Leveling control system and method of land leveller scraper

A control system, a technology for leveling shovels, applied in the safety of fluid pressure actuation systems, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of ineffective use of energy, large system power loss, and low control flow, etc. Achieve the effect of efficient energy, small power loss and reduced machine wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

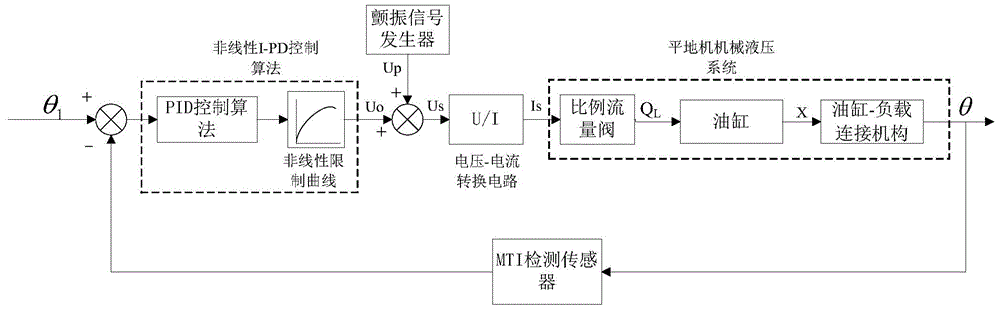

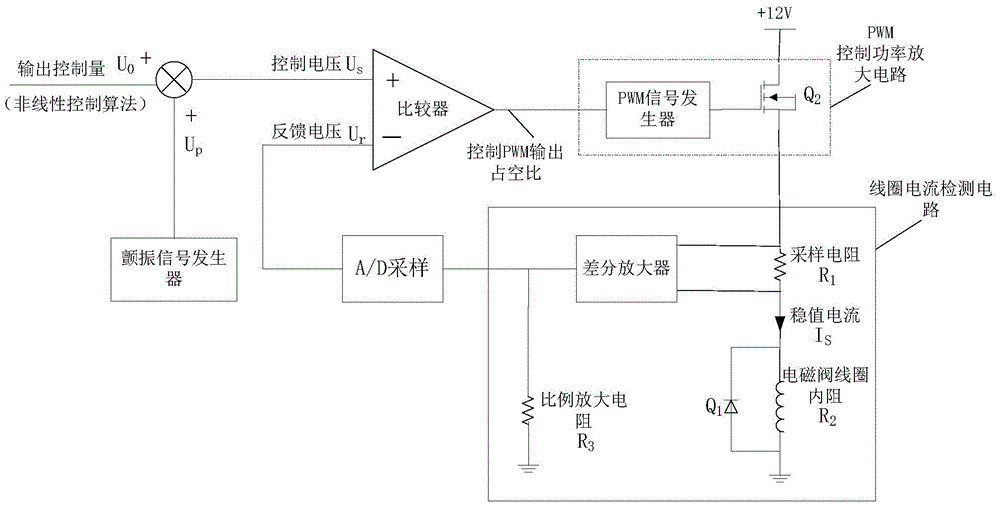

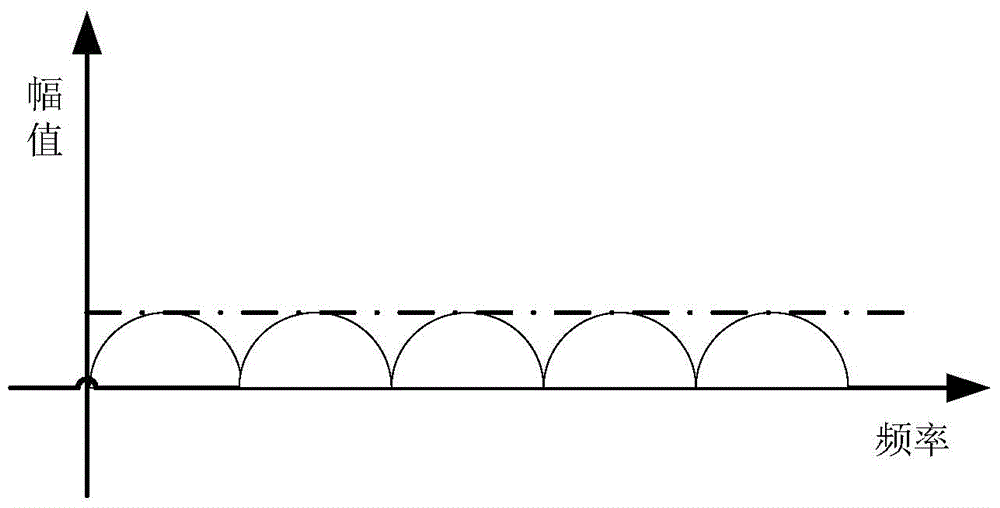

[0054] Such as figure 1 , 2 3. A leveling control system for a grader leveling shovel, including an O-type proportional solenoid directional valve, a hydraulic system, and a detection sensor, a microcontroller, a flutter signal generator, and a proportional flow valve drive circuit connected in sequence ,among them

[0055] The detection sensor detects the real-time horizontal inclination angle θ of the shovel, and transmits the horizontal inclination θ to the microcontroller for processing; the detection sensor is an MTI detection sensor, which is installed on the shaft of the shovel;

[0056] The microcontroller first calculates the angular velocity reference value ω from the horizontal inclination angle θ of the shovel through the I-PD control algorithm, and then sends ω into the nonlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com