Polyacrylonitrile as-formed fiber rinsing bath and application

A technology of primary fiber and polyacrylonitrile, which is applied in the direction of artificial filament cleaning/drying, etc., and can solve problems such as inability to adapt to large tows and small tows at the same time, low relative speed between tows and water flow, poor adjustability of water consumption, etc. , to facilitate real-time monitoring and adjustment, improve washing efficiency, and stabilize temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

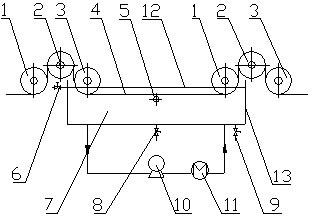

[0025] The washing tank 7 is composed of a housing 13, a water inlet 9, a water outlet 6, a circulating pump 10, a temperature measuring port 5, a heat exchanger 11 and a drafting roller. The housing 13 is a U-shaped tank, the circulating pump 10 and the heat exchange The device 11 is connected to the bottom of the housing 13 through pipes. There is a water outlet 8 in the middle of the bottom of the housing 13, a water inlet 9 at one end of the bottom of the housing 13, and a temperature measuring port 5 on the side of the housing 13. There are drafting rollers installed at both ends of the opening, and the drafting rollers are composed of the same size inlet drafting roller 1, middle drafting roller 2 and outlet drafting roller 3, and the inlet drafting roller 1 and outlet drafting roller The axis center of the roller 3 is on the same horizontal line, the axis center of the middle drafting roller 2 is located on the same horizontal line as the upper top of the feeding draftin...

Embodiment 2

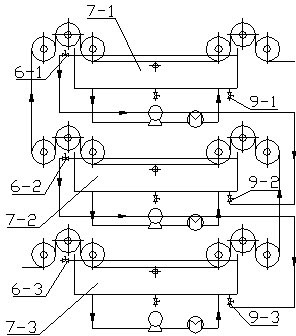

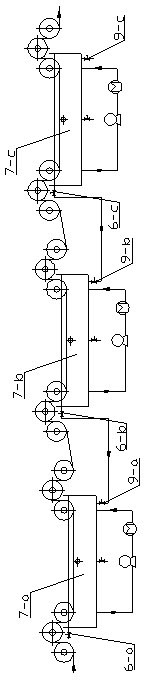

[0029] The three water washing tanks are sequentially distributed on the ground at different heights to form a stepped water washing device, which are 7-a, 7-b, and 7-c from left to right. Deionized water enters the washing tank 7-c through the water inlet 9-c of the 7-c, and the upper water outlet 6-c of the washing tank 7-c is connected with the water inlet 9-b of the washing tank 7-b, and the washing tank 7- The upper water outlet 6-b of b is connected with the water inlet 9-a of the washing tank 7-a, and finally the water is discharged by the upper water outlet 6-a of the washing tank 7-a. The polyacrylonitrile as-spun fiber enters the deionized water in the washing tank 7-a from the drawing roll at one end of the washing tank 7-a, comes out from the drawing roll at the other end of the washing tank 7-a, and enters the washing tank 7-b and 7-c, finally come out from the washing tank 7-c, the as-spun fibers are 1K tow.

[0030] The highest temperature of the water in the w...

Embodiment 3

[0032] The three water washing tanks are sequentially distributed on the ground at different heights to form a stepped water washing device, which are 7-a, 7-b, and 7-c from left to right. Deionized water enters the washing tank 7-c through the water inlet 9-c of the 7-c, and the upper water outlet 6-c of the washing tank 7-c is connected with the water inlet 9-b of the washing tank 7-b, and the washing tank 7- The upper water outlet 6-b of b is connected with the water inlet 9-a of the washing tank 7-a, and finally the water is discharged by the upper water outlet 6-a of the washing tank 7-a. The polyacrylonitrile as-spun fiber enters the deionized water in the washing tank 7-a from the drawing roll at one end of the washing tank 7-a, comes out from the drawing roll at the other end of the washing tank 7-a, and enters the washing tank 7-b and 7-c, finally come out from the washing tank 7-c, the as-spun fiber is 6K tow.

[0033] The highest temperature of the water in the was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com