Textile equipment with uniform drying function

A kind of textile equipment and uniform technology, applied in the field of textile equipment with uniform drying function, can solve the problems that affect the quality of fabrics, the service life of finished fabrics, fabric wrinkles, and the function of not setting fabric leveling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

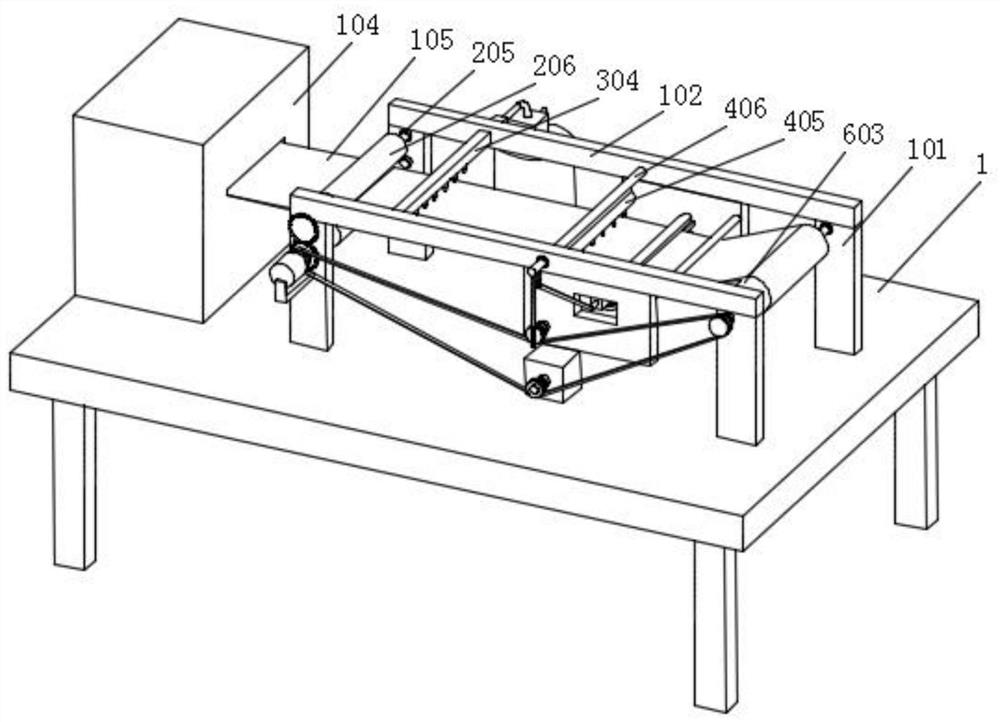

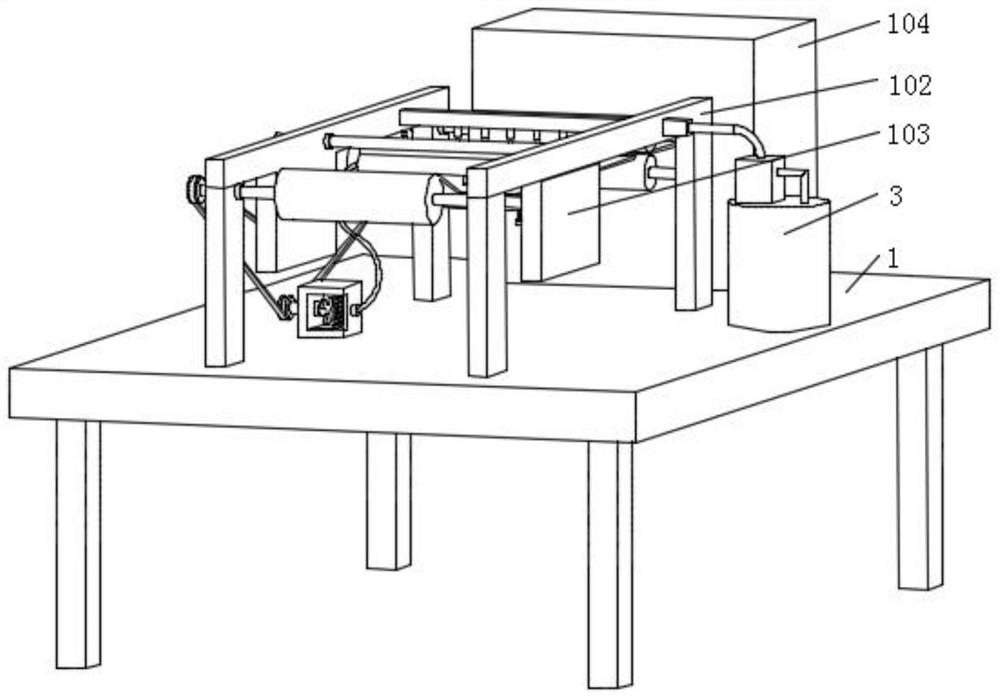

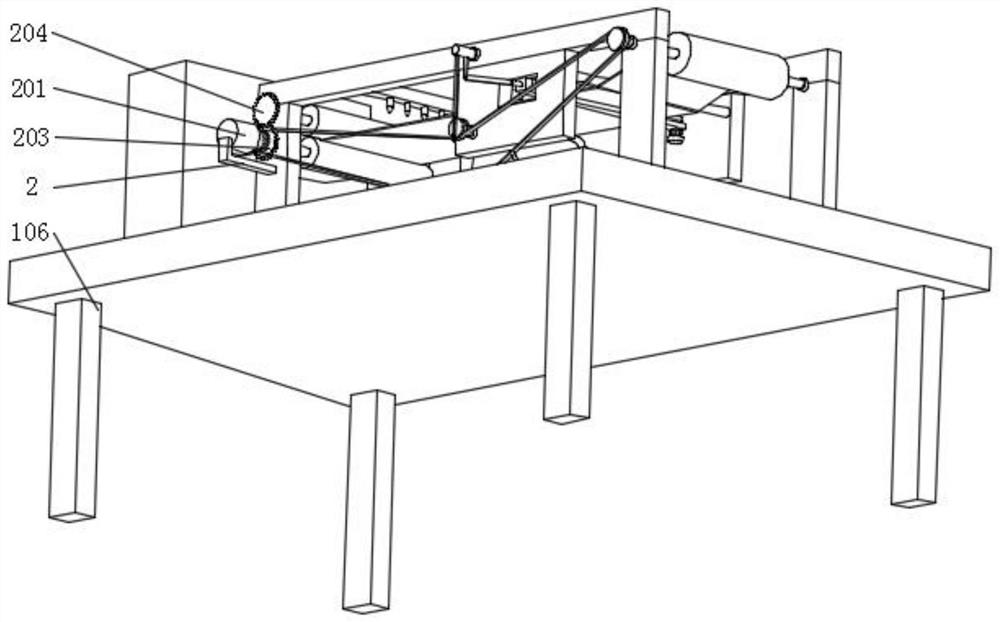

[0041] Example: Reference Figure 1-8 As shown, a textile equipment with uniform drying function includes a workbench 1, four support blocks 101 are fixedly installed on the top of the workbench 1, and the same cross bar 102 is fixedly installed on the top of every two support blocks 101 , the bottoms of the two crossbars 102 are fixedly installed with a fixed plate 103, and the fixed plate 103 is welded to the bottom of the crossbar 102 for fixing.

[0042] The top of the workbench 1 is fixedly installed with an installation box 4, and one side of the installation box 4 is provided with a rotating hole on the inner wall, and an annular sleeve is fixedly installed in the rotating hole, and a rotating roller 401 is installed in the annular sleeve, and the two ends of the rotating roller 401 Both extend to the outside of the annular sleeve, one side of one of the fixed plates 103 is rotatably equipped with a rotating rod 409, and the rotating rod 409 and the rotating roller 401 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com