Patents

Literature

225results about How to "Good use effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous zinc ion battery

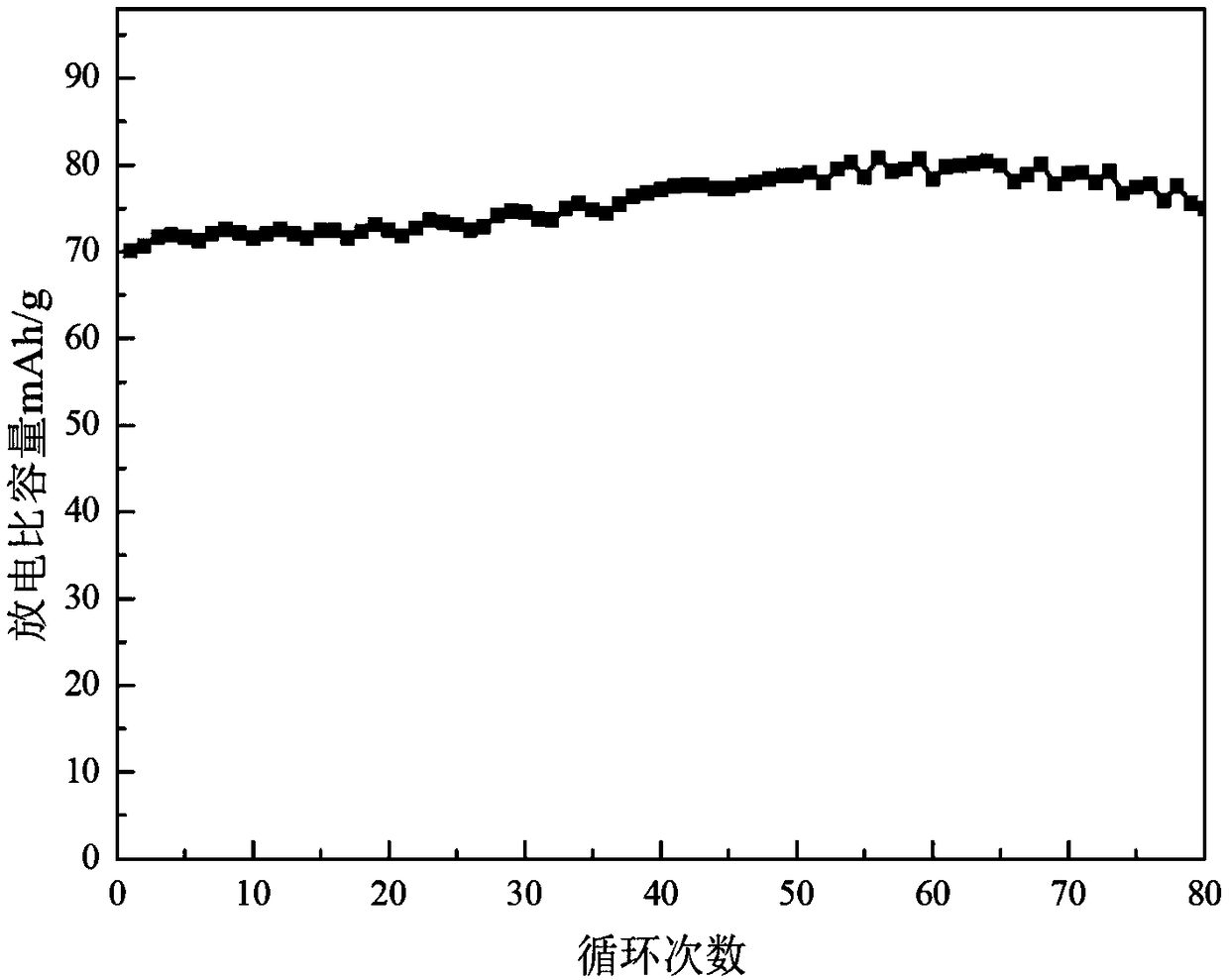

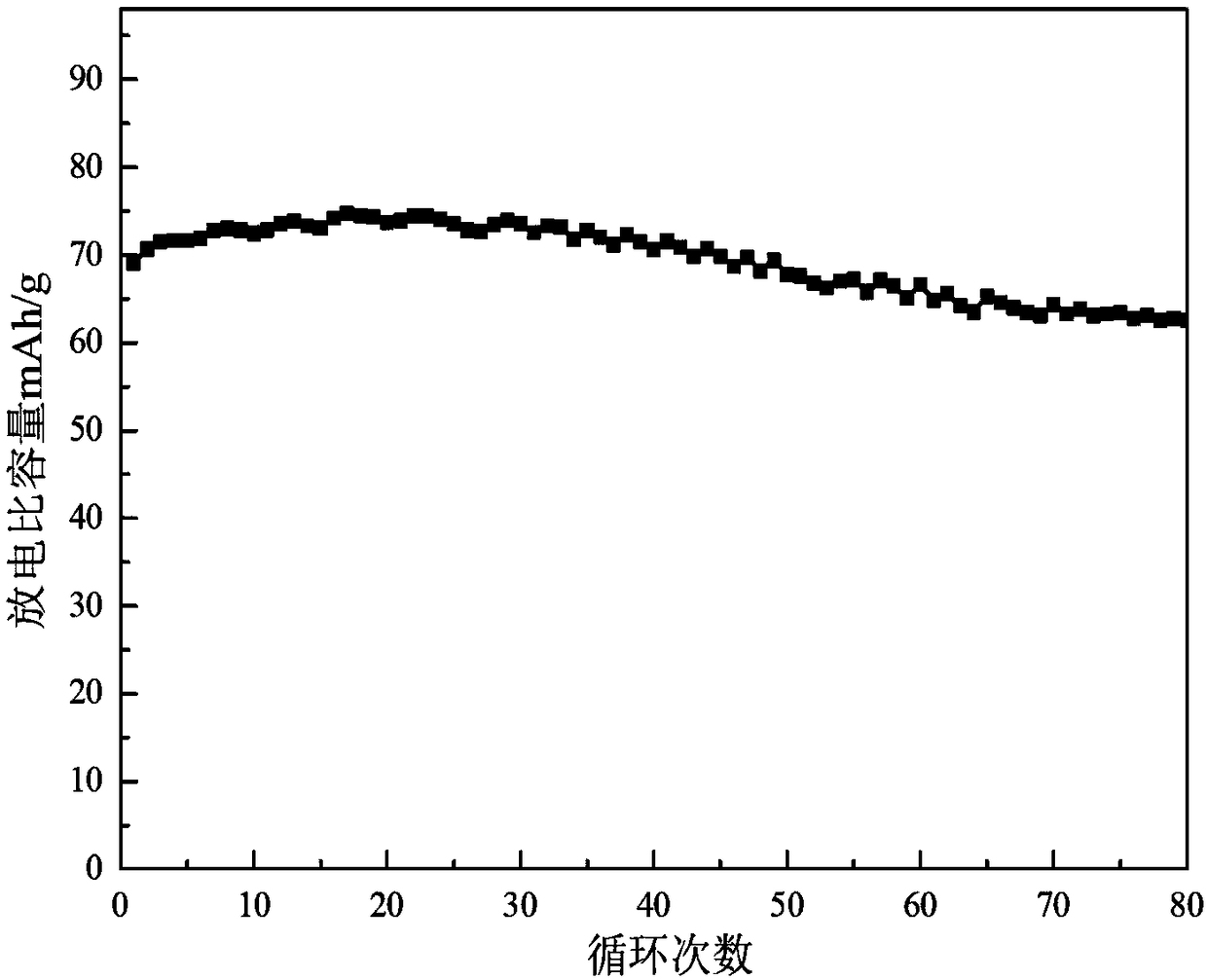

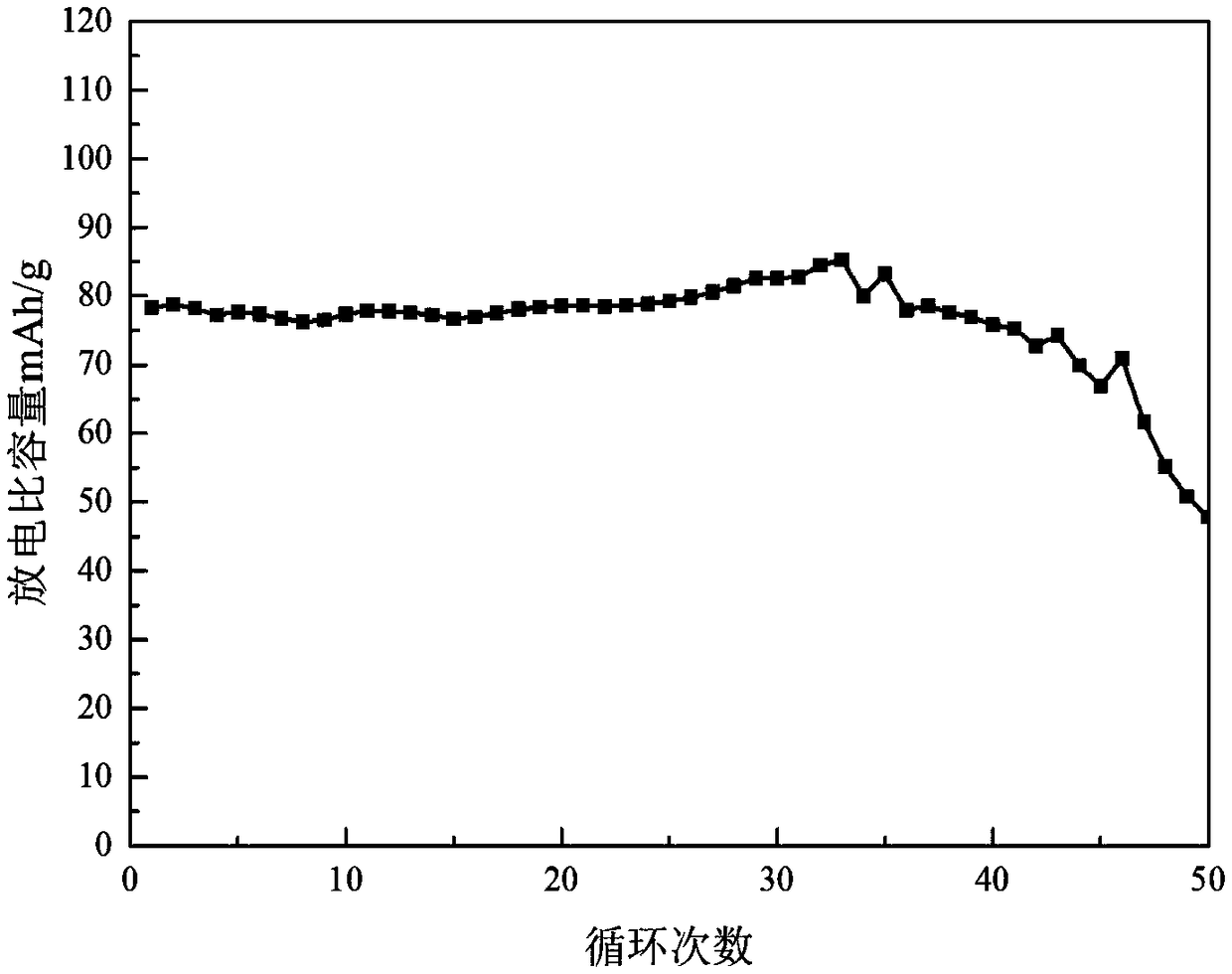

InactiveCN108807910APromote circulationSimple preparation processFinal product manufactureSecondary cellsElectrical batteryZinc ion

The invention belongs to the technical field of batteries, and particularly relates to an aqueous zinc ion battery. The aqueous zinc ion battery comprises an anode, a cathode, an electrolyte and a diaphragm, wherein the diaphragm is arranged between the anode and the cathode; the cathode is a graphene-assisted zinc cathode; the electrolyte comprises a solvent and a solute, the solvent is water, and the solute comprises soluble zinc salt and manganese salt. Compared with the prior art, the aqueous zinc ion battery has the advantages that the graphene-assisted zinc cathode is applied to the aqueous zinc ion battery system; by adopting the graphene with excellent property and stable structure, the stability and conductivity of the zinc cathode are enhanced, so that the cycle property of the graphene-assisted zinc cathode is enhanced; especially, by adding the trace manganese salt and the corrosion inhibitor into the electrolyte, the problems of zinc corrosion, passivating and the like canbe effectively relieved; the cycle life of the graphene-assisted zinc cathode is further prolonged.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

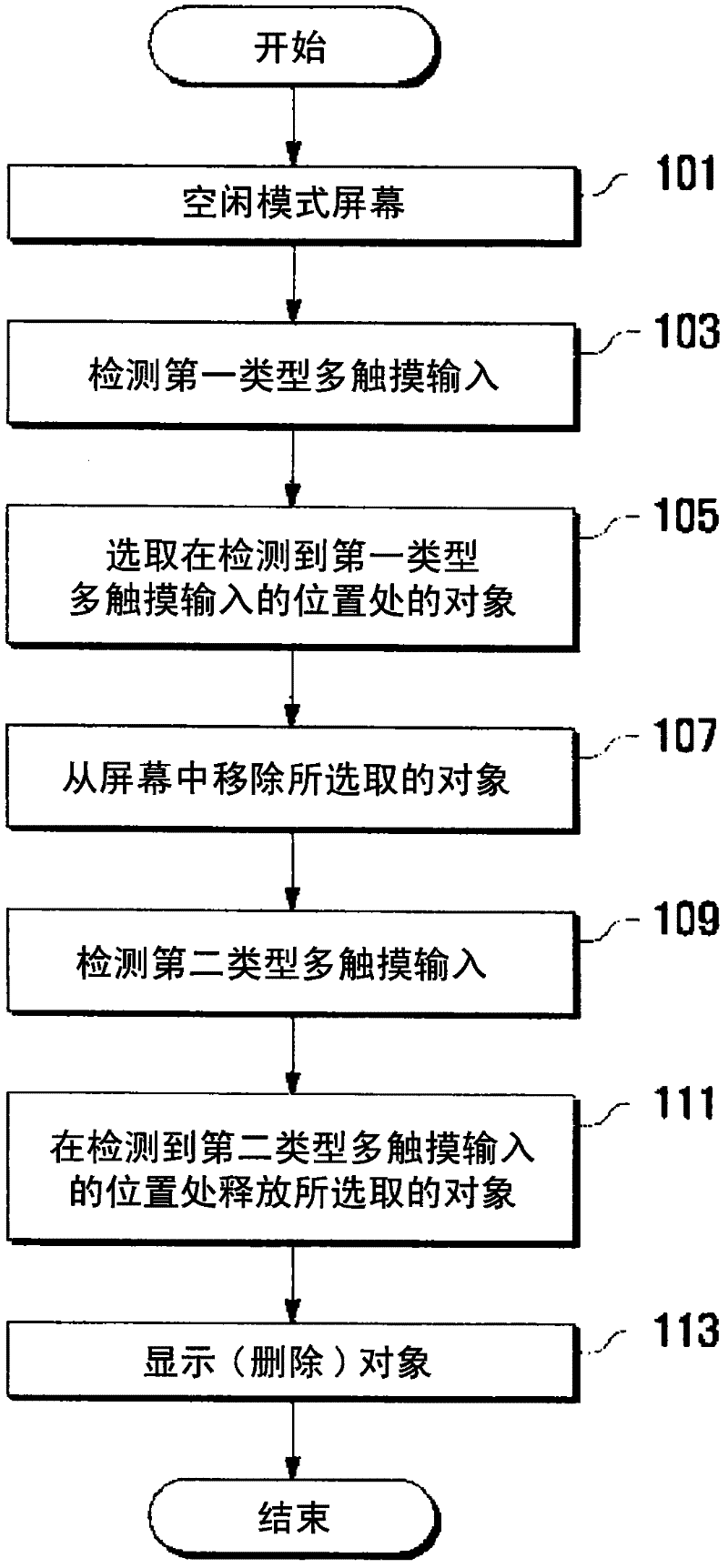

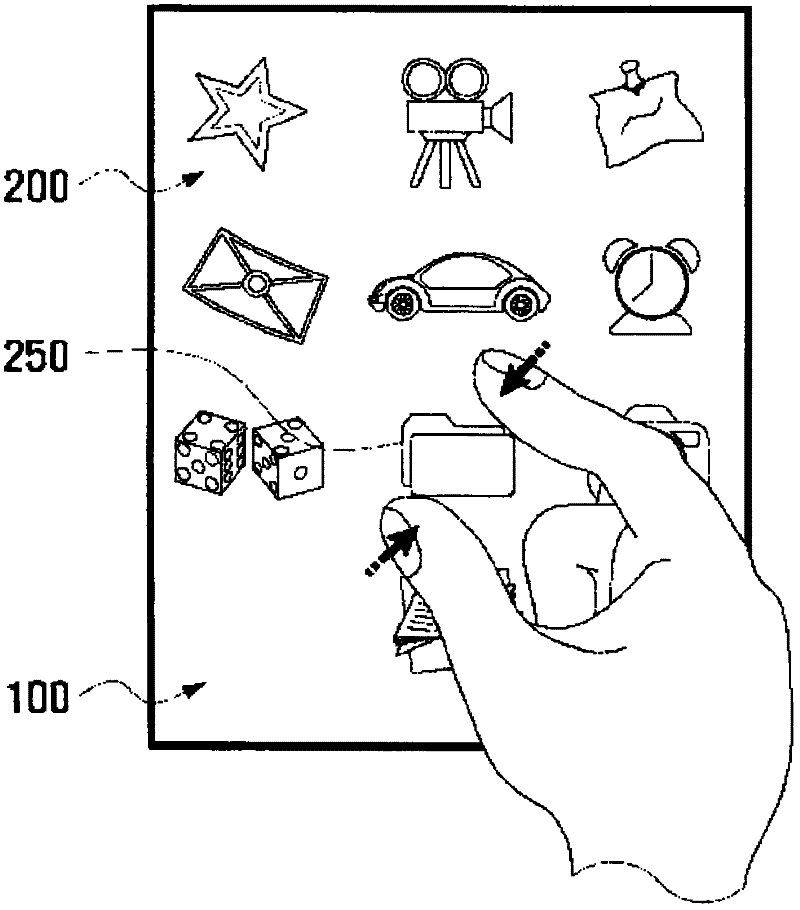

Object management method and apparatus using touchscreen

InactiveCN102187303AEfficient and intuitive handlingImprove convenienceExecution for user interfacesDigital output to display deviceComputer hardwareComputer graphics (images)

An object management method and apparatus for a device having a touchscreen is provided for handling objects displayed on the screen with diverse multi-touch gestures. An object management method for a touchscreen-enabled device according to the present invention includes the sensing and identification of picking up at least one object displayed on the touchscreen in response to a first type multi-touch input and releasing the at least one object on the another portion of the touchscreen, or a different area or a different display on the touchscreen, in response to a second type multi-touch input. The invention includes release to the touchscreen of another device that is in wireless communication with the device having the picked up object.

Owner:SAMSUNG ELECTRONICS CO LTD

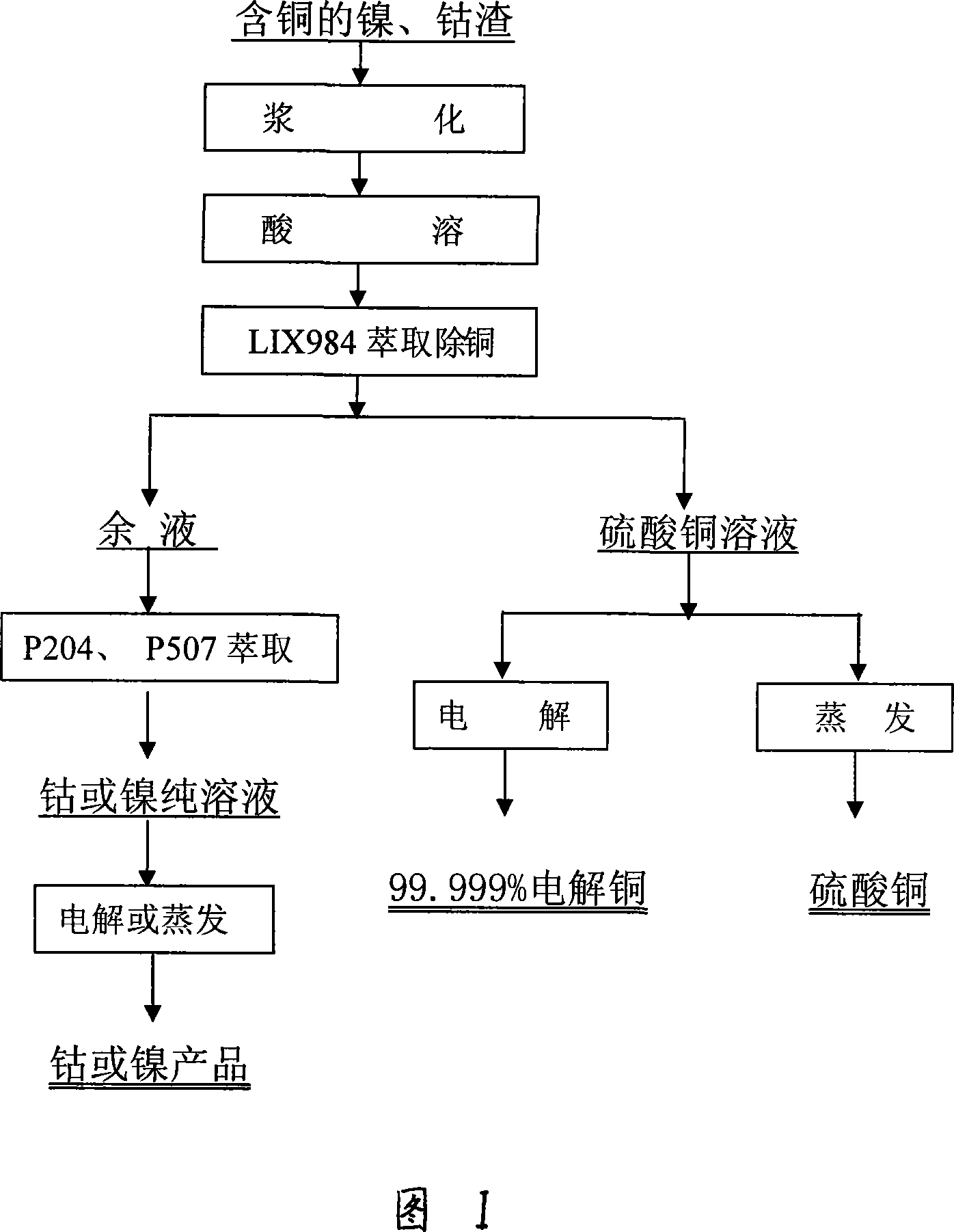

Method for separating copper from nickel and cobalt solution

InactiveCN101195861AReduce consumptionHigh recovery rateProcess efficiency improvementKeroseneHydrometallurgy

The invention discloses a method of separating copper from nickel cobalt solution, which relates to a method of separating copper from nickel cobalt solution during the technical process of producing high quality nickel or cobalt through a hydrometallurgy method. The invention is characterized in that LIX<QUESTION MARK> series of extracting agent is adopted to extract and separate copper in the nickel cobalt solution, the conditions of the extracting process are as follows: firstly, the pH value of the feed solution of the nickel cobalt solution is 1.5 to 2.5; secondly, the organic compounding ratio is 5 percent to 35 percent; thirdly, organic thinning agent is number 260 solvent oil or sulfonated kerosene; fourthly, the copper in the feed solution is extracted out through adopting two to three-stage countercurrent extraction; loading organic phase is washed through adopting zero to two-stage diluted acid solution; the copper in the loading organic phase is circularly and back washed through adopting 1 to 3 stages; fifthly, the concentration of the washing loading organic dilute sulfuric acid is 0 to 50 g / l; the concentration of the sulfuric acid for back washing the copper in the loading organic phase is 140 to 190 g / l; sixthly, the temperature during the extracting process is controlled to 15 to 35 DEG C. Compared with the traditional copper removal process, the method of the invention has the advantages that the process flow is short, the adaptability of the raw material is strong, the raw material consumption and energy consumption are few, the metal recovery ratio is high, and the comprehensive utilizing effect is good.

Owner:JINCHUAN GROUP LIMITED

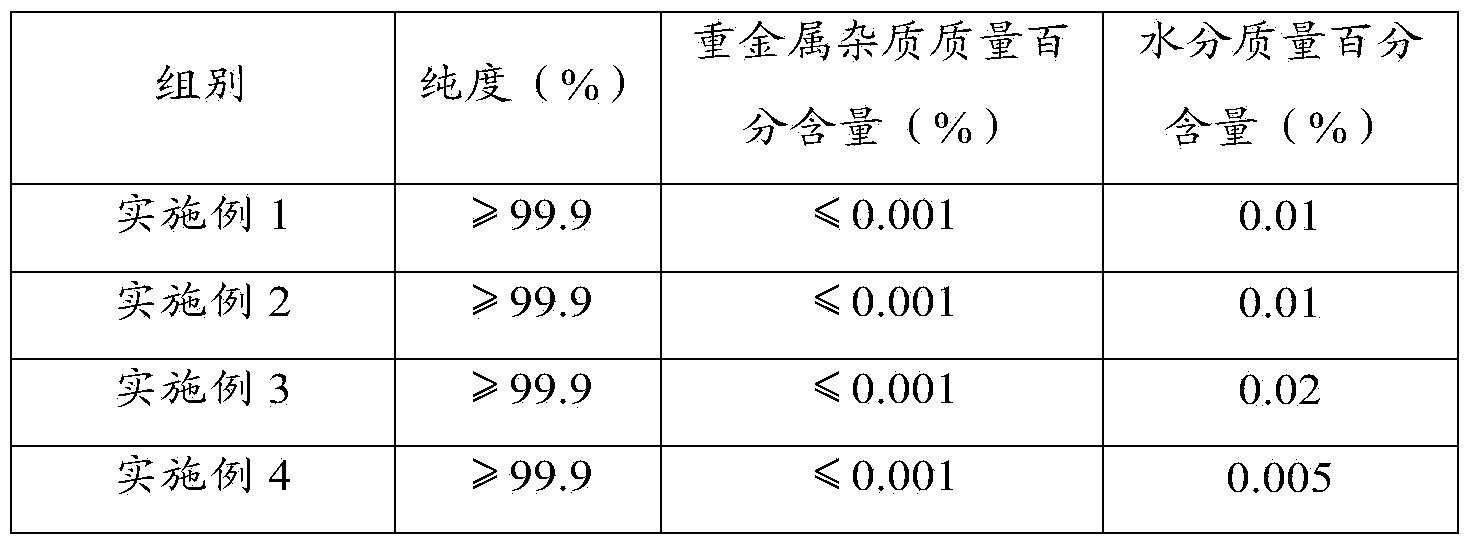

Method for collaborative treatment of positive and negative active materials of waste lithium-ion batteries

ActiveCN110835682AHigh reactivityAchieving auto-redoxWaste accumulators reclaimingBattery recyclingPhysical chemistryManganese

The invention discloses a method for collaborative treatment of positive and negative active materials of waste lithium-ion batteries, and belongs to the technical field of lithium-ion battery material recovery. Appropriate amount of concentrated sulfuric acids are added into a mixture of positive active materials and negative active materials obtained by crushing and separating the waste lithium-ion batteries for reaction and maturation to obtain solidified clinker, the obtained solidified clinker is leached with water or dilute acids, a leached solution containing cobalt, lithium, nickel, titanium and other useful metal elements is obtained from leached pulp through sedimentation and separation, high-quality graphite and residues are obtained from leached residues through centrifugal classification to achieve collaborative intensified treatment of the positive and negative active materials of the waste lithium-ion batteries, nickel, cobalt, manganese, lithium, graphite powder and other components can be recovered comprehensively, the recovery process of active materials in waste batteries is conducive to simplifying, the recovery rate of useful elements is high, and the purity ofrecovered graphite products is high. Main consumption agents of the method are sulfuric acids, and the cost is low.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

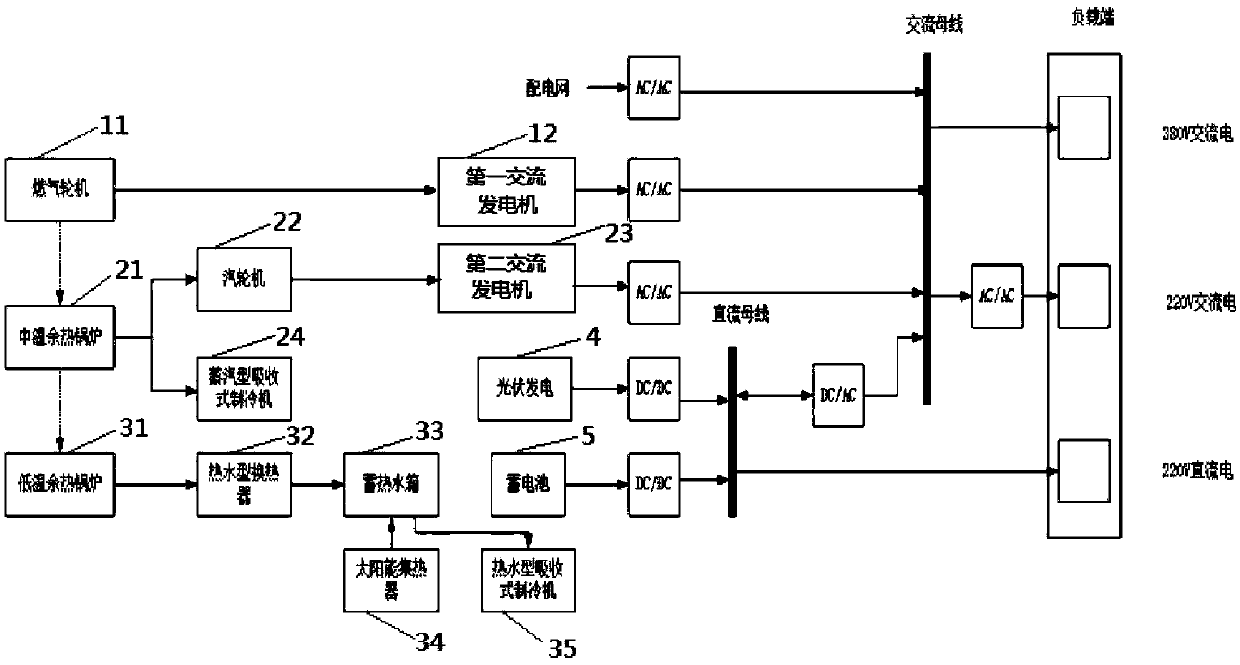

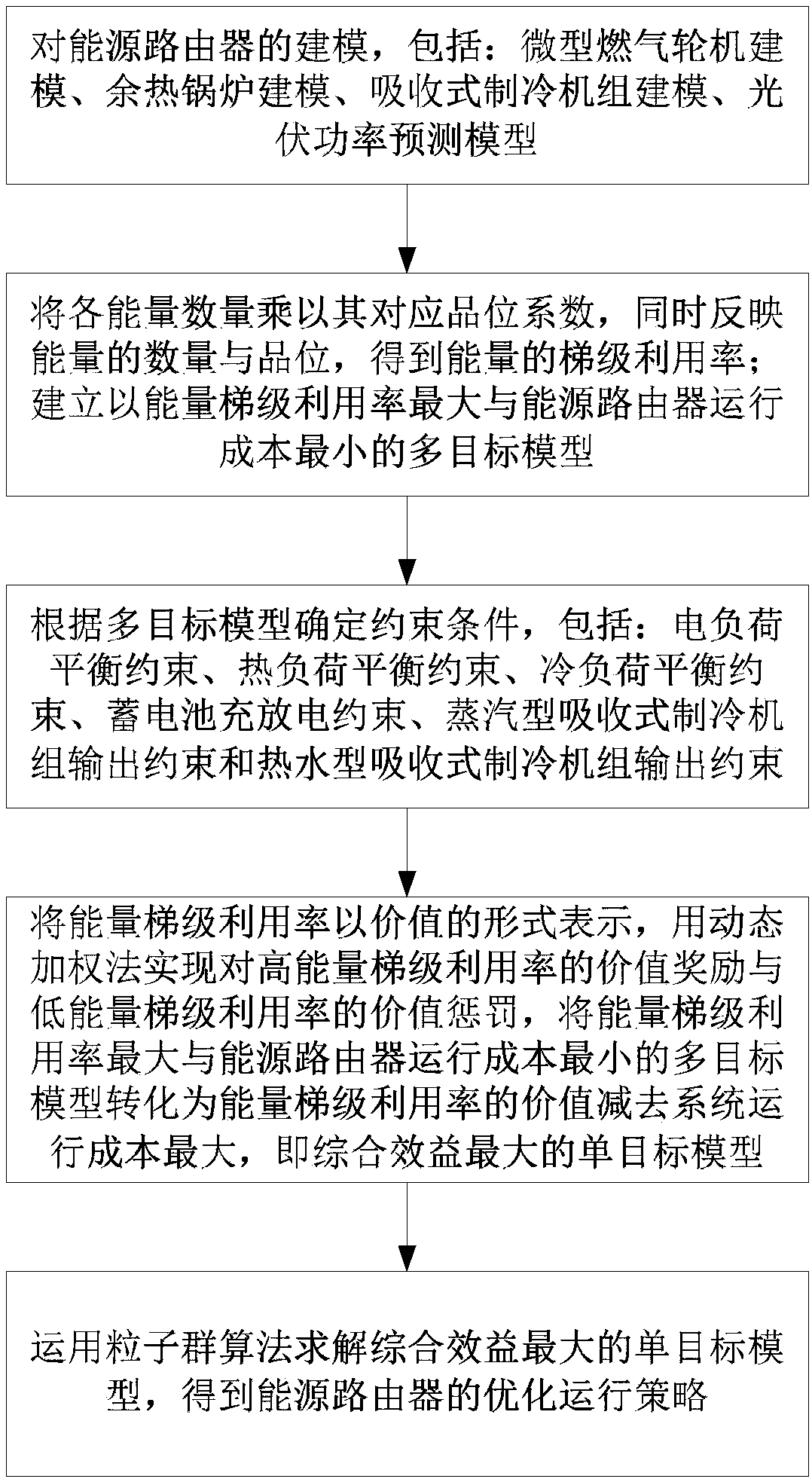

Energy router based on energy gradient utilization and operation optimization method thereof

ActiveCN108206543ARealize comprehensive utilizationGood use effectSingle network parallel feeding arrangementsGas turbine plantsEnergy gradientEnergy source

The invention discloses an energy router based on energy gradient utilization and an operation optimization method thereof. The energy router comprises a gas turbine, a steam turbine, a waste heat boiler, an absorption refrigerating machine, a heat exchanger, a storage battery, a heat storage water tank and a photovoltaic battery. The system converts the fuel into electric energy according to thequality and the grade of the energy, and the waste heat is used for refrigeration, heat supply or power generation, so as to realize the gradient utilization of energy sources. According to the operation optimization strategy of the system, an optimized objective function is established by establishing a system model of the energy router, and optimizing scheduling solving is carried out after an optimization scheduling constraint condition is selected, and an optimized scheduling strategy is finally obtained, so that the system equipment can be correspondingly controlled according to the change of the user demands, and the optimization goal of maximizing the energy gradient utilization rate and minimizing the operation cost is achieved.

Owner:NORTHEASTERN UNIV

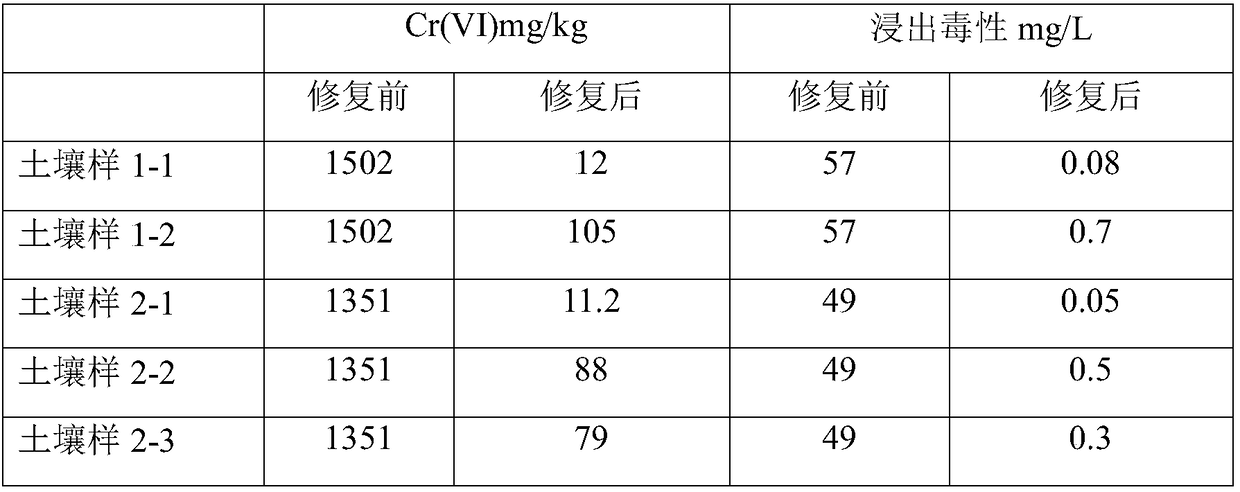

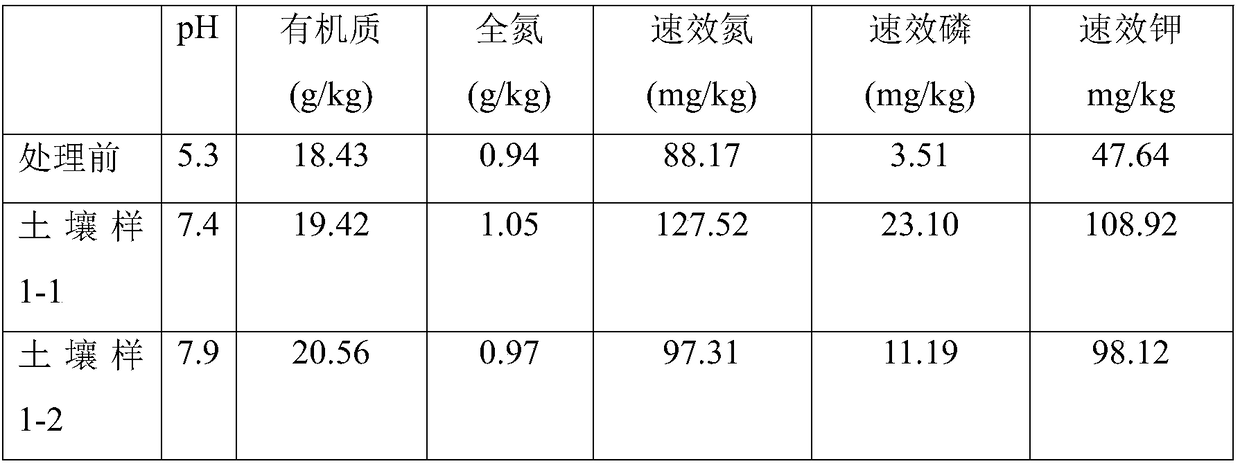

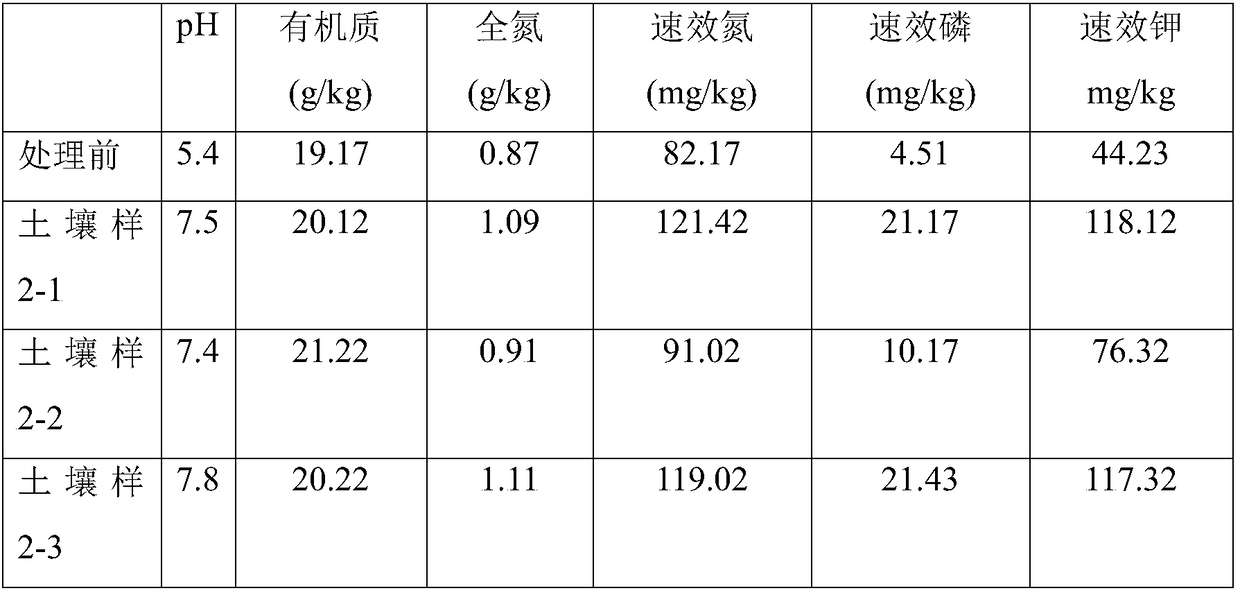

Fertilizer for Cr (VI) polluted soil remediation and improvement and preparation method of fertilizer

InactiveCN108276228AGuaranteed neutral and slightly alkalinePrevent acidificationCalcareous fertilisersBio-organic fraction processingMicrobial agentPollution

The invention discloses fertilizer for Cr (VI) polluted soil remediation and improvement and a preparation method of the fertilizer. The preparation method of the fertilizer comprises the following steps: spraying an EM microbial agent to the surfaces of bagasse and pig manures, then uniformly mixing the bagasse with the pig manures, and composting the mixture to obtain a cured material; adding anOneida silva microbial agent, the EM microbial agent and a desulfovibrio microbial agent into the cured material, uniformly mixing the microbial agents with the cured material, and composting the mixture to obtain a microbial compound; and mixing ferrous sulfate, modified coal ash, ground calcium carbonate and the microbial compound, and granulating the mixture to obtain the fertilizer. The fertilizer can improve the soil structure, improve the soil fertility and remediate and improve a microecological structure of the soil when effectively remediating chromium pollution, finally remetiates and improves the chromium-contaminated soil, and restores the ecological functions.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

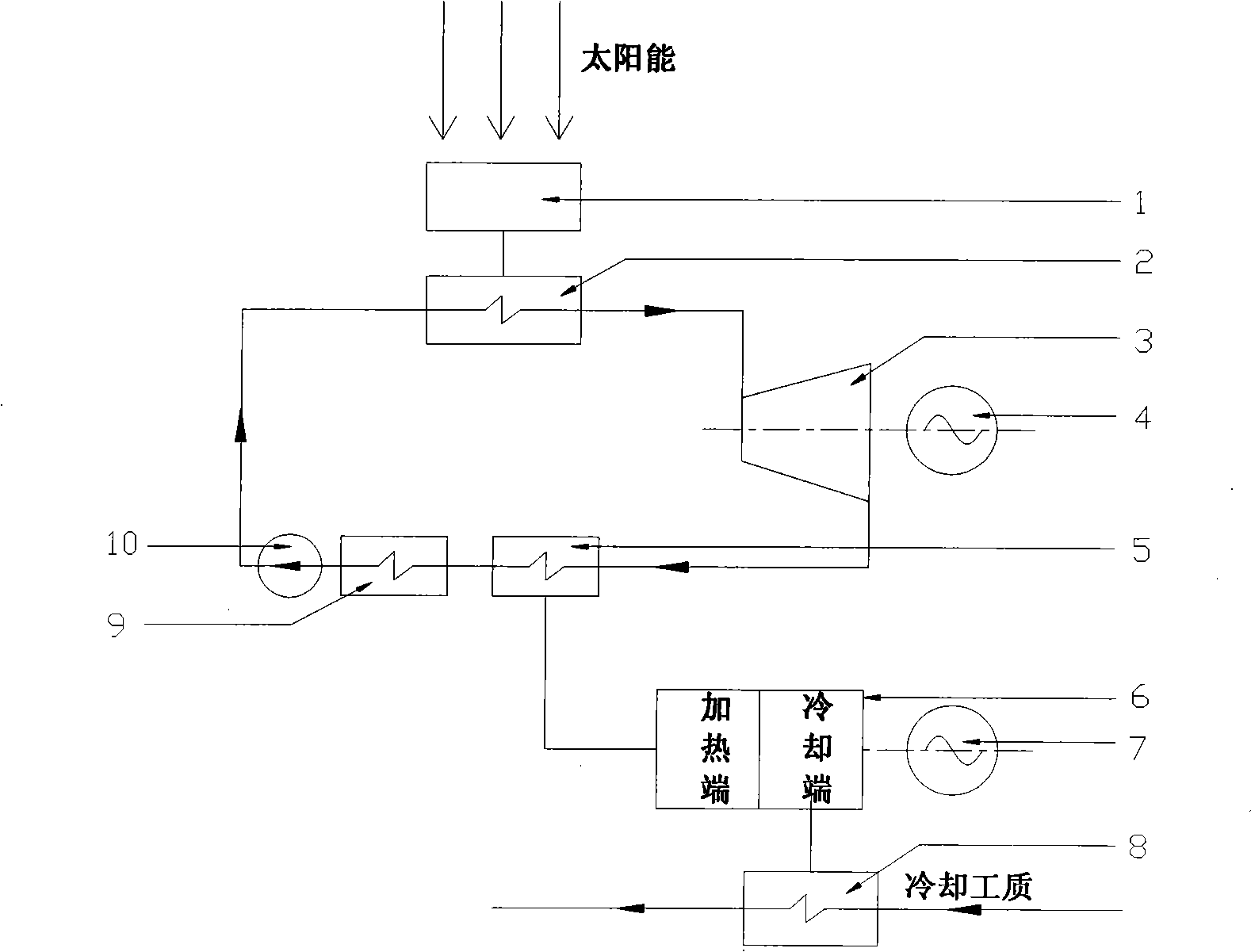

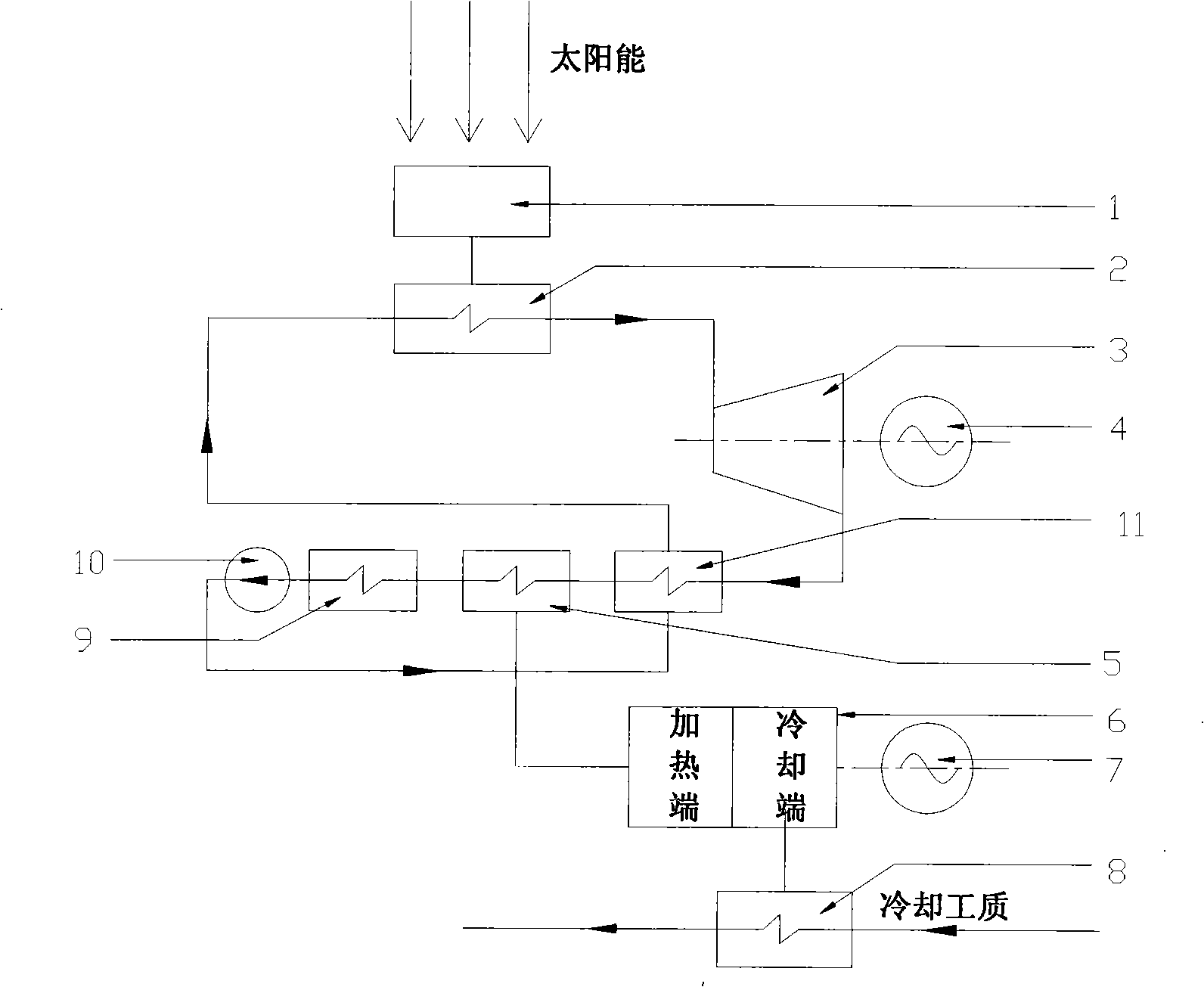

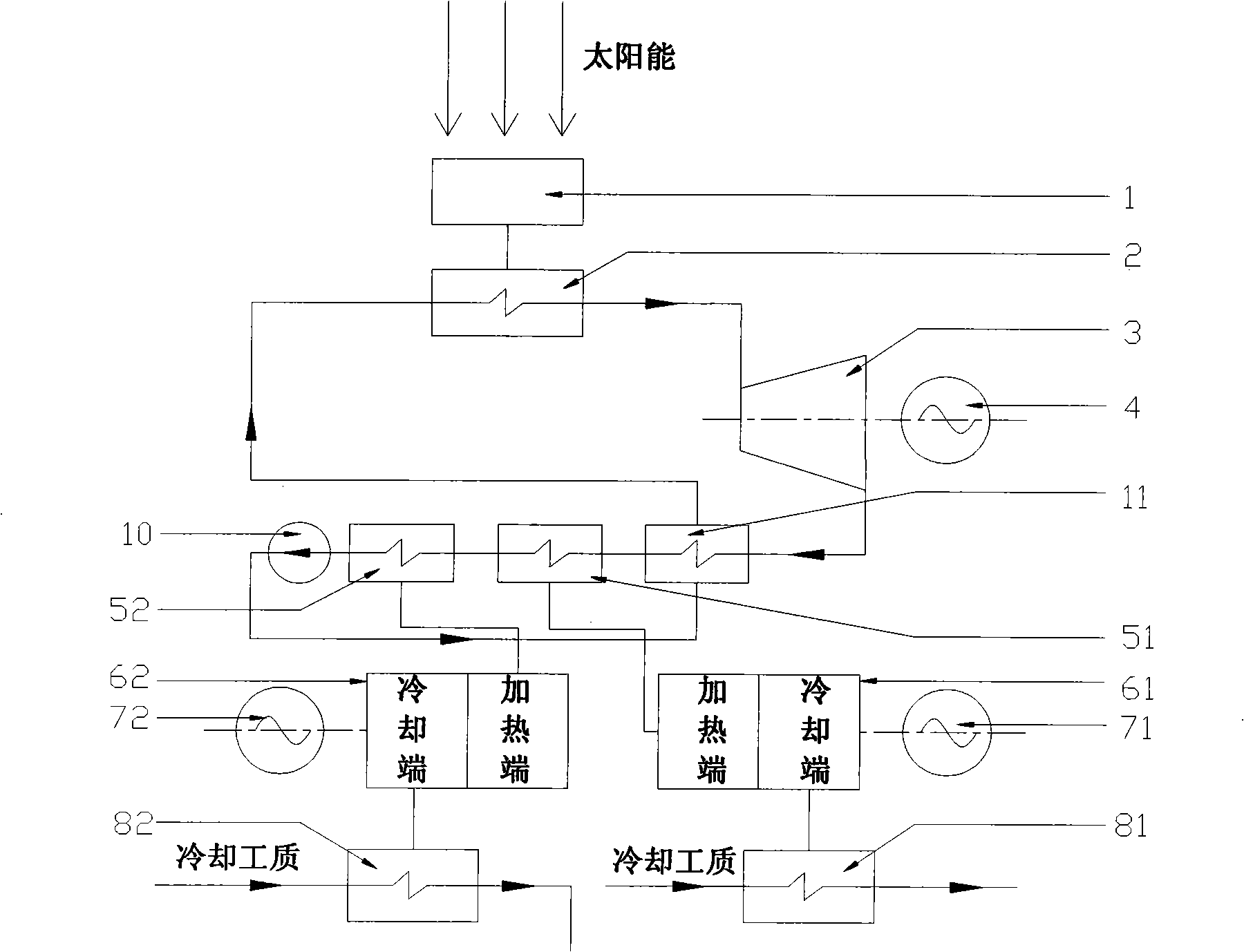

Distributed solar energy utilization system

InactiveCN101334012ASimple equipmentLow costFrom solar energySteam engine plantsStirling engineChiller

The invention discloses a distributed type solar energy utilizing system, which belongs to the solar energy utilization technology. The distributed type solar energy utilizing system comprises a solar heat collector, a main heat utilizing device and a waste heat utilizing device and is characterized in that the main heat utilizing device comprises a main heat exchanger, a midget high-speed turbine, a waste heat exchanger and a circulating pump which form a circulating closed circuit in sequence, wherein, the main heat utilizing device is connected with the solar heat collector to absorb heat; the waste heat utilizing device comprises a stirling engine and a cooler which is connected with a cooling end of the stirling engine, wherein, a heating end of the stirling engine is connected with the waste heat exchanger to absorb heat.

Owner:XI AN JIAOTONG UNIV

Vegetation concrete and preparation method thereof

InactiveCN103283573APromote growthPromote absorptionCultivating equipmentsSoilless cultivationVegetationArbuscular mycorrhizal fungi

The invention relates to vegetation concrete, and belongs to the field of ecological restoration engineering. The vegetation concrete comprises base concrete located at the bottom and surface concrete located at the top, the base concrete is sprayed by vegetation concrete matrix materials, the surface concrete is sprayed by the vegetation concrete matrix material mixed with grass seeds, and the vegetation concrete matrix materials comprise, by mass, 75-85% of raw planting soil, 6-12% of cement, 2-5% of organic matters, 2-5% of concrete greening additives and 2-5% of arbuscular mycorrhizal fungi inoculant which are compatible. The problems that vegetation growth is stressed by matrix materials, and vegetation is easy to degrade in a maintenance process on existing vegetation concrete technical conditions are solved, and pollutant intercepting capacity when a vegetation concrete technology is applied to a buffer zone is enhanced.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION

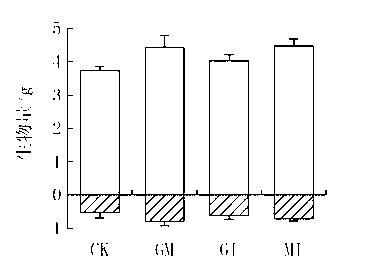

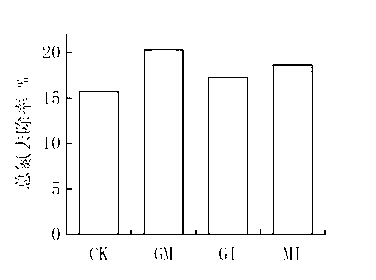

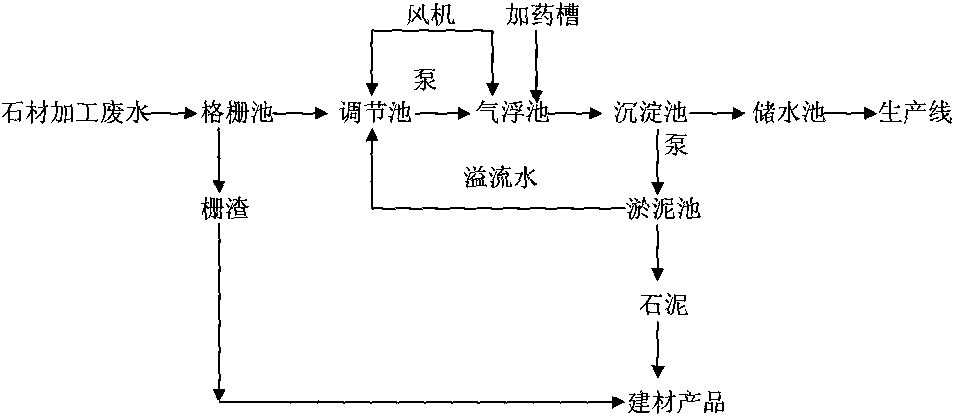

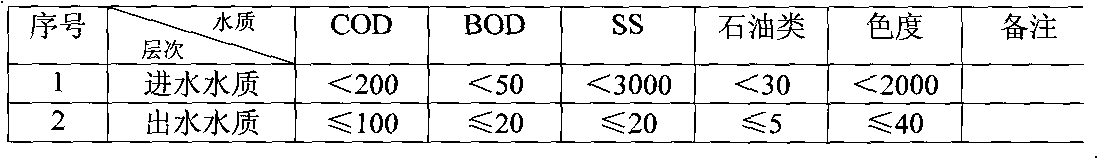

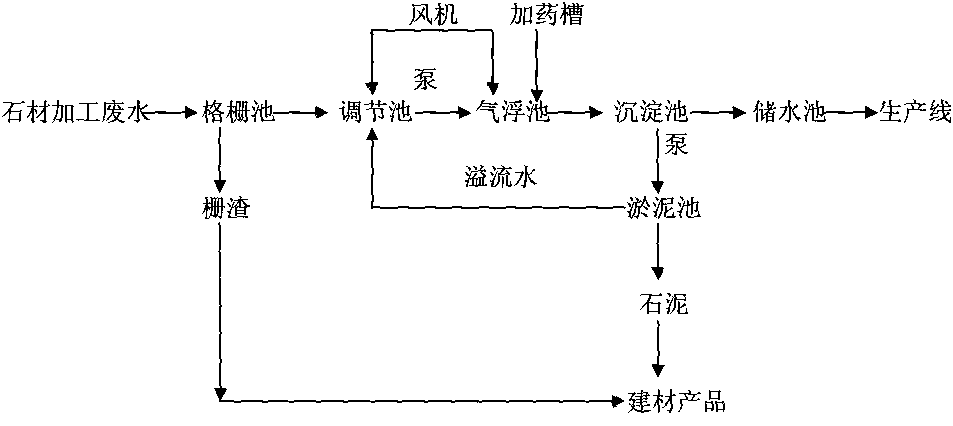

Technology for deeply treating stone processing wastewater

InactiveCN102531235AGood use effectSimple processMultistage water/sewage treatmentSocial benefitsSludge

The invention relates to the field of environment protection, in particular to a method for treating wastewater, more particularly to a technology for deeply treating stone processing wastewater. The technical effect of deeply treating the stone processing wastewater is achieved by adopting deep physicochemical treatment processes such as regulation, addition of an active flocculating agent, air floatation, beam current and sedimentation. The technology has the advantages of advanced process, high recycling efficiency of the treated water, good comprehensive utilization effect and low operation cost of the treating process, is beneficial to environment protection, energy saving, emission reduction and development of stone processing industry, and has remarkable environment benefit, social benefit and economic benefit.

Owner:FUZHOU LVMING ENVIRONMENTAL PROTECTION ENG

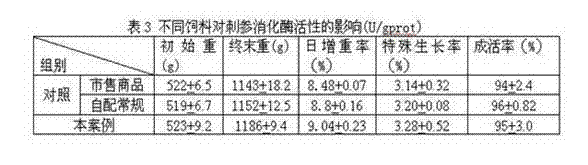

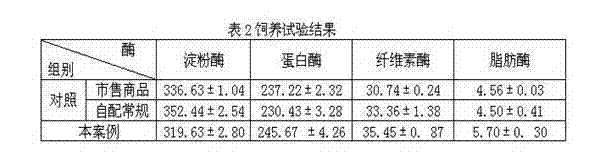

Method for preparing turtle breeding feed

The invention relates to a turtle breeding feed and a method for preparing the same. The turtle breeding feed is prepared from the following raw materials in parts by weight: 24-41 parts of fish meal, 17-20 parts of potato starch, 20-24 parts of extruded soybeans, 7-9 parts of brewer yeast, 8-11 parts of fish oil, 1-2 parts of beef liver powder, 0.8-1.2 parts of mussel powder, 1.0-1.8 parts of amino acid, 1-2 parts of calcium dihydrogen phosphate, 1.2-2.0 parts of minerals and 2-3 parts of traditional Chinese medicine powder, wherein the traditional Chinese medicine powder is prepared from the following raw materials in parts by weight: 0.5-0.7 part of hawthorns, 0.2-0.4 part of medicated leaven, 0.3-0.5 part of malt, 0.4-0.6 part of rice sprouts, 0.3-0.4 part of the fruit of Chinese magnoliavine and 0.3-0.4 part of endothelium corneum gigeriae galli. The turtle breeding feed disclosed by the invention is prepared according to needs of turtles, is rich in nutrients, is free from hormones and chemical residues and has the efficacies of promoting the appetite and the digestion of the turtles.

Owner:广西神龙王农牧食品集团有限公司

Gordonia alkanivorans and application in oil degradation

InactiveCN101974466AGood use effectBroad application prospect of bioremediationBacteriaMicroorganism based processesBioremediationNonadecane

The invention discloses a Gordonia alkanivorans and application in oil degradation, and belongs to the field of biotechnology. The Gordonia alkanivorans S104 is separated from a sea mud sample in Dalian area, and was collected in the Chinese General Microbial Culture Collection (CGMCC) on October 12th, 2010, wherein the collection number is 4224. The Gordonia alkanivorans is gram positive bacteria, has a rodlike shape, is determined by 16SrDNA sequence, and has high similarity (99.7 percent) with Gordonia alkanivorans, so the Gordonia alkanivorans is named Gordonia alkanivorans; however, the colonial morphology and the physiological and biochemical characters of the Gordonia alkanivorans are different from those of the model strains of the Gordonia alkanivorans. A plurality of hydrocarbons and aromatic compounds can be used by the Gordonia alkanivorans as sole carbon source, which comprises decane, undecane, hexadecane, nonadecane, docosane, octacosane, naphthalene, anthracene, phenanthrene, fluorene and terphenyl; the Gordonia alkanivorans can degrade oil, such as crude oil, diesel oil, soybean oil, olive oil and the like; and the Gordonia alkanivorans grows better in the diesel oil at 2 percent concentration, can degrade the crude oil, and has a promising application prospect in bioremediation of pollution of the crude oil and the diesel oil.

Owner:DALIAN UNIV OF TECH

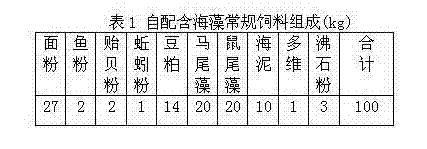

Preparation method of stichopus japonicus fermented feed capable of replacing alga

InactiveCN103039727AAlleviate the pressure of overharvestingProtect the environmentAnimal feeding stuffWater contentHerb

A preparation method of stichopus japonicus fermented feed capable of replacing alga is prepared by taking water caltrop, hydrilla varticillata, water hyacinth, aggregation of grass, alfalfa and common seepweed herb as the alga replacing raw material and additionally adding four, sea mud, multi-vitamin, fish meal, mussel powder, bean pulp, earthworm powder and zeolite powder with the steps of: drying all materials till the water content is less than 12%, and crushing to be 60 meshes, so as to obtain a fermentation substrate; mixing water, brown sugar, table salt and flour, adding rhizopus, trichoderma, saccharomyces cerevisiae, bacillus subtilis and lactic acid bacteria, mixing uniformly, standing and fermenting for 2h, so as to obtain a feed fermenting bacteria solution; and inoculating the fermentation substrate according to the ratio of 0.4% to 0.5% at the environment temperature of 25 DEG C to 30 DEG C, carrying out solid fermentation, and then drying and crushing, thereby obtaining the stichopus japonicus fermented feed. The preparation method has the advantages that the raw material source is stable, the cost is low, the process is simple and east to operate, and a great significance is provided in reducing culture cost of stichopus japonicas, maintaining an ecological environment, reasonably using idle resource and prompting the health sustainable development of stichopus japonicu culture industry.

Owner:JINZHOU MEDICAL UNIV

Method for preparing vanadium pentoxide

ActiveCN104261473AProduced noNo pollution in the processVanadium oxidesDecompositionAmmonium metavanadate

The invention relates to the field of production of vanadium pentoxide and in particular relates to a method for preparing vanadium pentoxide. The method comprises the following steps: (A) adding a sulfuric acid solution and an additive into stone coal, thereby obtaining a first mixture; (B) adding the first mixture into deionized water, stirring, and performing solid-liquid separation; (C) standing the liquid phase, thereby obtaining a first precipitate, separating the first precipitate, adding ammonium bicarbonate into the first supernatant, stirring to be uniform, continuously standing and separating a second precipitate, thereby obtaining the second supernatant; (D) adding calcium hydroxide and / or calcium oxide into the second supernatant, thus obtaining a third precipitate and the third supernatant; (E) saturating an ion exchange resin, eluting by using sodium hydroxide, thereby obtaining a vanadium solution; and (F) adding a pH regulator into the vanadium solution, adding hydrogen peroxide, finally adding ammonium chloride, performing centrifugal separation, obtaining a precipitate ammonium metavanadate, carrying out an ammonium metavanadate decomposition reaction, thereby obtaining the vanadium pentoxide. According to the preparation method disclosed by the invention, the cost is low, and three wastes are avoided.

Owner:江西钒业科技有限公司

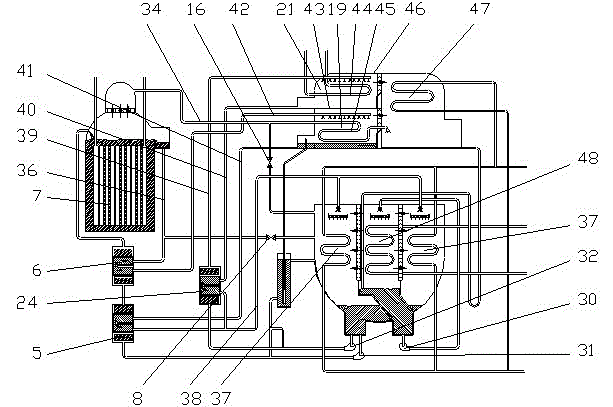

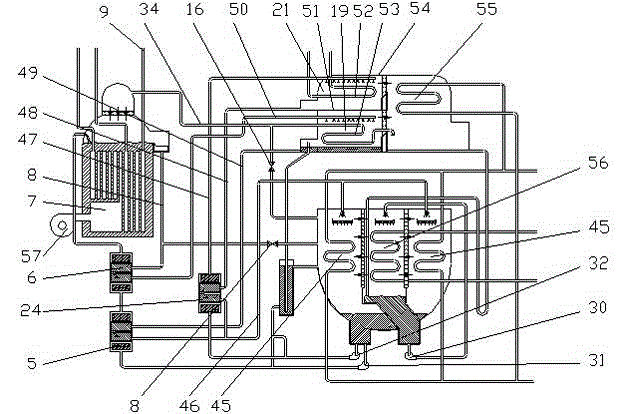

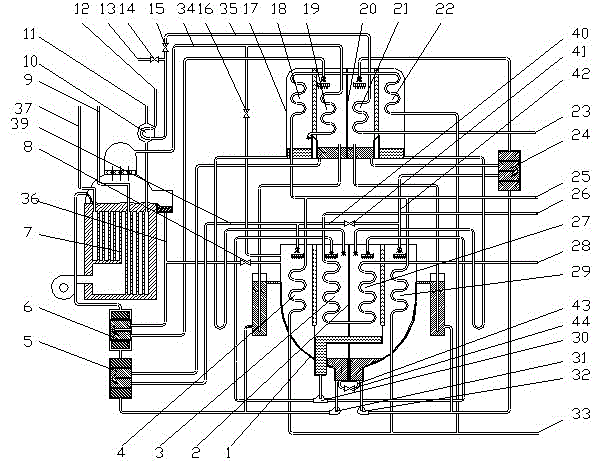

Two-section flue gas hot-water single/double-effect composite lithium bromide absorption type refrigerating unit

InactiveCN102914081AImprove waste heat utilizationRelieve pressureClimate change adaptationEnergy efficient heating/coolingFlue gasLithium bromide

The invention relates to a two-section flue gas hot-water single / double-effect composite lithium bromide absorption type refrigerating unit which comprises a flue gas type high-pressure generator (7), an evaporator, an absorber, a steam generator (19), a hot-water generator (21) and a condenser, and is characterized in that the condenser comprises a single-effect condenser (22) and a double-effect condenser (18); a heat exchange tube bundle of the hot-water generator (21) and a heat exchange tube bundle of the single-effect condenser (22) are arranged in a cavity; a heat exchange tube bundle of the steam generator (19) and a heat exchange tube bundle of the double-effect condenser (18) are arranged in another cavity; the cooling water process of the single-effect condenser (22) and the double-effect condenser (18) is a series process; and cooling water flows into the single-effect condenser (22) and flows out of the double-effect condenser (18). According to the two-section flue gas hot-water single / double-effect composite lithium bromide absorption type refrigerating unit, the generation pressure of the hot-water generator can be reduced, the dilute solution concentration of a hot-water single-effect cycle is reduced, and the waste heat flue gas outlet temperature is reduced.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

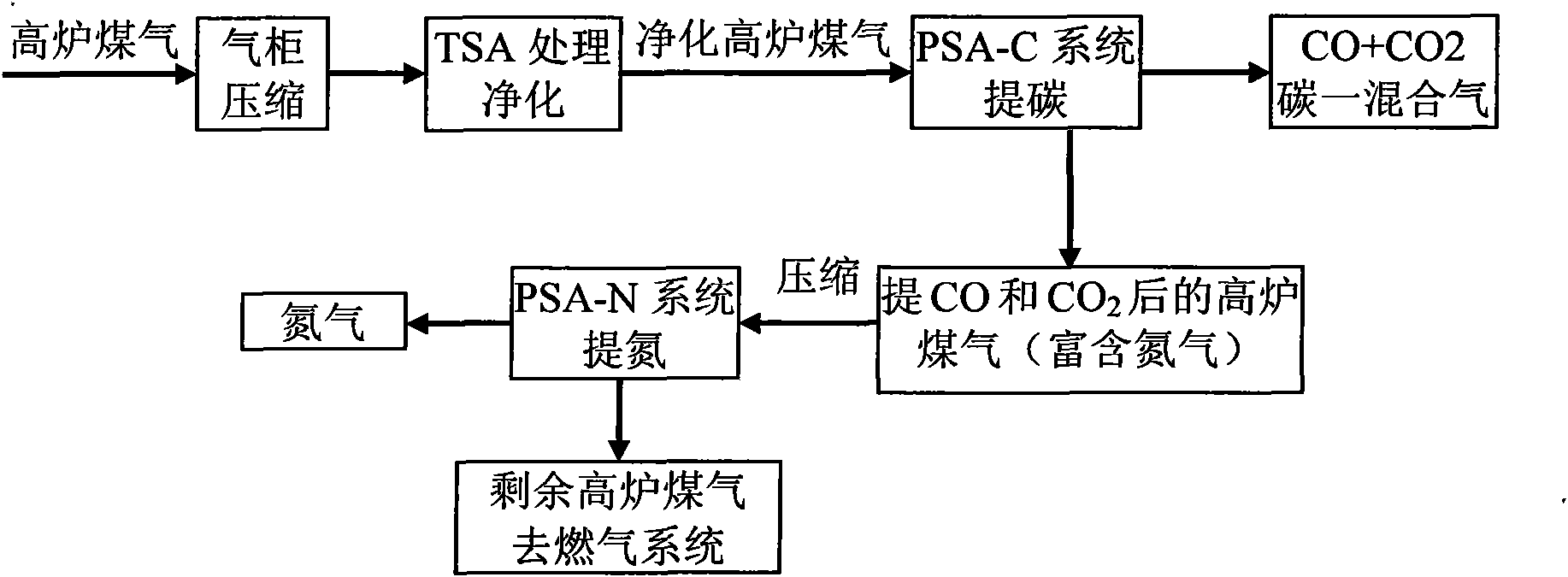

Method for recycling blast furnace gas

InactiveCN101892334AGuaranteed uptimeIncrease added valueBlast furnace detailsOrganic synthesisNitrogen

The invention relates to a method for recycling blast furnace gas, and solves the problems of low additional value and poor using effect of the blast furnace gas because the advantages of the composition and chemical properties of the blast furnace gas cannot be brought into full play in the conventional method for recycling the blast furnace gas. The method comprises the following steps of: firstly, compressing the blast furnace gas and then allowing the compressed blast furnace gas to enter a temperature swing adsorption system for treatment to obtain purified blast furnace gas; secondly, pressurizing the purified blast furnace gas and then conveying the pressurized blast furnace gas to a pressure swing adsorption carbon extraction system for adsorption and purification to obtain carbon mixed gas; thirdly, pressurizing the rest blast furnace gas and then conveying the pressurized blast furnace gas to a pressure swing adsorption nitrogen extraction system to separate and recycle nitrogen; and finally, returning the rest blast furnace gas to a gas fuel system. The volume purity of the CO and CO2 mixed gas is over 95 percent and the mixed gas provides a synthesis air source for methanol and an organic synthesis and processing system; the volume purity of the nitrogen is over 99.5 percent, so that the problem that steel enterprises need the nitrogen with the volume purity of over 99 percent is solved; and the blast furnace gas has high additional value.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

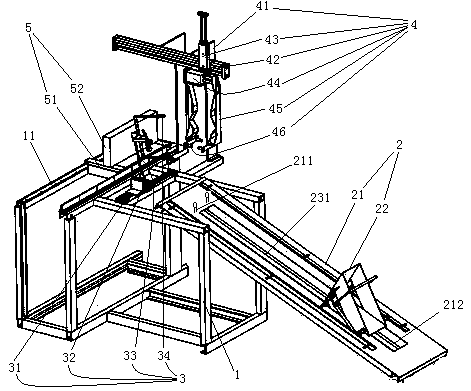

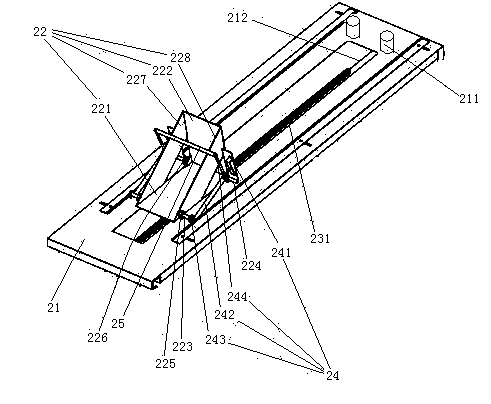

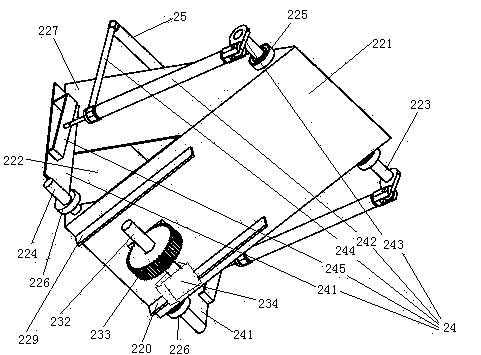

Upper bag body mechanism and bag body loading method

ActiveCN104249487ANo collapseGood use effectPaper-makingBox making operationsTransfer mechanismEngineering

The invention relates to a paper bag processing device and a paper bag processing method. An upper bag body mechanism comprises a frame and a bag body storing mechanism, wherein the bag body storing mechanism comprises a support plate which is arranged obliquely and of which the upper end is connected together with the frame, a blocking-pushing frame positioned on the support plate, and a driving mechanism for driving the blocking-pushing frame to move along the inclination direction of the support plate; a bag body transferring mechanism, a bag body opening and loading mechanism and a bag opening and holding frame are arranged on the frame; the bag body transferring mechanism is positioned between the bag body storing mechanism and the bag body opening and loading mechanism; the bag opening and loading mechanism is positioned between the bag body transferring mechanism and the bag body opening and holding frame. According to the upper bag body mechanism, a bag body plate on which a hand rope is to be arranged can be changed into an open bag body, and the bag body is kept in an open state, so that the problem of limitation on realization of automatic installation of the hand rope since a mechanism for changing the bag body on which the hand rope is to be arranged to the open state and keeping the bag body in the open state is unavailable is solved.

Owner:杭州汇八科技有限公司

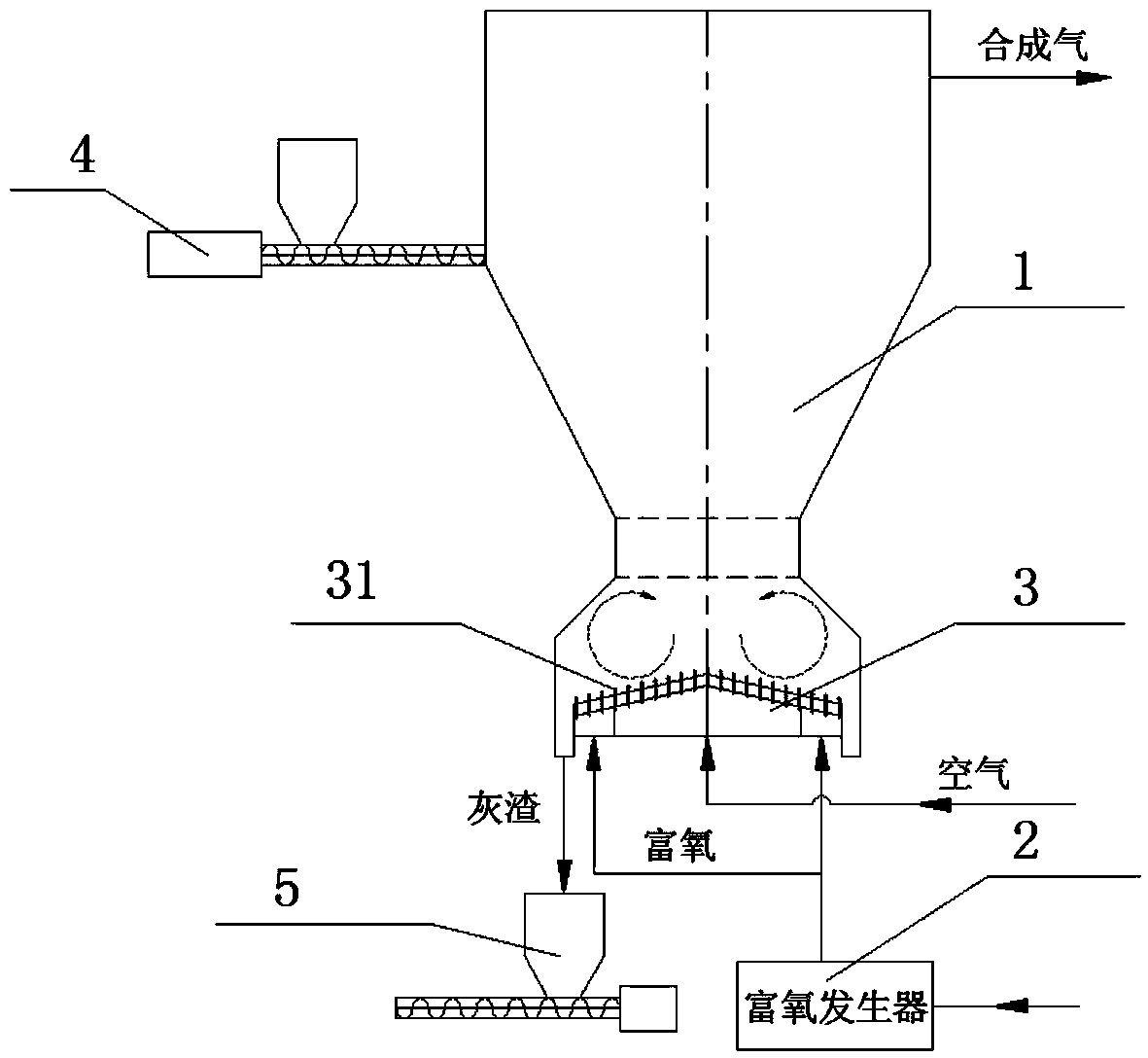

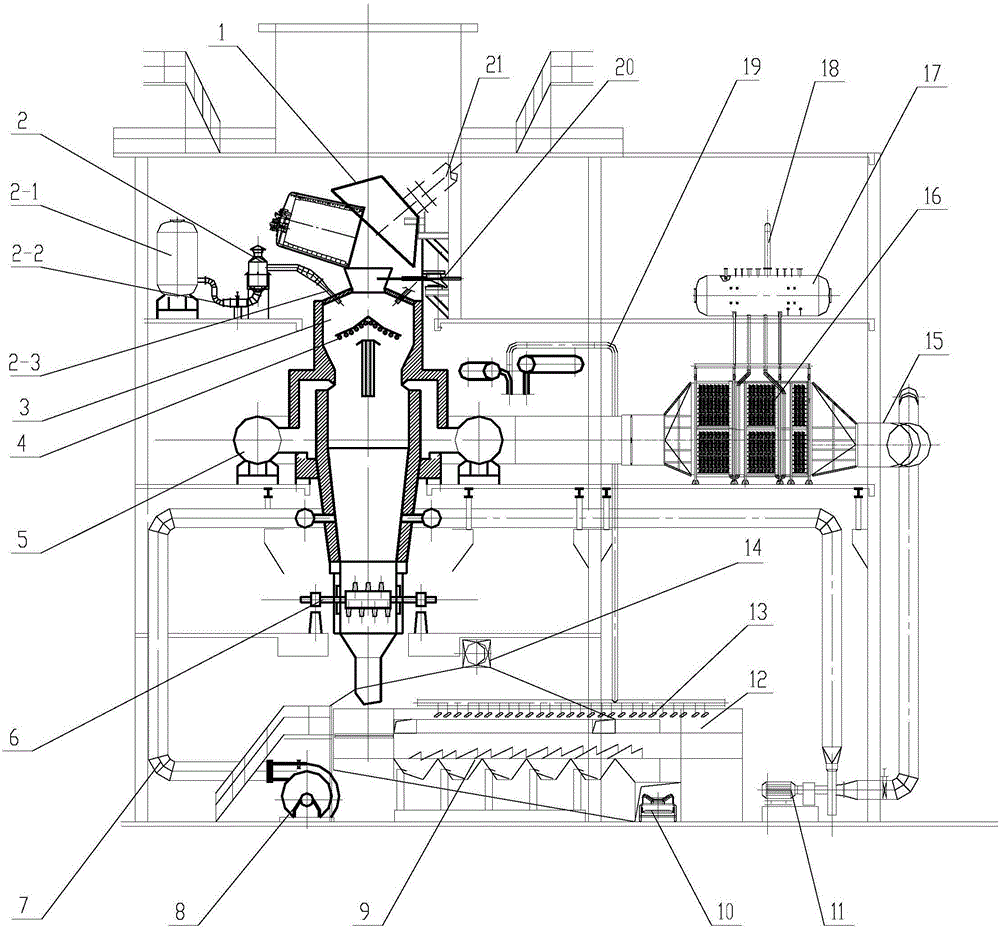

Internal circulating fluidized-bed oxygen-enriched gasification device

ActiveCN103471104AHigh calorific valueGood use effectIndirect carbon-dioxide mitigationIncinerator apparatusFluidized bedSlag

The invention provides an internal circulating fluidized-bed oxygen-enriched gasification device. The device comprises a gasifier body, a rich oxygen generation device, a multi-air-chamber air distribution device, a feeding device and a deslagging device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; the dense-phase region is connected with the dilute-phase region through a throat region; the multi-air-chamber air distribution device which is provided with directional wind caps is arranged at the bottom of the dense-phase region and is connected with the rich oxygen generation device; an outlet of the feeding device is arranged at the junction of the dense-phase section and the dilute-phase section; a slag outlet is arranged at a gap of the multi-air-chamber air distribution device and the gasifier body at the bottom of the dense-phase section; the deslagging device is arranged below the slag outlet. The system can efficiently realize pyrolysis and gasification of waste solid organic matters such as garbage and biomass, and has the advantages of high gasification speed, high conversion efficiency, less deslagging carbon residue, easiness in control over pollutants and the like.

Owner:XI AN JIAOTONG UNIV

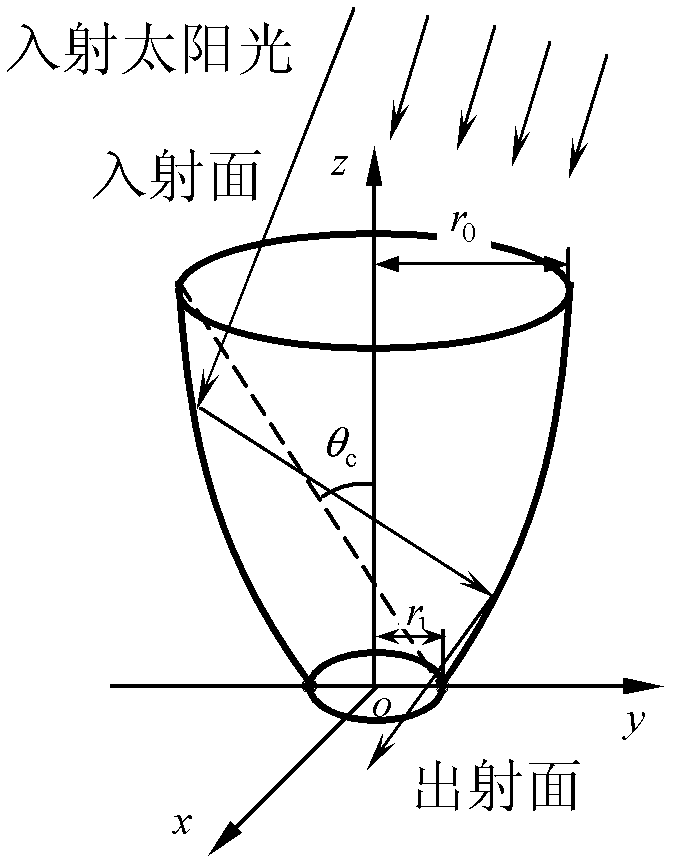

Compound parabolic concentrator (CPC) solar energy concentration and photovoltaic power generation combined application device

InactiveCN102628613AImprove power generation efficiencyReduce heat loadSolar heat devicesPhotovoltaicsEngineeringElectric power

A compound parabolic concentrator (CPC) solar energy concentration and photovoltaic power generation combined application device relates to a solar energy concentration and photovoltaics combined application device, belongs to the technical field of solar energy application, aims at separately using infrared light and visible light in solar radiation energy, and has good utilization efficiency. A solar photovoltaic battery, foam quartz glass and quartz glass are sequentially arranged on the inner surface of a CPC, wherein visible light is covered on the quartz glass in plating mode to reflect feature films of infrared. Reflected infrared waves enter a heat absorber to be converted into heat energy, visible light penetrates through the quartz glass and is reflected and refracted for multiple times by the foam quartz glass and uniformly irradiated onto the surface of the solar energy, and electric power is output. According to changes of sunlight incident angles, distribution proportion of optothermal quantity and photoelectrical quantity of a system is adjusted. The CPC solar energy concentration and photovoltaic power generation combined application device comprehensively uses solar energy, can provide heat energy and power supply power, is simple in processing and operating, and has huge application potential.

Owner:HARBIN INST OF TECH

Feed additive for sea crabs and preparation method of feed additive

InactiveCN108208318APromote growthImprove immunityAnimal feeding stuffAccessory food factorsNutritive valuesFood additive

The invention discloses a feed additive for sea crabs and a preparation method of the feed additive. The feed additive is prepared from the component in parts by weight as follows: 105-120 parts of anoleic acid solution of saline-alkali-resistant modified and irradiation splitting modified bamboo leaf extract. The feed additive is mainly applied to high-quality sea crabs, the specially extractedbamboo leaf extract is subjected to targeted modification treatment and is reasonably combined and properly applied, the advanced feed additive which is resistant to saline-alkali, capable of improving meat quality, improving cold nature of sea crab meat and increasing nutritive value of the sea crabs and adaptive to coastal reclamation free-ranging is obtained, the blank of the industry is filledup, and the feed additive has great significance for environment-friendly ecological sea crab breeding.

Owner:浙江新篁生物技术有限公司

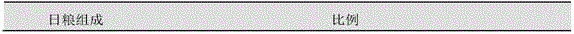

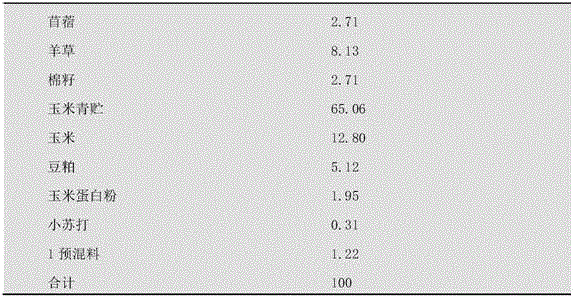

Rumen by-pass coating product and preparation method thereof

The invention relates to a rumen by-pass coating product and a preparation method thereof, and discloses the rumen by-pass coating product; a pH dependent type IV resin is selected as a wall material, and a feed which is arbitrary one of fat soluble vitamins, choline chloride or amino acids is a core material; the weight ratio of the wall material to the core material is 1 to 1. The prepared coating product can obtain better protection in rumen, is well released in real stomach small intestines, is uniformly coated on the surface of raw materials, can form uniform-size particles, and can achieve good use effect.

Owner:山东阜力康动物营养有限公司

Waterway system, control method, water purifier and machine readable storage medium

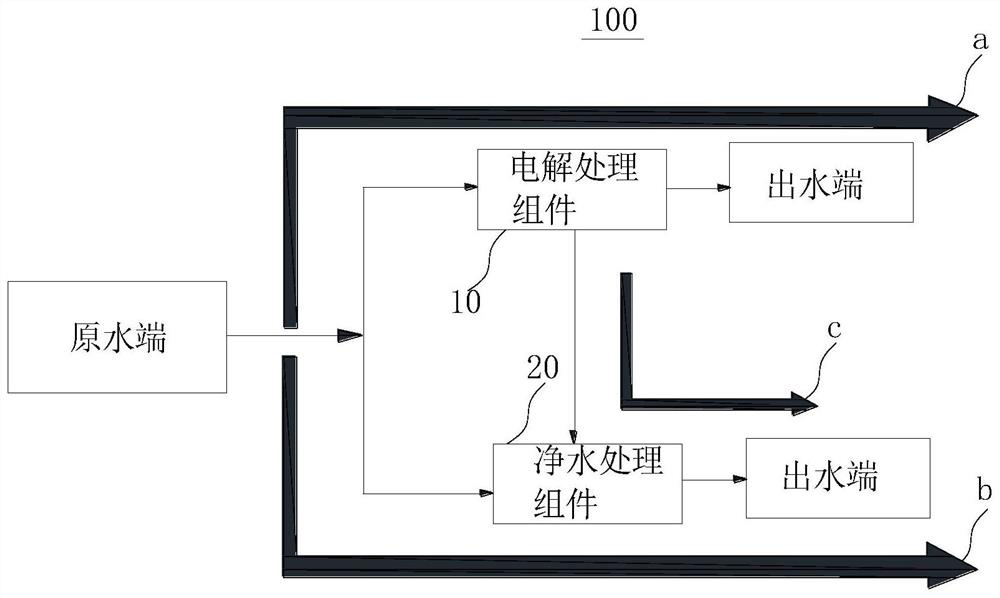

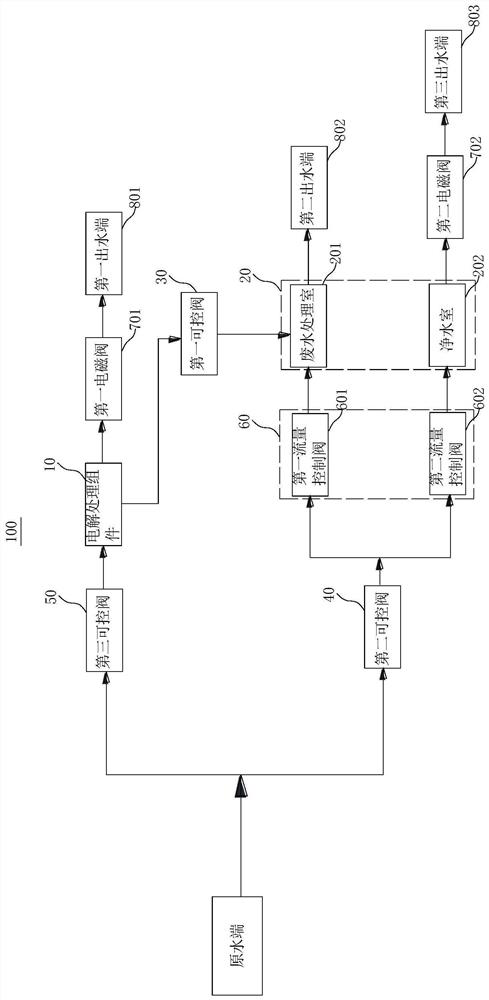

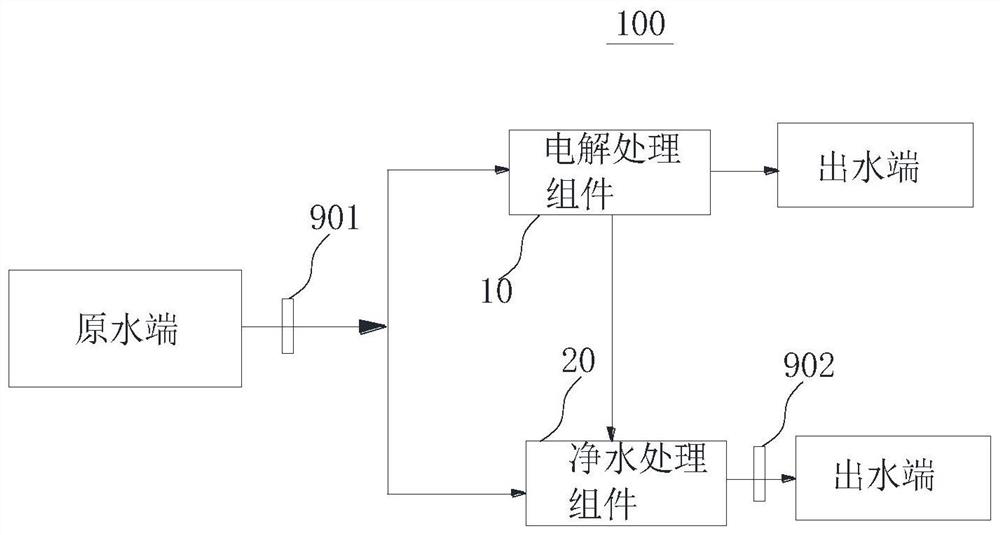

InactiveCN112591858AAvoid badMeet diverse needsWater treatment parameter controlSpecific water treatment objectivesElectrolysisOutfall

The embodiment of the invention provides a waterway system, a control method, a water purifier and a machine readable storage medium. The waterway system comprises: an electrolytic treatment assemblywhich is communicated with a raw water end through a pipeline and is used for electrolyzing raw water from the raw water end; the water purification treatment assembly is communicated with the raw water end through a pipeline and is used for purifying raw water; a water outlet of the electrolytic treatment assembly is communicated with a water inlet of the water purification treatment assembly through a pipeline; the first controllable valve is used for controlling connection and disconnection between the water outlet of the electrolytic treatment assembly and the water inlet of the water purification treatment assembly; and the controller is configured to control the electrolysis treatment assembly and / or the water purification treatment assembly to work. Under the condition that the water purification treatment assembly needs to be descaled, controlling the first controllable valve to be opened so as to input the raw water electrolyzed by the electrolysis treatment assembly into thewater purification treatment assembly.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG

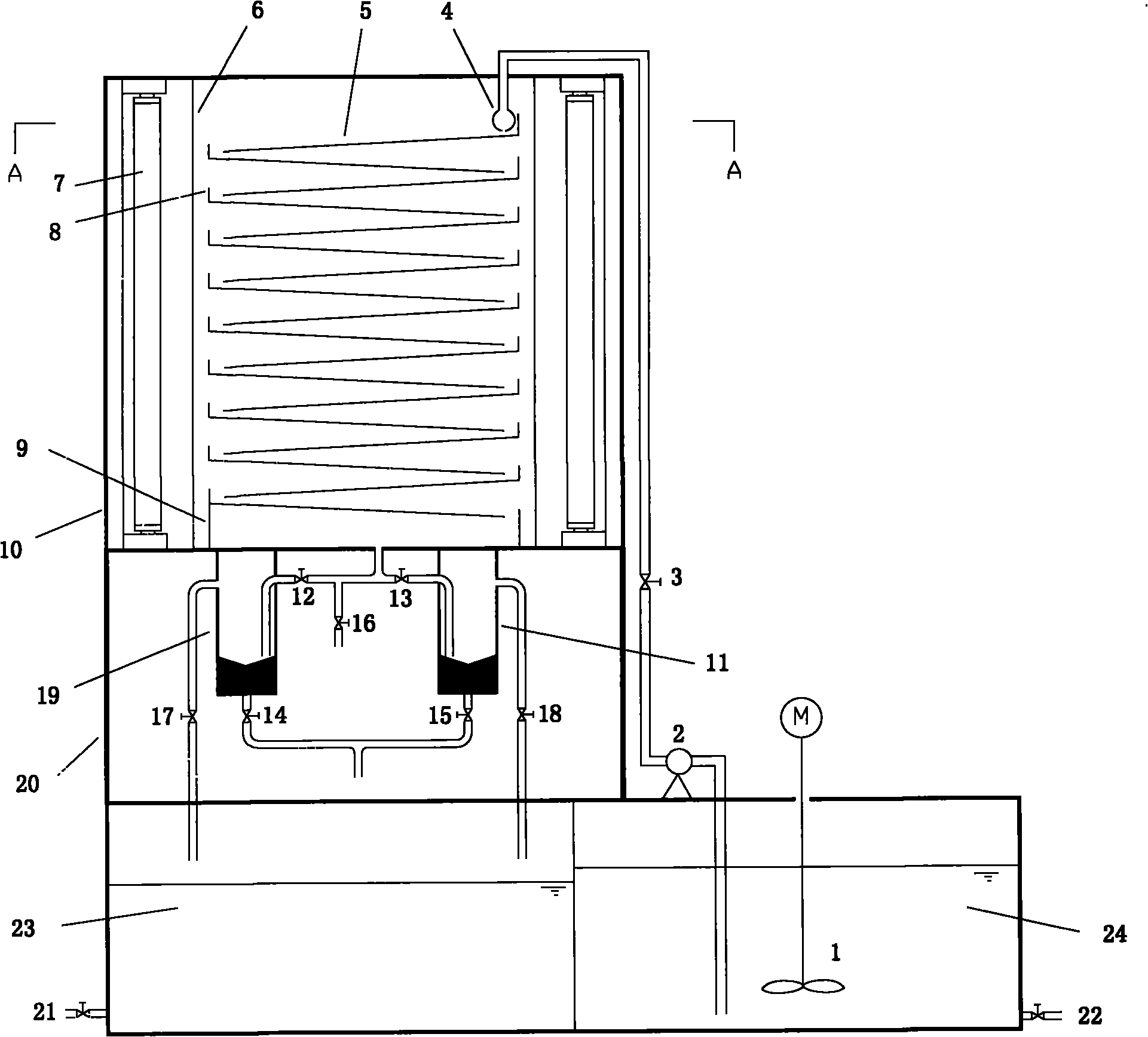

Sequencing batch photocatalytic reactor

InactiveCN101851014AEasy to recycleWell mixedWater/sewage treatment by irradiationMagnetic separationPhotocatalytic reactionSoft magnet

The invention provides a sequencing batch photocatalytic reactor, which comprises a reaction section, a separation section, a separation section, a clean water tank and a sewage tank; the reaction section comprises a shell, an inclined plate section and light sources, wherein the inclined plate section is positioned in the middle of the shell, the light sources are positioned on both sides of the inclined plate section, the inclined plate section consists of upright plates, inclined plates and baffles, which are connected, a water distributor is arranged over the inclined plate on the upmost layer, and is connected with the sewage tank through a conduit, a control valve and a water supply pump, and a water-receiving tank is arranged under the inclined plate on the lowest layer; the separation section comprises separators, each separator comprises an upper water accumulator and a bottom soft magnet, the separators are connected with the water-receiving tank through conduits and valves, and each water accumulator is provided with an overflow tube and a discharge tube. The reactor operates by the way of sequencing batch; catalyst and pollutant can be uniformly mixed, so the contact effect is good; liquid is shaped like a film when flowing on the inclined plates of the reactor, so the effect of utilizing direct light and reflected light is good; and sampling inspection is convenient. Catalyst can be conveniently recovered; the catalyst load can be flexibly adjusted; and the operation is simple and flexible.

Owner:HARBIN ENG UNIV

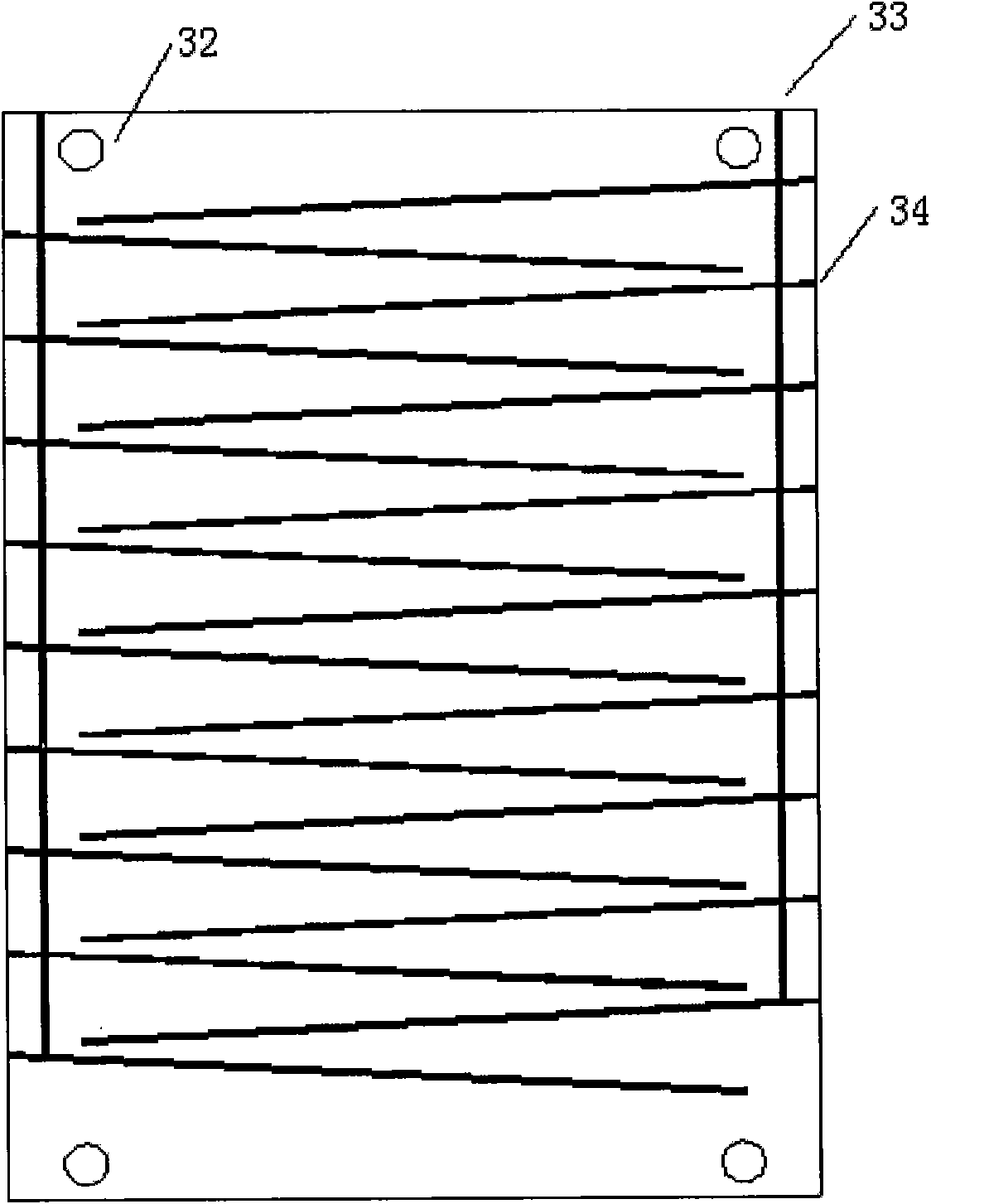

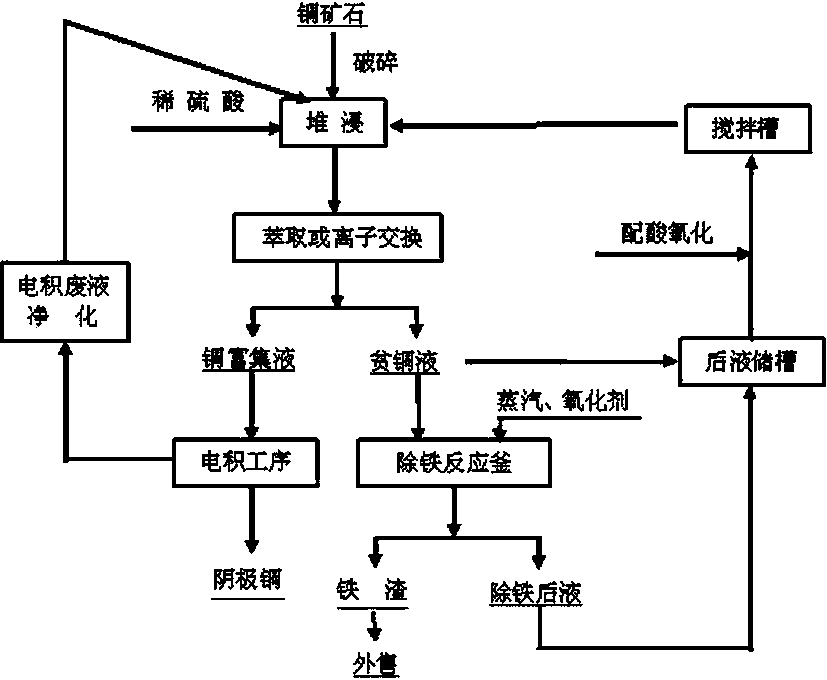

Copper extraction and iron removal method of copper ore acid leaching liquid

ActiveCN104232924AImprove the effect of iron removalSimple stepsRotary drum furnacesCrucible furnacesSlagIon exchange

The invention discloses a copper extraction and iron removal method of copper ore acid leaching liquid. The method comprises the following steps: breaking secondary copper oxide ore and secondary copper sulfate ore, mixing and performing wet-process dump leaching; using dilute sulphuric acid as a leaching agent for conducting spraying and leaching to obtain faintly acid leaching liquid; extracting copper from the leaching liquid through extraction or ion exchange to obtain copper-rich liquid and copper-deficient liquid; electrodepositing the copper-rich liquid to obtain cathode copper; performing high-temperature high-pressure continuous iron removal on the copper-deficient liquid in an oxidizing atmosphere to obtain ore pulp, filtering to obtain hematite slag, acidifying and oxidizing part of the copper-deficient liquid, and feeding to a stock dump for cyclic leaching. According to the method, iron ions and the copper sulfate ore are subjected to oxidative reduction in the dump leaching process; iron ions in the dump leaching liquid mainly exist in the form of divalent iron ions, so that the step of reducing divalent iron ions is removed for subsequent copper extraction; iron is removed by a high-temperature high-pressure process, so that the slag yield is low, the environmental protection pressure is small, and the iron slag can be reutilized; sulfuric acid generated in the iron removal process does not need to be neutralized and directly returns to the stock dump for cyclic leaching, so that the comprehensive utilization effect is good.

Owner:HENAN GONGXIN ENVIRONMENTAL PROTECTION & TECH CO LTD

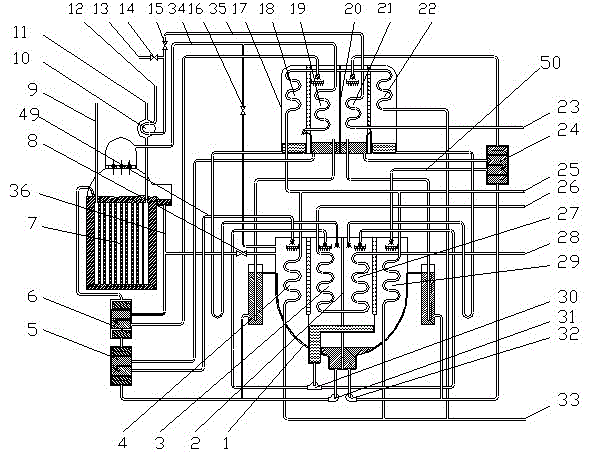

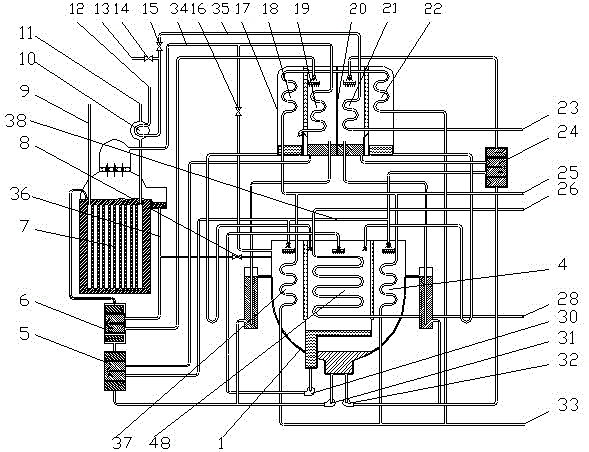

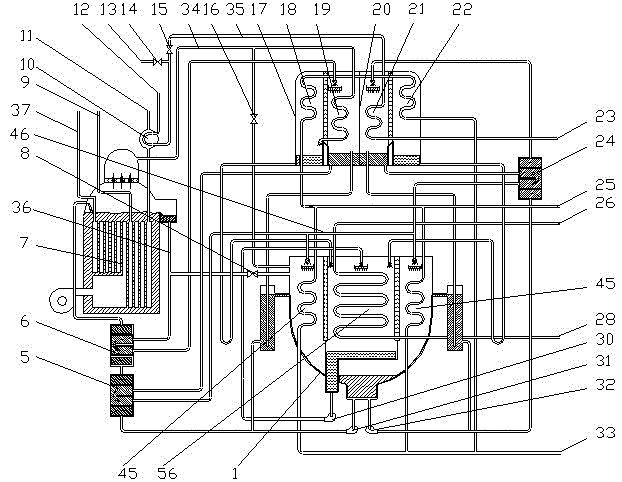

Two-stage single-effect and double-effect lithium bromide absorption refrigerating unit with smoke and hot water afterburning

InactiveCN102914080AImprove waste heat utilizationRelieve pressureBoilers/analysersClimate change adaptationComing outLithium bromide

The invention relates to a two-stage single-effect and double-effect lithium bromide absorption refrigerating unit with smoke and hot water afterburning. The two-stage single-effect and double-effect lithium bromide absorption refrigerating unit with smoke and hot water afterburning comprises a smoke-afterburned high pressure generator (7), an evaporator, an absorber, a steam generator (19), a hot water generator (21), a condenser, a heat exchanger, a solution pump and a coolant pump and is characterized in that the condenser comprises a single-effect condenser (22) and a double-effect condenser (18), a heat exchange tube bundle of the hot water generator (21) and a heat exchange tube bundle of the single-effect condenser (22) are disposed in one chamber, a heat exchange tube bundle of the steam generator (22) and a heat exchange tube bundle of the double-effect condenser (18) are disposed in another chamber, cooling water flow paths of the single-effect condenser (22) and the double-effect condenser (18) are serially connected, and cooling water enters from the single-effect condenser (22) and comes out of the double-effect condenser (18). Generating pressure of the hot water generator can be lowered, concentration of dilute solution in hot-water single-effect circulation is lowered, and temperature of a waste heat smoke outlet is lowered.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Method for preparing fertilizers by comprehensively utilizing oil residue

InactiveCN104072250AImprove efficiencyQuality improvementFertilising methodsFertilizer mixturesEnzymeINCREASED EFFECT

The invention relates to a method for preparing fertilizers by comprehensively utilizing oil residues. The method comprises the following steps: firstly, decomposing grease in the oil residues by using lipase preparation, and further decomposing protein by using a neutral protease preparation so as to generate amino acid and plant active substances; subsequently separating an product, wherein an enzymolysis liquid is taken as a leaf fertilizer and enzymolysis solid is taken as a raw material of an organic fertilizer; and further adding other organic materials for normal fermentation so as to produce the organic fertilizer. By adopting the method, two products, namely, the leaf fertilizer and the solid organic fertilizer are simultaneously produced, and the field experiment shows that the fertilizers prepared by using the method are good in yield-increasing effect.

Owner:SHANDONG GUANGDA FERTILIZER INDAL TECHCO

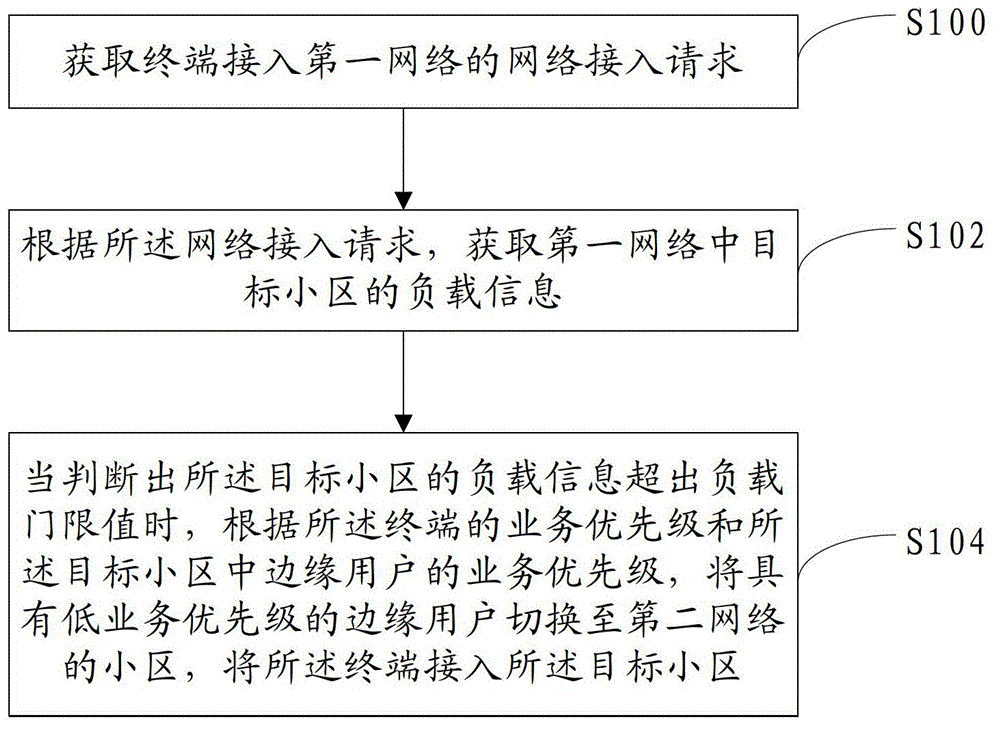

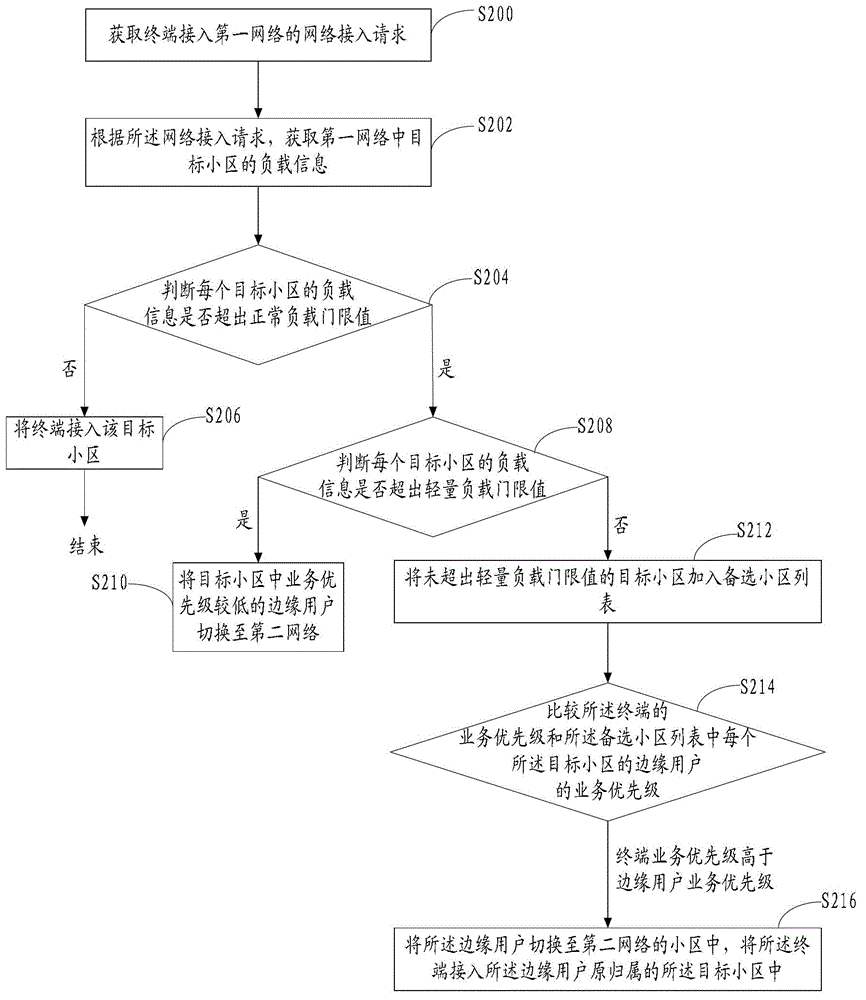

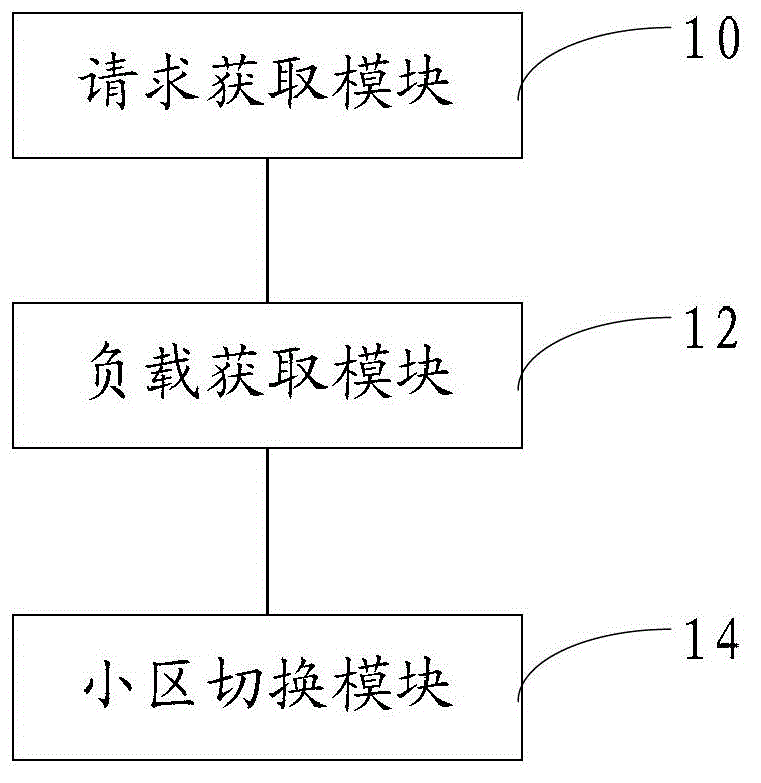

Method and device for switching inter-systems

ActiveCN102752824AHigh business priorityConducive to loadWireless communicationComputer networkWeb resource

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Method for manufacturing composite particle fertilizer by employing straw slurry paper-making waste

InactiveCN101177356ASolve pollutionGood use effectClimate change adaptationSewage/sludge fertilisersLiquid wasteSlurry

The invention relates a method using waste liquid of straw pulp and solid waste residue of papermaking to produce a granule compound fertilizer of slow release nitrogen and effective silicon, which ischaracterized in that the ammonium sulfite and the urea are used to steam and boil the straw for preparing the soft pulp; then the waste liquid with solids more than 10% of the content is extracted after the steaming and boiling; in the condition of adding oxygen gas with 0.8MPa to 1.2MPa and 90 to 110 DEG C; the waste liquid is reacted for 80 to 100 minutes to increase the content of organonitrogen from 1 to 2% to 4 to 8%; the waste liquid after the oxidation and ammonolysis reaction is concentrated, now the concentration can be increased from 10% to 35 to 45%; the shattered and dried grasspowder, the boiler clinker and the pulverized fuel ash can be even mixed with the waste liquid according to the weight ratio of 2 to 30%, 25 to 30% and 40 to 50%, finally, the product can be packed after granulation and dryness to keep the moisture less than 85%. The nitrogen content of the product is 3 to 6%, the organonitrogen content is 1 to 3%, the effective silicon content is 1 to 5% and thehumic acid content is 25 to 40%.

Owner:DALIAN POLYTECHNIC UNIVERSITY

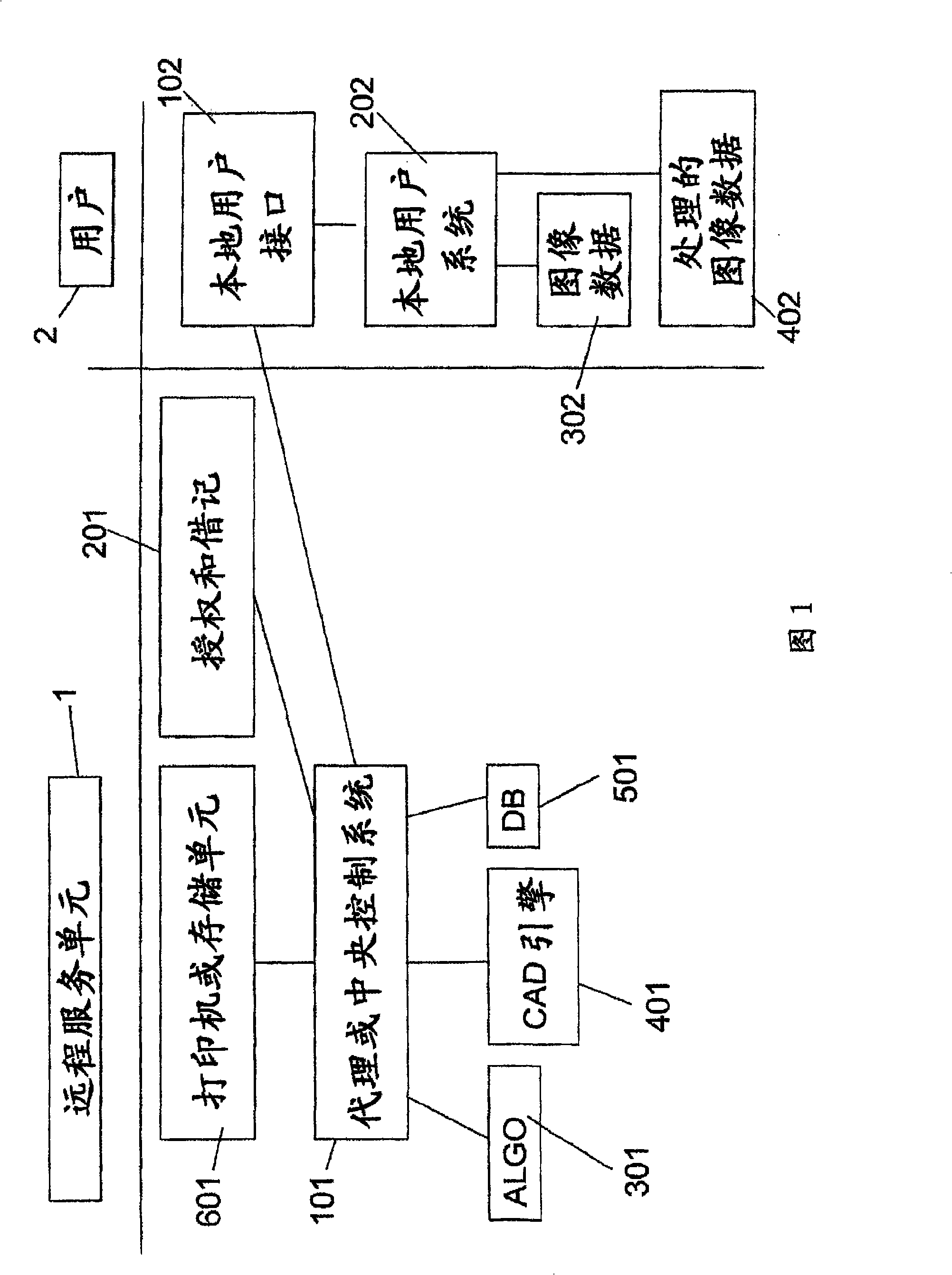

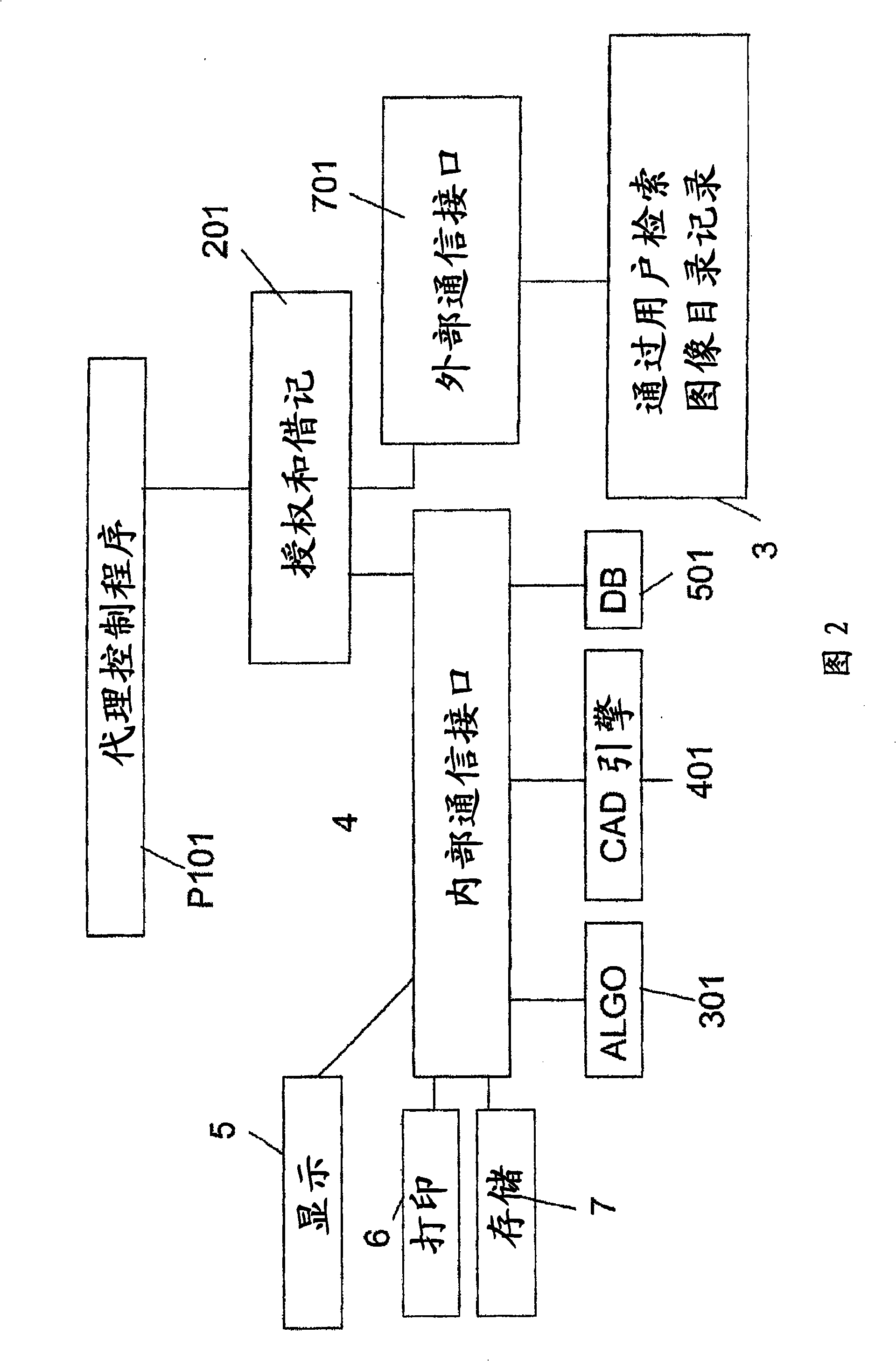

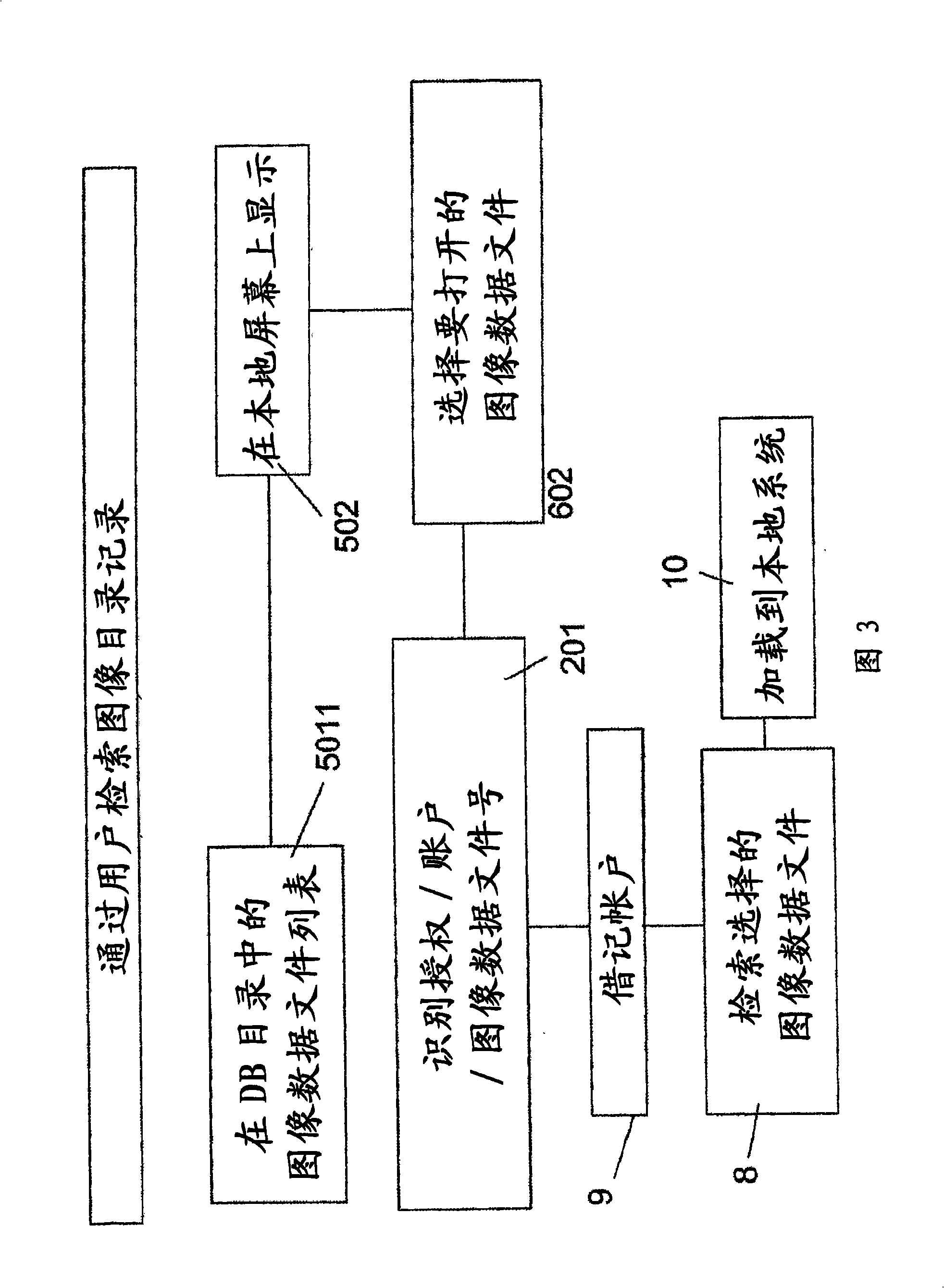

Image processing system, particularly for use with diagnostic images

InactiveCN101297324AGood use effectReduce overheadImage analysis2D-image generationImaging processingCentral unit

An image processing system particularly for use with diagnostic images, comprises at least one processing unit, which receives digital images acquired by one or more imaging apparatus and provides output images, processed by means of an image processing program loaded in the memory of the processing unit and executed thereby, characterized in that it consists of a central service unit, comprising an interface to be accessed by remote users, which connect to said central unit by remote communication means.

Owner:BRACCO IMAGINIG SPA

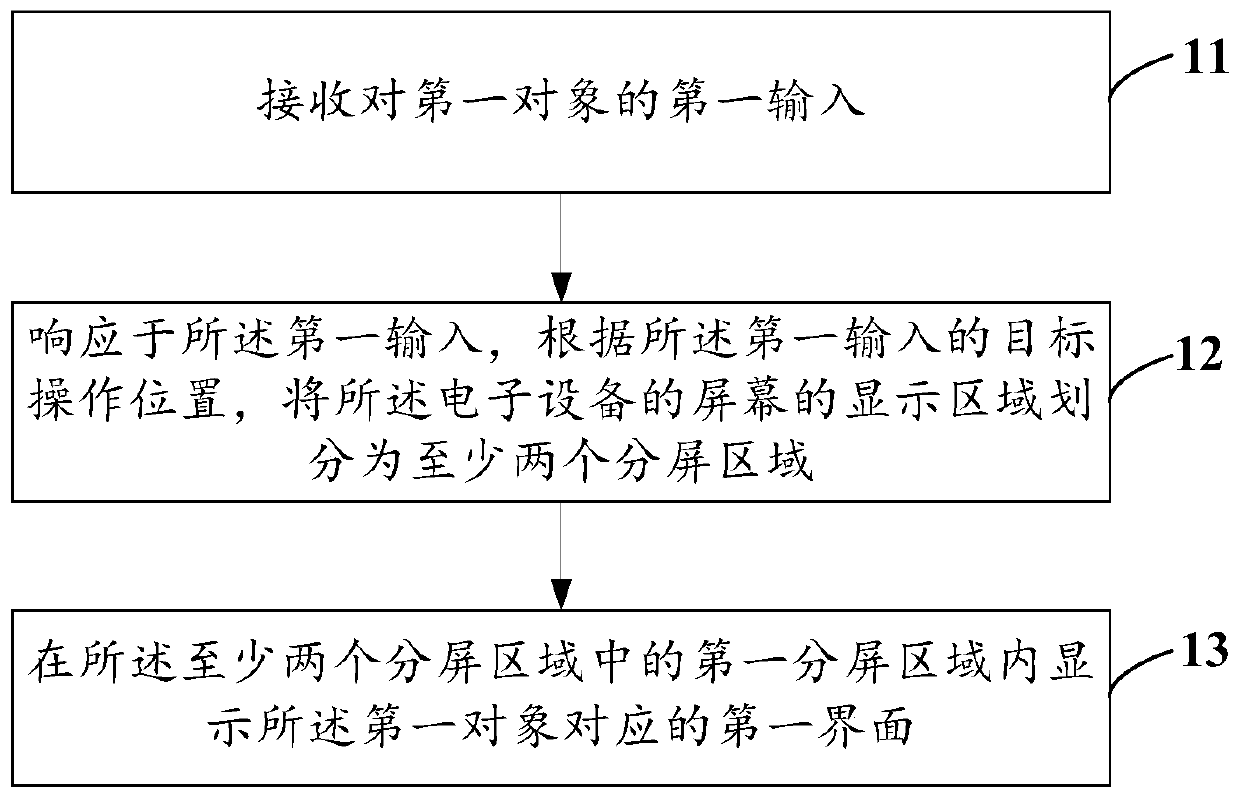

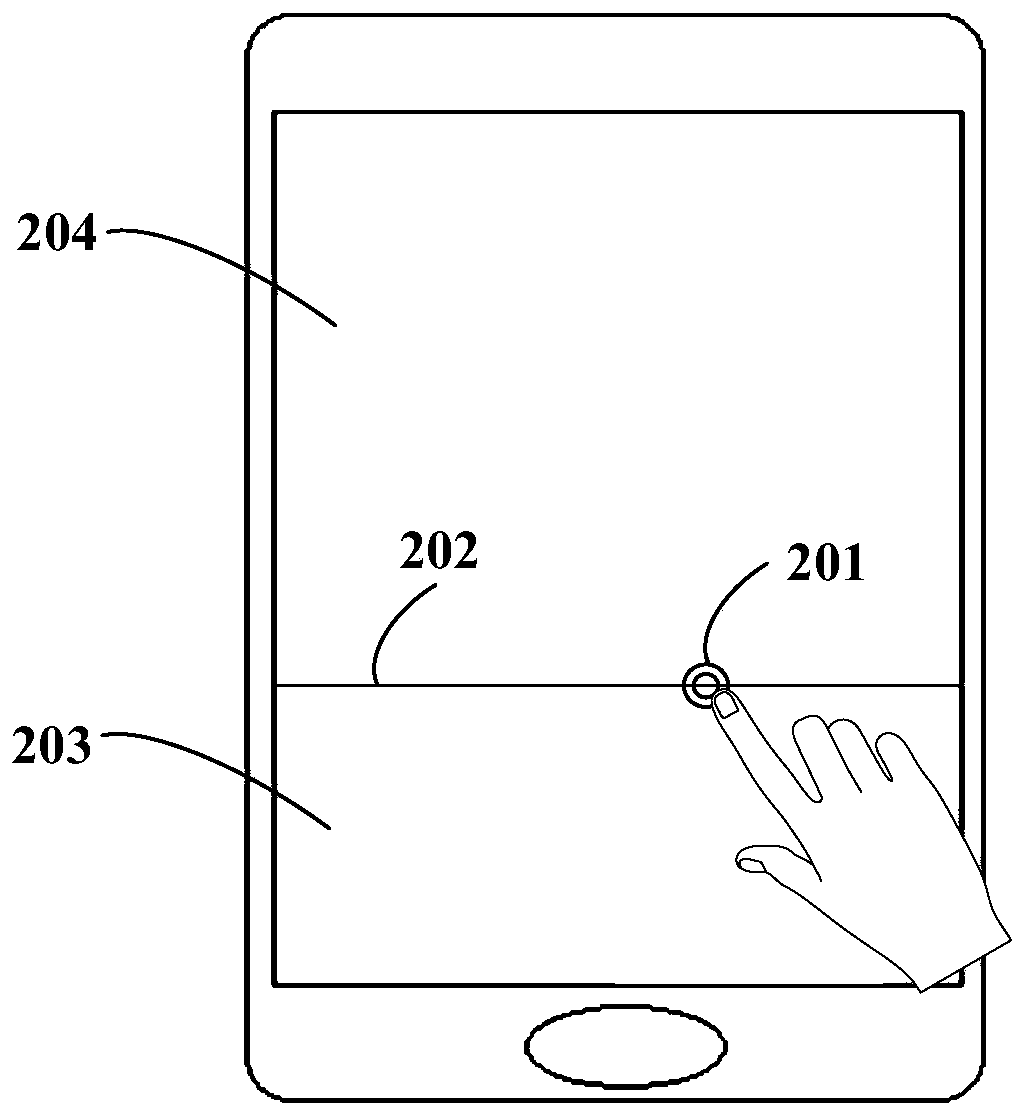

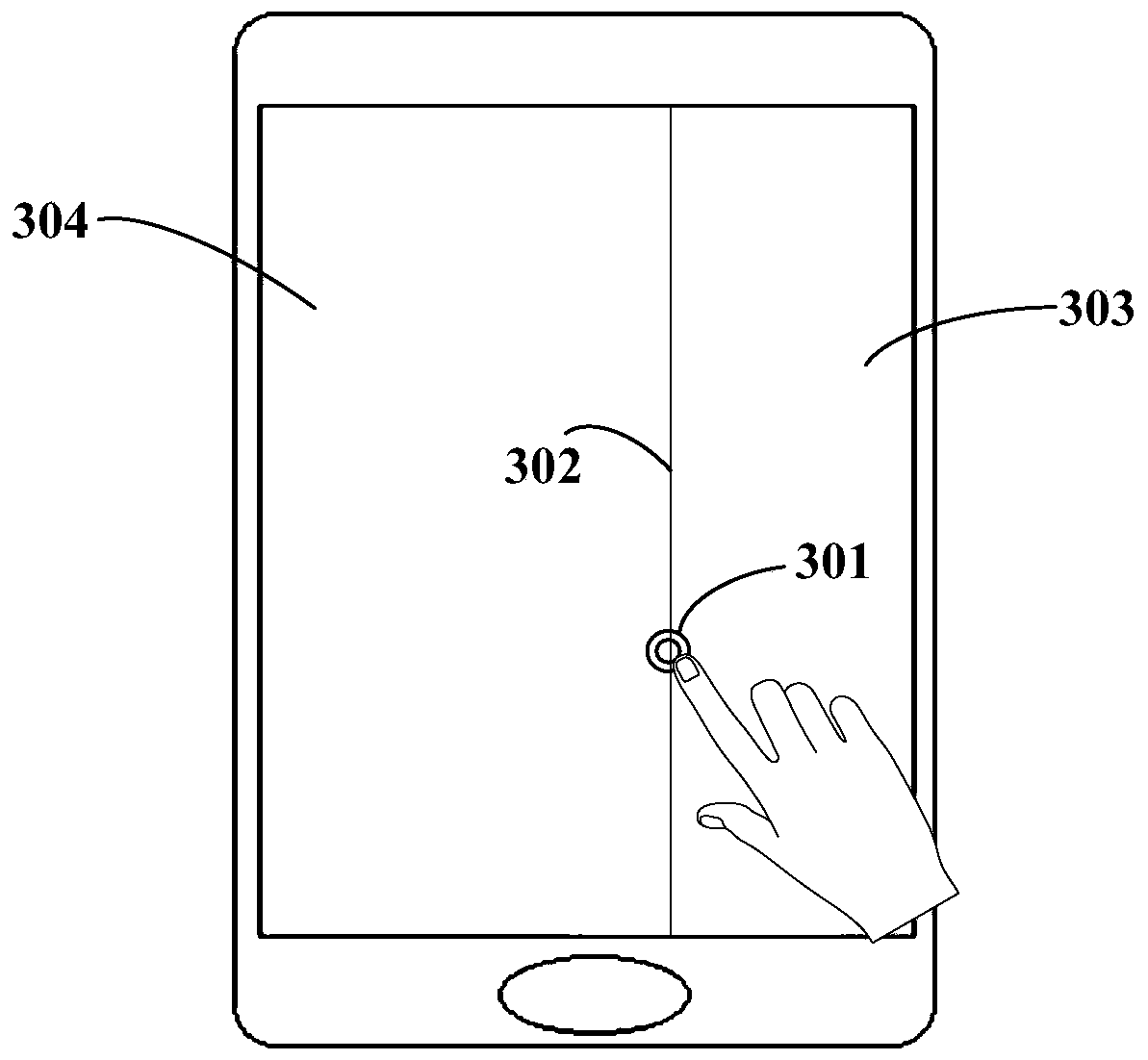

Split-screen display method and electronic equipment

InactiveCN111142769AEasy to operateFlexible divisionDigital output to display deviceSplit screenMultiple applications

The invention provides a split-screen display method and electronic equipment. The method comprises the following steps: receiving a first input to a first object; in response to the first input, dividing a display area of a screen of the electronic equipment into at least two split screen areas according to a target operation position of the first input; and displaying a first interface corresponding to the first object in a first split screen area in the at least two split screen areas. According to the invention, rapid screen splitting and simultaneous operation of multiple applications canbe realized, user operation can be simplified, flexible division of the screen splitting area according to the operation position is realized, the problem of single screen splitting mode in the priorart is solved, and the utilization effect of the display area is further facilitated.

Owner:VIVO MOBILE COMM CO LTD

Converter molten red slag sensible heat recovery device and afterheat recovery method

ActiveCN106191345AImprove use valueGood use effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodCold air

The invention discloses a converter molten red slag sensible heat recovery device and an afterheat recovery method. The device comprises a charging opening dust collecting cover, a vertical cooling device, a desorption agent spraying coating device, a slag disintegrating sealing chamber, a cold air pipeline system, a hot air pipeline system, an afterheat boiler heat exchange device and a return air pipeline system; the charging opening dust collecting cover is arranged above a charging opening of the vertical cooling device; the desorption agent spraying coating device is arranged at the upper end of the vertical cooling device and communicates with the interior of the vertical cooling device; the slag sealing chamber sealing chamber is formed below a discharging opening of the vertical cooling device; a vapour-water pipeline system of the vertical cooling device communicates with the slag disintegrating sealing chamber; the hot air pipeline system and the cold air pipeline system communicate with the vertical cooling device; and the hot air pipeline system is connected with the return air pipeline system through the afterheat boiler heat exchange device. According to the converter molten red slag sensible heat recovery device and the afterheat recovery method, quick cooling of molten slag, gradient utilization of temperature, a continuous afterheat recovery process, high automation degree of device operation, energy conversation, and emission reduction are realized, and meanwhile, the economy of subsequent comprehensive utilization of converter molten slag is met.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com