Patents

Literature

279 results about "Headframe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A headframe (also known as a gallows frame, winding tower, hoist frame, pit frame, shafthead frame, headgear, headstock or poppethead) is the structural frame above an underground mine shaft.

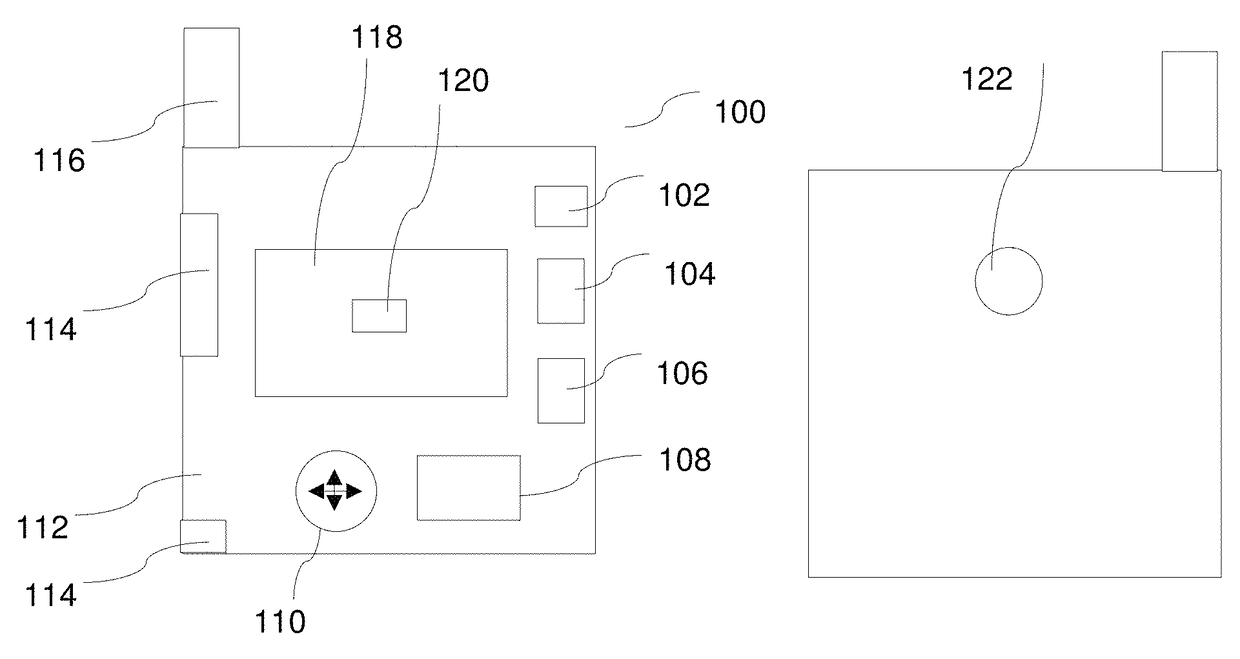

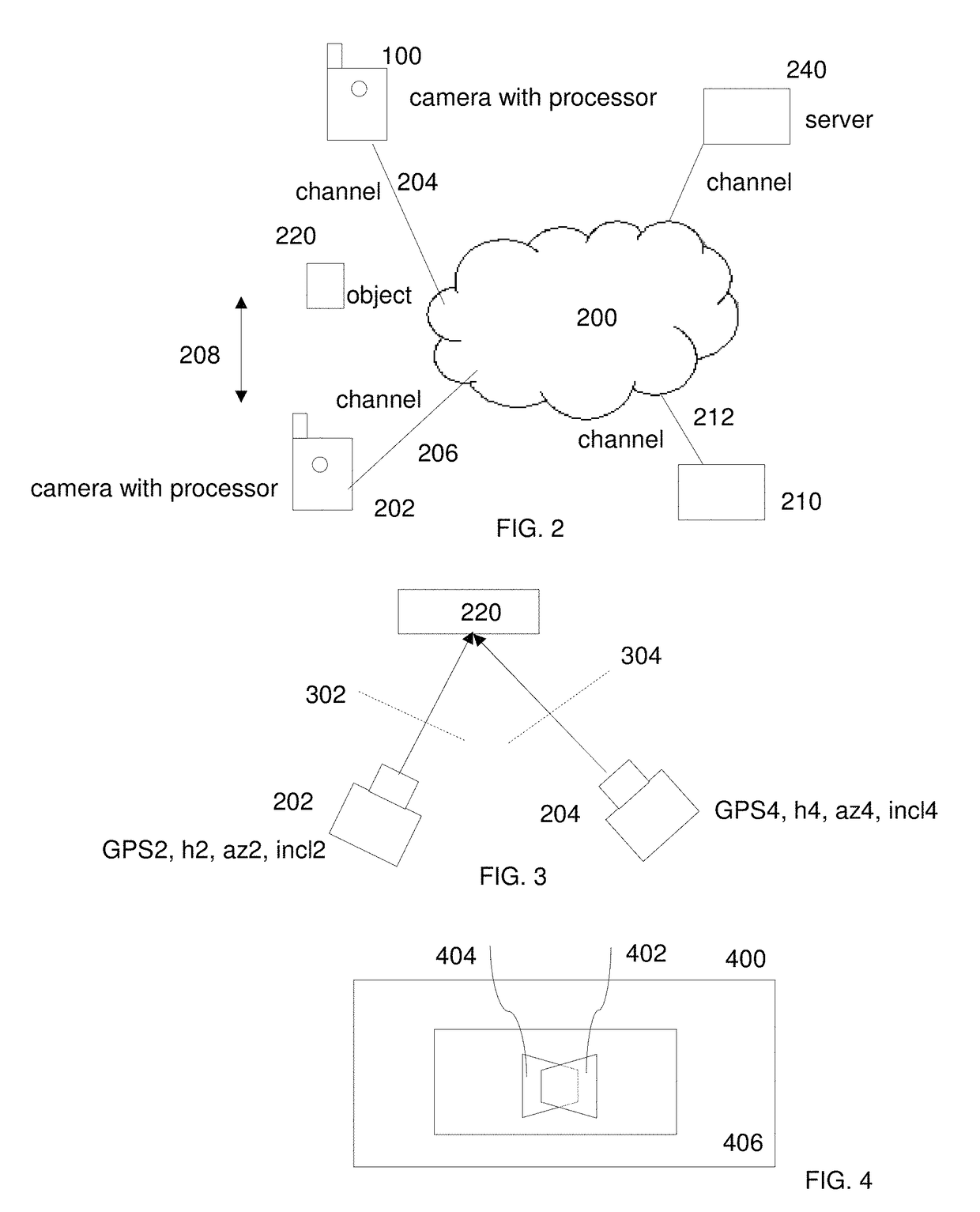

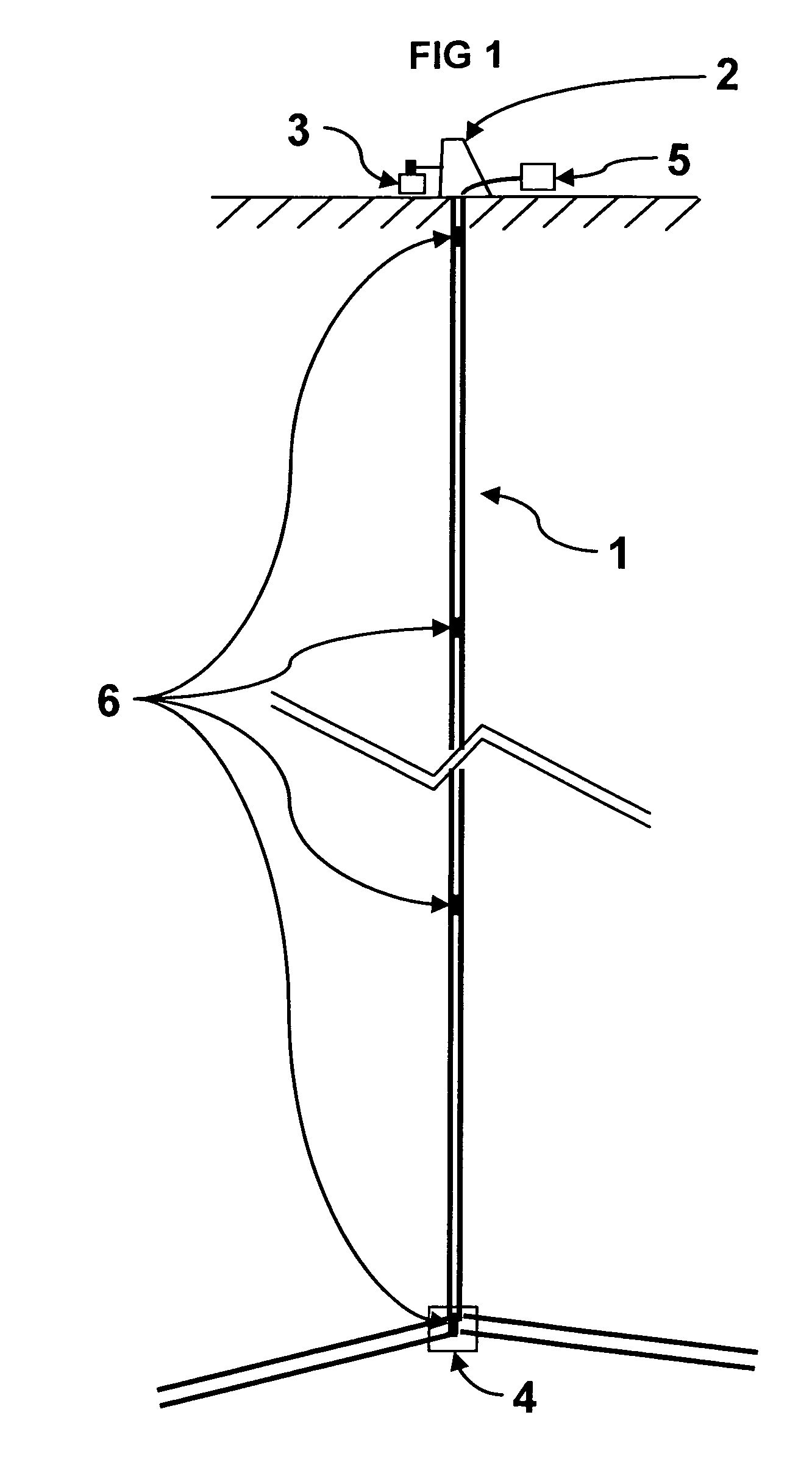

Camera in a Headframe for Object Tracking

ActiveUS20140267775A1Minimize the differenceTelevision system detailsImage enhancementAccelerometerHeadframe

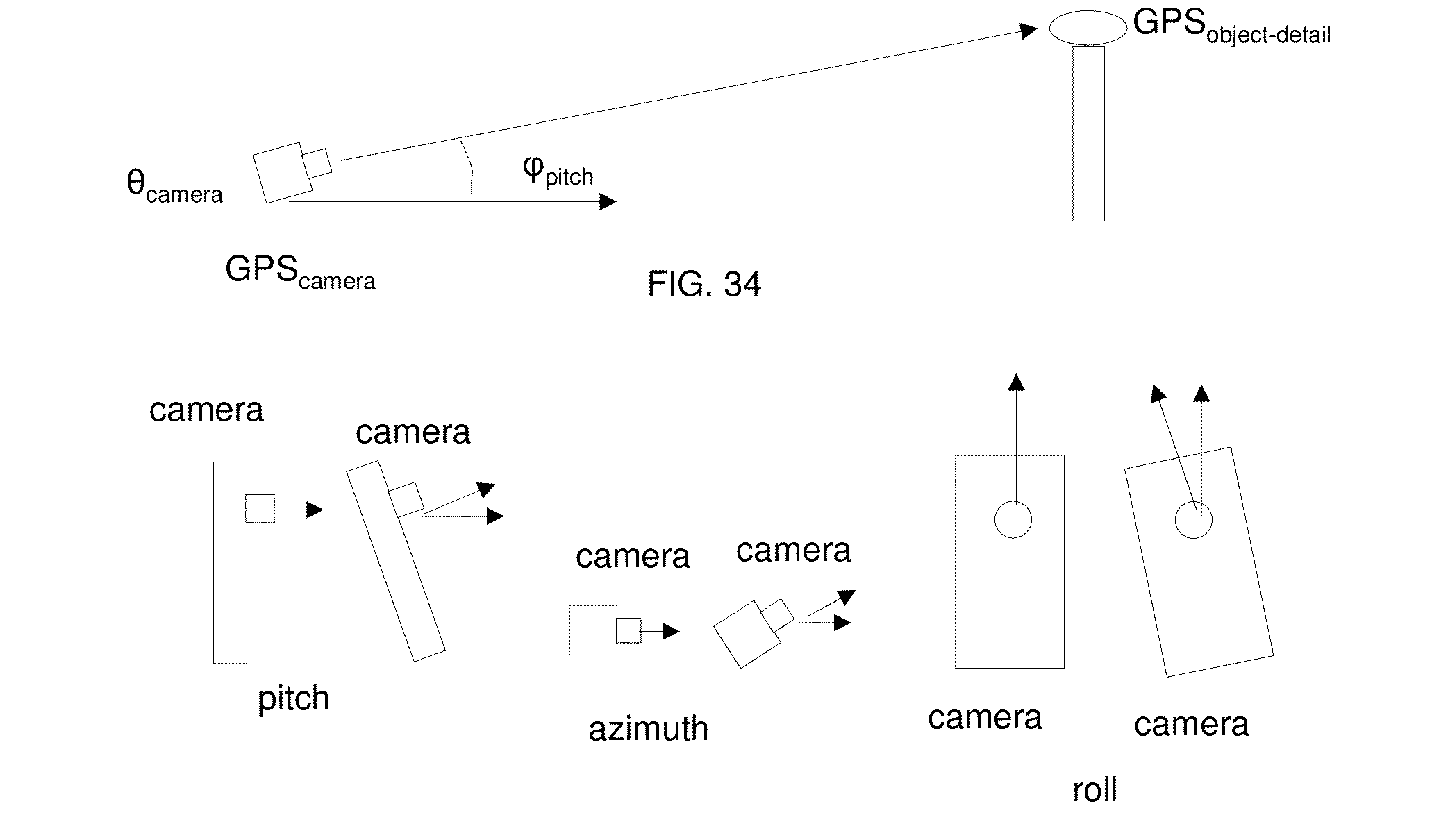

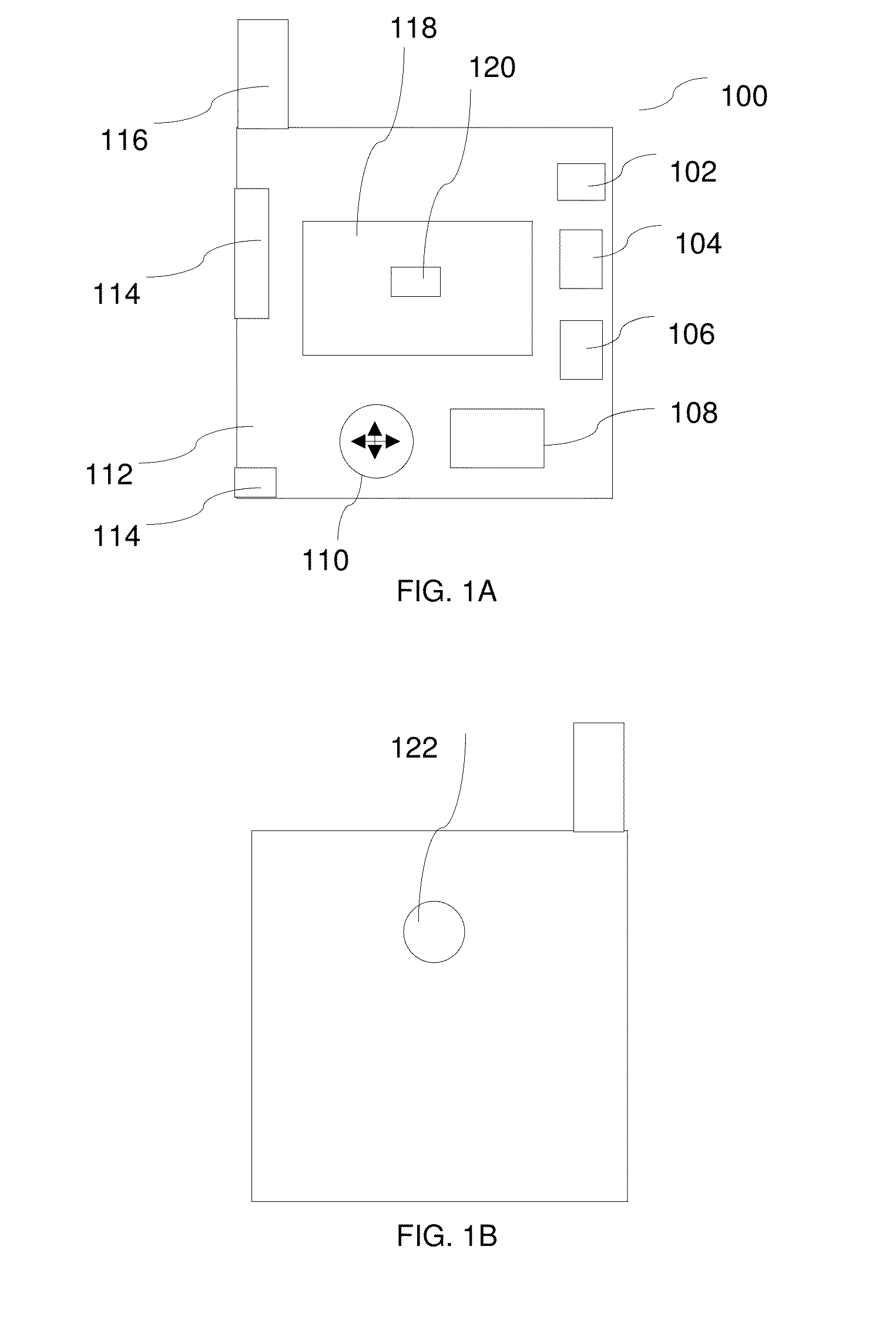

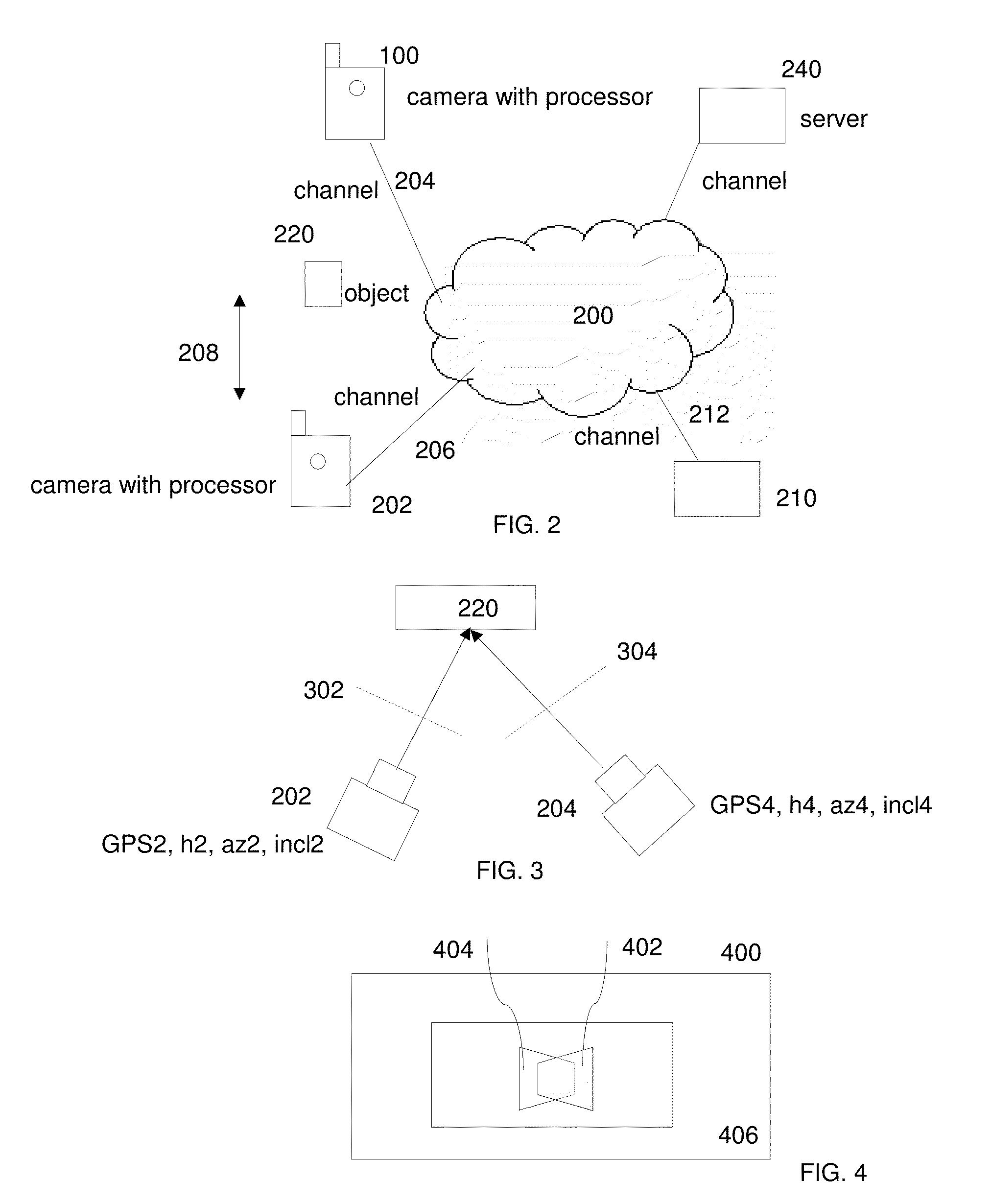

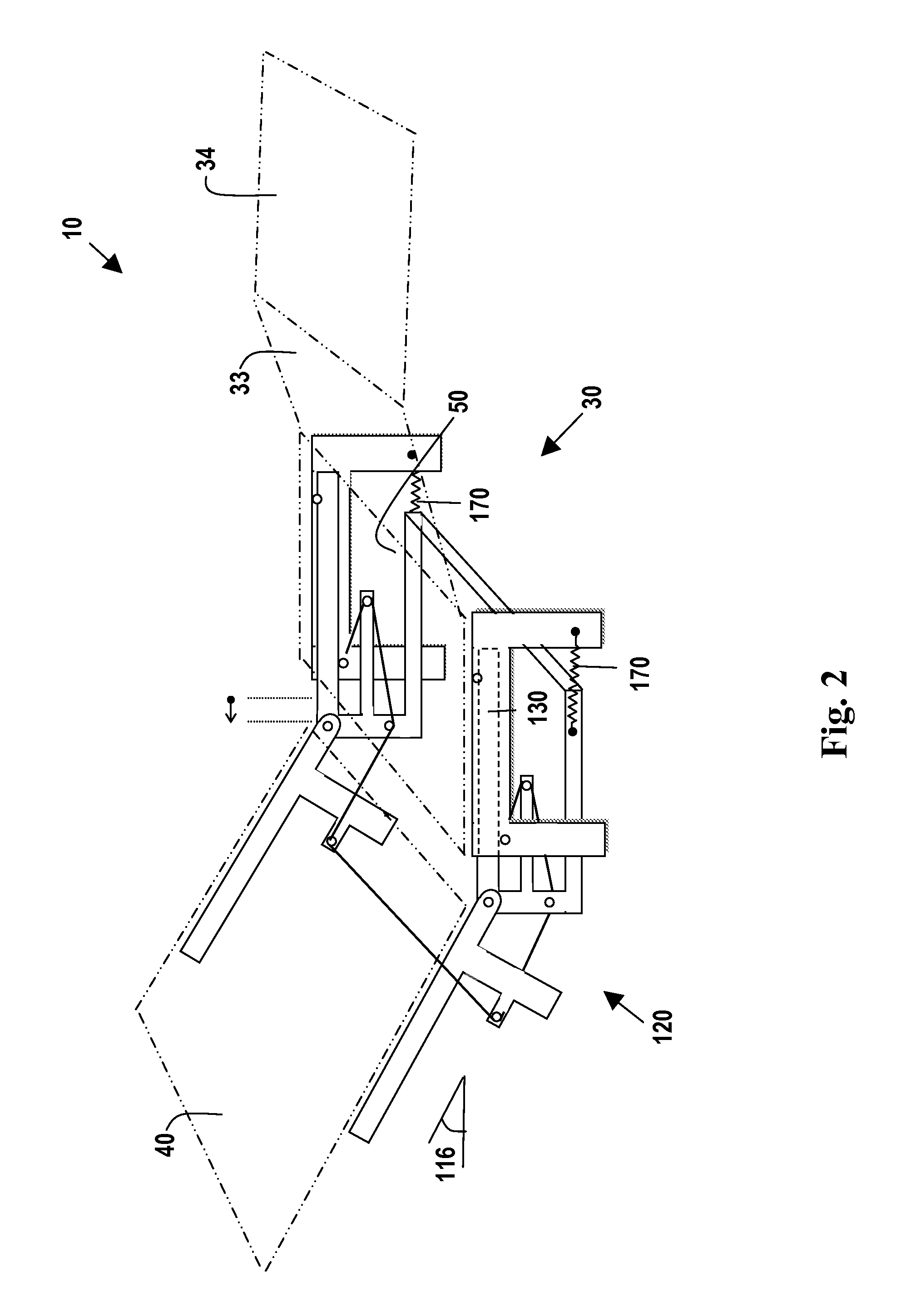

Methods and apparatus track an object with a first camera causing a second camera to also track the object. The object is a moving object. Geospatial coordinates, including an elevation or altitude of a camera are determined on the camera. A pose of the camera, including a pitch angle and an azimuth angle are also determined. Azimuth is determined by a digital compass. A camera pose including pitch is determined by accelerometers and / or gyroscopes. Cameras are communicatively connected allowing to display an image recorded by one camera being displayed on a second camera. At least one camera is on a movable platform with actuators. Actuators are controlled to minimize a difference between a first image of the object and a second image of the object. Cameras are part of a wearable headframe.

Owner:SPATIAL CAM

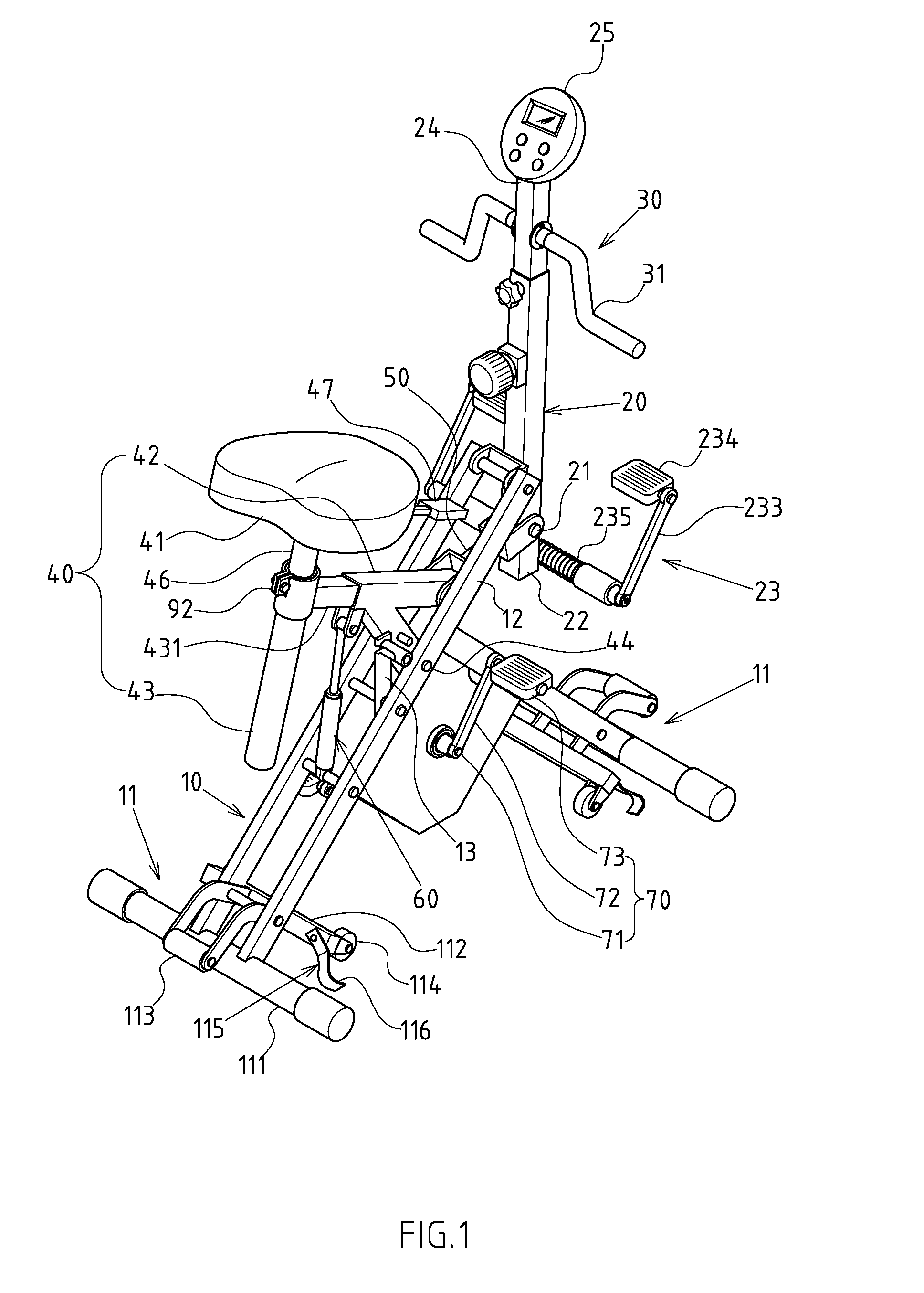

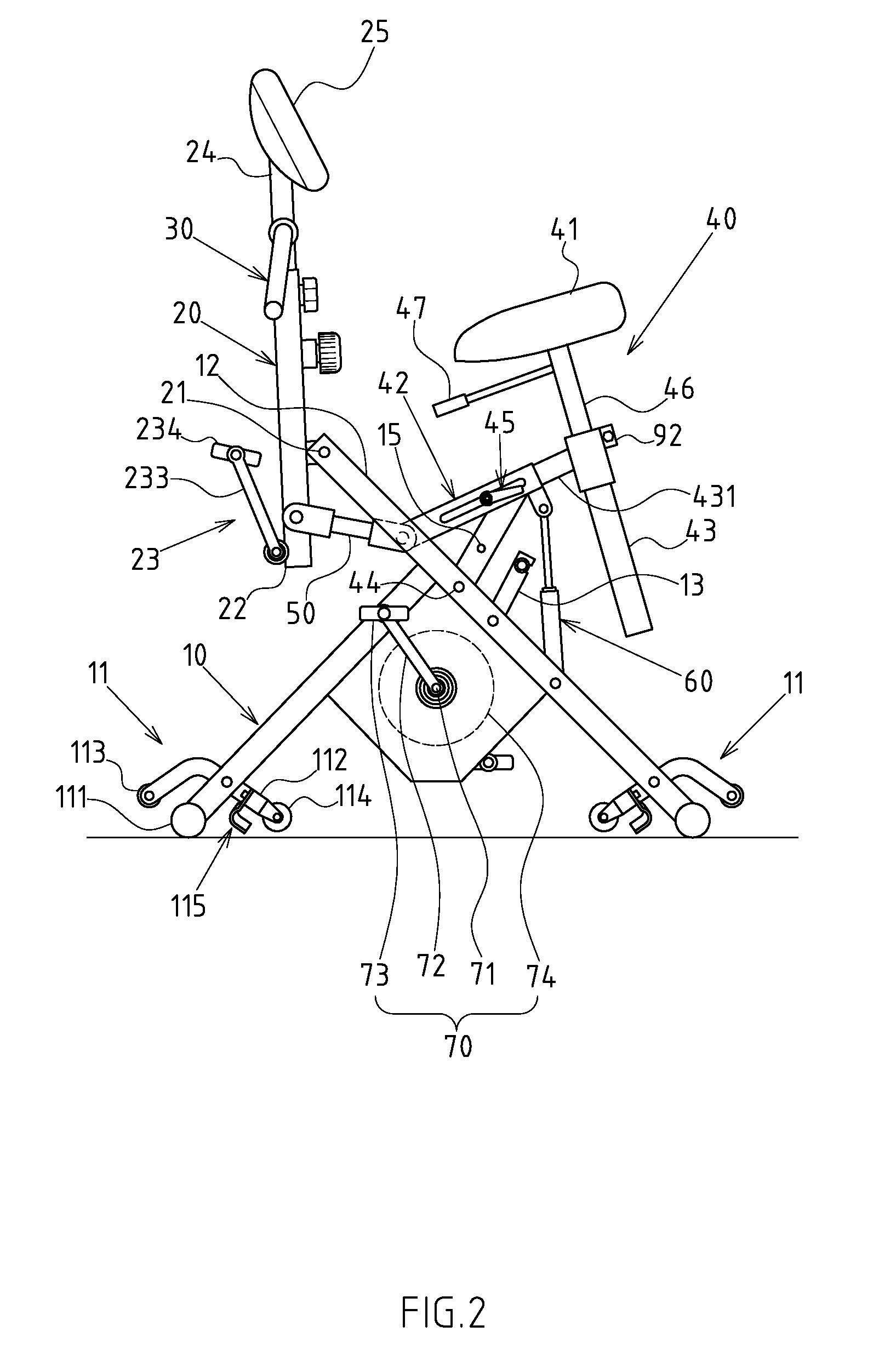

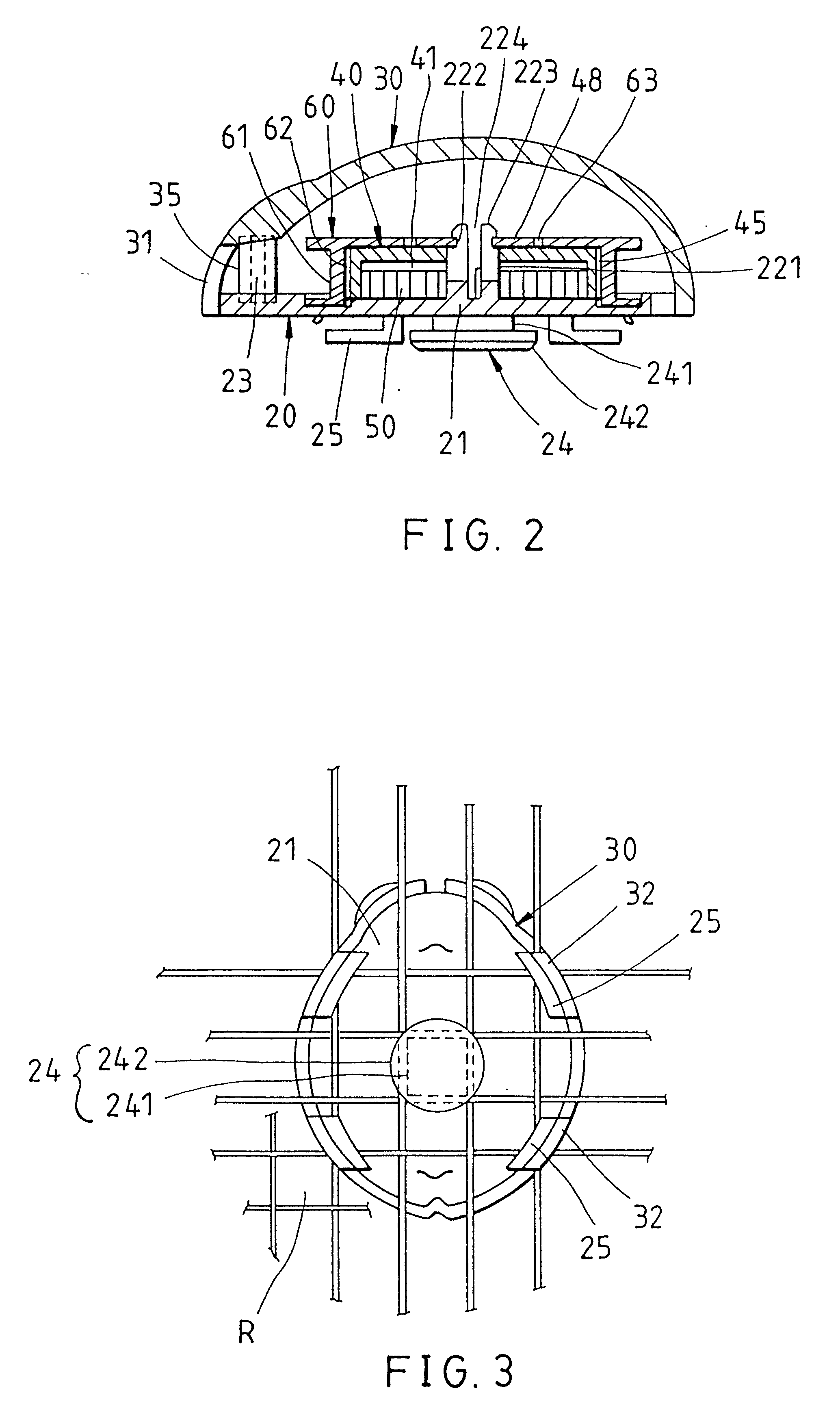

Fitness equipment with multiple functions

InactiveUS7393308B1Save spaceLow costMovement coordination devicesMuscle exercising devicesHeadframeExercise equipment

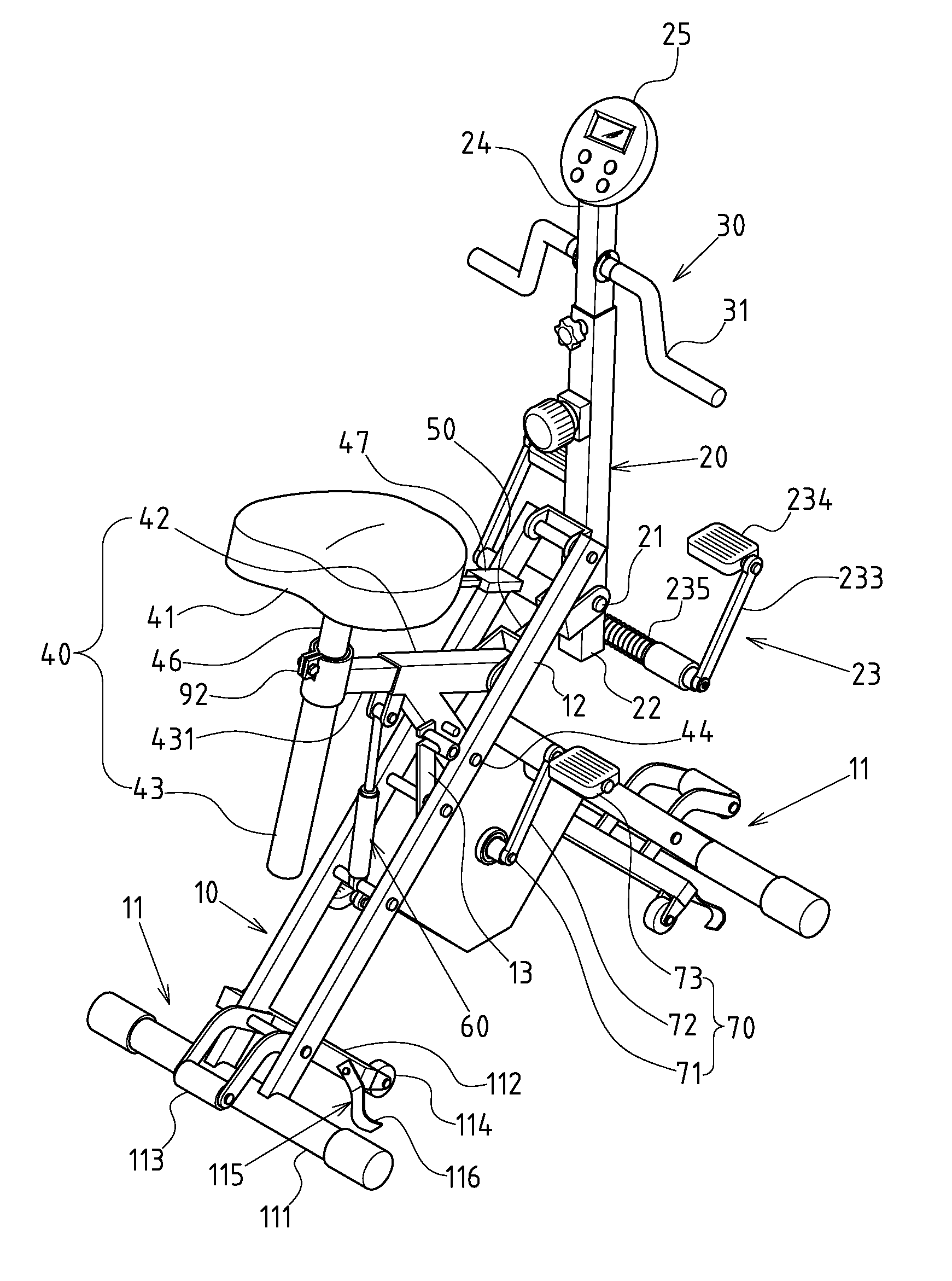

The present invention is fitness equipment with multiple functions. The fitness equipment includes a main frame, rotatable head rack, handrail rack, seat set, linkage bar, damping device and a rotatable treadle device. With the coupled configuration of rotatable head rack, seat set, linkage bar and damping device, trampling, hand-pulling and buttock lifting exercises can be achieved. The fitness equipment meets diversified requirements for both horse-riding and trampling, and also saves the space and cost.

Owner:HUANG LING YUN

Adjustable bed with sliding subframe for torso section

A sliding subframe mounted to the derriere-supporting section of an articulating bed is adapted to translate the rotational axis of the torso-supporting section of the bed toward the headframe as the torso-supporting section is raised to an inclined position, and back toward the footboard as the torso-supporting section is lowered to a level position. This mechanism reduces compression of the lumbo-sacral area of the patient during bed articulation.

Owner:BEDLAB

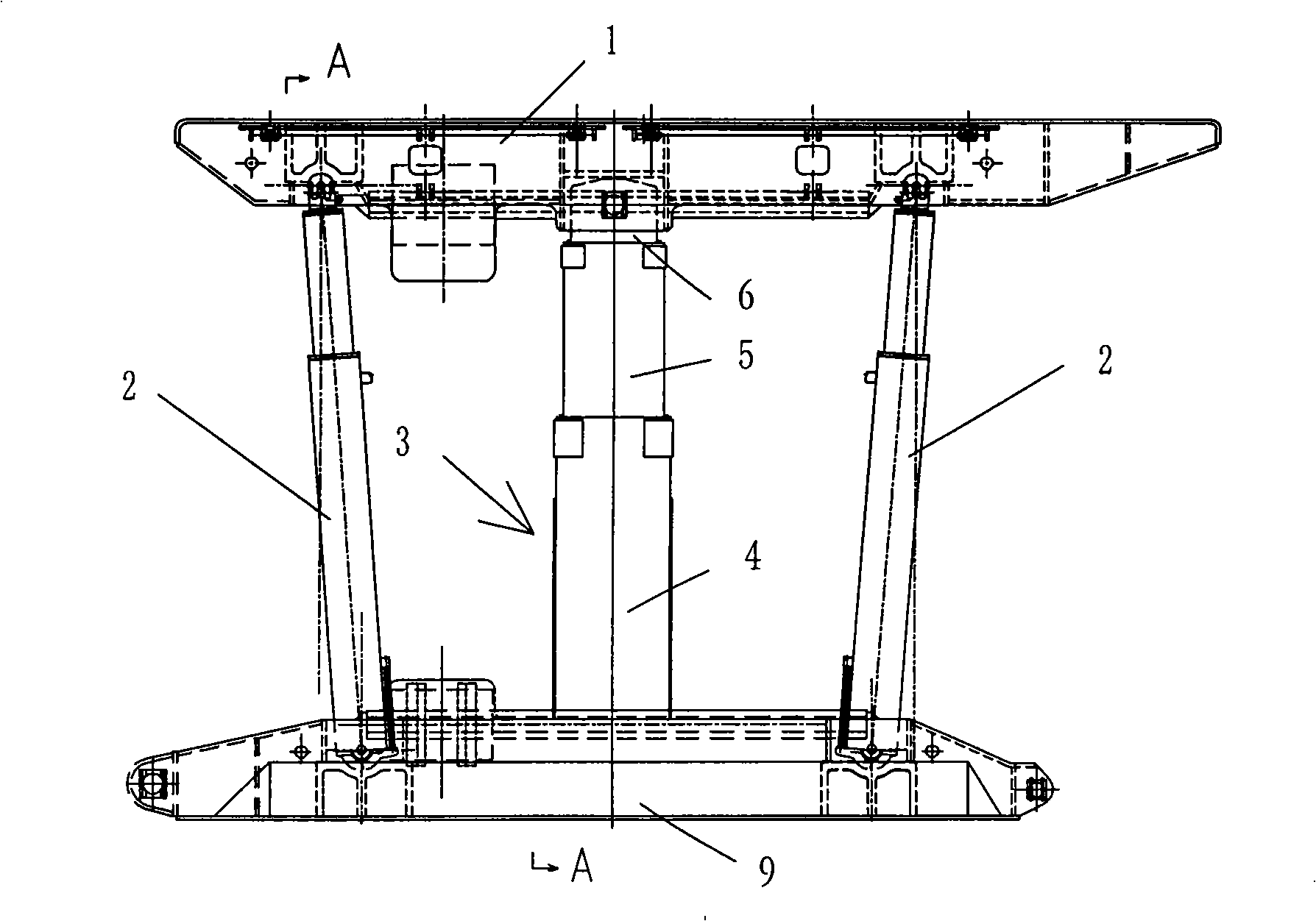

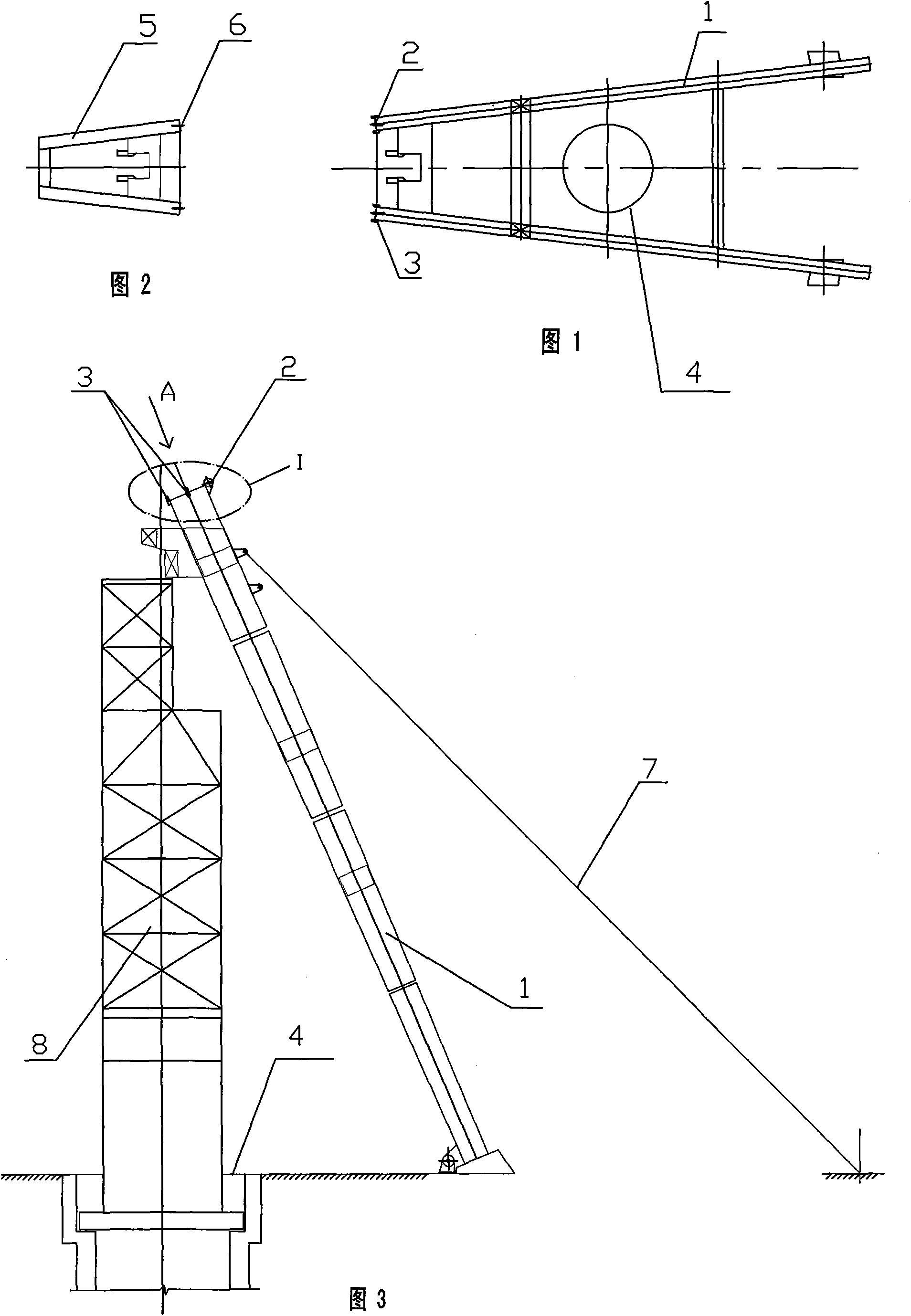

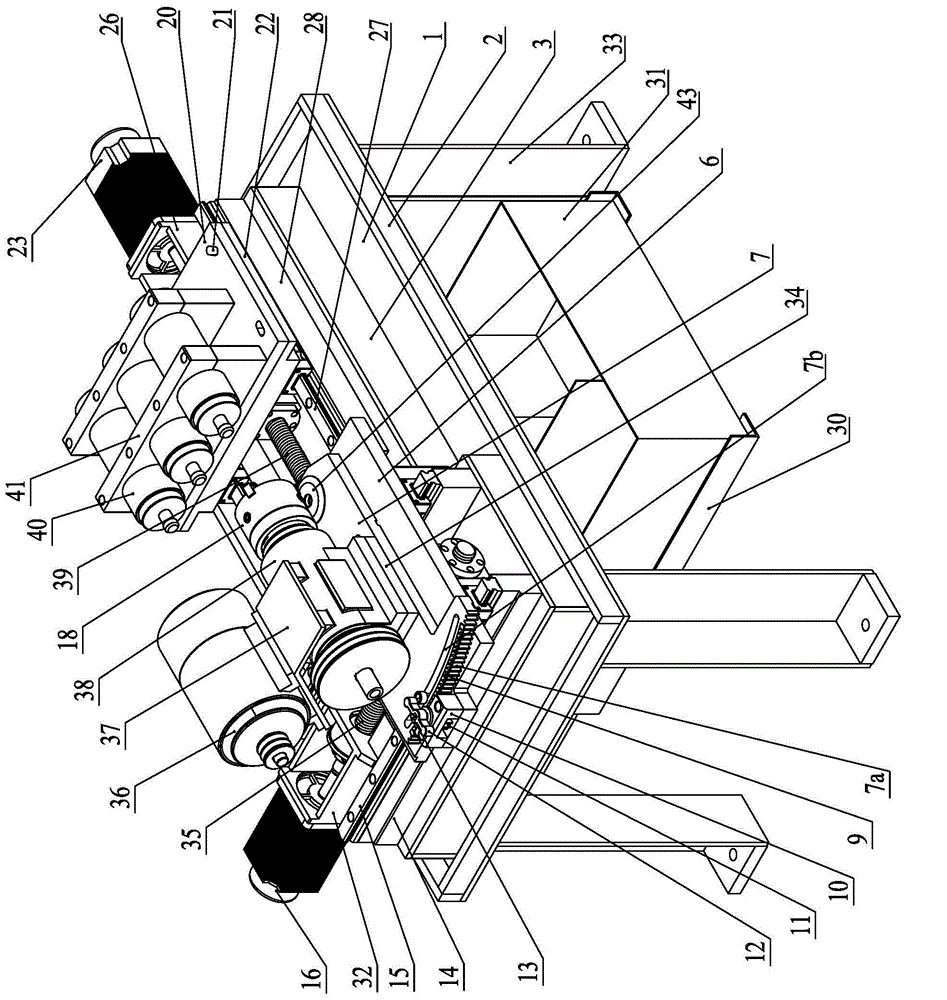

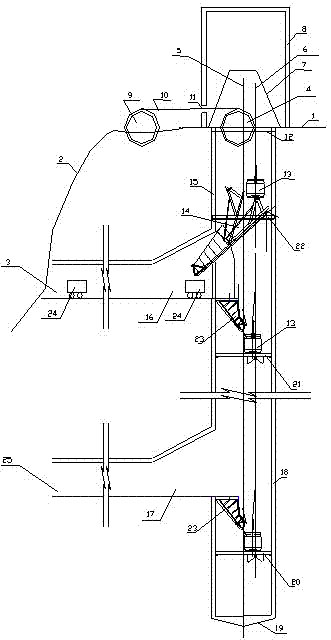

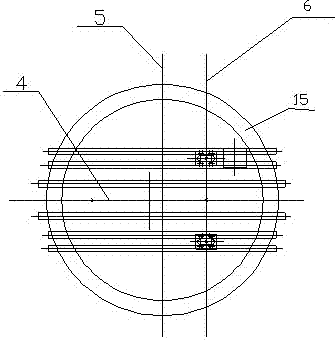

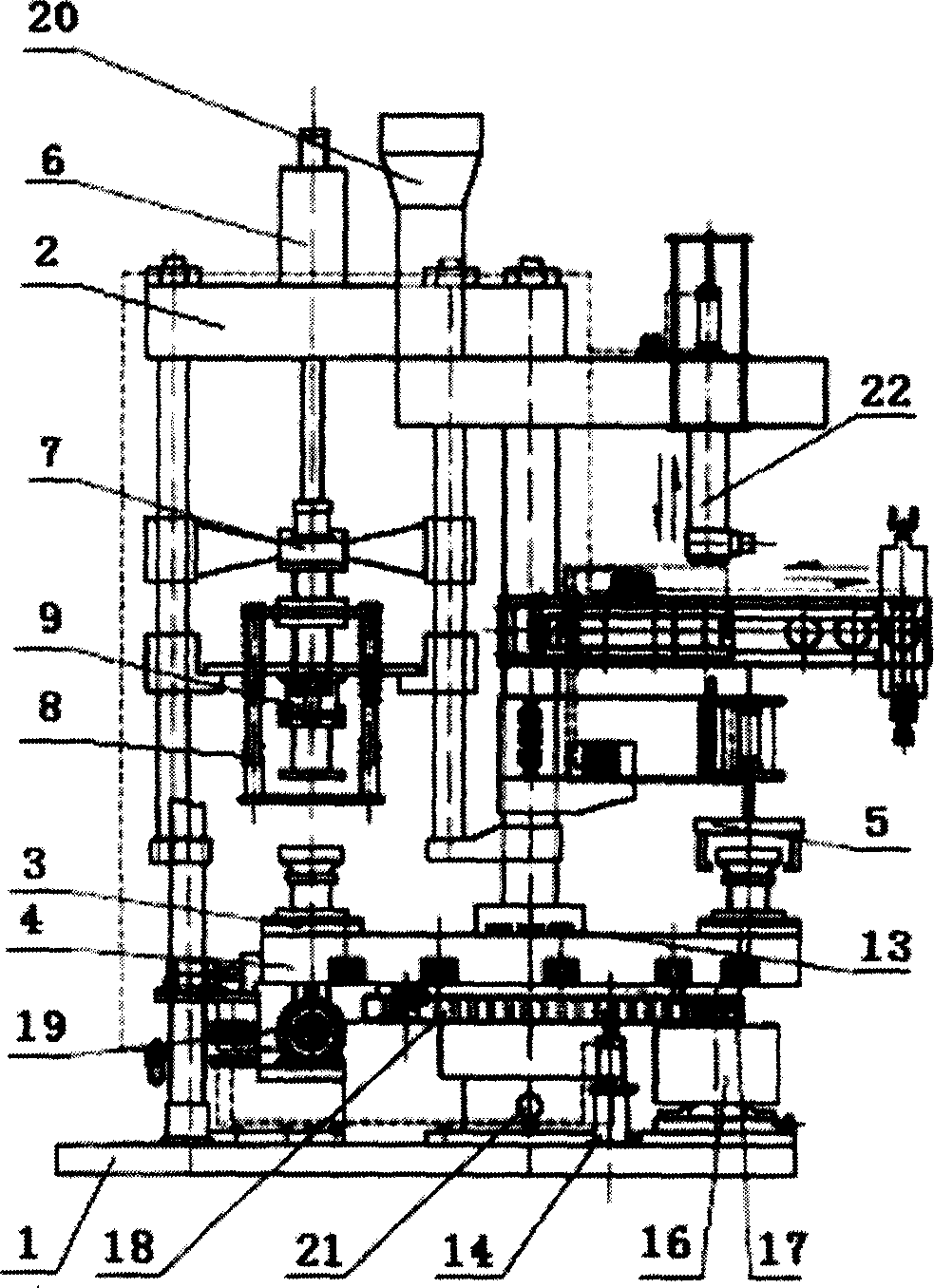

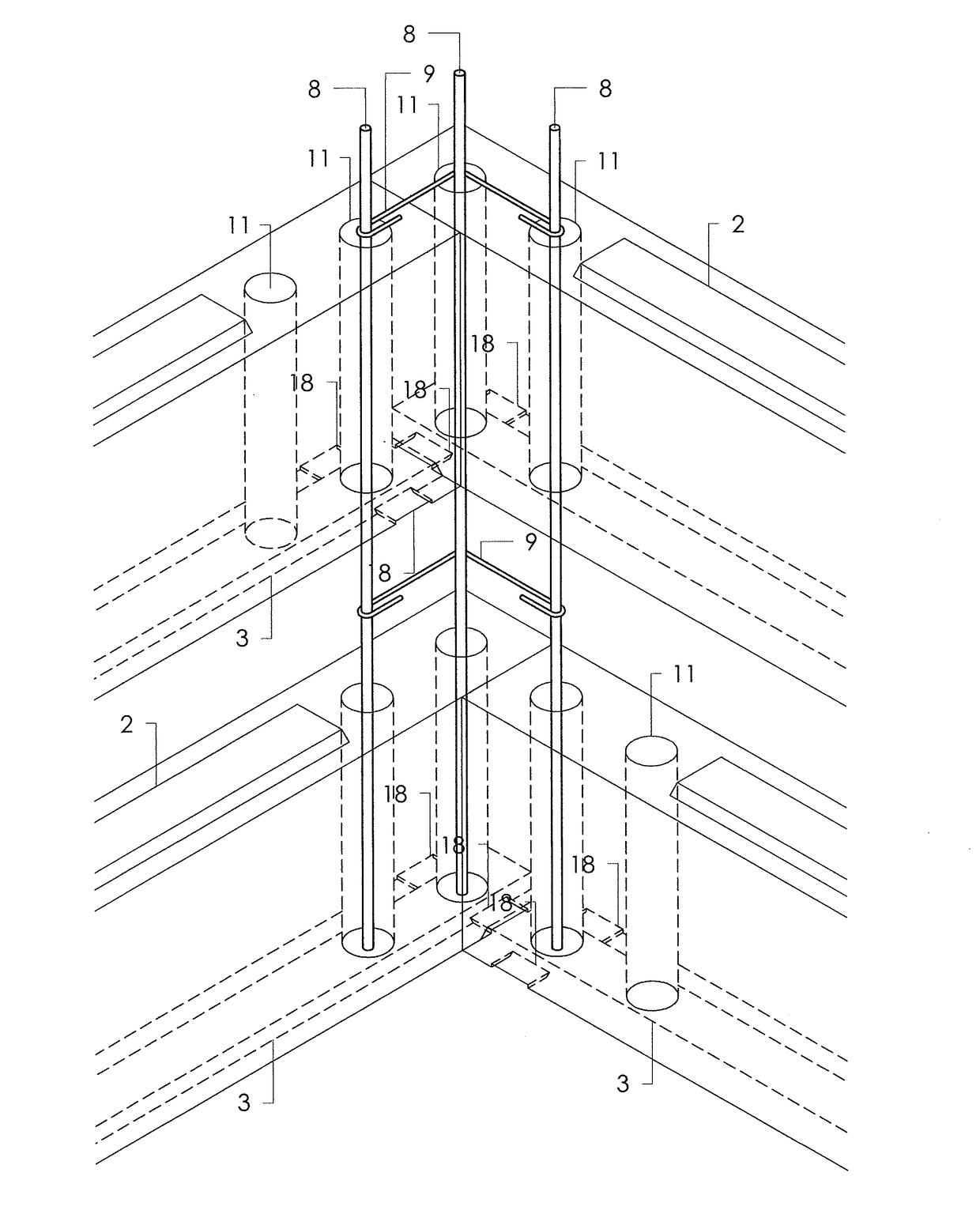

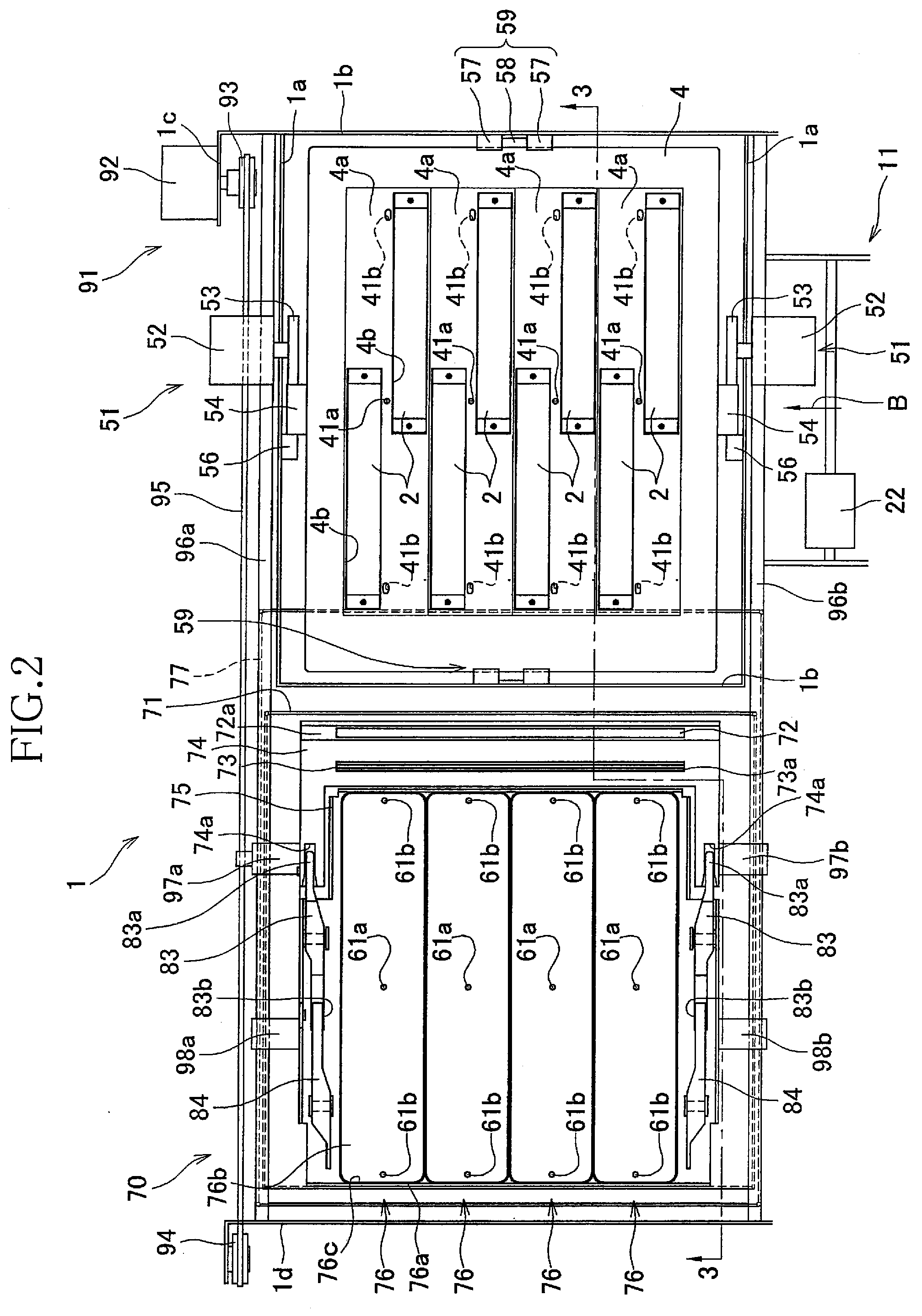

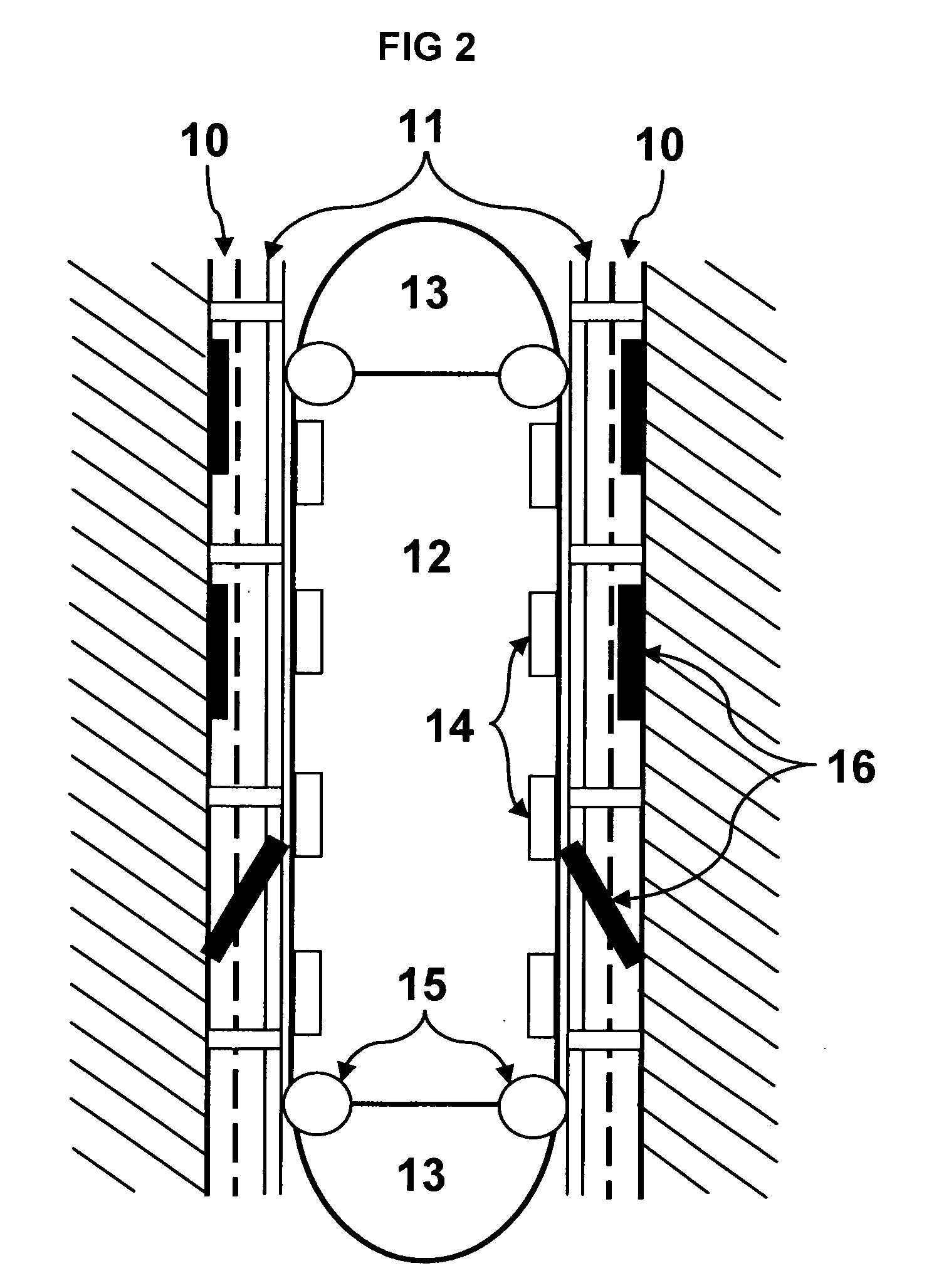

Combined guided slipping type forepoling hydraulic support

ActiveCN101338684AReduce the number of supportsNot easy to fallMine roof supportsHeadframeEngineering

The present invention provides a combined guide slippage type forepoling hydraulic bracket which comprises an internal support unit and an external support unit (12 and 11) which are symmetrical to each other at left and right. Each support unit comprises a top beam (1), a pedestal, a guide stabilizing mechanism and a hydraulic support component upright post. An upright post is articulated between the top beam and the pedestal. A telescopic link type guide stabilizing mechanism is arranged at the middle parts of the top beam and the pedestal. The outer side of the internal support unit is provided with the external support unit. Connecting slide rods (7) are respectively connected between the top beams and the pedestal beams at the same side of the adjacent internal and external support units. An inter-frame jack (8) is articulated between the top beam and the pedestal of the symmetrical internal support unit to form a section of bracket. The bracket forms an independent motor unit. The hydraulic bracket consists of a plurality of independent motor units. An advancing jack (17) is connected between the pedestals (9) of the independent motor units. The front end of the pedestal (9) of a section of bracket at the front end of the hydraulic bracket is connected with a head frame pulling and moving mechanism. The hydraulic bracket can effectively support a big section laneway and realizes the forepoling and the forepoling automatization of the big section laneway.

Owner:TIANDI SCI & TECH CO LTD

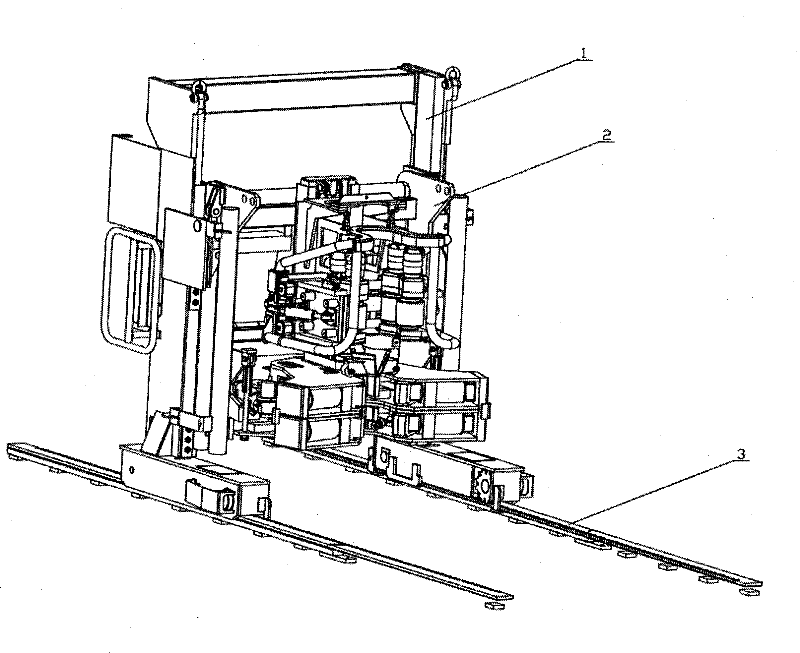

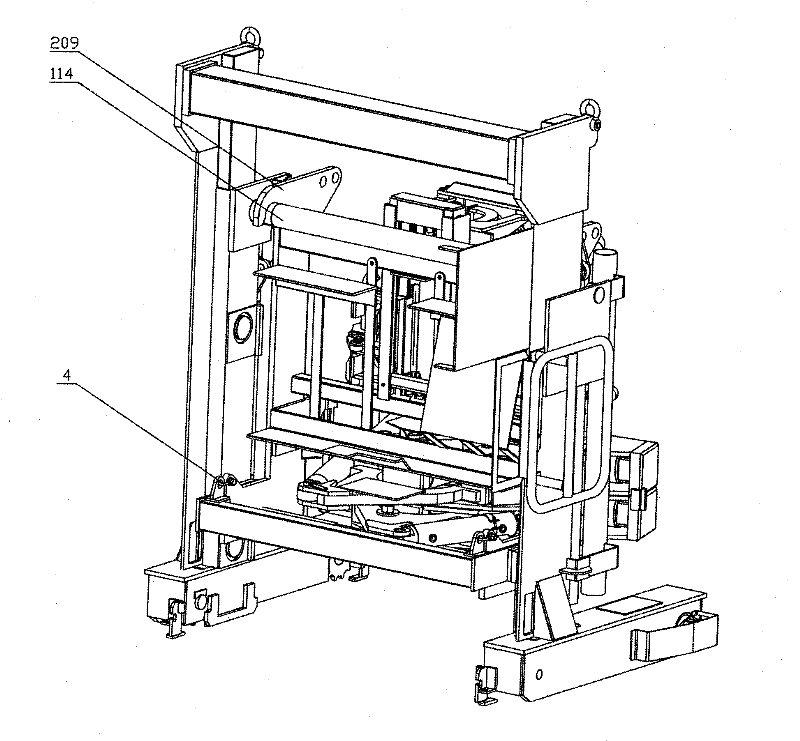

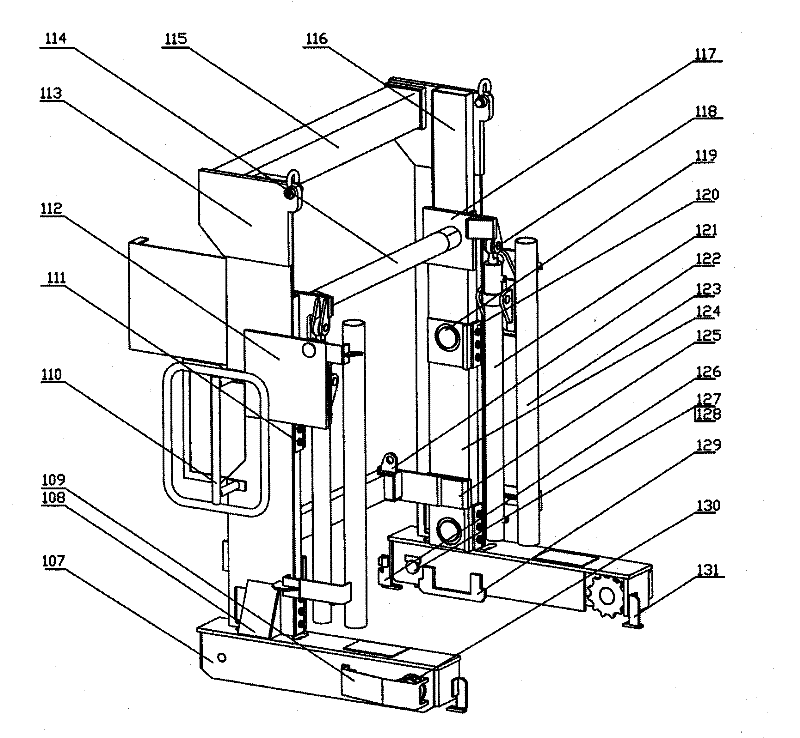

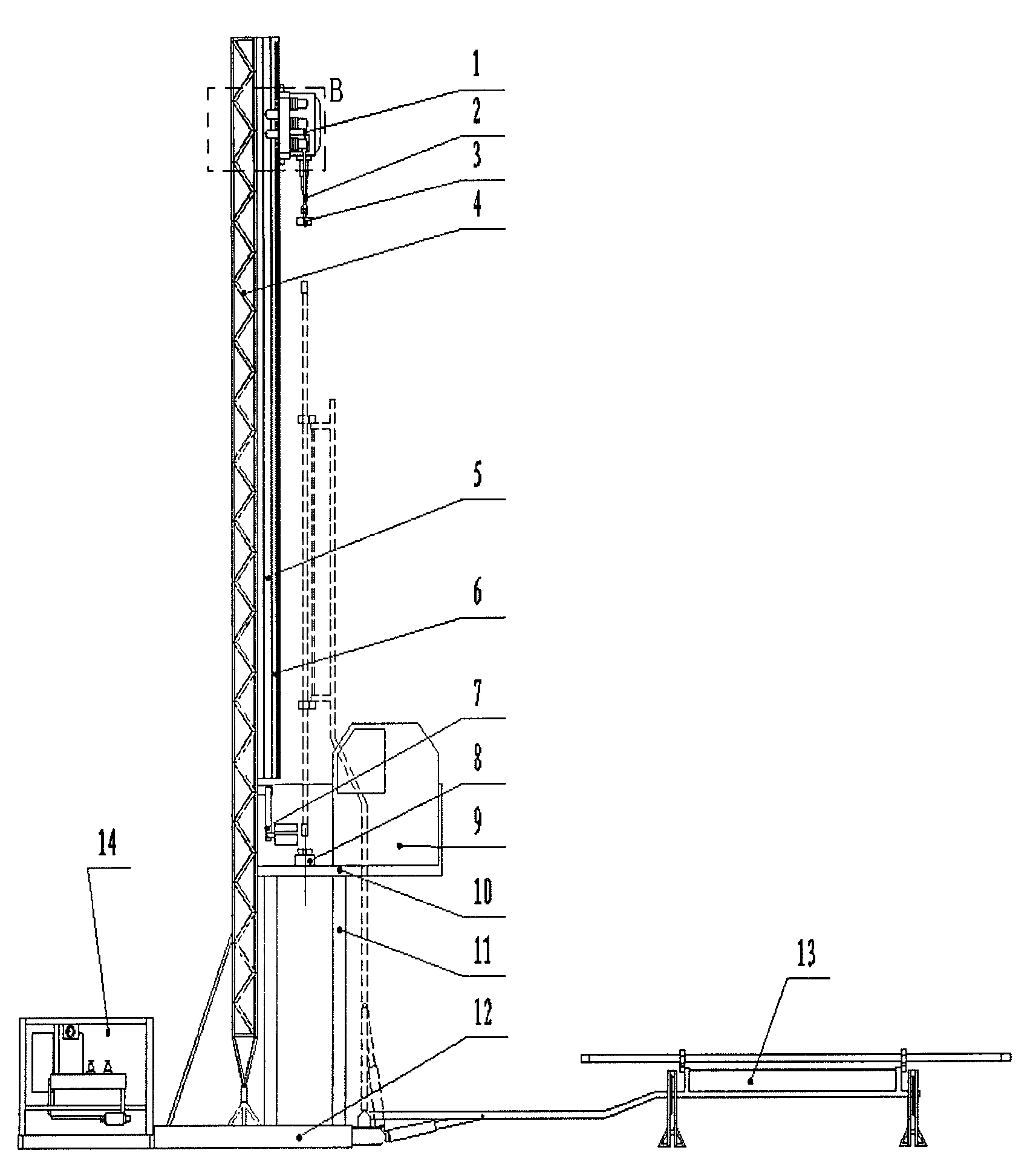

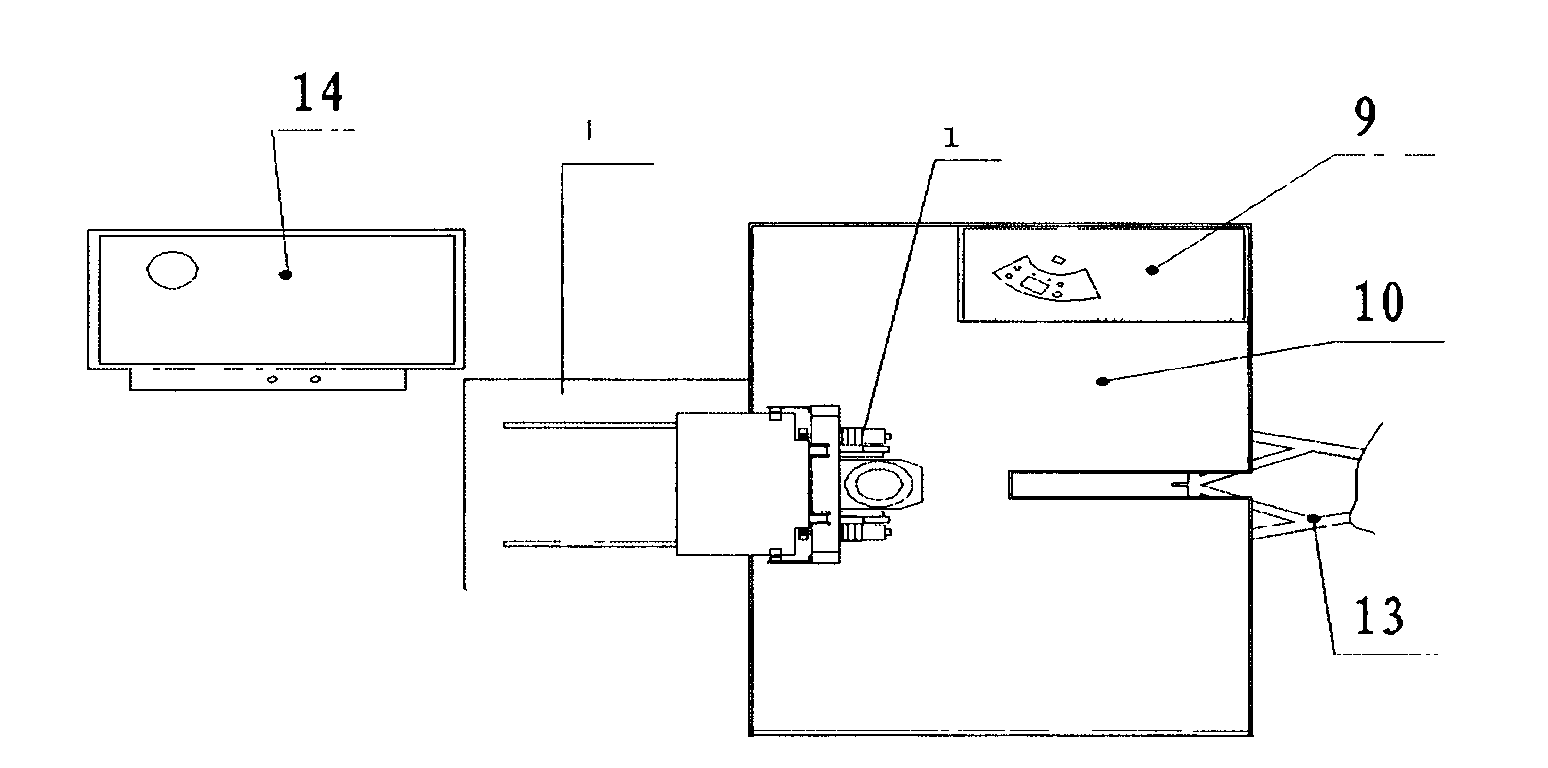

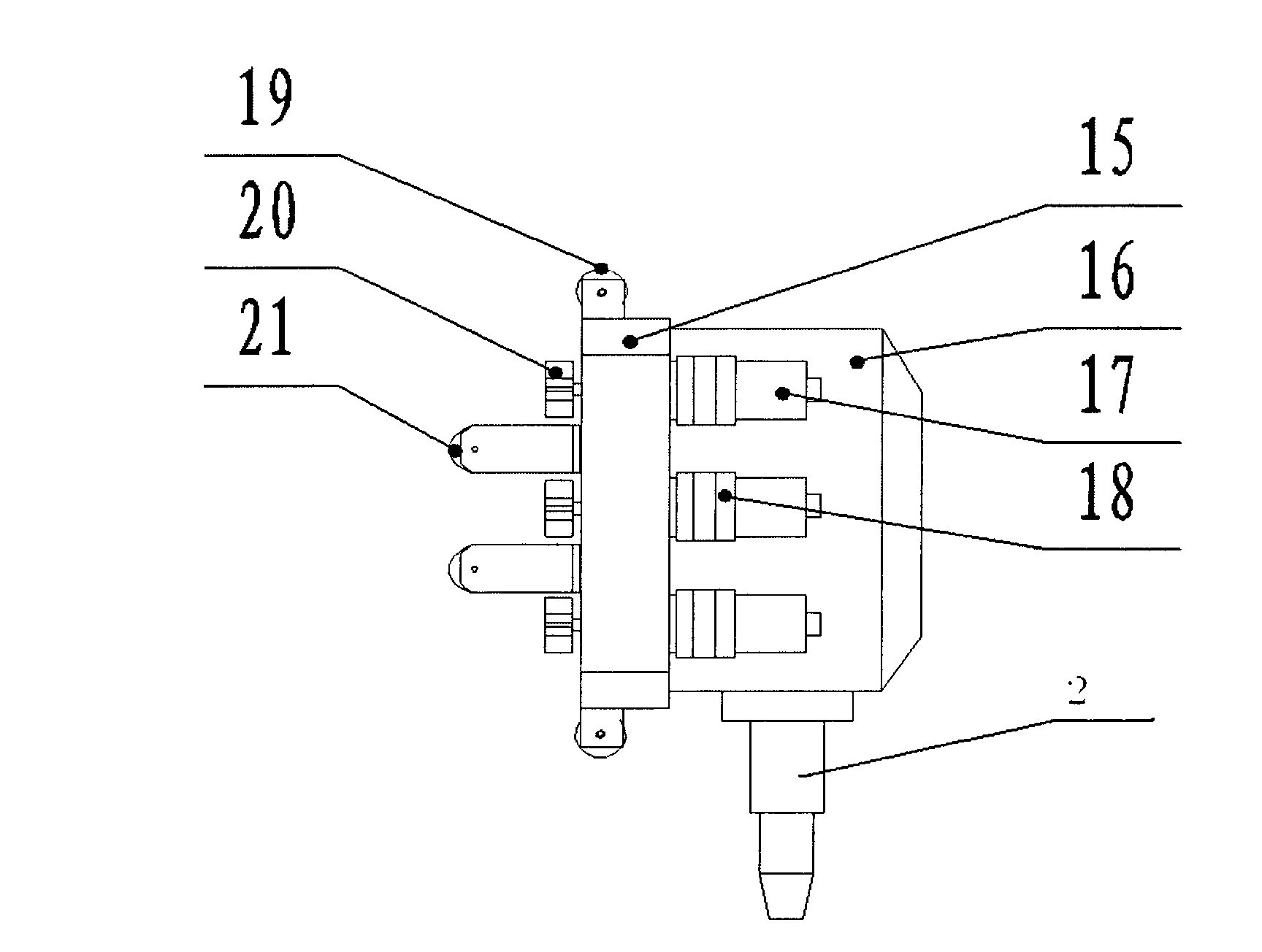

A floor rail type highly integrated intelligent iron driller

InactiveCN102287150AHigh degree of automationRealize full automationDrilling rodsDrilling casingsHydraulic motorHeadframe

The invention provides a floor rail type highly integrated intelligent iron roughneck, which integrates a lift car, a clamp head frame, a main back clamp and guide rails into a whole and consists of the lift car, the clamp head frame and the guide rails, wherein the lift car moves on the guide rails, the upper part of the clamp head frame is suspended and connected onto the lift car, in addition,the connection between the lift car and the lower part of the clamp head frame is realized through unscrewing, the lift car consists of a left side frame, a right side frame and a cross beam, the left side frame and the right side frame are respectively arranged on the two guide rails, the lift car drives a transmission gear to rotate through a lift car hydraulic motor for realizing the moving onthe guide rails. The floor rail type highly integrated intelligent iron roughneck can realize the application of a large-torque and wide-pipe-diameter-range rotary thread punching device and is applicable to the unscrewing on drill rods in any dimensions. The lift car, the clamp head frame, the main back clamp and the guide rails are integrated into a whole, so the weight of the whole equipment is greatly reduced, and the work efficiency is improved. The floor rail type highly integrated intelligent iron roughneck has the advantages that the automation degree is high, the full-process automatic operation of the work process can be realized, and the rotary thread punching operation of the whole site can be completed by one worker.

Owner:金华萨博思石油机械有限公司

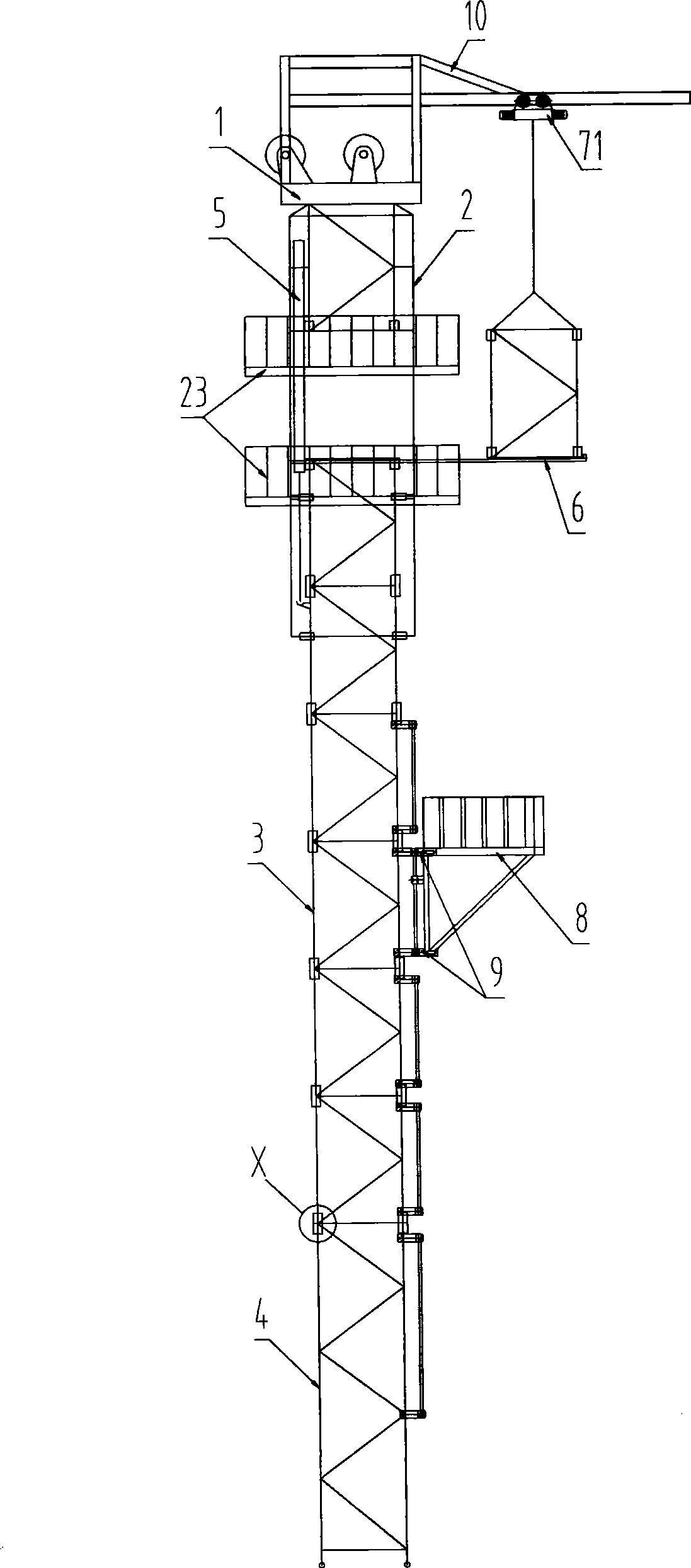

Top butt-joint type oil rig headframe

InactiveCN101435313AFlexible structureSmall installation forceDrilling rodsDerricks/mastsHeadframeButt joint

The invention relates to an overhead butting oil drill derrick which comprises an overhead travelling crane, an upper segment, a plurality of middle segments, a lower segment, an upper segment telescoping mechanism, a middle segment moving and limiting device, a lifting transportation device arranged on the maintenance rig of the overhead travelling crane, two layers of working table and the like. The upper segment, a plurality of middle segments and the lower segment all adopt an upright truss structure with the front being opened which is welded by four columns and a plurality of inclined struts, transverse beams and transverse bracings; and the lower segment, the plurality of middle segments and the upper segment respectively adopt a mode of aligning the head and the tail of the columns, contacting directly the end surfaces of the columns and passing through adapter sleeves arranged at the side surfaces of the columns, or connecting base plates by pin rolls or bolts. The butting of each segment of the derrick by bolts is realized at the top of space by the upper segment telescoping mechanism, the middle segment moving and limiting device and the lifting transportation device. The derrick has the characteristics of little and constant telescoping power when carrying out butting installation, light lifting weight, independent transportation of each segment, short moving length and adjustable butting height, and is especially applied in well fields with serious installation spaces of planes, or low requirements on module weight, or poor transportation conditions.

Owner:RG PETRO MACHINERY GROUP

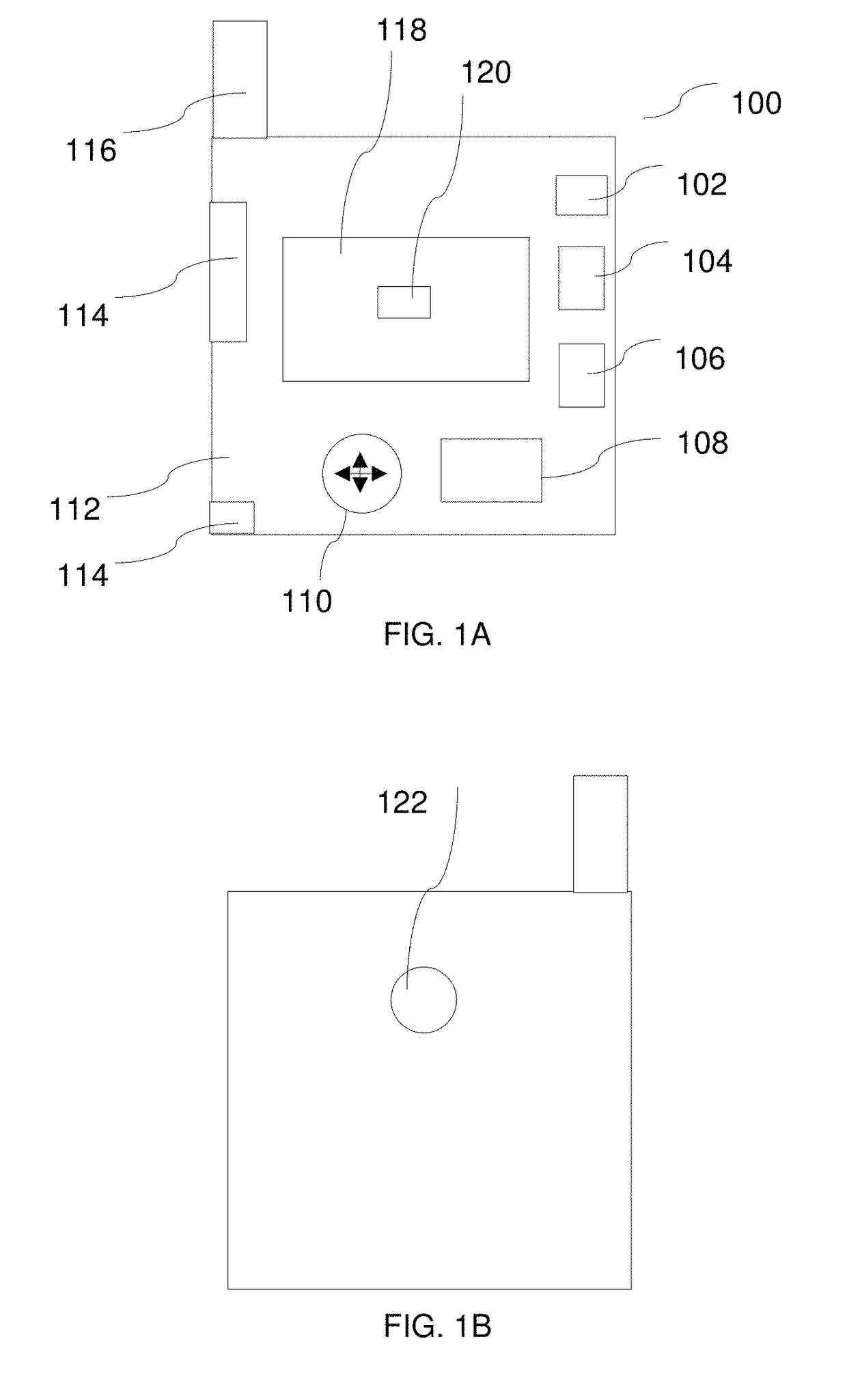

Camera in a headframe for object tracking

ActiveUS9736368B2Minimize the differenceTelevision system detailsImage enhancementHeadframeAccelerometer

Methods and apparatus track an object with a first camera causing a second camera to also track the object. The object is a moving object. Geospatial coordinates, including an elevation or altitude of a camera are determined on the camera. A pose of the camera, including a pitch angle and an azimuth angle are also determined. Azimuth is determined by a digital compass. A camera pose including pitch is determined by accelerometers and / or gyroscopes. Cameras are communicatively connected allowing to display an image recorded by one camera being displayed on a second camera. At least one camera is on a movable platform with actuators. Actuators are controlled to minimize a difference between a first image of the object and a second image of the object. Cameras are part of a wearable headframe.

Owner:SPATIAL CAM

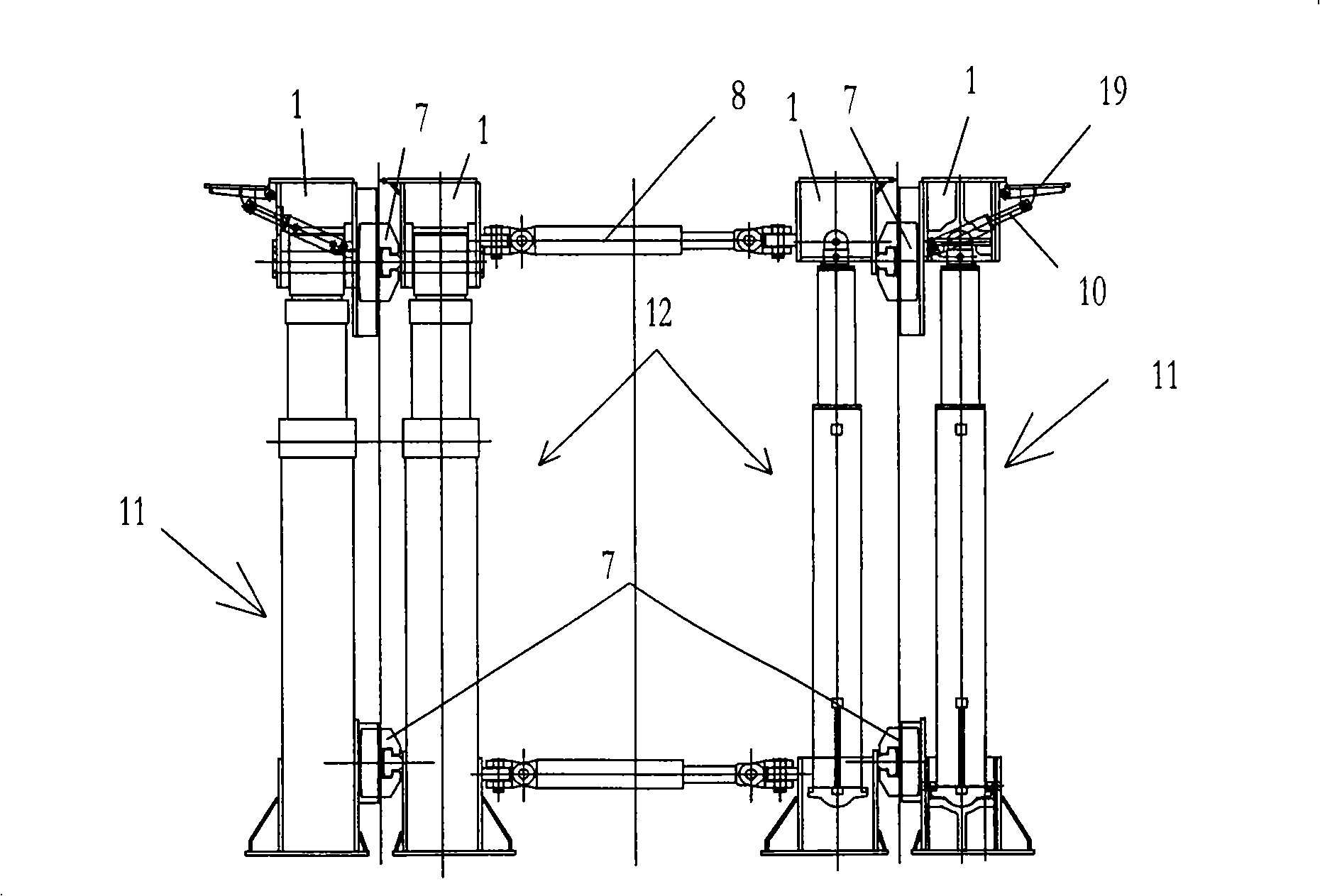

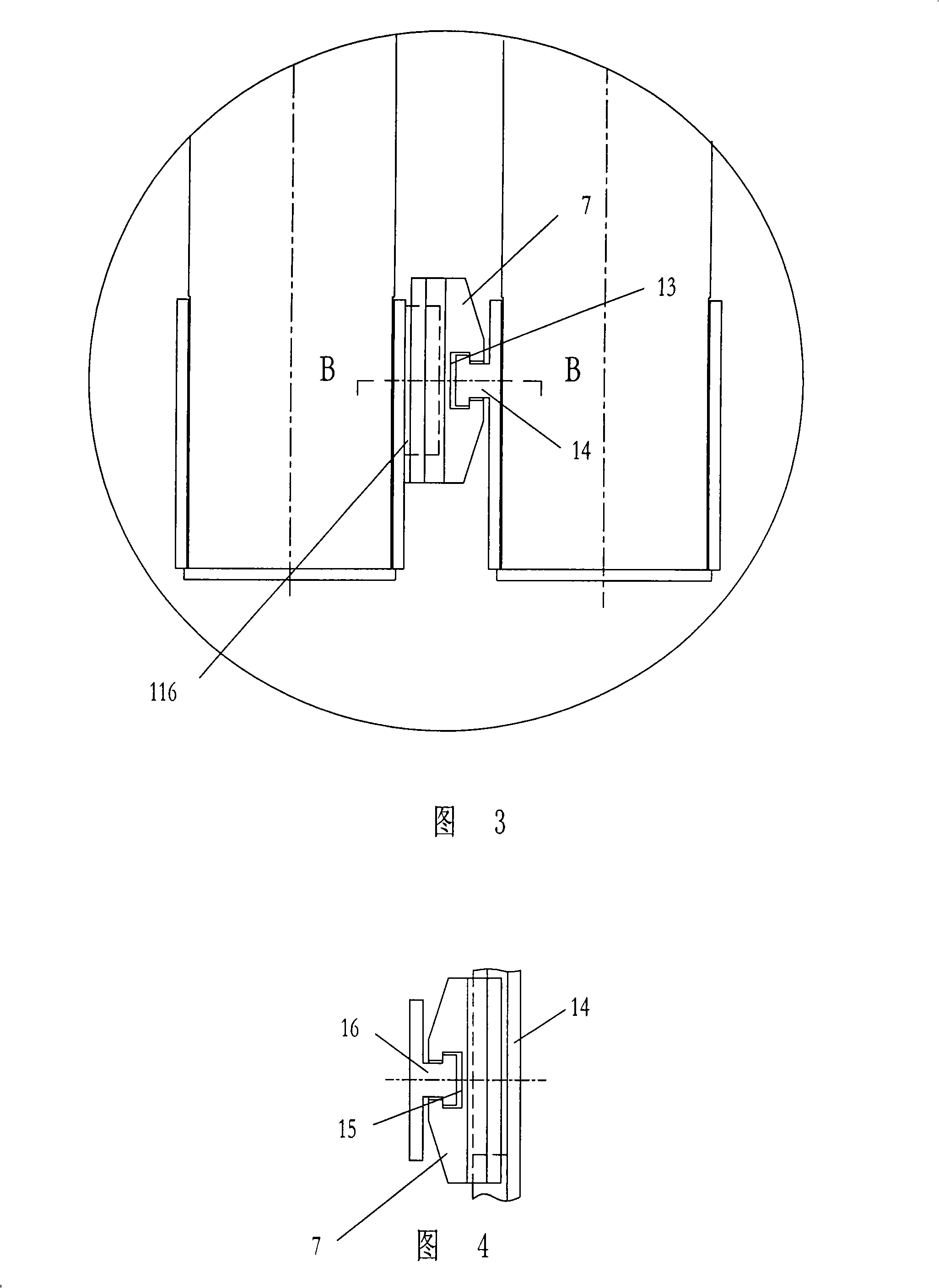

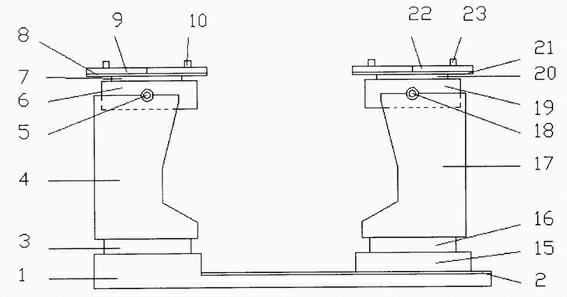

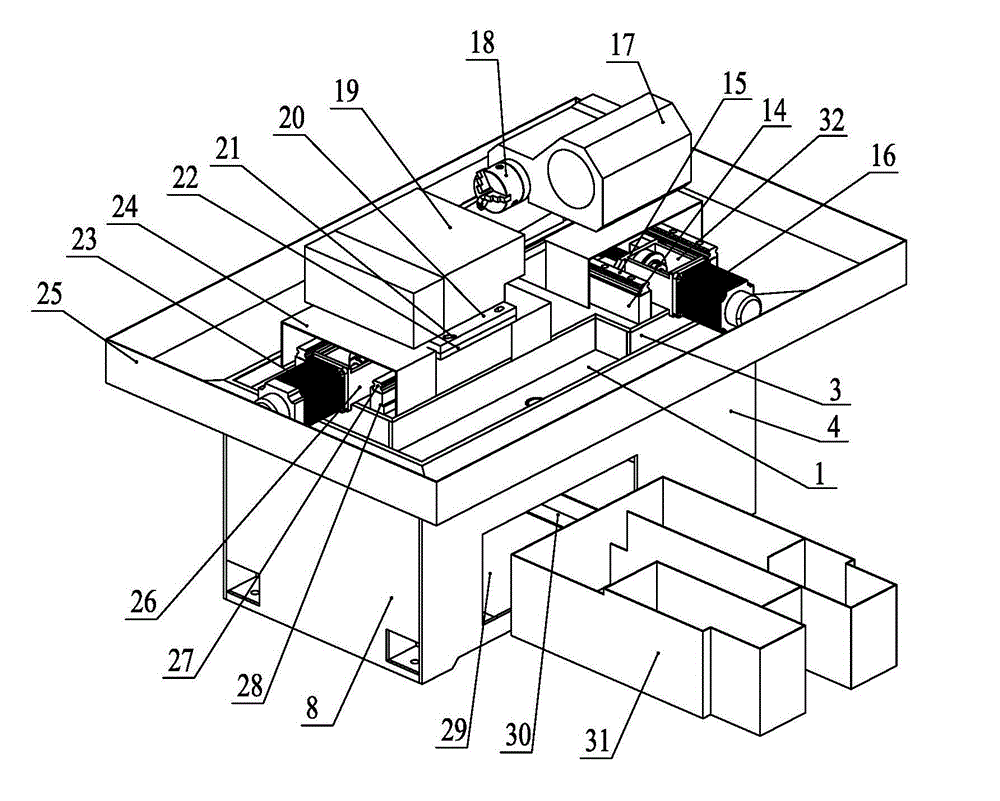

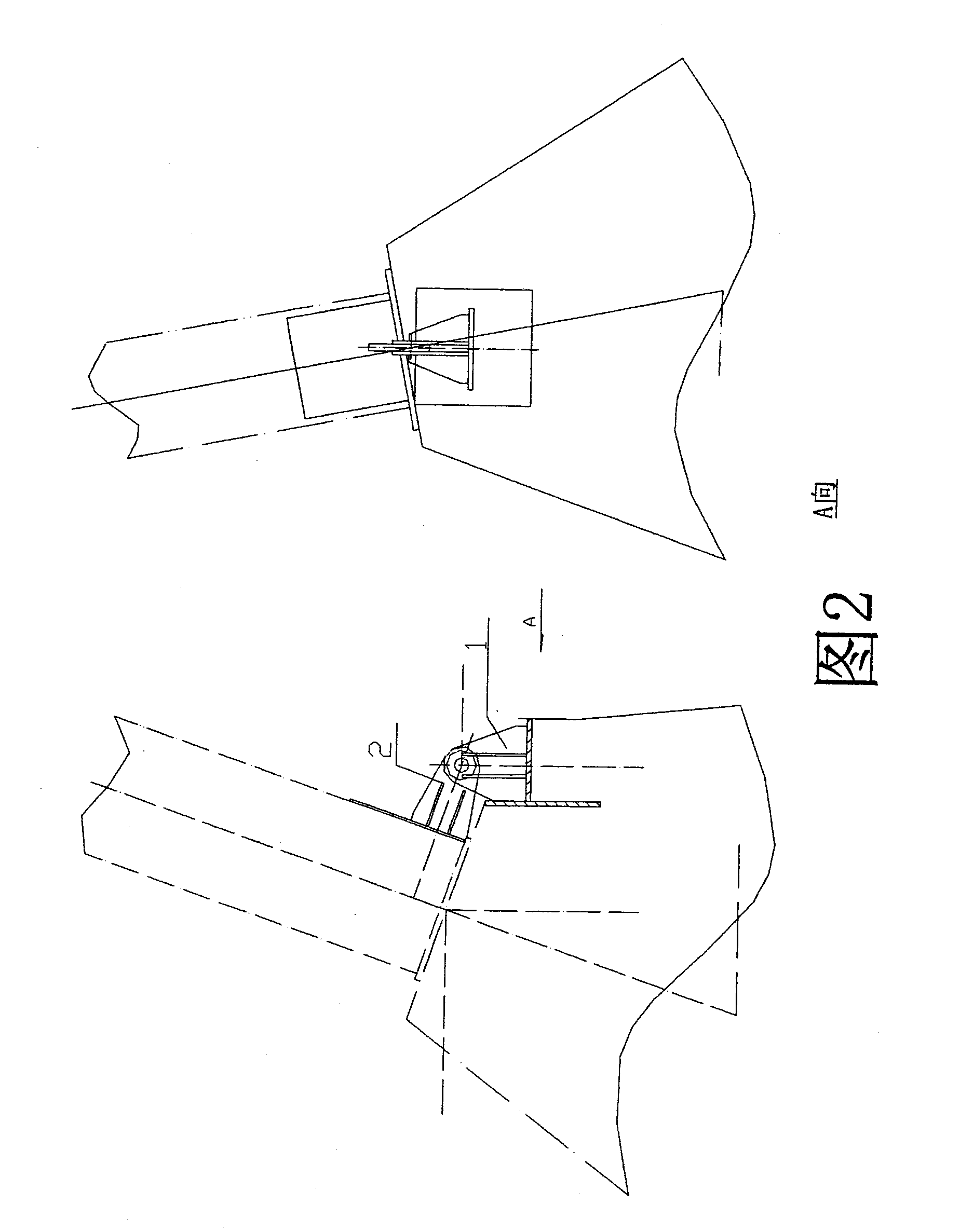

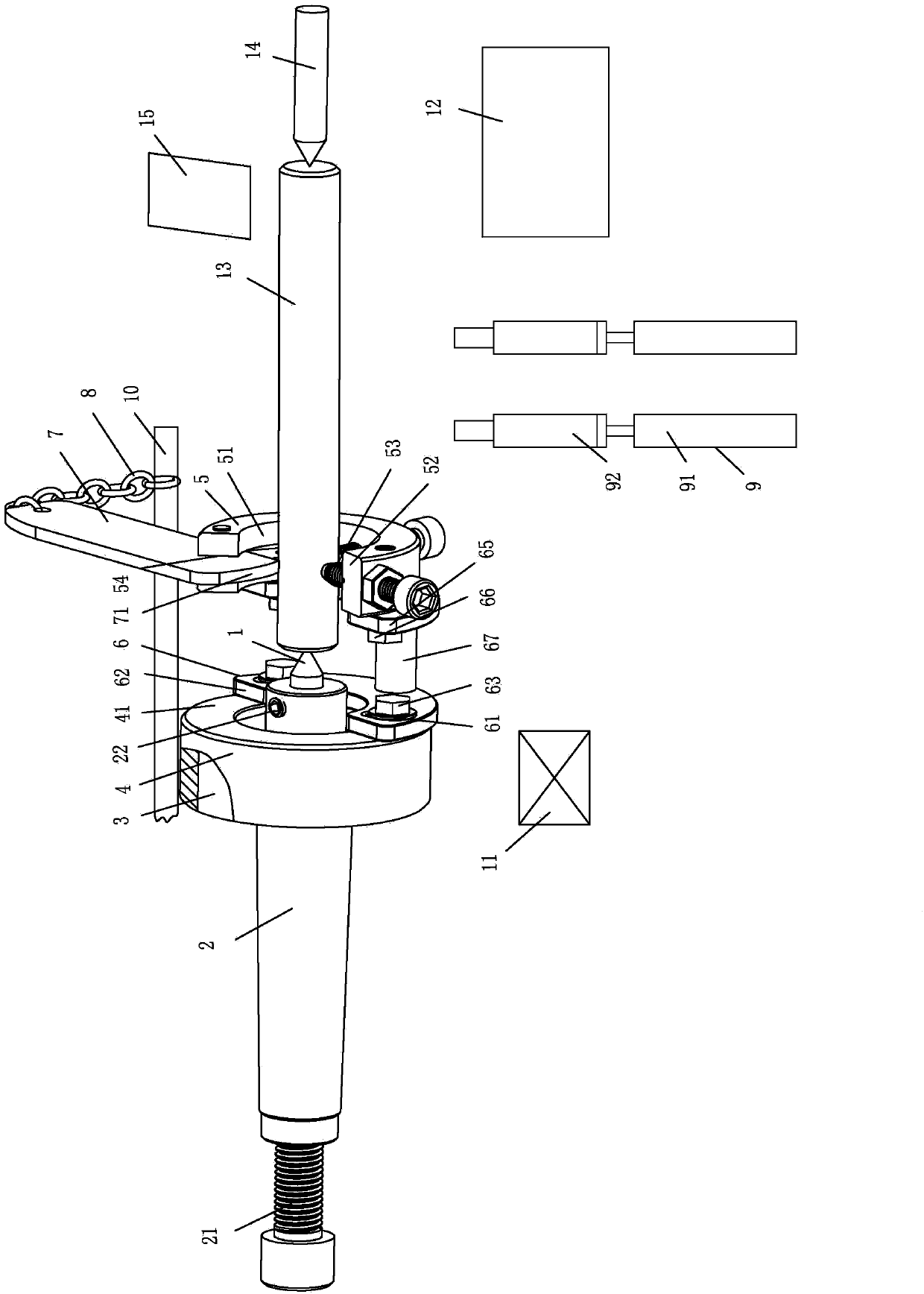

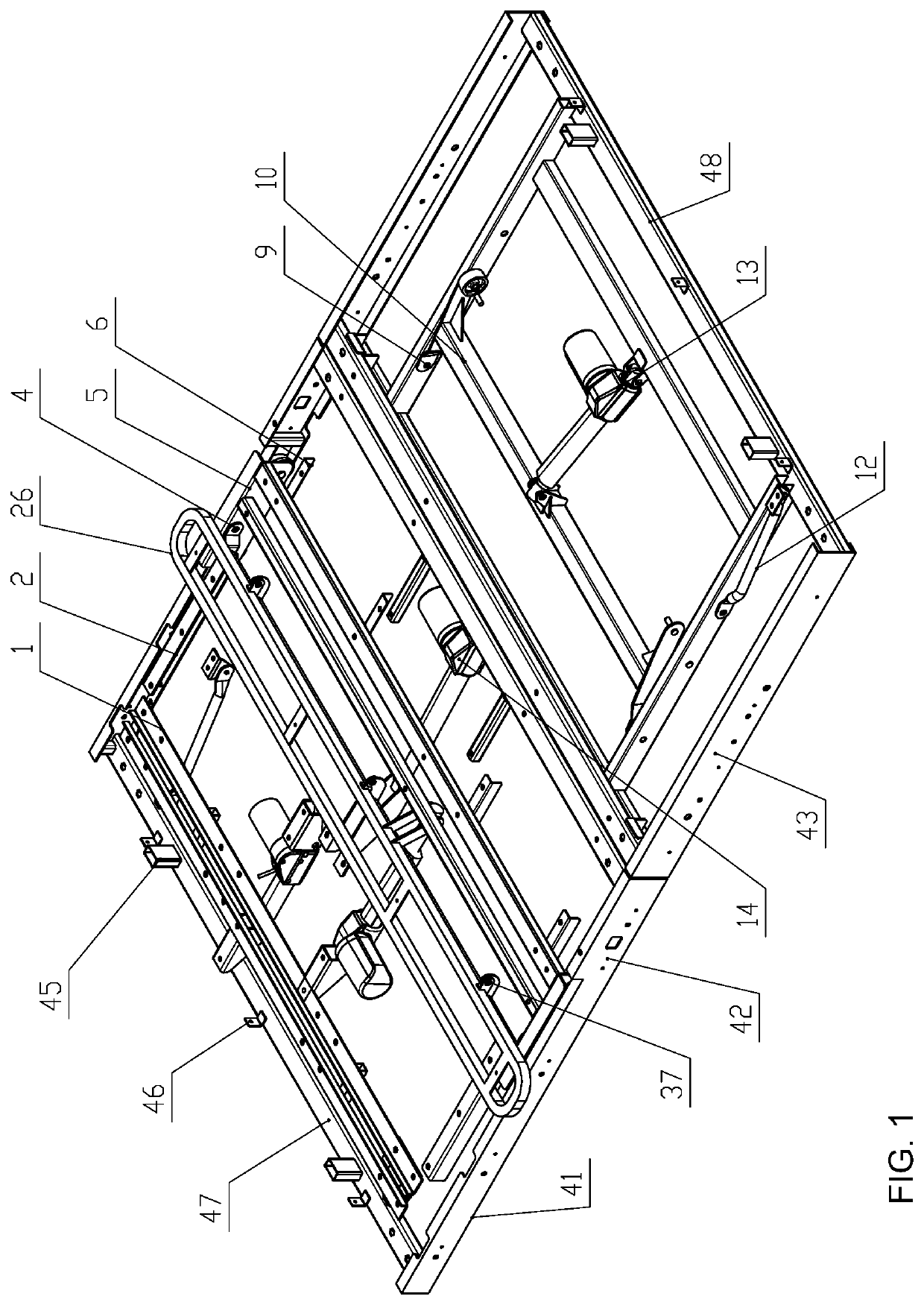

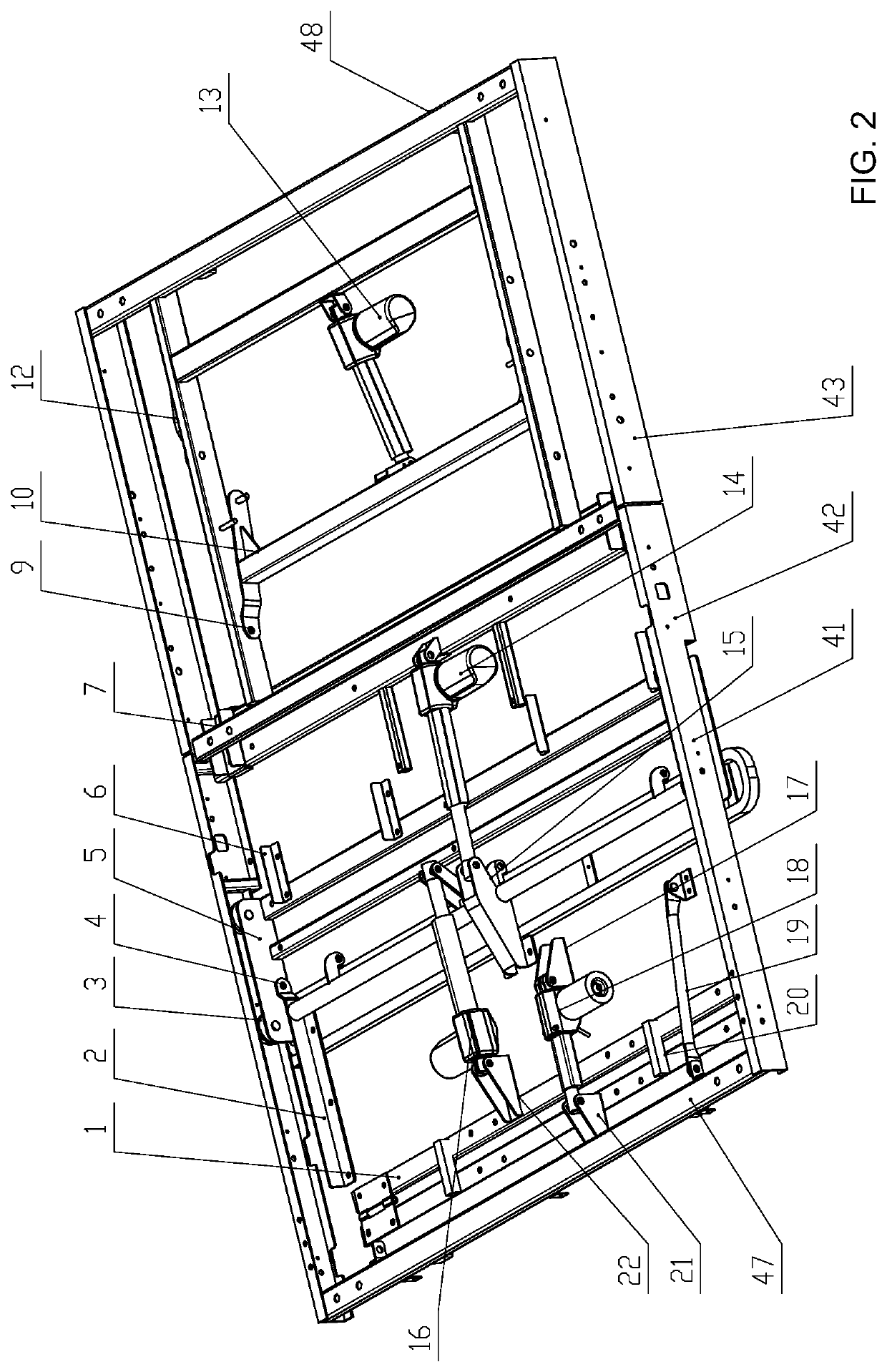

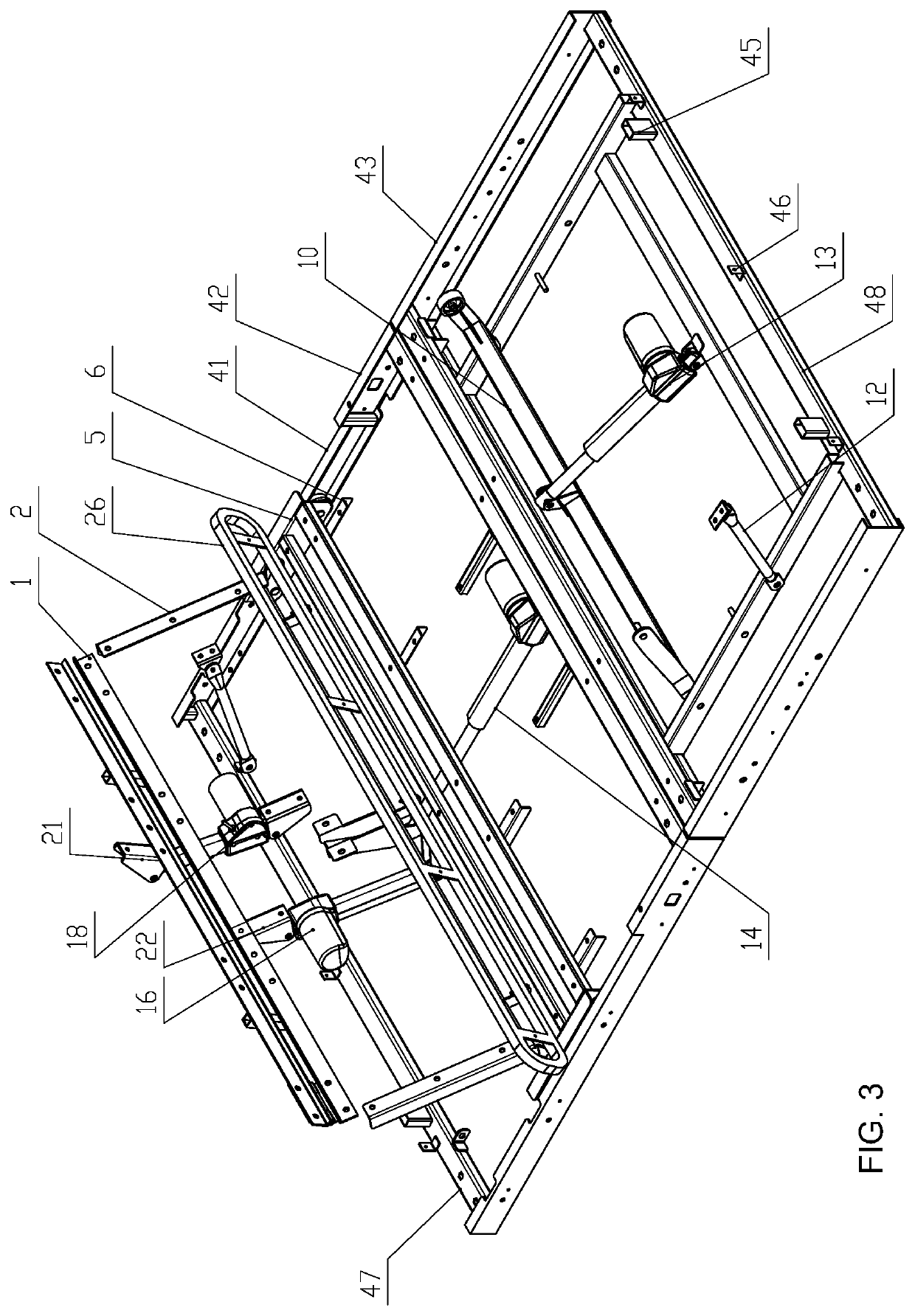

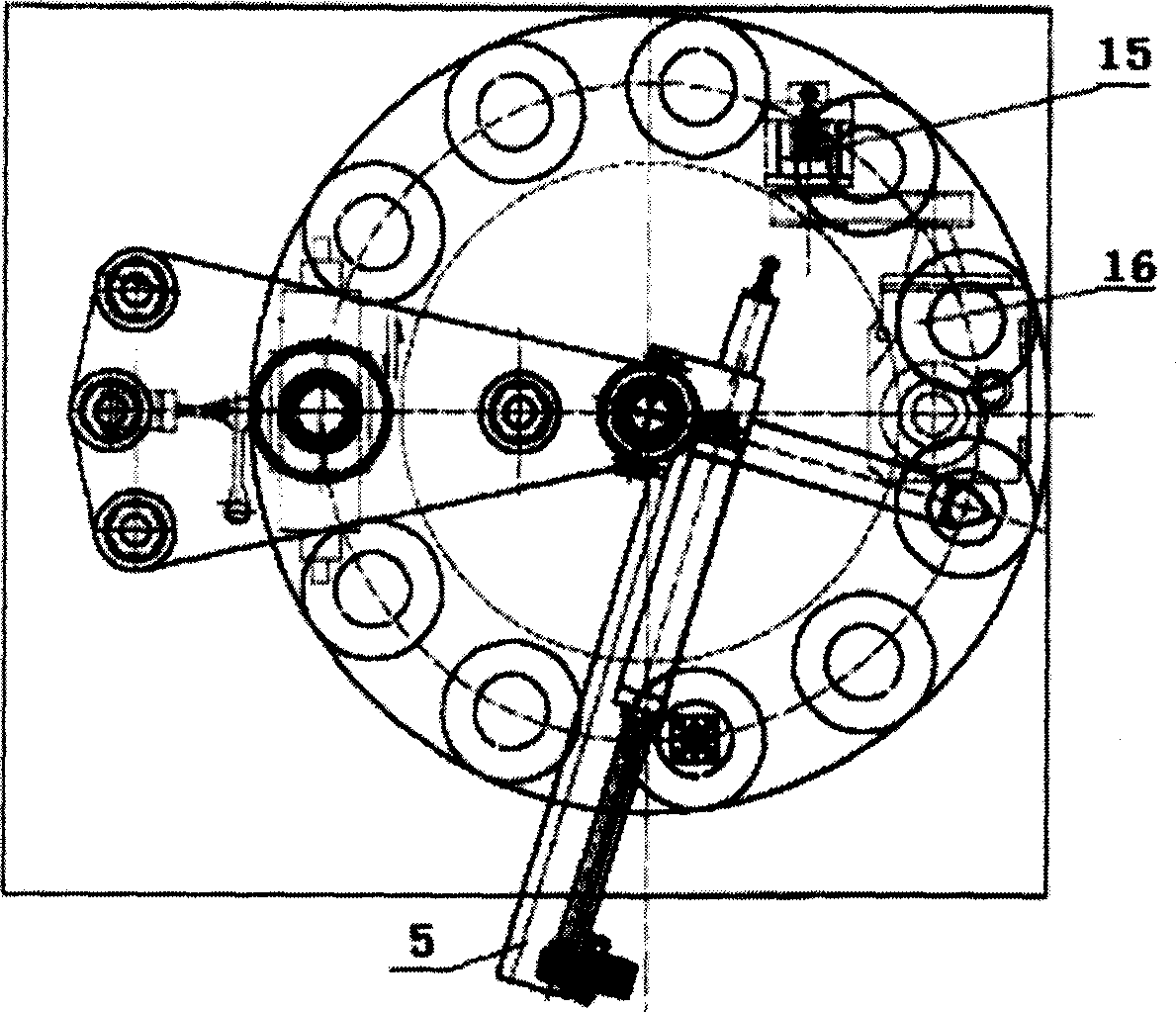

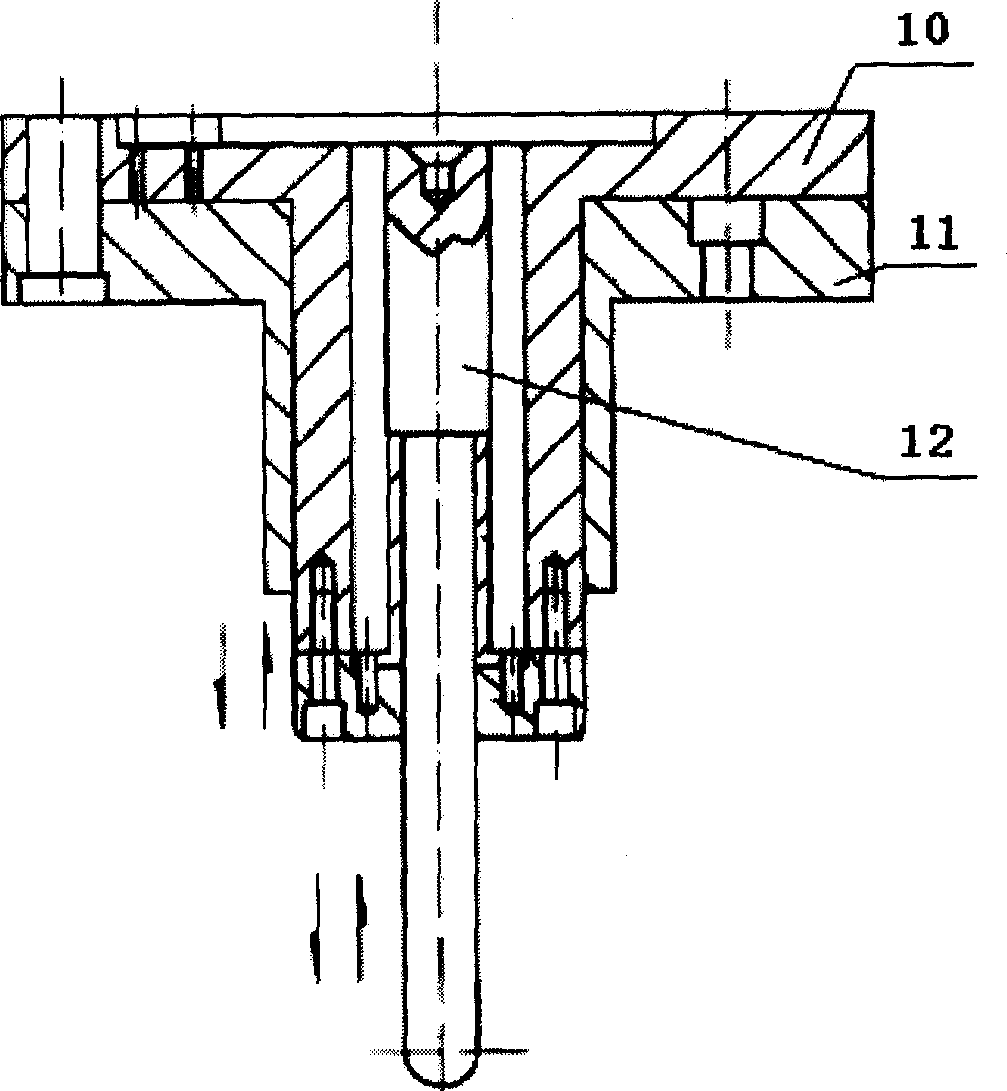

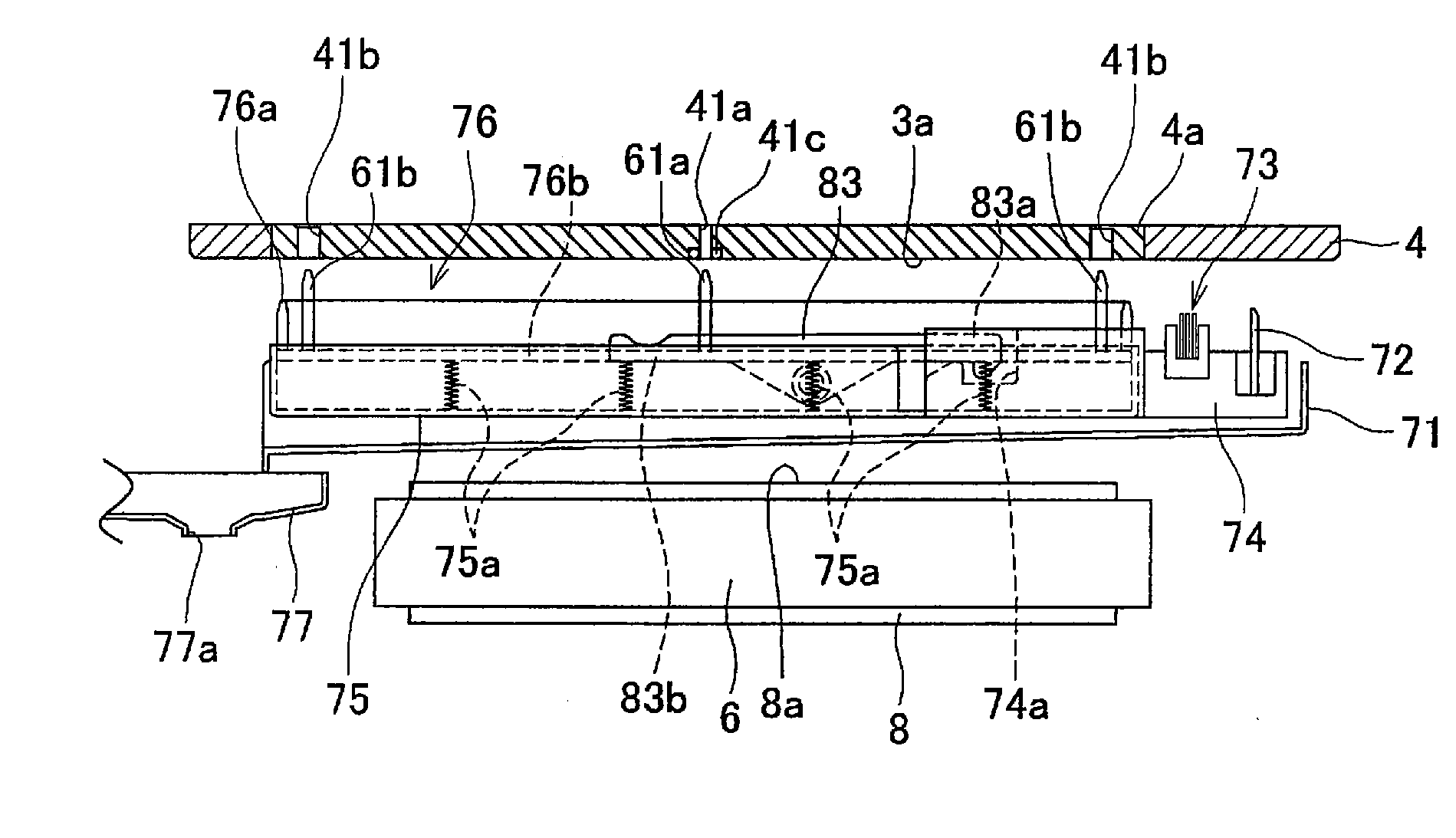

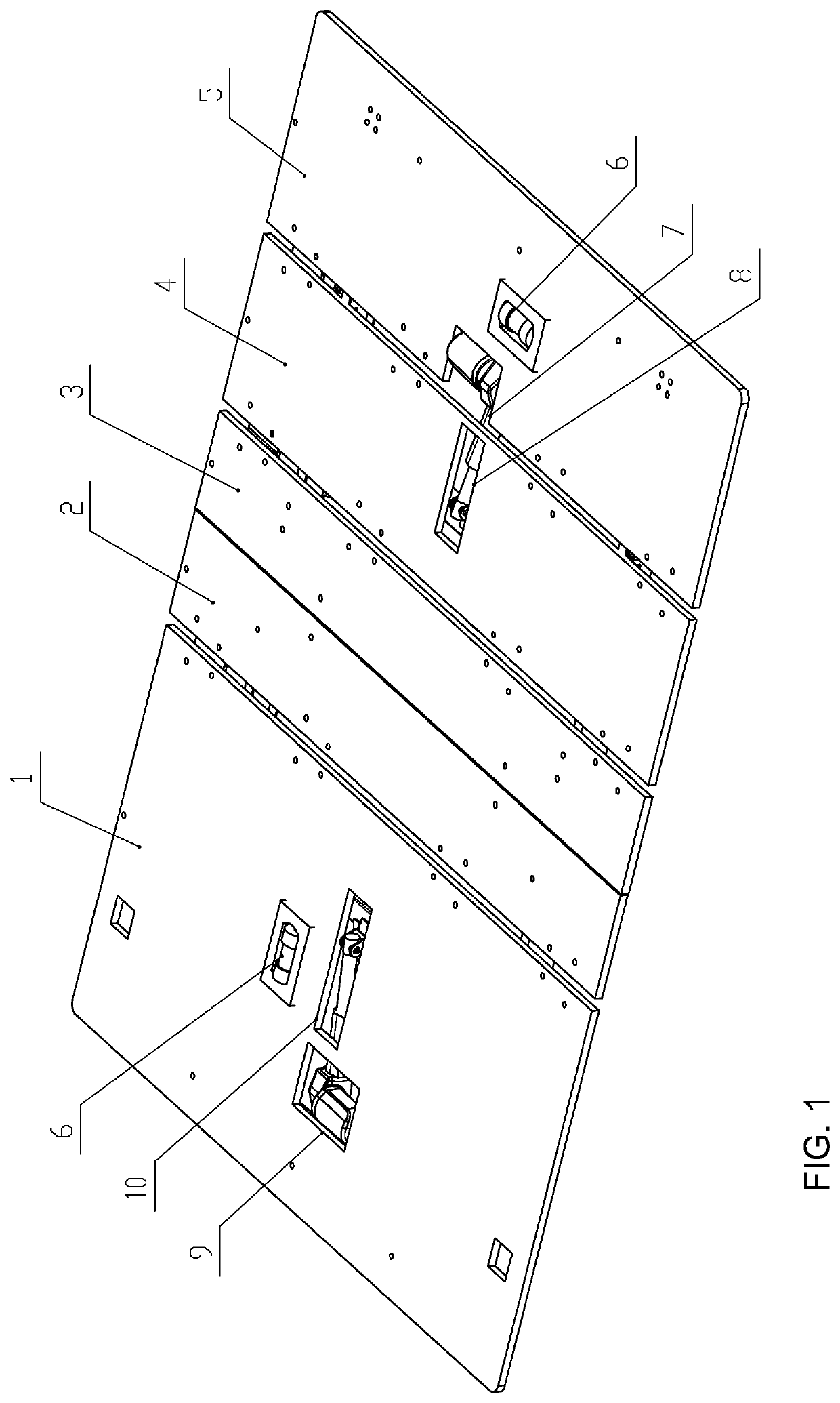

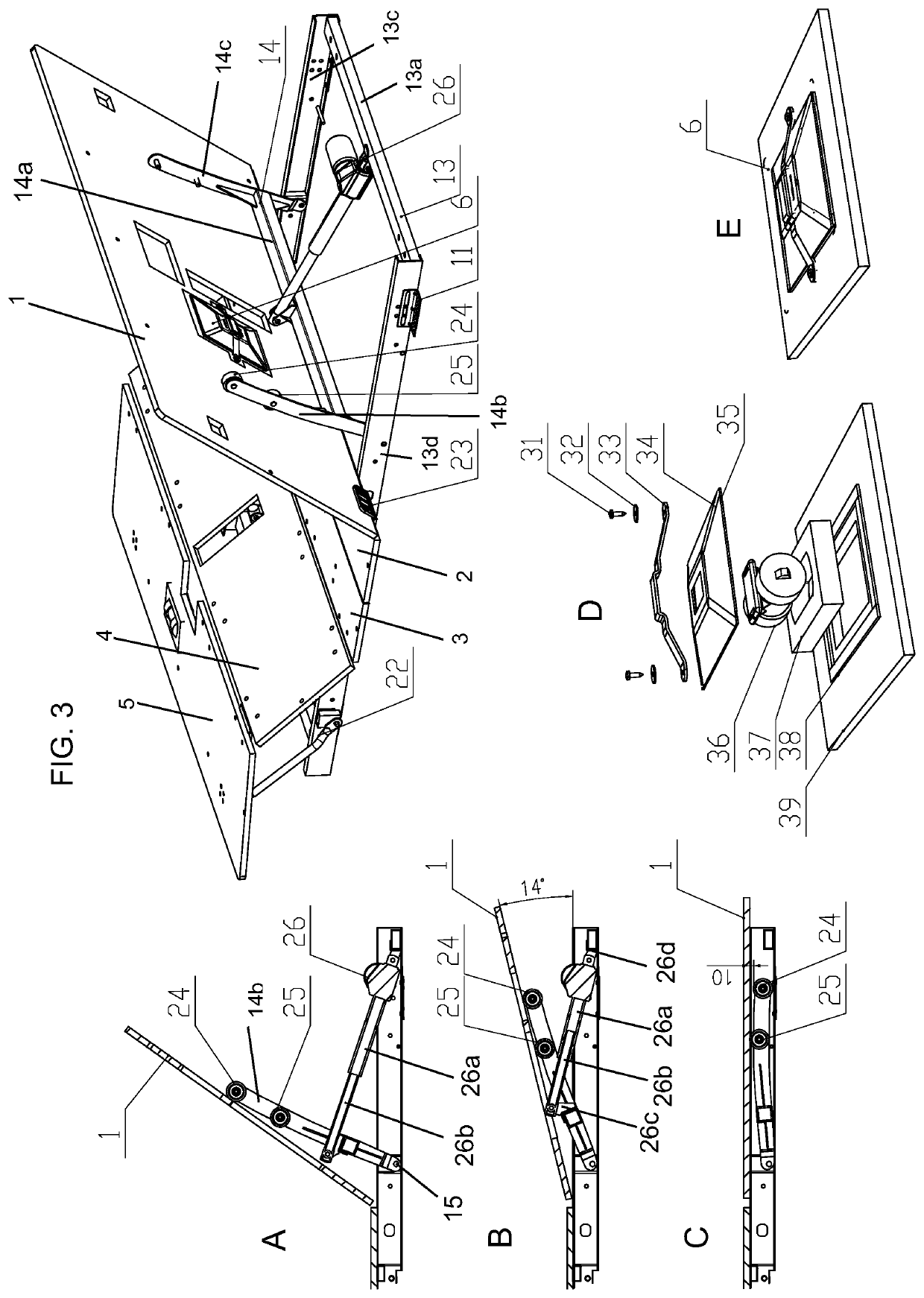

Position changing machine for measurement reproduction system of folding pipe

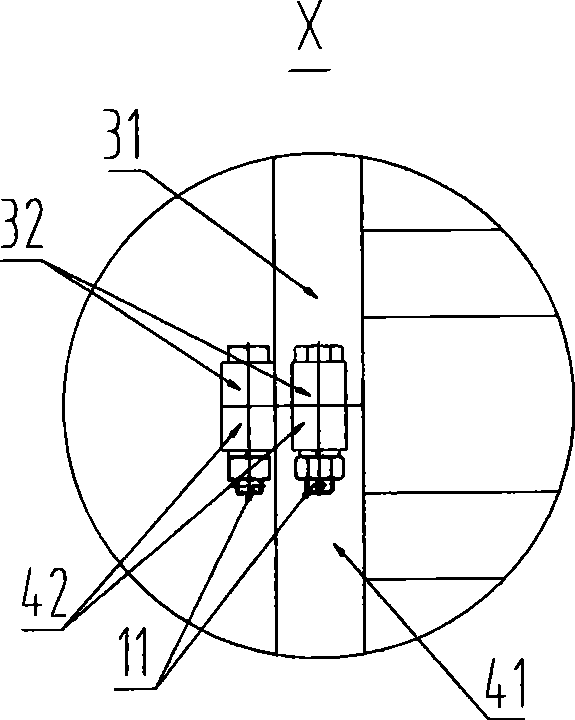

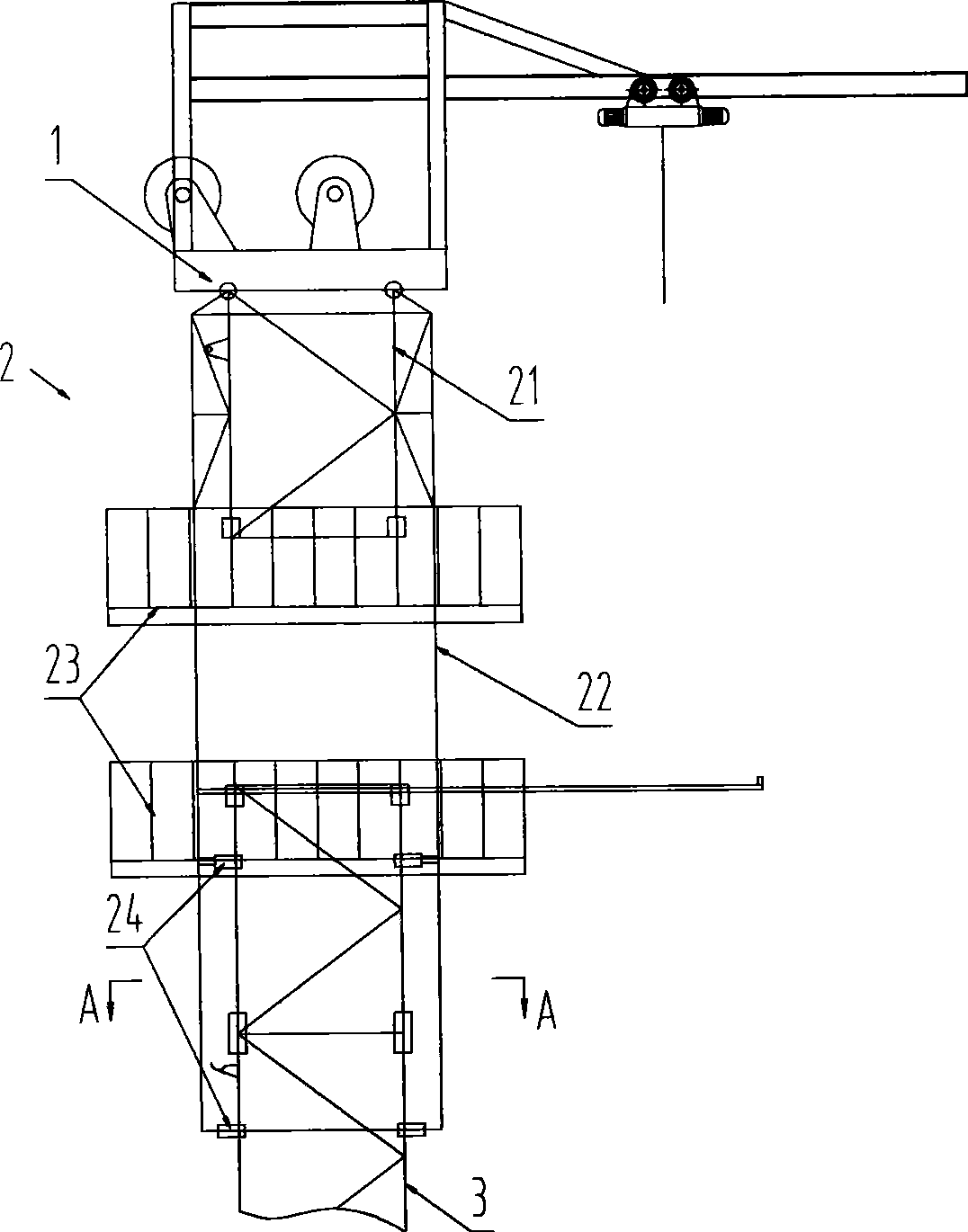

ActiveCN102350605AEasy to adjustPrecise processingWelding/cutting auxillary devicesAuxillary welding devicesRotational axisHeadframe

The invention discloses a position changing machine for a measurement reproduction system of a folding pipe, wherein a pedestal (1) of the position changing machine is stepped; a headstock (4) is connected with an upper step of the pedestal through a headstock rotating shaft (3); a headstock overturning platform (6) is connected with the headstock through a headstock overturning shaft (5); a headstock chuck (8) is fixed on the headstock overturning platform through a chuck rotating shaft (7); four headstock lead screw jaws (9) are installed on the headstock chuck, and four headstock locating blocks (10) are installed on the headstock lead screw jaws; a lead screw rotating handle (13) is connected with the headstock lead screw jaws through threads of the lead screw; the four headstock lead screw jaws are engaged together through a bevel gear box (14); a locating groove (11) is installed on the headstock chuck along a direction vertical to the headstock overturning shaft, and a zero point locating block (12) is installed on the locating groove; guide rails (2) are arranged on the lower step of the pedestal, a tailstock pedestal (15) is installed on the guide rails and is capable of moving along the guide rails; and the structural designs of other devices on the tailstock are same as the structural design of the headstock.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

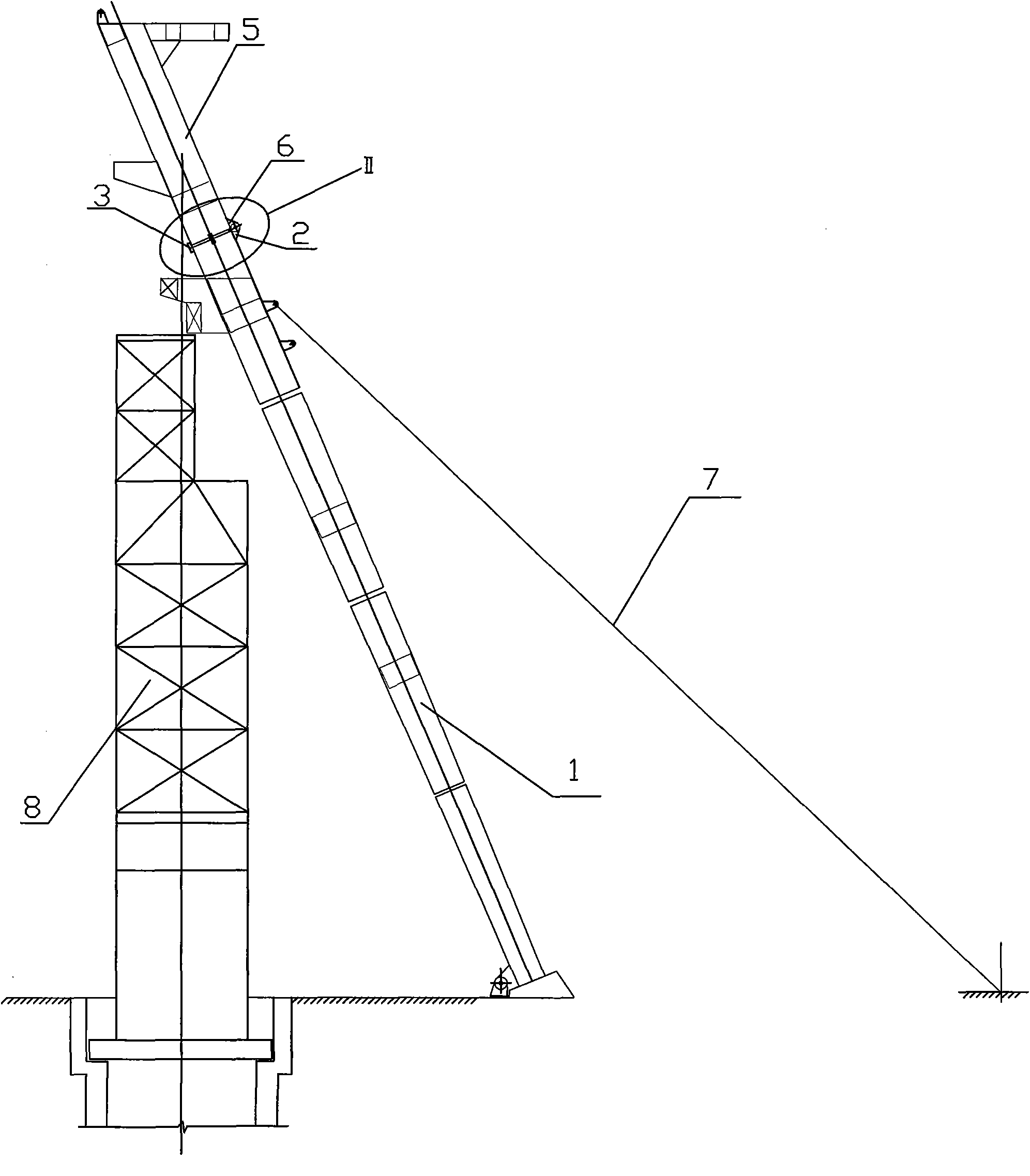

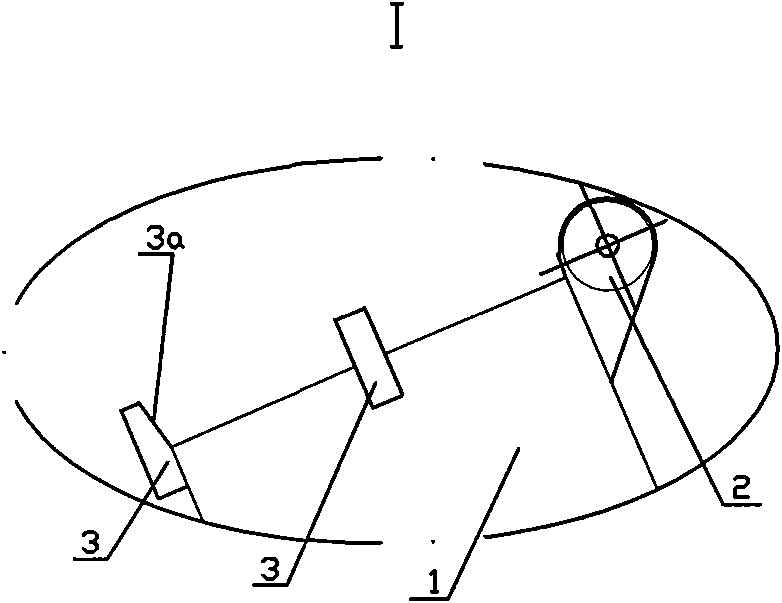

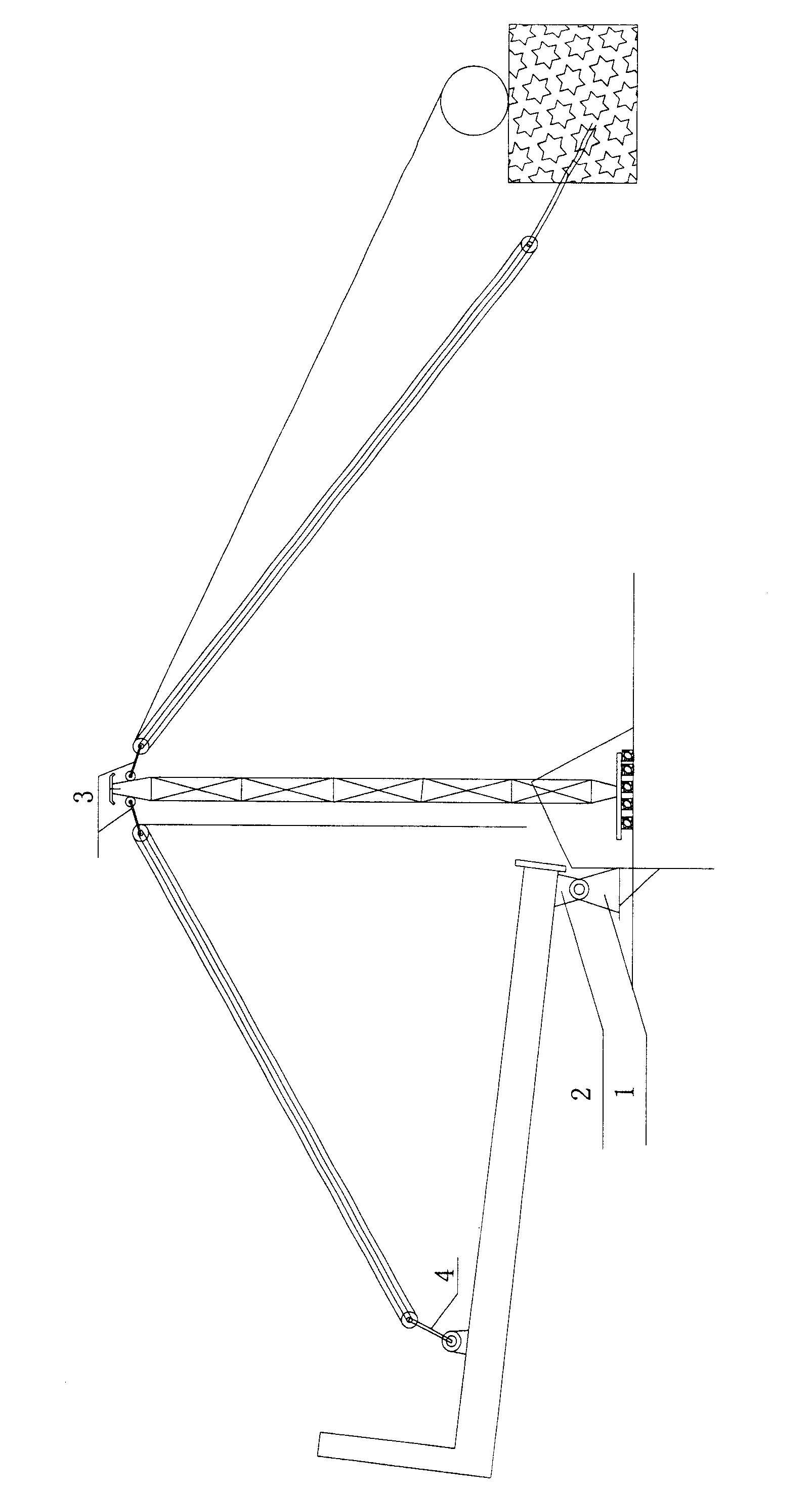

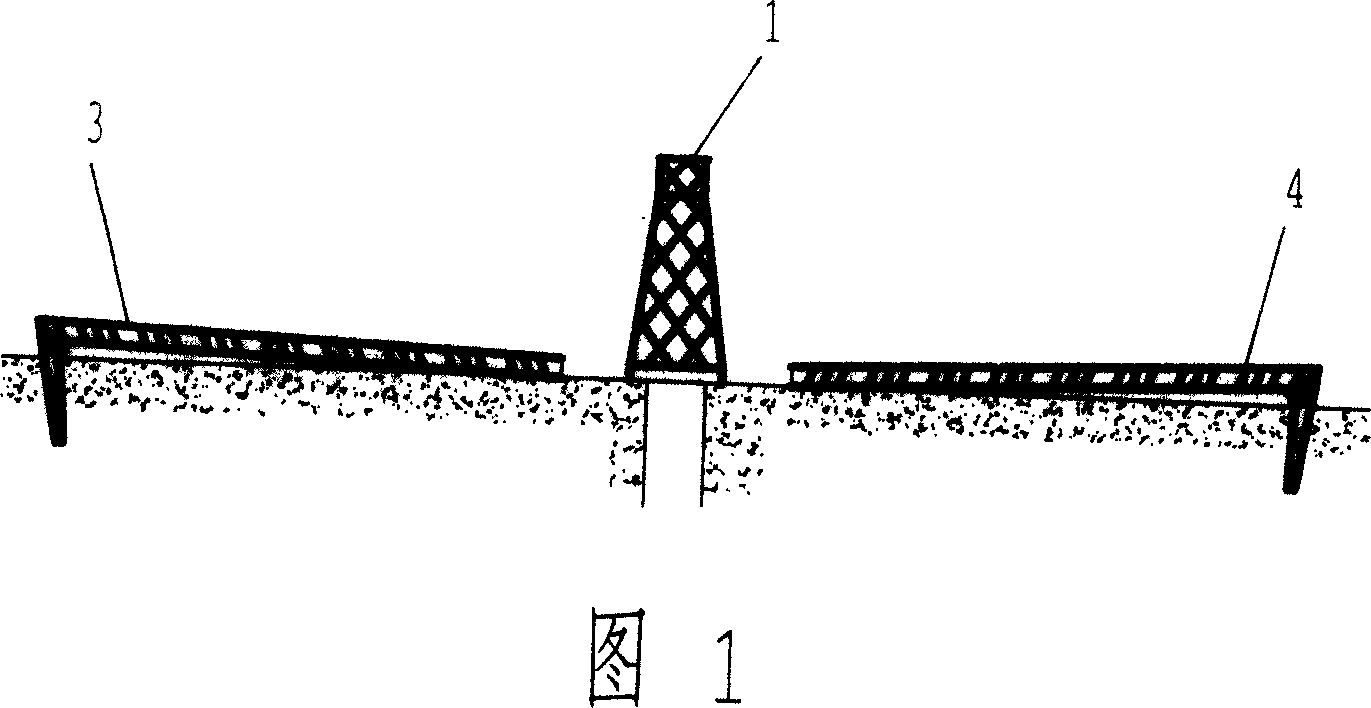

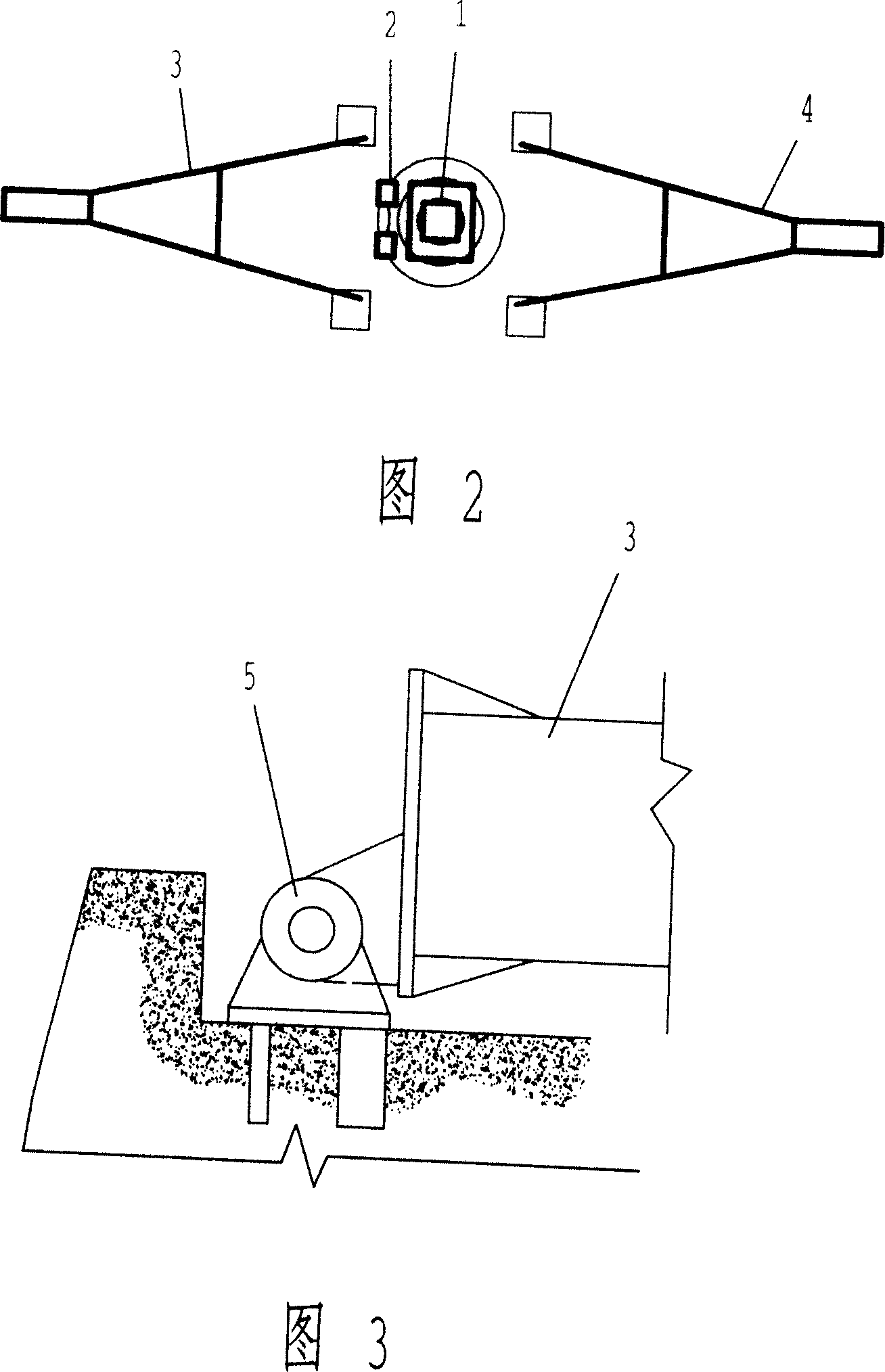

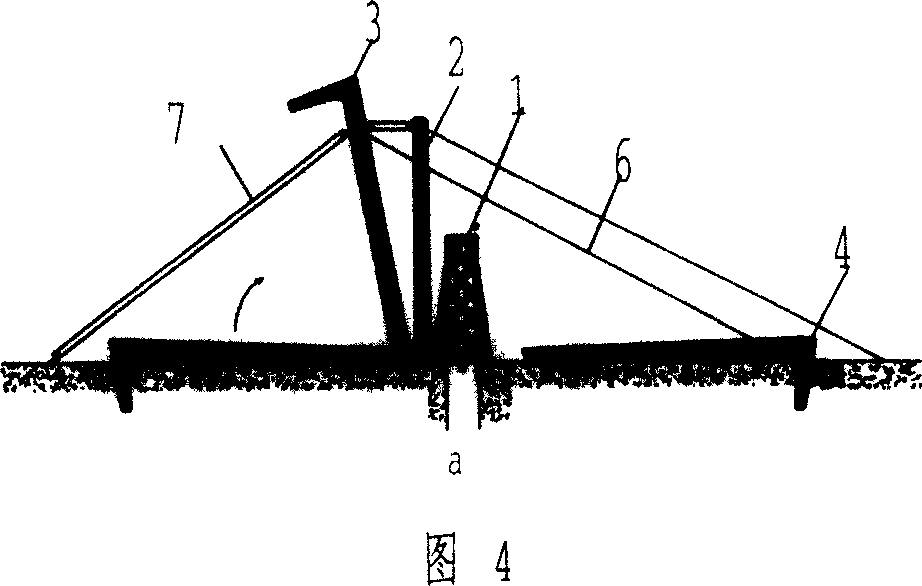

Overhead hoisting and butt-joint method for box-type headframe

InactiveCN101581198ASmall footprintShorten the well construction periodDrilling rodsDerricks/mastsHeadframeButt joint

The invention relates to an overhead and butt-joint method for a box-type headframe, which is characterized in that the method comprises the following steps of: a. manufacturing the box-type headframe as two parts: a mainbody headframe (1) and a hoisting headframe (5); b. installing a well head vertical frame (8) and the mainbody headframe (1) at the proper place according to a normal installation method; c. adopting a hoisting equipment to hoist the hoisting headframe (5) so as to carry out butt-joint positioning with the mainbody headframe along a positioning block; and d. welding the joint of the hoisting headframe and the mainbody headframe, thus forming the box-type headframe entirety. The method has the advantages of: 1. manufacturing and installing the box-type haedframe by section, breaking through the traditional hoisting process, thus reducing the space occupying of the construction field; 2. carrying out installation without stopping production, thus avoiding the loss due to production stopping; and 3. being capable of being applied to the technical renovation engineering of old coal mine and reducing the removal expense of the original building and the loss owning to production stopping.

Owner:中煤第七十一工程处 +1

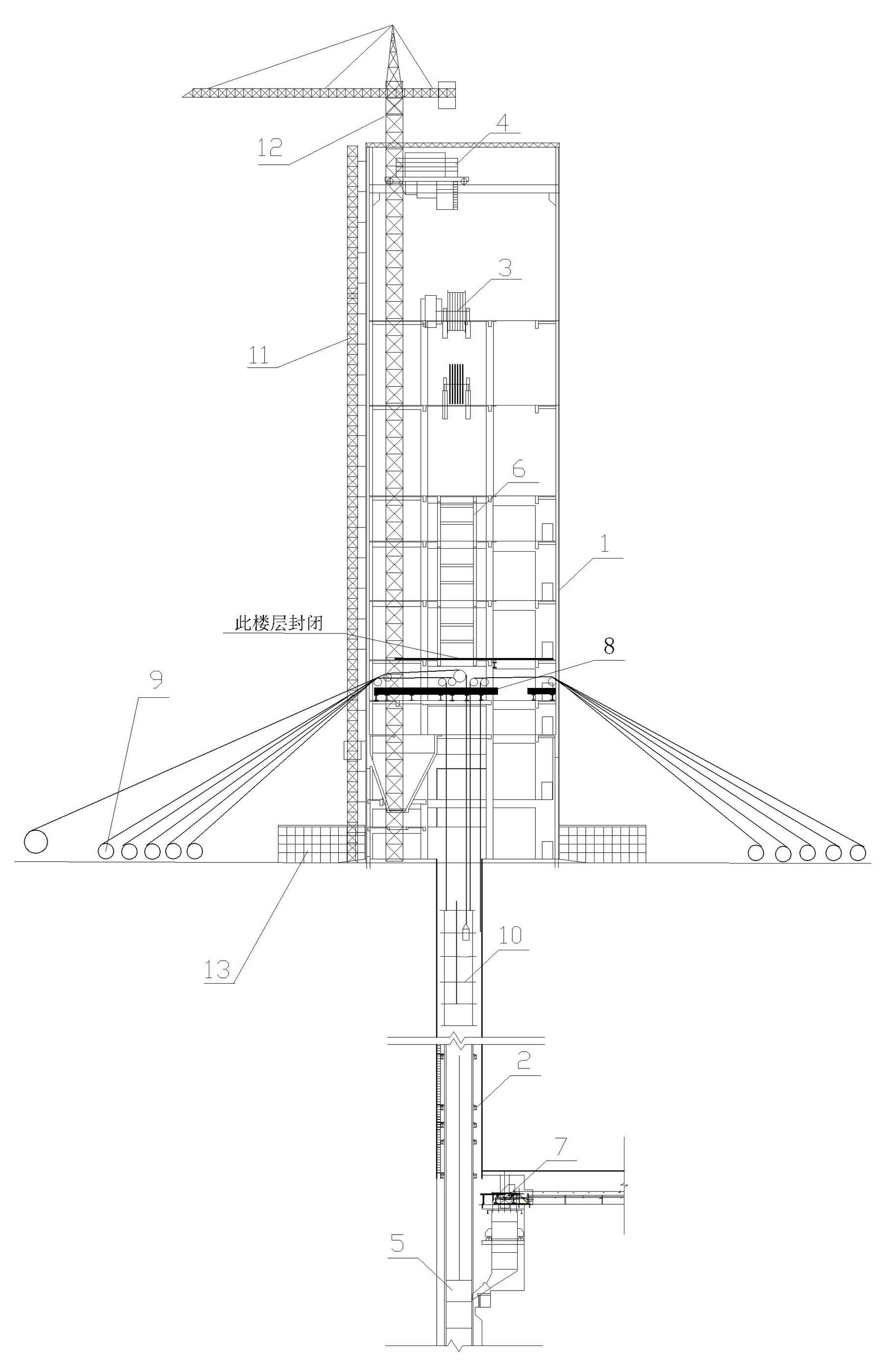

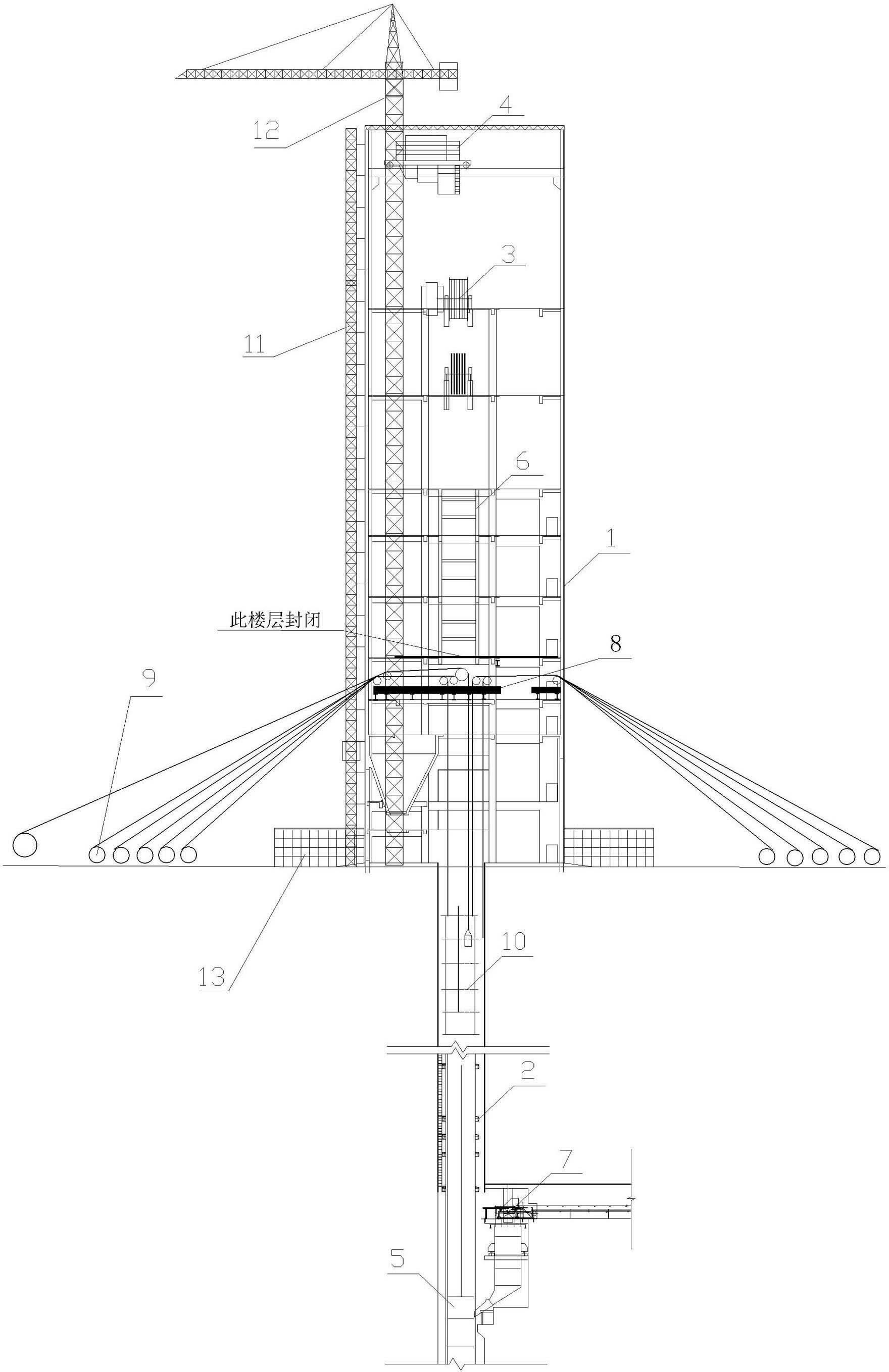

Fast construction method of headframe lifting system

InactiveCN102536249AHigh speedShorten construction timeShaft equipmentHeadframeArchitectural engineering

The invention discloses a fast construction method of a headframe lifting system, which belongs to the technology of construction of mines. When a headframe foundation and a headframe main body are constructed to about 23 meters, shaft equipment components are processed, large temporary facilities of shaft equipment are arranged, during construction of the headframe main body above about 23 meters, the shaft equipment is mounted, a crane above a hall of an elevator is hoisted before the headframe main body is finished and the top of the headframe main body is sealed, the crane is installed, and the elevator is hoisted and mounted after the top of a headframe is sealed. After the top of the headframe is sealed, the constructed headframe is decorated, simultaneously, the elevator and a sleeve frame in the headframe are mounted, after the headframe equipment is mounted, equipment of upper and lower openings is mounted, ropes are wound and a lifting container is hung after the elevator is mounted, finally, debugging running is carried, and then construction and installation operations of the headframe lifting frame are totally finished. The fast construction method of the headframe lifting system has the advantages that work hour utilization rate is high, construction speed is fast, and engineering quality is improved advantageously. Constructors, equipment and materials are reasonably allocated via parallel cross operation, and engineering manufacturing cost is lowered.

Owner:CHINA COAL NO 5 CONSTR

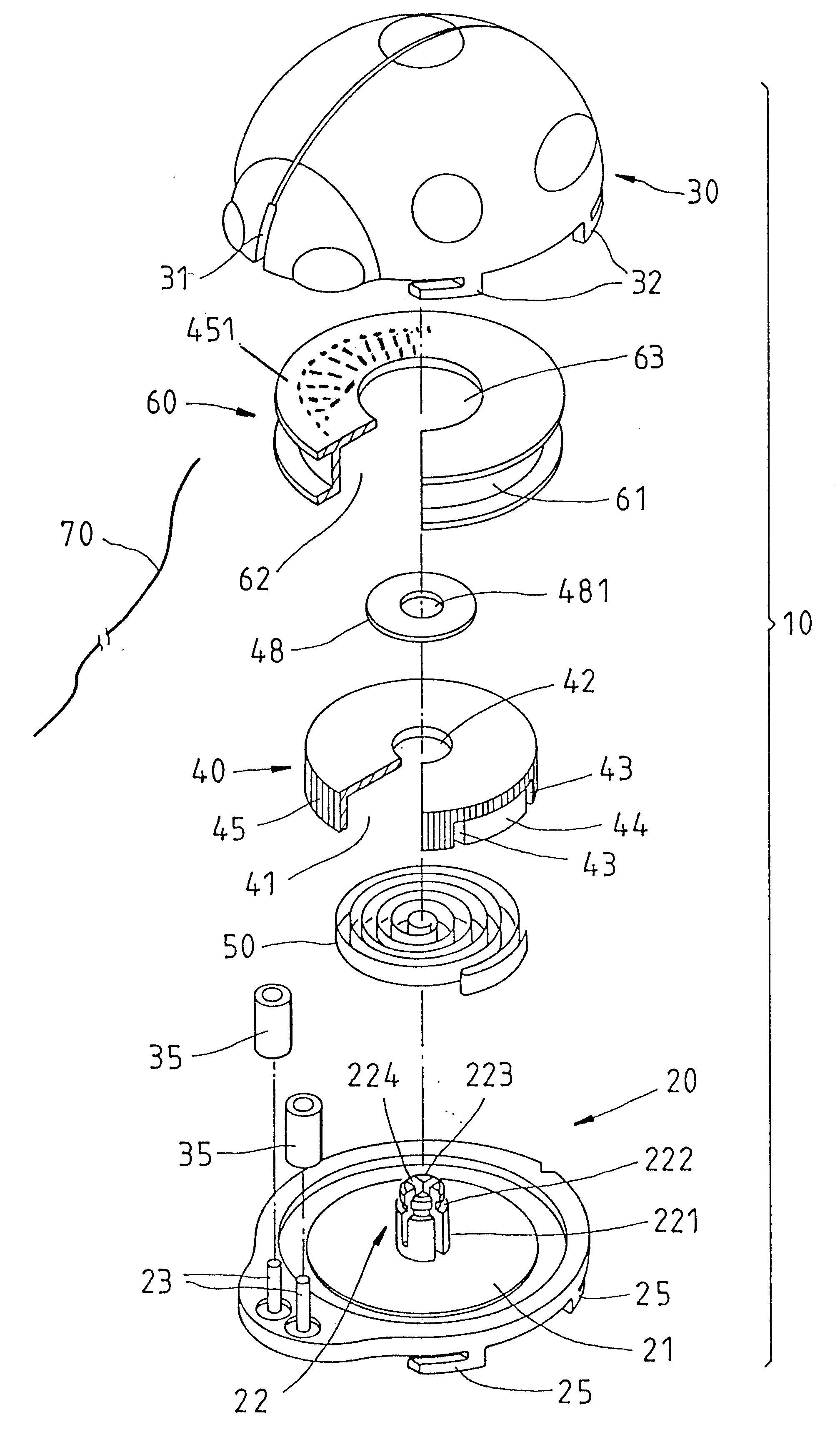

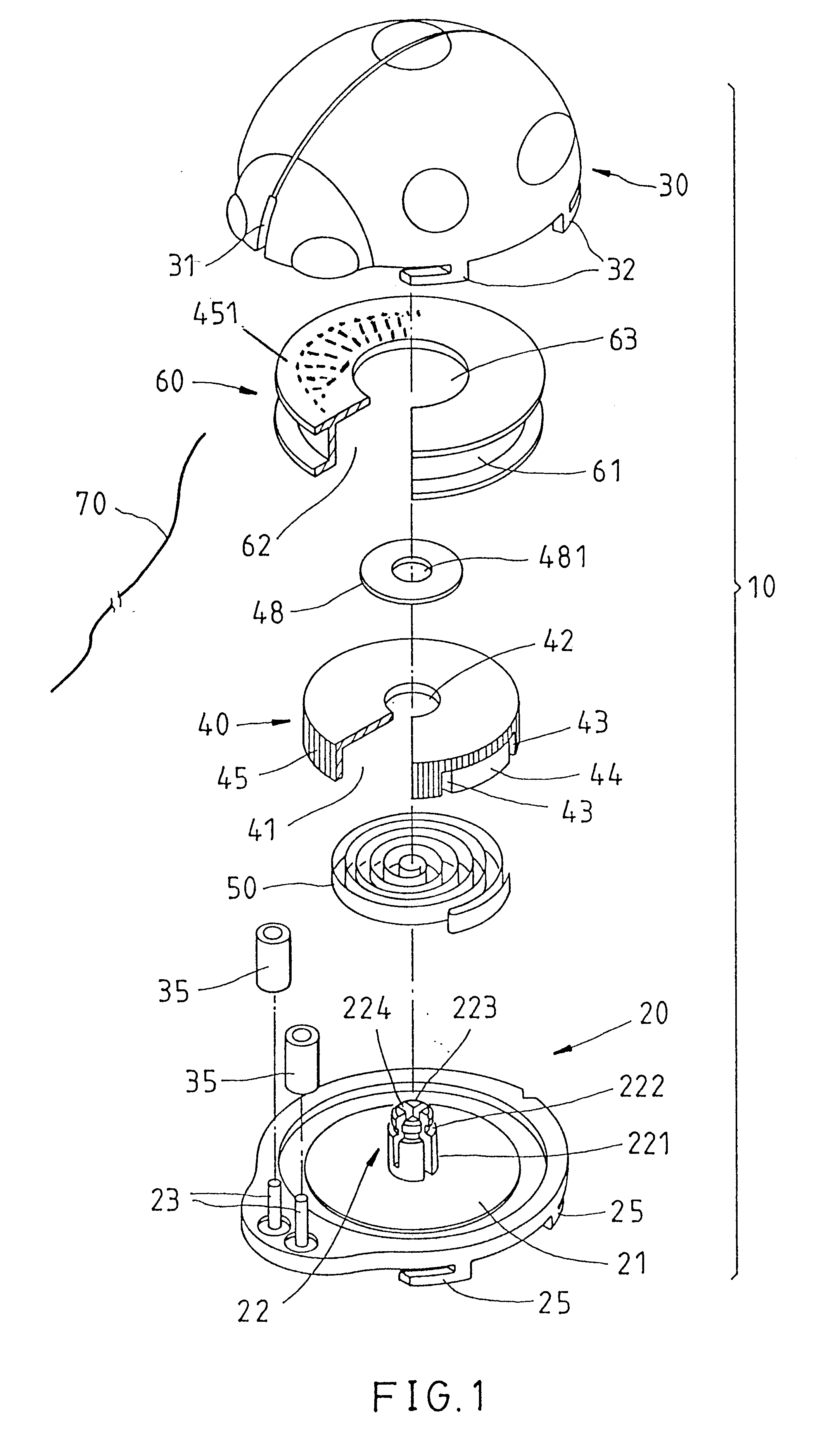

Cord controller of exercise device

A cord controlling device is used in conjunction with a game racket and is composed essentially of a housing formed of a base and an upper cover. The base is provided with a fastening portion by which the device is fastened with the head frame network of the game racket. The base is provided at the center of the upper side thereof with a shaft on which a rotary seat is rotatably mounted. The rotary seat is provided with a receiving chamber in which a volute spring is located such that the volute spring is fastened at one end thereof with the rotary, seat, and at other end thereof with the shaft of the base. A cord reel is mounted on the rotary seat for winding up or letting out a cord which is wound on the cord reel such that the cord is fastened at one end thereof with the cord reel, and that other end of the cord is let out via a cord outlet of the housing for fastening with a ball.

Owner:PENG HSIN HSING

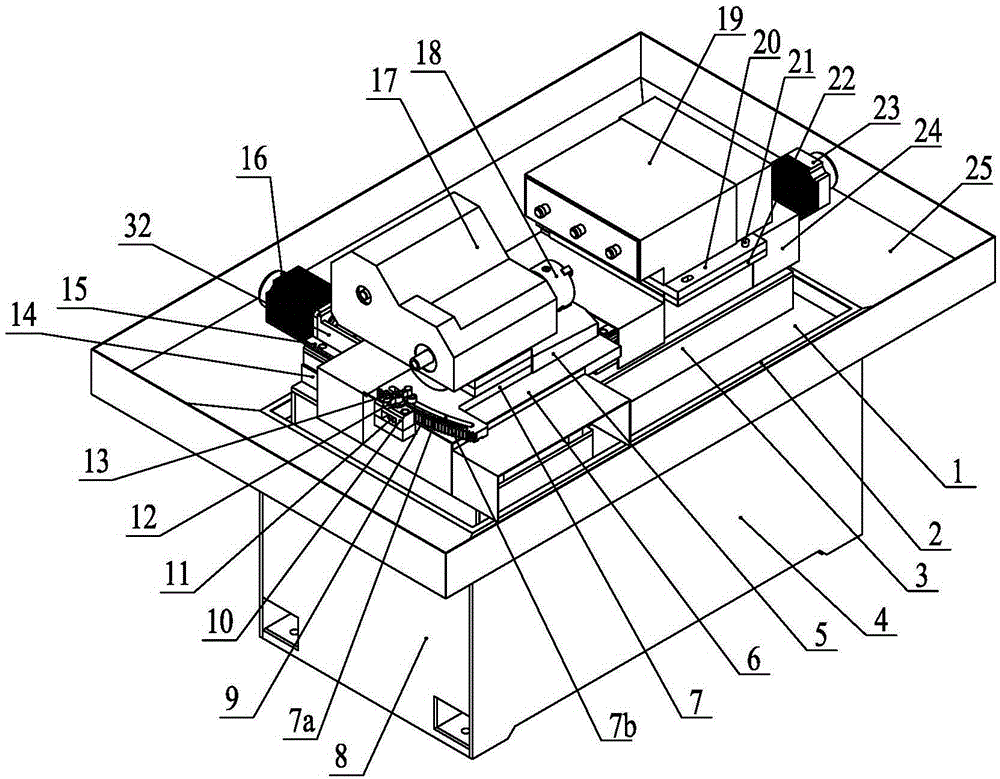

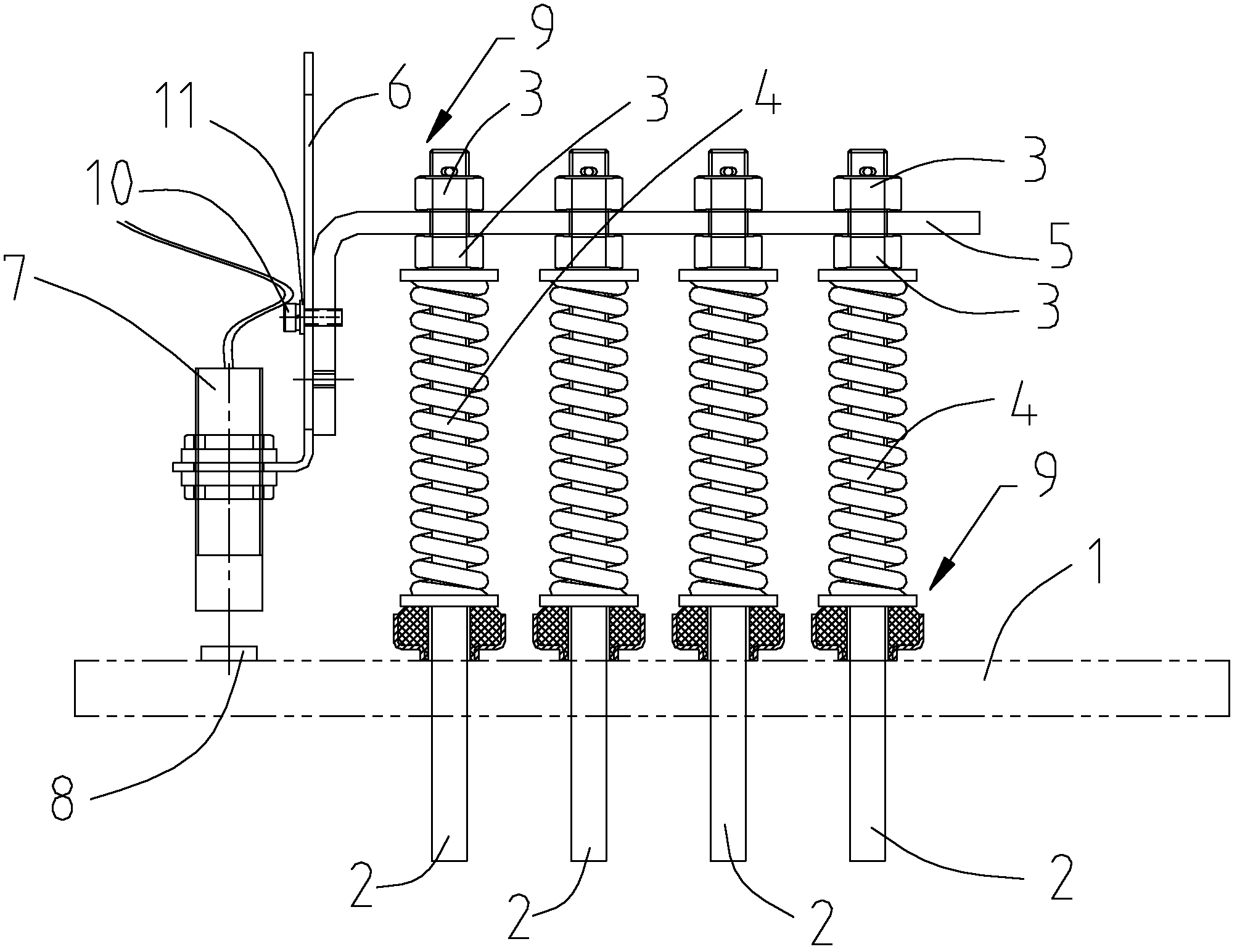

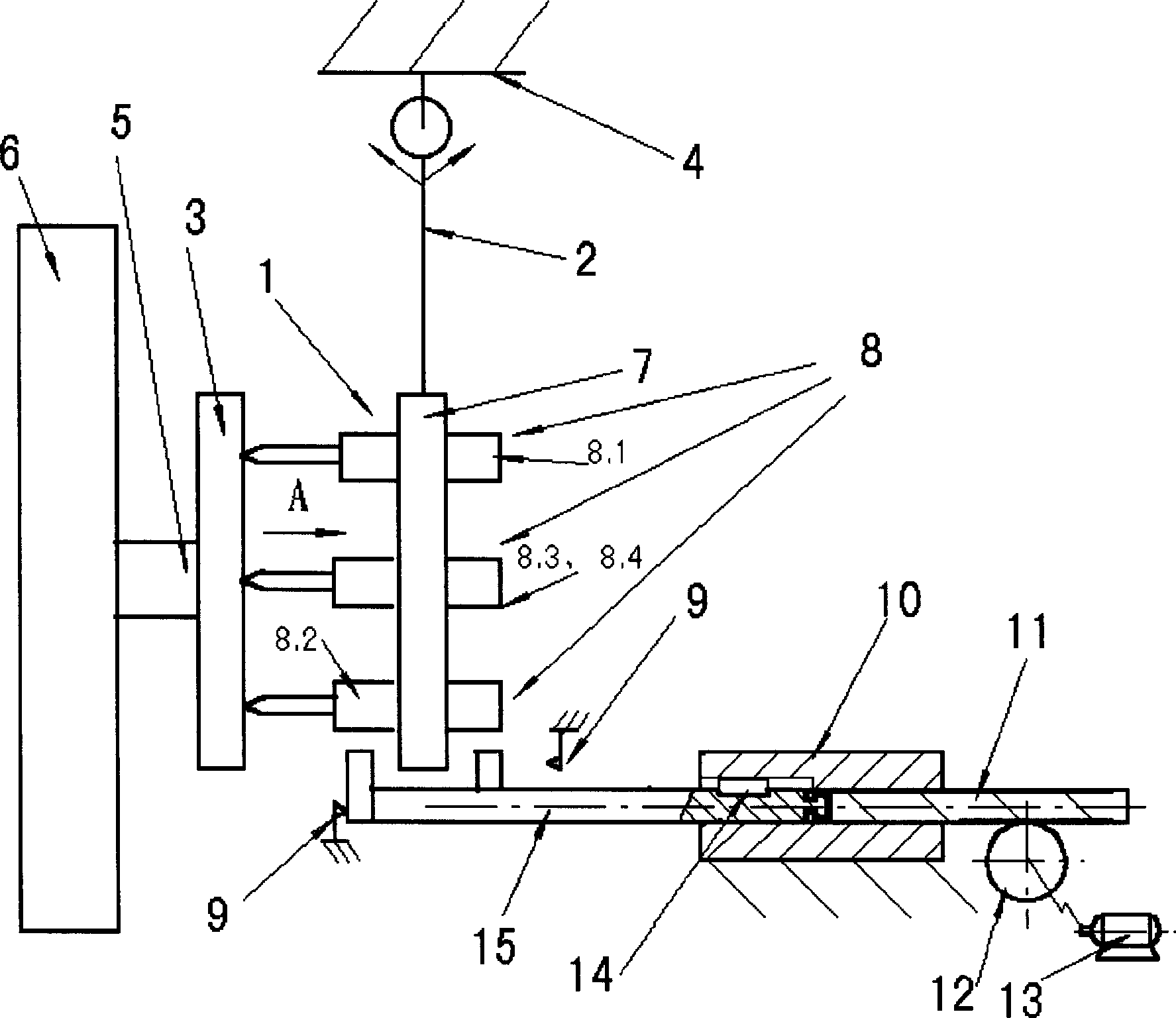

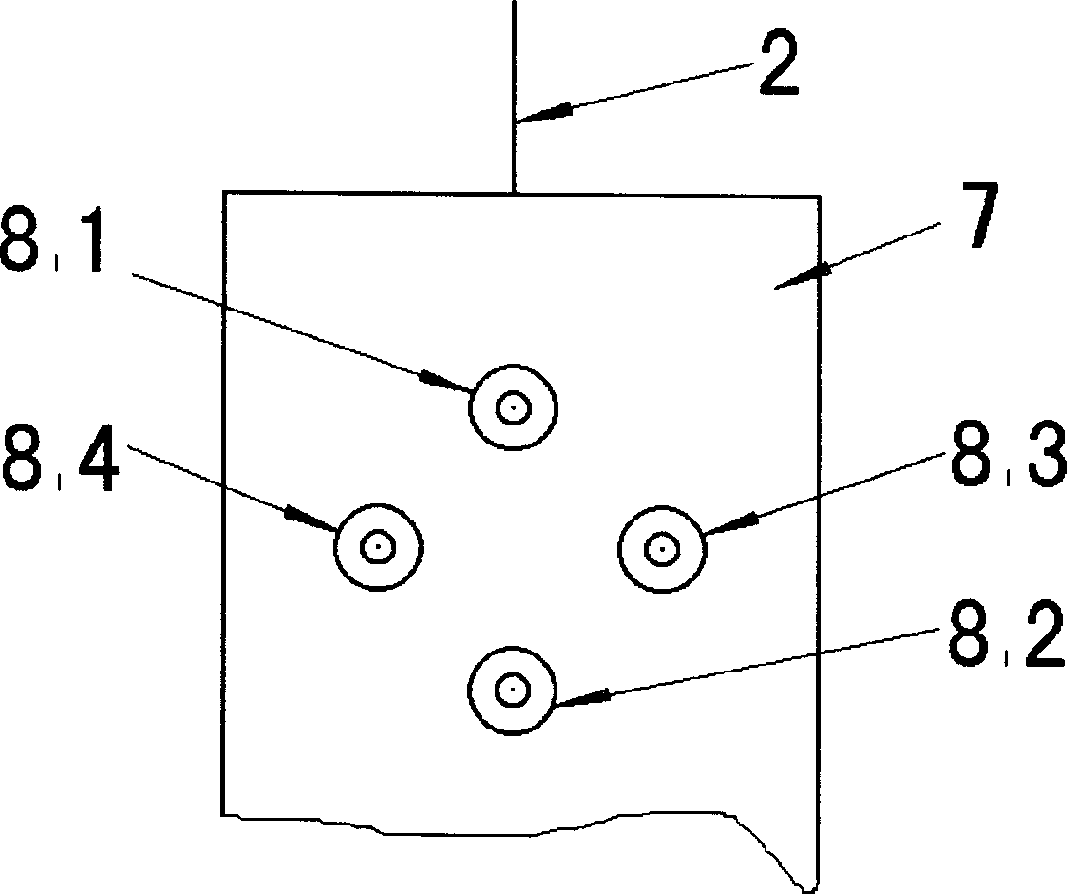

High-speed internal grinding machine

ActiveCN104440425AWide range of machining anglesReasonable and ingenious structural designGrinding carriagesRevolution surface grinding machinesHeadframeWater flow

The invention relates to a high-speed internal grinding machine which comprises a machine body, a worktable base, a water tank, a headstock device and a grinding device. The high-speed internal grinding machine is characterized in that the machine body comprises a main platform, the four corners of the main platform are supported by four supporting legs, the four side edges of the main platform are each provided with a water baffle side plate higher than the main platform face, the worktable base is installed on the main platform, a water flow channel is formed between the periphery of the worktable base and the water baffle side plates on the four edges of the machine body, the main platform is provided with a drainage tube communicated with the water flow channel, the water tank is connected with the lower end of the drainage tube, the headstock device is installed on the left side of the top of the worktable base, the headstock device is used for clamping a workpiece and driving the workpiece to rotate, the grinding device is installed on the right side of the top of the worktable base, and a grinding wheel is installed on the grinding device for grinding the internal circle of the workpiece. The high-speed internal grinding machine is ingenious and reasonable in structural design, the machining angle range of the internal circle of the workpiece is large, the high machining speed is achieved, and the machining precision and efficiency can be greatly improved.

Owner:HEZE BOILER FACTORY

Development method of blind shaft frame for surface and underground parallel construction

The invention relates to a development method of a blind shaft frame for surface and underground parallel construction, which belongs to underground mining and shaft construction techniques, in particular to a construction method of a main shaft development system. The method comprises the following steps that a sinking headframe is arranged on the ground; a shaft neck section is dug downward; a shaft hole, a shaft body and all horizontal horseheads are constructed; the sinking headframe is removed; a sheave wheel platform is arranged on the ground; a shaft tower foundation is constructed; slip-form construction is performed, so that the height of a shaft tower is 10 m; a hoisting rope is arranged in a penetrating manner; all horizontal development tunnels and chambers under a main shaft are constructed; additionally, a slip-form technique is adopted to construct the shaft tower on the ground, and surface and underground installation is performed at the same time. The development method has the advantages of novel concept, safety, reliability, surface and underground parallel construction and obvious benefits, the labor productivity is improved, the construction period is shortened, and a shaft is put into operation in advance.

Owner:安徽马钢张庄矿业有限责任公司

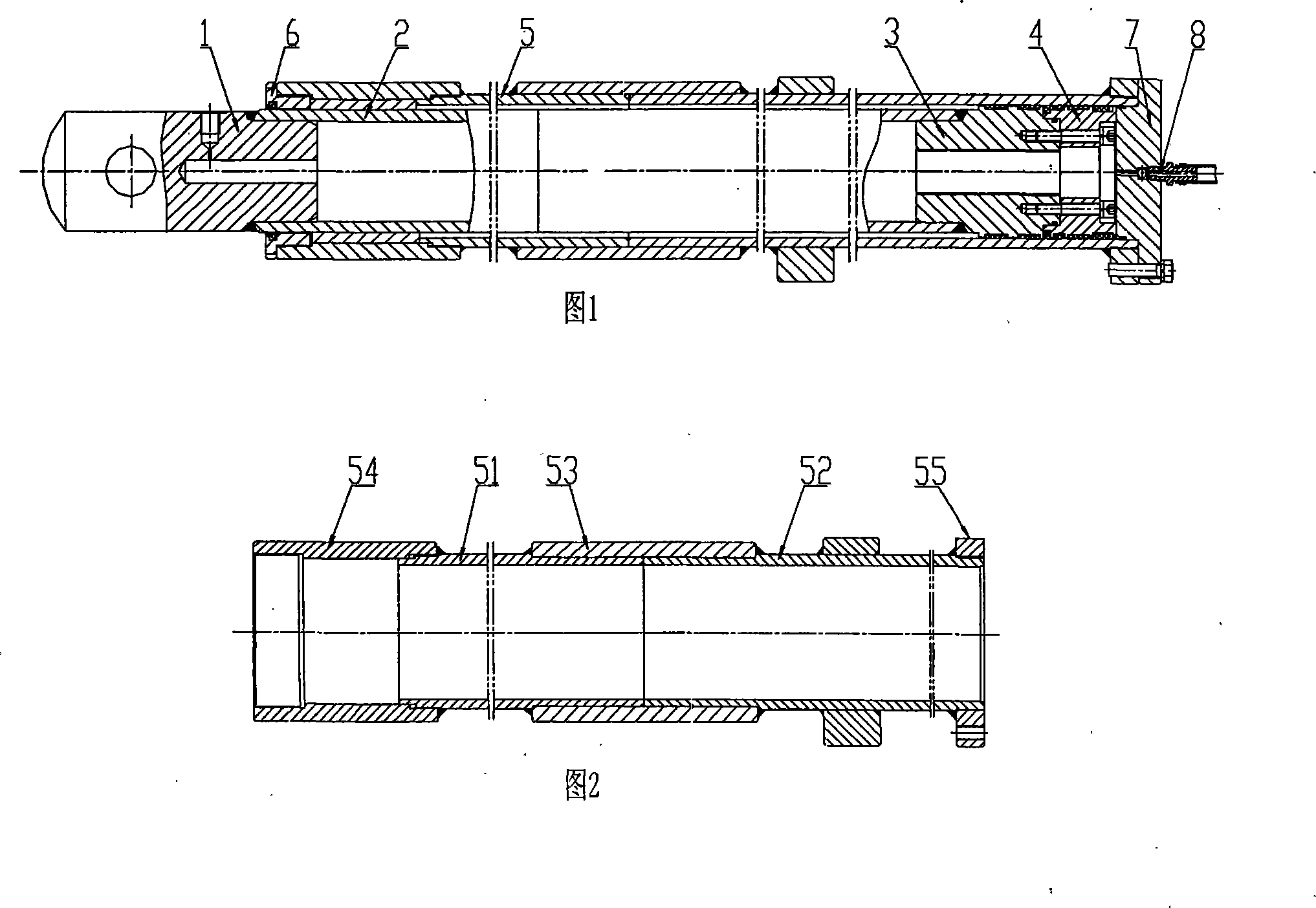

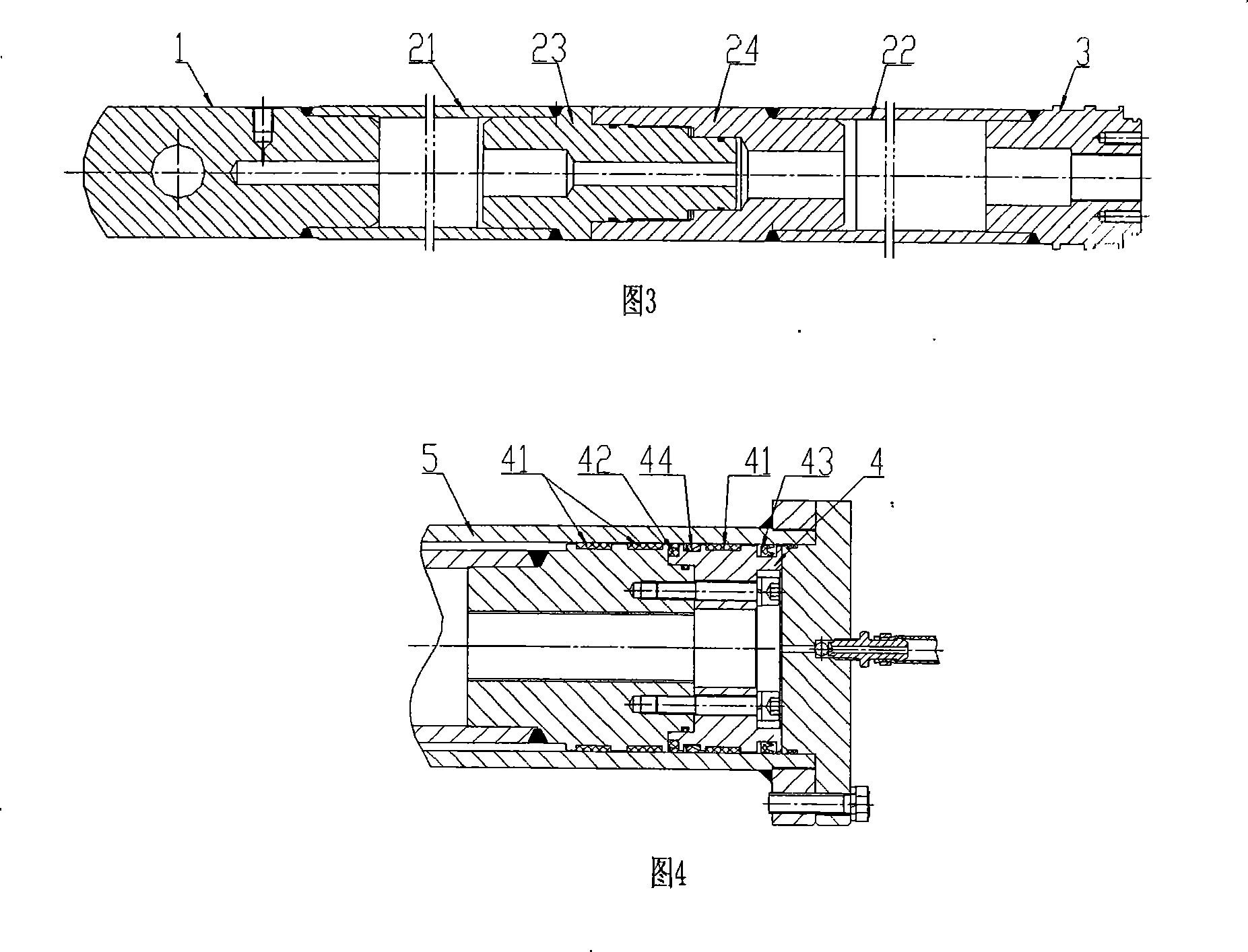

Large journey low-temperature extension hydraulic cylinder manufacture method

InactiveCN101216056AMeet the intensityImprove low temperature toughnessPiston ringsPlungersHeat-affected zoneAlloy

The invention relates to the technology for manufacturing a hydraulic cylinder, in particular to a method for manufacturing a large-stroke low temperature stretching hydraulic cylinder. The large-stroke low temperature stretching hydraulic cylinder is used on an oil well rig or a service machine working in cold areas and is used for stretching of a nesting headframe. In the technological process of the invention, low temperature resistant alloy structural steel is selected to be blanked and machined into components; the components are conventionally heated; a low temperature process is adopted to weld, connect and assemble the components; low temperature resistant sealing elements are arranged in the four sealed grooves of a piston. In this way, the large-stroke low temperature stretching hydraulic cylinder is manufactured. The large-stroke low temperature stretching hydraulic cylinder manufactured through the method has good low temperature property; the performance of the welds and the heat-affected zones of the cylinder tube and a piston rod reaches the following indices: Sigma b is more than or equal to 410MPa; Delta s is more than or equal to 20 percent; Akv (-45 DEG C) is more than or equal to 27J; the large-stroke low temperature stretching hydraulic cylinder can meet the requirements for intensity, toughness, rigidity and elasticity under low temperature (-45 DEG C), and works reliably with high sealing performance.

Owner:NANYANG NANSHI LITIAN PETROLEUM EQUIP CO LTD

Mine using great steel derrick lifting special tool

When erecting a steel structure headframe, by traditional operation method, when using a tackle, the tackle is fixed on a holding rod by a steel wire rope and easily rotates and wrings, and causes uneven stress of the rope; therefore, a headframe can not be accurately hoisted to a correct position, which thus brings about bigger security hidden trouble. A main inclined frame part is fixed by a leg-stumble ground anchor to overcome horizontal thrust of the main inclined frame; but larger emplacement deviation is caused on the main inclined frame; when hoisting by using a plurality of steady vehicles, discrepant stress of each vehicle can create lopsidedness of a single vehicle and cause safety accident. In order to remove the three technological obstacles, in operation process of 60 headframes in recent 20 years, three technologies of a special fixture for holding a rod head, a steel foldout and a balance rope threading method and equipments (1. the special fixture for holding a rob head; 2. the foldout; 3. the balance rope threading method) are progressively researched and developed. Hidden troubles in the process of erecting the headframe are thoroughly overcome.

Owner:CHINA COAL NO 3 CONSTR GRP +1

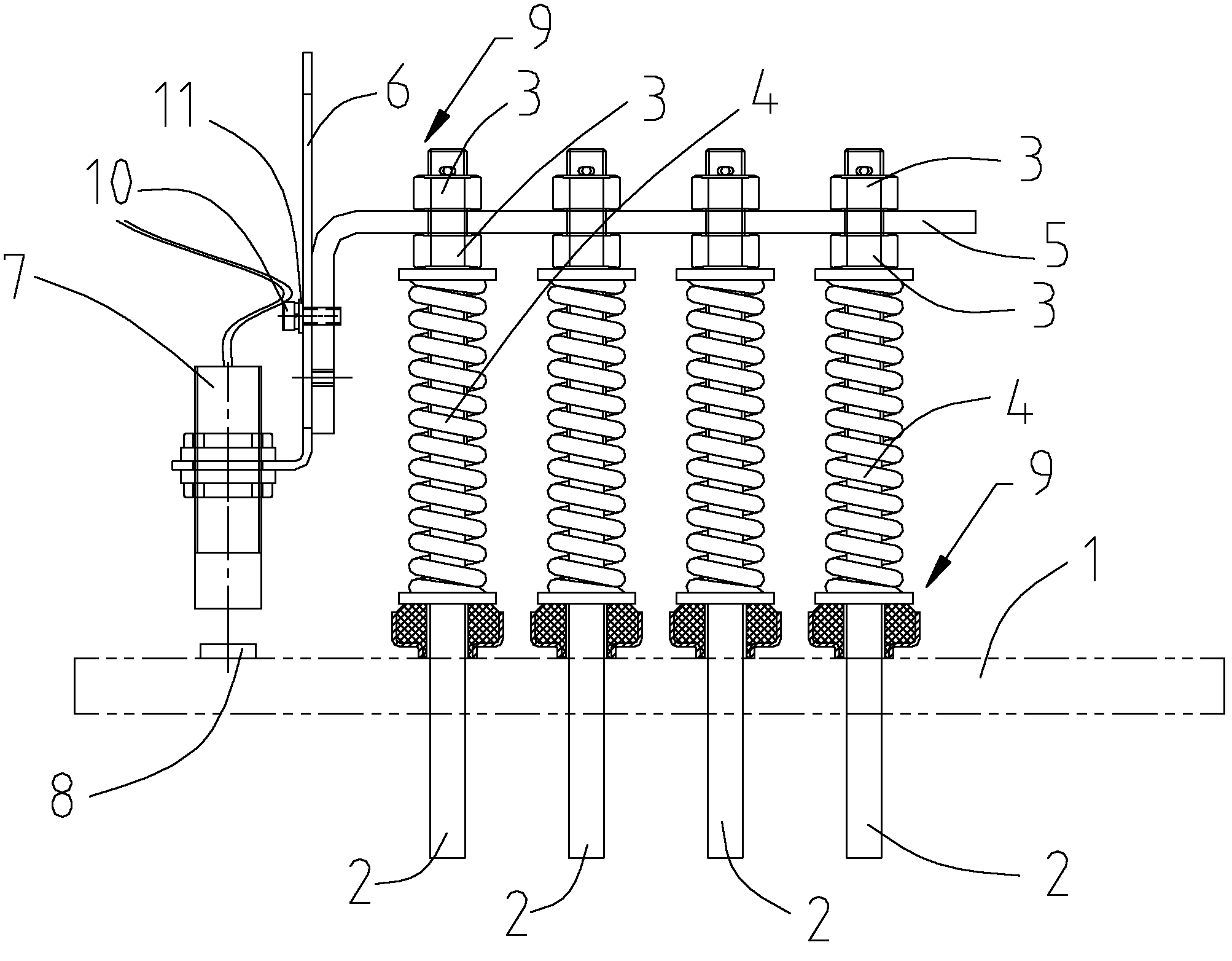

Elevator lift car load weighing device

InactiveCN102351120AOvercome elastic resistanceAccurate measurementElevatorsHeadframeMechanical engineering

The invention discloses an elevator lift car load weighing device, which comprises an installing plate, a sensor probe and sensor square magnetic steel, wherein the sensor probe is arranged on the installing plate, the sensor square magnetic steel is arranged on a rope end plate, the sensor probe is over against the sensor square magnetic steel, in addition, a sensing distance is left between the sensor probe and the sensor square magnetic steel, an installing hole is arranged in the installing plate, a screw rod is penetrated in the installing plate, and the installing plate is tightly clamped between a pair of screw nuts. The lift car load measurement is based on the displacement generated through the lift car load stress and is irrelevant with whether the lift car load is balanced or not, so the measurement is accurate. During the lift car load measurement, the sensor probe and the square magnetic steel are arranged on a rope end assembly and the rope end plate, so the installation and the debugging of elevators with equipment rooms can be directly carried out in the equipment rooms, for elevators without equipment rooms, installation personnel can directly install the sensor probe and the square magnetic steel during the installation of a lift car or a counterpoise rope end frame, the lift car is stopped in a proper position during the debugging, the operation can be carried out on the top of the lift car, and the operation is very convenient.

Owner:SUZHOU FUSHI ELEVATOR

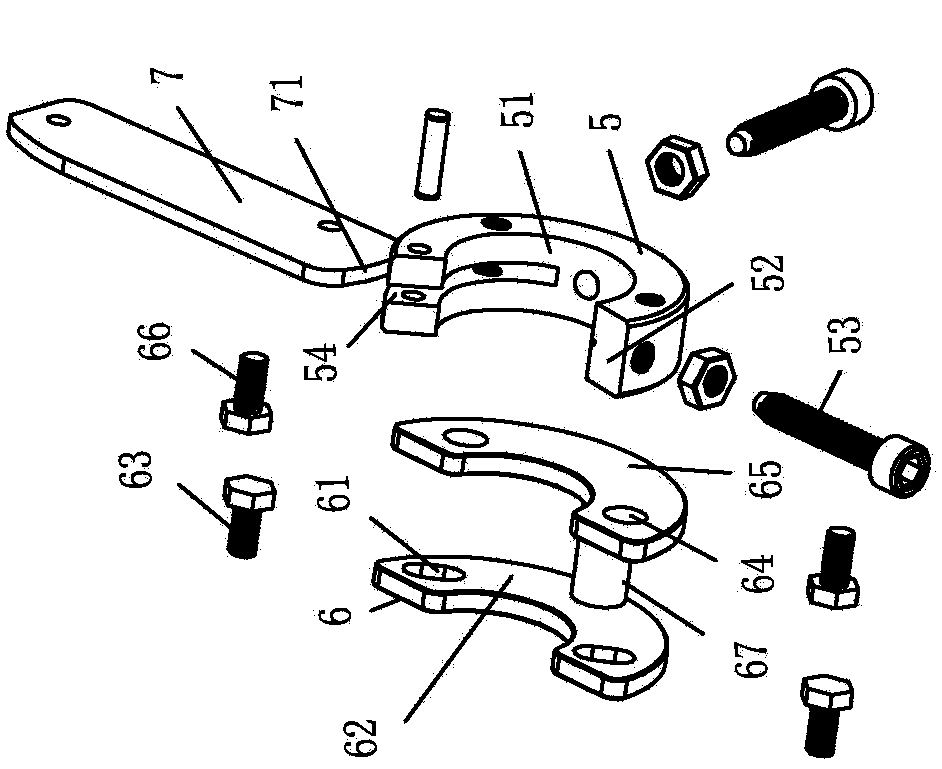

Workpiece clamping device and workpiece clamping method for cylindrical grinding machine

InactiveCN104209857AGuaranteed coaxialityImprove clamping efficiencyRevolution surface grinding machinesGrinding work supportsHeadframeMachine

The invention relates to the field of a grinding fixture, aiming at providing a workpiece clamping device and a workpiece clamping method for a cylindrical grinding machine. The workpiece clamping device for the cylindrical grinding machine comprises a connecting handle, a headstock center, a one-way bearing, a bearing seat, a workpiece clamping body, an adjusting component, a clamping toggle piece, a toggle piece opening stay rope, a deflector rod position sensor and a controller, wherein the front end of the connecting handle is provided with a center hole; the rear end of the headstock center is arranged in the center hole; an inner ring of the one-way bearing is connected with the connecting handle in a transmission way; the bearing seat is provided with a front check ring and is connected with an outer ring of the one-way bearing; the workpiece clamping body is provided with a middle hole and an opening; the adjusting component is respectively connected with the workpiece clamping body and the front check ring; the clamping toggle piece is provided with a clamping arc surface at the inner end and is articulated with the opening side end; a plurality of clamping adjusting screws which are distributed along the circumference are arranged at the side periphery of the workpiece clamping body; the two ends of the toggle piece opening stay rope are respectively connected with the outer end of the clamping toggle piece and a deflector rod of the cylindrical grinding machine. After the workpiece clamping device for the cylindrical grinding machine is used, the coaxiality between the clamping axis and the workpiece axis can be maintained, clamping is conveniently carried out, and the clamping efficiency is higher.

Owner:余姚市锋利电动工具厂(普通合伙)

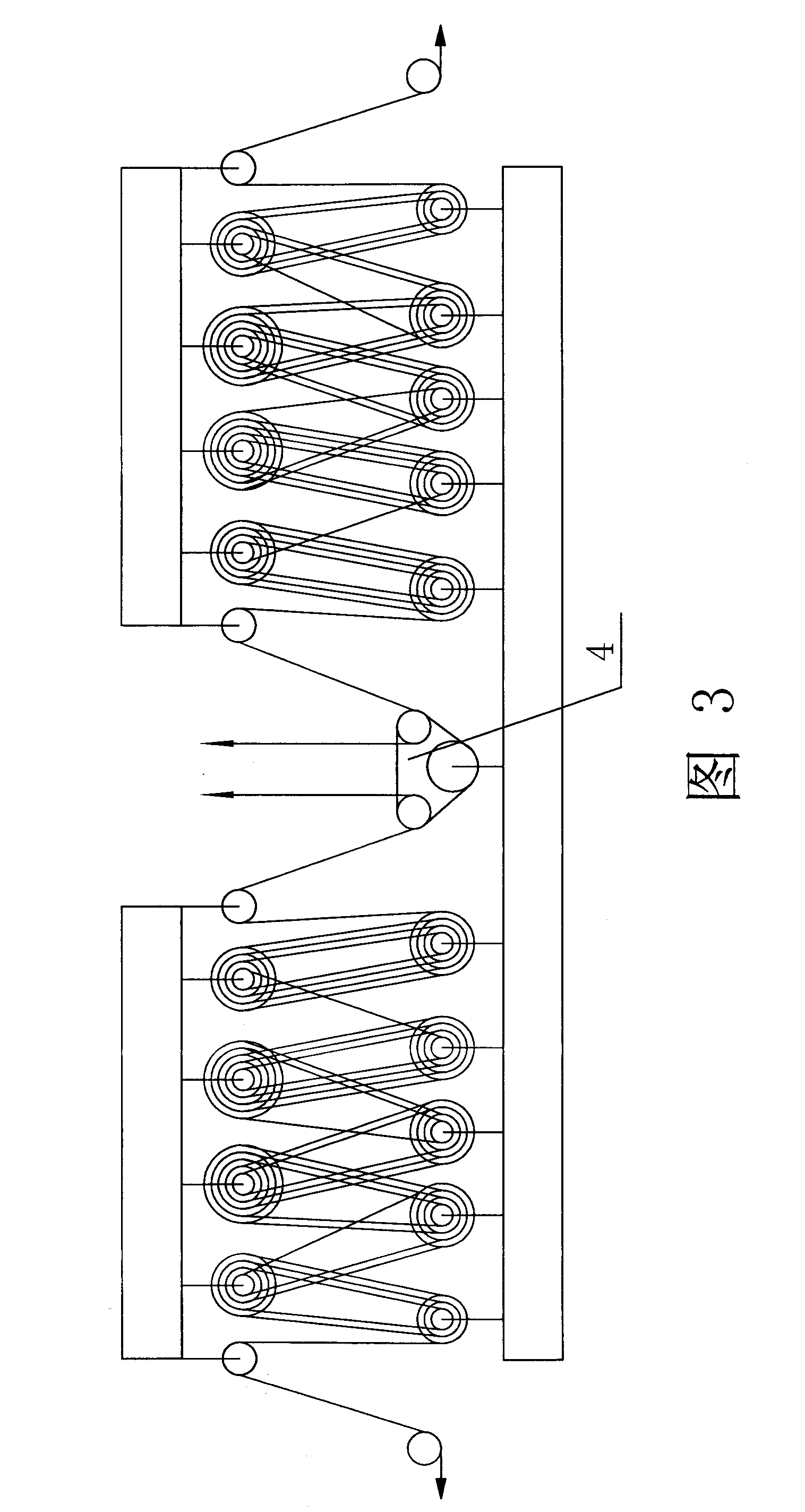

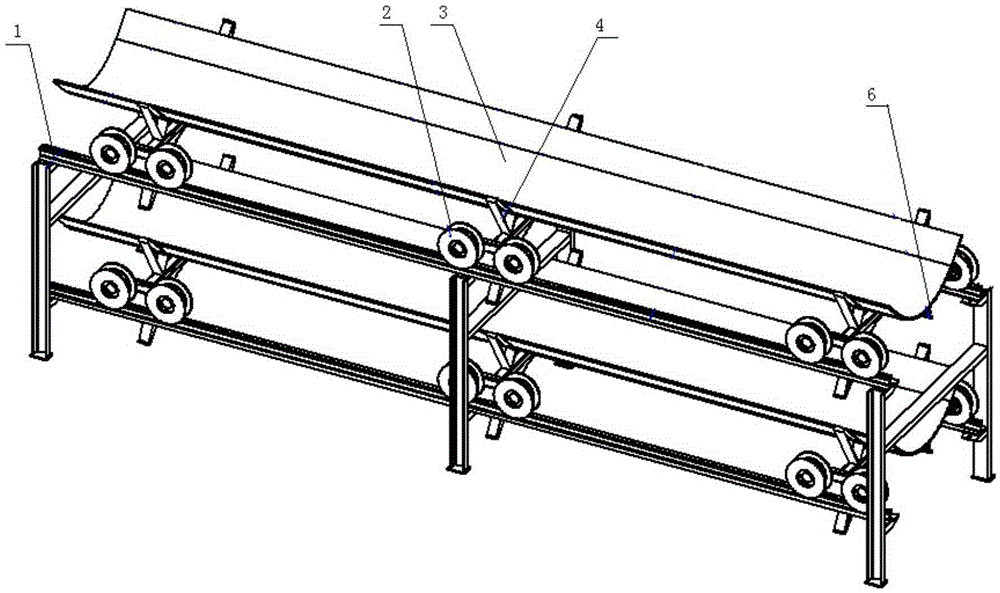

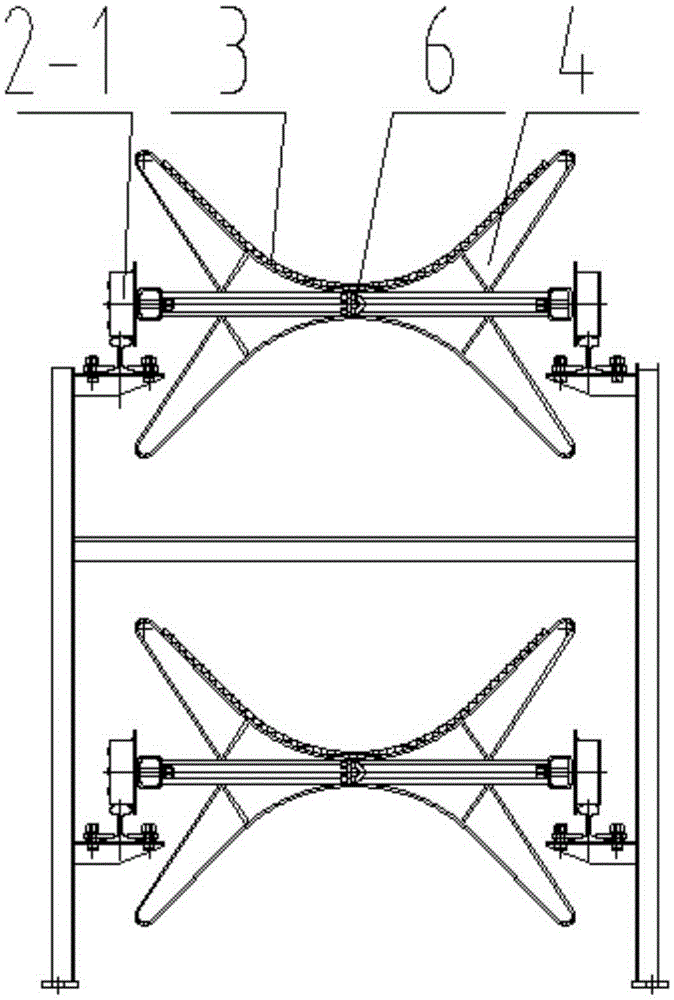

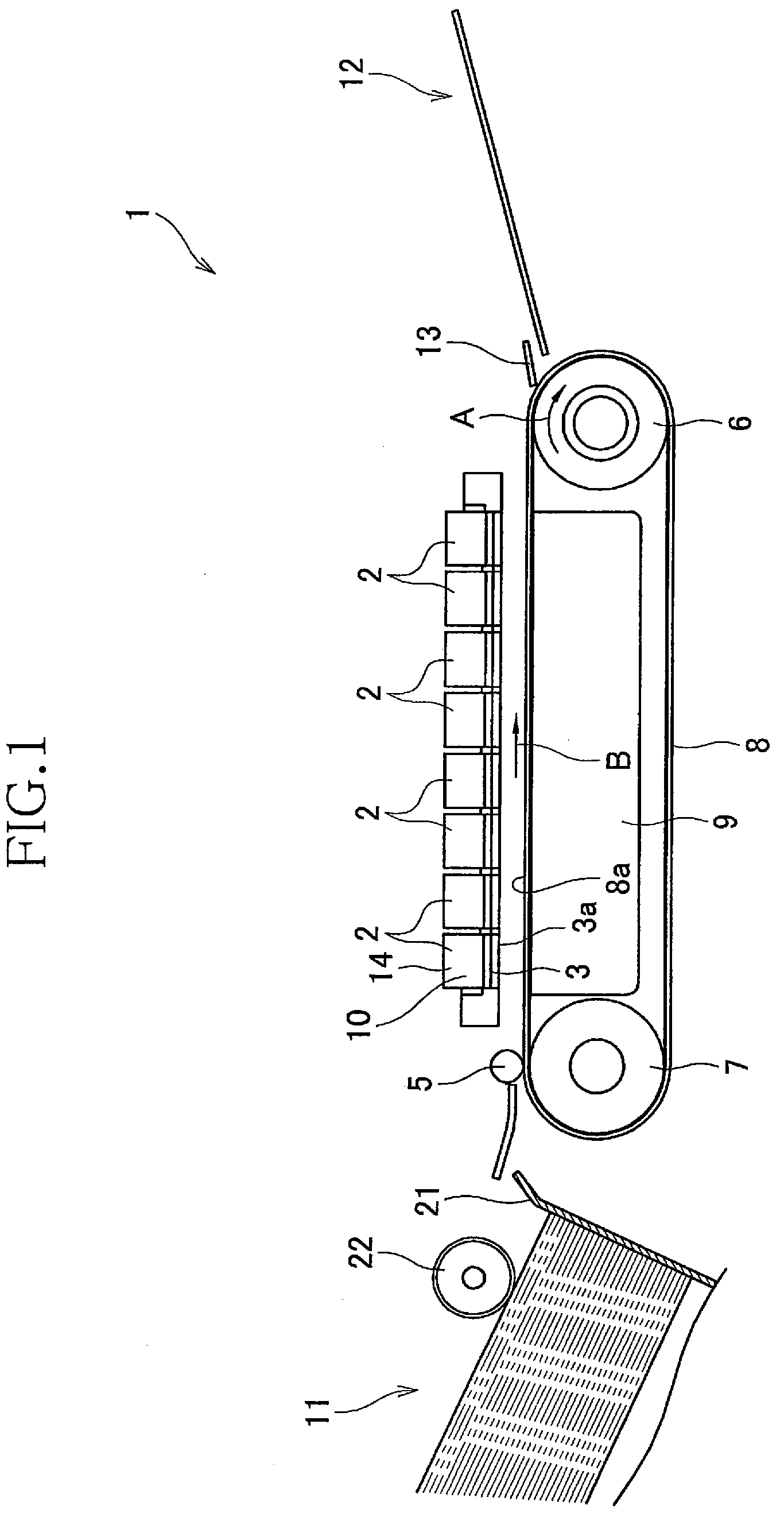

Rail type belt conveyor

The invention relates to a rail type belt conveyor. The rail type belt conveyor comprises a support, a machine head frame, a machine tail frame, an upper guide rail, a lower guide rail, a towing trolley, a rubber belt, a steel wire rope, closed-loop systems, a driving roller, an elevating supporting roller set, a redirection frame and a triangular frame. The elevating supporting roller set is mounted at the position, close to the machine head frame, of the support, the redirection frame is mounted on the machine tail frame, a redirection drum is arranged on the machine head frame, and a tensioning vehicle is arranged at the position, close to one side of the redirection drum, of the support; and the triangular frame is arranged at the position, between the two closed-loop systems, of the support, and the rubber belt is wound around the elevating supporting roller set, the redirection drum, the tensioning vehicle, a supporting roller on the redirection frame and a supporting roller on the triangular frame. The rail type belt conveyor has the beneficial effects that a traditional rubber belt machine structure is removed, a supporting belt trolley is used for replacing a part of a common supporting roller, the cost and the mounting cost are reduced, and revolutionary innovation is brought to bulk conveying.

Owner:LIBO HEAVY MACHINE TECH

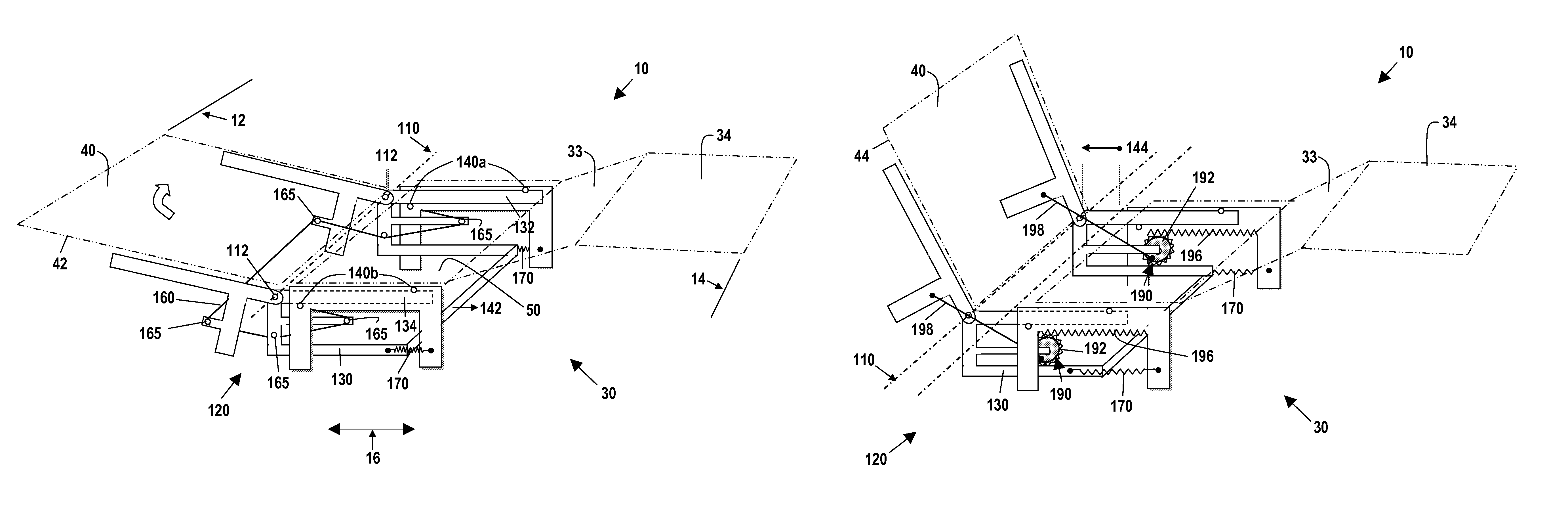

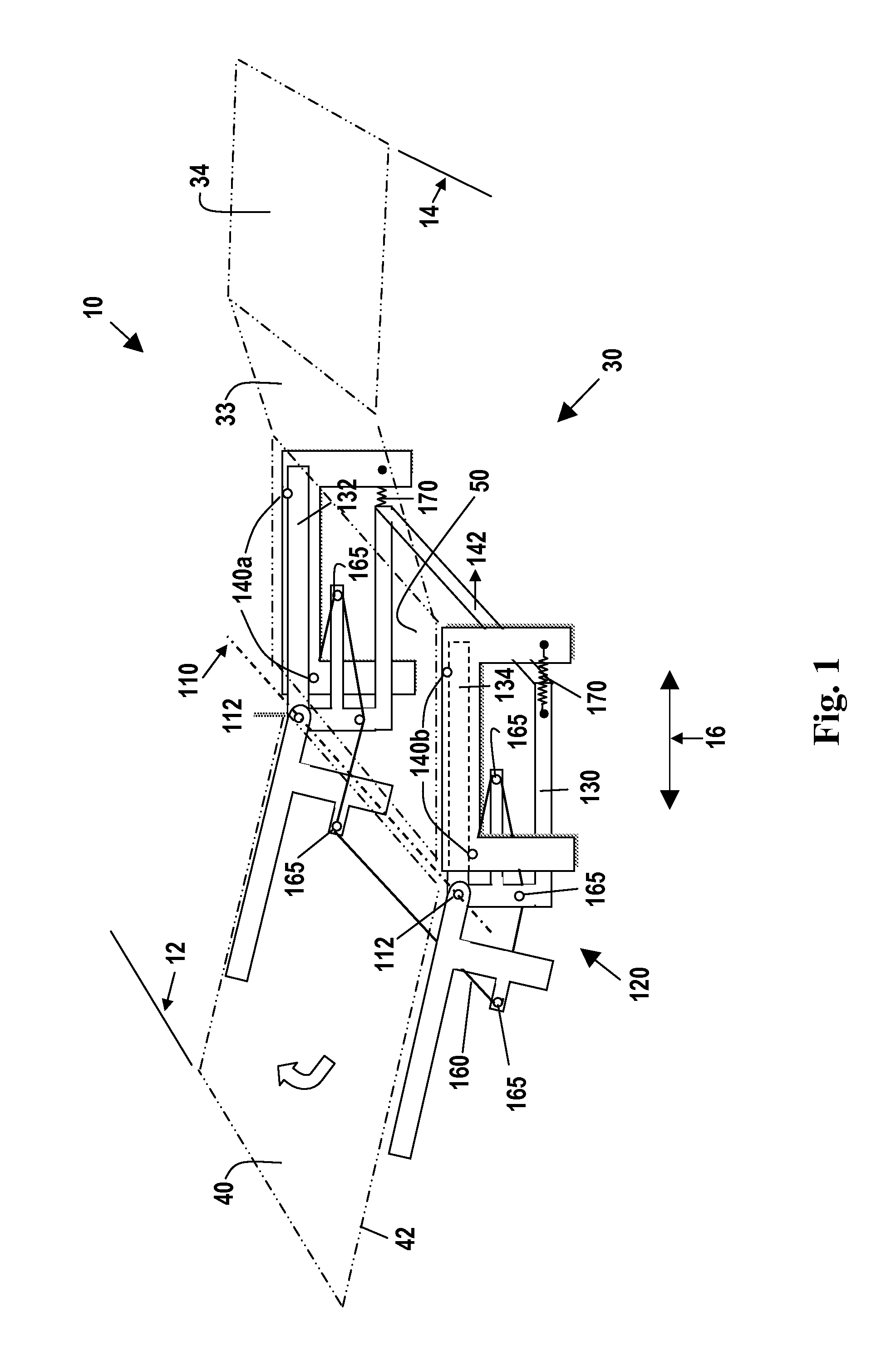

Knockdown adjustable bed with a slidable assembly

An adjustable bed includes: a head frame assembly; a foot frame assembly; a knockdown connecting bracket; a slidable assembly having a pair of slidable assembly sides slidable within a pair of lower C steel brackets in a slidable assembly upward direction or a slidable assembly downward direction; a plurality of slidable assembly angle steels; a pair of head lift arm bracket assemblies; a second head tilt angle bracket; a head tilt platform; a head lift platform; a lumbar lift bracket assembly; an upper seat platform; a support platform; a lower seat platform; a head lift motor, secured to the head frame assembly for driving the pair of head lift arm bracket assemblies in a head lift forward direction or a head lift backward direction; and a head support tube, having an upper end pivotally connected to a L bracket and a lower end connected to the head lift platform.

Owner:NISCO

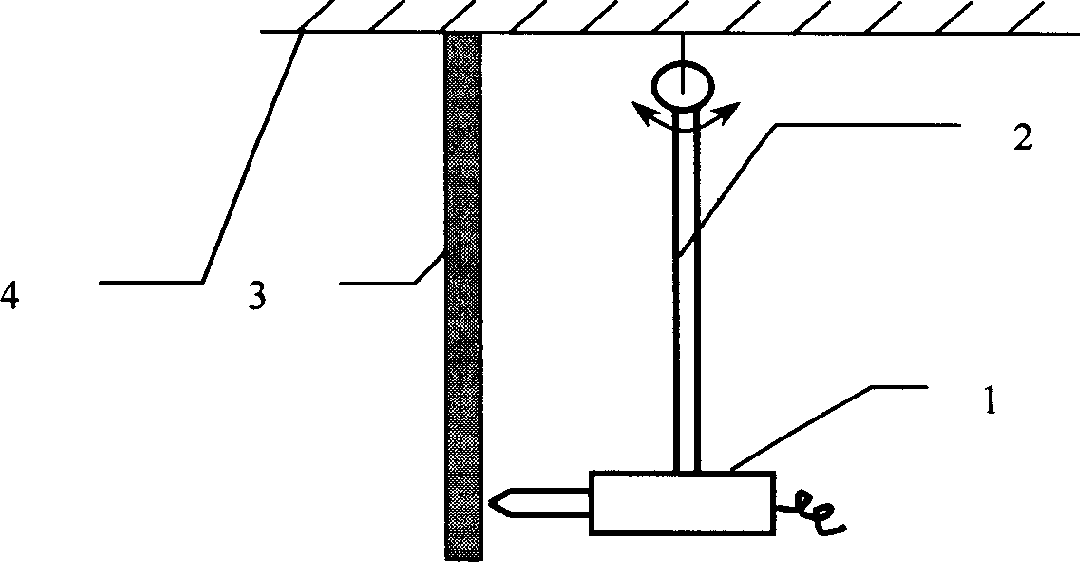

Autoamtic monitor method and device for safety of mining headframe

InactiveCN1397785ASave monitoring dataReliable measurementFluid removalIncline measurementSignal conditioning circuitsHeadframe

A method and device for monitoring the safety of mining headframe is disclosed. A measuring plate is arranged on the headframe. A shift sensor on gravity pendulum is used to measure the relative shift between the said measuring plate and sensor. The measured signal is processed by circuits and then sent to lower-position unit. The upper-position and lower-position units are communicated with each other via telephone line. The actual shift value is calculated by upper-position unit for displaying, storing, or printing. If the value is higher than a threshold, an alarm signal is autoamtic generated.

Owner:WUHAN UNIV

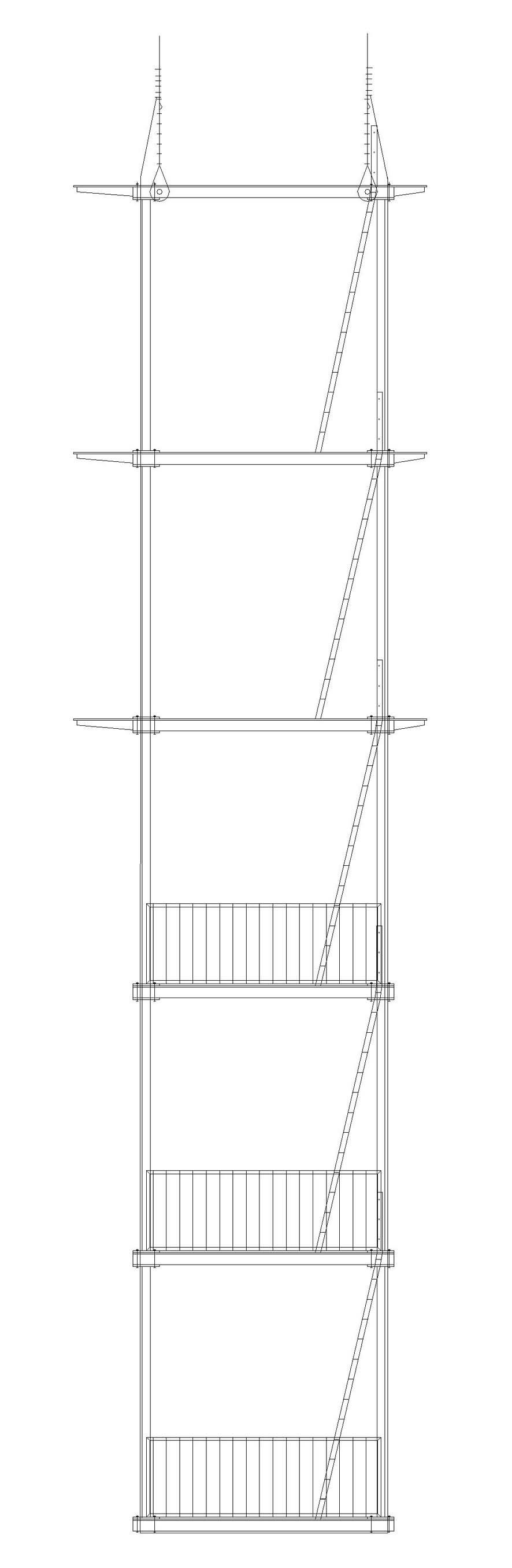

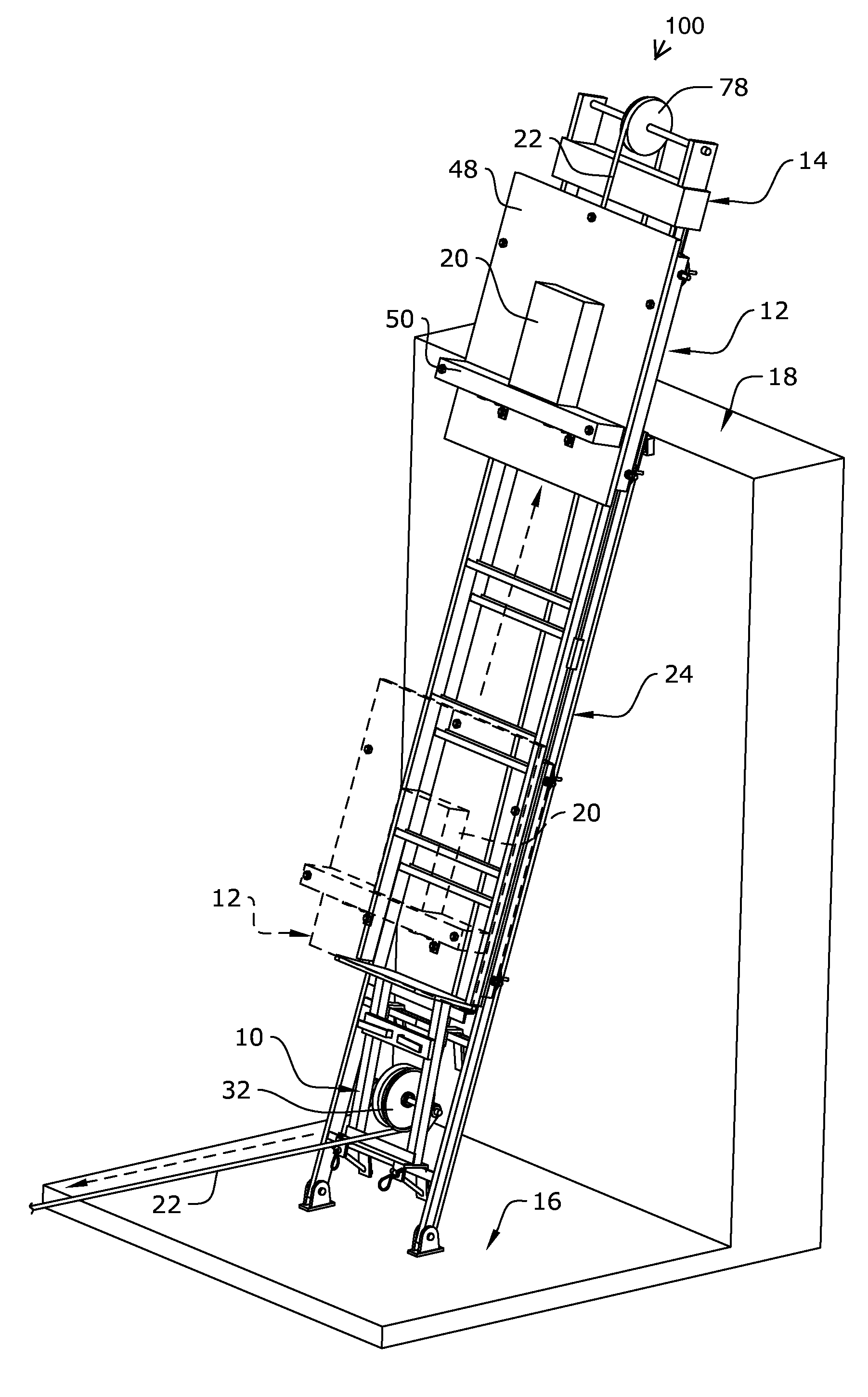

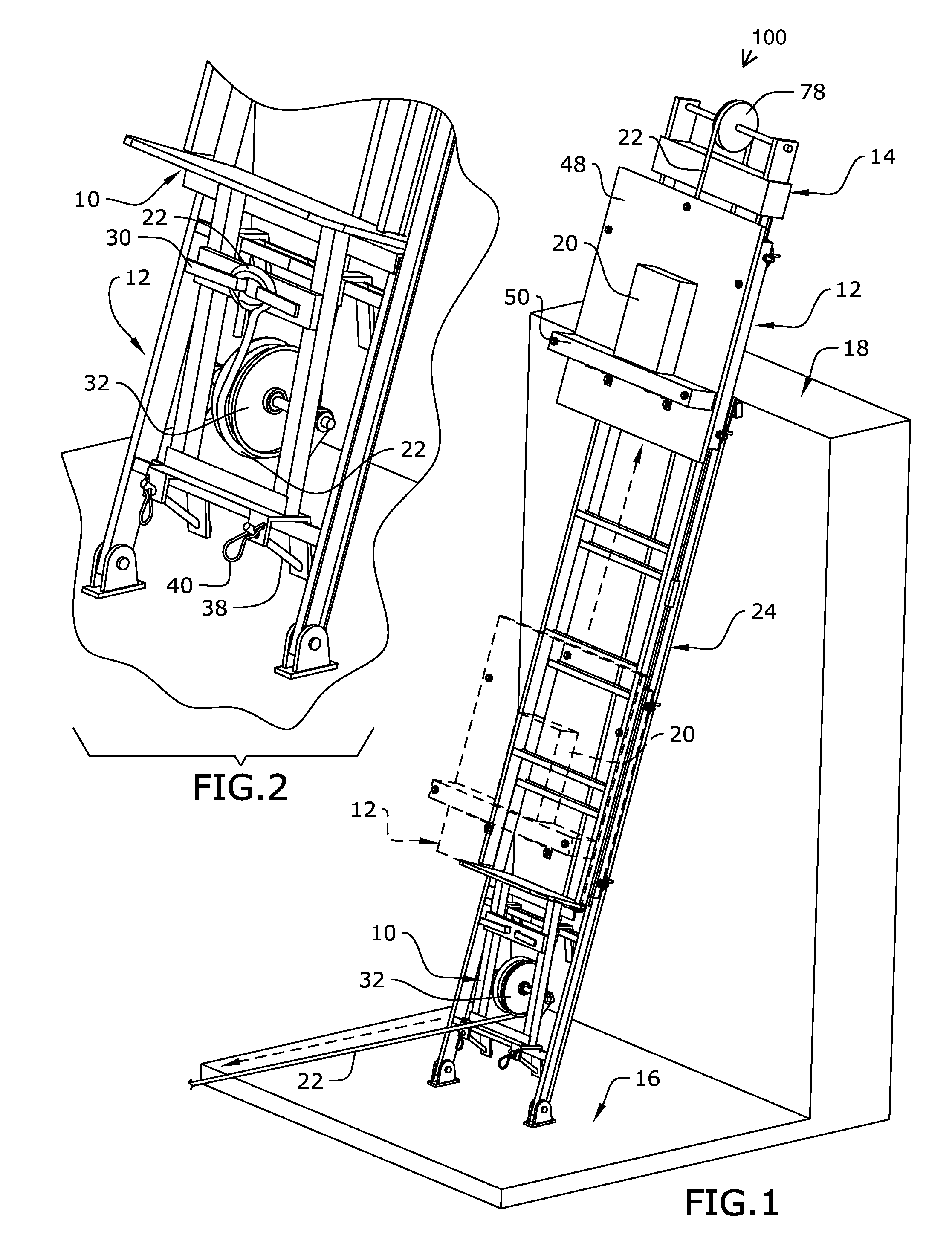

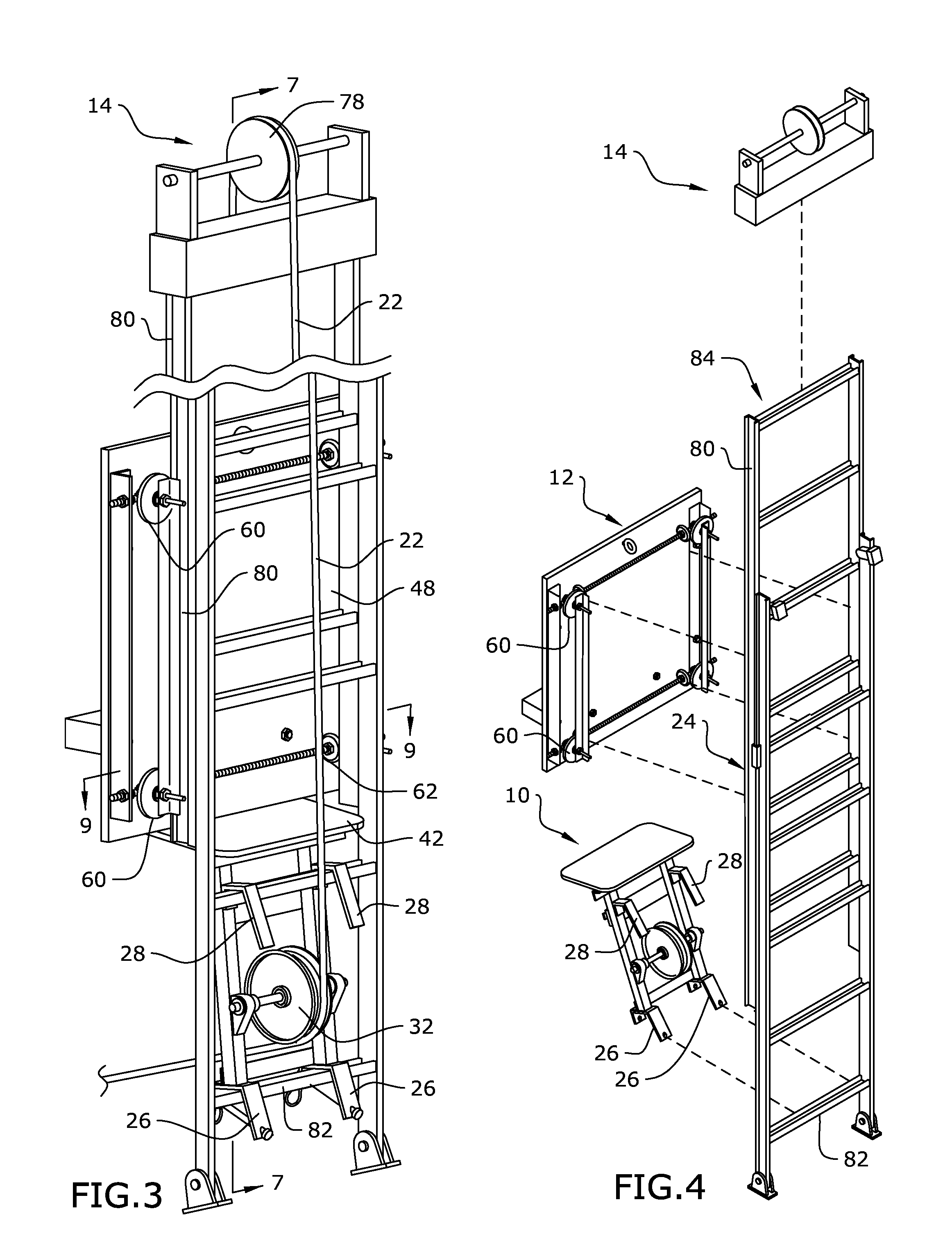

Ladder lift system

A manually-powered, adaptive ladder lift system for hoisting objects along a ladder to a predetermined height is provided. The ladder lift system may include a stop assembly, a trolley assembly, and a headstock assembly adapted to engage the ladder, whereby the trolley assembly rolls along the side rails of the ladder between the headstock assembly mounted to the top of the ladder and the stop assembly mounted to a lower portion thereof. The headstock assembly is adapted to various types and sizes of ladders. The stop assembly is adapted to retain the trolley assembly at the predetermined height anywhere between the stop assembly and the headstock assembly.

Owner:STRAND WARREN

Multifunctional servo driven glass press with gears

The invention discloses a multifunctional servo driven glass press with gears, which comprises a base, an upper bracing frame, a stamping apparatus, a die holder, a big disc, a moving mechanical arm, a cooling facility and a servo transmission device, the servo transmission device comprises a servo motor, a gear shifting box, a big gear and a small gear, a centrifuging device is arranged between the big gear and the small gear, a moving mechanical arm is arranged between the upper bracing frame and the big disc.

Owner:TAICANG HUANG FA JI MACHINERIES & MOLDS

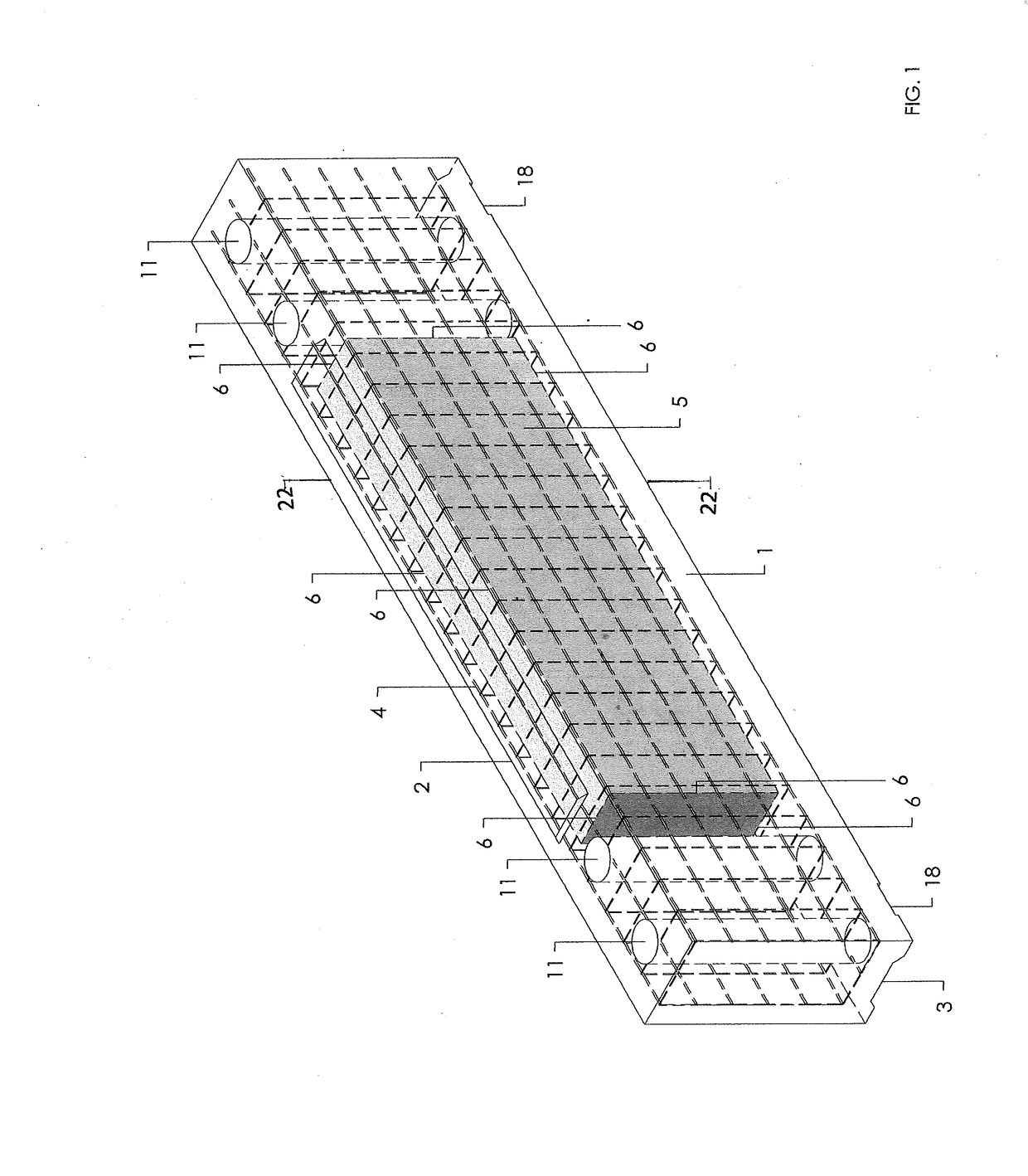

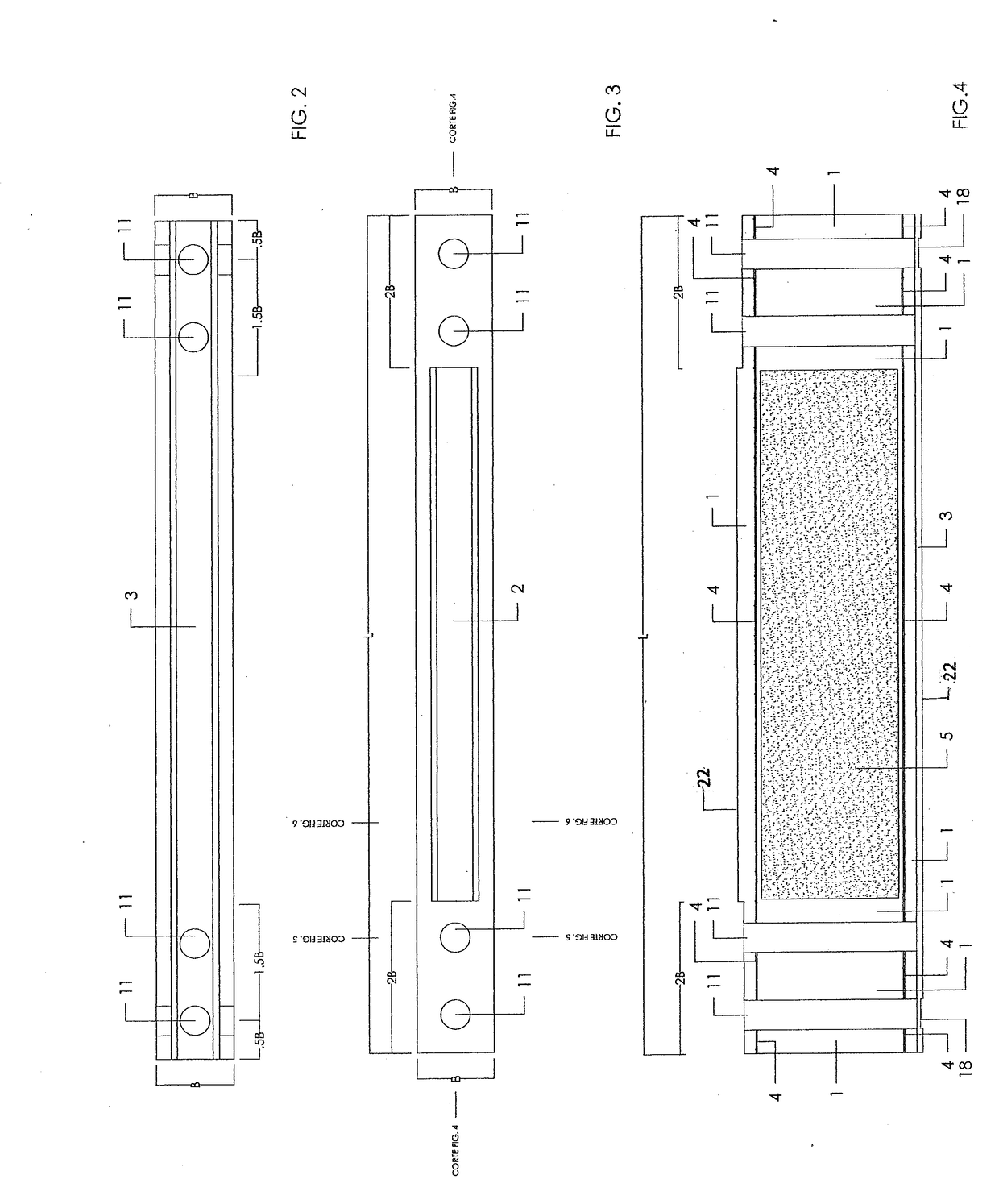

Precast Block and Installation System for Construction of Walls and Slabs

ActiveUS20180100302A1Easily and rapidly manuallyBring safety and stabilityConstruction materialWallsHeadframeTongue and groove

Precast blocks with a rectangular or quadrangular prism shape contain a normal weight hydraulic concrete casing, lightweight concrete or similar material, for building walls or slabs. The steel-reinforced blocks for walls, mezzanine or rooftop slabs have the length of the wall or slab to build. An acoustic, thermal-insulating lightweight material housed in the interior simultaneous provides for blocks sufficiently lightweight to transport and install manually on-site. For walls, the blocks are tongued and grooved on the top and bottom sides and placed horizontally one on top of the other using block or similar adhesive therebetween. In the corners or “T” intersections, blocks are alternatively placed and form armed headframes for stability and resistance. For blocks for slabs, the tongue and groove system is on the sides, installed one beside the other, using block or similar adhesive therebetween. Transversal rods to the slab are placed to avoid temperature retraction.

Owner:OLARTE MICHEL MANUEL HUMBERTO

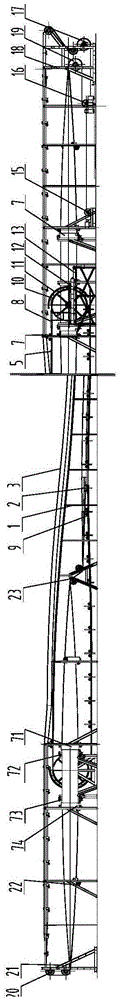

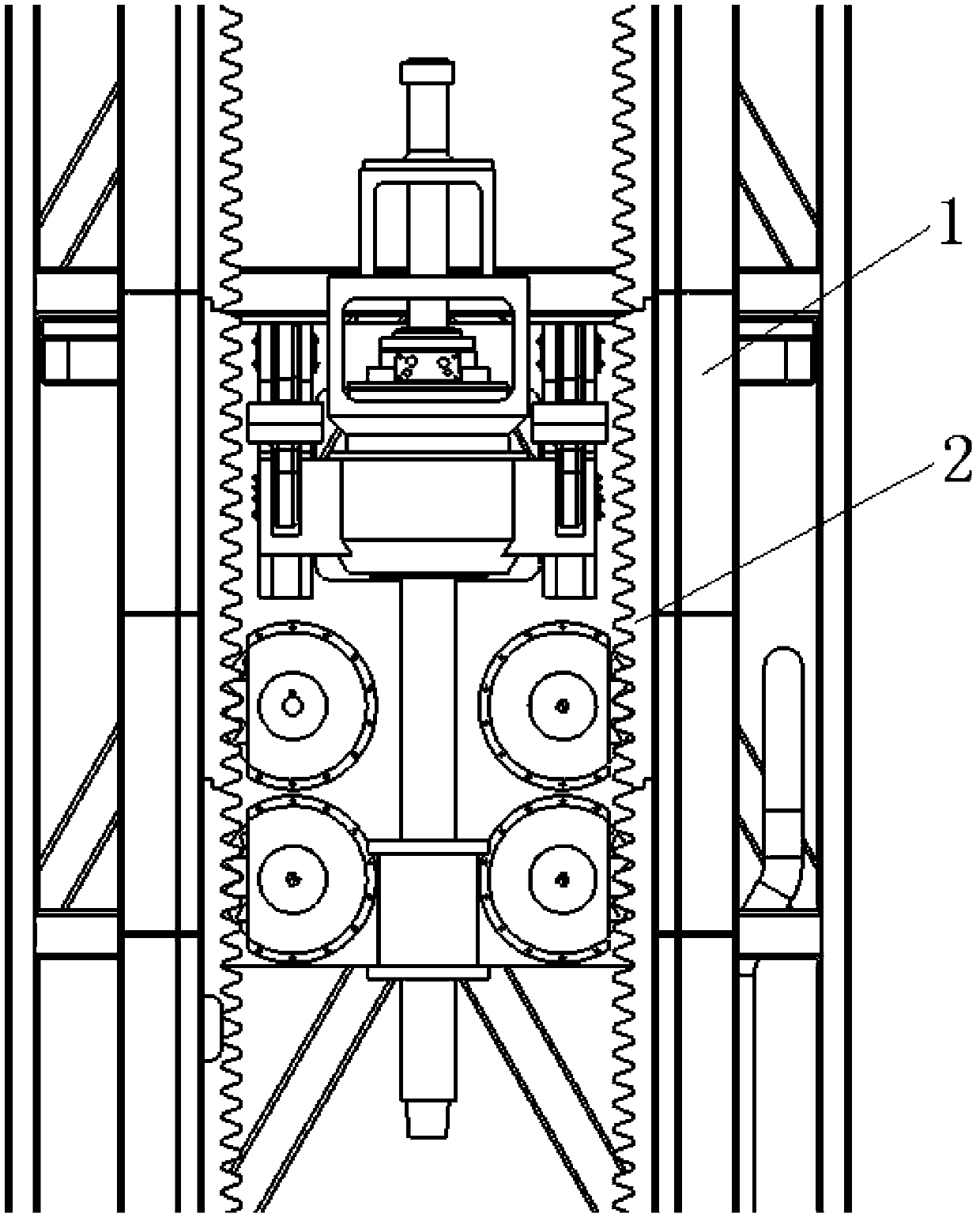

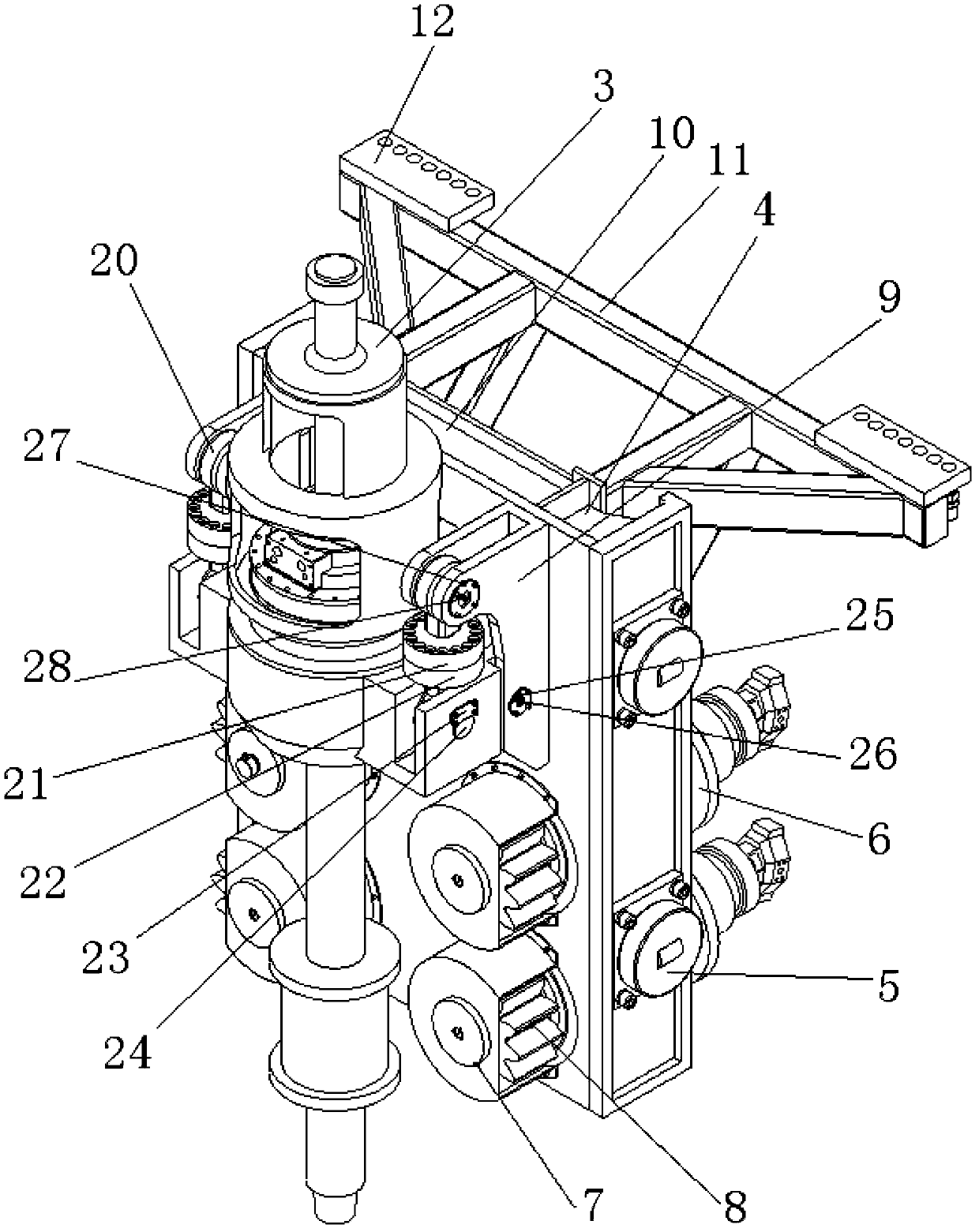

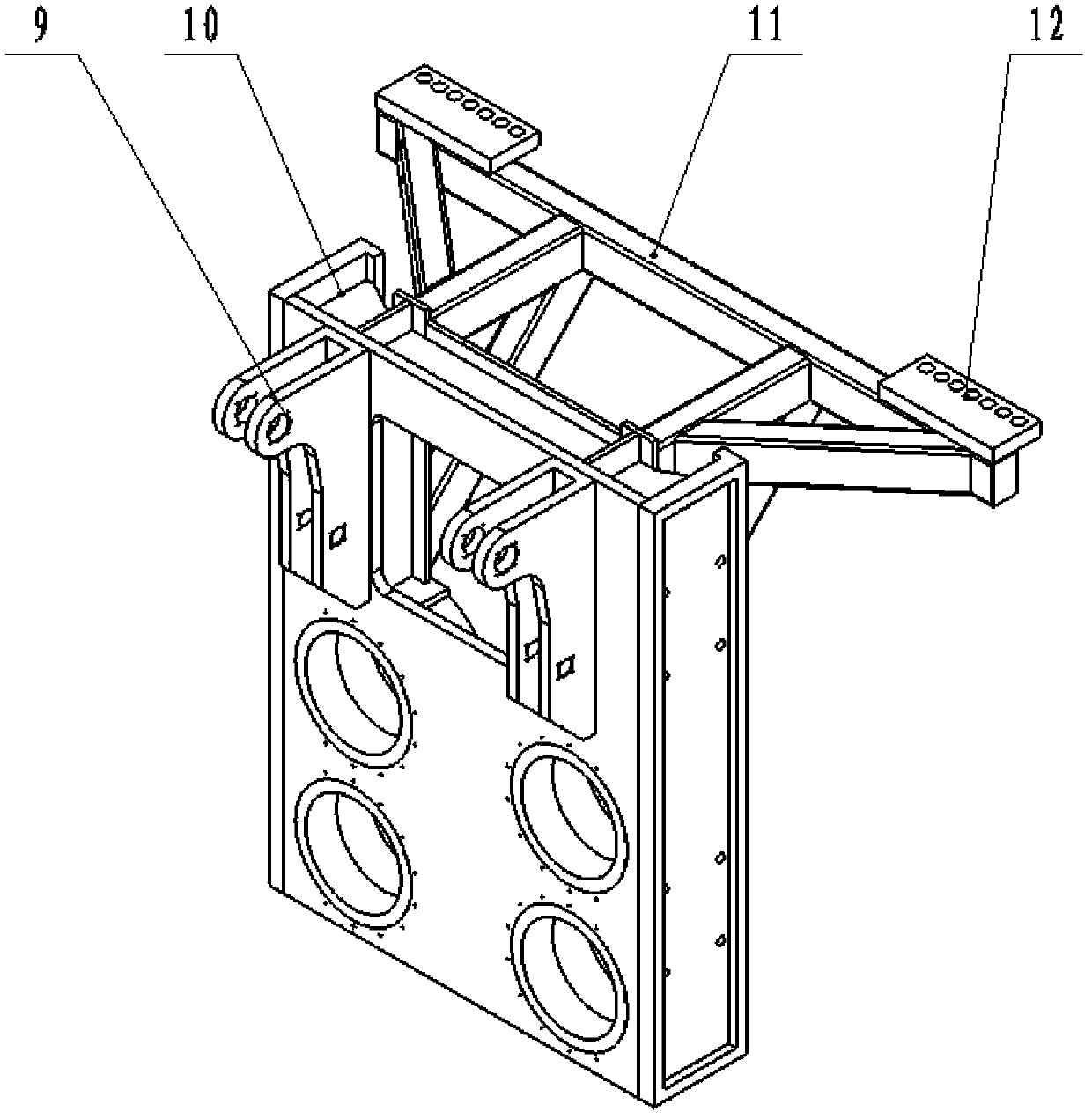

Gear rack coal bed methane drilling rig hoisting system

InactiveCN103397848ASimple structureCompact structureDrilling rodsDerricks/mastsVehicle frameReduction drive

The invention relates to the technical field of coal bed methane drilling rig operation, in particular to a gear rack coal bed methane drilling rig hoisting system. A rack of the system is welded to a headframe of a gear rack drilling rig. Four cylindrical gears on a sliding device are meshed with the rack. The sliding device is composed of a sliding cart body, a guide pulley, a gear component, a hydraulic motor and a reducer. The sliding cart body comprises a sliding cart frame. A power water faucet fixing lug plate and a hoisting system valve plate frame are welded on the sliding cart frame. A hoisting system valve plate is welded on the hoisting system valve plate frame. The guide pulley is composed of a combined bearing and a combined bearing flange. The combined bearing is connected with the combined bearing flange in a welding mode. The gear rack coal bed methane drilling rig hoisting system can apply pressure on a drill bit on the lower portion of a drilling rod, improves working efficiency, enables the structure of the whole drilling rig to be simple and compact, brings convenience to installation and maintenance, and is safe and reliable in work.

Owner:CNPC BOHAI EQUIP MFG +1

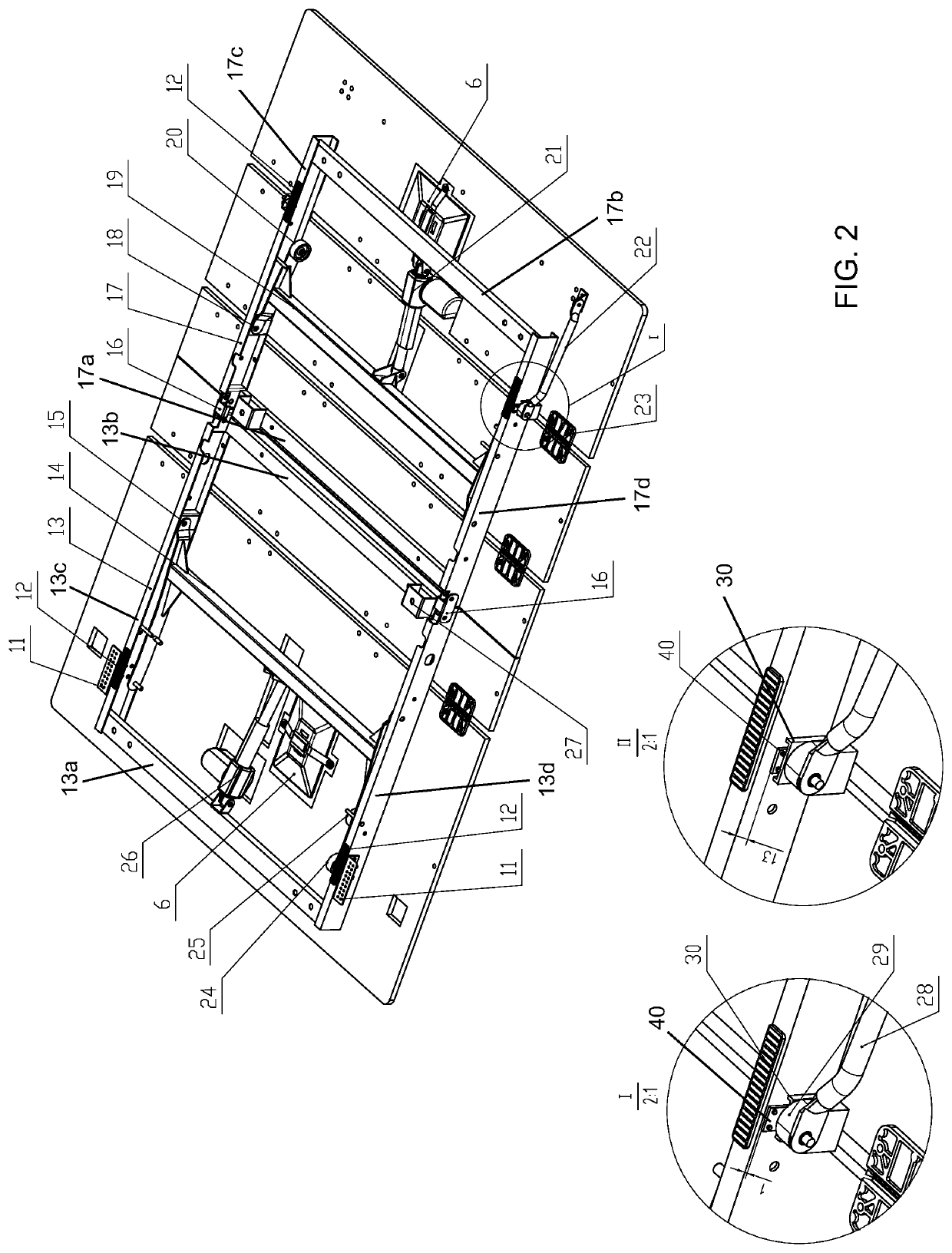

Gear rack lifting drilling machine

InactiveCN101666208ASimple structureEasy to installDerricks/mastsDrilling machines and methodsHydraulic cylinderTop drive

The invention relates to the technical field of petroleum drilling machines and equipment, in particular to a gear rack lifting drilling machine. The gear rack lifting drilling machine comprises a headframe body, a base, a tripping device, a drill stem moving device, a chuck, an upper makeup and breakout mechanism, an operating platform and a control device, wherein the headframe body comprises a headframe vertically connected above the base by chains, and two racks and guide rails symmetrically arranged on the same side of the headframe; the tripping device comprises a main body panel, a top driving head arranged on the main body panel, an elevator arranged under the top driving head, a driving motor arranged on the driving panel and roller wheels, wherein after being interlocked with gear wheels, the driving motor is matched with the racks on the headframe, and the roller wheels are matched with the guide rails on the headframe; and the drill stem moving device comprises a lifting arm the inner end of which is hinged with the base, a lifting hydraulic cylinder supporting the lifting arm to rise and fall and a drill stem gripping mechanism arranged on the outer end part of the lifting arm. The invention has the advantages of simplified structure of the drilling machine, convenient installation and transportation, low maintenance cost, long service life, convenient matching with automated devices and wide application.

Owner:山东胜利石油石化装备研究中心 +1

Recording apparatus

Owner:BROTHER KOGYO KK

Adjustable bed with folding mechanism

An adjustable bed includes: a head frame and a foot frame; a head lifting assembly including a head lifting bracket pivotally connected to the head frame, and a head lifting actuator pivotally connected between the head lifting bracket and the head frame for operably driving the head lifting bracket to pivotally move in an upward rotating direction or a downward rotating direction; a foot lifting assembly including a foot lifting bracket pivotally connected to the foot frame, and a foot lifting actuator pivotally connected between the foot lifting bracket and the foot frame for operably driving the foot lifting bracket to pivotally move in an upward rotating direction or a downward rotating direction; and a folding mechanism connecting the head frame and the foot frame such that the head frame and the foot frame are pivotably foldable to one another at the folding mechanism.

Owner:NISCO

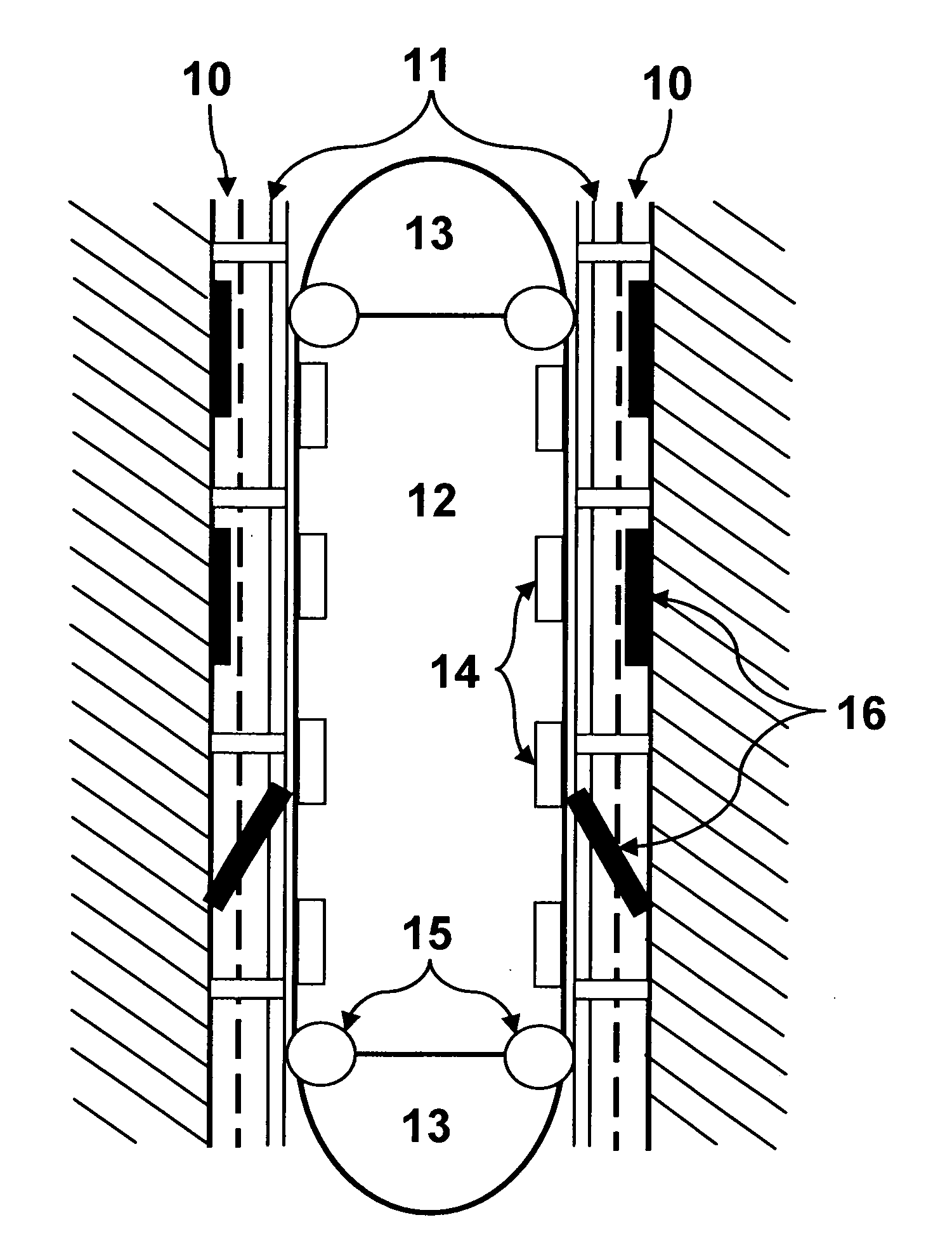

Transportation of underground mined materials utilizing a magnetic levitation mass driver in a small shaft

InactiveUS20100276253A1Improve efficiencyEasy to transportElevatorsBuilding liftsLevitationHeadframe

A conveyance system that utilizes an electromagnetic levitation motor acting as a mass driver to transport mined materials via a small shaft wherein multiple small skips are in transit simultaneously and which allows for return of the skips via the same route wherein the mass driver is used as a braking mechanism. The system also includes guideways to keep the skips in the correct position during transit, a safety system to prevent skips from falling back during a power failure, a system for feeding the skips to the mass driver at the lower end, and a headframe system for capturing skips at the upper end, unloading them, and feeding them back to the mass driver for the descent to the bottom.

Owner:ASHLEY KEVIN JOHN

Method for short-time on-line replacement of coke dry quenching furnace water sealed tank

The invention discloses a method for short-time on-line replacement of a coke dry quenching furnace water sealed tank. Through material level lowering, circulating fan ceaselessness, circulating air volume reduction, and heat preservation, the method can finish replacing a water sealed tank in a short time. And the method comprises: before replacing, lowering a material level, keeping a circulating fan operating, reducing a circulating air volume, and discharging coke in a small amount for heat preservation and pressure maintaining; welding lifting lugs on the peripheries of the water sealed tank, passing a wire rope through the lifting lugs, and transversely shifting a coke pot cover to a position over the water sealed tank with a hoisting device; letting an operator hoist the water sealed tank to a position higher than a loading device with a hand-chain hoist, then utilizing the hoisting device to shift a coke pot and the water sealed tank transversely to a hoisting headframe, and placing them on a beforehand made trolley under the headframe; and installing a new water sealed tank, and placing it into place accurately, thus finishing replacing the water sealed tank. The method of the invention realizes replacement of a water sealed tank in a shortest time without stopping the furnace, thus guaranteeing the relative enhancement of dry quenching rate, steam quantity and power generation.

Owner:NANJING IRON & STEEL CO LTD

Method for setting up large box type steel structure permanent headframe during well drilling period

InactiveCN1944920AImprove craftsmanshipSolve the problem of erecting permanent derrickTowersHeadframeWell drilling

The present invention relates to lifting technology, and is especially method of uprising large box type steel structure of permanent headframe while well drilling construction. The technological scheme of uprising the large box type steel structure of permanent headframe includes splitting the large box type steel structure into two parts, including sprag A and sprag B, assembled symmetrically onto on two sides of the well; erecting hoist tower between the sprag A and the well drilling headframe; hoisting the sprag A with the hoist tower; laying down the hoist tower; hoisting the sprag B with the sprag A; and healing up the sprag A and the sprag B with cables and welding the top. The said process can uprise large box type steel structure of permanent headframe without need of interrupting the well drilling construction.

Owner:TANGSHAN KAILUAN CONSTR (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com