Patents

Literature

1011results about How to "Small flow resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

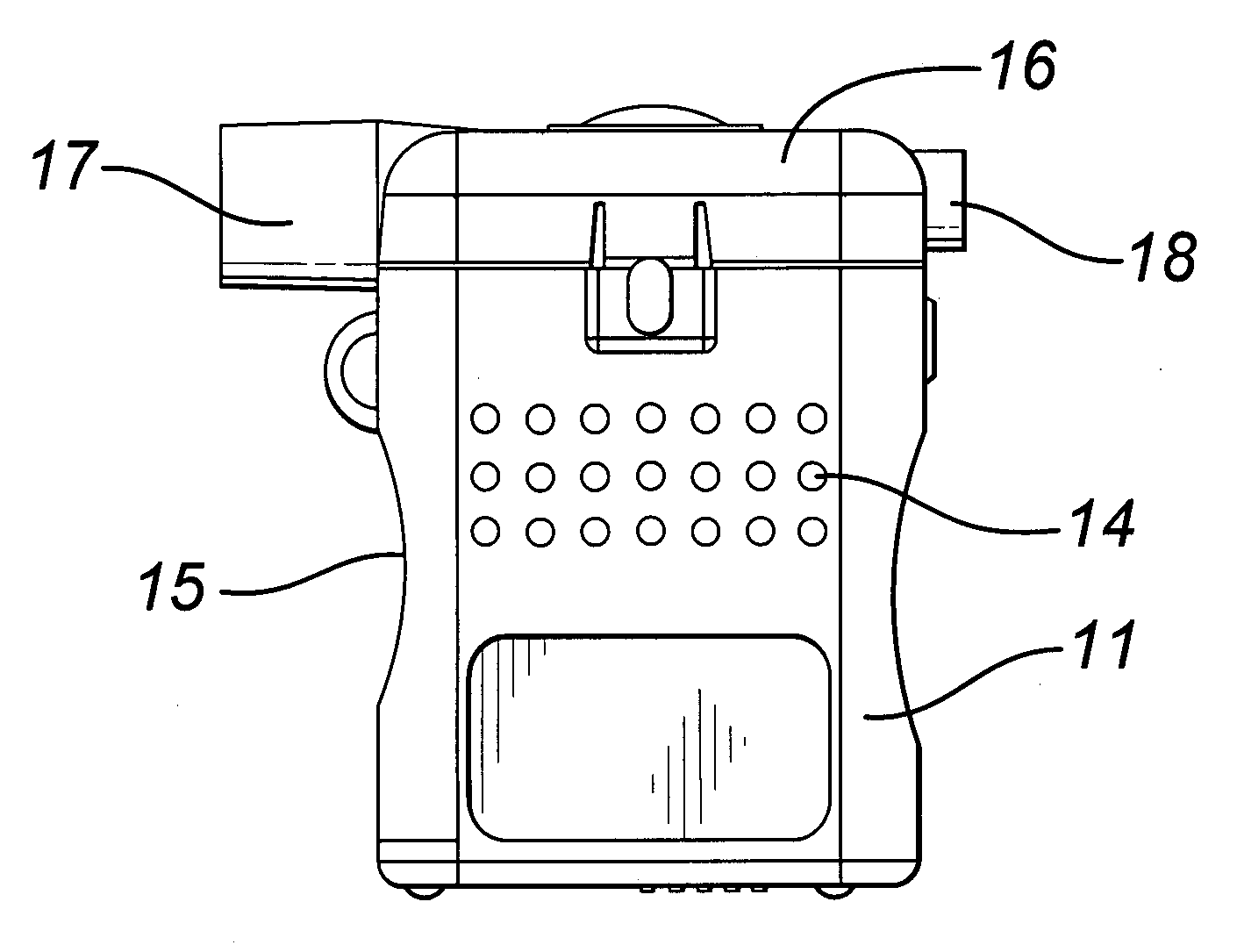

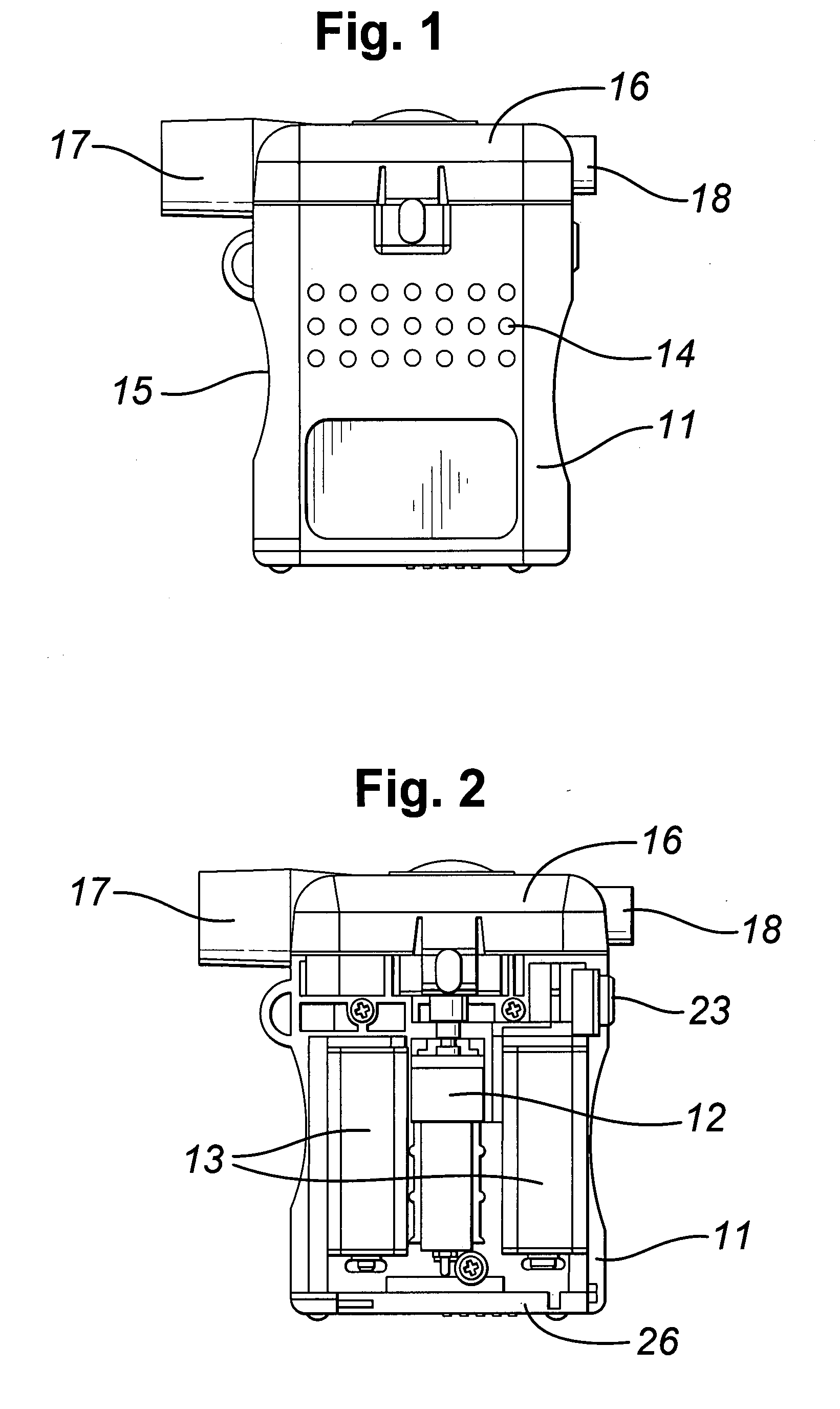

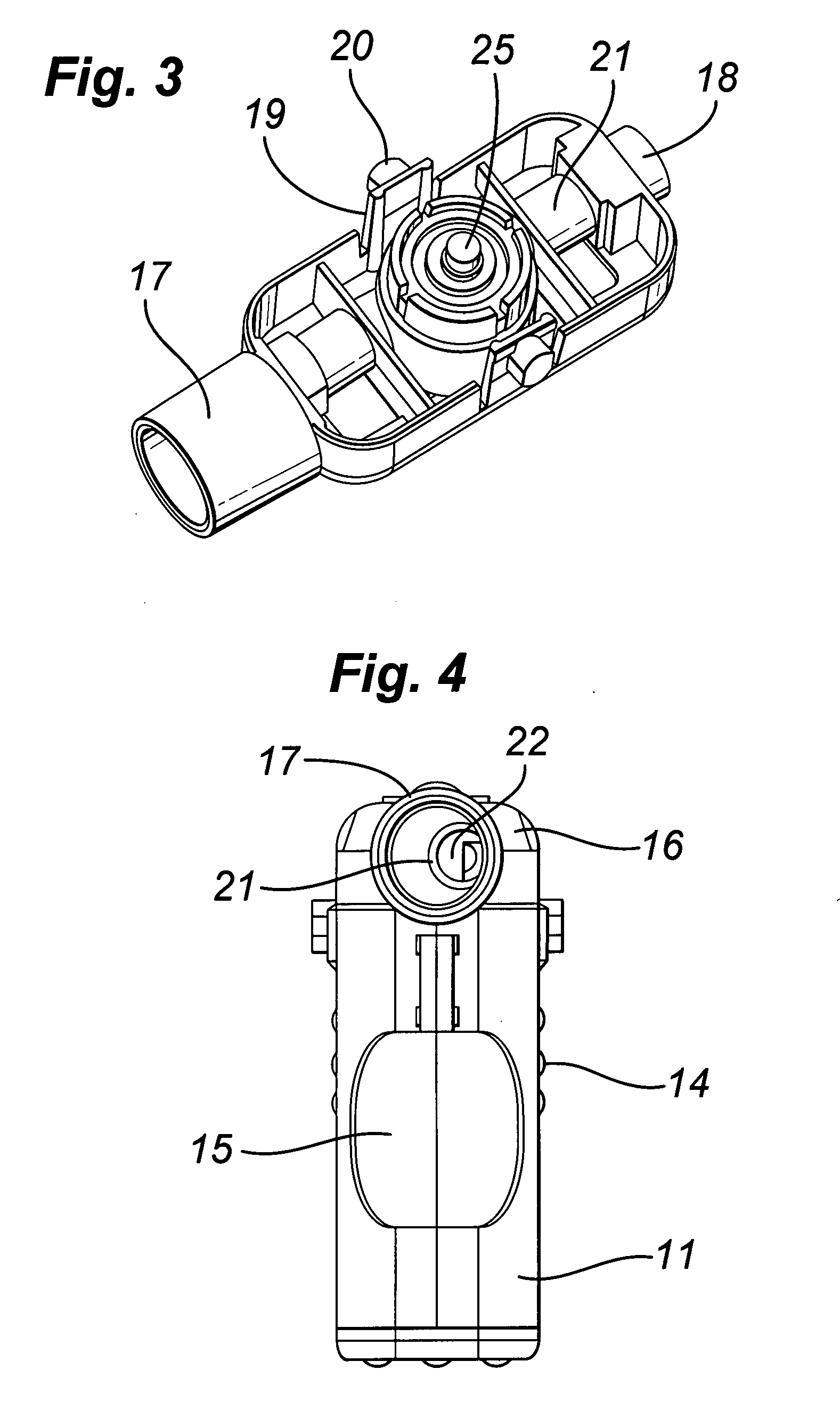

Portable breathing device

ActiveUS20080053456A1Freer great exchangeImprove efficiencyRespiratorsOperating means/releasing devices for valvesEngineeringControl circuit

A pulsed breathing device has a base unit containing a motor and control circuit and a detachable head unit containing a valve, driven by the motor, which can interrupt the flow of air being breathed.

Owner:MOLEX INC +1

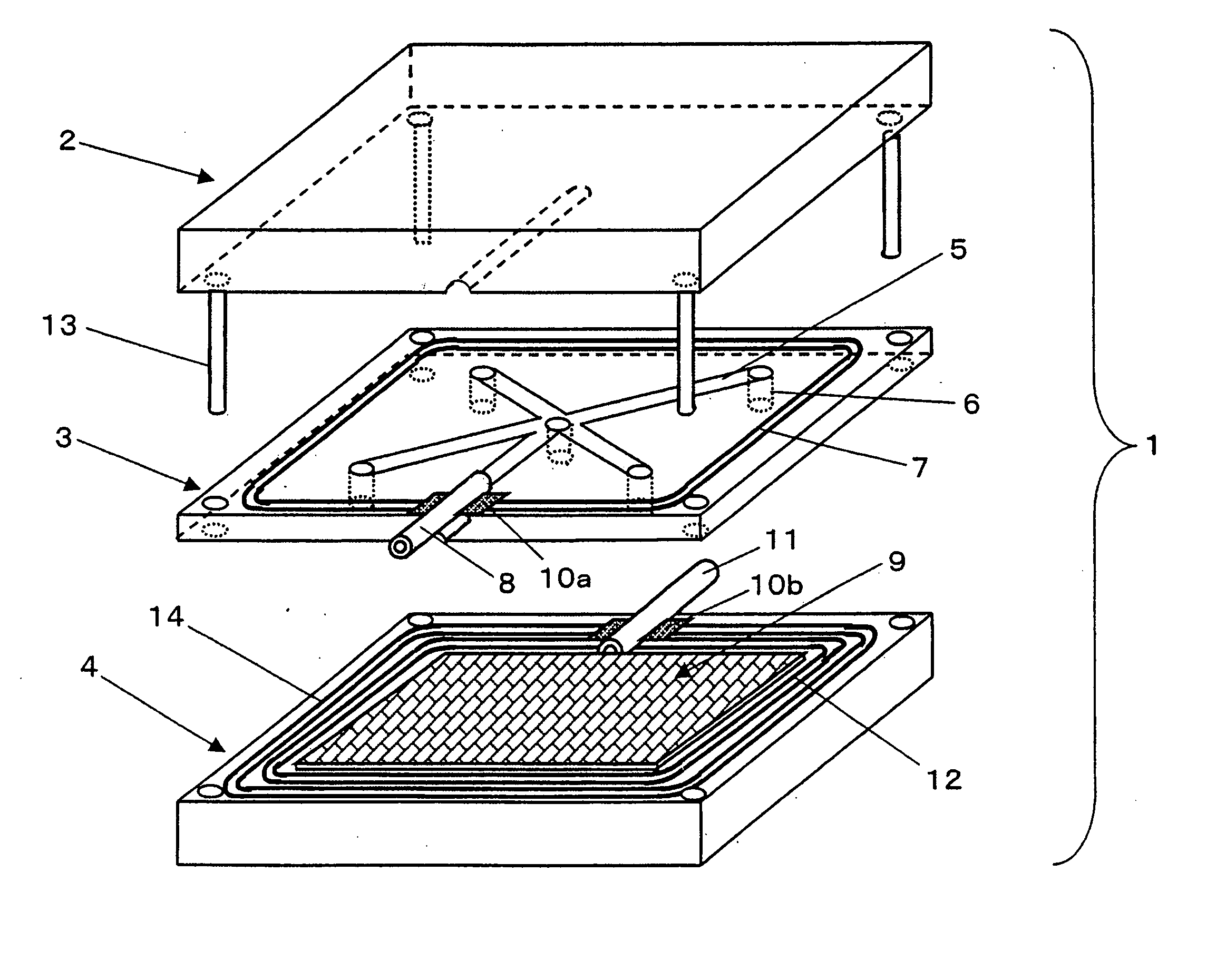

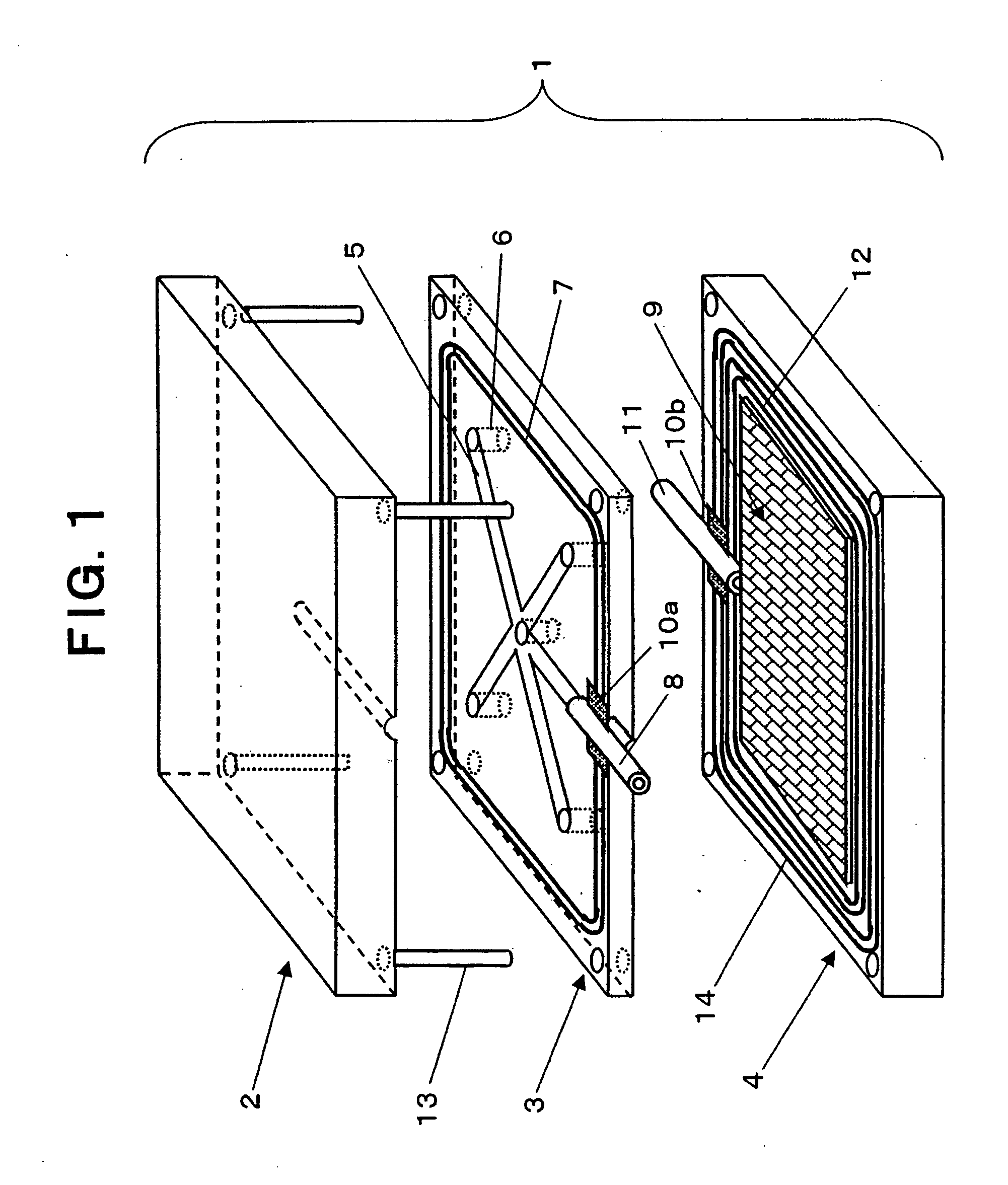

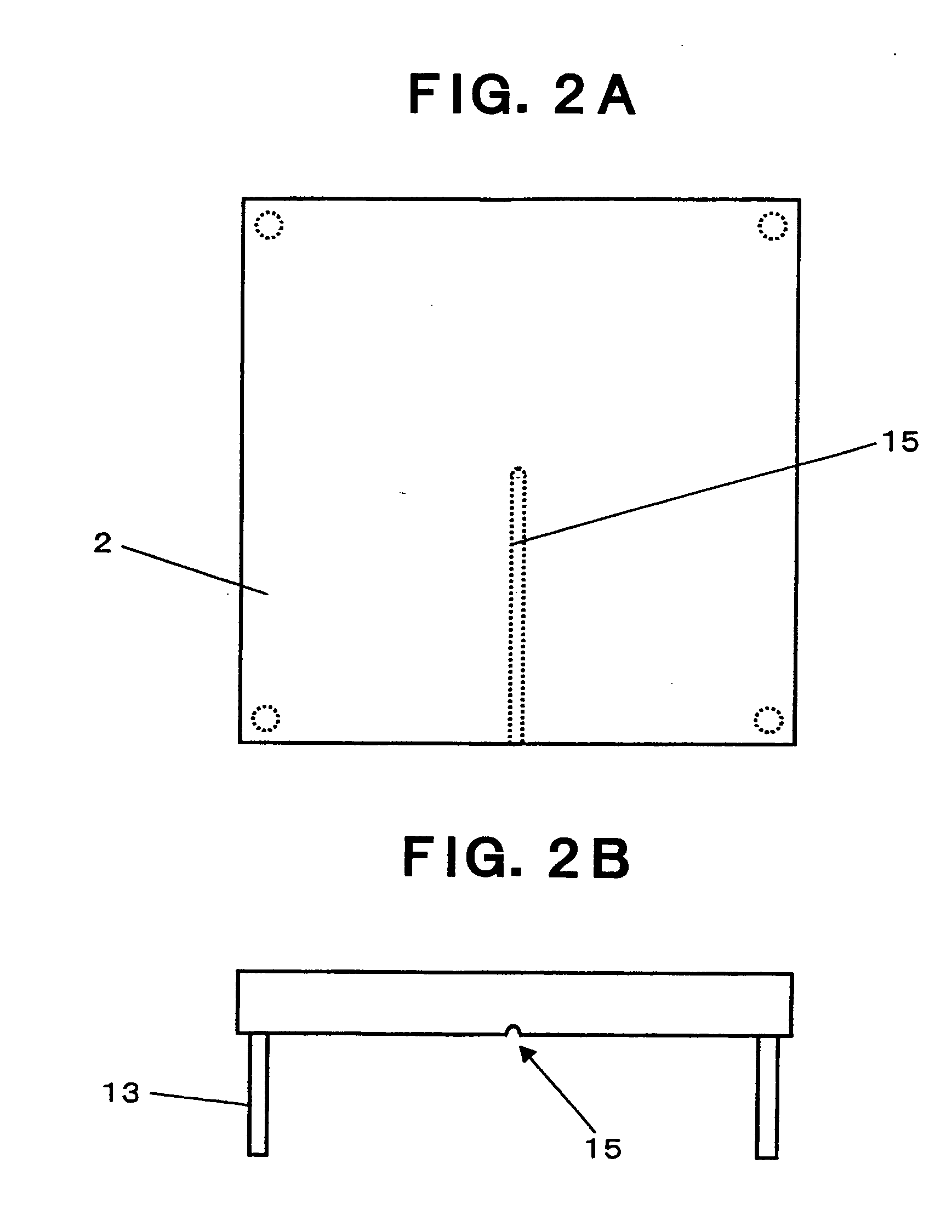

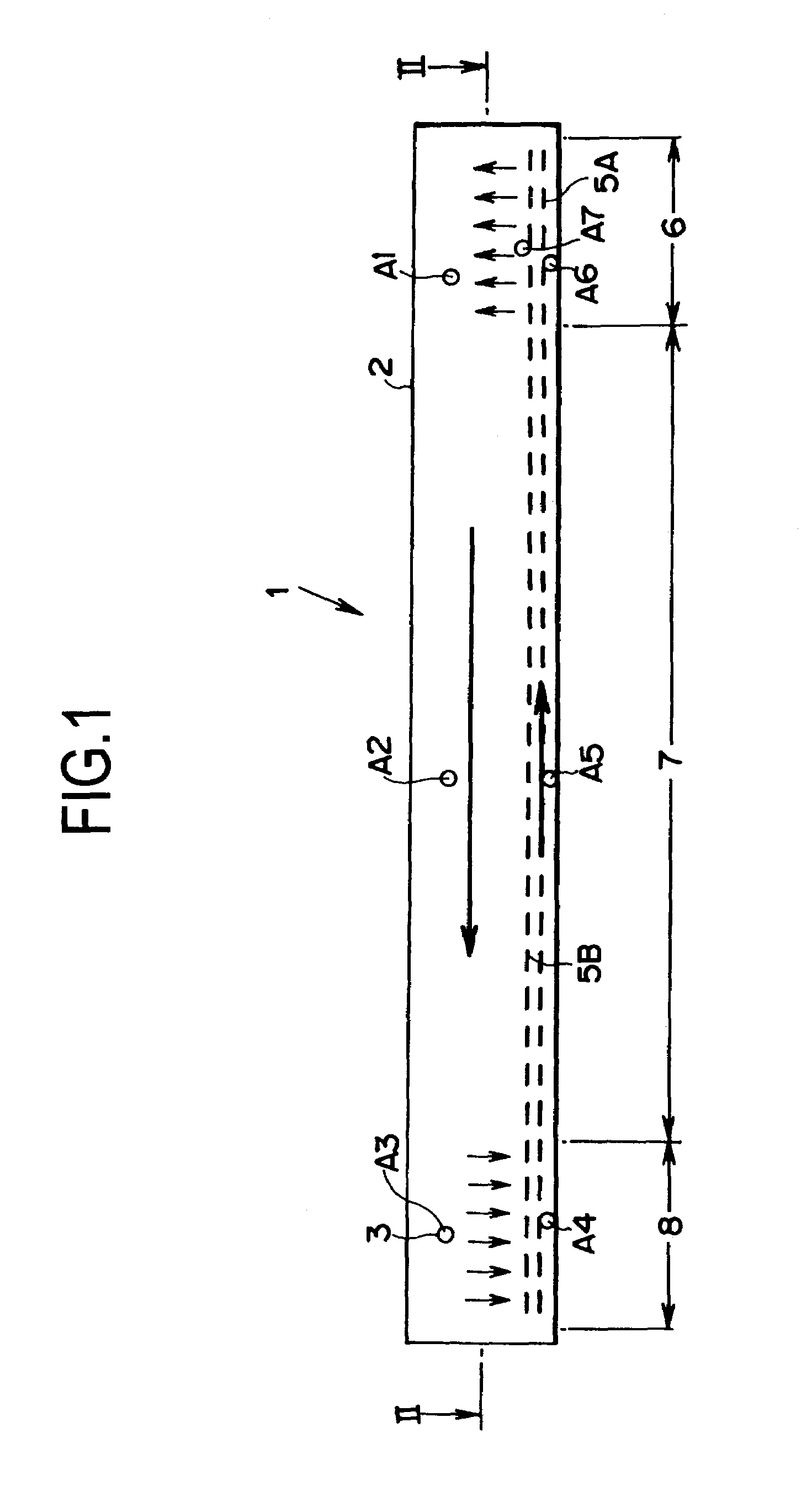

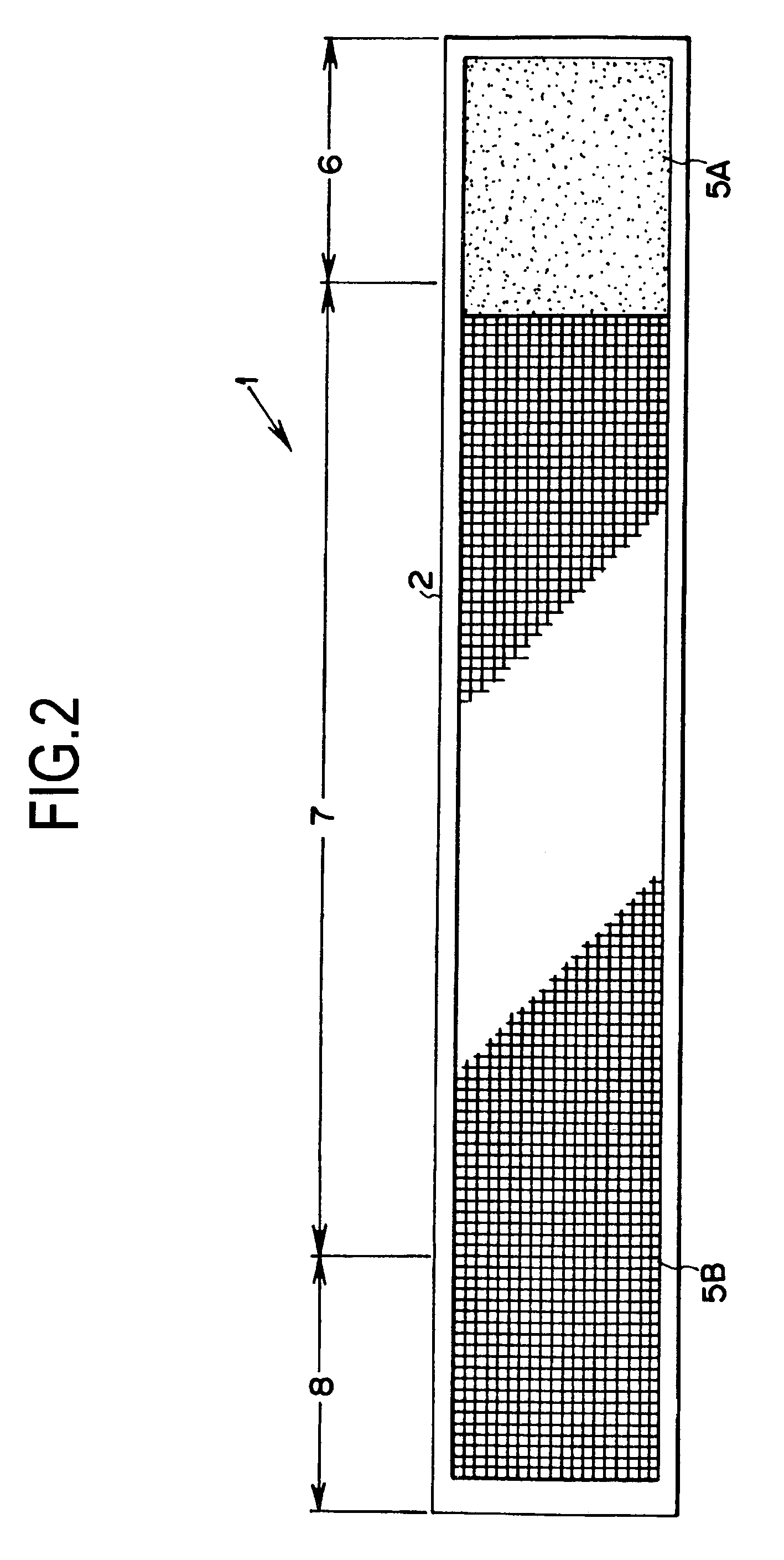

Rtm molding method and device

InactiveUS20070182071A1Shorten molding timeReduce the amount of solutionConfectioneryWood working apparatusFiber

An RTM molding method comprising disposing a reinforcing fiber substrate in a cavity of a mold consisting of a plurality of dies, clamping the mold, and thereafter injecting resin to complete molding, characterized in that divided areas with respect to the surface direction of the reinforcing fiber substrate are assumed, each divided area is one in which injected resin expands over the entire surface in the area and can be substantially uniformly impregnated in the thickness direction of the substrate, and resin introducing paths are formed for respective assumed divided areas for introducing the injected resin into the respective divided areas; and an RTM molding device. When a relatively large molded product is to be molded, a molding step from resin injection to impregnating / curing can be implemented at high speed without generating a non-resin-flowing area, thereby enabling a high-quality molded product to be produced free from voids, etc., with a molding time shortened and production speed and volume increased.

Owner:TORAY IND INC

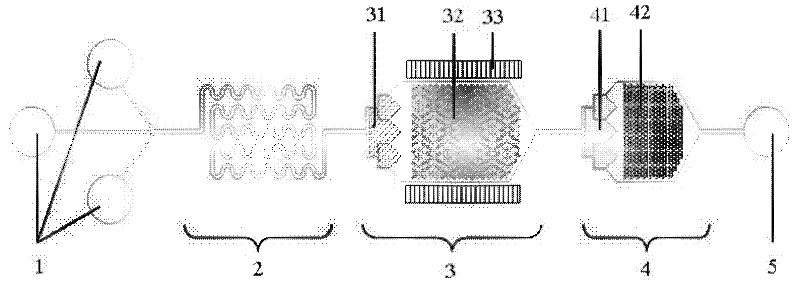

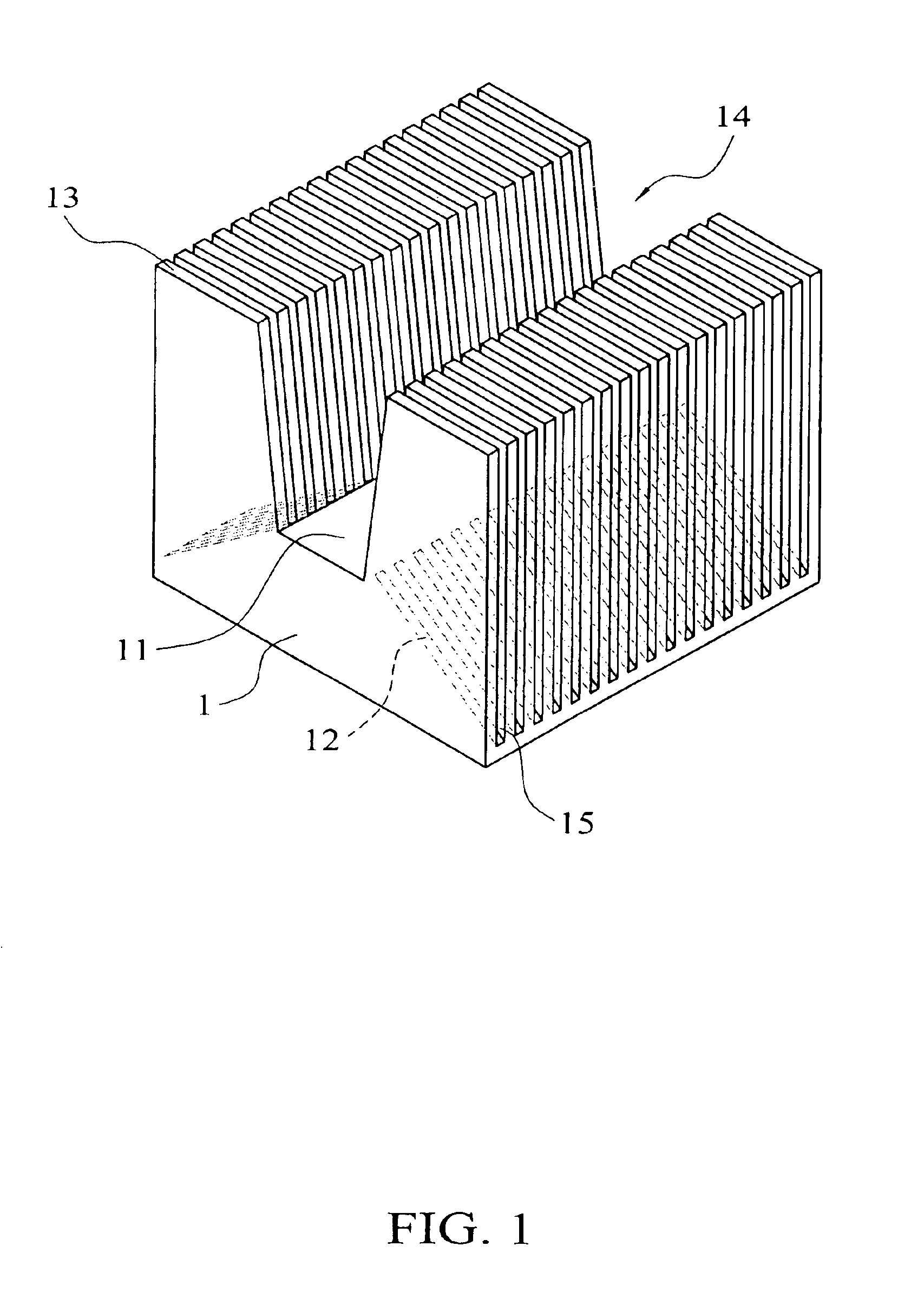

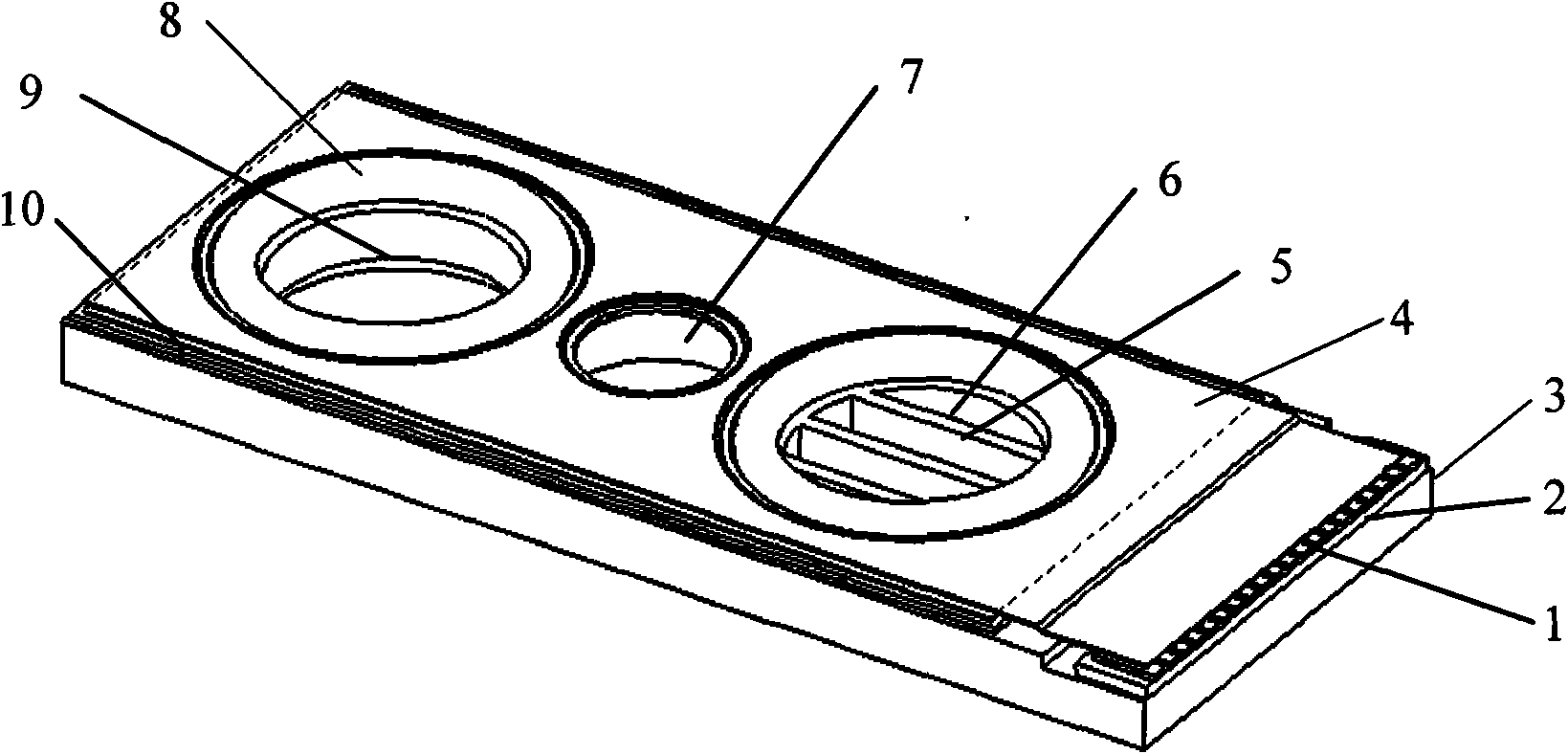

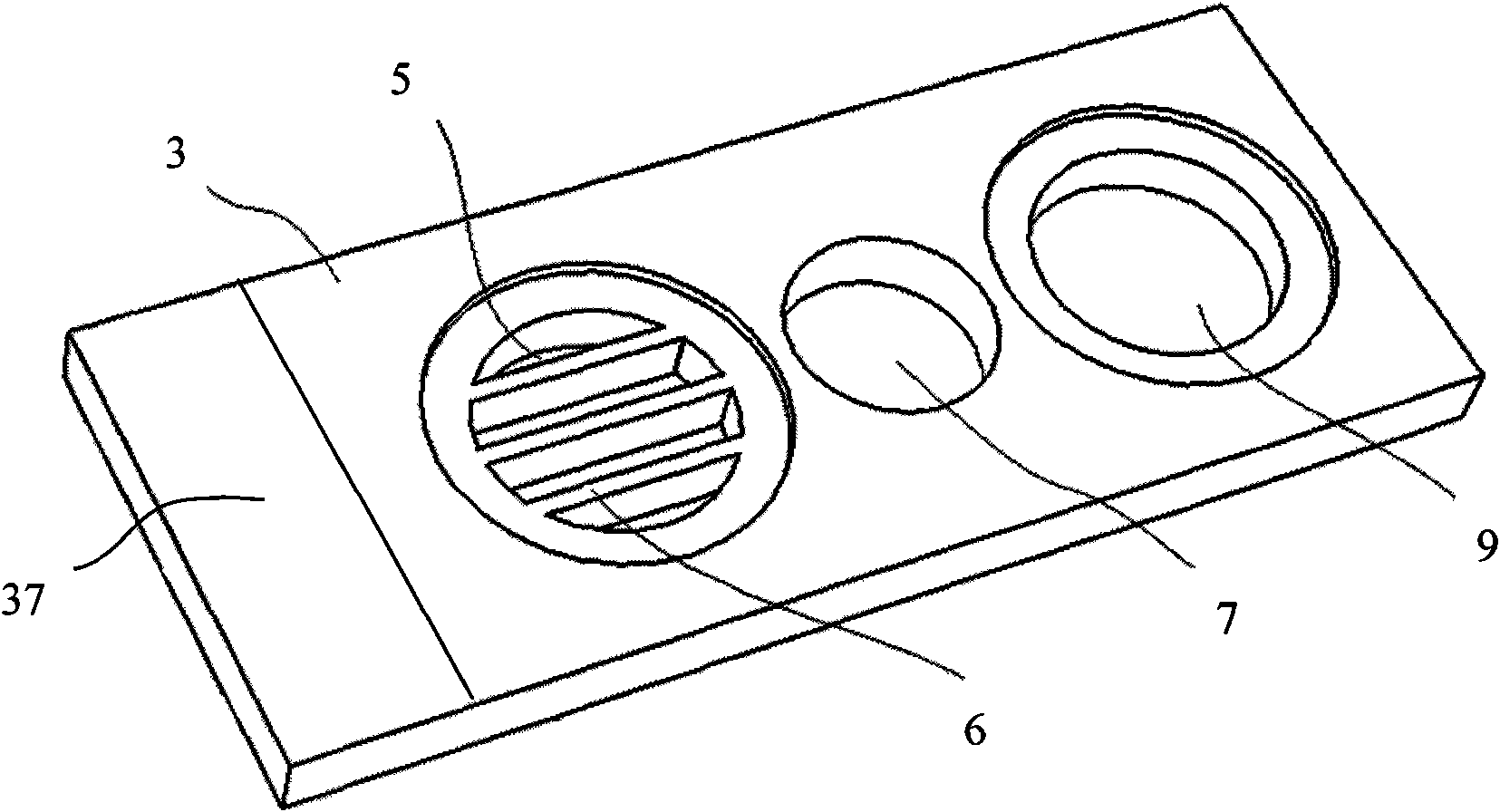

Integrated microfluidic chip for capture of cancer cells in whole blood

The invention relates to an integrated microfluidic chip for capture of cancer cells in whole blood. The integrated microfluidic chip for capture of cancer cells in whole blood comprises three inlets, an erythrocyte lysis unit, a leucocyte capture unit, a cancer cell capture unit and an outlet, wherein the three inlets, the erythrocyte lysis unit, the leucocyte capture unit, the cancer cell capture unit and the outlet are connected orderly. The leucocyte capture unit comprises a first diverter, a soft magnetic microcolumn array and permanent magnets. The first diverter is connected with the soft magnetic microcolumn array. The permanent magnets are arranged at two sides of the soft magnetic microcolumn array. The cancer cell capture unit comprises a second diverter and a capture microstructure array, wherein the second diverter and the capture microstructure array are connected orderly. Compared with the prior art, the integrated microfluidic chip for capture of cancer cells in whole blood has the advantages of high integration degree, simple operation, high cell capture efficiency, simple manufacture processes and the like.

Owner:SHANGHAI JIAO TONG UNIV

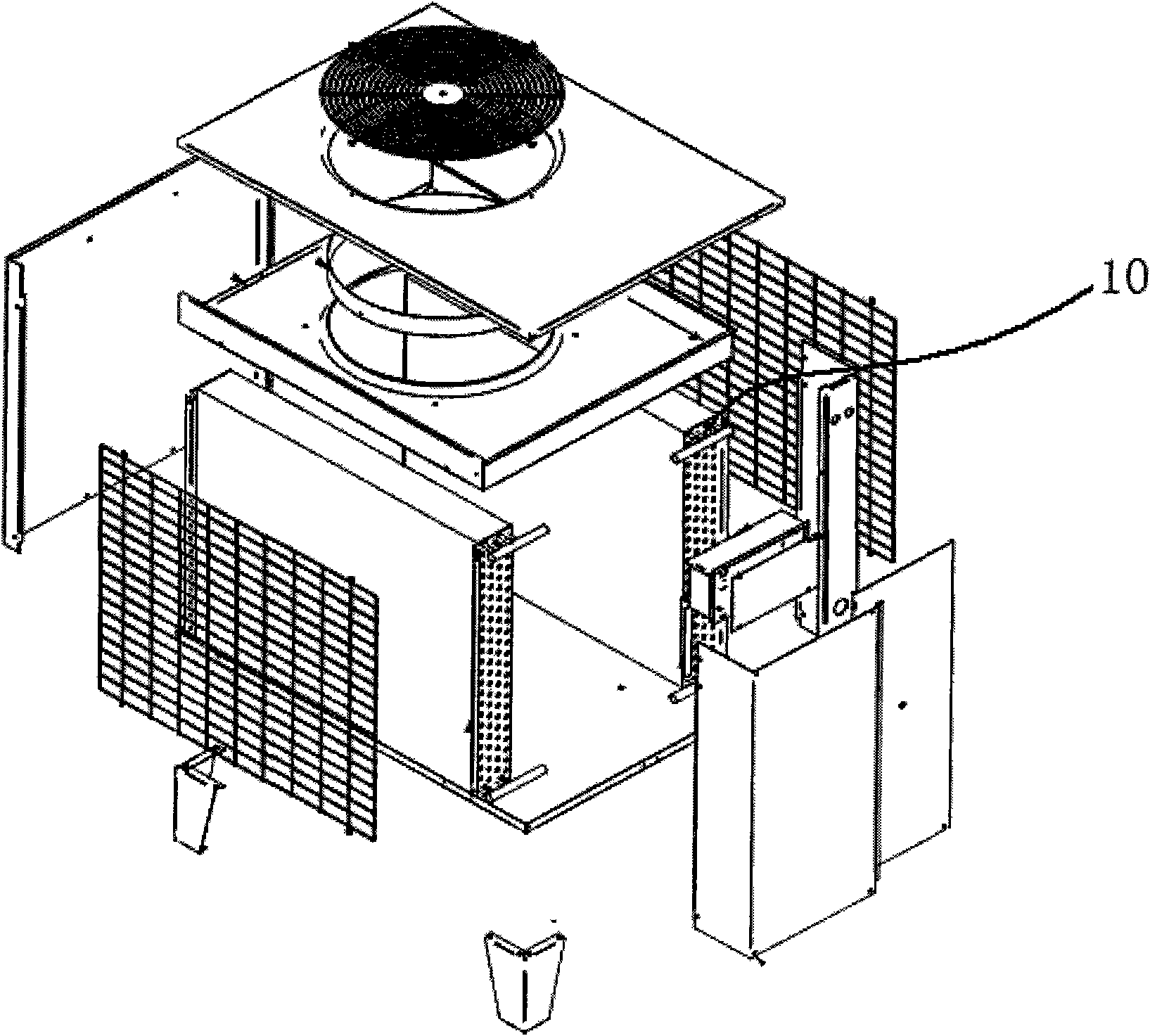

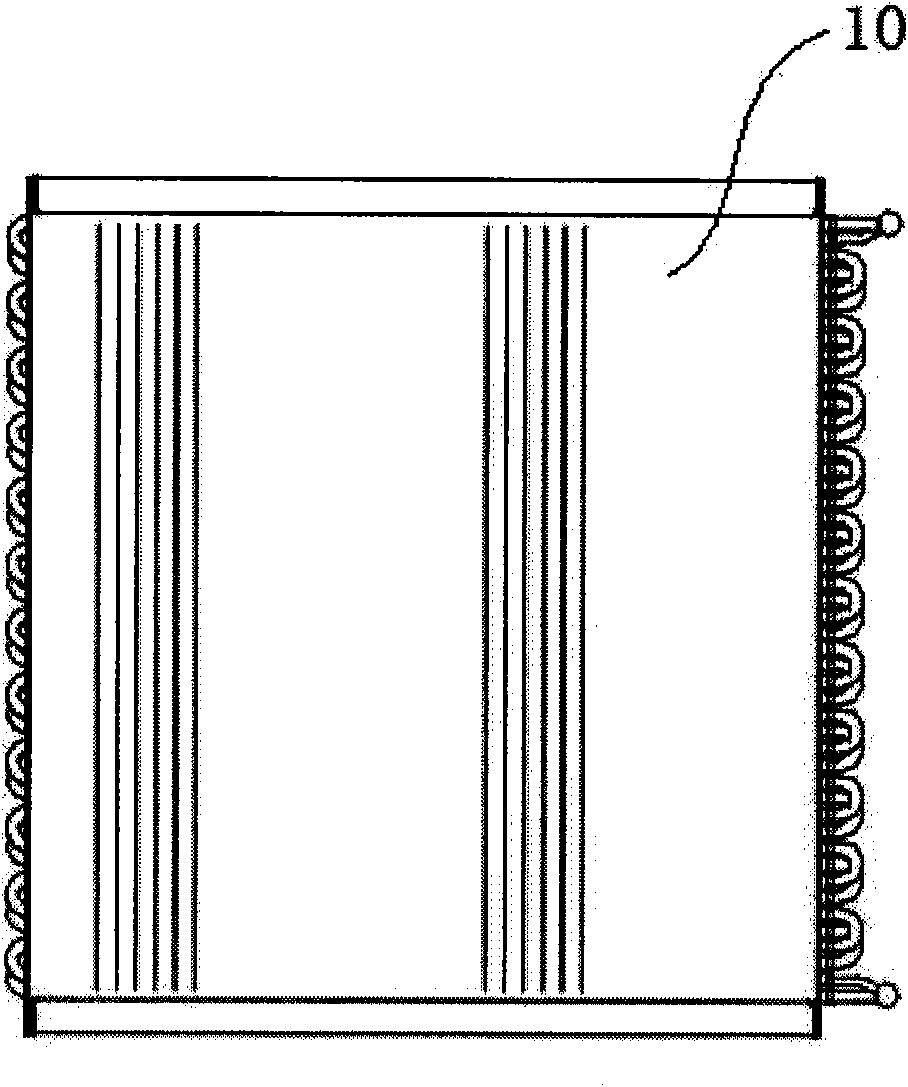

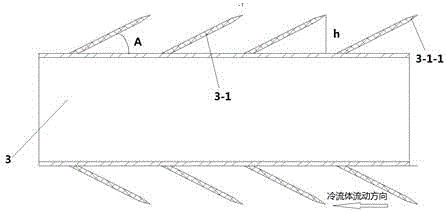

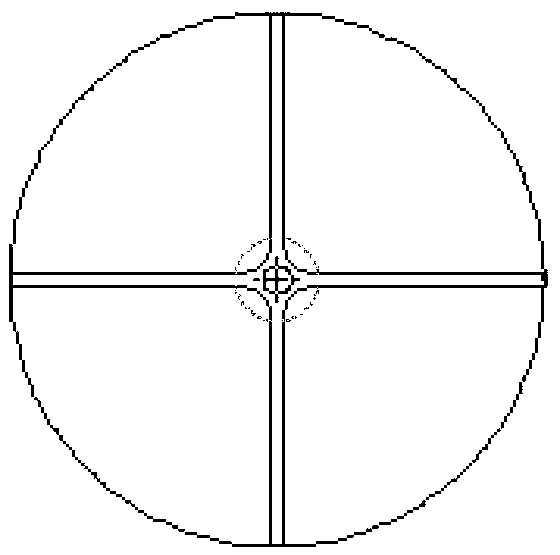

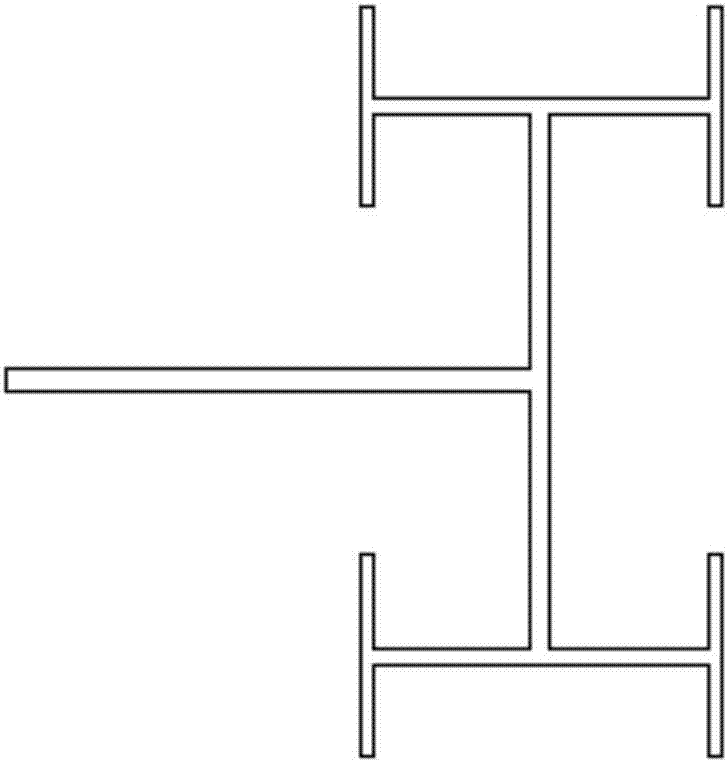

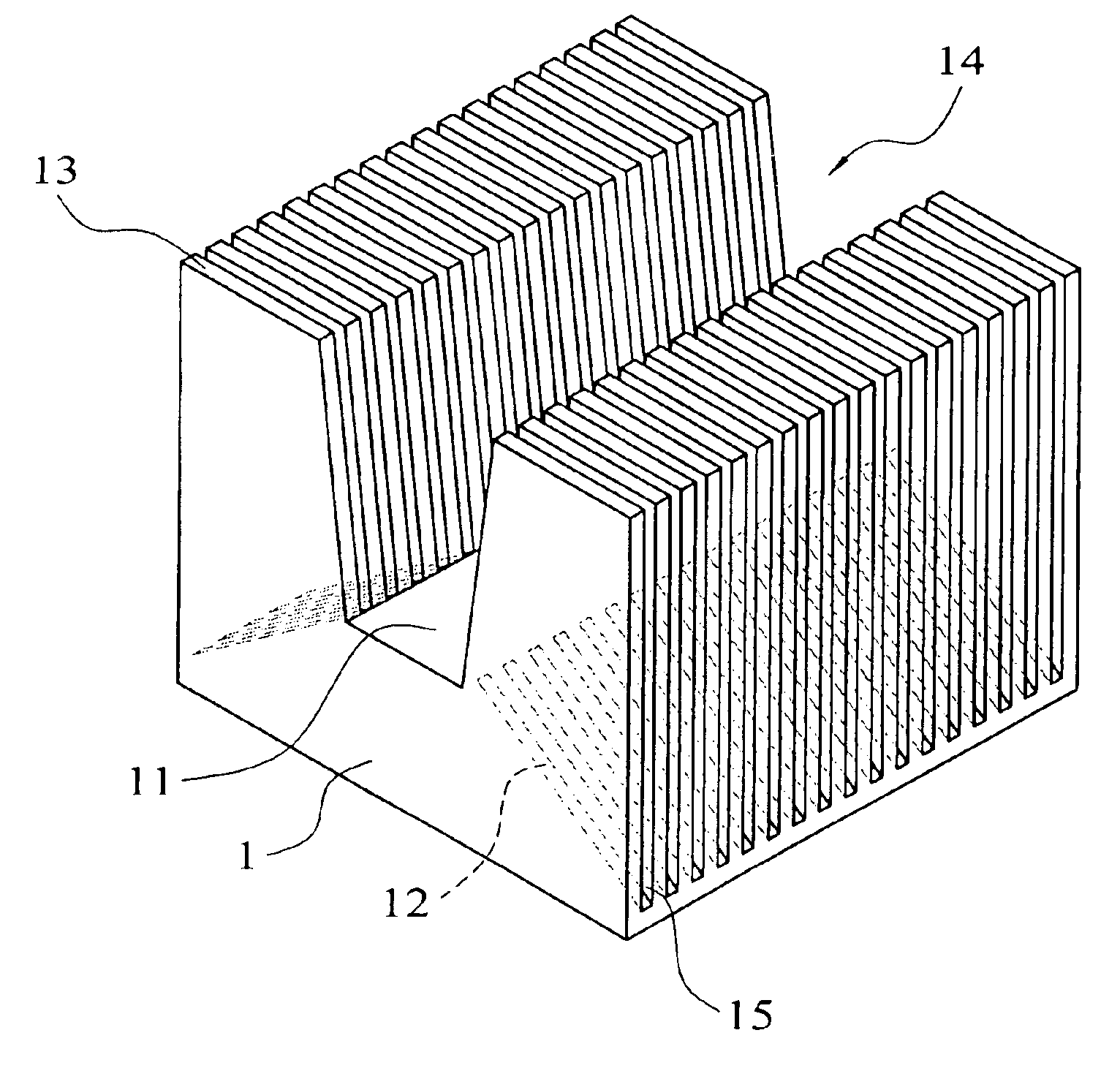

Heat exchanger with micro-channel, parallel-flow and all-aluminum flat pipe welding structure and application

InactiveCN101936670ASmall flow resistanceImprove heat transfer efficiencyEvaporators/condensersStationary conduit assembliesPotential differenceEngineering

The invention discloses a heat exchanger with a micro-channel, parallel-flow and all-aluminum flat pipe welding structure. The heat exchange part of the heat exchanger is formed by arranging flat pipes consisting of aluminum extruded thin-walled sections in parallel. Compared with the prior art, the heat exchanger with the micro-channel, parallel-flow and all-aluminum flat pipe welding structure has the advantages that: 1, the heat exchange efficiency of a refrigerant and the inner walls of the flat pipes is improved by 40 percent, and the flow resistance of the refrigerant in collecting pipes of the heat exchanger is reduced by 40 percent; 2, the heat exchange efficiency of fins on an air side is improved by 40 percent, and the wind resistance of the heat exchanger on the air side is reduced by 40 percent; 3, the heat exchange performance of the whole heat exchanger is improved by 40 percent; 4, compared with the prior art, the heat exchanger consumes 40 percent less refrigerant; and5, compared with the conventional copper-aluminum structure, the all-aluminum structure endows the heat exchanger with longer service life because of no copper-aluminum potential differences. The heat exchanger adopting the flat pipes has the characteristics of capability of bearing the conventional limitation of high-pressure resistance value of the refrigerant, compact product structure, light unit weight, short process flow, high manufacturing reliability and relatively lower cost. The invention also discloses the application of the heat exchanger.

Owner:王磊

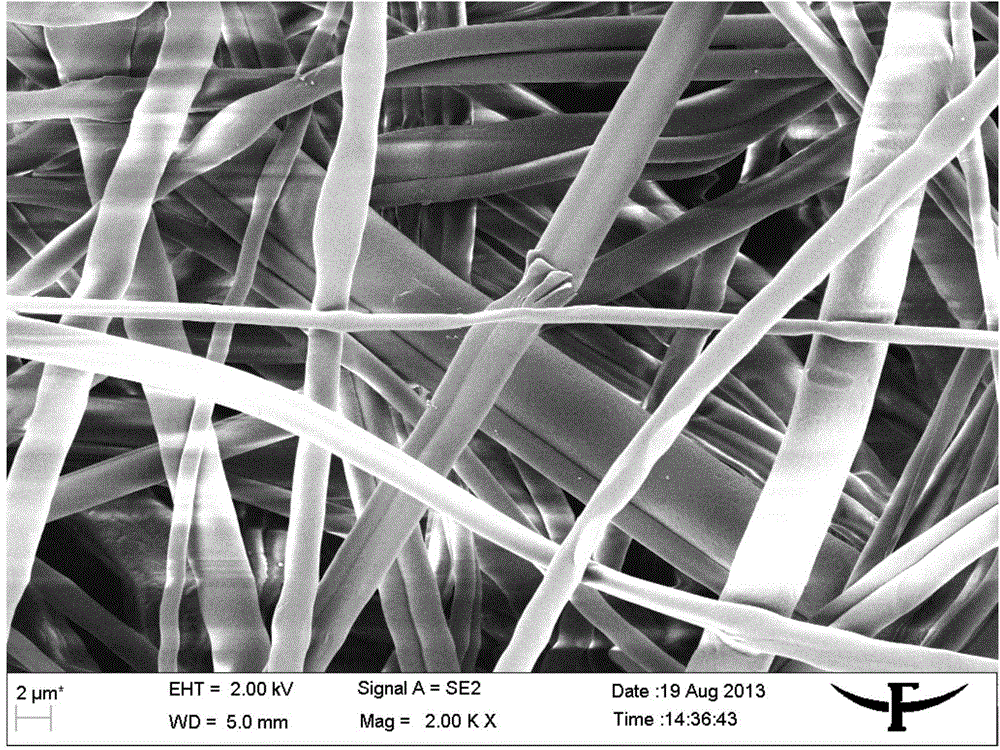

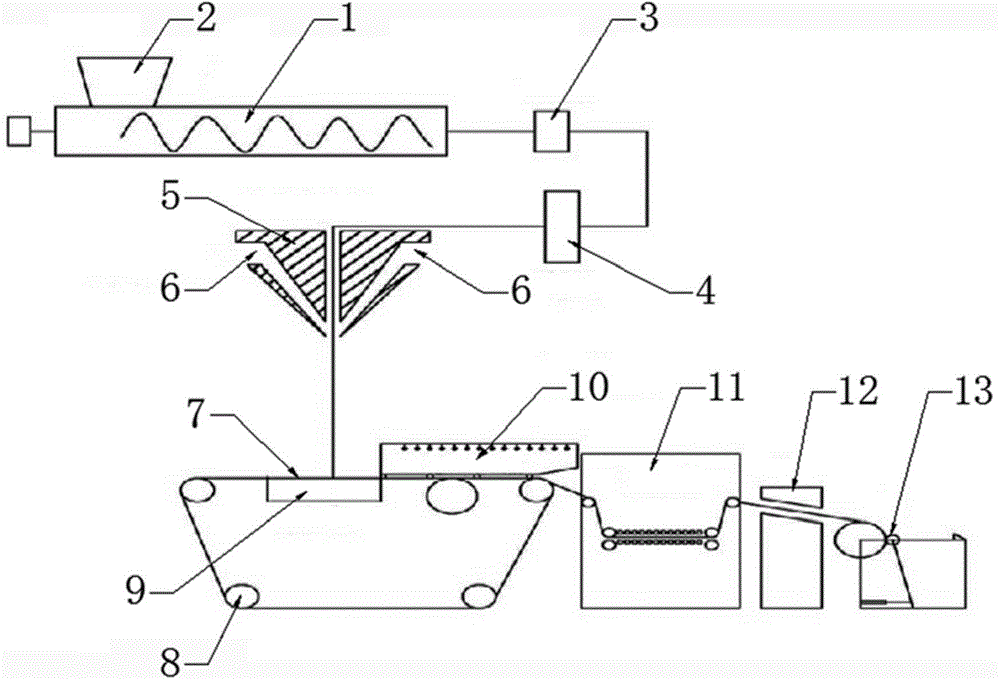

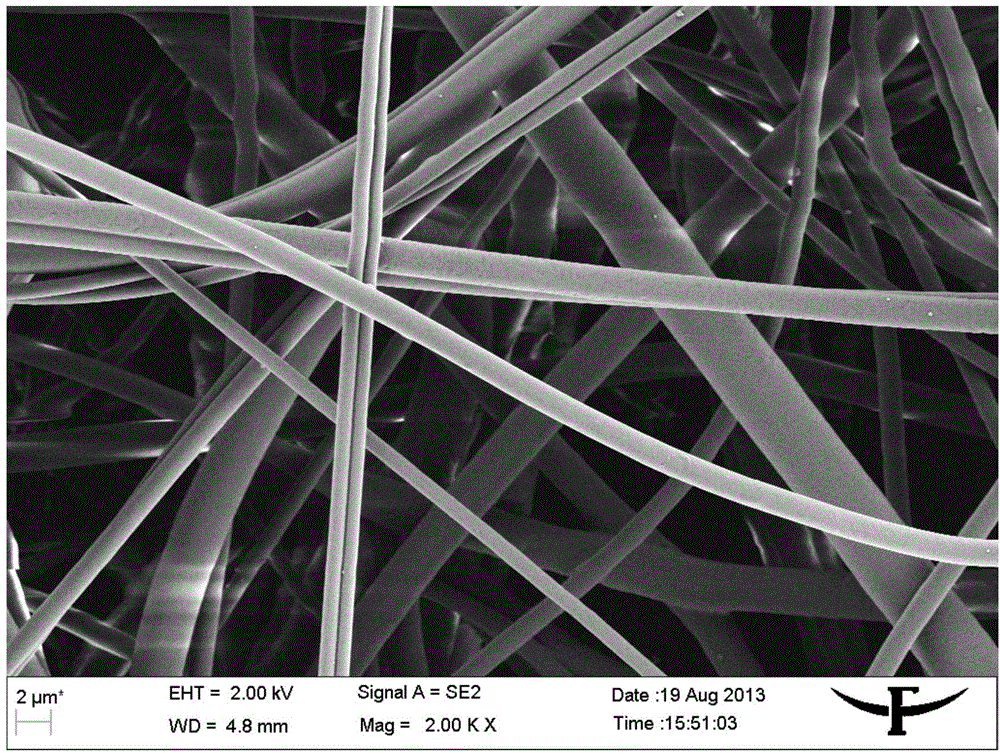

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

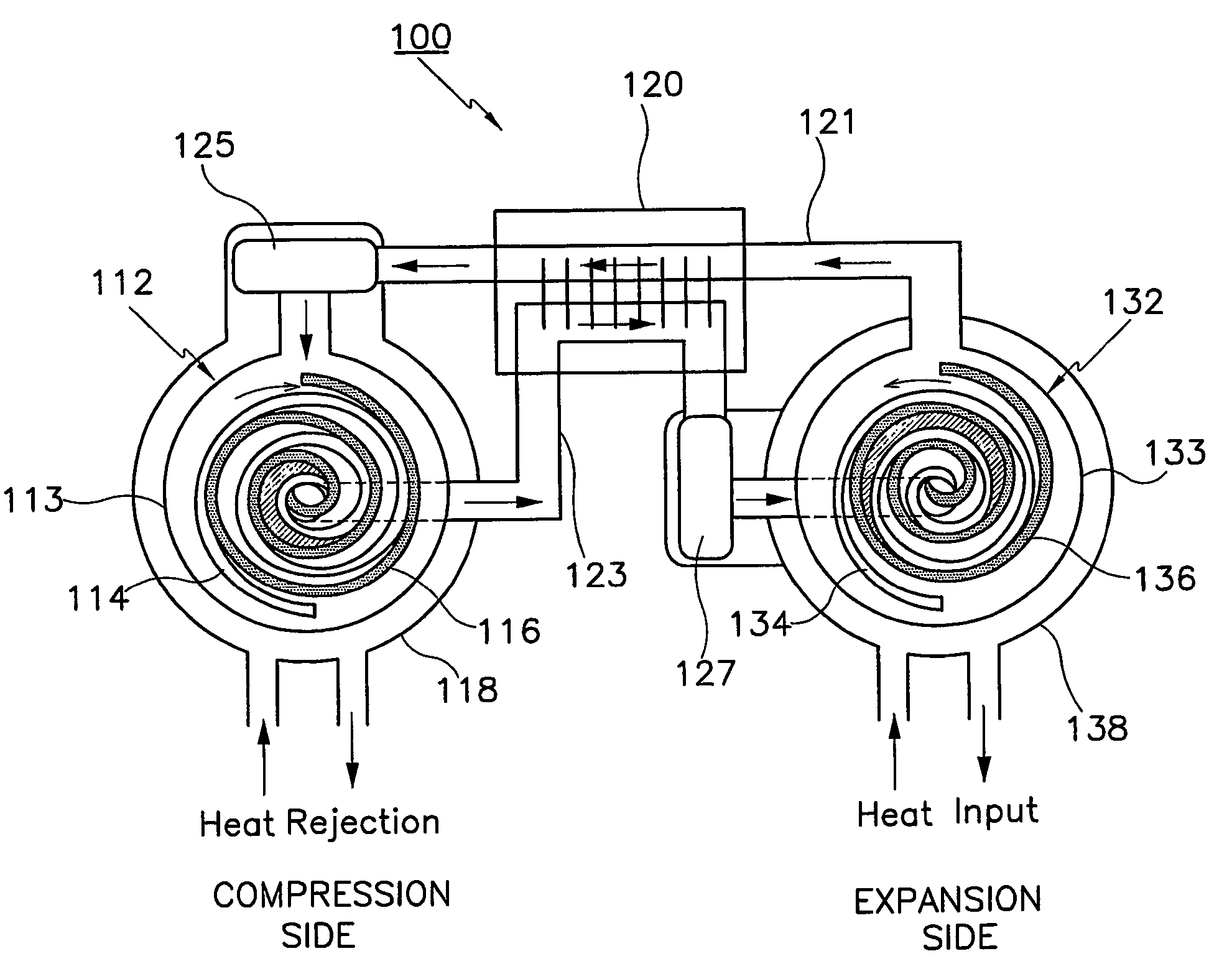

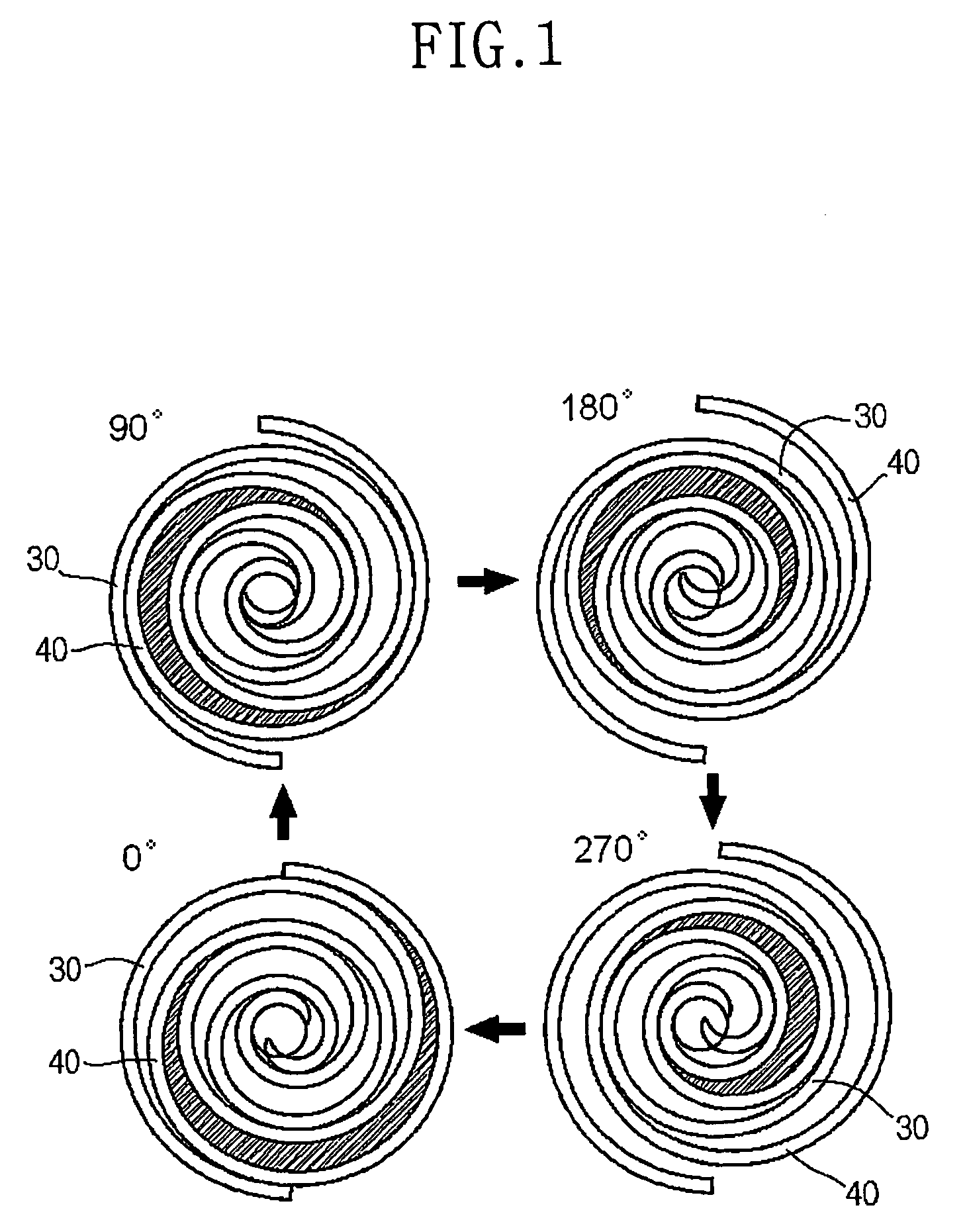

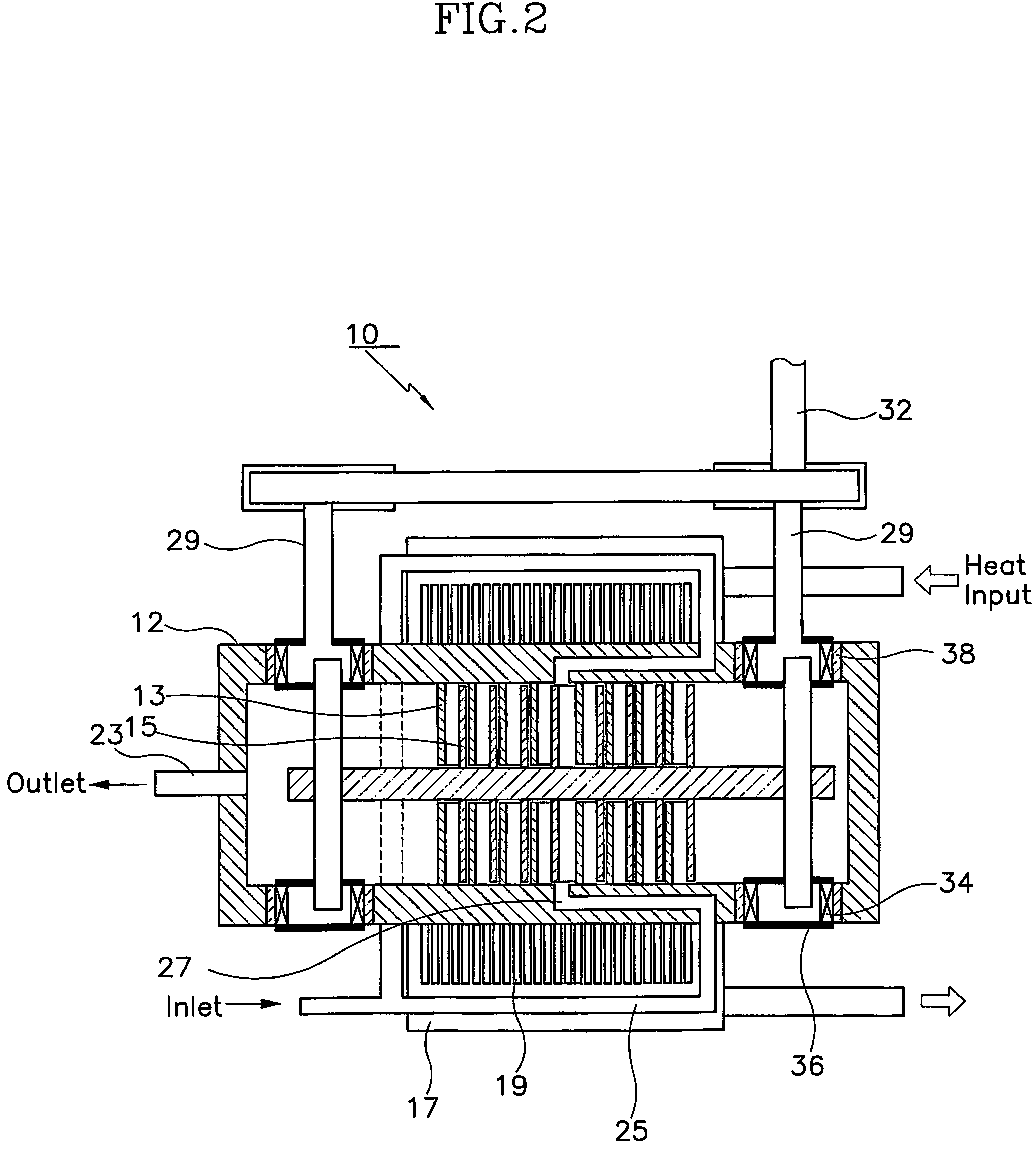

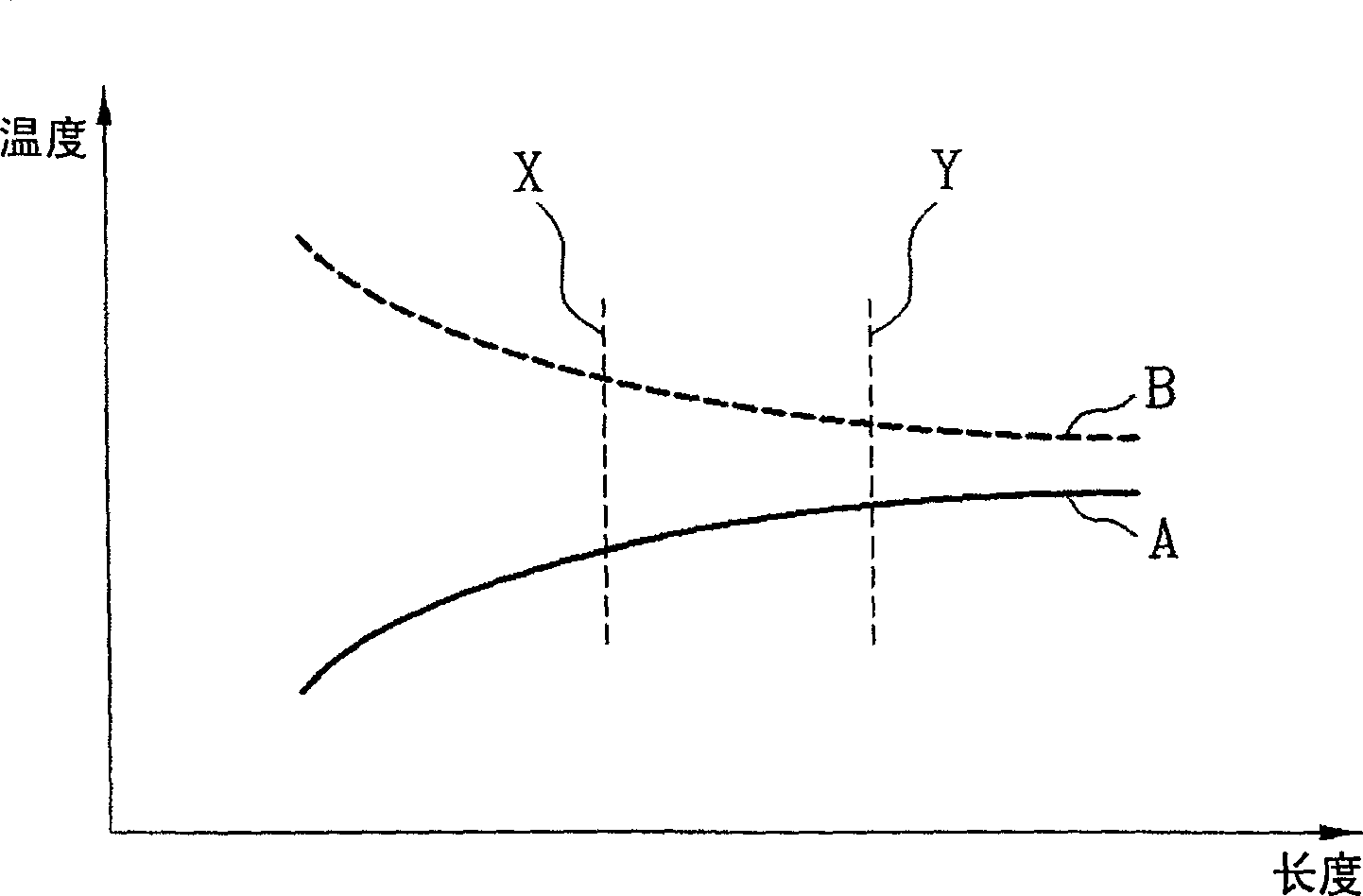

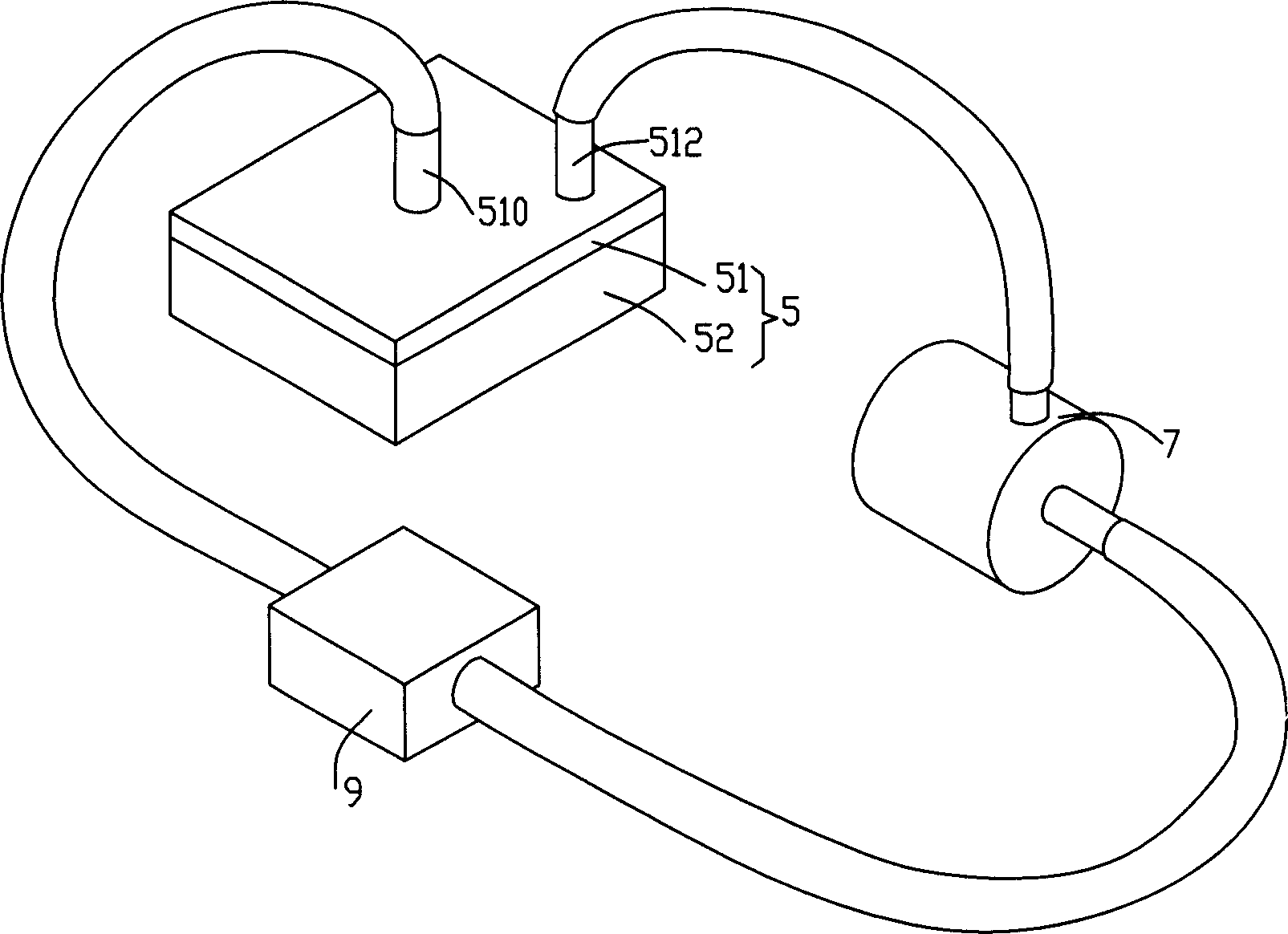

Scroll-type expander having heating structure and scroll-type heat exchange system employing the expander

InactiveUS7124585B2No reduction in efficiencyMinimizes difference in temperatureRotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesWorking fluidEngineering

The present invention provides a scroll-type expander that simultaneously performs expansion and re-heating such that efficient expansion is realized and there is no reduction in efficiency caused by pressure loss occurring during the supply of an working fluid to the scroll-type expander, and that minimizes a difference in temperature between a stationary scroll member and a rotating scroll member, as well as a temperature distribution of a scroll wrap. The present invention also relates to a heat exchange system that uses a scroll-type expander to replace pistons in a conventional reciprocating Stirling engine or refrigerator with a pair of scroll-type compressor and expander such that the heat exchange system may be used as a Stirling engine or refrigerator. The present invention also provides a steam engine, in which a steam turbine in the conventional steam engine (Rankine system) is replaced with a scroll-type expander such that the steam cycle has both a re-heating cycle and a regeneration cycle.

Owner:KOREA INST OF MACHINERY & MATERIALS

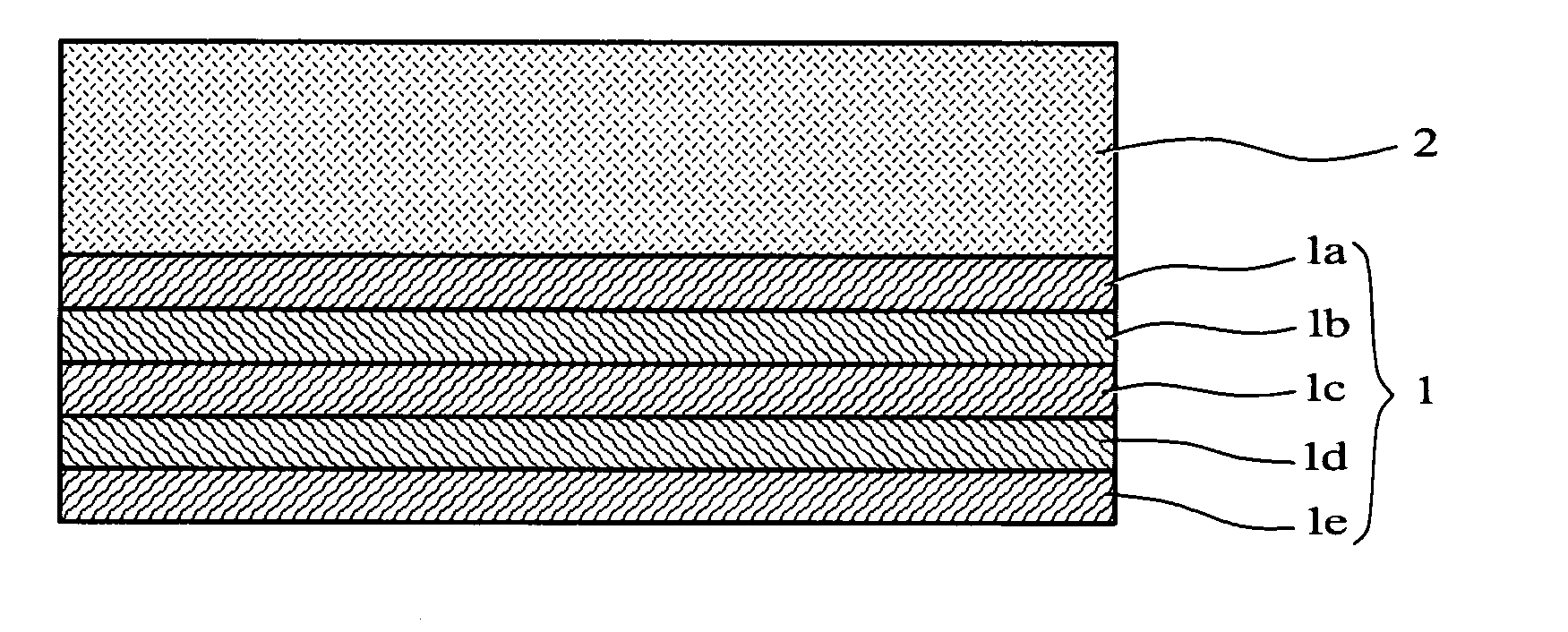

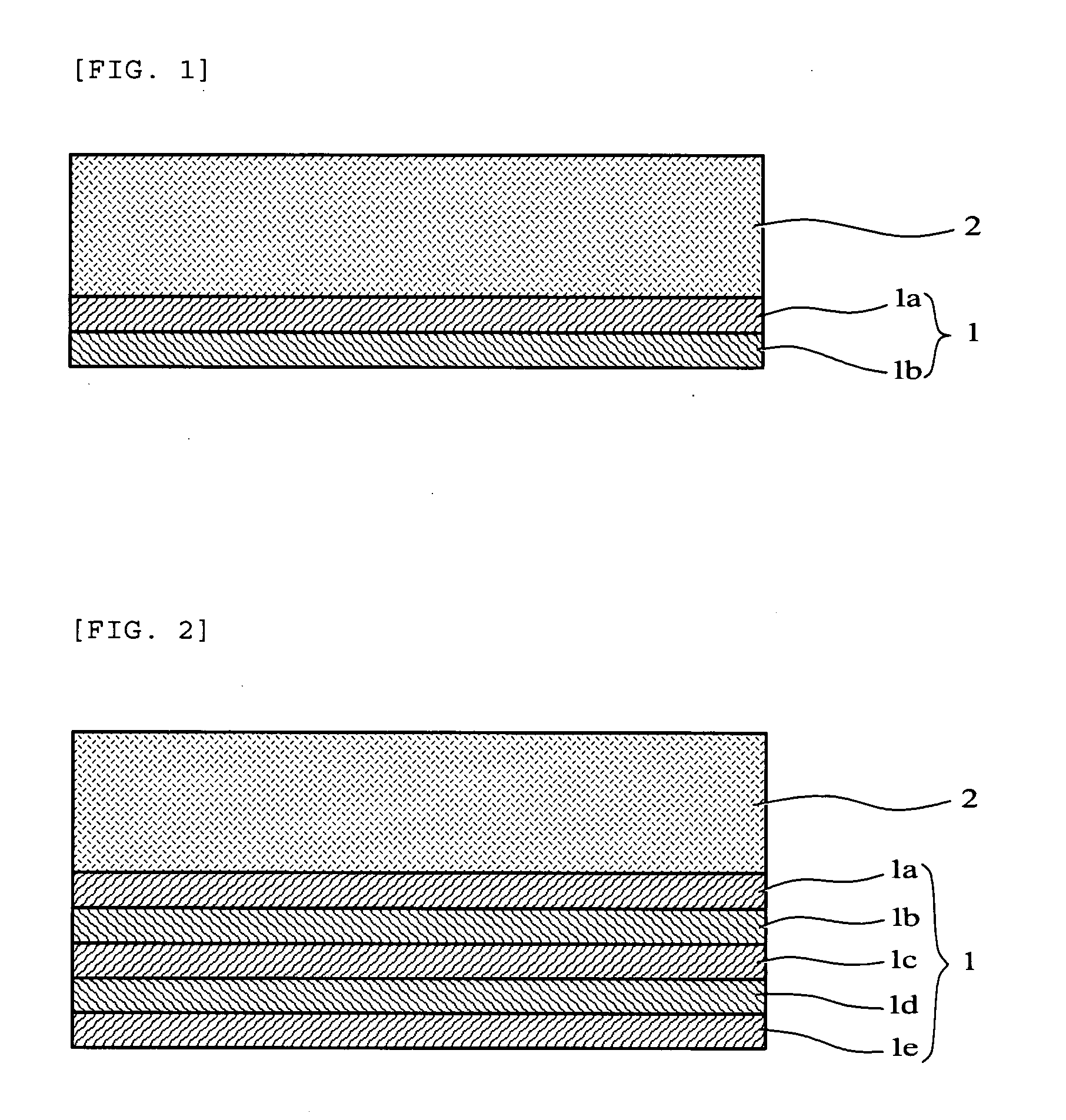

Air filter material

ActiveUS20080070022A1Small flow resistanceUniform processCombination devicesDispersed particle filtrationAir filtrationAir filter

An air filter material includes a laminate of an air inlet layer and an air outlet layer, and has a mean flow pore size of 20 μm to 40 μm, a minimum pore size of 2.4 μm to 3.8 μm, and a maximum pore size of 80 μm or less. The air inlet layer is a needle punched nonwoven fabric layer having an areal fiber weight of 55 g / m2 to 100 g / m2. The air outlet layer is a laminated spunlace nonwoven fabric made by laminating at least two or more spunlace nonwoven fabric layers having an areal fiber weight of 20 g / m2 to 60 g / m2, a mean flow pore size of 50 μm to 90 μm, a minimum pore size of 3.0 μm to 10.0 μm, and a maximum pore size of 180 μm or less.

Owner:DYNIC CORPORATION

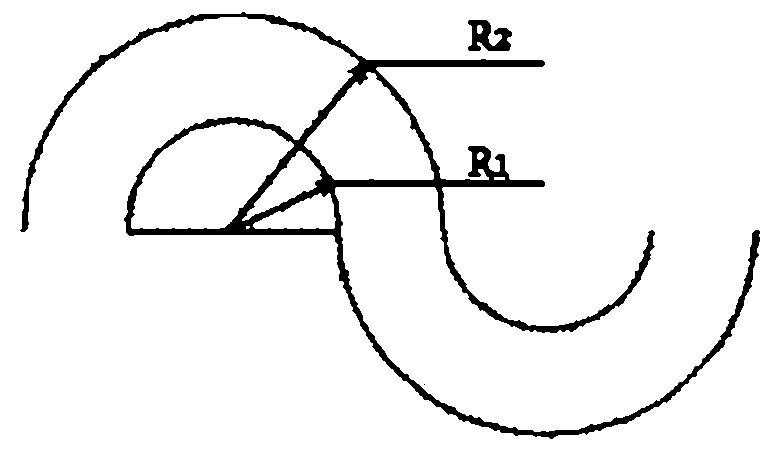

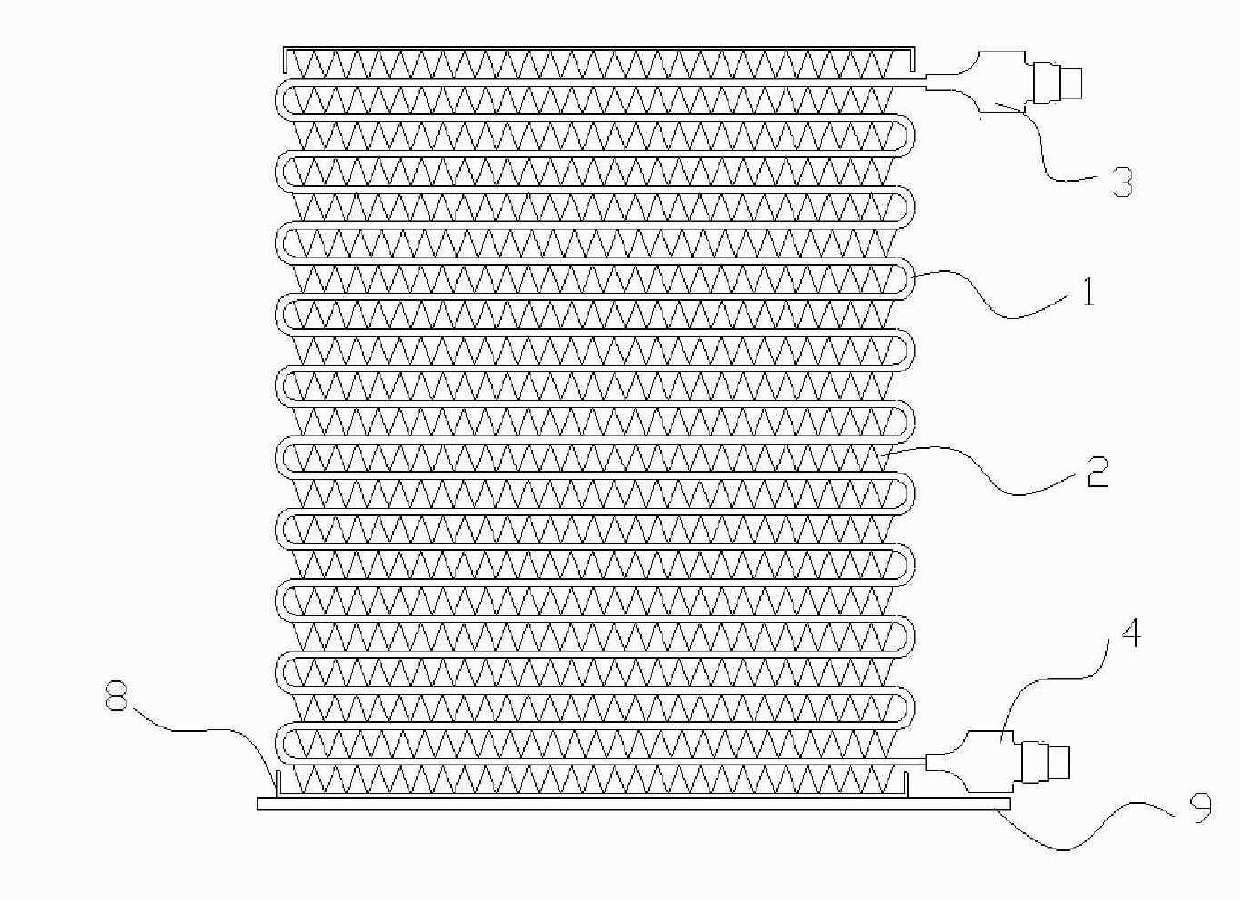

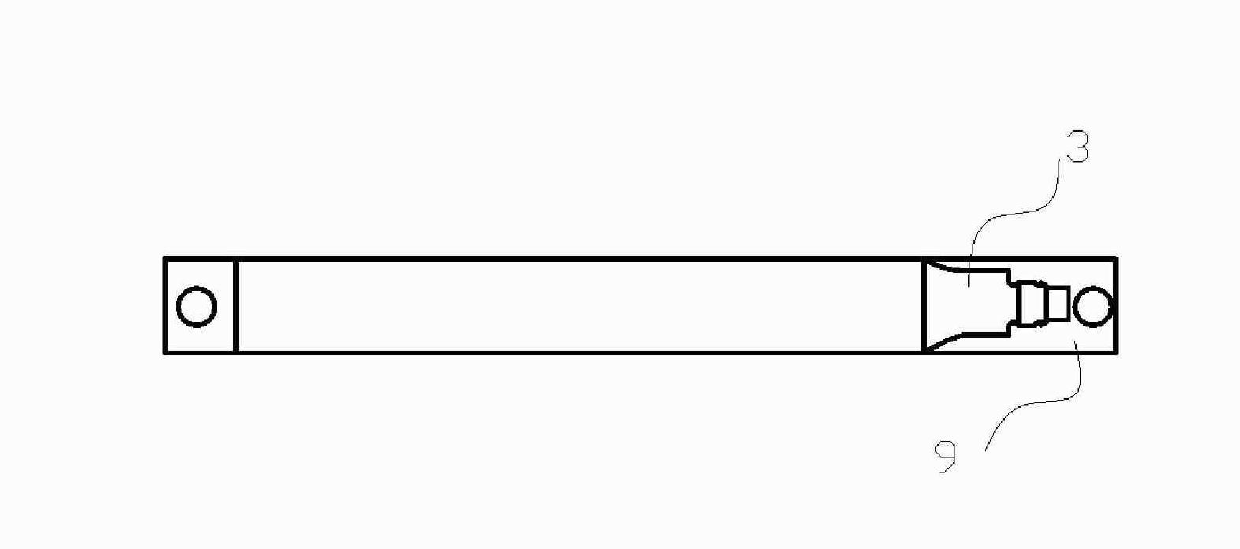

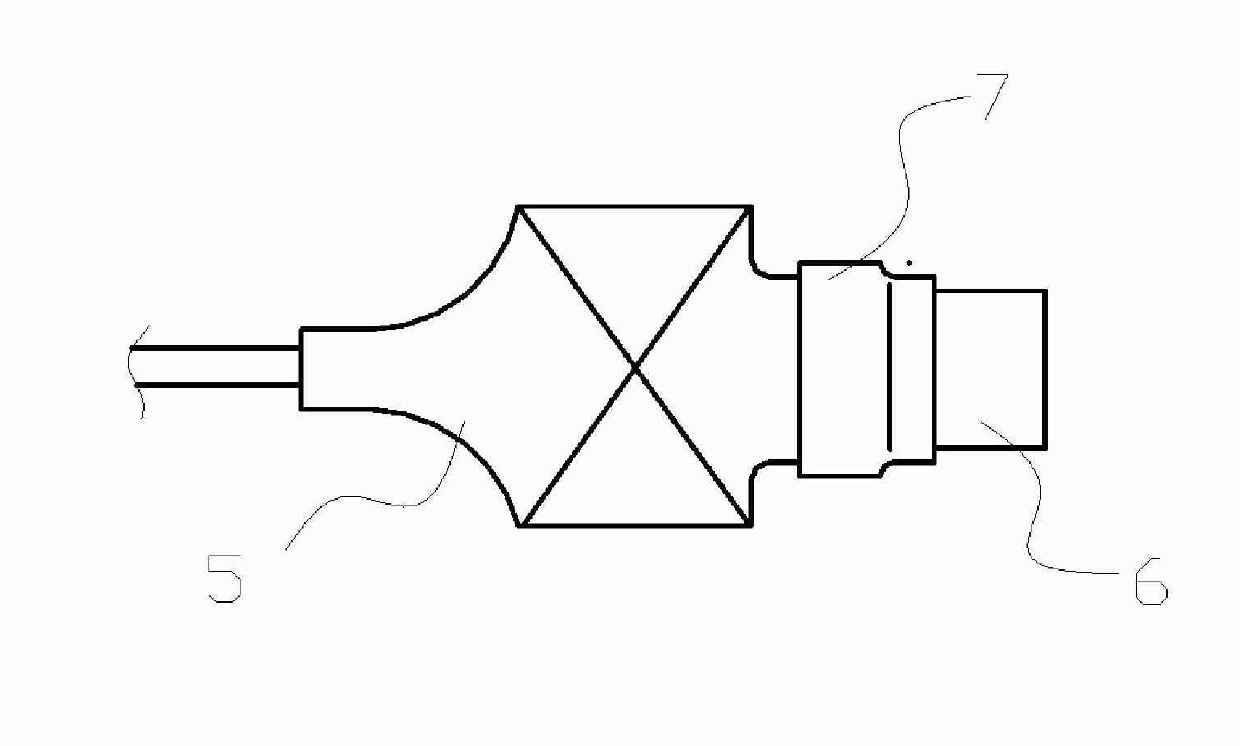

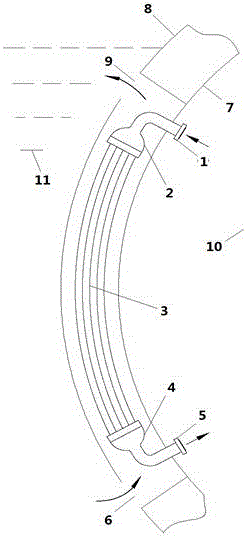

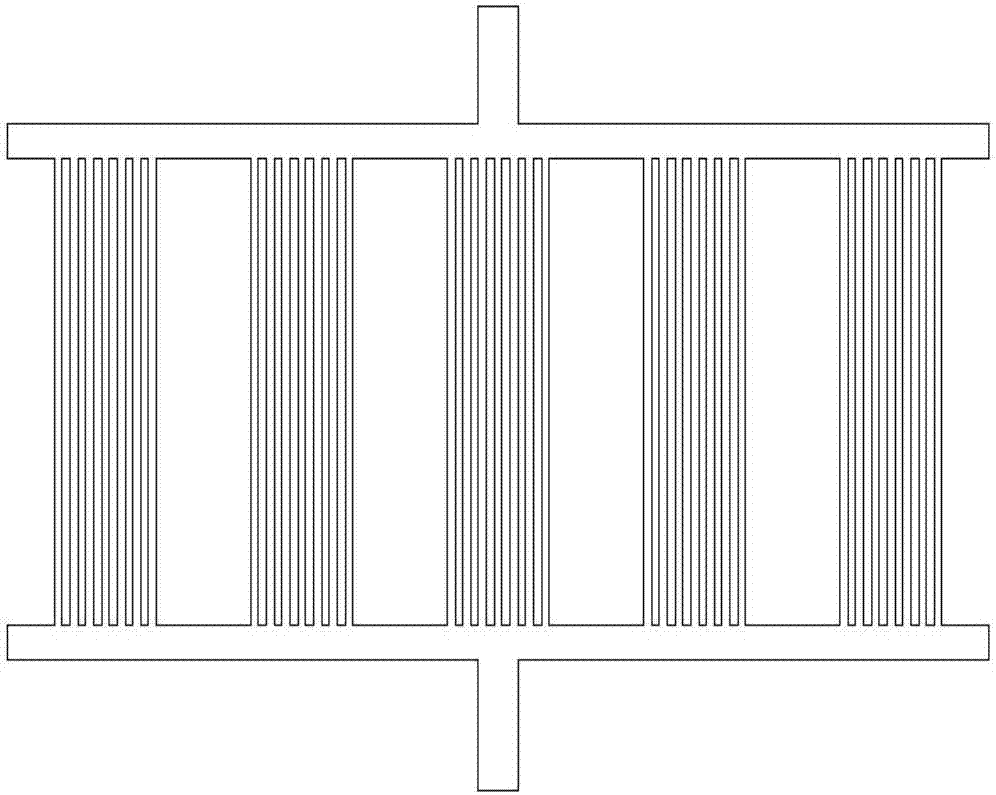

Coiled parallel flow condenser for refrigerator

InactiveCN101769656AReduce chargeCompact structureEvaporators/condensersMaterial consumptionEngineering

The invention relates to the technical field of refrigerating components, in particular to a coiled parallel flow condenser for a refrigerator, which is bent into a multi-layer coiled shape by using aluminum flat pipe at a certain radius of arc. The condenser comprises a flat pipe, fins, an inlet pipe assembly and an outlet pipe assembly, and is characterized in that the flat pipe in a coiled shape is formed by multiple bending arcs and straight lines; radiation sheets are equipped between adjacent coiled flat pipes; radiation sheets on outer side on both ends are equipped with side plates; inlet and outlet ends of the flat pipe are connected with the inlet pipe assembly and the outlet pipe assembly, respectively; the inside of the flat pipe is equipped with multiple micro-passages through which refrigerant passes. The condenser is compact in structure, high in heat exchange performance in unit volume, small in flow resistance, less in material consumption, less in cold medium filling quantity.

Owner:ZHEJIANG KANGSHENG CO LTD

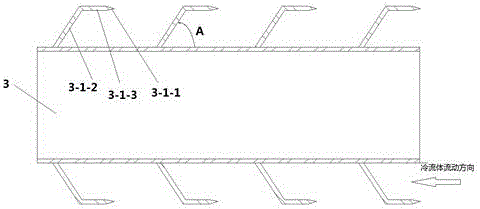

Heat exchange provided with sharp structure out of pipe

ActiveCN106767007ADoes not increase flow resistanceIncrease heat transfer areaStationary conduit assembliesHeat exchanger casingsInlet channelGas phase

The invention provides a heat exchanger. The heat exchanger comprises a pipe pass side and a shell pass side; the pipe pass side includes an inlet pipe, an inlet cavity, a heat transfer pipe bundle, an outlet cavity and an outlet pipe; a hot fluid enters the inlet cavity from the inlet pipe to pass through the heat transfer pipe bundle, the outlet cavity and the outlet pipe in sequence; the shell pass side includes an inlet channel, an inner shell, an outer shell and an outlet cavity; a cold fluid passes through space limited by the inlet channel, the inner shell and the outer shell and the outlet cavity in sequence; the inlet cavity, the heat transfer pipe bundle and the outlet cavity are arranged in space limited by the inner shell and the outer shell; a metal rod outwards extends from the outer wall of the heat transfer pipe bundle; the end part of the metal rod is a sharp structure; and the direction from the outer wall of the heat transfer pipe bundle to the end part of the metal rod is opposite to the flowing direction of the cold fluid. The rod with the sharp end part is arranged at the external of the heat exchange pipe; in flowing of a gas-liquid two-phase flow, on the one hand, the laminar flow bottom layer can be broken, and the heat transfer area is increased for forced heat transfer; because of the rod, the flowing resistance is low, and the shell pass flowing resistance cannot be increased; and as the sharp end part is provided, bubbles can be punctured to realize increment of a gas-liquid interface and a gas-phase boundary layer and reinforcement of the disturbance.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Heat pipe

Owner:FU ZHUN PRECISION IND SHENZHEN +1

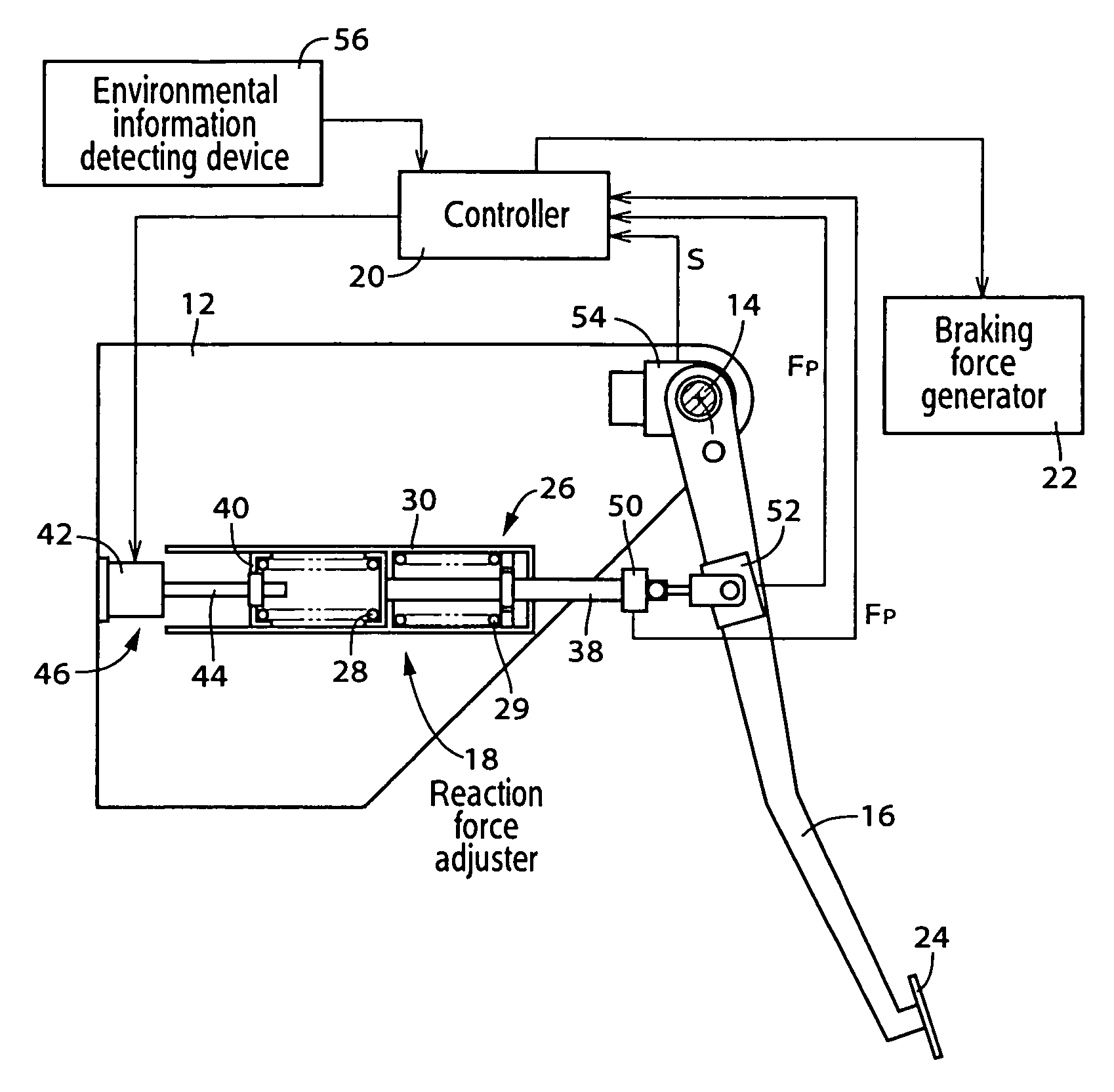

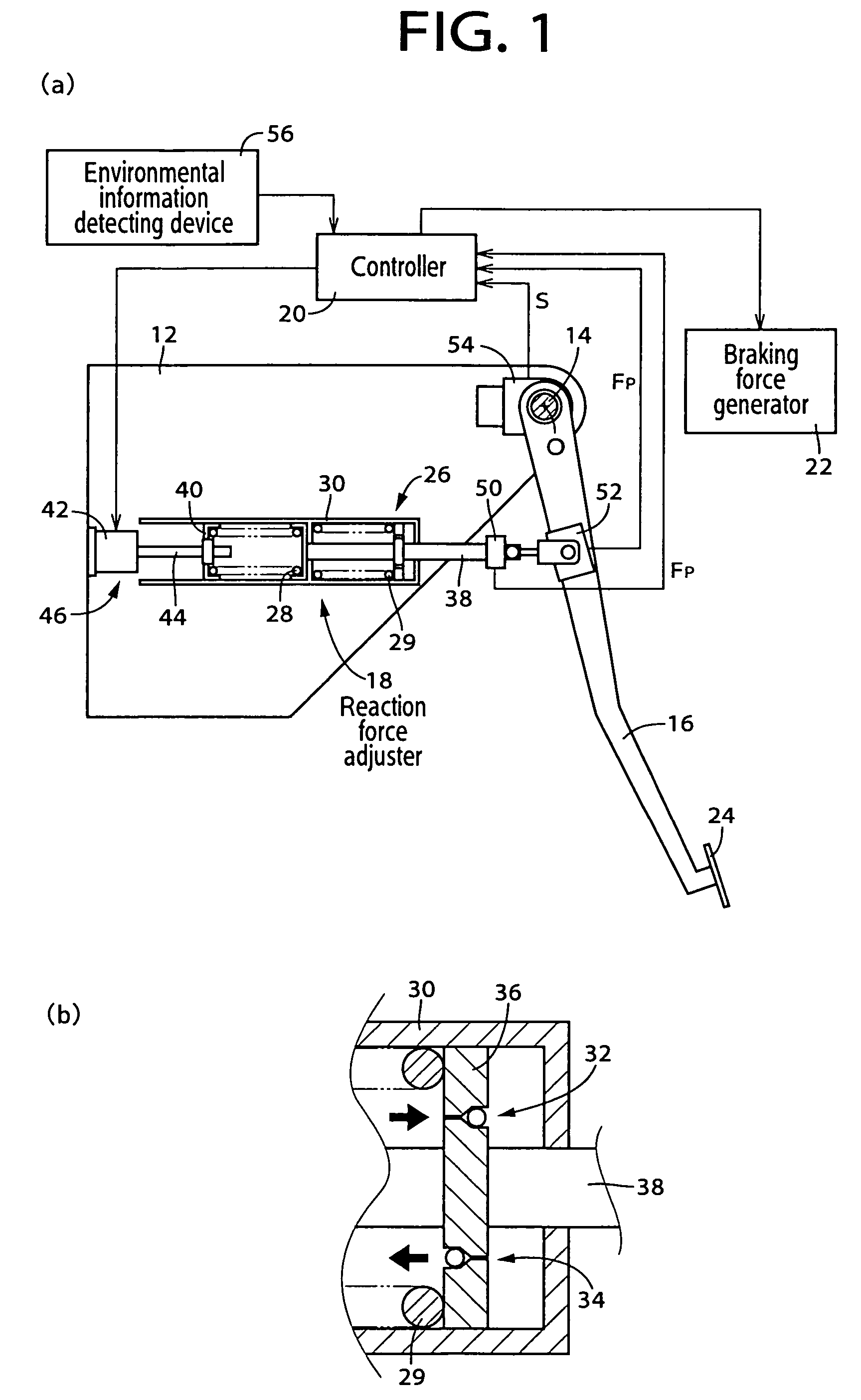

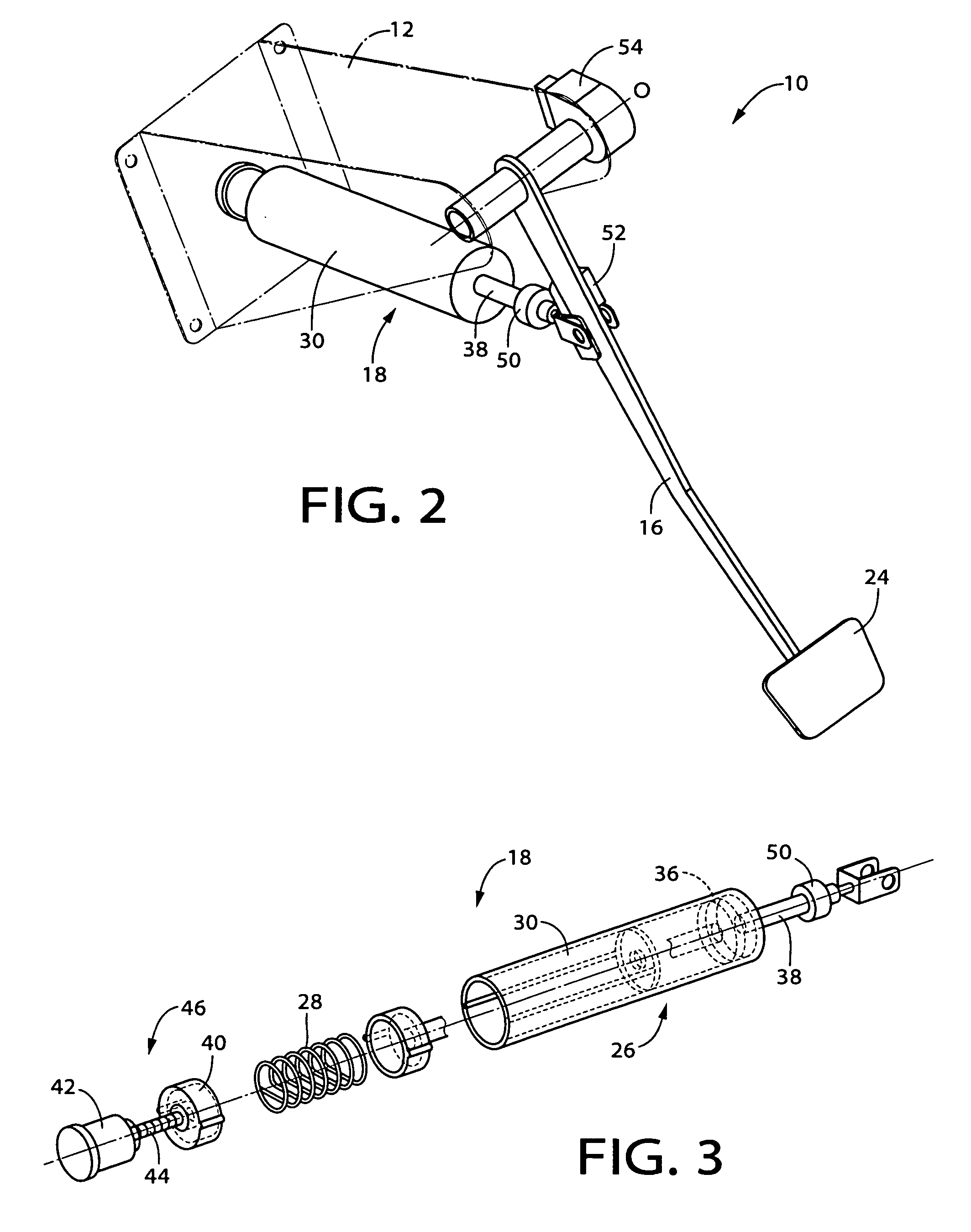

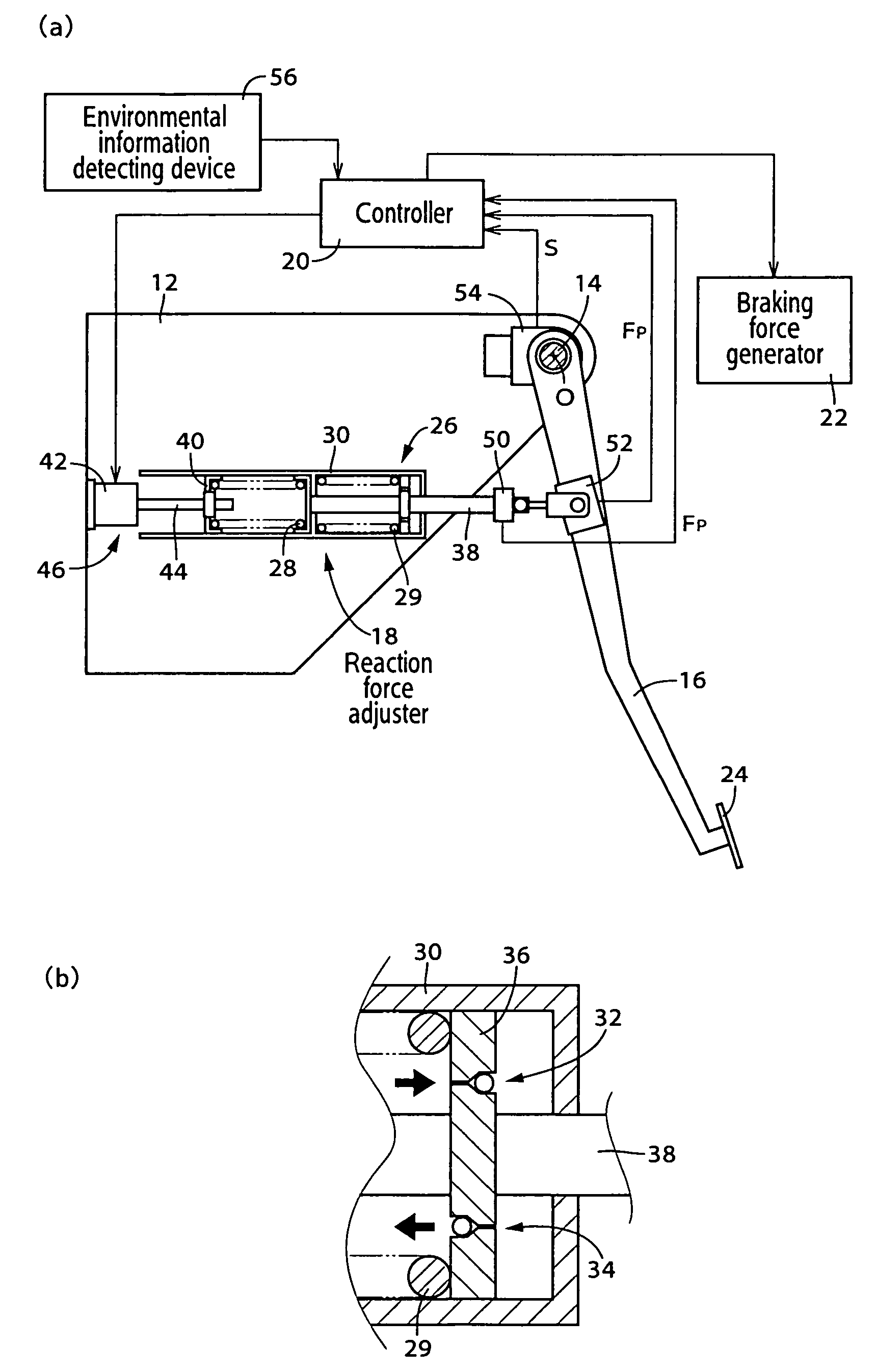

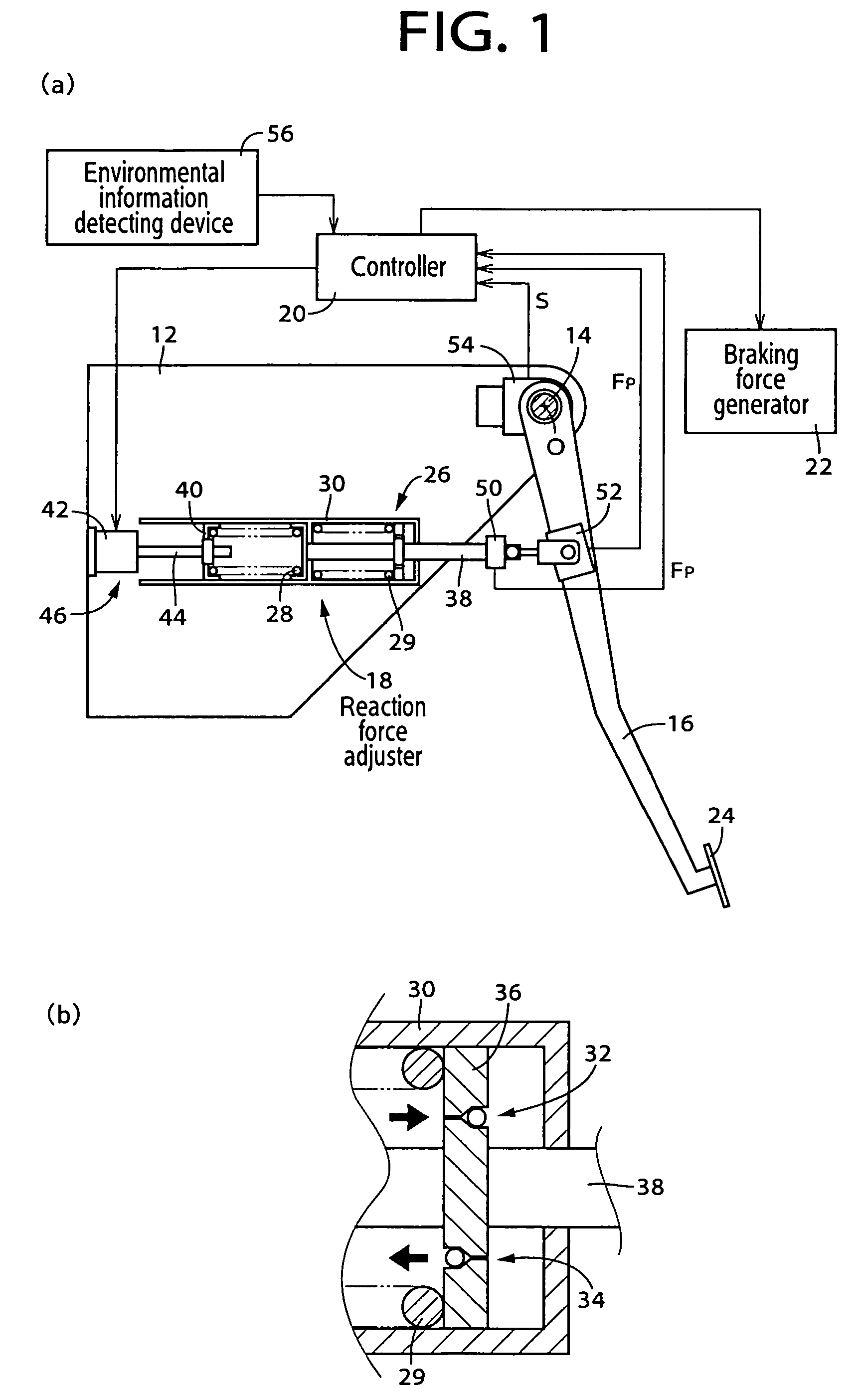

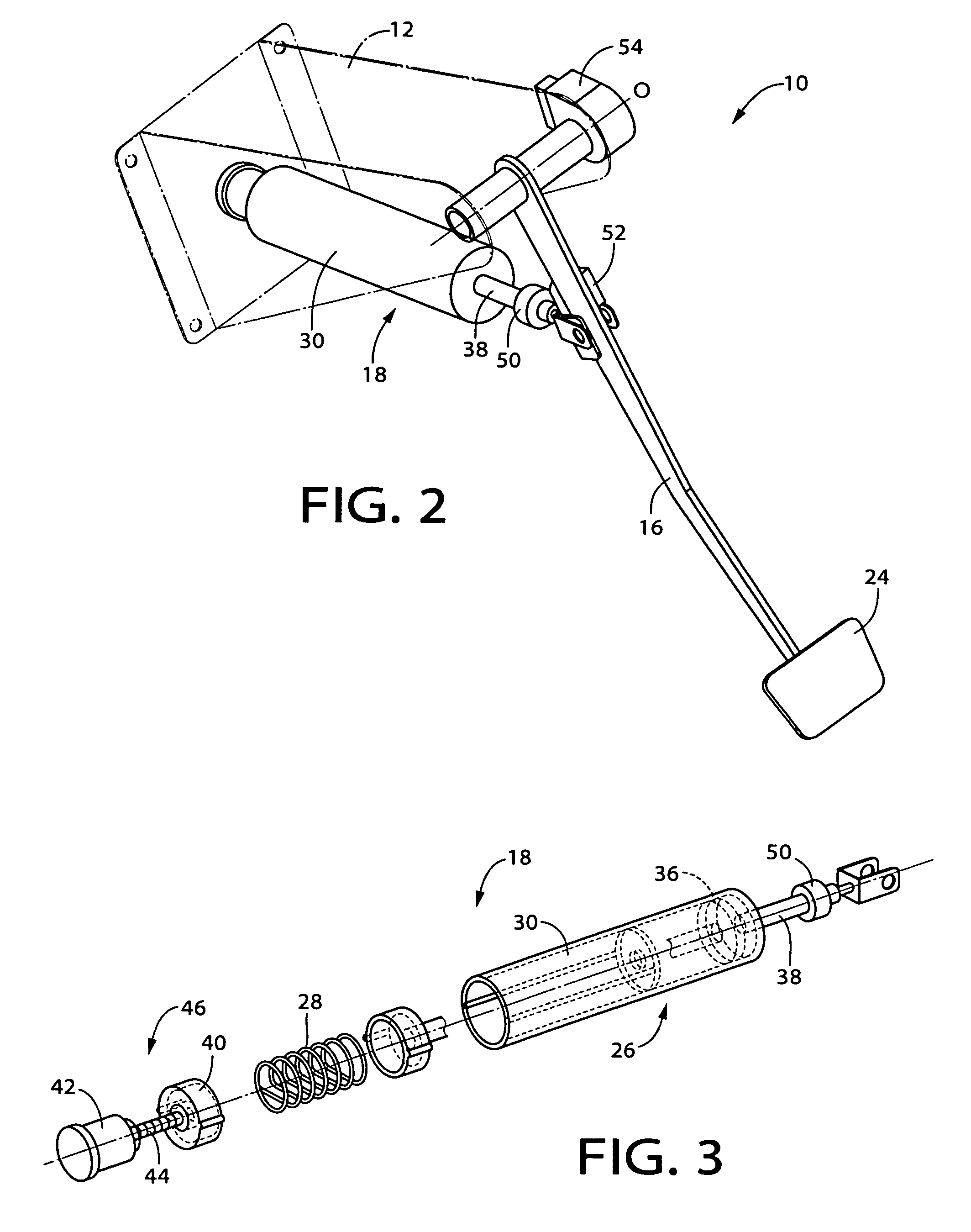

Electric operating apparatus for vehicle

InactiveUS20050235820A1Appropriate braking forceEasy to implementControlling membersSpringsElectricityInformation control

Owner:TOYODA IRON WORKS CO LTD

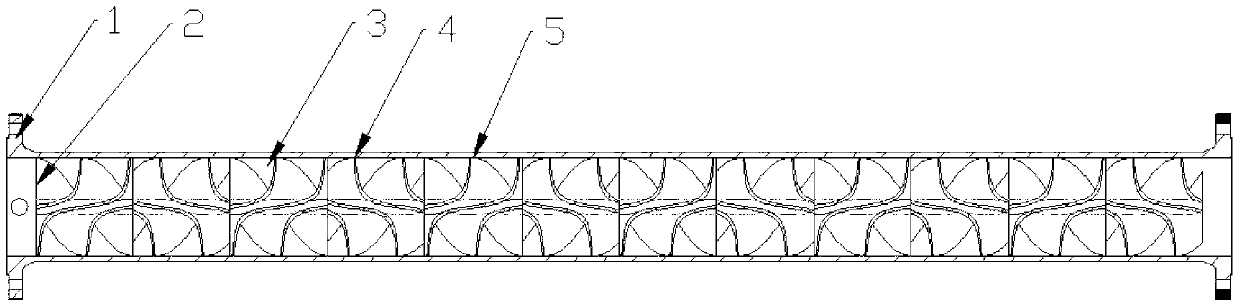

Spiral static mixer

The invention discloses a spiral static mixer which is applied to mixing of multiple materials and particularly mixing of high-viscosity materials. The spiral static mixer comprises a shell, mounting flanges, left rotating blades and right rotating blades and is characterized in that the mounting flanges are respectively arranged at the two ends of the shell, the left rotating blades and the right rotating blades are in multiple-spiral blade structures and sequentially and alternately arranged from an inlet of the shell to an outlet of the shell, the adjacent left rotating blades and right rotating blades are fixedly connected at the periphery in a staggering manner, and a washing lifting ring is connected at one end of a blade group formed by the left rotating blades and the right rotating blades. The spiral static mixer provided by the invention has the advantages of simple structure, high mixing efficiency, convenience and fastness in installation, low cost, convenience in washing and suitability for long-time working; a mixed blade unit can be replaced; and the spiral static mixer is more widely applied to mixing of the high-viscosity materials in the chemical engineering industry.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

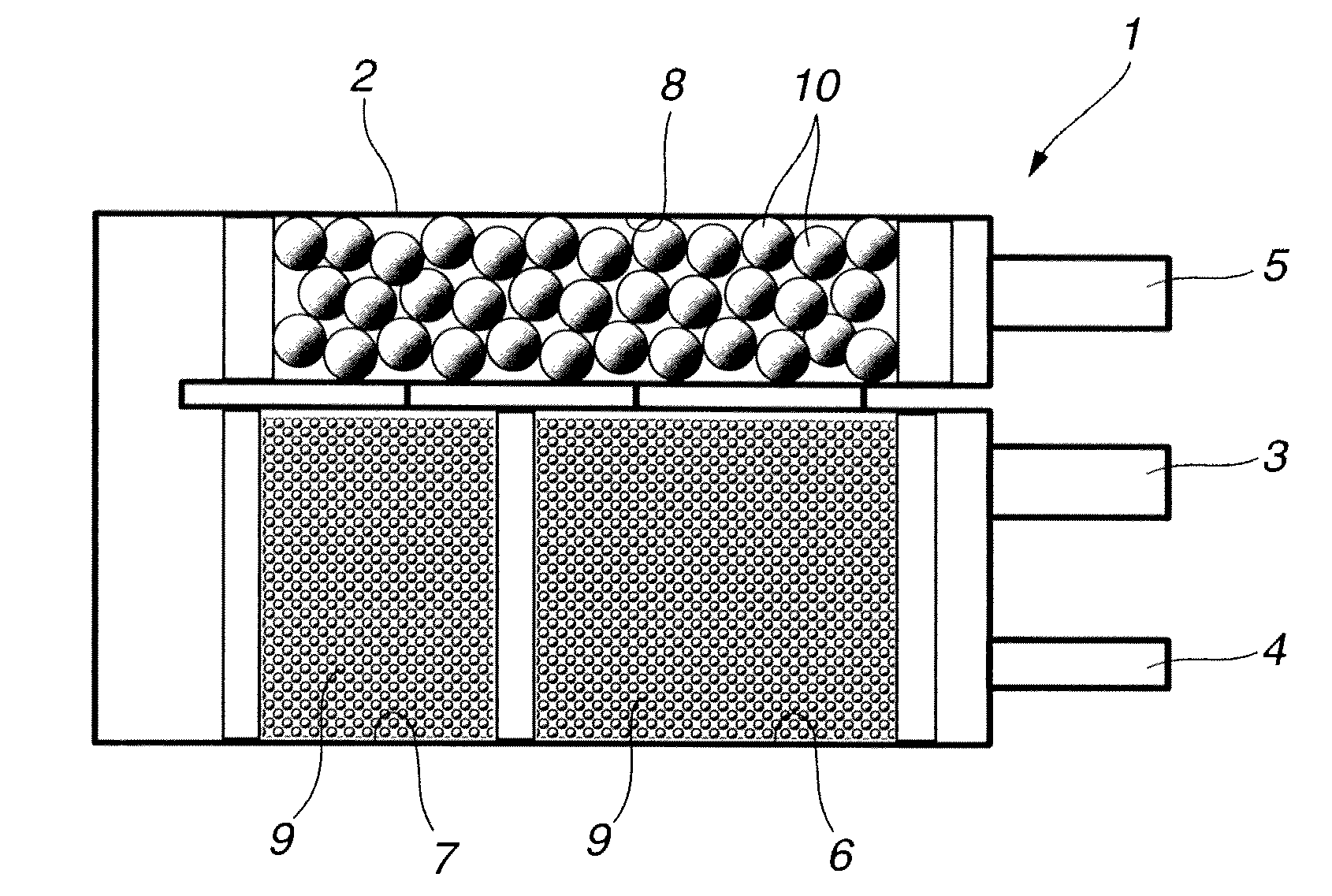

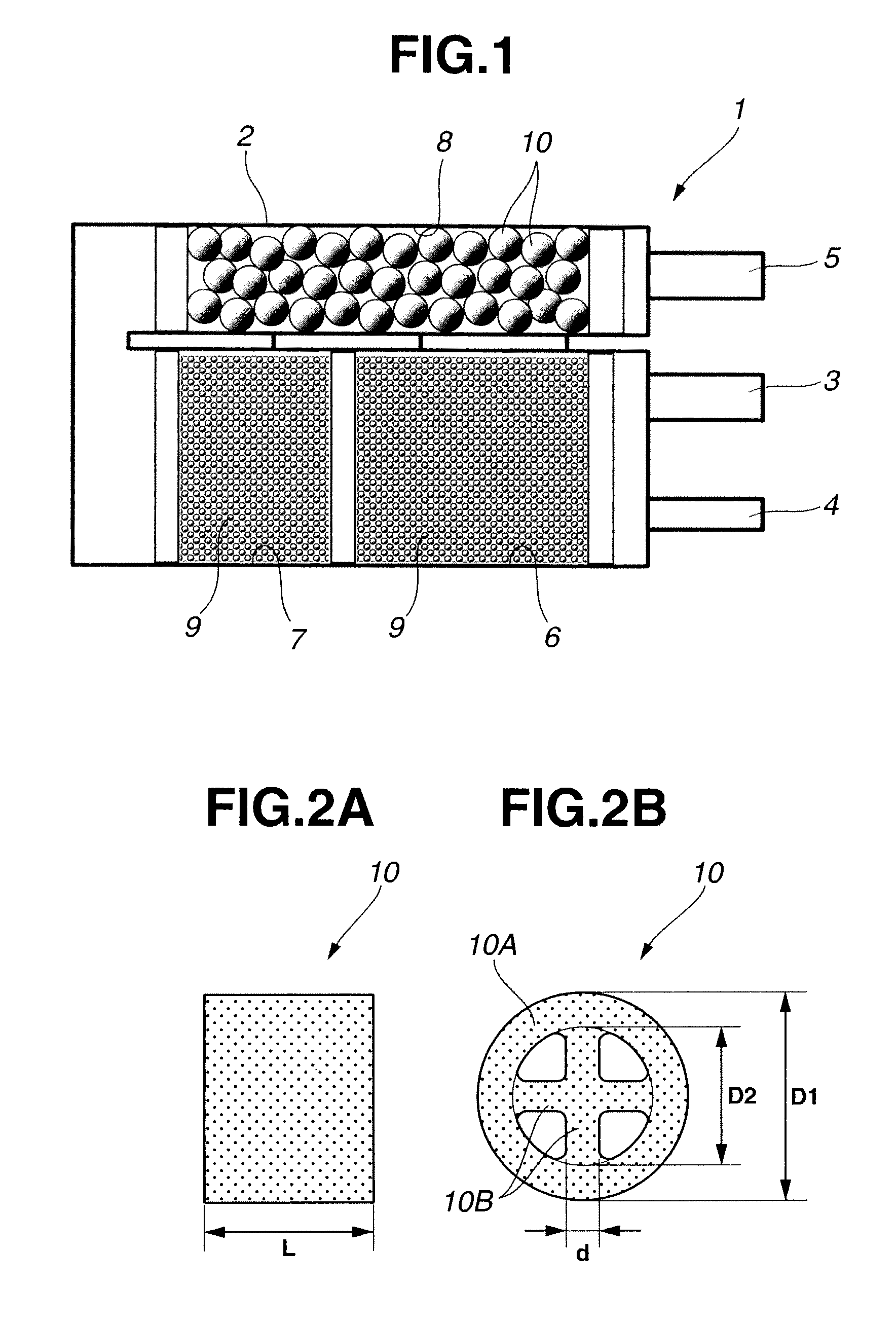

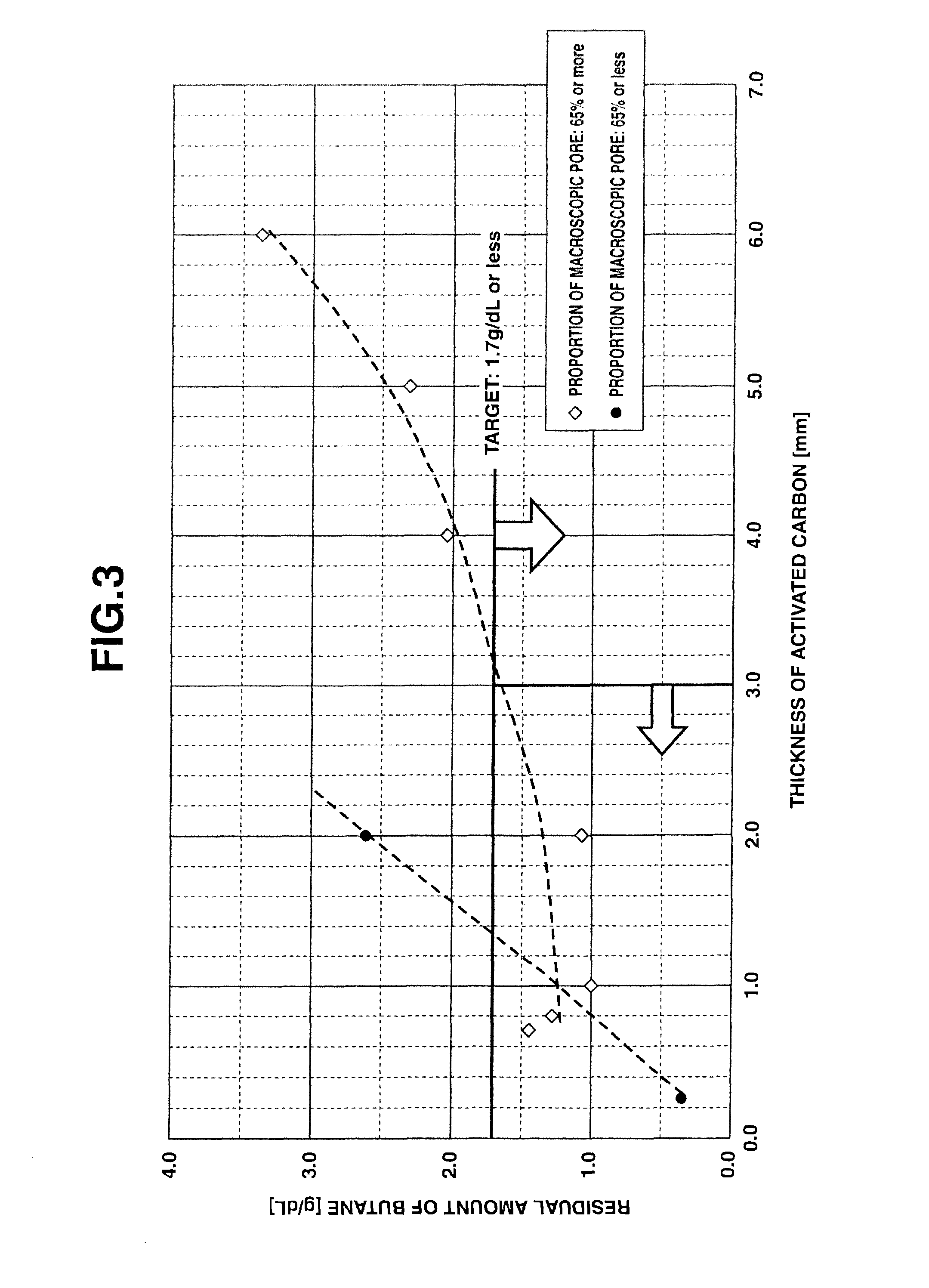

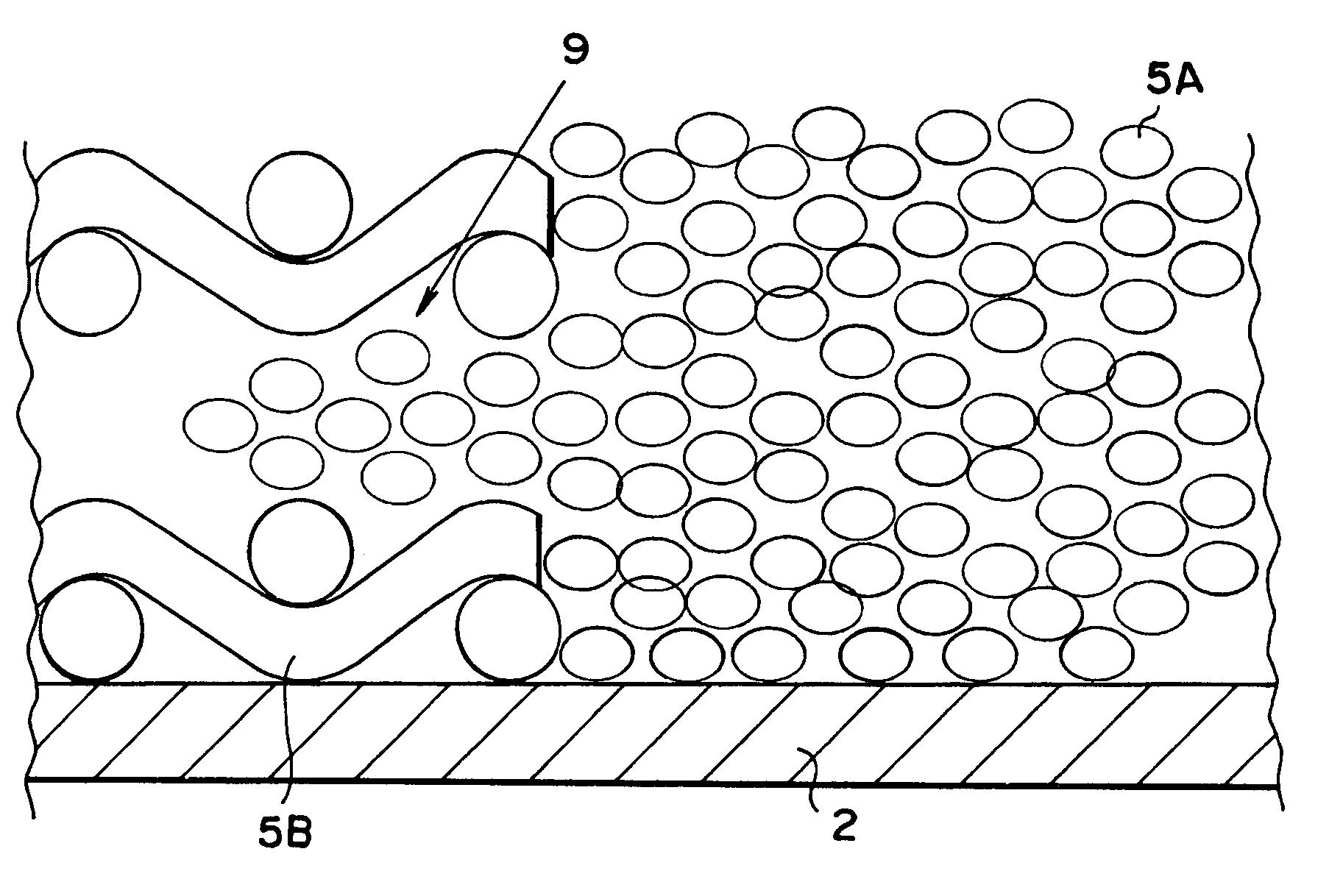

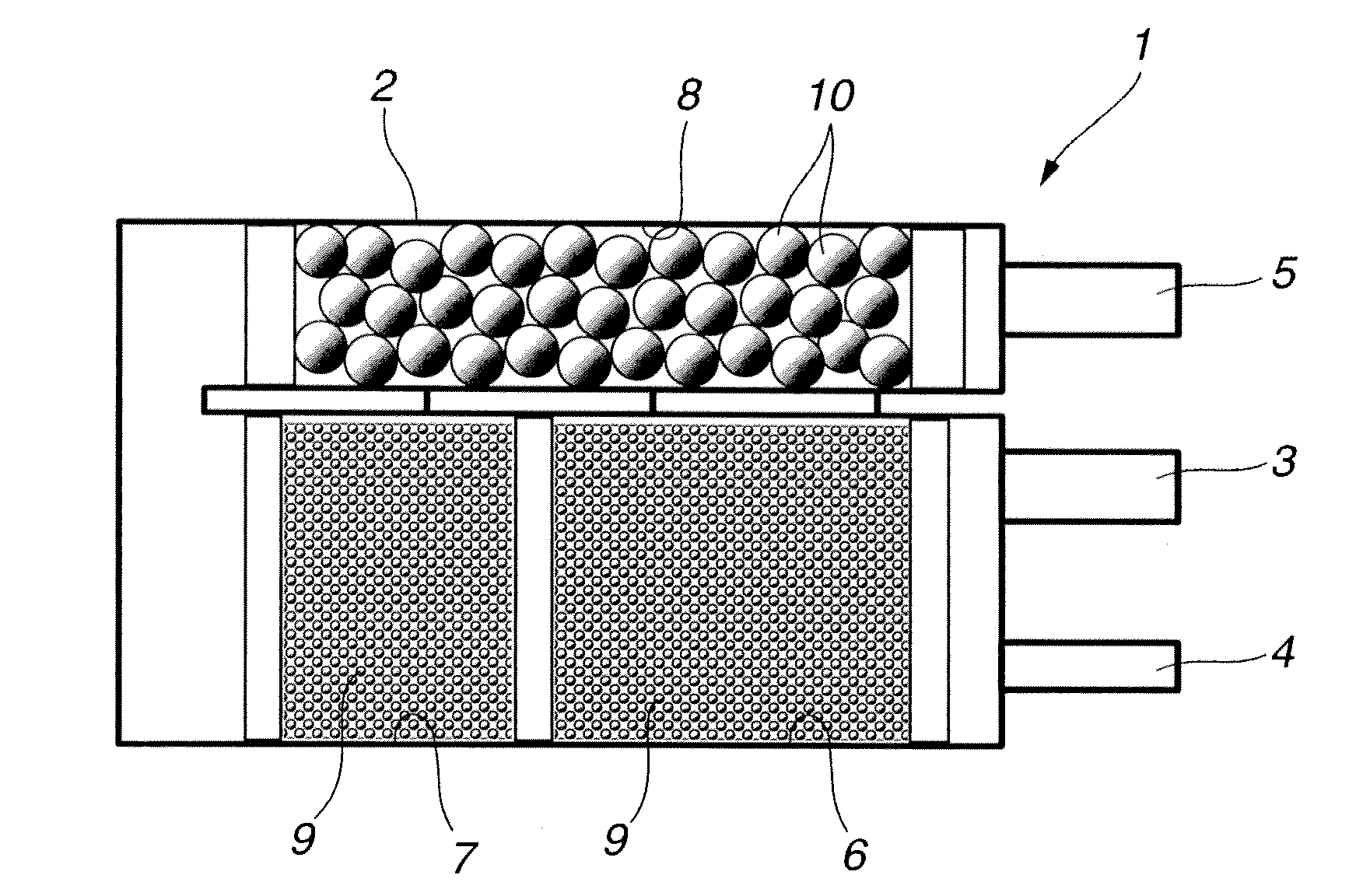

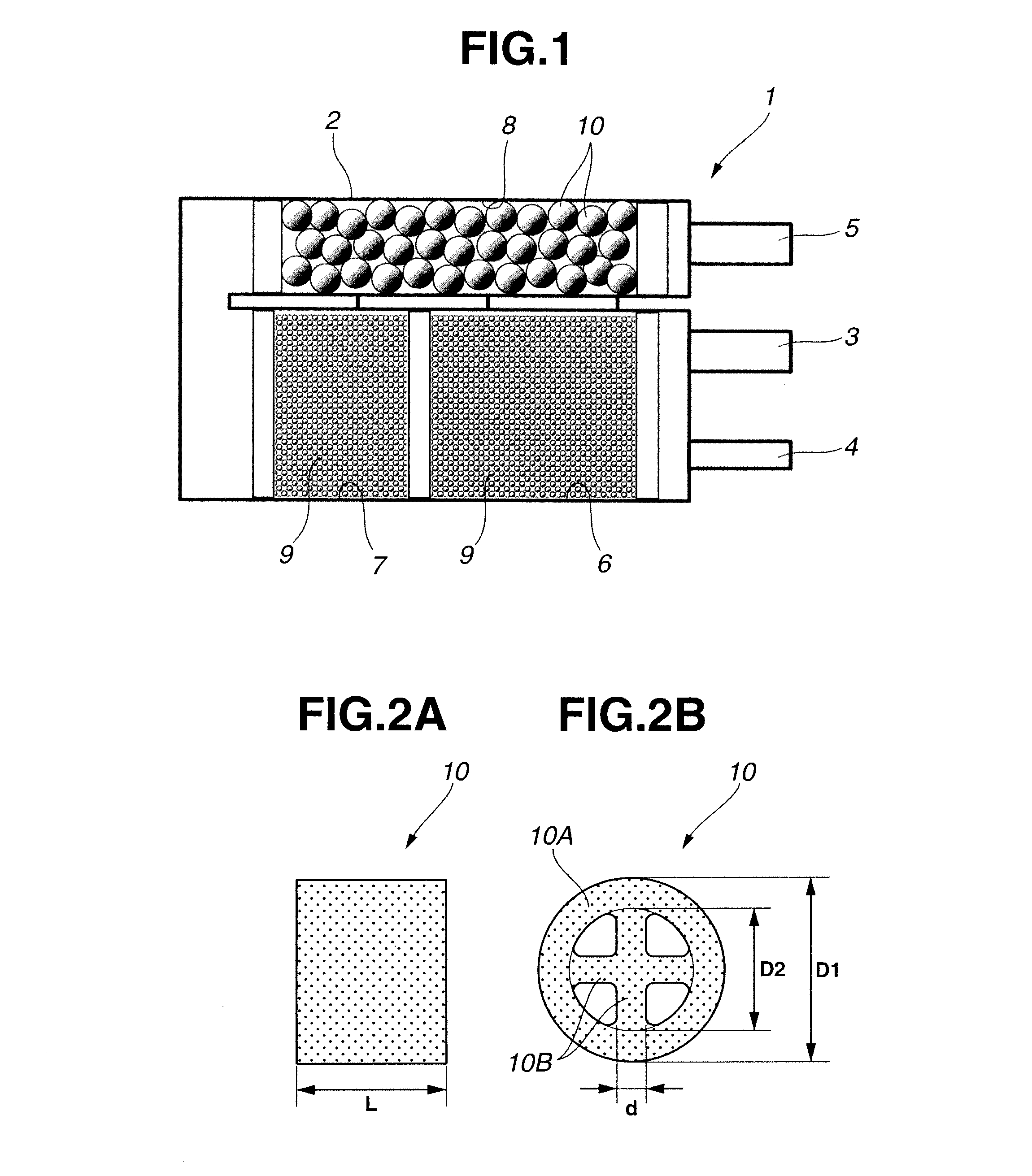

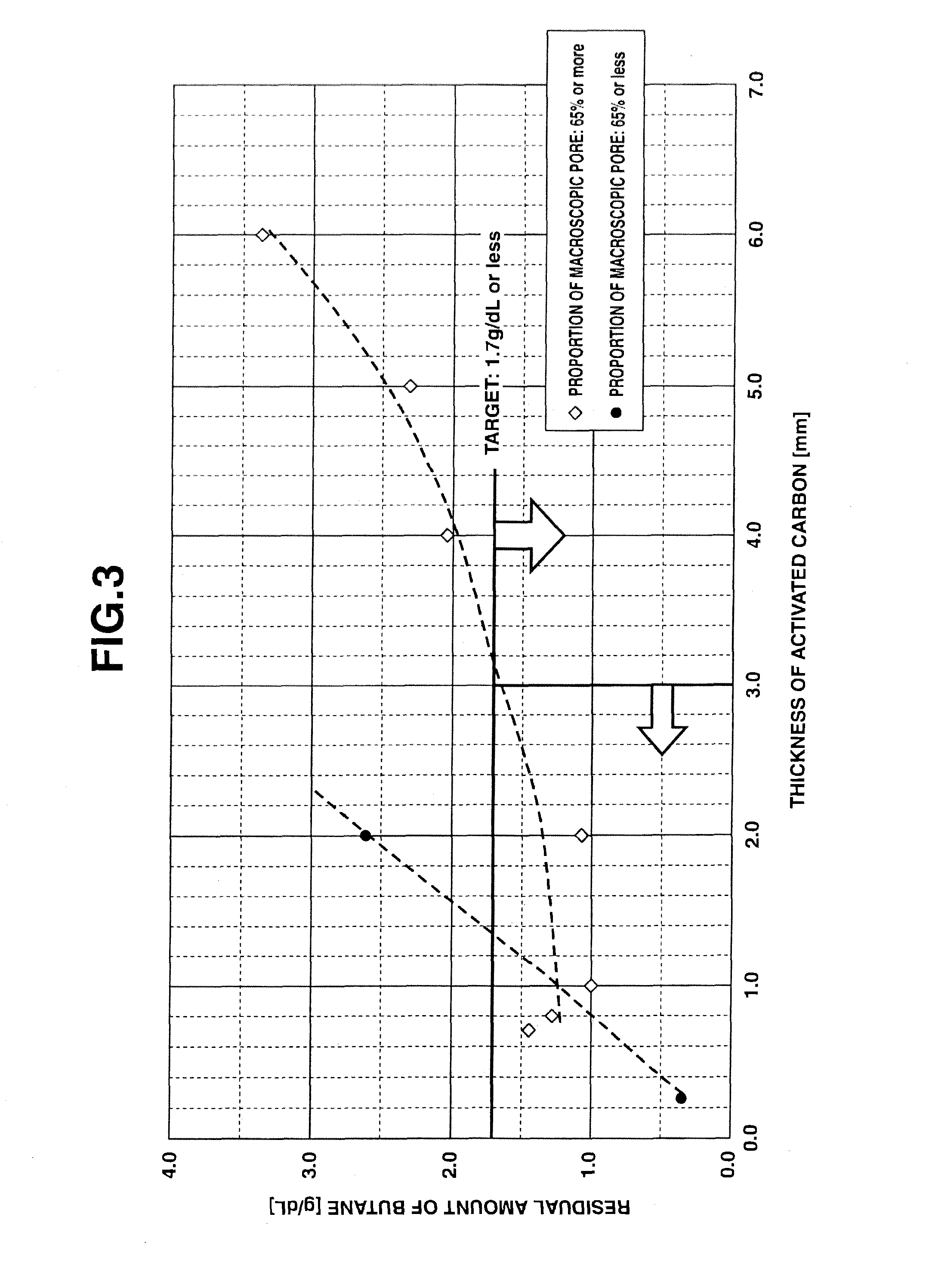

Adsorbent for canister, and canister

ActiveUS9174195B2Small flow resistanceCanister can be kept lowGas treatmentNon-fuel substance addition to fuelActivated carbonSorbent

Owner:MAHLE JAPAN LTD +1

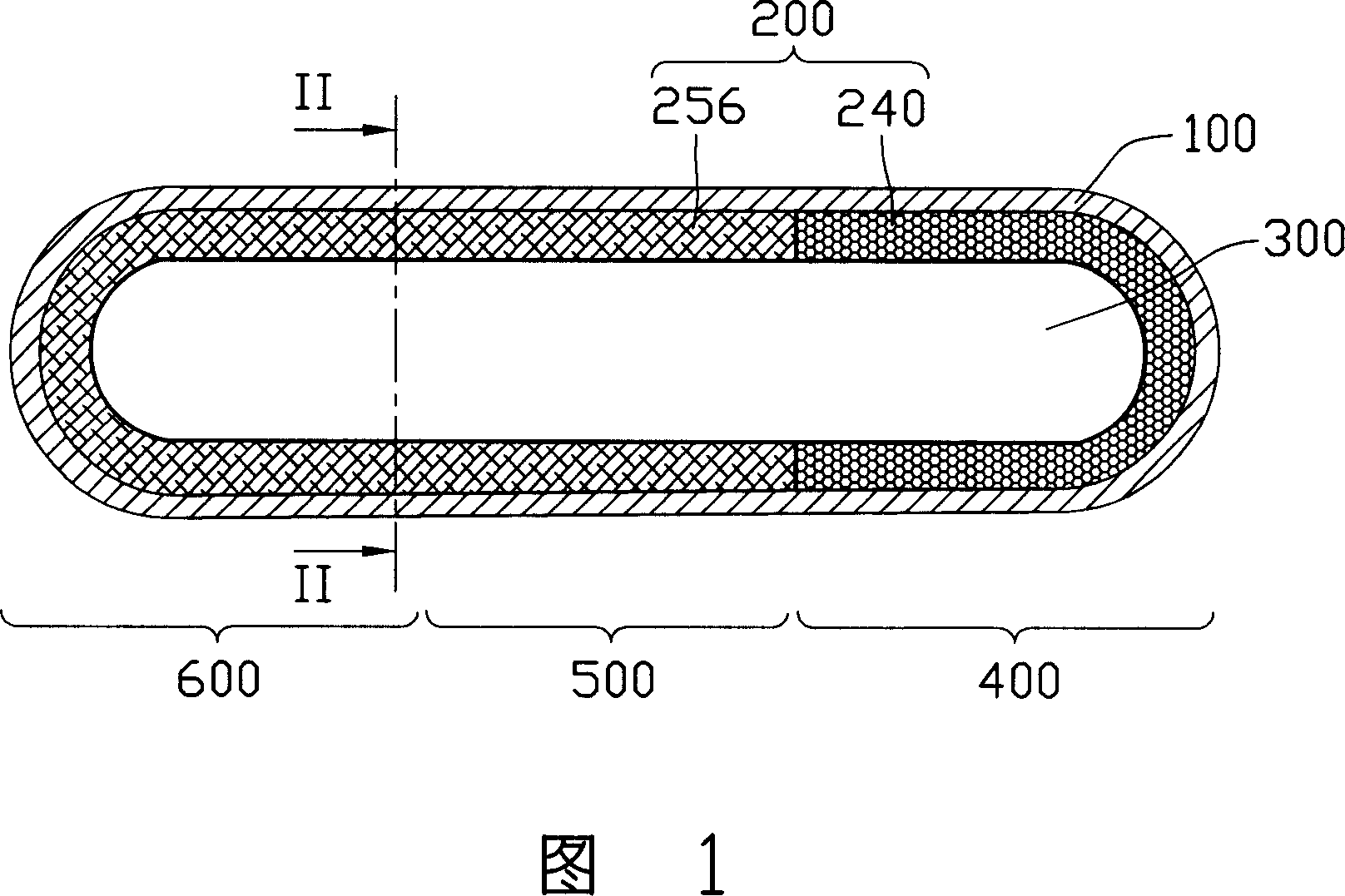

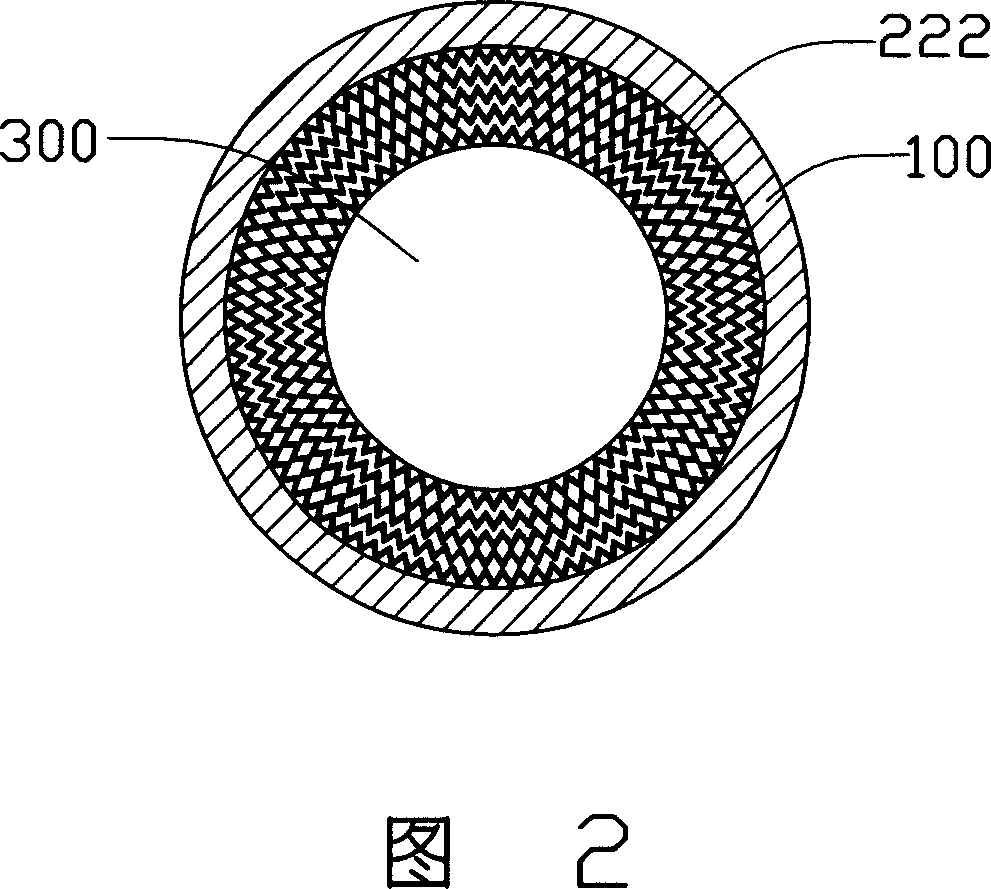

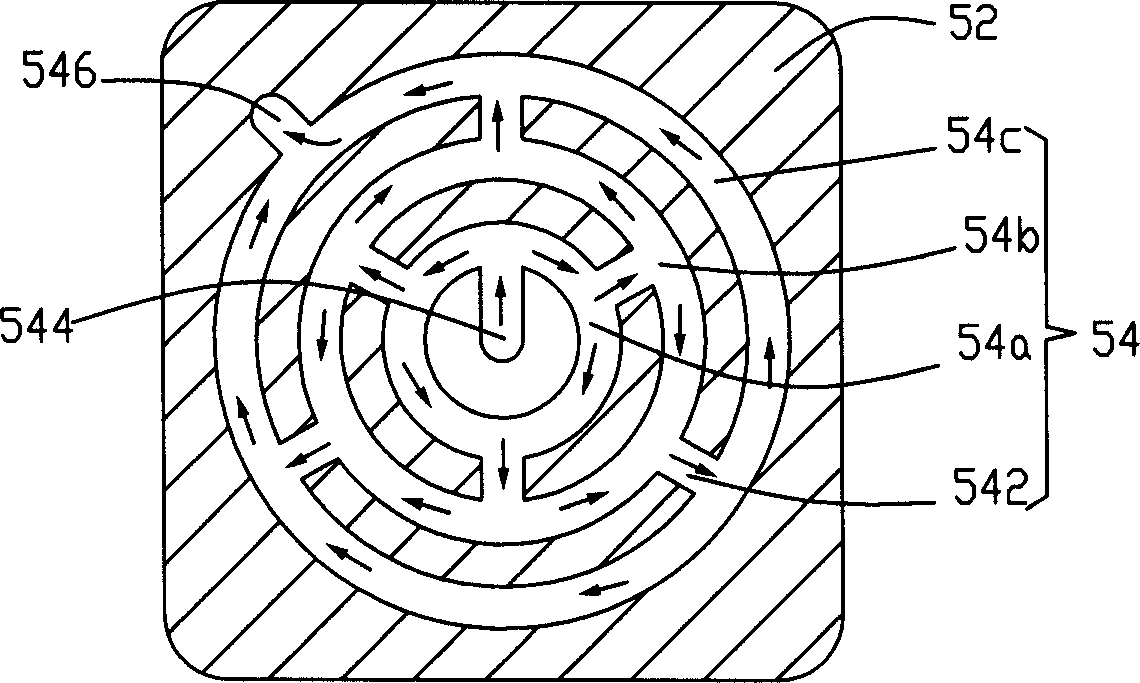

Vapor chamber

ActiveUS7137442B2Good heat transfer performanceIncrease pressureIndirect heat exchangersWorking fluidCapillary pressure

A vapor chamber, in which a condensable fluid, which evaporates and condenses depending on a state of input and radiation of a heat, is encapsulated in a hollow and flat sealed receptacle as a liquid phase working fluid; and in which the wick for creating the capillary pressure by moistening by the working fluid is arranged in said sealed receptacle, comprising: a wick for creating a great capillary pressure by being moistened by said working fluid, which is arranged on the evaporating part side where the heat is input from outside; and a wick having a small flow resistance against the moistening working fluid, which is arranged on the condensing part side where the heat is radiated to outside.

Owner:THE FUJIKURA CABLE WORKS LTD +1

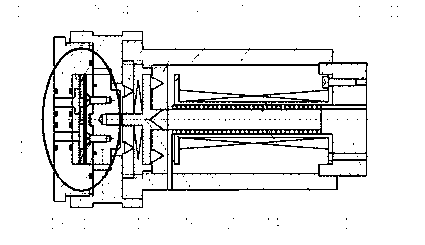

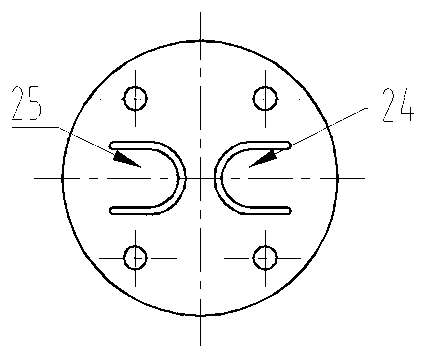

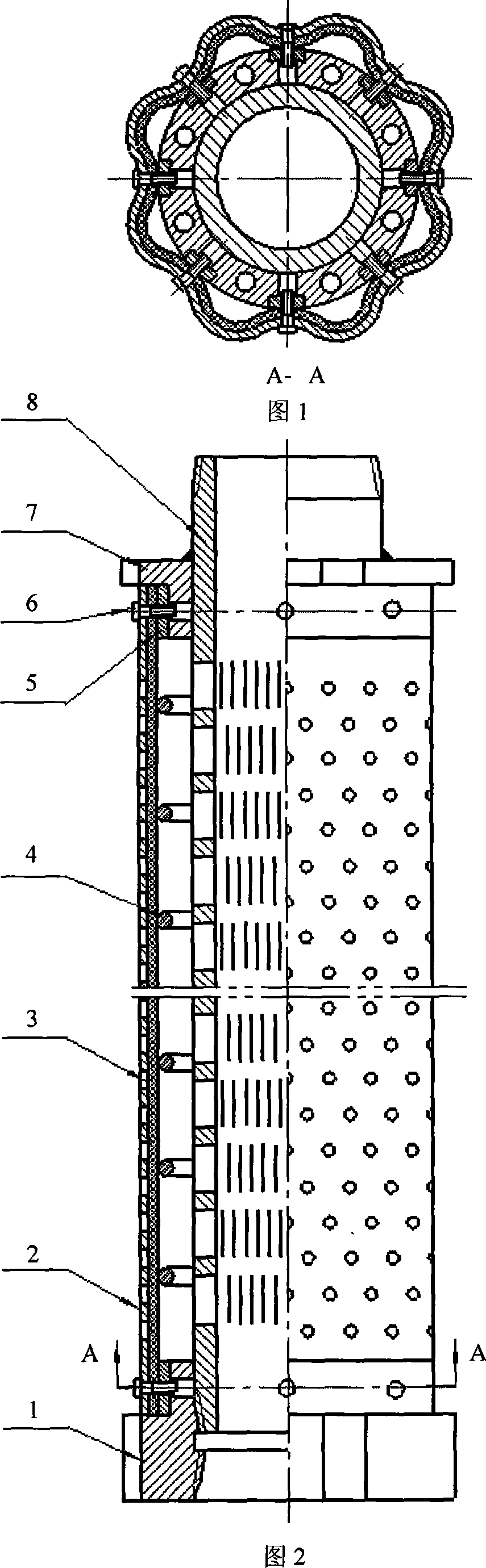

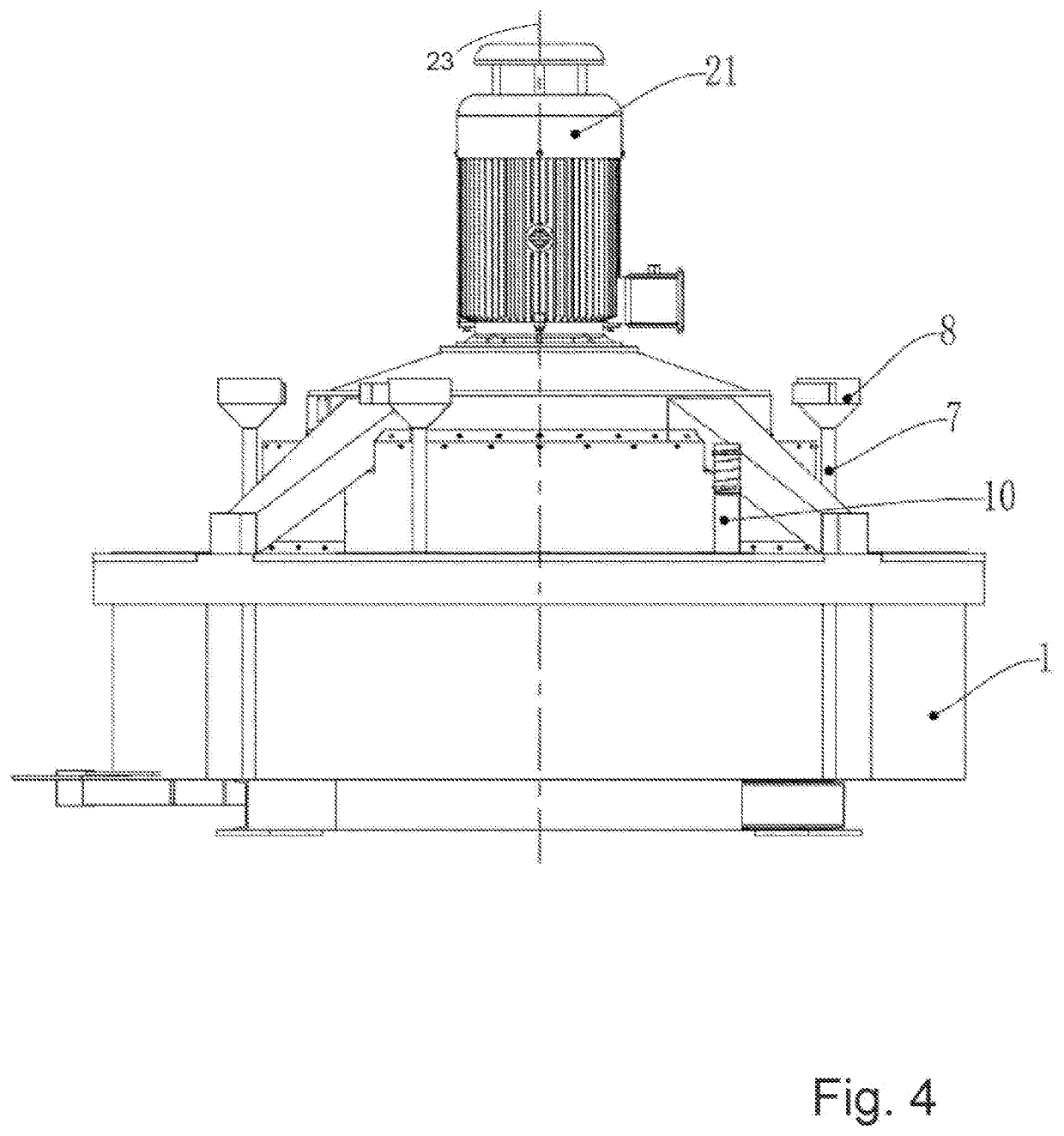

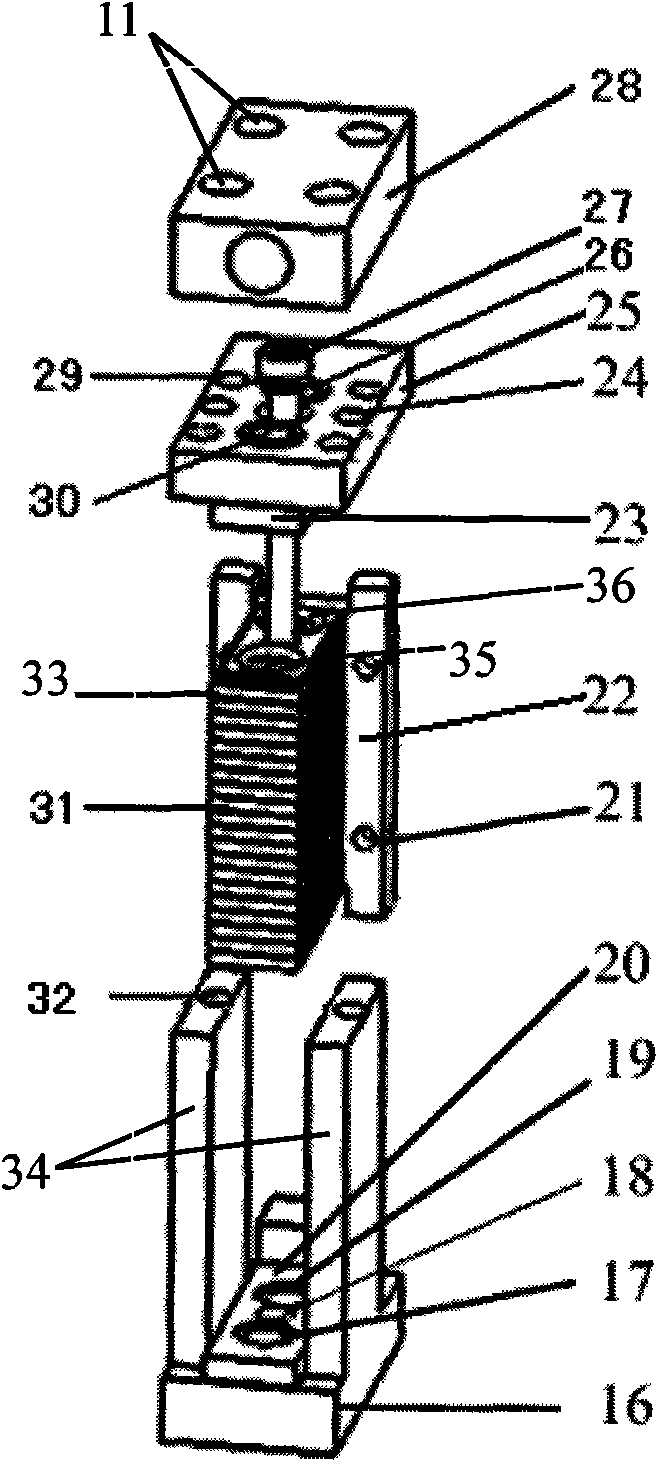

Giant magnetostrictive hydraulic pump and working method thereof

ActiveCN103291578ANot easy to twist offIncrease temperaturePiezoelectric/electrostriction/magnetostriction machinesPumpsConvertersElectric machine

The invention relates to a giant magnetostrictive hydraulic pump and a working method thereof, which belong to the technical field of hydraulic control. A giant magnetostrictive electric-mechanical converter includes a base (12), an outer cover (8), an end cover (5), a precompression disc spring (16), a magnetic block (6), a cooling pipe (13), a coil former (7), a generation unit (10) for a bias magnetic field and a drive magnetic field, a giant magnetostrictive rod (9), a centre (14) and an output rod (15). A hydraulic pump head includes a pump shade (17) and a pump cover (1), as well as a plunger assembly and a valve body. According to the invention, precompression can be exerted and adjusted conveniently, so that the giant magnetostrictive rod cannot be twisted off, the valve block of the check valve is high in respond speed and low in flow resistance, and the temperature rise of the giant magnetostrictive rod can be effectively controlled.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

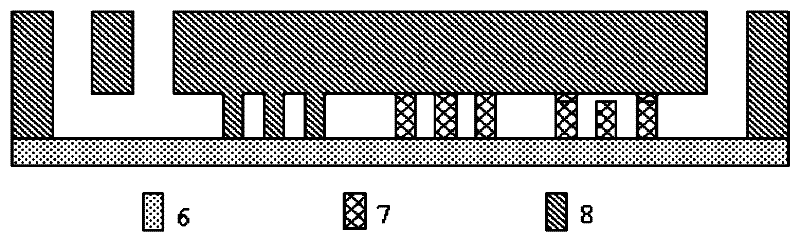

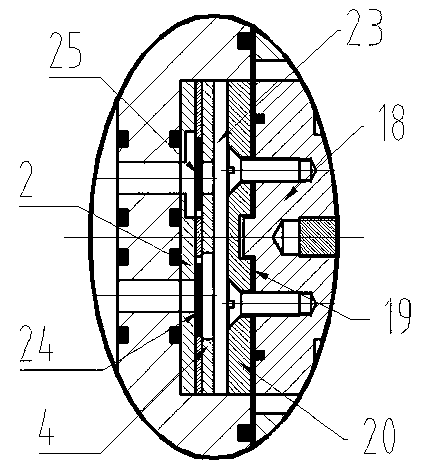

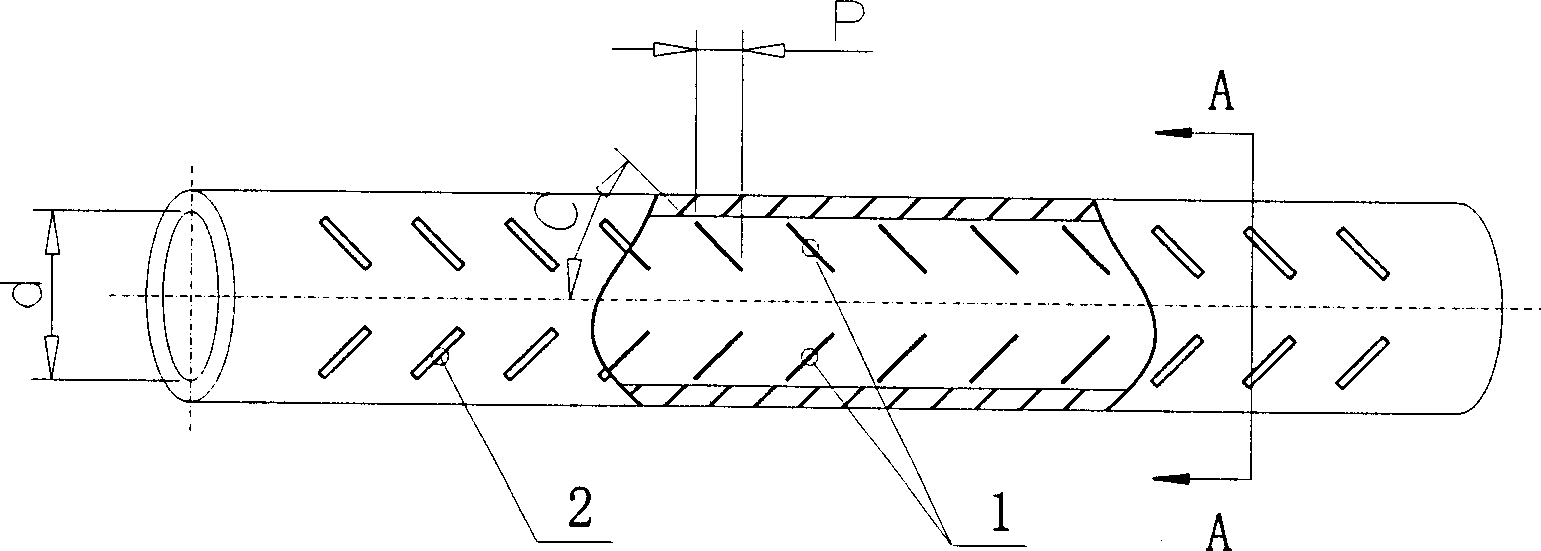

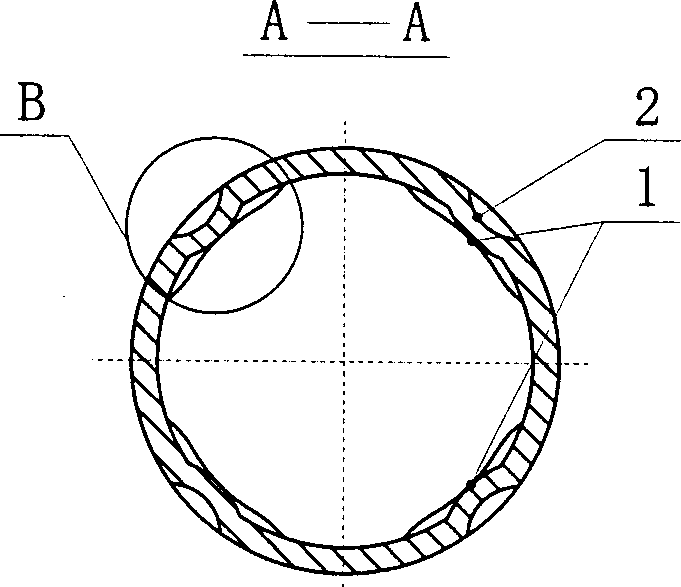

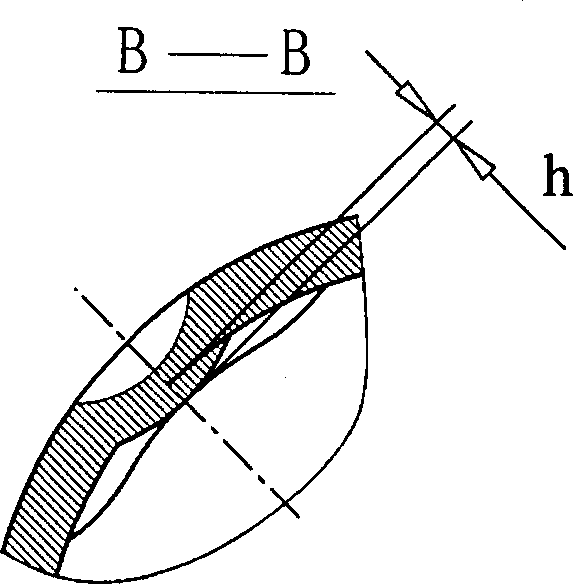

Non-continuous double diagonal internal rib reinforced heat exchange tube

InactiveCN1451937ASignificant effect of enhanced heat transferSmall flow resistanceHeat exchanger casingsTubular elementsEngineeringHigh heat

A heat exchanging tube is characterized by that on its inner surface there are discontinuous internal ribs which have a certain included angle (5-85 deg.) relative to axis of tube and are inclined intwo directions. Its advantages are high heat exchange efficiency, low flow resistance and not scaling.

Owner:TSINGHUA UNIV

Adaptive filling expansion scree tube and expanding method thereof

ActiveCN101067370AReduce expansion forceReduce operating costsFluid removalEngineeringSolid particle

The present invention provides one kind of adaptive filled expanding sieve tube for preventing sand in oil and gas well, and belongs to the field of petroleum drilling and extracting tool technology. The adaptive filled expanding sieve tube consists of supporting slotted tube, special filling coupler, radial expanding cover, radial expanding composite filter element, supporting rack, expanding block, expanding screw, plug and other parts. During well operation, the adaptive filled expanding sieve tube is set in the oil reservoir and filled with high pressure carrying solid particles, so that the composite filter element and the radial expanding cover can expand radially to contact with the inner wall of the production casing or the uncased hole to block sand and control the size of the passed sand. Compared with available technology, the present invention has the advantages of lowered expanding force, low operation cost and other advantages.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

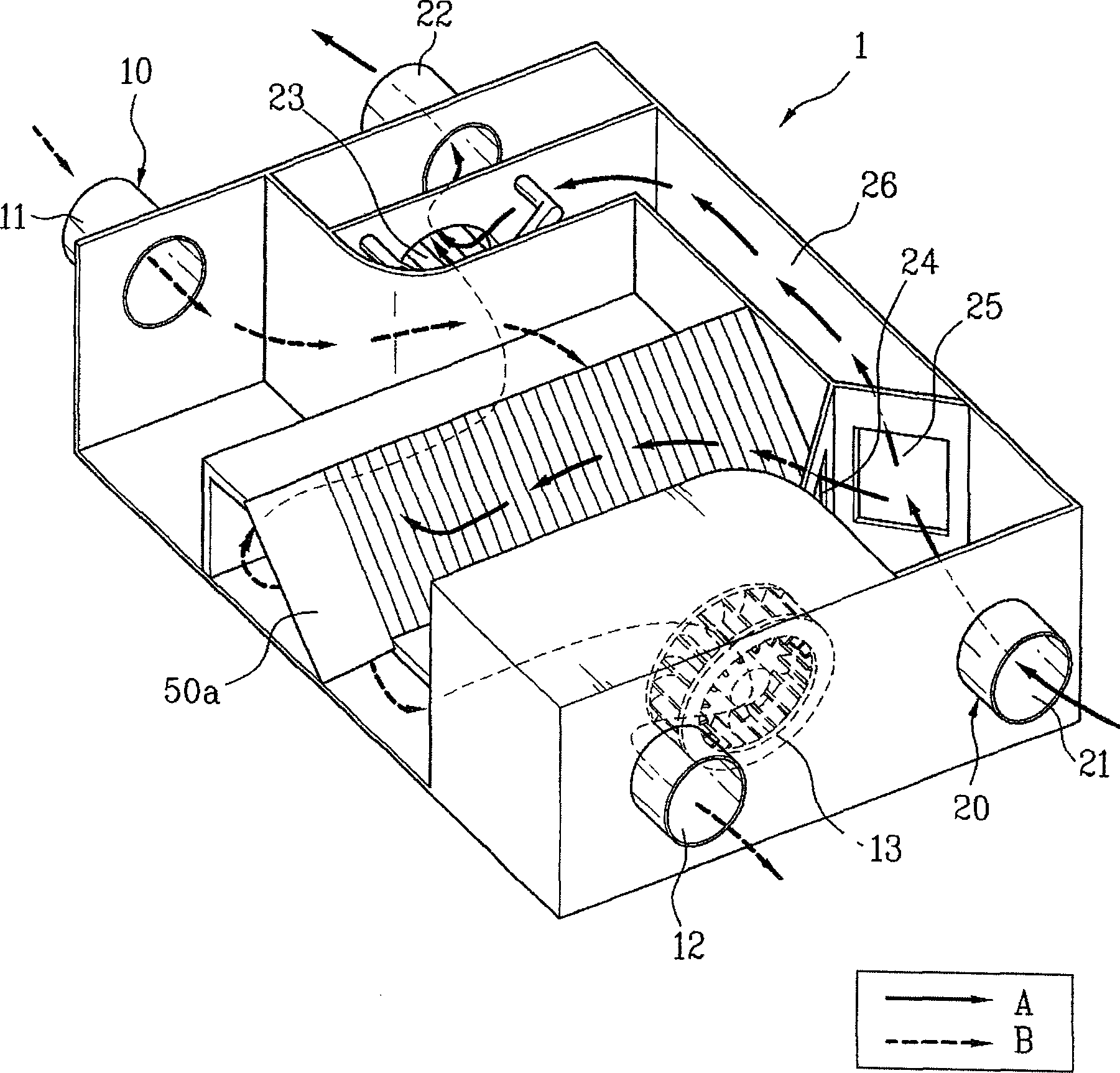

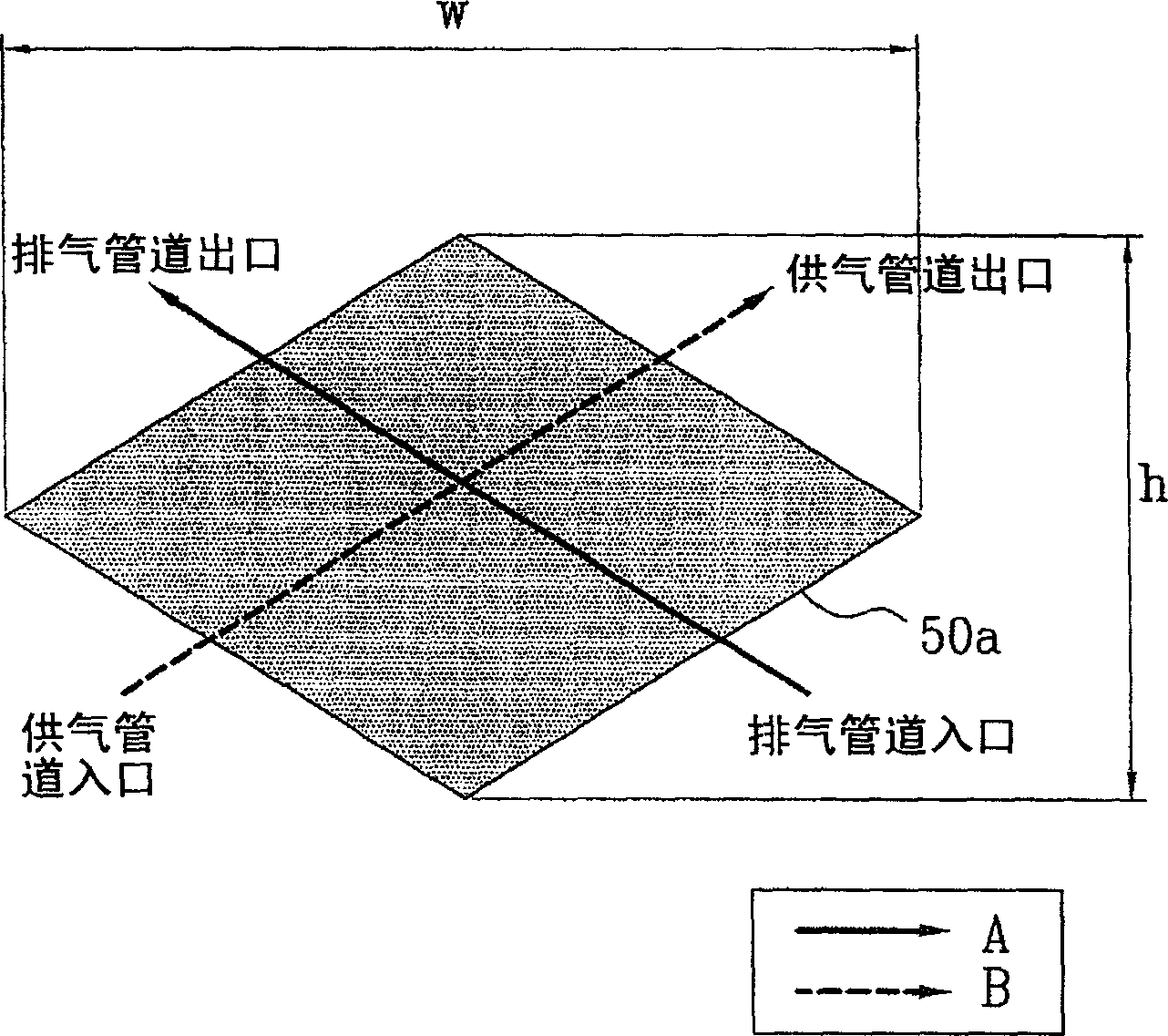

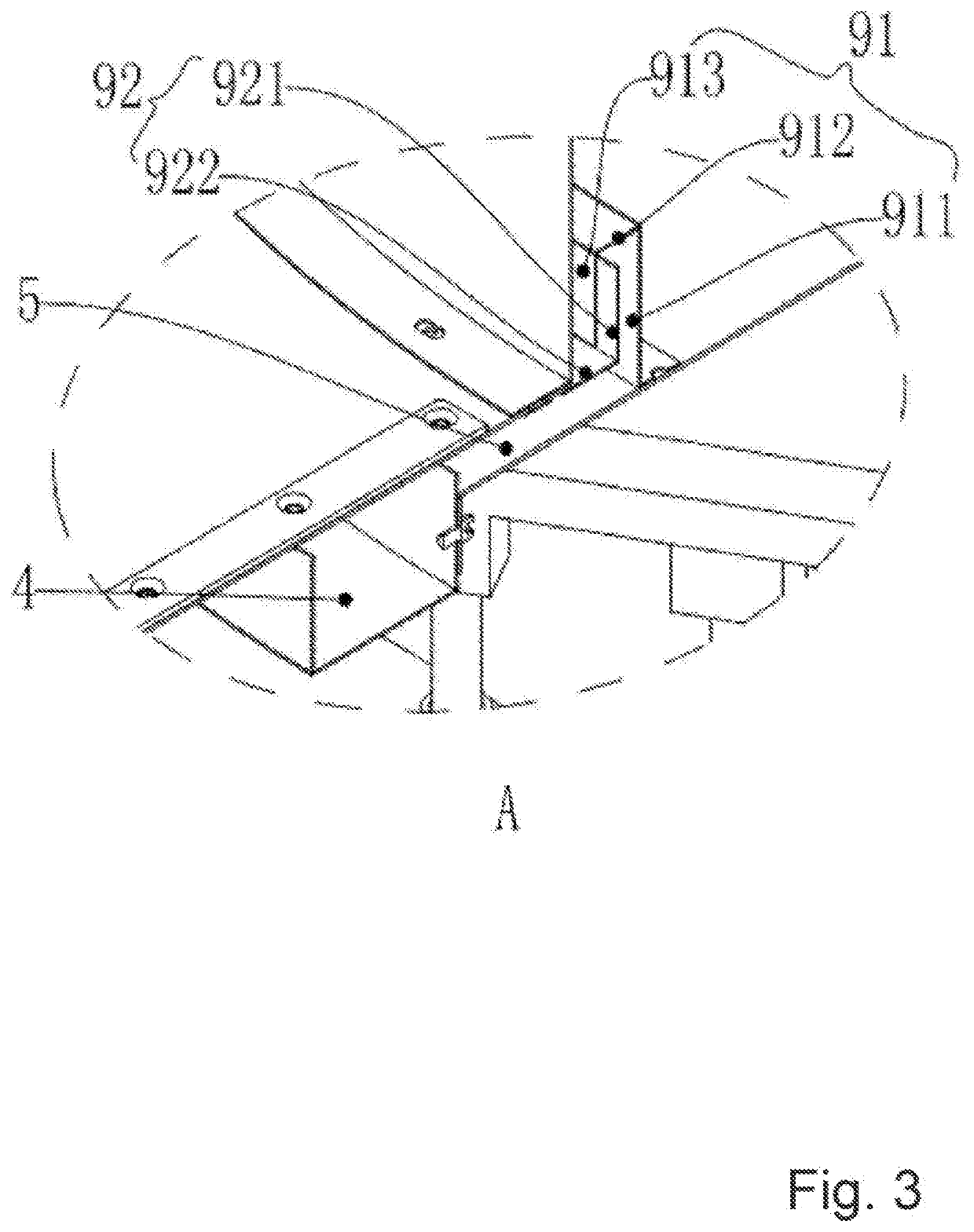

Total heat exchanger and ventilation system using the same

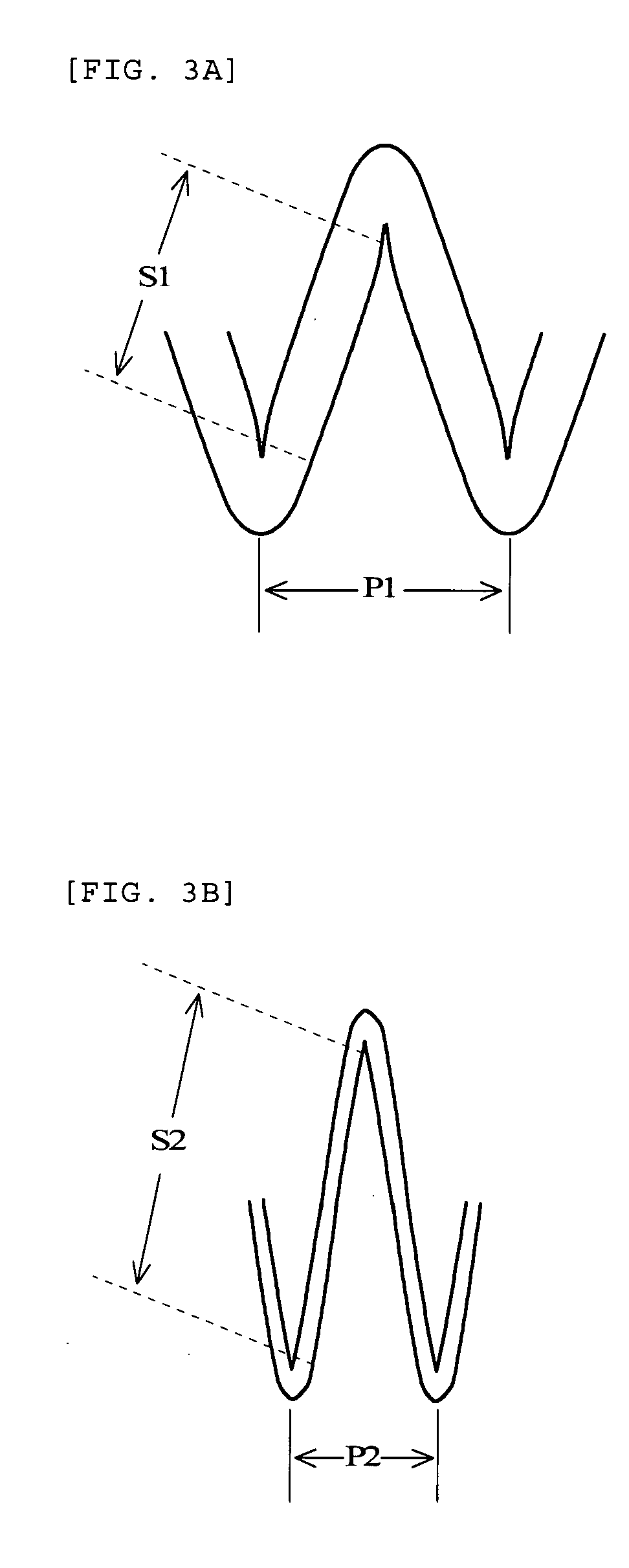

InactiveCN1873335AImprove thermal efficiencySmall flow resistanceEnergy recovery in ventilation and heatingHeat recovery systemsPlate heat exchangerAcute angle

A total heat exchanger having a structure capable of achieving an enhancement in total heat efficiency, and a ventilation system using the total heat exchanger are disclosed. The total heat exchanger includes an air supply duct for guiding outdoor air to an indoor space, an air discharge duct for guiding indoor air to the outdoors, an air supply fan arranged at one side of the air supply duct, the air supply fan sucking the outdoor air, and supplying the sucked air to the indoor space, an air discharge fan arranged at one side of the air discharge duct, the air discharge fan sucking the indoor air, and discharging the sucked air to the outdoors, and a heat exchanging element arranged at a region where the indoor air and the outdoor air cross each other, the heat exchanging element heat-exchanging the indoor air with the outdoor air. The heat exchanging element has a shape causing the indoor air and the outdoor air to flow through the heat exchanging element while forming an acute angle with respect to each other.

Owner:LG ELECTRONICS INC

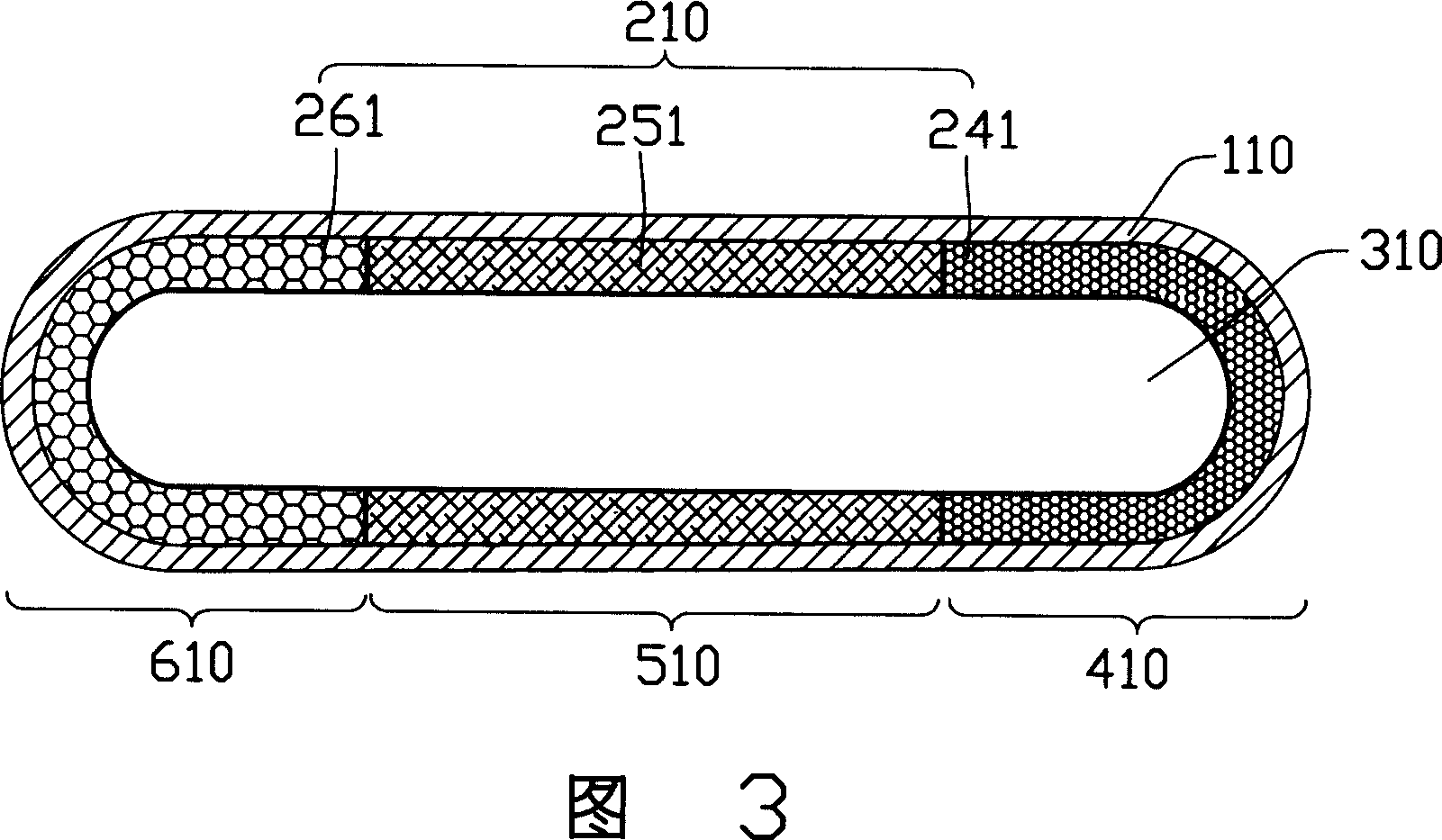

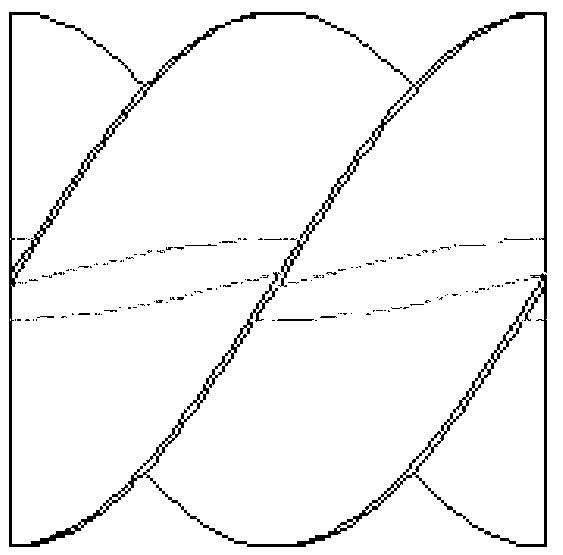

Adsorbent for canister, and canister

ActiveUS20140124385A1Decrease resistance to flowSmall flow resistanceGas treatmentNon-fuel substance addition to fuelActivated carbonSorbent

To obtain adsorbent (10), meltable core which melts away during baking and binder are added to powdery activated carbon having microscopic pore whose size is less than 100 nm together with water and mixed together, then this mixture is molded into hollow cylindrical shape whose outside diameter is 4˜6 mm and baked. Although macroscopic pore whose side is 100 nm or more is formed by the meltable core, proportion of volume of the macroscopic pore to volume of the microscopic pore is adjusted to 65%˜150%. The adsorbent (10) has shape in cross section formed from cylindrical wall (10A) and cross-shaped radial wall (10B), and thickness of each part is within a range of 0.6˜3 mm. The adsorbent (10) of the present invention can satisfy adsorbing / desorbing performance of fuel vapor, flow resistance as a canister and strength of the adsorbent at the same time.

Owner:MAHLE JAPAN LTD +1

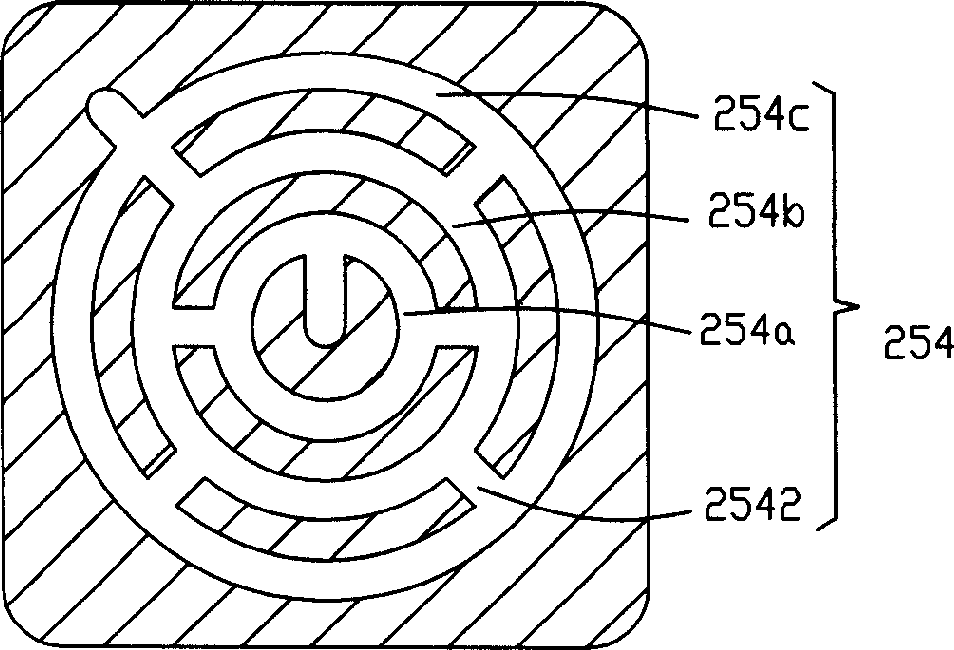

Liquid-cooling heat sink

InactiveCN1870255ASmall flow resistanceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat sink

A heat radiation device with cooling liquid consists of a heat absorbing body, a heat radiation body, a cooling liquid channel and driving unit of cooling liquid. It is featured as connecting multiple passageway being arranged along heat absorbing body center to body periphery with channel of cooling liquid and connecting two adjacent passageways to each other, setting two branches leading to far point from heat absorbing body center on passageway near heat absorbing body center to let cooling liquid flow to passageway far from heat absorbing body center along two said branches.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

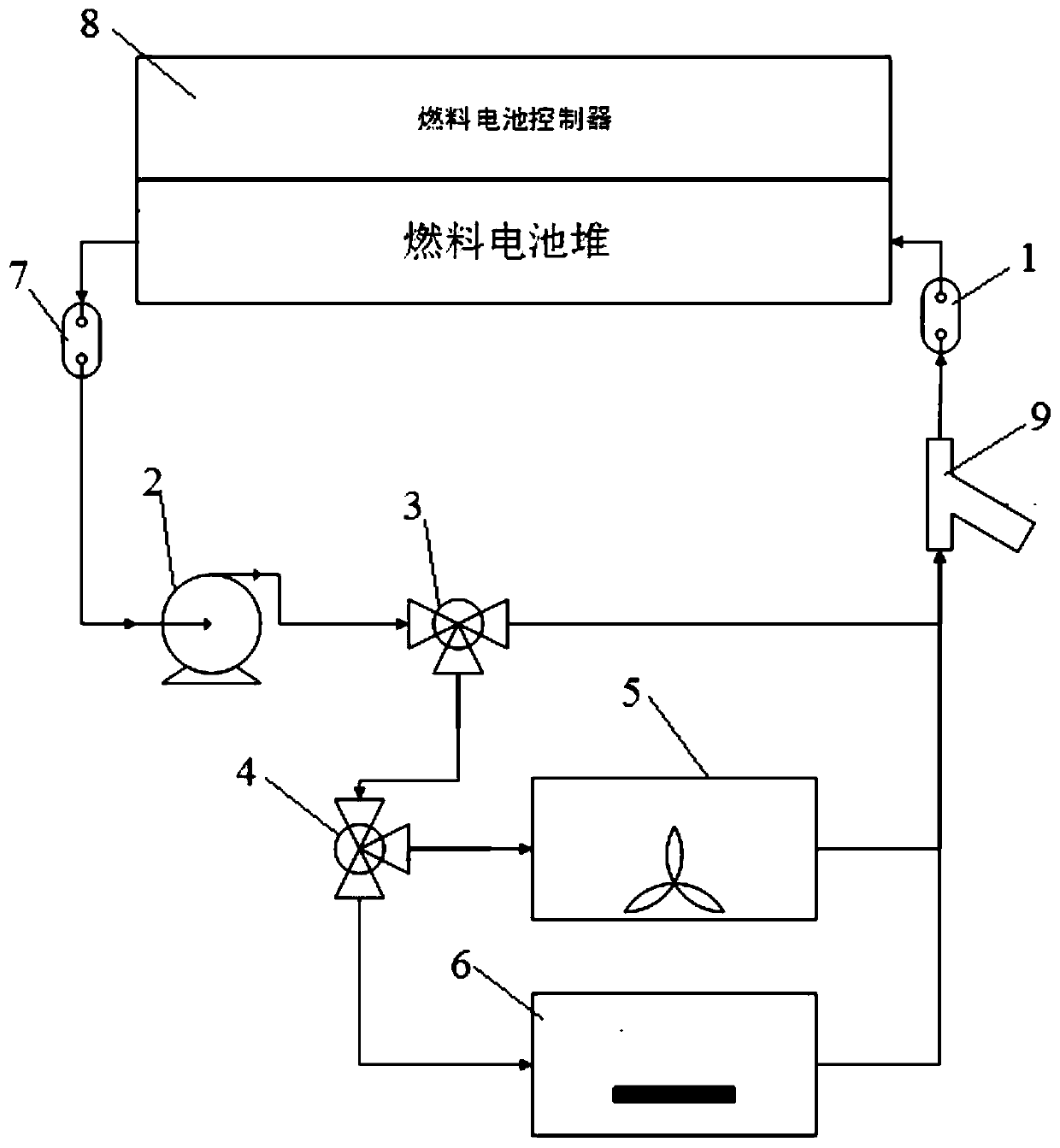

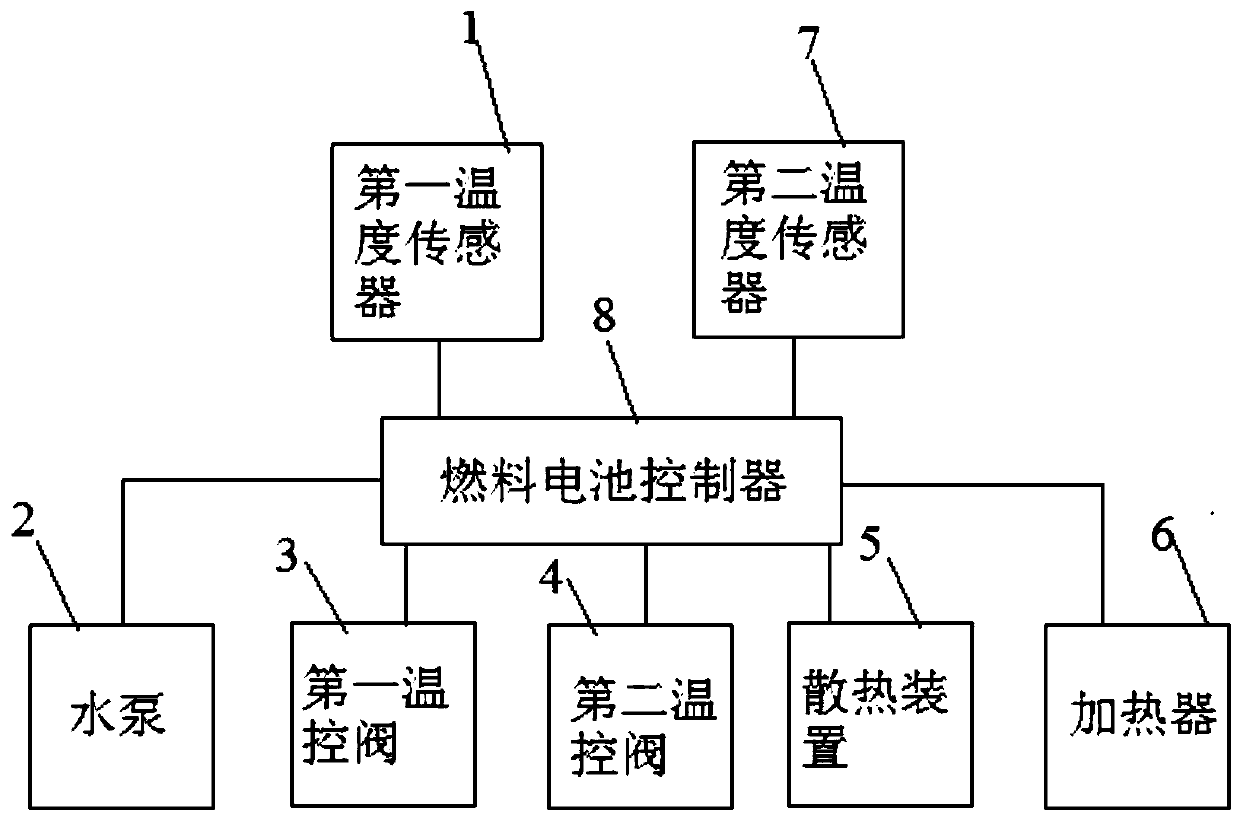

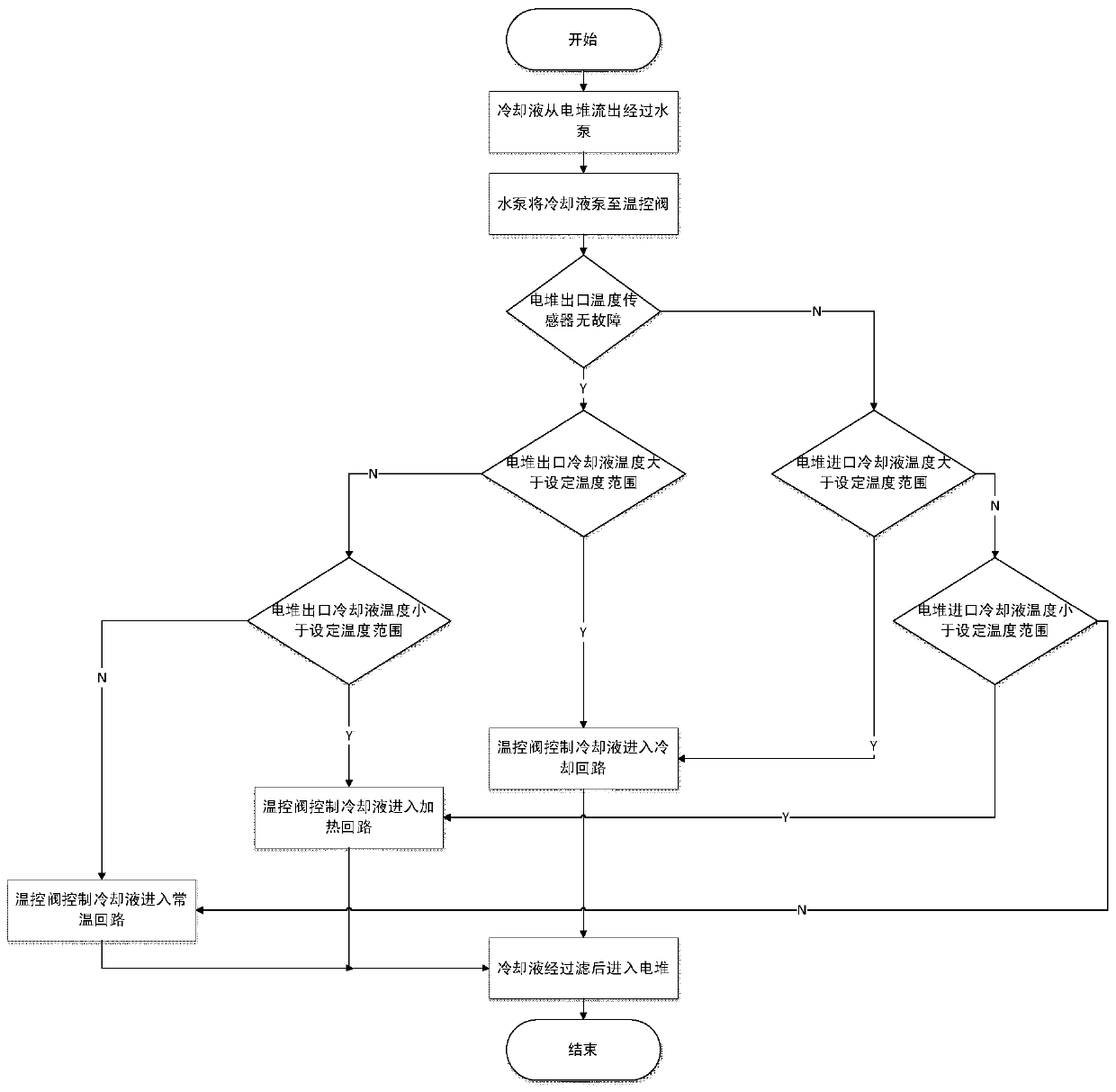

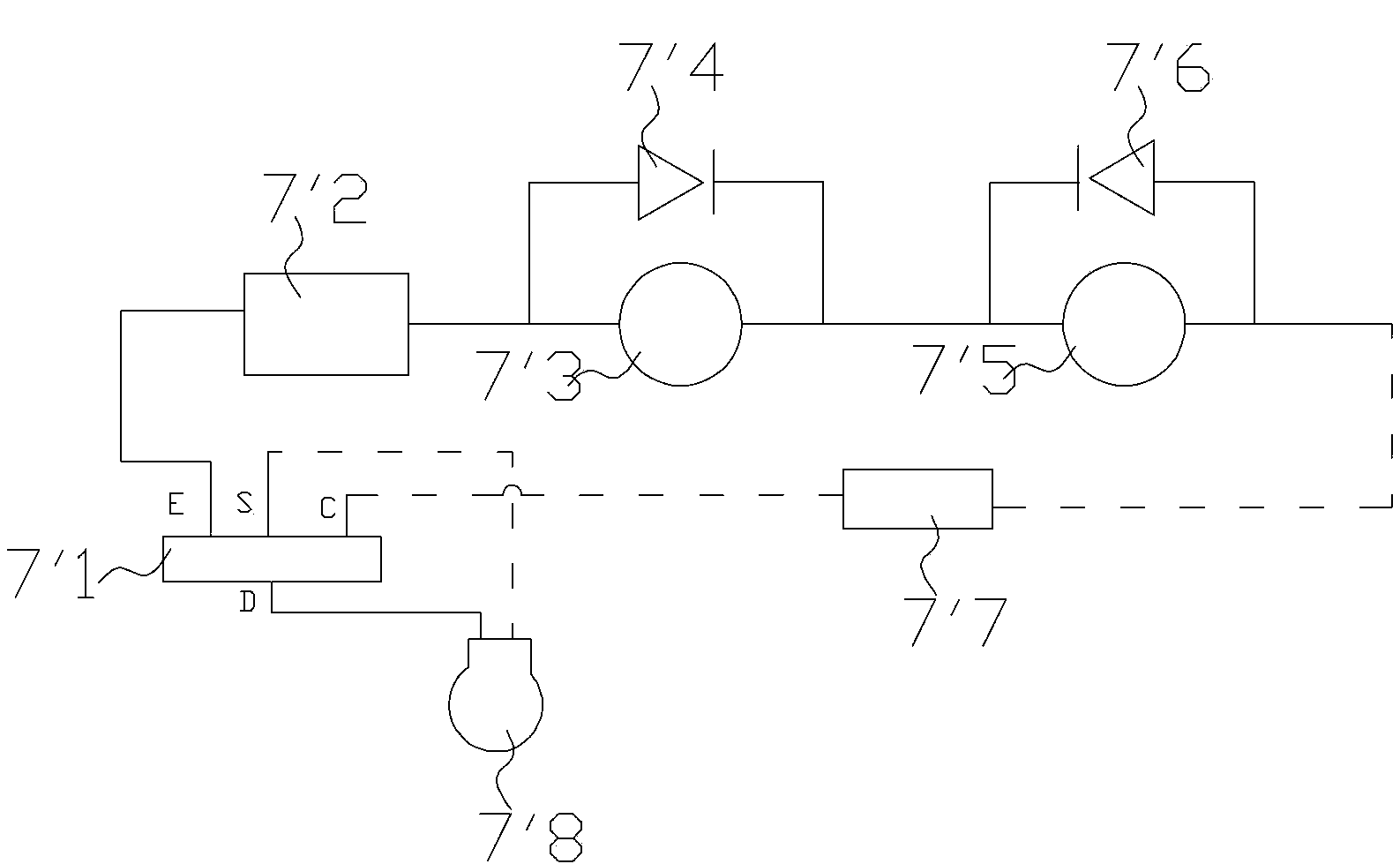

Fuel cell vehicle cooling system and control method thereof

ActiveCN110993987AIncrease temperatureNormal chemistryFuel cell heat exchangeMotive system fuel cellsTemperature controlFuel cells

The invention relates to a fuel cell vehicle cooling system. A first temperature sensor and a second temperature sensor are respectively arranged at an inlet and an outlet of a fuel cell stack; signaloutput ends of the first temperature sensor and the second temperature sensor are respectively connected with the fuel cell controller; the input end of the water pump is connected with a fuel cell stack outlet; the output end of the water pump is connected with the input end of the first temperature control valve; a first output end of the first temperature control valve is connected with a cooling liquid inlet of the fuel cell stack; the second output end of the first temperature control valve is connected with the input end of a second temperature control valve, the first output end of thesecond temperature control valve is connected with a cooling liquid inlet of the fuel cell stack through a heat dissipation device, and the second output end of the second temperature control valve is connected with a cooling liquid inlet of the fuel cell stack through a heater. According to the invention, the temperature of the cooling liquid flowing into the galvanic pile can be maintained within a set range in different external environments, so that the chemical reaction in the galvanic pile is ensured to be normally carried out, and power energy is provided for the whole vehicle.

Owner:DONGFENG MOTOR CORP HUBEI

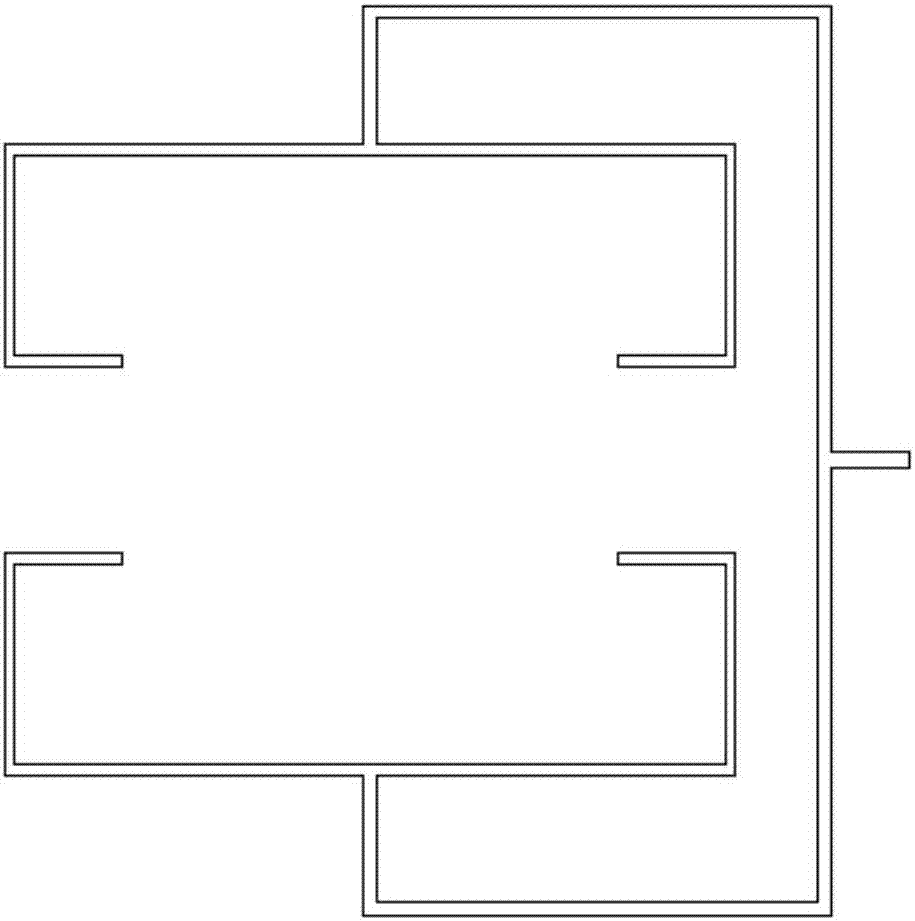

Micro-channel cold plate structure

InactiveCN107146938ASpeed up the flowImprove temperature consistencyDe-icing/drying-out arrangementsChannel networkEngineering

The invention discloses a micro-channel cold plate structure. The micro-channel cold plate structure comprises a substrate and a micro-flowing-channel network processed on the substrate; and the micro-flowing-channel network comprises a shunting structure, a partial micro-channel network and a confluence structure in a combined manner. The micro-channel cold plate structure has the beneficial effects as follows: reasonable flow deploying of a cooling working medium is realized through T-shaped flowing channels, and then heat transfer is strengthened by tree-like and parallel micro channels; finally, energy re-confluence is realized through inverse Y-shaped two-furcation flowing channels, so that high channel distribution uniformity is realized, and the network can be uniformly distributed in the whole to-be-dissipated region; the overall micro-fluid network is in all-parallel-connection way, so that high temperature consistency is achieved; the cooling working medium flows smoothly in the flowing channels, so that low flowing resistance is formed; and furthermore, the micro channels in each group of the partial micro-channel network are arranged in parallel, and the channels are more in branches and high in span, so that the process can be realized conveniently, partial pressure loss can be lowered, and the heat dissipation performance of the micro-channel cold plate can be further improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

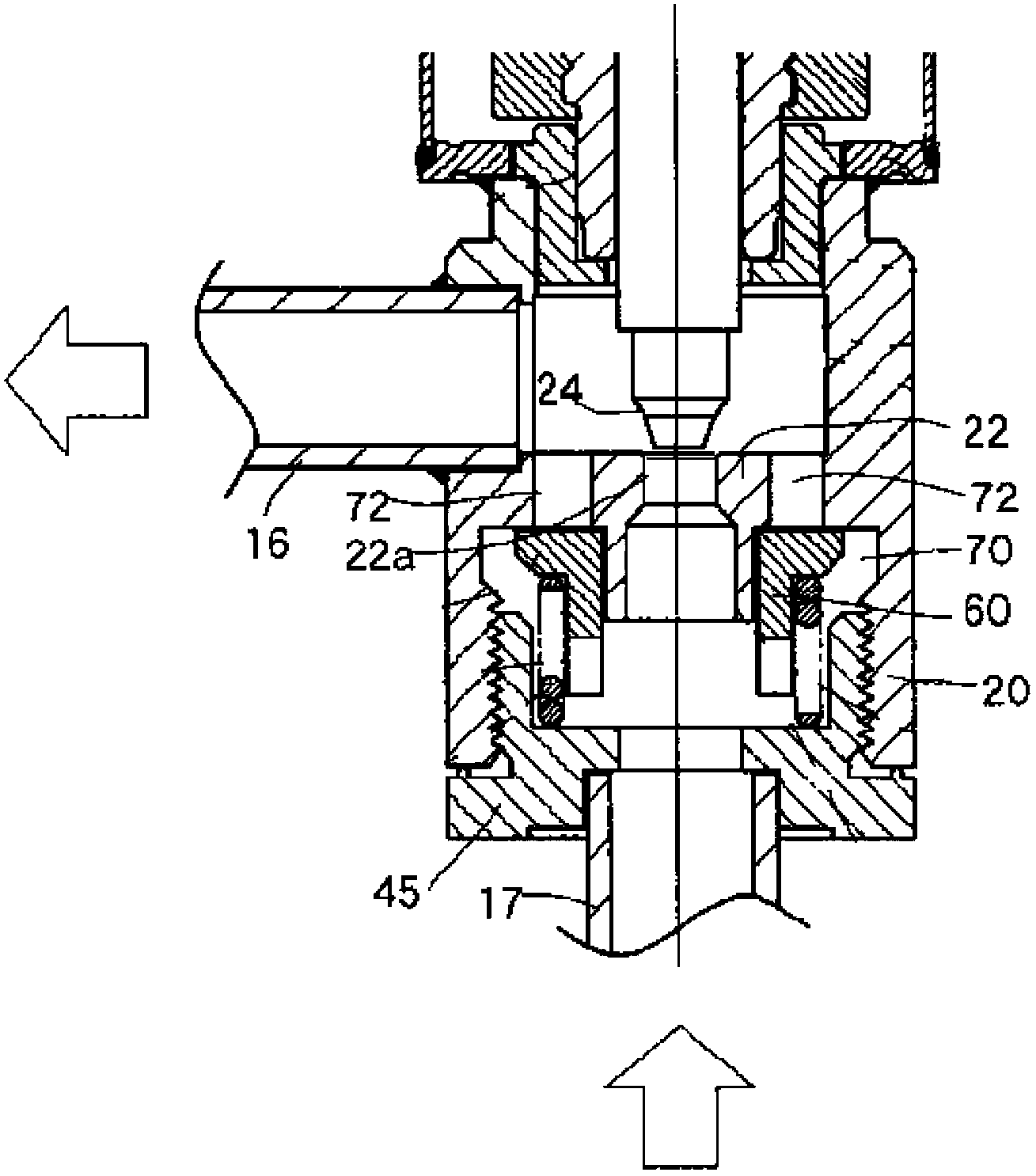

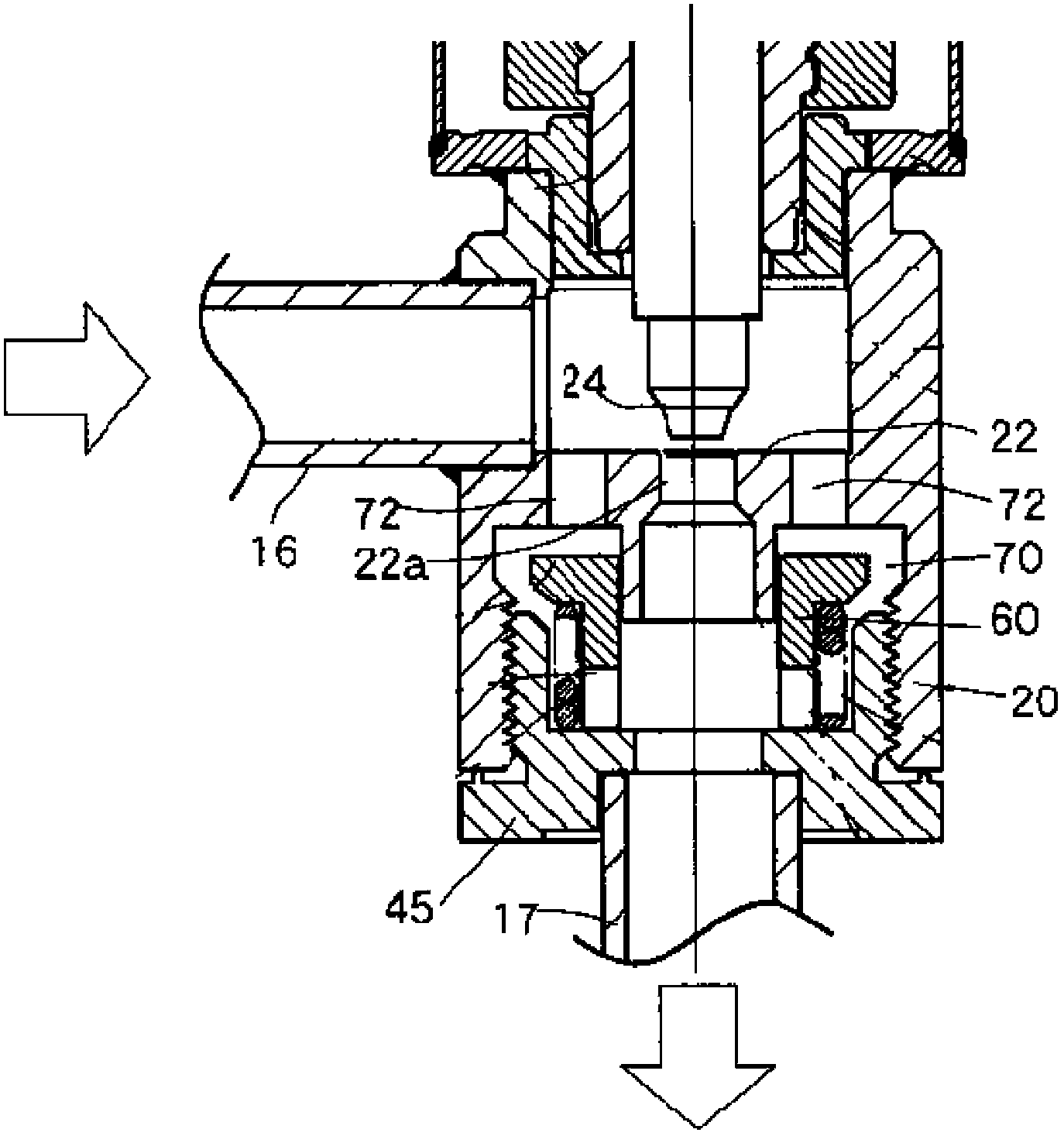

Electronic expansion valve

ActiveCN103512288AThe spring force can be set smallReduce settingsCheck valvesEfficient regulation technologiesEngineeringHigh pressure

The invention discloses an electronic expansion valve. According to the electronic expansion valve, a piston part (4) and a valve needle part (3) are located on the same side of a valve element seat (2) so that a bypass through hole (212) can be blocked by the piston part (4) when a refrigerant flows in the forward direction, the refrigerant flows to one end of a vertical connecting pipe (52) through a valve element valve port (211), and the valve needle part (3) moves in the axial direction to adjust the open degree of the valve element valve port (211); when the refrigerant flows in the backward direction, the piston part (4) moves upwards in the axial direction to open the bypass through hole (212), and the refrigerant flows to one end of a transverse connecting pipe (51) through the bypass through hole (212). According to the electronic expansion valve, on one hand, the valve element valve port can be sealed easily by the valve needle part under the high-pressure condition when the refrigerant flows in the forward direction, and the valve needle part is prevented from being ejected open by the high-pressure refrigerant; on the other hand, the axial size and radial size of a valve seat can be reduced, and flow resistance when the refrigerant flows in the backward direction is reduced.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Heat sink with guiding fins

InactiveUS6899164B1Small flow resistanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

The present invention is a heat sink with guiding fins comprising a base with a plate part, wherein each side of a pair of two opposite sides of the plate part comprises a declining part; and two groups of fins expanded upwardly from each said declining part, wherein a channel whose top width is wider than its bottom width is form by the tow groups of fins and the base and there is a gap properly set between each two fins. By doing so, the heat sink can guide the flow generated by a fan to form a streamline with pressure and so obtains smaller wind resistance and better heat dissipation for the heat sink.

Owner:DATECH TECH CO LTD

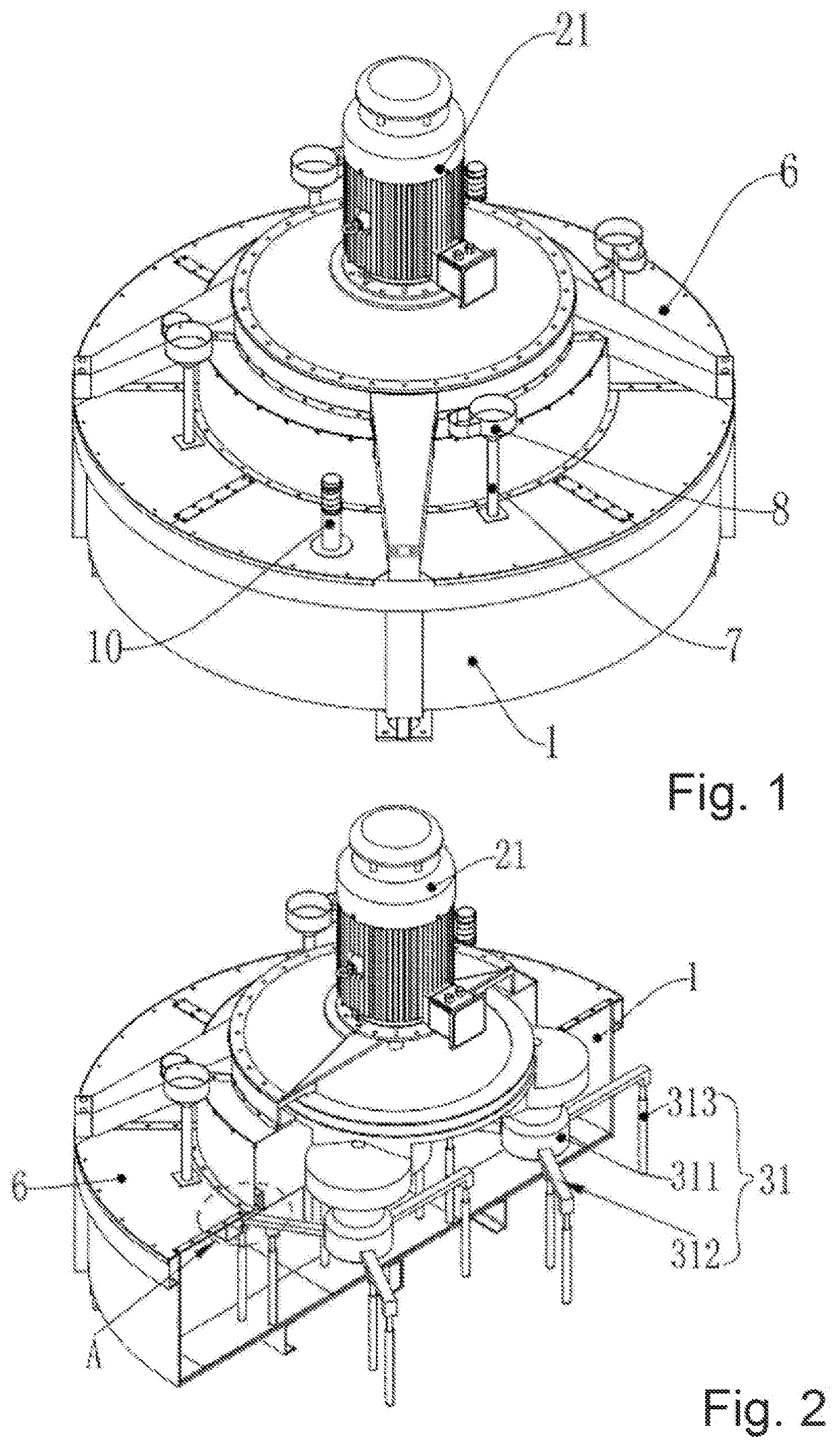

Mixer for synthetic quartz

InactiveUS20200261871A1Easy to cleanSmall flow resistanceRotary stirring mixersMixing operation control apparatusEngineeringMixing tank

A mixer for synthetic quartz includes a mixing barrel (1), a power transmission system (2), a mixing system (3), and multiple material receiving receptacles (4). The power transmission system is provided above the mixing tank. The mixing system is provided inside the mixing tank. The power transmission system is used to drive the mixing system to move. An opening is arranged at each of two ends of the material receiving receptacle. The multiple material receiving receptacles (4) are arranged at a top portion of the mixing tank, and end portions of two adjacent material receiving receptacles are spaced apart from each other without contact there between. A resin experiences low flow resistance in the material receiving receptacle, and thus can fall smoothly without accumulating in the material receiving receptacle. Moreover, the material receiving receptacle can be cleaned easily.

Owner:VEEGOO TECH CO LTD

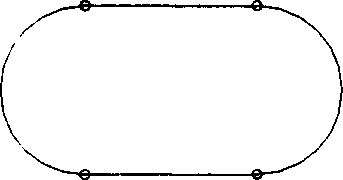

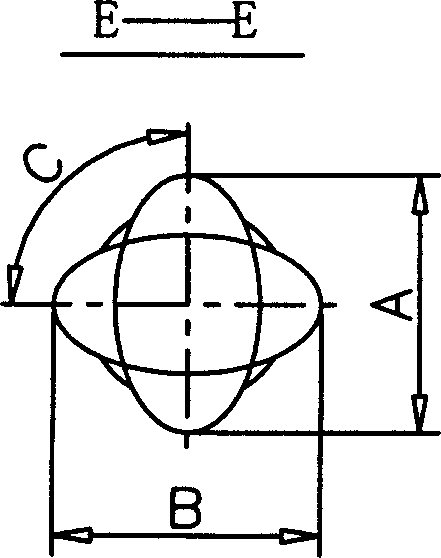

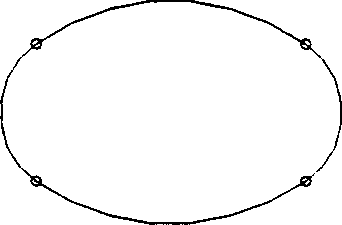

Tubulation and/or sepcial-section tubulation reforced heat exchange tube

InactiveCN1455220AGood heat exchange enhancement effectSmall flow resistanceTubular elementsEllipseEngineering

Owner:TSINGHUA UNIV

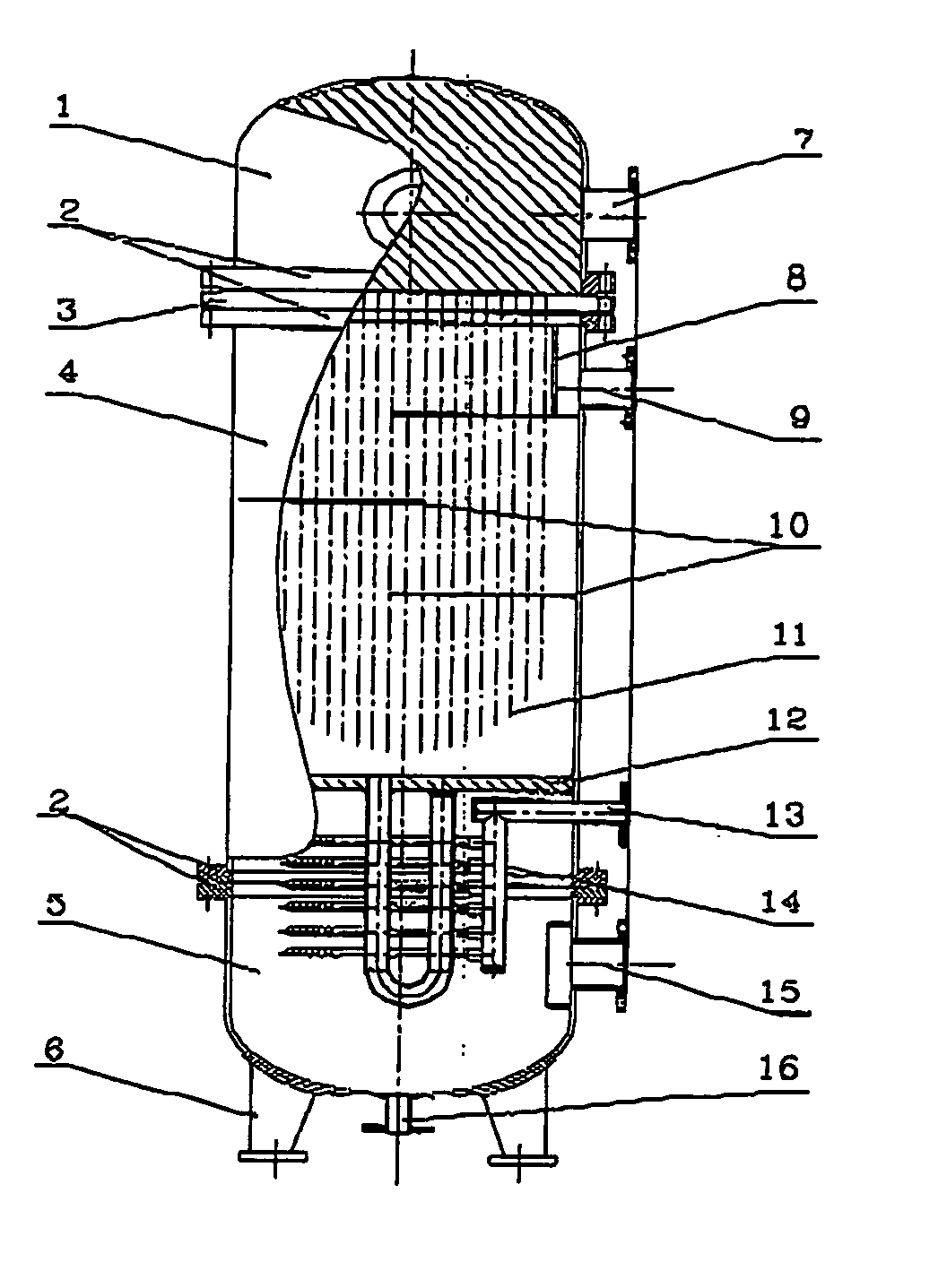

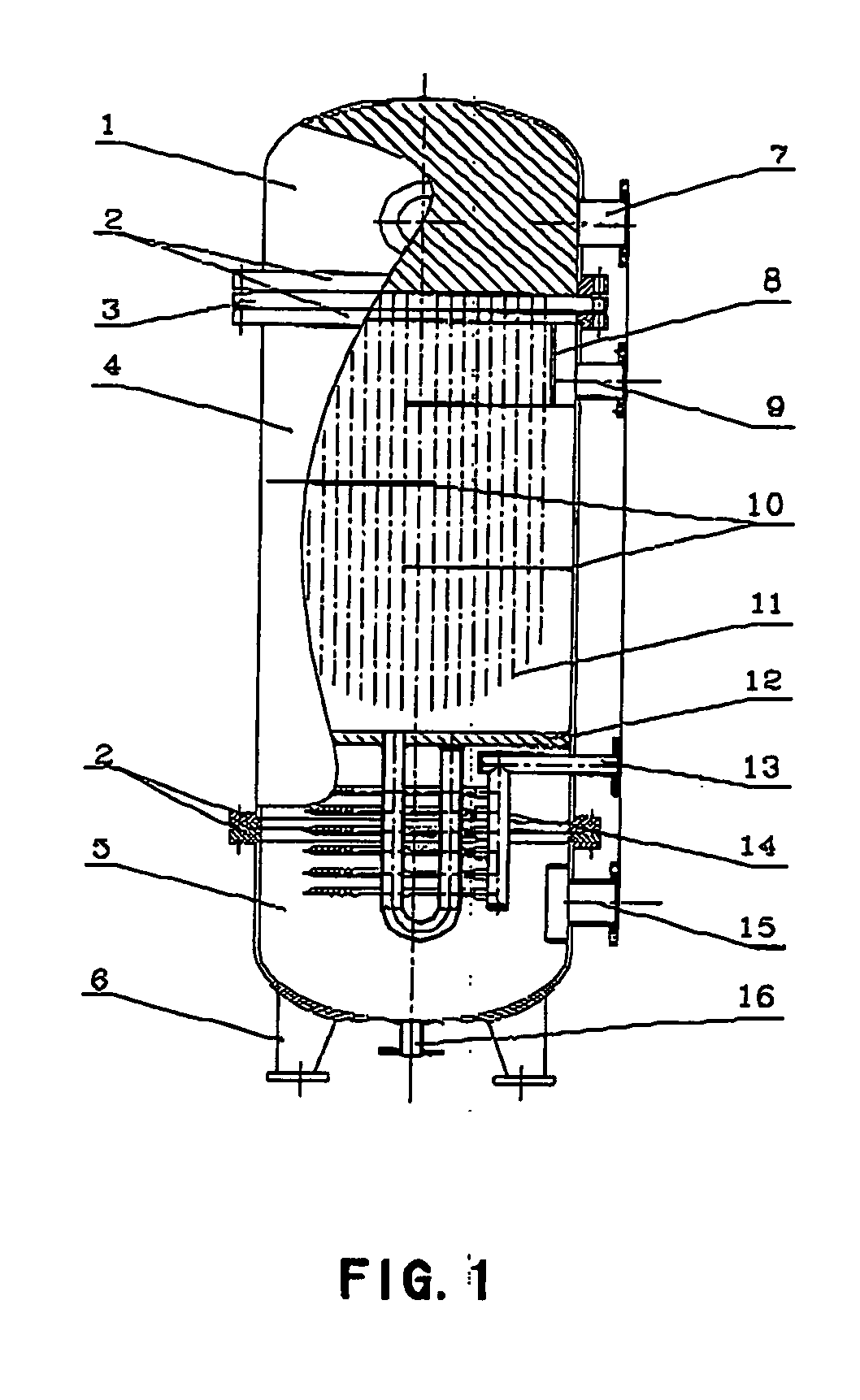

Complex flow-path heat exchanger having U-shaped tube and cantilever combined coil

InactiveUS20050109495A1Small flow resistanceIncrease water speedStationary conduit assembliesStationary tubular conduit assembliesWater flowEngineering

A complex flow-path heat exchanger having U-shaped tube and cantilever combined coil, which can achieve, in this type heat exchanger, a simple construction, a complex flow of steam within the same one heat exchange shell body, a high heat exchange efficiency, and a low energy loss. The technical gift of the present invention is that, after entering into the heat exchanger, steam firstly effects heat exchange on the U-shaped tube flow path shell side to be cooled and condensed, thereafter entering into flow path tube side of the cantilever combined coil, which are disposed within the same one shell, for a secondary heat exchange, and subsequently flowing out of the heat exchanger after being subcooled. Such steam-water heat exchanger having a complex flow path are advantageous in a small steam flow resistance of the U-shaped tube flow path shell side; a higher condensate water flow velocity in the cantilever combined coils flow path tube; a high heat exchange coefficient; good coordination of the temperature difference fields of the hot and cold fluids in the heat exchanger; and a high heat exchange efficiency. Therefore, the present heat exchanger can be a new generation product relative to the currently-used conventional low-temperature, low-pressure and corrosion-free heat exchangers.

Owner:SHANDONG UNIV

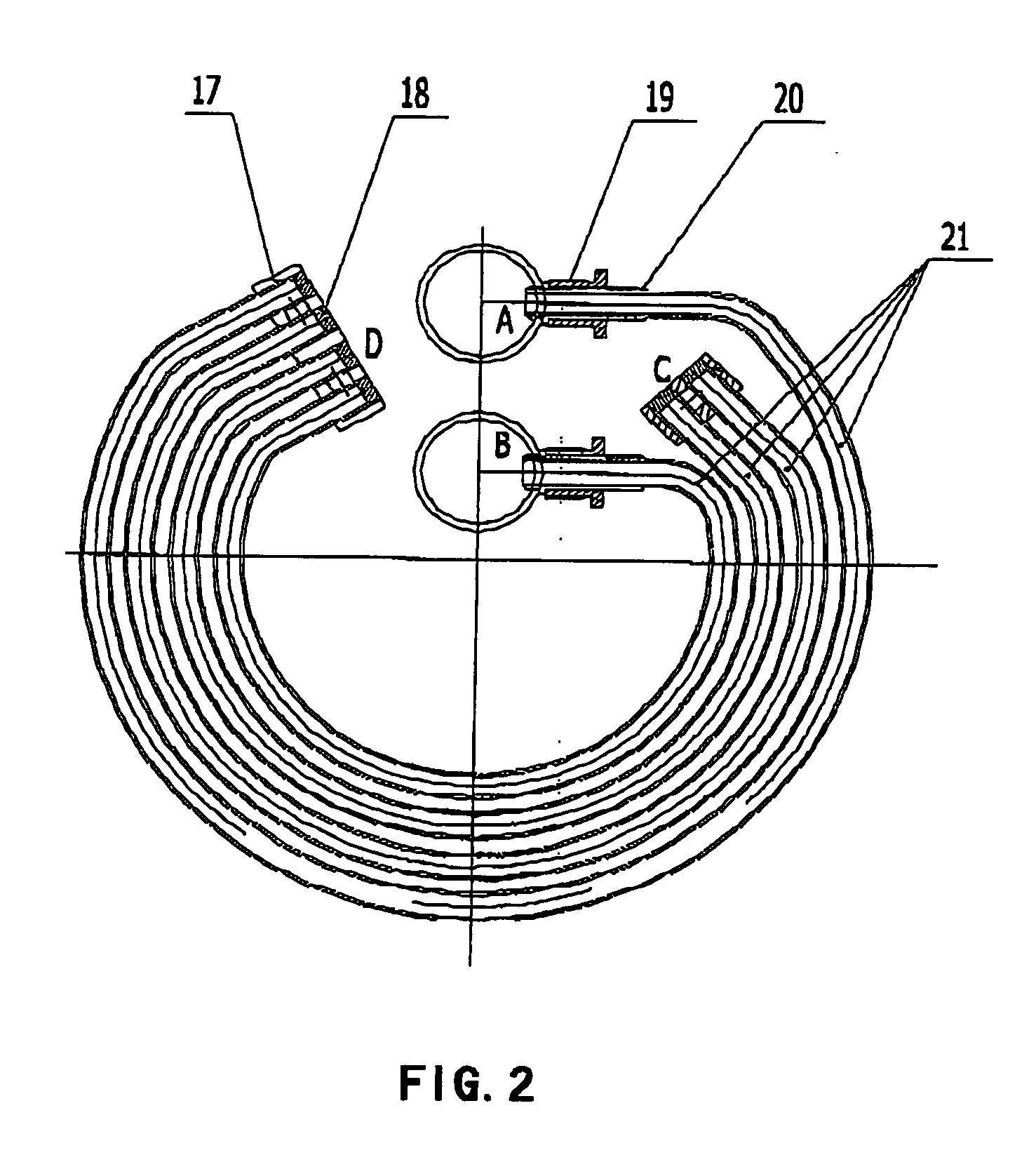

Novel low-cost stack-up array liquid refrigeration semiconductor laser and manufacturing method thereof

ActiveCN101640379AEasy to manufactureReduce manufacturing costSemiconductor laser arrangementsSemiconductor laser structural detailsEngineeringRefrigeration

The invention discloses a novel low-cost stack-up array liquid refrigeration semiconductor laser and a manufacturing method thereof. The laser comprises a lower base plate, an anode block, micro-refrigeration modules with chips, a cathode block, an upper pressing block and a liquid refrigeration block which are arranged from bottom up in turn. The micro-refrigeration modules with chips are two ormore and stacked up to form a multiple bar series module group, and the lower base plate is provided with side plates on both sides; the anode block, the multiple bar series module group and the cathode block are sequentially stacked up and arranged between the two side plates on the lower base plate, the upper pressing block is arranged on the upper side of the cathode block and fixedly connectedwith upper ends of the two sides plates of the lower base plate, and the upper side of the upper pressing block is fixedly connected with the liquid refrigeration block. The laser has simple manufacturing method and low production cost, and effectively reduces flow resistance of cooling fluid, causes obviously reduced pressure drop of the cooling fluid, has easier sealing of the cooling fluid andstrong heat emission capability, effectively prolongs service life of the semiconductor laser and improves reliability by replacing a traditional micro channel structure with fins.

Owner:FOCUSLIGHT TECH

Electric operating apparatus for vehicle

InactiveUS7425042B2Feel goodEasy to implementControlling membersVehicle fittingsInformation controlElectricity

Owner:TOYODA IRON WORKS CO LTD

Polytetrafluoroethylene composite micro porous film for air purifying and its producing method

ActiveCN1820831AImprove filtration efficiencySmall flow resistanceSemi-permeable membranesFiberAir purification

The present invention discloses composite microporous polytetrafluoroethylene film for air purification and its production process. The composite microporous polytetrafluoroethylene film is one kind of capillary microporous film comprising microporous polytetrafluoroethylene film to ensure the filtering efficiency and its composited protecting and supporting material. The protecting and supporting material is polymer or inorganic fiber material. The microporous polytetrafluoroethylene film has thickness of 3-20 microns and pore size of 0.050-10.0 microns, the protecting and supporting material has the thickness of 10-3000 microns. The present invention has the features of low cost, easy manufacture and simple technological process, etc.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com