Diamond abrasive wire cutting fluid for semiconductor precision sheet and preparation method of diamond abrasive wire cutting fluid

A diamond sand and semiconductor technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of large energy release, increase in specific surface area, and decrease in activation energy, and achieve the goal of being gentle on the human body, low in cost, and easy to recycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

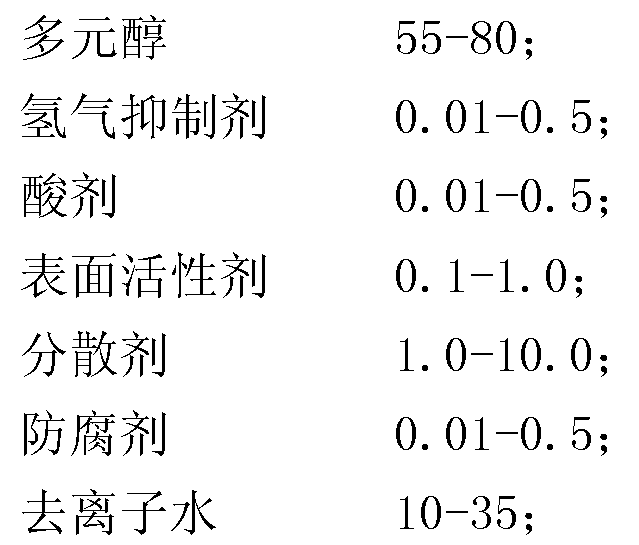

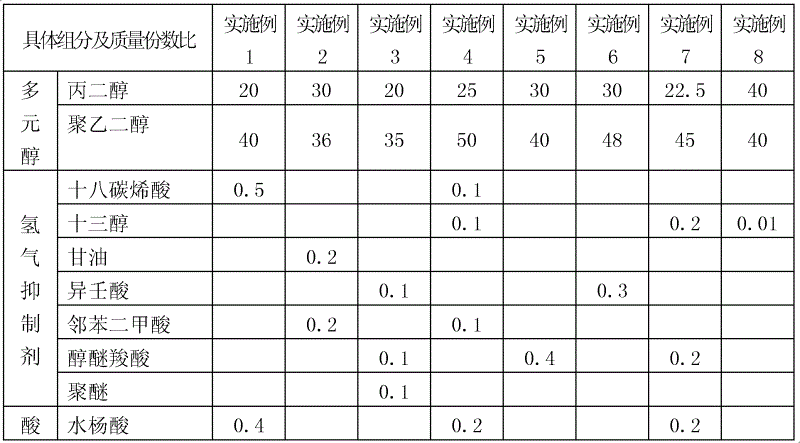

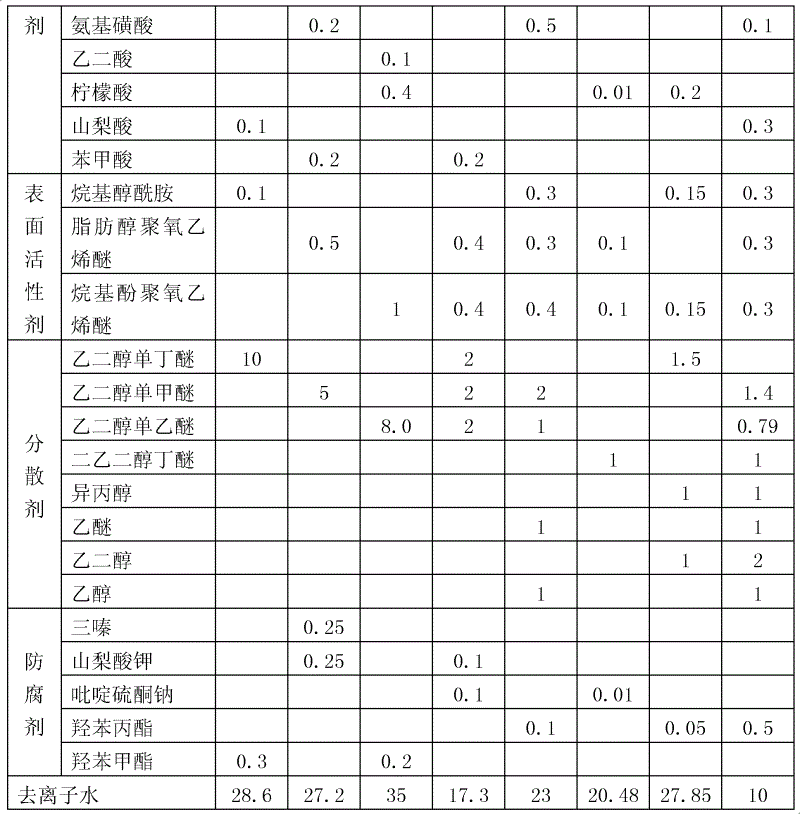

[0019] The raw material of the semiconductor precision thin diamond sand wire cutting fluid of the present invention is composed of the following components in mass parts ratio, including 55-80 polyol; 0.01-0.5 hydrogen inhibitor; 0.01-0.5 acid agent; 0.1- 1.0 surface active agent; 1.0-10.0 dispersant; 0.01-0.5 preservative; 10-35 deionized water; wherein: the polyol of the present invention is a mixture of propylene glycol and polyethylene glycol at a ratio of 1 to 1:2, And the molecular weight of polyethylene glycol is between 100 and 600. The use of propylene glycol mixed with polyethylene glycol has better lubricity than simply using polyethylene glycol.

[0020] The hydrogen inhibitor of the present invention is one or a mixture of any two or more of octadecenoic acid, tridecanol, glycerin, isononanoic acid, phthalic acid, alcohol ether carboxylic acid or polyether, and the mixture is such as A mixture of octadecenoic acid and tridecyl alcohol, or a mixture of octadecenoic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com