Intelligent photoelectric hybrid detecting optical cable and production method thereof

A technology for photoelectric hybrid and detection optical cables, which is applied in the direction of communication cables, cable/conductor manufacturing, cables, etc., can solve the problems of poor bearing capacity and high temperature resistance of photoelectric hybrid cables, and achieve reasonable structural design, unique production process methods, The effect of improving bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

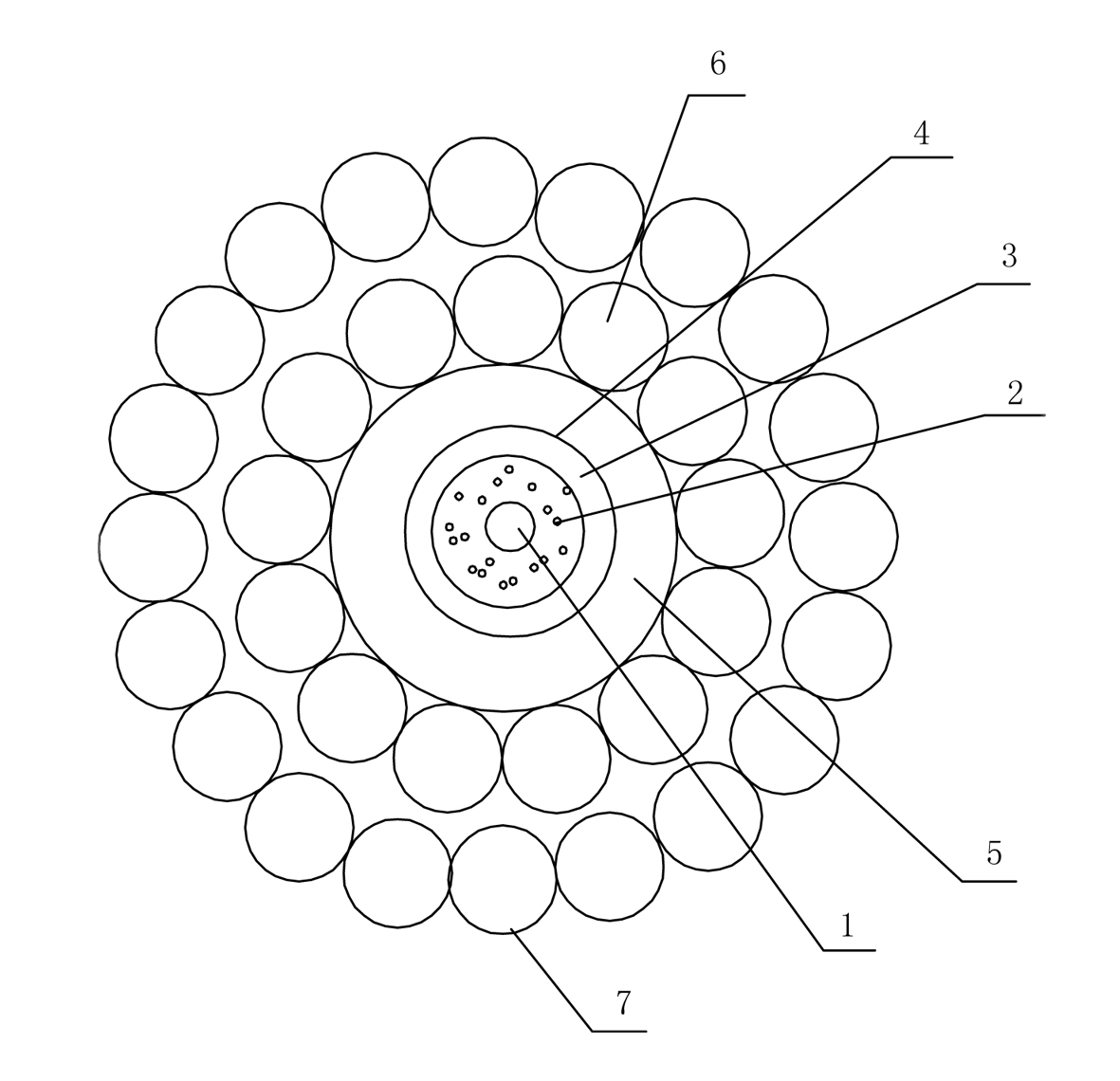

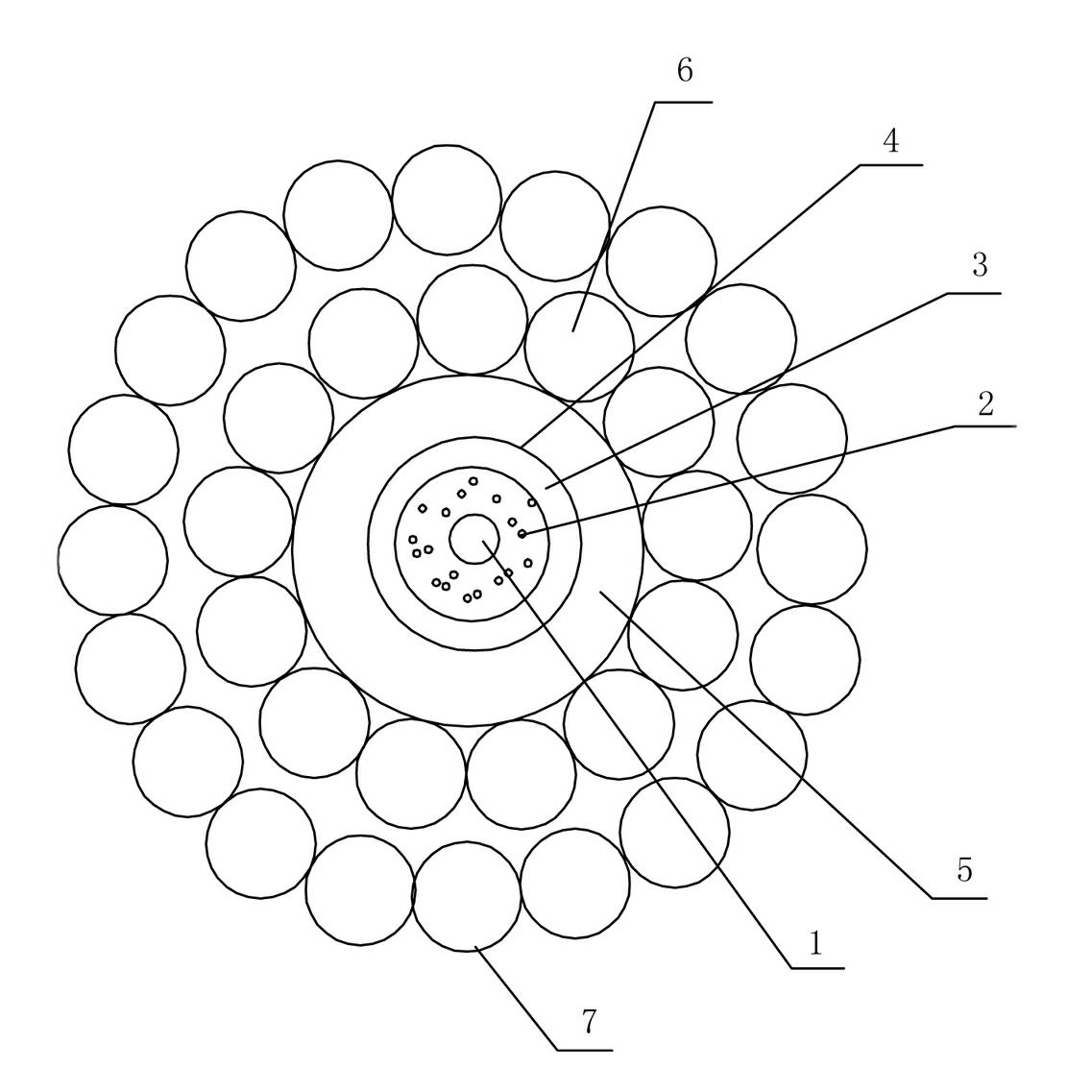

[0034] Refer to attached figure 1 An intelligent photoelectric hybrid detection optical cable includes a miniature tight-packed optical fiber unit, a meshed copper conductor conductive unit 4, a high-temperature-resistant fluoroplastic insulating layer 5 and a high-strength stainless steel wire armored unit. A mesh copper conductor unit 4 is wrapped outside the miniature tight-packed optical fiber unit, and a high temperature resistant fluoroplastic insulating layer 5 is arranged outside the mesh copper conductor unit 4 for sheathing, and a high temperature resistant fluoroplastic insulating layer 5 is arranged outside a high strength Stainless steel wire armored unit.

[0035] The miniature tight-packed optical fiber unit is composed of a high-temperature optical fiber 1, a miniature stainless steel tube 3, and a high-temperature fiber paste 2. The miniature tight-packed optical fiber unit adopts a tight-packed structure. High temperature fiber paste 2 is filled around the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com