Composite sanitary product profile without containing wood pulp fibers and preparation method thereof

A technology for sanitary products and composite profiles, applied in the fields of application, medical science, clothing, etc., can solve the problems of unenvironmental protection, high production cost, easy lumps, etc., and achieve the effect of saving energy consumption, good environmental protection, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

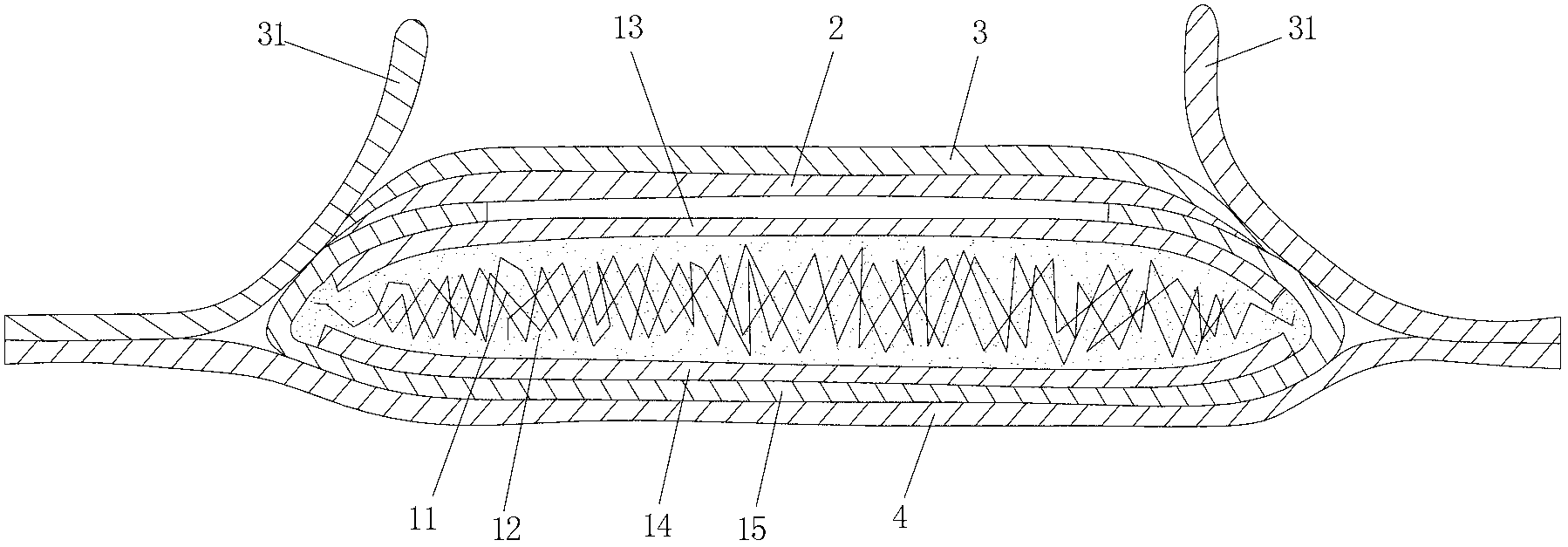

[0016] see figure 1 , the hygienic product composite profile without wood pulp fiber in the present invention is provided with an absorbent core, a non-woven fabric diversion layer 2, a non-woven fabric surface layer 3 (with three-dimensional guards 31 on both sides) and an anti-penetration bottom layer (PE Membrane impermeable bottom layer) 4.

[0017] The absorbent core is composed of a core material and a wrapping layer of a non-woven fabric core material; the core material is composed of a bulky non-woven fabric fiber 11 (indicated by a curved line) and a polymer water-absorbent resin 12 (dumping point) infiltrated into the bulky non-woven fabric fiber 11 Indicates) composition. The non-woven fabric core material wrapping layer is wrapped around the core material, and the non-woven fabric core material wrapping layer is composed of a non-woven fabric surface layer 13, a non-woven fabric bottom layer 14, and a non-woven fabric cladding layer 15. The non-woven fabric surfac...

Embodiment 2

[0024] Similar to Example 1, the only difference is that the anti-permeation bottom layer is a layered anti-penetration bottom layer of PE film and non-woven fabric. The lamination of PE film and non-woven fabric is glued together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com