Spraying-type automatic airing washing machine

A spray type washing machine technology, which is applied to other washing machines, oscillating washing machines, washing machines with containers, etc., can solve the problems of high cost, easy to damage clothes, and difficult to achieve the effect of washing clothes, so as to prevent damage to clothes and save Time and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

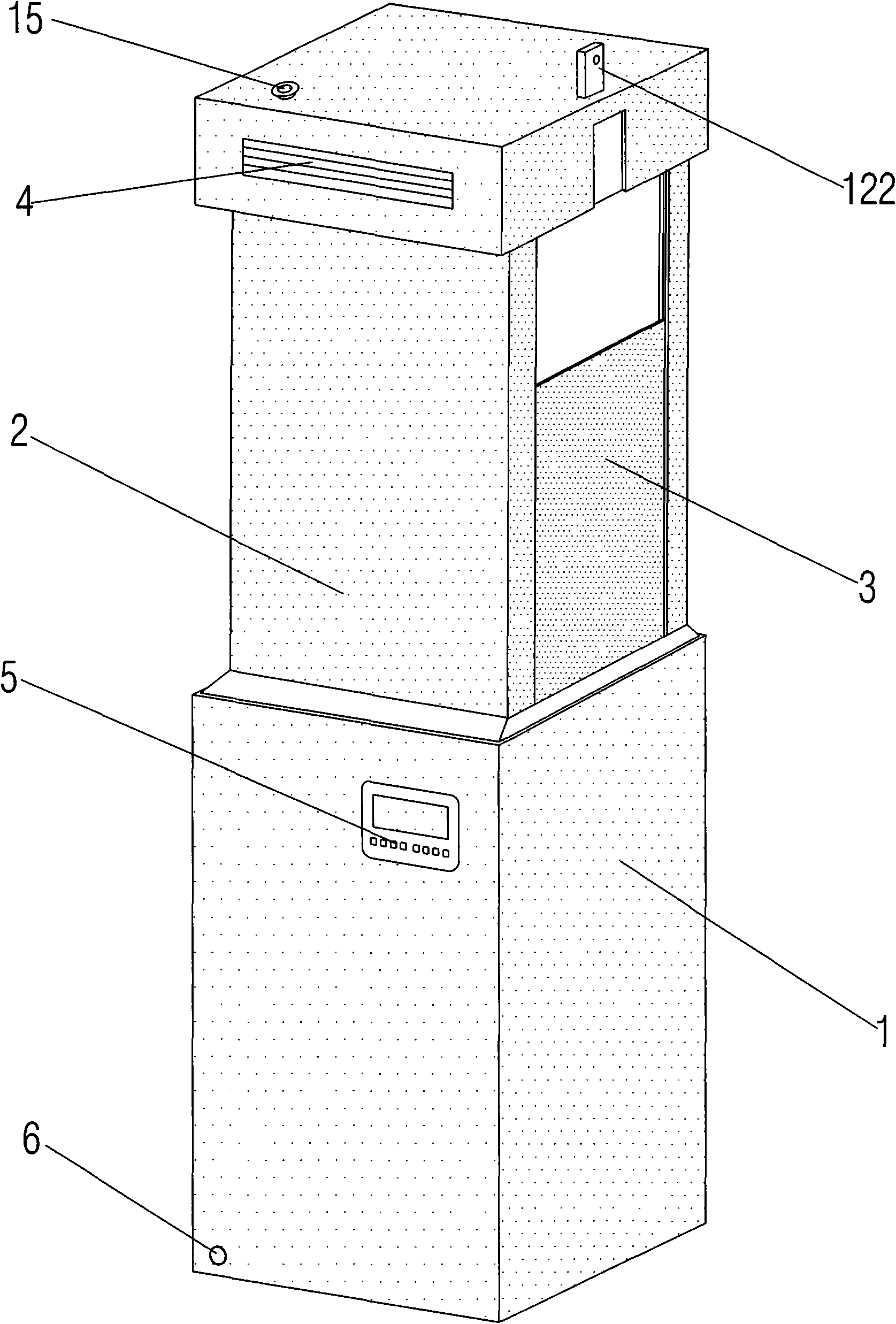

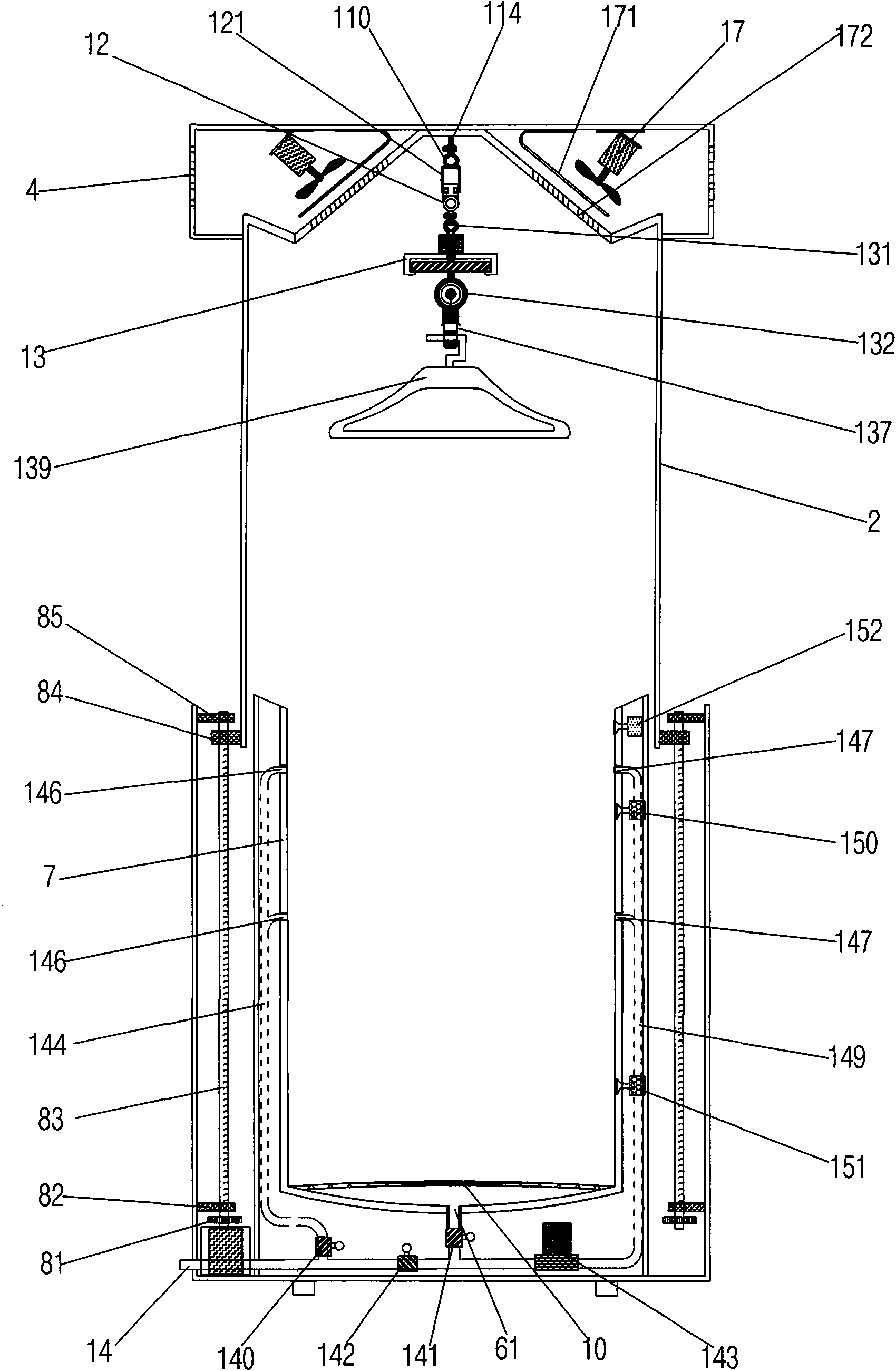

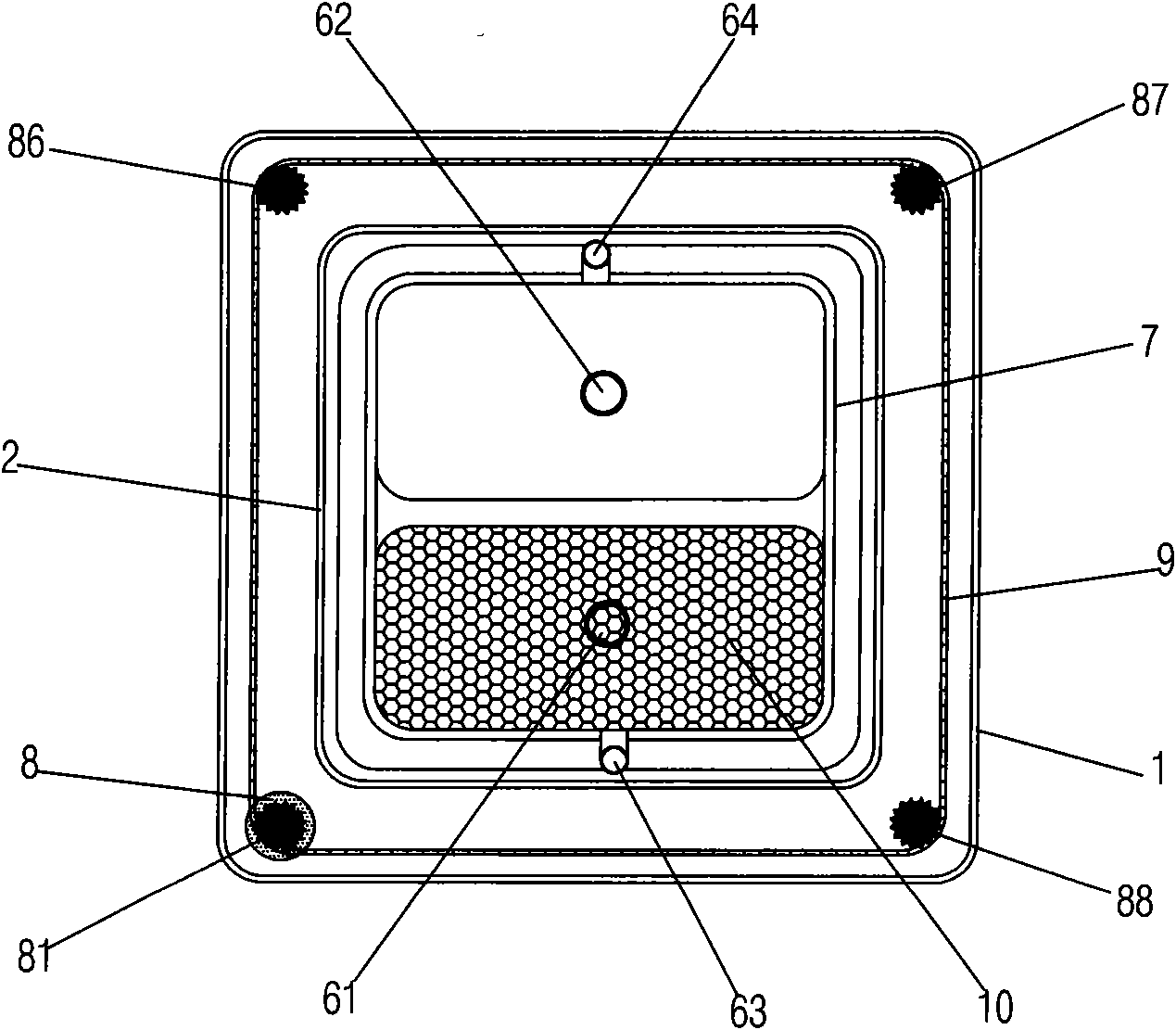

[0042]As shown in the attached figure, the spray type automatic laundry washing machine includes an outer shell 1, an inner shell 2, a movable door 3, an air outlet 4, a program controller 5, a drainage pipe 6, an inner tub 7, a lifting motor 8, a transmission chain 9, a filter screen 10. Primary motor 11, sliding mechanism 12, turntable casing 13, water inlet pipe 14, humidity sensor 15, winch motor 16, fan 17, drainage solenoid valve 60, water pumping port 61, drain port 62, overflow port 63, overflow pipe 64. Transmission gear A81, lower support code 82, lifting shaft 83, lifting nut 84, upper support code 85, transmission gear B86, transmission gear C87, transmission gear D88, support sleeve 110, primary shaft 111, hanging code A112 , sliding support pipe 113, hanging code B114, primary bearing 115, limit hanging code 121, hook 122, tension steel rope 123, upper shock-absorbing ring 124, rotating motor 125, lower shock-absorbing ring 126, sliding boom 127 , boom 128, turnt...

Embodiment 2

[0069] as attached Figure 11 As shown, it is basically the same as Embodiment 1, except that the program of air-drying (hot air) clothes in Embodiment 1 is changed into a steam drying program, that is, blower fan 17 and heater 171 in Embodiment 1 are canceled; An evaporator 175 is provided on one side of the top of the shell 2. One end of the steam-water pipe 174 is connected to the water inlet end of the evaporator 175, and the other end is connected to the water inlet pipe 14 through a steam-water solenoid valve 173. The steam outlet of the evaporator 175 passes through The steam pipe 176 is connected with the steam nozzle 177; after the laundry program is finished, the steam-water solenoid valve 173 is opened, the evaporator 175 is fed with water and starts to be energized for heating, and the steam generated by the heating of the evaporator 175 is ejected from the steam nozzle 177 through the steam pipe 176, and its temperature The temperature sensor 152 detects and trans...

Embodiment 3

[0071] as attached Figure 12 As shown, it is basically the same as Embodiment 1, except that the four lifting shafts 83 at the four corners of the lifting system of the washing machine in Embodiment 1 are changed to two lifting shafts 83 on both sides, that is, the embodiment is cancelled. One of the two lifting shafts in the middle; change it to: the inner shell 2 is respectively provided with lifting nuts 84 on the middle symmetrical sides of the outer bottom, and the middle symmetrical sides of the other outer bottom are respectively provided with positioning bushings 18, and the guide shaft 19 is inserted and free Through the round hole of the positioning shaft sleeve 18, its upper and lower ends are respectively inserted into the round holes of the upper support code 85 and the lower support code 82 and fixed. The lower ends of the two lifting shafts 21 are respectively provided with a left transmission gear 20 and a right transmission gear 24. , transmission chain 23 wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com