Liquid-cooling heat sink

A liquid-cooled heat dissipation and heat-dissipating body technology, applied in instruments, electrical digital data processing, electrical components, etc., can solve problems such as waste of heat transfer methods, waste of driving horsepower, uneven heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of each form disclosed by the present invention will be described in detail below with specific examples.

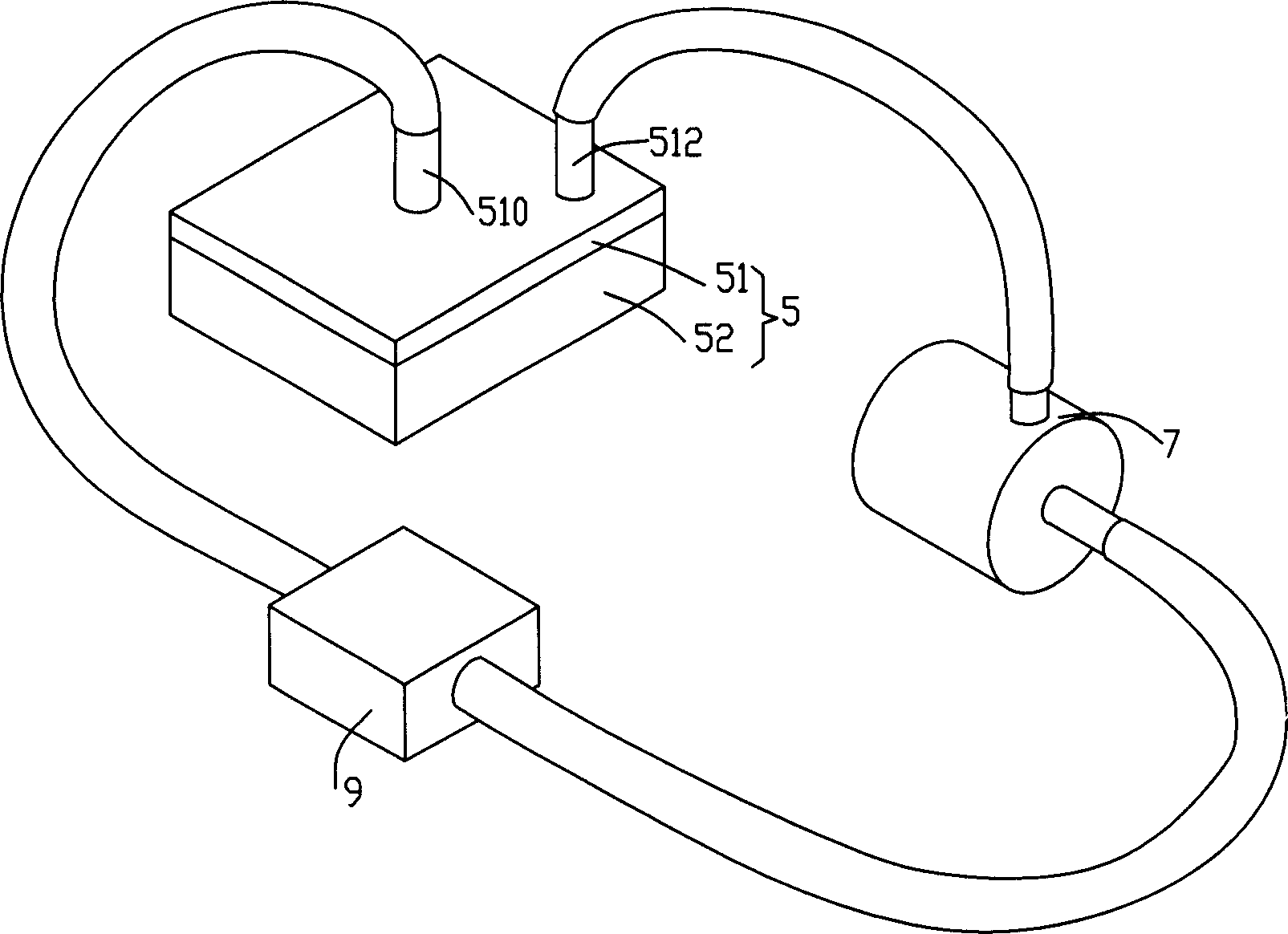

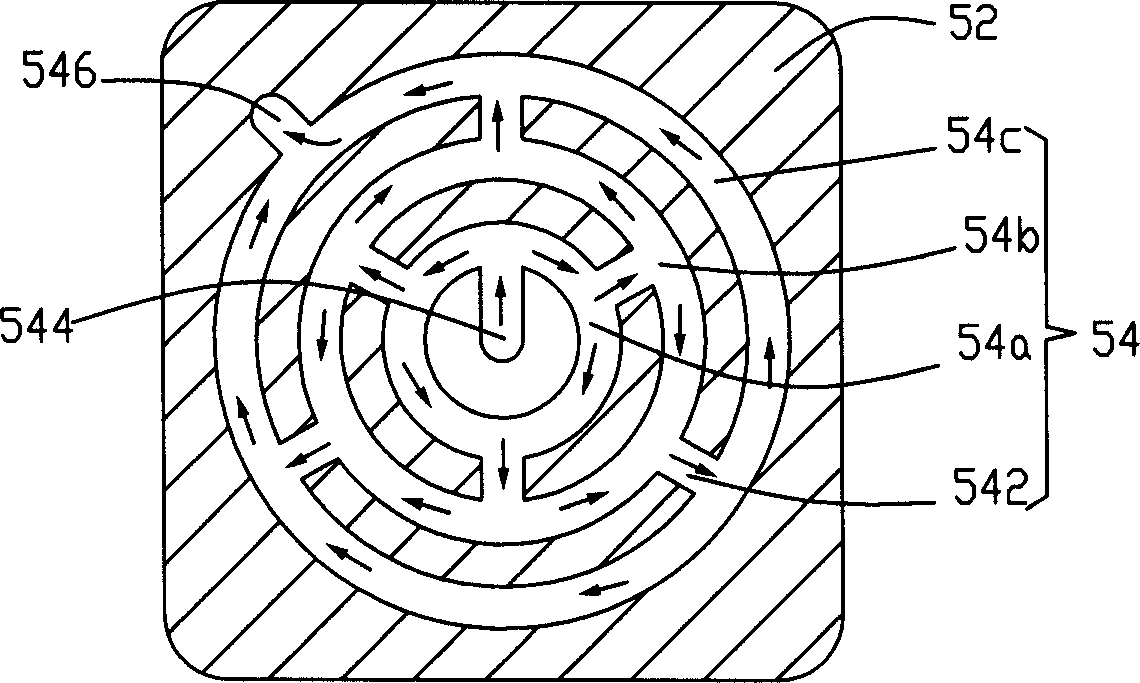

[0027] like figure 1 Shown is a schematic diagram of a first embodiment of a liquid cooling heat dissipation device. The liquid-cooled heat dissipation device includes a heat absorber 5, a heat sink 7 and a coolant driving device 9, the coolant drive device 9 can be a pump, which is used to drive the cooling liquid between the heat absorber 5 and the heat sink Cycle between 7. The heat absorber 5 includes an upper cover body 51 and a lower cover body 52 which are hermetically combined. The upper cover body 51 is provided with a liquid inlet pipe 510 at the central part, and a liquid outlet pipe 512 is provided at the side. The lower cover plate 52 faces the upper cover plate 51 side to excavate a groove to form a coolant channel 54 (such as figure 2 shown).

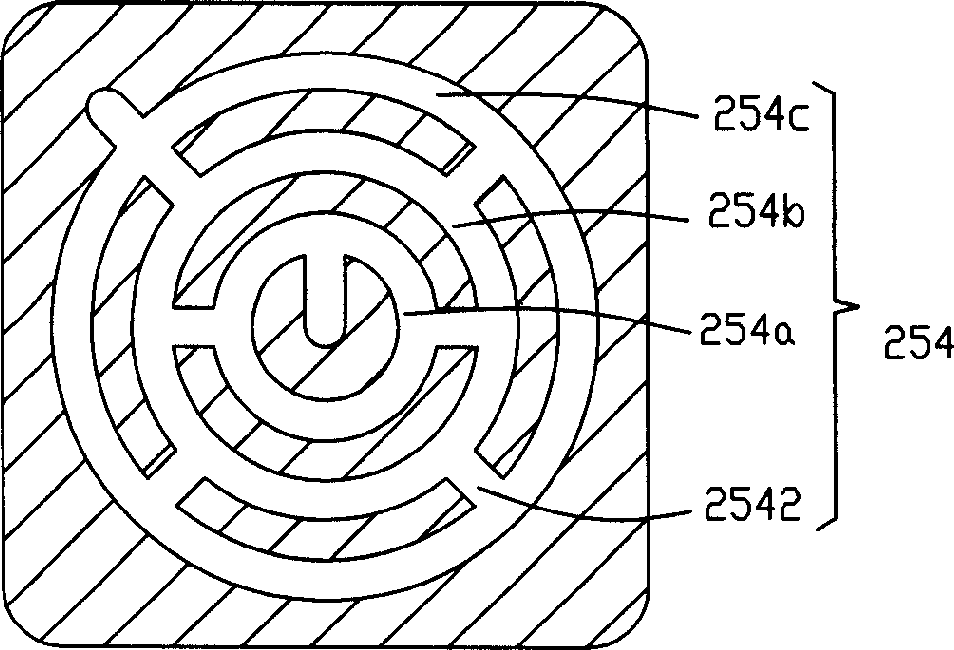

[0028] see figure 2 The coolant passage 54 includes a plurality of first concentric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com