Method for preparing vanadium pentoxide

A technology of vanadium pentoxide and sodium hydroxide, which is applied in the direction of vanadium oxide, etc., can solve the problems of increasing production cost, pollution, environmental pollution, etc., and achieve the effect of improving utilization rate, low cost, and good comprehensive utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

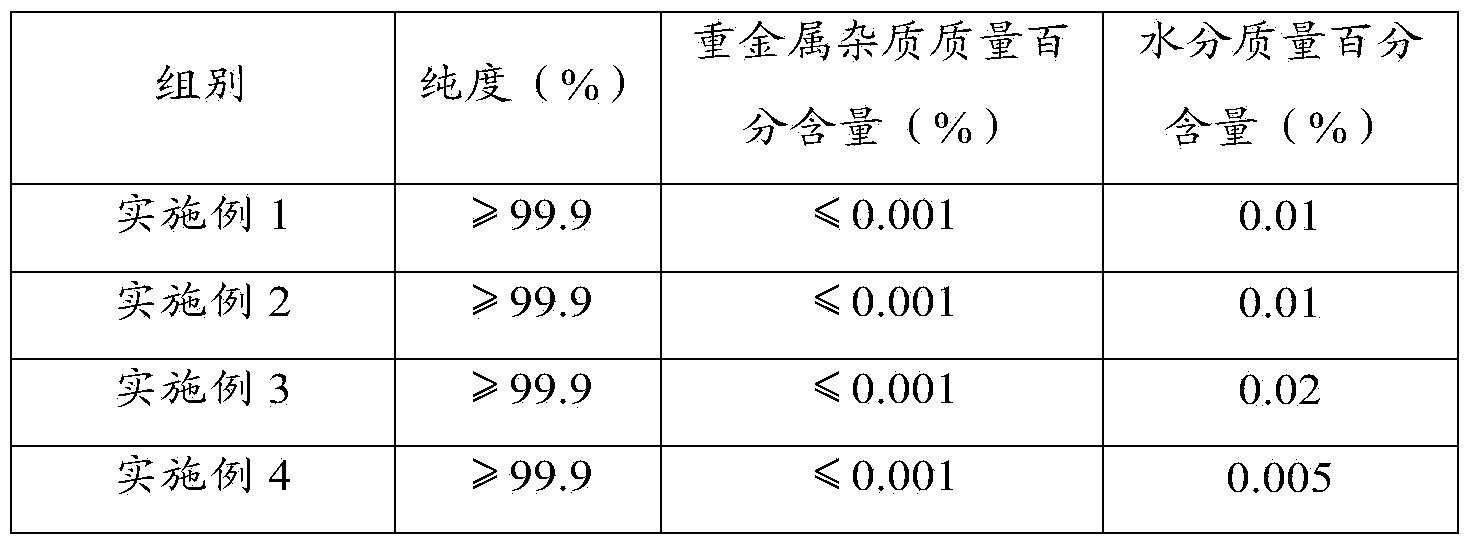

Examples

Embodiment 1

[0034] The preparation method of vanadium pentoxide is as follows:

[0035] (A) After pulverizing the stone coal, adding sulfuric acid solution and sodium chlorate in turn, stirring evenly and fermenting at constant temperature for 7 days, to obtain the first mixture;

[0036] (B) Add deionized water with a mass ratio of 1:1 to the first mixture at a temperature of 90° C., stir for 30 minutes and then carry out solid-liquid separation. The solid phase is cinder with a water mass percentage of 20%, and the liquid phase It is a mixed solution of various metal elements mainly containing vanadium;

[0037] (C) the liquid phase is left to stand to obtain the first precipitate potassium alum, after separating the first precipitate, add ammonium bicarbonate in the first supernatant and stir evenly, continue to stand for 3h and separate the second precipitate ammonium alum, And obtain the second supernatant;

[0038] (D) Calcium hydroxide is added to the second supernatant, and the ...

Embodiment 2

[0042] The preparation method of vanadium pentoxide is as follows:

[0043] (A) Put the stone coal into a ball mill after pulverizing it to a particle size of 2-3cm until the particle size is more than 120 mesh, then add sulfuric acid solution and sodium chloride and potassium chloride successively, and stir evenly After fermenting at a constant temperature for 10 days at a temperature of 150° C., the first mixture is obtained, and the first mixture is ground and pulverized until the particle size is above 80 mesh;

[0044] (B) Add the first mixture to the first mixture at a temperature of 80°C and add deionized water with a mass ratio of 1:3 to the first mixture, add 1% calcium oxide to the first mixture, and perform solid-liquid separation after stirring for 50 minutes. The solid phase is Coal slag with a water mass percentage of 30%, the liquid phase is a mixed solution of various metal elements mainly containing vanadium;

[0045] (C) the liquid phase is left to stand to ...

Embodiment 3

[0050] The preparation method of vanadium pentoxide is as follows:

[0051] (A) Pulverize the stone coal with a pulverizer to a particle size of 2-3 cm, put it into a ball mill for ball milling until the mesh particle size is above 120 mesh, add sulfuric acid solution and potassium chlorate in sequence, and stir evenly at a temperature of 150°C After stacking and fermenting at a constant temperature for 8 days, the first mixture was obtained, and the first mixture was ground and pulverized until the mesh particle size was above 80 mesh;

[0052] (B) Add the first mixture at a temperature of 80°C to the deionized water whose mass is 1:2 with the first mixture, add 2% calcium oxide to the first mixture, stir for 40 minutes and perform solid-liquid separation, the solid phase is Coal slag with a water mass percentage of 25%, and the liquid phase is a mixed solution of various metal elements mainly containing vanadium;

[0053] (C) the liquid phase is left to stand to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com