Mine using great steel derrick lifting special tool

A technology of derrick and fixture, applied in cranes and other directions, can solve problems such as occupying space, and achieve the effects of reasonable layout, convenient lifting and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

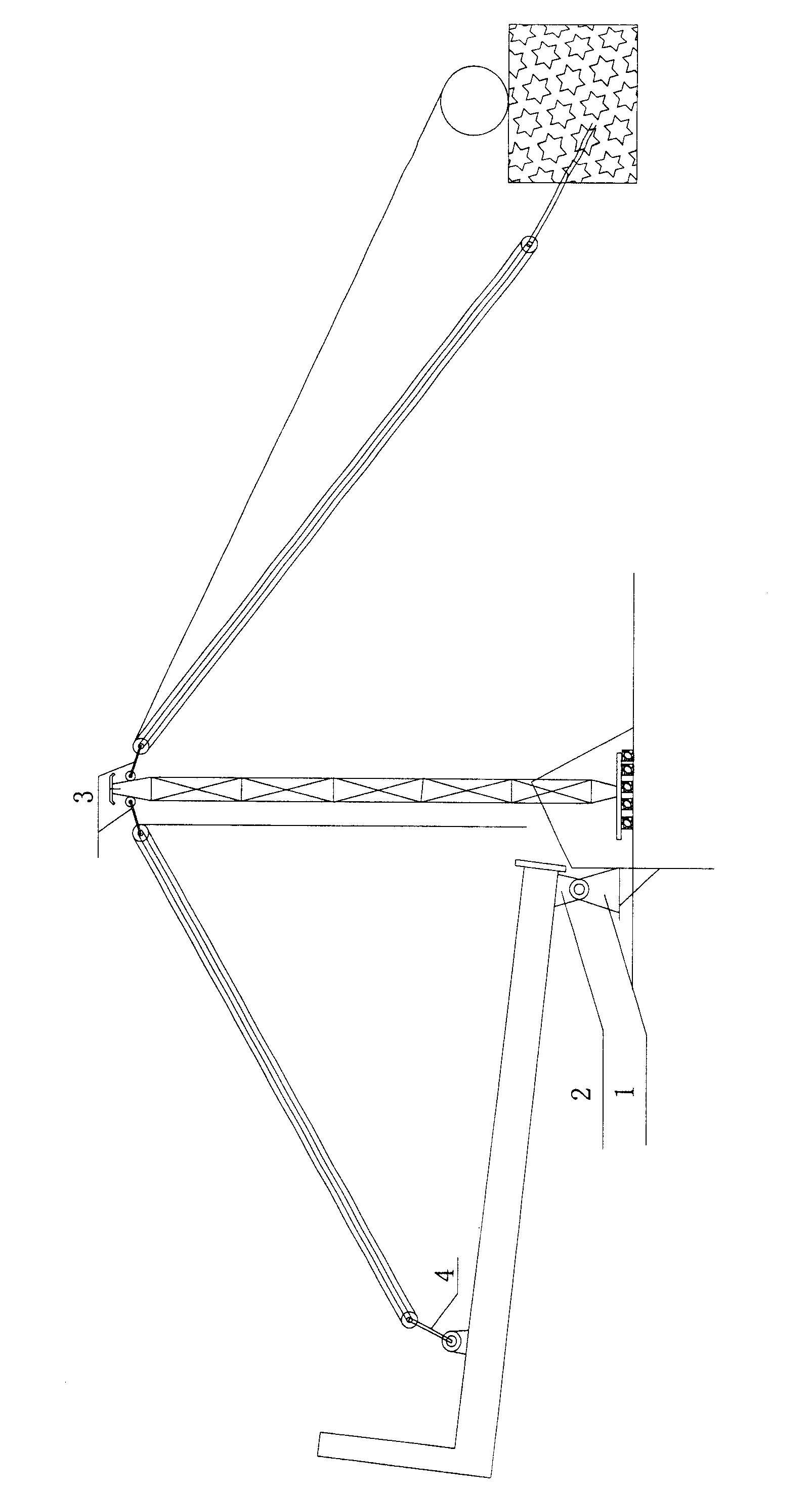

[0028] 1. Implementation of the pole head fixture

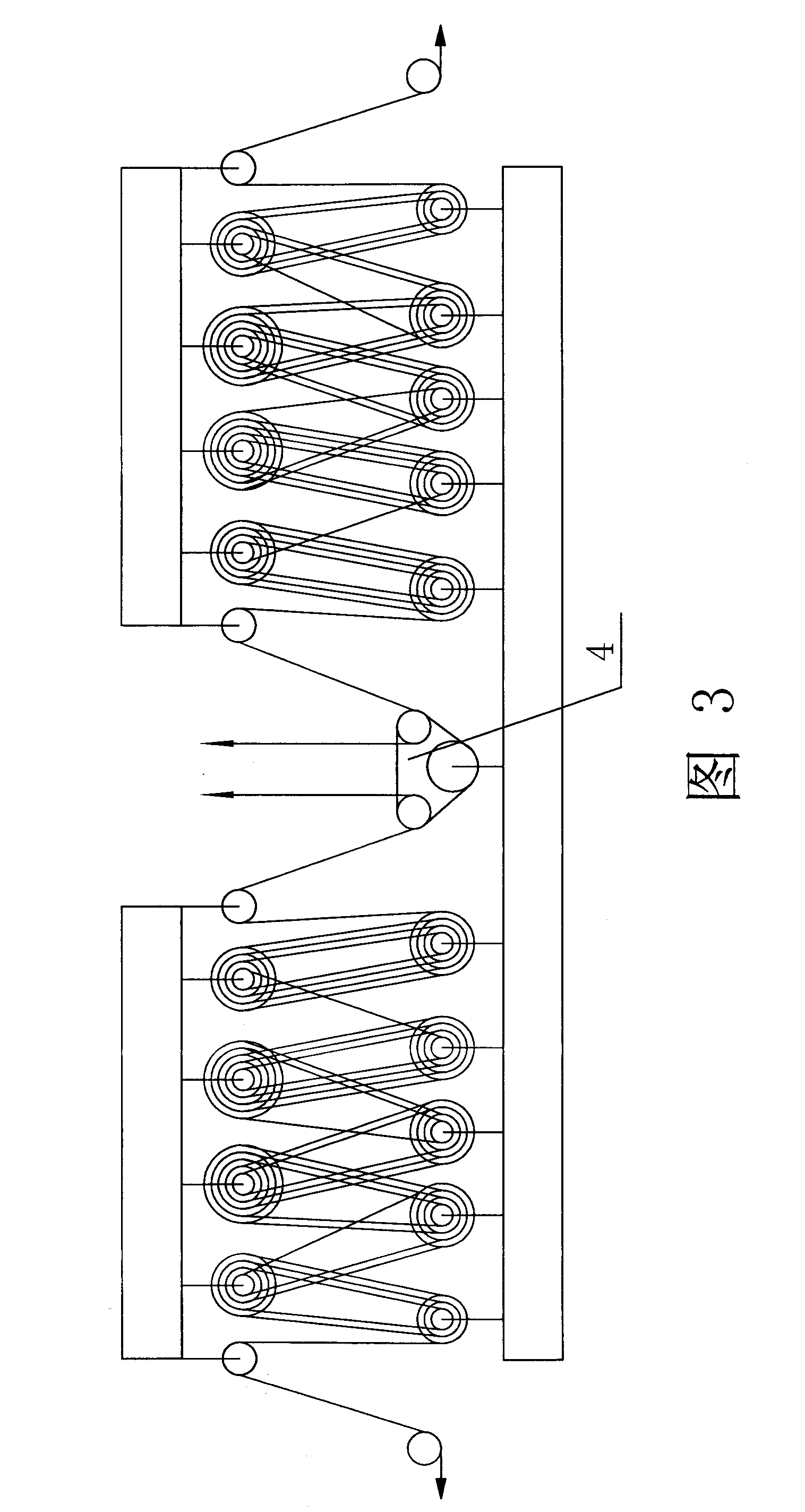

[0029] In accompanying drawing 1, fixture (3) is processed earlier, and is transported to the construction site, and fixture (3) is connected to the head of the pole before the pole head is erected, and the pulley block to be used is hung on the fixture. The normal wire rope threading process can be carried out after the pole is erected. When the clamp is hung on the pole, it is ensured that the clamp (3) can rotate along with the lifting angle of the derrick during the erection process of the derrick.

[0030] 2. Folding implementation

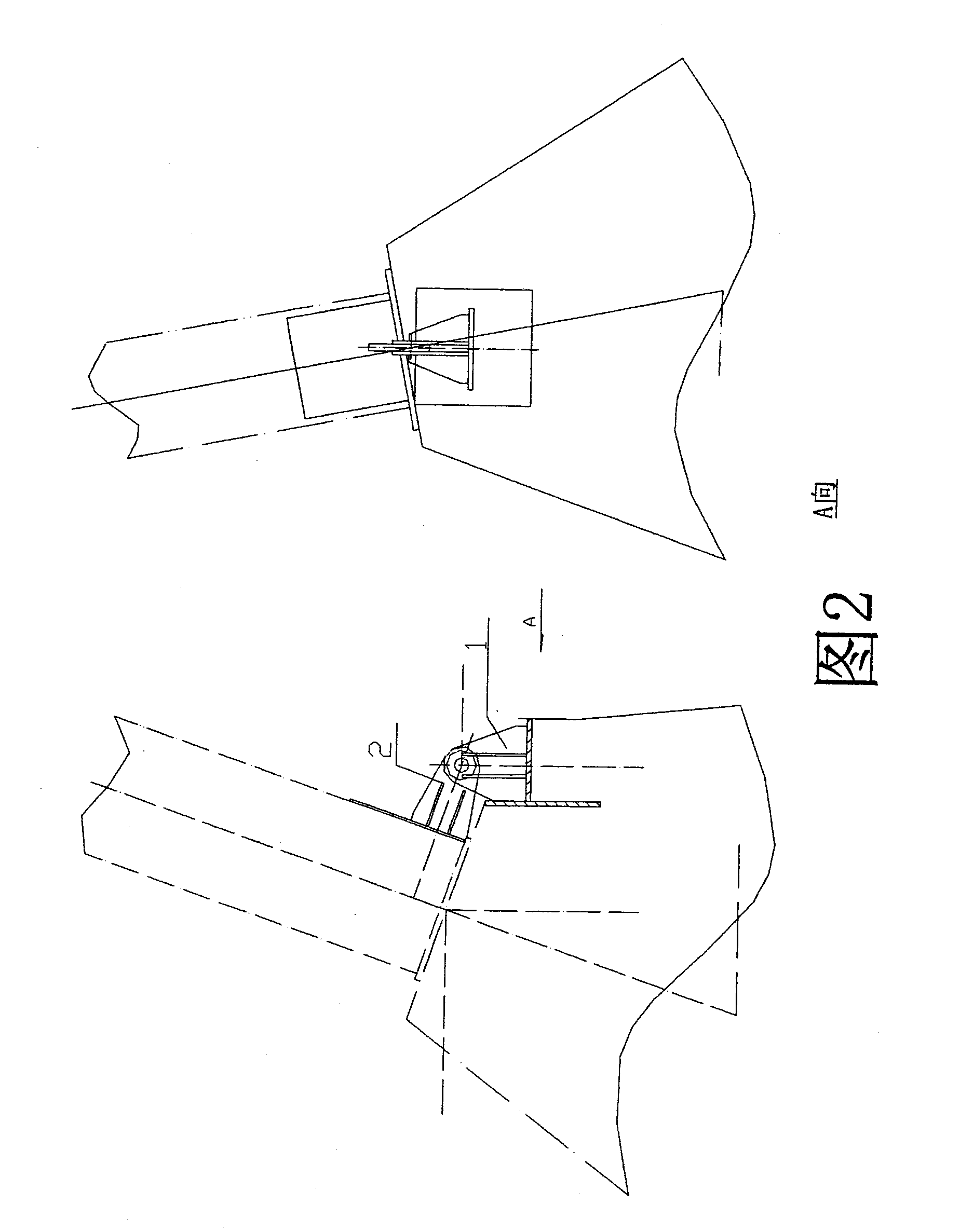

[0031] According to the design requirements in attached drawing 2, during civil construction, the fixed hinge (1) pre-embedded plate is embedded in the foundation, and its anchoring force, elevation and other data must meet the requirements of the technical measures of the construction organization, and the movable hinge (1) 2) That is, the connecting bottom plate and the derrick are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com