High efficiency and energy saving blowback device used for gas turbine air inlet system

An air intake system, high-efficiency and energy-saving technology, applied in gas turbine devices, jet propulsion devices, mechanical equipment, etc., can solve problems such as waste of compressed air source and energy, poor injection effect, and reduced working efficiency of air filtration systems. The effect of working time, improving work efficiency, saving energy and air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

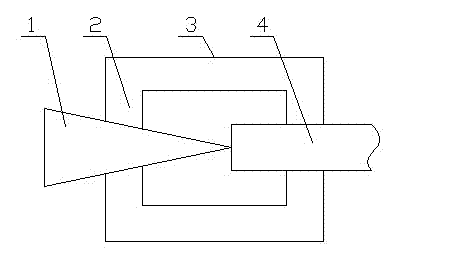

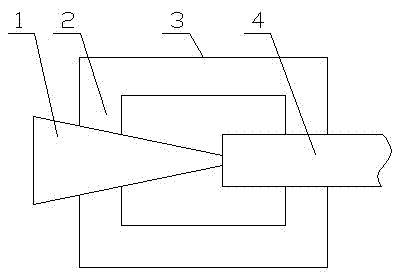

[0039] The high-efficiency and energy-saving blowback device for the gas turbine intake system of the present embodiment includes a blowback pipe communicated with a compressed air source through a pipeline, and also includes a conical flow guiding device, the center line of the flow guiding device and the center of the blowback pipe Lines are on the same straight line, the center line of the flow guide device is on the same line as the center line of the air filter cartridge; the top of the flow guide device is flush with the end face of the blowback pipe or the top of the flow guide device extends into Inside the blowback pipe; the bottom surface of the flow guiding device is facing the center of the air filter cartridge.

Embodiment 2

[0041] The high-efficiency and energy-saving blowback device for the gas turbine intake system of the present embodiment includes a blowback pipe communicated with a compressed air source through a pipeline, and also includes a frustum-shaped flow guide, and the center line of the flow guide is connected to the center of the blowback pipe. line on the same straight line, the centerline of the guide device and the center line of the air filter cartridge are on the same straight line; the upper bottom surface (end face with smaller radius) of the guide device is flush with the end face of the blowback pipe Or the upper bottom surface (end surface with larger radius) of the flow guide device extends into the blowback pipe; the lower bottom surface (end surface with larger radius) of the flow guide device is facing the center of the air filter cartridge.

Embodiment 3

[0043] The high-efficiency and energy-saving blowback device for the gas turbine intake system of the present embodiment includes a blowback pipe communicated with a compressed air source through a pipeline, and also includes a conical flow guiding device, the center line of the flow guiding device and the center of the blowback pipe Lines are on the same straight line, the center line of the flow guide device is on the same line as the center line of the air filter cartridge; the top of the flow guide device is flush with the end face of the blowback pipe or the top of the flow guide device extends into Inside the blowback pipe; the bottom surface of the flow guiding device is facing the center of the air filter cartridge; the flow guiding device is connected with the blowback pipe through a fixing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com