Filtering material for cigarette filter tip and its preparation method

A filter material and cigarette filter technology, which is applied to the preparation of tobacco, smoke oil filter elements, tobacco, etc., can solve the problems of tobacco leaf raw material loss, lack of toughness of materials, and increased number of shutdown accidents, and achieve convenient and feasible operation, simple preparation method, and increased production capacity. The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

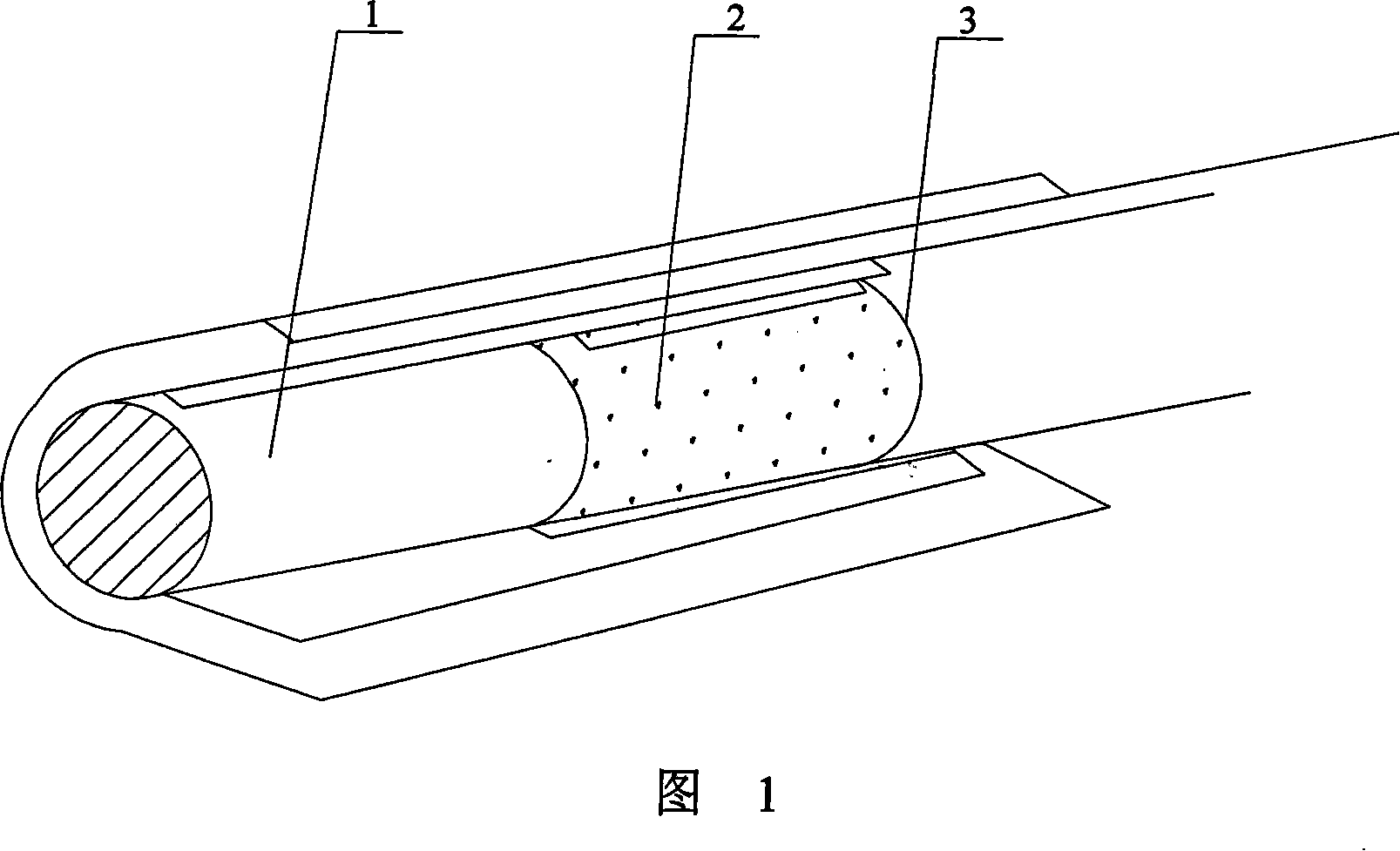

Image

Examples

Embodiment 1

[0052] The expanded tobacco stem particles prepared by the technical solution disclosed in "A Preparation Method and Equipment for Expanded Tobacco Stem Granules" (Application No.: 200710065892.3) are used as raw materials. The expanded tobacco stem particles are prepared by the following method: scanning the content of total sugar, reducing sugar, nicotine and total nitrogen in tobacco stems of different origins, years, grades and types with a near-infrared spectrometer. According to the scanning results, a mixing test was carried out on different origins, different years, different grades, and different types of tobacco stems, so that the total sugar content of each batch of mixed tobacco stem raw materials ranged from 12% to 15%, and the reducing sugar content ranged from 12% to 15%. 10% to 15%, the range of nicotine content is 0.6% to 1.1%, and the range of total nitrogen content is 1.3% to 1.8%, finally forming a raw material blending scheme. Mix the tobacco stem raw mate...

Embodiment 2

[0056] Repeat Example 1, the following difference is arranged: select ethanol as extraction agent, the weight ratio of raw material particle and extraction agent is 1: 3, setting extraction temperature is 90 ℃, extraction time 2h, extraction 3 times, measure particle's weight after extraction Moisture is 8.0%. After the extracted expanded tobacco stem particles are crushed and ground, the particles with a particle size of 50 mesh are screened to be the required filter material for cigarette filters.

Embodiment 3

[0058] Repeat Example 1, with the following differences: petroleum ether is selected as the extraction agent, the weight ratio of the raw material particles to the extraction agent is 1: 12, the extraction temperature is set at 20°C, the extraction time is 100h, the extraction is performed twice, and the particle size is measured after extraction. The moisture is 15.0%. After the extracted expanded tobacco stem particles are crushed and ground, the particles with a particle size of 150 mesh are screened to be the required filter material for cigarette filters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com