Dust collecting unit of vacuum cleaner

A technology for vacuum cleaners and dust collection, which is applied in the directions of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problem of low air purification ability, and achieve the effect of improving air purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

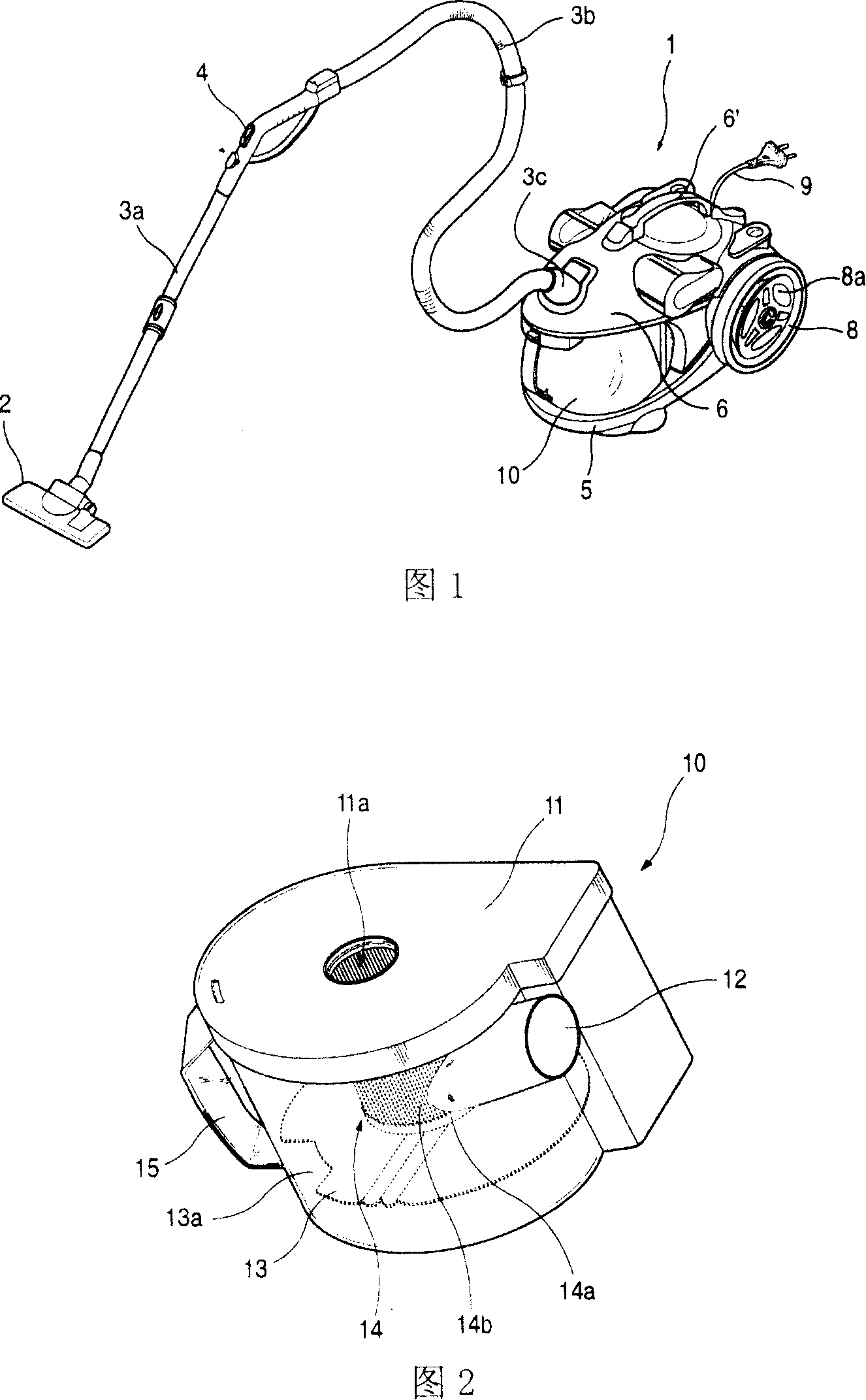

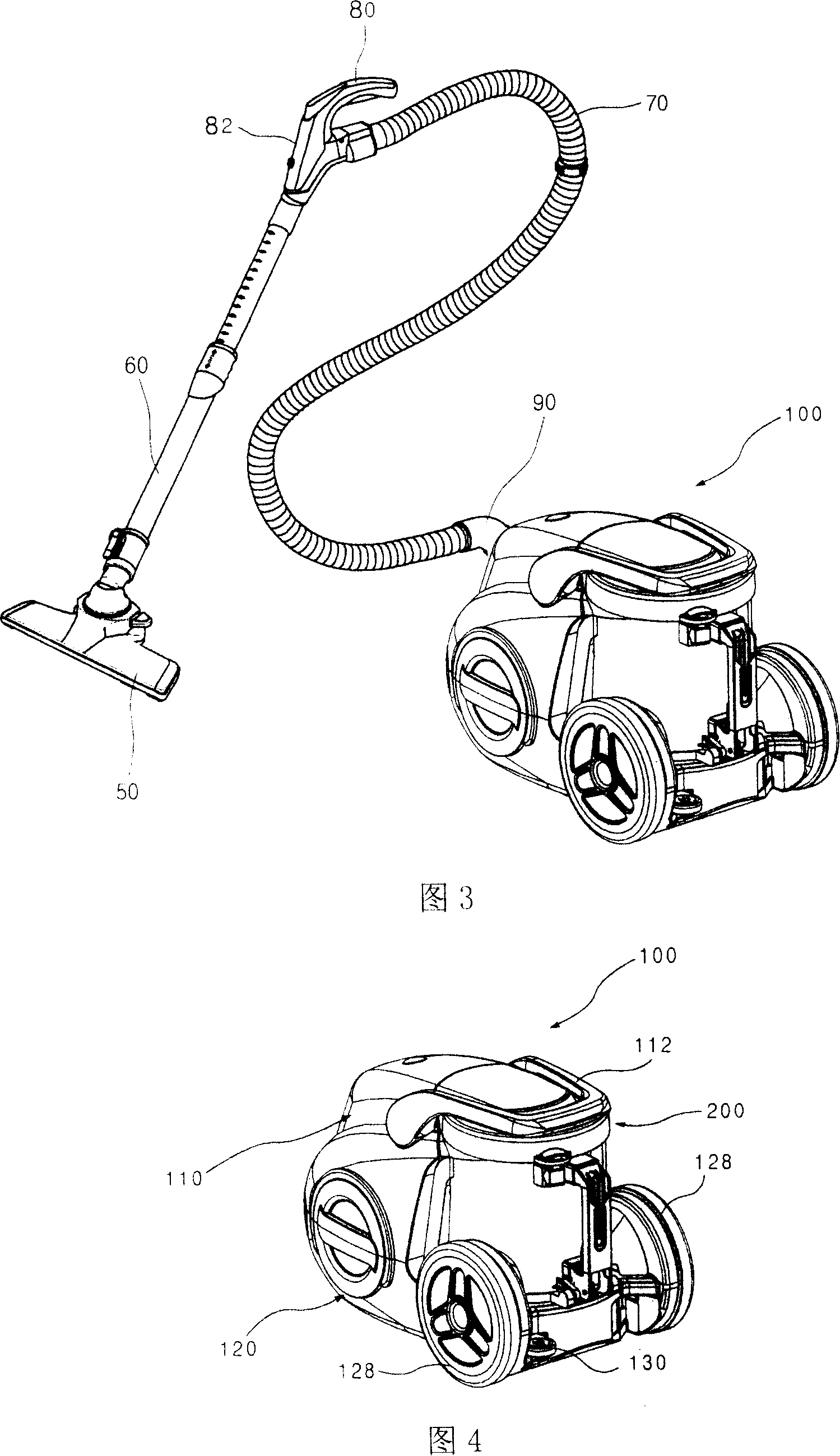

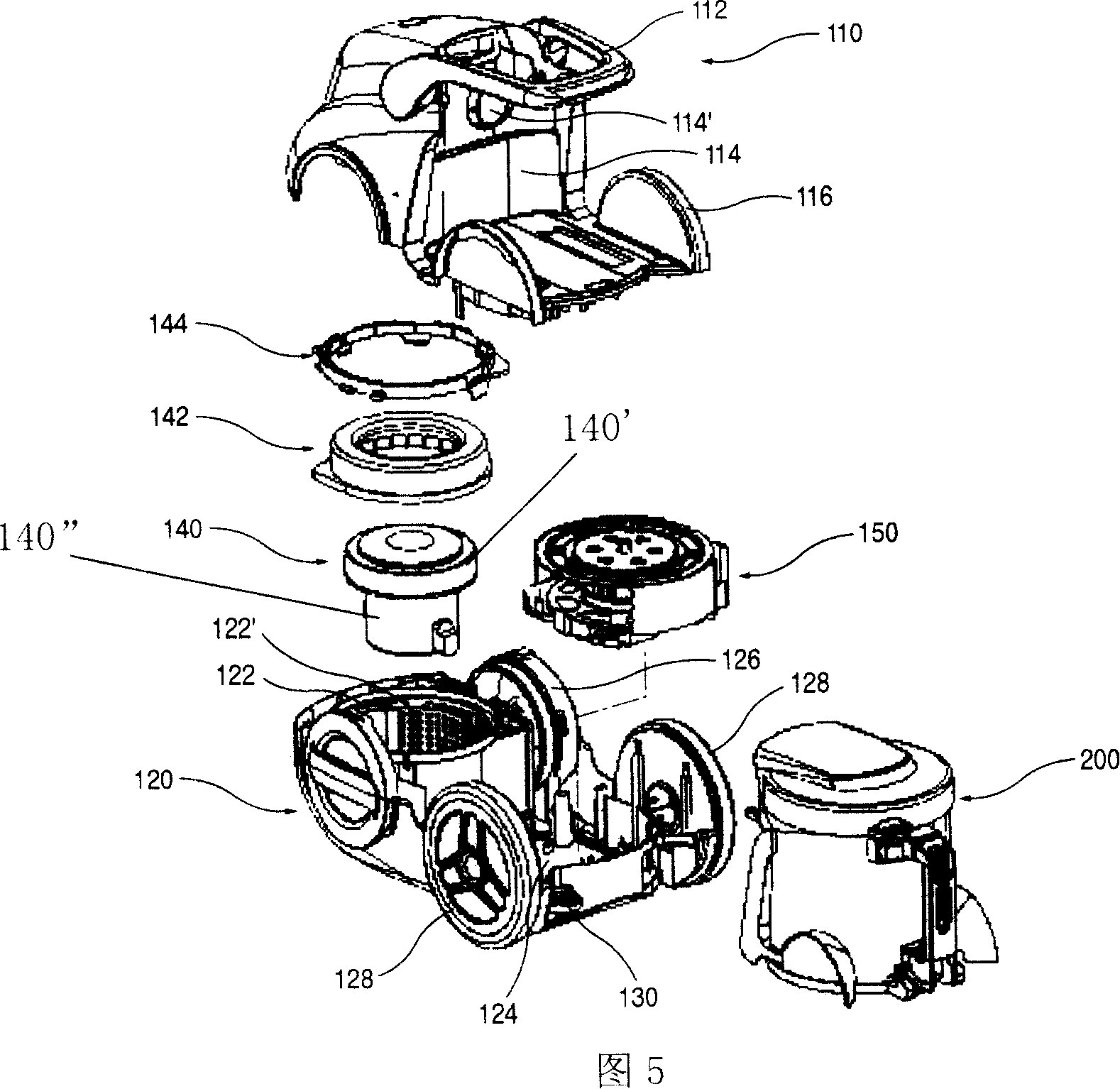

[0050] Below, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0051] The present invention provides a dust collection unit of a vacuum cleaner. The dust collection unit of the vacuum cleaner mainly includes: a first cyclone device 240 for filtering foreign matter in the air for the first time, and a first cyclone device 240 for filtering foreign matter in the air passing through the first cyclone device 240 The second cyclone device 250 for secondary filtration and the dust collection cylinder 210 with more than 3 dust collection chambers 248, 256, 260 for separating and collecting foreign matter in the air; for covering the upper cover 220 above the dust collection cylinder 210; The bottom cover 230 of the bottom of the dust container 210 .

[0052] The first cyclone device 240 includes: a guide cylinder 242 with a diameter smaller than the dust collection cylinder 210 to guide the air flow, and a first dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com