Patents

Literature

169results about How to "Blow evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flocculation washing machine

ActiveCN104514122ARealize self-cleaningBlow evenlyOther washing machinesTextiles and paperFlocculationFilter effect

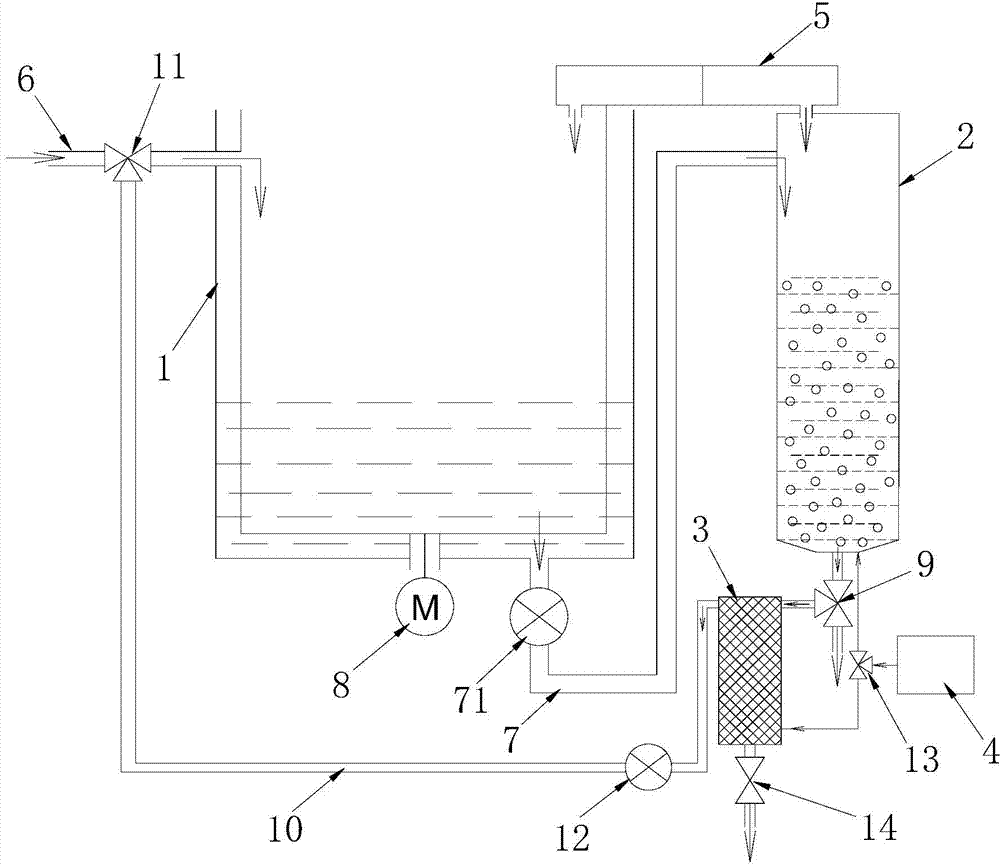

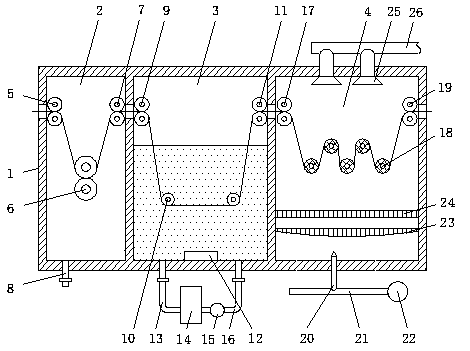

The invention discloses a flocculation washing machine. The flocculation washing machine comprises an outer barrel, a flocculation unit and a filtering unit which are circularly communicated in a sequence through pipelines. The washing machine further comprises an air pump which is respectively communicated with the flocculation unit and the filtering unit. According to the flocculation washing machine, air generated by the air pump is conveyed into a flocculation container through the same air pump so as to generate a mass of bubbles in the water into the flocculation container, thus the water fully flow to enable fully mixing of a flocculant and washed water to achieve flocculation reaction; in addition, the air exhausted by the air pump can be conveyed into a filtering container during washing a filtering unit to generate bubbles to drive water in the filtering container to fully flow as well as generating an instantaneous impact force to act on the surface of a filtering screen, so as to separate dirt attached on the surface of the filtering screen, and as a result, the filtering effect of the filtering screen can be improved. The flocculation washing machine is high in automation degree and simple in structure and saves the production cost.

Owner:HAIER GROUP TECHN R&D CENT +1

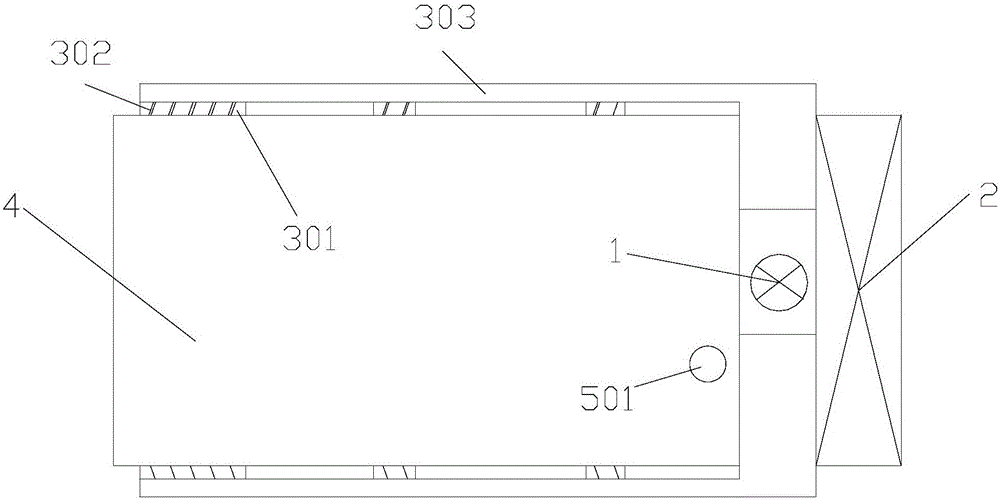

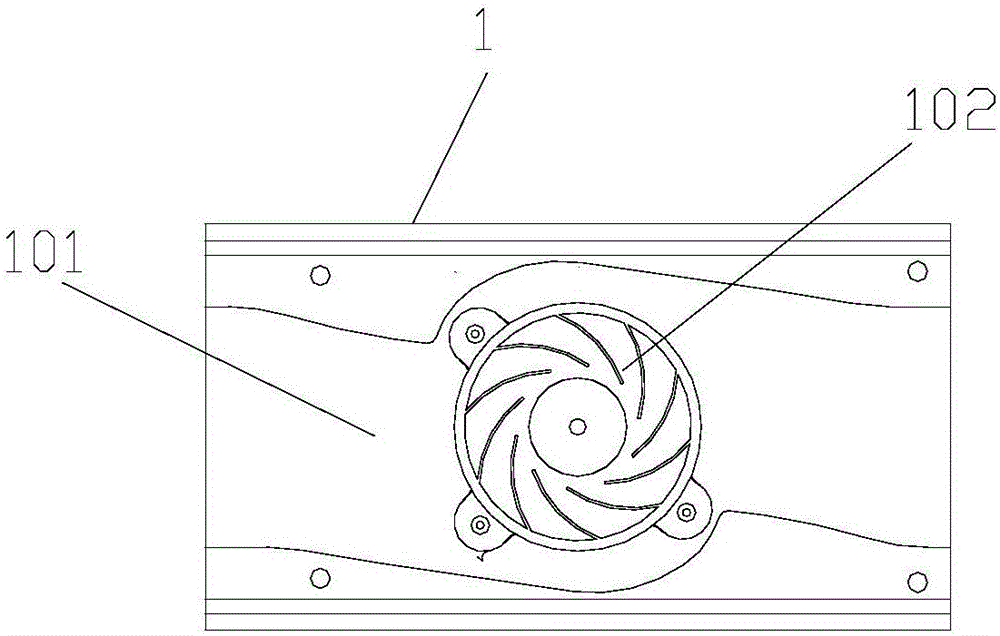

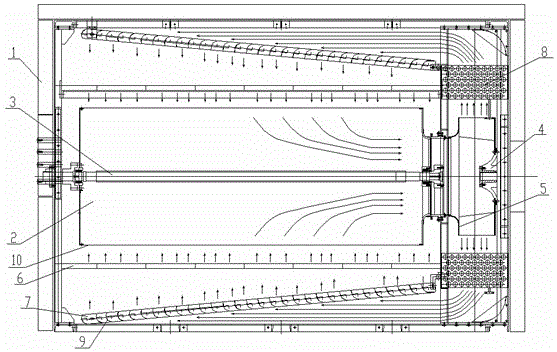

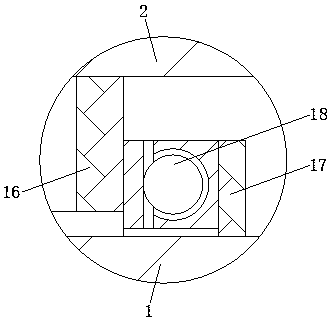

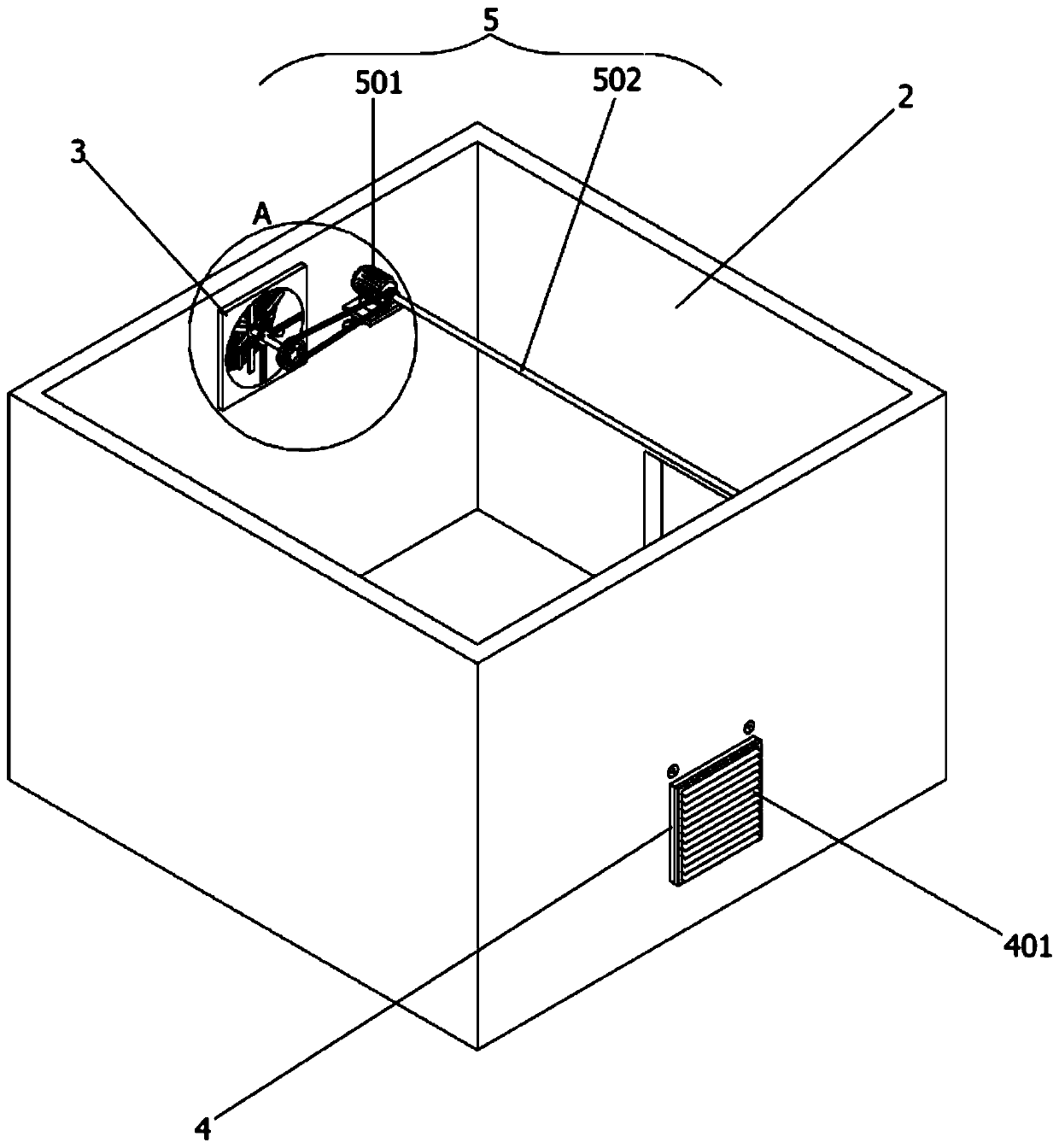

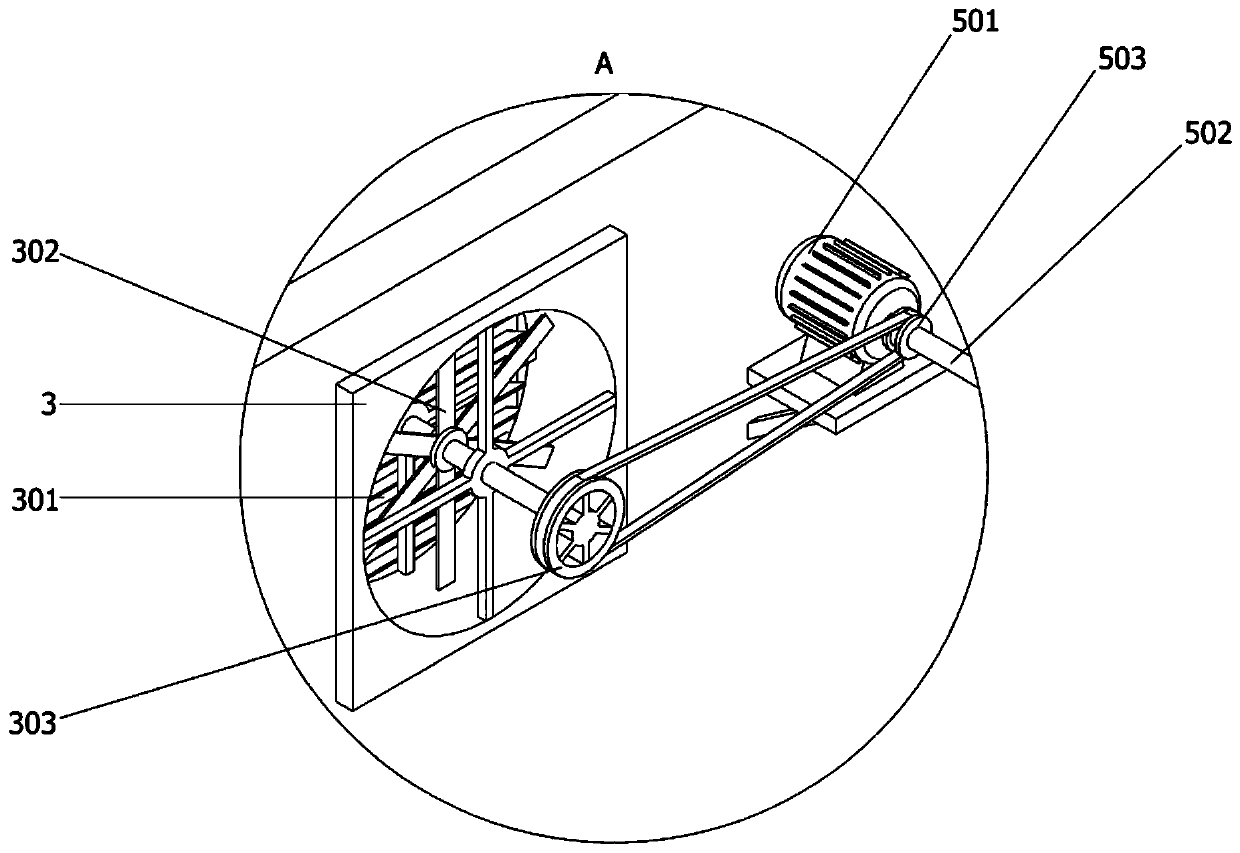

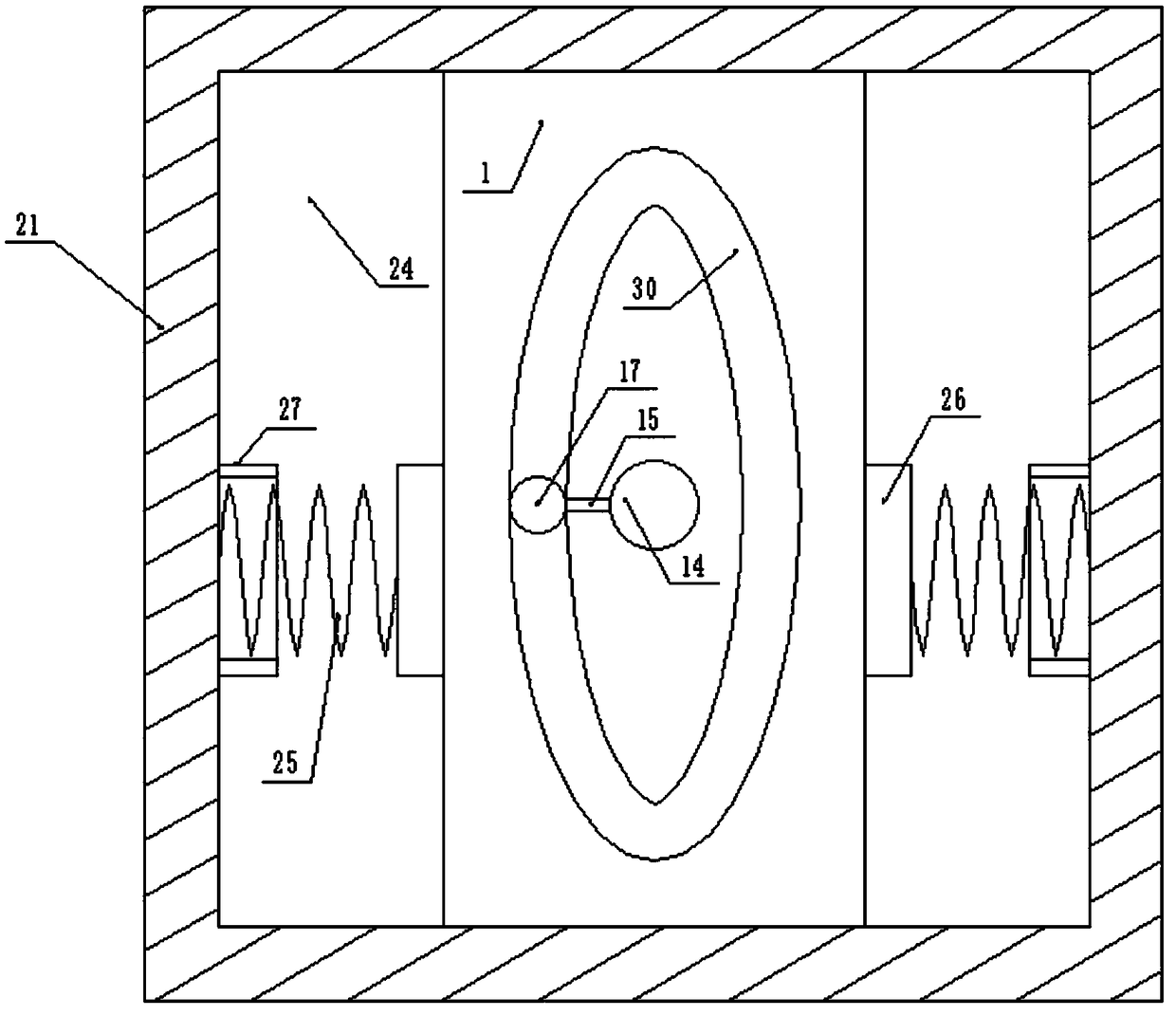

Air duct system of horizontal type freezer and freezer

InactiveCN106225389AImprove cooling efficiencyIncrease wind pressureLighting and heating apparatusDomestic refrigeratorsCold airEngineering

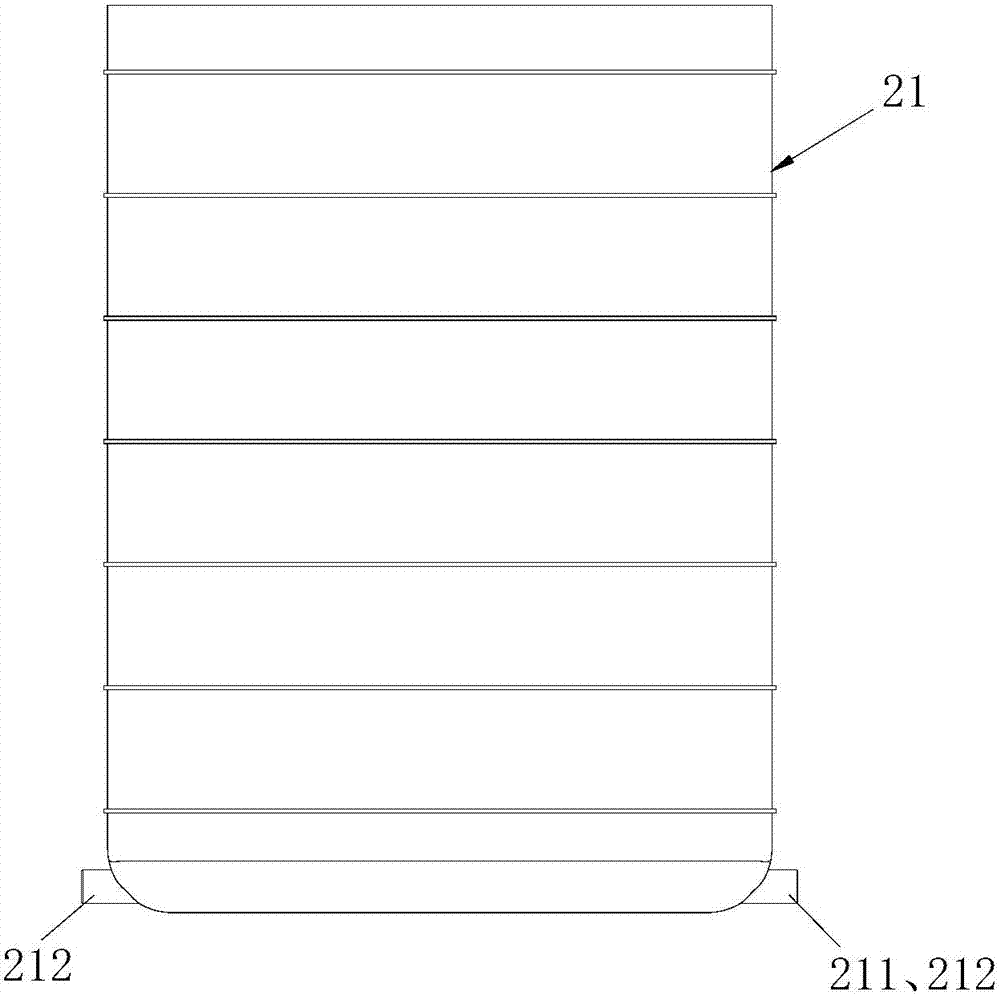

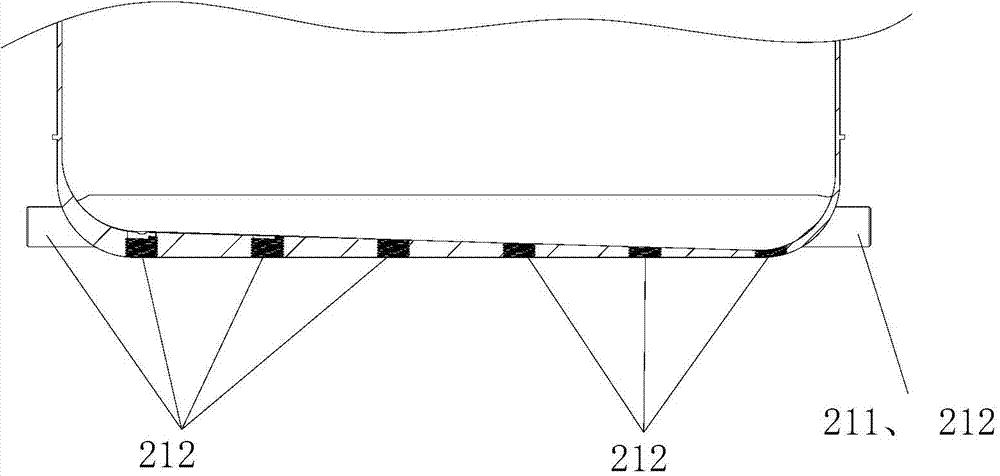

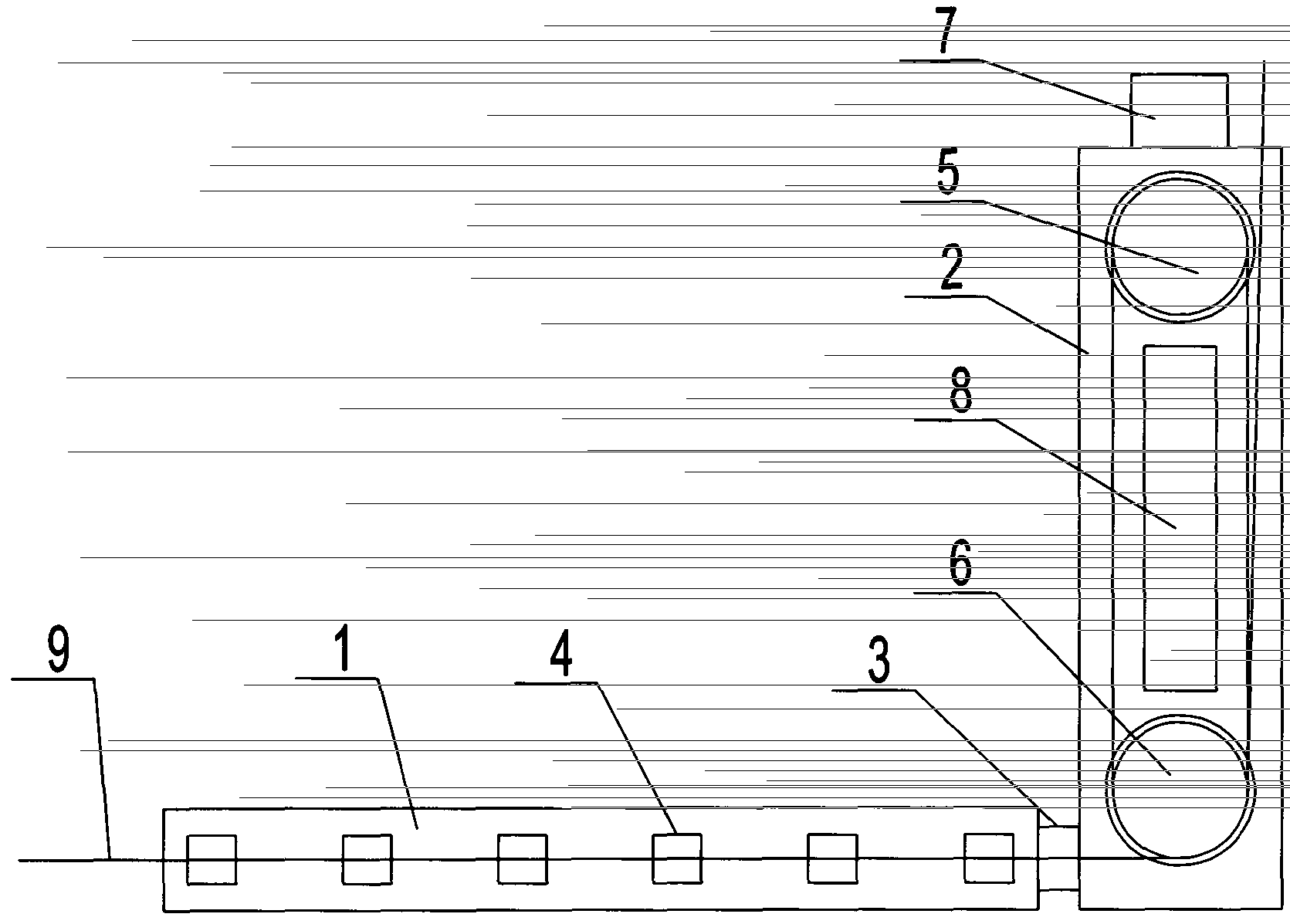

The invention discloses an air duct system of a horizontal type freezer and the freezer. The air duct system comprises an evaporator, a fan assembly, inlet air ducts, a return air duct, wherein the evaporator is located in an evaporator cavity; the evaporator cavity is located at one end of a box body in the length direction; the fan assembly is located above the evaporator; one end of each inlet air duct and one end of the return air duct respectively communicate with the upper part and the lower part of the evaporator cavity; the fan assembly is a centrifugal fan assembly with a volute structure; the inlet air ducts comprise two groups of inlet air ducts respectively arranged on two sides of a compartment; each group of inlet air ducts consist of a main inlet air duct and an auxiliary inlet air duct which are arranged in the vertical direction side by side; the main inlet air ducts and the auxiliary inlet air ducts extend to the other end of the box body in the length direction; and a plurality of air inlets communicating with the compartment are formed in the main inlet air ducts and the auxiliary inlet air ducts. The air duct system has the advantages that cold air is supplied to one end, away from the evaporator, of the horizontal type freezer through the inlet air ducts, and the refrigeration efficiency of the freezer is improved.

Owner:CHANGHONG MEILING CO LTD

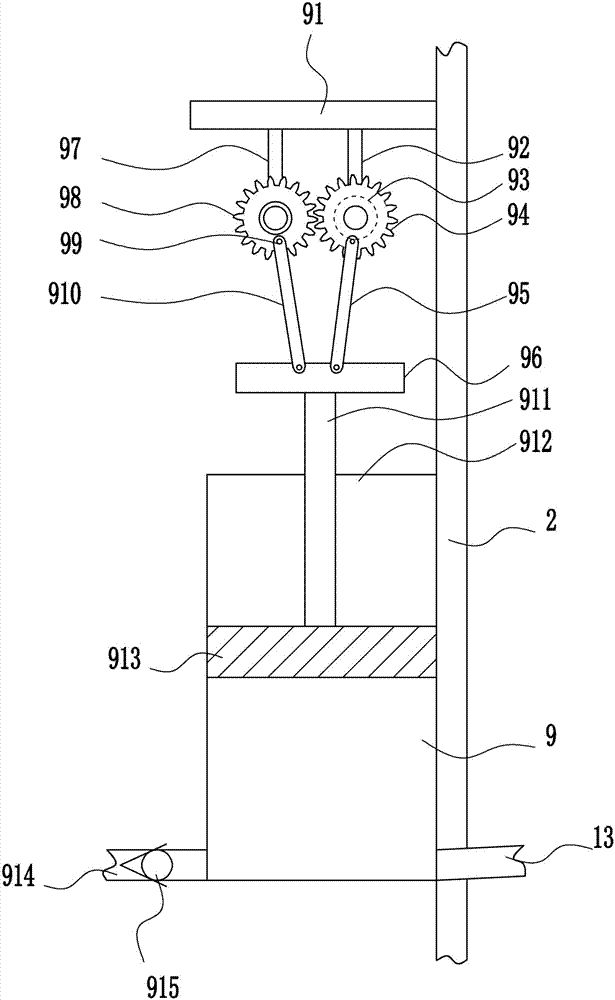

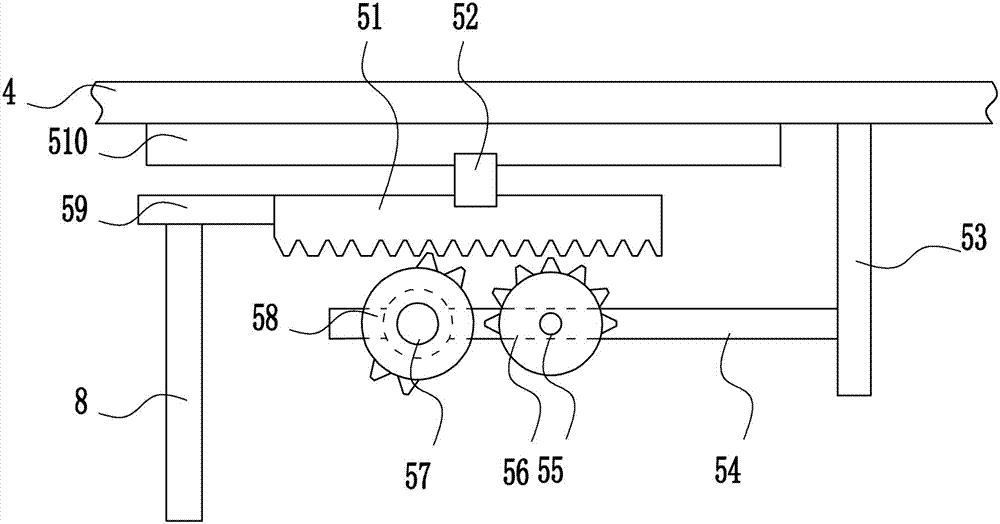

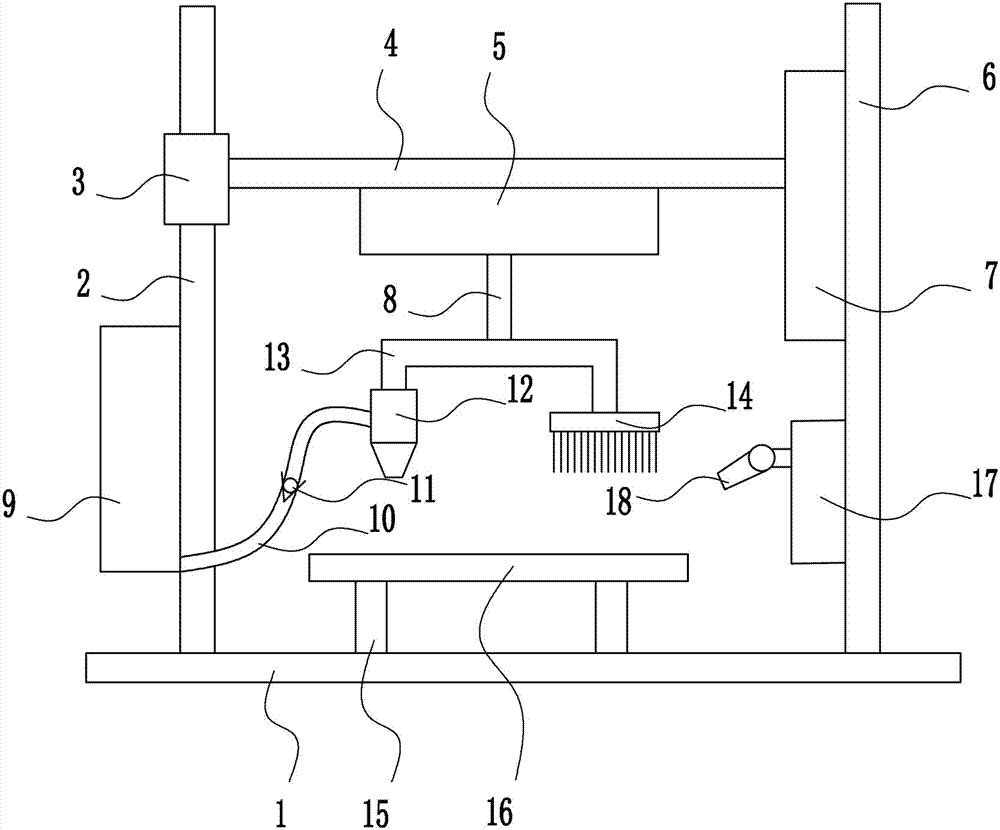

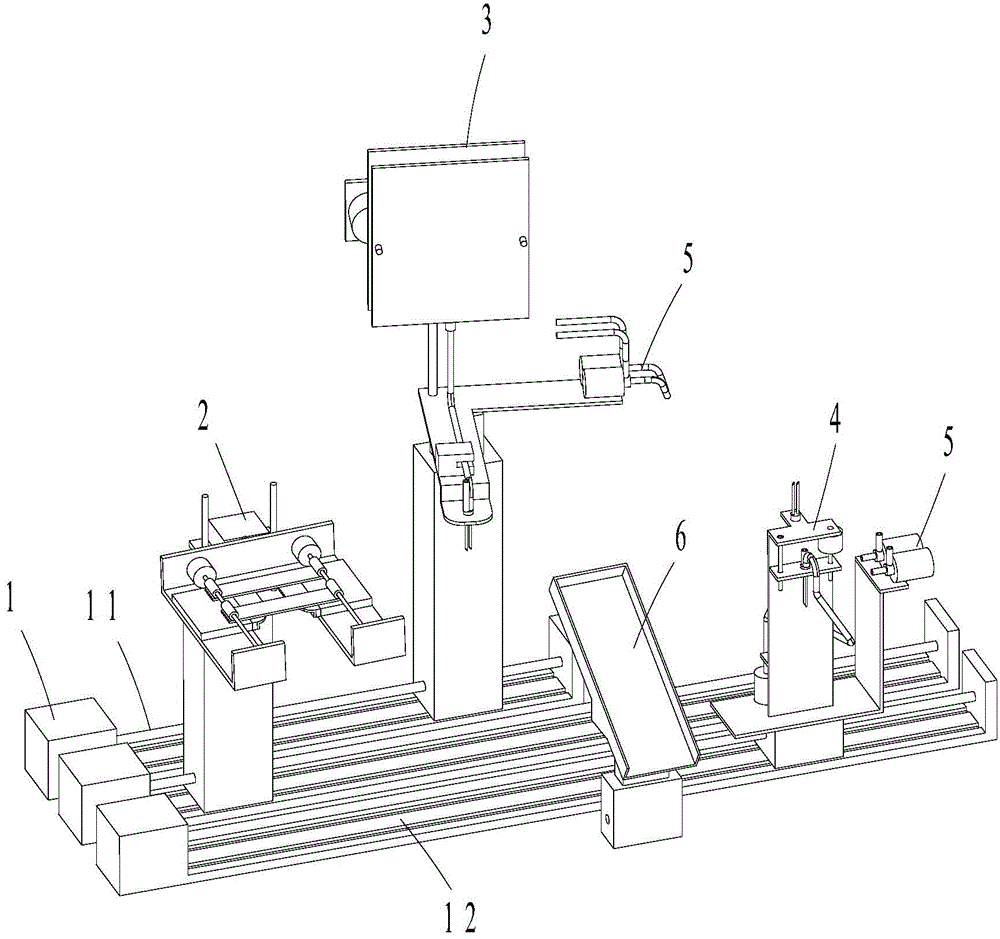

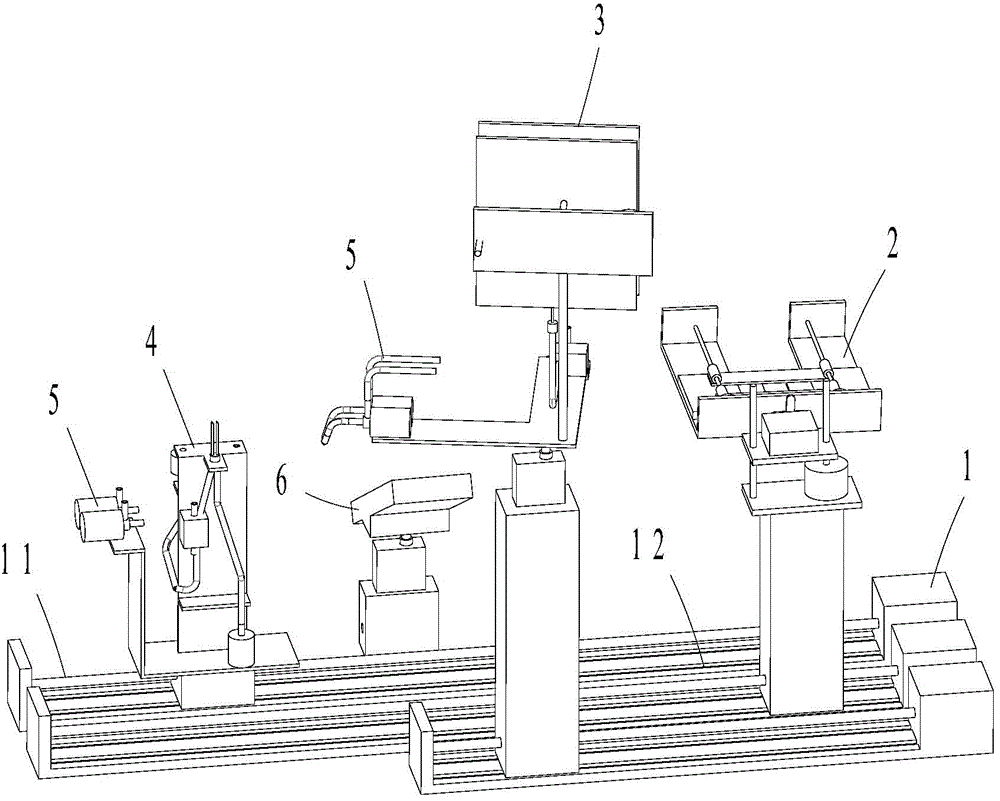

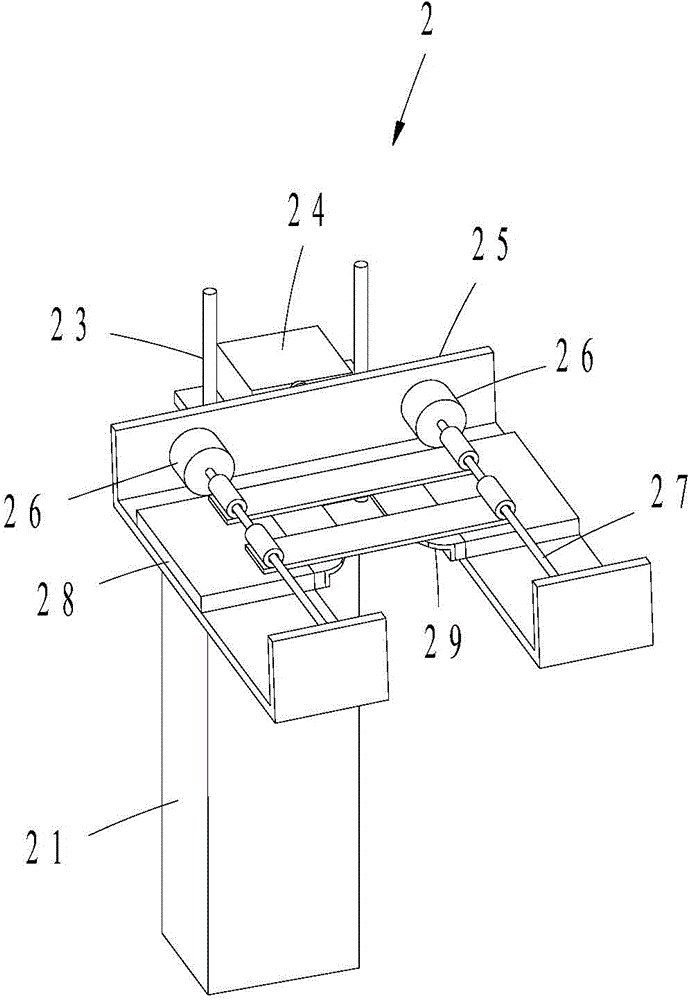

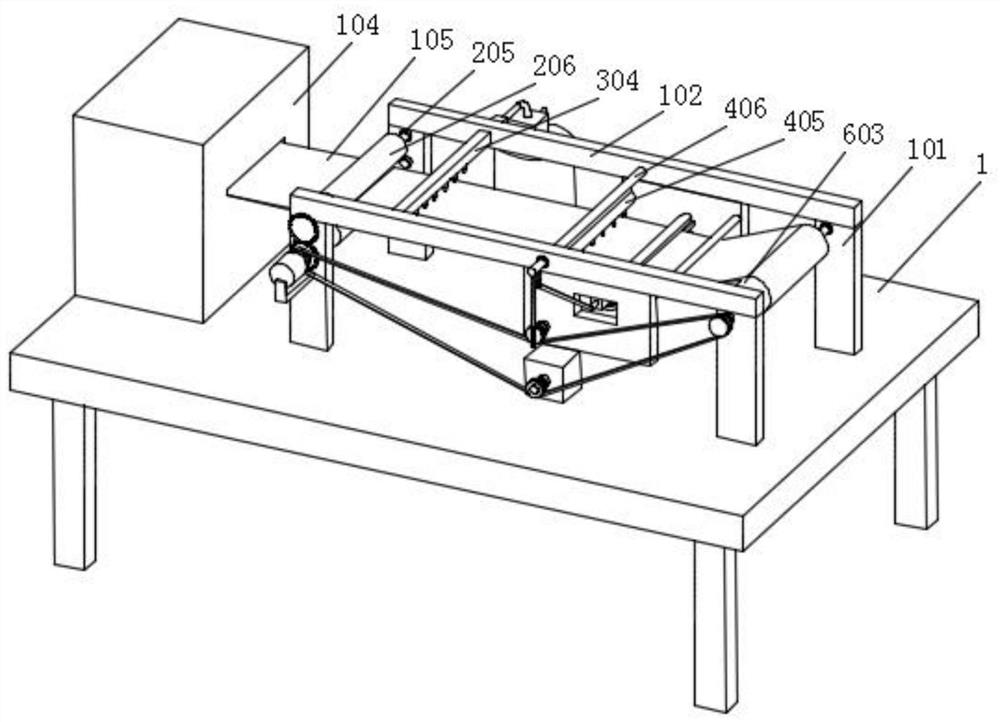

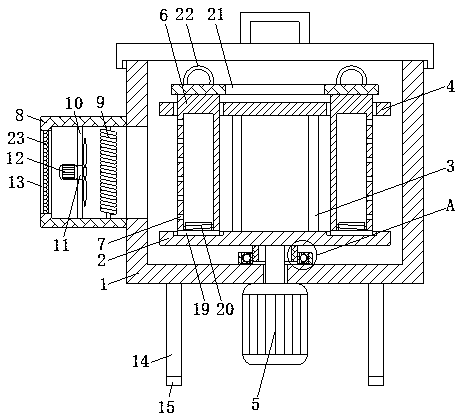

Surface gluing equipment for machining resistance elements

InactiveCN107185777AApply evenlyAchieve the effect of continuous dispensingLiquid surface applicatorsCoatingsEngineeringResistive element

The invention relates to gluing equipment, in particular to surface gluing equipment for machining resistance elements. The surface gluing equipment for machining the resistance elements is high in efficiency and uniform in coating. The surface gluing equipment for machining the resistance elements comprises a bottom plate, a first guiding rod, a first guiding sleeve, a lifting rod, a moving device, a right frame, a lifting device, a moving rod, a glue-conveying device, a flexible pipe, a first one-way valve and the like. The left side of the top of the bottom plate is welded to the first guiding rod. The first guiding rod is connected with the first guiding sleeve in a sleeved mode. The right side of the top of the bottom plate is welded to the right frame. The moving device is arranged above the left side of the right frame. The left side of the moving device is connected with the lifting rod. According to the surface gluing equipment for machining the resistance elements, the height of a solder dispensing tool and a brush is controlled through the lifting device, the surface gluing equipment is more humanized, by cooperative using of the moving device and the glue conveying device, the coating is more uniform, and the effect is better.

Owner:周福明

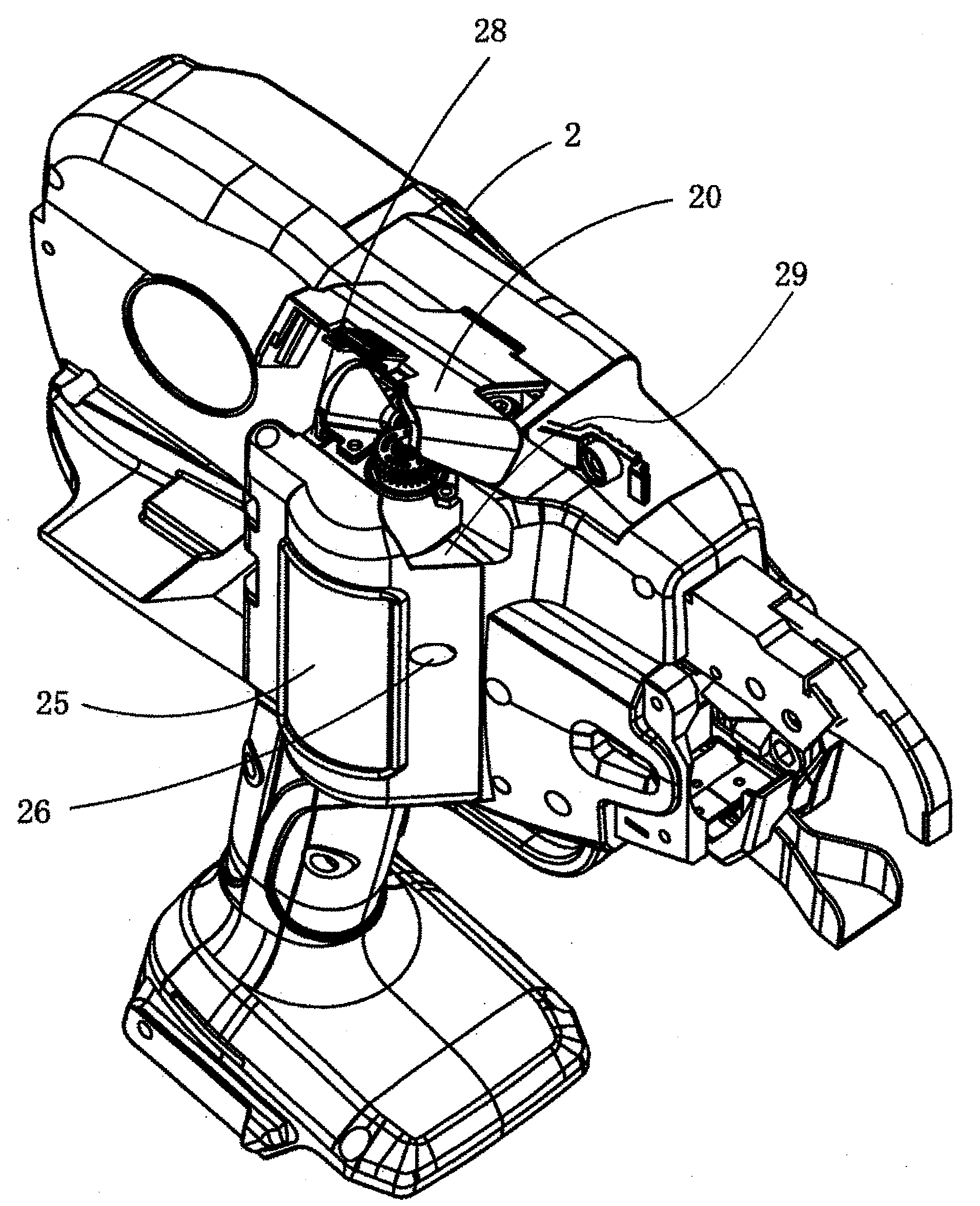

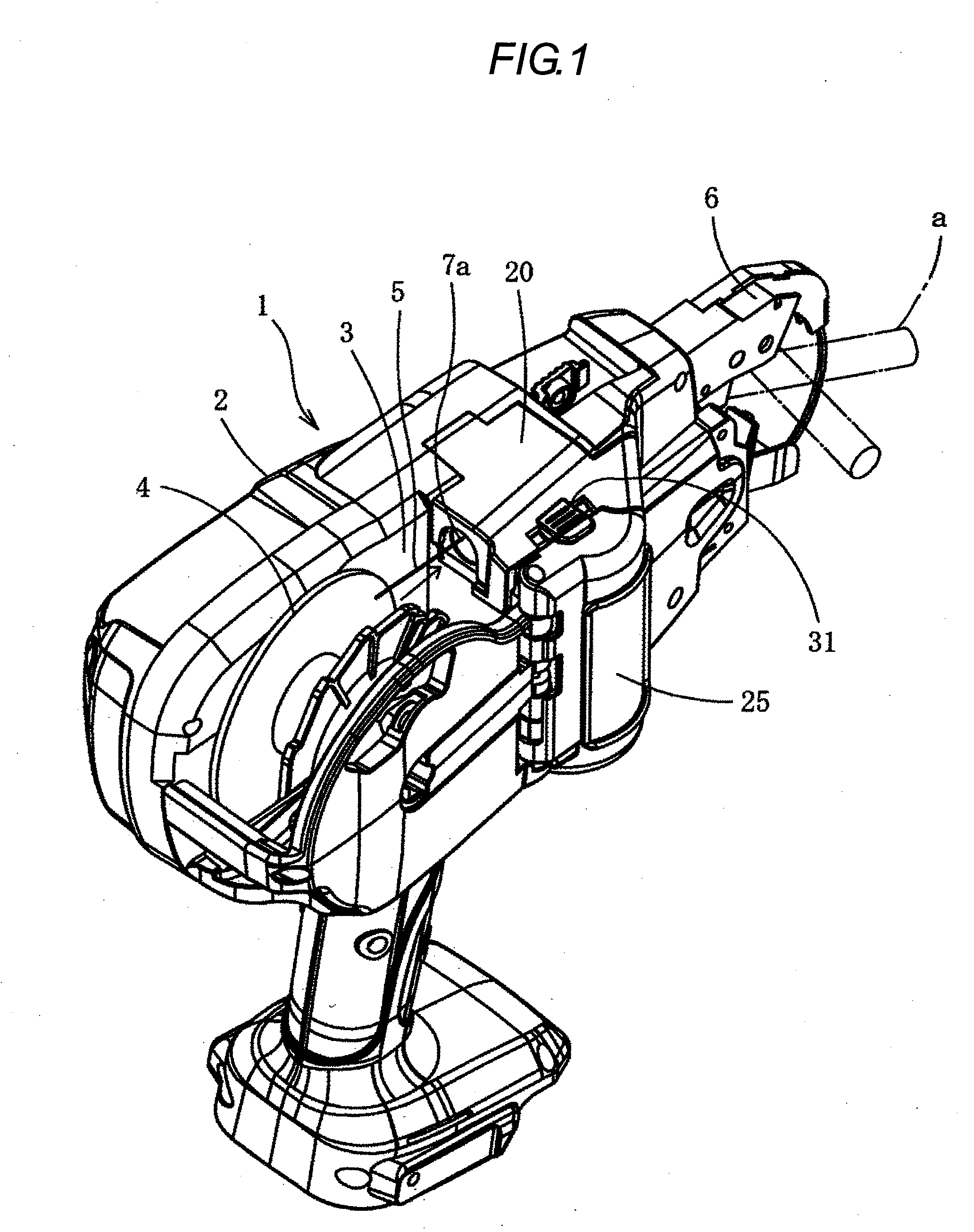

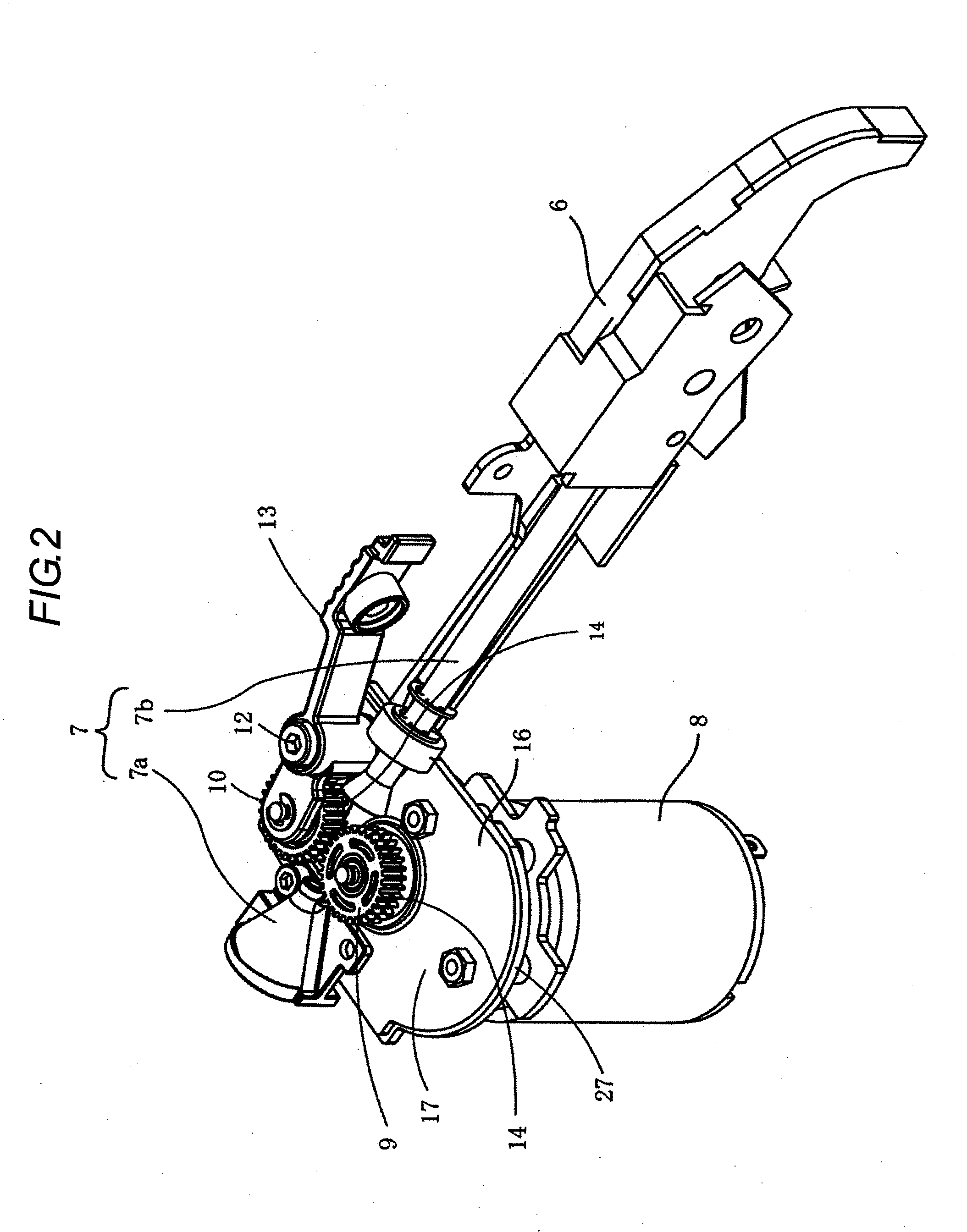

Reinforcing bar binding machine

A reinforcing bar binding machine is provided with a pair of feed gears for feeding a wire from a wire reel mounted on a binding machine body; an electric motor for driving the feed gears; a partition plate provided between the feed gears and the electric motor to partition the feed gears and the electric motor; and first and second discharge portions for discharging wire shavings. The partition plate is surrounded by a wall except for portions of the partition plate being adjacent to the first and second discharge portions. The first and second discharge portions are disposed so that the partition plate positions between the first and second discharge portions.

Owner:MAX CO LTD

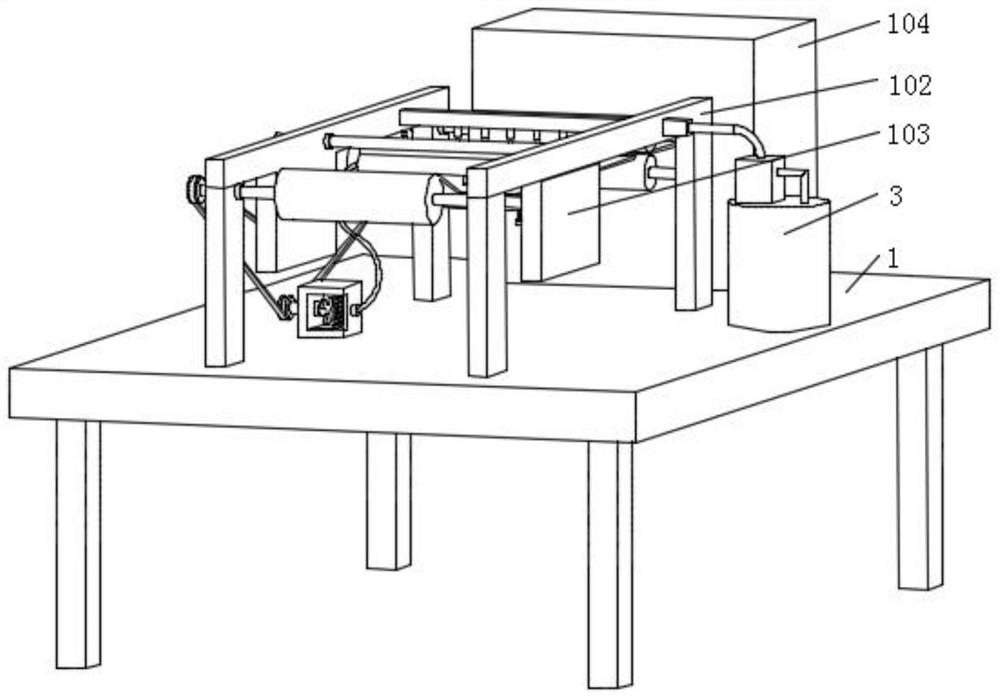

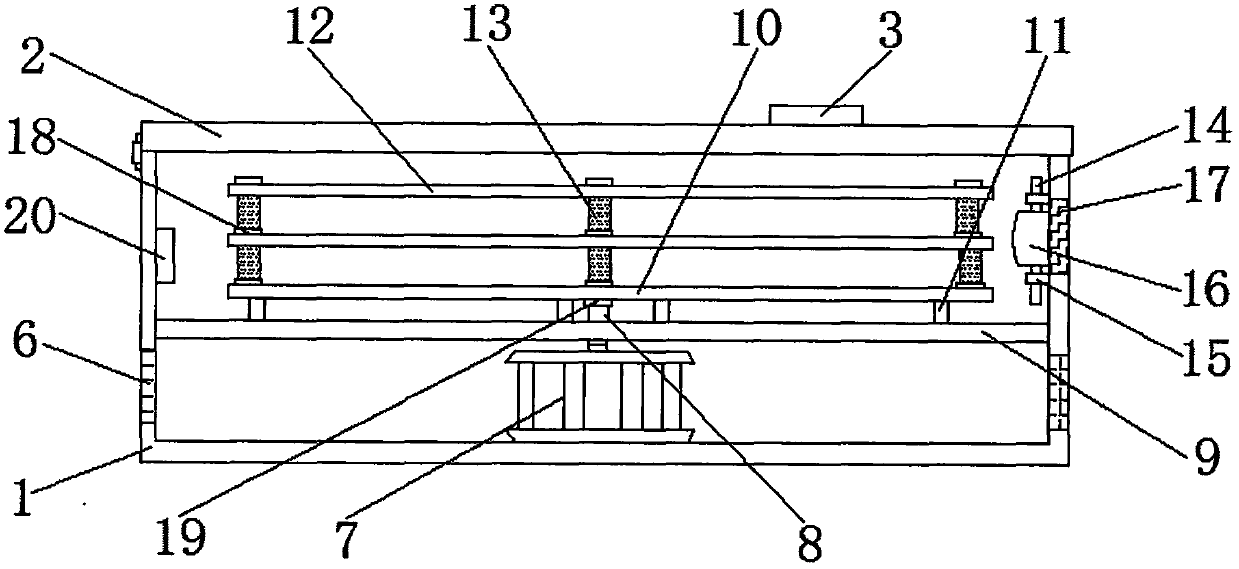

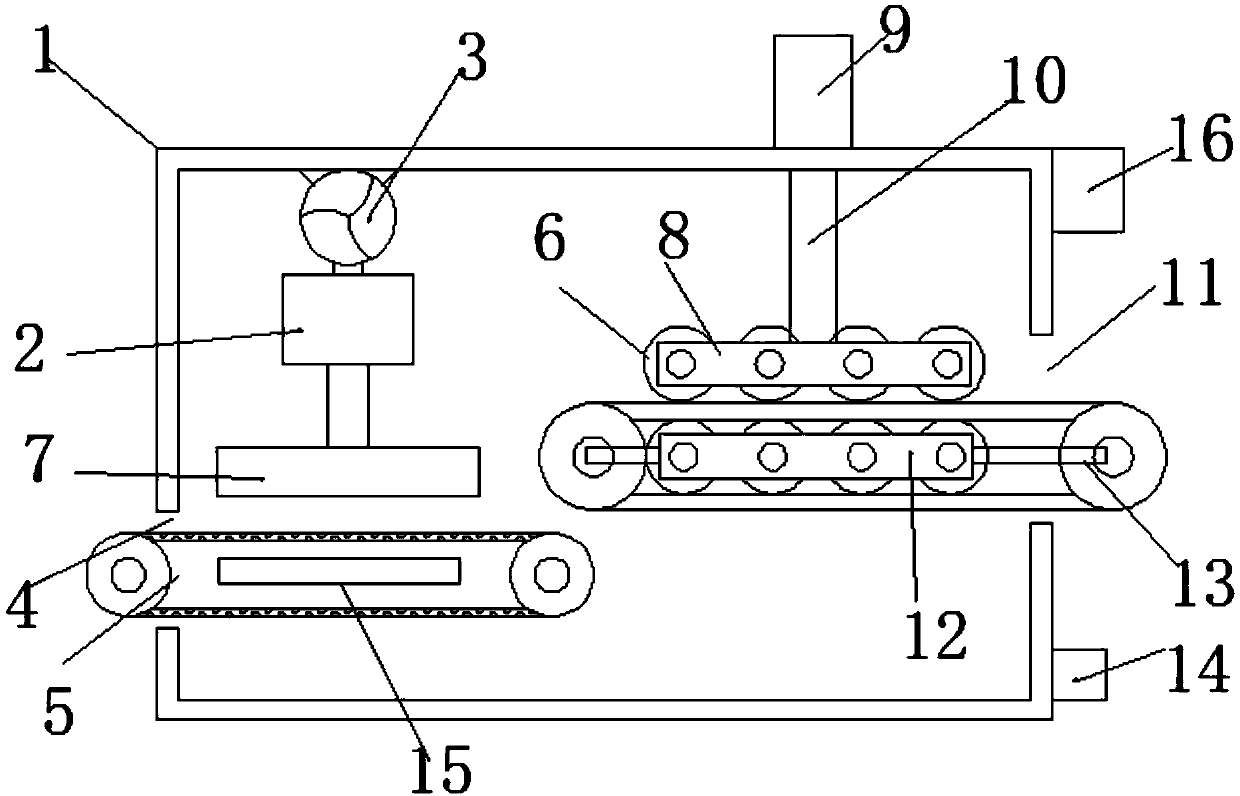

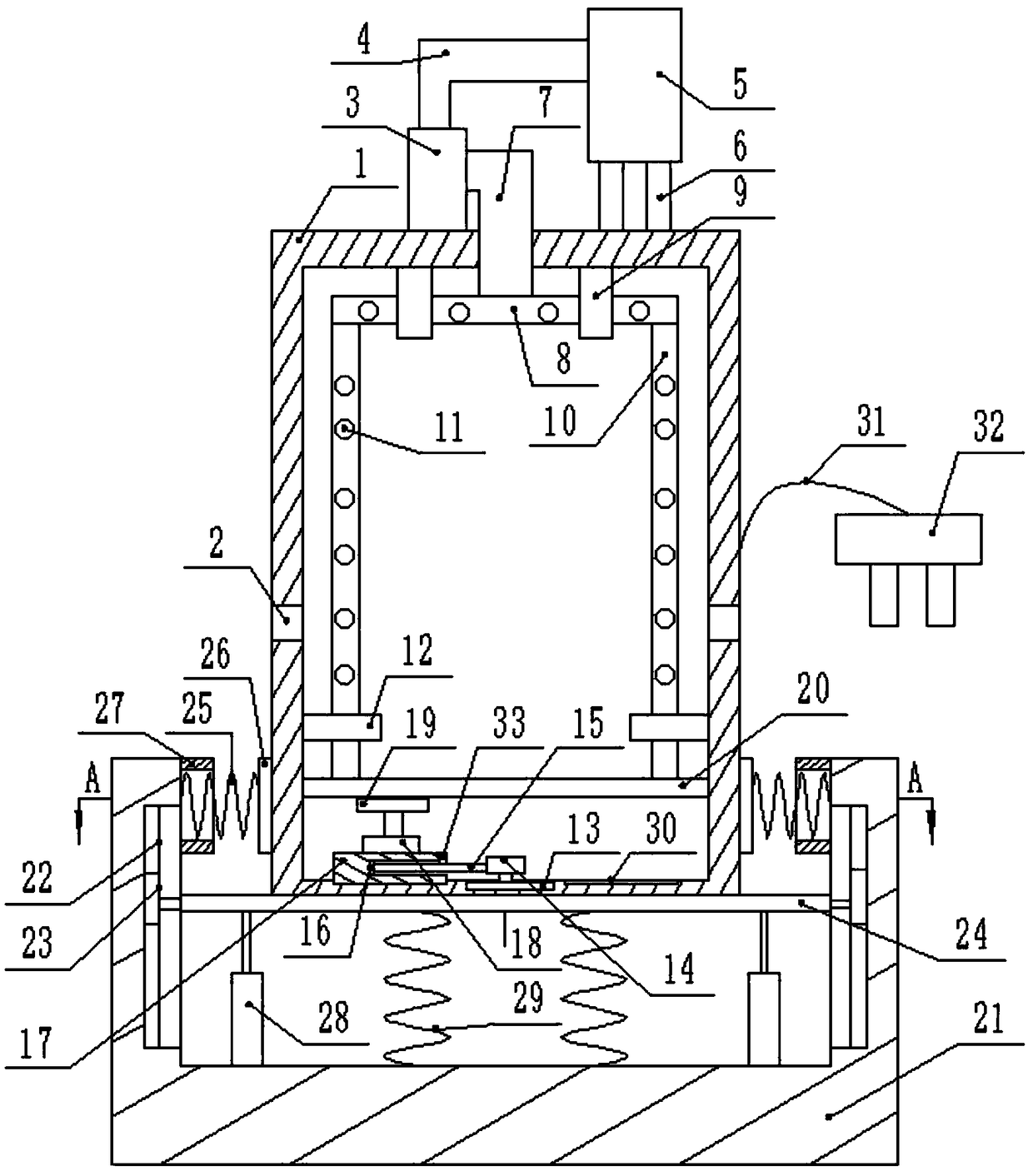

Dosage device and dosage method for powder injection bottle

ActiveCN104800913AFully automatedSimple structurePharmaceutical containersMedical packagingDisinfectantBottle

The invention discloses a dosage device for a powder injection bottle. The dosage device comprises a base, wherein a clamping component for clamping and rotating the powder injection bottle, a liquid injection component which is used for communicating a liquid injection bag with the powder injection bottle and injecting medicinal liquor in the liquid injection bag into the powder injection bottle, a suction injection component which is used for communicating the powder injection bottle with an injection bag and sucking and injecting the medicinal liquor in the powder injection bottle into the injection bag, and a disinfection air blowing component for spraying disinfectant to the powder injection bottle and the injection bag for disinfection are arranged on the base. According to the dosage device for the powder injection bottle, the clamping component is used for clamping the powder injection bottle, the liquid injection component is used for injecting the medicinal liquor in the liquid injection bag into the powder injection bottle, the suction injection component is used for sucking the medicinal liquid in the powder injection bottle into the injection bag, and the disinfection air blowing component is used for disinfecting bottle covers of the powder injection bottle and the injection bag, so that dosage of the powder injection bottle can be completed efficiently, and automation of dosage and injection of the medicinal liquor into the powder injection bottle is realized; the dosage device is simple in structure, easy and convenient to operate, high in automation degree, safe and reliable; the labor intensity is reduced.

Owner:成都彼维仕科技有限公司

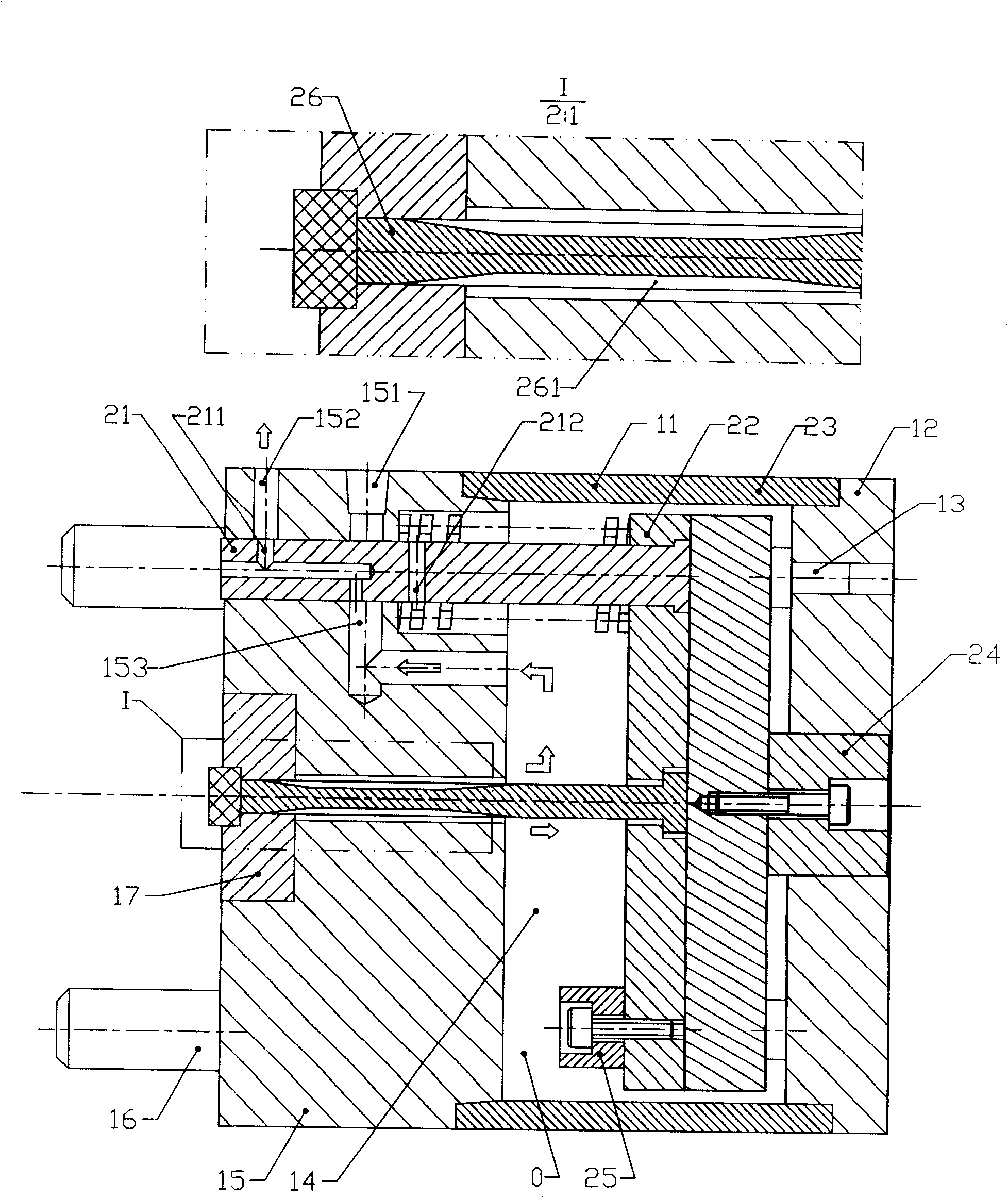

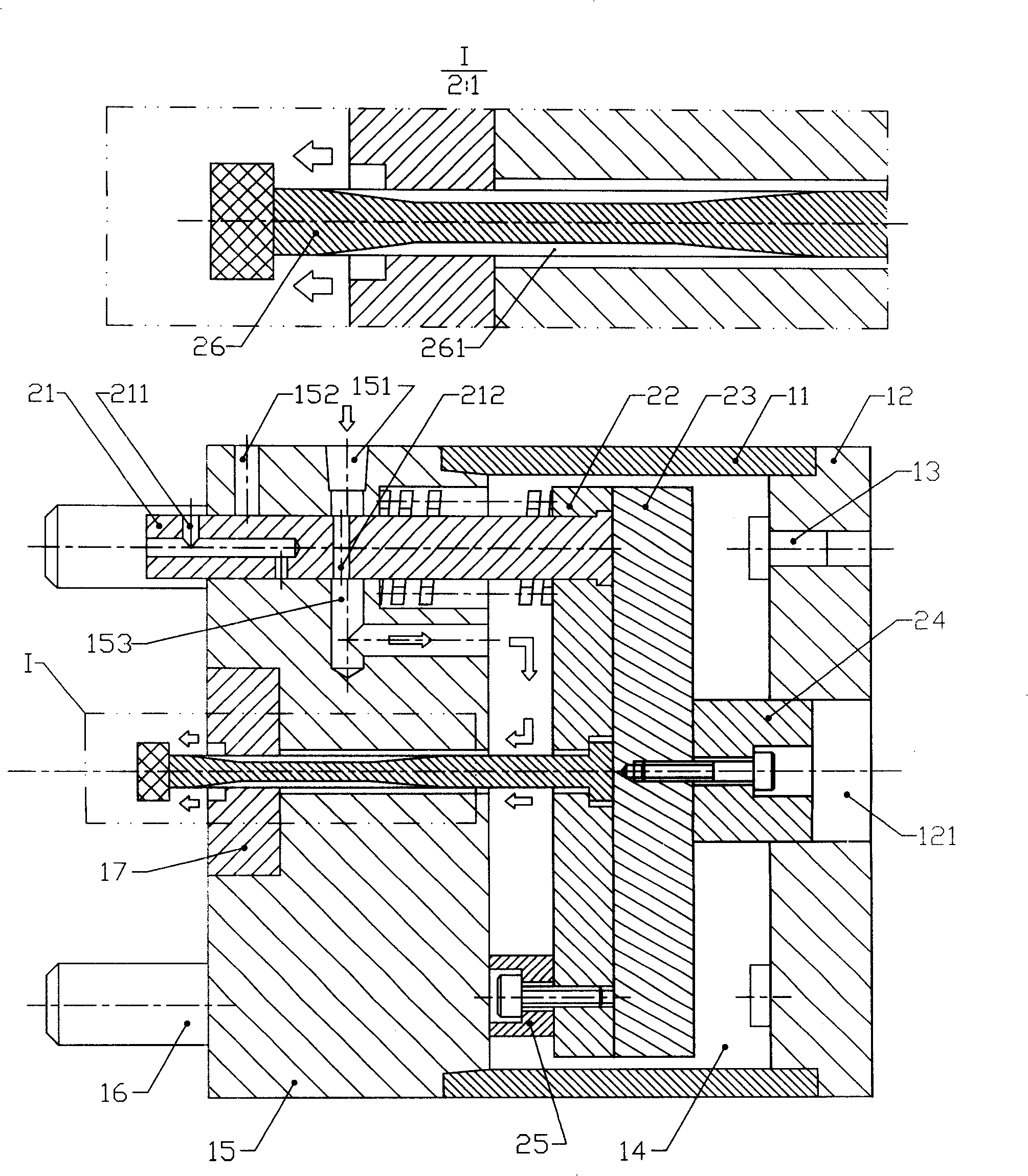

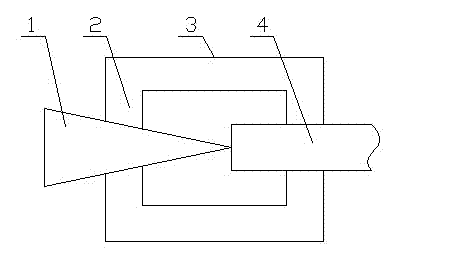

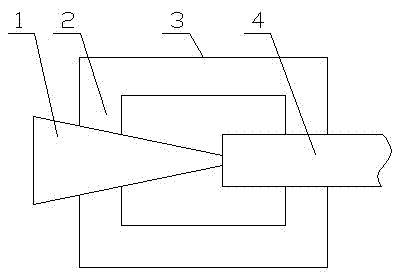

Mechanism of plastic rubber mold and compressed-air linked ejection mechanism

The invention discloses a die mechanism with compressed air linkage push-out added on an original ejection mechanism. Two ends of a support block of a traditional die are respectively provided with a sealing plate. A jacking block sealed with an ejector hole of a bottom plate is arranged under a lower ejector retainer plate to form a sealing space (air chamber for short) among a core plate, the bottom plate and the sealing plate. The air chamber is connected with the compressed air through a valve control mechanism. An axial blowing groove is arranged on an ejector retainer. The bottom of the blowing groove is communicated with the air chamber, and the top part is certain distance away from a formed part. During the push-out, the ejector retainer is driven by an ejector to be pushed out for a certain distance. A plastic part is detached from the formed part. Then, the valve control mechanism leads the compressed air to enter the air chamber. Meanwhile, the top end of the blowing groove on the ejector retainer is higher than a formed surface. Blowing force can be applied on the plastic part by the compressed air through the air chamber and the blowing groove to lead to the detachment of the plastic part from the ejector retainer. The die mechanism can be applied to dies of formed miniature products. One time of the push-out can lead to the total detachment of the plastic part from the die. Small products can be prevented from being absorbed by the ejector retainer to be demoulded hardly.

Owner:李庆辉

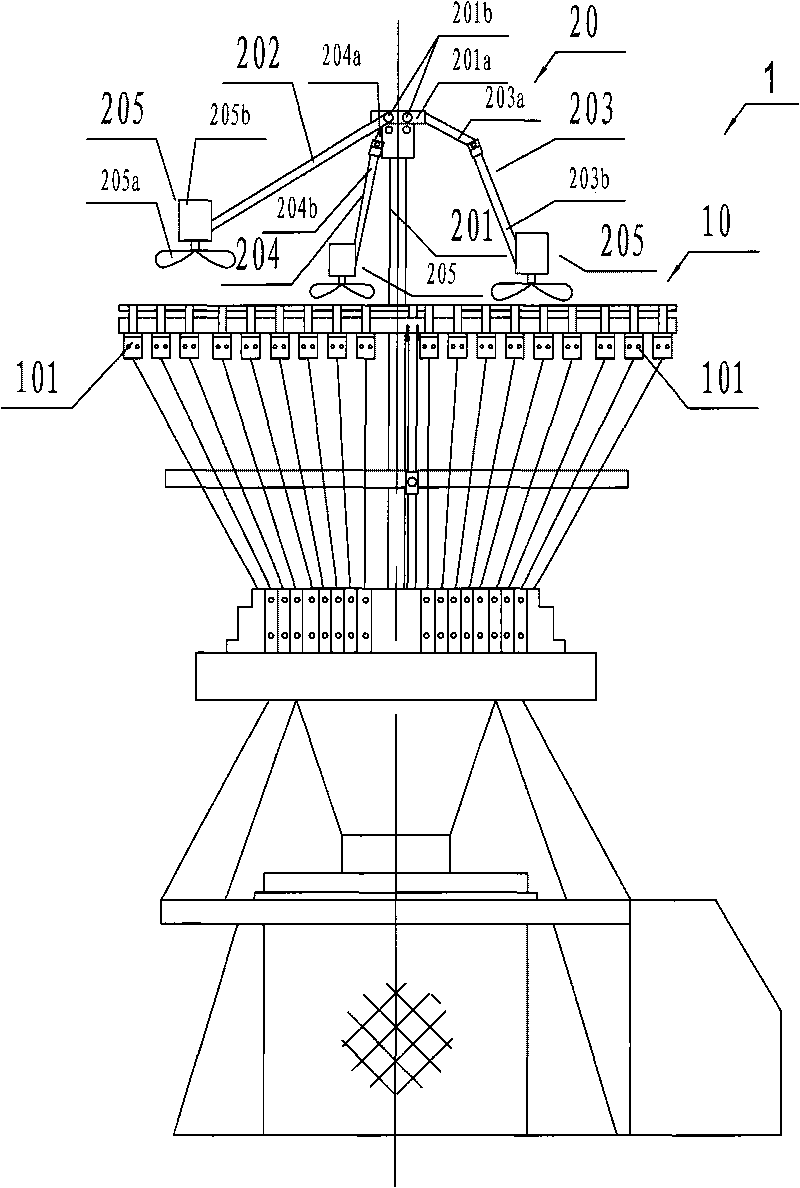

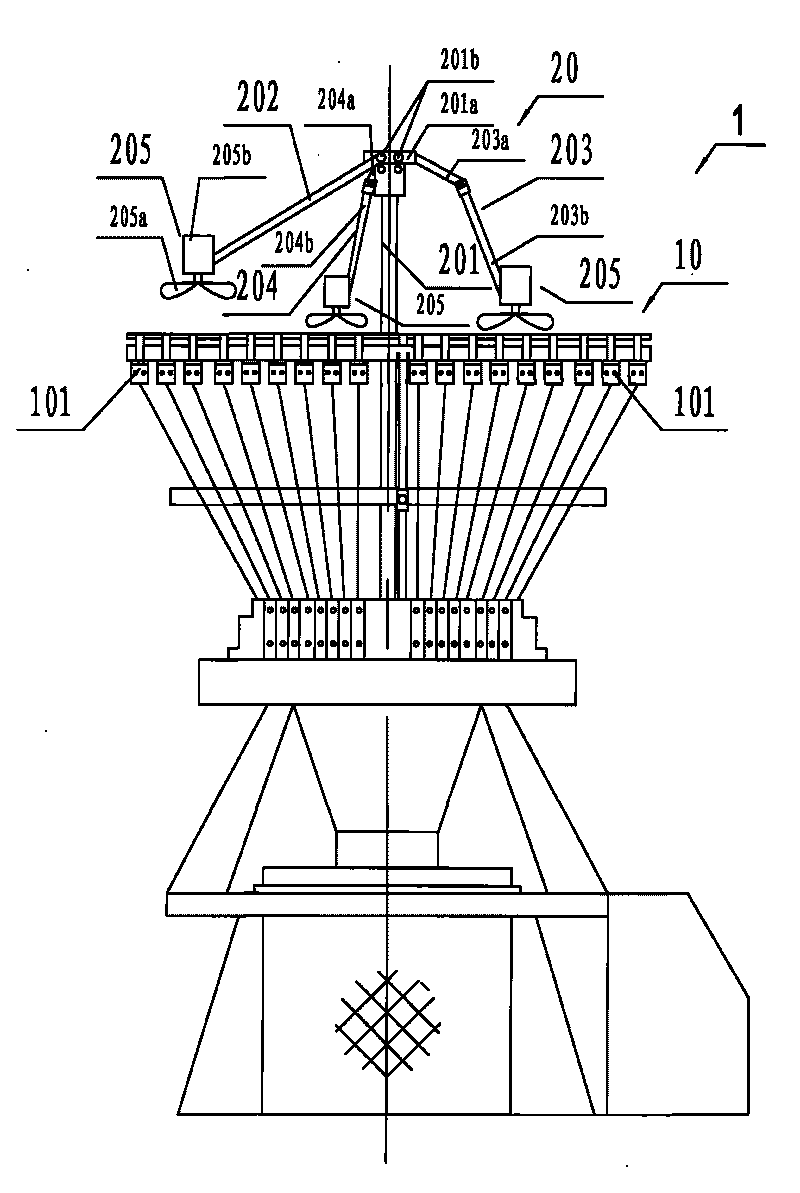

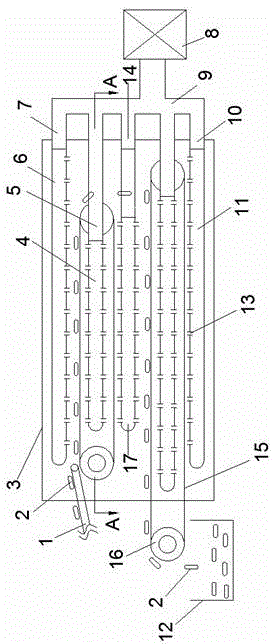

Knitting circular weft knitting machine

The invention relates to a knitting circular weft knitting machine, which is used for knitting yarns into a double faced fabric, wherein the knitting is finished by a needle cylinder. The top part of the circular weft knitting machine is provided with a plurality of yarn feeders distributed on the circumference; the central part of the circular weft knitting machine is provided with a rotating rod; a plurality of brackets are distributed on the rotating rod; the brackets are provided with electric fans which are used for blowing away flying cotton wools near the yarn feeders and blow uniformly; in a plurality of the brackets, at least part of the brackets are provided with bendable structures to ensure that the electric fans arranged on the brackets can blow to different positions. The knitting circular weft knitting machine treats the flying cotton wools near the yarn feeders in time, has a large treatment range, and effectively prevents the flying cotton wools from being adhered to the yarn feeders, so the working efficiency of the yarn feeders is improved.

Owner:吴江天龙针织有限公司

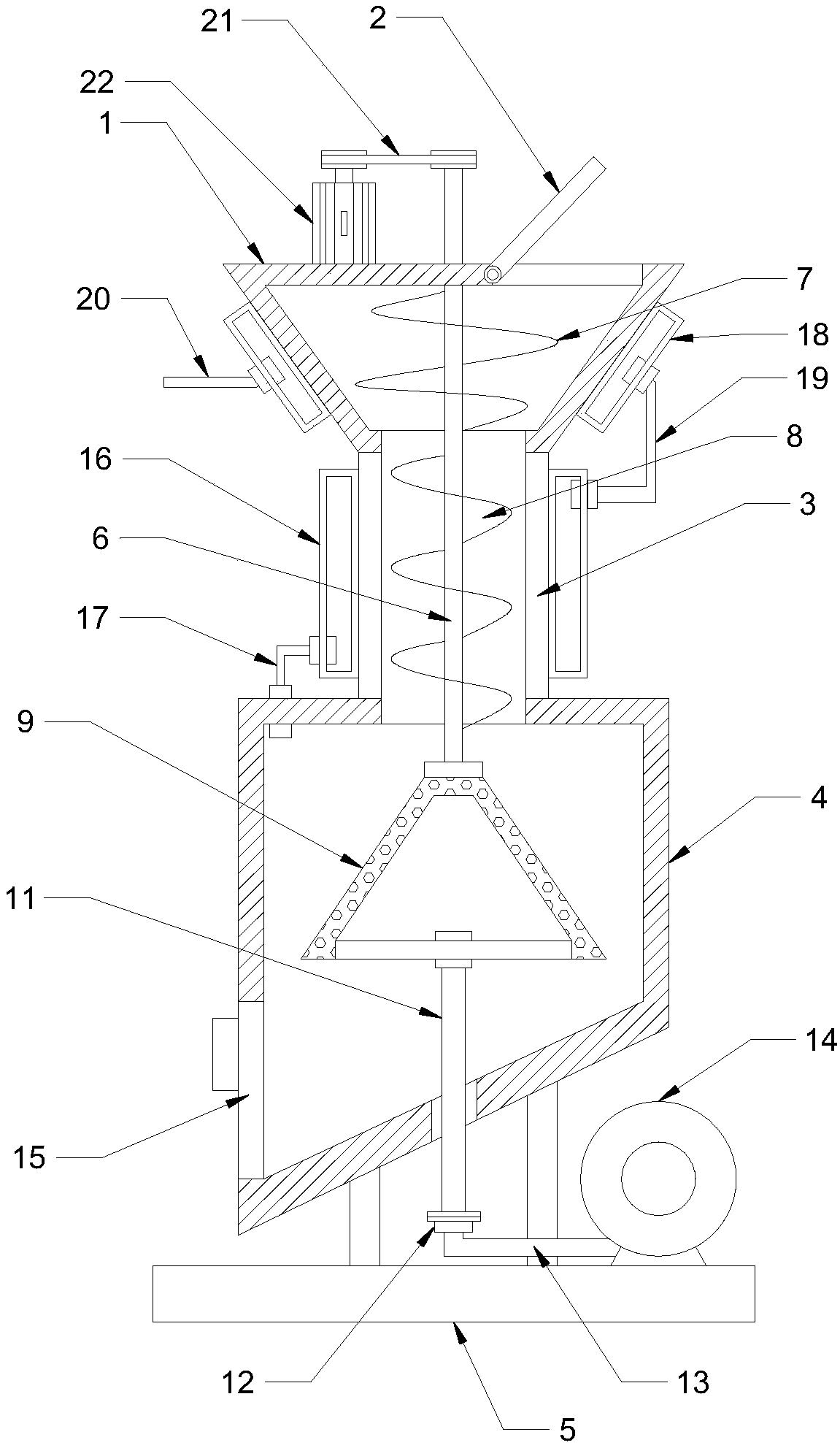

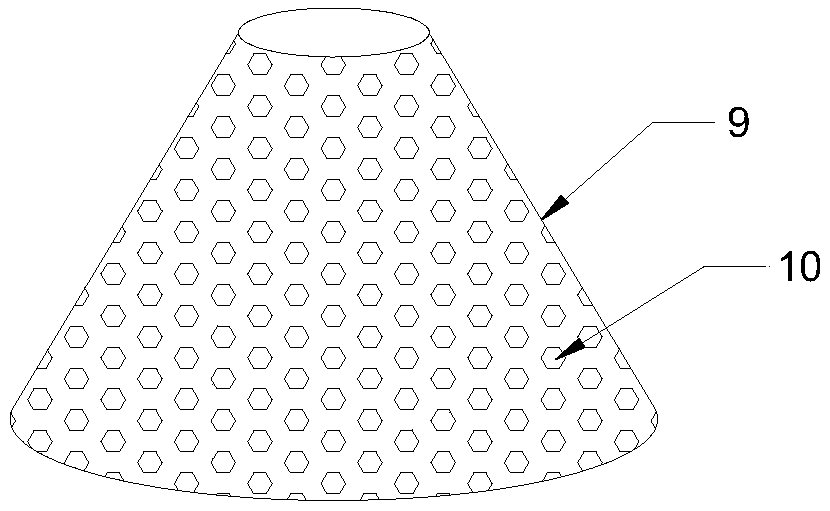

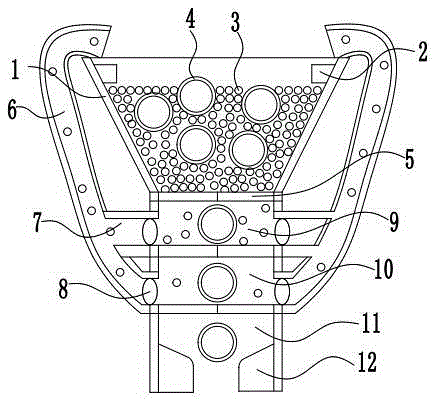

Energy-saving feed particle drying equipment

InactiveCN109631498ABlow evenlyEven and efficient dryingGranular material dryingDrying gas arrangementsEngineeringExhaust pipe

The invention discloses energy-saving feed particle drying equipment. The energy-saving feed particle drying equipment comprises a storage hopper, a feeding pipe and a drying box. The drying box communicates with the lower end of the storage hopper through the feeding pipe. A first preheating jacket sleeves the outer side of the feeding pipe, the first preheating jacket communicates with the innercavity of the drying box through a first communicating pipe. A second preheating jacket sleeves the outer side of the storage hopper, the second preheat jacket communicates with the first preheat jacket through a second communicating pipe, and the second preheating jacket communicates with an exhaust pipe. According to the energy-saving feed particle drying equipment, through a drying cylinder being a hollow cone, a drum, a rotating joint and an air heater, the uniform blowing of hot air from meshes of the drying cylinder is realized, feed particles spread and sliding down from the surface ofthe drying cylinder are evenly and efficiently dried, and the drying uniformity and the drying effect are improved; and the feed particles are preheated by arranging the first preheat jacket and thesecond preheat jacket, subsequent drying is facilitated, and meanwhile, heat is used fully.

Owner:柳良红

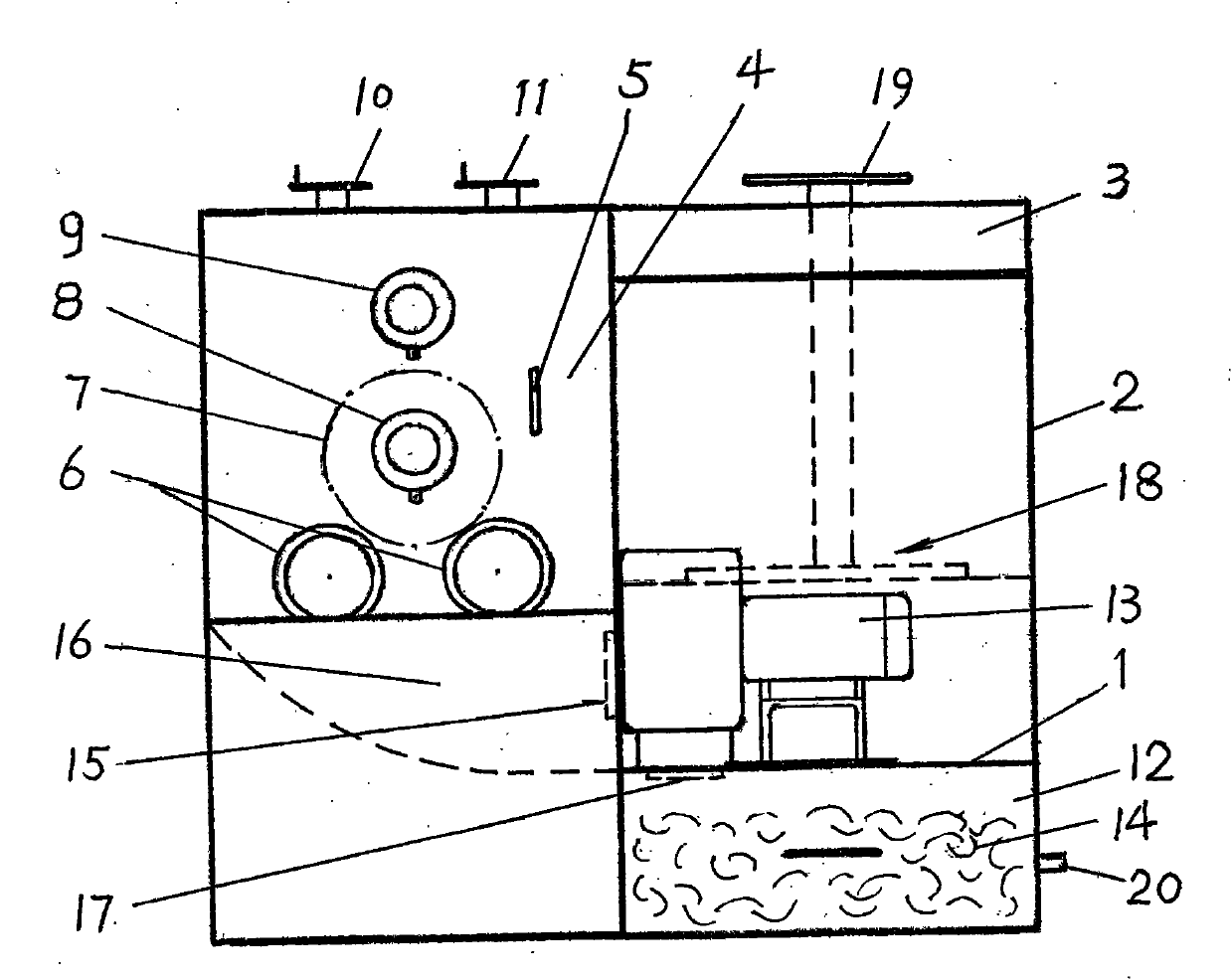

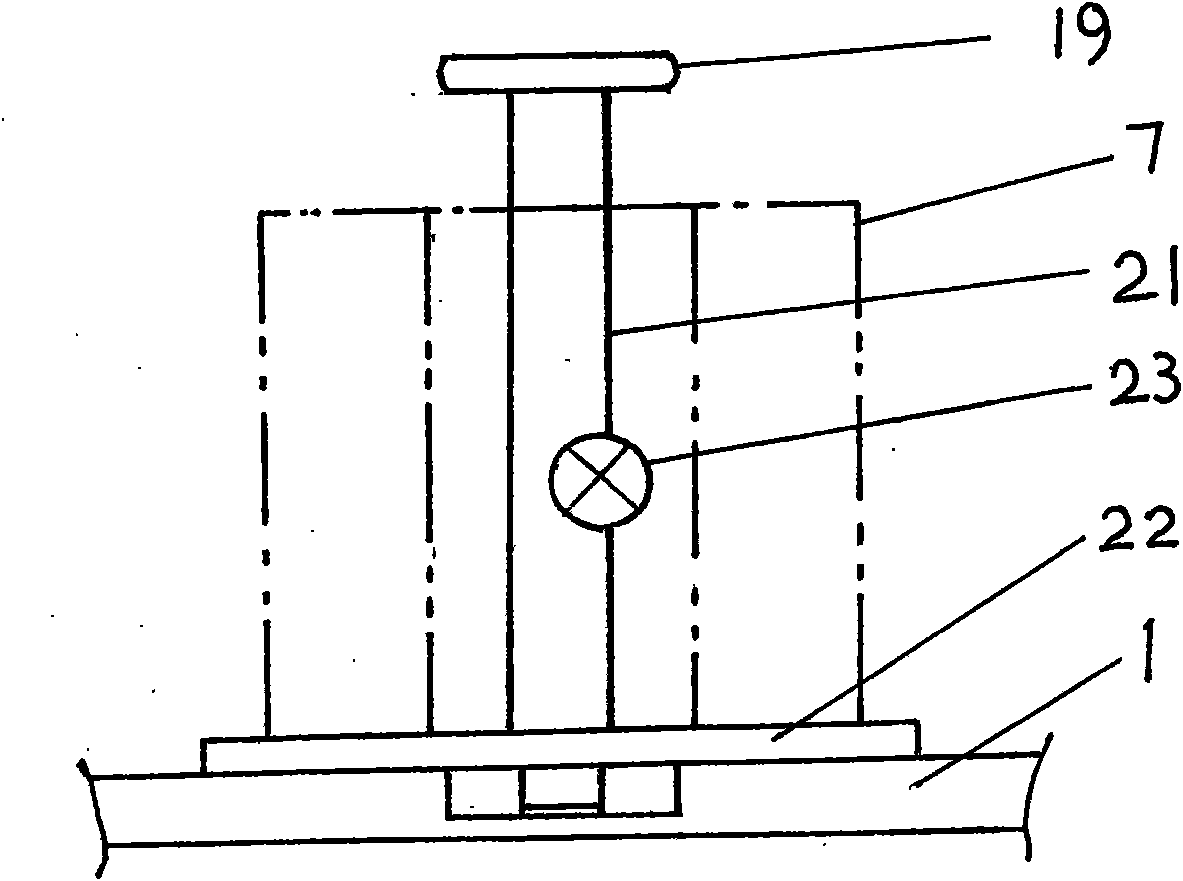

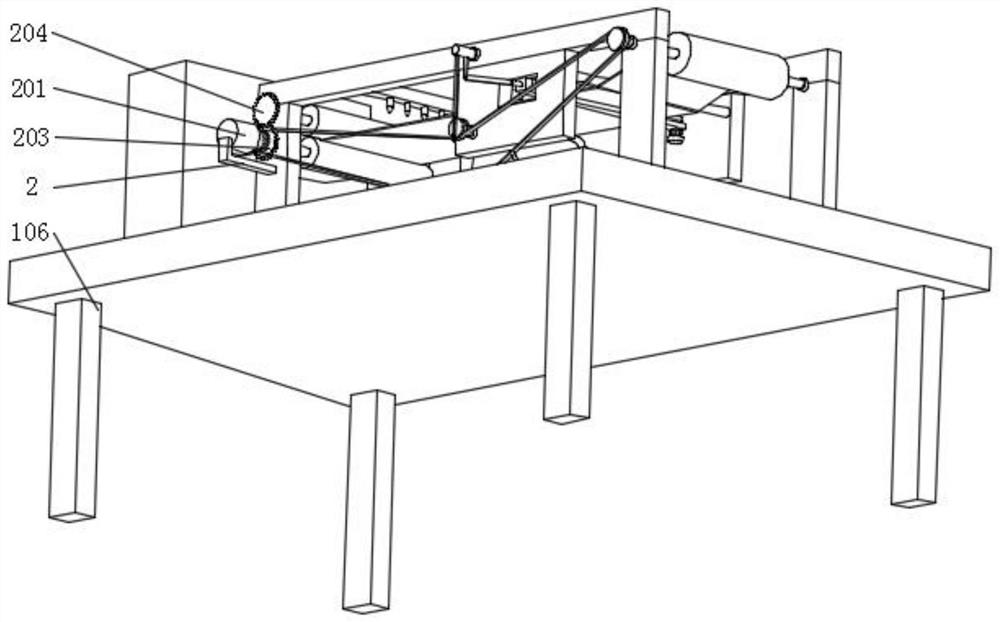

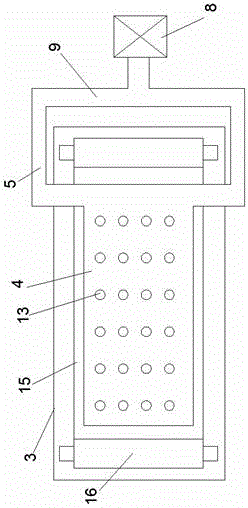

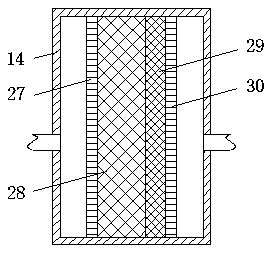

Dust removal device for air filter cartridge

InactiveCN101994614AAdapt to dust removal needsEasy to useAir cleaners for fuelElectricityAir filter

The invention relates to a dust removal device for an air filter cartridge. The dust removal device is provided with a frame, an electric control panel, a dust removal chamber with a closed structure, and a sealed dust collection device, wherein a double-roller mechanism and a nozzle guide rod mechanism capable of spraying air to remove dust inside and outside are arranged in the dust removal chamber; under the drive of an speed-adjustable motor and a feed screw nut, an inner nozzle and an outer nozzle in the nozzle guide rod mechanism can do uniform rectilinear motion to and fro inside and outside the air filter cartridge to be dedusted and uniformly apply compressed air to the internal and external surfaces of the air filter cartridge for dust removal; the dust collection device consists of a vacuum pump and a dust collection chamber positioned below the vacuum pump; and one side of the frame is provided with a detection platform for detecting whether the filter cartridge is broken or not. The dust removal device has the dust removal rate of over 95 percent, can realize dust removal and detection functions, is easy to operate and control, can blow the air uniformly in multiple directions, does not damage the air filter cartridge, is labor-saving, time-saving, safe and environmental-friendly, is favorable for protecting the body health of workers and improving labor efficiency, saves production and operation cost, and can clean and maintain various types of cylindrical air filter cartridges in engines of all Europe III buses and other transport vehicles, ships and the like.

Owner:FUZHOU PUBLIC TRANSPORT GROUP

Textile equipment with uniform drying function

InactiveCN112815680ADry evenlyBlow evenlyDrying gas arrangementsLavatory sanitoryElectric machineryEngineering

The invention discloses textile equipment with a uniform drying function, and relates to the field of uniform drying. The textile equipment comprises a workbench, four supporting blocks are fixedly mounted at the top of the workbench, and the same cross rod is fixedly mounted at the top ends of every two supporting blocks. In the textile equipment, a motor is started to drive a rotating shaft to rotate, the rotating shaft rotates to drive a transmission wheel, a transmission belt, a rotating roller and a rotating rod to rotate, the rotating roller rotates to drive air blowing fan blades to blow air, hot air enters an air guide pipe through a ventilation pipe and is sprayed out through an air spraying pipe, meanwhile, the rotating rod rotates to drive a cylindrical block to rotate, the cylindrical block rotates to drive a swing rod, a swing rod and the air guide pipe to swing in a reciprocating manner, then air can be evenly blown, and therefore cloth can be uniformly dried; and a sliding plate moves in a reciprocating manner to drive an extrusion plate to move in a reciprocating manner, then the extrusion plate can swing on the cloth in a reciprocating manner, and therefore the cloth can be flattened and prevented from being wrinkled during rolling.

Owner:广州贺生网络科技有限公司

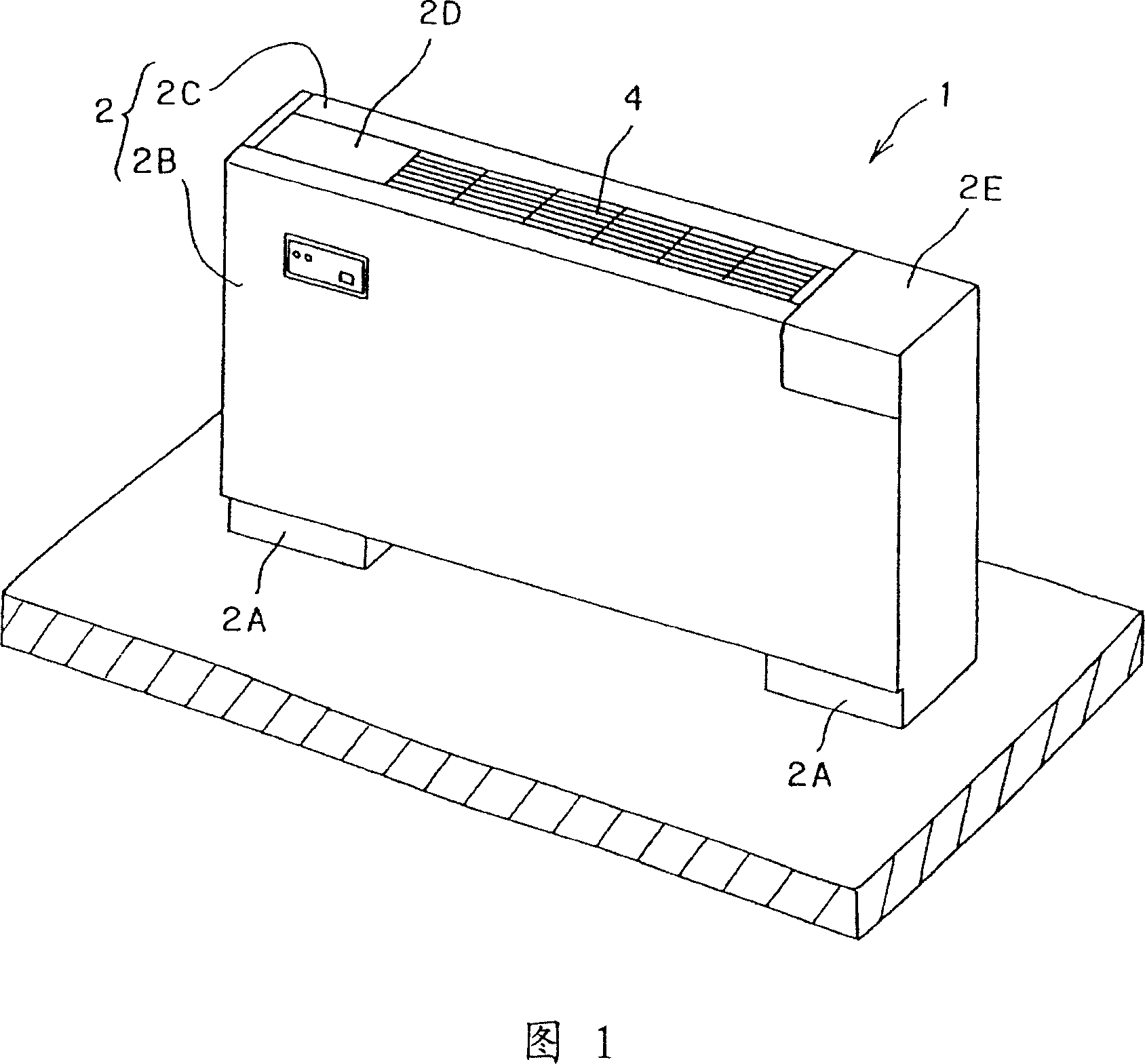

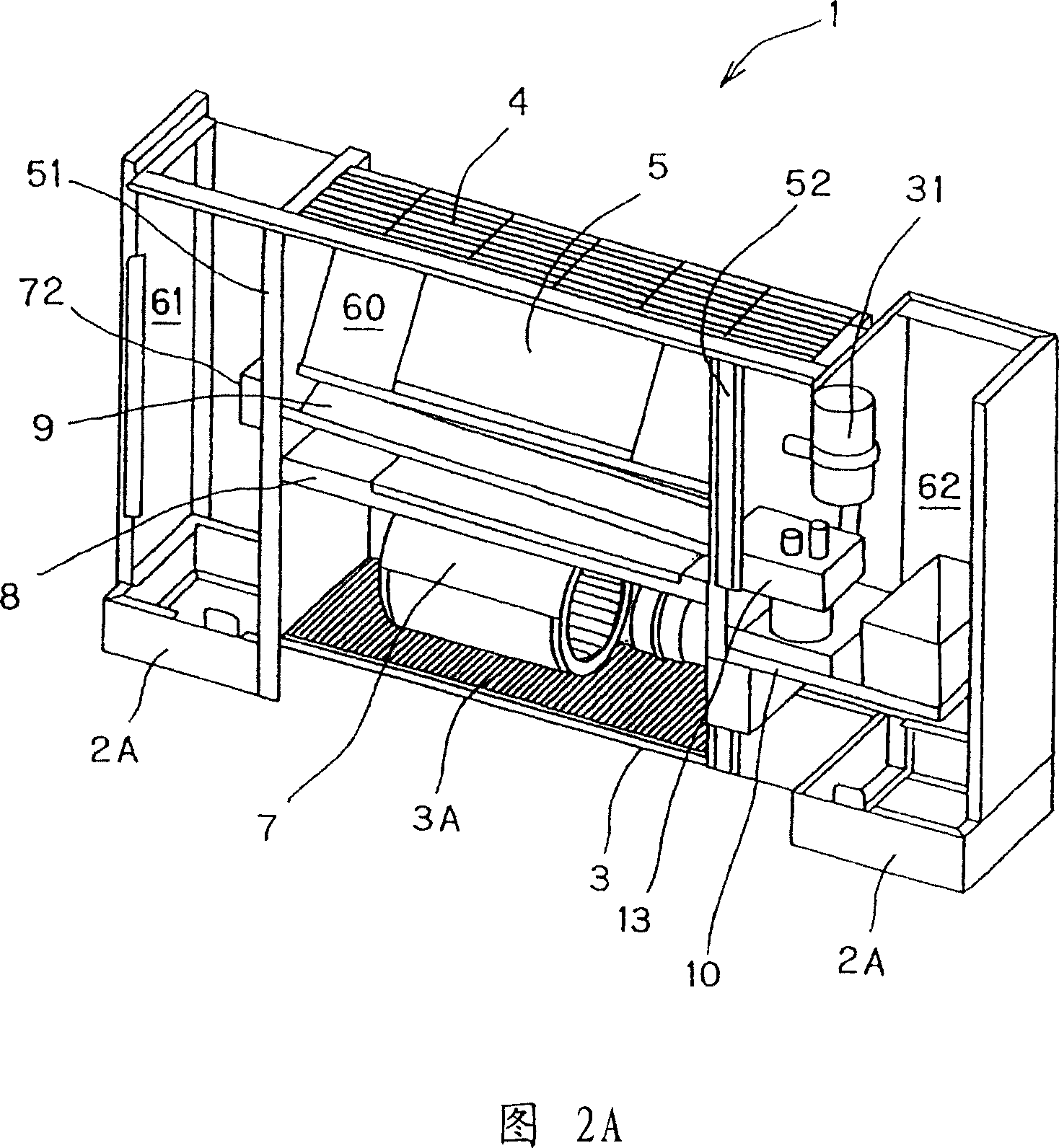

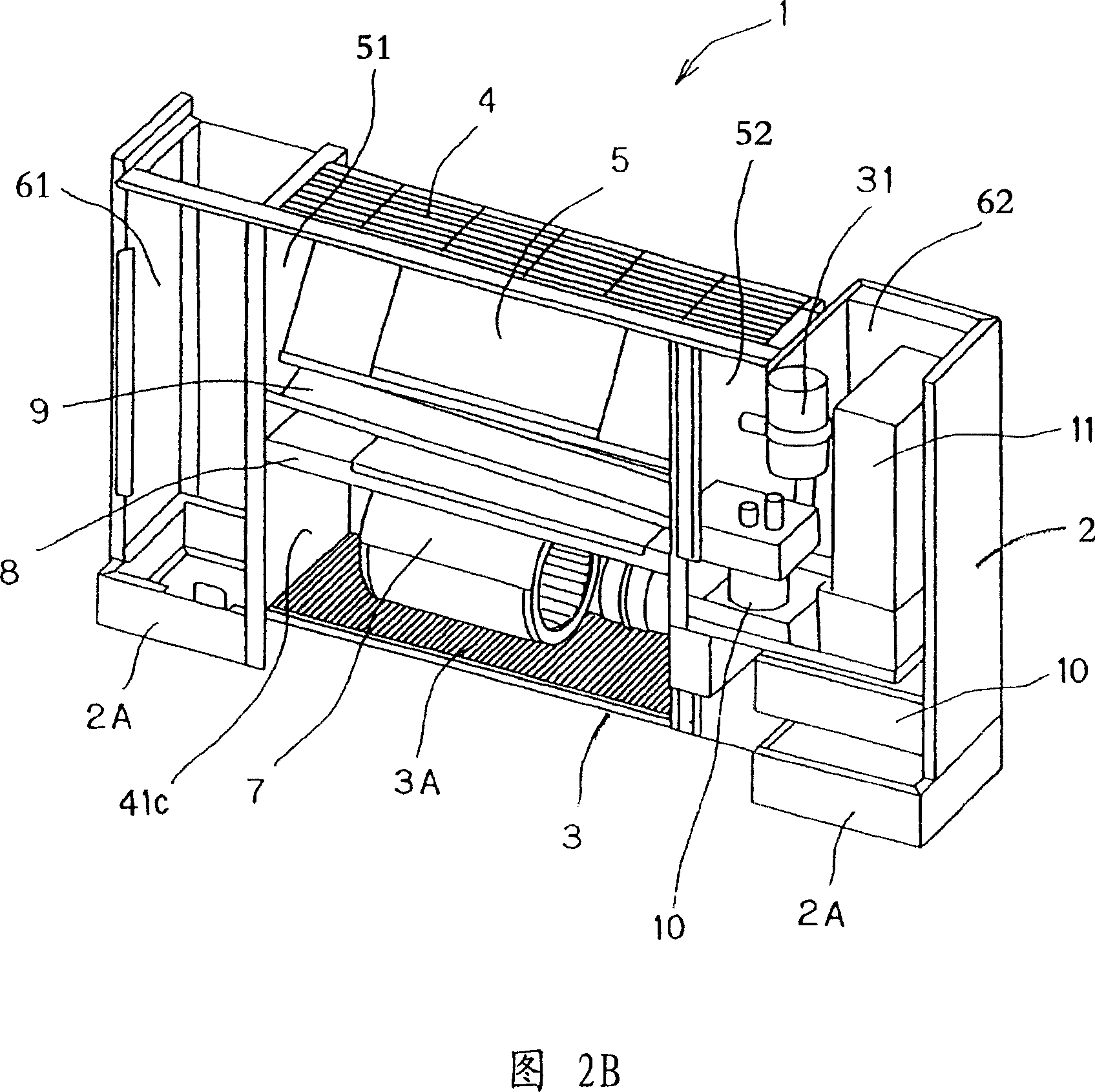

Vertical air degermation apparatus

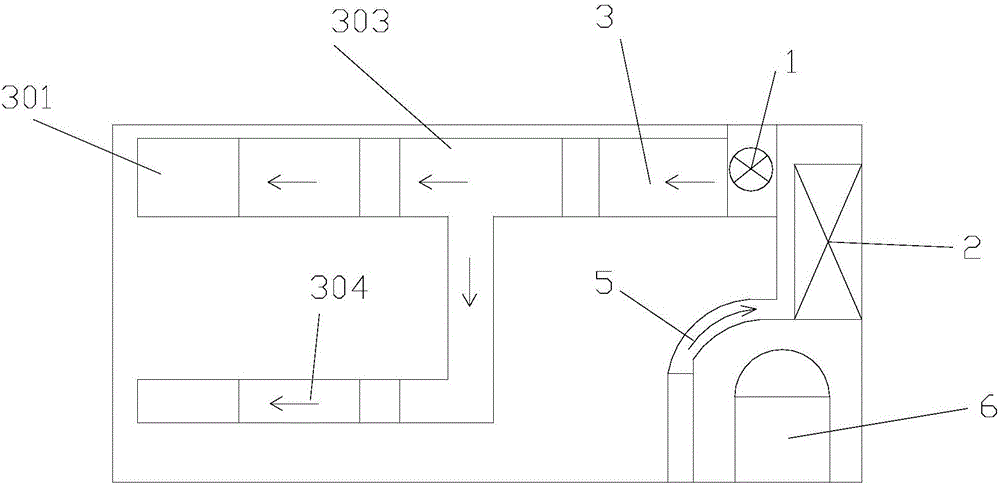

InactiveCN1991261AReduce air volumeShorten speedLighting and heating apparatusDeodrantsAir filterWater flow

An air filtering apparatus according to the present invention including a housing (2), at least one partition plate (51, 52) for partitioning the inside of the housing into at least two chambers (60, 61, 62), a gas-liquid contact member (5) for receiving electrolytic water from an electrolytic water supply unit, an air blowing fan (7) for blowing air to the gas-liquid contact member so that the air is brought into contact with the electrolytic water flowing along the gas-liquid contact member, a controller (52, 53) for controlling the floor-mount type air filtering apparatus, and a water receiving tray (9) for receiving the electrolytic water flowing out from the gas-liquid contact member, wherein the gas-liquid contact member (5) and the air blowing fan (7) being disposed in one of the chambers (60), and one of the controller and the electrolytic water supply unit being disposed in the other chamber (61, 62) of the at least two chambers.

Owner:SANYO ELECTRIC CO LTD

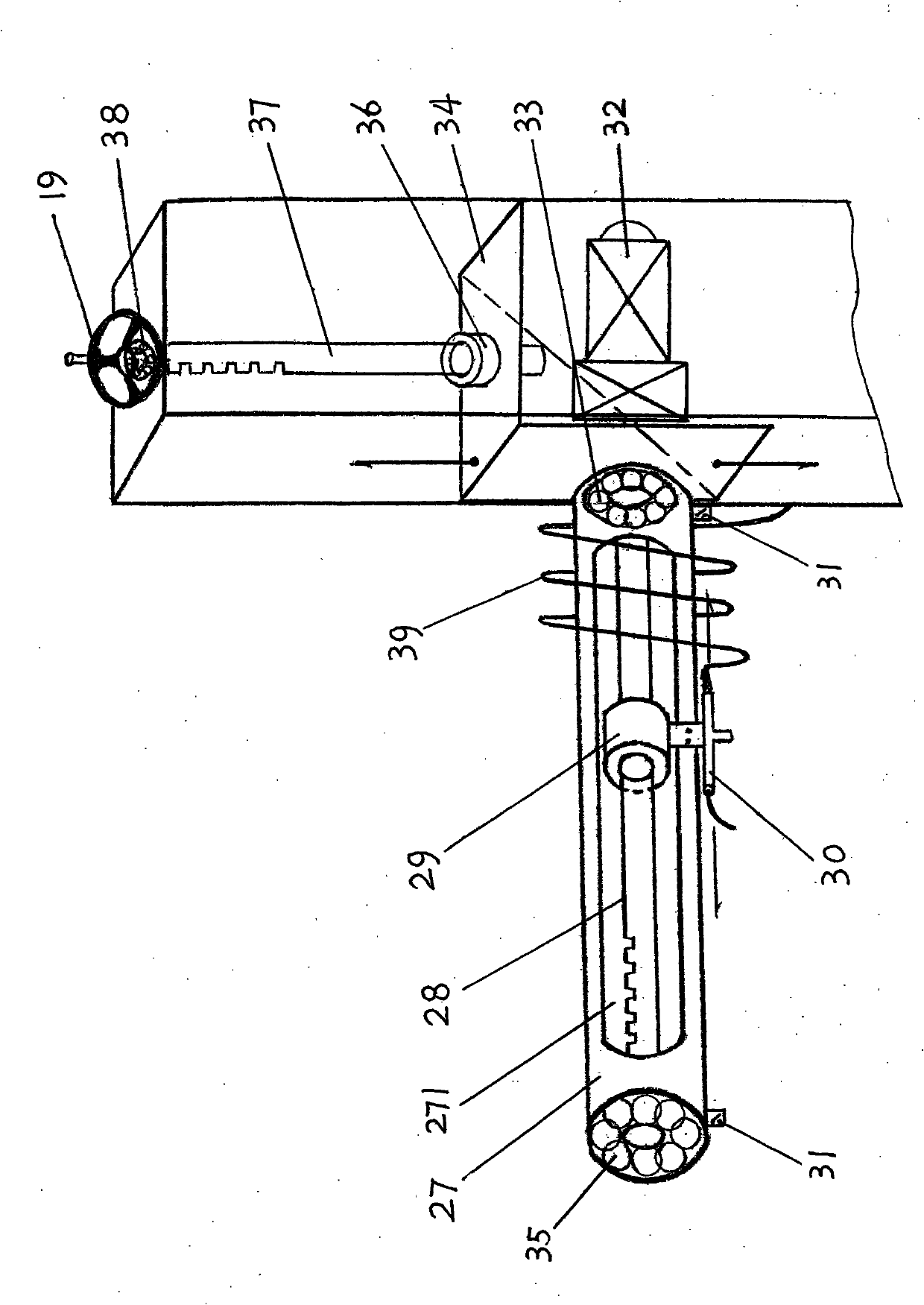

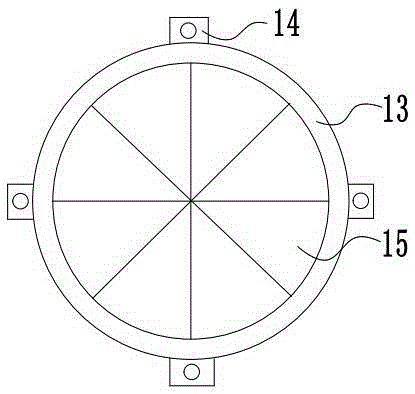

Rotary screen dryer

InactiveCN104061768ABlow evenlyDry evenlyDrying gas arrangementsDrying machines with progressive movementsHeat spreaderBreathing

The invention relates to a rotary screen dryer which comprises a rack and a rotary screen, wherein the rotary screen is mounted in the rack through a rotating shaft, a suction fan is arranged at the right end of the rotary screen and mounted on the rack, an opening is formed in the right end of the rotary screen, an air guide pipe is mounted at the opening, upper and lower ventilation openings are formed in the air guide pipe, air uniformizing plates are arranged at the upper end and the lower end of the rotary screen, a plurality of through holes are formed in the air uniformizing plates, air deflectors are arranged between the upper end and of the rack and one air uniformizing plate as well as between the lower end of the rack and the other air uniformizing plate, and radiators are arranged at the upper and lower ventilation openings of the air guide pipe. The rotary screen dryer is simple in structure, the air deflectors are arranged outside the air uniformizing plates, so that hot air can blow to fabric uniformly, and the quality stability of the fabric is guaranteed.

Owner:YIZHENG SIFANG LIGHT TEXTILE MACHINERY

Midday tea drying device

InactiveCN107664405ABlow evenlyImprove work efficiencyDrying gas arrangementsDrying chambers/containersActive storageMotor shaft

The invention discloses an afternoon tea drying device, which comprises a box body, a chassis is movably installed inside the box body, a fixed rod is fixedly connected to the top of the chassis, and a fixed plate is fixedly connected to the top of the fixed rod. The bottom of the box body is fixedly connected with a motor, and the rotating shaft of the motor extends to the inside of the box body and is fixedly connected with the center of the bottom of the chassis. The top of the chassis is movably connected with tea storage tanks located on both sides of the fixed rod. The tea storage tanks are far away from the fixed rod. One side of the rod is provided with a ventilation hole, and the top of the tea storage tank passes through the fixed plate and extends to the outside of the fixed plate. The noon tea drying device can heat and dry the tea leaves by setting the tea storage tank, electric heating wire and fan, and the chassis is driven by the motor to rotate, so that the tea inside the tea storage tank can be blown by the hot air more evenly, thereby Improve the working efficiency of drying tea, can quickly remove the moisture on the surface of tea, so that it is convenient for people to use.

Owner:HUNAN LOTUS FLOWERS ON WATER TEA IND CO LTD

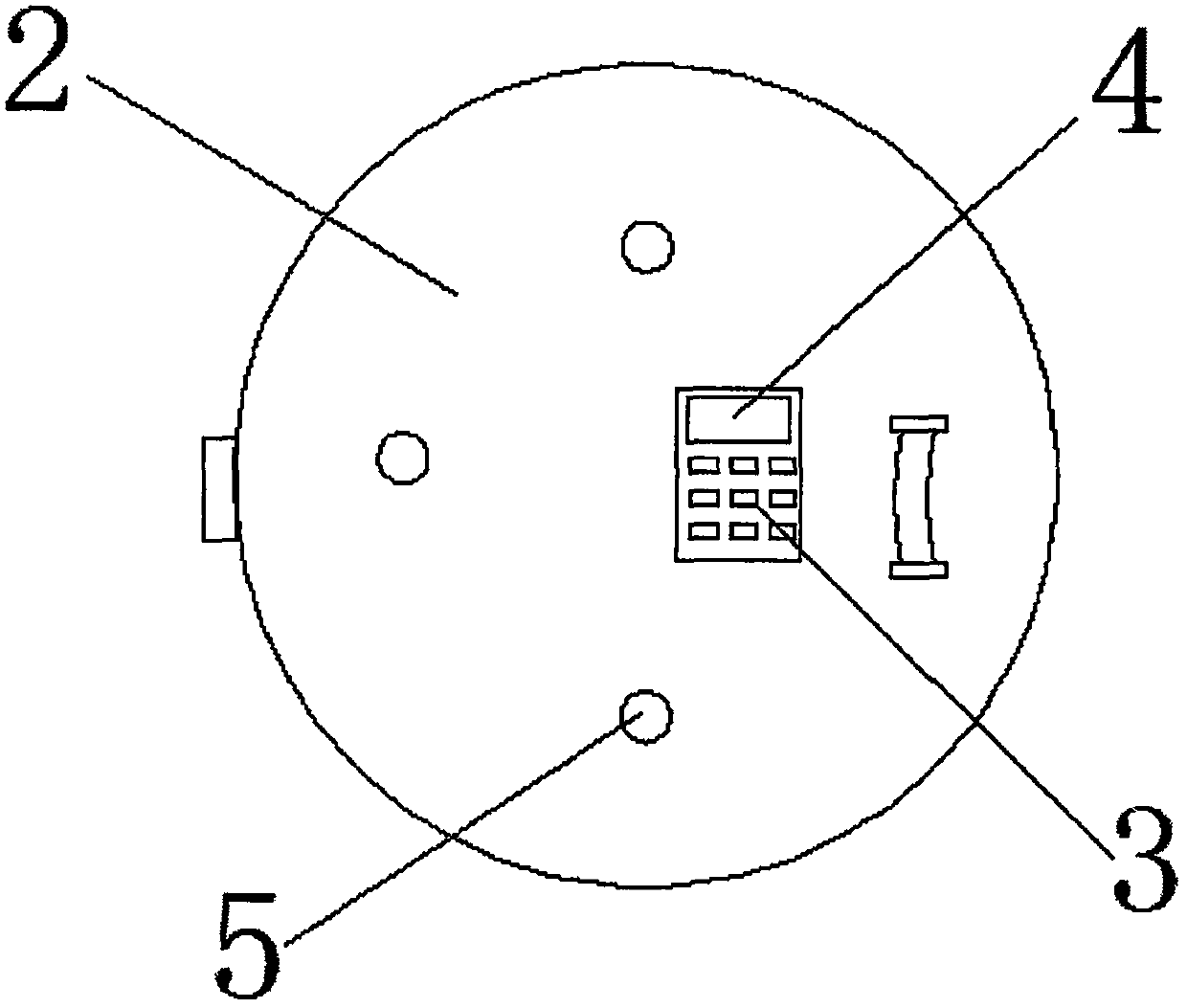

Xinhui pericarpium citri reticulatae drying device

InactiveCN109668409AHeating evenlyBlow evenlyDrying gas arrangementsDrying solid materialsElectric heatingPericarpium citri reticulatae

The invention provides a Xinhui pericarpium citri reticulatae drying device, and relates to the technical field of pericarpium citri reticulatae processing. The Xinhui pericarpium citri reticulatae drying device comprises an oven, the top of the oven is movably connected with an oven cover through a hinge, a control panel is fixedly arranged on the top of the oven cover, and a temperature displayscreen is arranged on the top of the control panel. Ventilation holes are formed in the top of the oven cover, and the side, away from the hinge, of the top of the oven cover is fixedly provided witha handle. According to the Xinhui pericarpium citri reticulatae drying device, a motor drives a bottom-layer drying plate to rotate through a screw, an electric heating pipe increases the temperaturein the oven through heating, so that pericarpium citri reticulatae is dried, the pericarpium citri reticulatae constantly rotates on the top of the drying plate, and heating is more uniform; meanwhile, a draught fan evenly blows away air heated by the electric heating pipe in the oven, pericarpium citri reticulatae heating is more uniform, and the effect is better; and meanwhile, the temperature in the oven is displayed on the temperature display screen through the temperature sensor, the temperature in the oven can be visual and clear, and the drying work is more convenient to control.

Owner:江门市新会区和昌隆陈皮茶制品有限公司

High efficiency and energy saving blowback device used for gas turbine air inlet system

InactiveCN104500230ASave time at workImprove work efficiencyDispersed particle filtrationGas turbine plantsAir filtrationAir filter

The invention belongs to the technical field of a gas turbine, and discloses a high efficiency and energy saving blowback device used for a gas turbine air inlet system which is used for solving the problems of poor blowing effect, compressed air source and energy waste, and reduction of the working efficiency of the whole air filtration system of a blowback device in the prior art. The high efficiency and energy saving blowback device includes a blowback pipe which is communicated with a compressed air source by a pipe, also includes a conical guiding device, the center line of the guiding device and the center line of the blowback pipe are in the same straight line, the center line of the guiding device and the center line of an air filter filtering cartridge are in the same straight line, the top of the guiding device and the end surface of the blowback pipe are flushed, or the top of the guiding device stretches into the blowback pipe, and the bottom surface of the guiding device just faces toward the center of the air filter filtering cartridge.

Owner:CHENGDU BOOST ENERGY TECH

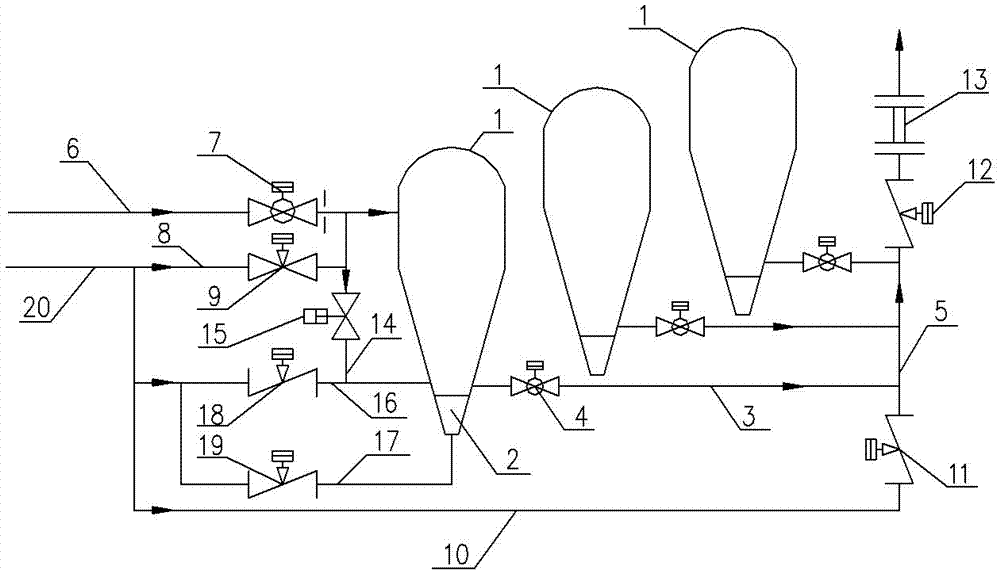

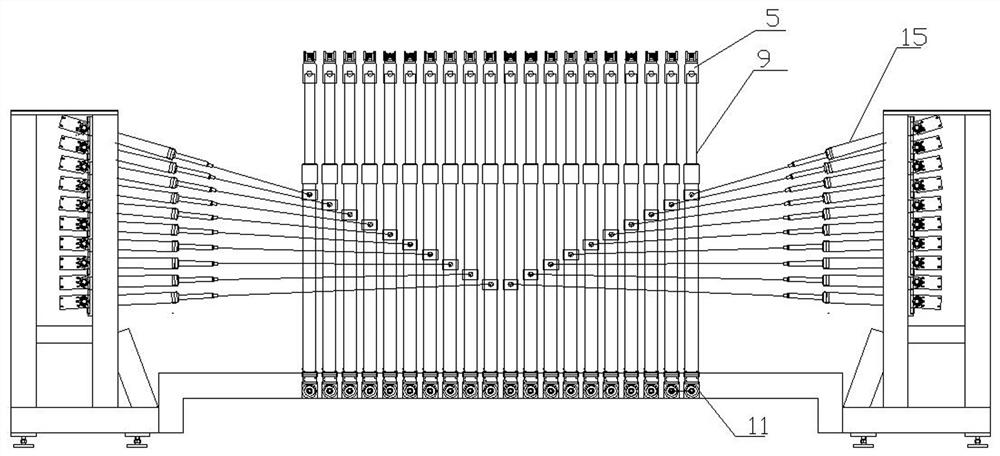

System and process for pulverized coal injection of blast furnace

ActiveCN102787191AEvenly distributedGuaranteed gas adjustment functionBlast furnace componentsBlast furnace detailsEngineeringTransportation technology

The invention provides a system and a process for pulverized coal injection of a blast furnace. The system comprises a plurality of parallel injection tanks, fluidization tanks, injection branch pipes, coal injection valves, an injection main pipe, a charging pipeline, a charging valve, a pressure stabilizing pipeline, a pressure stabilizing valve, a gas supplementing pipeline, a gas supplementing regulating valve, a pulverized coal flow regulating valve and a pulverized coal flow meter, wherein one fluidization tank is arranged at the bottom of each injection tank, one injection branch pipe is connected with an outlet of each injection tank, one coal injection valve is arranged on each injection branch pipe, the charging pipeline and the pressure stabilizing pipeline are connected with each injection tank, the injection main pipe is vertically arranged, the pulverized coal flow regulating valve and the pulverized coal flow meter are arranged on the injection main pipe from bottom to top, the gas supplementing pipeline is connected to the bottom end of the injection main pipe, and the gas supplementing regulating valve is arranged on the injection main pipe and below the joints of the injection branch pipes and the injection main pipe. By the aid of the system and the process, pulverized coal can be uniformly and stably injected, injection quantity is accurately controlled, pulverized coal dense phase transportation technology can be realized, gas consumption is low, and pipeline abrasion is less.

Owner:WISDRI ENG & RES INC LTD

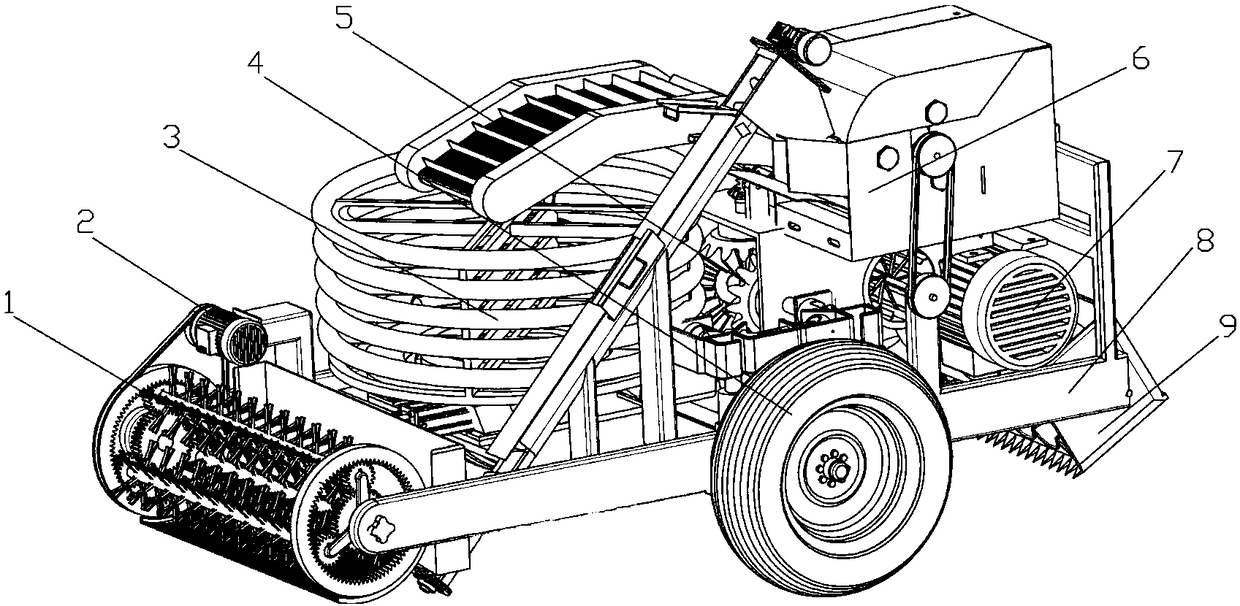

Yam bean harvester integrating seedling, digging, collecting and storing,mud removing and straw turnover

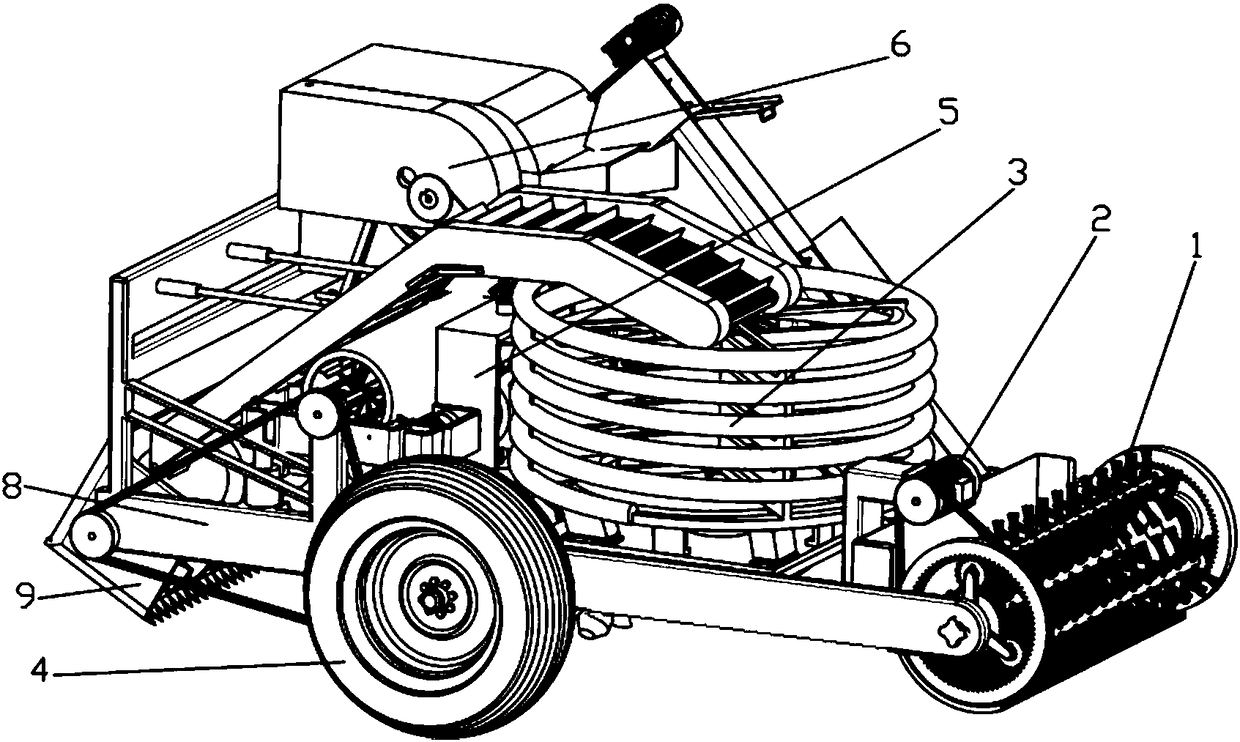

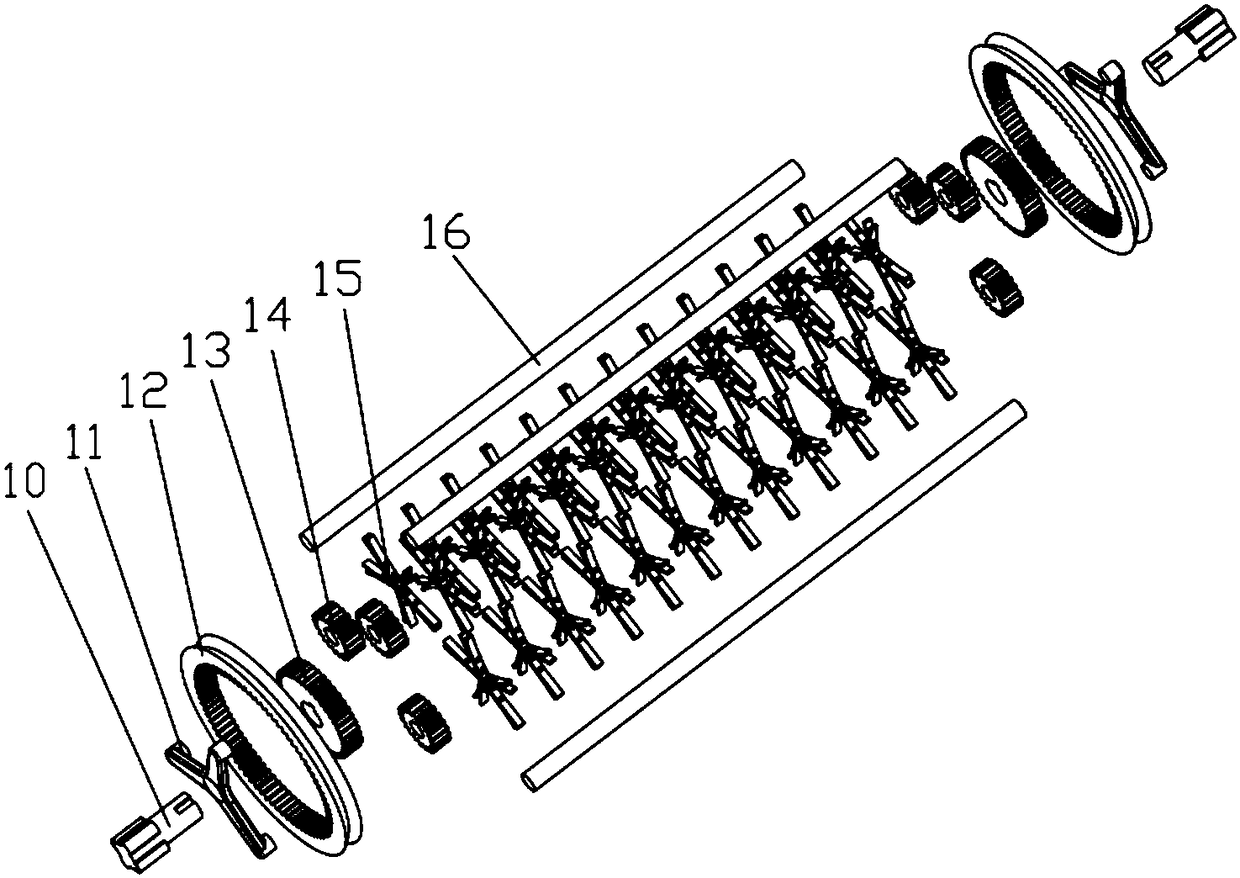

PendingCN108513786AImprove return efficiencyWork resistance is smallLiftersTopping machinesAgricultural engineeringTurning frames

The invention discloses a yam bean harvester integrating seedlings, digging, collecting and storing, mud removing and straw turnover, which comprises a planetary gear type seedling device, a first motor, a yam bean collecting and storing device, wheels, a soil turning device, a straw turnover device, a second motor, a frame and a digging device. The frame is a main bracket; the planetary gear typeseedling device and the first motor are arranged at the front end of the frame and are connected through a belt; the straw turnover device, the soil turning device and the digging device are all driven by the second motor through a belt wheel; aconveying belt is fixed on the rear end of the frame through a hydraulic rod; the yam bean collecting and storing device is arranged in the middle of theframe and is arranged at the tail end of the conveying belt; According to the invention, a plurality of functions, such as seeding, digging, collecting and storing, mud removing, straw turnover and the like, are integrated, the energy consumption is effectively reduced when the seedling is planted, the soil turning is sufficiently and the yam bean is difficult to damage, the working efficiency ofthe potato harvesting machine can be obviously improved, and the energy consumption is low.

Owner:QUZHOU UNIV

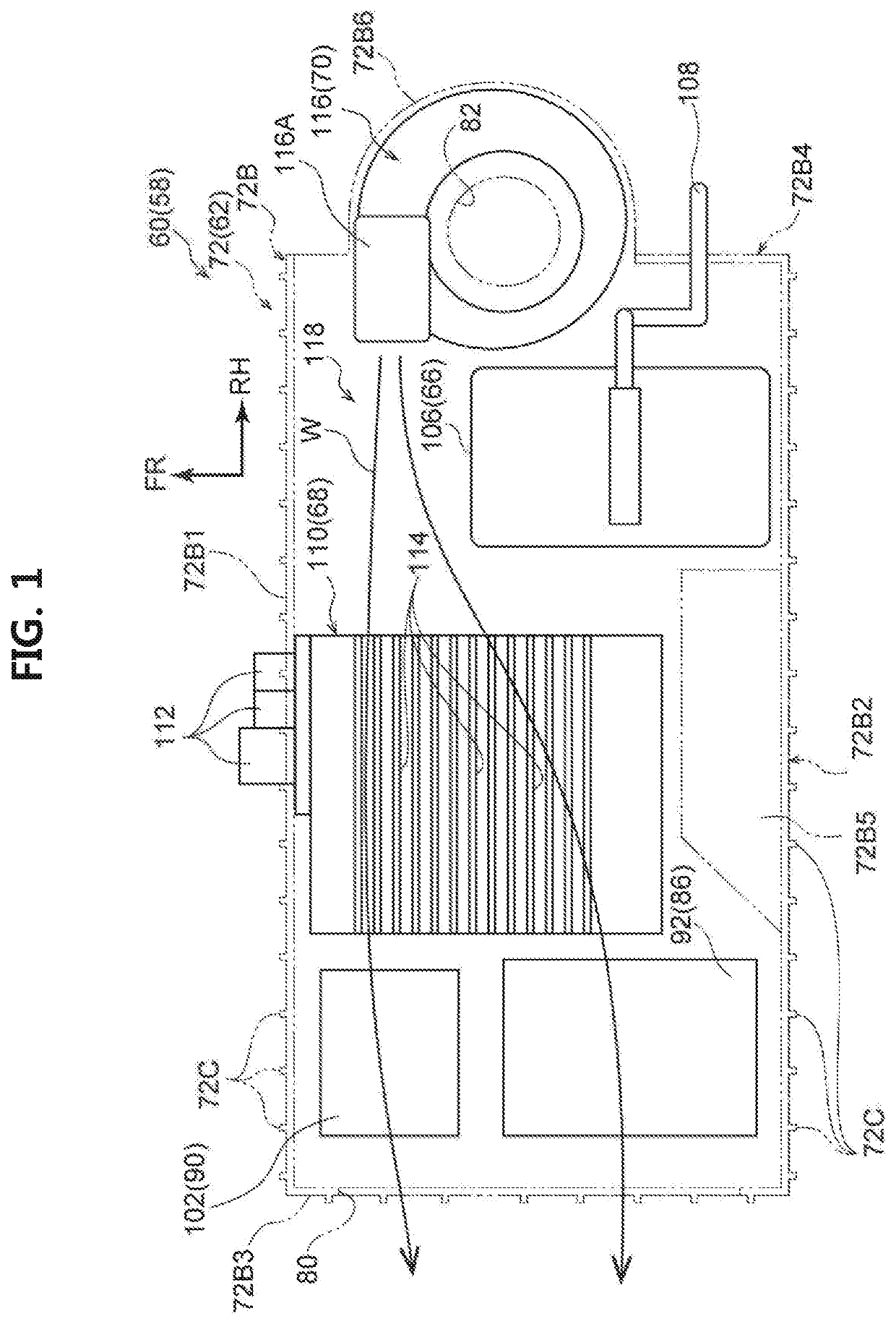

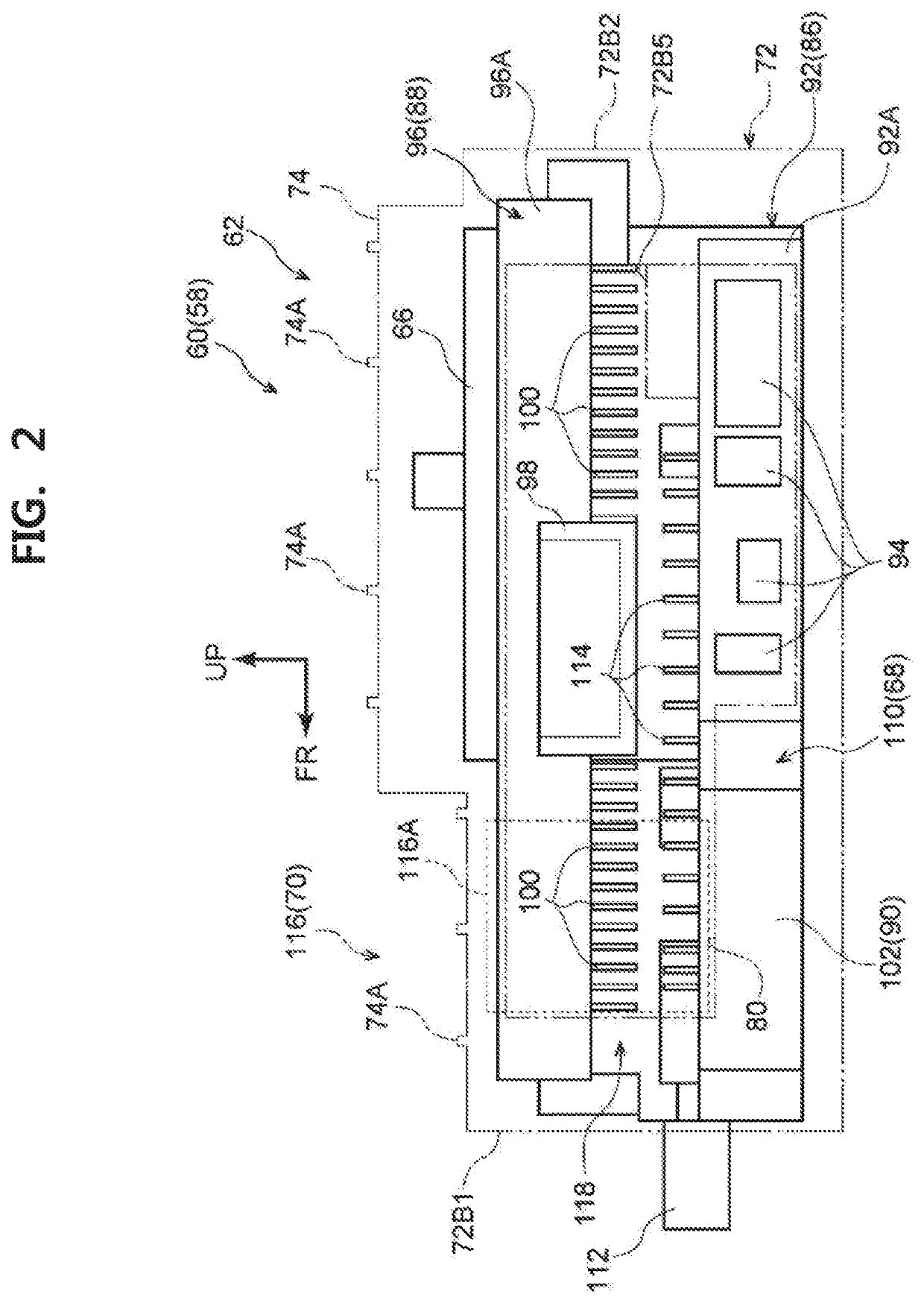

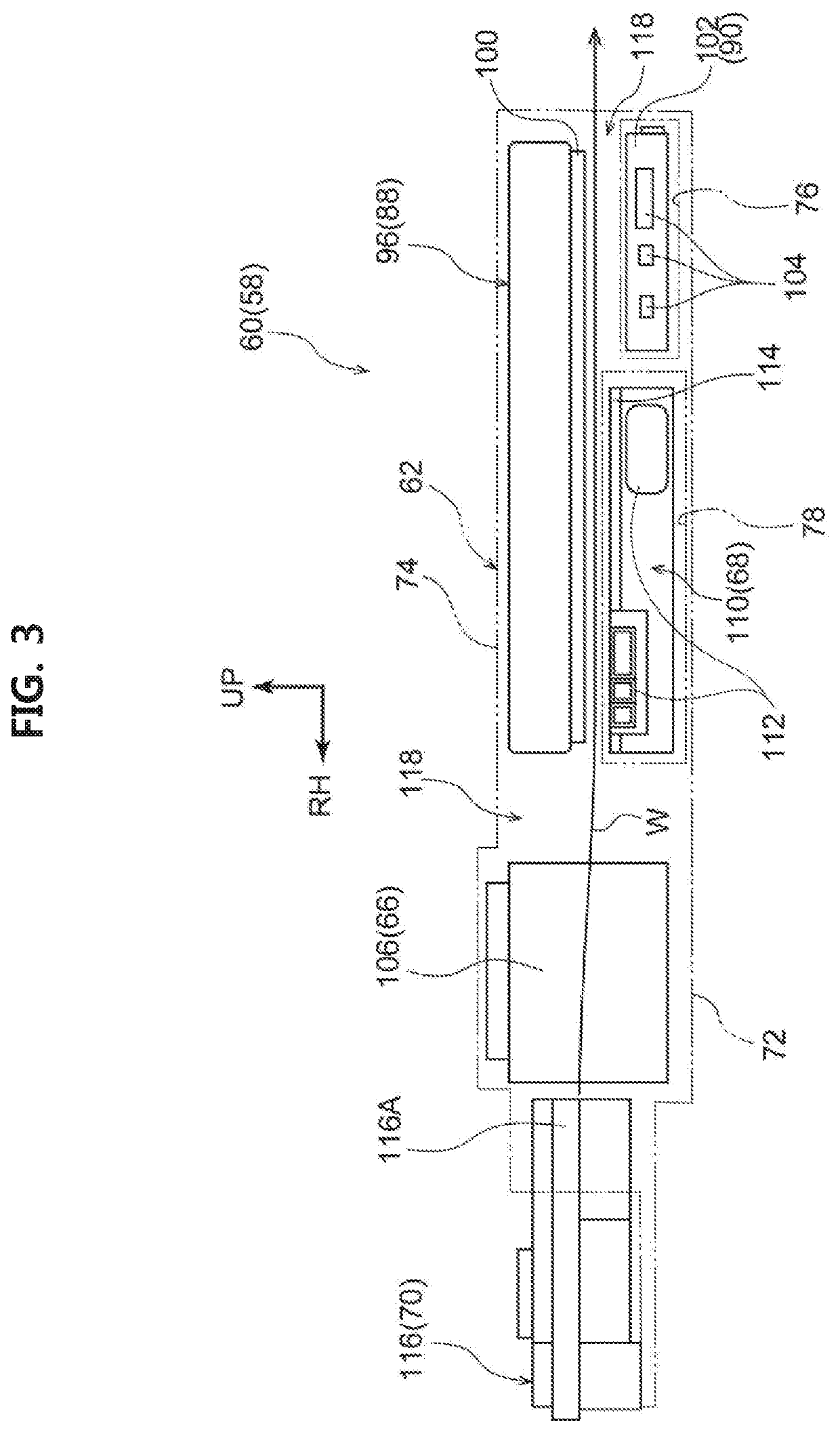

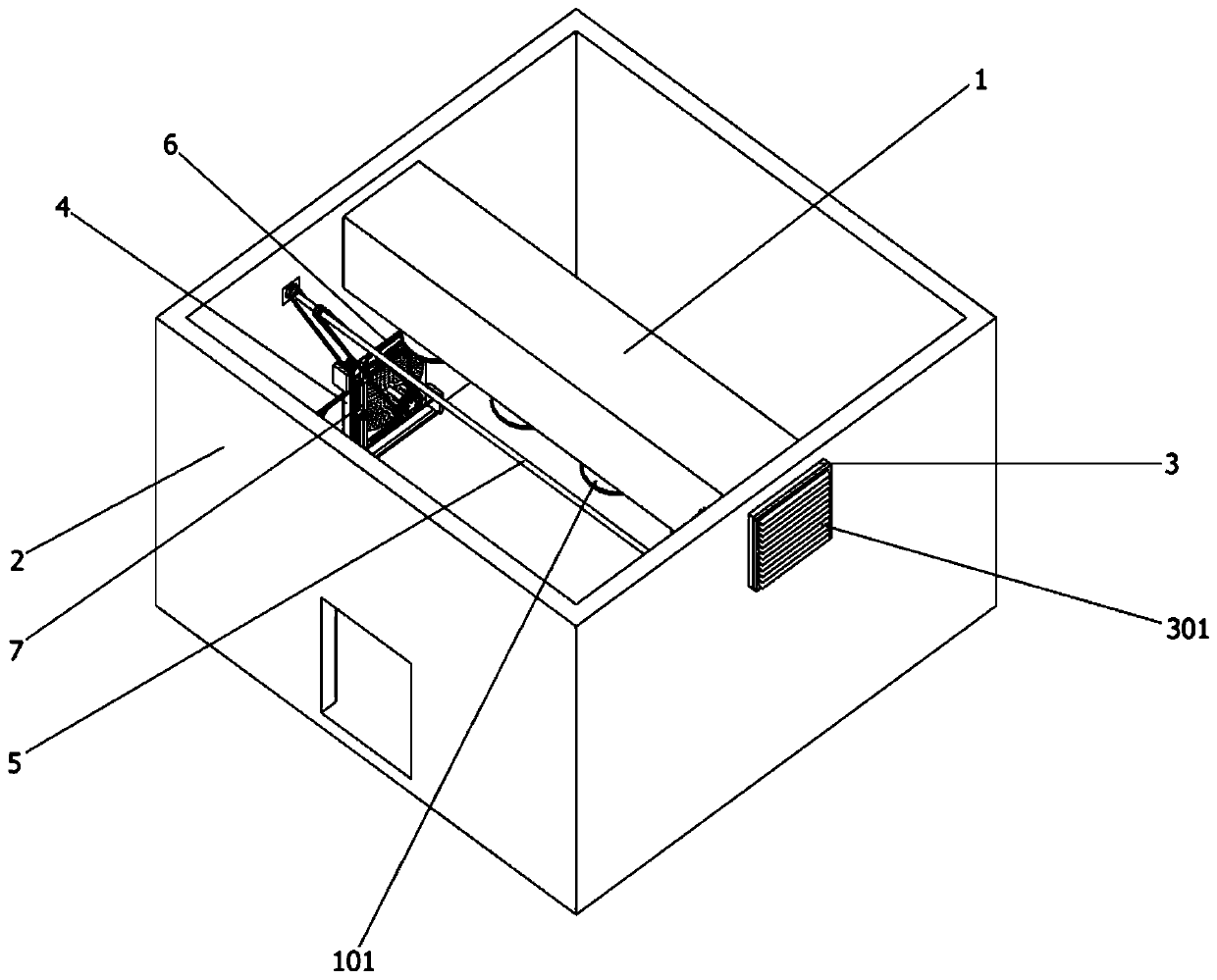

Autonomous driving device module mounting structure and autonomous driving electric vehicle

ActiveUS20200148136A1Amount of heat dissipated also increaseSucking smoothVehicle seatsAir-treating devicesElectric vehicleControl theory

Owner:TOYOTA JIDOSHA KK

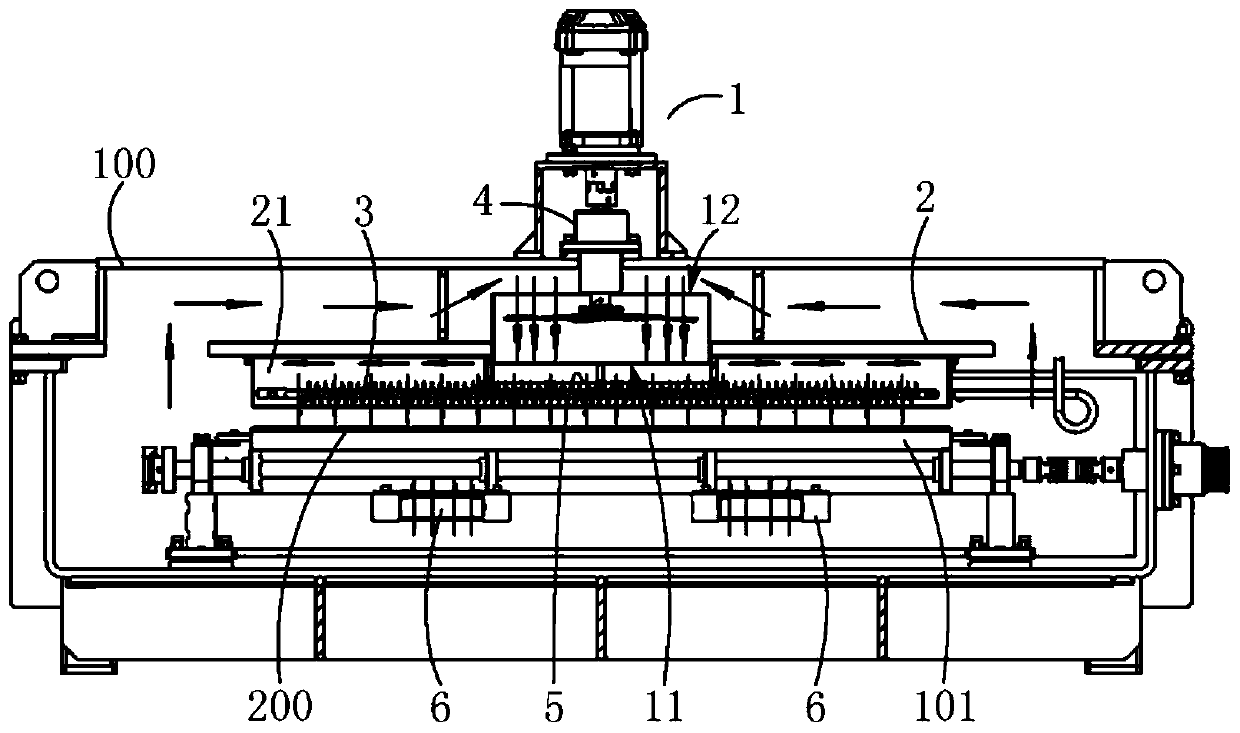

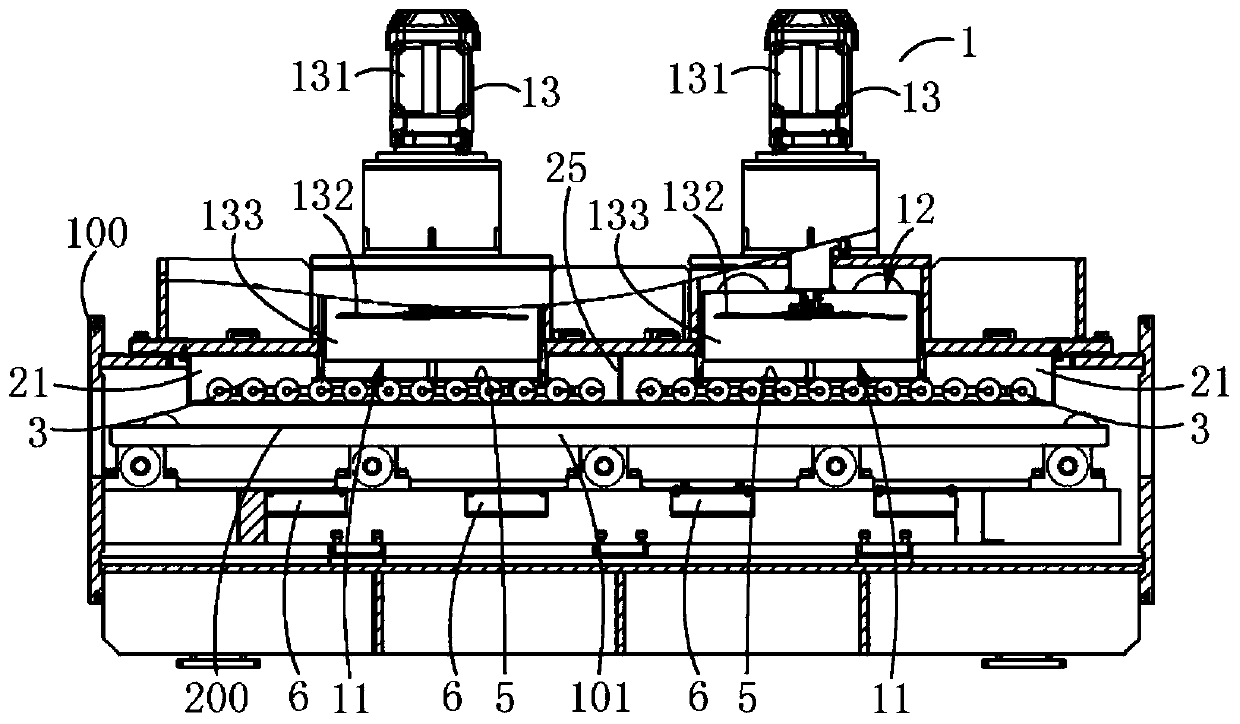

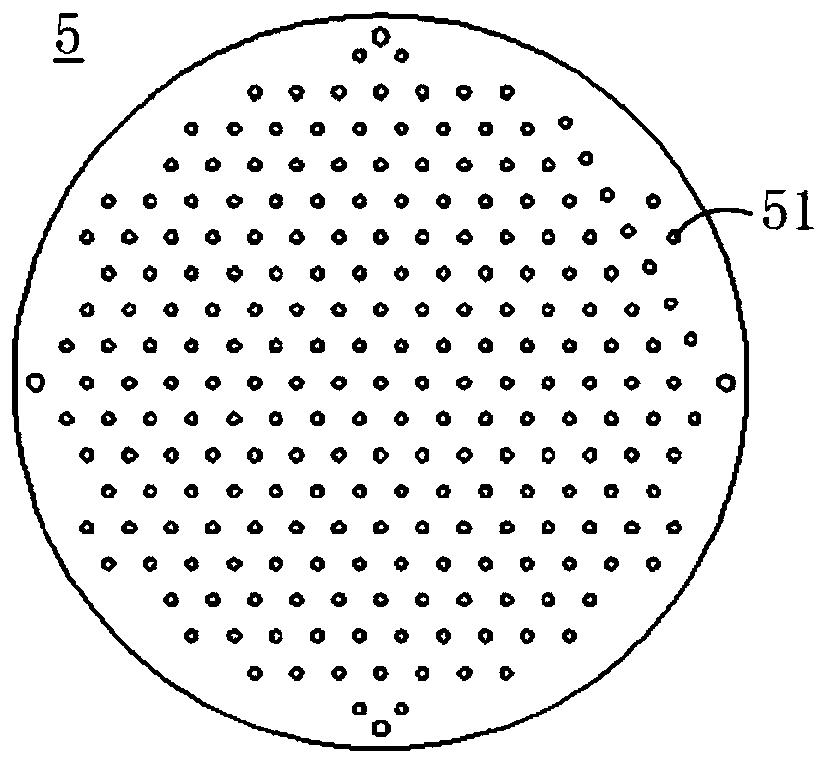

Semiconductor process equipment and cooling device thereof

ActiveCN111477532AImprove cooling efficiencyIncrease productivityElectric discharge tubesVacuum evaporation coatingThermodynamicsProcess equipment

The invention provides semiconductor process equipment and a cooling device thereof. The cooling device is arranged on a process chamber of the semiconductor process equipment, is used for cooling a tray in the process chamber and a to-be-processed workpiece borne on the tray, and comprises an air blowing mechanism, a flow uniformizing mechanism and a cooling mechanism; the air blowing mechanism is arranged on an upper cover of the process chamber; an air outlet of the air blowing mechanism faces the middle of the process chamber, and an air return port of the air blowing mechanism deviates from the middle of the process chamber; the flow uniformizing mechanism is arranged below the air blowing mechanism and comprises a flow uniformizing cavity connected with the air outlet; the cooling mechanism is arranged in the flow uniformizing cavity; airflow generated by the air blowing mechanism enters the flow uniformizing cavity through the air outlet and exchanges heat with the tray and theworkpiece to be processed after being cooled by the cooling mechanism, and the airflow subjected to heat exchange enters the air blowing mechanism through the air return port. According to the embodiment of the invention, the cooling efficiency of the to-be-processed workpiece is greatly improved, so that the production efficiency of coating is effectively improved, and the production takt is accelerated.

Owner:北京七星华创集成电路装备有限公司

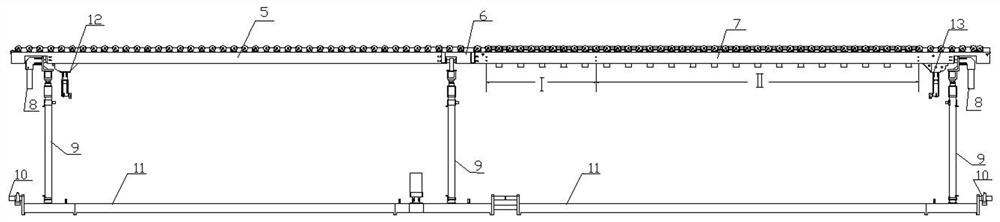

Efficient cocoon drying machine capable of evenly distributing hot air

ActiveCN105135848ACompact structureIngenious structural designDrying gas arrangementsDrying machines with progressive movementsAgricultural engineering

The invention provides an efficient cocoon drying machine capable of evenly distributing hot air. The efficient cocoon drying machine comprises a cocoon drying chamber, a feeding belt, a receiving box, a plurality of conveying belts and a hot air system. The hot air system comprises a hot air furnace, a main blast pipe, a top air distribution plate tank, a top blast pipe, air distribution plate tanks in the belts, blast pipes in the belts, air distribution plate tanks among the belts, blast pipes among the belts, a bottom air distribution plate tank and a bottom blast pipe. The lower surface of the top air distribution plate tank is evenly provided with a plurality of air outlet nozzles. The upper surfaces and the lower surfaces of the air distribution plate tanks in the belts and the air distribution plate tanks among the belts are each evenly provided with a plurality of air outlet nozzles. The upper surface of the bottom air distribution plate tank is evenly provided with a plurality of air outlet nozzles. According to the efficient cocoon drying machine, hot air is conveyed in the cocoon drying chamber, the hot air distribution range of the hot air is wider, the conveying belts and cocoons can be blown with hot air more sufficiently and evenly, and the cocoons are well dried.

Owner:HAIMEN CITY RUITAI TEXTILE TECH CO LTD

Simple towel drying device

InactiveCN109868626ABlow evenlyBlow evenly Blow evenlyWringing machinesTextiles and paperEngineeringDrive motor

The invention discloses a simple towel drying device which comprises a drying box, a discharging port and a feeding port. The left and right ends of the drying box are provided with the discharging port and the feeding port respectively, the feeding port is higher than the discharging port, a squeezing conveying belt is arranged at the position, with the feeding port, in the drying box, the rightend of the squeezing conveying belt extends out of the feeding port, an input shaft of the squeezing conveying belt is connected with a driving motor, the driving motor is electrically connected witha control panel on the upper right side of the drying box, water leaking holes are uniformly distributed in the surface of the squeezing conveying belt, a lower fixing plate is arranged between the upper and lower belt surfaces of the squeezing conveying belt, a plurality of squeezing rollers are arranged on the lower fixing plate, an upper fixing plate is arranged above the squeezing conveying belt, and a plurality of squeezing rollers are also arranged on the upper fixing plate. The simple towel drying device is simple and reasonable in structure, facilitates fast drying and disinfection oftowels, eliminates the threat of traditional towels to people's health, and has high practicability.

Owner:张凯

Energy-saving ventilation and air exchange equipment matched in building

ActiveCN111536649AUniform coverageBlow evenlyMechanical apparatusDispersed particle filtrationGas passingAir change

The invention provides energy-saving ventilation and air exchange equipment matched in a building. The energy-saving ventilation and air exchange equipment comprises a ventilation pipeline, the ventilation pipeline is installed at the upper end of the inner part of a breeding house, the ventilation pipeline further comprises air supply ports, circular air diffusing outlets and a rectangular vent,four air supply ports are formed in the lower part of the ventilation pipeline, and the circular air diffusing outlets are correspondingly formed in air outlets of the air supply ports. According to the energy-saving ventilation and air exchange equipment, a driving mechanism is arranged, a second driven pulley is driven by a driving pulley on the left side to rotate through a belt, so that an exhaust fan blade starts to rotate under the drive of an internal rotating shaft of an exhaust mechanism, harmful gas in the breeding house is discharged by the exhaust fan blade through the inner part of the exhaust mechanism, thus the air quality in the breeding house can be improved, the retention of bacteria, viruses and other pathogenic microorganisms in the breeding house is effectively reduced, through the arrangement of the driving mechanism, an air suction fan blade and the exhaust fan blade on the ventilation equipment do not need to motors to drive, and thus the energy consumption of the ventilation equipment is effectively reduced.

Owner:重庆强全暖通设备安装有限公司

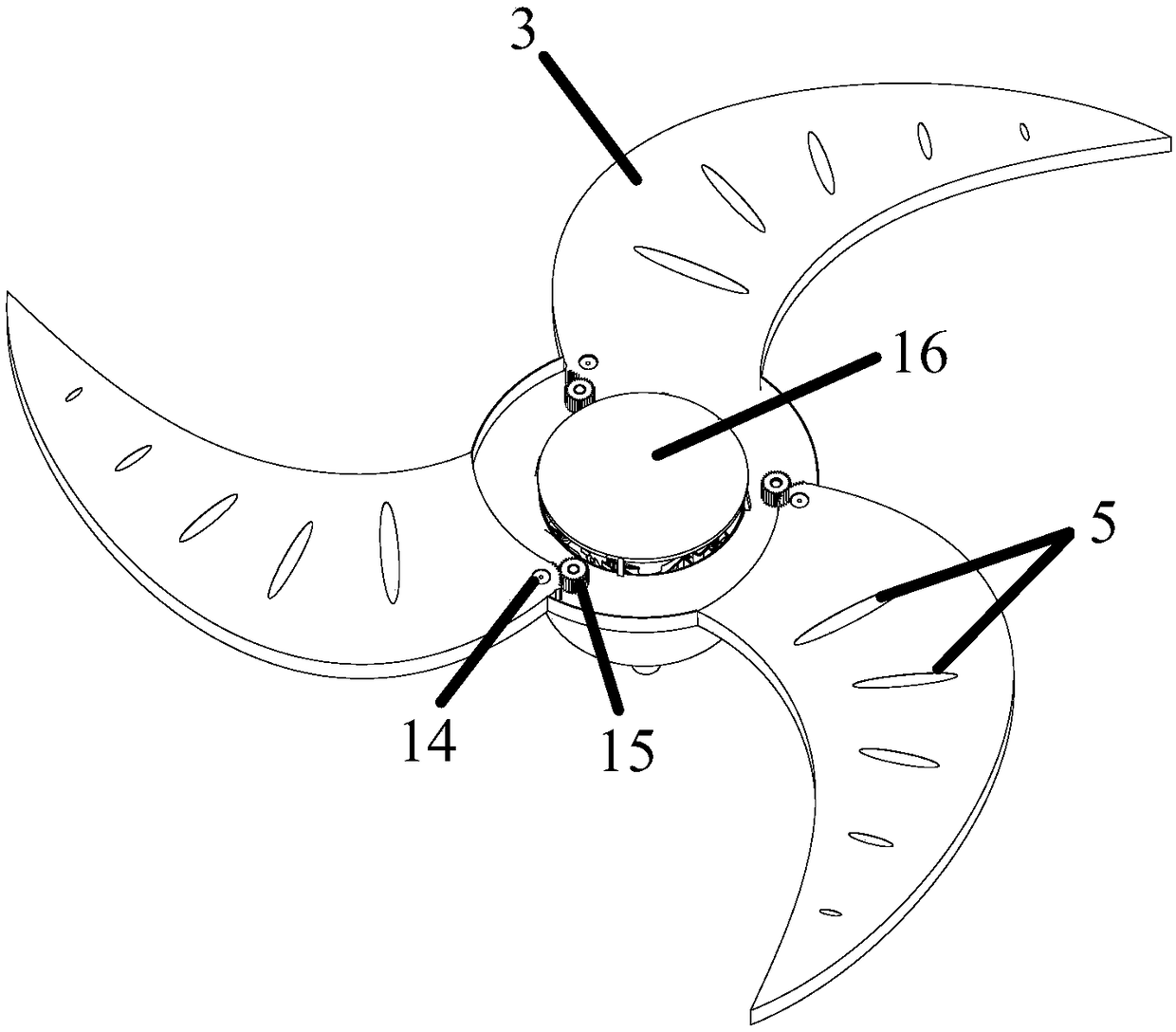

Multifunctional electric heater

InactiveCN108980972AIncrease profitImprove cooling effectLighting and heating apparatusElectric heating systemEngineeringFan blade

The invention discloses a multifunctional electric heater. The multifunctional electric heater comprises a heating element assembly and a fan blade assembly, wherein the fan blade assembly comprises hollow fan blades, a fan blade fixing frame and fan blade driving parts; an installing cavity is formed inside the fan blade fixing frame; the hollow fan blades are arranged in the circumferential direction of the fan blade fixing frame; cavities of the hollow fan blades communicate with the installing cavity; air outlets communicating with the cavities of the hollow fan blades are also formed in the surfaces of the hollow fan blades; the heating element assembly is arranged in the installing cavity; and air passes through the heating element assembly, enters the cavities of the hollow fan blades through the installing cavity and finally is blown out from the air outlets. The multifunctional electric heater has a heating function and a blowing refrigeration function at the same time so as to solve the problem that as an electric heater in the prior art has a single function, the utilization rate of the product is low, and the family space needs to be occupied all the time.

Owner:GREE ELECTRIC APPLIANCES INC

Computer heat dissipation device

InactiveCN108693944AEasy to operateAchieve long-term useDigital processing power distributionCold airAir blower

The invention discloses a computer heat dissipation device, which comprises a computer case, heat dissipation holes, a refrigerator, a first L-shaped pipe, an air blower, a bracket, a second L-shapedpipe, a horizontal pipe, a first lantern ring, a vertical pipe, a second lantern ring, a first motor, a rotary block, a cross bar, a sliding block, a round sliding block, a second motor, a vane, a pore plate, a barrel body, a T-shaped chute, a T-shaped sliding block, a cross plate, a first spring, a vertical plate, a rubber sleeve, an expansion link, a second spring, a chute, an electric wire anda plug, wherein the bottom surface of the computer case is provided with the barrel body. The device is easy in operation and can quickly carry out heat dissipation, cold air is blown out of the pipeto blow air to a computer component so as to quickly take heat on the component away, in addition, the rotary block is arranged, so that the computer component can receive air in an omnibearing way, and in addition, air can be evenly blown. The first spring and the second spring are arranged, omnibearing vibration reduction can be realized, components in the computer case can be effectively guaranteed, a purpose that the computer is used for a long time is achieved, and the service life of the computer is prolonged.

Owner:江苏慧学堂系统工程有限公司

Copper foil drying equipment capable of reducing wrinkles

InactiveCN111375577AGuaranteed tensionReduce tensionDrying solid materials without heatDrying gas arrangementsCopper foilStructural engineering

The invention discloses copper foil drying equipment capable of reducing wrinkles. The copper foil drying equipment comprises a machine body, wherein a feeding chamber, a cleaning chamber and a dryingchamber are sequentially arranged inside the machine body from left to right; a feeding roller, a liquid squeezing roller and a first feeding roller are sequentially arranged inside the feeding chamber from left to right, a second feeding roller, a plurality of tensioning rollers and a third feeding roller are sequentially arranged inside the cleaning chamber from left to right, and a third feeding roller, a plurality of brush rollers and a discharging roller are sequentially arranged inside the drying chamber from left to right; a plurality of nozzles are arranged at the bottom end inside the drying chamber, the input ends of the nozzles are connected with an external hot air pipe, and the hot air pipe is arranged on an hot air pump. The copper foil drying equipment capable of reducing the wrinkles is reasonable in structural design, high in copper foil drying efficiency and good in drying effect, and effectively prevents the wrinkling phenomenon.

Owner:江西铜博科技有限公司

Continuous annealing cooling device of alloy aluminum wires

InactiveCN103397169AImprove cooling effectBlow evenlyFurnace typesHeat treatment furnacesCooling effectAlloy

The invention discloses a good-cooling-effect continuous annealing cooling device of alloy aluminum wires; the continuous annealing cooling device comprises a lateral strong cold chamber and a vertical strong cold chamber which are arranged on a body, the lateral strong cold chamber and the vertical strong cold chamber are connected through a single-way control valve, a plurality of air-blowing coolers are uniformly arranged in the lateral strong cold chamber, an upper cooling wheel and a lower cooling wheel are arranged in the vertical strong cold chamber, an air outlet is arranged on the upper end of the vertical strong cold chamber, and a vertical flow-guide baffle is arranged between the upper cooling wheel and the lower cooling wheel in the vertical strong cold chamber. The continuous annealing cooling device has the advantages of good cooling effect, even air blowing, simple structure and convenient installation.

Owner:JIANGSU NANHAI CABLE EQUIP

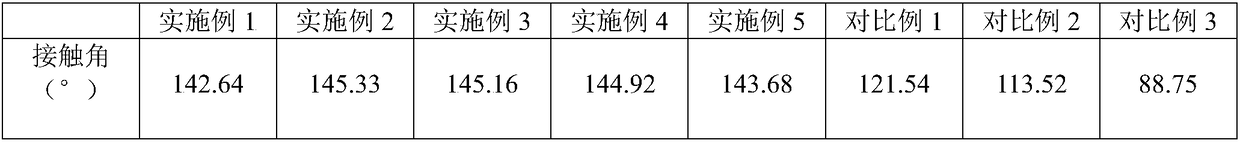

Method for preparing super-hydrophobic high-intensity thin ceramic glaze layer based on 3D printing and surface micron/ nanoparticles coating

InactiveCN108249961AIncrease roughnessImprove hydrophobic propertiesAdditive manufacturing apparatusCeramic shaping apparatusCeramicCeramic glaze

The invention relates to the technical field of ceramics, and discloses a method for preparing a super-hydrophobic high-intensity thin ceramic glaze layer based on 3D printing and surface micron / nanoparticles coating. The method comprises the following steps: scanning the outer shape of a formed ceramic blank through a three-dimensional canner to obtain a ceramic blank model; constructing a ceramic glaze 3D thin-layer model on the outer surface of the ceramic blank model; inputting the model data into a 3D printer; depositing the thin ceramic glaze layer on the surface of the ceramic glaze by3D printing; dipping micron / nano sizing; and then sintering to obtain the super-hydrophobic high-intensity thin ceramic glaze layer. The thin ceramic glaze layer is super-hydrophobic, and capable ofsaving raw materials.

Owner:QINGDAO UNIV OF SCI & TECH

Hopper

ActiveCN105329565AAvoid collisionAvoid scratchesLarge containersConoidElectrical and Electronics engineering

The invention relates to a hopper, and particularly discloses a hopper used for conveying bearings. The hopper comprises a big-end-up conical charging barrel and a connecting pipe connected with the bottom end of the charging barrel; three screening plates are sequentially arranged in the connecting pipe from top to bottom and divide the connecting pipe into a first cavity, a second cavity and a third cavity from top to bottom; the top end of the first cavity and the bottom end of the charging barrel are isolated through one screening plate, and the bottom end of the third cavity is in an opening state; branch pipes are arranged on the lateral walls of the first cavity and the second cavity, and a draught fan is arranged in each branch pipe; the branch pipes are communicated with recycling pipes; outlets of the recycling pipes are located at the inlet of the charging barrel; a plurality of lubricating balls used for isolating the bearings are arranged in the charging barrel; the screening plates are hinged to the connecting pipe and can be reset automatically; an annular boss is arranged on the lateral wall of the third cavity, and a gap allowing only one bearing to pass through is formed in the middle of the boss. The hopper can independently convey the bearings and avoid the bearings from being scratched in the conveying process.

Owner:CHONGQING YUANCHUANG WHOLE LINE INTEGRATION

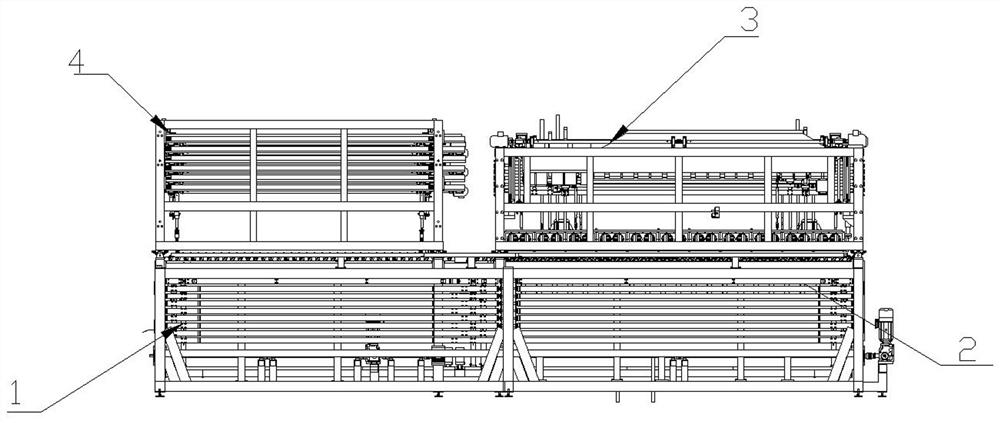

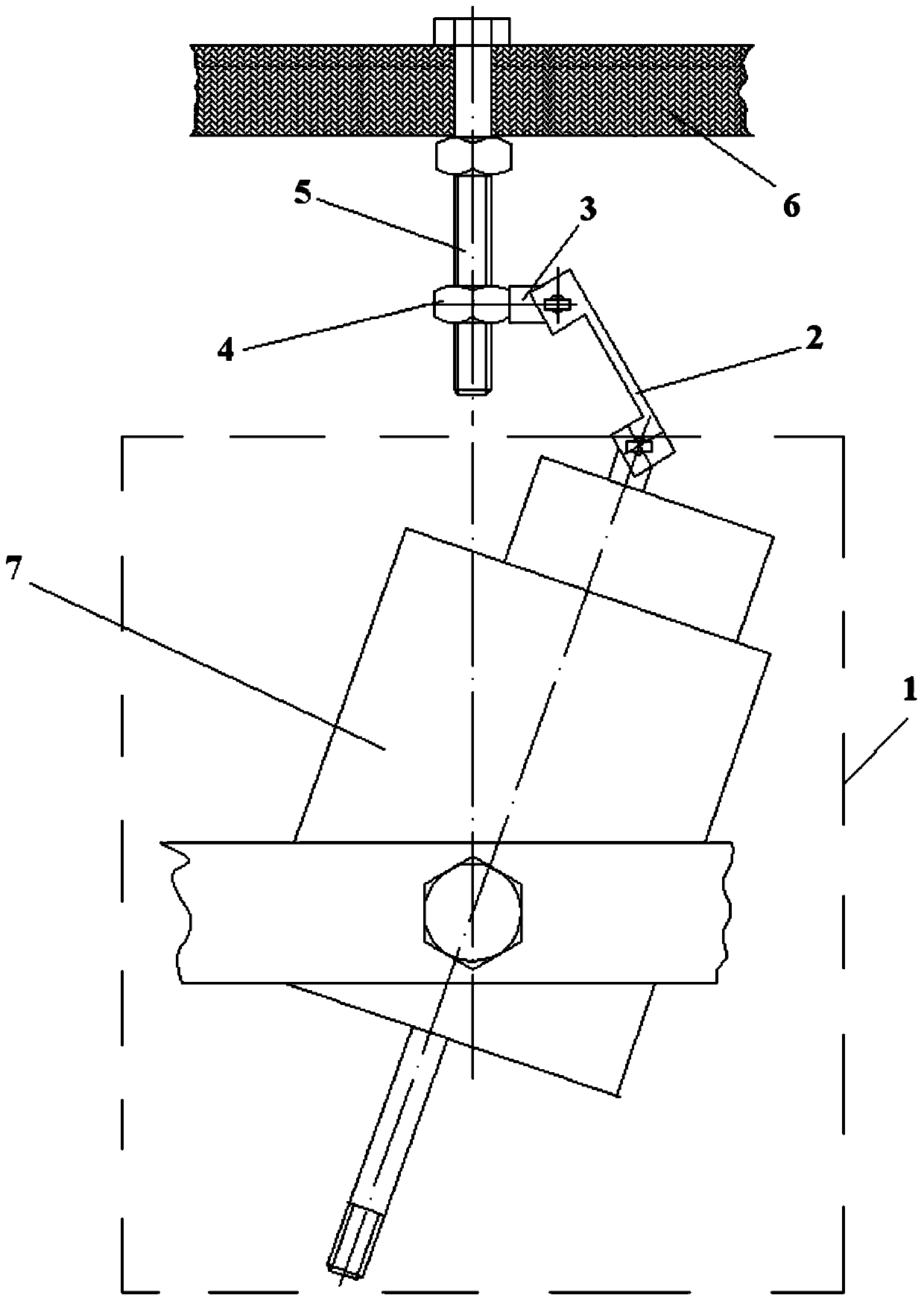

Forming and tempering method and forming and tempering equipment of tempered glass

ActiveCN111977947AReduce usageReduce manufacturing costGlass reforming apparatusGlass tempering apparatusElectric machineryToughened glass

The invention relates to a forming and tempering method and forming and tempering equipment of tempered glass. In the method, forming requirements of a variety of glass are satisfied through lifting,horizontal swinging and self torsion of forming section beams and tempering section beams; in the equipment, multiple forming section beams and tempering section beams are respectively arranged at thelower part of a forming section and the lower part of a tempering section; the forming section beams and the tempering section beams are arranged at intervals along the direction vertical to the glass conveying direction; the forming section beams and the tempering section beams are respectively provided with a first roller conveying mechanism and a second roller conveying mechanism; a wind box is also arranged on the tempering section beams; the forming section beams and the tempering section beams are rotatably connected with a lifting mechanism respectively; the lifting mechanism is connected with a side pushing mechanism; the bottom of the lifting mechanism is rotatably connected with a machine frame of the equipment; and the forming section beams and the tempering section beams are also connected with a torsion motor. The forming and tempering method and the forming and tempering equipment in the invention not only can be used for producing single curved glass and hyperbolic glass, but also can be used for producing a variety of specially-shaped glass; and thus, the adaptation is very high.

Owner:LUOYANG LANDGLASS TECH CO LTD

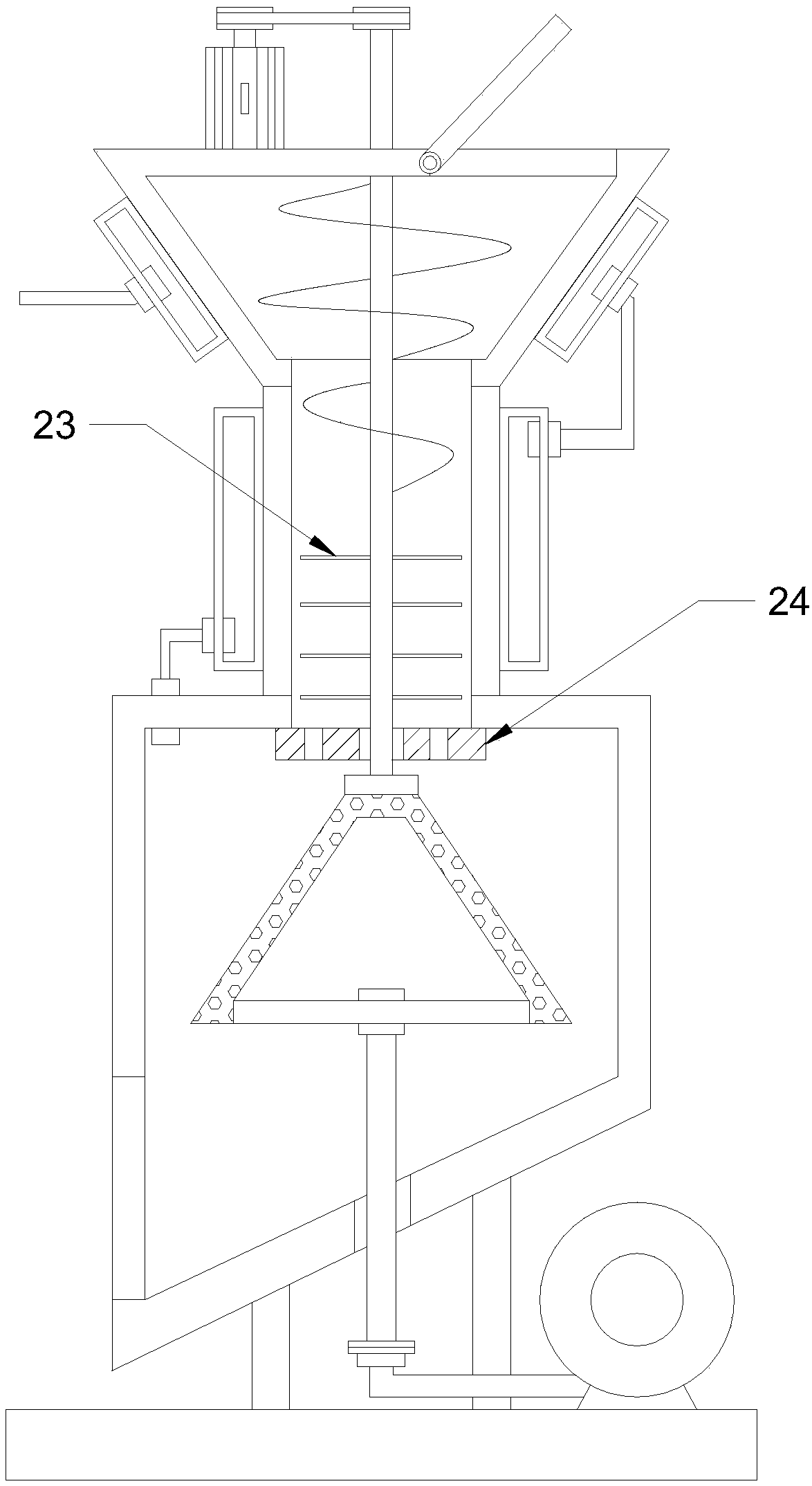

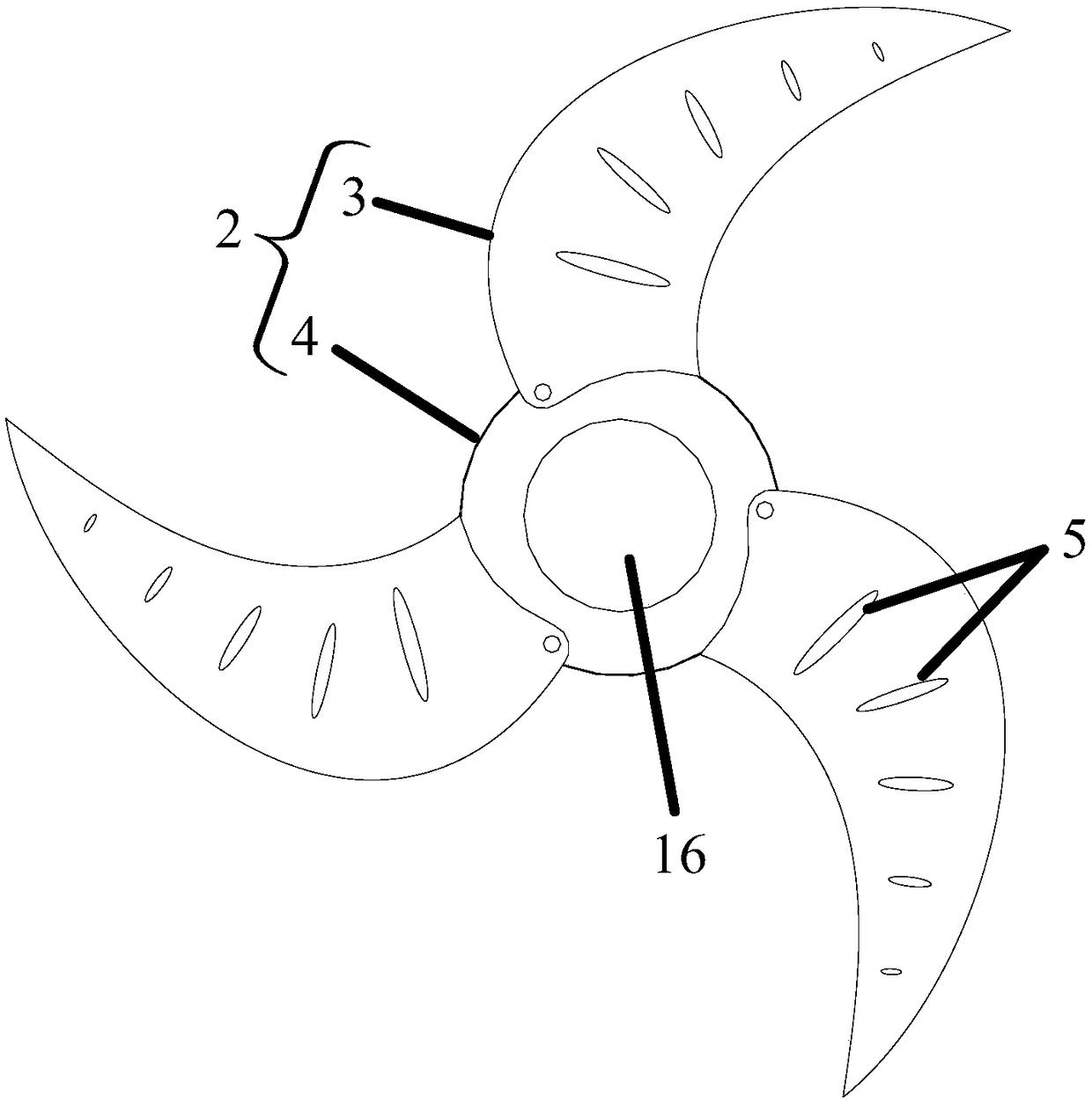

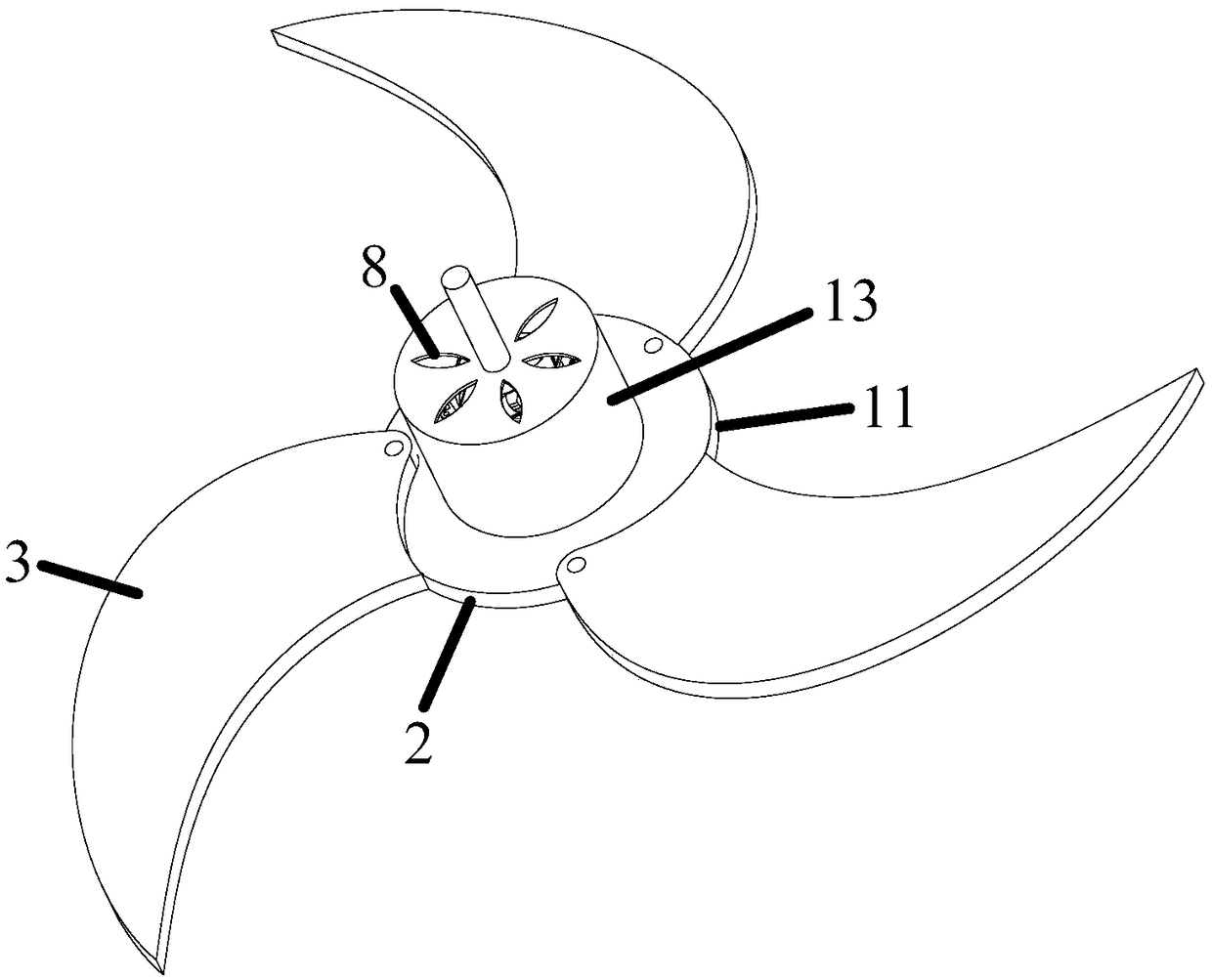

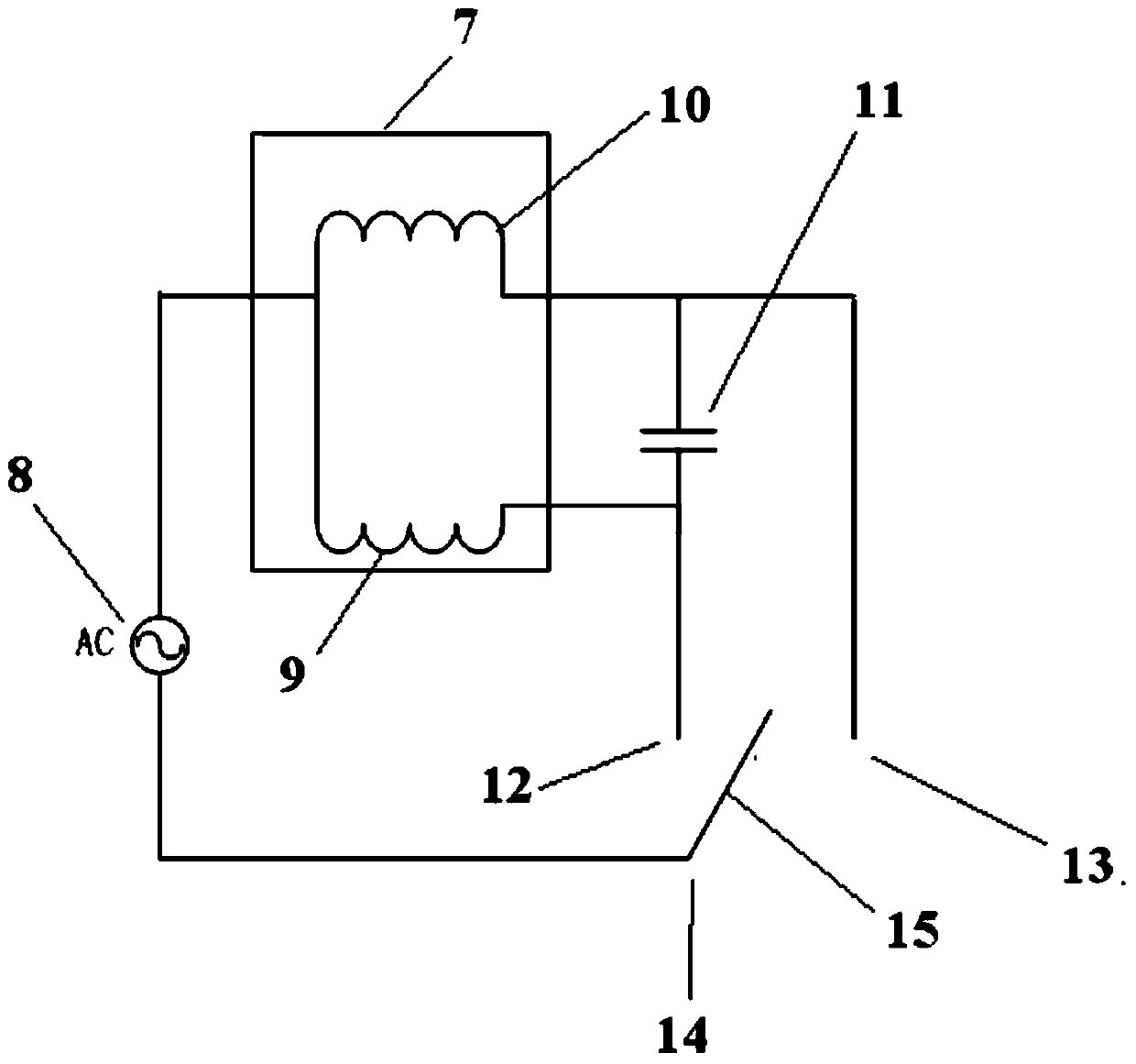

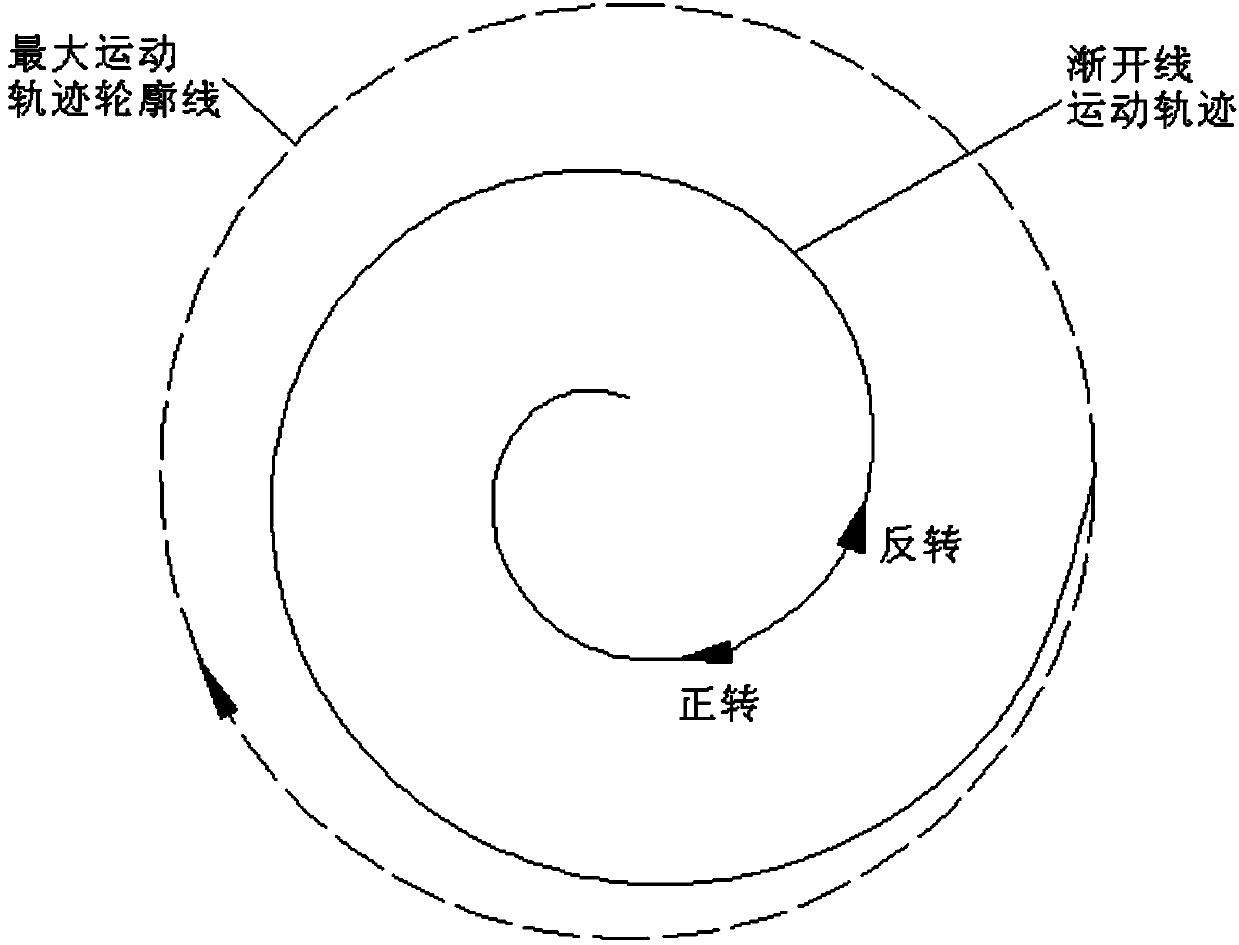

Ceiling fan and method for large-range full-coverage blowing

InactiveCN104179703AIncrease freedomChange blowing rangePump installationsNon-positive displacement fluid enginesCeiling fanDynamic balance

The invention provides a ceiling fan and a method for large-range full-coverage blowing. The ceiling fan comprises a ceiling fan power body, the top end of the ceiling fan power body is hinged to one end of a rigid connecting member, the other end of the connecting member is hinged to a fixed connecting block which is fixedly connected on an ascending and descending nut, and the ascending and descending nut is mounted on a spiral ascending and descending rod which is vertical fixed on a ceiling of the ceiling fan power body; a motor in the ceiling fan power body is controlled through a forward and reverse rotation control circuit, and when the motor rotates forwards, the ascending and descending nut spirally ascends along a thread on the spiral ascending and descending rod; when the motor rotates reversely, the ascending and descending nut descends along the thread on the spiral ascending and descending rod. On the basis that existing dynamic balance of the ceiling fan is maintained, blowing range is changed when a rotating shaft of the ceiling fan moves up and down along the spiral ascending and descending rod, so that no blowing dead angle exists in the whole large range, and more uniformity in blowing of each position is realized.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com