Polytetrafluoroethylene composite micro porous film for air purifying and its producing method

A technology of polytetrafluoroethylene and air purification, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems such as the decrease of filtration efficiency and air flow resistance, and achieve low production cost, reliable performance and excellent manufacturing process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

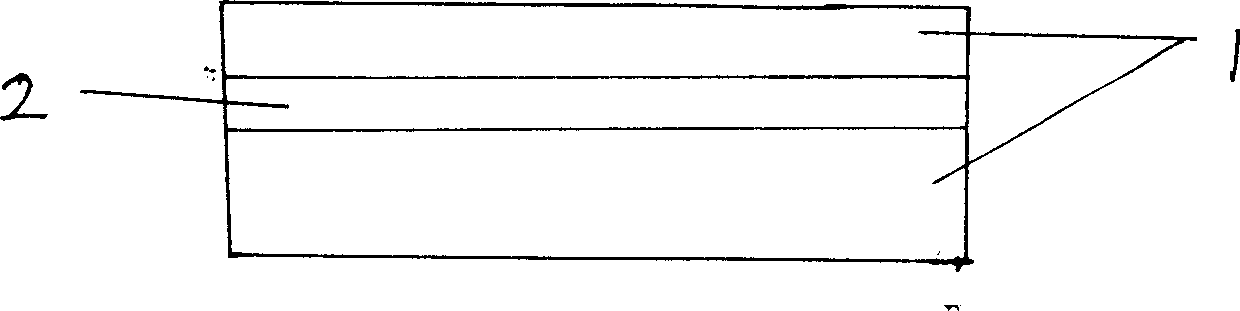

[0024] Polypropylene short fibers with a melting point of 125°C and polyester medium-long fibers are made into a non-woven fabric 1 by hydroentanglement in a ratio of 1:9, and then hot-rolled, one of which is 15g / m 2 , the other one is 75g / m 2 , as a polytetrafluoroethylene microporous membrane 2 to protect the supporting material up and down. Select polytetrafluoroethylene microporous membrane 2 with a pore size of 1.2um, a porosity ≥ 88%, and a thickness of 6um as the material for ensuring efficiency, three layers of thermal lamination, the thermal lamination temperature is controlled at 114-117°C, and the line pressure is 0.45MPa The speed is 1.5m / min, and the thickness of the prepared film is 0.28-0.30mm. The structure is as follows figure 1 .

[0025] According to the conventional membrane performance evaluation method, the membrane has a filtration efficiency of 99.995% for 0.3-0.4um DOP at an air velocity of 5.3cm / sec, and a pressure drop of 142Pa, meeting the efficie...

Embodiment 2

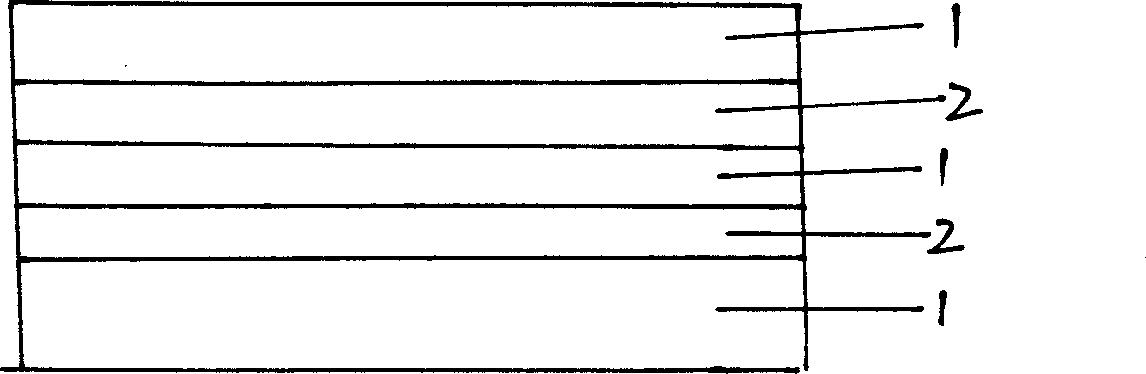

[0027] Nonwovens 1 were manufactured as described in Example 1, two of which were 15 g / m 2 , the other one is 75g / m 2 , as a polytetrafluoroethylene microporous membrane 2 to protect the supporting material up and down. Select polytetrafluoroethylene microporous membrane 2 with a pore diameter of 1.2um, a porosity ≥ 88%, and a thickness of 5um and place it in two kinds of 15g / m. In the middle of the non-woven fabric 1, select a polytetrafluoroethylene microporous membrane 2 with a pore size of 0.7um, a porosity ≥ 88%, and a thickness of 5um and place it at a density of 15g / m 2 and 75g / m 2 In the middle of non-woven fabric 1, five layers of thermal lamination, the thermal lamination temperature is 15g / m 2 . One side of the non-woven fabric is controlled at 114~117°C, at 75g / m 2 One side of the non-woven fabric is controlled at 116-118°C, the linear pressure is 0.45MPa, and the composite speed is 1.0m / min. The thickness of the prepared film is 0.35-0.38mm. The structure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com