Patents

Literature

125results about How to "Lower gas temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

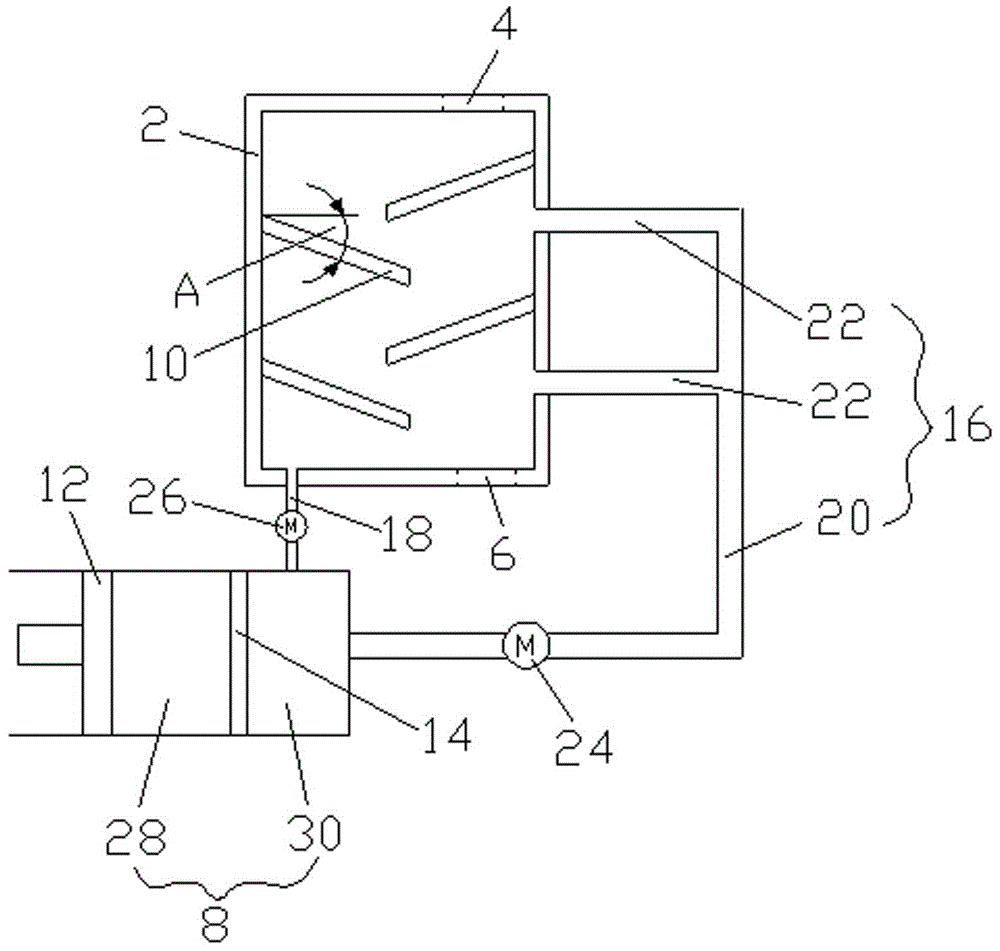

Atomic vapor generation method and device based on dielectric barrier discharge

ActiveCN102519938AReduce distractionsLow detection limitAnalysis by electrical excitationMaterial analysis by electric/magnetic meansHydrogenSignal-to-noise ratio (imaging)

The invention discloses an atomic vapor generation method and device based on dielectric barrier discharge. The method comprises subjecting a mixture of inert gas and hydrogen gas to dielectric barrier discharge under the action of alternating electric field to generate plasma; and allowing a to-be-measured element in a to-be-measured sample to form atomic vapor under the action of the plasma. The inventive device adopts dielectric barrier discharge in which a large number of free radicals and quasi-molecules, such as H, having a very active chemical property are generated, and the free radicals and the quasi-molecules easily react with to-be-measured atoms or other free radicals to generate hydride vapor, so as to effectively separate from the matrix and enter a to-be-measured region; matrix interference brought in by a sample pre-treatment process is reduced to therefore improve the signal to noise ratio of the analyzer and reduce the instrument detection limit, and the device is simple and easy to operate; and dielectric barrier discharge can be realized under the atmospheric pressure, so as to realize small volume, low energy consumption and low gas temperature.

Owner:TSINGHUA UNIV

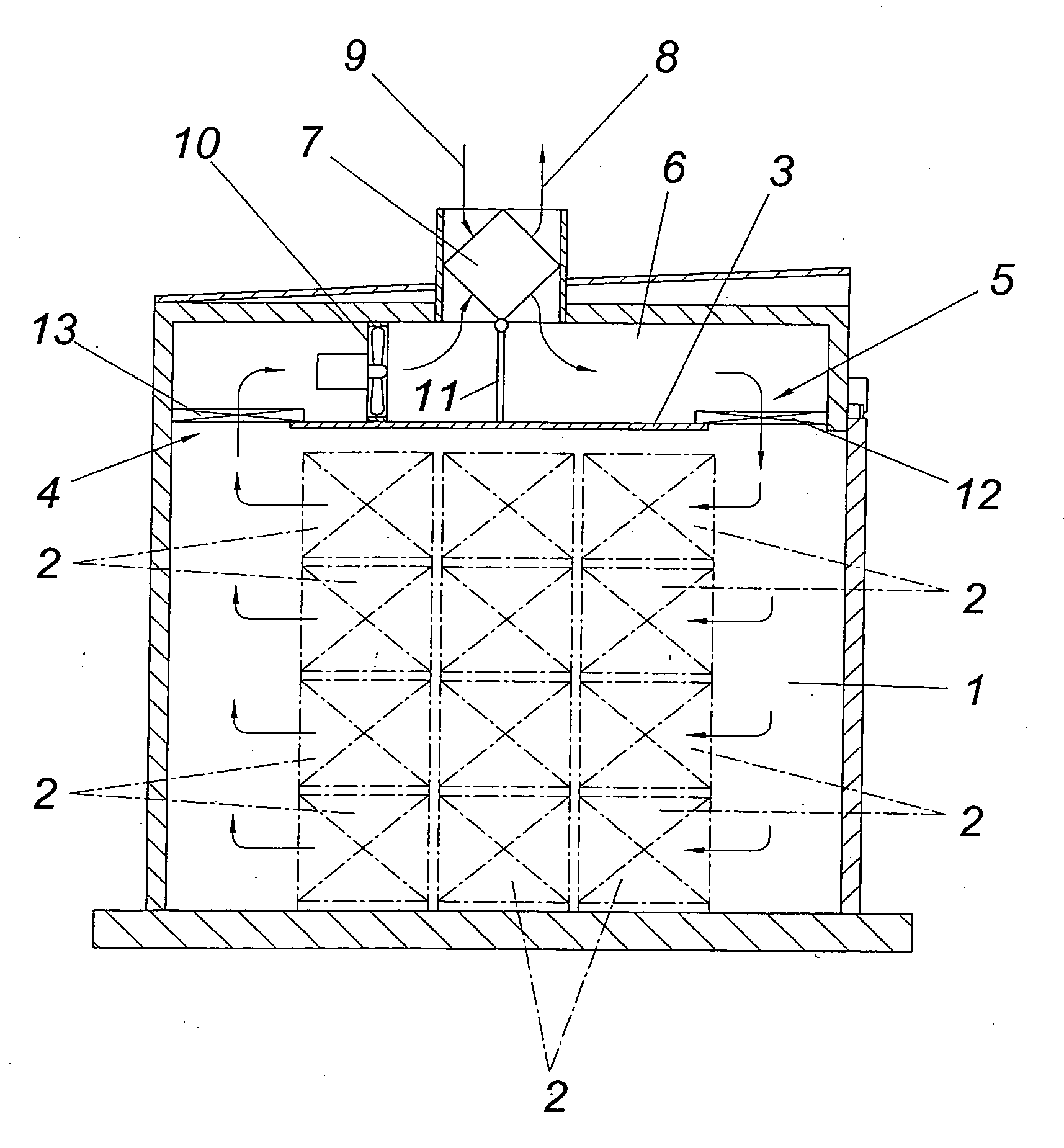

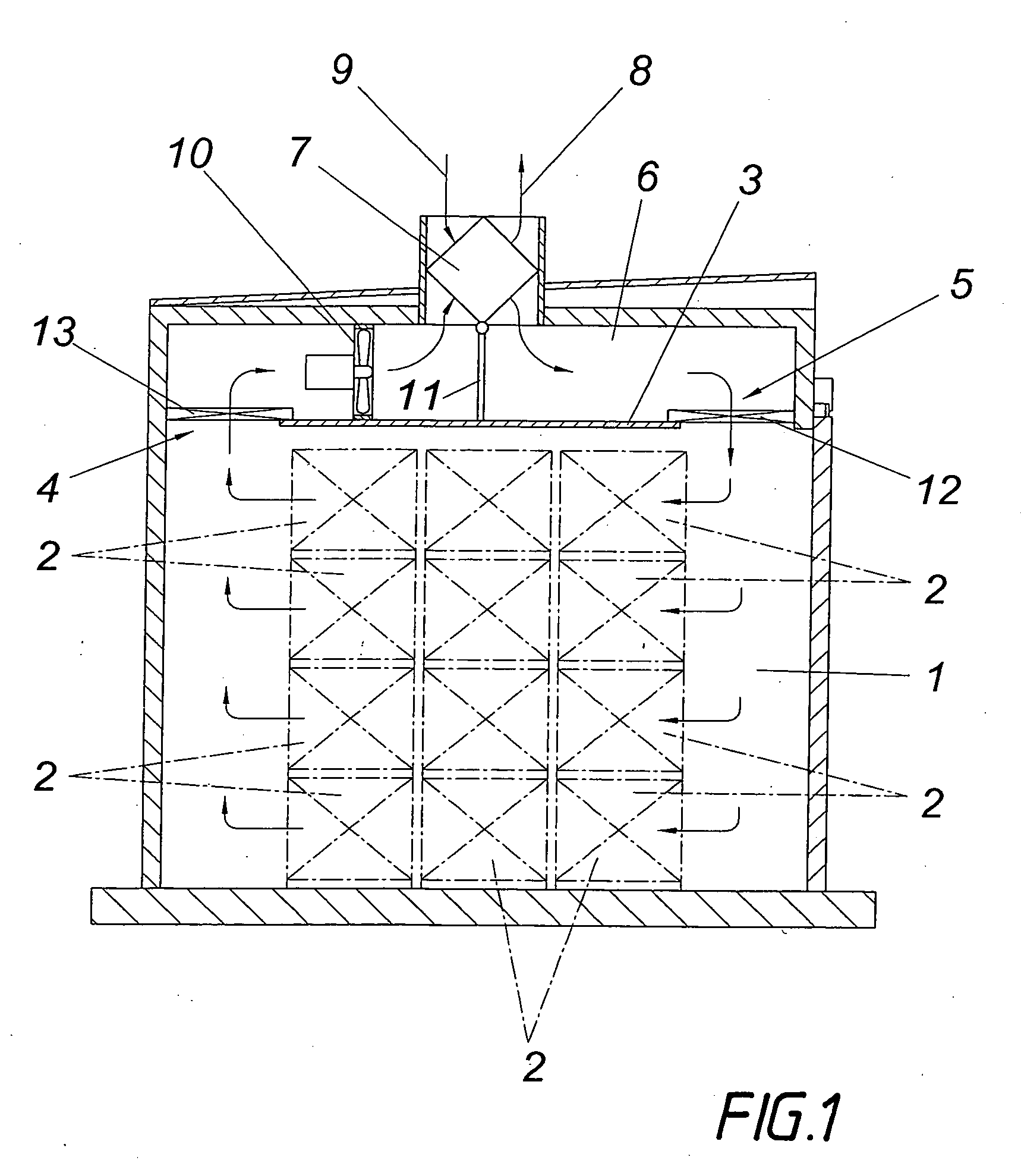

Moisturizing refrigerator and moisturizing control method thereof

ActiveCN101915486AEnhance the water vapor cycleReduce moisture lossLighting and heating apparatusDomestic refrigeratorsRefrigerated temperatureCold store

The invention discloses a moisturizing refrigerator and a moisturizing control method thereof. The moisturizing refrigerator comprises a refrigerating chamber in which a moisturizing buffer space for generating condensate water is arranged; and an air guiding device and a moistening device are also arranged in the refrigerating chamber, wherein the air guiding device is used for guiding air in the refrigerating chamber into the moisturizing buffer space, and the moistening device is used for moistening the refrigerating chamber by utilizing the condensate water generated in the moisturizing buffer space. Because the water vapor circulation in the refrigerating chamber is enhanced, the humidity in the refrigerating chamber can be effectively increased and kept at 80%-90%, andthe refreshing effect of the refrigerating chamber is obviously improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

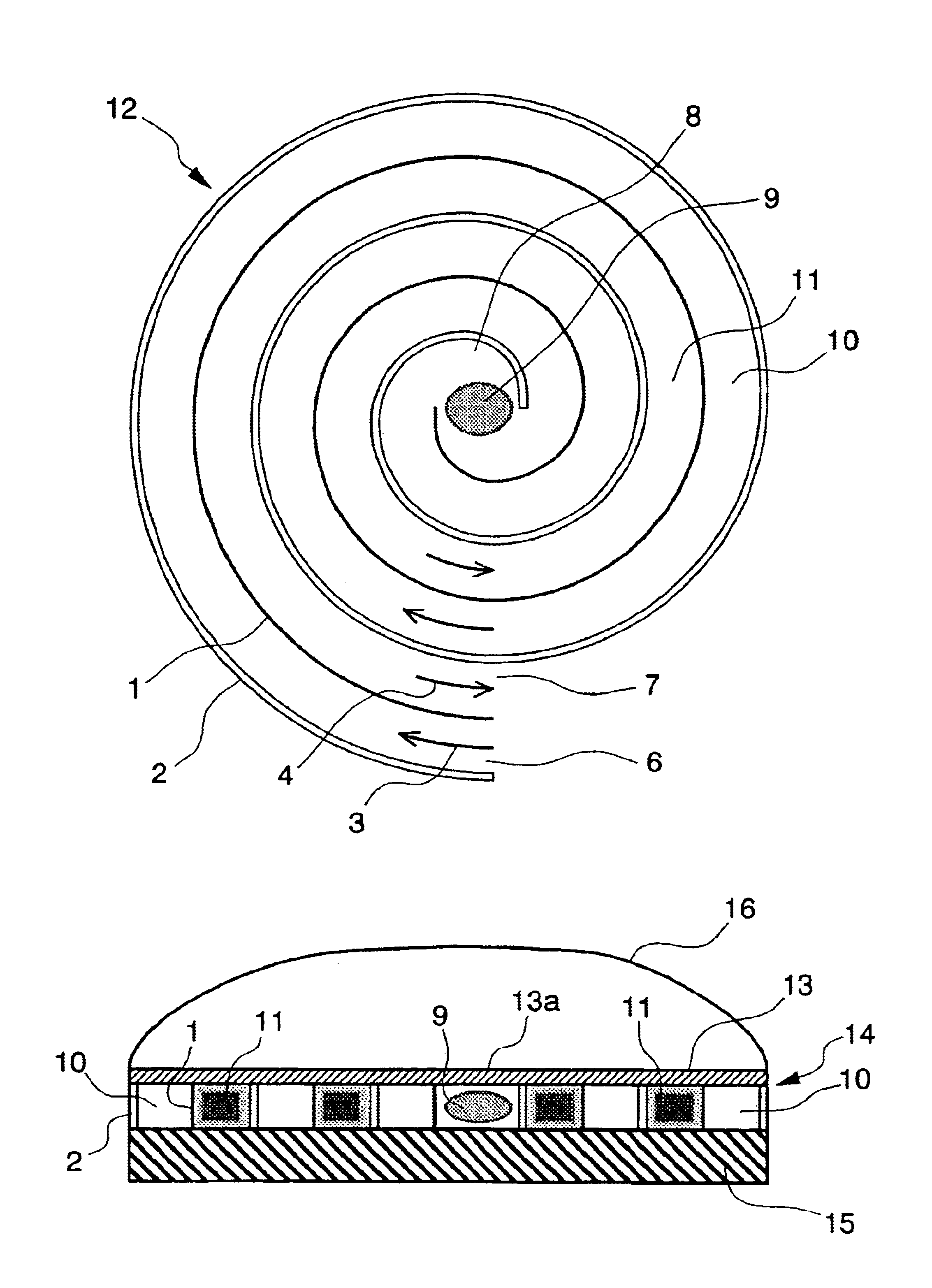

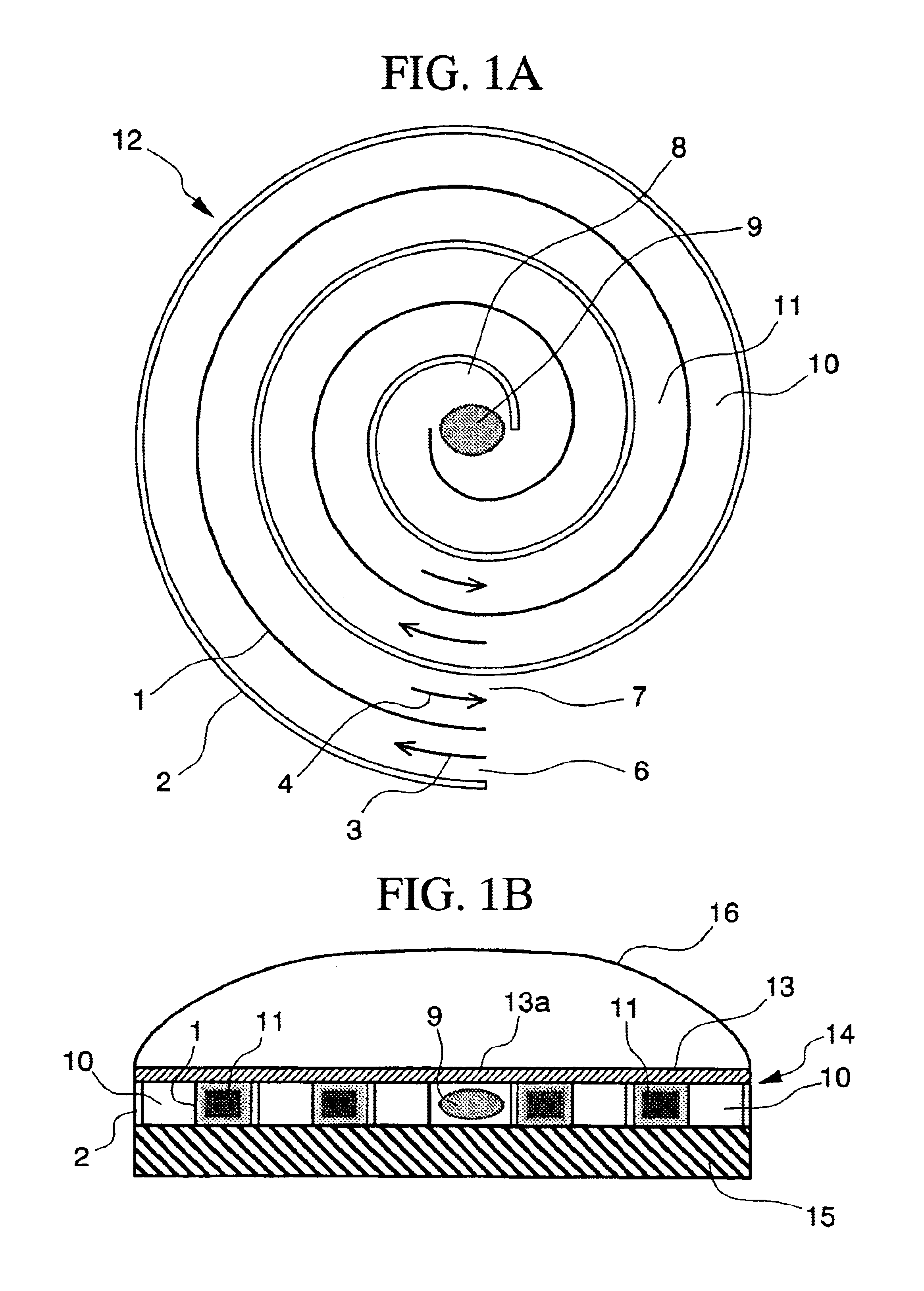

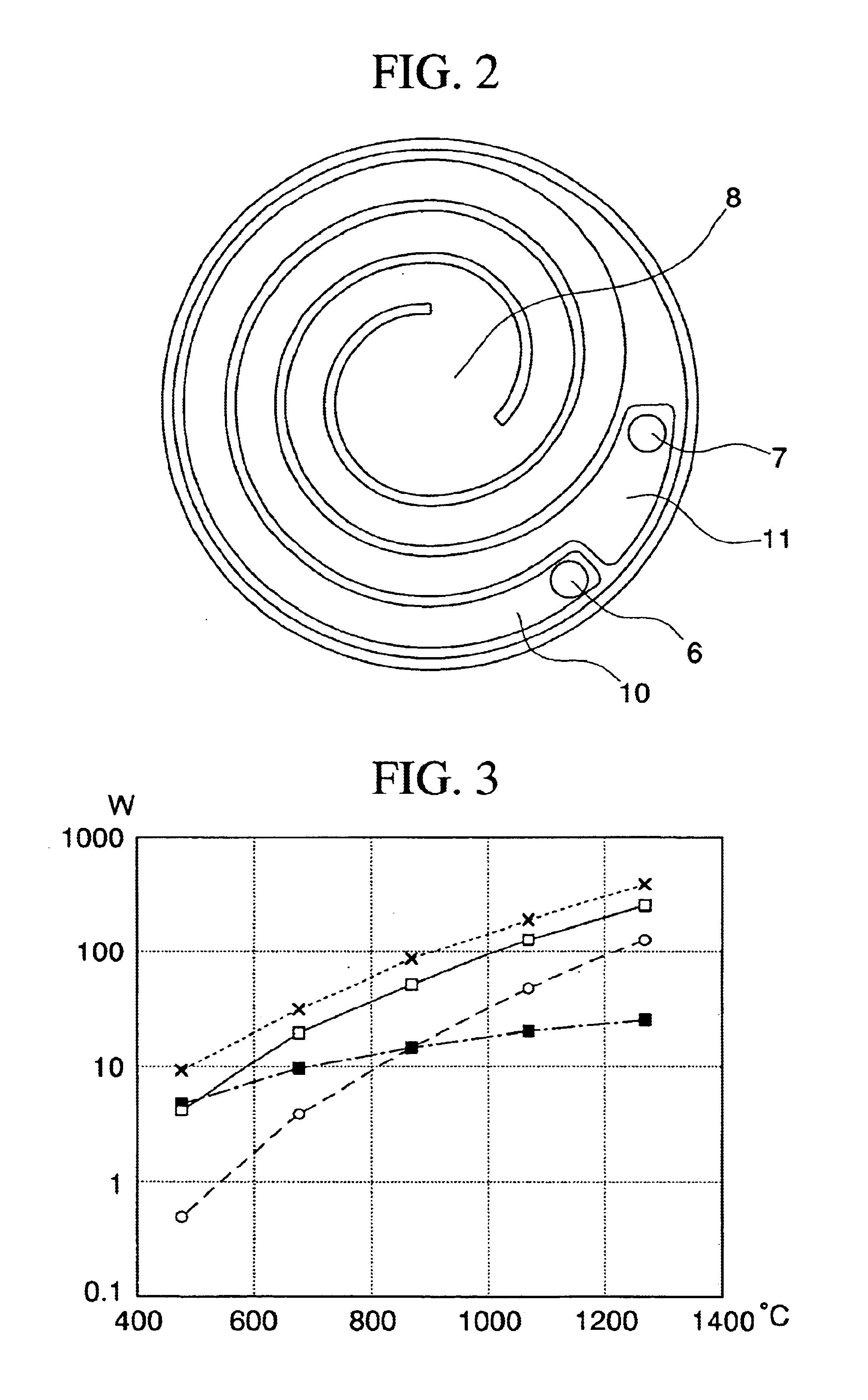

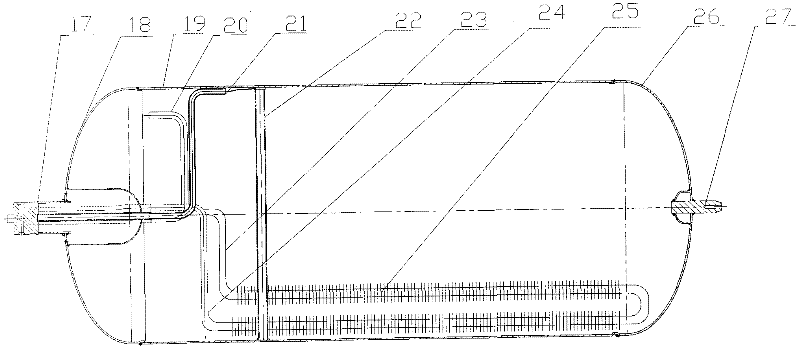

Microcombustion heater having heating surface which emits radiant heat

InactiveUS6840762B2Reliable combustionHigh thermal efficiencyFurnace componentsIndirect carbon-dioxide mitigationRadiant heaterCombustion chamber

A small microcombustion heater which can realize reliable combustion. The heater has a premixed gas passage which reaches a combustion chamber, and a passage for a combustion gas drawn from the combustion chamber. The passages are arranged in a spiral form in a manner such that a heating wall is provided between the passages. The width of the premixed gas passage is a quenching distance or less, where the quenching distance is determined depending on the premixed gas. The heater has two outer faces for holding the spiral passages from both sides of the upper and lower edges of the heating wall, and at least one of the outer faces is a heating surface for emitting radiant heat. Typically, the spiral passages are placed between a heat-resisting heating plate and a heat insulating plate, and an outer face of the heat-resisting heating plate functions as the heating surface.

Owner:MARUTA KAORU +1

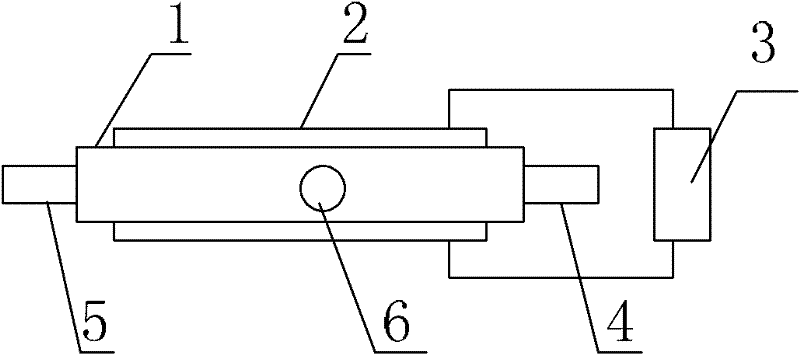

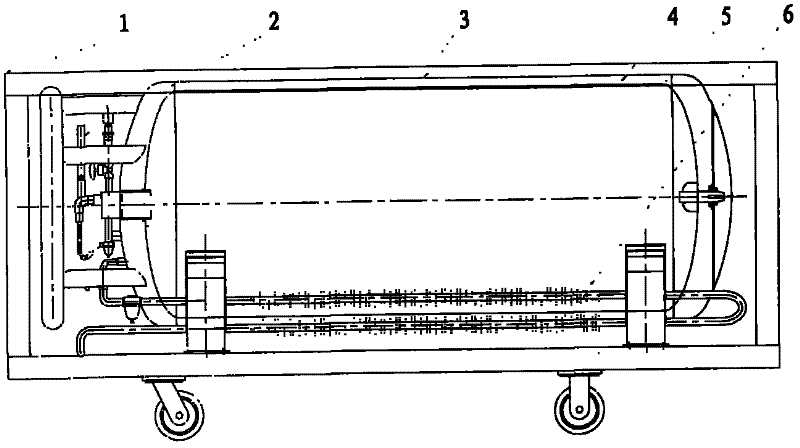

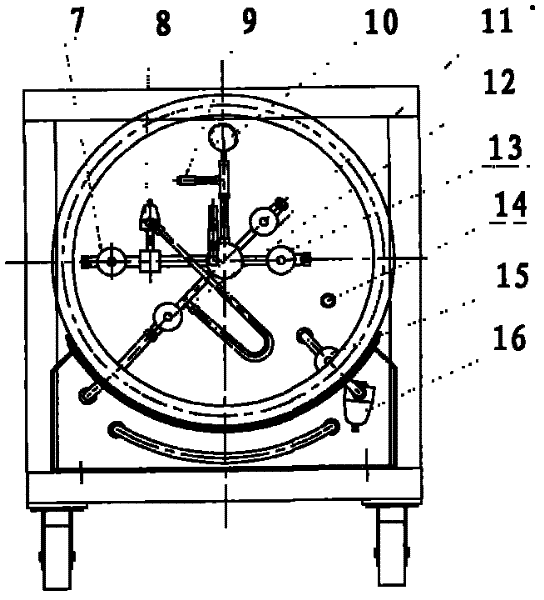

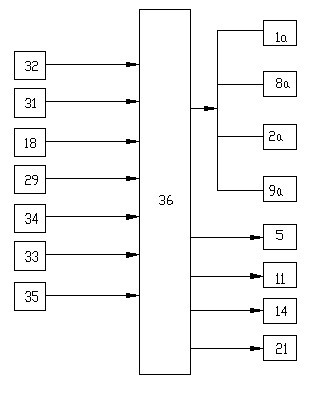

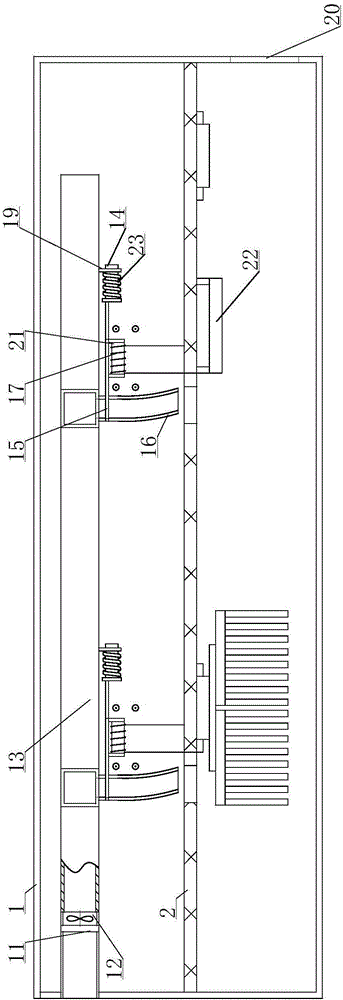

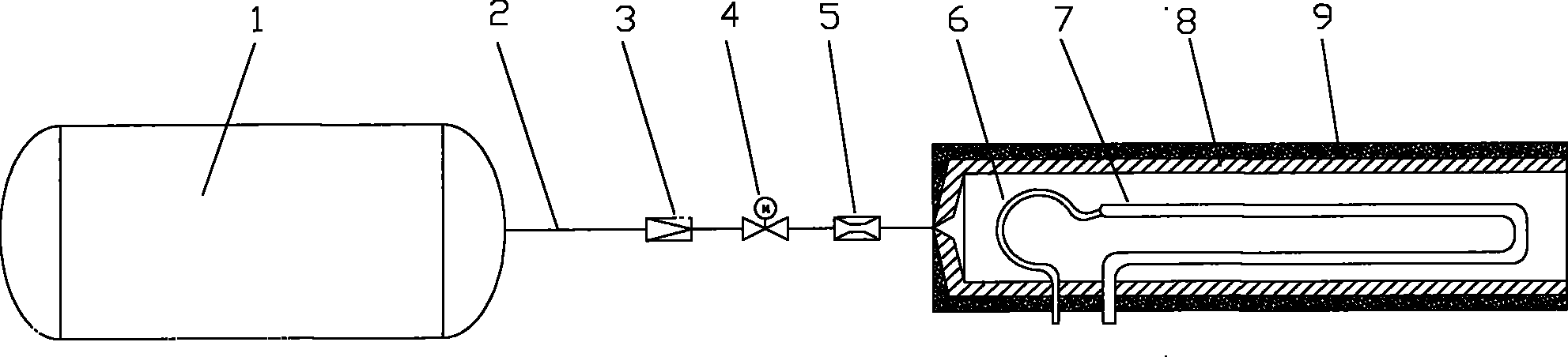

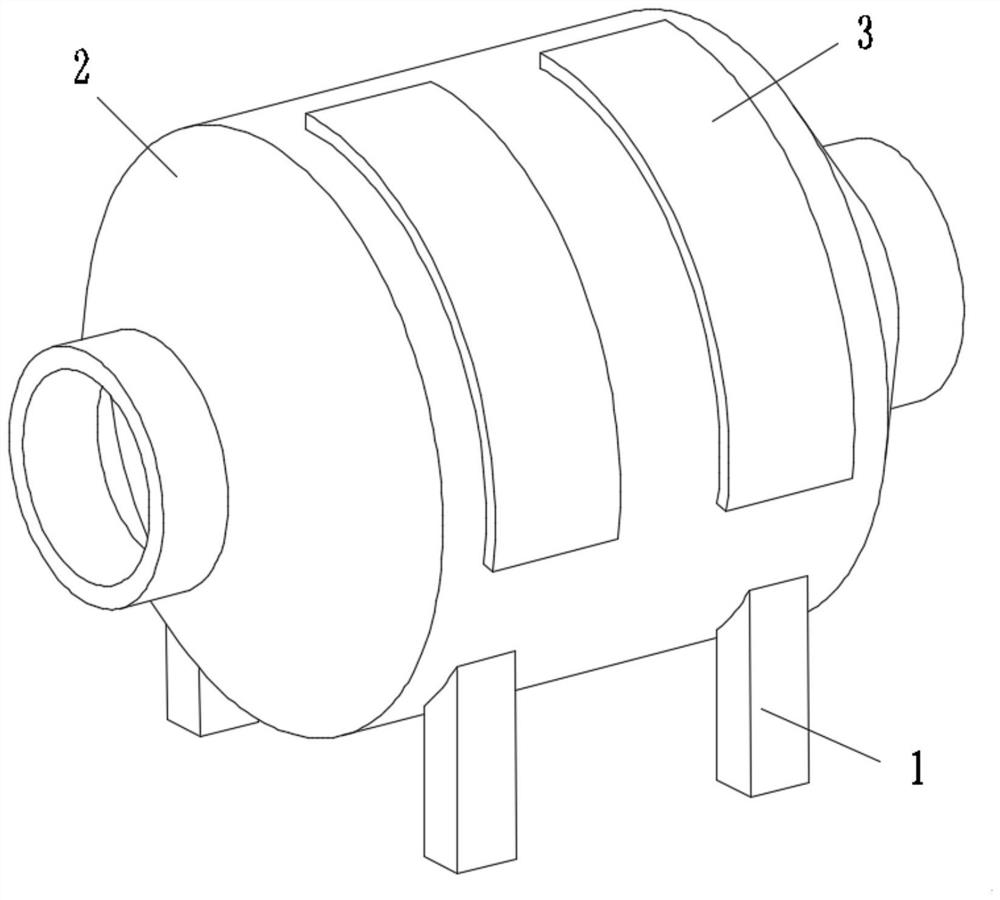

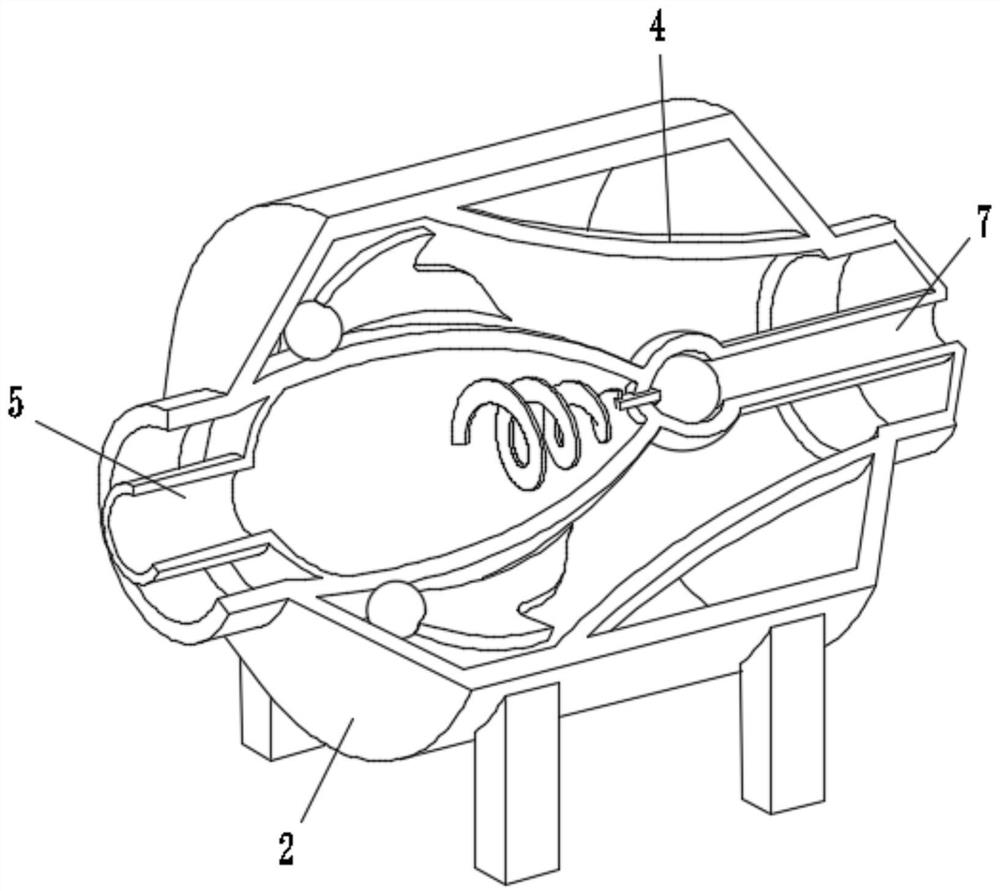

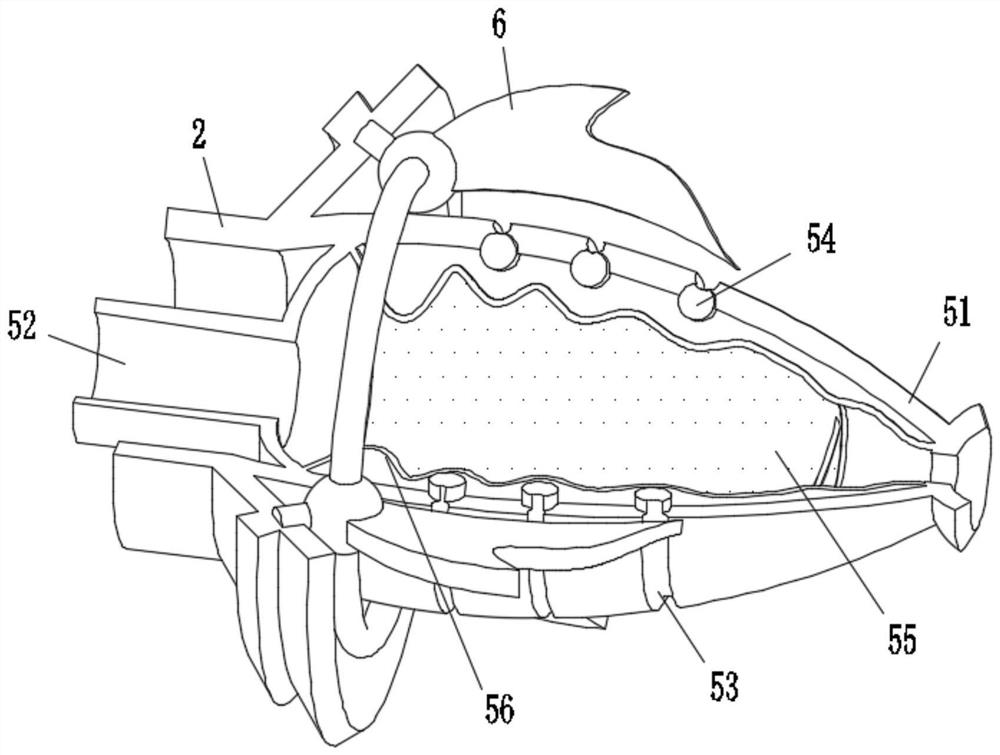

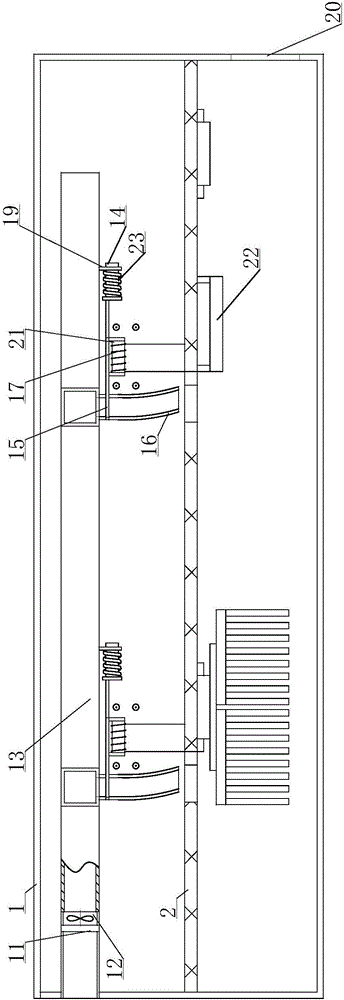

A low-temperature gas supply device

InactiveCN102261558AImprove methodReduce energy consumptionContainer filling methodsPressure vesselsProcess engineeringGas supply

The invention relates to a gas supplying apparatus, and discloses a low temperature gas supplying apparatus. The low temperature gas supplying apparatus comprises a supporting carriage, a valve and pipe system, a housing, a heat insulation interlayer, an inner liner, a vaporizer, a front supporting component, a rear supporting component, and a cooling shield. The housing is fixed on the supporting carriage. The inner liner is connected to the housing through the front supporting component and the rear supporting component. The valve and pipe system is arranged on the front part of the housing. The vacuum insulation interlayer is formed between the inner liner and the housing. The cooling shield is arranged in the lower part of the inner liner. With the apparatus provided by the present invention, low temperature liquid can be stored, and low temperature gas can be supplied. The apparatus has advantages of simplified structure, complete functions, and convenient and flexible low temperature gas supplying capacity. The apparatus is safe, environment protecting, energy saving, and is readily available. The apparatus is suitable for scientific institutions, and is suitable for scientific research fields of aeronautics and astronautics.

Owner:青岛瑞丰气体容器设备有限公司

Gas generating agent for automobile safe gasbag and preparing method thereof

InactiveCN101234943AEasy to mold and releaseImprove adsorption capacityPressure gas generationCarboxymethyl celluloseSesquioxide

The invention discloses an automobile airbag gas generating agent and a preparation method thereof. The invention is characterized in that 30 to 50 percent of guanidine nitrate, 5 to 20 percent of basic cupric nitrate, 10 to 25 percent of strontium nitrate, 3 to 10 percent of ammonium perchlorate, 2 to 6 percent of iron sesquioxide, 2 to 10 percent of sodium carboxymethyl cellulose and 2 to 5 percent of caoline taken in accordance with the weight percentages are mixed thoroughly; after distilled water is added, the mixture is heated and kneaded and cooled for granulation; obtained particles are then dried and sieved to get the gas generating agent. Raw materials for products to be made with the method of the invention are easy to acquire and have low prices. The production process is safe and conducive to safety of automobile occupants and also to environment protection.

Owner:烟台安泰德汽车安全系统有限公司

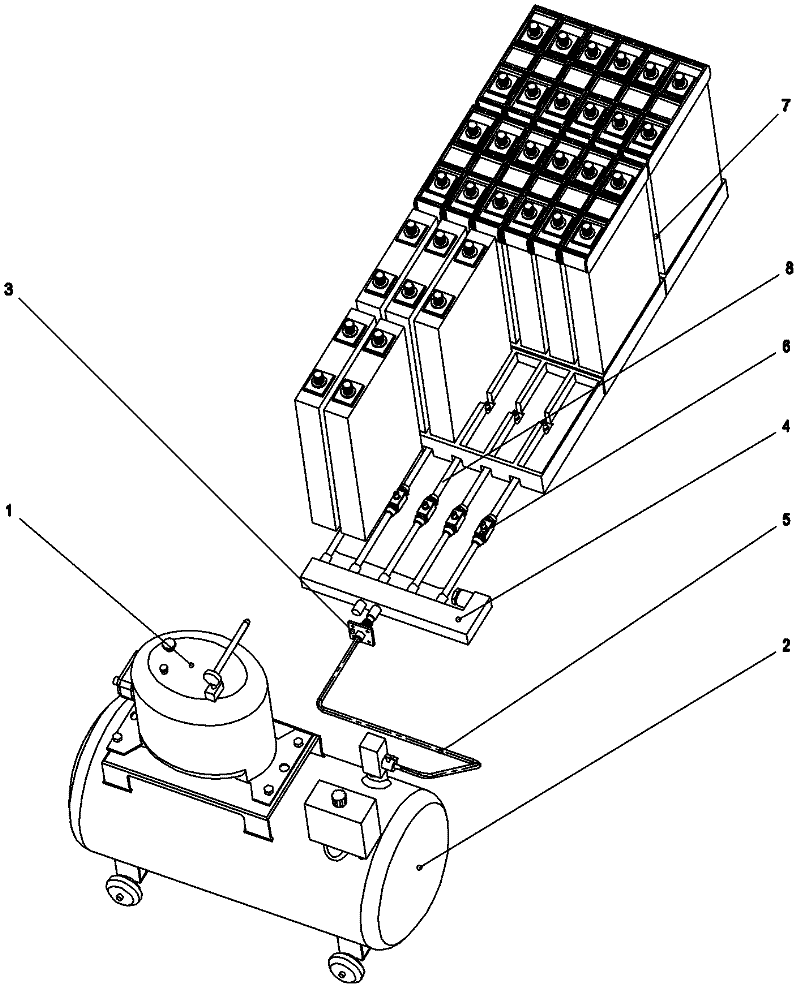

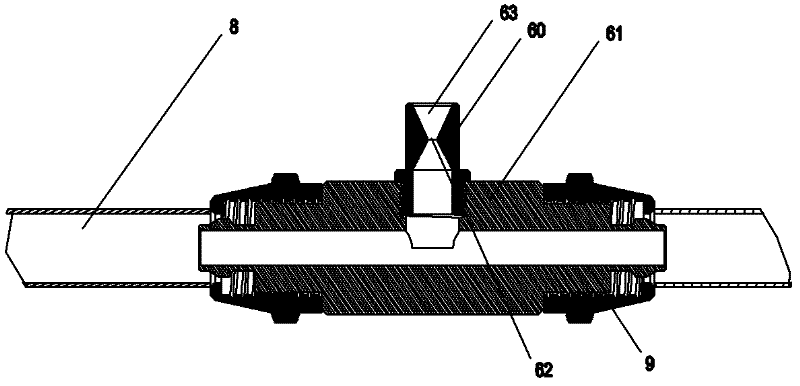

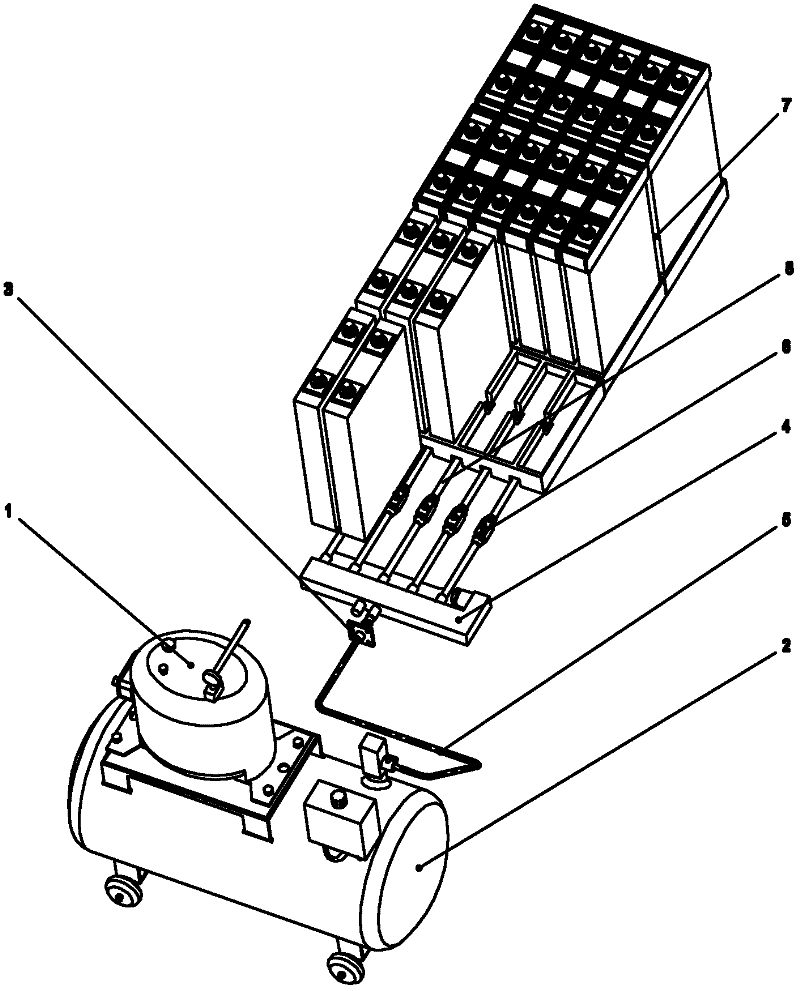

Forced air cooling system for large assembled lithium ion battery

ActiveCN102386460AInstantaneous pressure drop at ejectionReduce the temperatureSecondary cellsSolenoid valveUltrasonic nozzle

The invention provides a forced air cooling system for a large assembled lithium ion battery. The system is characterized in that: the system comprises a compressor, an air storage tank with a condenser, an air inlet interface, a solenoid valve, an air supply tube, ultrasonic nozzles, and an air outlet channel; the air storage tank is connected with the compressor, and compressed air which is compressed by the compressor enters the air storage tank and is cooled; the air storage tank is connected with one or more air supply tubes which are connected with the solenoid valve through the air inlet interface, the solenoid valve is connected with one or more branched air supply tubes which are respectively provided with one or more ultrasonic nozzles, and the one or more ultrasonic nozzles arearranged in a storage container of the assembled lithium ion battery. The system of the invention, which has the characteristics of simple structure, small occupation space, obvious cooling effect, light weight and the like and provides air cooling for assembled batteries of an automobile power battery pack module, an energy storage battery pack module and the like, has a very high practical value and a wide market prospect, and especially has a wide application space in fields of large capacity high voltage energy storage batteries and power batteries.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

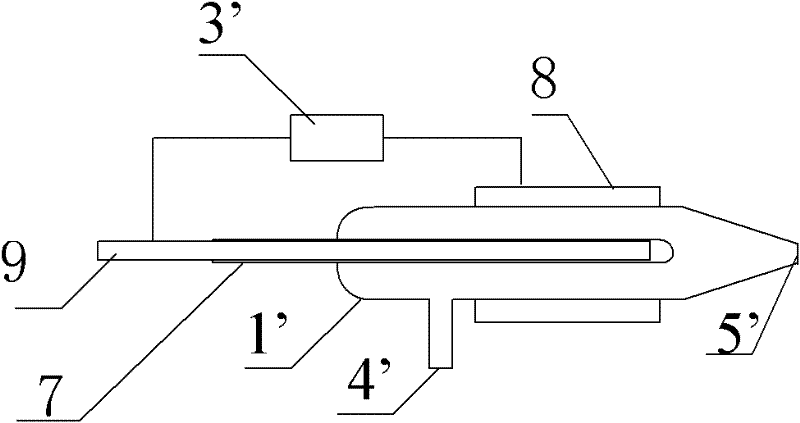

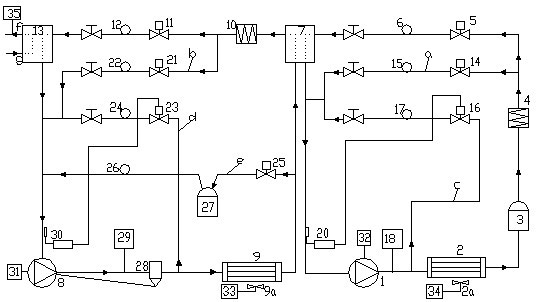

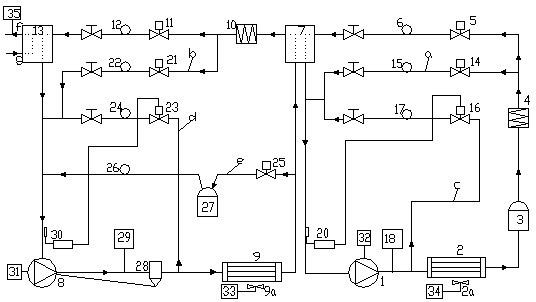

Low temperature cold air two-stage refrigeration system and cold air jet machine thereof

ActiveCN102003823AReduce jet velocityLower gas temperatureCompression machines with cascade operationFluid circulation arrangementEngineeringCold blast

The invention discloses a low temperature cold air two-stage refrigeration system and a cold air jet machine thereof. A two-stage refrigeration structure is used, and the gas temperature at a cold air jet outlet can be effectively decreased to -60 DEG C minimum; an air cooler is used, thereby having high jet speed, being beneficial to breaking and removing chips, and having low cooling temperature suitable for high speed and high accuracy machining; and simultaneously, the two-stage refrigeration structures is respectively with a refrigeration bypass used for cooling a medium at the inlet of a compressor; therefore, along with the prolonged life cycle, the temperature of the compressor can not rise without limit, thereby keeping a long-time proper operating state. Through the regulation of the flow rate of the medium of the refrigeration bypass, the temperature of the cold air is capable of being regulated indirectly; the structure is simple, the operation is convenient, and the use cost is decreased.

Owner:重庆高洁绿色机械设备智能制造研究院有限公司

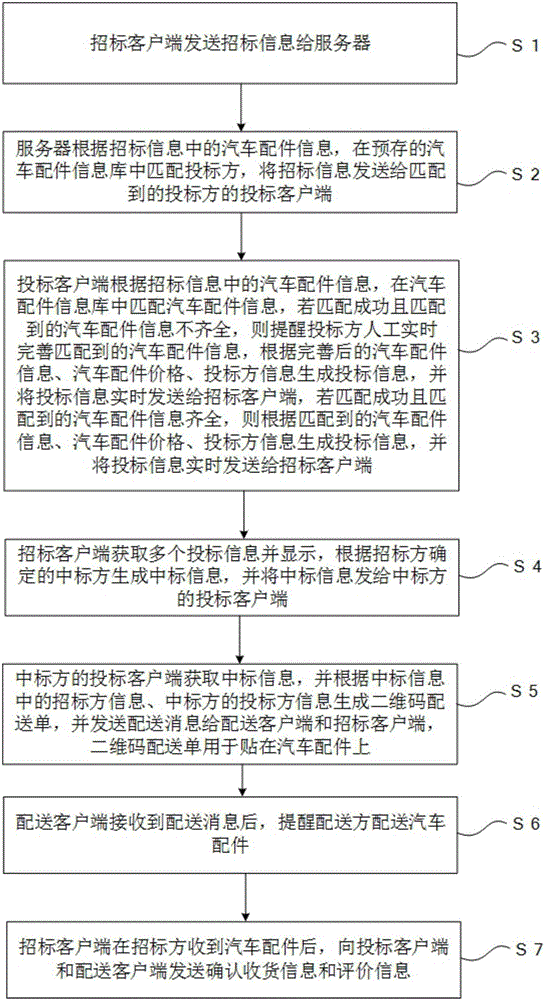

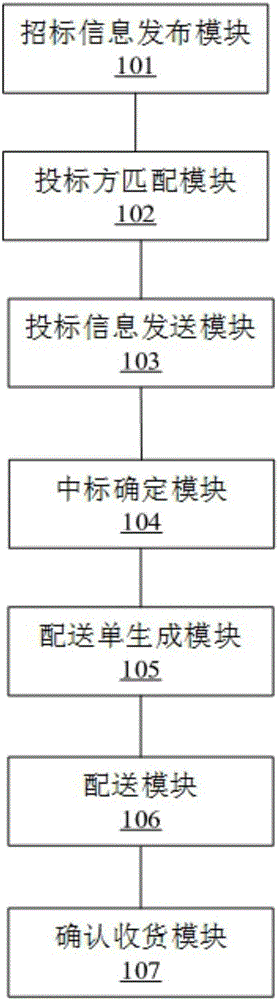

Automobile part network transaction method and system

PendingCN106327302AFast and convenient deliveryEasy to buy and sellFinanceDigital data processing detailsClient-sideComputer science

The invention concretely relates to an automobile part network transaction method and system. The method comprises the steps that a bid inviting client side transmits bid inviting information to a server; the server performs matching of appropriate bid winners and transmits the bid inviting information to bidders; bidding client sides perform matching of automobile parts according to the bid inviting information and perform automatic bidding or artificial bidding according to the matching result so as to generate bidding information and transmit the bidding information to the bid inviting client side; the bid inviting client side acquires and displays multiple pieces of bidding information, determines the bid winner and generates bid winning information and transmits the bid winning information to the bid winner; the bidding client side of the bid winner generates a two-dimensional code delivery order and transmits a delivery message to a delivery client side; the delivery client side prompts a delivery side to perform delivery according to the delivery message; and the bid inviting side receives the automobile parts and then confirms receiving of the automobile parts through the bid inviting client side and performs evaluation. According to the automobile part network transaction method and system, buying and selling and delivery of the automobile parts are enabled to be more convenient and rapid through smooth interaction and cooperation of the three side of the bid inviting client side, the bidding client sides and the delivery client side.

Owner:张军

Liquid-propellant rocket engine injector integrated with electric igniter

PendingCN109798202ASimple structureSimple designRocket engine plantsIndirect carbon-dioxide mitigationLiquid-propellant rocketOxidizing agent

The invention discloses a liquid-propellant rocket engine injector integrated with an electric igniter. The liquid-propellant rocket engine injector comprises a bottom plate, an outer barrel, fuel nozzles, oxidizing agent nozzles, a top cover and an igniter plug; the outer barrel is connected with the top cover and provided with a center shaft, and the center shaft is connected with the barrel wall of the outer barrel through an annular transverse plate; an inner cavity of the outer barrel is divided into an upper cavity and a lower cavity through the annular transverse plate; the side wall ofthe lower cavity is provided with fuel through holes, and the bottom of the lower cavity is connected with the bottom plate; the bottom plate is uniformly provided with a plurality of fuel nozzle fixing holes, the annular transverse plate is uniformly provided with a plurality of oxidizing agent nozzle fixing holes, the oxidizing agent nozzle fixing holes correspond to the fuel nozzle fixing holes one by one, and each fuel nozzle and the corresponding oxidizing agent nozzle are connected between each pair of fuel nozzle fixing hole and oxidizing agent nozzle fixing hole in a matched mode; theposition, in the upper cavity, of side wall of the center shaft is uniformly provided with oxidizing agent through holes, and the position, in the lower cavity, of side wall of the center shaft is uniformly provided with a set of upper fuel through holes and a set of lower fuel through holes. The liquid-propellant rocket engine injector is suitable for a double-component liquid-propellant rocketengine, the electric igniter and the injector are combined into a whole, and system simplified design is achieved.

Owner:北京宇航推进科技有限公司

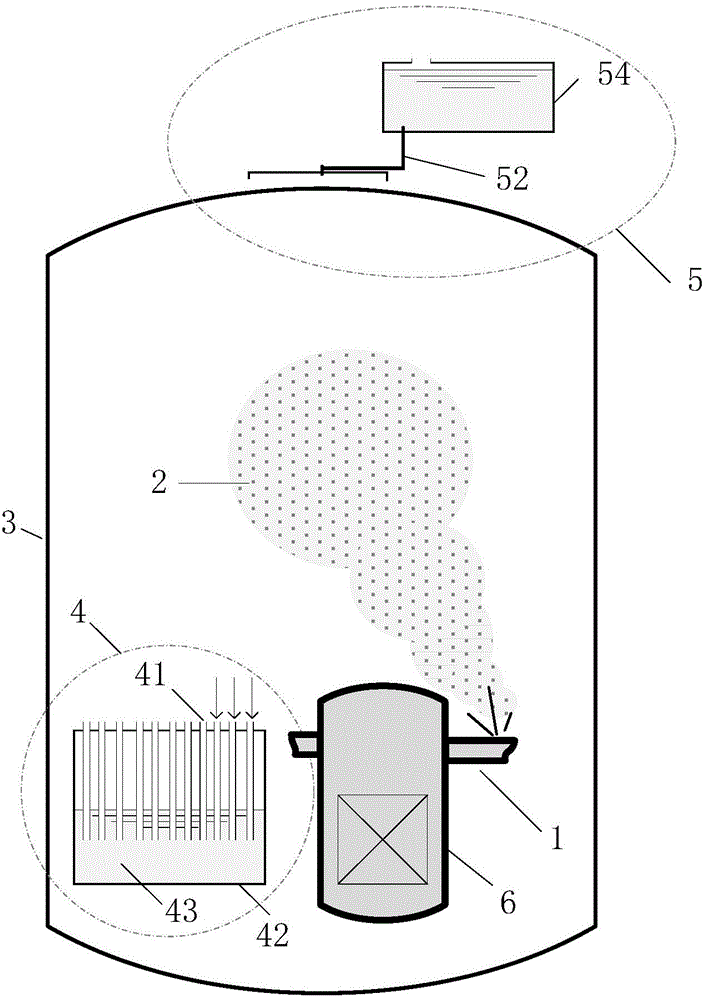

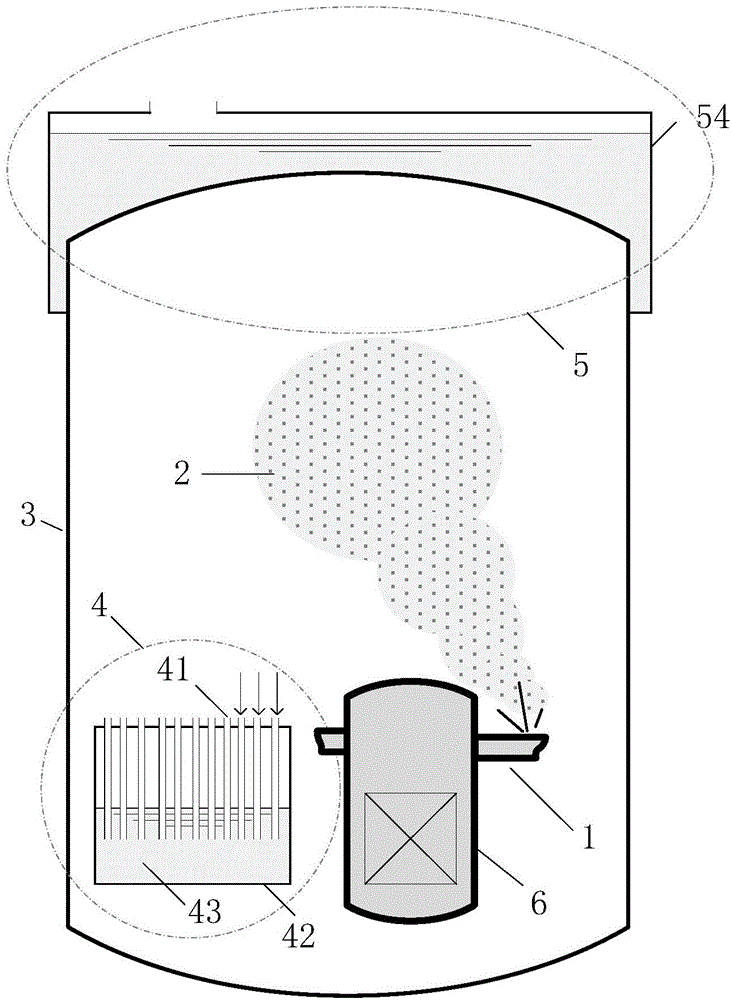

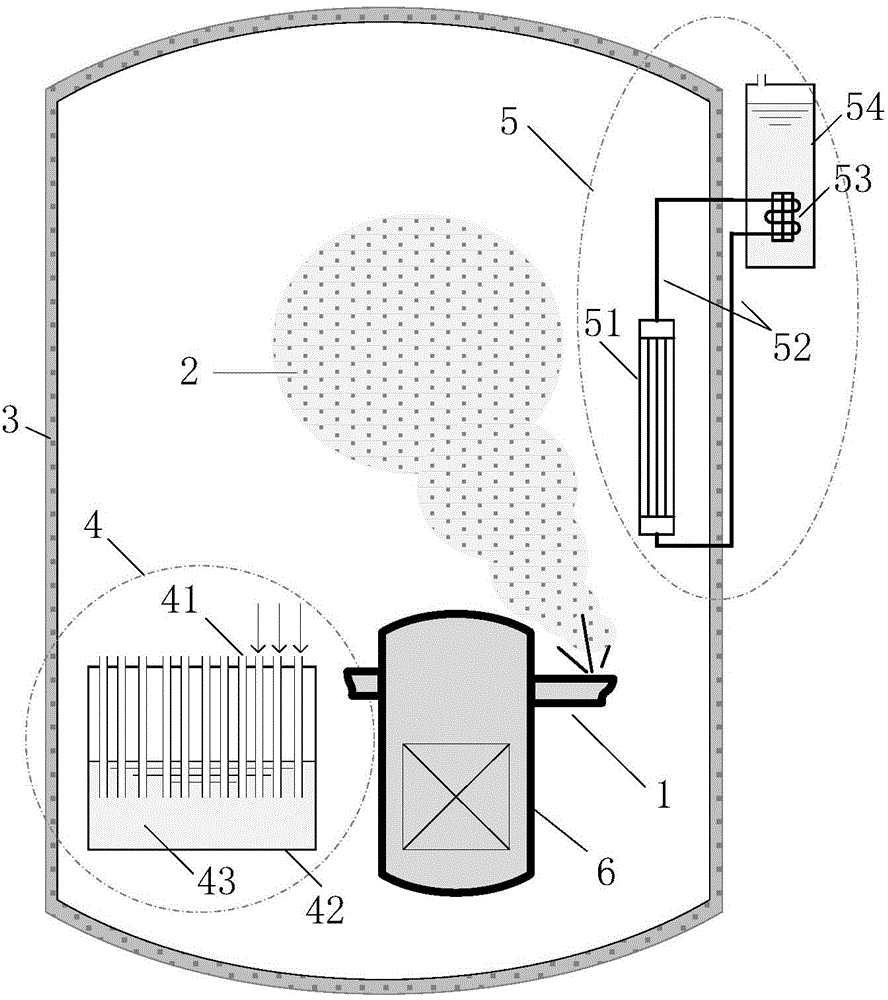

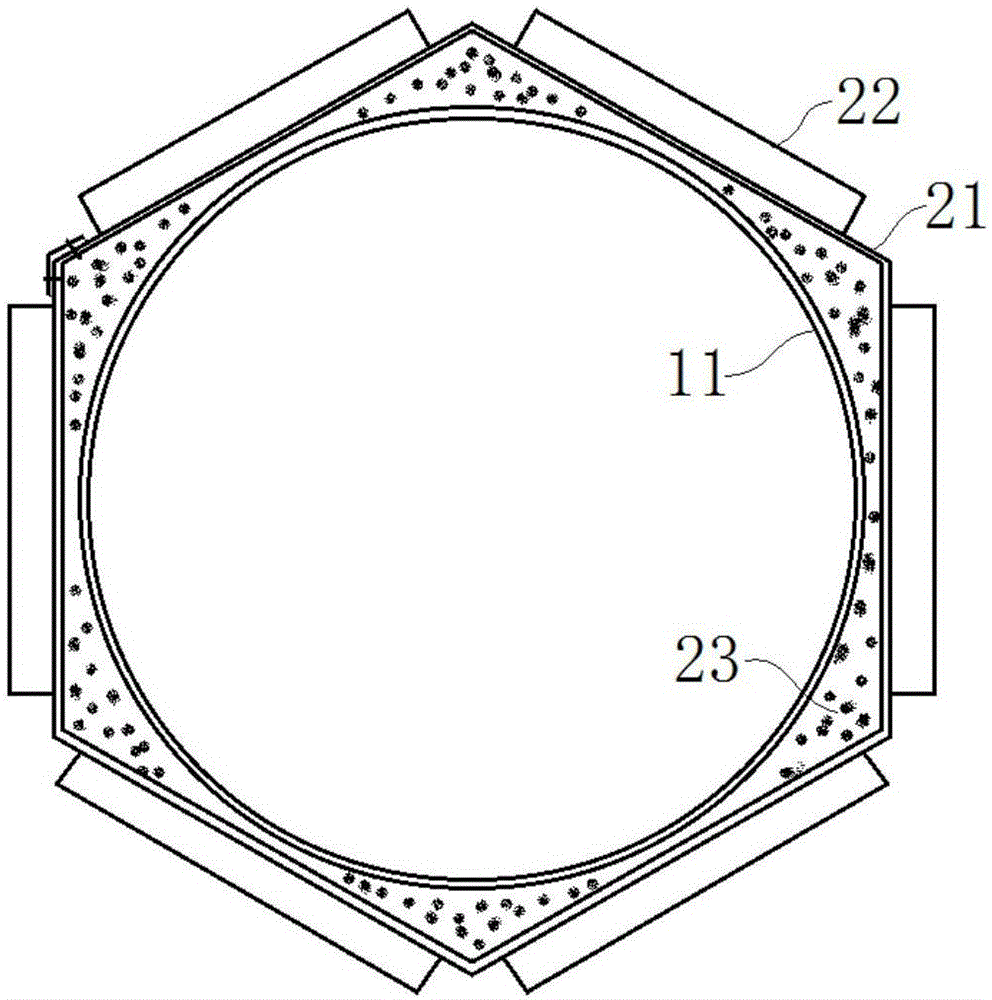

Passive containment cooling and pressure-reducing system

InactiveCN104835541AImprove securityControl pressureNuclear energy generationEmergency protection arrangementsNuclear engineeringWater tanks

The invention provides a passive containment cooling and pressure-reducing system. A reactor is arranged in the containment. The system includes a containment pressure-inhibiting sub system and a containment cooling sub system, wherein the containment pressure-inhibiting sub system includes a pressure-inhibiting water tank and a discharge channel arranged in the containment. The containment cooling sub system can be arranged in various structures. The containment cooling sub system and the containment pressure-inhibiting sub system are passive and are free from being driven by external power supplies. In the invention, by means of the passive measurement for reducing vapor amount and reducing gas temperature, the pressure in the containment is reduced, so that not only are functions of early-stage peak clipping and pressure reducing and long-time cooling and pressure reducing satisfied but also the volume of the containment is not necessary to increase, thereby reducing design size of the containment and furthermore reducing cost.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

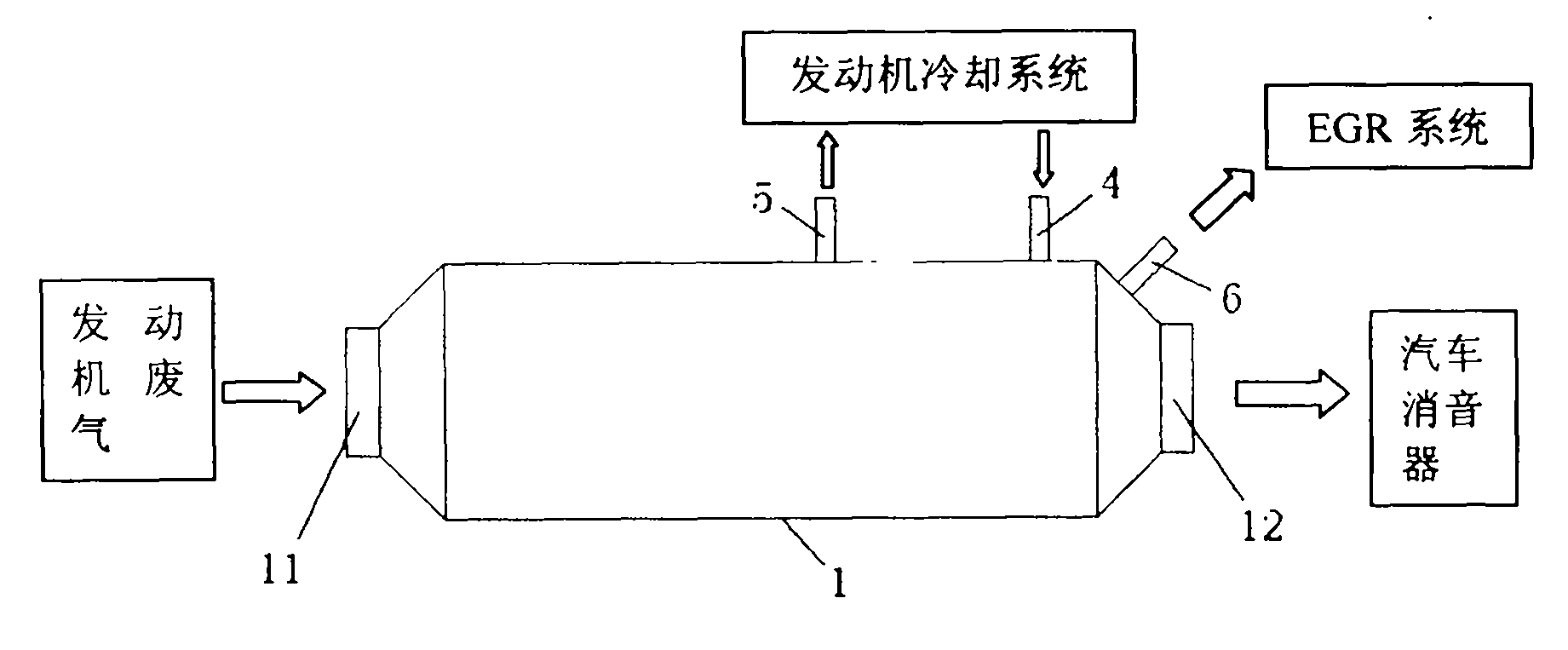

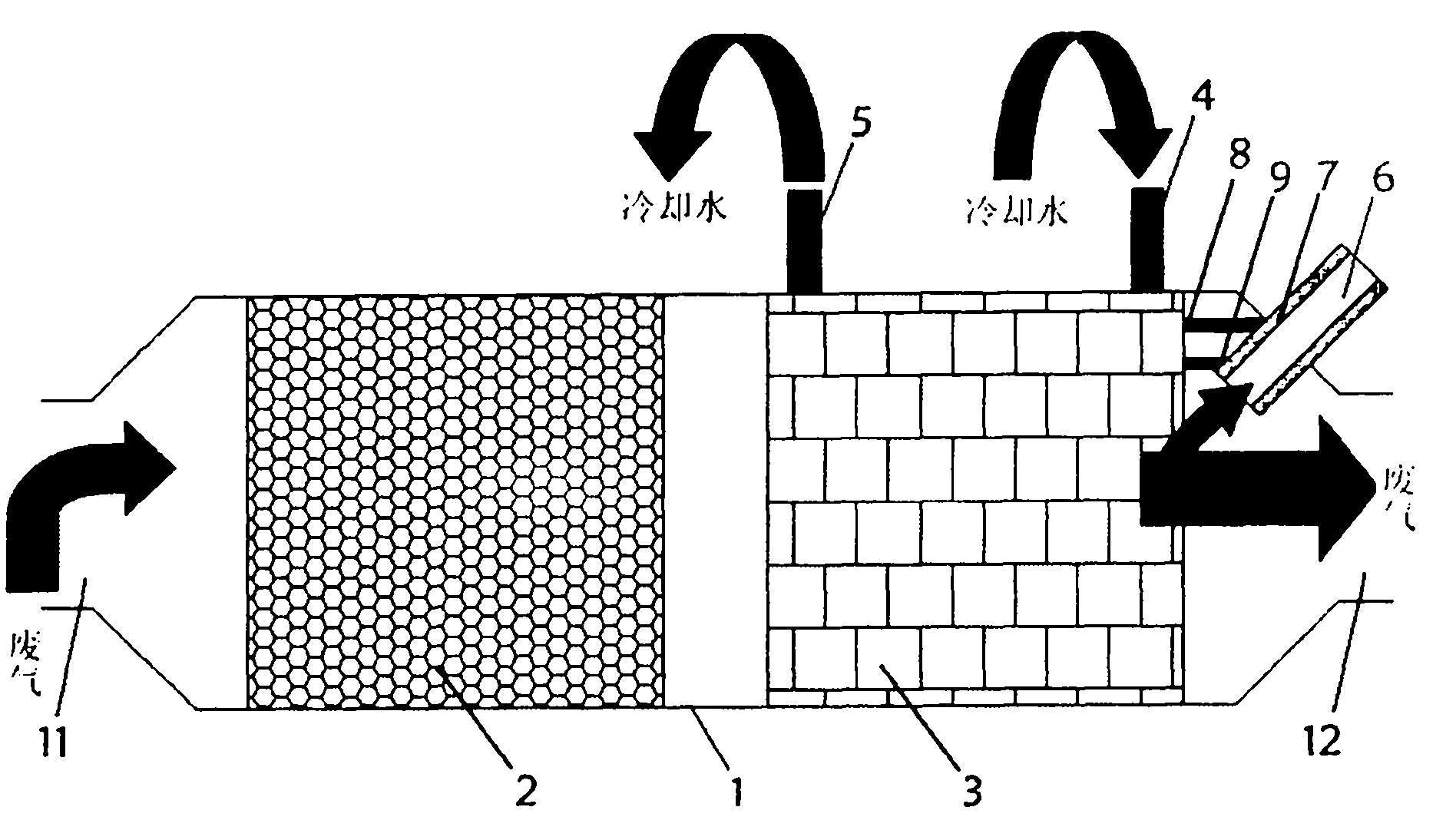

Engine waste gas energy utilization device and automobile using same

ActiveCN101956594ASimple structureCompact structureInternal combustion piston enginesExhaust apparatusHigh energyClosed loop

The invention provides an engine waste gas energy utilization device with a compact structure and high energy utilization rate and an automobile using the same. The device comprises a hollow shell with an air inlet and an air outlet, wherein a catalytic carrier of a three-way catalytic converter and a thermoelectric conversion element are arranged along the flowing direction of waste gas in the shell in turn; and a temperature difference generation device to be communicated with the cooling pipe of the automobile is arranged at the position close to the thermoelectric conversion element on the shell. The structure of the automobile using the engine waste gas energy utilization device is as follows: the waste gas outlet of the engine of the automobile is communicated with the air inlet of the shell of the engine waste gas energy utilization device; the air inlet of the muffler of the automobile is communicated with the air outlet of the shell of the engine waste gas energy utilization device; the cooling system of the automobile is communicated with the temperature difference generation device to form closed-loop circulation; and the electrodes of the storage battery of the automobile are connected with the electrode of the thermoelectric conversion element. The engine waste gas energy utilization device has a simple and compact structure and can utilize the waste gas for generating power and reduce oil consumption.

Owner:CHERY AUTOMOBILE CO LTD

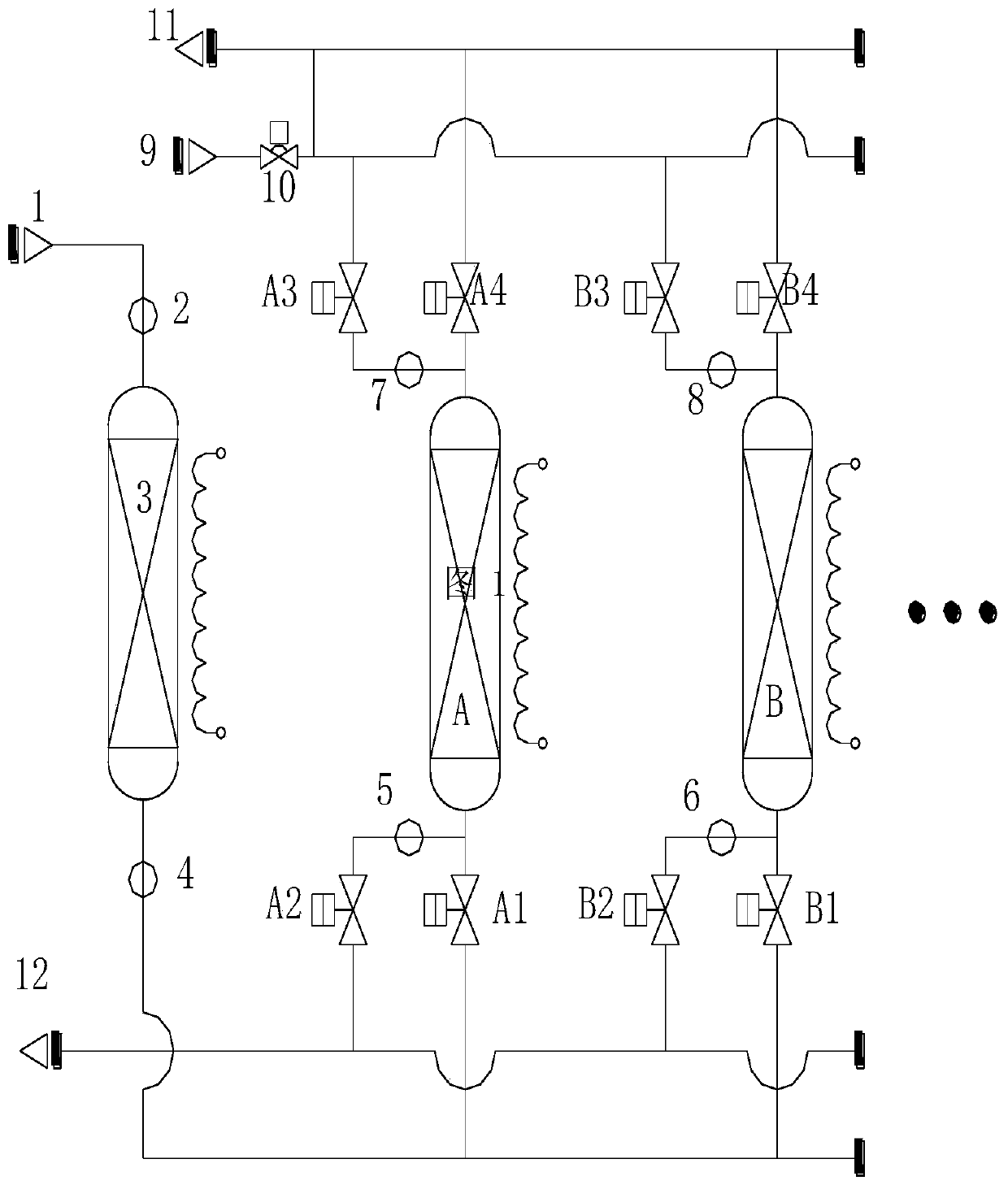

Ultrapure purification process and ultrapure purification system for nitrogen, argon and oxygen

PendingCN109748251ASimple system structureAvoid uneven flow ratesNitrogen purification/separationNoble gas compoundsChemistryCarbon dioxide

The invention relates to purification of bulk gases in the manufacturing field of semiconductor chips. An ultrapure purification process for nitrogen, argon and oxygen comprises the following steps: catalytic oxidation procedure: adopting an oxidation catalyst with metal oxide as a carrier to load palladium; heating raw gas to 300 DEG C, then enabling the heated gas to enter a catalytic reactor, and oxidizing methane, carbon monoxide, hydrogen and non-methane in the raw gas by an oxidation catalyst; adsorption procedure: enabling gas which is treated by the catalytic oxidation procedure and only contains three impurities, namely oxygen, water and carbon dioxide, to enter the subsequent adsorption procedure for purifying, adsorbing the oxygen, the water and the carbon dioxide by deoxidizerpurification, and removing the oxygen, the water and the carbon dioxide to below 1 ppb. The process disclosed by the invention is simple and no excess oxygen is needed to be additionally added into the raw gas, so that the regeneration period of the adsorption procedure is effectively prolonged; a deoxidizer has high adsorption capacity for the oxygen, the water and the carbon dioxide, and therefore, the operation cost of a purifier is reduced.

Owner:大连华邦化学有限公司

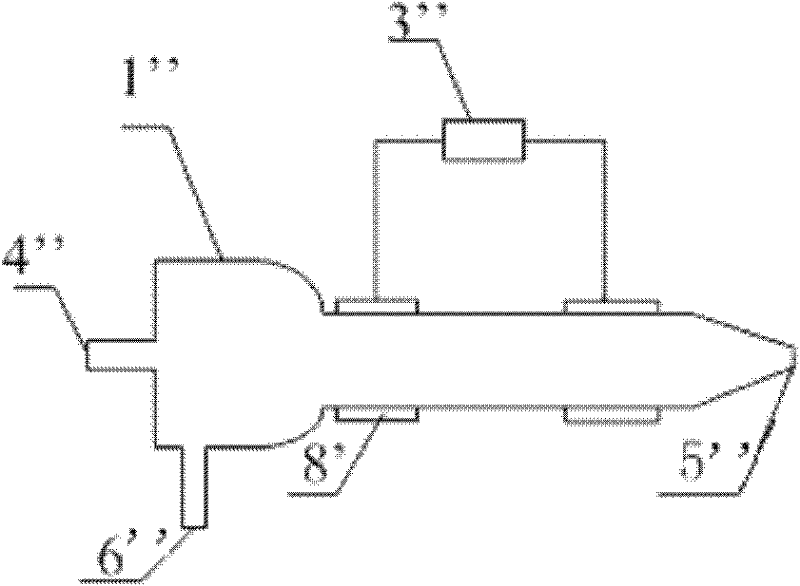

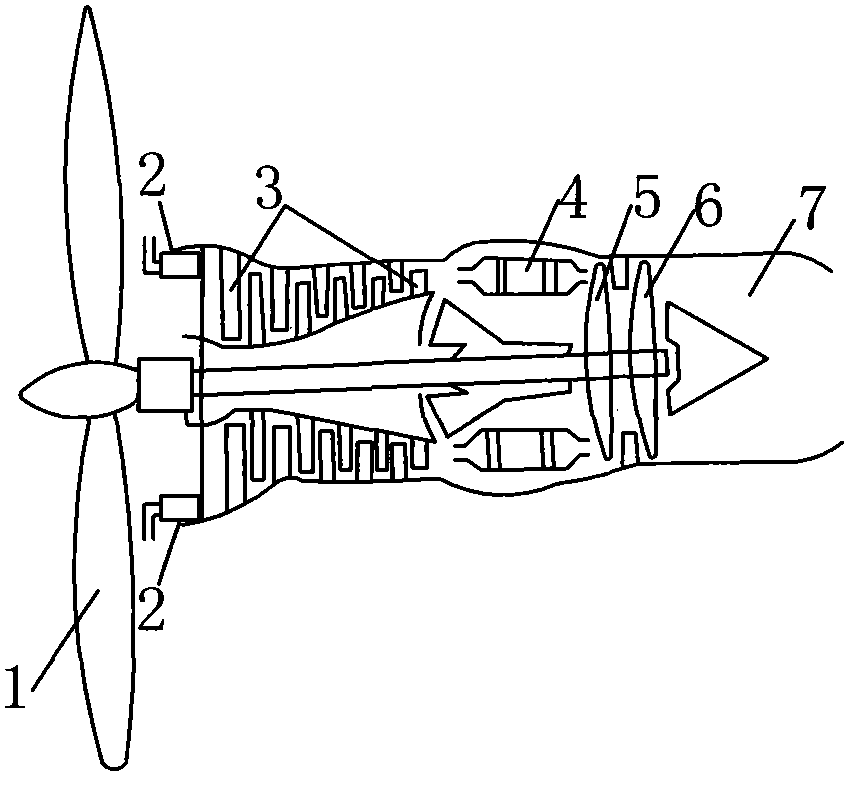

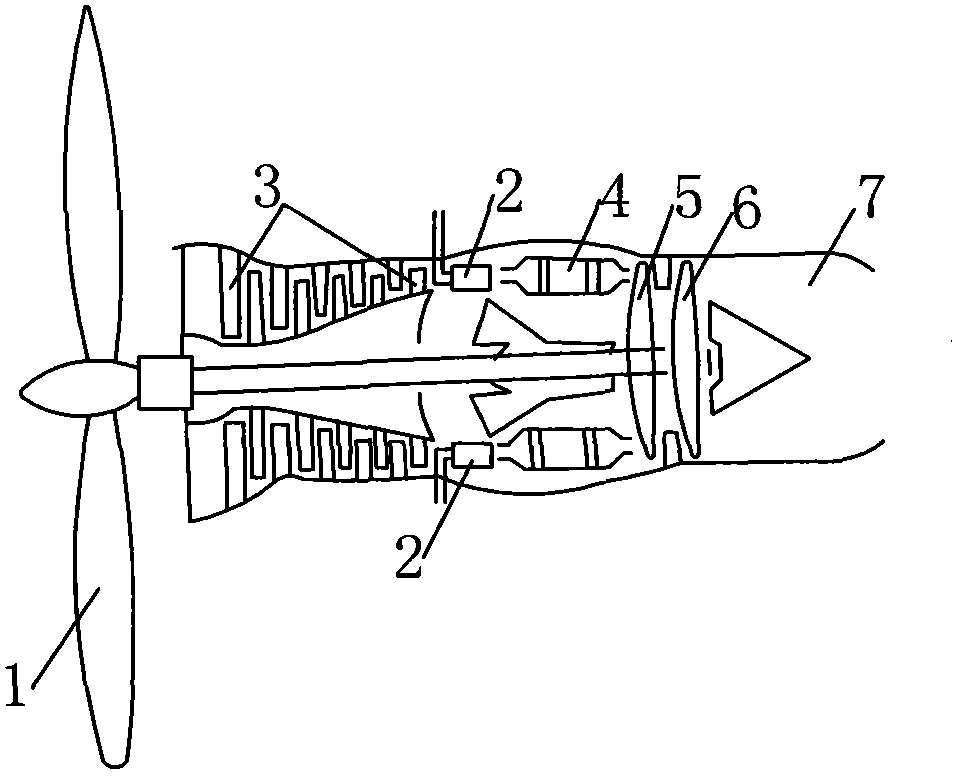

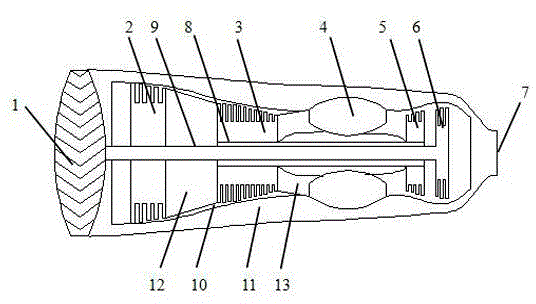

Turboprop engine and usage method thereof

InactiveCN103375302AIncrease powerLower gas temperatureJet propulsion plantsCombustion chamberEngineering

The invention discloses a turboprop engine and a usage method thereof. The turboprop engine comprises a propeller, an axial-flow compressor, a combustion chamber, high-pressure and low-pressure turbines and an exhaust nozzle and is characterized by also comprising a pressure-regulating nozzle. The method comprises that high-pressure air or liquid oxygen which is higher than and capable of increasing the air inlet pressure or the compressed air pressure inside the combustion chamber is ejected into an air inlet or the combustion chamber of the engine through the pressure-regulating nozzle after the engine is started, the high-pressure air or the liquid oxygen is compressed by the axial-flow compressor or is burnt directly in the combustion chamber to work, on the premise that the front gas temperature of the high-pressure turbine is not increased, the power of the engine is increased, after the power is increased and the intake air of the engine from the air satisfies the increased power requirement, ejection of the pressure-regulating nozzle is stopped, only the intake air from the air is used, then the fuel-injection quantity of a fuel nozzle inside the combustion chamber is controlled to keep the power unchanged or increase the power, the power-weight ratio of the engine is higher than that of the engine without ejection of the pressure-regulating nozzle, stages of the axial-flow compressor are not increased, and the front gas temperature of the high-pressure turbine is not increased.

Owner:李吉光

High-pressure exhaust gas recirculation (EGR) system of vehicle engine

InactiveCN106703978AImprove fuel saving effectReduce the difficulty of layoutInternal combustion piston enginesExhaust gas recirculationGasolineActuator

The invention discloses a high-pressure exhaust gas recirculation (EGR) system of a vehicle engine and relates to an EGR system. The high-pressure EGR system of the vehicle engine passes through the engine, wherein the engine is provided with a gas inlet and a gas outlet and comprises a gas inlet pipeline, a gas outlet pipeline, an EGR pipeline and an electronic pressurizer. The gas inlet pipeline is arranged in front of the gas inlet. The gas outlet pipeline is arranged behind the gas outlet. The ERG pipeline is connected between the gas inlet and the gas outlet pipeline of the engine and used for conducting ERG on part of gas exhausted by the gas outlet pipeline and then sending the exhaust gas to the engine again. The electronic pressurizer is arranged on one side of the gas inlet pipeline through a pipe. The electronic pressurizer is arranged on the gas inlet pipeline of the high-pressure EGR system, so that parts are fewer, the application cost is low, and the arrangement difficulty is relatively low; and actuators needing to be controlled are fewer, so that calibration is easy to conduct, the oil-saving effect of the electric pressurizer and the high-pressure EGR technology which are applied to a pressurizing gasoline engine is improved, and application of the electric pressurizer and the high-pressure EGR technology to the pressurizing gasoline engine is promoted.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

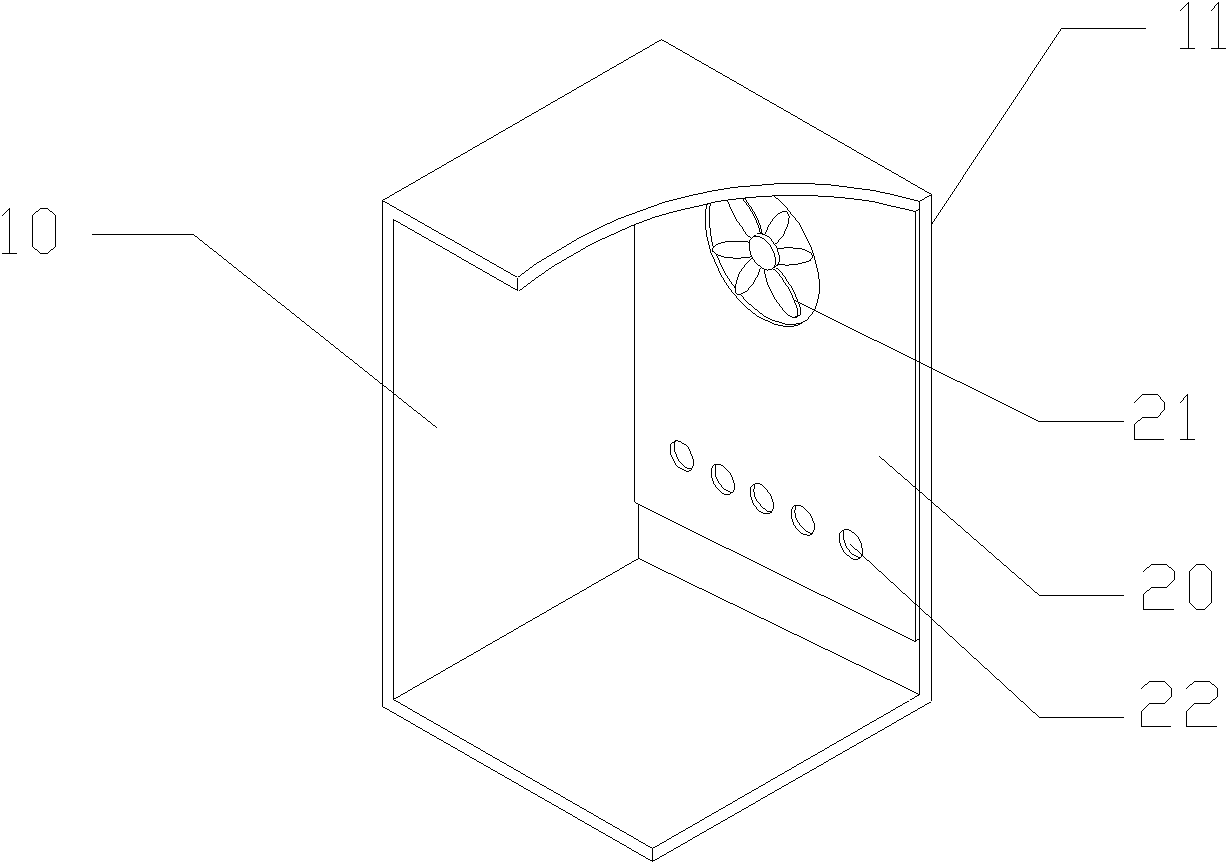

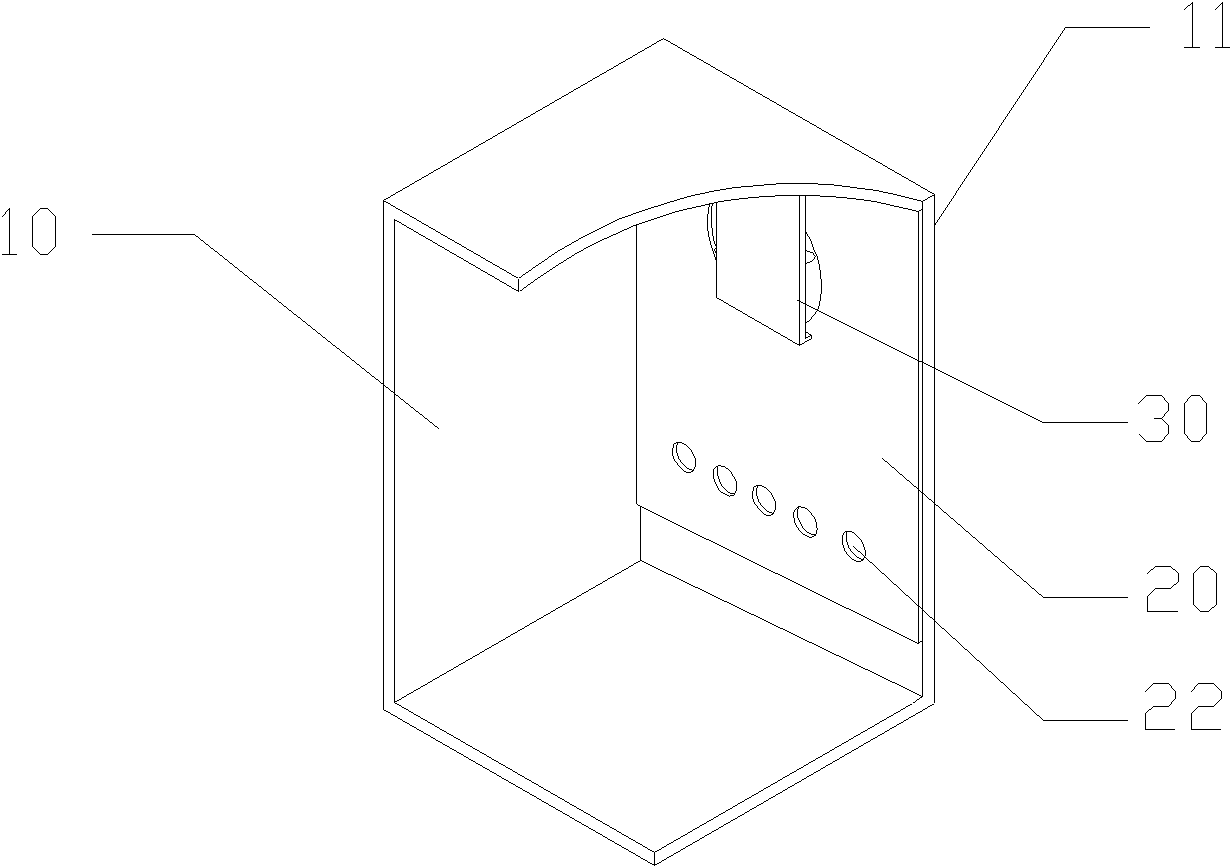

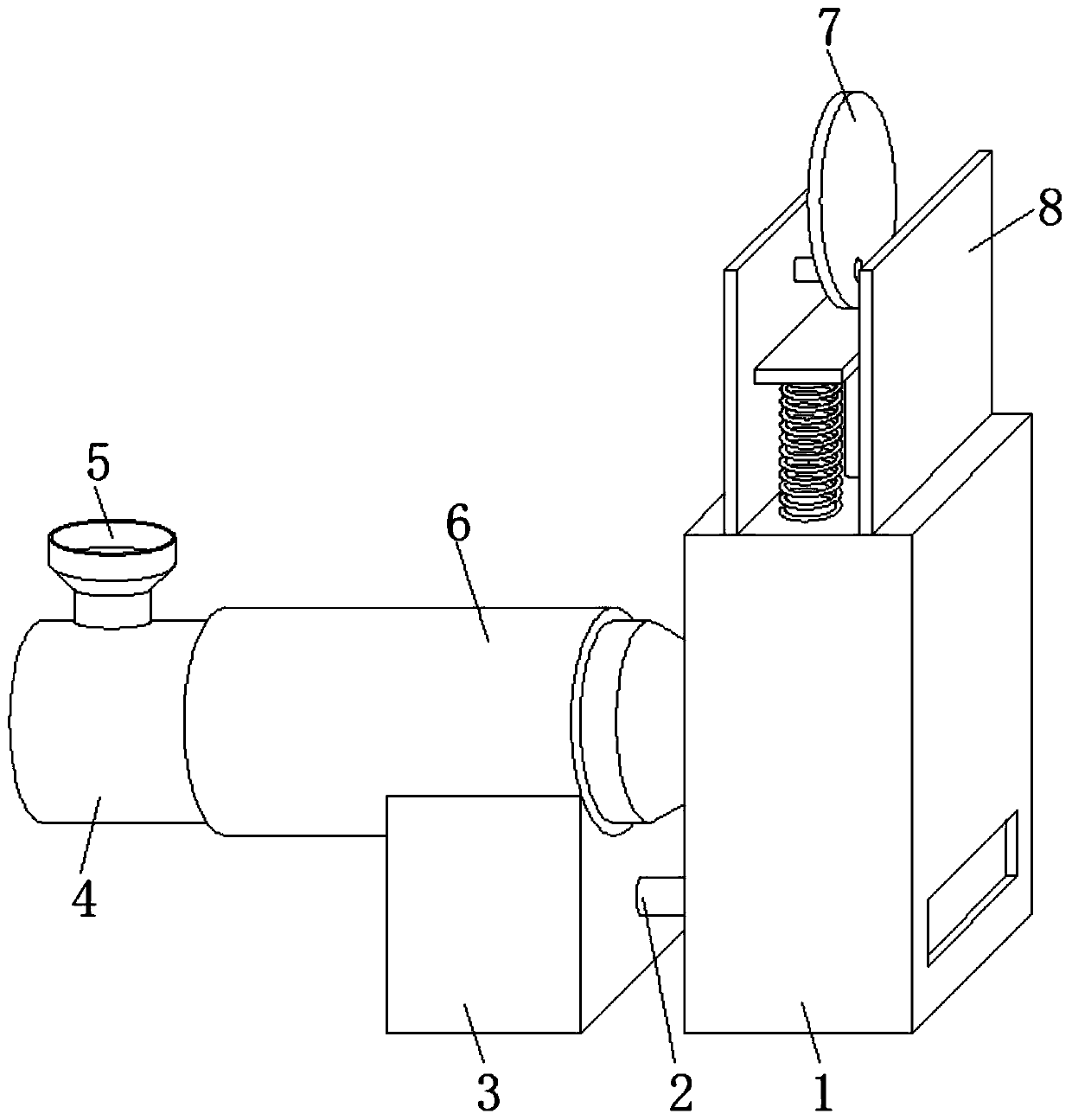

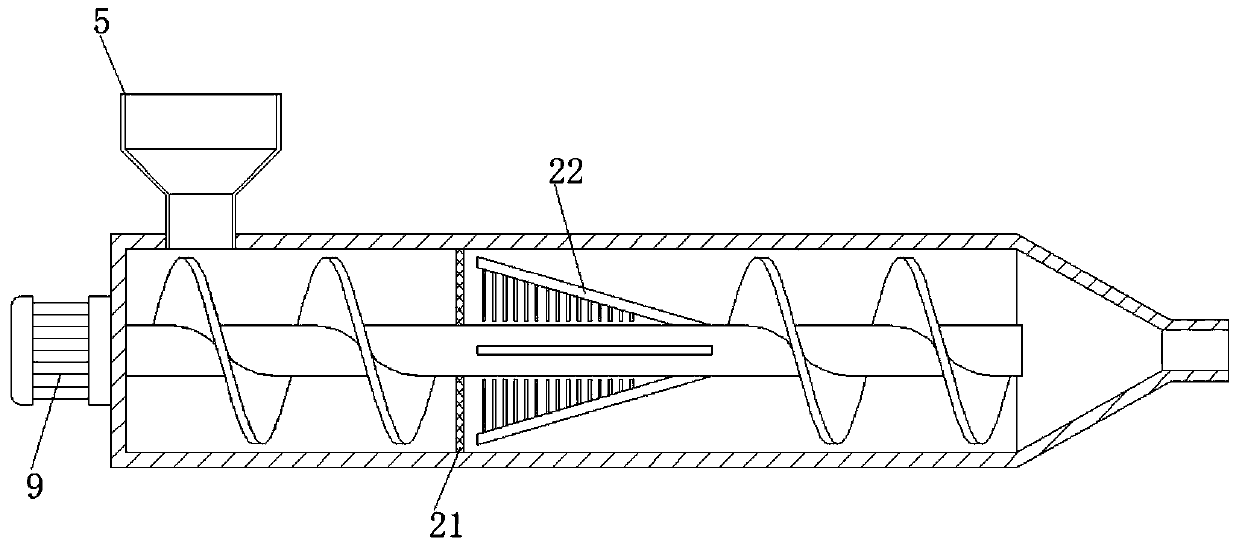

Extrusion forming device for curing agent coating production

InactiveCN110640993AGuaranteed temperatureImprove product qualityGrain treatmentsCold airMechanical engineering

The invention discloses an extrusion forming device for curing agent coating production. The device comprises a forming box, a cold air box and an extrusion tube, wherein a mounting opening is formedin the middle of the outer wall of one side of the forming box, the extrusion tube is fixed to the inner wall of the mounting opening through screws, air supply pipe inserting holes are formed in thebottoms of the outer walls of the opposite sides of the cold air box and the forming box, the inner walls of the two air supply pipe inserting holes are connected with a same air supply pipe, a waterbath box is welded to the outer wall of the extrusion tube, the water bath box is fixed to the cold air box through screws, a mounting groove is formed in the outer wall of the bottom of the water bath box, a semiconductor chilling plate is fixed to the inner wall of the mounting groove through screws, and a draught fan is fixed on the inner wall of one side of the cold air box through screws. According to the device, the temperature in the product extrusion process can be ensured, the product quality is improved, formed product cooling can be accelerated, the production efficiency is improved, a cutter cuts off extrusion raw material, and meanwhile, a extrusion block carries out extrusion forming, so that the convenient and fast degree of operation is improved.

Owner:湖北汉耐尔新材料科技有限公司

Flange plate heat exchange type automobile tail gas power generation device

ActiveCN106368774AHigh heat transfer efficiencyImprove power generation efficiencyInternal combustion piston enginesExhaust apparatusExhaust gasInternal cavity

The invention discloses a flange plate heat exchange type automobile tail gas power generation device, and belongs to the field of automobile tail gas power generation. The flange plate heat exchange type automobile tail gas power generation device comprises a tail gas pipe, the tail gas pipe is divided into a high temperature section, a power generation and heat dissipation section and an exhaust section, and a first power generation module is arranged on the periphery of the high temperature section; the power generation and heat dissipation section is provided with at least two flange plates in the circumferential direction, the flange plates are respectively of a shell structure, internal cavities of the flange plates communicate with the tail gas pipe, included corners formed by the two sides of each flange plate and the tail gas pipe communicate with the exterior, and second power generation modules are arranged on the flange plates; and through the flange plates, the surfaces making contact with air are expanded, and the power generation modules can be fixed more easily. According to the device, through improved design of the structure of the tail gas pipe, the heat dissipation performance of the tail gas pipe is not influenced on the premise of thermoelectric power generation, power generation and heat dissipation are effectively combined, and the development of the tail gas power generation technology is greatly promoted.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

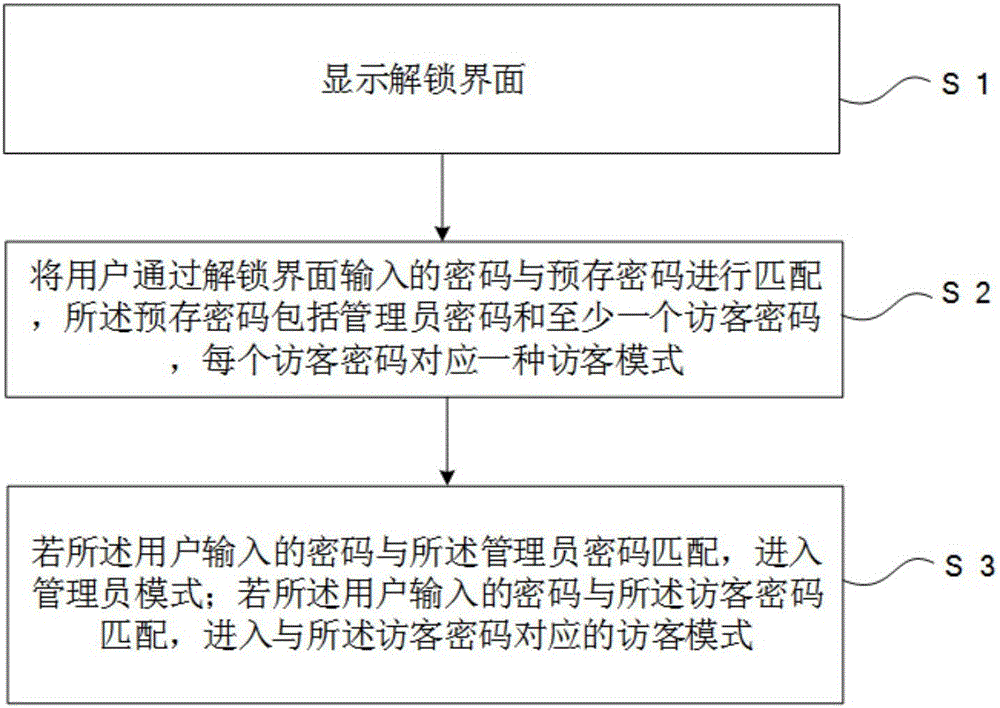

Phone information safety managing method based on multi-password unlocking

InactiveCN106231073AImprove information securityProtect personal privacyUser identity/authority verificationSubstation equipmentPasswordUser input

The invention belongs to the technical field of phone information safety, providing a phone information safety managing method based on multi-password unlocking. The method includes steps as follows: displaying an unlocking interface; matching a password which is input from the unlocking interface by a user with a preset password which includes an administrator password and a visitor password; entering an administrator mode if the password input by user is matched to the administrator password; and entering a visitor mode if the password input by user is matched to the visitor password. By setting multiple unlocking passwords and allocating different permissions to the unlocking passwords, the method disclosed can protect the user's privacy and improve the information safety of a phone when the phone is lent to others.

Owner:温美玲

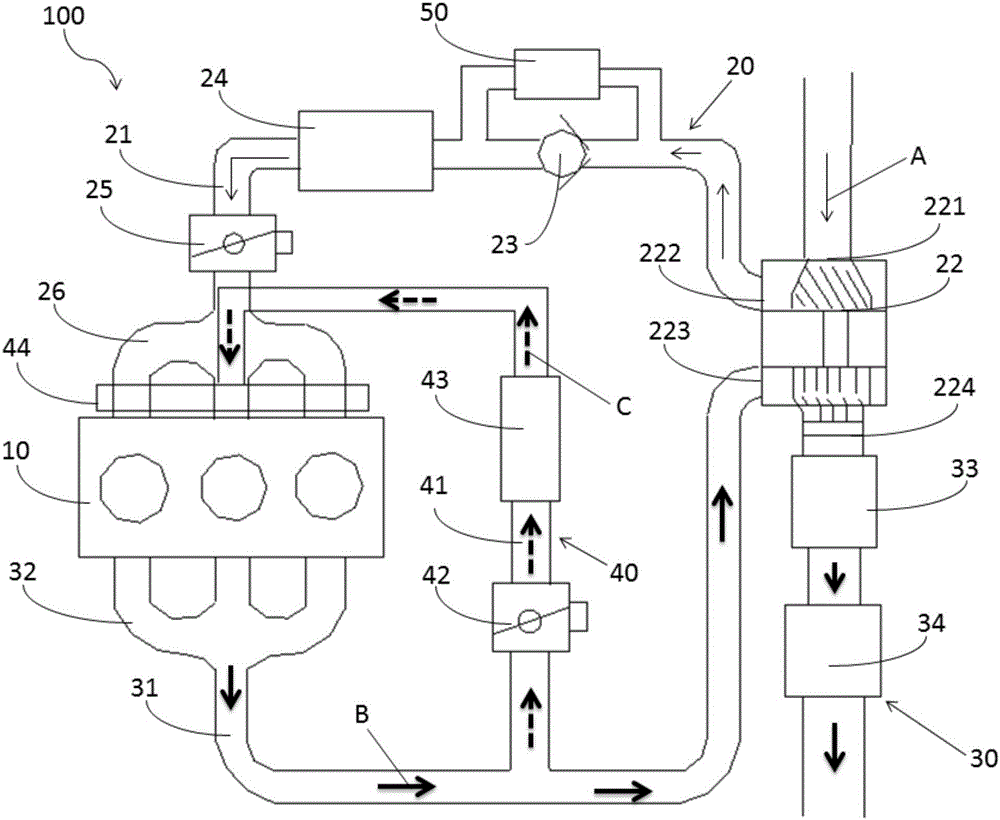

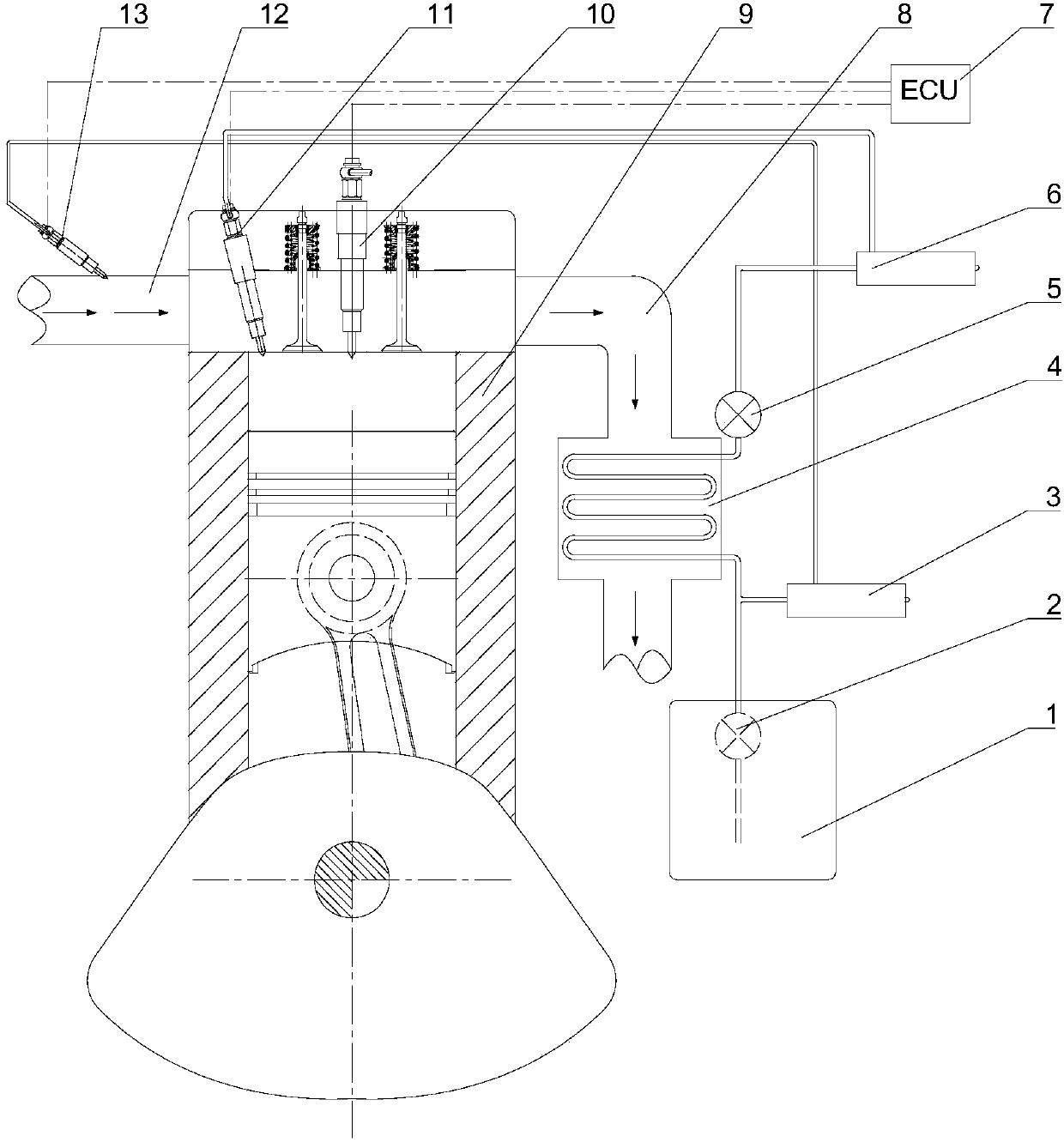

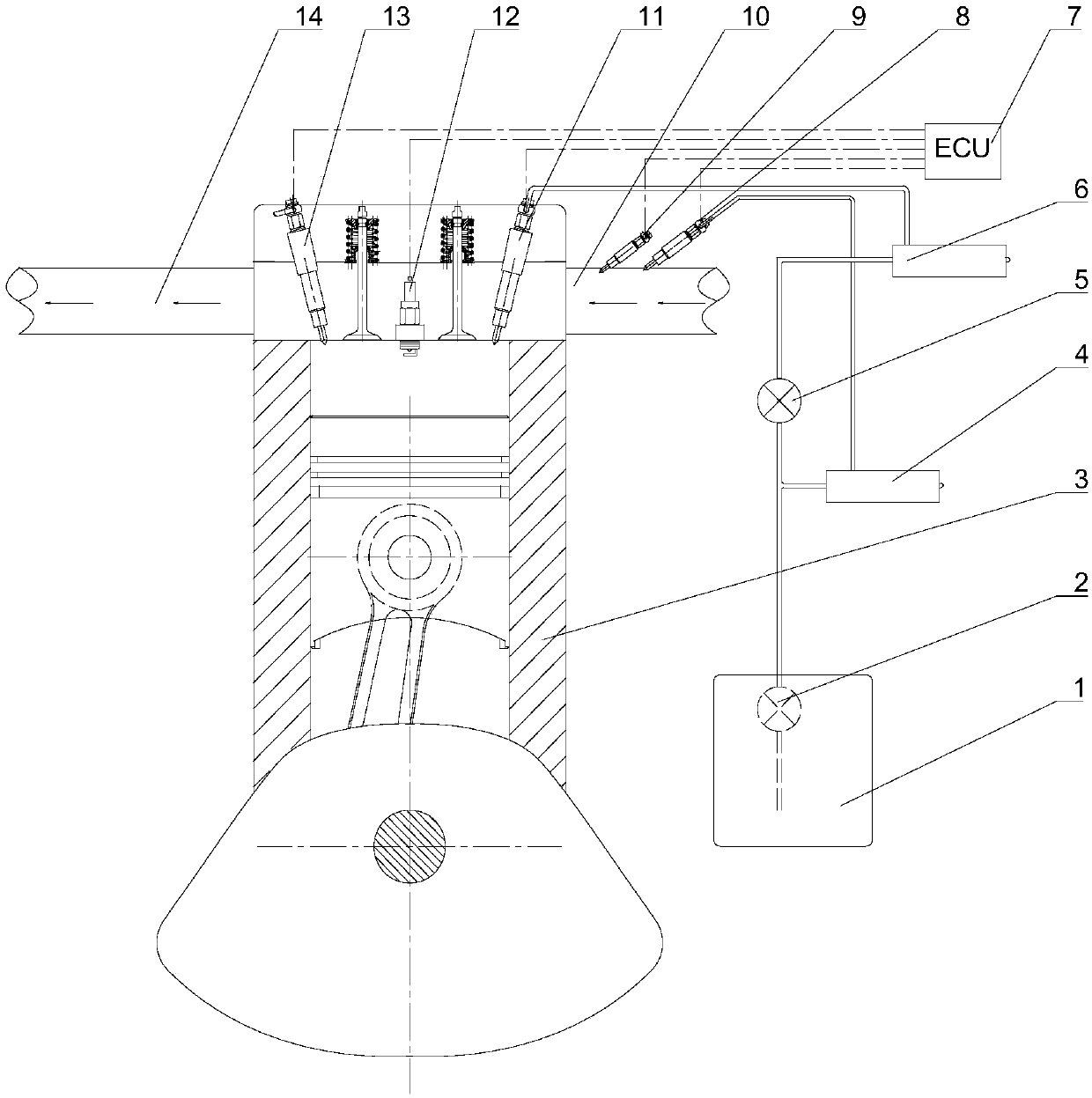

Air-cylinder-exterior cold water and air-cylinder-interior hot water integrated double injection diesel engine structure

InactiveCN108049991AReduce the temperatureEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesElectronic controllerEvaporation

The invention relates to an air-cylinder-exterior cold water and an air-cylinder-interior hot water integrated double injection diesel engine structure. The air-cylinder-exterior cold water and the air-cylinder-interior hot water integrated double injection diesel engine structure includes a diesel engine body, an inlet manifold, an exhaust manifold, an air-cylinder-interior sprinkler and an oil atomizer which are arranged in the diesel engine body, a high pressure water pump unit which communicates with the air-cylinder-interior sprinkler, an air-cylinder-exterior sprinkler which is arrangedin the inlet manifold, a low pressure water pump unit which communicates with the air-cylinder-exterior sprinkler, a heat exchanger which is arranged between the low pressure water pump unit and the high pressure water pump unit, and an electronic controller which is electrically connected with the oil atomizer, the air-cylinder-interior sprinkler, the high pressure water pump unit, the air-cylinder-exterior sprinkler and the low pressure water pump unit. Compared with the prior art, according to the air-cylinder-exterior cold water and the air-cylinder-interior hot water integrated double injection diesel engine structure, hot water sprayed in the air cylinder is rapidly vaporized and the energy is absorbed, the temperature in the air cylinder nearby the combustion top dead center can belowered, and the emission of NOx can be reduced; cold water is sprayed to the inlet manifold at the same time, heat energy is absorbed through evaporation of water, the gas temperature entering the air cylinder is decreased, and the air inlet density is increased; and the charging efficiency is increased, the output per liter of the diesel engine is improved, and the dynamic property is improved.

Owner:TONGJI UNIV

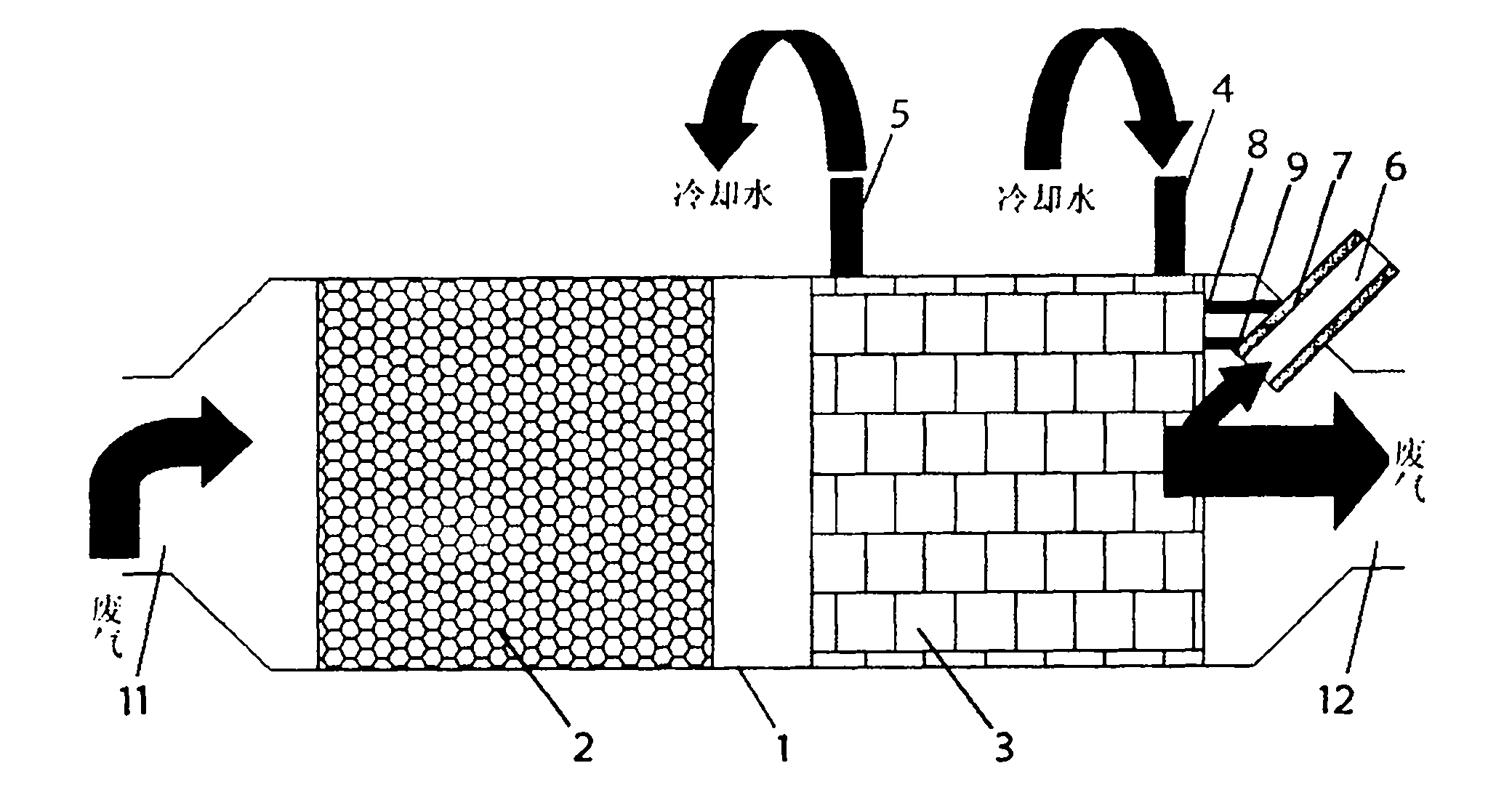

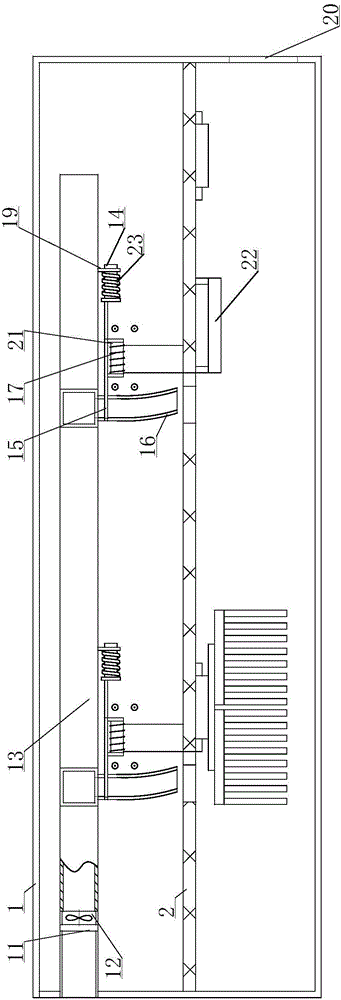

Method for Drying Wood Combined Into Stacks

InactiveUS20090158615A1Shorten drying timeReduce energy inputDrying solid materials with heatDrying gas arrangementsFiberProduct gas

A method is described for drying wood combined into stacks (2) with the aid of a drying gas stream which flows through the wood stacks (2), which, by removing moist waste gas (8) after the wood stacks (2) and supplying fresh gas (9) before the wood stacks (2), is passed through the wood stacks (2) partially in circulation, wherein the wood is dried more rapidly with a moisture content above the fibre saturation than with a moisture content below the fibre saturation. In order to provide advantageous, economical drying conditions, it is proposed that before its slower drying with the aid of the drying gas stream guided partially in circulation, the wood is dried more rapidly with a drying gas stream consisting substantially only of fresh gas.

Owner:MUEHLBOECK KURT

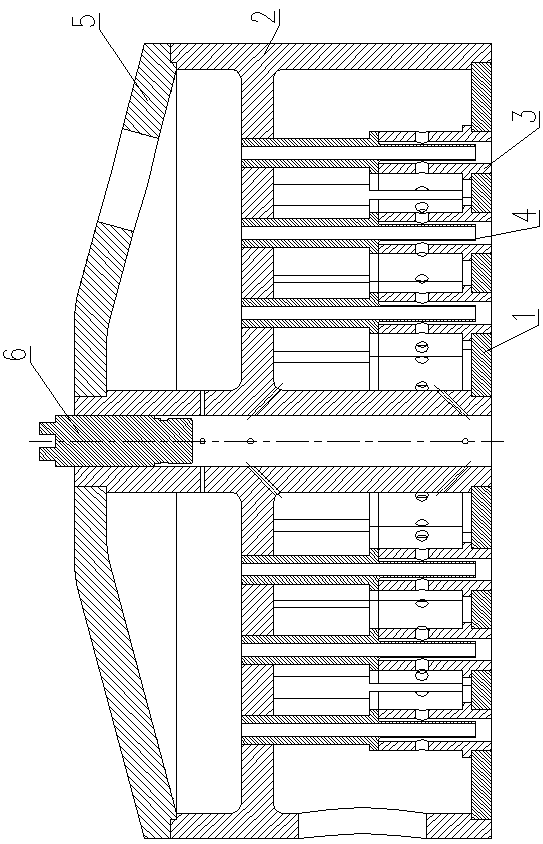

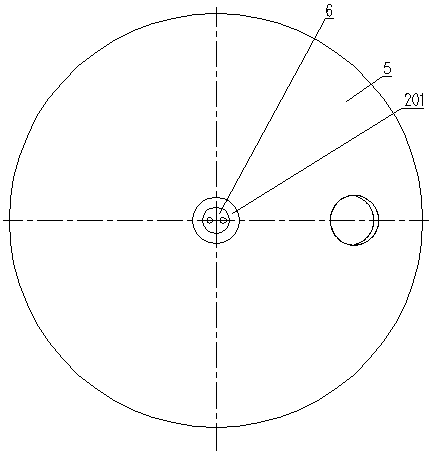

Simulating device for on-rocket liquid-hydrogen temperature zone cold-helium heater

The invention discloses a simulating device for an on-rocket liquid-hydrogen temperature zone cold-helium heater and the simulating device is used for simulating the work performance of a cold-helium heater of a carrier-rocket engine. The simulating device includes devices such as a high-pressure nitrogen storage tank, a connection pipe, a reducing valve, an electromagnetic valve, a bore plate, an on-rocket heat exchange pipe, a process heat exchange pipe and an insulating layer and the like. Normal-temperature nitrogen enters an entrance of a casing after being limited in flow by the bore plate and scours the outer wall faces of the on-rocket heat exchange pipe and the process heat exchange pipe so as to carry out heat exchange. Code helium internally flows in the on-rocket heat exchange pipe and the process heat exchange pipe and carries out heat exchange with the inner wall faces of the pipes so that the temperature of the cold helium is enabled to rise to a specific value and then the helium goes to a user pipe via an exit of the process heat exchange pipe. When the temperature of helium at the exit of the process heat exchange pipe needs to be adjusted, only the opening degree of the reducing valve needs to be adjusted. The cold-helium heat exchange pipes are capable of working at a liquid-hydrogen temperature zone and the entrance temperature can be lower than 20k and when the flow of the helium is at XX-XXg / s, the exit temperature is within a range of XX-XX K. The simulating device is capable of simulating the on-rocket heater in a comparatively well manner and the exit temperature range of the low-temperature helium is adjustable and operation is simple and convenient; and the outer walls of the cold-helium heat exchange pipes are free from freezing so that the work reliability is high and cost input is low.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

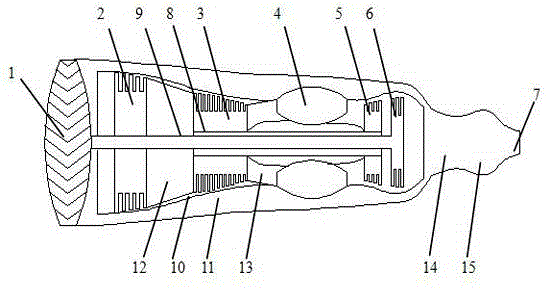

Turbofan type vehicle engine

InactiveCN105298685ALight in massIncrease output powerJet propulsion plantsCombustion chamberEngineering

The invention discloses a turbofan type vehicle engine. The turbofan type vehicle engine mainly consists of a fan, a low-pressure compressor, a high-pressure compressor, a combustion chamber, a high-pressure turbine, a low-pressure turbine, a spraying pipe, a high-pressure shaft, a low-pressure shaft, an inner duct and an outer duct, wherein the inner duct is supported on the outer duct through a front bracket and a back bracket; the high-pressure shaft and the low-pressure shaft are respectively supported in the inner duct through a front bearing and a back bearing; the high-pressure shaft is hollowed; the low-pressure shaft penetrates through the high-pressure shaft; the fan, the low-pressure compressor and the low-pressure turbine are mounted on the low-pressure shaft through a one-way bearing; and the high-pressure compressor and the high-pressure turbine are mounted on the high-pressure shaft through a one-way bearing. The turbofan type vehicle engine has such advantages as light mass, high output power, strong power and high thrust-weight ratio, and in particular, is suitable for such vehicles having higher requirements on speed as sports cars.

Owner:丁义存

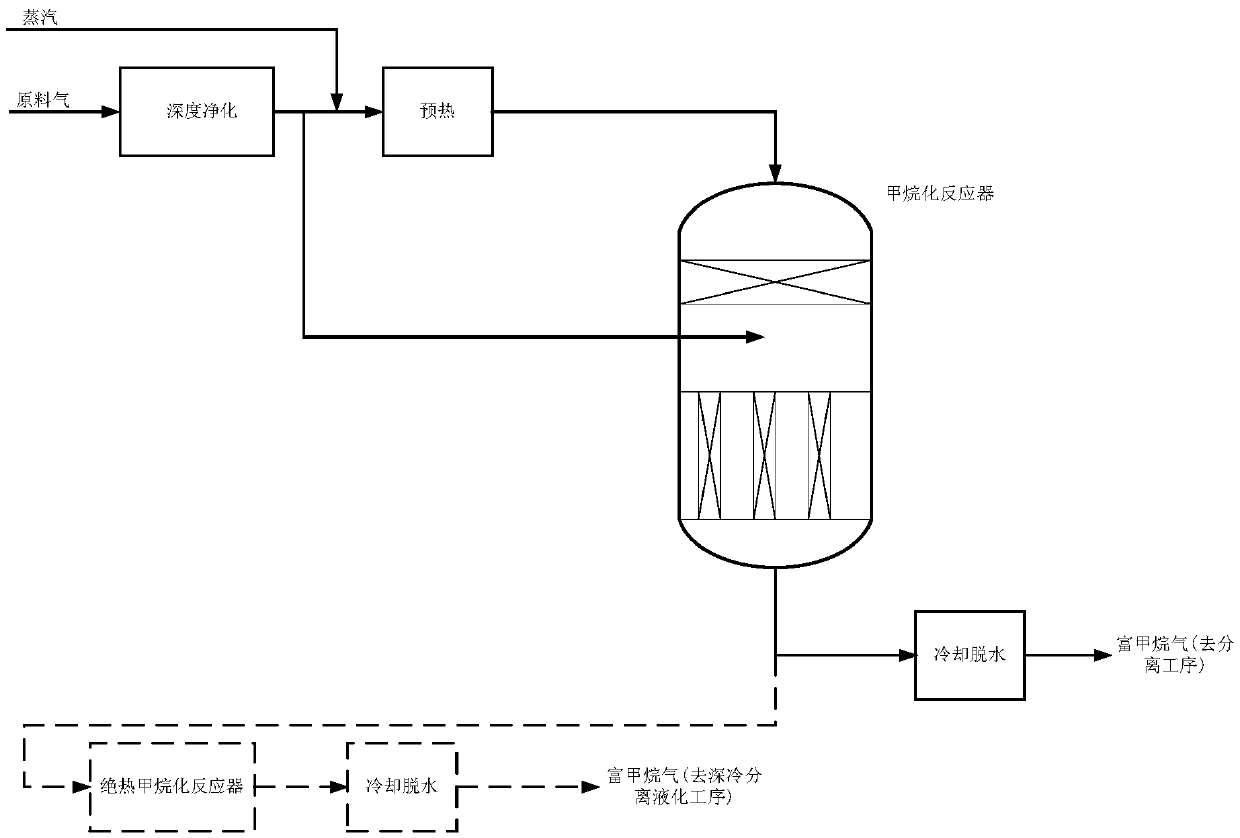

Quenching type methanation process with heat removing internally

InactiveCN105542889AReduce the maximum temperatureReduce material requirementsGaseous fuelsMethanationSmall footprint

The invention relates to a quenching type methanation process with heat removing internally, and belongs to the field of methanation process of H2, CO and CO2 gas. The methanation process comprises the following steps: after deep purification of feed gas, the feed gas is divided into two parts; a first part and water vapour are mixed and heated, and enter into the upper part of a methanation reactor, and high temperature methane-rich gas is produced after production reaction; a second part of the feed gas enters into the middle part of the reactor, and the part of feed gas mixes and quenches the high temperature methane-rich gas; the quenched mixed gas enters the lower part of the reactor for a methanation reaction, and a methanated product methane-rich gas is obtained. The feed gas is divided into two part, and a quenching segment is additionally installed in the middle, heat from the methanation reaction of the first part of the feed gas heats the second part of the gas, so that amount of the feed gas which needs preheating in the first part is effectively reduced, preheaters are reduced, and apparatus cost is reduced. The methanation process has the advantages of good controllability, a small amount of heat exchangers, low investment of the whole methanation equipment, small land occupation area, and low production cost, and recycle gas is not needed.

Owner:SHANXI HIGH CARBON ENERGY LOW CARBON RES & DESIGN INST CO LTD +1

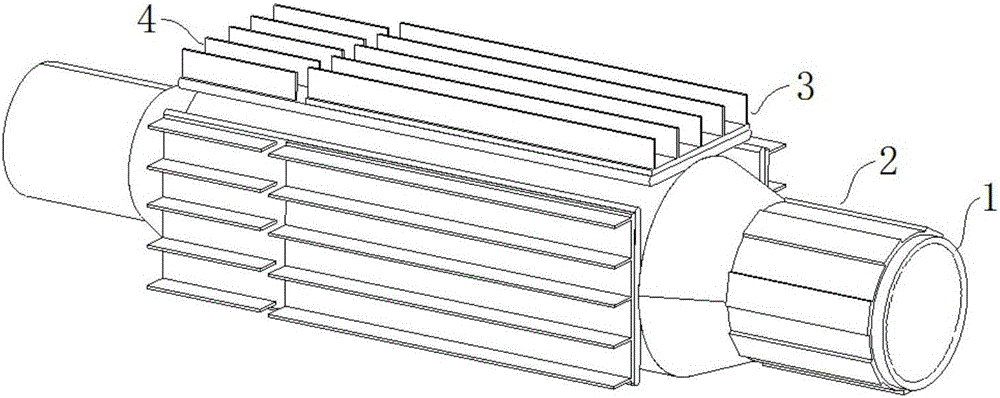

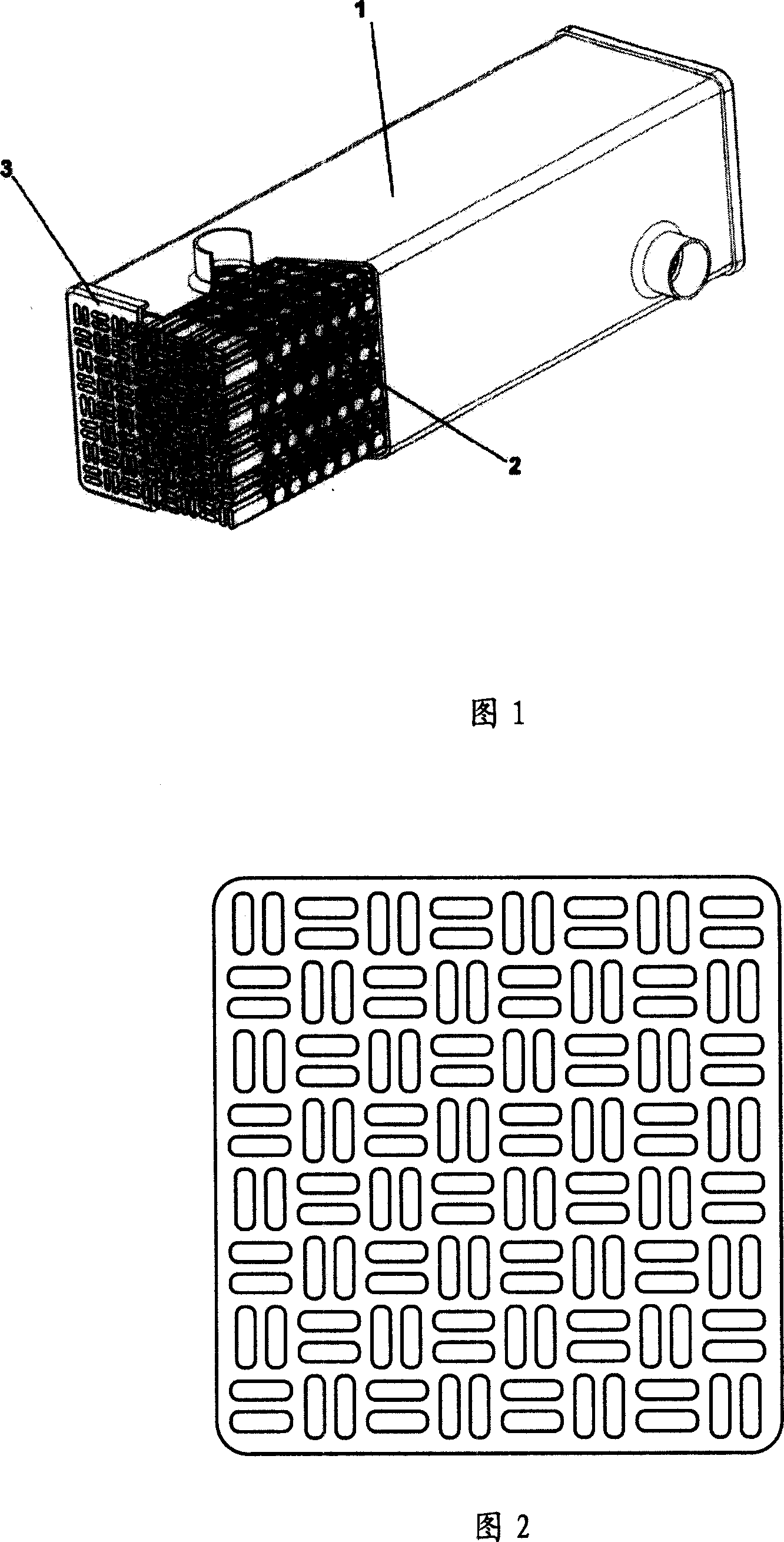

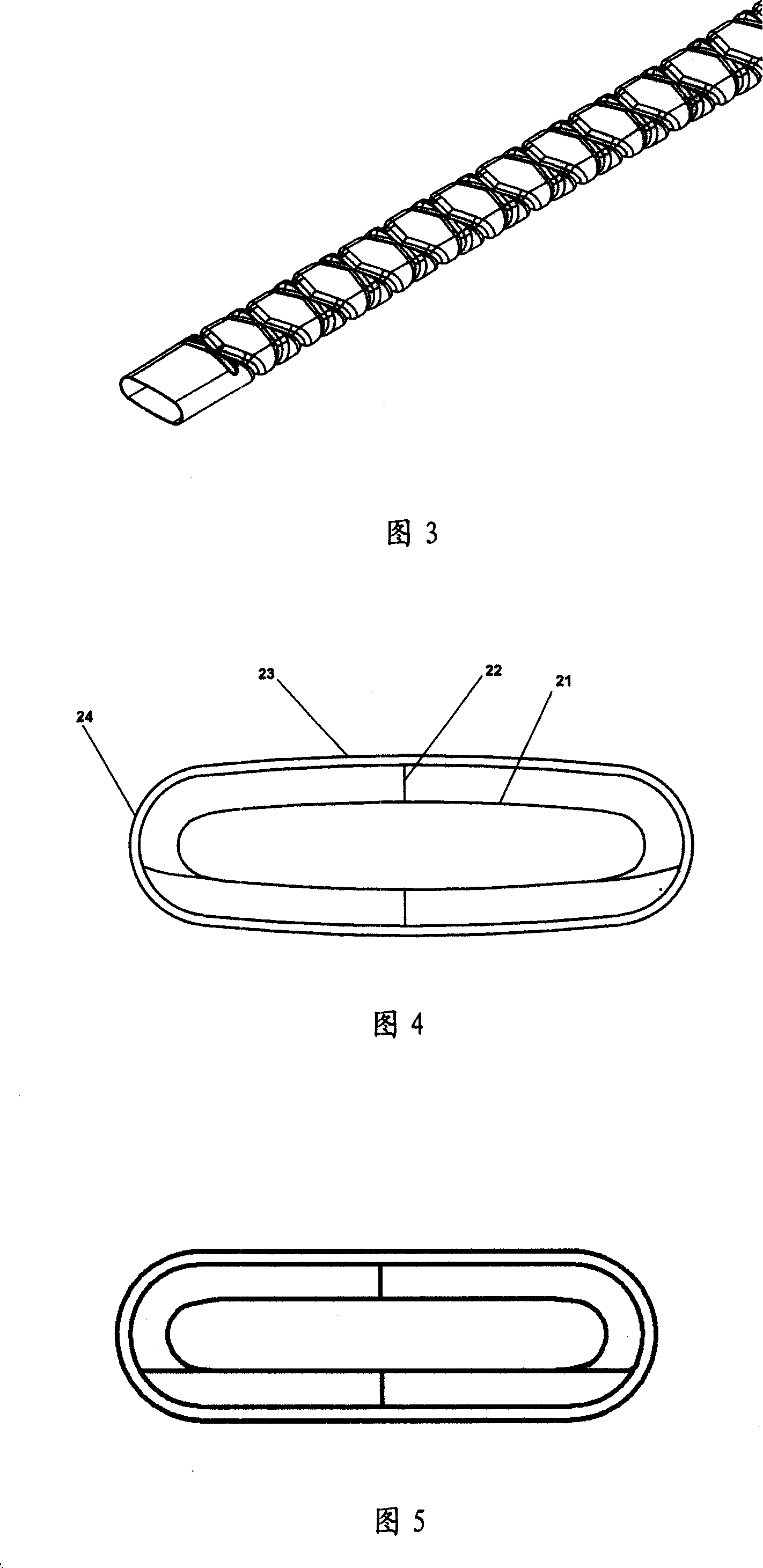

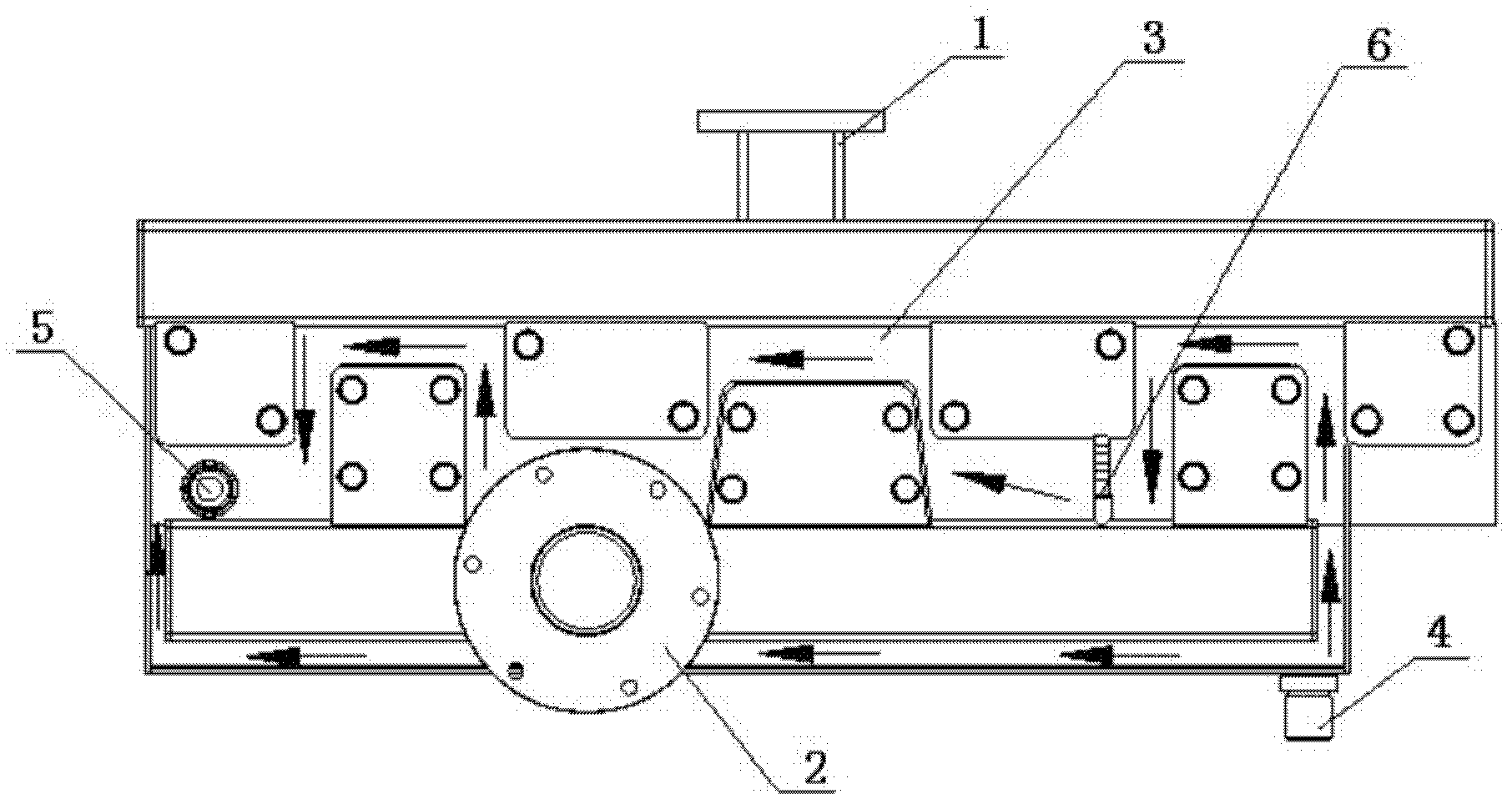

Heat exchanger employing crossed spiral tube

ActiveCN101101185ARapid coolingGood use effectStationary conduit assembliesTubular elementsPlate heat exchangerEngineering

The invention relates to a heat exchanger which used the cross-helical tube, involving an exhaust recycle heat exchanger. For improving the engine exhaust recycle heat exchanger and increasing the heat exchange efficiency. The exchanger includes the heat exchange tube, shell and the tube board. Of which the heat exchange tube is the stainless steel tube which has the entad raised cross-helical groove on the surface, and the section shape of the tube is the flat shape. The height and width of the section shape in the flat shape heat exchange tube are unlikeness, and the opposite rotating direction helix line cross on the relative long edge of the tube as the 'X' shape. Because of the application of the cross-helical heat exchange tube, the tube inside and outside is not easy to dirty and increased the heat exchange efficiency, the heat exchanger is particularly suitable for the exhaust gas recycle coolers of a vehicle engine, reduce the exhaust discharge temperature and enhance the vehicle engine discharge performance indicators to meet environmental discharge requirement. At the same time, the invention can also be used in a turbocharger system to improve the engine performance.

Owner:辽宁联友博科技有限公司

Natural gas engine structure for mixed double-injection of cylinder outer cold water and in-cylinder hot water

InactiveCN108049987AImprove powerImprove economyInternal combustion piston enginesNon-fuel substance addition to fuelElectronic controllerHigh pressure water

The invention relates to a natural gas engine structure for mixed double-injection of cylinder outer cold water and in-cylinder hot water. The natural gas engine structure comprises a natural gas engine body, an air inlet manifold, an exhaust manifold, a natural gas injector, a spark plug, an in-cylinder water sprayer, a high-pressure water pump unit, a cylinder outer water sprayer, a low-pressurewater pump unit, a heat exchanger and a electronic controller; and the in-cylinder water sprayer is arranged in the natural gas engine body, the high-pressure water pump unit communicates with the in-cylinder water sprayer, the cylinder outer water sprayer is arranged in the air inlet manifold, the low-pressure water pump unit communicates with the cylinder outer water sprayer and the electroniccontroller is electrically connected with the natural gas injector, the spark plug, the in-cylinder water sprayer, the high-pressure water pump unit, the cylinder outer water sprayer and the low-pressure water pump unit. Compared with the prior art, the natural gas engine structure has the advantages that hot water sprayed in a cylinder is used for rapidly vaporizing to absorb heat, so that the temperature in the part, close to a combustion top dead center, of the cylinder is reduced, and the generation of knocking is inhibited; meanwhile, the heat for heating the water comes from recovering tail gas energy by a exchanger, so that the working medium in the combustion process is increased, the heat loss is reduced, and the heat efficiency of the natural gas engine is improved.

Owner:TONGJI UNIV

Cylinder interior and exterior cold water mixing double spraying natural gas engine structure

ActiveCN107905917AImprove powerImprove economyNon-fuel substance addition to fuelMachines/enginesElectronic controllerHigh pressure water

The invention relates to a cylinder interior and exterior cold water mixing double spraying natural gas engine structure. The cylinder interior and exterior cold water mixing double spraying natural gas engine structure comprises a natural gas engine body, an inlet manifold, an exhaust manifold, a natural gas injector, a sparking plug, a cylinder interior water spraying device, a high-pressure water pump unit, a cylinder exterior water spraying device, a low-pressure water pump unit and an electronic controller, wherein the sparking plug and the cylinder interior water spraying device are arranged in the natural gas engine body; the high-pressure water pump unit is connected to the cylinder interior water spraying device; the cylinder exterior water spraying device is arranged in the inletmanifold; the low-pressure water pump unit is connected to the cylinder exterior water spraying device; and the electronic controller is electrically connected to the natural gas injector, the sparking plug, the cylinder interior water spraying device, the high-pressure water pump unit, the cylinder exterior water spraying device and the low-pressure water pump unit. Compared with the prior art,the cylinder interior and exterior cold water mixing double spraying natural gas engine structure has the beneficial effects that the purposes of improving a power performance, economical efficiency and an emission performance can be achieved simultaneously by arranging the two water spraying devices in a cylinder and on the inlet manifold; the heat efficiency and power per liter of a natural gasengine can be improved; the emission of nitrogen oxide is reduced; and the engine knocking can be effectively inhibited.

Owner:TONGJI UNIV

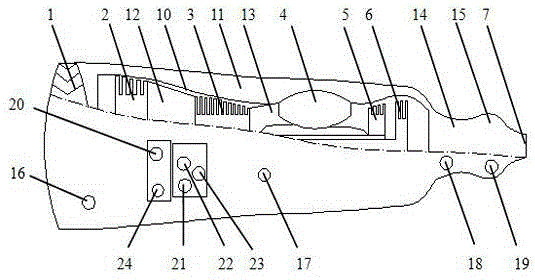

Intake-exhaust manifold of explosion-proof diesel engine

InactiveCN103133111ALower gas temperatureLow air resistanceInternal combustion piston enginesExhaust apparatusWater channelExhaust pipe

The invention discloses an intake-exhaust manifold of an explosion-proof diesel engine. The intake-exhaust manifold of the explosion-proof diesel engine comprises an intake pipe, an exhaust pipe and a cooling water channel, wherein the intake pipe and the exhaust pipe are a whole. The whole penetrates through the inner space of the cooling water channel, and a water inlet and a water outlet are formed in the cooling water channel. The intake-exhaust manifold of the explosion-proof diesel engine can reduce the gas temperature of the intake pipe and the exhaust pipe, thus safety performances of the intake pipe and the exhaust pipe are improved, and meanwhile, airflow resistances in the intake pipe and the exhaust pipe are reduced.

Owner:江苏科意达机械有限公司

Efficient purification activated carbon environment-friendly waste gas treatment equipment

PendingCN113694638ASolve the problem of greatly reduced adsorption capacityResolve inactivationGas treatmentDispersed particle filtrationActivated carbonTemperature control

The invention discloses efficient purification activated carbon environment-friendly waste gas treatment equipment, and relates to the technical field of waste gas treatment.The efficient purification activated carbon environment-friendly waste gas treatment equipment comprises a base, a tank body is fixedly connected to the top of the base, a charging door is fixedly connected to the surface of the tank body, and a protection mechanism is fixedly connected to the left side of the inner side face of the tank body; an activated carbon interlayer is fixedly connected to the side, away from the protection mechanism, of the inner side face of the tank body, a temperature control mechanism is fixedly connected to the right side of the surface of the tank body, and the protection mechanism comprises a connecting wall. According to the efficient-purification environment-friendly activated carbon waste gas treatment equipment, through cooperative use of a protection mechanism, a stirring mechanism, a temperature control mechanism, a heat transfer mechanism and other mechanisms, the problems that activated carbon is inactivated due to the fact that lampblack in waste gas blocks activated carbon adsorption holes, and the adsorption capacity of the activated carbon is greatly reduced due to high-temperature waste gas are solved.

Owner:安徽四邦环境科技有限公司

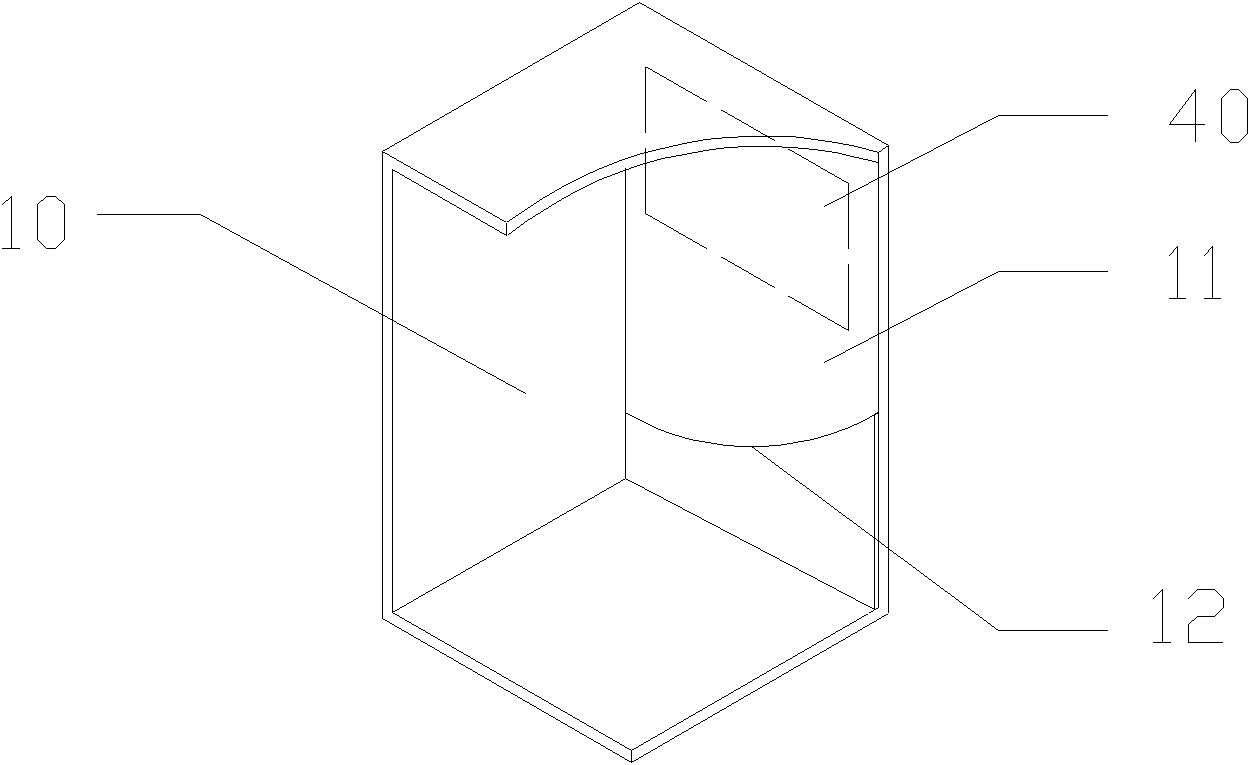

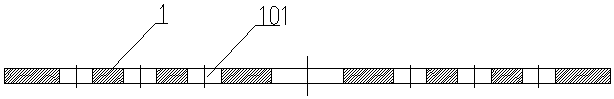

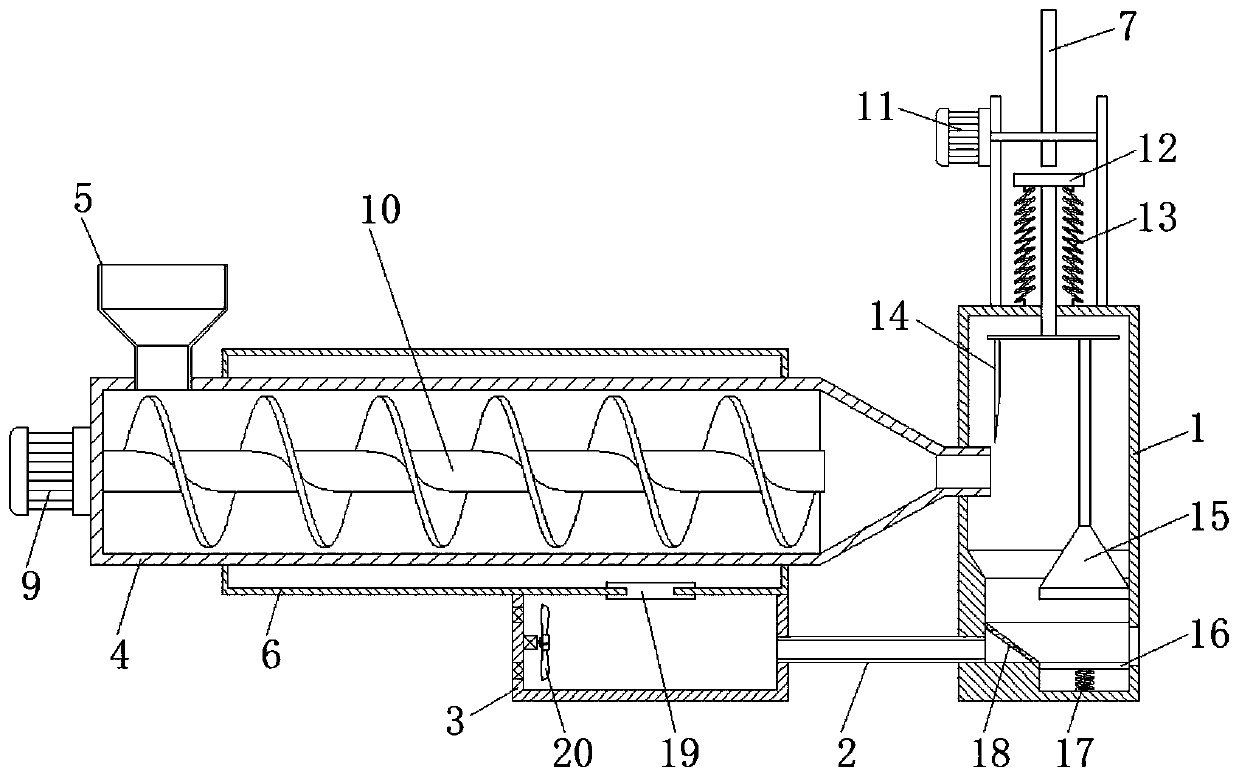

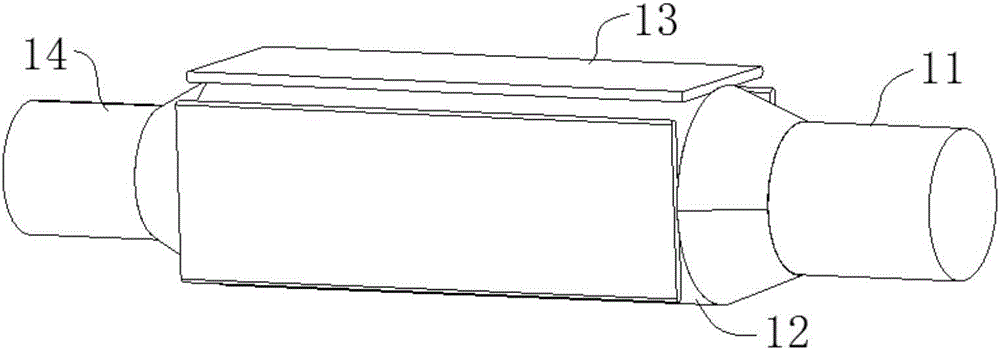

Master batch collecting device

The invention relates to a master batch collecting device. The master batch collecting device comprises a material tank, a feeding inlet and a discharging outlet which are respectively formed in the top end and the bottom end of the material tank, as well as a cavity chamber positioned outside the material tank, wherein two groups of inclined plates are arranged in the material tank in a staggered manner; each inclined plate group comprises at least two inclined plates which are vertically arranged; a piston and a partition are arranged in the cavity chamber; an air inlet pipe and an air outlet pipe are arranged between the cavity chamber and the material tank; the air inlet pipe comprises a main pipe and at least two branch pipes which communicate with the main pipe; a first air pump is arranged on the main pipe; and a second air pump is arranged on the air outlet pipe. The master batch collecting device provided by the invention has the advantages that through compressed air, air in the first cavity of the cavity chamber can be liquefied for cooling; through heat conduction by the partition, air in the second cavity of the cavity chamber can be cooled; and when air is blown towards a master batch in the material tank, heat of the master batch can be dissipated.

Owner:SUZHOU WANSHENG PLASTIC TECH CO LTD

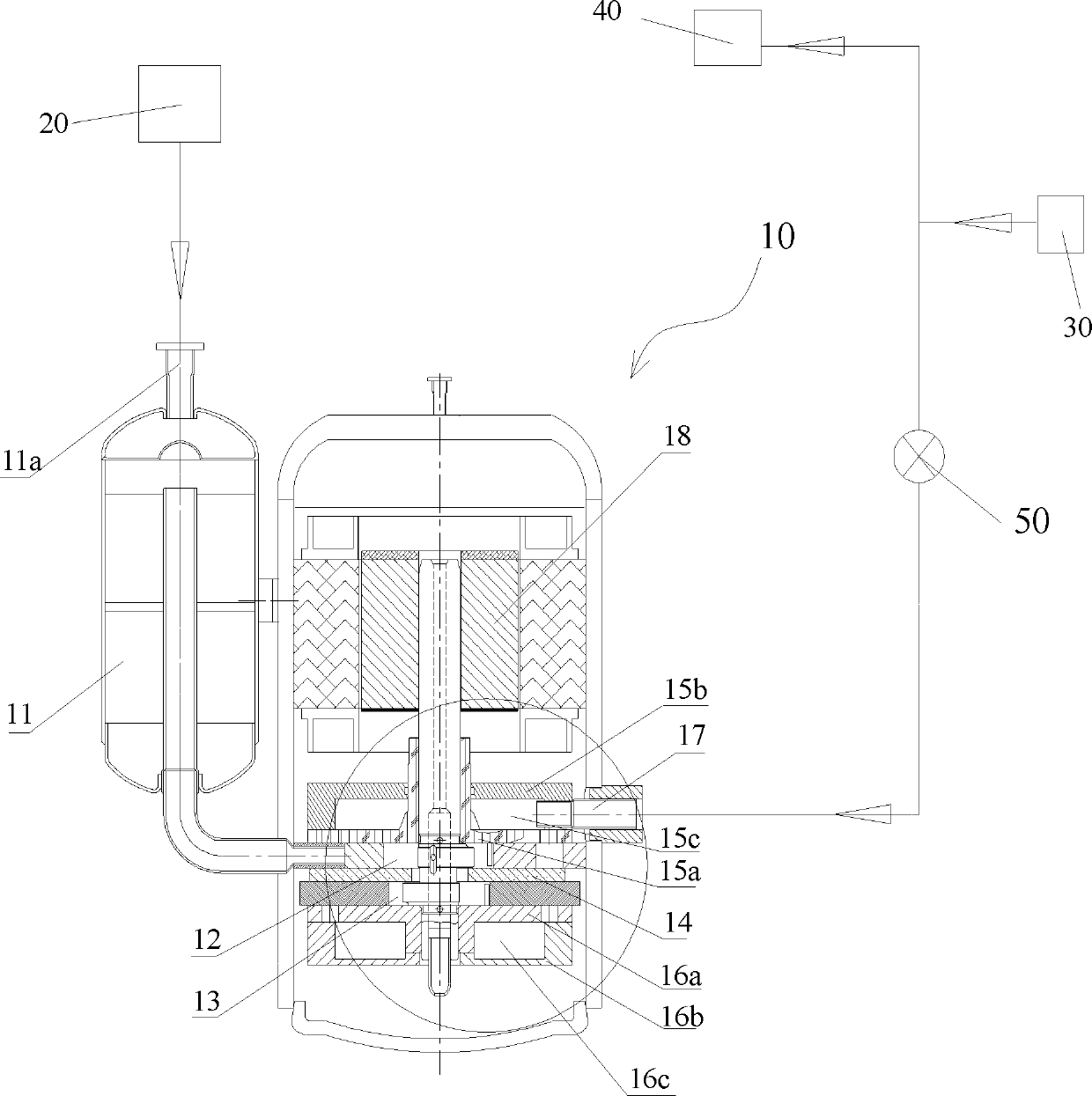

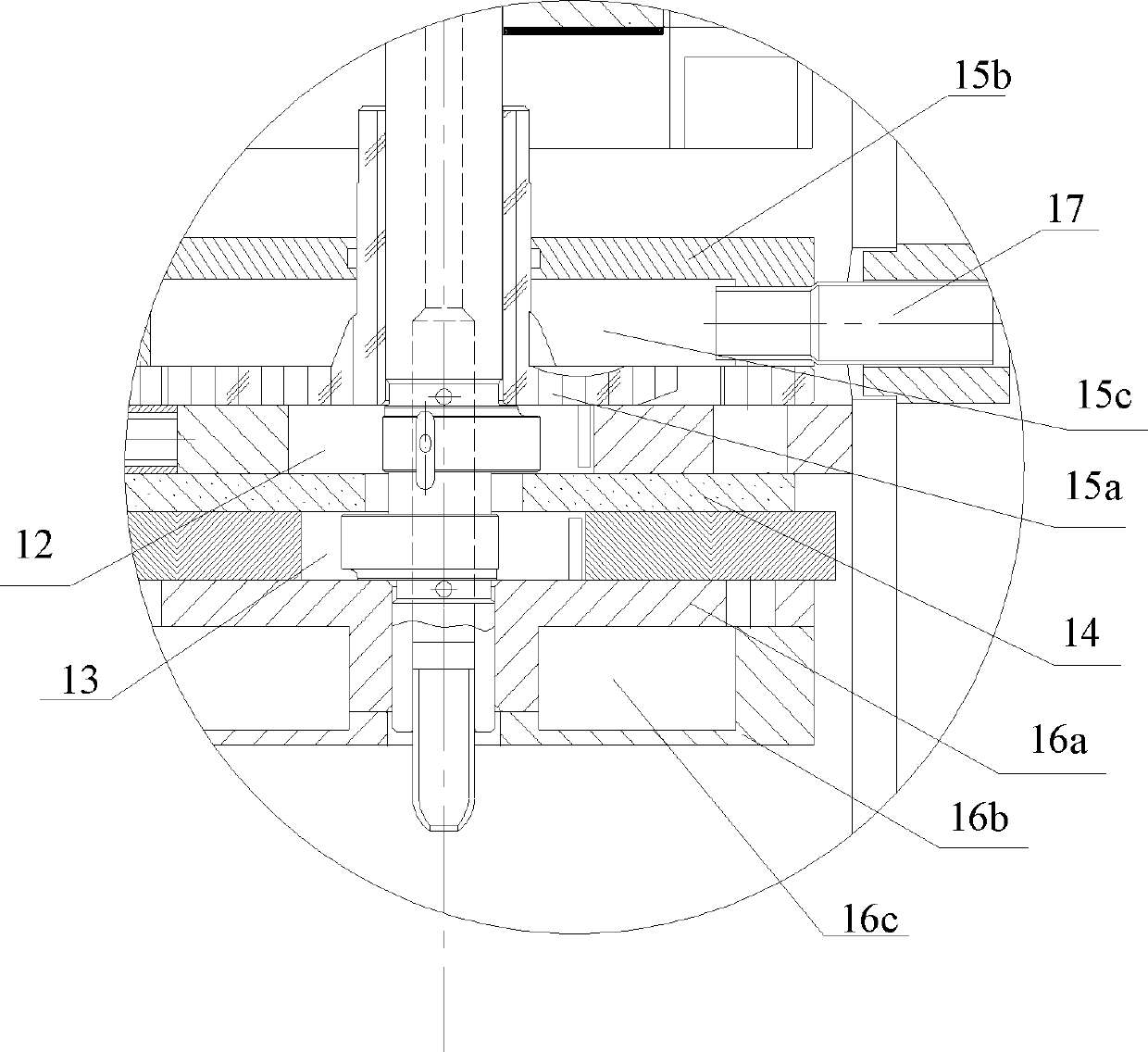

Compressor as well as air conditioning system and heat-pump water heater with same

InactiveCN103375405AReduce exhaust temperatureLower gas temperatureCompressorRotary/oscillating piston combinations for elastic fluidsLiquid stateEngineering

The invention provides a compressor as well as an air conditioning system and a heat-pump water heater with the same. The compressor provided by the invention comprises a low-pressure air cylinder and a high-pressure cylinder which are arranged in series, as well as a mixing cavity arranged between the low-pressure air cylinder and a high-pressure cylinder in series, wherein the mixing cavity is internally provided with a liquid spraying device. The invention also provides the air conditioning system and the heat-pump water heater with the compressor. According to the compressor as well as the air conditioning system and the heat-pump water heater with the same, the mixing cavity is arranged between the low-pressure air cylinder and a high-pressure cylinder in series and is internally provided with a liquid spraying structure, a condensed refrigerating fluid with high temperature and middle pressure in the low-pressure air cylinder is discharged in the mixing cavity so as to be mixed with a refrigerating fluid of a gas-liquid two-phase mixed state and sprayed by the liquid spraying structure when in operation, the liquid state refrigerating fluid absorbs heat so as to gasify, the gas temperature of the refrigerating fluid with the high temperature and middle pressure is reduced, the suction temperature of the high-pressure cylinder is reduced, and the exhaust gas temperature of the compressor is effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

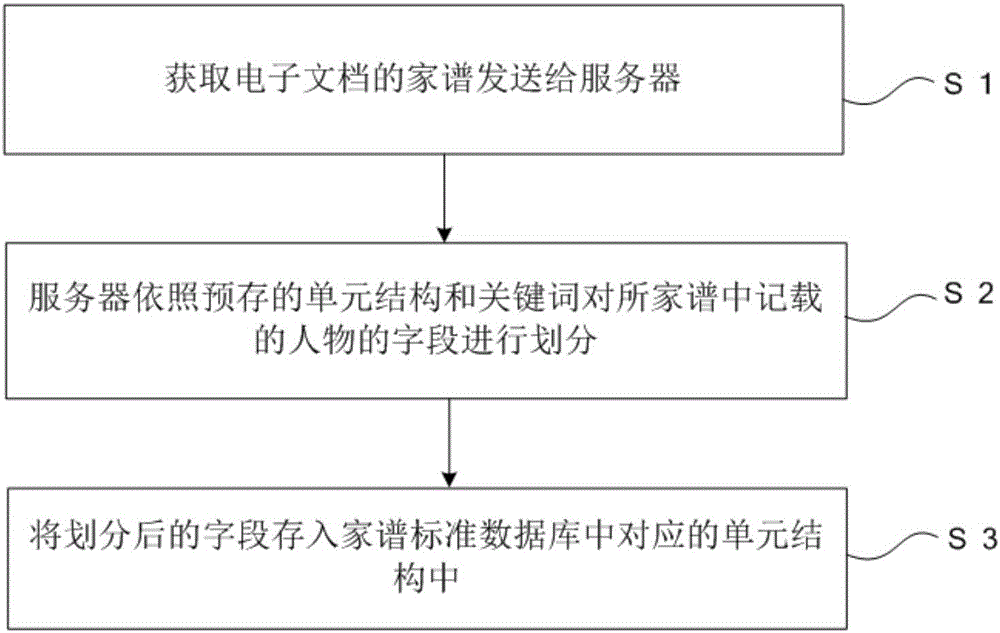

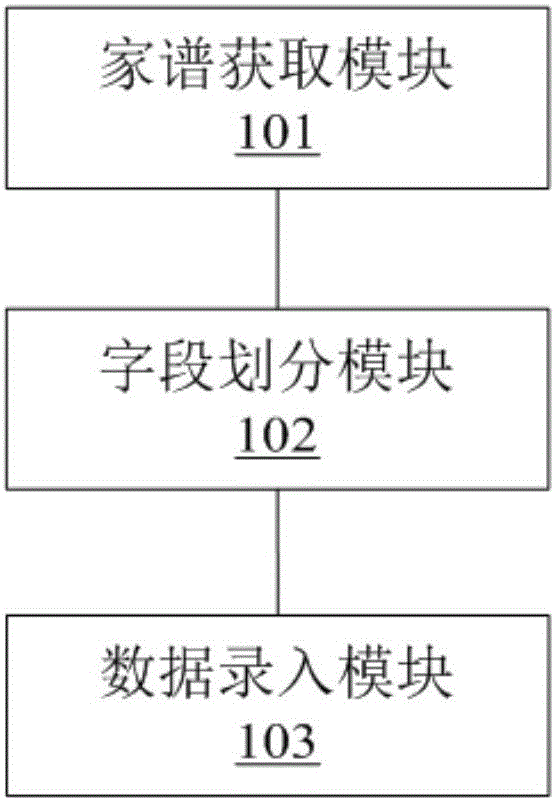

Family tree standard database building method and system

InactiveCN106227879AAchieving processing powerReduce investmentDigital data processing detailsNatural language data processingElectronic documentUnit structure

The invention relates to the technical field of data classification, in particular to a family tree standard database building method and system. The family tree standard database building method comprises the following steps: acquiring a family tree of an electronic document, and transmitting the acquired family tree to a server; classifying fields of figures stored in the family tree according to pre-stored unit structures and keywords by the server; storing the classified fields in corresponding unit structures in a family tree standard database. By adopting the family tree standard database building method and system, the standard database of the family tree can be built, and the data processing and analyzing capabilities specific to the family tree are realized, so that the aims of inquiring and calculating information more rapidly and making data-associated information more stereoscopic and richer are fulfilled.

Owner:王华勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com