Patents

Literature

2347results about "Fluid-pressure actuator safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

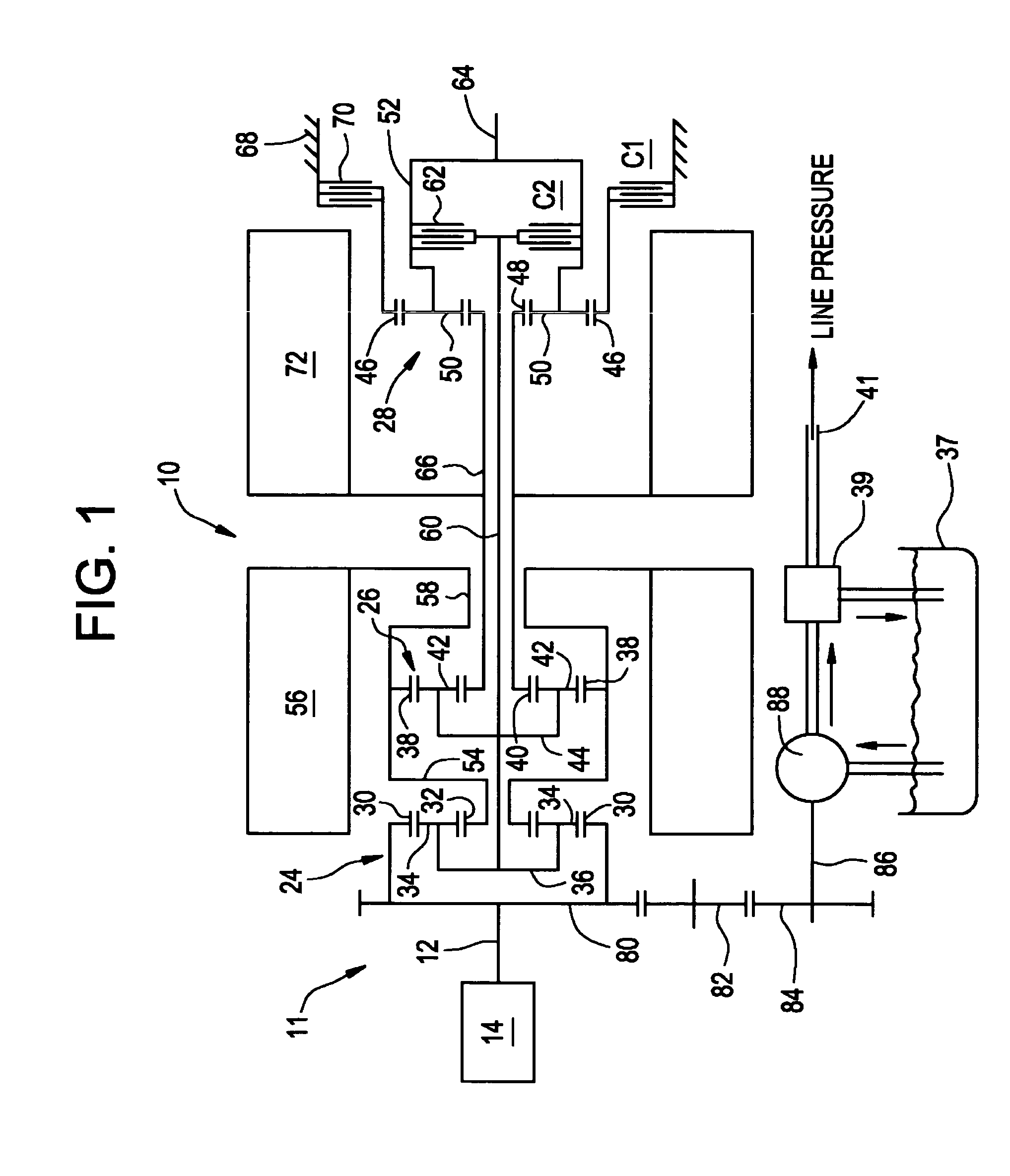

Hydraulic circuit for automatic transmission

ActiveUS9488197B2Rapidly and effectively removing foreign materialFluid-pressure actuator safetyClutchesProportional controlAutomatic transmission

A hydraulic circuit may include a proportional control solenoid valve controlling hydraulic pressure such that an operating hydraulic pressure required by the friction member is supplied to the friction member; a supply hydraulic path connecting the proportional control solenoid valve with the friction member, and adapted to supply hydraulic pressure controlled by the proportional control solenoid valve to the friction member; and a switch valve disposed in the supply hydraulic path so as to selectively open / close the supply hydraulic path.

Owner:HYUNDAI MOTOR CO LTD

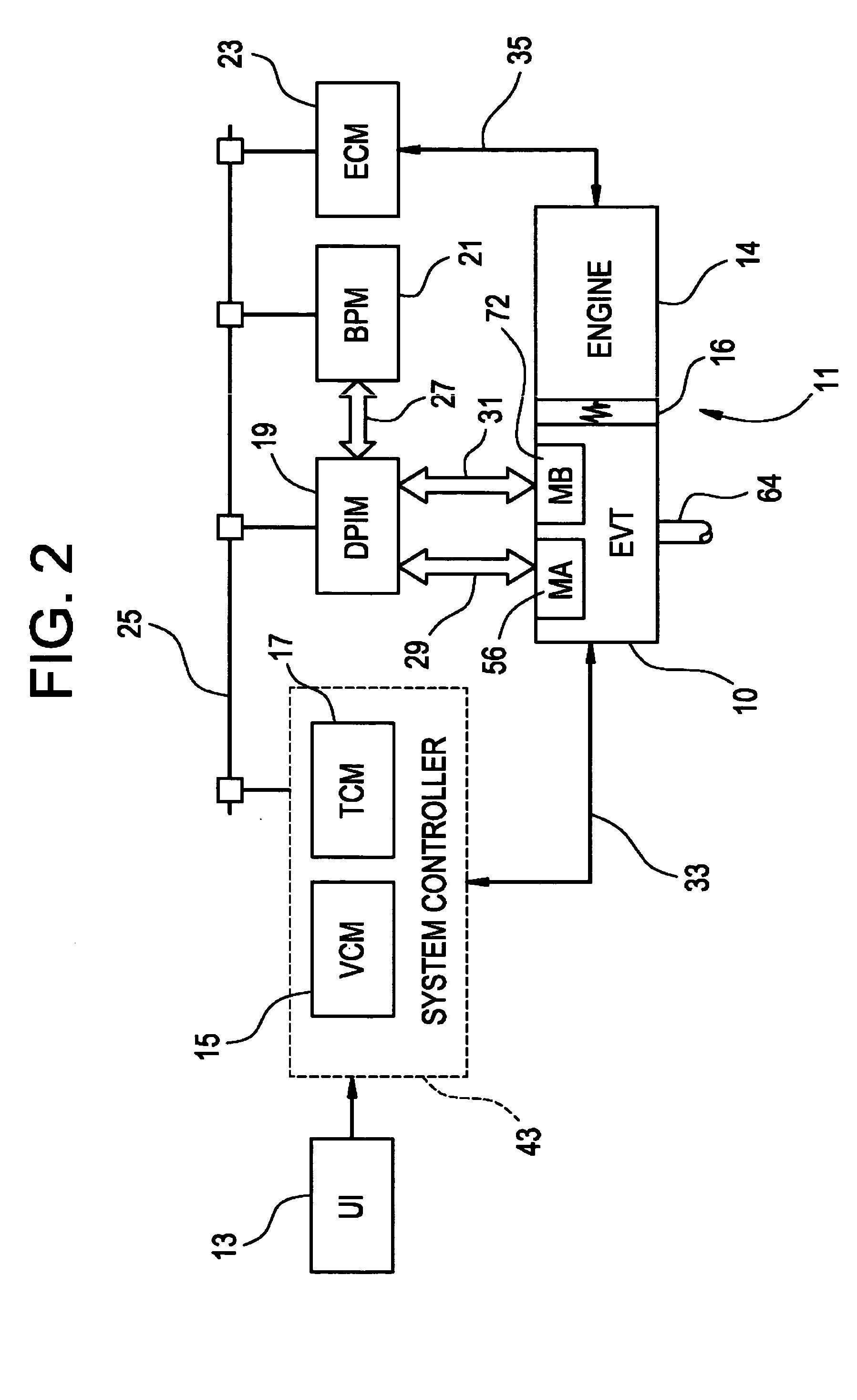

Control apparatus, method and diagnostic for hydraulic fill and drain

ActiveUS20050076958A1Improve robustnessHybrid vehiclesFluid-pressure actuator safetyControl theoryControl equipment

Hydraulic fill and drain of a clutch chamber is controlled with a blocking valve and a trim valve. The blocking valve selectively provides pressurized fluid to the trim valve which in turn selectively provides the pressurized fluid to the clutch chamber. Exhausting of the clutch chamber is effected through one of two alternate paths utilizing deactivation of one of the trim and blocking valves. Back up exhausting of the clutch chamber is effected through the other of the alternative paths. Such system allows for determination of valve failures and continued operation until such failures can be rectified.

Owner:ALLISON TRANSMISSION INC

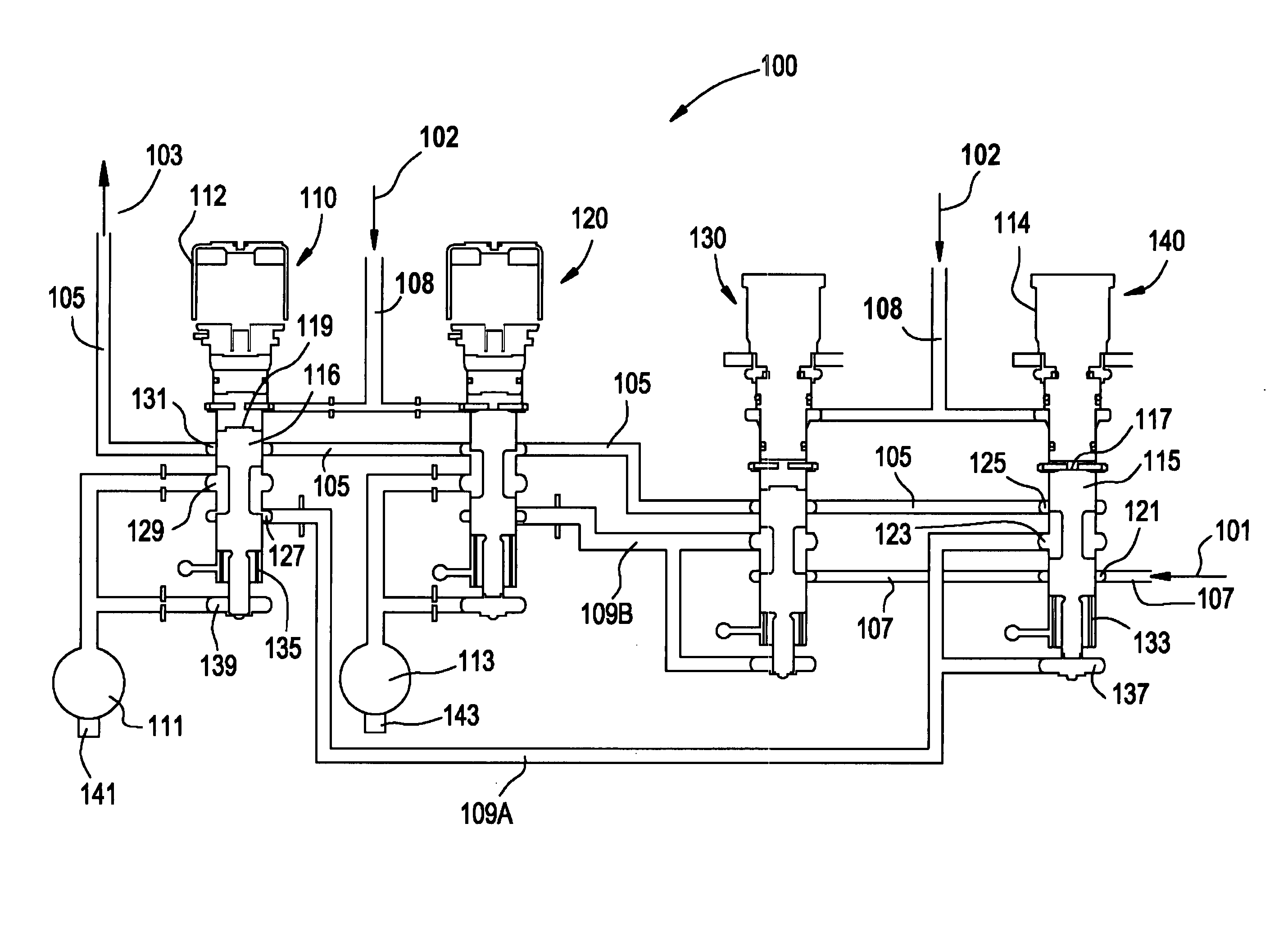

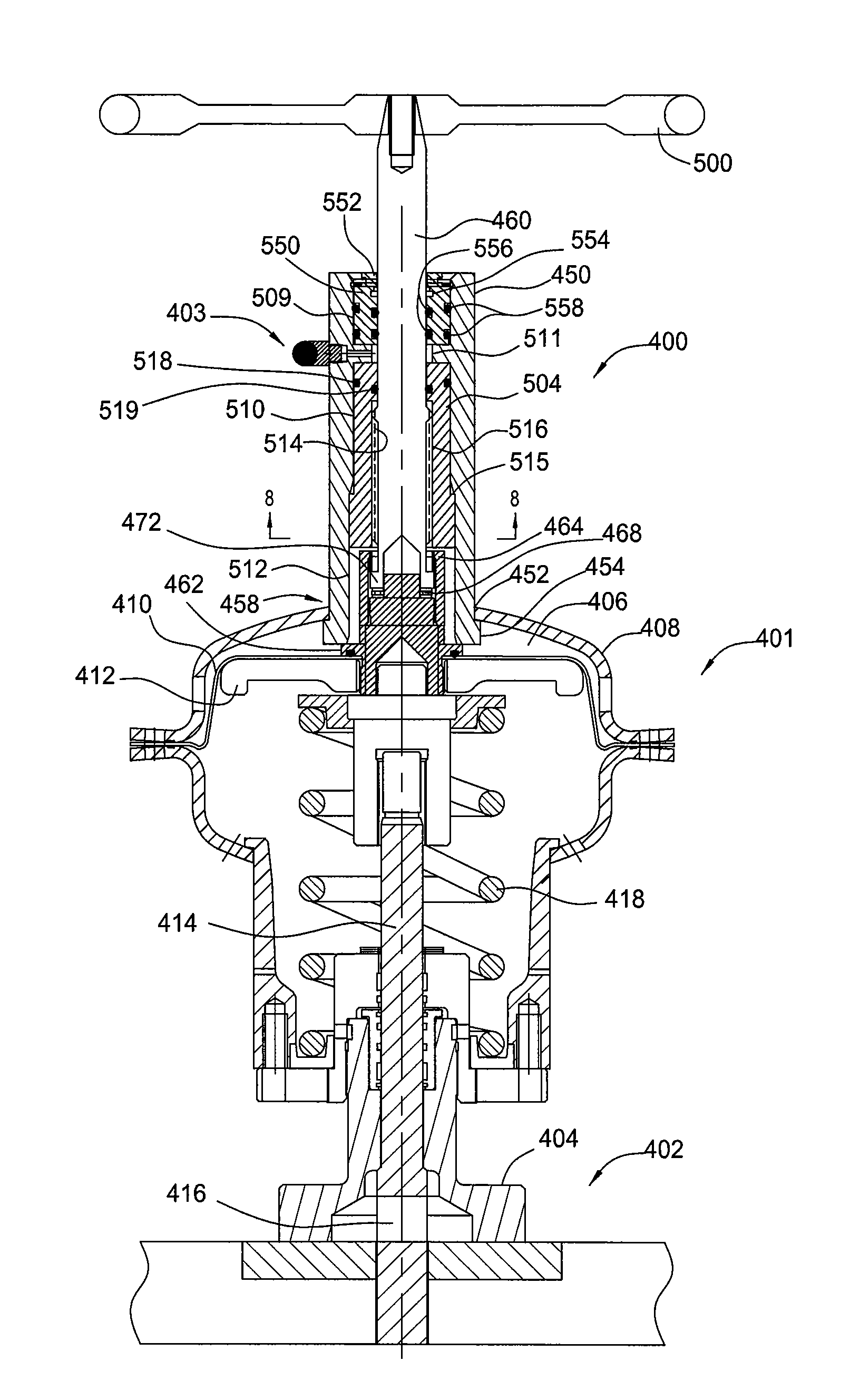

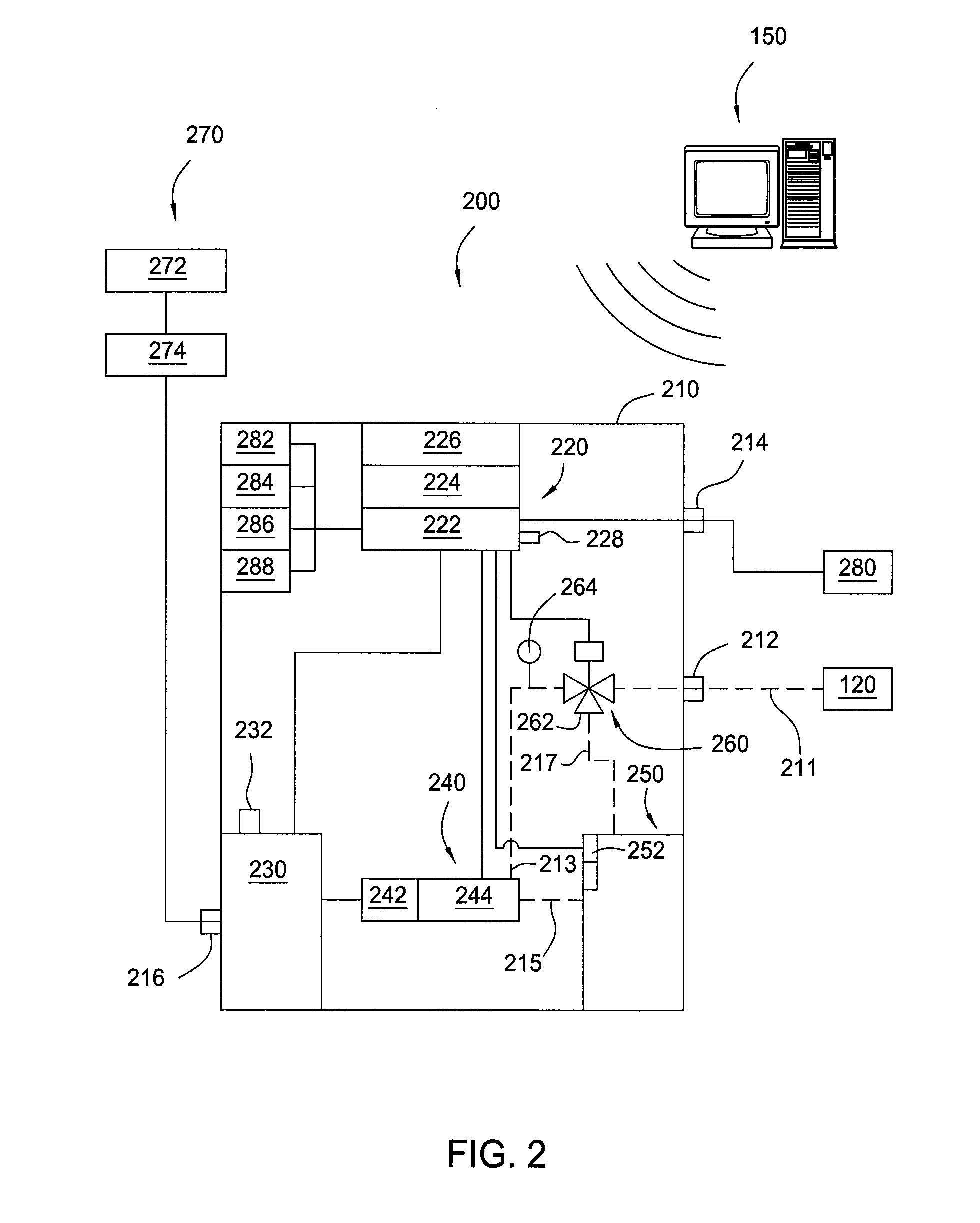

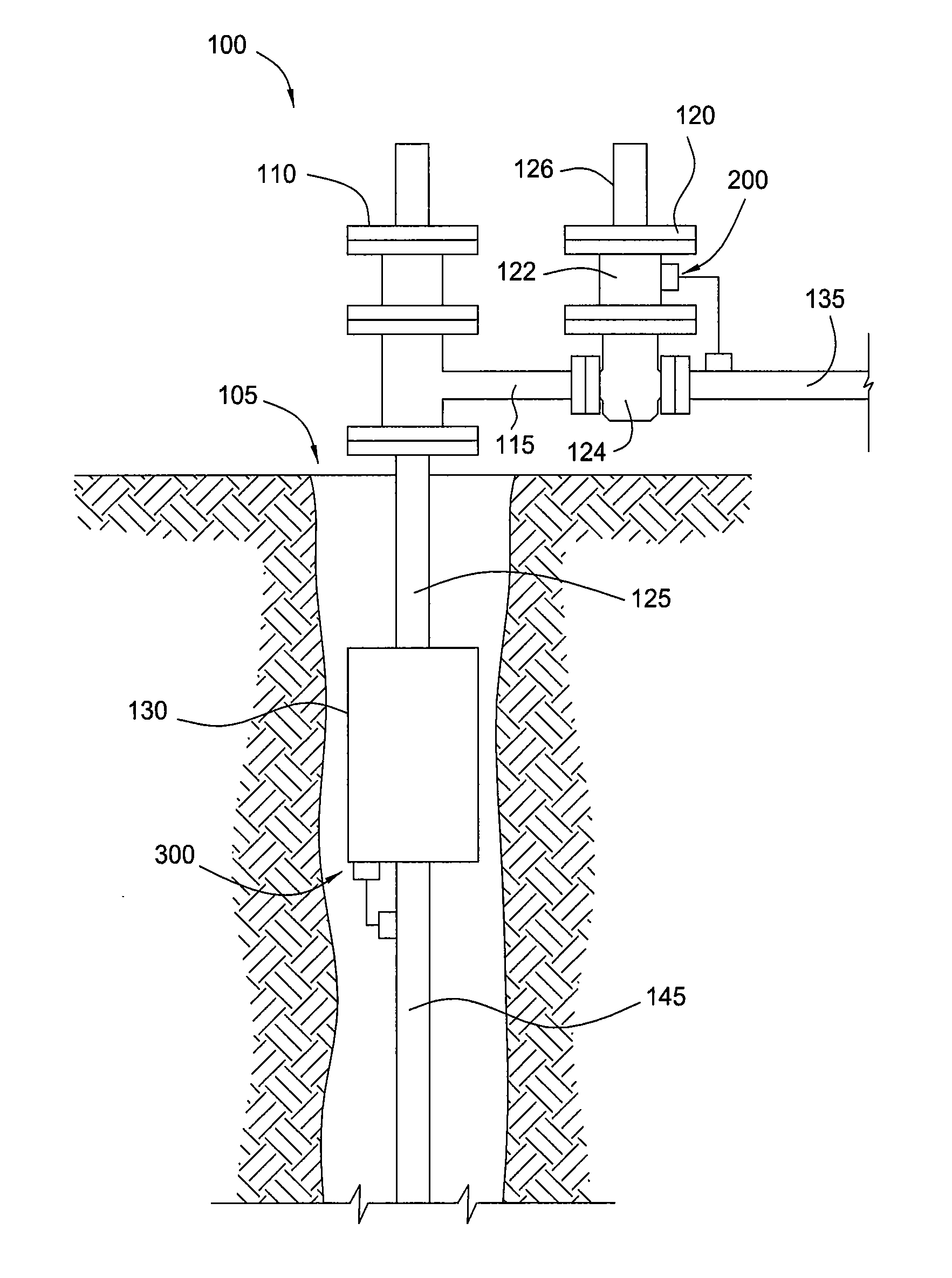

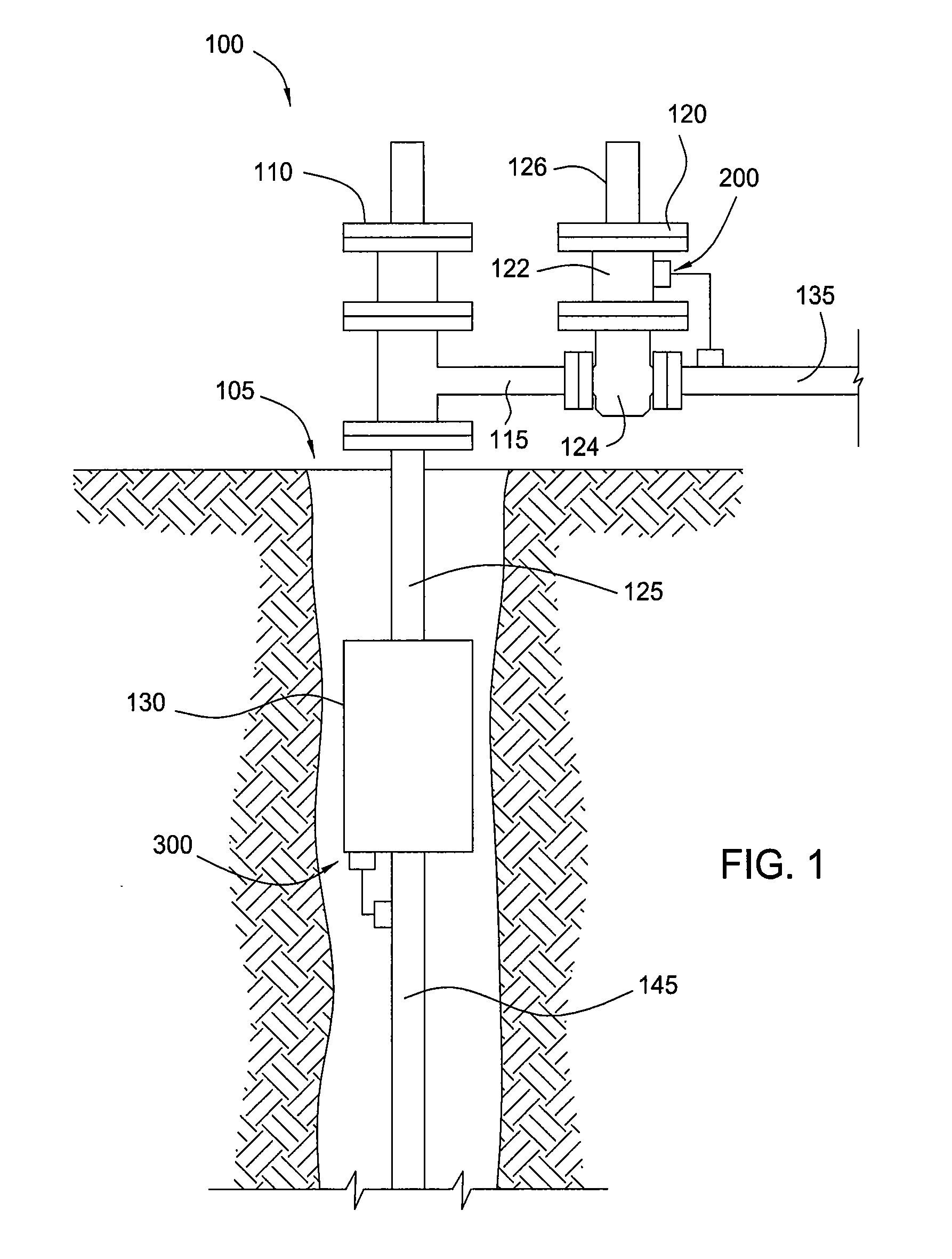

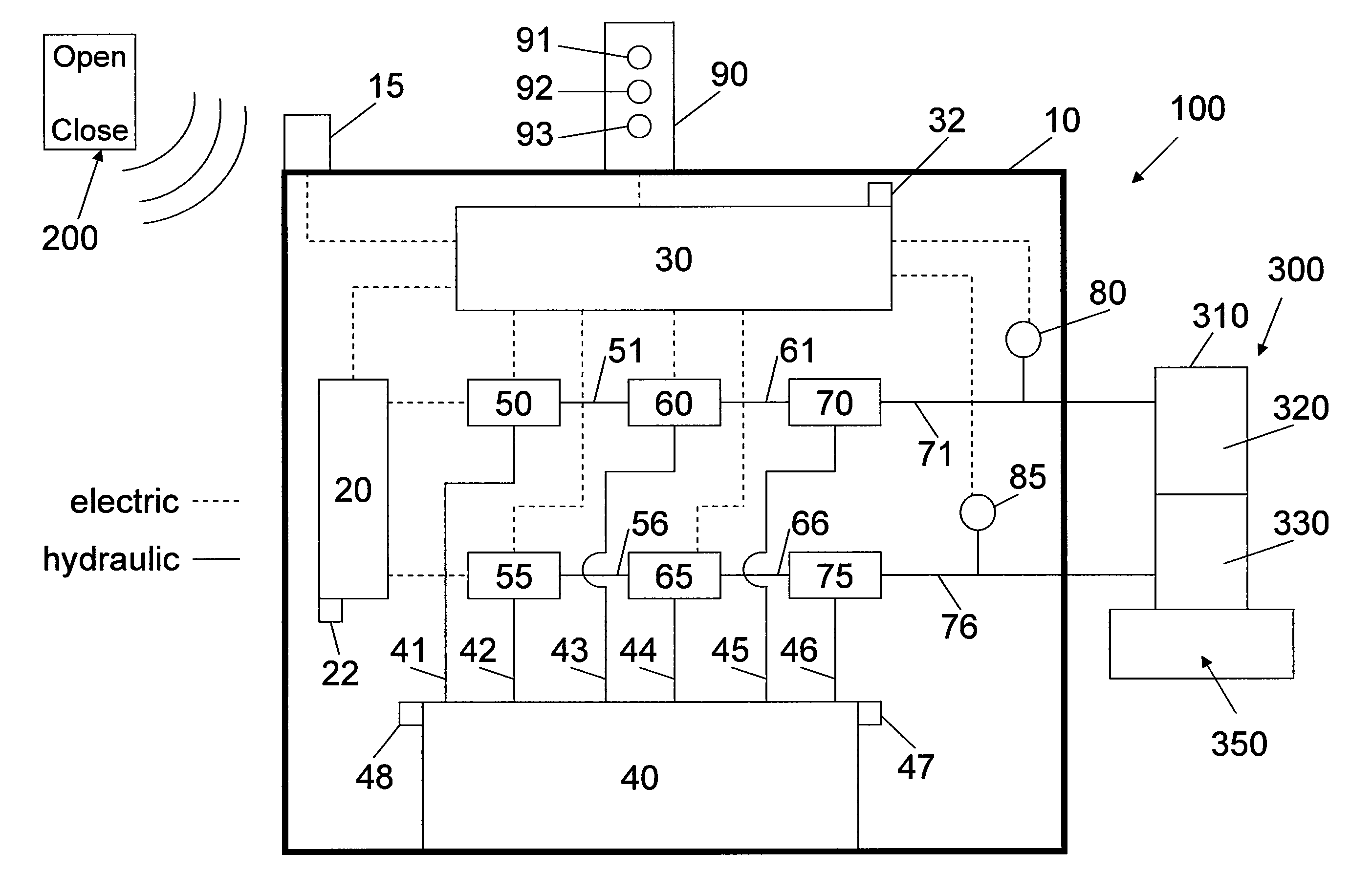

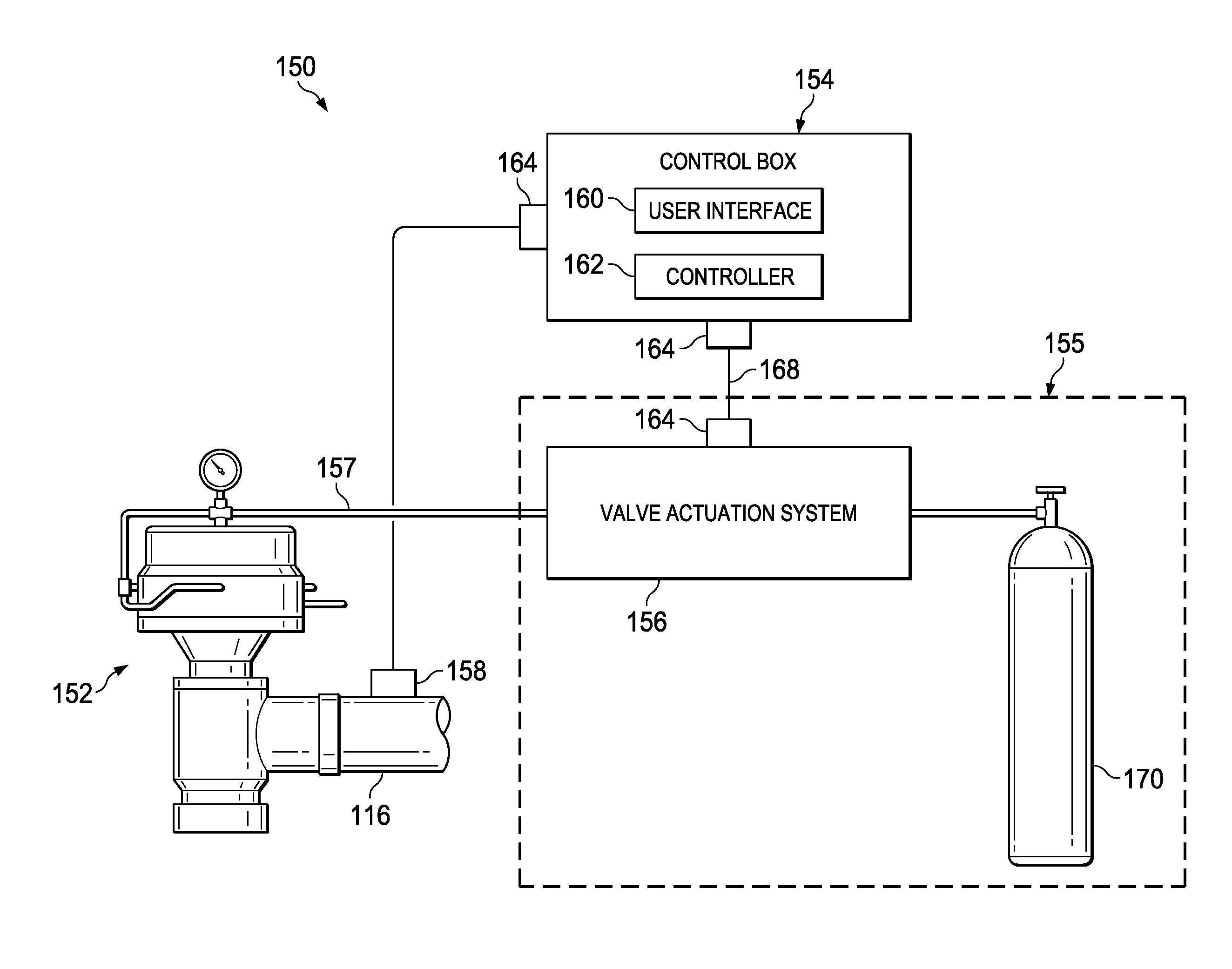

Safety valve control system and method of use

ActiveUS20120227983A1Reduce fluid pressureFluid-pressure actuator safetyEqualizing valvesControl systemTransducer

A safety valve control system may include a remotely operable control assembly, a first transducer, a valve assembly, and a compressor assembly in communication with the control assembly. The control assembly is operable to actuate the pump and valve assemblies to supply fluid to actuate the safety valve into open and closed positions, in response to one or more signals received from the first transducer. A method of operation may include maintaining the safety valve in an open or closed position while sensing a physical property with the control system; communicating a signal corresponding to the sensed physical property to the control system; and automatically closing or opening the safety valve in response to a comparison of the sensed physical property to a pre-set condition.

Owner:SAFOCO

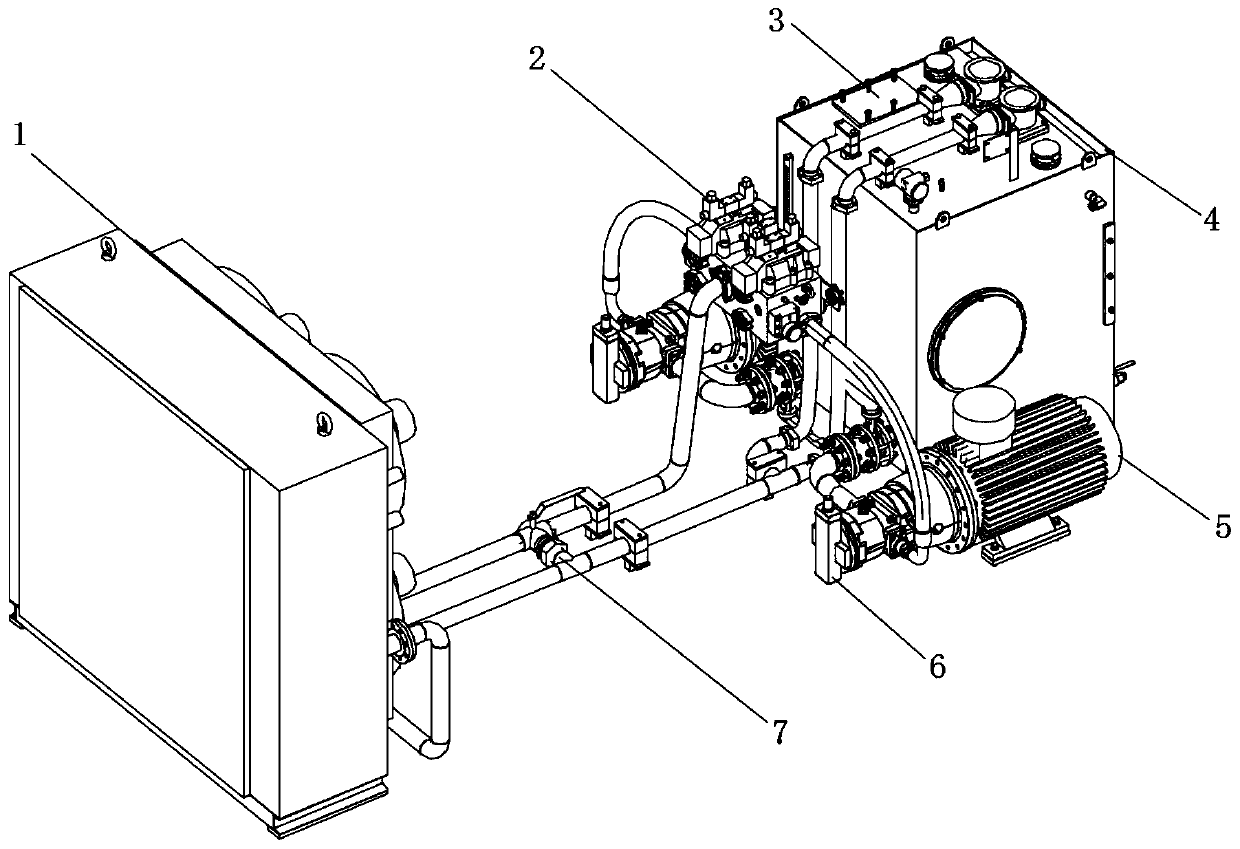

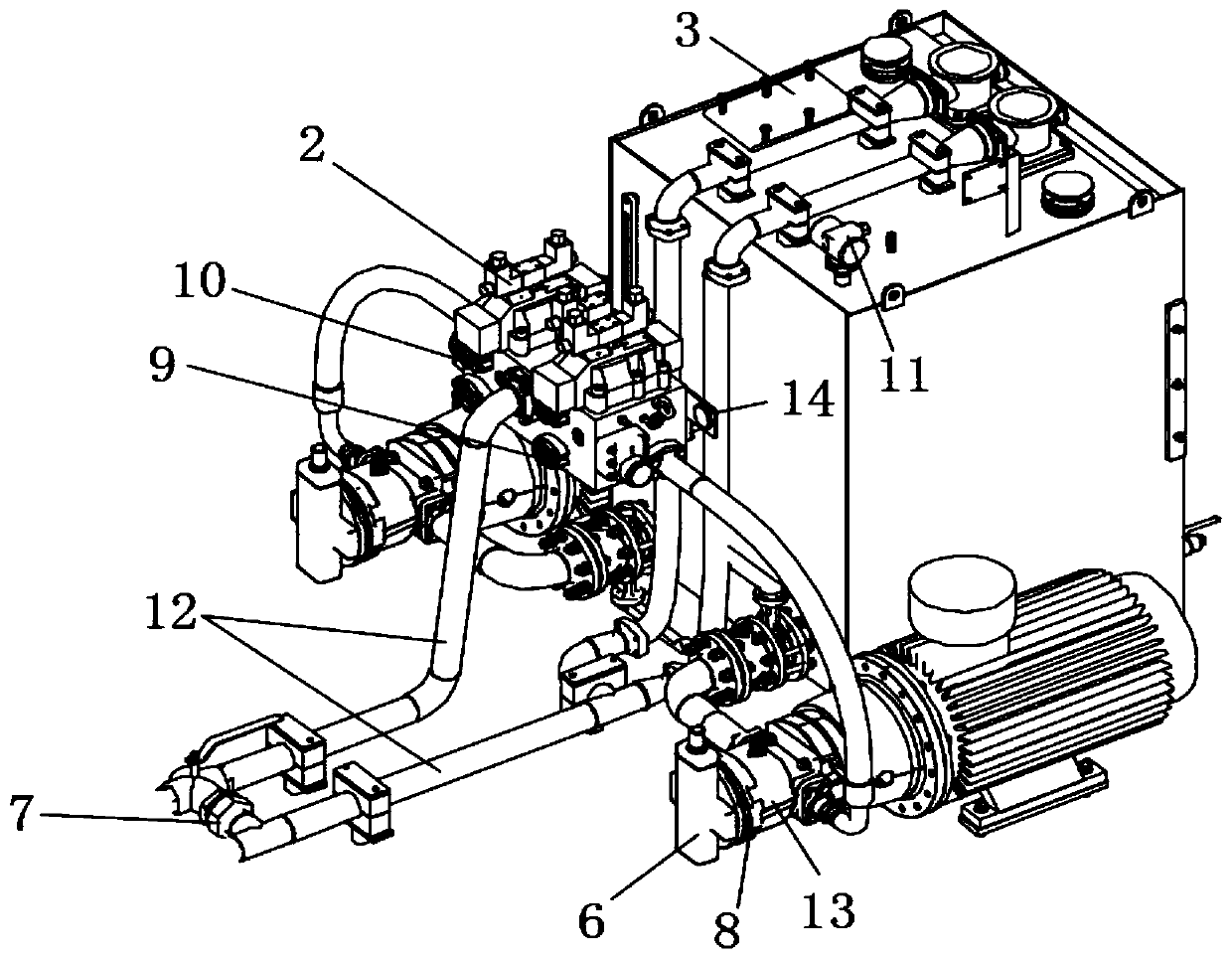

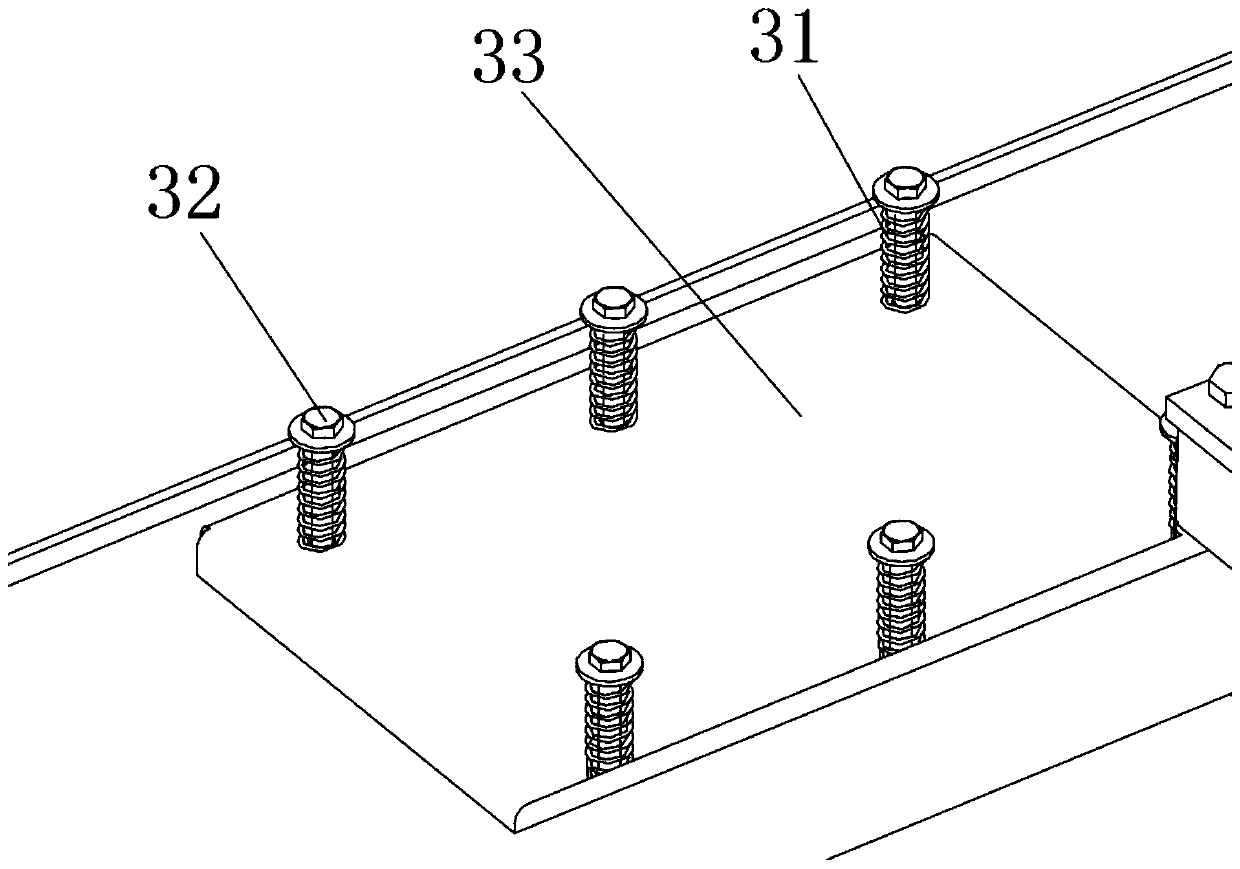

Integrated hydraulic station

InactiveCN110873093AAchieve high integrationRealize automatic control functionFluid-pressure actuator safetyFluid-pressure actuator componentsCompressed natural gasPressure difference

The invention belongs to the technical field of compressed natural gas filling, and particularly relates to an integrated hydraulic station which realizes high integration of an oil tank, plunger pumps, motors, a valve block, a cooler, an instrument and a sensor. The reversing function of hydraulic oil is provided through cooperation of an electro-hydraulic reversing valve and a proximity switch on a hydraulic cylinder, the functions of circulating heating of the low-temperature hydraulic oil, discharging of the high-pressure hydraulic oil and avoiding the hydraulic oil channeling back betweenthe double pumps are realized through cooperation of an unloading valve, a one-way valve and the electro-hydraulic reversing valve in the valve block, the high-pressure difference automatic stop function and the high-pressure gas discharging function are provided, combustible gas leakage and expansion deformation of the oil tank which cannot be recovered caused by high-pressure gas channeling back are avoided, the functions of low oil level monitoring alarm, temperature monitoring alarm and low oil temperature automatic circulating heating before starting of the hydraulic oil tank are provided, a three-way ball valve is adopted to replace an oil return valve block in the aspect of cooling oil return of the hydraulic oil, thus the oil return control function is realize, and the cost and space of the hydraulic station are also reduced.

Owner:JEREH OIL & GAS ENG

Safety valve control system and method of use

A safety valve control system may include a remotely operable control assembly; a first transducer, a valve assembly, and a pump assembly in communication with the control assembly; and a fluid reservoir in communication with the valve and pump assemblies and a safety valve. The control assembly is operable to actuate the pump and valve assemblies to supply and return fluid from the fluid reservoir to actuate the safety valve into open and closed positions, in response to one or more signals received from the first transducer. A method of operation may include maintaining the safety valve in an open position while sensing a physical property with the control system; communicating a signal corresponding to the sensed physical property to the control system; and automatically closing the safety valve in response to a comparison of the sensed physical property to a pre-set condition.

Owner:SAFOCO

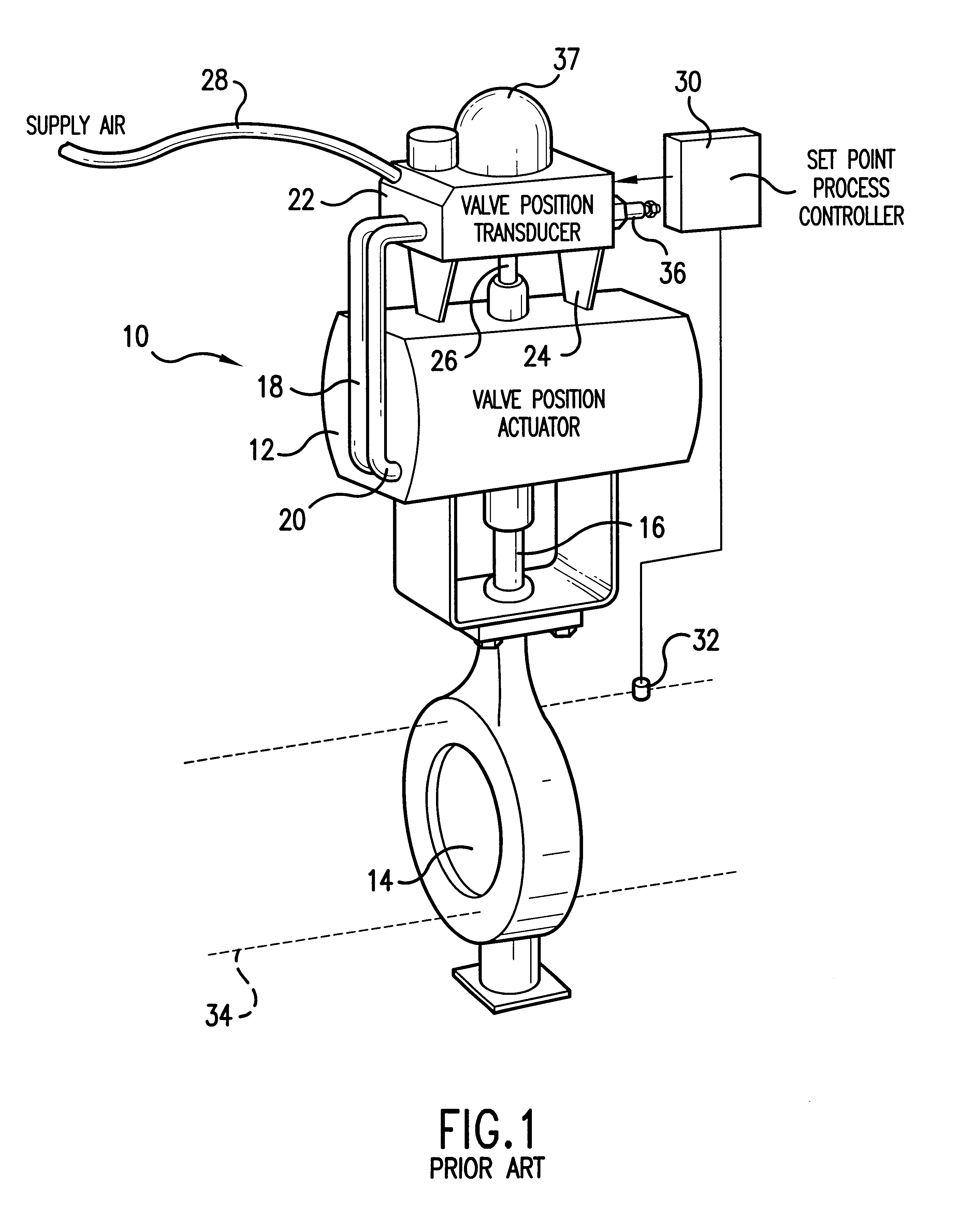

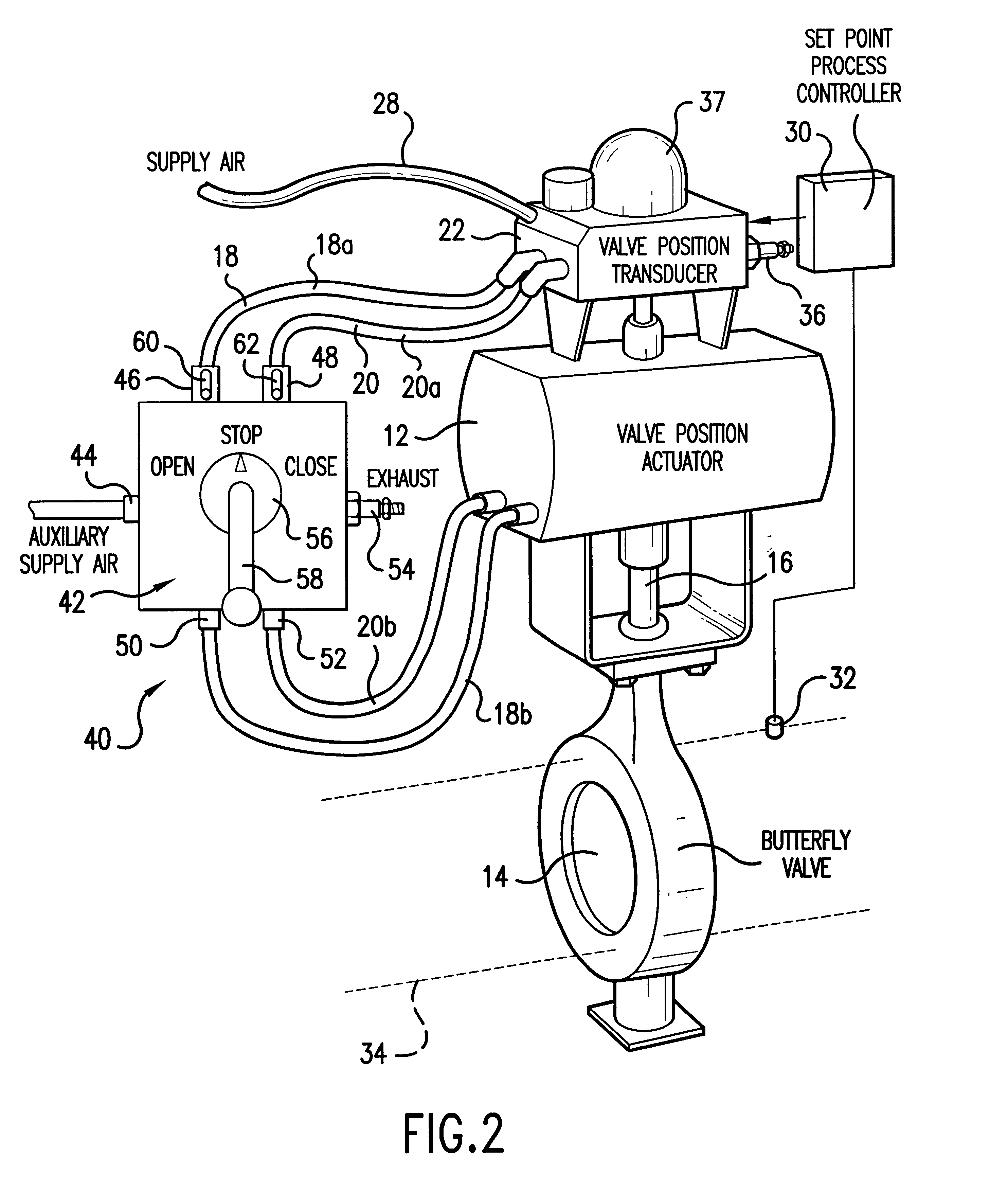

Automatic position-control valve assembly

InactiveUS6354327B1Fluid-pressure actuator safetyOperating means/releasing devices for valvesTransducerActuator

According to principles of this invention, an override controller is structured for being placed in pressurized fluid lines between a valve position transducer and a valve position actuator of an automatic position-controlled valve assembly, with the override controller receiving uncontrolled supply pressurized fluid and having an exhaust. The override controller receives pressurized fluid at first and second inlet ports from the valve position transducer and furnishes this pressurized fluid to the valve position actuator through first and second outlet ports for controlling the position of the valve during normal operation. However, valve mechanisms of the override controller can also be placed in positions for stopping flow of pressurized fluid through the first and second inlet ports and providing fluid flow from the uncontrolled pressurized fluid to the first and second outlet ports for controlling the position of an industrial valve during override operation.

Owner:HENRY PRATT CO +1

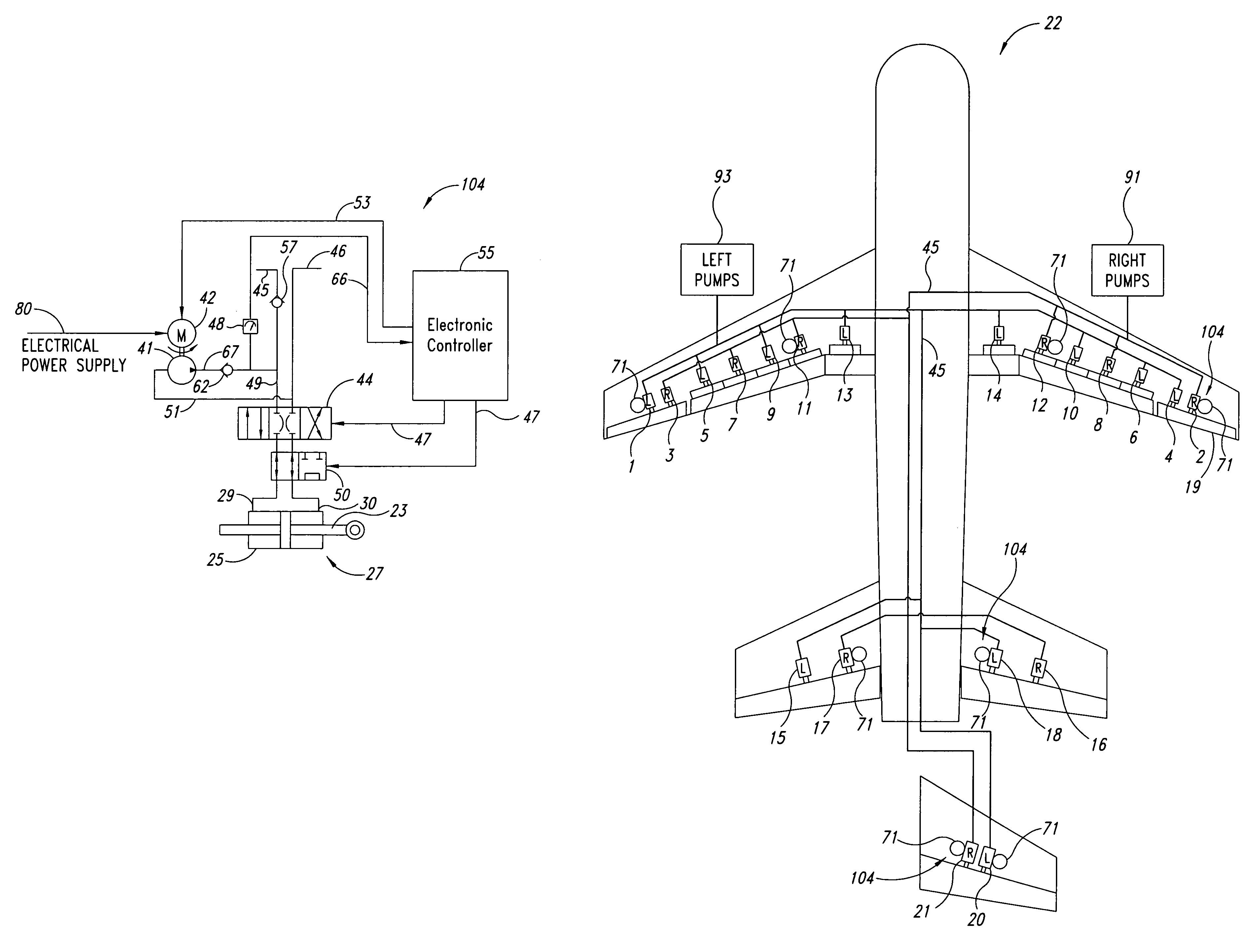

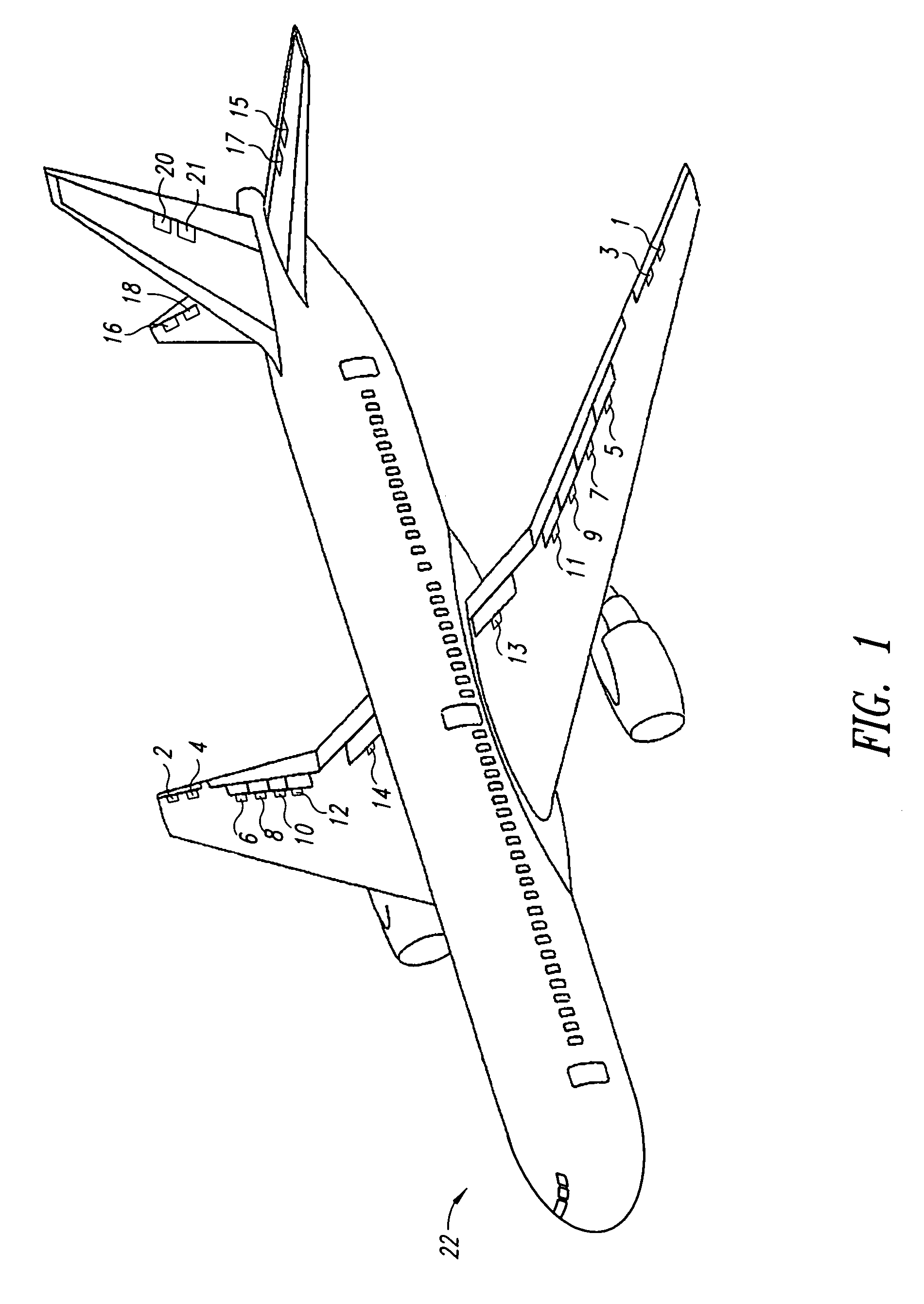

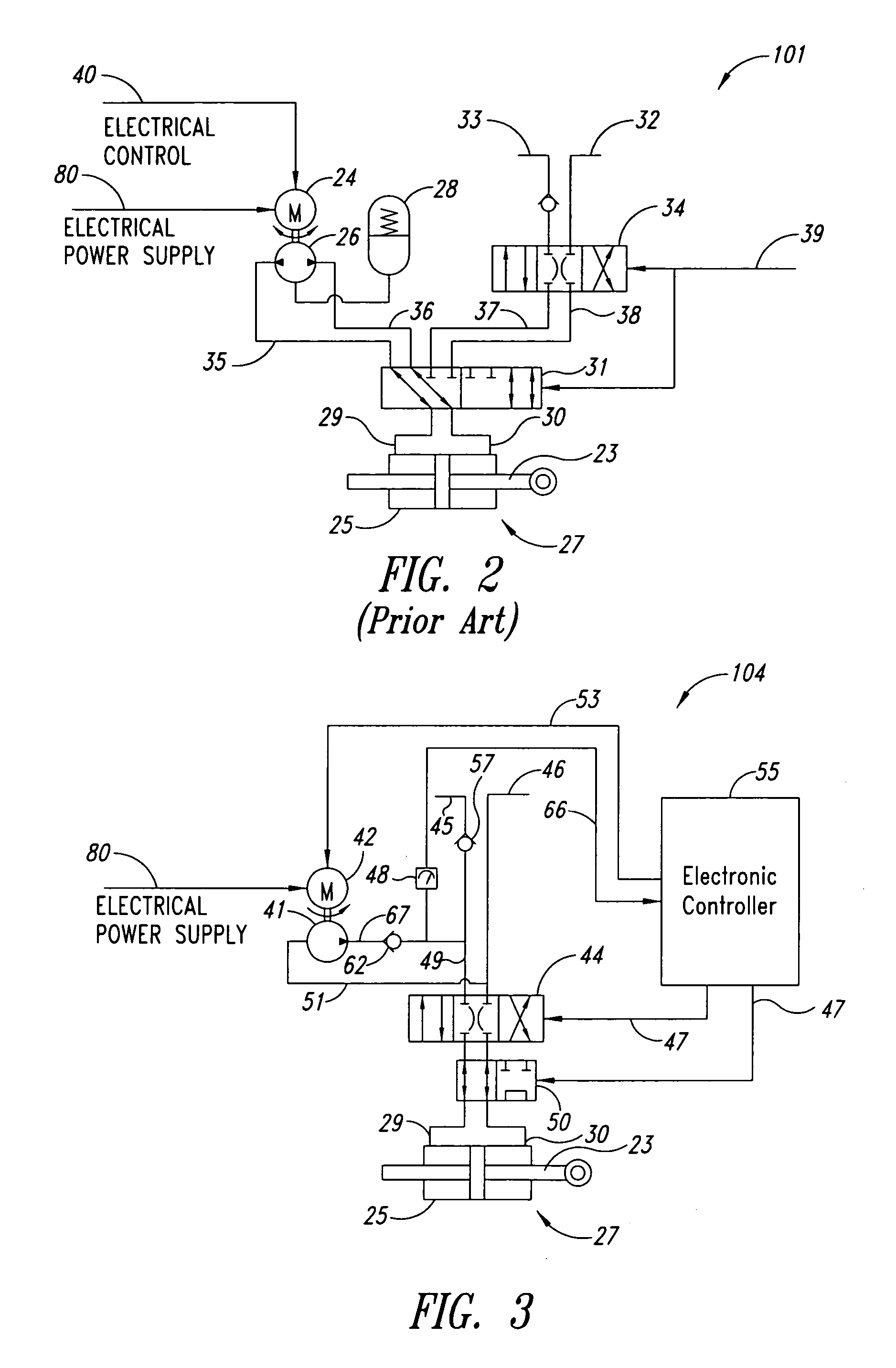

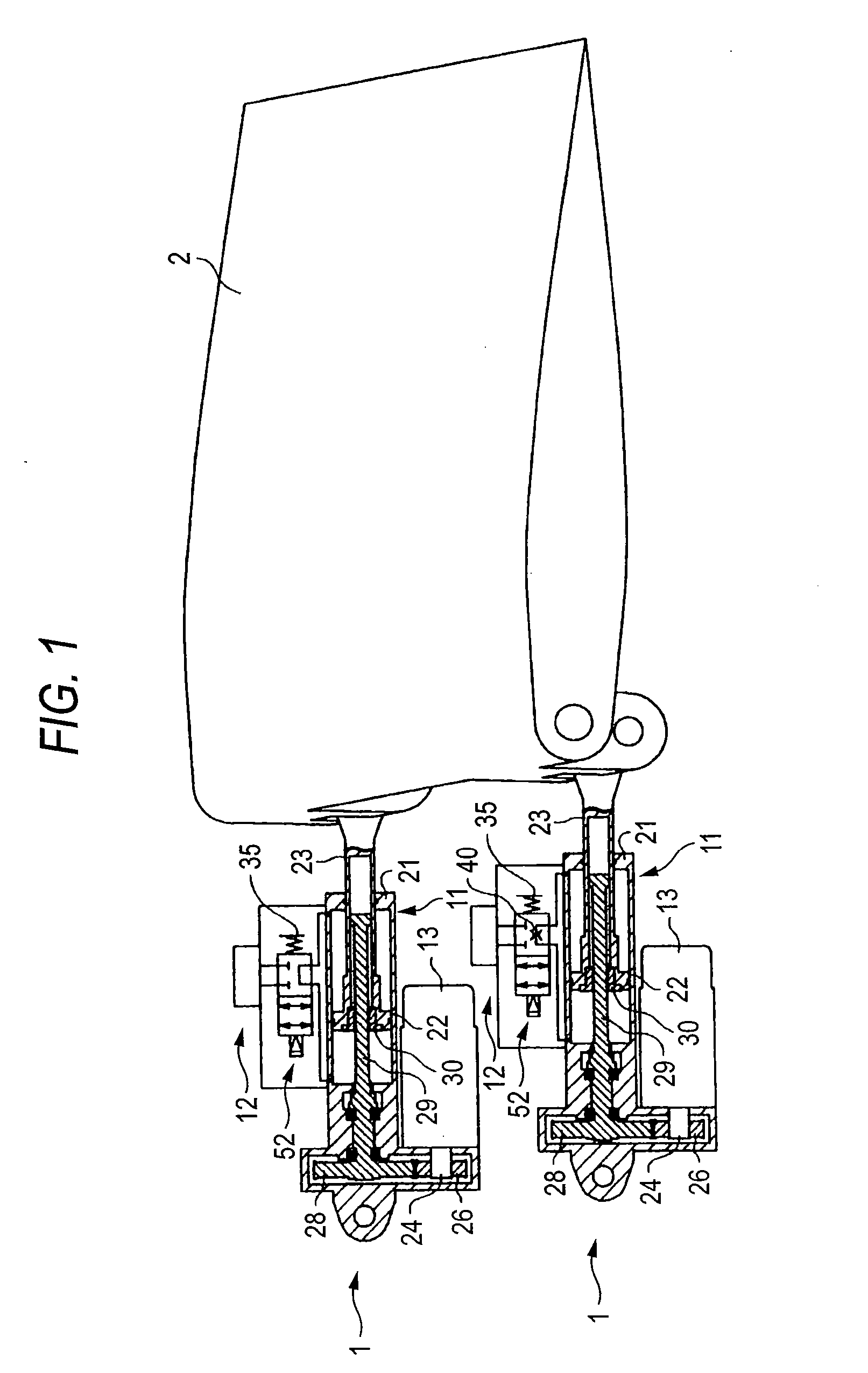

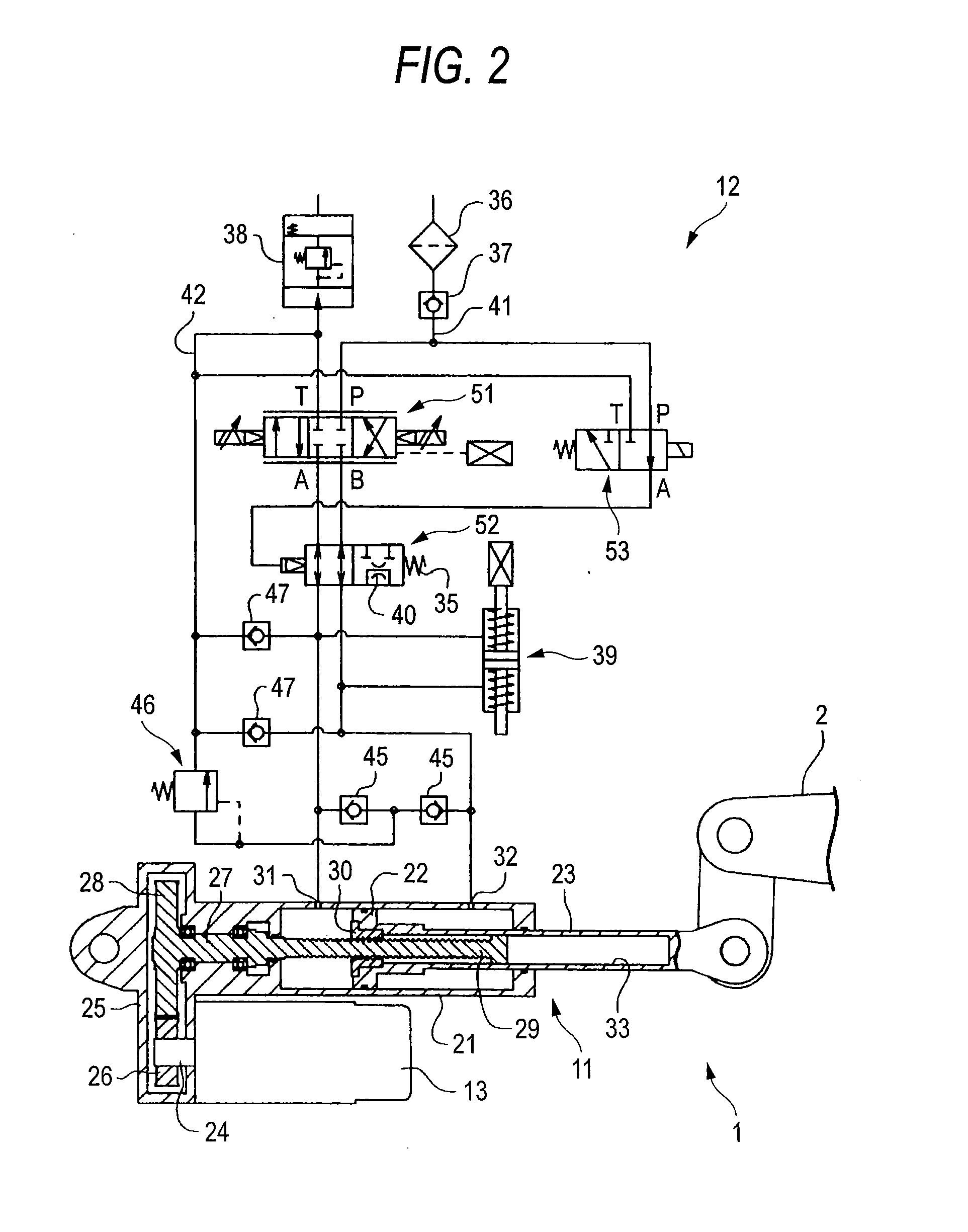

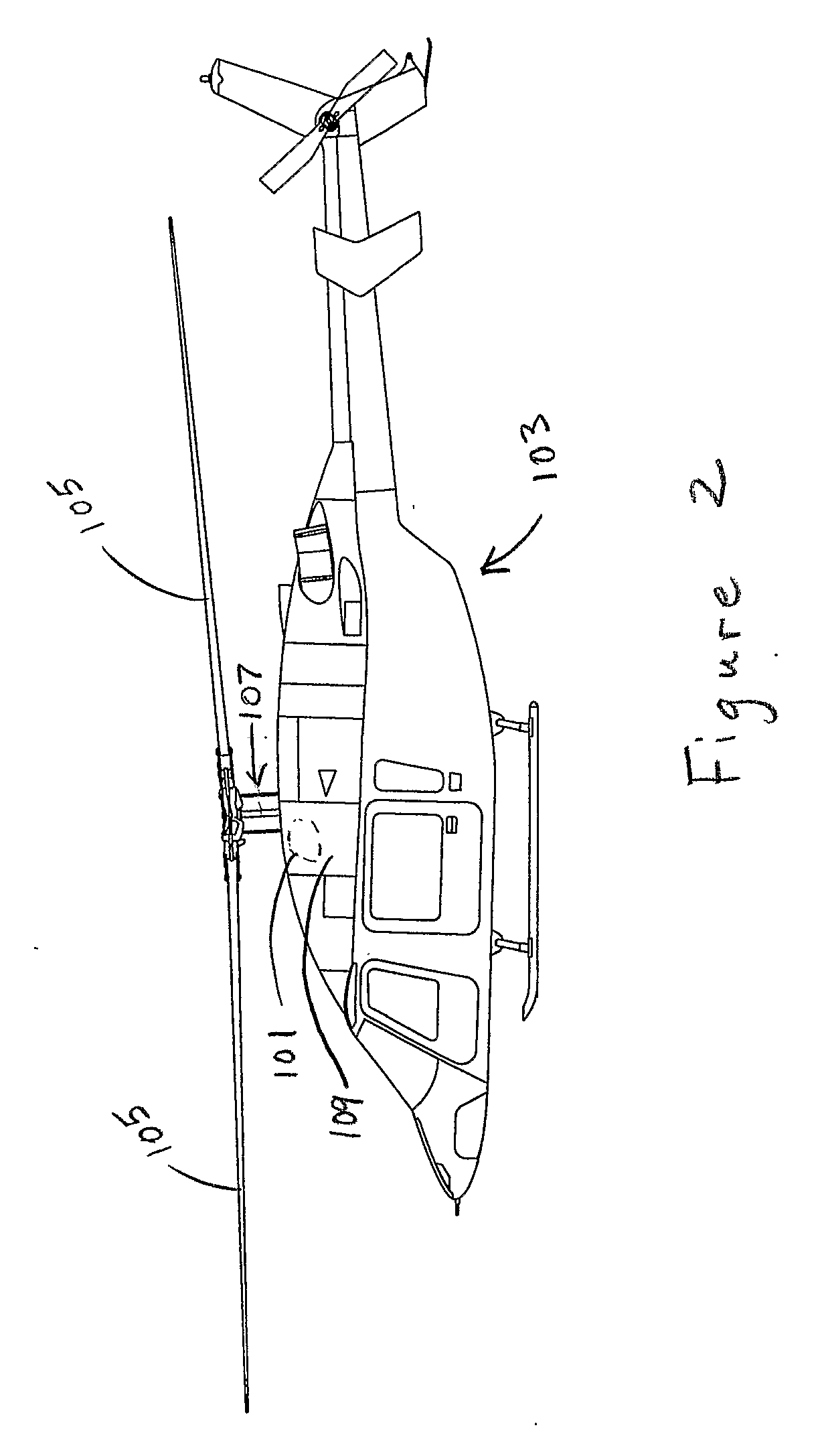

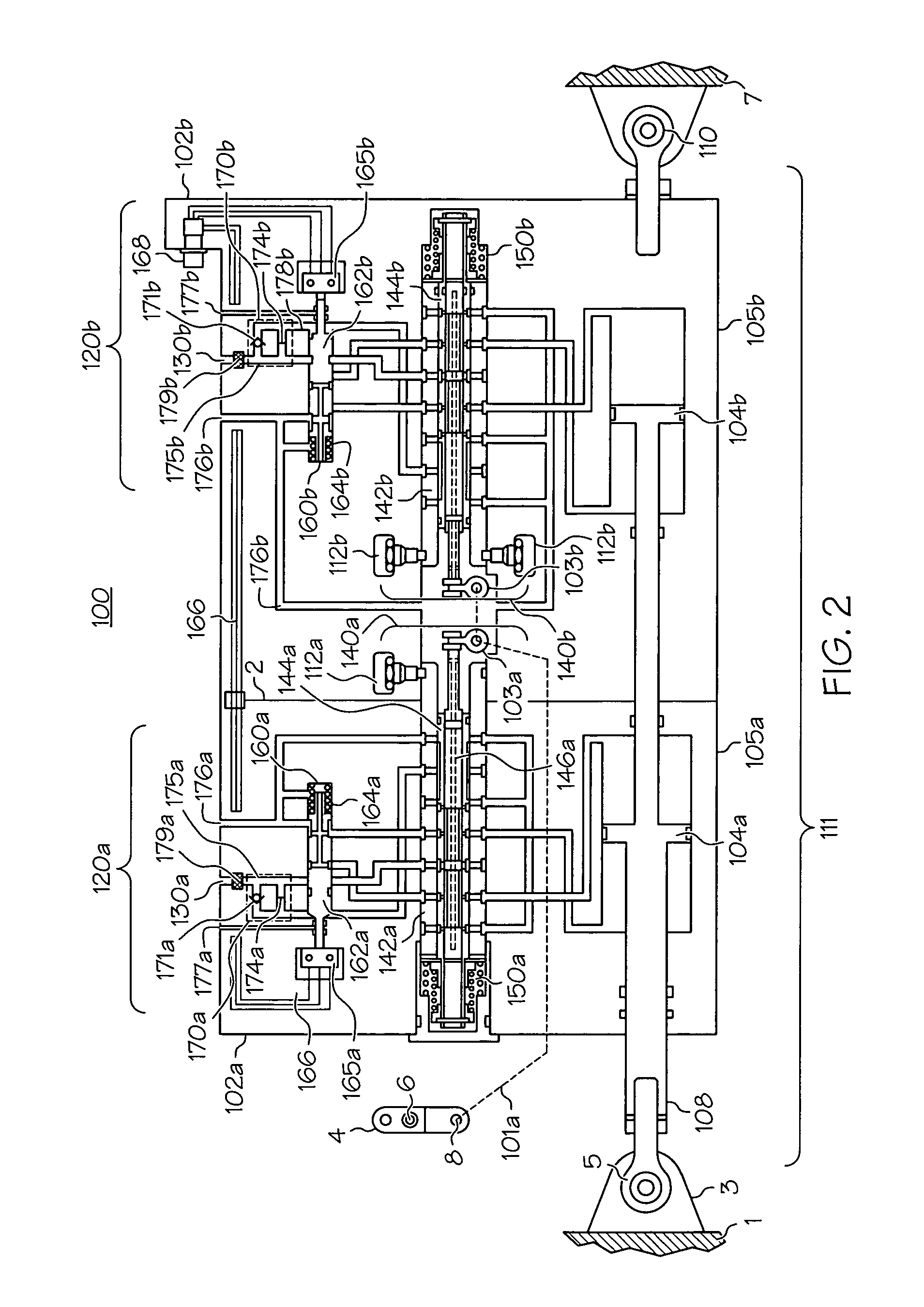

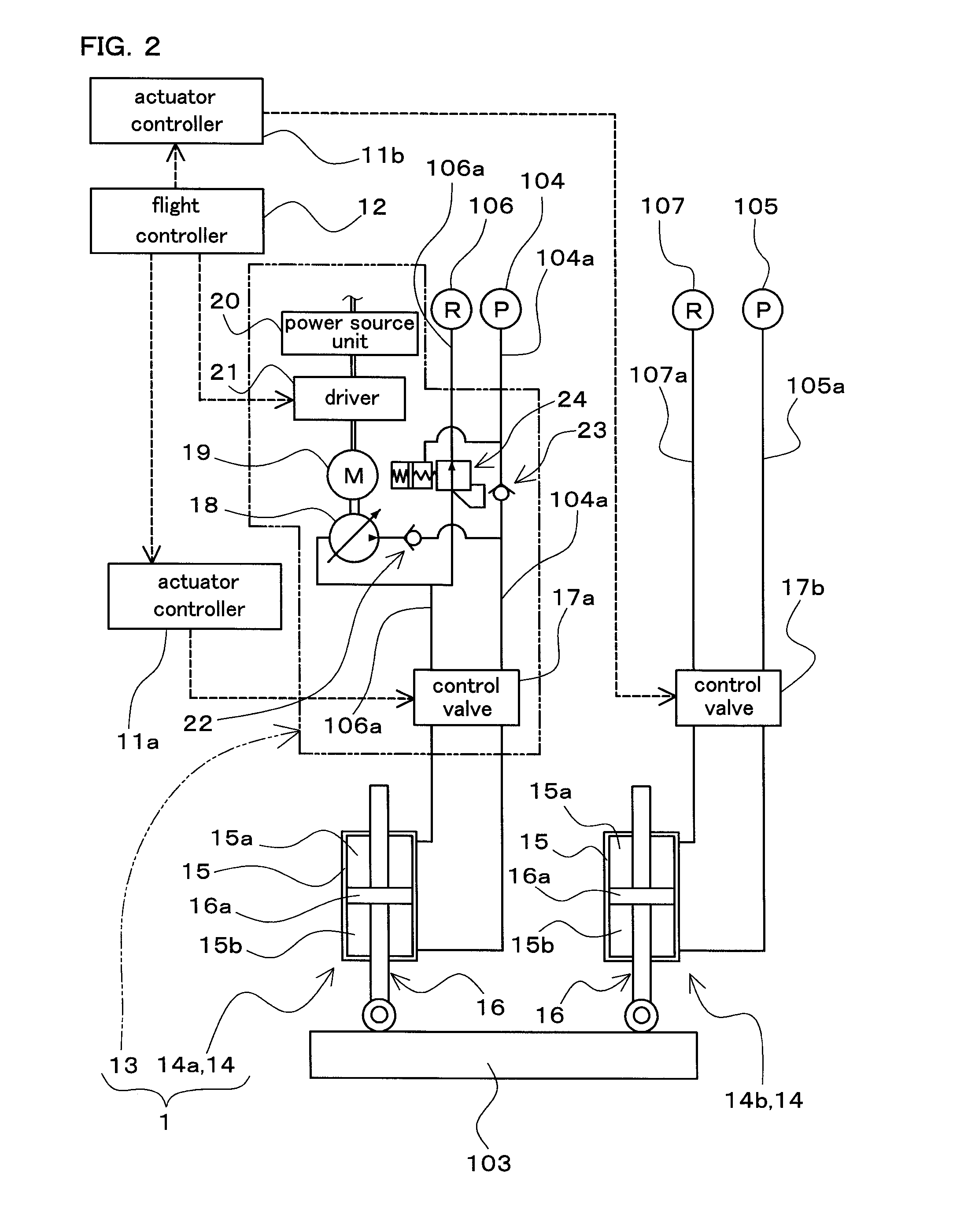

Local backup hydraulic actuator for aircraft control systems

ActiveUS7600715B2Reduce in quantityImprove usabilityFluid-pressure actuator safetyFluid couplingsElectronic controllerControl system

Owner:NABLESCO CORP

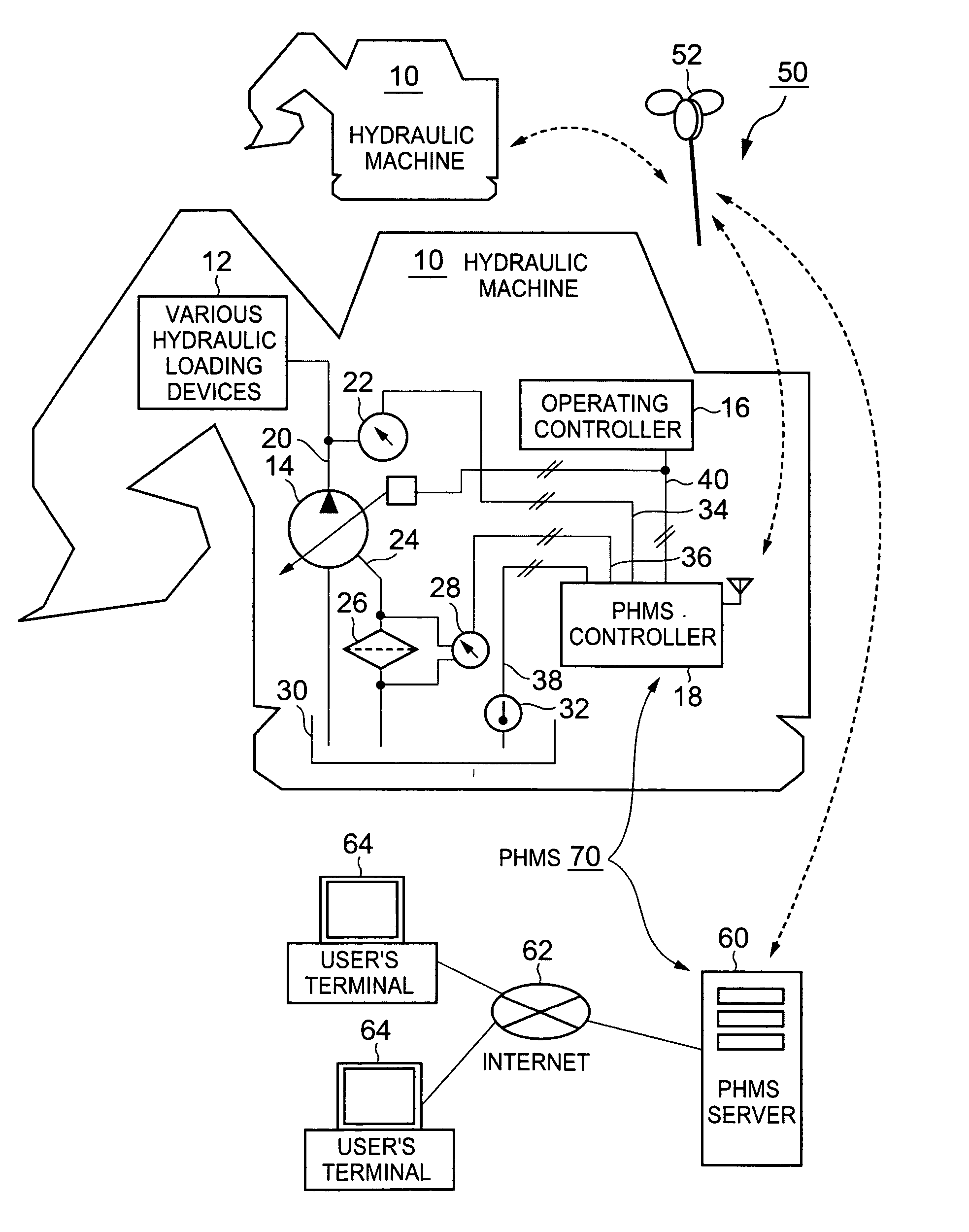

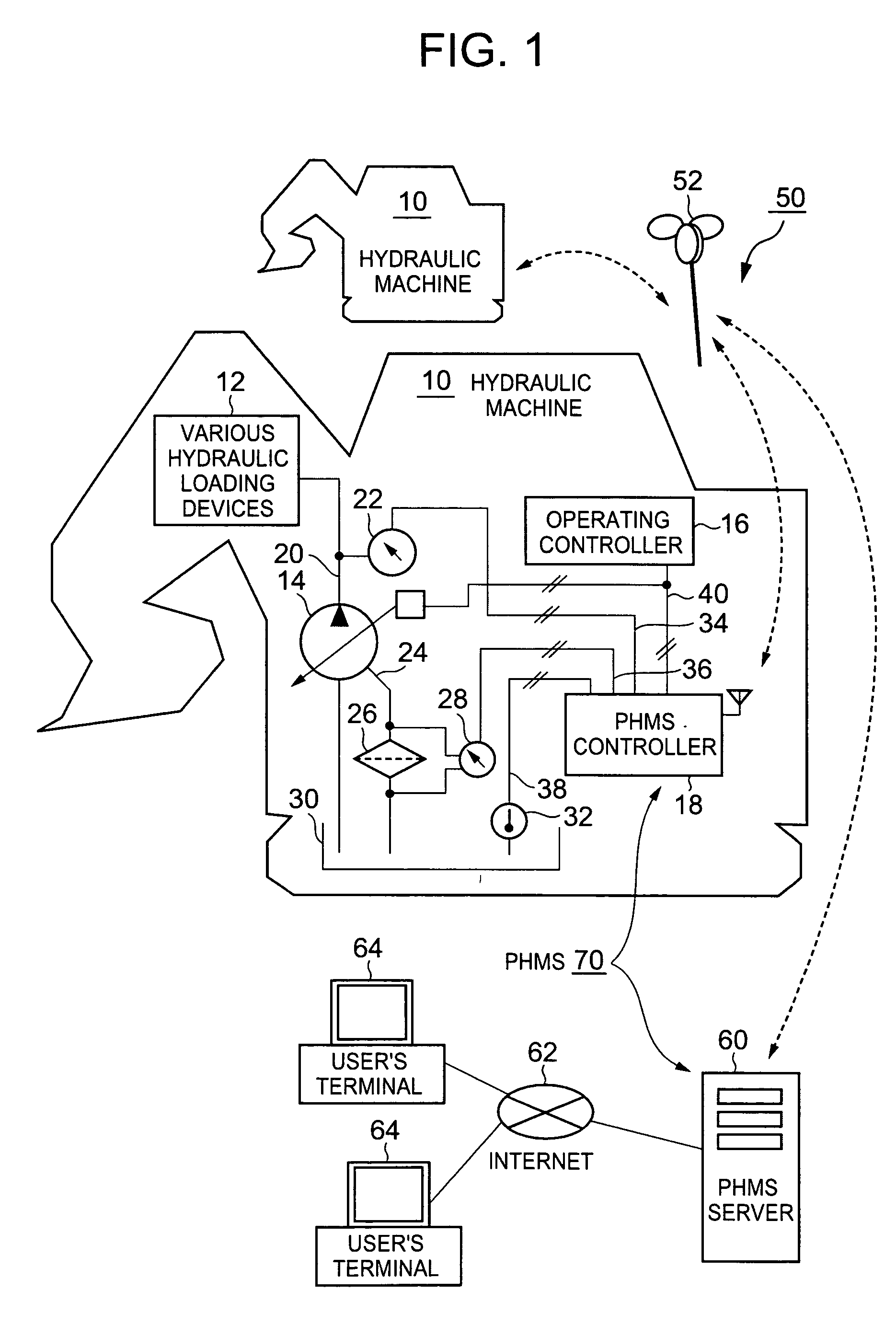

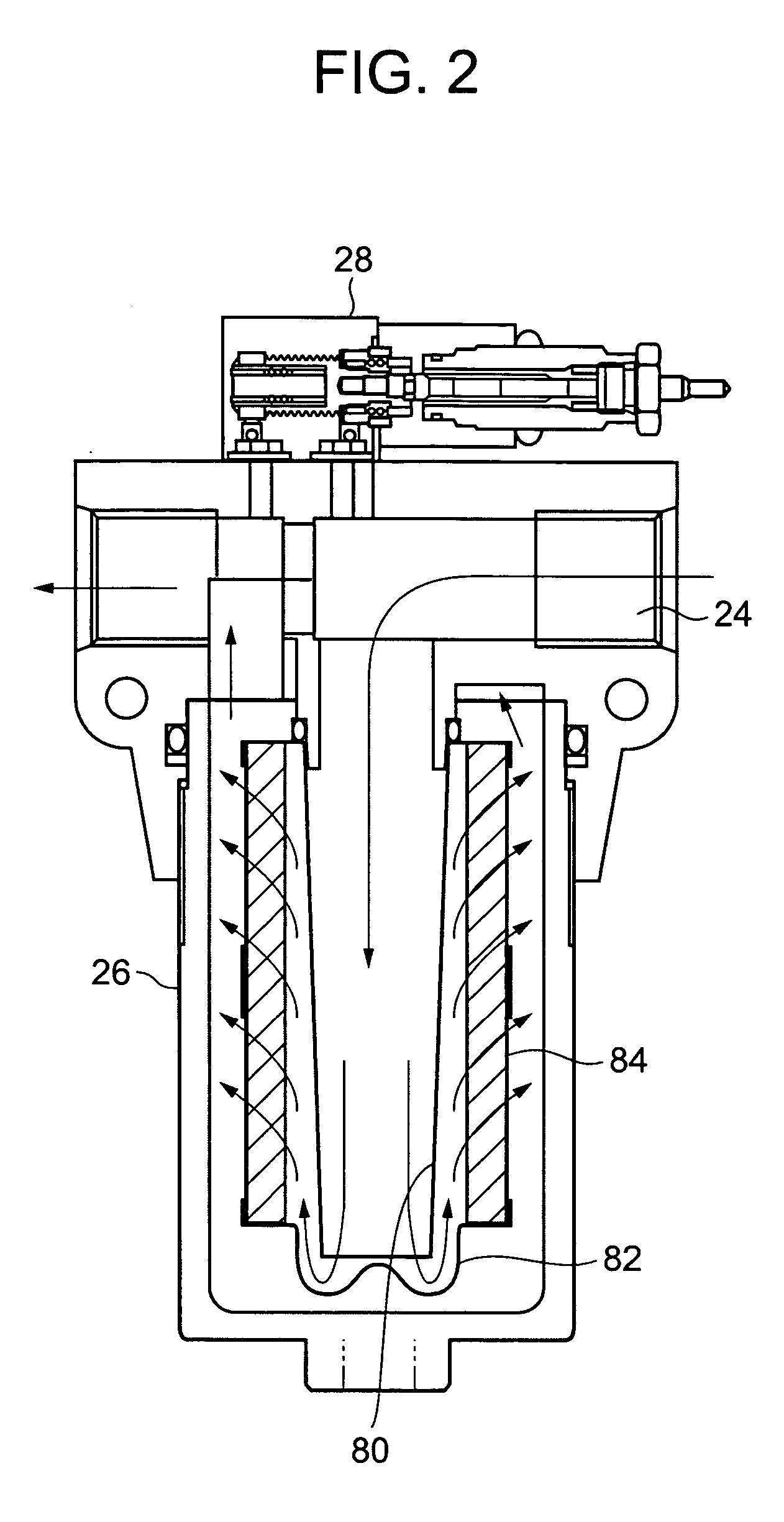

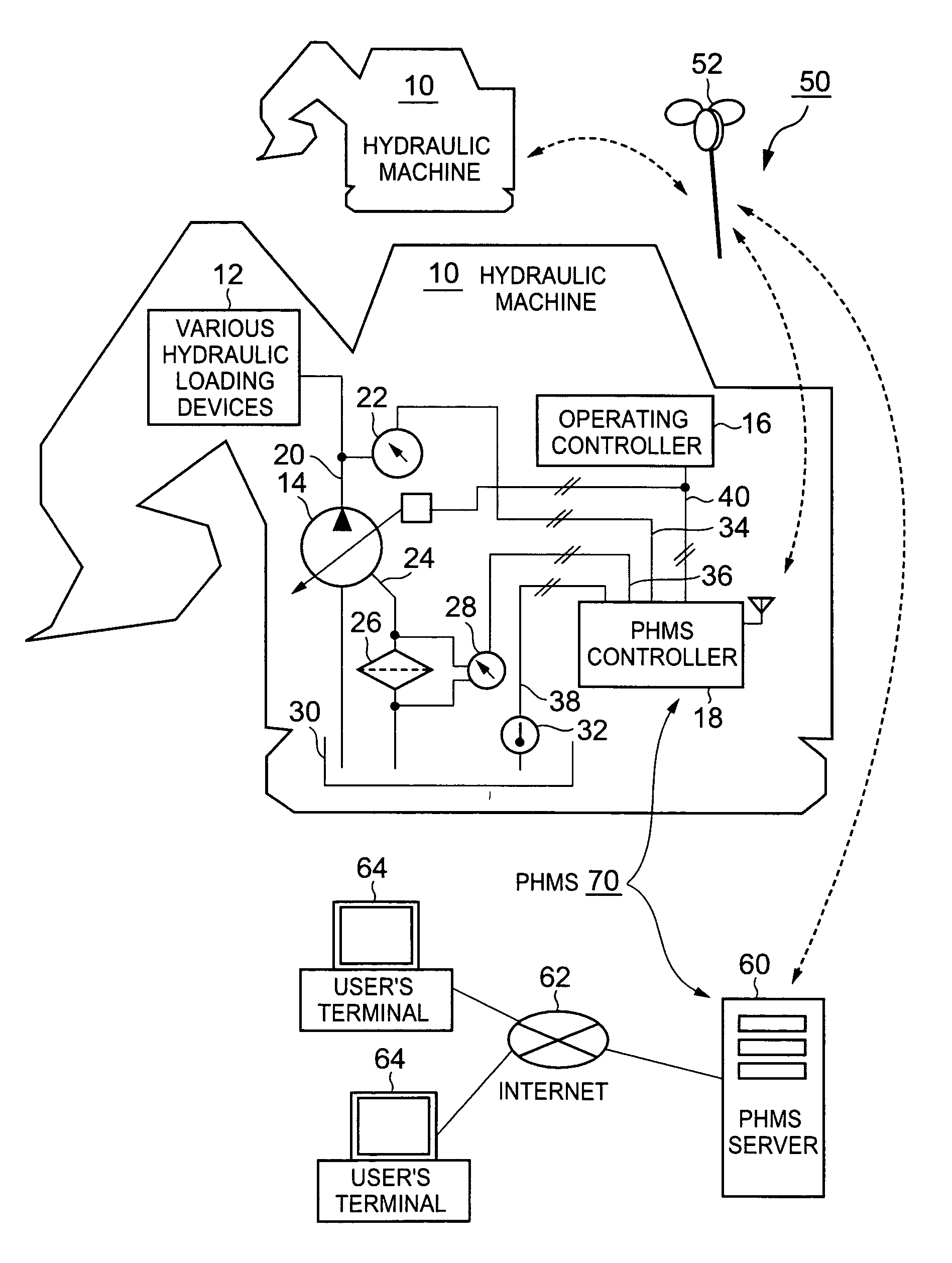

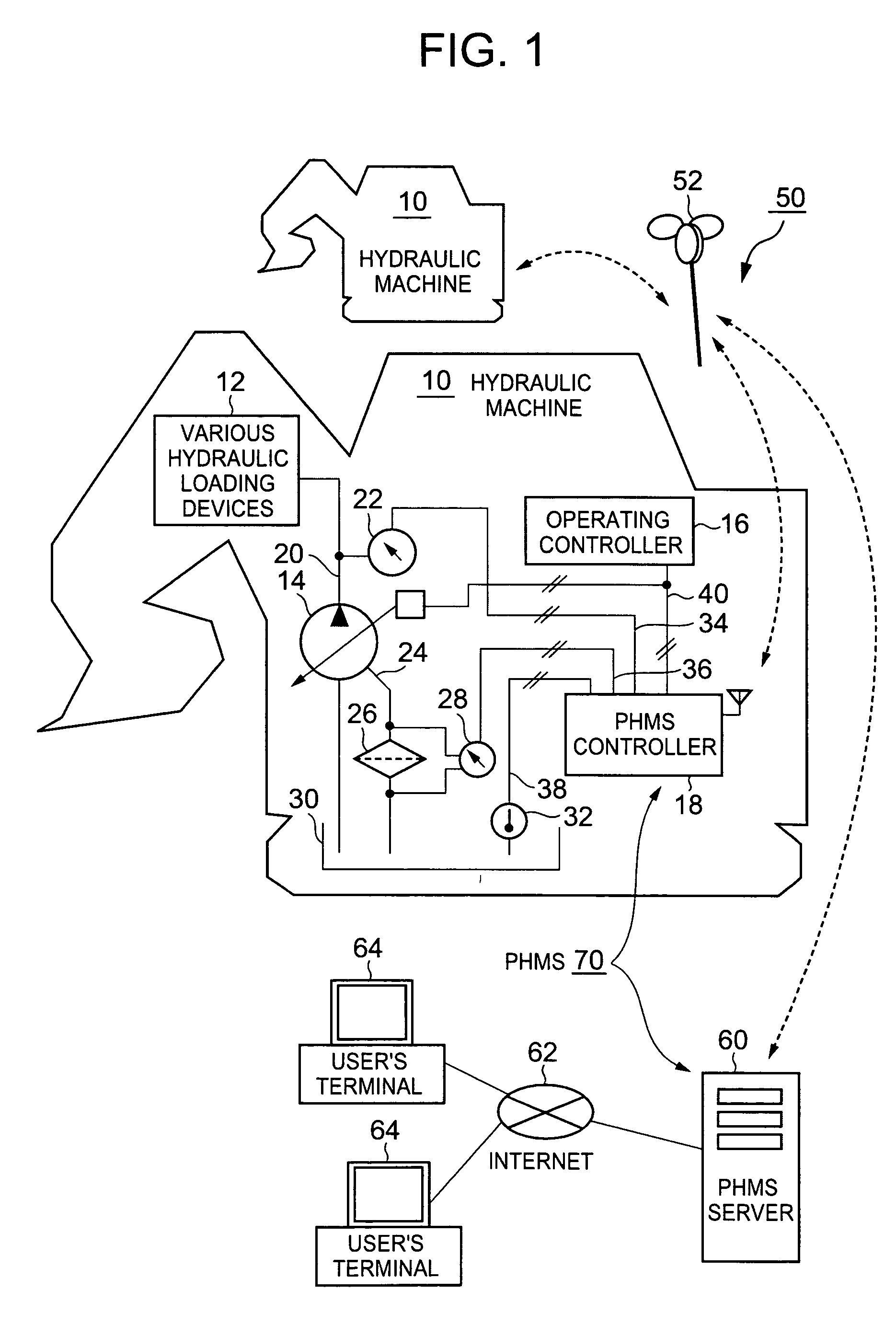

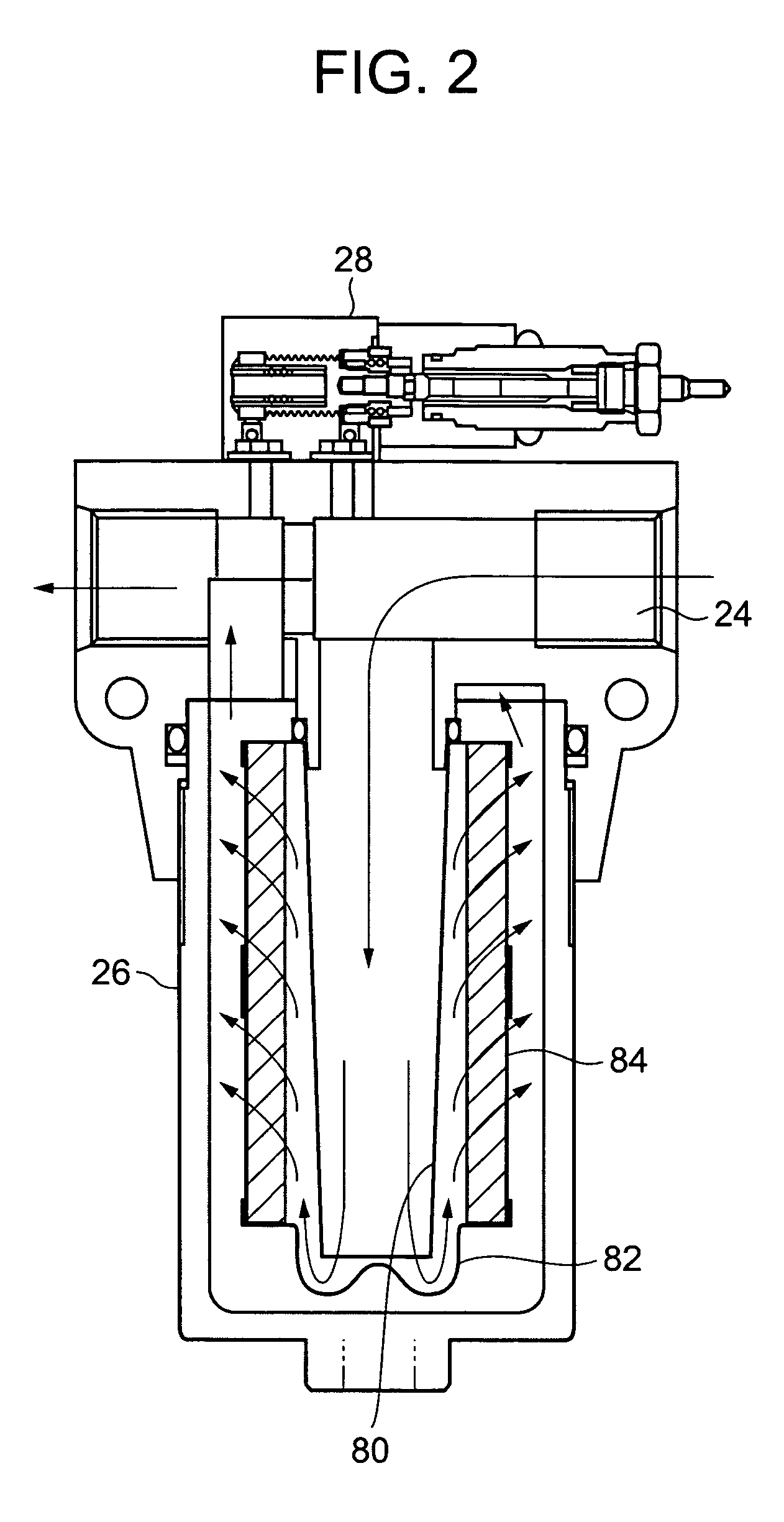

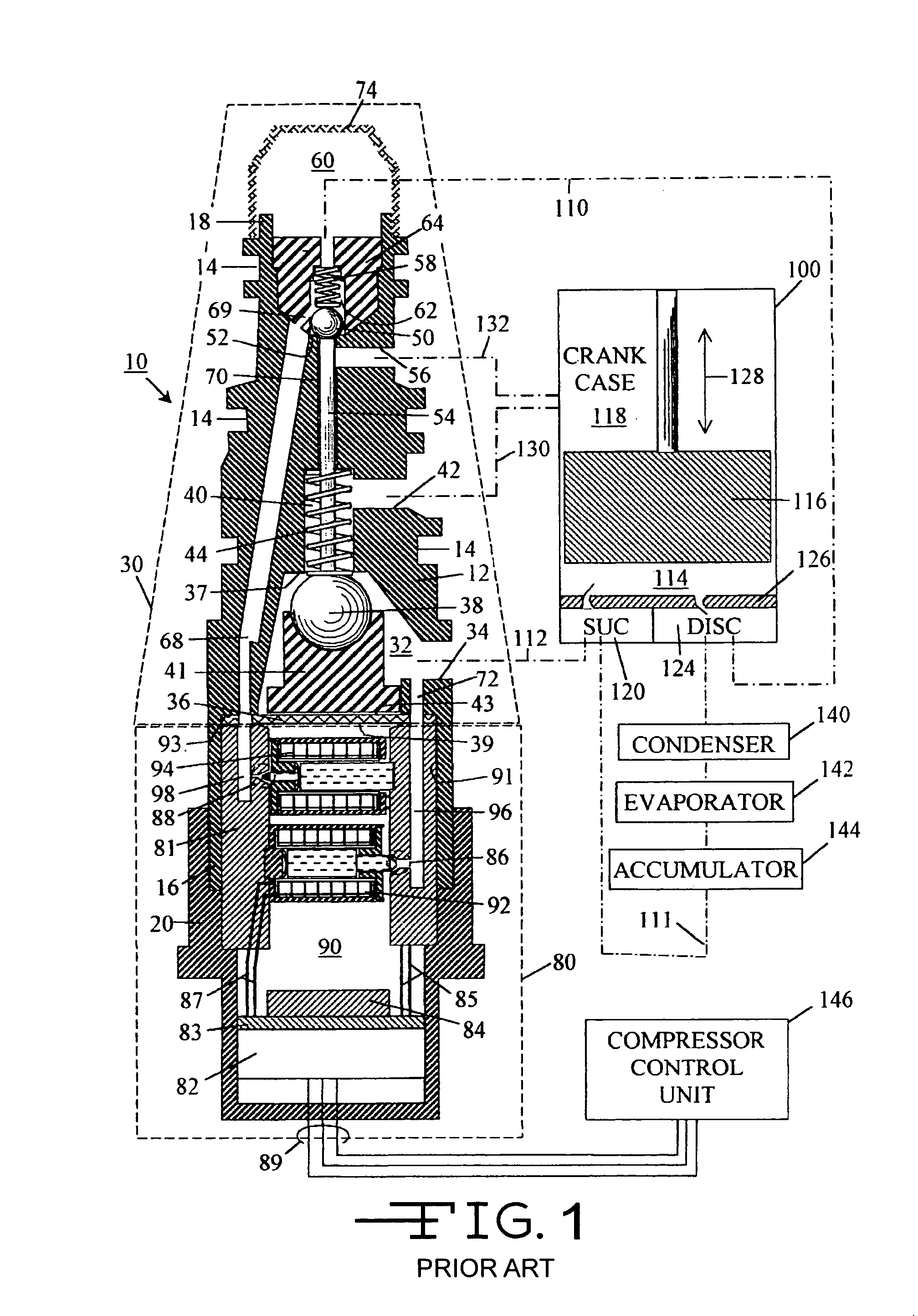

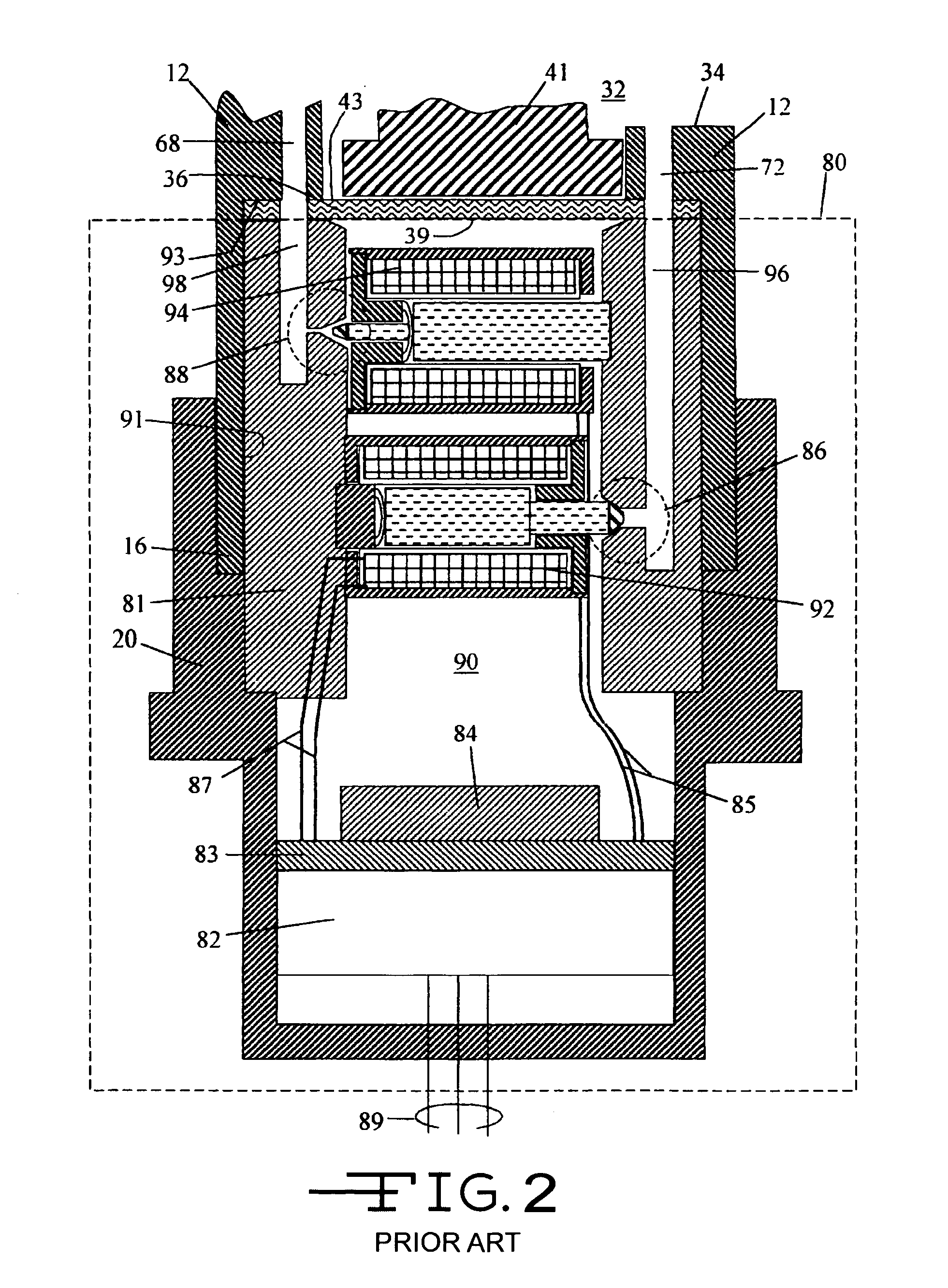

Hydraulic machine, system for monitoring health of hydraulic machine, and method thereof

InactiveUS20050262838A1Improve reliabilityAvoid failureFluid-pressure actuator safetyMachine part testingDifferential pressureCorrelation function

In a hydraulic machine, hydraulic pump failure is detected and the pump lifespan is estimated before the pump failure occurs. The discharge pressure 122, oil temperature 126, and drain filter differential pressure 120 are measured, a correlative relationship 128 between the filter differential pressure and the discharge pressure is determined, and a representative filter differential pressure 130 is calculated from this correlative relationship. Using an oil temperature-differential pressure correlation function, the representative differential pressure value 130 is corrected so that the variable component 132 caused by the oil temperature 126 is eliminated therefrom. The long-term trend and the short-term trend of the increase over time of the corrected differential pressure is calculated. A pump failure is predicted or the pump lifespan is estimated based on the degree of deviation between the long-term trend and the short-term trend.

Owner:KOMATSU LTD

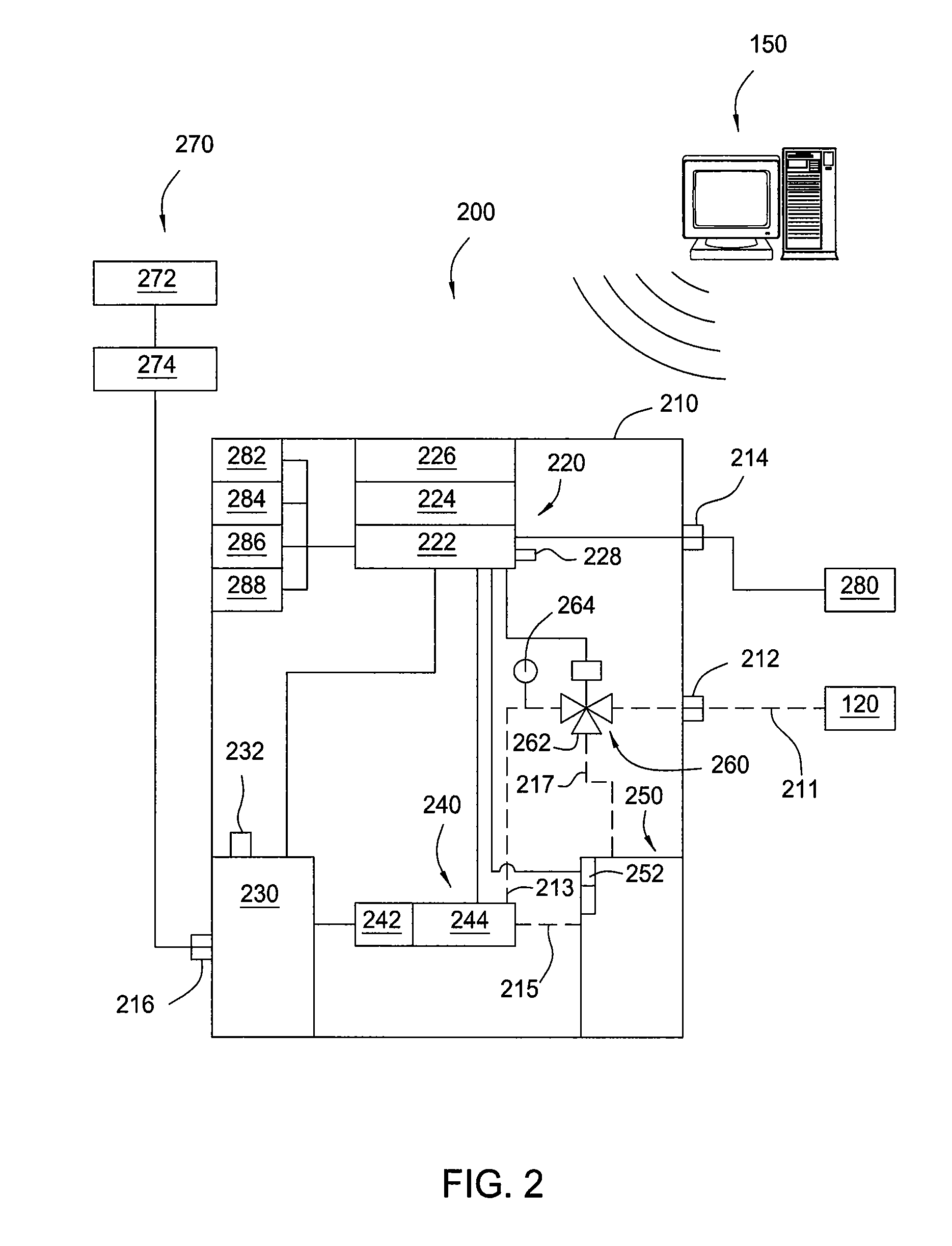

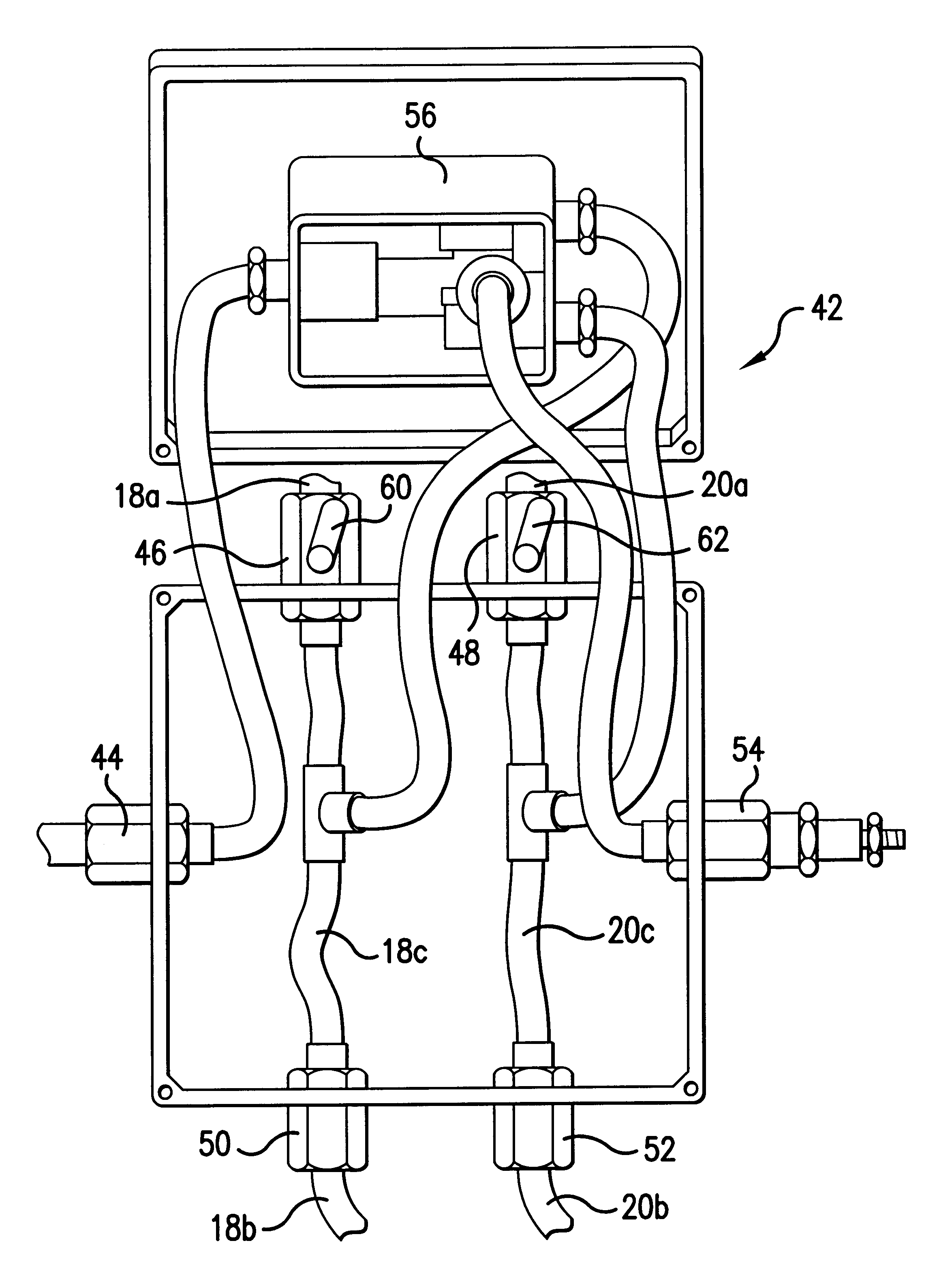

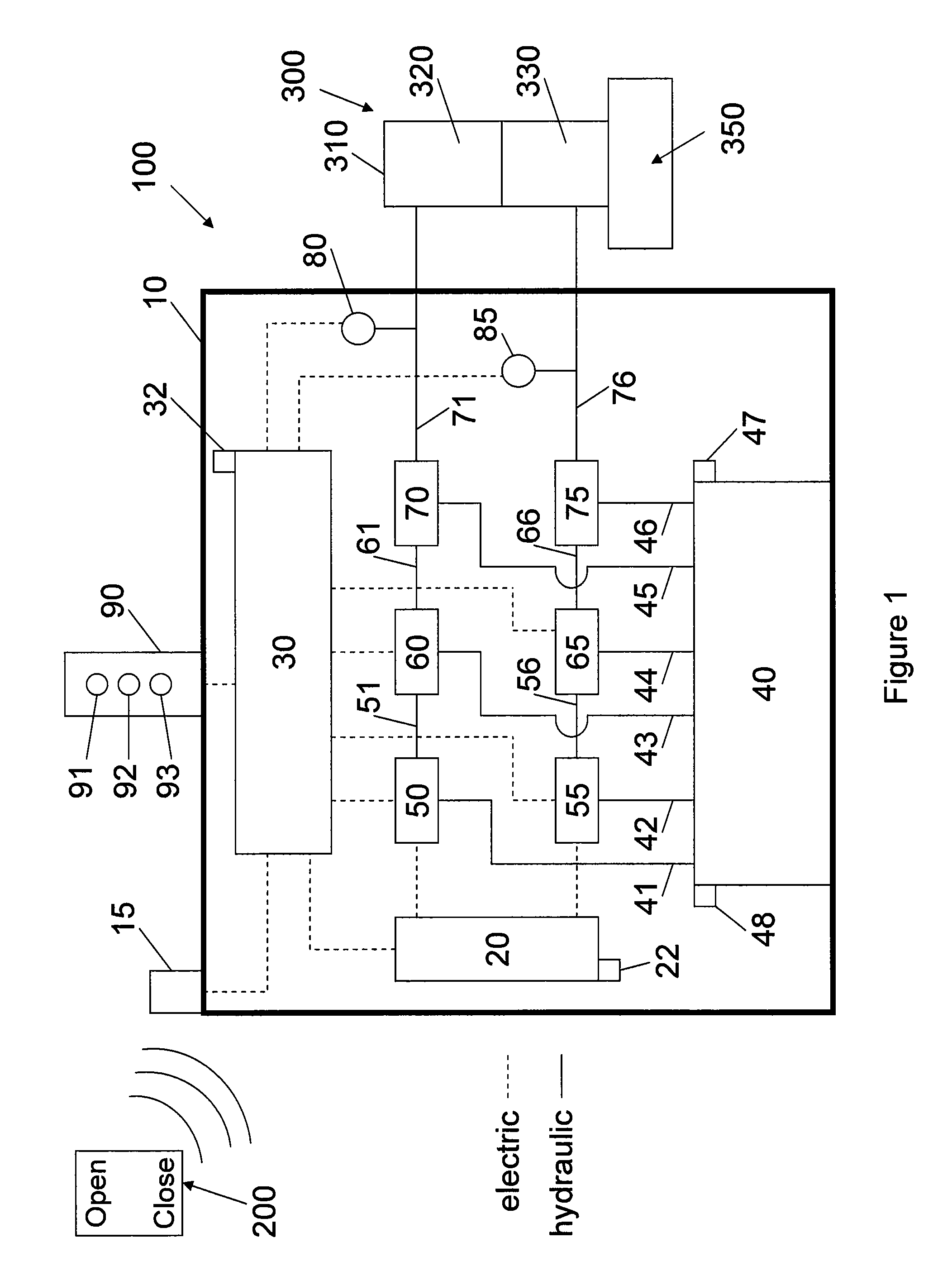

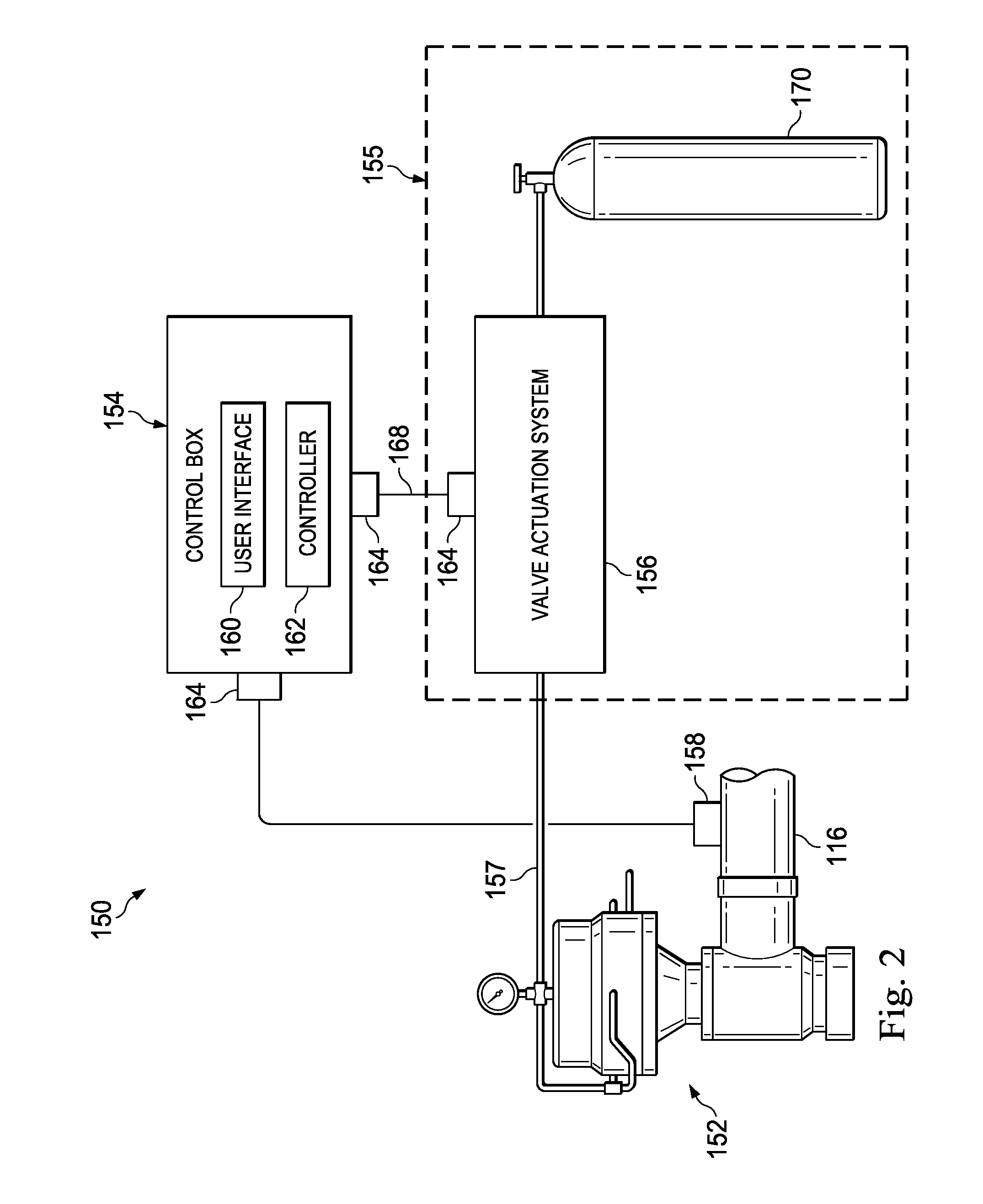

Valve actuator control system and method of use

ActiveUS20120073670A1Fluid-pressure actuator safetyOperating means/releasing devices for valvesValve actuatorControl system

A valve actuator control system for use with a valve actuator may include two pump assemblies, two control valve assemblies, two transducers, a fluid reservoir, and a controller assembly. The controller assembly may actuate the pump assemblies to direct fluid from the fluid reservoir to the valve actuator, and may actuate the control valve assemblies to direct fluid from the valve actuator to the fluid reservoir. A method of actuating a valve actuator using a valve actuator control system may comprise sending a signal to the valve actuator control system, injecting pressurized fluid from a fluid reservoir of the valve actuator control system into a first chamber of the valve actuator, discharging pressurized fluid from a second chamber of the valve actuator into the fluid reservoir, and actuating the valve actuator from a first position to a second position.

Owner:SAFOCO

Hydraulic machine, system for monitoring health of hydraulic machine, and method thereof

InactiveUS7082758B2Improve reliabilityFluid-pressure actuator safetyMachine part testingDifferential pressureCorrelation function

In a hydraulic machine, hydraulic pump failure is detected and the pump lifespan is estimated before the pump failure occurs. The discharge pressure 122, oil temperature 126, and drain filter differential pressure 120 are measured, a correlative relationship 128 between the filter differential pressure and the discharge pressure is determined, and a representative filter differential pressure 130 is calculated from this correlative relationship. Using an oil temperature-differential pressure correlation function, the representative differential pressure value 130 is corrected so that the variable component 132 caused by the oil temperature 126 is eliminated therefrom. The long-term trend and the short-term trend of the increase over time of the corrected differential pressure is calculated. A pump failure is predicted or the pump lifespan is estimated based on the degree of deviation between the long-term trend and the short-term trend.

Owner:KOMATSU LTD

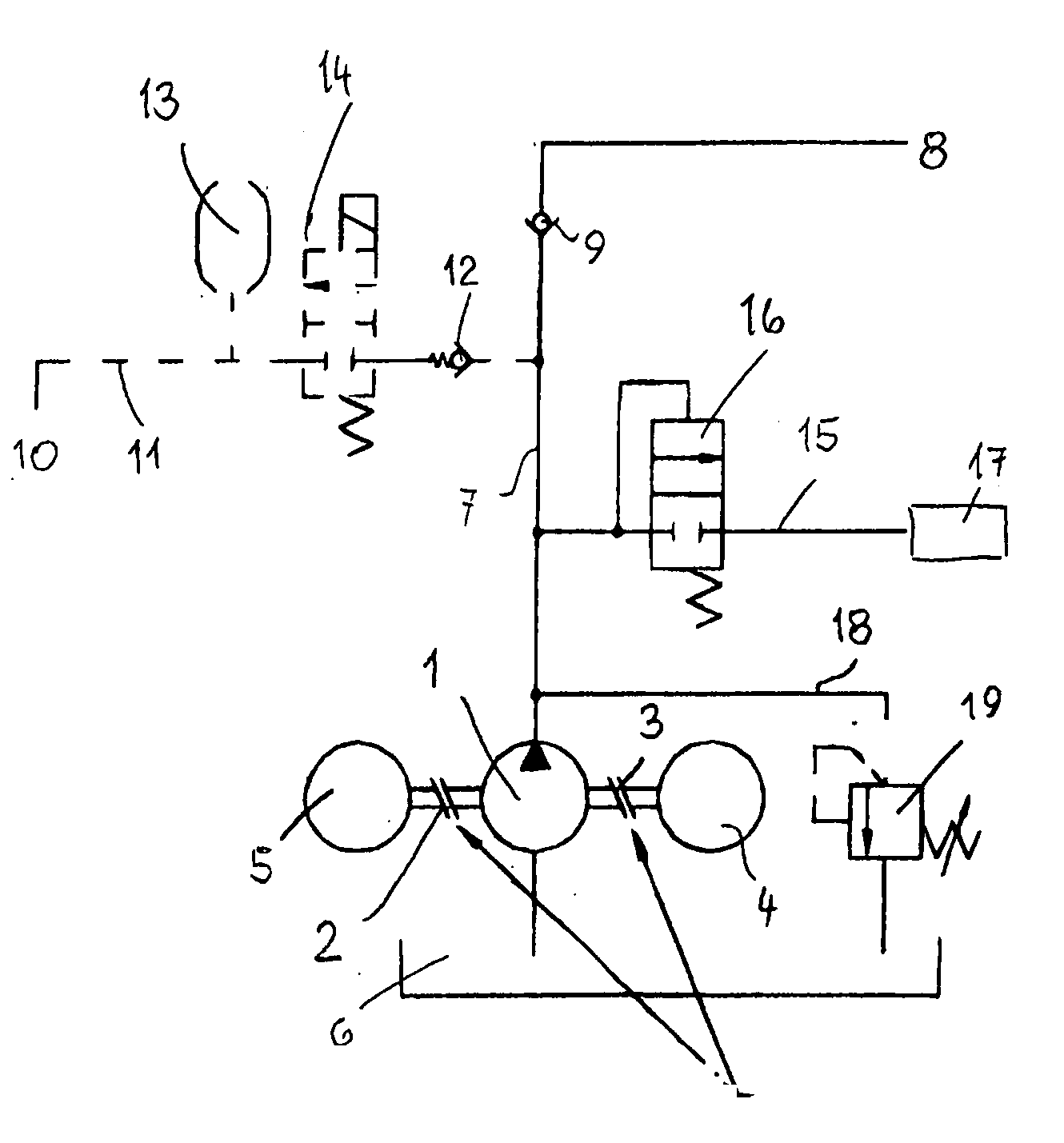

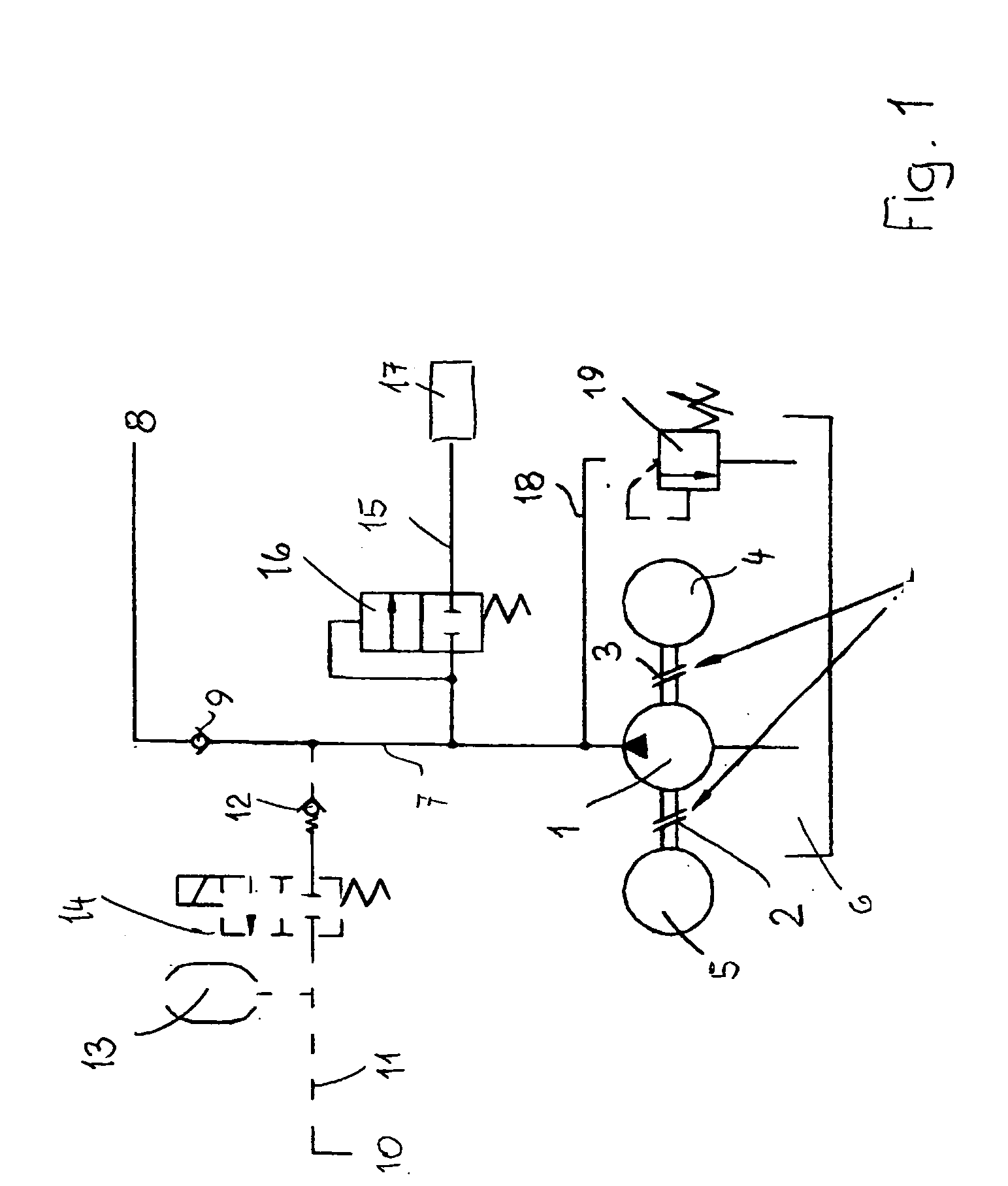

Control device for at least one consumer, such as a camshaft adjuster, automatic transmsion and the like, of motor vehicles

InactiveUS20050072397A1Increase supplyFluid-pressure actuator safetyValve arrangementsMobile vehicleAutomatic transmission

A control device for at least one consumer of a motor vehicle, having an engine and at least one pump for supplying a medium via at least one pressure line to the at least one consumer, is configured to supply the medium to the at least one consumer before the engine is started. The pump can be driven by an electric motor or by the engine of the motor vehicle or alternatingly by the electric motor and the engine.

Owner:HYDRAULIK RING

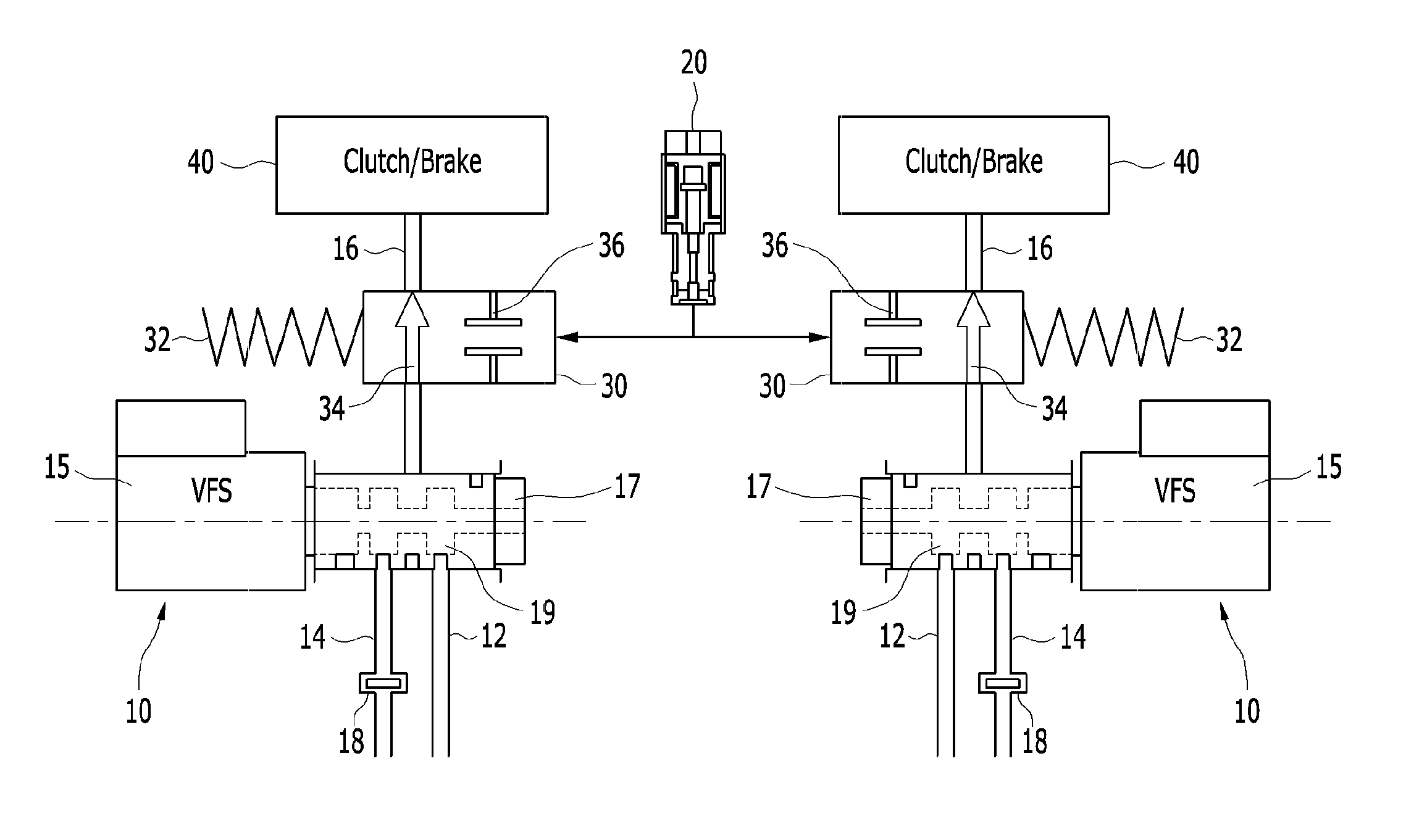

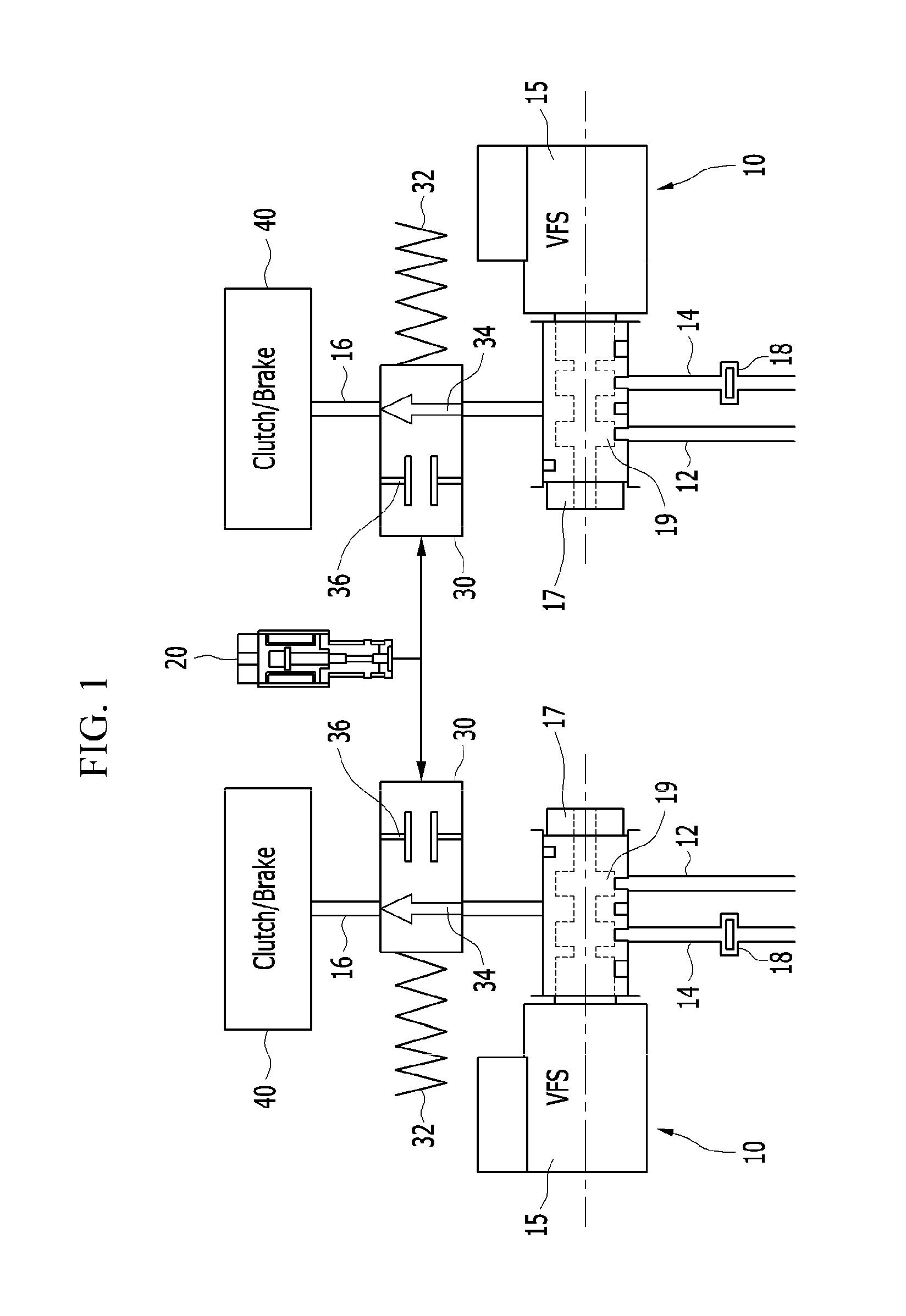

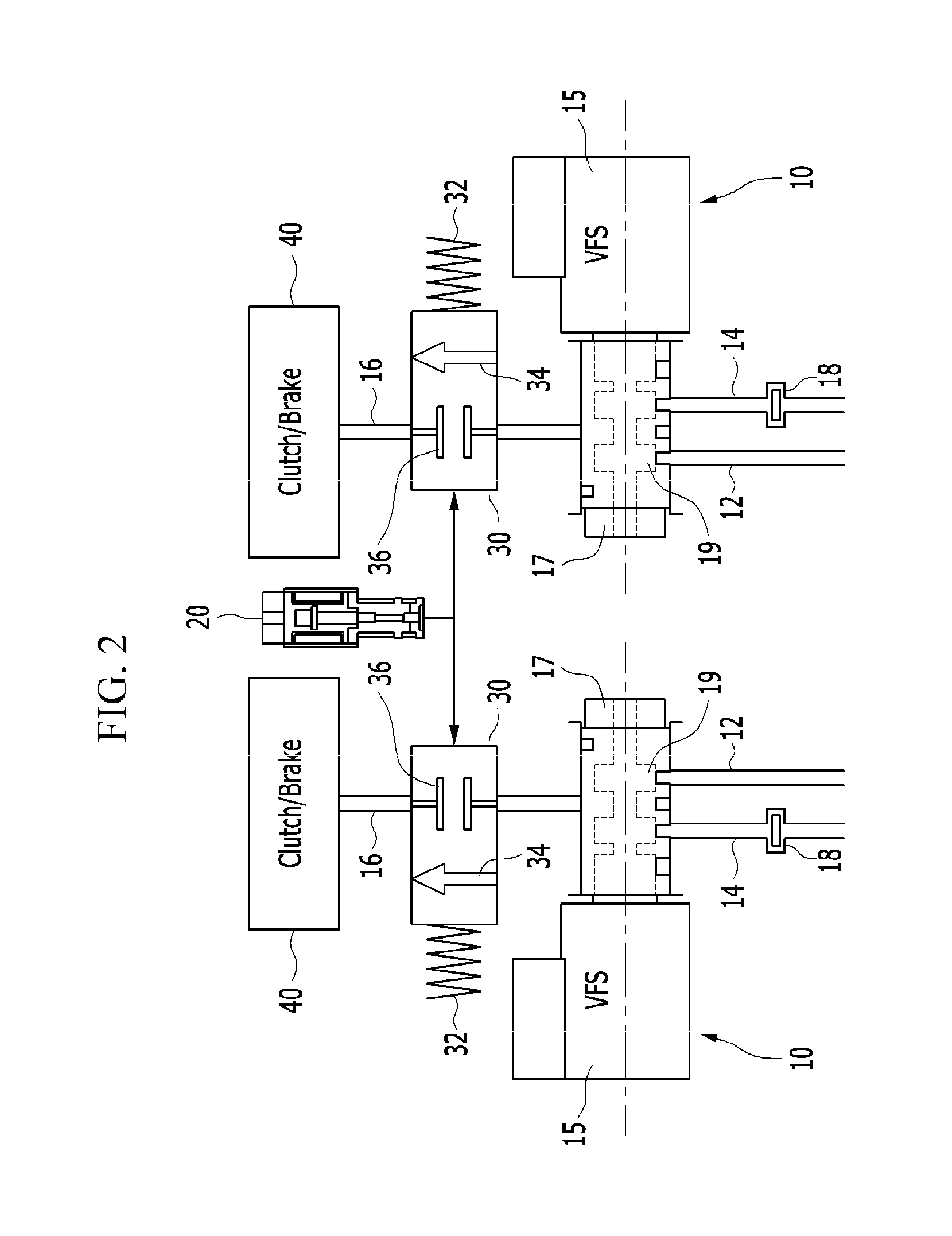

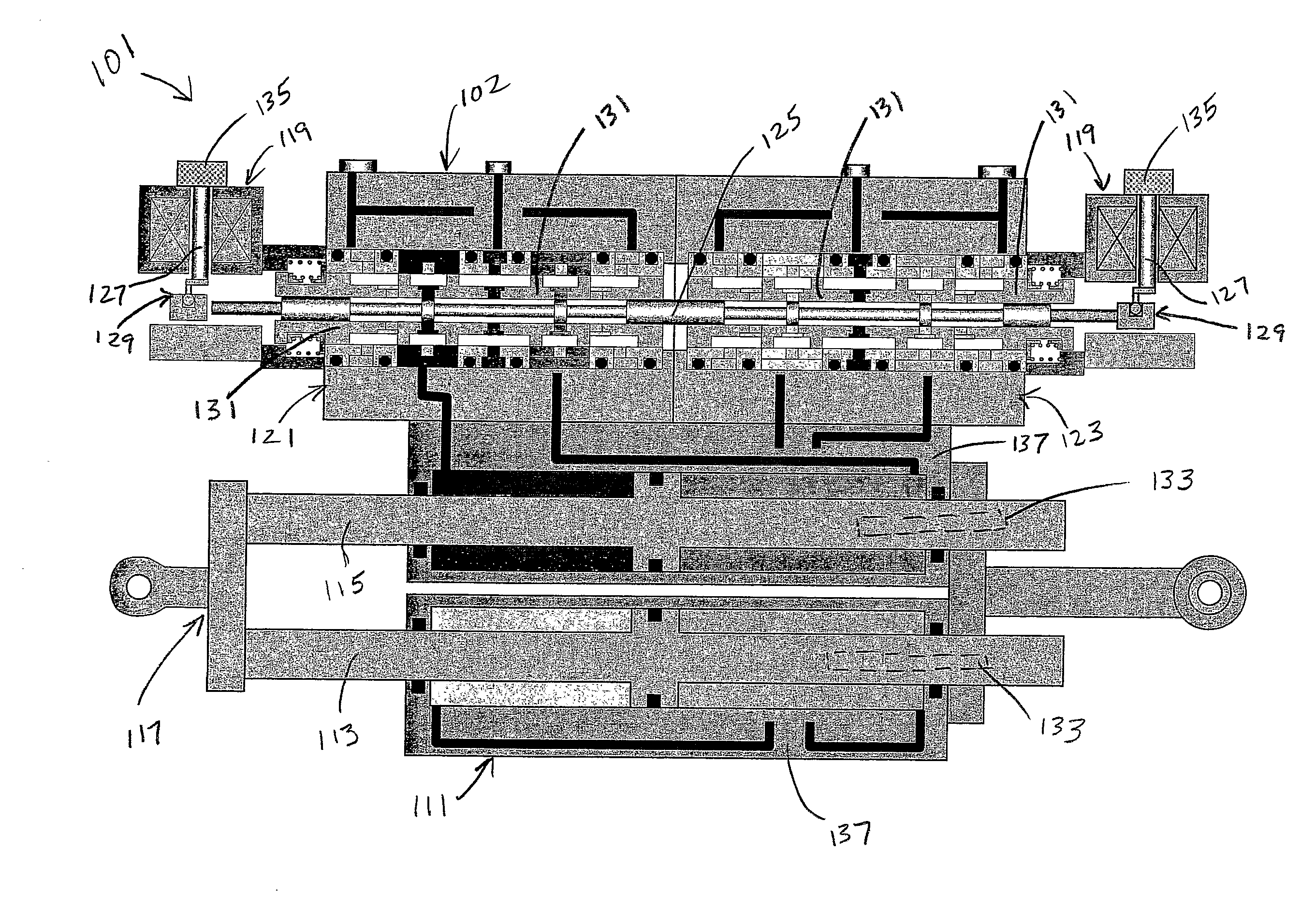

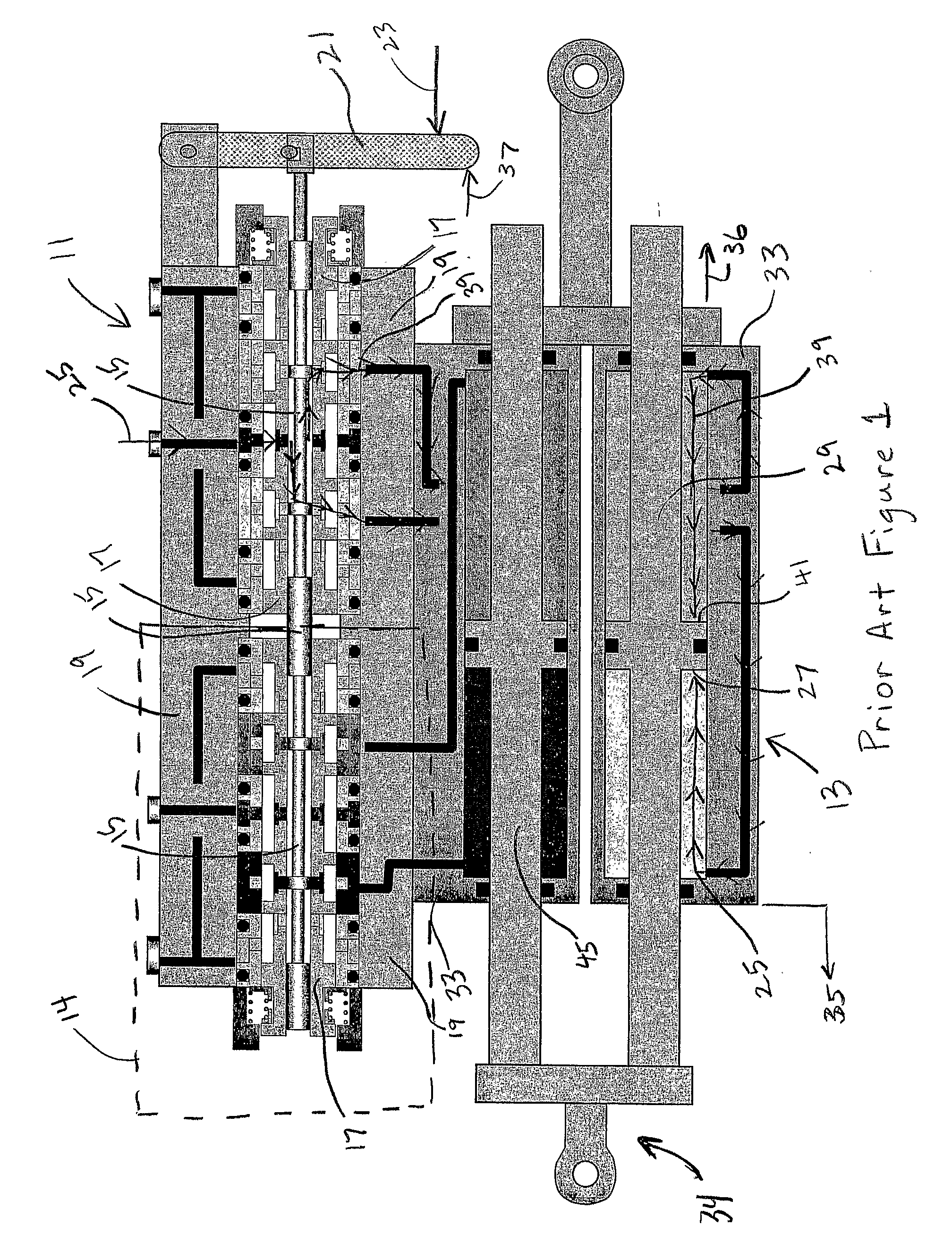

Redundant flow control for hydraulic actuator systems

Two or more flow control valves may be used to provide redundant flow control for a hydraulic actuator or servoactuator. The flow control valves include a sleeve, a bypass control spool, and a primary control spool. Under normal operating conditions, each bypass control spool is stationary relative to the sleeve and the flow control valve functions as a four-way hydraulic flow control valve. Each flow control valve is connected to a bypass-shutoff valve including a bypass spool that is moveable from a shut-off position to a bypass position. Upon supply pressure failure to one flow control valve, the bypass spool moves to the bypass position, reducing pressure in the corresponding actuator piston chambers. When a primary control spool becomes jammed, the corresponding bypass control spool moves within its sleeve allowing a bypass groove to port control pressure to the return line, thereby reducing pressure in the corresponding actuator piston chambers.

Owner:HR TEXTRON

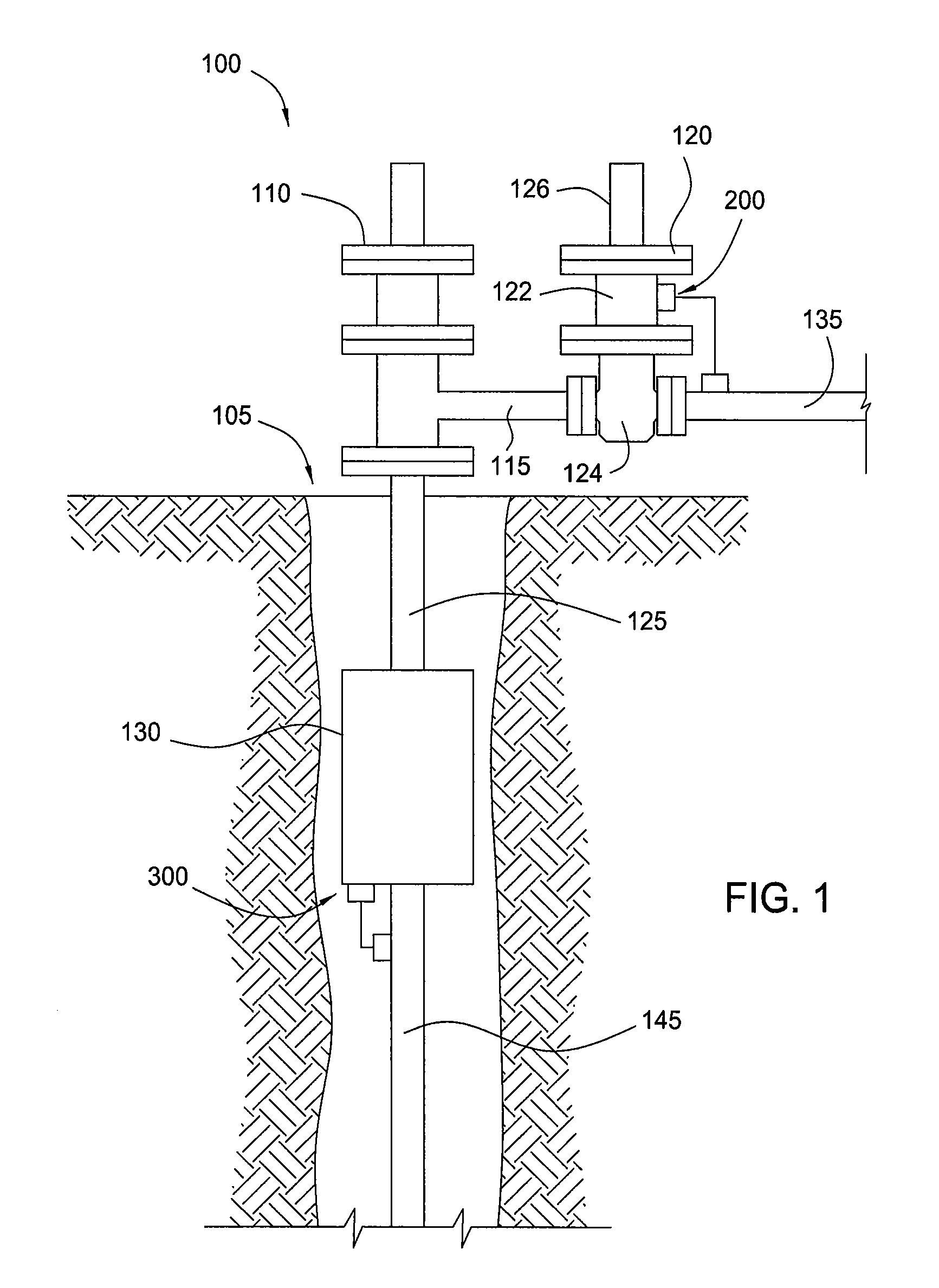

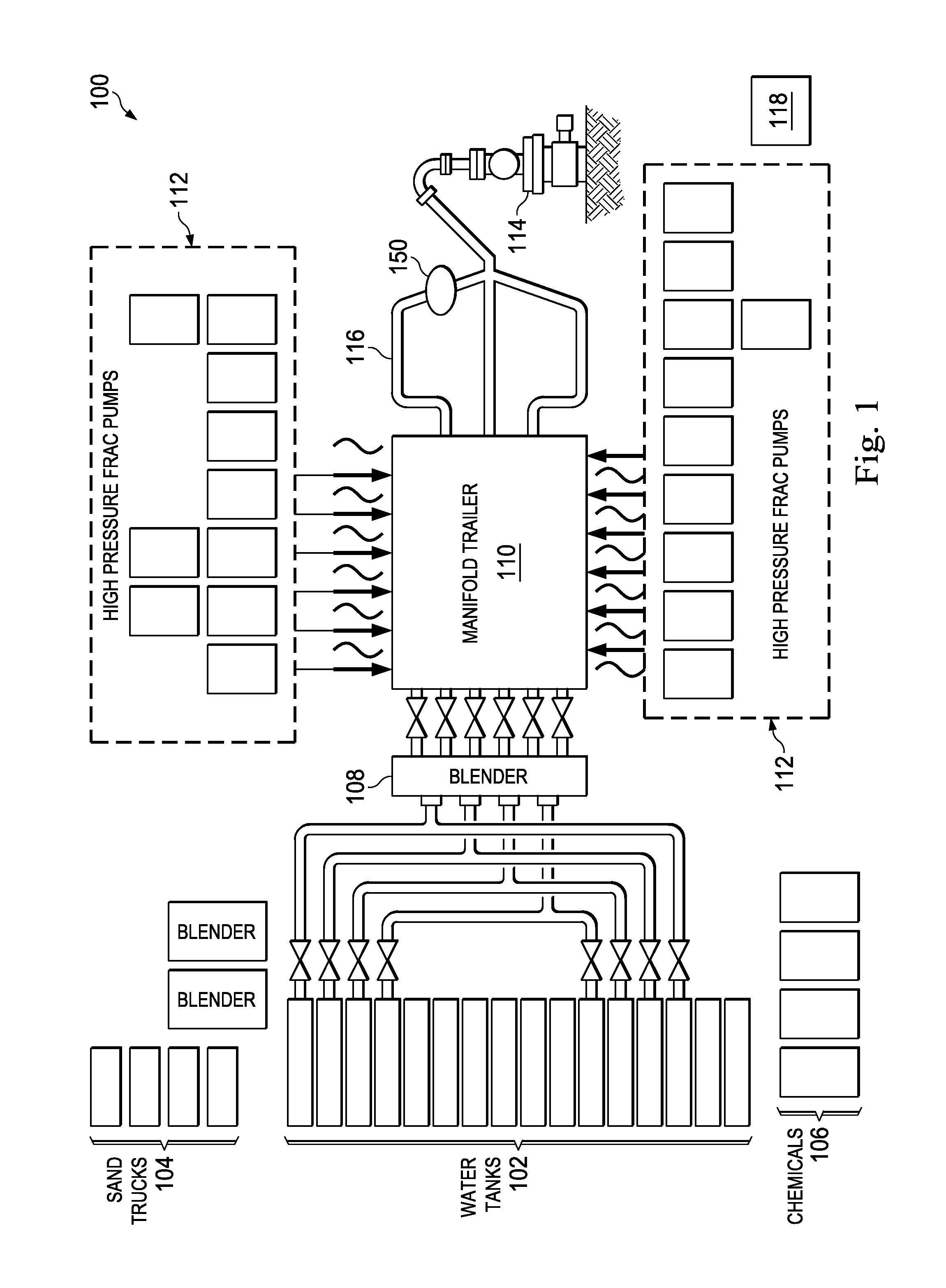

Automated relief valve control system and method

ActiveUS20140048255A1Reduce pressureIncrease pressureFluid-pressure actuator safetySurveyControl systemEngineering

A pressure relief valve system for use in a downhole operation may include a pressure relief valve configured to relieve pressure from high pressure tubing extending between a pump and a wellhead, and may include a sensor operably disposed to detect pressure in the high pressure tubing. The pressure relief valve system also may include a controller having a pressure threshold stored therein. The controller may be configured to receive data from the sensor and compare the detected pressure to the stored pressure threshold. A valve actuation system may be in communication with the pressure relief valve and in communication with the controller. The valve actuation system may be configured to change the state of the pressure relief valve from a closed state to an open state in response to a command signal from the controller.

Owner:SPM OIL & GAS INC

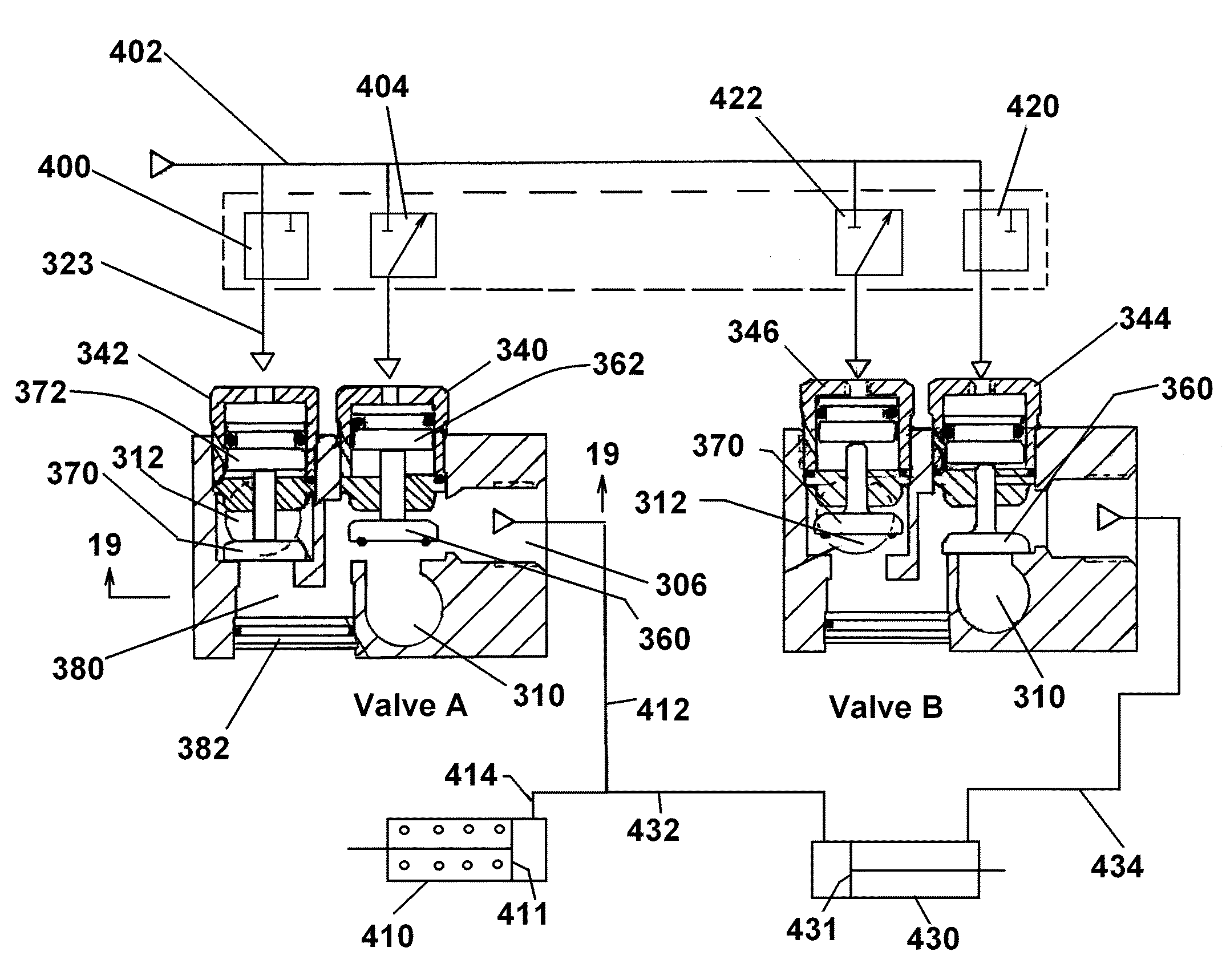

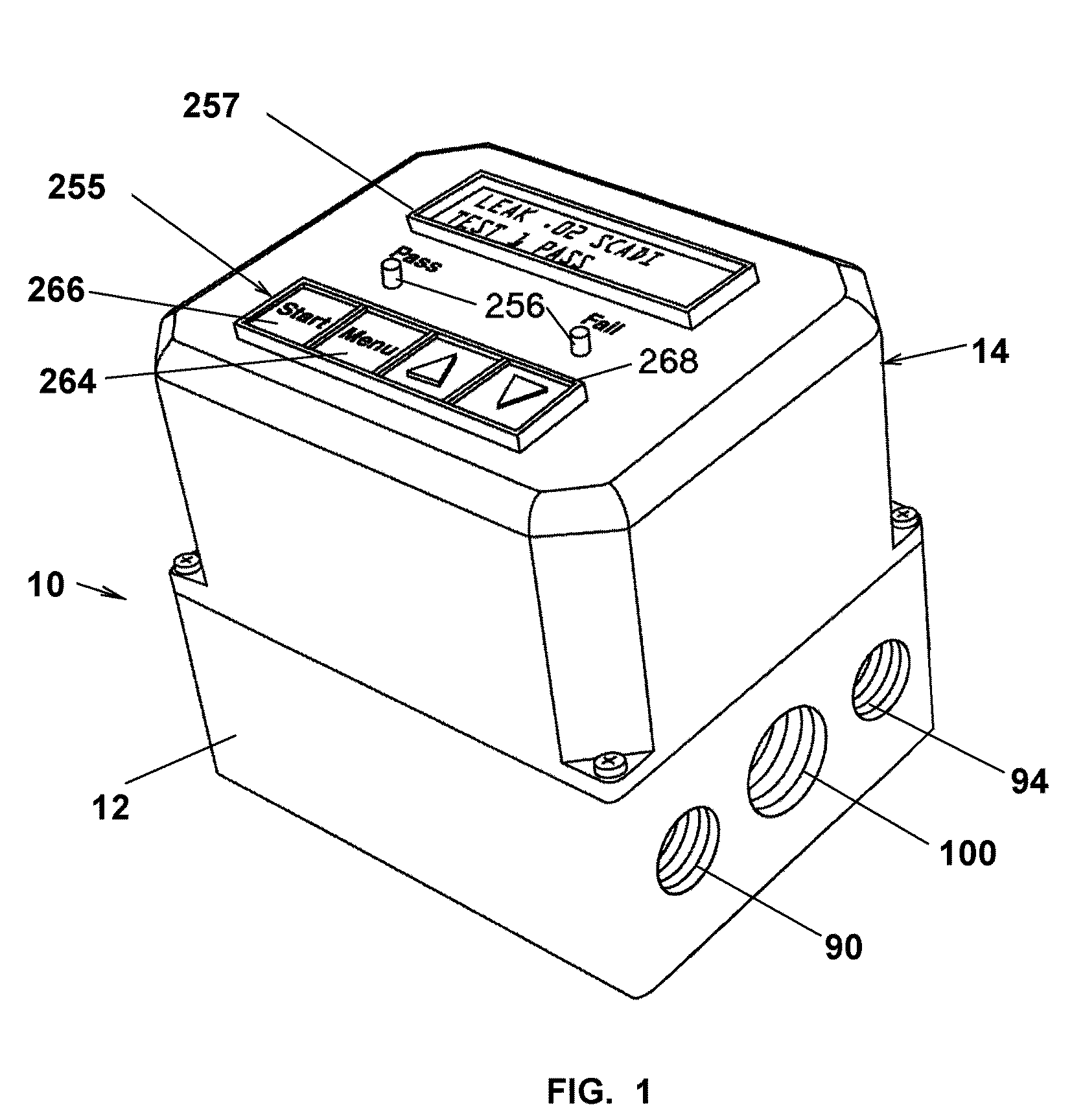

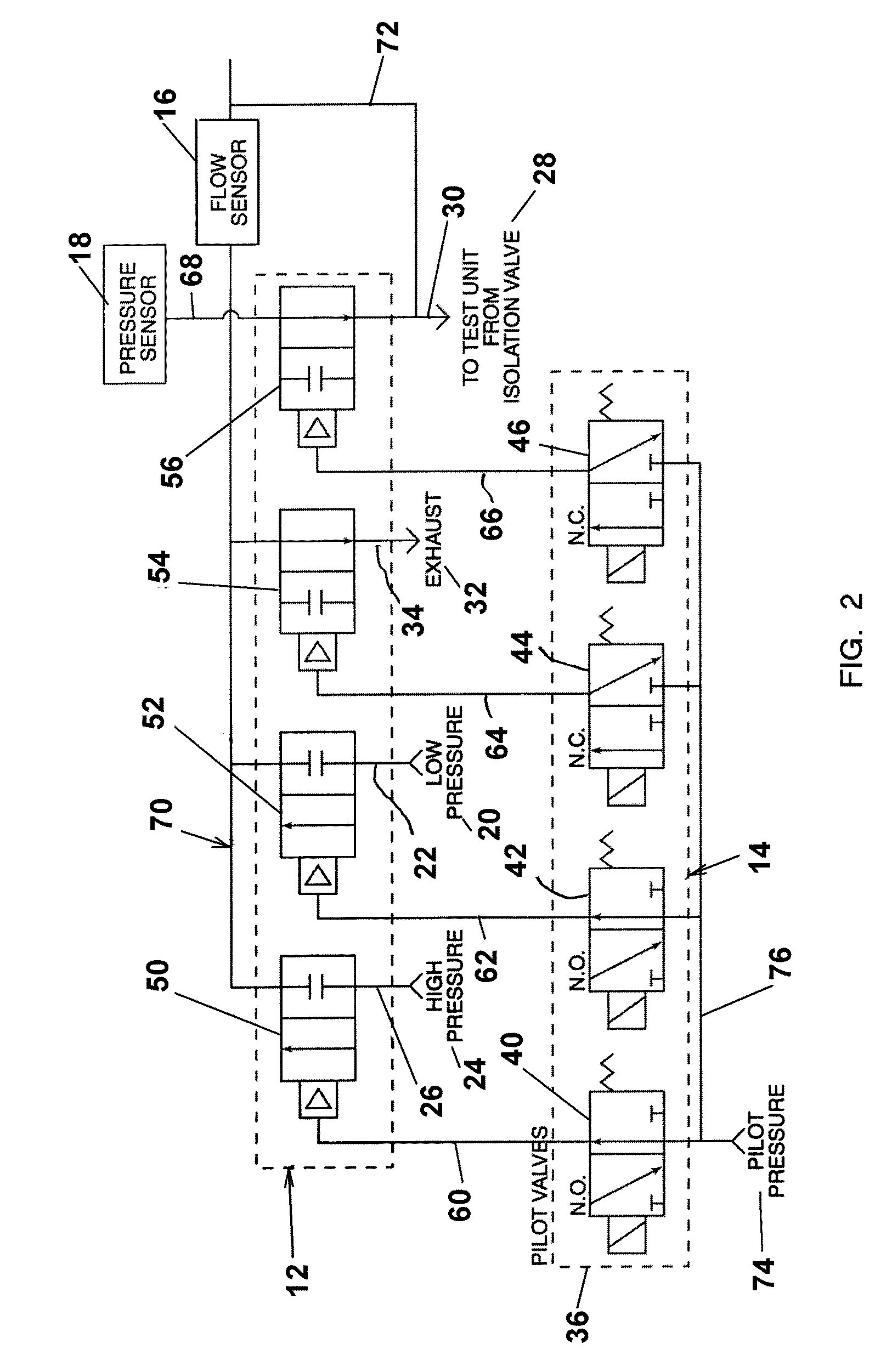

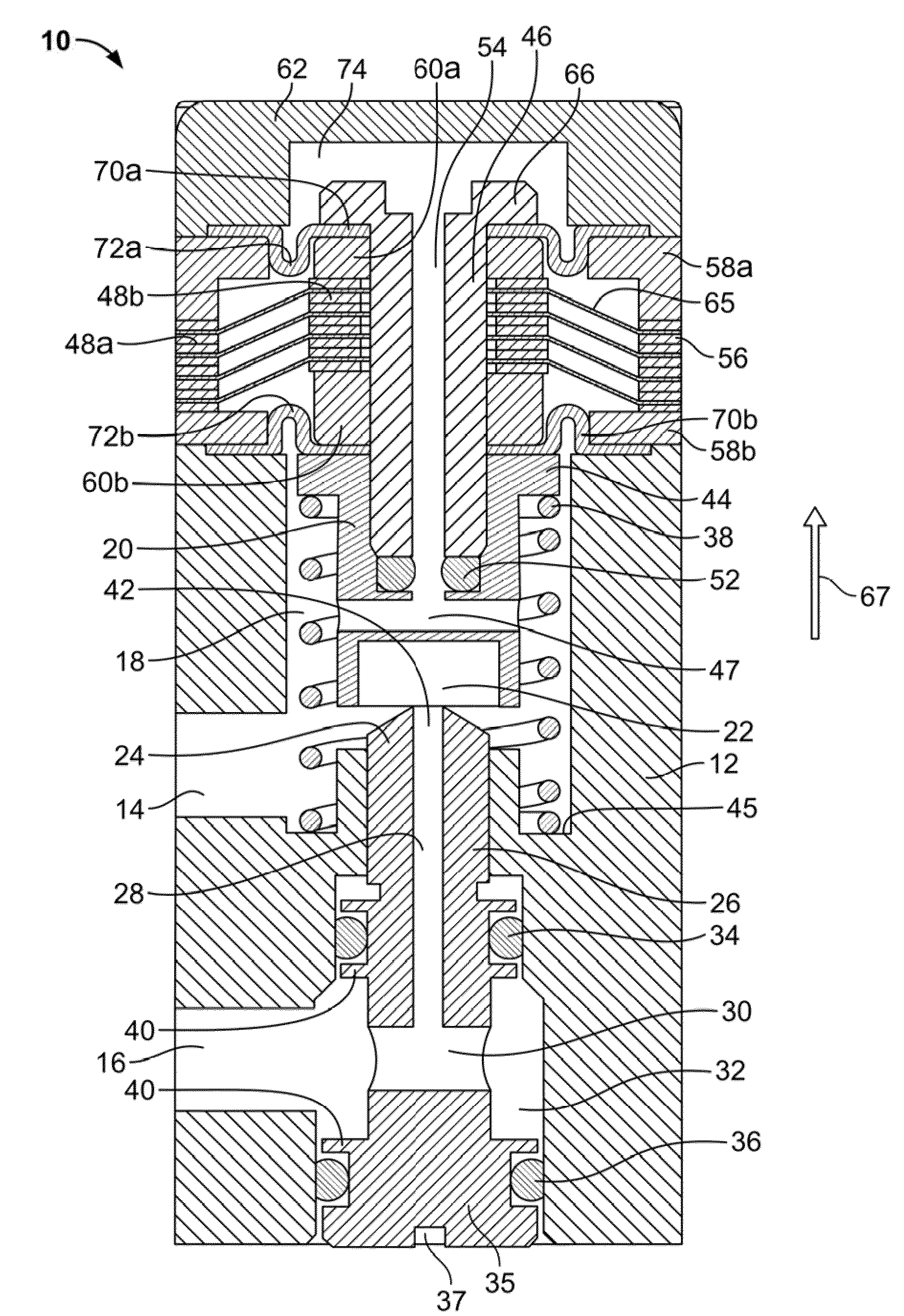

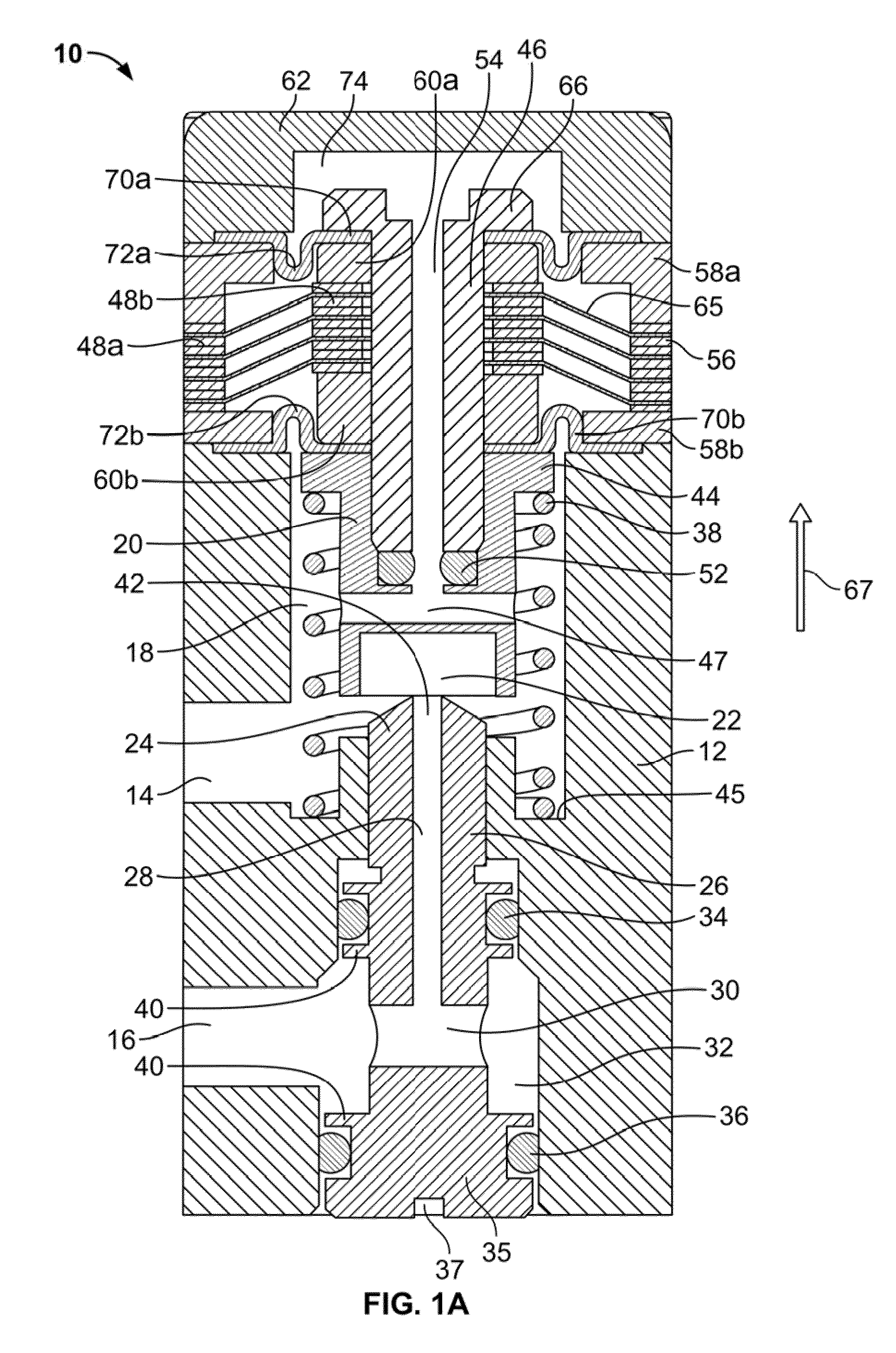

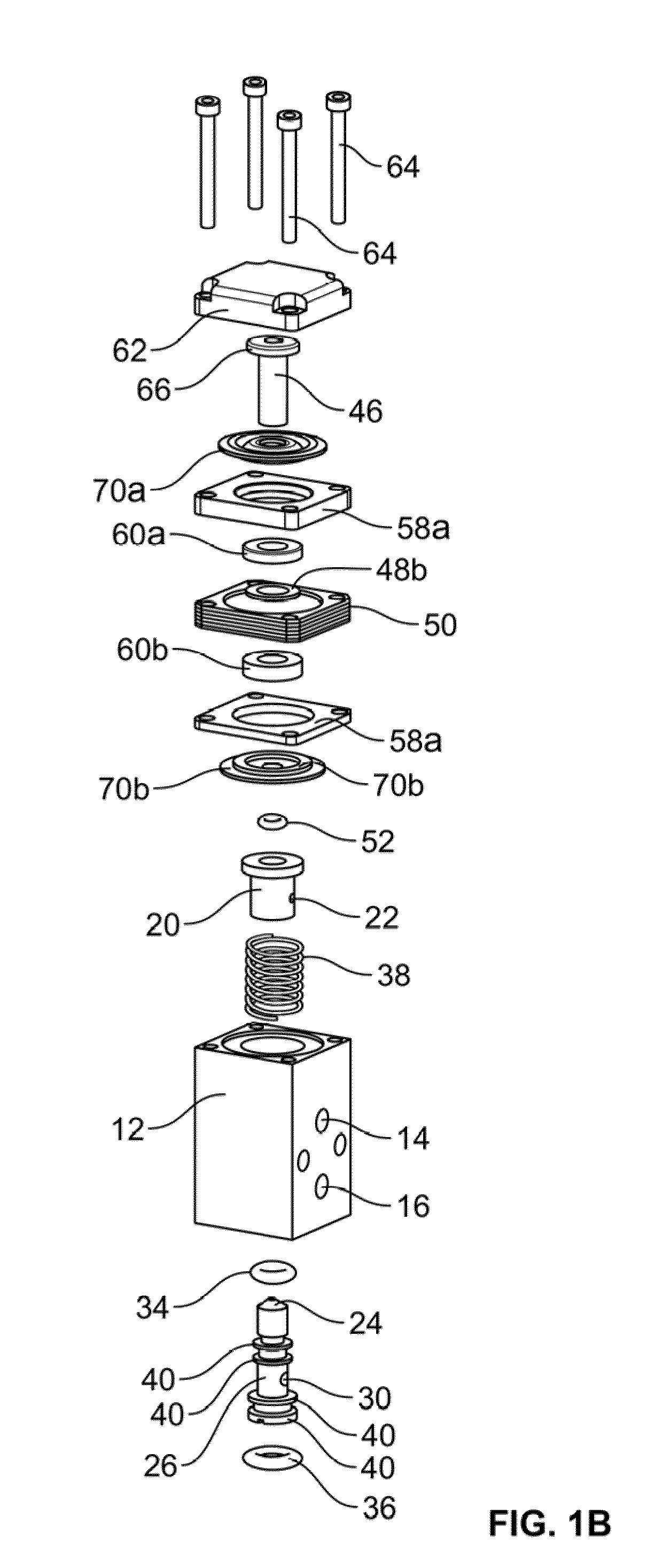

Pilot valve manifold

InactiveUS7490625B1Fluid-pressure actuator safetyDetection of fluid at leakage pointEngineeringVALVE PORT

A valve manifold includes a valve body carrying pairs of laterally spaced piston actuated valves controlled by control modules operative to selective pressurize and exhaust an outlet port connected to a fluidic device and configured in grouping permitting varying valve functionalities.

Owner:JOHNSON JOHN LESLIE +1

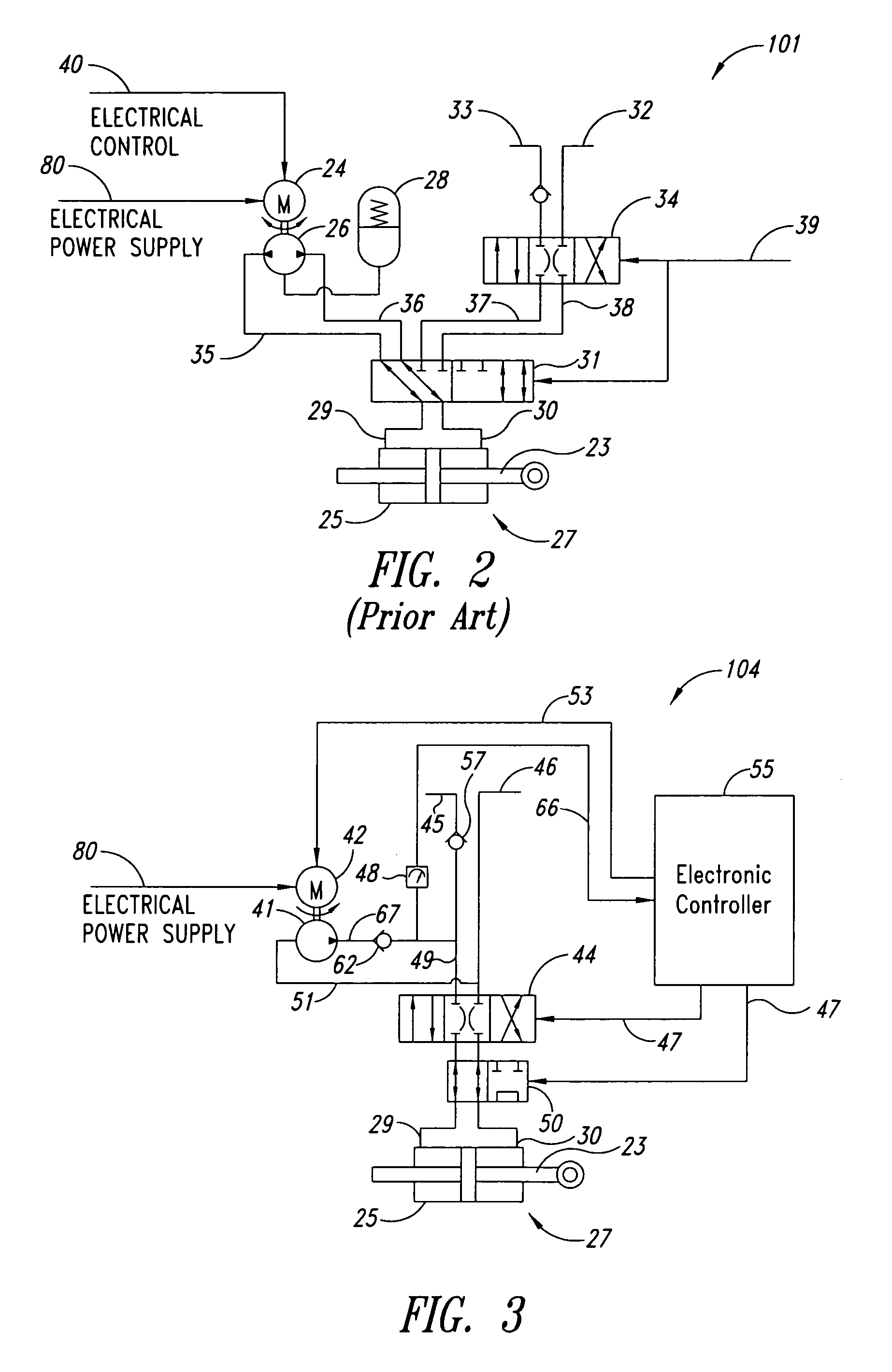

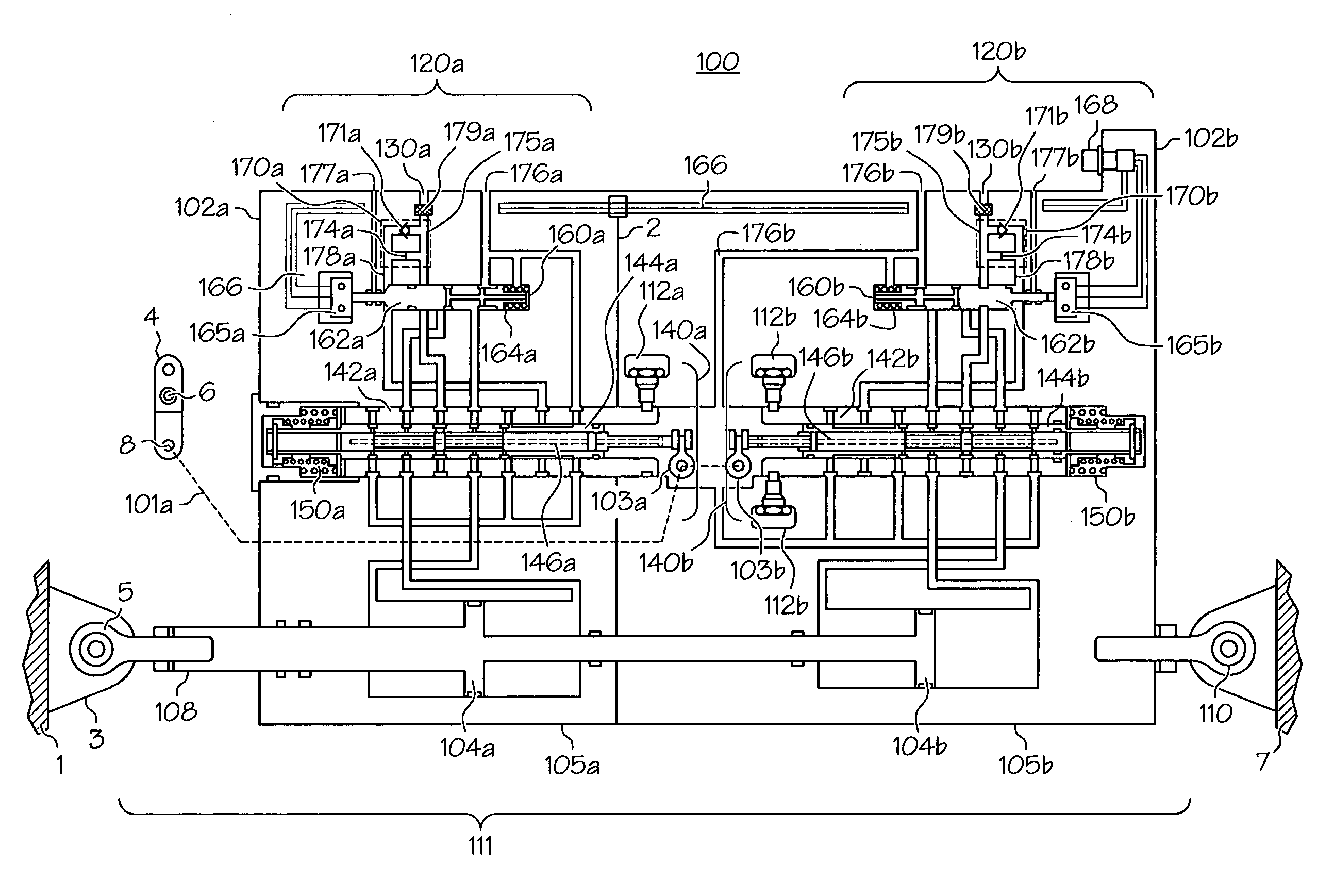

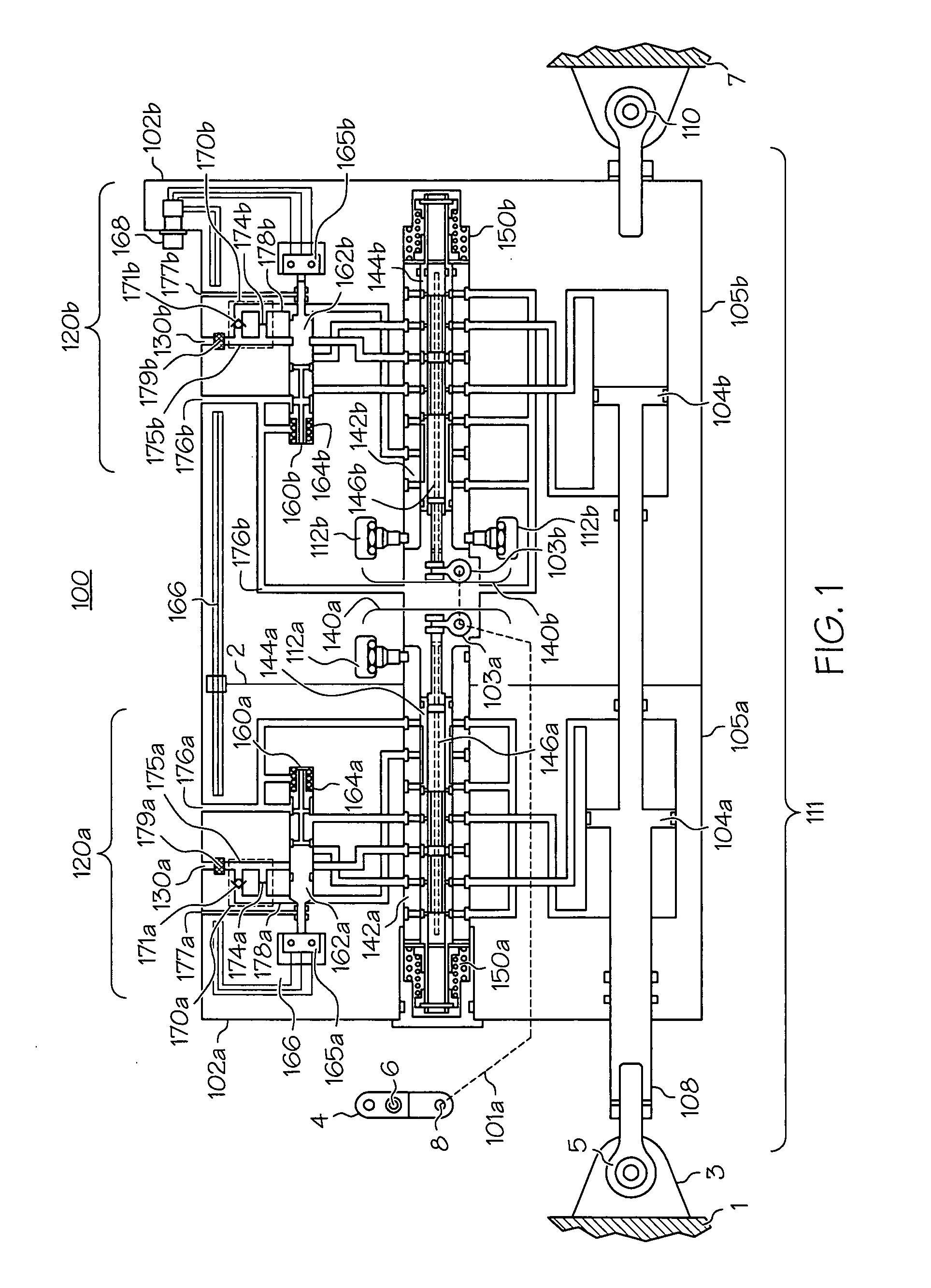

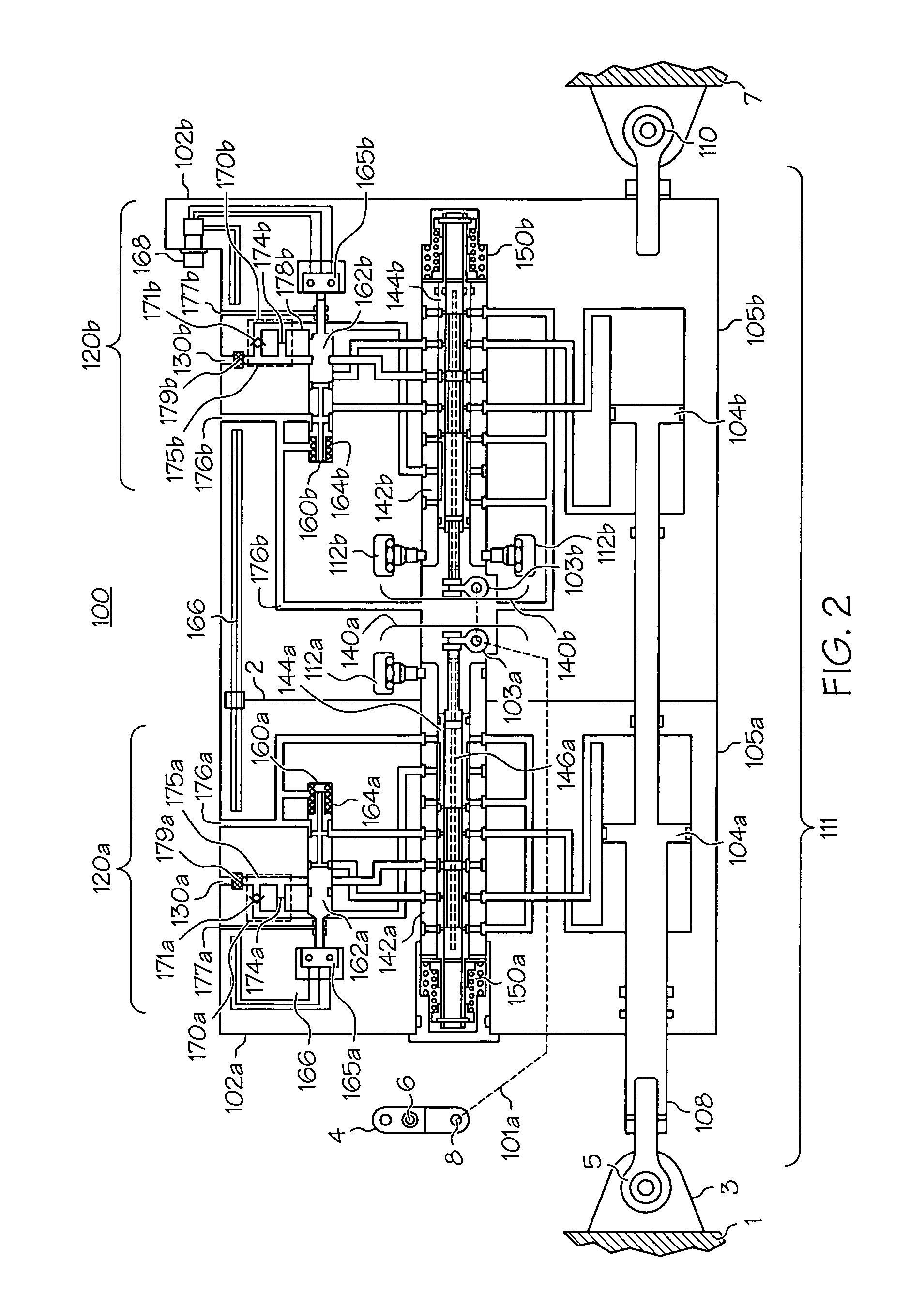

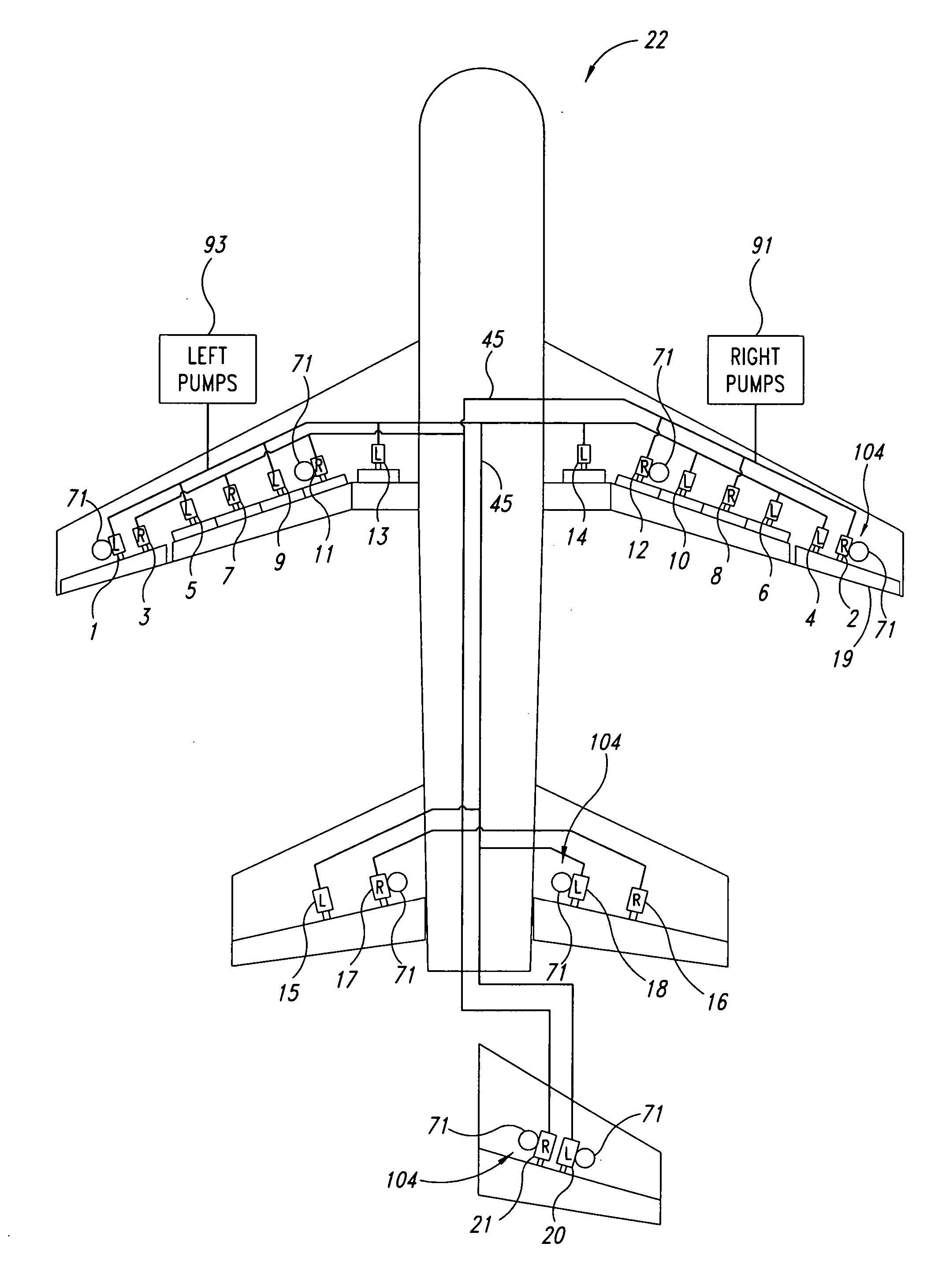

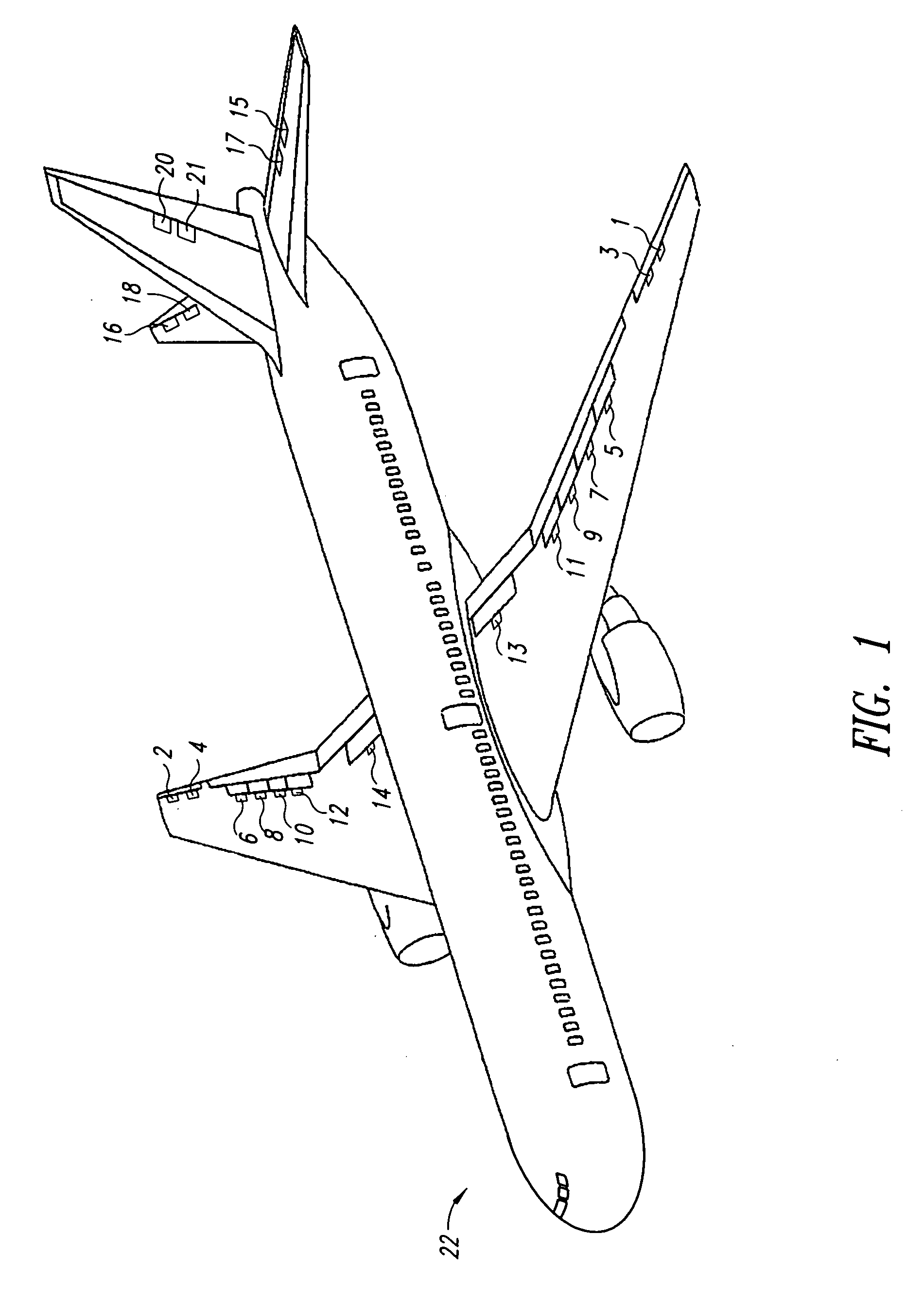

Local backup hydraulic actuator for aircraft control systems

ActiveUS20060226285A1Reduced force fightLower Reliability RequirementsFluid-pressure actuator safetyFluid couplingsElectronic controllerControl system

A backup system is provided that has a local electric motor and pump for some or all of the hydraulic actuators on an aircraft. A local backup hydraulic actuator has two power sources, hydraulic as primary and electrical as backup. During normal operation, the hydraulic actuator receives pressurized fluid from a hydraulic system and the fluid flow to the chambers is controlled by a servo valve. If the hydraulic system fails, the electronic controller detects the failure by observing the signal indicative of the pressure from the pressure sensor, and the controller powers the local hydraulic pump to provide high pressure hydraulic fluid to the hydraulic actuator via the servo valve.

Owner:NABLESCO CORP

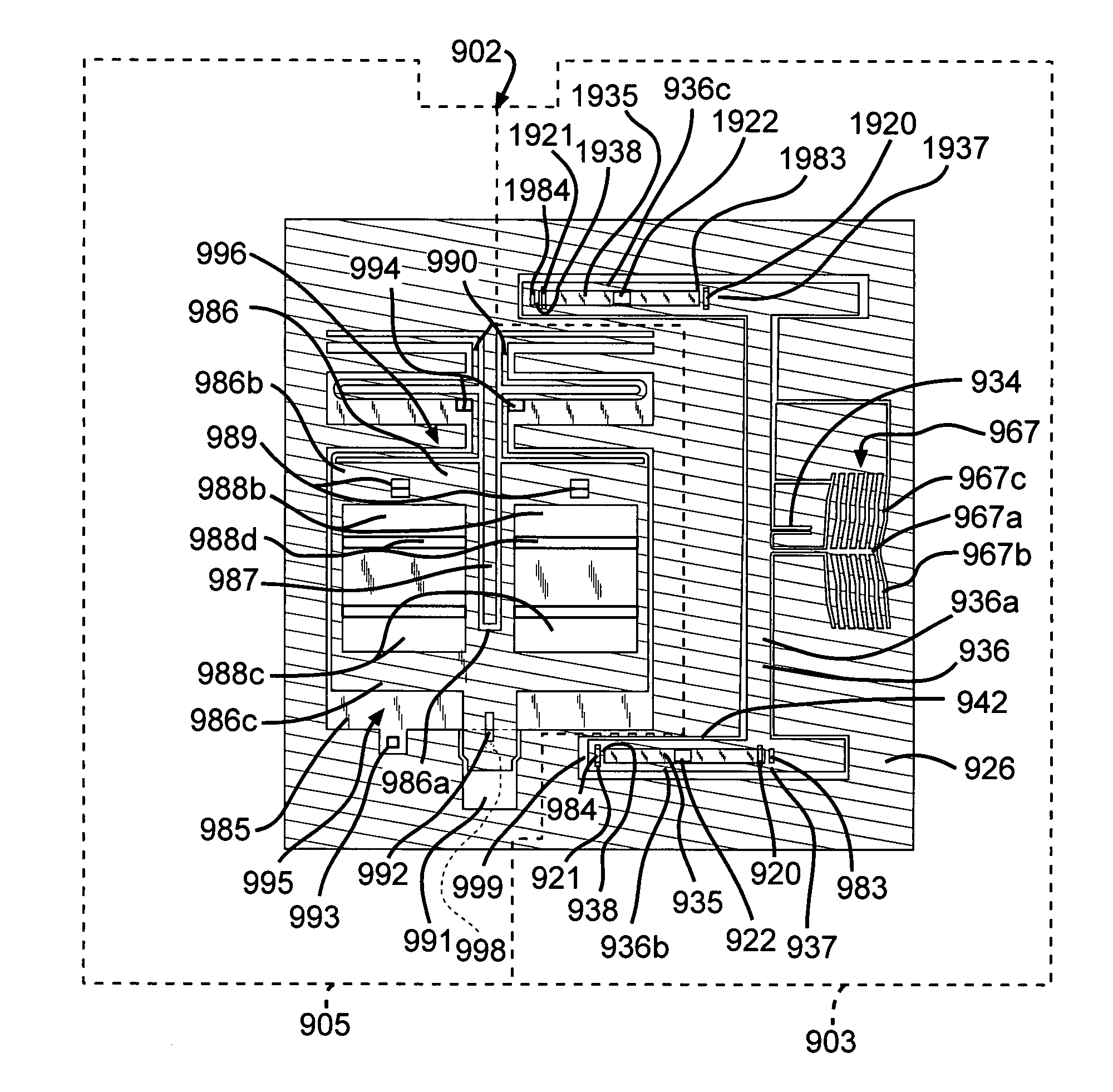

Microvalve device suitable for controlling a variable displacement compressor

ActiveUS7210502B2Fluid-pressure actuator safetyOperating means/releasing devices for valvesSpool valveEngineering

A device is disclosed for controlling a variable displacement compressor. The device comprises a microvalve operated control valve. A microvalve device for controlling fluid flow and a micro spool valve for use as a microvalve are also disclosed.

Owner:DUNAN MICROSTAQ

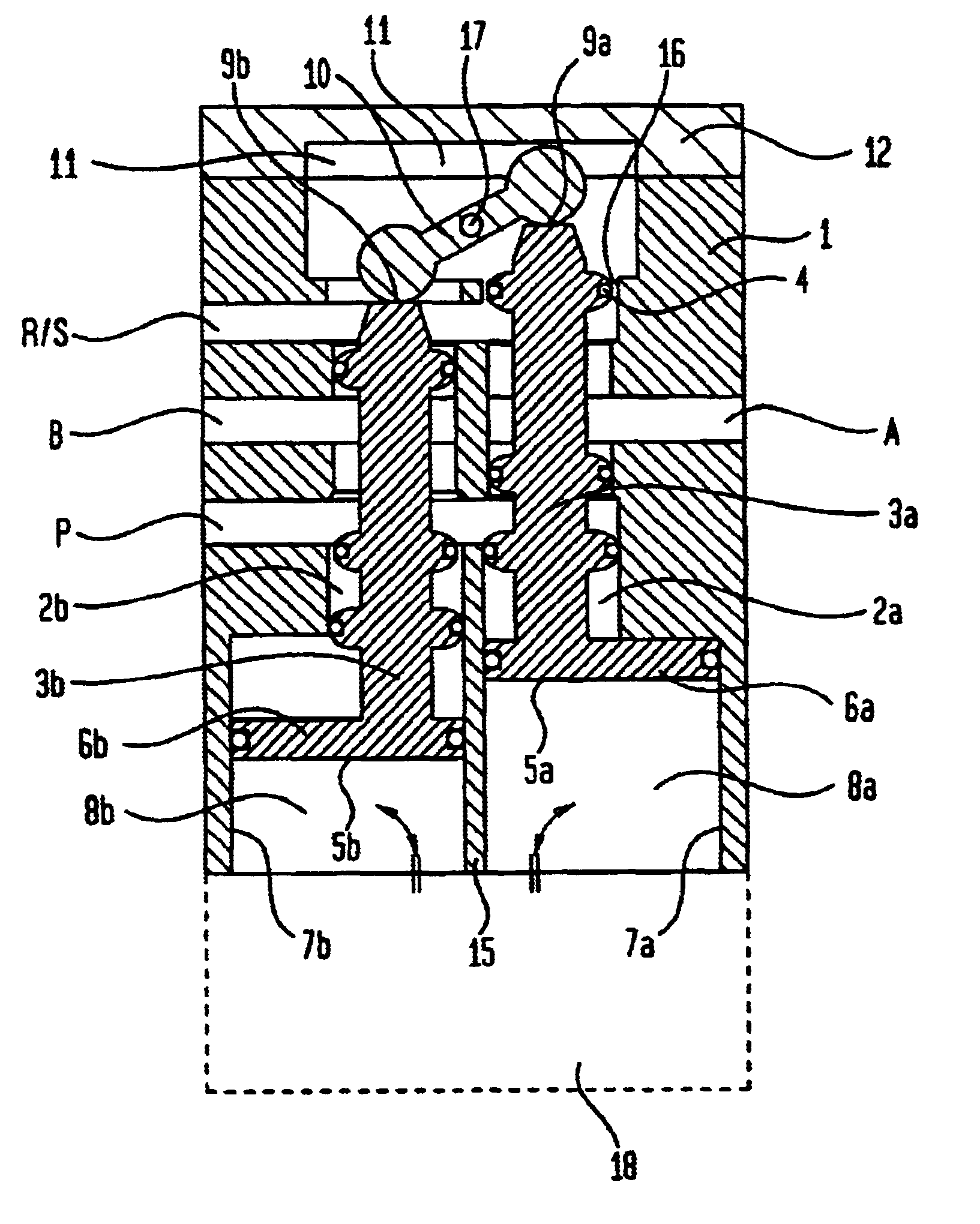

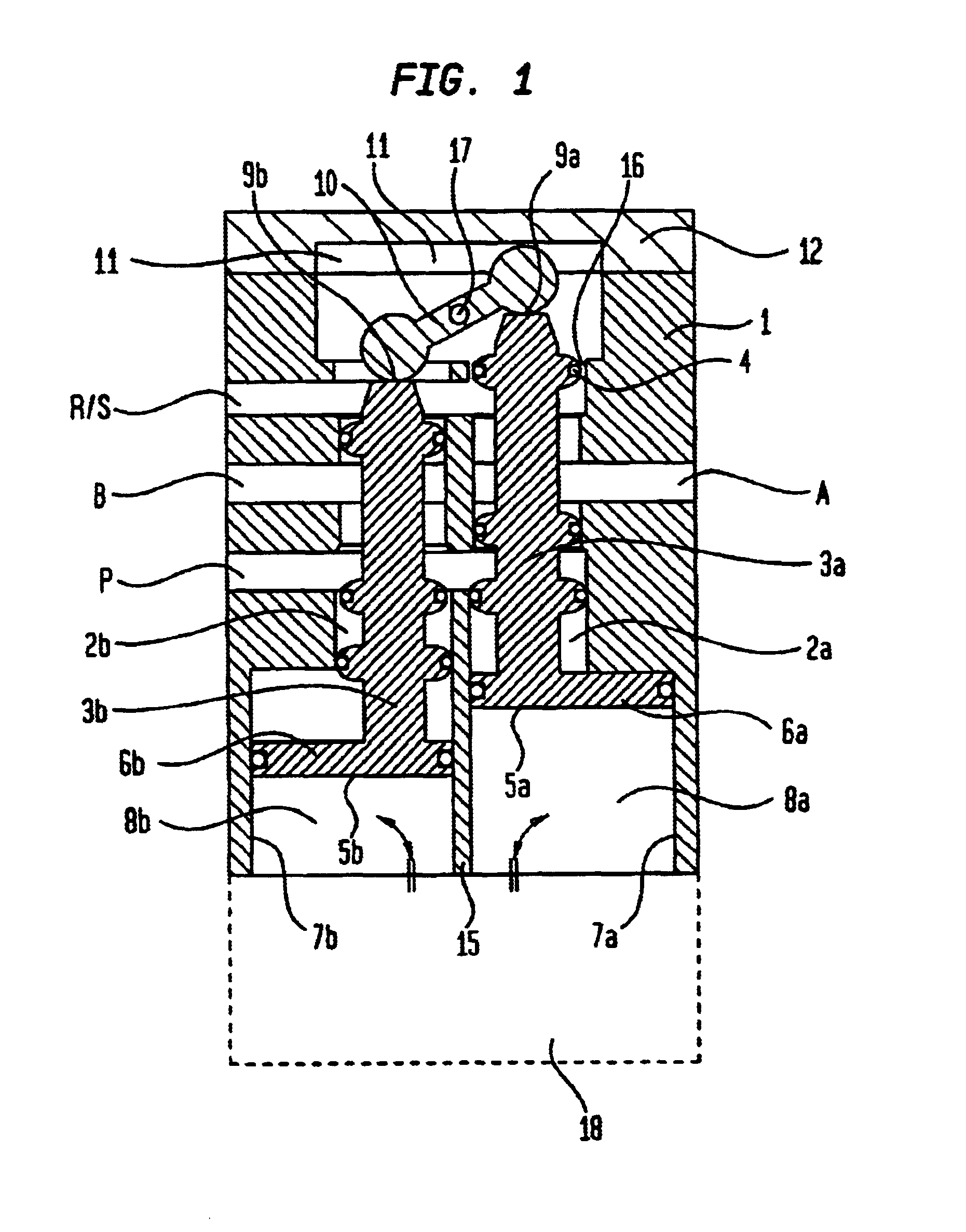

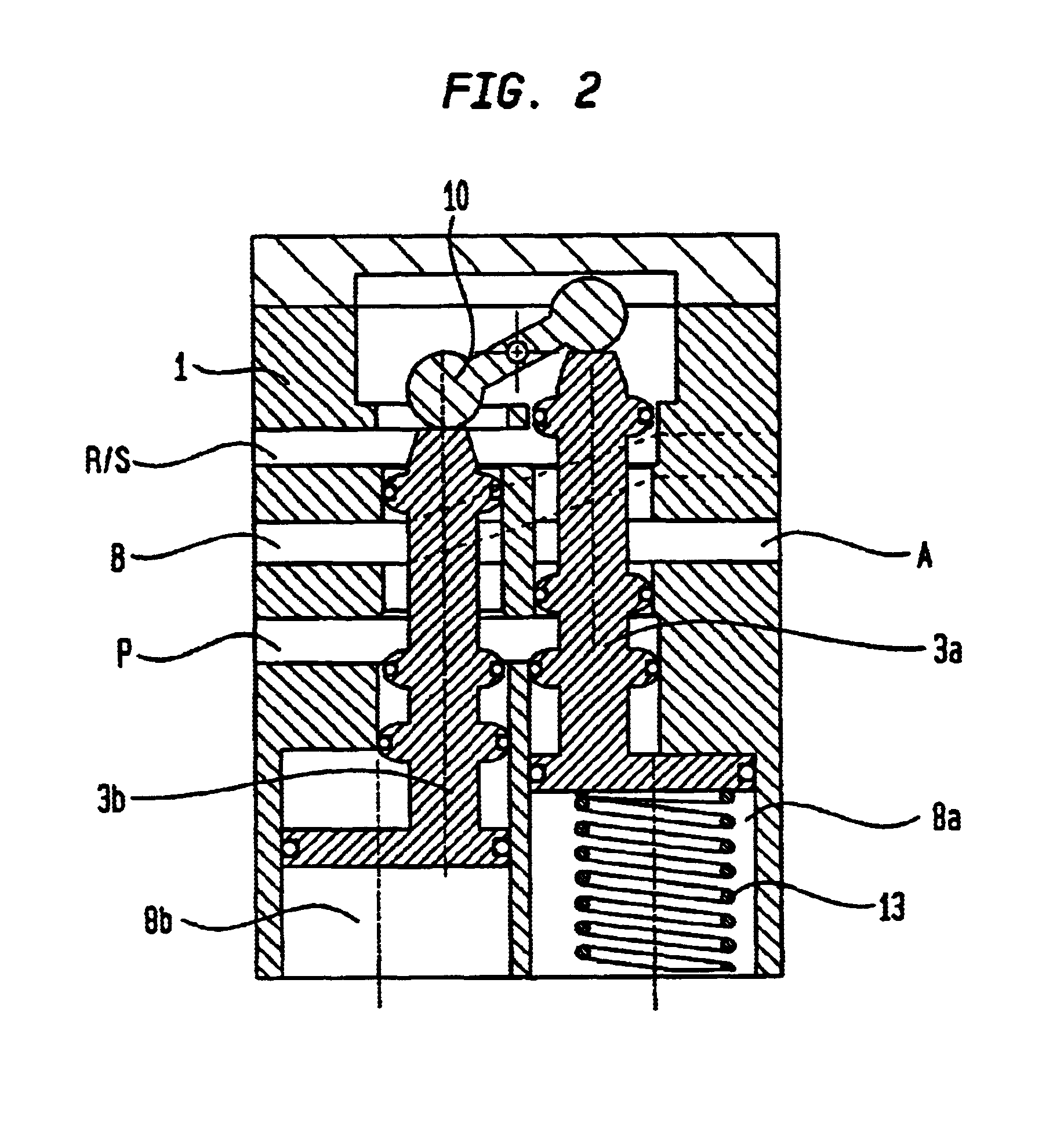

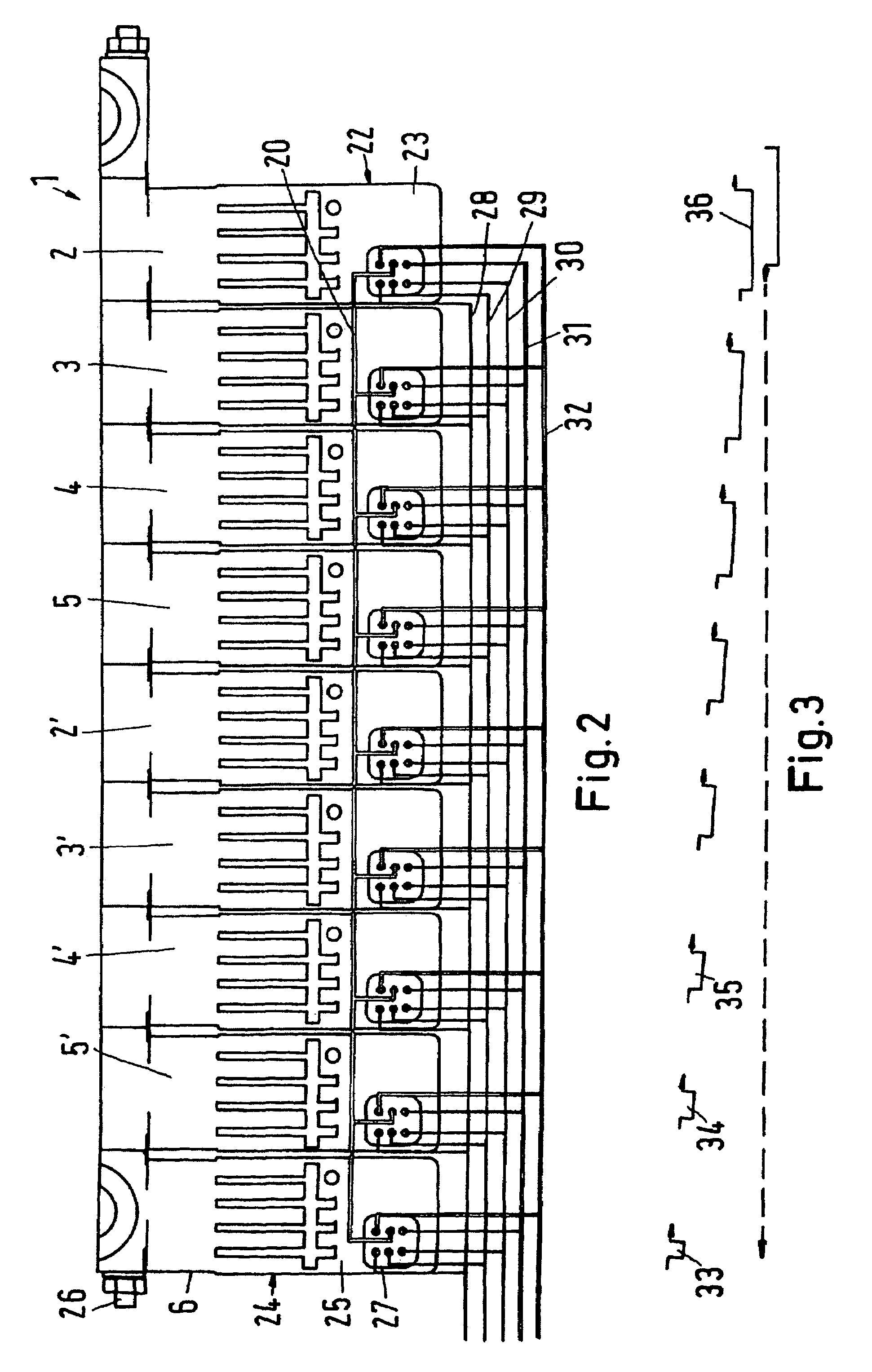

Multiway valve for switching a flow of fluid under pressure with parallel disposition of valve bores, and valve assembly kit

InactiveUS6688332B2Eliminate needCompact configurationFluid-pressure actuator safetyOperating means/releasing devices for valvesCouplingEngineering

A multiway valve for controlling a flow of fluid under pressure, includes a valve housing having fluid ports and a plurality of bores in side-by-side parallel disposition substantially at a same level. Each bore is configured for accommodation of a valve spools which are sealed in the bores against the valve housing. The spools have opposite first and second end faces, and include portions of greater diameter and portions of smaller diameter. Acting on the first end face of the spools is an actuation unit for moving the spools in a longitudinal direction to thereby direct a flow of fluid under pressure between the ports, whereas a mechanical coupling mechanism, which is secured to the valve housing, interacts with the second end faces of the spools.

Owner:AB REXROTH MECMAN

Actuator

ActiveUS20070194738A1Excessive vibrationIncrease freedomFluid-pressure actuator safetyDC motor speed/torque controlEngineeringActuator

An actuator includes a cylinder, a piston that is disposed in the cylinder and moves by supply and exhaust of working oil to and from the cylinder, a movable rod that is connected to the piston, a screw shaft, at least a part of which is inserted into the movable rod, a nut that is threaded to the screw shaft and moves integrally with the piston, and an electric motor that rotates the screw shaft forward or backward.

Owner:NABLESCO CORP

Dual Motor Dual Concentric Valve

ActiveUS20080185476A1Scalable/modular redundancyMitigates force fightingFluid-pressure actuator safetyServomotor componentsControl systemEngineering

An actuator control system has a dual concentric servo valve having a spool and at least one motor adapted to selectively displace the spool.

Owner:TEXTRON INNOVATIONS

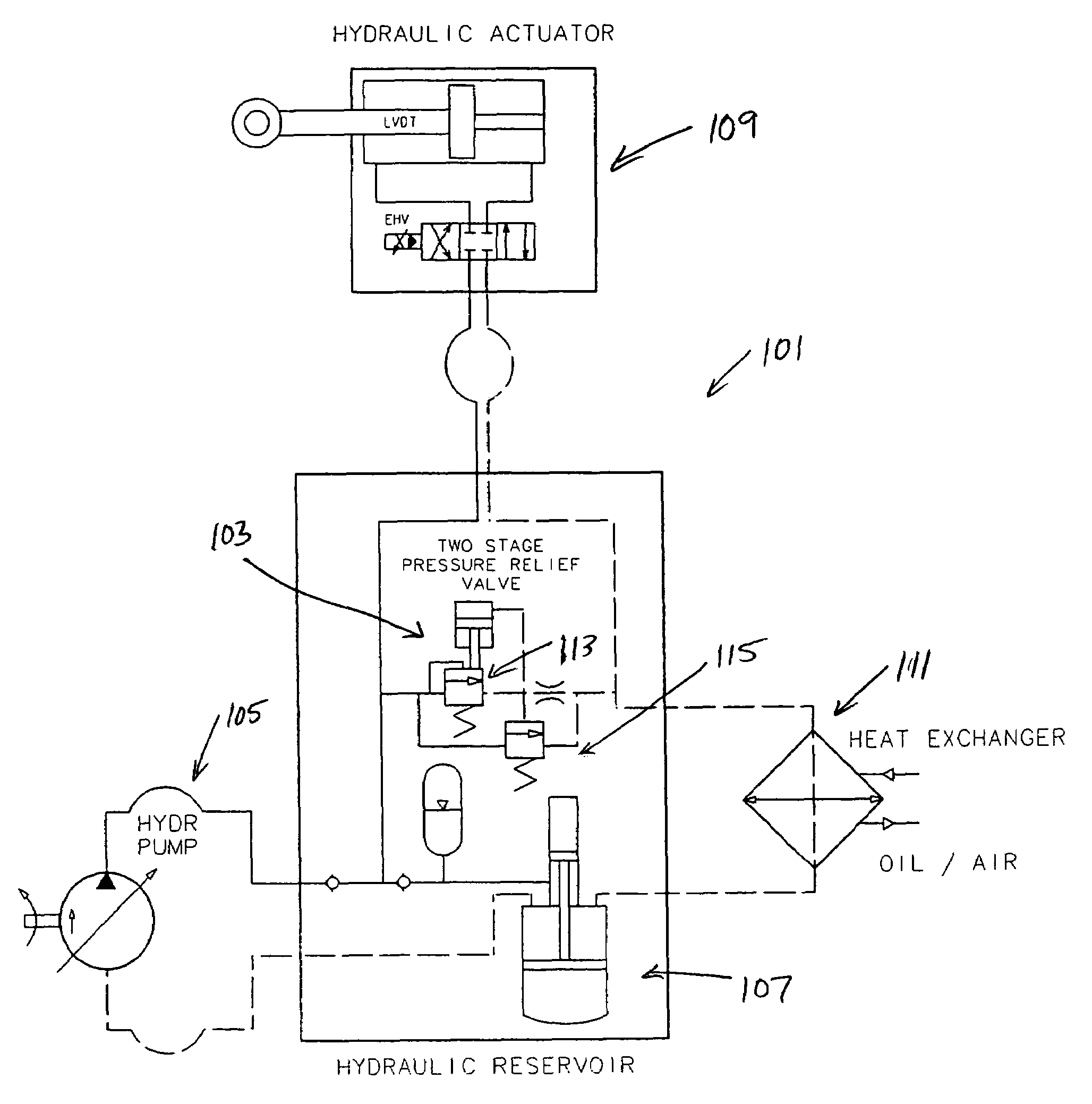

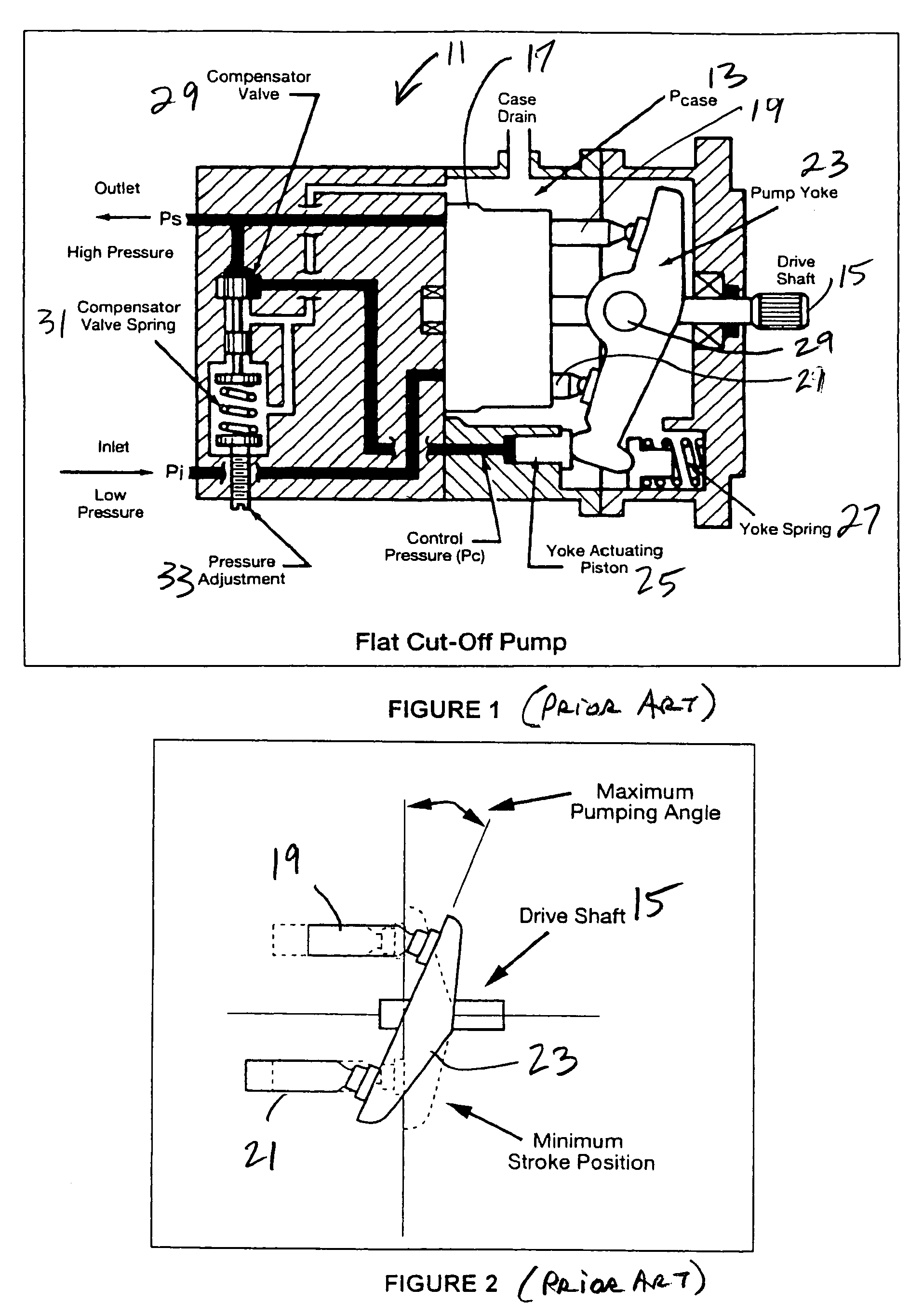

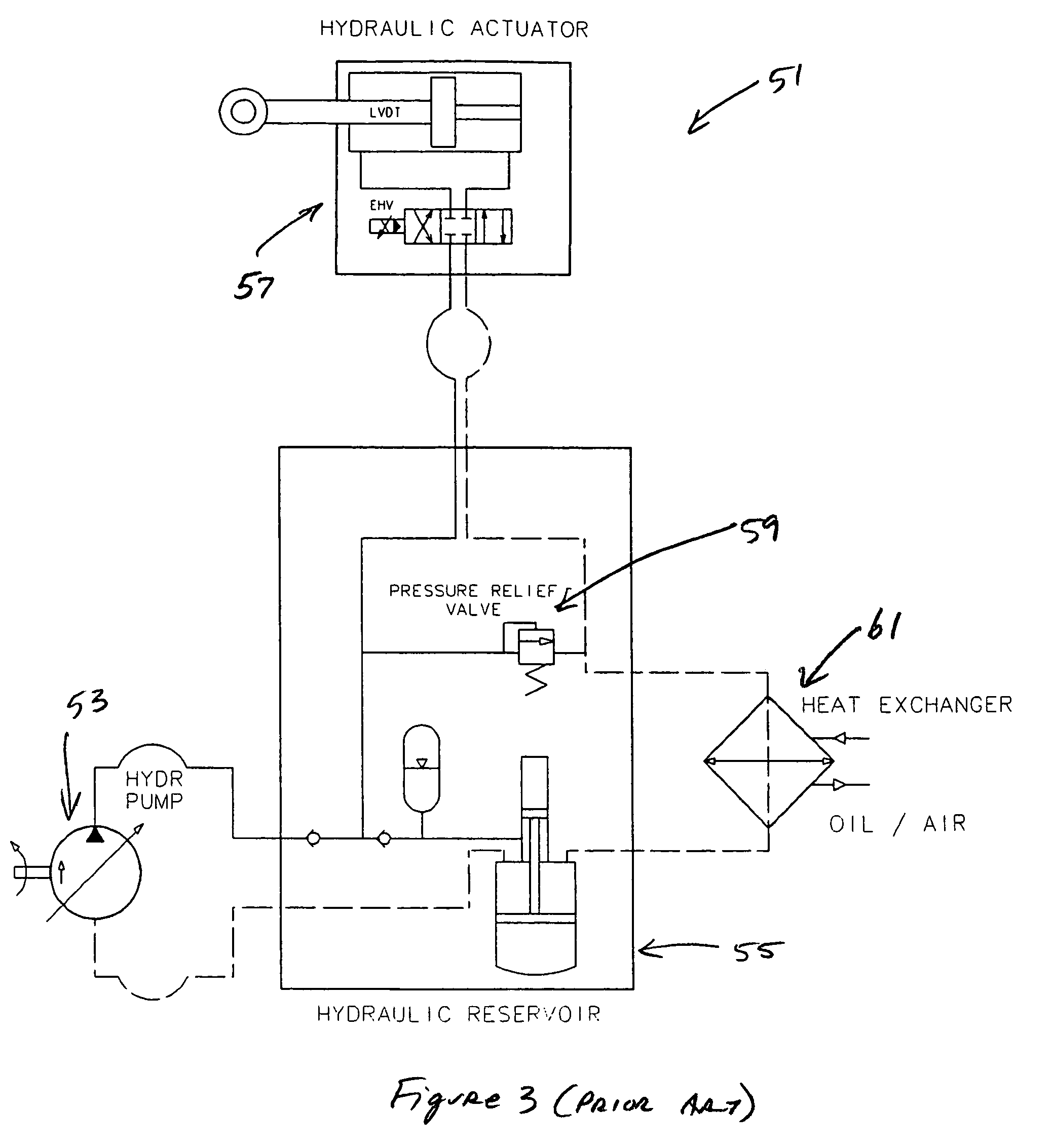

Two-stage pressure relief valve

ActiveUS7165950B2More reliableLess expensiveFluid-pressure actuator safetyServomotor componentsDecreased pressureSystem pressure

A two-stage pressure relief valve for use with hydraulic systems is disclosed. The two-stage pressure relief valve has a first stage that relieves increases in hydraulic system pressure over the normal operating pressure and up to a selected threshold pressure level, and a second stage that brings the hydraulic system pressure down to a selected reduced operating pressure that is below the normal operating pressure in response to increases in the operating pressure over the threshold pressure level.

Owner:BELL HELICOPTER TEXTRON INC

Fluid control systems employing compliant electroactive materials

InactiveUS20090250021A1Easy to adjustLow profileFluid-pressure actuator safetyOperating means/releasing devices for valvesFluid controlControl system

Owner:PARKER HANNIFIN CORP

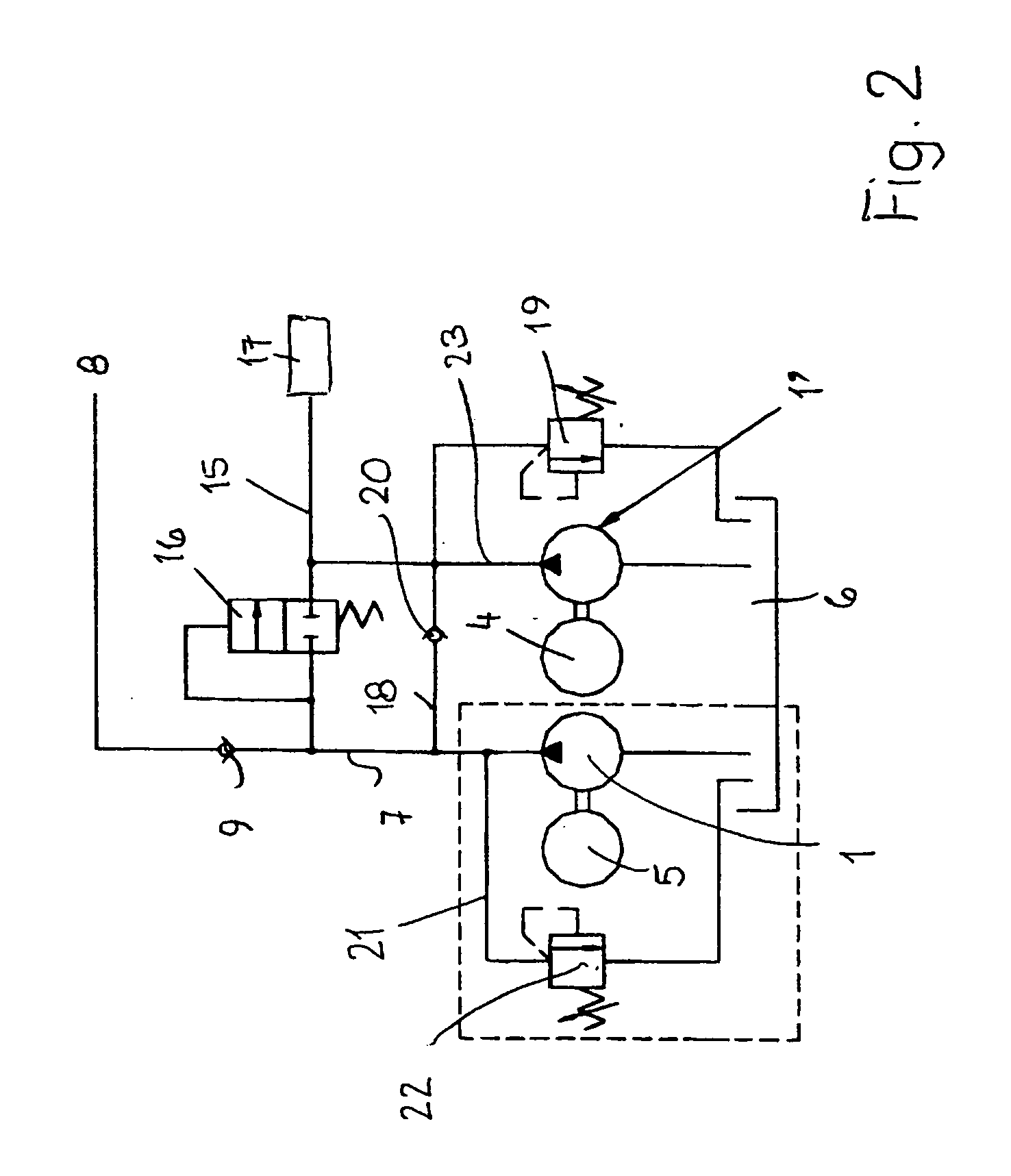

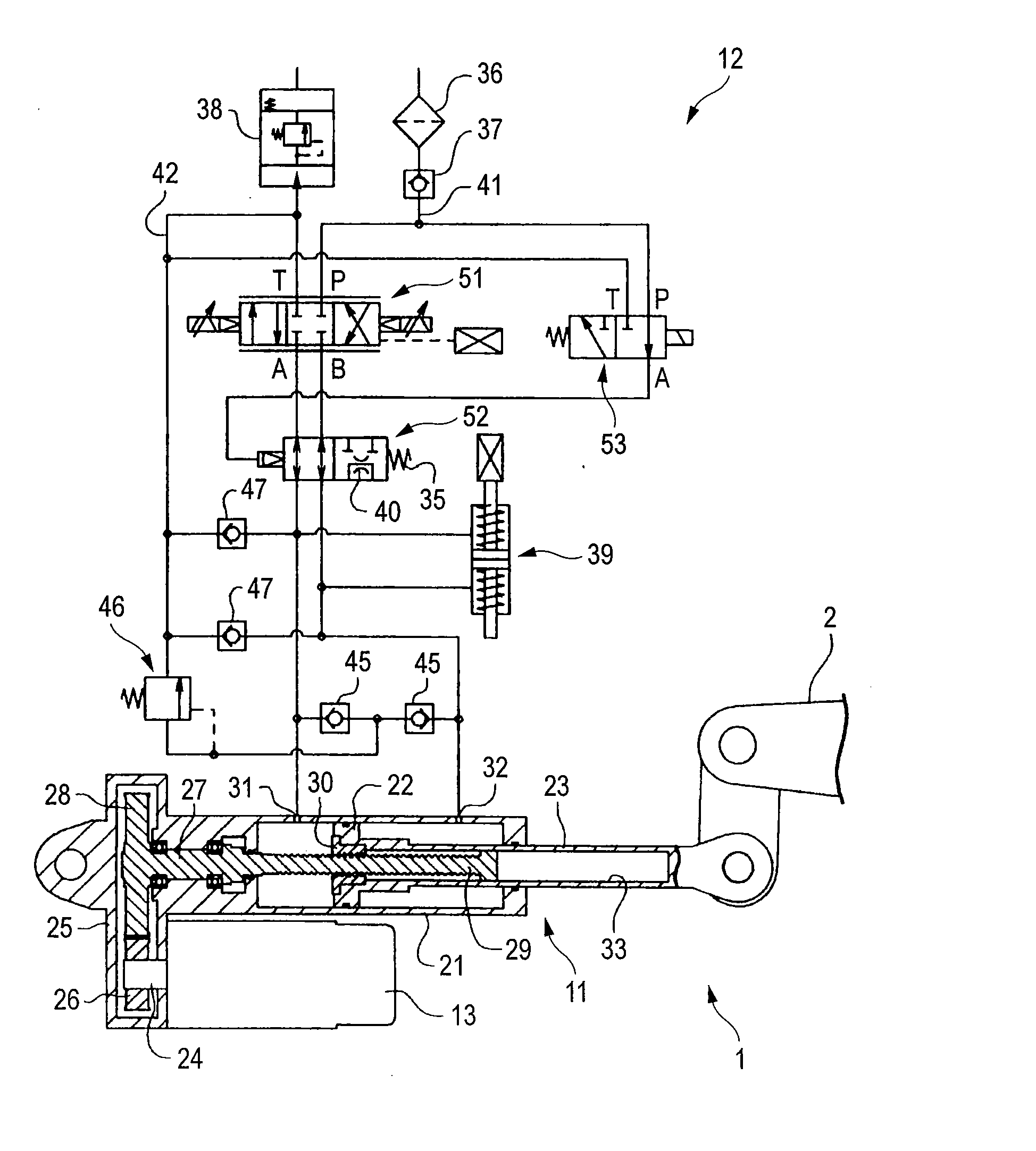

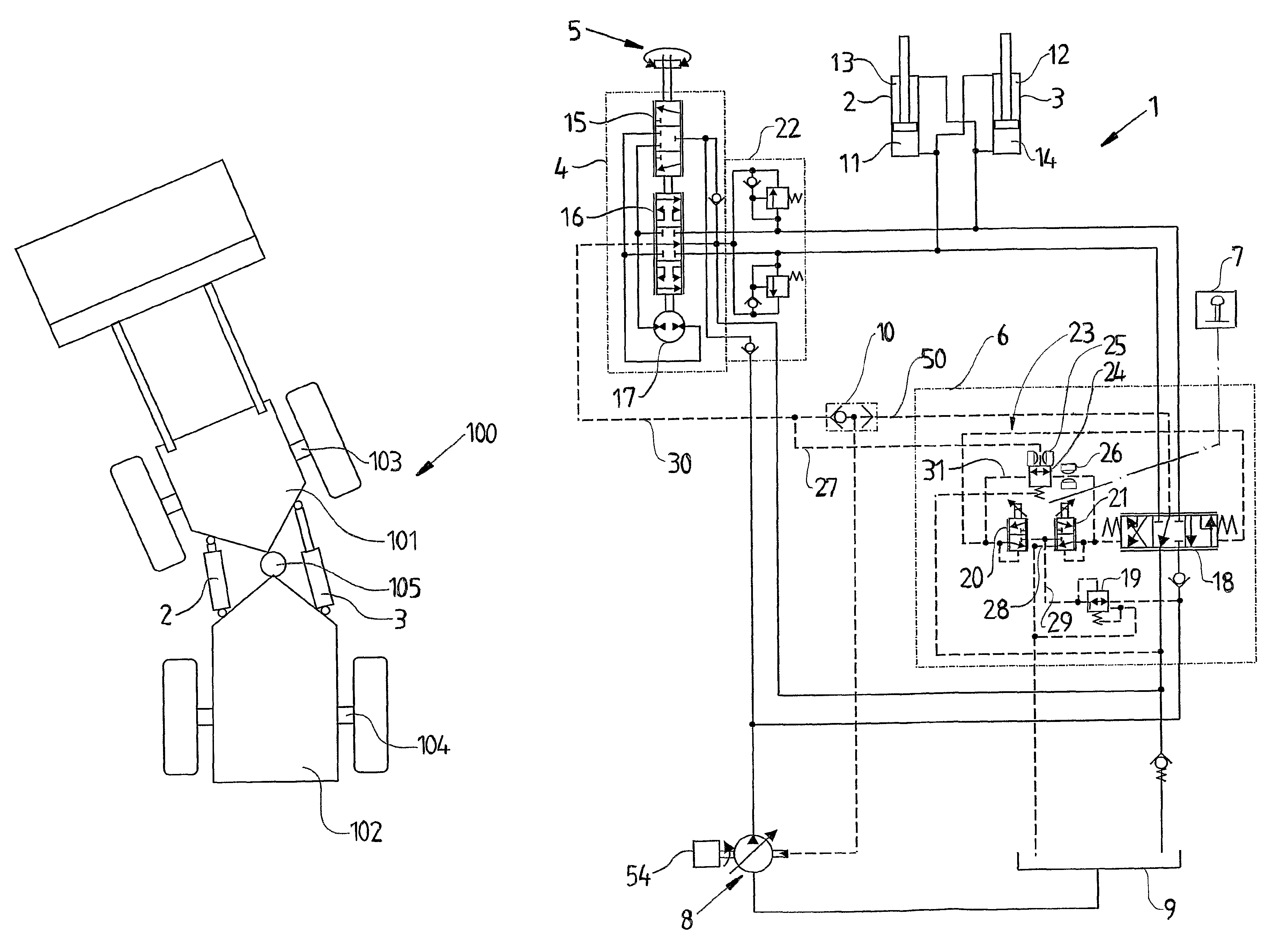

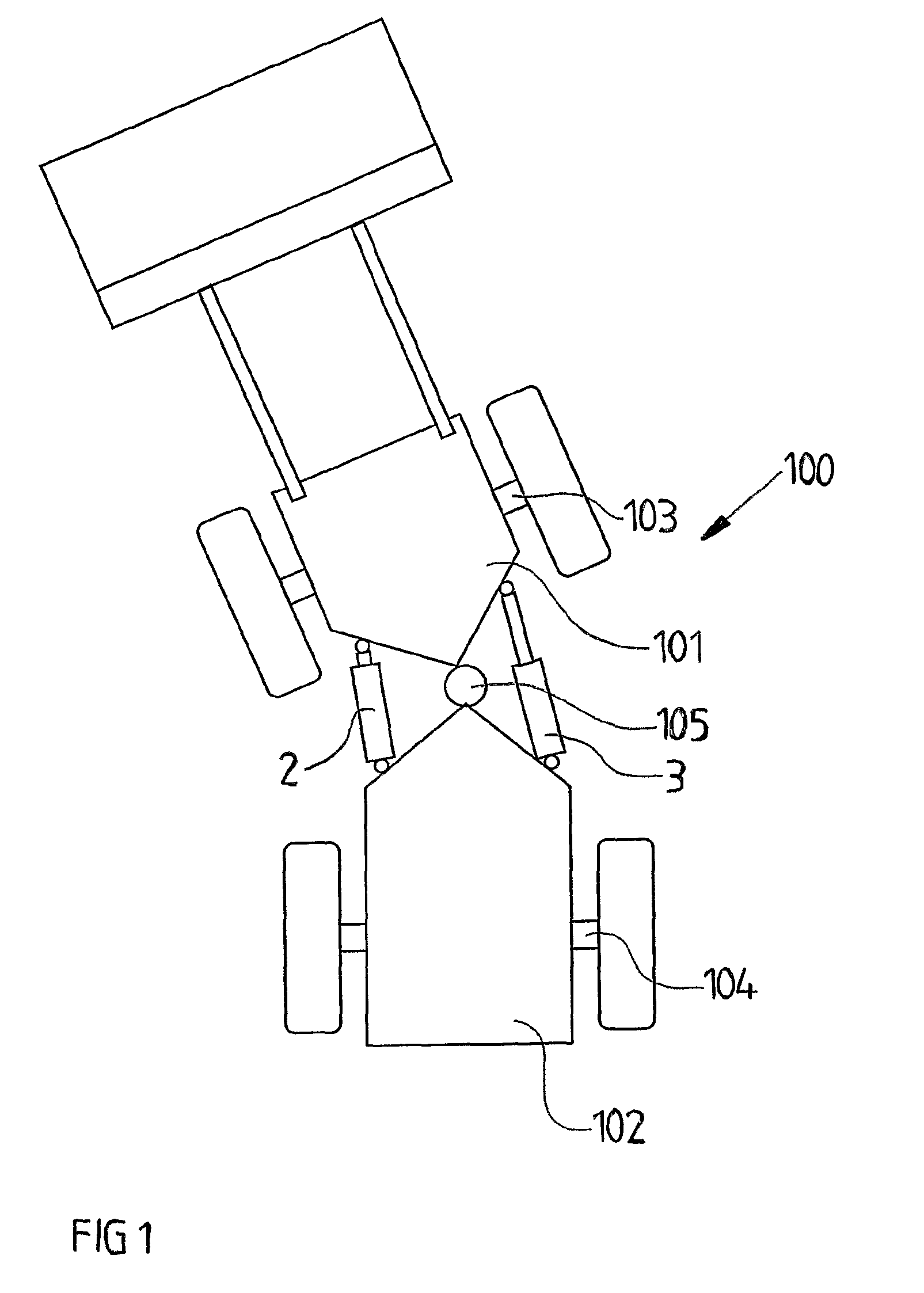

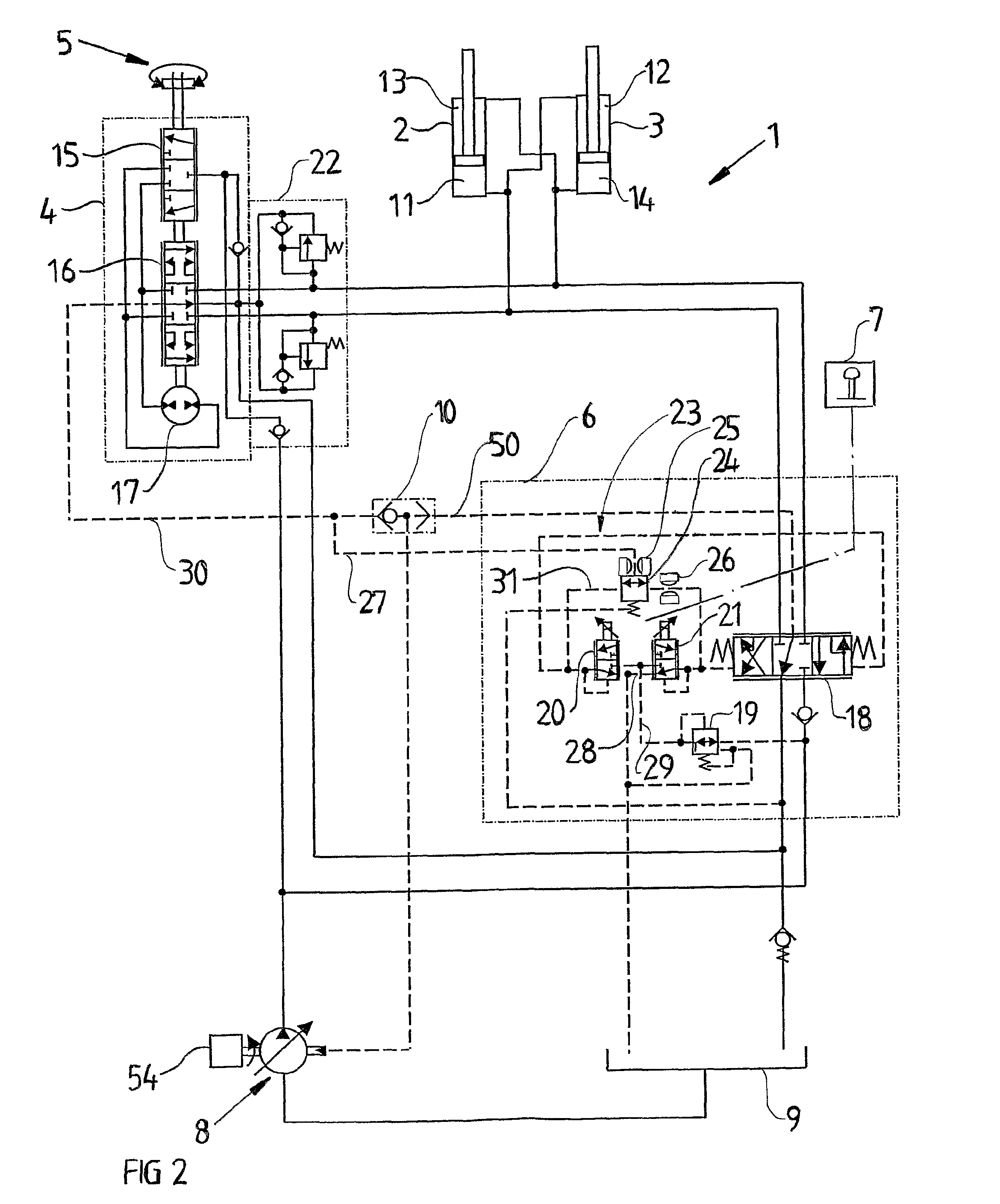

Control system and a vehicle comprising the control system

InactiveUS7610989B2Improve securityIncreased cost-effectivenessFluid-pressure actuator safetyAlternative steering controlHydraulic cylinderControl system

System for controlling at least one hydraulic cylinder (2, 3) having a first control valve unit (4) connected to the hydraulic cylinder for regulation thereof. A first operable control means (5) is included and which is adapted for controlling the first control valve unit. A second control valve unit (6) is also included that is connected to the hydraulic cylinder for regulation thereof, and a second operable control means (7) is further provided and which is adapted for controlling the second control valve unit. The system also includes means (23) for prioritizing the first control means. The prioritizing means (23) is controlled via hydraulics in such a way that the effect of the second control means (6) on the regulation of the hydraulic cylinder (2, 3) is at least substantially reduced as soon as the first control means (5) is operated.

Owner:VOLVO CONSTR EQUIP AB

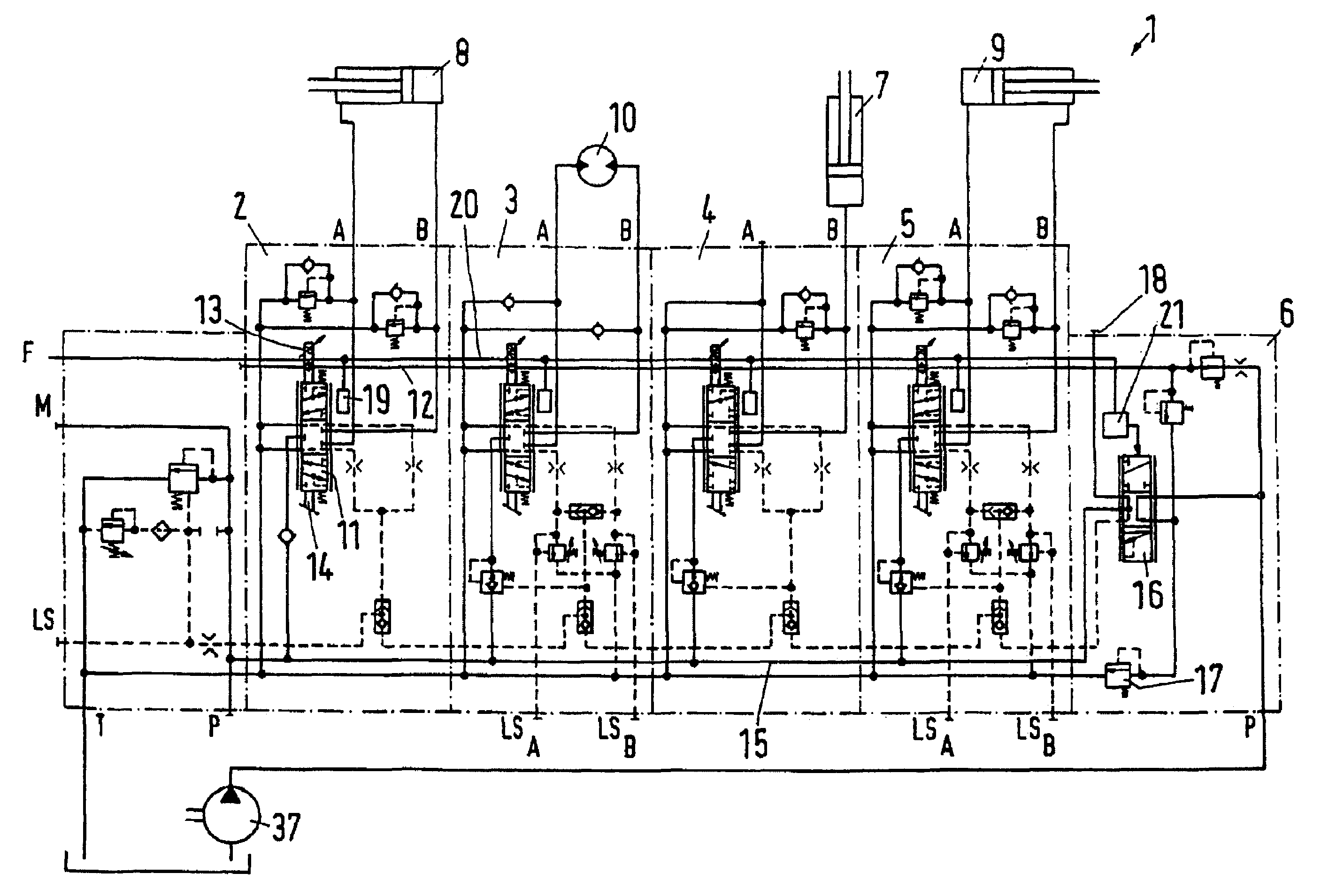

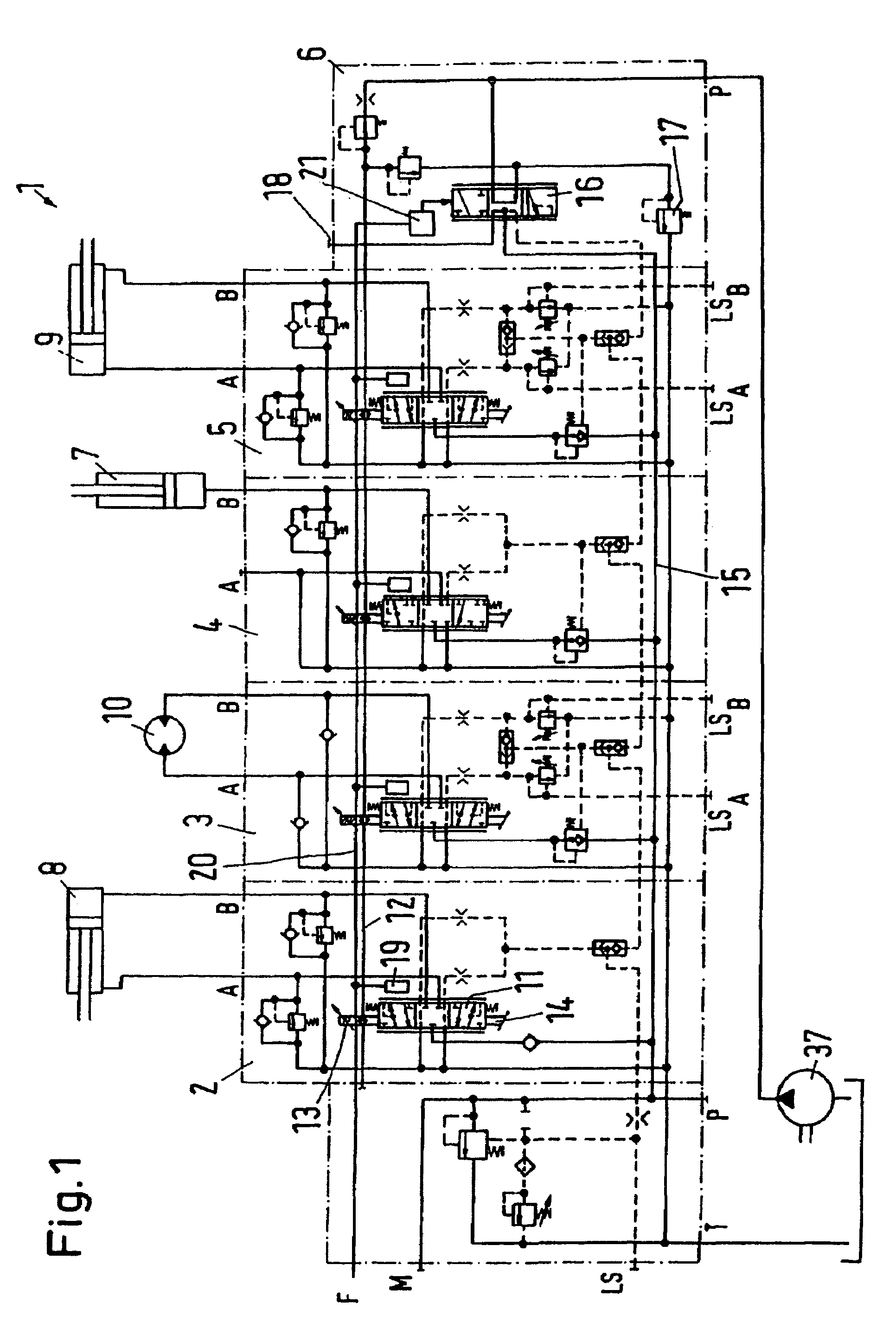

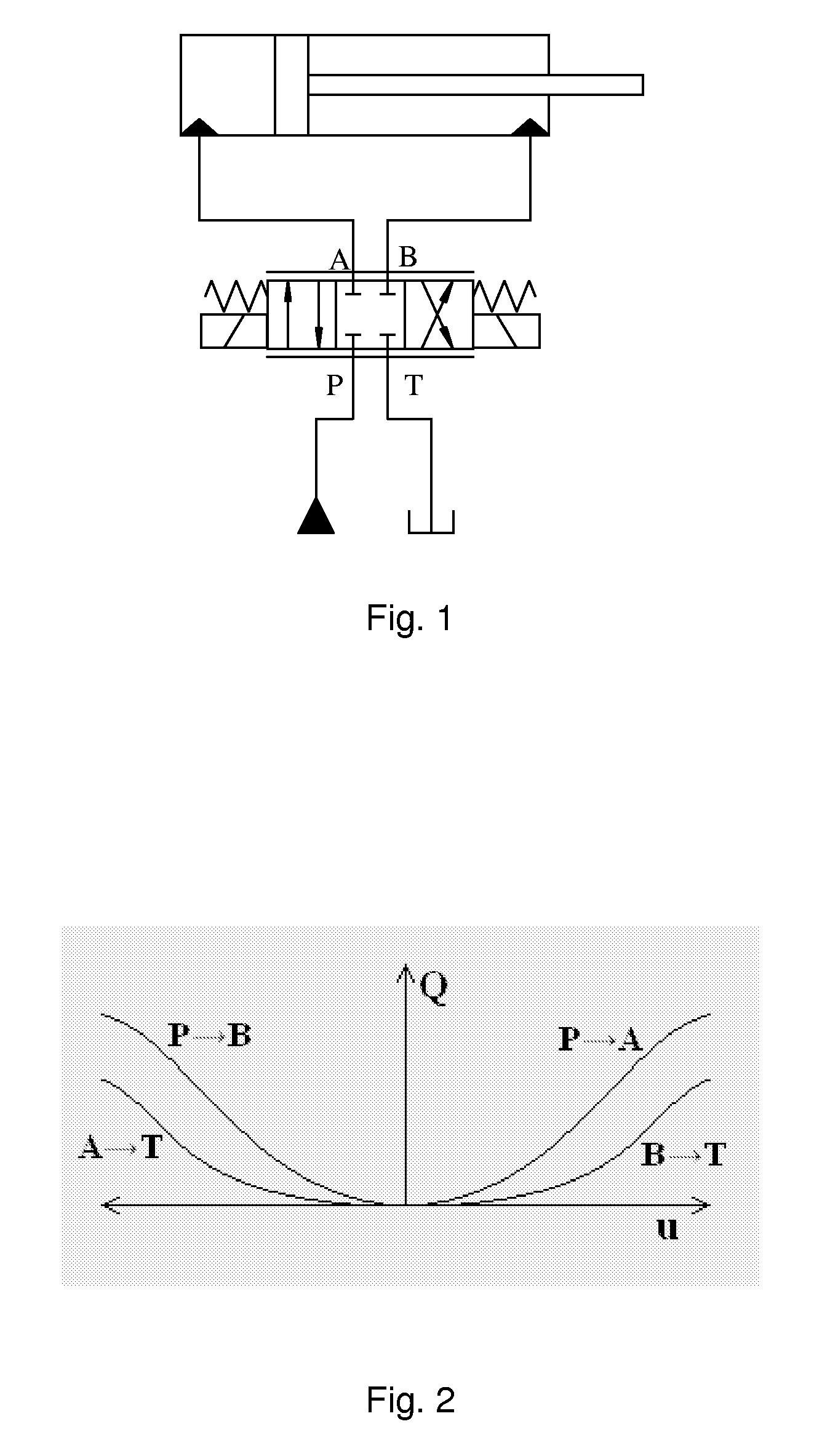

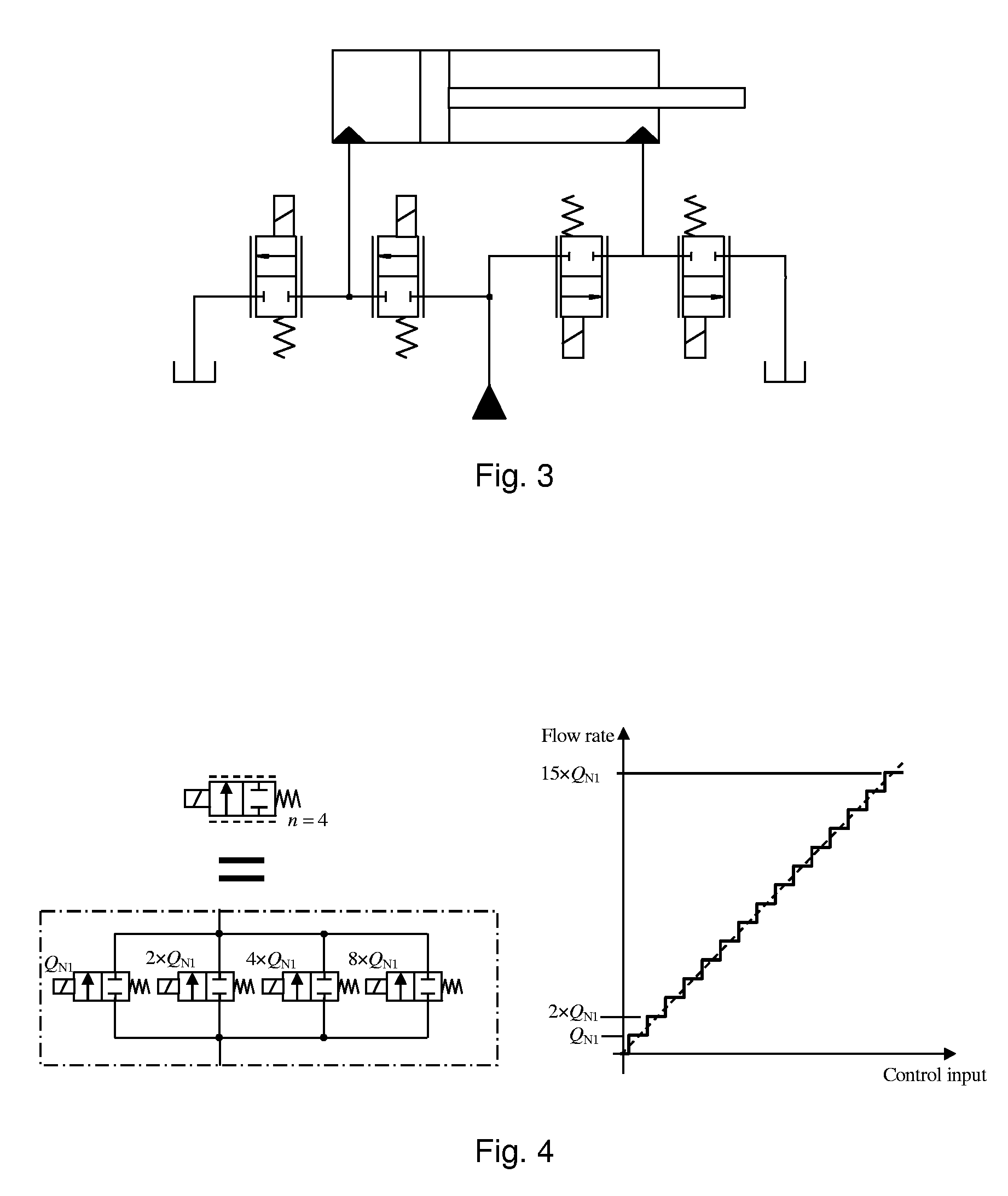

Valve arrangement

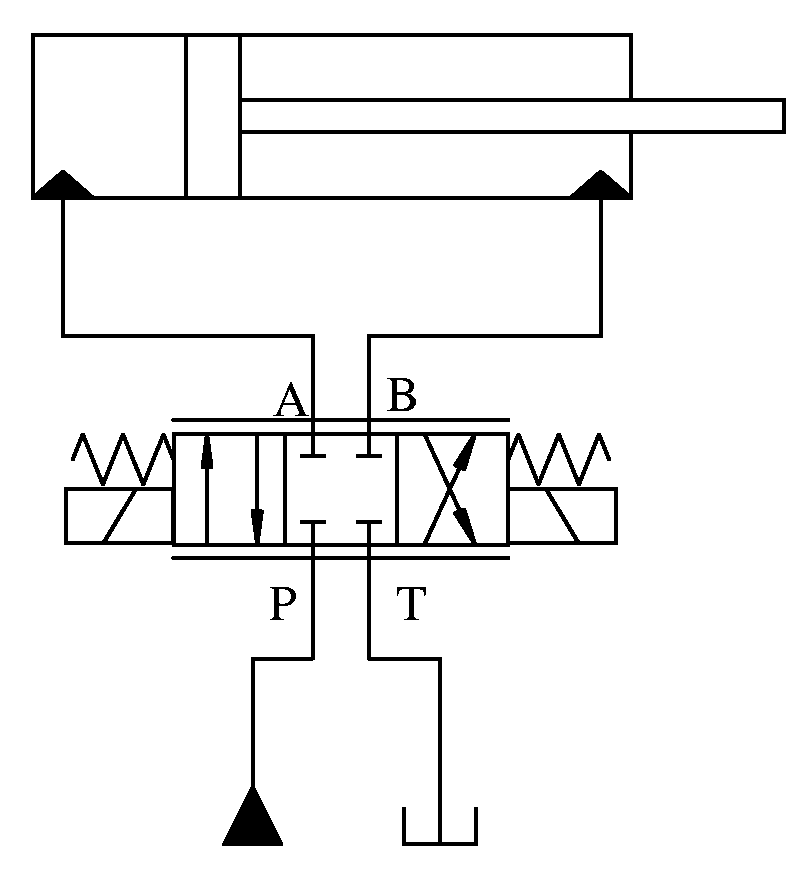

ActiveUS7398796B2Simplify workSimple designFluid-pressure actuator safetyServomotor componentsEngineeringHigh pressure

The invention concerns a valve arrangement (1) with a high-pressure connection (P), a low-pressure connection (T), at least one control valve (2 to 5), which is accommodated in a control valve module and has at least one working connection (A, B) for a hydraulic consumer (7 to 10), and a safety valve (6), which is accommodated in a safety valve module, and which releases or blocks a passage between the high-pressure connection (P) and the control valves (2 to 5), the control valve module (2 to 5) and the safety valve module (6) being connected to one component group. It is endeavoured to provide a valve arrangement with a high safety level. For this purpose, it is ensured that each control valve (2 to 5, 2′ to 5′) has an error detection device (19), that the safety valve module (6) has a safety switch device (21) and that the component group has a connection (20) between the safety switch device (21) and the error detection device (19).

Owner:DANFOSS PAUER SOLYUSHENS APS

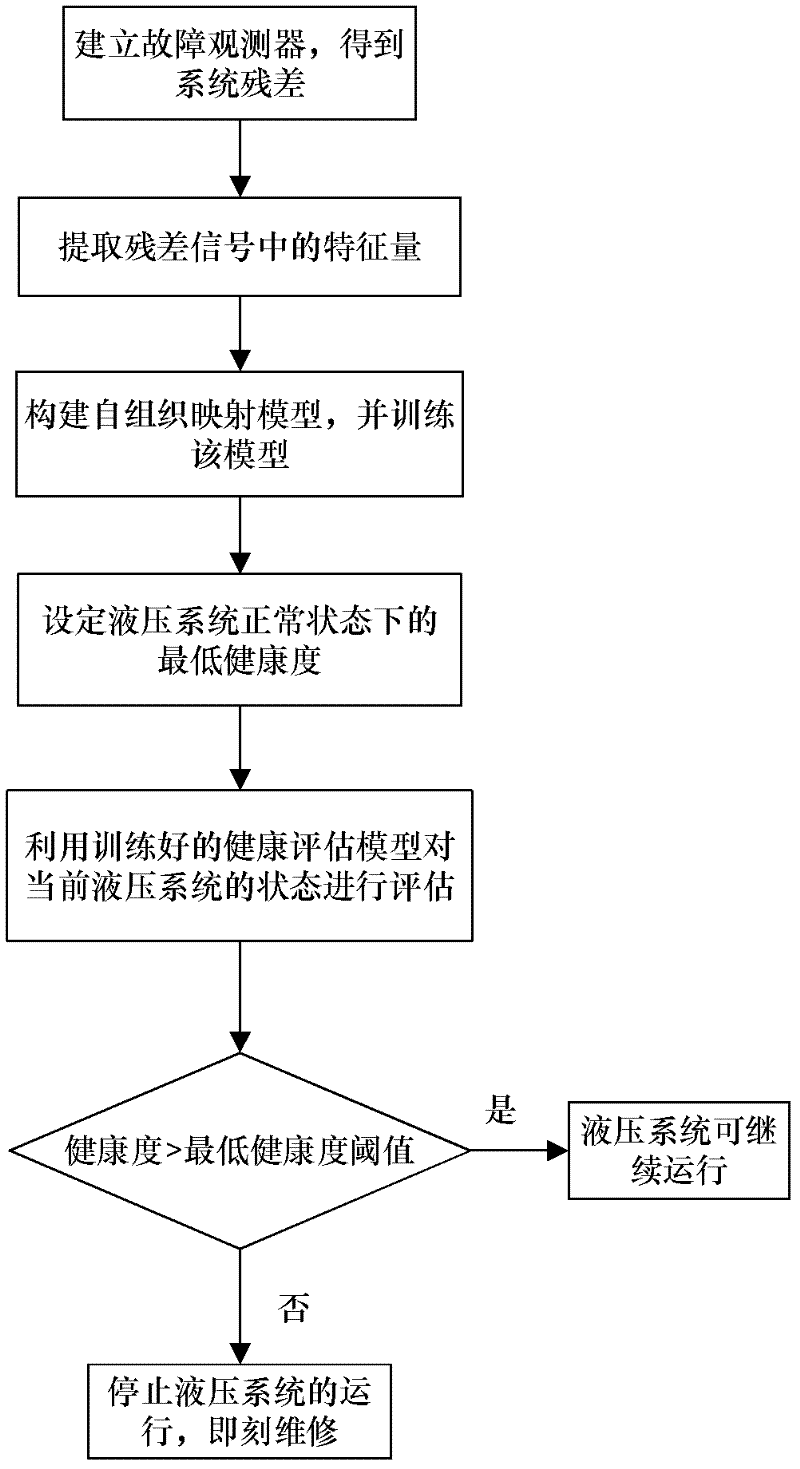

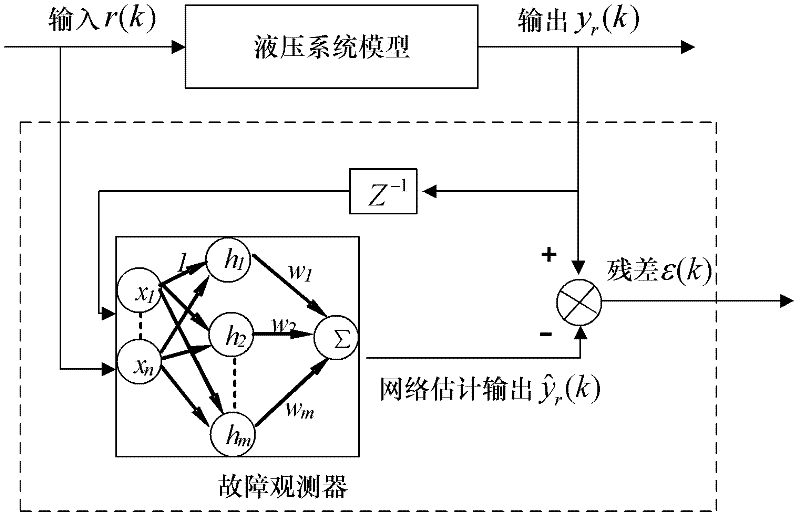

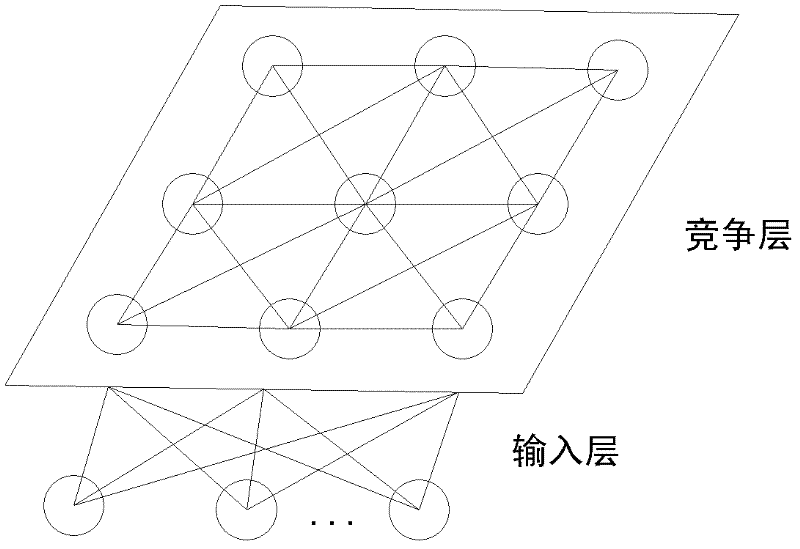

Health evaluation method for hydraulic system based on fault observer and SOM (self-organized mapping)

InactiveCN102606557AImprove robustnessEase of evaluationFluid-pressure actuator safetyFluid-pressure actuator testingTime domainControl system

The invention provides a health evaluation method for a hydraulic system based on a fault observer and SOM (self-organized mapping). The method includes: firstly, training the fault observer by the aid of input and output signals of the hydraulic system in a normal operation state to acquire residual signals in the normal state; secondly, acquiring residual signals of a certain component in a degenerate state through the fault observer by the aid of input and output signals of the degenerate component in the system; thirdly, extracting time-domain features of the residual signals in the two states and building a self-organized mapping model by the aid of residual features in the normal state; and finally, inputting residual features of the degenerate component to the self-organized mapping model to acquire the health degree of the hydraulic system in the corresponding states, and judging whether the current hydraulic system can continue running or not by the aid of the lowest health threshold value. The health evaluation method is used for evaluating health of the hydraulic control system in real time, is fine in evaluation effect, reduces dependency on historical data, and has engineering practicability.

Owner:BEIHANG UNIV

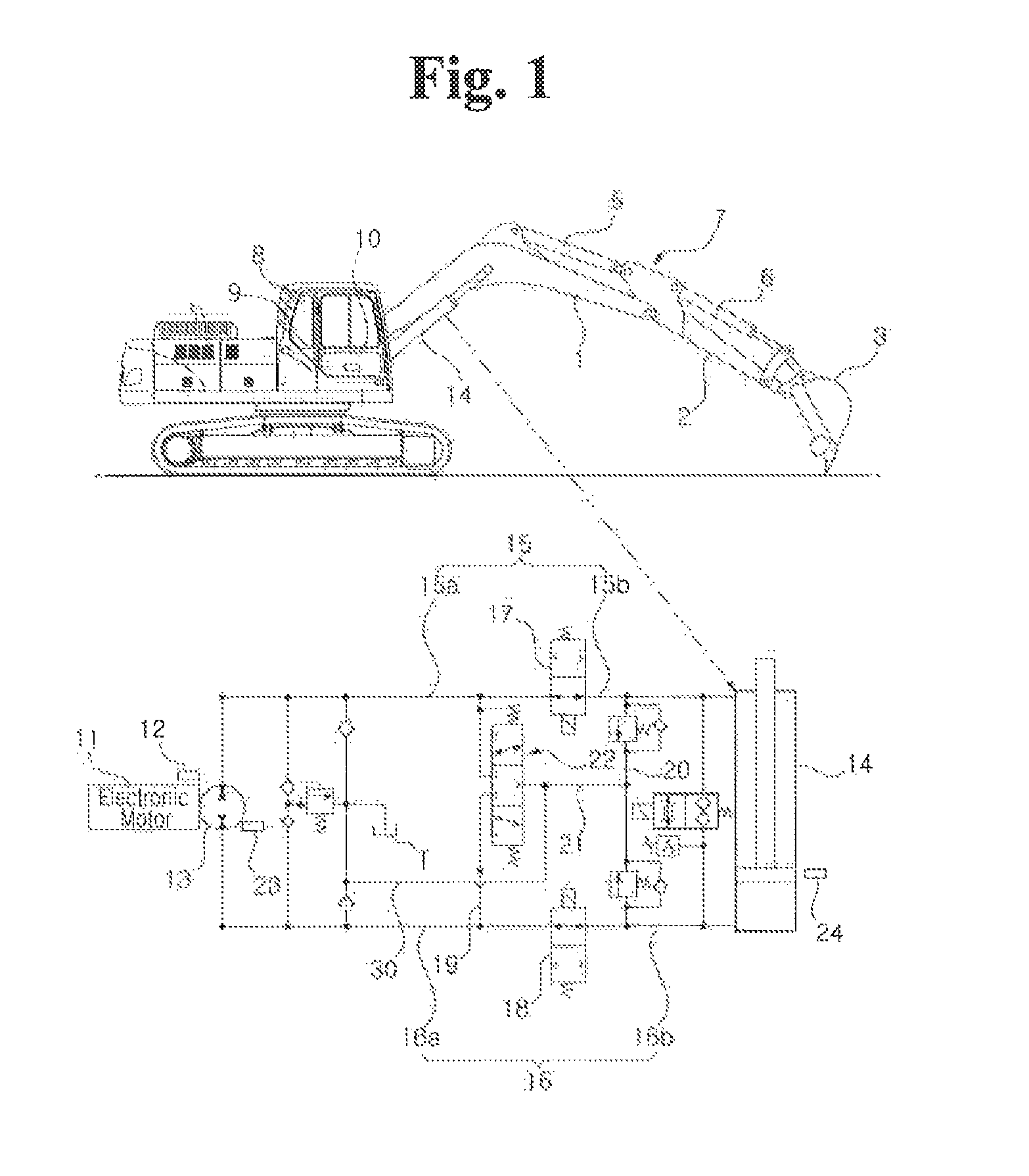

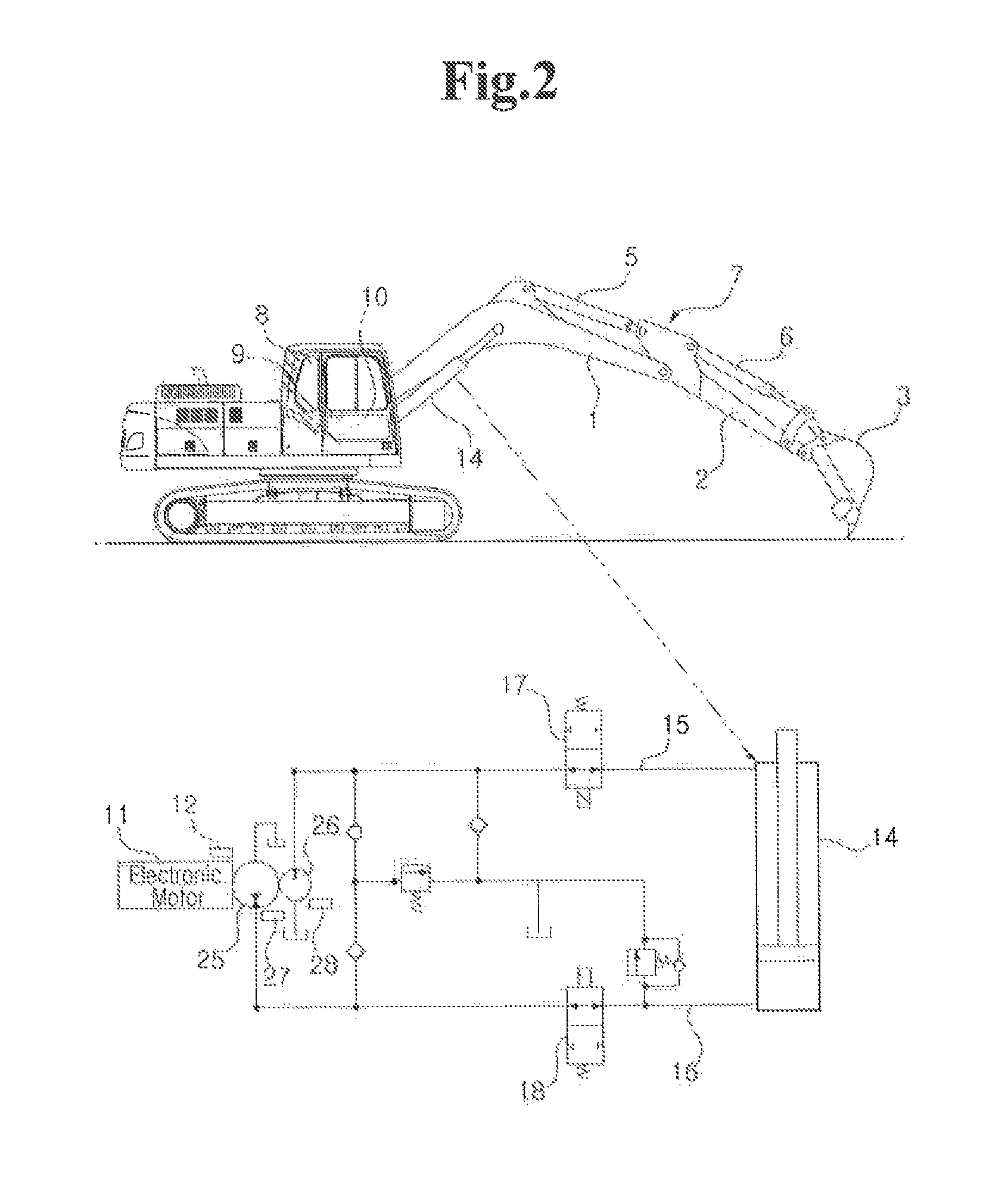

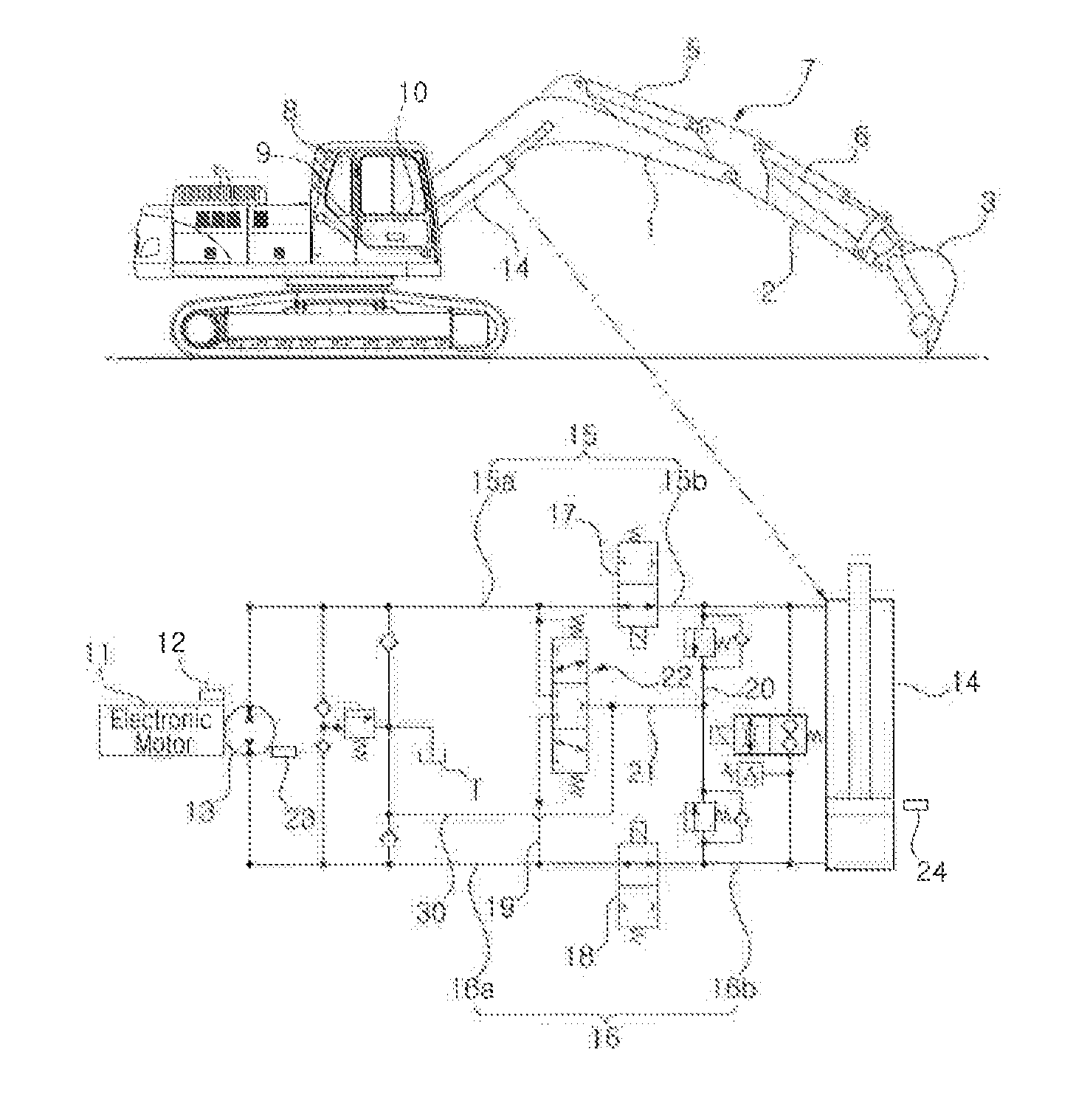

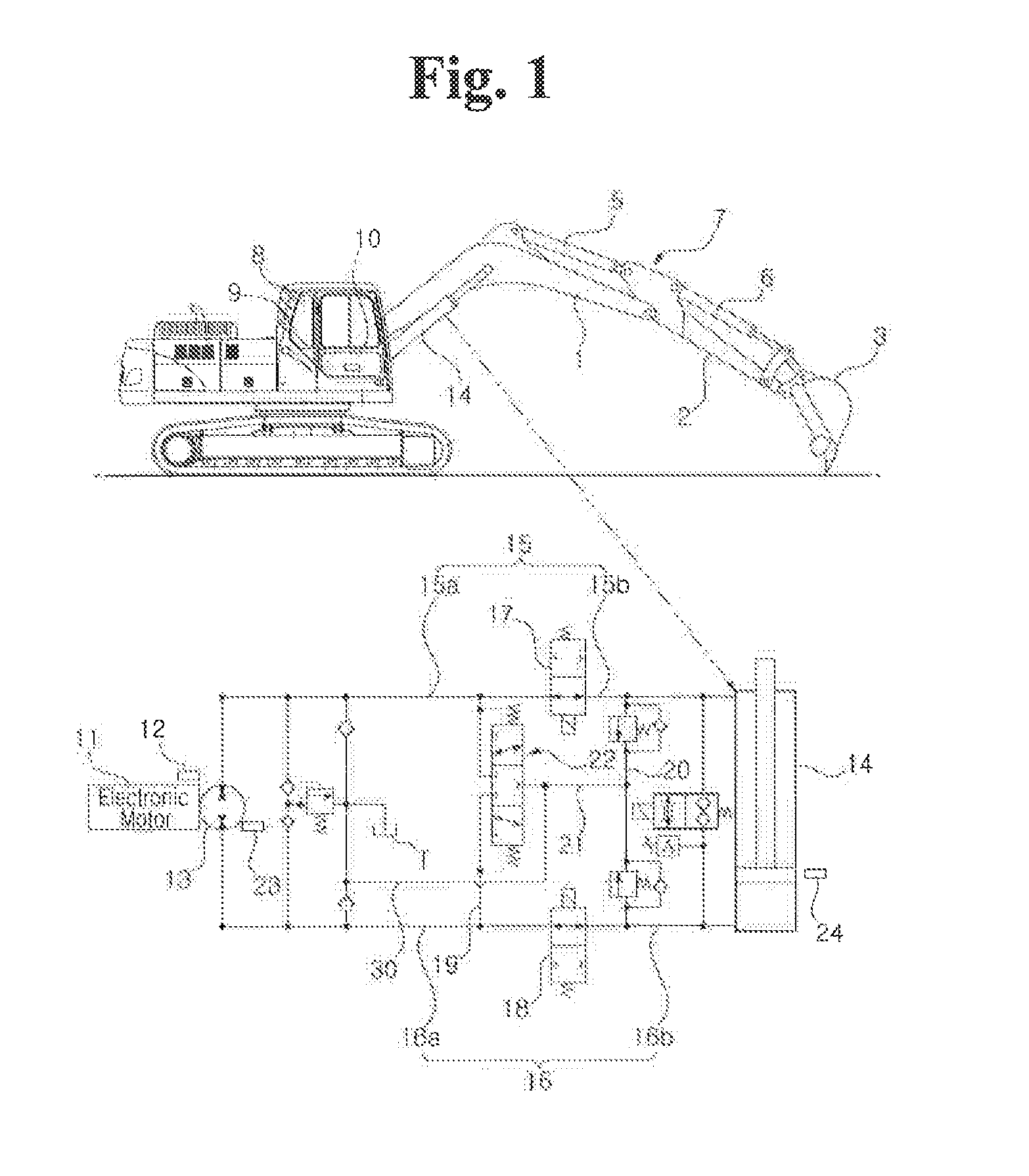

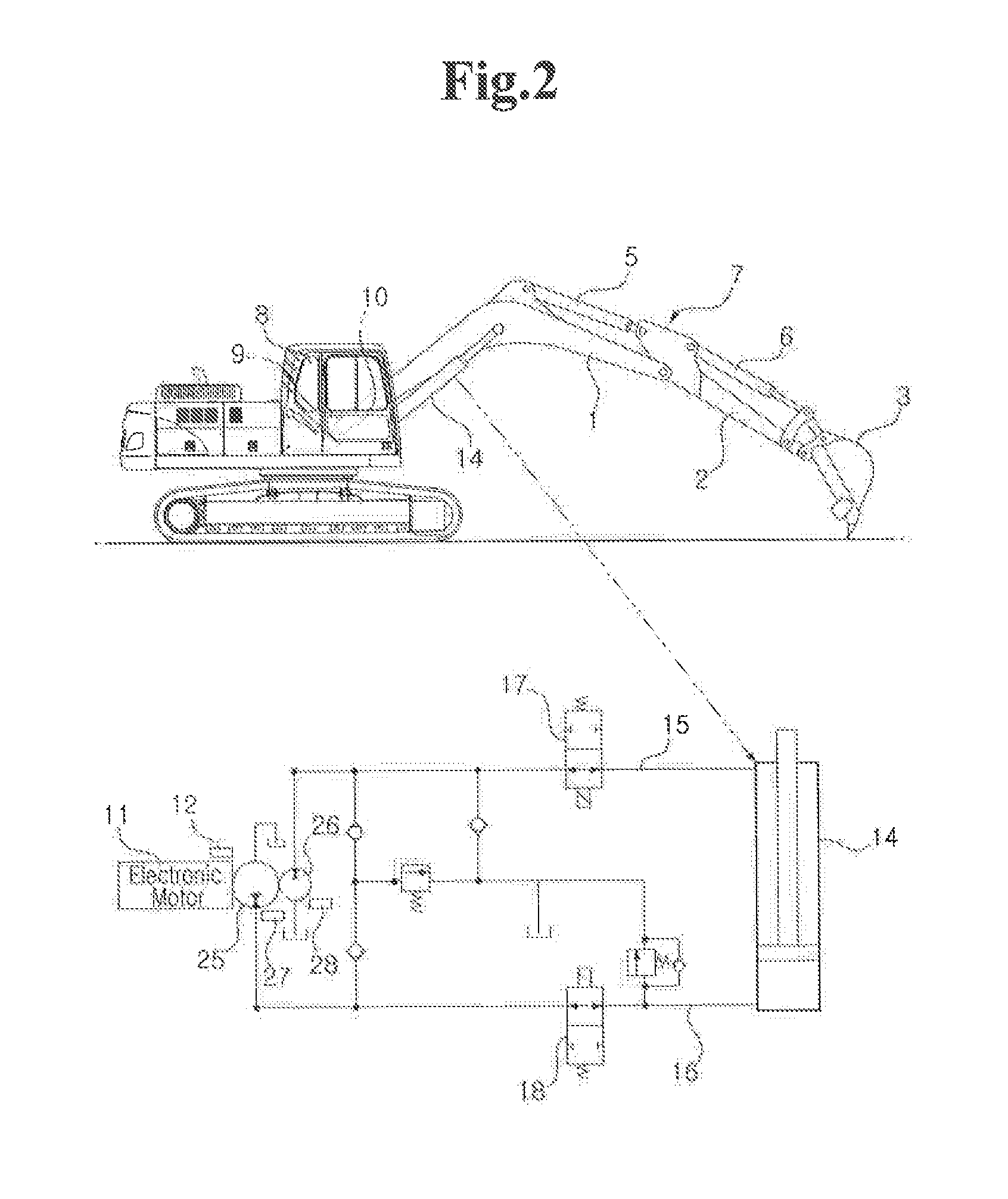

Hybrid excavator including a fast-stopping apparatus for a hybrid actuator

ActiveUS8869924B2Stop workingEnsure safetyHybrid vehiclesFluid-pressure actuator safetyHydraulic cylinderWorking fluid

The hybrid excavator includes: a first detection sensor for detecting an RCV-manipulated quantity; a second detection sensor for detecting the rotational speed of an electric motor; a hydraulic pump-motor connected to the electric motor; a hydraulic cylinder connected to the hydraulic pump-motor; first and second hydraulic valves installed in first and second passages, respectively, between the hydraulic pump-motor and the hydraulic cylinder; a third hydraulic valve for compensating for or bypassing a flow rate and a controller for receiving an RCV-manipulation signal from the first detection sensor and the rotational speed of the electric motor from the second detection sensor to compare the received values to data of previously stored working conditions, to output a control signal for switching the first and second hydraulic valves, and to block a working fluid from returning into the hydraulic cylinder, so as to thereby quickly stop the working device.

Owner:VOLVO CONSTR EQUIP AB

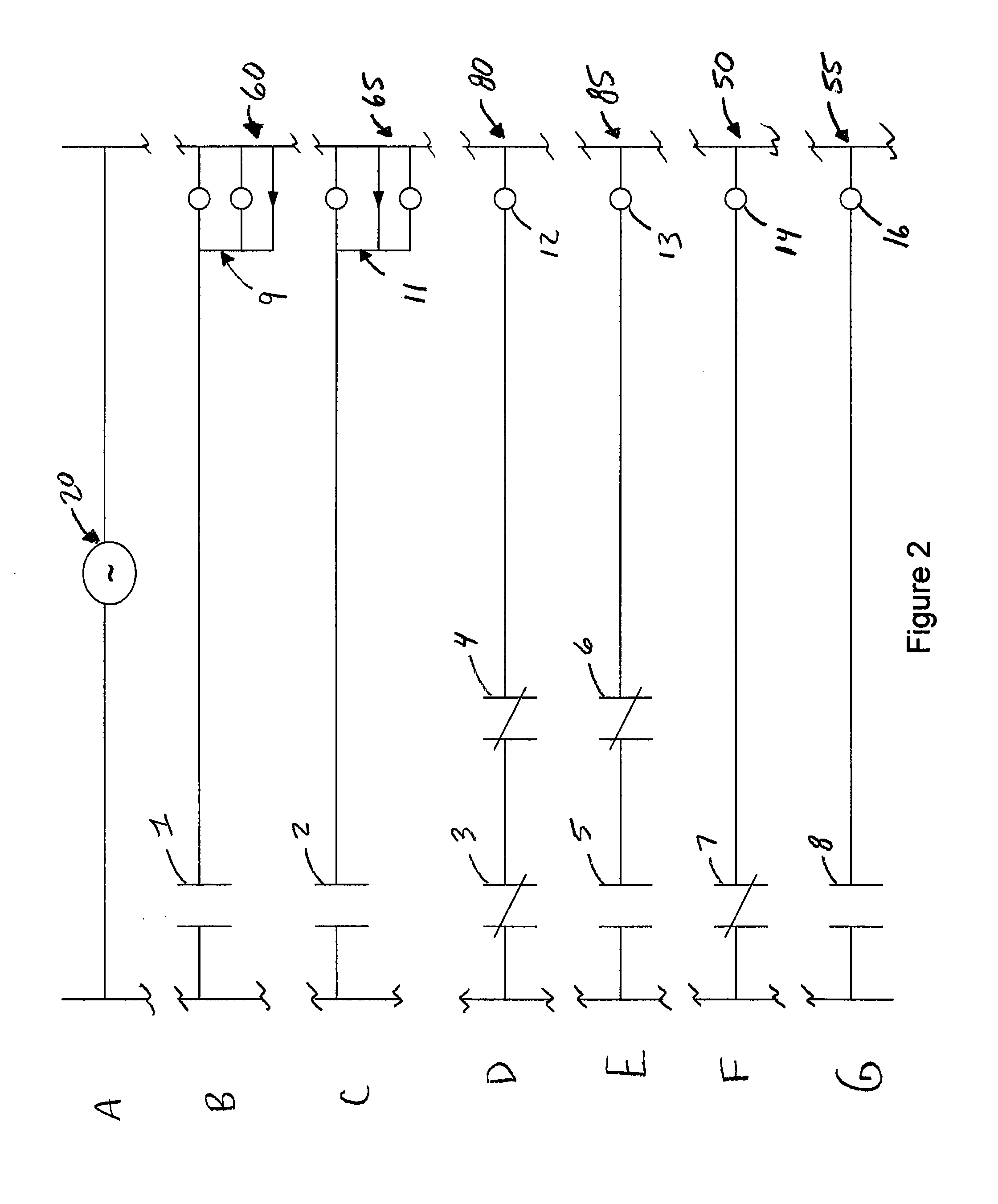

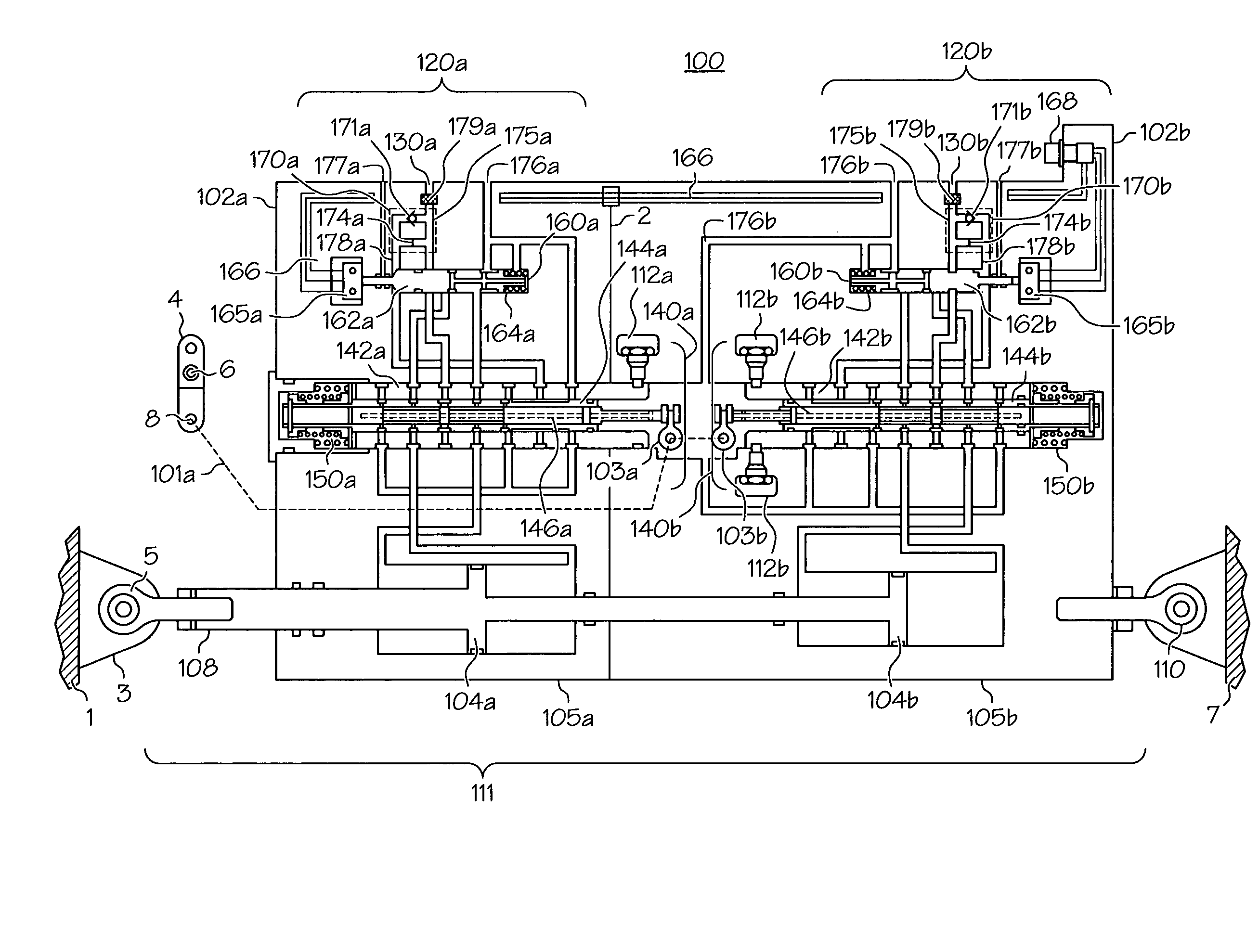

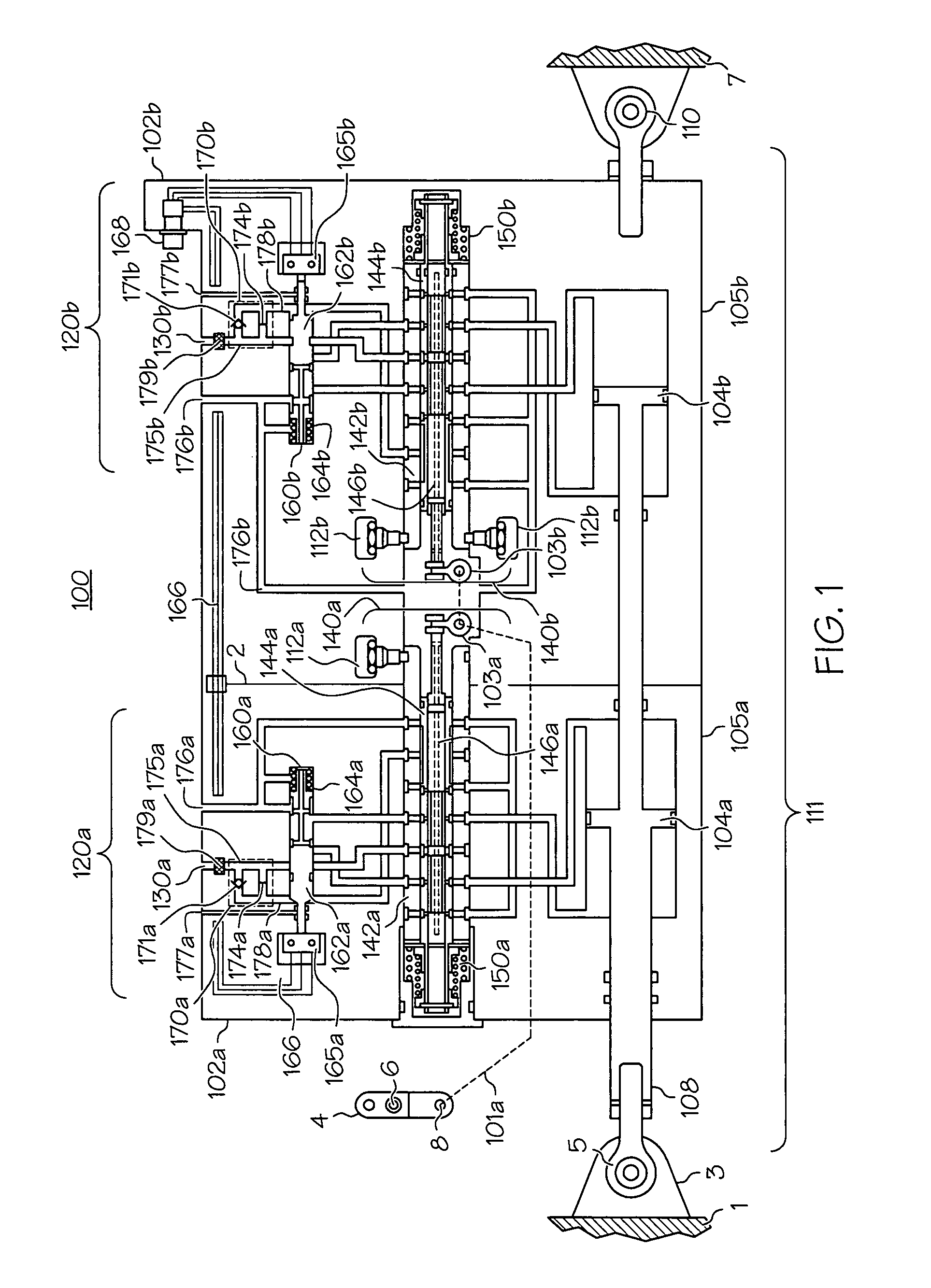

Detecting of faults in a valve system and a fault tolerant control

InactiveUS20090114284A1Fluid-pressure actuator safetyFluid-pressure actuator testingActuatorControl theory

In a method for controlling a valve system controlling an actuator, the first direction of motion of the actuator is controlled solely by the first and the second valve series; or, its second direction of motion is controlled solely by the third and the fourth valve series; and an error caused by a fault situation in the control of the actuator is compensated for by using, for the control of the first direction of motion, also the third valve series, the fourth valve series, or both of them; or, an error in the control of the actuator caused by a fault situation is compensated for by using, for the control of the second direction of motion, also the first valve series, the second valve series, or both of them. In the method, for searching for faults in the valve system controlling the actuator, the pressure of the inlet port of the valve system, the pressure of the first working port, and the pressure of the outlet port are determined; one or more valves of the first valve series and one or more valves of the second valve series are opened; the measured pressure of the first working port is compared with a situation corresponding to a system operating correctly; and on the basis of the comparison it is concluded whether the single valve is faulty or not.

Owner:ROBERT BOSCH GMBH

Redundant flow control for hydraulic actuator systems

Two or more flow control valves may be used to provide redundant flow control for a hydraulic actuator or servoactuator. The flow control valves include a sleeve, a bypass control spool, and a primary control spool. Under normal operating conditions, each bypass control spool is stationary relative to the sleeve and the flow control valve functions as a four-way hydraulic flow control valve. Each flow control valve is connected to a bypass-shutoff valve including a bypass spool that is moveable from a shut-off position to a bypass position. Upon supply pressure failure to one flow control valve, the bypass spool moves to the bypass position, reducing pressure in the corresponding actuator piston chambers. When a primary control spool becomes jammed, the corresponding bypass control spool moves within its sleeve allowing a bypass groove to port control pressure to the return line, thereby reducing pressure in the corresponding actuator piston chambers.

Owner:HR TEXTRON

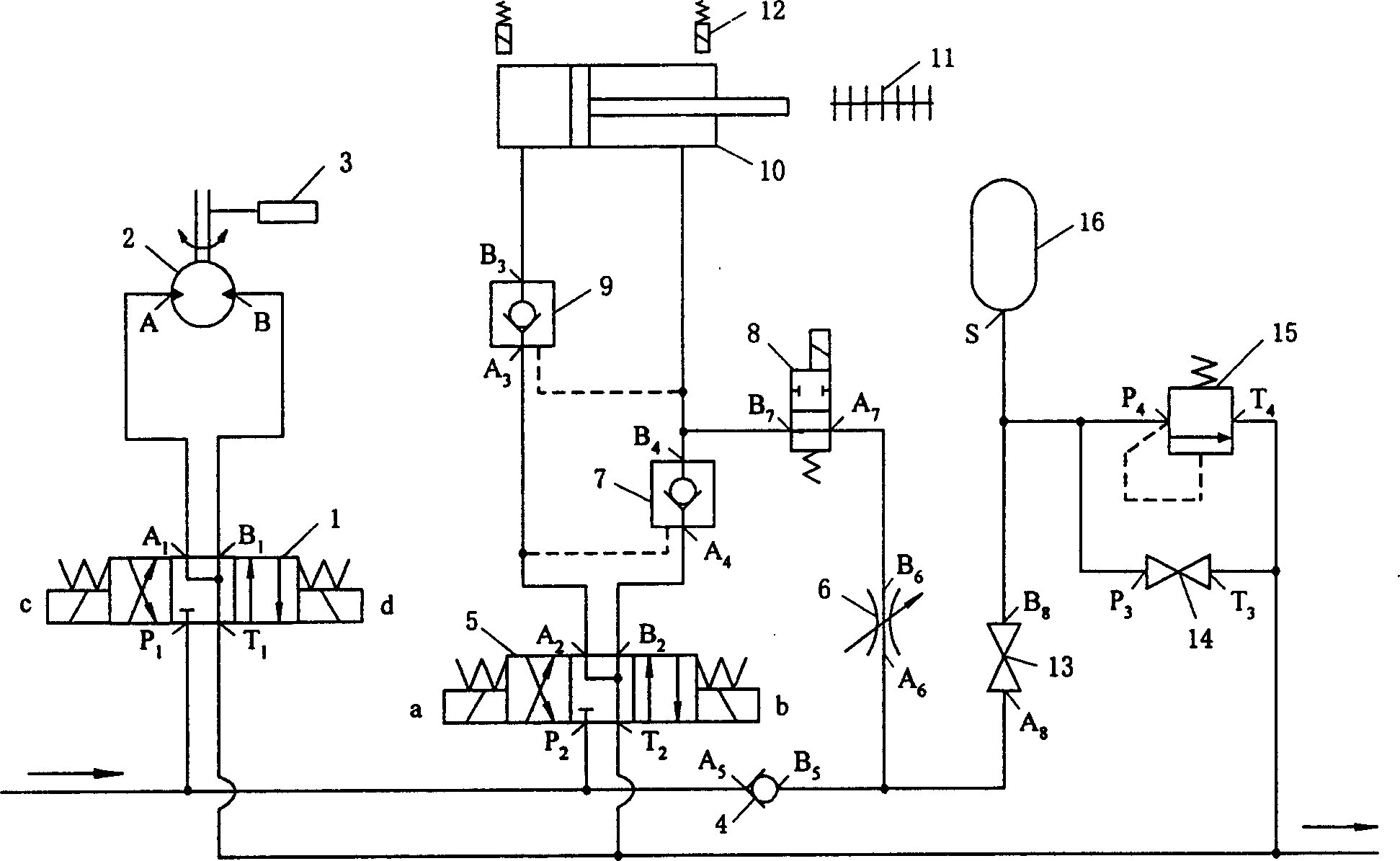

Shielding spiral conveyor hydraulic system with proportional feedback control and accumulator oil supplementary

InactiveCN1584346AControl disturbanceAdjustable speedFluid-pressure actuator safetyServomotorsEarth surfaceShuttle valve

A hydraulic system of shield spiral conveying machine with ratio feedback control and energy storing device for oil supplement consists of a three-position and four-way solenoid change valve, a motor, a rotation sensor, a one-way valve, a liquid-controlled one-way valve, a throttle valve, a two-position and two-way solenoid reversal valve, a shift sensor, a hydraulic cylinder, a range switch, a stop ball valve, a unloading valve, an overflow valve and an energy storing device. The machine has a sensor to monitor rotation and makes variable pump controlled according soil cabin pressure so as to control soil discharge volume and to achieve a hydraulic control system of a continuous real time controllable spiral-conveying machine. The energy-storing device is used oil supplement to close exhaust outlet reliably when accident occurs to guarantee safety for tunnel engineering. The electric feedback and ratio feedback are used to control turbulence to soil body when shield tunneling and reduce settlement of earth surface. The machine can be adaptable for various strata reliably.

Owner:ZHEJIANG UNIV

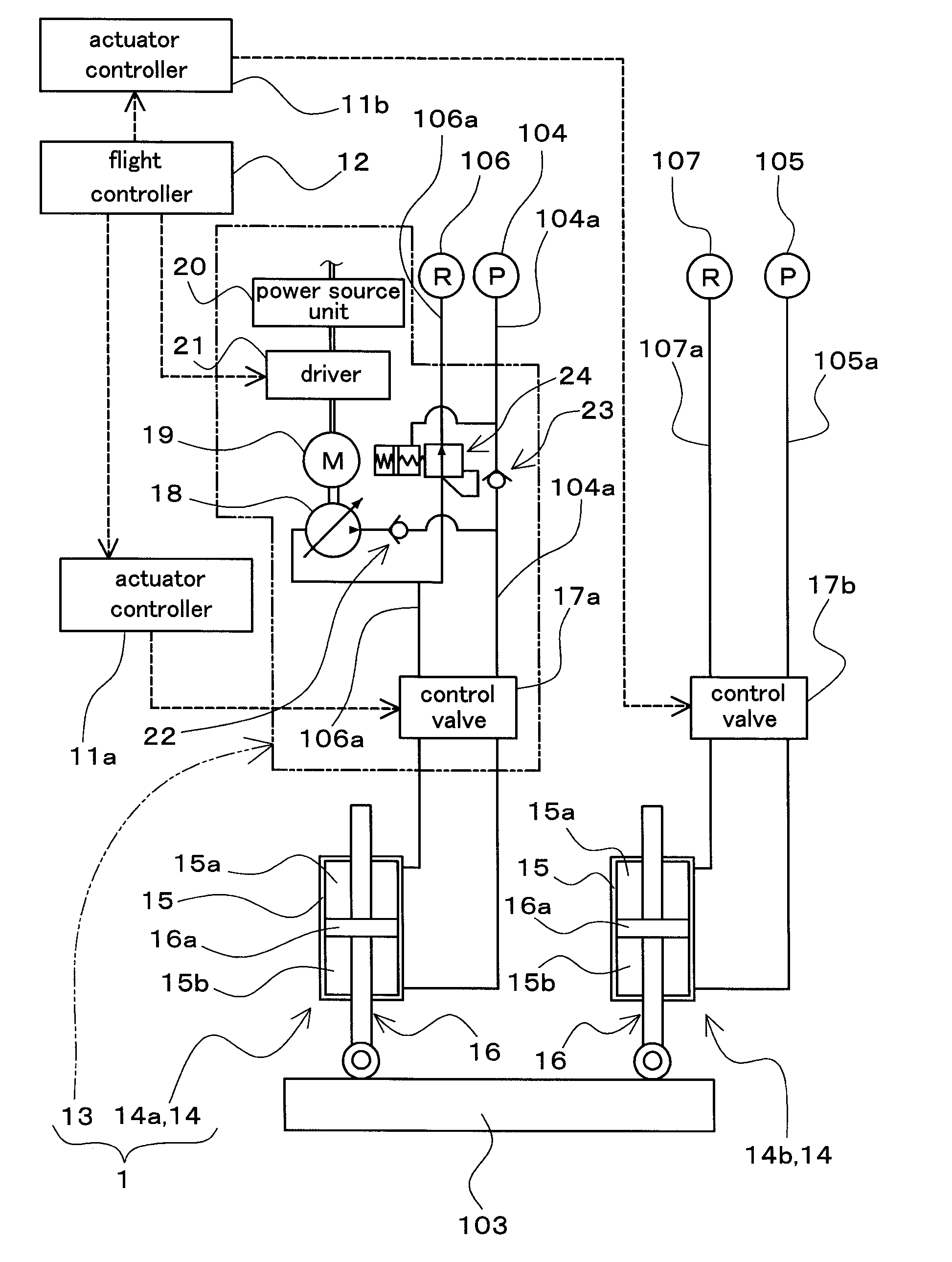

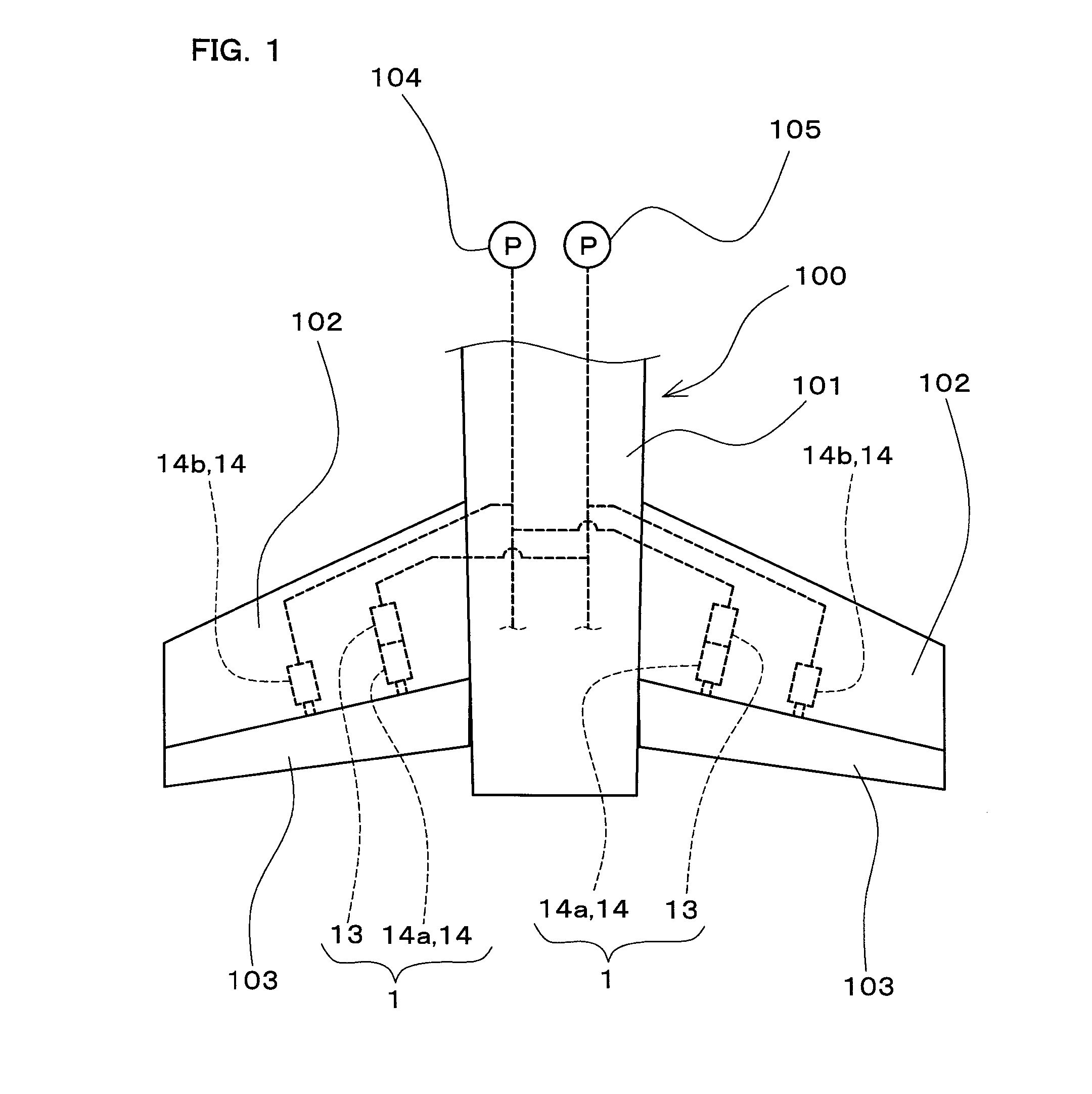

Hydraulic system for aircraft actuators

ActiveUS20110290353A1Reduce energy lossMinimize amount of heat generationFluid-pressure actuator safetyAircraft controlHydraulic pumpRotation velocity

An electric motor drives a variable capacity backup hydraulic pump that can supply pressure oil to an actuator when a loss or reduction occurs in the function of an aircraft central hydraulic power source. A power source unit rectifies electric power supplied from a variable frequency supply. A driver supplies the electric power from the power source unit, and drives the electric motor so as to rotate the pump at a predetermined constant rotational speed. The constant rotational speed is set, based on the change in the efficiency of each of the pump, the electric motor, and the driver with respect to the rotational speed of the pump, such that the overall efficiency, obtained as a product of these efficiencies, has a maximum value.

Owner:NABLESCO CORP

Hybrid excavator including a fast-stopping apparatus for a hybrid actuator

ActiveUS20140105714A1Easy to operateEnsure safetyFluid-pressure actuator safetyFluid couplingsHydraulic cylinderWorking fluid

The hybrid excavator includes: a first detection sensor for detecting an RCV-manipulated quantity; a second detection sensor for detecting the rotational speed of an electric motor; a hydraulic pump-motor connected to the electric motor; a hydraulic cylinder connected to the hydraulic pump-motor; first and second hydraulic valves installed in first and second passages, respectively, between the hydraulic pump-motor and the hydraulic cylinder; a third hydraulic valve for compensating for or bypassing a flow rate and a controller for receiving an RCV-manipulation signal from the first detection sensor and the rotational speed of the electric motor from the second detection sensor to compare the received values to data of previously stored working conditions, to output a control signal for switching the first and second hydraulic valves, and to block a working fluid from returning into the hydraulic cylinder, so as to thereby quickly stop the working device.

Owner:VOLVO CONSTR EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com