Patents

Literature

77results about How to "Improve fatigue durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

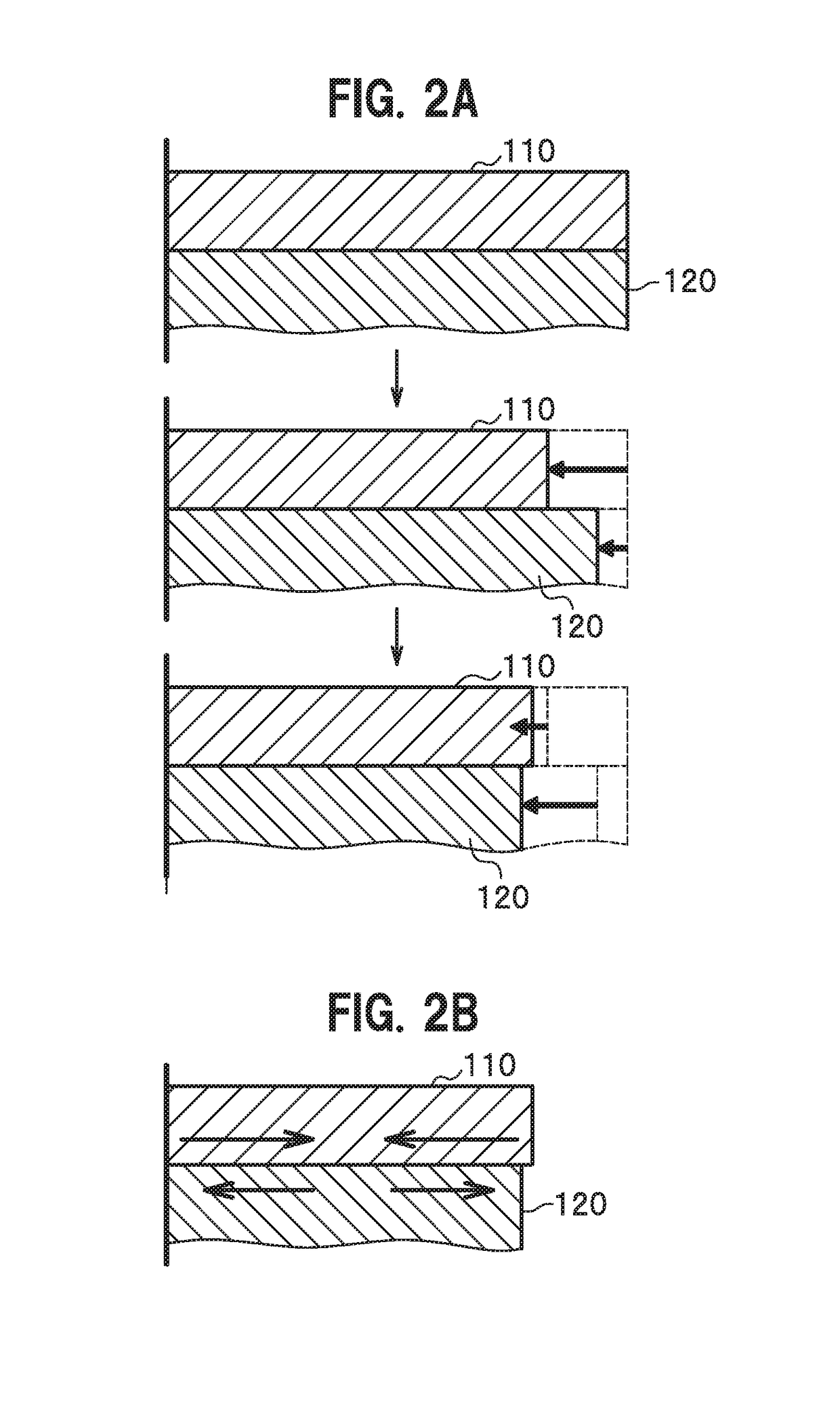

High-strength hot-dip galvanized steel sheet and process for producing same

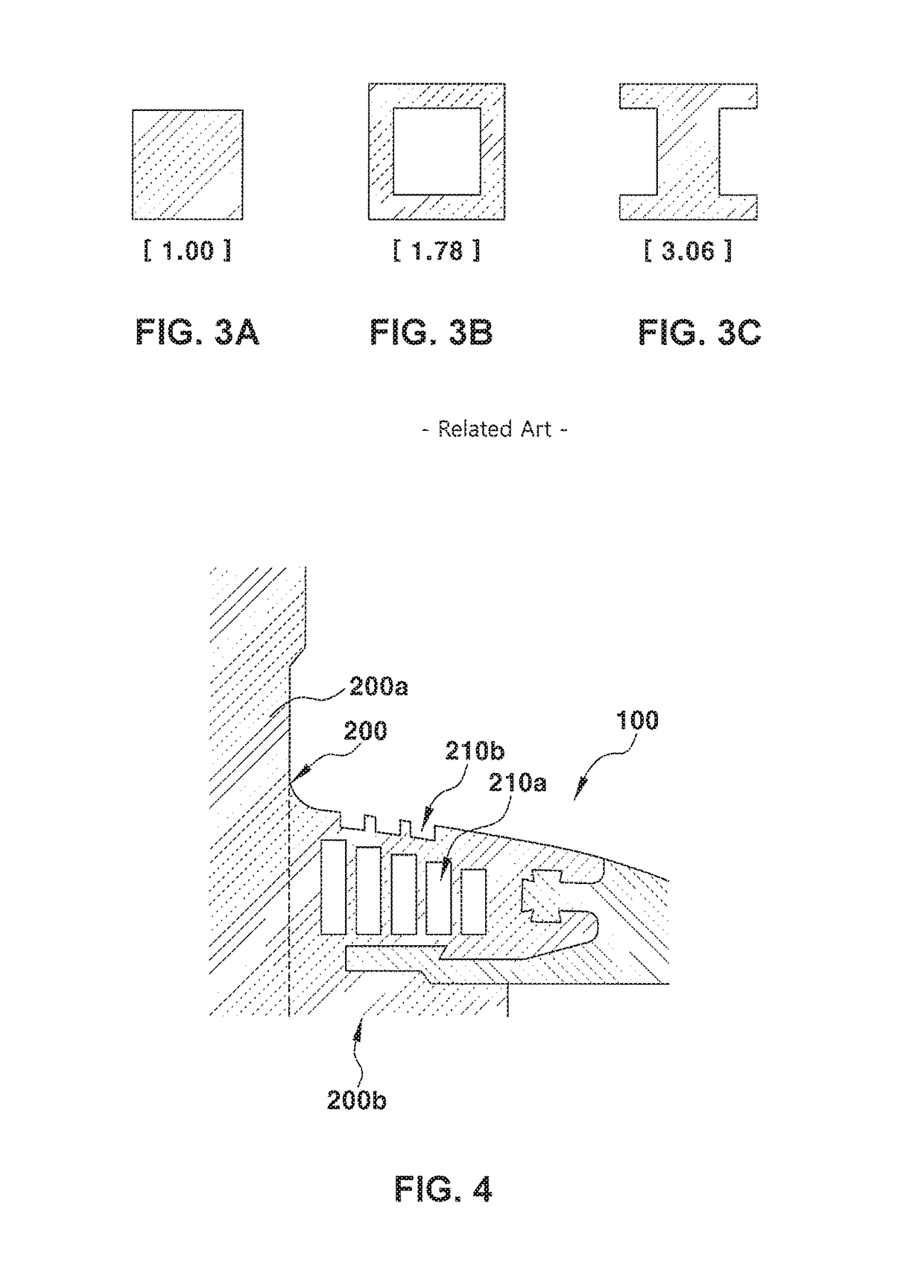

ActiveCN102482753AImprove fatigue durabilityExcellent resistance to hydrogen embrittlementHot-dipping/immersion processesFurnace typesSoft layerHigh intensity

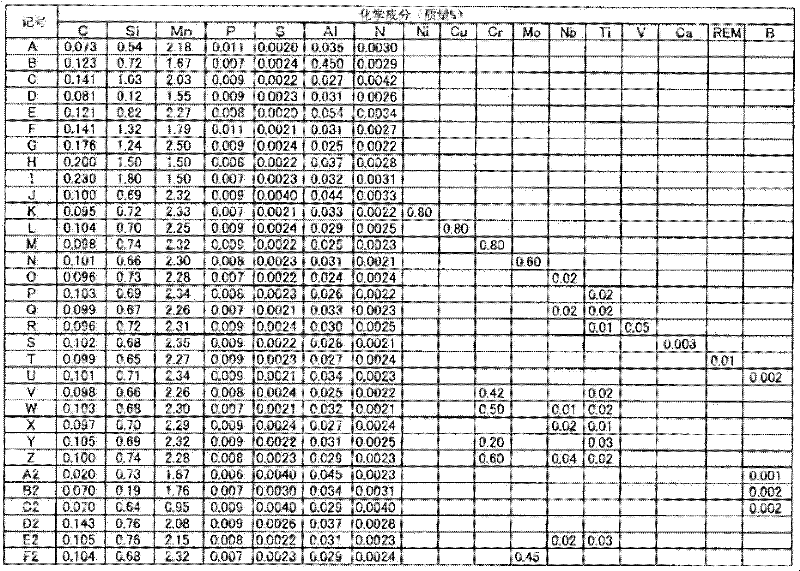

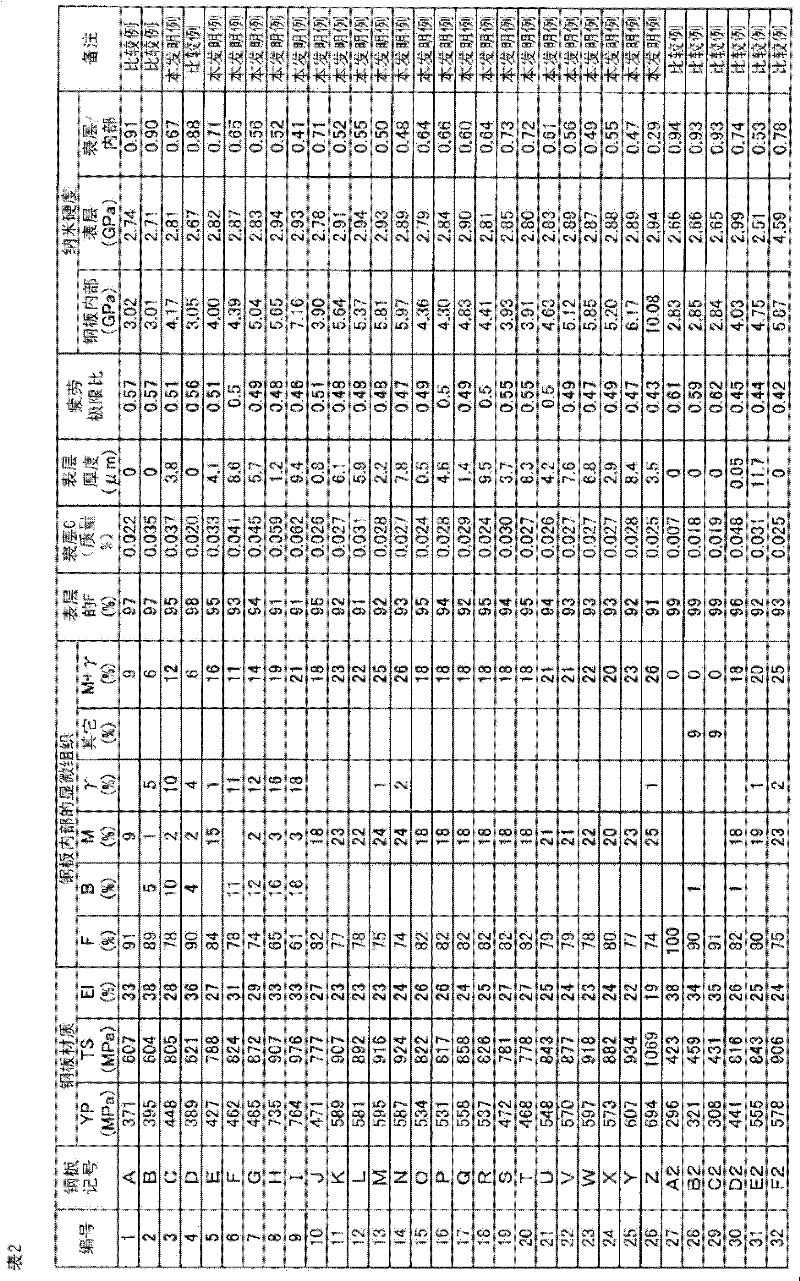

Disclosed is a hot-dip galvanized steel sheet which comprises a steel sheet part and a deposit formed on the surface of the steel sheet part and has a tensile strength of 770 MPa or higher, wherein the deposit is a zinc layer formed by hot-dip plating or an alloyed zinc layer formed by hot-dip plating, the steel sheet part comprises a soft layer, which is in direct contact with the deposit, and an inner layer, which is the part other than the soft layer, and the thickness (D) of the soft layer is 0.001 to 5% of the thickness (t) of the steel sheet part. In a cross-section along the thickness direction of the steel sheet part, when the hardness of the soft layer measured by a nanoindentation method is expressed by H1 and the representative hardness of the steel sheet part measured by the nanoindentation method is expressed by Ha, then H1 is 5-75% of Ha.

Owner:NIPPON STEEL CORP

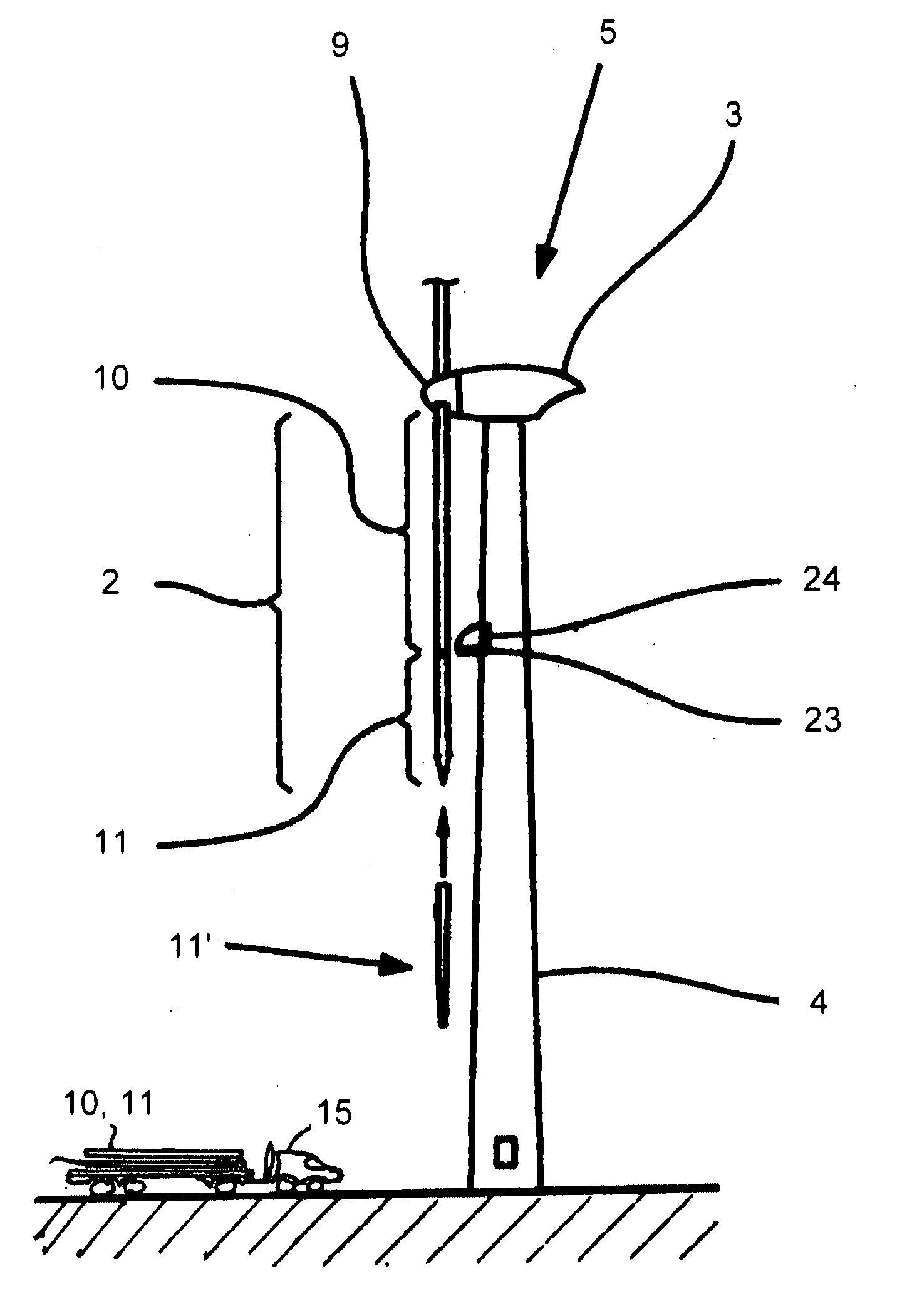

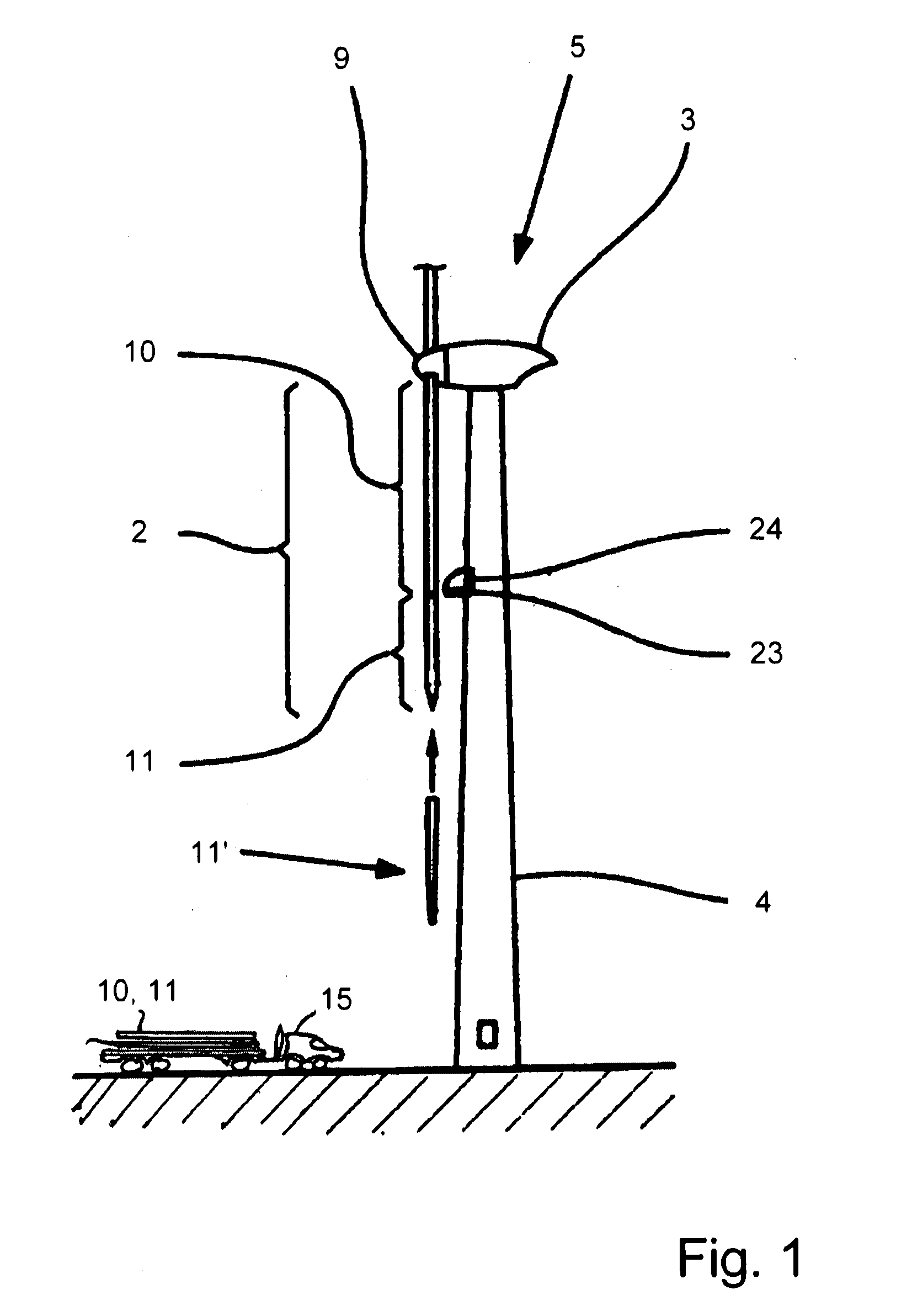

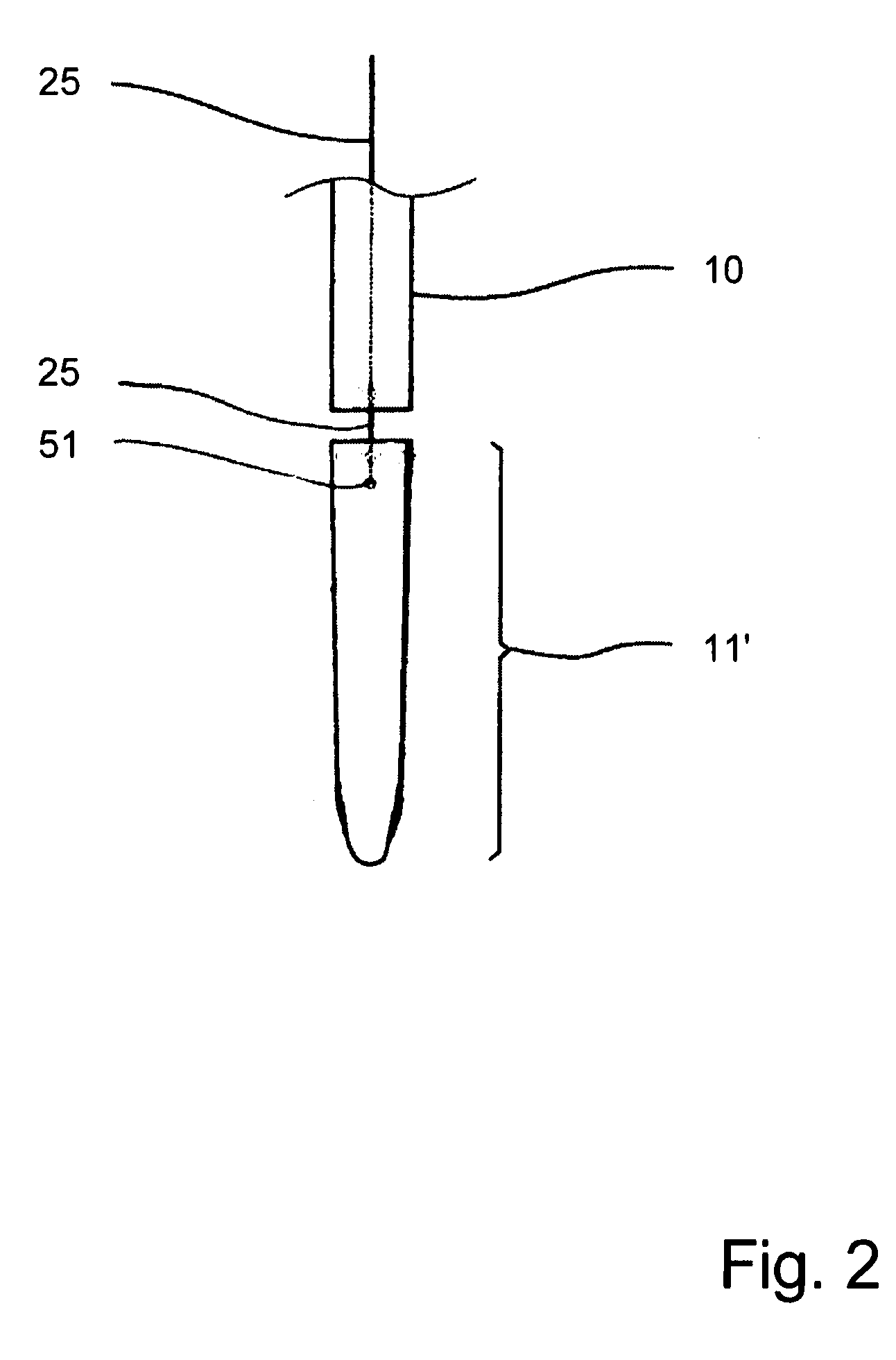

Modular rotor blade for a power-generating turbine and a method for assembling a power-generating turbine with modular rotor blades

InactiveUS20110020126A1Reduce shipping costsLow costEngine fuctionsBlade accessoriesEngineeringTurbine

A modular rotor blade for a power generating turbine allows simple replacement of individual rotor blade sections in case of damage to or malfunction of a section. The modular rotor blade includes at least two rotor blade sections, wherein each rotor blade section includes at least one connecting part having at least one conical opening. The connecting parts of adjacent rotor blade sections rest against each other such that the conical openings of the connecting parts are aligned with each other and form a continuous conical connecting opening. Receiving elements for receiving tensioning elements are arranged at the smaller diameter end of the conical connecting opening. A conical bolt corresponding to the continuous conical connecting opening is arranged therein, and at least one tensioning element passes through the conical bolt and tensions the conical bolt against the receiving element.

Owner:CLIPPER WINDPOWER INC

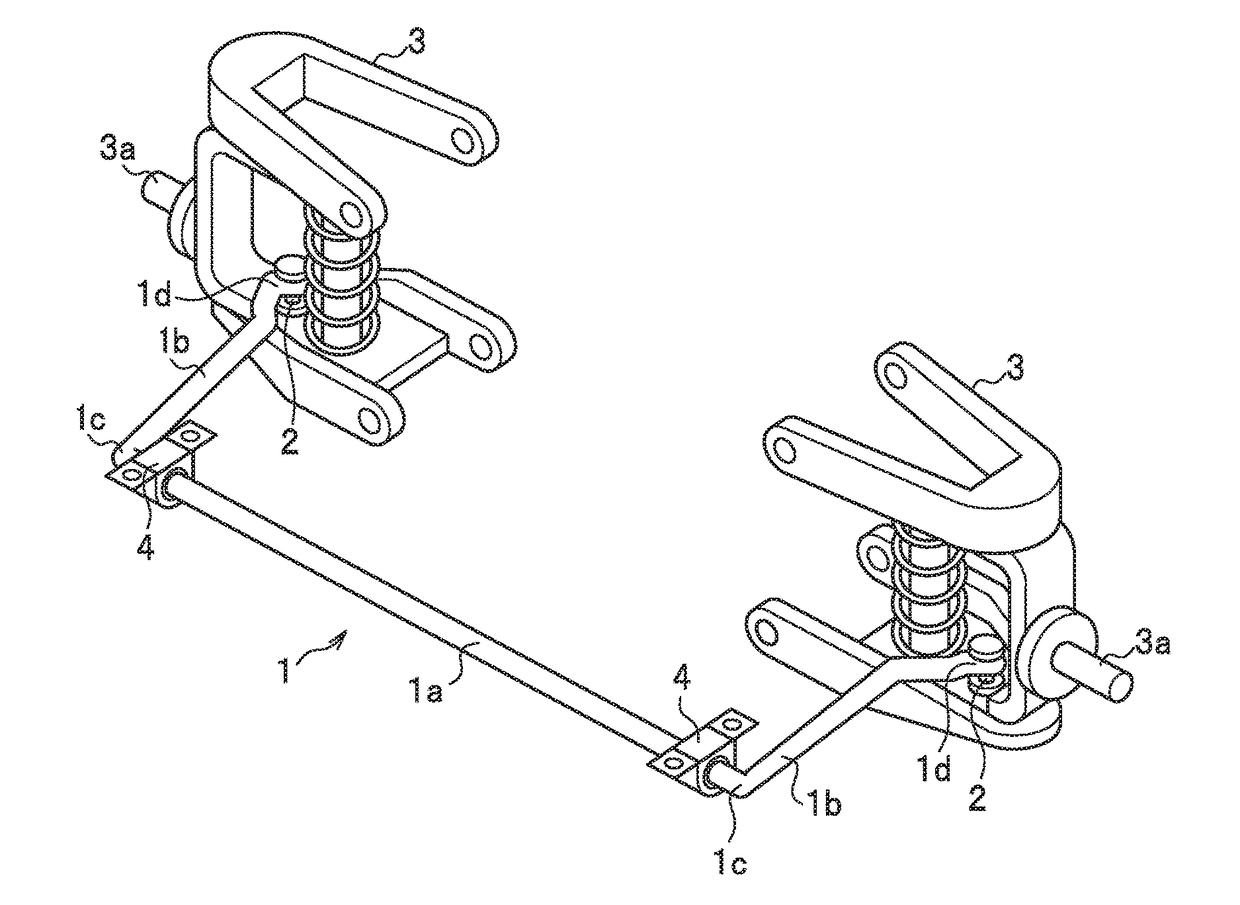

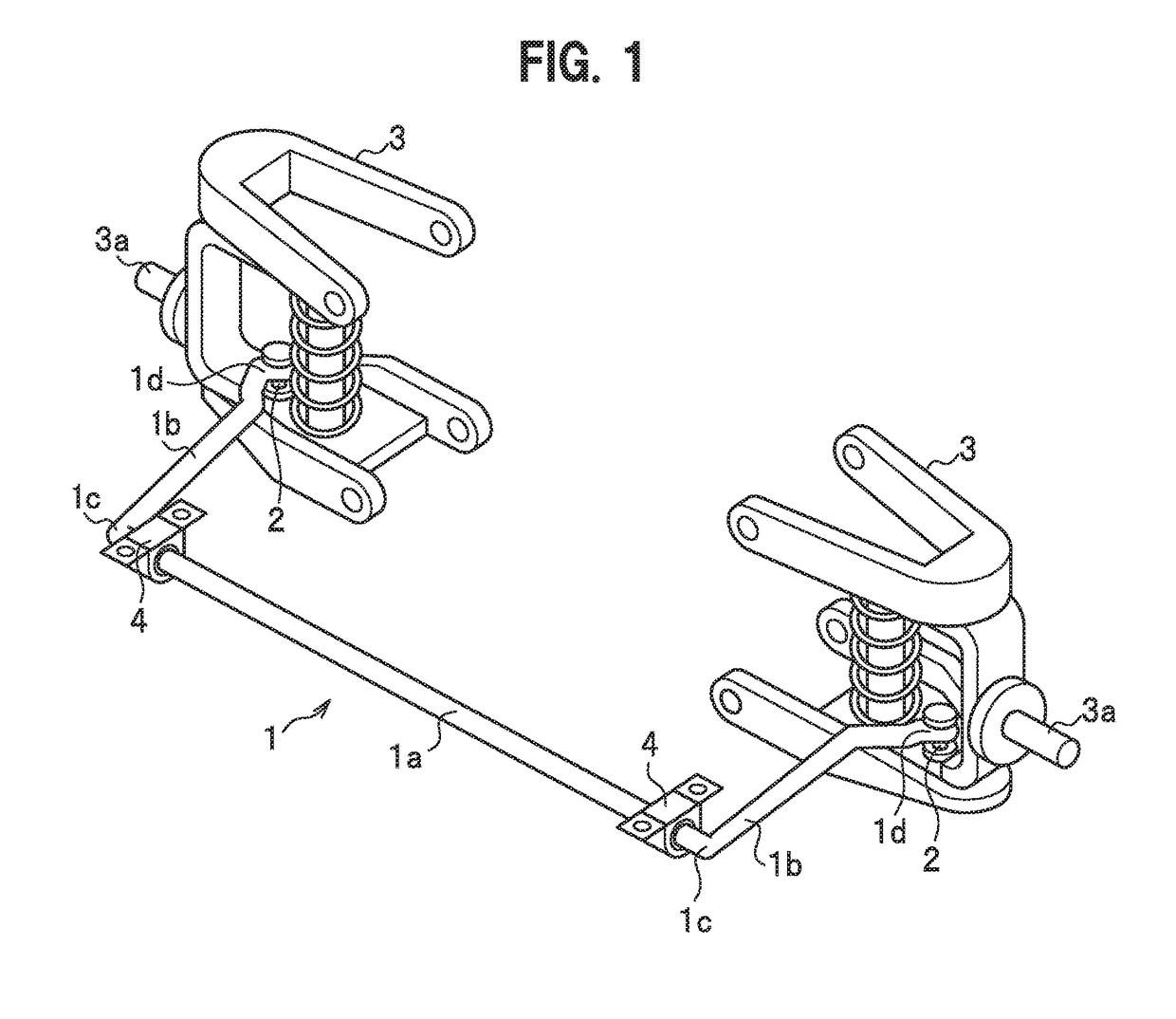

Hollow stabilizer, and steel pipe for hollow stabilizers and method for production thereof

ActiveCN104395487AImprove fatigue durabilityHigh strengthFurnace typesInterconnection systemsUltimate tensile strengthMartensite

A hollow stabilizer having a component composition containing 0.26 to 0.30% of C, 0.05 to 0.35% of Si, 0.5 to 1.0% of Mn, 0.05 to 1.0% of Cr, 0.005 to 0.05% of Ti, 0.0005 to 0.005% of B and 0.0005 to 0.005% of Ca, wherein the contents of Al, P, S, N and O are limited to 0.08% or less, 0.05% or less, less than 0.0030%, 0.006% or less and 0.004% or less, respectively, the remainder of the component composition is made up by Fe and unavoidable impurities, the value of the product of the Mn content and the S content is 0.0025 or less, and the critical cooling velocity (Vc90) represented by a given formula is 40°C / s or less, and wherein the metallic structure is composed of a tempered martensite, the length of stretched MnS occurring in a center part of the hollow stabilizer as observed in a thickness direction is 150 mum or less, an HRC value is 40 to 50, the thickness / (outer diameter) ratio is 0.14 or more, and the depth of a decarburized layer in the inner surface part of the hollow stabilizer is 20 mum or less from the inner surface, said hollow stabilizer having higher strength compared with conventional hollow stabilizers and also having excellent fatigue properties; and a steel pipe for hollow stabilizers, which is used as a material for the hollow stabilizer.

Owner:NIPPON STEEL CORP +1

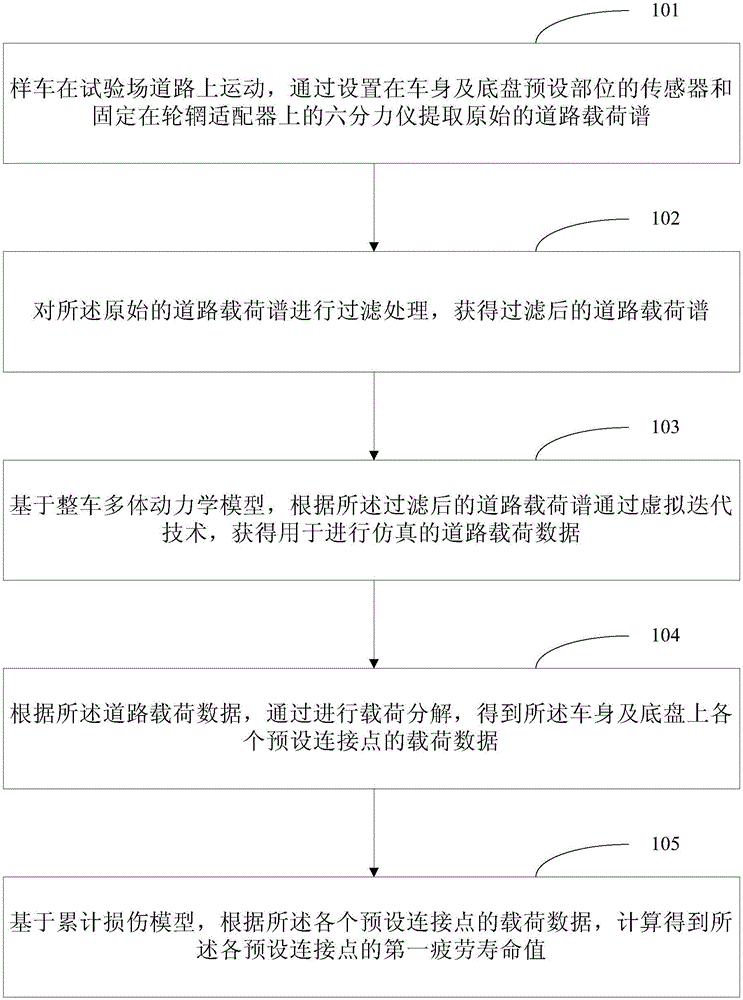

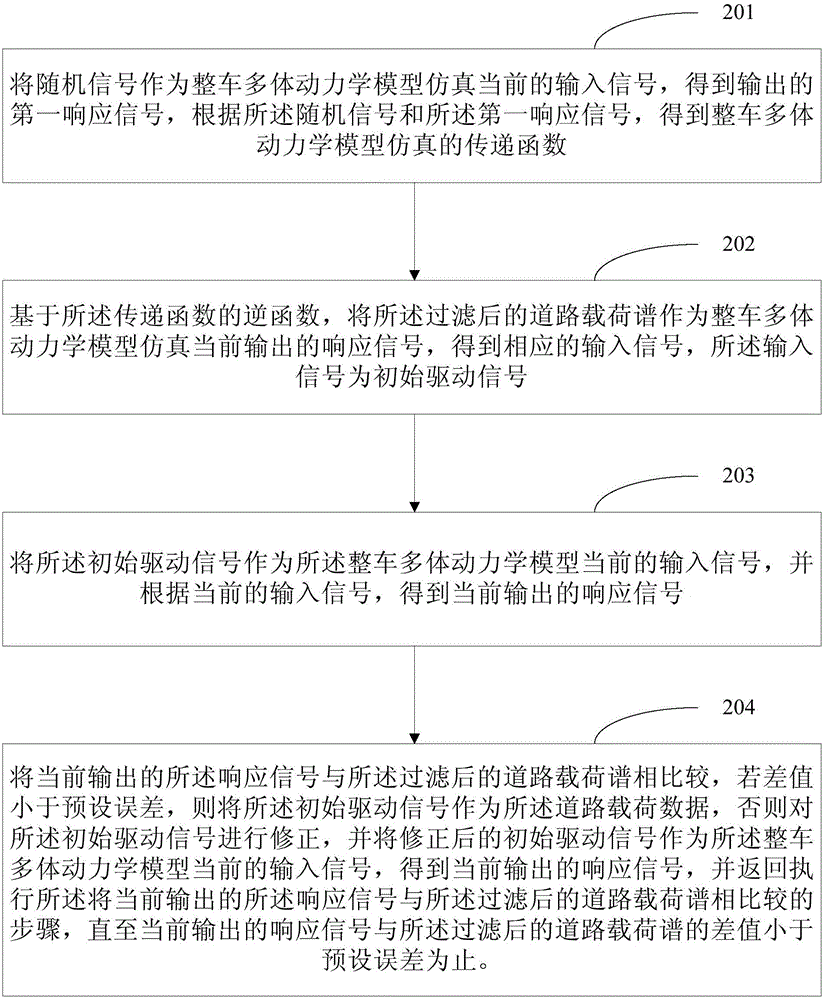

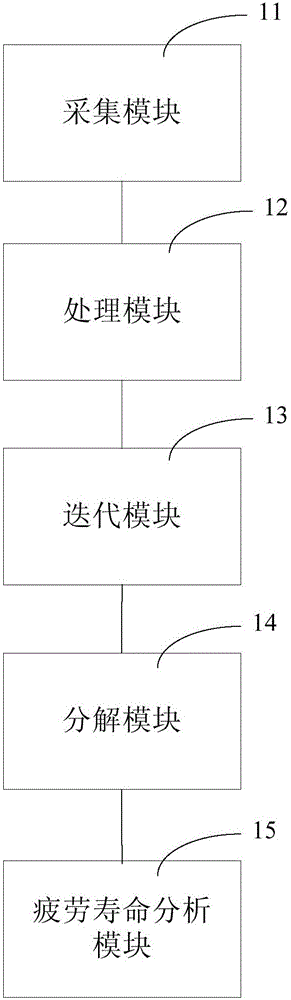

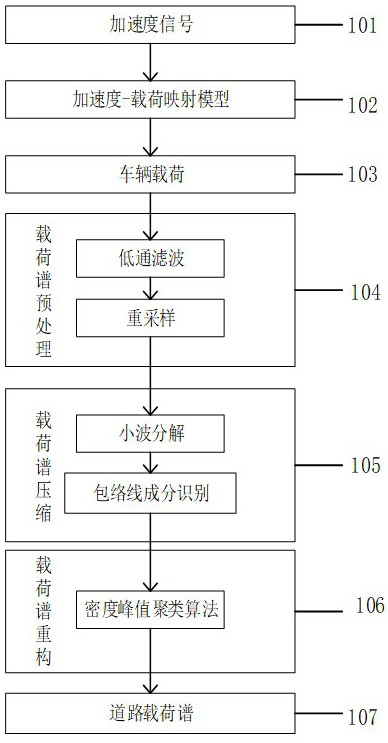

Road load test method and system

ActiveCN105092261AAccurate Fatigue Life PredictionImprove fatigue durabilityVehicle testingIn vehicleDecomposition

The invention discloses a road load test method and system. The method comprises the steps of: with a sample vehicle running on roads on a test site, extracting an original road load spectrum; filtering the original road load spectrum, and obtaining the road load spectrum which has been filtered; based on a multi-body dynamics automobile model and in accordance with road load spectrum which has been filtered, obtaining the road load spectrum for carrying out the simulation through virtual iteration technology; through load decomposition, obtaining load data at each preset connection point of the vehicle body and a chassis; and based on the load data, calculating a first fatigue endurance value of each preset connection point. The method can obtain the actual original road load spectrum on different test sites, and based on the actual original road load spectrum, can calculate the fatigue life value, and can further predict a more accurate fatigue life of the vehicle, which can effectively increase the fatigue endurance of the vehicle body and provide the effective basis for the optimization and improvement of a vehicle structure in vehicle design.

Owner:BAIC MOTOR CORP LTD

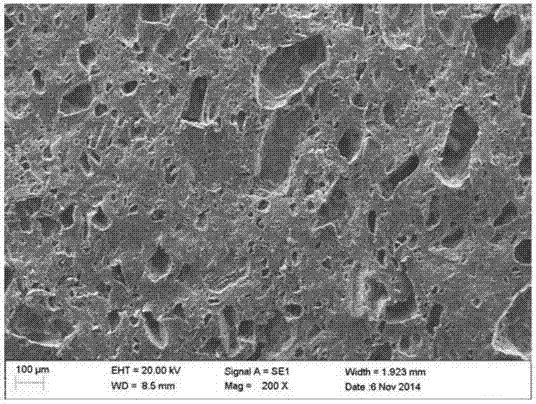

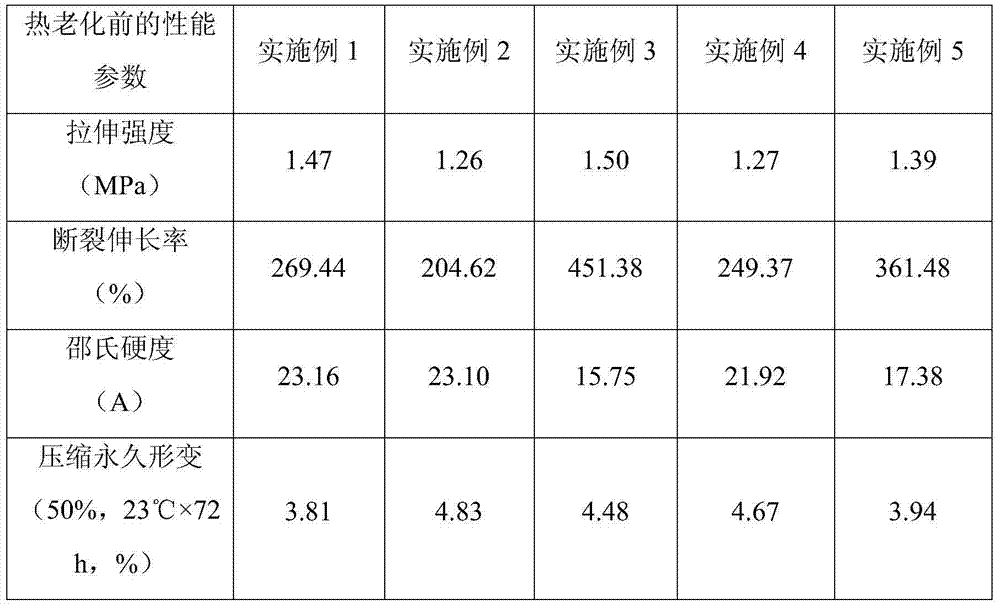

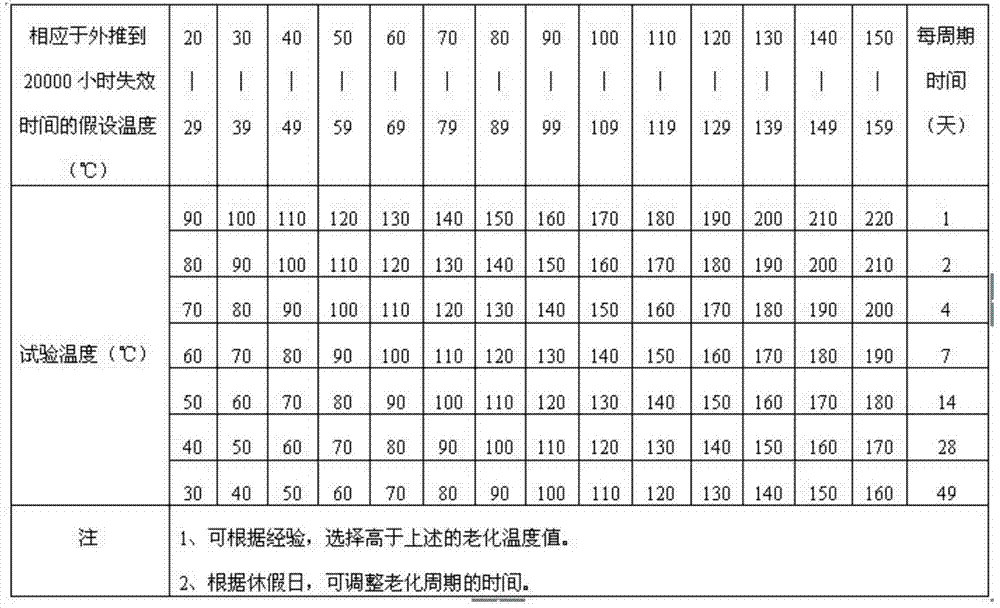

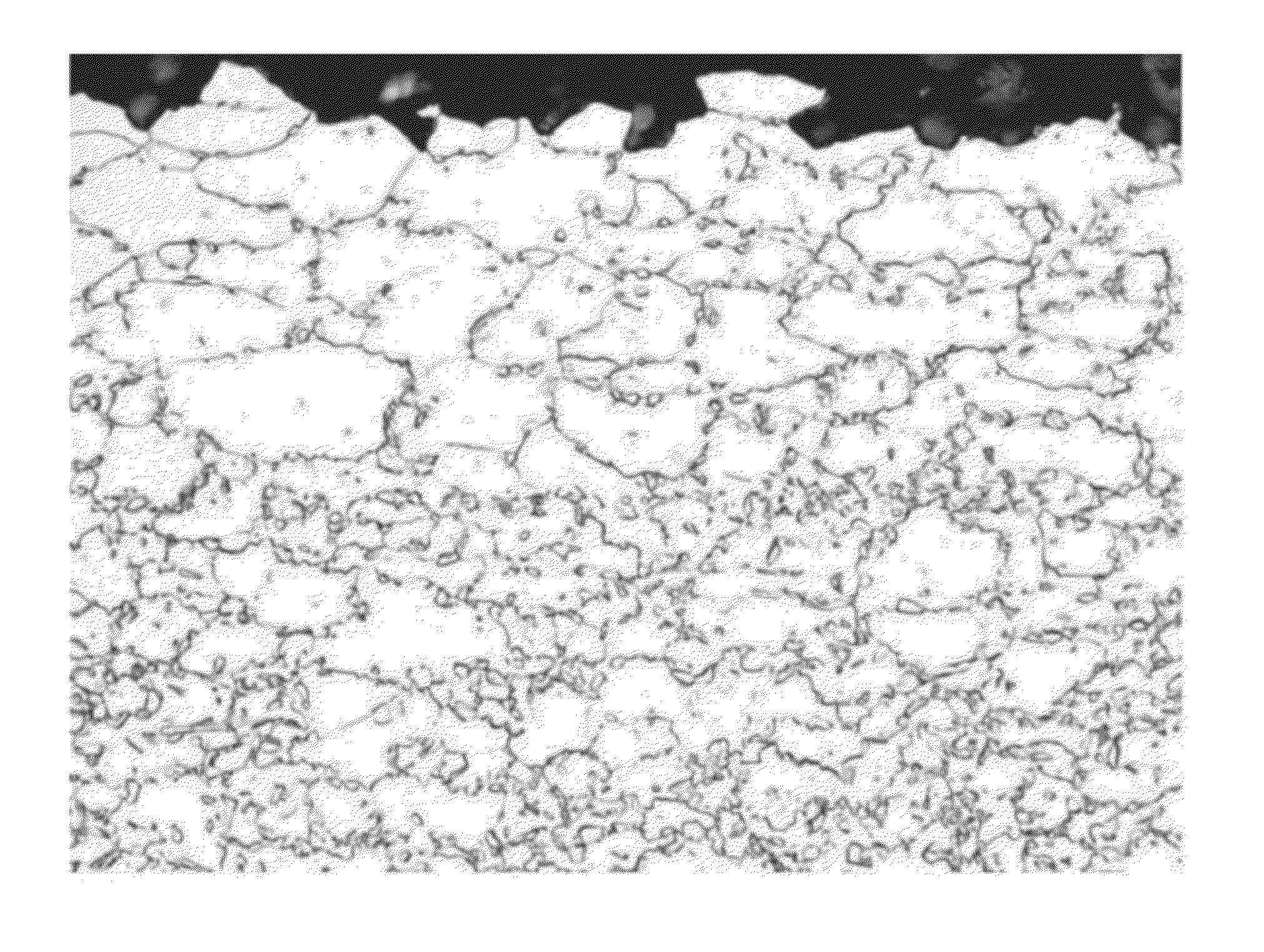

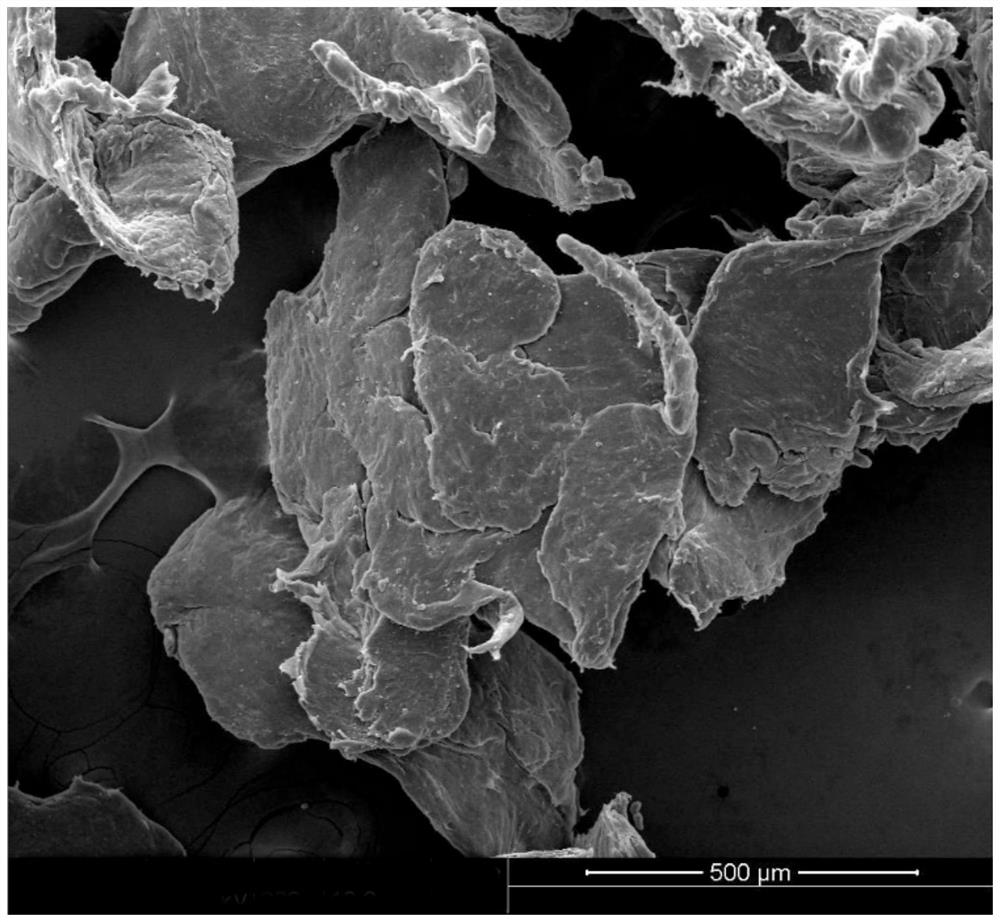

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

High-strength galvanized steel sheet and method of manufacturing the same

ActiveUS9109275B2Improve fatigue durabilityImprove bending performanceHot-dipping/immersion processesFurnace typesSoft layerUltimate tensile strength

Provided is a galvanized steel sheet having a tensile strength of 770 MPa or more including a steel sheet portion, and a plated layer formed on the surface of the steel sheet portion, in which the plated layer is a galvanized plated layer or an galvannealed plated layer, the steel sheet portion has a soft layer that directly adjoins the interface with the plated layer and an inside layer that is other than the soft layer, the thickness D of soft layer is 0.001% to 5% of thickness t of the steel sheet portion, and, when the hardness of the soft layer measured by nano-indentation method is indicated by H1, and the representative hardness of the steel sheet portion measured by the nano-indentation method is indicated by Ha in cross section that goes along the thickness direction of the steel sheet portion, H1 is 5% to 75% of Ha.

Owner:NIPPON STEEL CORP

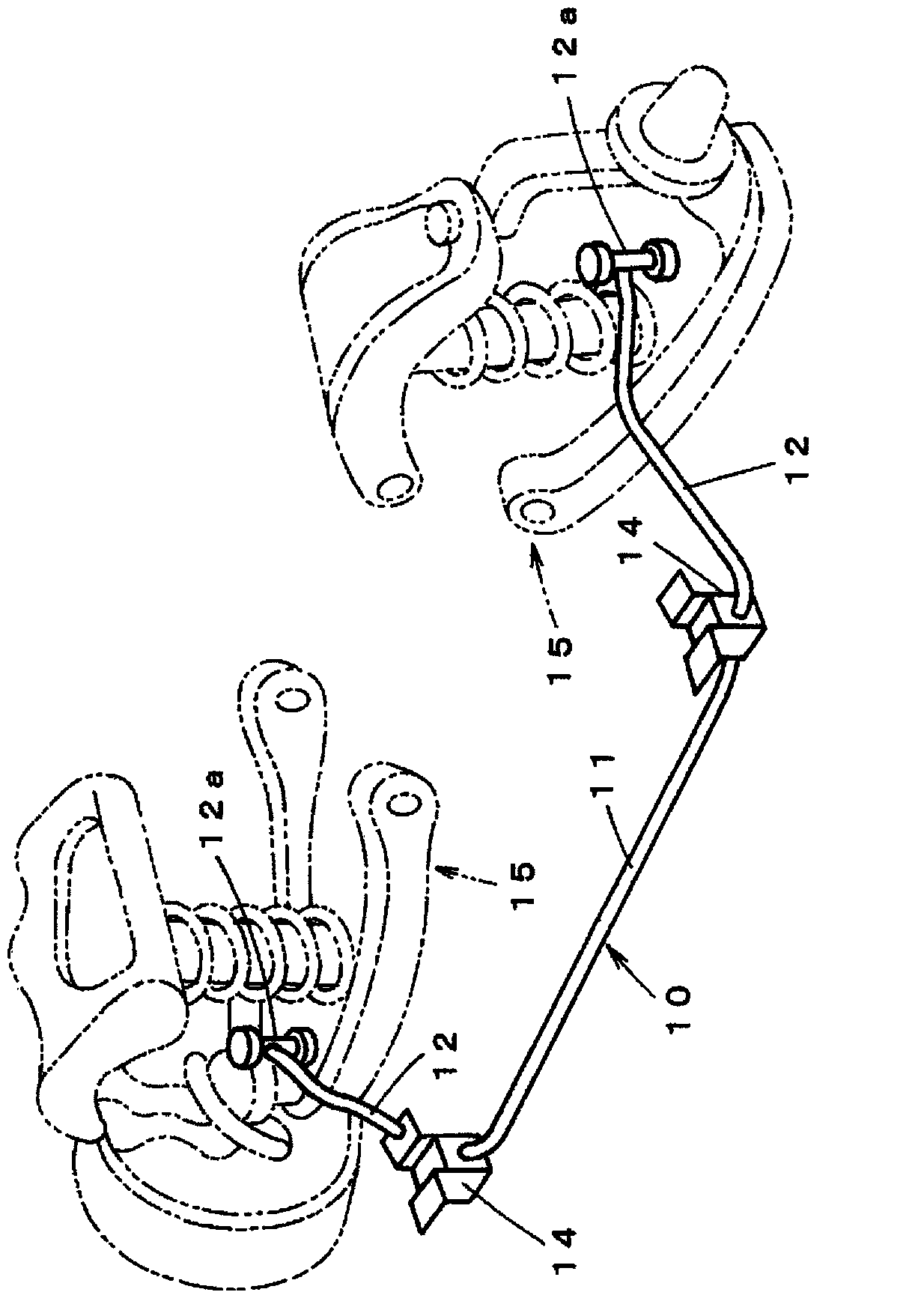

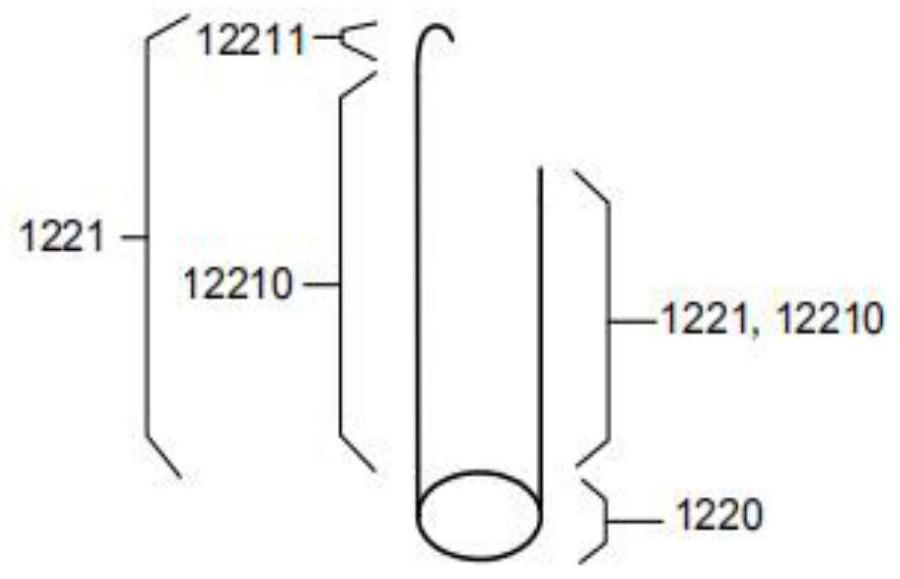

Dynamic liner sleeve for flexible coupling

ActiveUS20160003388A1Dampens natural vibration and frequencyReduce NVHSleeve/socket jointsPipeline expansion-compensationCouplingEngineering

A flexible coupling includes a liner, a bellow, and a liner sleeve preferably defined by a compressed woven mesh strip spirally wound around the liner between bellow and liner and moveable longitudinally with respect to the bellow and liner when the coupling expands linearly. An alternate sleeve in the form of a cylinder is disposed about the liner, under the bellow and is formed of a woven non-compressed mesh.

Owner:AMERICAN BOA

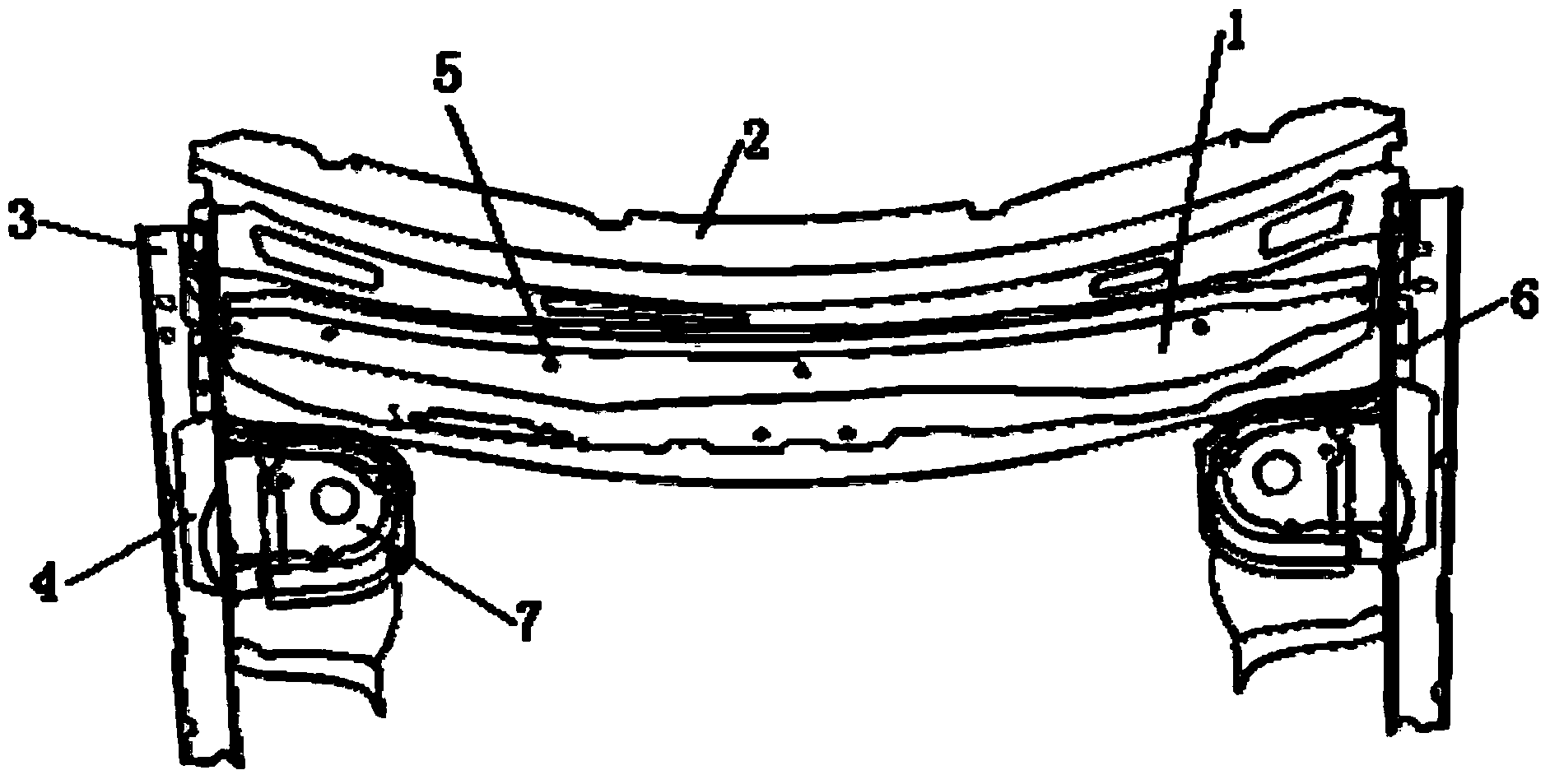

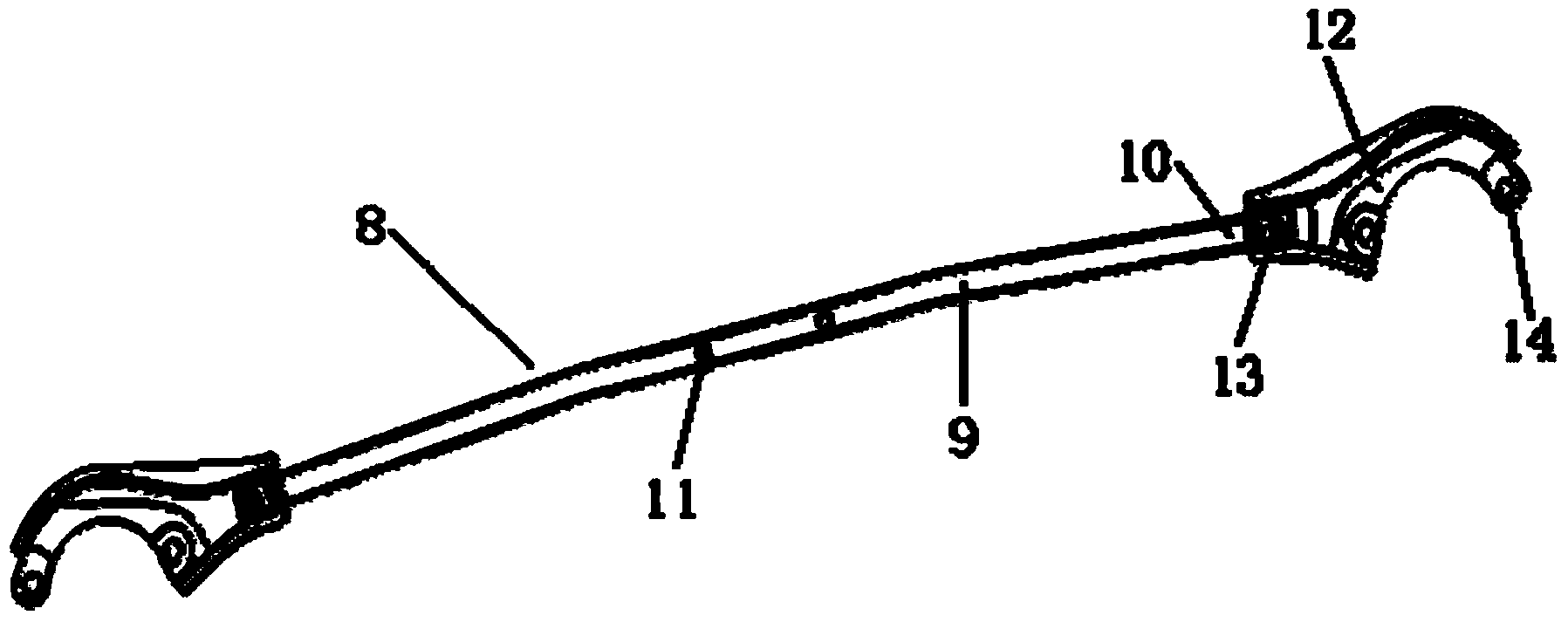

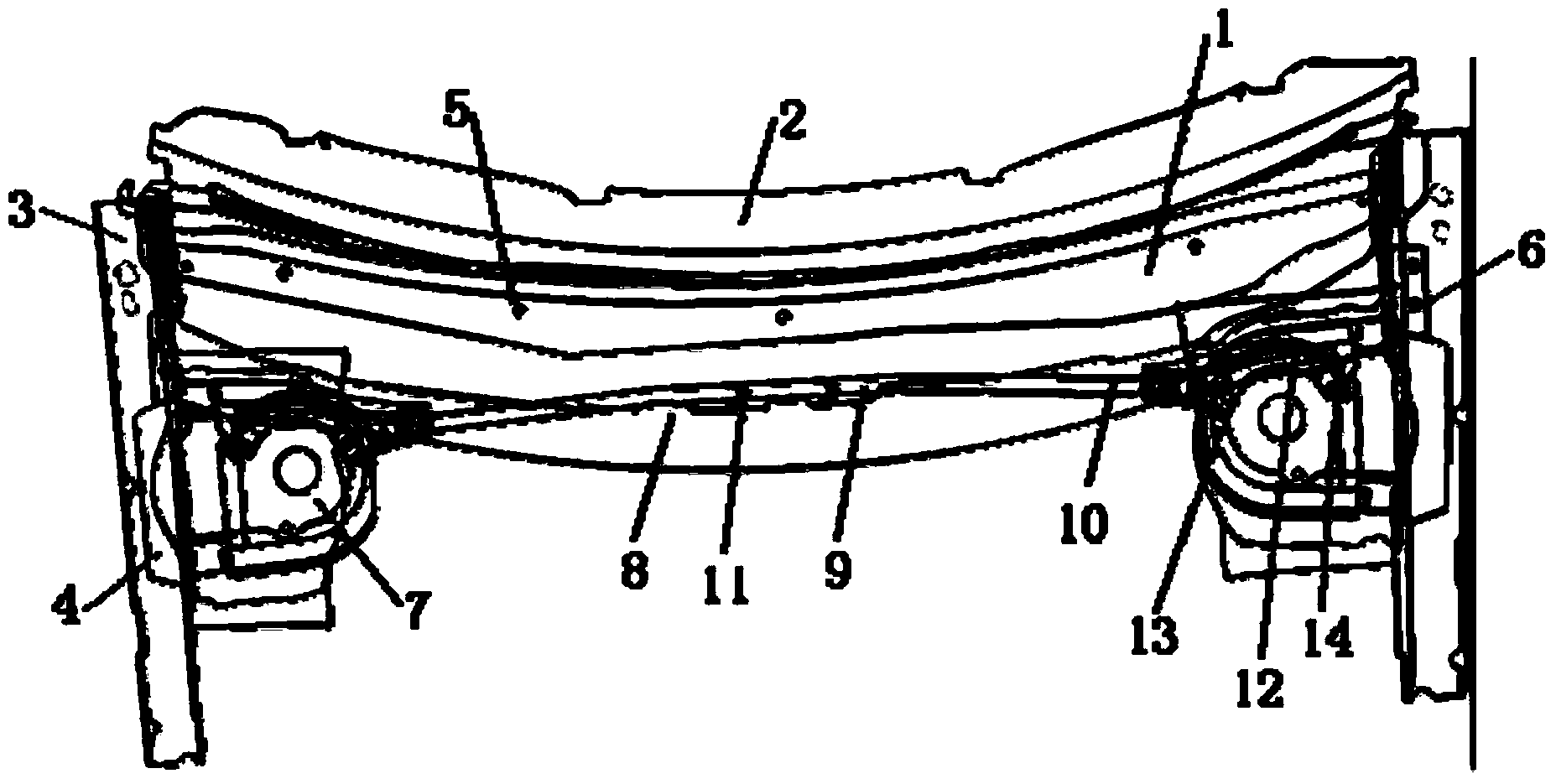

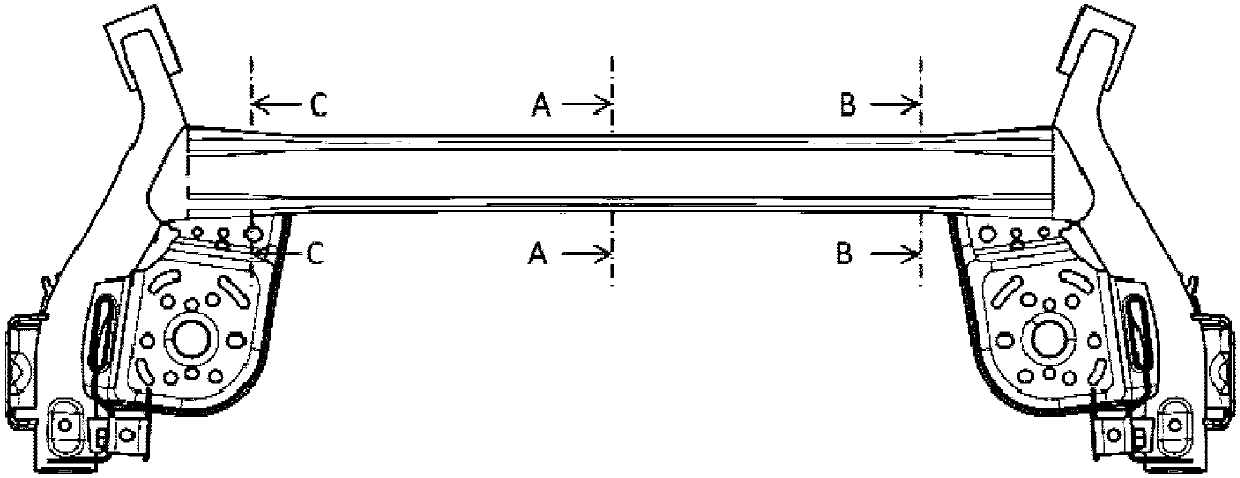

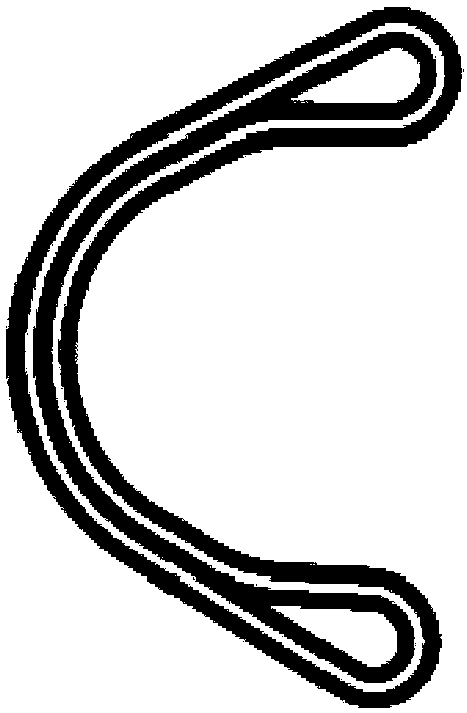

Automobile running water tank assembly, automobile front body structure and automobile

ActiveCN103963850AImprove versatilityIncrease lateral stiffnessSuperstructure subunitsShock absorberClosed state

The invention discloses an automobile running water tank assembly, an automobile front body structure and an automobile. The automobile running water tank assembly comprises a running water tank and a running water tank reinforcing beam. The running water tank reinforcing beam comprises a running water tank reinforcing beam body and running water tank reinforcing beam ends of the two ends of the running water tank reinforcing beam body. The running water tank reinforcing beam body is connected with the running water tank. The two running water tank reinforcing beam ends can be connected with two front shock absorber base bodies of the automobile respectively. According to the automobile running water tank assembly, the running water tank reinforcing beam is connected with the two front shock absorber base bodies so that the running water tank reinforcing beam and the running water tank can be in a closed state, transverse stress generated when a fore-cabin sways in the prior art is converted into tension and compression stress between the running water tank reinforcing beam and the two front shock absorber base bodies, the stress brought by swaying vibration of the fore-cabin is obviously reduced, the transverse rigidity of the fore-cabin is effectively improved, the integral torsion rigidity and the integral bending rigidity of an automobile body can be effectively improved, and endurance of the running water tank can be achieved.

Owner:CHERY AUTOMOBILE CO LTD

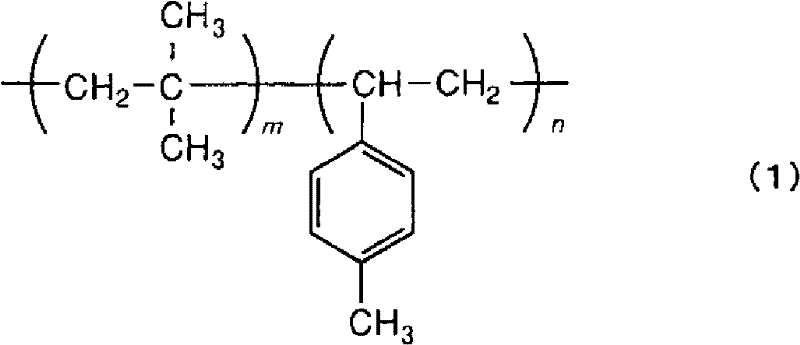

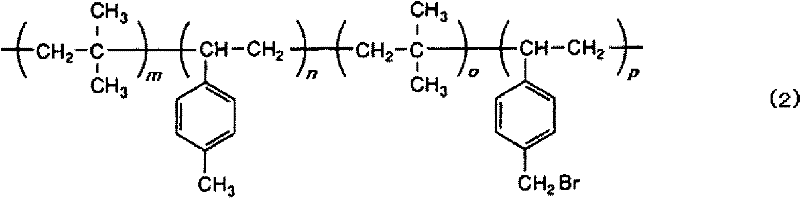

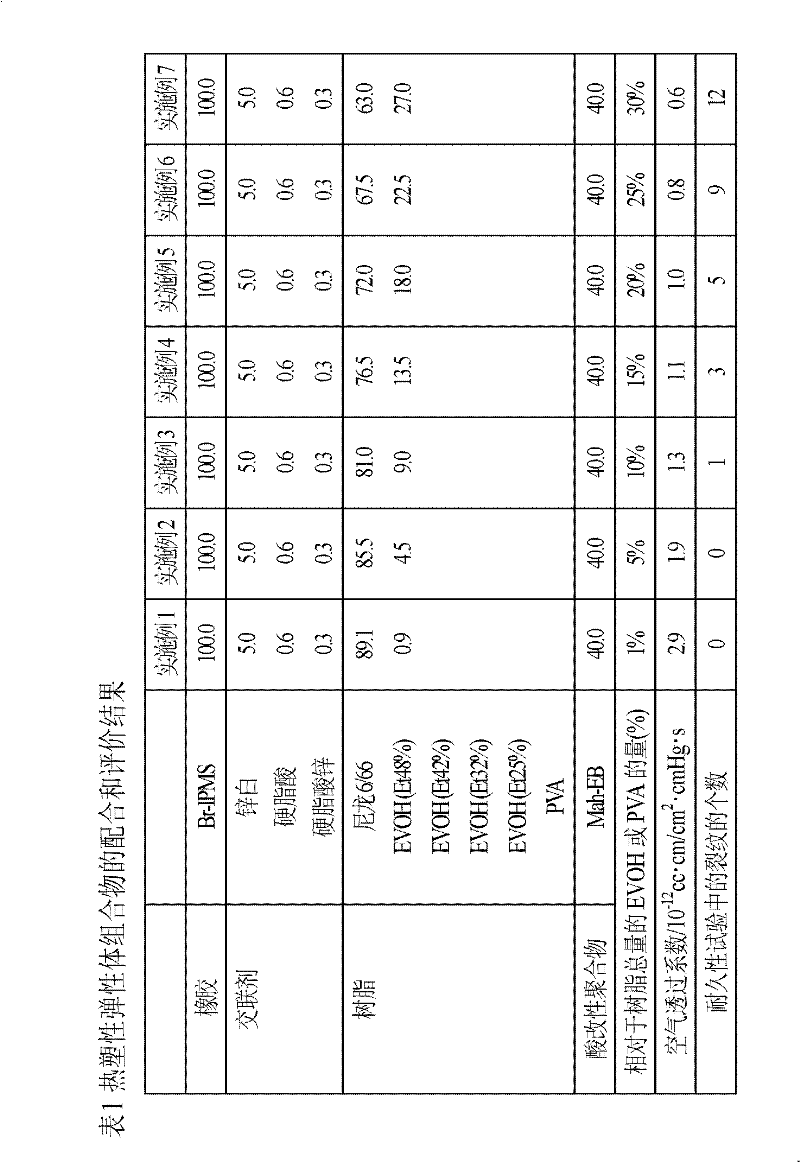

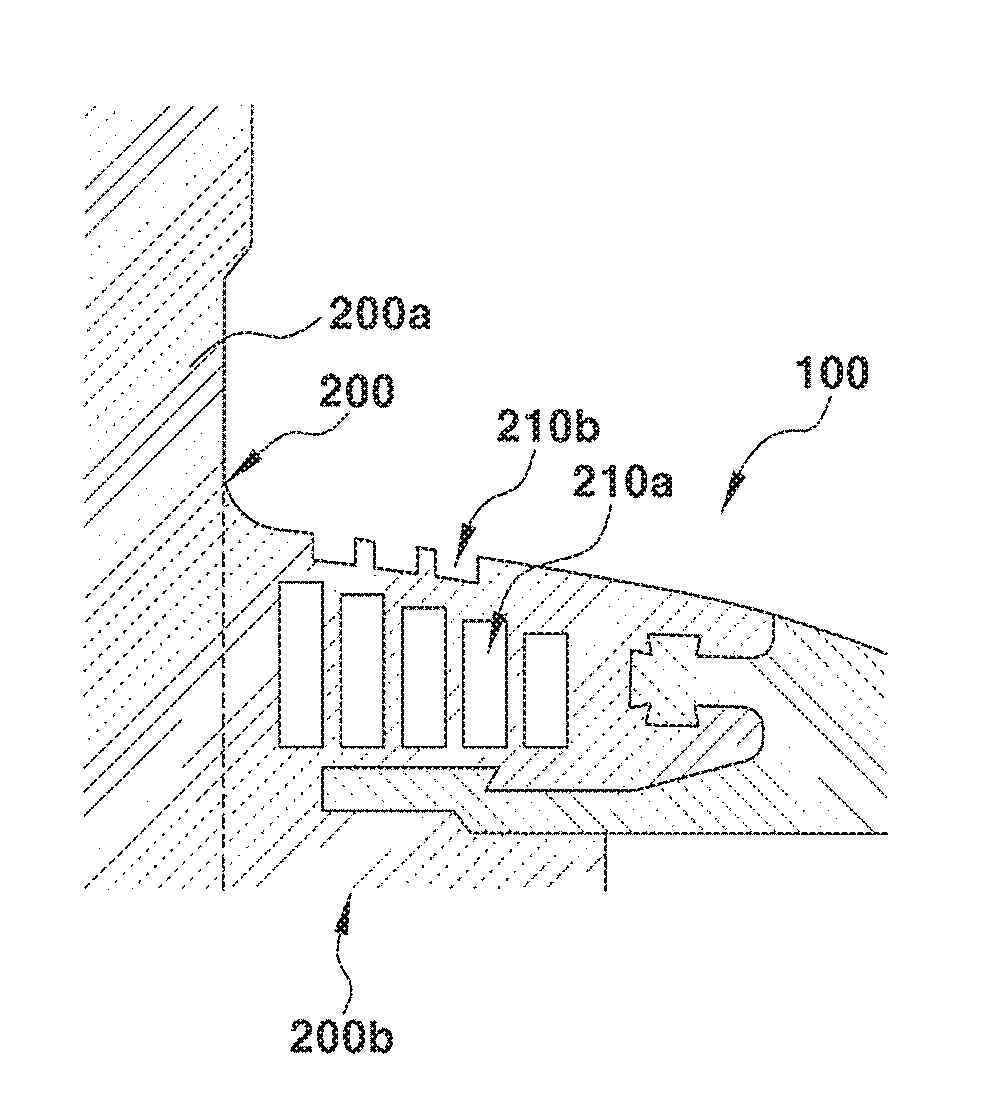

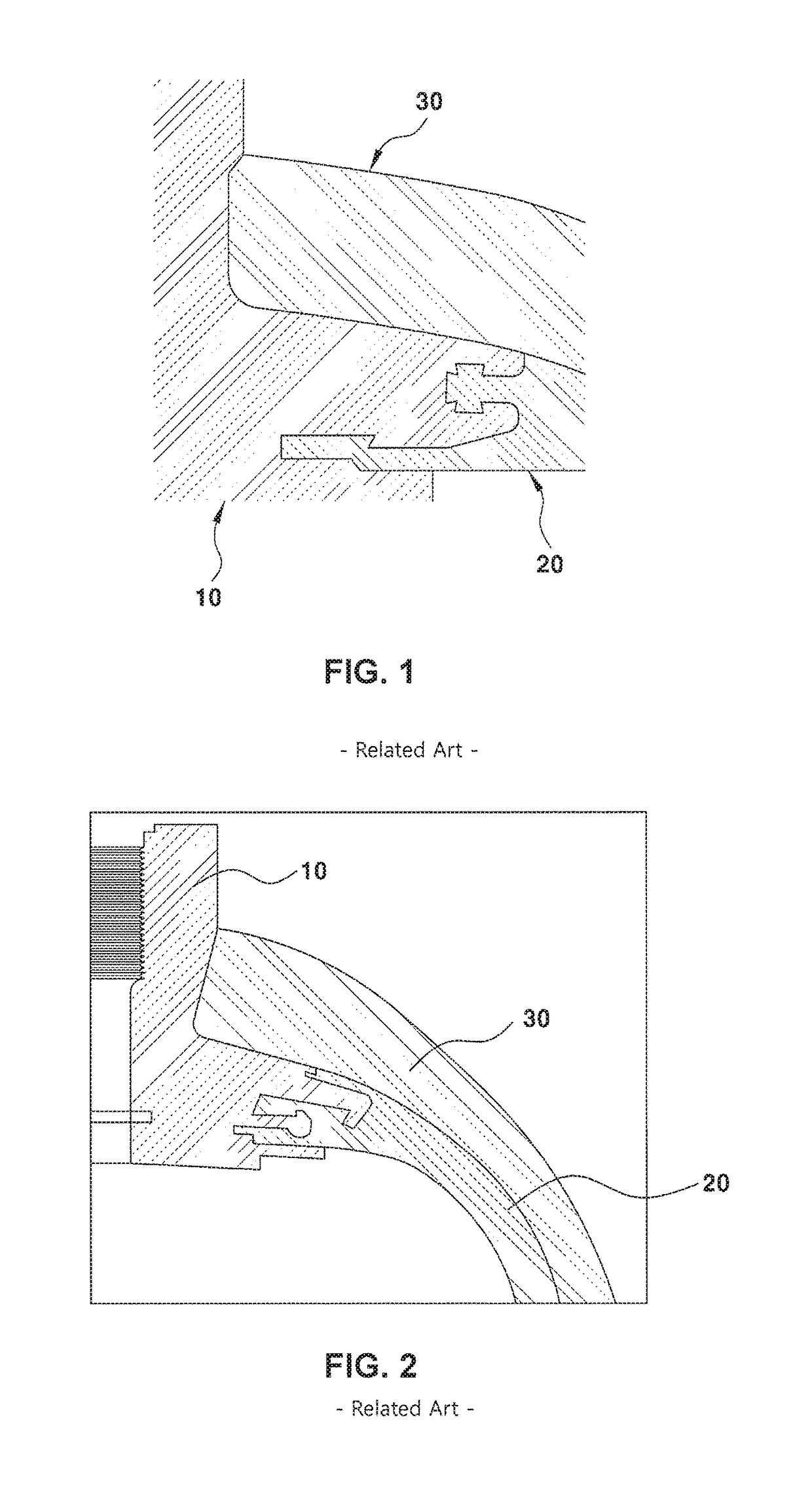

Thermoplastic elsatomer composition, and pneumatic tire using same

InactiveCN102482471AExcellent air barrierImprove fatigue durabilityWithout separate inflatable insertsSpecial tyresThermoplasticPolyvinyl alcohol

Provided is a thermoplastic elastomer composition suitable for use as an inner liner of a pneumatic tire, and exhibiting excellent air barrier properties and fatigue endurance. The thermoplastic elastomer composition has a rubber composition dispersed in a thermoplastic resin composition, said rubber composition containing a halogenated isoolefin para-alkylstyrene copolymer and being crosslinked, and said thermoplastic resin composition containing a polyamide and an ethylene vinyl alcohol copolymer / polyvinyl alcohol. The amount of the ethylene vinyl alcohol copolymer / polyvinyl alcohol is preferably 1-25 mass% of the total amount of the thermoplastic resin composition. The amount of the halogenated isoolefin para-alkylstyrene copolymer is preferably 80-200 parts by mass to 100 parts by mass of the total of the thermoplasic resin composition.

Owner:YOKOHAMA RUBBER CO LTD

Manufacture method for torsion cross beam with excellent fatigue performance

InactiveCN109797340AImprove fatigue durabilityGood formabilityFurnace typesHeat treatment furnacesWork in processStress relief

The invention provides a manufacture method for a torsion cross beam with excellent fatigue performance. The method includes steps of pipe welding, preforming, internal high pressure forming, and stress relief annealing, specifically, the pipe welding includes steps that according to the size of the cross beam, a steel plate is bent into a circular pipe with corresponding size by a pipe maker andthen welded to obtain a closed circular pipe; the preforming includes step that the circular pipe is subjected to cool stamping forming to obtain a semi-manufactured cross beam product; the internal high pressure forming includes steps that the two ends of the semi-manufactured cross beam product are filled with liquid, then sealed, and subjected to compression and bulging, and then the cross beamis pushed by punches of the two ends for feeding, so that the pipe product is against the model to obtain the manufactured cross beam product; and the stress relief annealing includes step that the manufactured cross beam product is required to be subjected to stress relief annealing treatment after forming. According to the method, the high-strength pipe has the tensile strength reaching 780-920Mpa, the yield strength reaching 600-730 Mpa, the ratio of the yield strength to the tensile strength no exceeding 0.86, and the elongation reaching 11% or more.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

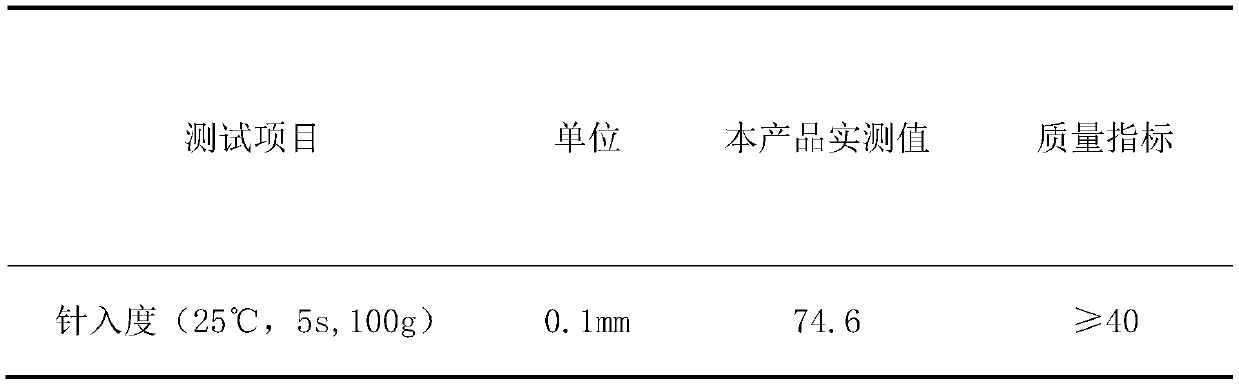

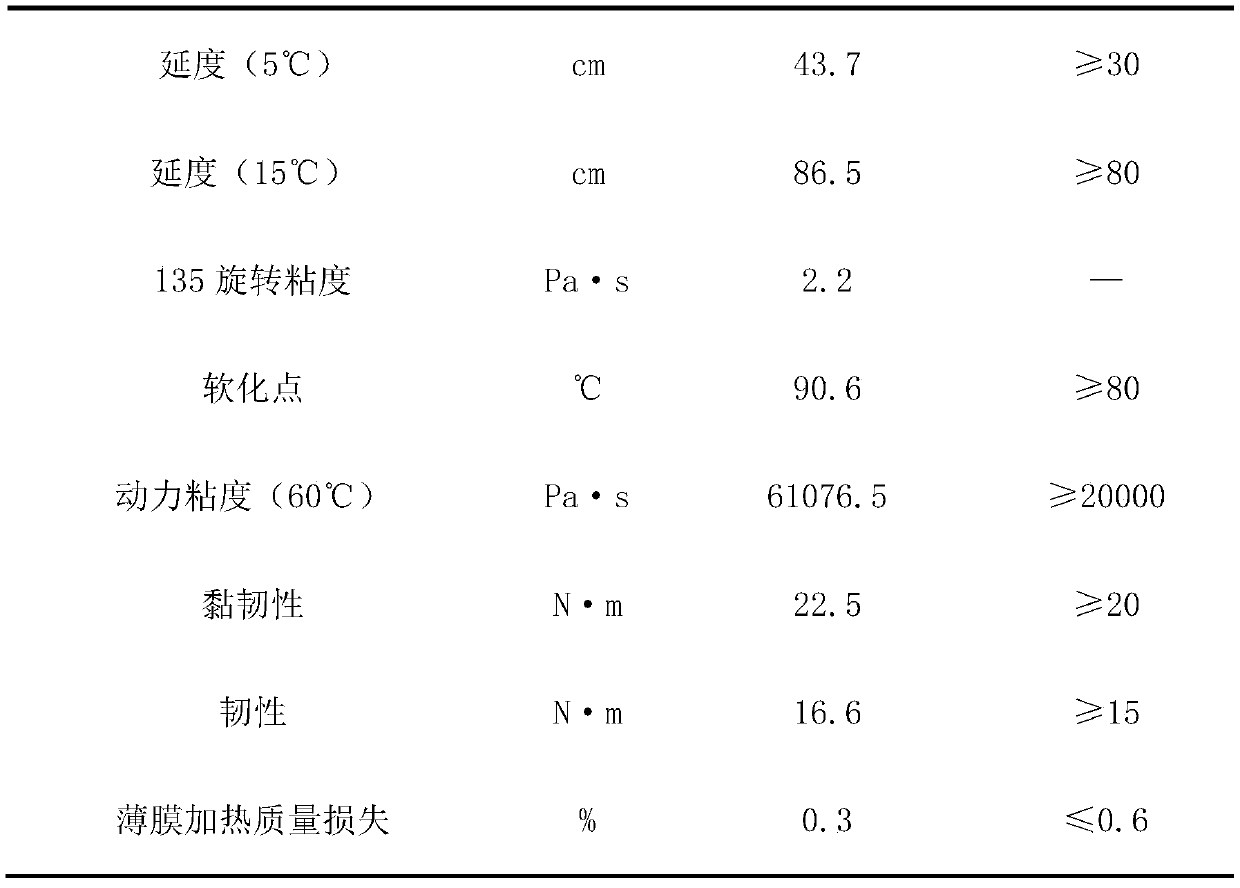

High-adhesion modified asphalt and preparation method thereof

InactiveCN109852085AIncreased durabilityImprove engineering structureBuilding insulationsPolyesterPolymer science

The invention discloses high-adhesion modified asphalt and a preparation method thereof, and belongs to the technical field of road engineering materials. The raw materials of the high-adhesion modified asphalt comprises 500 parts of base asphalt, 300-400 parts of an additive and 10-20 parts of composite reinforcing fibers, and the composite reinforcing fibers are prepared by compounding basalt fibers and polyester fibers and then being coated with base asphalt thin films. When preparing the high-adhesion modified asphalt, the composite reinforcing fibers are added, so that the adhesion, high-temperature stability, fatigue durability of asphalt pavements are greatly improved, and the asphalt has the properties of low-temperature crack prevention and reflection crack prevention. The tensile, shear, compressive and impact strength are effectively improved, and the thermal stability and low temperature resistance of the asphalt are improved.

Owner:河北长大交通科技有限公司

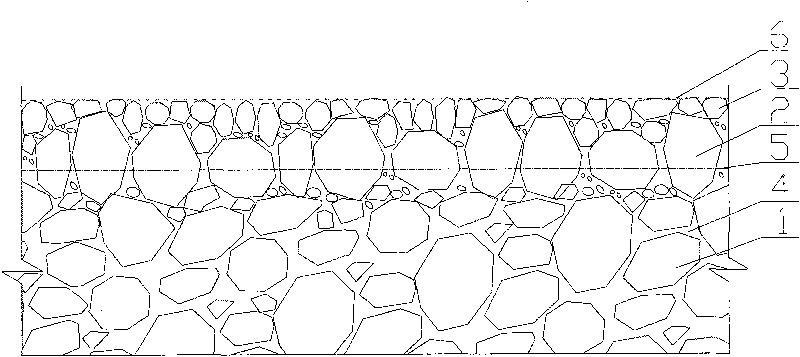

Epoxy asphalt and crushed stone drainage foundation

ActiveCN101886361AImprove fatigue resistanceImprove short service lifeIn situ pavingsEpoxyCrushed stone

The invention relates to epoxy asphalt and crushed stone drainage foundation and a paving process thereof. The conventional epoxy asphalt is an irreversible solid product of the solidification of asphalt by adding epoxy resin into the asphalt. Compared with the common ATPB, the epoxy asphalt and crushed stone is 2 to 3 times higher in stability than ATPB and more than 1.5 times higher in fatigue life than ATPB. The epoxy asphalt and crushed stone drainage foundation provided by the invention is a mixture formed by wet-mixing of epoxy resin serving as a bonding material and open-grade crushed stone serving as aggregate. The paving process of the epoxy asphalt and crushed stone drainage foundation comprises: firstly, sweeping the surface of a subbase layer; secondly, uniformly spraying an epoxy asphalt waterproof bonding layer while controlling the spray amount to be 0.4 to 0.6kg / m<2>; and thirdly, paving the epoxy asphalt and crushed stone drainage foundation, forming the epoxy asphalt and crushed stone drainage foundation by rolling till the porosity reaches 18 to 24 percent and constructing a surface layer at the end of an aging period. The epoxy asphalt and crushed stone drainage foundation and the paving process thereof solve the problems of low fatigue durability, low anticorrosion resistance, high construction cost, environmental pollution and the like in the prior art.

Owner:CCCC FIRST HIGHWAY CONSULTANTS +1

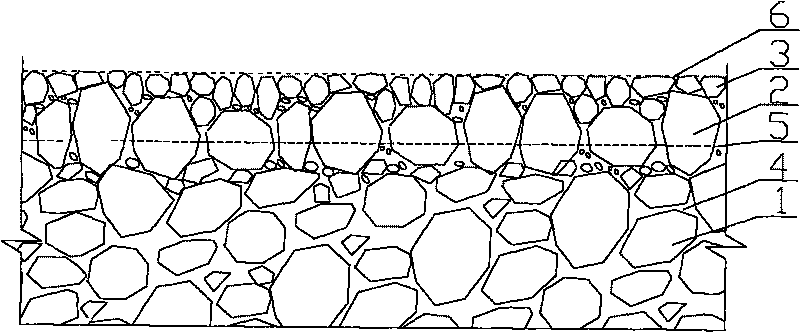

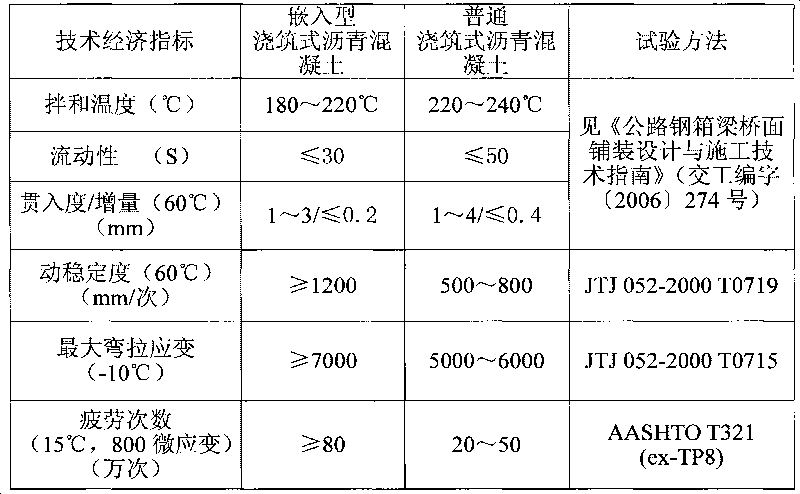

Embedded pouring asphalt concrete

ActiveCN101736672AIncreased durabilityLower mixing temperatureIn situ pavingsRoads maintainencePavement engineeringGranularity

The invention relates to paving structures and materials for pavement engineering, in particular to embedded pouring asphalt concrete. The coarse aggregate dosage of the embedded pouring asphalt concrete is reduced by 10-30 percent than the coarse aggregate dosage in the mixing proportion design of ordinary pouring asphalt concrete, and the embedded pouring asphalt concrete is prepared through the following steps of: mixing the coarse aggregate, uniformly stirring at the temperature of 180-220 DEG C, spreading and leveling by using a spreading machine, then spreading a first layer of aggregate with the granularity of 10-15mm and the dosage accounting for 10-25 percent of the quality of the designed pouring asphalt concrete, then spreading a second layer of aggregate with the granularity of 5-10mm and the dosage accounting for 10-15 percent of the quality of the designed pouring asphalt concrete and rolling once through a combined wheel road roller of which bearing wheel walking railways at both sides are provided with lower limited positions and can vibrate to form the embedded pouring asphalt concrete. The coarse aggregate dosage of the embedded pouring asphalt concrete is reduced before the mixture is spread to improve the fluidity, thereby lowering the construction temperature and improving the fatigue durability; the dosage of spread broken stones is increased, and the compaction process and the power are adjusted and increased, thereby ensuring the embedding ratio of the broken stones and improving the high temperature stability.

Owner:重庆市智翔铺道技术工程有限公司

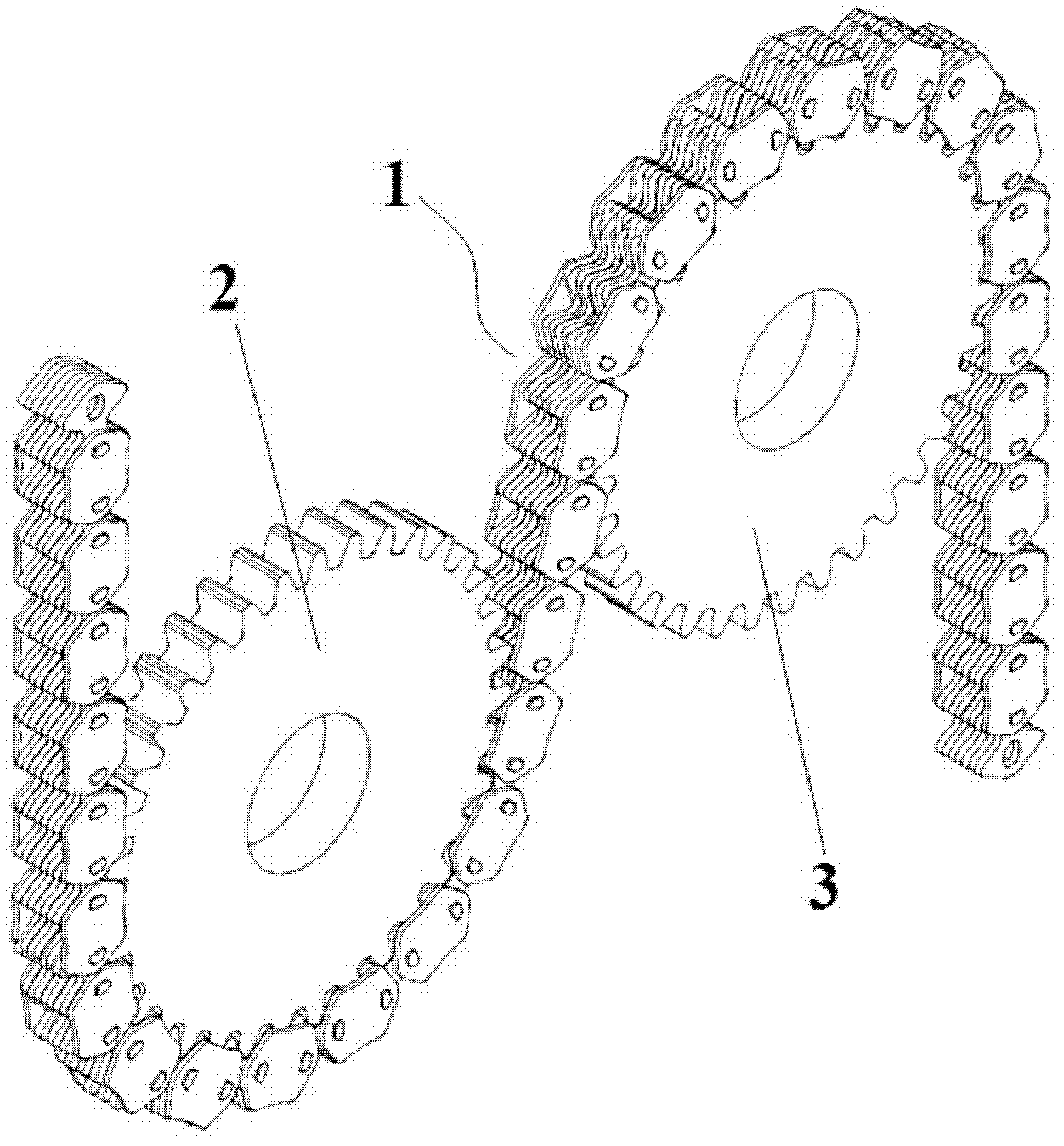

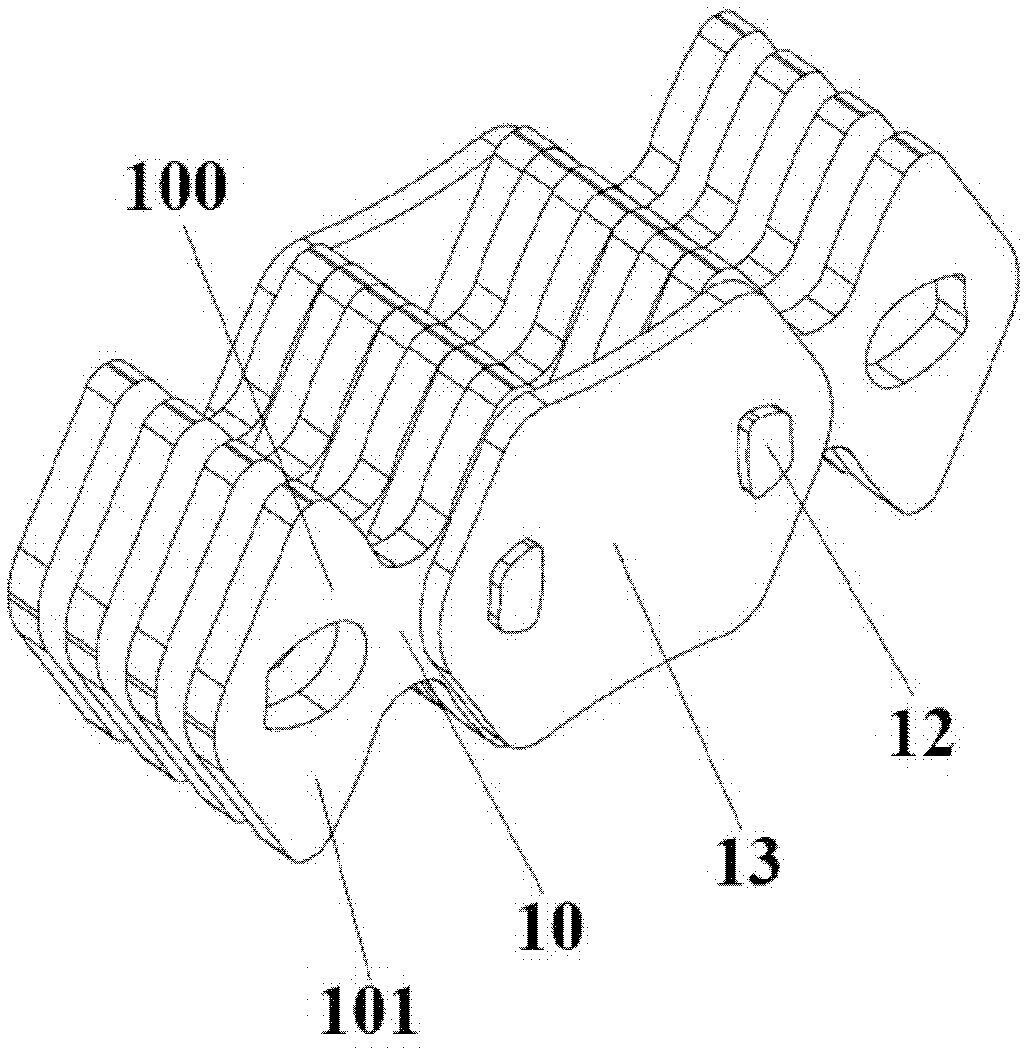

Pitch-varying two-sided internal and external composite-meshing silent chain transmission system

The invention discloses a pitch-varying two-sided internal and external composite-meshing silent chain transmission system which is mainly composed of a chain, a chain wheel A and a chain wheel B. One side of the chain is in meshed transmission with the chain wheel A, and the other side of the chain is in meshed transmission with the chain wheel B so that transmission of force and torque is achieved. The chain is mainly composed of a plurality of groups of working chain plates, short roll pins, long roll pins and guide pieces, wherein the short roll pins and the long roll pins penetrate through the chain plate holes of the working chain plates to enable the plurality of groups of working chain plates to be connected in a head-to-tail mode, and the guide pieces enable exposed portions located at two ends of two adjacent long roll pins to be fixed. The pitch-varying function of transmission of pitch-varying two-sided internal and external composite-meshing silent chains is achieved, the polygon effect, impact and vibration of the silent chain are remarkably reduced, the abrasion is reduced, and an S-shaped transmission function is achieved. Simultaneously, the pitch-varying two-sided internal and external composite-meshing silent chain transmission system has the advantages of meshing stability of an internal-meshing silent chain and positioning stability of an external-meshing silent chain.

Owner:JILIN UNIV

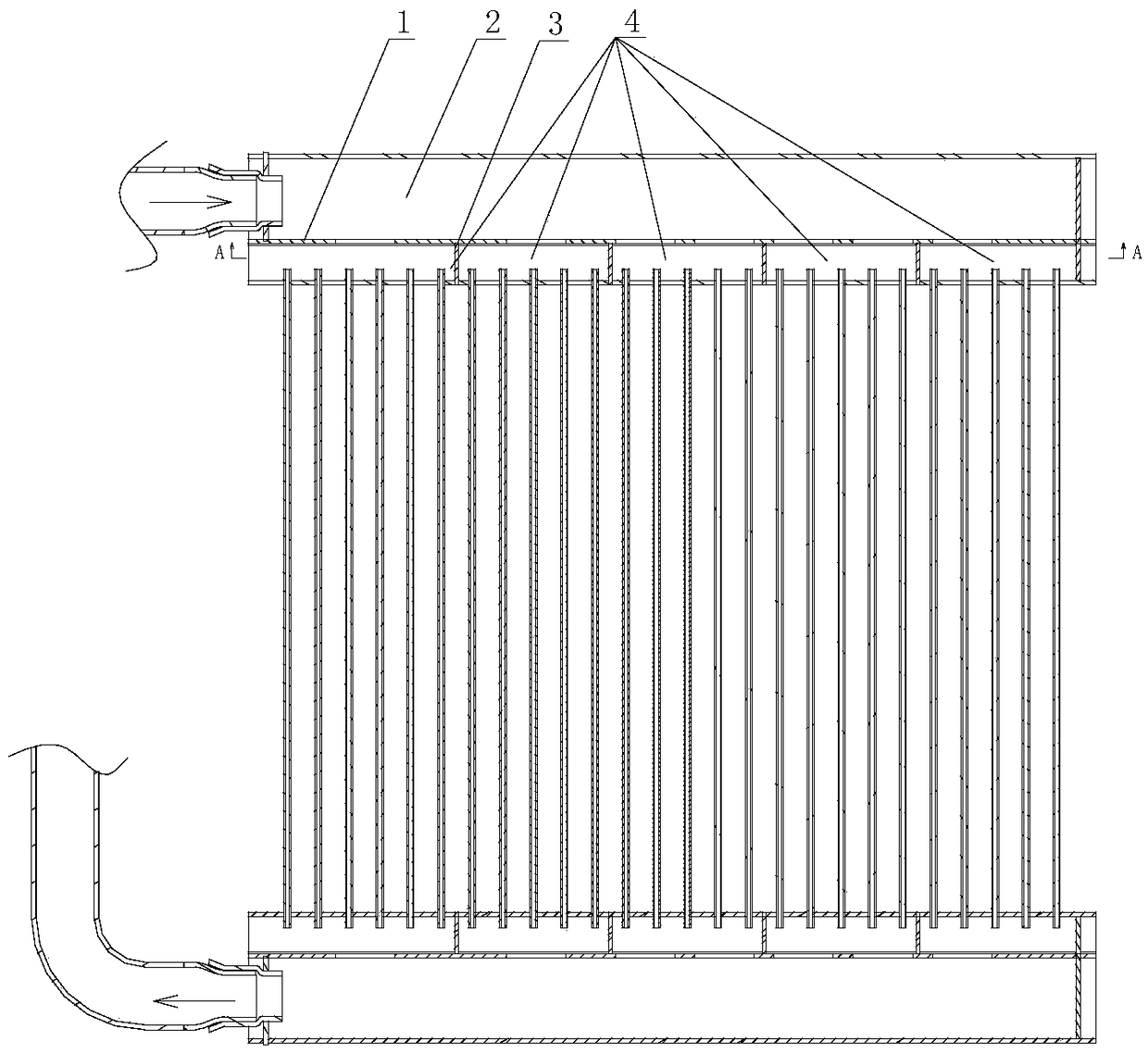

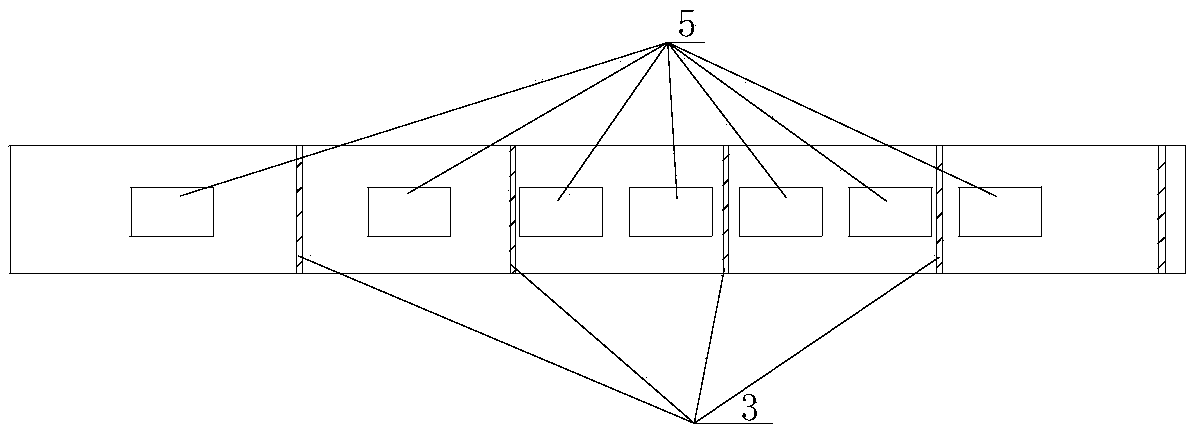

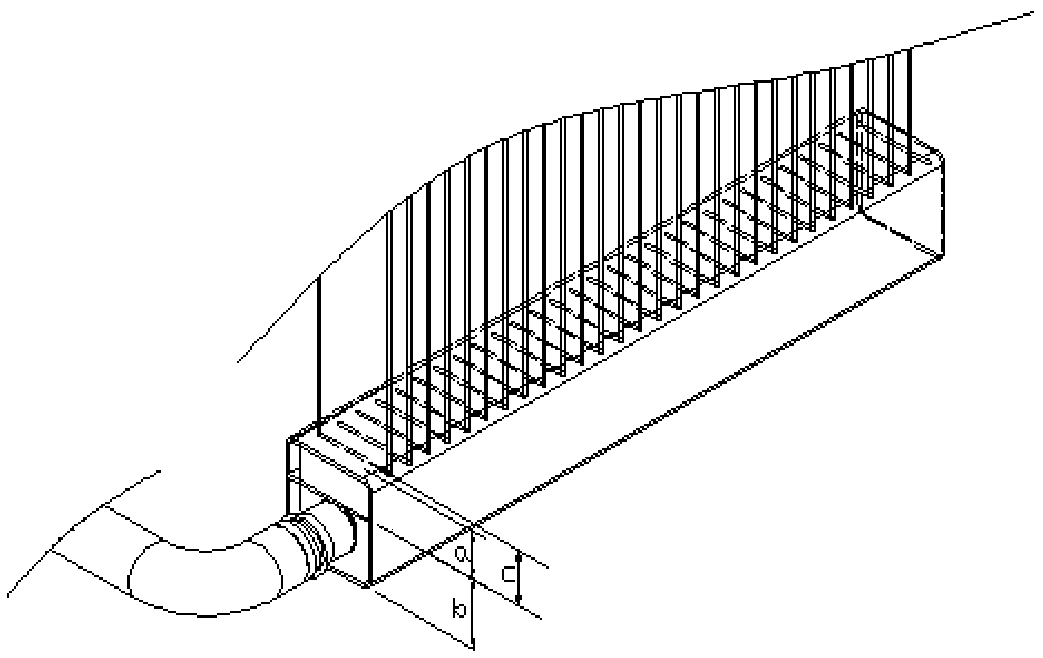

Shunting structure for use in collecting pipe of heat exchange unit of automobile

PendingCN108895880APrecise flow controlImprove uniformityIndirect heat exchangersHeat exchanger casingsEngineeringAirflow

The invention relates to a shunting structure for use in a collecting pipe of a heat exchange unit of an automobile. The shunting structure includes a longitudinal dividing plate disposed along the axial direction of the collecting pipe and dividing an inner cavity of the collecting pipe into a first longitudinal cavity and a second longitudinal cavity. The first longitudinal cavity is communicated with a working medium inlet, the second longitudinal cavity is communicated with heat exchange pipes, a plurality of horizontal dividing plates are distributed in the second longitudinal cavity, andthe second longitudinal cavity is divided into a plurality of shunting areas. The number of the heat exchange pipes corresponding to the plurality of shunting areas is the same, and each shunting area corresponding to the longitudinal dividing plate is provided with shunting holes. In the direction from the liquid inlet end to the other end, in the length range of 0 to X, the circulation areas ofthe shunting holes of the corresponding shunting areas have a gradually increasing trend; in the length range of X to Y, the circulation areas of the shunting holes of the corresponding shunting areas the equal; in the length range of Y 1, the circulation areas of the shunting holes of the corresponding shunting areas have a gradually reduced trend; wherein X is 0.3+ / -0.15, and Y is 0.6+ / -0.15. The shunting structure improves the evenness of air flow passing across the surface of the heat exchange unit.

Owner:TIANJIN SANDEN AUTO AIR CONDITIONING

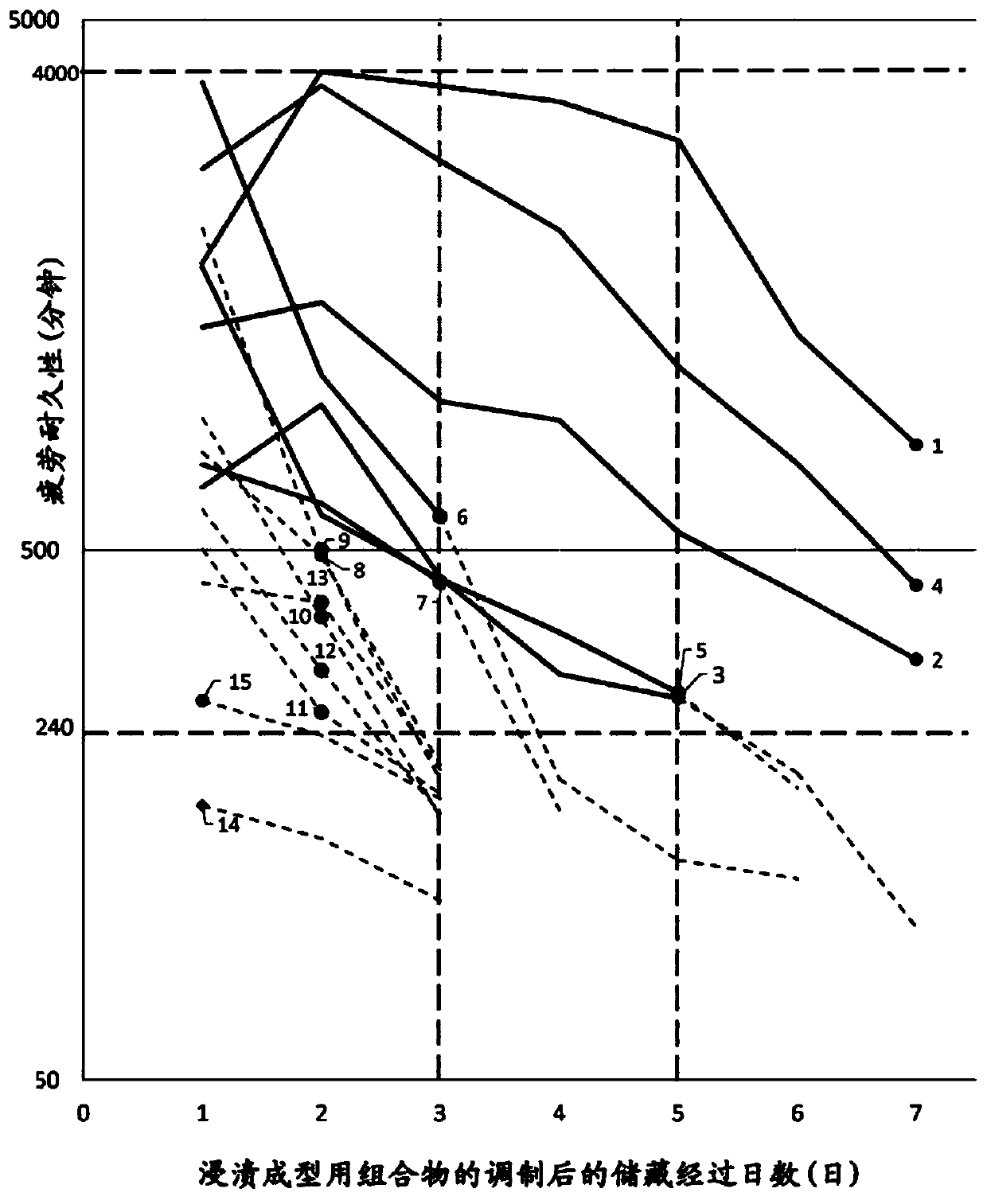

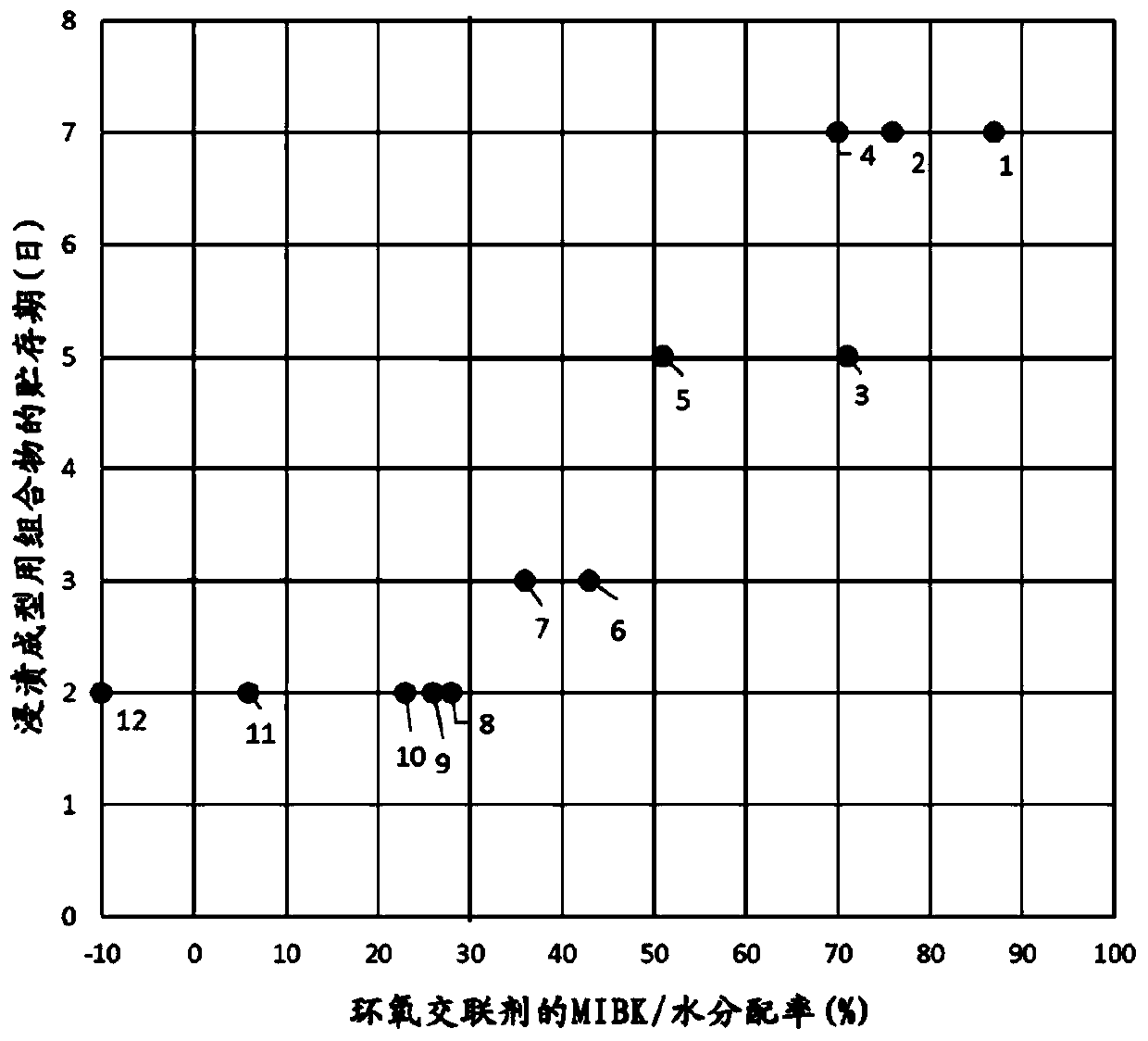

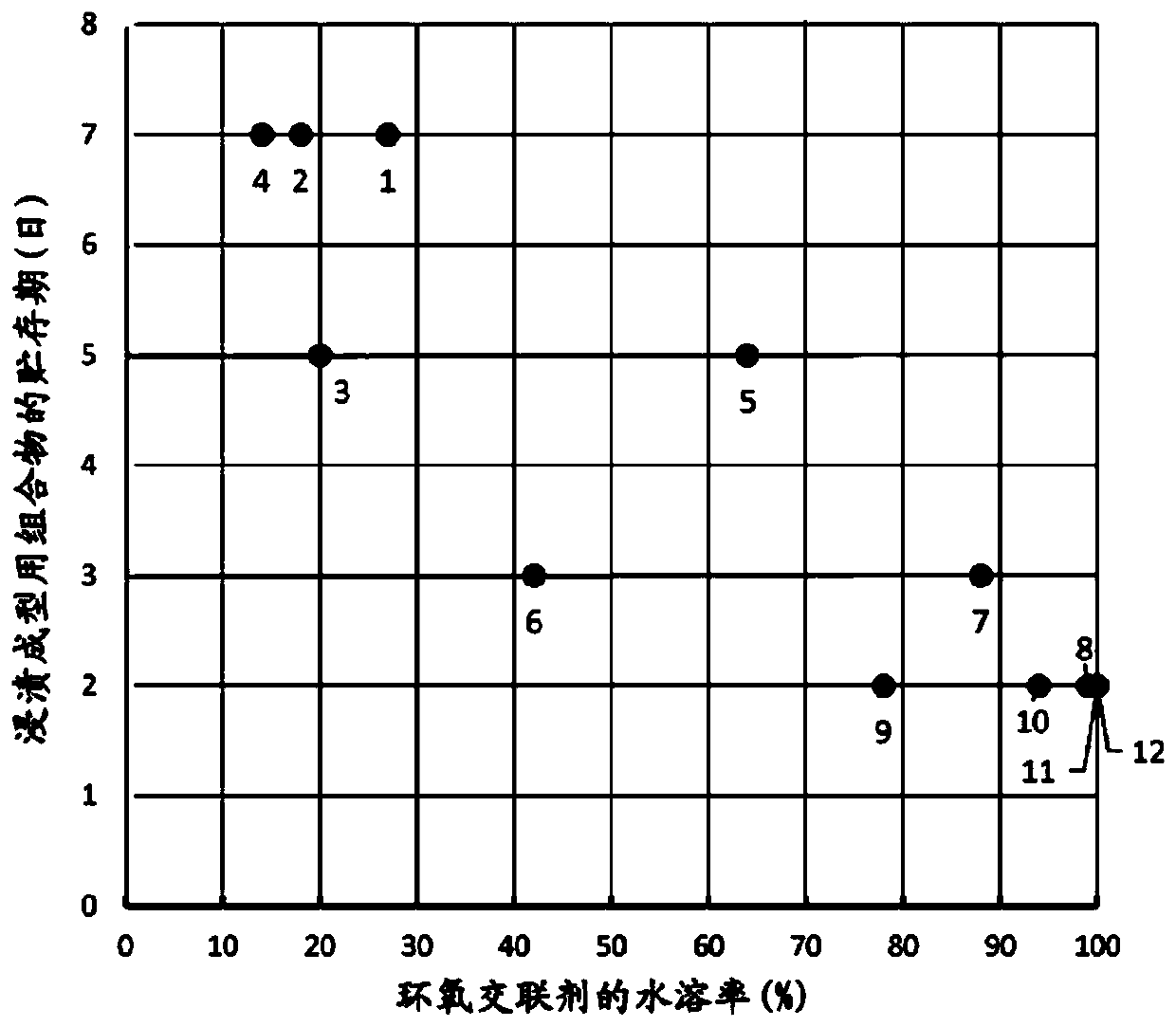

Made in composition, gloves and gloves for immersion molding

ActiveCN110582534AImprove fatigue durabilityStable manufacturingGlovesConjugated diene hydrocarbon coatingsElastomerMeth-

The present invention provides a composition for dip molding comprising at least an elastomer, an epoxy crosslinking agent, water, and a pH adjuster, the elastomer comprising a structure derived from (meth)acrylonitrile on a polymer main chain Units, structural units derived from unsaturated carboxylic acids, and structural units derived from butadiene, in the above elastomer, structural units derived from (meth)acrylonitrile account for 20 to 40% by weight, and structural units derived from unsaturated carboxylic acids The structural unit of an acid is 1 to 10% by weight, and the structural unit derived from butadiene is 50 to 75% by weight, and the above-mentioned epoxy crosslinking agent includes an epoxy compound having 3 or more epoxy groups in one molecule. The epoxy crosslinking agent has a water solubility of 10 to 70% obtained by a specific measurement method.

Owner:MIDORI ANZEN

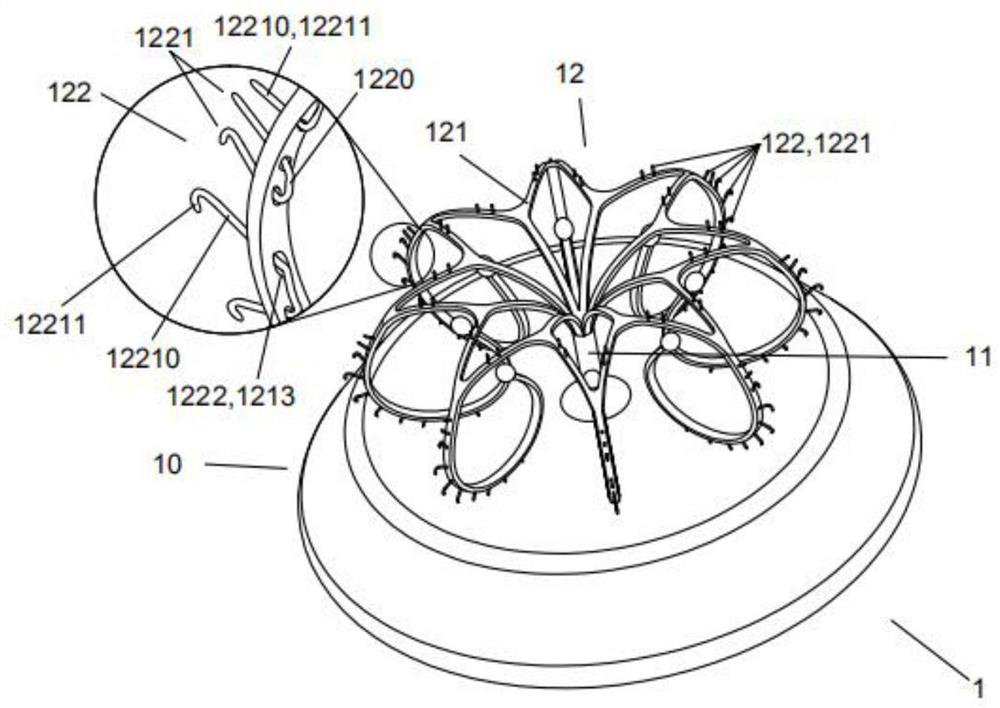

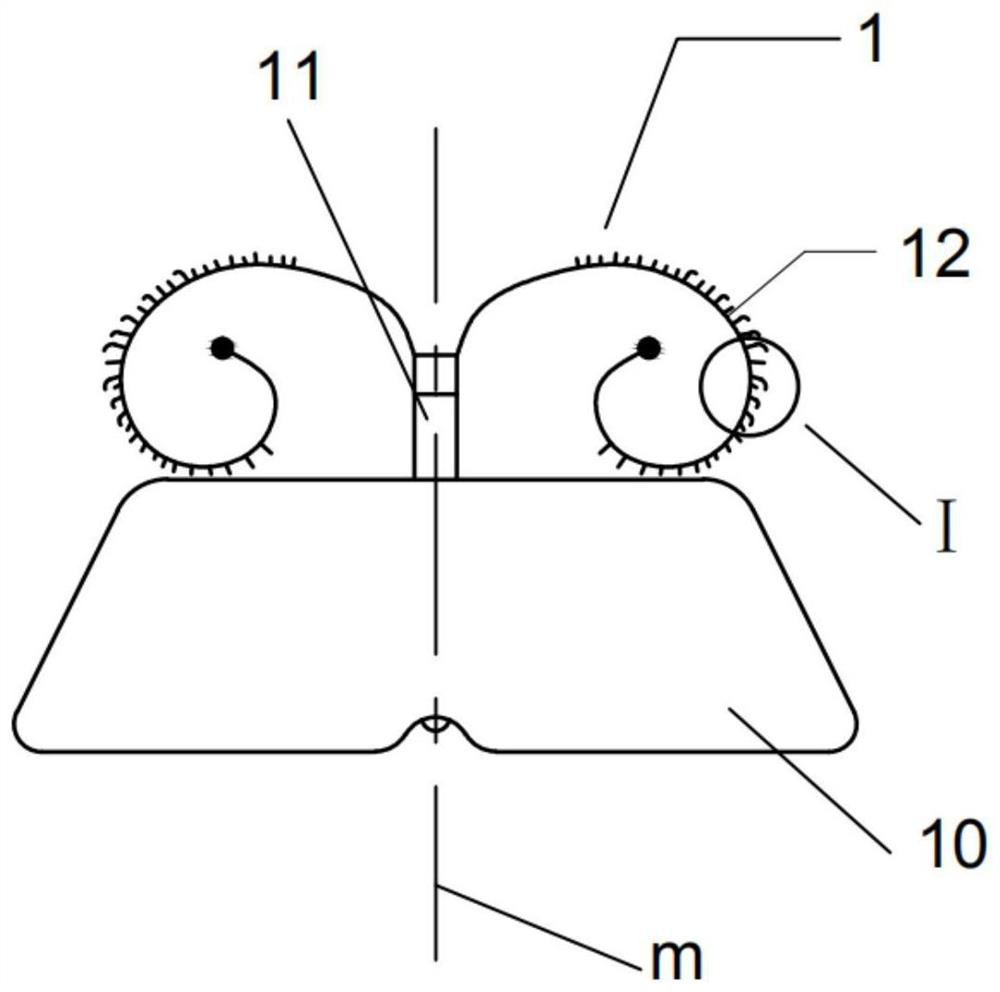

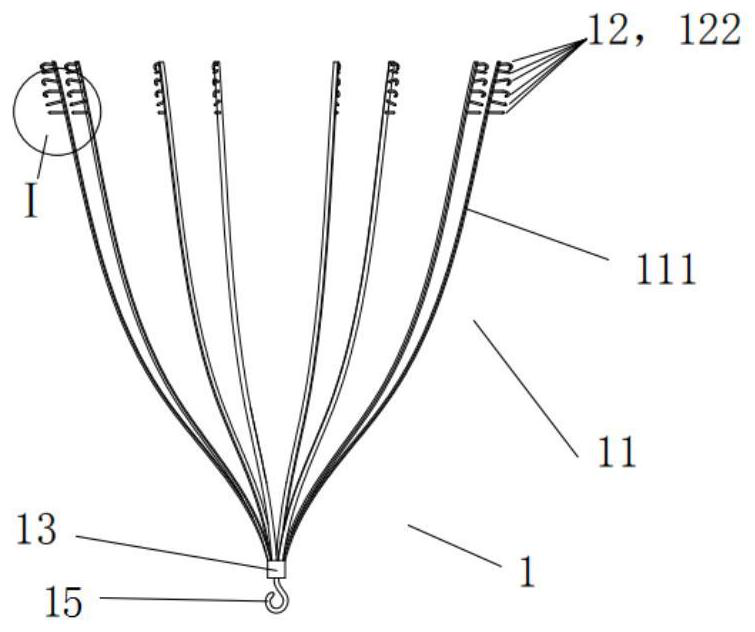

Left auricle occluder with bionic spinule attachment structures

PendingCN112155627AImprove fitEnhanced anchoring effectivenessOcculdersBiomedical engineeringGeneral surgery

The invention relates to a left auricle occluder with bionic spinule attachment structures. The left auricle occluder at least comprises an attachment frame; the attachment frame includes a pluralityof elastic skeletons and a plurality of bionic spinule attachment structures; under a natural unconstrained state, the plurality of skeletons diverge outwards from the center and define a three-dimensional structure, and the attachment frame has anatomical form adaptability; the bionic spinule attachment structures are arranged on outer surfaces of the skeletons; each of the bionic spinule attachment structures has a form of imitating sparse spinules on the surface of a plant; each bionic spinule attachment structure includes a spinule root and a spinule; each spinule consists of a spinule body and a spinule tip; each spinule is in a straight line shape or a J shape or a combination of the straight line shape and the J shape; and the spinule bodies and / or the spinule tips can touch left auricle inner cavity tissues, thus realizing an attachment-type anchoring function. The left auricle occluder has a wide adaption range, has no injury during anchoring, is firm, has high safety, has excellent occluding effectiveness, and also facilitating realization of personalized customization aiming at clinical demands of patients.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD +1

Road load spectrum preparation method based on density peak machine learning algorithm

PendingCN112395940AAccurate predictionImprove body fatigue durabilityGeometric CADVehicle testingWavelet transformEngineering

The invention provides a road load spectrum preparation method based on a density peak machine learning algorithm. The method comprises the steps: testing the movement of a vehicle on an actual road,and obtaining an initial road load spectrum and speed information; performing statistical modeling on the load and the acceleration to obtain an acceleration signal-road load model; performing preprocessing such as low-pass filtering and resampling on the initial road load spectrum to obtain a preprocessed road load spectrum; based on a wavelet transform method, subjecting the preprocessed load spectrum to compression and noise reduction processing, and shortening the load spectrum time history while effective data is reserved; and performing clustering reconstruction on the compressed load spectrum based on a density peak clustering TNDP machine learning method to obtain an accurate road load spectrum. According to the method, real and accurate road load spectrums can be obtained on different test roads, the load spectrums can be collected only by installing an acceleration sensor in the test of the same type of vehicle model, the cost and the test complexity are greatly reduced, andfinally the compiled accurate load spectrum is obtained. The loaded conditions of automobile parts in the actual driving process can be rapidly reproduced for bench experiments, and high-precision load input is provided for automobile part fatigue reliability research.

Owner:HAINAN UNIVERSITY +1

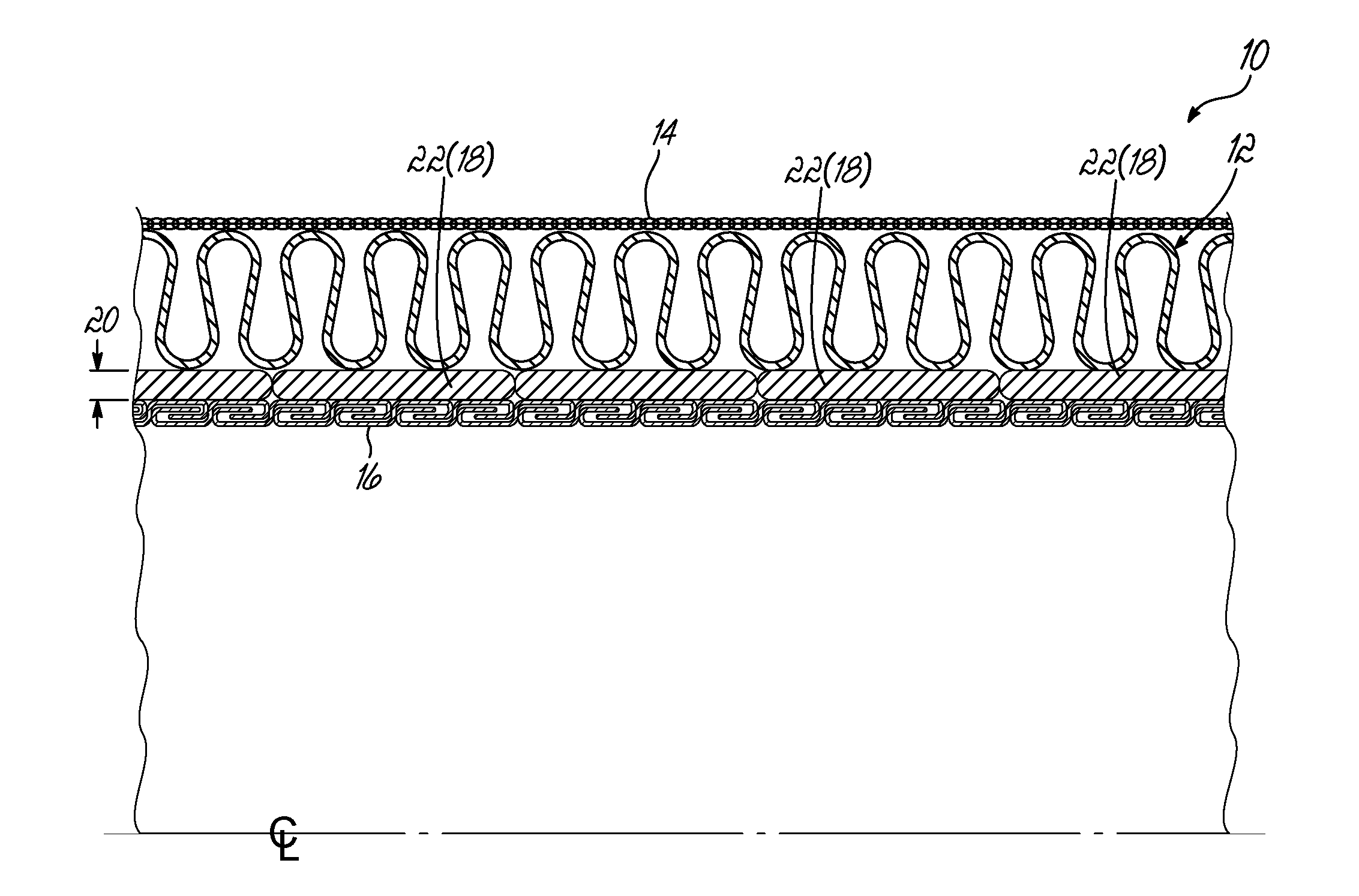

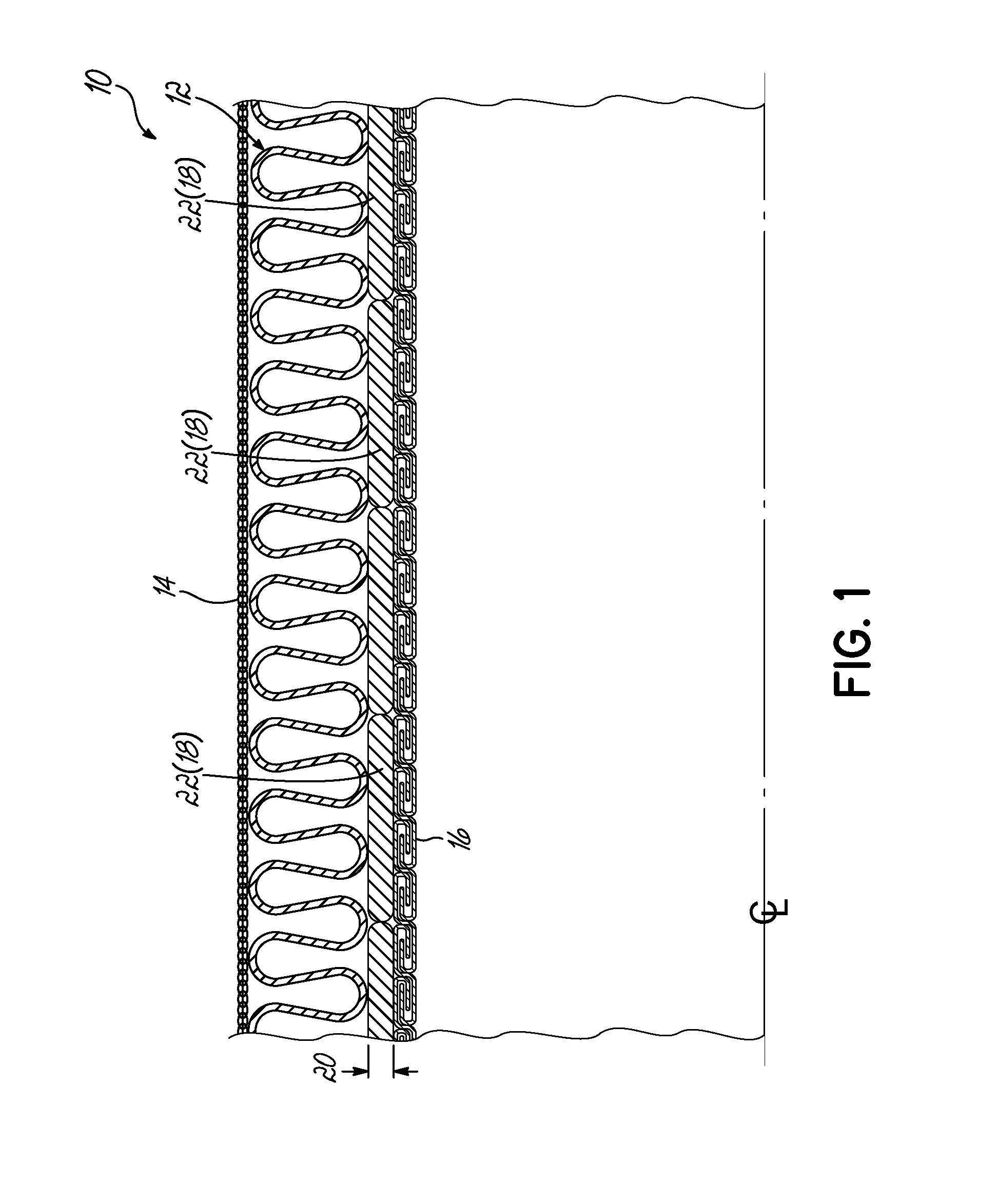

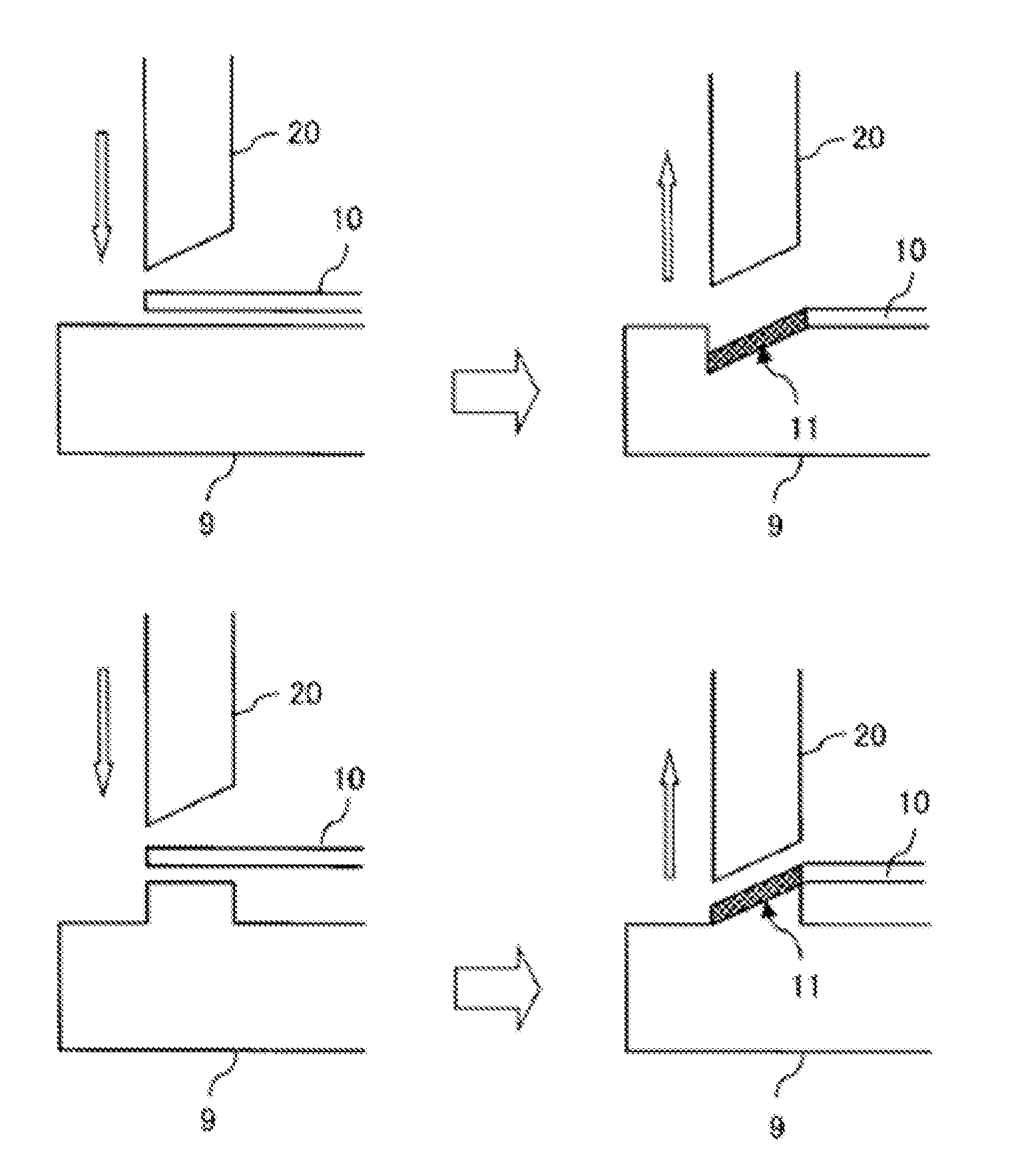

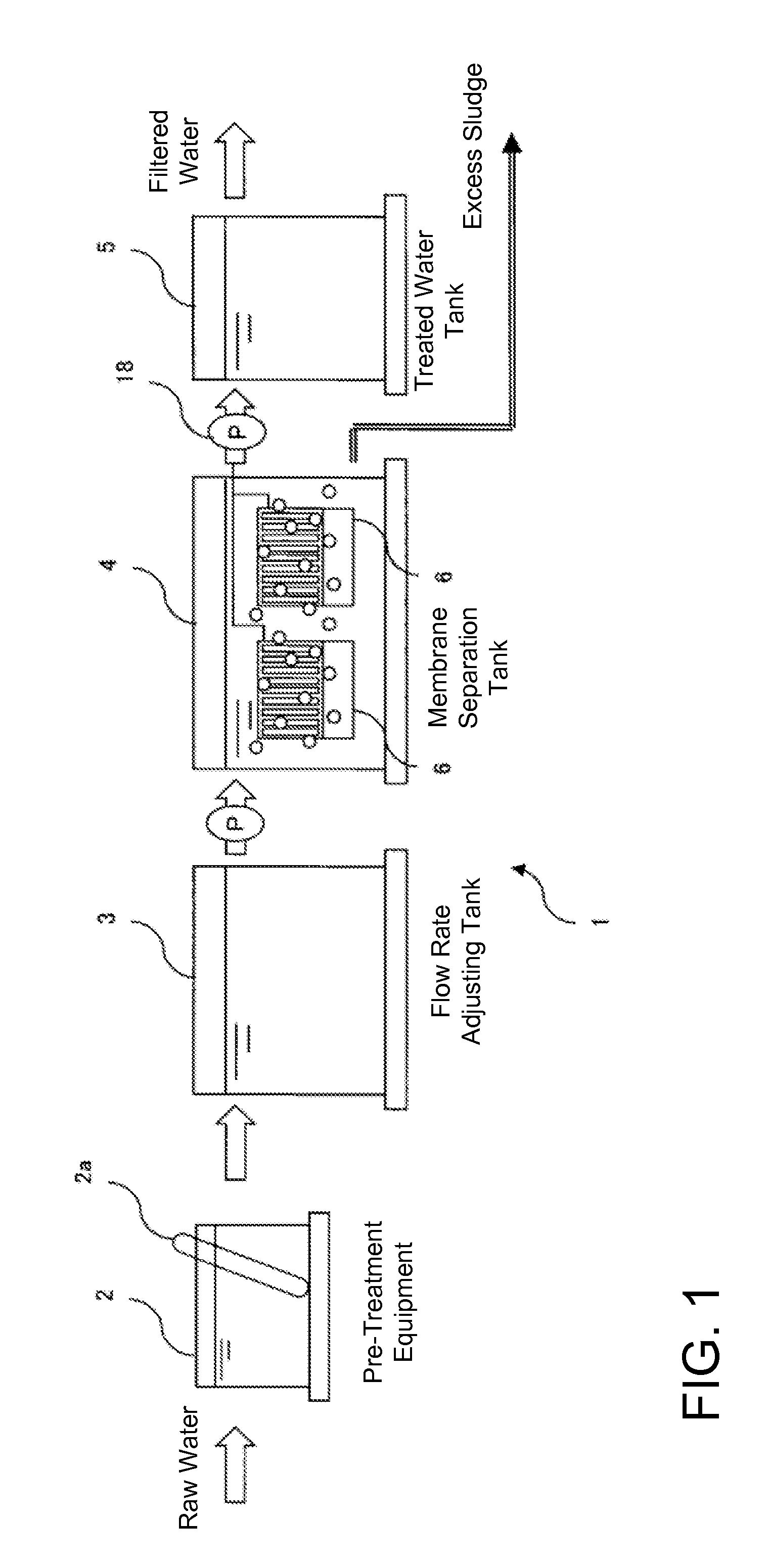

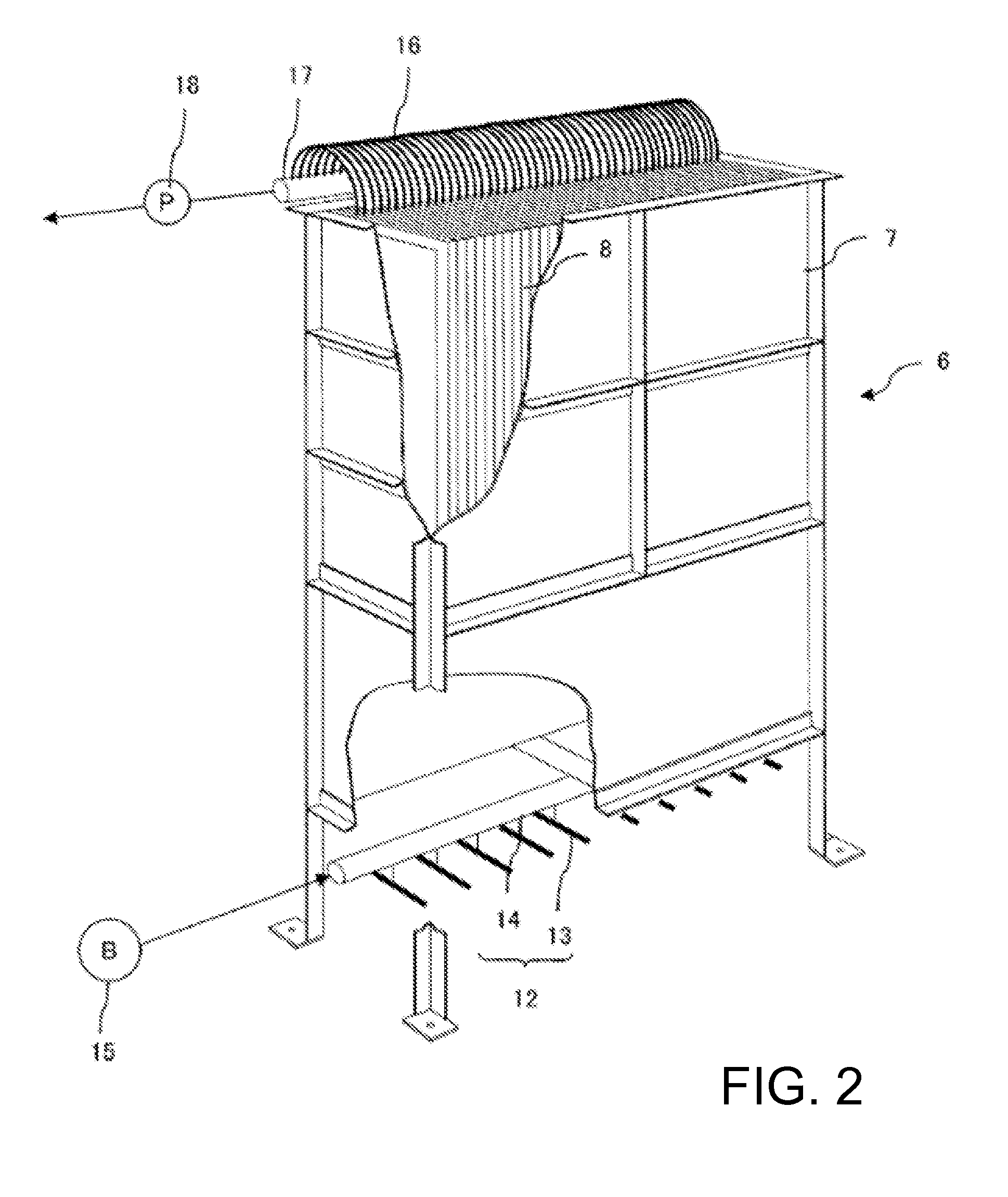

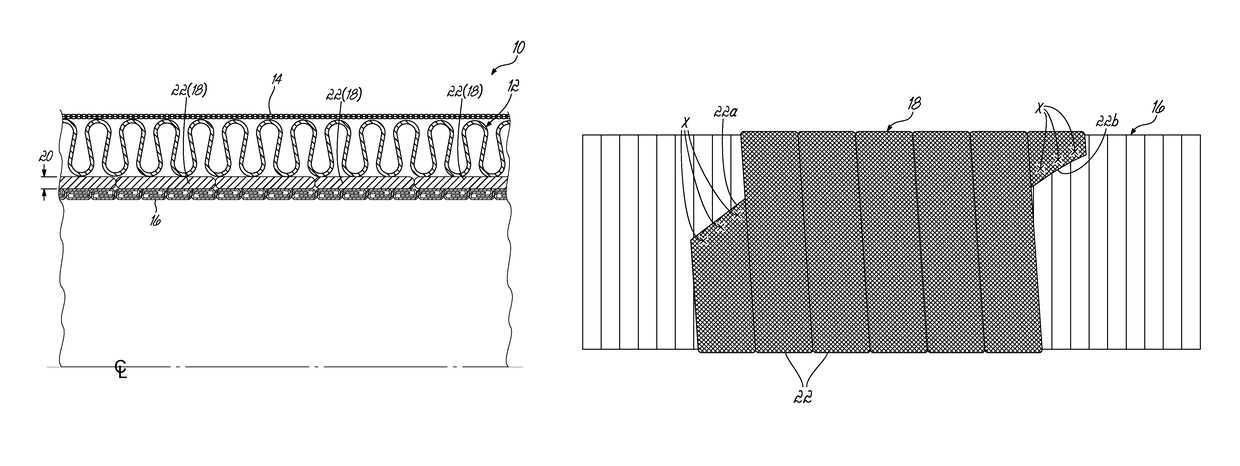

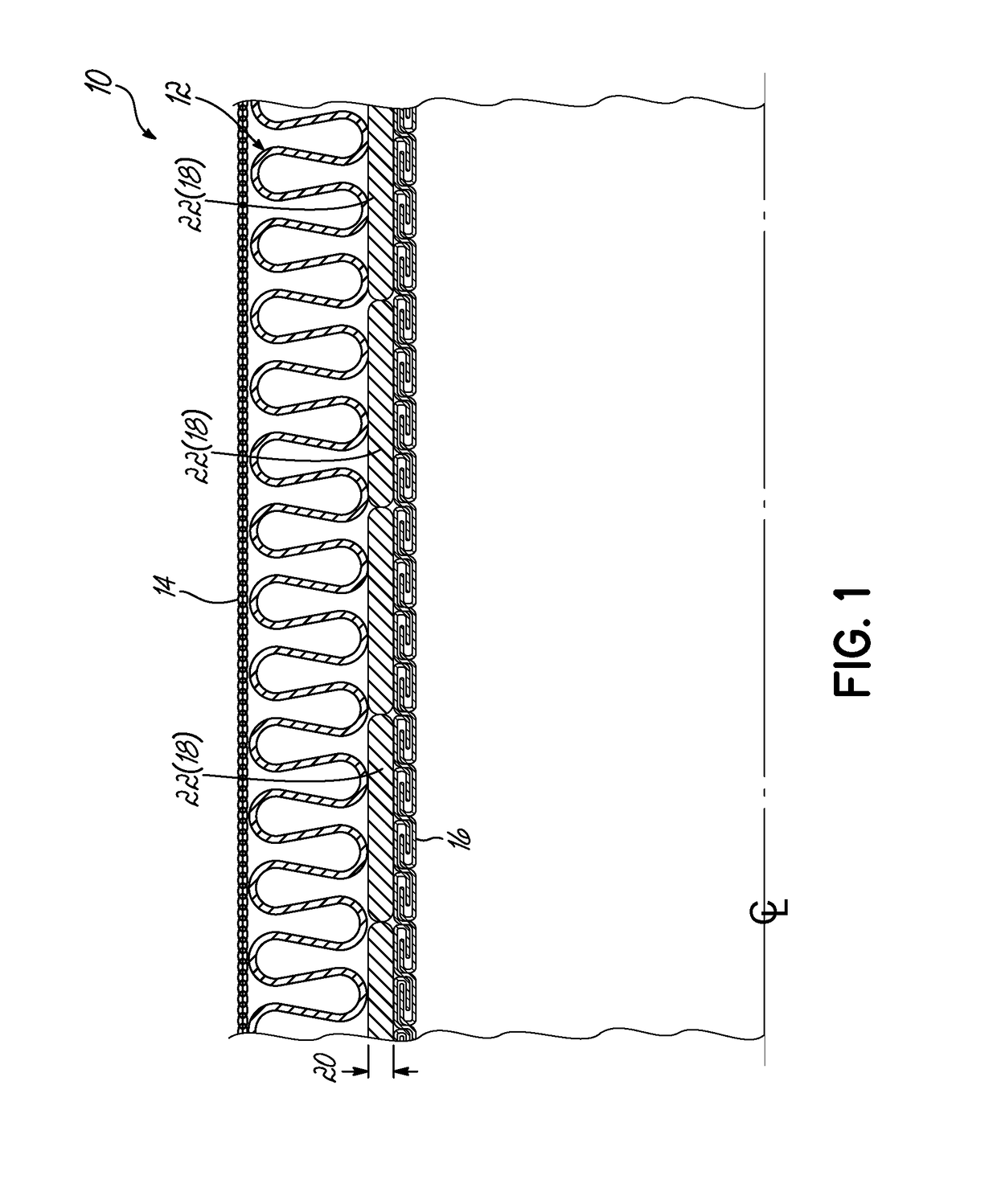

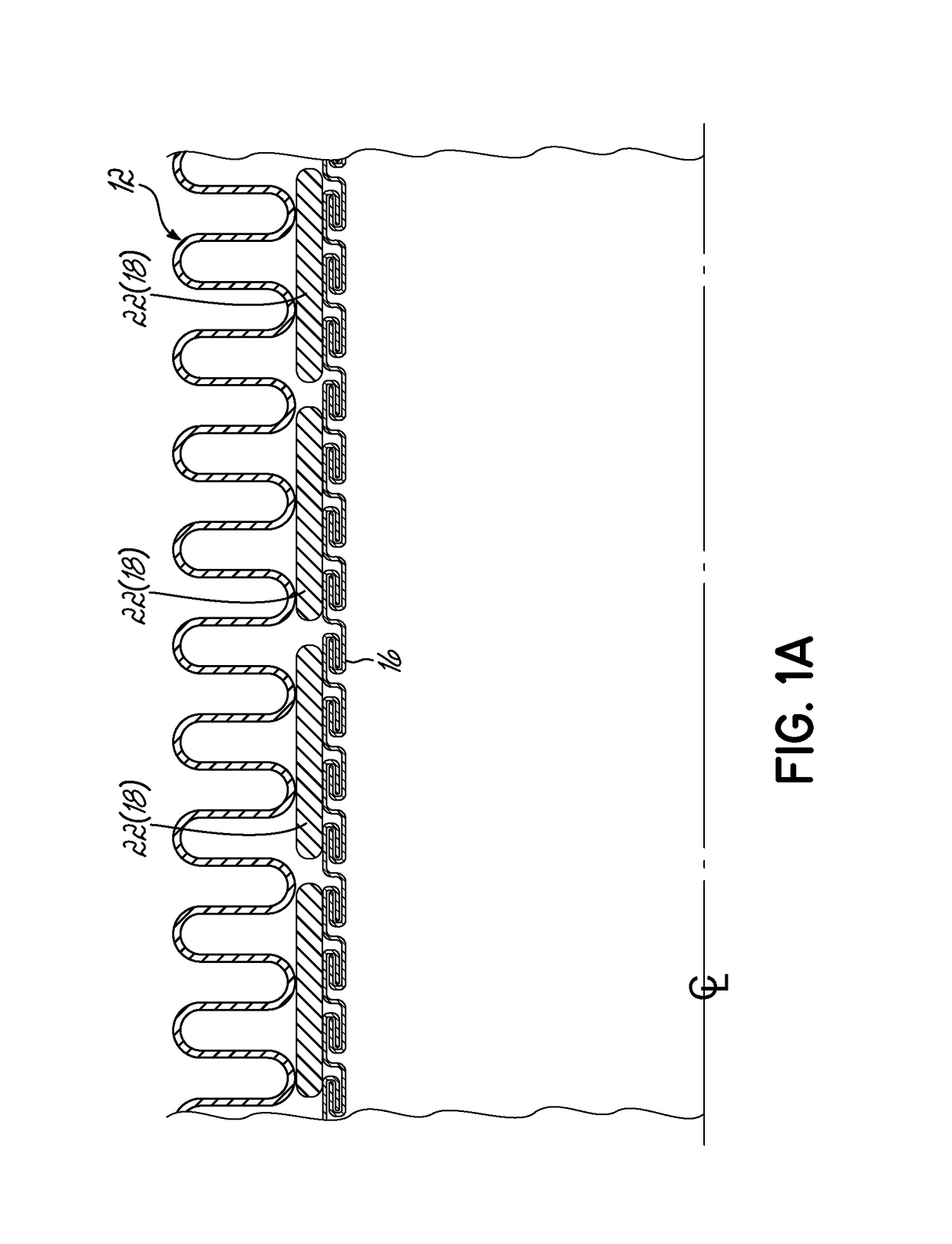

Membrane cartridge and membrane-cartridge production method

ActiveUS20160016123A1Low costImprove fatigue durabilityMembranesUltrafiltrationFiltration membraneChemistry

A low-cost membrane cartridge and a low-cost method for producing a membrane cartridge, in which fatigue durability can be increased with a simple structure, are provided by focusing on a bonding position of the filtration membrane onto the filtration plate. The membrane cartridge includes a filtration membrane disposed on both faces of a filtration plate made of a thermoplastic resin, such that a joining portion provided at the periphery of the filtration membrane is joined to the filtration plate. At least an inner edge portion of the joining portion has a downward inclination with respect to the surface of the filtration plate inside of the inner edge portion at an angle in a range of 10 to 45 degrees toward an outer peripheral edge of the filtration membrane. The joining portion is pressed and welded using a heating plate or an ultrasonic horn having such an inclined surface.

Owner:KUBOTA LTD

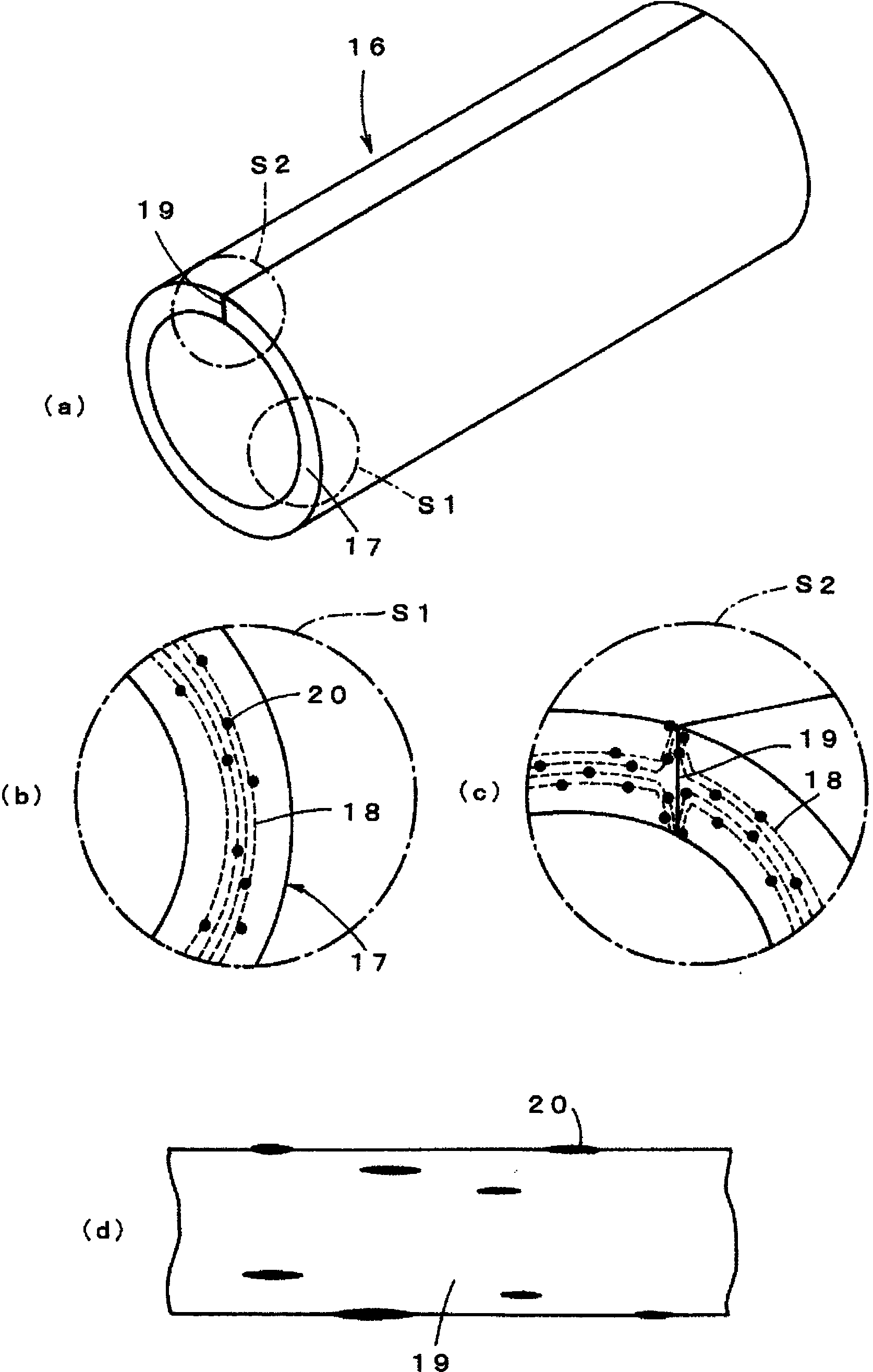

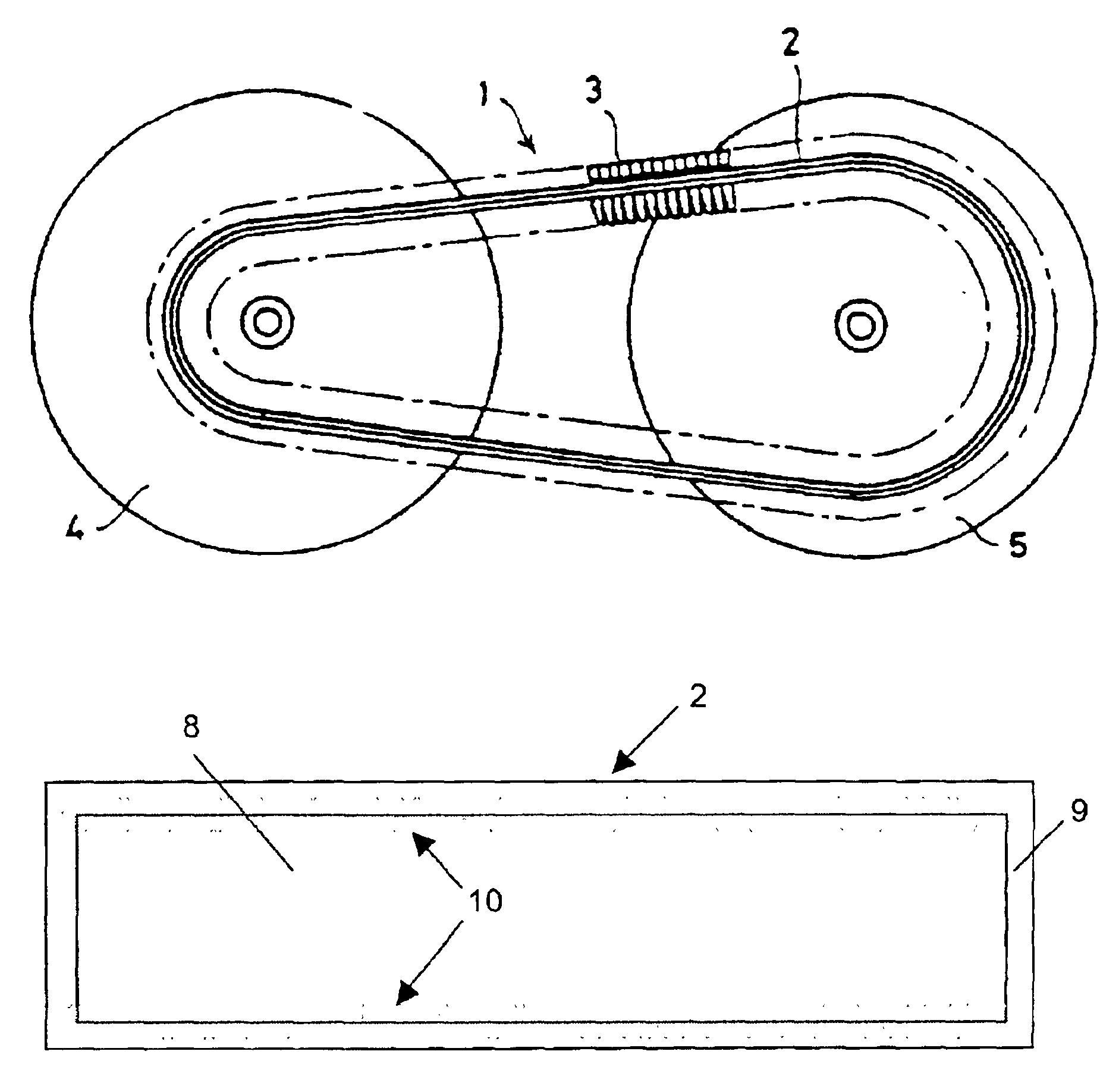

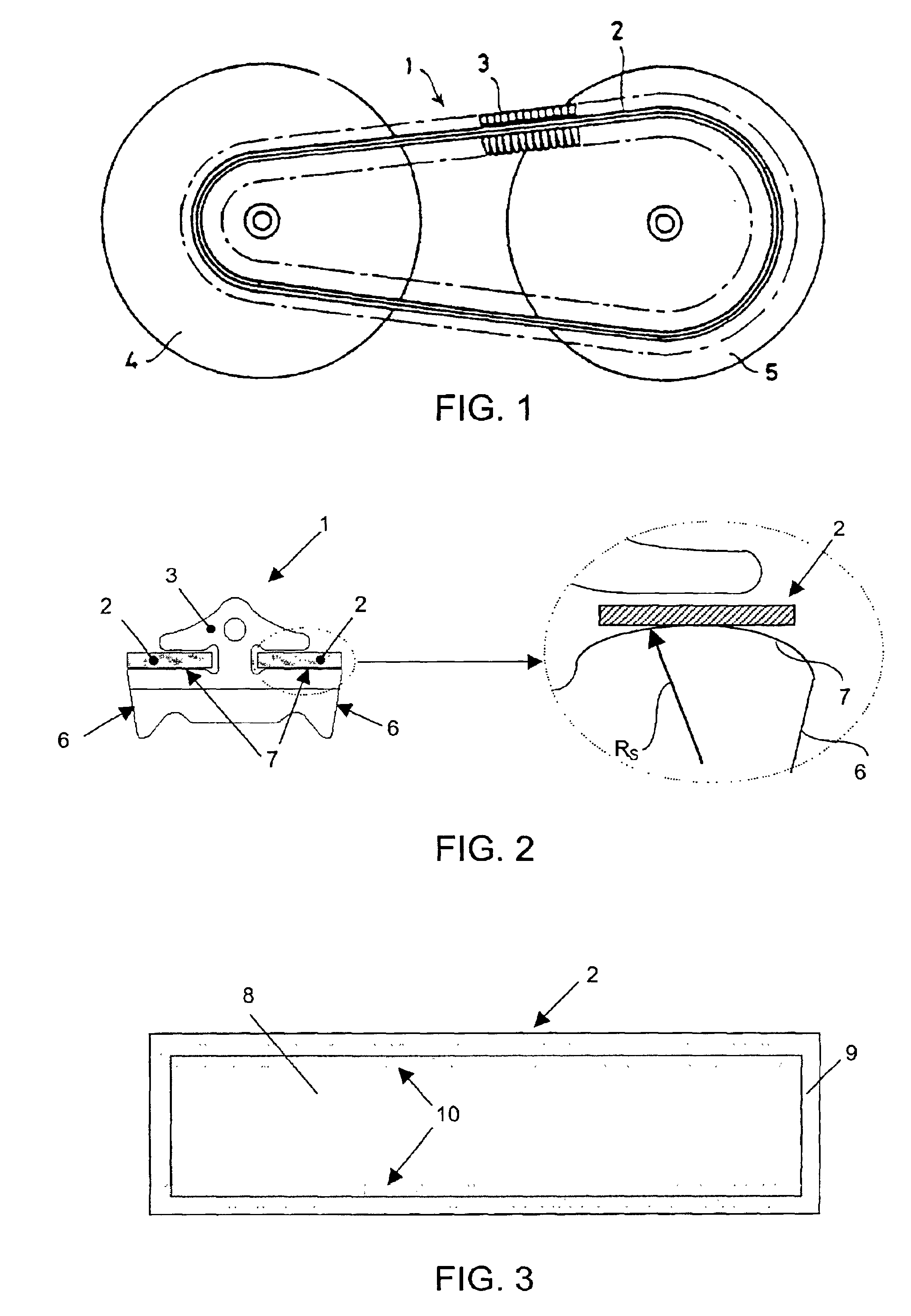

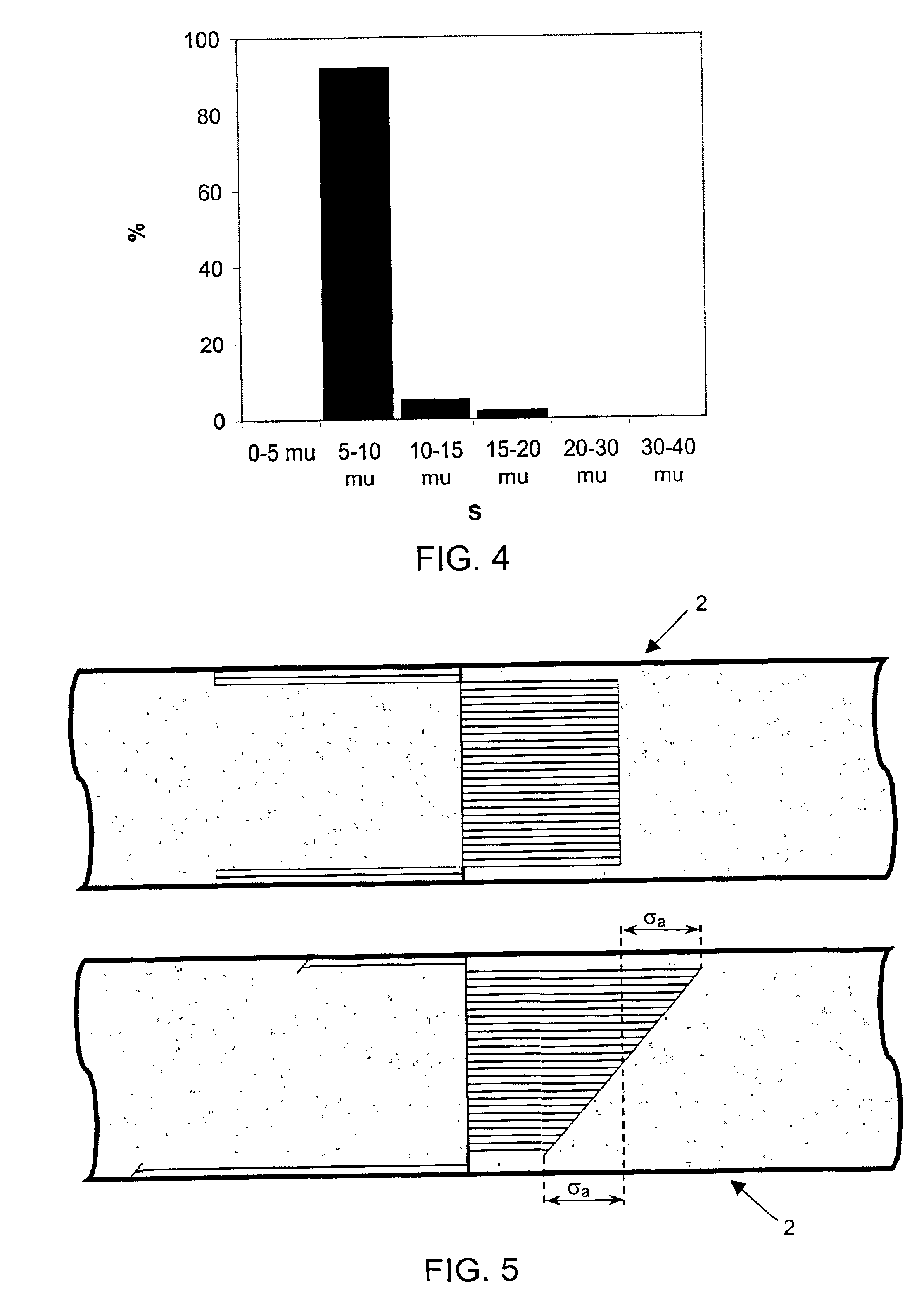

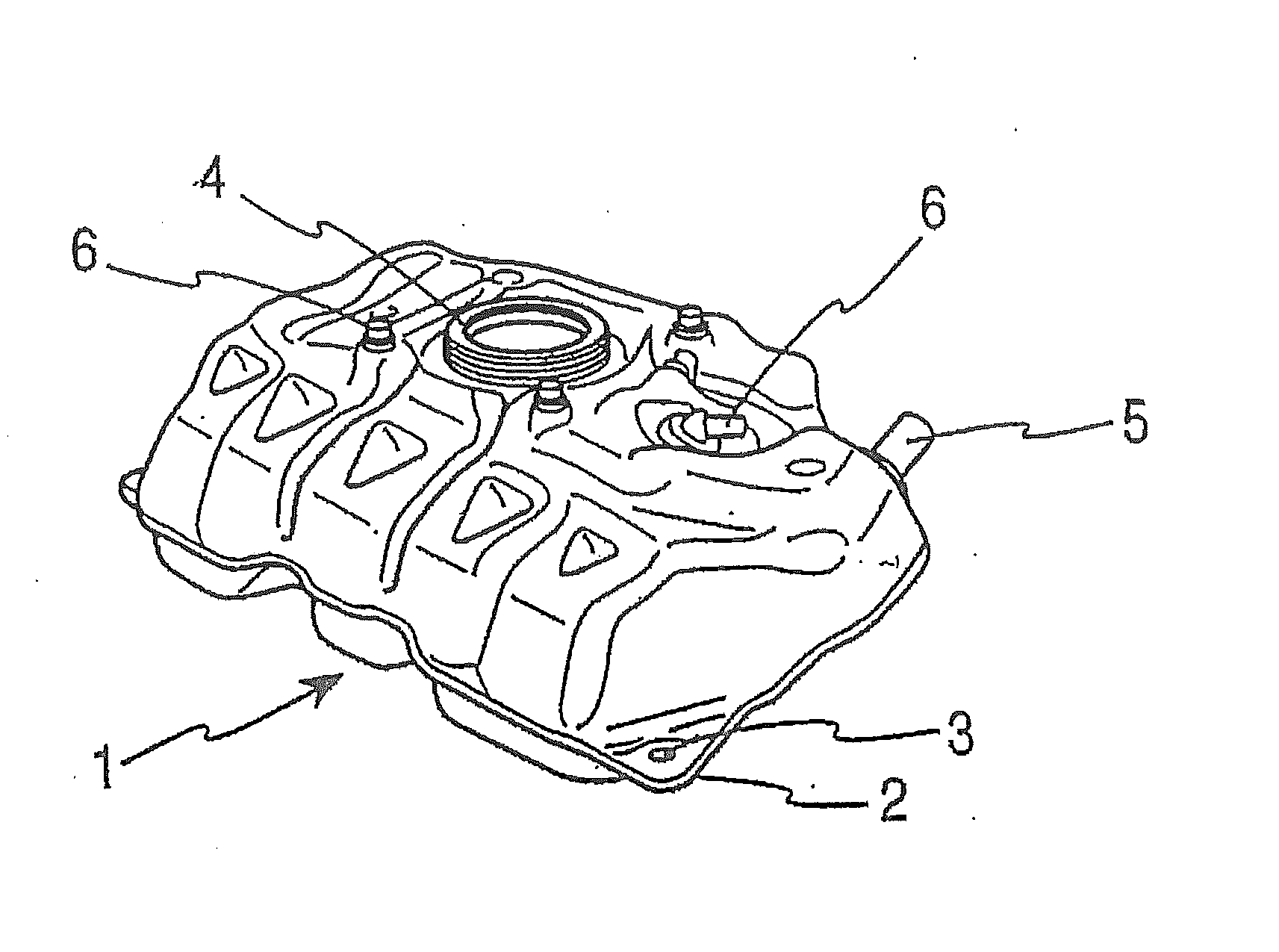

Metal push belt and material therefor

InactiveUS6869376B2Improve fatigue durabilityProduction is complicated and expensiveV-beltsDriving beltsNon-metallic inclusionsStructural engineering

A metal push belt (1) for application in a continuous variable transmission, includes at least one endless tensile member (2), and transverse elements being provided freely moveable in the endless direction of the tensile member (2). The tensile member is produced of steel, containing non-metallic inclusions of predetermined sizes as observed in the micro-structure of a material section, in accordance with a specified diameter Dcircle of a circle relating to the surface occupation of such an inclusion observed in such micro structure, in which the steel is produced in a constitution having a nominal inclusion size distribution with diameters ranging up to 30 μm, the inclusion diameter range between 10 μm and 30 μm being less than 20% of the total number of inclusions per square unit of sliced material counted by inclusions having a size larger than 2 μm.

Owner:VAN DOORNES TRANSMISSIE BV

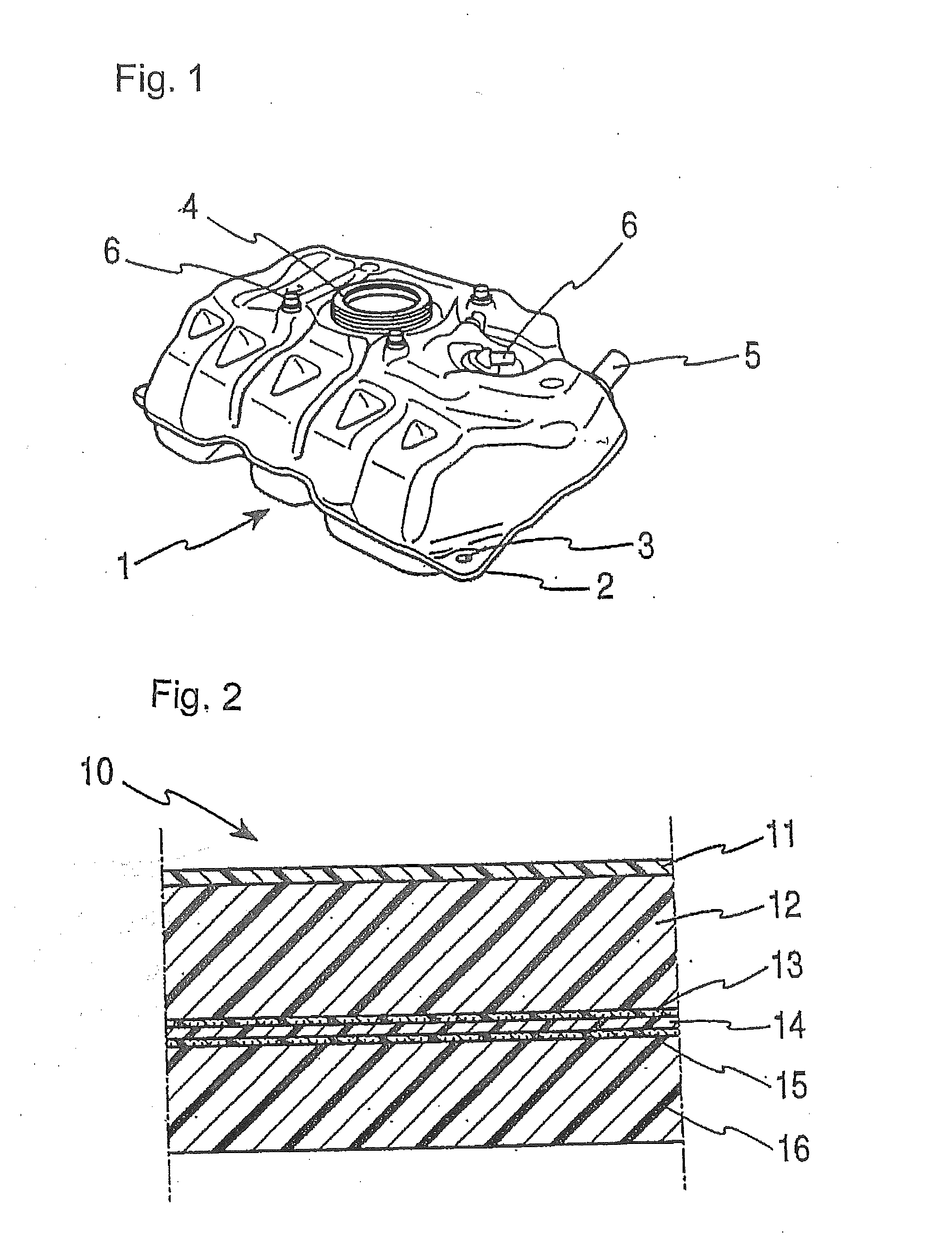

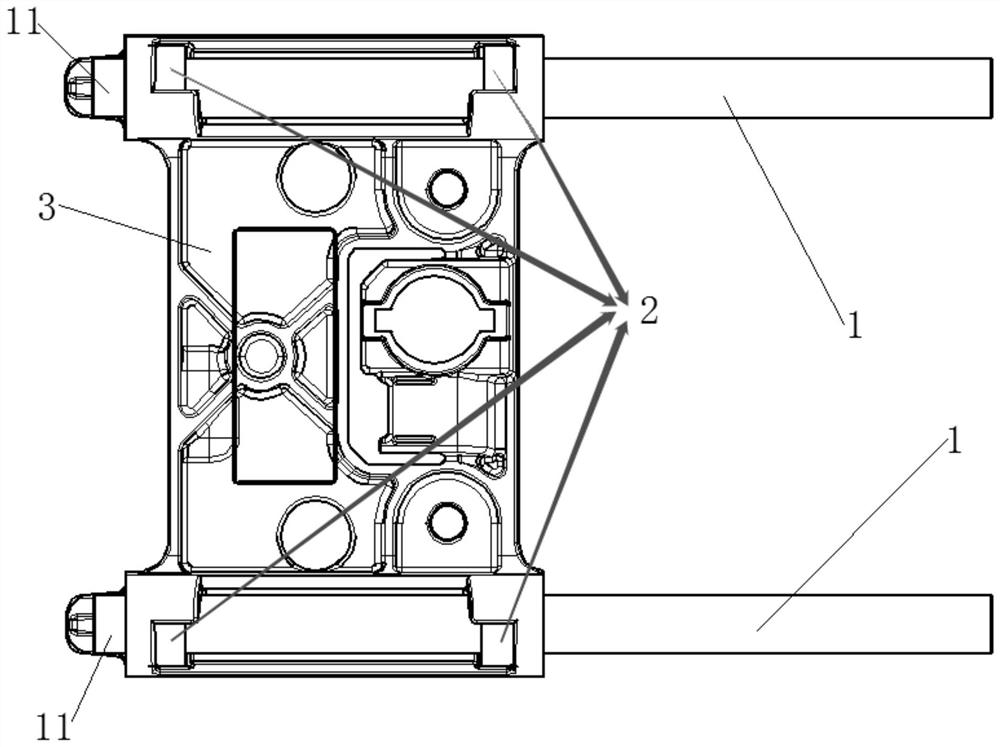

Automobile fuel tank

ActiveUS20140197175A1Reduce deformationImprove impact resistanceSynthetic resin layered productsLarge containersFuel tankEngineering

{Problem} To provide a fuel tank with excellent blow moldability, high deformation-suppressing properties and high heat resistance.{Solution} In an automobile fuel tank, a high-density polyethylene (HDPE) of an outer body layer 12 and an inner body layer 16 of an outer wall 10 has the following physical properties: 1) a modulus of elasticity of 1100 to 1400 MPa at 23° C.; 2) a modulus of elasticity of 340 to 430 MPa at 65° C.; 3) a modulus of elasticity of 400 to 510 MPa at 23° C. after being immersed in Fuel D for 200 hours at 65° C.; 4) a Charpy impact strength of 7 to 14 kJ / m2 at −40° C.; 5) a full-notch creep test (FNCT) result of 50 to 300 hours at 80° C.; 6) a melt flow rate (MFR) result of 4 to 6 (g / 10 minutes) at 190° C. and a load of 21.6 kg; and 7) a melt tension of 18 to 25 g when a sample that has been melted at 210° C. is extruded from a nozzle with a diameter of 2.095 mm and a length of 8 mm at an extrusion rate of 15 mm / minute, and drawn at a take-up speed of 7.5 m / minute.

Owner:FTS +1

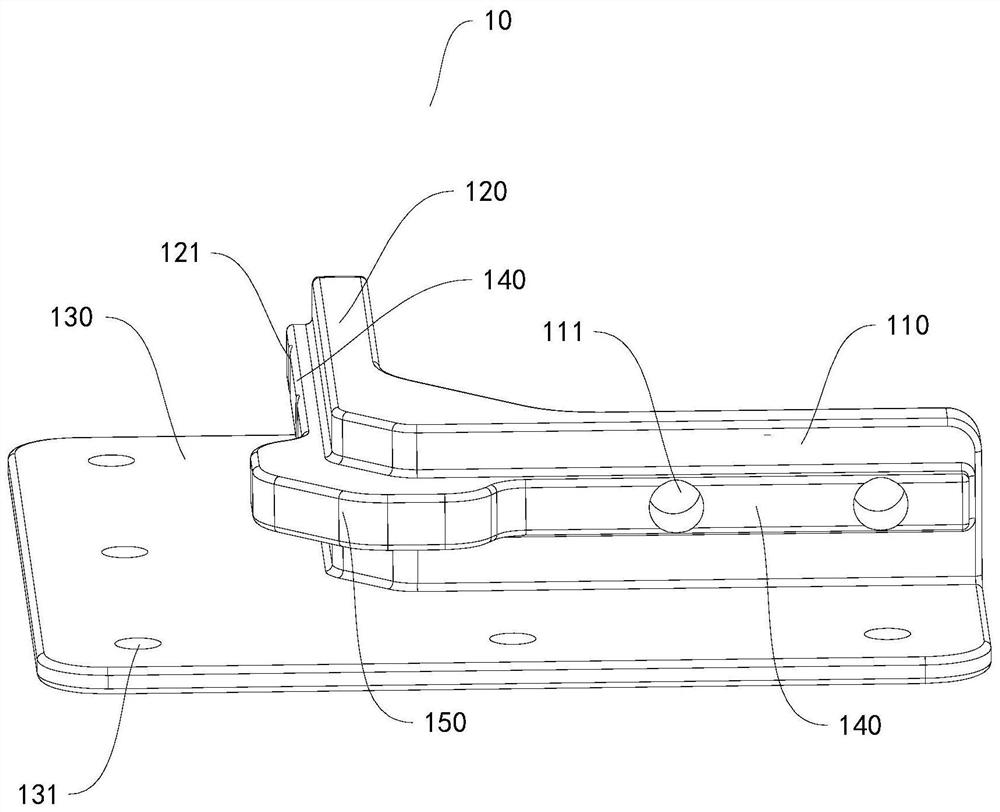

Base sliding rail mechanism with hovering function

PendingCN112572301AHigh precisionEnsure consistencyPassenger spaceDrawersClassical mechanicsEngineering

The invention relates to a base sliding rail mechanism with a hovering function. The mechanism comprises a base, a sliding rail and friction rings, through holes are formed in the two sides of the base, the friction rings are arranged in the through holes in the two sides of the base, and the two friction rings are arranged in the through holes in each side of the base and located at the two endsof the base. A sliding rail penetrates through the through holes of the base and the friction rings in the through holes, the sliding rail makes contact with the friction rings, the base can move on the sliding rail through the friction rings, and the base can be suspended on the sliding rail through a friction force generated between the sliding rail and the friction rings. Compared with the prior art, the mechanism is supported by the base, the sliding rail makes contact with the friction rings, and the hovering function is achieved through the friction force between the sliding rail and thefriction rings. A product is high in fatigue durability, and a force value is attenuated by 10% after 20,000 times of tests; and the sliding force value can be adjusted according to use requirementsso that various requirements are met.

Owner:SHANGHAI QIUMING STANDARD PARTS +2

Quaternary cobalt-nickel-chromium-molybdenum fatigue resistant alloy for intravascular medical devices

InactiveUS20060096672A1Simple and inexpensive to manufactureLess brittleStentsBlood vesselsCobalt-nickel-chromium-molybdenum alloyAlloy

A biocompatible solid-solution alloy may be formed into any number of implantable medical devices. The solid-solution alloy comprises a combination of elements in specific ratios that improve its fatigue resistance while retaining the characteristics required for implantable medical devices. The biocompatible solid-solution alloy is a quaternary cobalt-nickel-chromium-molydenum alloy having substantially reduced titanium content.

Owner:CORDIS CORP

Implanting instrument with bionic micro-thorn attachment structures

PendingCN112022260AReduce retraction and release resistanceImprove fatigue durabilityStentsOcculdersClassical mechanicsStructural engineering

The invention relates to an implanting instrument with bionic micro-thorn attachment structures. The implanting instrument at least comprises an attachment frame, wherein the attachment frame is a self-expanding type support or a ball-expanding type support and comprises a plurality of frameworks and a plurality of bionic micro-thorn attachment structures; the bionic micro-thorn attachment structures are arranged on the outer surfaces of the frameworks; the bionic micro-thorn attachment structures are in the form of bionic plant surface sparse micro-thorns; each bionic micro-thorn attachment structure comprises a thorn root and a micro-thorn; each micro-thorn is composed of a thorn body and a thorn tip; each micro-thorn is linear or J-shaped or the combination of the linear micro-thorn andthe J-shaped micro-thorn; and the thorn bodies and / or the thorn tips of the micro-thorns can touch cavity tissue to achieve an attachment type anchoring function. The implanting instrument is wide inapplication range, free of anchoring damage, firm and high in safety.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

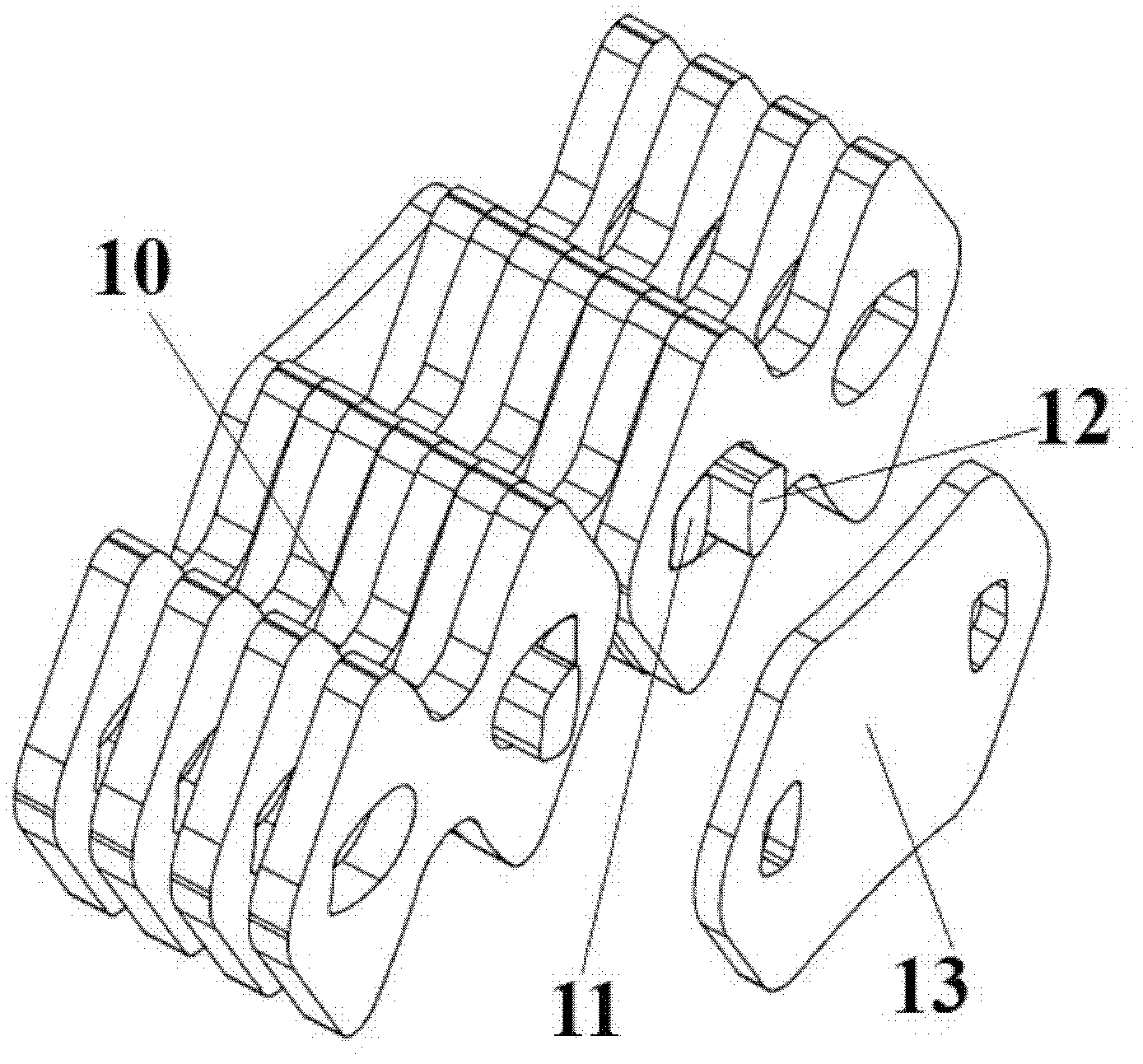

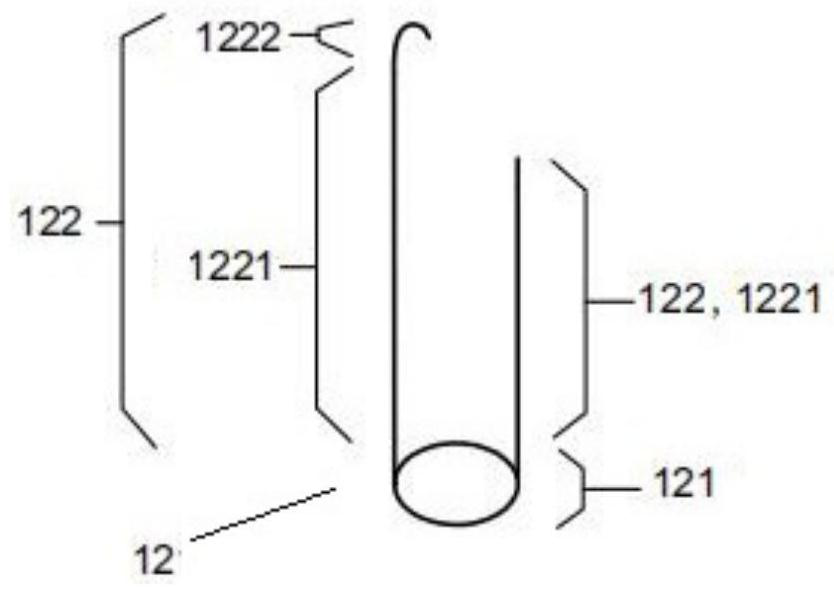

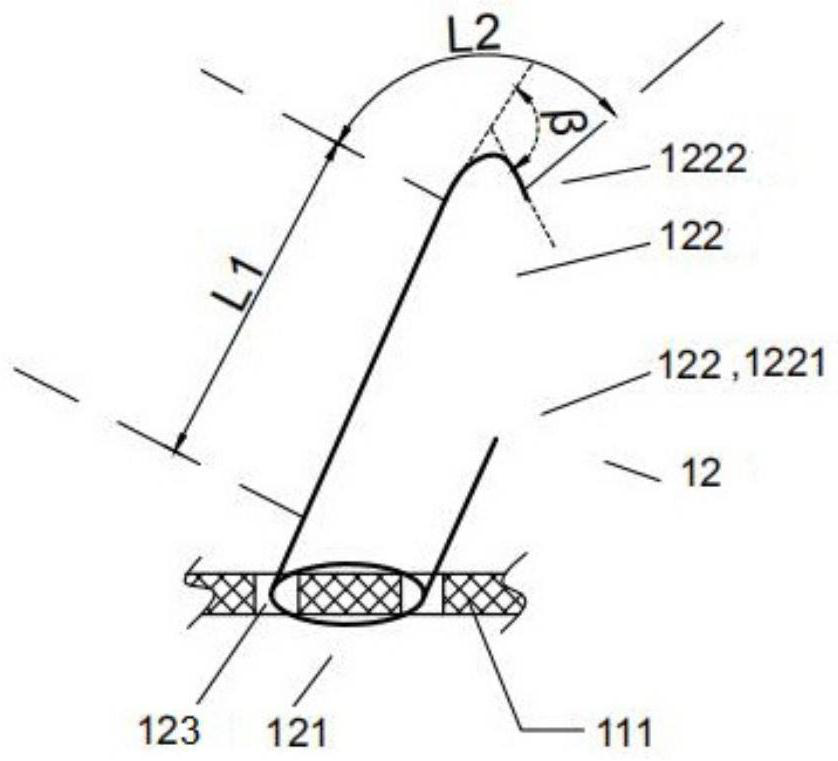

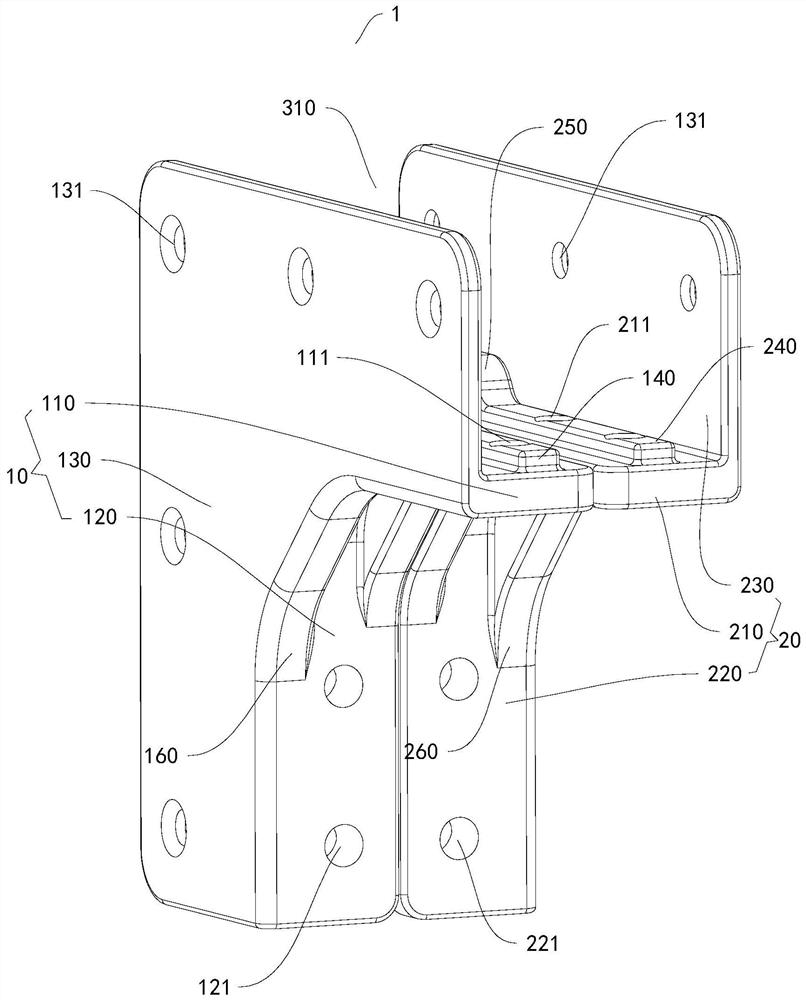

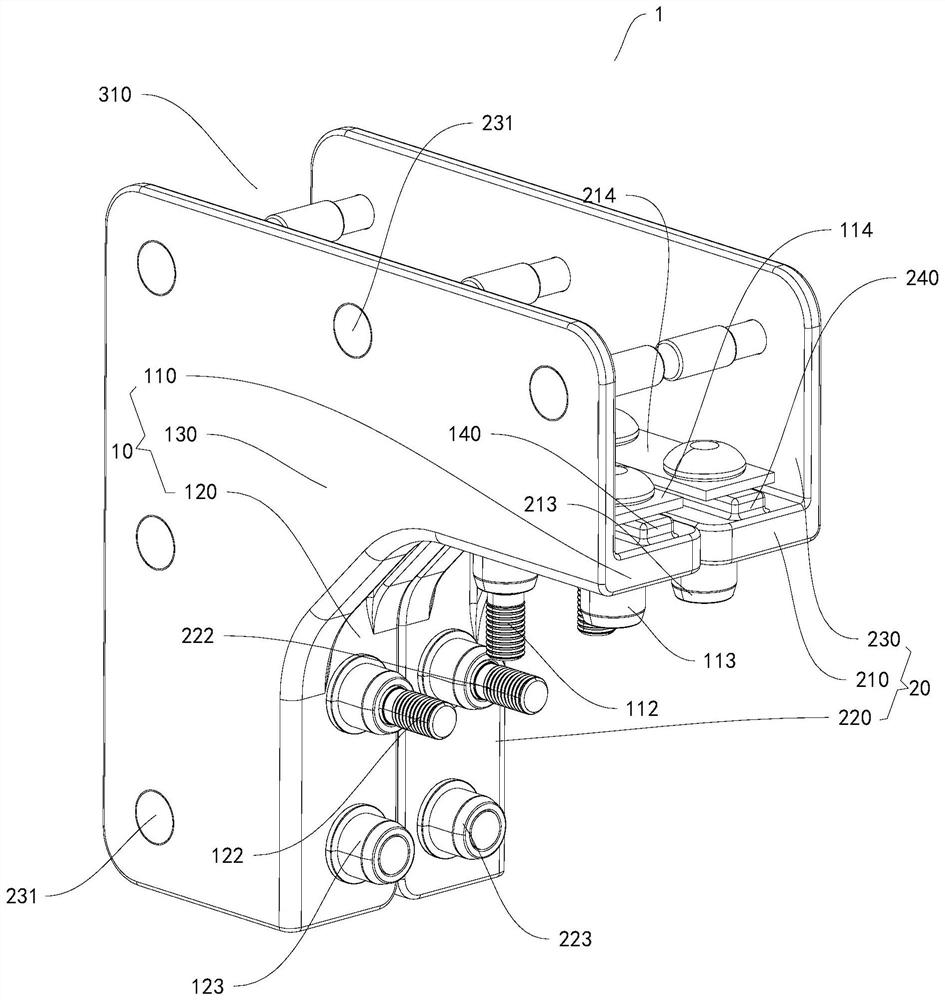

Vehicle body framework joint and vehicle with same

ActiveCN112441142AImprove connection strengthEasy to assembleRod connectionsSuperstructure connectionsControl theoryMechanical engineering

Owner:BYD CO LTD

Dynamic liner sleeve for flexible coupling

ActiveUS9970578B2Dampens natural vibration and frequencyReduce NVHSleeve/socket jointsPipeline expansion-compensationCouplingEngineering

A flexible coupling includes a liner, a bellow, and a liner sleeve preferably defined by a compressed woven mesh strip spirally wound around the liner between the bellow and liner and moveable longitudinally with respect to the bellow and liner when the coupling expands linearly. An alternate sleeve in the form of a cylinder is disposed about the liner, under the bellow and is formed of a woven non-compressed mesh.

Owner:AMERICAN BOA

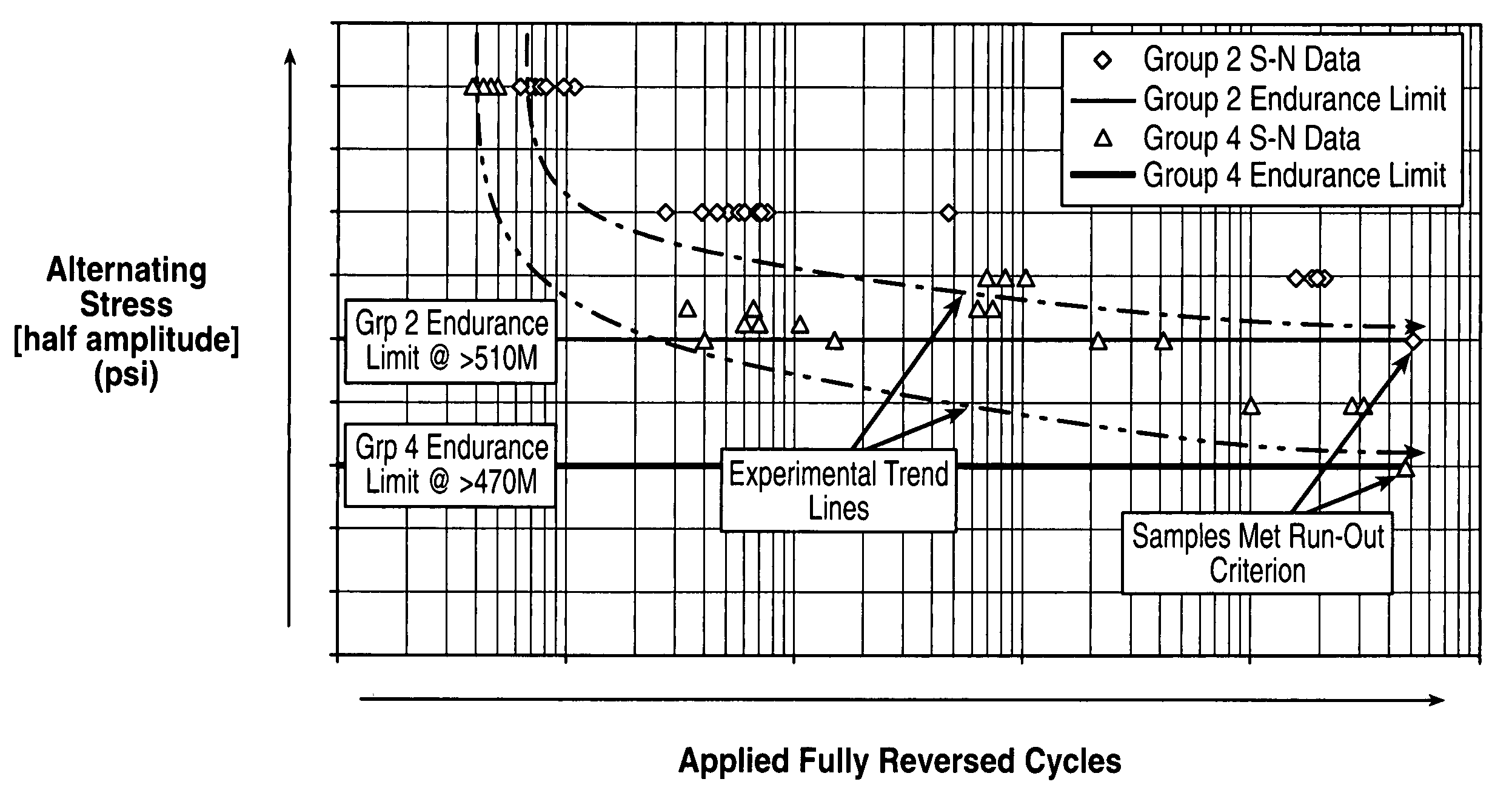

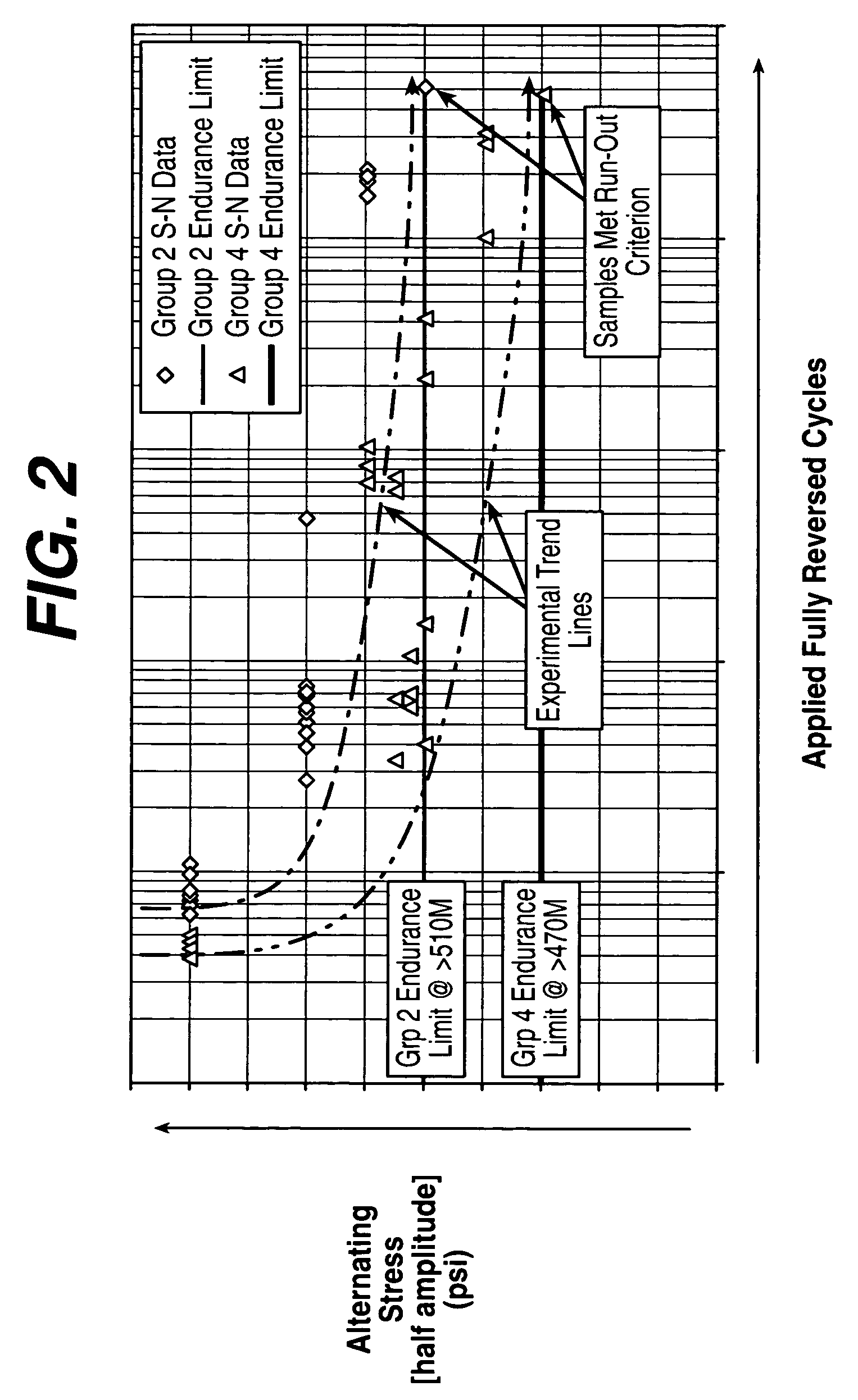

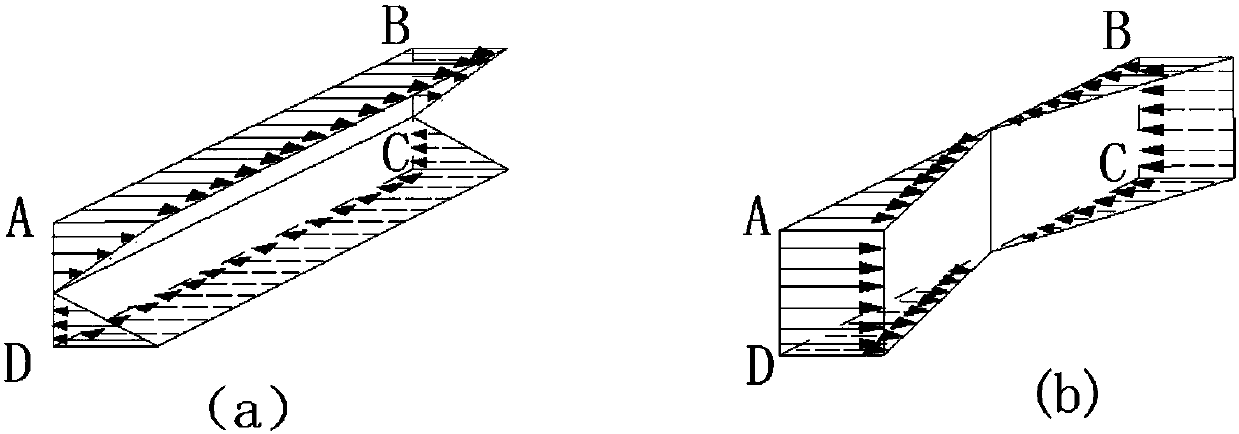

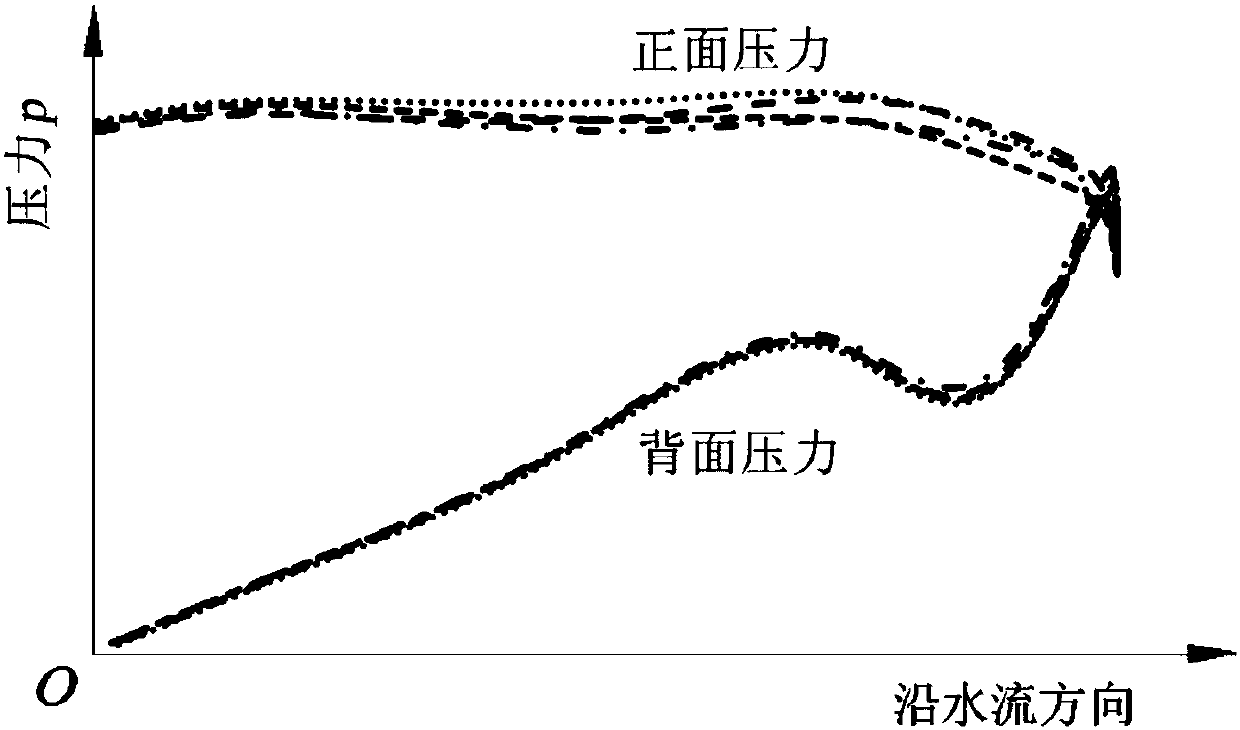

Method for predicting fatigue service life of water pump vane and confirming optimal space with guide vane

ActiveCN108108577AReasonably determine the overhaul periodFatigue Life PredictionDesign optimisation/simulationPump controlAxial-flow pumpMixed flow

The invention discloses a method for predicting fatigue service life of a water pump vane and confirming optimal space with a guide vane, and belongs to the technical field of reliable durability of apower machinery device. the method includes confirmation of fatigue rupture hazardous section and hazardous points of the water pump vane, fluid field numerical value simulation in different workingconditions of the water pump and CFD calculation of impulse water pressure distribution of vane surface; calculation of hazardous point alternating stress at root section of water pump vane; calculation of fatigue service life of vane under different working conditions of water pump; calculation of alternating stress and fatigue service life of vane hazardous point when the space between the waterpump vane and the guide vane is different; replacement, dismounting and overhaul costs for comprehensively considering the vane fatigue rupture in service life of water pump; influence of water pumpefficiency change caused by space change on running cost; influence of axial dimension of water pump on installing layout; final determination of optimal space between vane and the guide vane. The method can exactly predict the fatigue service life of the axial flow pump and the guide vane type mixed flow pump vane, optimize the space between the vane and the guide vane, and improve the vane fatigue durability.

Owner:YANGZHOU UNIV

Stabilizer

ActiveUS20170349962A1Improve fatigue durabilityFatigue durabilityTorsion springsMetal-working apparatusChemical compositionSolid structure

A stabilizer formed by using a metal bar having a solid structure and configured to reduce a displacement between right and left wheels, including a torsion part extending in a vehicle width direction, being capable of a torsional deformation, and having a diameter of 10 to 32 mm, is provided. The stabilizer has a chemical composition containing at least C: 0.15% by mass or more to 0.39% by mass or less, Mn, B, and Fe, and also has a metal structure 90% or more of which is a martensite structure.

Owner:NHK SPRING CO LTD

High pressure tank having reinforced boss part

ActiveUS20180172208A1Increase section modulusReduce stressContainer filling methodsGas handling applicationsEngineeringHigh pressure

A high pressure tank having a reinforced boss part includes: a liner; a dome formed at each end of the liner; and a boss formed at one end of the dome. The boss includes: a head including a flow path through which fuel flows into and out of the high pressure tank; and a shoulder extending in a radial direction from the head and surrounding the head. The shoulder has one or more hollow portions formed therein.

Owner:HYUNDAI MOTOR CO LTD +1

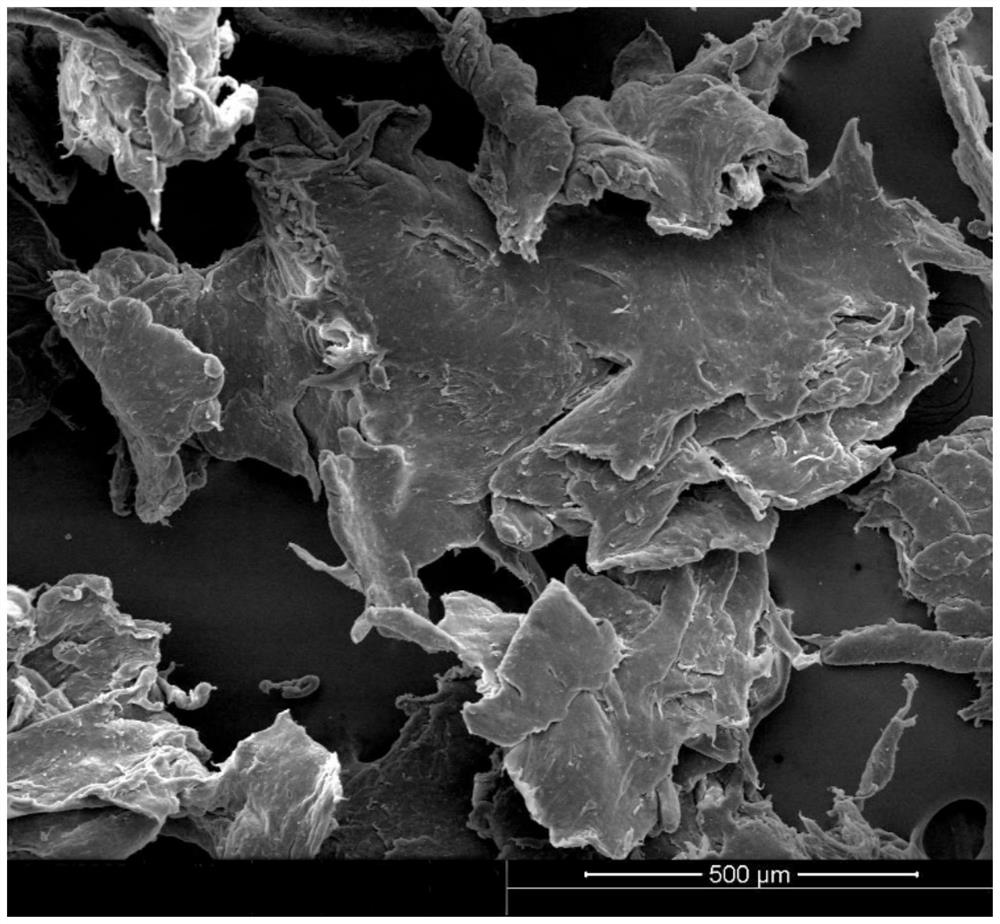

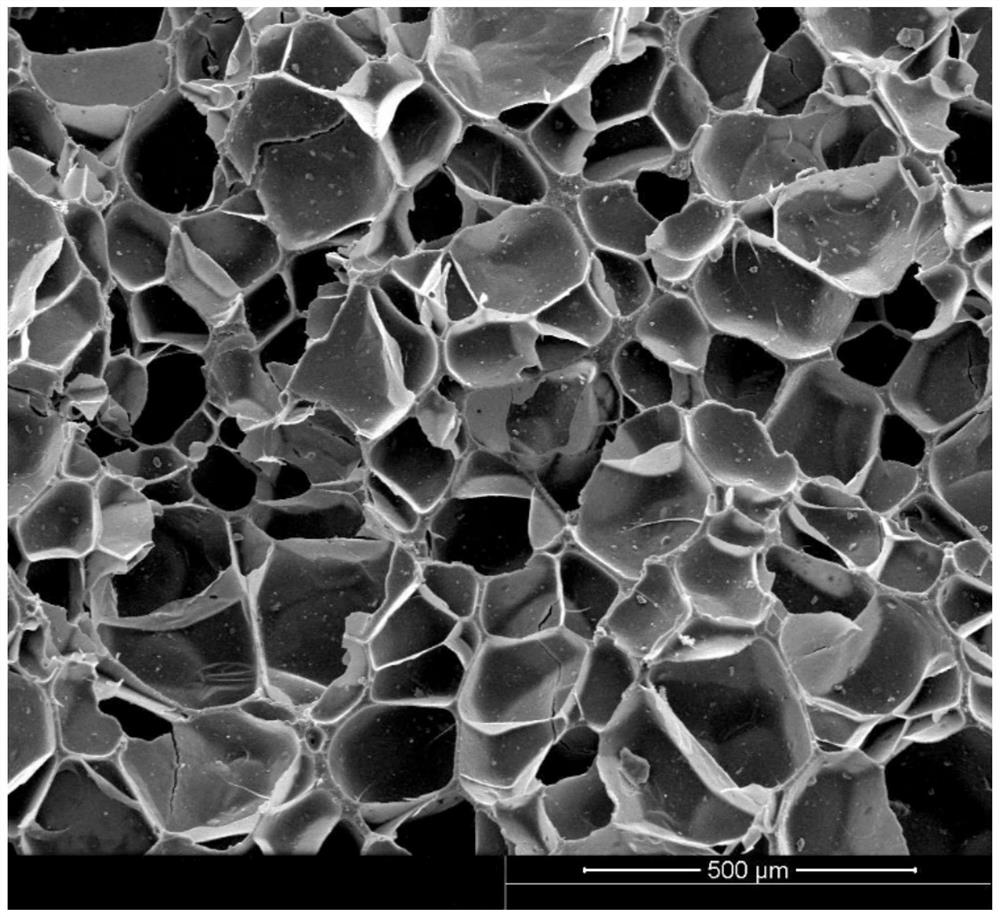

Method for preparing composite regenerated foam material by using waste EVA-based material

ActiveCN113997464APowder particle size is smallLow costPlastic recyclingParticle-size distributionSupercritical carbon dioxide

The invention provides a method for preparing a composite regenerated foam material by using a waste EVA-based material. The method is characterized in that waste EVA-based superfine flaky powder is obtained under adaptive conditions by using a solid-phase shearing and grinding technology and further limiting grinding process parameters, the waste EVA-based superfine flaky powder and TPU are blended and compounded, and further the TPU / waste EVA-based composite foam material is prepared by using a supercritical carbon dioxide foaming technology. According to the method, the particle size and particle size distribution of the waste EVA-based powder are greatly reduced, and the surface activity of the powder is further improved through the flaky morphology, wherein compared with granular or strip-shaped powder, the flaky powder has the advantages that melt blending and compounding with TPU are further improved, and finally, a TPU / waste EVA-based composite foam material / product with higher performance is prepared by combining a supercritical carbon dioxide foaming technology.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com