Automatic reverse zipper head attaching mechanism

A zipper puller and automatic technology, which is applied in the direction of container manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of inconvenience and inconformity with usage habits, and achieve the effects of high production efficiency, novel design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with specific embodiments.

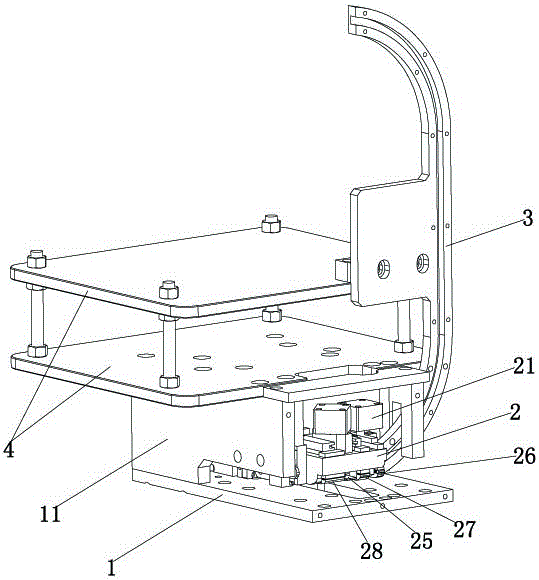

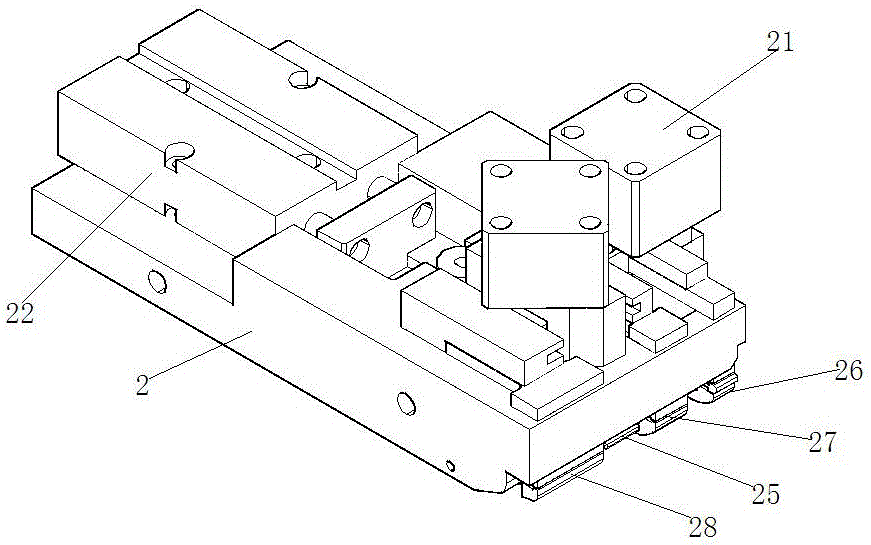

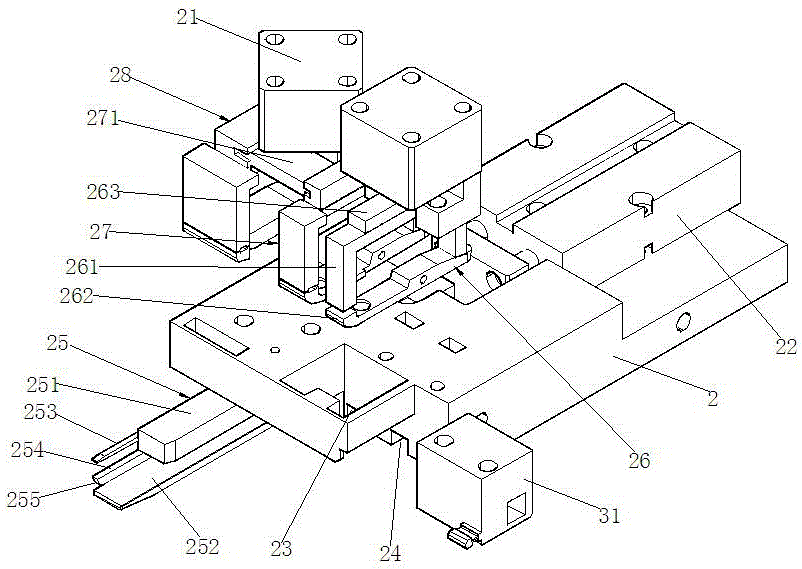

[0017] Such as Figure 1-3 As shown, an automatic reverse zipper head mechanism includes a horizontally arranged installation base plate 1, a main board 2 is installed on the upper end of the installation base plate 1, and at least two bone bar clamping cylinders 21 and pushing materials are installed on the upper end of the main board 2. Cylinder 22, the left side of the main board 2 is connected with a vertically arranged material channel 3, the material channel 3 is connected to the main board 2 through the feed port 31, the upper end of the installation base plate 1 is located at the side end of the main board 2, and a vertical plate 11 is installed on the upper end of the vertical plate 11. A fixed plate 4 arranged horizontally and horizontally is installed;

[0018] The upper end of the main board 2 is provided with a pusher chute 23 and at least three bone clamping grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com