Heat exchanger employing crossed spiral tube

A heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of high manufacturing cost and complex structure, and achieve compact structure, small volume, and processing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

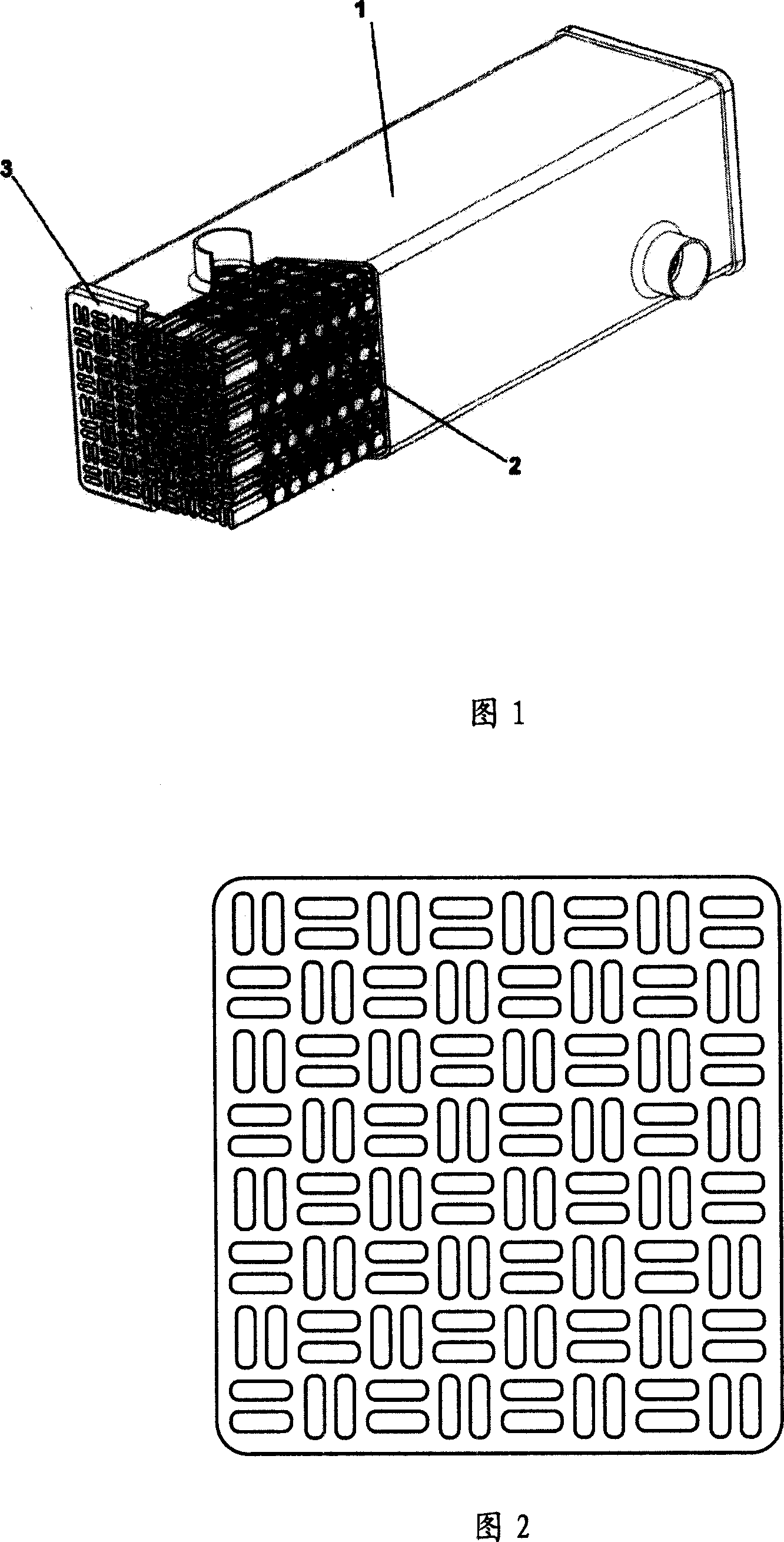

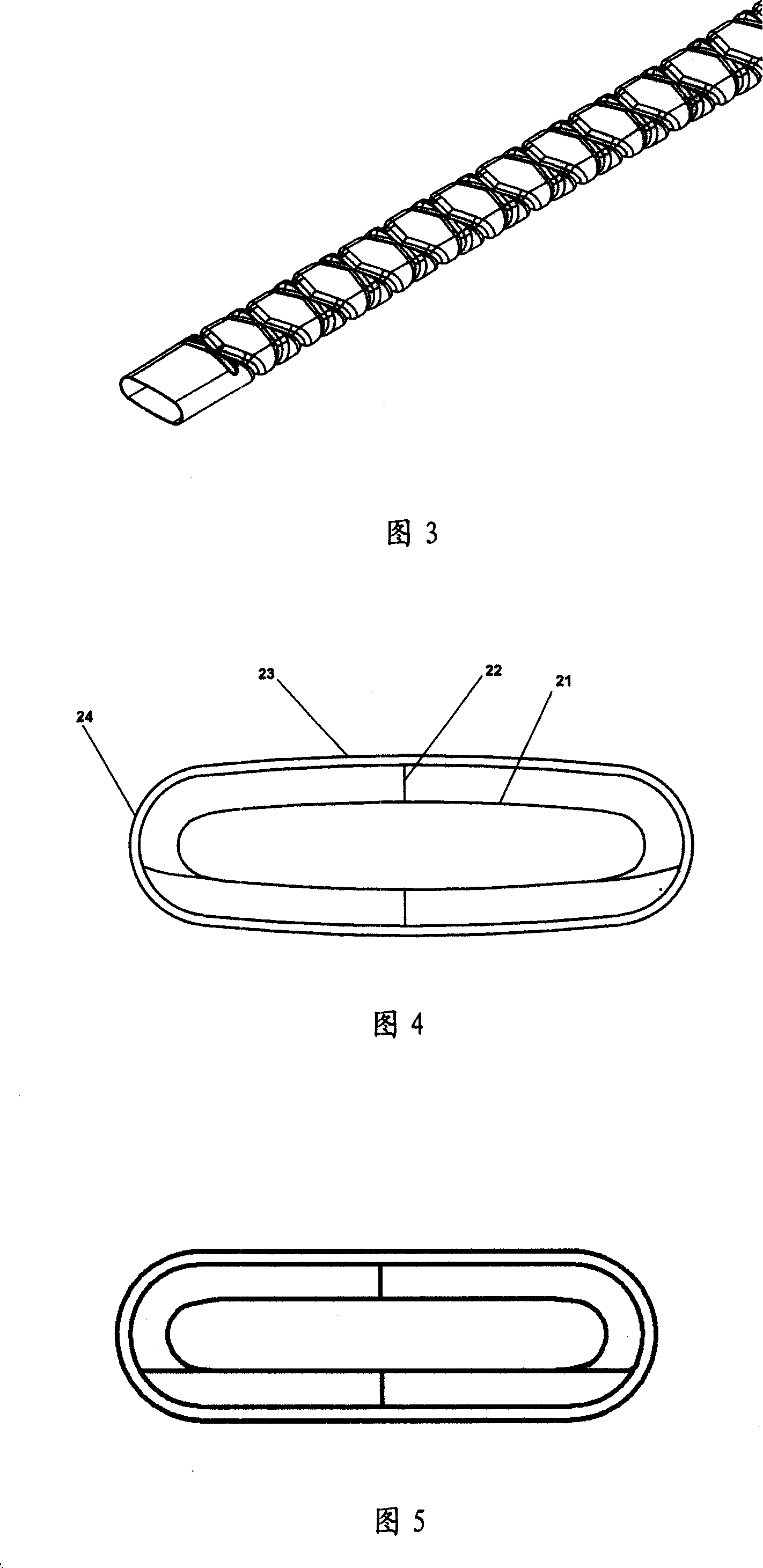

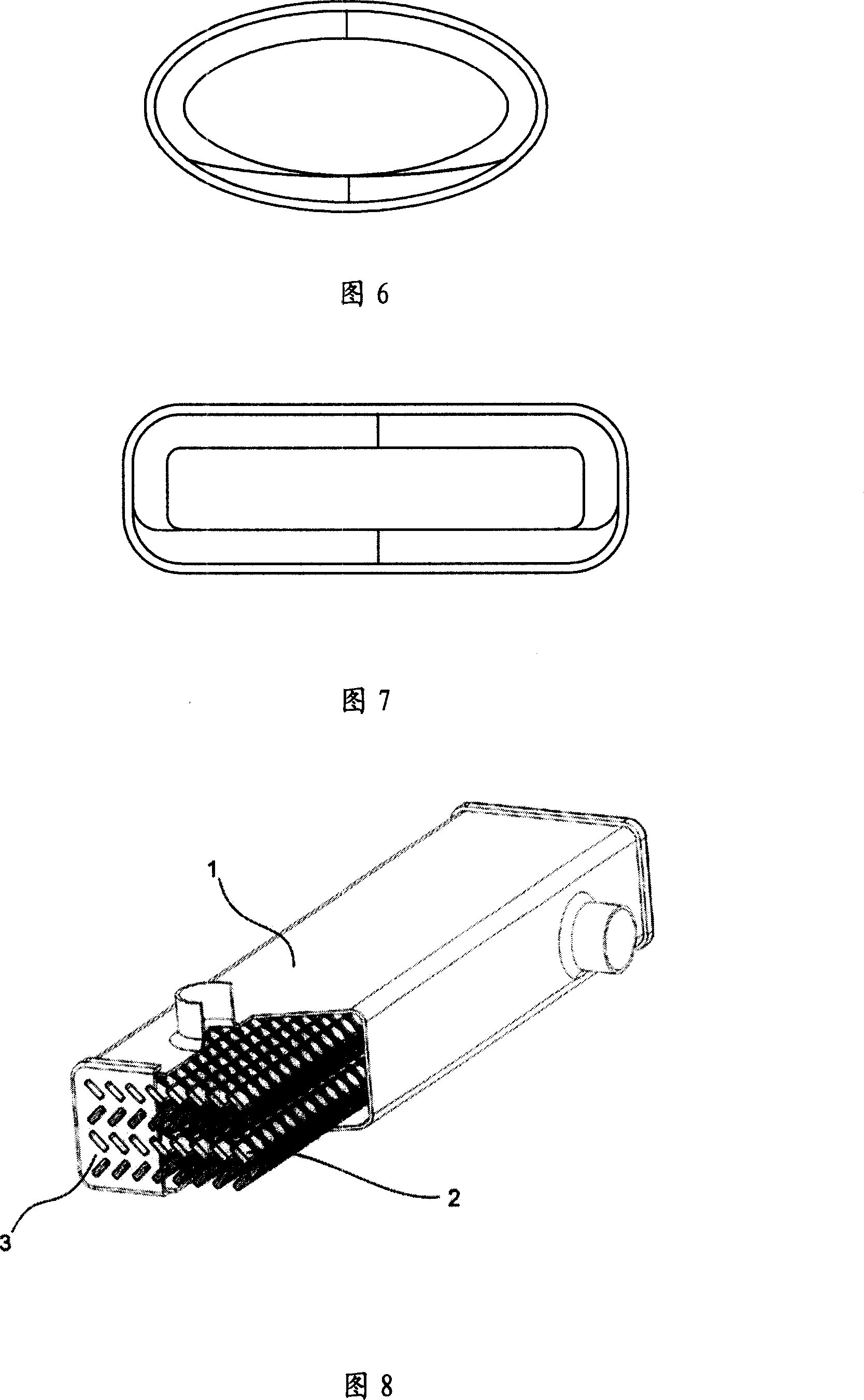

[0023] Figures 1 and 2 are respectively a three-dimensional structural schematic diagram and a cross-sectional shape schematic diagram at the tube sheet of the first embodiment of the present invention. The serial numbers in the figure represent: 1. Shell, 2. Heat exchange tube, 3. Tube sheet. As shown in Figure 1, when the shell 1 of the heat exchanger has a rectangular cross-section, a flat cross-helical groove heat exchange tube 2 is arranged in the shell 1; the heat exchange tube 2 is compactly arranged in the shell 1 , and the heat exchange tubes 2 are staggeredly arranged in the shell in parallel and vertical ways, and the two ends of the nozzles of the heat exchange tubes 2 are welded and fixed on the tube plates 3 at both ends of the shell. The application of flat intersecting spiral tubes and the arrangement shown in Figure 1 not only enhance the flow strength of the fluid in the tube, but also enhance the disturbance of the fluid of the coolant outside the tube, maki...

Embodiment 2

[0032] The cross-sectional shape of the heat exchange tube in this embodiment is another oblate shape, as shown in FIG. 5 . The difference between this embodiment and the first embodiment described in Figure 4 above is that the cross-sectional shape of the stainless steel pipe body is flat, the two opposite long sides are straight lines, and the opposite short sides are arc-shaped raised semicircular arcs from the inside to the outside. On the other hand, such a setting can improve the heat exchange efficiency.

[0033] The flat spiral heat exchange tube arranged in the exhaust gas recirculation cooler not only increases the heat exchange area compared with the circular tube, but also strengthens the disturbance of the fluid in the tube. Because the flat tube is not symmetrical to the center of the round tube, the distance between the geometric center of the flat spiral tube and the tube wall is smaller than the distance between the circular spiral tube and the tube wall, and ...

Embodiment 3

[0035] Fig. 6 is a sectional view of the heat exchange tube in this embodiment. This embodiment is a modification based on the embodiment described in Figure 4 above, connecting the entire cross-section of the heat exchange tubes smoothly, that is, for the sake of processing, in the case of removing the cross-sectional shape of the spiral groove, the The cross-sectional shape of the pipe body is set as an ellipse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com