Shunting structure for use in collecting pipe of heat exchange unit of automobile

A heat exchange unit and header technology, which is applied to the heat exchanger shell, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of inconsistent temperature at the outlet, no technical solution found, and uneven heating temperature. , to reduce the detour time, facilitate consistent design management, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

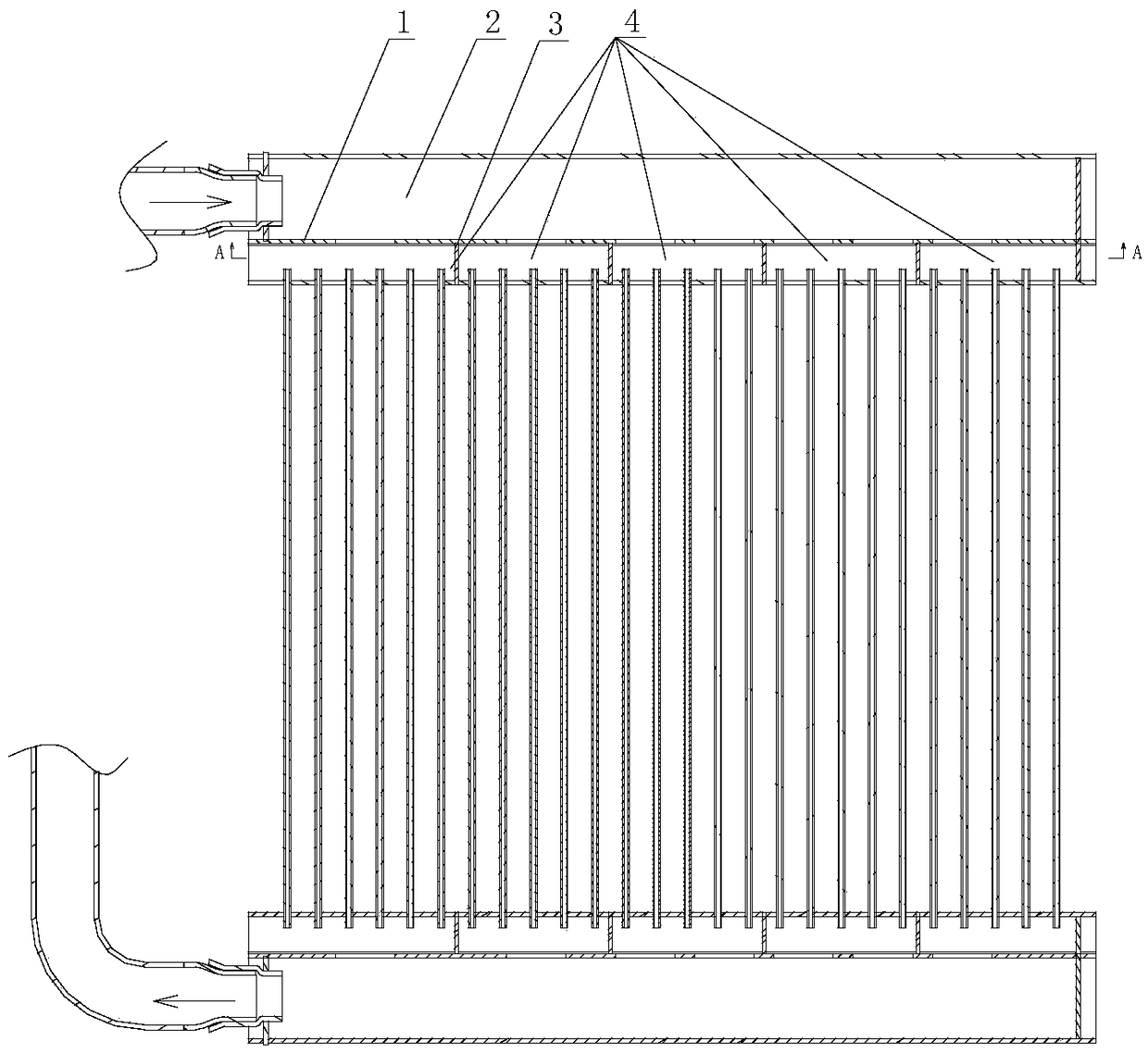

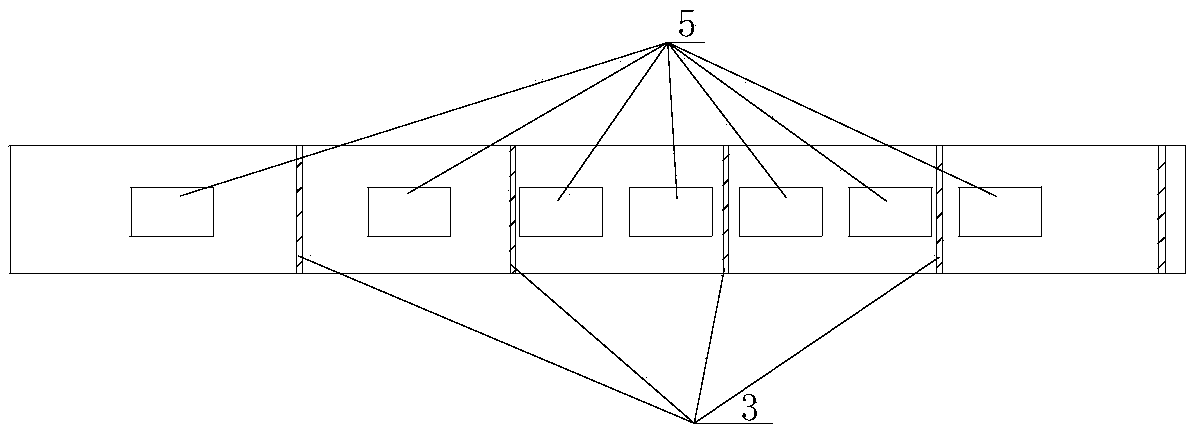

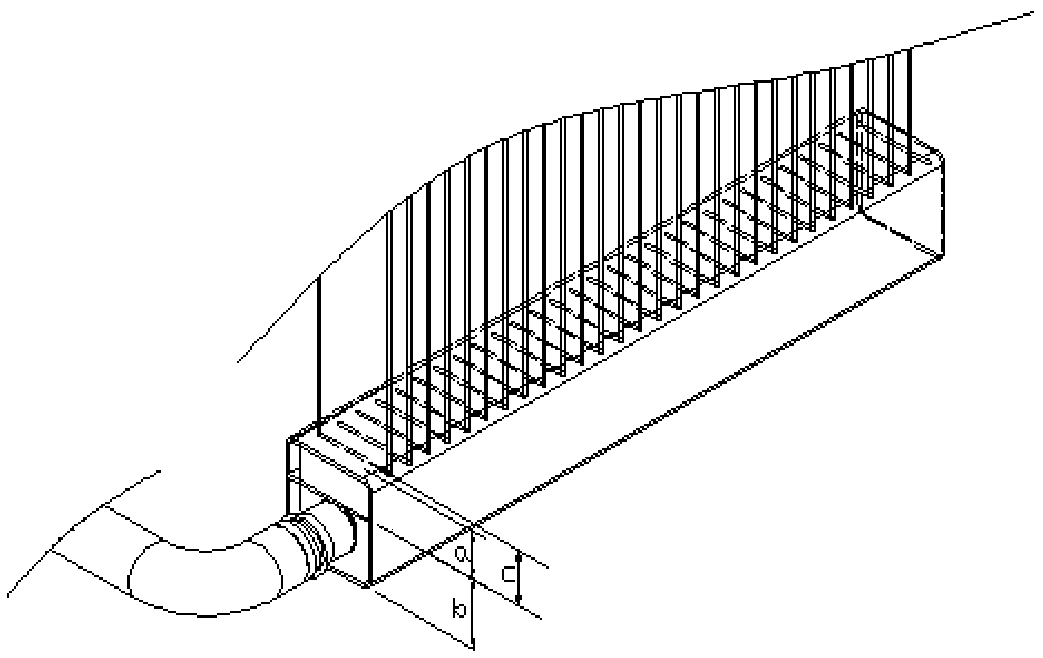

[0024] A kind of shunt structure used in the collector pipe of automobile heat exchange unit, please refer to Figure 1~5 , its invention point is:

[0025] It includes a longitudinal partition plate 1 arranged along the axial direction of the collector. The longitudinal partition plate can be a flat plate or a curved plate. The longitudinal partition plate divides the inner cavity of the collector tube into a first longitudinal cavity 2 and a second longitudinal cavity. The first longitudinal chamber communicates with the working medium inlet, and the second longitudinal chamber communicates with the heat exchange tube. In the second longitudinal chamber, there are a plurality of transverse partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com