Patents

Literature

495results about How to "Increase water speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

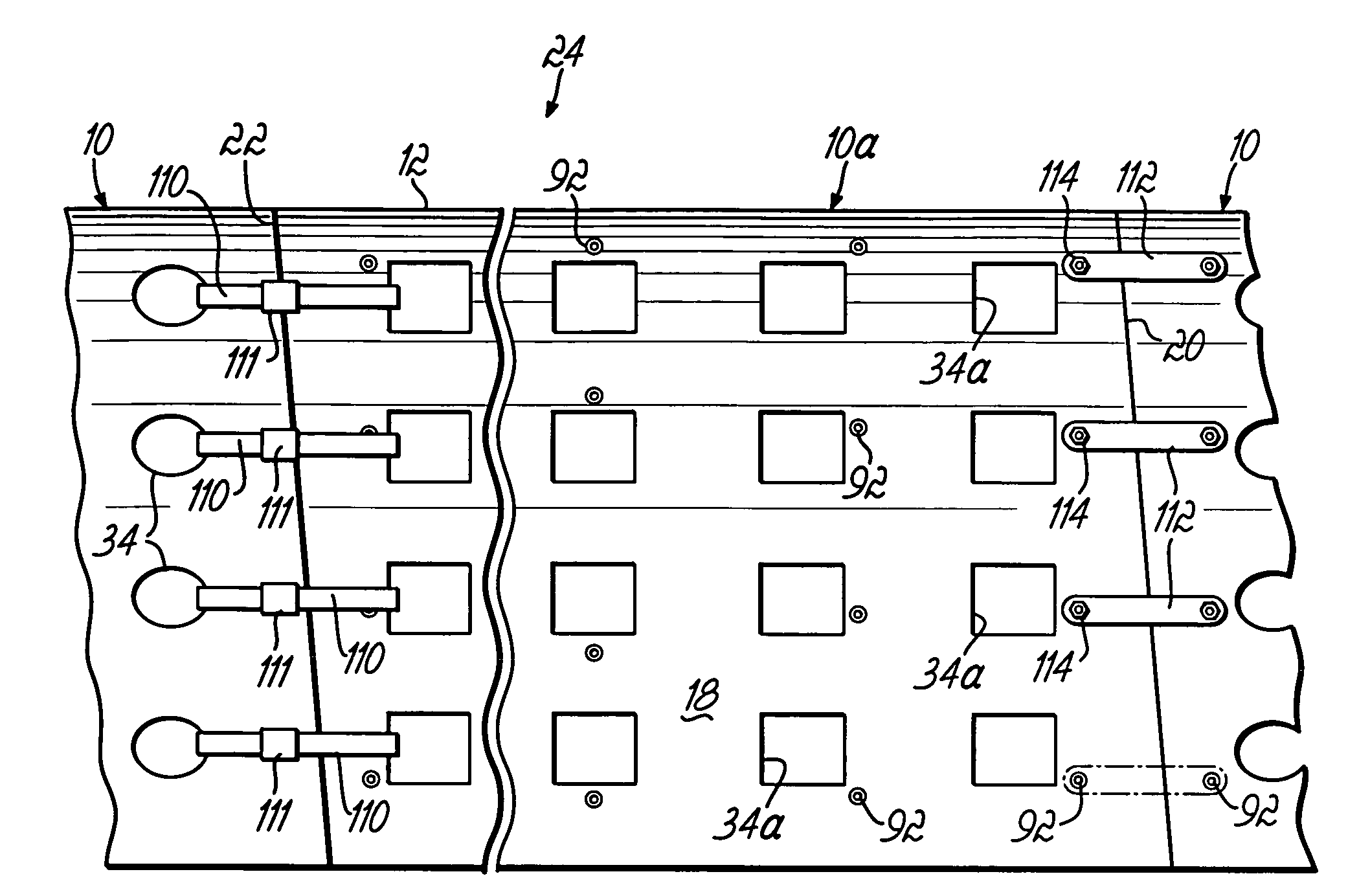

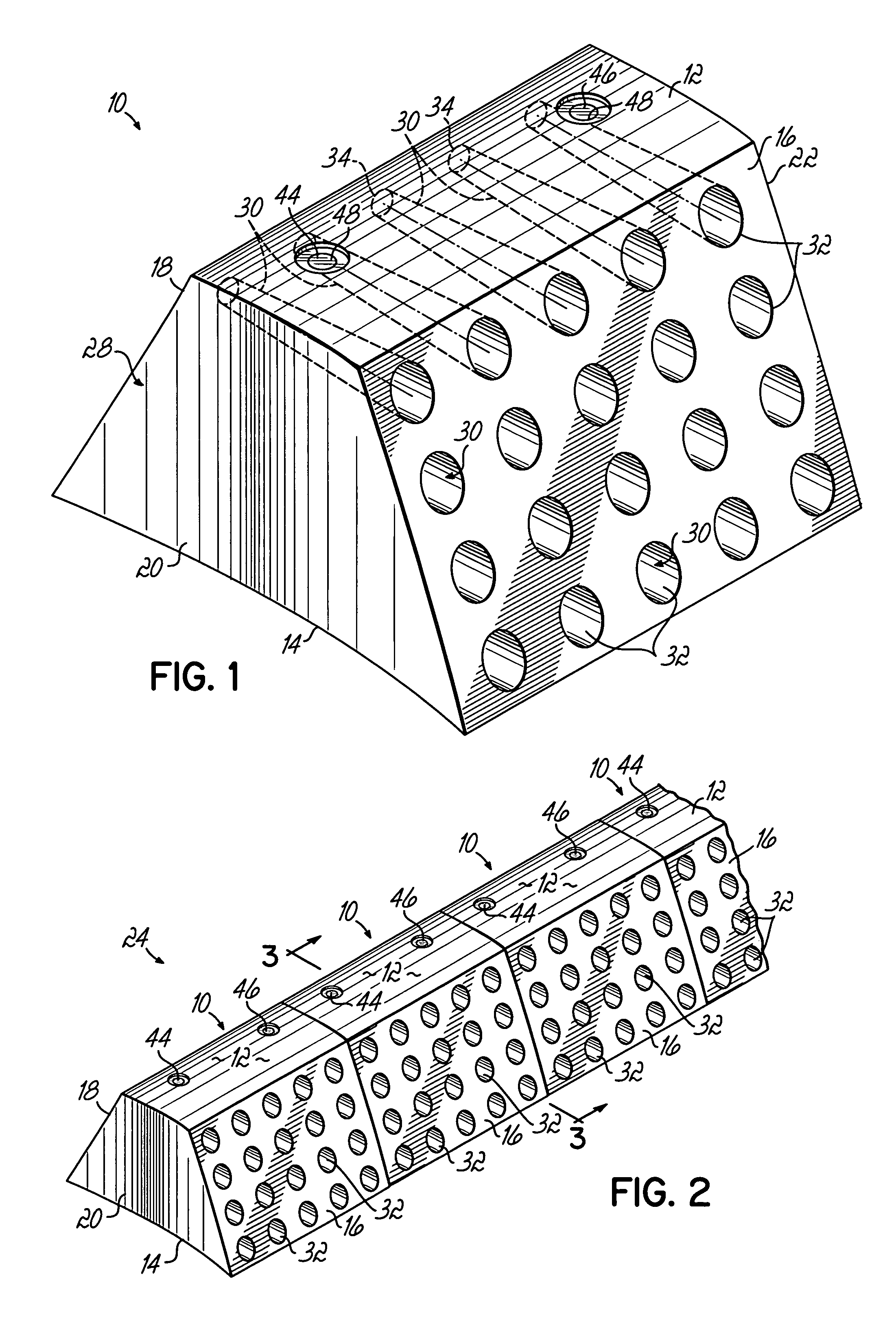

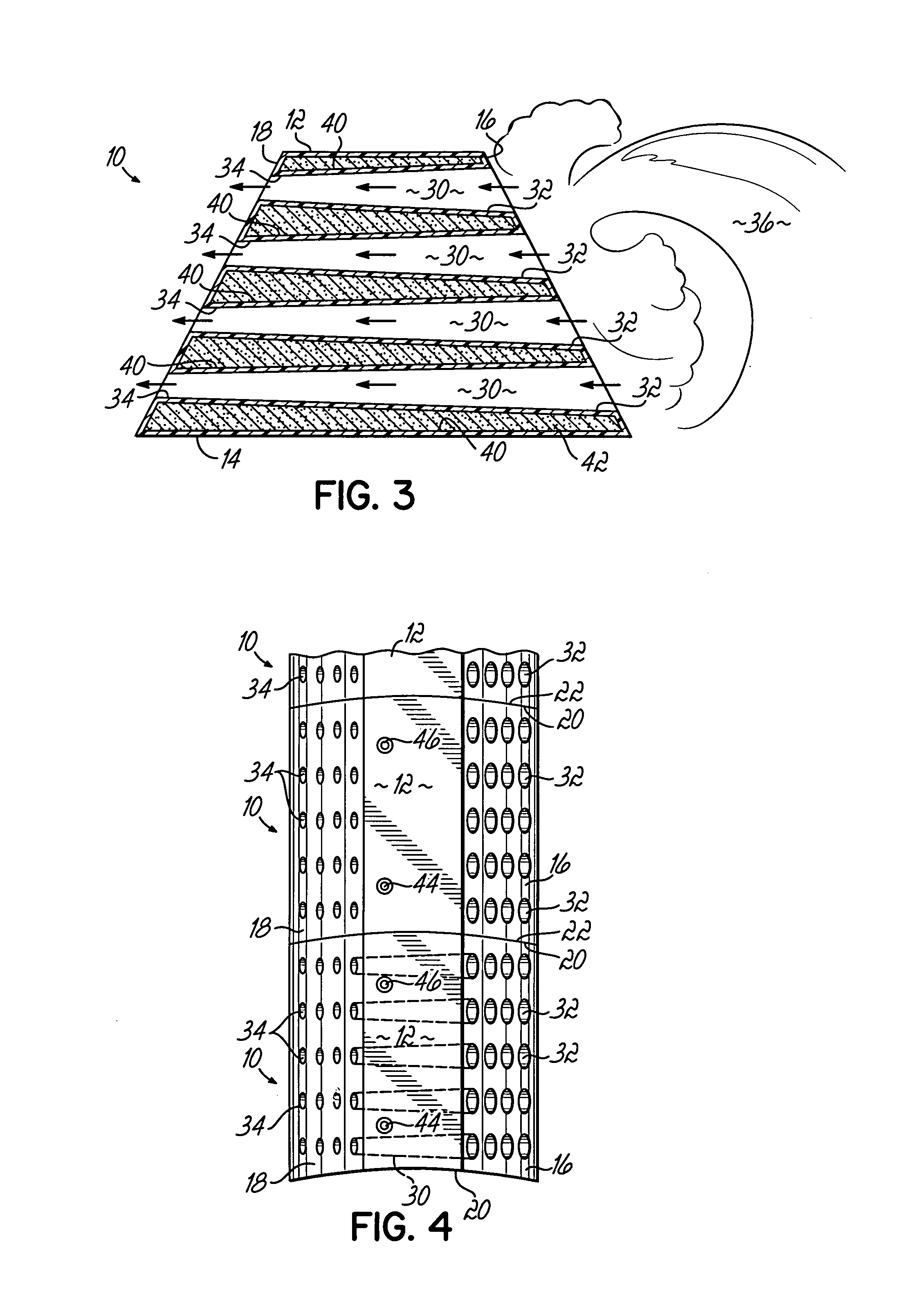

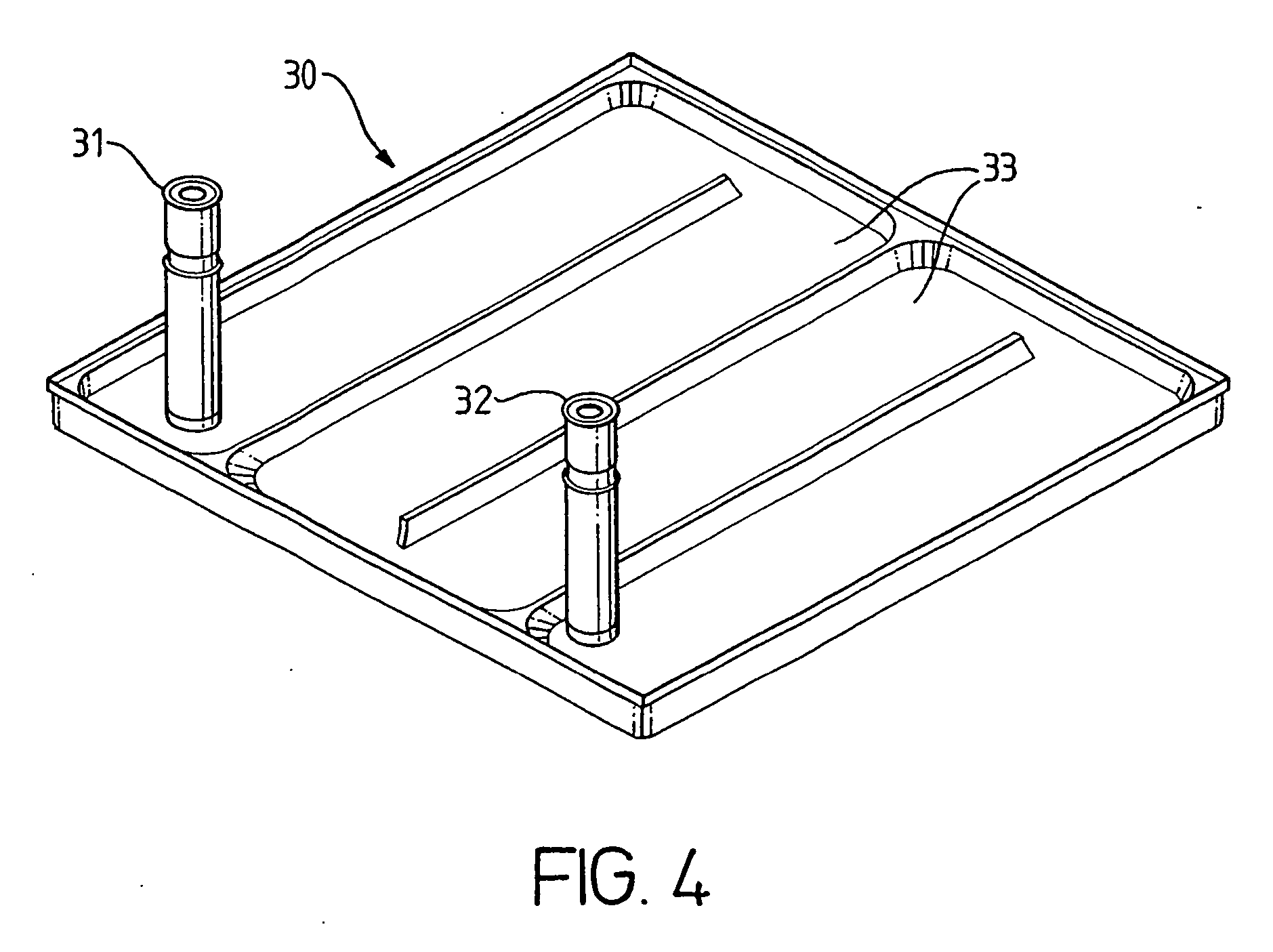

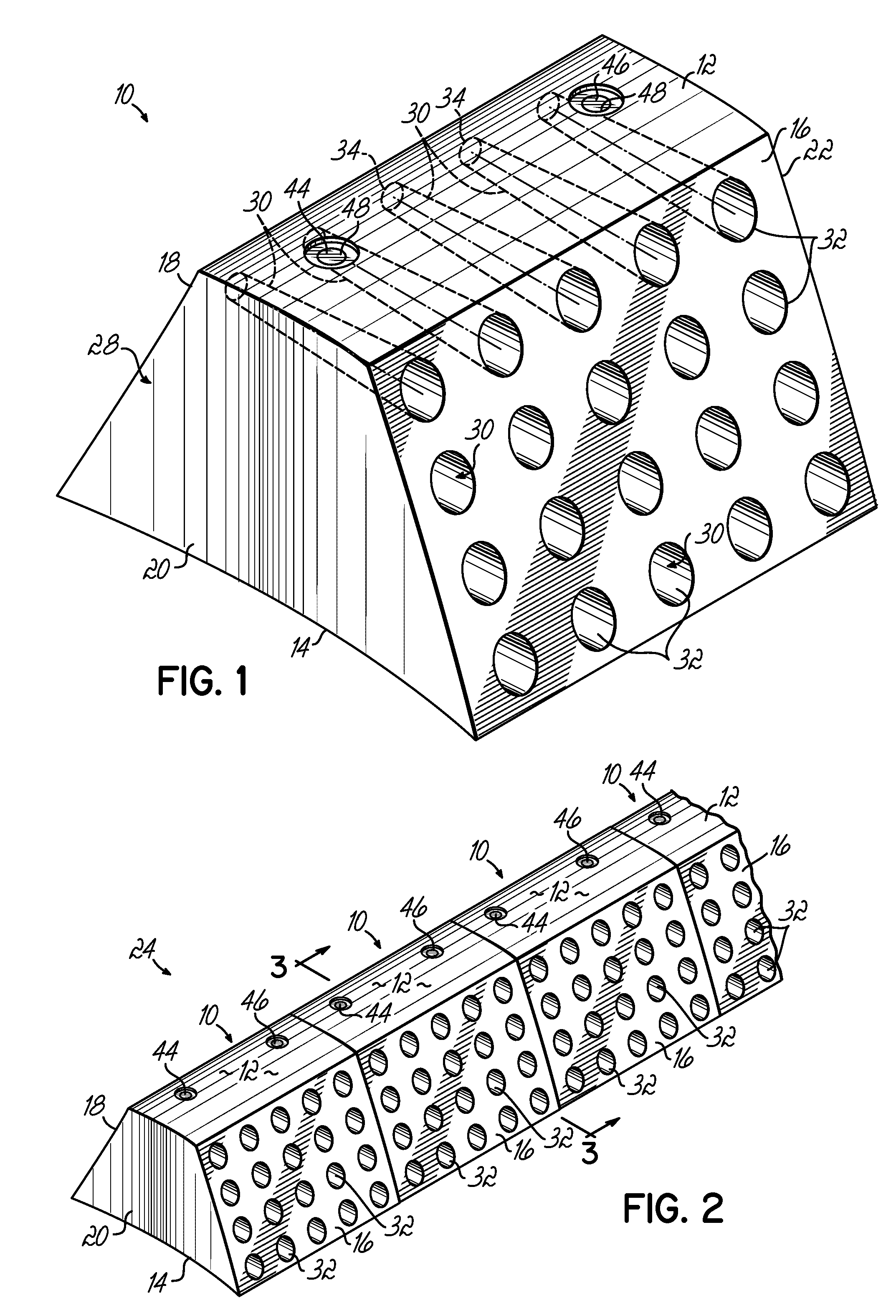

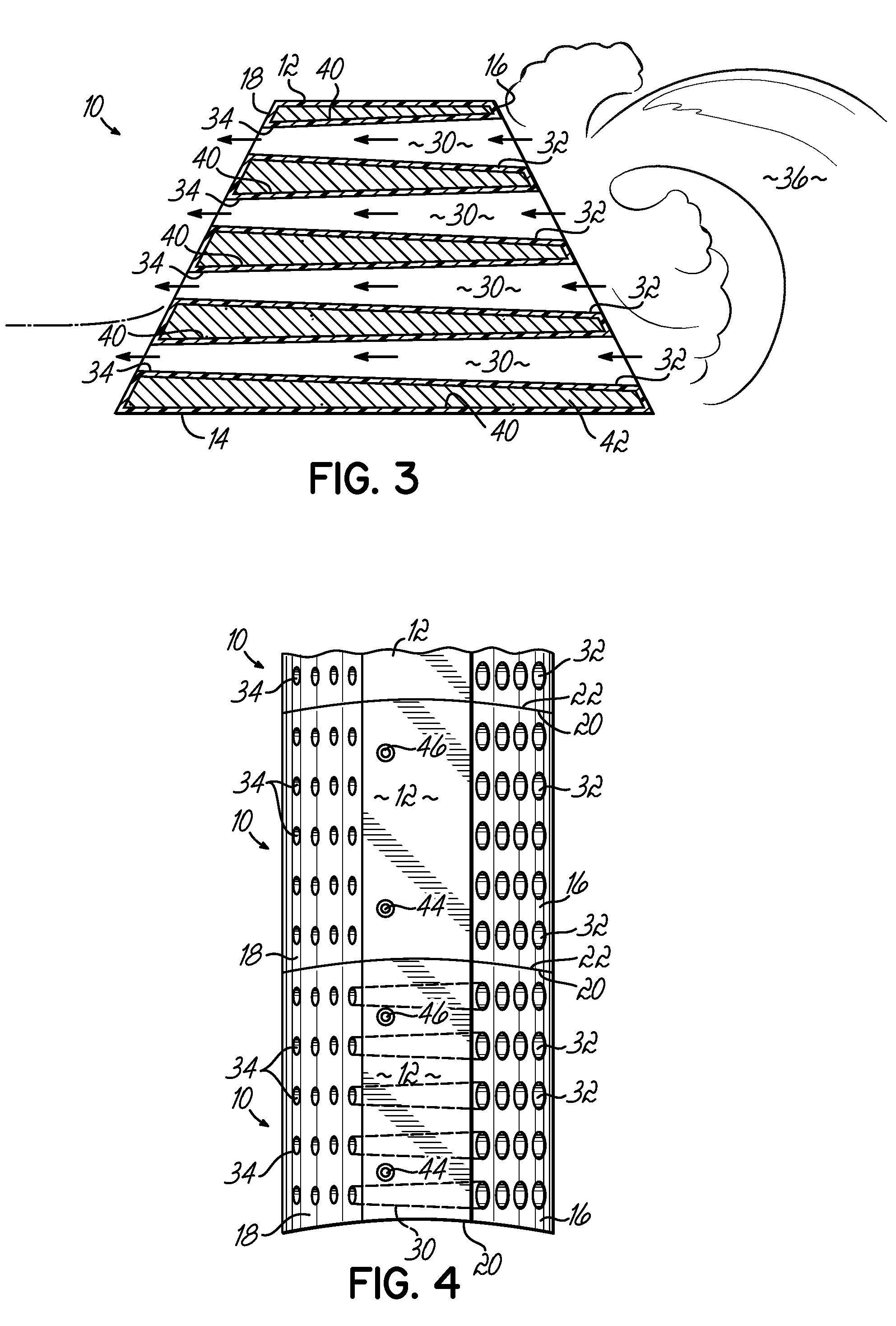

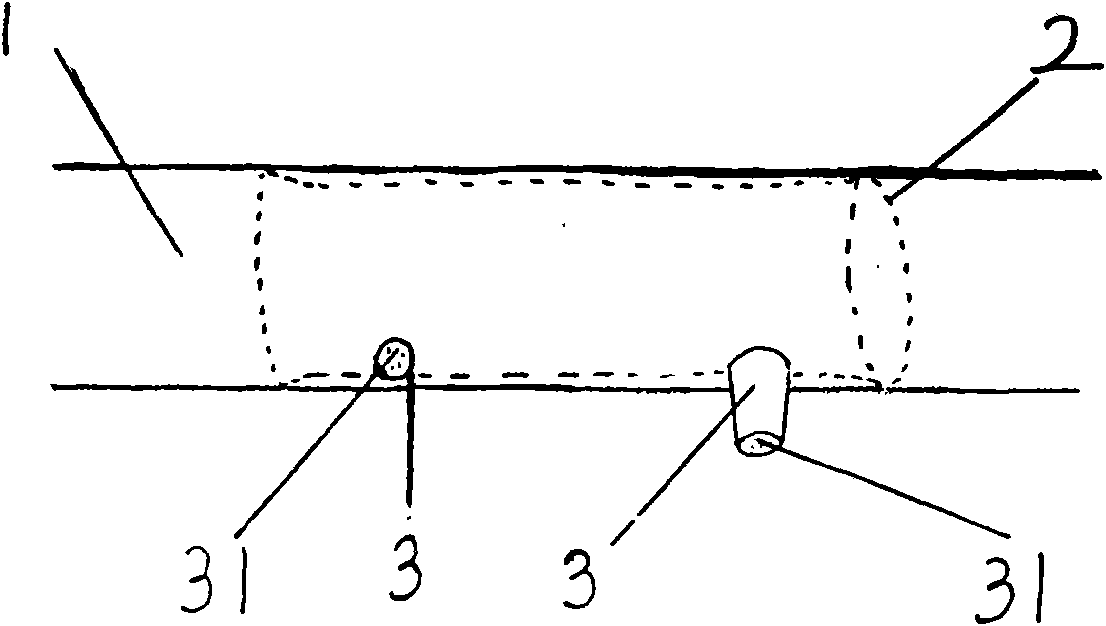

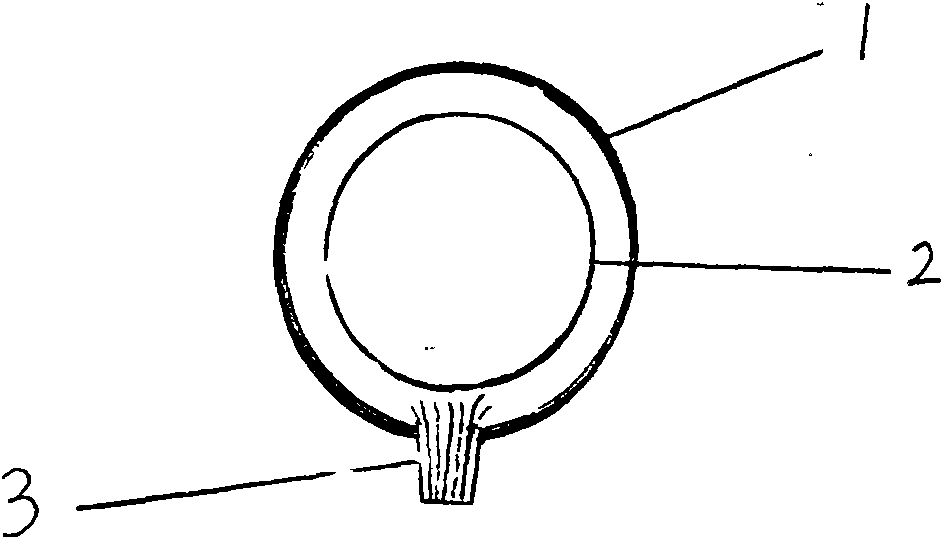

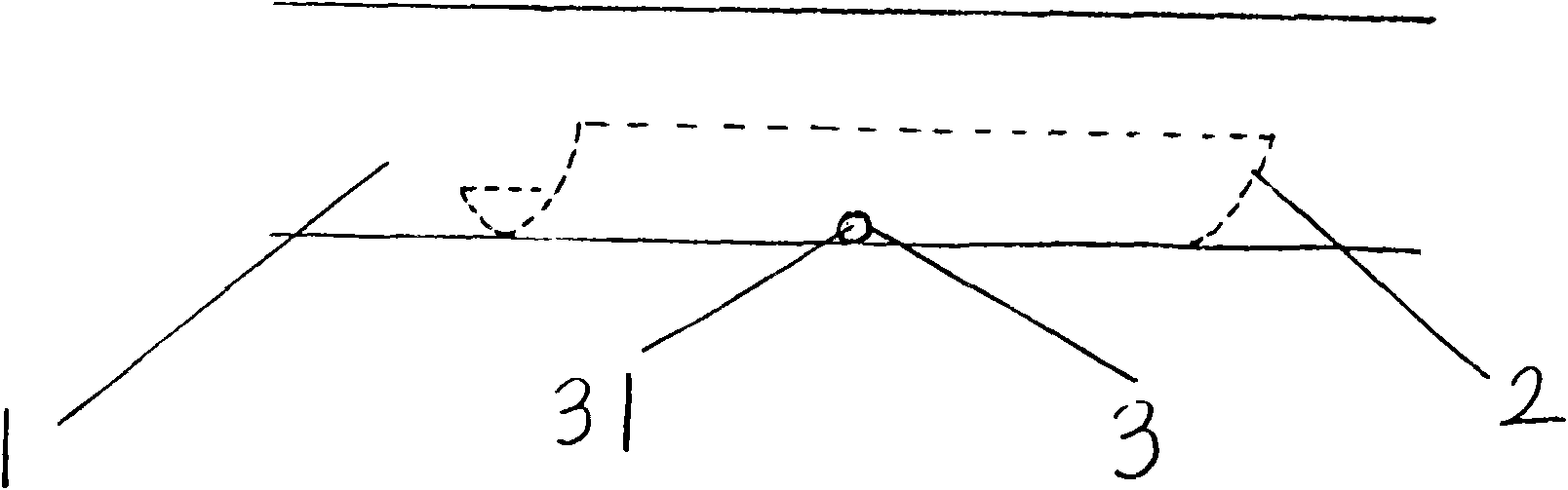

Shoreline erosion barrier

A barrier for reducing erosion along shorelines includes a barrier body formed as a unitary, molded plastic structure. In one embodiment, the barrier body has at least one elongate passage extending through it, between oppositely disposed first and second sides, and an interior reservoir. A port formed into the barrier body communicates with the interior reservoir to facilitate filling the reservoir with material to thereby add weight to the barrier. The barrier further includes at least one anchor formed into a side of the barrier body and associated with the passage to control shrinkage of the barrier body as it is being molded. In another embodiment, a method of making the barrier body includes placing plastic material in a mold, manipulating the mold to distribute the plastic material within the mold and thereby form the barrier body as a unitary piece, and reducing the shrinkage of the molded barrier body with the anchor.

Owner:GRANGER PLASTICS

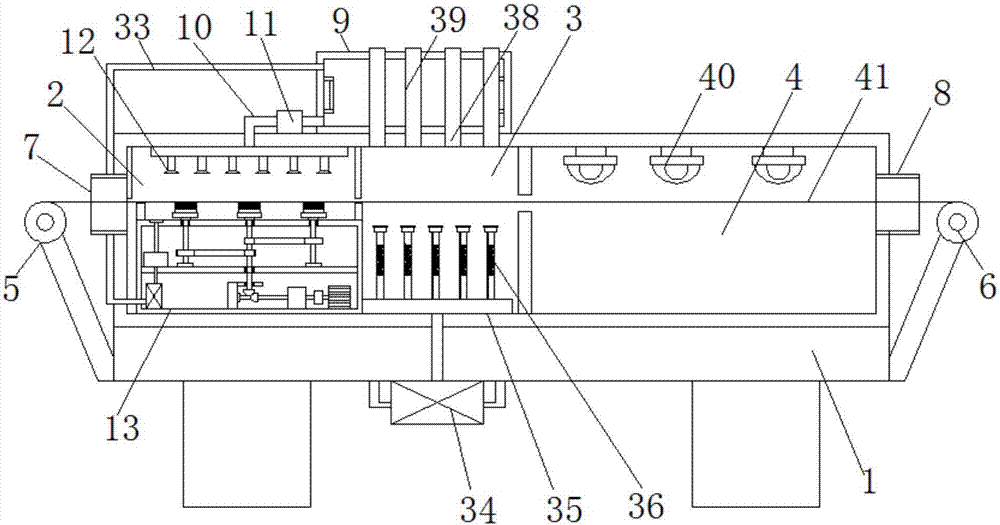

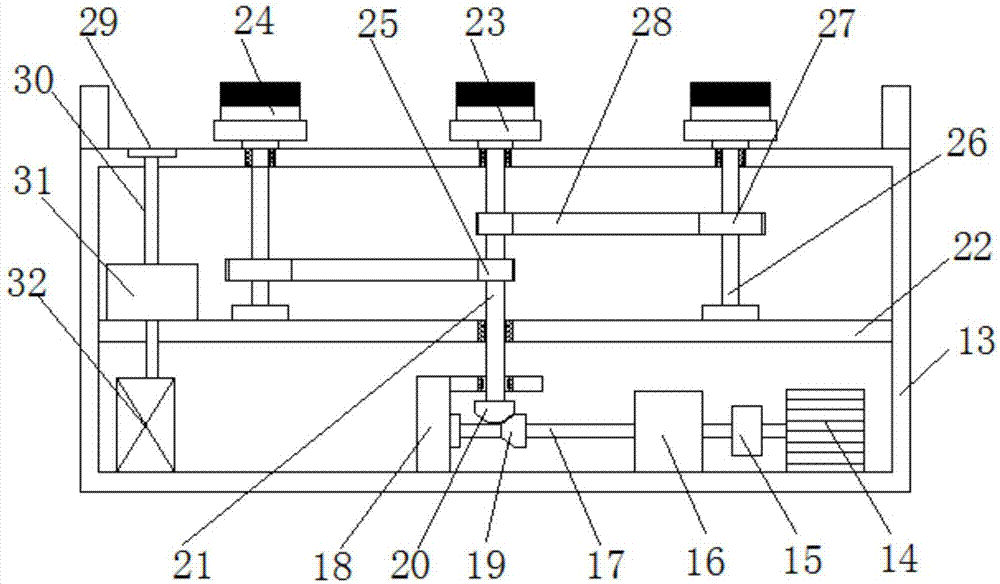

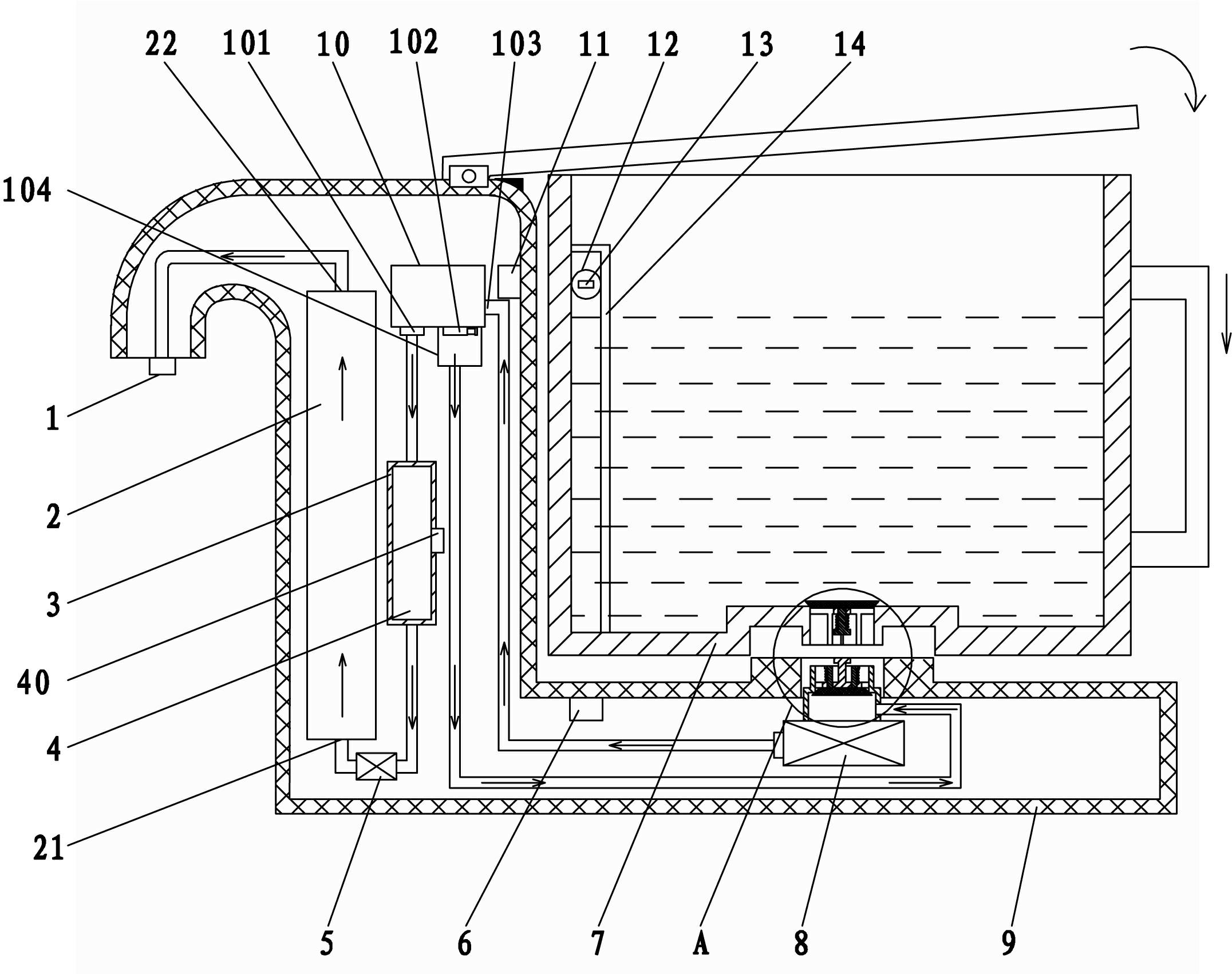

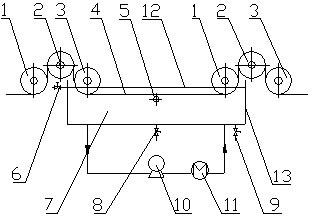

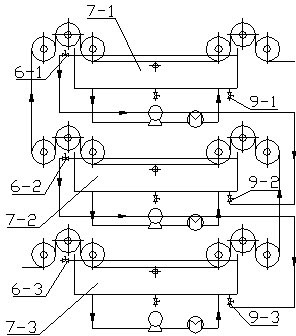

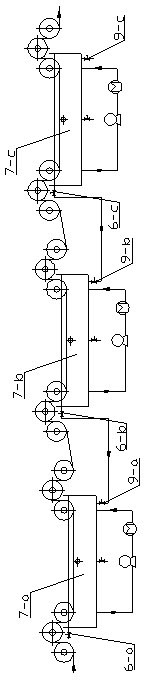

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

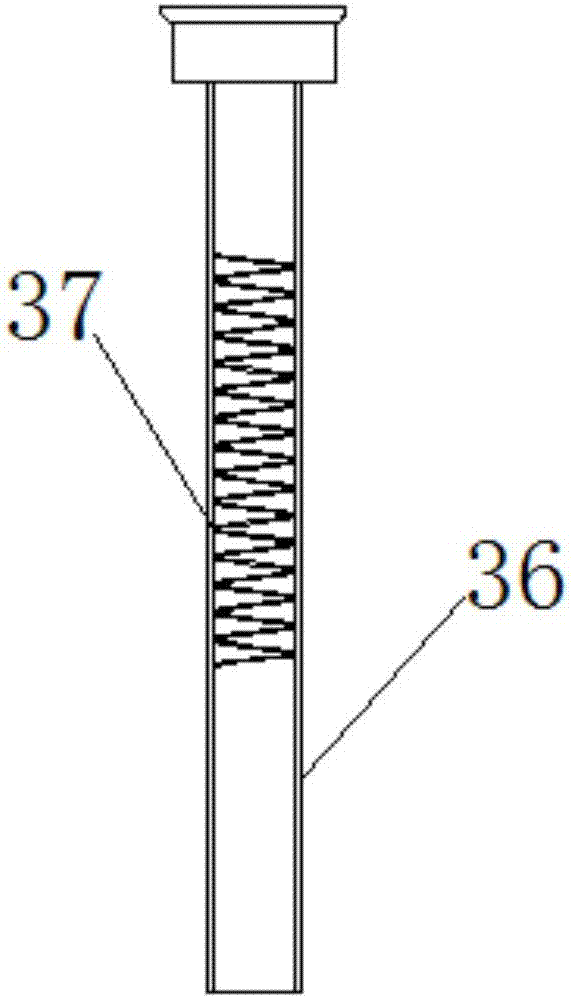

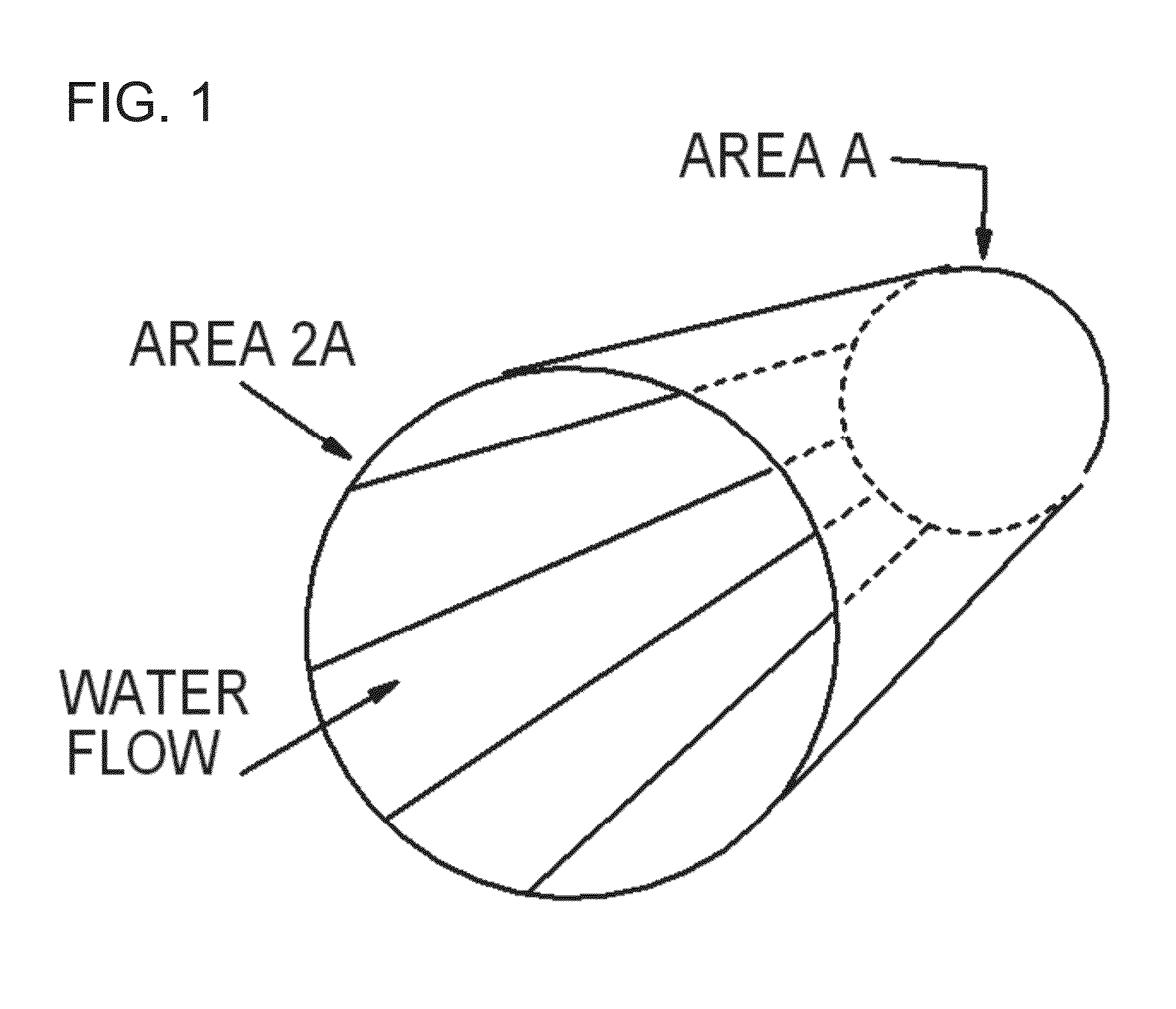

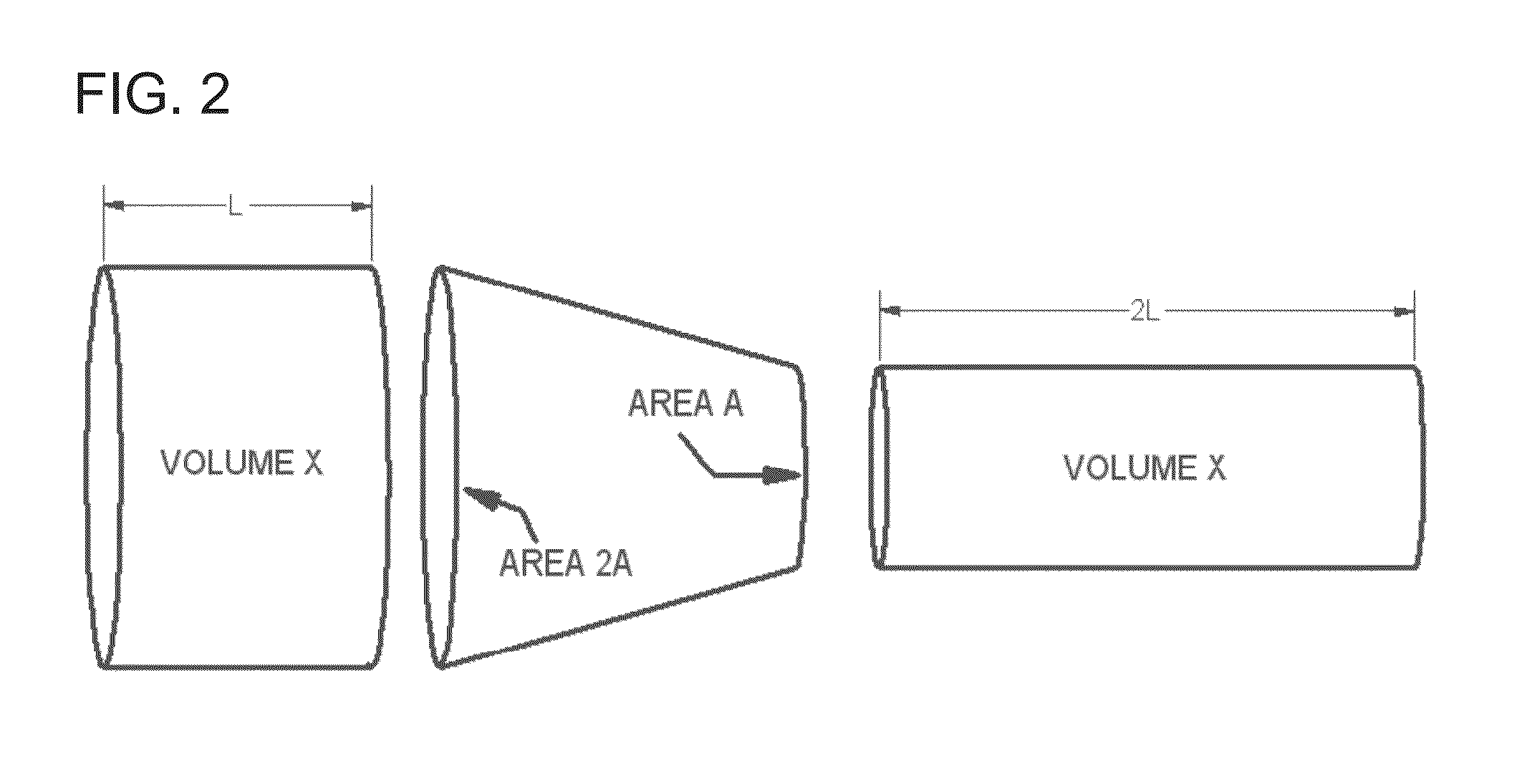

Coiled reverse osmosis membrane element

ActiveCN101708433AReduce pollution rateExtended service lifeSemi-permeable membranesConcentration polarizationWater velocity

The invention discloses a coiled reverse osmosis membrane element, which is formed by winding at least one group of water purification membranes on a central water yielding pipe, wherein the water purification membrane group consists of a purified water guide net, a reverse osmosis membrane and a water inlet guide net which are overlapped; a water inlet flow channel is formed by folding the inner surface of the reverse osmosis membrane, and a water yielding flow channel is formed between the adjacent outer surfaces; the water inlet guide net is positioned in the water inlet flow channel; the purified water guide net is positioned in the water yielding flow channel; the water yielding flow channel only has a purified water outlet facing the central water yielding pipe, and other three sides of the water yielding flow channel are closed and sealed; the partial zones, far away from the central water yielding pipe, on the two sides, adjacent to a folded side, of the water inlet flow channel which are closed and sealed; so a small section raw water inlet is formed on the two sides close to the central water yielding pipe respectively and a thick water outlet is formed on the side of the water inlet flow channel opposite to the folded side. Through improvement, the reverse osmosis membrane element of the invention increases the water velocity on the surface of the membrane, reduces the concentration polarization on the surface of the membrane, and reduces the pollution speed of the coiled membrane element so as to prolong the service life of the membrane element.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD +1

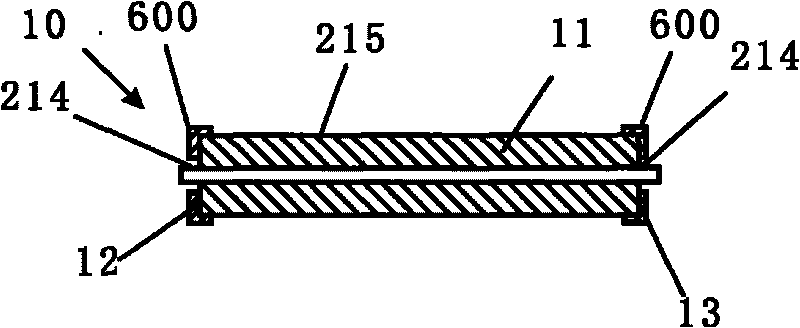

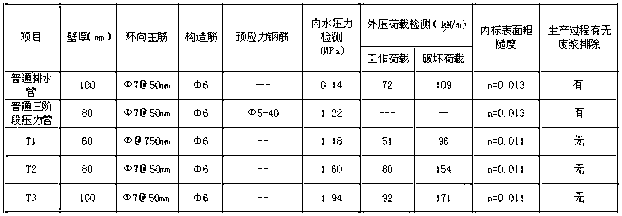

Green environmentally-friendly powder reinforced concrete water delivery pipe

ActiveCN103224356ALow costReduce pollution treatment costsCeramic shaping apparatusSlagMesh reinforcement

The invention belongs to the field of water delivery engineering and relates to a green environmentally-friendly powder reinforced concrete water delivery pipe. The green environmentally-friendly powder reinforced concrete water delivery pipe is manufactured by uniform distribution of concrete on a reinforcement mat. The concrete is prepared from 450 to 500 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 90 to 130 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 130 to 160 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 520 to 600 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 800 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 12 to 20 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 45 to 50 weight parts of a high-efficiency expanding agent, 130 to 150 weight parts of water, 0.8 to 1.2 weight parts of polypropylene fibers, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The reinforcement mat is manufactured by weaving hard-drawn wires having the diameter of 4.0 to 6.0 millimeters as reinforcements and cold-rolled ribbed bars having the diameter of 5.0 to 10.0 millimeters as hoop reinforcements.

Owner:黄贺明

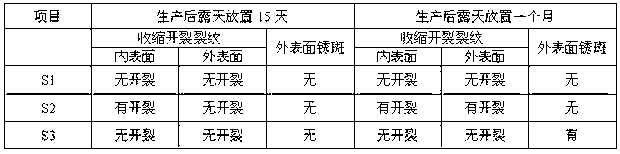

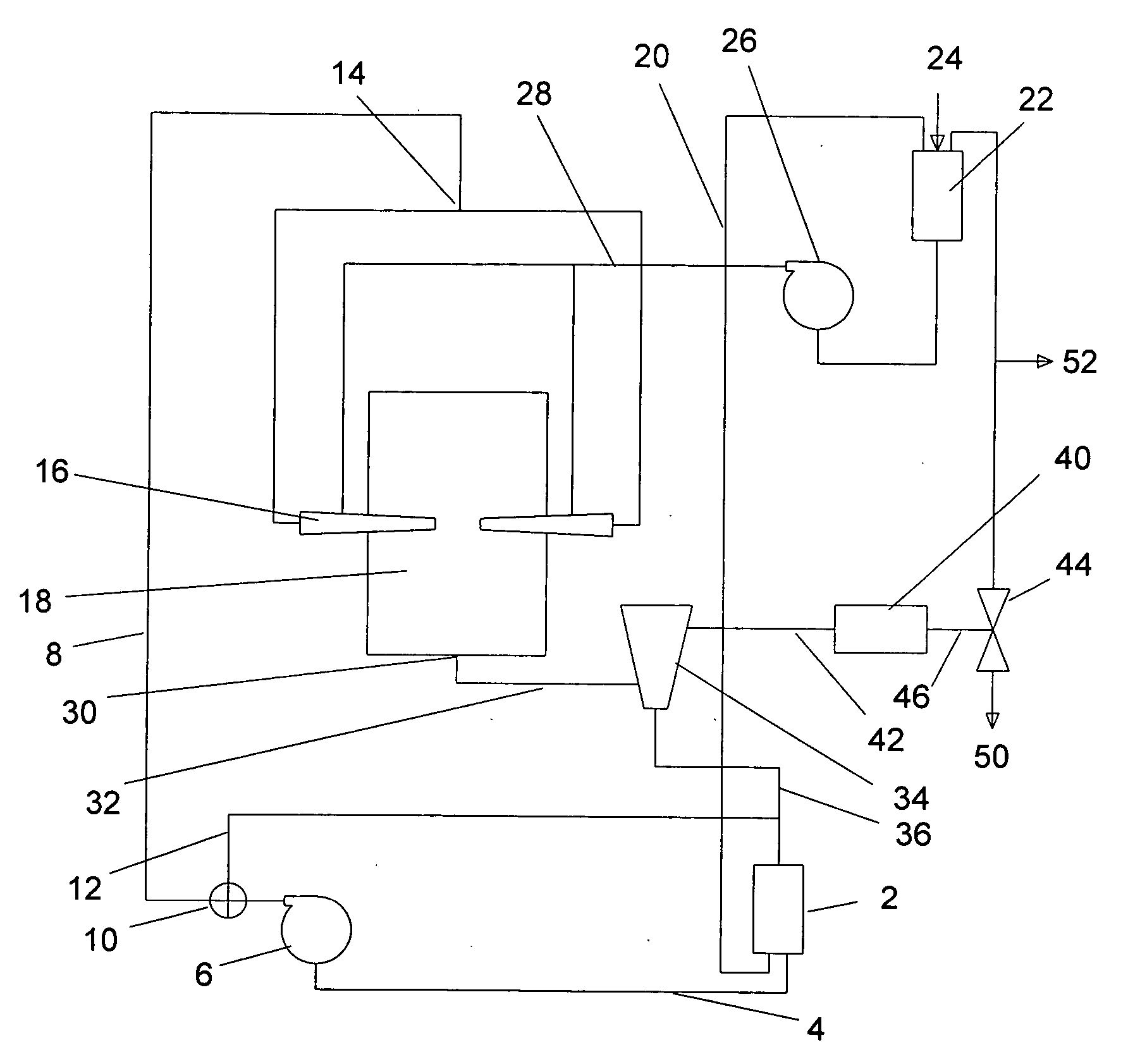

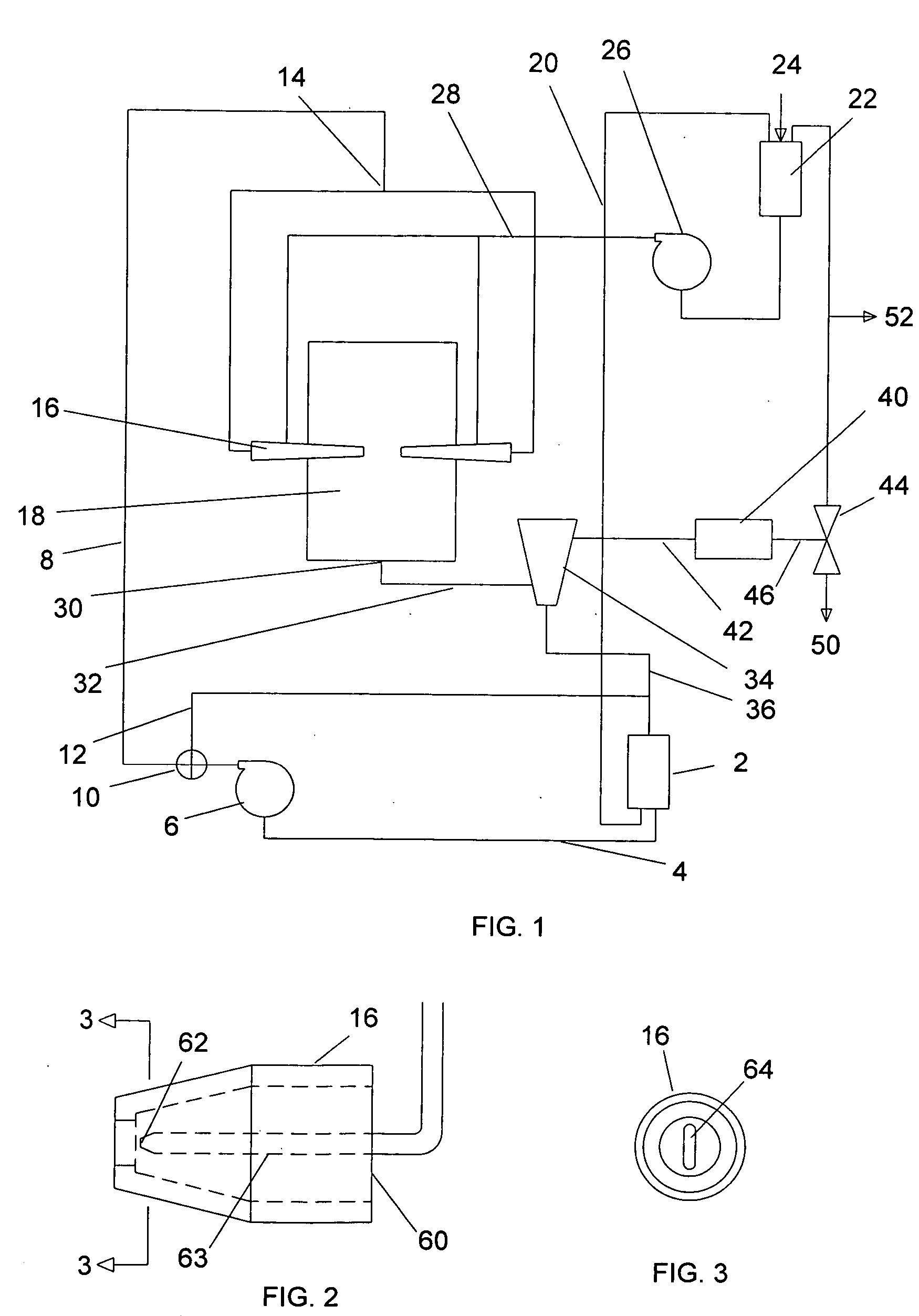

Ultra high efficiency power generation system and water turbine

InactiveUS20140265335A1Increase water velocityLow costHydro energy generationMechanical energy handlingPower generation systemWater turbine

An electrical generation system. A floating vessel is anchored in flowing water. Inlets in the hull of the vessel capture flowing water and direct the water to one or more turbines. The system is designed so that all flows are two-dimensional to the extent possible. The latter feature greatly simplifies both design and construction.

Owner:ANDREIS BRUNO PETER

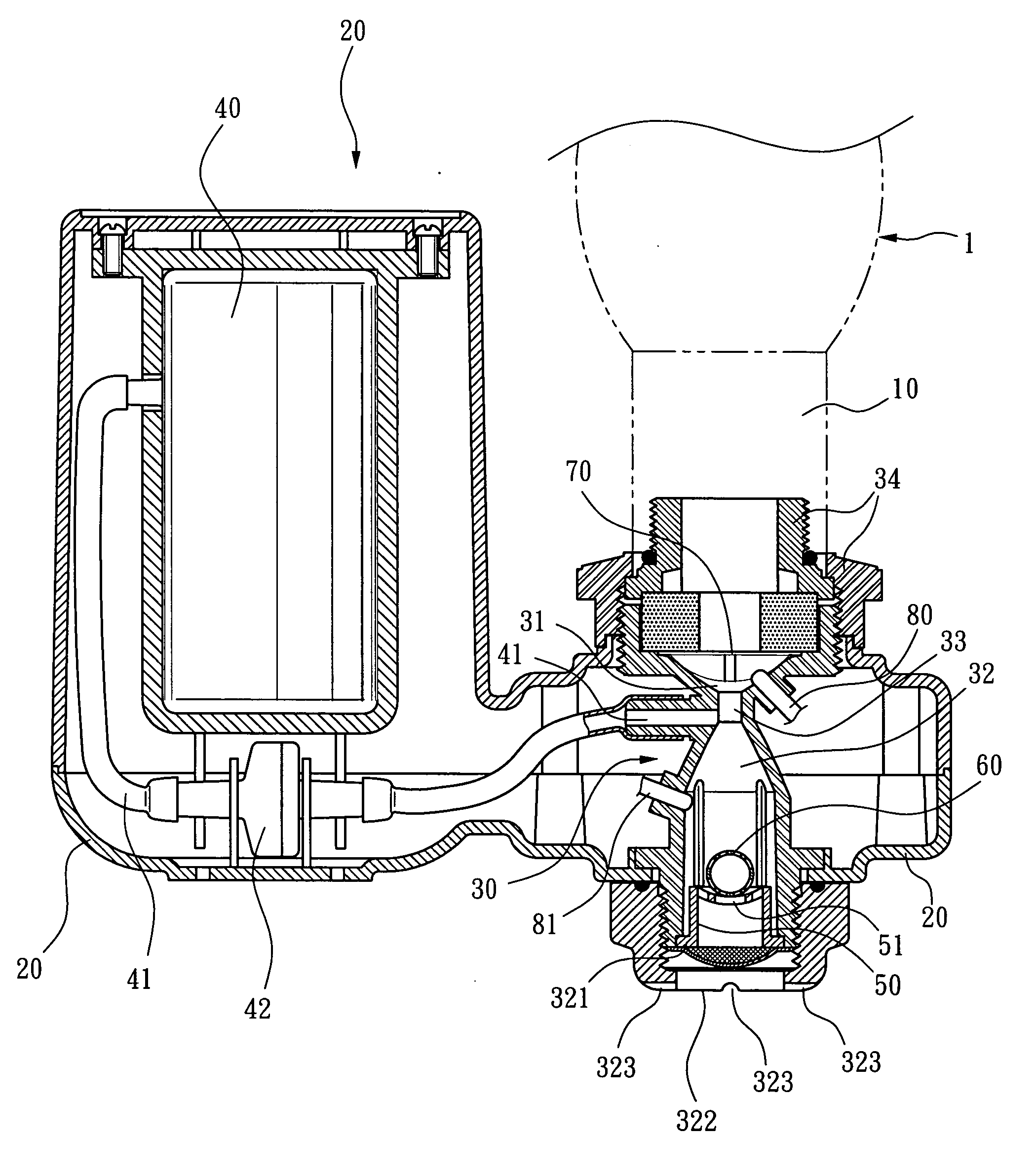

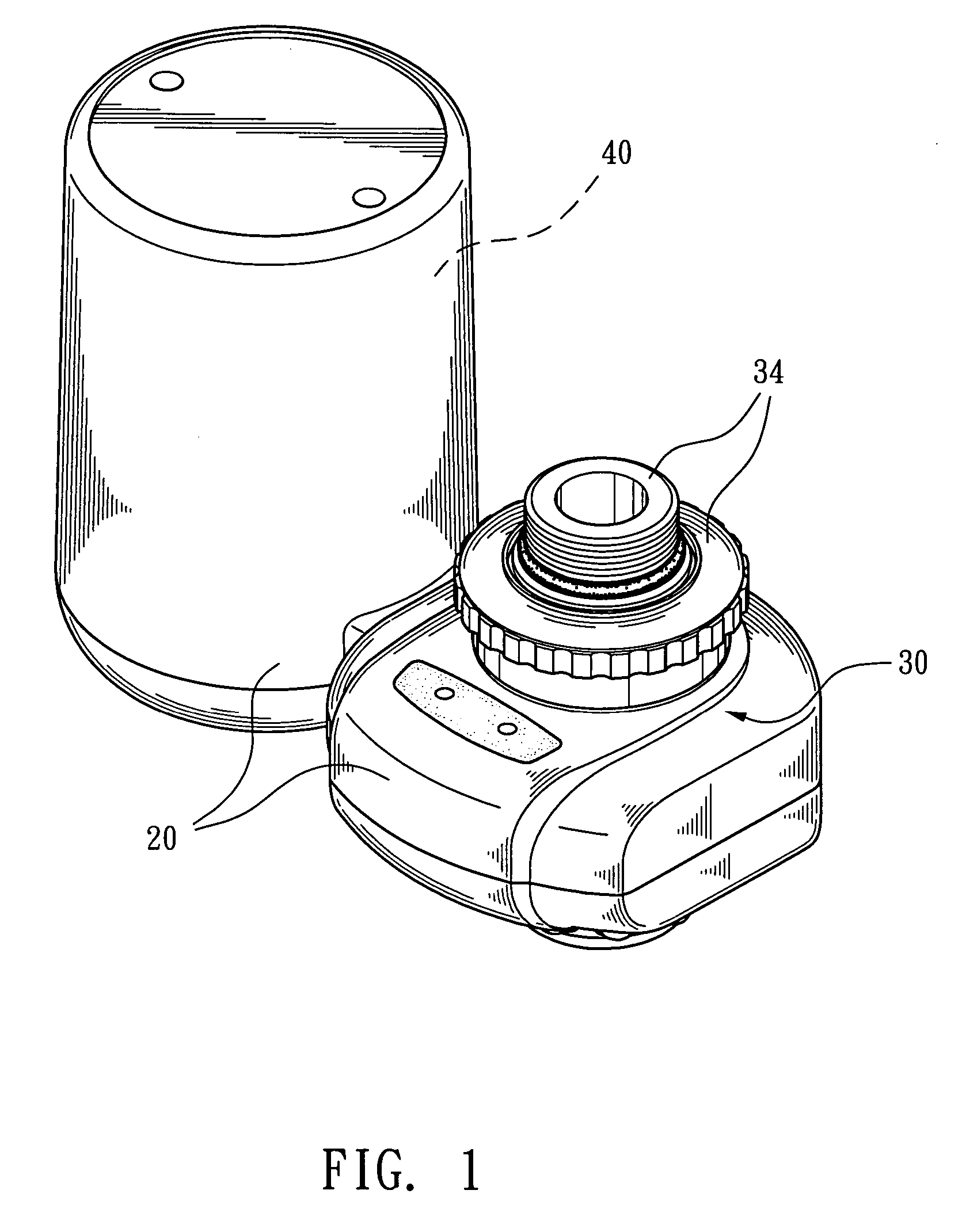

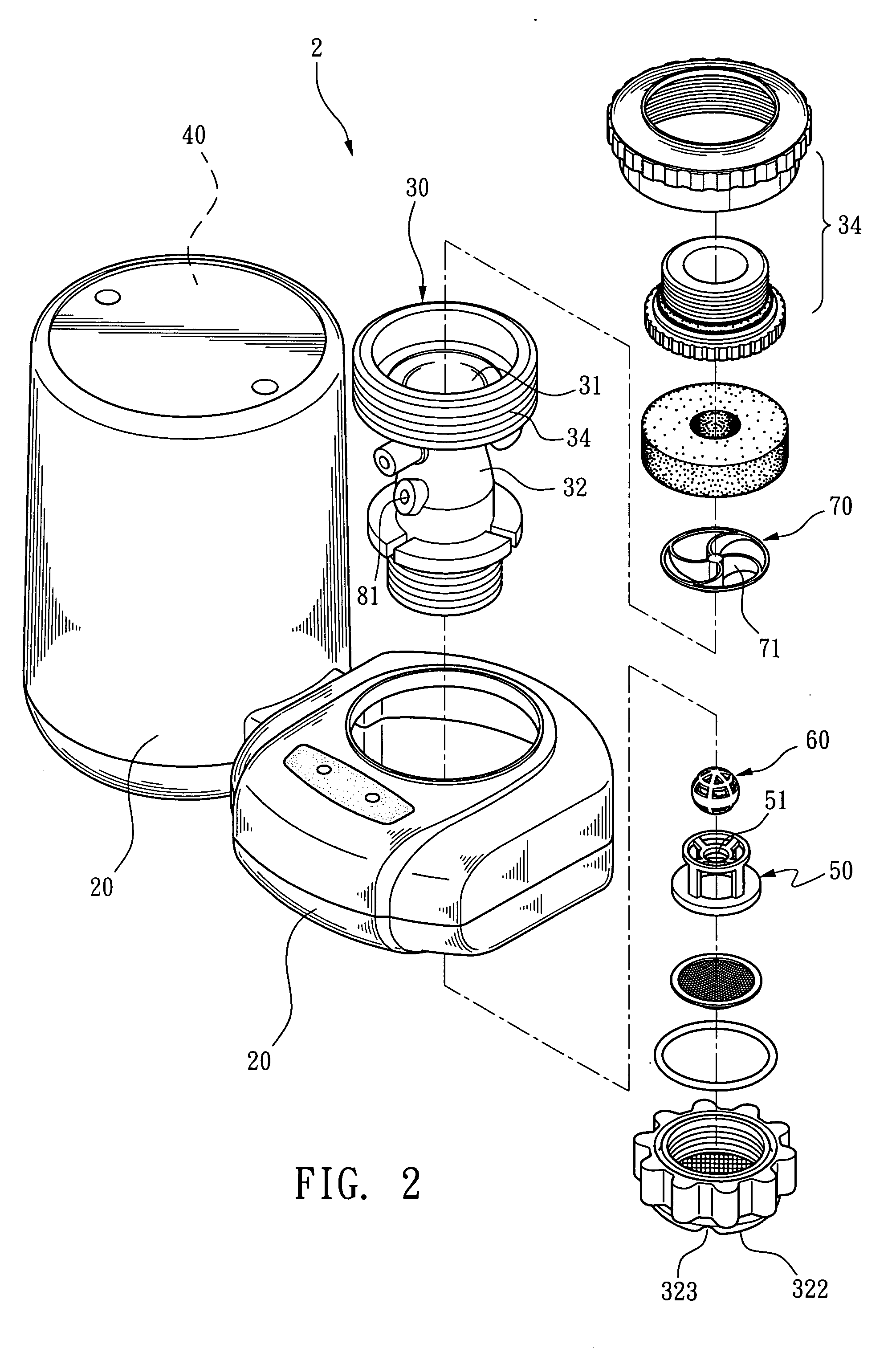

Ozone water faucet

InactiveUS20060266683A1Good disintegrationEfficient mixingOther chemical processesSolid sorbent liquid separationOzone generatorWater flow

An ozone water faucet having an ozone supplier disposed on an outcome of a faucet is disclosed. The ozone supplier consists of a gas-liquid mixing tube and an ozone generator. The gas-liquid mixing tube is composed by a water intake section, a water drainage section, and a diameter-reducing throat therebetween. The ozone from the ozone generator flows through the diameter-reducing throat, into the gas-liquid mixing tube. A cut out bearing is arranged inside the water drainage section for mounting a cut out stirring ball that moves freely. When water flows through the diameter-reducing throat, into the water drainage section, it flushes the cut out stirring ball as well as the bearing and drives the cut out stirring ball moving upwards and downwards so as to have better disintegration effect on the water.

Owner:SUNG WEI MING

Hydraulic opposed jet mill

InactiveUS20060032953A1Increase water speedHigh speedGas current separationGrain millingWater flowMineral particles

Embodiments of an hydraulic opposed jet mill are disclosed which may be used to crush various minerals, including mica, or other materials to sub-micron size. At least one positive displacement pump forces an incompressible liquid, such as water, through a pair of opposed jets such that the two streams of water collide between the jets. A slurry of an incompressible liquid, such as water, and the mineral to be crushed is introduced into the jets at a point near the outlet end of the jets. The entrained mineral particles are forced out of the jets with great energy which causes multiple collisions and pulverization. In a second embodiment of the instant invention the slurry strikes an impingement plate rather than an opposed slurry stream.

Owner:KRUSE GEORGE

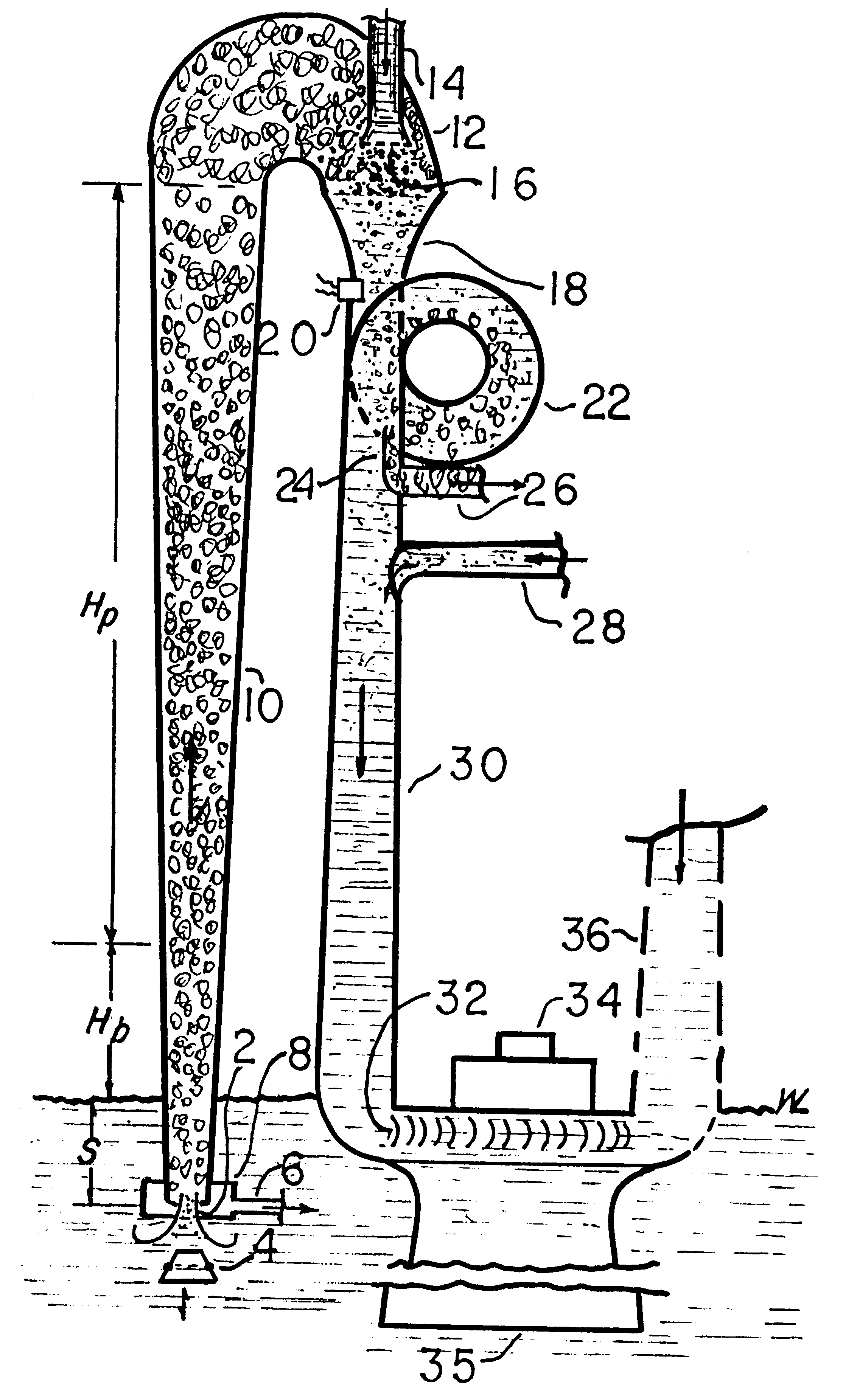

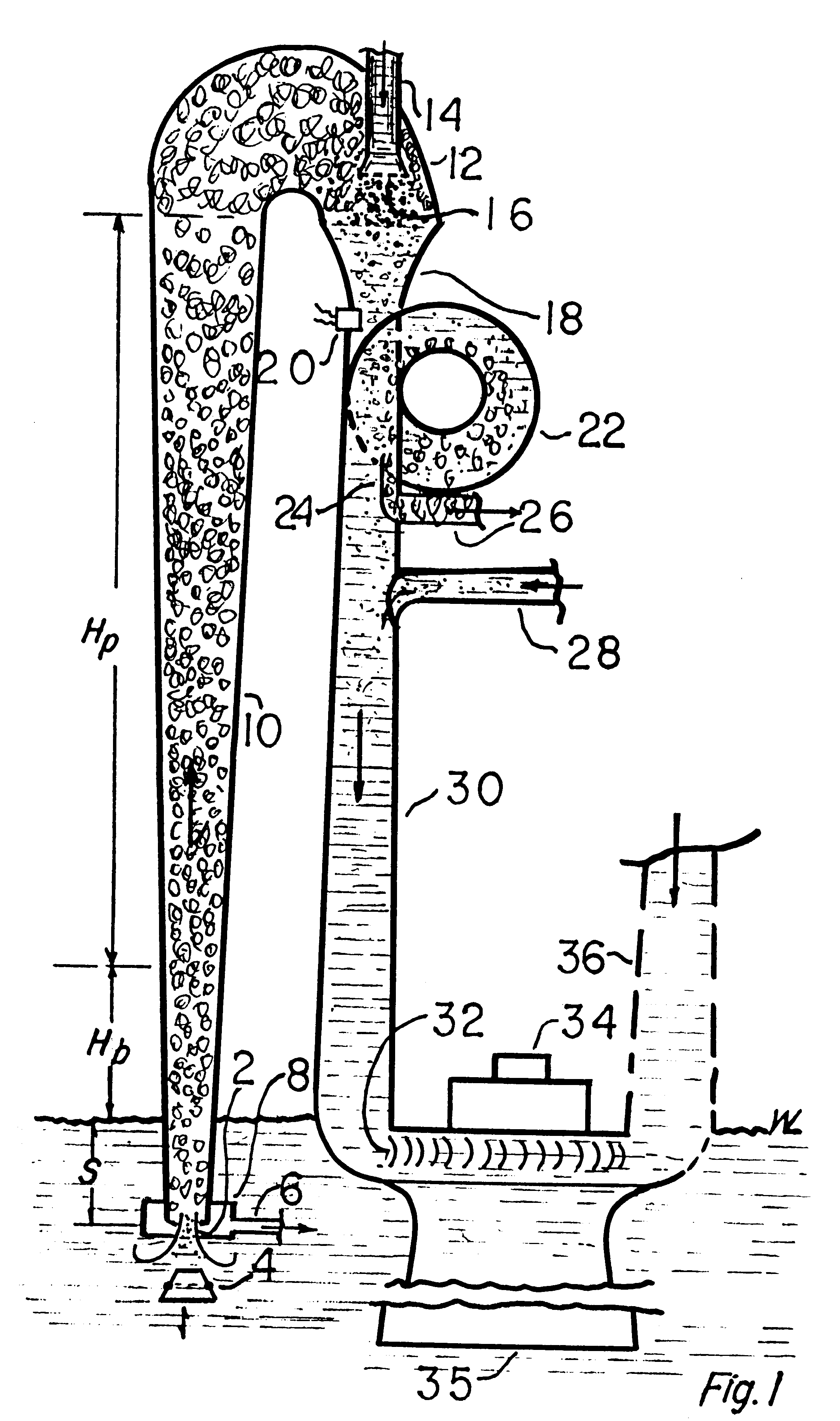

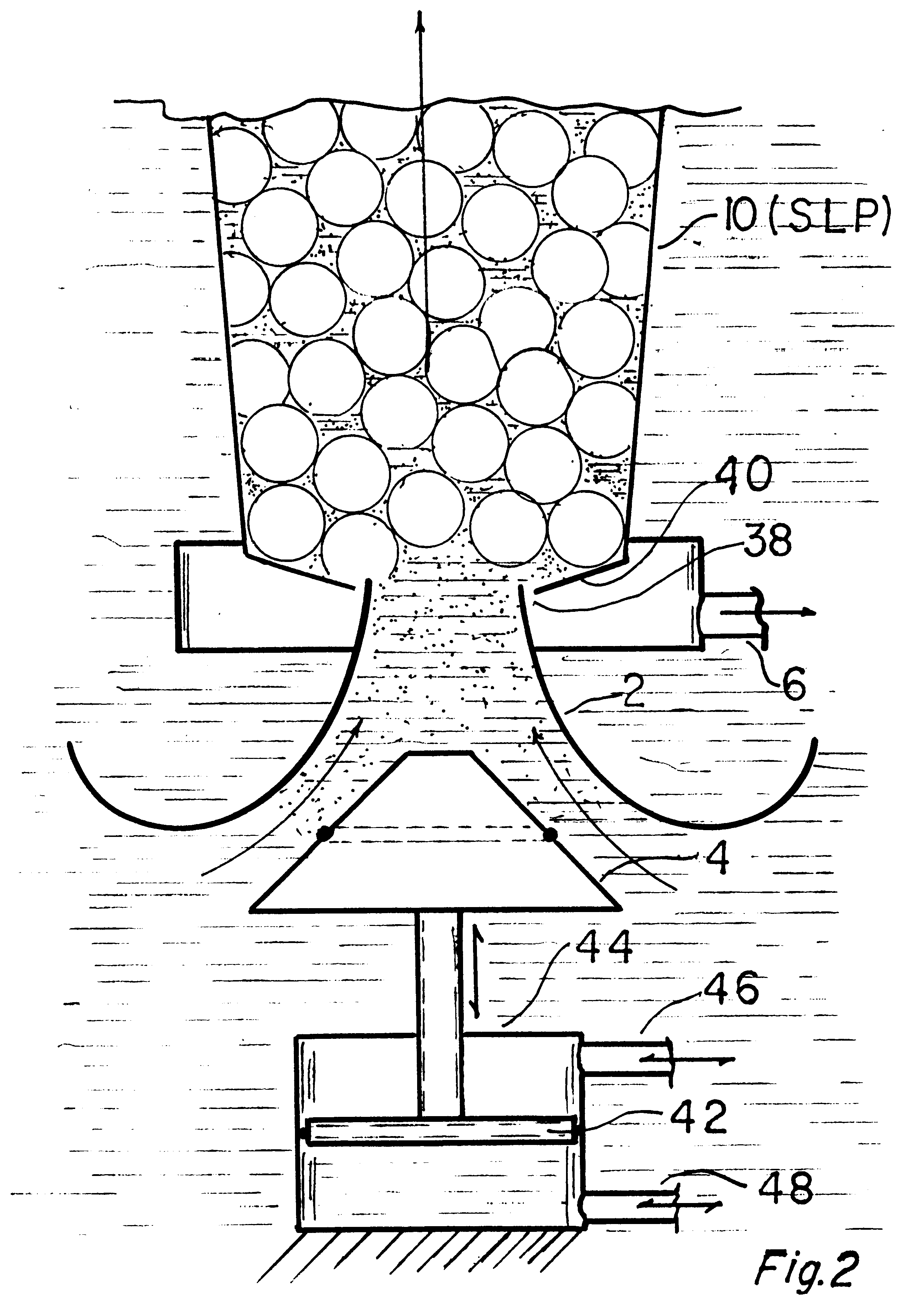

Ocean thermal gradient hydraulic power plant

InactiveUS6202417B1Improve cycle efficiencyIncrease the lengthLiquid degasificationMachines/enginesPower stationEngineering

Owner:BECK EARL J

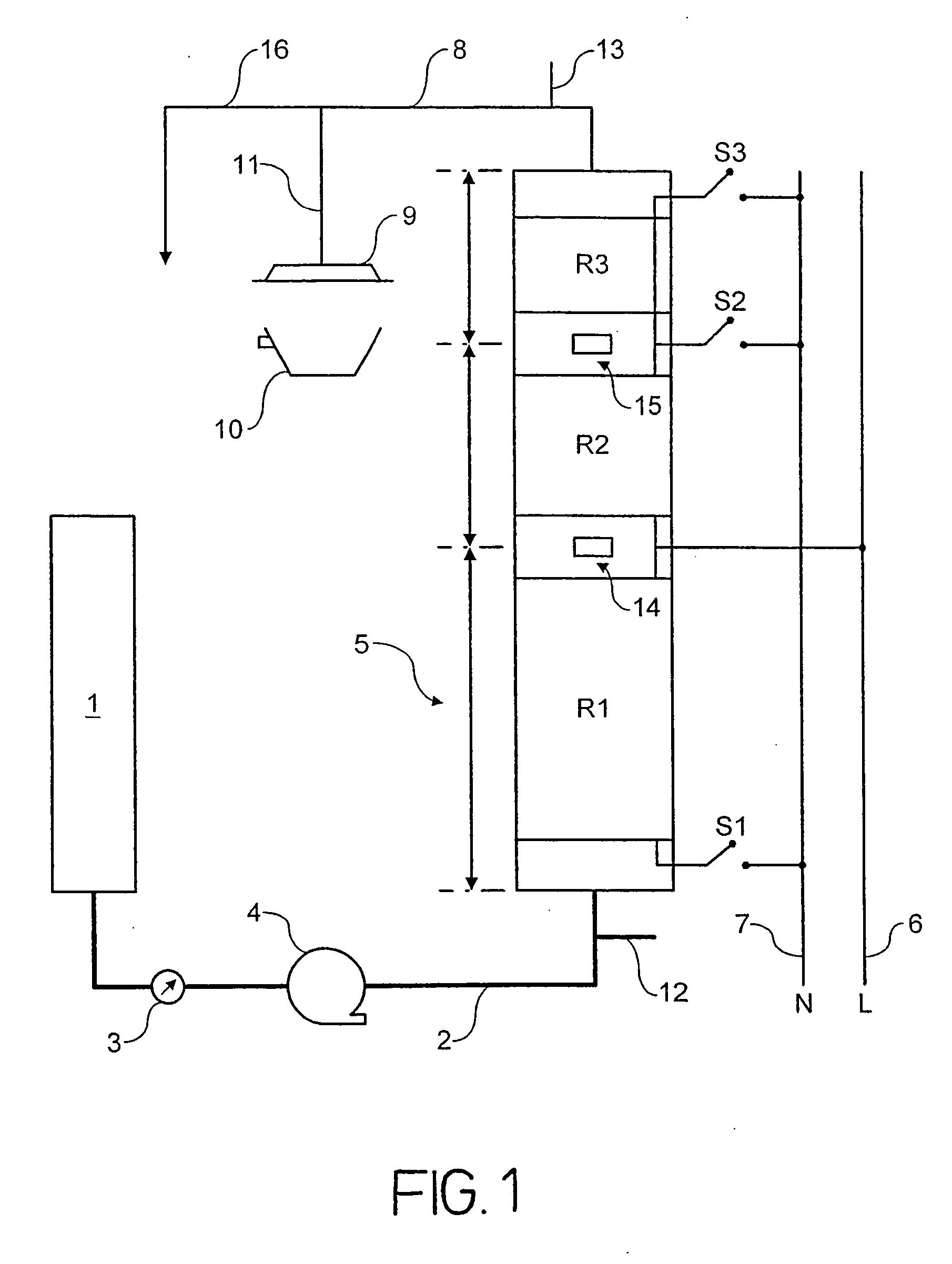

Device for the heating of a liquid

InactiveUS20060027103A1Improve heat transfer performanceEasy transferImmersion heating arrangementsLiquid transferring devicesElectricityLiquid temperature

The present invention concerns a device for the heating of a liquid in a beverage machine comprising at least one set of at least two resistors, wherein said resistors are electrically linked together so as to use one resistor of each set individually or in serial with one or more of the resistors of the same set, at least one individual resistor and at least one set of two resistors, wherein said resistors are electrically linked together so as to use the first resistor of a set individually or in serial with one or more of the following resistors of the same set, said resistors transferring the maximum of energy to the flow of liquid and allowing a finer control of the liquid temperature.

Owner:NESTEC SA

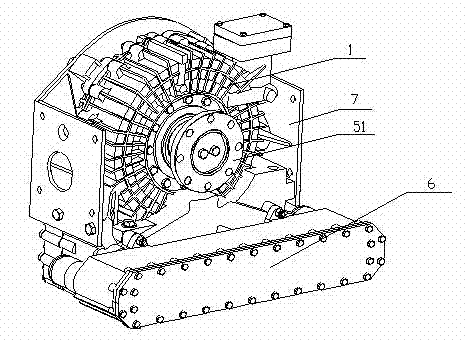

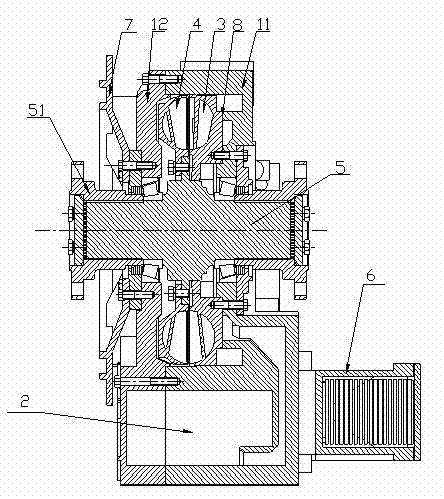

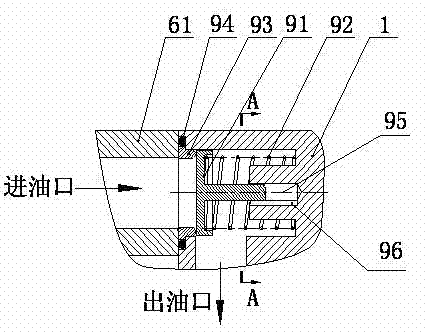

Hydraulic retarder

InactiveCN103047322APrevent movementIncrease the oil inlet speedLiquid resistance brakesPiston GuideEngineering

The invention discloses a hydraulic retarder. The hydraulic retarder comprises a hydraulic retarder shell, an oil storage tank, a stator, a rotor and a heat exchanger, wherein the oil storage tank, the stator and the rotor are all arranged in the hydraulic retarder shell, and the heat exchanger is fixedly arranged outside the hydraulic retarder shell; oil inlet holes a and oil outlet holes are arranged on the stator and along the periphery of the stator; and a second oil inlet channel is internally provided with a check valve, the check valve comprises a piston, a spring, a piston guide hole and an oil discharge groove, one end of the piston is pressed at the end part of the heat exchanger shell to block an oil inlet, the other end of the piston extends into the piston guide hole to be matched with the piston guide hole in a sliding mode, the spring is sheathed on the piston, one end of the spring is pressed on the piston, the other end of the spring is pressed on the hydraulic retarder shell, and the piston guide hole is communicated with an oil outlet by the oil discharge groove. When oil in the piston guide hole is compressed by the piston, the oil is discharged by the oil discharge groove, so that the counter-acting force is not generated to the piston to block the movement of the piston, the oil feeding speed of the retarder is enhanced, and the response time of the retarder is improved.

Owner:韦健全

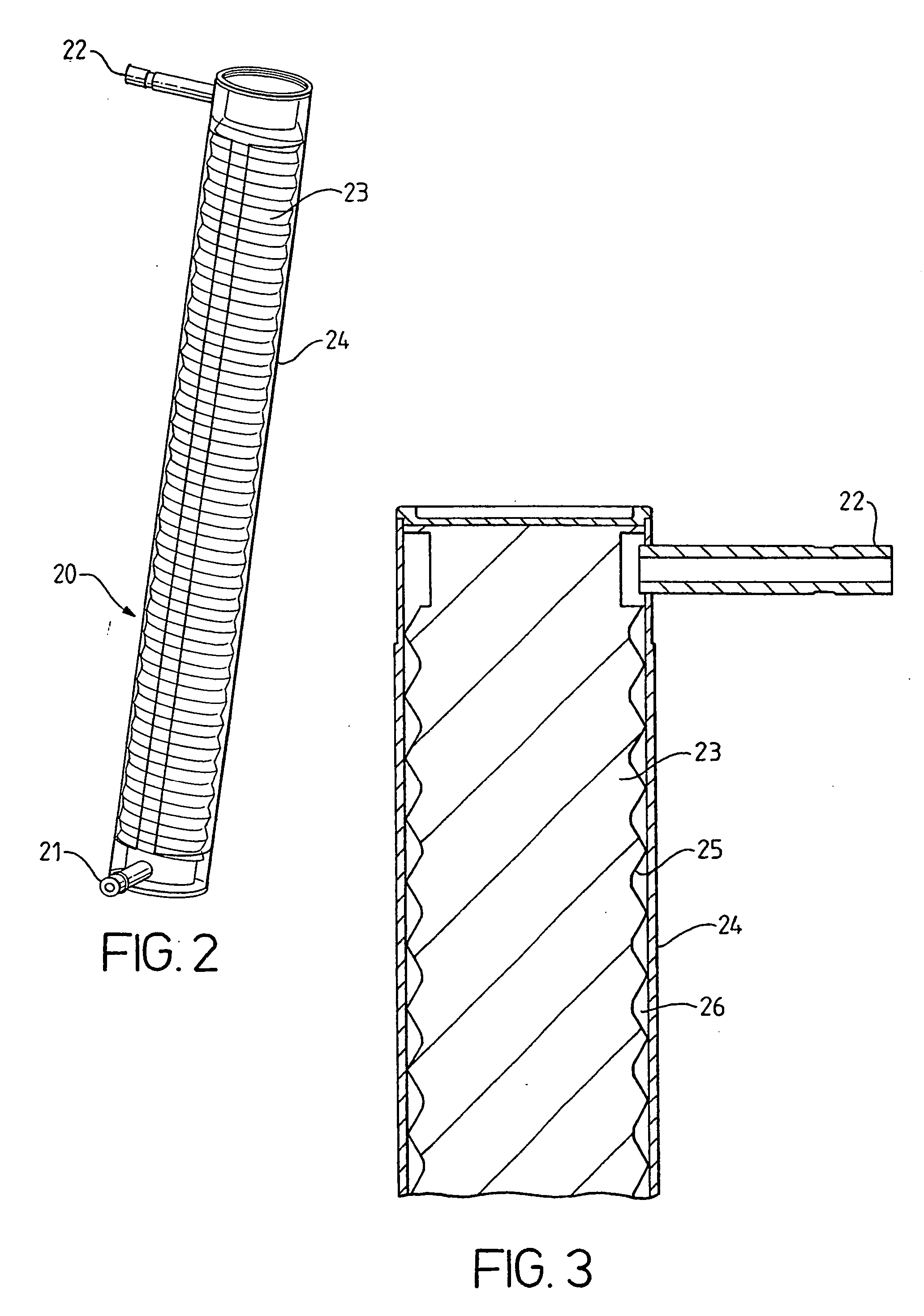

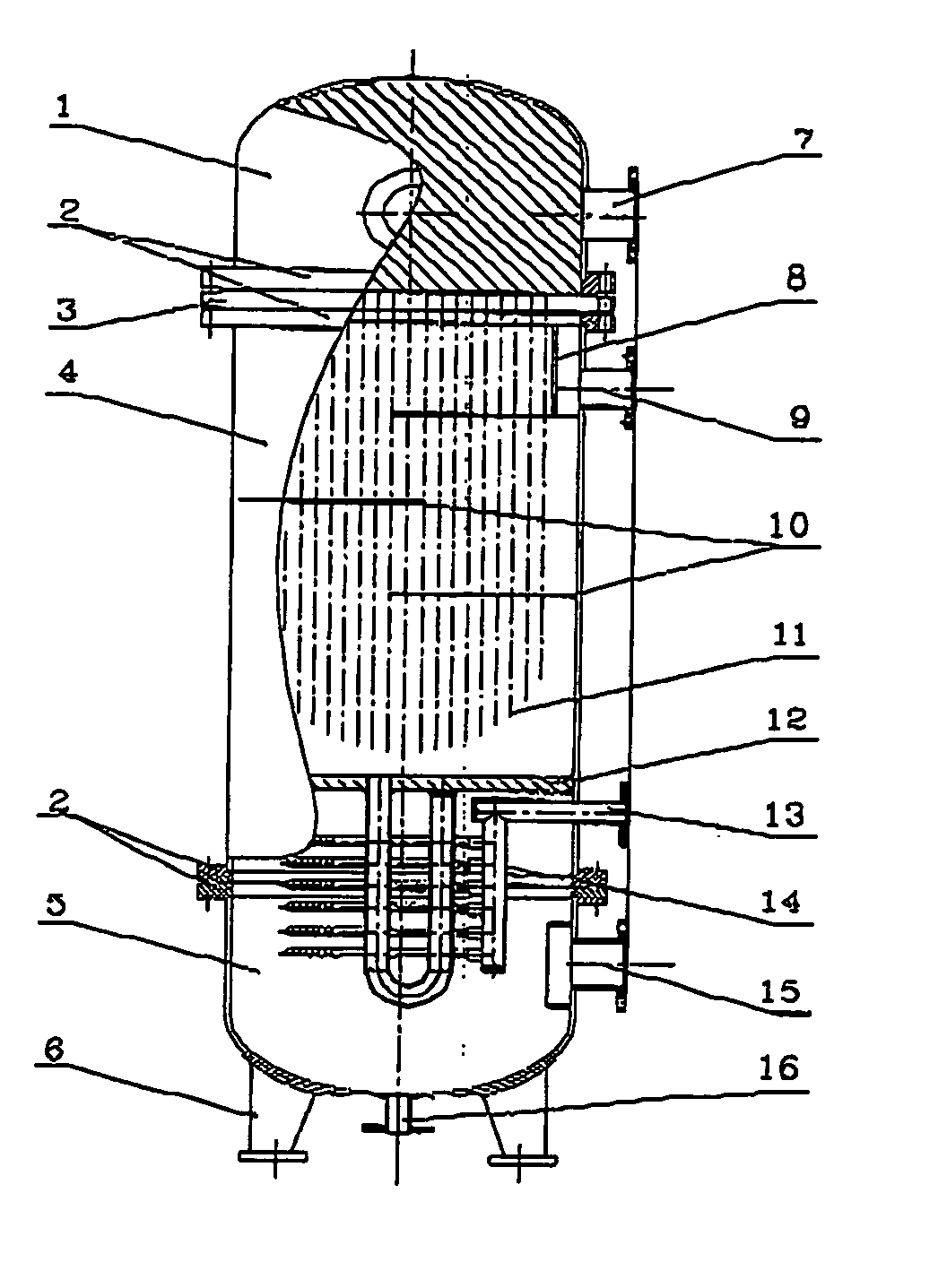

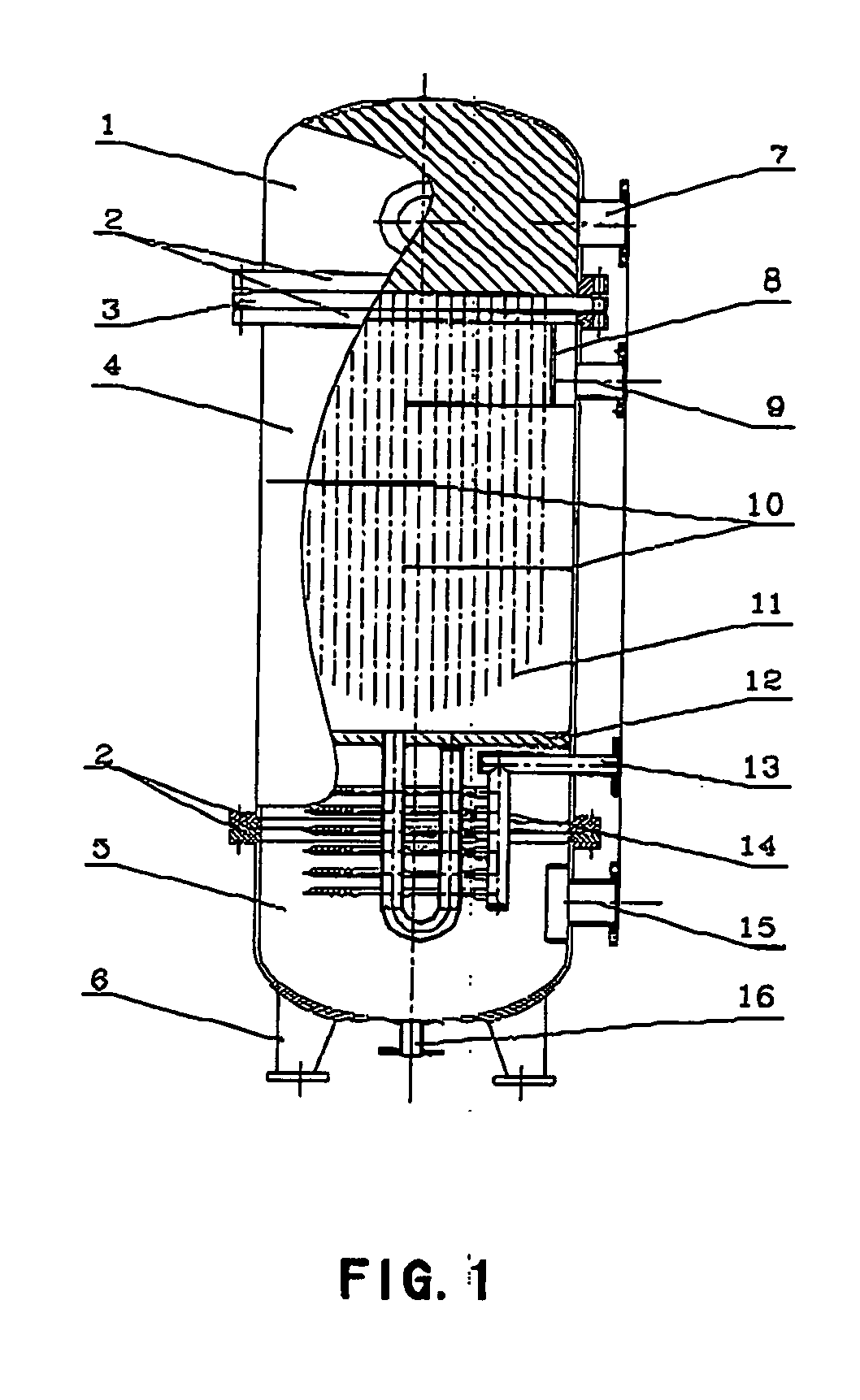

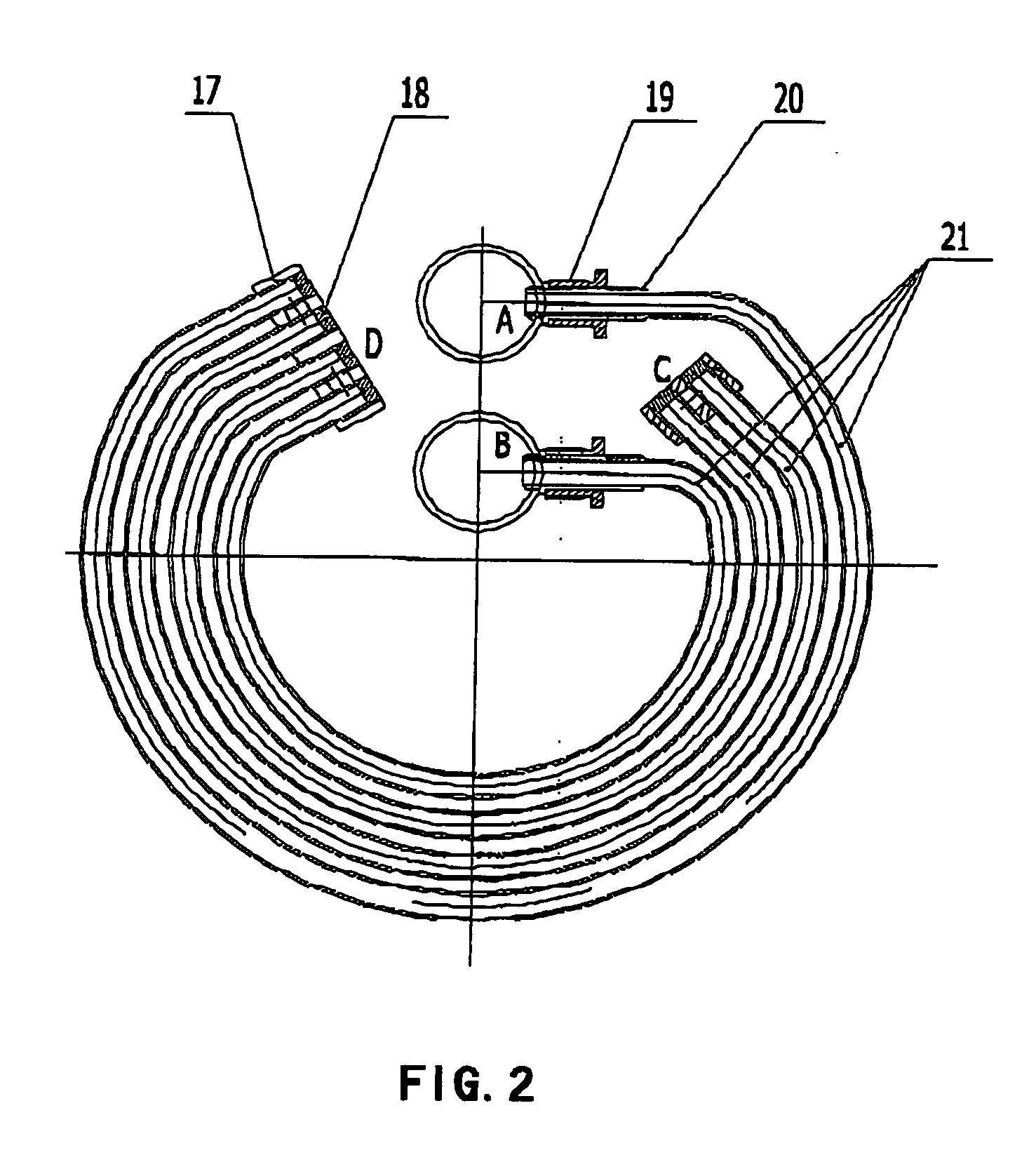

Complex flow-path heat exchanger having U-shaped tube and cantilever combined coil

InactiveUS20050109495A1Small flow resistanceIncrease water speedStationary conduit assembliesStationary tubular conduit assembliesWater flowEngineering

A complex flow-path heat exchanger having U-shaped tube and cantilever combined coil, which can achieve, in this type heat exchanger, a simple construction, a complex flow of steam within the same one heat exchange shell body, a high heat exchange efficiency, and a low energy loss. The technical gift of the present invention is that, after entering into the heat exchanger, steam firstly effects heat exchange on the U-shaped tube flow path shell side to be cooled and condensed, thereafter entering into flow path tube side of the cantilever combined coil, which are disposed within the same one shell, for a secondary heat exchange, and subsequently flowing out of the heat exchanger after being subcooled. Such steam-water heat exchanger having a complex flow path are advantageous in a small steam flow resistance of the U-shaped tube flow path shell side; a higher condensate water flow velocity in the cantilever combined coils flow path tube; a high heat exchange coefficient; good coordination of the temperature difference fields of the hot and cold fluids in the heat exchanger; and a high heat exchange efficiency. Therefore, the present heat exchanger can be a new generation product relative to the currently-used conventional low-temperature, low-pressure and corrosion-free heat exchangers.

Owner:SHANDONG UNIV

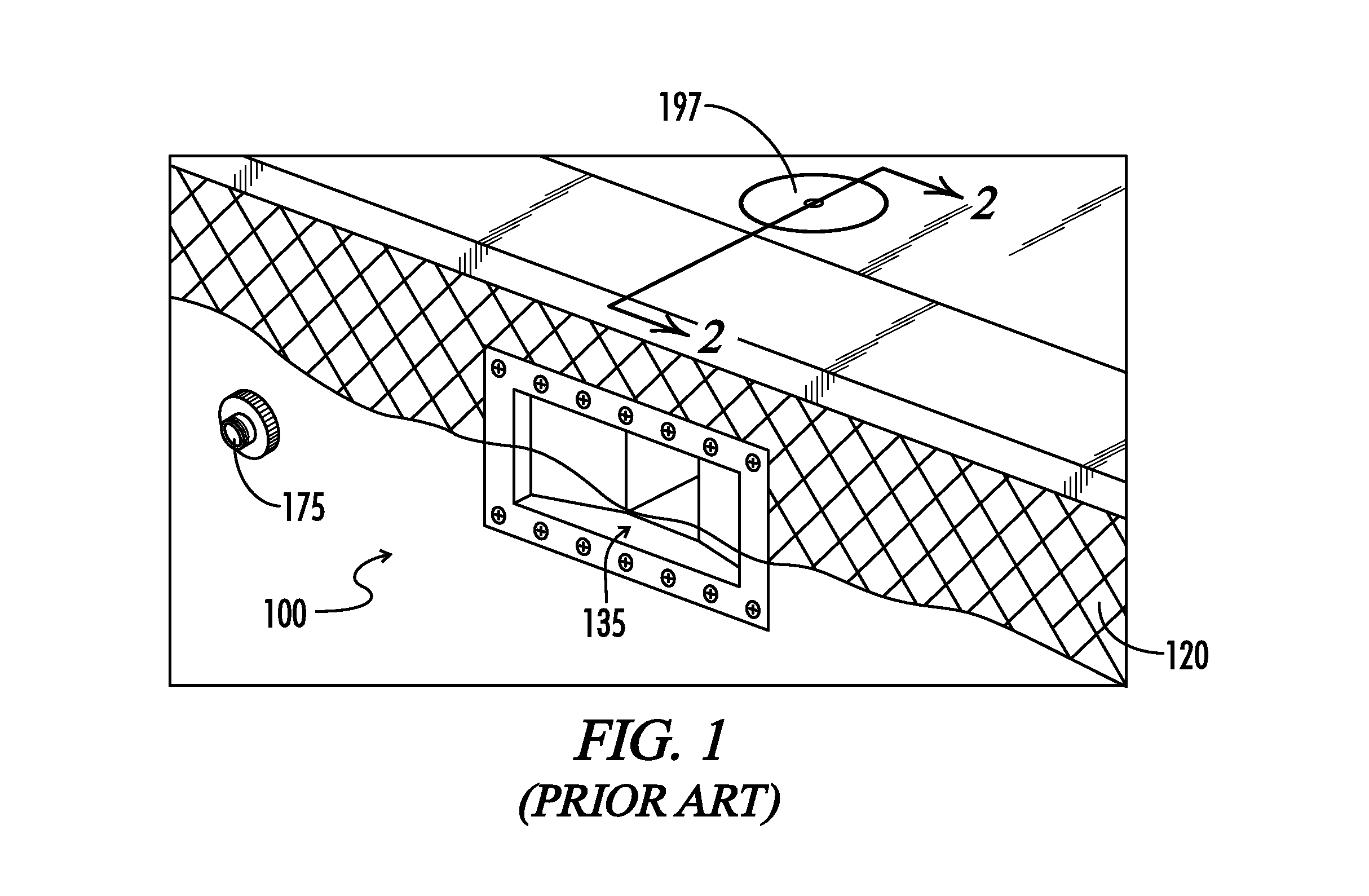

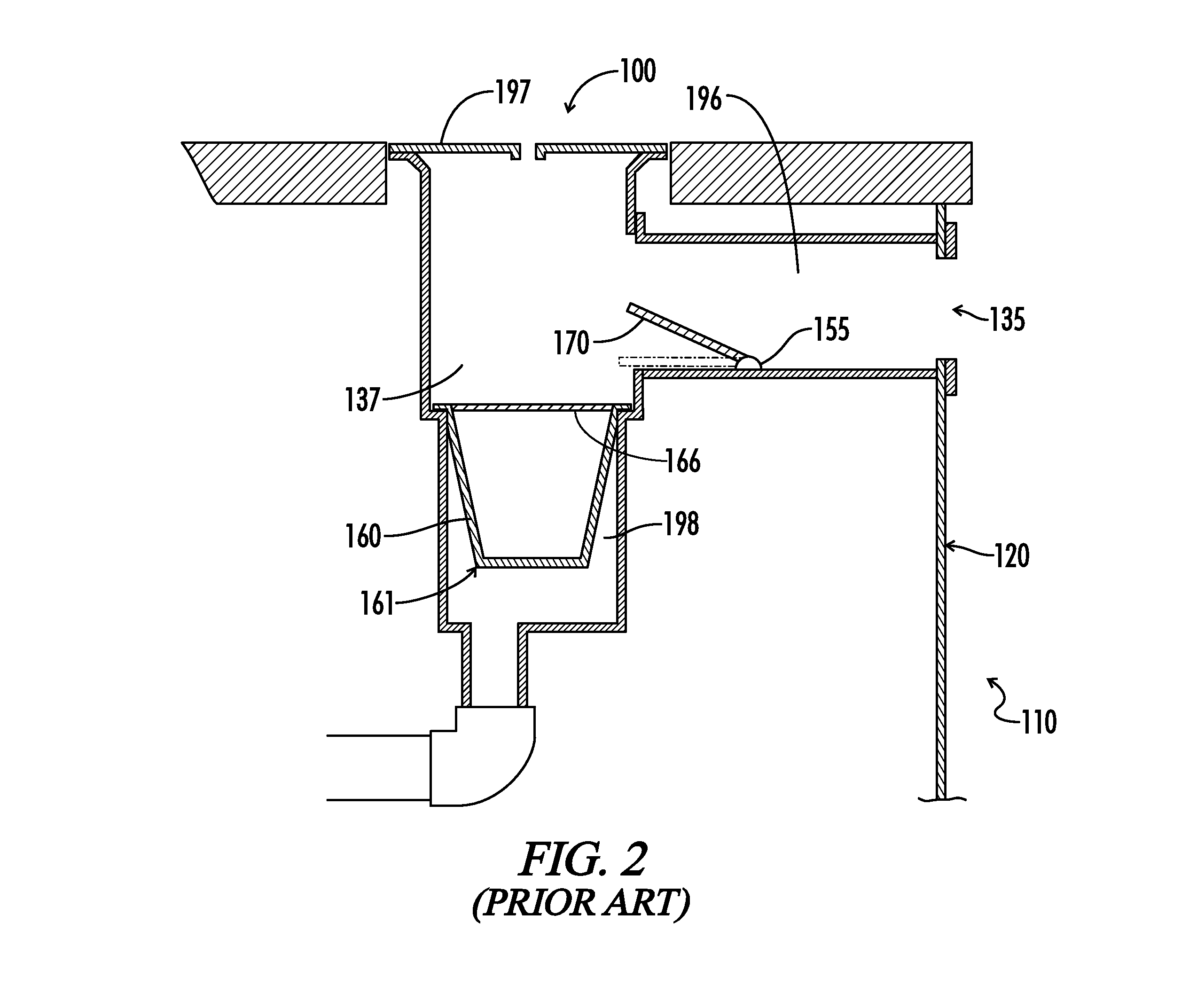

Shoreline erosion barrier and method

InactiveUS20060159518A1Easy to fillControl erosionLayered productsCoastlines protectionEngineeringMechanical engineering

A barrier for reducing erosion along shorelines includes a barrier body formed as a unitary, molded plastic structure. In one embodiment, the barrier body has at least one elongate passage extending through it, between oppositely disposed first and second sides, and an interior reservoir. A port formed into the barrier body communicates with the interior reservoir to facilitate filling the reservoir with material to thereby add weight to the barrier. The barrier further includes at least one anchor formed into a side of the barrier body and associated with the passage to control shrinkage of the barrier body as it is being molded. In another embodiment, a method of making the barrier body includes placing plastic material in a mold, manipulating the mold to distribute the plastic material within the mold and thereby form the barrier body as a unitary piece, and reducing the shrinkage of the molded barrier body with the anchor.

Owner:THE GRANGER PLASTICS

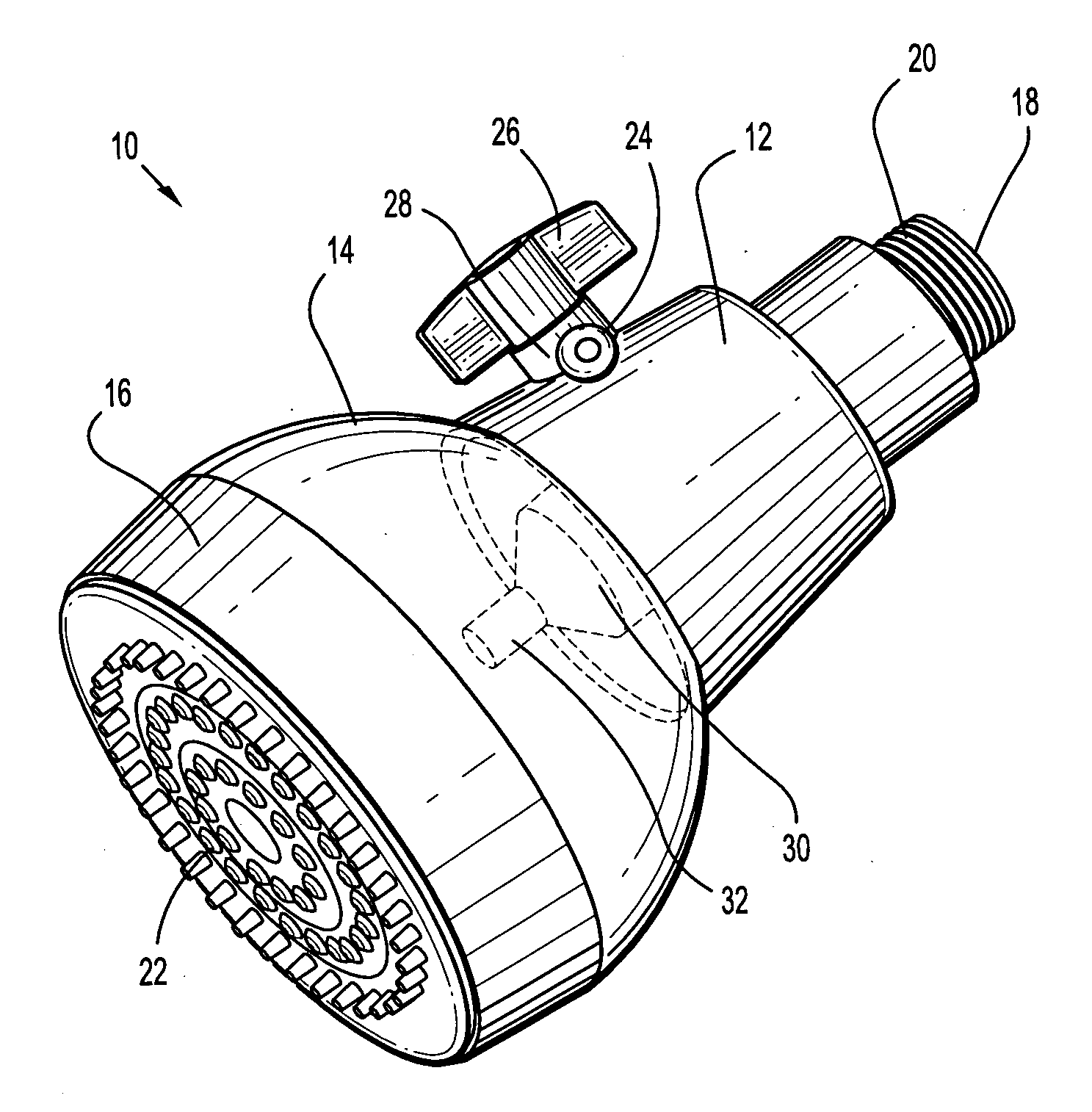

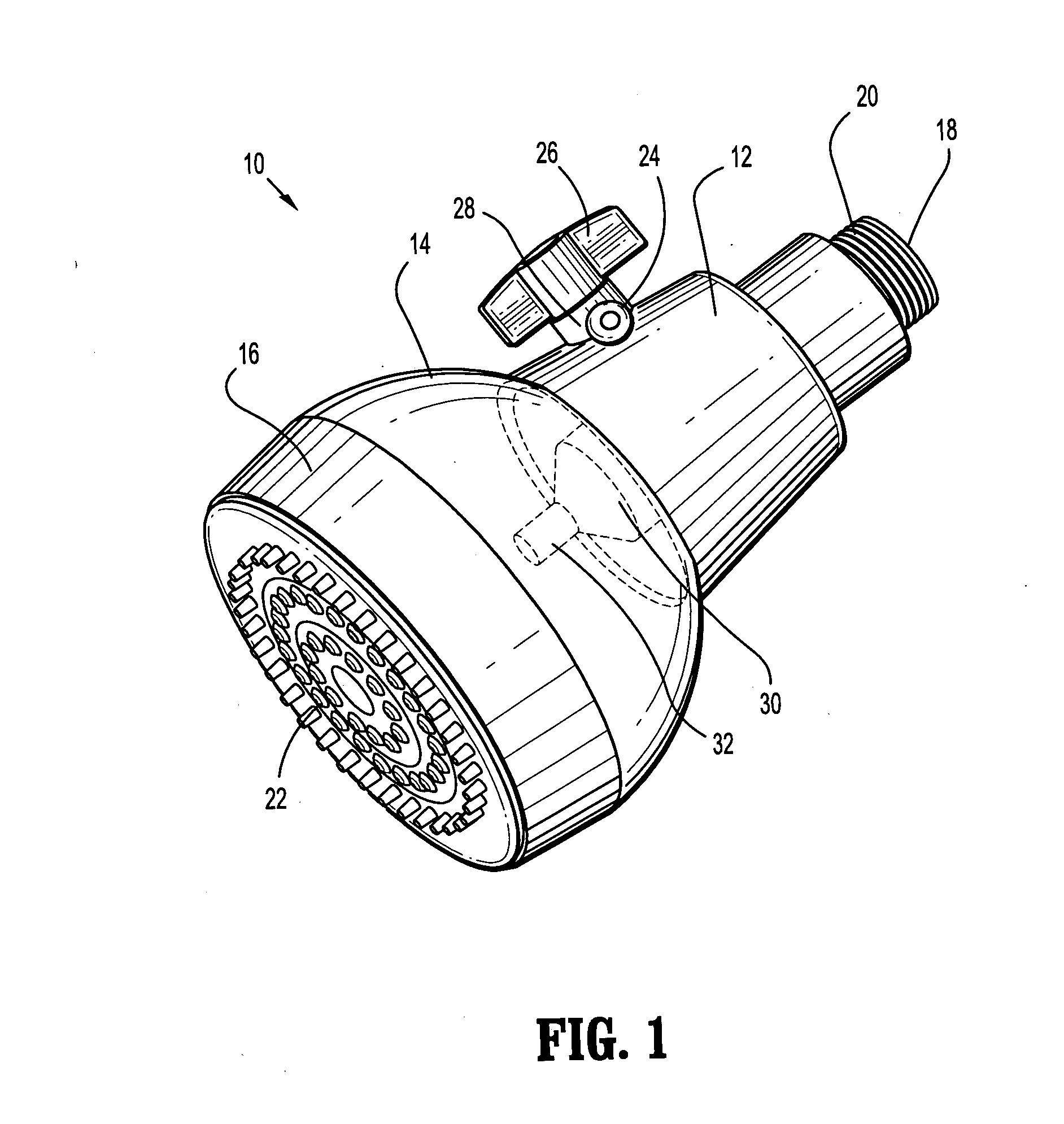

Oxygenating showerhead

InactiveUS20070158470A1Increase water speedReduce the overall diameterSpray nozzlesDomestic plumbingStreamflowMixing chamber

There is provided a showerhead device that includes a shower stem connector, a water / air mixing chamber, and an outlet cap. The shower stem connector includes a water inlet to receive water from a standard shower plumbing system and an air intake opening to receive air from outside the device. The preferred embodiment features an air intake opening located near the water inlet on the shower stem connector. A user can adjust the air intake knob in order to vary the amount of air that enters the device and mixes with the water flow. As the water progresses through a nozzle in the device, the speed of the water is increased by the decrease in diameter of the nozzle orifice. The water mixes with the air and the combination of water / air hits a plate on the inner wall of the outlet cap within the mixing chamber. This oxygenation of the water provides for a better water flow though the showerhead device. The mix of water and air provides for a stronger water flow and a better shower experience for a user. By having the air intake further upstream, it enables a user to adjust the amount of air mixed in.

Owner:CONAIR CORP

Drinking water heating device with pre-heating function

The invention relates to a drinking water heating device, in particular to a drinking water heating device with a pre-heating function, which comprises a seat body, a water outlet nozzle and an instant-heating heater, wherein the instant-heating heater is provided with an inlet and an outlet; the inlet is connected with a water inlet pipeline; the outlet is communicated with the water outlet nozzle. The drinking water heating device is characterized in that: the drinking water heating device also comprises a pre-heater; the pre-heater is arranged on the water inlet pipeline; the drinking water heating device pre-heats the water entering the instant-heating heater so as to primarily increase the water temperature; and the primarily heated water can be quickly heated to a boiling point or a temperature close to the boiling point after being heated by the instant-heating heater so that the heating time is saved and large water outlet flow can be ensured for drinking without increasing power of the instant-heating heater. The drinking water heating device is simple and rational in structure, simple and safe in use, low-carbon and energy-saving, and long in service life, and can satisfy various different drinking requirements of people, for example, making tea, making coffee and the like.

Owner:冯海涛

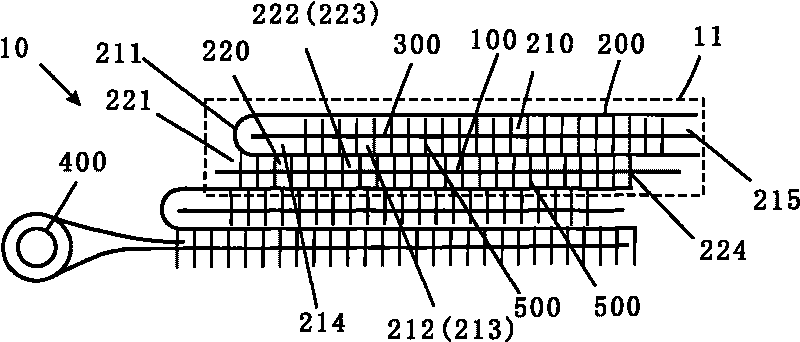

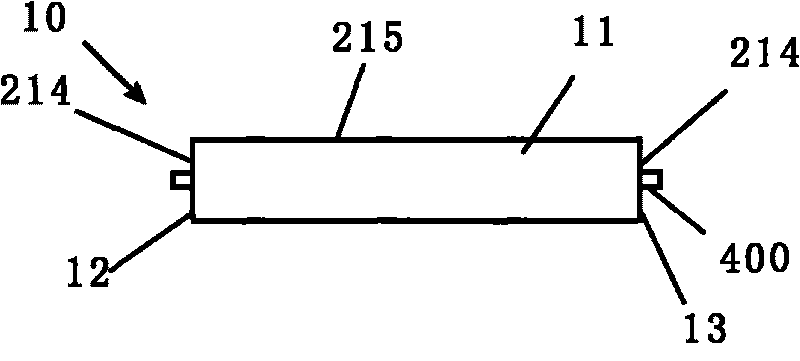

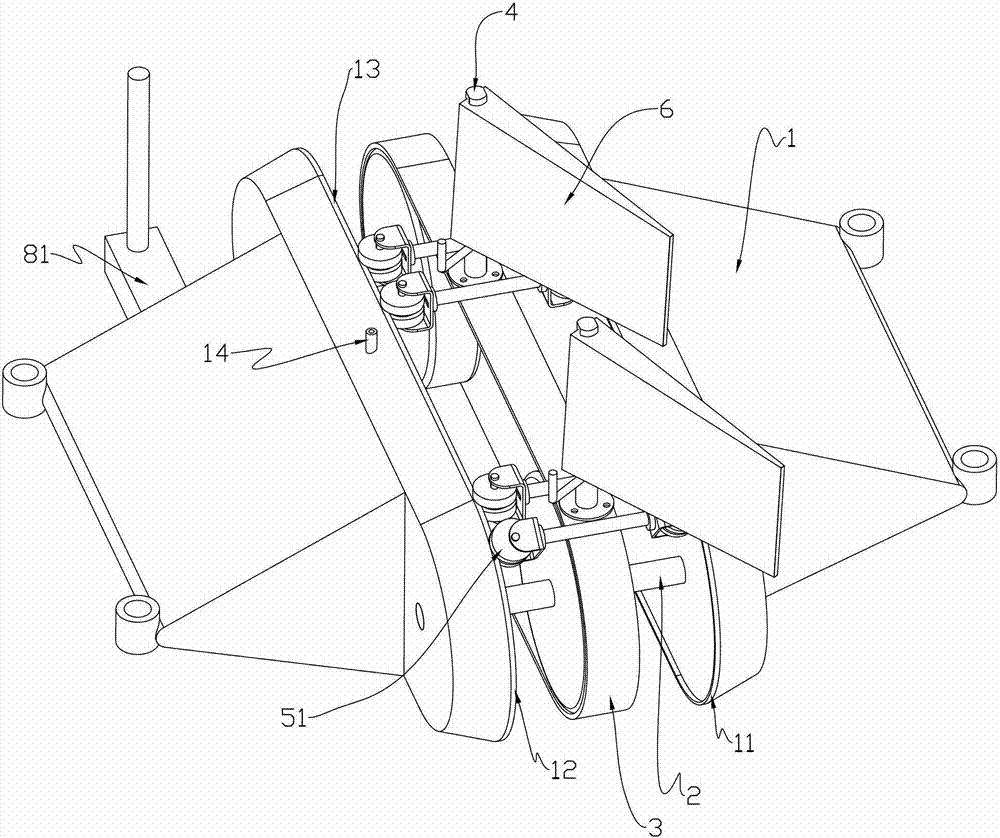

Polyacrylonitrile as-formed fiber rinsing bath and application

ActiveCN102677200AConserve waterFree to adjust the quantityArtificial filament washing/dryingOutfallPulp and paper industry

The invention provides a polyacrylonitrile as-formed fiber rinsing bath. The rinsing bath is characterized in that a shell (13) of the rinsing bath is a U-shaped bath; a circulating pump (10) and a heat exchanger (11) are connected with the bottom of the shell (13); an outfall (8) and a water inlet (9) are arranged at the bottom of the shell (13); a temperature measurement hole (5) is arranged on the side of the shell (13); drawing rollers are installed on the shell (13) and comprise silk entering drawing rollers (1), intermediate drawing rollers (2) and silk exiting drawing rollers (3), which are in the same size; a water outlet (6) is arranged on the shell (13) and is on the same level with a rinsing bath liquid level (12); and the water outlet and the water inlet (9) are arranged at the two ends of the shell (13). The rinsing bath has the advantages of uniform water temperature distribution, simultaneous suitability for big and small tows, high rinsing efficiency and good effect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

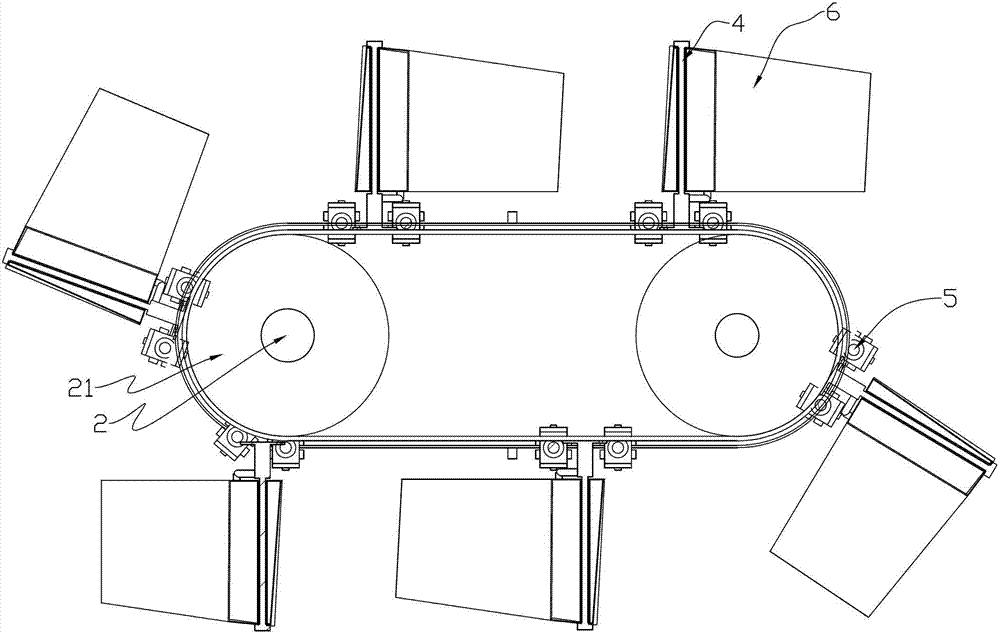

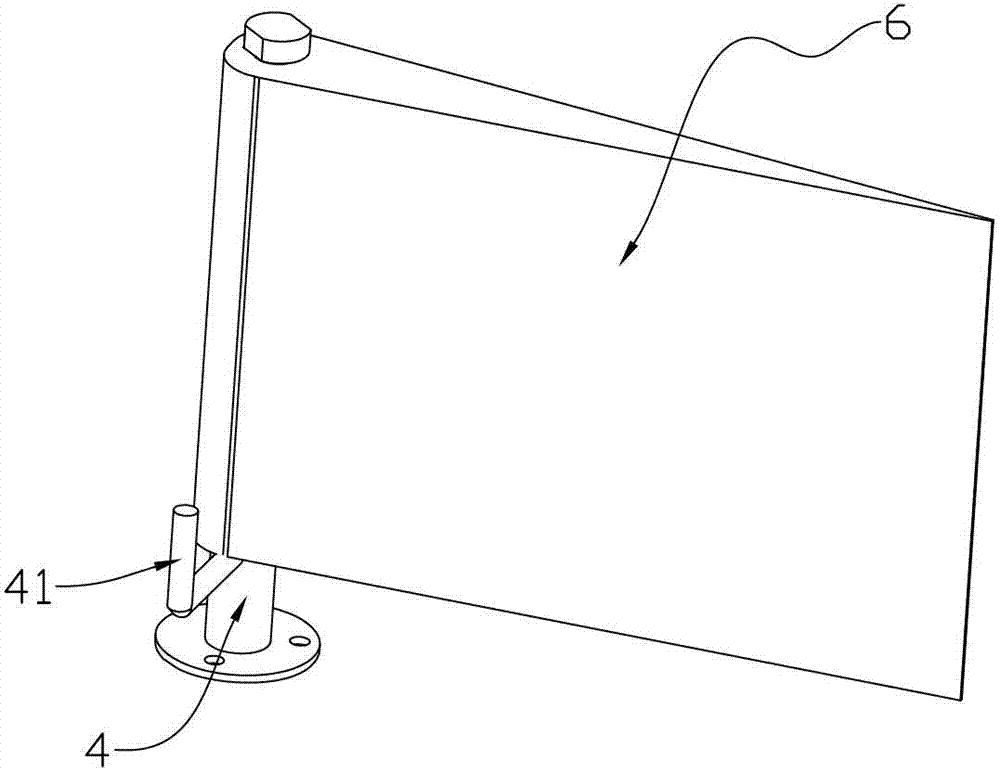

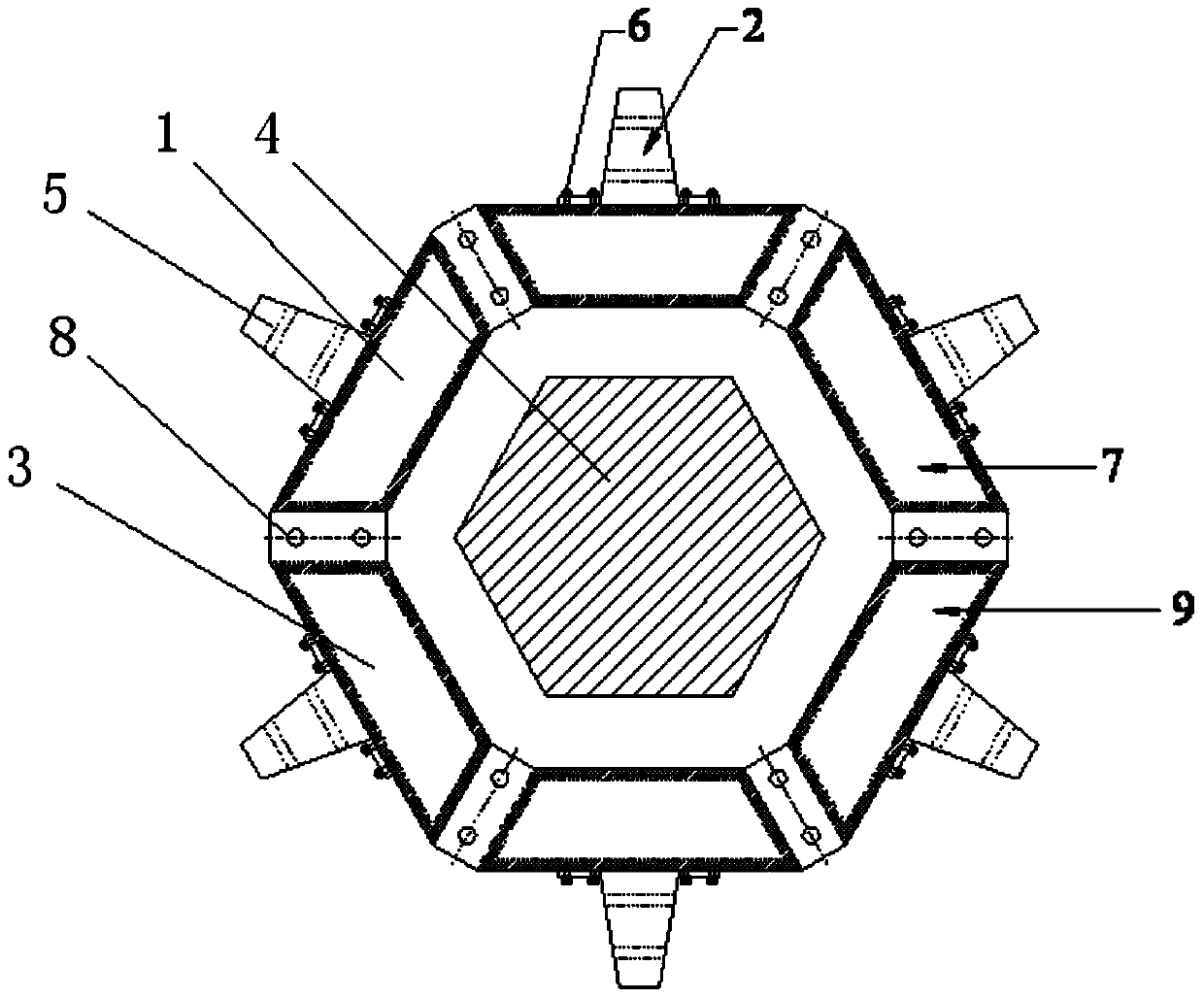

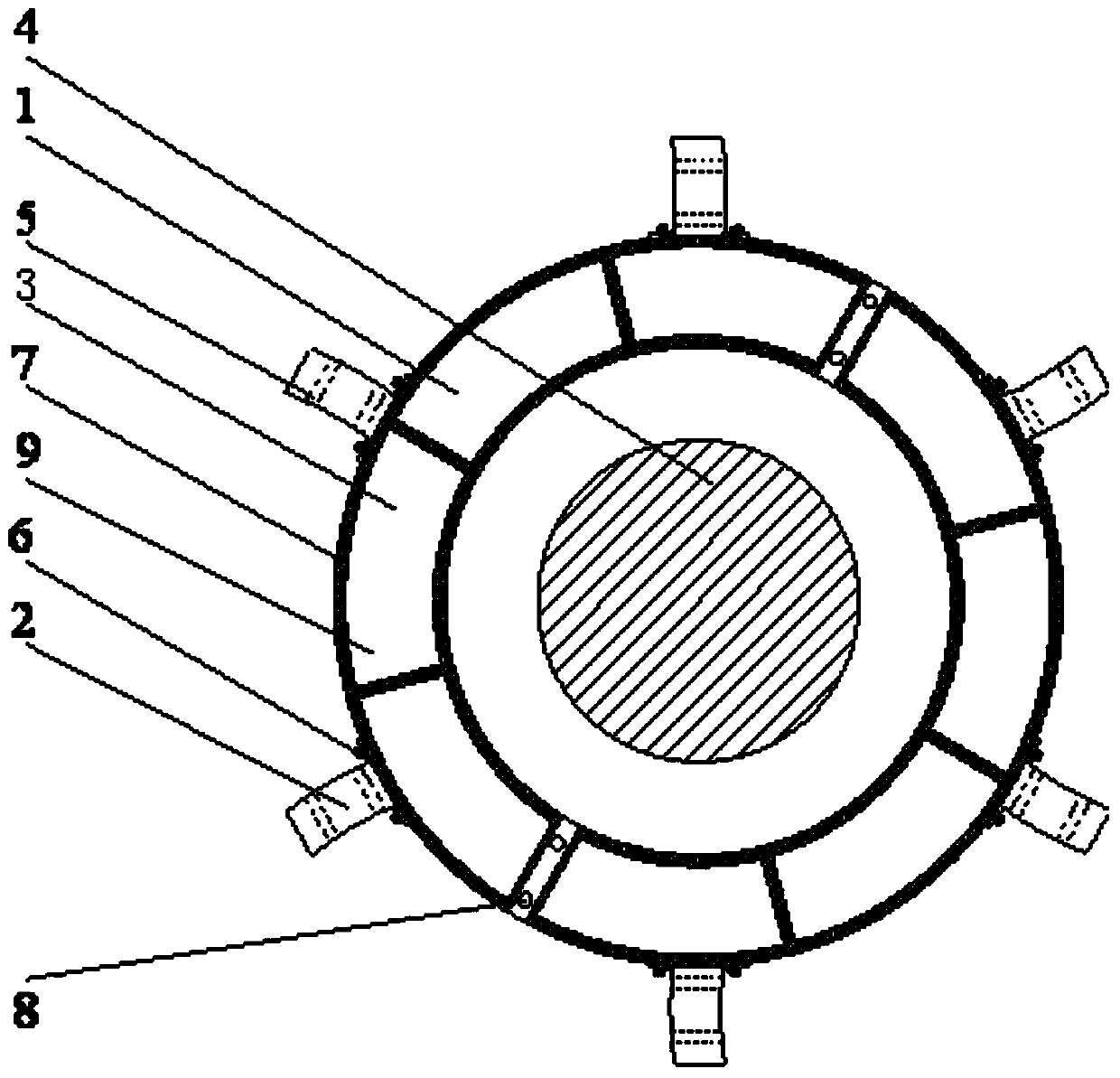

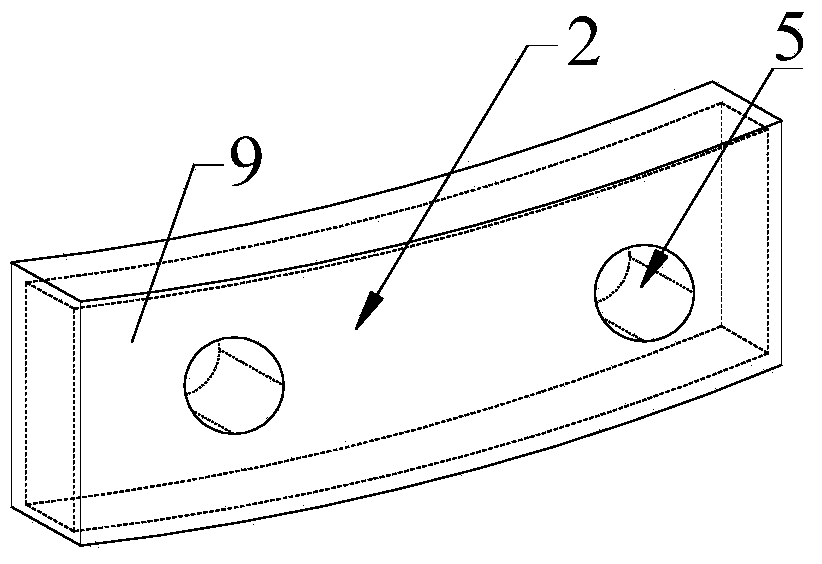

Ocean wave energy generating set

InactiveCN103089531AEasy to installGuaranteed uptimeFinal product manufactureMachines/enginesElectricityEngineering

The invention discloses an ocean wave energy generating set, and solves the problem that an existing power generation device cannot operate continuously without impact. The ocean wave energy generating set comprises a generator, belt wheel shafts, a belt, blades and supports. The generator is driven by the belt wheel shafts to generate electricity. The supports are mounted on the belt, and the blades are mounted on the supports. The ocean wave energy generating set is characterized by further comprising wedge-shaped waving dykes which are arranged in pairs, wherein at least two belt wheel shafts are mounted between the waving dykes in a parallel mode, rubber air-filled tires are arranged on the belt wheel shafts, the belt is placed between the rubber air-filled tires in a sleeved mode, a track guiding mechanism is arranged between each waving dyke and the belt, and each support is provided with a limiting stop block used for limiting the front-back swing angle of the blade on the support along a track surface of the belt. The ocean wave energy generating set is good in comprehensive performance and takes overall consideration of multiple factors such as manufacture, installation, maintenance and long-term power generation.

Owner:于传祖

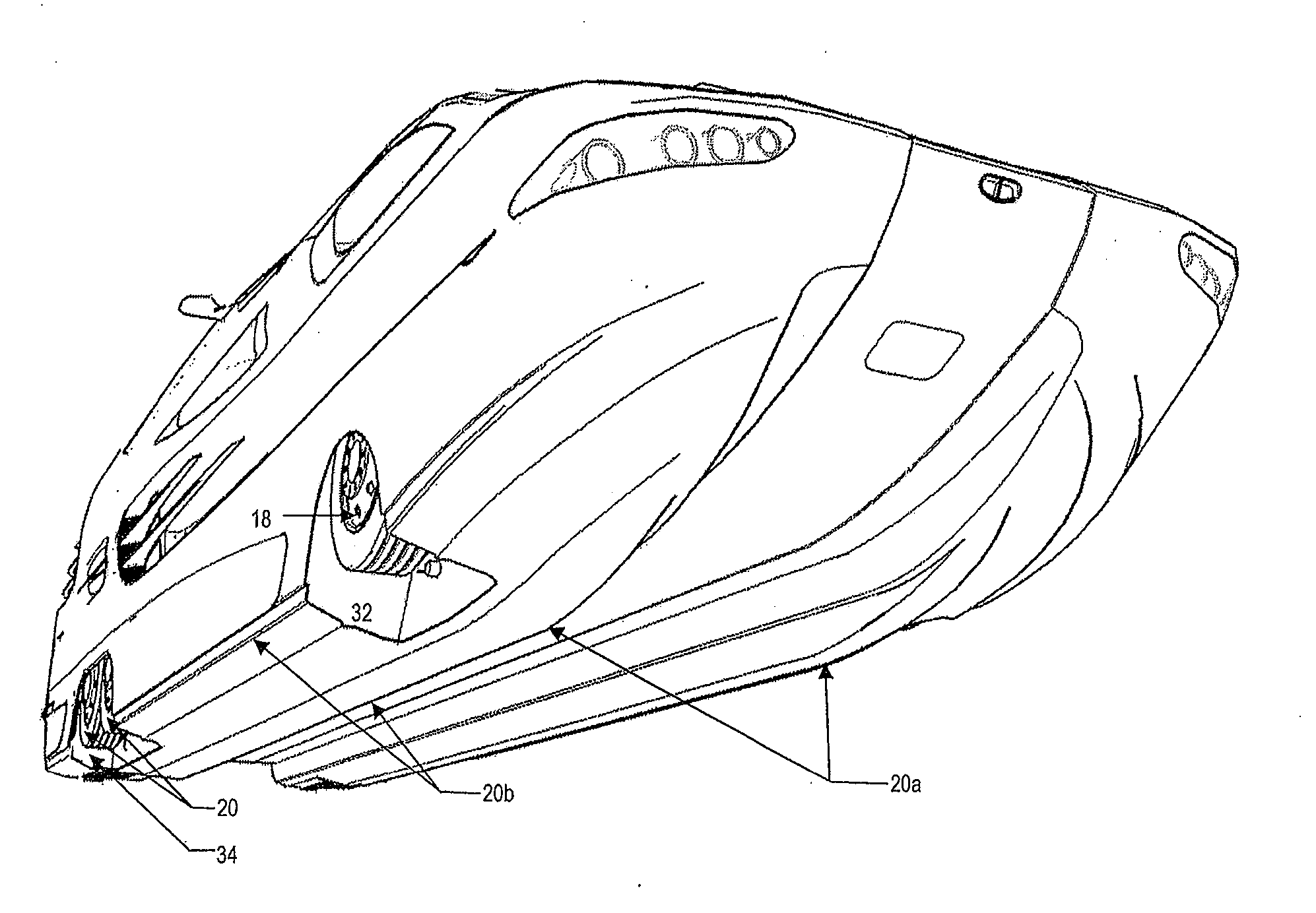

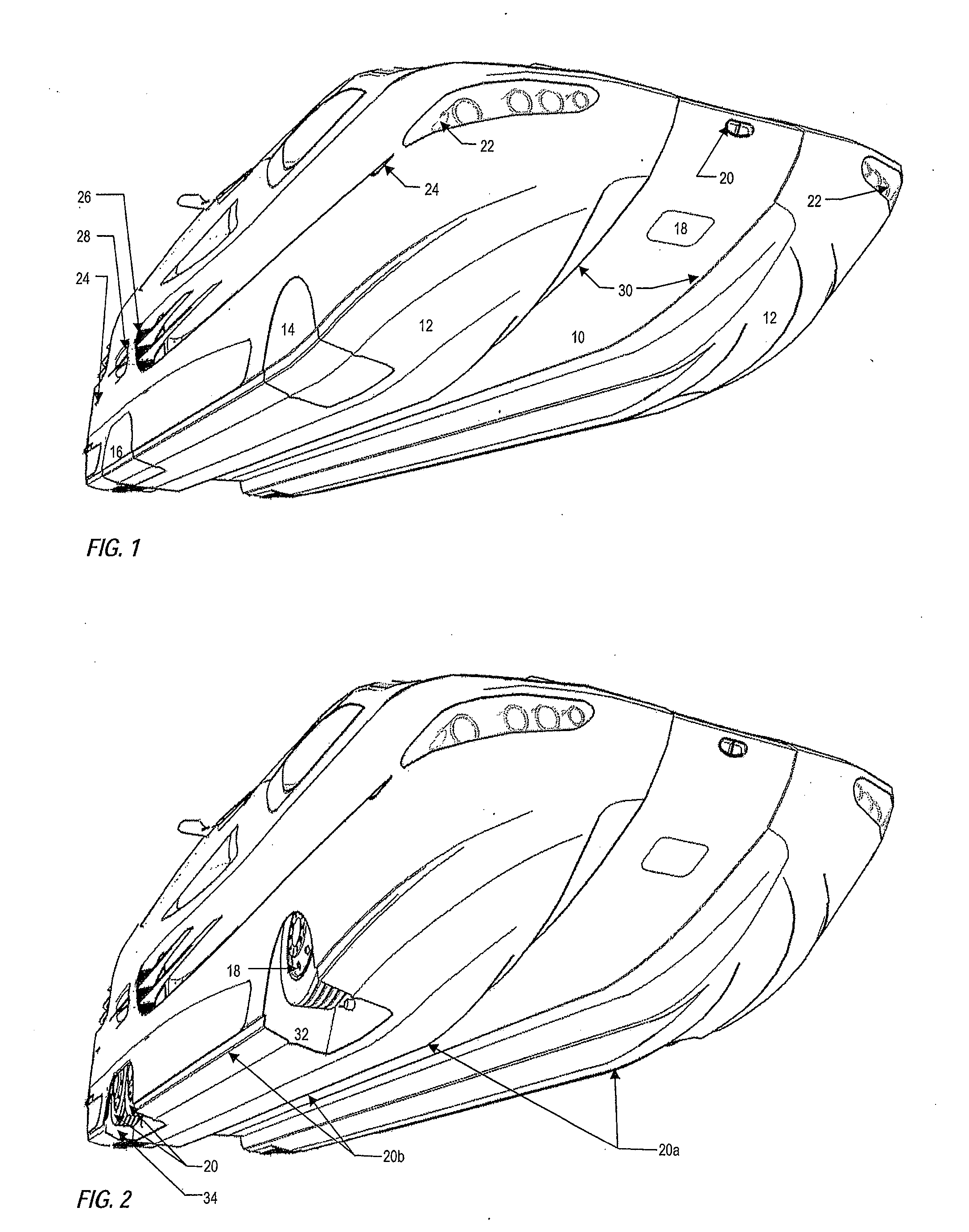

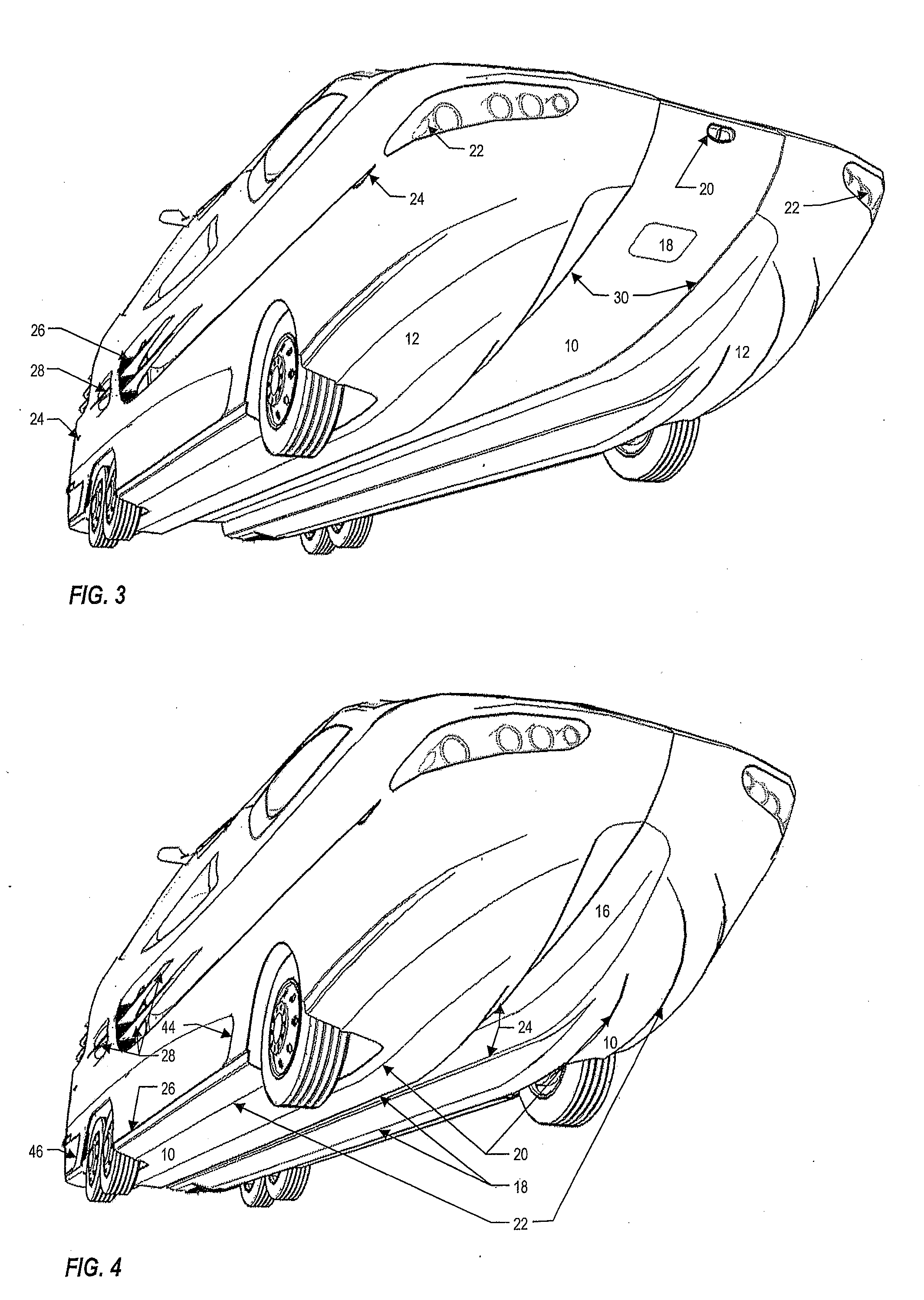

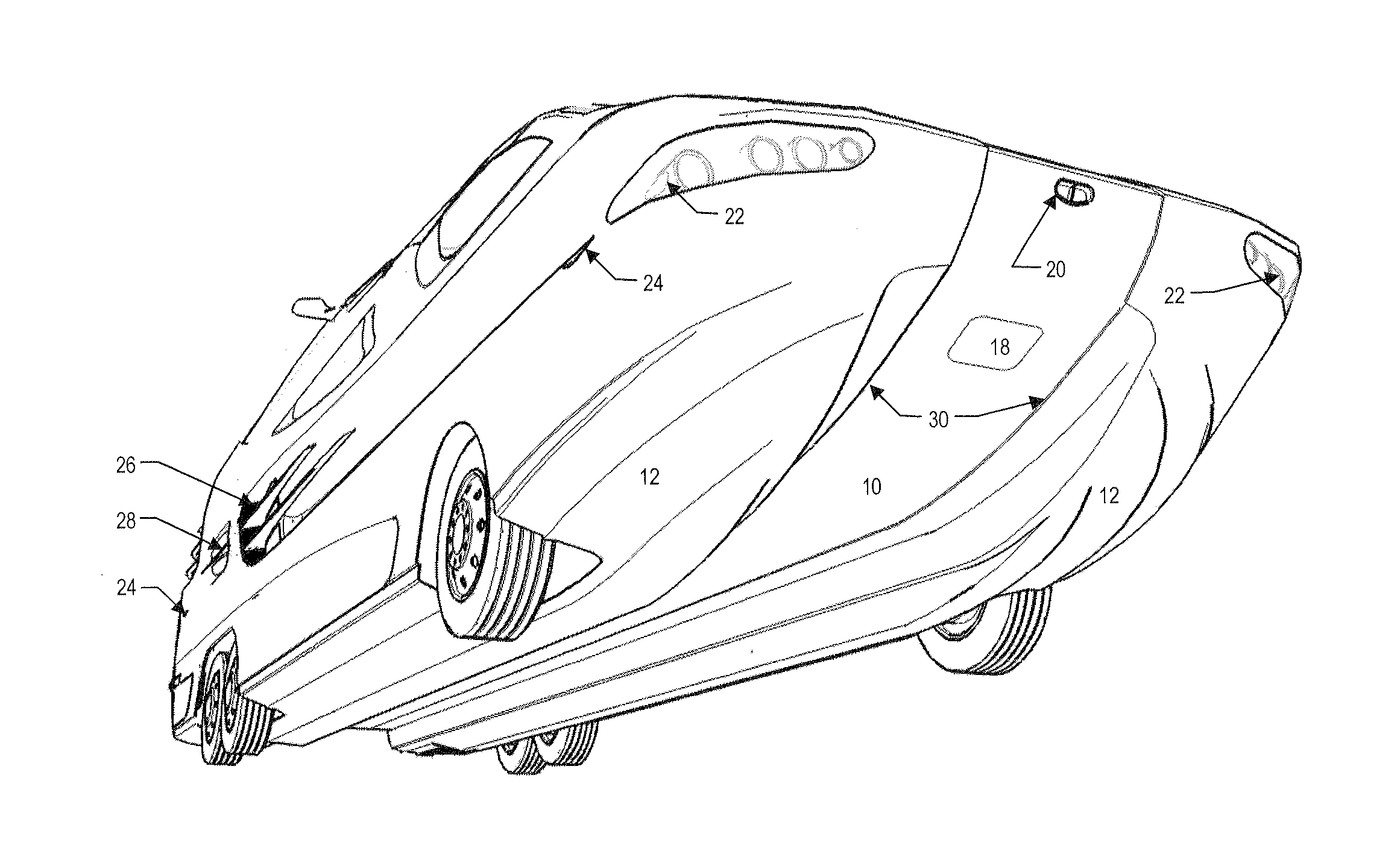

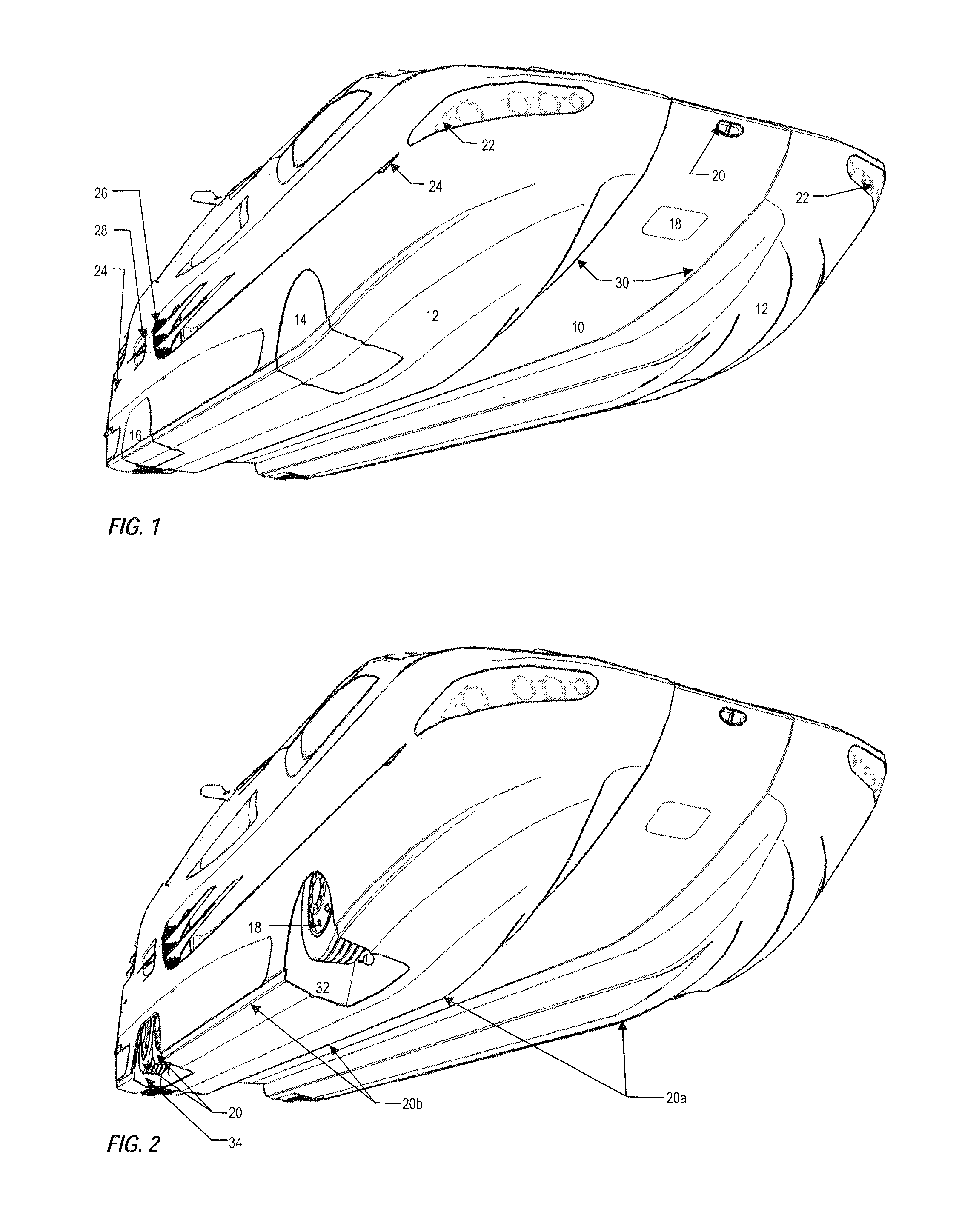

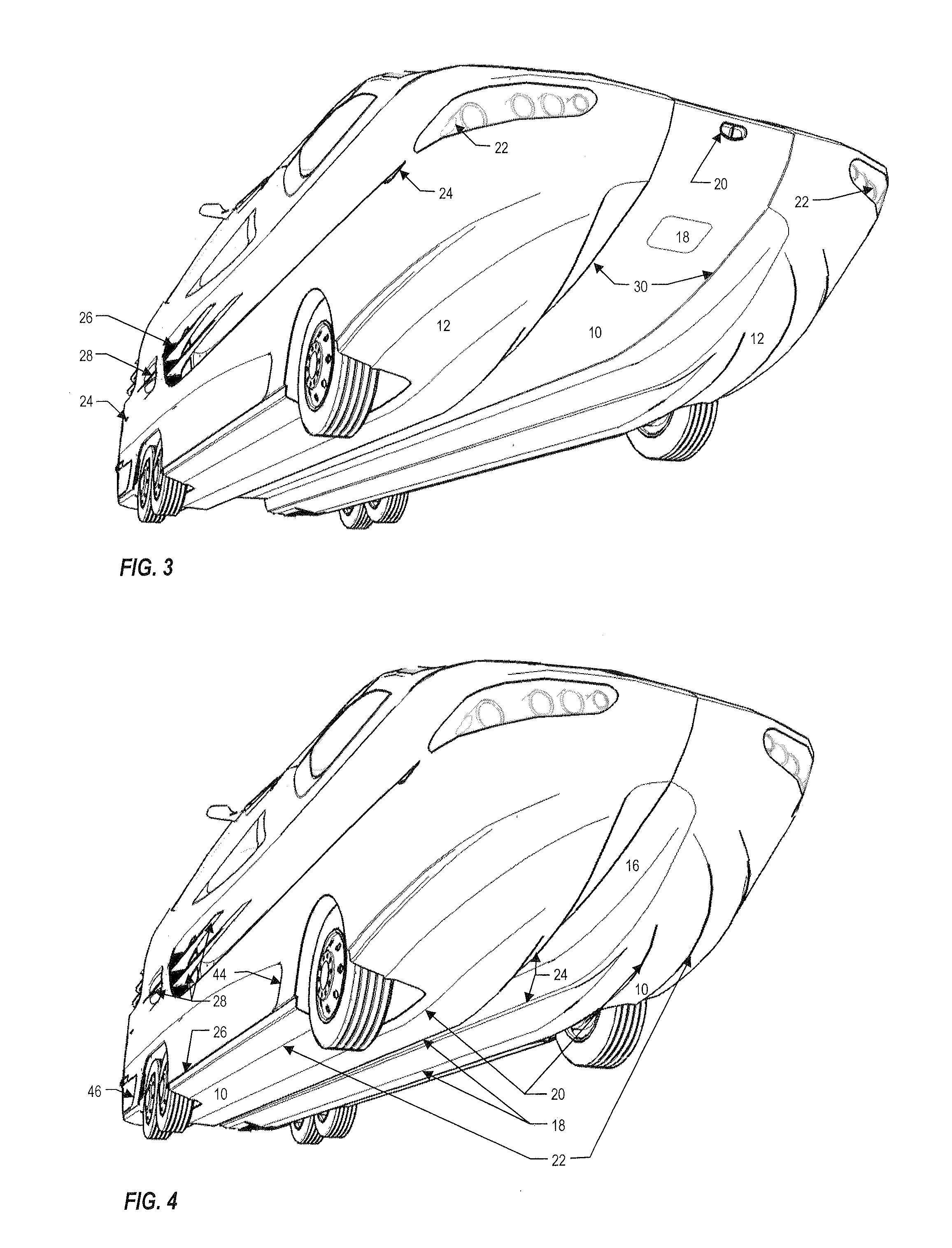

Amphibious yacht

ActiveUS20140004761A1Easy to manufactureEconomy of scaleAmphibious vehiclesCargo handling apparatusMarine engineeringMotor home

A streamlined amphibious, catamaran yacht is provided that may serve military or civilian purposes as a passenger or cargo carrying truck, limousine, bus, motor home or recreational vehicle on land, and extend those same functions on water, while matching the functionality and performance of similar length boats. The amphibious yacht includes a continuous reveal on the hull bottom from bow to transom that separates two asymmetric catamaran hulls. This reveal, or hull tunnel, may enhance sea stability and maneuverability, and create lift that helps the hull achieve plane and attain higher water speeds.

Owner:NEPRUD KEVIN R

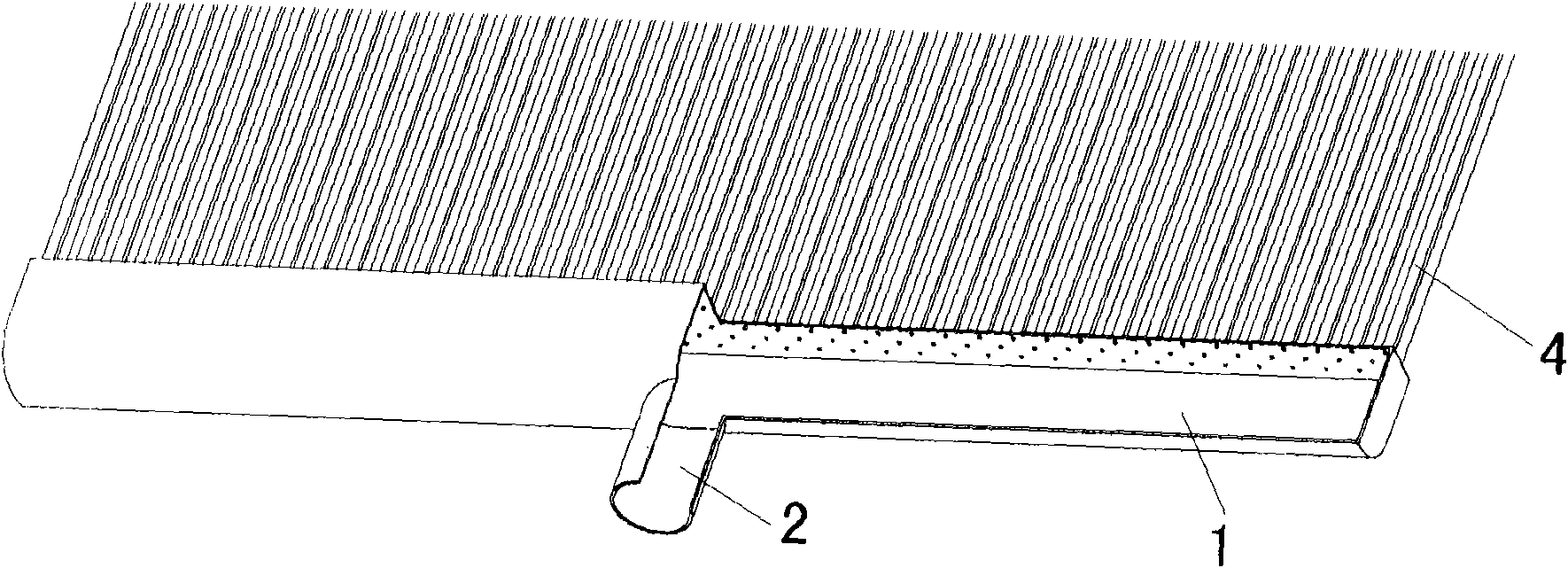

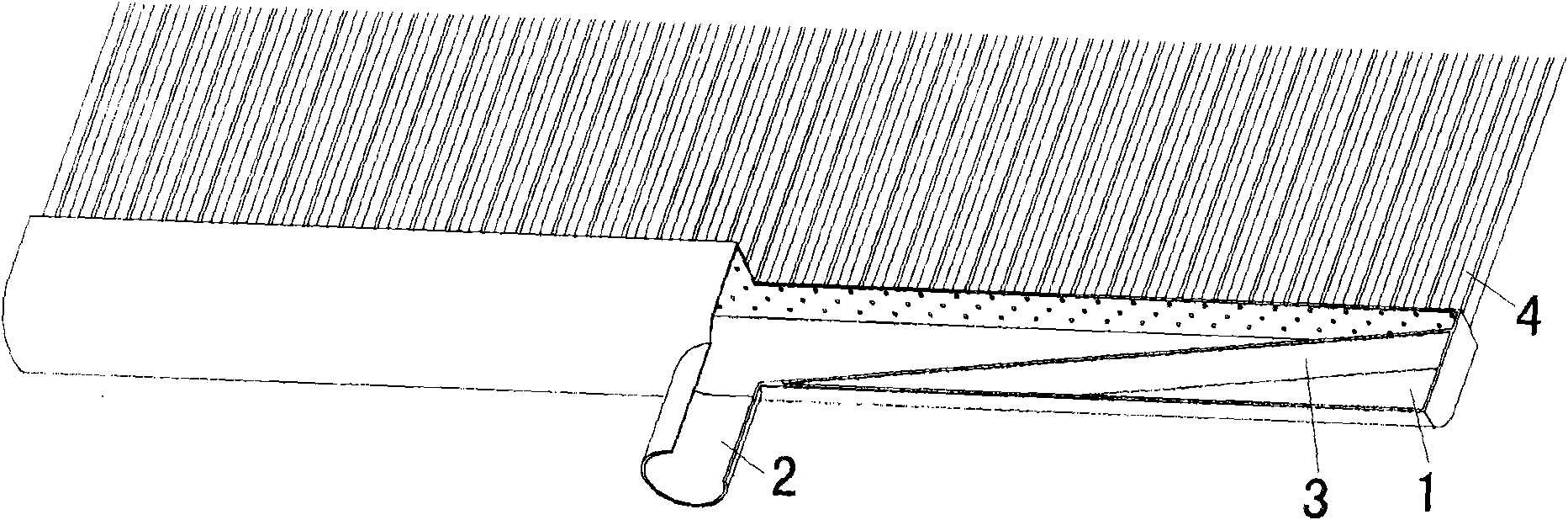

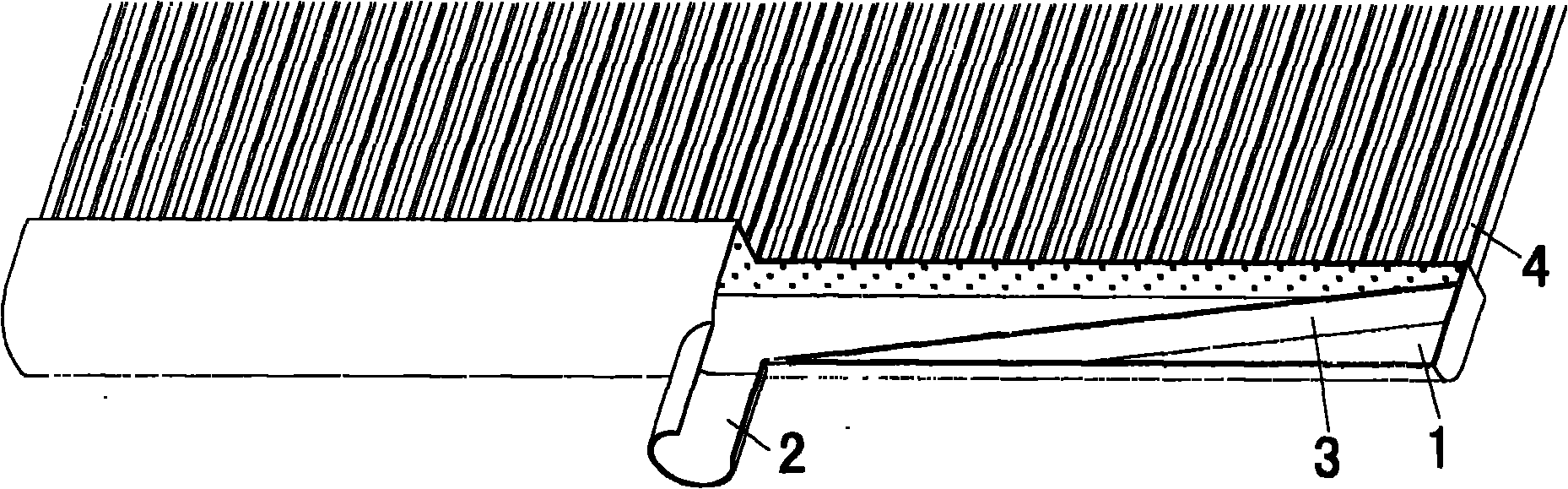

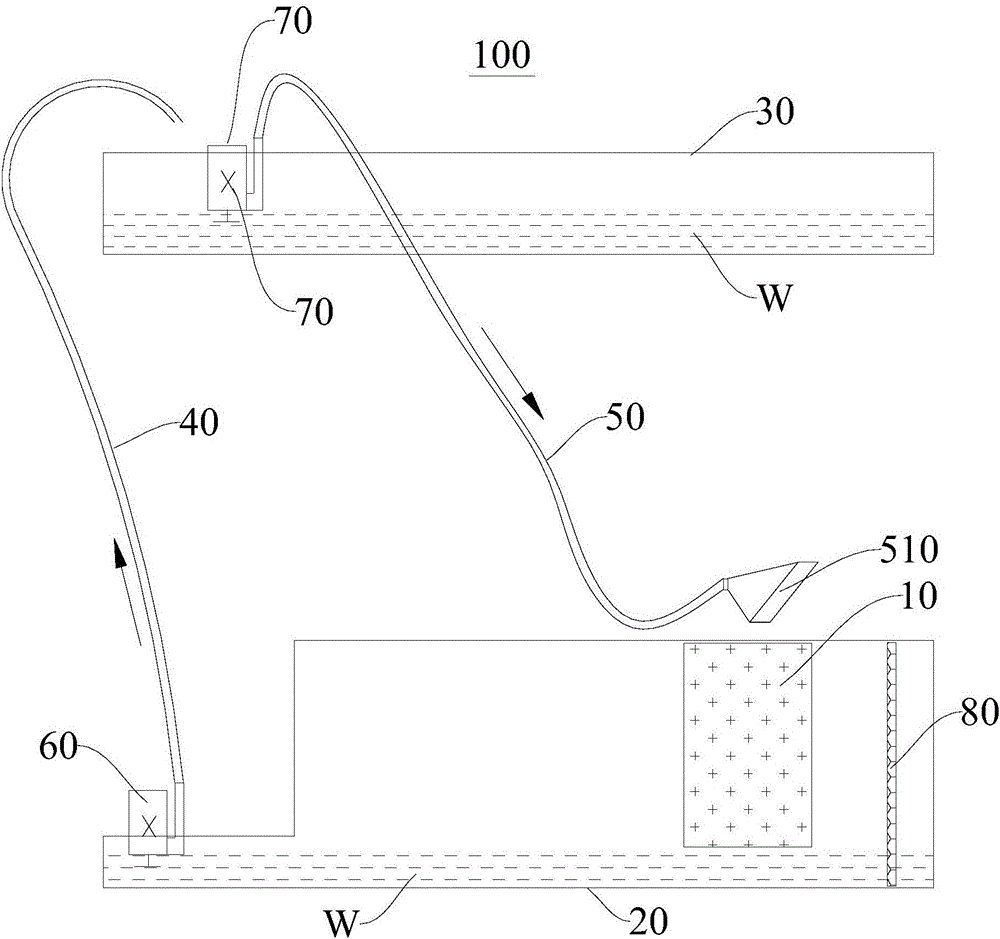

Filtration irrigation device

InactiveCN101549334AReduce impact speedExtended service lifeClimate change adaptationWatering devicesSurface layerFiltration

A filtration irrigation device consists of a tubular housing, a porous filter membrane and a flow snubber. Water in the tubular housing becomes irrigation water after passing through the porous filter membrane and the flow snubber sequentially. The porous filter membrane selects impurity grains having stronger pedesis characteristic as possible obstruction to be suspended on pores of the porous filter membrane, meanwhile, the flow snubber restricts extremely low flow velocity penetrating the porous filter membrane, so that the obstruction can only be suspended on the surface of the porous filter membrane; water flowing in the tubular housing plays a role of cleaning the obstruction on the surface layer of the porous filter membrane which can not be blocked for long-time use; the aperture of a limiting hole in the flow snubber is greater than the aperture of the porous filter membrane, so that the flow snubber can not be blocked. The filtration irrigation device can be used for a long time without being blocked.

Owner:诸钧

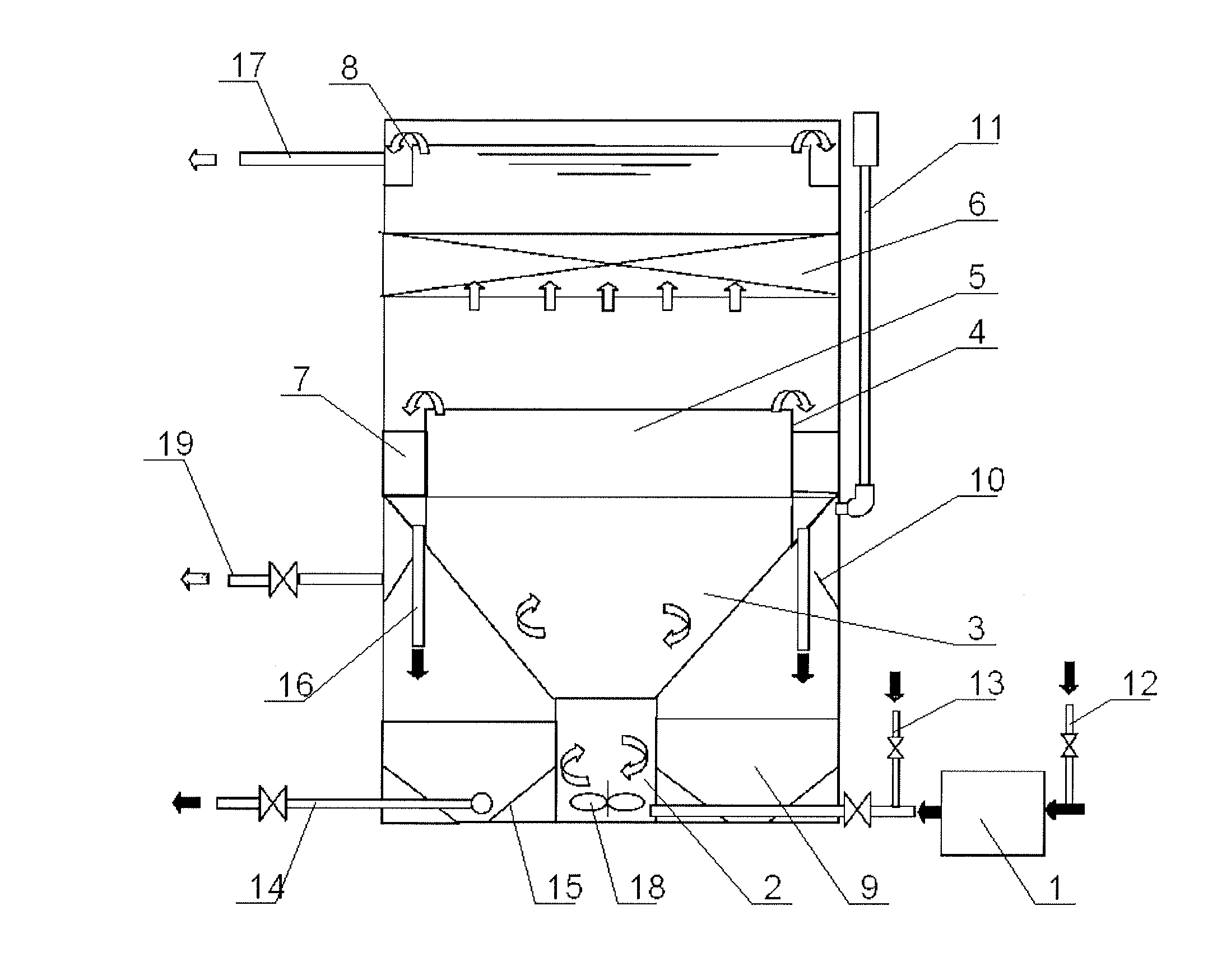

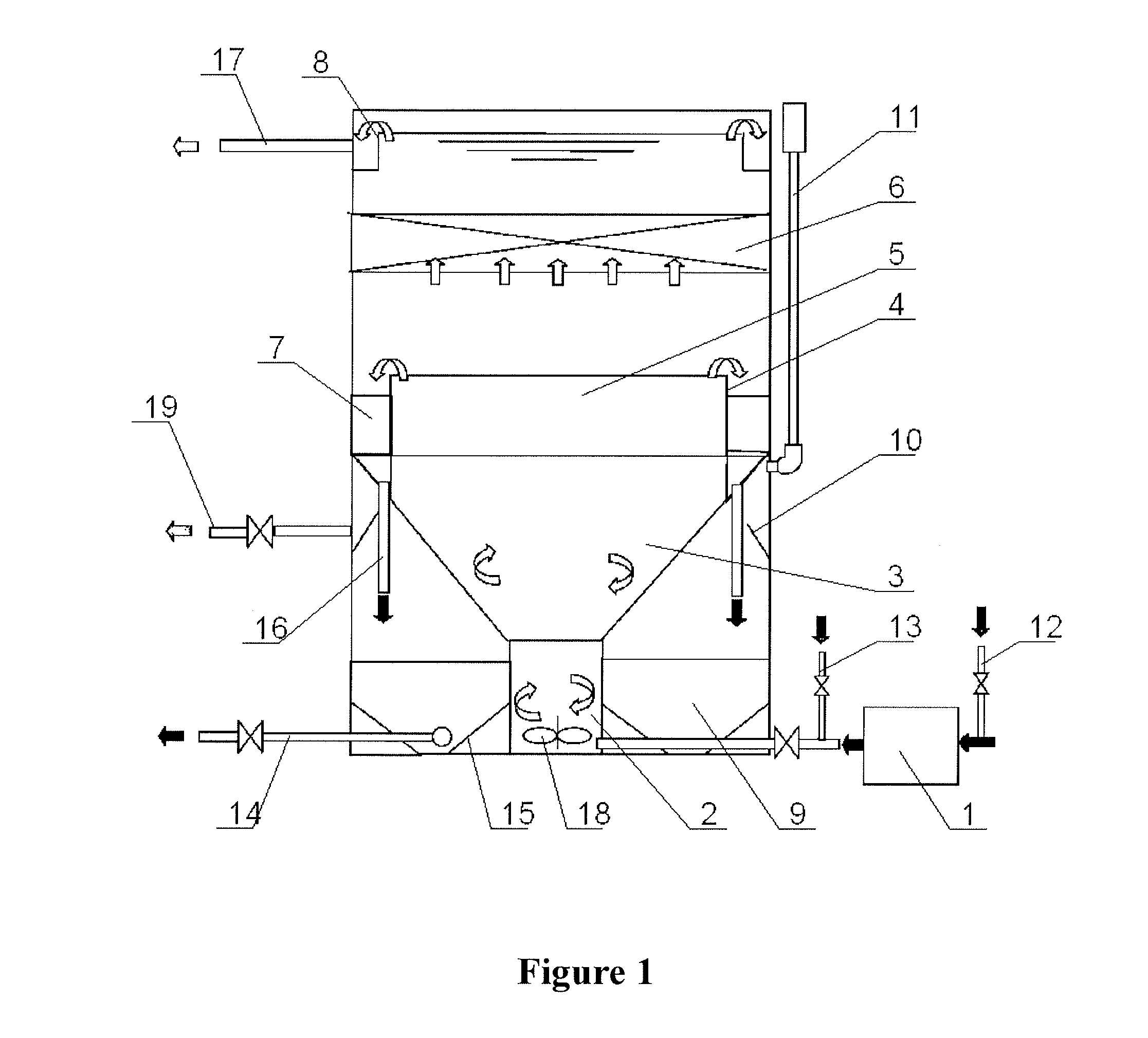

Device for Purifying Oily Wastewater

InactiveUS20130062272A1Increase settling velocityStrong turbulenceWaste water treatment from quariesSludge treatmentFlocculationFiltration

There is disclosed a device for purifying oily wastewater, including a vertical tank of an atmospheric pressure, inside which a central coagulation reaction tube, a reverse cone-shaped cyclone flocculation stage, a suspended sludge filtering zone and a purified water commutation stage of inclined plates are included from bottom to top sequentially, oily wastewater is sequentially subjected to a coagulation reaction, suspended sludge filtering and a purified water commutation process and then discharged, a sludge collecting groove collects and guides the suspended sludge to a sludge concentrating zone for further sedimentation and concentration processes and then discharges it to external to the tank, in this way, the purification reaction, flocculation and fine filtration of wastewater and the sludge concentration process are integrated within the same wastewater purifying device. Thus, the device is equivalent to the existing wastewater pretreatment system plus a fine filtration system.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

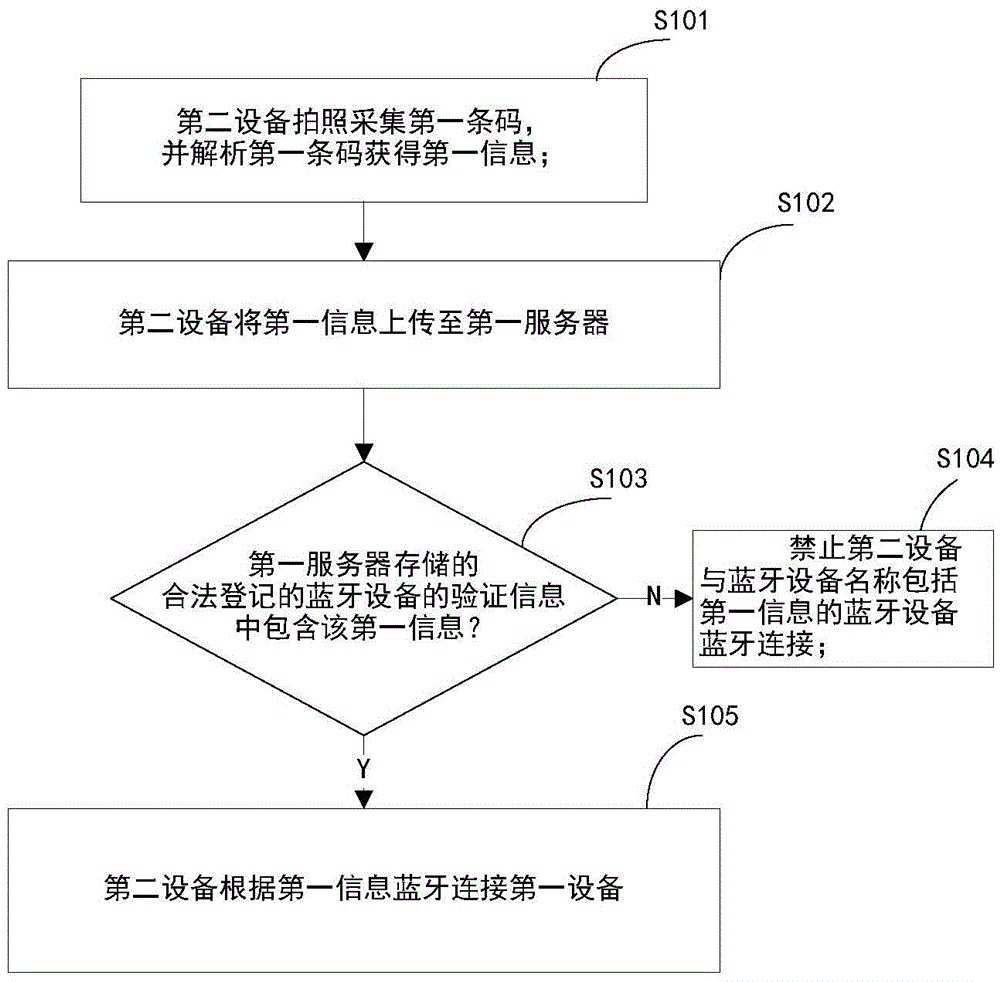

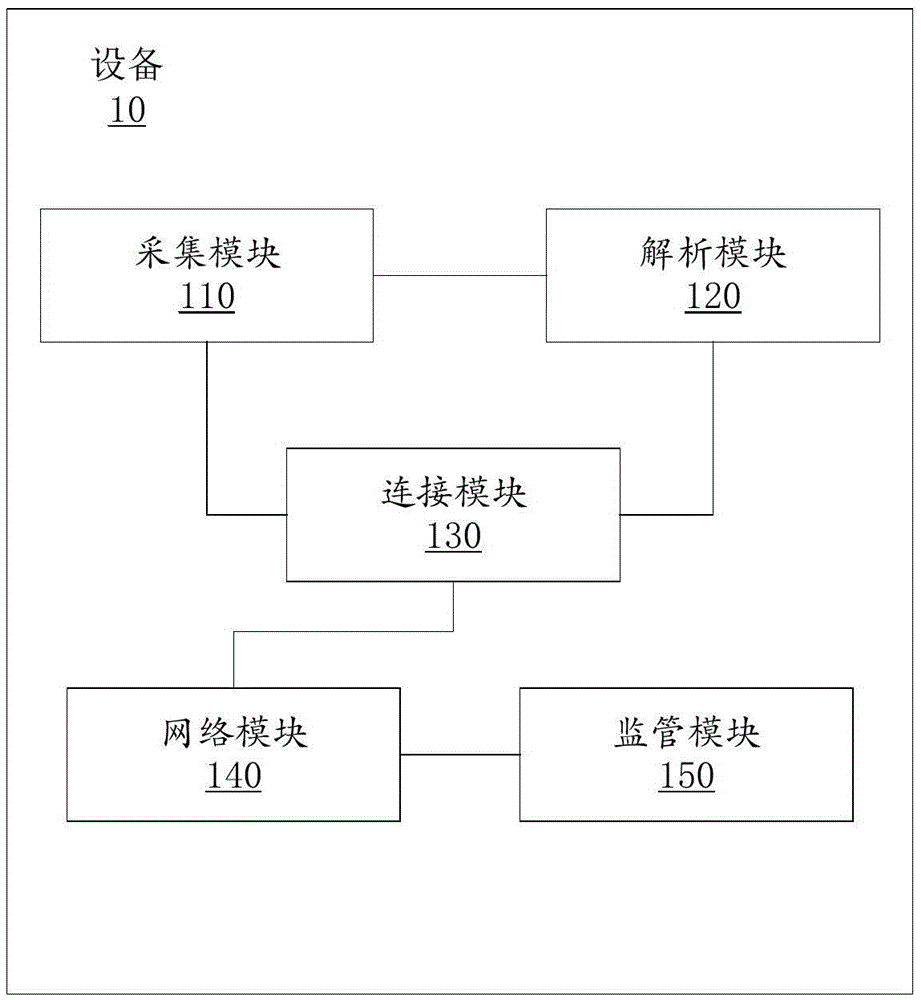

Method, master device, slave device and system for achieving code scanning automatic bluetooth connection

InactiveCN105554908ARaise the possibilityFirmly connectedConnection managementSensing by electromagnetic radiationComputer hardwareBluetooth

The inventor provides a method, master device, slave device and system for achieving code scanning automatic bluetooth connection, which solve the safety and automatic connection problems of bluetooth connection. The invention relates to a method for achieving connection of bluetooth devices, particularly rapid and automatic connection of the bluetooth devices. The method provided by the invention comprises the following steps: a first graphic code is corresponding to a first device, and a second device takes pictures to collect the first graphic code and analyzes the first graphic code to obtain first information; the second device uploads the first information onto a first server, and the first server stores verification information of legally registered bluetooth devices; if the verification information of the legally registered bluetooth devices which is stored in the first server does not contain the first information, then the second device is prohibited from being connected with a bluetooth device, whose name contains the first information, through bluetooth; if the verification information of the legally registered bluetooth devices which is stored in the first server contains the first information, then the second device is connected with the first device through bluetooth according to the first information.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

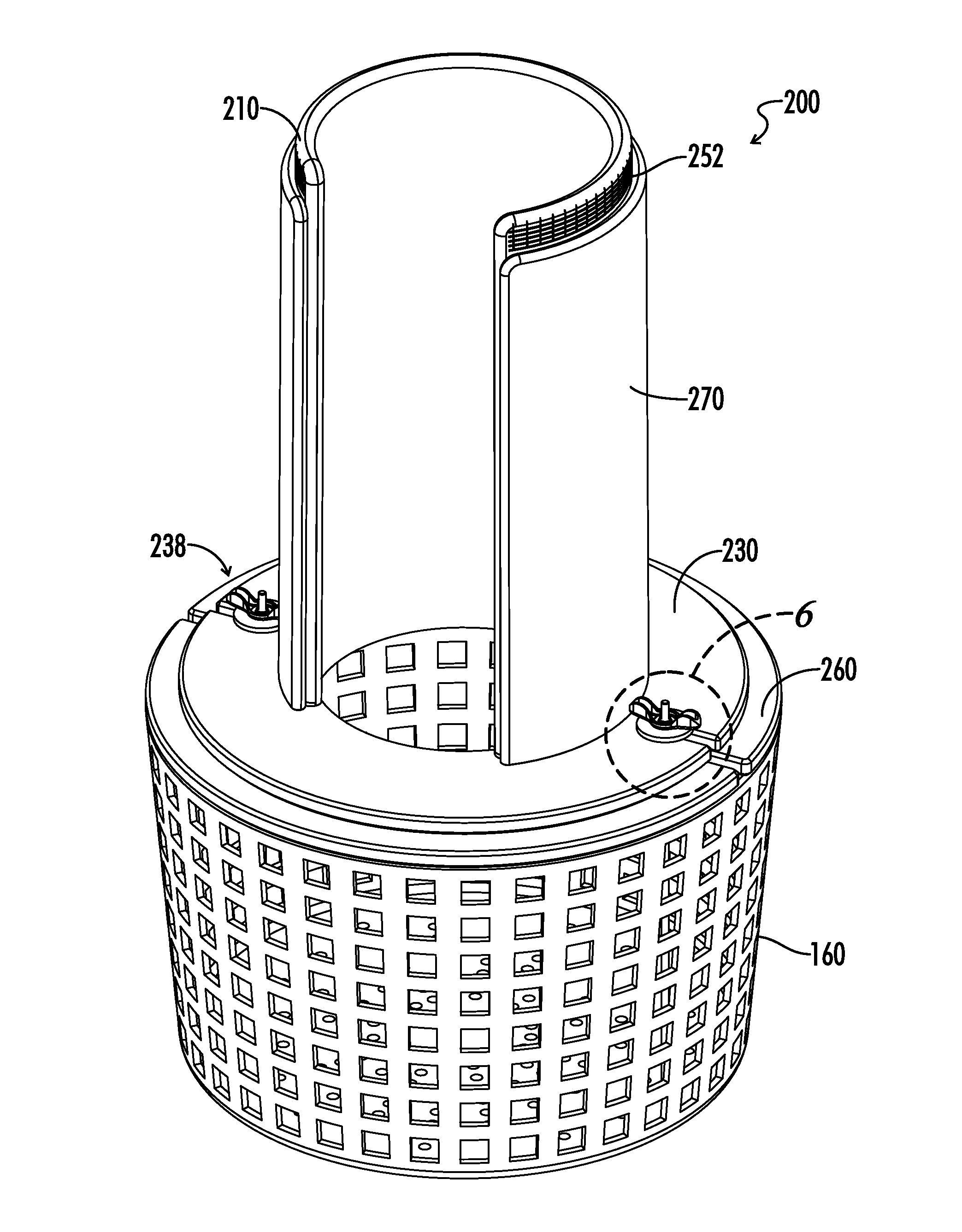

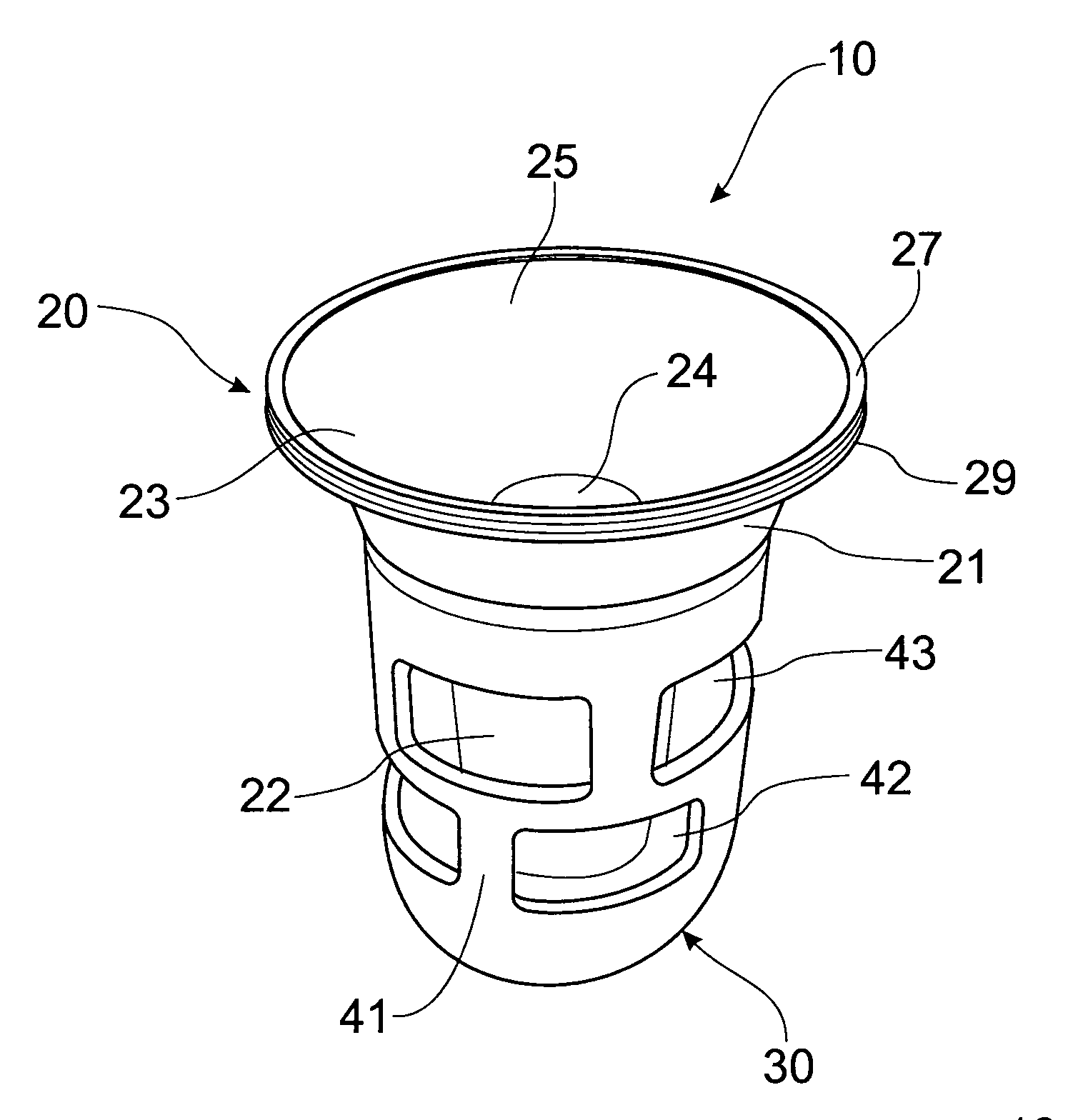

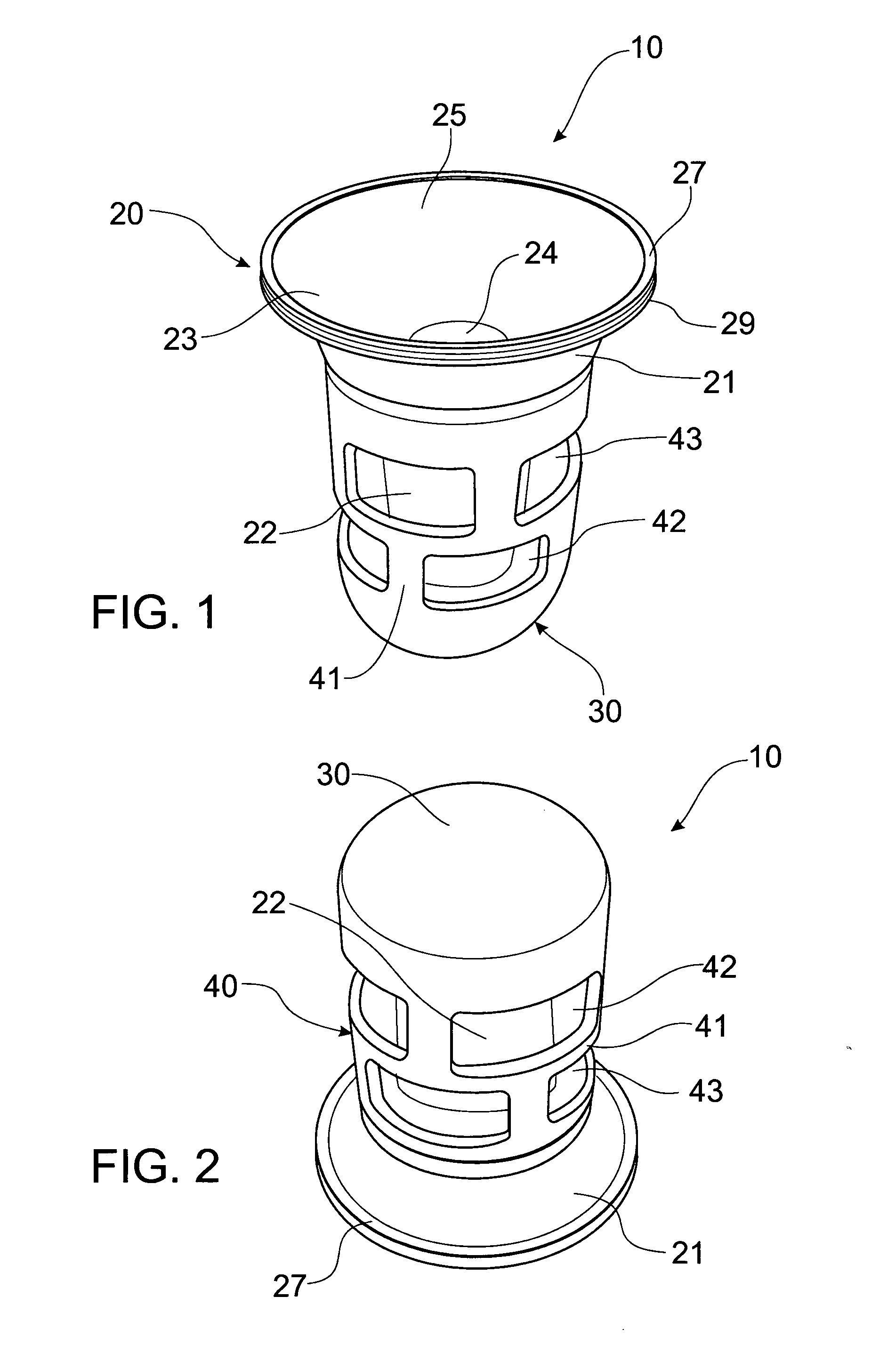

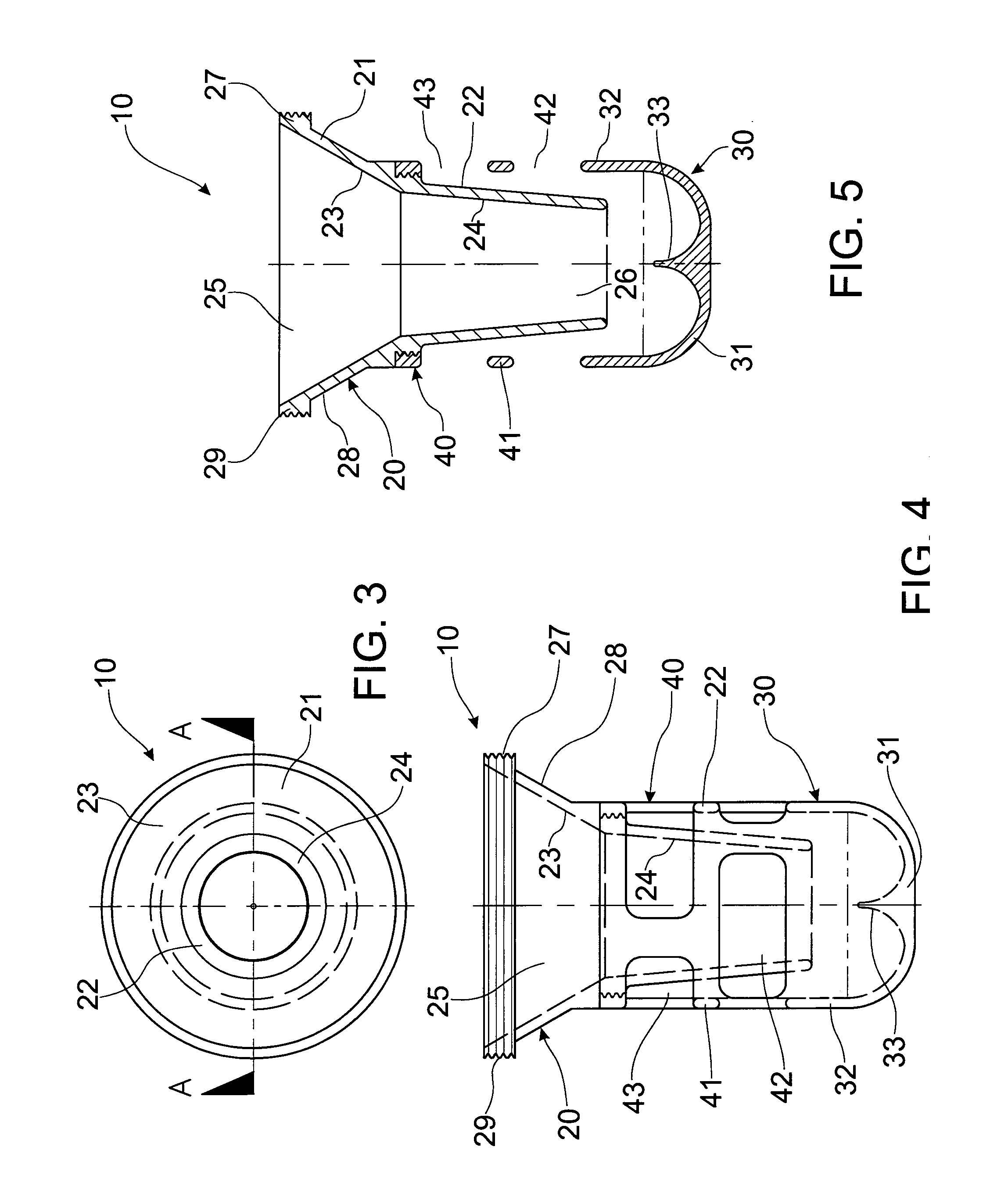

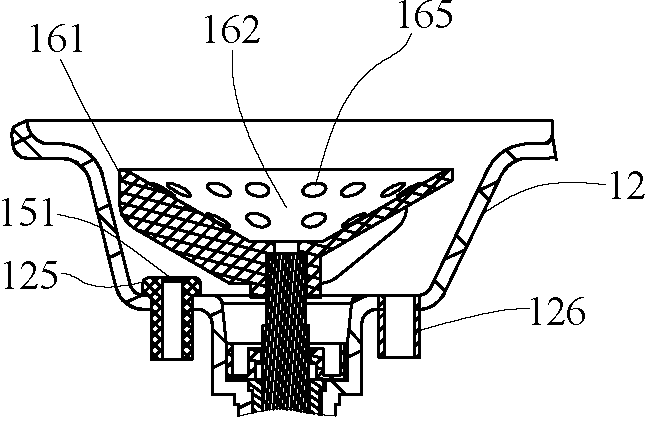

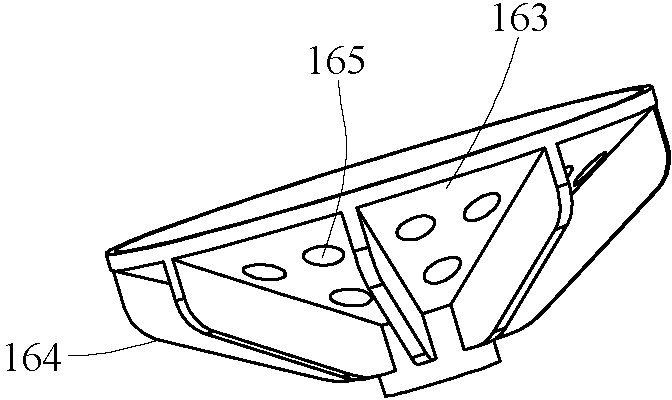

Pool skimmer basket system

The present invention relates to apparatuses for improving pool skimmers. In some embodiments, the apparatus is a pool skimmer basket system that includes a skimmer basket, a first tube that is attached to the skimmer basket, and a second tube that is adjacent to and rotatable relative to the first tube. The first tube includes a longitudinal slot that feeds water into the skimmer basket. Without being bound by any particular theory, it is believed that the slot increases the velocity of water flowing into the basket and that the system increases the debris-holding capacity and allows one to avoid having to reach through dirty water to remove the skimmer basket.

Owner:TOTALLY NEW TECH

Air cooler tube box provided with flow deflectors

InactiveCN102466426AIncrease water speedImprove heat transfer coefficientHeat exchanger casingsAnti freezingHeat resistance

The invention provides an air cooler tube box provided with flow deflectors. According to the air cooler tube box provided by the invention, two flow deflectors are symmetrically arranged in the air cooler tube box, and respectively incline towards two sides of the tube box from a water main of the air cooler tube box to gradually narrow sections of the inner part of the tube box in the directions of two sides. The air cooler tube box provided by the invention can be used for effectively preventing a water side of an air cooler from freezing in case of low-temperature climate in winter. According to the air cooler tube box, speed of the water side of an outlet of a collecting pipe is accelerated, so that the occurrence of a dead area can be effectively avoided, coefficient of convective heat transfer of the water side is increased, and heat resistance of the water side is reduced; and therefore anti-freezing capability of a system is greatly improved.

Owner:BEIJING SHOUHANG IHW RESOURCES SAVING TECH CO LTD

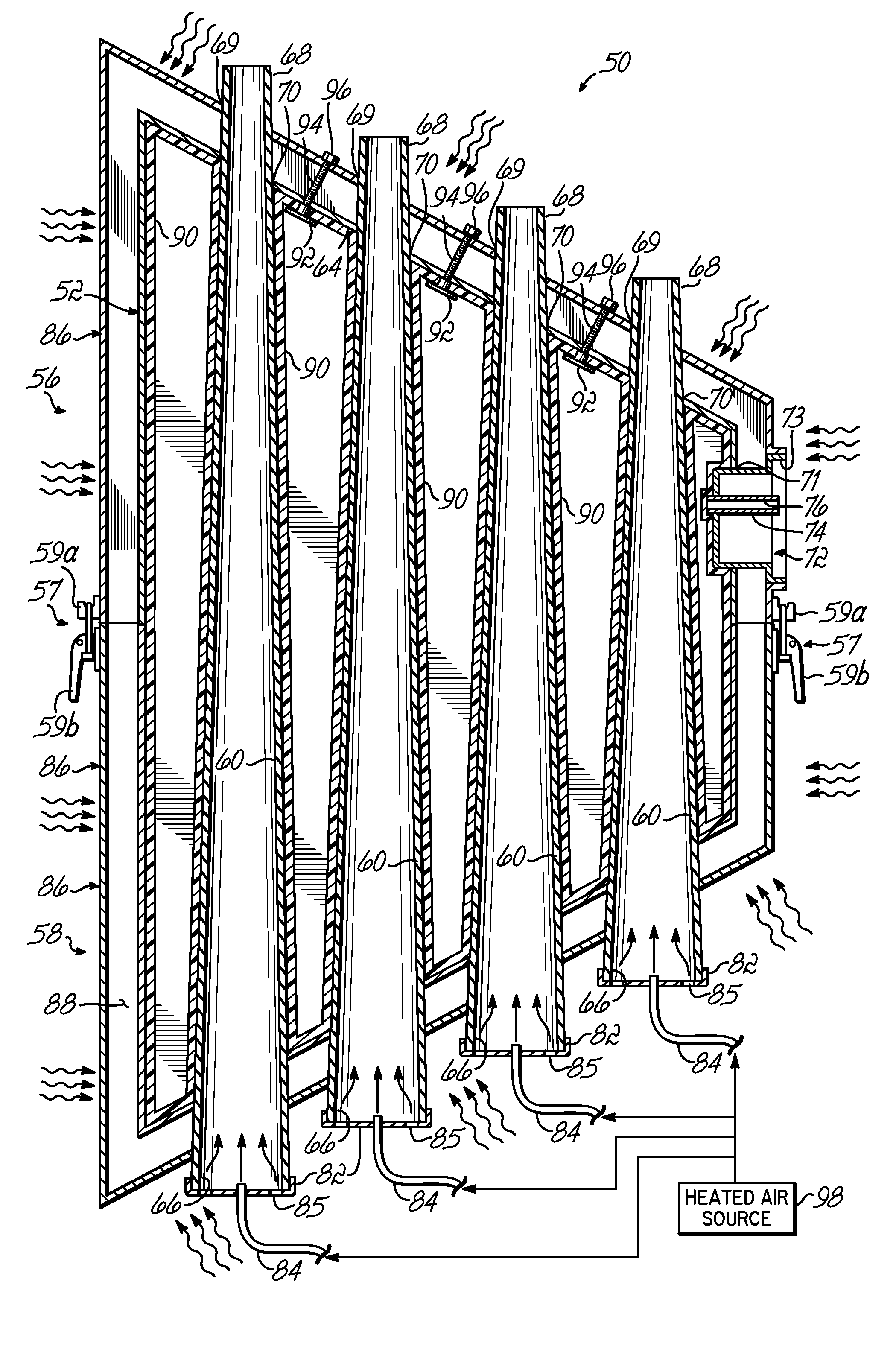

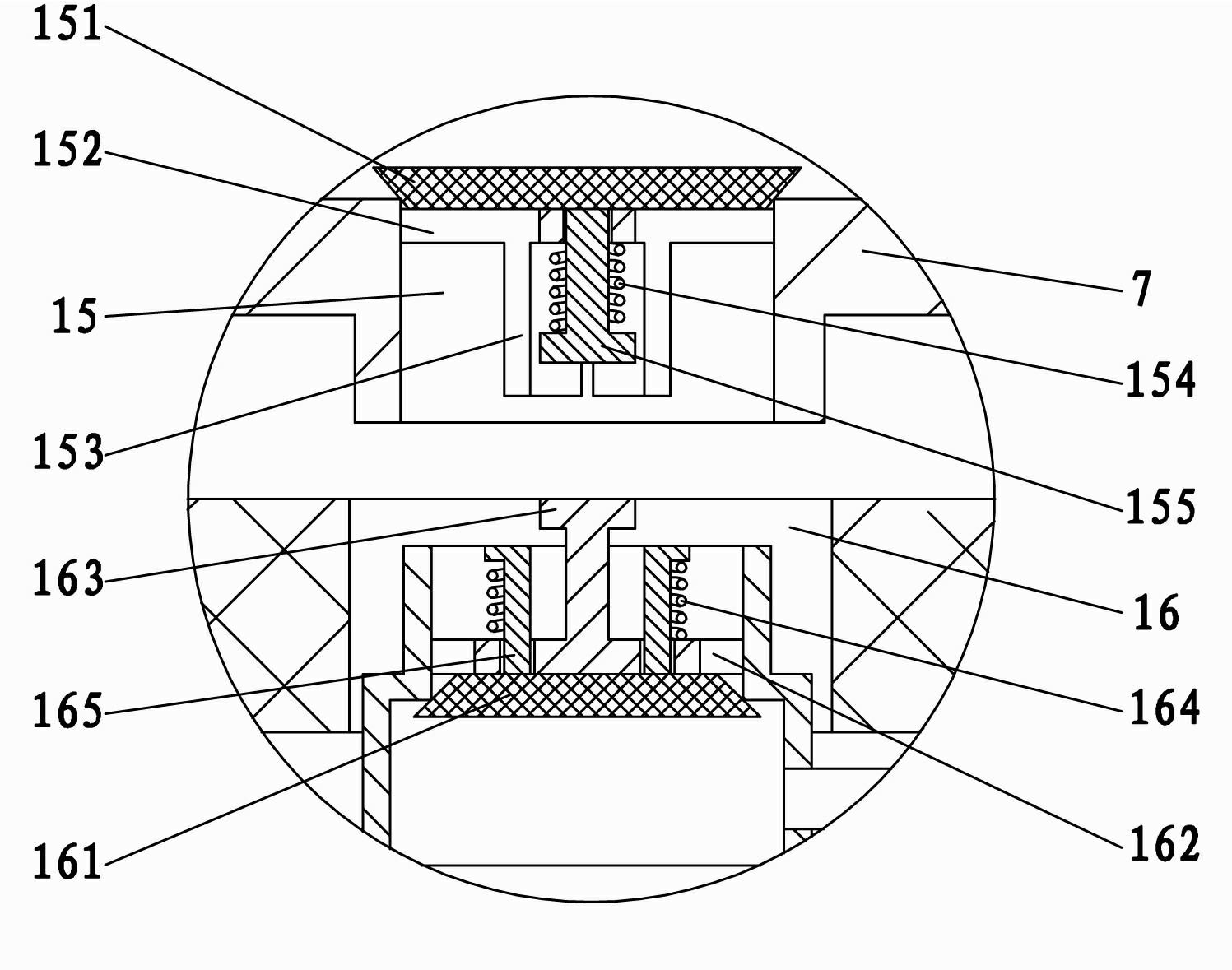

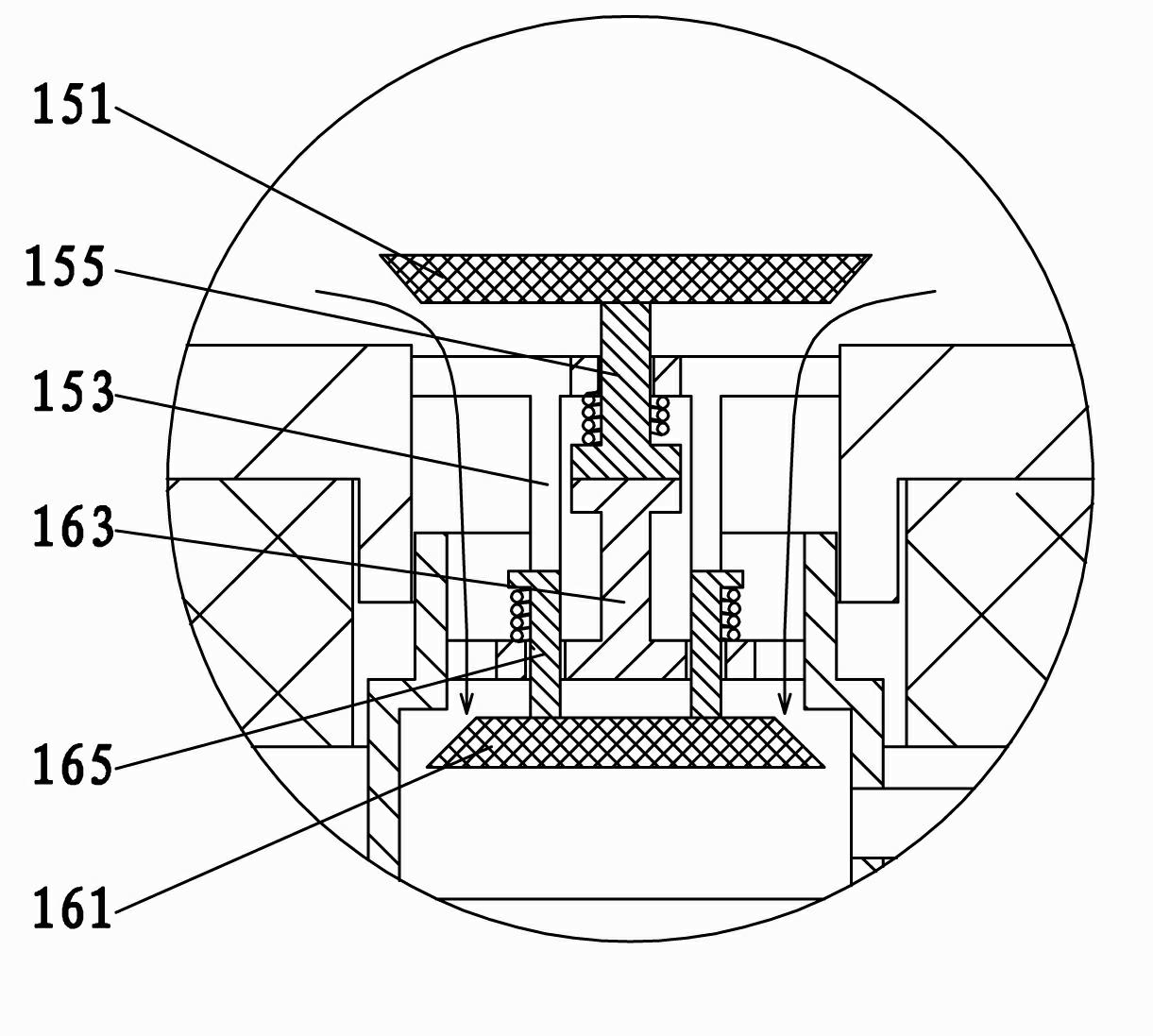

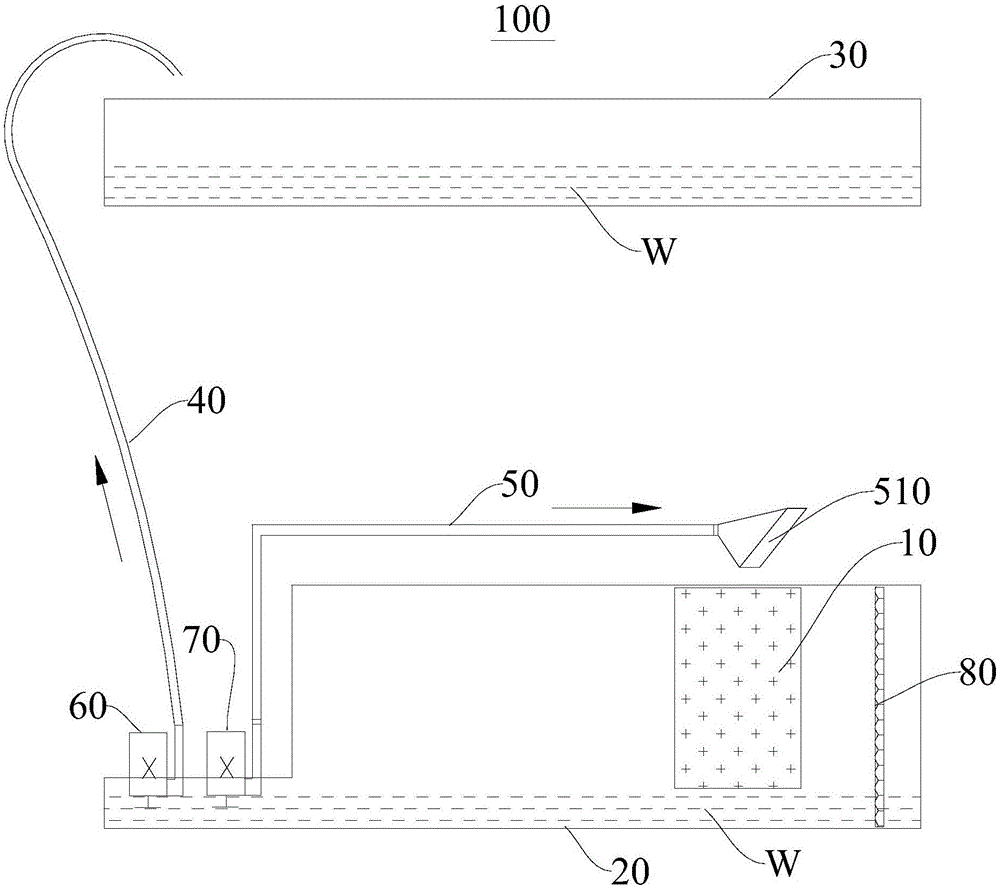

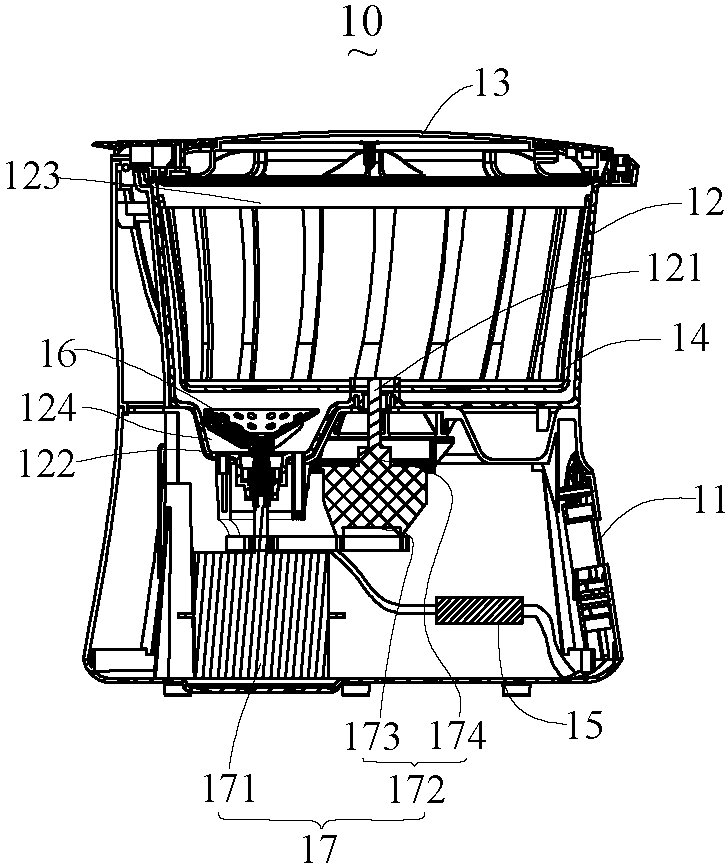

Clothes dryer and evaporator assembly for clothes dryer

ActiveCN106480676AIncrease profitReduce the number of manual cleaningsTextiles and paperLaundry driersWater flowEngineering

The invention discloses an evaporator assembly for a clothes dryer and the clothes dryer provided with same. The evaporator assembly comprises an evaporator, a water accumulation container, a water storage container, a water draining pipe and a cleaning pipe, wherein an upper end opening and a water accumulation cavity for receiving condensed water flowing from the evaporator are defined in the water accumulation container, the water draining pipe is communicated with the water accumulation container and the water storage container, a water draining pump for driving water in the water accumulation container to flow towards the water storage container is arranged on the water draining pipe, the cleaning pipe is communicated with at least one evaporator in the water accumulation container and the water storage container, and a cleaning pump is arranged on the cleaning pipe and used for driving water in at least one of the water accumulation container and the water storage container to flow towards the evaporator. According to the embodiment, the evaporator assembly for the clothes dryer can achieve condensed water discharge, meanwhile can utilize the condensed water of the clothes dryer to flush dirty flocks and the like on the evaporator so as to achieve the self-cleaning purpose, the water flowing speed and flow are improved, and a cleaning effect is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

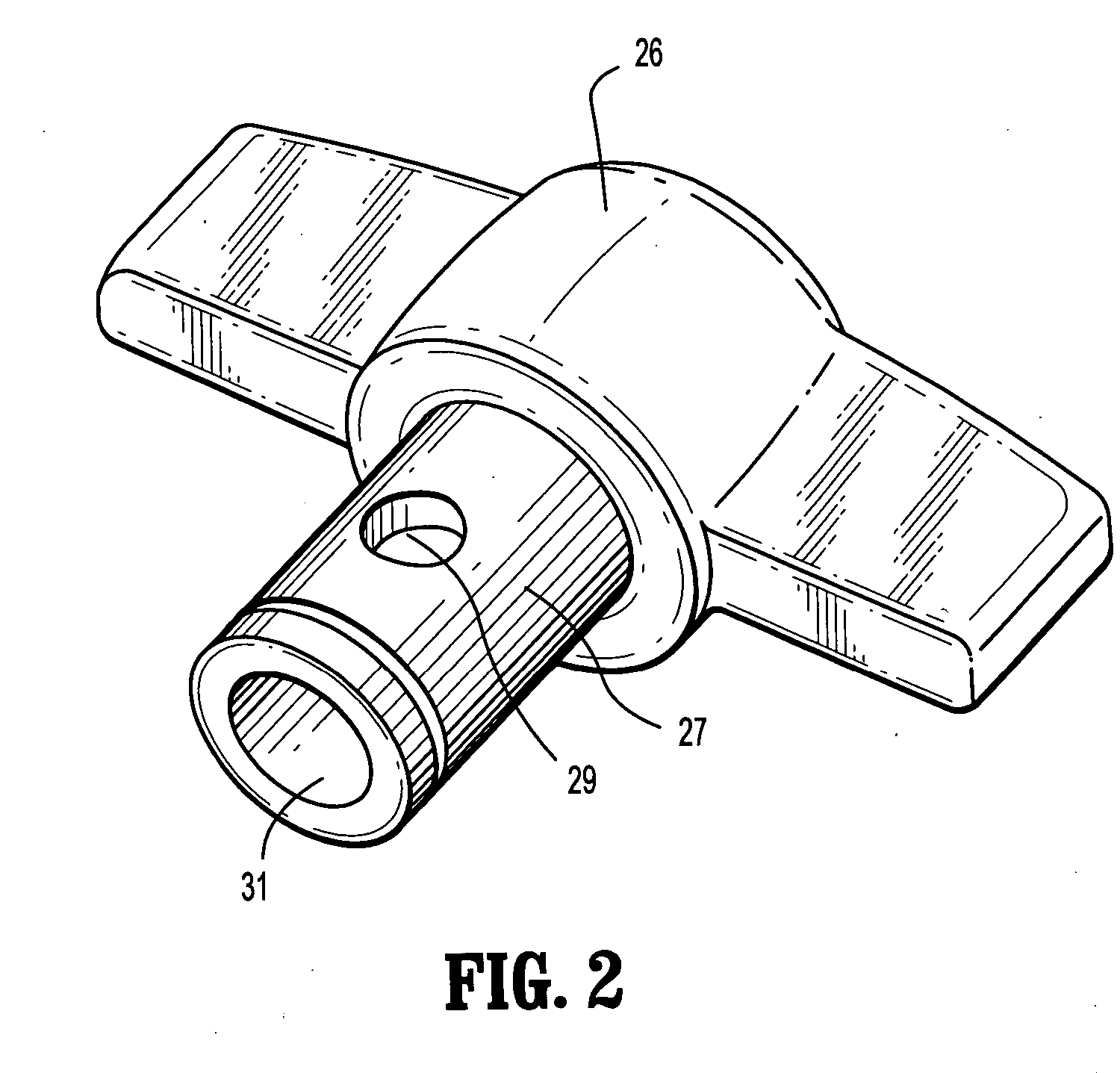

Drain fitting

InactiveUS20100000012A1Useful commercial choiceIncrease water speedSewerage structuresDomestic plumbingBiomedical engineeringGuide tube

Owner:TRILAUR

Pneumatic tire

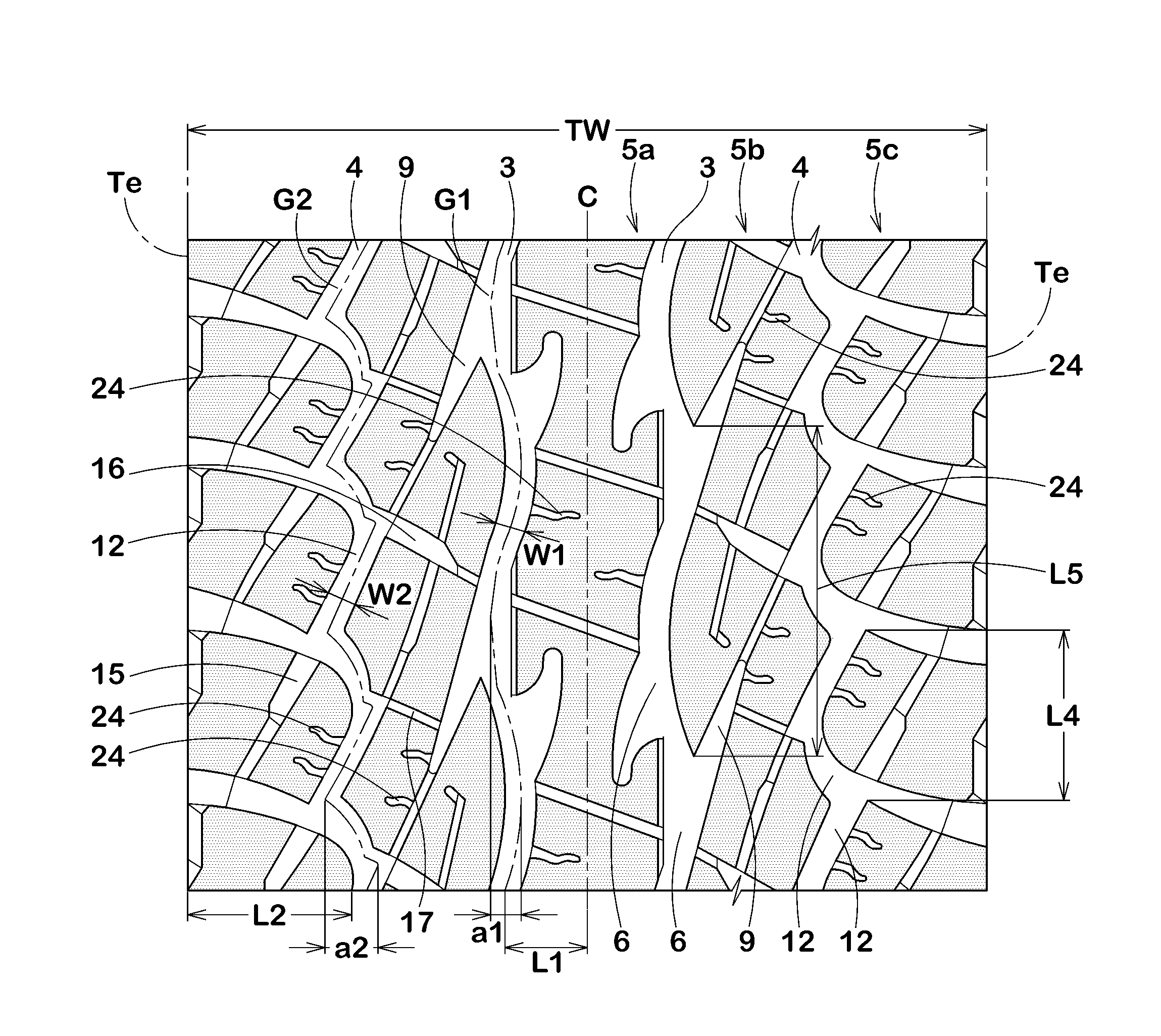

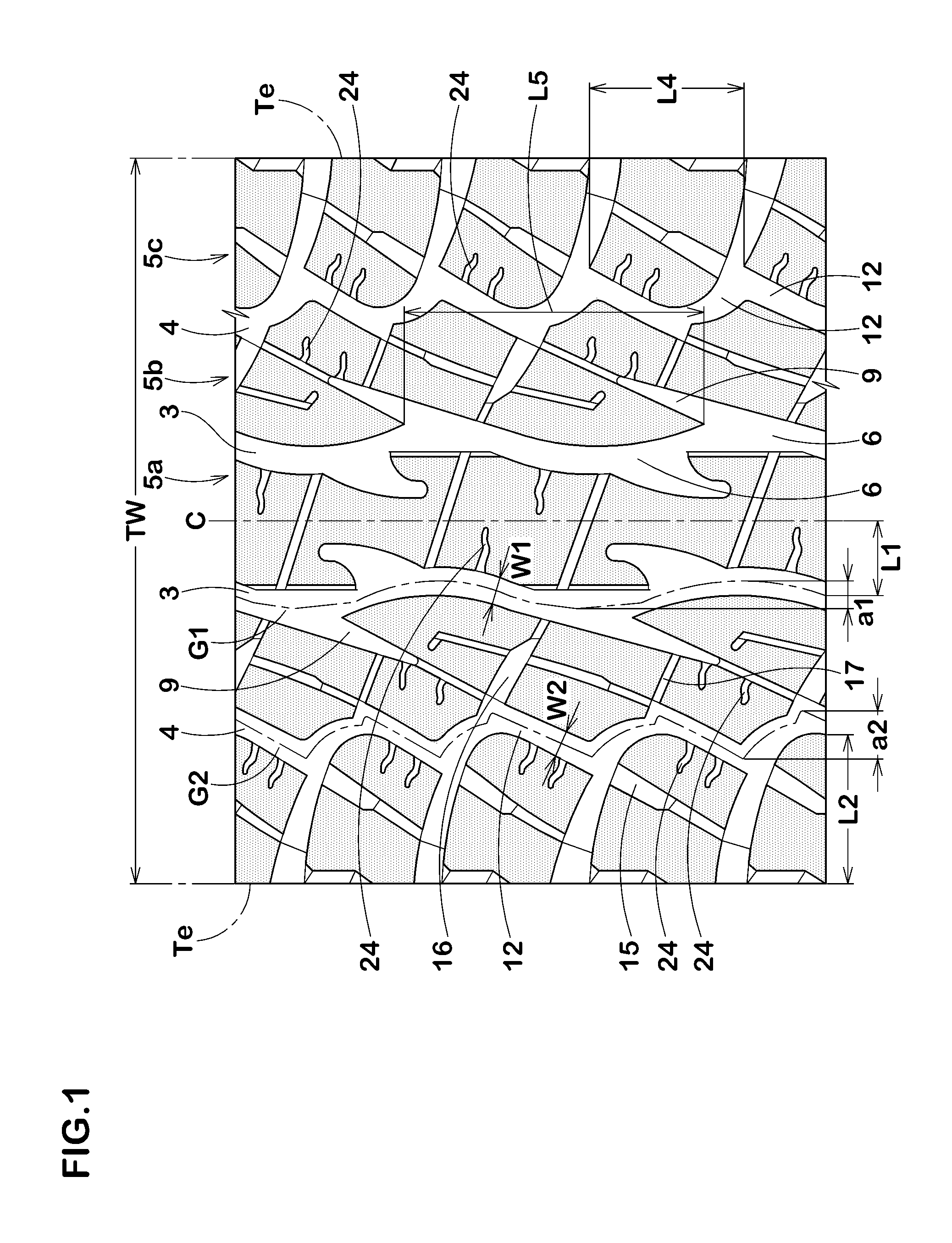

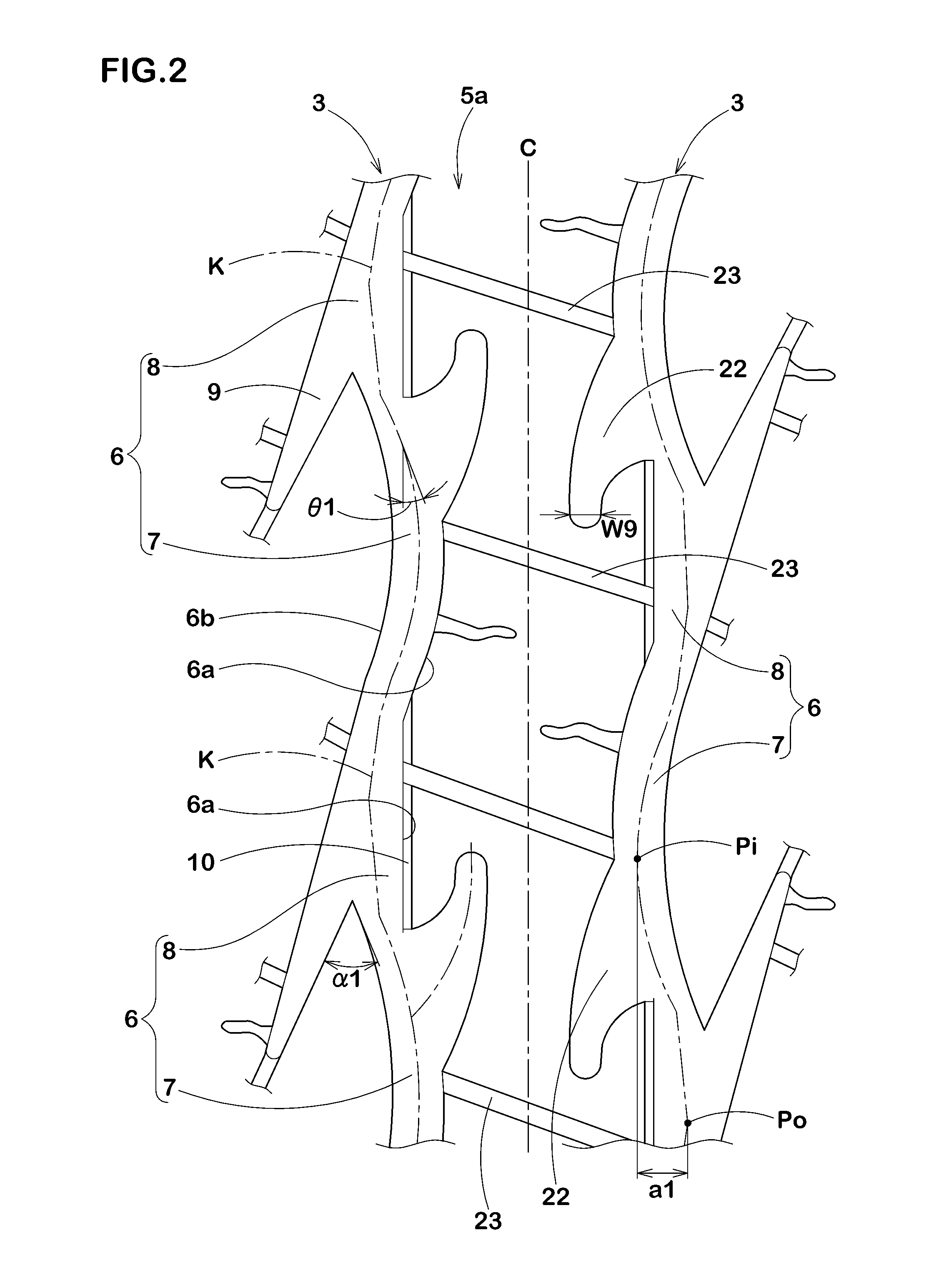

InactiveUS20120111466A1Improve drainage capacityMaintaining uneven wear resistanceTyre tread bands/patternsNon-skid devicesEngineering

In a pneumatic tire 1, a center land portion 5a between center main grooves 3, a middle land portion 5b between the center main groove 3 and a shoulder main groove 4, and a pair of shoulder land portions 5c extending on outer sides of the shoulder main groove 4 in a tire axial direction are divided from each other. The center main groove 3 includes arc groove pieces 6 which are continuously provided in a tire circumferential direction. The arc groove piece 6 includes an arc portion 7 which is curved to swell toward a tire equator C. The middle land portion 5b is provided with a middle inclined groove 9 which extends from an intersection portion K of the arc groove piece 6 toward the shoulder main groove 4.

Owner:SUMITOMO RUBBER IND LTD

Fruit and vegetable cleaning machine

ActiveCN102934955AGuarantee the effect of purification (sterilization and disinfection)Improve the effect of purification (sterilization and disinfection)Kitchen equipmentBiologyMechanical engineering

The invention relates to a fruit and vegetable cleaning machine. The fruit and vegetable cleaning machine comprises a machine body, a washing barrel for containing water, an upper cover and a washing basket for containing fruits and vegetables, wherein a washing rotating shaft is arranged in the washing barrel; the washing basket is arranged on the washing rotating shaft; the fruit and vegetable cleaning machine also comprises an ozone generator, an aerating apparatus and an aerating rotating shaft, and the aerating apparatus and the aerating rotating shaft are arranged on the washing barrel; the aerating apparatus is arranged on the aerating rotating shaft; an air inlet hole communicated with the ozone generator is formed on the washing barrel; a driving device for driving the washing rotating shaft and the aerating rotating shaft to rotate is arranged in the machine body; the aerating apparatus comprises a suction port and an aerating piece; ozone generated by the ozone generator enters the washing barrel through the air inlet hole to form ozone bubbles; and the ozone bubbles are aerated by the aerating apparatus to be broken up, micro-fined down and rapidly dissolved in water. Therefore, the drawback of the traditional aeration stone is avoided, the concentration of the ozone dissolved in and entering water is ensured to the maximum extent, the purification effect of fruits and vegetables is ensured, the utilization rate of the ozone is increased while the dissolving efficiency of the ozone is increased through repeated aeration, and energy sources are saved.

Owner:JOYOUNG CO LTD

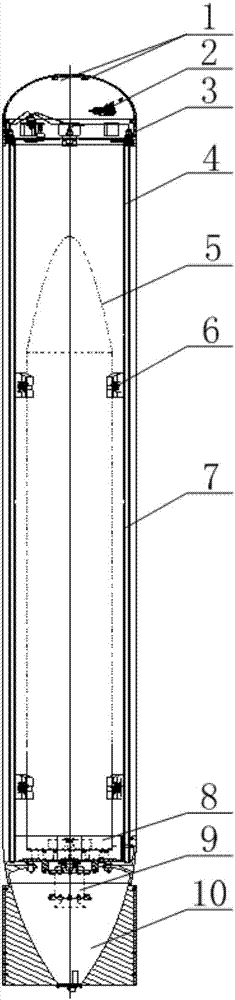

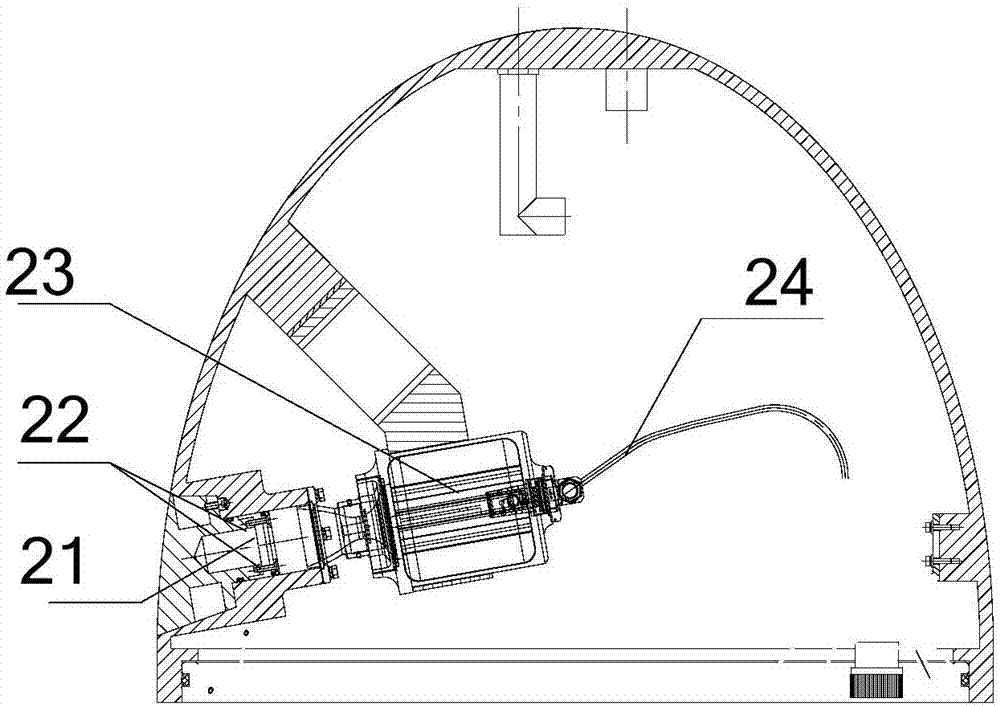

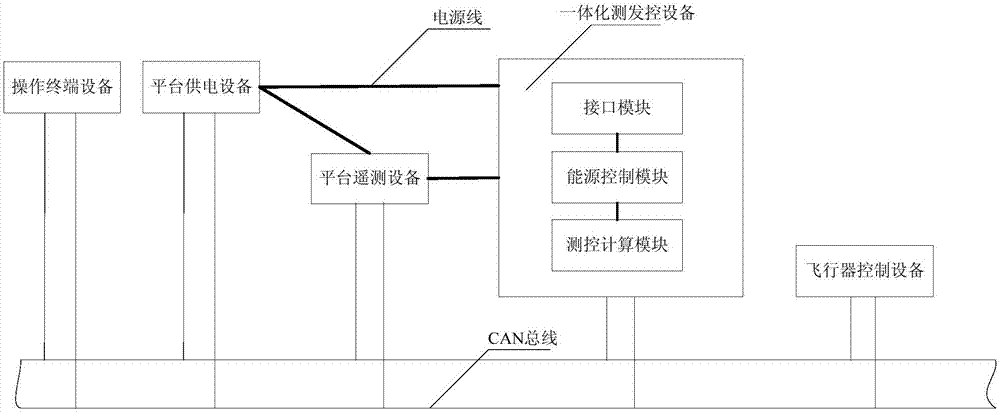

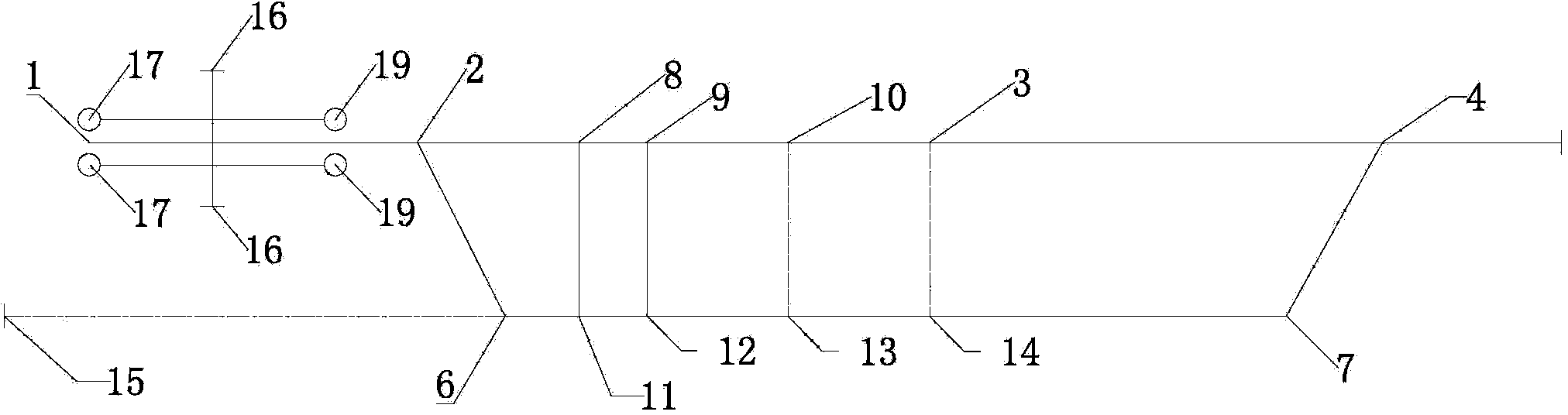

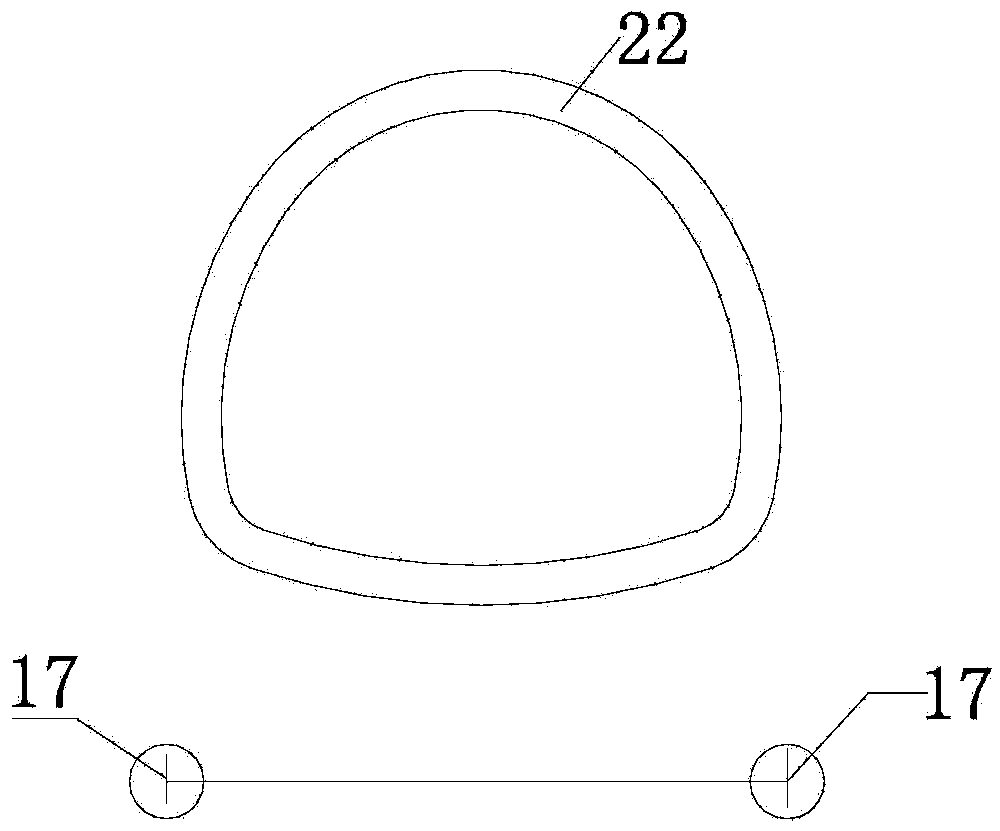

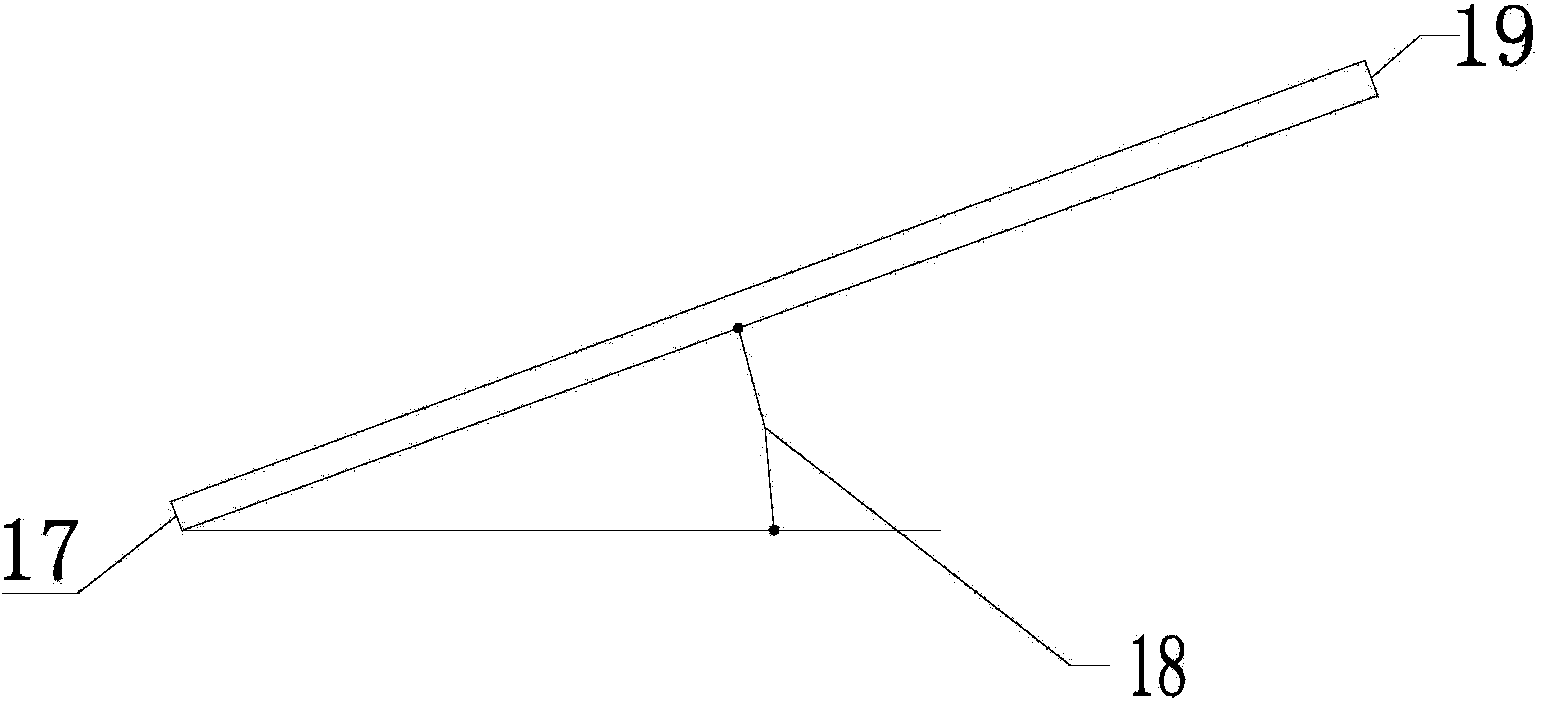

Large-diving-depth underwater unpowered aircraft transmitting system and method

ActiveCN107416226ALow design requirementsImprove portabilityLaunch systemsLaunching/towing gearUnderwaterControl system

The invention discloses a large-diving-depth underwater unpowered aircraft transmitting system and method. The transmitting system comprises an underwater autonomous measuring and control system, a transmitting cylinder with a front cover, a catapult arranged in the transmitting cylinder, and an aircraft arranged in the transmitting cylinder, wherein the transmitting cylinder, the catapult, the aircraft and the measuring and control system integrally adopt an axial deflection design; compared with a mass center, the axial buoyant center is closer to the front cover of the transmitting cylinder; the transmitting system is fixed to an underwater platform, after the transmitting system is separated from the underwater platform, the situation that upward buoyance is greater than the sum of gravity and floating resistance is changed into the situation that the upward buoyance and the sum of the gravity and floating resistance gradually tend to be balanced; the aircraft is fixed on one side of a sealing bottom plate in the transmitting cylinder, and the other side of the sealing bottom plate is connected with the catapult; and after the front cover is opened, the catapult produces thrust to push the aircraft to slide in the direction from the transmitting cylinder to the front cover, and the aircraft slides from the transmitting cylinder. According to the large-diving-depth underwater unpowered aircraft transmitting system disclosed by the invention, the maximum transmitting depth of the transmitting system is not less than 200 meters; and in the transmitting system, the aircraft does not bear water pressure limit directly, so that the aircraft is low in design condition requirements, and high in portability.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Permanent and temporary combined anti-freezing drainage structure and method for high altitude severe cold rich water tunnel

The invention discloses a permanent and temporary combined anti-freezing drainage structure and method for a high altitude severe cold rich water tunnel. A parallel pilot pit is arranged on the side lower than a tunnel cavity body section and communicated with the tunnel through a transverse channel. Full section grouting is conducted on a tunnel cavity opening section full section to form a superfine cement full section grouting blocking solidification ring. Two inclined drainage holes are formed in the outside of the blocking solidification ring at the positions lower than two sides of a cavity opening. At least one end of the parallel pilot pit is communicated with the outer portion of the tunnel through a drainage cavity arranged in an inclined mode. According to the tunnel running wind flowing characteristic of high altitude severe cold zones, the parallel pilot pit which is excavated in advance in a construction period and lower than the main line tunnel position is utilized to achieve main line tunnel bottom embedded heat insulation transverse drainage, and a tunnel vertical reversed V-shaped drainage pipe is matched to improve drainage of tunnel surrounding rock water. Smooth drainage of the high altitude severe cold rich water tunnel is achieved by means of the small cavity diameter and the large-slope drainage hole which are formed through a directional drilling and hole expanding technology by water in the tunnel and matched with the middle parallel pilot pit, and safety and stability of the tunnel structure are ensured.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Energy-consuming-type rotatable ship collision preventing device with fin plates

ActiveCN103696400AWeaken or avoidReduce kinetic energyClimate change adaptationBridge structural detailsWater basedMarine engineering

The invention discloses an energy-consuming-type rotatable ship collision preventing device with fin plates. The ship collision preventing device floats on the water, is arranged around a bridge pier on a shipping lane, is a device capable of rotating around the bridge pier and comprises multiple collision preventing fin plates and a collision preventing ring, the collision preventing fin plates are uniformly arranged around the collision preventing ring and mounted on the collision preventing ring through fastening members, or the collision preventing fin plates and the collision preventing ring are of an integrally-formed structure. The energy-consuming-type rotatable ship collision preventing device can effectively absorb kinetic energy of an offending ship, has high collision preventing capability, plays a role in effectively protecting safety of a bridge, the shipping lane and water-based facilities and is easy to mount, construct, repair and maintain.

Owner:NANJING UNIV OF TECH

Amphibious yacht

ActiveUS20120220176A1Easy to manufactureEconomy of scaleAmphibious vehiclesPropulsive elementsMotor homeMarine engineering

A streamlined amphibious, catamaran yacht is provided that may serve military or civilian purposes as a passenger or cargo carrying truck, limousine, bus, motor home or recreational vehicle on land, and extend those same functions on water, while matching the functionality and performance of similar length boats. The amphibious yacht includes a continuous reveal on the hull bottom from bow to transom that separates two asymmetric catamaran hulls. This reveal, or hull tunnel, may enhance sea stability and maneuverability, and create lift that helps the hull achieve plane and attain higher water speeds.

Owner:NEPRUD KEVIN R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com