Patents

Literature

110 results about "Product profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated product profiling apparatus and product slicing system using same

InactiveUS6882434B1Meat holding apparatusMethod using image detector and image signal processingProduct analysisVolumetric Mass Density

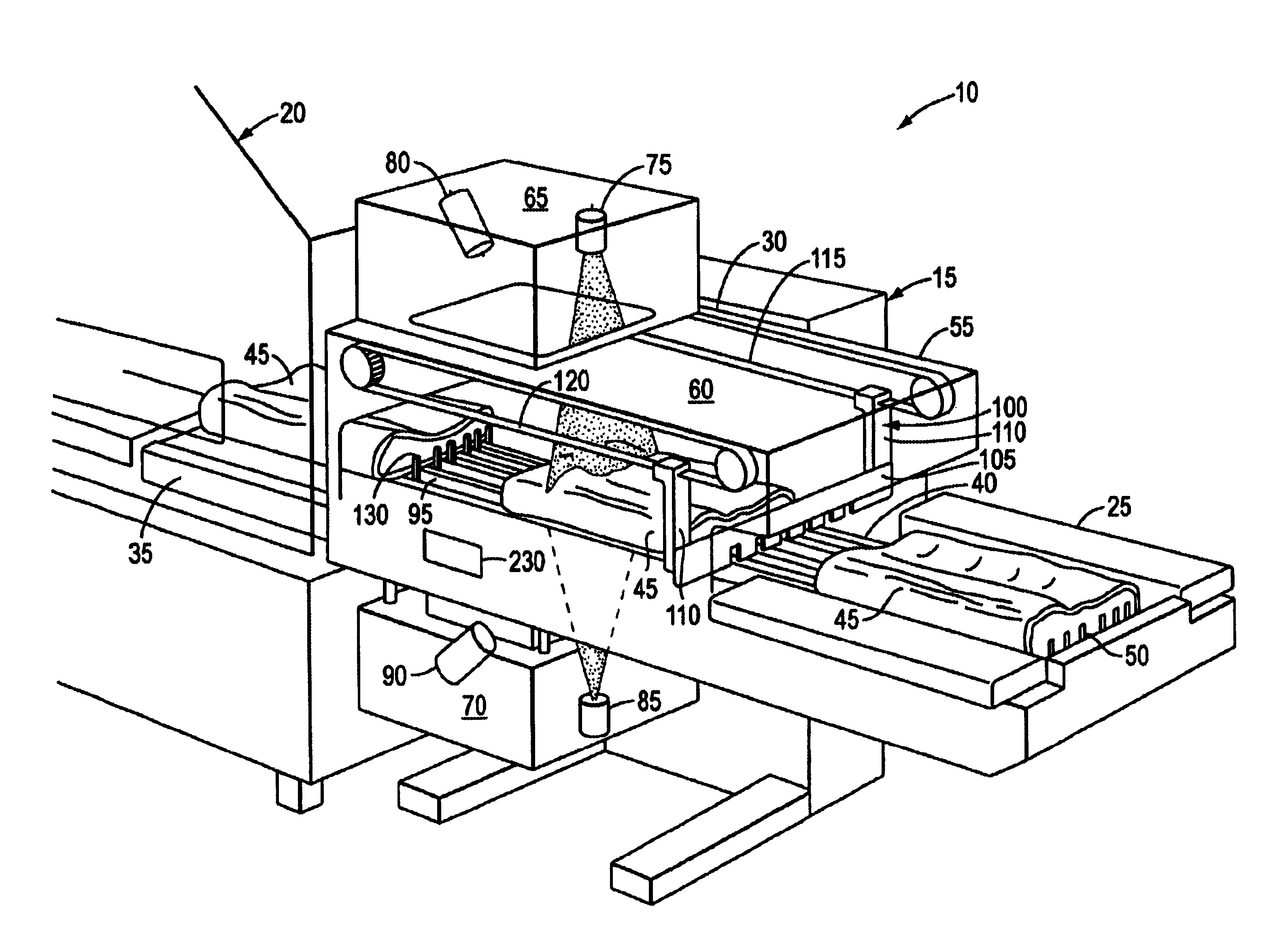

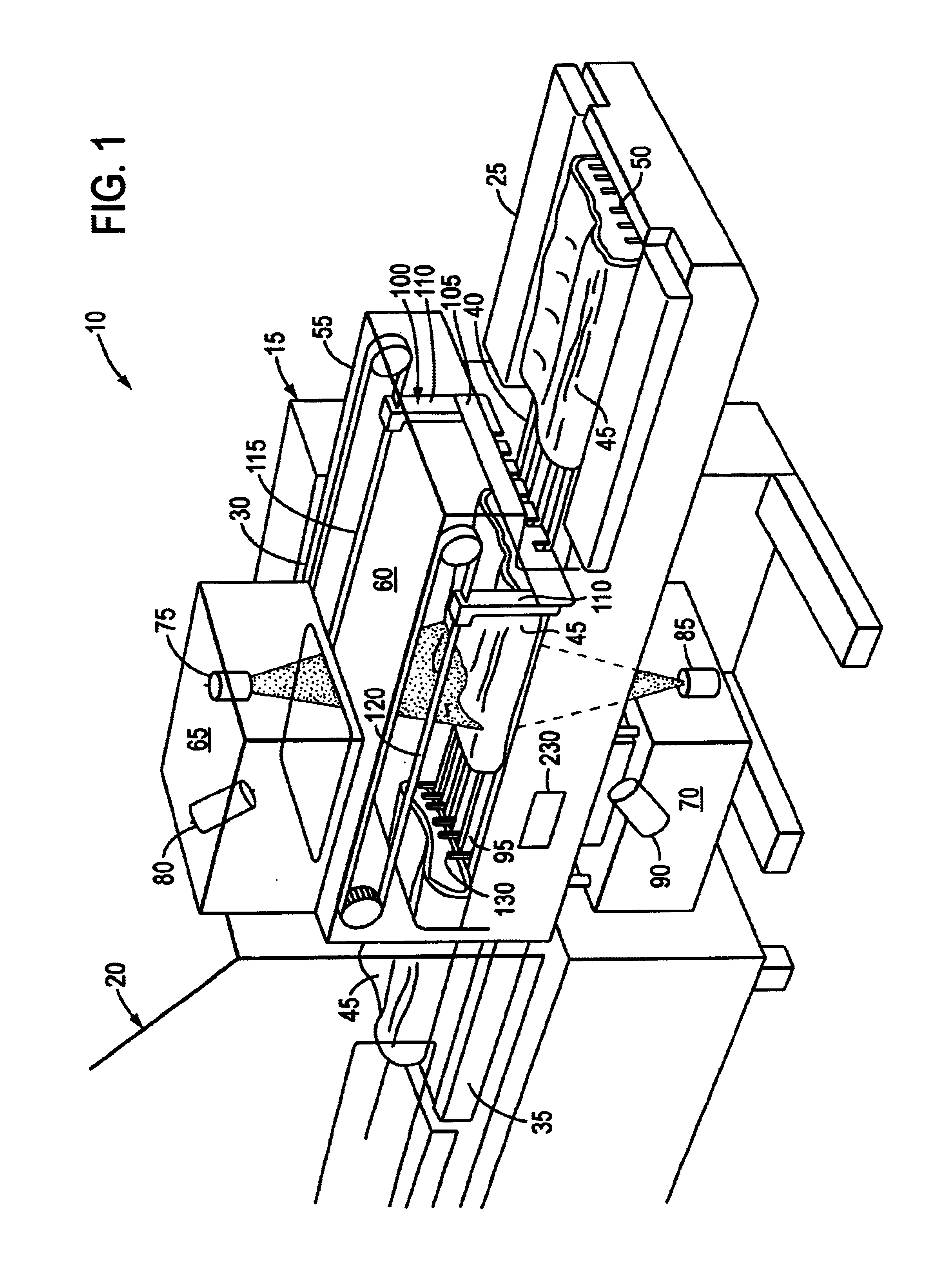

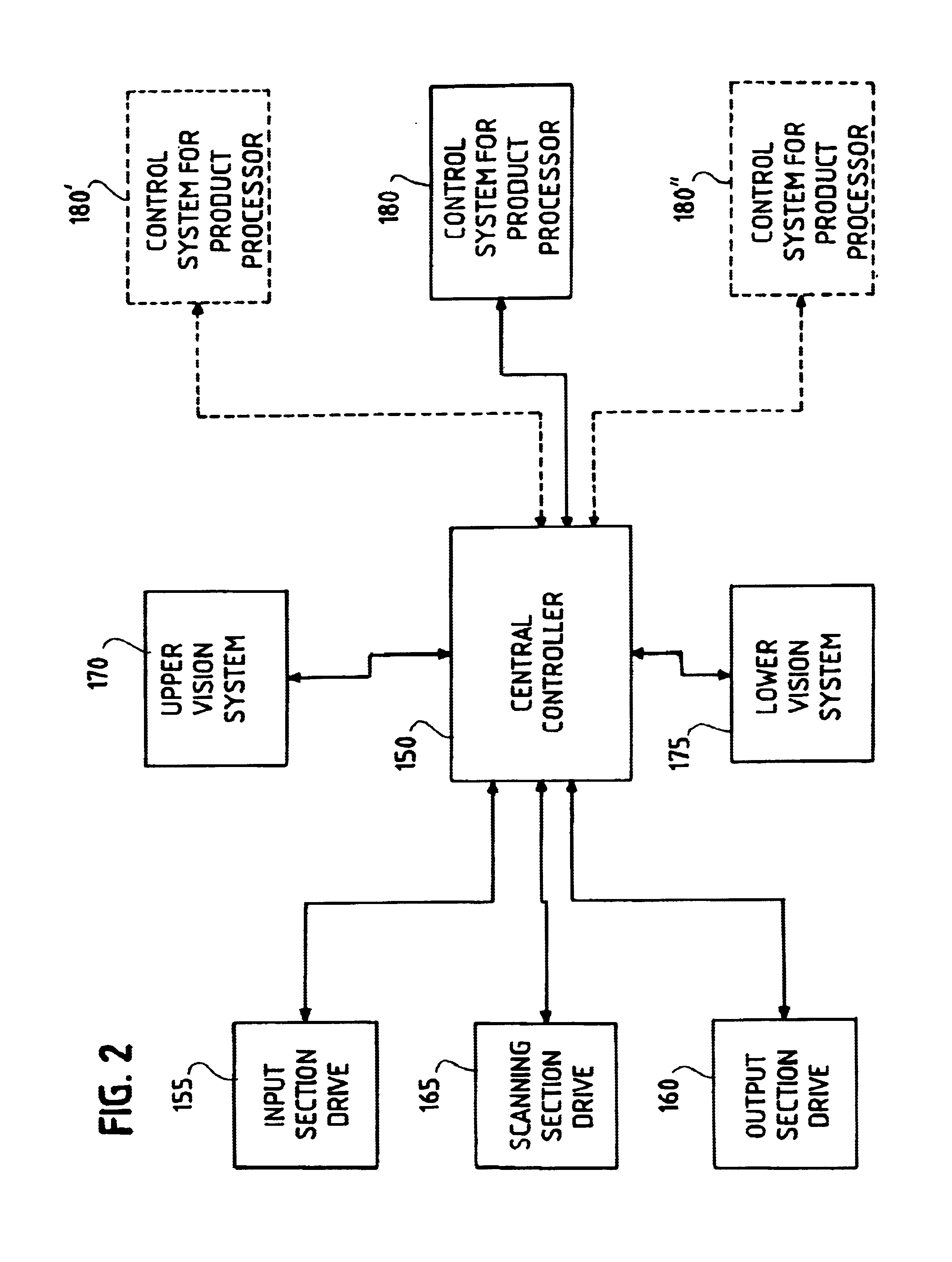

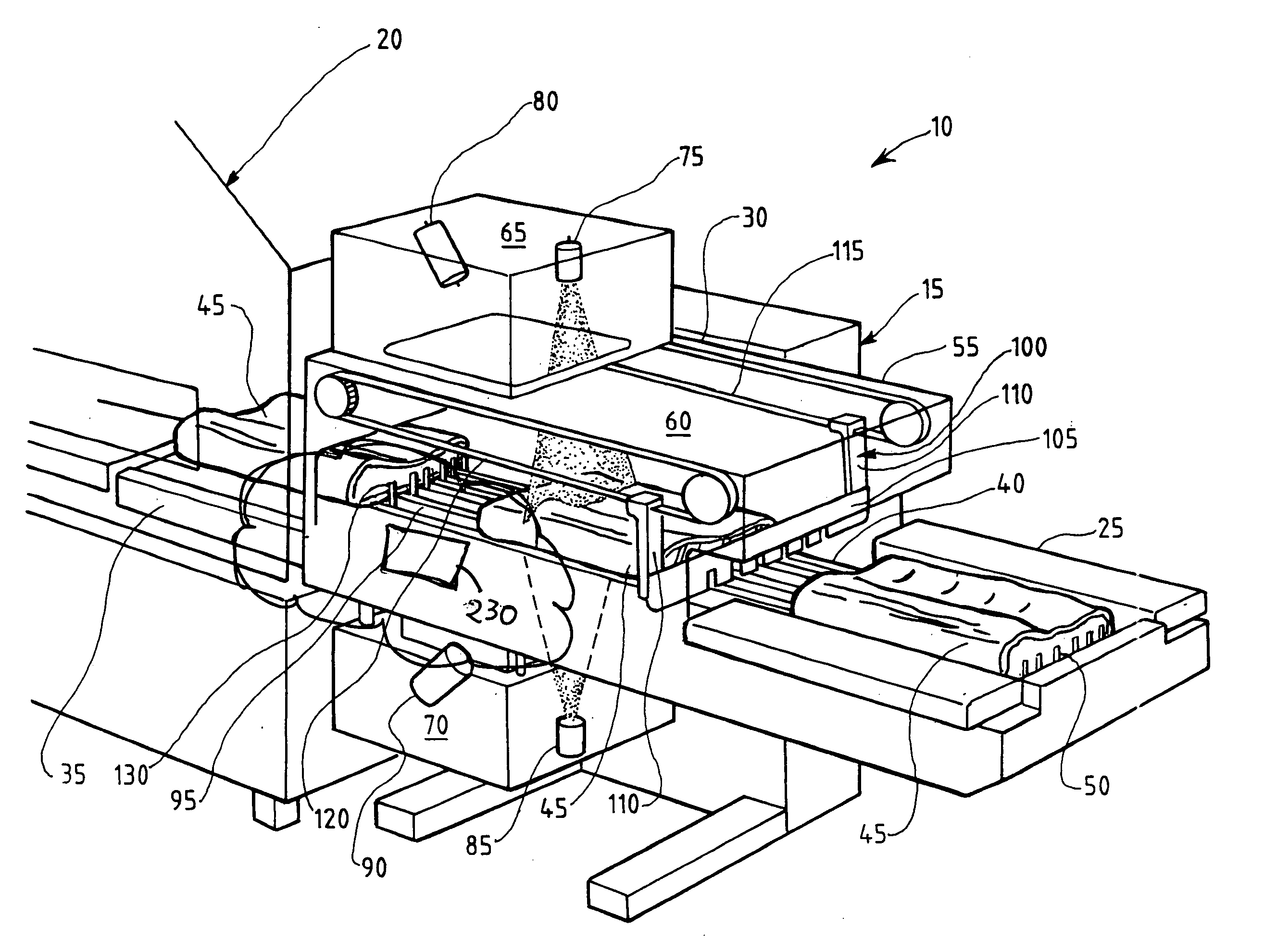

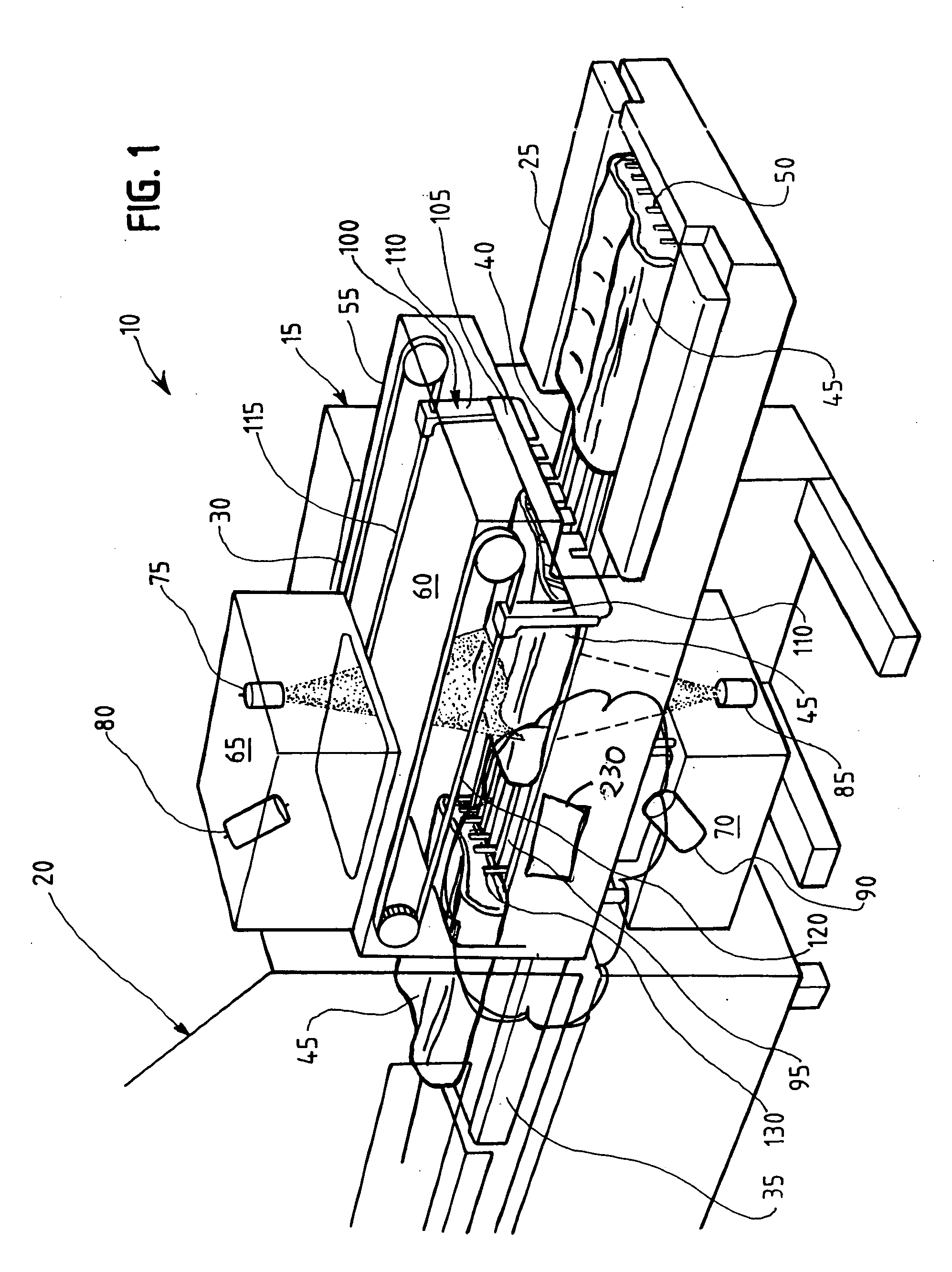

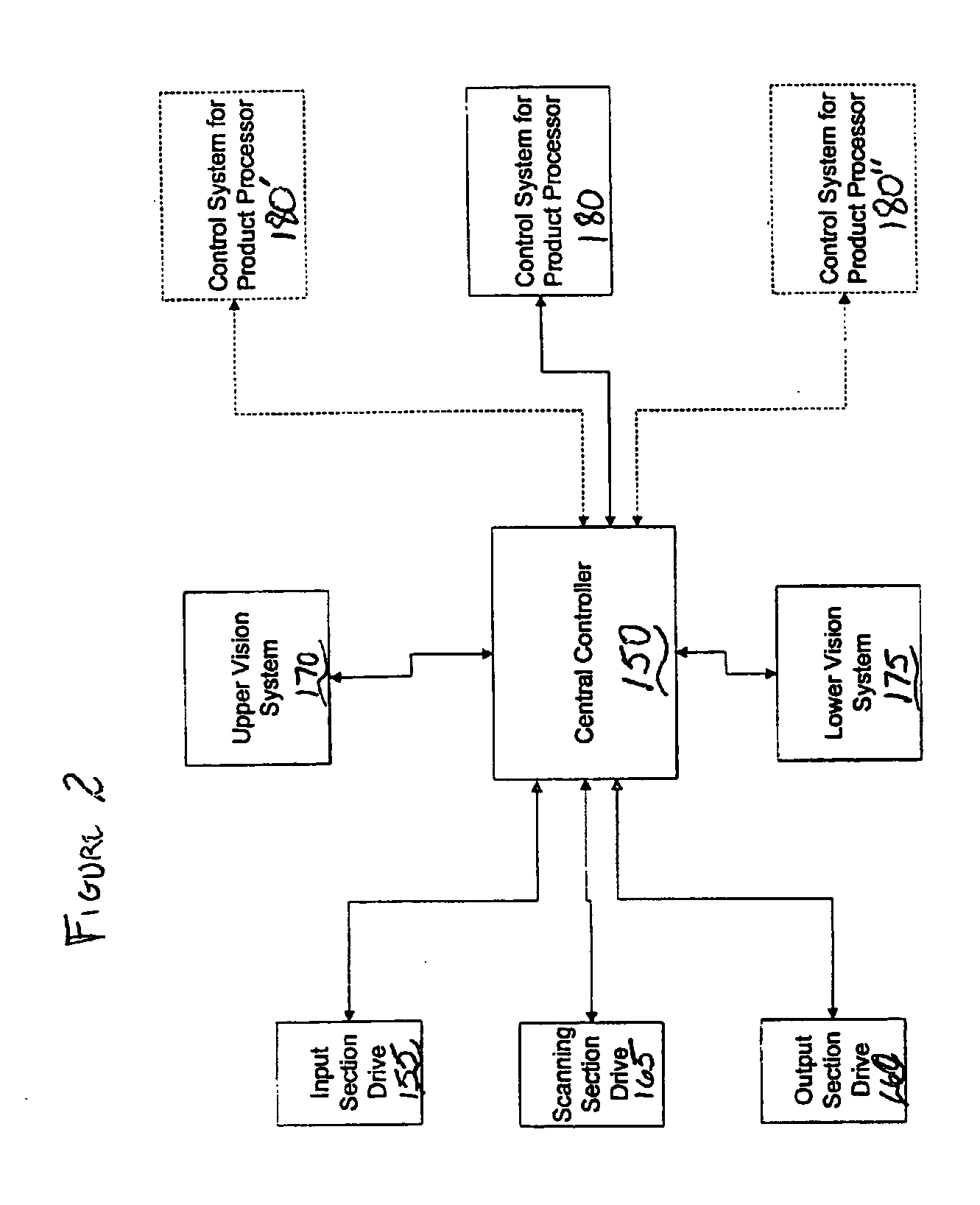

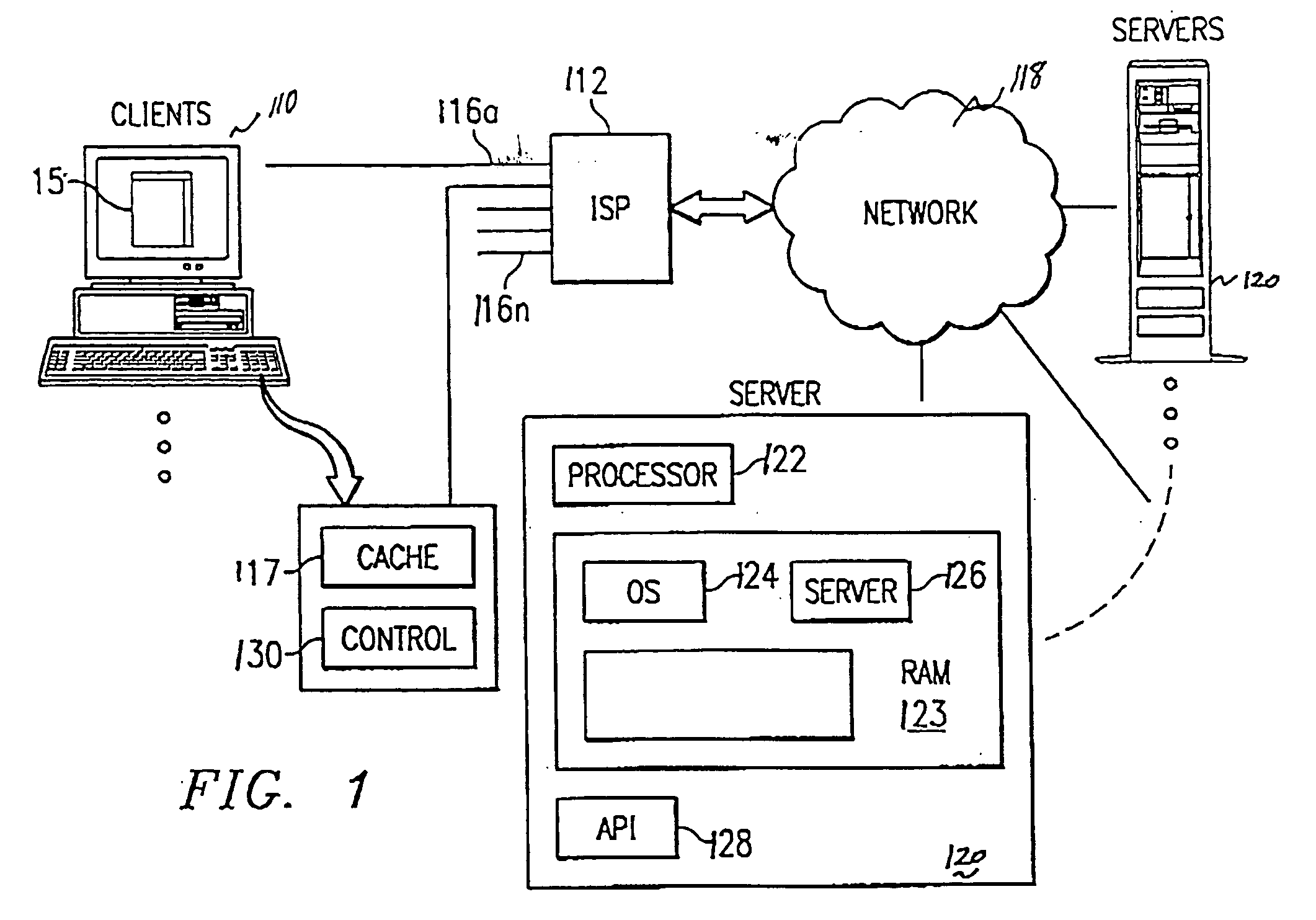

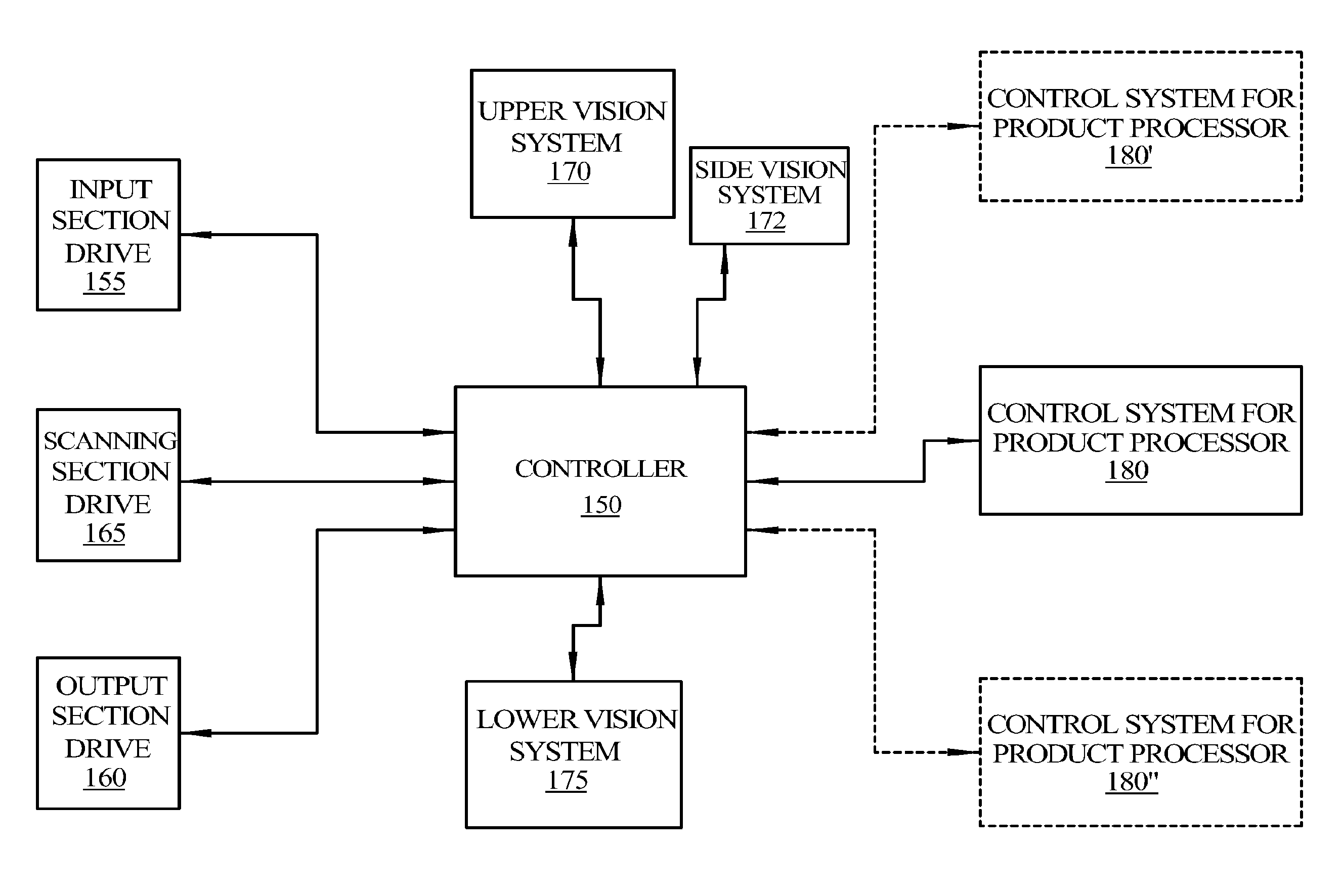

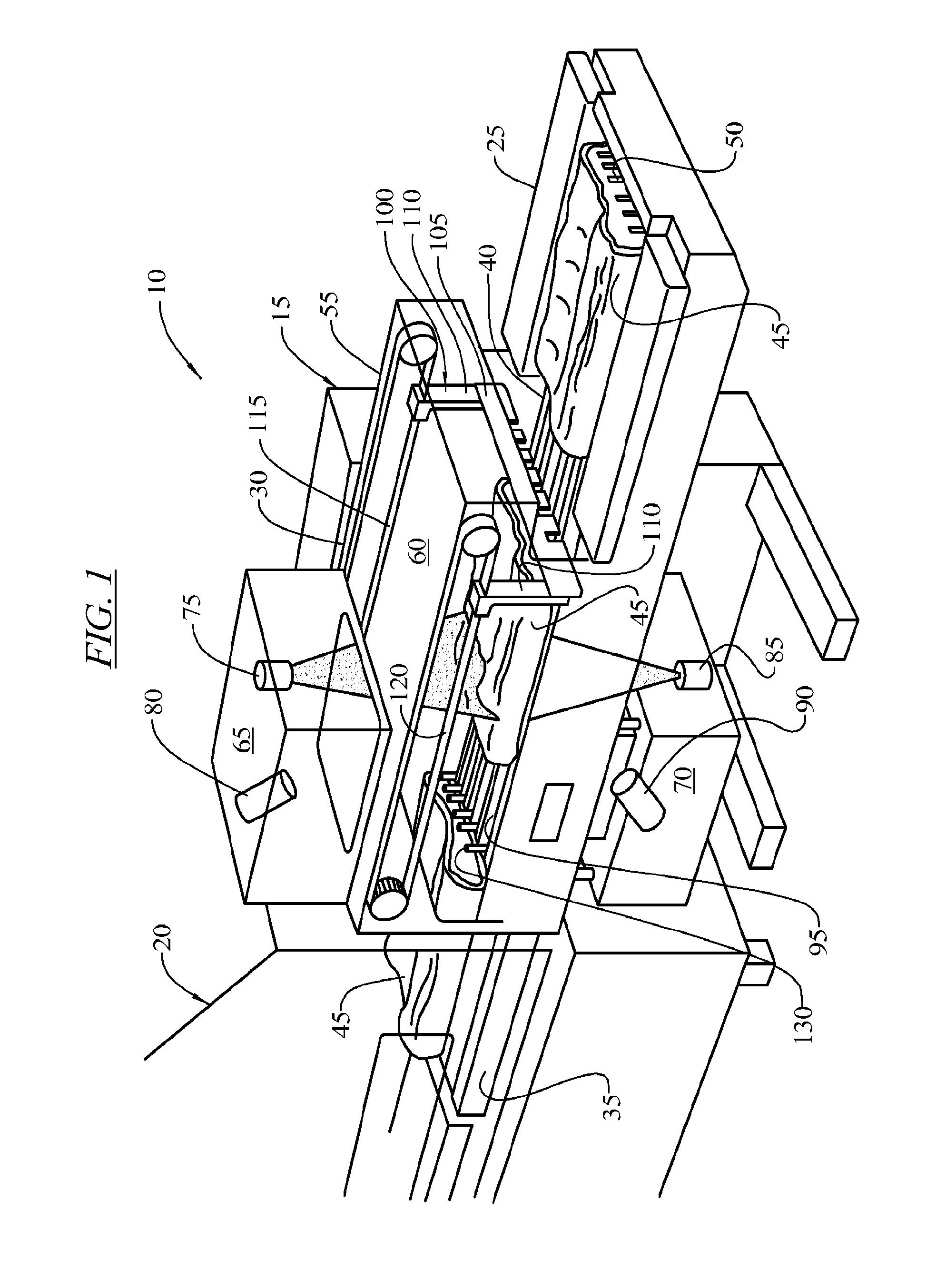

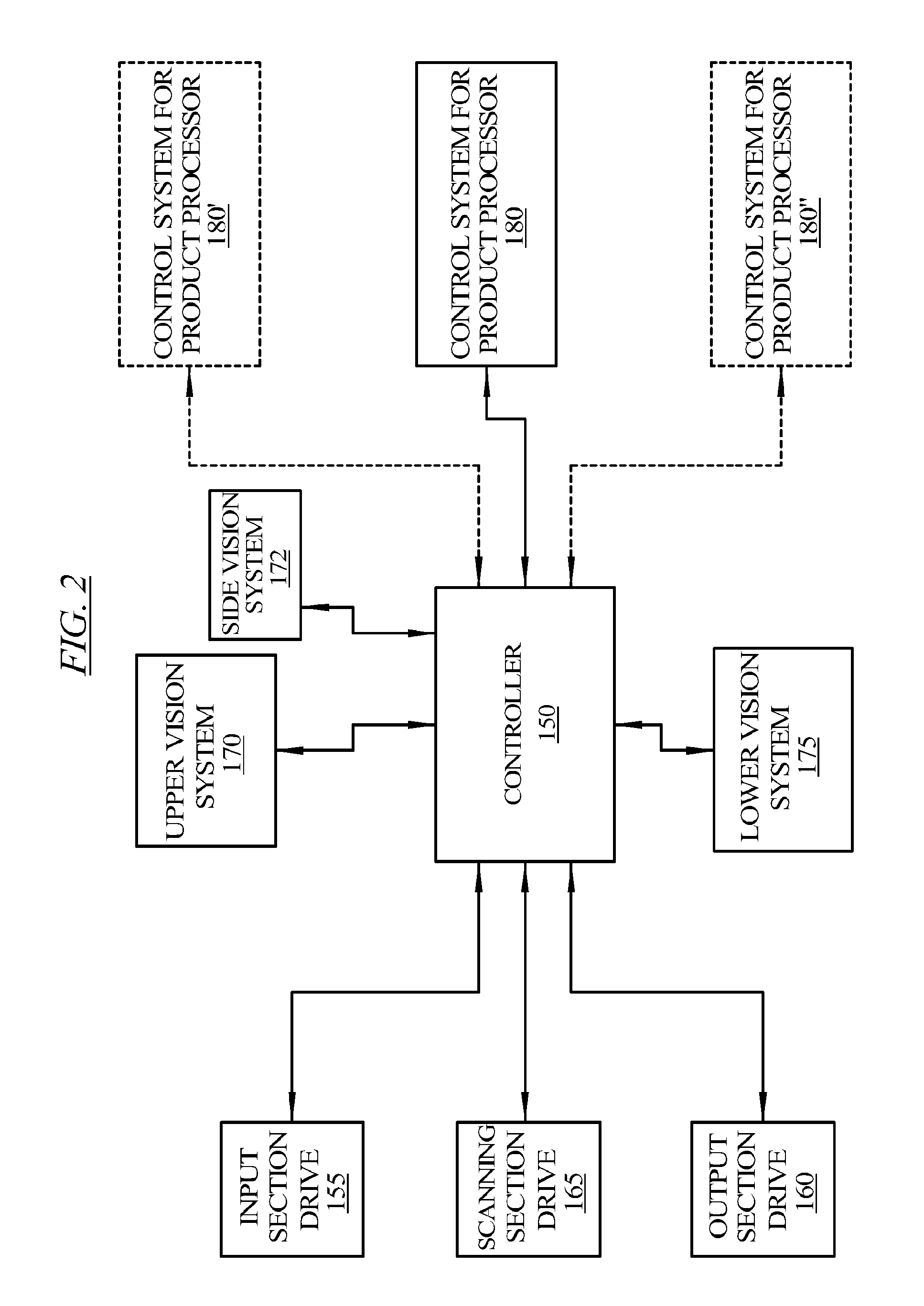

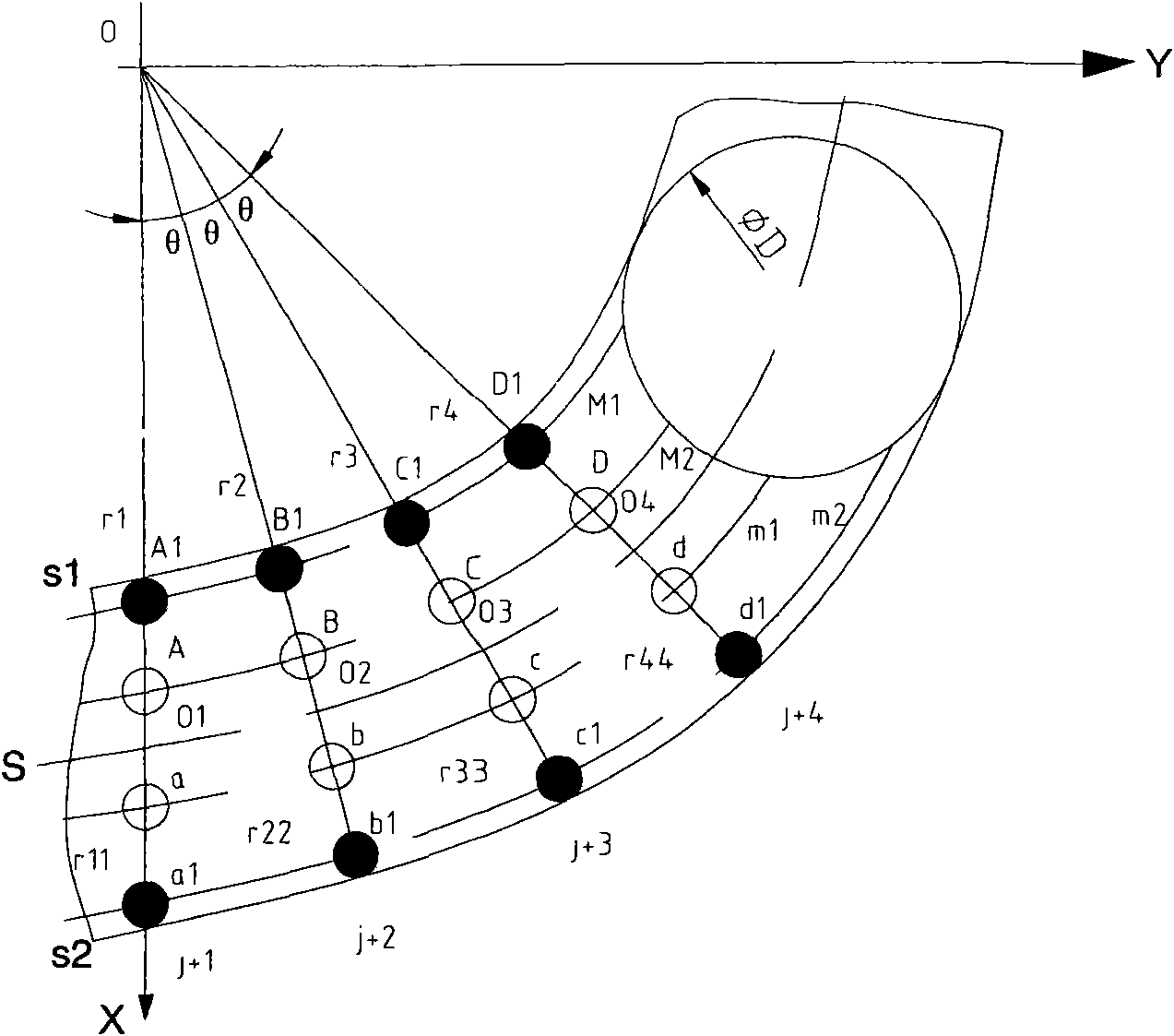

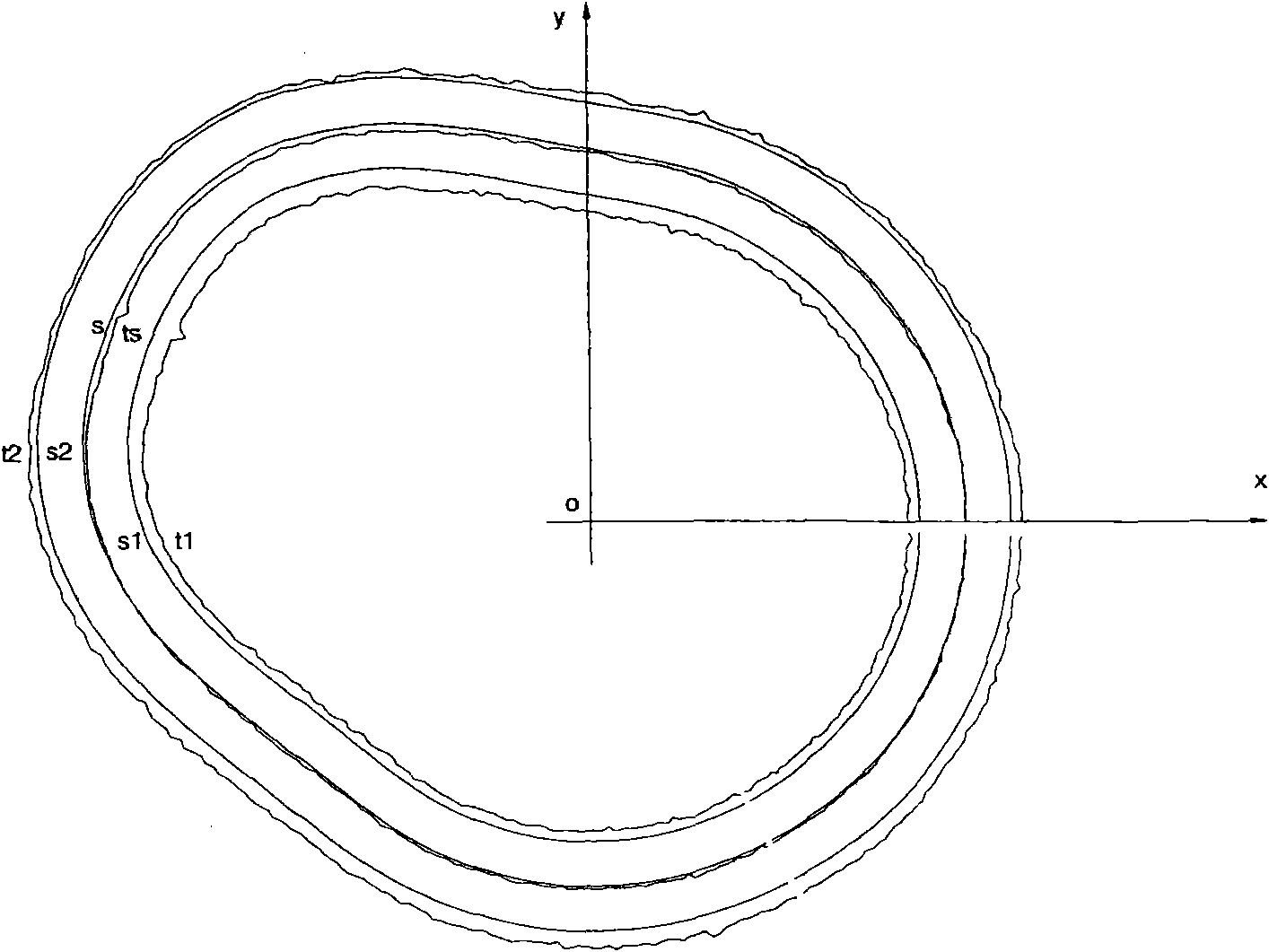

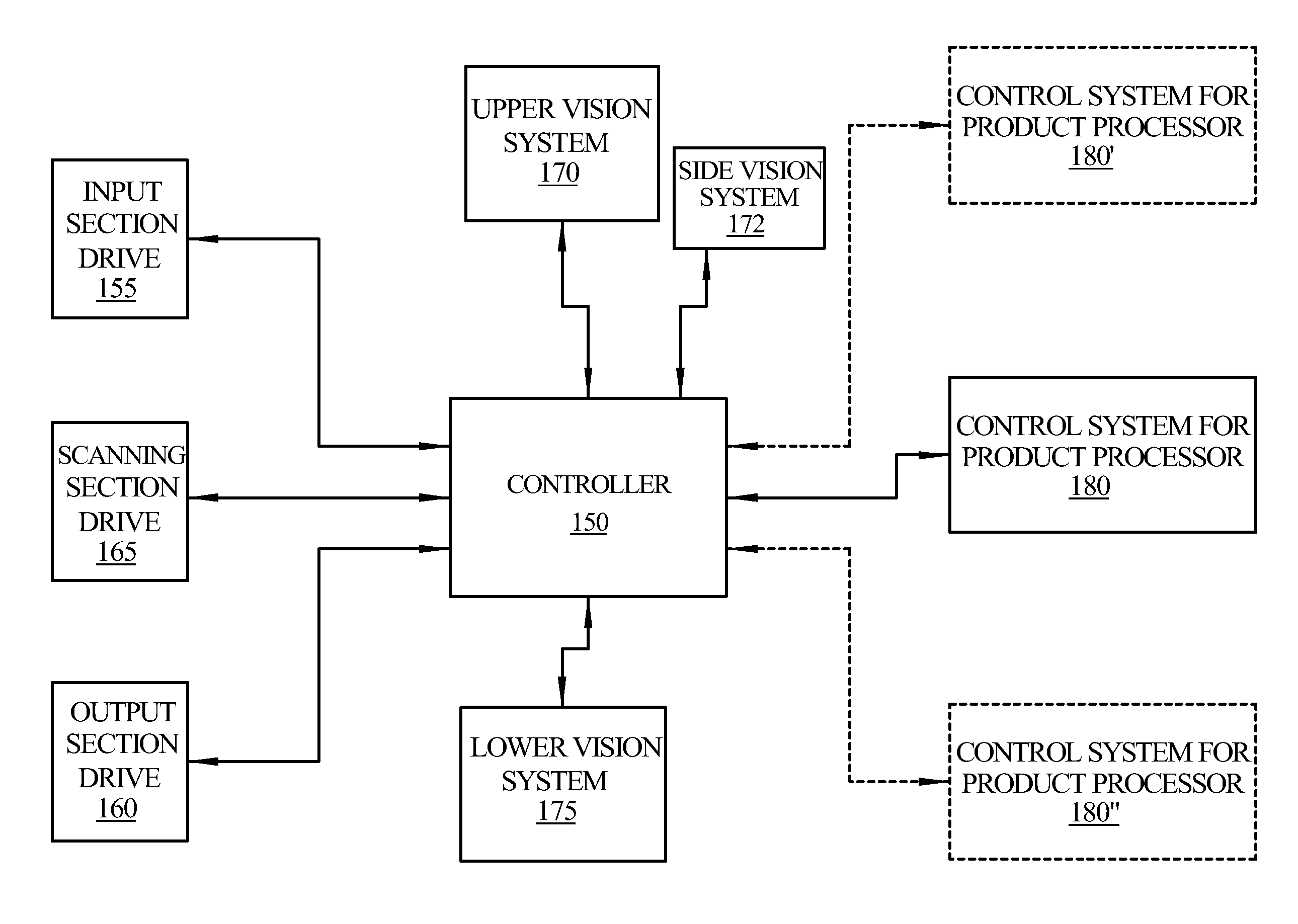

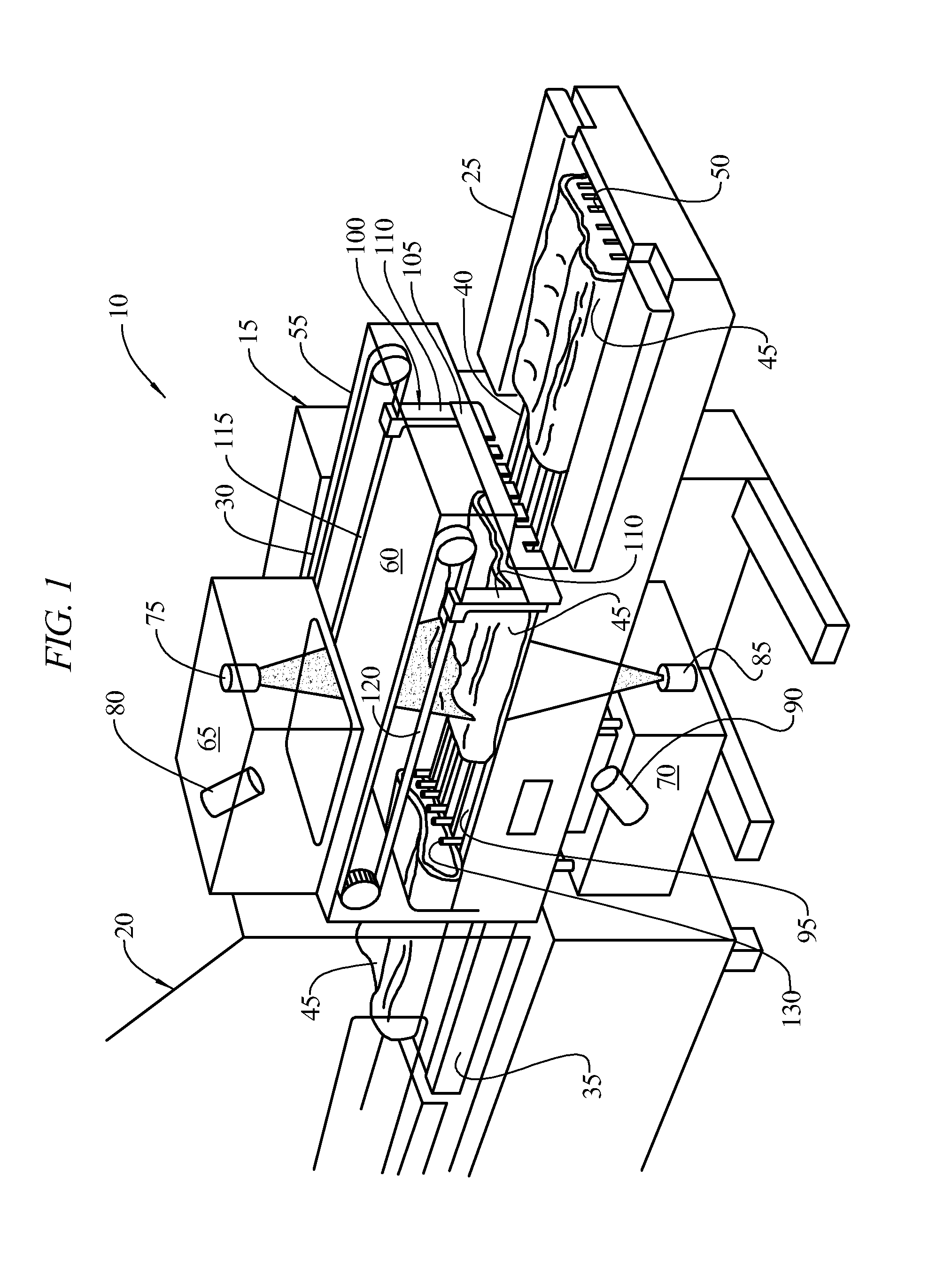

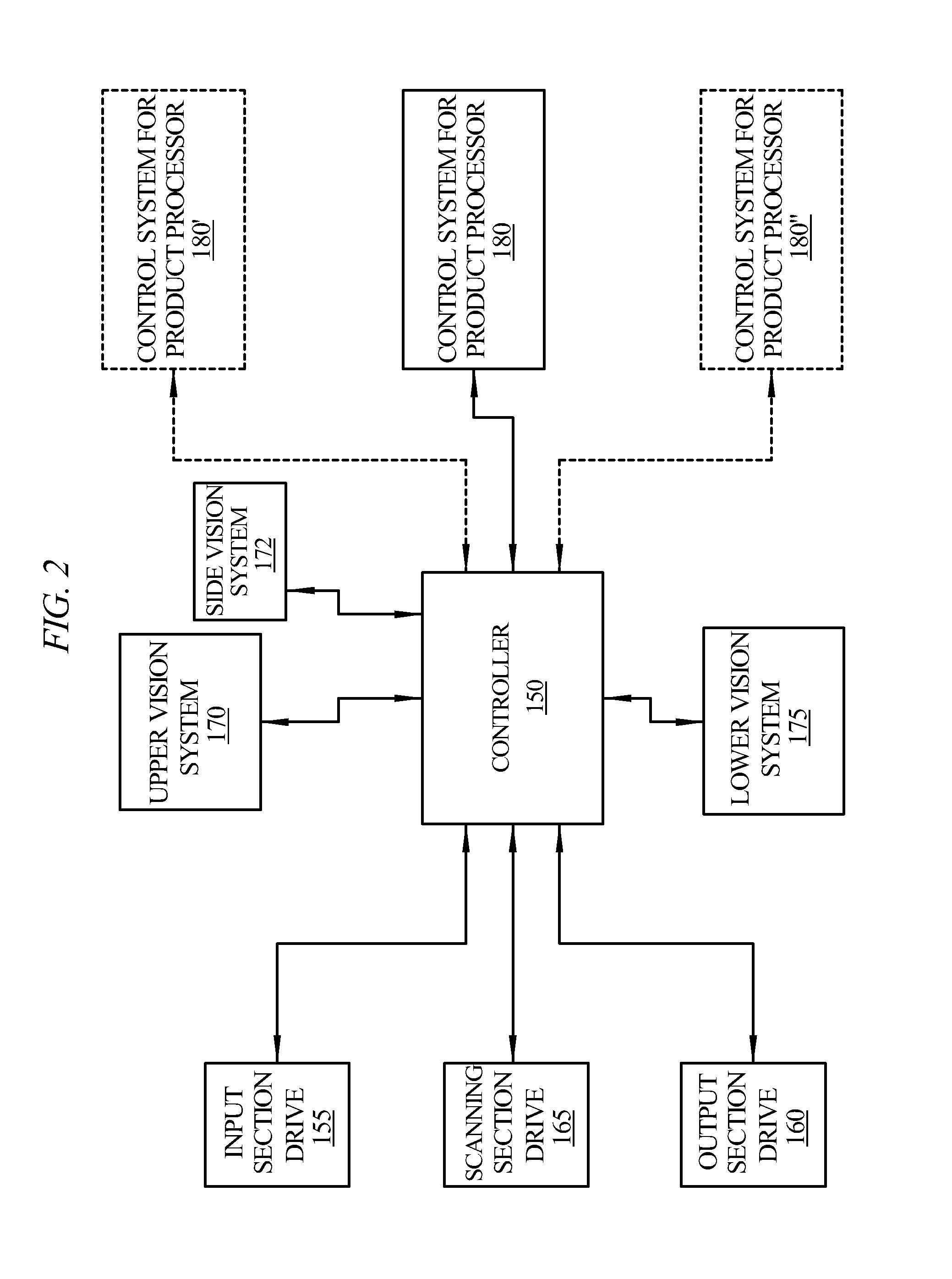

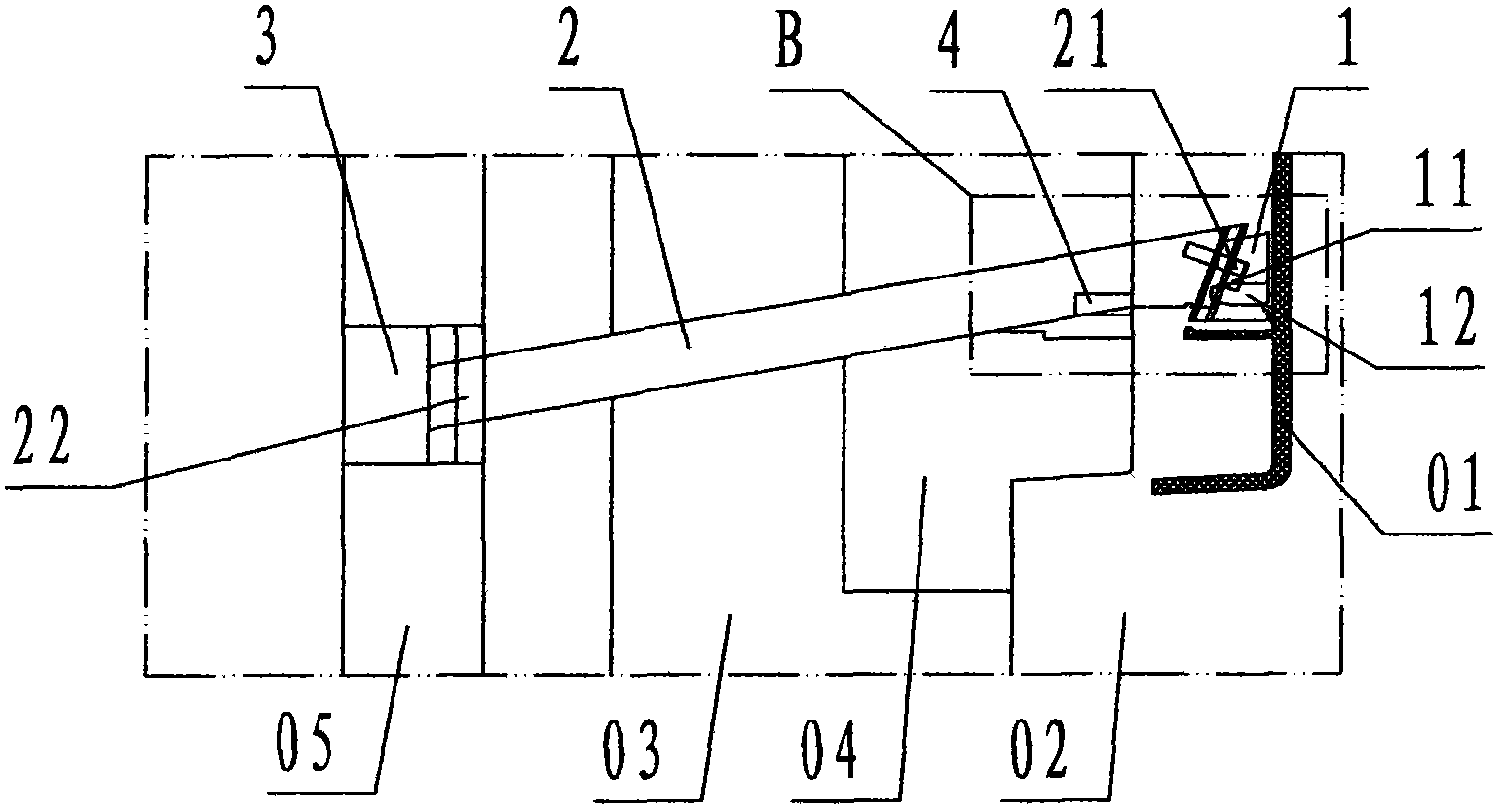

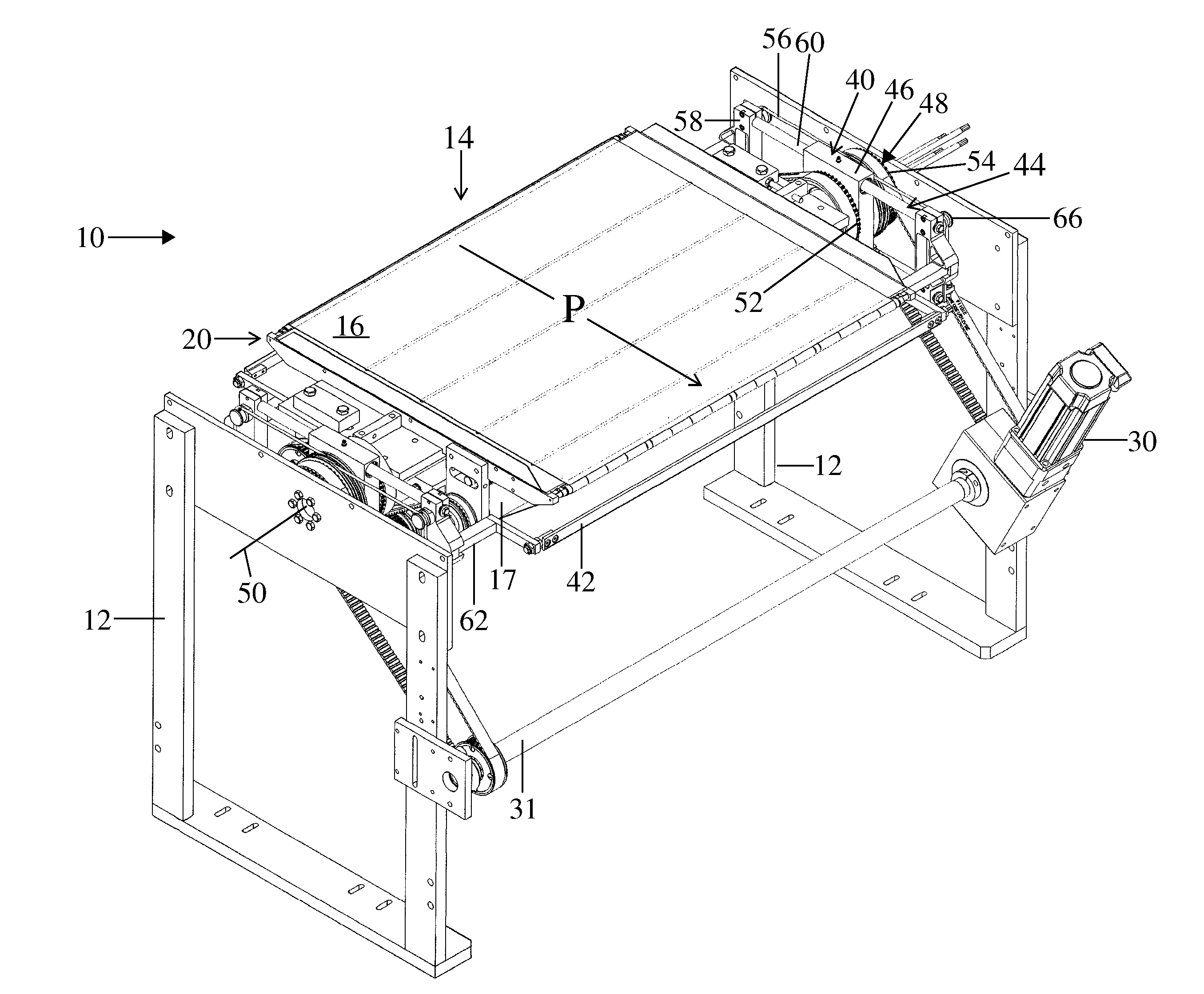

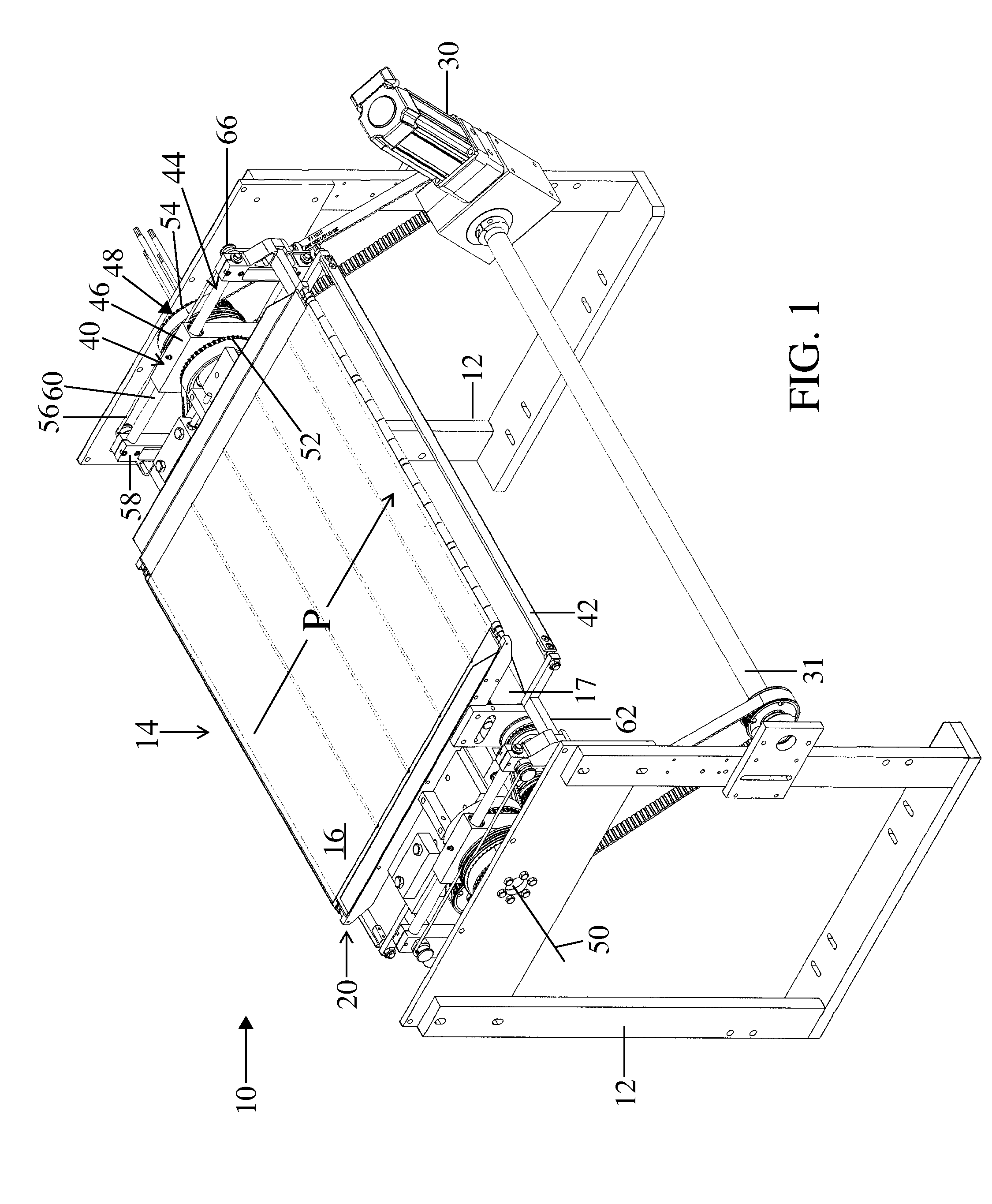

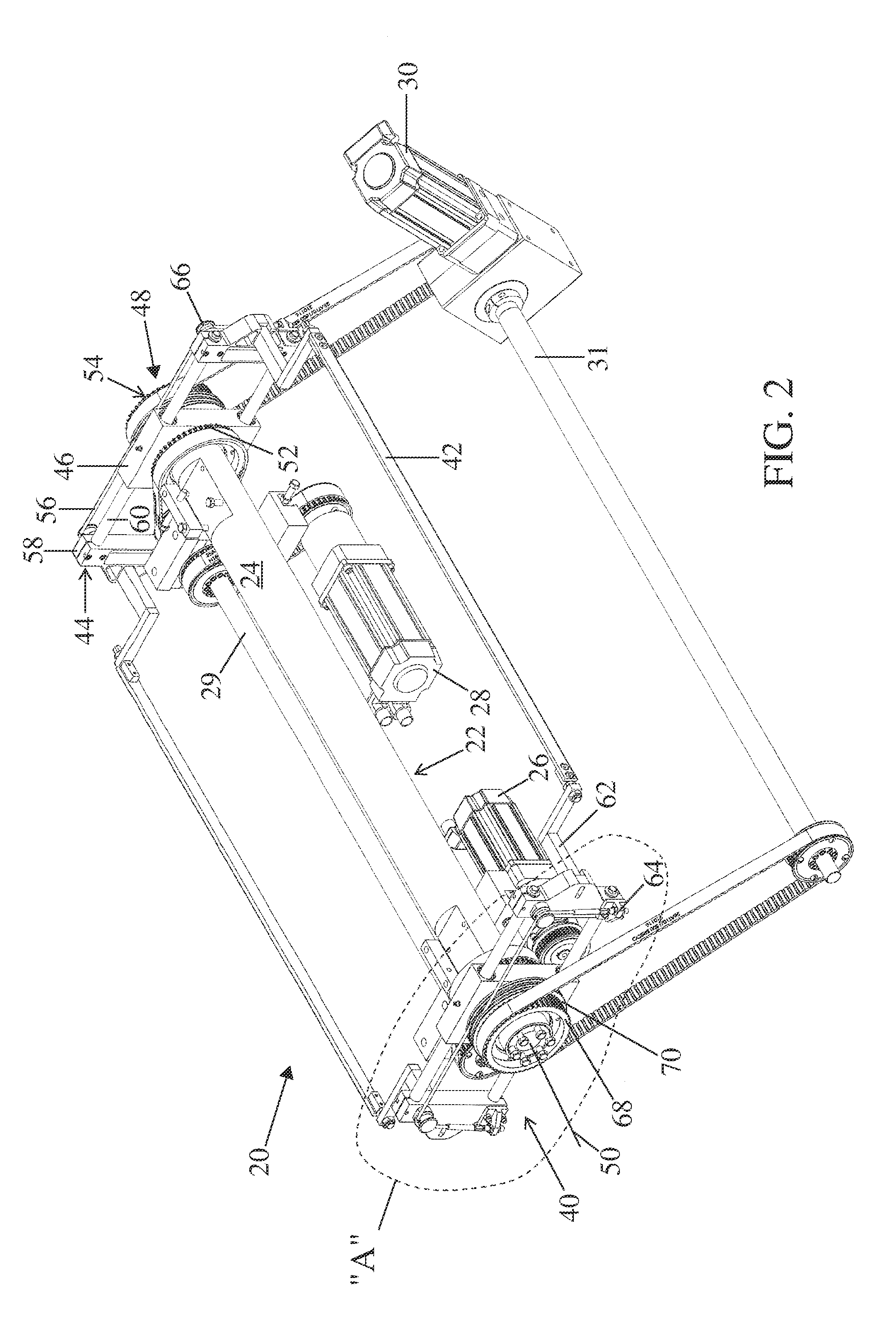

A system, suitable for high-speed operation, by which raw product (45), such as a slab of meat, can be accurately processed, such as by slicing into segments of desired weight, comprises a product profiling apparatus (15). The product profiling apparats (15) meassures the profile of the physical process. The product profiling apparatus (15) includes line lasers (75, 85) for directing a line of light across the upper and lower surfaces of the product (45) and visual image cameras (80, 90) directed toward the profile surface to capture, at fixed increments, the product profile. The product may also be weighed and the product density determined from the overall profile measurements. A controller (150) receives this data, and instructs the physical process accordingly.

Owner:PROVISUR TECHNOLOGIES INC

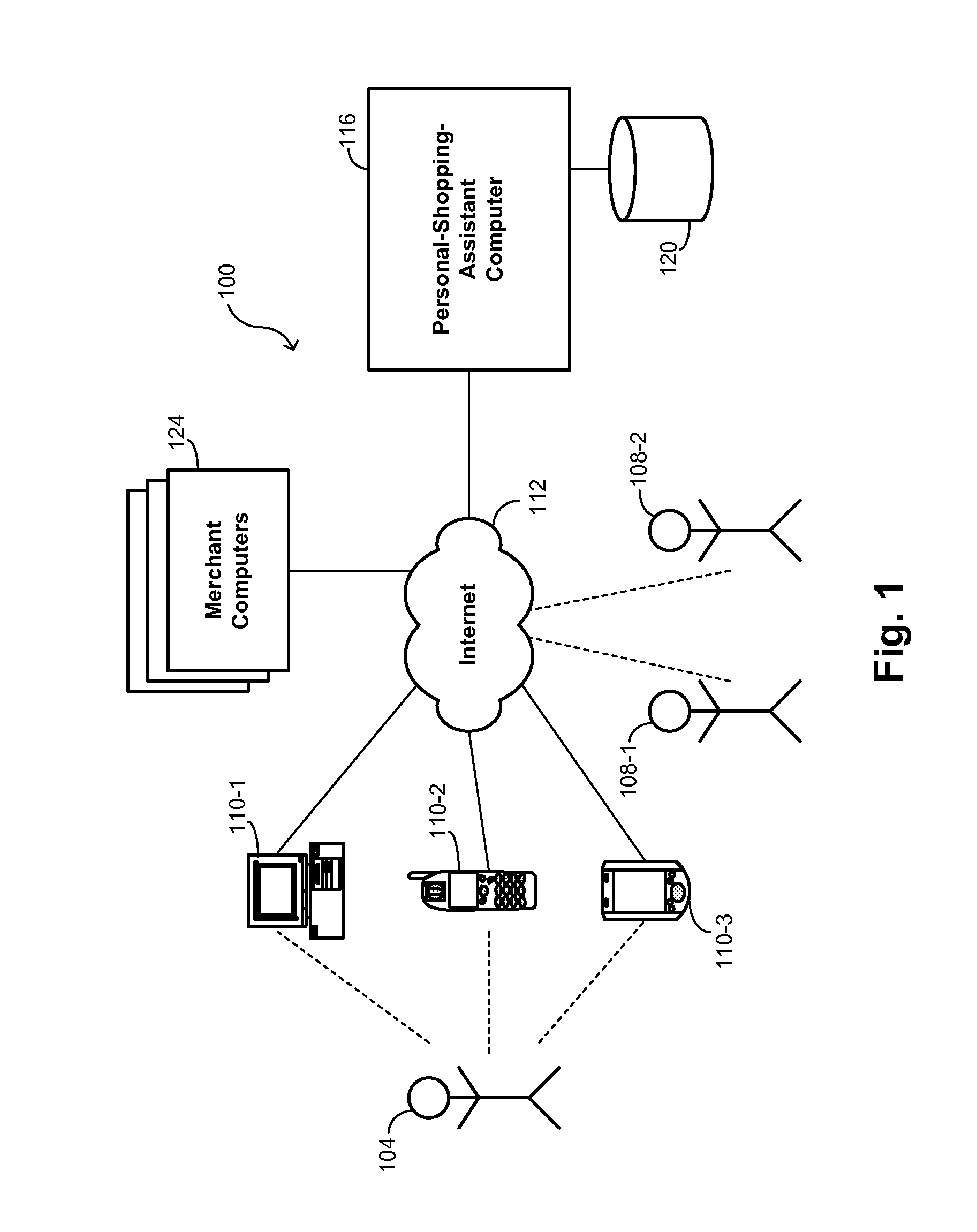

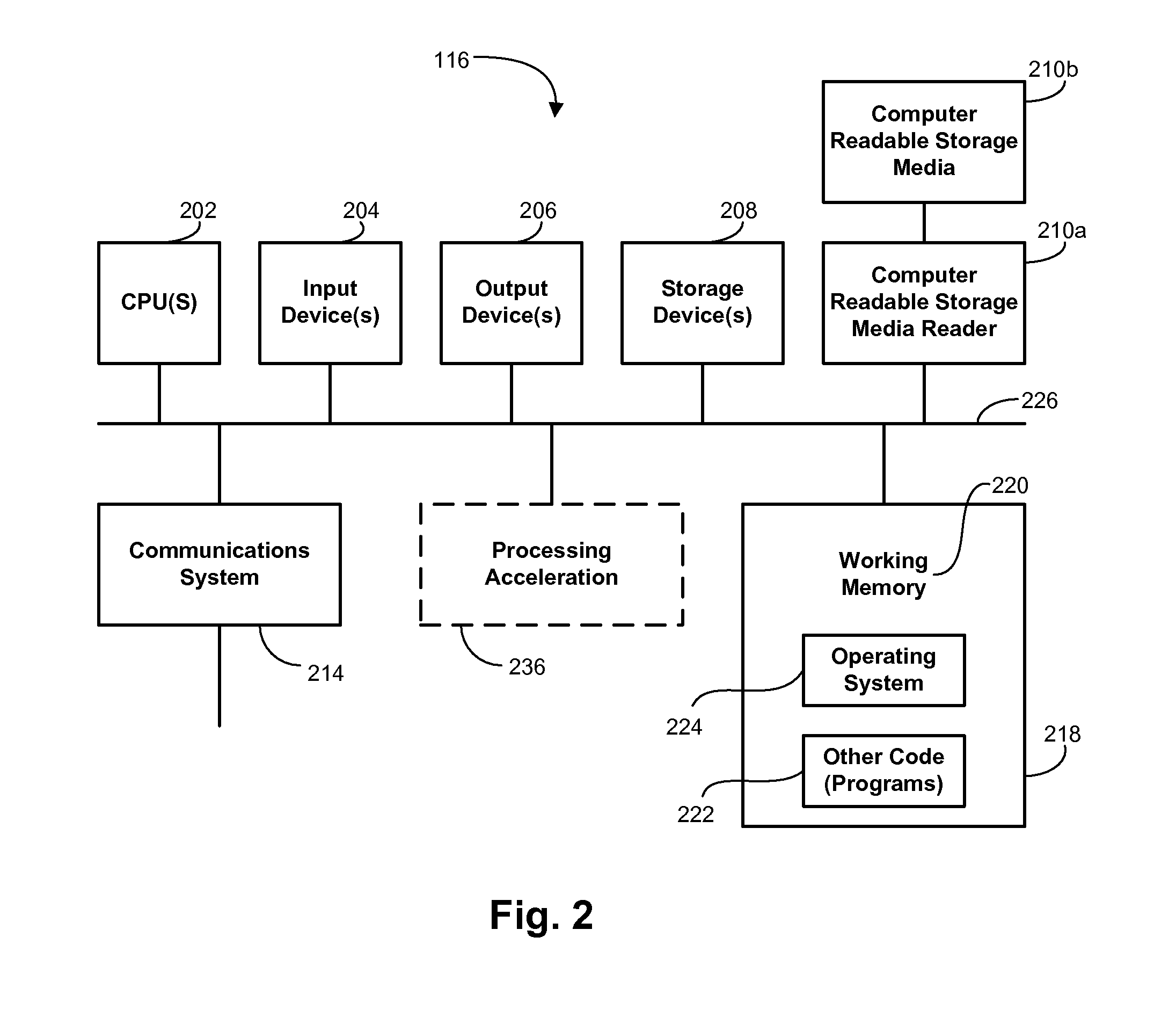

Methods and systems for dynamically generating personalized shopping suggestions

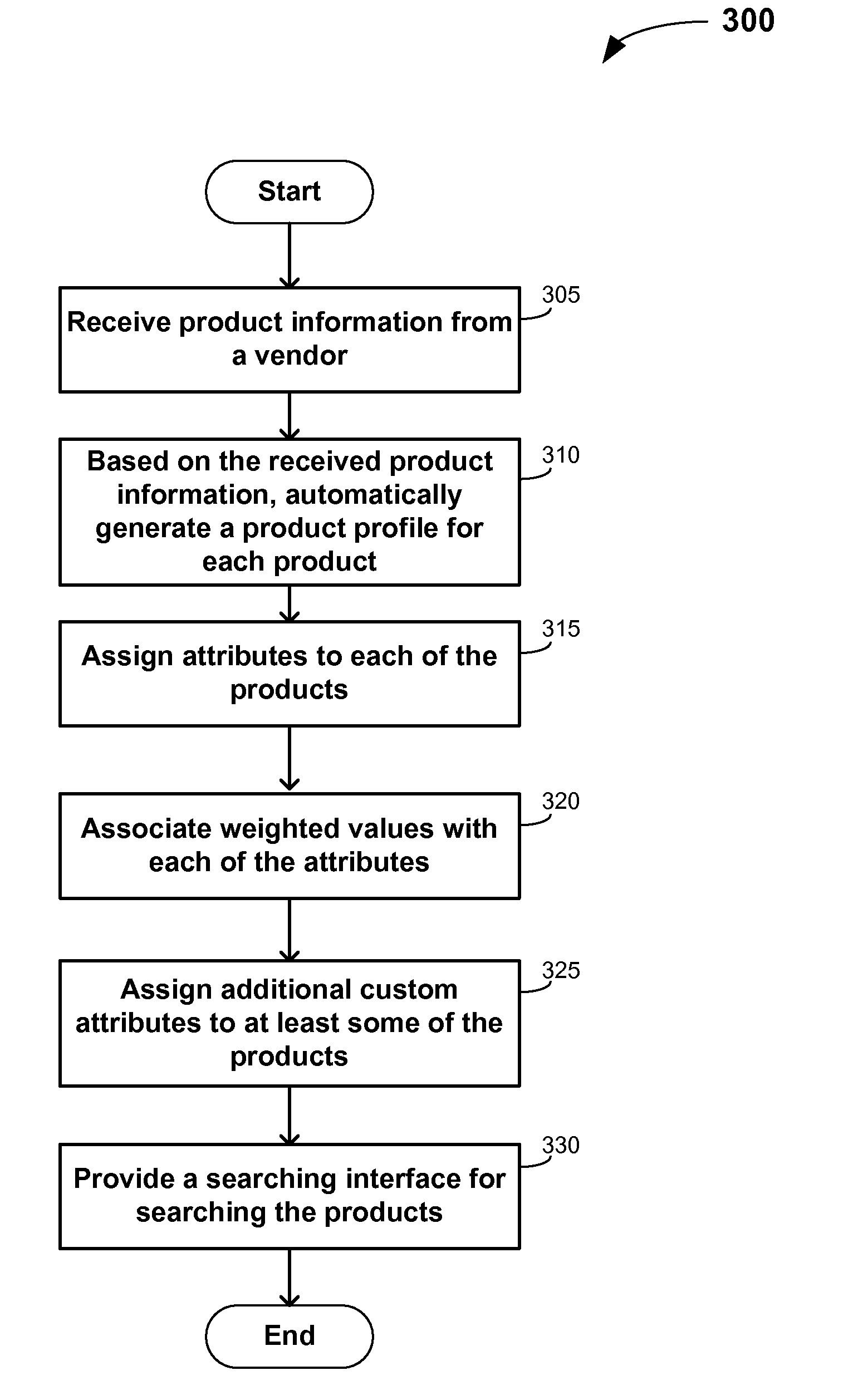

Methods and systems of establishing a shopping assistant utility are described. The method may include receiving product information for products, and based on the received product information, automatically generating a product profile for each of the products. Each product profile includes attributes assigned to the product. The method may further include receiving a search request including search criteria corresponding to at least one of the attributes, and comparing the search criteria with the attribute of the products to determine a level of correlation between each of the products and the search criteria. Further, the method may generate a score assigned to each of the products based on the determined level of correlation and present the products in an ordered list based on the generated scores assigned to each of the products.

Owner:INTERACTIVE LUXURY SOLUTIONS

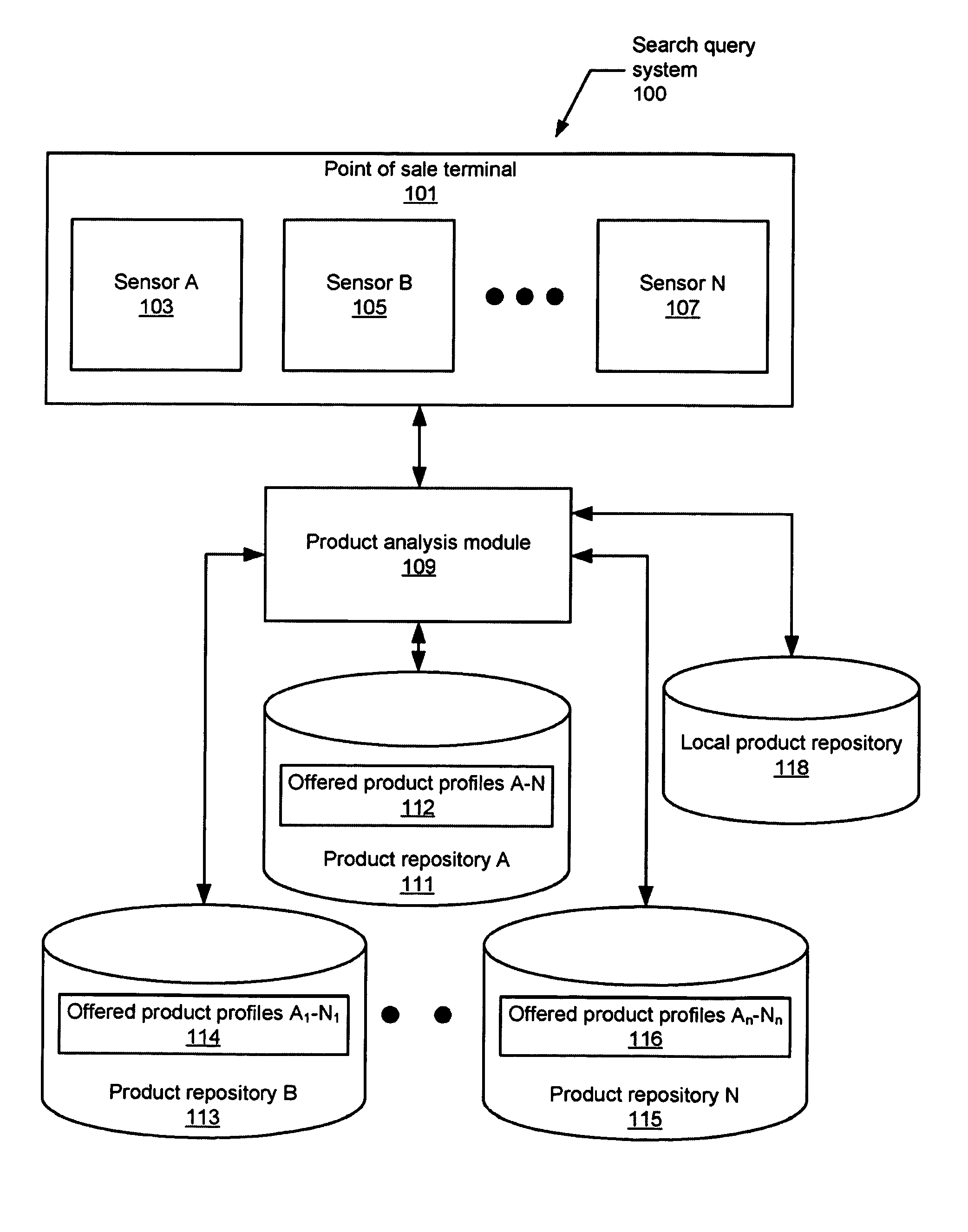

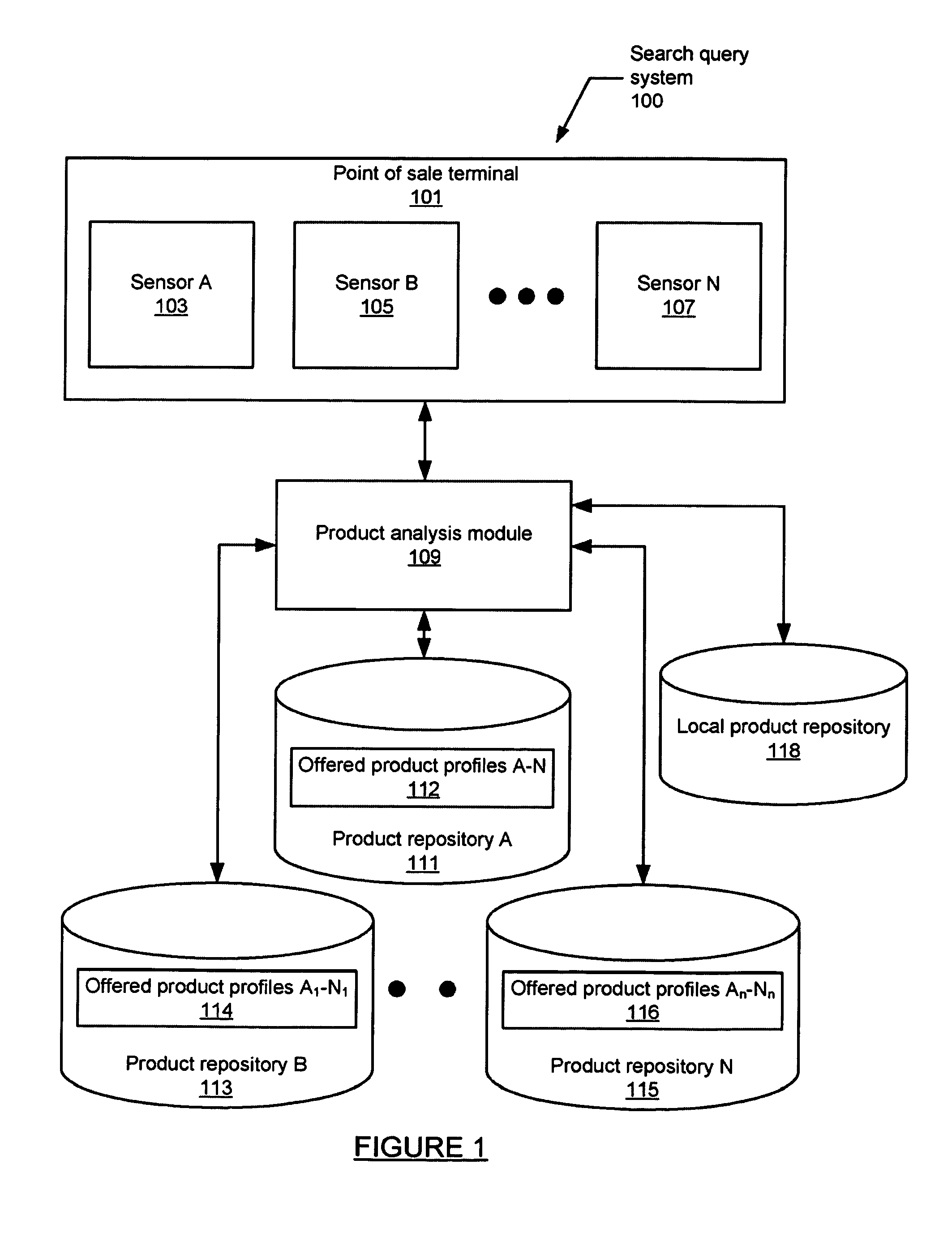

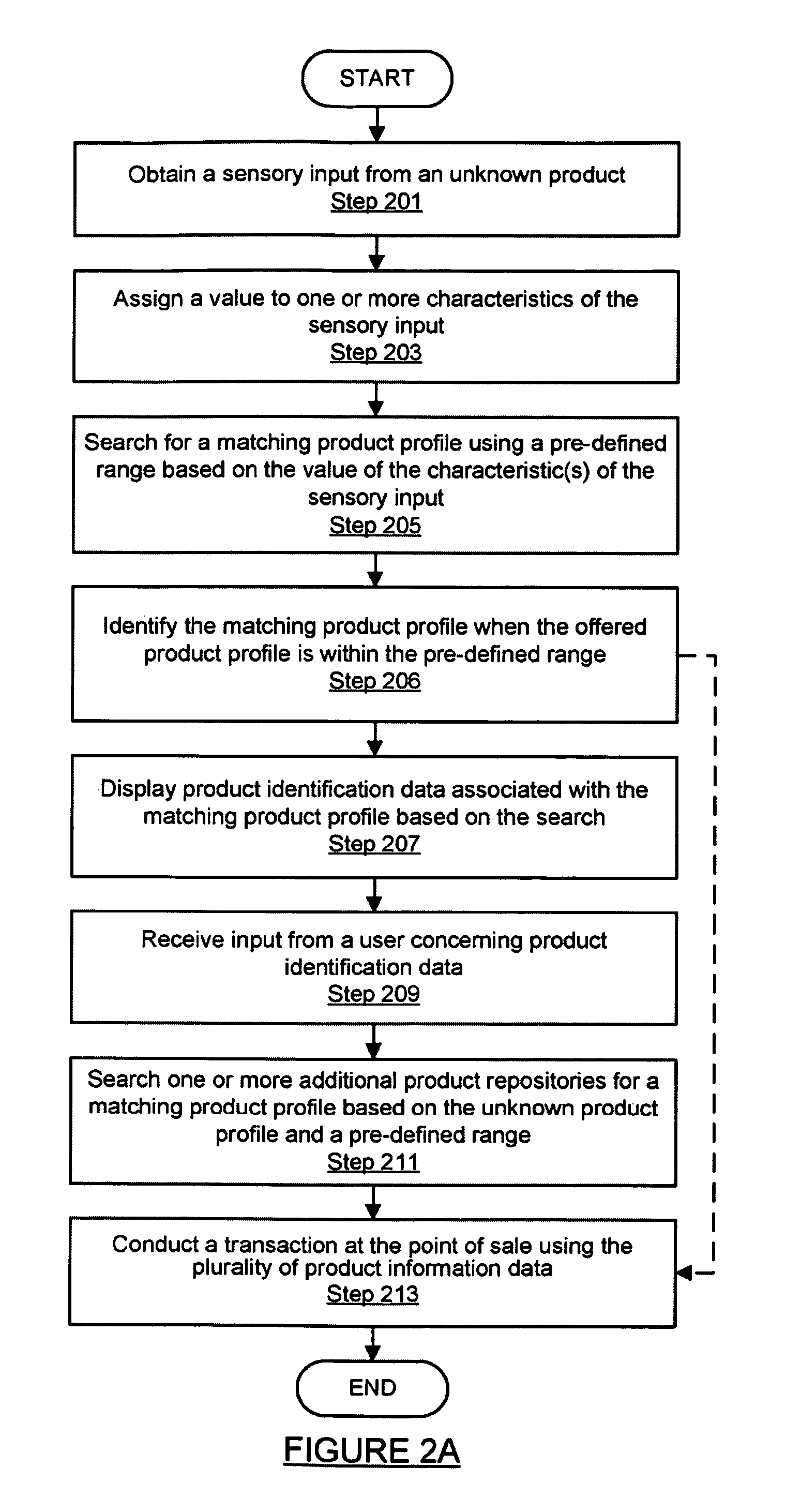

Method and system for matching via an image search query at a point of sale

A method for matching an unknown product to an offered product profile at a point of sale involves obtaining a first sensory input from the unknown product, where the first sensory input comprises at least a portion of an image, assigning a value to one or more characteristics of the first sensory input, searching a first product repository for a matching product profile using a pre-defined range based on the value of the one or more characteristics of the first sensory input, identifying the matching product profile on the first product repository when the offered product profile is within the pre-defined range, wherein the matching product profile includes a plurality of product information data, and conducting a transaction at the point of sale using the plurality of product information data.

Owner:INTUIT INC

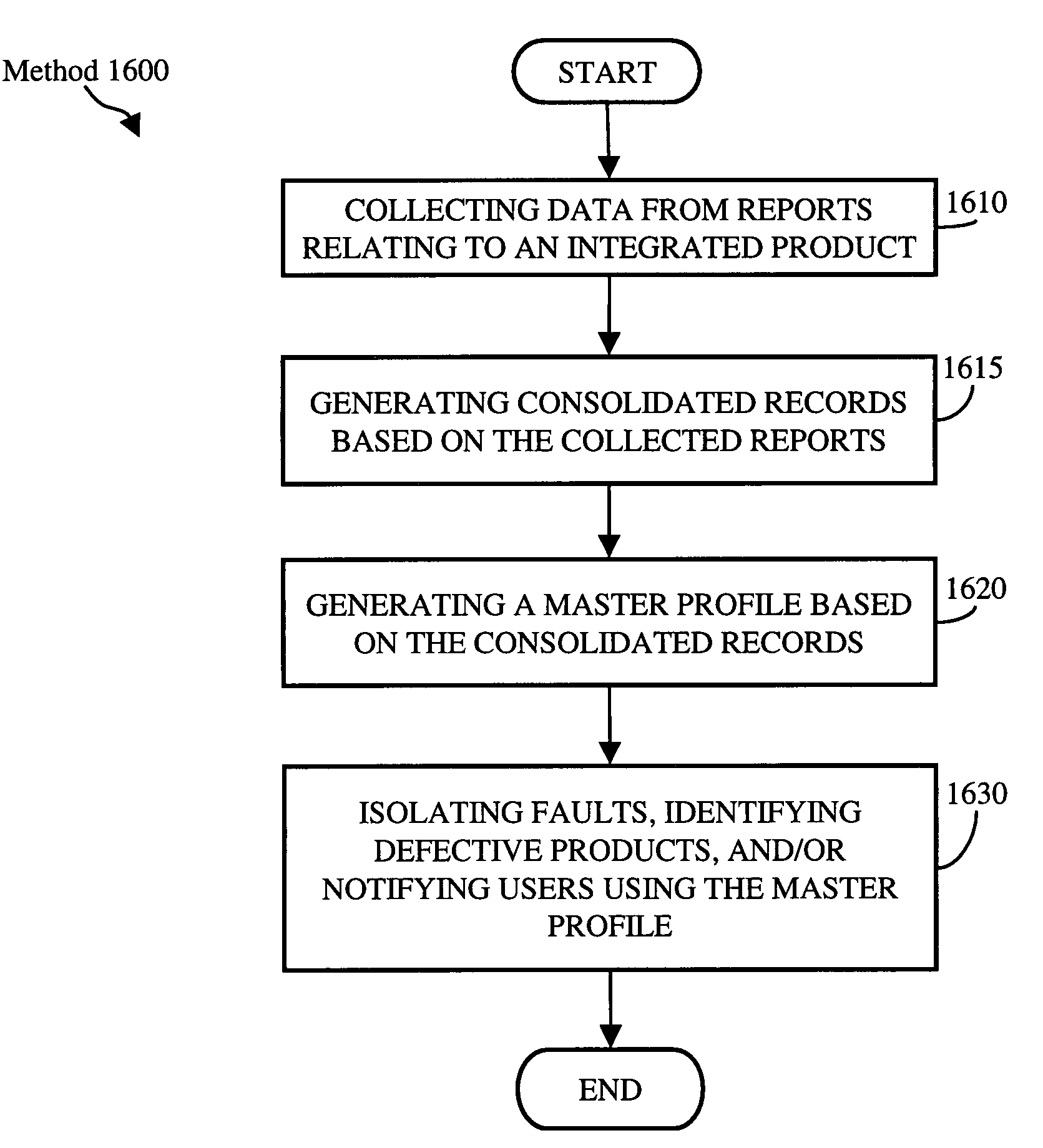

Computer implemented methods and systems for storing product history and/or failure data and/or analyzing causes of component and/or system failure

Methods and systems are provided for storing and analyzing product history data to determine root causes of performance anomalies and / or field failures. In accordance with some embodiments of the present invention, the life history of an integrated product and its constituent components may be consolidated into a master profile. The master profile may include one or more product profiles and behavior profiles that may be generated from data collected over the product's life history. In response to receiving an indication that an integrated product is defective, the master profile may be analyzed to isolate the component of the integrated product that caused the product to be defective.

Owner:TRACEABILITY SYST ARCHITECTS

Automated product profiling apparatus and product slicing system using same

InactiveUS20050199111A1Meat holding apparatusMethod using image detector and image signal processingProduct analysisVolumetric Mass Density

A system, suitable for high-speed operation, by which raw product (45), such as a slab of meat, can be accurately processed, such as by slicing into segments of desired weight, comprises a product profiling apparatus (15). The product profiling apparatus (15) measures the profile of the physical process. The product profiling apparatus (15) includes line lasers (75, 85) for directing a line of light across the upper and lower surfaces of the product (45) and visual image cameras (80, 90) directed toward the profile surface to capture, at fixed increments, the product profile. The product may also be weighed and the product density determined from the overall profile measurements. A controller (150) receives this data, and instructs the physical process accordingly.

Owner:PROVISUR TECHNOLOGIES INC

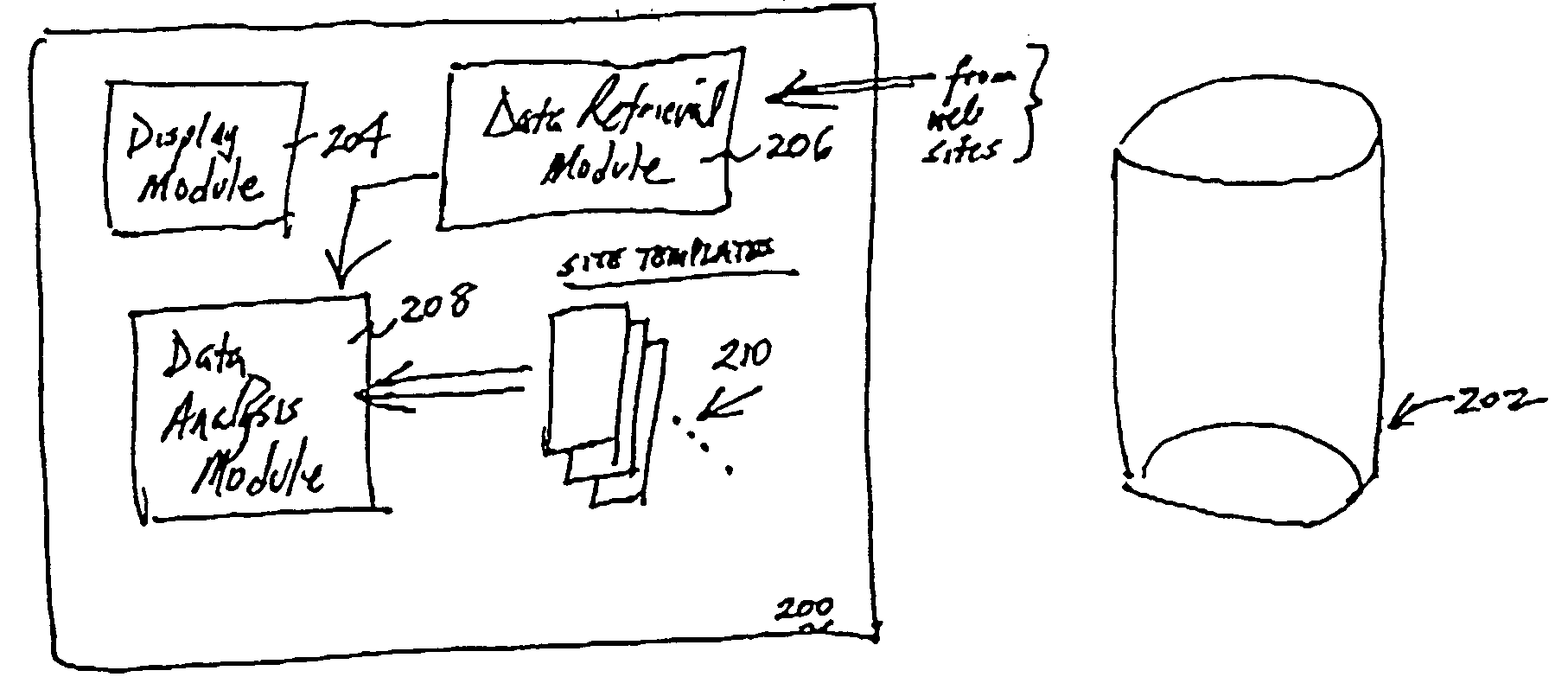

Client-side pricing agent for collecting and managing product price information over the internet

InactiveUS20050177785A1Buying/selling/leasing transactionsSpecial data processing applicationsWeb siteItem generation

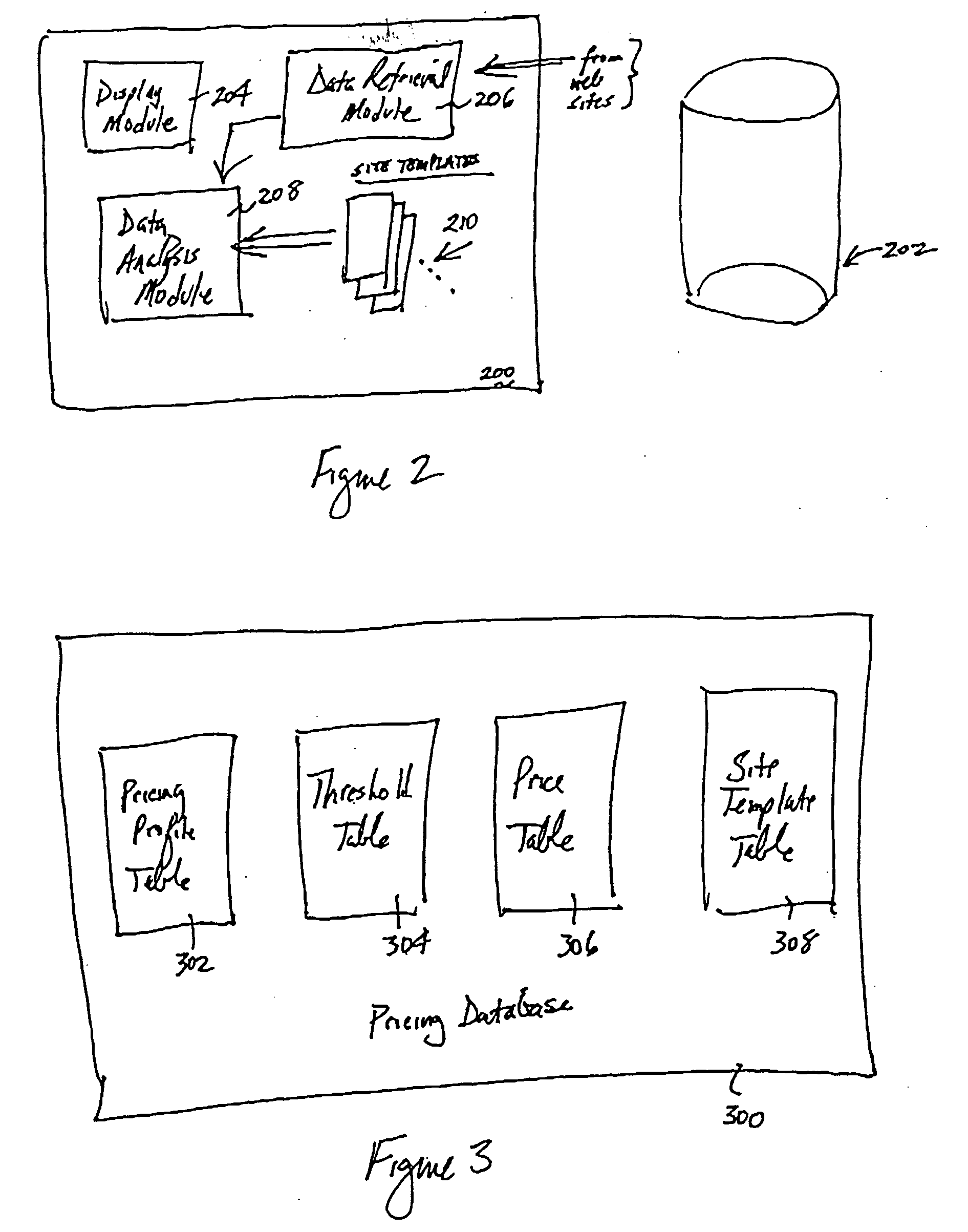

A method of collecting product data, e.g., from a plurality of web sites on the Internet. The method is operative from a client computer and utilizes a pricing agent. Using the agent, a user can generate a set of product profiles each identifying a given site URL, a list of one or more included items to be queried, a scan interval, and a site template. For a given product profile, the agent periodically retrieves data from the given site URL at the scan interval. It then parses the data retrieved according to the site template to generate a data record for each included item comprising an item name, an associated price value and, optionally, a secondary source. The retrieved data may also be compared against one or more threshold expressions to generate given actions.

Owner:SHRADER THEODORE JACK LONDON +1

Automated Product Profiling Apparatus and Product Slicing System Using the Same

An apparatus for acquiring a profile of a food product for use in subsequent processing of the food product includes a scanning area and one or more product drives for driving a product through the scanning area in a longitudinal direction. First line lasers project one first transverse laser line transversely to the longitudinal direction on the first surface and two first cameras arranged to capture different, overlapping first transverse image portions of the first transverse laser line. A reference laser projects a beam on the first surface that indicates a transverse reference position, and the two first cameras also capture the reference position. A control system uses the transverse reference position to combine the different first transverse image portions captured by the two first cameras to calculate a first profile of the first surface at multiple positions along a length of the first surface as the product is driven through the scanning area.

Owner:PROVISUR TECHNOLOGIES INC

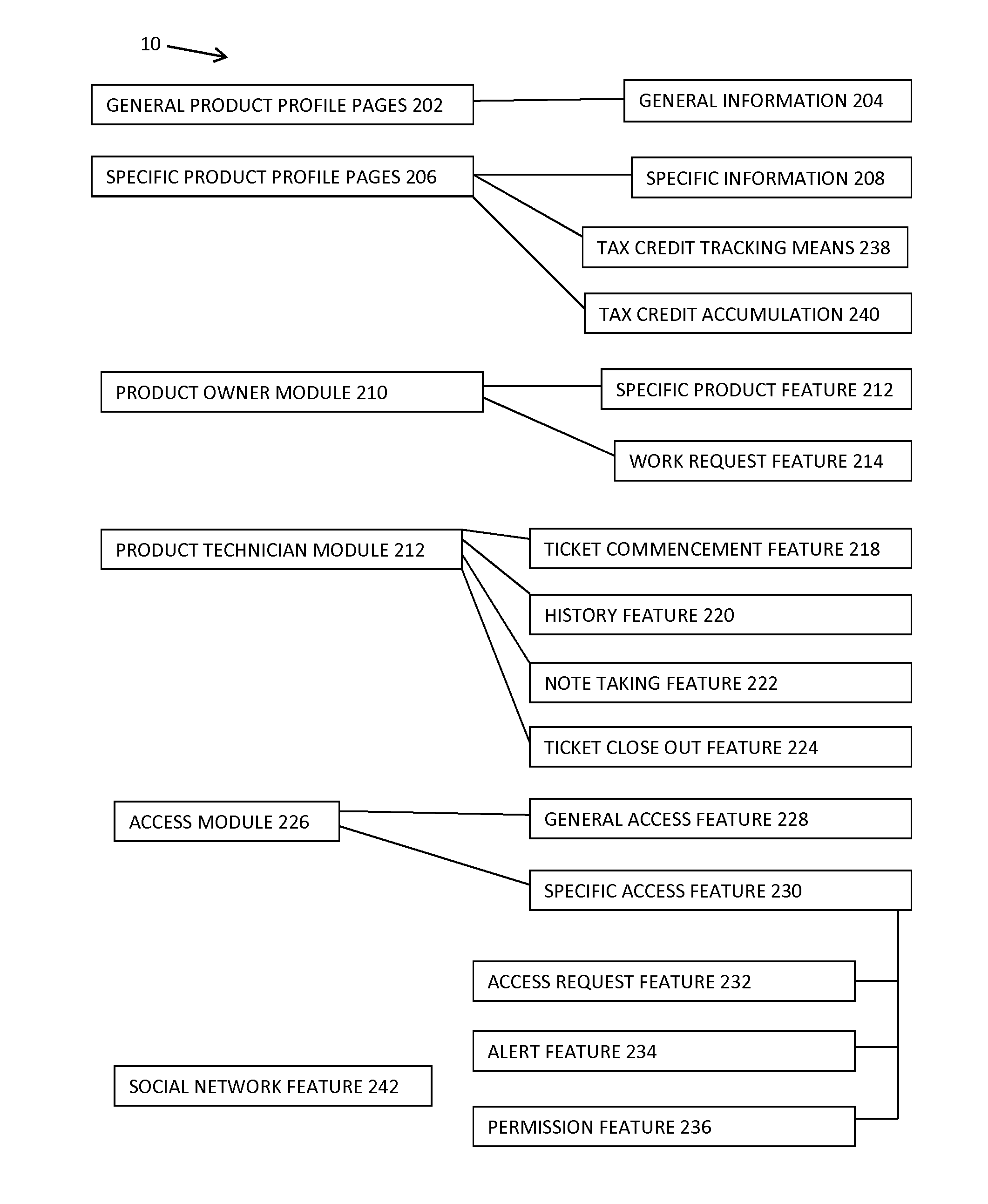

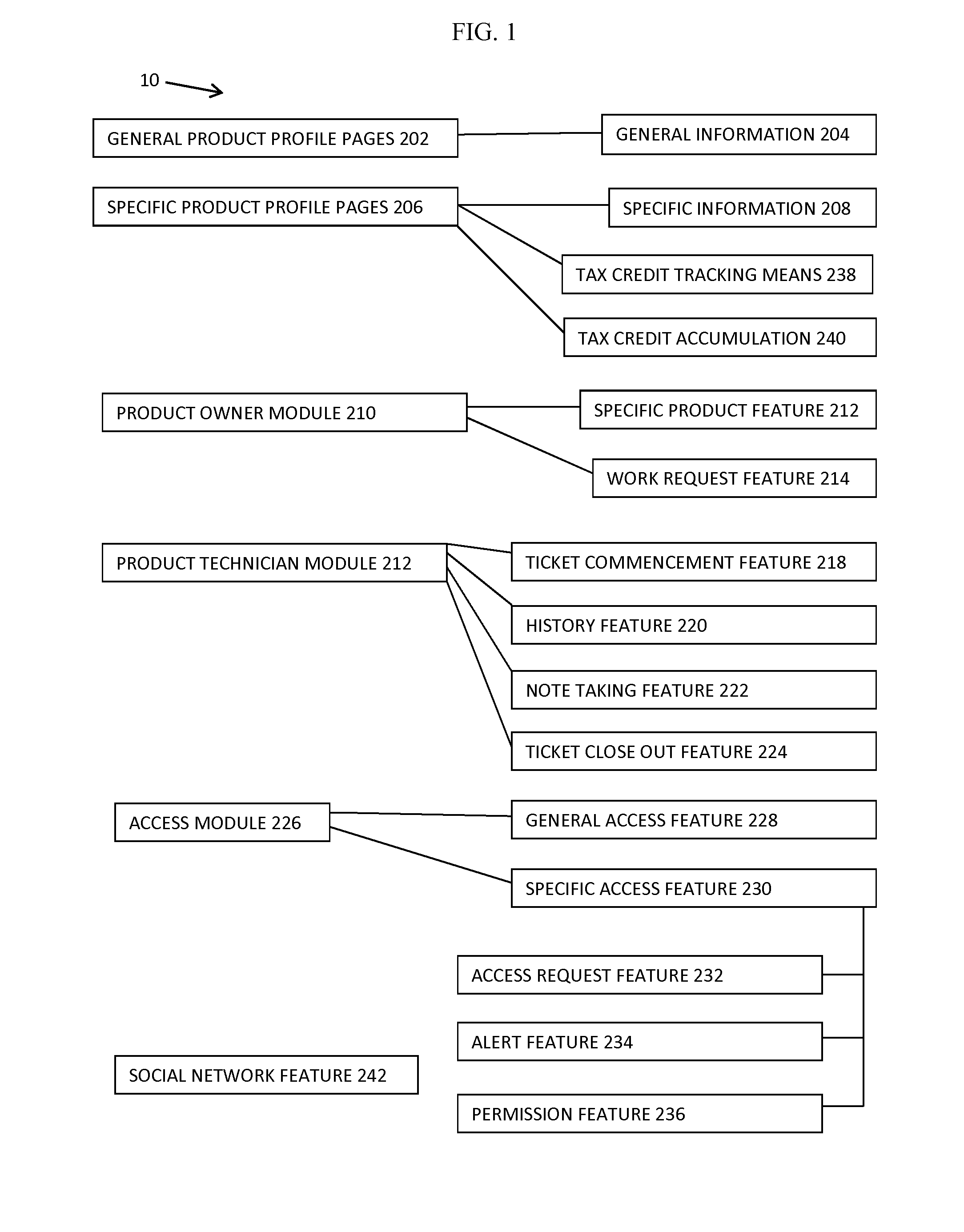

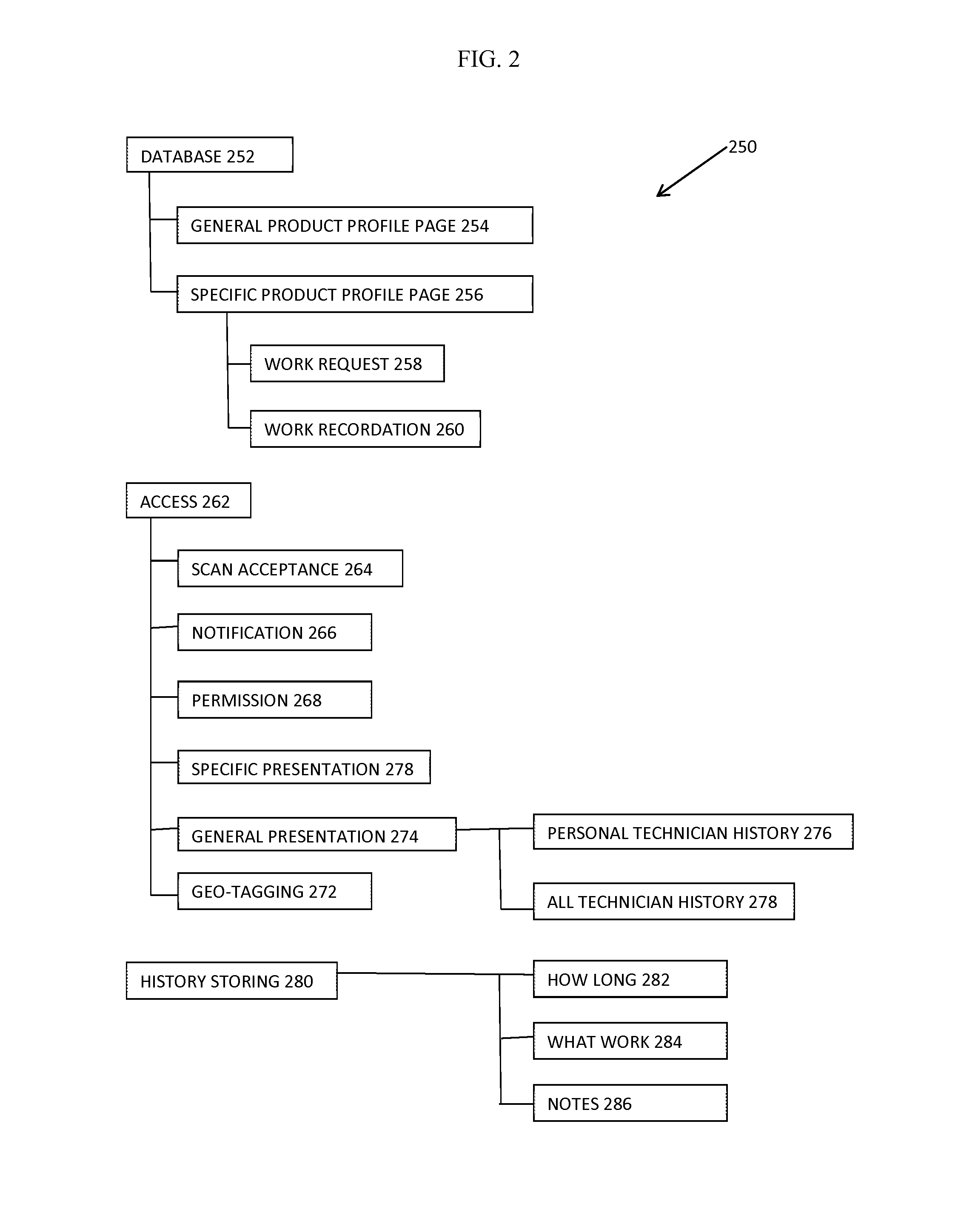

Web-based communication platform

InactiveUS20120330707A1Job easier and efficientBetter themselvesOffice automationResourcesGeneric ProductProduct profile

A web platform including a number of general product profile pages, a number of specific product profile pages, a product owner module, a product technician module, and an access feature.

Owner:LOUCKS MICHAEL

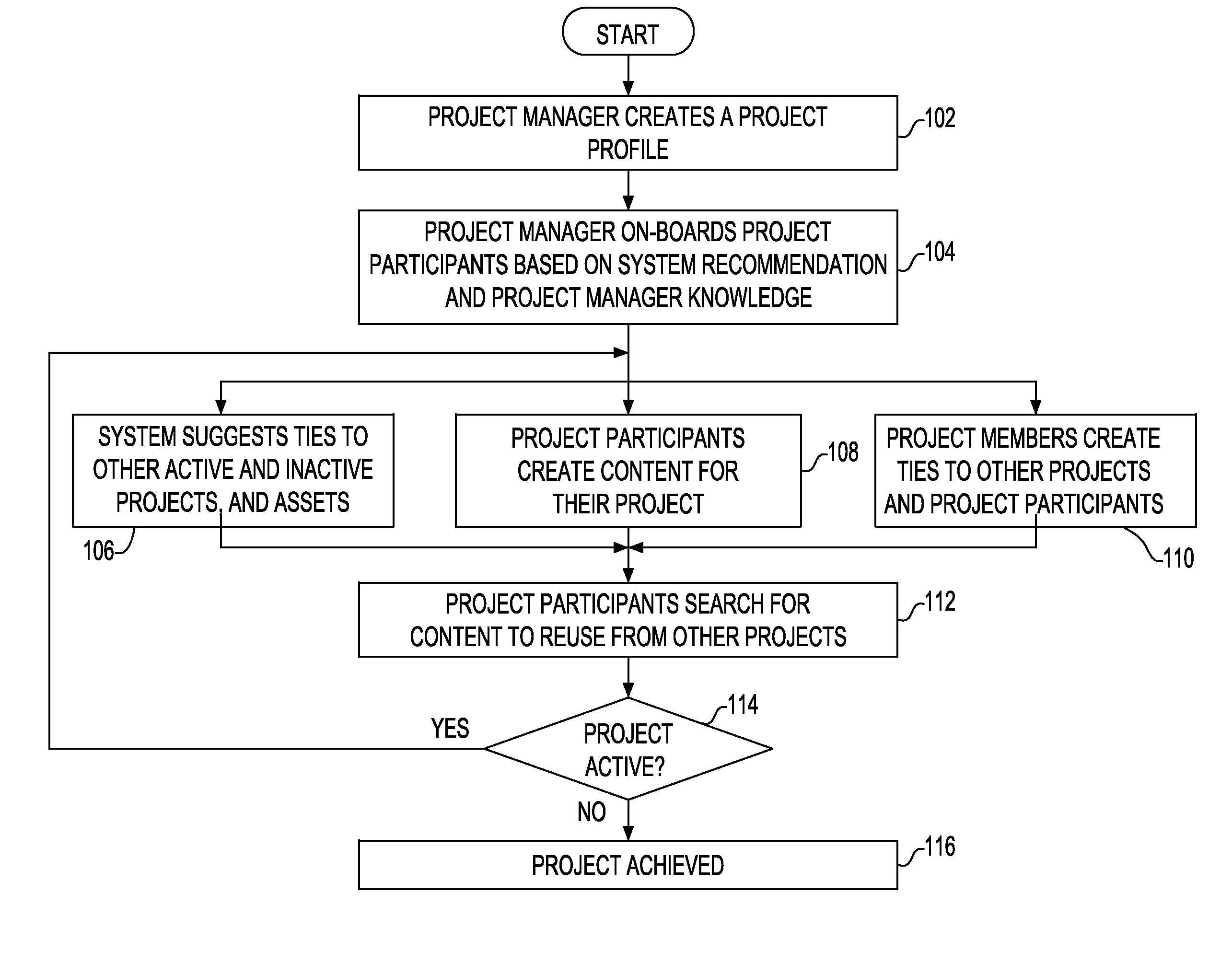

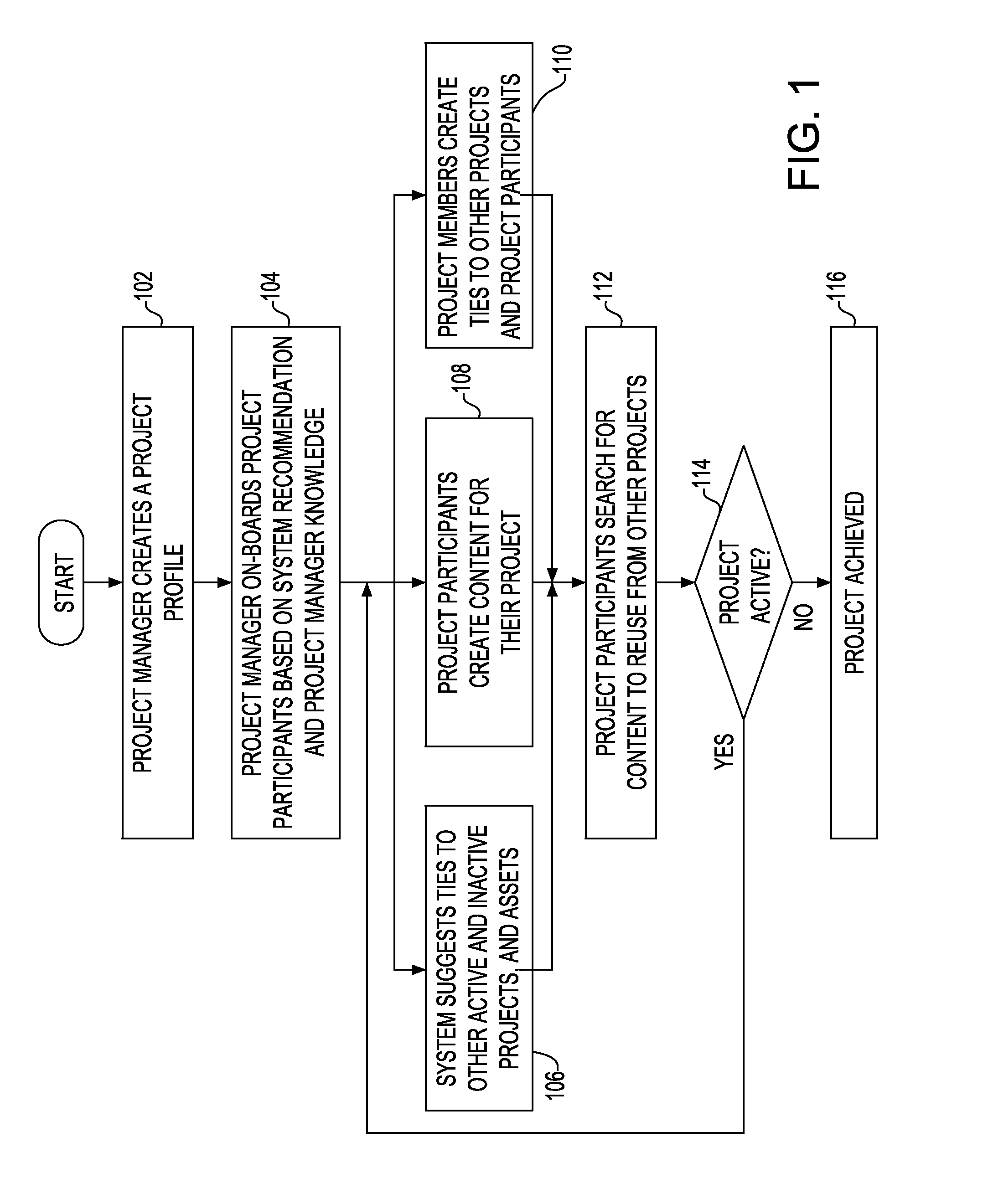

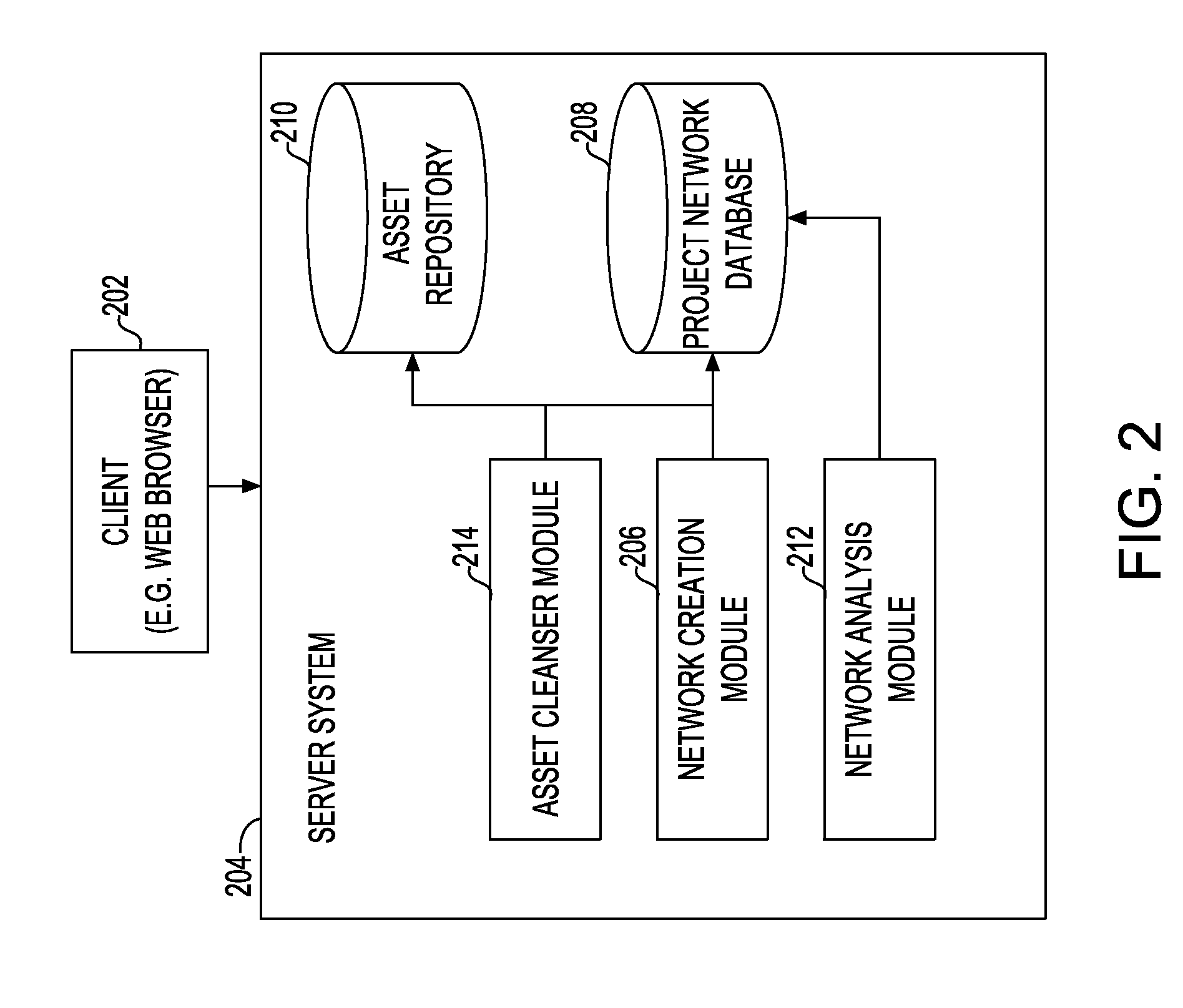

Model-based project network

One or more project profiles, one or more people profiles, one or more work product profiles are created and connections are made among the one or more project profiles, one or more people profiles, and one or more work product profiles that form a network of projects, people, work products and others. A profile database stores the network of the one or more project profiles, the one or more people profiles, the one or more work product profiles. Data stored in the profile database is analyzed and one or more people, work products and projects that are related to current project are recommended for use in the current project.

Owner:IBM CORP

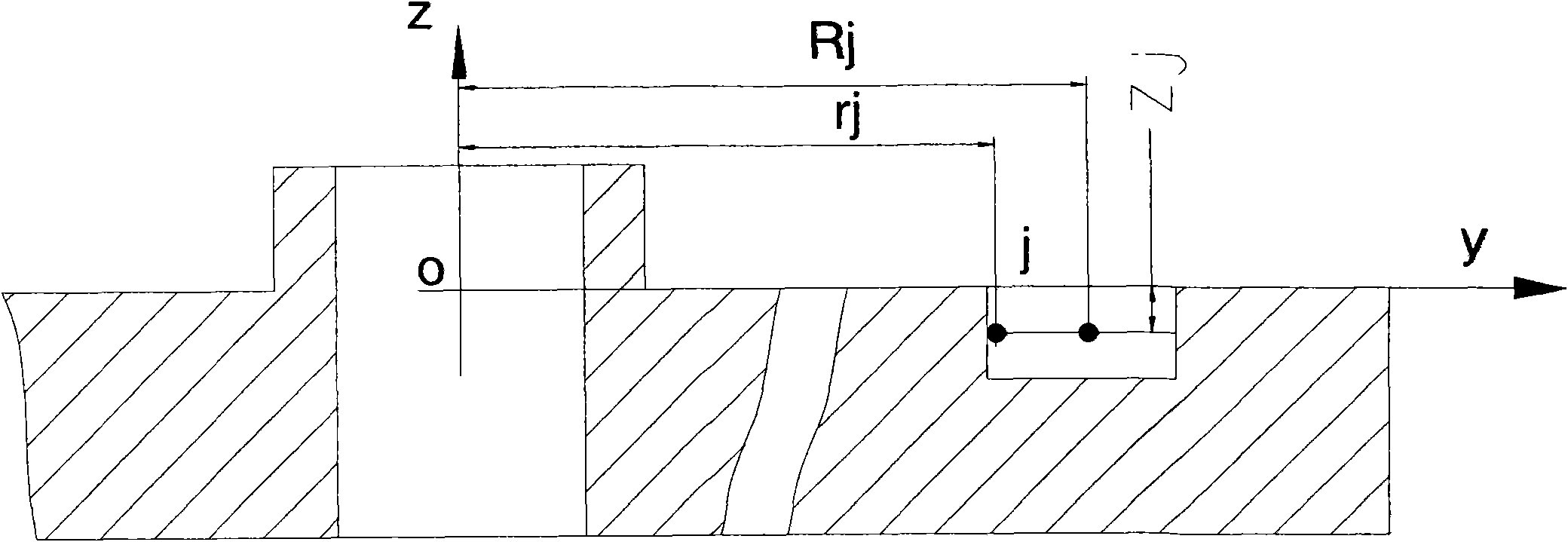

Method for examining data file of curve surface reverse product

The invention discloses a method for examining a data file of a curve surface reverse product, and is characterized by comprising the following steps of: (1) measuring a profile curve of a curve surface product by an identical-graduation measurement method, and generating a first data file corresponding to each point on the product profile curve; (2) manufacturing the curve surface reverse product by using the first data file; (3) measuring the profile curve of the curve surface reverse product by the identical-graduation measurement method; and (4) comparing characteristic variables of the first data file and a second data file, wherein a difference value of the characteristic variables of the first data file and the second data file is an error corresponding to each point on the curve surface reverse product.

Owner:HONGTA TOBACCO GRP

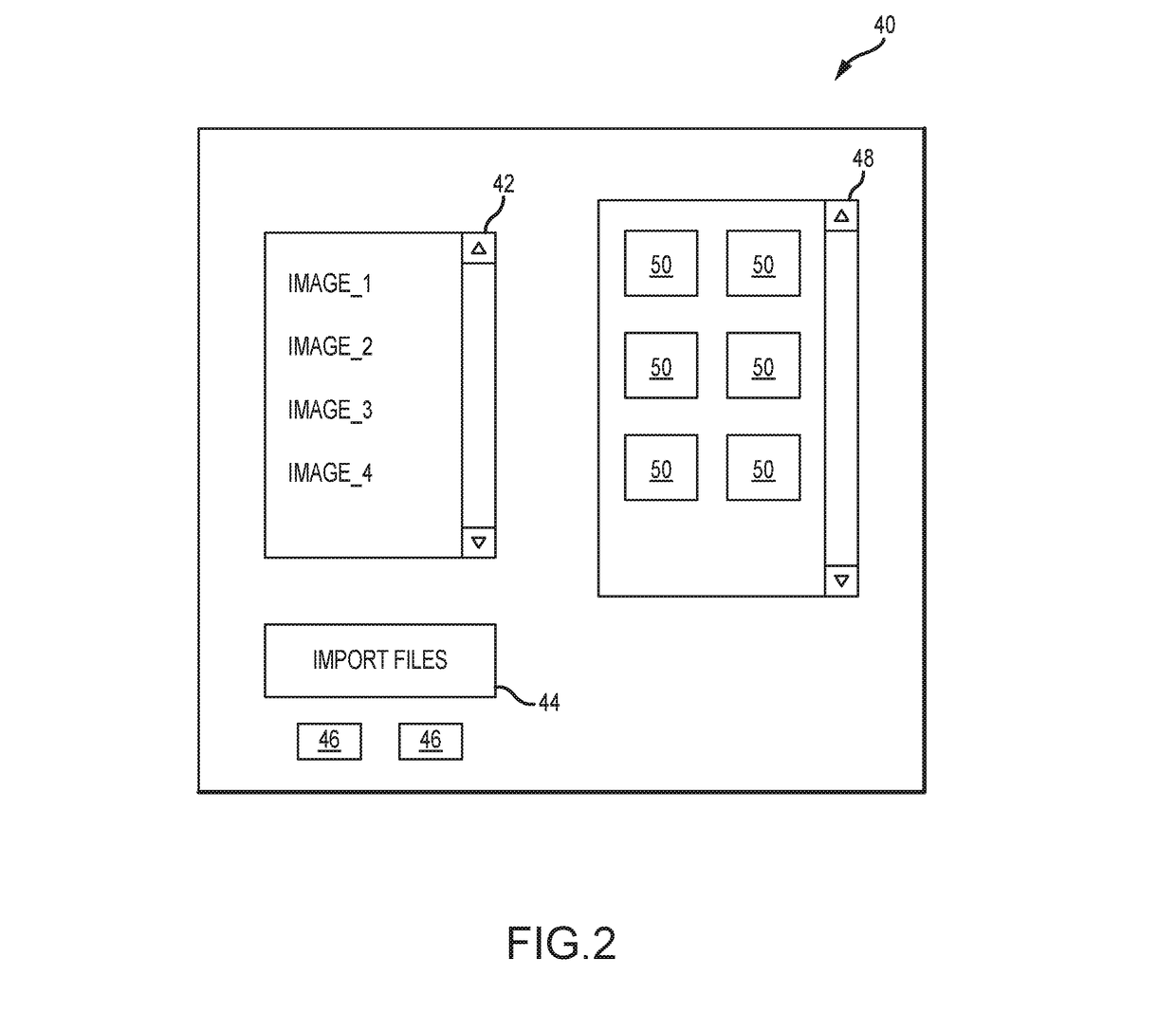

Method for image product recommendation

PendingUS20170193588A1Increase valueDigital data information retrievalBuying/selling/leasing transactionsDigital imageProduct profile

Embodiments of the present disclosure a method for determining product relevancy including extracting metadata from an image file of a digital image collection, the metadata being indicative of at least one feature of the image file. The method includes creating an input profile corresponding to the metadata extracted from the image files of the digital image collection. The method includes comparing the input profile to a product profile, the product profile having one or more rules corresponding to a consumer product, wherein the rules are indicative of the requirements of the product. The method includes determining a match score, the match score indicative of a relevancy of the product profile to the input profile such that a high relevancy correlates to a consumer product that is suited to the input profile and a low relevancy correlates to the consumer product that is not suited to the input profile.

Owner:KODAK ALARIS INC

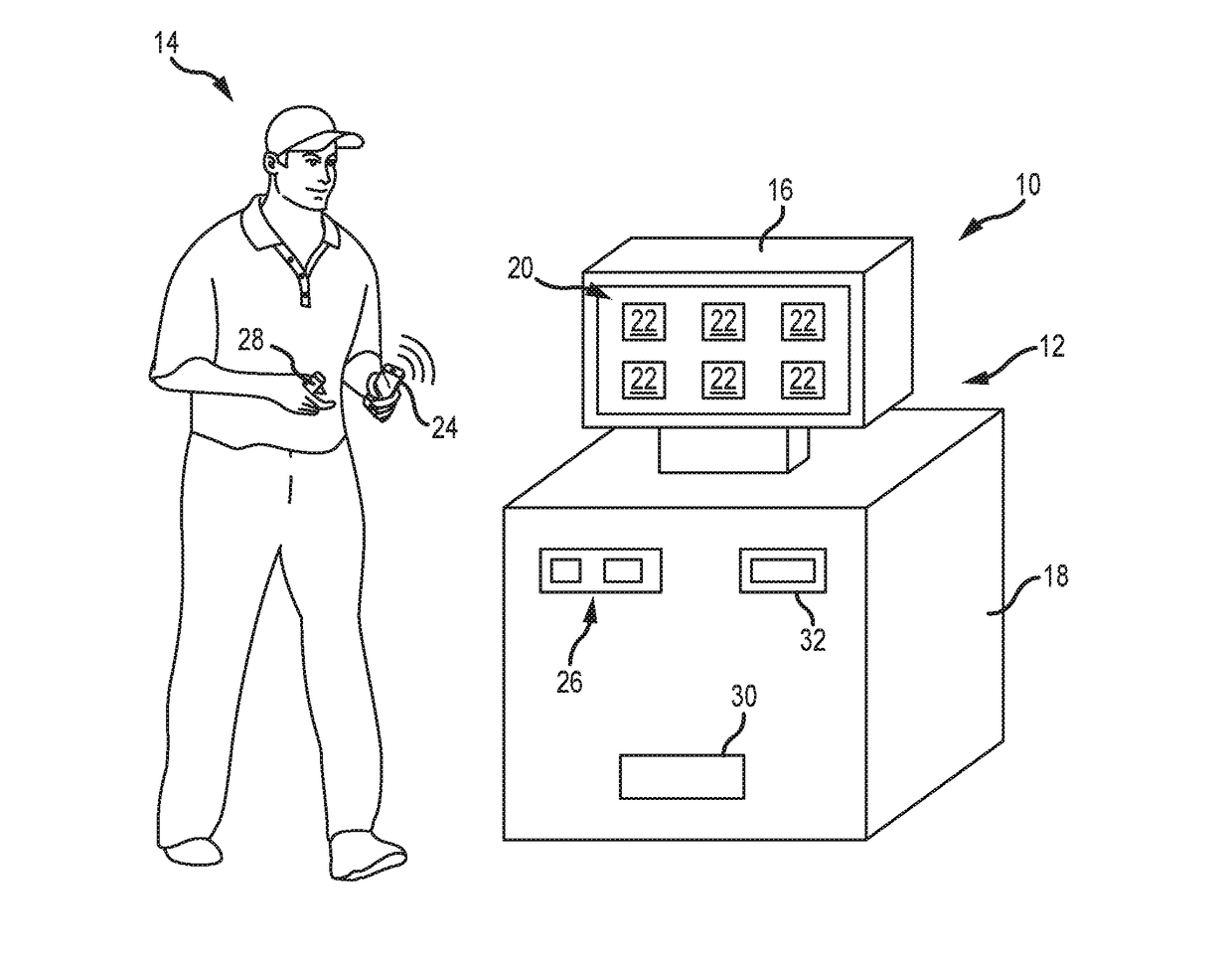

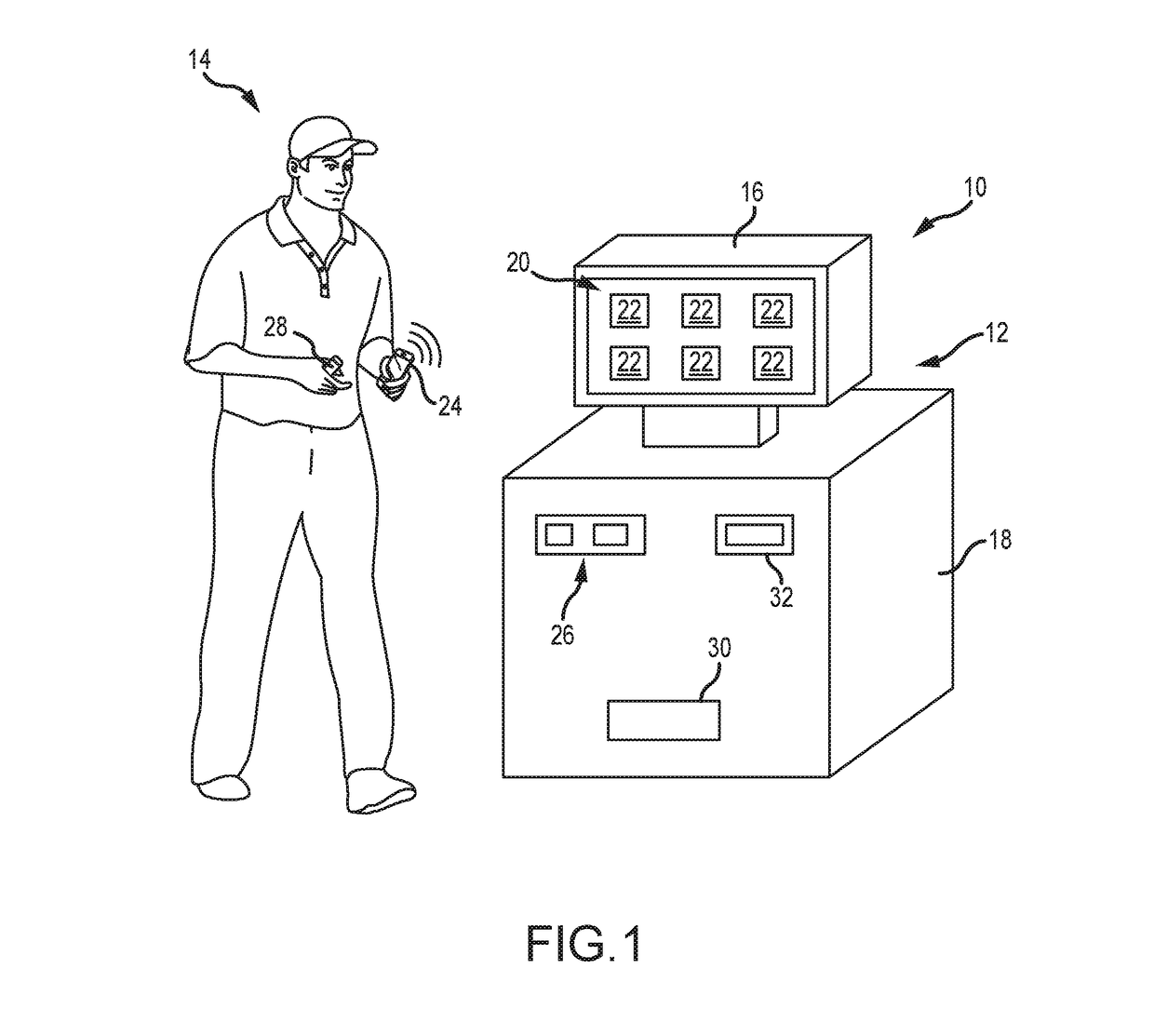

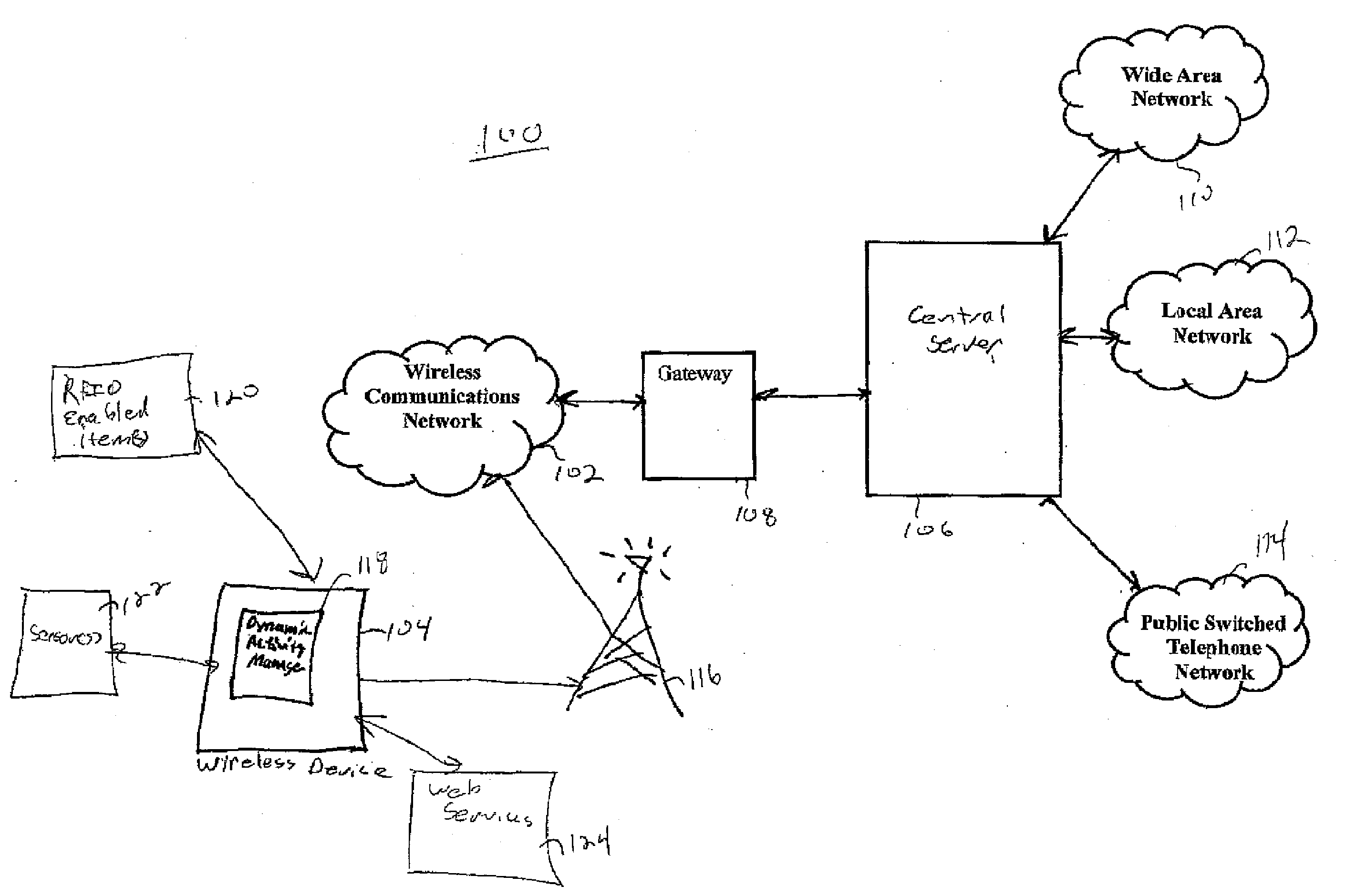

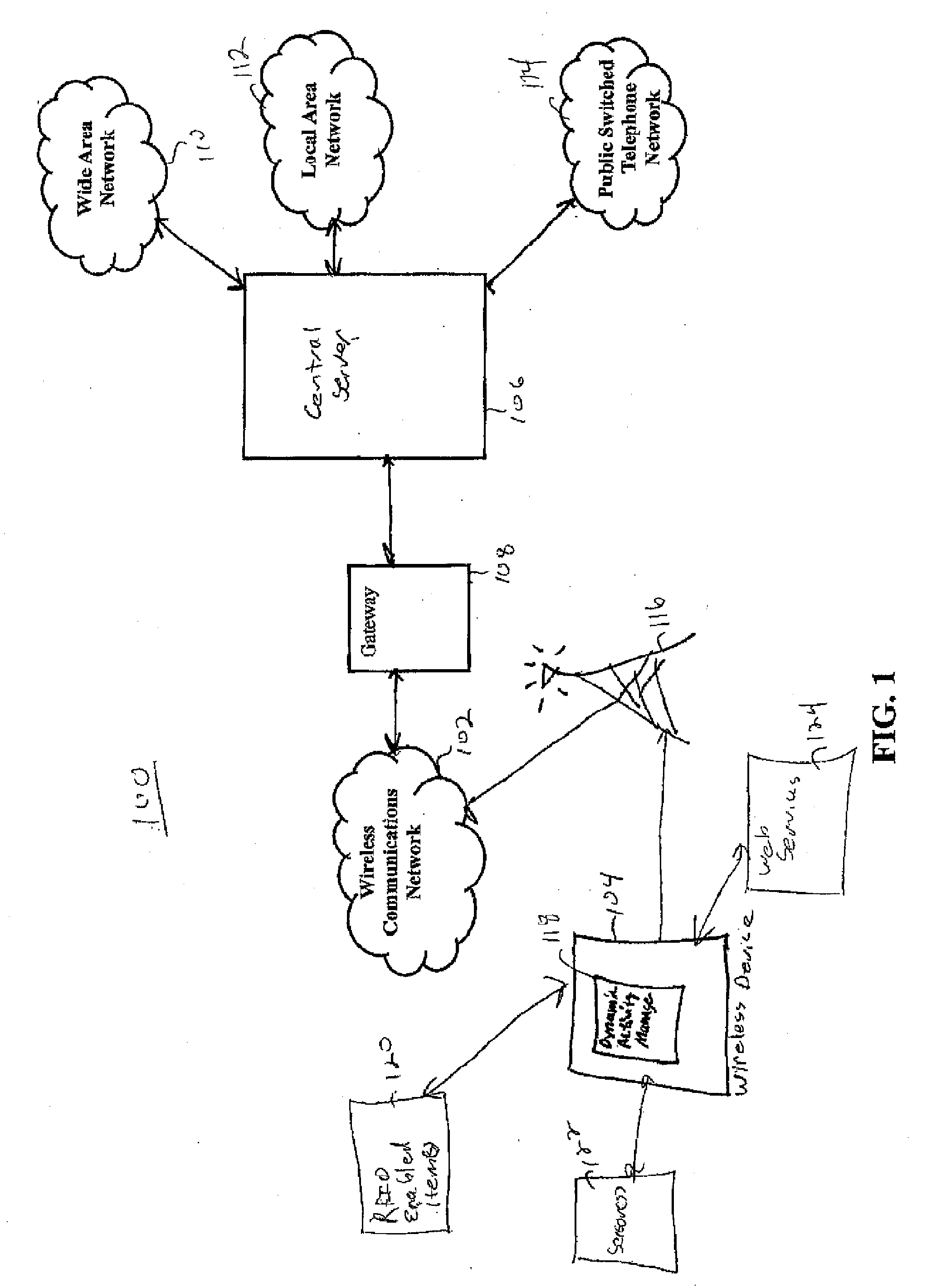

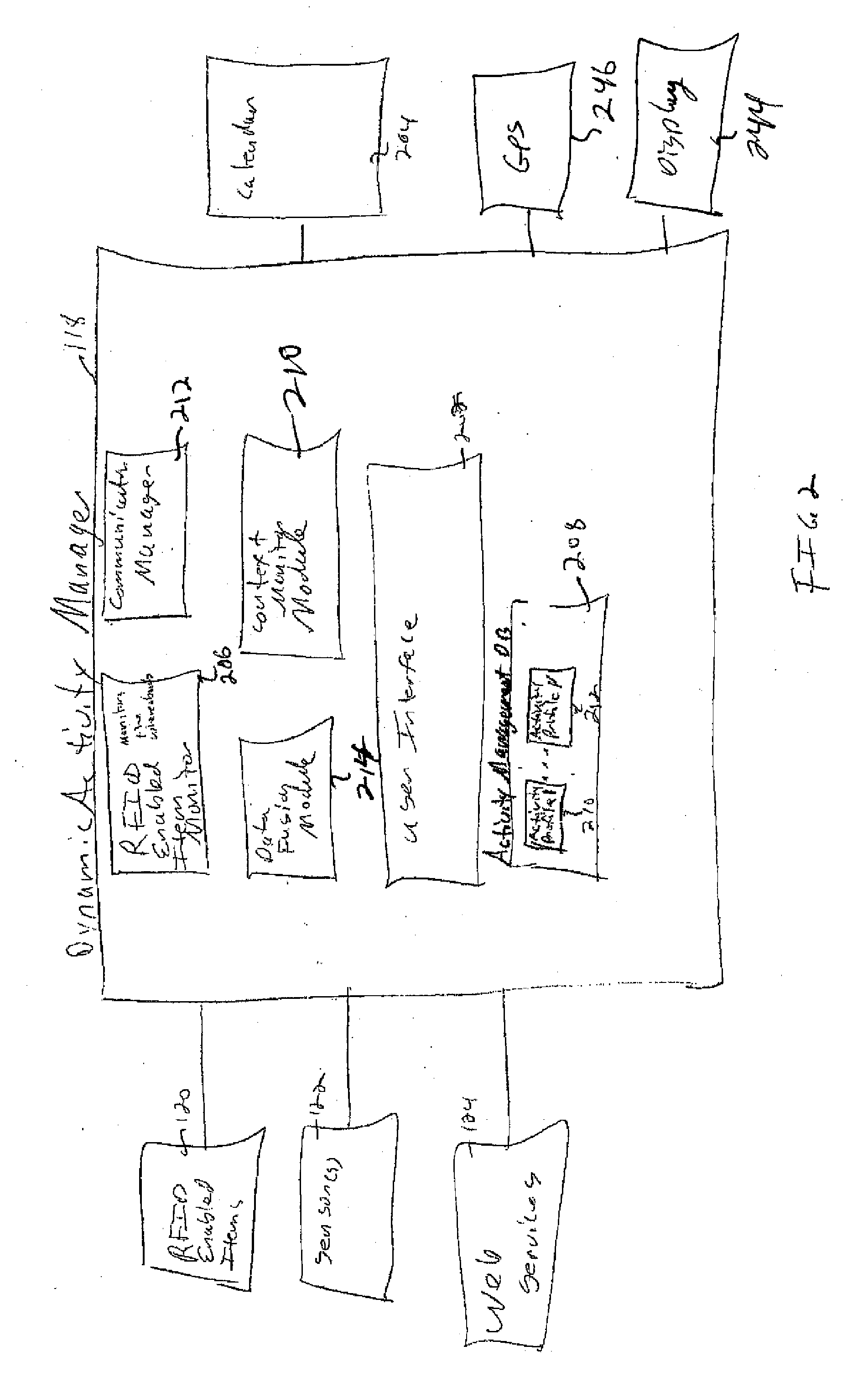

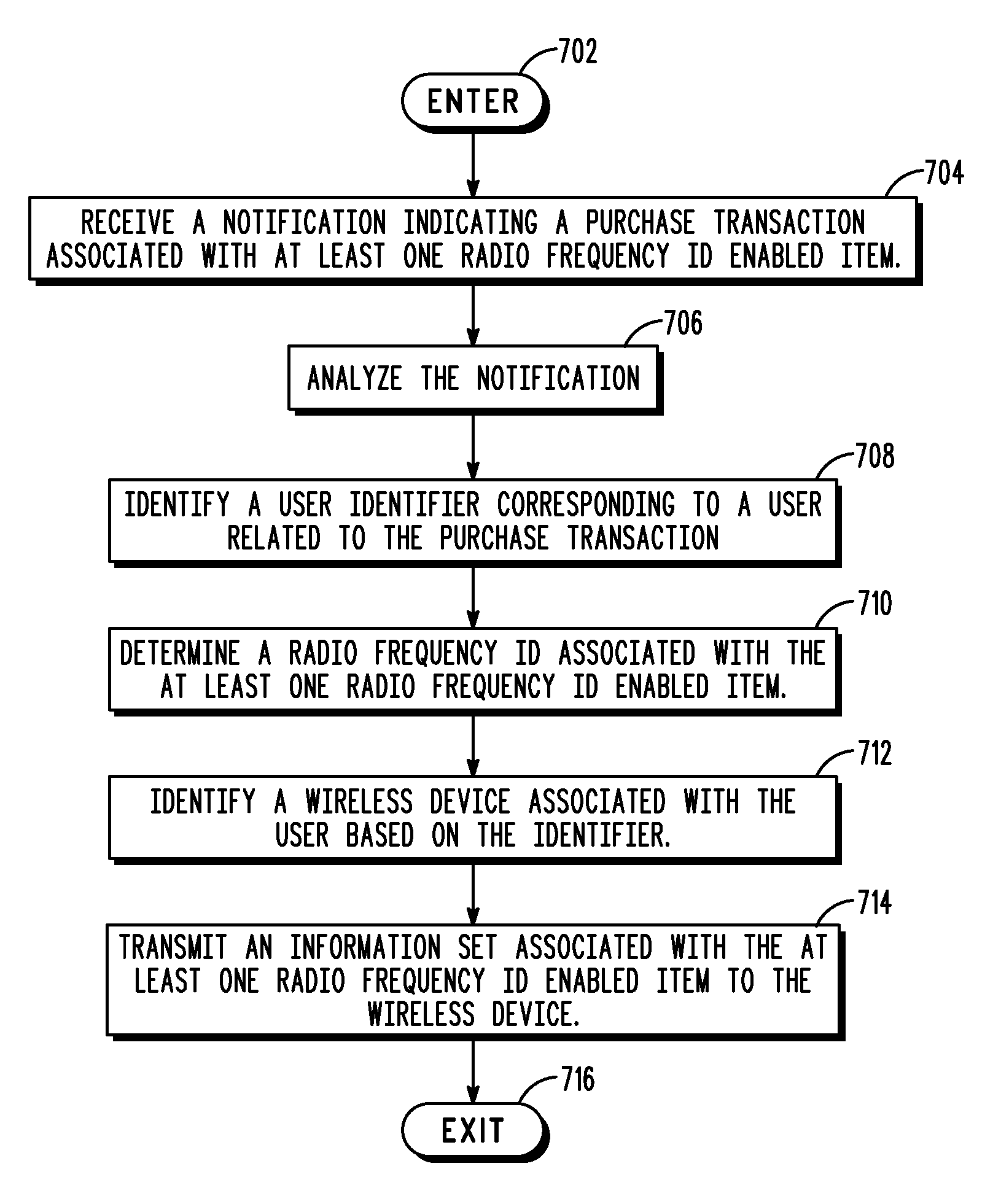

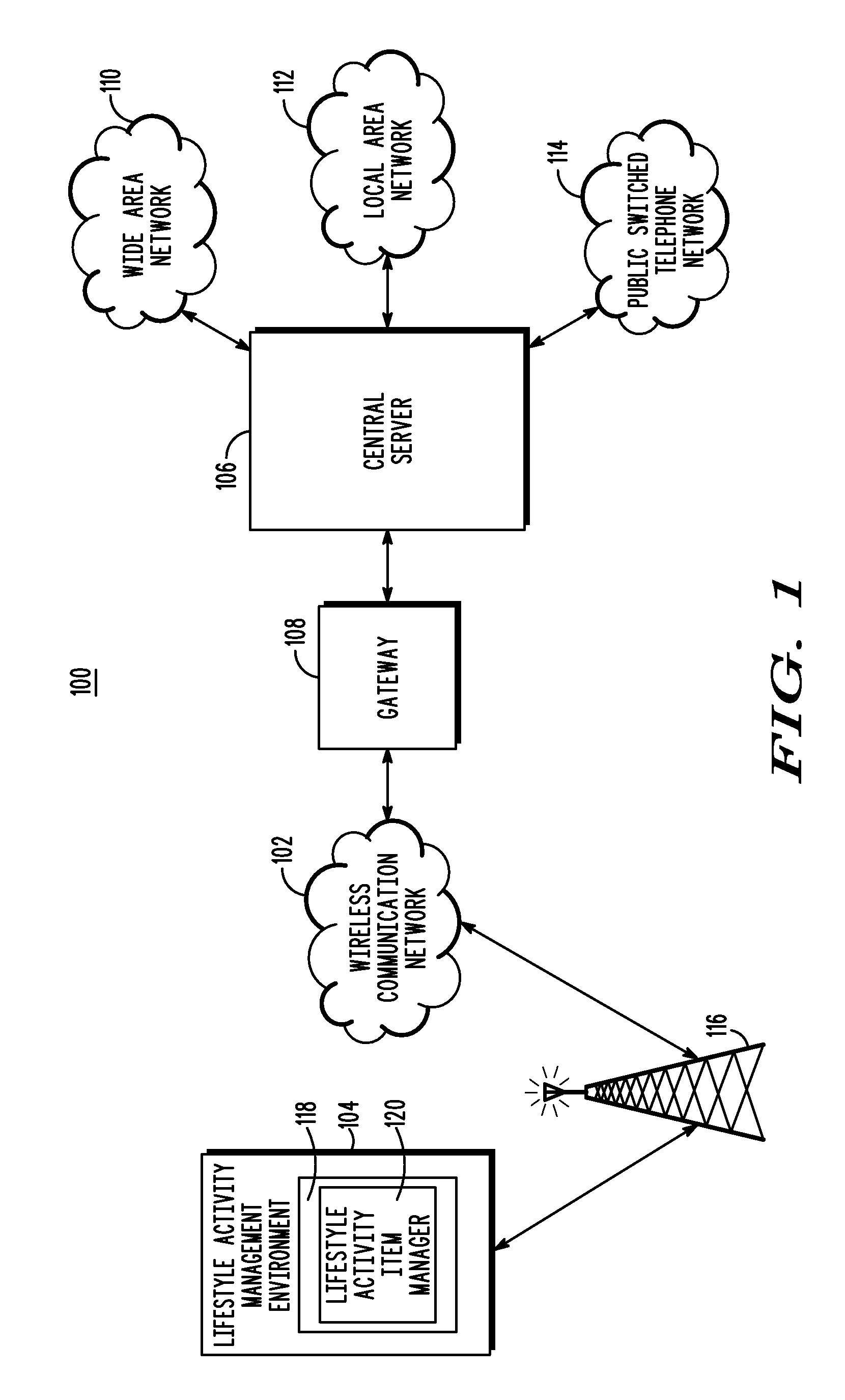

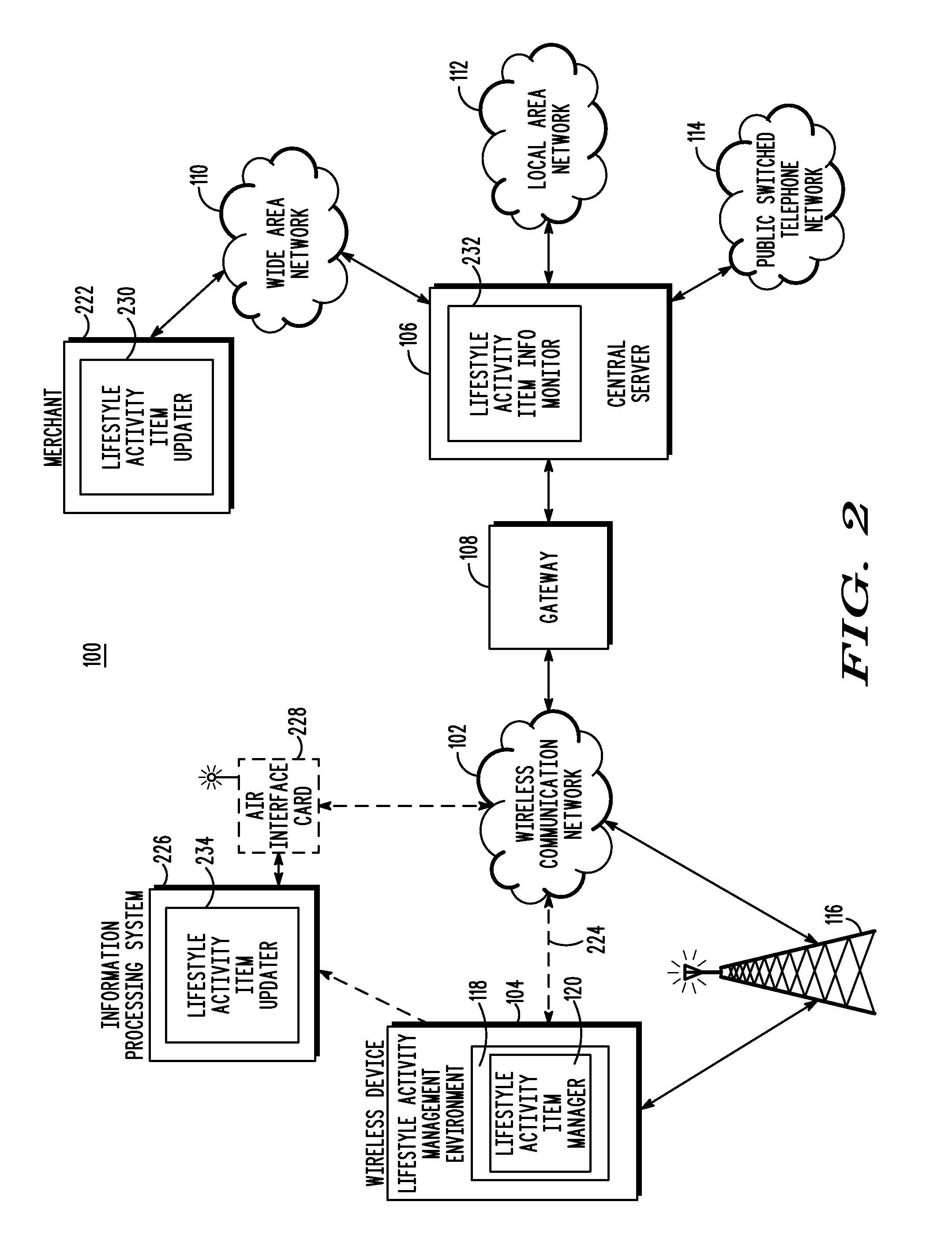

Dynamic updating of product profiles for active lifestyles

InactiveUS20080162291A1Buying/selling/leasing transactionsSubscribers indirect connectionUser identifierRadio frequency

A method and wireless communication device are provided for managing information associated with purchases of active lifestyle products. The method includes receiving a notification (704) indicating a purchase transaction associated with at least one radio frequency ID enabled item. The notification is analyzed (706) and in response to the analyzing a user identifier corresponding to a user related to the purchase transaction is determined (708). A radio frequency ID associated with the at least one radio frequency ID enabled item is also determined (710). A wireless device (104) associated with the user is identified based on the user identifier (712). An information set associated with the at least one radio frequency ID enabled item is transmitted (714) to the wireless device (104). The information set includes at least the radio frequency ID associated with the at least one radio frequency ID enabled item.

Owner:GOOGLE TECH HLDG LLC +1

Printing method of product profile in FDM (Fused Deposition Modeling) printing

ActiveCN107584757AReduced mobilityAvoid scratchesAdditive manufacturing apparatus3D object support structuresGraphicsProduct profile

The invention relates to a printing method of a product profile in FDM (Fused Deposition Modeling) printing, and belongs to the technical field of 3D printing. The method comprises the following steps: pre-identifying an internal profile and an external profile on each slice layer of a product; recording two-dimensional information of the inner profile and the outer profile; then, printing the outer profile and the inner profile of each pattern at once; then printing filling parts between the profiles; completing printing of one slice layer; then moving a printing head to a next slice layer, and repeating the printing process. By adopting the printing method disclosed by the invention, the moving times of the printing head on each slice layer and the printing idle stroke can be reduced greatly, scratches to a printing surface during idle stroke of the printing head are avoided, the printing efficiency is increased, and the printing quality is enhanced.

Owner:NINGXIA KOCEL MOLD

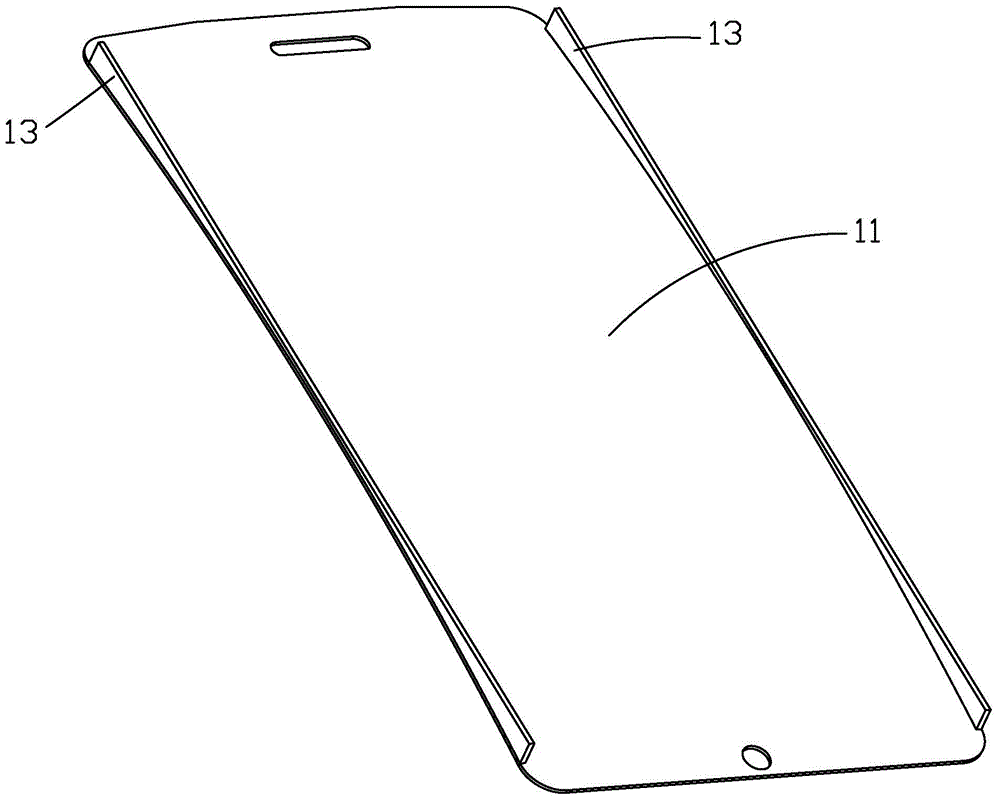

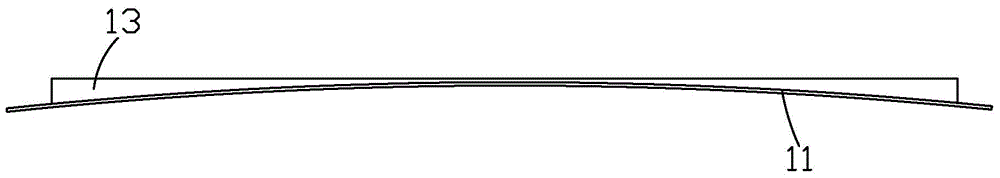

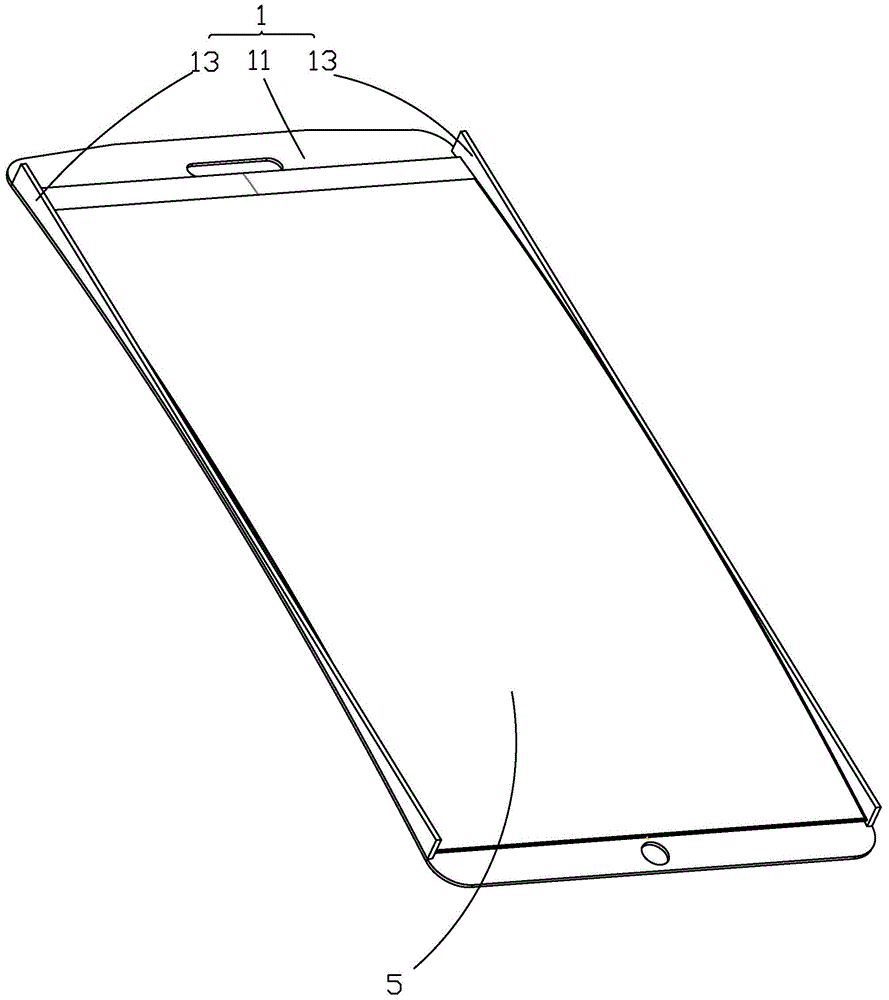

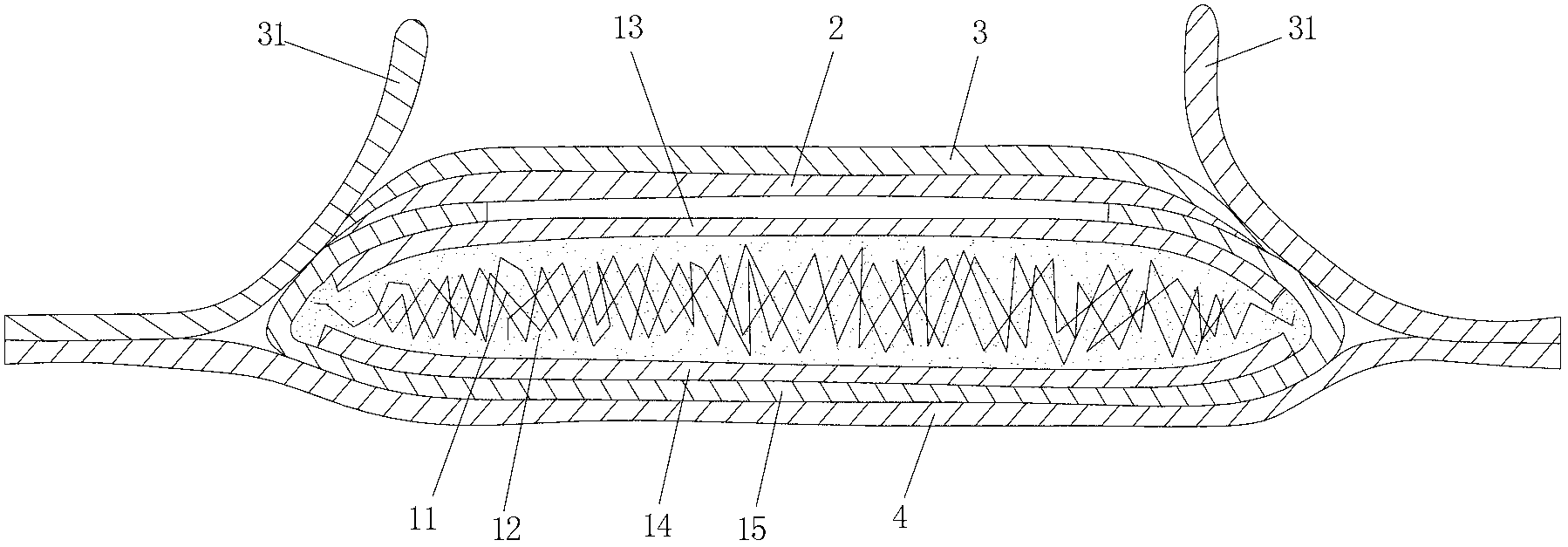

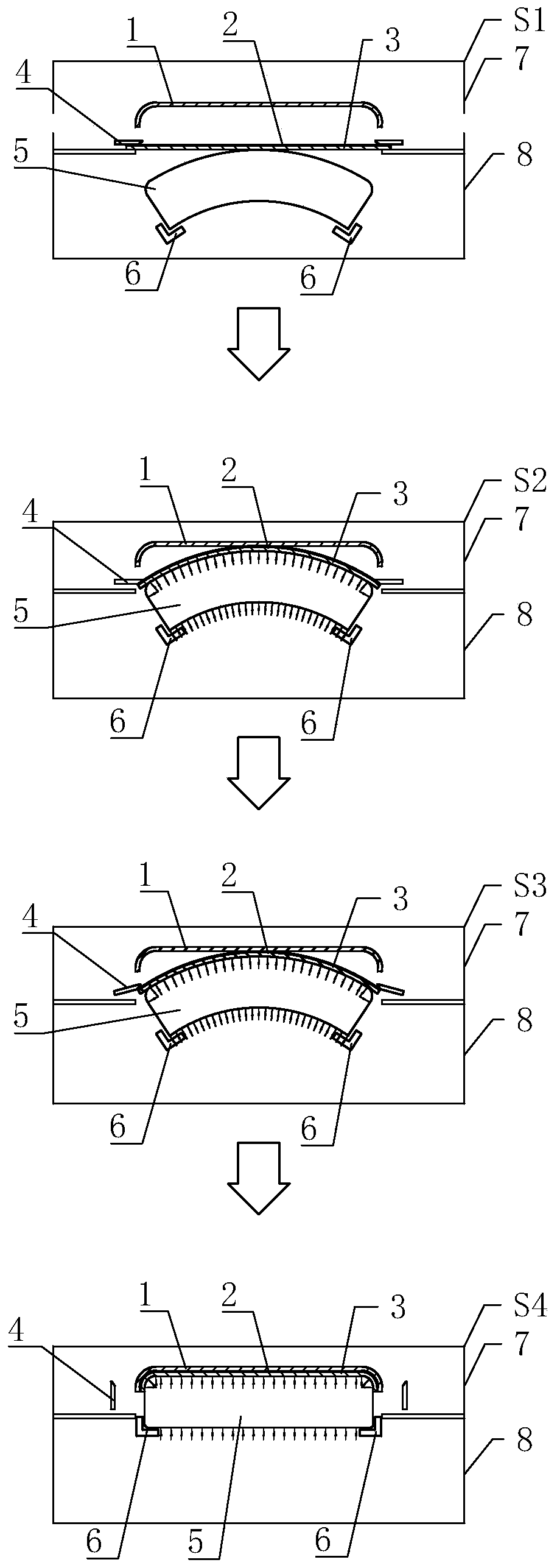

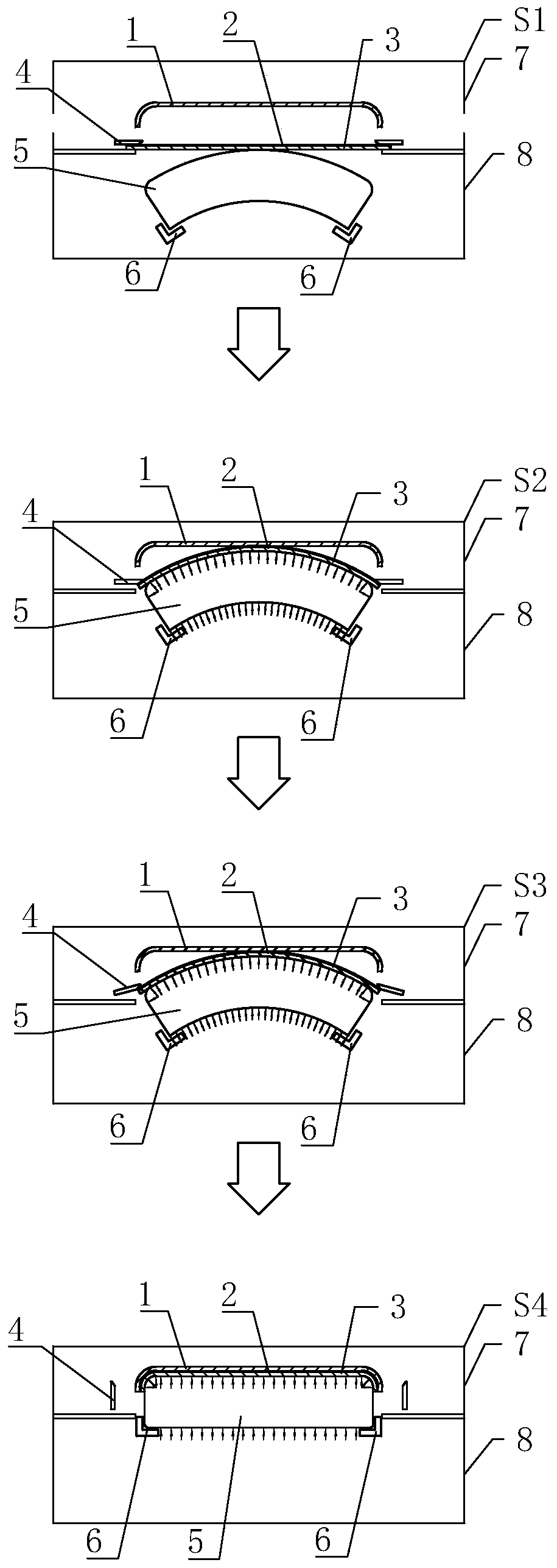

Curved glass cover plate and curved liquid crystal display apparatus

ActiveCN104977746ADimensionally stableFirmly assembledNon-linear opticsGlass coverLiquid-crystal display

The present invention provides a curved glass cover plate and a curved liquid crystal display apparatus. The curved glass cover plate comprises a body (11) and at least one reinforcer (13), the reinforcers (13) are fixed on the body (11) in a curvature change direction of the body (11) and restrict plastic resilience of the body (11) in the curvature change direction, so that influence of internal stress can be eliminated, and the curved glass cover plate can be provided with stable curvature profile and dimension. According to the curved liquid crystal display apparatus, a liquid crystal display module group (5) is attached to the curved glass cover plate (1) having the reinforcers (13), the curved glass cover plate (1) and the liquid crystal display module group (5) have stable curvature profiles and dimensions under the effect of the reinforcers (13), so that requirements of curved display on product profile and dimension can be easily satisfied, an intelligent terminal product can be assembled stably, and the structure is reliable.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

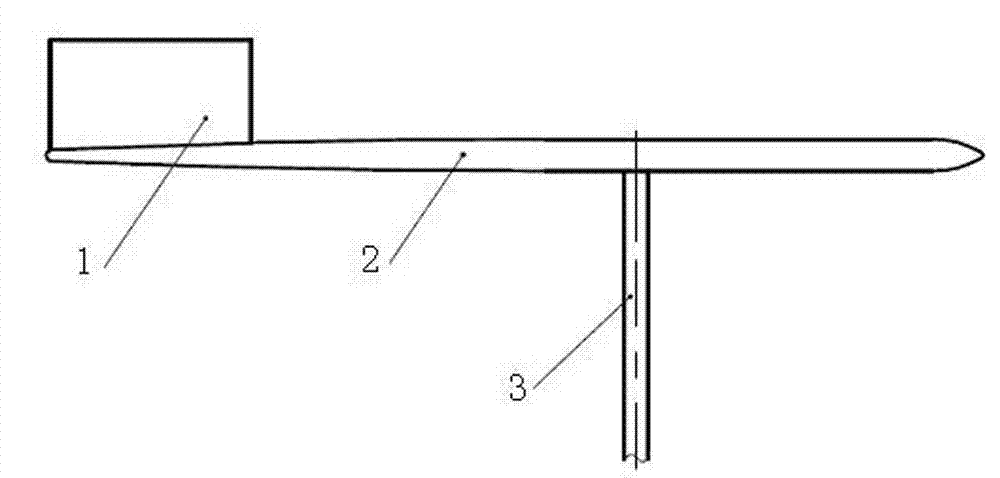

Small-size self-balancing type weather vane

ActiveCN103693203ASmall shaft radial momentLarge measuring rangeAircraft componentsMeasurement devicesEngineeringData system

The invention belongs to the technical field of measurement for attack angles and sideslip angles in an aircraft air data system and specifically relates to a small-size self-balancing type weather vane. The problems of a large influence on aircraft or product profiles and a smaller measurable angle scope of the present blade type weather vane are solved. The small-size self-balancing type weather vane comprises a rotating shaft, a weather vane rod and a weather vane made of aluminum alloy material, wherein the weather vane rod comprises a front half part made of stainless steel material and a rear half part made of aluminum alloy material; the front half part has an equal-diameter structure; the rear half part has a streamline contracting type structure; the diameter of the front end of the rear half part connected with the front half part is the same as the diameter of the front half part; the weather vane has a two-side symmetrical platy structure. The small-size self-balancing type weather vane can be used for effectively eliminating the influence on the aircraft or product surface and accurately outputting the attack angle and sideslip angle data; the measurement scope of an attack angle / sideslip angle sensor is greatly increased; the highest use mach number can reach 2.5 and the 340-degree measuring scope can be achieved.

Owner:TAIYUAN AERO INSTR

Production method of circular-blow multi-end bright profiled polyester filament yarns more than 3dpf (denier per filament)

InactiveCN102586906ASolve the cooling effectSolving Cooling UniformityFilament forming substance formingFilament/thread formingAir volumeProduct profile

The invention discloses a production method of circular-blow multi-end bright profiled polyester filament yarns more than 3dpf (denier per filament), which is characterized in that a melt conveying pipe is used for conveying melt within a temperature range of from 277 DEG C to 283 DEG C; a spinning box is used for spinning within a temperature range of from 288 DEG C to 295 DEG C, spinning components, each having one-spinneret two-yarn independent cavity for metering, are used for spinning, polyester melt enters the independent cavities of the spinning components and filtered and extruded to form, and 20 yarns are extruded to form at each spinning station; and a calm area of a circular blower is 50mm-65mm high, a circular blow cylinder is more than 230mm high, circular blow pressure is more than 35Pa, and circular blow position for the yarns is more than 900mm away from a nozzle. By the method, the problems of insufficiency in cooling air volume and cooling uniformity are solved effectively. The volume of circular air blow is only 30% of that of lateral air blow, energy consumption is lowered evidently, yarn levelness of products is high, and variation coefficient of product profile degree is small.

Owner:TONGXIANG ZHONGCHEN CHEM FIBER

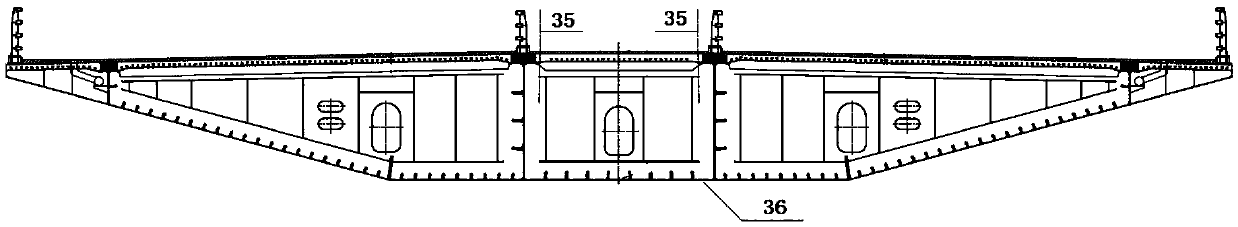

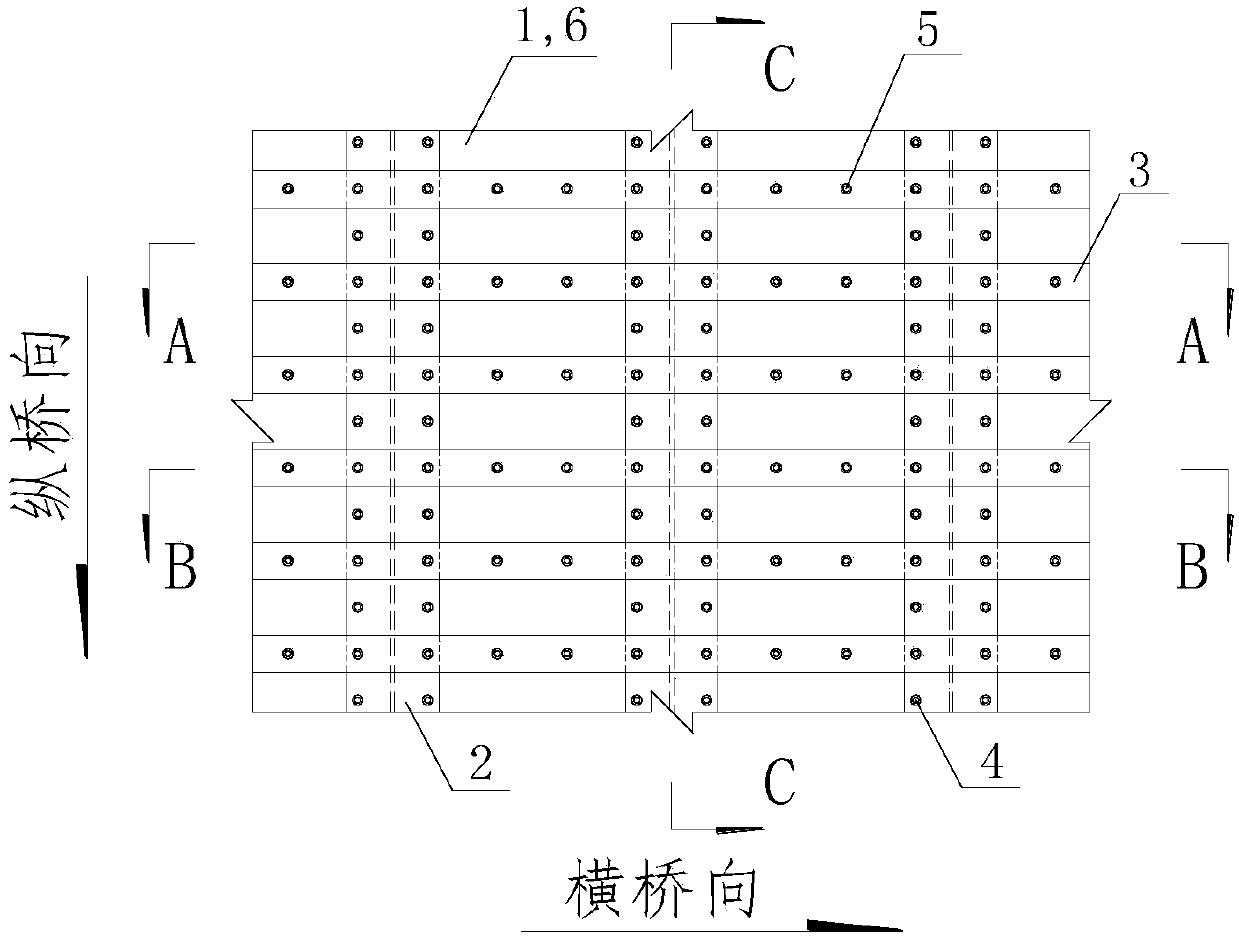

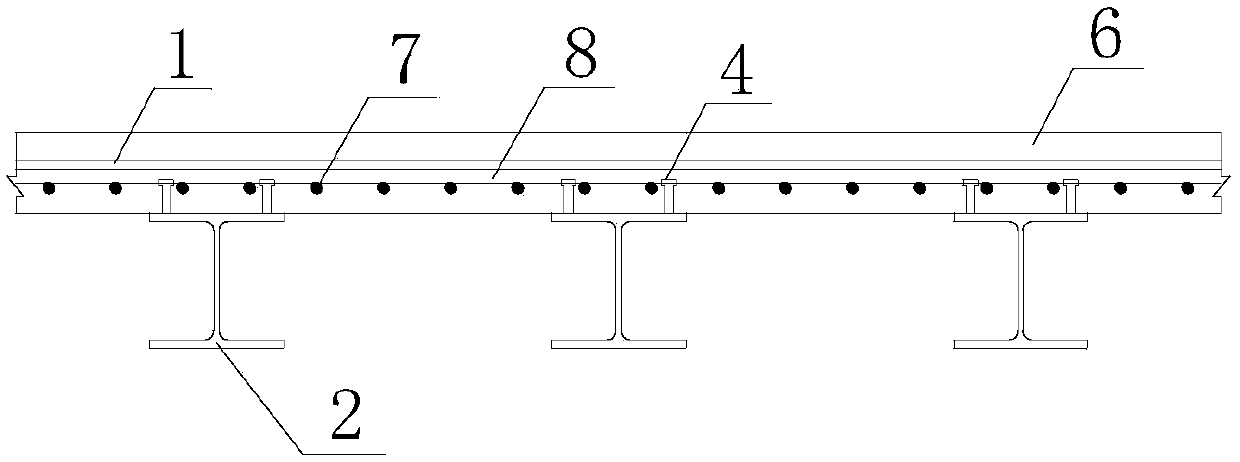

Profile steel-UHPC (ultra-high performance concrete) combined bridge deck structure suitable for cantilever state as well as construction method thereof

ActiveCN109610310ALight weightReduced risk of crackingClimate change adaptationBridge structural detailsPre stressBridge deck

The invention discloses a profile steel-UHPC (ultra-high performance concrete) combined bridge deck structure suitable for a cantilever state as well as a construction method thereof. A profile steel-UHPC lightweight combined bridge deck slab is mainly formed by combining profile steel, steel plate strips welded with short studs as well as an UHPC slab; the profile steel serving as a longitudinalrib is arranged in a transverse bridge direction at intervals; the steel plate strips are arranged on an upper flangeslab of the profile steel in the bridge direction at intervals; and longitudinal and transverse seam structures are T-shaped seams. Finished product profile steel is adopted, so that the manufacturing cost is low, the welding quantity is small and the risk of fatigue cracking is greatly reduced; meanwhile, higher bending-resistant inertia moment is achieved, the cracking risk of the bridge deck slab is reduced and the transverse tension resistance of the bottom surface of the bridge deck slab is enhanced; UHPC in the longitudinal seam position is converted from a pulled state to a pressed state, so that the fact that the operation stage is not cracked can be guaranteed without configuring a prestressing force when the bridge deck slab is under the transverse cantilever state; moreover, breakage in a high tensile stress area can be avoided, shrinkage crack can be avoided,the self weight of the bridge deck slab is reduced, and the method is simple to operate and easy to construct.

Owner:HUNAN UNIV

Dynamic updating of product profiles for active lifestyles

InactiveUS7924158B2Electric signal transmission systemsDigital data processing detailsUser identifierRadio frequency

A method and wireless communication device are provided for managing information associated with purchases of active lifestyle products. The method includes receiving a notification (704) indicating a purchase transaction associated with at least one radio frequency ID enabled item. The notification is analyzed (706) and in response to the analyzing a user identifier corresponding to a user related to the purchase transaction is determined (708). A radio frequency ID associated with the at least one radio frequency ID enabled item is also determined (710). A wireless device (104) associated with the user is identified based on the user identifier (712). An information set associated with the at least one radio frequency ID enabled item is transmitted (714) to the wireless device (104). The information set includes at least the radio frequency ID associated with the at least one radio frequency ID enabled item.

Owner:GOOGLE TECH HLDG LLC

Composite sanitary product profile without containing wood pulp fibers and preparation method thereof

InactiveCN102697603AOvercoming lumpsOvercome the disadvantage of easy breakageAbsorbent padsBaby linensSurface layerNonwoven fabric

The invention discloses a composite sanitary product profile without containing wood pulp fibers and a preparation method thereof, relates to a profile mainly used for making sanitary products such as paper diapers and sanitary towels, and provides a composite sanitary product profile which is environment-friendly, can reduce the preparation cost and does not contain wood pulp fibers and a preparation method for the profile. The composite sanitary product profile without containing the wood pulp fibers comprises an absorption core body, a non-woven fabric diversion layer, a non-woven fabric surface layer and an impenetrable bottom layer; the absorption core body consists of a core material and a non-woven fabric core material wrapping layer; the core material consists of bulky non-woven fabric fibers and macromolecular water absorption resin penetrating the bulky non-woven fabric fibers, and the non-woven fabric core material wrapping layer wraps the core material; the non-woven fabric diversion layer is bonded with the non-woven fabric core material wrapping layer; and the non-woven fabric surface layer and the impenetrable bottom layer are wrapped on the periphery of the absorption core body together and bonded with the non-woven fabric core material wrapping layer of the absorption core body.

Owner:厦门造福堂文化传媒有限公司

Automated product profiling apparatus and product slicing system using the same

An apparatus for acquiring a profile of a food product for use in subsequent processing of the food product includes a scanning area and one or more product drives for driving a product through the scanning area in a longitudinal direction. First line lasers project one first transverse laser line transversely to the longitudinal direction on the first surface and two first cameras arranged to capture different, overlapping first transverse image portions of the first transverse laser line. A reference laser projects a beam on the first surface that indicates a transverse reference position, and the two first cameras also capture the reference position. A control system uses the transverse reference position to combine the different first transverse image portions captured by the two first cameras to calculate a first profile of the first surface at multiple positions along a length of the first surface as the product is driven through the scanning area.

Owner:PROVISUR TECHNOLOGIES INC

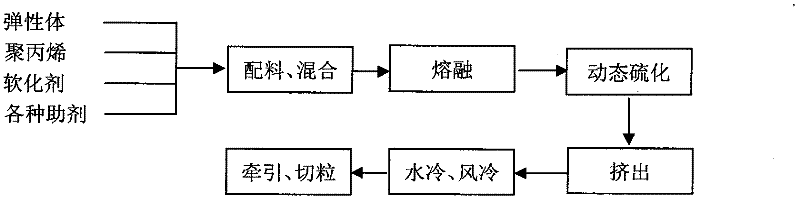

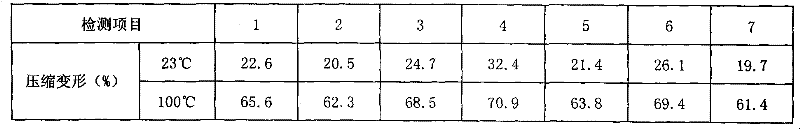

Preparation method of thermoplastic elastomer PP special material with high fluidity and excellent permanent deformation resistance

The invention relates to a preparation method of a thermoplastic elastomer PP special material with high fluidity and excellent permanent deformation resistance. The product related in the invention facilitates low pressure injection moulding and extrusion moulding, is easy for demoulding after moulding, and has a clear product profile. The product also has good impact resistance, weatherability, ultraviolet resistance, heat resistance, oil resistance, chemical resistance, and solvent resistance which are better than those of general chloroprene rubber. The particular preparation method comprises the following steps: adding polypropylene, an elastomer, a softener, an anti-oxidant, an additive into a high speed mixer for mixing, performing melt extrusion by a double screw extruder for granulation, metering and adding a vulcanizer at a glass fiber port position during melt extrusion, and performing vulcanization crosslinking. The invention relates to a formula which comprises 50-80 parts of polypropylene, 20-50 parts of elastomers, 0-0.5 parts of softeners, 0.1-2 parts of vulcanizers, 0.1-1 parts of assisted vulcanizers, 0.5-2 parts of anti-oxidants, 0.2-1.0 parts of additives.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

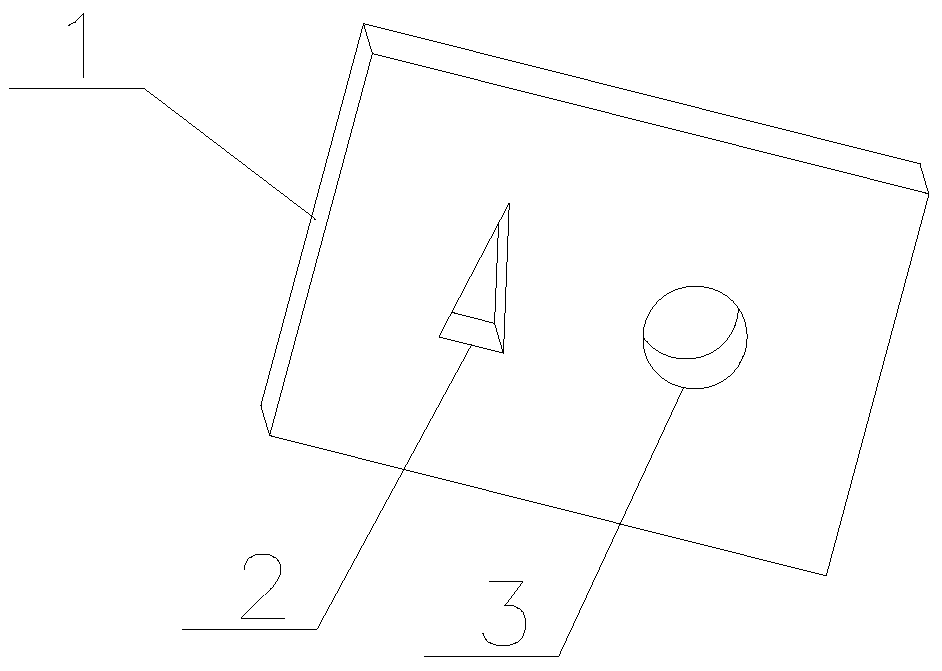

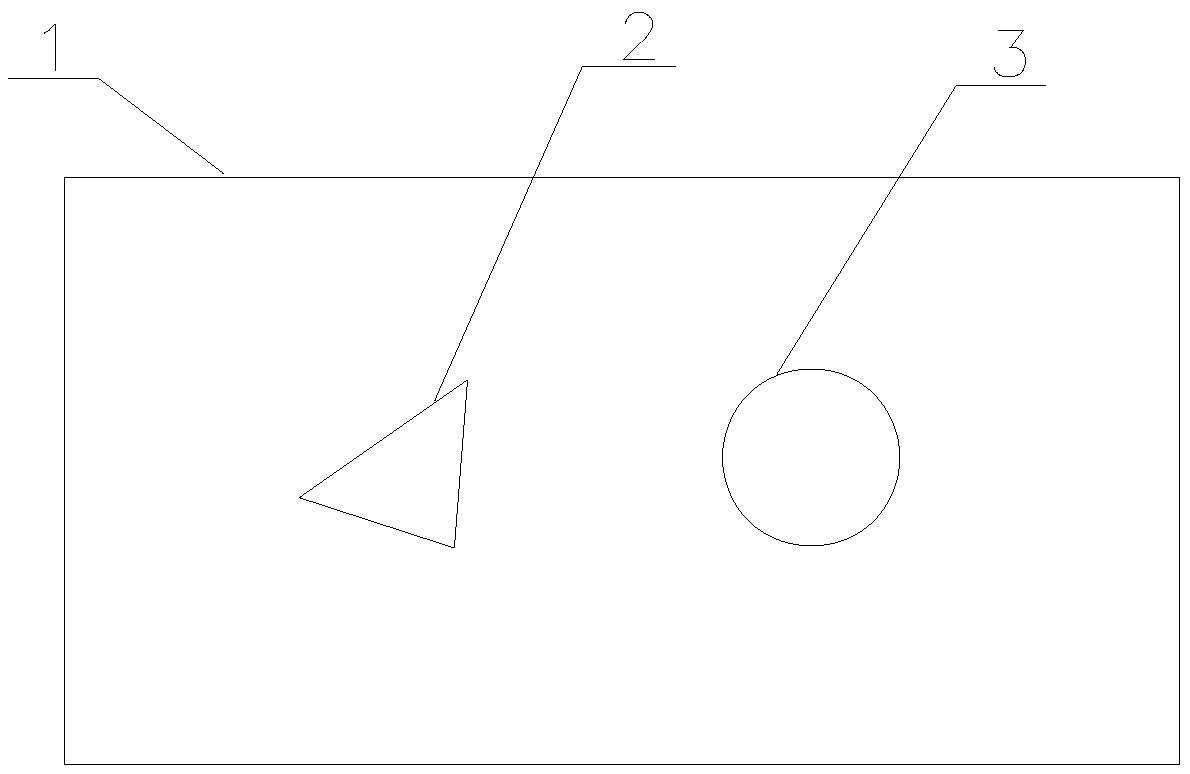

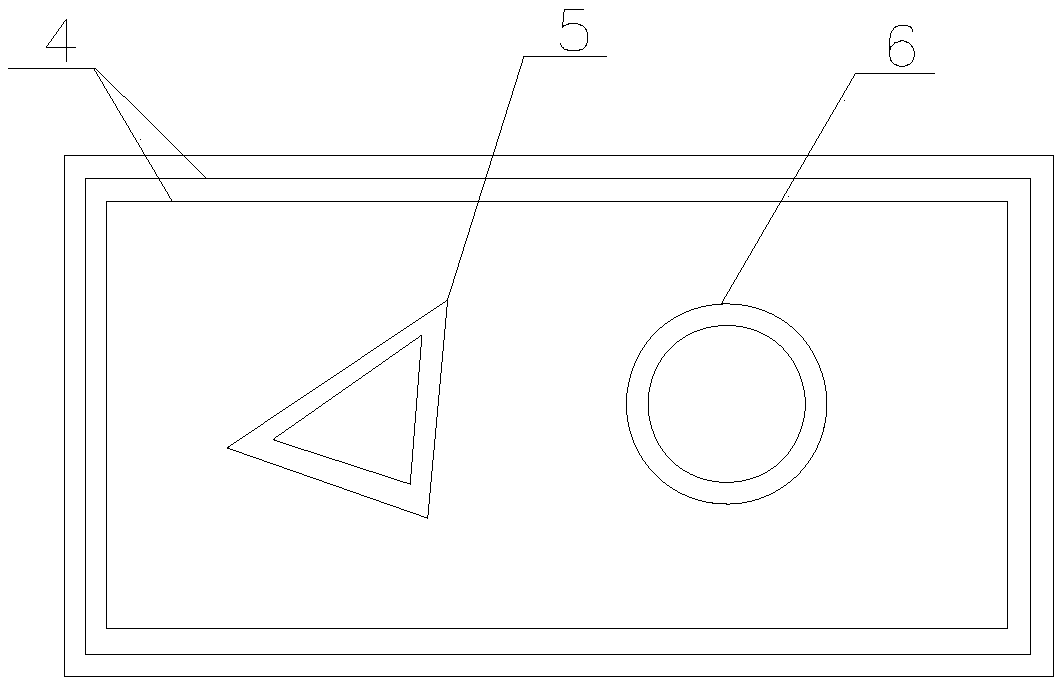

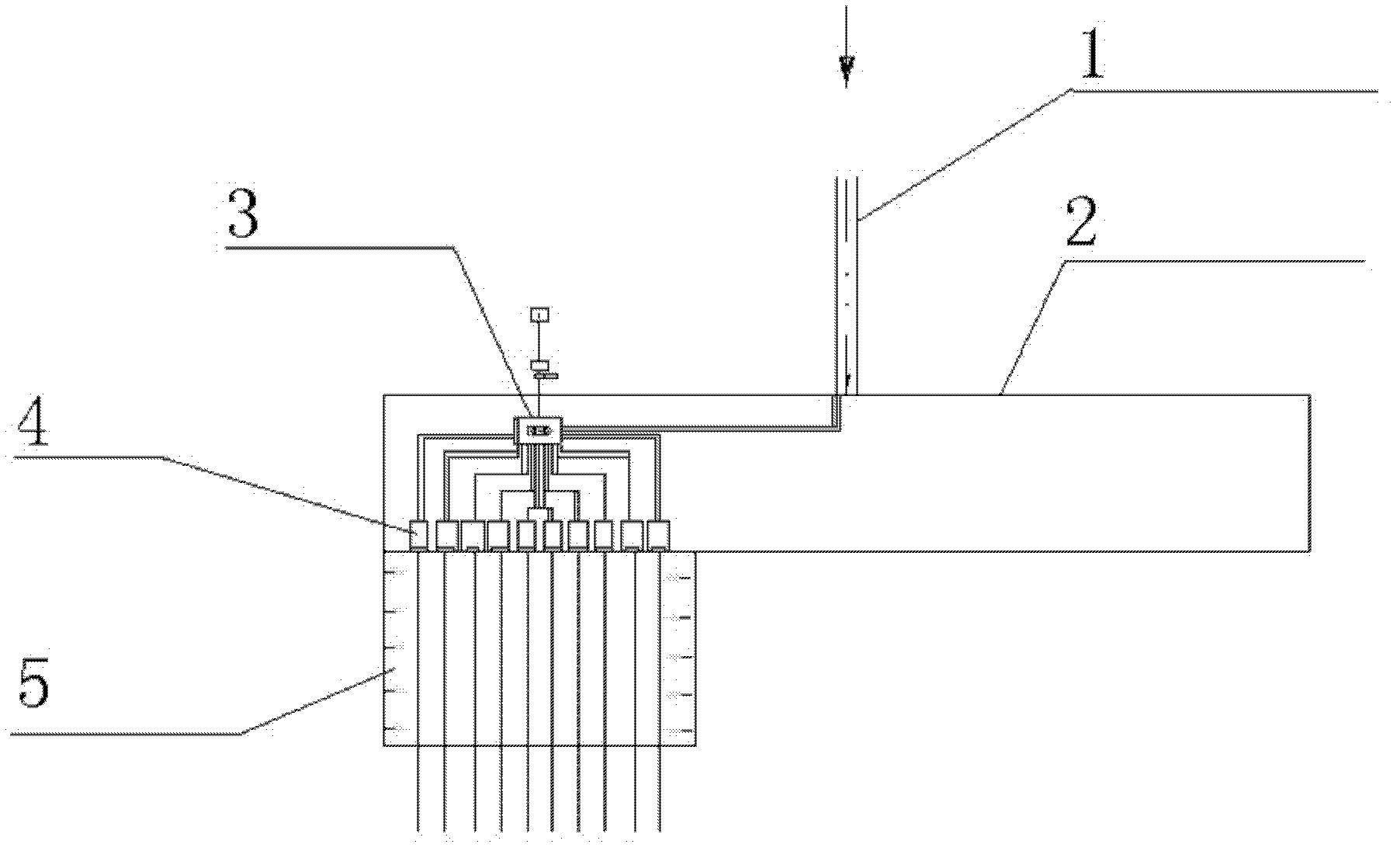

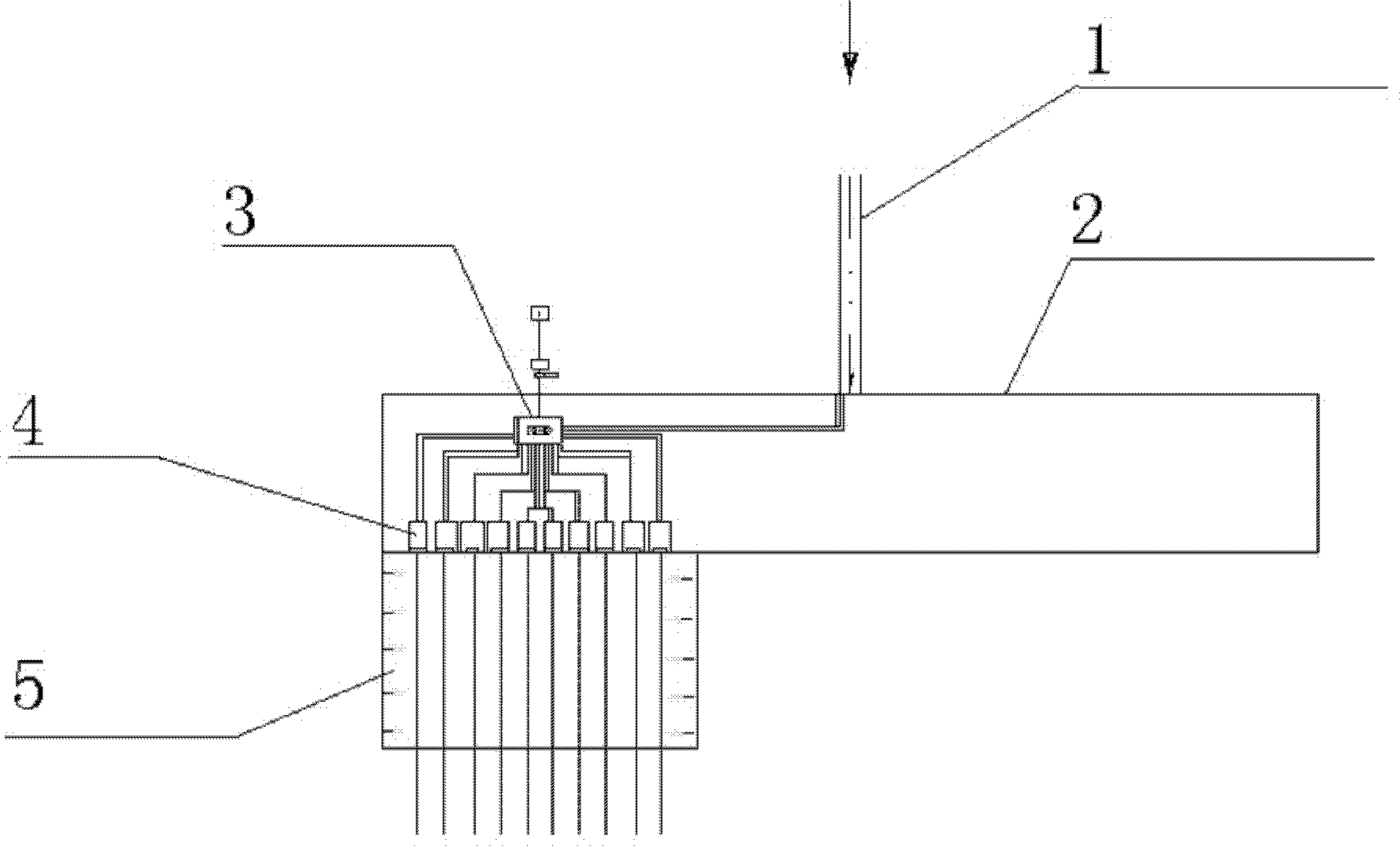

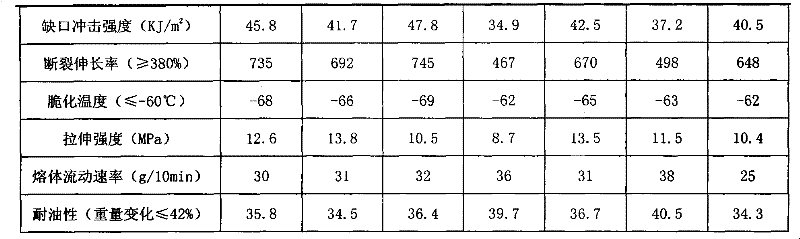

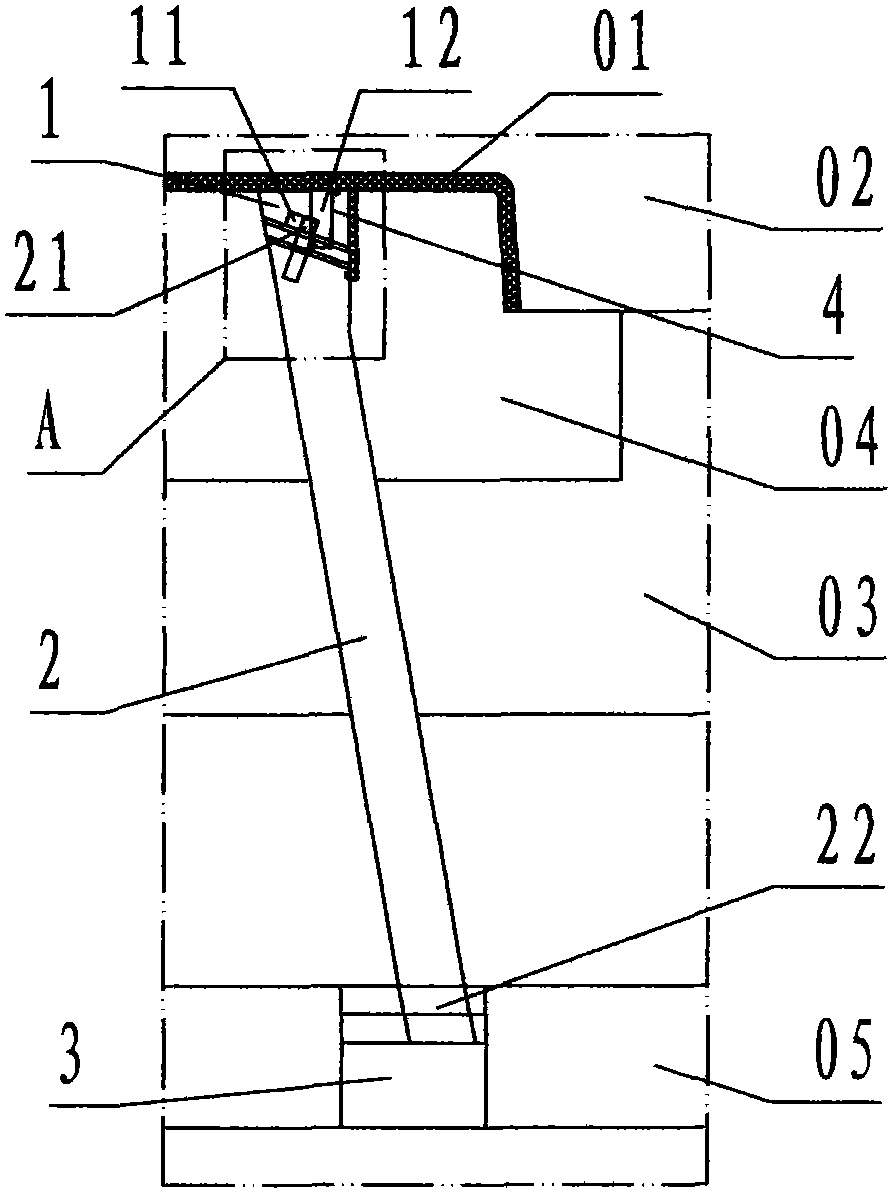

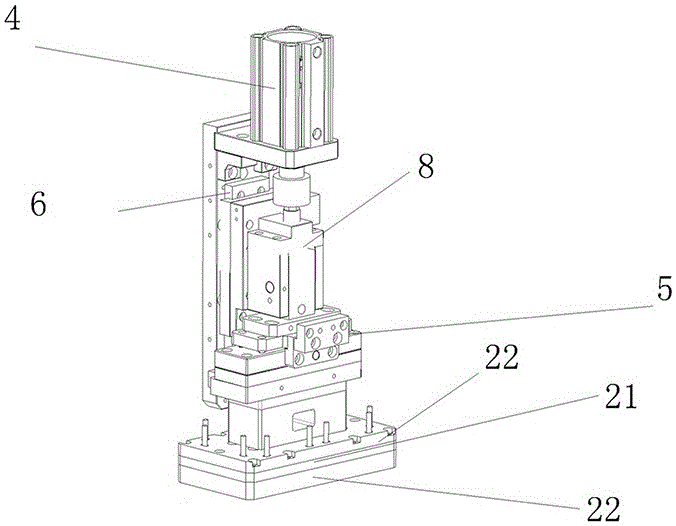

Lifting core-pulling device with angle-lift core block

The invention discloses a lifting core-pulling device with an angle-lift core block. The lifting core-pulling device comprises the angle-lift core block (1), a lifting rod (2), a lifting rod sliding seat (3) and a resetting slide groove (4). The technical scheme includes that a core-pulling block with a product profile is manufactured into the angle-lift core block capable of sliding obliquely, the angle-lift core block is slidably arranged on an oblique slide track on the top of the lifting rod, a limiting slide groove and a resetting key are arranged on the angle-lift core block, a limiting pin which is correspondingly matched with the limiting slide groove is arranged on the lifting rod, and the resetting slide groove which is correspondingly matched with the resetting key is arranged on a movable mold core. The shortcomings that yield is low and cost is high in the prior art are overcome. The angle-lift core block moves longitudinally and then moves transversely so as to be pulled out from a longitudinal convex rib and a transverse inverted fastener structure, which are close to each other, of the product, by means of limiting and oblique sliding, damage to the product due to forced mold stripping is avoided, and the purposes of increasing the yield of the product and reducing cost are achieved.

Owner:宁海胜利模具有限公司

Automatic shaping type film laminating device

ActiveCN109968786AReduce replacement costsImprove fitting accuracyLaminationLamination apparatusElastomerEngineering

The invention discloses an automatic shaping type film laminating device, and relates to the field of vacuum film lamination. The device comprises an elastomer having a curved product profiling end, and the elastomer in an elastic bent state acts on a flexible product to make the flexible product bend to the curved product; and the elastomer acts on the flexible product through deformation restoration in order to make the flexible product automatically shape along the inner chamber of the curved product. The profiling side of the elastomer faces the curved product, and when the elastomer is elastically bent towards the curved product, the elastomer can press the flexible product to bend to the curved product and be in contact with and laminated to the curved product; and when the elastomerrecovers deformation, the elastomer transfers a pressure to the flexible product, and the flexible product is forced to be closely laminated to the curved product, gradually fully fill the entire inner chamber of the curved product and complete the automatic shaping along the inner chamber of the curved product. The device has the advantages of adaptation to the lamination of complex curved surfaces, low shape replacement cost, high laminating precision, and remarkable bubble discharging effect.

Owner:WEIFANG LOKOMO PRECISION IND

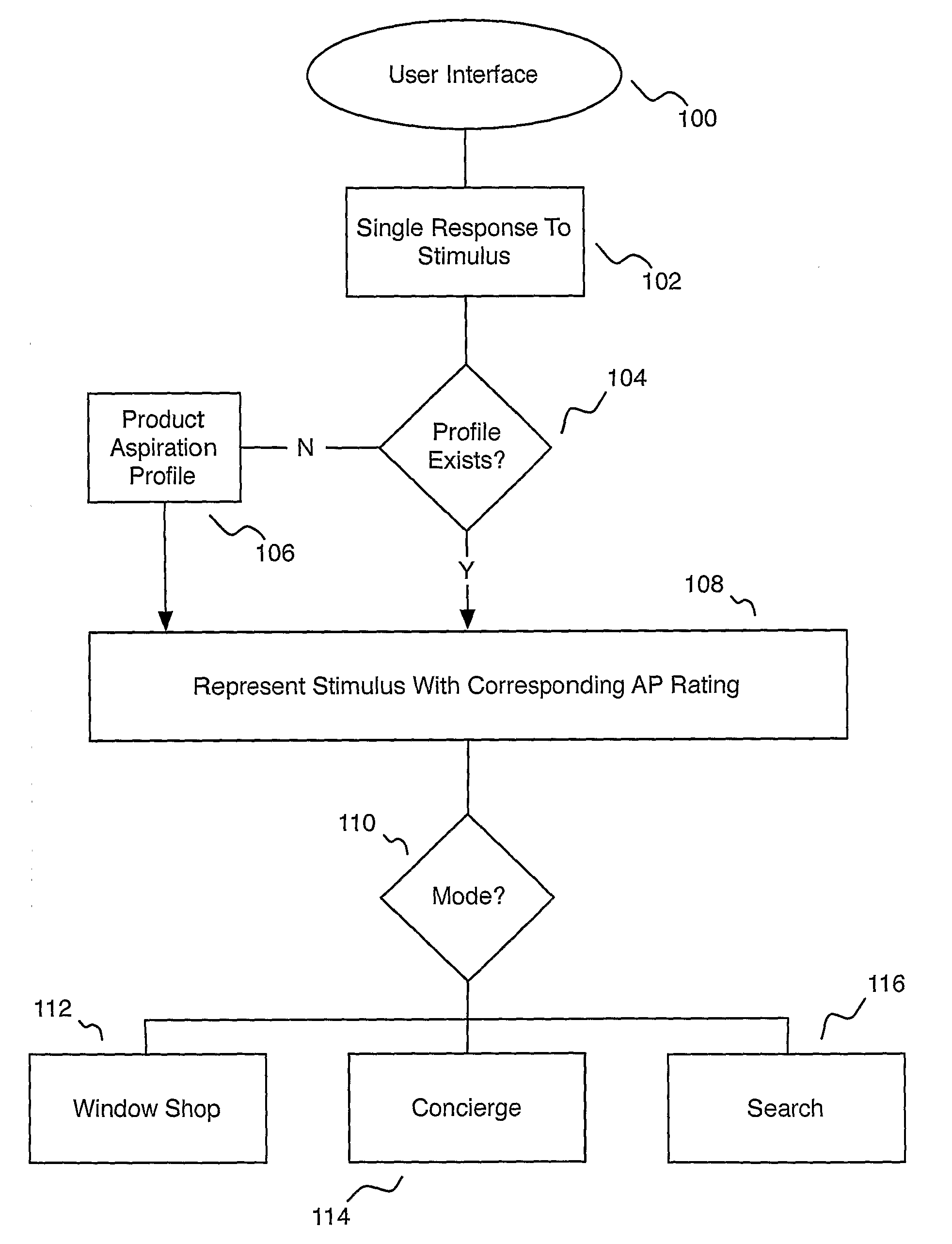

Method and System For Matching Pre-Indexed Product Profiles to Consumers

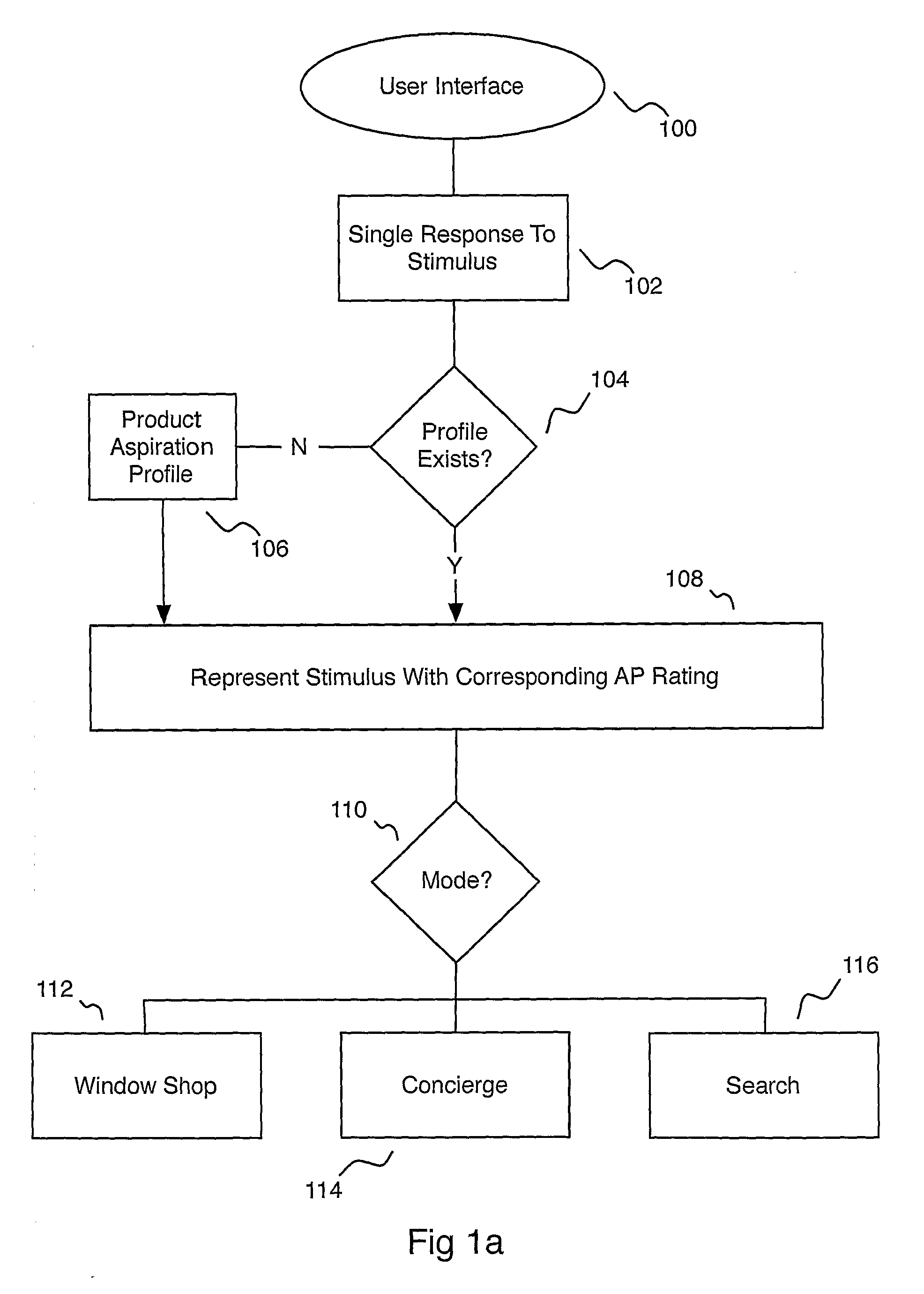

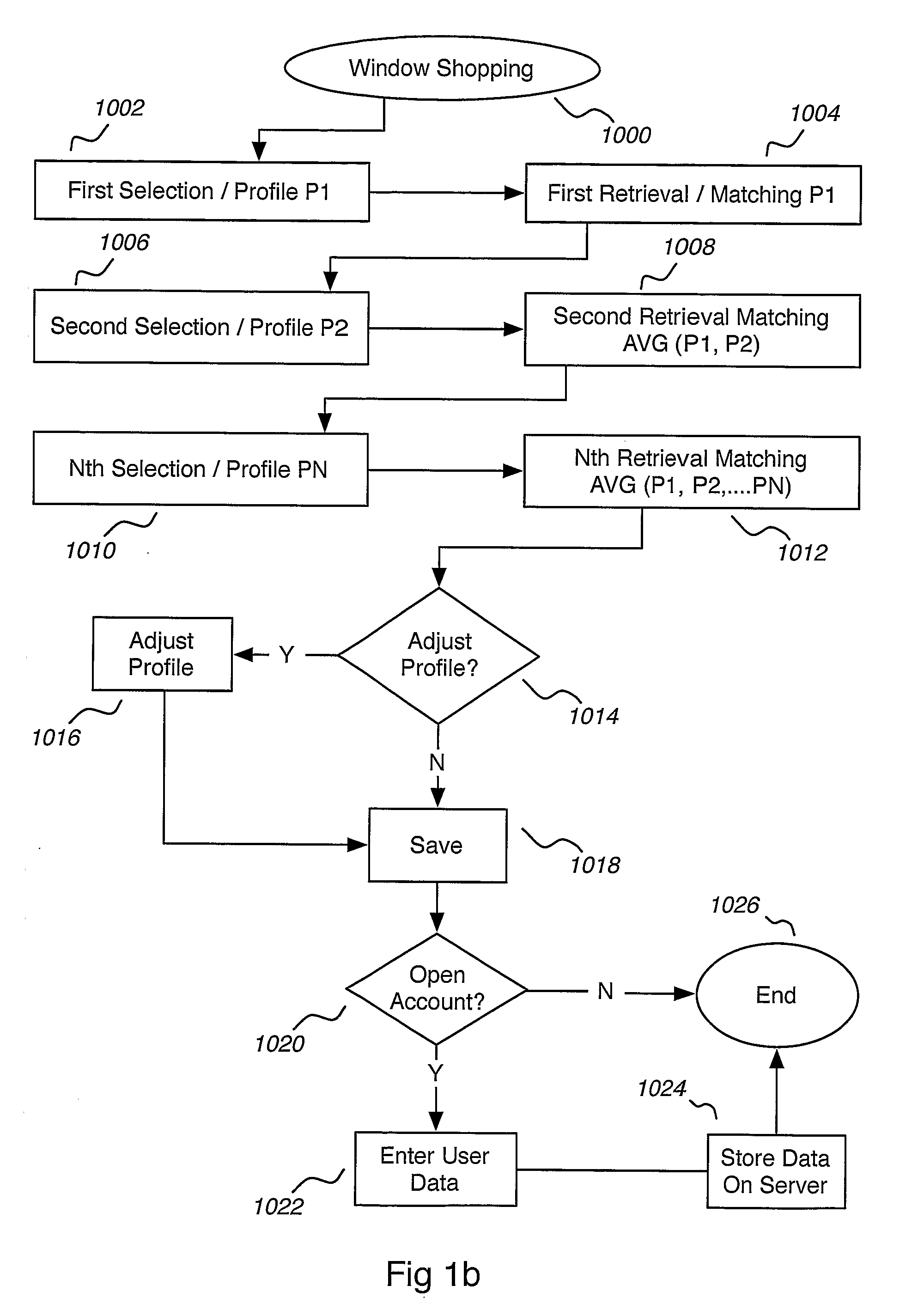

The invention provides a method and system for dynamically tailoring selection of products displayed to potential buyers based on a profile accounting for the buyer's personal interests, including future interests or goals. From a User interface connected to a communication network, products or other offerings are presented as selections that are relevant to User. Until a User completes a User Aspiration Profile (306), the first User action (e.g. a mouse click on or other single action to select a product or category of products depicted) causes the client to request the server to provide product data on products with User Aspiration Profile Ratings (308) similar to the rating of the first-clicked item. The User may also provide profile data, stating both current state and desired state personality characteristics. Such personality indexing corresponds to product indexing, such that the products or offerings presented to User bear a relevancy or match to his or he “User Aspiration Profile.”

Owner:SUE STEVEN JOHN

Apparatus for adjustable wrapping

InactiveUS8356456B2Wrapper folding/bending apparatusWrapper supporting apparatusEngineeringMechanical engineering

A wrapping apparatus, system, station and / or process is generally provided. As to the apparatus, it includes a wrap bar for engaging and directing a wrapper about the product, a wrap bar carrier from which the wrap bar extends, and a drive assembly operatively linked to the wrap bar carrier. The carrier block, which translatingly retains the carrier intermediate opposing end portions thereof, is adapted for driven rotation about a wrapping axis of the apparatus so as to thereby rotatingly drive the bar about the axis via rotation of the carrier. The drive assembly, which is operatively linked to the carrier, selectively translates the carrier in relation to the carrier block during driven rotation of the carrier such that a radial distance for the bar from the axis is thereby capable of selective establishment in furtherance of delimiting a wrap bar travel path commensurate with the product profile of the product.

Owner:DOUGLAS MACHINE LIABILITY

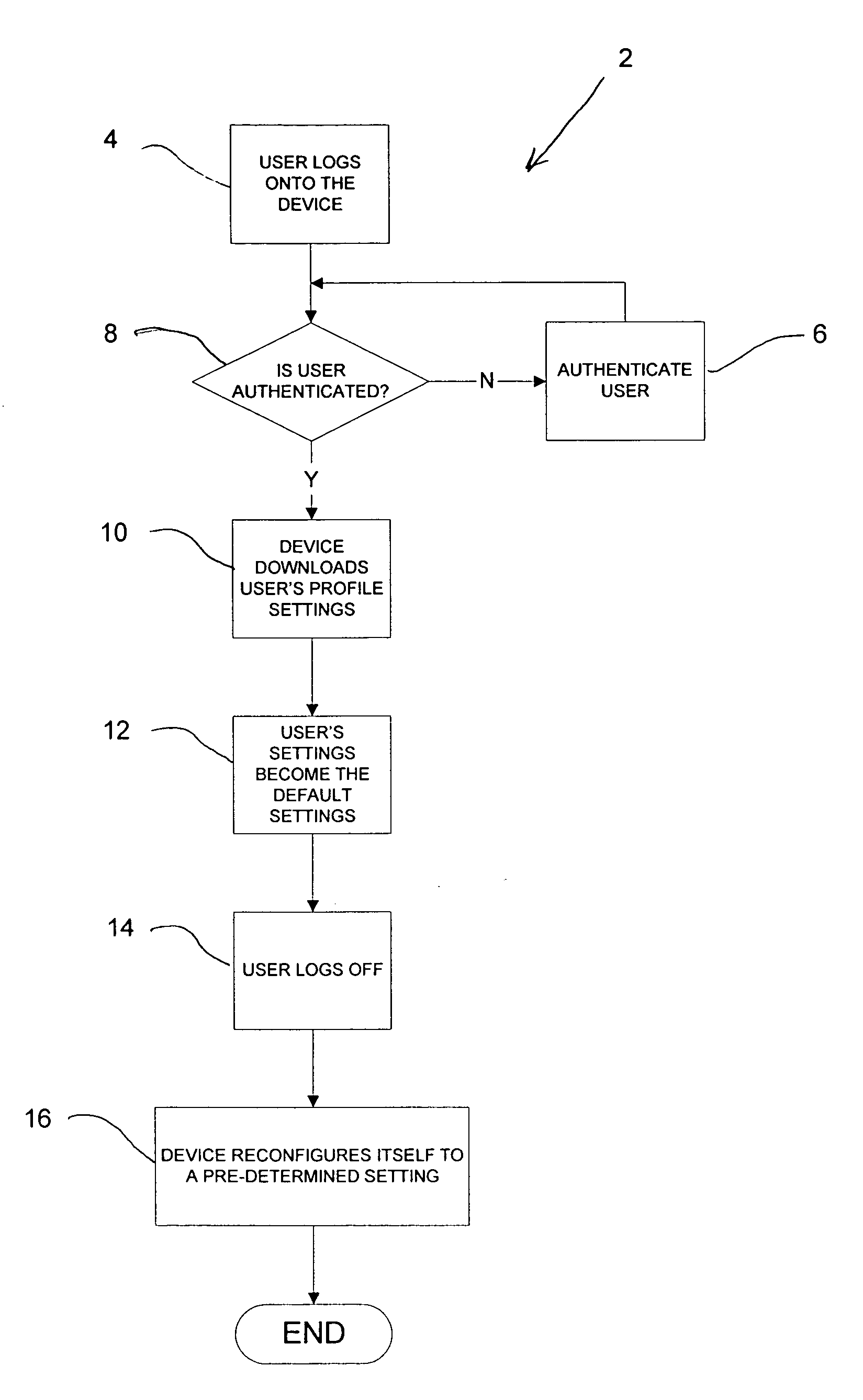

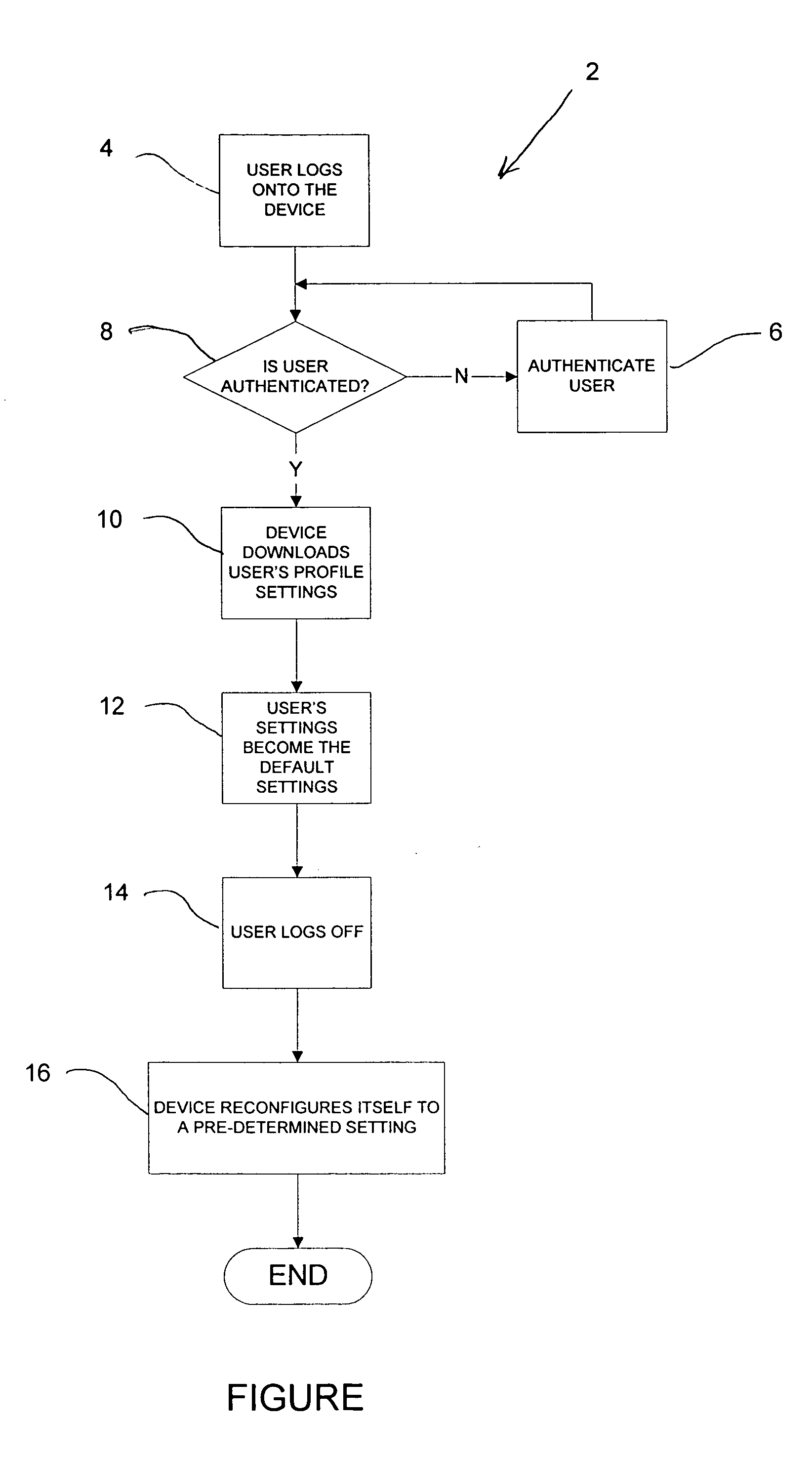

Multi-function product profile downloading after authentication

InactiveUS20050039007A1Improve user efficiencyImprove economyUser identity/authority verificationDigital data authenticationProduct profileWorld Wide Web

This invention relates to a system, that upon a user being authenticated on a device, such as a multi-function product or a digital sender, a profile that contains the user's most used settings and functions can be downloaded to the product. These settings would become the product's defaults until the user logs off of the device.

Owner:HEWLETT PACKARD DEV CO LP

Automatic product profile extraction method in visual detection

ActiveCN107909579AEasy extractionAvoid choppingImage enhancementImage analysisEdge extractionComputer vision

The invention relates to an automatic product profile extraction method in visual detection. The method comprises the following steps: step one, preprocessing an extracted image; step two, extractingan edge in the image; step three, searching for a regional contour in the edge image; to be specific, extracting all enclosed profiles in the edge image, filling all the enclosed profiles to obtain corresponding regions, calculating areas of all regions, finding out an area with the largest area and thus using the corresponding enclosed profile as a product profile; step four, carrying out morphological opening operation on the contour region and removing a vent hole or a bur on the profile; and step five, carrying out product profile restoration. According to the invention, with utilization of a multi-scale edge extraction operator and combination of methods like image gray correction ad morphological calculation methods, a good effect of product region extraction is realized in most of application scenes, so that the need of automatic product region extraction in visual detection of the printing industry is met; automatic extraction of the product region is realized; the step of manual product region drawing is removed; and the application range is wide.

Owner:BEIJING FOCUSIGHT TECH

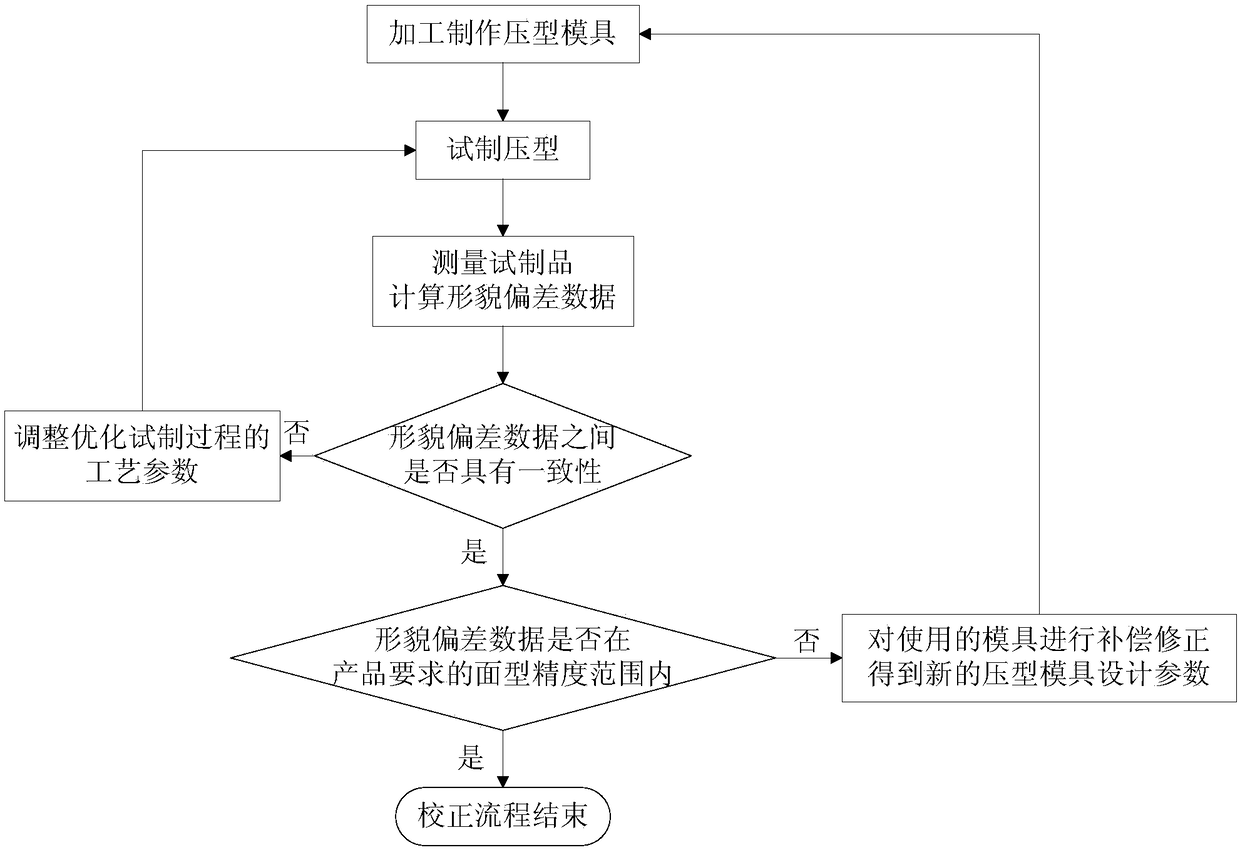

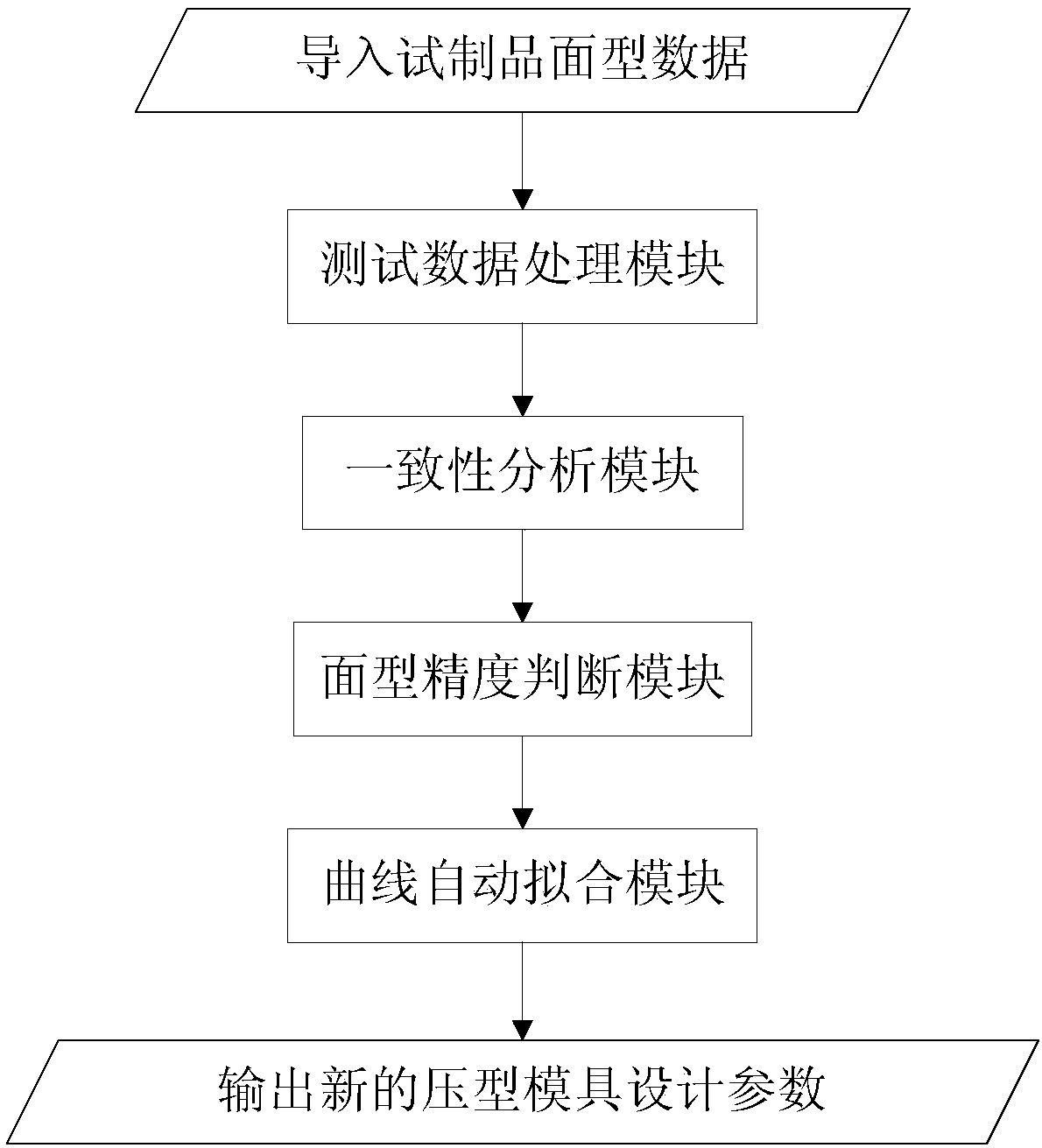

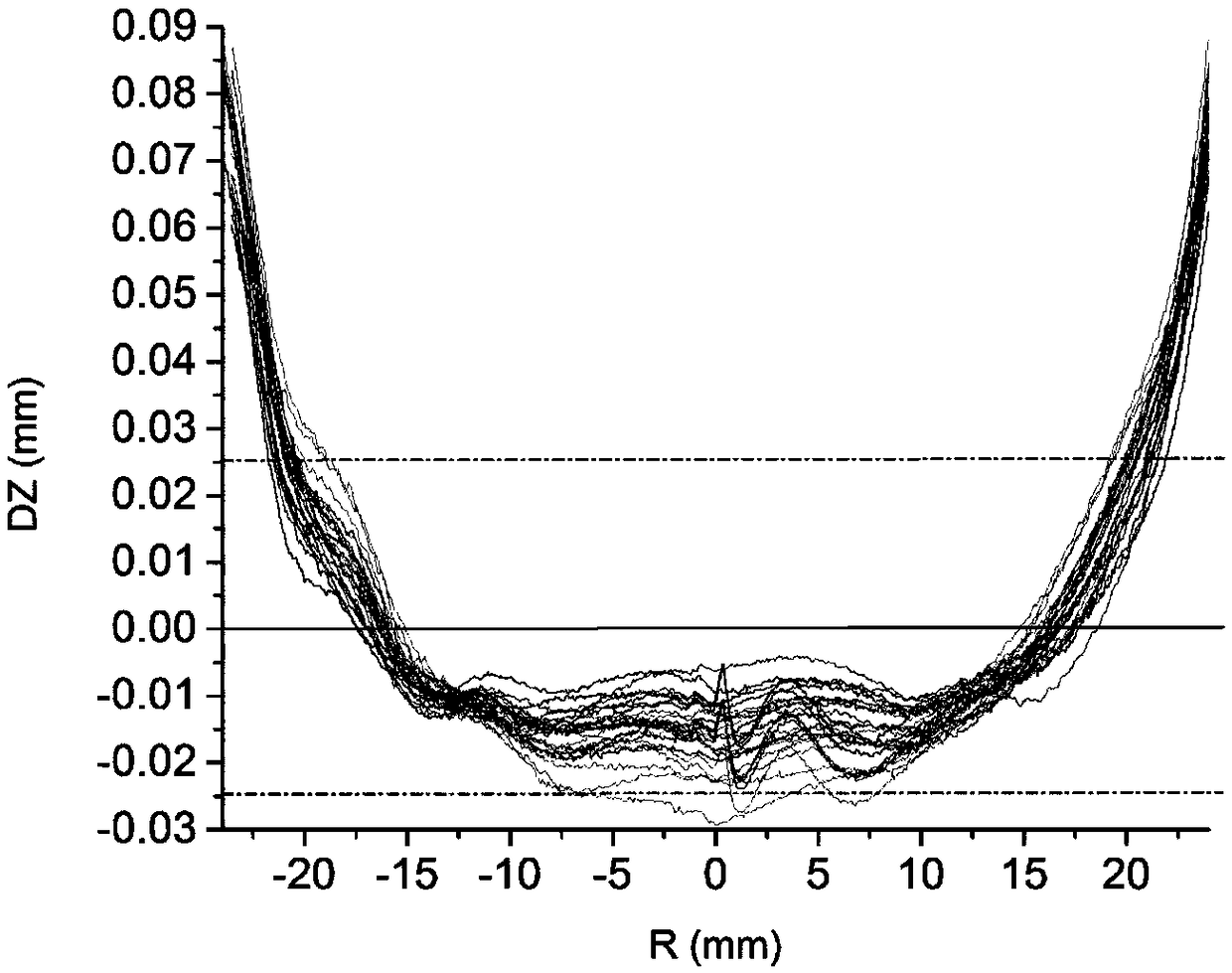

Method and system for morphology deviation correction of optical glass products

ActiveCN108088407AReduce instabilitySolve the problem of repeatedly correcting the shape deviationMeasurement devicesGlass pressing apparatusEngineeringOptical glass

The invention, which belongs to the technical field of calibration of compression type products, specifically discloses a method and system for morphology deviation correction of optical glass products so that problems of long morphology deviation correction period and large correction error of the existing compression type products in the prior art can be solved. The method comprises: making a compression type die and carrying out trial-manufacturing of an optical glass product; measuring morphology deviation data of a trial-manufacturing product; analyzing consistency of all groups of morphology deviation data; determining whether all groups of morphology deviation data meet a profile precision requirement; and correcting a compression die design parameter and the like. With the method disclosed by the invention, the influences on the morphology deviation correction process by an unstable factor of the compression type production process of the optical glass products, non-uniform expansion and contraction of the compression type product profile, and wearing of the compression type die cavity are reduced effectively.

Owner:CDGM OPTICAL GLASS

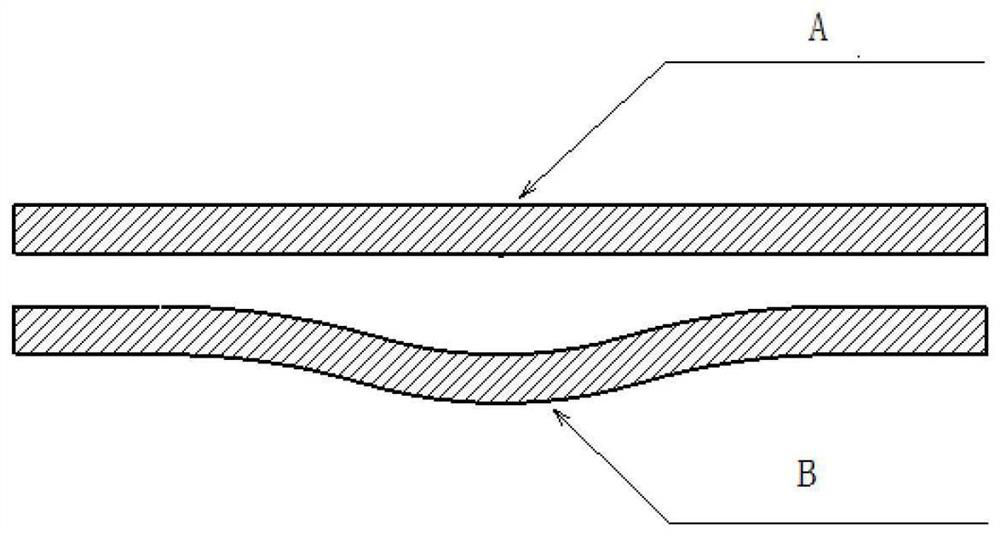

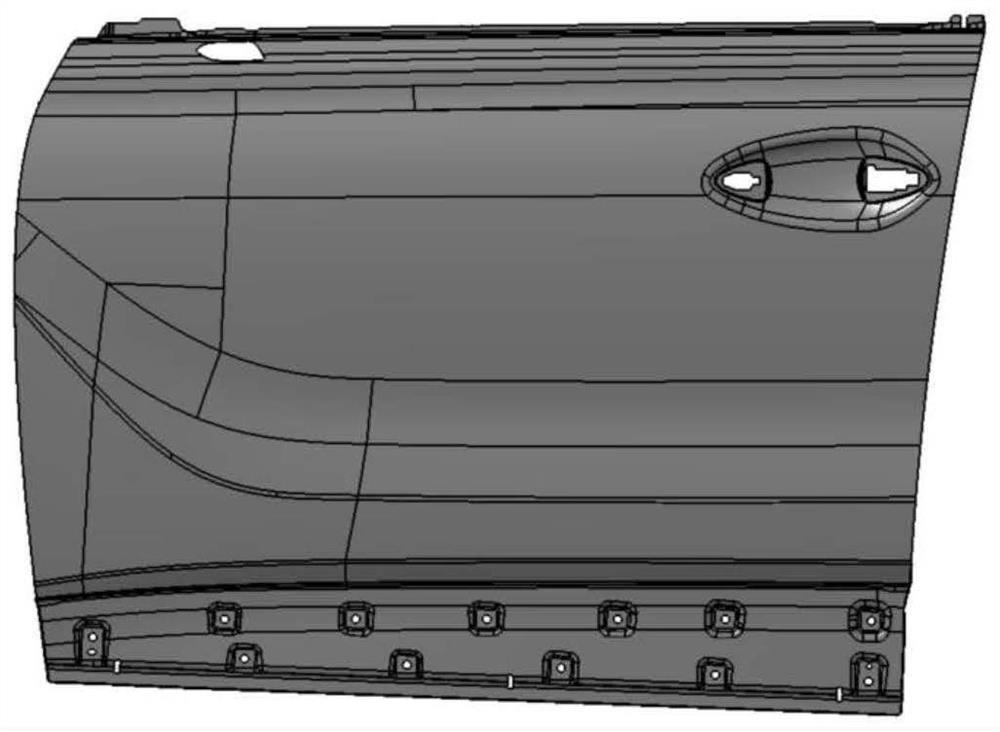

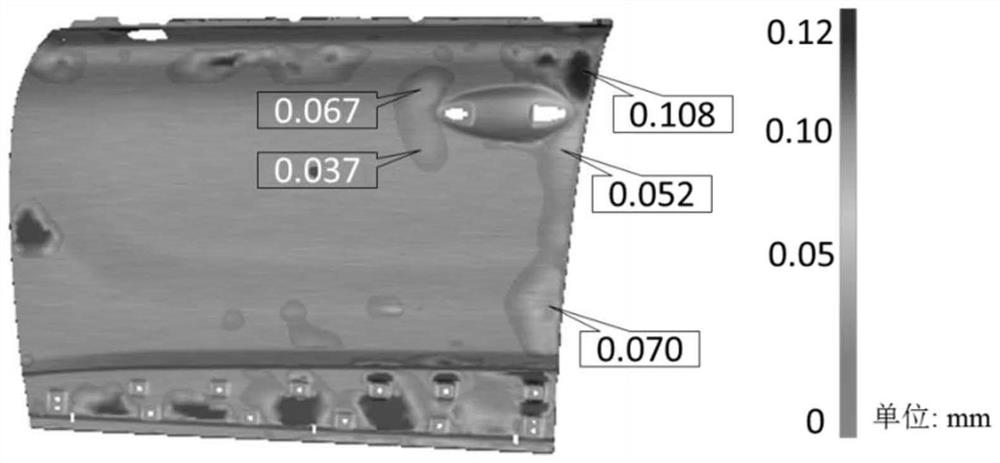

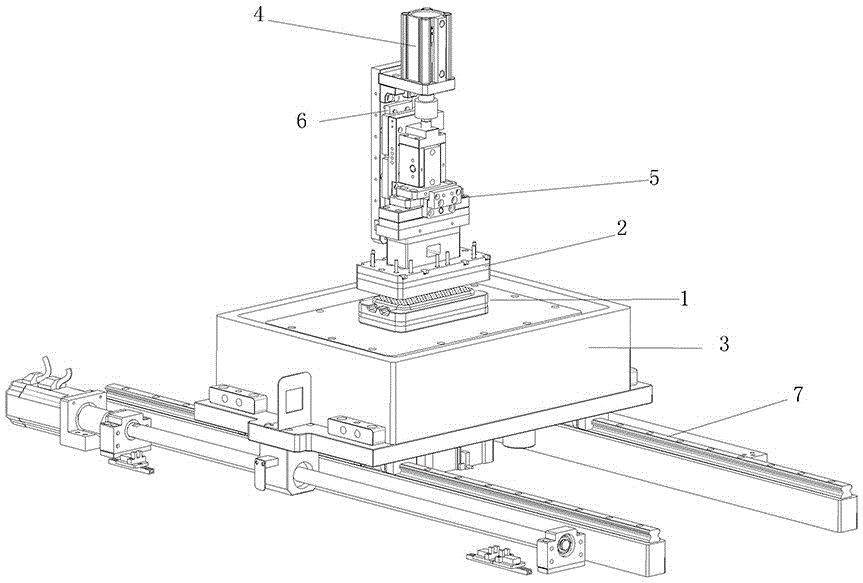

Method for compensating surface product defects of automobile outer covering part

InactiveCN111680439AShorten the debugging cycleReduce the workload of fitter manual trainingGeometric CADDesign optimisation/simulationFinite element analysis softwareMechanical engineering

The invention discloses a method for compensating stamping surface product defects of an automobile outer covering part. Firstly, obtaining a surface product defect analysis result before compensationby adopting plate forming finite element analysis software; compensating the molded surface of the product on the premise that the quality of the curved surface is not changed; outputting a compensated molded surface meeting the quality requirement of a surface product; importing the profile compensated by the plate forming finite element analysis software into Catia software; and comparing withthe product profile before compensation to form a surface product defect compensation amount reference cloud picture, and compensating the original product profile in a manner of manufacturing a driving curved surface according to the surface product defect position and the deviation value shown in the reference cloud picture, thereby realizing compensation of the surface product defect in the design stage. According to the invention, the workload of bench worker manual grinding and repairing caused by surface product defect rectification can be reduced, the surface product quality of the automobile outer covering part is rapidly improved, and the mold debugging period is shortened.

Owner:CHINA FIRST AUTOMOBILE +1

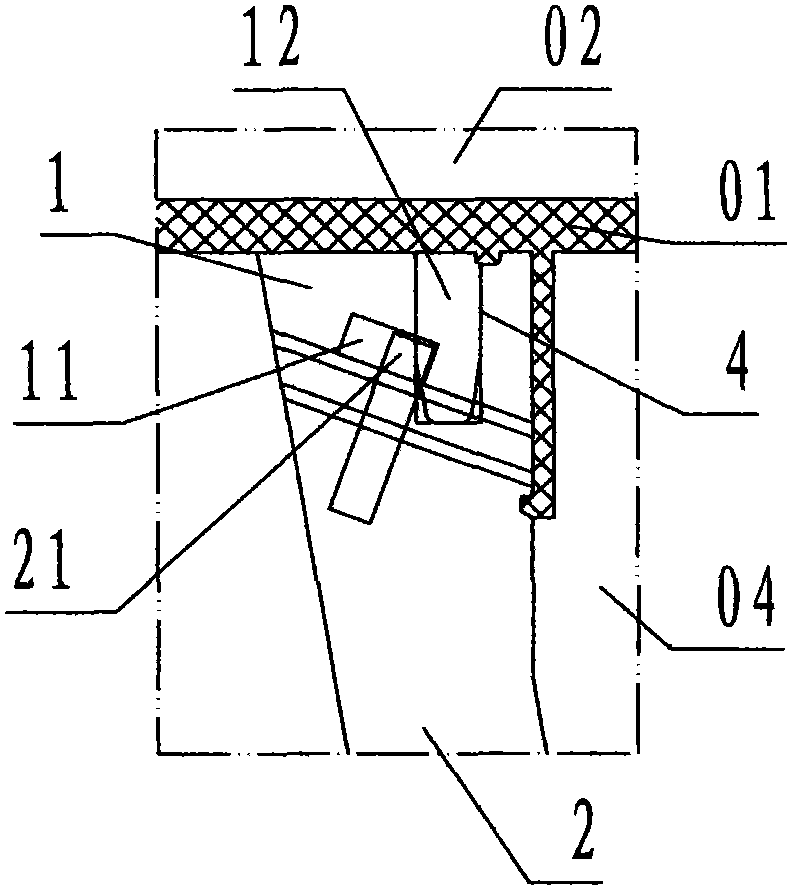

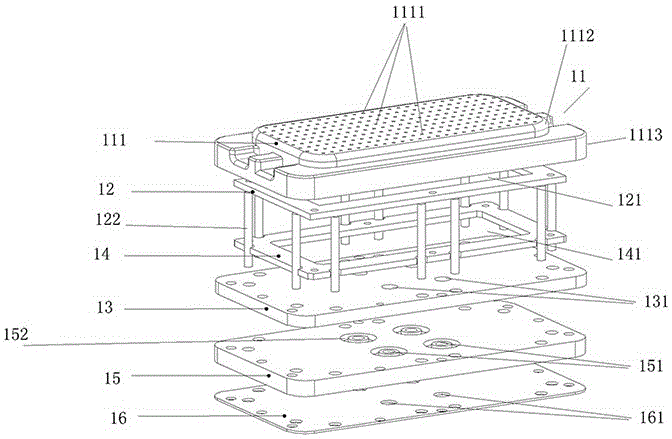

Hot press molding device for adhesive films

The invention discloses a hot press molding device for adhesive films, comprising an adhesive film carrier (1) and a hot press mold group (2), wherein the adhesive film carrier (1) comprises a carrier plate (11) and a lower heating plate (12), the carrier plate (11) is provided with a product profiling part (111), and a plurality of vacuum adsorbing through holes (1111) are formed in the surface of the product profiling part (111); the hot press mold group (2) comprises an upper press plate (21) and an upper heating plate (21), and the upper press plate (21) is provided with a concave part correspondingly matched with the product profiling part (111); and an adhesive film to be molded is vacuum adsorbed to the surface of the product profiling part (111) on the carrier plate (11), the upper heating plate (21) and lower heating plate (12) heat the adhesive film, and the hot press mold group (2) presses towards the adhesive film carrier (1) to mold the adhesive film. The hot press molding device for adhesive films can be applied to molding of OCA (Optical Clear Adhesive) optical adhesive films required by 3D curved glass or 3D curved screens.

Owner:SHENZHEN CEWAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com