Patents

Literature

1061results about "Catalyst protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero platinum group metal catalysts

The present invention pertains to catalyst systems for nitrogen oxide, carbon monoxide, hydrocarbon, and sulfur reactions that are free or substantially free of platinum group metals. The catalyst system of the present invention comprise a substrate and a washcoat, wherein the washcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst system may optionally have an overcoat, wherein the overcoat comprises at least one oxide solid, wherein the oxide solid comprises one or more selected from the group consisting of a carrier material oxide, a catalyst, and mixtures thereof. The catalyst comprises one or more selected from the group consisting of a ZPGM transition metal catalyst, a mixed metal oxide catalyst, a zeolite catalysts, or mixtures thereof.

Owner:CATALYTIC SOLUTIONS INC

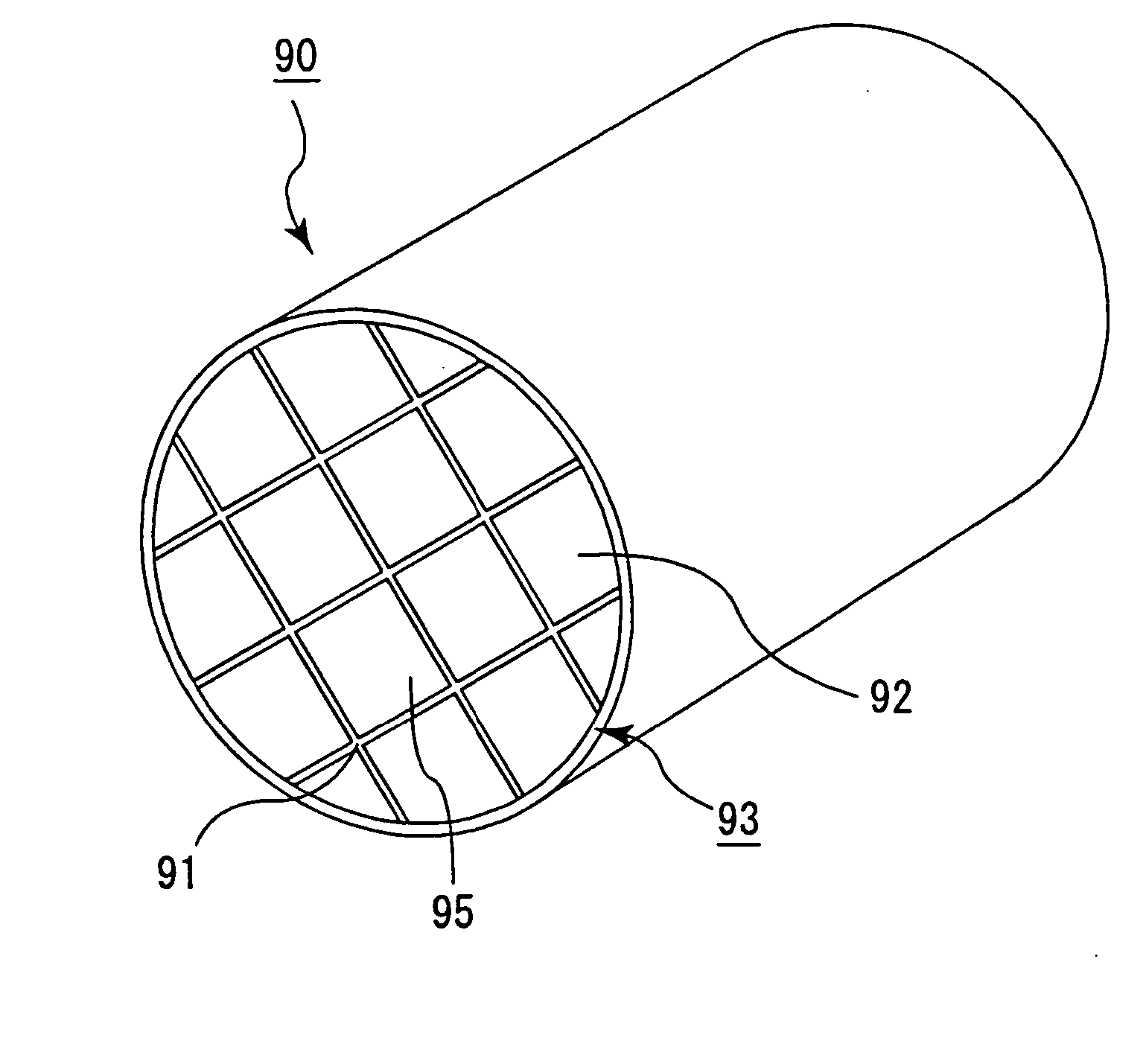

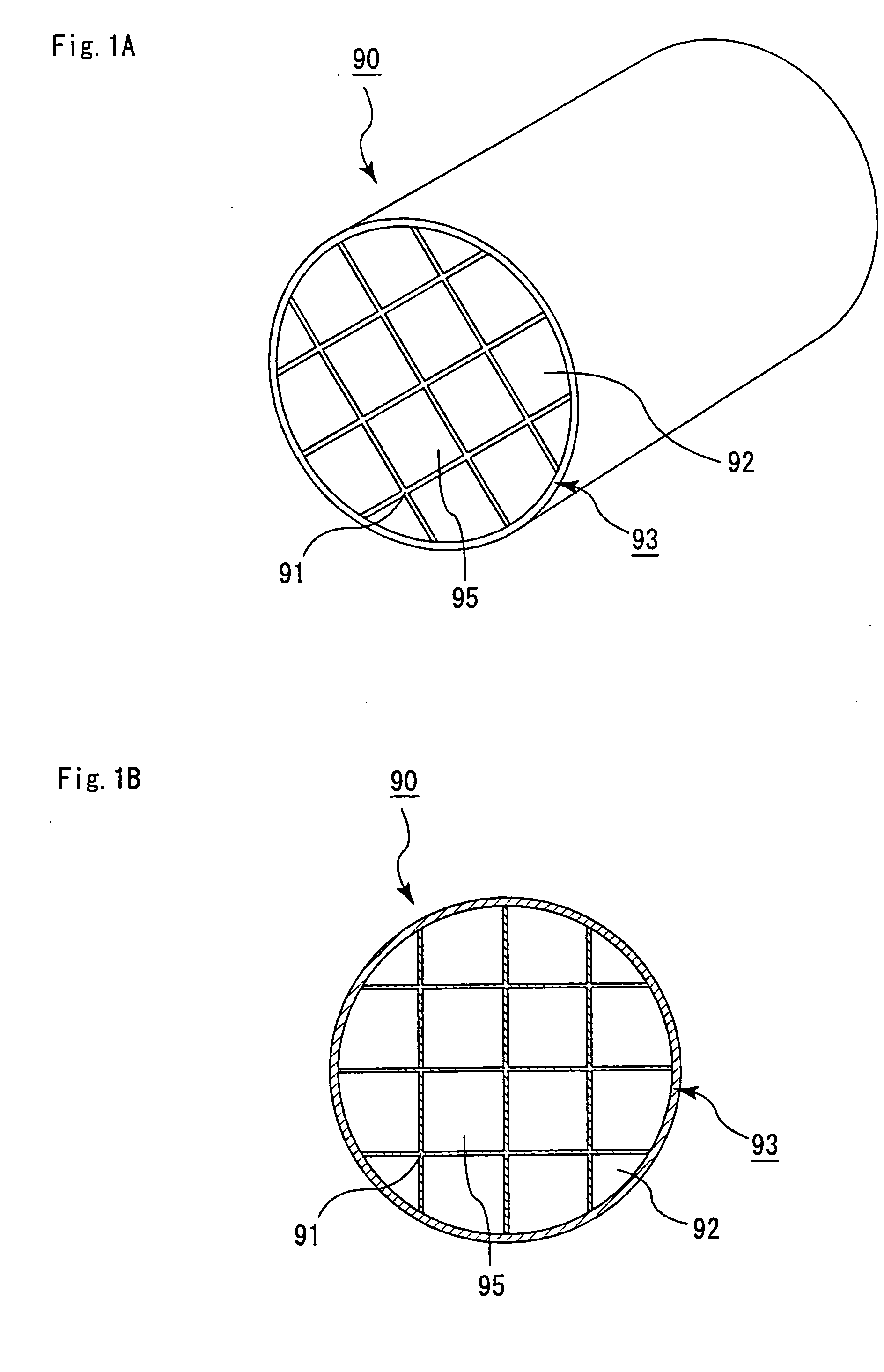

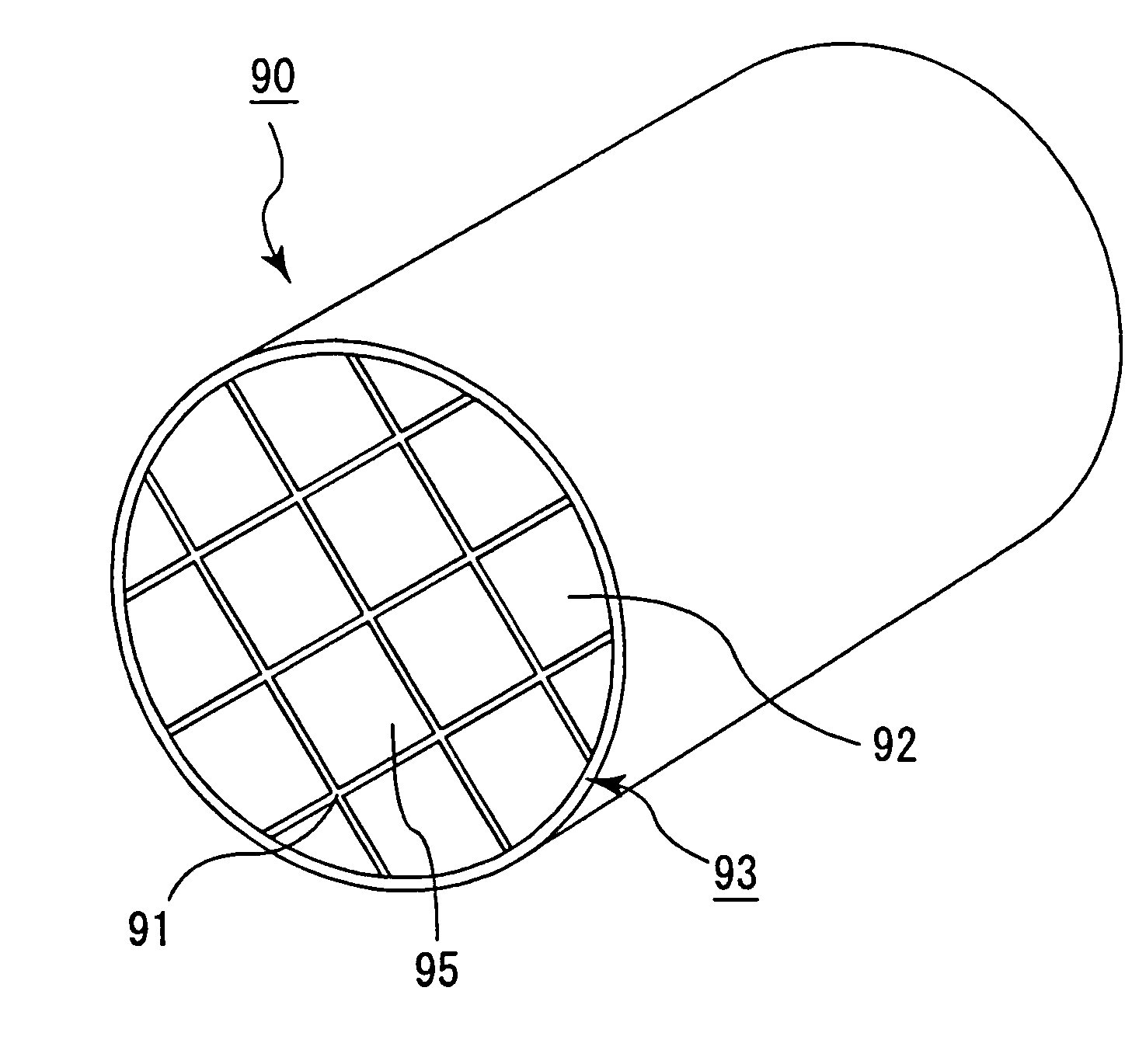

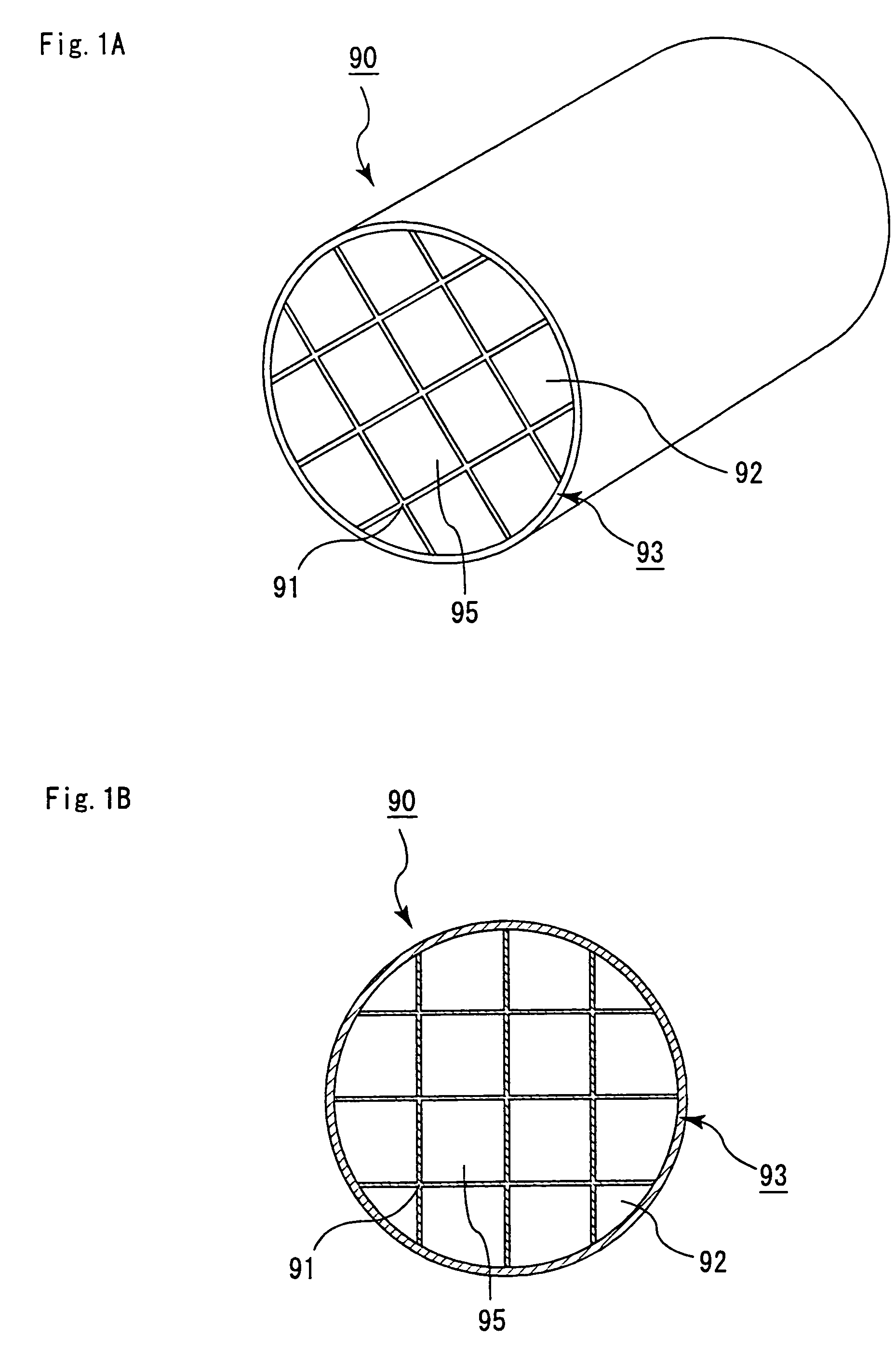

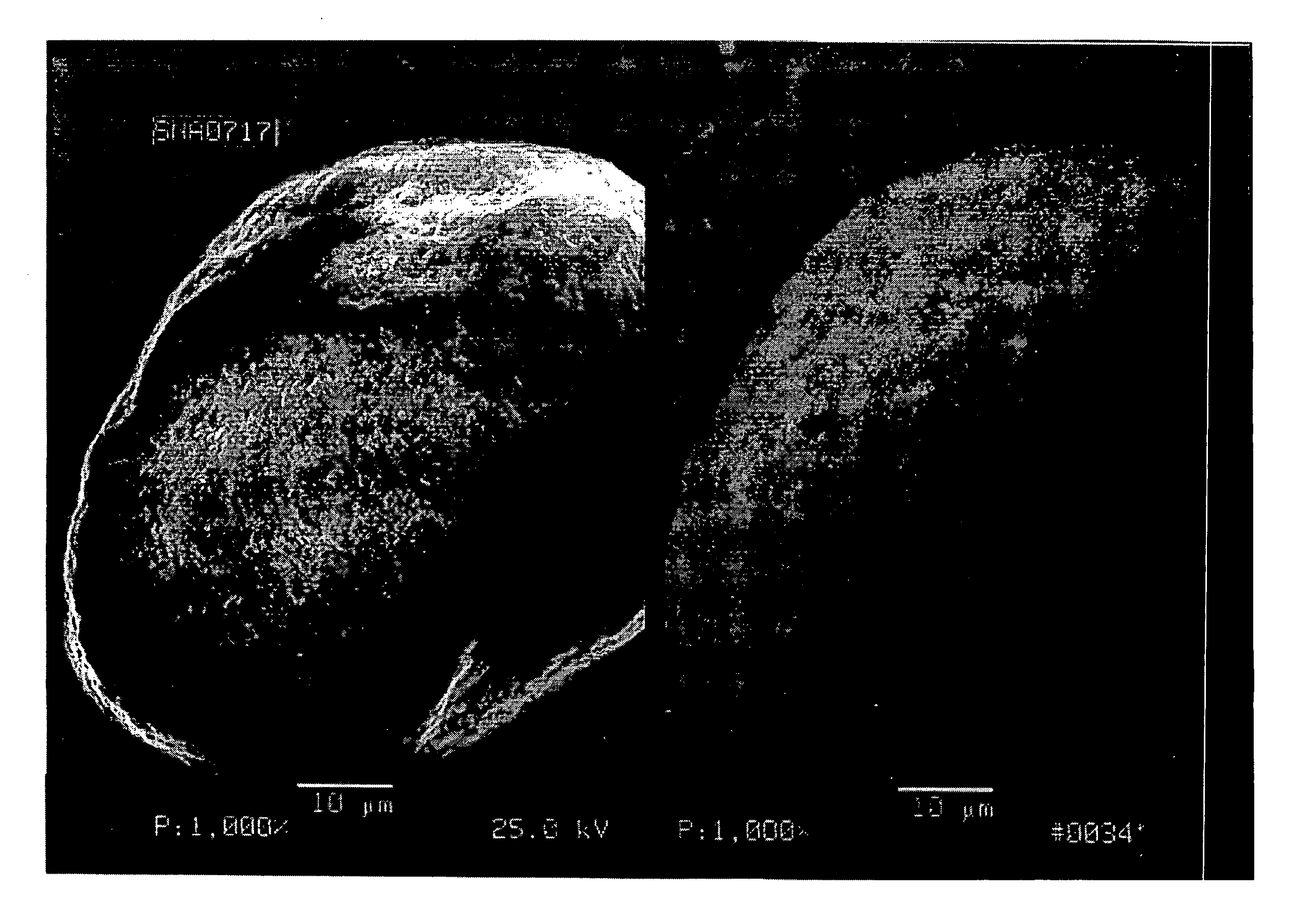

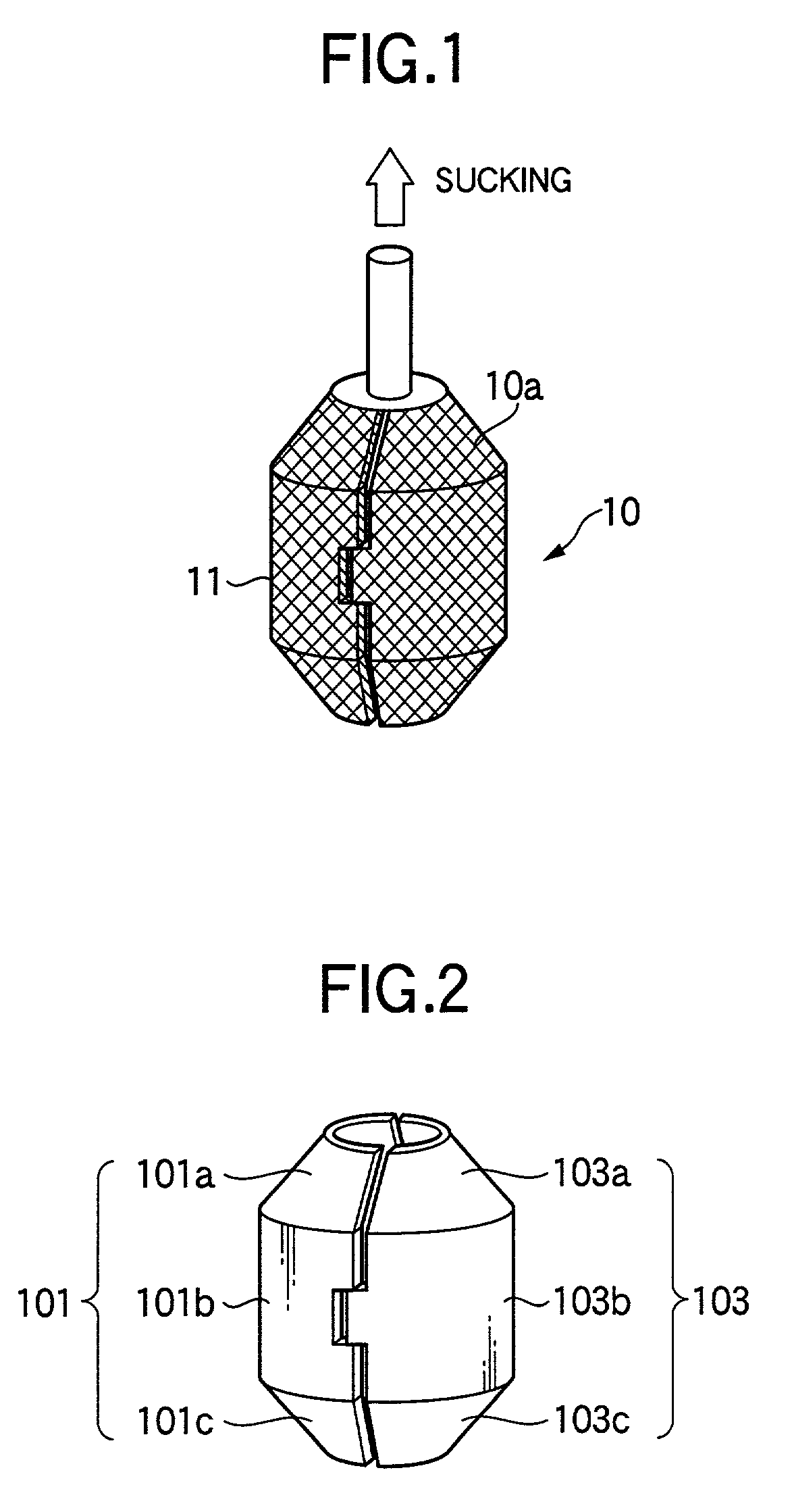

Honeycomb structural body, manufacturing method of the honeycomb structural body, and exhaust gas purifying device

ActiveUS20050229565A1High strengthIncreased durabilityCombination devicesCatalyst protectionLeast squaresHoneycomb structure

A honeycomb structural body comprising: a pillar-shaped ceramic block and a sealing material provided on an outer peripheral portion of said ceramic block, each of them having irregularities formed on an outer peripheral face wherein: when a least square curve is determined by a least square method on the basis of points constituting the contour of a cross-section, a center-of-gravity is defined as c1, a distance between a minimum concentric circumscribed curve having c1 and the center-of-gravity c1 is defined as D1, a distance between a maximum concentric inscribed curve having c1 and the center-of-gravity c1 is defined as D2, and the following inequality is satisfied: about 0.3 mm≦(D1−D2); same definition is applied to said ceramic block, a center-of-gravity thereof is defined as c2, a distance between a minimum concentric circumscribed curve having c2 and the center-of-gravity c2 is defined as D3, a distance between a maximum concentric inscribed curve having c2 and the center-of-gravity c2 is defined as D4, and the following inequality is satisfied: about 0.5 mm≦(D3−D4)≦about 7.0 mm.

Owner:IBIDEN CO LTD

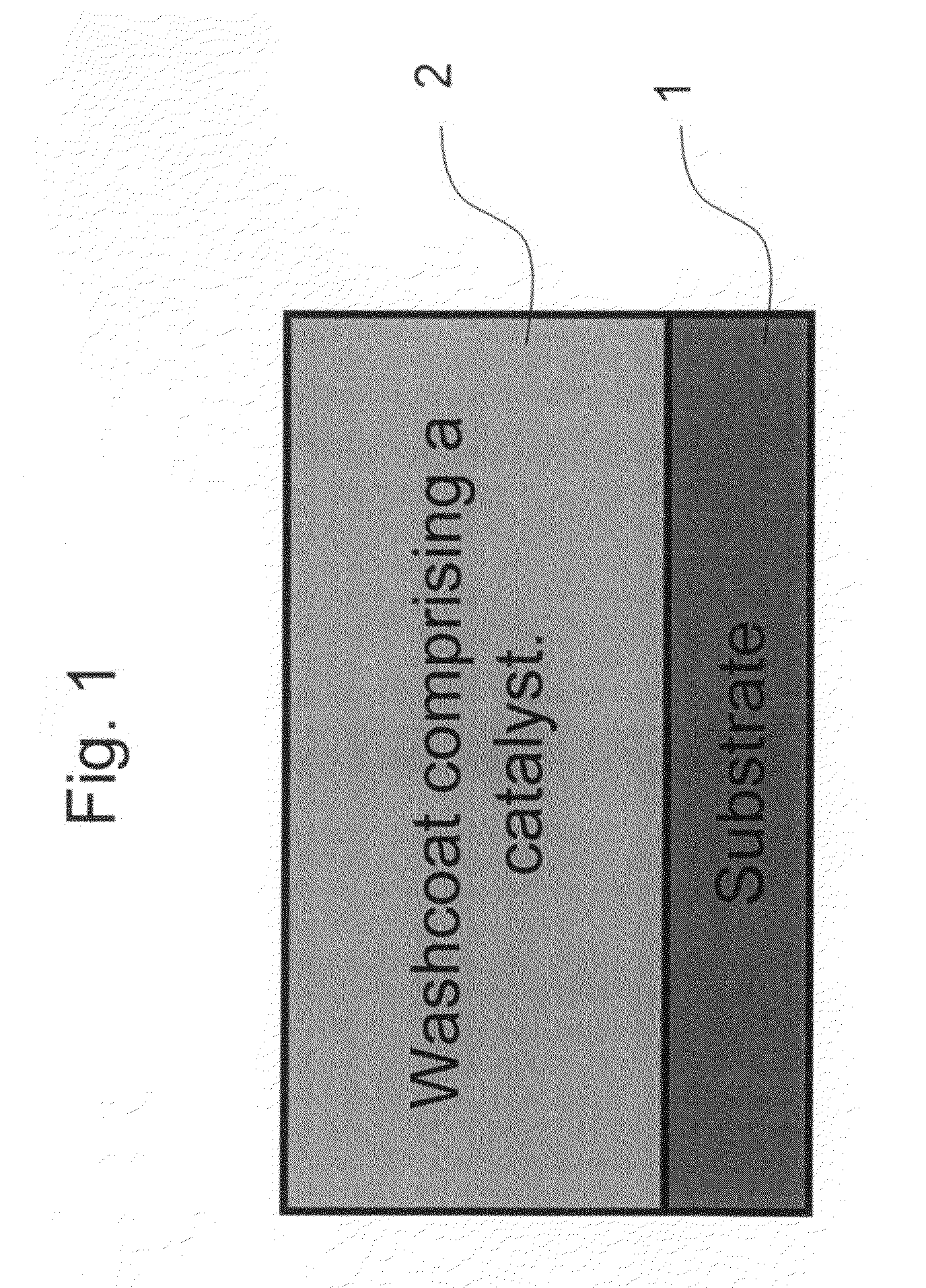

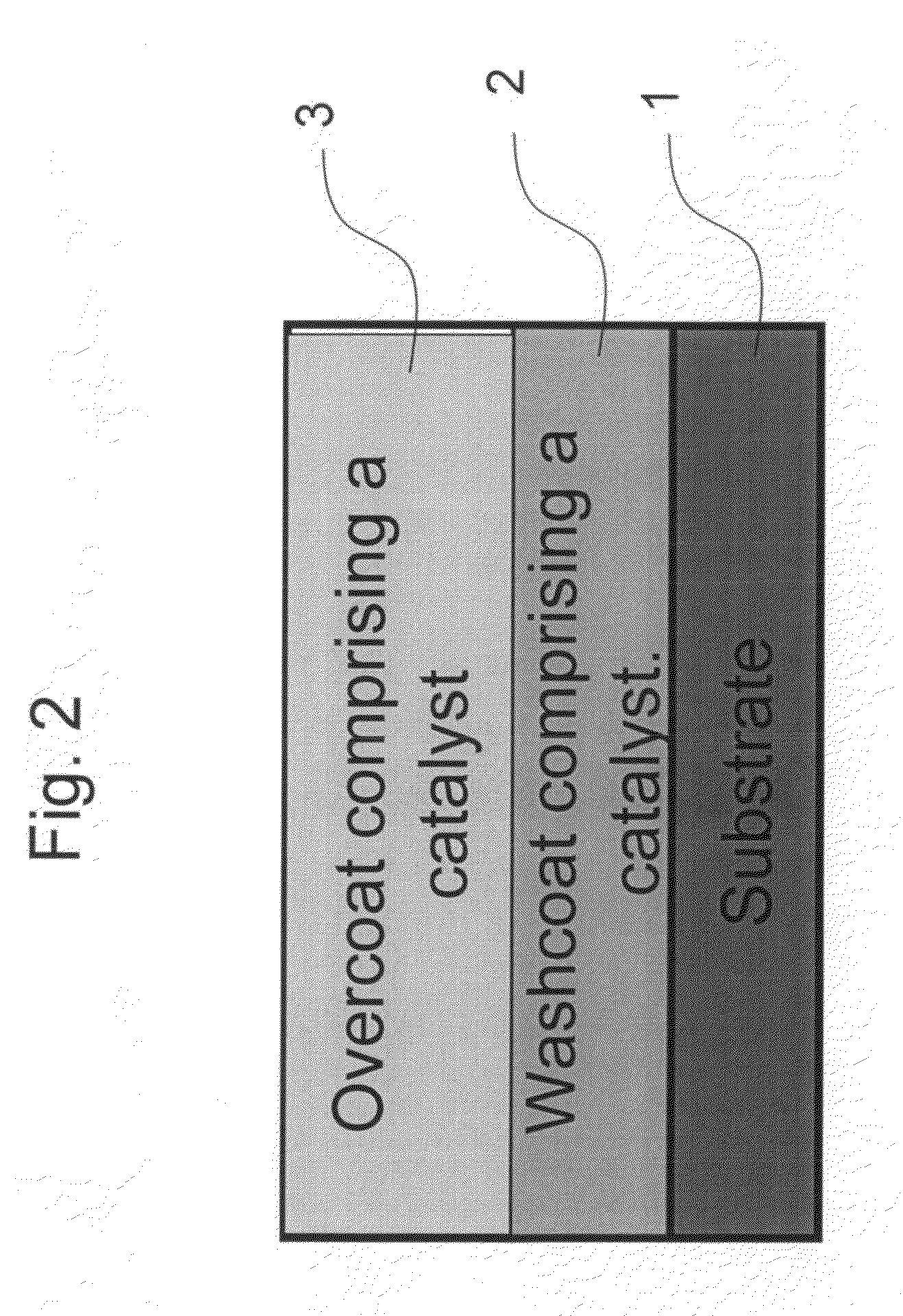

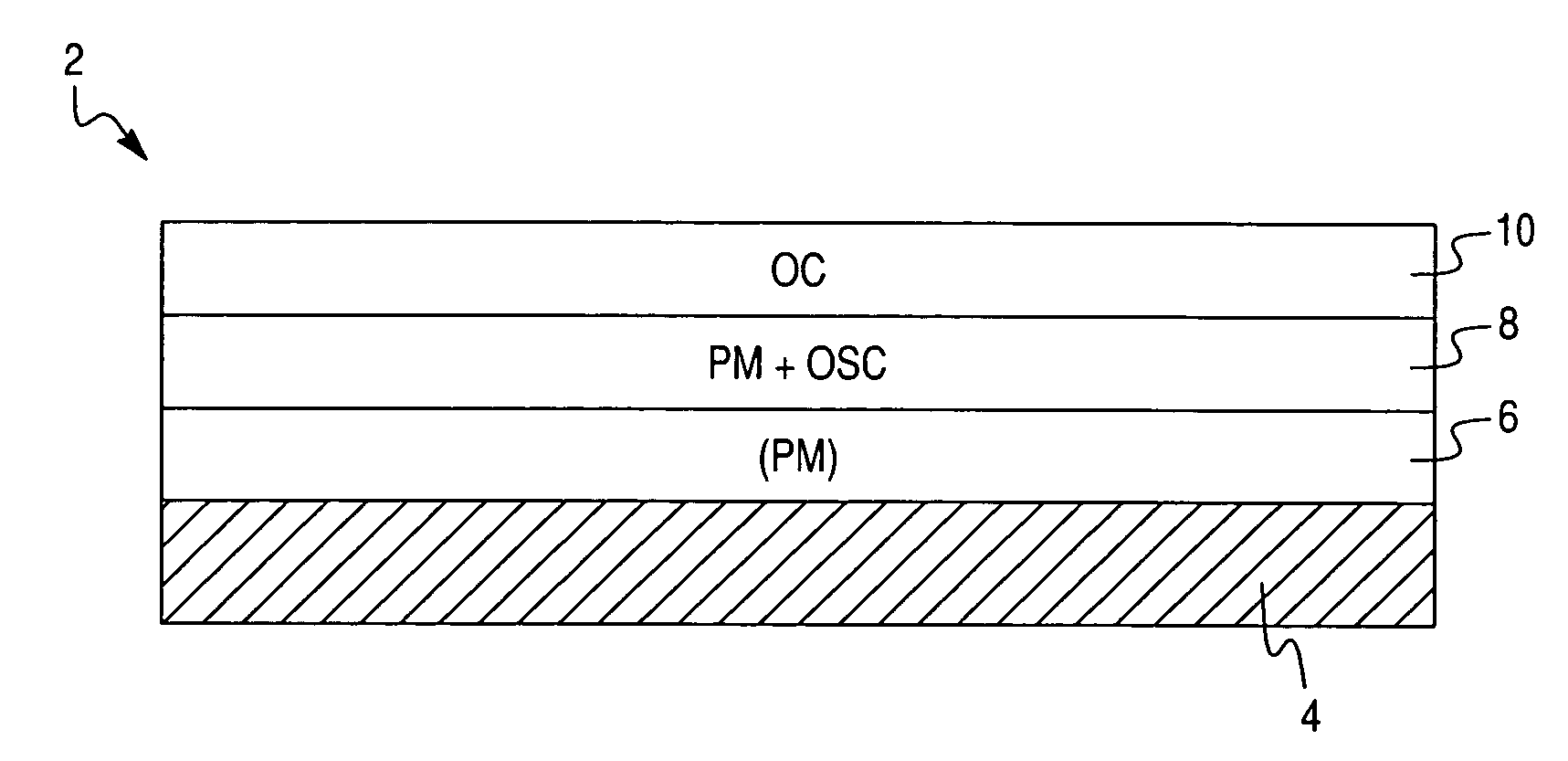

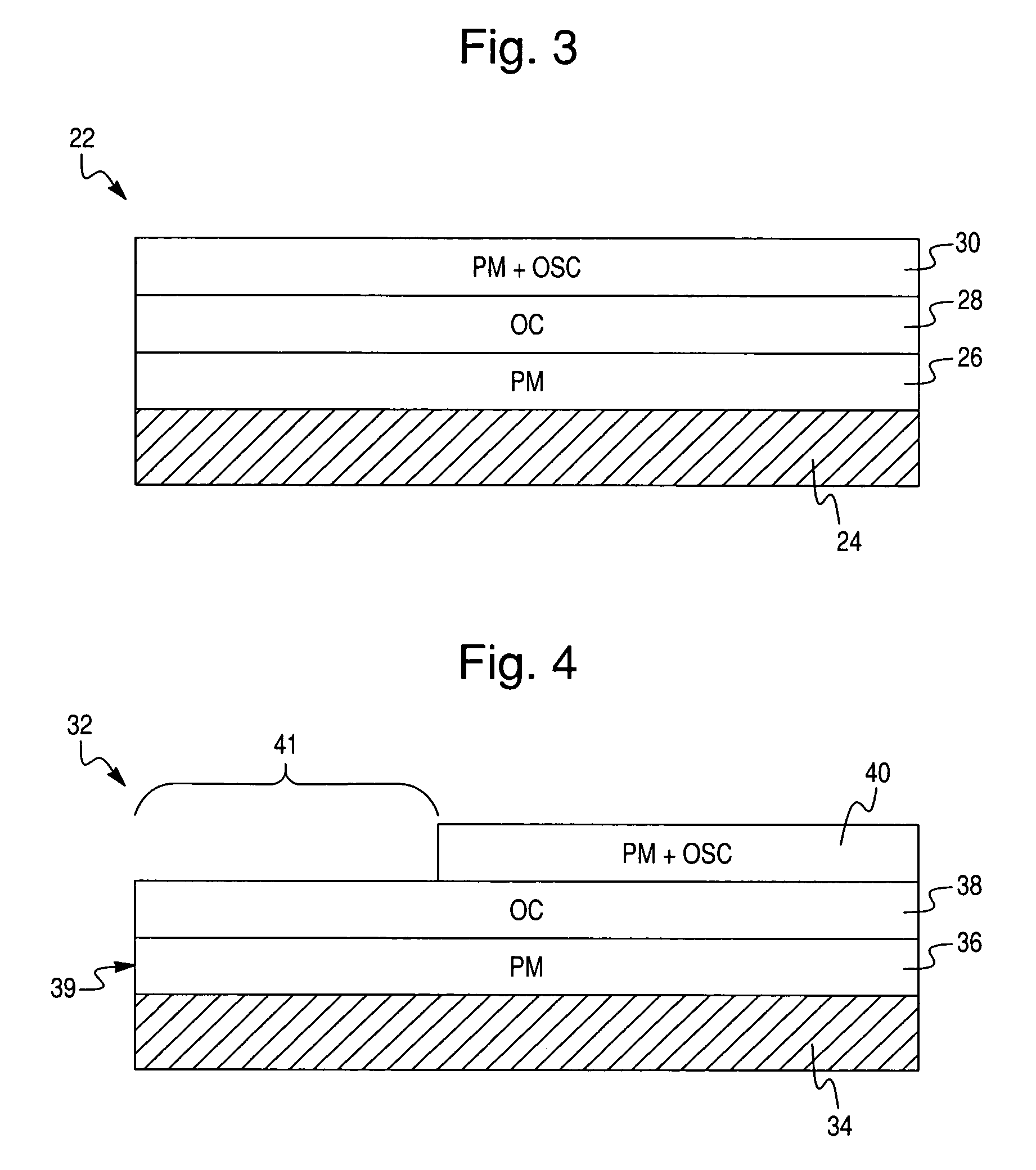

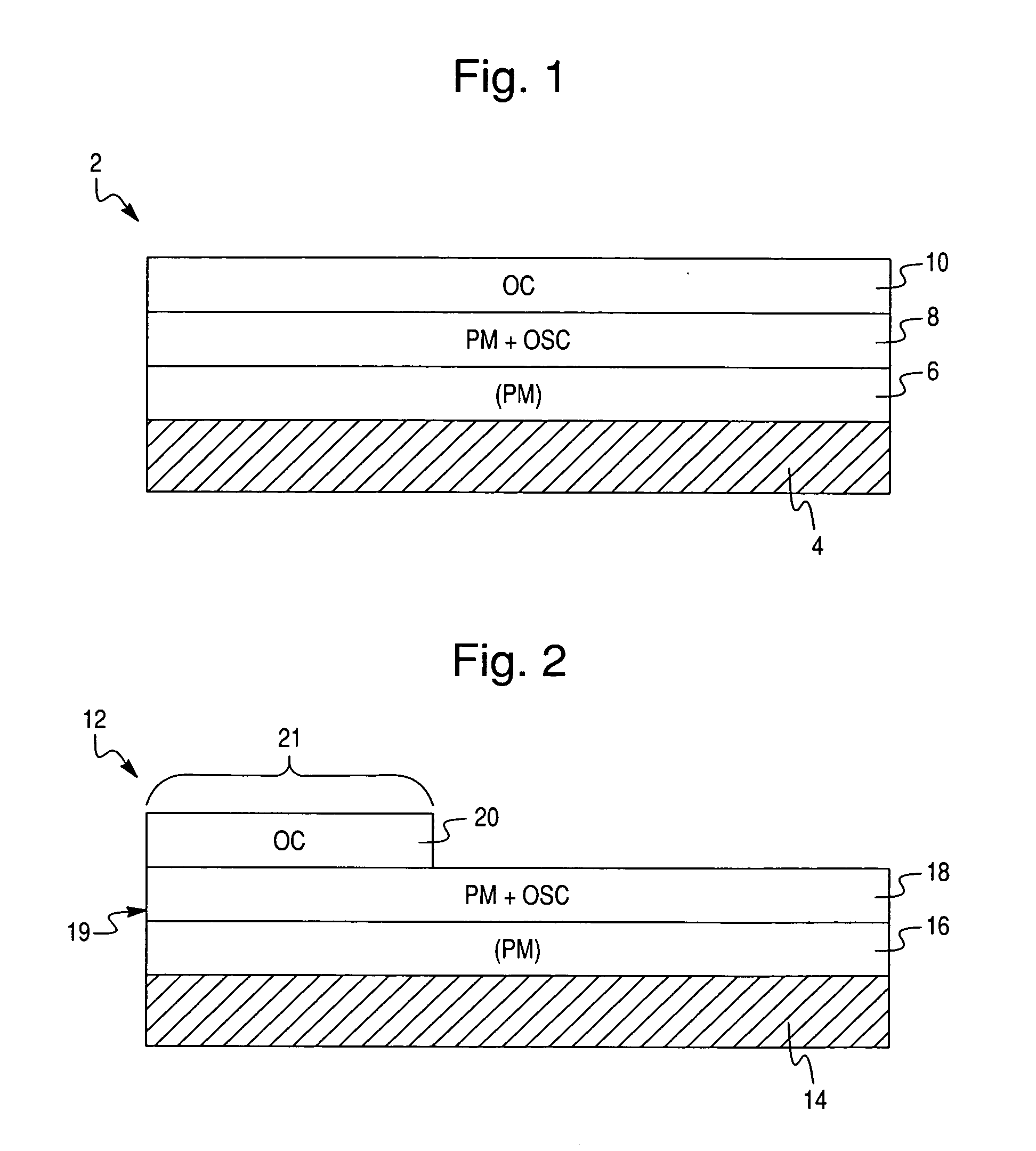

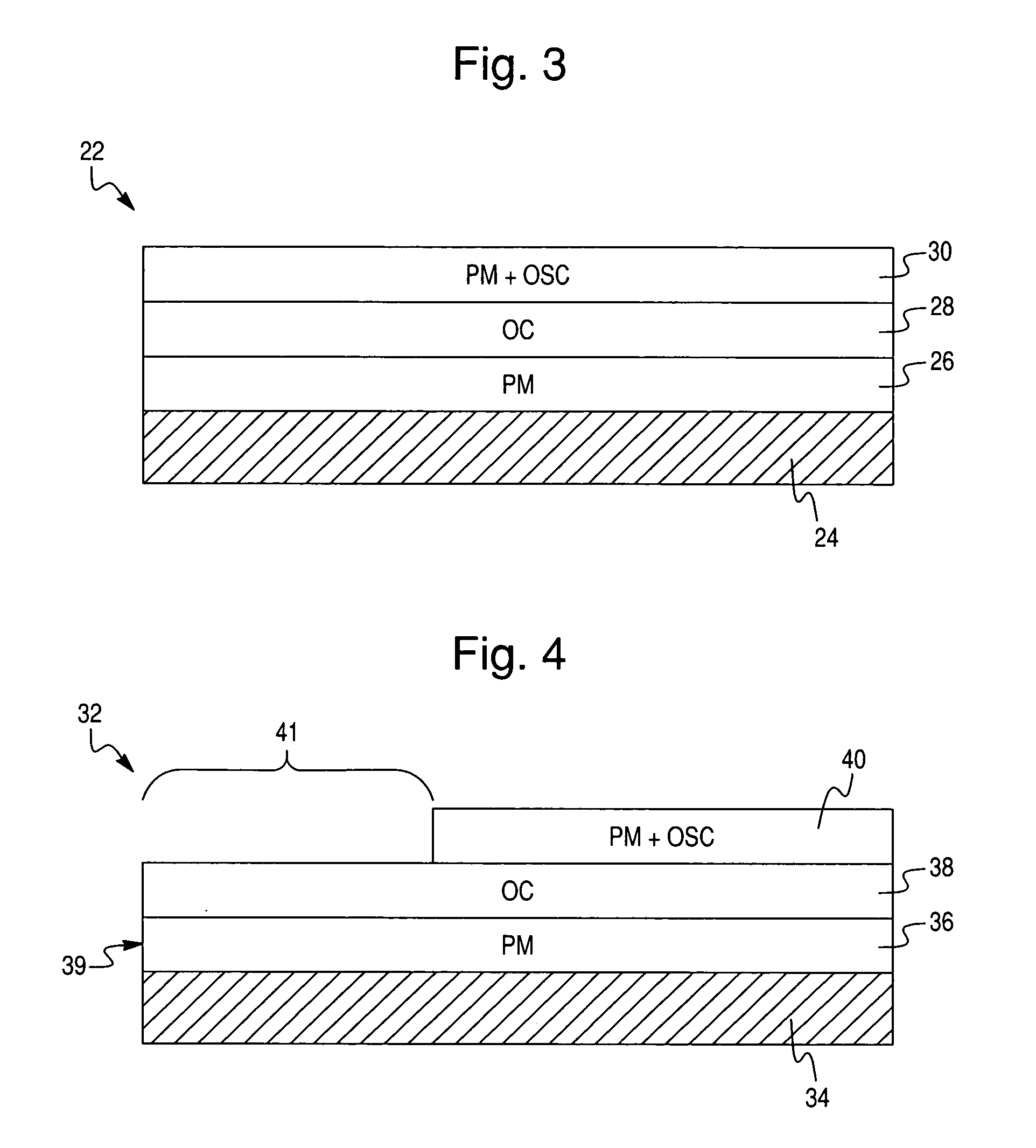

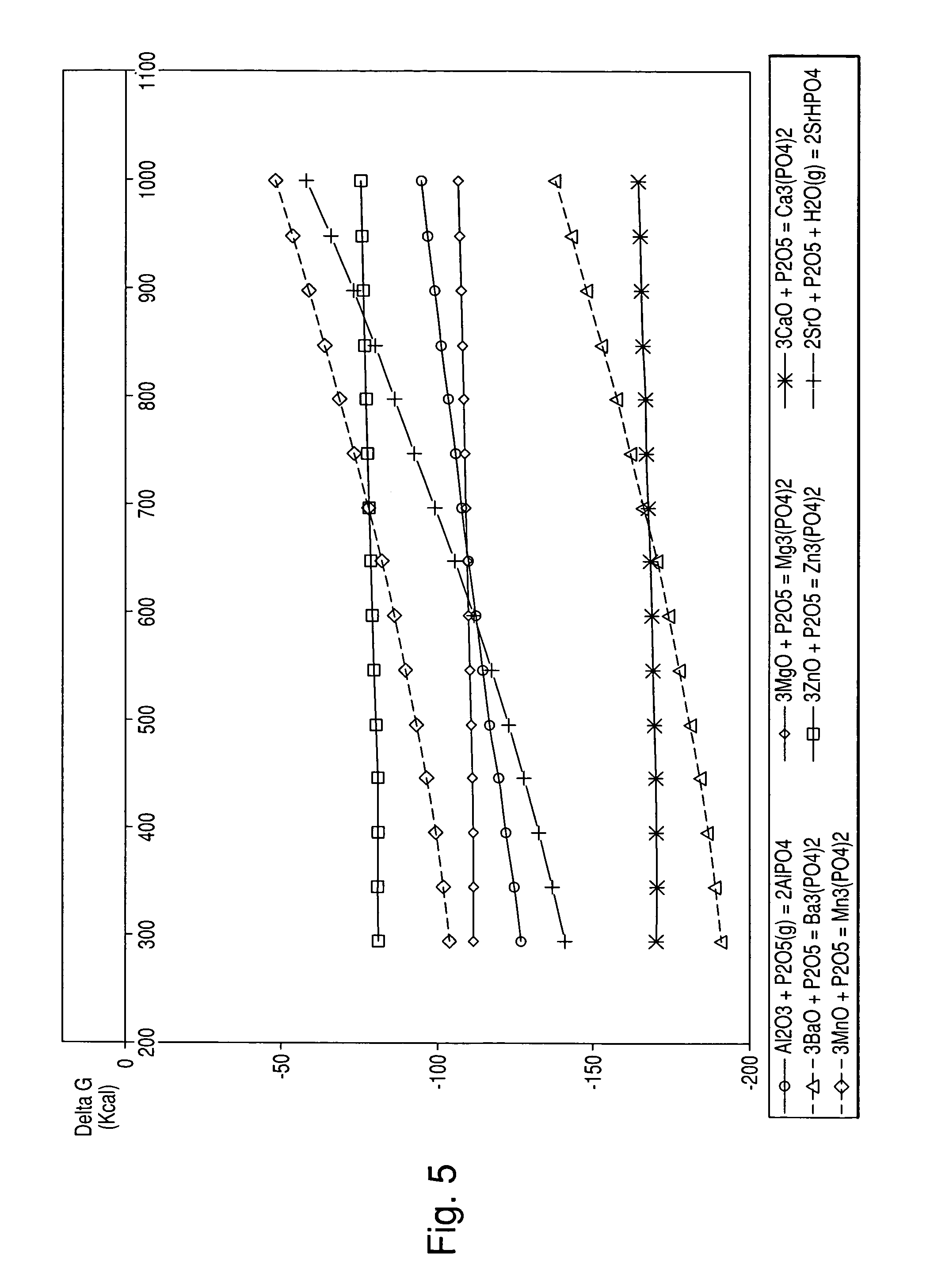

Phosgard, a new way to improve poison resistance in three-way catalyst applications

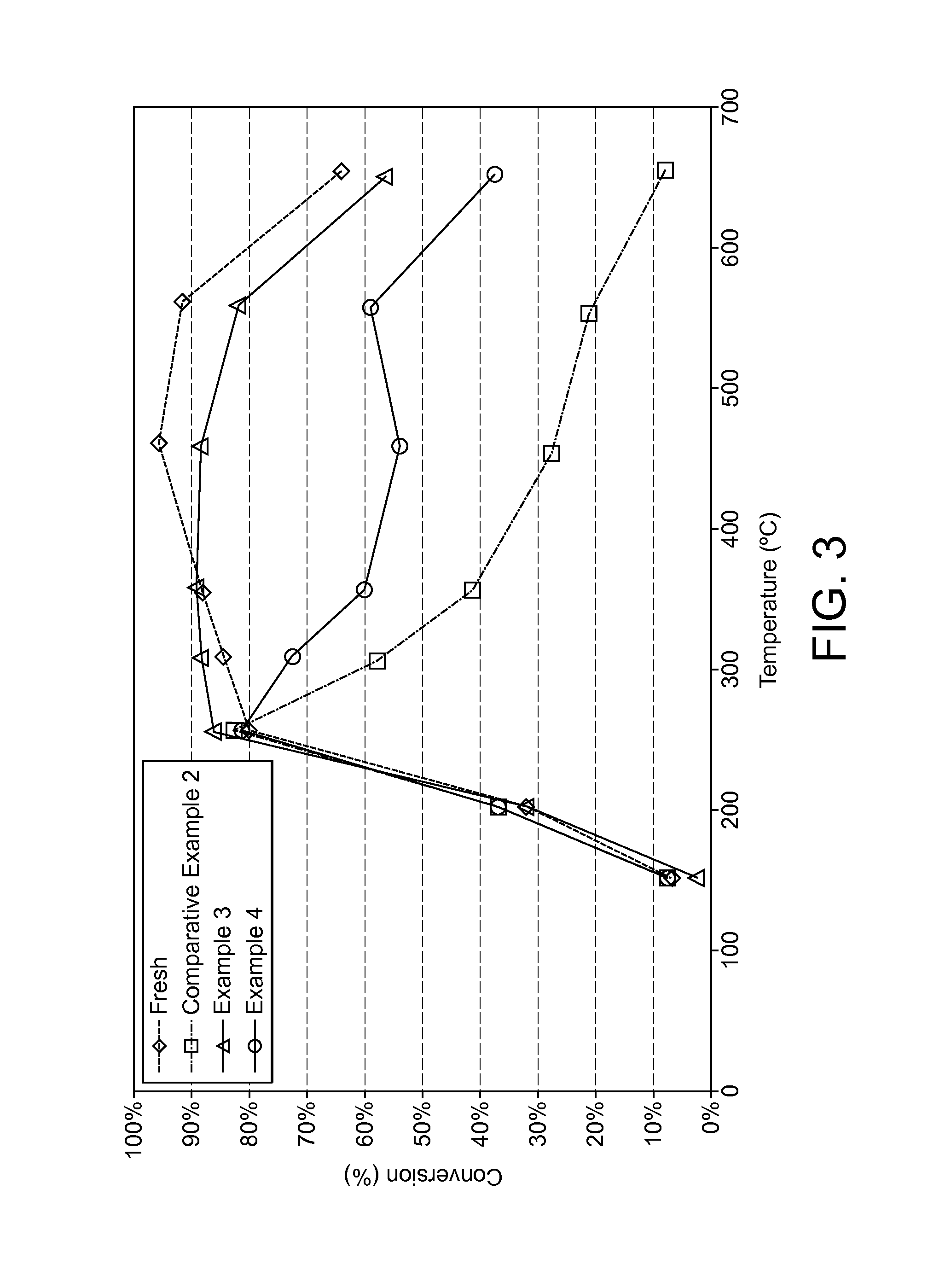

ActiveUS7749472B2Mitigates deleterious poisoning of a catalytic memberPreventing and reducing fouling and poisoningNitrogen compoundsInternal combustion piston enginesToxicantRefractory

The present invention provides for novel poisoning-resistant catalysts used for automobile exhaust gas treatment systems. To alleviate the detrimental affects of engine oil and / or fuel additive poisoning the present invention provides for an overcoat layer comprising a porous refractory oxide and one or more base metal oxides, which is coated over one or more precious metal containing washcoat layers. The overcoat of the present invention prevents phosphorous as well as other poisoning deposits, from fouling and / or negatively interacting with the underlying precious metal containing washcoats. In an alternative embodiment, the present invention provides for the coating of the upstream end of a catalytic member by the overcoat layer, thereby creating an upstream poison capture zone.

Owner:BASF CORP

Honeycomb structural body, manufacturing method of the honeycomb structural body, and exhaust gas purifying device

ActiveUS7348049B2High strengthReduce crackingCombination devicesCatalyst protectionHoneycomb structureMaterials science

A honeycomb structural body comprising: a pillar-shaped ceramic block and a sealing material provided on an outer peripheral portion of said ceramic block, each of them having irregularities formed on an outer peripheral face wherein: when a least square curve is determined by a least square method on the basis of points constituting the contour of a cross-section, a center-of-gravity is defined as c1, a distance between a minimum concentric circumscribed curve having c1 and the center-of-gravity c1 is defined as D1, a distance between a maximum concentric inscribed curve having c1 and the center-of-gravity c1 is defined as D2, and the following inequality is satisfied: about 0.3 mm≦(D1-D2); same definition is applied to said ceramic block, a center-of-gravity thereof is defined as c2, a distance between a minimum concentric circumscribed curve having c2 and the center-of-gravity c2 is defined as D3, a distance between a maximum concentric inscribed curve having c2 and the center-of-gravity c2 is defined as D4, and the following inequality is satisfied: about 0.5 mm≦(D3-D4)≦about 7.0 mm.

Owner:IBIDEN CO LTD

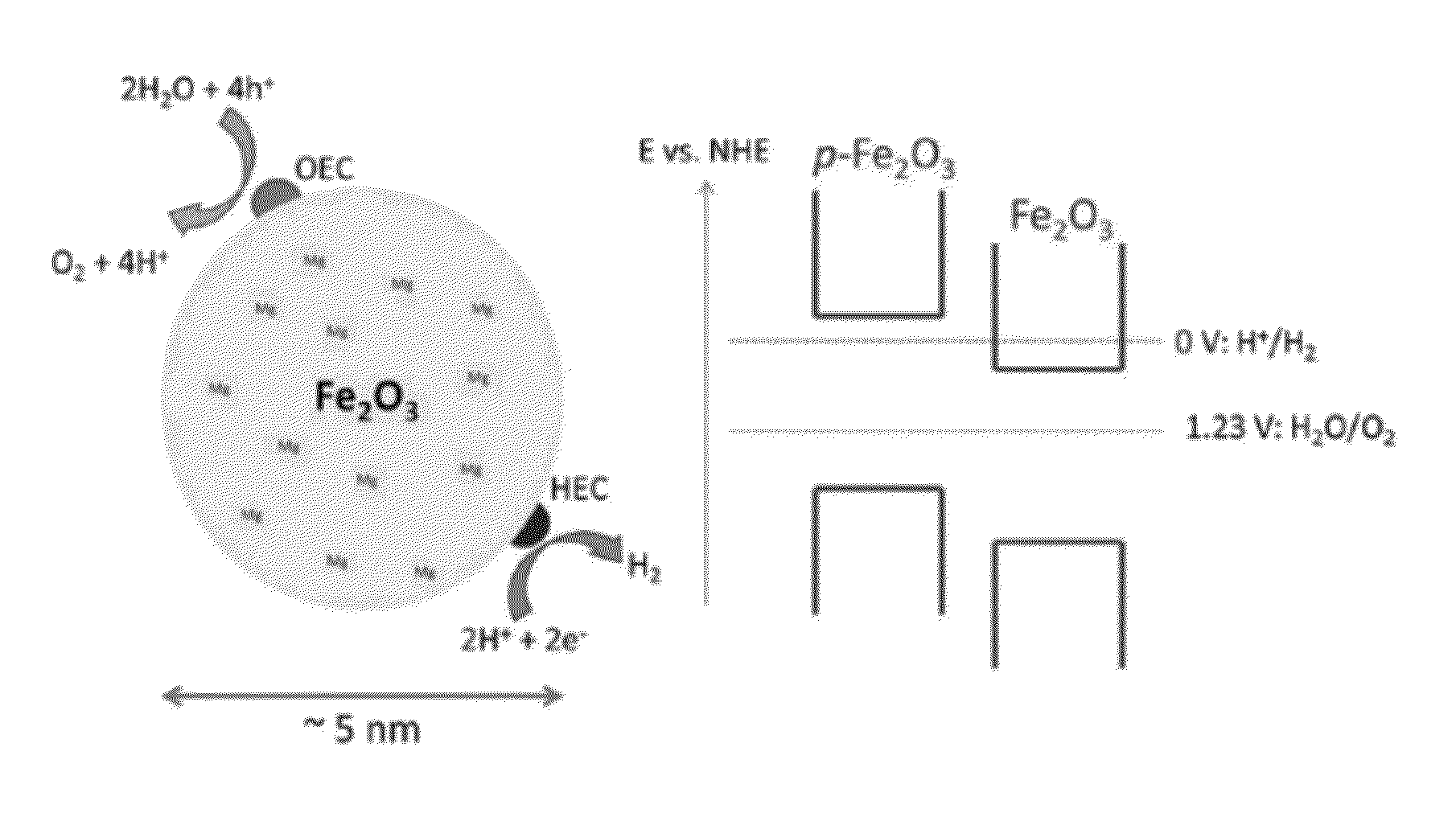

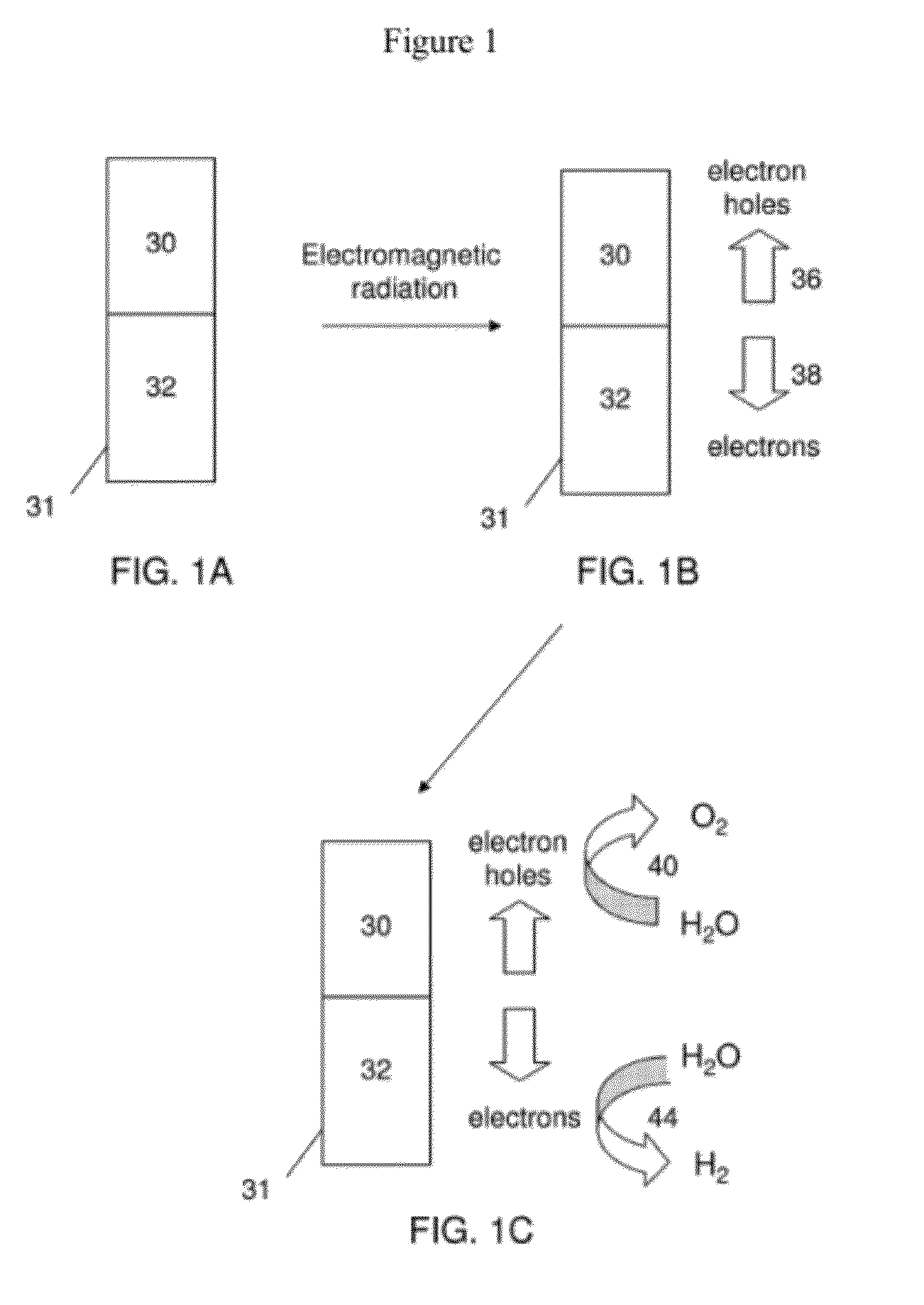

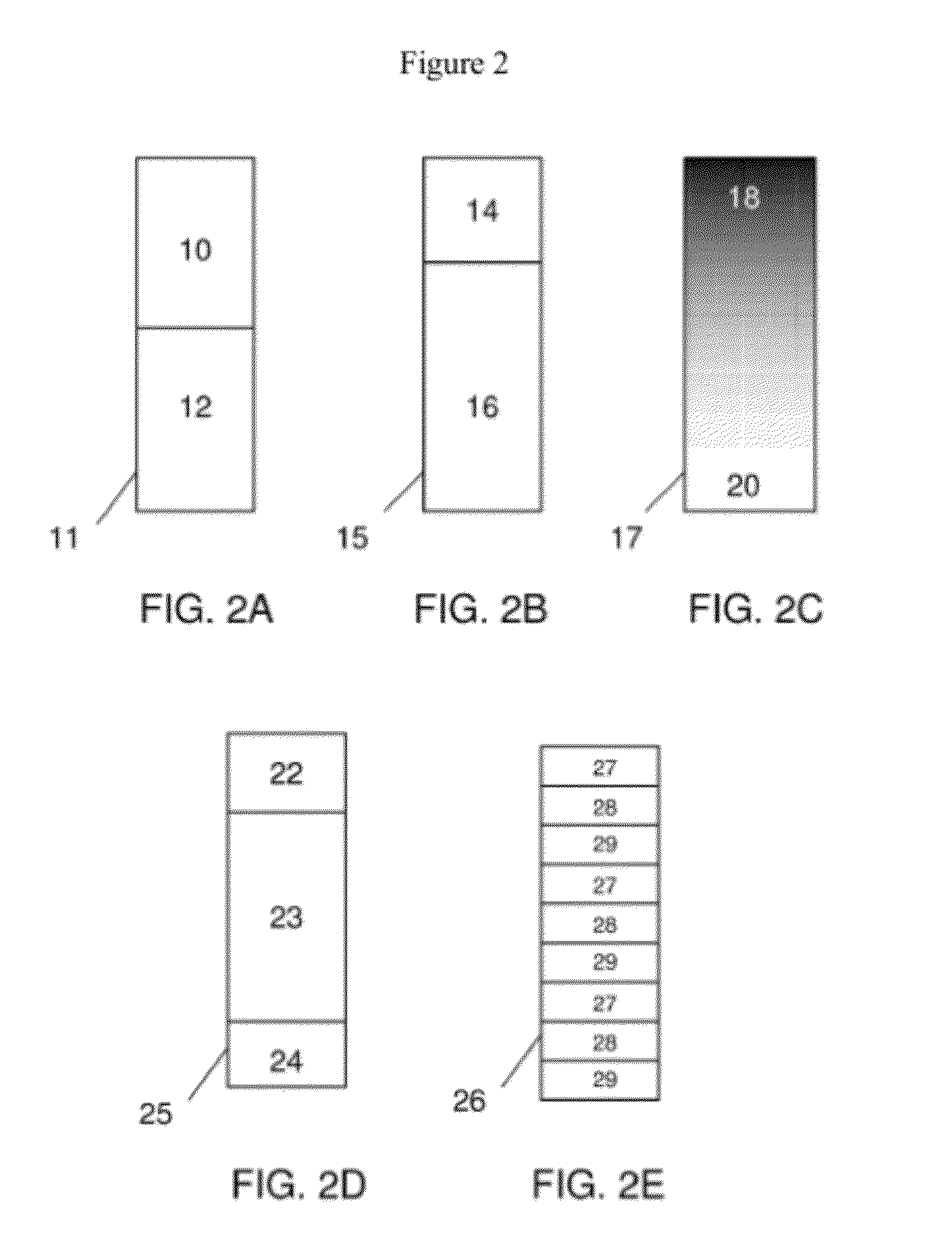

Nanostructures, Systems, and Methods for Photocatalysis

The present invention generally relates to nanostructures and compositions comprising nanostructures, methods of making and using the nanostructures, and related systems. In some embodiments, a nanostructure comprises a first region and a second region, wherein a first photocatalytic reaction (e.g., an oxidation reaction) can be carried out at the first region and a second photocatalytic reaction (e.g., a reduction reaction) can be carried out at the second region. In some cases, the first photocatalytic reaction is the formation of oxygen gas from water and the second photocatalytic reaction is the formation of hydrogen gas from water. In some embodiments, a nanostructure comprises at least one semiconductor material, and, in some cases, at least one catalytic material and / or at least one photosensitizing agent.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

High surface area, small crystallite size catalyst for Fischer-Tropsch synthesis

ActiveUS7452844B2Promote growthEvenly distributedCatalyst protectionMolecular sieve catalystsCobaltHigh surface area

Owner:CLARIANT INT LTD

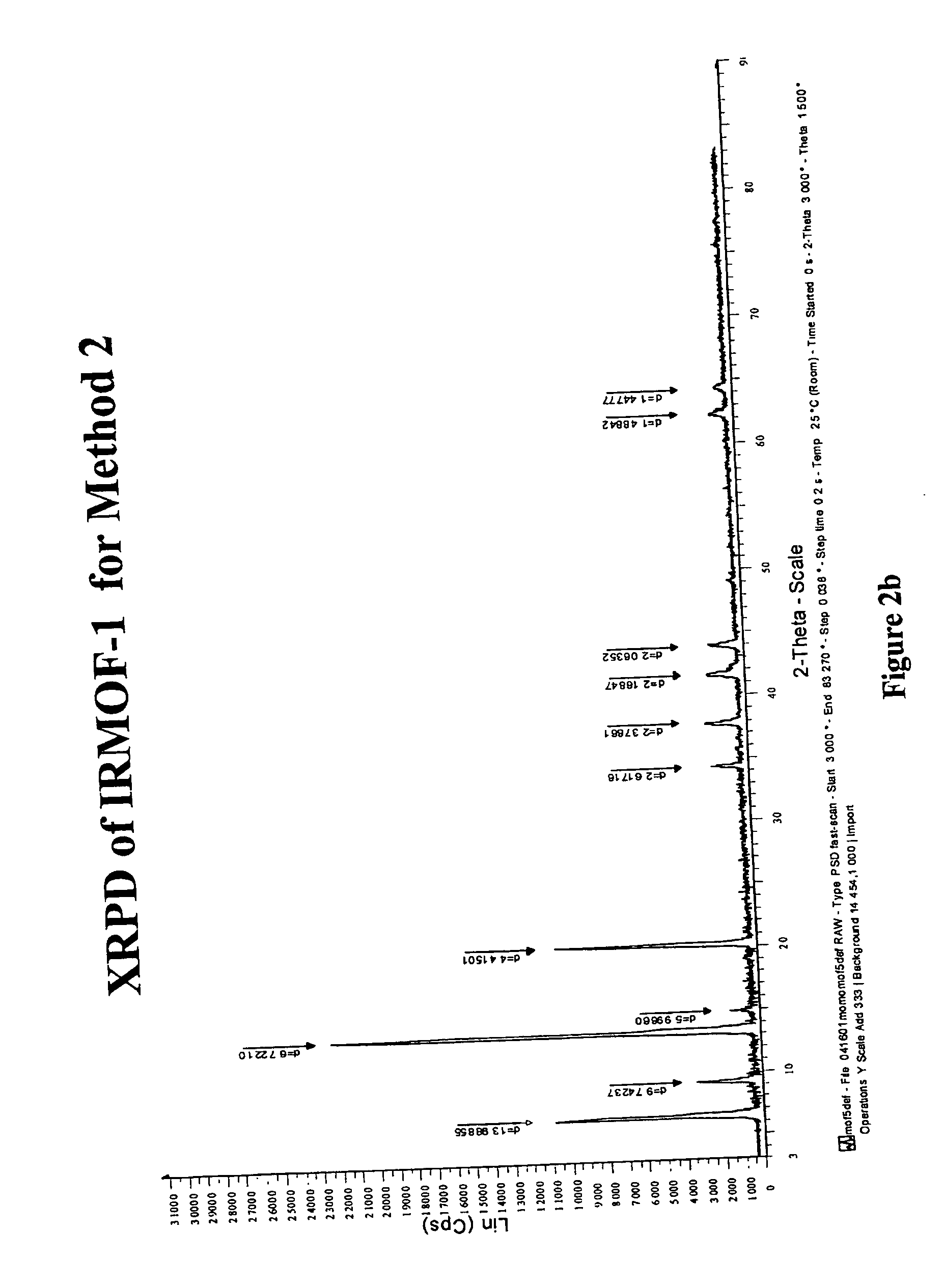

Isoreticular metal-organic frameworks, process for forming the same, and systematic design of pore size and functionality therein, with application for gas storage

InactiveUS20050192175A1Catalyst protectionMolecular sieve catalystsSystems designMetal-organic framework

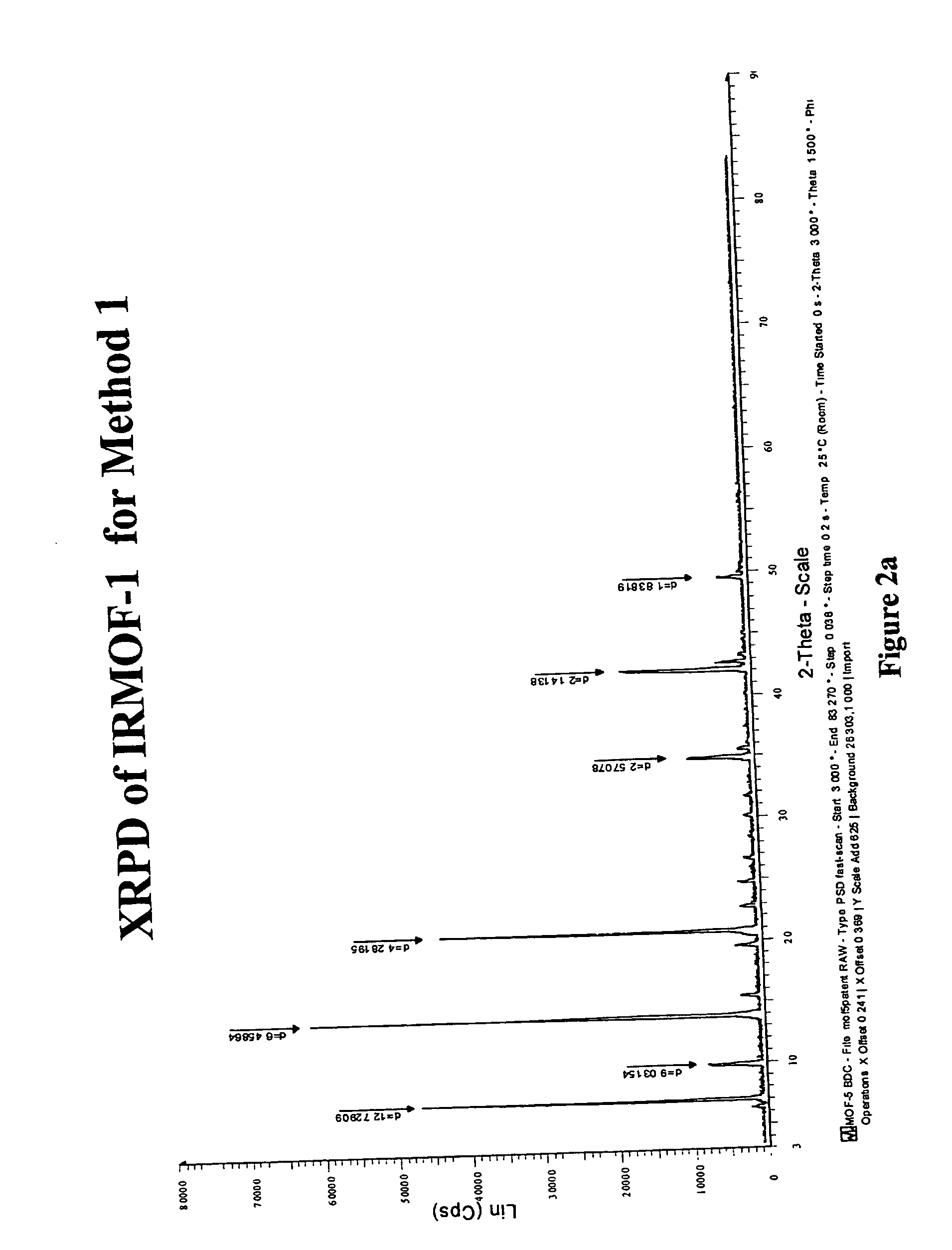

The ability to design and construct solid-state materials with pre-determined structures is a grand challenge in chemistry. An inventive strategy based on reticulating metal ions and organic carboxylate links into extended networks has been advanced to a point that has allowed the design of porous structures in which pore size and functionality can be varied systematically. MOF-5, a prototype of a new class of porous materials and one that is constructed from octahedral Zn—O—C clusters and benzene links, was used to demonstrate that its 3-D porous system can be functionalized with the organic groups, —Br, —NH2, —OC3H7, —OC5H11, —H4C2, and —H4C4, and its pore size expanded with the long molecular struts biphenyl, tetrahydropyrene, pyrene, and terphenyl. The ability to direct the formation of the octahedral clusters in the presence of a desired carboxylate link is an essential feature of this strategy, which resulted in the design of an isoreticular (having the same framework topology) series of sixteen well-defined materials whose crystals have open space representing up to 91.1% of the crystal volume, and homogeneous periodic pores that can be incrementally varied from 3.8 to 28.8 angstroms. Unlike the unpredictable nature of zeolite and other molecular sieve syntheses, the deliberate control exercised at the molecular level in the design of these crystals is expected to have tremendous implications on materials properties and future technologies. Indeed, data indicate that members of this series represent the first monocrystalline mesoporous organic / inorganic frameworks, and exhibit the highest capacity for methane storage (155 cm3 / cm3 at 36 atm) and the lowest densities (0.41 to 0.21 g / cm3) attained to date for any crystalline material at room temperature.

Owner:RGT UNIV OF MICHIGAN

Photocatalytically-activated self-cleaning appliances

InactiveUS6054227ASelf-cleaning stoves/rangesLiquid surface applicatorsCoated surfaceSufficient time

An appliance is rendered self-cleaning of accumulated organic contaminants on one or more surfaces of the appliance, by coating such surfaces of the appliance with a photocatalytically-activated self-cleaning coating. Upon exposing such coated surfaces to radiation of the appropriate wavelength, for a sufficient interval of time, at least a portion of the organic contaminants present on the photocatalytically-activated self-cleaning coating are removed. The coated surface is thereby cleaned without the need of manual effort or high temperatures. The radiation is generally actinic radiation, and more particularly includes ultraviolet radiation.

Owner:PPG IND OHIO INC

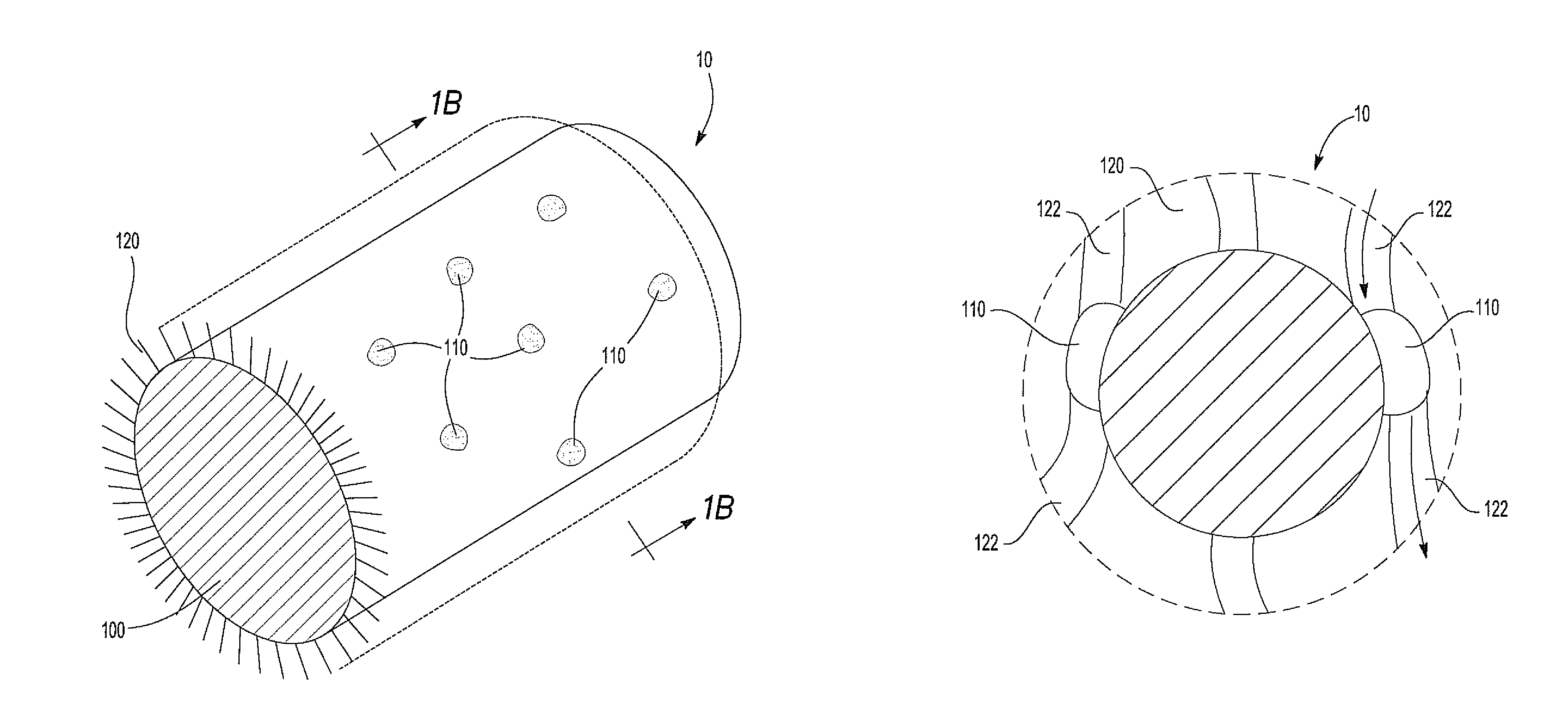

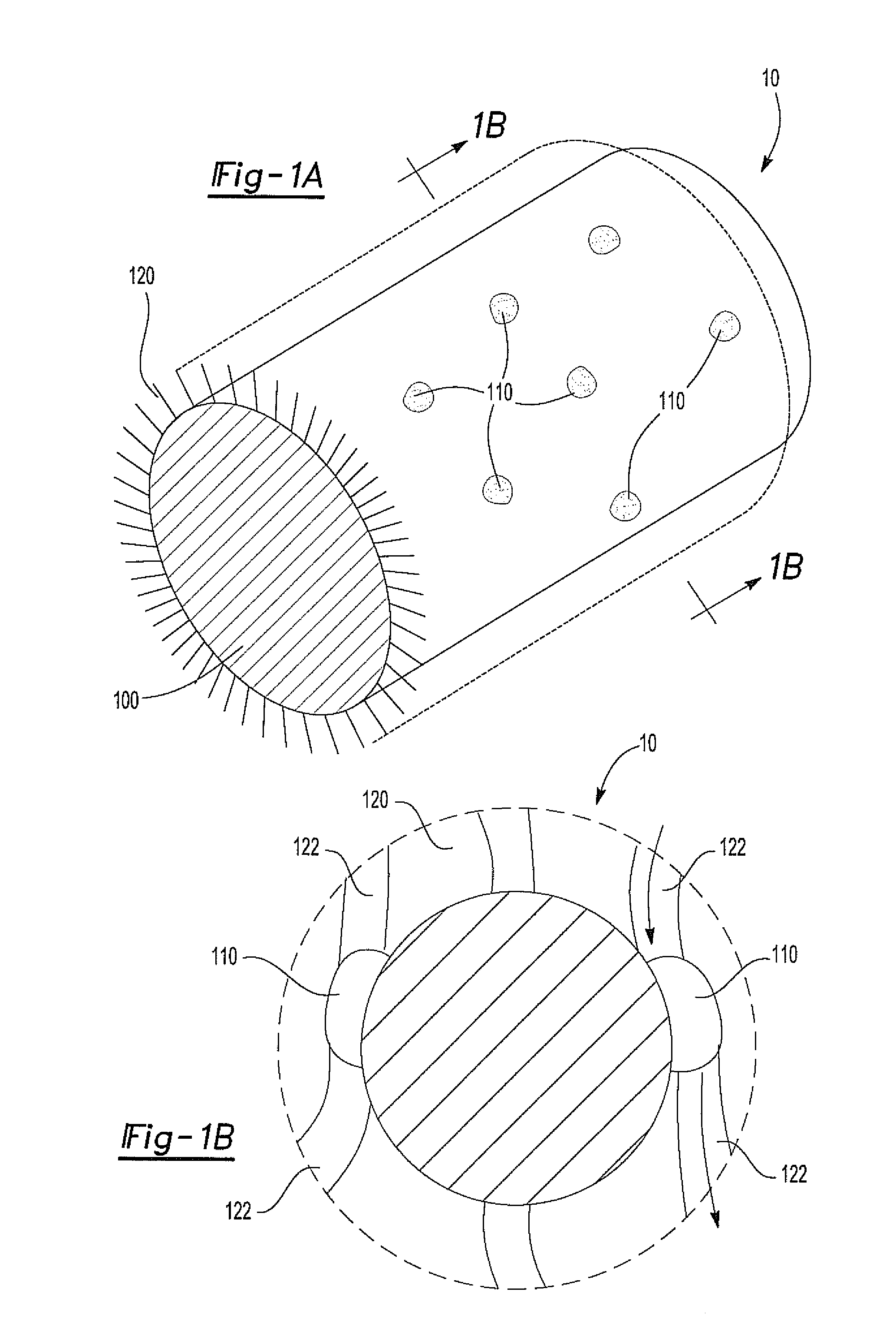

Dual-oxide sinter resistant catalyst

A catalyst material for use at elevated temperatures is provided. The material can include a plurality of fibers and a plurality of particles supported on the fibers. In addition, a porous layer can cover the plurality of particles and allow for process fluid to come into contact with the particles, and yet retard sintering of the particles at elevated temperatures is present. The plurality of fibers can be a plurality of nanofibers which may or may not be oxide nanofibers. The particles can be metallic nanoparticles and the porous layer can be a porous oxide layer.

Owner:TOYOTA MOTOR CO LTD +2

Catalysed substrate monolith

ActiveUS8667785B2Avoids and reduces problemReduce and prevent poisoningCombination devicesNitrogen compoundsInternal combustion enginePlatinum group

Owner:JOHNSON MATTHEY PLC

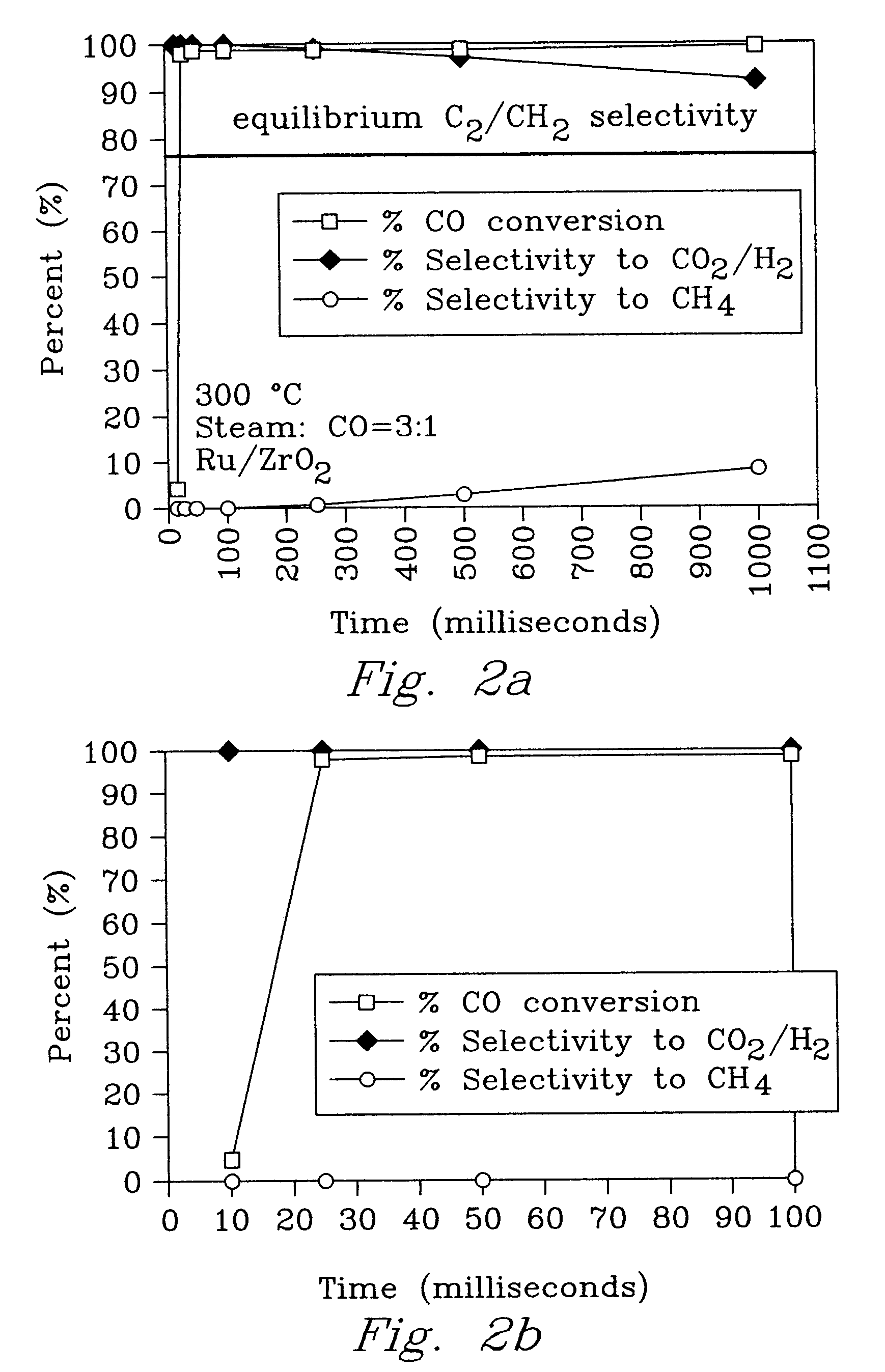

Method and apparatus for obtaining enhanced production rate of thermal chemical reactions

InactiveUS7045114B2Reduce formationReaction is slowOrganic chemistry methodsChemical/physical/physico-chemical microreactorsSteam reformingChemical reaction

Reactors and processes are disclosed that can utilize high heat fluxes to obtain fast, steady-state reaction rates. Porous catalysts used in conjunction with microchannel reactors to obtain high rates of heat transfer are also disclosed. Reactors and processes that utilize short contact times, high heat flux and low pressure drop are described. Improved methods of steam reforming are also provided.

Owner:BATTELLE MEMORIAL INST

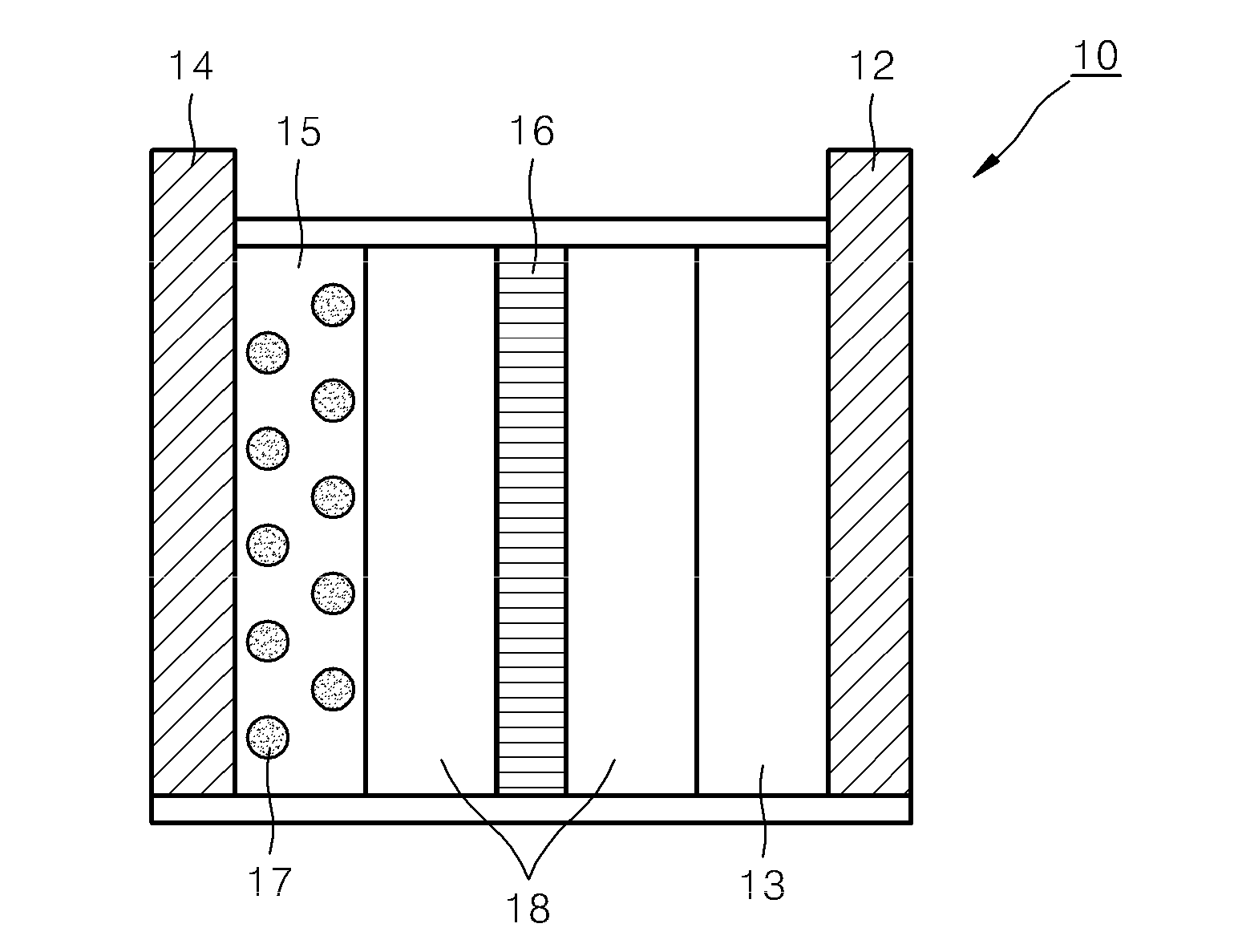

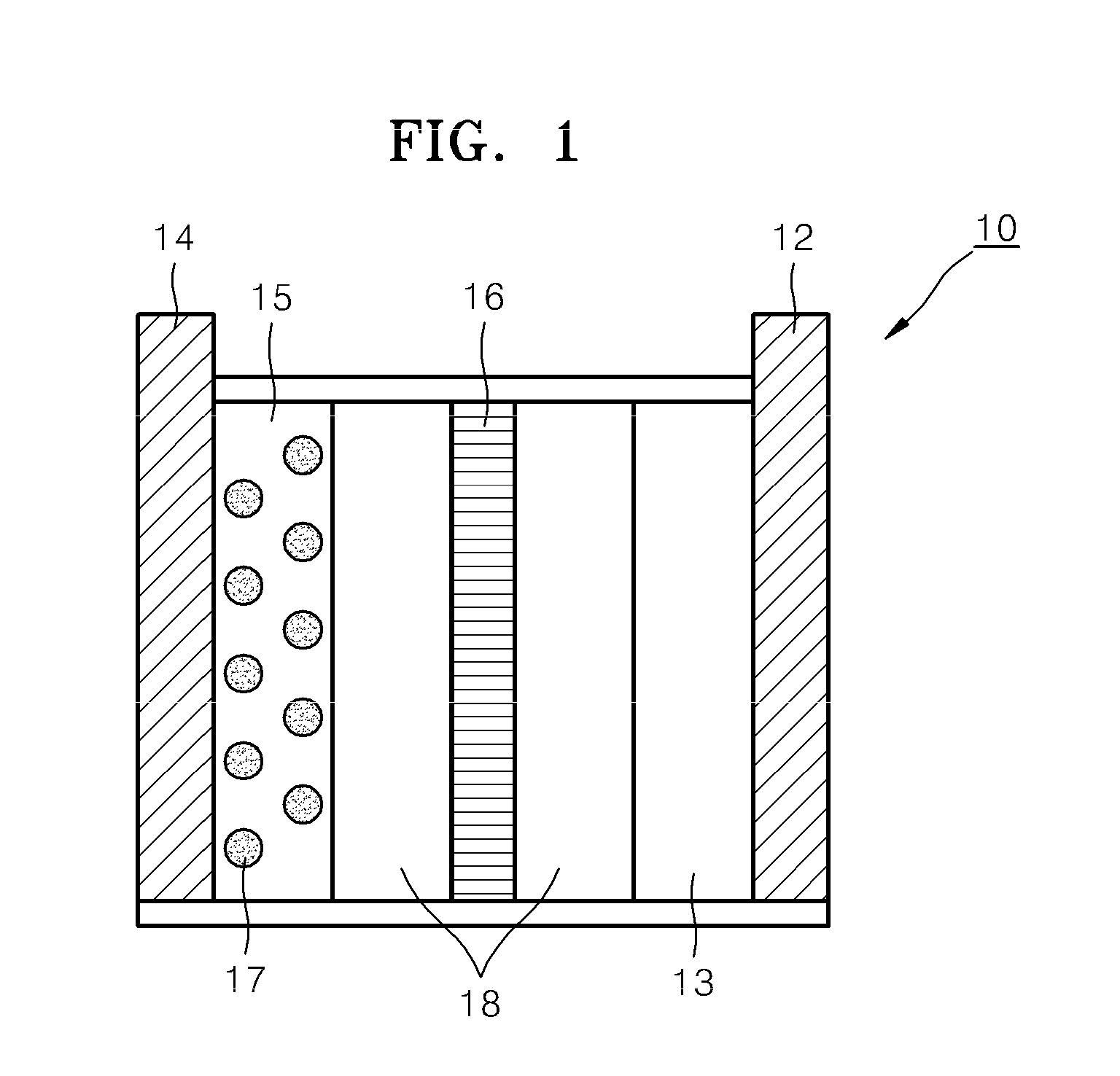

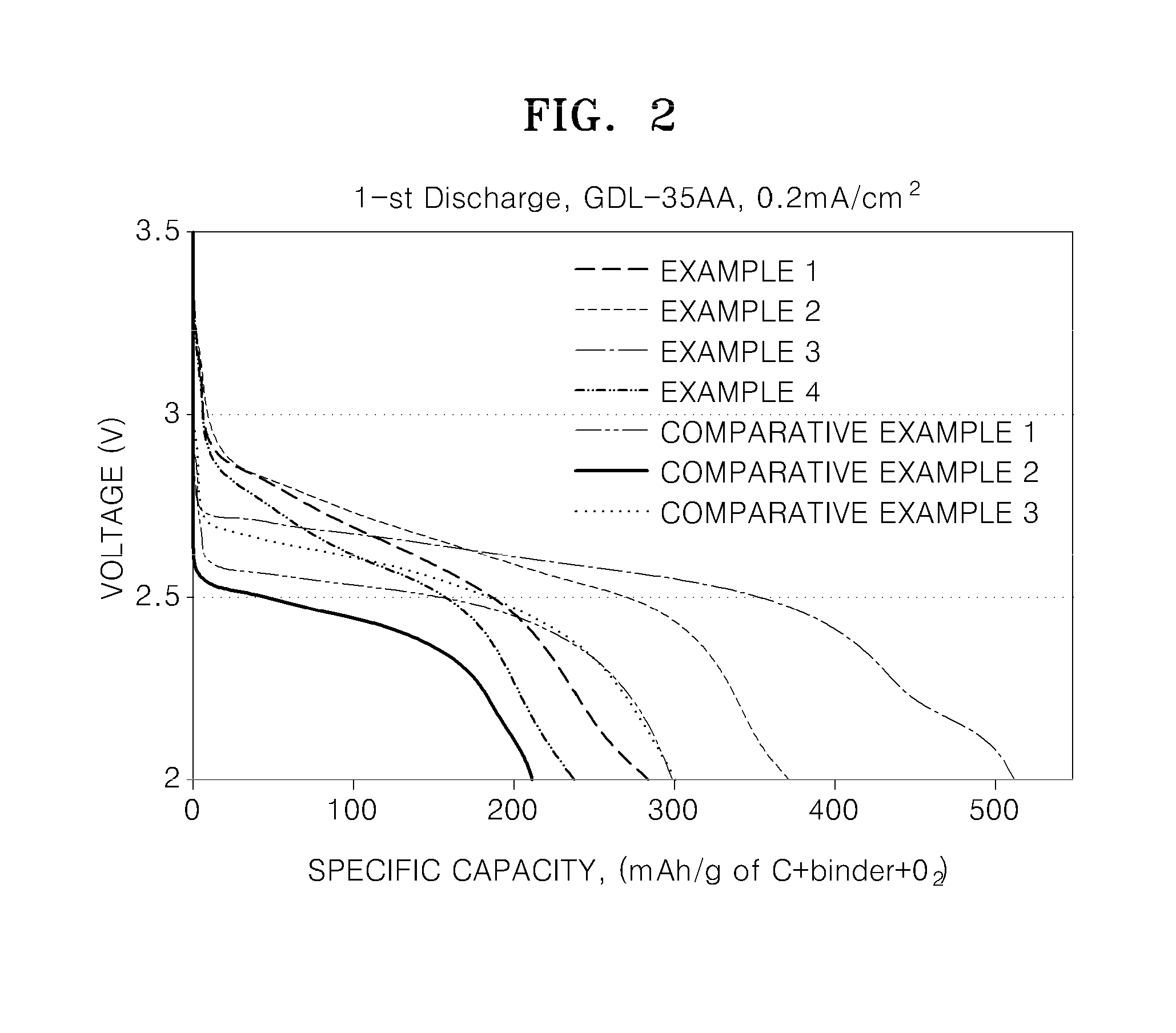

Positive electrode for lithium air battery, method of preparing the positive electrode, and lithium air battery including the positive electrode

InactiveUS20120115048A1Reduced responseMaterial nanotechnologyCatalyst protectionEngineeringLithium–air battery

Owner:SAMSUNG ELECTRONICS CO LTD

Phosgard, a new way to improve poison resistance in three-way catalyst applications

ActiveUS20080038172A1Preventing and reducing foulingPreventing and reducing and poisoningNitrogen compoundsInternal combustion piston enginesRefractorySediment

The present invention provides for novel poisoning-resistant catalysts used for automobile exhaust gas treatment systems. To alleviate the detrimental affects of engine oil and / or fuel additive poisoning the present invention provides for an overcoat layer comprising a porous refractory oxide and one or more base metal oxides, which is coated over one or more precious metal containing washcoat layers. The overcoat of the present invention prevents phosphorous as well as other poisoning deposits, from fouling and / or negatively interacting with the underlying precious metal containing washcoats. In an alternative embodiment, the present invention provides for the coating of the upstream end of a catalytic member by the overcoat layer, thereby creating an upstream poison capture zone.

Owner:BASF CORP

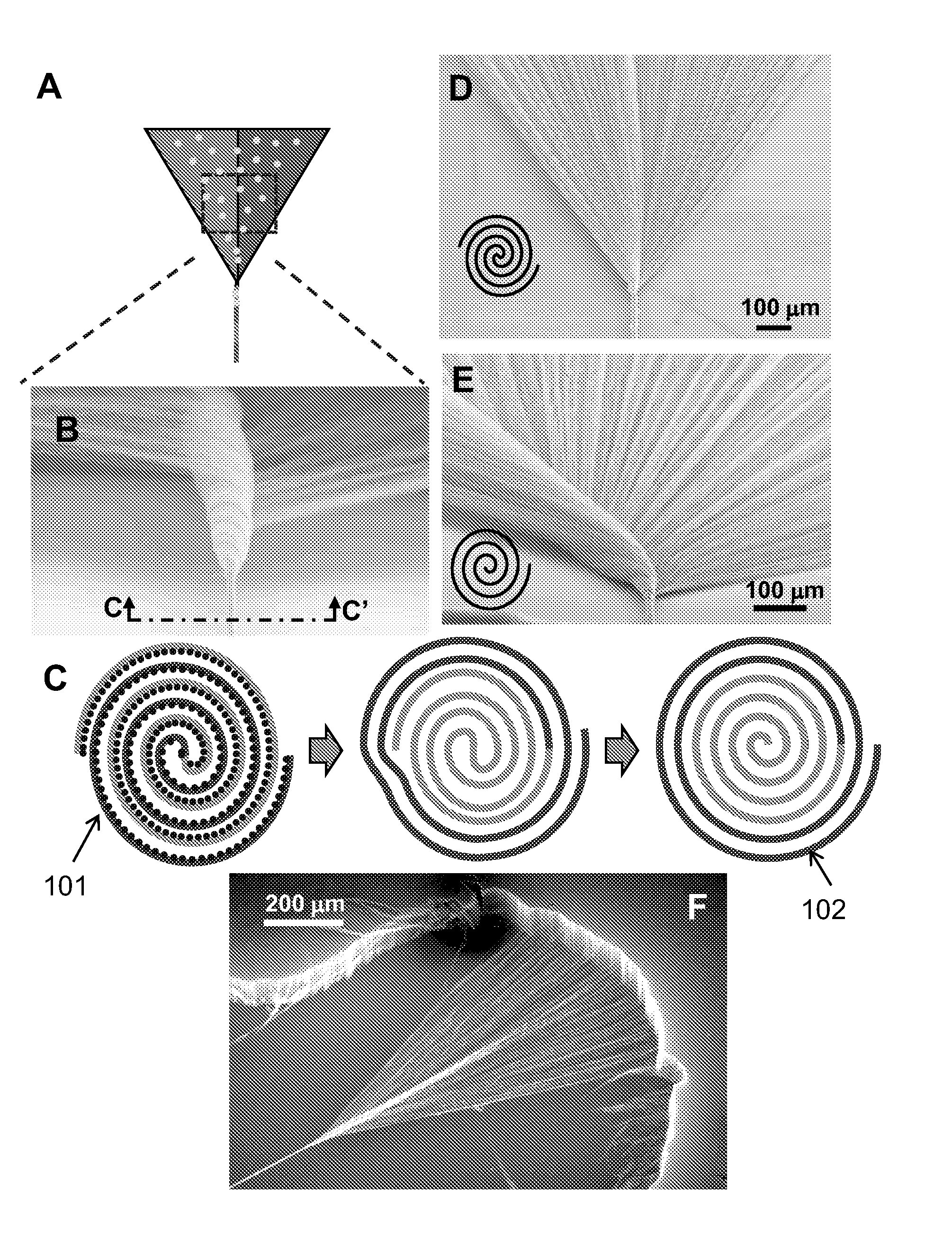

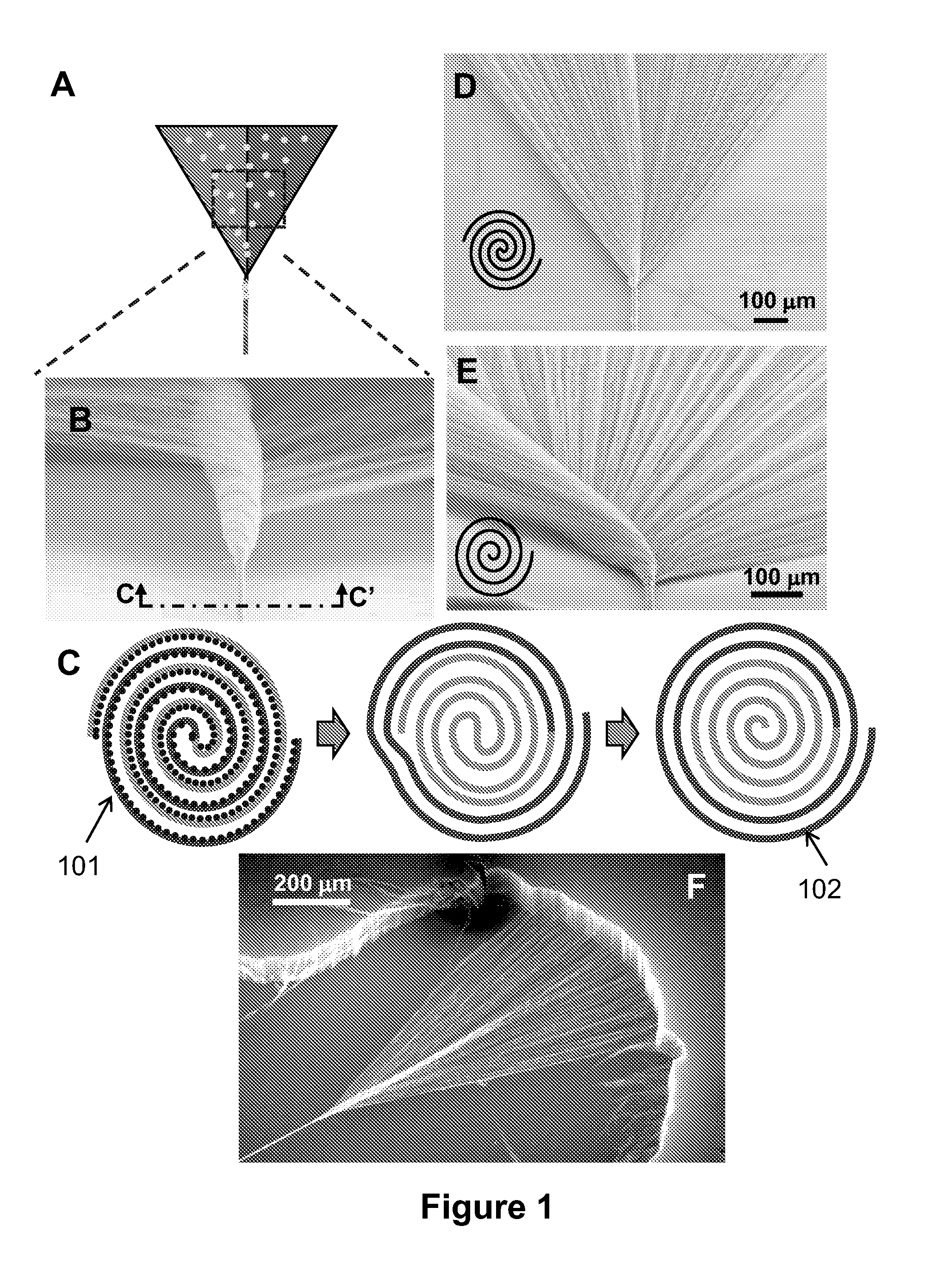

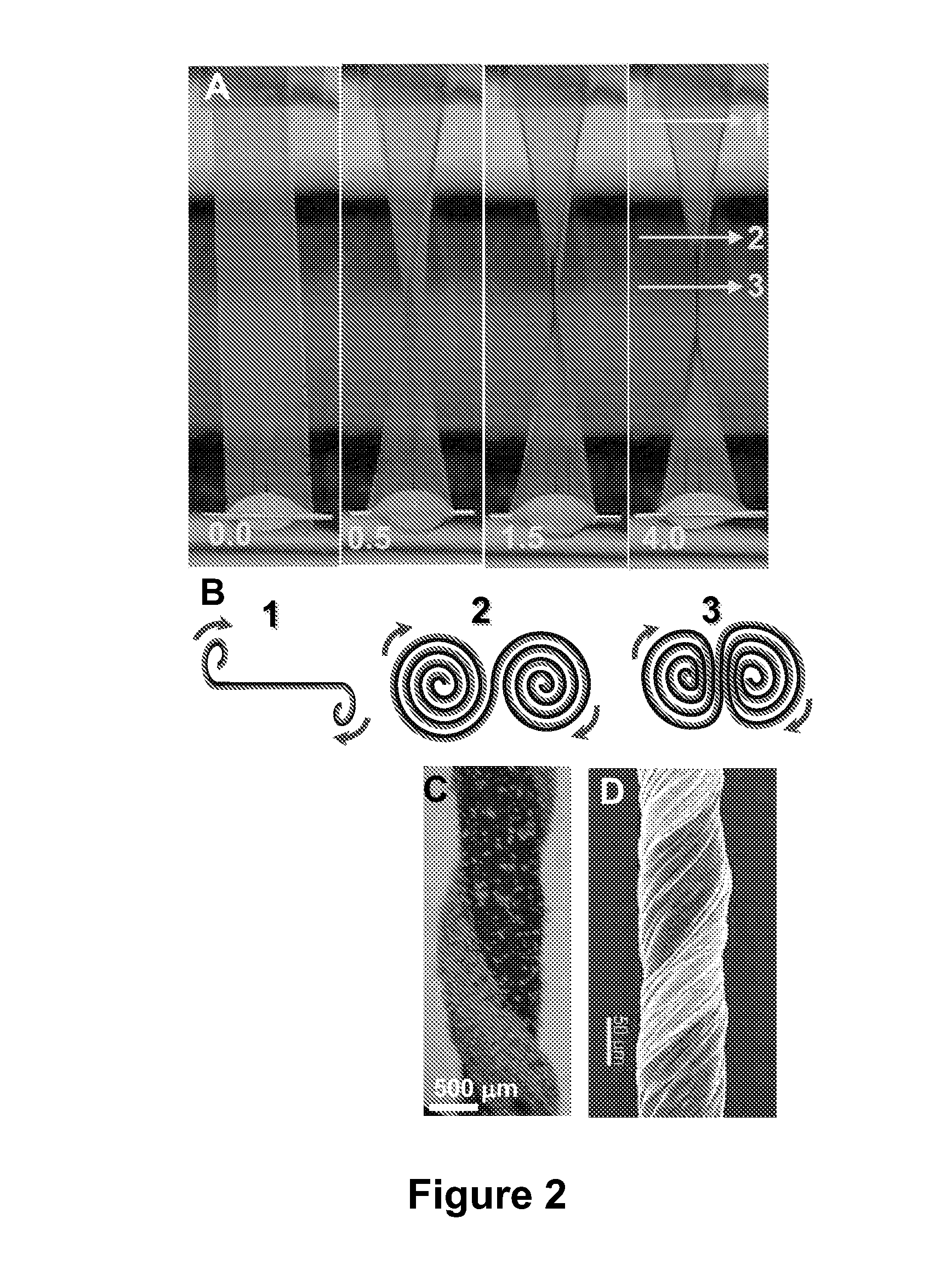

Fabrication of Biscrolled Fiber Using Carbon Nanotube Sheet

Fabrication of yarns or other shaped articles from materials in powder form (or nanoparticles or nanofibers) using carbon nanotube / nanofiber sheet as a platform (template). This includes methods for fabricating biscrolled yarns using carbon nanotube / nanofiber sheets and biscrolled fibers fabricated thereby.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

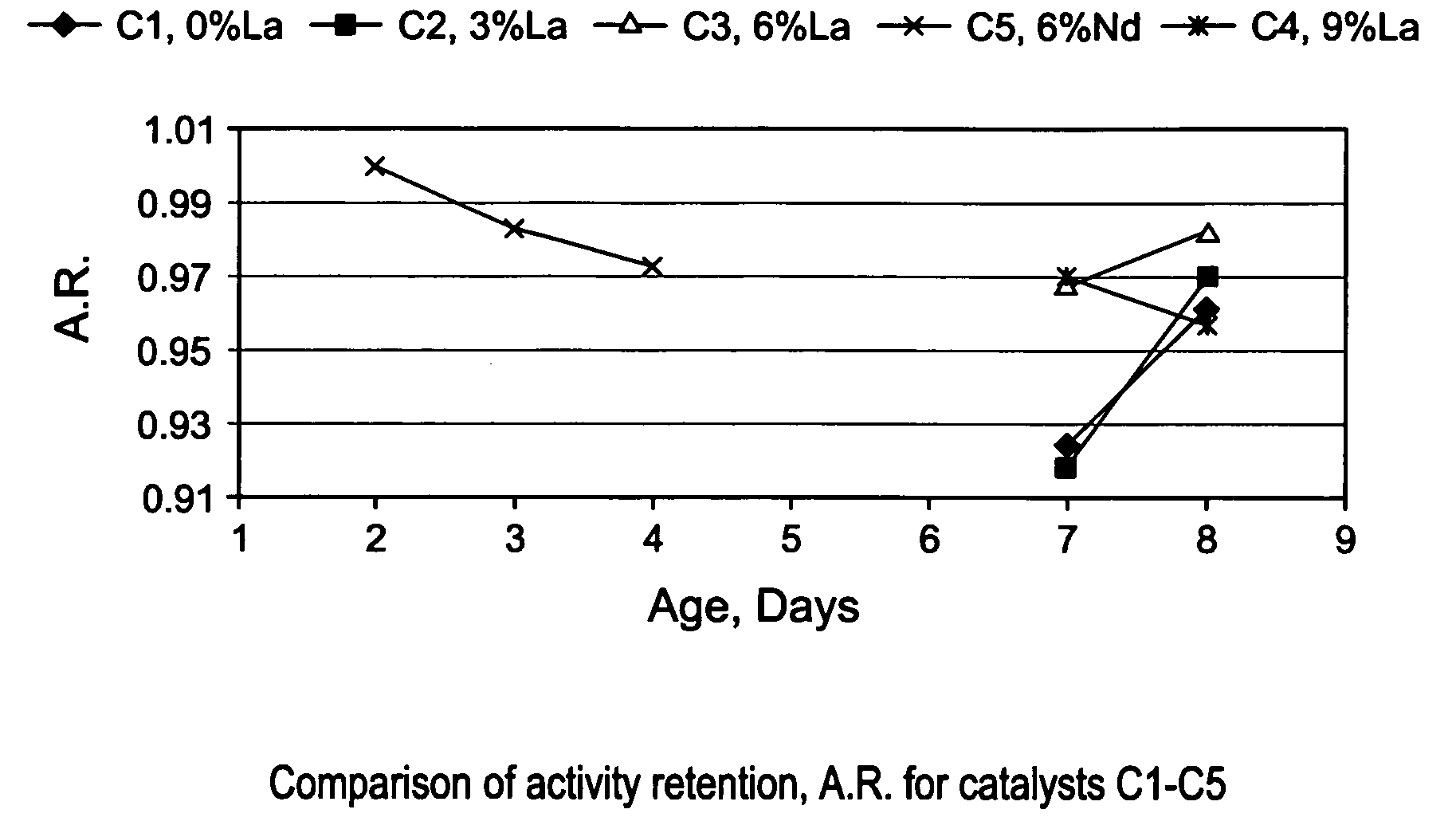

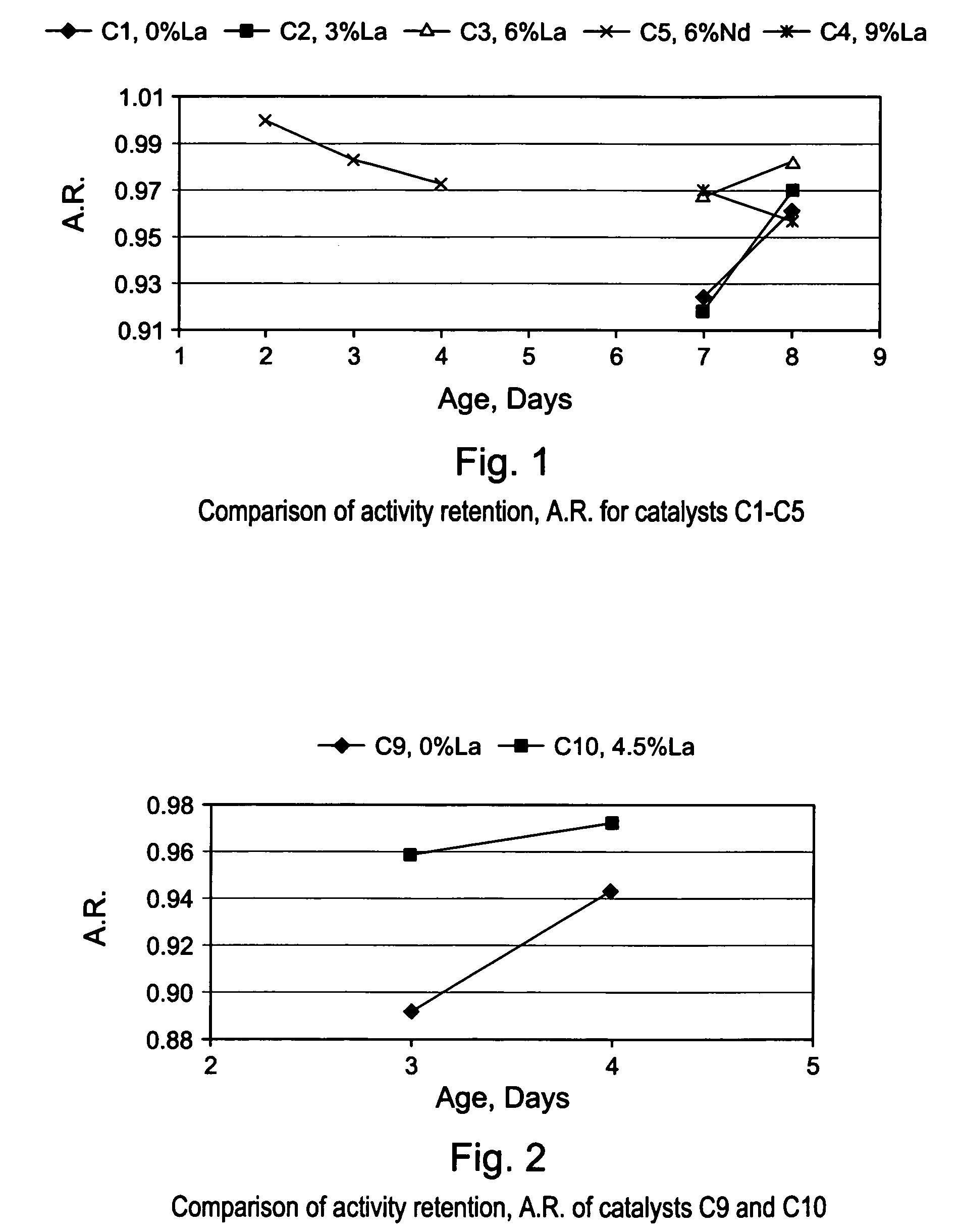

Chemically and thermally stabilized alumina for Fischer-Tropsch catalysts

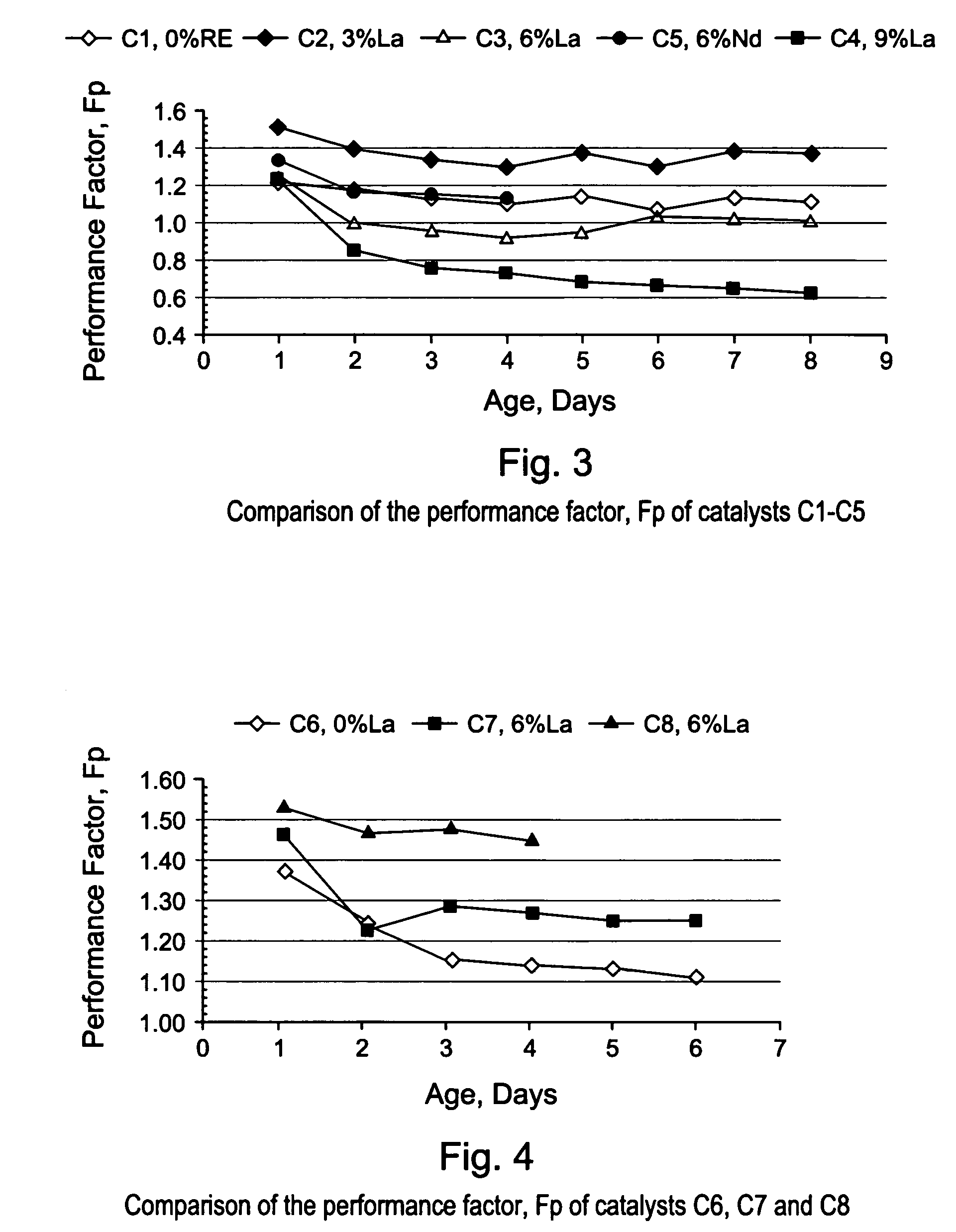

InactiveUS7163963B2Reduce formationReduced structureCatalyst protectionOther chemical processesRare earthMetal

Owner:CLARIANT INT LTD

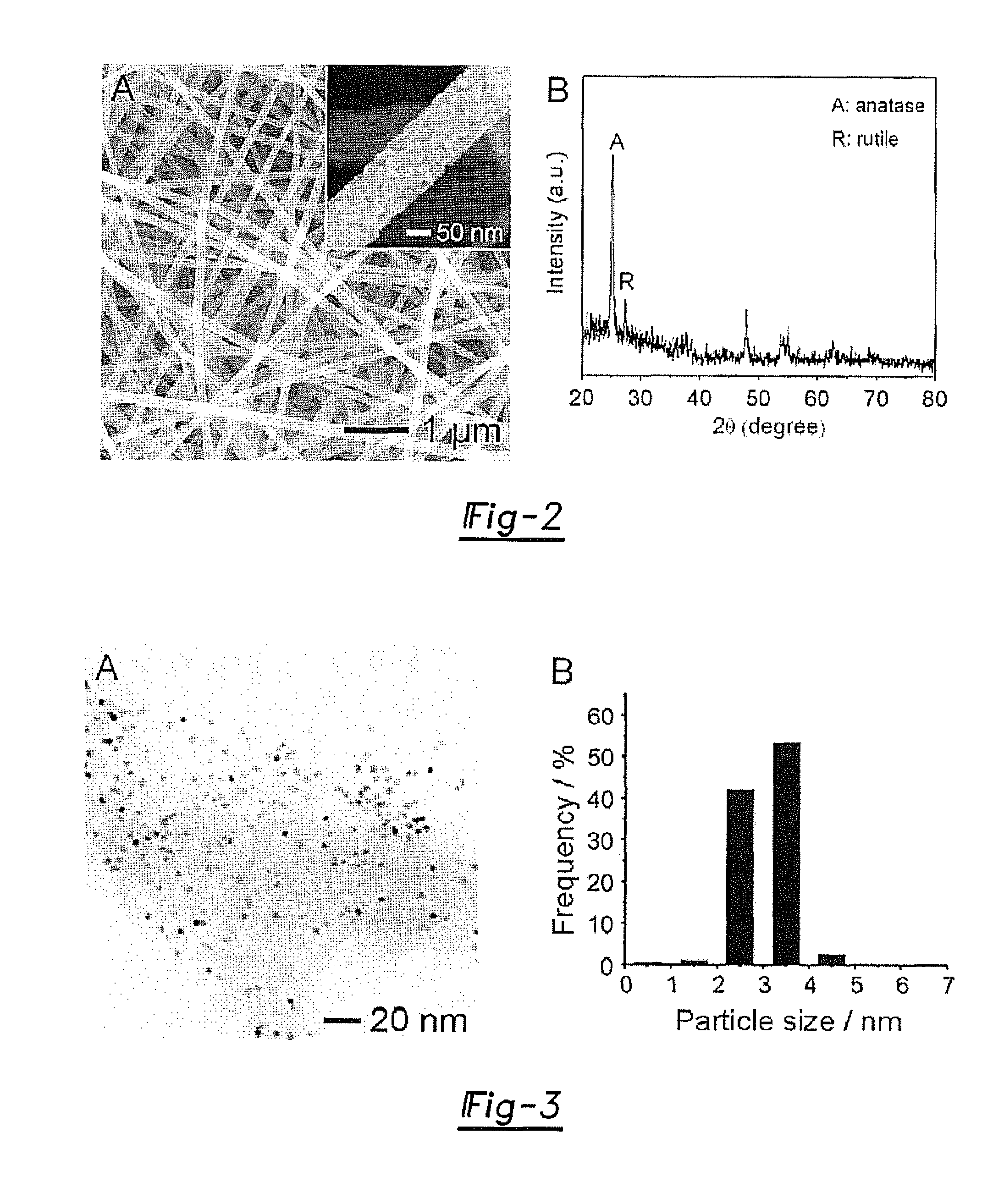

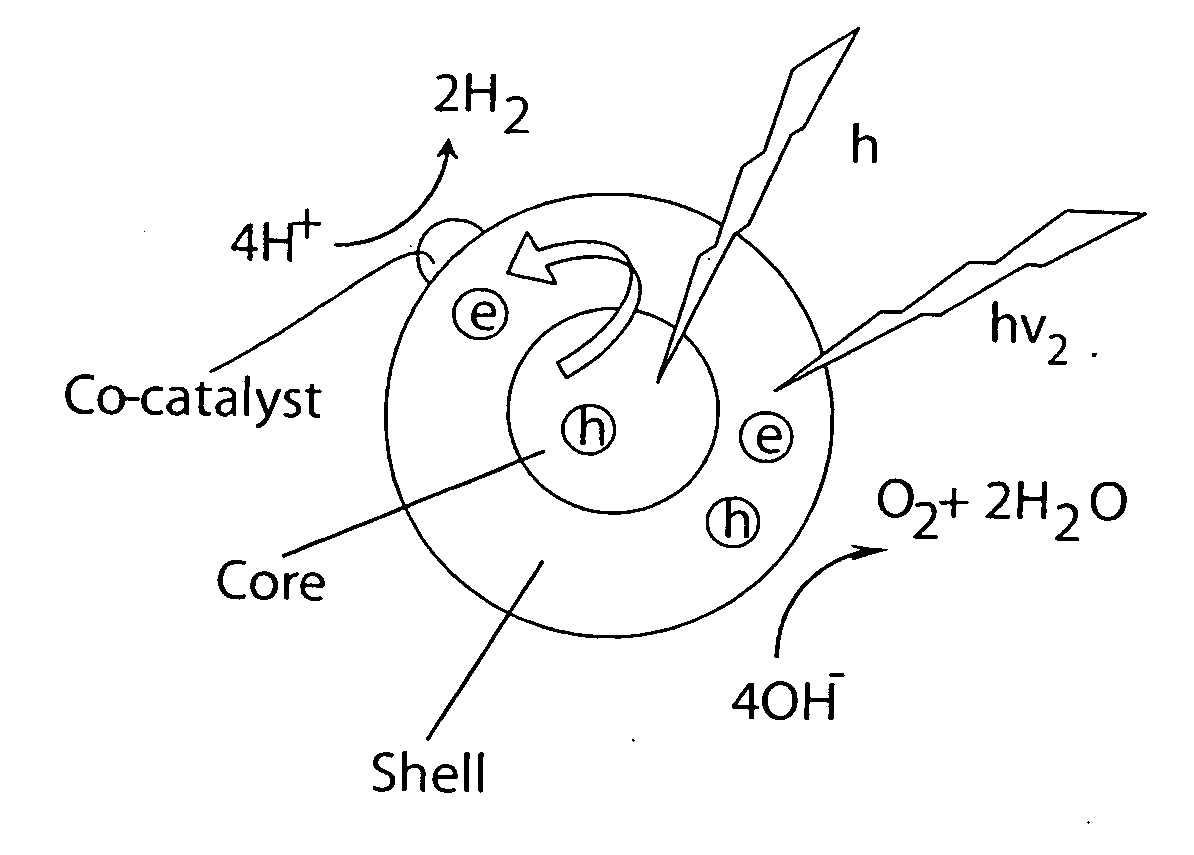

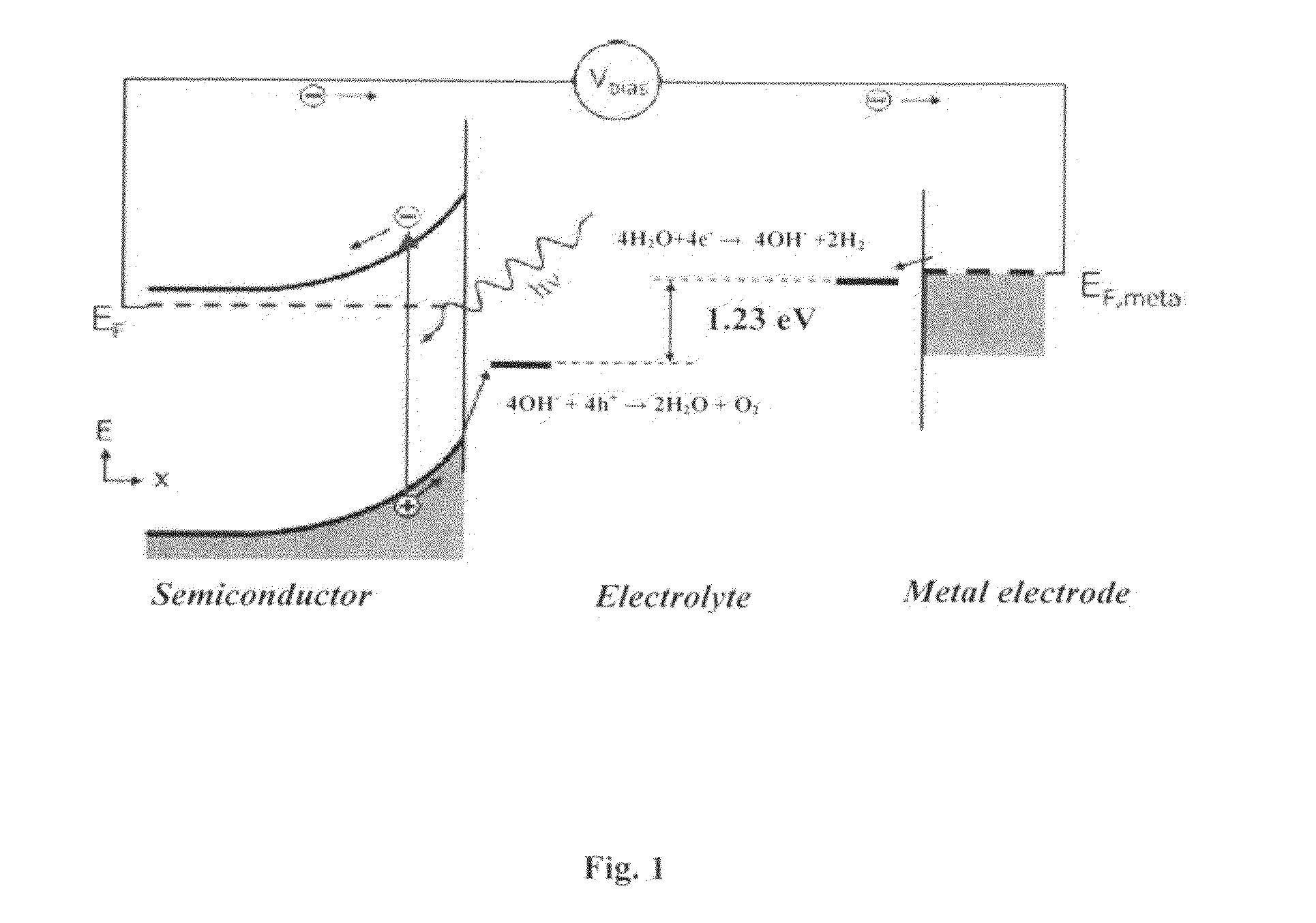

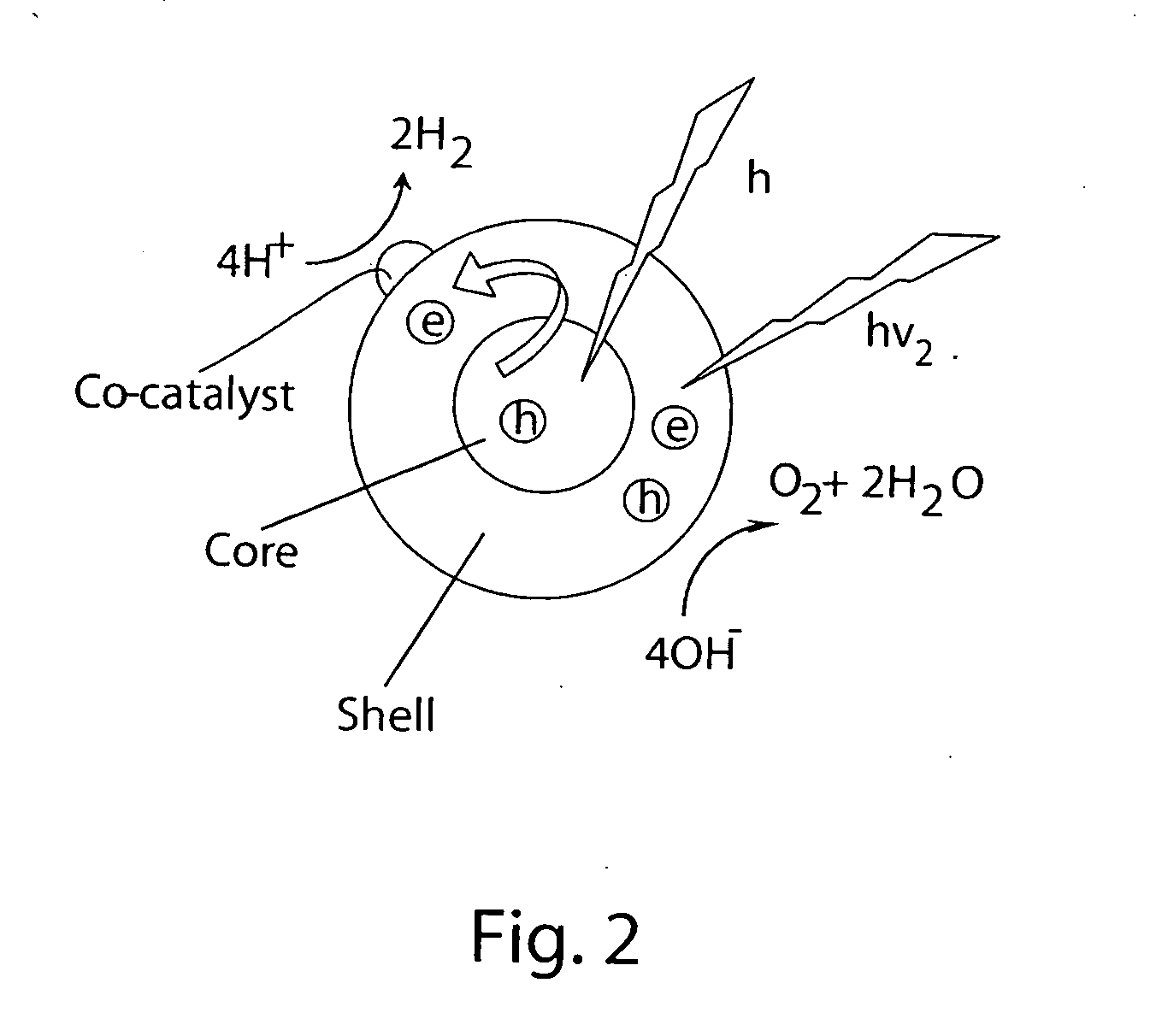

Efficient hydrogen production by photocatalytic water splitting using surface plasmons in hybrid nanoparticles

InactiveUS20120145532A1Material nanotechnologyCatalyst protectionPhotocatalytic water splittingSolar energy conversion efficiency

Photocatalytic water splitting is employed as a method to directly obtain clean hydrogen from solar radiation by using hybrid nanoparticles with metallic cores and semiconductor photocatalytic shells. Efficient unassisted overall photocatalytic splitting of water is based on resonant absorption from surface plasmon in metal core / semiconductor shell hybrid nanoparticles, which can extend the absorption spectra further towards the visible-near infrared range, thus dramatically increasing the solar energy conversion efficiency. When used in combination with scintillator nanoparticles, the hybrid photocatalytic nanoparticles can be used for conversion of nuclear energy into hydrogen.

Owner:STC UNM

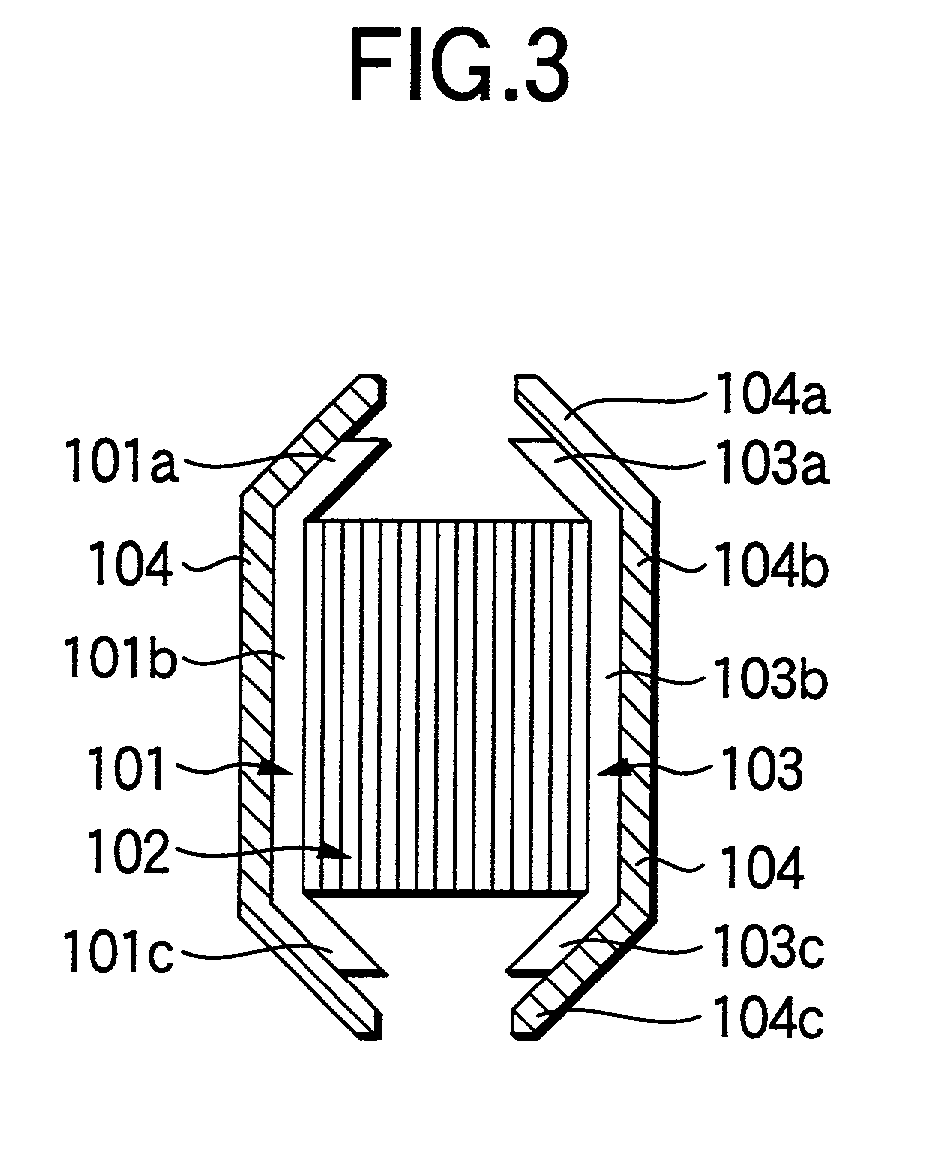

Catalyst carrier holding member, method of making the same and catalyst converter

InactiveUS20020025904A1Maintain stable propertiesLow costCatalyst protectionExhaust apparatusFiberShell molding

The present invention provides a catalyst carrier holding member to be fitted into a gap between a catalyst carrier and a casing accommodating the catalyst carrier. The catalyst carrier holding member includes a three-dimensional molded article having flexible inorganic fiber and an inorganic expansive admixture, if desired. The flexible inorganic fiber is bound together by a binder in a compression-deflected state. A surface in contact with the catalyst carrier is shaped substantially in conformity to the outer shape of the catalyst carrier, and a surface in contact with the casing is substantially in conformity to the inner shape of the casing. The catalyst carrier holding member has a thickness equal to or larger than the gap.

Owner:NICHIAS CORP

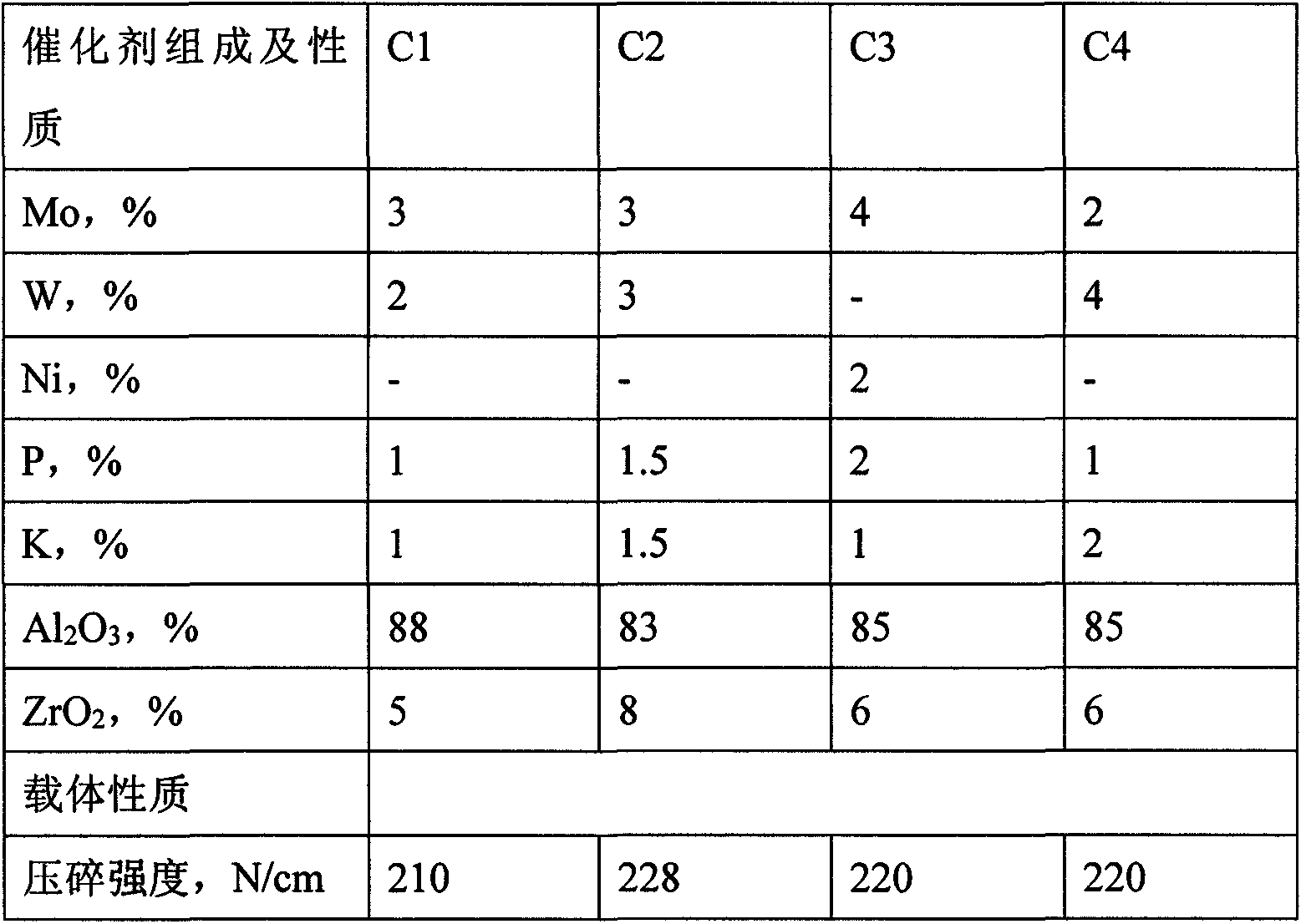

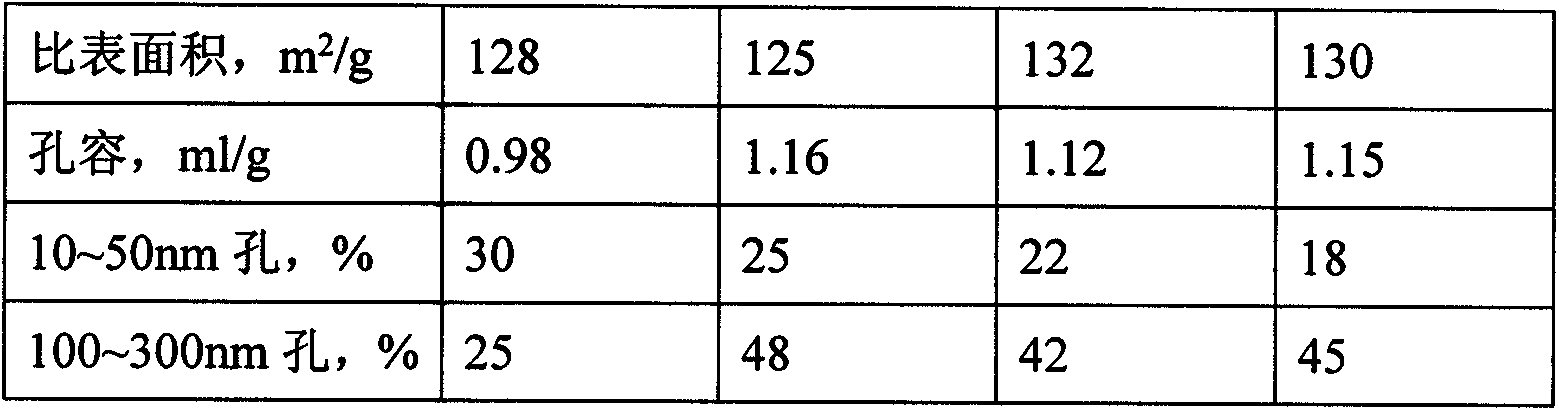

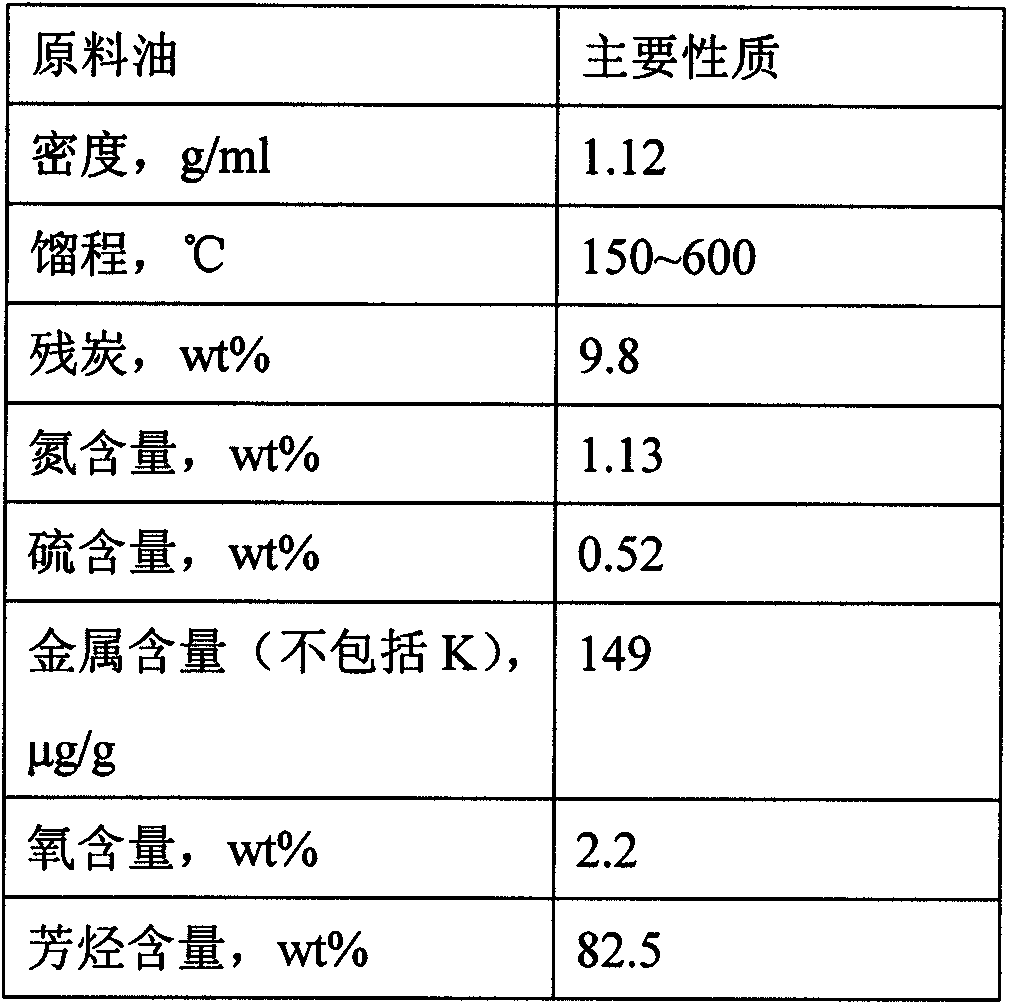

Protective agent of coal tar hydrogenation catalyst and preparation method of protective agent

ActiveCN103706408ASmall pressure dropHigh activityCatalyst protectionHydrocarbon oil crackingPotassiumMetal impurities

The invention discloses a protective agent of a coal tar hydrogenation catalyst and a preparation method of the protective agent. The protective agent is composed of three parts, namely carriers, active components and assistants, wherein the carriers include aluminium oxide and zirconium oxide in common; the active components include oxides of molybdenum, nickel or tungsten in common and account for 1-10% of total mass of the catalyst; the assistants include potassium and phosphorus in common, and account for 0.5-6% of total mass of the catalyst, and the balance is the carriers. The preparation method comprises preparation of the carrier and preparation of the protective agent. The protective agent has the advantages that the carrier comprises fine holes and thick holes, of which the apertures are relatively concentrated, wherein the thick holes are beneficial to containing metal impurities and carbon residue; a pressure drop of a catalyst bed is reduced, the hydrogenation catalyst is protected, removal of metal impurities such as vanadium is facilitated by the thin holes, the demetallization activity of the protective agent is properly improved, and different pore volumes and hole distribution of carriers can be prepared by adjusting the ratio of two pore forming materials. In addition, the preparation method of the protective agent is simple in technology, and convenient and stable to fabricate.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH +1

Method of treating flammable catalyst

A method used for manufacturing a catalyst used for hydrogenation treating and / or hydrogenation cracking a hydrocarbon flow or exhaust treating a thionic gas flow comprises heating a prevulcanized composition to 200-500 DEG C in the presence of hydrogen gas to form a sulfide of a metal, wherein said prevulcanized composition contains a prevulcanized catalyst loaded at a porous carrier and at least part of the catalyst is coated and / or infused by at least a containing oxygen hydrocarbon having at least 16 carbon atoms and an iodine value of not less than 60, with a condition that when said hydrocarbon is glycerin trifatty acid ester, the catalyst is not coated and / or infused by said hydrocarbon when or before it is prevulcanized, and when there is no hydrogen added existing in the catalyst coated and / or infused, said catalyst has undergone a heating treatment at not lower than 175 DEG C, with reduced self-heating characteristics of said catalyst.

Owner:CRI INT

Methods of making alkenyl alkanoates

InactiveUS20050181940A1Increase productivityCatalyst protectionOrganic compound preparationChloridePalladium

The present invention addresses at least four different aspects relating to catalyst structure, methods of making those catalysts and methods of using those catalysts for making alkenyl alkanoates. Separately or together in combination, the various aspects of the invention are directed at improving the production of alkenyl alkanoates and VA in particular, including reduction of by-products and improved production efficiency. A first aspect of the present invention pertains to a unique palladium / gold catalyst or pre-catalyst (optionally calcined) that includes rhodium or another metal. A second aspect pertains to a palladium / gold catalyst or pre-catalyst that is based on a layered support material where one layer of the support material is substantially free of catalytic components. A third aspect pertains to a palladium / gold catalyst or pre-catalyst on a zirconia containing support material. A fourth aspect pertains to a palladium / gold catalyst or pre-catalyst that is produced from substantially chloride free catalytic components.

Owner:CELANESE INT CORP +1

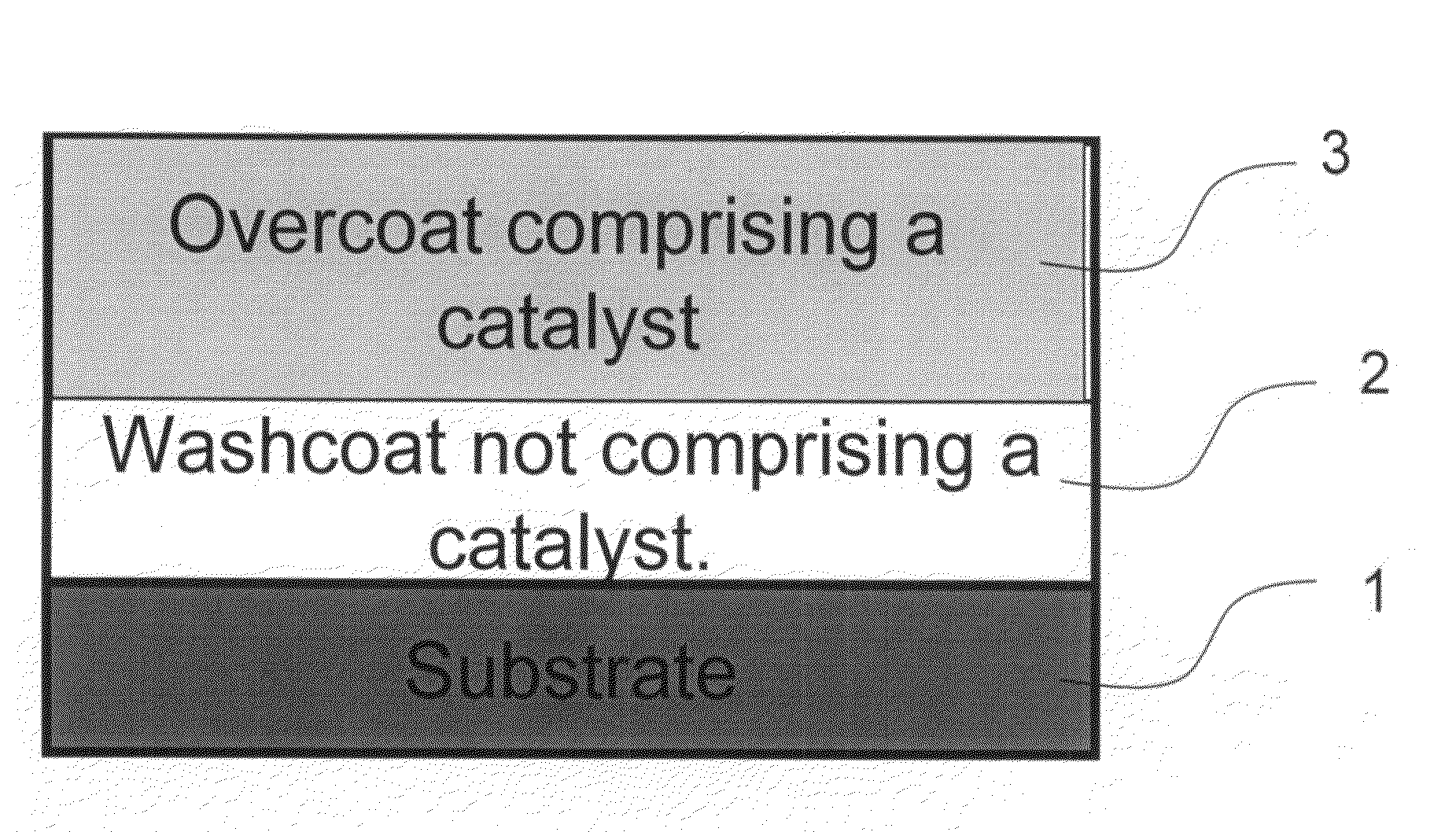

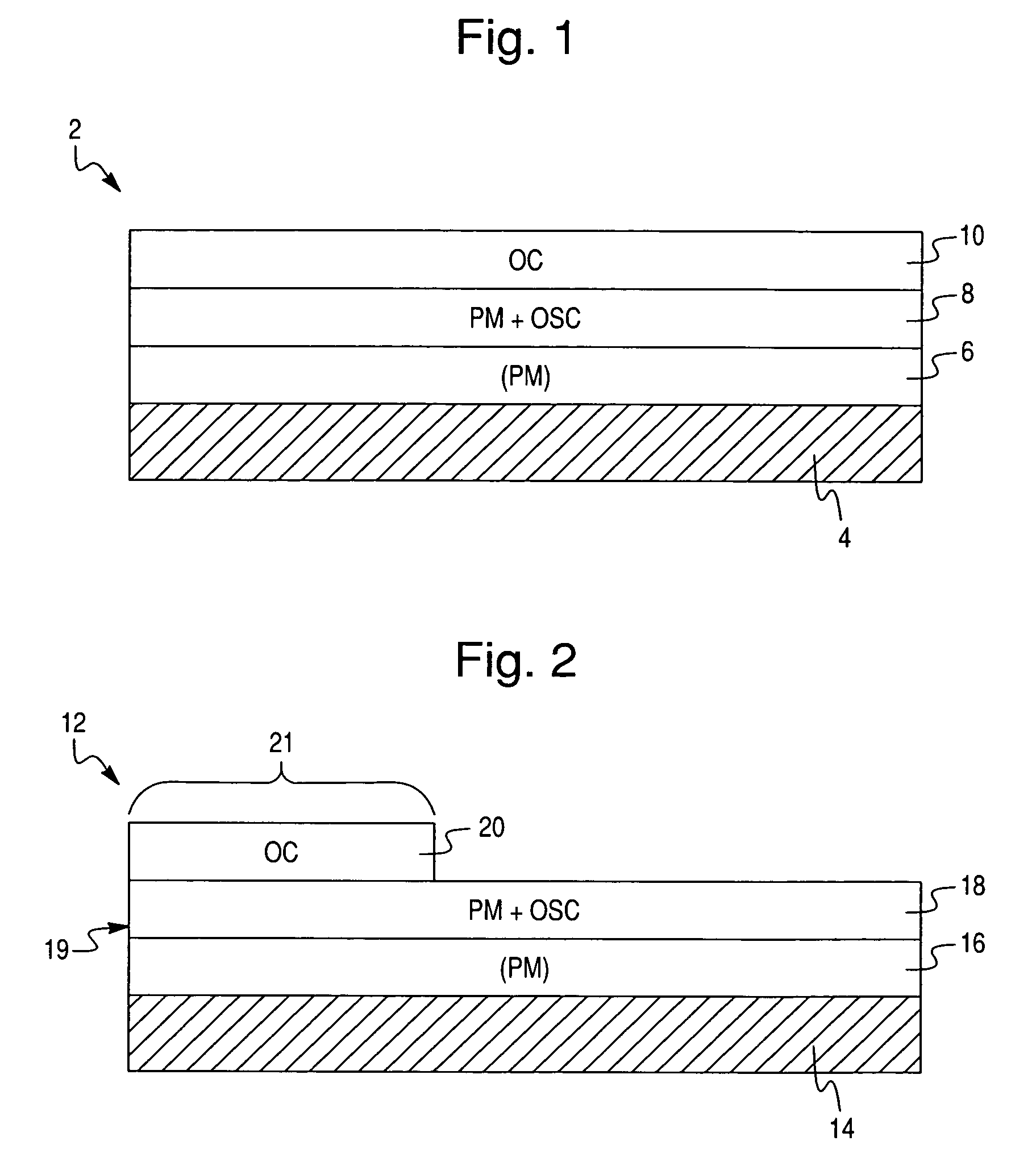

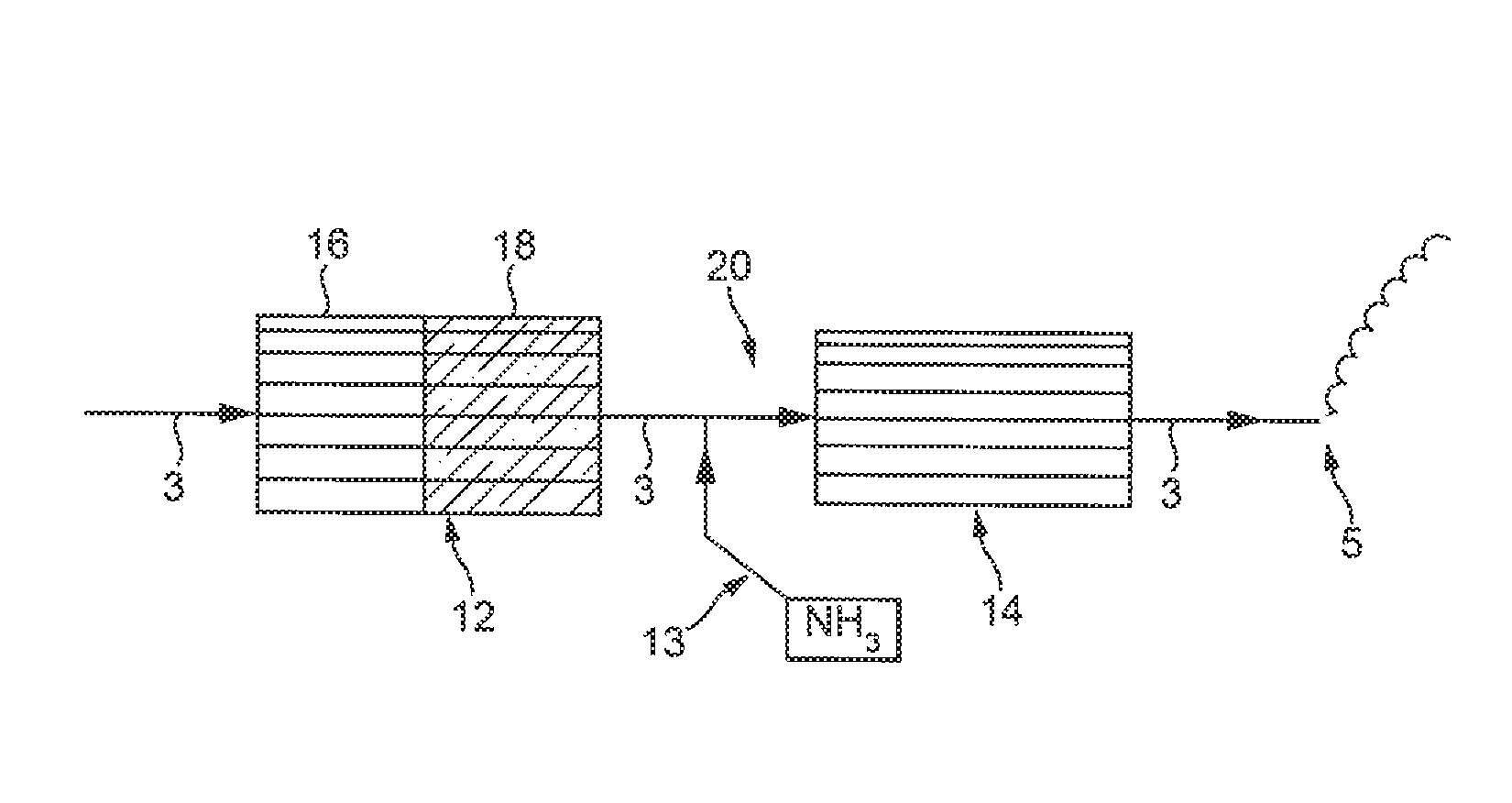

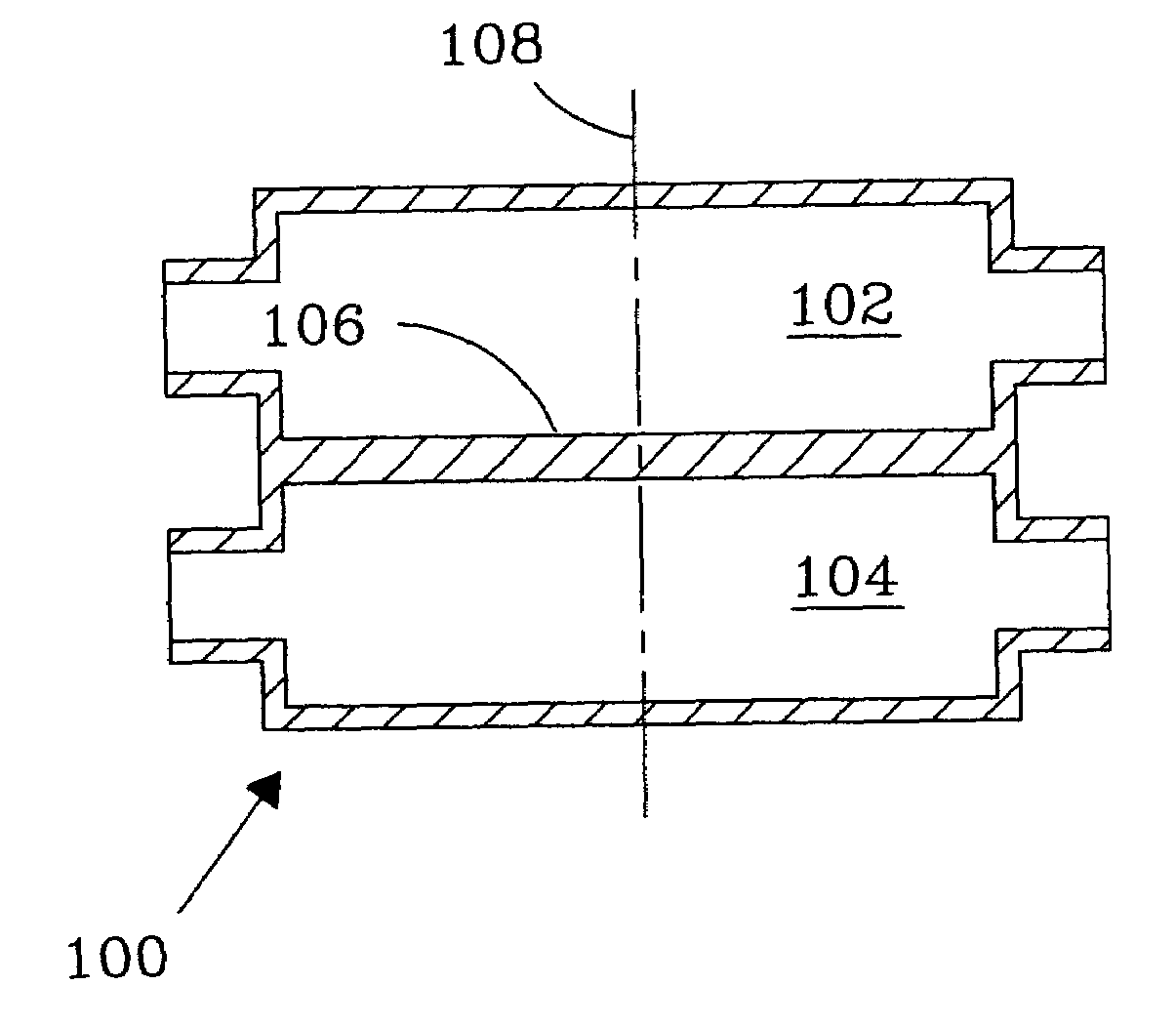

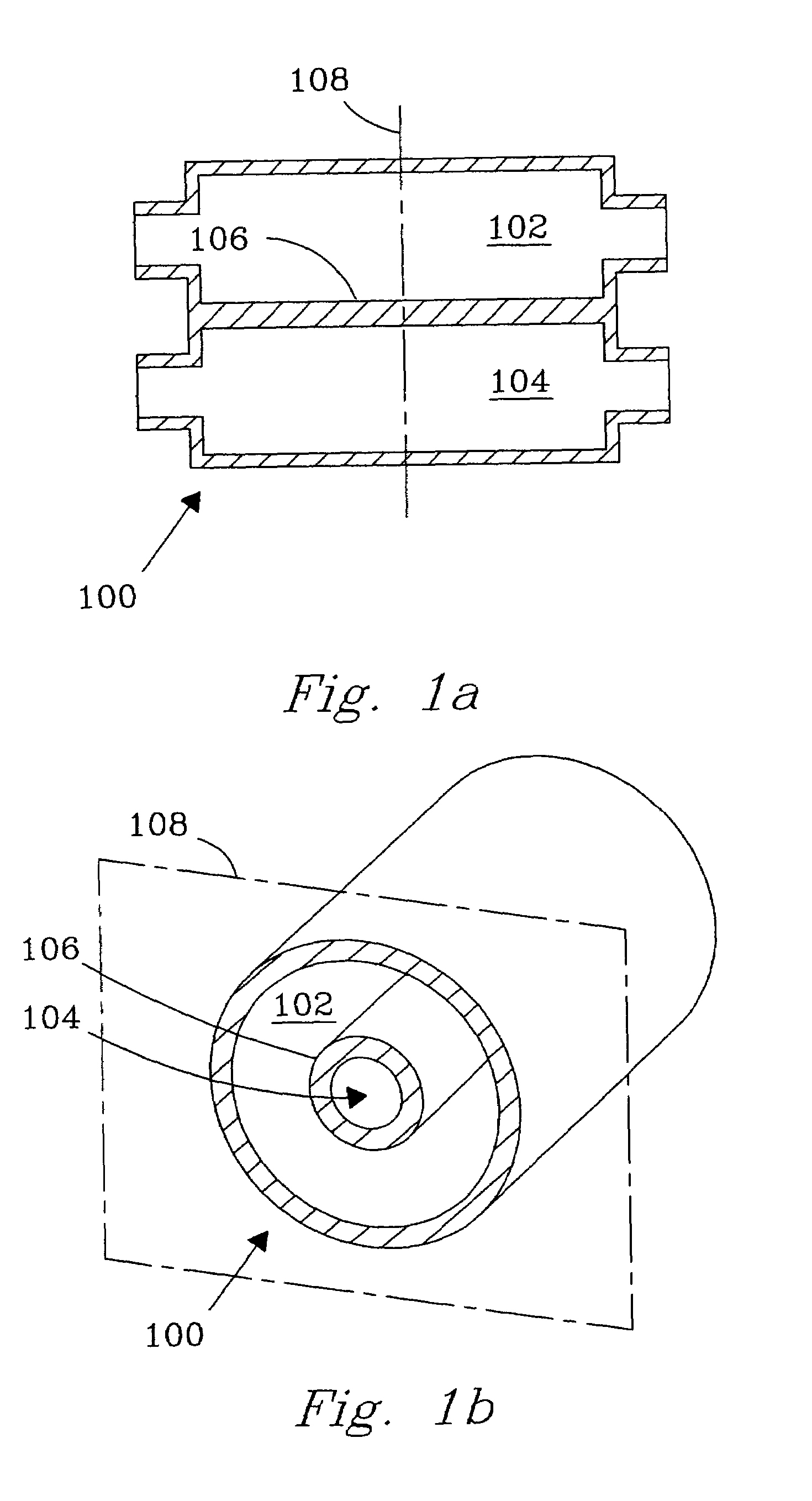

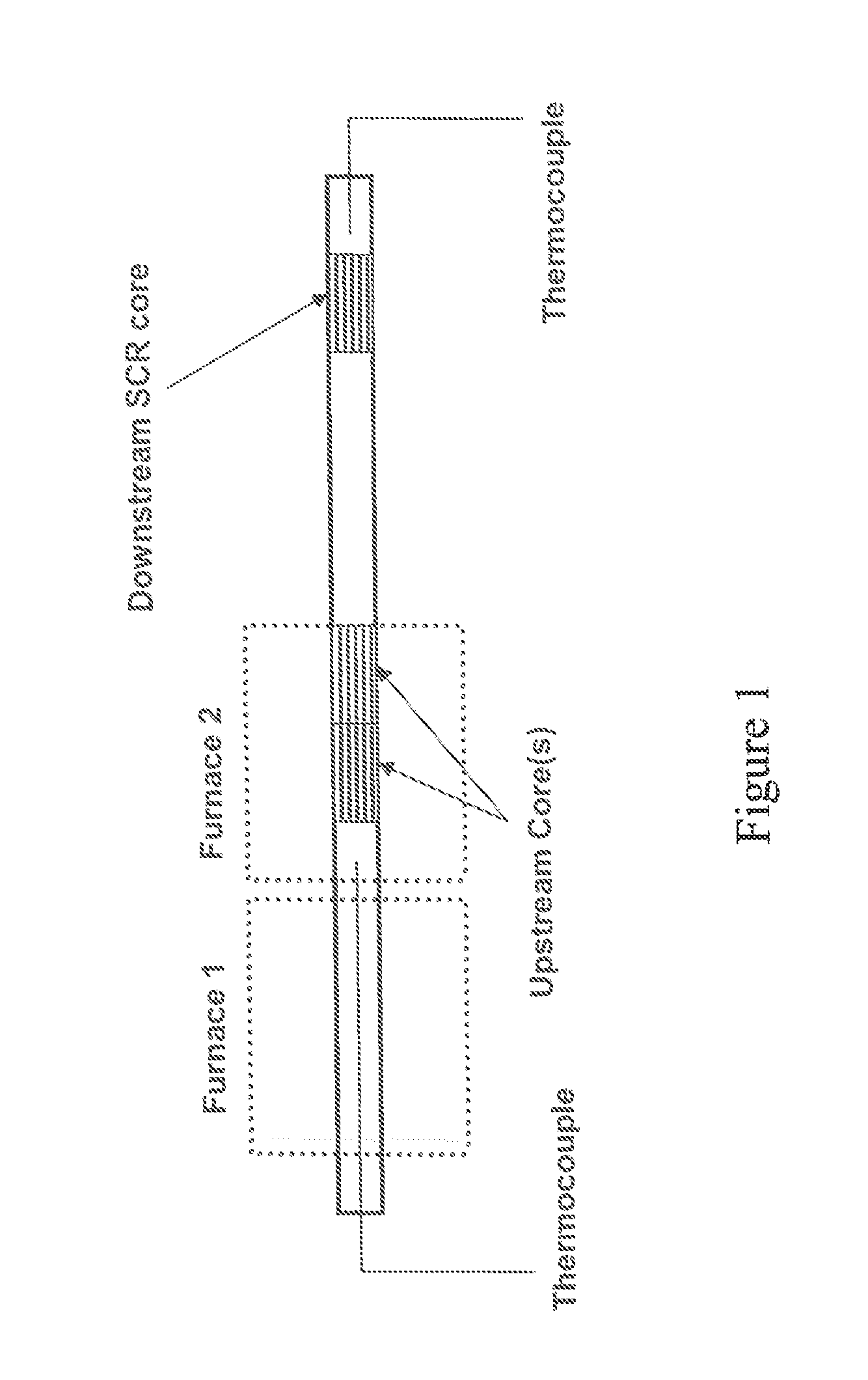

Catalysed substrate monolith

ActiveUS20130149221A1Avoids and reduces problemReduce and prevent poisoningCombination devicesNitrogen compoundsInternal combustion engineMetal

A catalysed substrate monolith 12 for use in treating exhaust gas emitted from a lean-burn internal combustion engine, which catalysed substrate monolith 12 comprising a first washcoat coating 16 and a second washcoat coating 18, wherein the first washcoat coating comprises a catalyst composition comprising at least one platinum group metal (PGM) and at least one support material for the at least one PGM, wherein at least one PGM in the first washcoat coating is liable to volatilise when the first washcoat coating is exposed to relatively extreme conditions including relatively high temperatures, wherein the second washcoat coating comprises at least one metal oxide for trapping volatilised PGM and wherein the second washcoat coating is oriented to contact exhaust gas that has contacted the first washcoat coating.

Owner:JOHNSON MATTHEY PLC

Catalysts

ActiveUS7365040B2Facilitates the eventual dislodging and washingReducing the catalyst precursorLiquid hydrocarbon mixture productionHydrocarbon oils refiningPtru catalystPhysical chemistry

A process for preparing a cobalt-based Fischer-Tropsch synthesis catalyst includes introducing a soluble modifying component precursor of the formula Mc(OR)x, where Mc is a modifying component selected from the group comprising Si, Ti, Cu, Zn, Zr, Mn, Ba, Ni, Na, K, Ca, Sn, Cr, Fe, Li, Tl, Sr, Ga, Sb, V, Hf, Th, Ce, Ge, U, Nb, Ta, W or La, R is an alkyl or acyl group, and x is an integer having a value of from 1 to 5, onto and / or into a cobalt-based Fischer-Tropsch synthesis catalyst precursor, which comprises a porous pre-shaped catalyst support supporting cobalt in an oxidized form. The resultant modified cobalt-based Fischer-Tropsch synthesis catalyst precursor is reduced to obtain a cobalt-based Fischer-Tropsch synthesis catalyst.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Silicon trap for coker naphtha and application thereof

ActiveCN102051202AInactivation achievedAvoid inactivationCatalyst protectionRefining to eliminate hetero atomsNaphthaSilicon dioxide

The invention discloses a silicon trap for coker naphtha and application thereof. In the silicon trap for the coker naphtha, alumina is taken as a carrier, silica is taken as an aid, W, Mo and Ni are taken as hydrogenation components, the pore volume of the silicon trap for the coker naphtha is 0.5-0.70ml / g, the specific surface area is 250-500m<2> / g, the hydrogenation components are 1 to 20 percent based on oxides, and the acid content is 0.3-0.5mmol / g. The silicon trap for the coker naphtha can effectively remove the silicon impurity contained in the coker naphtha, and protects a coker naphtha hydrofining catalyst against permanent deactivation caused by silicon poisoning.

Owner:CHINA PETROLEUM & CHEM CORP +1

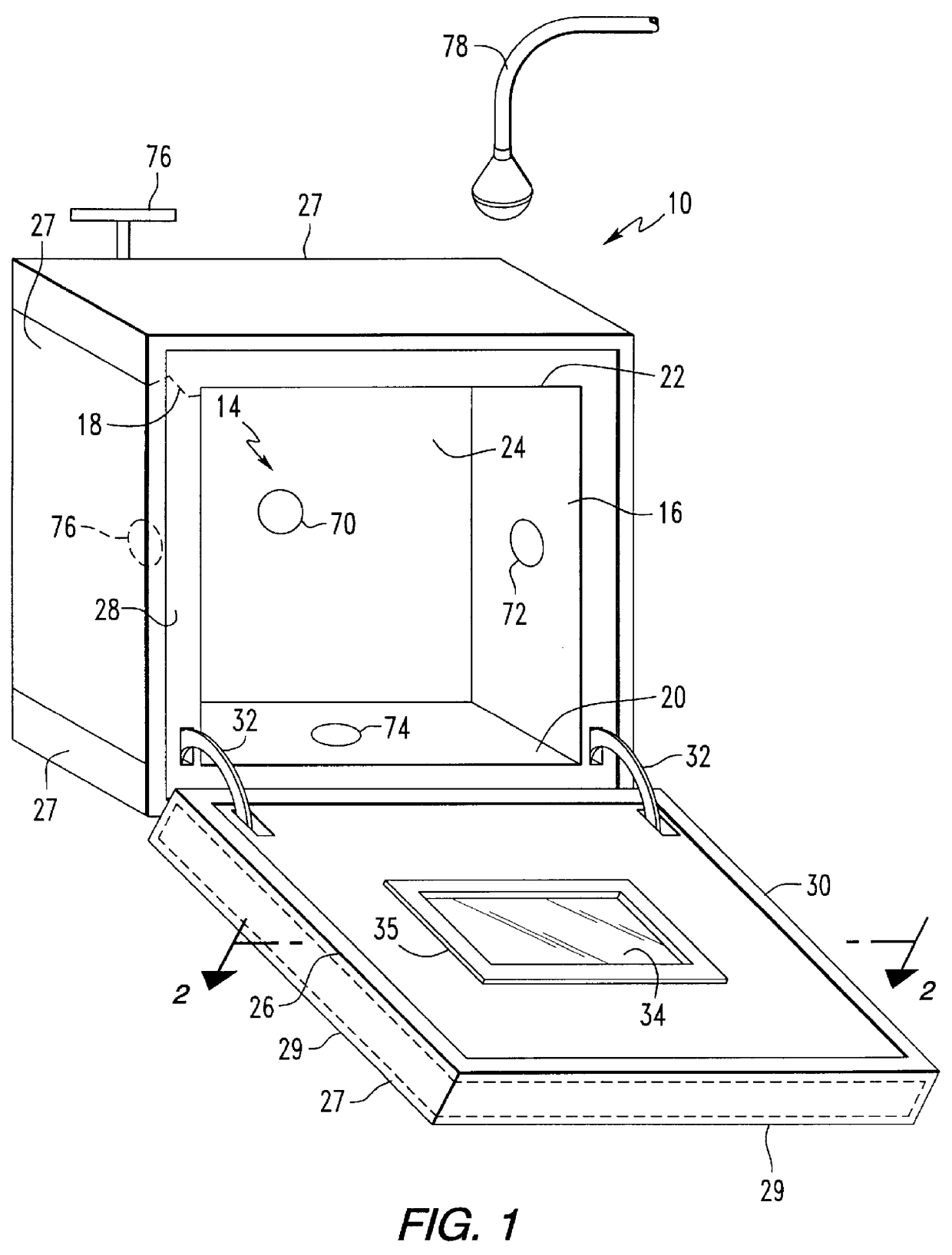

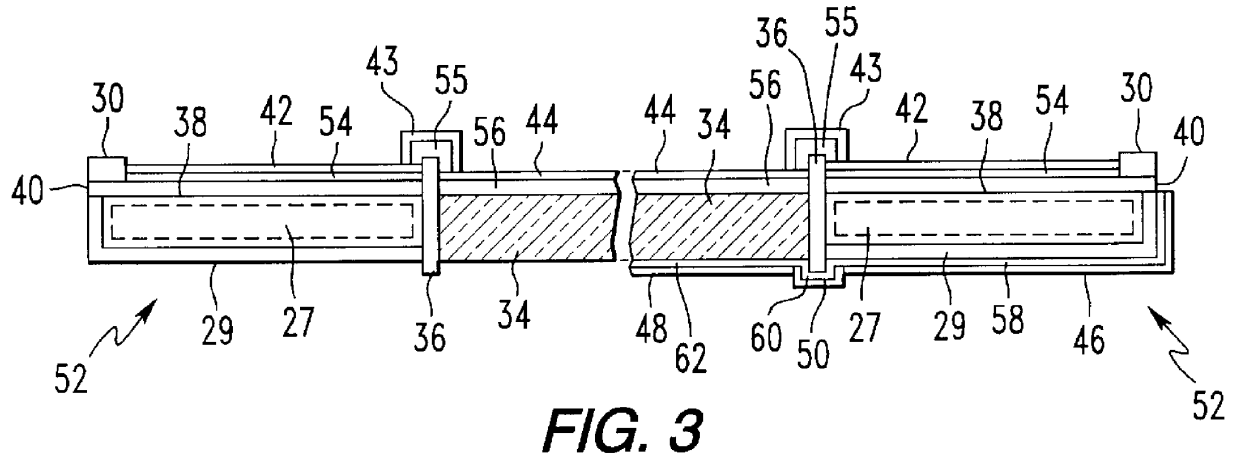

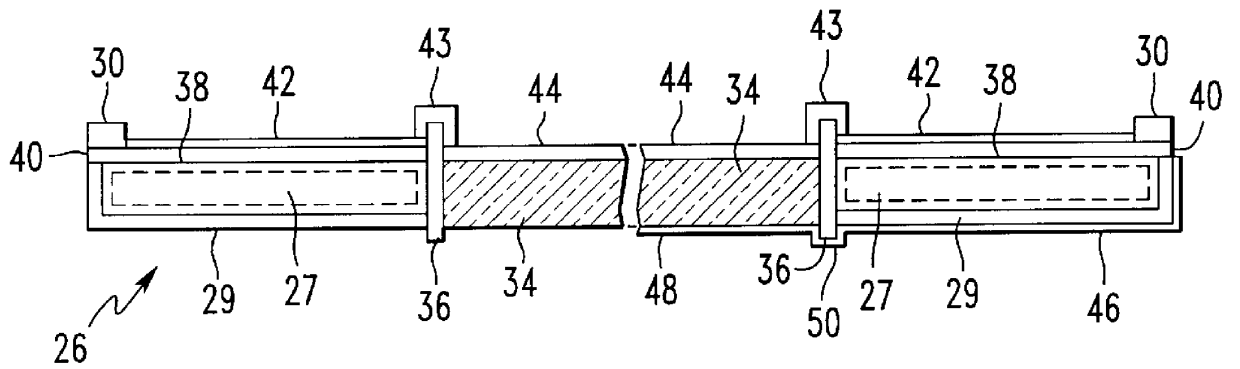

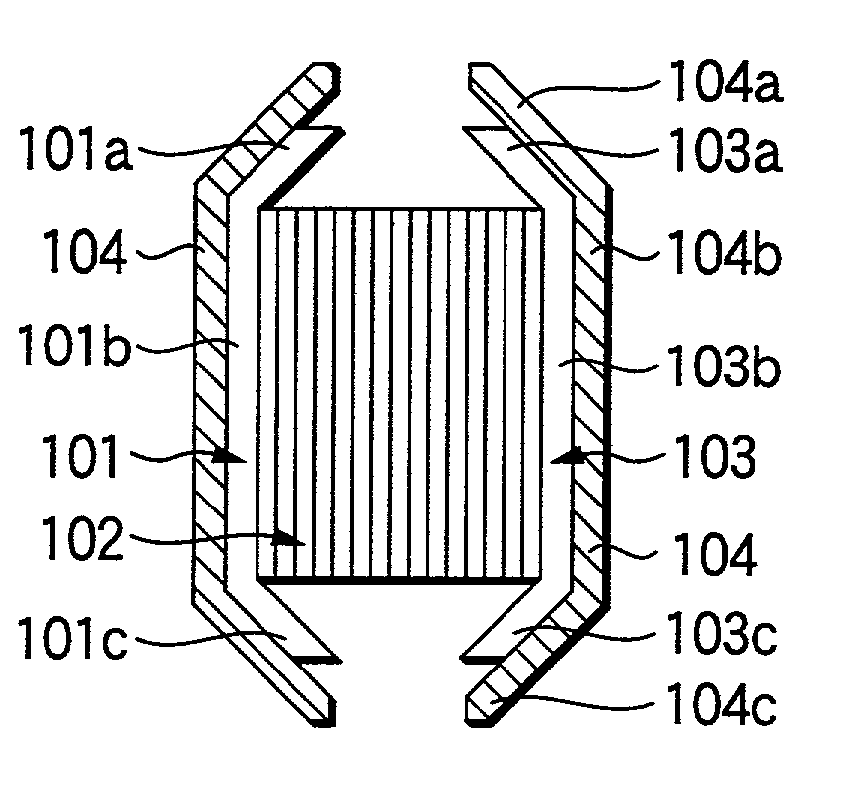

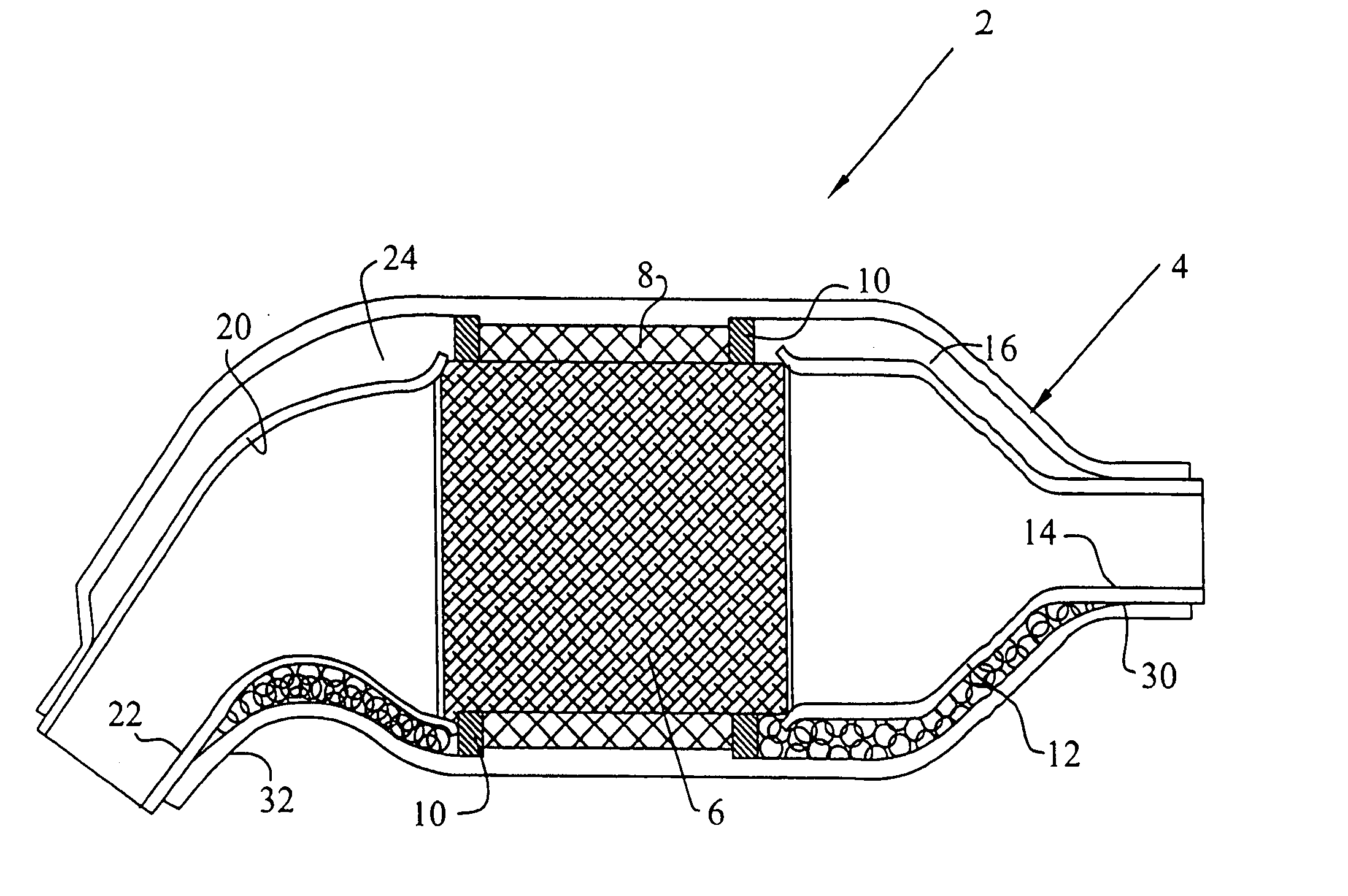

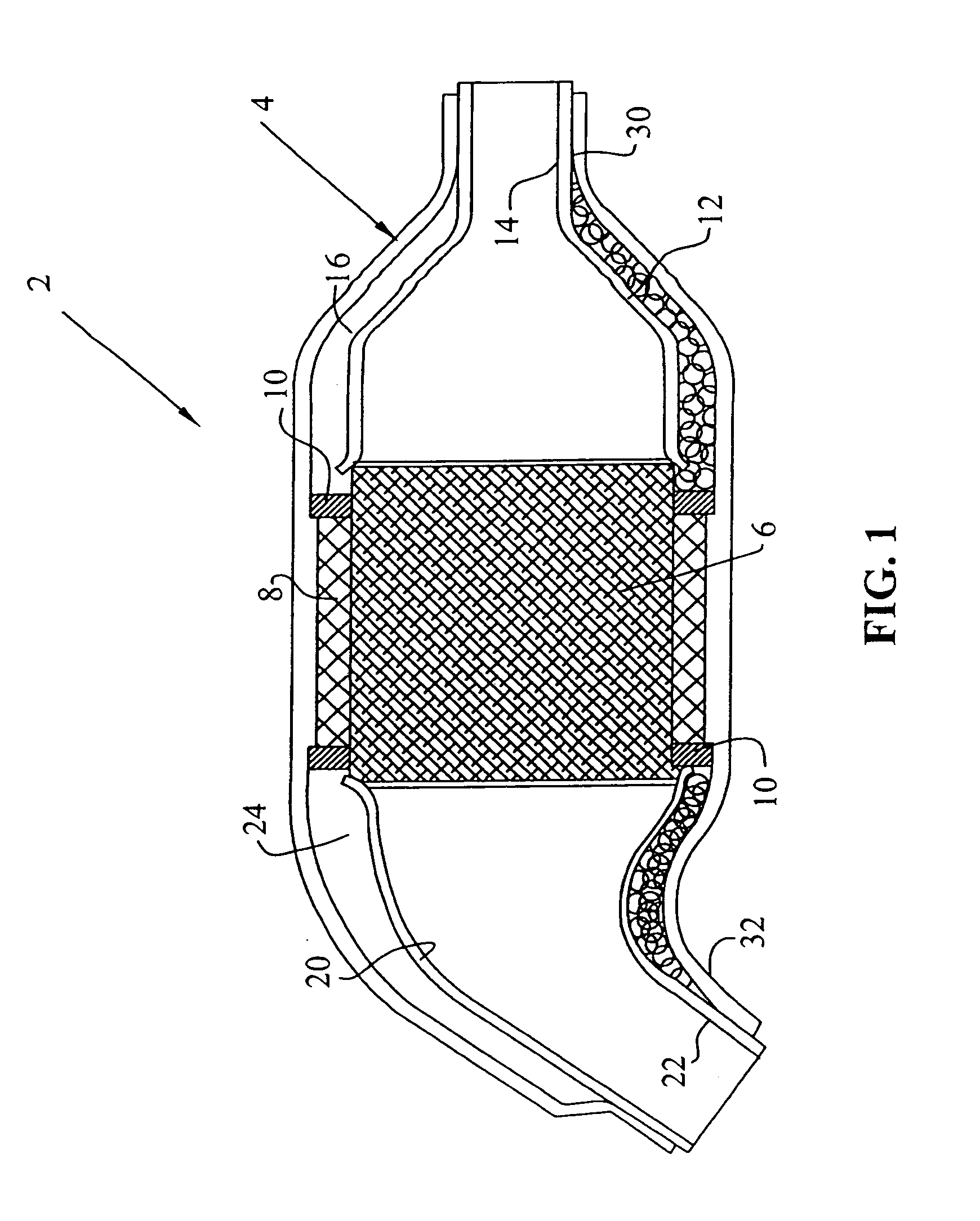

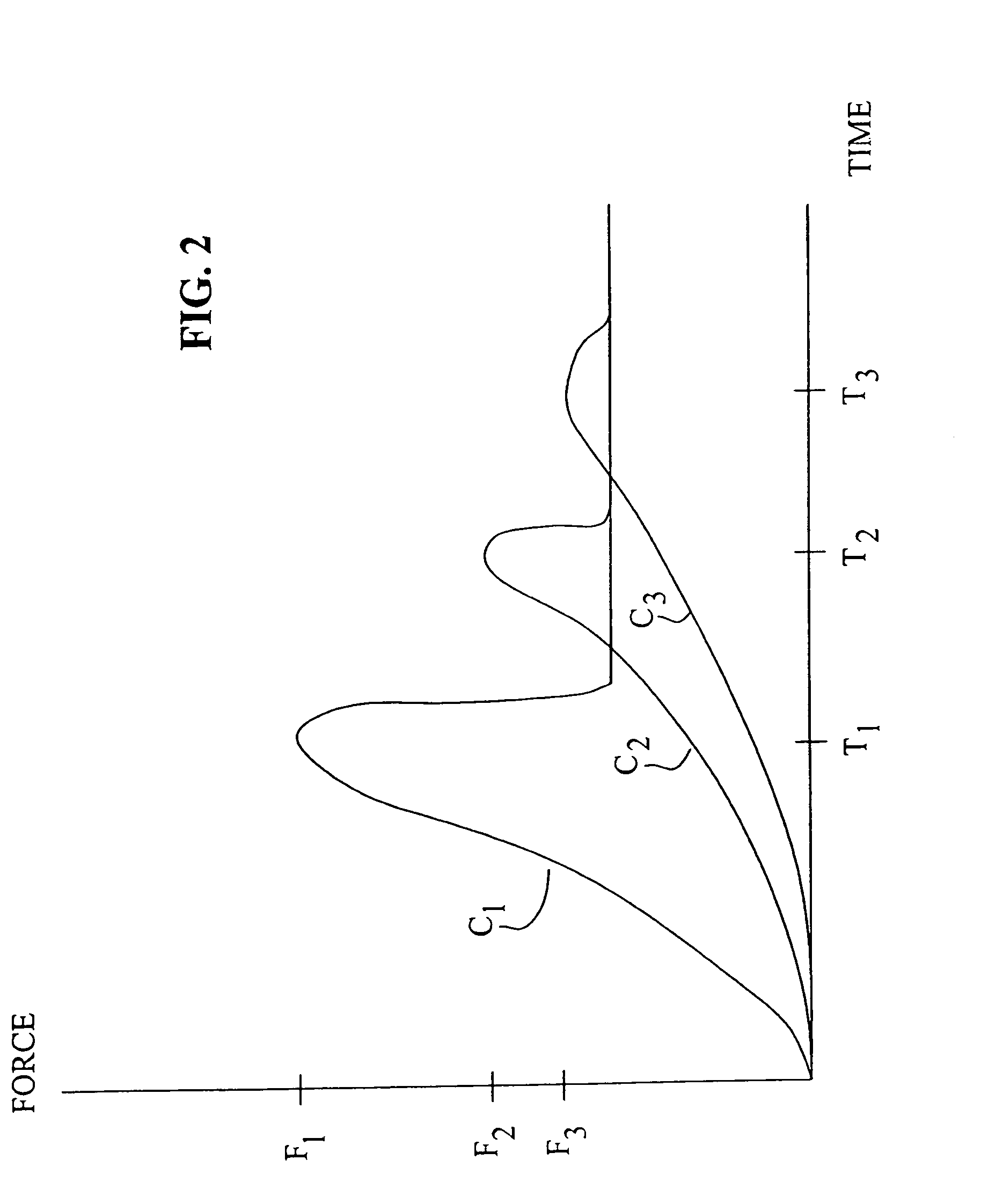

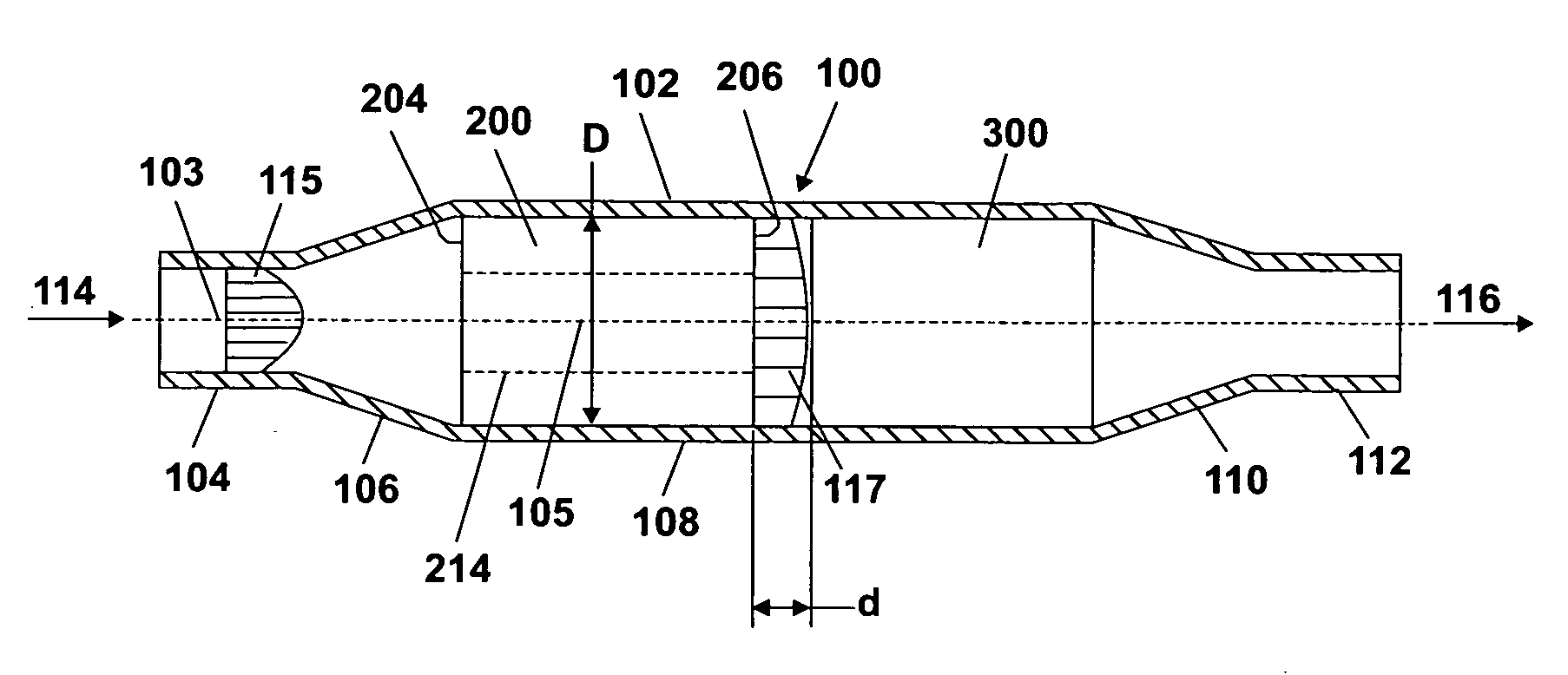

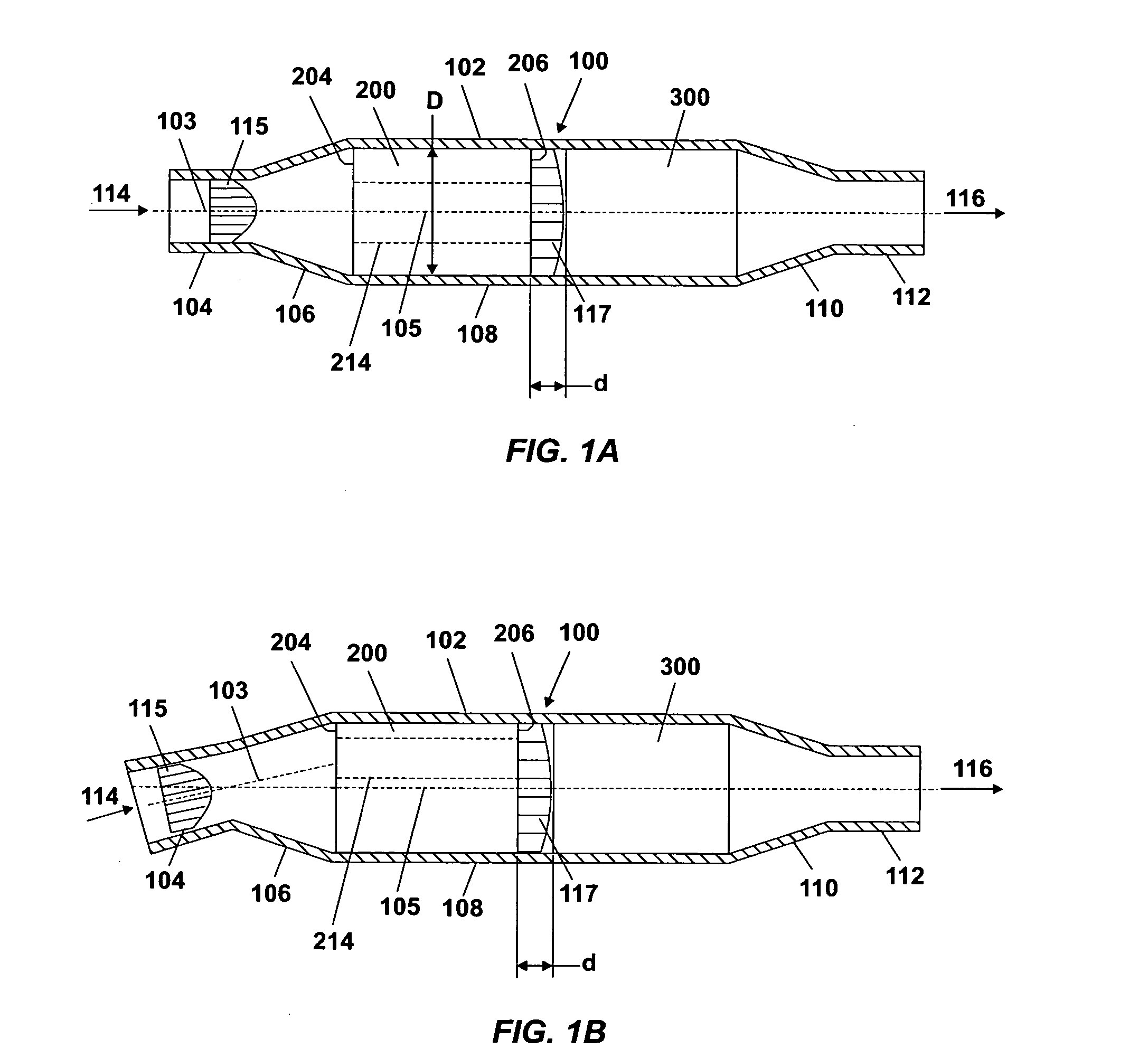

Method and apparatus for manufacturing a catalytic converter

InactiveUS6954988B2Small shapeSmall diameterCatalyst protectionDispersed particle separationHeat shieldBiomedical engineering

A method of manufacturing a catalytic converter is described where the catalytic converter is comprised of an outer tube member having a monolith substrate internally compressed therein with a wrapped mat material surrounding the monolith substrate and intermediate the outer tube. One or more monolith members can be applied within the outer tube and heat shields may also be applied internal to the outer tube and adjacent to the monolith substrate. The assembly of the catalytic converter includes measuring the sequence of compression of the mat material to the monolith substrate in order to understand the possible force characteristics which can be applied during the assembly thereof. The mat material is therefore compressed within the outer tube by way of compression jaws, by compression rollers, and / or by spinning. The compression of the mat material can be in single or multiple steps.

Owner:COMERICA BANK +1

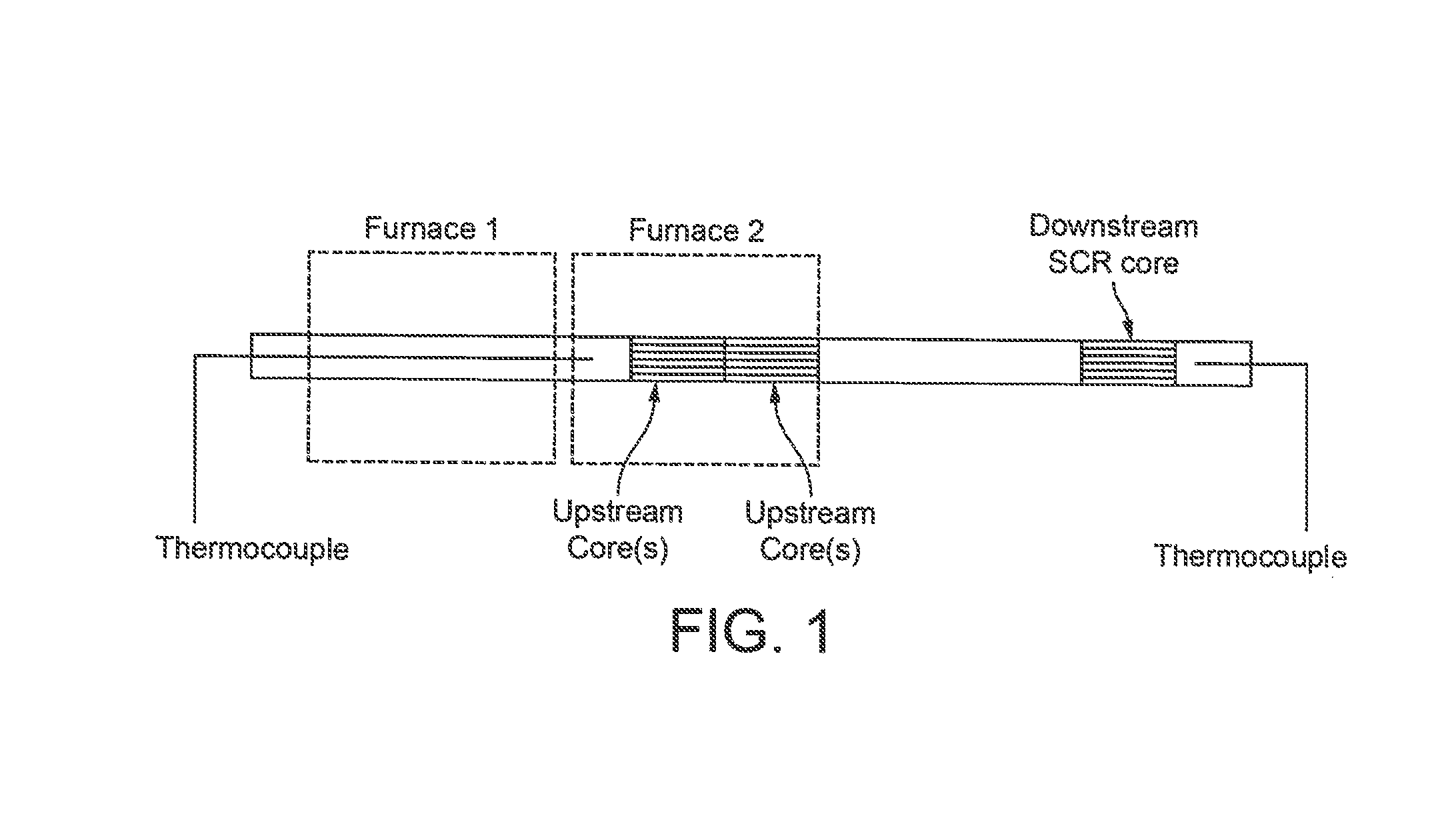

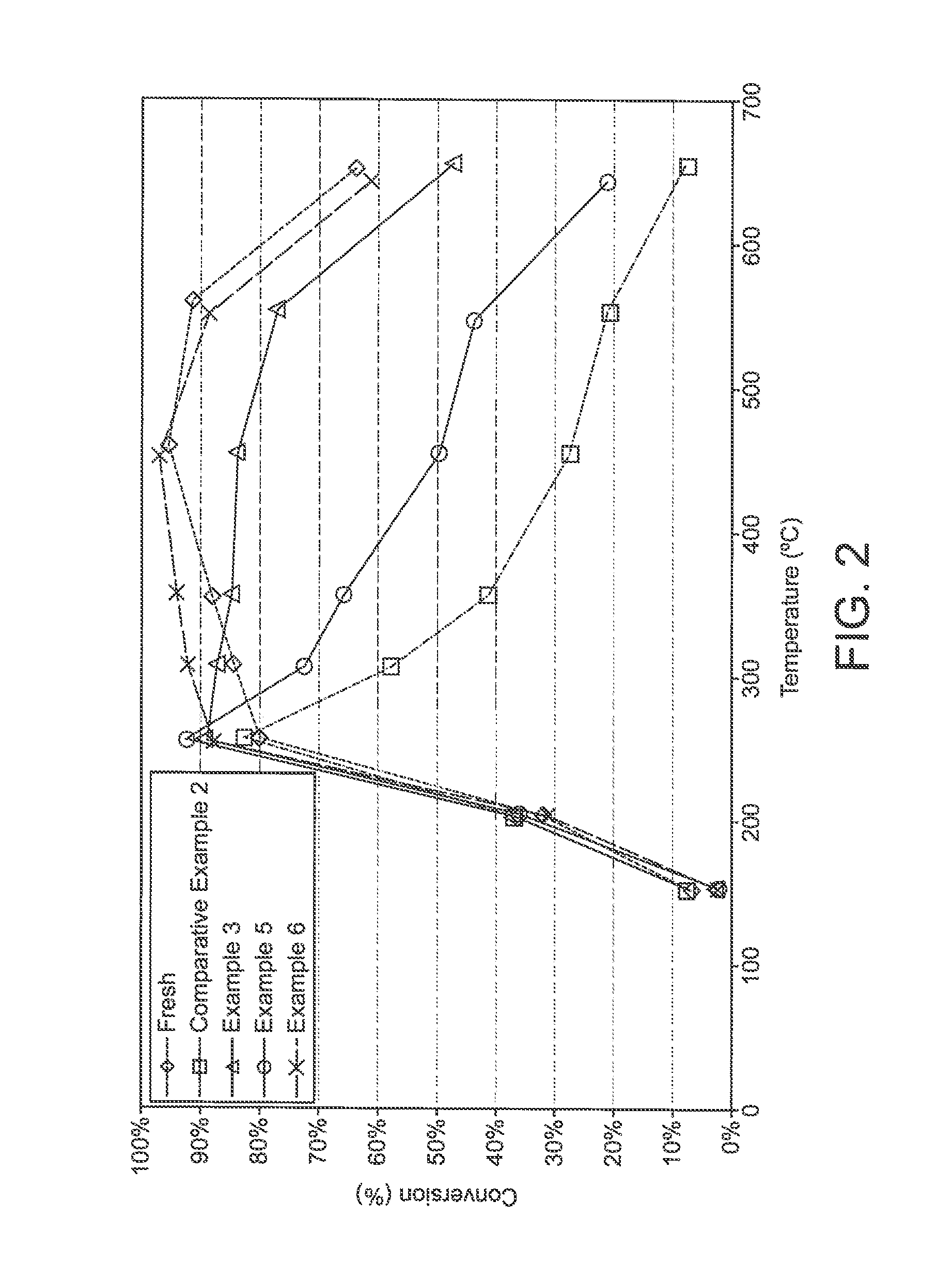

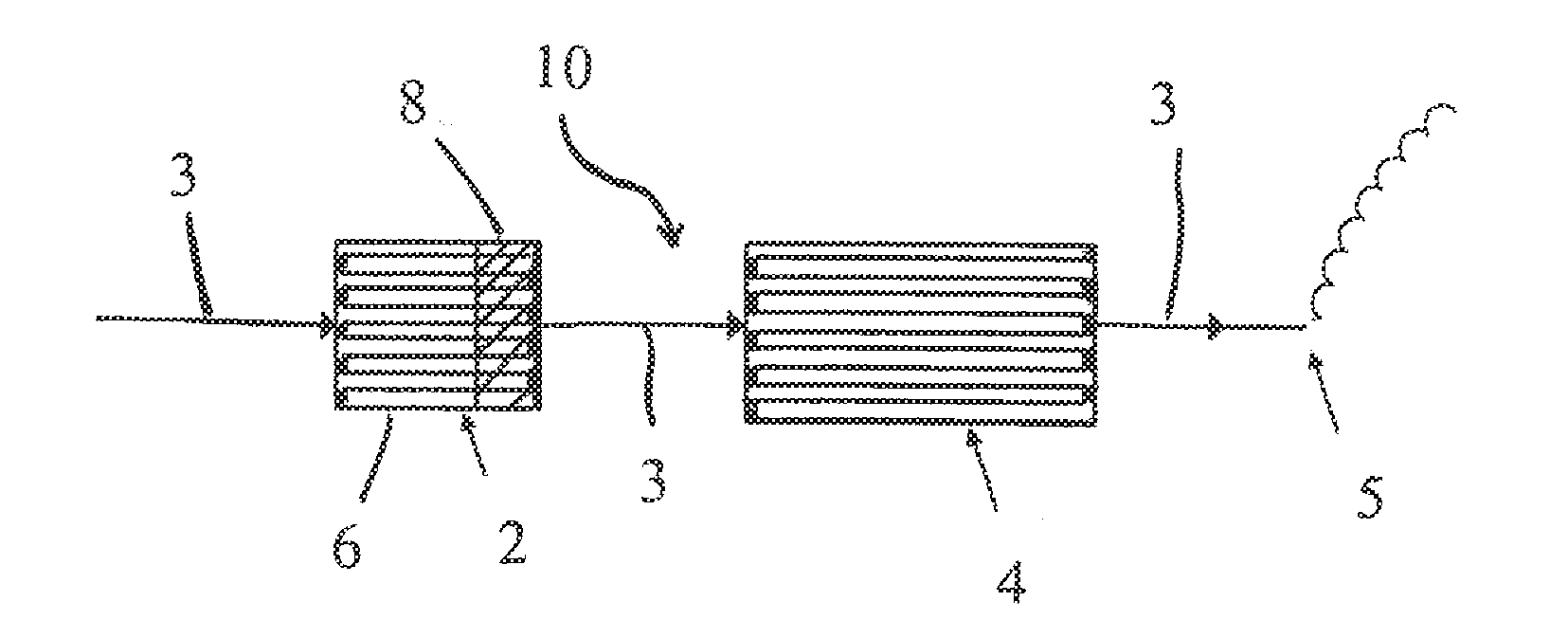

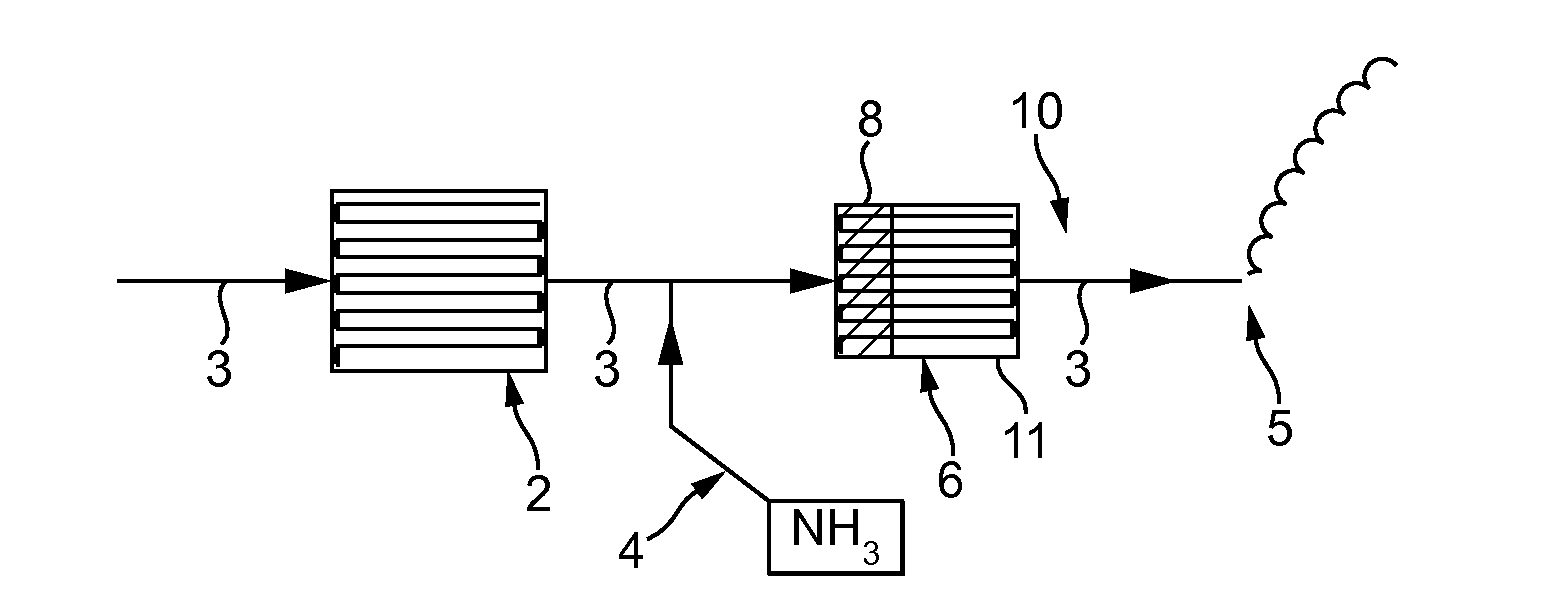

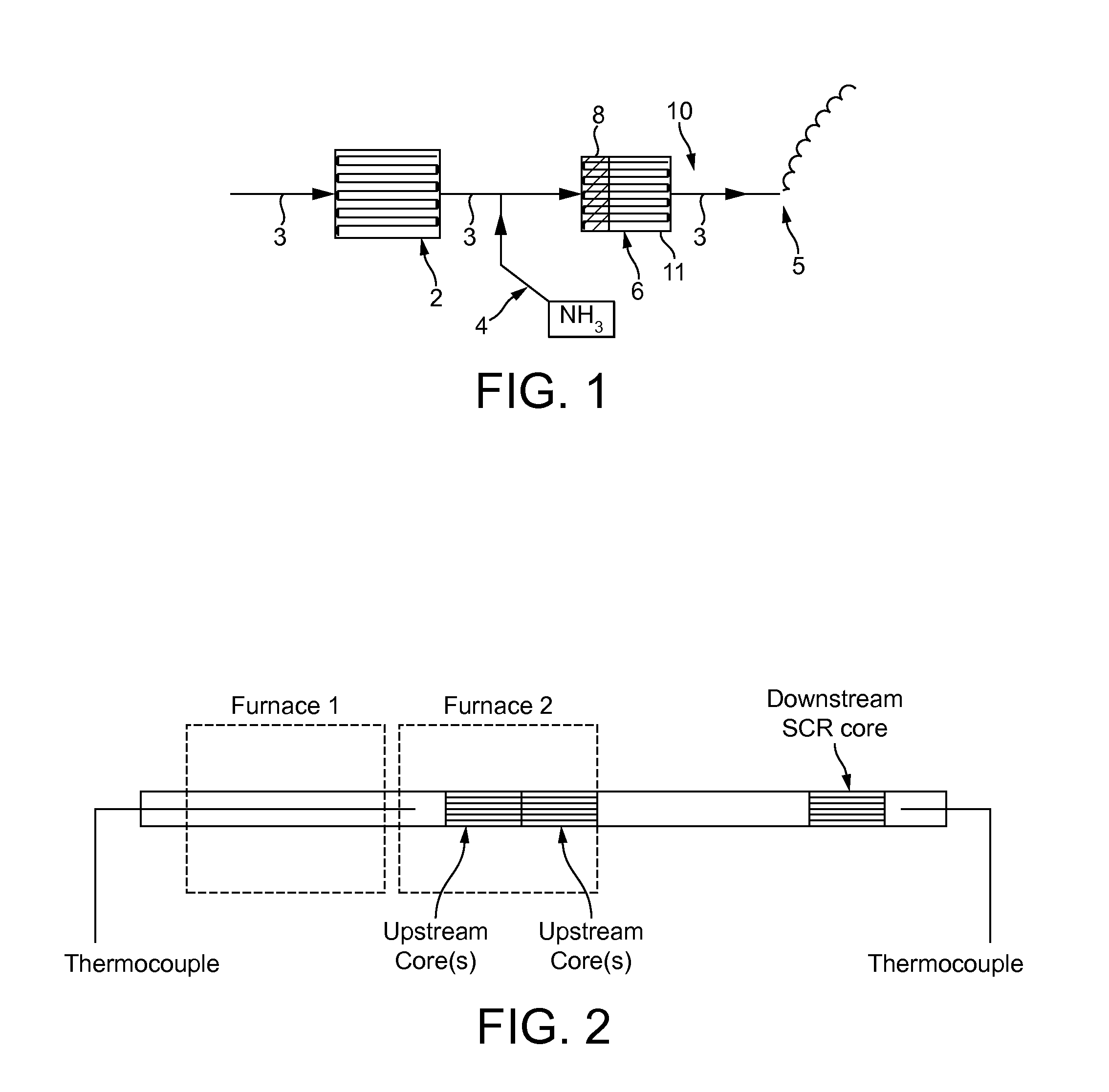

Substrate monolith comprising scr catalyst

ActiveUS20130149207A1Reduce and prevent poisoningAvoids and reduces problemCombination devicesInternal combustion piston enginesPtru catalystExhaust fumes

A substrate monolith 6 having a length L and comprising a first zone 11 of substantially uniform length defined at one end by a first end of the substrate monolith, which first zone comprising a selective catalytic reduction (SCR) catalyst for reducing oxides of nitrogen with a nitrogenous reductant in exhaust gas emitted from an internal combustion engine and a second zone 8 of substantially uniform length less than L defined at one end by a second end of the substrate monolith, which second zone comprising (a) at least one particulate metal oxide or a mixture of any two or more thereof for trapping gas phase platinum group metal (PGM), which at least one particulate metal oxide does not act as a support for any other catalytic component; or (b) a component capable of trapping and / or alloying with gas phase PGM.

Owner:JOHNSON MATTHEY PLC

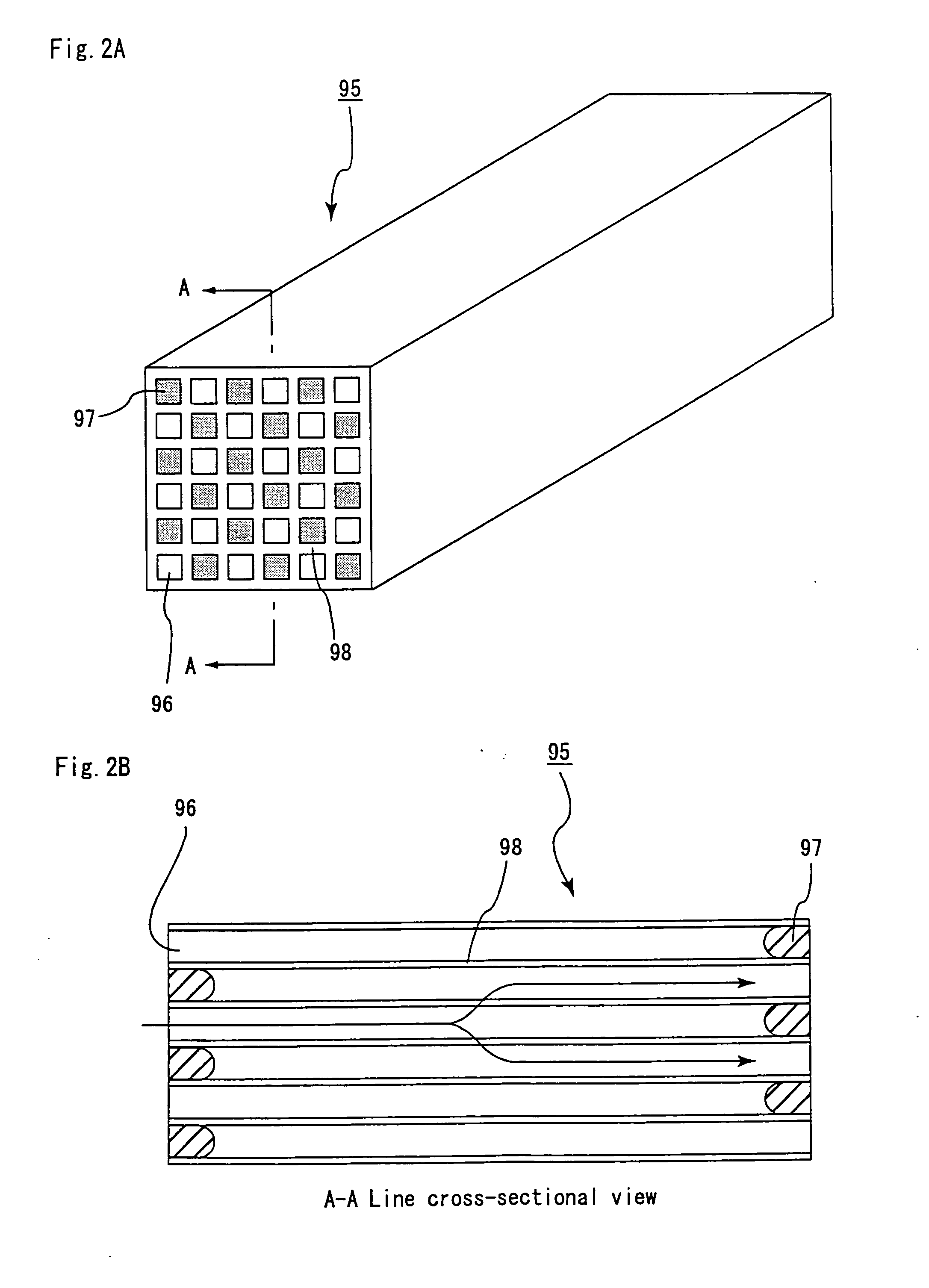

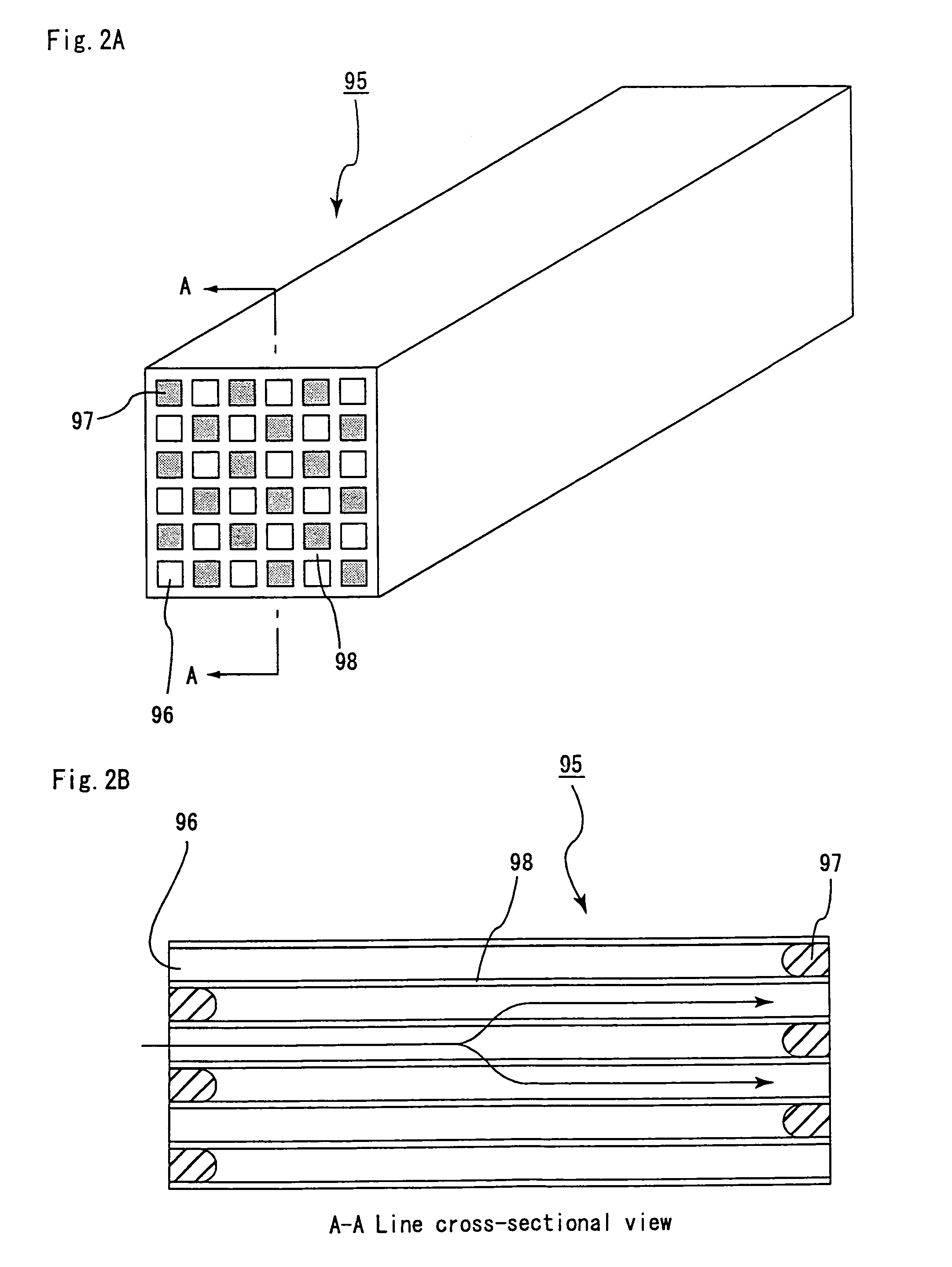

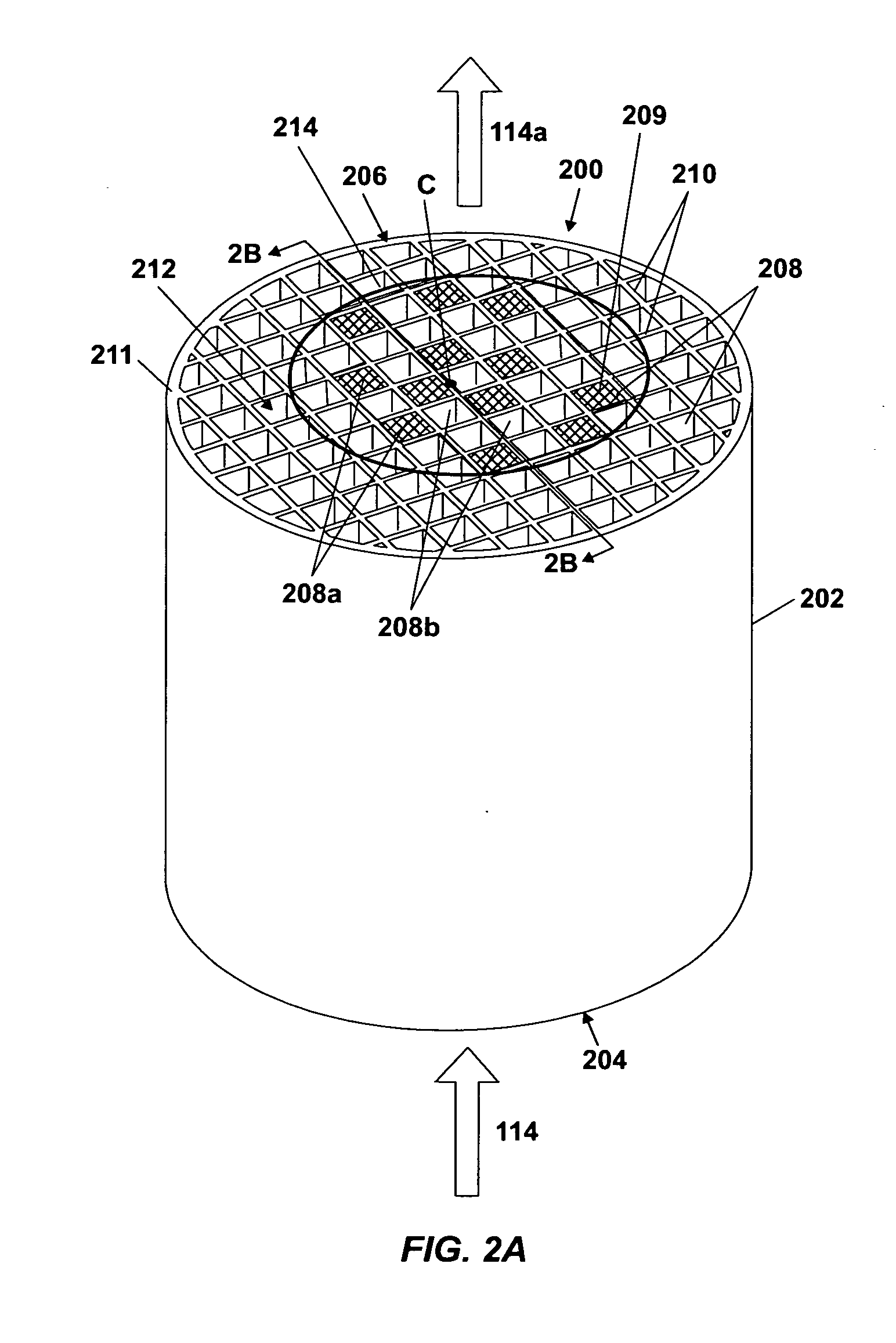

Flow-through honeycomb substrate and exhaust after treatment system and method

InactiveUS20080110341A1Weakening rangeReduce the temperatureCombination devicesAuxillary pretreatmentParticulatesAfter treatment

A system and method including a radially non-uniformly plugged flow-through honeycomb substrate positioned upstream of a wall-flow particulate filter for controlled thermal regeneration of the wall-flow particulate filter. The flow-through honeycomb substrate has an inlet face and an outlet face and a plurality of longitudinal walls extending between the inlet face and the outlet face. The longitudinal walls define a plurality of parallel channels extending between the inlet face and the outlet face. The honeycomb substrate has a flow-through region including a first portion of the parallel channels and a flow-control region including a second portion of the parallel channels. The first portion of the parallel channels includes unplugged channels and the second portion of the parallel channels includes plugged channels. The flow-control region adjusts flow distribution through the substrate such that flow having a first flow distribution received at the inlet face emerges at the outlet face with a second flow distribution, different than the first flow distribution.

Owner:CORNING INC

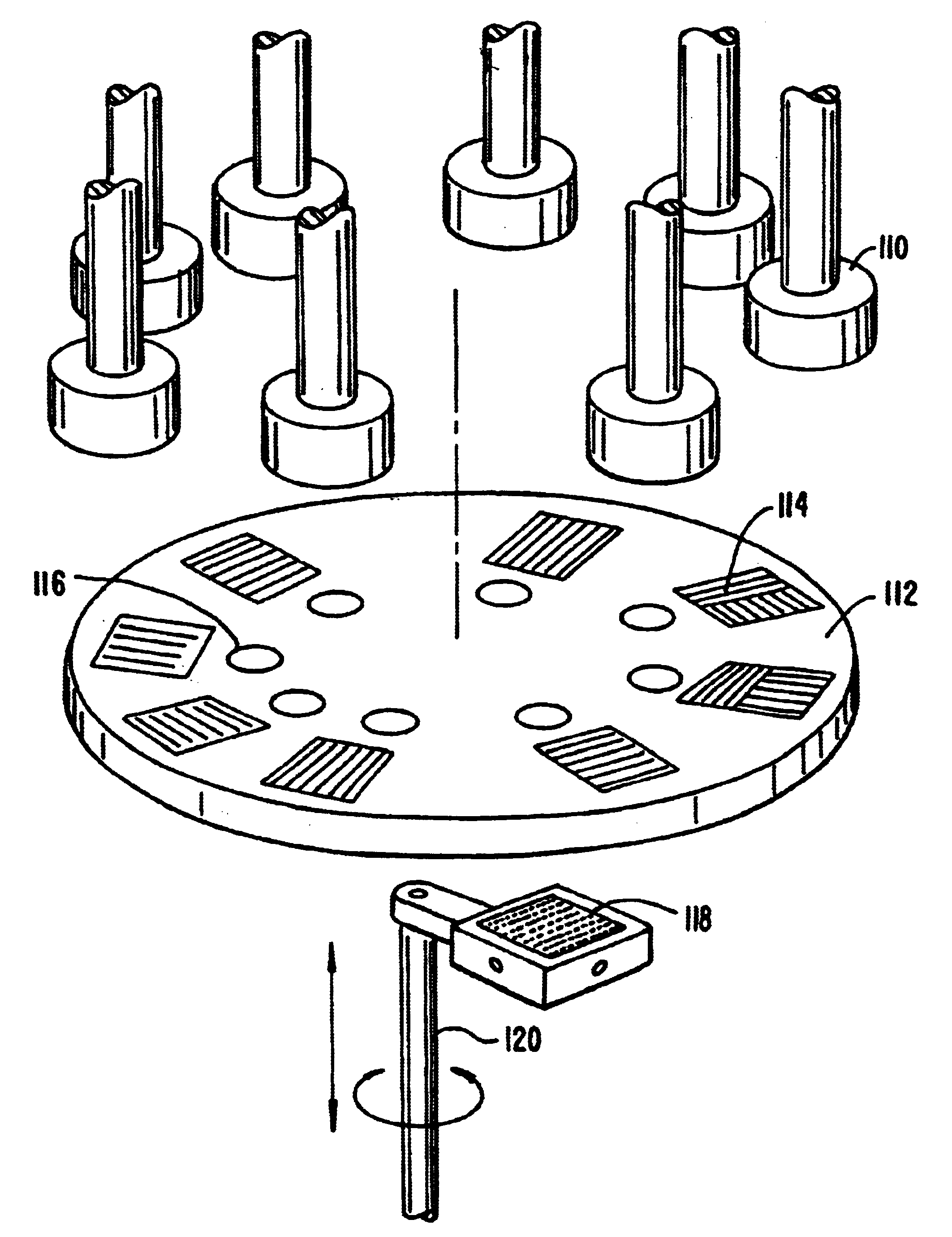

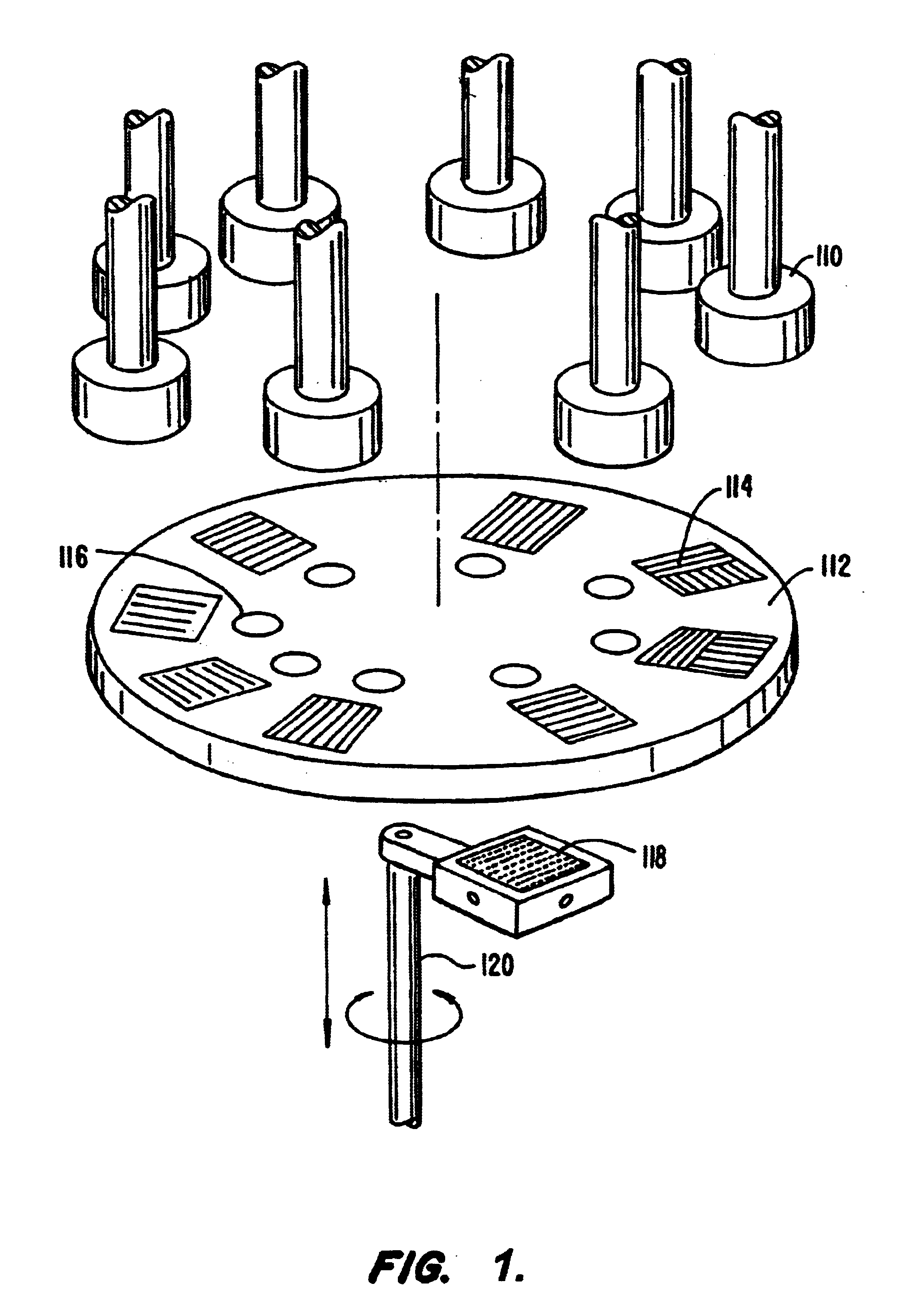

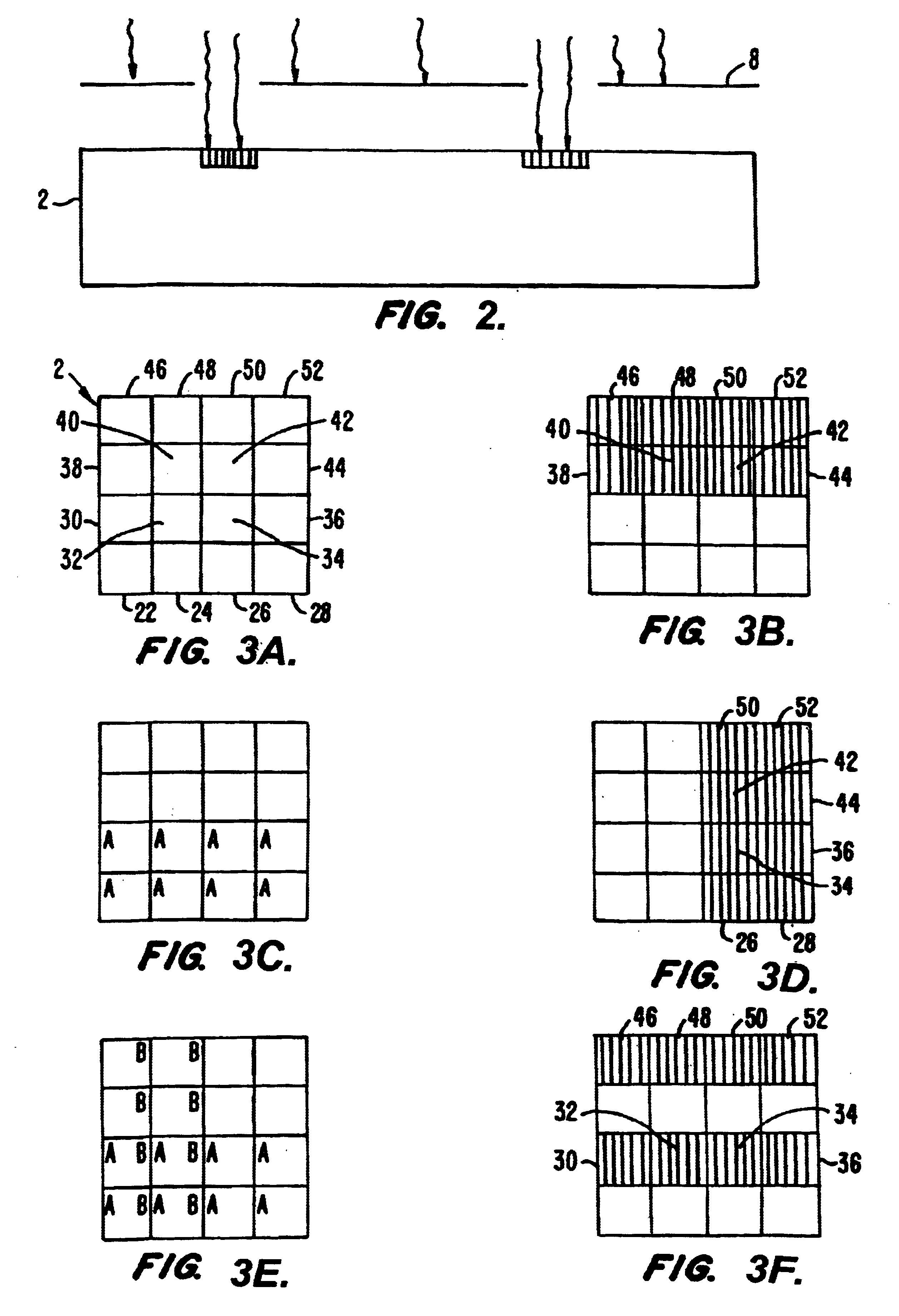

Preparation and screening of crystalline zeolite and hydrothermally-synthesized materials

Methods and apparatus for the preparation and use of a substrate having an array of diverse materials in predefined regions thereon. A substrate having an array of diverse materials thereon is generally prepared by delivering components of materials to predefined regions on a substrate, and simultaneously reacting the components to form at least two materials. Materials which can be prepared using the methods and apparatus of the present invention include, for example, covalent network solids, ionic solids and molecular solids. More particularly, materials which can be prepared using the methods and apparatus of the present invention include, for example, inorganic materials, intermetallic materials, metal alloys, ceramic materials, organic materials, organometallic materials, non-biological organic polymers, composite materials (e.g., inorganic composites, organic composites, or combinations thereof), etc. Once prepared, these materials can be screened for useful properties including, for example, electrical, thermal, mechanical, morphological, optical, magnetic, chemical, or other properties. Thus, the present invention provides methods for the parallel synthesis and analysis of novel materials having useful properties.

Owner:INTERMOLECULAR

Hydrophobic multicomponent catalyst useful for direct oxidation of hydrogen to hydrogen peroxide

InactiveUS6346228B1High selectivitySelectivity for in directHydrogen peroxideCatalyst protectionHydrogenHydrophobic polymer

The present invention relates to a novel hydrophobic multicomponent catalyst useful in the direct oxidation of hydrogen to hydrogen peroxide and to a method for the preparation of such catalyst. More specifically, this invention relates to a novel hydrophobic muticomponent catalyst comprising a hydrophobic polymer membrane deposited on a Pd containing acidic catalyst, useful for the direct oxidation of hydrogen by oxygen to hydrogen peroxide, an a method for preparing the same.

Owner:COUNCIL OF SCI & IND RES

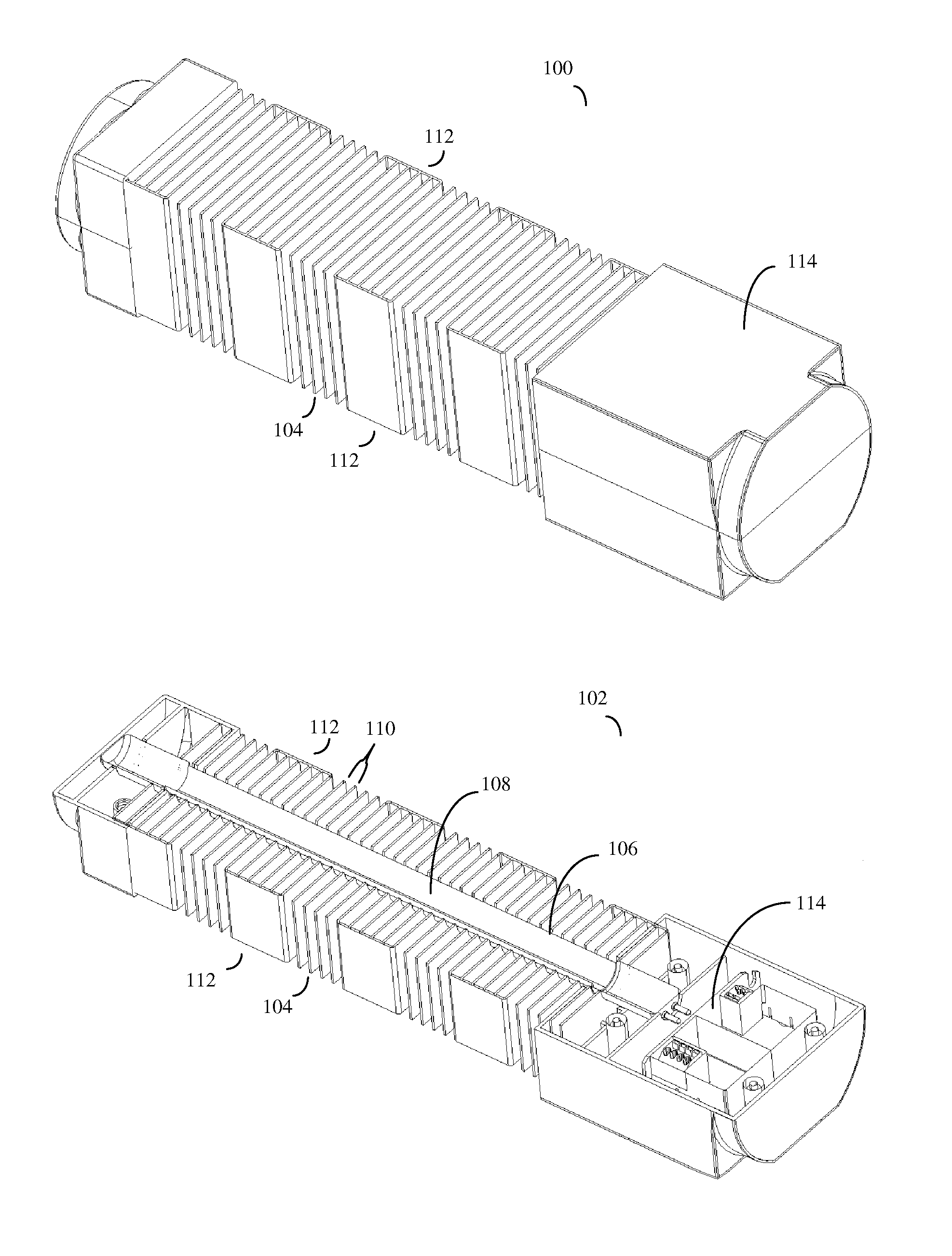

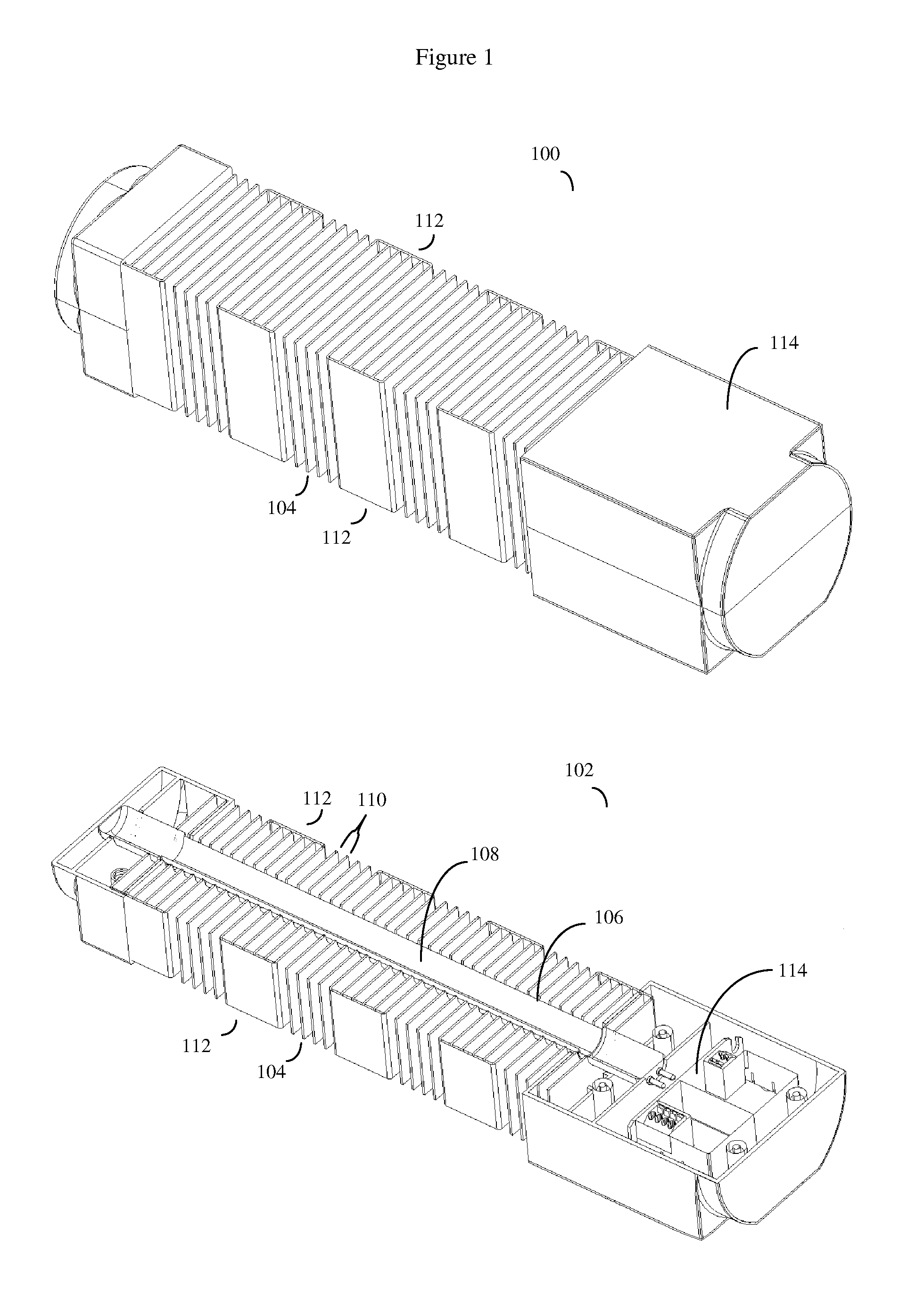

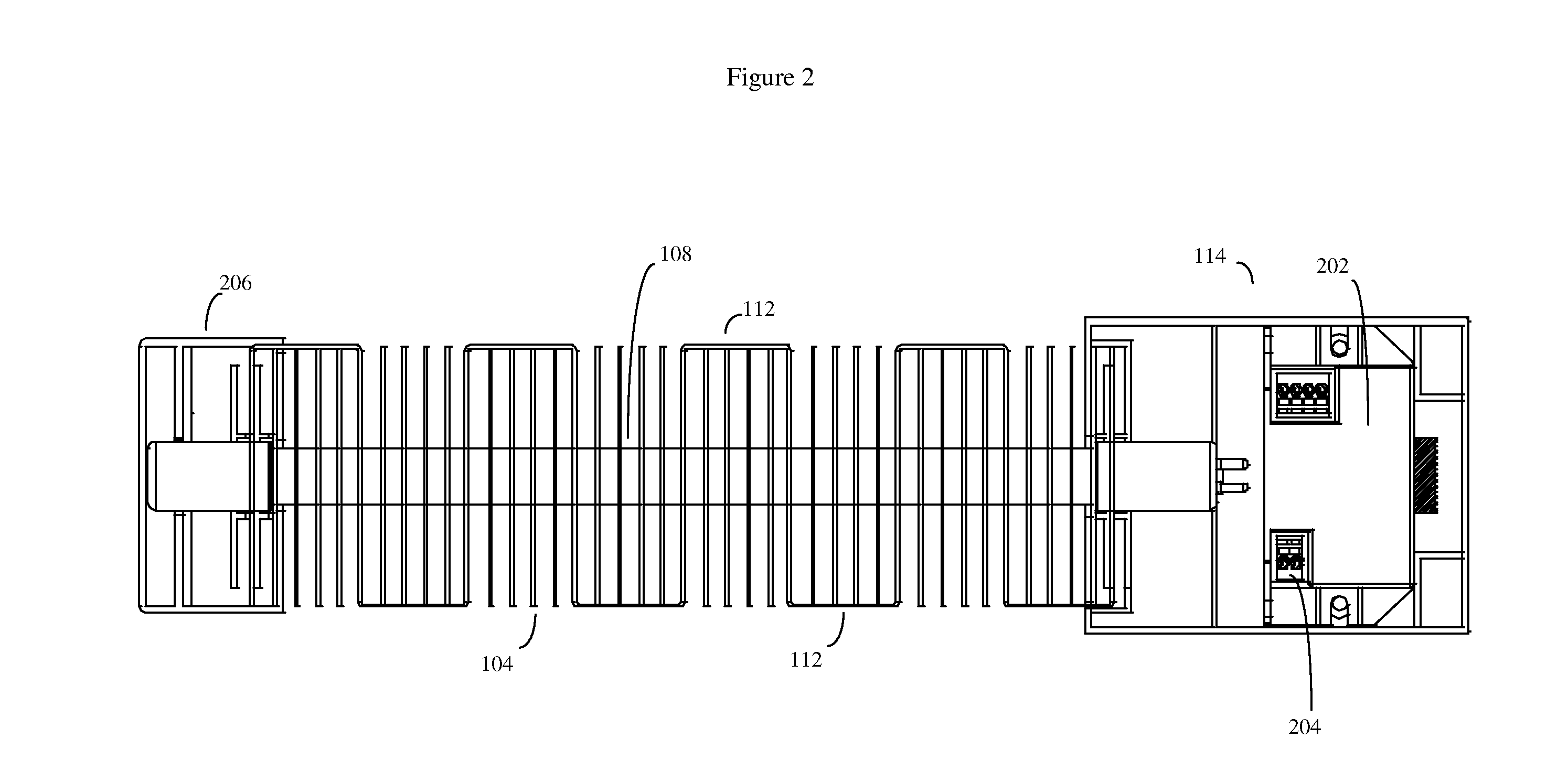

Unitized photocatalytic air sterilization device

ActiveUS20110171080A1Improve sterilization efficiencyMaximize air flowCatalyst protectionWater/sewage treatment by irradiationSingle-Use DeviceHand held

A UV photocatalytic air purifier / sterilizer in which the multiple limited-lifetime components (such as the UV light, UV light electronics, and catalytic portion) of a photocatalytic UV air purifier / sterilizer are packaged together to form a single, handheld, unitized package, designed for easy insertion and removal into an air purifier. The invention may be configured enable maximum air flow through the photocatalytic portions of the device, thus further improving air cleaning efficiency by allowing many volumes of room air to be recirculated through the device and cleaned / purified / sterilized over the course of a day. In a preferred embodiment, the device may package a series of stacked TiO2 coated parallel metal catalytic plates, a UV germicidal lamp with a fluorescent tube form factor, and a UV lamp ballast into a single disposable or recyclable unit. This disposable unit can be easily clipped into a motorized air purifier unit designed for rapid servicing.

Owner:LO YANG ZHEN

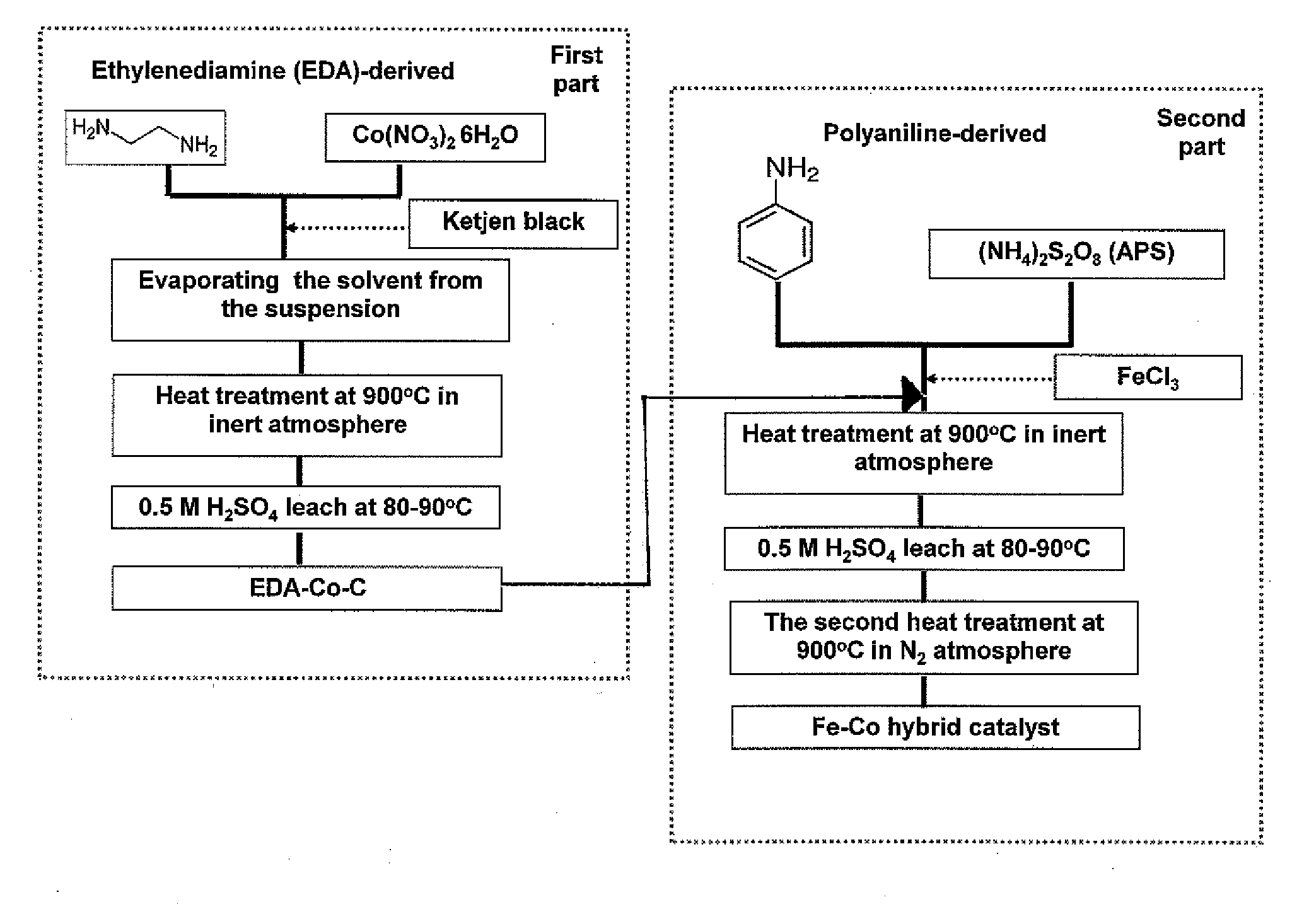

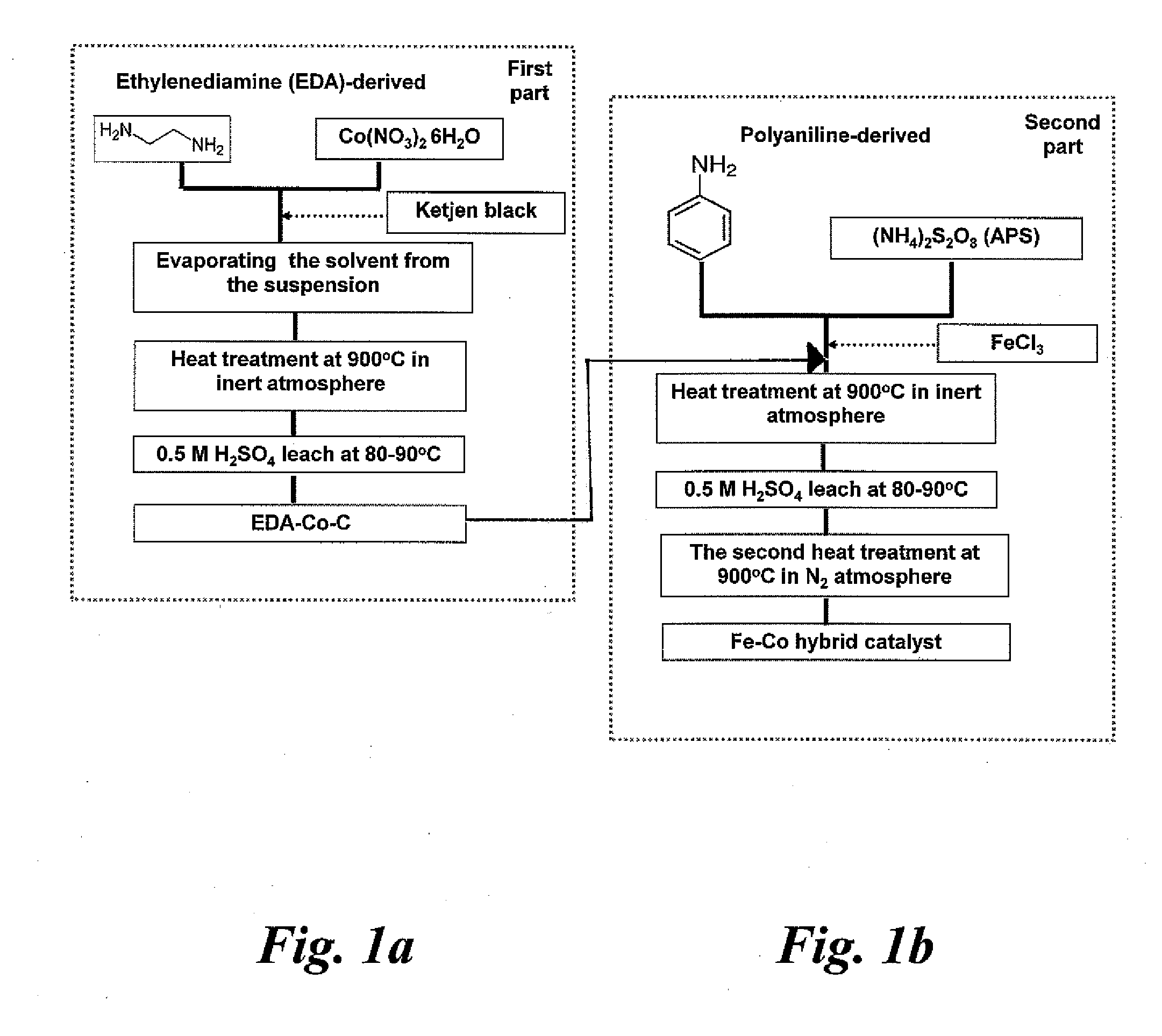

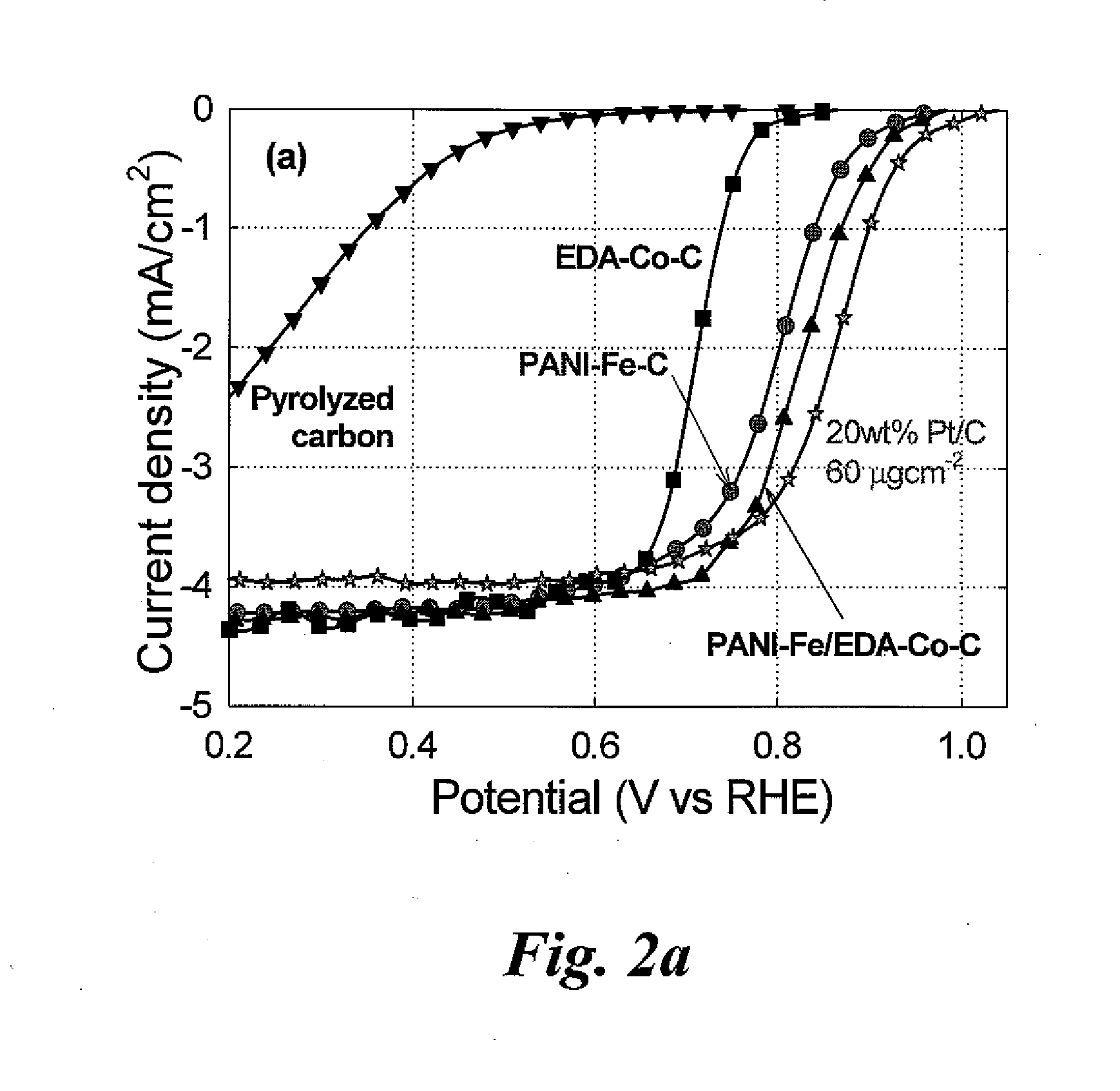

Nitrogen-doped carbon-supported cobalt-iron oxygen reduction catalyst

A Fe—Co hybrid catalyst for oxygen reaction reduction was prepared by a two part process. The first part involves reacting an ethyleneamine with a cobalt-containing precursor to form a cobalt-containing complex, combining the cobalt-containing complex with an electroconductive carbon supporting material, heating the cobalt-containing complex and carbon supporting material under conditions suitable to convert the cobalt-containing complex and carbon supporting material into a cobalt-containing catalyst support. The second part of the process involves polymerizing an aniline in the presence of said cobalt-containing catalyst support and an iron-containing compound under conditions suitable to form a supported, cobalt-containing, iron-bound polyaniline species, and subjecting said supported, cobalt-containing, iron bound polyaniline species to conditions suitable for producing a Fe—Co hybrid catalyst.

Owner:TRIAD NAT SECURITY LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com