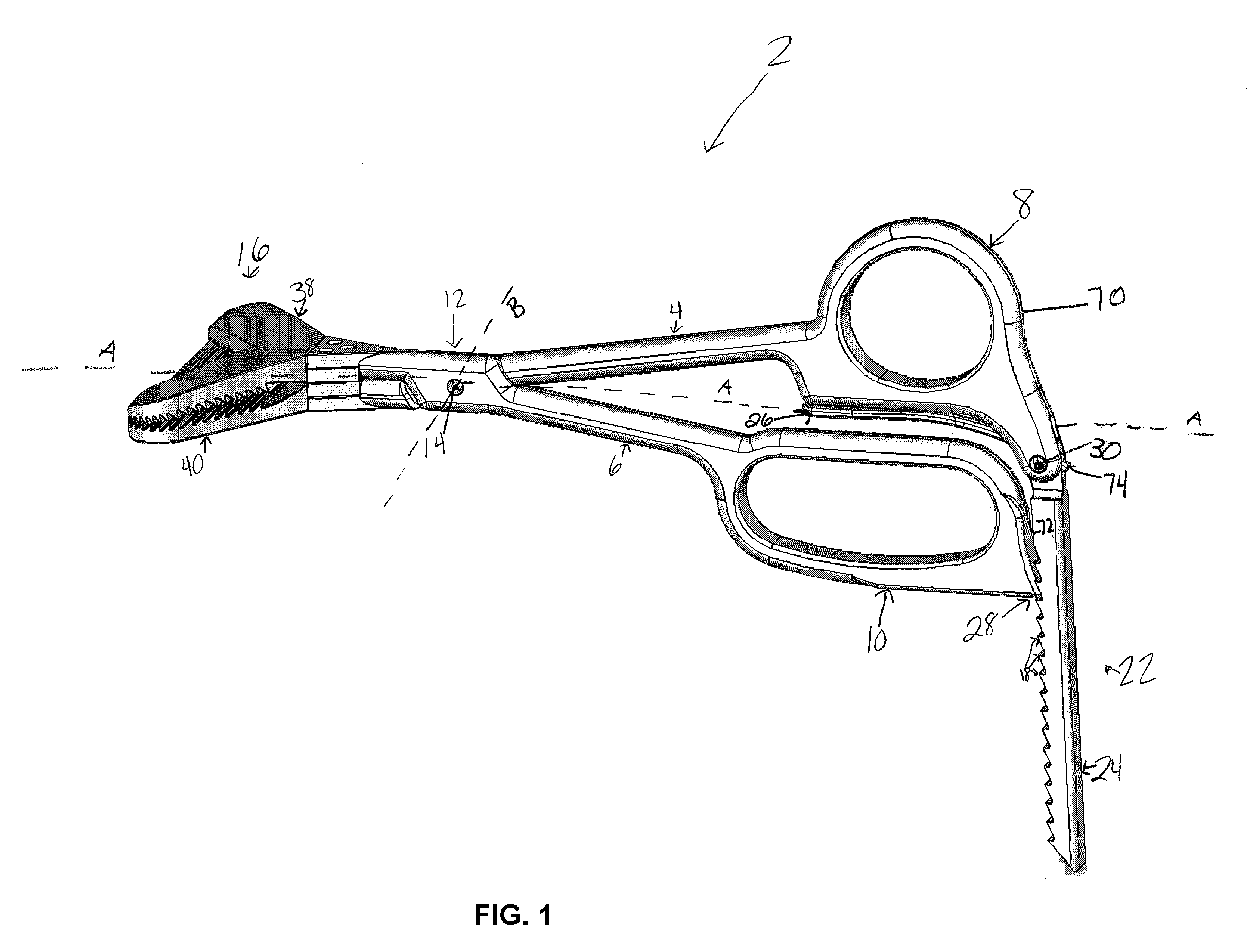

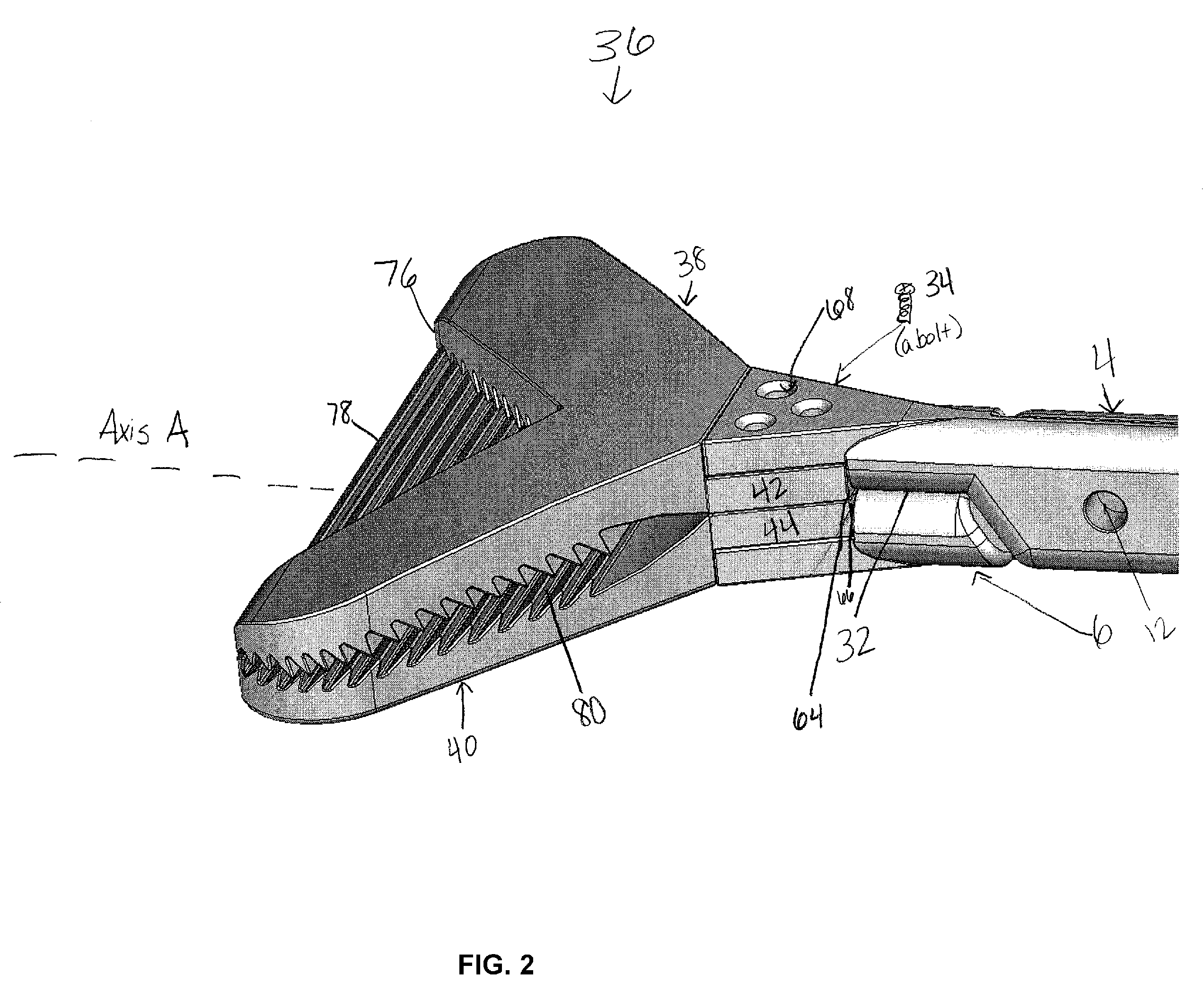

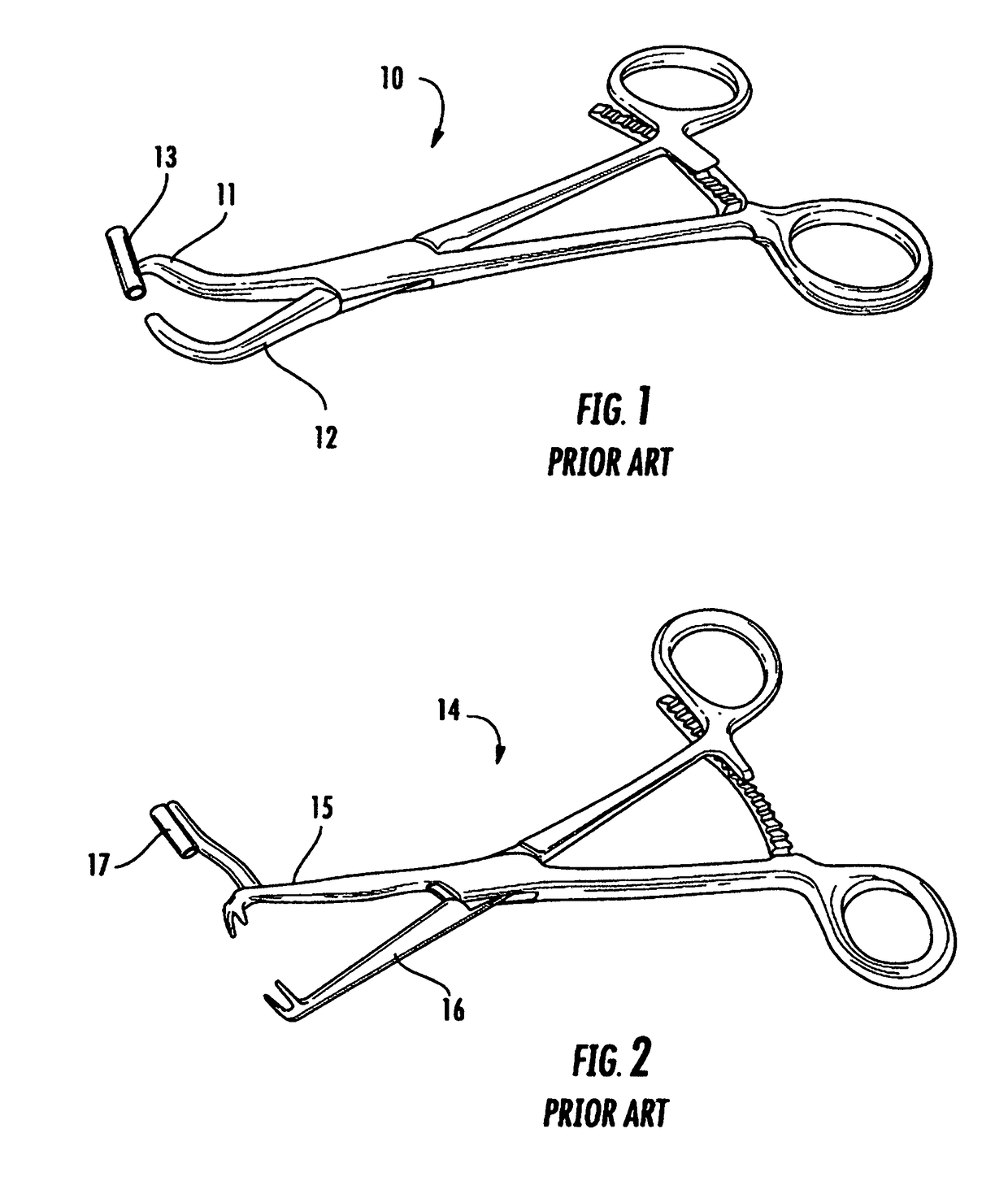

Surgical bone clamp

InactiveUS20100114154A1Easy to operateEasy constructionSuture equipmentsLigamentsGrip forceTotal knee replacement surgery

The surgical bone clamp securely grasps and removes bone and other tissue during surgery, such as total knee replacement surgery. In one embodiment, the device includes a handle portion, a clamp portion, and a ratchet portion. The handle portion includes two handle arms that are pivotally connected, and the ratcheting portion permits the handle arms to be spaced at any one of a plurality of step settings. One of the handle arms provides a finger loop to engage the thumb, while the other handle arm provides a finger loop to engage at least one opposing finger. The clamp portion includes two serrated clamping jaws designed to engage the bone or other tissue surface and to provide adequate gripping force to allow for removal of the bone piece or tissue from the body cavity. The device provides significant mechanical advantage to the user, may be operated with one hand, and may include removable clamping jaws.

Owner:SNELL CHRISTOPHER

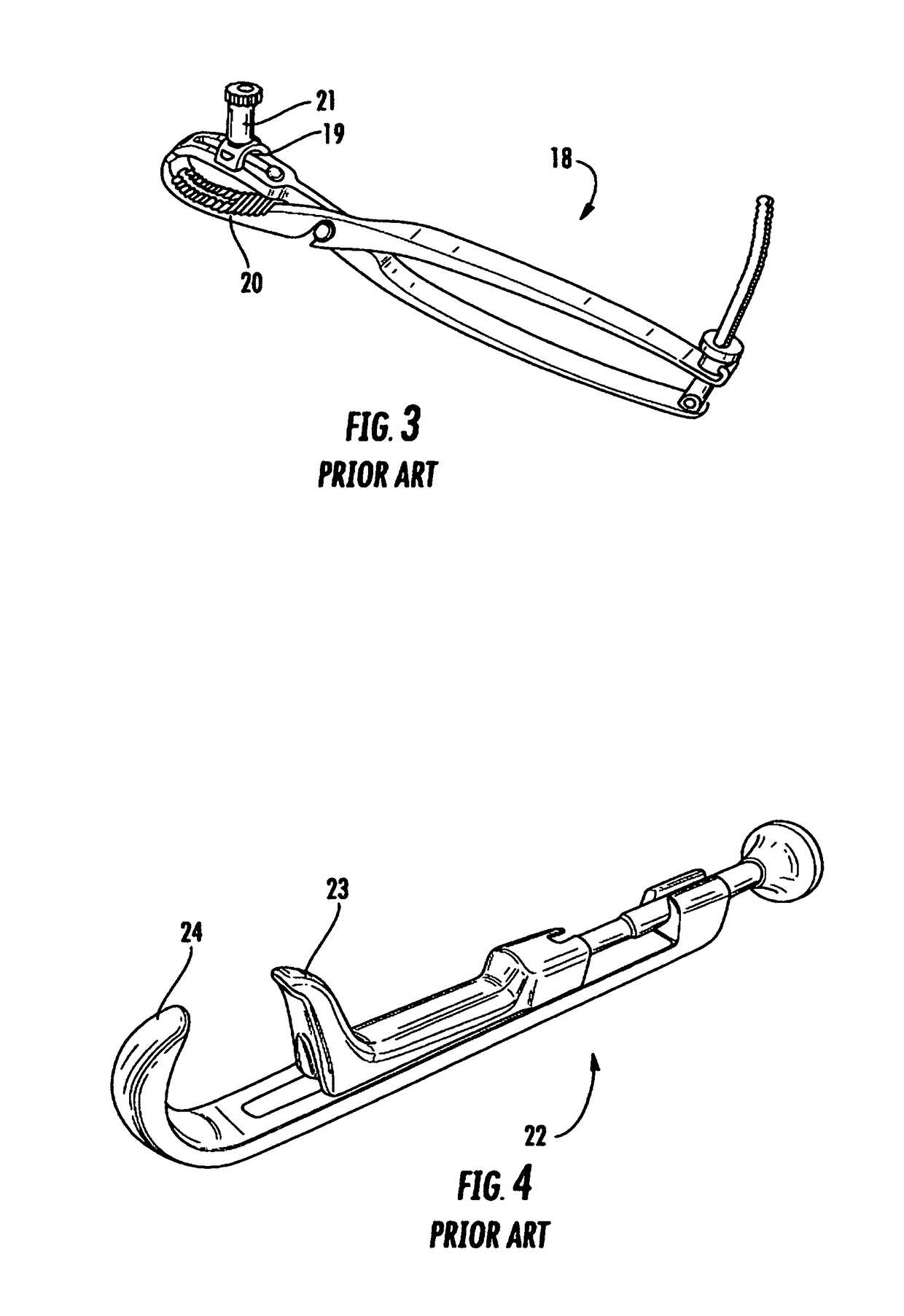

Tools and methods for orthopedic surgery

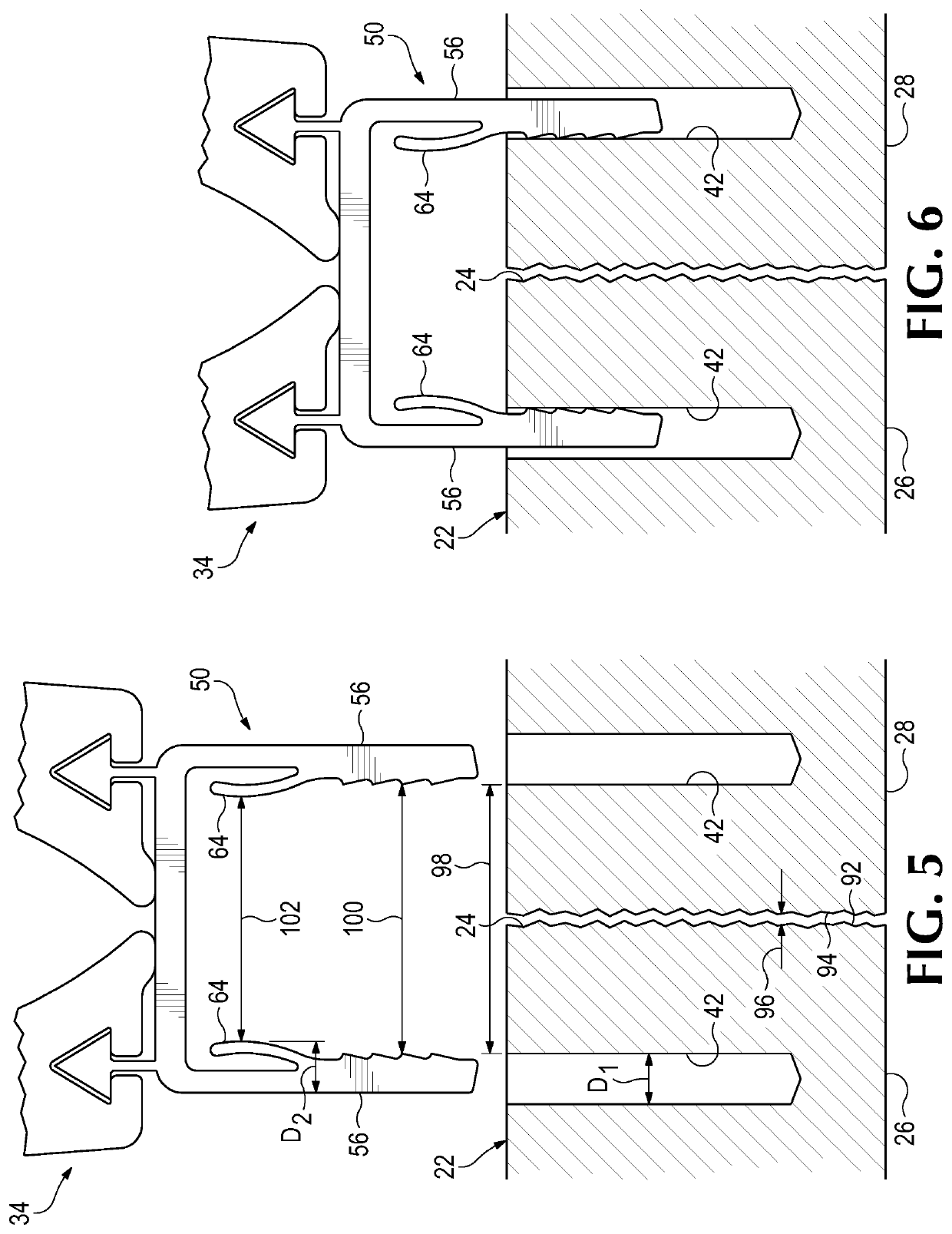

InactiveUS20100023016A1Easy accessGuaranteed to workNon-surgical orthopedic devicesOsteosynthesis devicesTibiaRasp

Tools may be used individually and / or in combination to allow minimally invasive and safer orthopedic surgery. A femur adjustment tool lifts and lateralizes the proximal end of the femur during hip replacement surgery by pivoting on a ball temporarily placed in the acetabulum. A tissue protection and broach (rasp, cutting, drilling) guide tool may retract tissue at the incision, protect tendons and soft tissue, and provides a curved, elongated surface that cradles and guides the broaching tool. A tip of the main body of the protection and guide tool, and a hook protruding from the main body, may extend along opposite surfaces of the femur to help “capture” a portion of the femur for tool stability and to effectively and positively protect the piriformus tendon that will reside in the “V” between the hook and tip. A bone clamp is used when a generally transverse cut is made across a bone, for example, a knee surgery proximal tibial cut, wherein the clamp improves control of the bone portion for safer freeing of the bone portion from soft tissue and extracting the bone portion from the incision. A broad, flat plate of the bone clamp may be slid between the bone and the bone portion into the narrow space that has been created by cutting the bone, and a relatively narrow gripping member may be slid along / across the opposing surface of the bone portion, which allows the narrow gripping member to fit into the intercondylar notch of the femur.

Owner:BOTIMER GARY

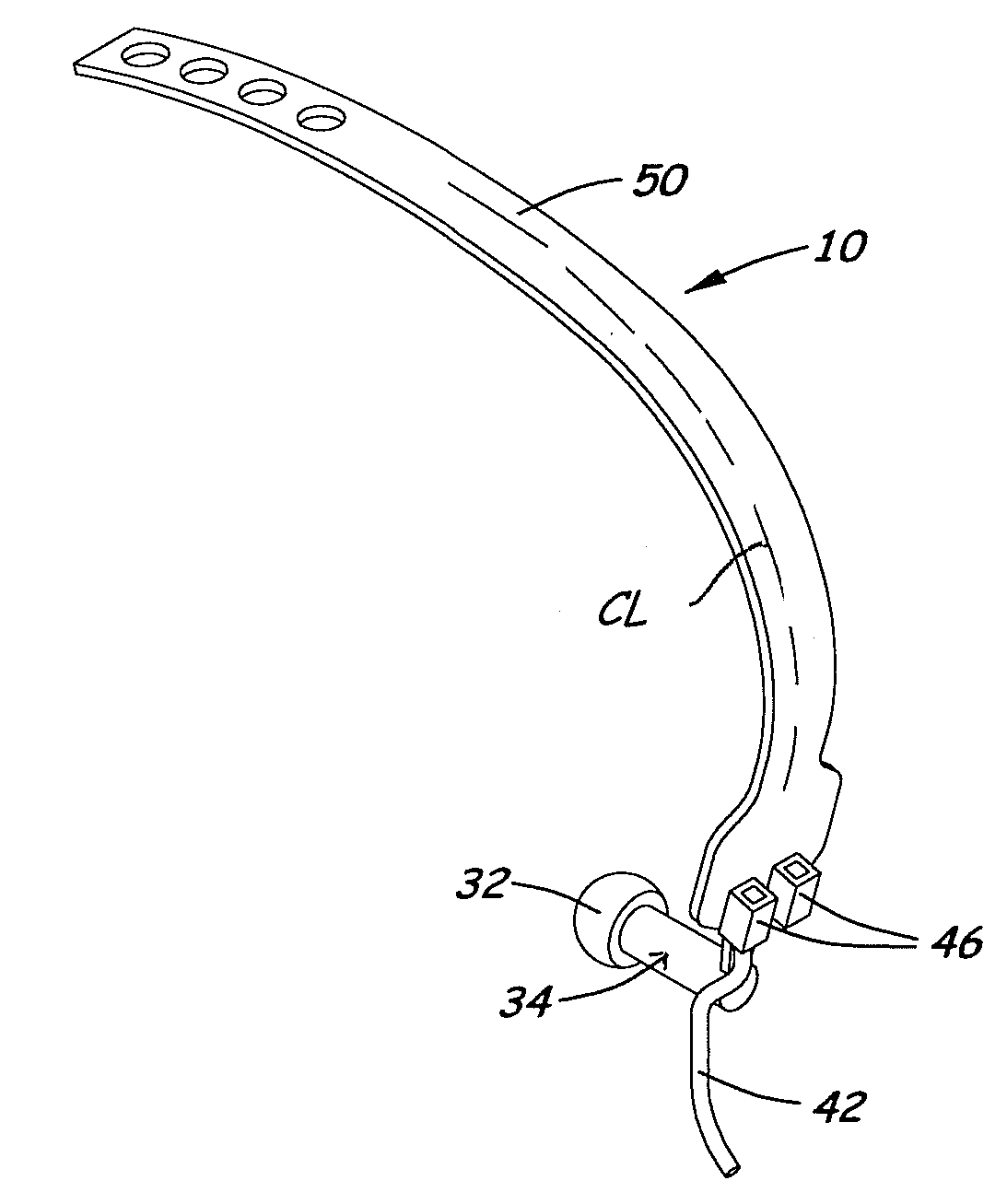

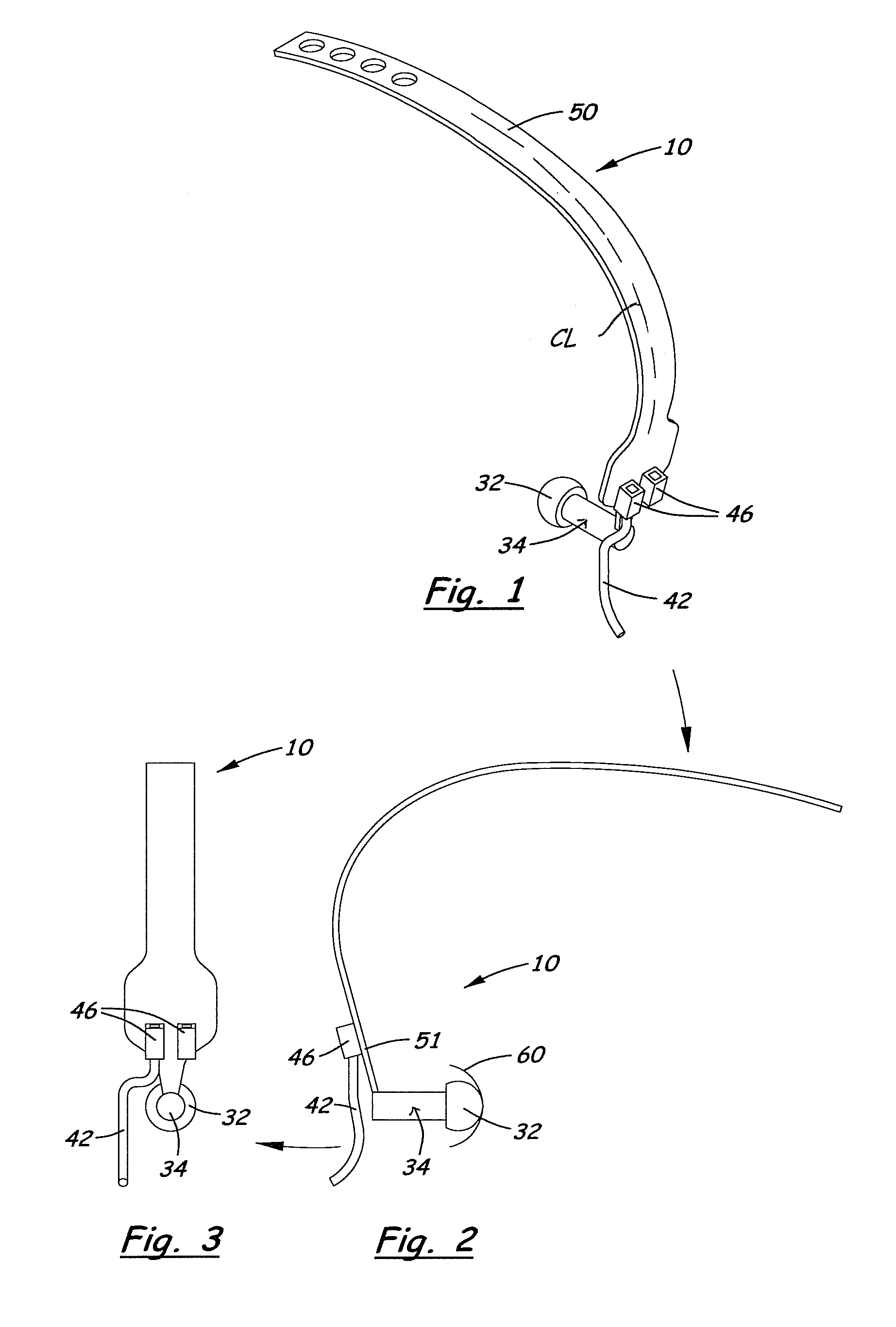

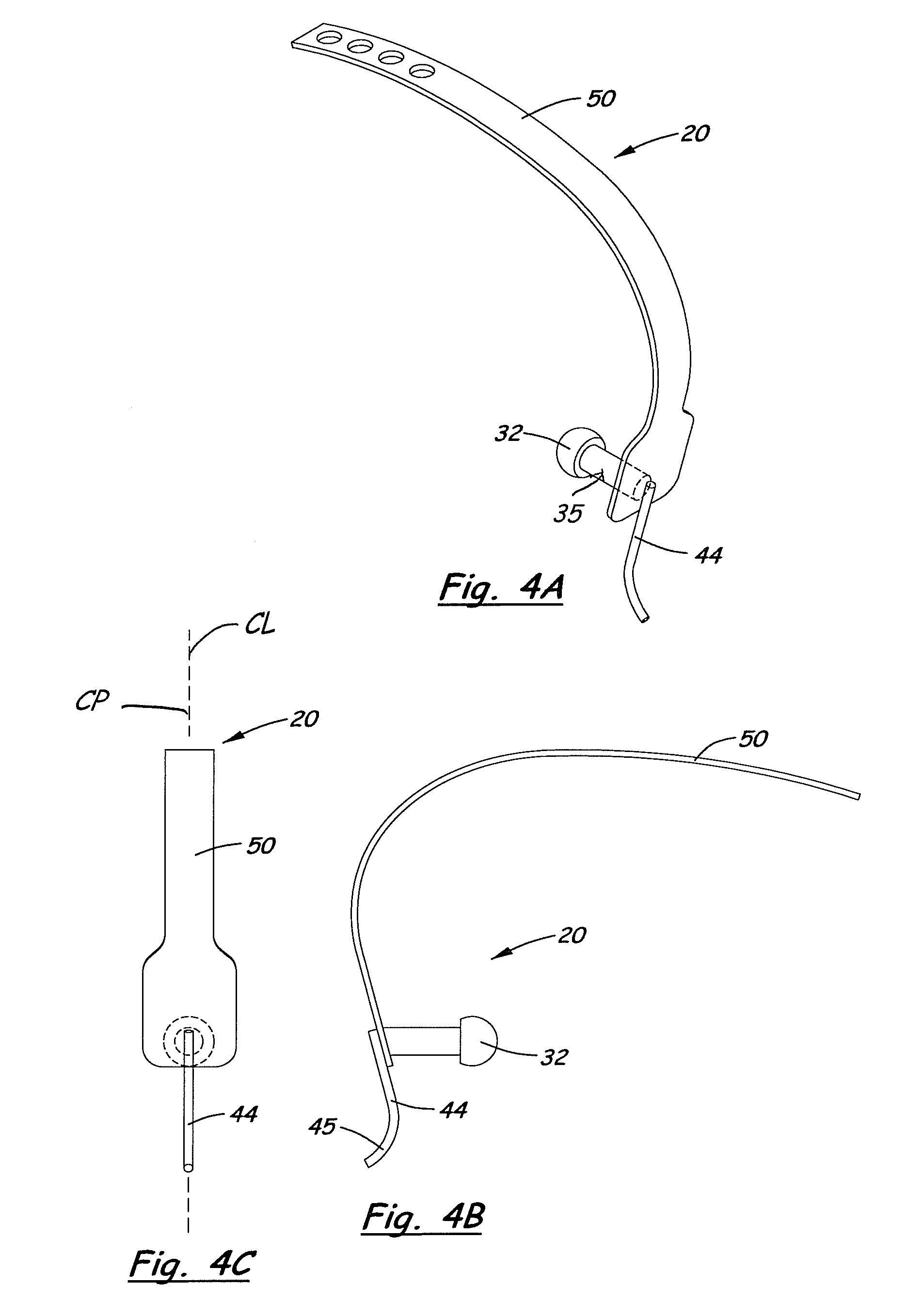

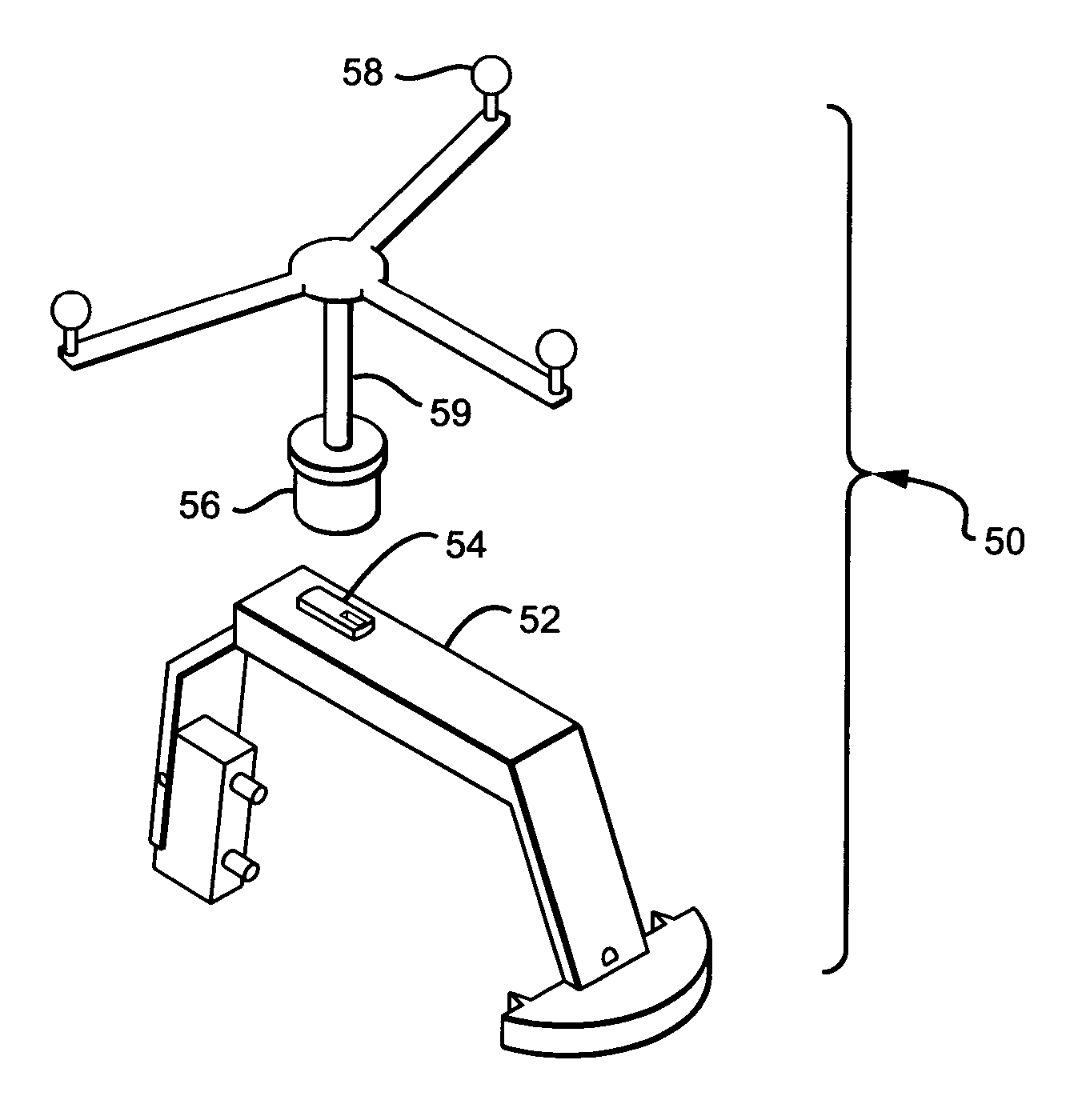

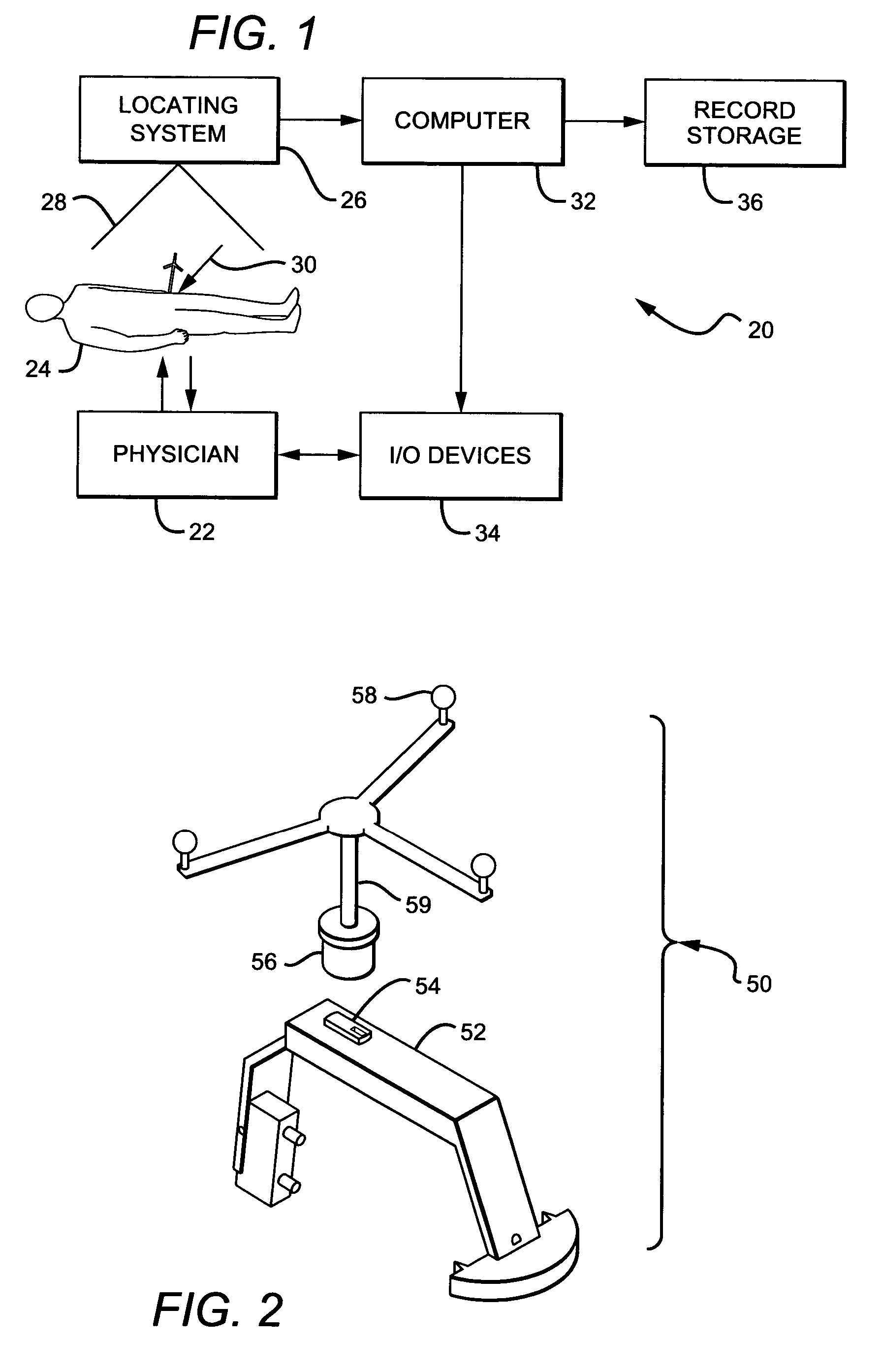

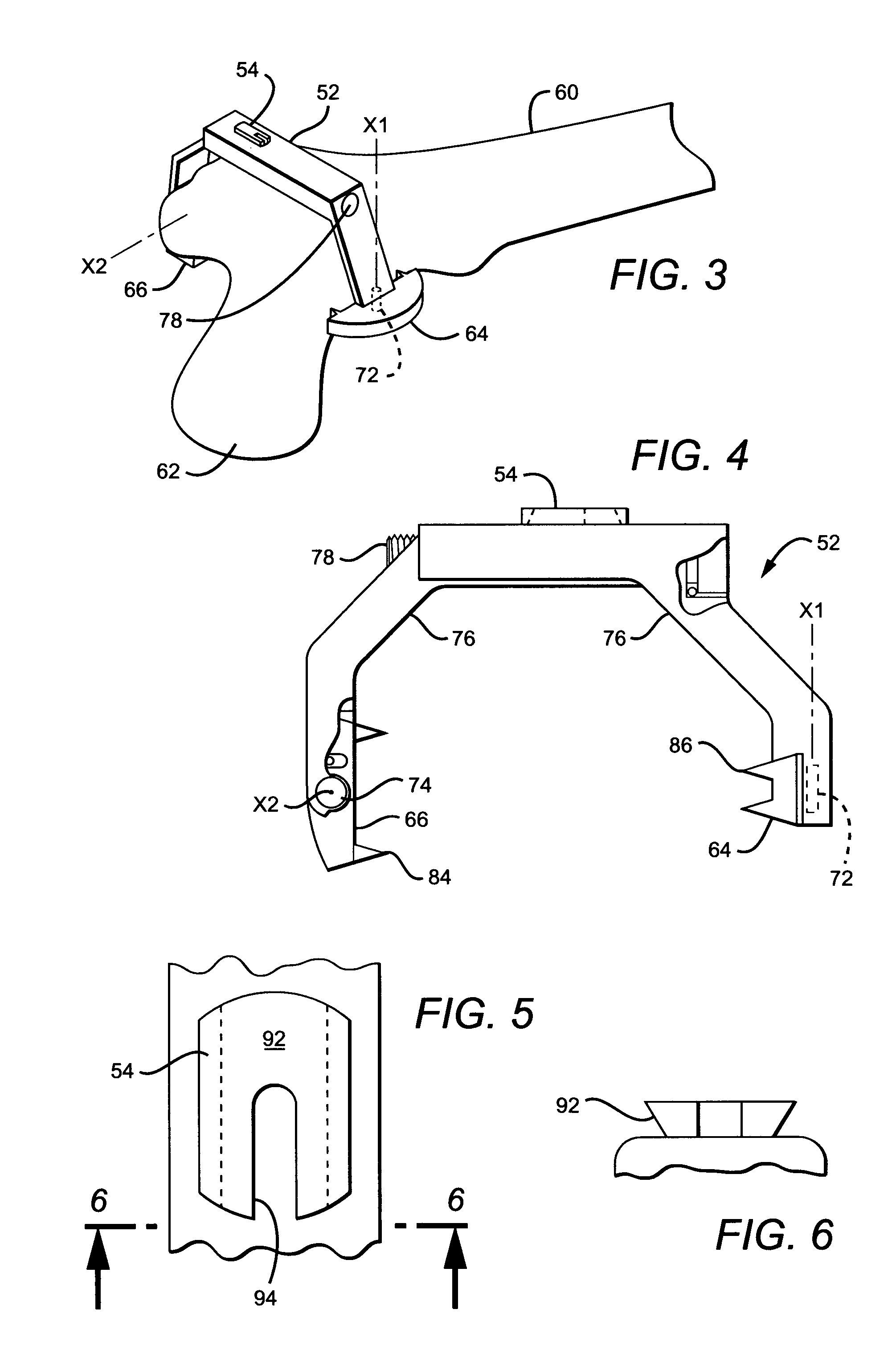

Non-imaging tracking tools and method for hip replacement surgery

ActiveUS8002772B2Snap fastenersDiagnostic recording/measuringHip joint replacement operationCoupling

A surgical tool for mounting a trackable target to a human bone, suitable for fixation to a human femur. The tool includes a removable bone clamp and a releasable coupling member which is integrated with the removable bone clamp. The releasable coupling member is arranged to mate with a compatible coupling member mounted on the trackable target to establish a predetermined spatial relationship between the bone clamp and trackable target. The releasable and compatible coupling members form a releasable connection which is mechanically constrained to re-engage only in a re-engaged position that accurately recaptures the predetermined spatial relationship.

Owner:KINAMED

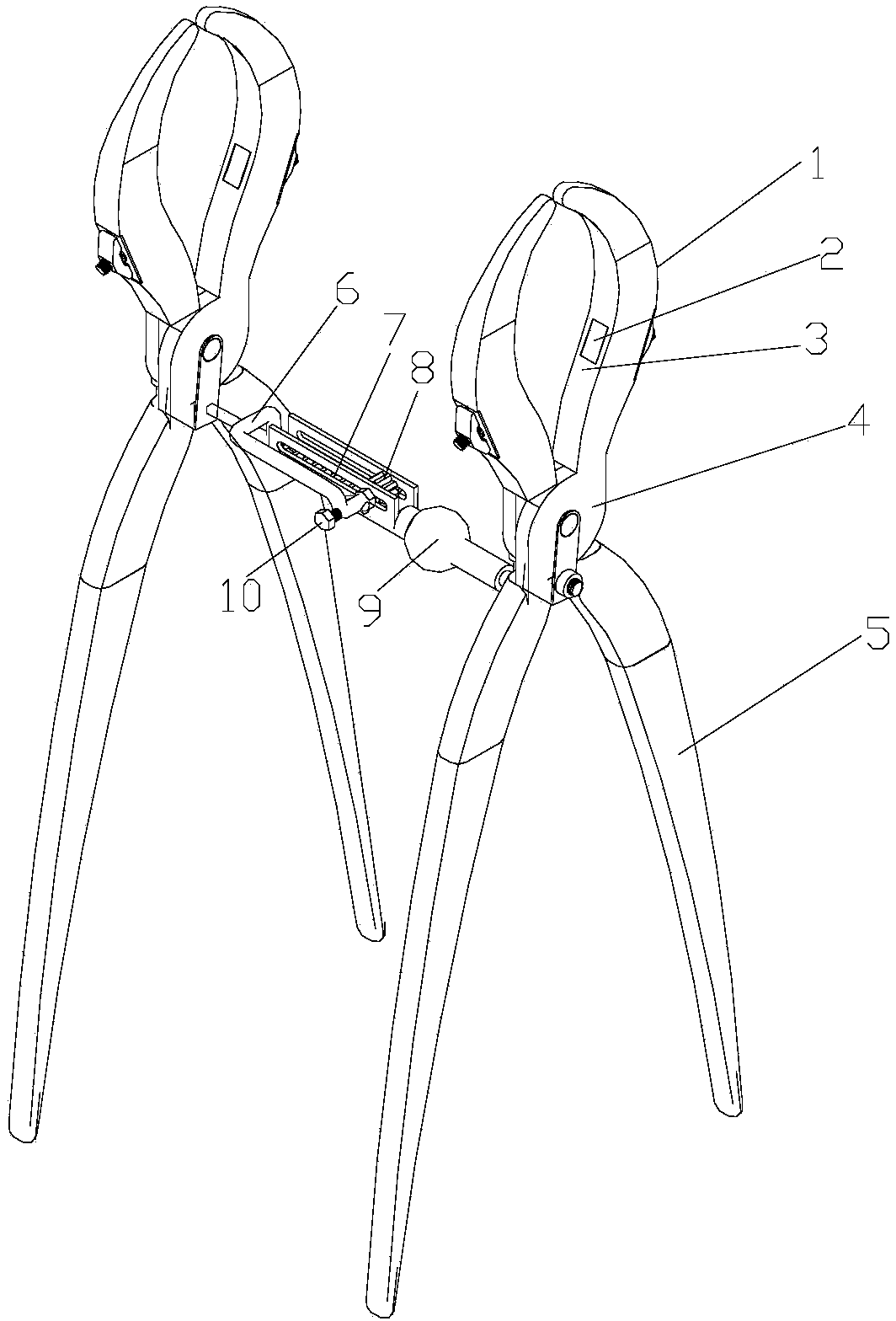

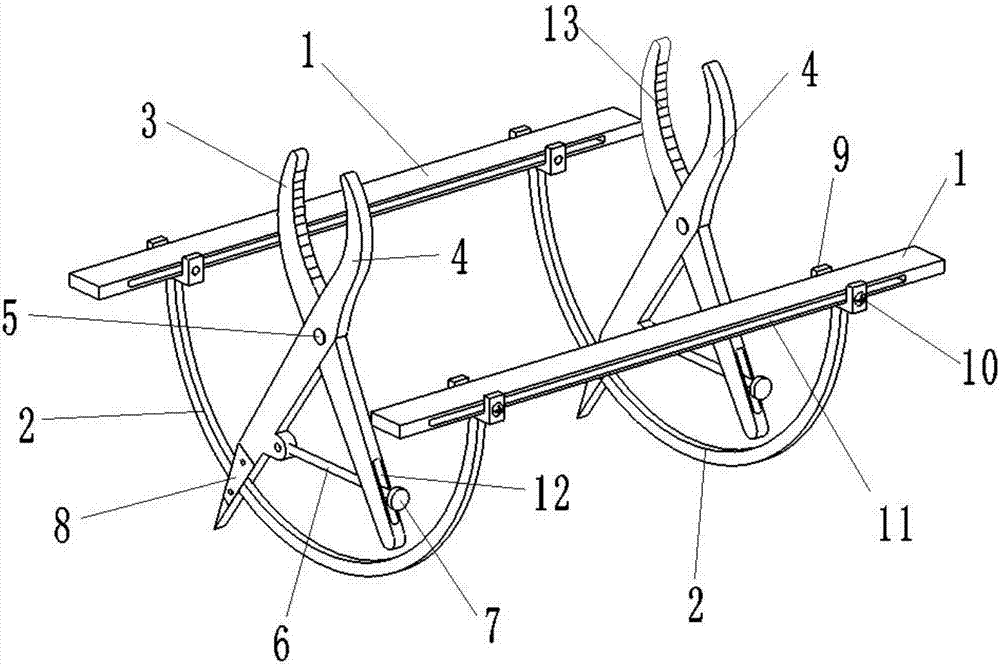

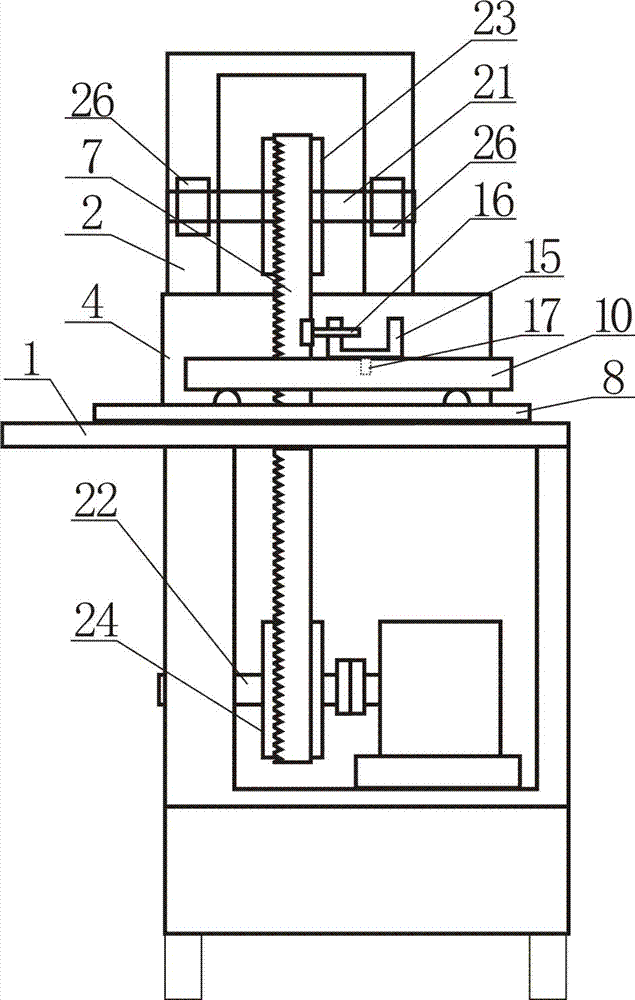

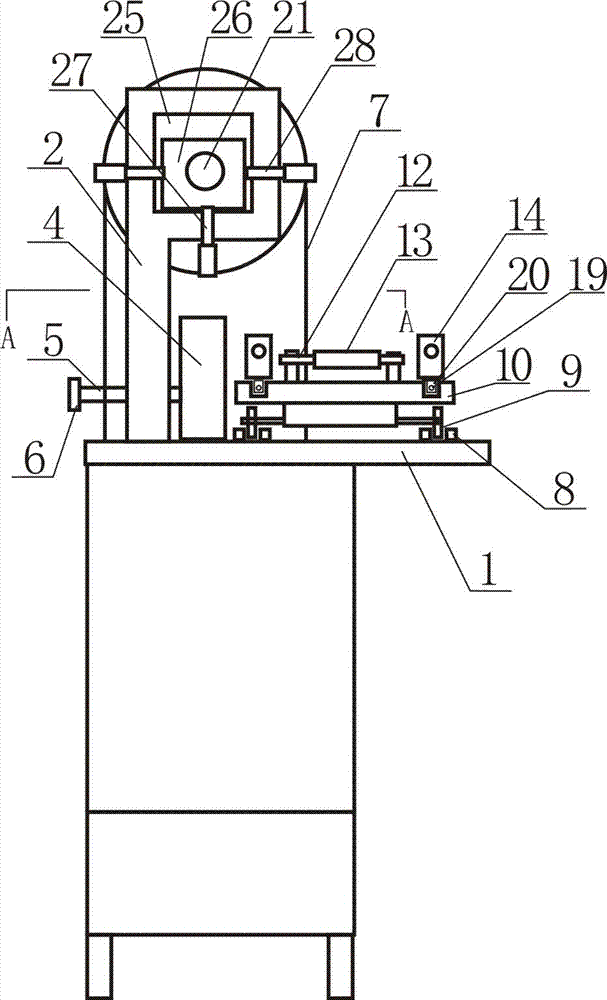

Reduction forceps

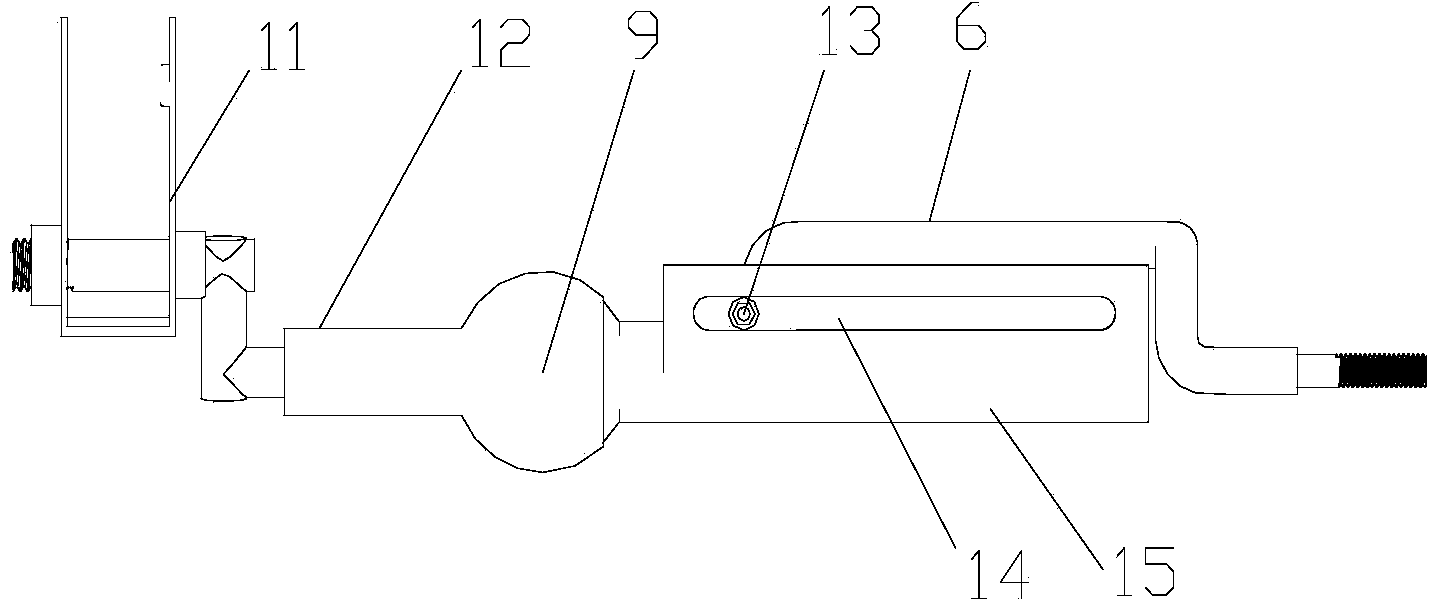

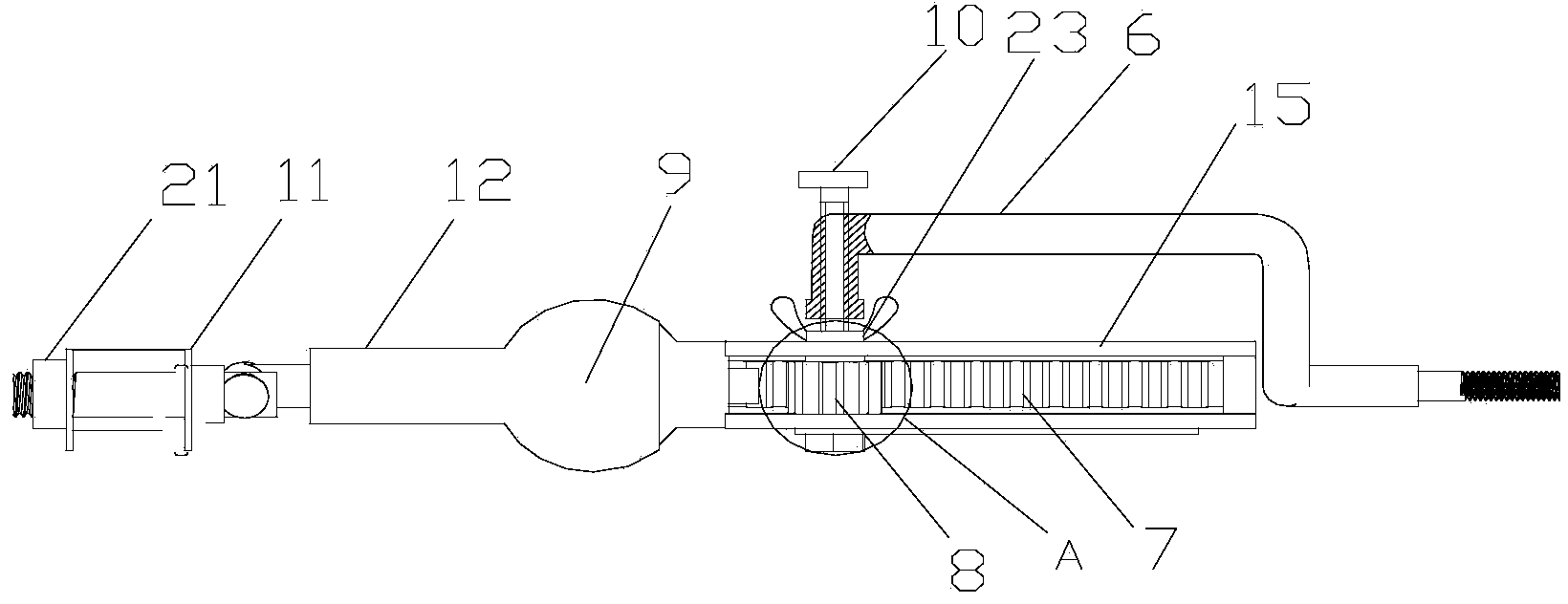

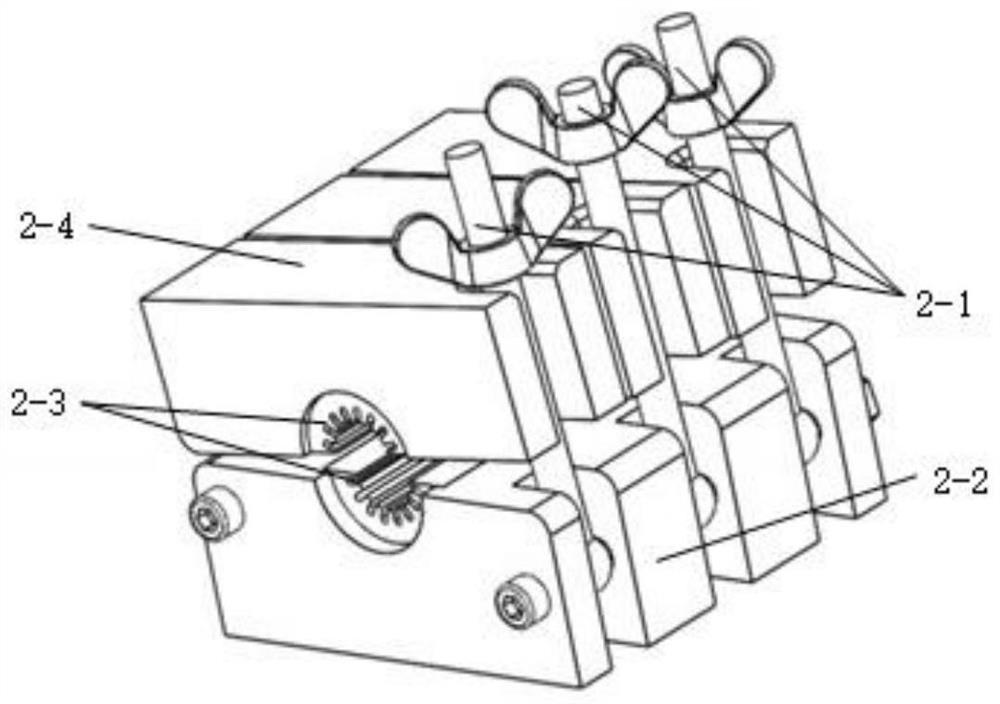

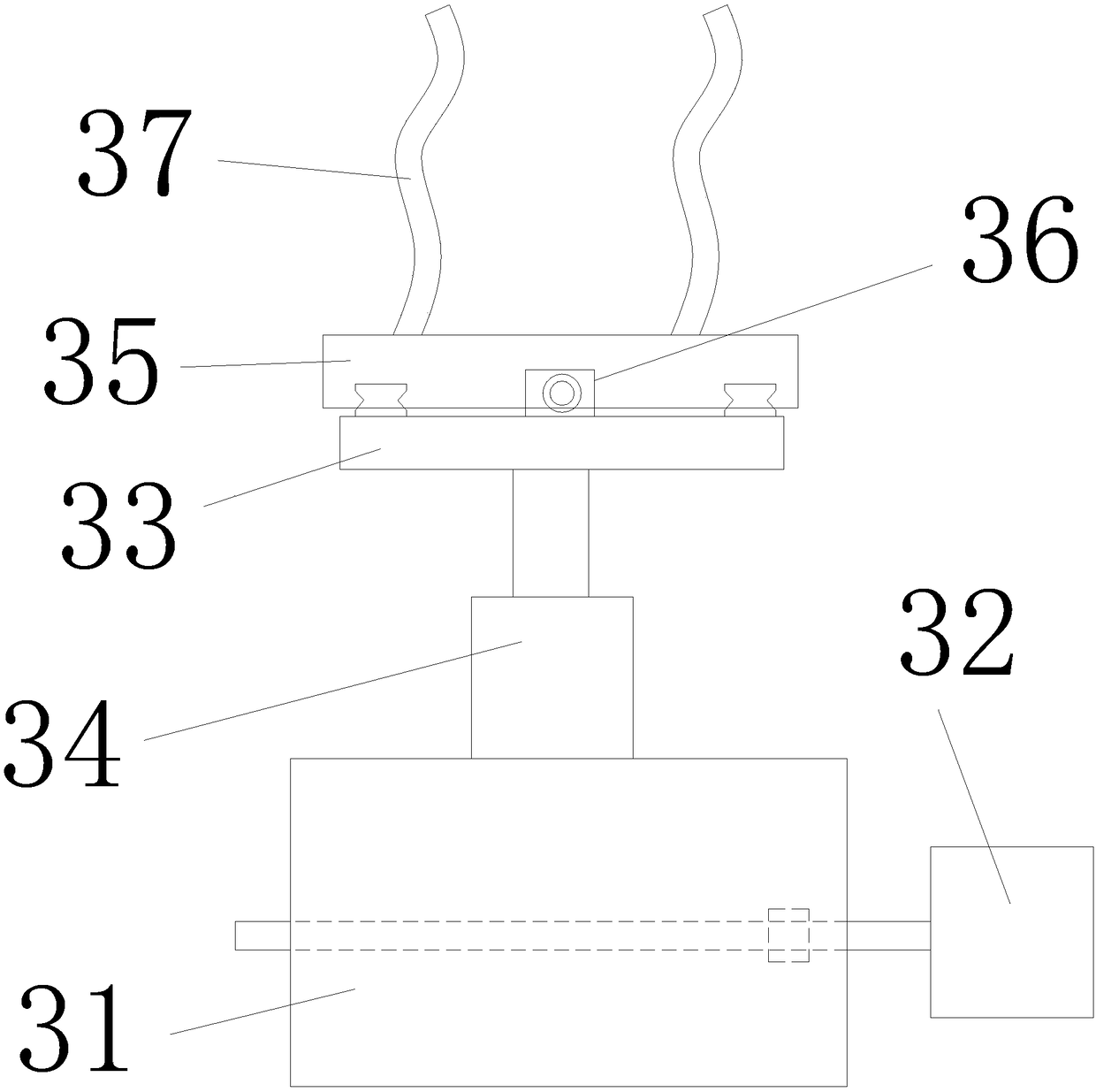

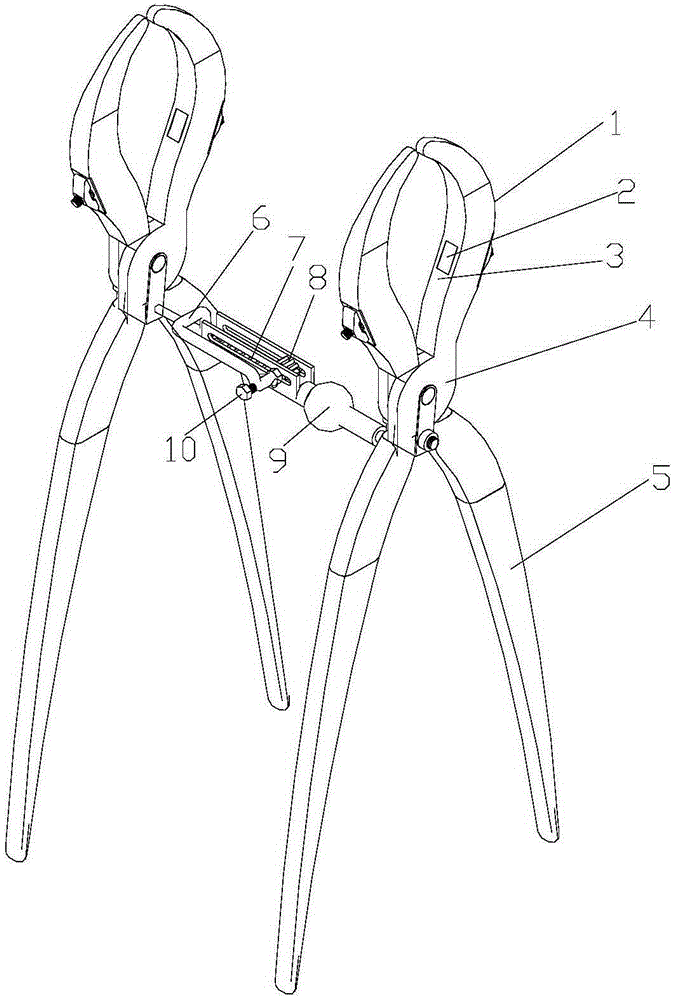

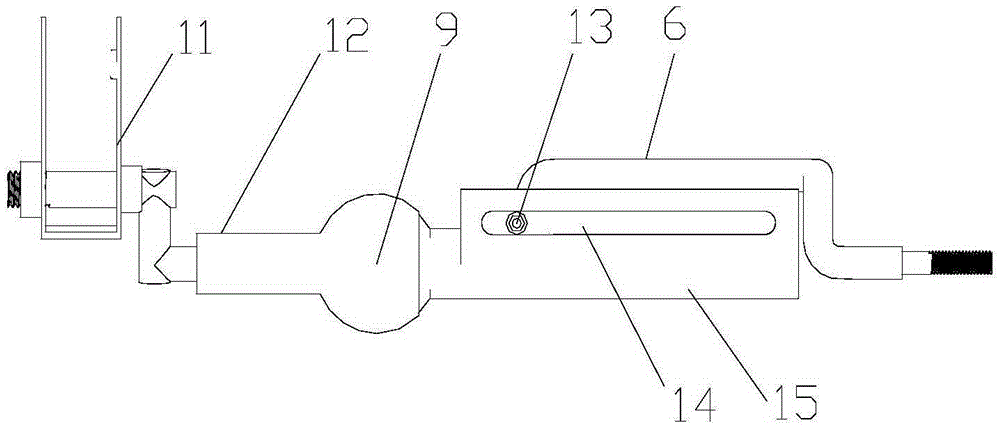

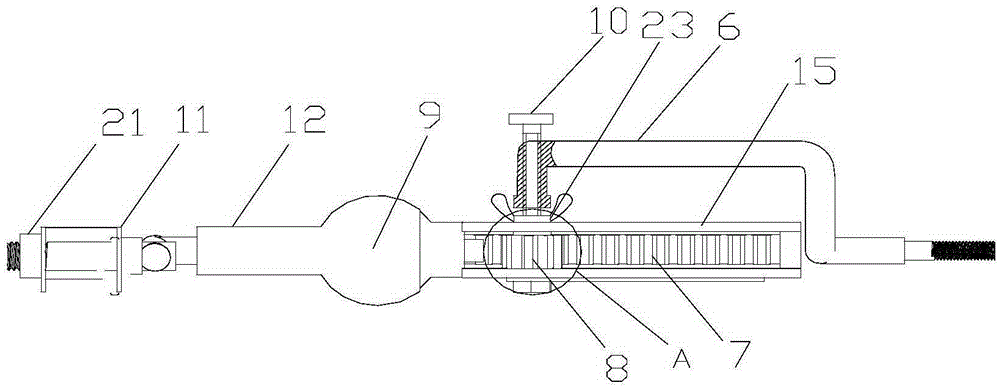

ActiveCN103976773AReduce work intensityRelieve painOsteosynthesis devicesSurgical forcepsBone clampForceps

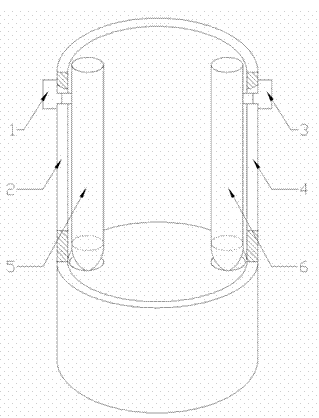

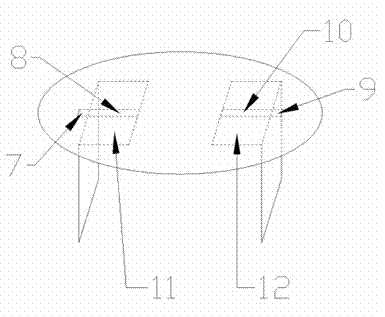

The invention discloses a pair of reduction forceps. The pair of the reduction forceps comprises at least two bone clamping forceps bodies and a connection rod connecting the two bone clamping forceps. The connection rod comprises a connection rod body, an adjusting rod and a longitudinal adjusting mechanism enabling the connection rod body to move relative to the adjusting rod in the longitudinal direction. According to the reduction forceps, people only need to adjust rotation of a gear so that broken bones can move relatively along the connection rod in the longitudinal direction, and accordingly reduction of the broken bones is achieved. Manual adjustment is not needed, the positions of the broken bones do not need to be fixed, after broken bone reduction is finished, the relative position of the two bone clamping forceps bodies can be locked through the connection rod body, and accordingly the relative position of the broken bones is locked. The situation that the broken bones are dislocated after subsequent operation of an operation is avoided, so that labor intensity of medical staff is lightened, and pains of patients are relieved.

Owner:江苏惠骨医疗器械有限公司

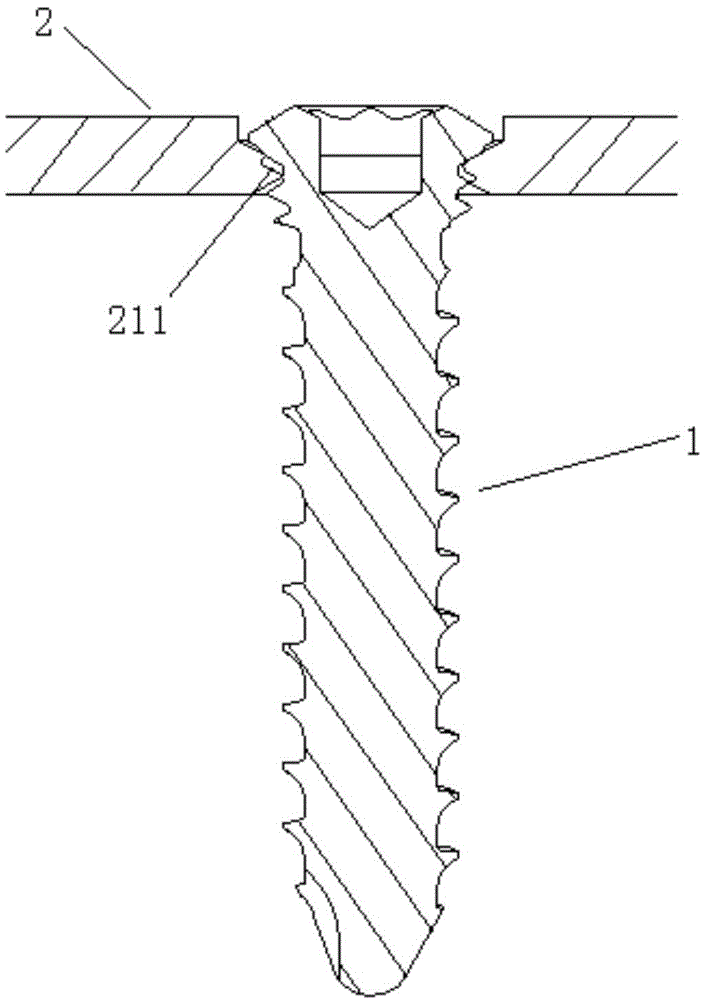

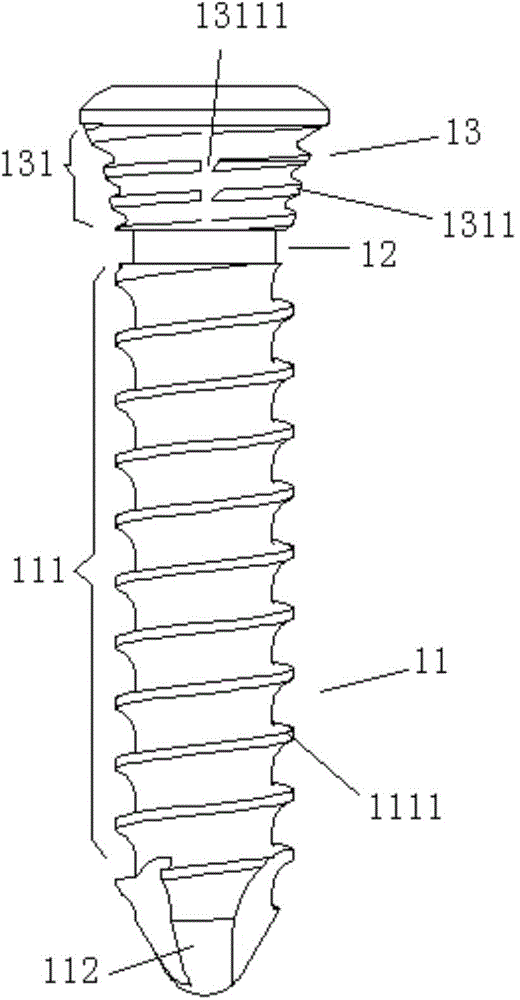

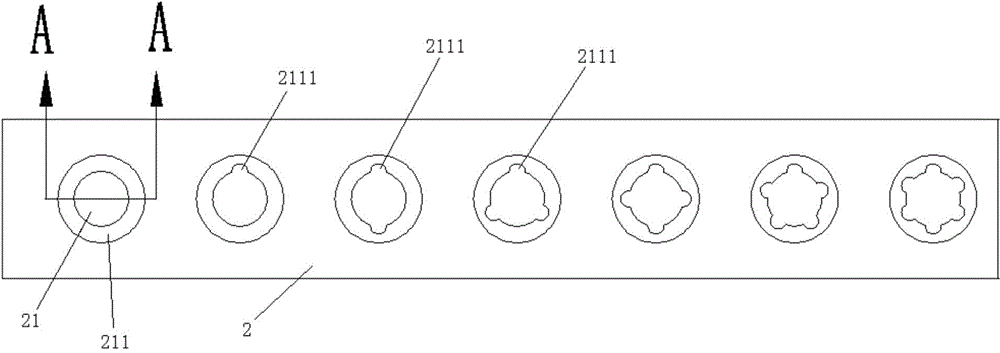

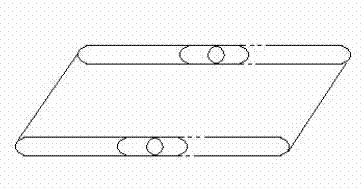

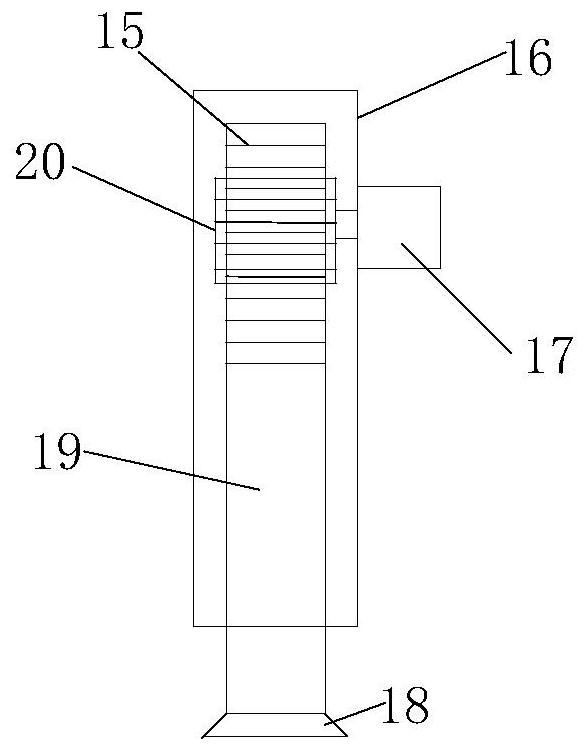

Small bone clamping device

The invention discloses a small bone clamping device comprising a bone screw and a bone plate. The bone screw comprises a rod, a neck and a head. The neck is arranged between the rod and the head. The rod comprises a first threaded section provided with a first-level thread. The head comprises a second threaded section provided with a second-level thread. The neck has no threads. The bone plate is provided with locking holes. Width of inner edge sides of the locking holes is less that thickness of the bone plate. According to the arrangement, the multi-level threads are formed on the bone screw, and through the thread formed on the head, the bone screw is effectively locked with the bone plate; a flange is adopted to replace a locking thread of the conventional bone plate, thus the thickness of the bone plate is maximally decreased.

Owner:无锡市闻泰百得医疗器械有限公司

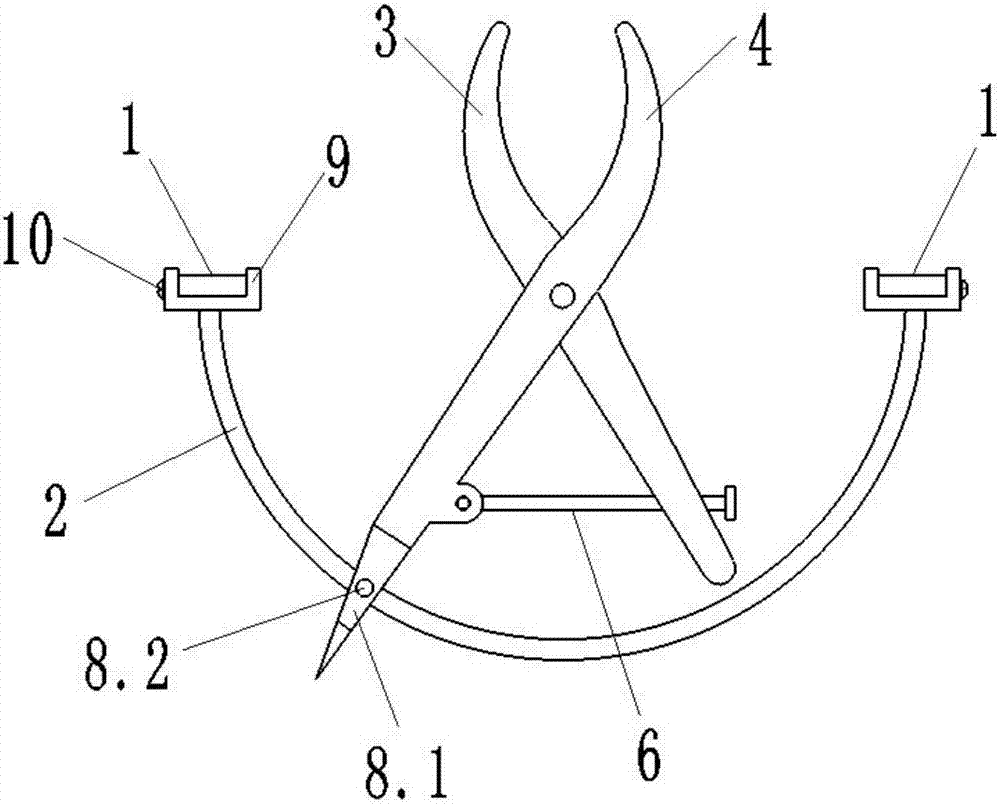

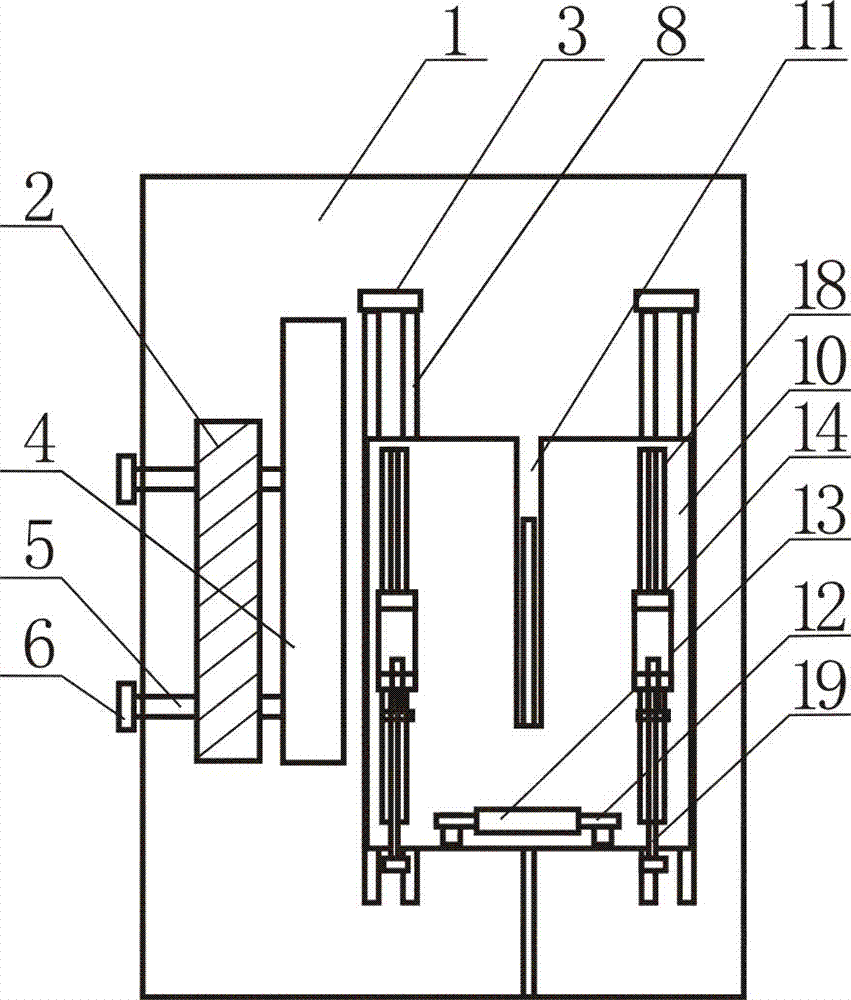

Long bone cutting device

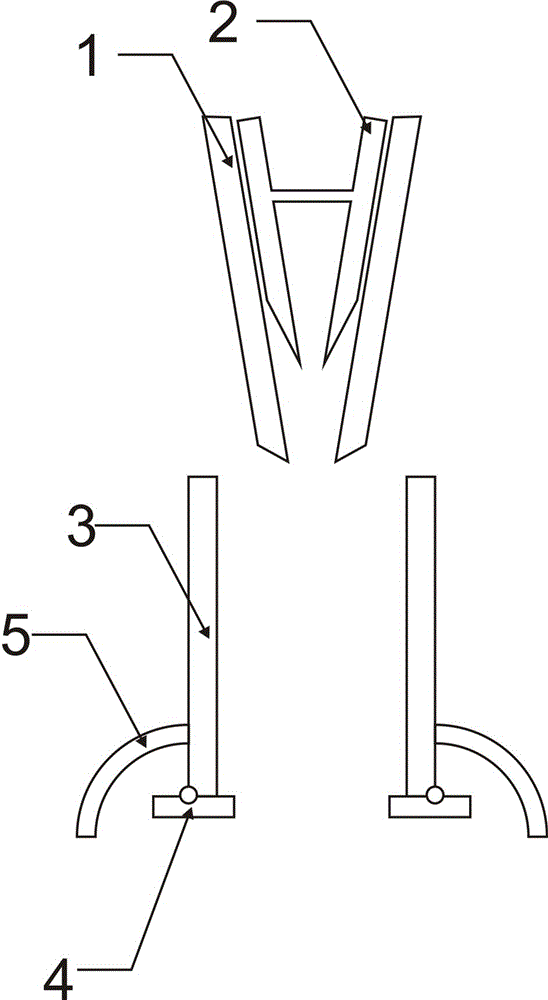

InactiveCN107184260AEasy to fixEasy to controlOsteosynthesis devicesSurgical forcepsBone clampForceps

The invention discloses a long bone cutting device which comprises two sliding rails arranged in parallel. Two arc guide rails are symmetrically arranged at the two ends of the two sliding rails. The arc guide rails are connected with the two sliding rails in a sliding mode through U-shaped forks at the two ends. Two bone clamping forceps are symmetrically arranged on the two arc guide rails. Each bone clamping forcep comprises a left forcep body and a right forcep body which are symmetrically arranged, forcep handles of the left forcep body and the right forcep body are connected through a rotating shaft hinge, the lower end of the right forcep body is connected with the arc guide rails through sliding locks in a sliding mode, an adjusting screw is connected to a hinge on the inner side of the right forcep body, and the adjusting screw penetrates through a through hole in the lower end of the left forcep body to be connected with an adjusting nut. The two bone clamping forceps can transversely move along the sliding rails and can also rotate around the arc guide rails, and two cut-off thighbones can be conveniently fixed to the proper position during surgery; due to the fact that scale marks are arranged on the sliding rails and the arc guide rails, the motion distance and the rotating angle of the bone clamping forceps can be precisely controlled.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

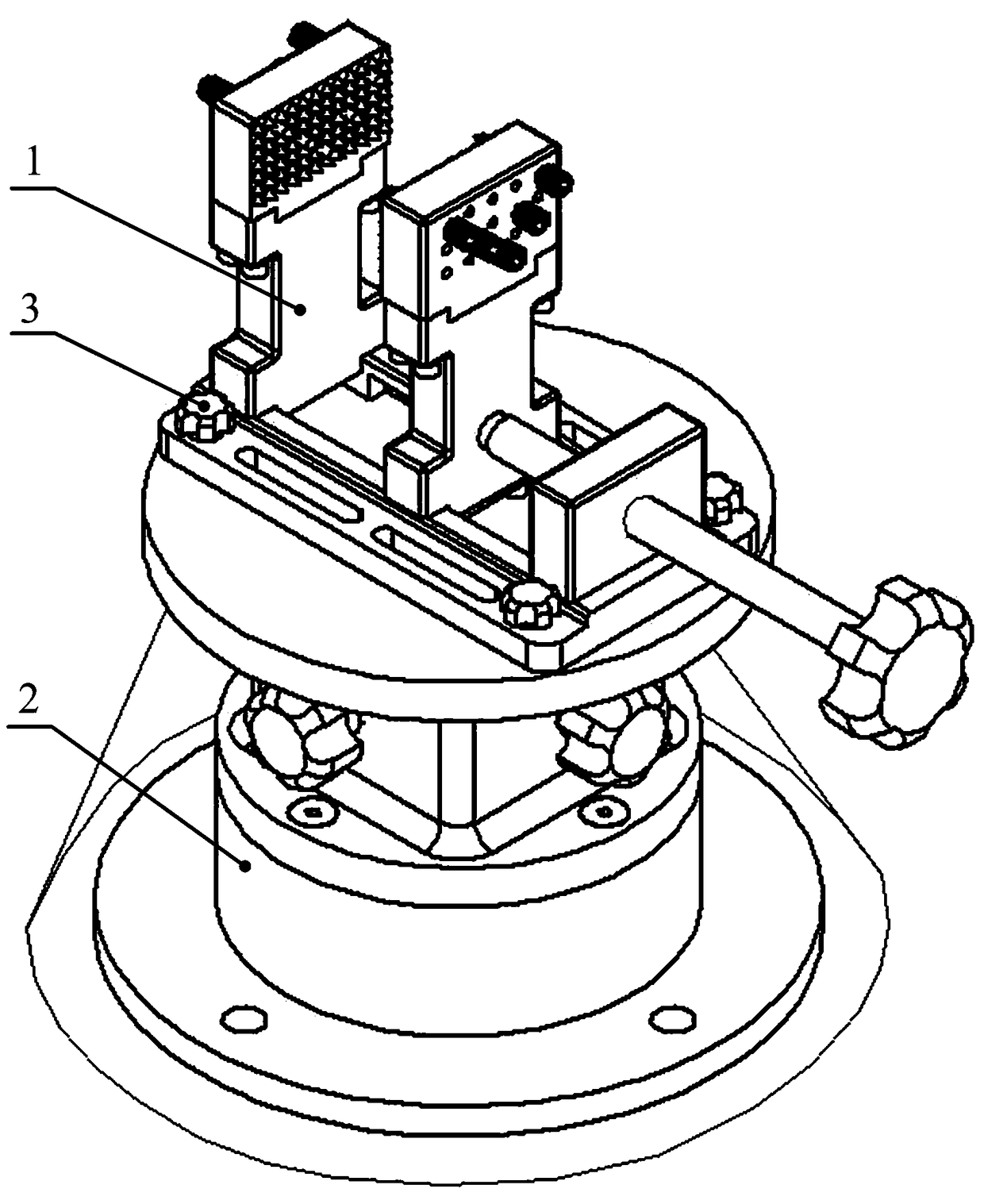

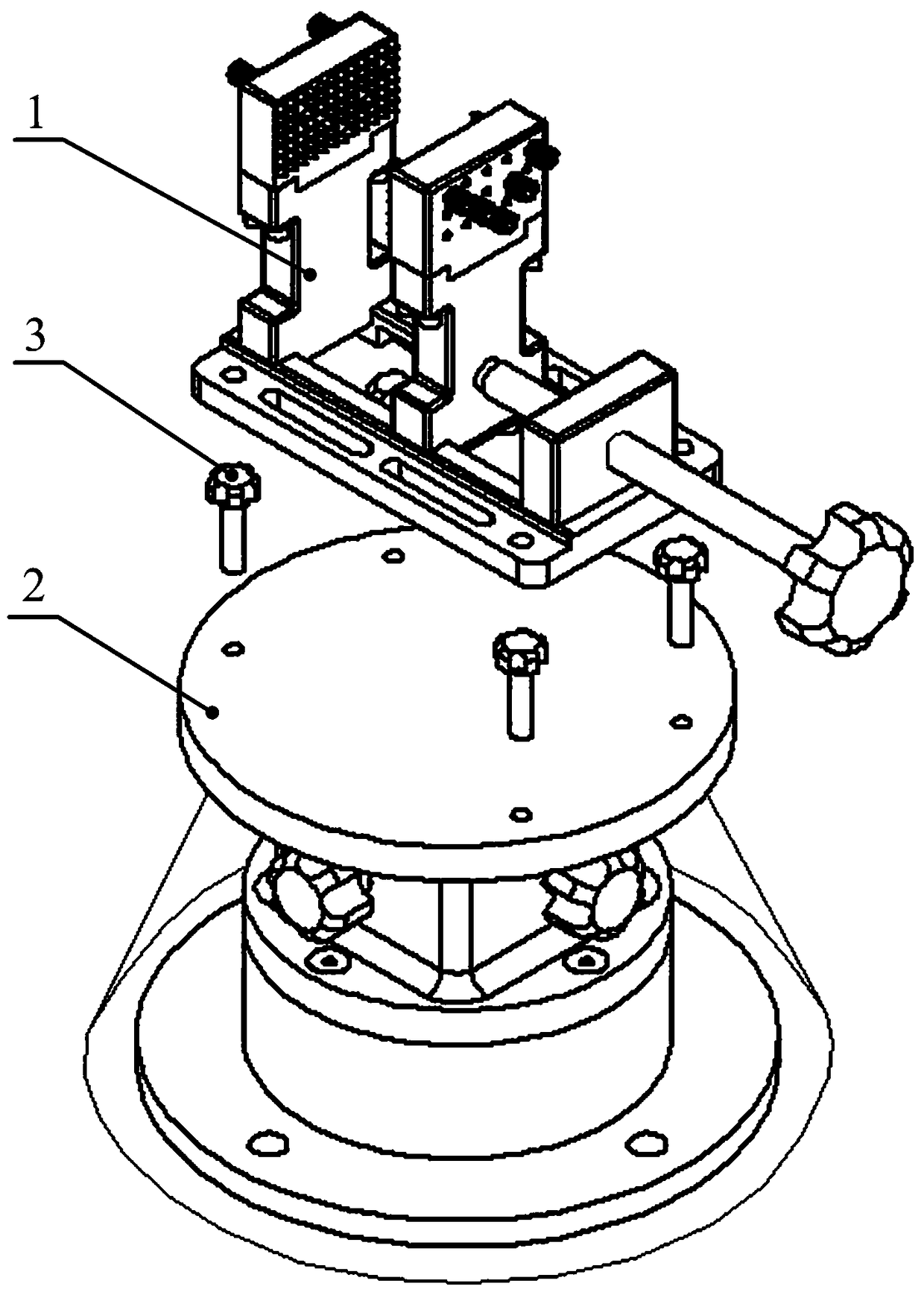

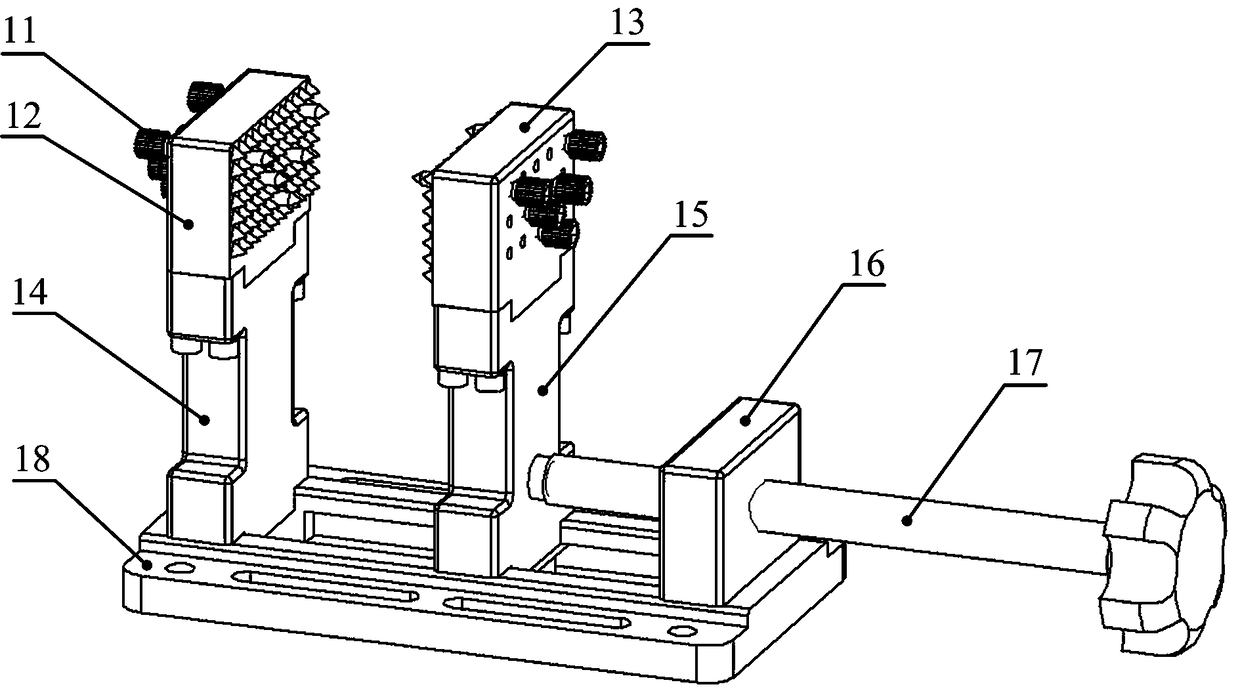

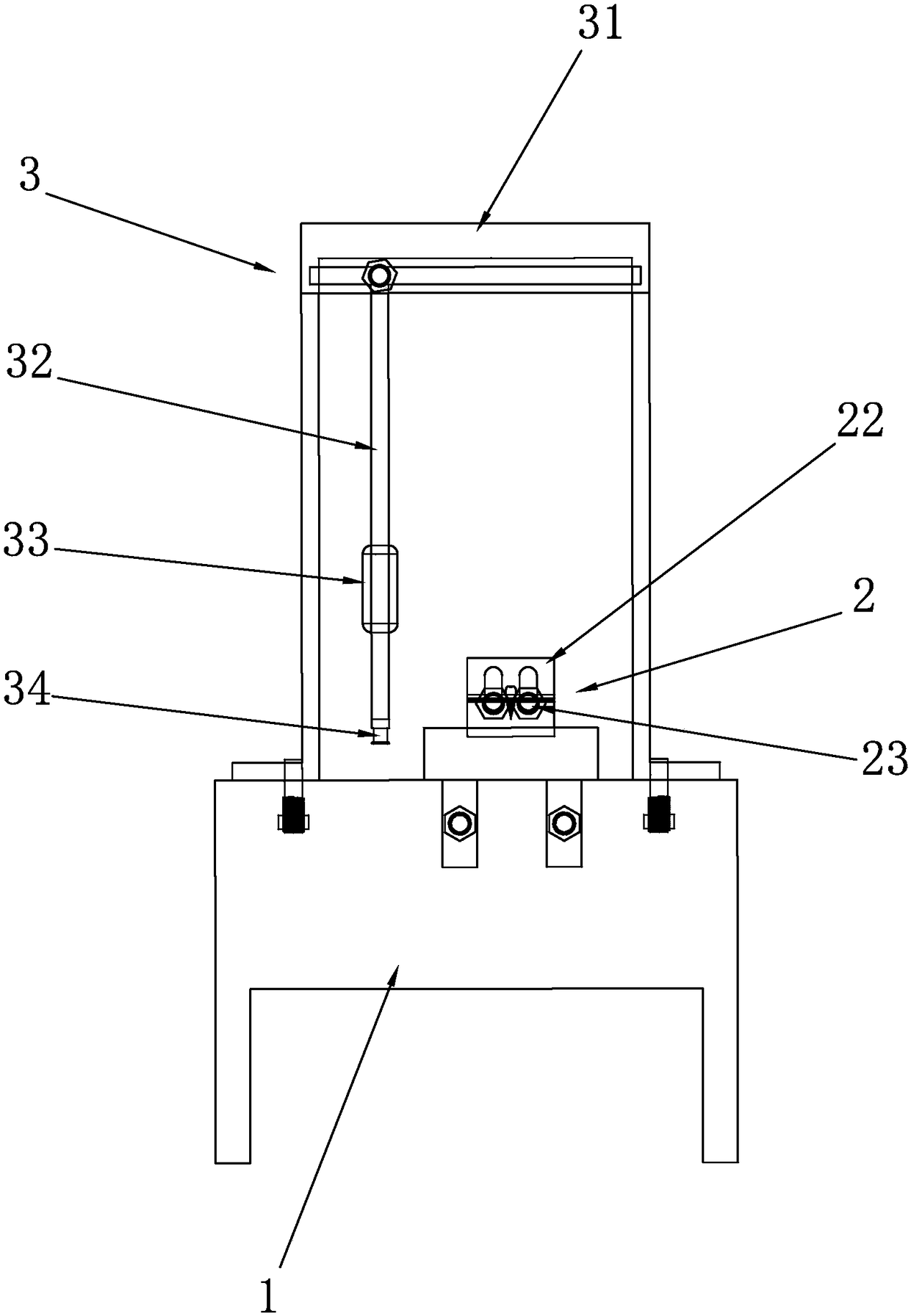

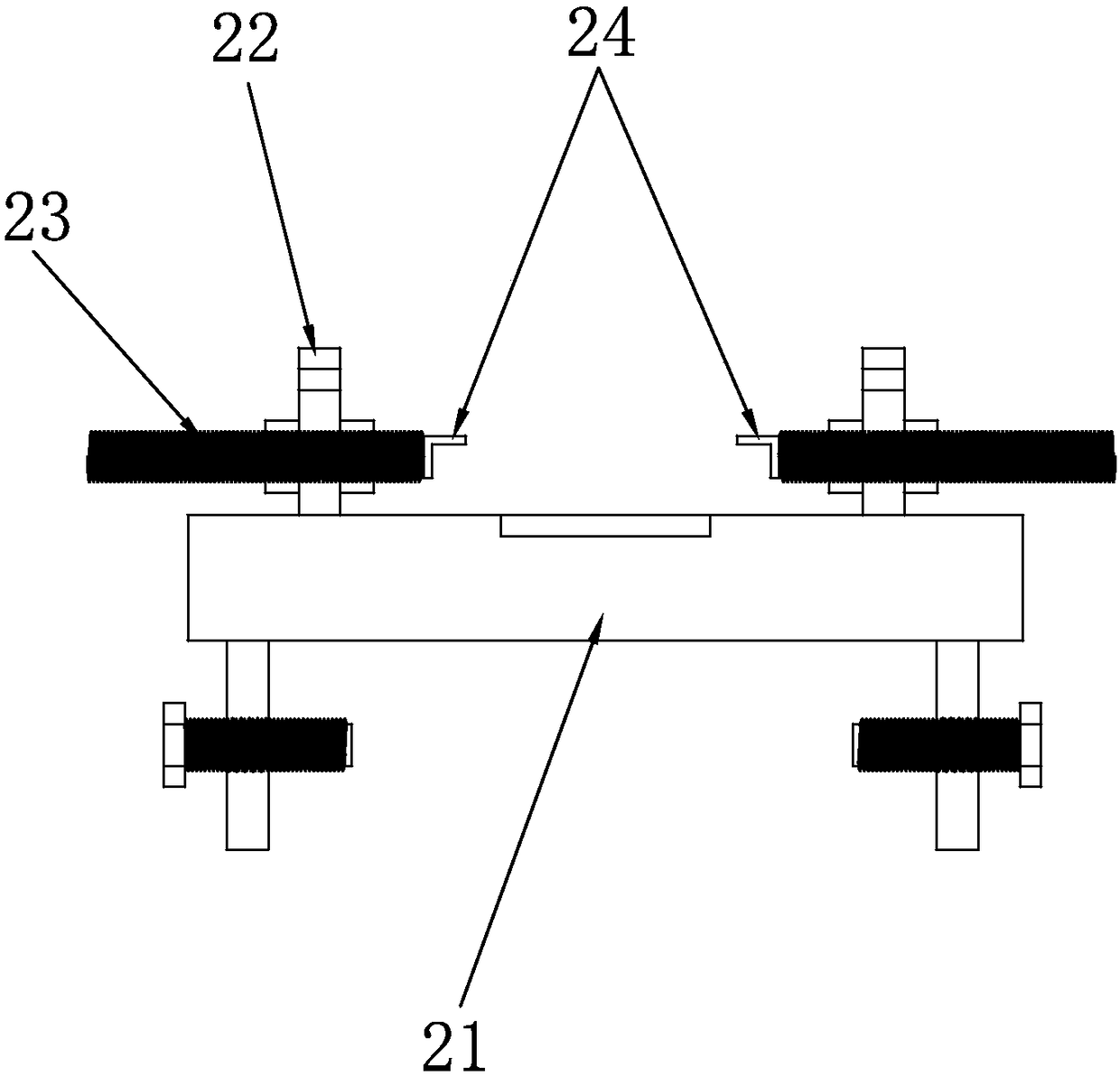

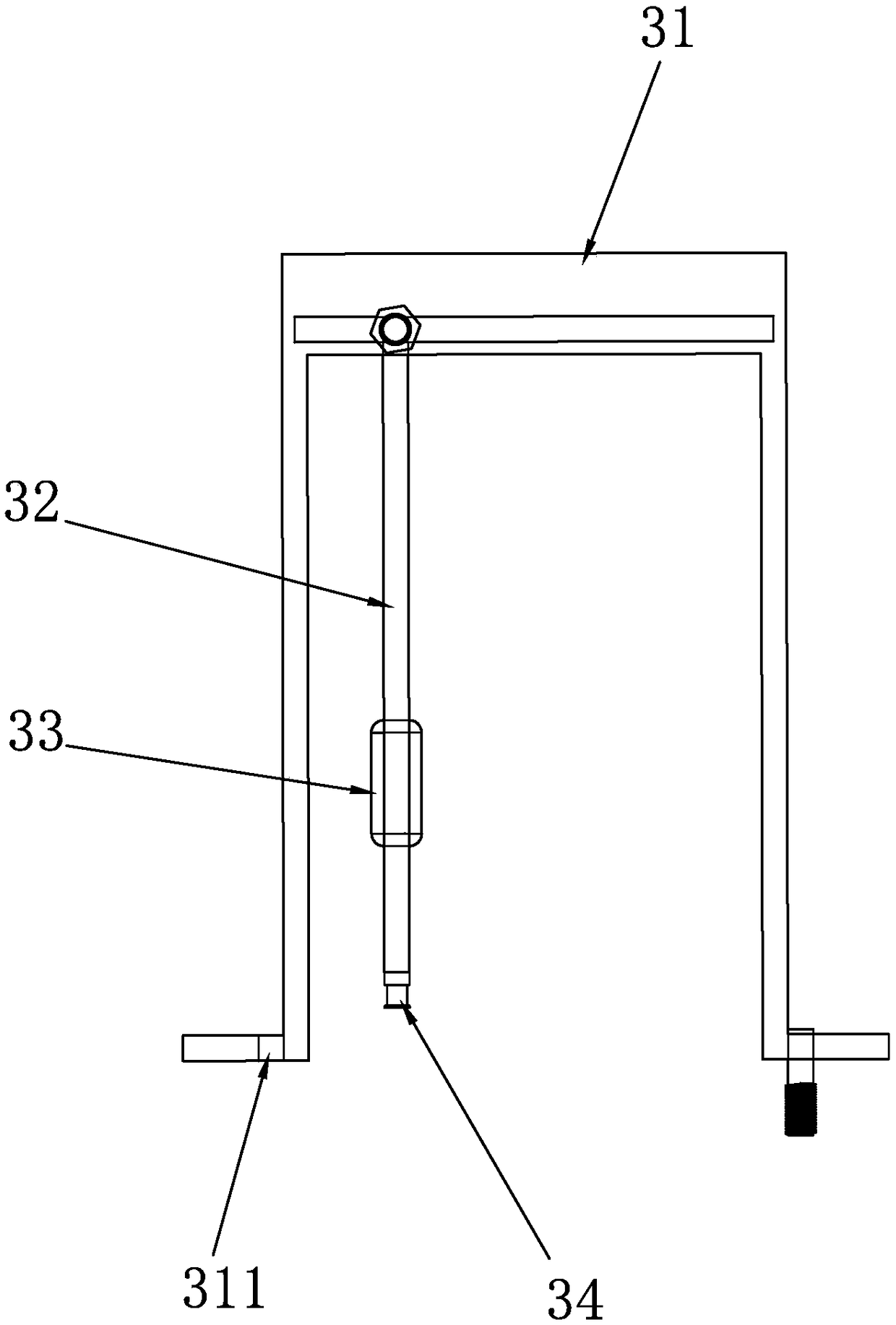

Bone clamping device

PendingCN108524015AAchieve clampingAchieve fixationInstruments for stereotaxic surgeryBone clampOrthopedic department

The invention discloses a bone clamping device, and belongs to the field of medical instruments. The device comprises a clamping portion and a rotary working table; the clamping portion is fixed by the rotary working table through a torx connecting bolt; and the bone clamping device can be integrally or separately used according to actual conditions, and is suitable for various application scenarios. The shortcoming that a special bone clamping instrument does not exist in various replacements of traditional allograft bones can be overcome, problems that a traditional auxiliary tool cannot maintain clamping stability and cannot bear spraying cooling of normal saline, the types of clamped bones are limited, a large clamping range cannot be provided, a sufficient operation space cannot be provided, flexible rotary positioning cannot be carried out, and the operation is complicated are solved, surgical bones can be stably clamped, the bone clamping device is suitable for most of types ofbones, a sufficient operation space is provided for robots or doctors in an orthopedics department, the bone clamping device is simple to operate and controllable in power, precision of operation to bones is improved, and the surgery efficiency is improved.

Owner:苏州尚贤医疗机器人技术股份有限公司

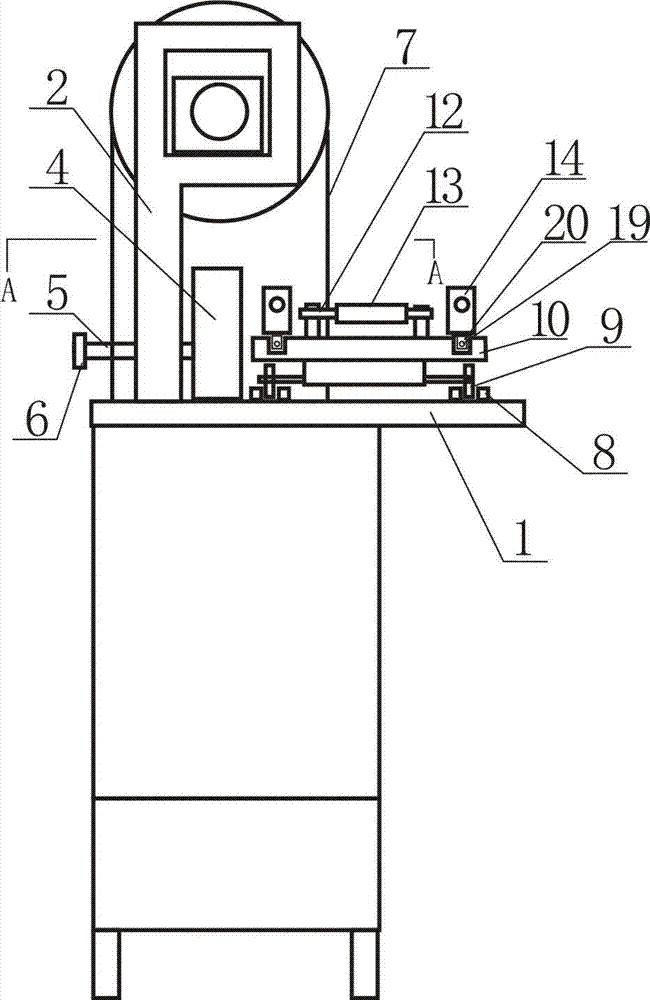

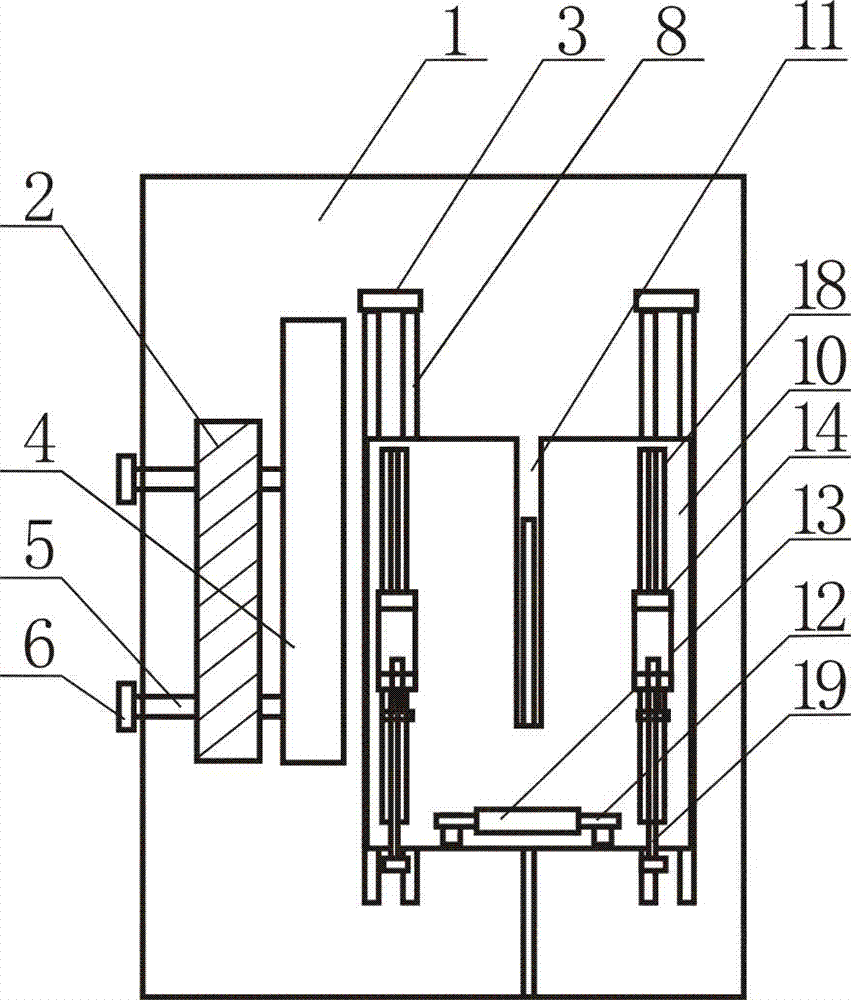

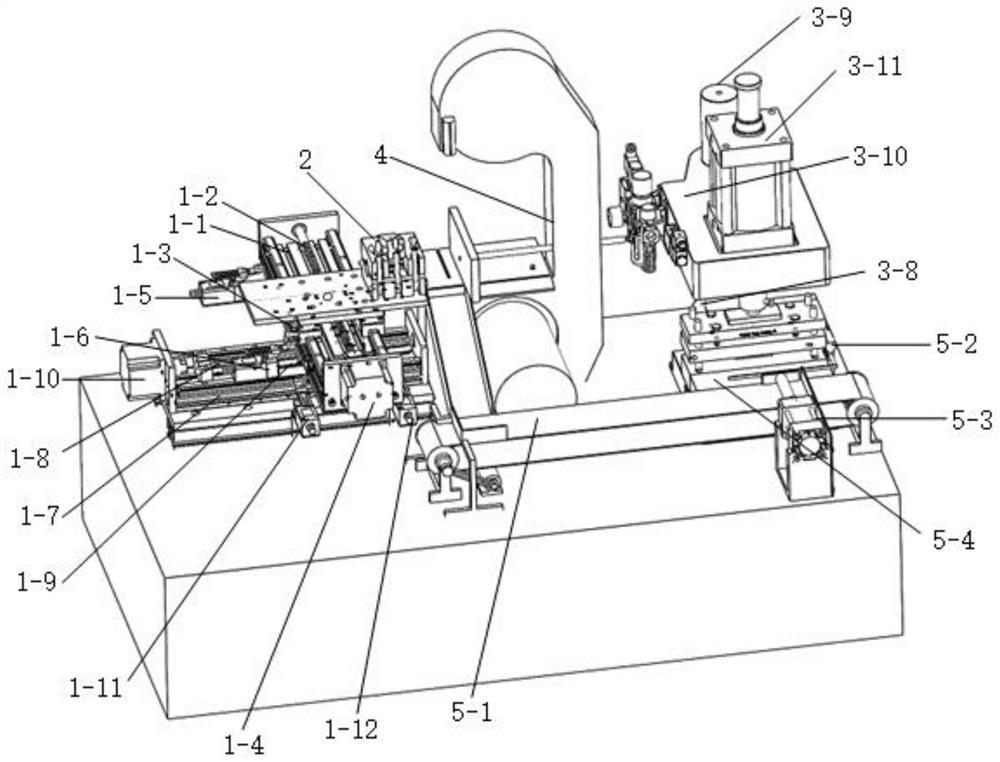

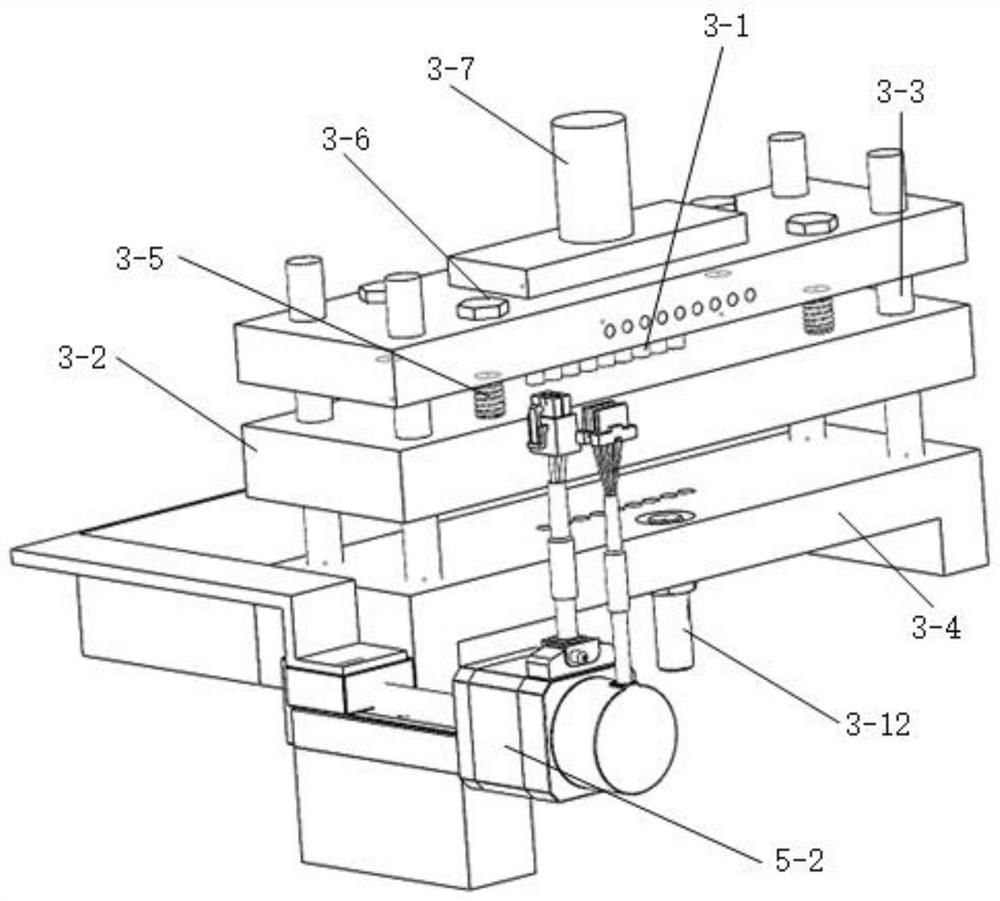

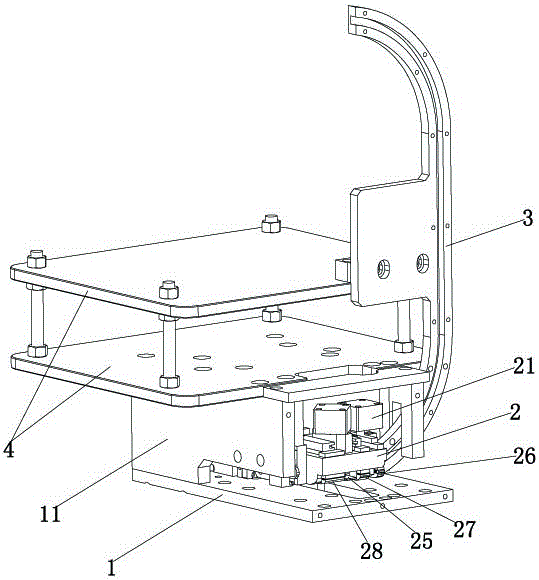

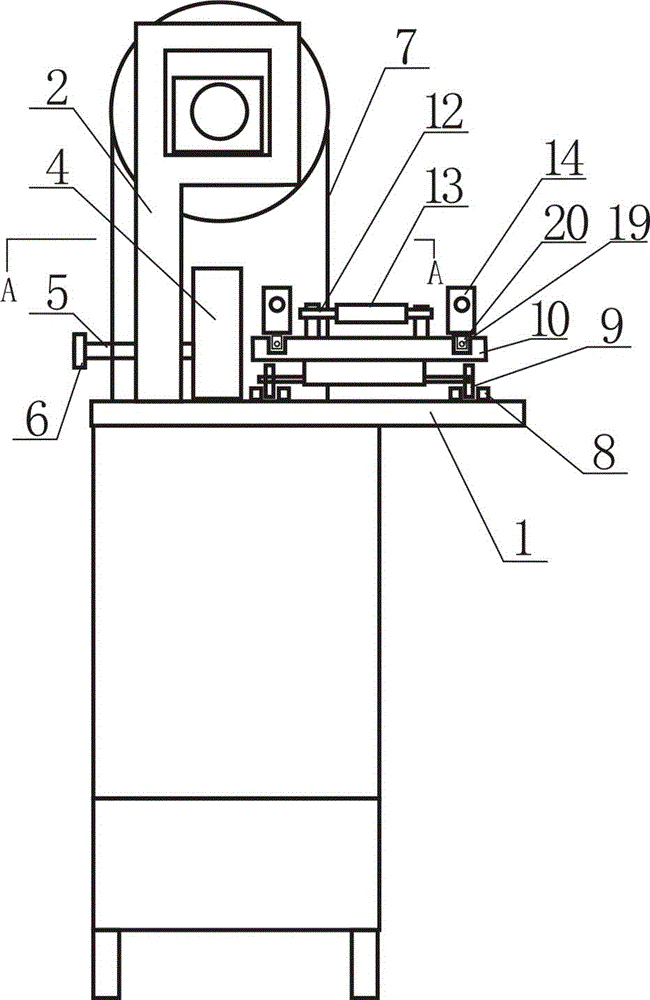

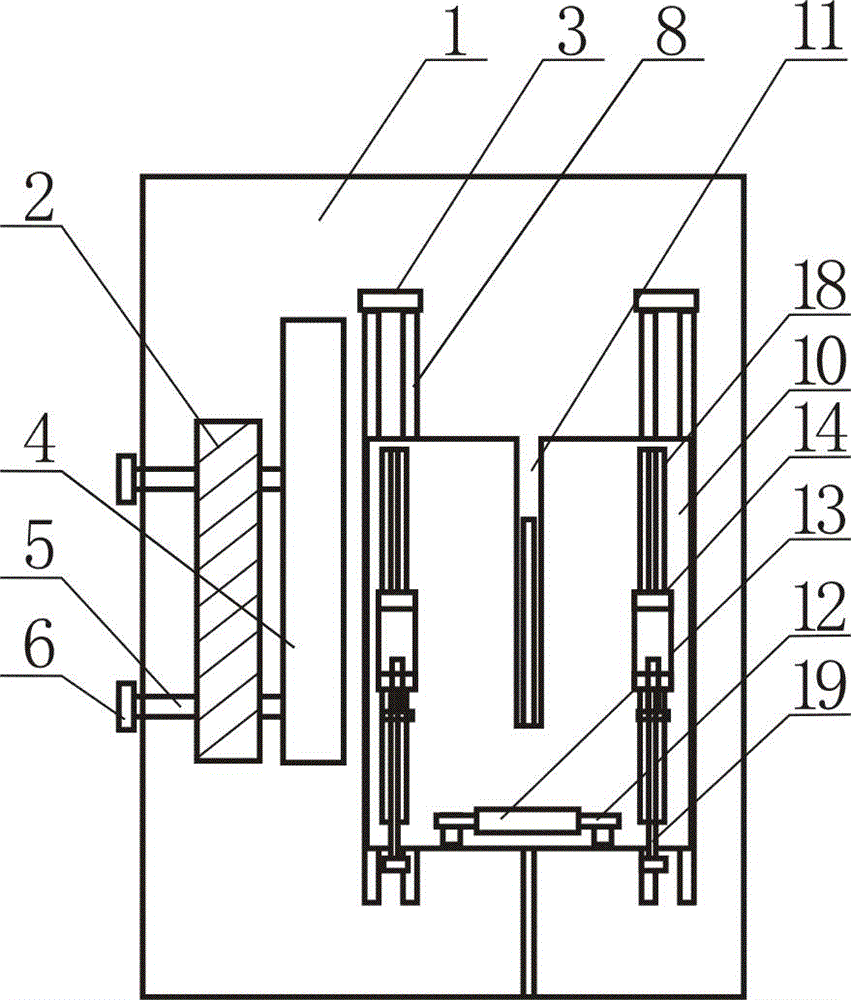

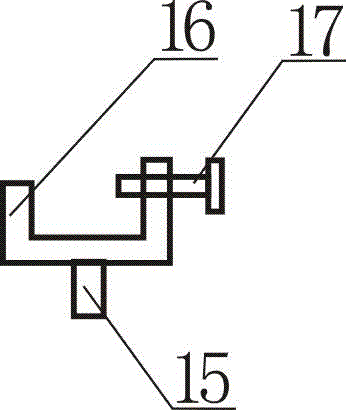

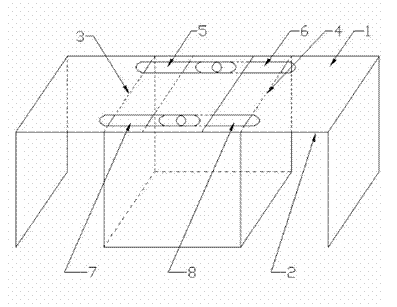

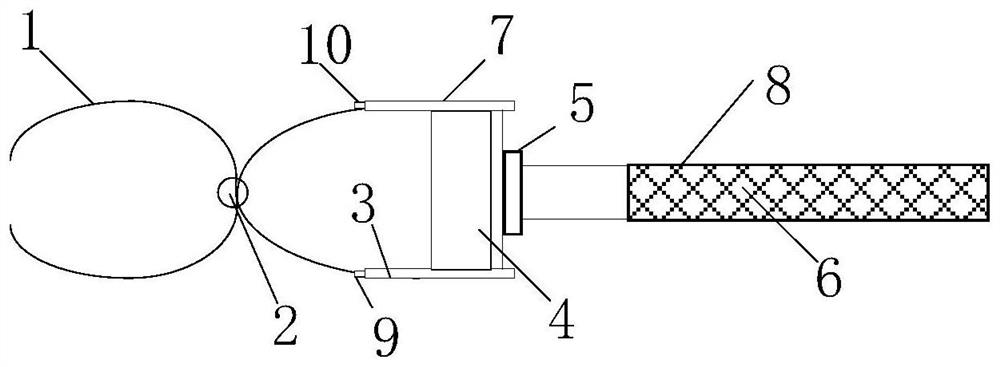

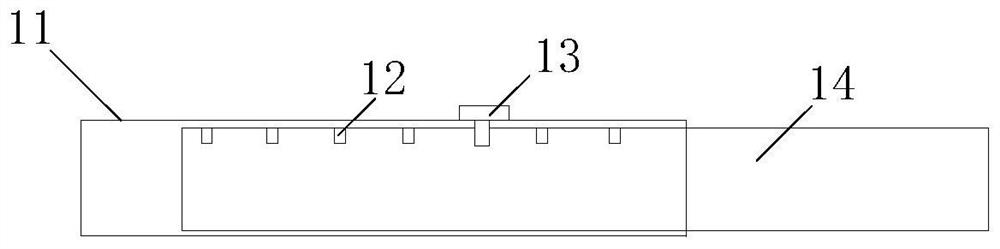

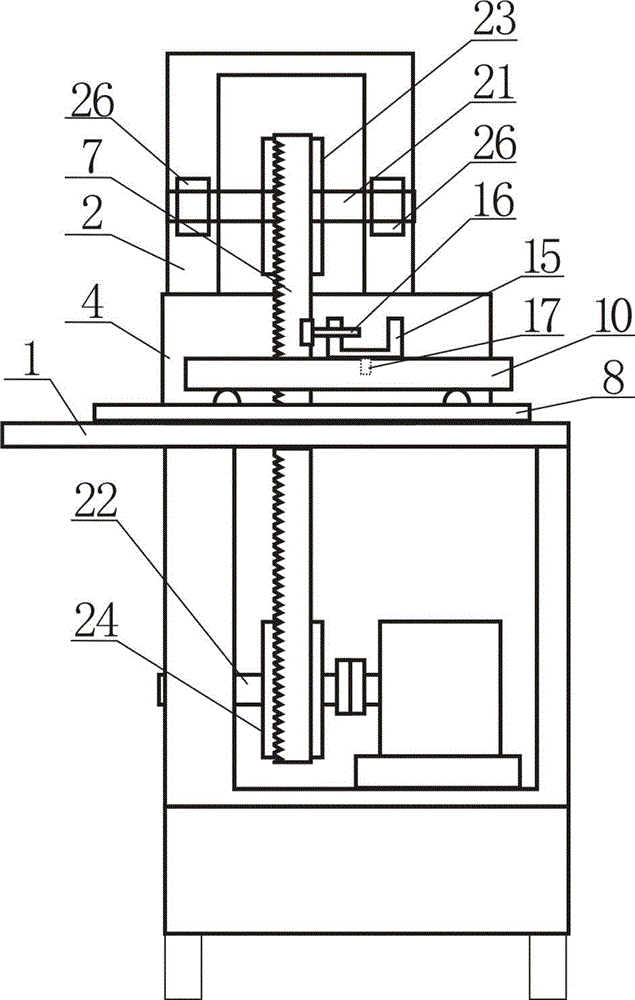

Experiment platform and experiment method for individual dental implant performance detection

PendingCN108132185ACompact structureGuaranteed uptimeStrength propertiesSpecific detectionBone clamp

The invention discloses an experiment platform for individual dental implant performance detection. The experiment platform comprises a platform rack, wherein an alveolar bone clamp, an analog load loading mechanism, a torque sensor, a tension sensor and a resonance frequency analyzer are arranged on the platform rack. The invention further provides a method using the experiment platform, which comprises the following steps: acquiring related parameters; manufacturing a dental implant model and an alveolar bone model according to the acquired parameters, and combining into a whole; and detecting the alveolar bone model in the alveolar bone clamp in a fixed experiment platform. According to the invention, the highly simulated individual experiment platform is established by collecting specific key parameters of a user, and the performance of an individual dental implant in the true oral environment of a specific patient by individual experiment specific detection, so that the measured data has more reference value. The experiment platform has compact structure, stable operation and simple operation.

Owner:广东健齿生物科技有限公司

Adjustable-length simple-and-convenient-to-operate bone drill device

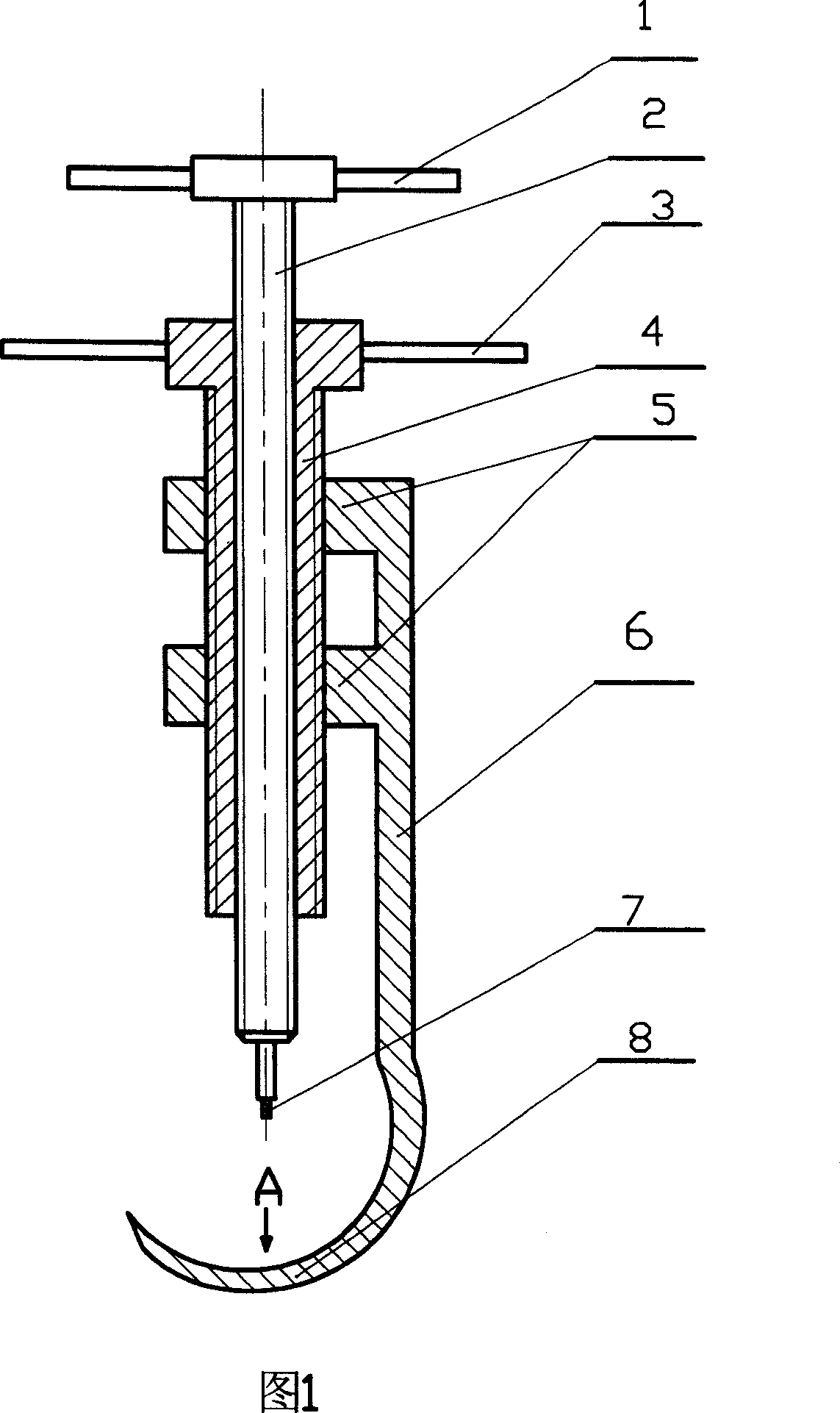

The invention provides an adjustable-length simple-and-convenient-to-operate bone drill device. The bone drill device comprises a hollow cylinder, a bone drill rod group and a positioning device, wherein the bone drill rod group is movably connected onto the hollow cylinder, and the positioning device is used for positioning the bone drill device; the bone drill rod group comprises a first bone drill rod and a second bone drill rod; a first sliding groove and a second sliding groove are respectively formed in the two sides of the hollow cylinder; a first sliding block is arranged on one side of the first bone drill rod, the first sliding block is matched with the first sliding groove, a second sliding block is arranged on one side of the second bone drill rod, and the second sliding block is matched with the second sliding groove; the positioning device comprises a positioning support and the positioning support is arranged at the bottom of the hollow cylinder; a bone clamping device is movably connected onto the positioning support. The adjustable-length simple-and-convenient-to-operate bone drill device has the advantages that not only is the device simple in structure and convenient to carry, but also the depth of bone drilling after bone positioning can be accurately adjusted by the user according to the actual situation, and the operation is simple and convenient to conduct.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

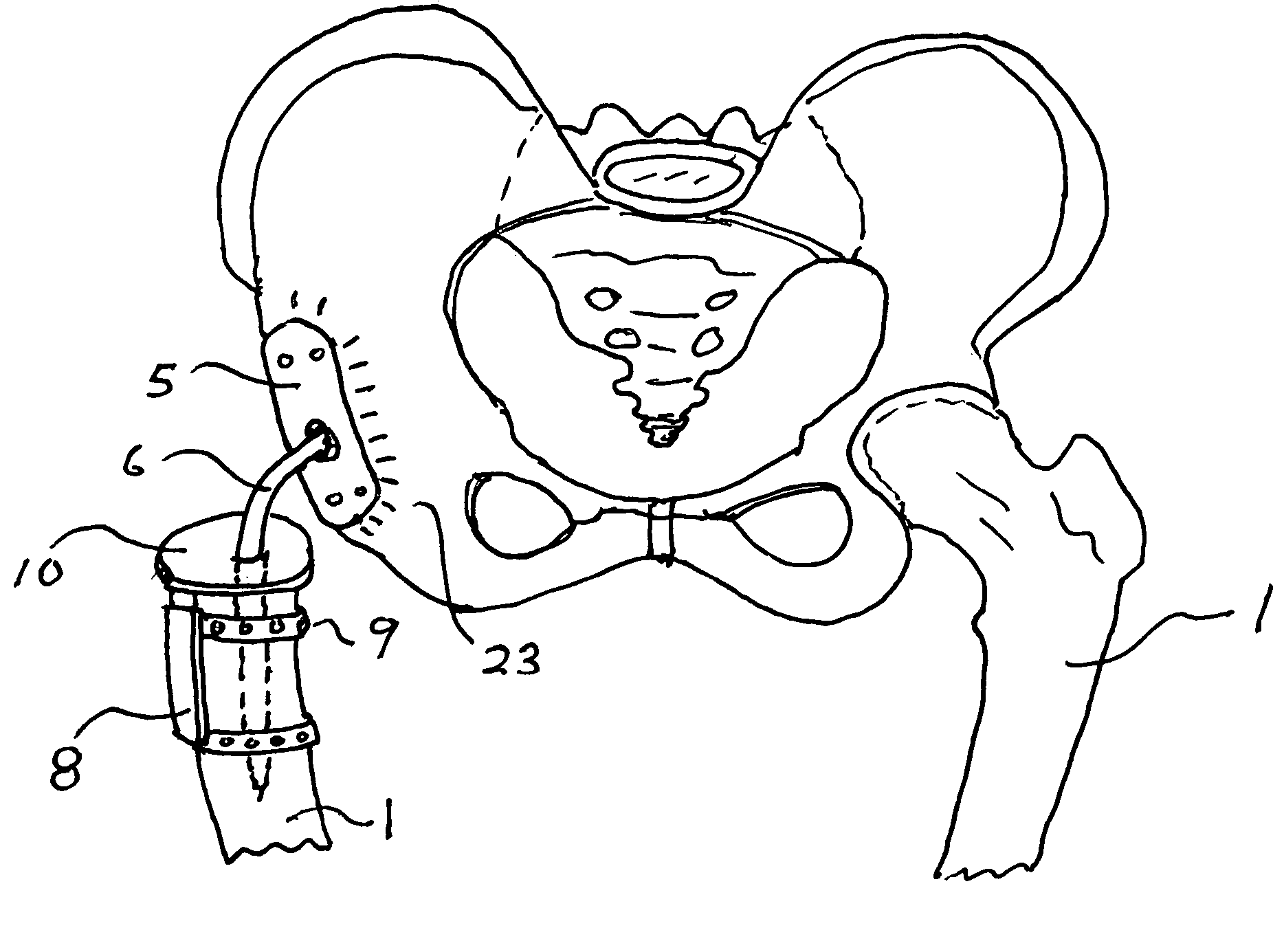

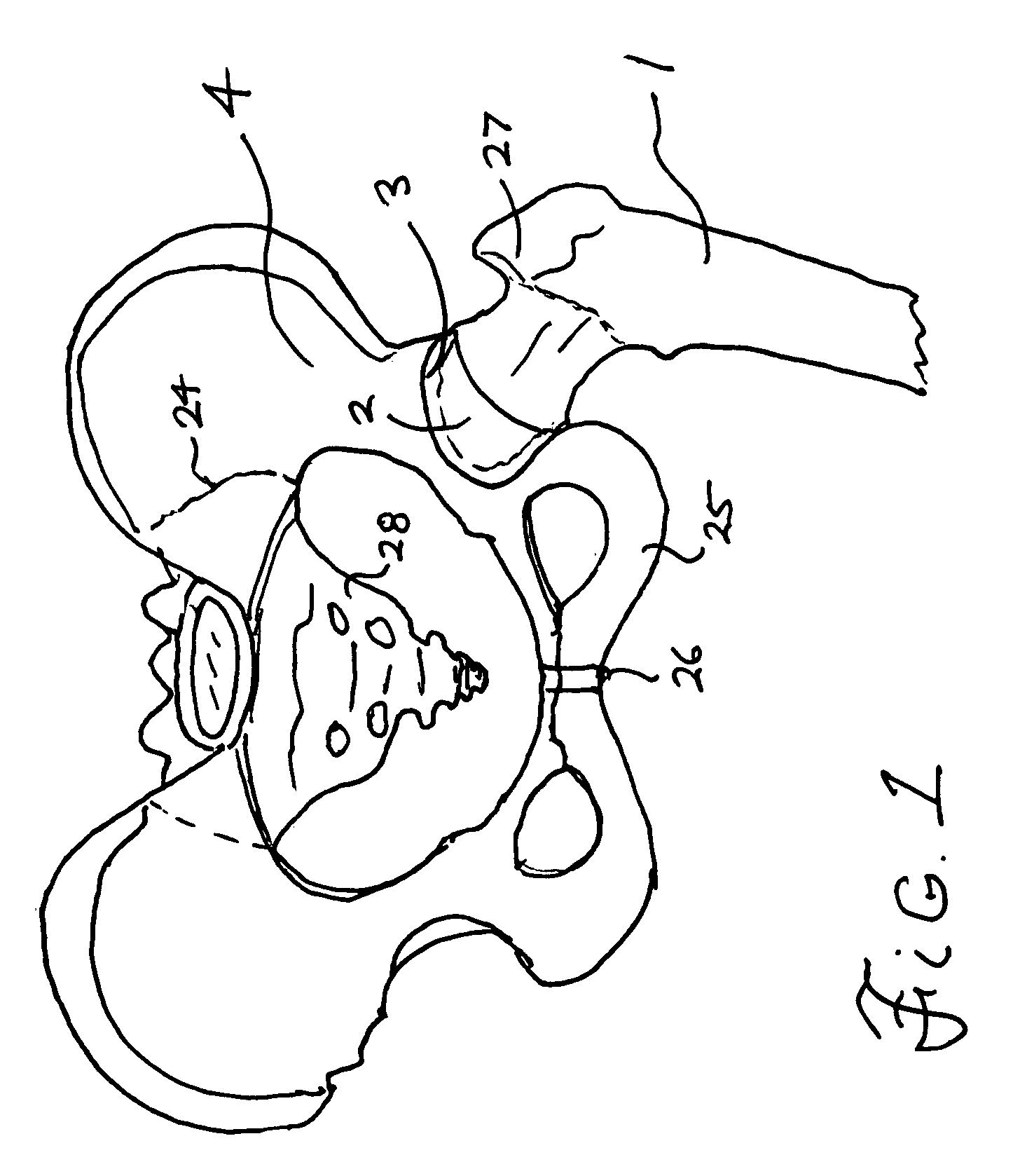

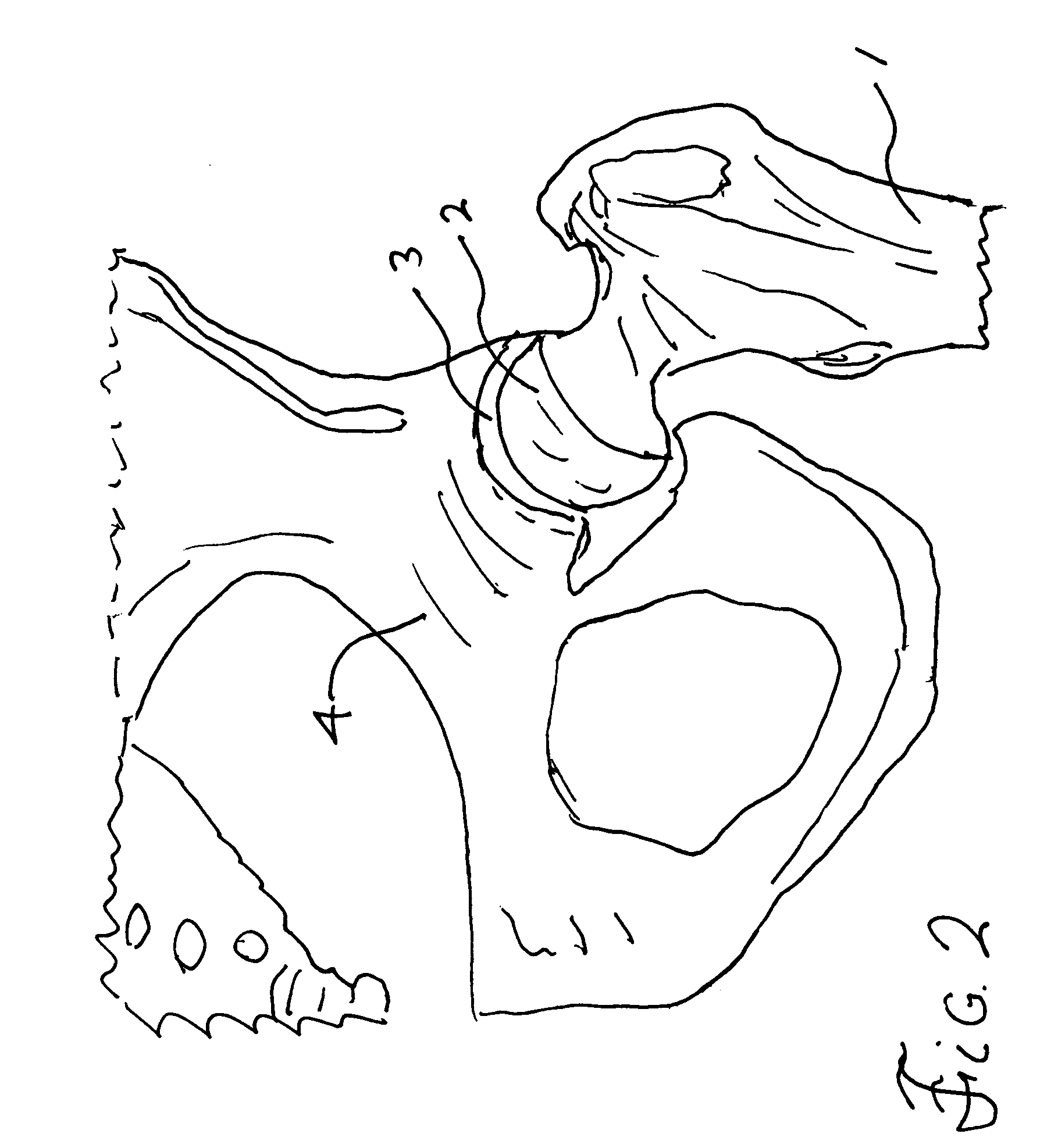

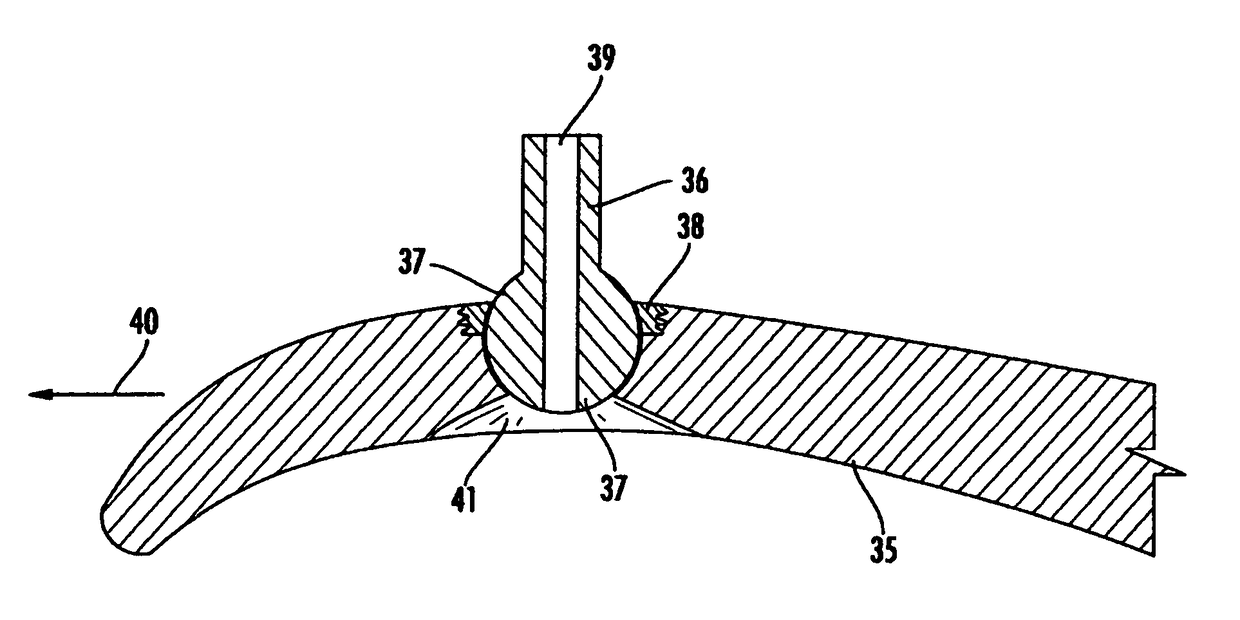

Apparatus for total hip replacement for cases of hip ankylosis and severe joint infection

A hip replacement apparatus that normally includes a supporting rod bent into an acute angle at its center with a rounded head on one end. This supporting rod can be received at the pelvis into a pre-assembled housing with a backplate and front plate where the unit can be cemented and / or screwed into the prepared bone at the hip joint. The backplate can have an anchoring protrusion that mates into the trimmed-out bone at the joint. The front plate can have a center hole that receives, and holds the rounded head of the supporting rod from escaping. The head (and hence the supporting rod) freely rotates captively in the housing with the housing firmly attached to the pelvis. The bottom end of the supporting rod can penetrate into the center of the cut-off femur and can be cemented into the bone. The supporting rod can be held to the femur with a bone clamp apparatus including a side plate that can be banded firmly to the femur with one or a more bands.

Owner:DJURIVIC ZARIJA

Clamping-installation type bone sawing machine with bone sawing length adjustable

The invention discloses a clamping-installation type bone sawing machine with bone sawing length adjustable. The clamping-installation type bone sawing machine comprises a workbench, a machine frame, a saw blade, guide rails and a feeding sliding plate. The guide rails are arranged on the workbench, the feeding sliding plate is arranged on the guide rails through pulleys arranged at the bottom of the feeding sliding plate, sliding grooves are formed in the two sides of the feeding sliding plate, adjusting screw rods are arranged in the sliding grooves, sliding blocks are arranged on the adjusting screw rods and located in the sliding grooves, and a bone clamp which rotates horizontally relative to the sliding blocks is hinged to each sliding block. Adjusting screw rods are arranged on the machine frame, a bone sawing length setting plate is fixed on one end portion of each adjusting screw rod, and a rotating handle is arranged at the other end of each adjusting screw rod. Due to the bone clamps, cutting safety is further enhanced. Due to the fact that the bone clamps are arranged on the sliding blocks and can rotate horizontally relative to the sliding blocks, the relative position of the bone clamps on the two sides can be adjusted, and therefore bones in different shapes can be clamped. Due to the fact that the position of the bone sawing length setting plate can be adjusted, the bone sawing length can be adjusted through adjustment of the distance between the saw blade and the bone sawing length setting plate.

Owner:韩小兵

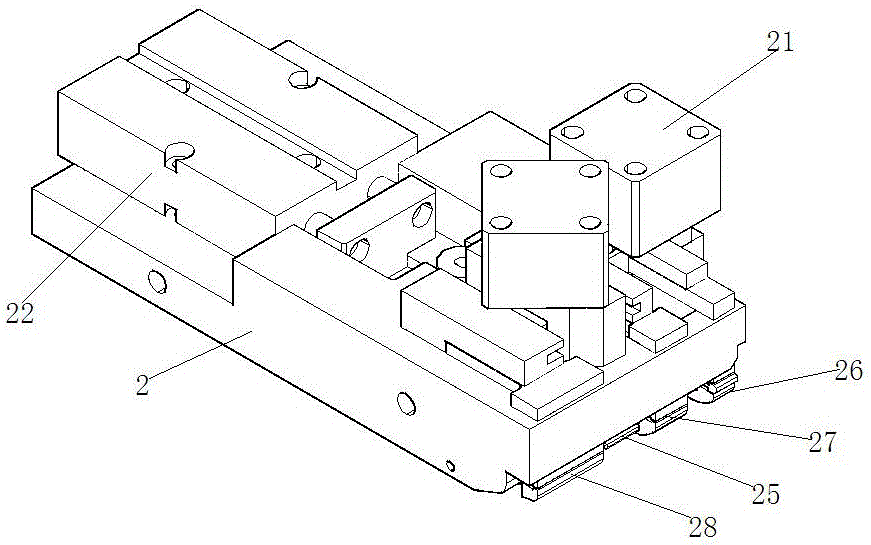

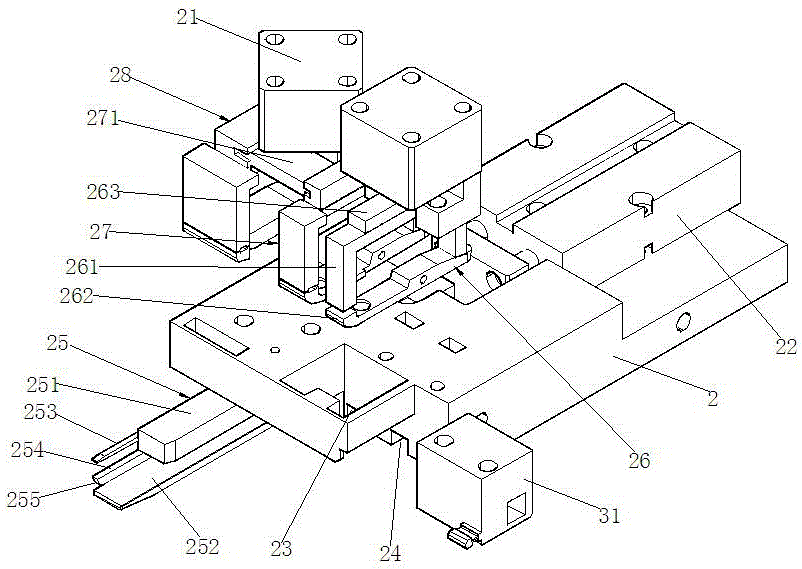

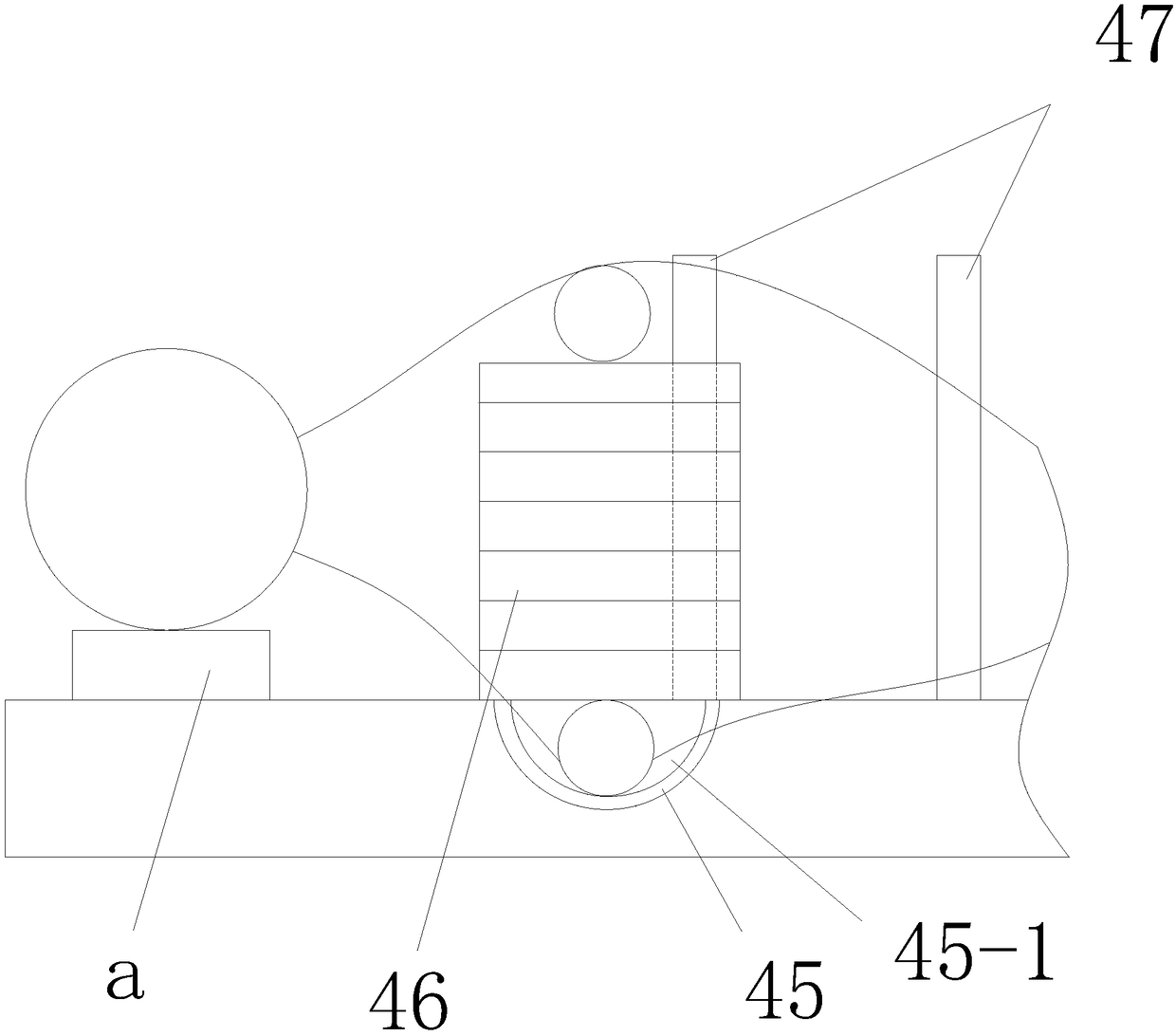

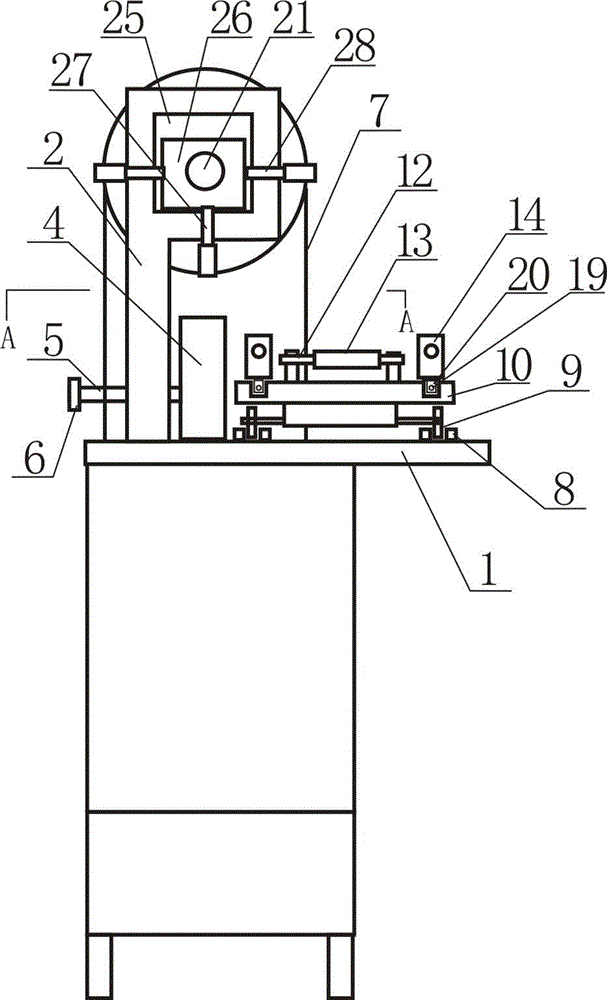

Saw-punching forming preparation device and method for round cancellous bone pieces

ActiveCN112659239AImprove processing efficiencyReduce manual operationsMetal working apparatusPunchingBone clamp

The invention discloses a saw-punching forming preparation device and method for round cancellous bone pieces. At present, no efficient circular cancellous bone piece sawing-punching forming preparation device and method exist. The device comprises a two-axis linkage workbench, a large bone clamping device, a bone sawing machine, a middle feeding and discharging device and a punching machine; a feeding end of a discharging sliding way of the middle feeding and discharging device is arranged below the bone sawing machine and the big bone clamping device; the big bone clamping device is driven by the two-axis linkage workbench; the middle feeding and discharging device conveys cancellous bone piece base materials cut off by the bone sawing machine to the punching machine to be punched, the cancellous bone piece base materials are pushed forwards intermittently, and therefore the punching machine can punch the cancellous bone piece base materials many times; and the punching machine punches the round cancellous bone pieces from the cancellous bone piece base materials. Manual operation in the production process of the round cancellous bone pieces is reduced, and the processing efficiency of the round cancellous bone pieces is greatly improved.

Owner:HANGZHOU DIANZI UNIV +1

Bone clamp

A bone clamp having a first jaw, an opposed second jaw and a drill guide, the drill guide being attached to the first jaw so that bone held between the first jaw and the second jaw can be drilled by a drill inserted through the drill guide, the first jaw having a longitudinal axis. The drill guide can be ball shaped at one distal end thereof that is positioned sufficiently within and retained within a corresponding cavity of the first jaw so that the angle of the drill guide can be adjusted to compound angles in the longitudinal and transverse directions in relation to the longitudinal axis of the first jaw. The bone clamp preferably comprises an organic polymer that is relatively transparent to X-rays.

Owner:KIM ALEXANDER D +1

Saw blade leveling type clamping-installation bone sawing machine with sliding plate for feeding

ActiveCN103518821AReduce laborSolve the problem of easy deviation and derailmentMeat holding apparatusLeveling mechanismDrive shaft

The invention discloses a saw blade leveling type clamping-installation bone sawing machine with a sliding plate for feeding. The clamping-installation bone sawing machine comprises a workbench, a machine frame, a saw blade, guide rails and the feeding sliding plate. The guide rails are arranged on the workbench, the feeding sliding plate is arranged on the guide rails through pulleys arranged at the bottom of the feeding sliding plate, and a through groove where the saw blade can penetrate through is formed in the plate face of the feeding sliding plate. Sliding grooves are formed in the two sides of the feeding sliding plate, adjusting lead screws are arranged in the sliding grooves, sliding seats are arranged on the adjusting lead screws and located in the sliding grooves, and a bone clamp is hinged to each sliding seat and can rotate horizontally relative to the sliding seat. The two sides of the upper portion of the machine frame are respectively provided with a leveling mechanism of a driven shaft. Due to the fact that the bone clamps are arranged on the sliding seats and can rotate horizontally relative to the sliding seats, the relative position of the bone clamps on the two sides can be adjusted, and therefore bones in different shapes can be clamped. Due to the fact that the vertical sliding grooves, sliding blocks and leveling bolts are additionally arranged on the machine frame, the levelness of the driven shaft can be adjusted through adjustment of the leveling bolts, and therefore the problem that the saw blade is prone to deviation or being pulled broken is solved.

Owner:韩小兵

Automatic reverse zipper head attaching mechanism

The invention discloses an automatic reverse zipper head attaching mechanism. The automatic reverse zipper head attaching mechanism comprises a mounting baseplate, a main plate, bone clamp air cylinders as well as a material pushing air cylinder and a material channel, wherein the material channel is connected with the main plate through a feed inlet; vertical plates are mounted on the mounting baseplate and positioned at the side ends of the main plate; fixing plates are mounted at the upper ends of the vertical plates; a material pushing slide groove and at least three bone clamp grooves are formed at the upper end of the main plate; a material pushing device is mounted in the material pushing slide groove, and comprises a material pushing slide block connected with the material pushing air cylinder and a slide block seat arranged at the lower end of the material pushing slide block; a bag opening needle is arranged at one side end of the material pushing slide block; a bag opening needle slide seat positioned at the lower end of the bag opening needle is arranged at the upper end of the slide block seat; a bone clamp I, a bone clamp II and a bone clamp III which are connected with the bone clamp air cylinders are mounted in the bone clamp grooves; and the material pushing device is arranged in the material pushing slide groove between the bone clamp II and the bone clamp III. The automatic reverse zipper head attaching mechanism is novel in design, simple in structure, high in production efficiency and low in cost; and by adoption of the automatic reverse zipper head attaching mechanism, the habit that a sealing bag is closed or opened when a zipper head is pulled to the left or right can be met.

Owner:YANTAI BAGMART PACKAGING

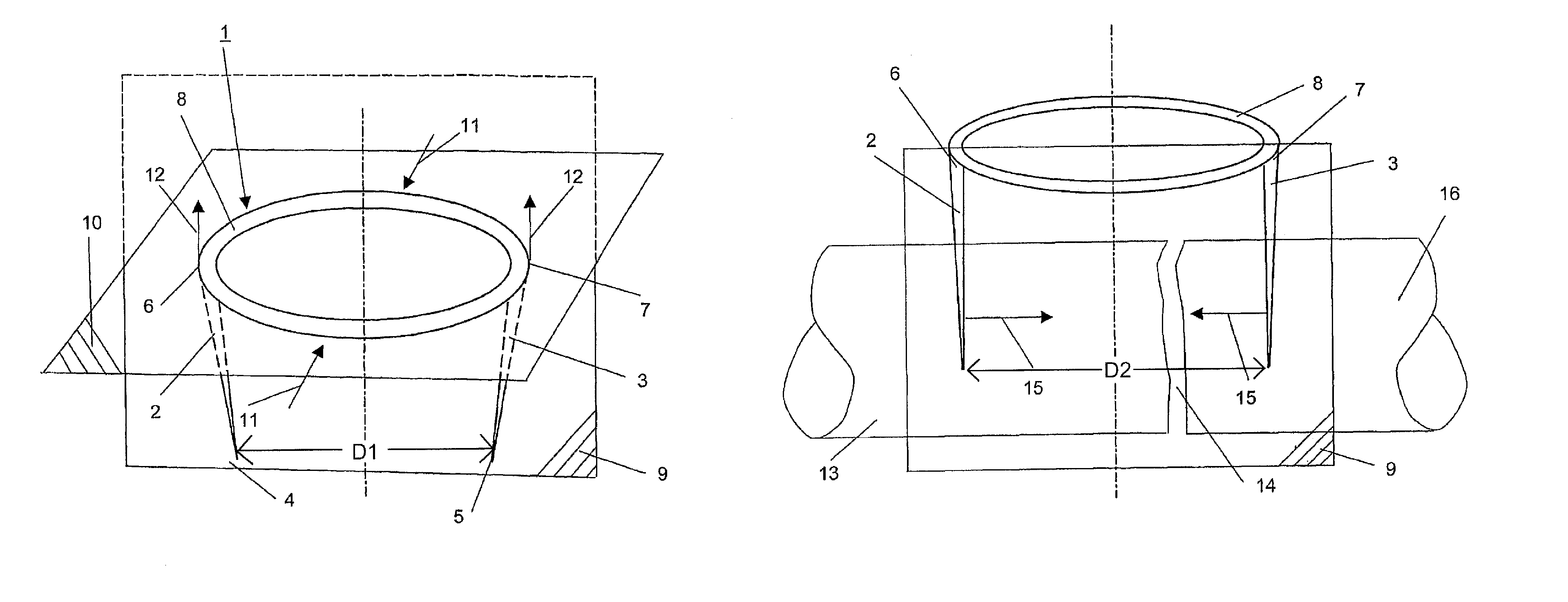

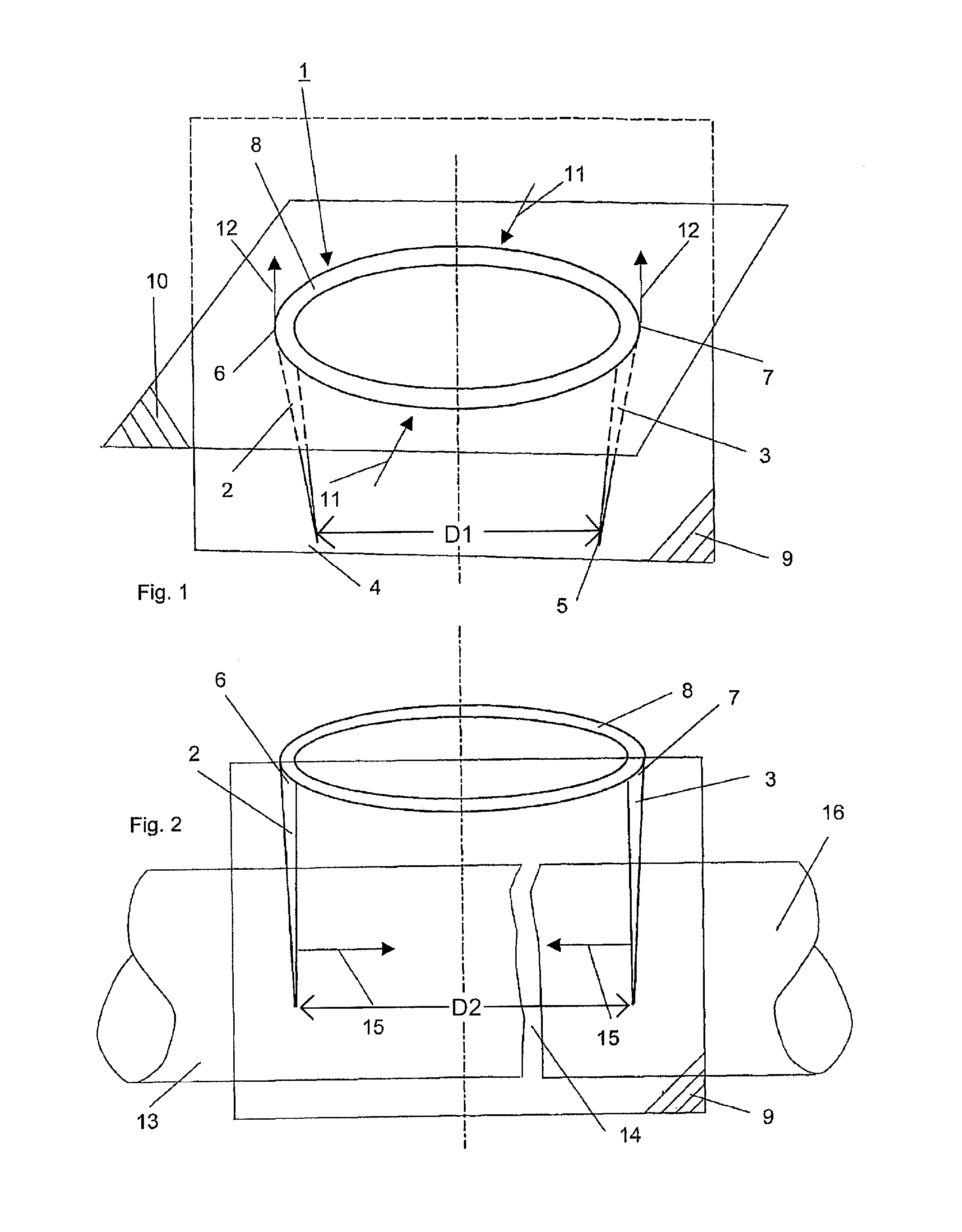

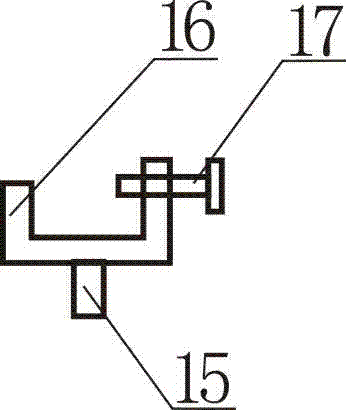

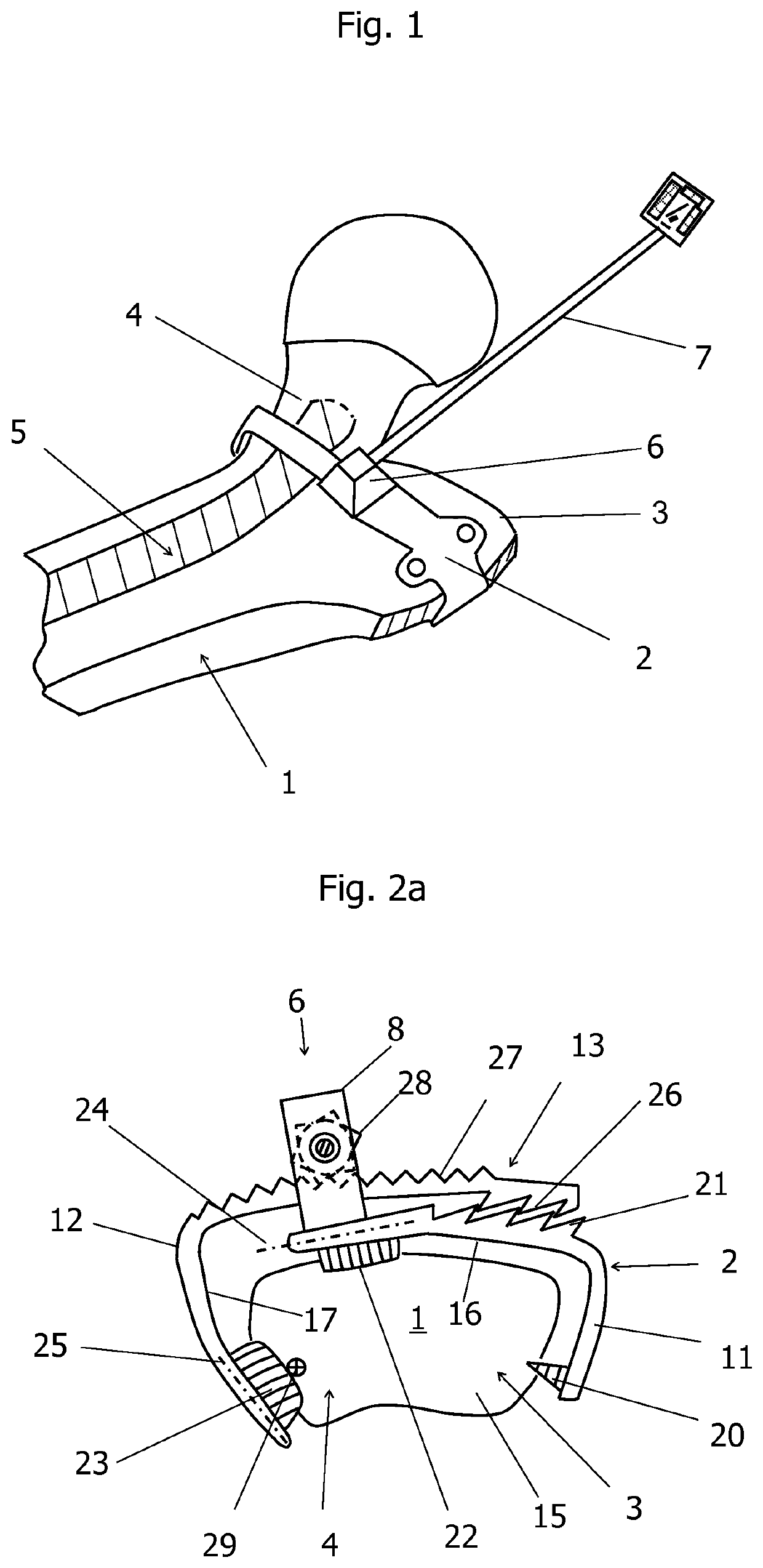

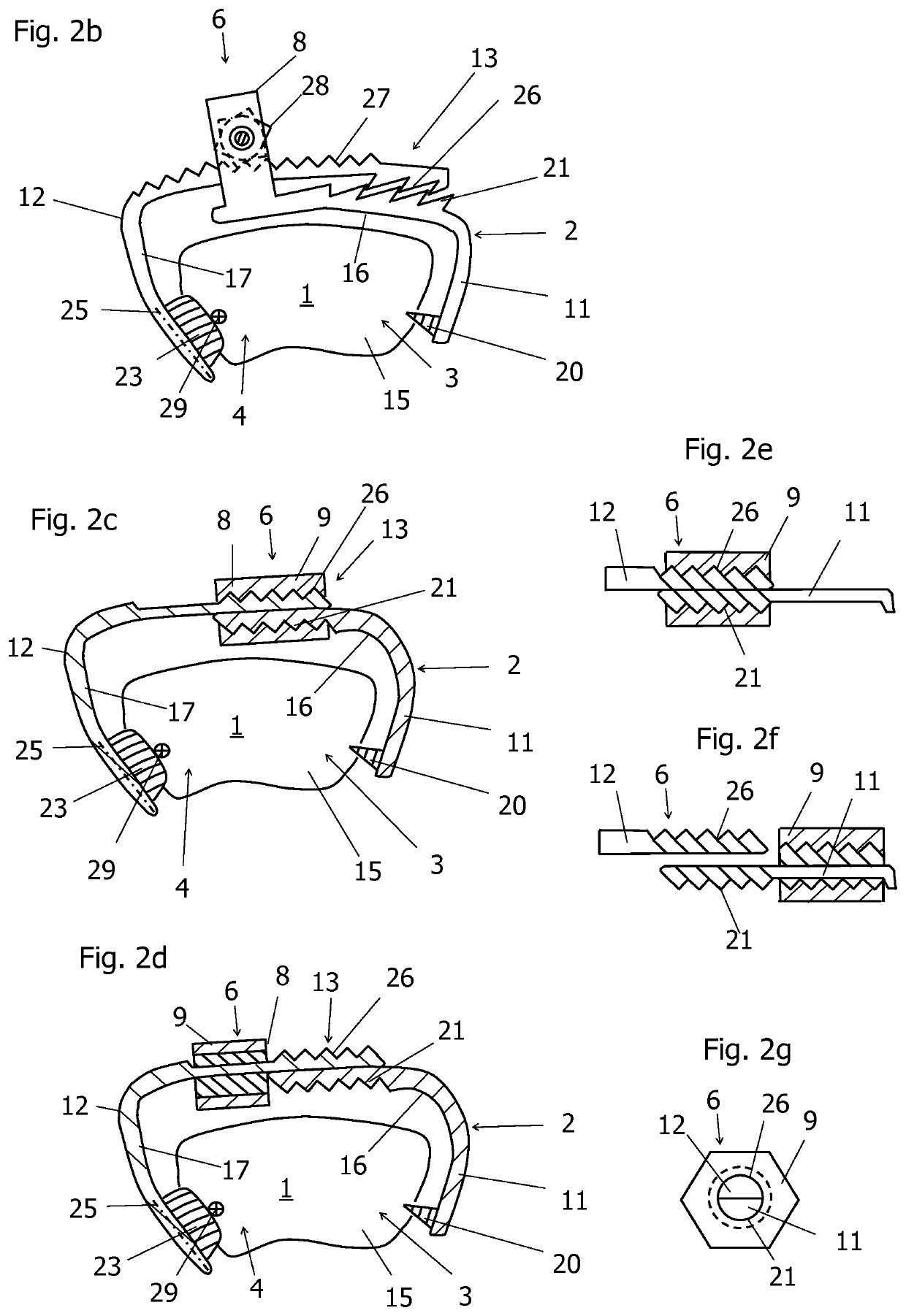

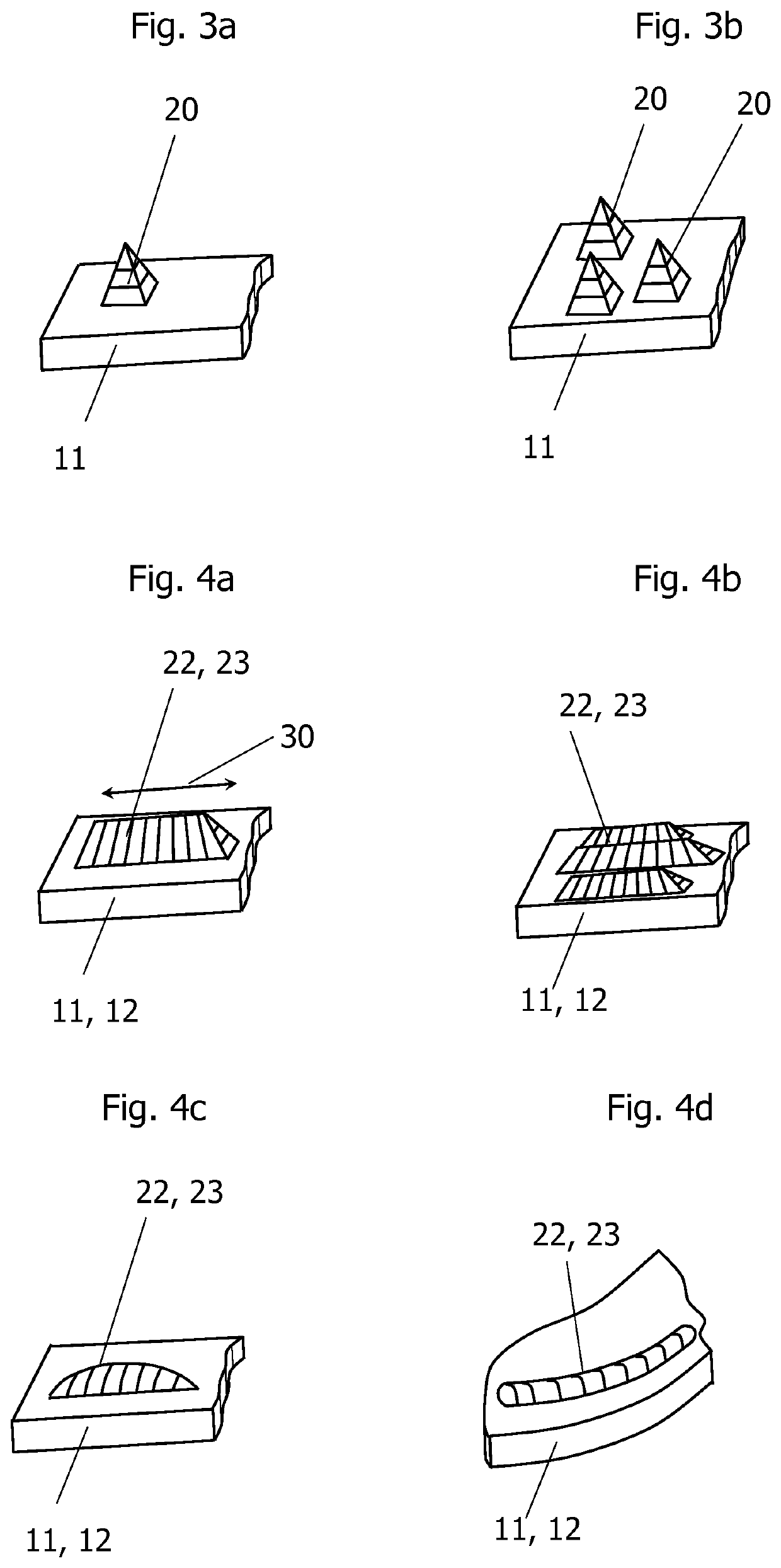

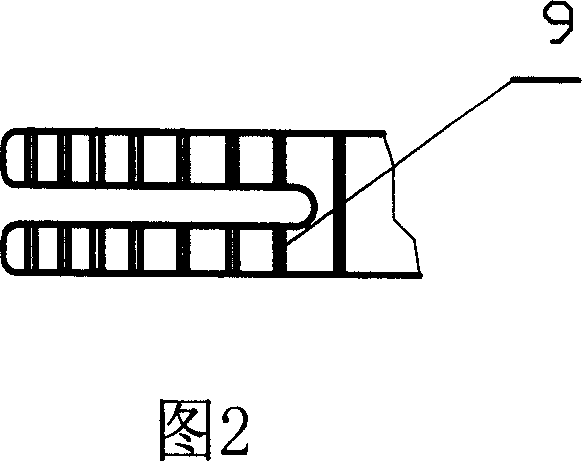

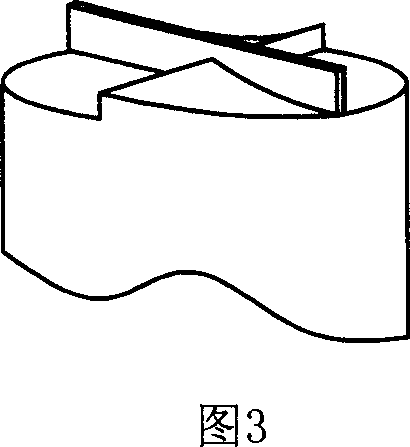

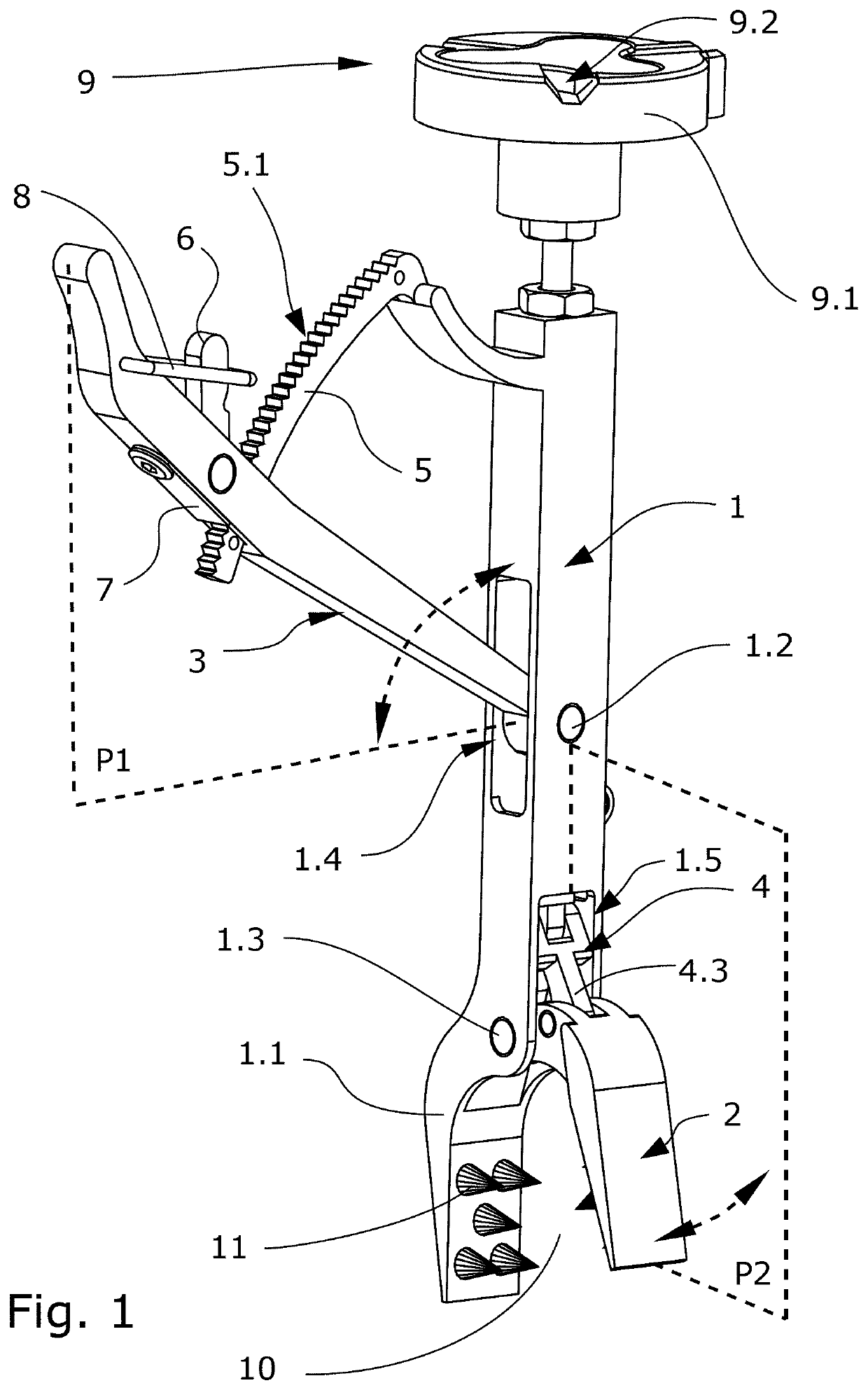

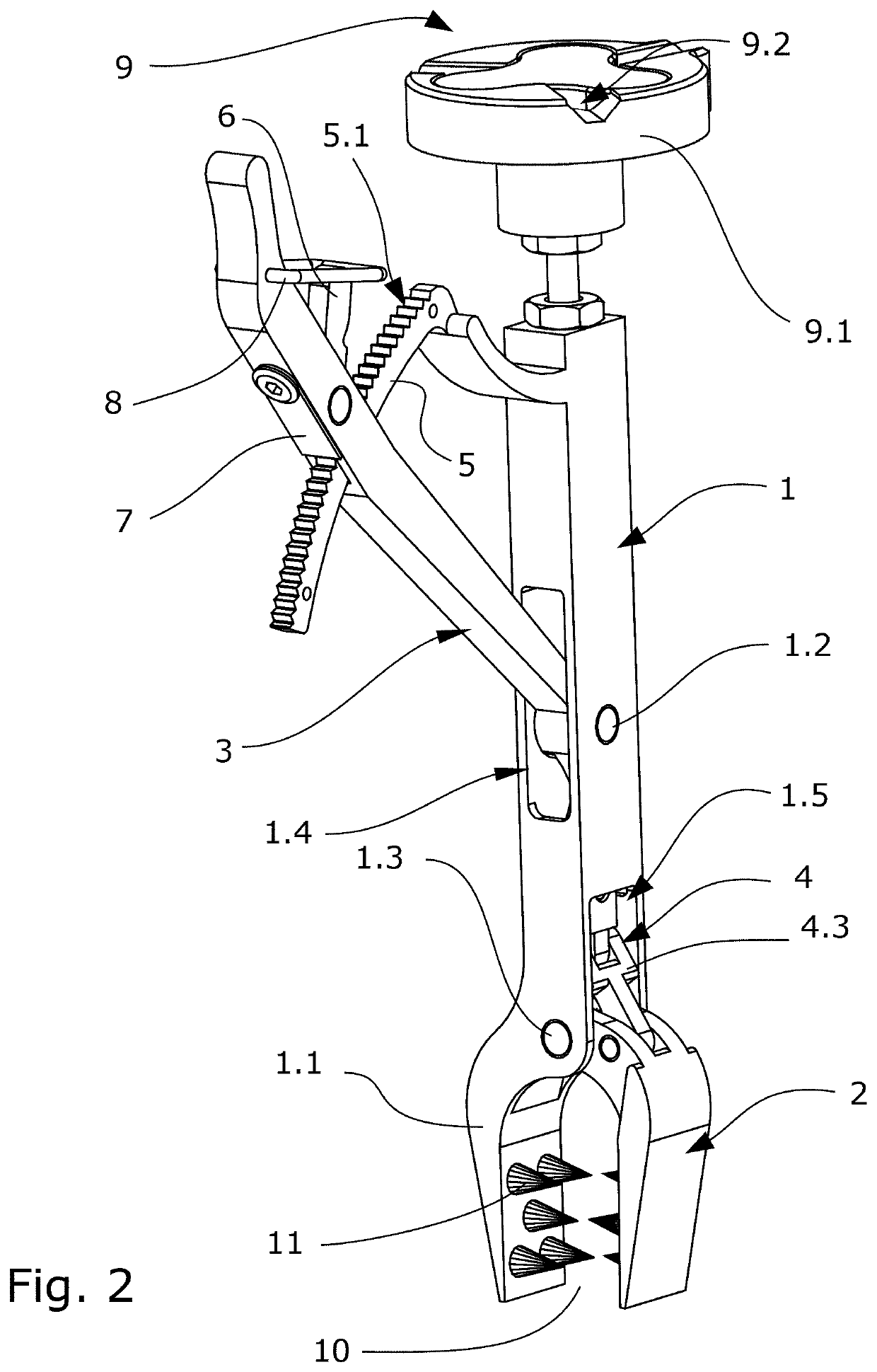

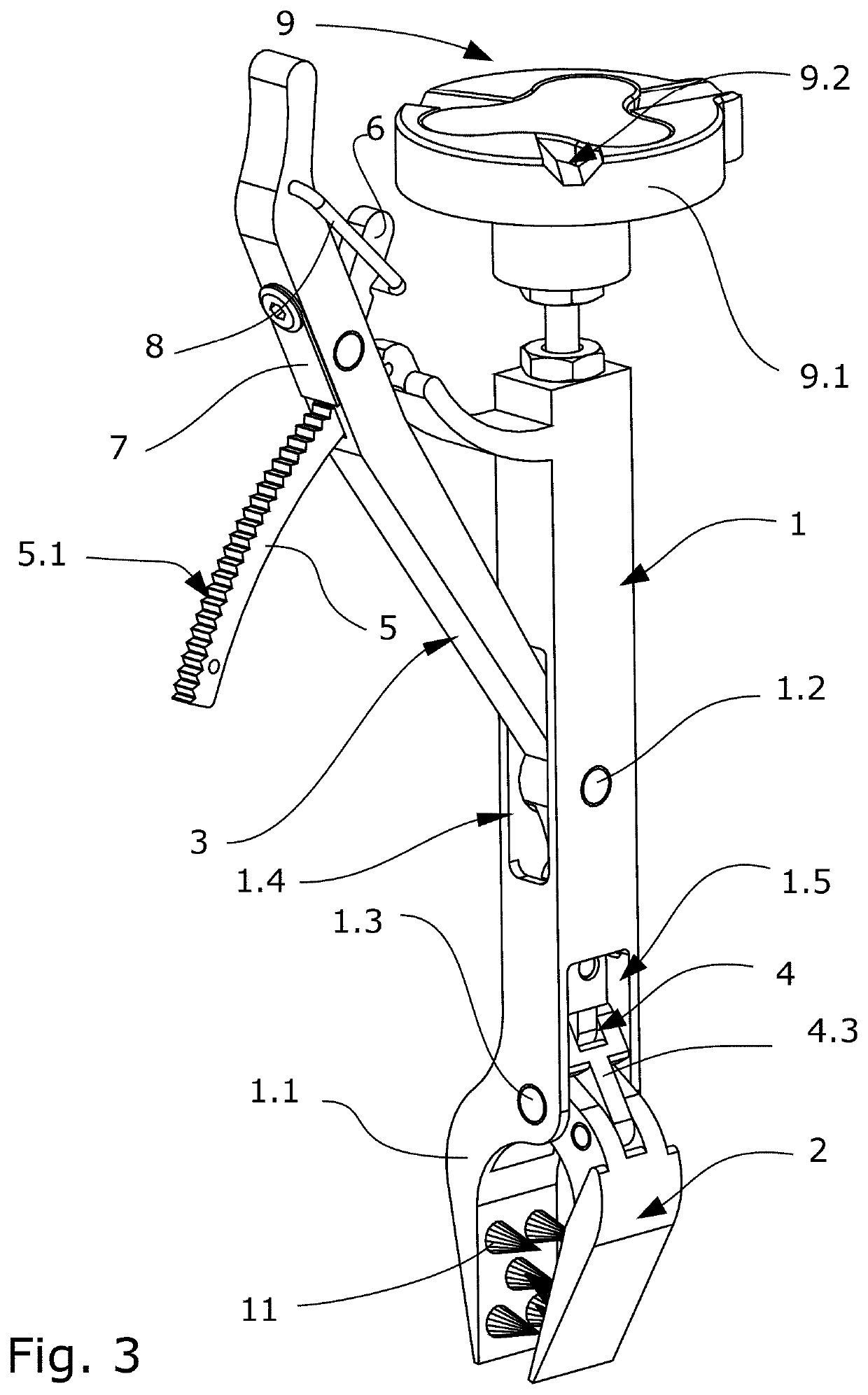

Bone clamp with adapter for measurement aids

ActiveUS10987148B2Stable positionImplementation supportInternal osteosythesisSurgical navigation systemsPhysical medicine and rehabilitationBone clamp

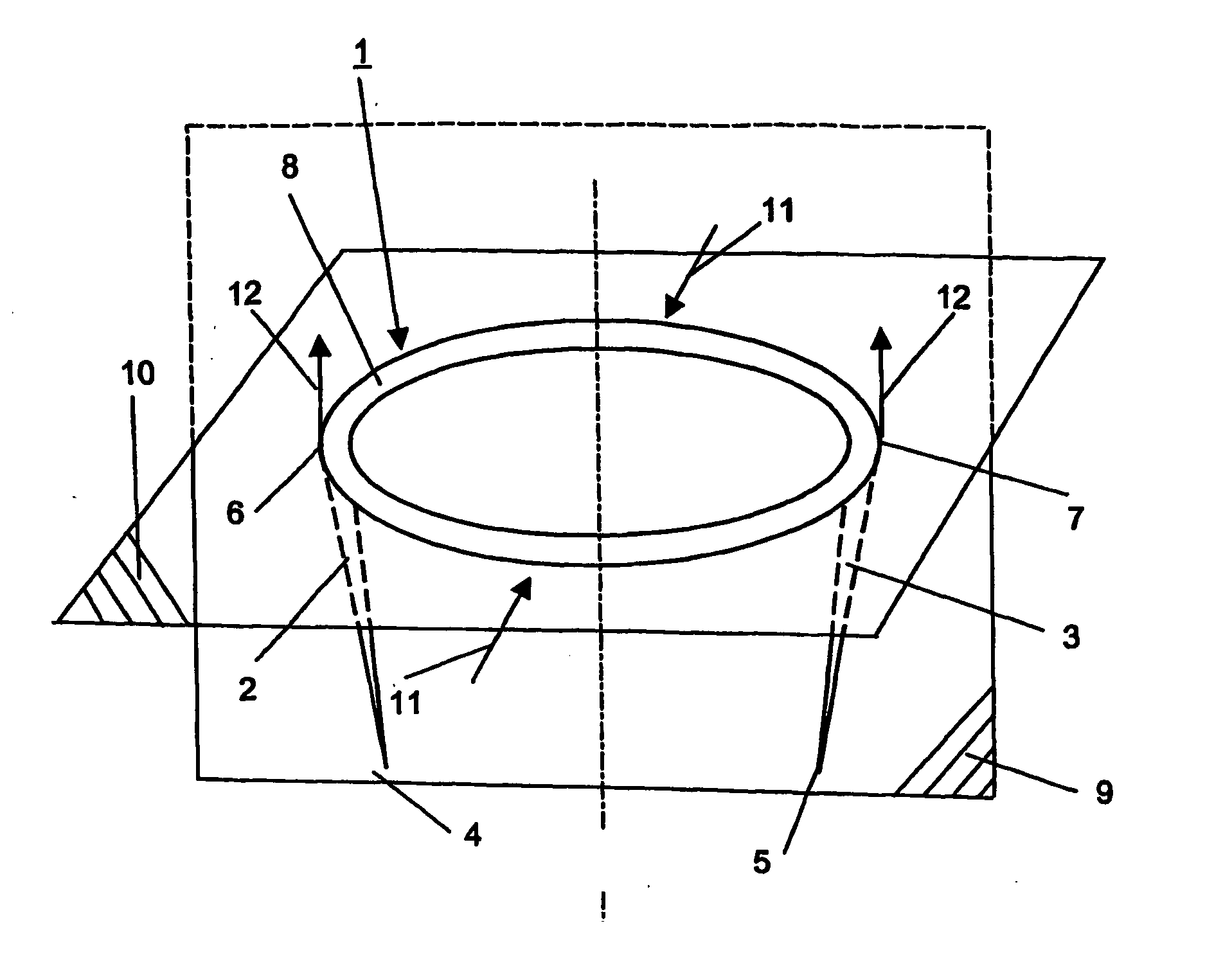

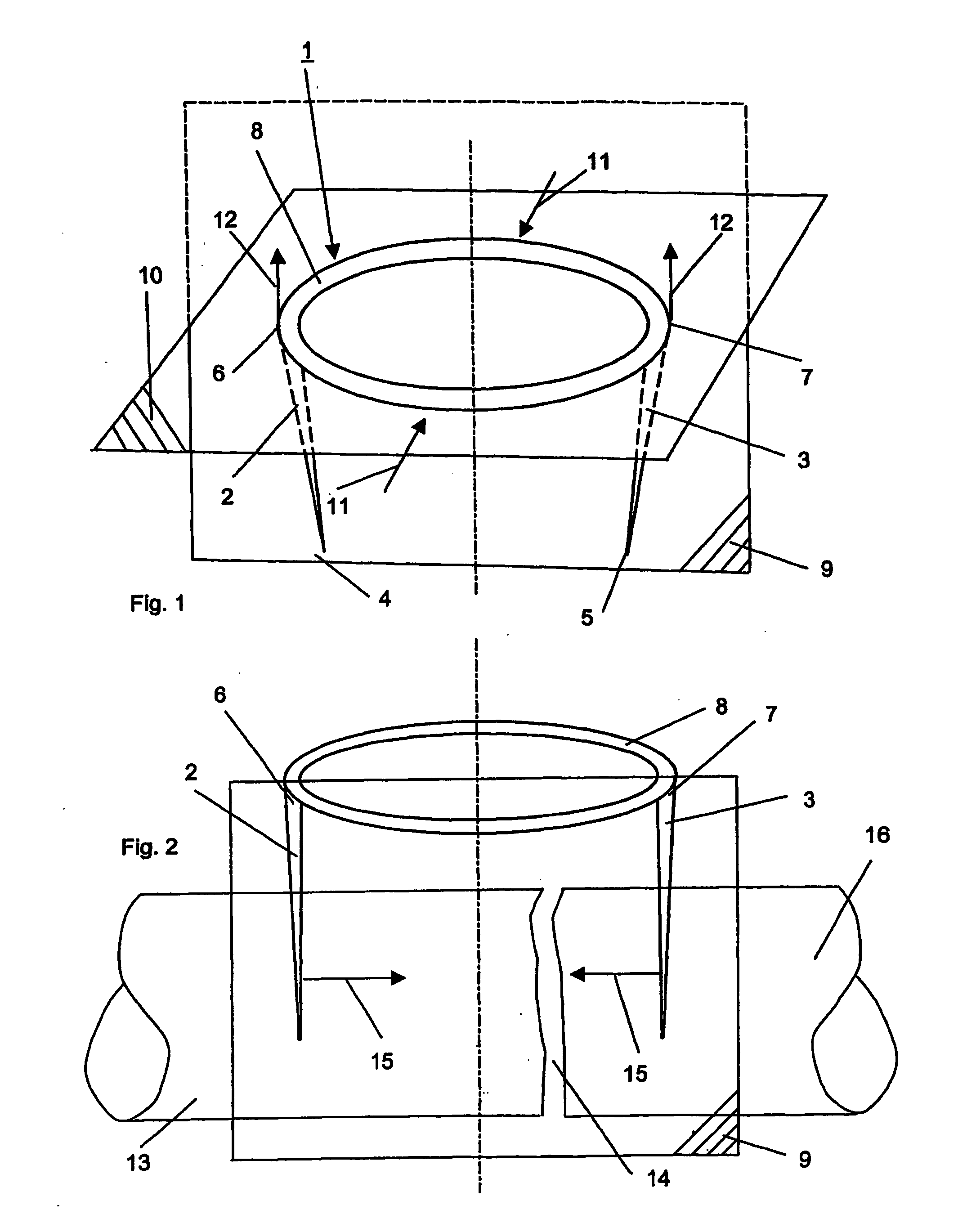

A bone clamp for securing of a measurement aid to a bone comprises a first clip and a second clip and an adapter. The adapter comprises a pulling mechanism and a locking mechanism, whereby the position of the first clip relative to the second clip can be altered by actuation of the pulling mechanism, wherein the position of the first clip relative to the second clip can be fixed by actuation of the locking mechanism. The first clip and the second clip each have an inner face which is oriented in the direction of the bone, wherein the first clip has one or more spikes on the inner face and wherein the second clip has a sliding edge on the inner face.

Owner:NAVISWISS

Bone Saw Bone Length Adjustable Clamp Type Bone Saw Machine

The invention discloses a clamping-installation type bone sawing machine with bone sawing length adjustable. The clamping-installation type bone sawing machine comprises a workbench, a machine frame, a saw blade, guide rails and a feeding sliding plate. The guide rails are arranged on the workbench, the feeding sliding plate is arranged on the guide rails through pulleys arranged at the bottom of the feeding sliding plate, sliding grooves are formed in the two sides of the feeding sliding plate, adjusting screw rods are arranged in the sliding grooves, sliding blocks are arranged on the adjusting screw rods and located in the sliding grooves, and a bone clamp which rotates horizontally relative to the sliding blocks is hinged to each sliding block. Adjusting screw rods are arranged on the machine frame, a bone sawing length setting plate is fixed on one end portion of each adjusting screw rod, and a rotating handle is arranged at the other end of each adjusting screw rod. Due to the bone clamps, cutting safety is further enhanced. Due to the fact that the bone clamps are arranged on the sliding blocks and can rotate horizontally relative to the sliding blocks, the relative position of the bone clamps on the two sides can be adjusted, and therefore bones in different shapes can be clamped. Due to the fact that the position of the bone sawing length setting plate can be adjusted, the bone sawing length can be adjusted through adjustment of the distance between the saw blade and the bone sawing length setting plate.

Owner:韩小兵

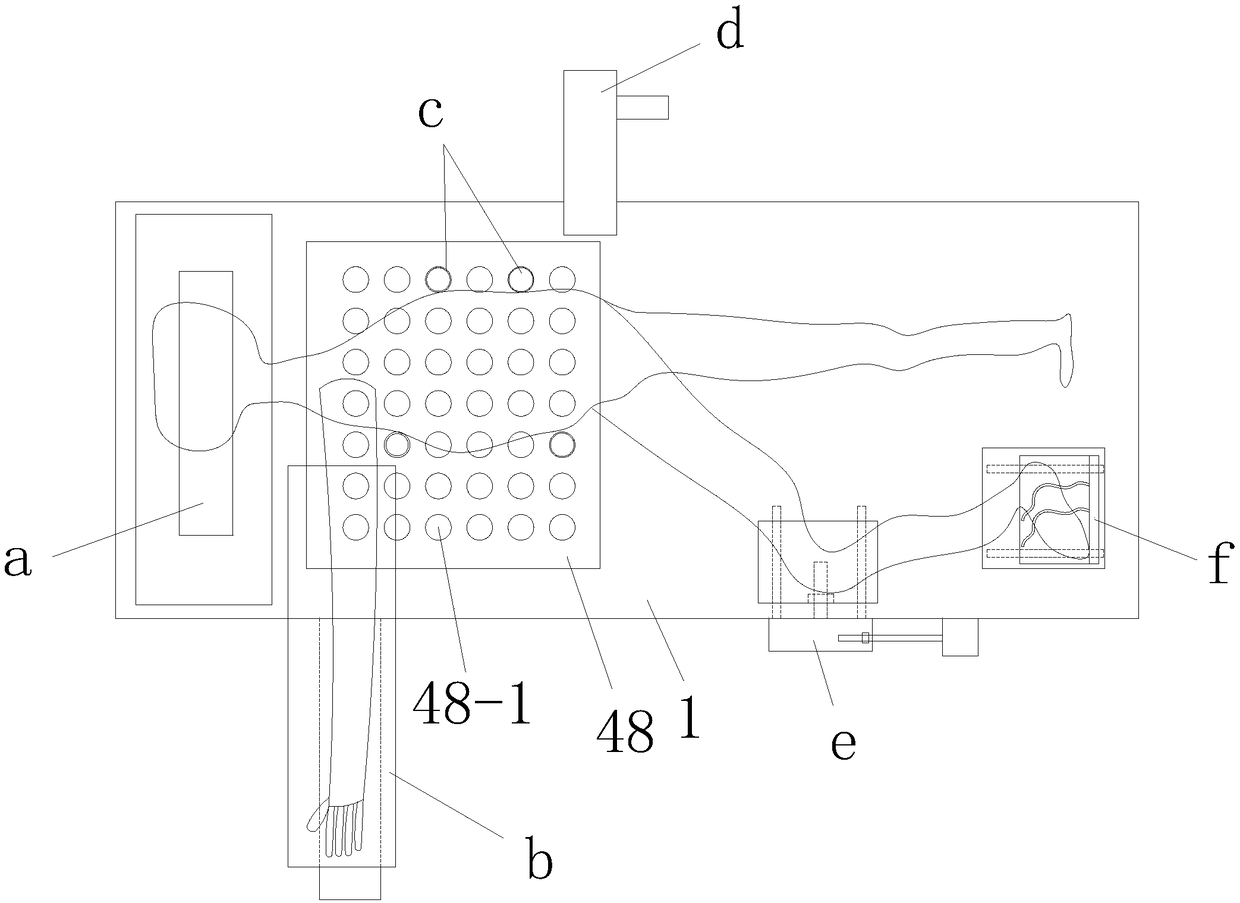

Positioning, opening and clamping device for minimally invasive total hip arthroplasty

InactiveCN108113840AReduce complicationsEasy to operateOperating tablesDiagnosticsHip joint replacement operationTotal hip arthroplasty

The invention discloses a positioning, opening and clamping device for minimally invasive total hip arthroplasty. The device comprises a bed body, wherein a head supporting pad, a hand positioning device, a body positioning device, a bone clamping device and a to-be-operated leg positioning traction device are arranged on the bed body. According to the device disclosed by the invention, the head,hands, body and legs of a patient can be respectively positioned by virtue of each device, so that the patient lies on the side on the hospital bed and keeps a comfortable posture, influences on operative procedures are avoided, the operated leg can be moved in a multi-directional manner, an operation panel can be connected to control the movement of the leg, and a doctor is easy to operate. Moreover, the total hip is easily taken out, the operation efficiency is improved, the operative complications are decreased, and wide popularization is facilitated.

Owner:王波

Slicing and bone removal device for fish slicer

InactiveCN106720166ASolve the problem of lack of live fish open side and bone removal deviceSimple structureFish filletingFixed frameBone clamp

A slicing and bone removal device for a fish slicer comprises a fixture and a slicing device arranged above the fixture, wherein the fixture comprises two clamping pieces; the clamping pieces are articulated with fixing frames; arc push arms are arranged on the backs of the clamping pieces and linked with a motor; the slicing device comprises blades arranged on the left side and the right side, and a bone clamping fork arranged between the two blades; the slicing and bone removal device solves the problem that a live fish slicing and bone removal device is not available at present; and the slicing and bone removal device is simple and practical in structure and has a great market popularization value.

Owner:GUANGDONG YUJIA AQUATIC FOOD

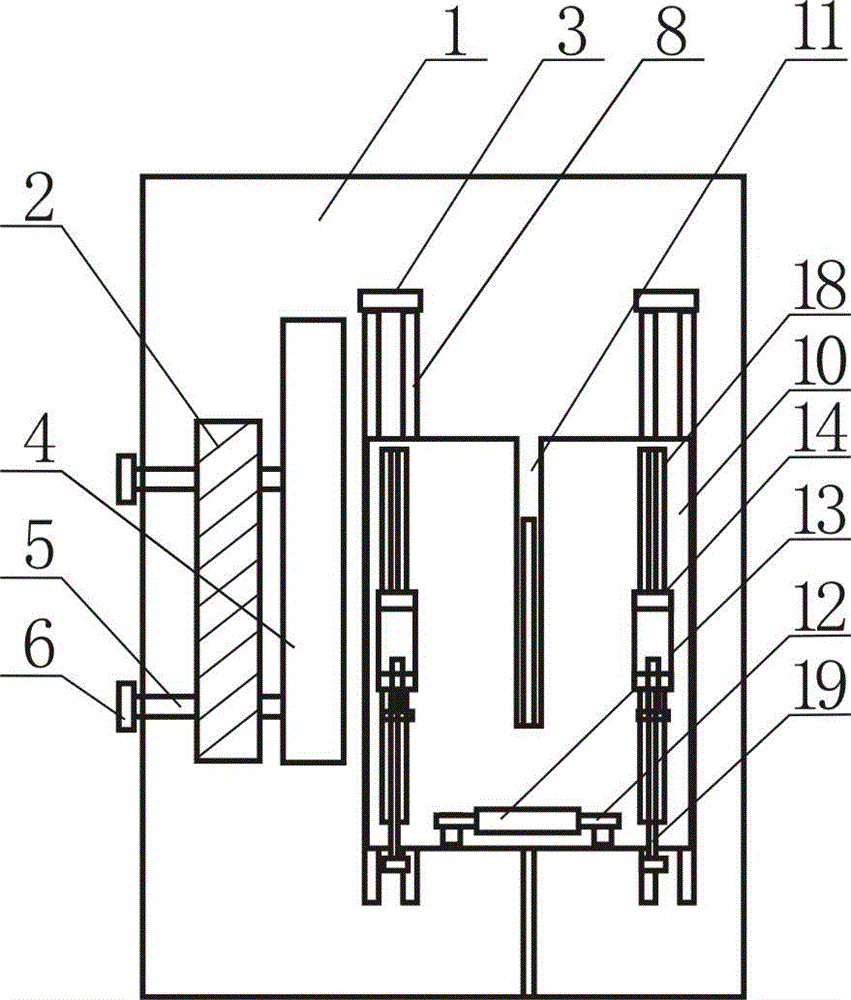

Positioning device for bone drilling

The invention provides a positioning device for bone drilling. The positioning device for bone drilling comprises a bone clamping device and a shifter; the shifter is used for shifting the bone clamping device; the shifter comprises a first support, a second support and a guide rail group; the bone clamping device comprises a first bone clamping plate and a second bone clamping plate; the first bone clamping plate and the second bone clamping plate are respectively and movably connected between the first support and the second support through the guide rail group; the first bone clamping plate and the second bone clamping plate are arranged in parallel; the first support and the second support are arranged in parallel; the first bone clamping plate is vertical to the first support and the second support; the second bone clamping plate is vertical to the first support and the second support. According to the positioning device provided by the invention, before bone drilling, accurate positioning is performed on a bone drilling position, and moreover, proper adjustment can be performed according to the specific position; the positioning device is simple in structure and convenient in operation.

Owner:SUZHOU RENJIERUI AUTOMATION TECH

Multifunctional device for screwing out bone nail

Disclosed a multifunctional bone peg spin-out device comprises an inner screw and spin-out carrier. Wherein, the inner screw with screw thread outer has been mounted with a handle of inner screw; the lower end of spin-out carrier has bone-clamp claws while the inner surface of inner bone-clamp claw has anti-slip groove; the outer layer of screw has a screw muffle whose inner wall has inner screw thread and the outer wall has outer screw thread; the inner screw is screwed into the screw muffle which has be mounted with a handle of screw muffle; the spin-out carrier is connected with a nut into which the screw muffle is screwed; the lower end of inner screw has the blade of spin-out device whose end surface is in the straight shape or cross wing whose side surface has blade; the outer screw thread of inner screw is reverse to the outer screw thread of outer wall of screw muffle, to shorten the distance of run. The invention can be utilized to press the bolt and the side surface of blade of spin-out device has edge, therefore, it can clamp the bolt tightly to skid the screw which can be screwed out too.

Owner:谢福广

Bone clamp

PendingUS20220125496A1Easy to startEasy to operateDiagnostic markersSurgical instrument supportSurgical operationSpinal column

The present disclosure is related to surgical devices, more particular it refers to a surgical clamp that attaches to a patient's bone to assist in surgical procedures. The surgical clamp is configured in such a manner that the clamping elements show a movement in a plane different from the plane of the actuator intended for opening and closing said clamping elements. As a result, the surgical clamp provides a broader working space to the surgeon when carrying out surgical work on the spine.

Owner:CYBER SURGERY SL

A rib bone-synthesizing device and its control system for thoracoscopy

ActiveCN111467011BImprove accuracyImprove efficiencyInternal osteosythesisDiagnosticsMedical equipmentBone clamp

The invention belongs to the technical field of medical equipment, and discloses a rib bone-synthesizing device for thoracoscopic use and a control system thereof. The housing of the electric telescopic rod is fixed with a fixed block through screws, and the fixed block is connected with a handle through screws; the electric telescopic rod is fixed through screws. There is an arc-shaped movable rod, and the upper and lower sides of the arc-shaped movable rod are respectively fixed by screws with an upper side plate and a lower side plate, a camera is embedded in the side of the upper side plate, and a lighting lamp is embedded in the lower side plate; the arc-shaped movable rod is divided into two parts: The two sections of arc-shaped movable rods are connected by pin shafts, and the two sections of arc-shaped movable rods are respectively welded with bone clips. According to the set pressure value, the present invention adjusts the clamping degree between the bone clamping clamps through the electric telescopic rod according to the set pressure value; at the same time, adjusts the length of the handle according to the operation needs of the medical staff. During the bone-setting process, the illuminating lamp is used to provide corresponding illumination; the camera is used to obtain corresponding images. The invention is convenient for medical personnel to operate and improves the efficiency of bone setting.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Saw Blade Leveling Type Skateboard Feed Clamp Type Bone Saw Machine

ActiveCN103518821BReduce laborSimple and fast operationMeat holding apparatusLeveling mechanismDrive shaft

Owner:韩小兵

Reset forceps

ActiveCN103976773BReduce work intensityRelieve painSurgical forcepsOsteosynthesis devicesBone clampForceps

The invention discloses a pair of reduction forceps. The pair of the reduction forceps comprises at least two bone clamping forceps bodies and a connection rod connecting the two bone clamping forceps. The connection rod comprises a connection rod body, an adjusting rod and a longitudinal adjusting mechanism enabling the connection rod body to move relative to the adjusting rod in the longitudinal direction. According to the reduction forceps, people only need to adjust rotation of a gear so that broken bones can move relatively along the connection rod in the longitudinal direction, and accordingly reduction of the broken bones is achieved. Manual adjustment is not needed, the positions of the broken bones do not need to be fixed, after broken bone reduction is finished, the relative position of the two bone clamping forceps bodies can be locked through the connection rod body, and accordingly the relative position of the broken bones is locked. The situation that the broken bones are dislocated after subsequent operation of an operation is avoided, so that labor intensity of medical staff is lightened, and pains of patients are relieved.

Owner:江苏惠骨医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com