Patents

Literature

246results about "Meat holding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

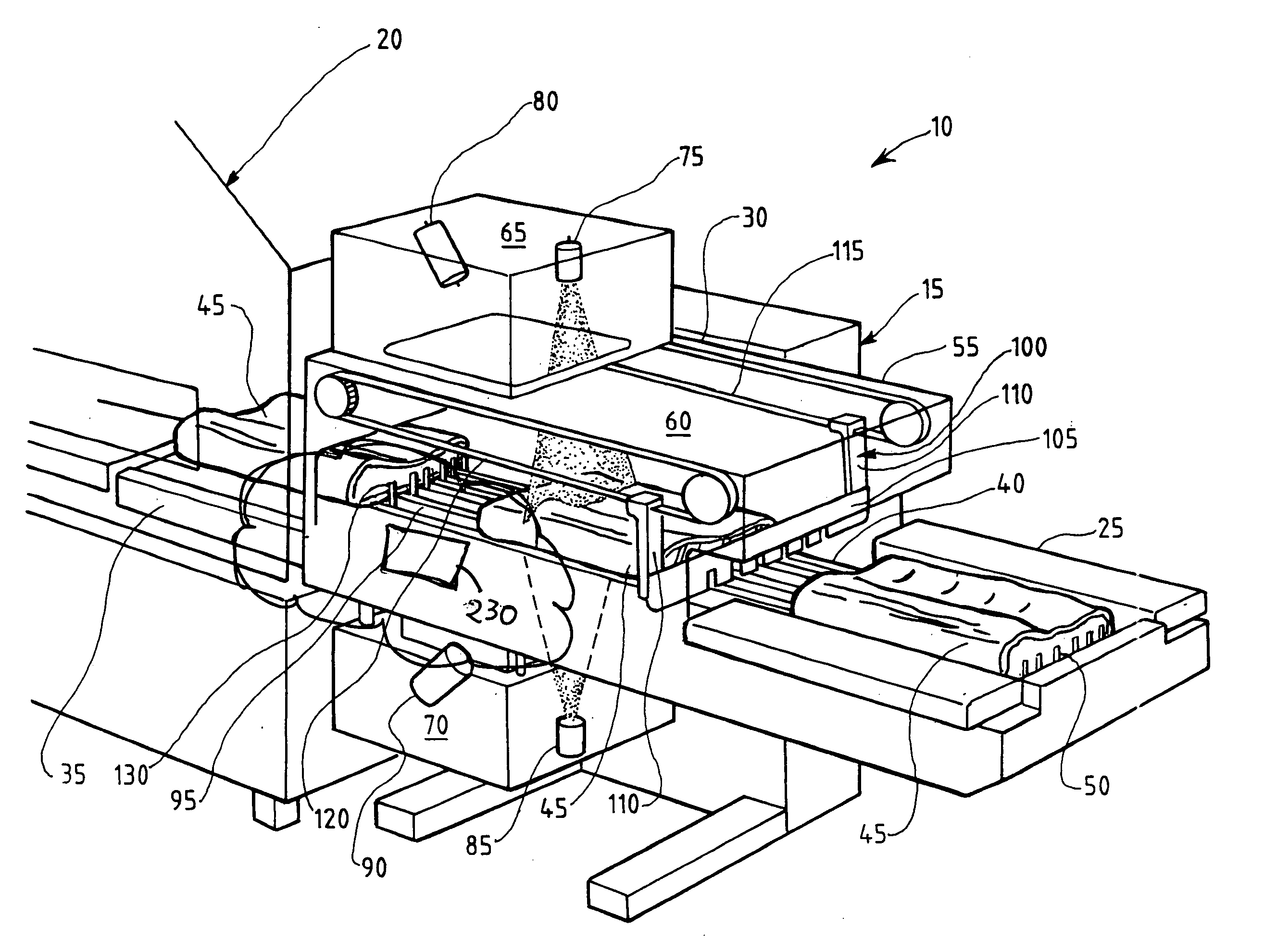

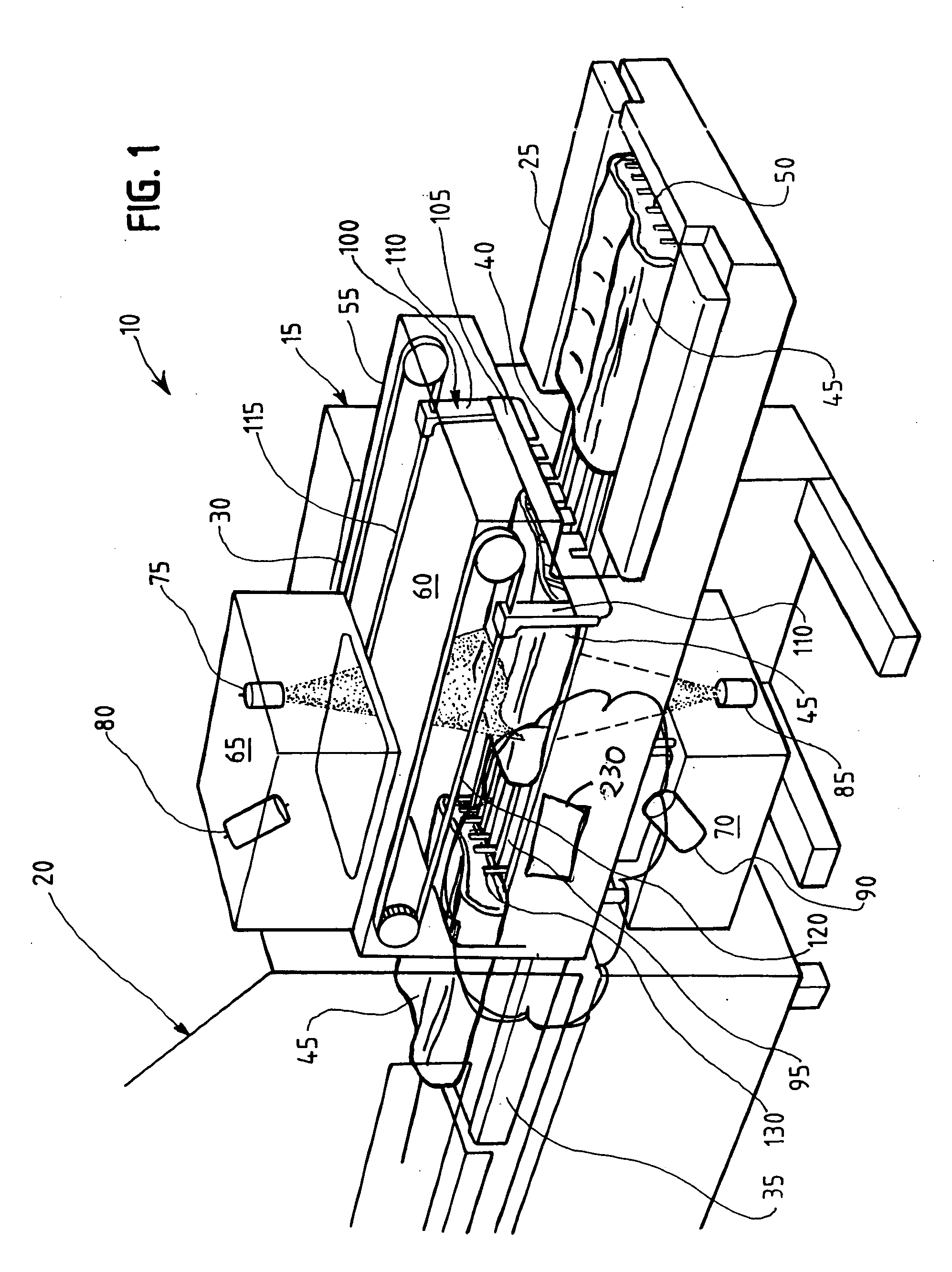

Automated product profiling apparatus and product slicing system using same

InactiveUS6882434B1Meat holding apparatusMethod using image detector and image signal processingProduct analysisVolumetric Mass Density

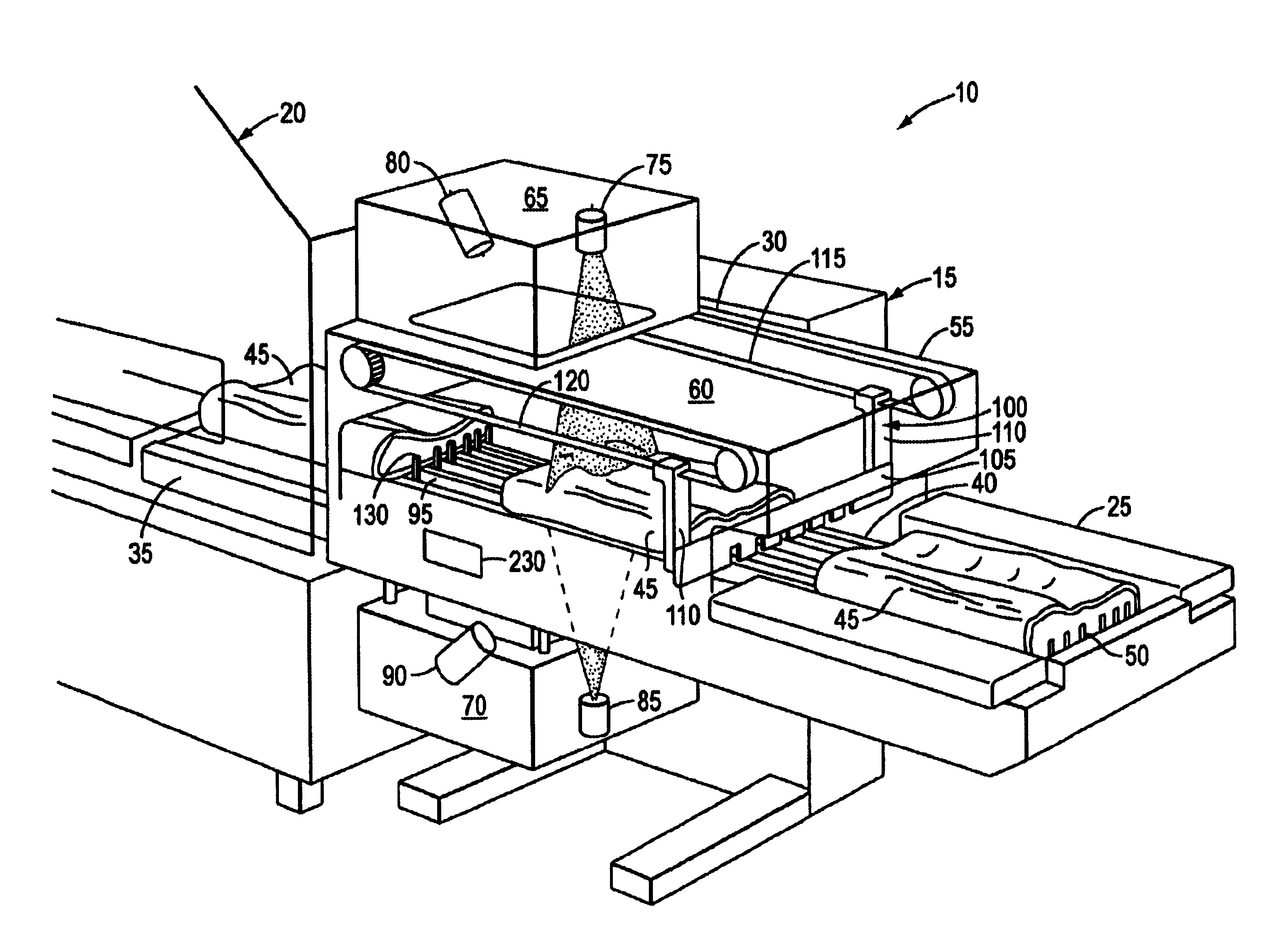

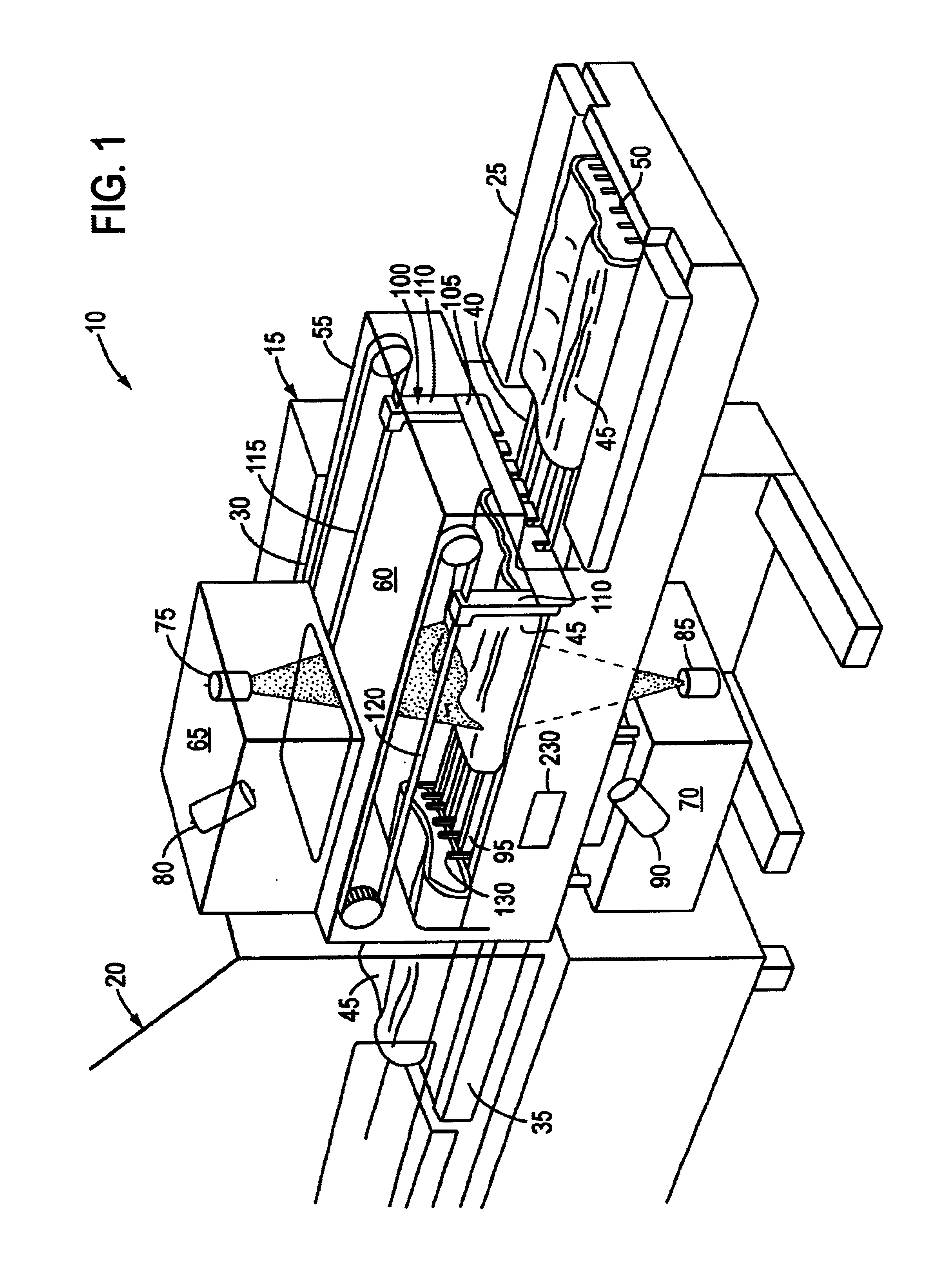

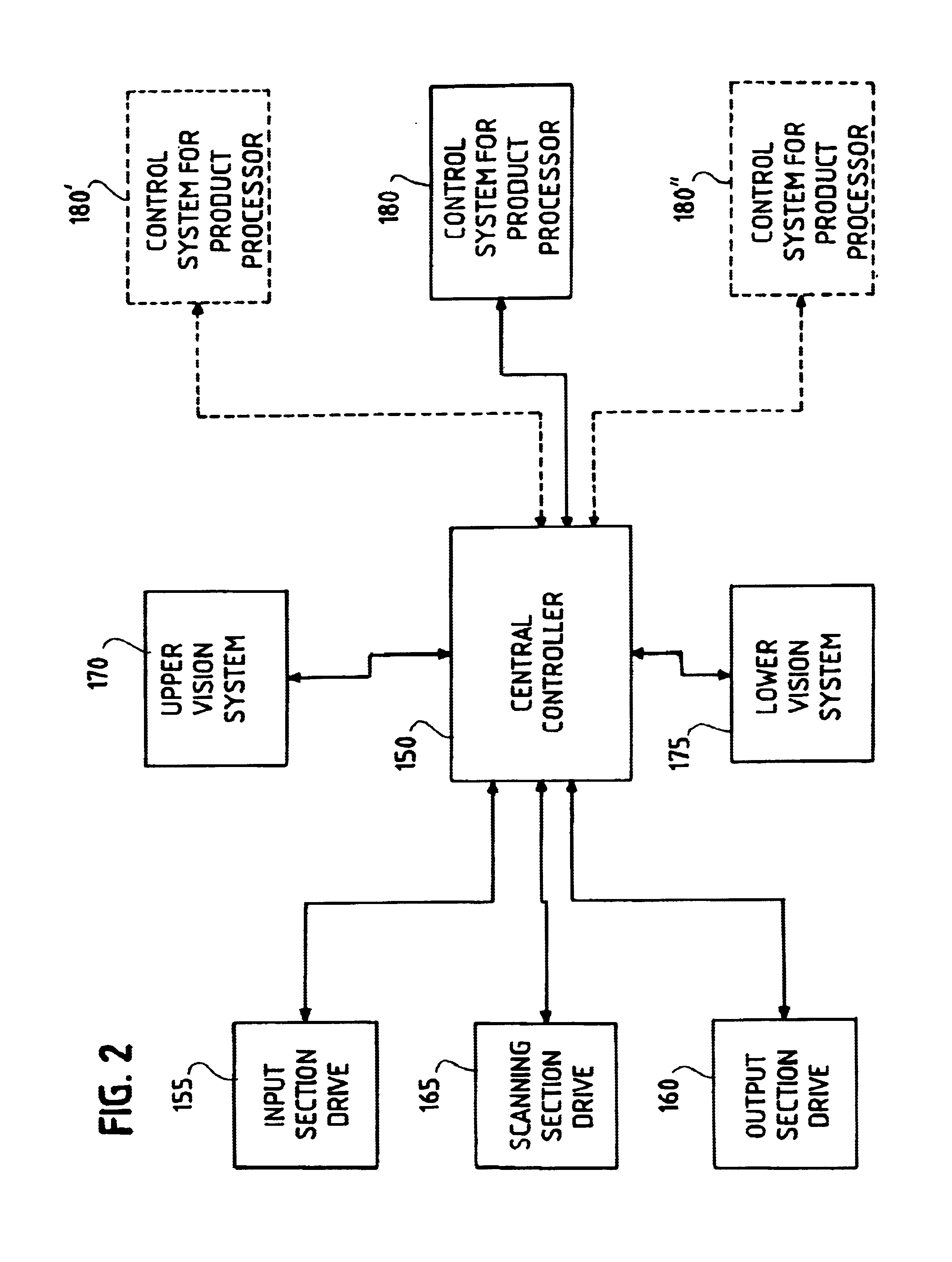

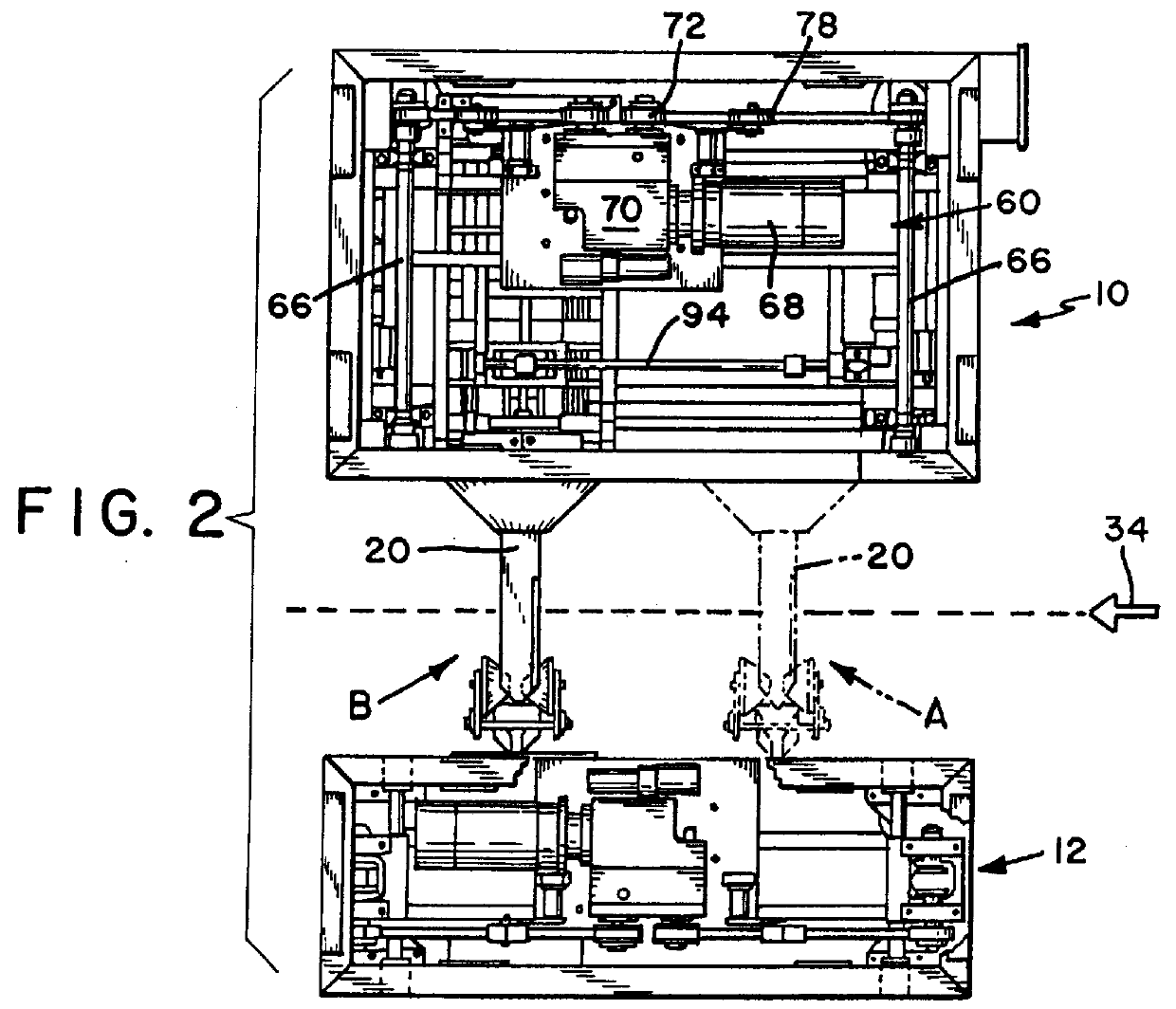

A system, suitable for high-speed operation, by which raw product (45), such as a slab of meat, can be accurately processed, such as by slicing into segments of desired weight, comprises a product profiling apparatus (15). The product profiling apparats (15) meassures the profile of the physical process. The product profiling apparatus (15) includes line lasers (75, 85) for directing a line of light across the upper and lower surfaces of the product (45) and visual image cameras (80, 90) directed toward the profile surface to capture, at fixed increments, the product profile. The product may also be weighed and the product density determined from the overall profile measurements. A controller (150) receives this data, and instructs the physical process accordingly.

Owner:PROVISUR TECHNOLOGIES INC

Method and device for processing a poultry leg

InactiveUS7059954B2Drawback can be obviatedEliminate needMeat holding apparatusPoultry skinningEngineeringTarsal Joint

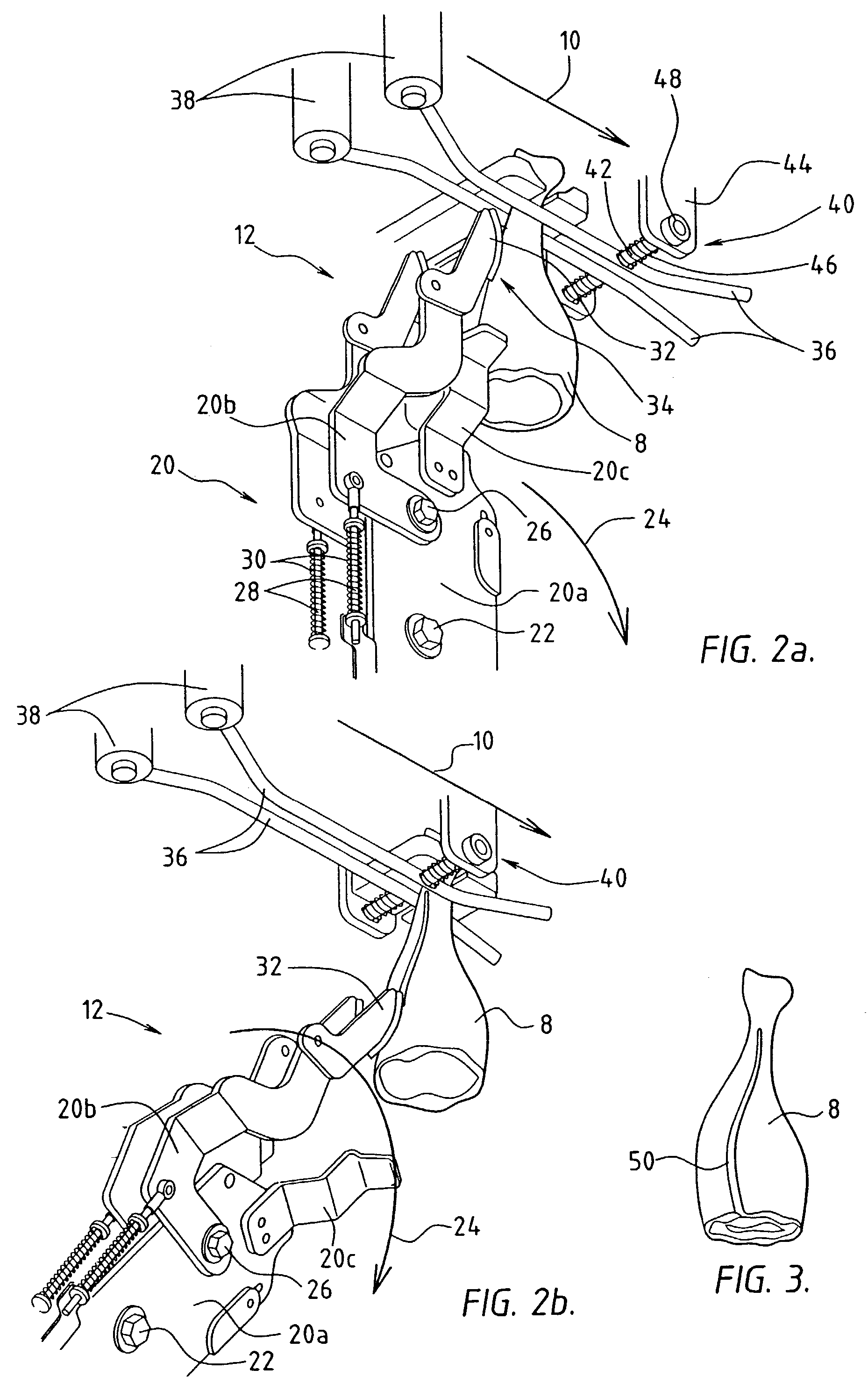

In a method and device for processing a poultry leg which is hanging from a carrier and comprises at least a drumstick, the operations are carried out: cutting into the drumstick substantially around the drumstick in the vicinity of the tarsal joint by means of at least one incision; and at least partially separating a part of the leg which comprises the at least one incision. The carrier is moved onwards during the cutting.

Owner:STORK PMT

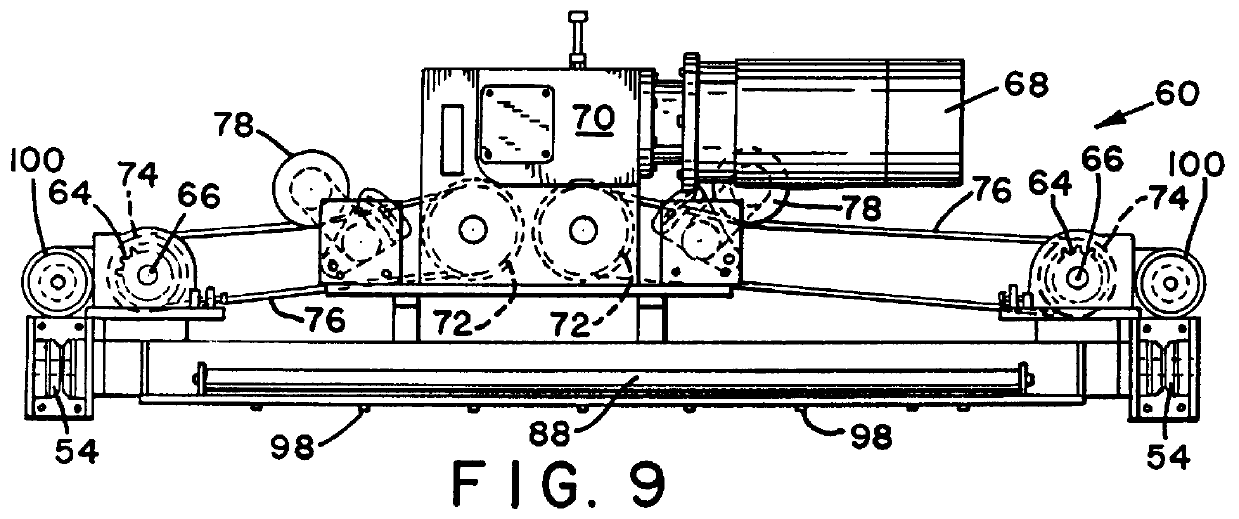

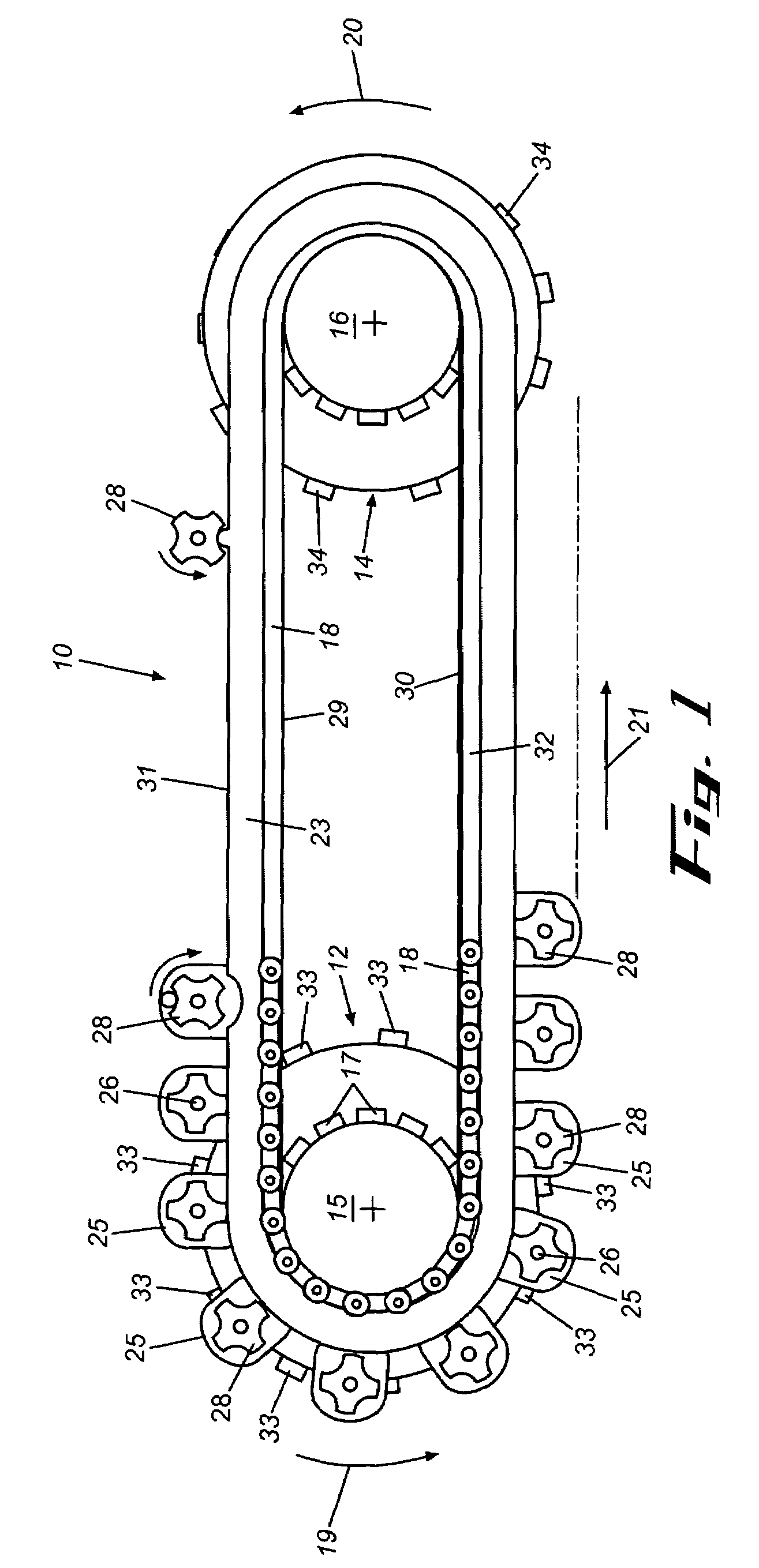

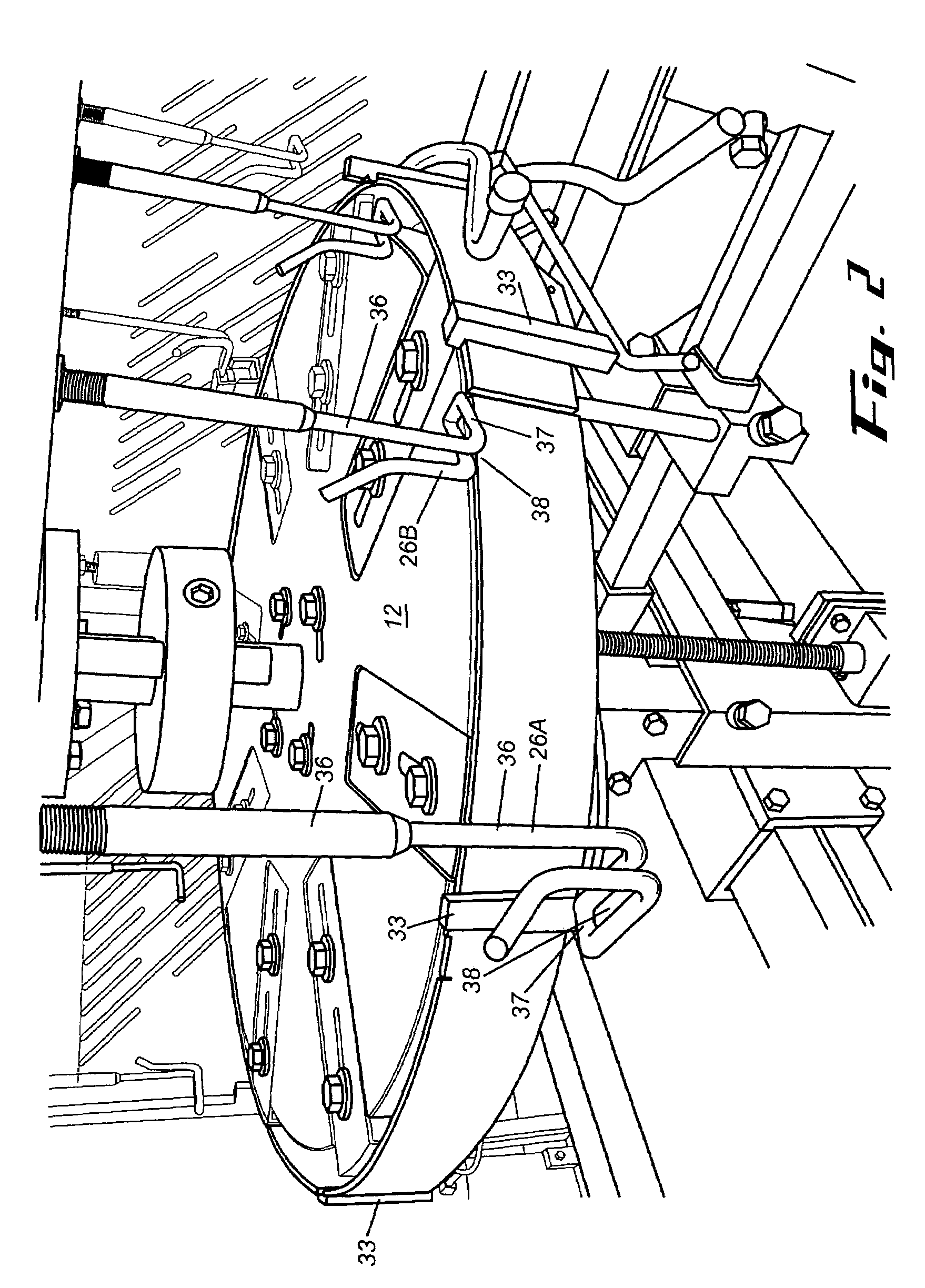

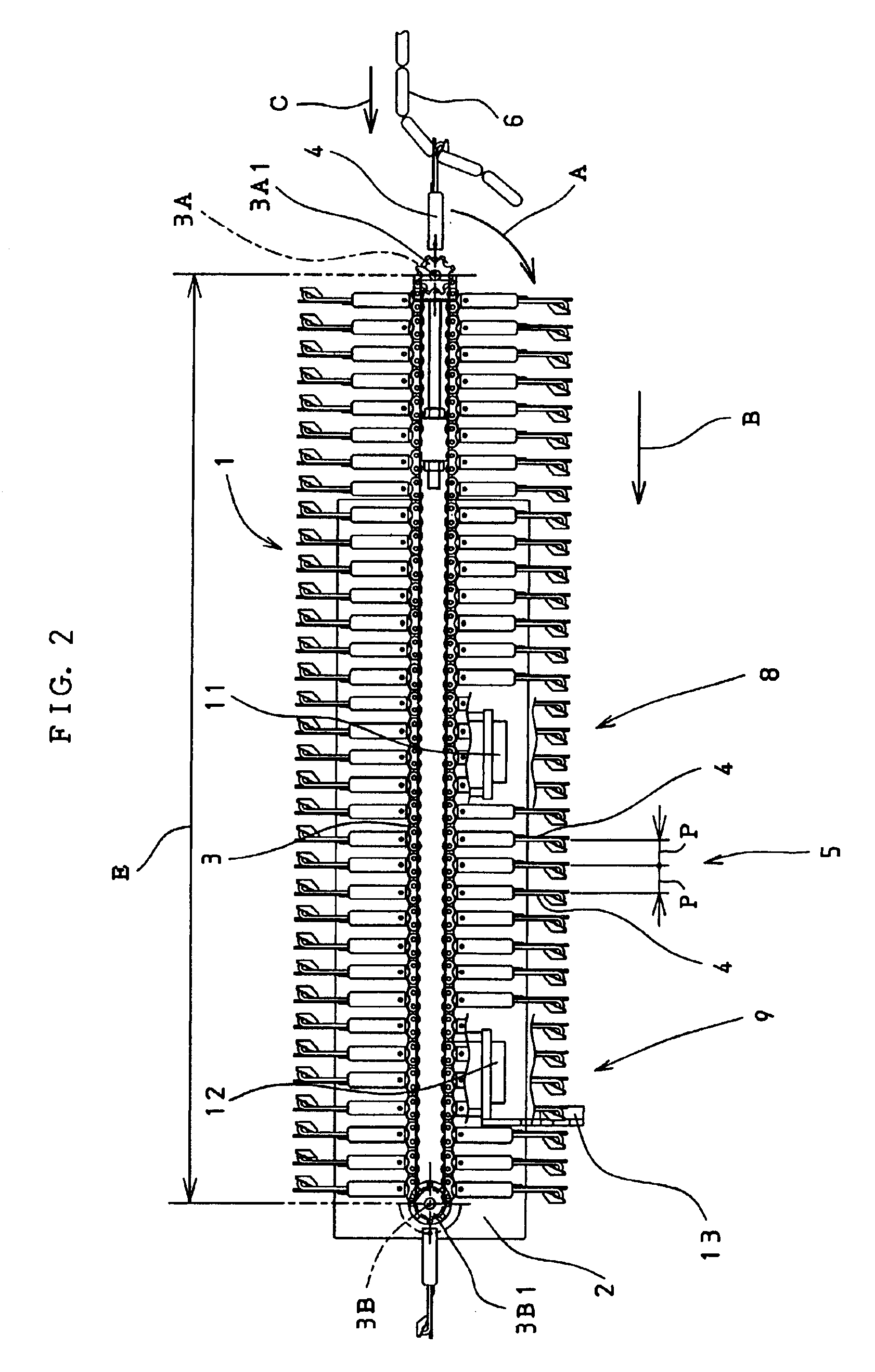

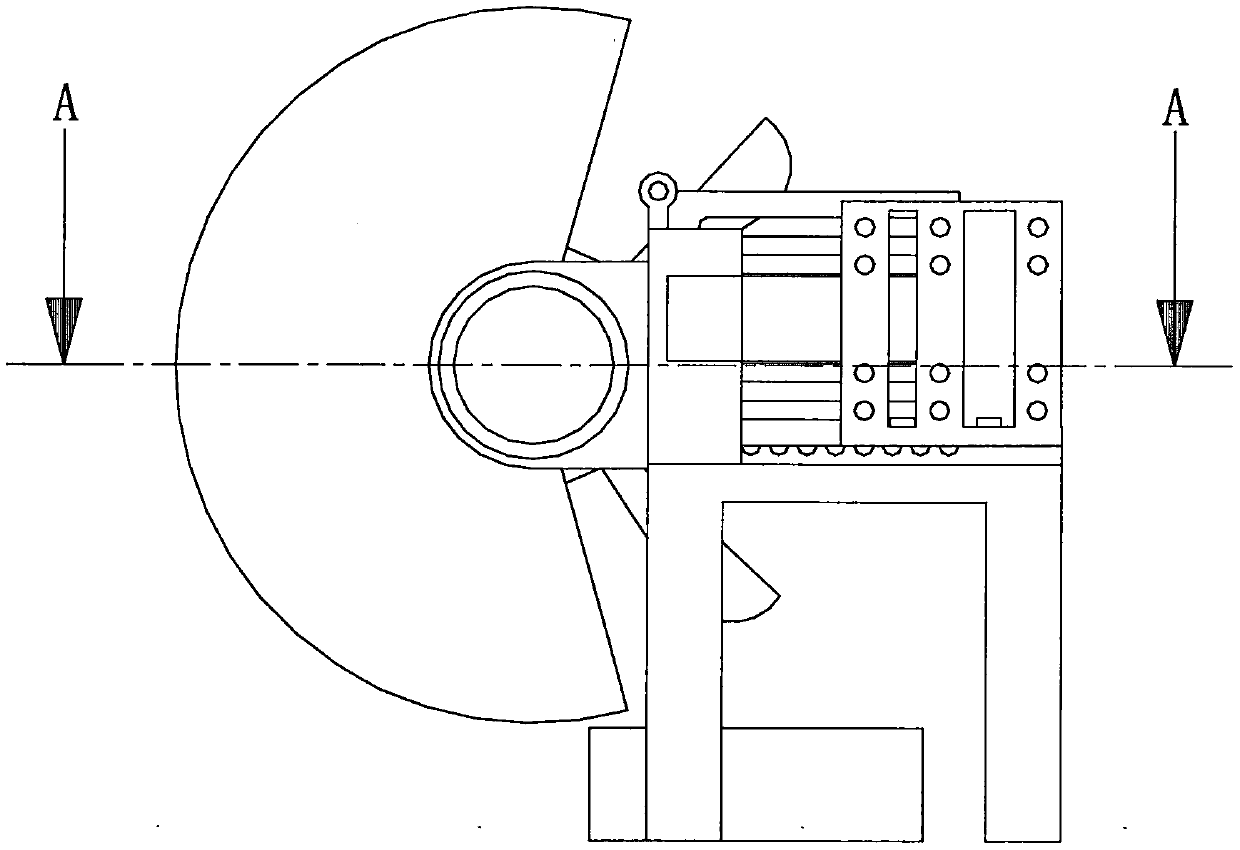

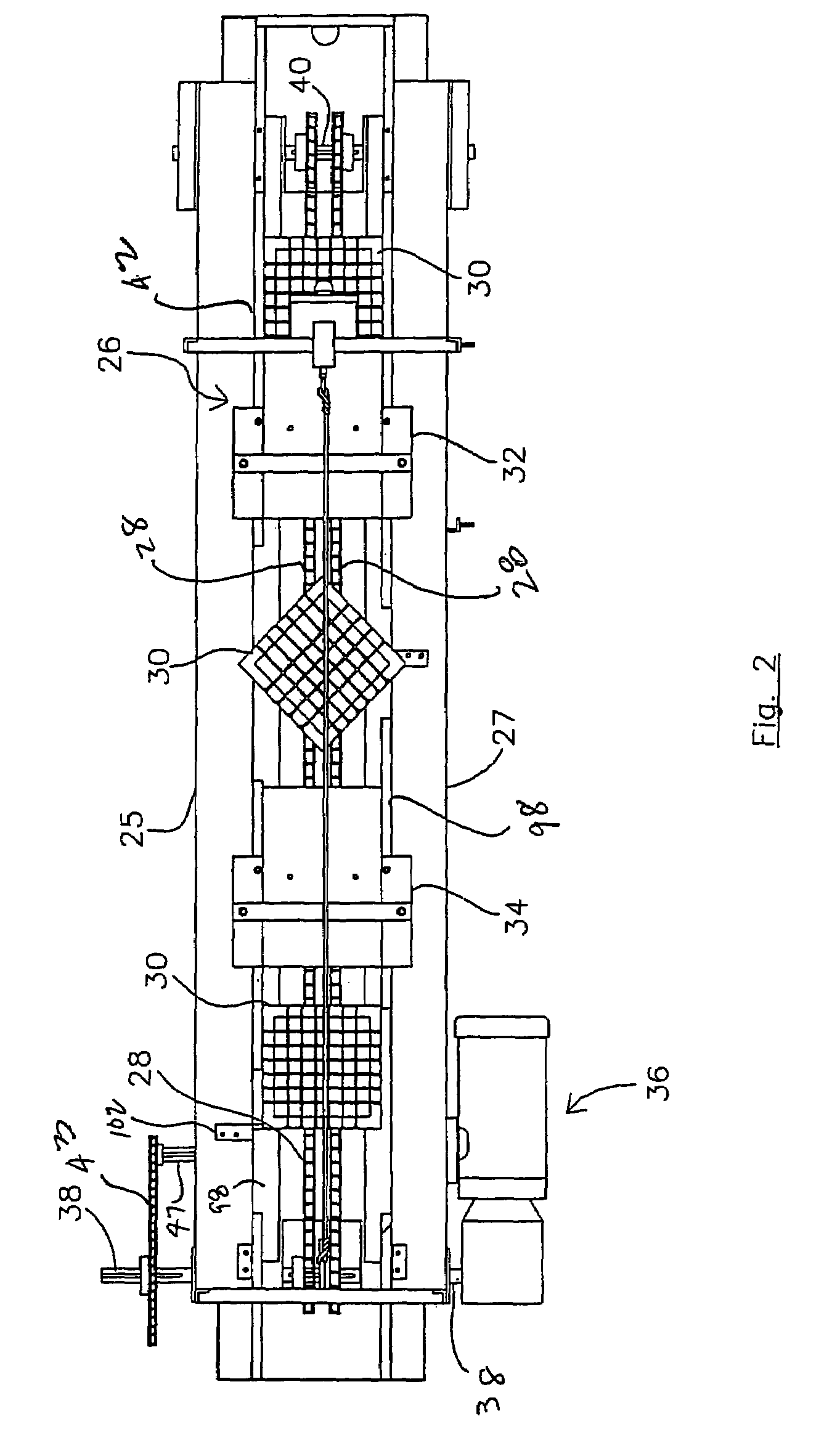

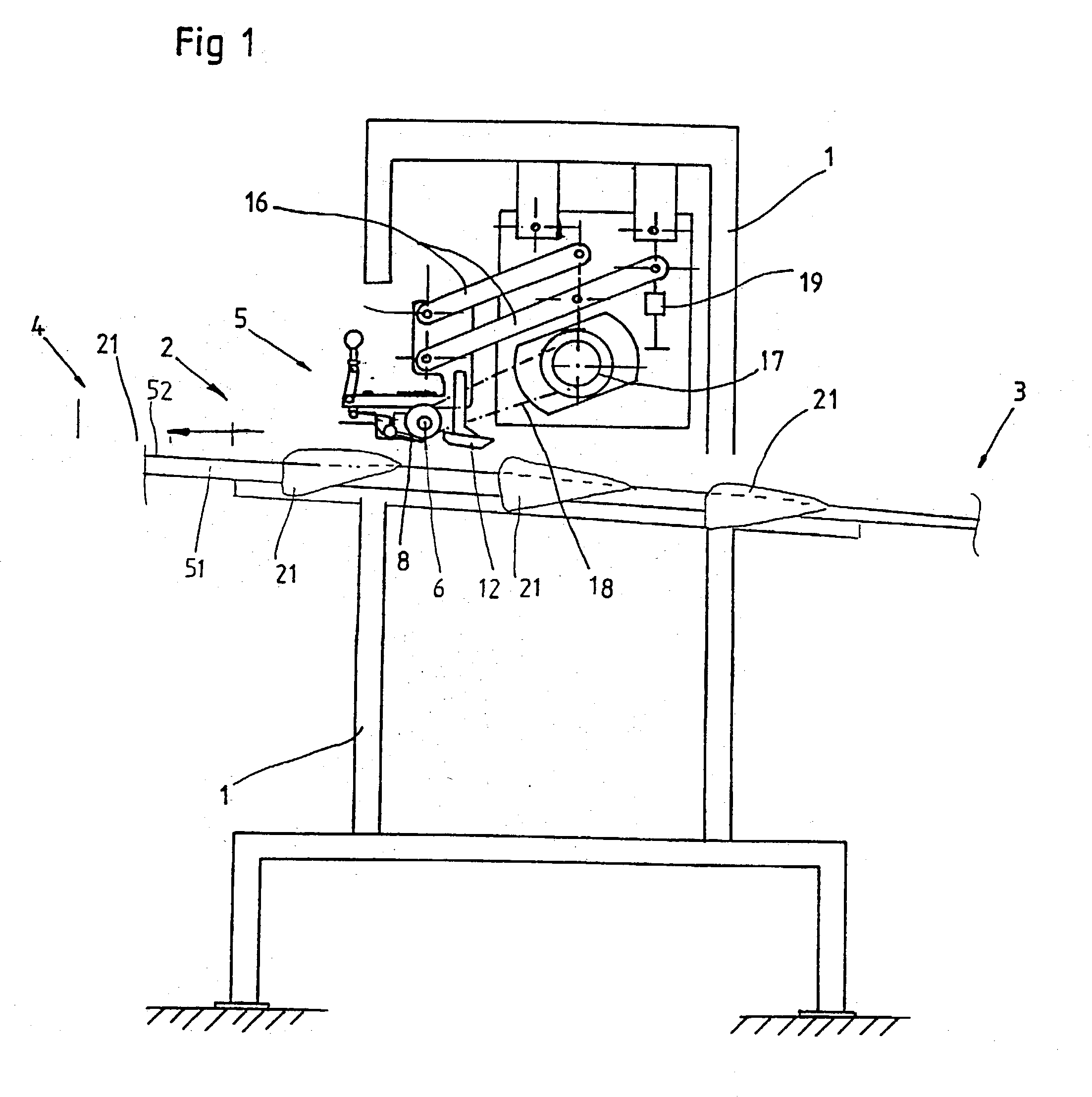

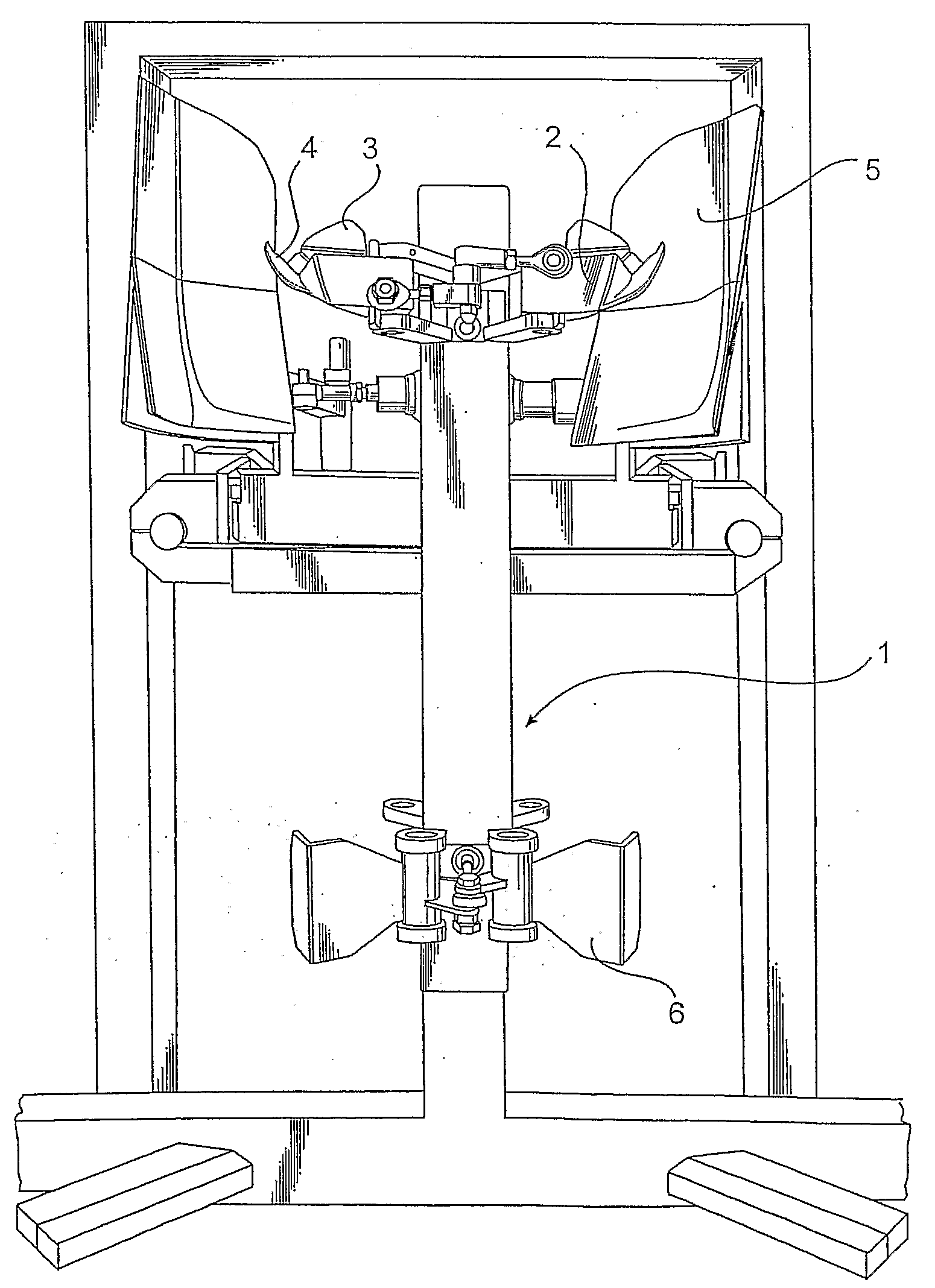

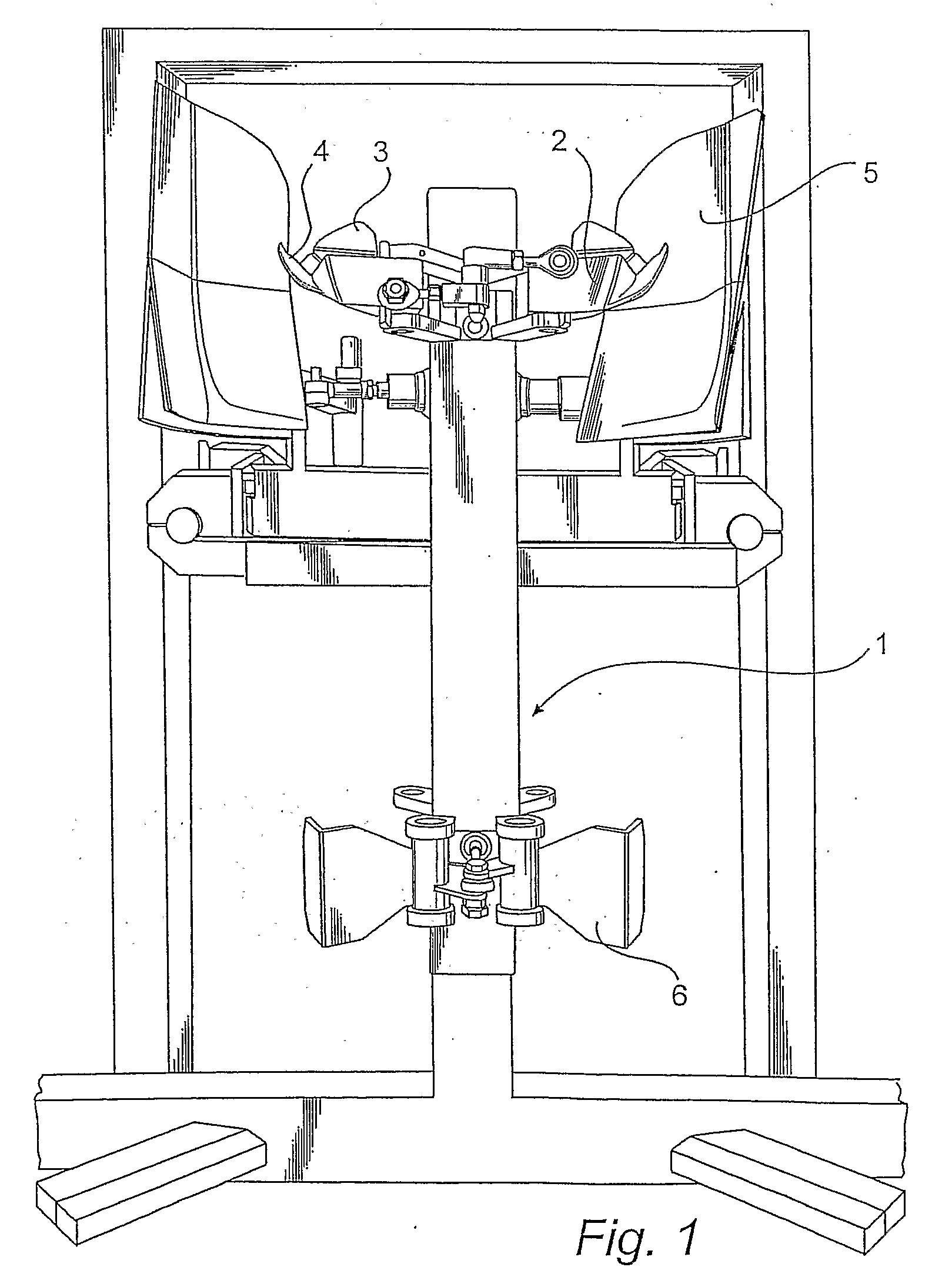

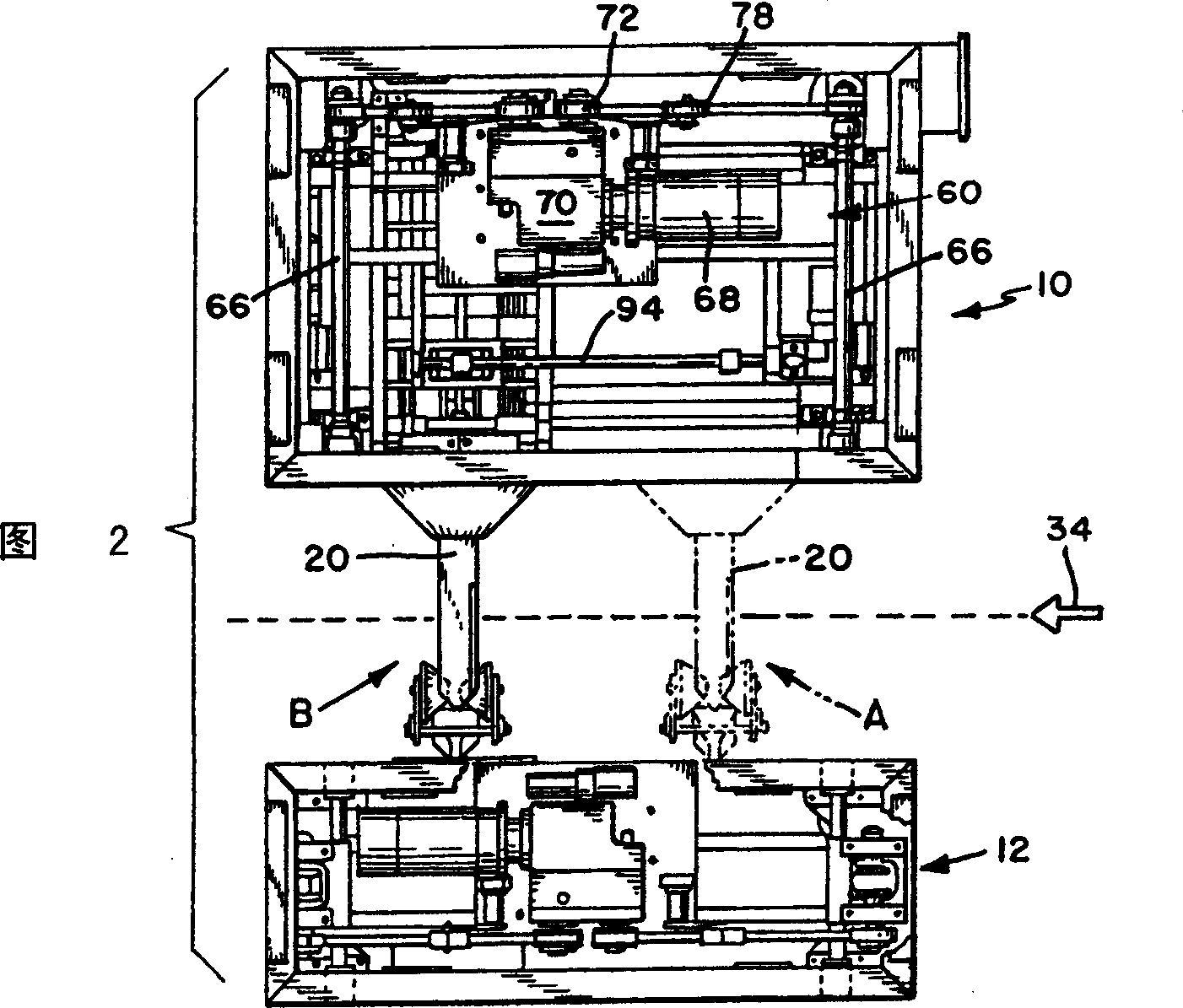

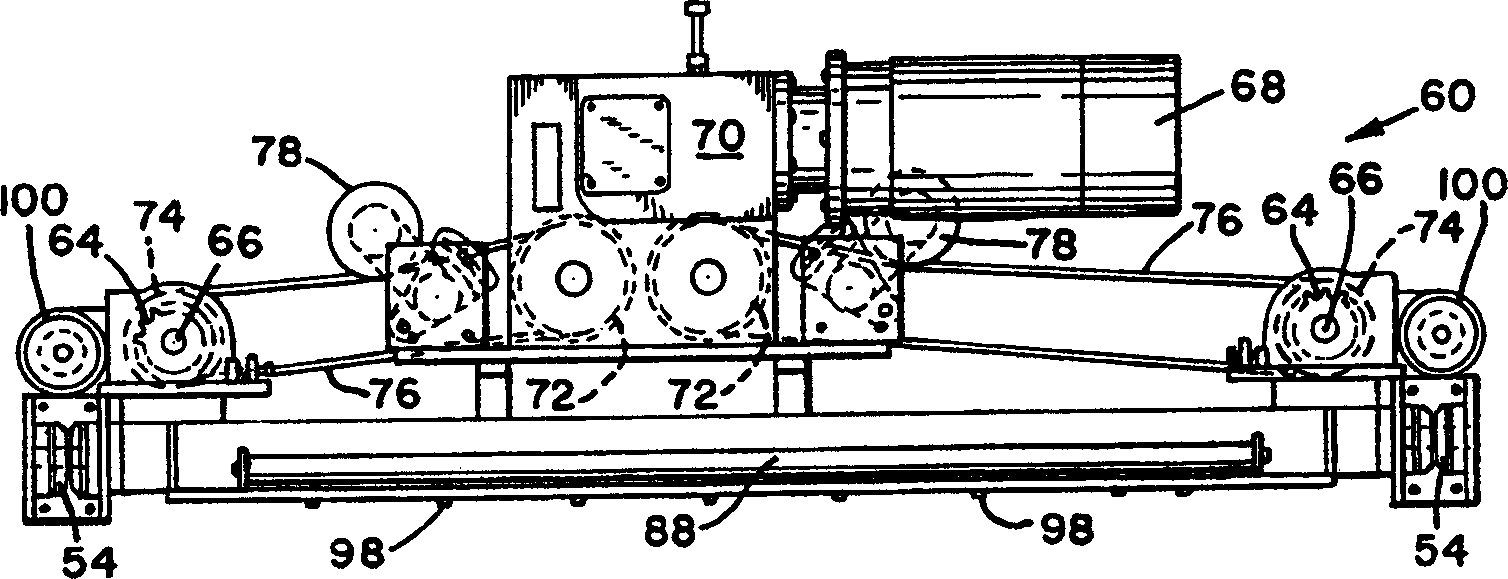

Automated saw for splitting carcasses

InactiveUS6126536AIncrease speedPrecise positioningMeat holding apparatusSplitting instrumentsMechanical engineeringEngineering

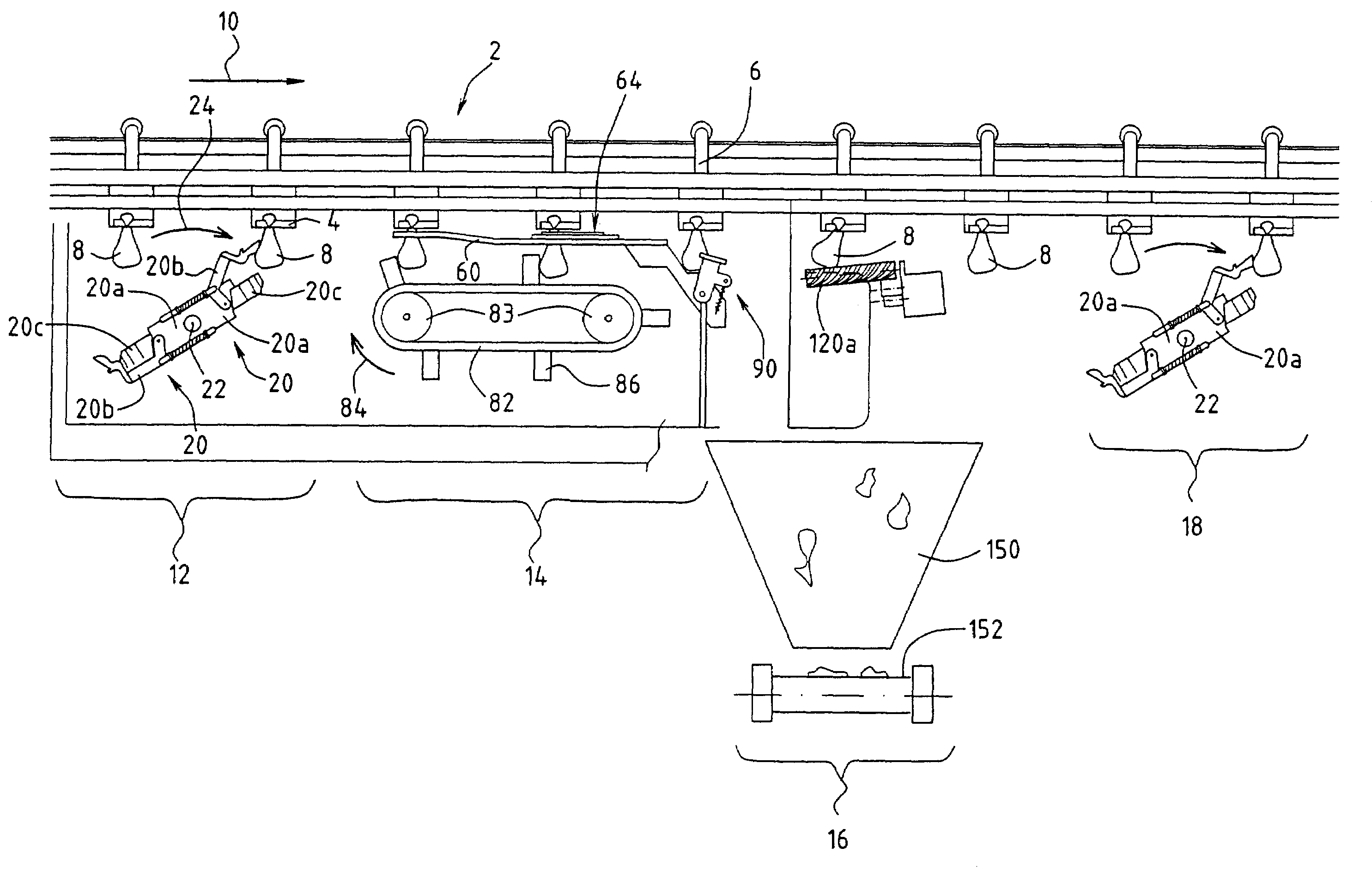

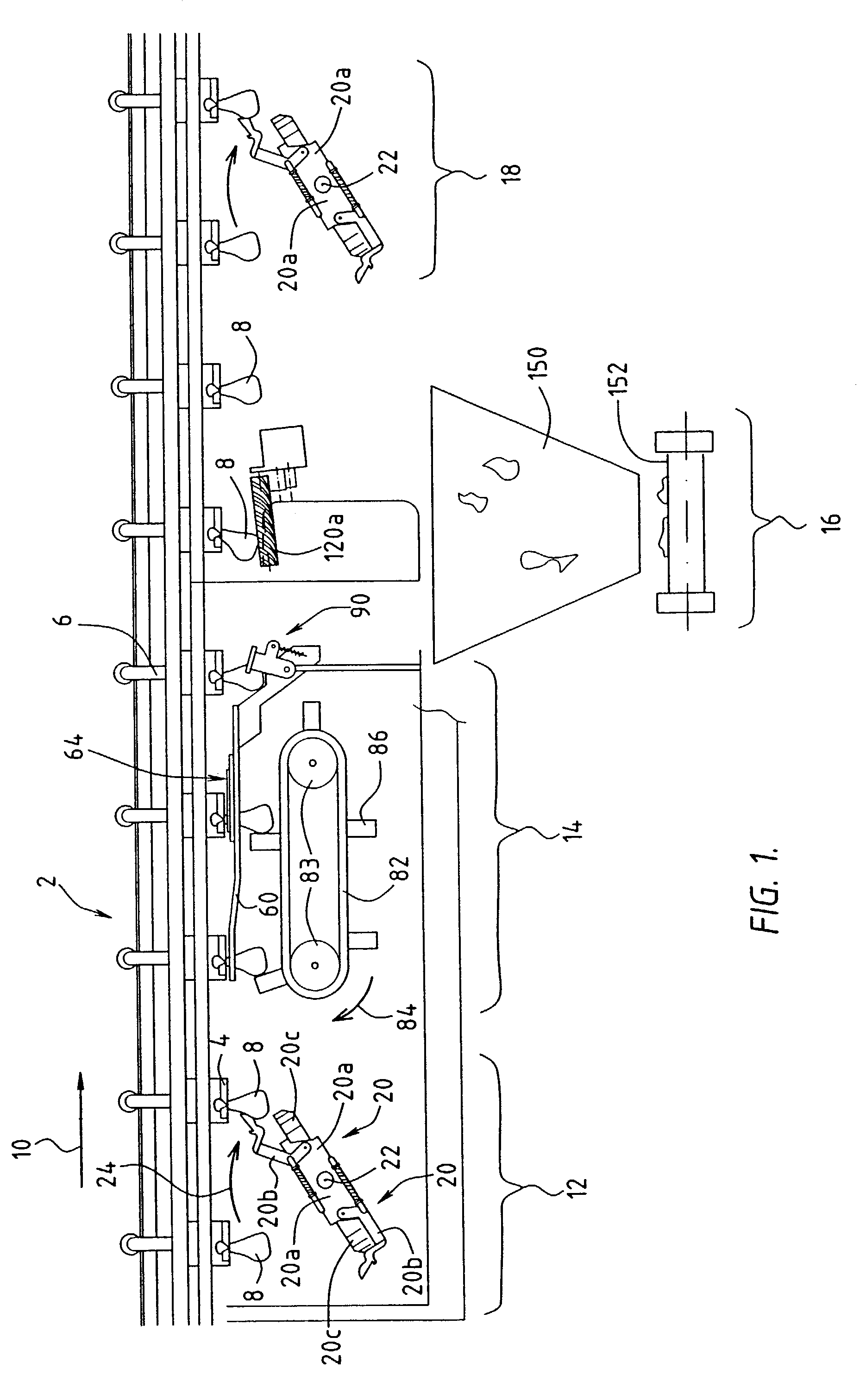

An automated saw for high speed splitting of suspended carcasses, such as hog carcasses, through the backbone as the carcasses continuously move along a carcass rail includes a splitting station and a back roller station located on opposite sides of the carcass rail. The splitting station includes a splitting saw that can be driven in three directions, including horizontally towards a carcass to begin cutting, vertically down to make the cut and horizontally parallel to the carcass rail to match the speed of the moving carcass as the cut is made. A guide roller carried by the splitting station positions the backbone in a known position relative to the saw. The back roller station includes a back roller for positioning the carcass relative to the saw as the cut is made. The back roller is also movable in three directions, including horizontally in to contact the carcass, vertically down, and horizontally parallel to the carcass rail to match the motion of the saw. The back roller and saw are structurally independent, but are accurately driven to maintain the relative position of the saw and the back roller as the cut is made.

Owner:JARVIS PROD

Apparatus for trussing a bird

InactiveUS7476148B2Reduced risk of breakageReduce rotationMeat holding apparatusMeat/sausage hanging-upKeelEngineering

An apparatus for trussing a bird comprising a main body having a platform for supporting the bird, the platform and main body having a bird keel end and a bird wishbone end, clamping means movably mounted on the main body for securing the bird on the platform and releasing the bird from the platform, shackle means mounted on the main body and being disposed above the bird keel end of the platform for receiving and at least temporarily securing the legs of the bird, a leg engaging and supporting means movably mounted on opposite lateral locations of the main body for tightening leg knuckles of a bird into the shackle means before flexing, for preventing twisting of the legs and for bending the legs over the wings, a first drive means operably engagable with the clamping means, the shackle means and the leg engaging and supporting means to sequentially clamp the bird, shackle, stretch and flex the clamped birds legs and to release the clamped bird.

Owner:MAREL STORK POULTRY PROCESSING

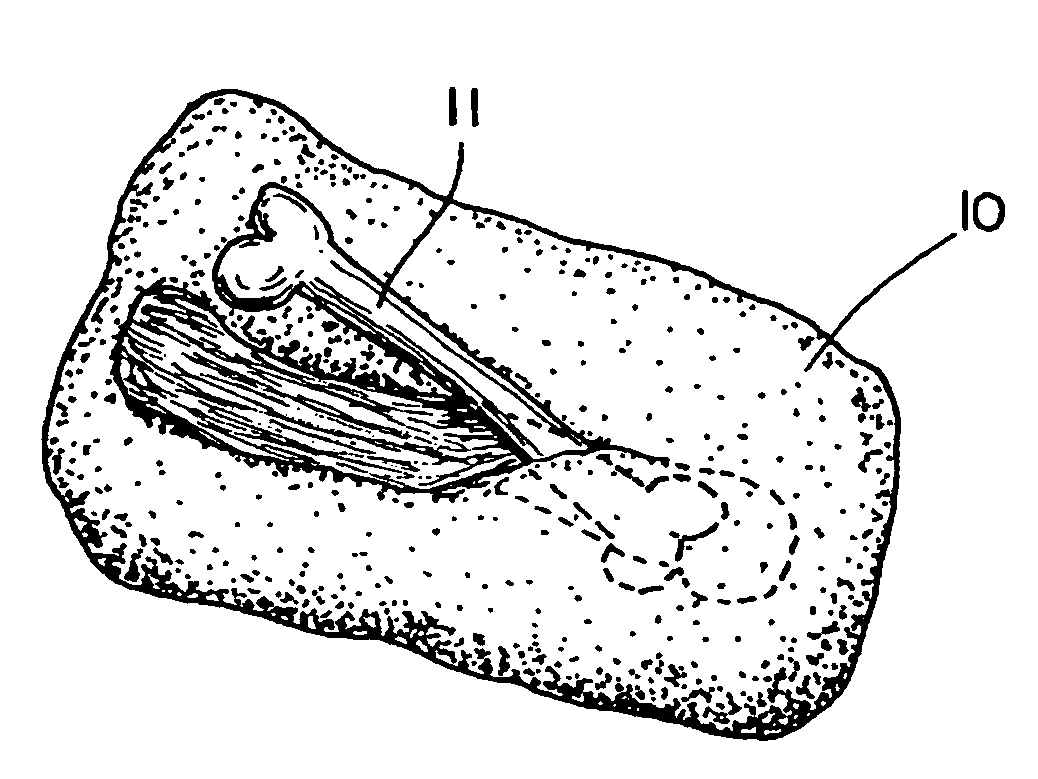

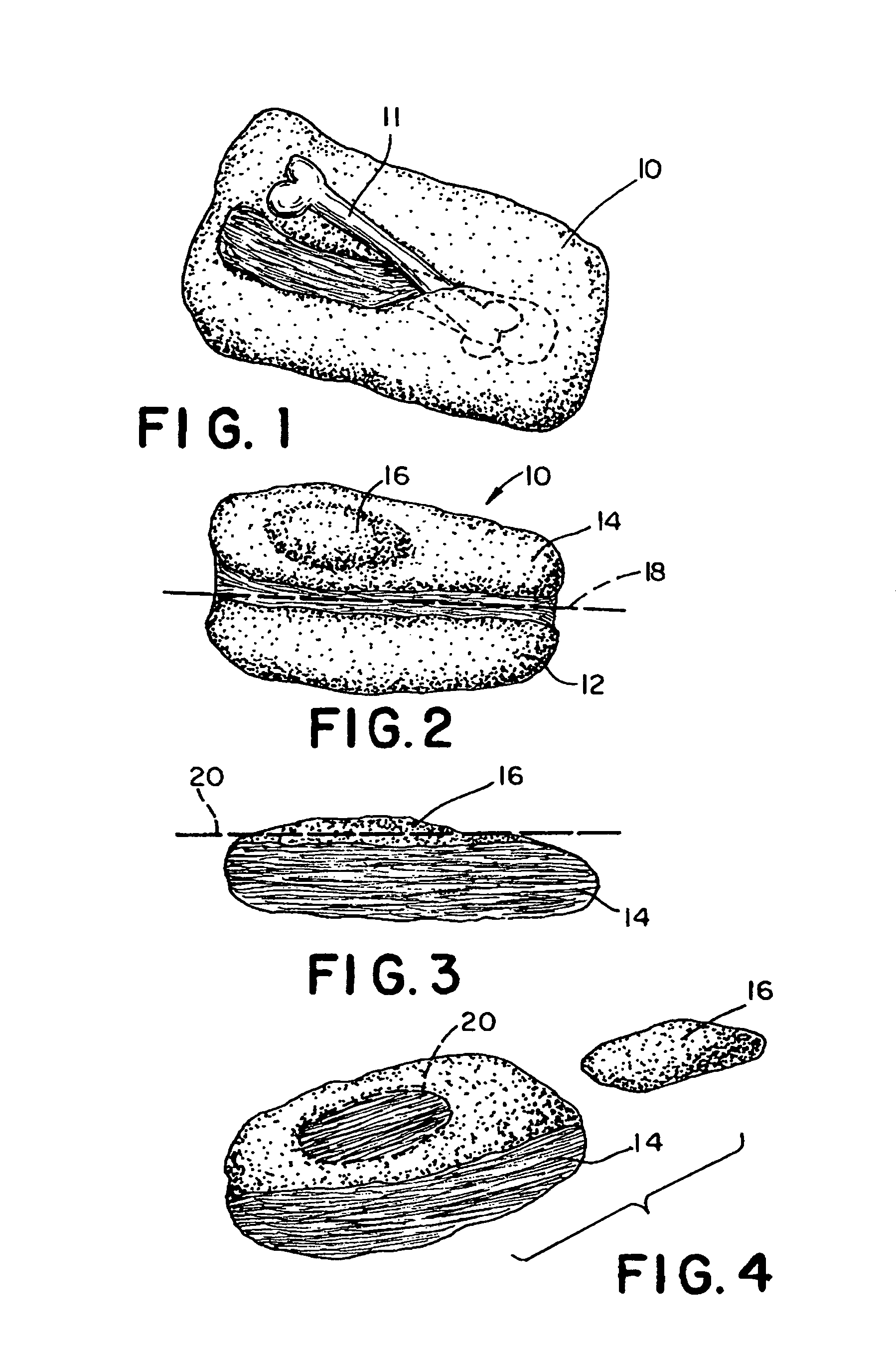

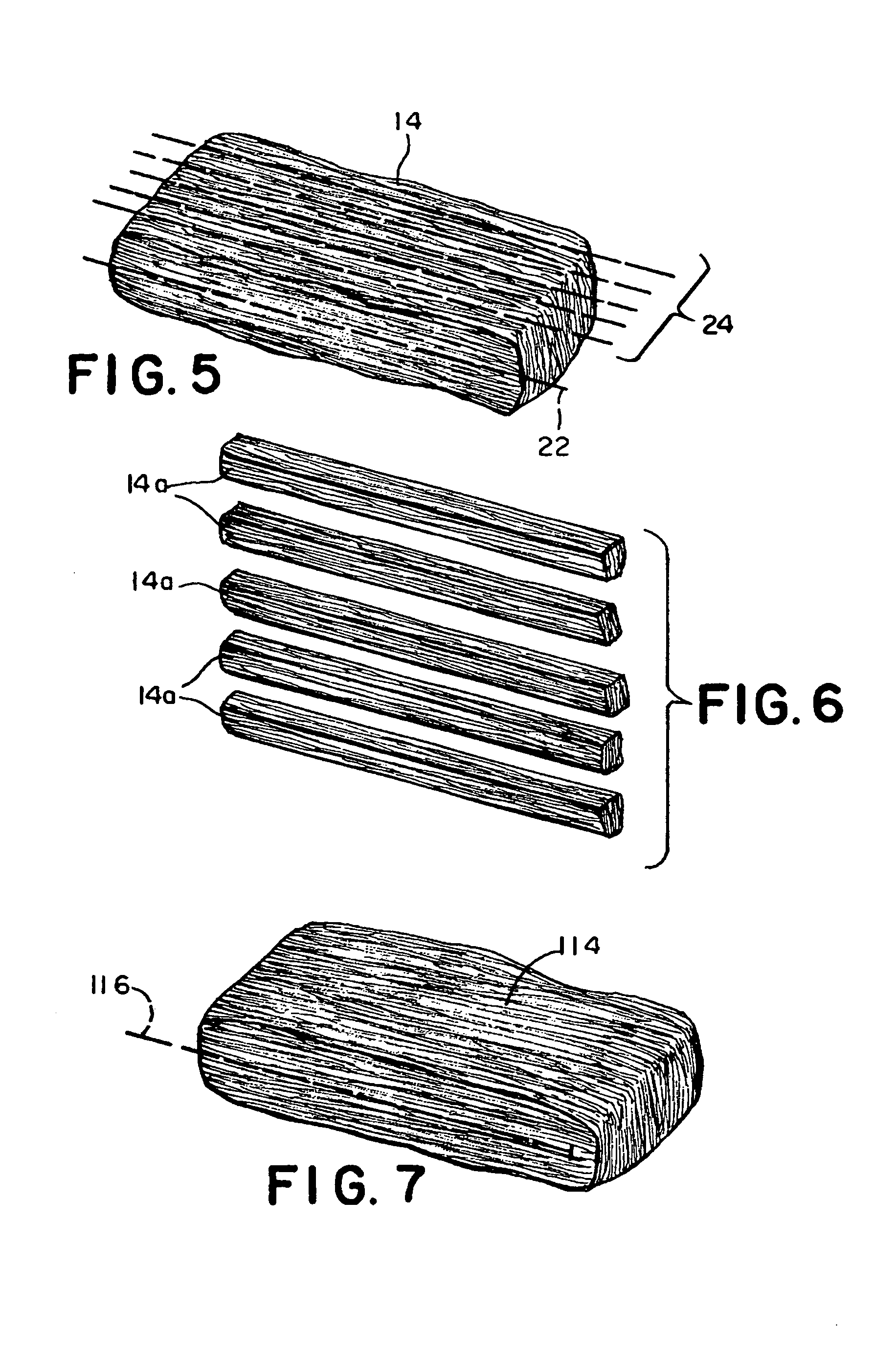

Method of making food products from the thigh of a bird and food products made in accordance with the method

A method of cutting the thigh of a bird forms a boneless thigh meat product. The thigh has a bone, first and second lateral sides, top and bottom surfaces, a thin muscle proximate the first lateral side and a thick muscle proximate the second lateral side. The method comprises removing the bone and any other inedible components from the thigh to provide a boneless thigh. The boneless thigh is cut from the top surface to the bottom surface along a first cut line to remove the thin muscle. The thick muscle is cut along a second cut line extending generally parallel to the top surface to remove a small top (red) muscle. The thick muscle is then cut along a third cut line extending generally parallel to the top and bottom surfaces and generally half way between the top and bottom surfaces to create two generally equal sized thigh meat pieces. The generally equally sized thigh meat pieces are cut along a plurality of generally parallel, generally equally spaced, generally longitudinally extending fourth cut lines to create a plurality of elongated boneless thigh meat strips.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC +1

Poultry wing separator and partial deboner

Poultry wings are suspended by their tip segments and oriented so that their outside surfaces face one side of the processing path, with right wings oriented with their elbows leading, and left wings oriented with their elbows trailing. The lower, primary segments are bent at the elbow joints by a bending guide, laterally and upwardly about an elbow guide, opening the elbow joints. The open joints are cut so as to release the primary segments. The mid-wing segments are compressed and the bone ends are moved laterally from the wing tip segments, causing the bone ends of the mid-wing segments to pop out of the tip segments. In both instances, the bones of the segments are exposed in the final products, so when the products are cooked, the exposed bone ends are free of grease, etc. and are suitable for grasping by the fingers of the hand for eating as finger food.

Owner:SYSTATE GROUP

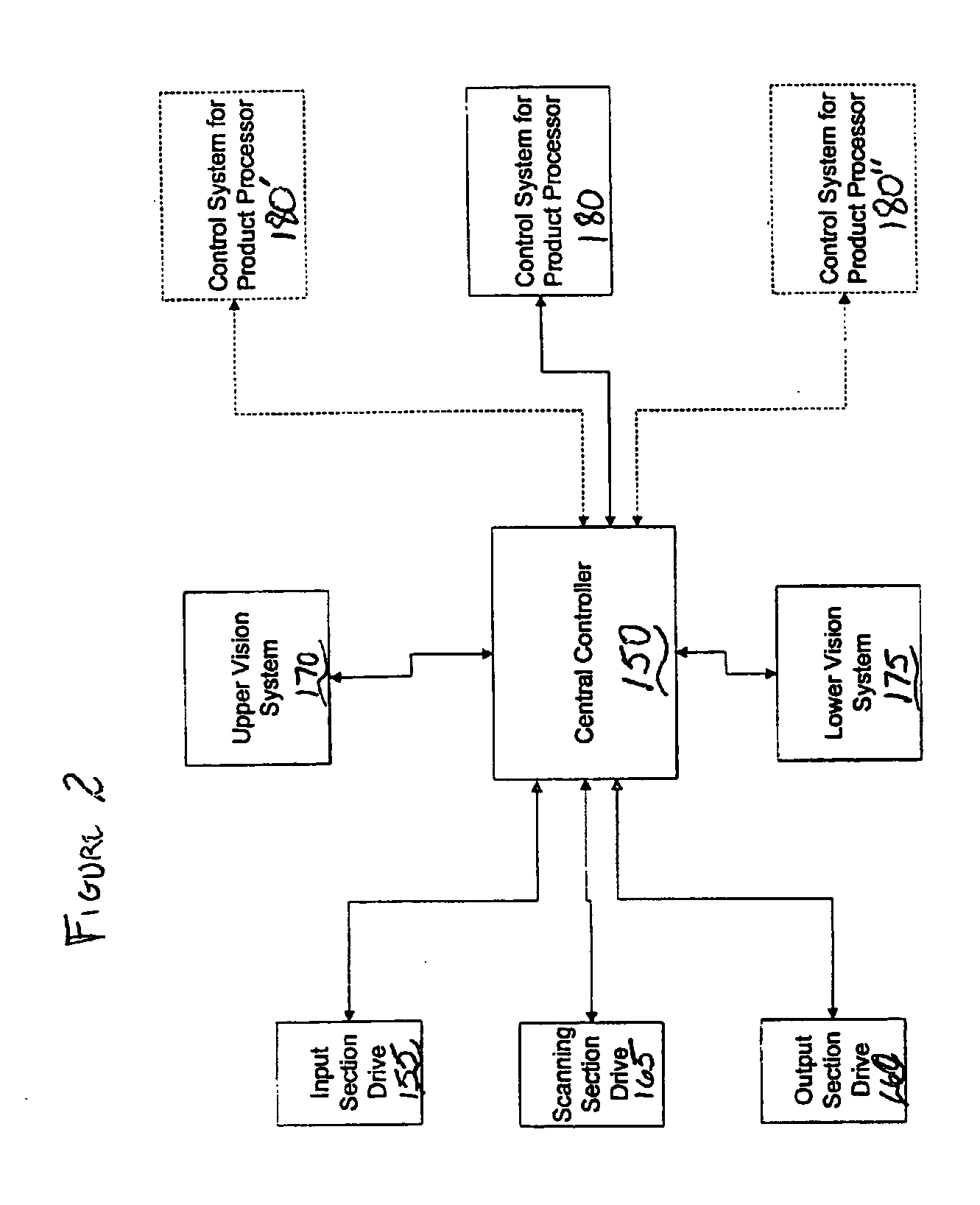

Automated product profiling apparatus and product slicing system using same

InactiveUS20050199111A1Meat holding apparatusMethod using image detector and image signal processingProduct analysisVolumetric Mass Density

A system, suitable for high-speed operation, by which raw product (45), such as a slab of meat, can be accurately processed, such as by slicing into segments of desired weight, comprises a product profiling apparatus (15). The product profiling apparatus (15) measures the profile of the physical process. The product profiling apparatus (15) includes line lasers (75, 85) for directing a line of light across the upper and lower surfaces of the product (45) and visual image cameras (80, 90) directed toward the profile surface to capture, at fixed increments, the product profile. The product may also be weighed and the product density determined from the overall profile measurements. A controller (150) receives this data, and instructs the physical process accordingly.

Owner:PROVISUR TECHNOLOGIES INC

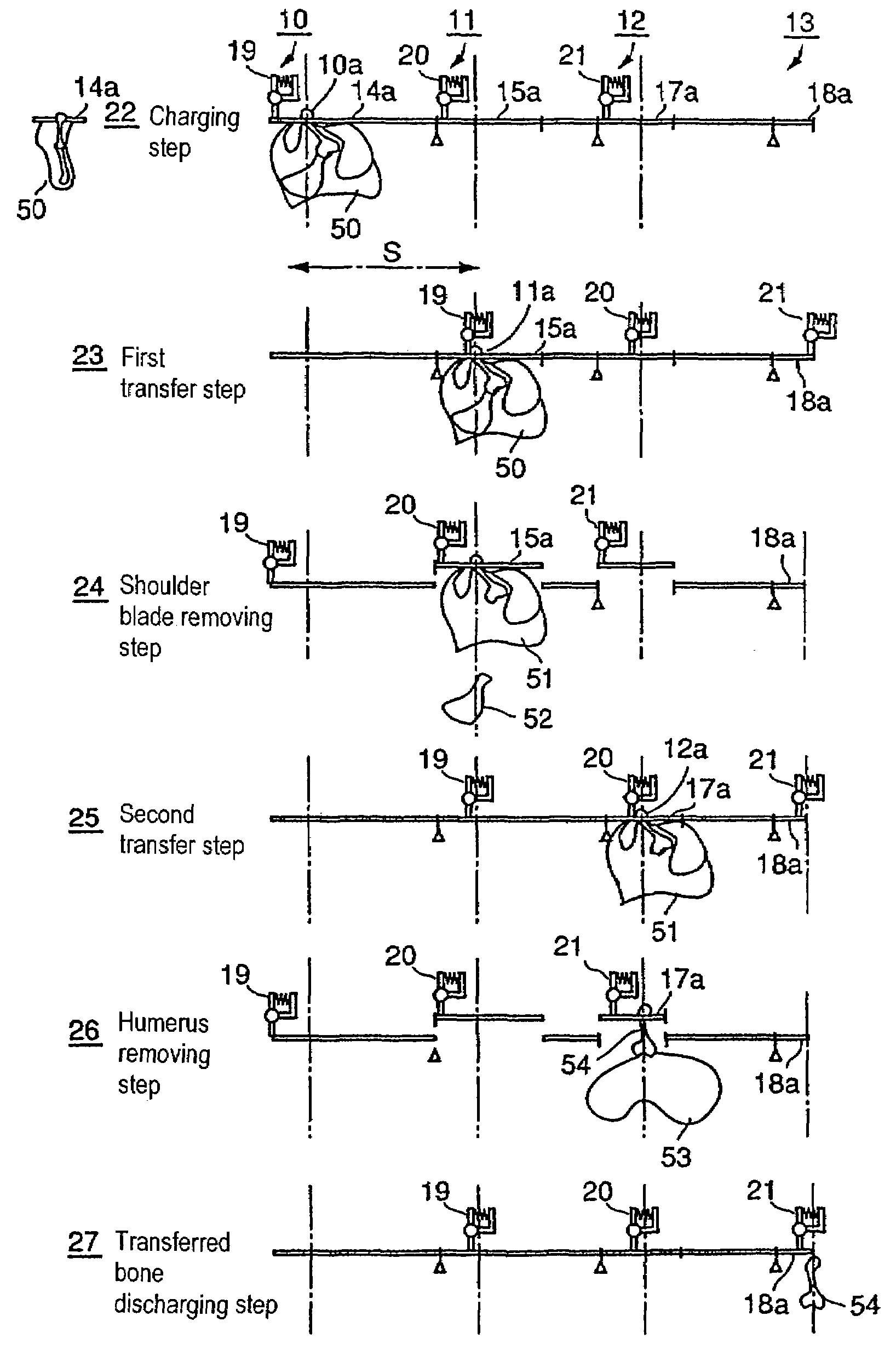

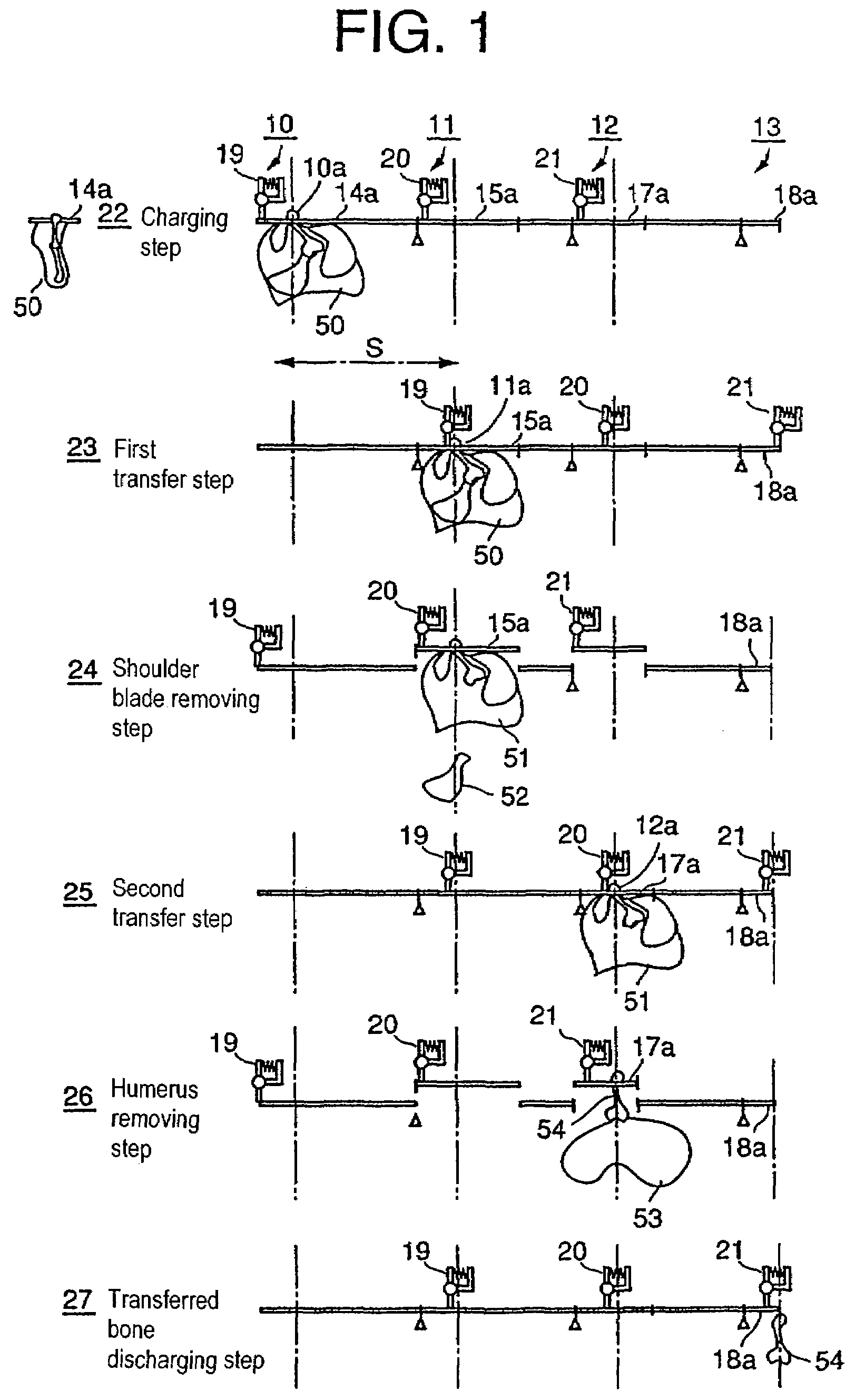

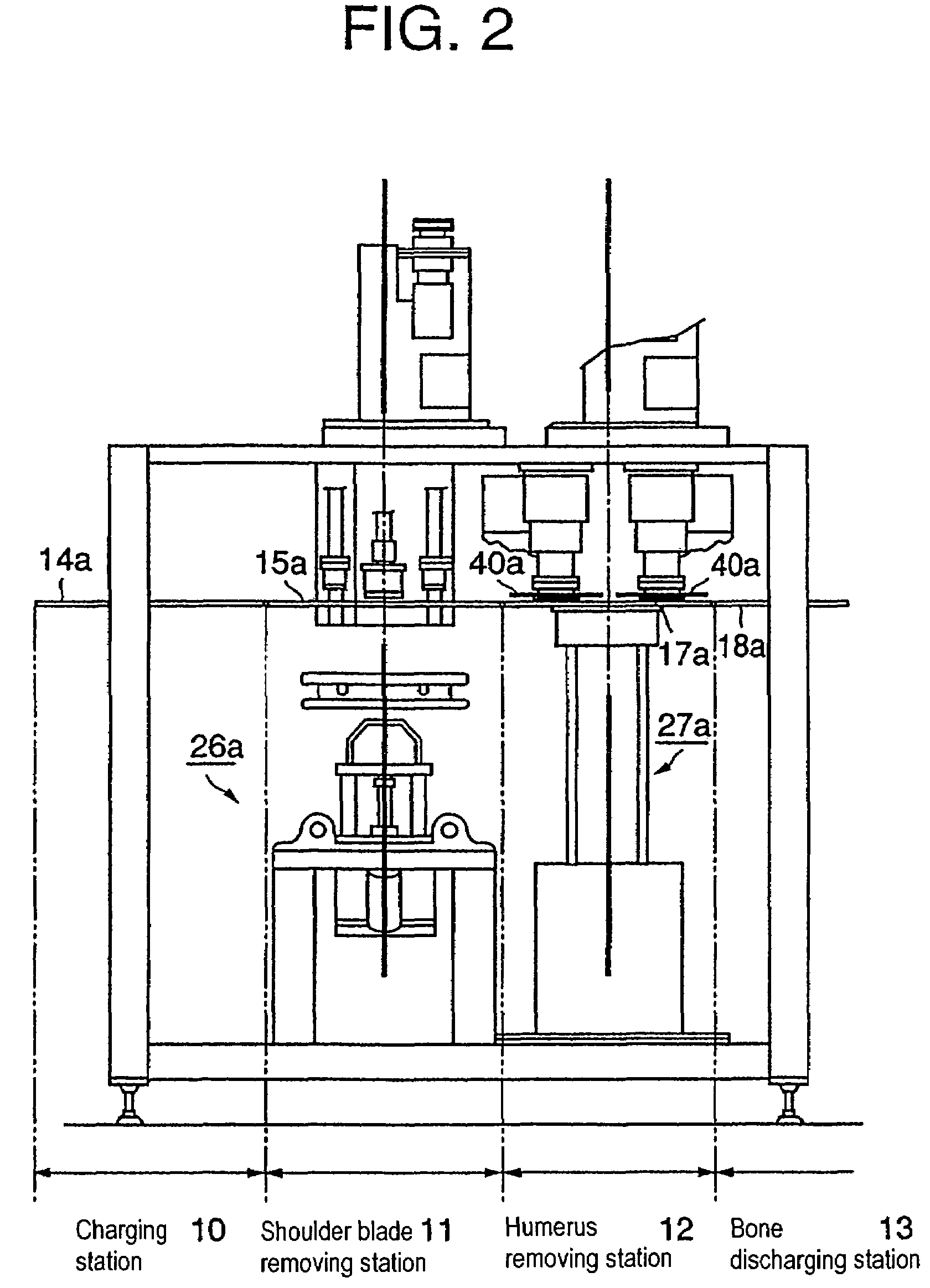

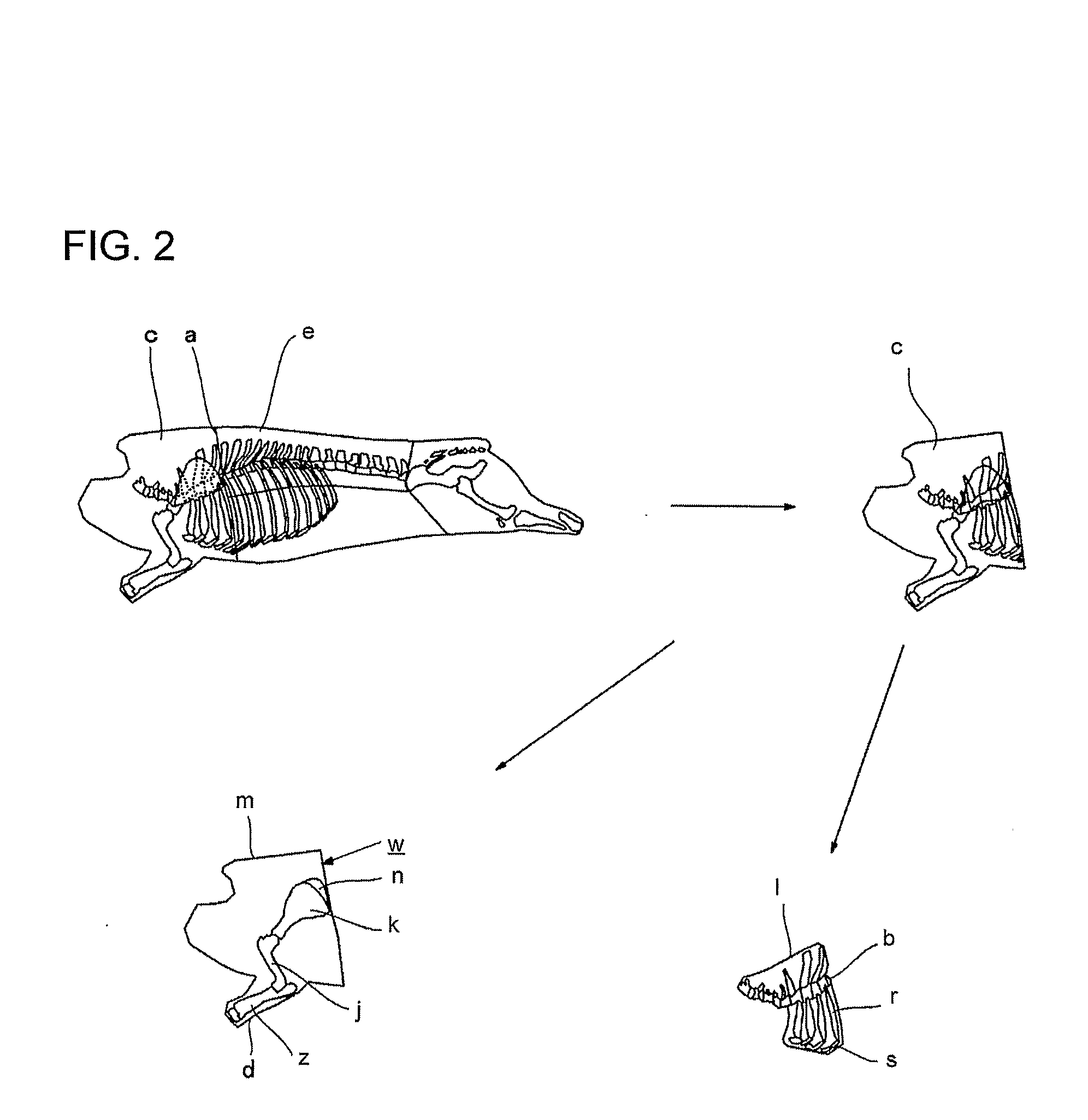

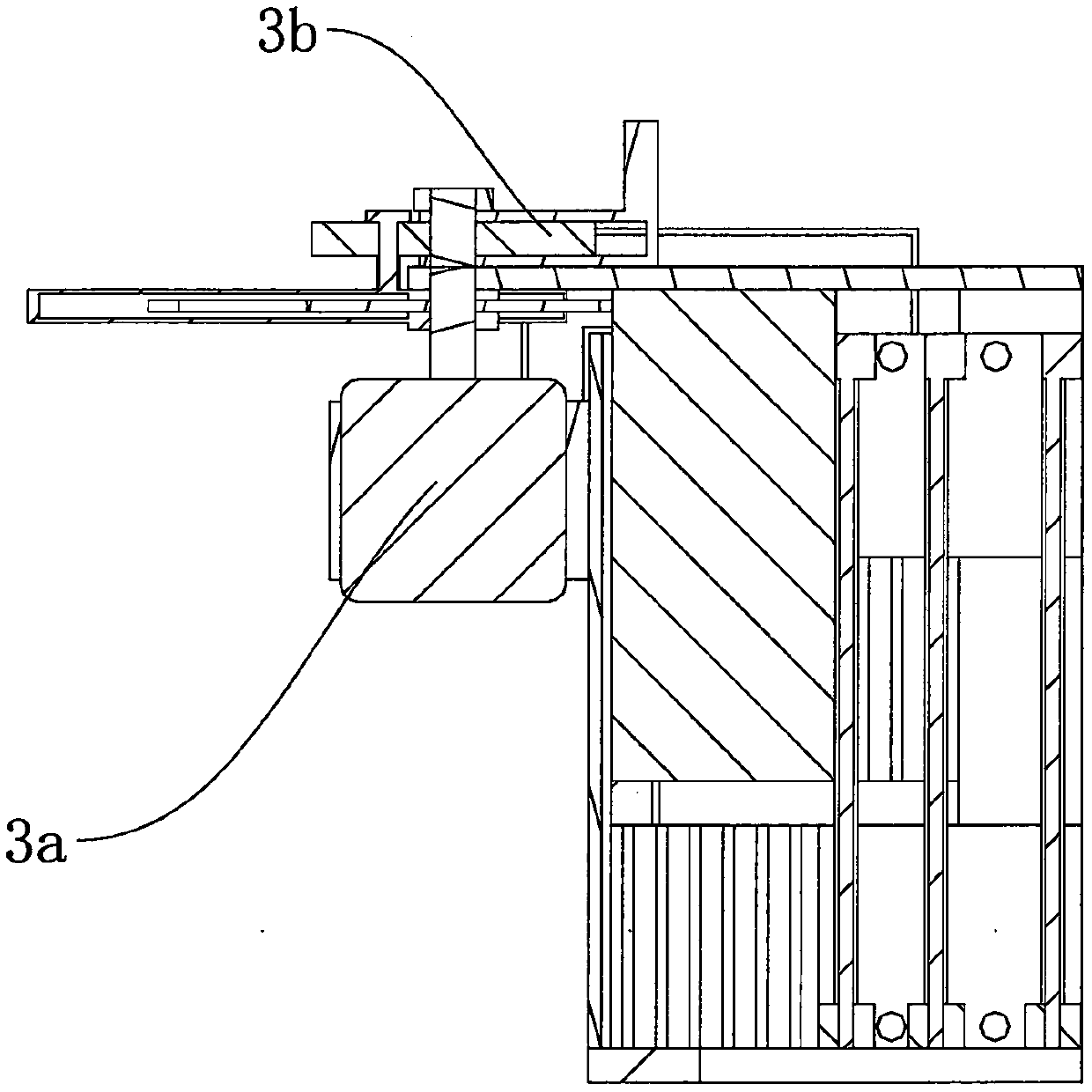

Deboning system of meat

InactiveUS7198564B2Low costMaximum efficiencyMeat holding apparatusPoultry processingShoulder BladesEngineering

Owner:MAYEKAWA MFG CO LTD

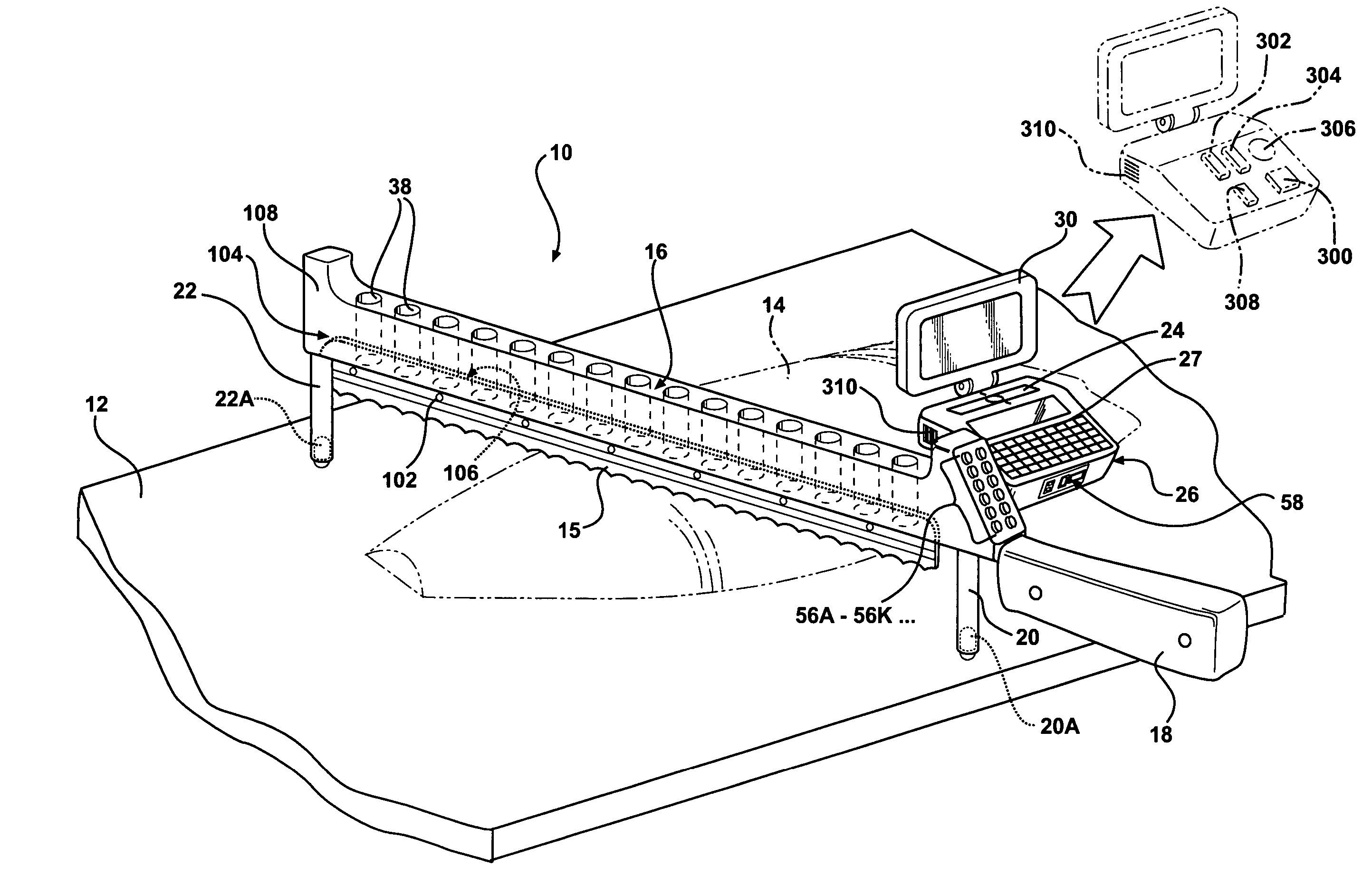

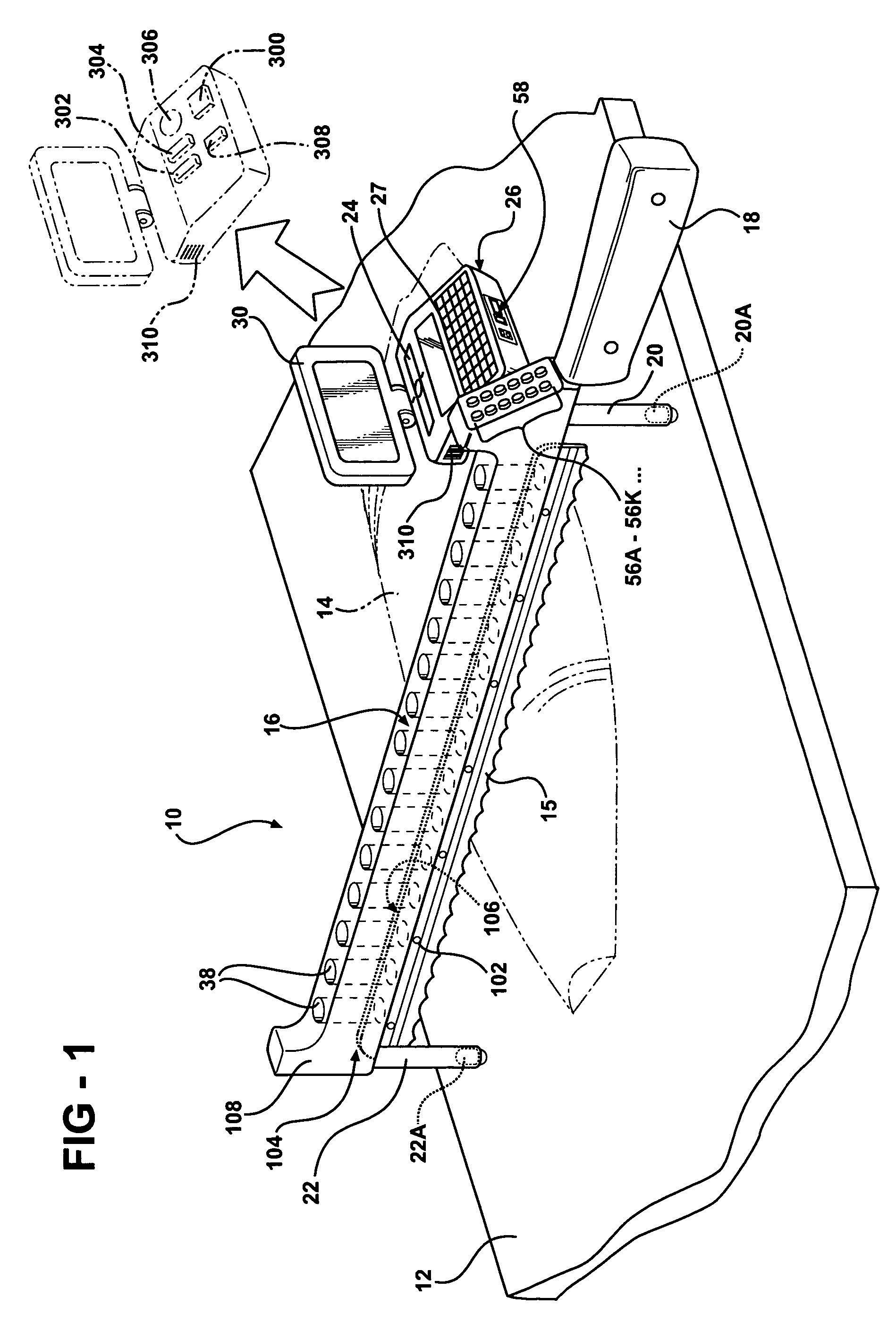

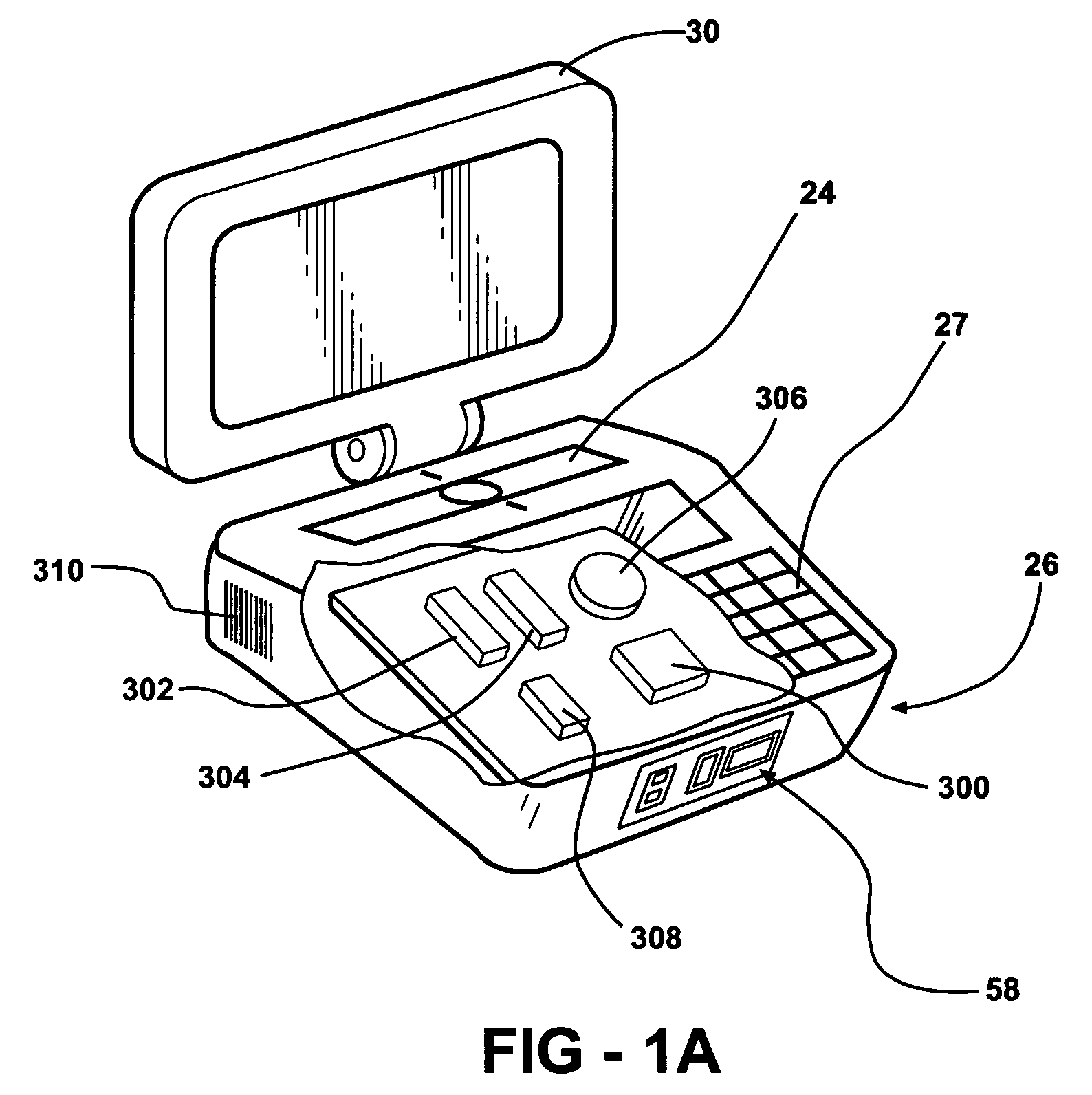

Apparatus and method for displaying numeric values corresponding to the volume of segments of an irregularly shaped item

ActiveUS7158915B2Low costFast and accurate determinationMeat holding apparatusFeeler-pin gaugesNumeric ValueWeight value

An apparatus and method for displaying the weight or cost of segments of an irregularly shaped item involves passing a sensor bar supported above a supporting surface over the item lying on the surface. A compact hand-held embodiment of the sensor bar enables the operator to move the sensor bar in various linear or non-linear motions over the item surface as the sensor bar moves laterally across the item surface while the sensor bar support posts remain in constant contact with the supporting surface. The sensor bar contains one or more sensors which generate signals corresponding to the height of the item as the sensor bar traverses the item. At the same time, a displacement detector arrangement generates signals corresponding to displacement of the sensor bar relative to the support surface. These signals are processed in a signal processor to determine the volume of an uncut segment of the item lying behind the sensor bar at successive positions. Each of these cumulative volume determinations may be continuously converted into numeric weight values based on the density factor for the particular type of item, whereby numeric weight and cost values (based on weight) are continuously displayed as the sensor bar is stroked over the item, thus enabling the operator to accommodate an on-looking consumer's specific requests as per the particular portion desired based on the physical appearance, weight, and cost of an item before the item is cut.

Owner:WARGON KENNETH

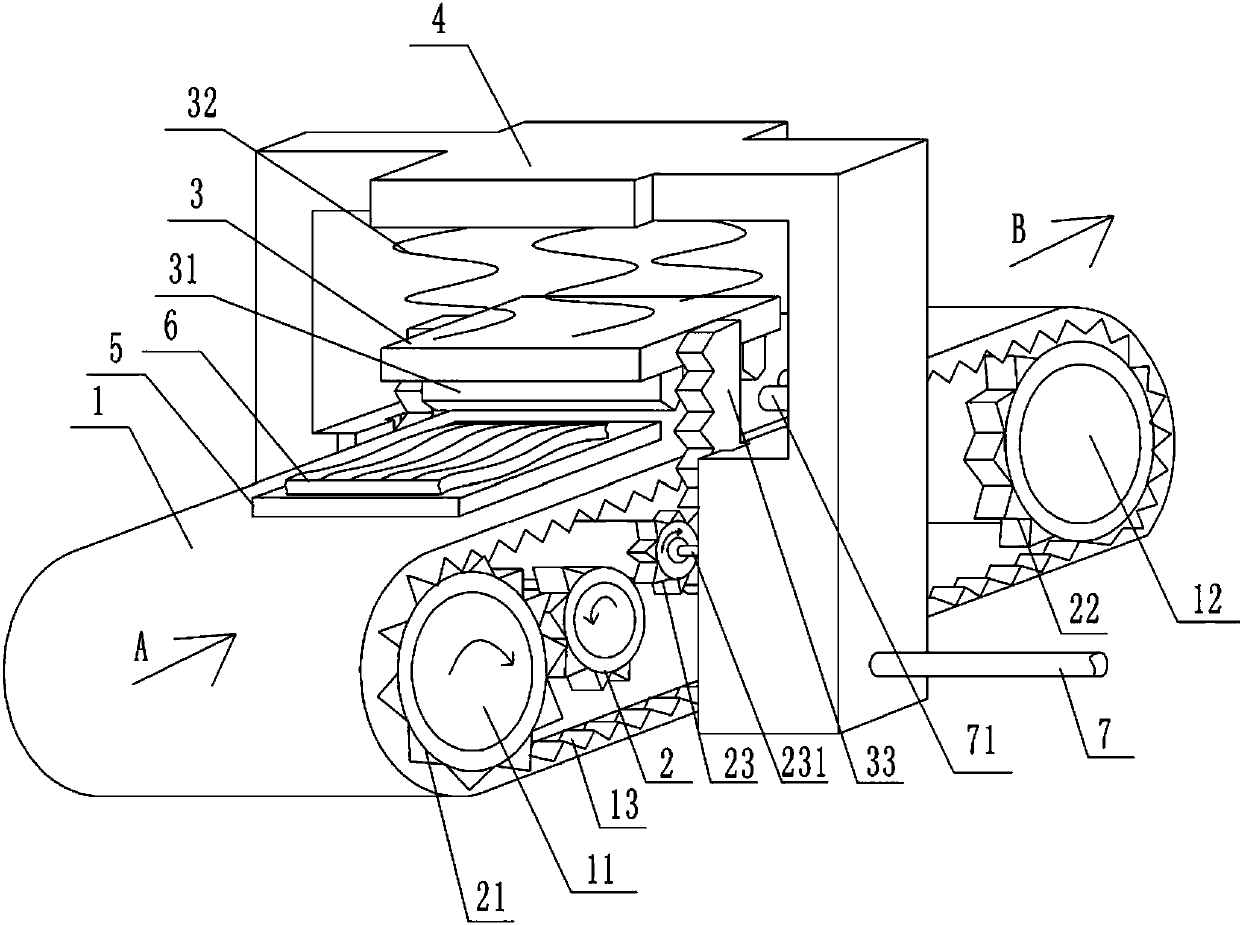

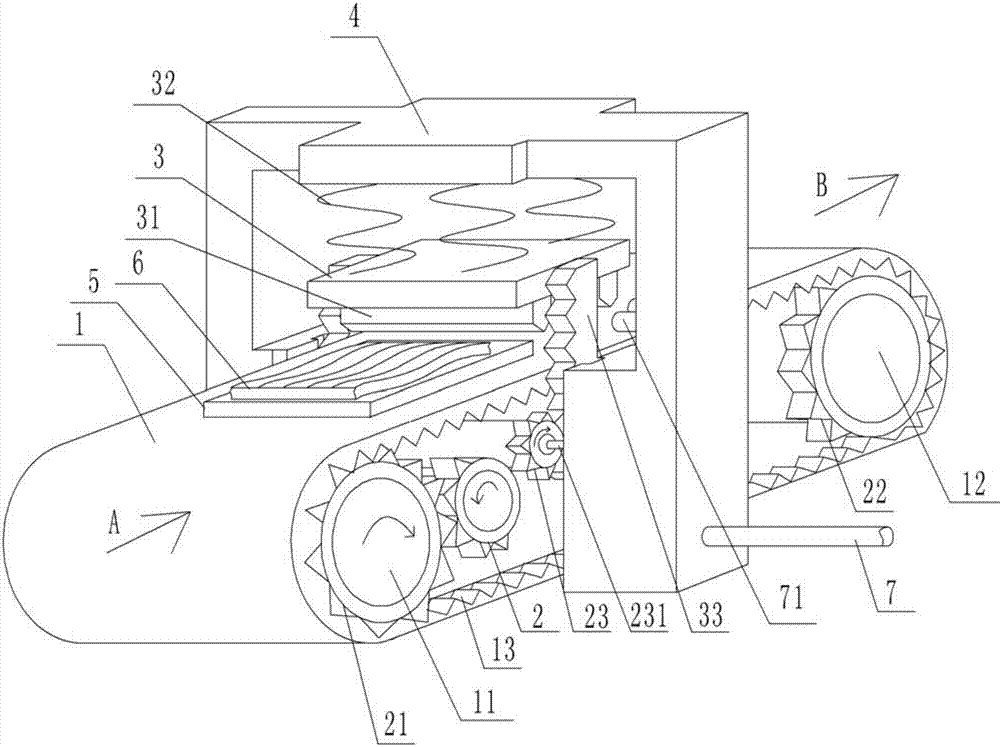

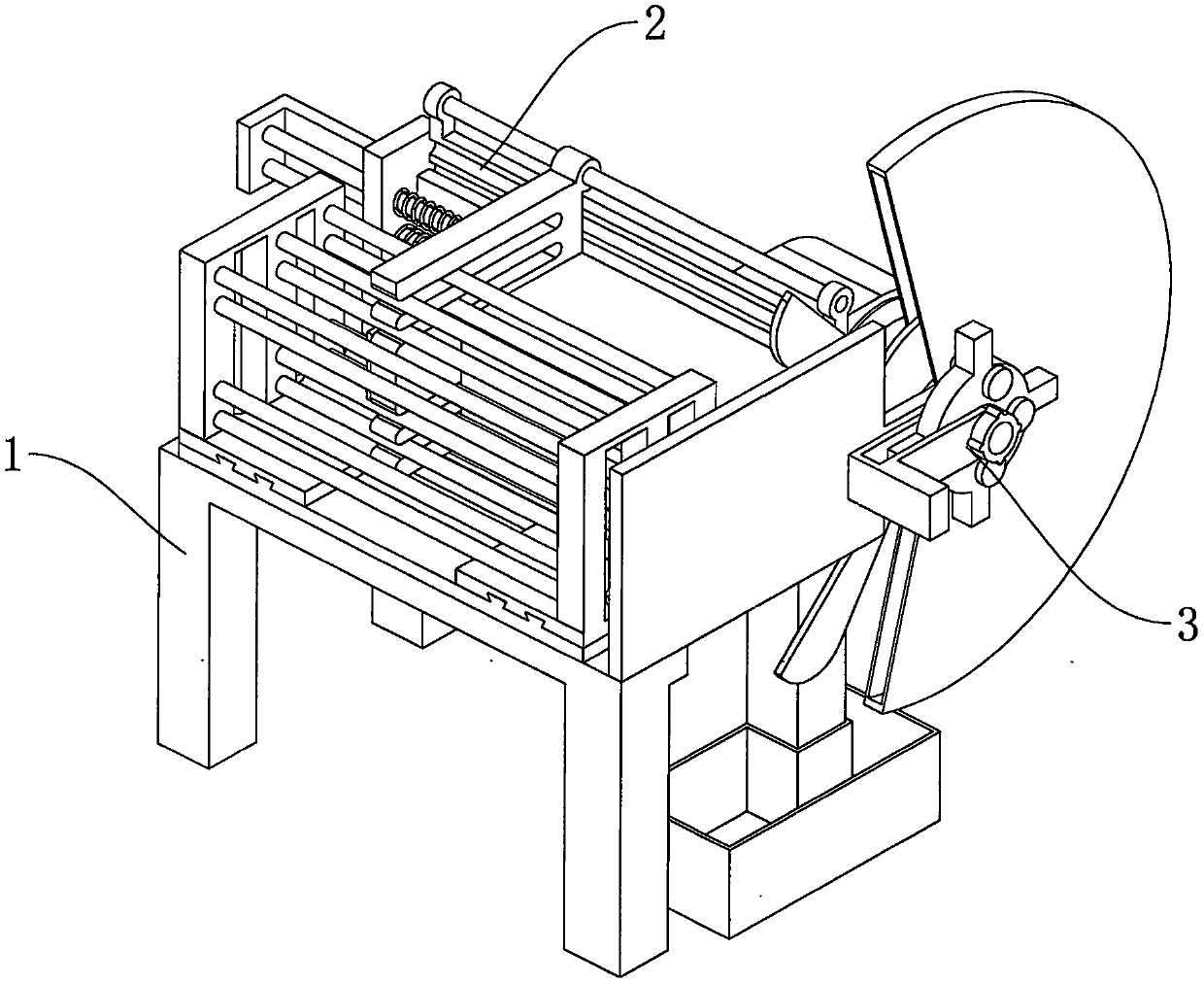

Fresh meat cutting and shredding device

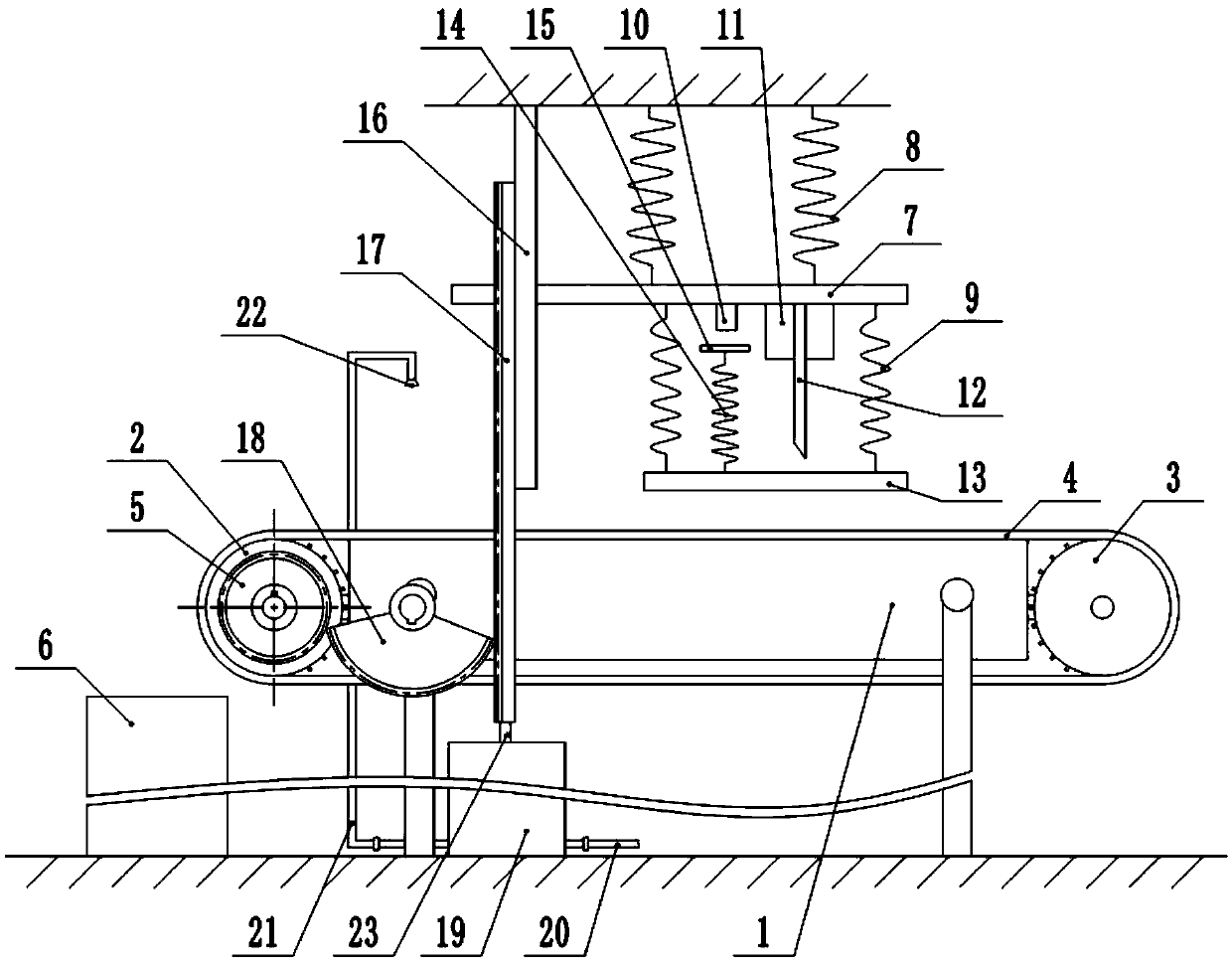

InactiveCN109591091ARealize automatic dischargeImprove cutting and decomposition efficiencyMeat holding apparatusMetal working apparatusDrive wheelEngineering

The invention relates to the technical field of food processing, and in particular discloses a fresh meat cutting and shredding device. The fresh meat cutting and shredding device comprises a rack anda cutting table, where the two ends of the cutting table are rotationally connected with a driving wheel and a driven wheel respectively, the driving wheel and the driven wheel are jointly wound witha plate-chain conveying belt, and the driving wheel is coaxially connected with a gear; a transverse plate is arranged above the cutting table and is connected onto the rack through a spring, and a press plate is arranged under the transverse plate and is connected with the transverse plate through a spring; a cutting knife is arranged on the side, facing the press plate, of the transverse plate,and a knife seam for enabling the cutting knife to pass is formed in the pres plate; the rack is fixedly connected with a fixed strip, and the fixed strip is vertically connected with a toothed rackvertically; the toothed rack is meshed with an incomplete gear; and the incomplete gear can be meshed with the gear in the rotation process. According to the fresh meat cutting and shredding device, by the meshing of the incomplete gear and the gear, the driving wheel is driven to rotate, and therefore automatic feeding and discharging of fresh meat is realized; by the meshing of the incomplete gear and the gear, the cutting knife is driven to move, and therefore cutting and shredding of the fresh meat are realized; and thus, the working efficiency is improved.

Owner:CHONGQING NIANJI FOOD

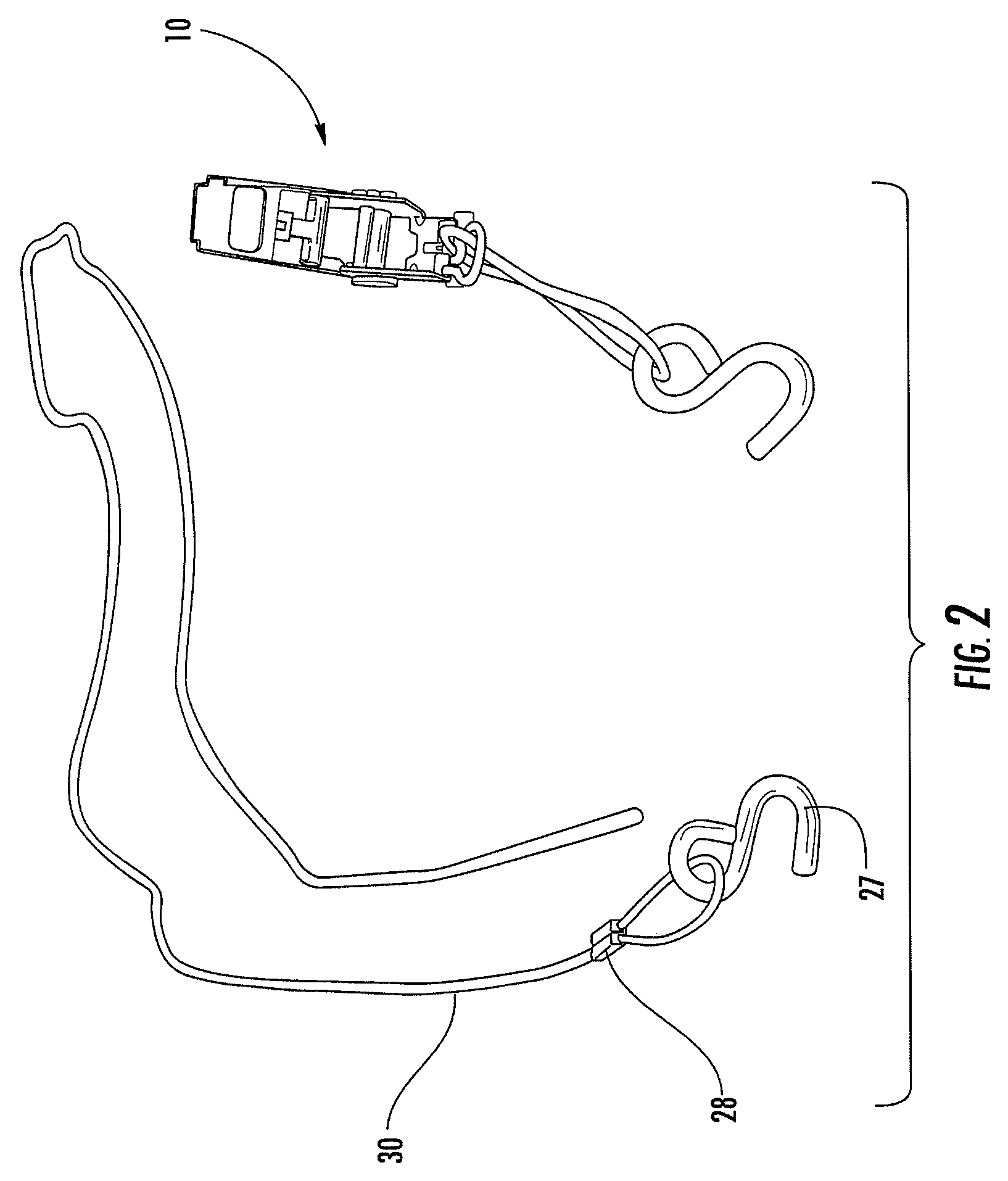

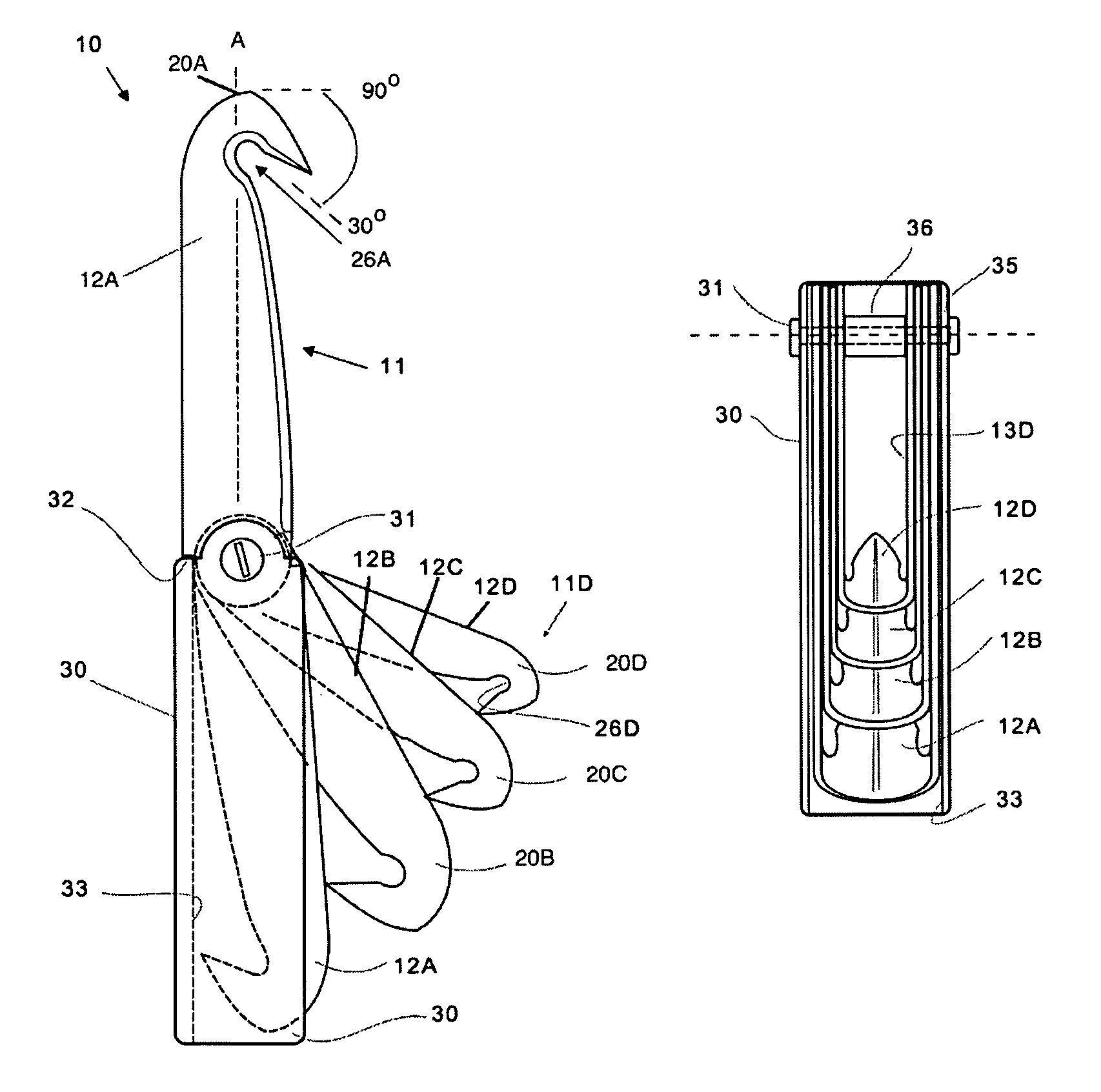

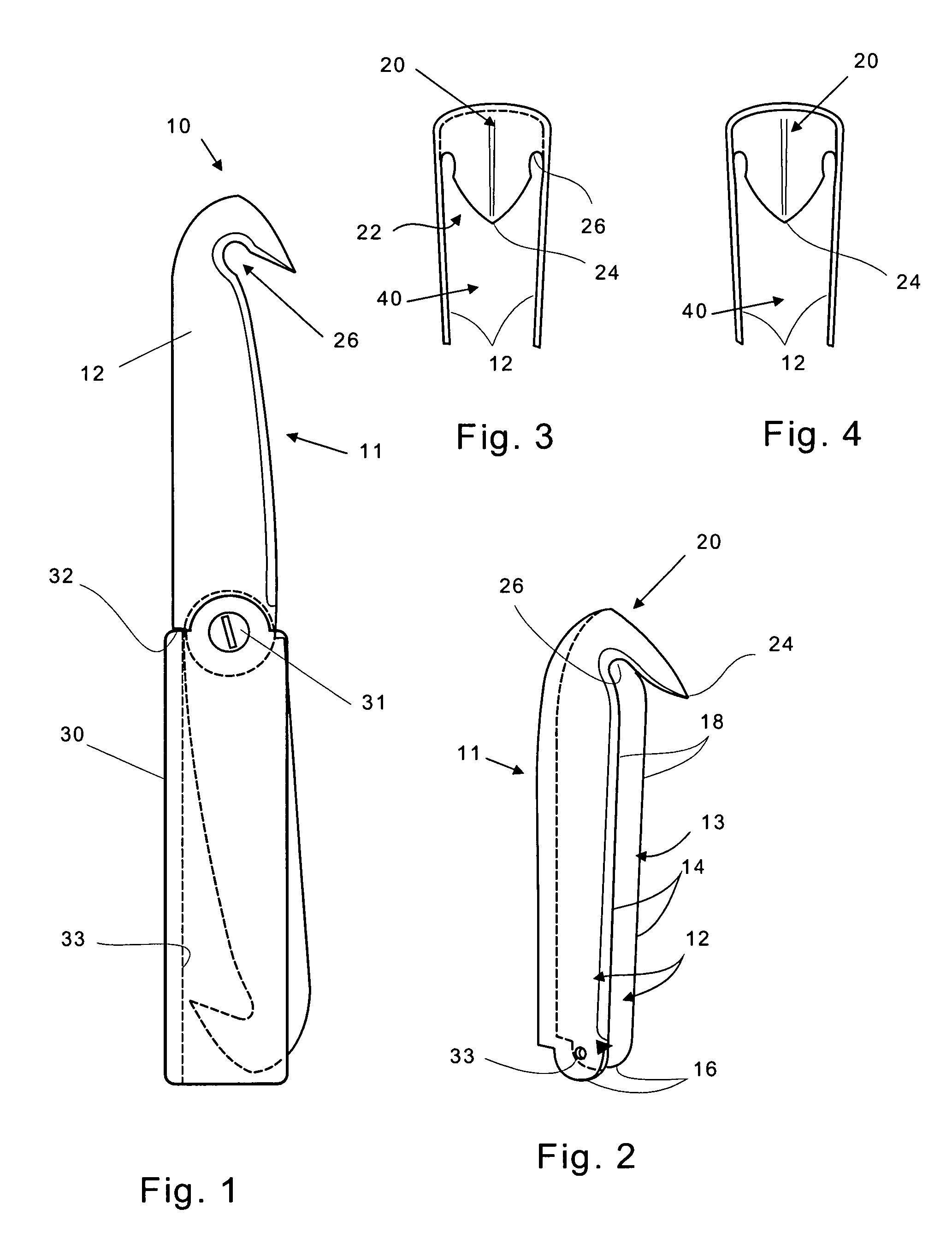

Tree stand lock apparatus and method of use

ActiveUS7584940B2Easily and conveniently employedEasy to adjustMeat holding apparatusSnap fastenersTree standEngineering

A tree stand lock apparatus comprises a ratchet buckle part and a wire rope part. The ratchet buckle part comprises a spool with a transaxial bore, a ratcheting lever handle, a locking means and a base affixed to a hook. The wire rope part comprises a wire rope, one end of which is affixed to a hook. The lock may be employed by wrapping the wire rope around a portion of a tree stand, hooking the hook of the rope to the hook of the ratchet buckle and threading the wire rope through the transaxial bore. The ratchet buckle is operated to render the wire rope taut and the buckle is locked in the closed position.

Owner:LONE FOUNTAIN HLDG LLC +1

Decoring saw

InactiveUS6120367ASpeed up removalQuantity minimizationMeat holding apparatusBone cleaning devicesEngineeringKnife blades

Owner:TYSON FRESH MEATS

Food processing method

InactiveCN107932571ASave spaceSave resourcesMeat holding apparatusMetal working apparatusEngineeringFood item

The invention relates to the technical field of devices for processing meat or bones, in particular to a food processing method. The food processing method is carried out through a food processing device. A food processing device is used for carrying out processing. The food processing method comprises the following steps that firstly, pork ribs to be cut are prepared, wherein a storage plate is put on a conveyor belt, the pork ribs needing to be cut are put on the storage plate, bones of the pork ribs are vertically put and are parallel to the conveyor belt, and a motor is started; secondly,after the pork ribs in the first step are cut, the storage plate is taken down from the conveyor belt, and the cut pork ribs are drained dry; thirdly, the dried pork ribs in the second step are put into boiling water and taken out 3-6 minutes later; and fourthly, a cutter is used for slicing the pork ribs in the third step. By means of the scheme, bone debris on the cutter in the cutting process can be cleaned, and it can be guaranteed that the cut pork ribs are tidy in appearance.

Owner:重庆多笠原食品有限公司

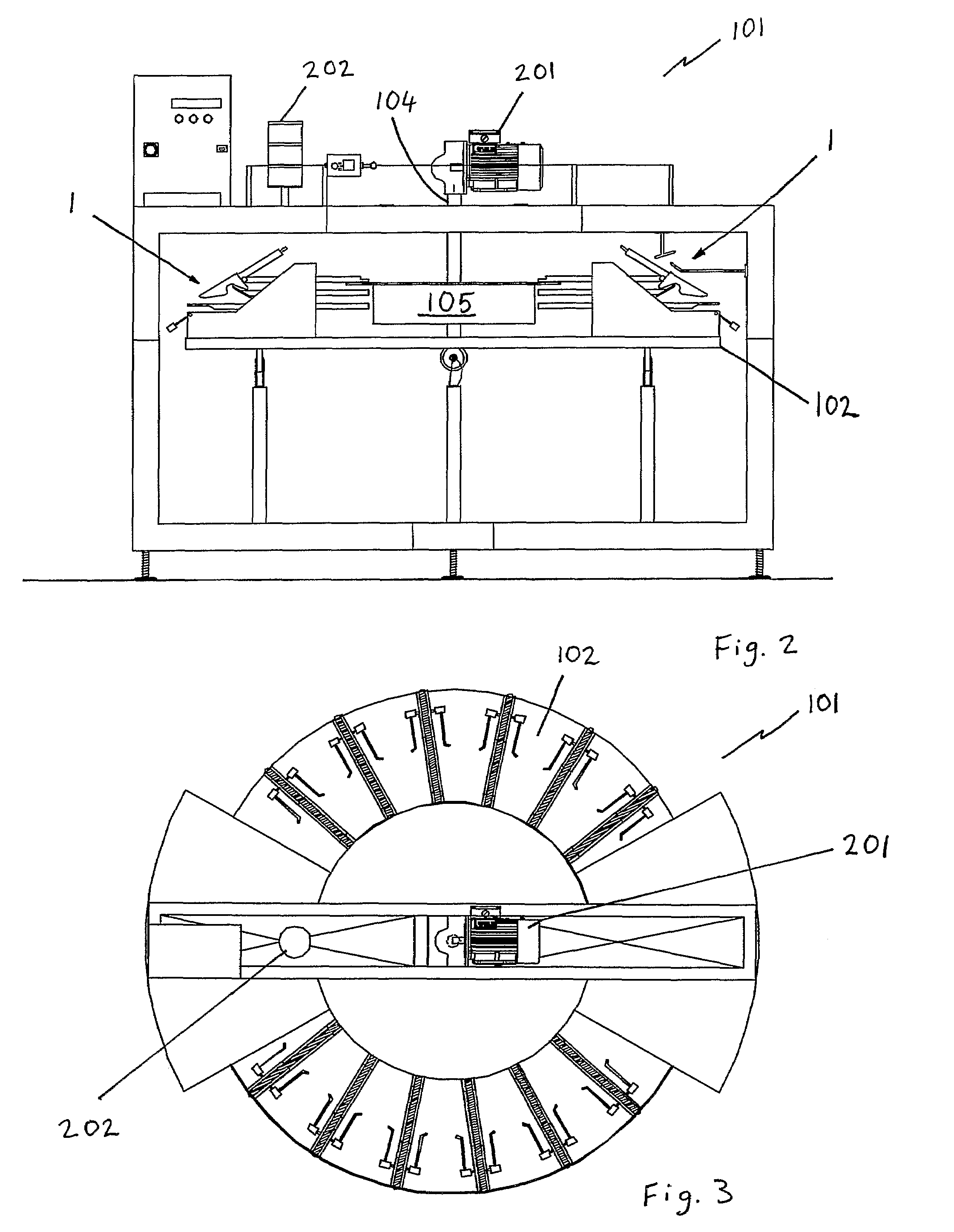

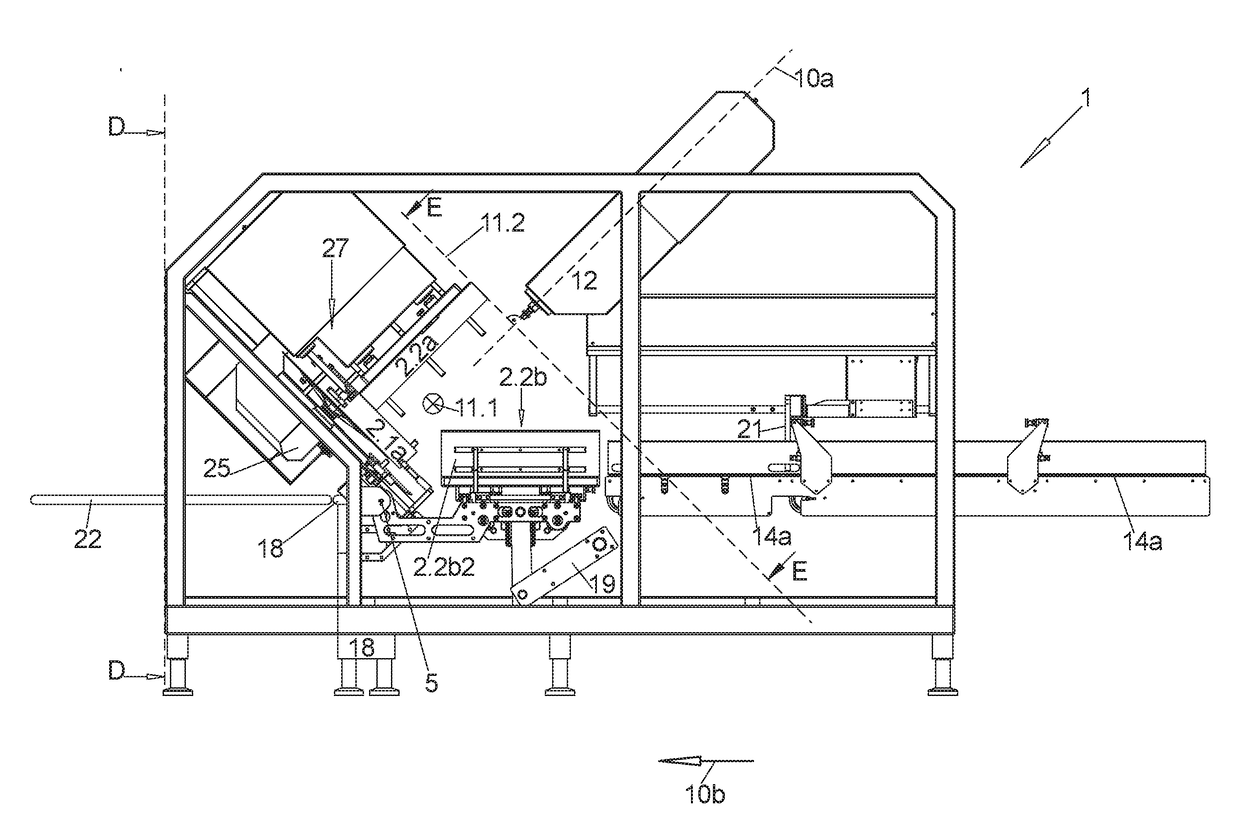

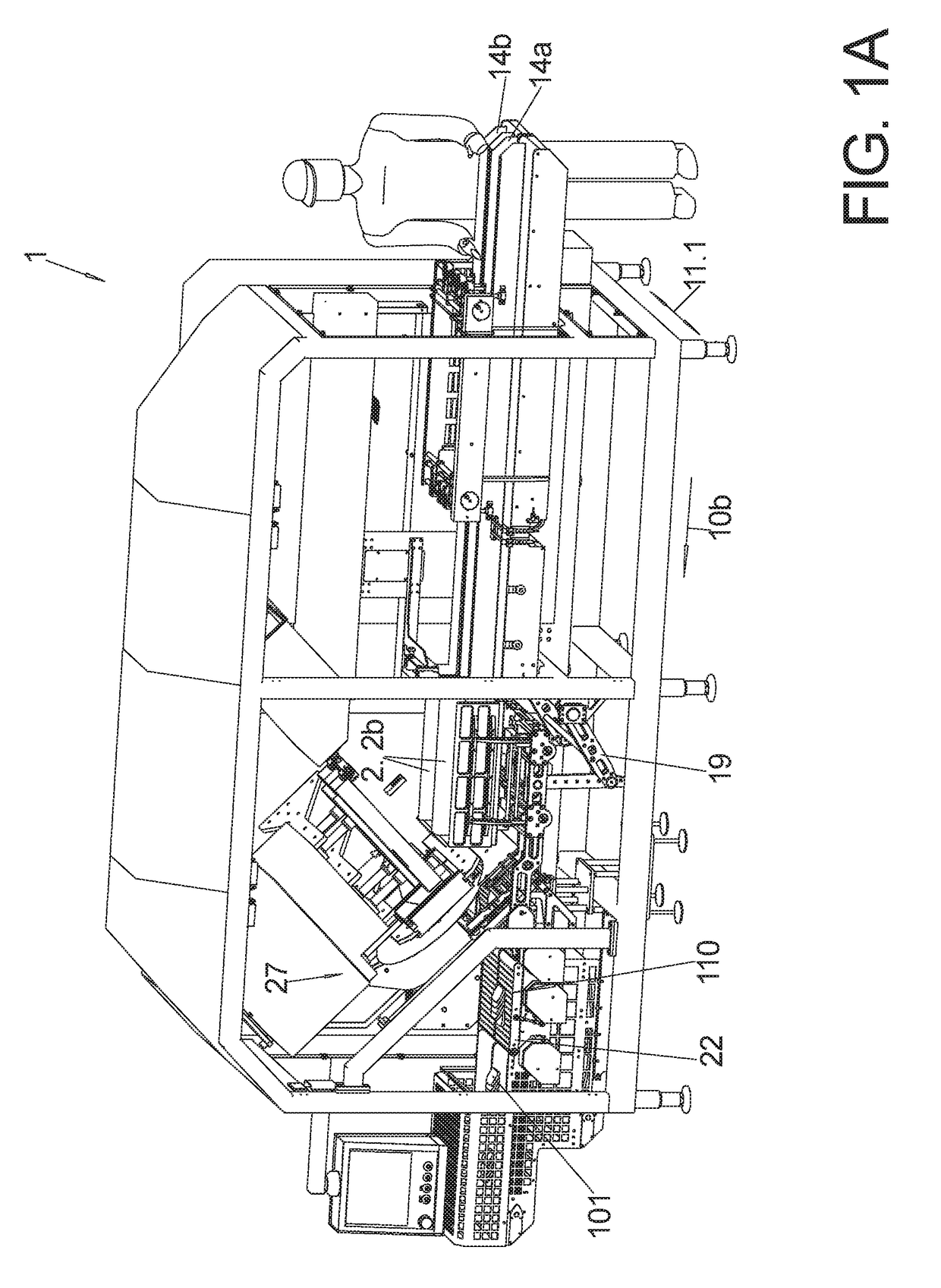

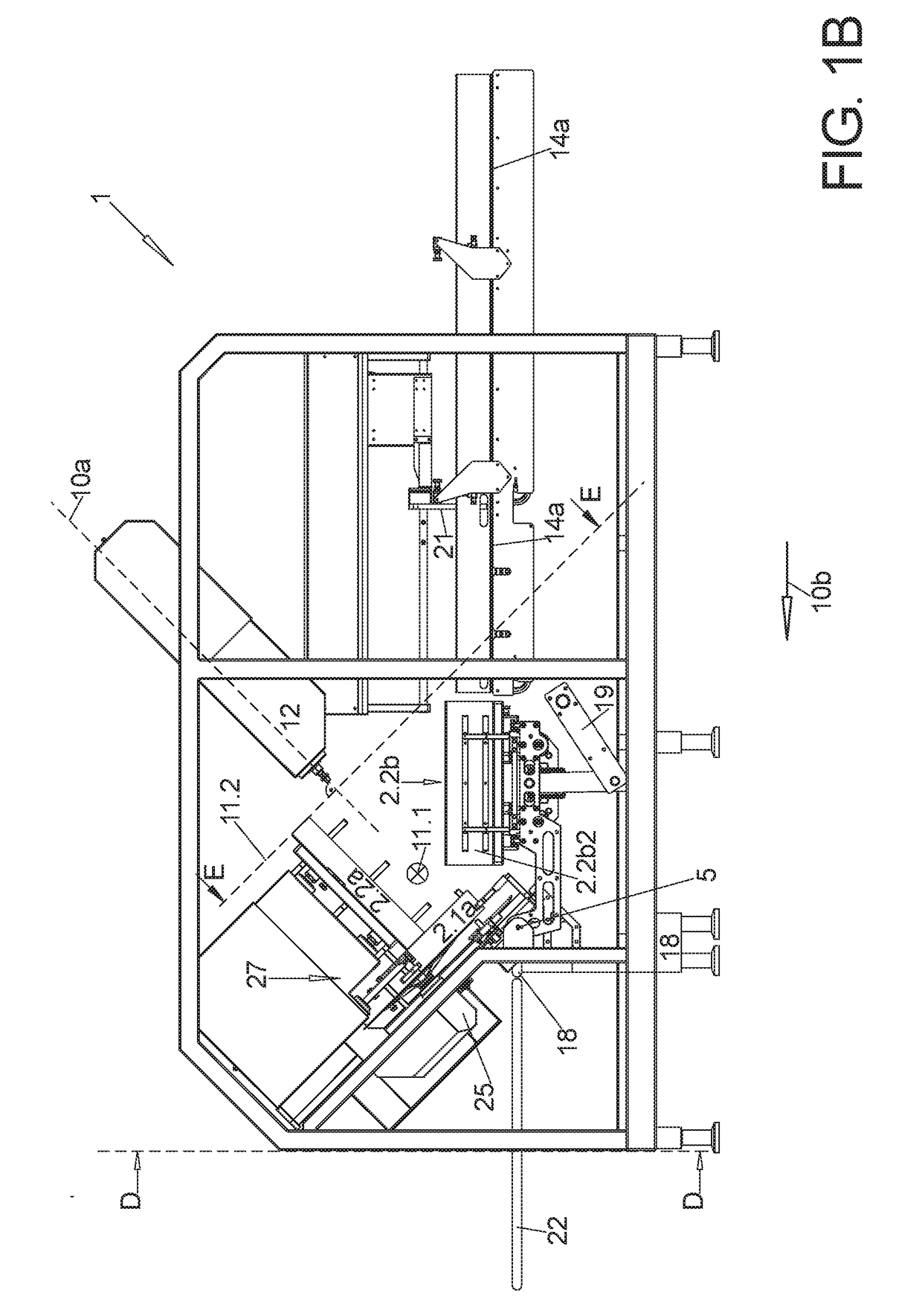

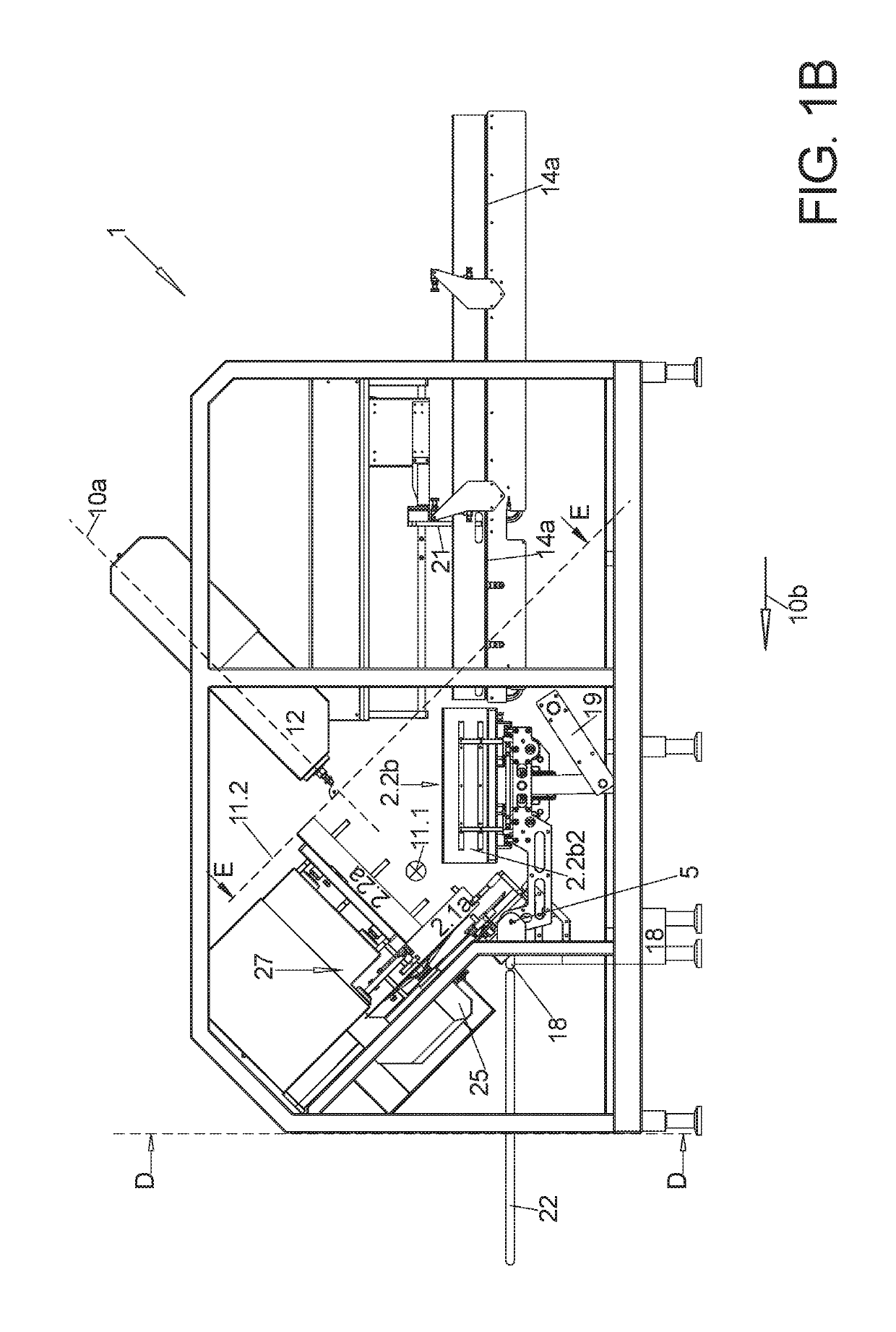

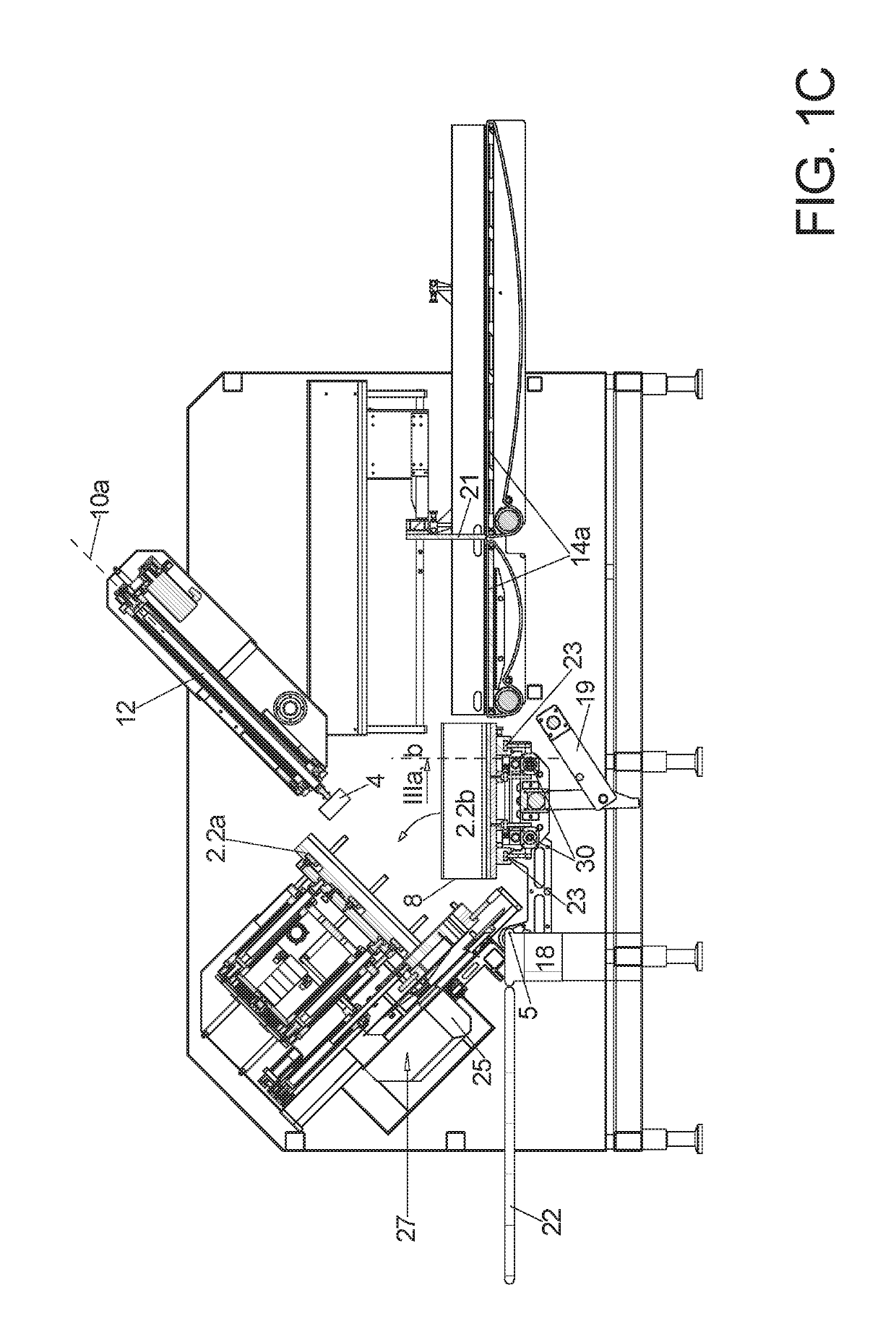

Slicing machine and method for slicing elastic strands in particular meat strands

ActiveUS20170312931A1Facilitates short idle timeImprove throughputMeat holding apparatusFish threading devicesEngineeringMechanical engineering

A slicing machine for slicing meat strands that have a cross section that varies over a longitudinal extension in large numbers and as quickly as possible into weight precise slices. In one embodiment, two meat strands are received adjacent to each other in a respective form tube and pushed against a respective separately adjustable stop plate independently from each other by a controlled longitudinal press plunger and compressed in the longitudinal direction. In addition, a cross section of the form tubes may be reduced in a first transversal direction jointly and in a second transversal direction independently from each other and thus the respective meat strand is transversally compressed to a constant cross section prior to slicing.

Owner:TVI ENTWICKLUNG & PROD GMBH

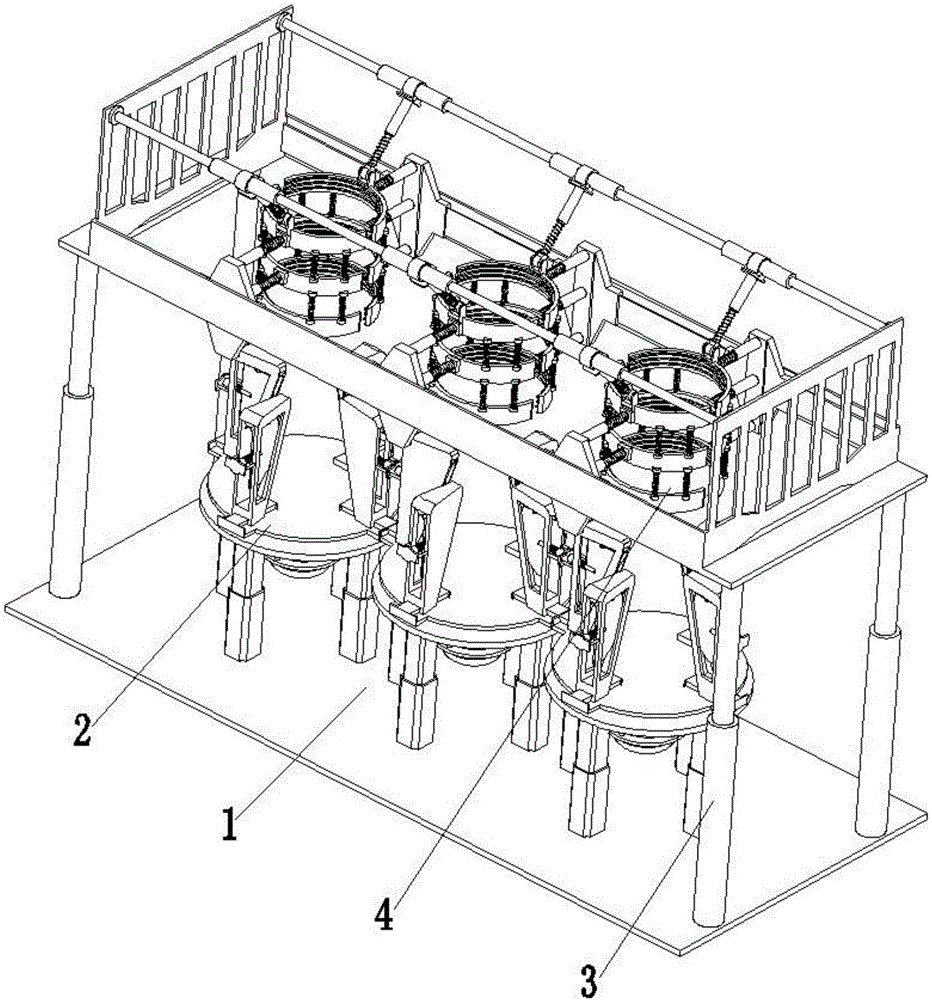

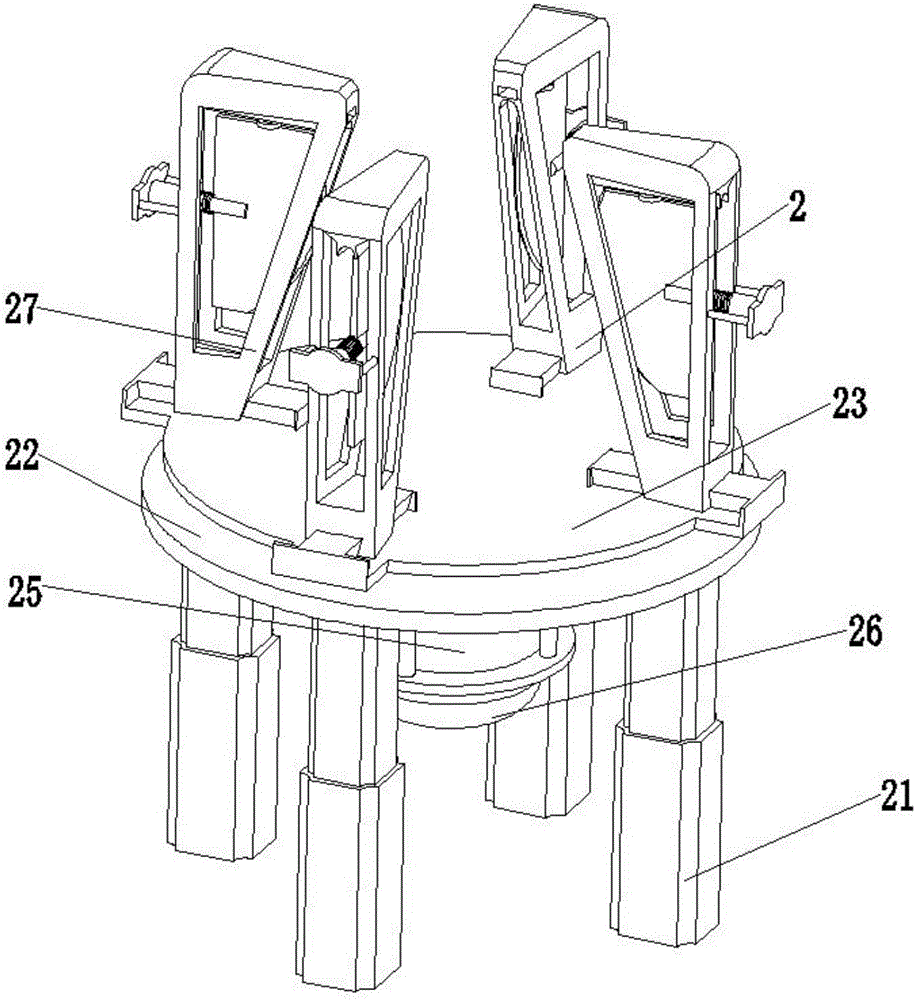

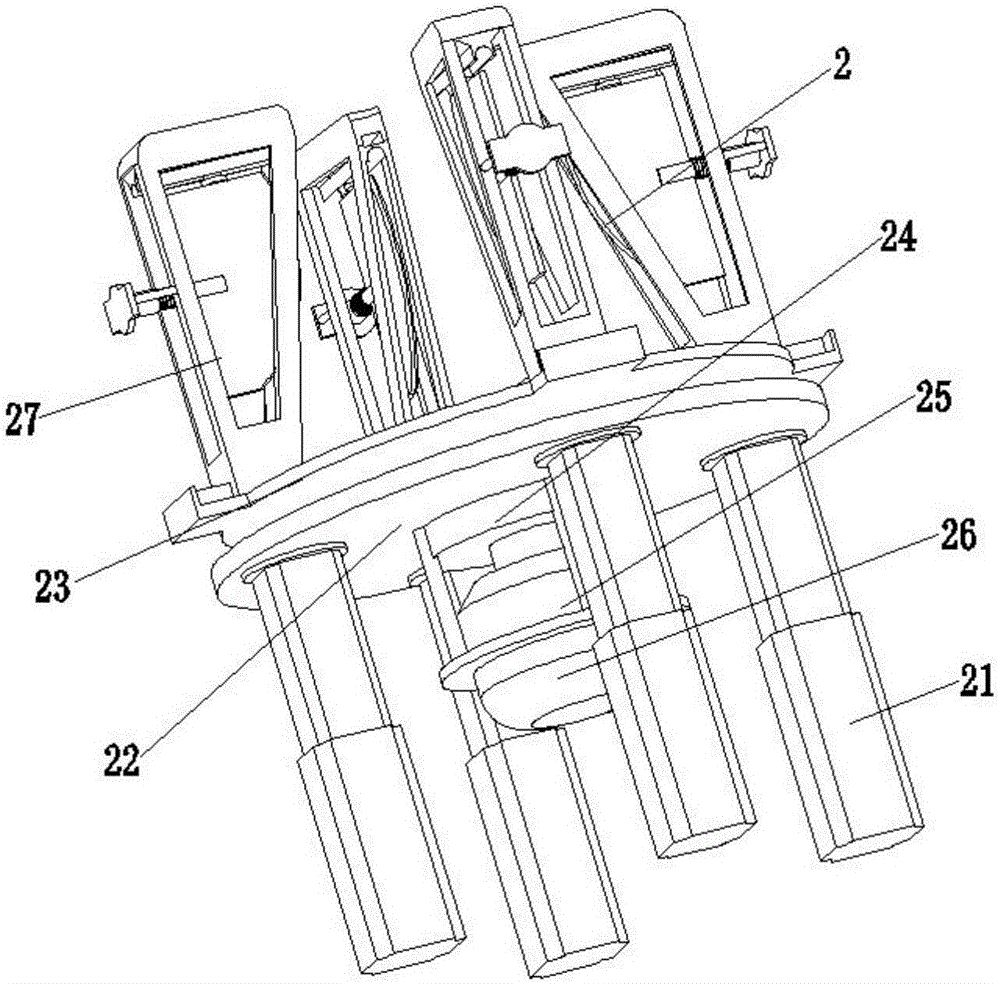

Auxiliary processing robot for pig trotter meat products

ActiveCN106386997AQuick removalReduce manufacturing costMeat holding apparatusElectric driveEngineering

The invention relates to an auxiliary processing robot for pig trotter meat products. The auxiliary processing robot comprises a bottom plate, three hulling manipulators, a lifting supporting rod and fixing devices, wherein the hulling manipulators are linearly distributed along the lateral central axis of the bottom plate at intervals, and the lower ends of the hulling manipulators are fixedly connected with the bottom plate; the fixing devices are located directly over the hulling manipulators, and the fixing devices and the bottom plate are connected through the lifting supporting rod; and the lifting supporting rod can adopt an electric-driven push rod, a pneumatic push rod and a hydraulic pressure push rod, and the whole heights of the fixing devices can be adjusted by the lifting supporting rod. According to the auxiliary processing robot disclosed by the invention, nail hulls at pig trotter tips can be quickly removed, the mechanical automation degree is high, the removing speed is high, and the effects of being clean and free from residuals are realized. The problem that in the deep processing course of pig trotters, the working procedure of removing nail hulls at the pig trotter tips consumes massive labor force is solved, the production cost for deep processing of the pig trotters is saved, the function that batch mechanized operation for deep processing of the pig trotters is realized, and the production and making efficiency is improved.

Owner:安徽鑫松亚食品科技股份有限公司

Device for mounting on a vehicle for hoisting and transporting a big-game carcass

Owner:BILCIK LAWRENCE STEPHEN

Method and apparatus for suspending a sausage from a stick

InactiveUS6869353B2Space minimizationReliable supplyMeat holding apparatusMeat/sausage hanging-upEngineering

Owner:HITEC

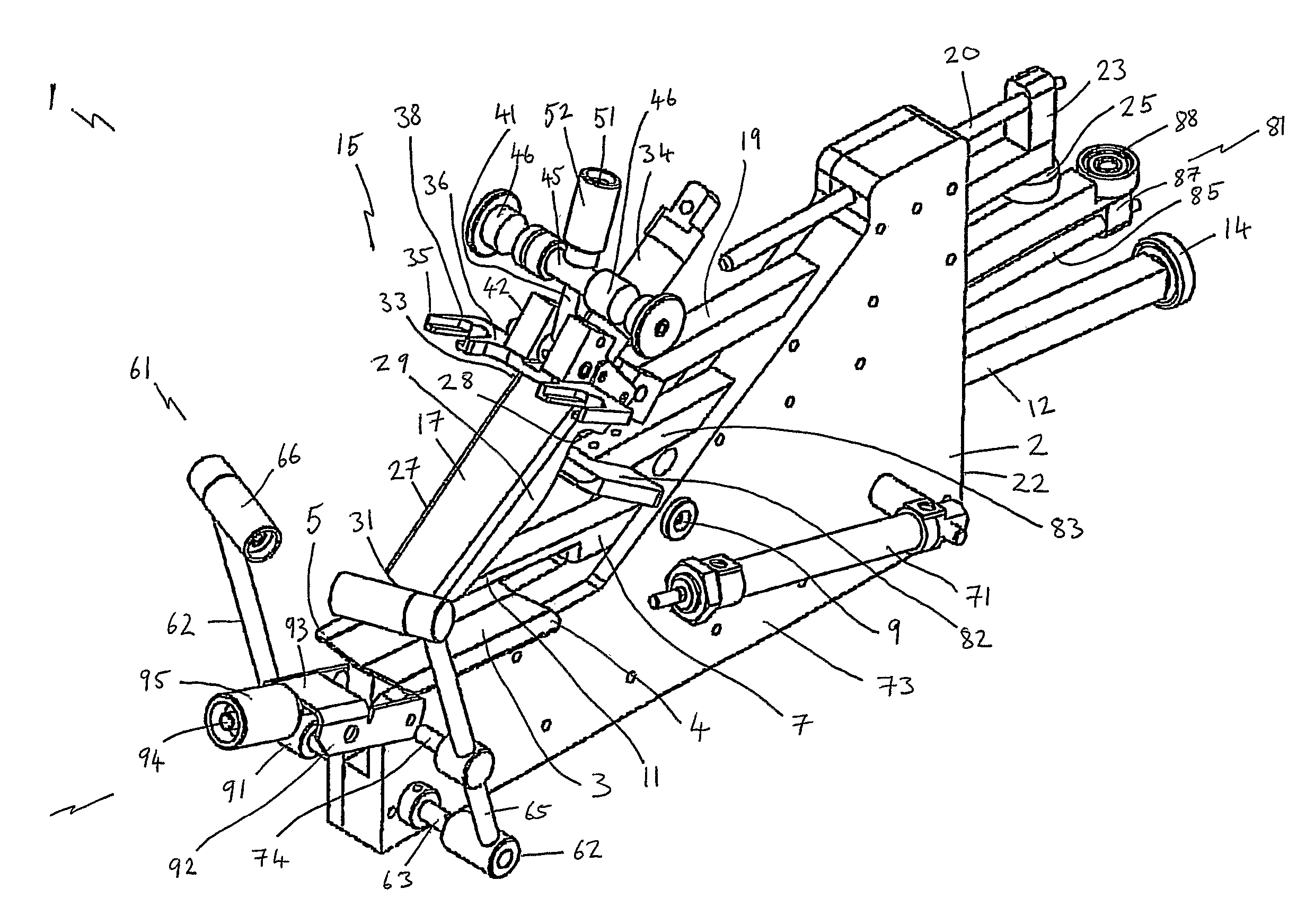

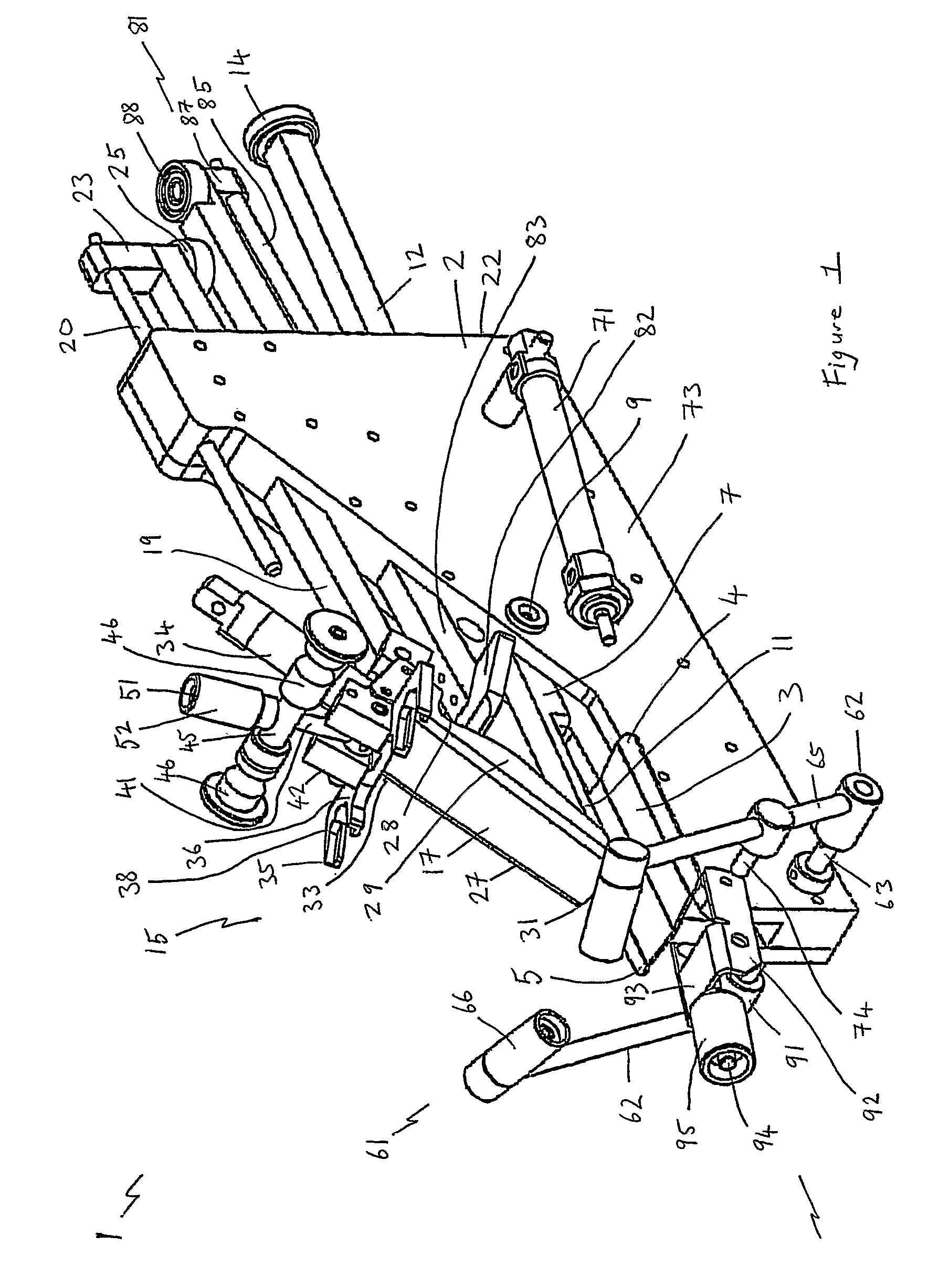

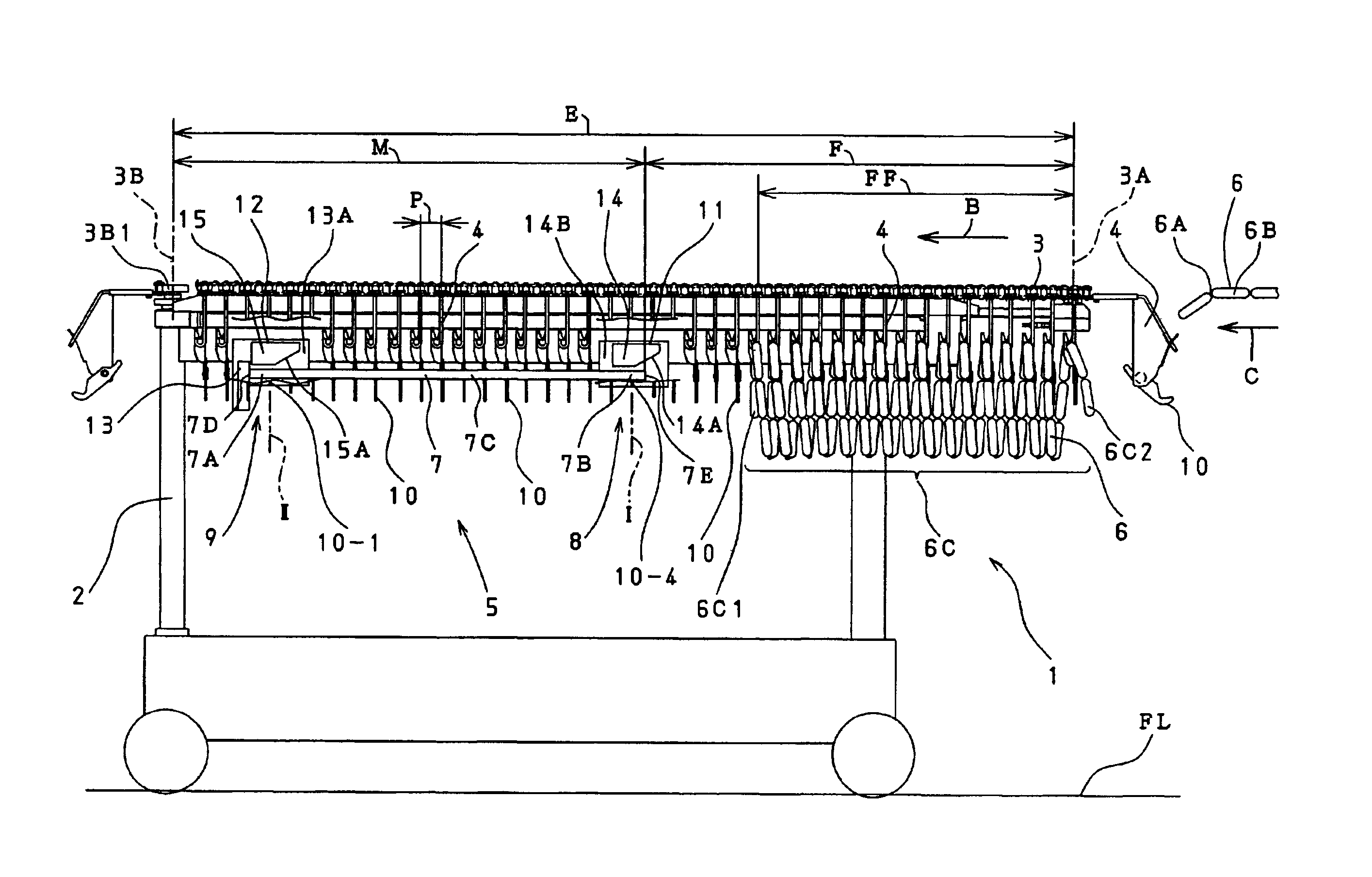

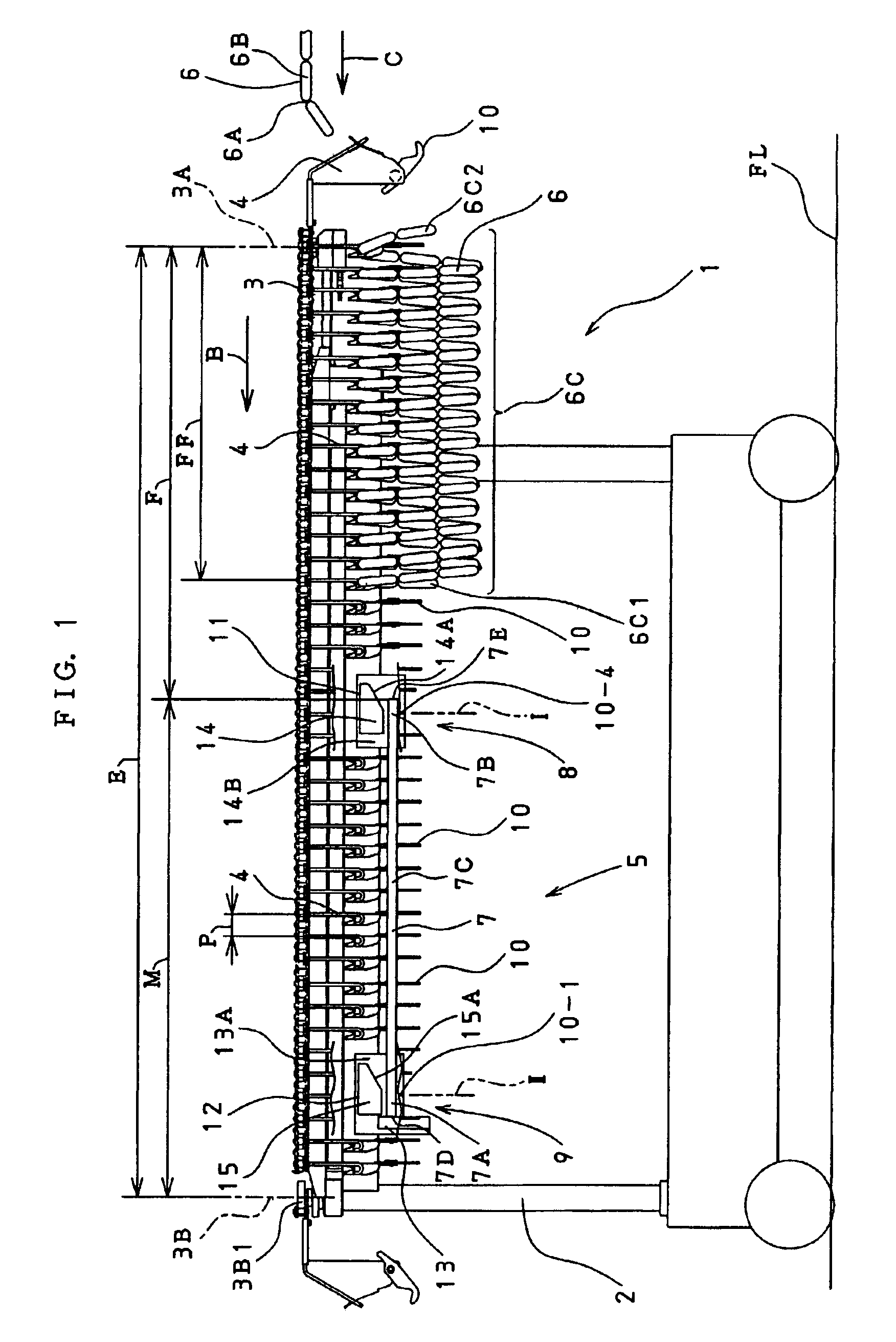

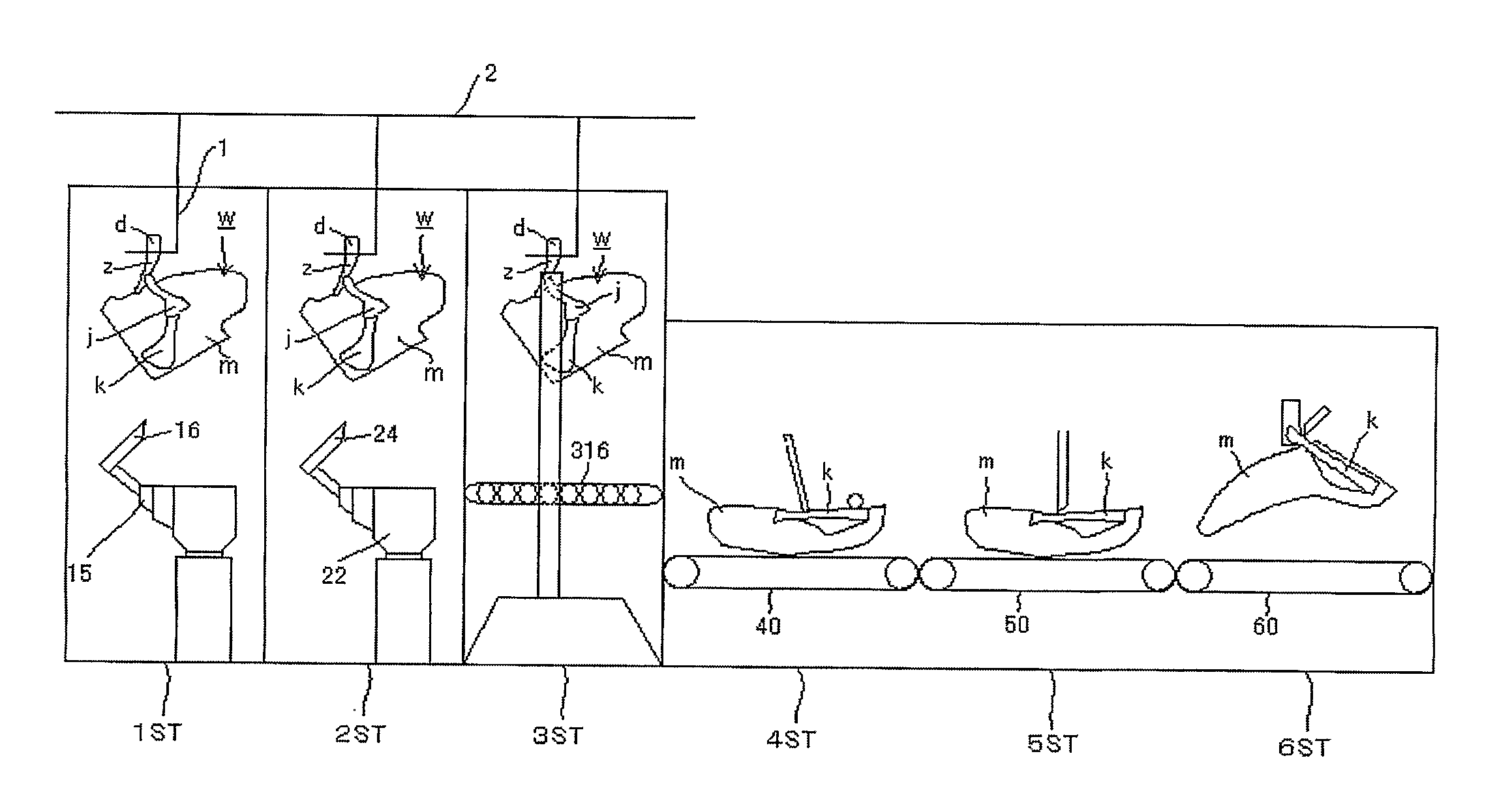

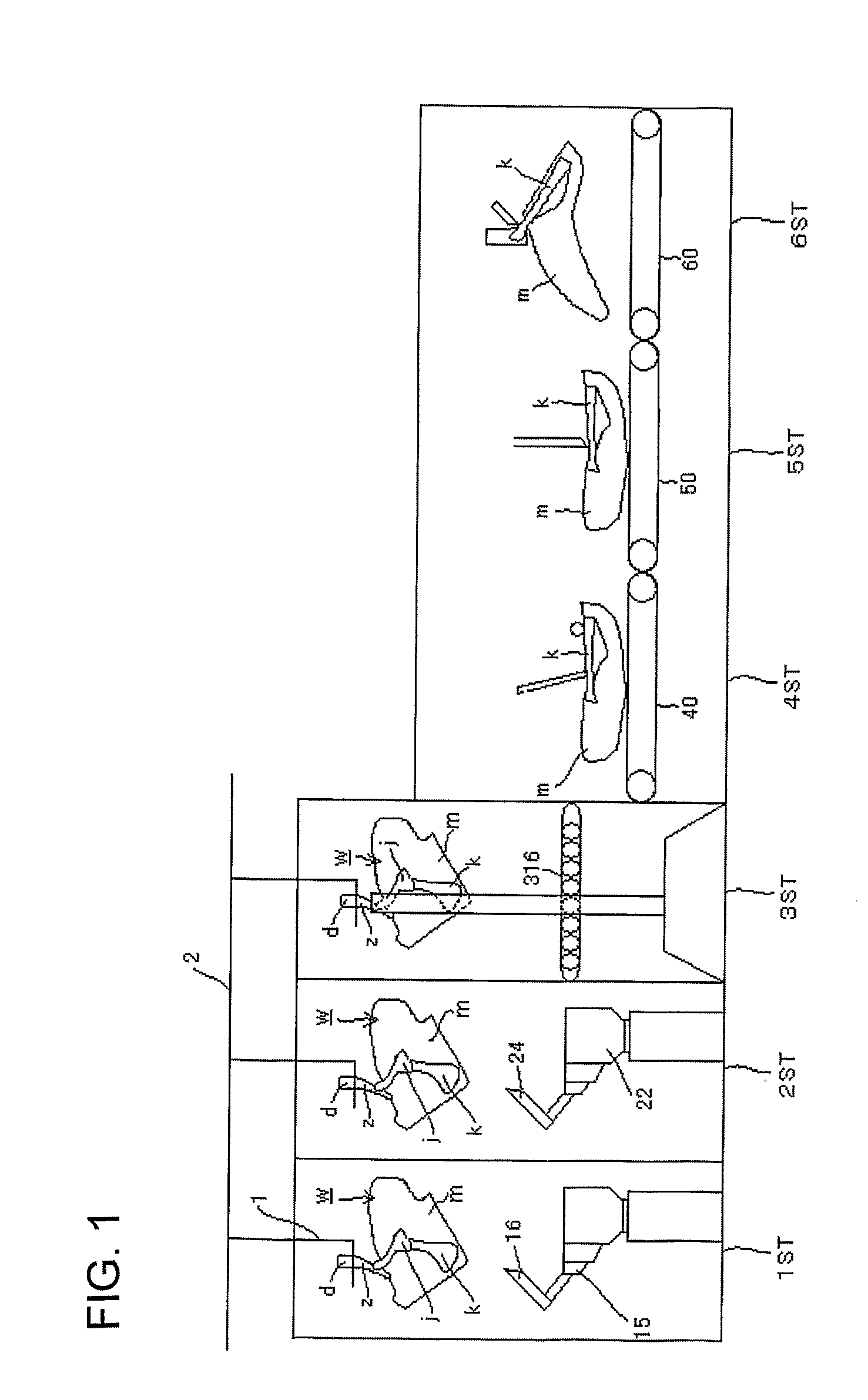

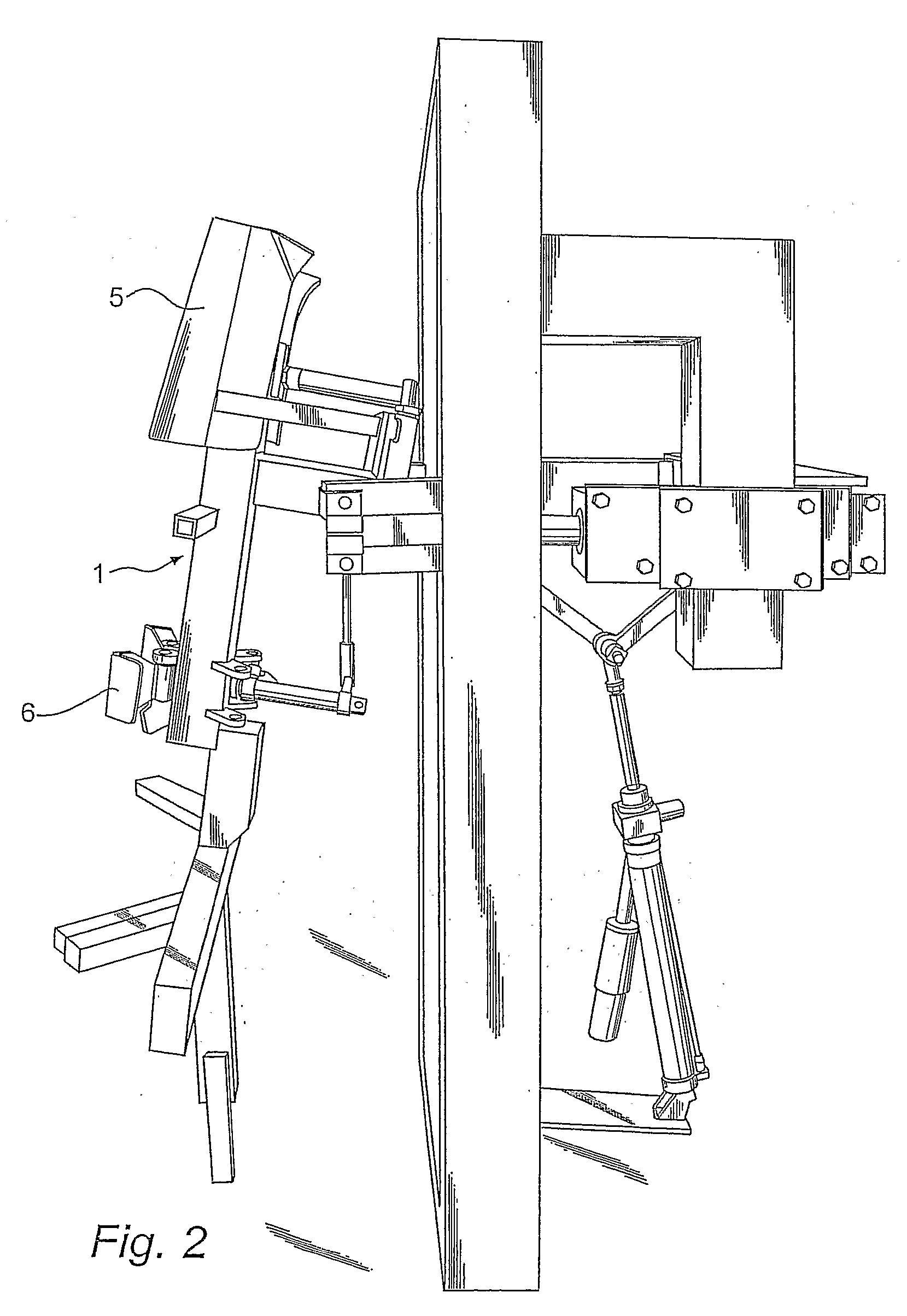

Automatic deboning method and apparatus for deboning bone laden meat

ActiveUS20090270021A1Easy to operateHigh degree of automationMeat holding apparatusBone cleaning devicesEngineeringBiomedical engineering

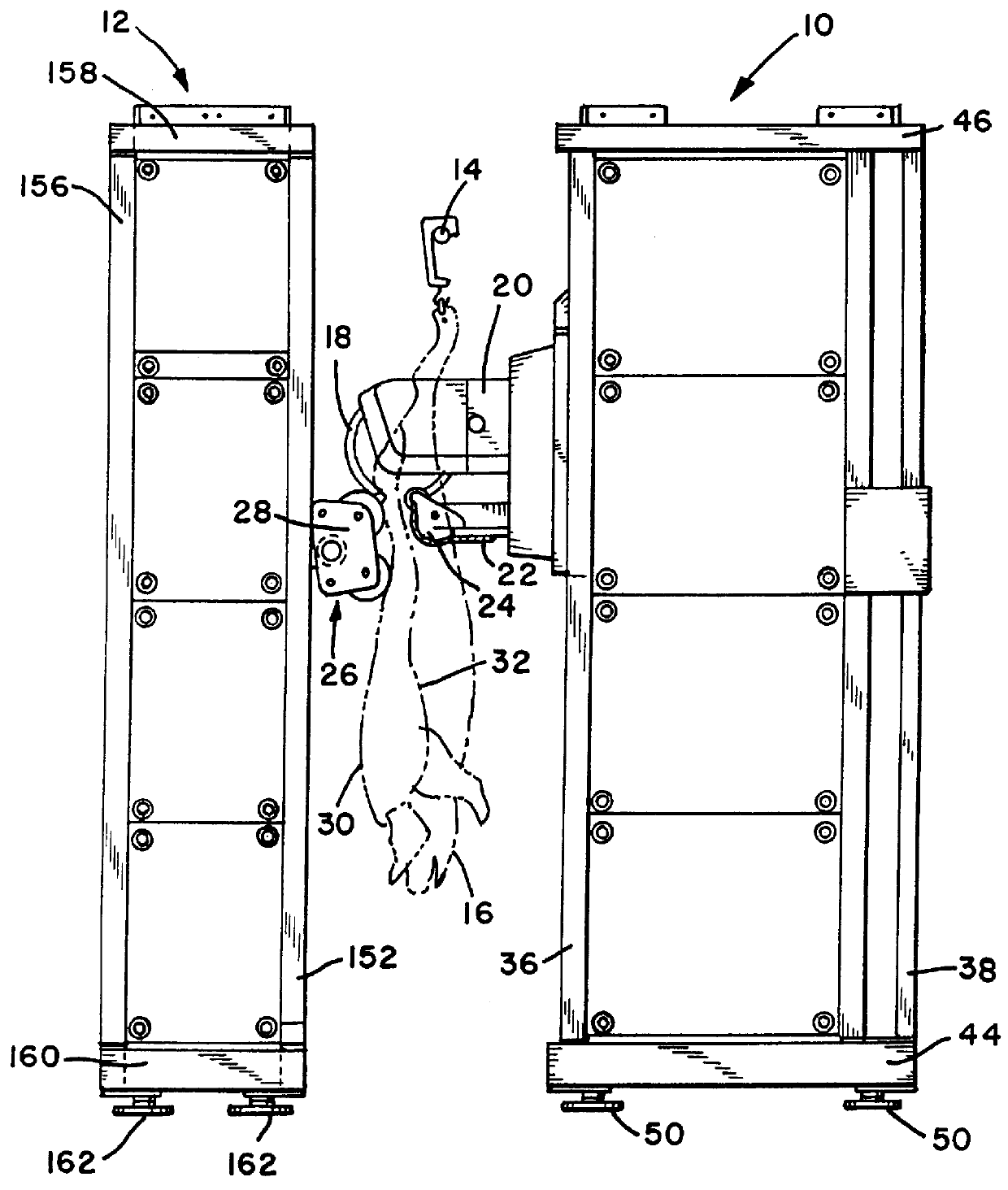

A de-boning method and apparatus for automating incision making to the meat of bone laden meat and scraping operation of meat from the bone laden meat by a meat separator, are proposed.The apparatus has a clamping device 1 for clamping an end part ‘d’ of unconcealed part of the bone of bone laden meat, a meat separator 31 having meat scraping plates 317a, 317b for pinching a bone of the bone laden meat, a cutter 33 located between the clamping device 1 and the meat separator 31, a clamping device lifting means 30, and rotation drive means 303 and 313 for rotating for rotating the clamping device 1 and the meat separator 31 in synchronism with each other, whereby spiral incision is made to a part of the meat of the bone laden meat by rotating the clamping device 1, and remaining part of the meat is scraped off as the clamping device is lifted while rotating in synchronism with the meat scraper.

Owner:MAYEKAWA MFG CO LTD

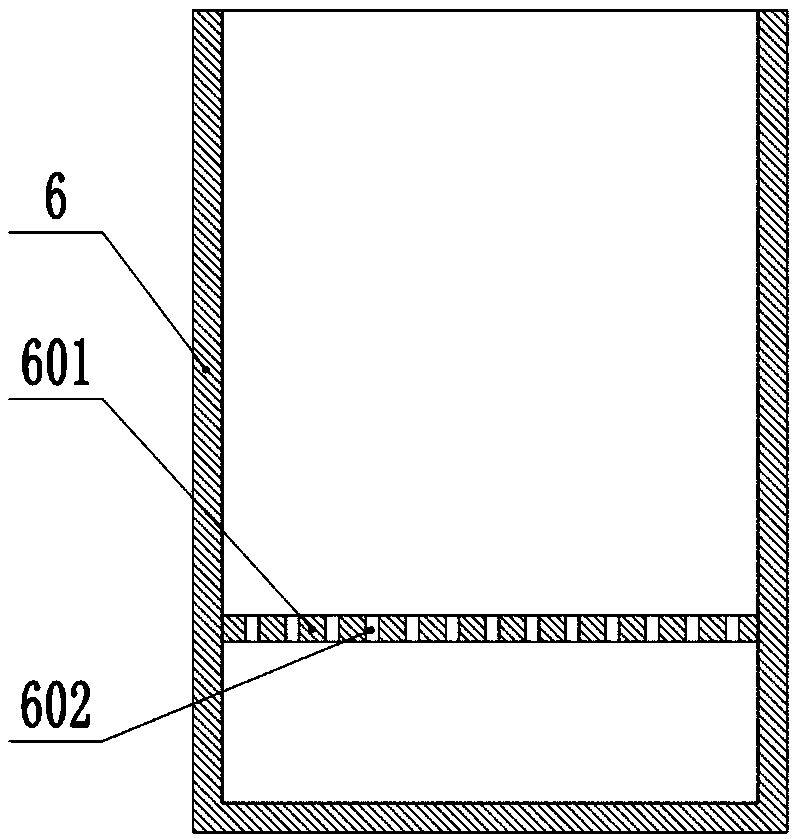

Food making device

InactiveCN107972081ASave spaceSave resourcesMeat holding apparatusMetal working apparatusGear driveEngineering

The invention relates to the technical field of device for processing meat or bones, in particular to a food making device. The food making device comprises a conveying mechanism, a cutting mechanism,a supporting mechanism, a flushing mechanism and a storage plate. The conveying mechanism comprises a conveying belt, conveying gears and a driving gear driven by a motor, and the driving gear is anincomplete gear. The conveying gears include the first conveying gear and the second conveying gear. The first conveying gear is driven by the driving gear and rotates towards the discharging end of the conveying belt. A spring is arranged between the supporting mechanism and the upper portion of the cutting mechanism. The two sides of the cutting mechanism are fixedly connected with racks. The racks are slidably connected with the two sides of the supporting mechanism correspondingly. A power gear is engaged with the racks. The first conveying gear and the power gears rotate intermittently. The flushing mechanism comprises water inlet pipes, stop valves and spray heads used for spraying the cutting mechanism. The stop valve is controlled by the power gear to be opened and closed. By adoption of the scheme, bone debris on a cutting knife can be removed in the cutting process.

Owner:重庆多笠原食品有限公司

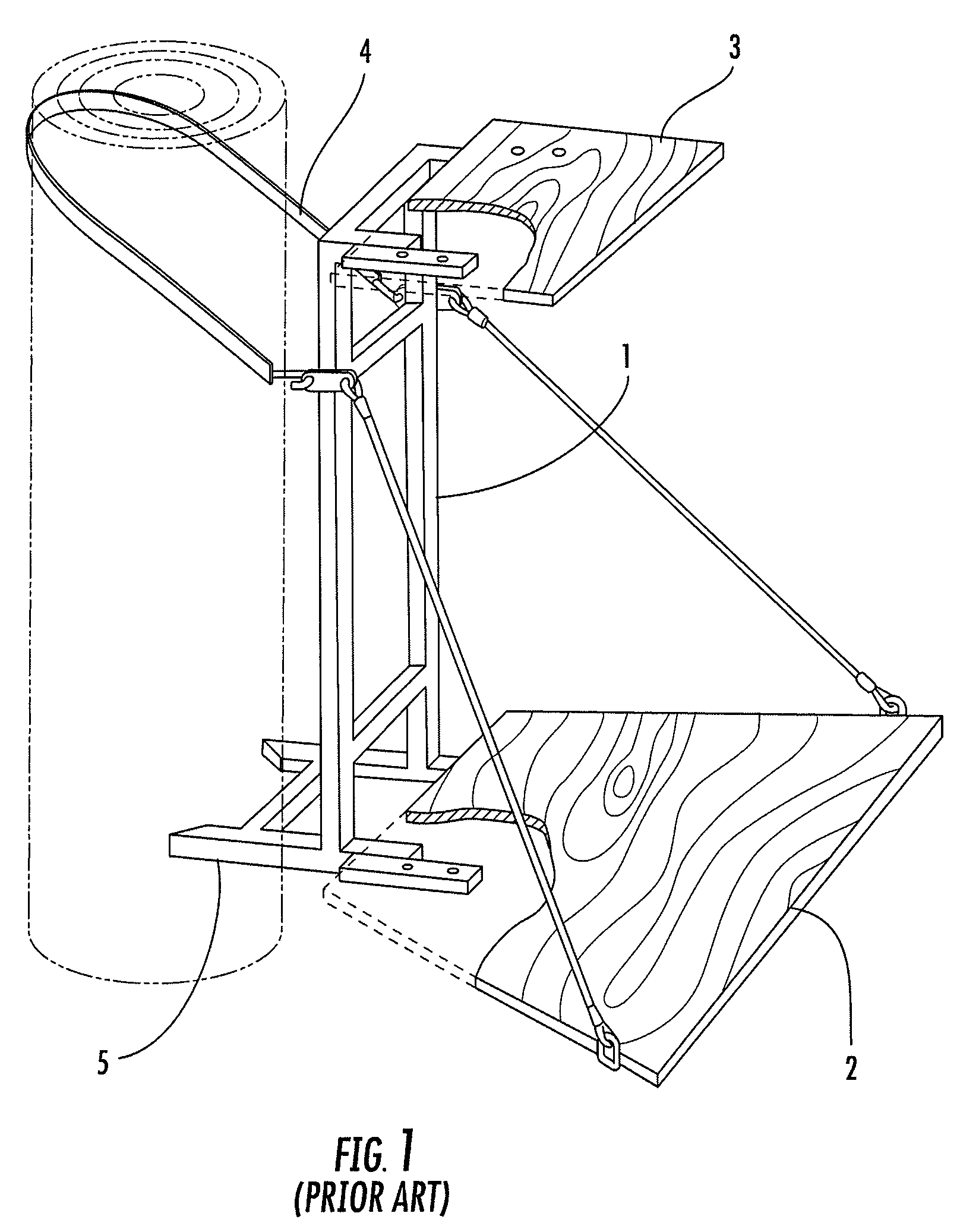

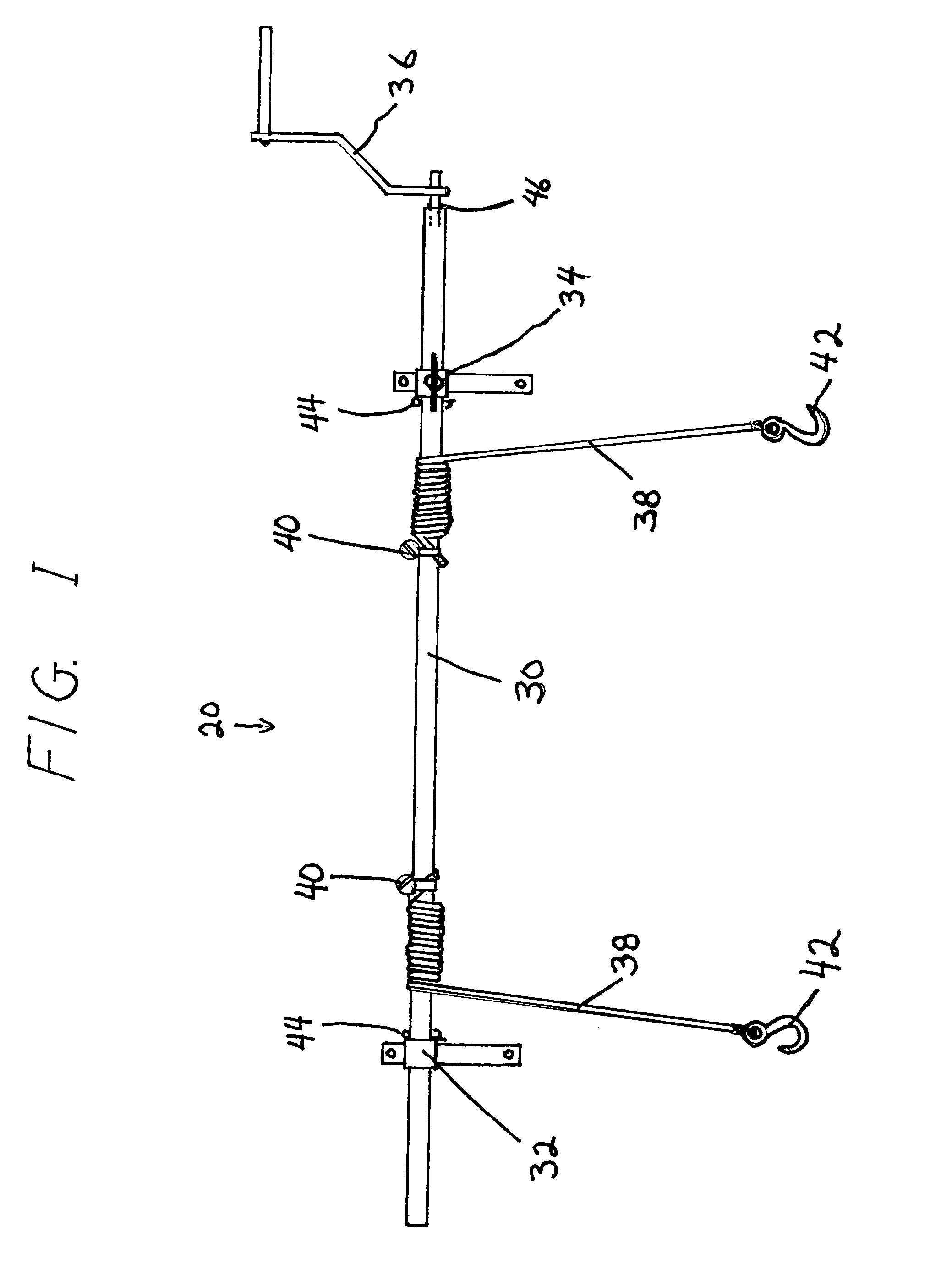

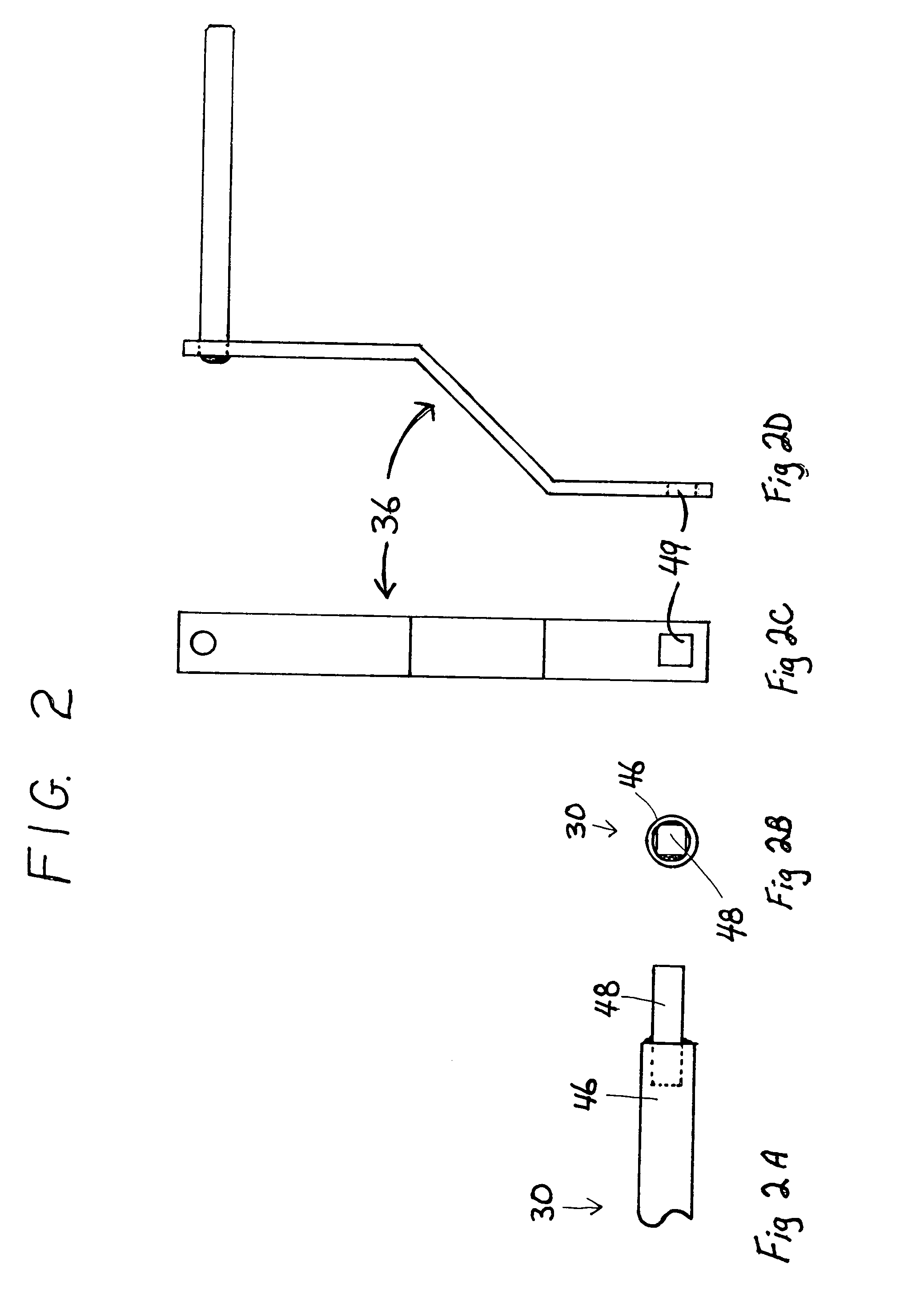

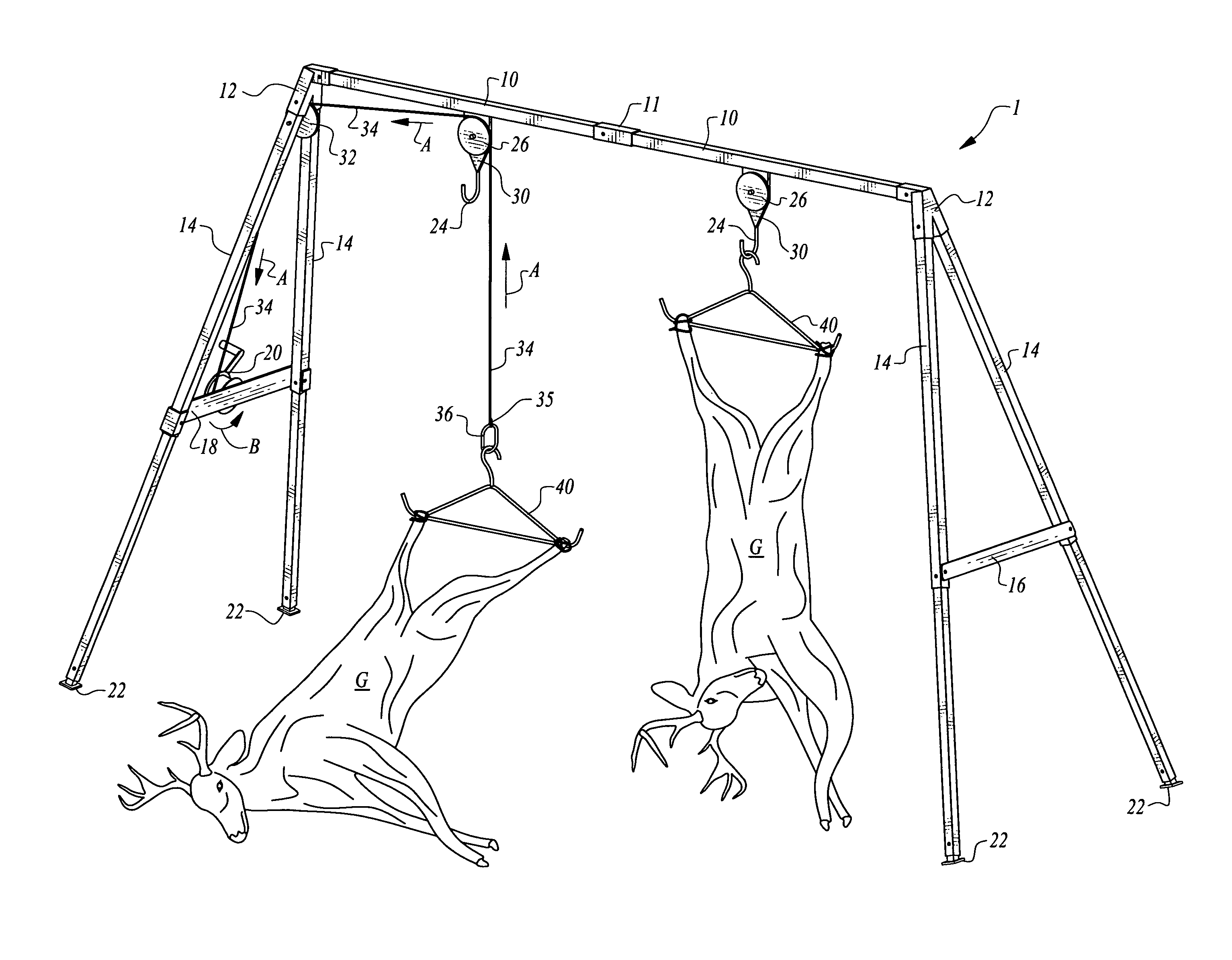

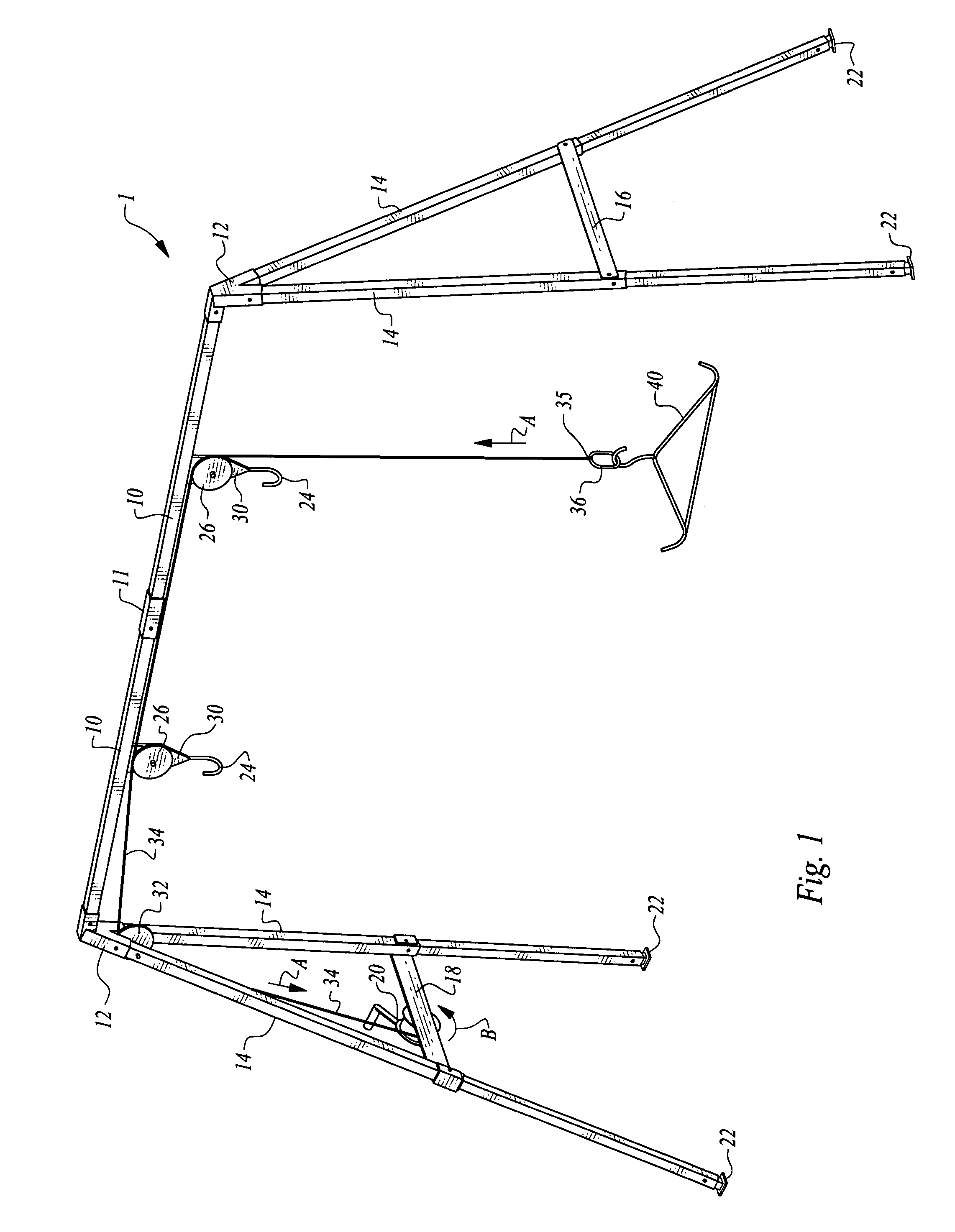

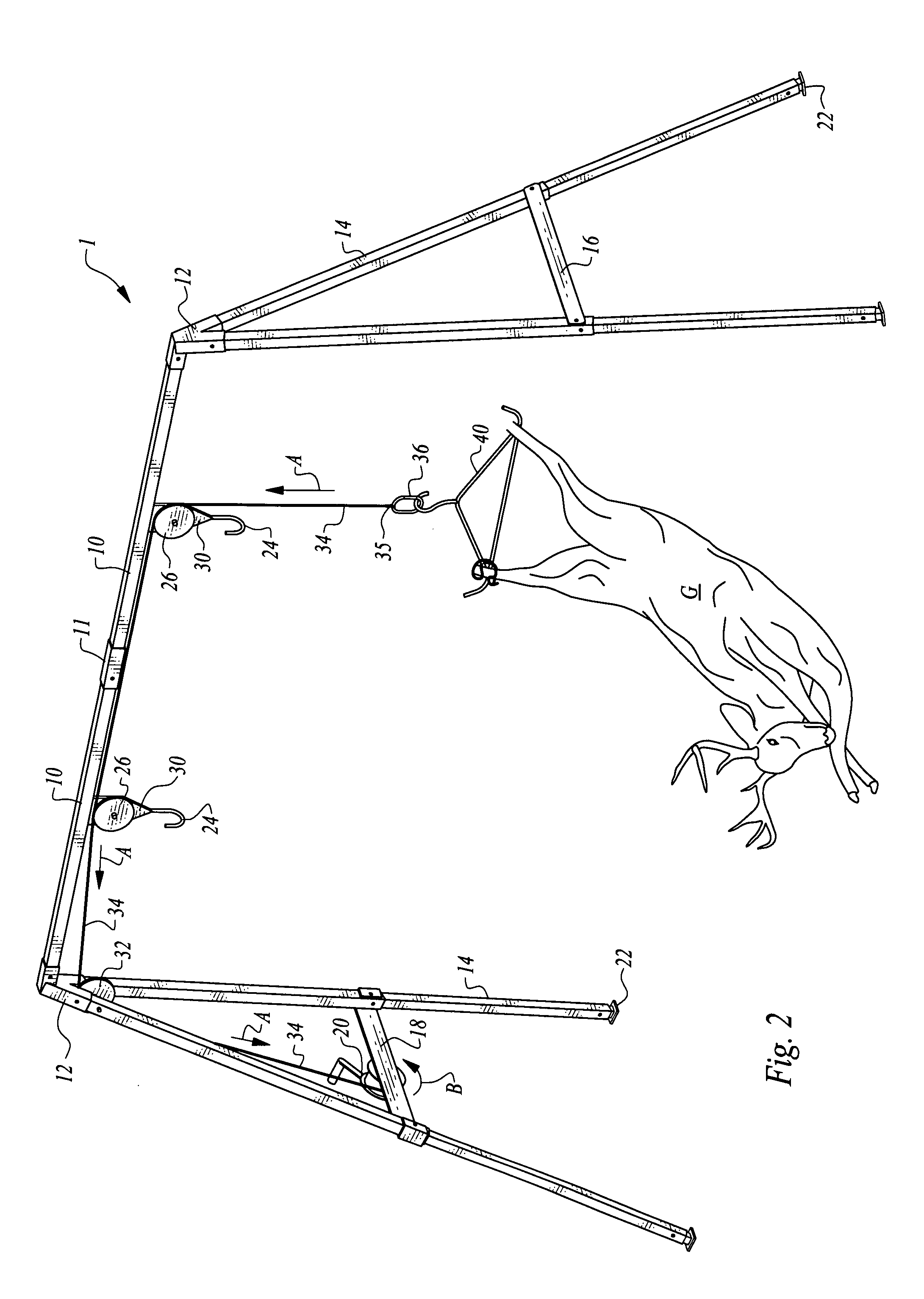

Free-standing collapsible game hoist

A portable game hoist supports game in the field without requiring attachment to a tree, vehicle or other separate structure. The hoist includes free-standing legs in pairs at opposite ends of a crossbeam. The crossbeam has a pulley mounted thereto, preferably upon a bracket with a hook on the bracket and below the pulley. A hanger is provided to which a game animal is attached. A cable is routed over the pulley and also over an end pulley adjacent one of the ends of the crossbeam. The cable is then routed down to a winch so that when the hanger is coupled to the cable, the hanger and game can be elevated. Once fully elevated, the hanger can be shifted to the hook adjacent the pulley and the cable removed for reuse on a second game animal, routing of the cable over a separate pulley suspended below the crossbeam.

Owner:MARTINELLI DAVID E +1

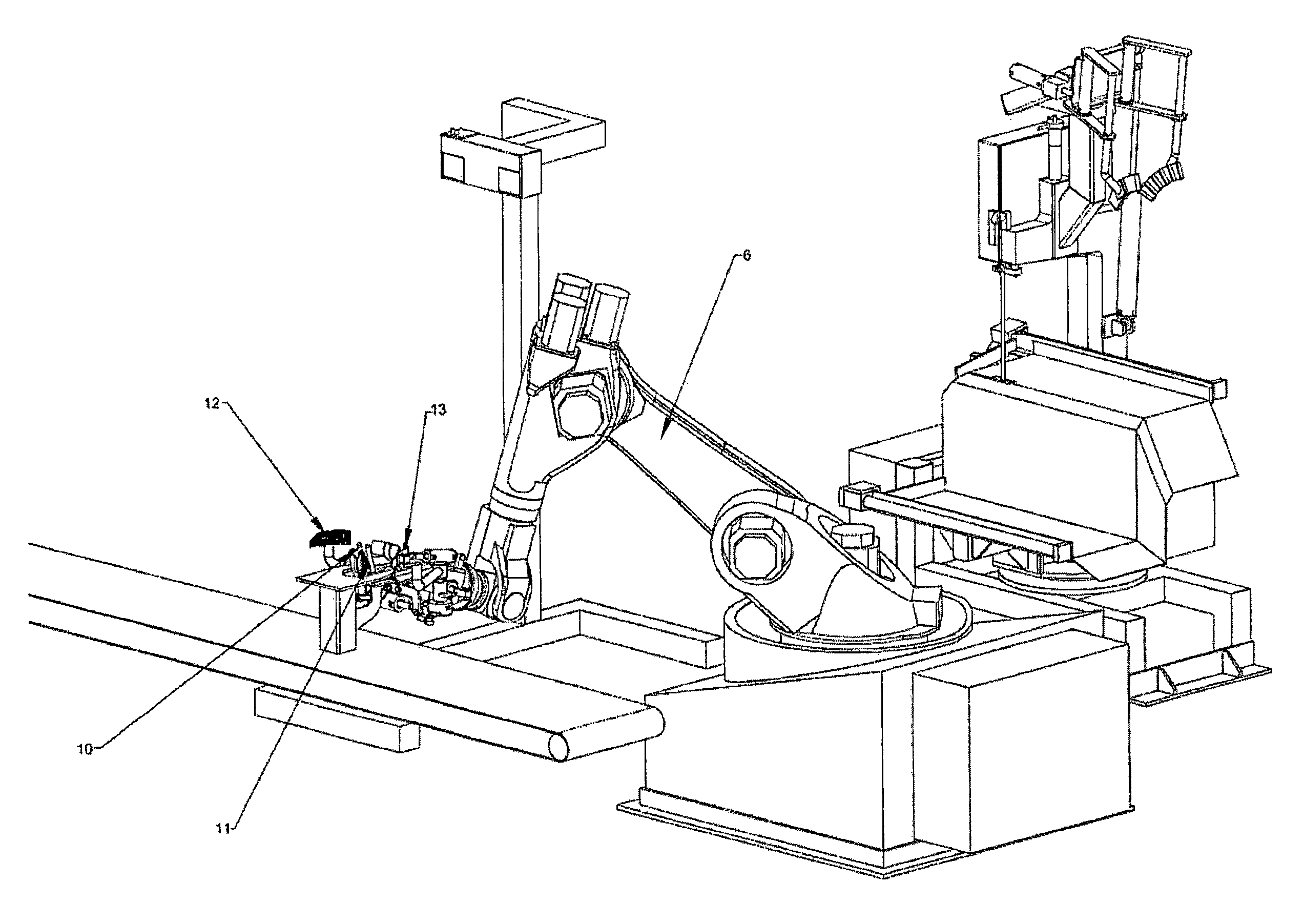

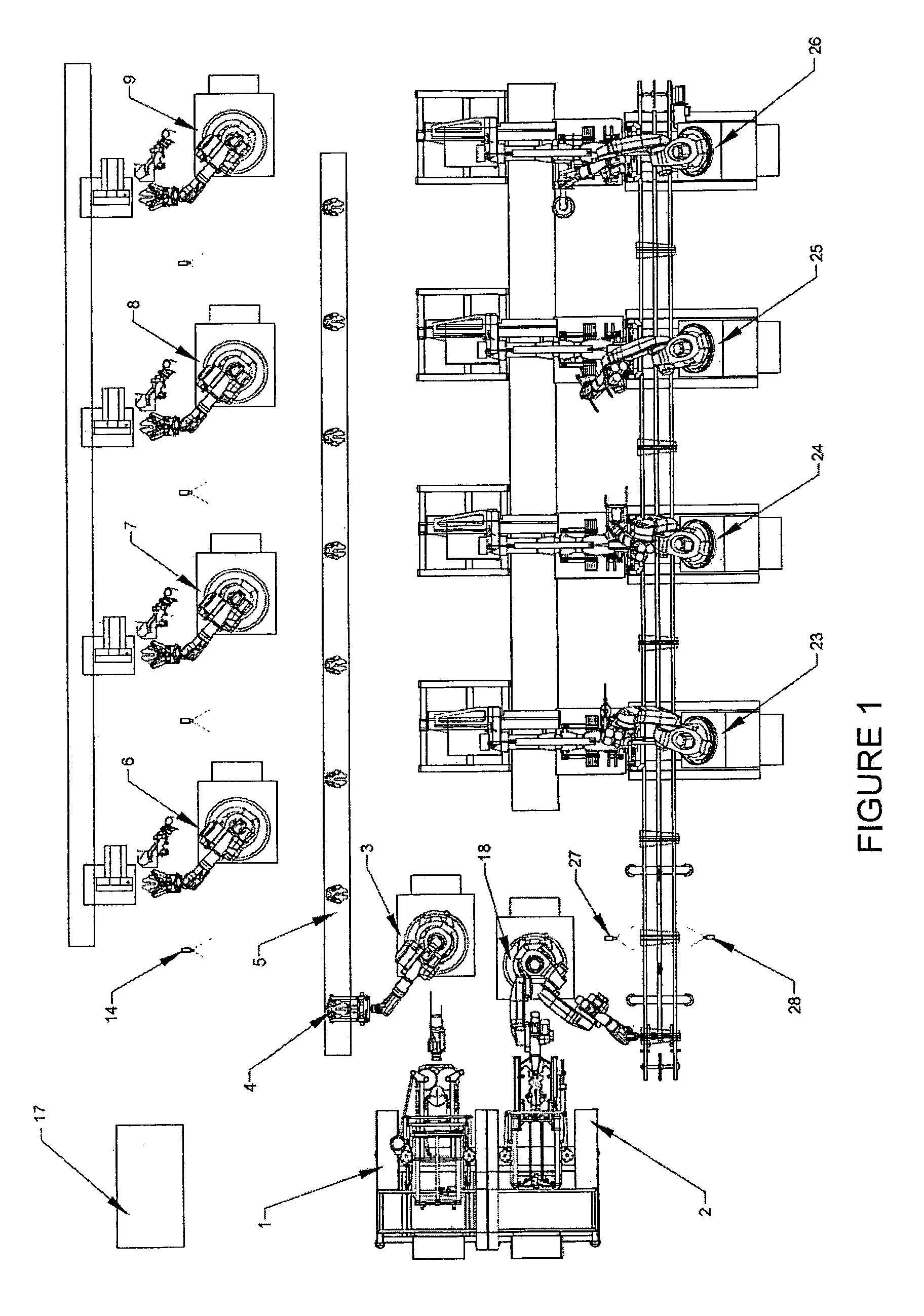

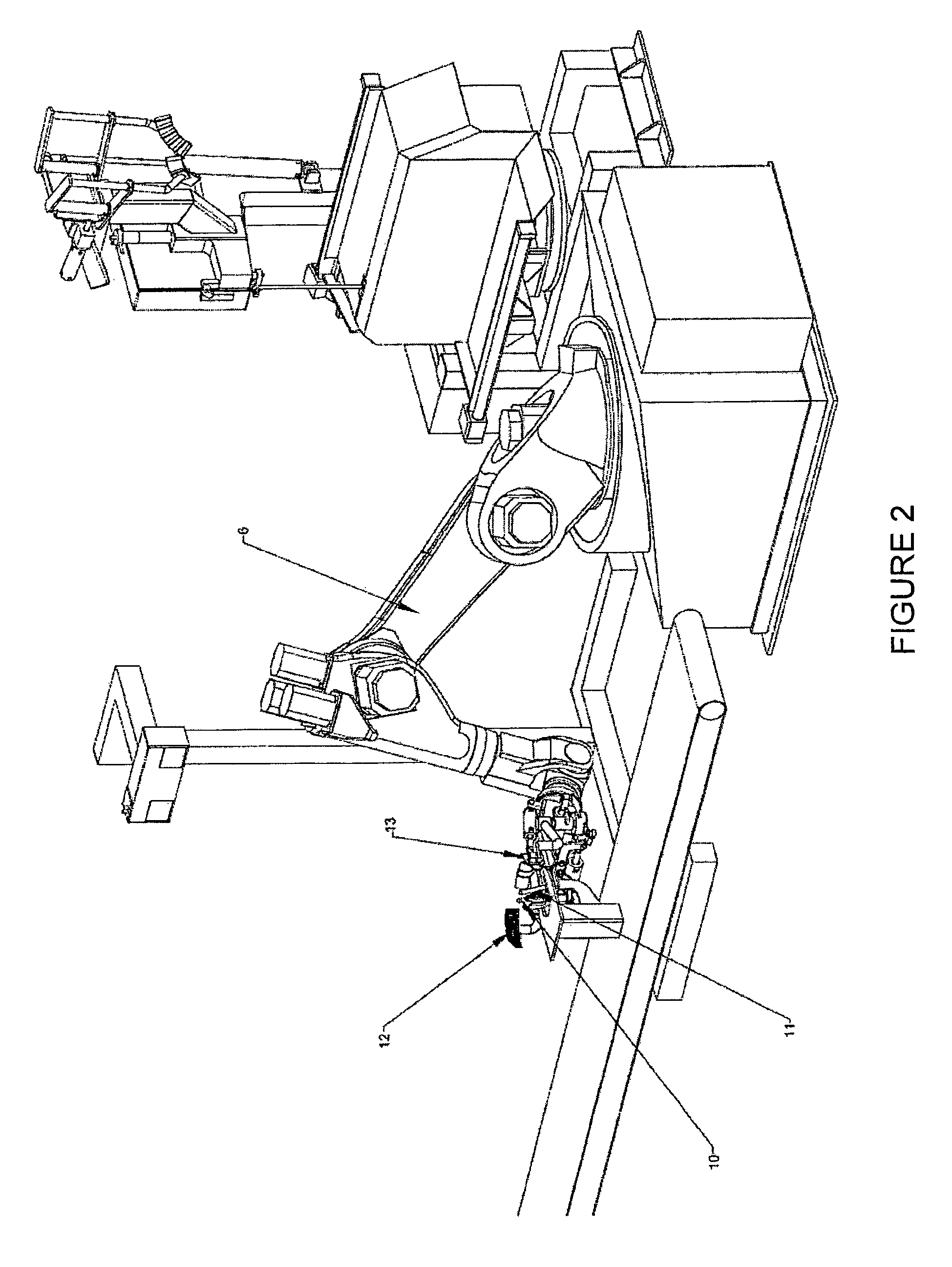

Carcass cutting methods and apparatus

Methods of automated meat processing including an end to end processing method in which carcasses are cut into major portions at a first robotic processing station and into minor portions at robotic processing sub-stations. In one processing method carcass portions are acquired by a robotic arm, imaged and then cuts performed without transfer. In another a first series of processing steps are performed by rotating carcass portions through a plurality of processing stations and a second series of processing steps are performed as carcass portions are advanced along a linear conveyor. In another processing method a plurality of clamps are employed to stabilize a saddle section during a flap cut. In another processing method split pins are used to position a saddle section for a vertebrae cut. In another method a spinal cord is removed by applying a pressurized fluid stream against one end of the spinal cord and applying suction at the other end of the spinal cord.

Owner:ROBOTIC TECH

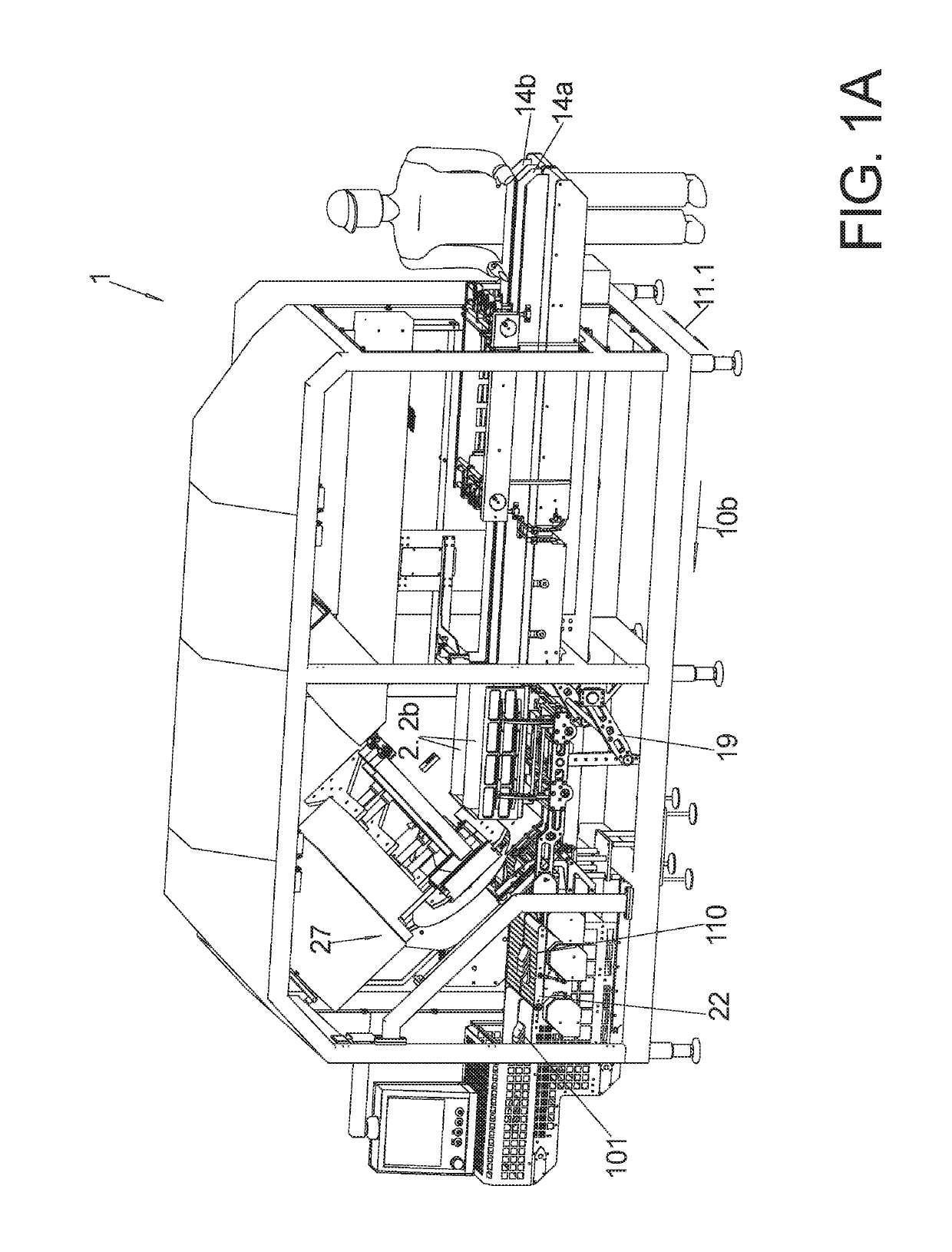

Slicing machine and method for slicing elastic strands in particular meat strands

ActiveUS10245745B2Short idle timeImprove throughputMeat holding apparatusFish threading devicesEngineeringMechanical engineering

A slicing machine for slicing meat strands that have a cross section that varies over a longitudinal extension in large numbers and as quickly as possible into weight precise slices. In one embodiment, two meat strands are received adjacent to each other in a respective form tube and pushed against a respective separately adjustable stop plate independently from each other by a controlled longitudinal press plunger and compressed in the longitudinal direction. In addition, a cross section of the form tubes may be reduced in a first transversal direction jointly and in a second transversal direction independently from each other and thus the respective meat strand is transversally compressed to a constant cross section prior to slicing.

Owner:TVI ENTWICKLUNG & PROD GMBH

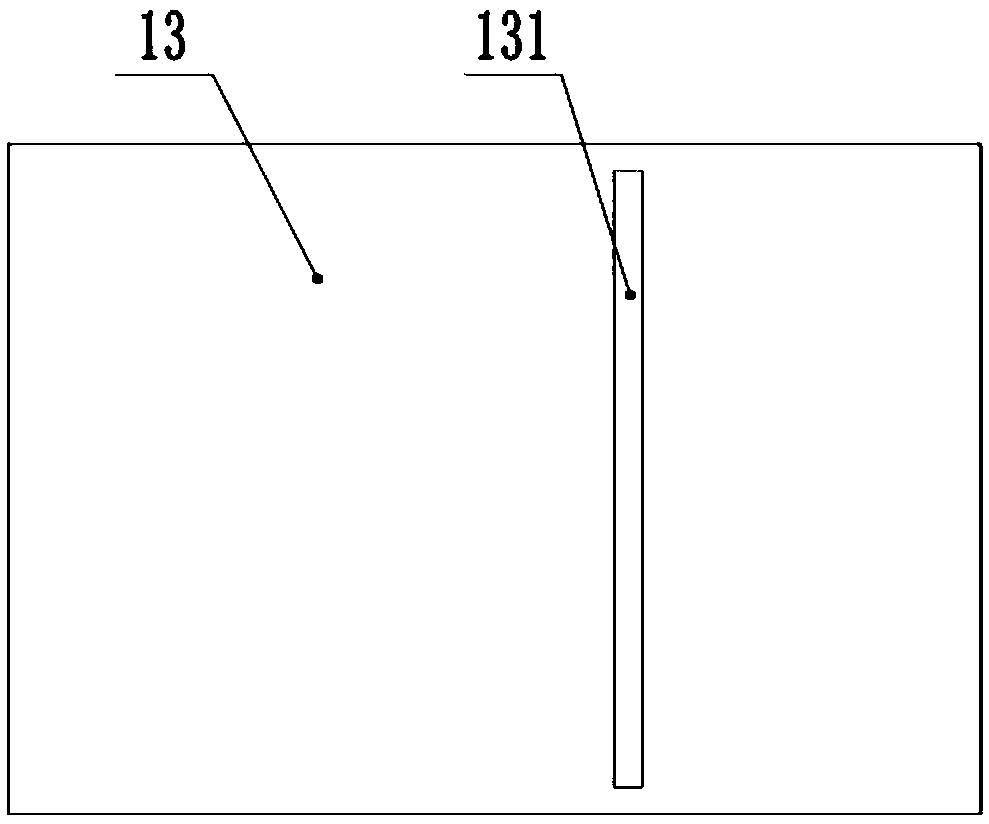

Multifunctional integrated meat cutter

PendingCN109664355AAdjustable thicknessSlicing is fastMeat holding apparatusMetal working apparatusEngineeringMeat cutter

The invention relates to the field of meat cutters, in particular to a multifunctional integrated meat cutter. The multifunctional integrated meat cutter comprises a workbench, a fixed device and a slicing device, wherein the fixed device comprises a placing plate, a clamping assembly and a pushing assembly; the slicing device comprises a drive assembly and a thickness regulating assembly; the drive assembly is fixedly arranged on the side wall of the workbench; and the thickness regulating assembly is fixedly arranged on the workbench, and is arranged on the drive assembly in a sleeving mode.When the multifunctional integrated meat cutter needs to cut meat, frozen and shaped meat blocks are placed on the placing plate, and the pushing assembly can push the meat blocks forwards, so that the meat blocks abut against a baffle plate, and the clamping assembly is blocked into the pushing assembly from the side surface for clamping the meat blocks from the side surface; and the drive assembly can be driven to rotate to cut the meat blocks, so that the meat blocks are cut into slices; and the thickness regulating assembly can regulate the thickness of meat slices cut each time, is highin slicing speed, and is adjustable in thickness.

Owner:JINHUA VOCATIONAL TECH COLLEGE

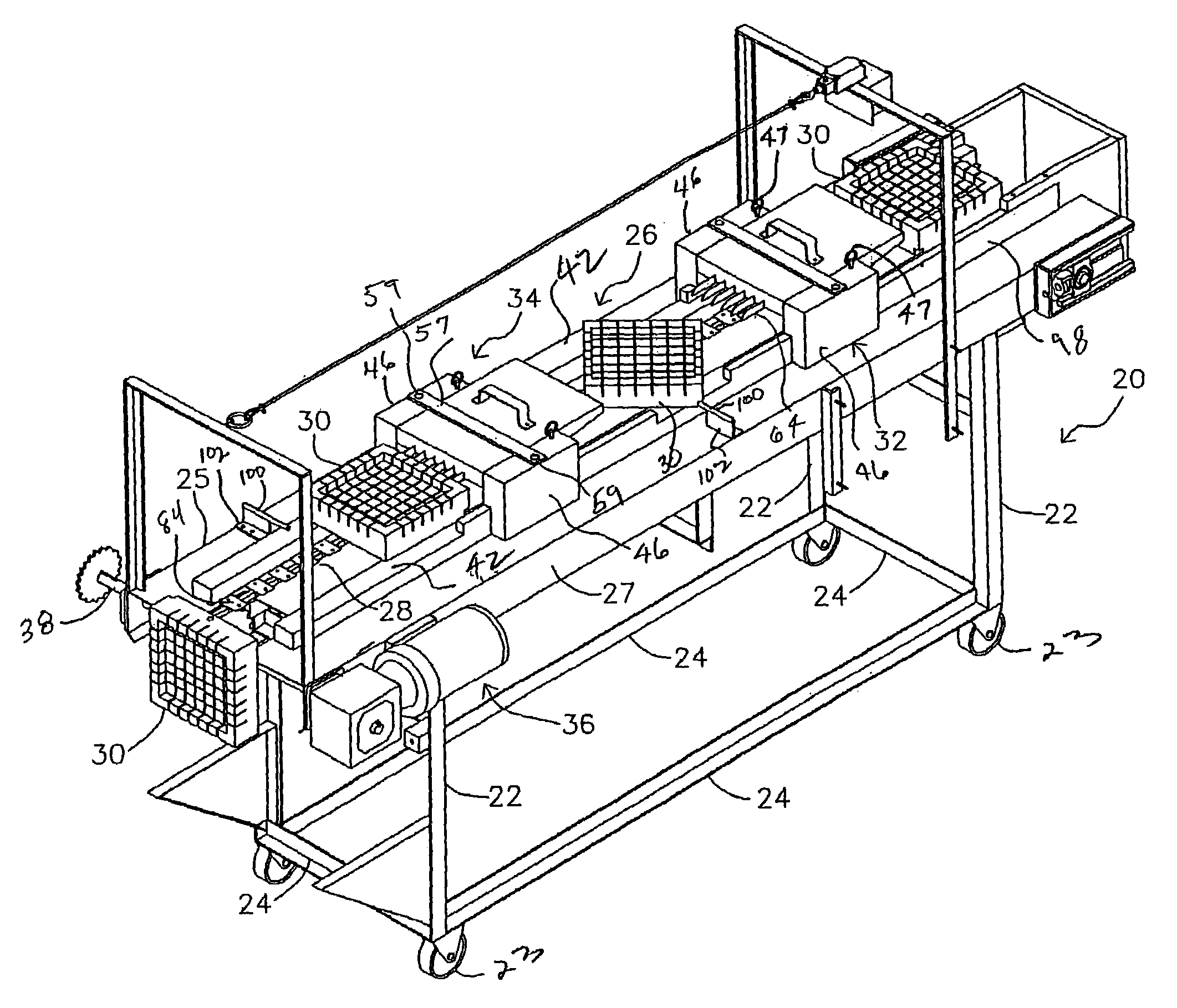

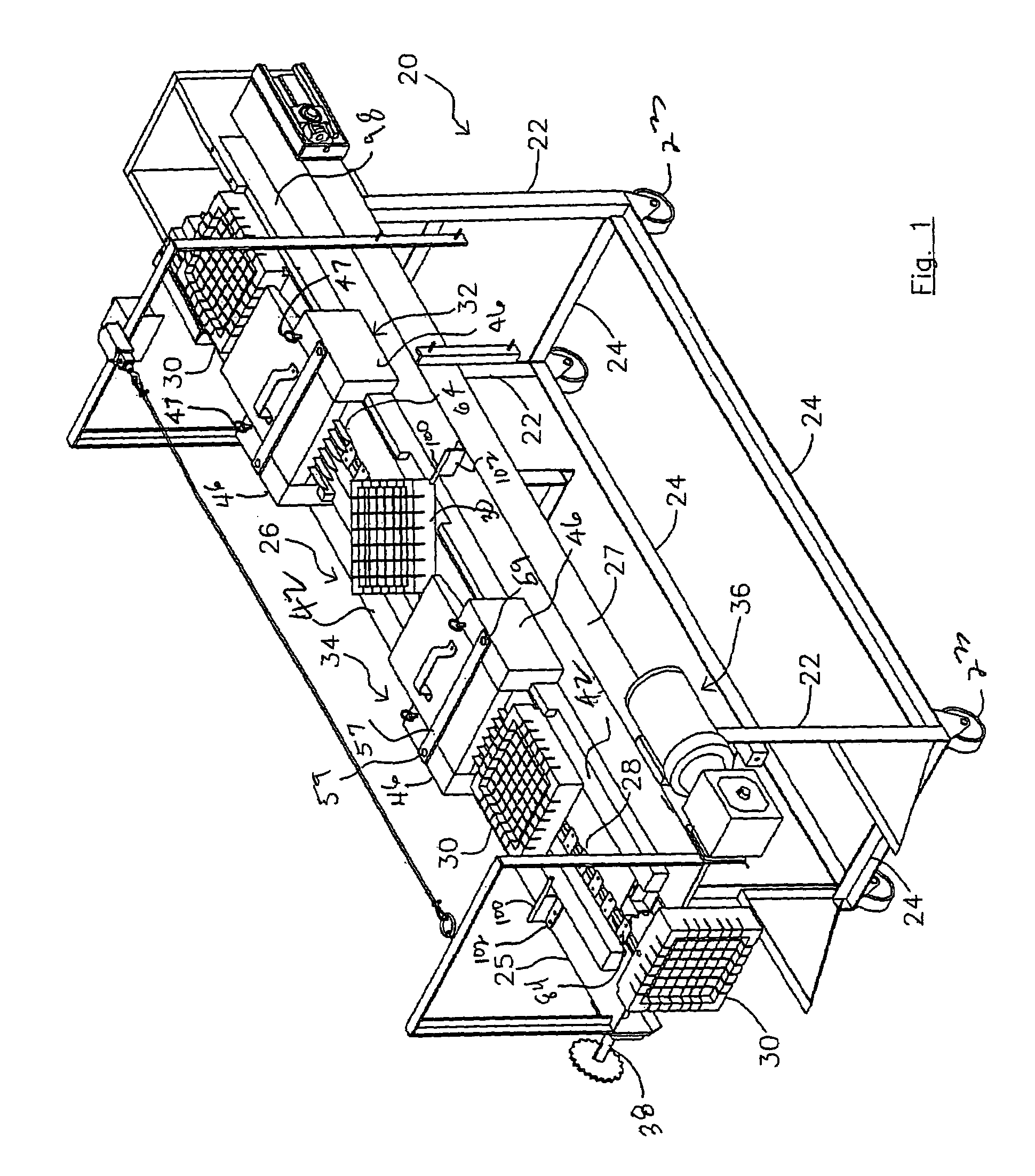

Apparatus and method for producing controlled portions of meat products

ActiveUS7364504B2Consistent controlReduce wasteMeat holding apparatusMeat processing plantsKnife bladesVertical axis

Owner:PRIME EQUIP GRP LLC

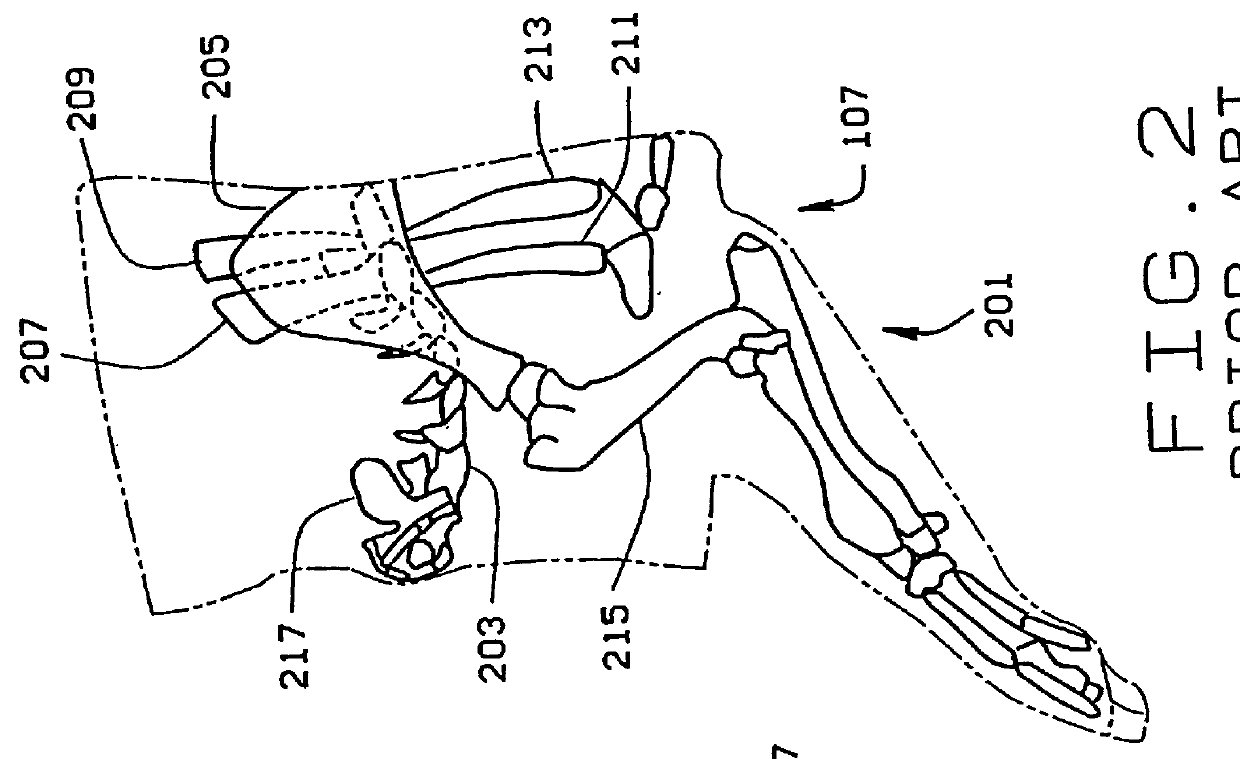

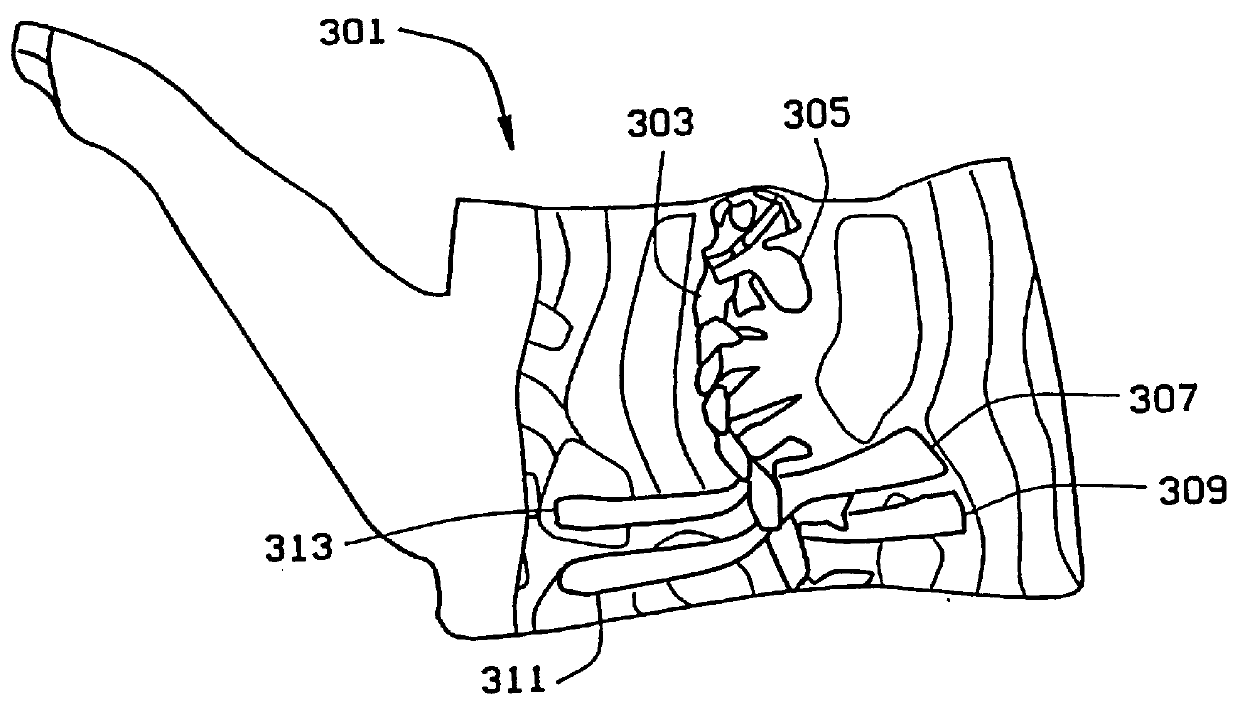

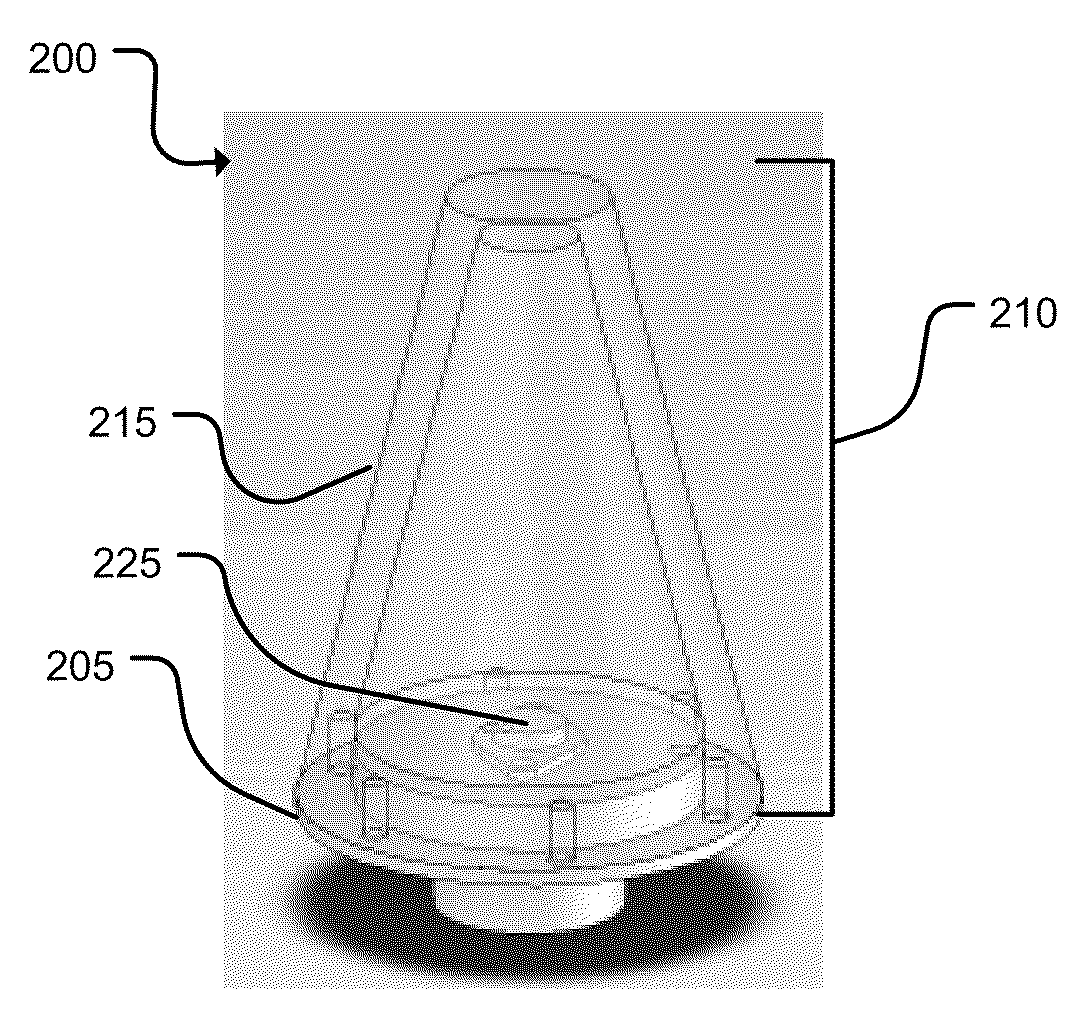

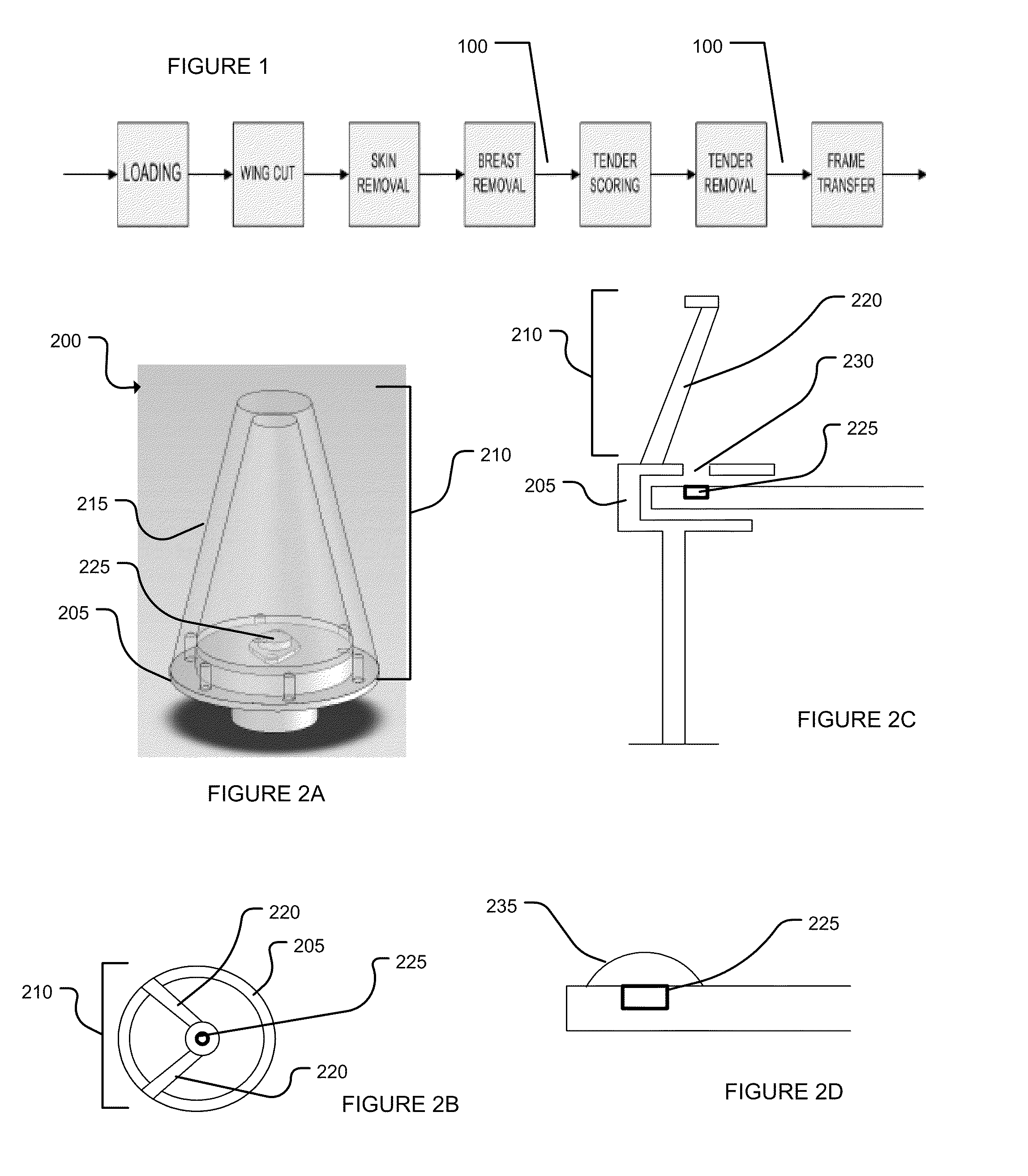

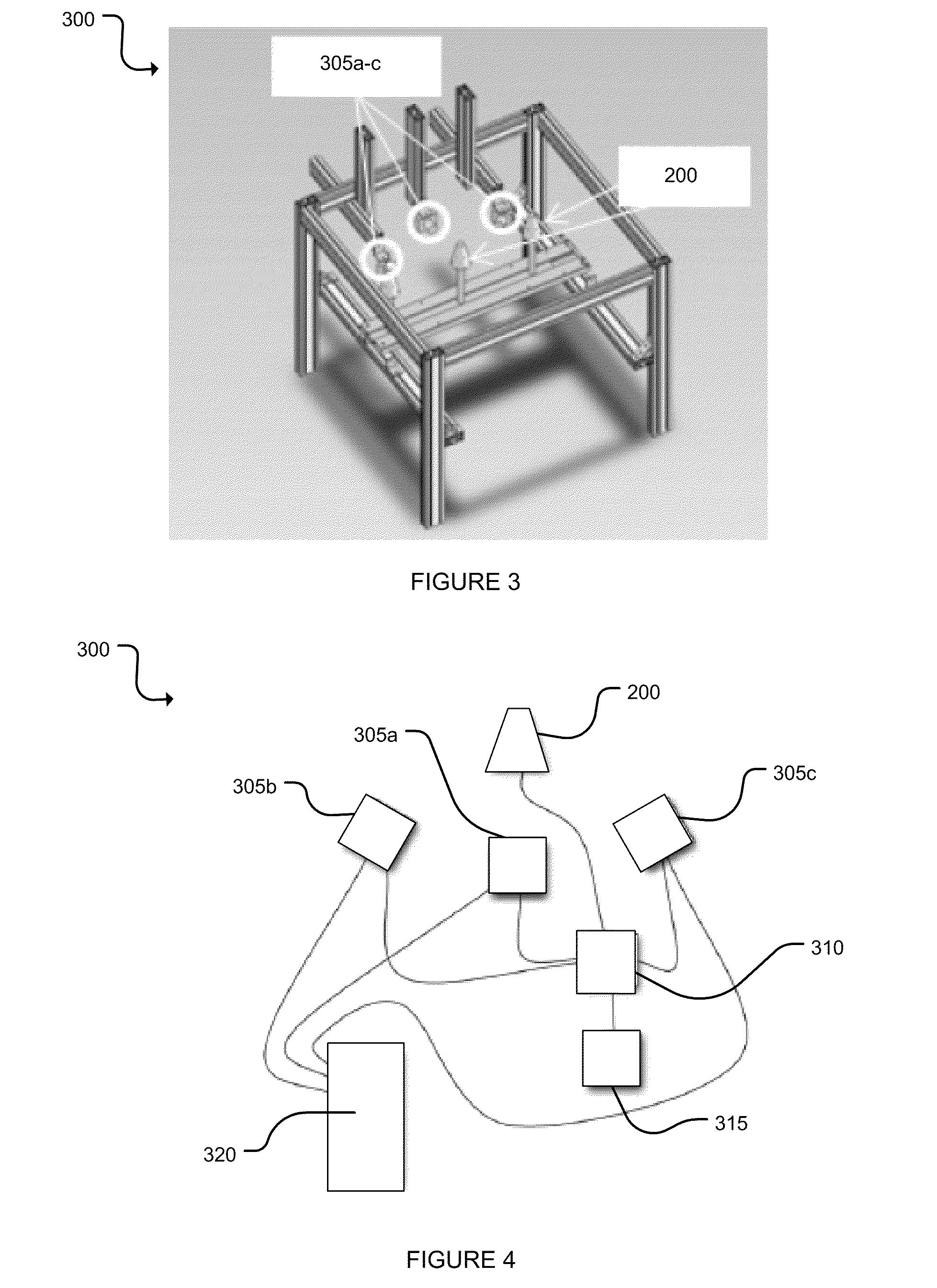

Systems and methods for the detection of anatomical structures and positions thereof

The various embodiments of the present disclosure relate generally to systems and methods for the detection of anatomical structures and anatomical positions. More particularly, the various embodiments of the present disclosure are directed to the detection of musculoskeletal elements, such as bones, tendons, ligaments, cartilage, and the like, which could be useful for example in poultry processing for bone screening as well as for guidance of machines for processing. For example, a system for detecting a bone in a carcass comprises: a device for supporting a carcass comprising a base and a frame attached to the base, wherein the frame is configured to contact at least a portion of a cavity of a carcass; and an electromagnetic radiation source, wherein the electromagnetic radiation source is configured to irradiate at least a portion of a cavity of a carcass;

Owner:GEORGIA TECH RES CORP

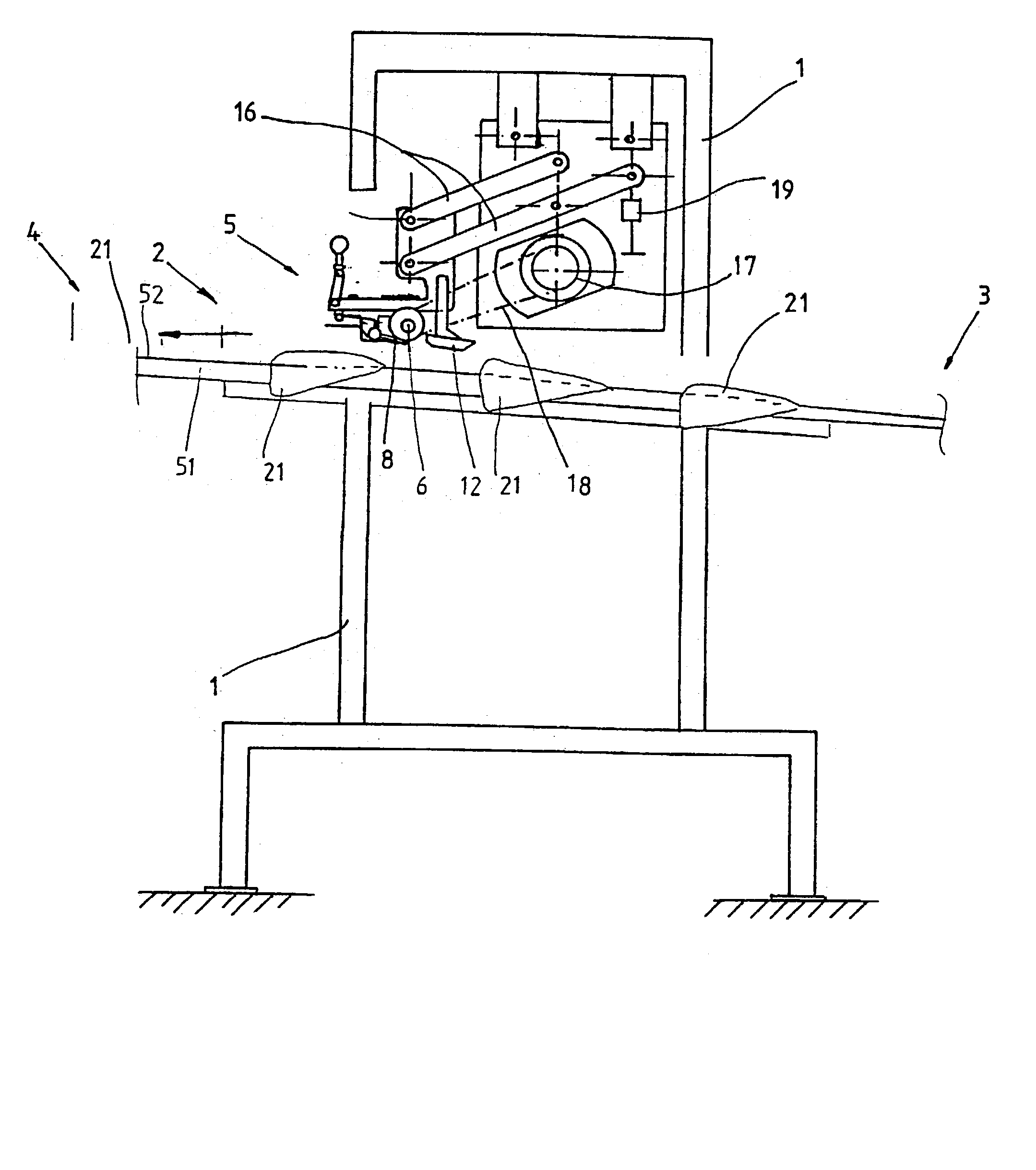

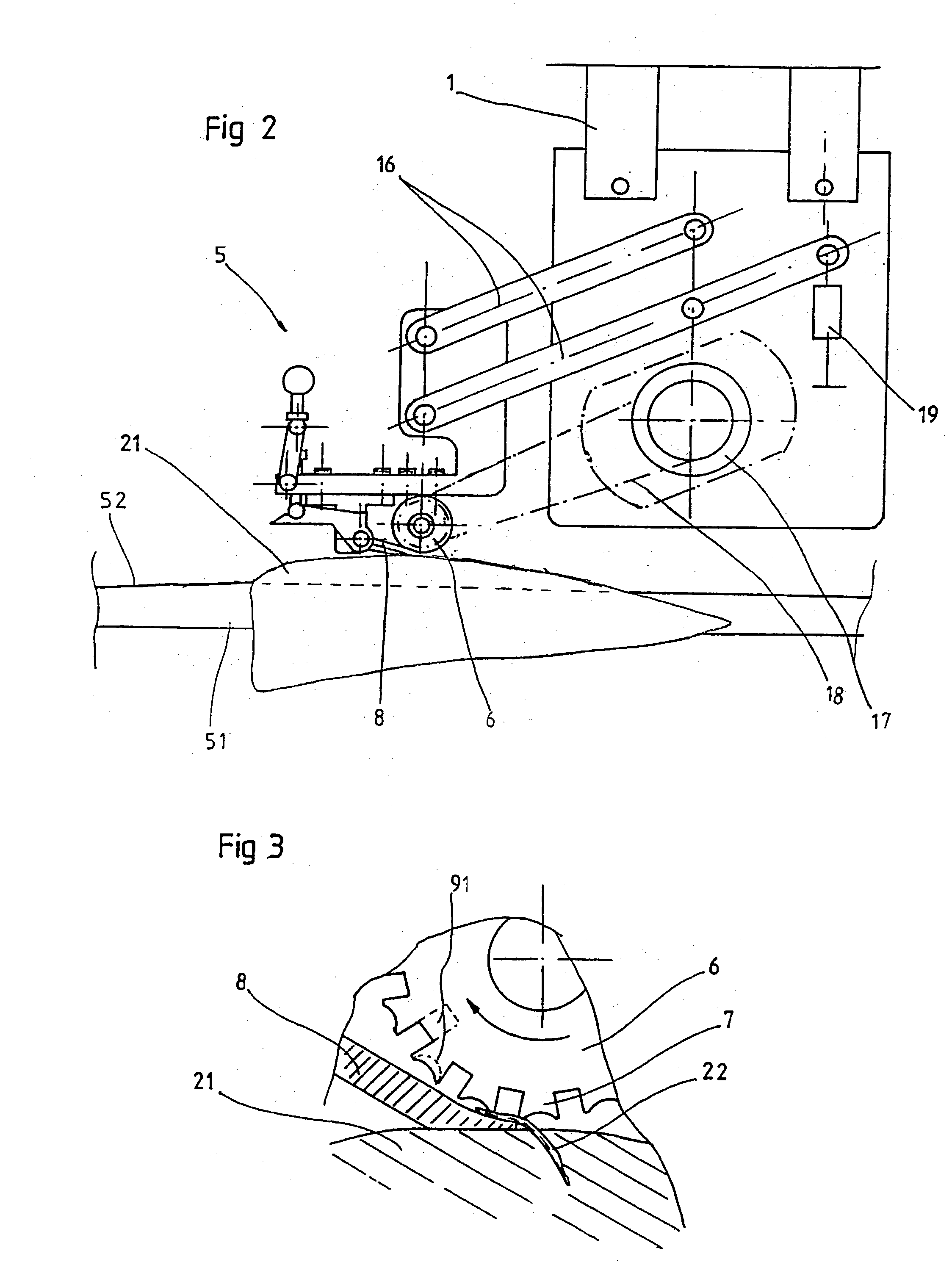

Method and apparatus for bone removing

The invention relates to method and apparatus for removing bones from meat, such as pin-bones from fish filet e.g. whitefish such as cod comprising a conveyor (2) for transporting the meat and a bone removing unit (5) for removing the bones as the meat is transported along the conveyor. The bone removing unit (5) is movably hinged to the frame (1) of the apparatus and moveable in an approximated up- and downward direction toward the conveyor (2). The conveyor comprises an upwardly extending edge (52) allowing the bone removal unit to be brought into contact with a particular area to remove the bones that are primarily located therein. In this manner it is possible to adjust the apparatus according to the configuration figure of each individual fish filet.

Owner:CARNITECH

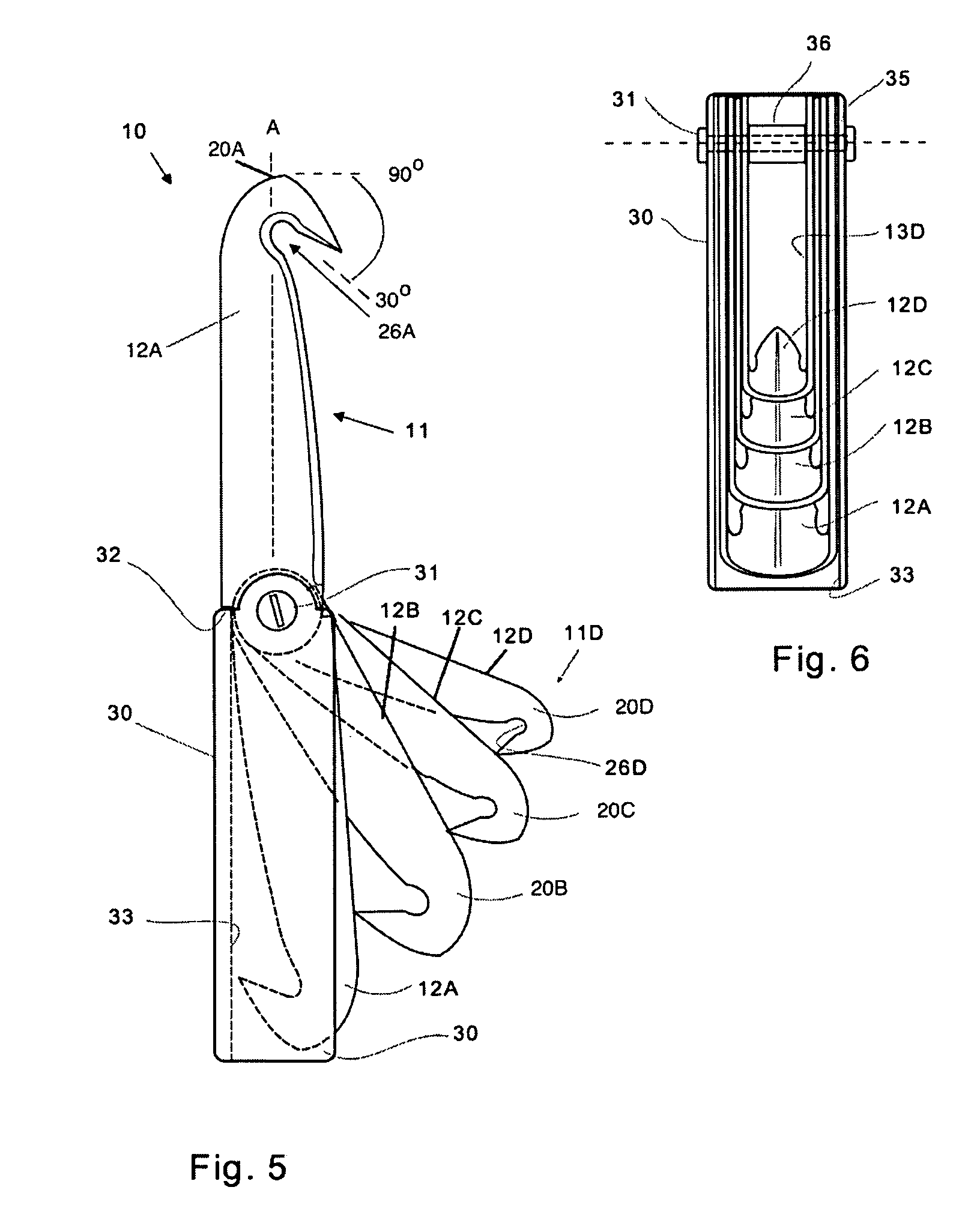

Deboning knife

InactiveUS8382562B1Shorten the timeMeat holding apparatusFish washing/descalingMechanical engineeringEngineering

A knife for deboning rib meat from ribs includes a plurality of spaced apart blades arranged in side by side relation, each blade having forward end, a rearward end and a sharp bottom edge, a deboning head transversely interconnecting the blades and which includes a sharp bottom edge, wherein a sharp grooved surface interconnects a forward end of both blades and the deboning head and a handle connected to the rearward end of the blades. The sharp grooved surface is contoured to a rib of predetermined animal.

Owner:LAVRETABKY PHILIP

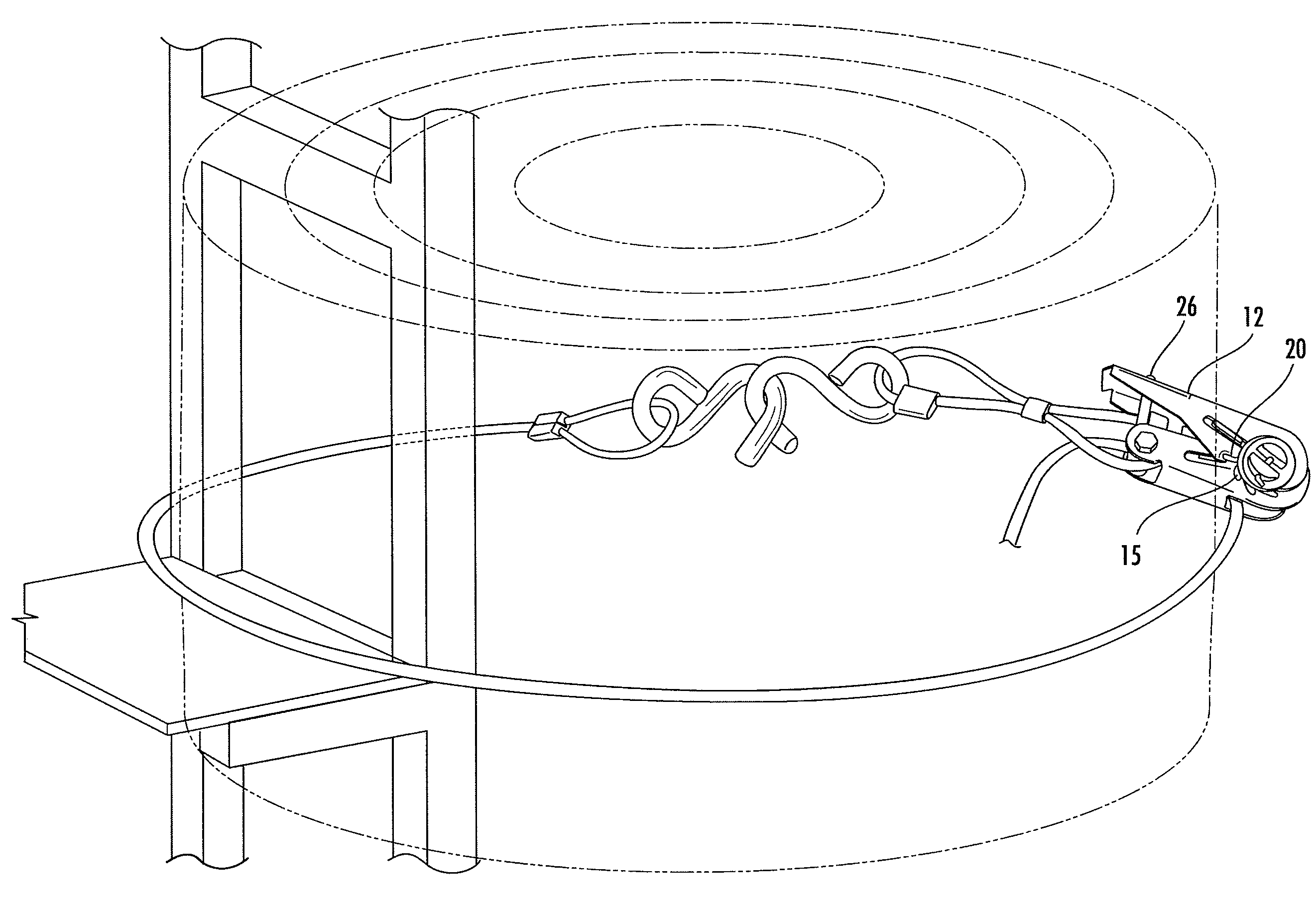

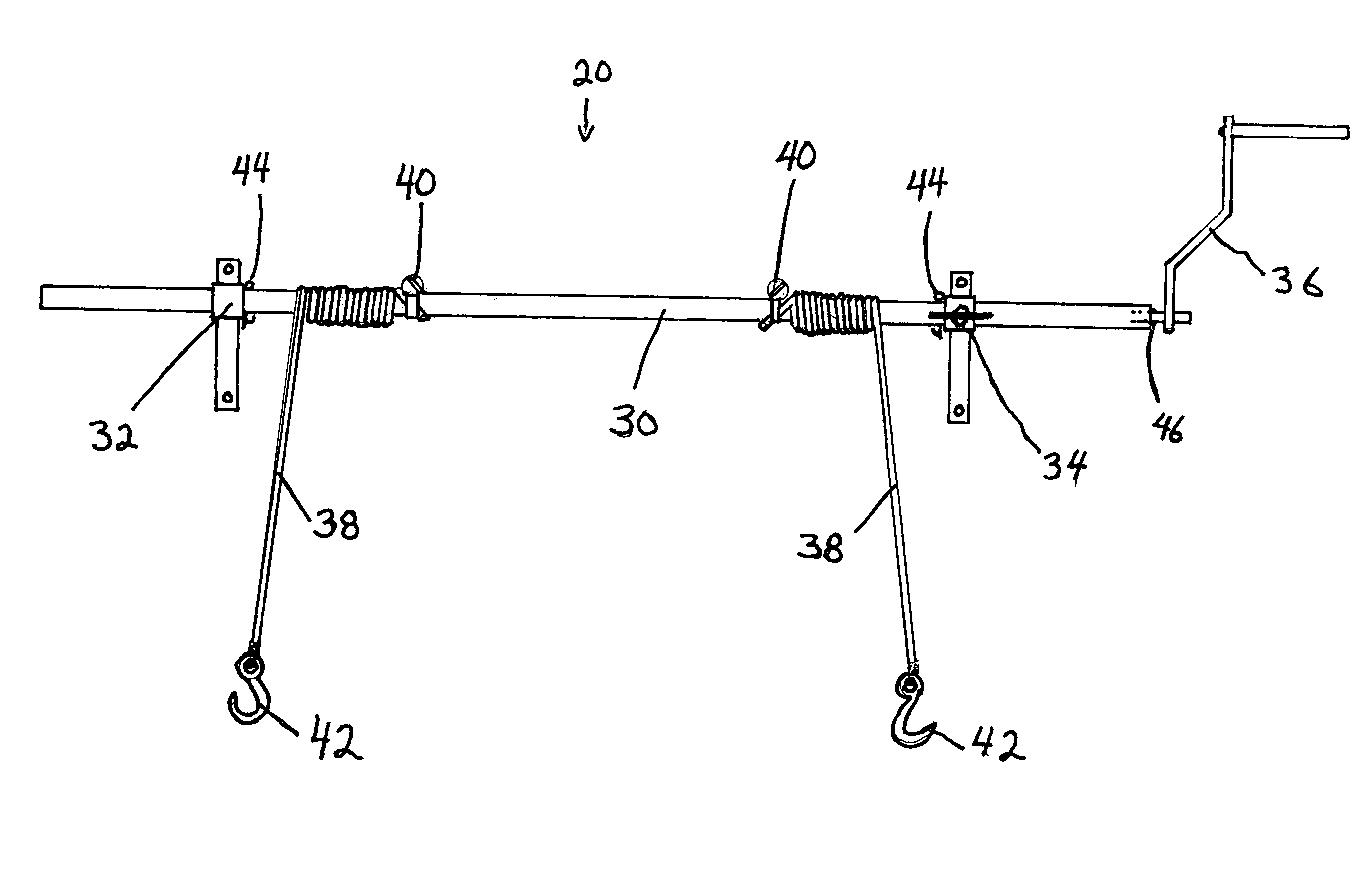

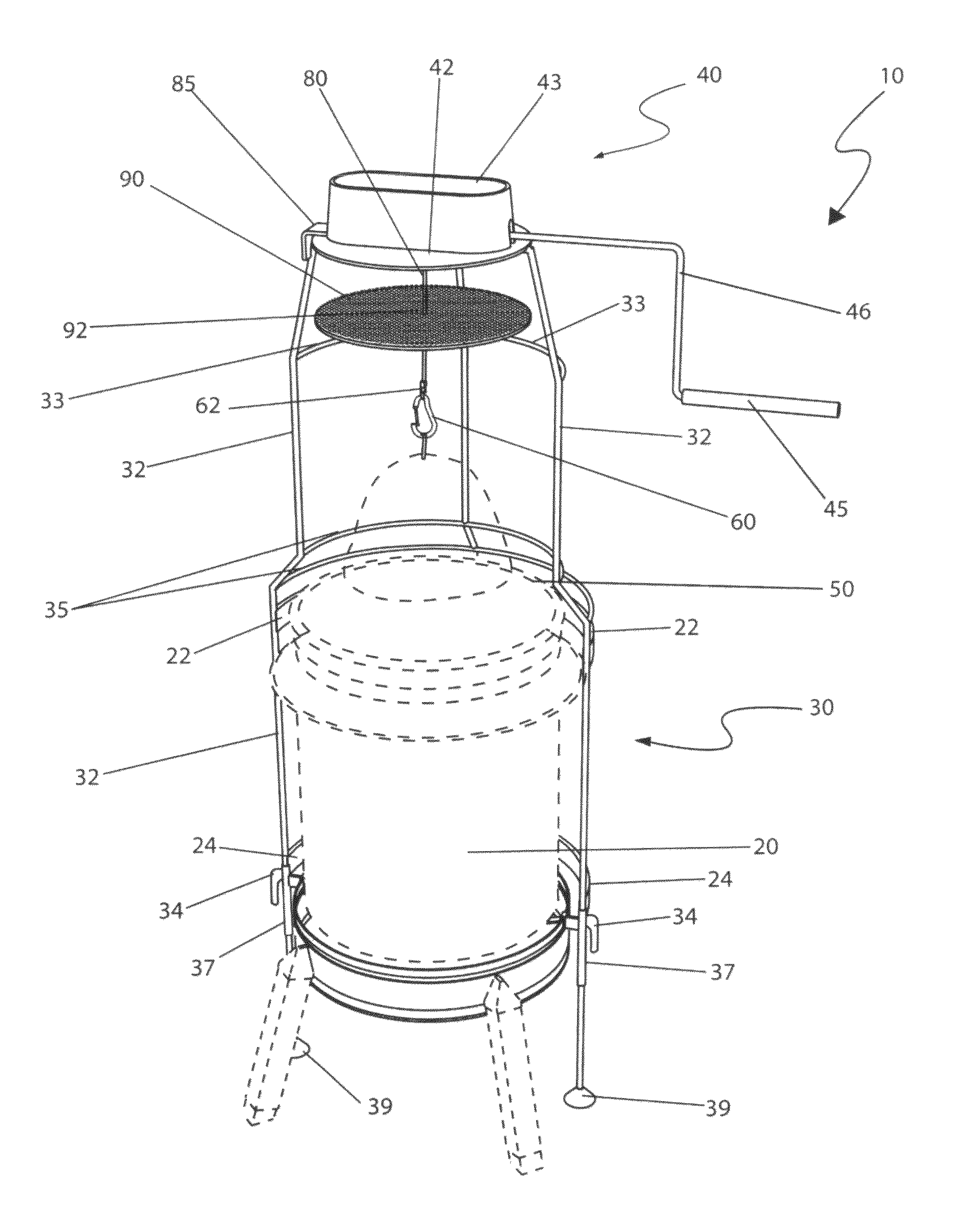

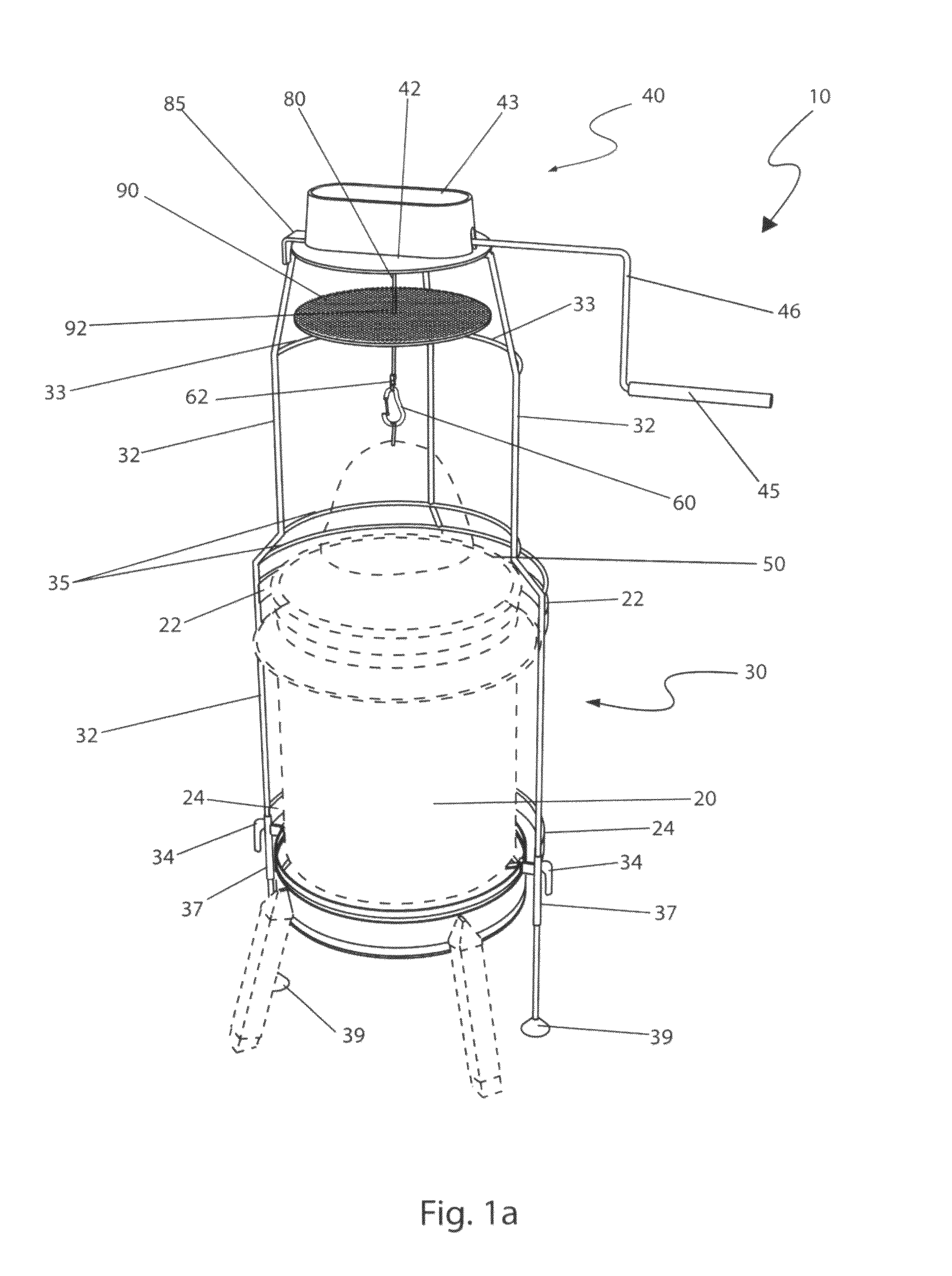

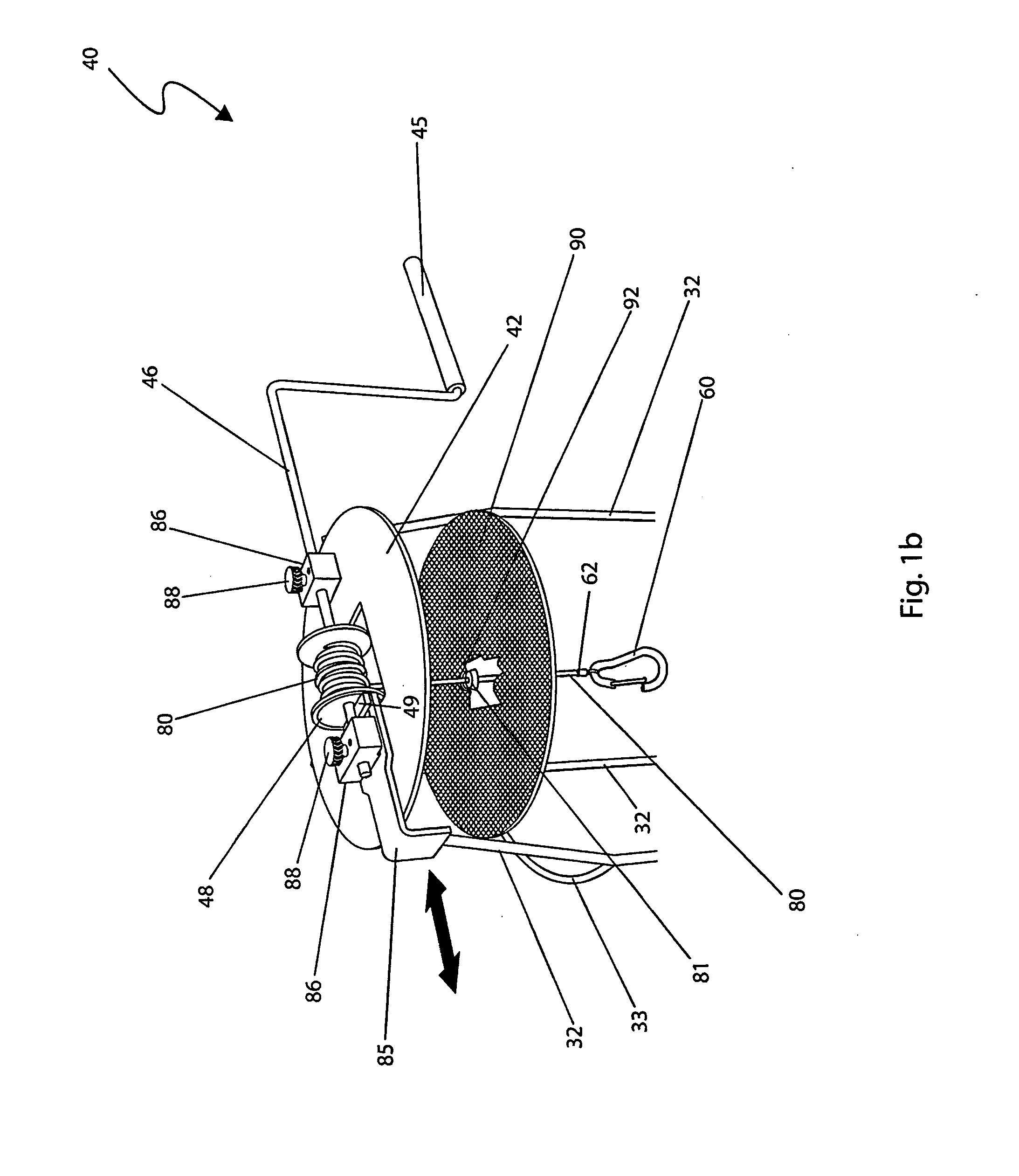

Winch for turkey deep fryers

InactiveUS8375847B1Improve stabilityReduce riskMeat holding apparatusMeat/sausage hanging-upControl mannerWinch

A mechanical apparatus that lowers and raises a turkey, or similar food item, into a large fry pot is herein disclosed. The apparatus has a vertically-adjustable tripod stand that is positioned over the top center of a fry pot. A manual cranking mechanism lowers and raises a steel cable having a grasping hook at the distal end. Additionally, the steel cable can have a basket at its distal end. In operation, the turkey to be fried is placed thereon the hook or therein the metal basket. Then, with the user a safe distance removed, the crank lowers the food into the hot oil in a controlled manner. When the food has finished cooking, the cranking mechanism is reversed to raise the food from the fryer. The apparatus may also be provided having an alternate electric-powered winch.

Owner:ANGANES WILLIAM P

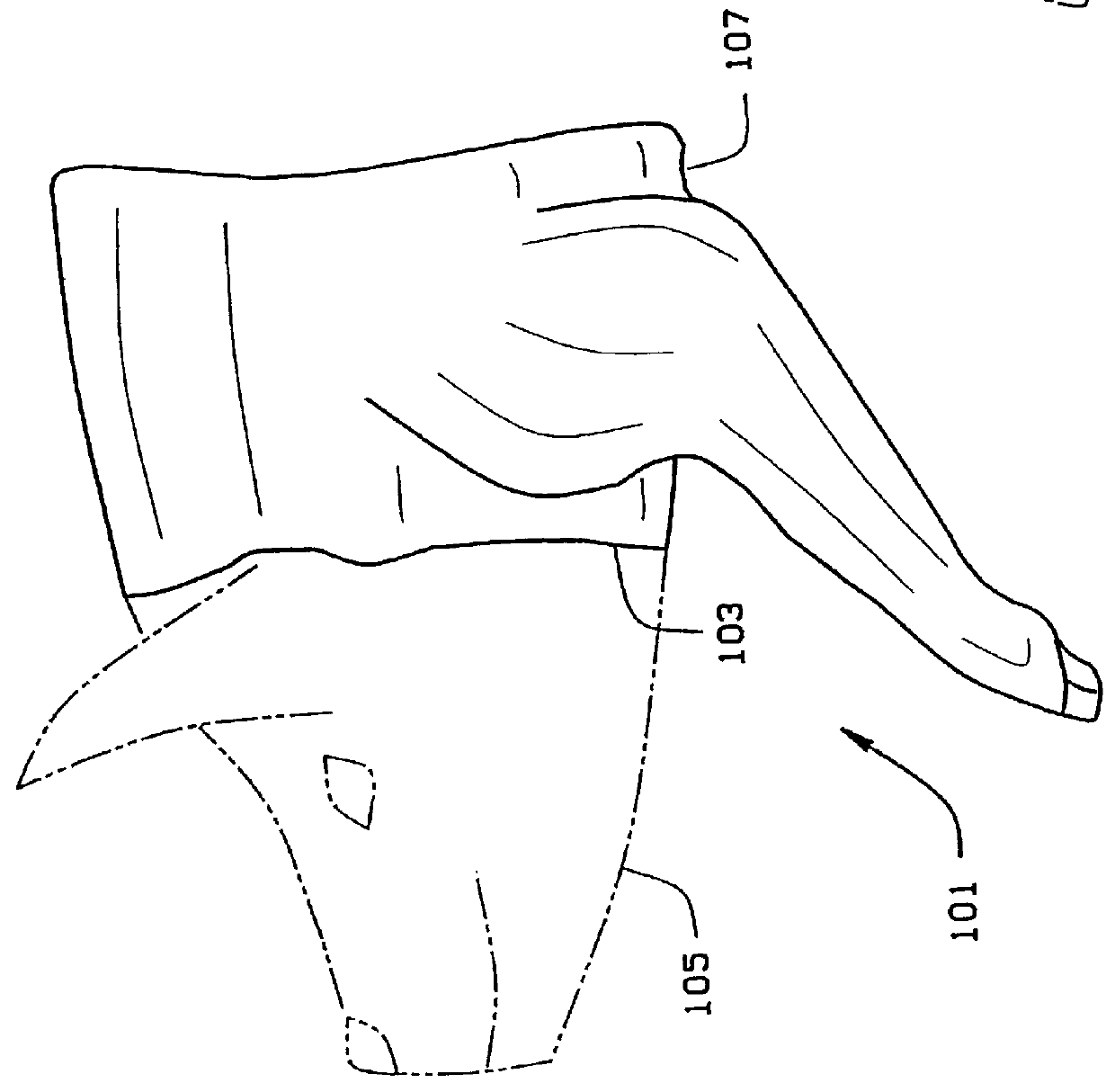

Apparatus and Method for Cutting-Free of Tender-Loin

InactiveUS20080274682A1Manual stepEasy to keep stableMeat holding apparatusMeat/sausage hanging-upAnatomyBiomedical engineering

The invention relates to an apparatus for cutting free of at least a part of a tenderloin in a suspended half-carcass. The apparatus comprises a fixture (1) having a pubic bone catch (2) for positioning and support of the half-carcass by the pubic bone thereof. Further the apparatus comprises a cutting device (7) having a sharp edge (9) curving transversely to the edge (9), and a moving device for the cutting device (7) for moving the cutting device (7) with the sharp edge (9) foremost during cutting free of at least a part of the tenderloin in a half-carcass positioned in the pubic bone catch. Moreover, the invention relates to a fixture for a half-carcass or a hindquarters thereof, a pubic bone catch (2) for use in the above apparatus, a cutting device, and a method for cutting free of at least a part of a tenderloin in a suspended half-carcass.

Owner:TEKNOLOGISK INST

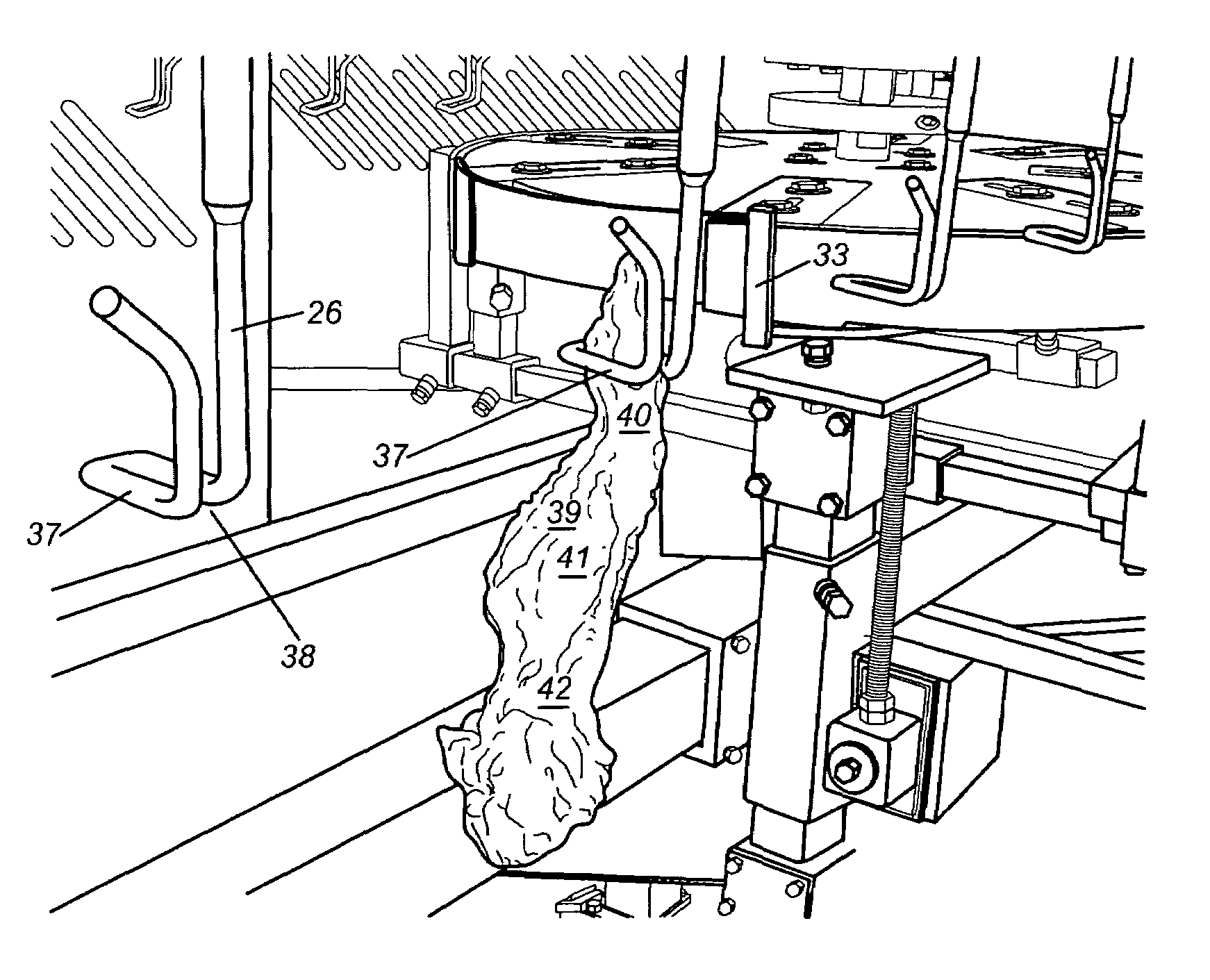

Automated saw for splitting carcasses

An automated saw for high speed splitting of suspended carcasses, such as hog carcasses, through the backbone as the carcasses continuously move along a carcass rail includes a splitting station and a back roller station located on opposite sides of the carcass rail. The splitting station includes a splitting saw that can be driven in three directions, including horizontally towards a carcass to begin cutting, vertically down to make the cut and horizontally parallel to the carcass rail to match the speed of the moving carcass as the cut is made. A guide roller carried by the splitting station positions the backbone in a known position relative to the saw. The back roller station includes a back roller for positioning the carcass relative to the saw as the cut is made. The back roller is also movable in three directions, including horizontally in to contact the carcass, vertically down, and horizontally parallel to the carcass rail to match the motion of the saw. The back roller and saw are structurally independent, but are accurately driven to maintain the relative position of the saw and the back roller as the cut is made.

Owner:JARVIS PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com