Patents

Literature

292results about How to "Improve blowing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

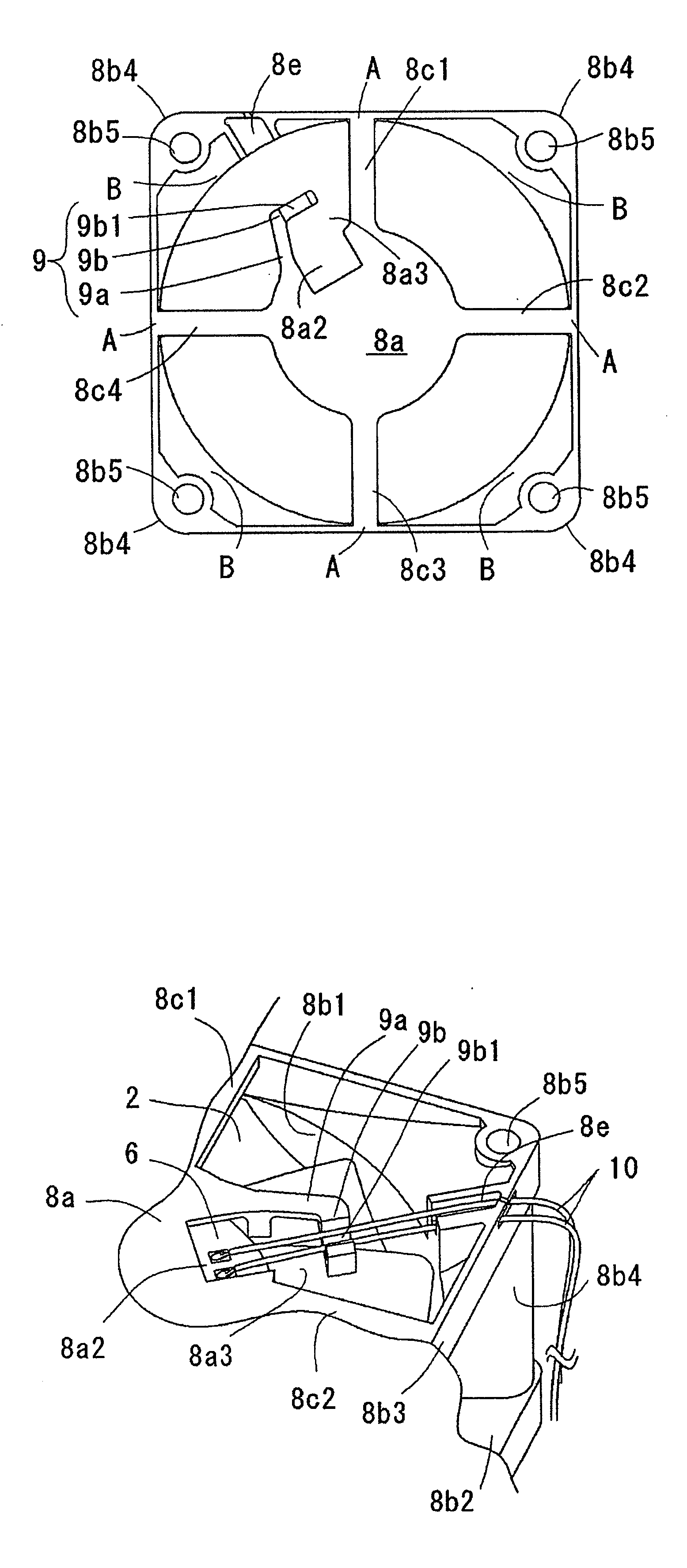

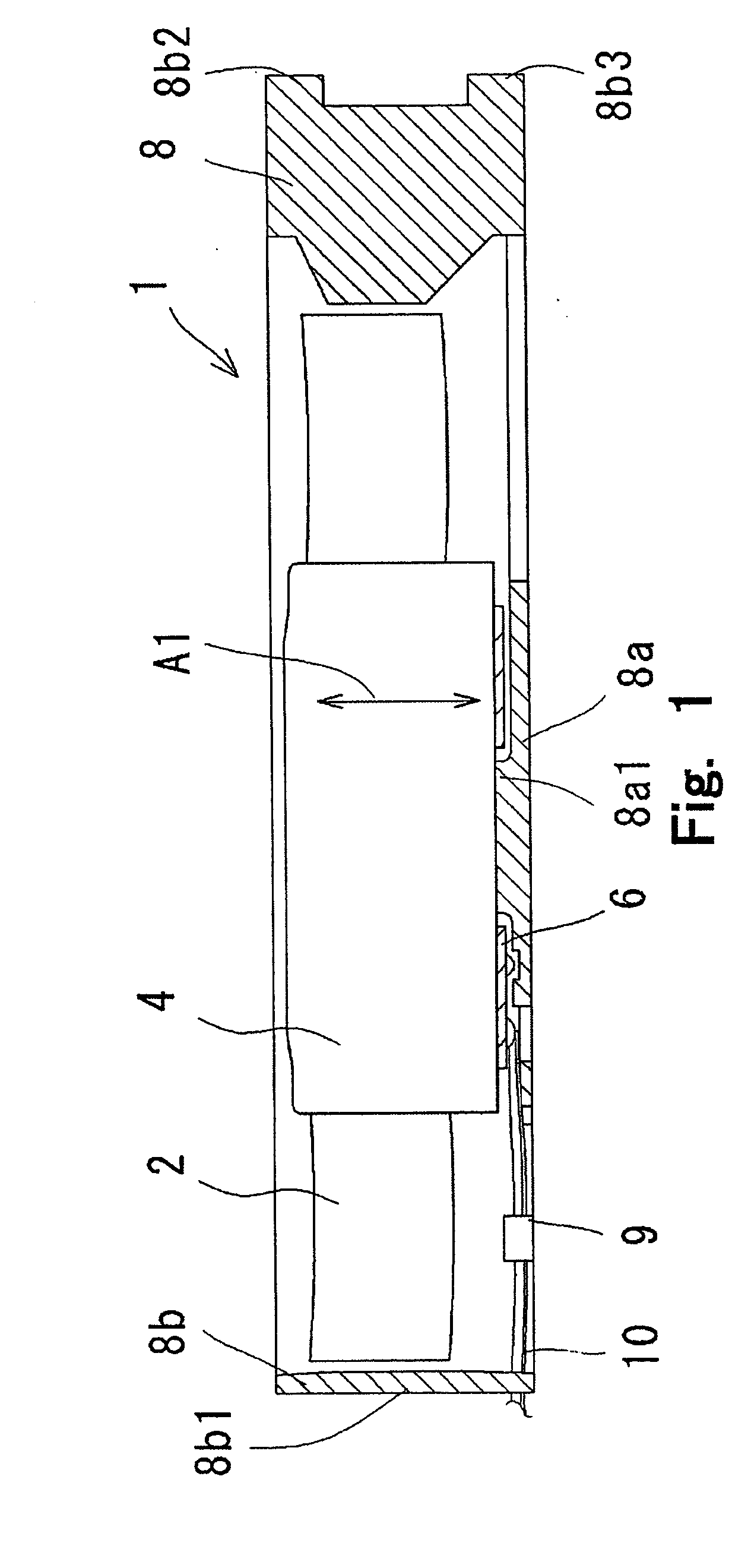

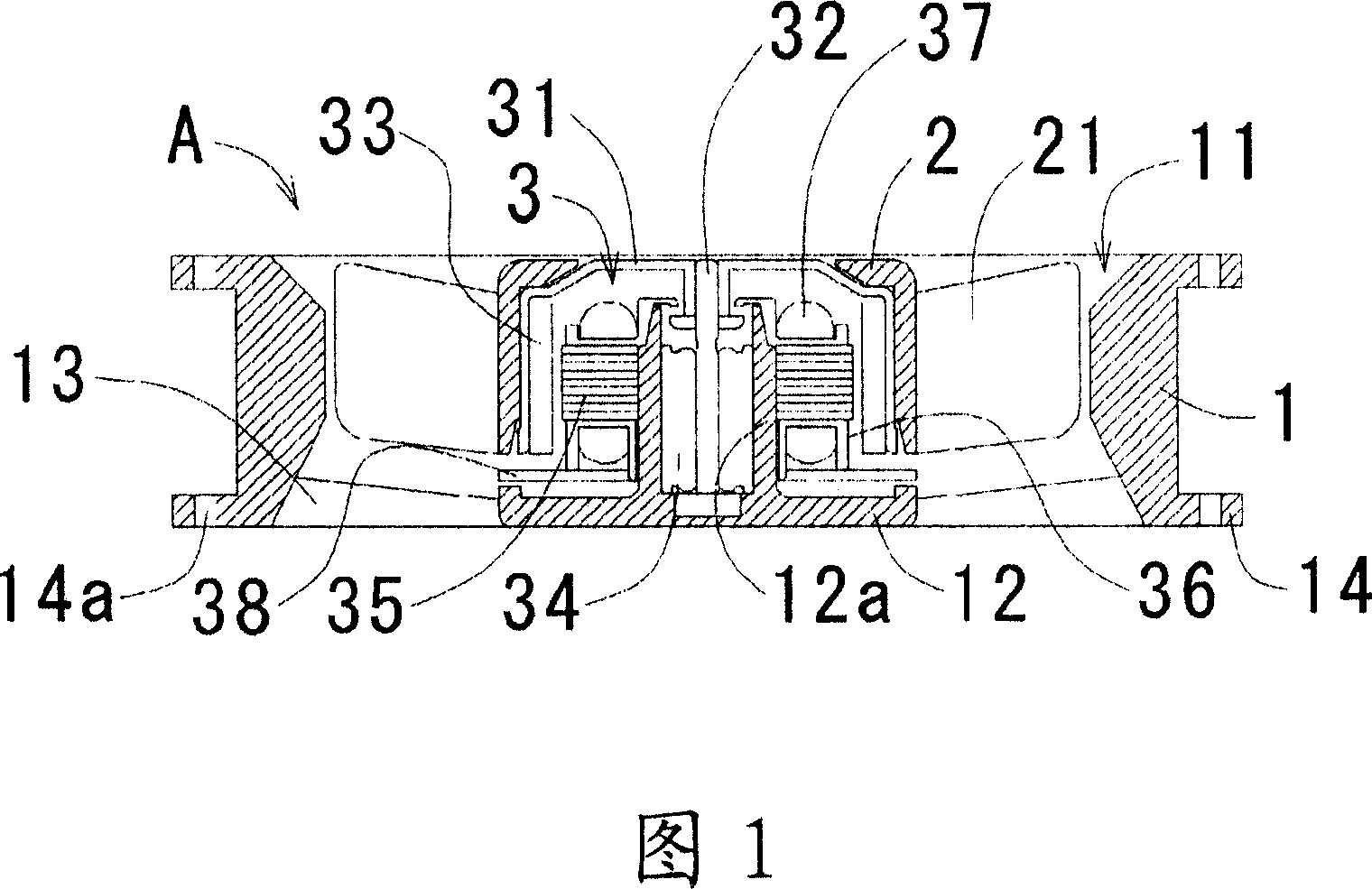

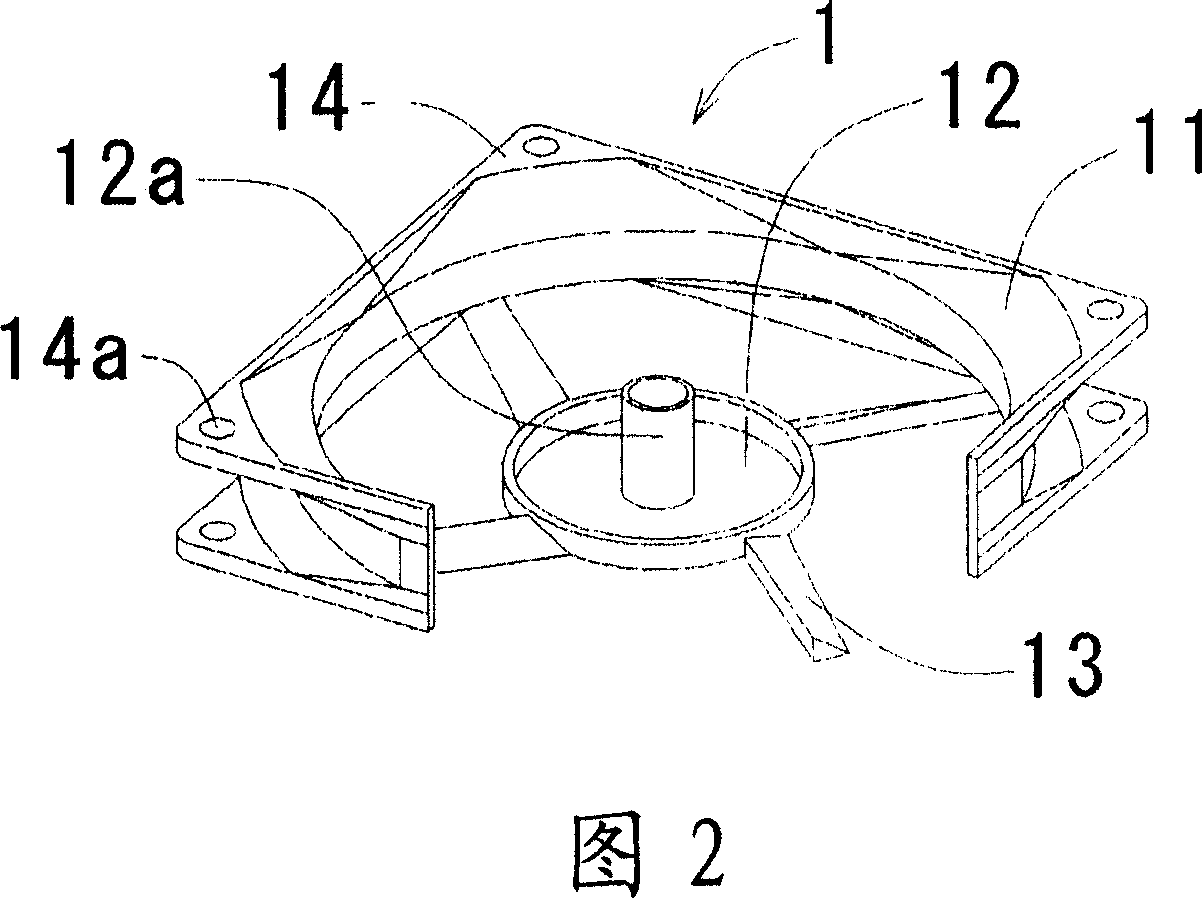

Structure of fan devices for leading out wires

InactiveUS20050180867A1Small wind resistance lossMinimize windage lossPump componentsDigital data processing detailsEngineeringMechanical engineering

Owner:NIPPON DENSAN CORP

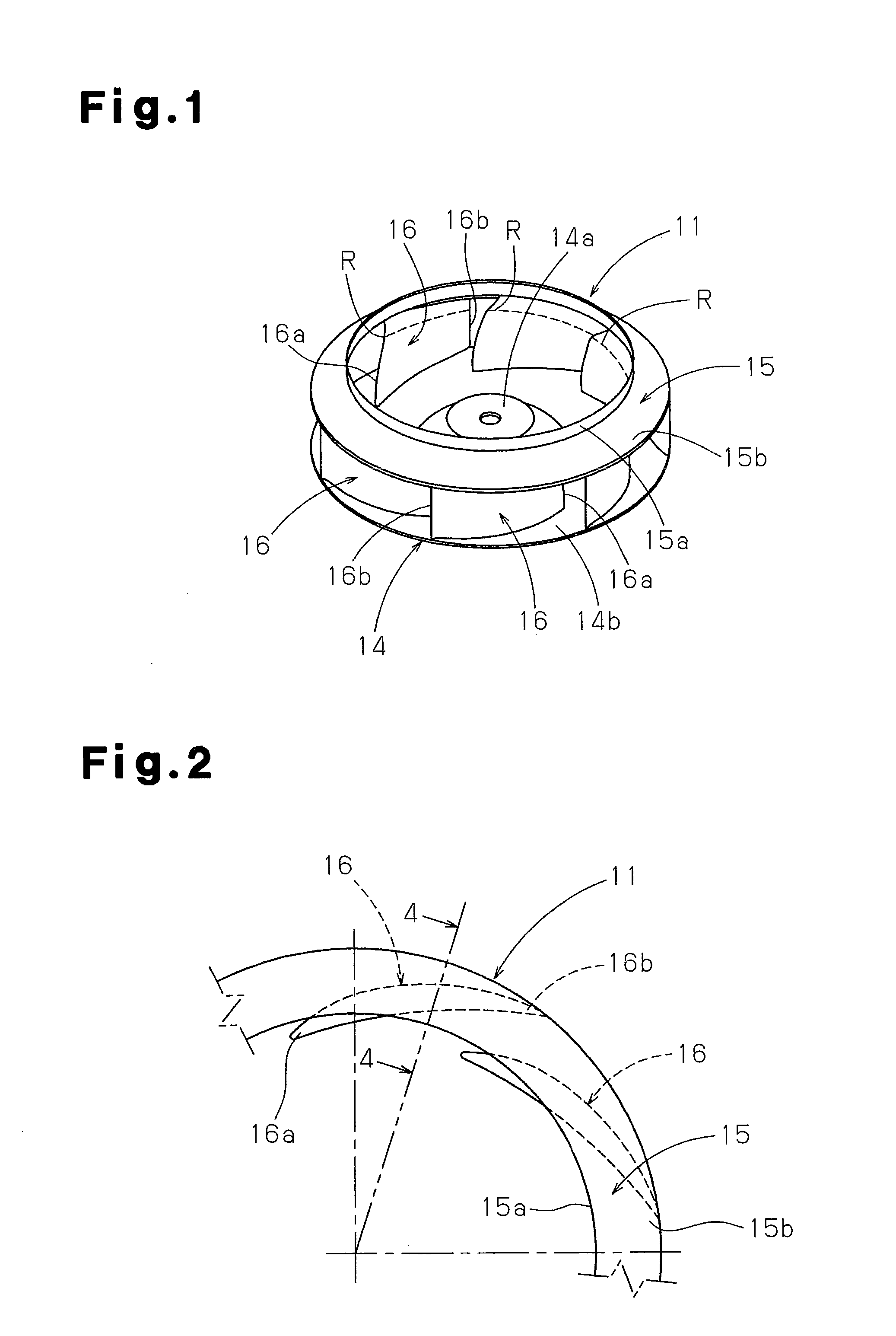

Centrifugal fan

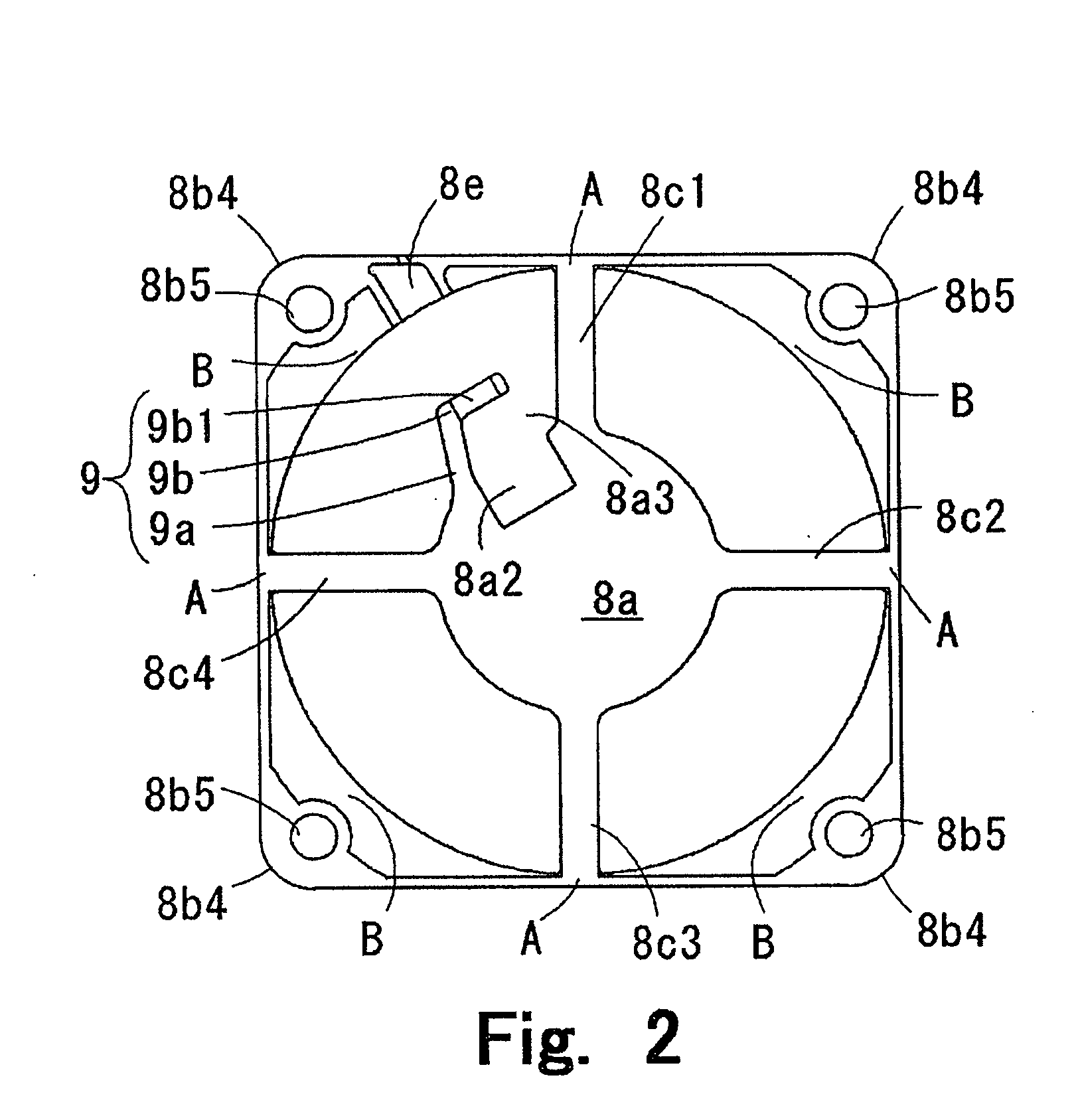

ActiveUS20100202886A1Reduce air turbulenceEffectively reducing fan noisePropellersRotary propellersEngineeringDead water

A centrifugal fan has a circular main plate driven and rotated by a motor rotary shaft, a plurality of blades fixed to an outer circumferential portion of the main plate and spaced apart at predetermined intervals in a circumferential direction of the main plate, and a side plate attached to ends of the blades opposite to the main plate. An air inlet port is formed at the center of the side plate. The side plate inclines outward in centrifugal directions from the air inlet port and has an arcuate cross section with a predetermined radius of curvature. A dead water region reducing space is formed between the blades and the side plate. The dead water region reducing space forms a smooth flow between the two surfaces of each blade, bringing about desirable blade performance.

Owner:DAIKIN IND LTD

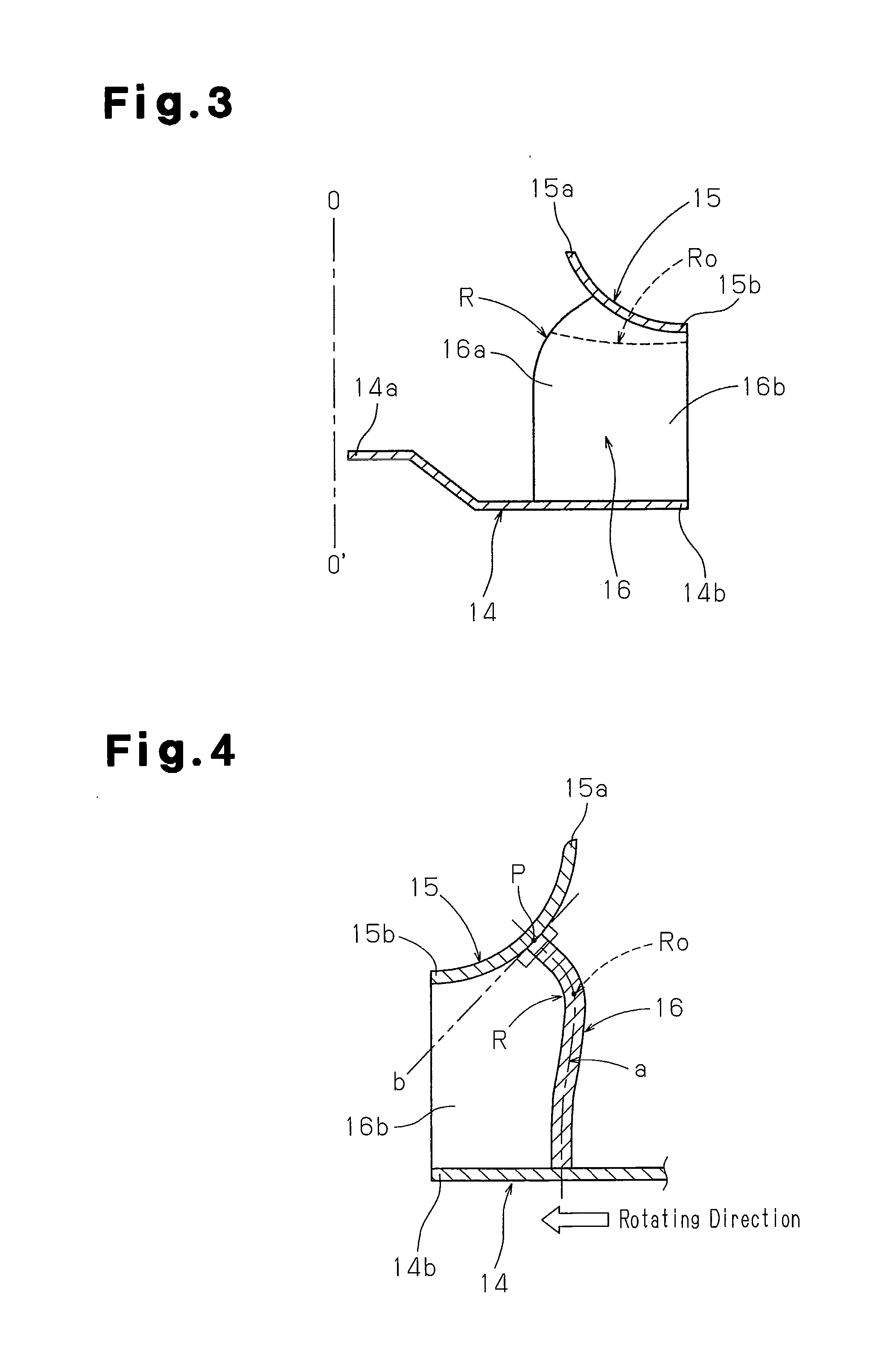

Blower

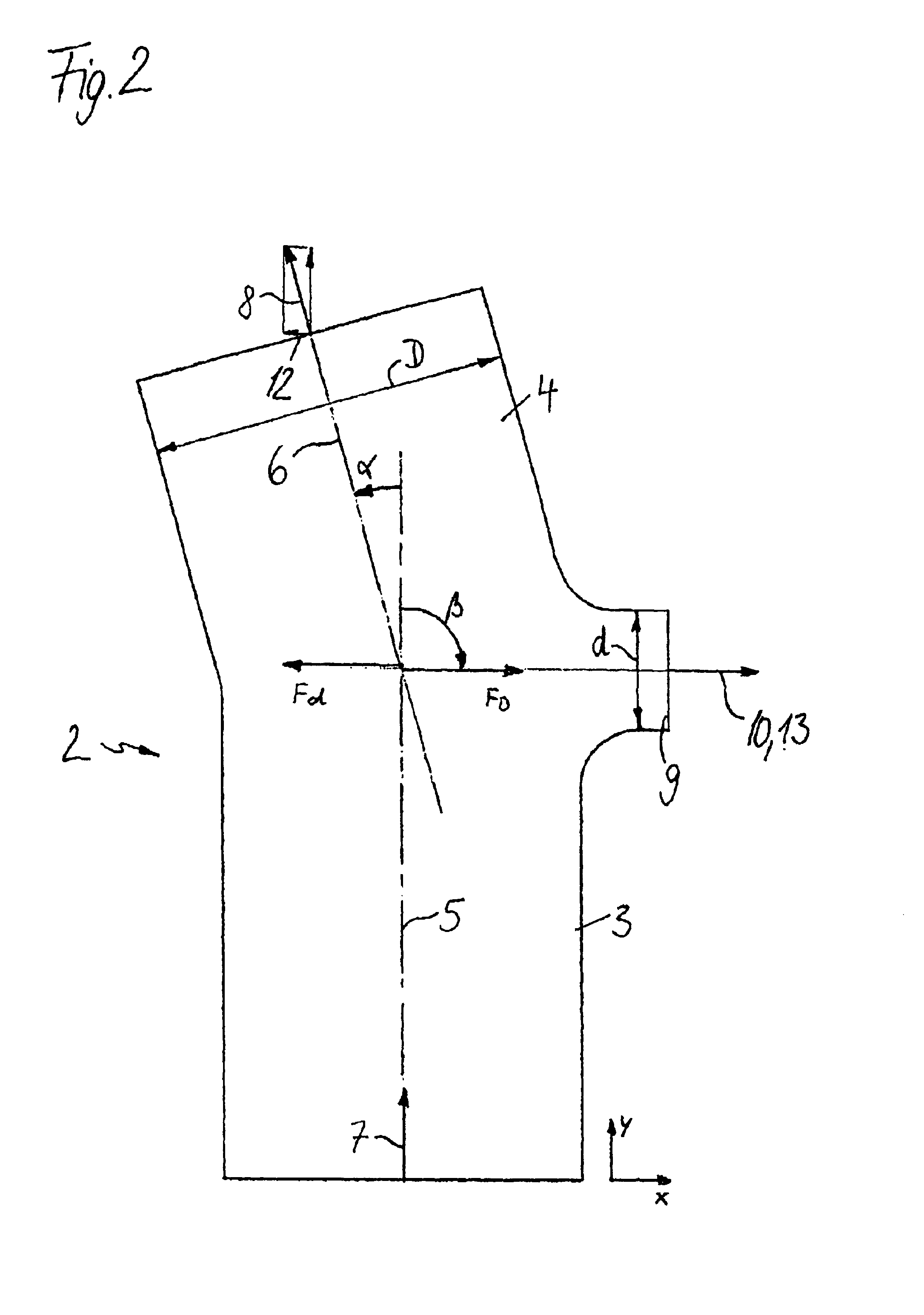

InactiveUS6843639B2Non-reduced blowing effectImprove retentionPump componentsStatorsTransverse forceWaste management

A blower having a discharge tube, which can be secured to a housing, for guiding a stream of air is provided. The air stream flows in a main stream direction in the discharge tube and in a discharge stream direction out of the discharge tube. The discharge stream direction forms an angle of greater than 0° with the main stream direction. The discharge stream direction has a transverse component that extends perpendicular to the main stream direction, which produces a force in the discharge tube perpendicular to the main stream direction. To reduce the transverse force produced in the discharge tube, a partial air stream is branched off out of the discharge tube and flows in a partial stream direction that has a compensation component that is directed opposite to the transverse component.

Owner:ANDREAS STIHL AG & CO KG

Wafer transmission device having blowing-off function

ActiveCN106505023AIncrease usageLow costSemiconductor/solid-state device manufacturingCleaning using gasesIdentification deviceSemiconductor

The invention relates to a wafer transmission device having a blowing-off function. At least one blowing-off contact disc surface and a blowing-off module are configured in the wafer transmission device, wherein each blowing-off contact disc surface comprises at least one inflation nozzle, at least one air outlet nozzle and an identification device, and the blowing-off module comprises an inflation inlet, an air outlet, at least one temperature / humidity sensor, at least one flow metering table and at least one pressure sensor. The wafer transmission device which does not possess a blowing-off technology possess the blowing-off technology after the blowing-off contact disc surface and the blowing-off module are configured, the problem of cleanness of a traditional wafer transmission device on a front opening unified pod is solved, and the wafer yield in a semiconductor process can be effectively improved.

Owner:BRILLIAN NETWORK & AUTOMATION INTEGRATED SYST

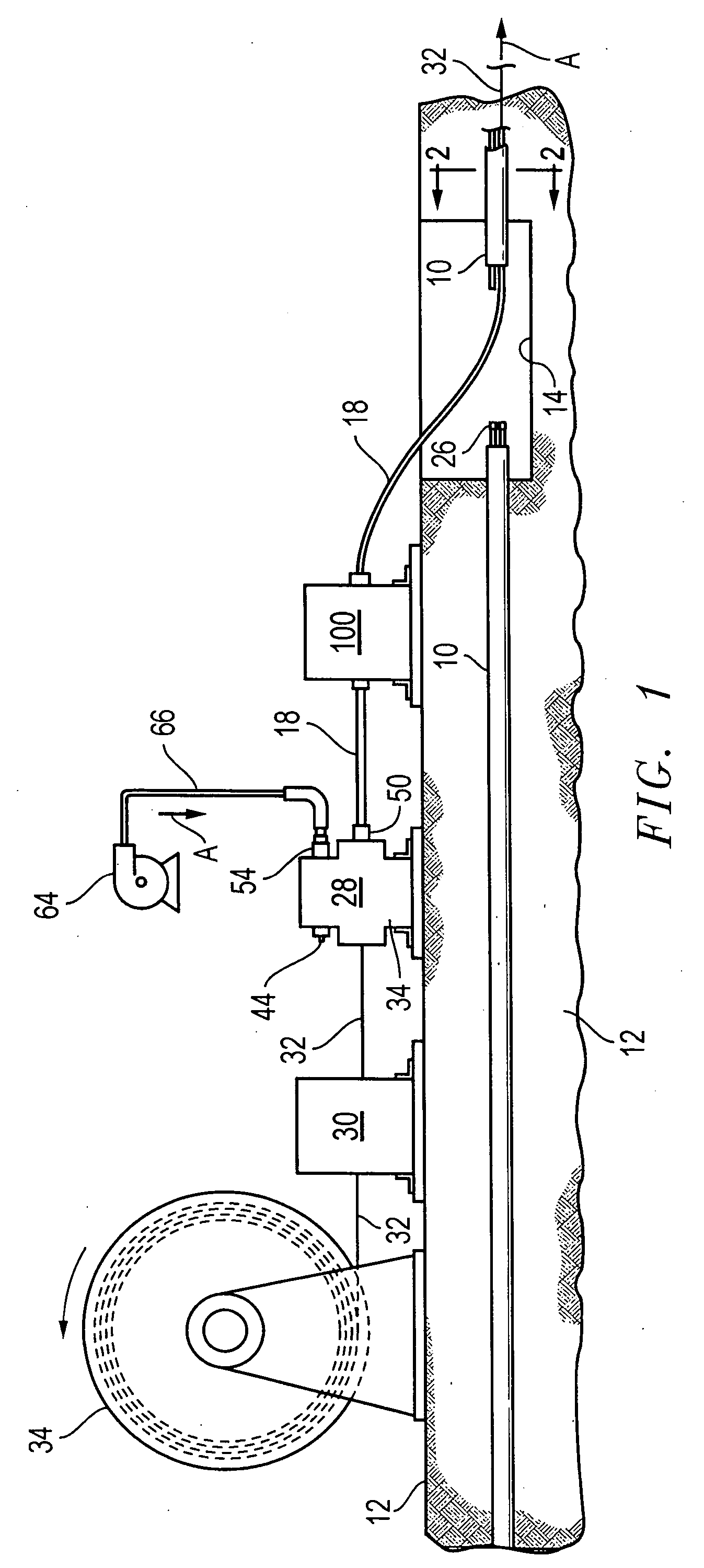

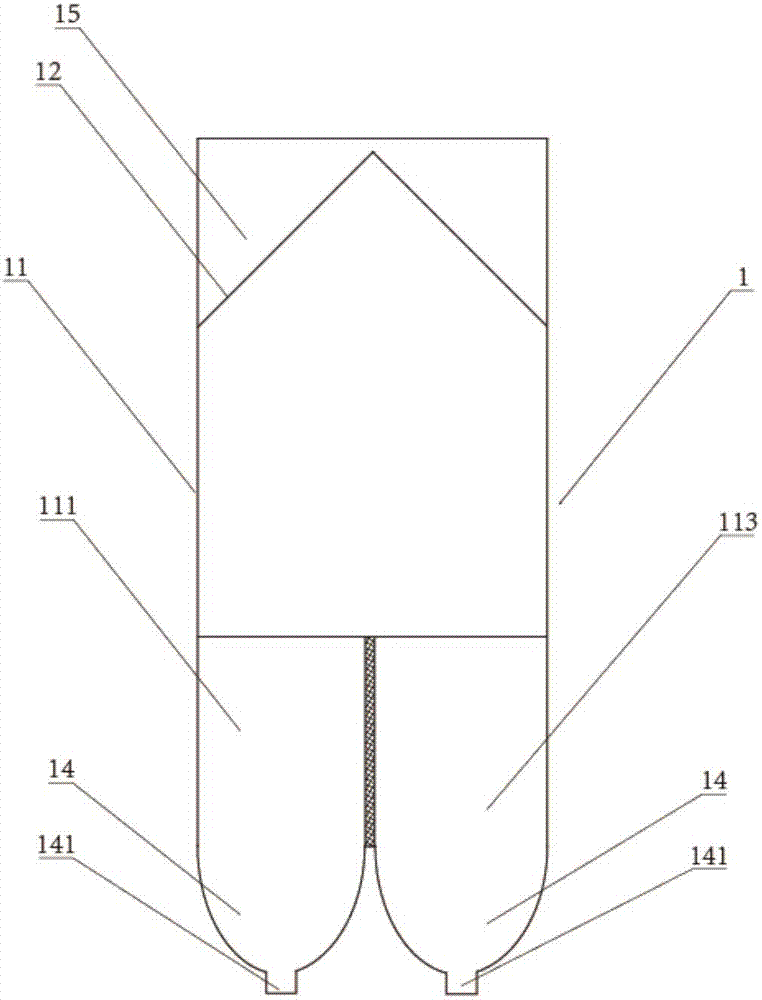

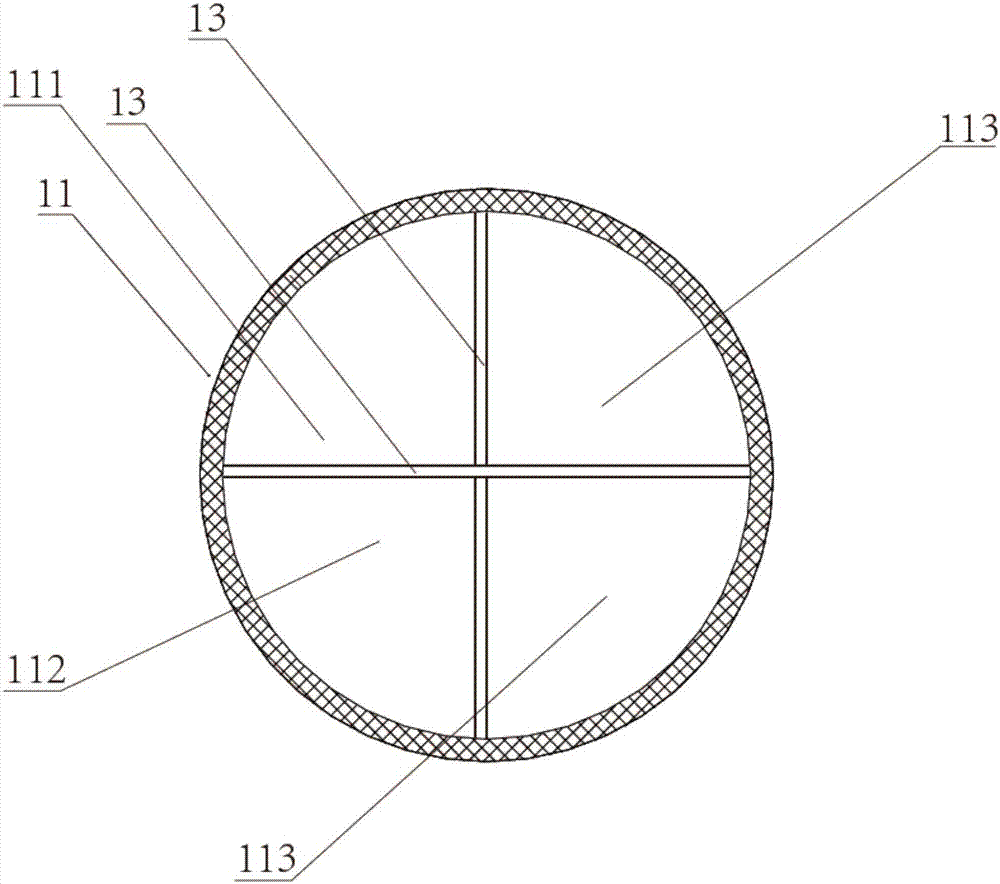

Optical Fiber Microcable with Multilayer Protective Sheath

InactiveUS20090087153A1Raise countImprove blowing effectFibre mechanical structuresFiberSynthetic materials

Disclosed is a central loose tube fiber optic microcable that includes a protective sheath enclosing a plurality of optical fibers. The microcable protective sheath is composed of two layers of different synthetic materials, namely an inner layer having an elasticity modulus of about 1500-3000 MPa and an outer layer having an elasticity modulus of about 600-1200 MPa.

Owner:DRAKA COMTEQ BV

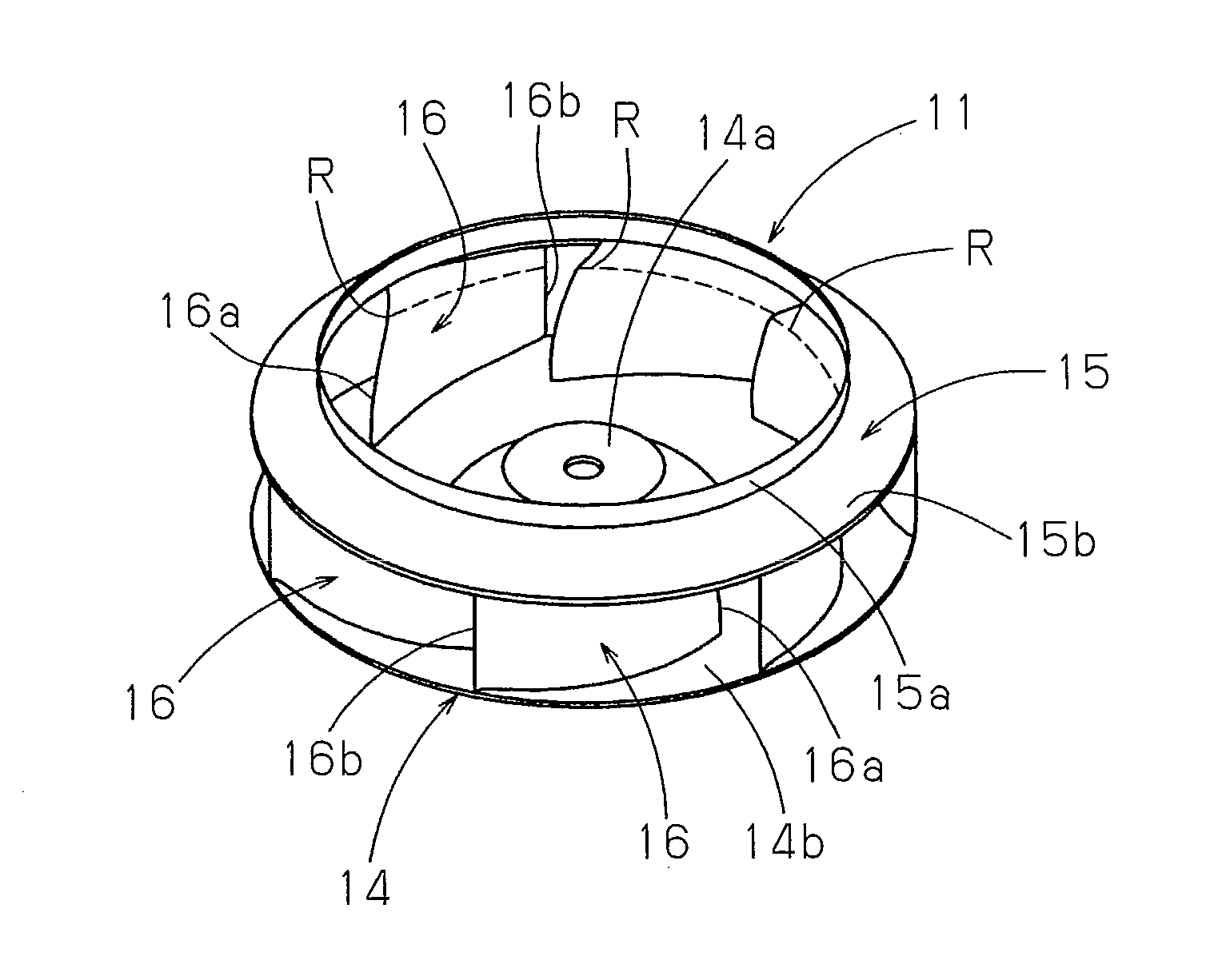

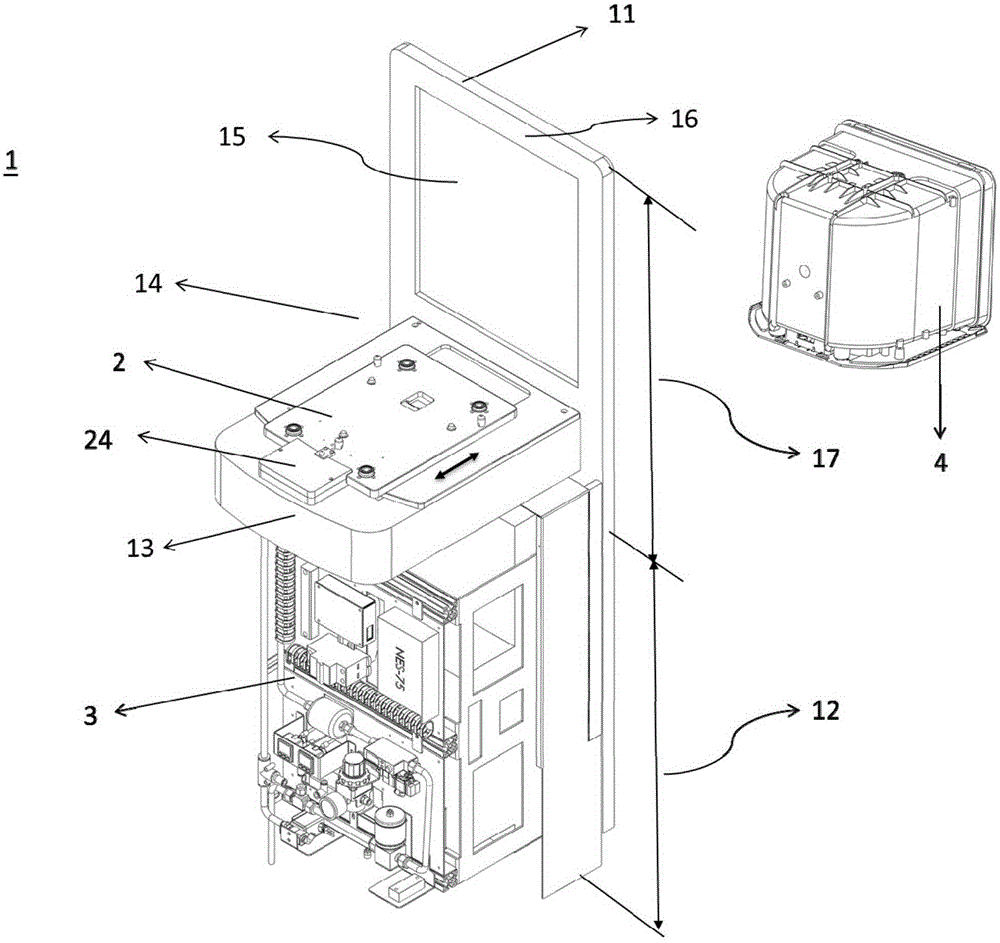

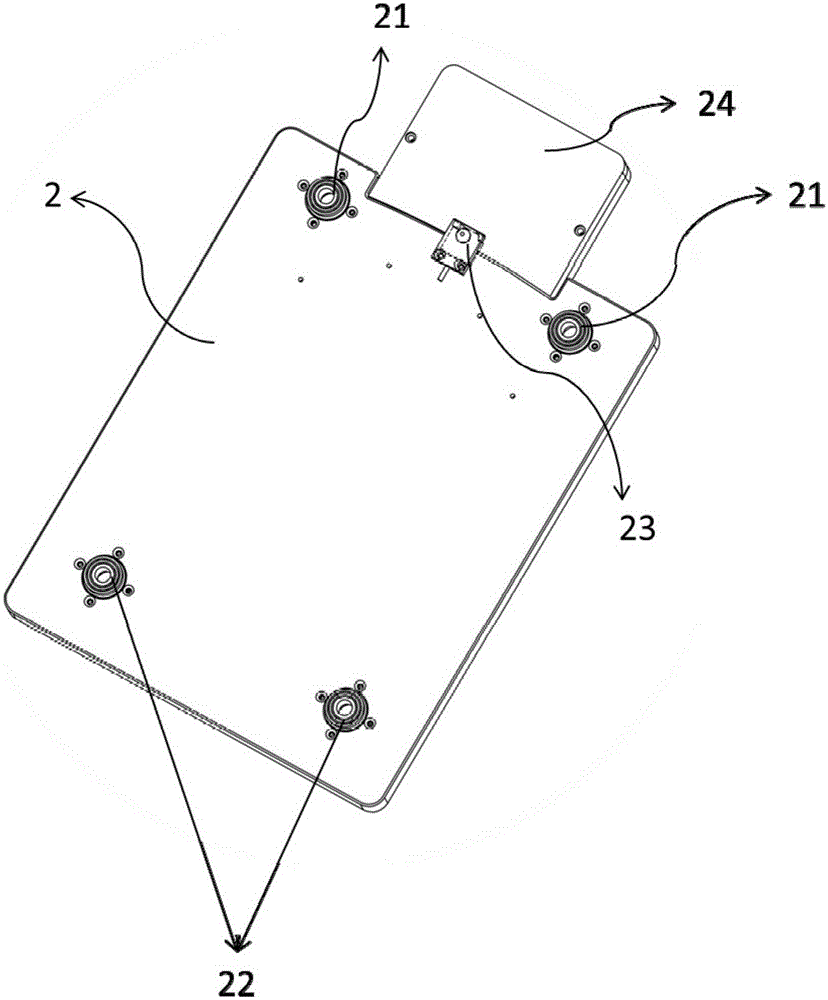

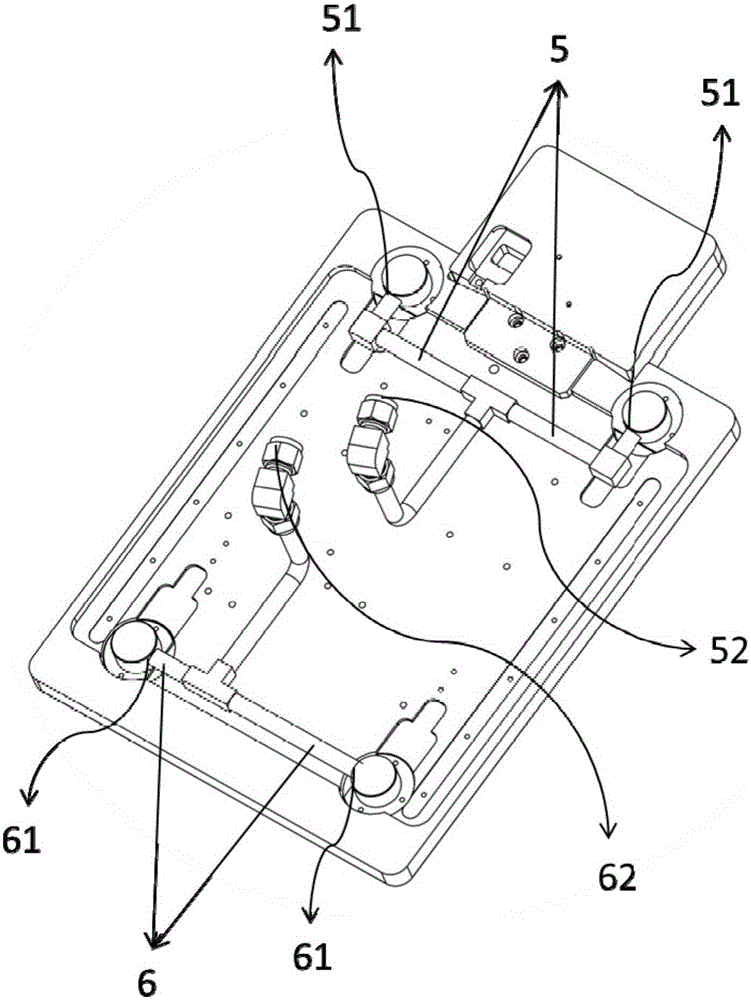

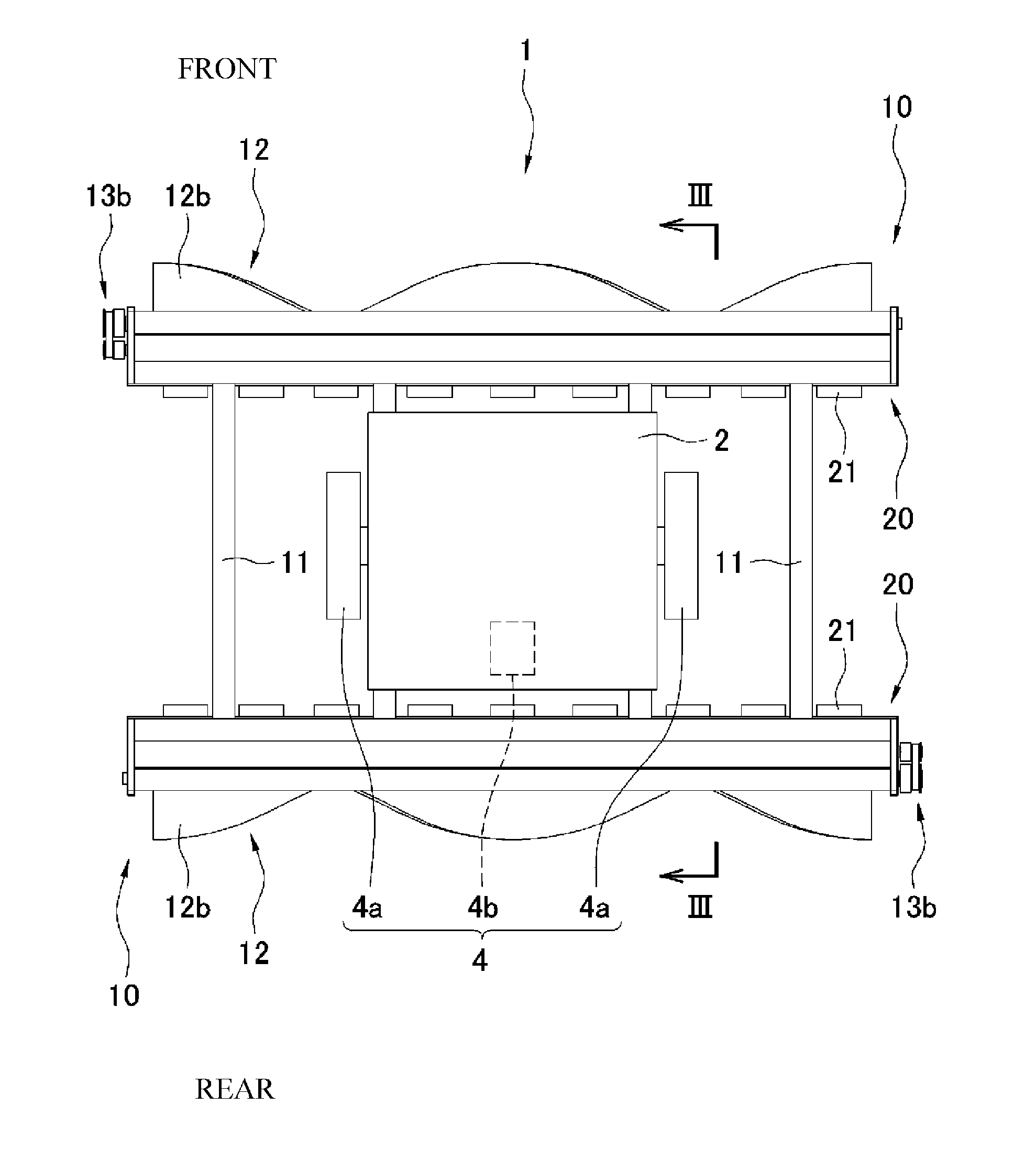

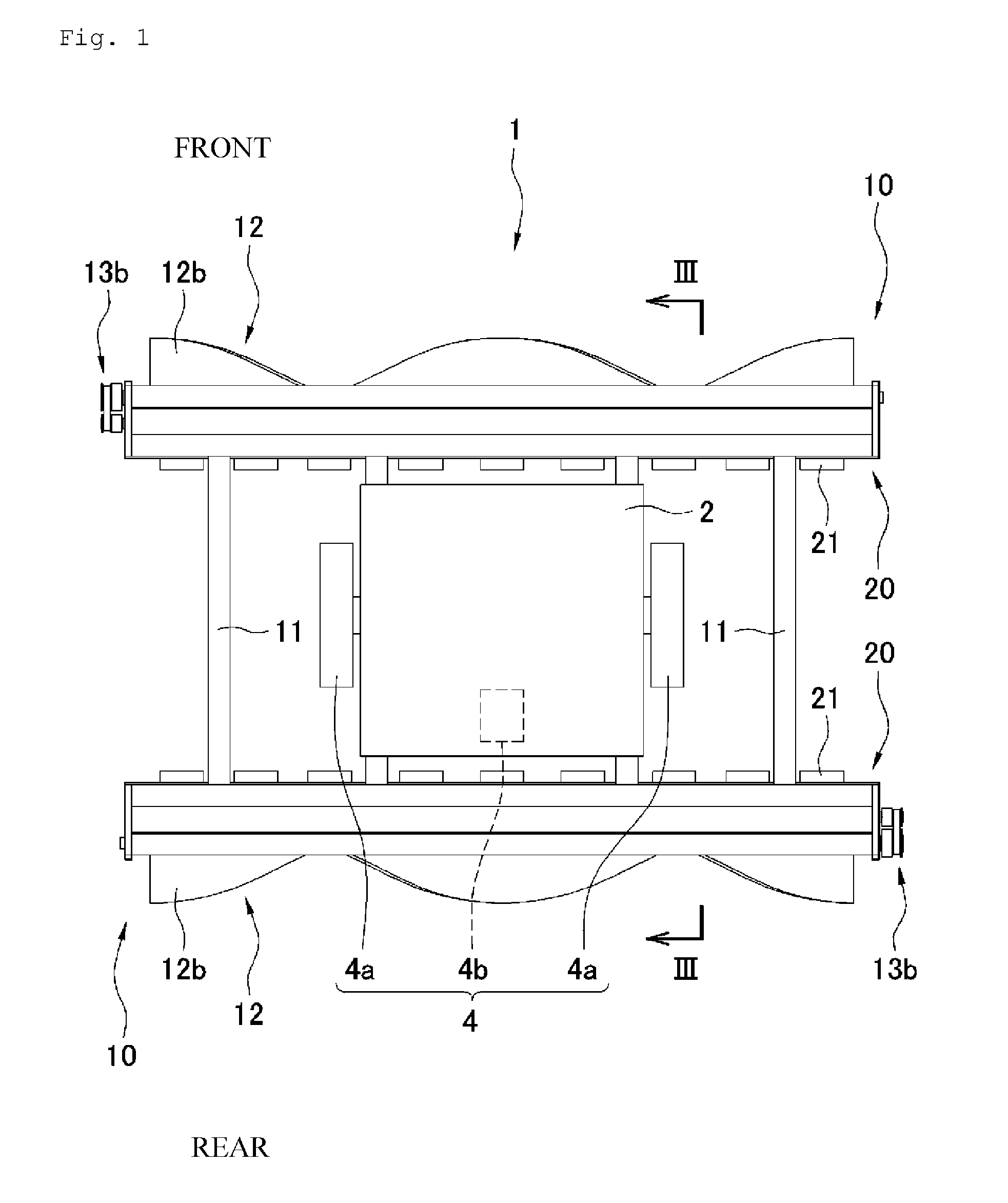

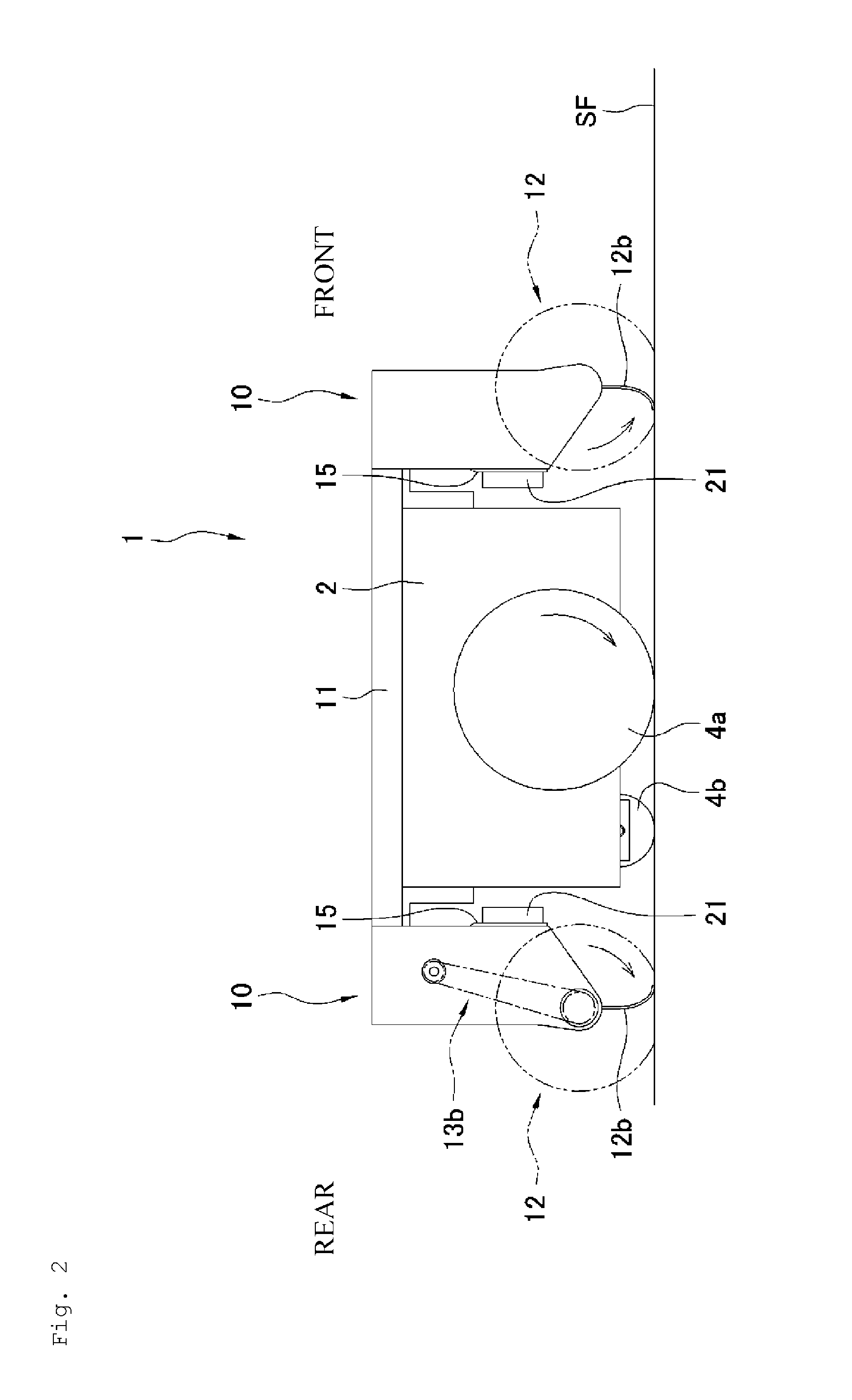

Autonomous-travel cleaning robot

InactiveUS20150236640A1Continuous cleaningReduce necessitySolar heating energySolar heat devicesEngineeringAirflow

A self-propelled cleaning robot that can continuously perform cleaning even on a large space can be provided without increasing in size. The self-propelled cleaning robot that self-travels on and cleans a target flat surface (SF) of a structure (SP) installed outside, the self-propelled cleaning robot includes: a robot body (2) in which a self-propelled moving means is provided and a cleaning unit (10) that is provided in a side surface of the robot body (2). The cleaning unit (10) includes a rotatable brush (12) that includes a shaft unit (12a) and a brush unit (12b) provided on the shaft unit (12a) and an airflow forming cover (15) that is provided so as to cover a portion located on a side of the robot body (2) and on an opposite side to the flat surface in the brush (12) during cleaning of the flat surface. The robot body (2) is not enlarged because the provision of a dust collecting portion in the robot body (2) is not required. Because dust suction is not required, power consumption necessary can be reduced, and an extremely large space can continuously be cleaned.

Owner:MIRAIKIKAI

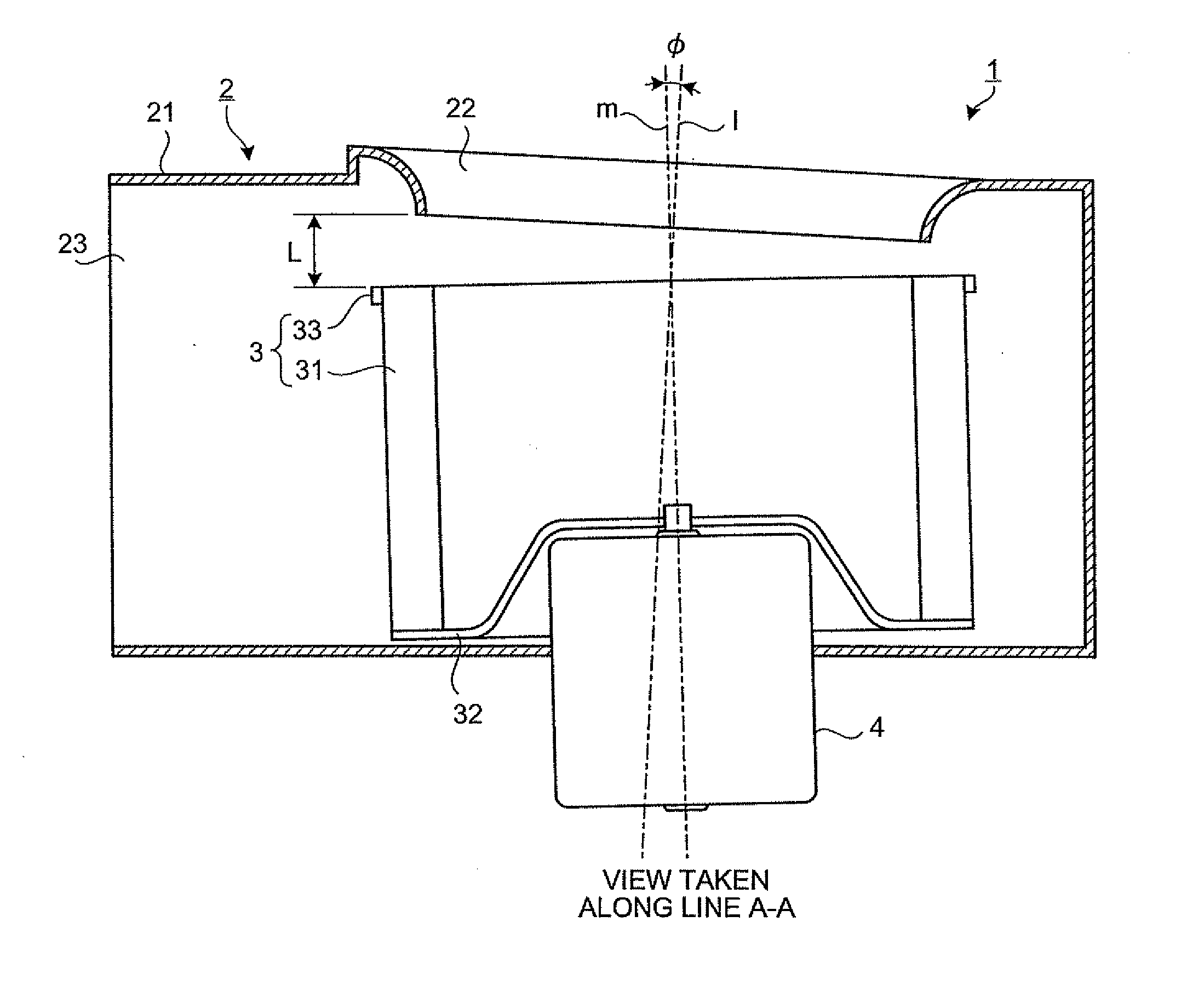

Fan and air conditioner

InactiveUS20070116559A1Convenient guidanceMaintain performancePump componentsLighting and heating apparatusImpellerEngineering

An air conditioner includes a centrifugal fan and a unit casing that houses the centrifugal fan. The centrifugal fan includes an impeller and a scroll casing that houses the impeller. The unit casing has a unit intake port that opens in a direction crossing an opening direction of a scroll intake port. At a circumferential portion of the scroll intake port of the scroll casing, there is formed a bulged portion with an inner surface that is formed evenly in a circumferential direction and an outer surface portion formed away from the unit intake port that bulges out to a side opposite the impeller.

Owner:DAIKIN IND LTD

Cotton slitter with inward wind blowing function

ActiveCN103305969AEasy to dryCompact structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersNozzle

The invention discloses a cotton slitter with an inward wind blowing function. The cotton slitter comprises a rack box, a feed hopper, a discharging port, a beating roller and a blowpipe, wherein a working cavity is designed inside the rack box; the feed hopper and the discharging port are mounted on opposite surfaces of the rack box respectively and communicated with the working cavity; the bearing roller is mounted in the working cavity, and vertical round rods are distributed on the outer surface of the beating roller; the outer surface of the bearing roller adopts a framework and wire netting structure; the inside of the blowpipe is communicated with an air supply device, and the blowpipe is mounted on the axis of the bearing roller; an air nozzle facing the discharging port is designed on the blowpipe; the lower part of the beating roller is wrapped with a separation net for removing impurities. The cotton slitter has a simple structure, a smaller size, a drying function and a good cotton slitting effect.

Owner:临沂鑫润建铜业有限公司

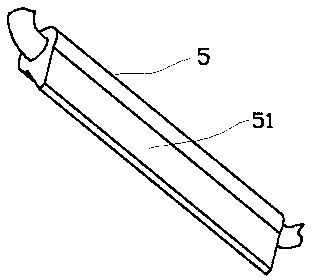

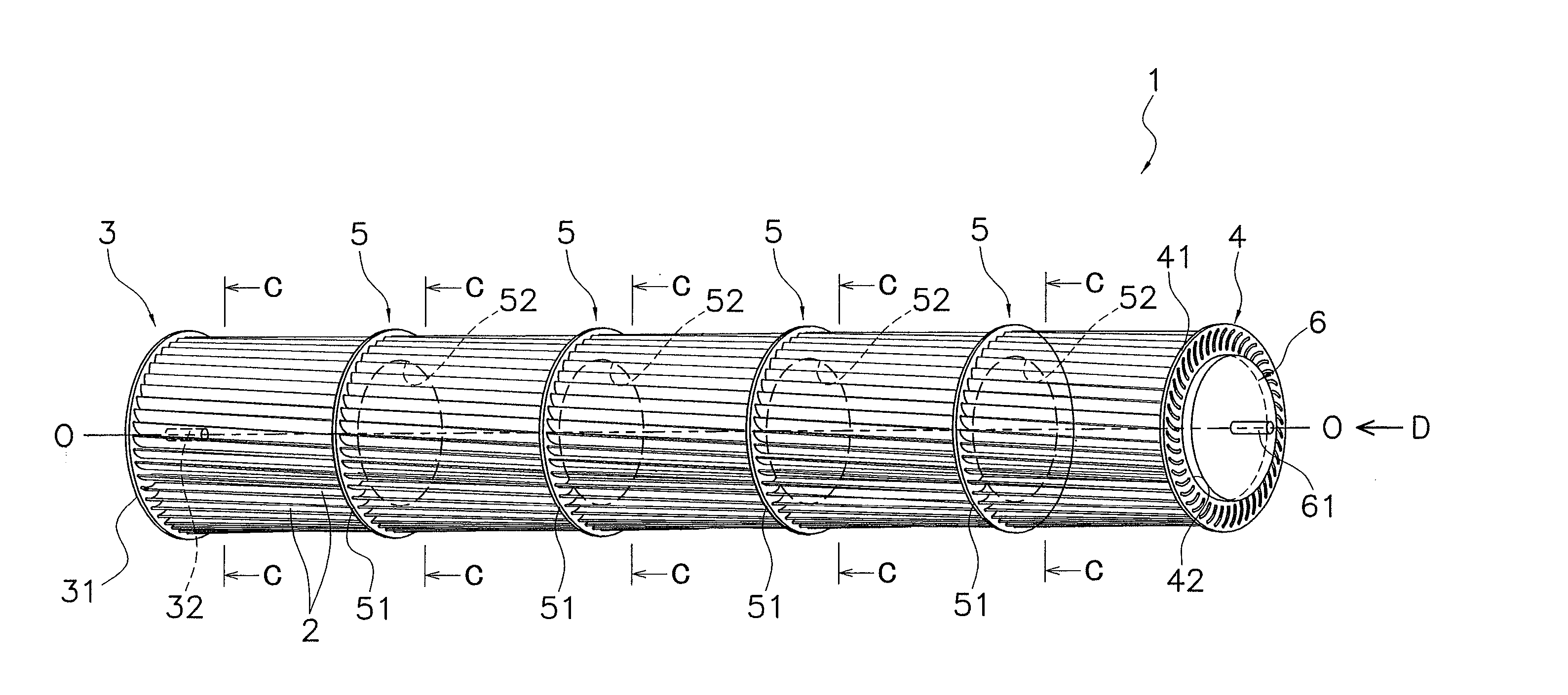

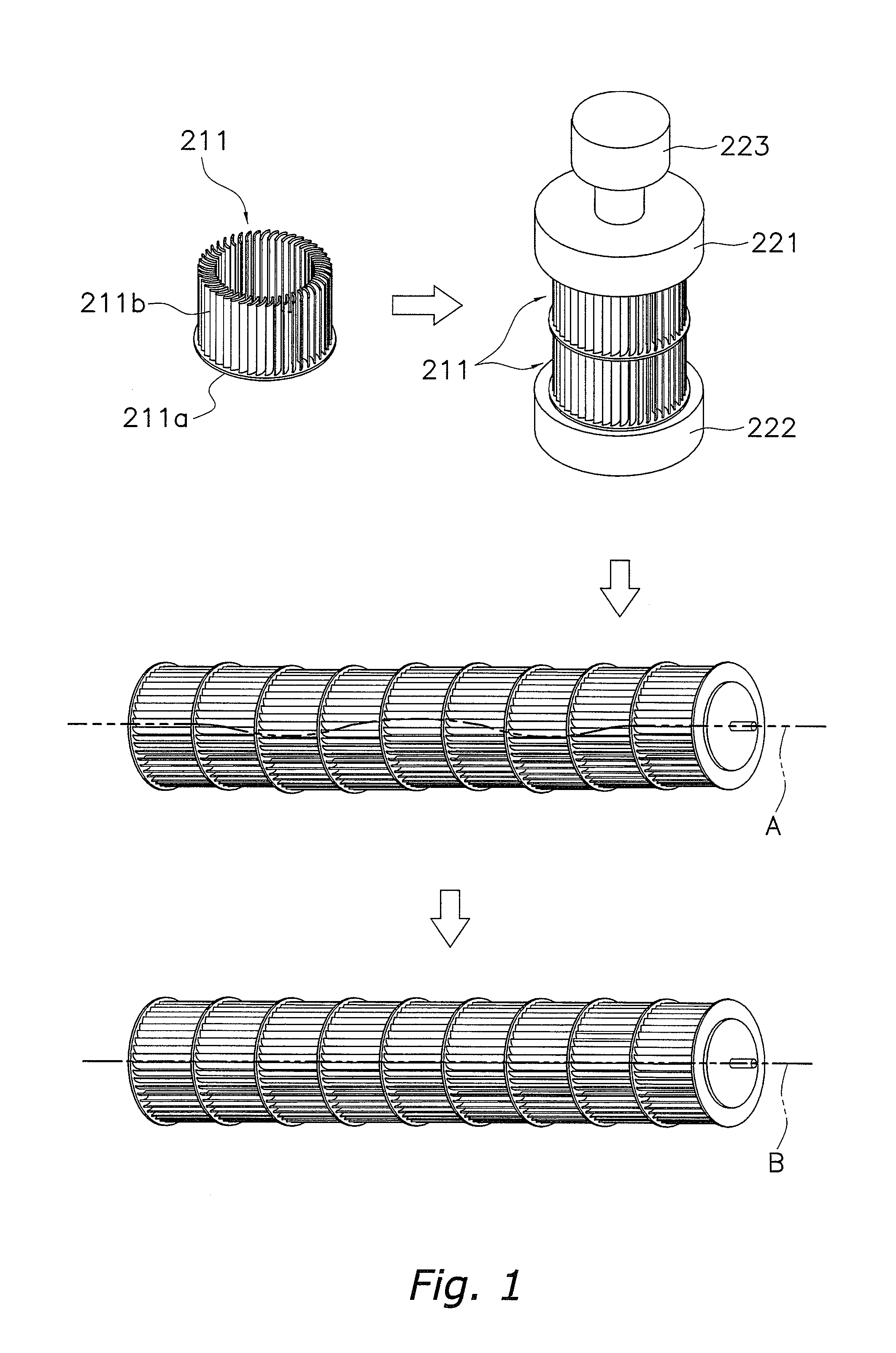

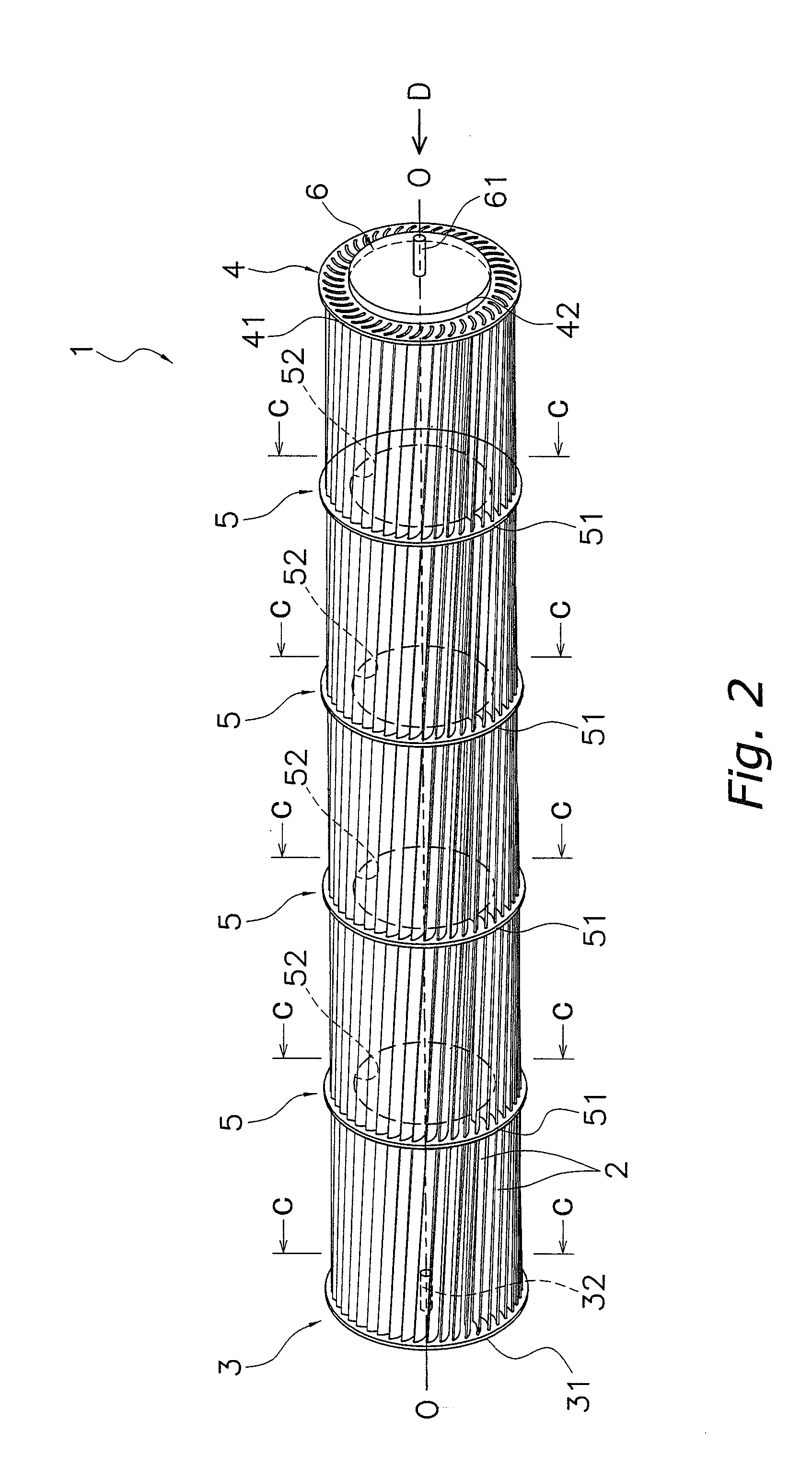

Cross-flow fan made of resin and method of manufacturing the same

InactiveUS20100158689A1Reduce in quantityRemove distortionPropellersMixer accessoriesCircular discLaser

A resin cross flow fan and a method for manufacturing a resin cross flow fan are provided in which an annealing step can be omitted and the number of circular disks can be reduced, and which provides improved fan strength and air blowing performance. A resin cross flow fan is disposed with a plurality of blades and a plurality of plates. The plurality of blades are annually disposed about a rotation axis. Insertion portions each constituted by a hole or a groove into which each blade is inserted and projecting portions that projects from the periphery of the insertion portions in a direction of the rotation axis are formed on each of the plurality of plates disposed spaced apart in the direction of the rotation axis. Each blade is fixed to the projecting portions by laser welding.

Owner:DAIKIN IND LTD

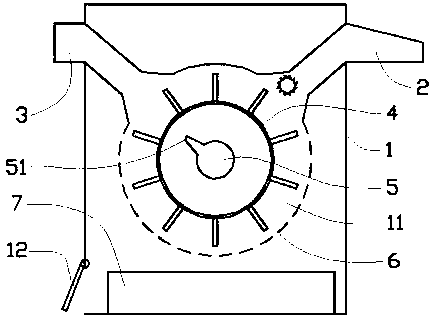

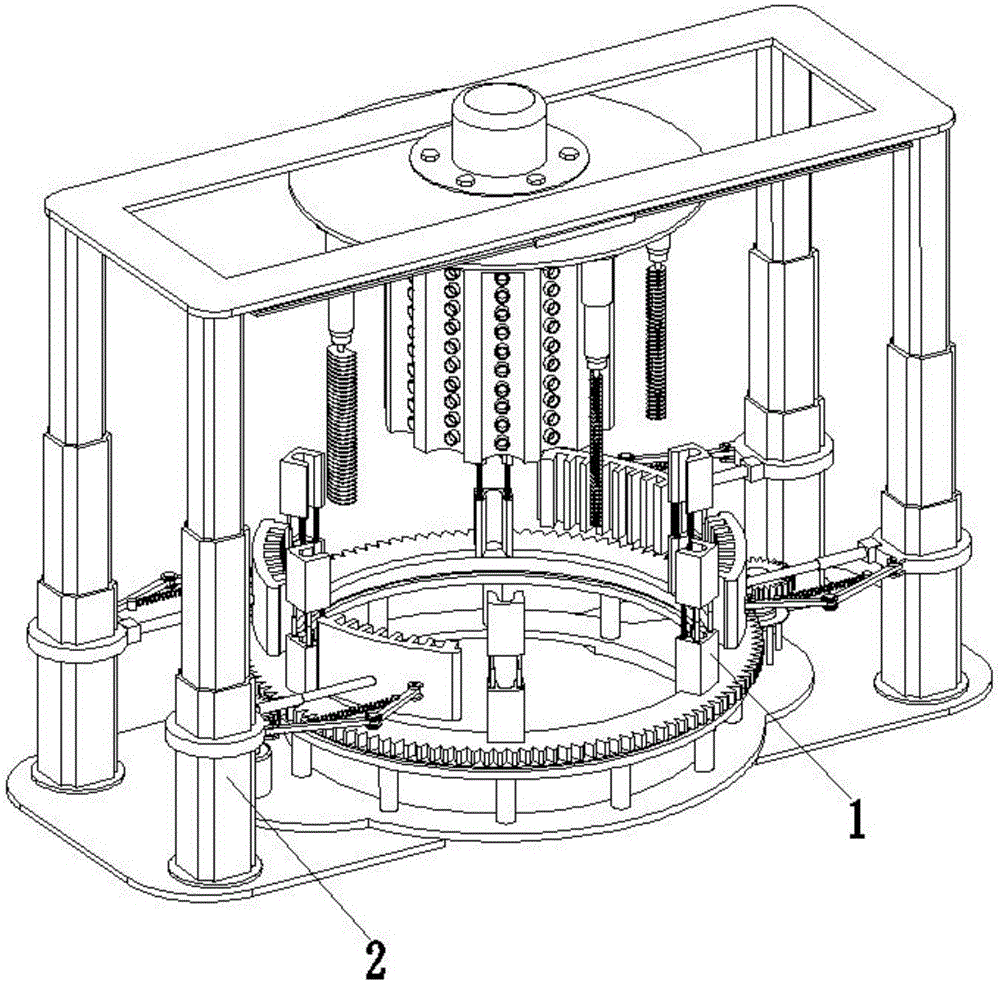

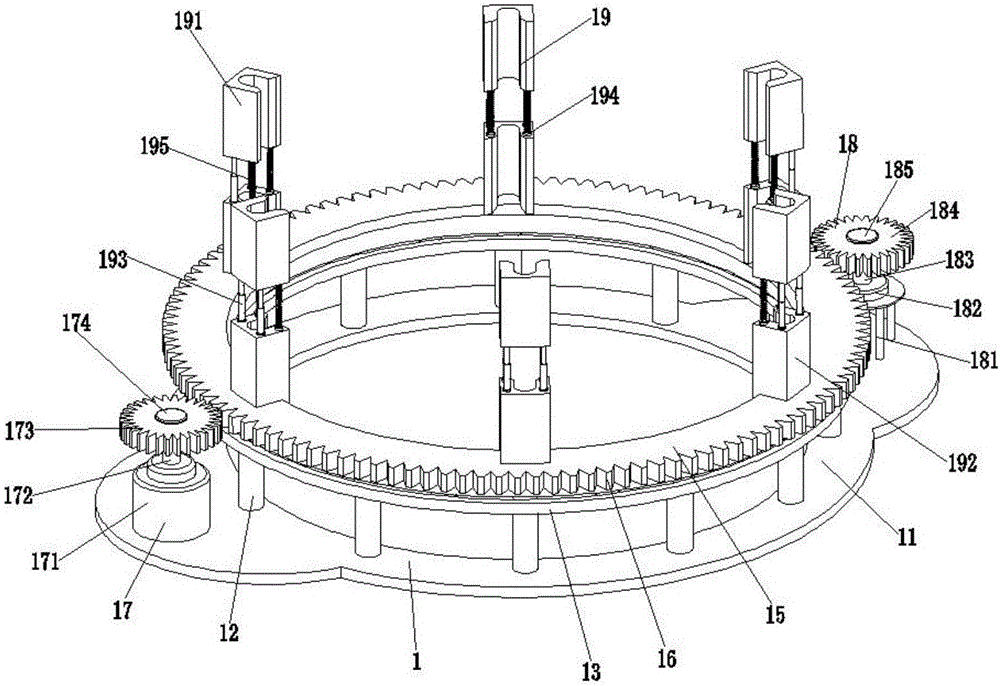

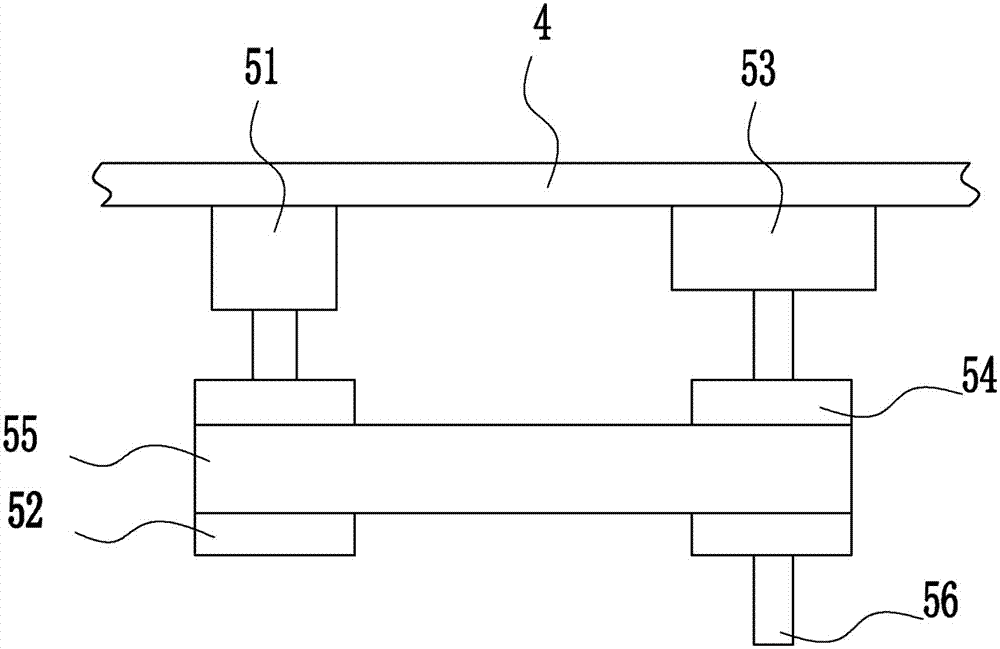

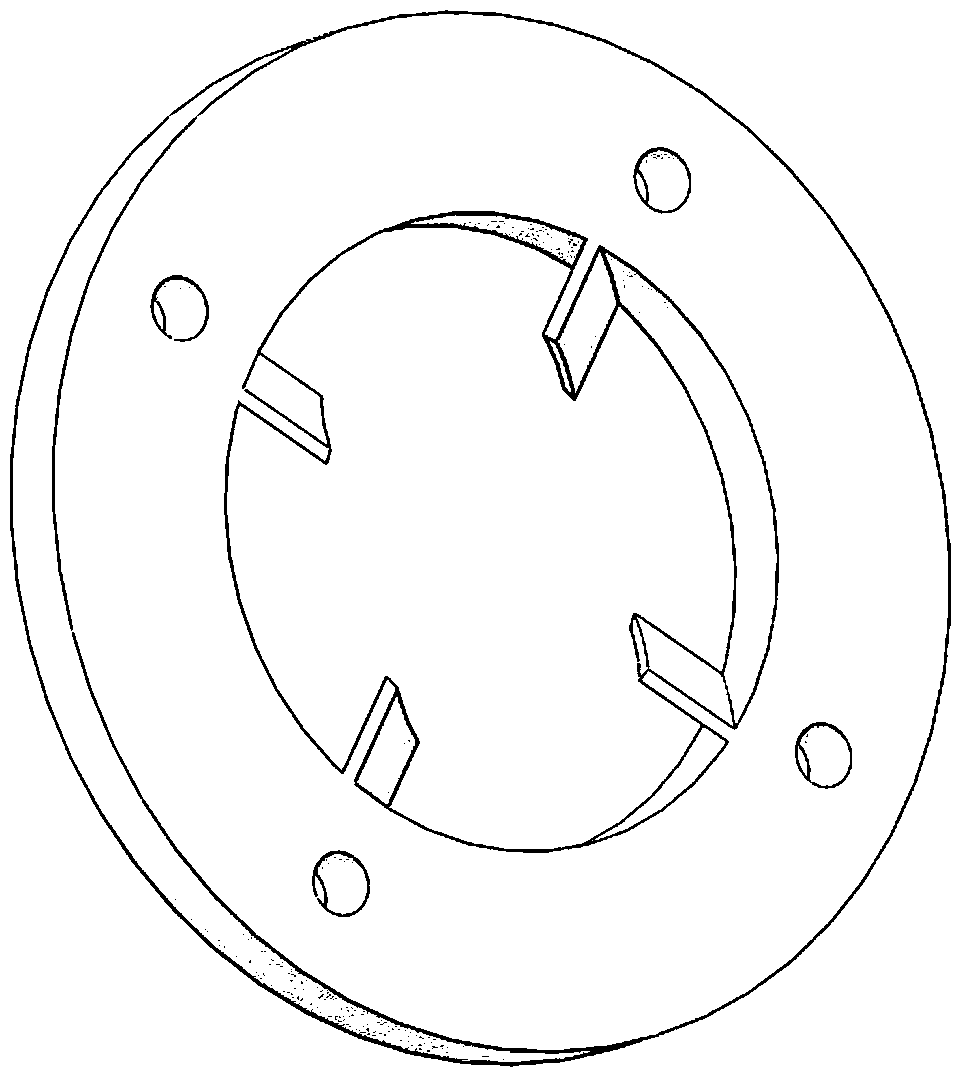

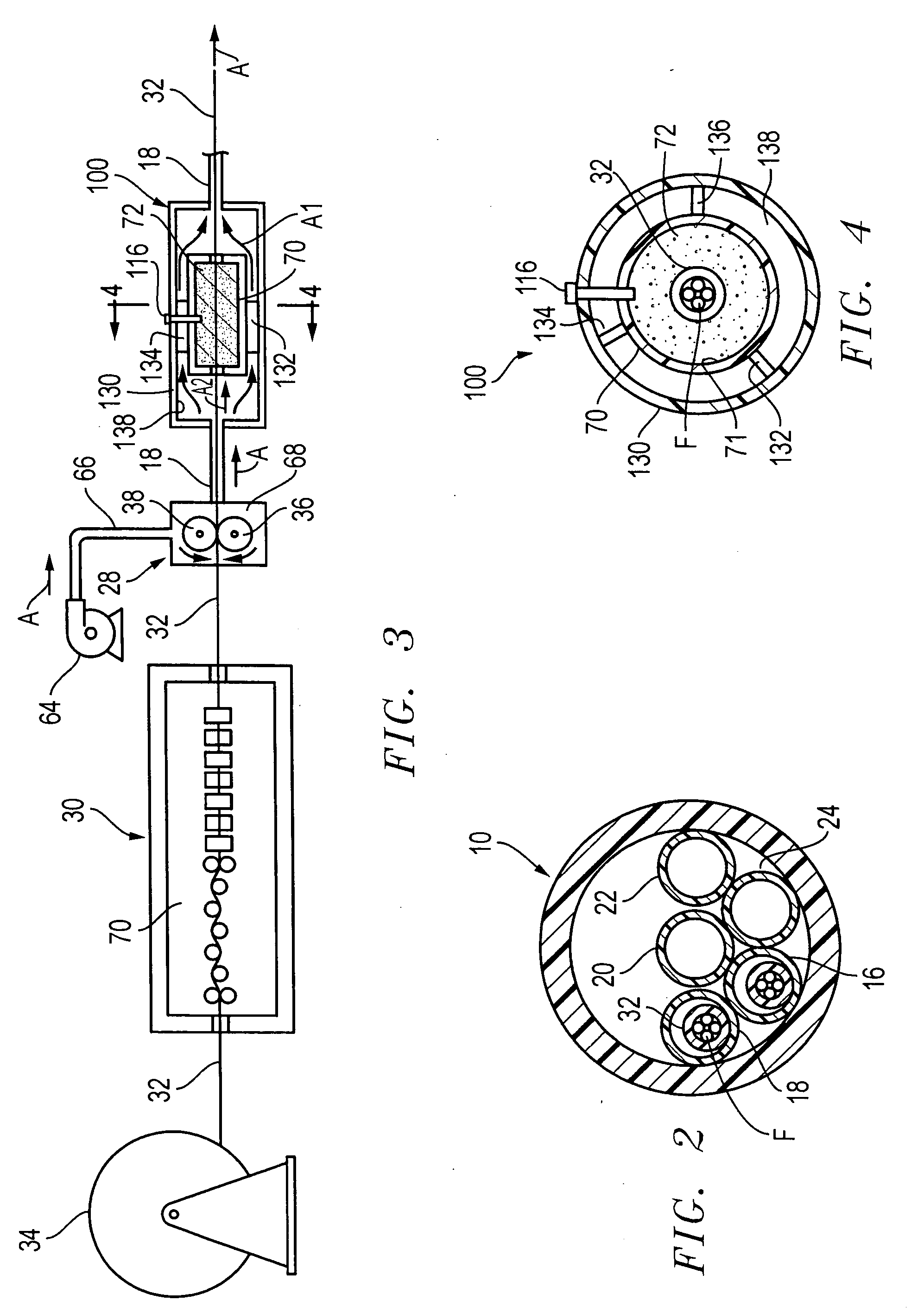

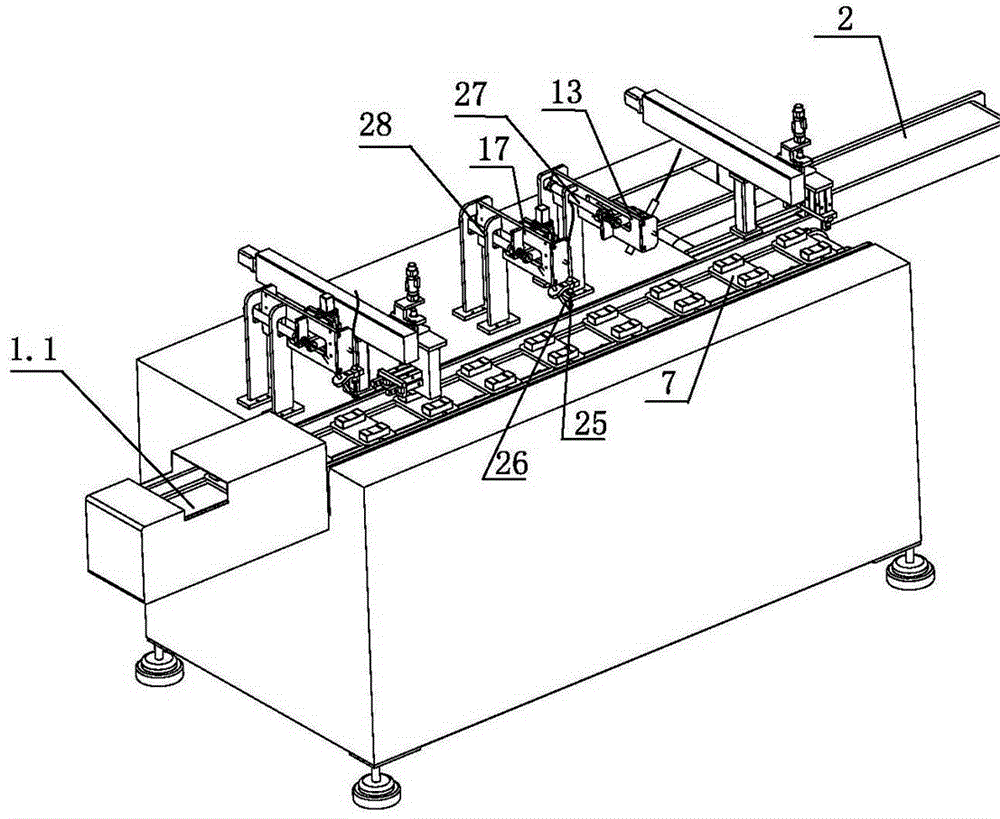

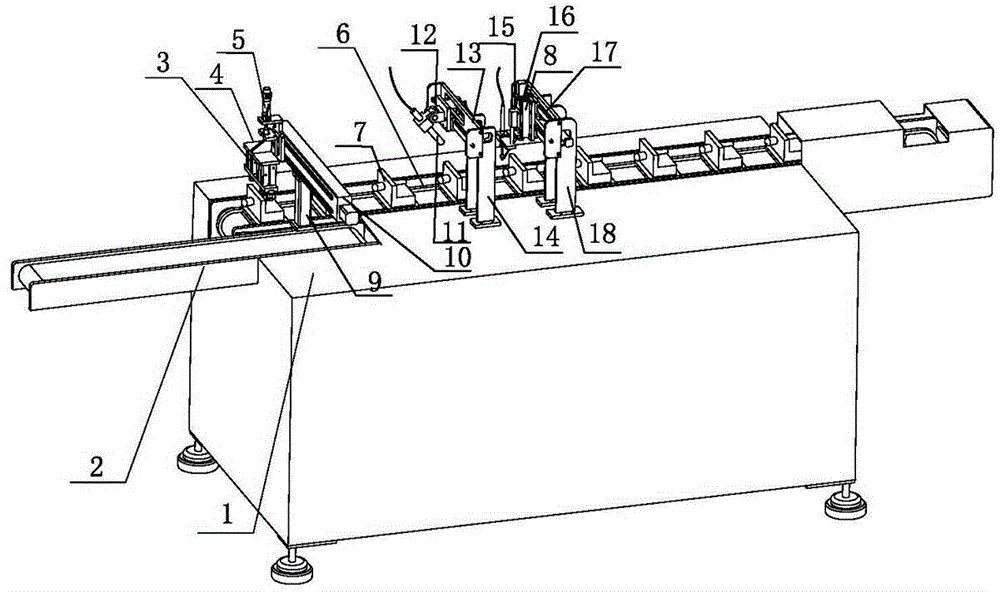

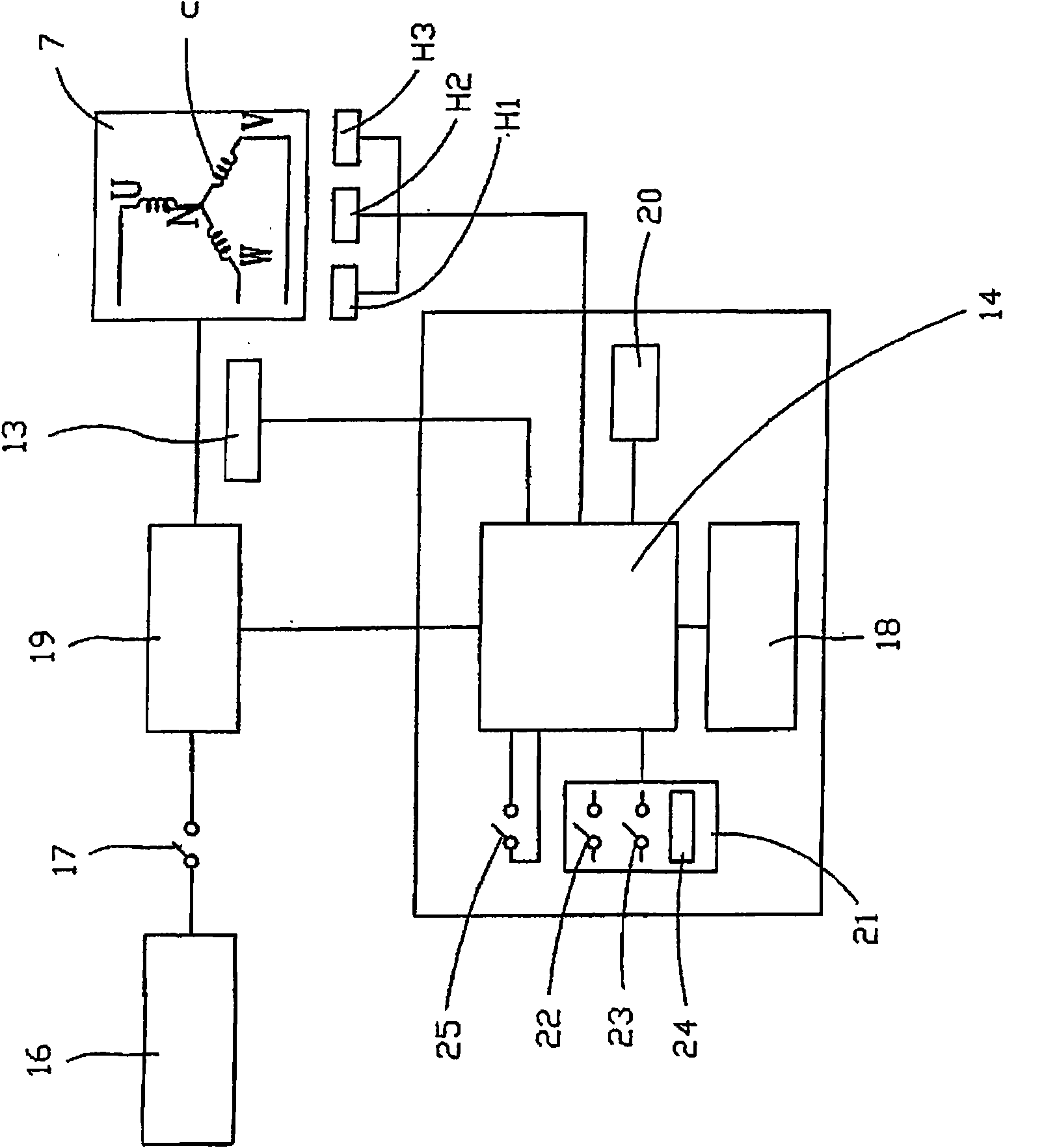

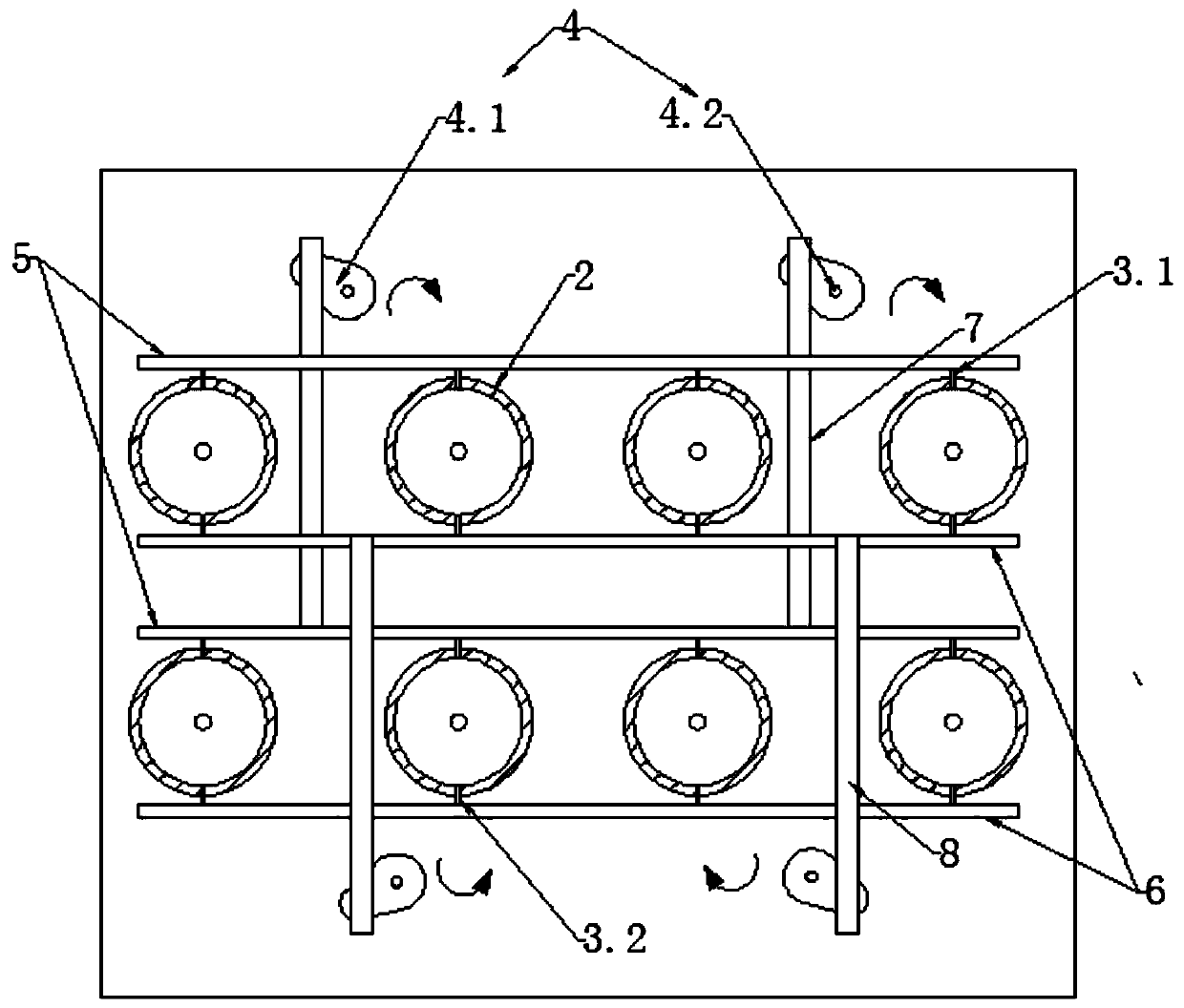

Full-automatic electromotor stator core cleaning equipment of power distribution station

ActiveCN106533080AAvoid misalignmentRealize the function of rotating position adjustmentManufacturing stator/rotor bodiesEngineeringAutomation

The invention relates to full-automatic electromotor stator core cleaning equipment of a power distribution station. The full-automatic electromotor stator core cleaning equipment comprises a fixing device and a cleaning device, wherein the fixing device is arranged at a position right below the middle part of the cleaning device. By the full-automatic electromotor stator core cleaning equipment, an electromotor stator core of the power distribution station can be fixed and cleaned, the full-automatic electromotor stator core cleaning equipment is convenient and rapid to fix and has the advantages of high firmness, cleaning thoroughness, high cleanness and high integral mechanism automation, the labor is greatly saved, and the electromotor production efficiency of the power distribution station is improved.

Owner:江苏华洋电力机械制造有限公司

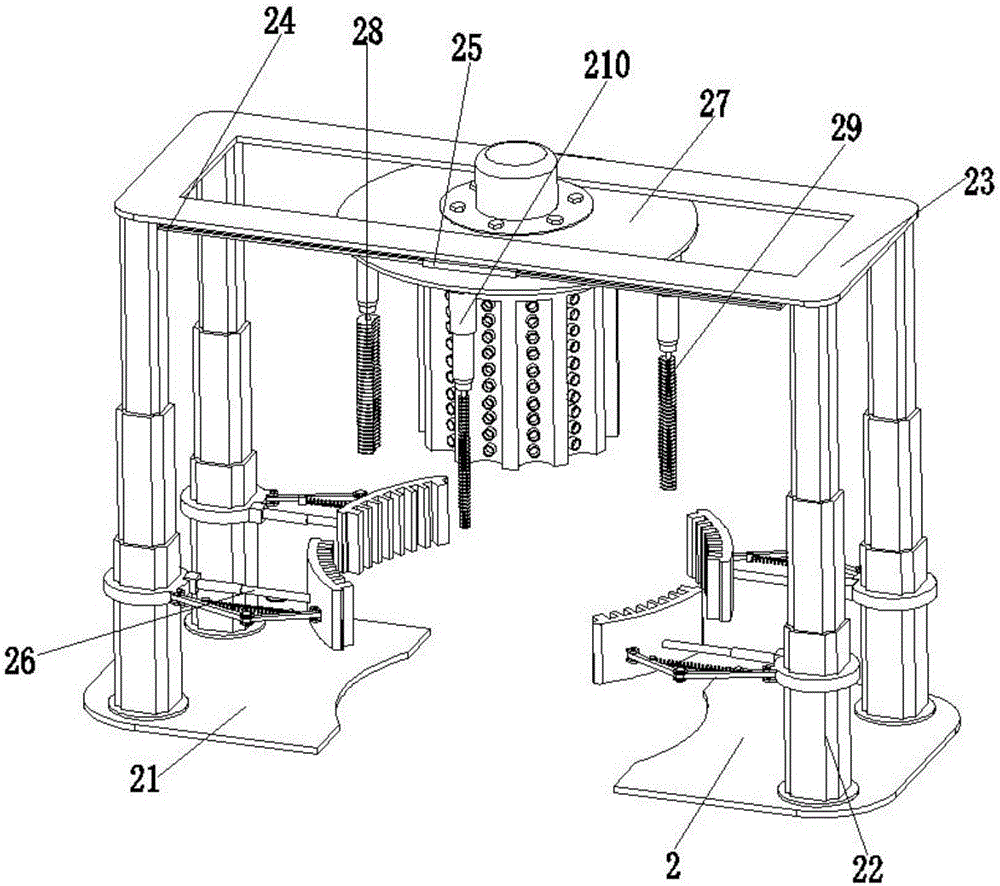

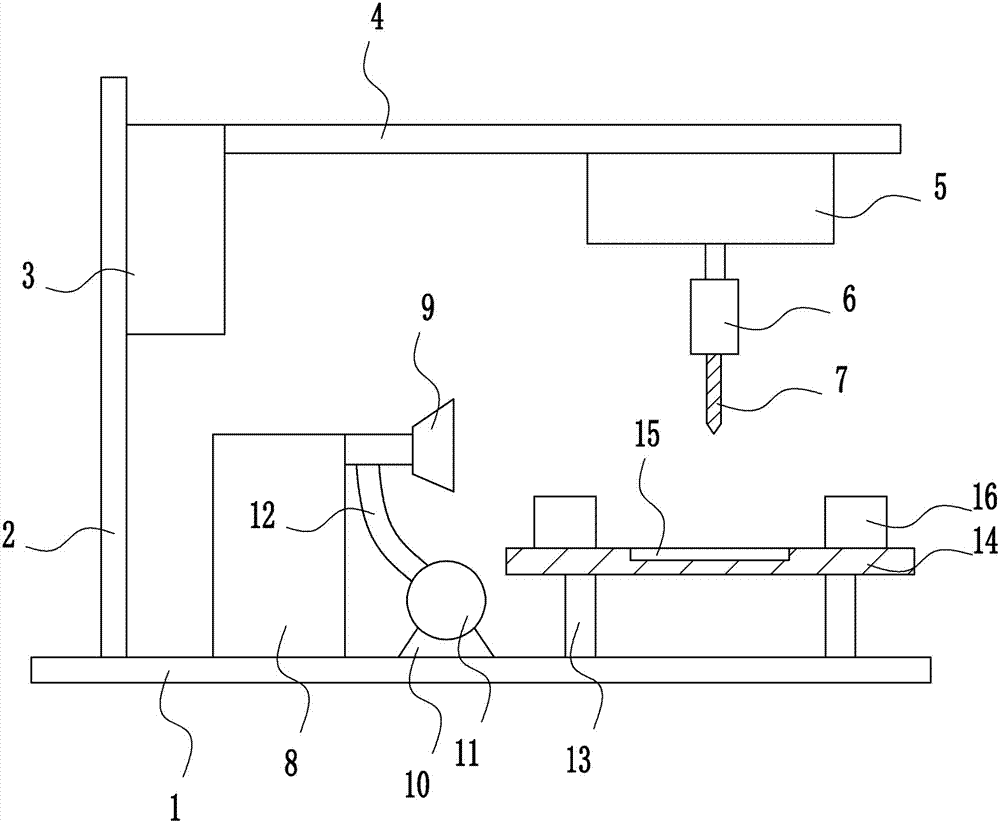

Plate-shaped part drilling equipment for hardware tool machining

ActiveCN107297522ATo achieve the effect of drillingThe effect of drilling is simpleFeeding apparatusDriving apparatusHardware toolMachining

The invention relates to drilling equipment, in particular to plate-shaped part drilling equipment for hardware tool machining. The plate-shaped part drilling equipment for hardware tool machining is simple in operation and capable of easily adjusting drilling positions. In order to achieve the technical purposes, the plate-shaped part drilling equipment for the hardware tool machining comprises a bottom plate, a left frame, a lifting device, a first mounting plate, a rotating device, a knife sleeve, a drill bit, a swinging device, a sprayer, a first mounting base, an air pump, a pipeline and the like; the left frame is welded to the left end of the top of the bottom plate, the lifting device is welded to the upper side of the right end of the left frame, and the first mounting plate is welded to the upper side of the right end of the lifting device. Hardware tools are fixed through a fixing device, the lifting device is controlled to work to drive the drill bit at the bottom of the rotating device to move to the drilling positions, and the drill bit works by controlling the rotating device.

Owner:江苏刘一刀精密机械有限公司

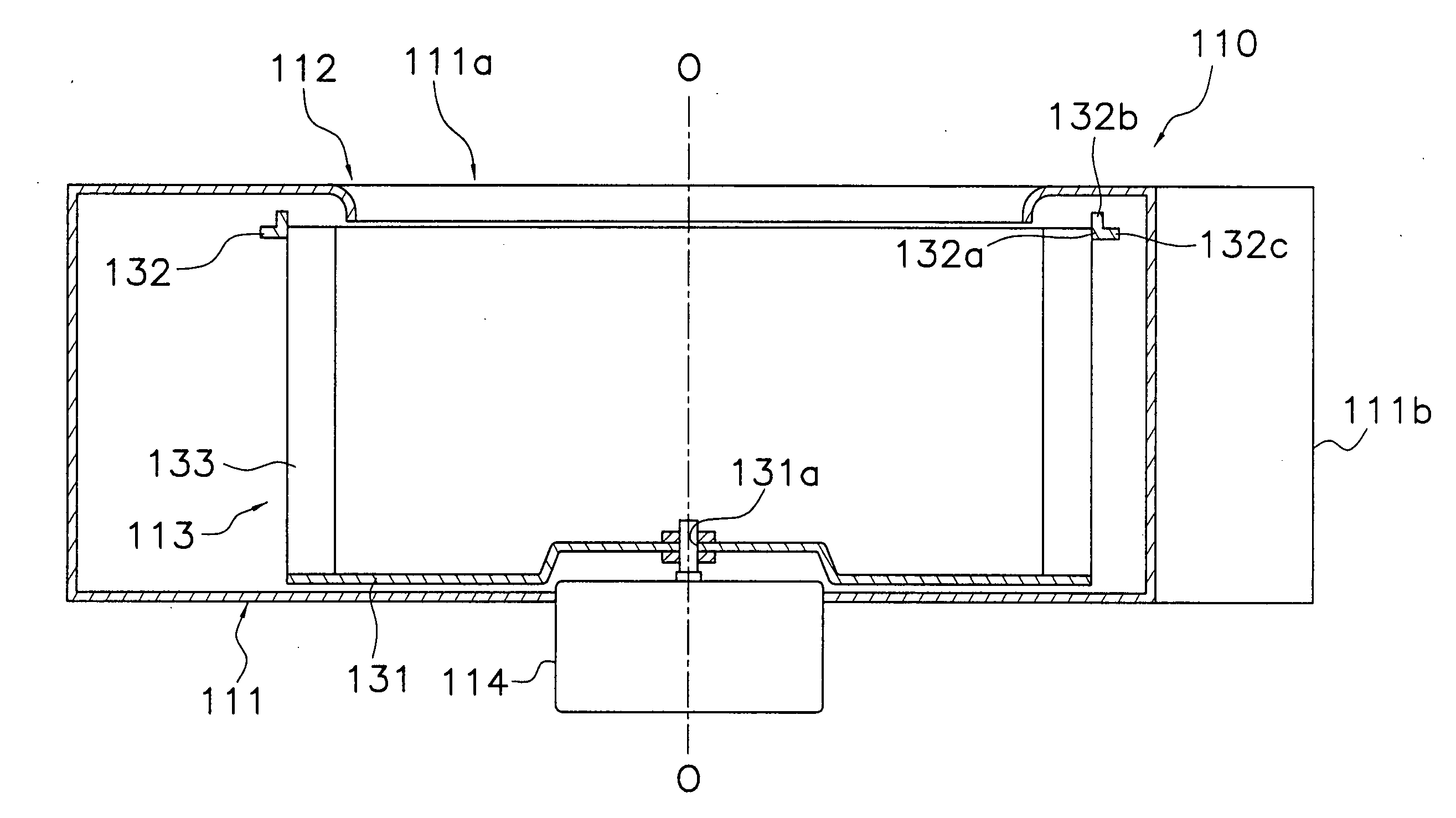

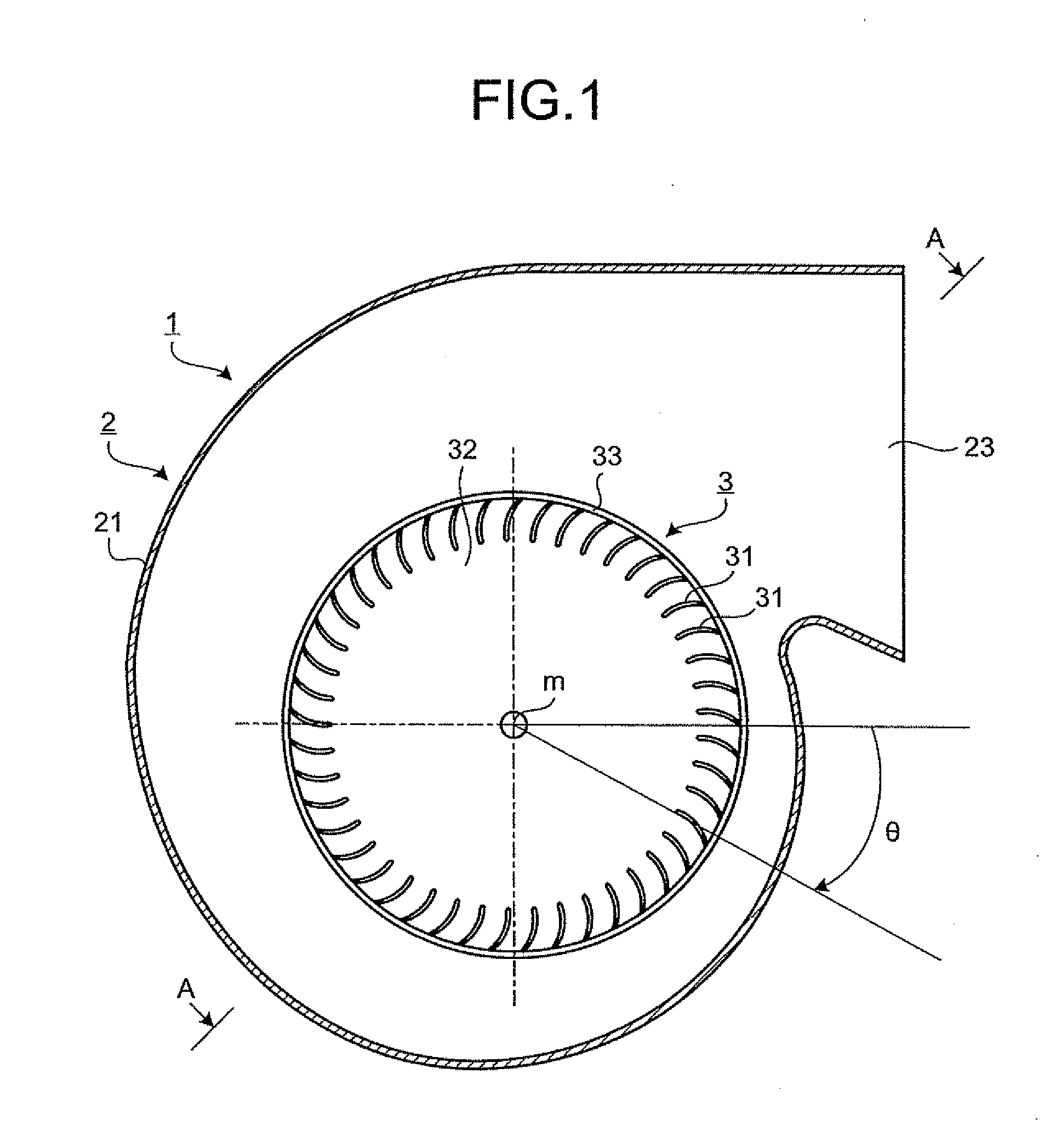

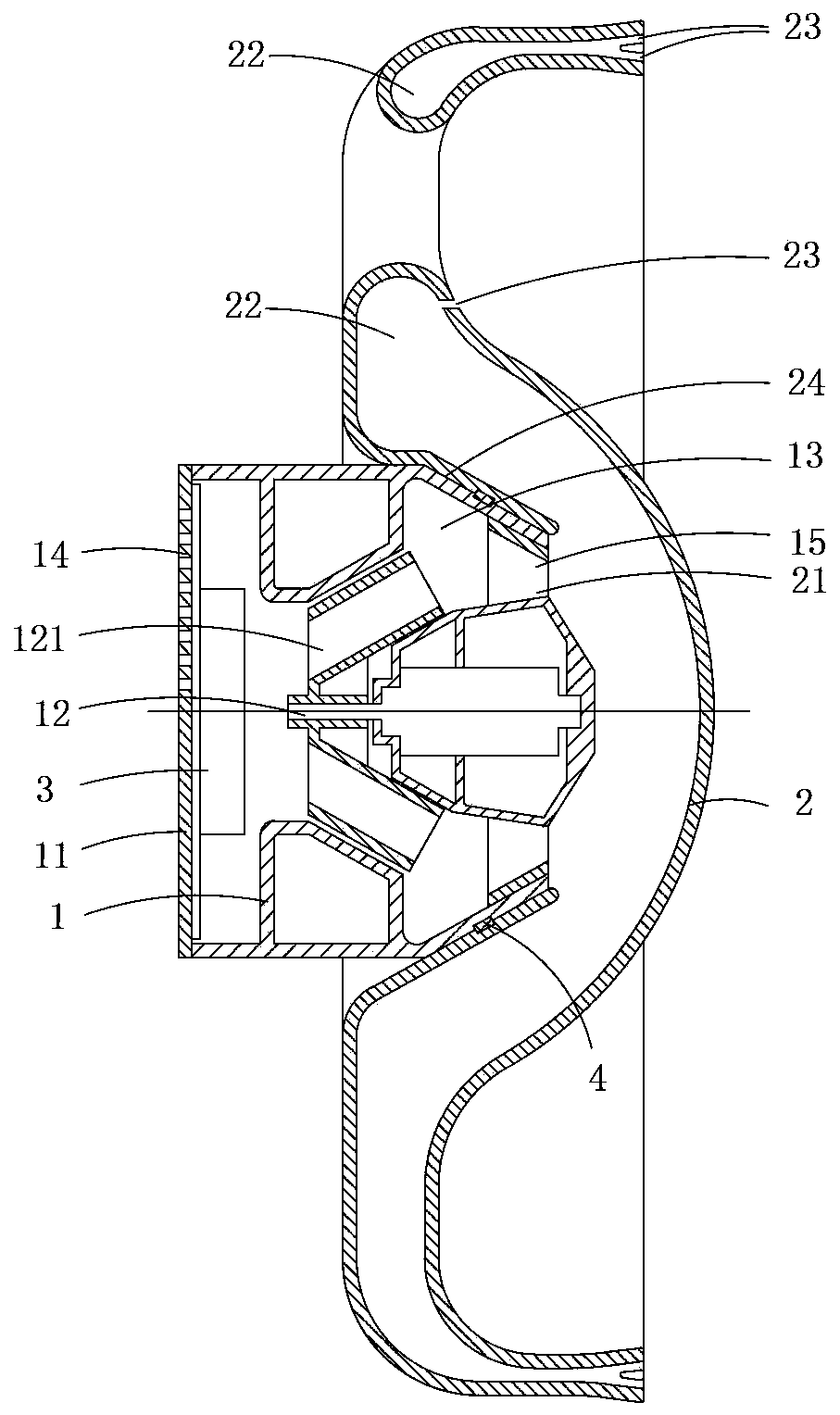

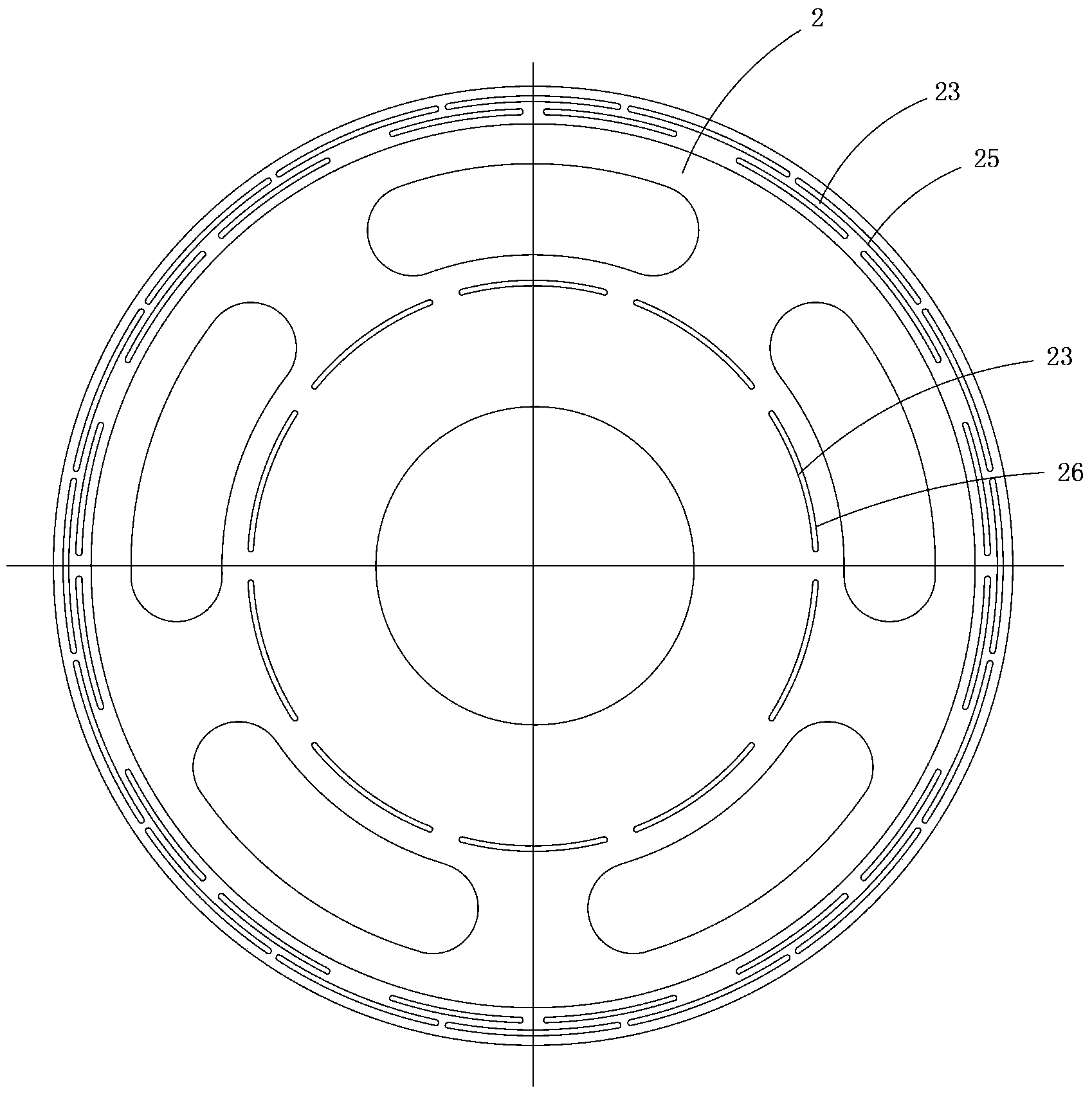

Impeller Of Multiblade Fan And Multiblade Fan Having The Same

To provide an impeller of a multiblade fan capable of reducing noise and improving blowing performance and a multiblade fan having the same. An impeller (113) of a multiblade fan (110) includes a discoid main plate (131) that rotates about a rotational axis, plural blades (133), and a side plate (132). The plural blades (133) are disposed annularly about the rotational axis on one side of the main plate (131), with one end of each of the blades being fixed to an outer peripheral portion of the main plate (131). The side plate (132) includes an annular side plate body portion (132a) that joins outer peripheral edges of the other ends of the plural blades (133) to each other, an axially extending portion (132b) that extends from the opposite-main plate side end of the side plate body portion (132a) further toward the opposite-main plate side in the rotational axis direction than the opposite-main plate side ends of the blades (133), and a radially extending portion (132c) that extends from the outer peripheral end of the side plate body portion (132a) further toward the outer peripheral side than the radial-direction outer peripheral end of the axially extending portion (132b).

Owner:DAIKIN IND LTD

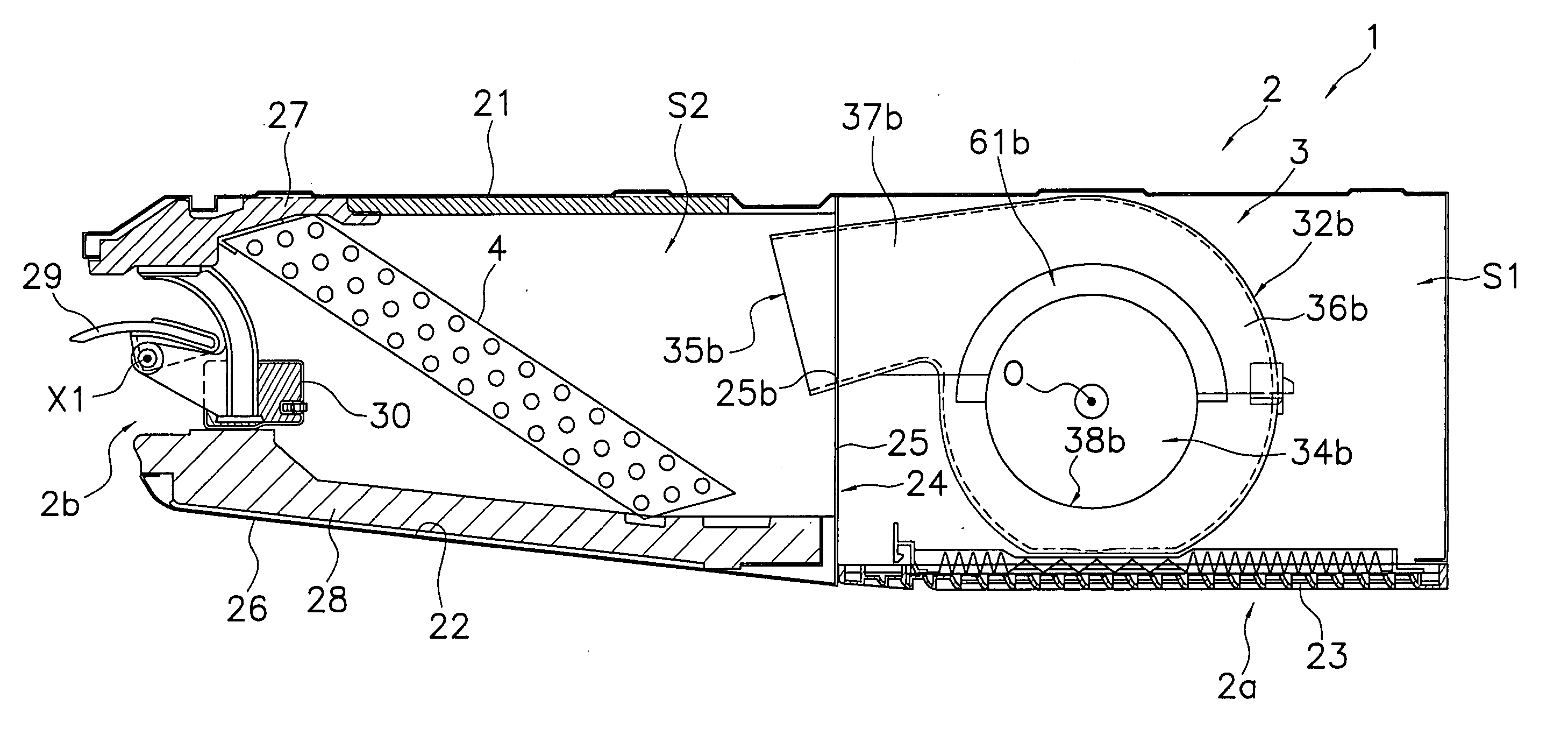

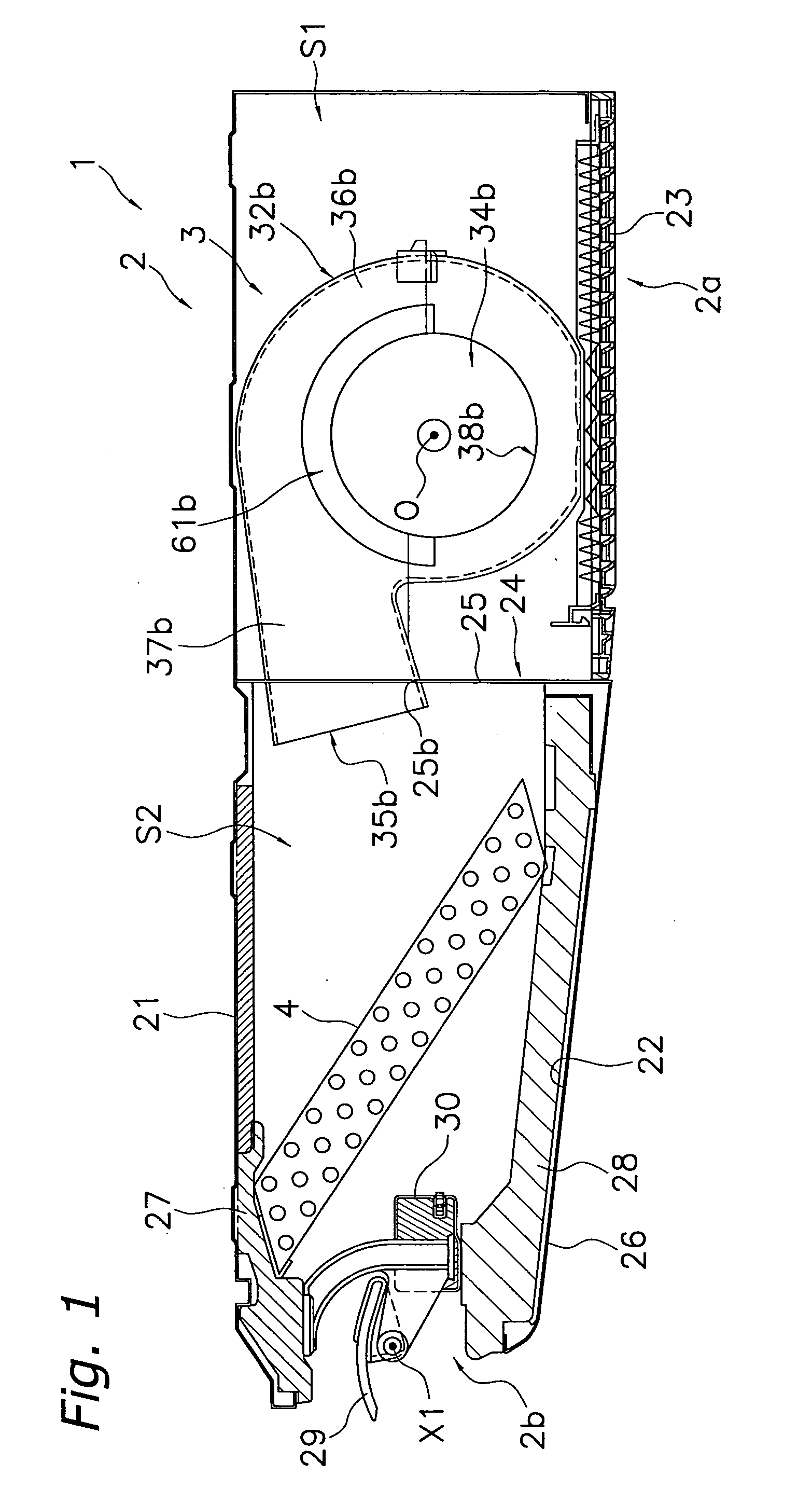

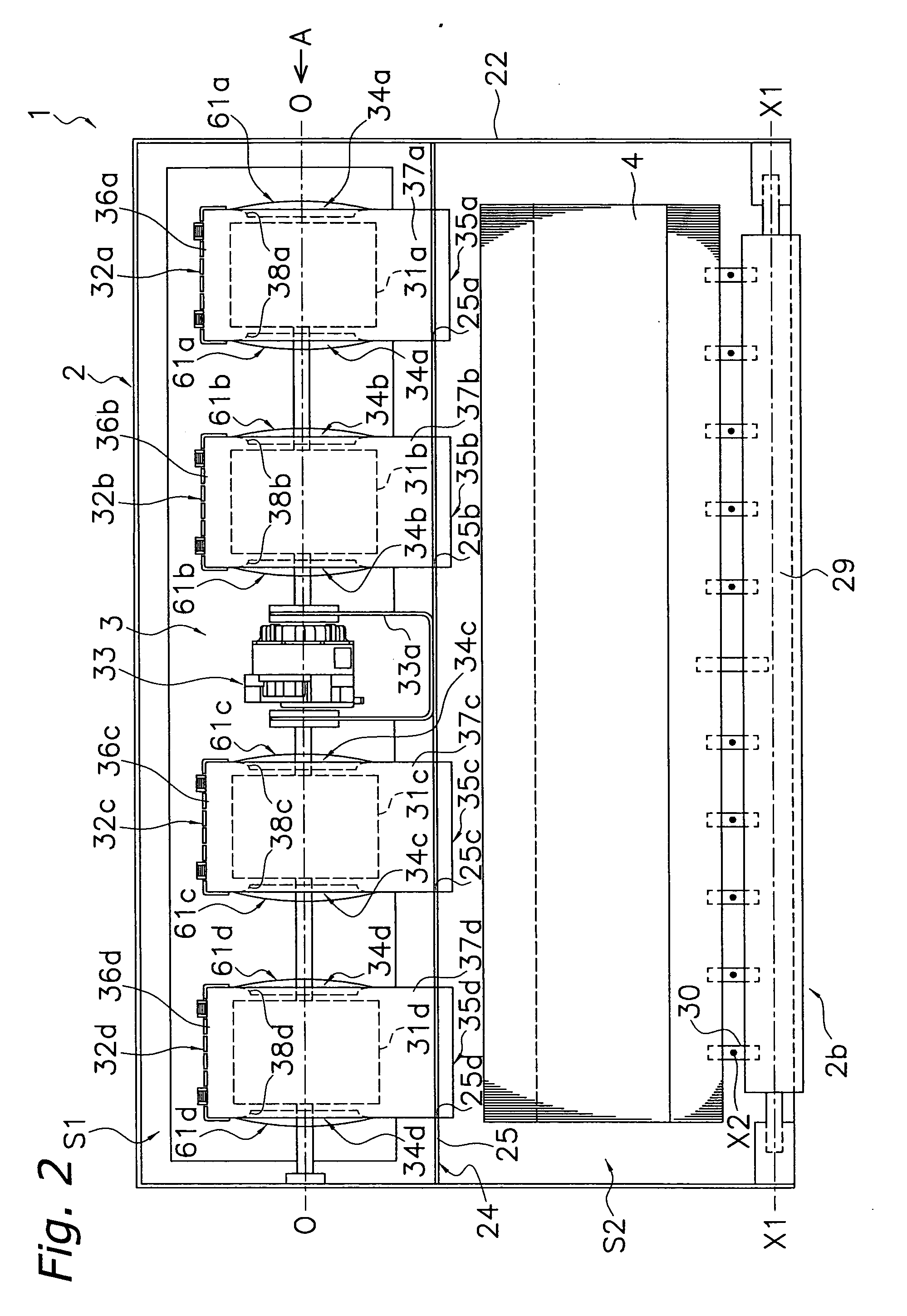

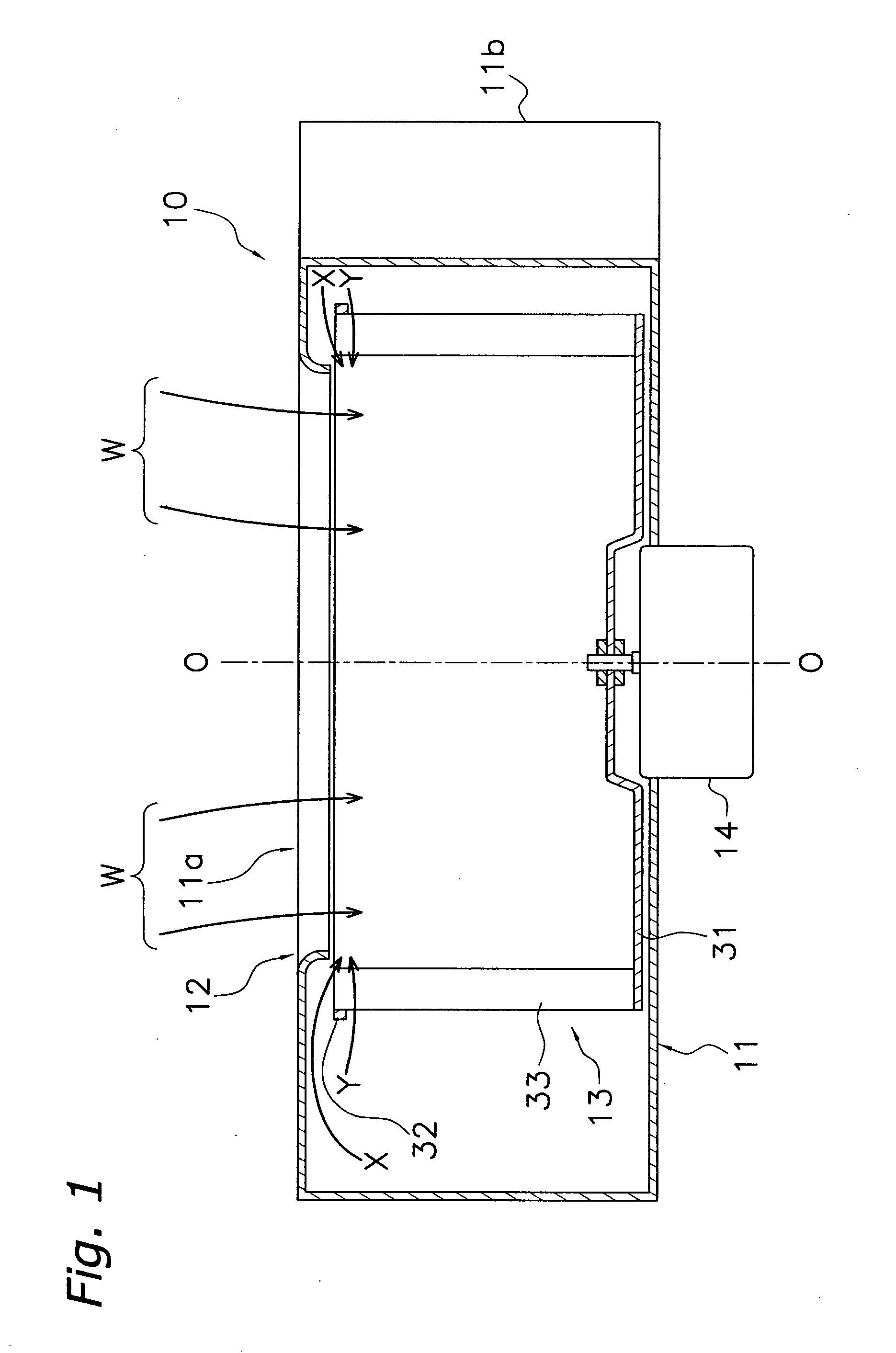

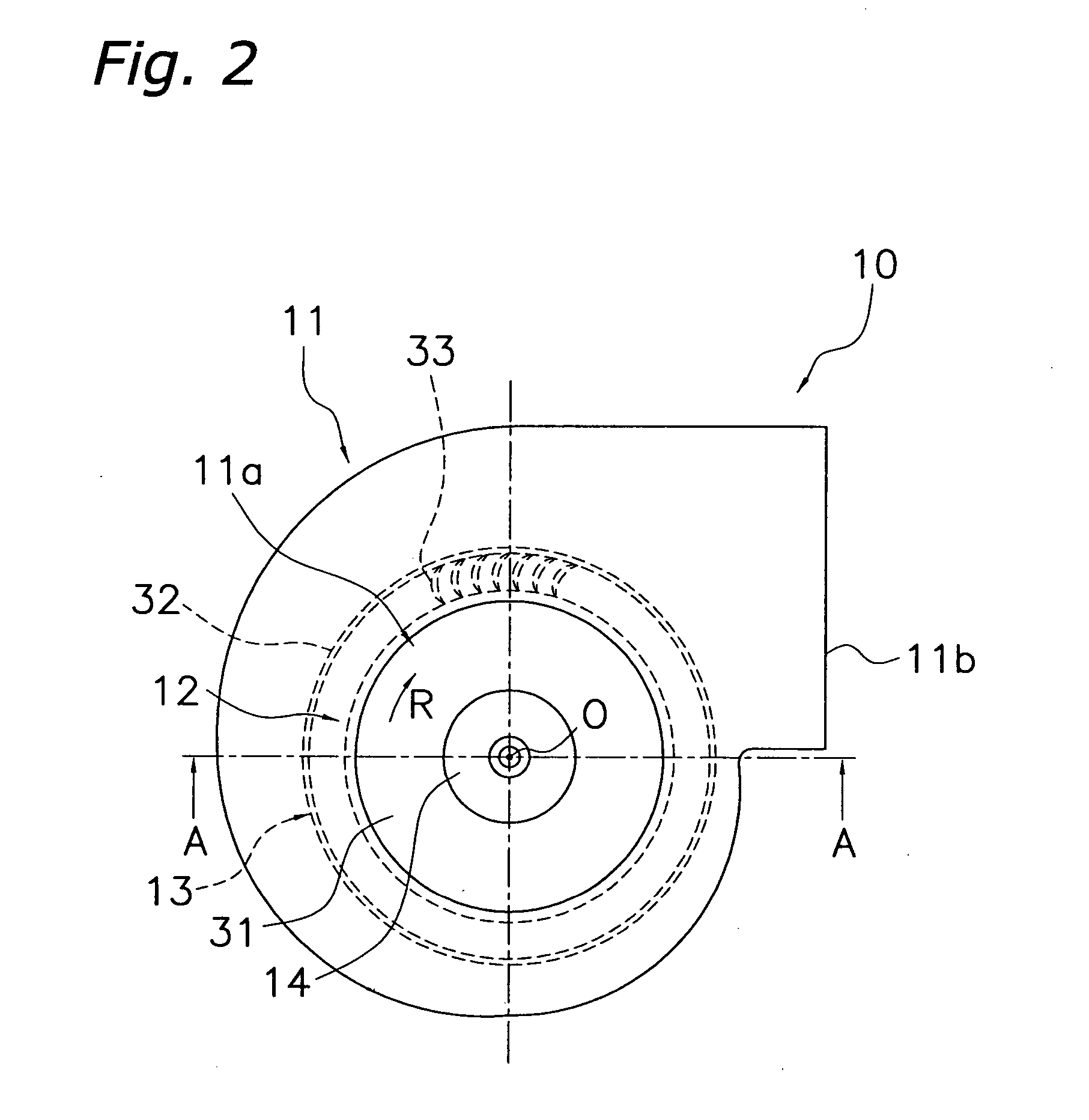

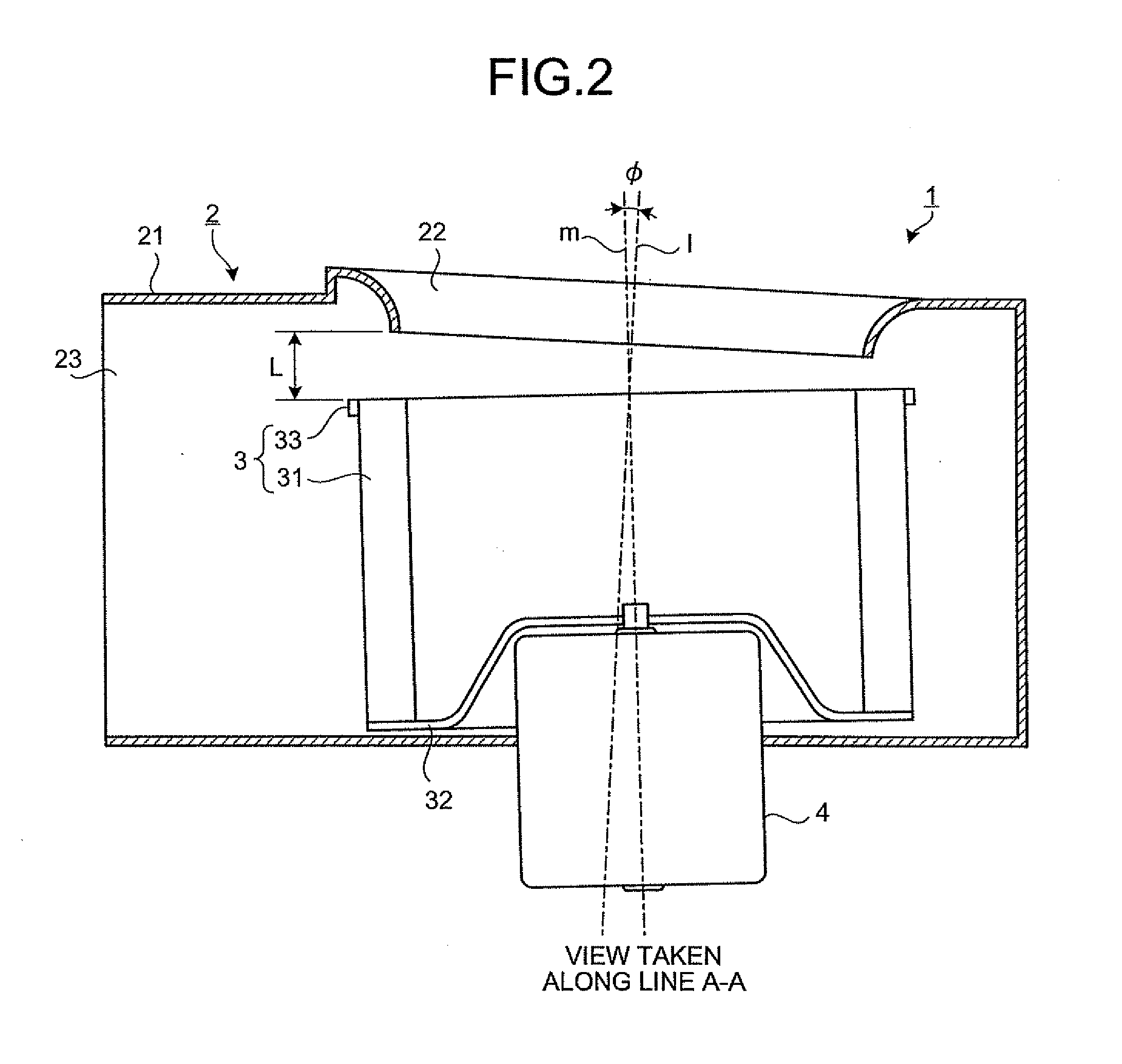

Multiblade fan

InactiveUS20120009059A1Blow performance be advantageously improveNoise characteristicEngine manufactureCircumferential flow pumpsImpellerBell mouth

To provide a multiblade fan that enables an improvement in noise characteristics or blowing performance. The multiblade fan includes a scroll type casing that has a bell-mouthed inlet and an impeller housed in the casing. The impeller includes a plurality of blades and a rotation axis m oriented toward the inlet of the casing. The blades are annularly arranged. In the multiblade fan, a center axis of the inlet and the rotation axis of the impeller are arranged at a tilt angle to each other and in any one of an intersecting positional relationship and a skew-lines positional relationship so that a space between the inlet and the impeller increases from the rotation axis of the impeller toward an outlet of the casing.

Owner:MITSUBISHI ELECTRIC CORP

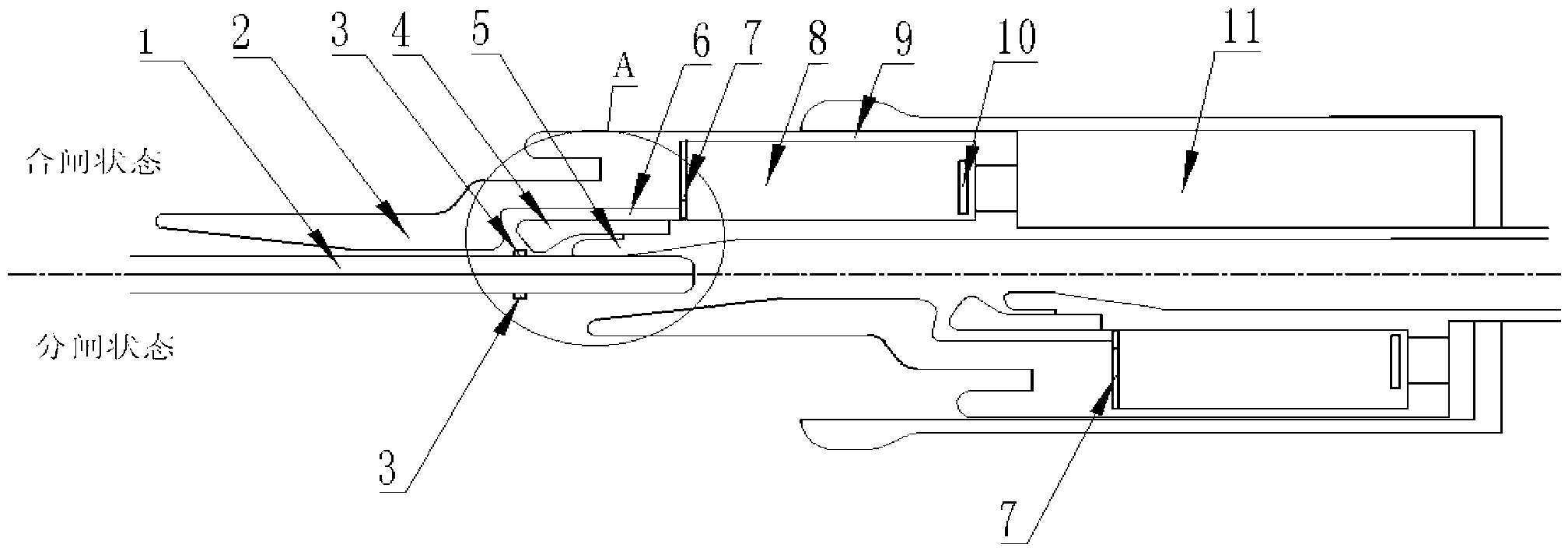

High-voltage gas circuit breaker

ActiveCN102938349AImprove the blocking effectImprove pressure building efficiencyHigh-tension/heavy-dress switchesAir-break switchesMixed effectsHigh pressure

The invention relates to a high-voltage circuit breaker with a blocking ring contact and a vortex generator and belongs to the field of high-voltage electrical technology. The high-voltage circuit breaker comprises a static arc contact, a main spraying nozzle, an auxiliary spraying nozzle, a dynamic arc contact, a blocking ring, the vortex generator and a piston, wherein the main spraying nozzle, the auxiliary spraying nozzle, the dynamic arc contact and the vortex generator are respectively and fixedly connected with the piston to form an arc extinguishing chamber moving part which rightly faces to the static arc contact. The breaking of the arc extinguishing chamber moving part is achieved by means of the driving of a circuit breaker mechanism. A heating channel is formed between the main spraying nozzle and the auxiliary spraying nozzle. According to the high-voltage circuit breaker, the blocking ring contact is used for strengthening air blocking effect between the static arc contact and the main spraying nozzle during arcing, the vortex generator is used for generating swirling airflow to improve mixed effect of the airflow in an expansion chamber, and accordingly, breaking capability of the self-energy circuit breaker is improved.

Owner:SHANGHAI SIEYUAN HIGH VOLTAGE SWITCHGEAR

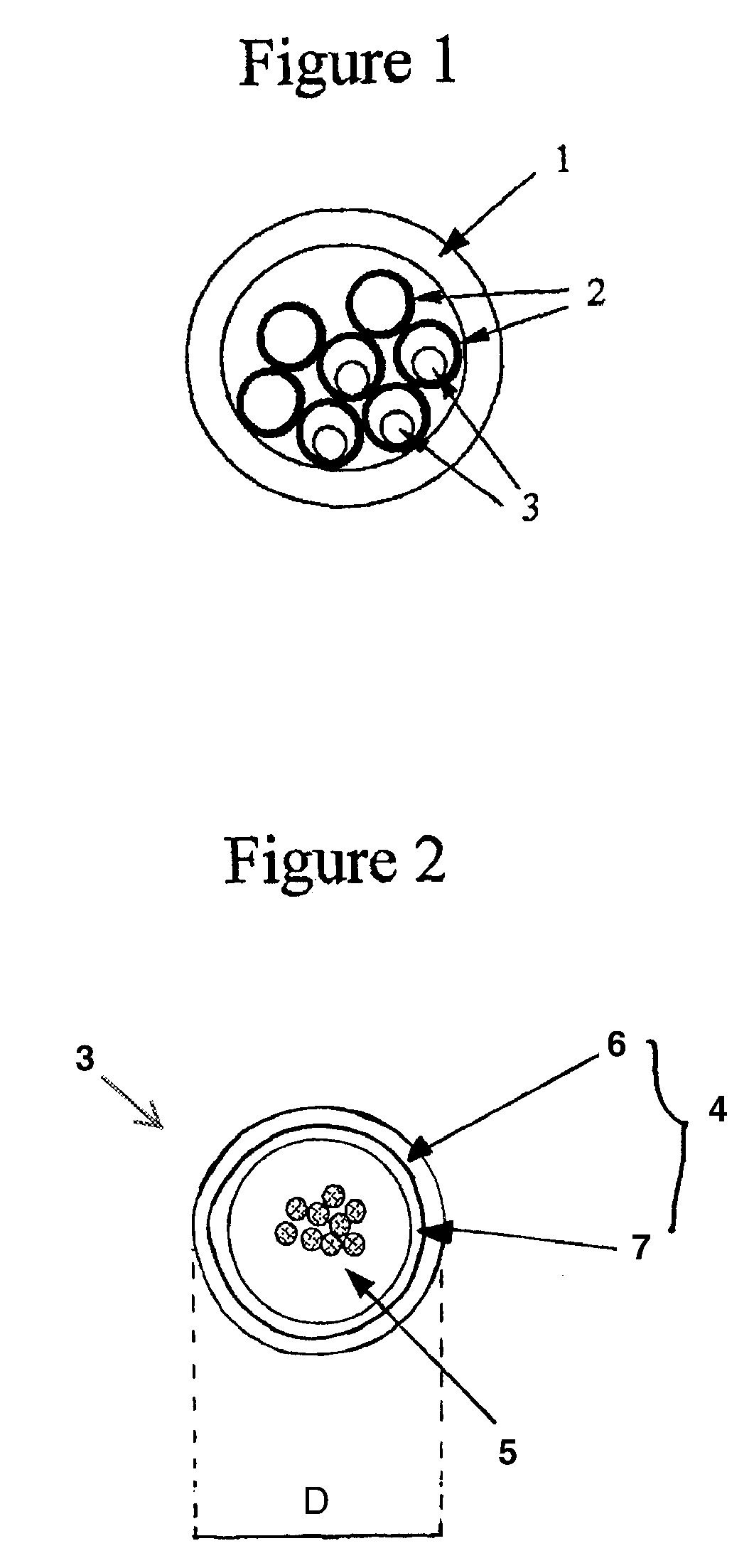

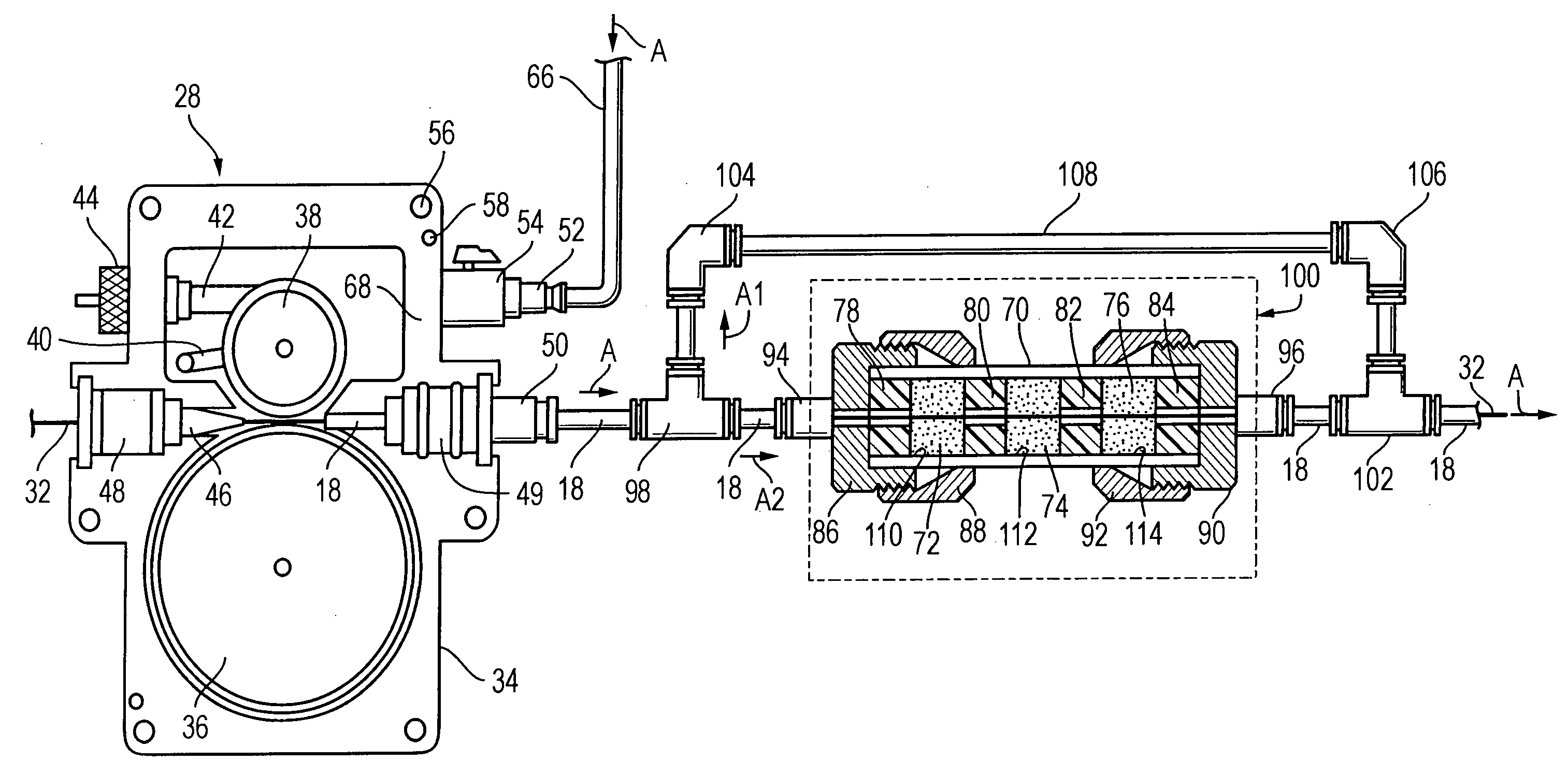

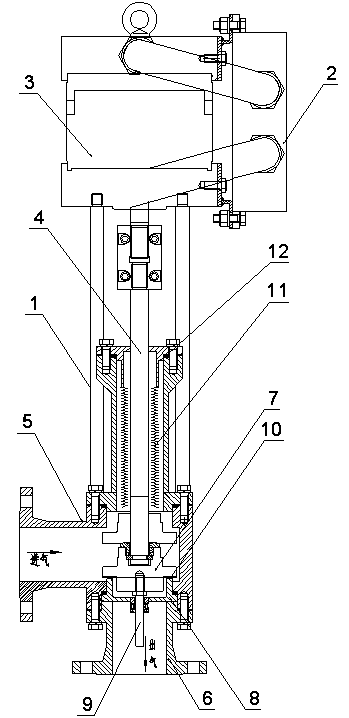

Optical cable lubricator with reservoir

InactiveUS20060102430A1Improve performanceImprove blowing effectLubricating pumpsCable installation apparatusGuide tubeLubricant

A cable is installed in a duct by means of blowing (and, optionally, synergetic pushing) and lubricating the cable during field installation. Lubricating the cable is done after the cable exits from the cable blowing equipment and hence takes place in a pressurized airflow passage. Lubricant supplied from an external reservoir drains into a pressurized lubricator space through which the cable moves. Foam-plugs seal the entrance and the exit of the lubricator space. The cable is wetted by the lubricant as it moves through the lubricator space, and excess lubricant is wiped by the foam plug, leaving only a thin film of lubricant on the cable as it moves out of the lubricator. In one embodiment, the lubricator is fitted with a single wiping member in the form of an annular plug of open cell foam material, and the cable passes through laterally opposite sections of the annular plug. The lubricator housing is formed in mating sections, and the internal lubricator is also formed in mating sections. The lubricator is integrated with cable blowing equipment in one embodiment. A bundle of guide tubes is lubricated in another embodiment.

Owner:DRAKA COMTEQ BV

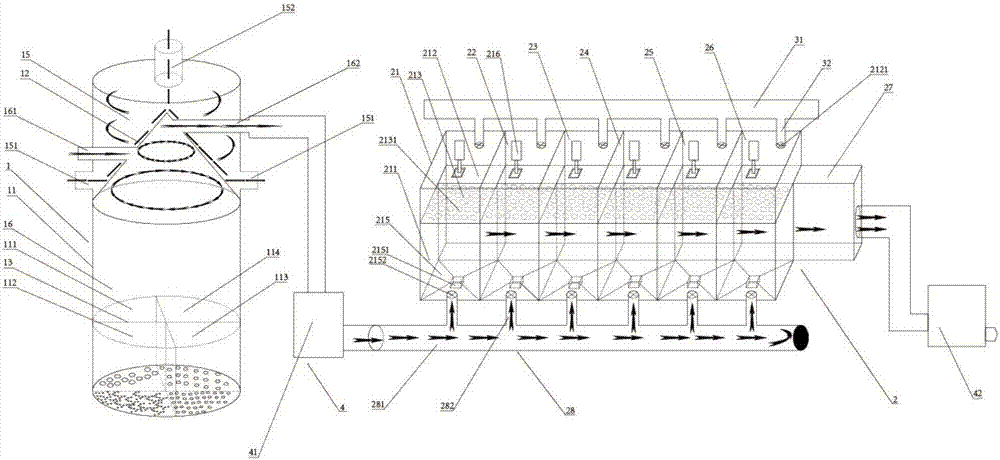

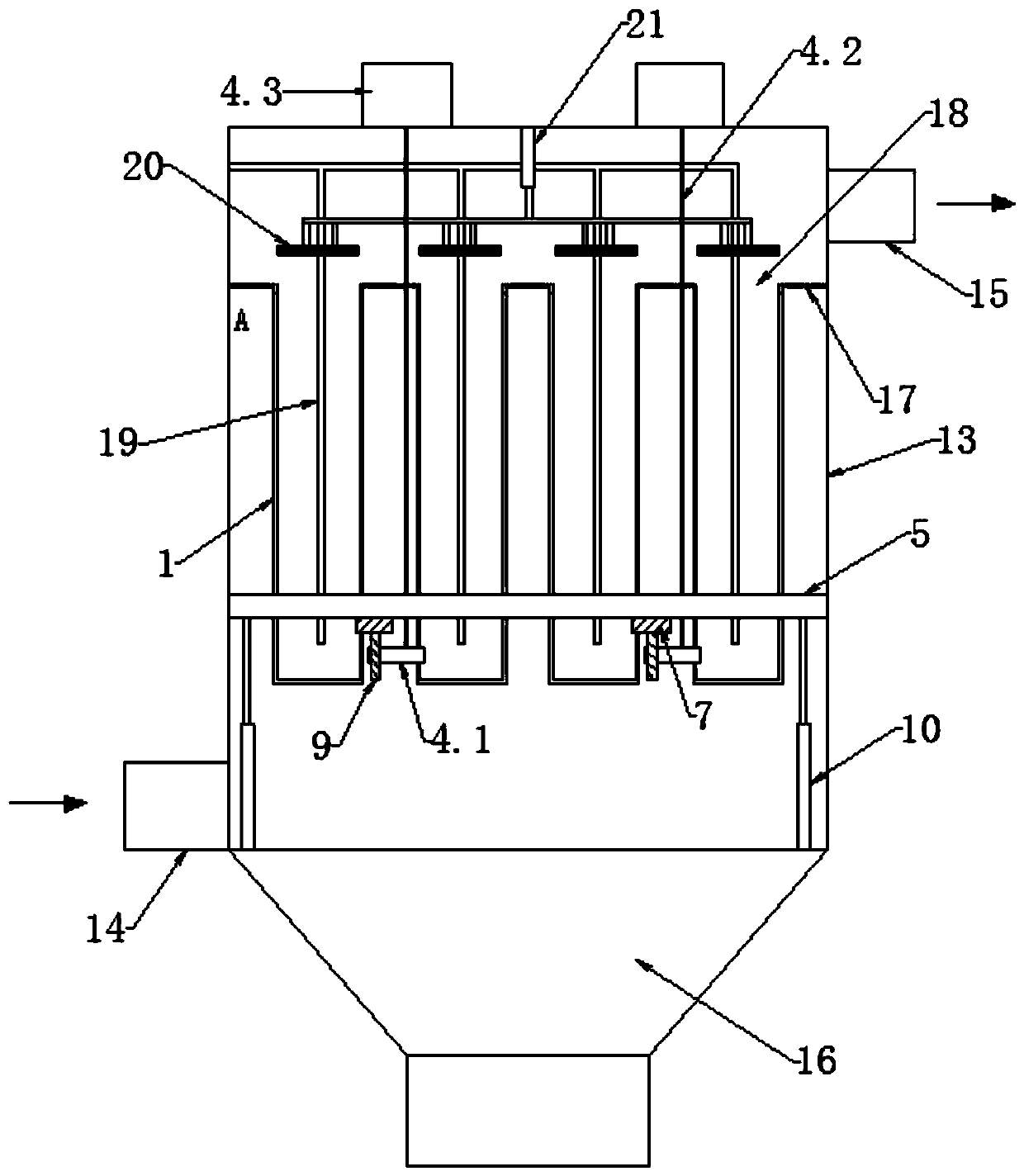

Pulsed type bag dedusting device

PendingCN107297107AImprove efficiency and effectivenessAchieving Recoil JitterDispersed particle filtrationTransportation and packagingEngineeringInlet channel

The invention discloses a pulsed type bag dedusting device which comprises a box combined type bag dust collector, a pulse airflow back-flushing cooling device and a second draught fan, wherein the pulse airflow back-flushing cooling device is arranged on the box combined type bag dust collector; the second draught fan is used for forming negative pressure suction in the pulse airflow back-flushing cooling device; the box combined type bag dust collector comprises at least two dedusting boxes, an exhausting channel, an air inlet channel and a dust collecting device; the dedusting boxes are successively arrayed from left to right; each dedusting box comprises a lower dust filtering chamber, an upper sealing air chamber, a sealing pattern plate, a cloth bag, a dust collecting hopper and a lifting valve device; the sealing pattern plate with a plurality of through holes is arranged between the lower dust filtering chamber and the upper sealing air chamber; the cloth bag is arranged on the position corresponding to the through holes on the sealing pattern plate; and an air inlet port of a second high temperature draught fan is communicated with an air outlet of the exhausting channel. The pulsed type bag dedusting device has the characteristics of reasonable structure design, complete function, high dedusting efficiency, safety, reliability, long service life and ultrahigh marketing value.

Owner:广东盛达穗南环保科技有限公司

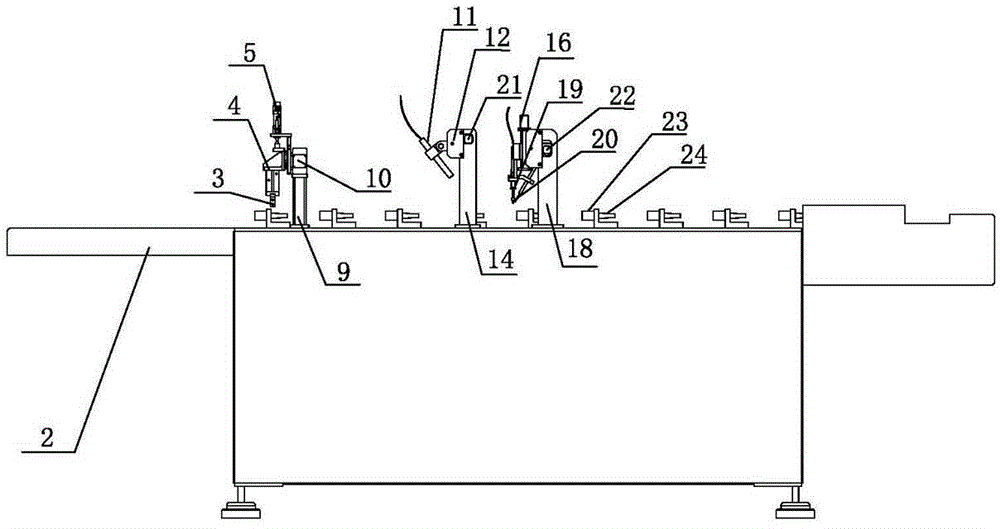

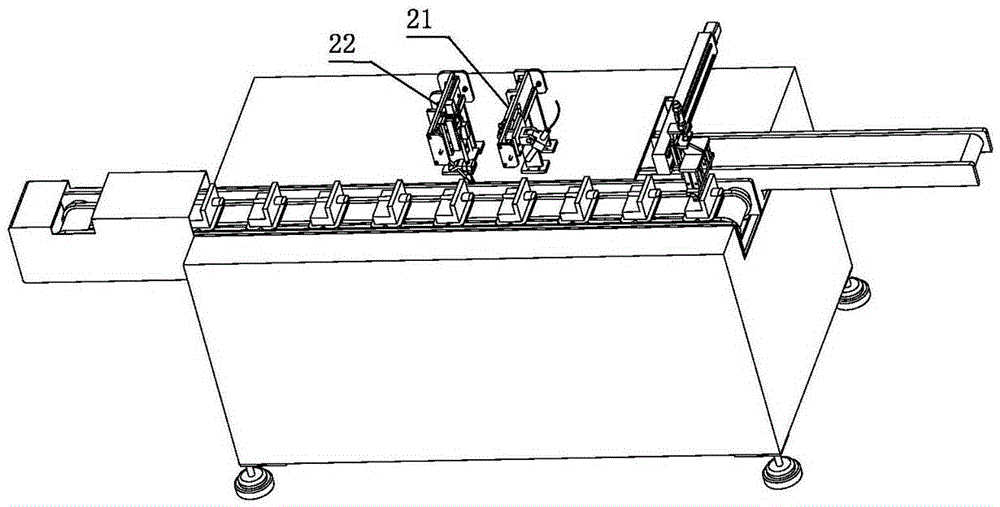

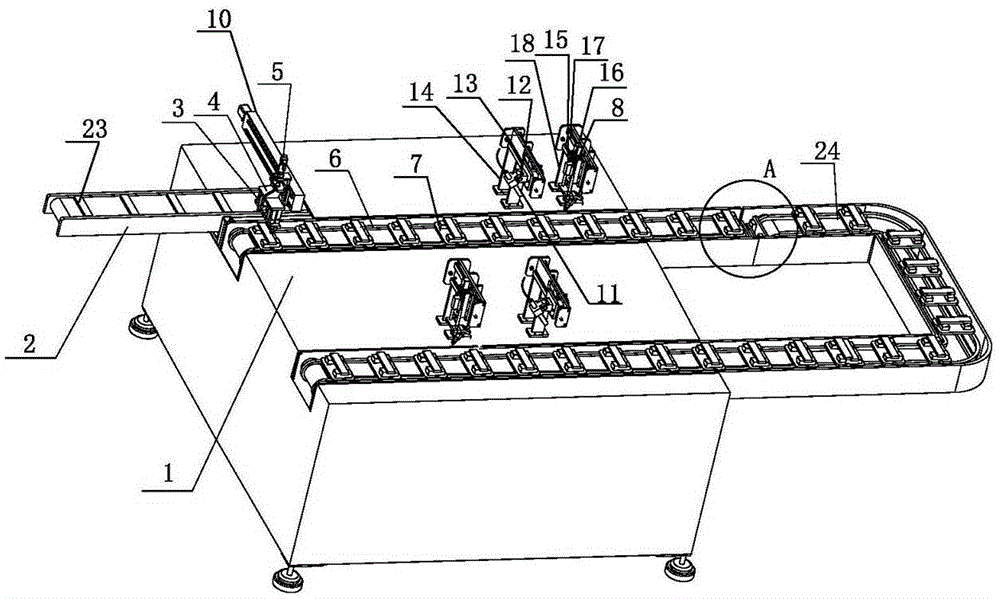

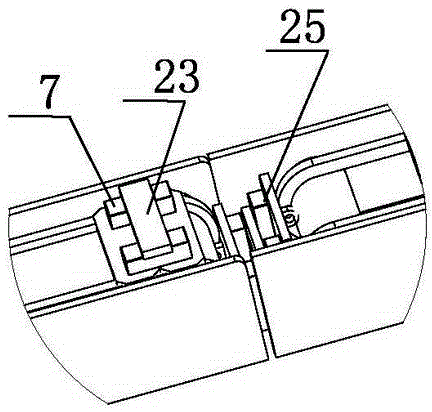

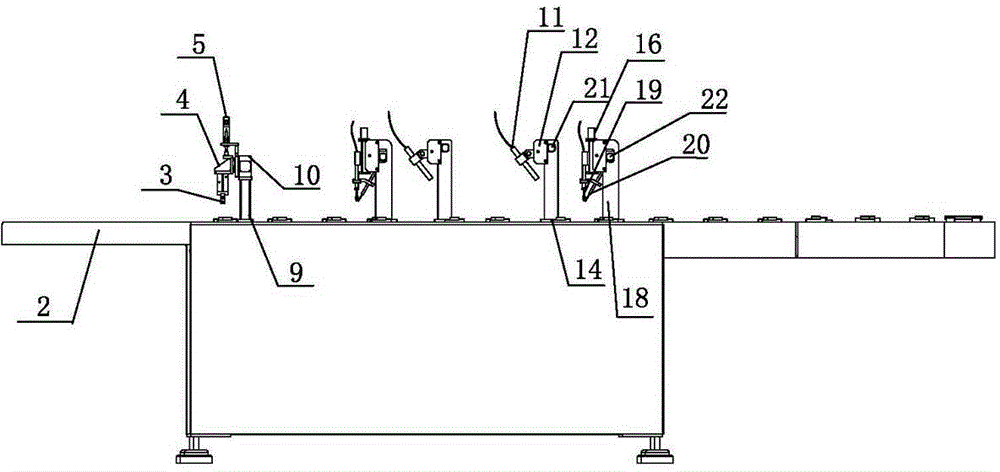

Automatic double-faced cleaning device for magnetic element

InactiveCN104475401AImprove blowing effectLaser cleaning effect is goodCleaning using gasesControl systemEngineering

The invention discloses an automatic double-faced cleaning device for a magnetic element. The automatic double-faced cleaning device for the magnetic element comprises a control system, a workbench, a transmission mechanism, a feeding manipulator component, and an air blowing mechanism, a first laser cleaning mechanism, an overturning mechanism and a second laser cleaning mechanism arranged on the workbench in sequence, wherein the transmission mechanism, feeding manipulator component, air blowing mechanism, first laser cleaning mechanism, overturning mechanism and second laser cleaning mechanism are controlled by the control system, and the air blowing mechanism comprises a first bracket, an air blowing nozzle and an air blowing nozzle translation mechanism arranged on the workbench; each of the first laser cleaning mechanism and second laser cleaning mechanism comprises a second bracket, a laser head, an auxiliary air blowing pipe, a laser head lifting mechanism and a laser head translation mechanism; the overturning mechanism comprises a third bracket arranged on the workbench, an overturning component composed of an overturning motor and an overturning manipulator, an overturning lifting mechanism and an overturning translation mechanism, and the rear end of the overturning manipulator is arranged on the output shaft of the overturning motor. The automatic double-faced cleaning device for the magnetic element is convenient to operate, high in cleaning efficiency and capable of effectively removing the ferromagnetic substance which adheres to the surface of the magnetic element.

Owner:李东风

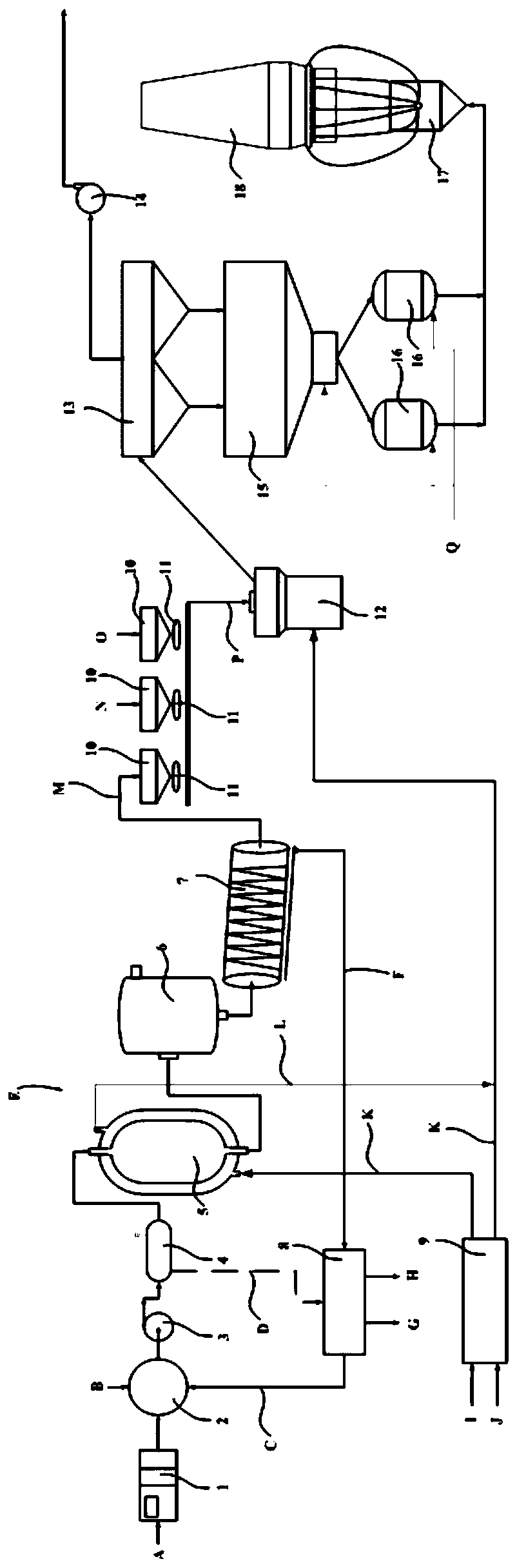

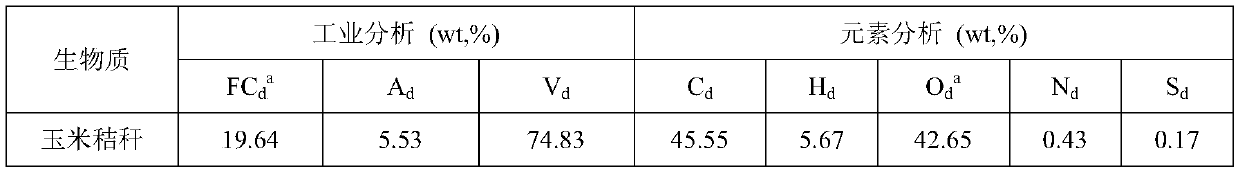

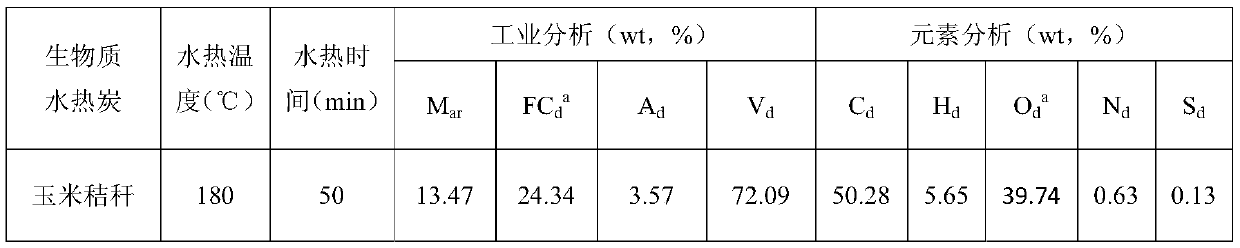

Method for carrying out blast furnace blowing on biomass hydrothermal carbon

ActiveCN110218826AImprove milling performanceEasy to transportBiofuelsSolid fuelsMetallurgyWaste rubber

The invention belongs to the technical field of blast furnace ironmaking, and particularly discloses a method for carrying out blast furnace blowing on biomass hydrothermal carbon. The method solves the problem that an optimal utilization method of biomass resources in blast furnace blowing process. The method can also be used for heat treatment of waste plastics, waste rubbers and other municipalcombustible solid waste water to prepare the hydrothermal carbon and the method can be efficiently applied to determination of a blast furnace blowing scheme. Under the condition that the influencesof biomass hydrothermal carbonization treatment, biomass hydrothermal carbon powder preparing, conveying and blowing on blast furnace smelting key process parameters are considered, the optimal utilization method for carrying out blast furnace blowing on biomass hydrothermal carbon is formed. According to the method, the system is analyzed by aiming at different biomass hydrothermal carbon, important assessment index of the blast furnace smelting downstream behavior is adopted, and the safe and efficient blast furnace blowing on the biomass hydrothermal carbon is realized, so that the comprehensive utilization efficiency of biomass resources is improved, and the emission of CO2 produced by the ironmaking is reduced.

Owner:UNIV OF SCI & TECH BEIJING

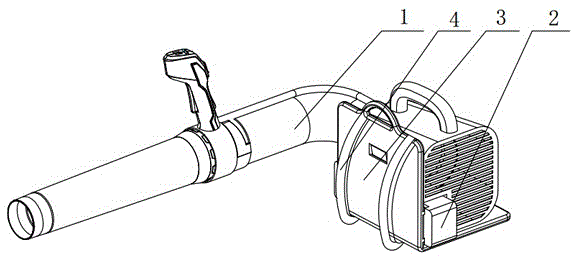

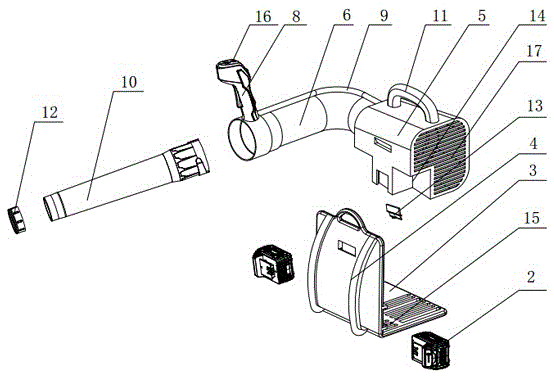

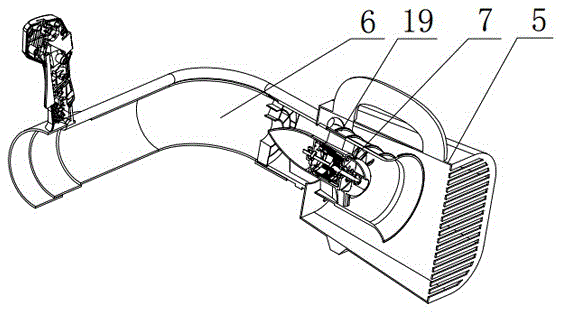

Backpack blower

ActiveCN105485033AVarious assembly methodsVersatilePump componentsHops/wine cultivationEngineeringInstalled base

Owner:ZHEJIANG LERA NEW ENERGY POWER TECH CO LTD

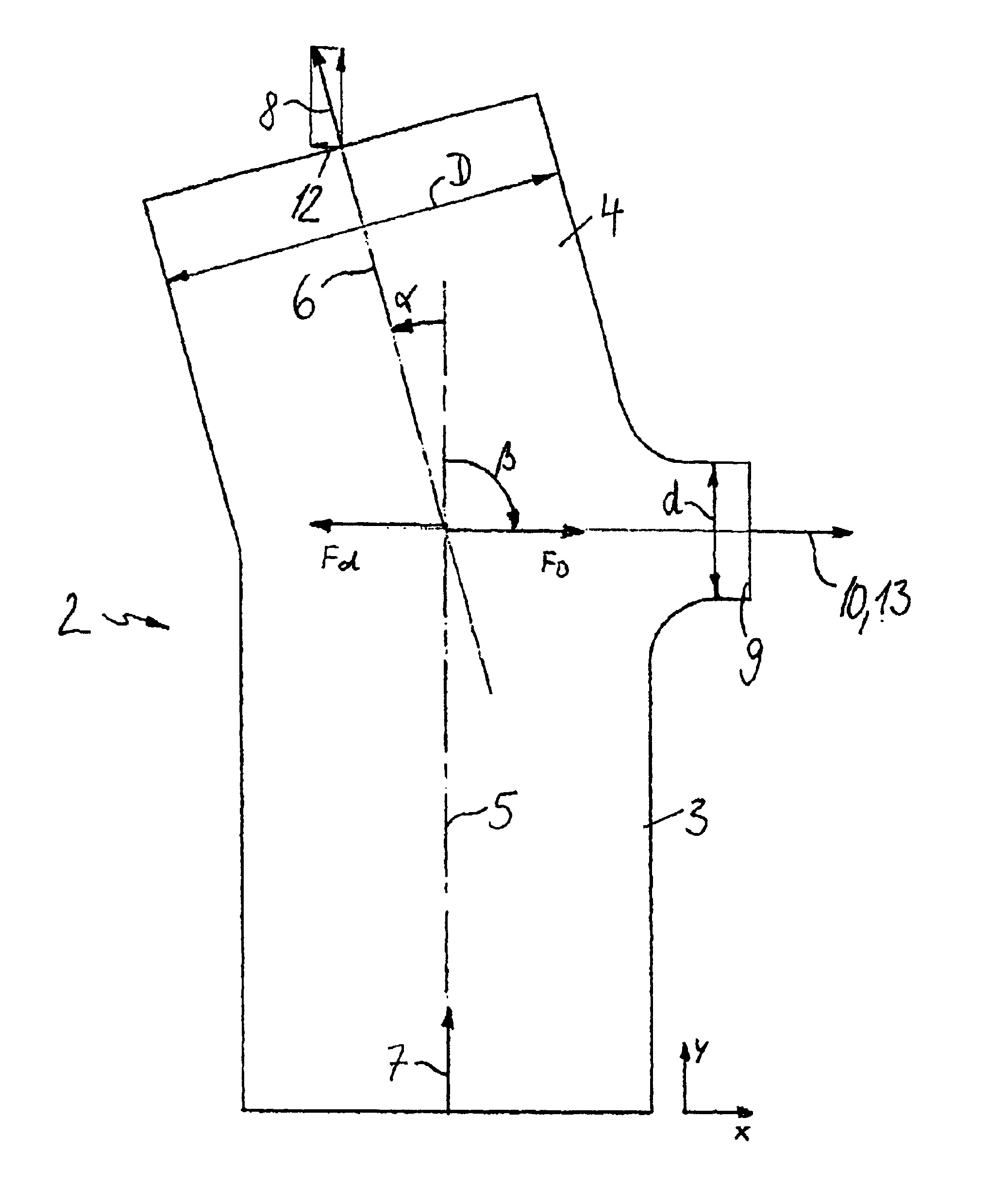

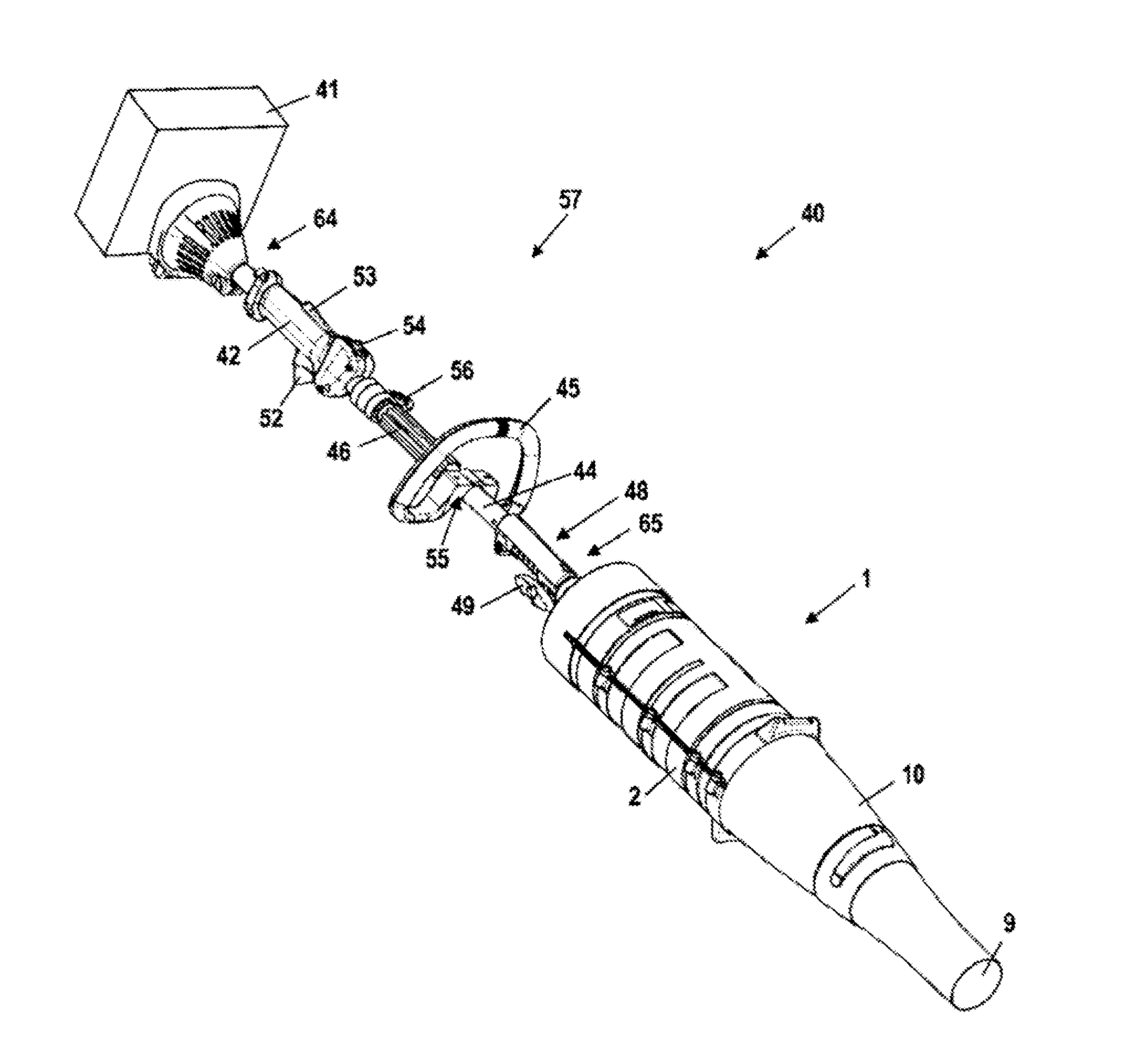

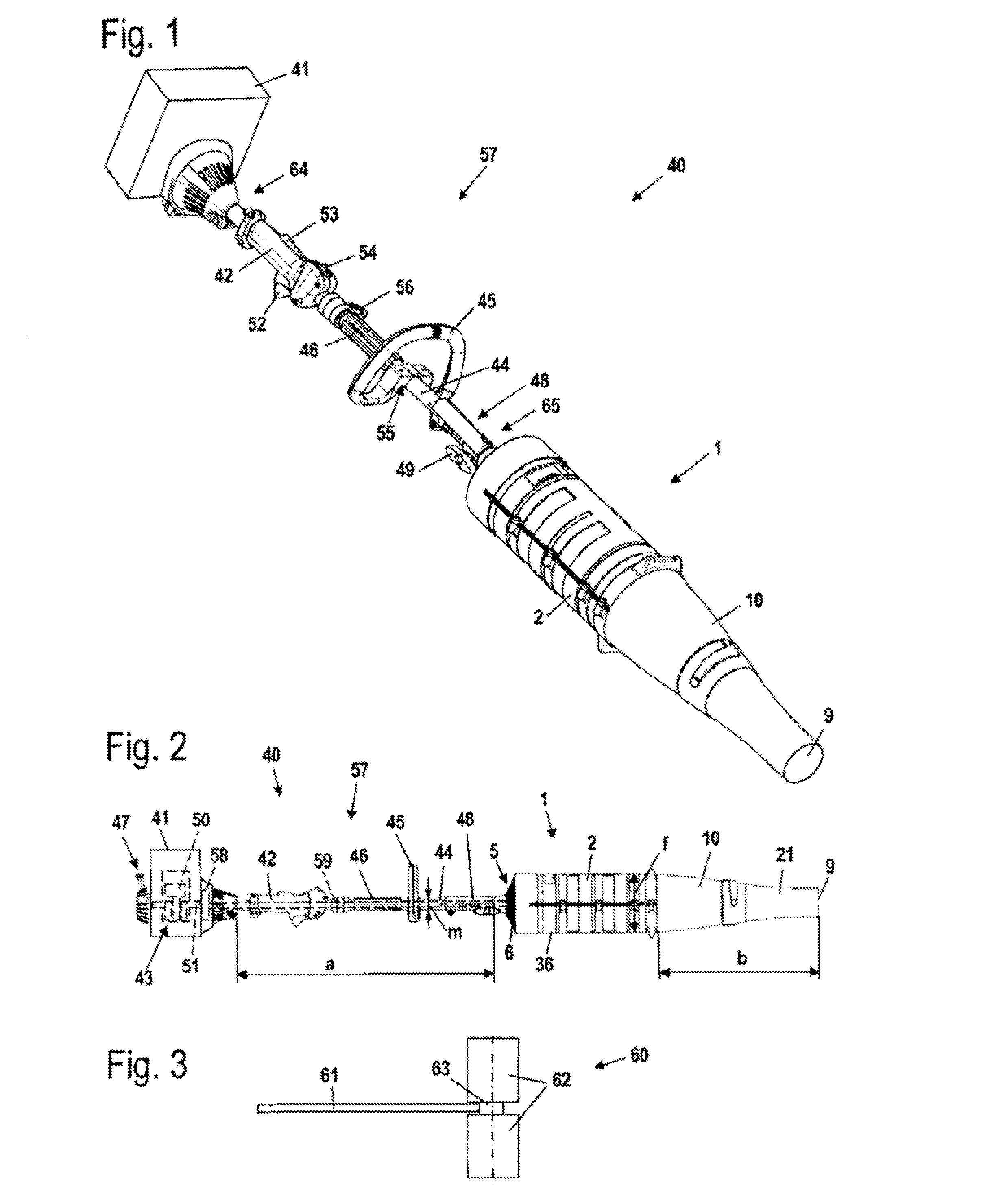

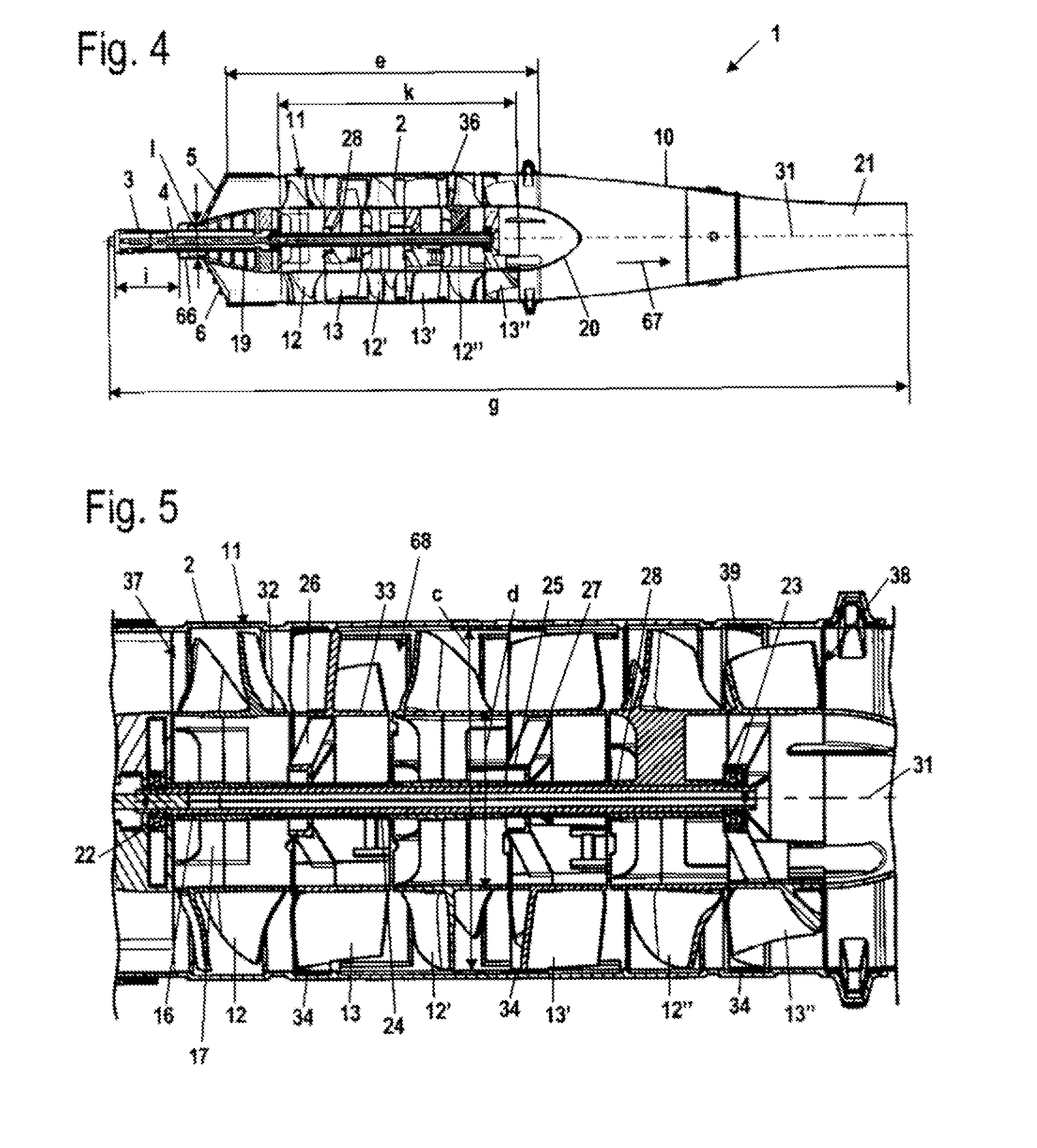

Portable Blower

ActiveUS20080189904A1Increase powerReduce resistancePositive displacement pump componentsRoad cleaningDrive shaftDrive motor

A portable blower having a motor unit that includes a drive motor disposed in an engine housing. The blower has a blower unit that is provided with a blower housing that is separate from the engine housing. The blower unit includes an axial fan that is driven by the drive motor via a drive shaft. During operation the axial fan conveys operating air in the direction of the axis of rotation of the axial fan through a blower tube disposed downstream of the axial fan. An ergonomic operation and a good operating result can be achieved if the motor unit includes a guide tube on which is secured at least one handle. The engine housing is disposed at one end of the guide tube and the blower unit is disposed at the other end of the guide tube. The drive shaft extends through the guide tube. The length of the guide tube between the engine housing and the blower unit corresponds to at least half of the length of the blower tube.

Owner:ANDREAS STIHL AG & CO KG

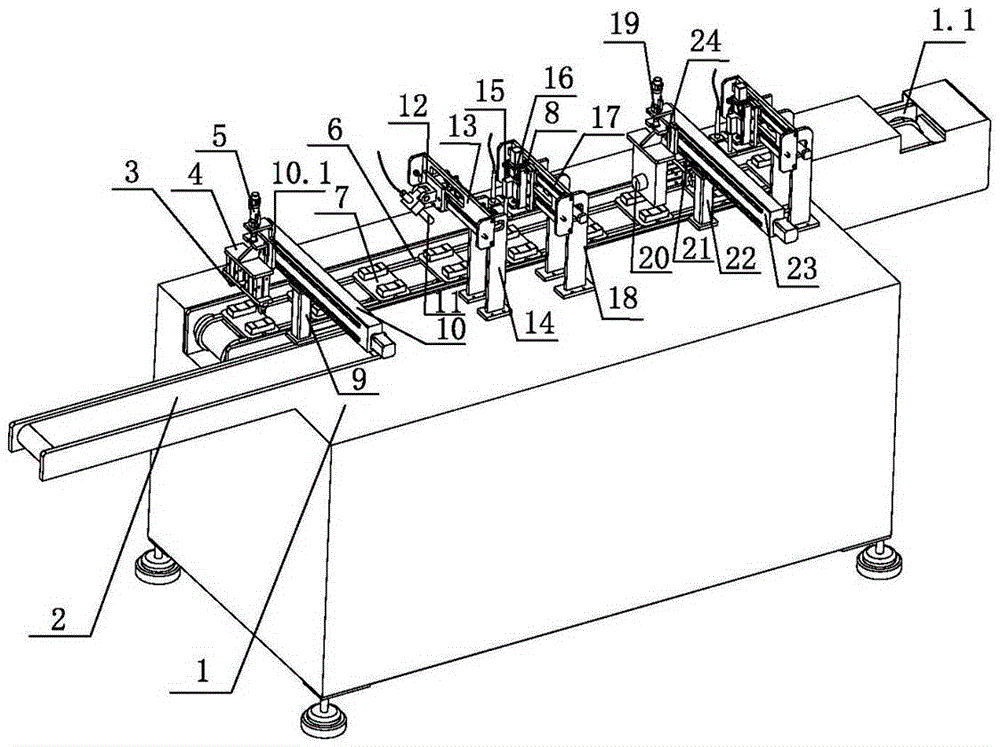

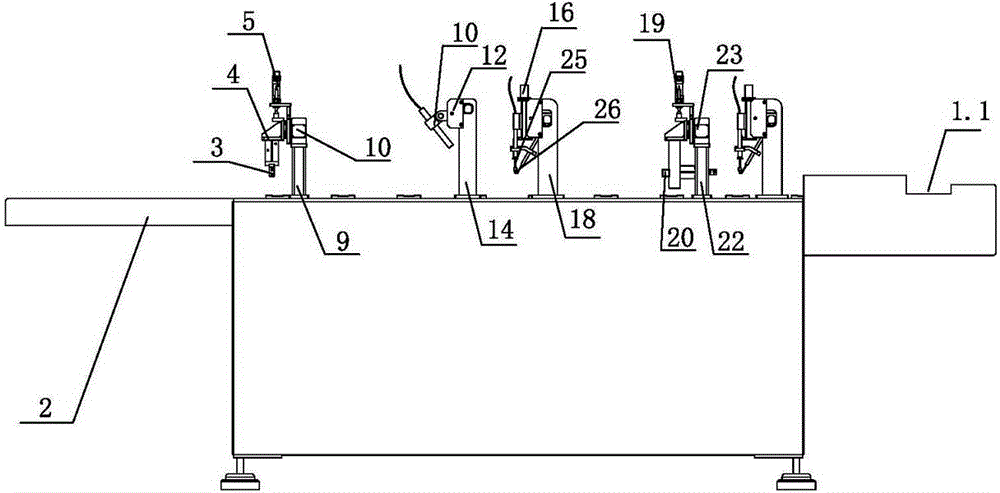

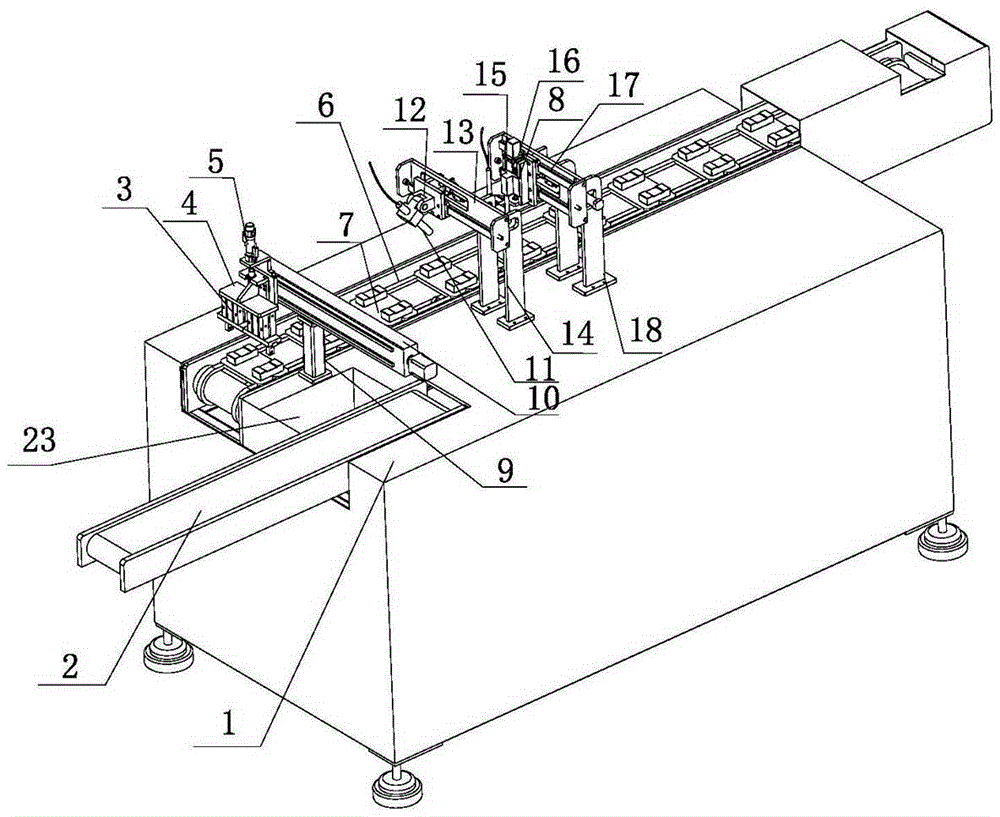

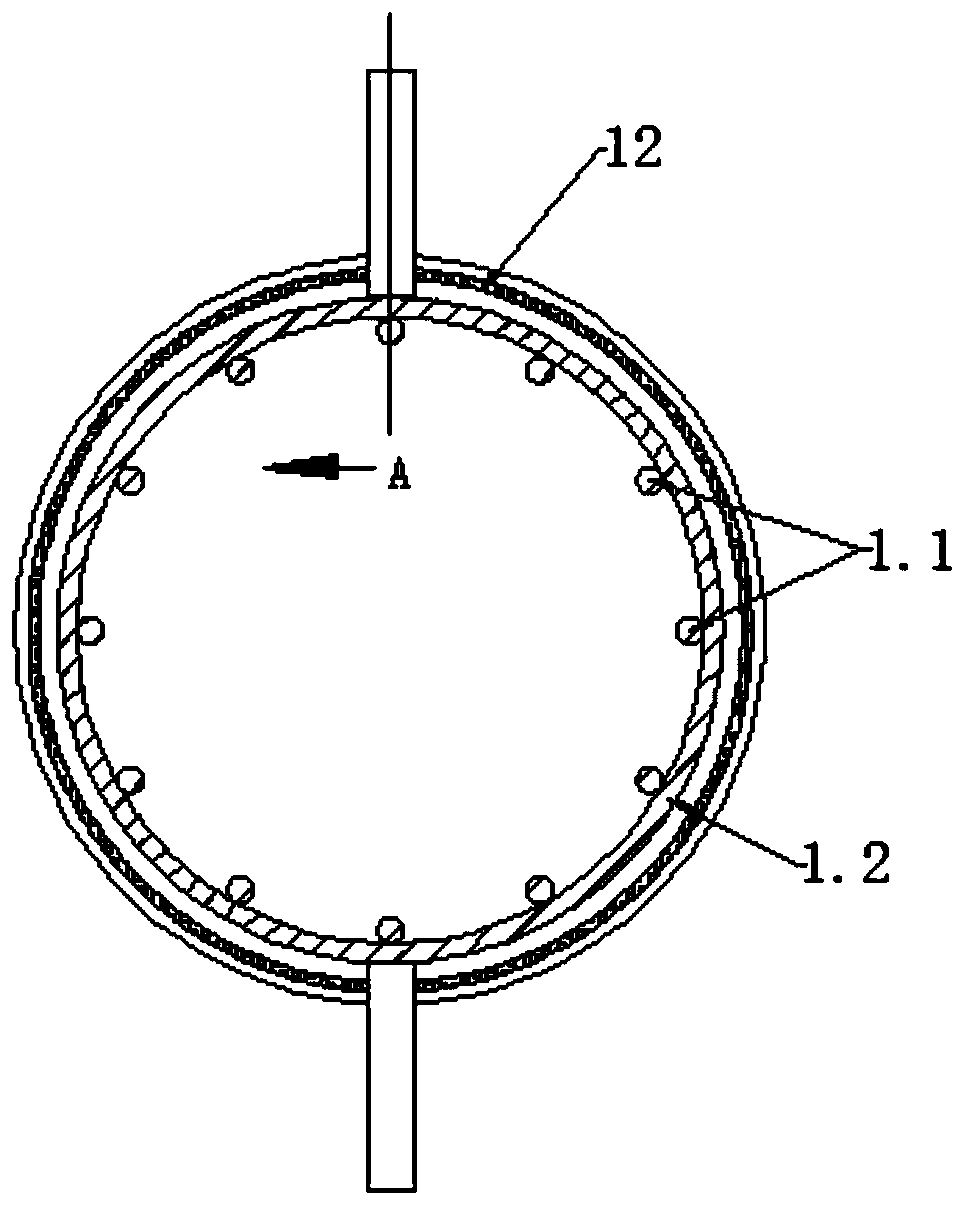

Laser cleaning device for annular magnetic steel

ActiveCN104526158AAchieve cleaningImprove blowing effectCleaning using gasesLaser beam welding apparatusControl systemManipulator

The invention discloses a laser cleaning device for annular magnetic steel. The laser cleaning device comprises a control system, a workbench, a transport mechanism, a feeding manipulator assembly, a blowing mechanism and a laser cleaning mechanism, wherein the transport mechanism and the feeding manipulator assembly are controlled by the control system; the blowing mechanism and the laser cleaning mechanism are arranged on the workbench sequentially. The transport mechanism comprises a first conveying belt and a second conveying belt, the first conveying belt is arranged at one end of the workbench, and the second conveying belts is arranged in the length direction of the workbench. A plurality of L-shaped substrates are arranged on the second conveying belt at intervals, a motor is arranged on the side wall of each L-shaped substrate, and a rotating shaft is arranged on an output shaft of each motor. The blowing mechanism comprises a first support, a blowing nozzle and a blowing nozzle translation mechanism. The laser cleaning mechanism comprises a second support, a laser head, an auxiliary blowing pipe, a laser head lifting mechanism and a laser head translation mechanism. The laser cleaning device for annular magnetic steel is convenient to operate and high in cleaning efficiency, and can especially remove ferromagnetic substances adhered to the surfaces.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

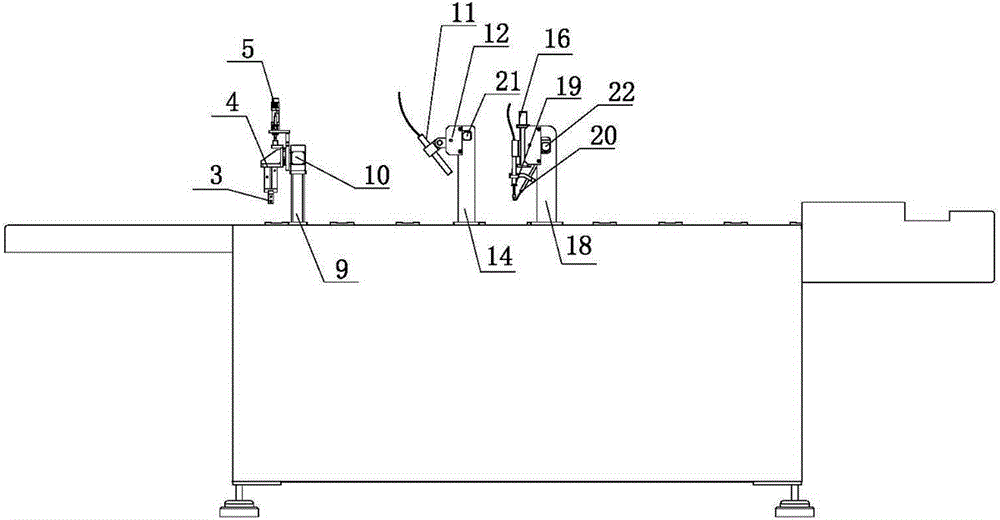

Automatic magnetic element cleaning system

InactiveCN104399714AImprove blowing effectLaser cleaning effect is goodCleaning using gasesCleaning using liquidsControl systemMegasonic cleaning

The invention discloses an automatic magnetic element cleaning system. The automatic magnetic element cleaning system comprises a control system, a workbench, a transmission mechanism and a feeding manipulator assembly which are controlled by the control system and a ultrasonic cleaning groove, a blowing mechanism and a laser cleaning mechanism which are sequentially arranged on the workbench; the ultrasonic cleaning groove is formed between a rear section of a first conveying belt and a front section of a second conveying belt in a parallel mode; the blowing mechanism comprises a first support, a blowing nozzle and a blowing nozzle translation mechanism; the laser cleaning mechanism comprises a second support, a laser head, an auxiliary blowing pipe, a laser head lifting mechanism and a laser head translation mechanism; the blowing nozzle, the laser head and the auxiliary blowing pipe are arranged right above the second conveying pipe. The automatic magnetic element cleaning system is convenient to operate and high in cleaning efficiency and particularly can effectively remove ferromagnetic substances adhered to the surface.

Owner:南通北外滩建设工程有限公司

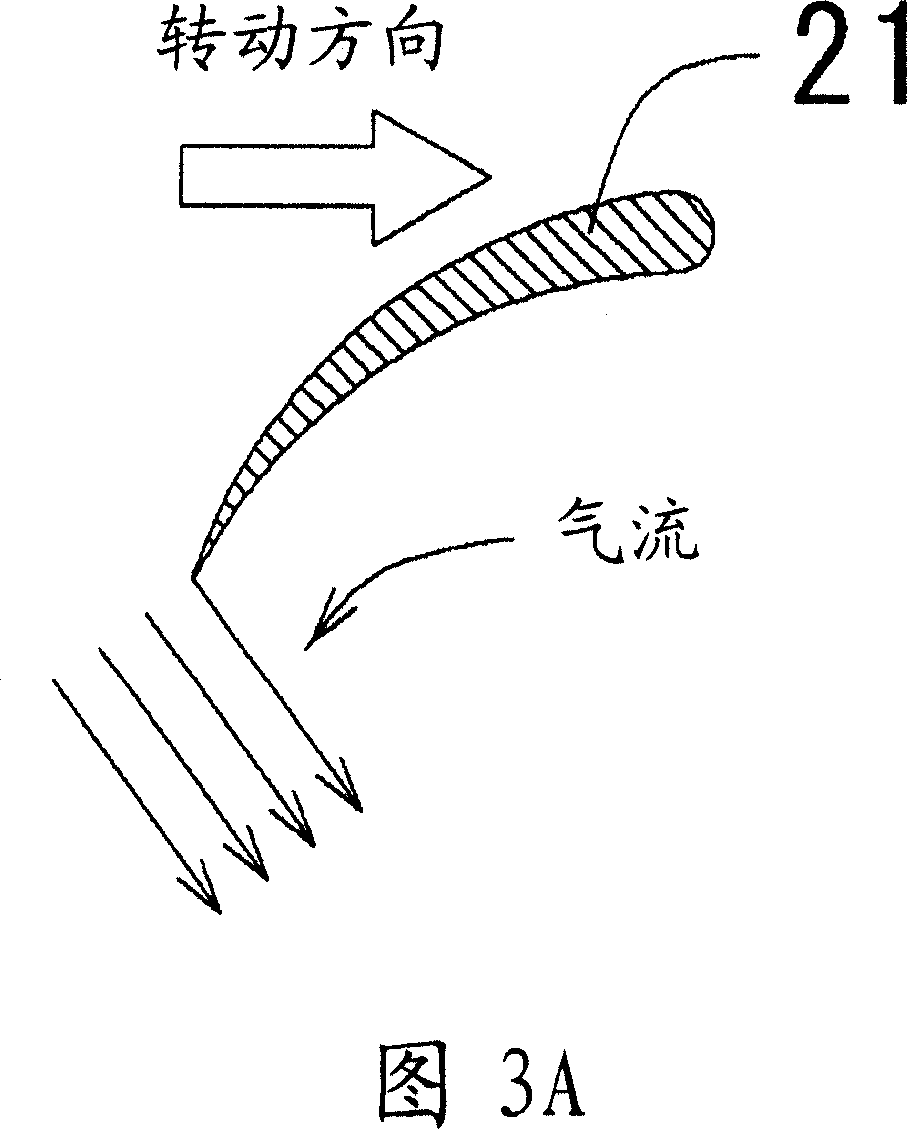

Axial flow fan

ActiveCN1987122ADoes not have poor noise characteristicsImprove blowing effectPump componentsPump installationsImpellerEngineering

An axial flow fan includes a motor placed on a frame and including a rotor rotatable around a rotation axis. An impeller is attached to an outer circumference of the rotor to rotate around the rotation axis and includes blades for generating an air flow when the rotor rotates. A housing surrounds the impeller to form a passage for the air flow. Ribs extend from the frame to the housing, thereby securing the frame to the housing. Each rib includes an air guide face which faces the impeller. An angle of average inclination of the air guide face with respect to the rotation axis decreases in a direction away from the rotation axis. The average inclination of the air guide face is defined as inclination of a straight line approximately connecting both ends of the air guide face on a plane perpendicular to a radial direction.

Owner:NIDEC CORP

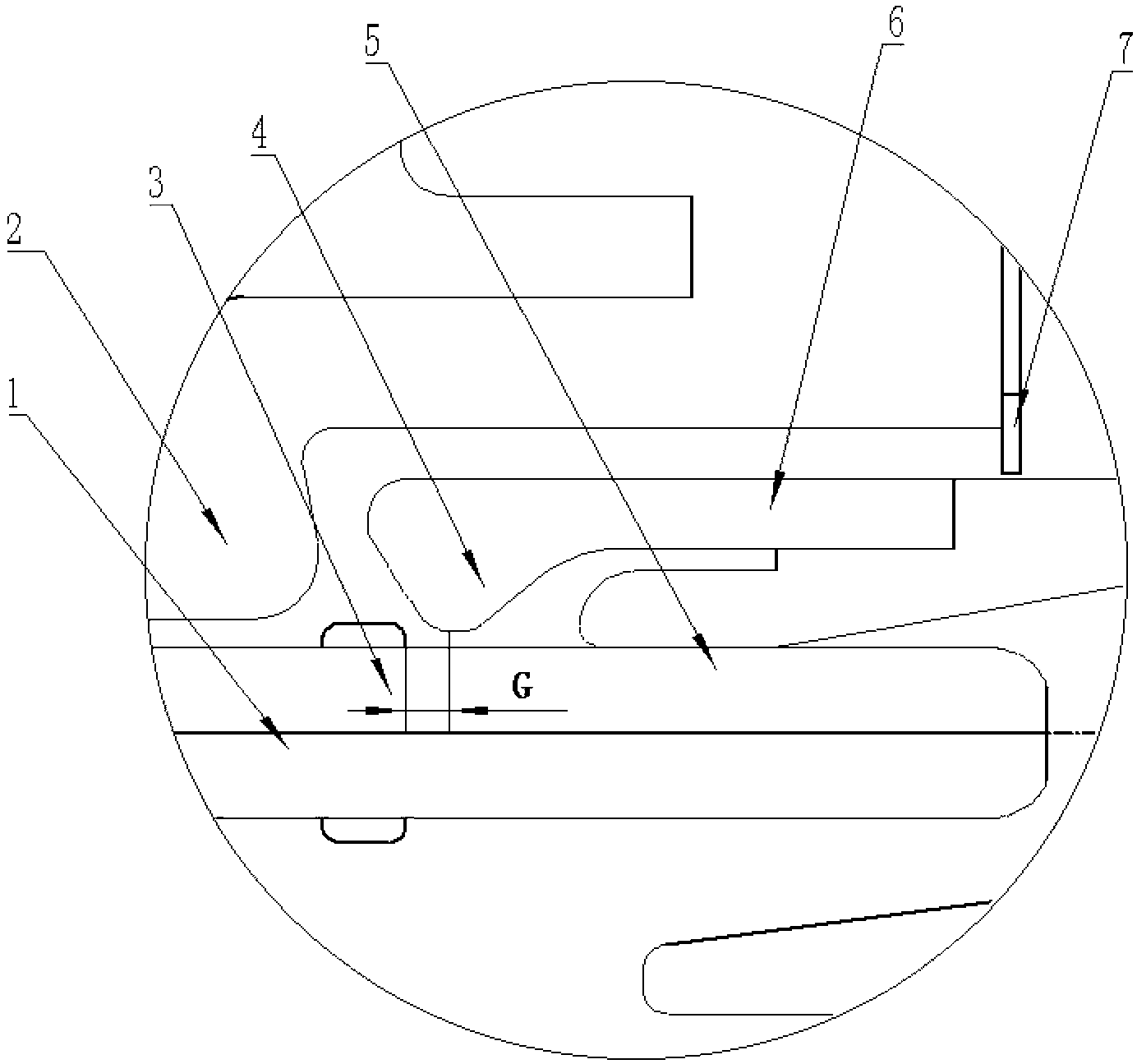

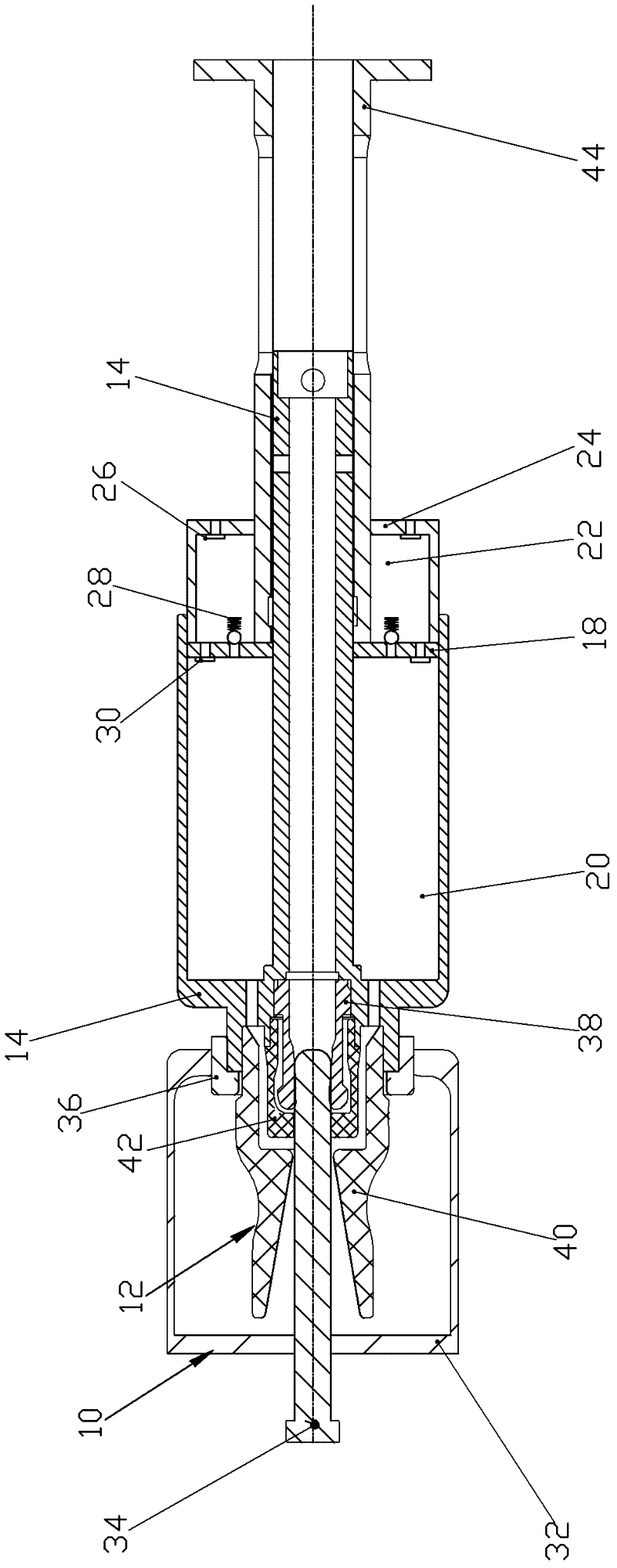

Arc extinguishing chamber of circuit breaker

ActiveCN102306590AImproved breaking capacity and product reliabilityAir chamber reaction force decreasesHigh-tension/heavy-dress switchesAir-break switchesPistonProcess engineering

The invention discloses an arc extinguishing chamber of a circuit breaker, which comprises a static contact module (10), a dynamic contact module (12), a gas pressing cylinder (14), a piston (18), a gas storing chamber (22) and a valve unit, wherein a gas pressing chamber (20) is formed between the piston (18) and the gas pressing cylinder (14); the movable contact module (12) and the gas pressing cylinder (14) are connected together; the valve unit is arranged between the gas pressing chamber (20) and the gas storing chamber (22); when a pressure difference between the gas pressing chamber and the gas storing chamber is higher than a preset value, gas in the gas pressing chamber is charged into the gas storing chamber; and when the pressure of the gas storing chamber is higher than the pressure of the gas pressing chamber, gas in the gas storing chamber is poured back into the gas pressing chamber for realizing the process of firstly storing and then supplementing the gas in the gas pressing chamber by the gas storing chamber, so as to generate the following technical effects of: preventing the gas pressing chamber from generating over-high air pressure when the circuit breaker is opened, reducing the operating work of an operating mechanism, extending effective gas blowing time for electric arcs, enhancing opening capability of the circuit breaker and product reliability andreducing the cost of the operating mechanism.

Owner:XIAMEN HUADIAN SWITCHGEAR

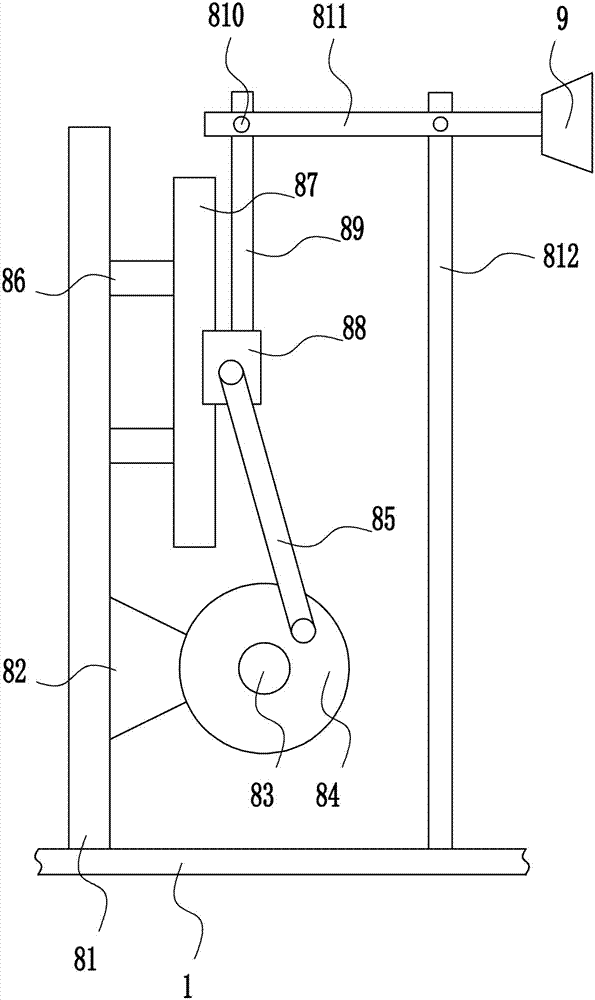

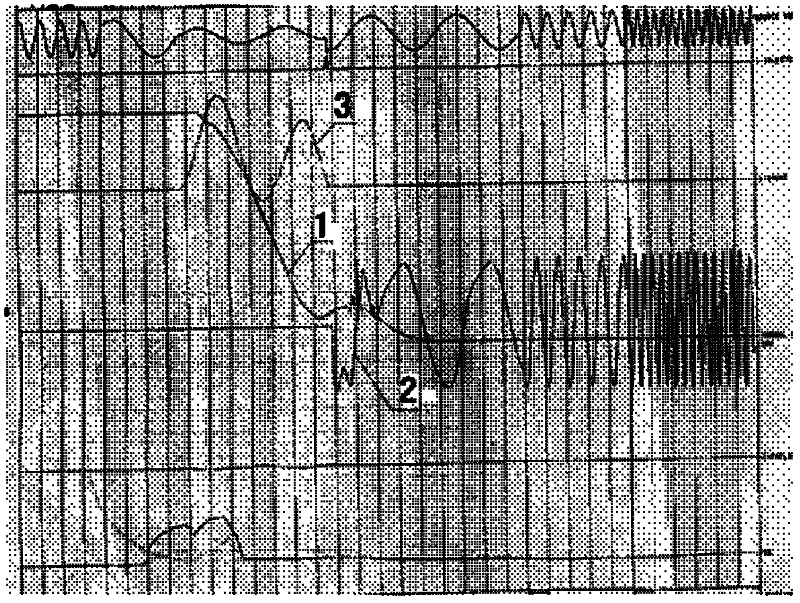

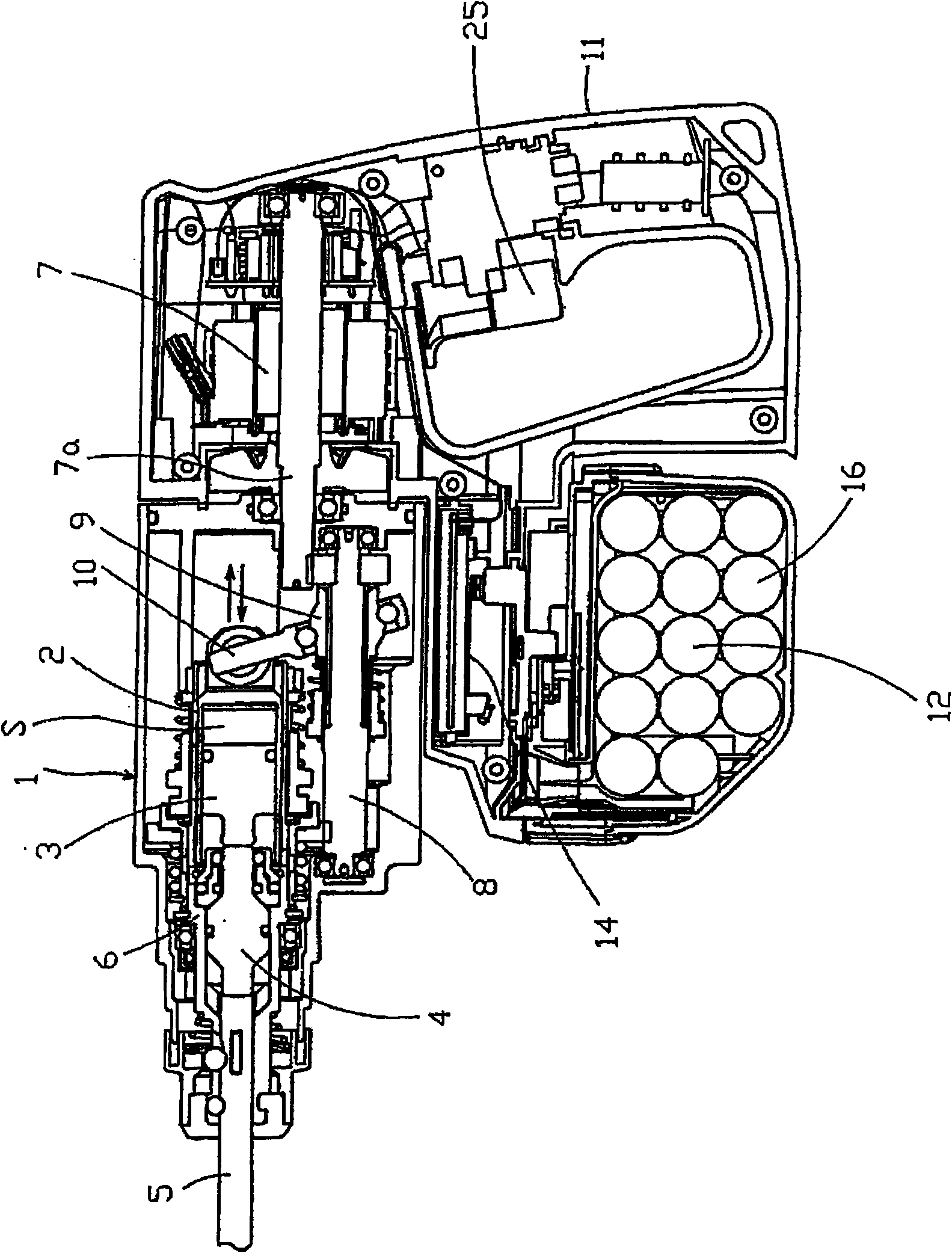

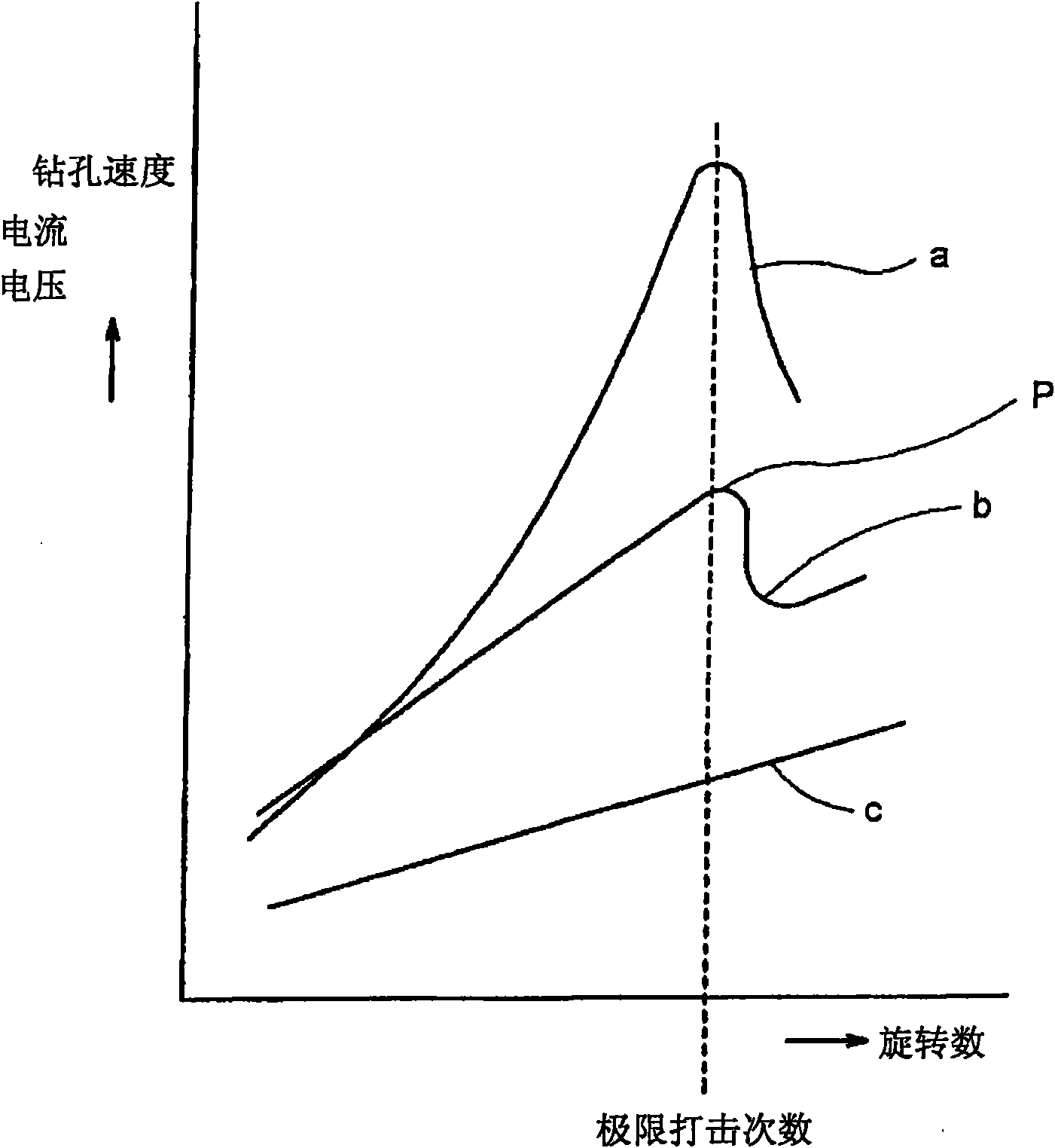

Hammer tool

ActiveCN101678543ASmall sizeReduce weightPortable percussive toolsMeasurement deviceReciprocating motion

A hammer tool has, in a tool body (1), a piston (2) reciprocated by drive force of a motor (7), a hammer element (3) for performing hammering operation in association with the reciprocation of the piston (2), and an intermediate element (4) for transmitting hammering force of the hammer element (3) to a head tool (5) inserted and attached to the head of the tool body. The tool body has a measurement device (13) for measuring the condition of hammering by the hammer element (3) and also has a control device for controlling the speed of the motor (7). The control device (13) determines, based onthe result on measurement by the measurement device (13), the limit number of times of hammering which makes the hammer element (3) unable to follow the reciprocation of the piston (2), and the control device controls the speed of the motor (7) according to the result of the determination.

Owner:MAX CO LTD

Safety type electric fan

InactiveCN103410753AReduce noiseLarge air volumePump componentsMachines using electric/magnetic effectsWaste management

The invention discloses a safety type electric fan which comprises an air suction assembly and an air outlet mask. The air outlet mask is provided with an air inlet hole, air guiding channels, air outlet narrow holes and an installing part. The air inlet hole is arranged on the back of the air outlet mask, the air outlet narrow holes are arranged on the front of the air outlet mask, and the installing part is arranged at the position of the center of the back of the air outlet mask. The air suction assembly comprises a casing, a suction fan arranged in the casing and an air duct arranged in the casing. One end of the casing is provided with a mesh plate serving as an air duct air inlet, the other end of the casing is provided with an air duct air outlet, one of the casing provided with the air duct air outlet is fixed in the installing part, and the air duct air outlet is communicated with the air inlet hole of the air outlet mask. The safety type electric fan is small in noise and large in air outlet quantity.

Owner:佛山市顺德区北滘镇信威电器有限公司

Low-resistance ultra-clean generation-two cloth bag dust collector

ActiveCN110538525ASimple structureReduce dismantling and maintenanceCombination devicesDispersed particle filtrationPush and pullBaghouse

The invention discloses a low-resistance ultra-clean generation-two cloth bag dust collector which comprises a filtering component, wherein a dust cleaning structure is arranged on the filtering component; the dust cleaning structure comprises an annular elastic part which is arranged on the outer side of the filtering component in a sleeving manner; a connecting part is arranged on the annual elastic part; the connecting part is connected with a cam mechanism which is connected with the cloth bag dust collector; and the connecting part is used for pushing and pulling the annular elastic partto deform to leave away from the filtering component through the cam mechanism. In dust cleaning, because of rotation of a cam, the connecting part is pushed to move in a direction far away from the filtering component, the annular elastic part is pulled by the connecting part to make intermittent deformation / resilience, a function of similarly beating the outer side of the filtering component canbe achieved, furthermore, dust on the outer wall of the filtering component can be beaten and cleaned, dust adhered to the outer wall of the filtering component can be reduced, the dust cleaning effect of a filtering bag can be improved, and the filtering bag replacement cycle can be prolonged.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Right-angle type HTHP (High Temperature High Pressure) pulse-jet valve

InactiveCN103470782AAvoid offsetRealize the spray effectSpindle sealingsOperating means/releasing devices for valvesHigh pressureValve stem

The invention discloses a right-angle type HTHP (High Temperature High Pressure) pulse-jet valve which comprises a valve body, an electromagnetic valve, a two-way cylinder, a valve stem, a valve sealing component, an air inlet end and an air outlet end, wherein the valve stem is coaxial to the air outlet end; the tail end of the valve stem is connected with the two-way cylinder, and the front end of the valve stem is connected with the valve sealing component; the valve sealing component comprises a seal valve clack and a seal valve base which are matched for use; the front end of the seal valve clack is provided with a guide piece which penetrates through the seal valve base. According to the right-angle type HTHP pulse-jet valve, the electromagnetic valve controls the two-way cylinder to perform bidirectional movement so as to drive the ascending and descending of the valve stem as well as separation and combination of the seal valve clack and the seal valve base, so that a jetting effect is realized; the guide piece is arranged, so that not only can the opening and closing direction be controlled, but also primary impact of HTHP gases can be avoided; in addition, a metal sealing part can be used for avoiding burning loss of a film, under the condition of ensuring the high-temperature sealing effect and the favorable jetting effect, the service life is improved manyfold, and the right-angle type HTHP pulse-jet valve has favorable popularization and use value.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

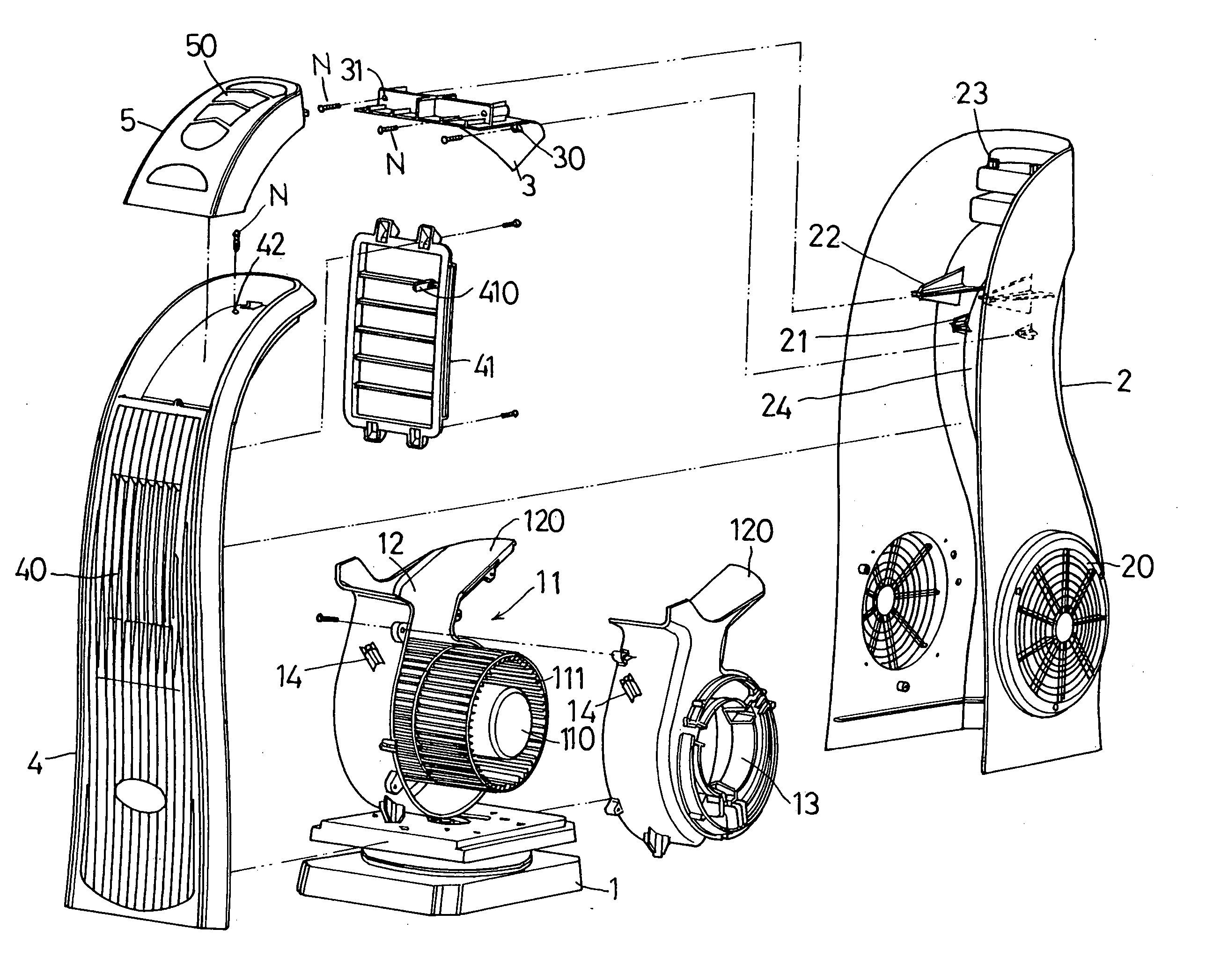

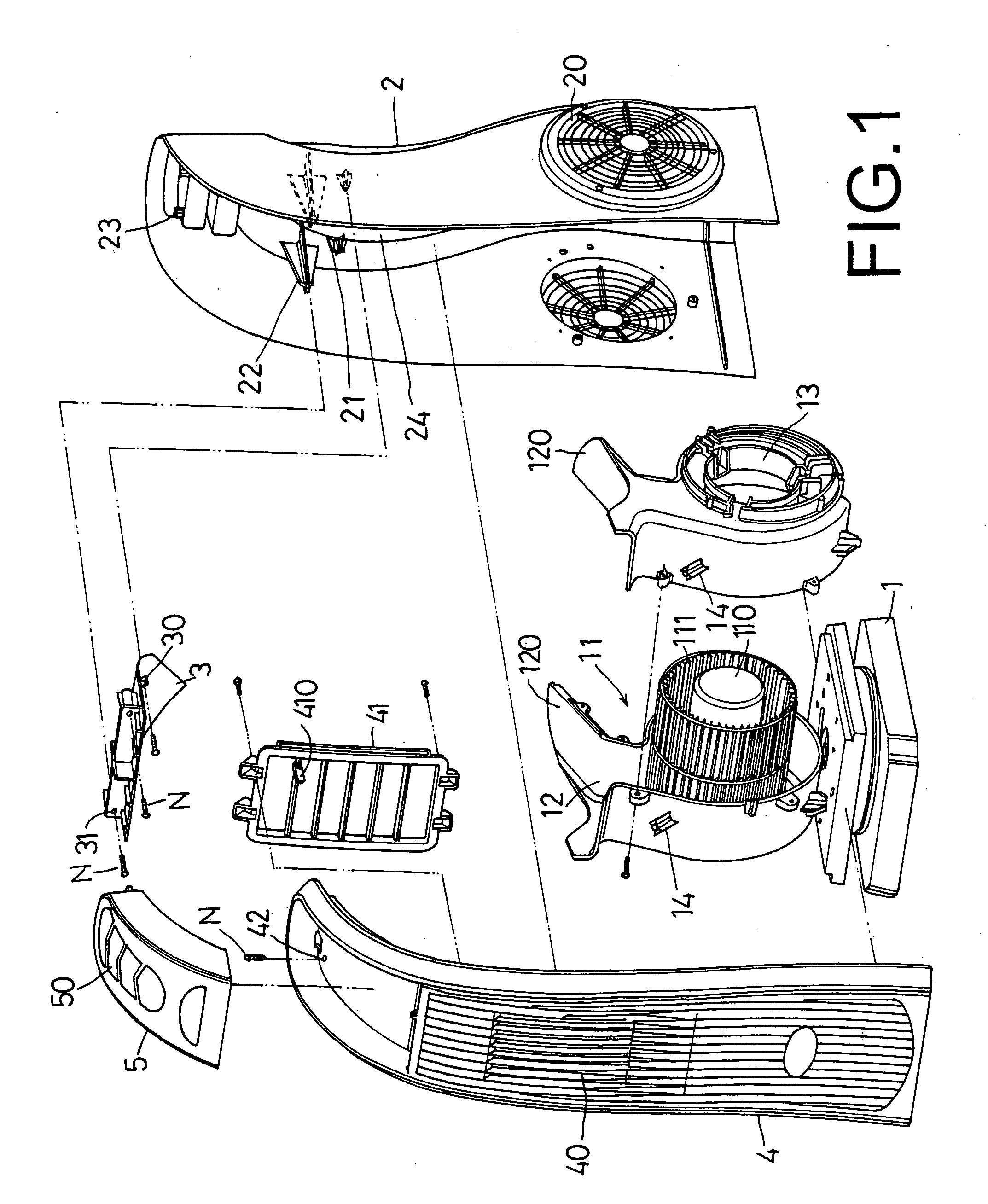

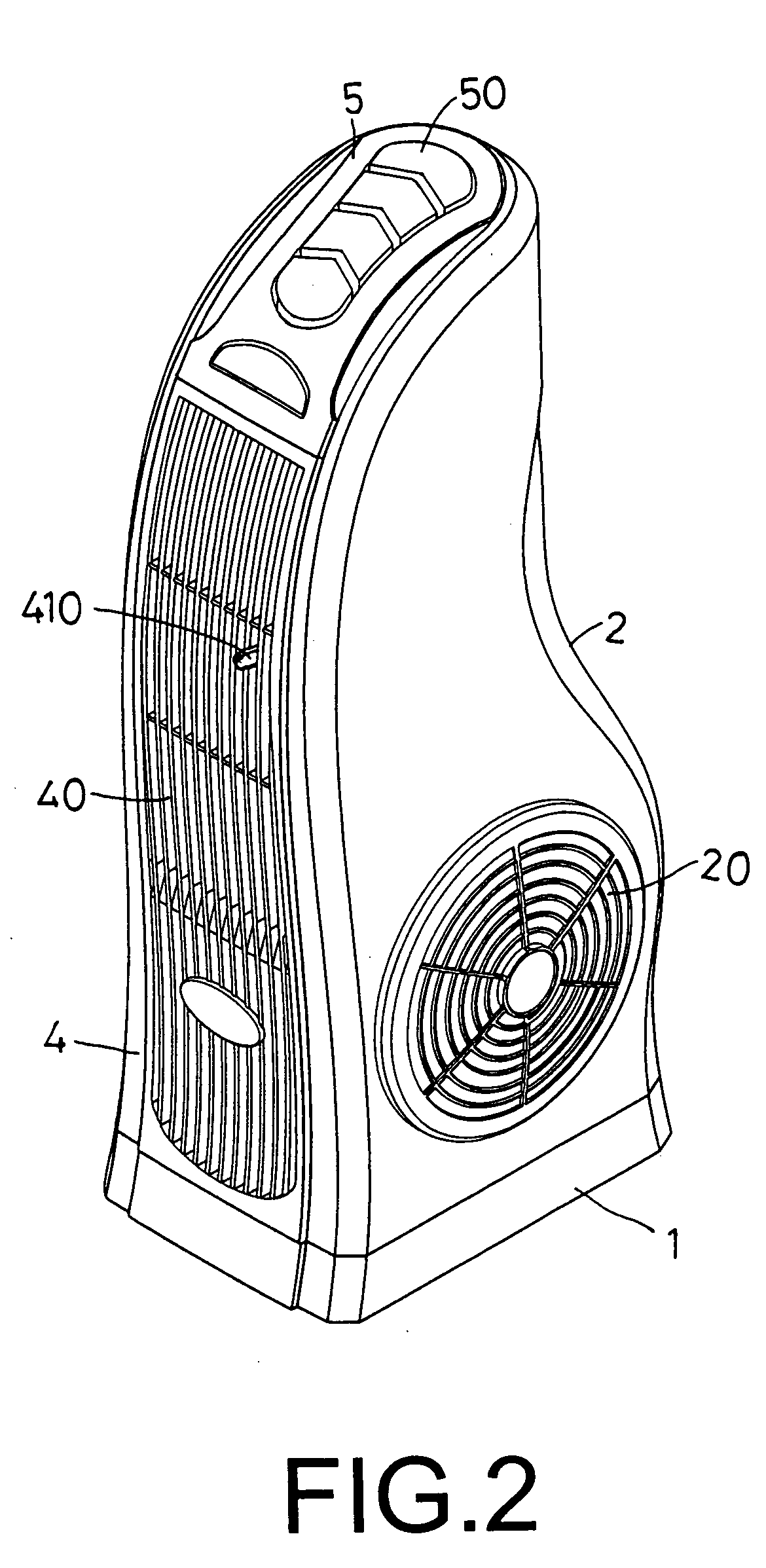

Electric fan

An electric fan includes a base; a turbine fan fixed on the base; a housing installed on the base; a guide plate; a front cover in the front side of the housing; and an upper cap on top of the front cover. The turbine fan has a wind passage, a sloped guide surface, and two wind inlets in two sides. The housing has grid inlets facing the wind inlets of the turbine fan and a curved surface. The guide plate is fixed on the curved surface of the housing. The front cover has grid outlets and adjust leaves. When the turbine fan operates, air is sucked in through the grid inlets of the housing, the wind inlets and out of the wind outlets, guided by the sloped guide surface, the curved surface of the housing, blown out of the grid outlets of the front cover in changeable directions.

Owner:LEE MING TSUNG

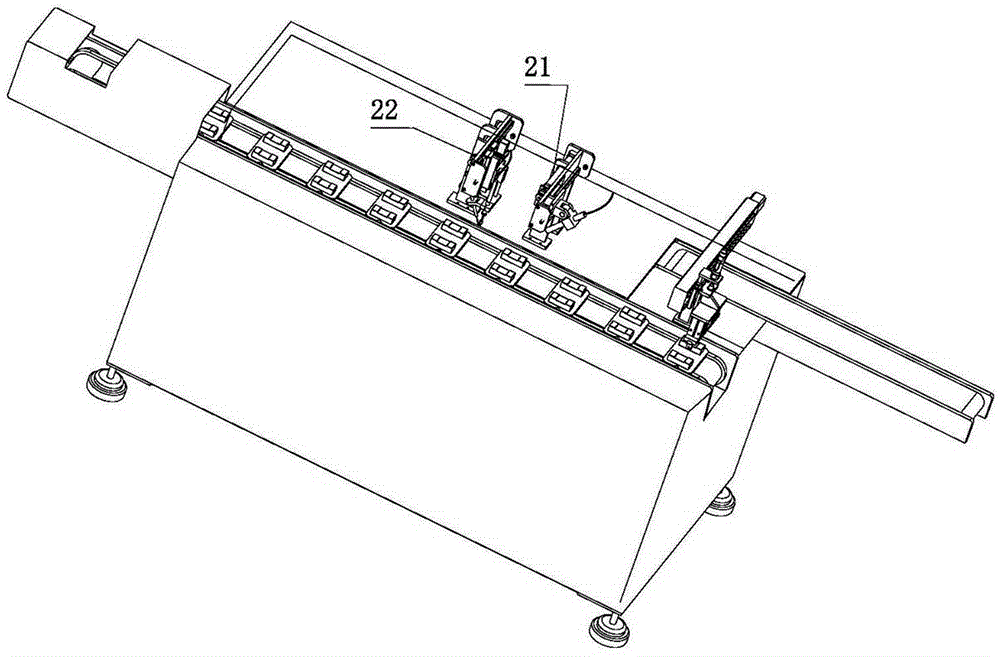

Double-faced laser cleaning device for magnetic steel

ActiveCN104475402AImprove blowing effectImprove cleaning efficiencyCleaning using gasesControl systemEngineering

The invention discloses a double-faced laser cleaning device for magnetic steel. The double-faced laser cleaning device for the magnetic steel comprises a control system, a workbench, a transmission mechanism, a feeding manipulator component, a first air blowing mechanism and a first laser cleaning mechanism arranged at one side of the workbench in sequence, and a second air blowing mechanism and a second laser cleaning mechanism arranged at the other side of the workbench in sequence, wherein the transmission mechanism, feeding manipulator component, first air blowing mechanism, first laser cleaning mechanism, second air blowing mechanism and second laser cleaning mechanism are controlled by the control system, and each of the first air blowing mechanism and second air blowing mechanism comprises a first bracket, an air blowing nozzle and an air blowing nozzle translation mechanism; each of the first laser cleaning mechanism and second laser cleaning mechanism comprises a second bracket, a laser head, an auxiliary air blowing pipe, a laser head lifting mechanism and a laser head translation mechanism, the transmission mechanism comprises a first conveying belt, a second conveying belt and a third conveying belt, and a magnetic steel push mechanism for overturning is arranged between the end of the second conveying belt and the initial end of the third conveying belt. The double-faced laser cleaning device for the magnetic steel is convenient to operate, high in cleaning efficiency and capable of effectively removing the ferromagnetic substance which adheres to the surface of the magnetic steel.

Owner:桐乡市恒达经编股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com