Hammer tool

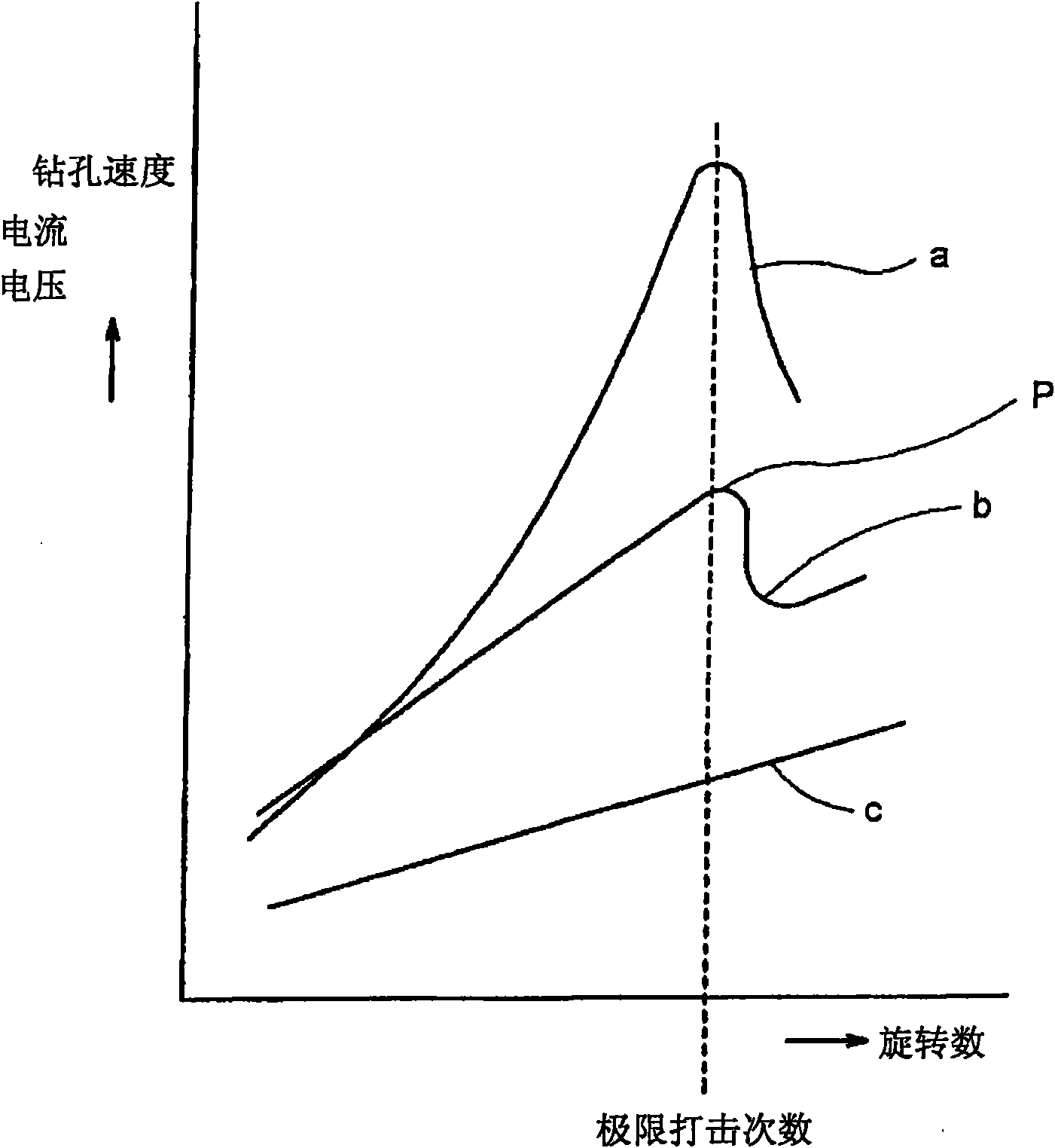

一种打击工具、工具的技术,应用在打击工具、轻便冲击工具、制造工具等方向,能够解决回转数降低、打击次数从极限打击次数降低、打击构件打击效率降低等问题,达到提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

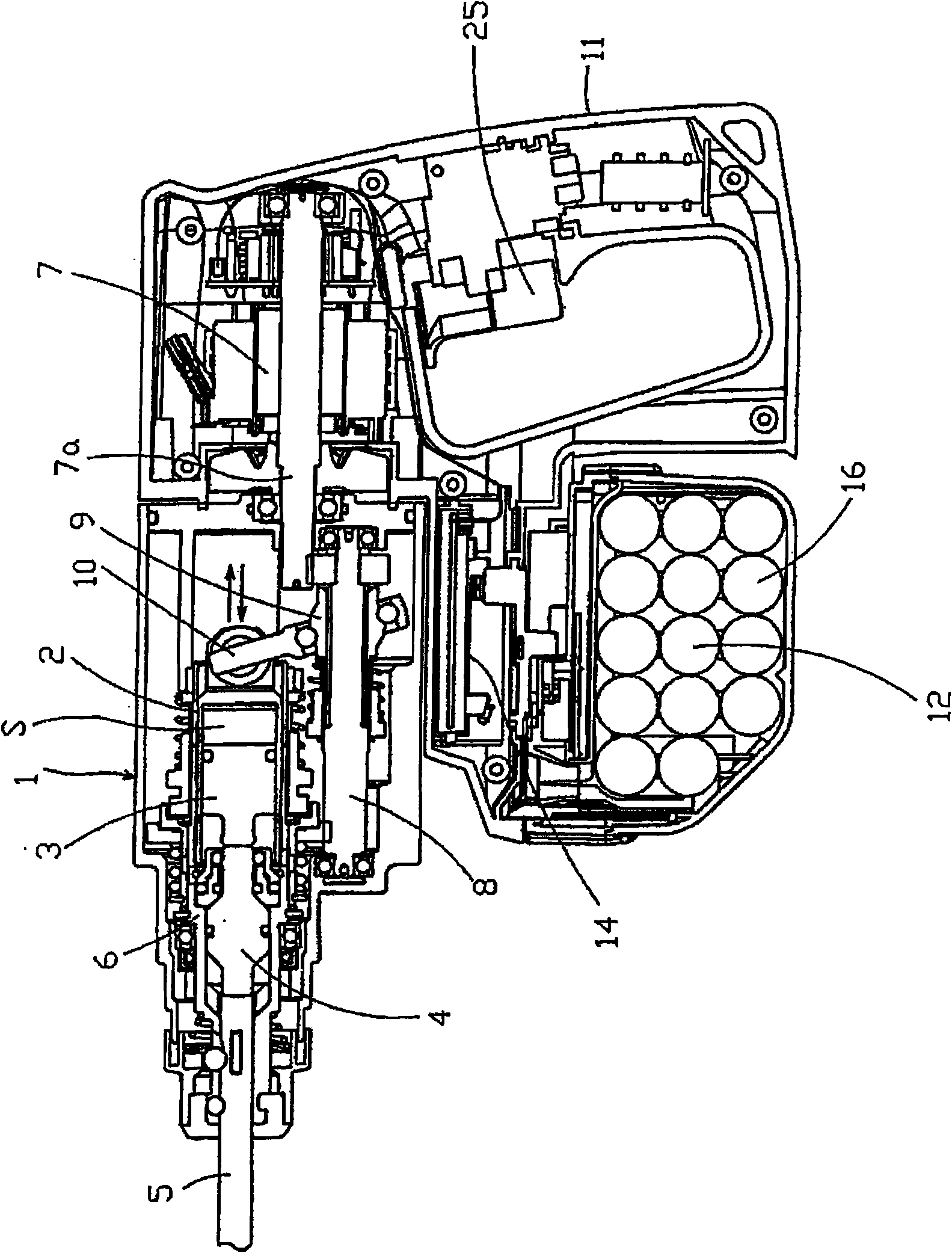

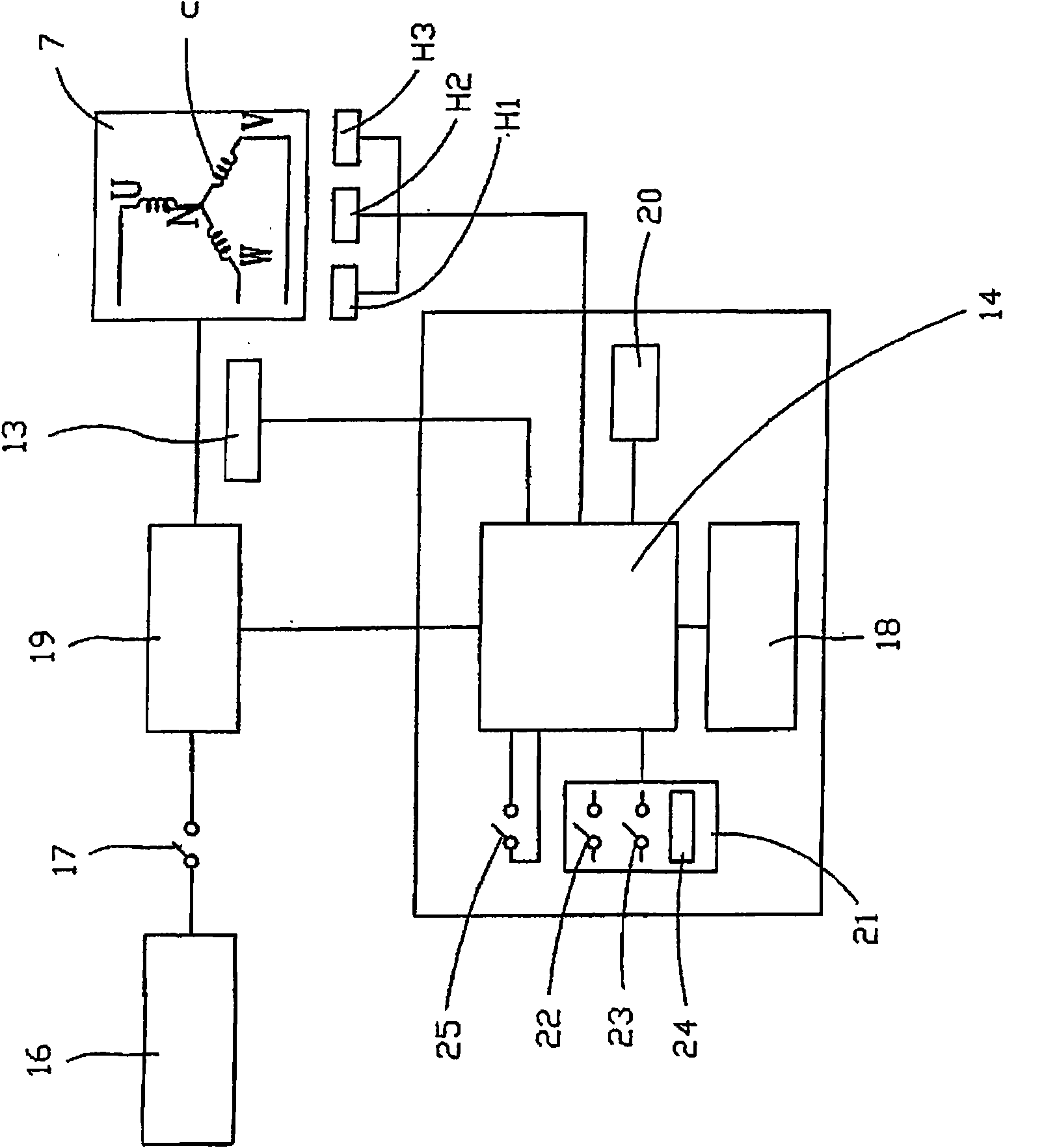

[0026] figure 1 It is a longitudinal sectional view of the main part of the hammer drill. exist figure 1 In , reference numeral 1 indicates the tool body. The tool body 1 includes: a piston 2 with a cylindrical bottom, capable of reciprocating movement; a striking member 3, which is slidably arranged in the piston 2; an intermediate member 4, to which the striking force of the striking member 3 is transmitted, The striking member 3 is capable of performing its striking motion in conjunction with changes in the air pressure of the air chamber S formed between the piston 2 and the striking member 3 due to the back and forth reciprocating motion of the piston 2; Pass to the top tool 5. Piston 2 , intermediate member 4 and tip tool 5 are slidably accommodated in cylinder 6 .

[0027] The motor 7 is housed in the rear of the tool main body 1 , and the output shaft 7 a of the motor 7 engages with the intermediate shaft 8 in a meshing manner. A motion conversion member 9 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com