Method for preparing fluid with layered density

A density layered, fluid technology, applied in fluid dynamics test, machine/structural component testing, instrument, etc., can solve the problem of occupying space, inability to obtain layered form, etc., to achieve high application flexibility, layered Time-controllable and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

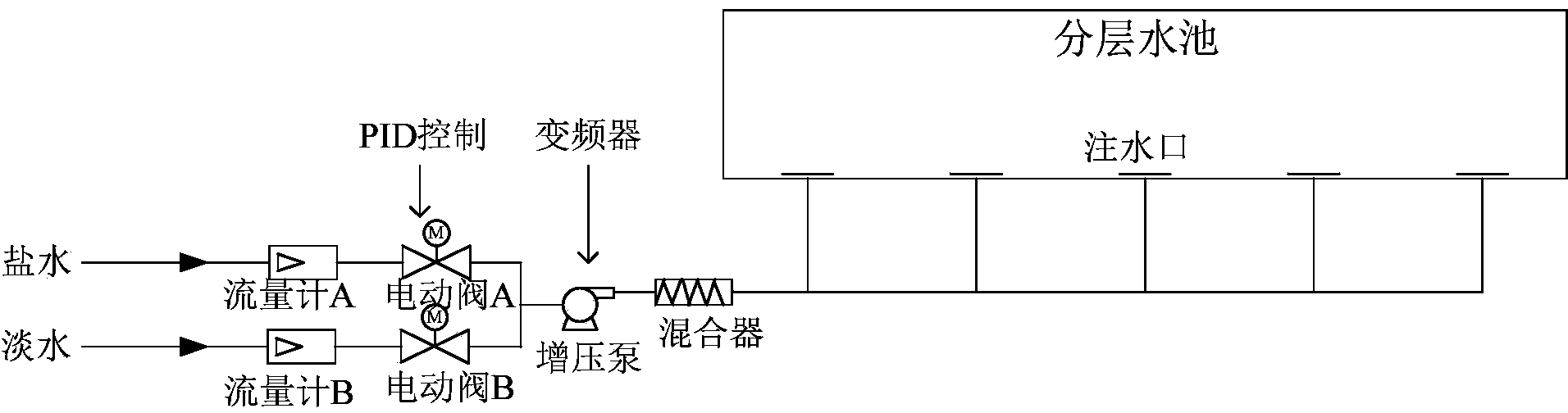

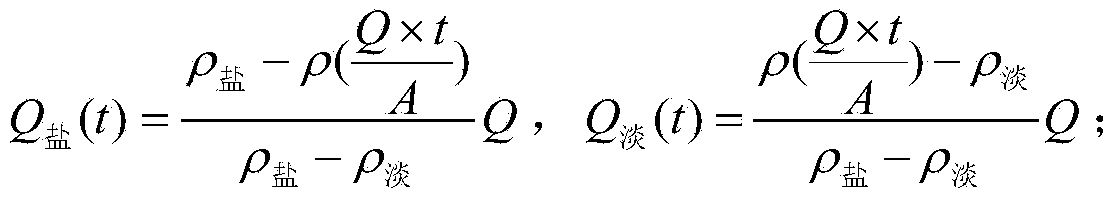

[0019] Such as figure 1 As shown, the density stratification system of the present invention consists of a salt water tank, a fresh water tank, a flow meter, an electric valve, a PID control device, a booster pump, a frequency converter, a mixer, a water injection device, a stratified water tank and connecting pipes. Flow meters are used to measure the flow of salt water and fresh water, and feed back to the PID control device in real time. The electric valve accepts the instruction of the PID control device, maintains a certain opening degree, and maintains a certain flow rate. The PID control device adjusts the opening of the electric valve in real time. The booster pump is the power source for fluid delivery, and the speed can be controlled by a frequency converter to adjust the flow. The frequency converter controls the speed of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com