Automatic product profile extraction method in visual detection

A visual detection and automatic extraction technology, applied in the field of image processing, can solve problems such as inability to interfere with other areas, inability to automatically adapt to automatic extraction of product areas, poor classification of product areas and non-product areas, etc., to achieve a wide range of adaptation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

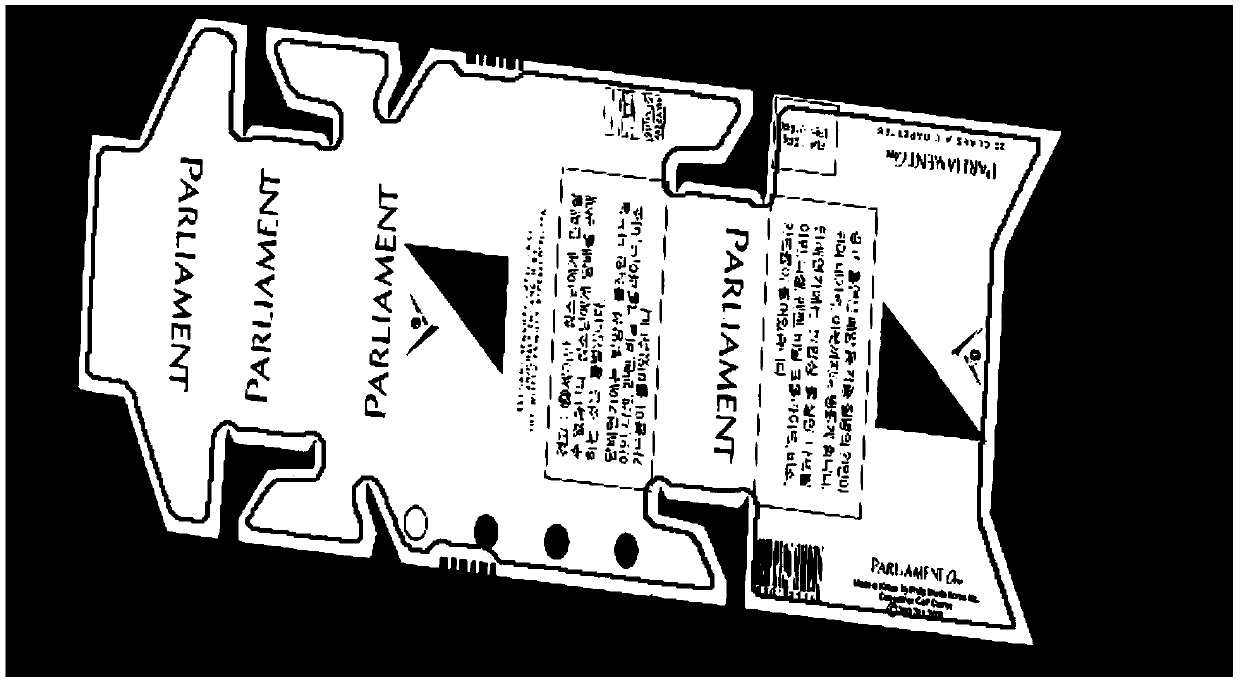

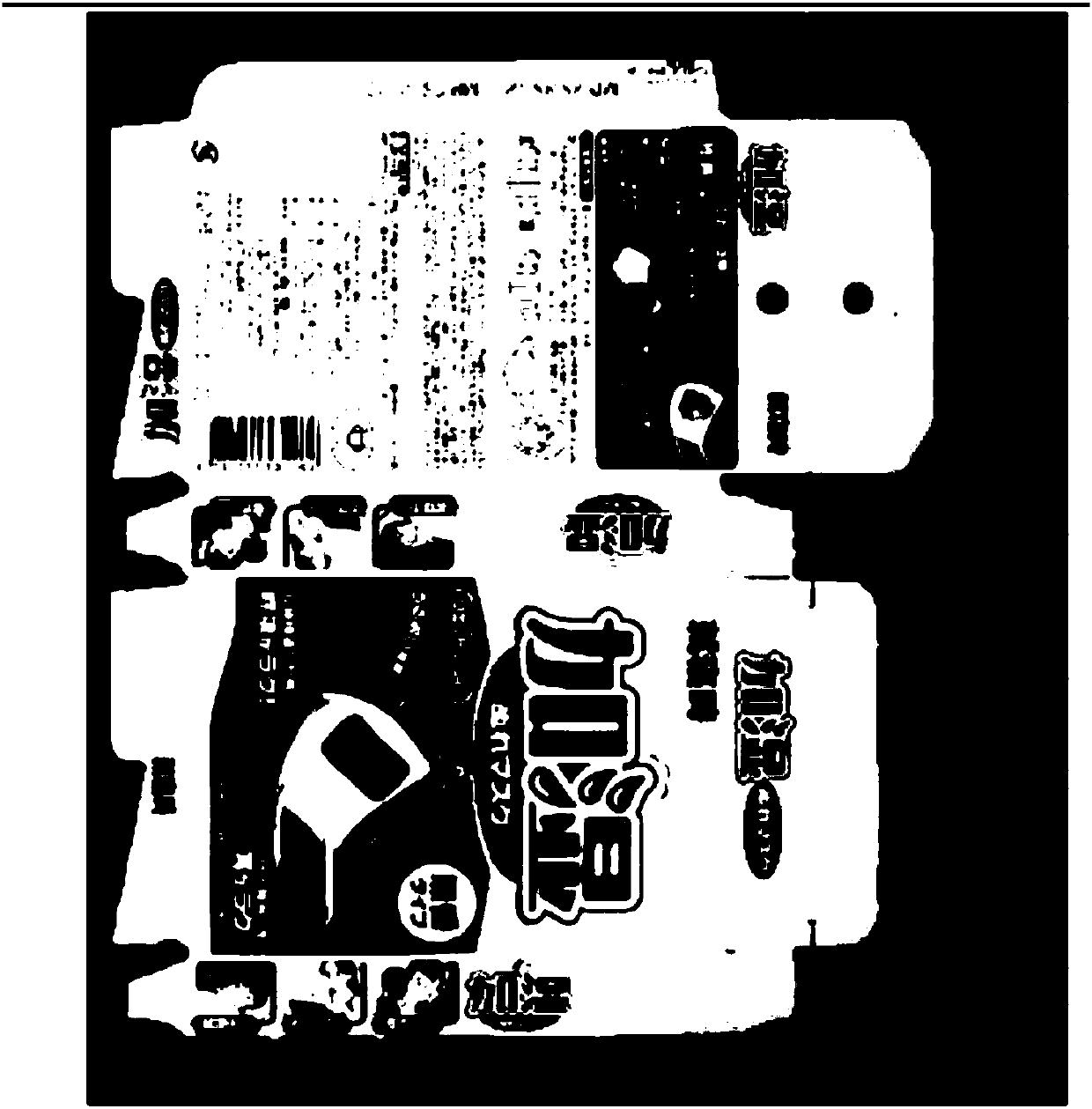

Image

Examples

Embodiment Construction

[0030] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0031] An automatic product contour extraction method in visual inspection, by automatically searching for a suitable threshold for contour edge detection, to solve the problem that the gray scale of the image is different under different imaging environments, and the fixed threshold for edge detection cannot meet the product area of different images The problem of edge detection; due to the different sizes of images, whether it is canny, sobel or other similar edge operators, the size of the edge operator does not exceed 3×3, and the edge of a large-sized image is a slow transition zone, so use The edge operator is diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com