Arc extinguishing chamber of circuit breaker

An arc extinguishing chamber and circuit breaker technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of slow rise of gas pressure in the compressed air chamber, reducing the gas quality in the compressed air chamber, and hindering the opening movement of the circuit breaker. The effect of prolonging the effective air blowing time, improving the breaking capacity and product reliability, and improving the breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

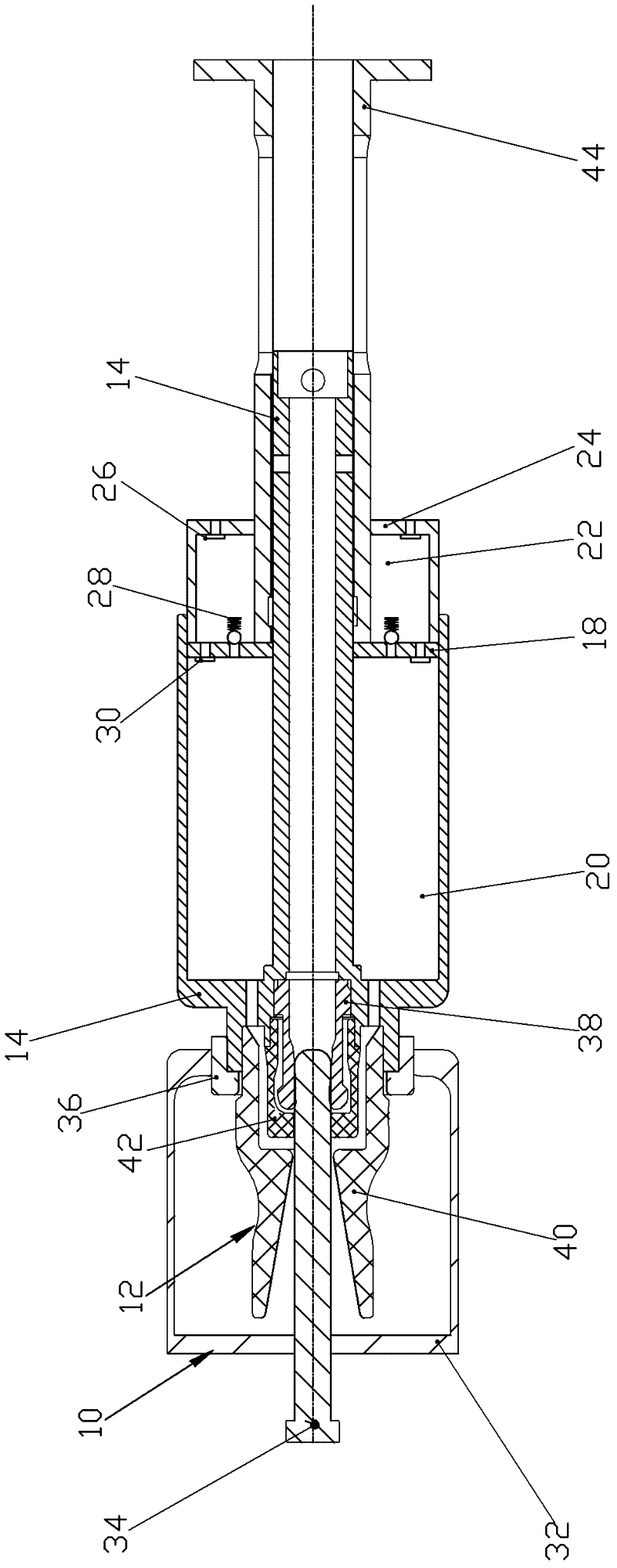

[0026] Please check image 3 and Figure 4 , Circuit breaker interrupter, which includes a static contact module 10, a moving contact module 12, a pressure cylinder 14, a piston 18, a storage chamber 22 and a valve unit.

[0027] The static contact module 10 includes a static main contact 32 and a static arc contact 34 coaxially fixed together.

[0028] The moving contact module 12 includes a moving main contact 36 , a moving arc contact 38 , a large nozzle 40 and a small nozzle 42 . In this embodiment, the moving contact module 12 is matched with the static contact module 10, and the contact and disconnection can be controlled through relative movement. In this embodiment, the moving main contact 36 is compatible with the static main contact 32 , and the moving arc contact 38 is compatible with the static arc contact 34 .

[0029] The cylinder 14 has a cylinder part and a tie rod part, the cylinder part includes a peripheral wall and a front seat arranged at the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com