Patents

Literature

238results about How to "Produced no" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

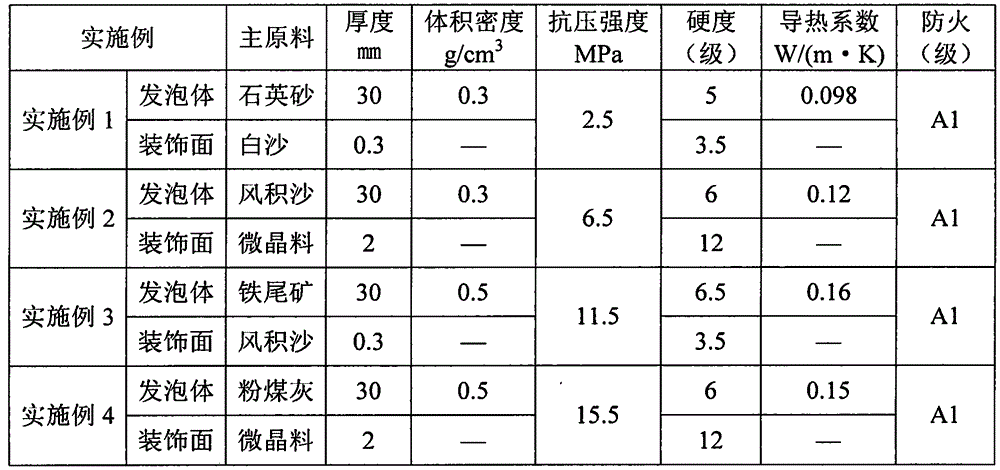

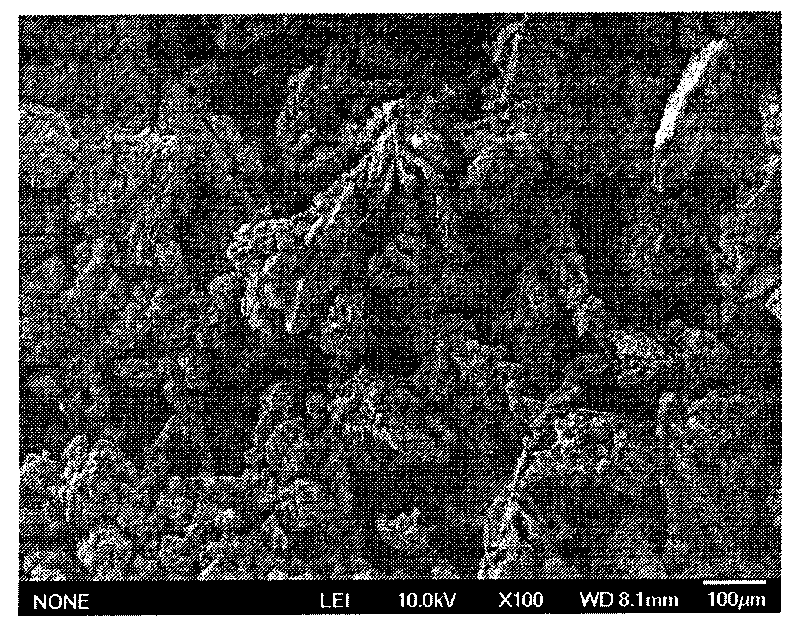

Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

ActiveCN104631688AProduced noRelieve pressureBuilding componentsCeramicwareWeather resistanceSurface layer

The invention discloses a microcrystalline foamed wall block produced by use of tailings and a manufacturing method of the microcrystalline foamed wall block. According to the microcrystalline foamed wall block, a decorative surface layer is sintered on a tailing microcrystalline foamed base body manufactured by use of a tailing composite material at a high temperature. The manufacturing method comprises the following steps: (1) preheating, namely increasing the temperature to the range of 800-950 DEG C and preserving heat for 10-40 minutes; (2) integrated sintering, namely increasing the temperature to the range of 1000-1350 DEG C and preserving heat for 30-120 minutes; (3) annealing cooling, namely cooling to below 280 DEG C and then taking out of a kiln; (4) naturally cooling to below 100 DEG C and then performing mold stripping, thereby obtaining a microcrystalline foamed wall block board; naturally placing the microcrystalline foamed wall block board for more than 60 hours to eliminate stress, and then grinding or polishing, cutting and drying to obtain the microcrystalline foamed wall block. The microcrystalline foamed wall block has a plurality of functions of high strength, fire resistance, heat preservation and thermal insulation, moisture and water proofing, decoration, light weight, weathering resistance, environmental protection and the like.

Owner:BEIJING HUIERJIU MATERIAL TECH

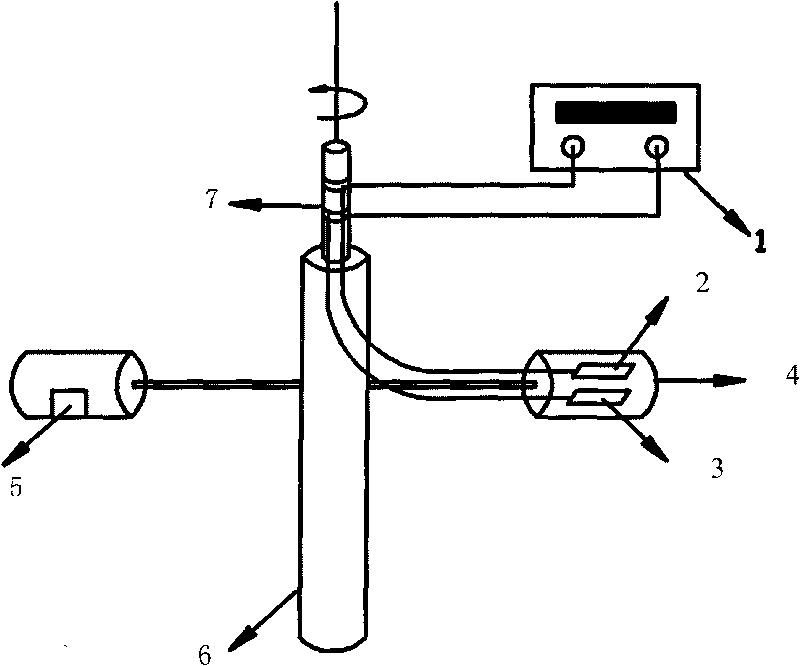

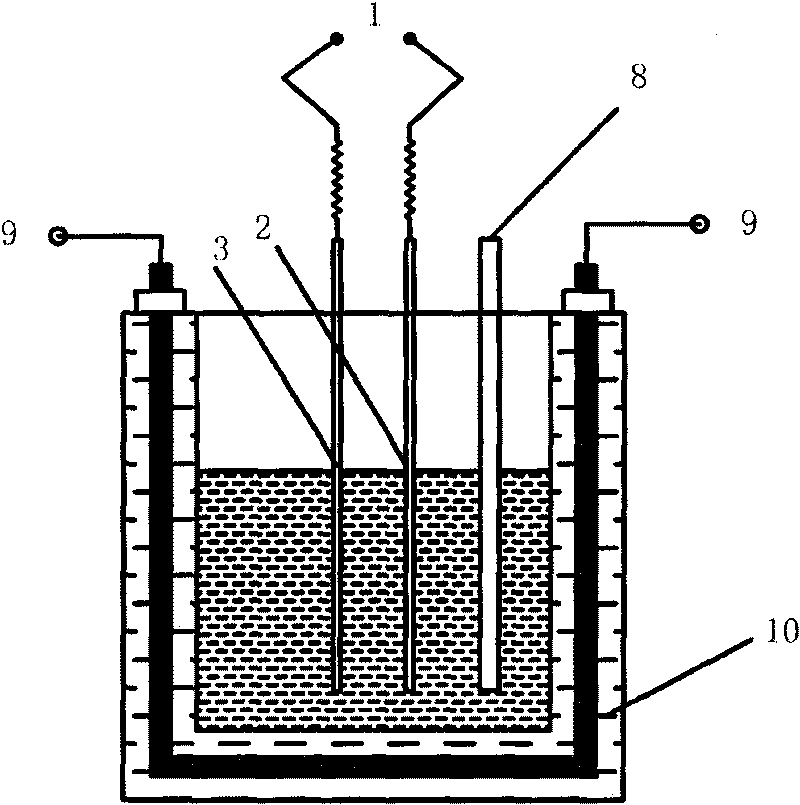

Method for electrolyzing aluminum from ionic liquid on hyper-gravity basis

InactiveCN101760758AEnhance convection and diffusion processesFacilitates ion mass transferPhotography auxillary processesProcess efficiency improvementIonAluminum matrix composites

The invention discloses a method for electrolyzing aluminum from an ionic liquid on a hyper-gravity basis and belongs to the field of metal electrodeposition under special conditions. The method of the invention comprises the following step: electrolyzing aluminum and subjecting an electrolytic tank to centrifugal rotation to generate a hyper-gravity field simultaneously, wherein aluminum sheets or aluminum-based composite material constitute the anode; stainless steel sheets or aluminum sheets constitute the cathode; the ionic liquid of chloroaluminate salt constitutes the electrolyte; and nitrogen or argon constitutes the protective gas. Accordingly, the electrolyzation of aluminum can be achieved in the hyper-gravity field, so as to obtain an aluminum deposition layer. The invention has the following advantages: the hyper-gravity field is capable of enhancing the processes of convection and dispersion, improving the mass transfer of ions, increasing the rate of deposition and reducing the preparation period of aluminum; finer aluminum grains and denser deposition layers can be obtained in the hyper-gravity field; moreover, the adhesion of the aluminum deposition layers can be obviously improved by the contingent mechanical effects, thereby preventing the dendritic crystal aluminum from being generated; the method can solve the problem that the deposition layer is likely to drop off; and no gas is generated at the anode during the refining process, thereby preventing the environmental pollution.

Owner:BEIJING UNIV OF CHEM TECH

Aqueous anticorrosive paint of steel structure and preparation method thereof

ActiveCN102993846AStir wellImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention provides an aqueous anticorrosive paint of a steel structure and a preparation method thereof, belonging to the technical field of steel surface anticorrosive coating. The paint comprises the following materials in percentage by weight: 15-25% of rust transforming agent, 6-10% of epoxy emulsion, 40-60% of cation styrene-acrylic emulsion, 0.1-0.2% of penetrating agent, 0.1-0.5% of glycol ether, 0.1-0.3% of dispersion stabilizer and 10-20% of deionized water. The product prepared by the preparation method provided by the invention has the characteristics such as a simple preparation process, low cost, excellent performances, and the like.

Owner:马鞍山市安工大智能装备技术研究院有限公司

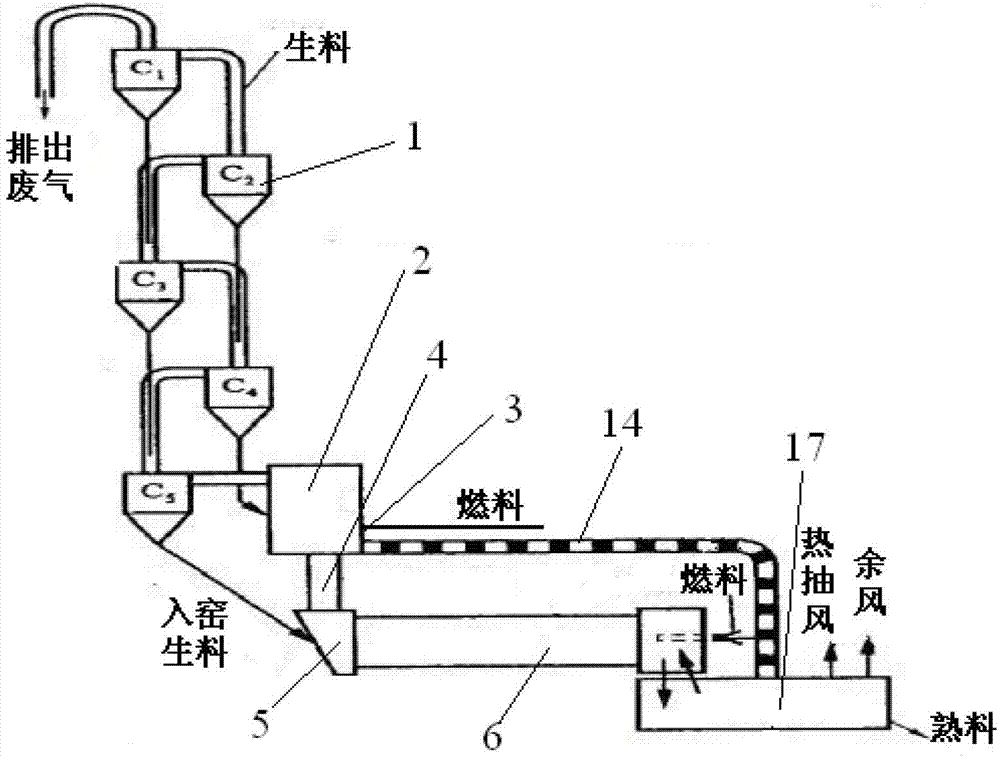

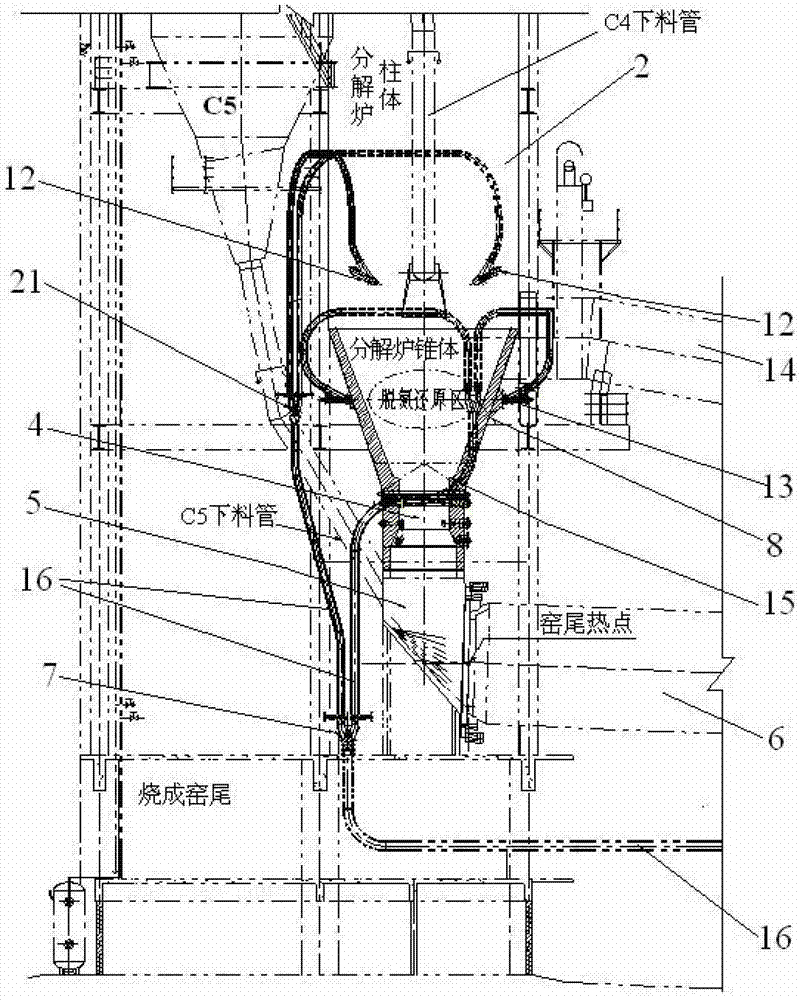

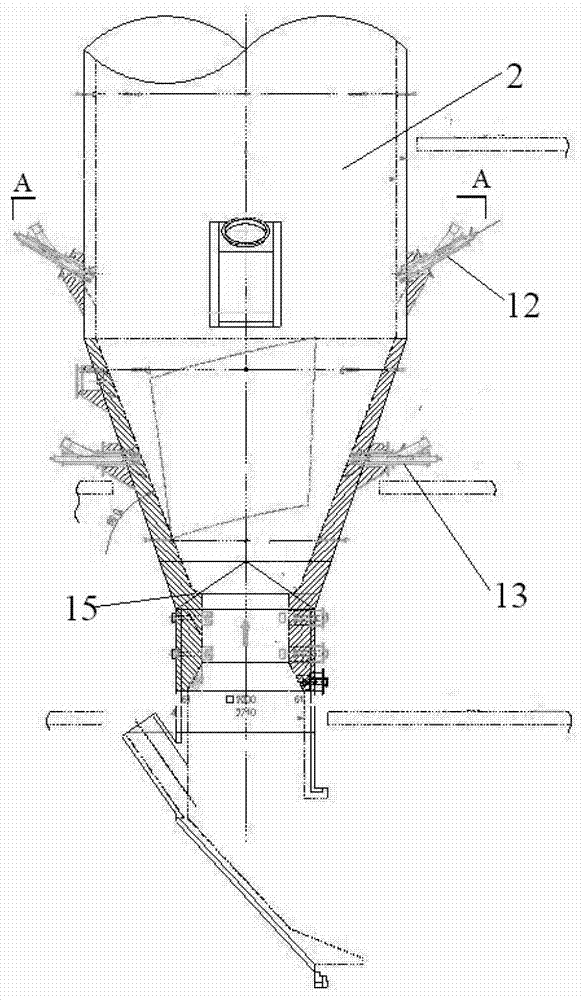

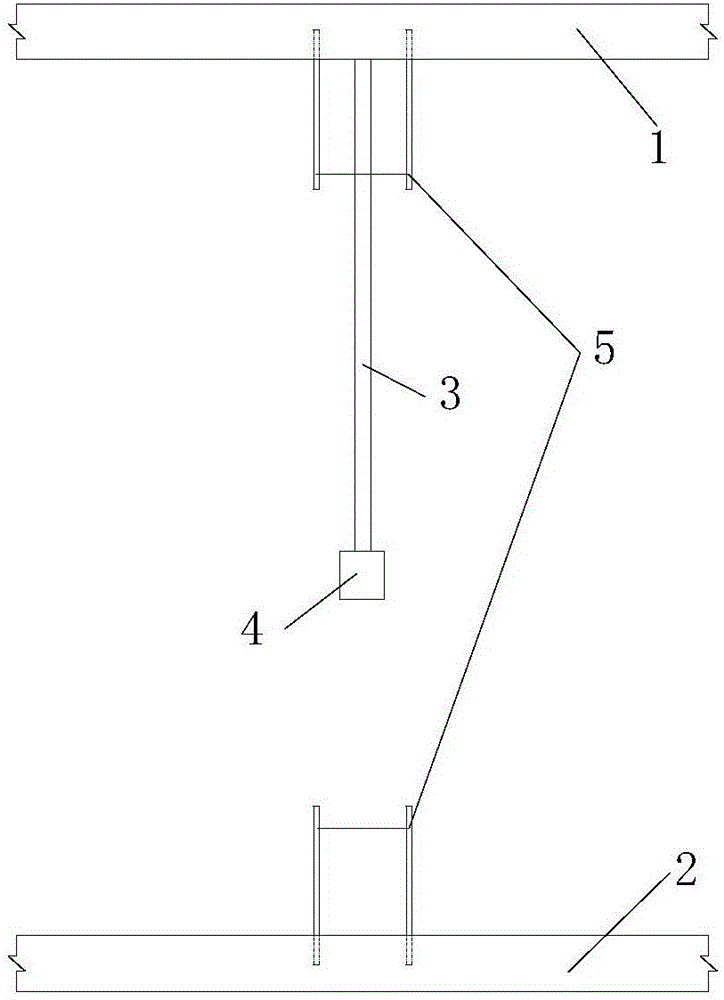

Clinker production line for novel dry process cement kiln and denitration process method for clinker production line

ActiveCN102923979AReduce generationSuppress generationClinker productionProduction lineCoal pipeline

The invention discloses a clinker production line for a novel dry process cement kiln. Pulverized coal in a pulverized coal pipeline which is communicated with the tail of the kiln is divided into two channels by a first pulverized coal distributor, wherein one channel is communicated with a column body on the upper part of a decomposition furnace, and the pulverized coal is divided into two channels again by a second pulverized coal distributor and symmetrically enters the column body on the upper part of the decomposition furnace; and the other channel is communicated with a cone on the lower part of the decomposition furnace, and the pulverized coal is divided into two channels again by the second pulverized coal distributor and symmetrically enters the cone on the lower part of the decomposition furnace. The invention also provides a denitration process method adopted by the production line. By the technical scheme, thermal NOx generated in the kiln is decreased and reduced, and the generation of fuel NOx is inhibited, so that NOx can be effectively reduced from the source; and after process improvement, operation parameters are optimized, the operation quality and stability of the system are promoted, and a certain energy-saving effect is achieved.

Owner:ANHUI CONCH GRP +2

Coffee-containing bagged buccal tobacco product

The invention discloses a coffee-containing bagged buccal tobacco product. The product comprises a granular tobacco mixture consisting of a tobacco material, water, sodium chloride, an acidifying or alkalizing agent, a flavoring agent and a humectant and is characterized in that coffee, a coffee extract or the mixture of the coffee and the coffee extract is added in the mixture. The product has the advantages that: the product can provide similar satisfaction of the traditional cigarette products for tobacco consumers like the conventional tobacco product, but do not generate smog and harm ofsecond-hand smoke; and the product enriches the taste of the tobacco product due to the added coffee and coffee extract and can play a role in dissipating fatigue, refreshing the mind, relieving asthma and the like. The invention diversifies buccal tobacco products.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

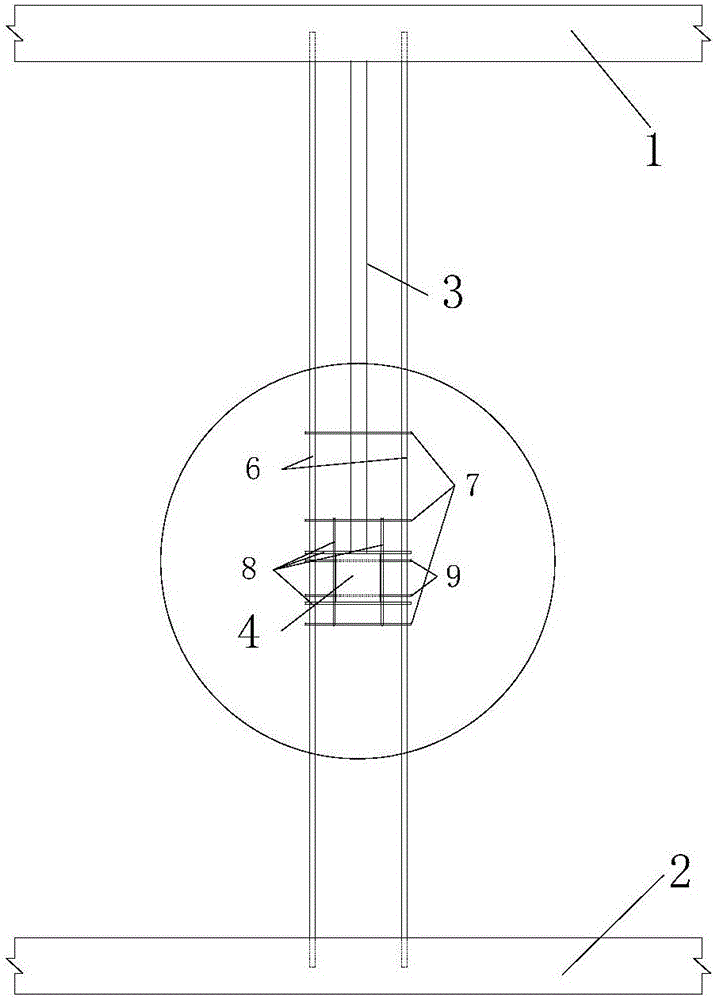

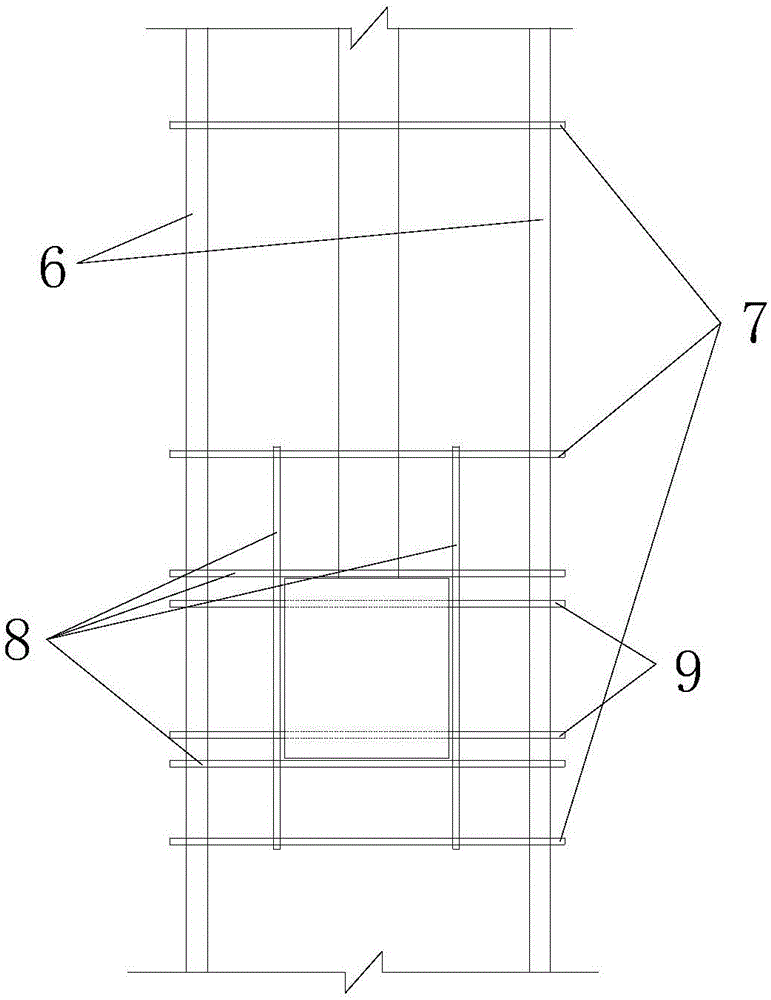

Masonry-wall line-pipe, line-groove and line-box burying construction method

InactiveCN106320706APrevent the occurrenceProduced noBuilding material handlingCable installation apparatusArchitectural engineeringRebar

The invention discloses a masonry-wall line-pipe, line-groove and line-box burying construction method. The construction method includes the steps that in the pre-construction method, reinforcing steel bars are pre-buried or post-implanted into a top plate and a bottom plate on the peripheries of a line pipe and a line groove buried in a masonry wall, the line pipe, the line groove and a line box are completely arranged, then the corresponding pre-buried reinforcing steel bars of the bottom plate and the top plate are bound and woven into a whole in a concrete-constructional-column mode, the line pipe, the line groove and the line box are fixed, a formwork is installed, and concrete pouring is carried out; in the post-construction method, reinforcing steel bars are pre-buried or post-implanted into a top plate and a bottom plate on the peripheries of a line pipe and a line groove buried in a masonry wall, the portion is reserved when wall masonry is carried out, and after masonry construction is completed, the line pipe, the line groove and a line box are installed, then the corresponding pre-buried reinforcing steel bars of the bottom plate and the top plate are bound and woven into a whole in a concrete-constructional-column mode, the line pipe, the line groove and the line box are fixed, a formwork is installed, and concrete pouring is carried out. According to the construction method, the wall does not need to be slotted, cracks or fractures of the wall can be avoided, environment pollution is reduced, labor strength is reduced, construction is simple, construction time is short, the cost is low, and the installing quality is reliable.

Owner:CHINA FIRST METALLURGICAL GROUP

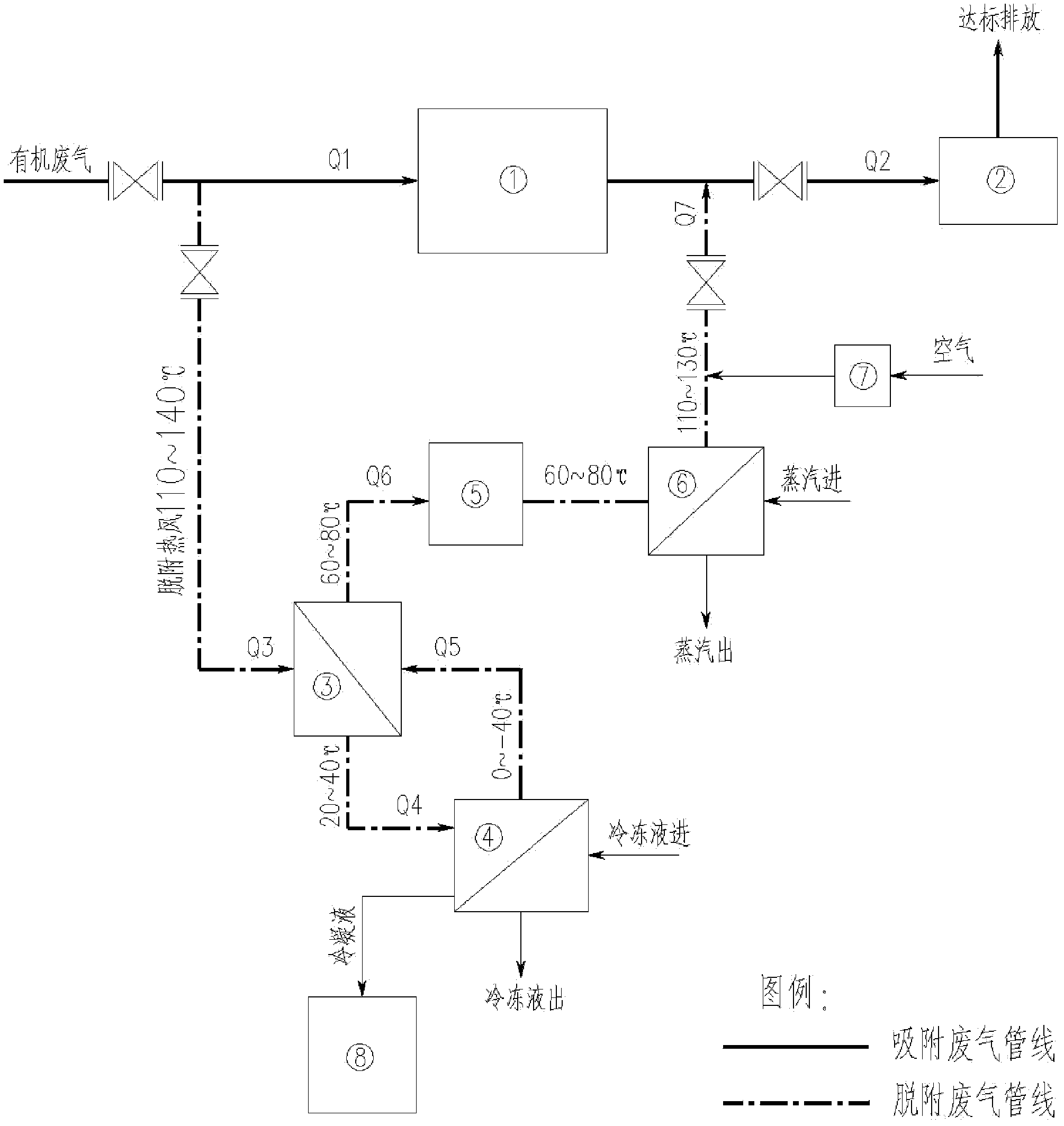

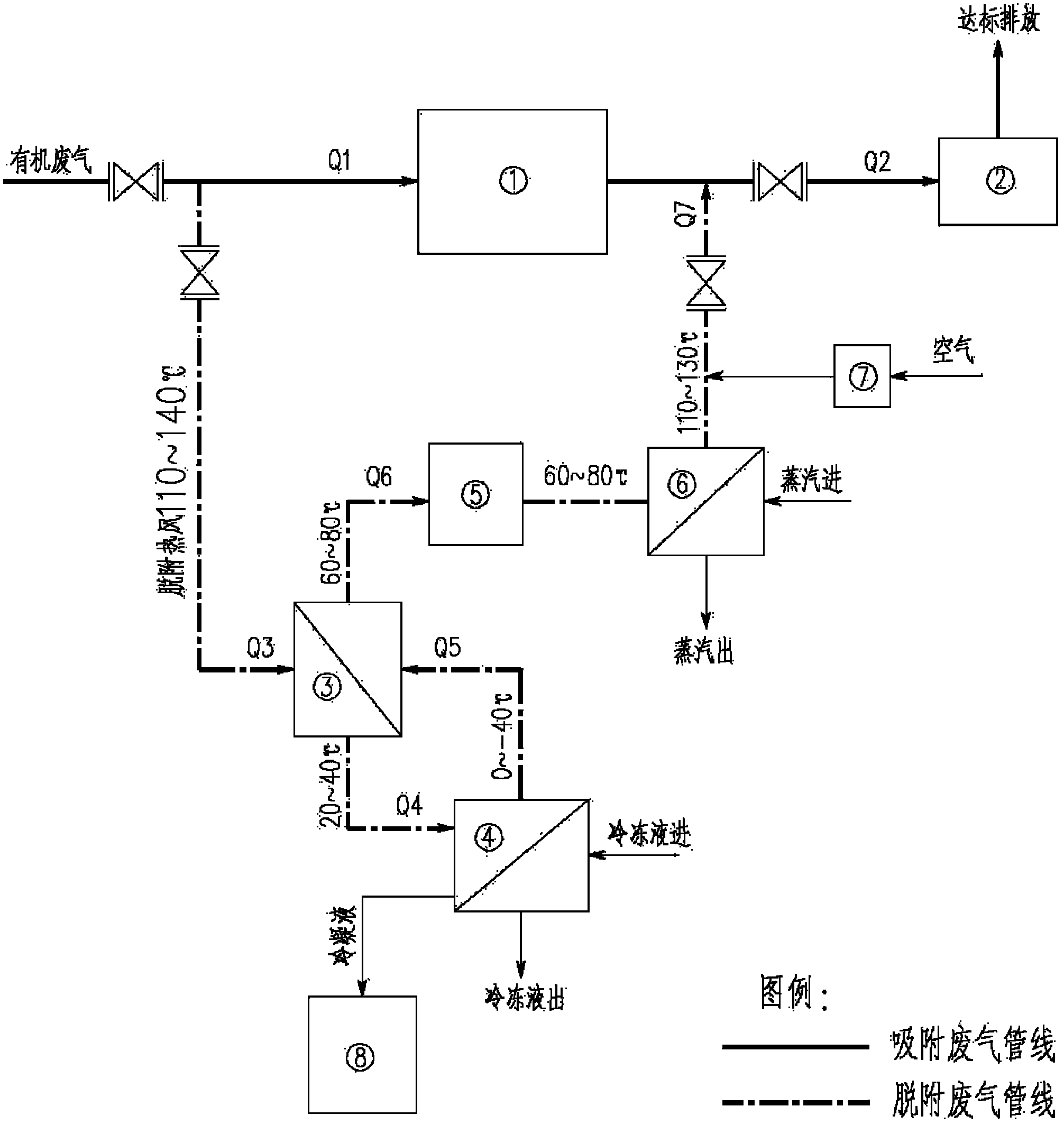

Method for recovering organic solvent from organic water gas

InactiveCN102489113ANo emissionsNo secondary pollutionDispersed particle separationVapor condensationEnvironmental resistanceDesorption

The invention belongs to the technical field of treatment of organic waste gas, and relates to a method for recovering an organic solvent from organic waste gas. The method comprises the following steps of: adsorbing the organic solvent in the organic waste gas into active carbon, purifying, and discharge within controlling indexes of a national standard; when the active carbon is saturated by adsorbing, heating the residual organic waste gas in a pipeline, desorbing the organic solvent which is absorbed by the active carbon, and regenerating the active carbon; performing heat exchange on thedesorbed organic solvent gas, condensing into liquid, and recovering; and heating condensed waste gas, reentering the desorbed saturated active carbon again, circulating, and finishing one-time desorption. The method has the advantages of simple process flow, convenience for operating, saving in energy, reduction in production cost, lowering of the organic substance content of the waste gas to reach an environmentally-friendly emission standard, capability of recycling organic substances in the waste gas as resources, regeneration of active carbon, no emission of secondary pollutants, remarkable economic benefit and wide application field.

Owner:SHANGHAI TONGJI CLEARON ENVIRONMENTAL PROTECTION EQUIP ENG CO LTD +1

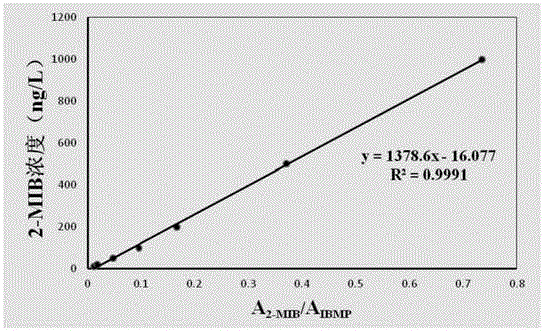

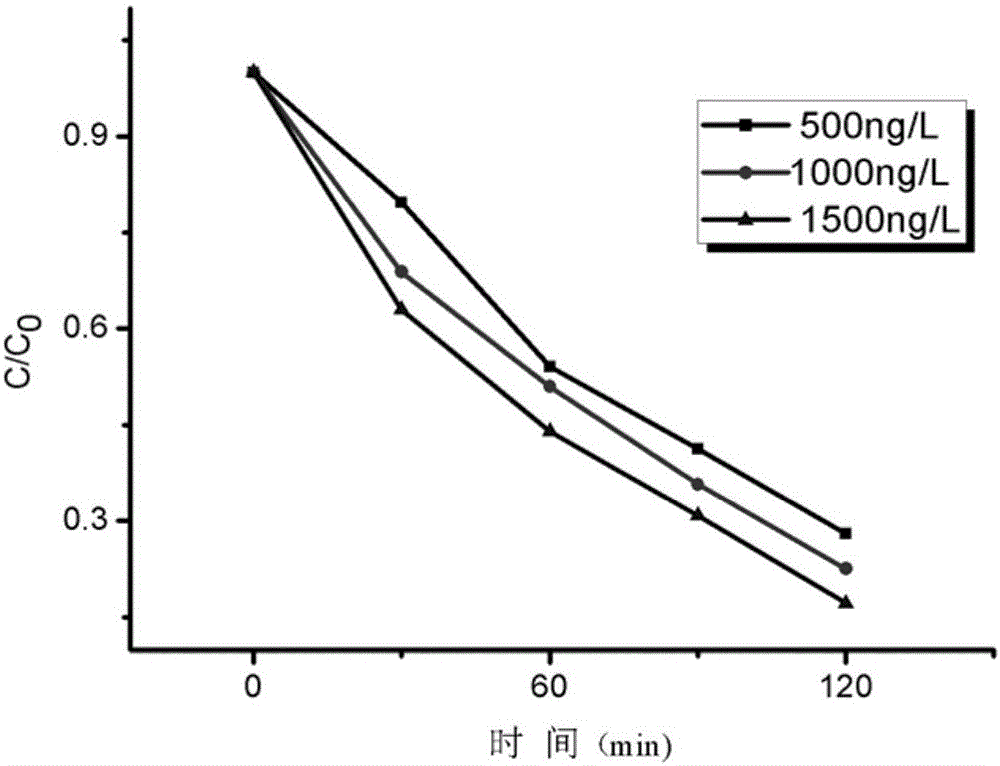

Method for degrading smelly substance in water through oxidizing agent activated by ultraviolet light

InactiveCN105036291AApplicable to a wide range of pHProduced noWater/sewage treatment by irradiationWater/sewage treatment by oxidationNeutral phPersulfate

The invention discloses a method for degrading a smelly substance in water through an oxidizing agent activated by ultraviolet light. The method includes the following steps that an oxidizing agent solution is added into the water with the smelly substance, reaction is performed under illumination of the ultraviolet light, and sampling analysis is performed after the reaction to obtain the degradation result of the smelly substance in the water. The smelly substance is 2-methylisoborneol or geosmin, the oxidizing agent is persulfate or mono potassium peroxysulfate, and the illumination intensity of the ultraviolet light is 103 mj / cm<2>-410 mj / cm<2>. The method is environmentally friendly and will not generate secondary pollution, a good effect can be achieved at a normal temperature just by adding the reagent into the water with the smelly substance needing to be degraded under illumination of the ultraviolet light, the good degradation effect can be achieved no matter whether under neutral pH or acidic pH, it is unnecessary to arrange other devices, operation is simple, storage and transportation are easy, and the method can be used for degrading the smelly substance in the water.

Owner:TONGJI UNIV

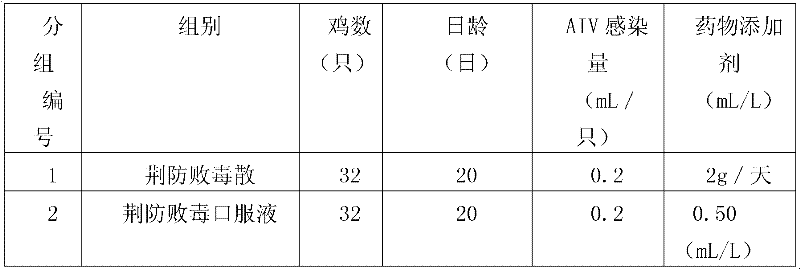

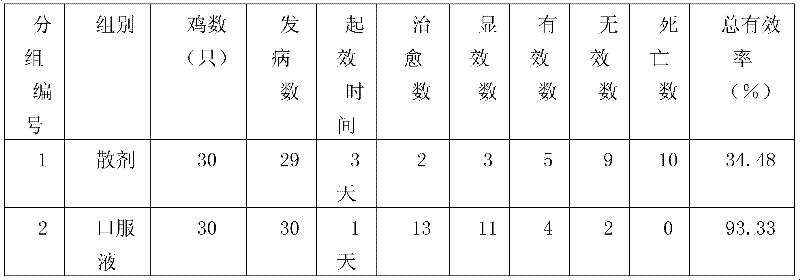

Method for preparing schizonepeta and divaricate saposhnikovia root oral liquid for removing toxin

The invention relates to a method for preparing schizonepeta and divaricate saposhnikovia root oral liquid for removing toxin. The method comprises the following steps of: (1) distilling schizonepeta, divaricate saposhnikovia root, incised notopterygium rhizome, heracleum, bitter orange, ligusticum wallichii, whiteflower hogfennel root and mint to extract volatile oil, and collecting an aqueous solution obtained after distillation in a container; (2) treating the decoction dregs of ligusticum wallichii and bitter orange, and tuckahoe by a percolation method to obtain colature, namely adding 25 weight percent of ethanol into the aqueous solution obtained after distillation in the step (1) to obtain a mixture serving as a solvent, performing percolation, collecting colature, and recovering ethanol under reduced pressure; and (3) adding water into decoction dregs of schizonepeta, divaricate saposhnikovia root, incised notopterygium rhizome, heracleum, and whiteflower hogfennel root, and bupleurum chinense, platycodon grandiflorus, and liquorice, and decocting for three times, filtering, mixing filtrate, concentrating until the solution is 1,300ml, mixing the solution and colature which is obtained in the step (2), standing, filtering, concentrating until the solution is 1,000ml, adding 3 parts of sodium benzoate, and the volatile oil which is obtained in the step (1), uniformly stirring, and adding water to ensure the solution is 1,000ml to obtain the oral liquid. Ethanol which is produced when the schizonepeta and divaricate saposhnikovia root oral liquid for removing toxin is produced can be recovered by equipment special for recovering ethanol; the produced decoction dregs can be used for manure collection or agriculture supporting; and waste gases are avoided.

Owner:TIANJIN BIJIA PHARMA CO LTD

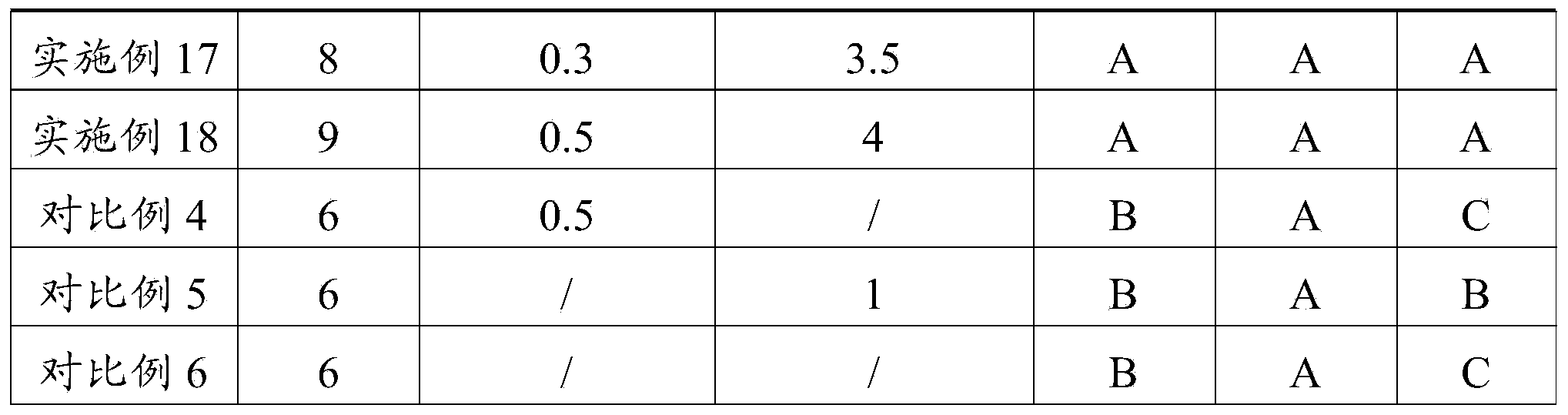

Method for preparing bio-organic fertilizer by utilizing chicken manure fermentation

ActiveCN105036853AInhibitionProduced noBio-organic fraction processingOrganic fertiliser preparationEscherichia coliLactarius

The invention discloses a method for preparing bio-organic fertilizer by utilizing quick odorless fermentation of chicken manure. The bio-organic fertilizer is prepared from microbial liquid inoculum, auxiliaries and chicken manure by means of two-step fermentation, and no foul smell, ammonia gas or other pollution gases is generated in the whole process. The bio-organic fertilizer is grayish brown odorless particles without mechanical impurities. By detection, in the bio-organic fertilizer, the content of lactic acid bacteria is more than or equal to 10<8>CFU / g, the content of total viable bacteria is more than or equal to 10<9>CFU / g, the content of organic matters is 57.67 percent, the content of total nutrient is 7.8 percent, no alive roundworm egg or pathogenic bacterium is contained, and the content of escherichia coli is less than or equal to 10<2>CFU / g, which is in accordance with the specification in the national standard of bio-organic fertilizer (NY 884-2012).

Owner:玉溪牛易拉农业科技有限公司

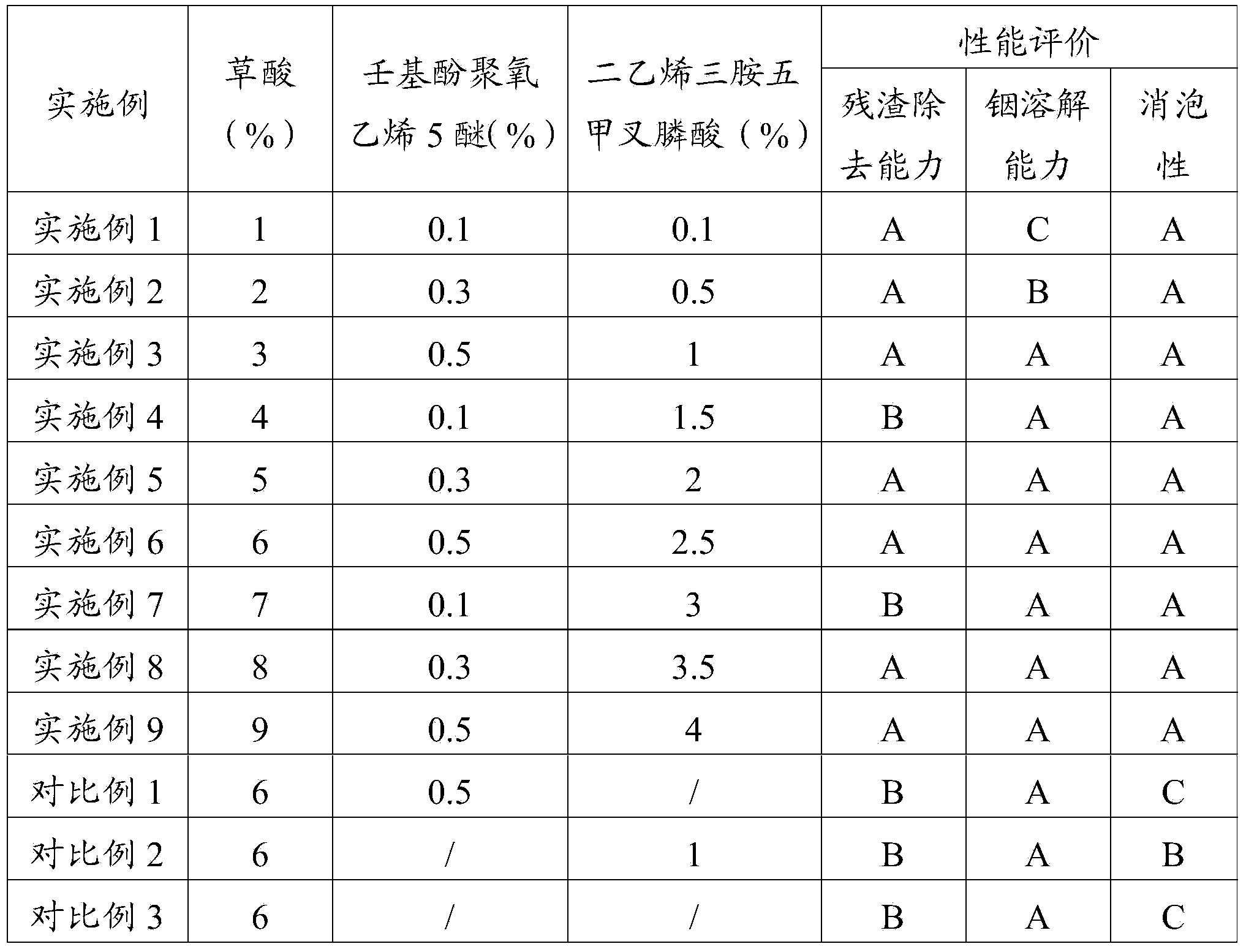

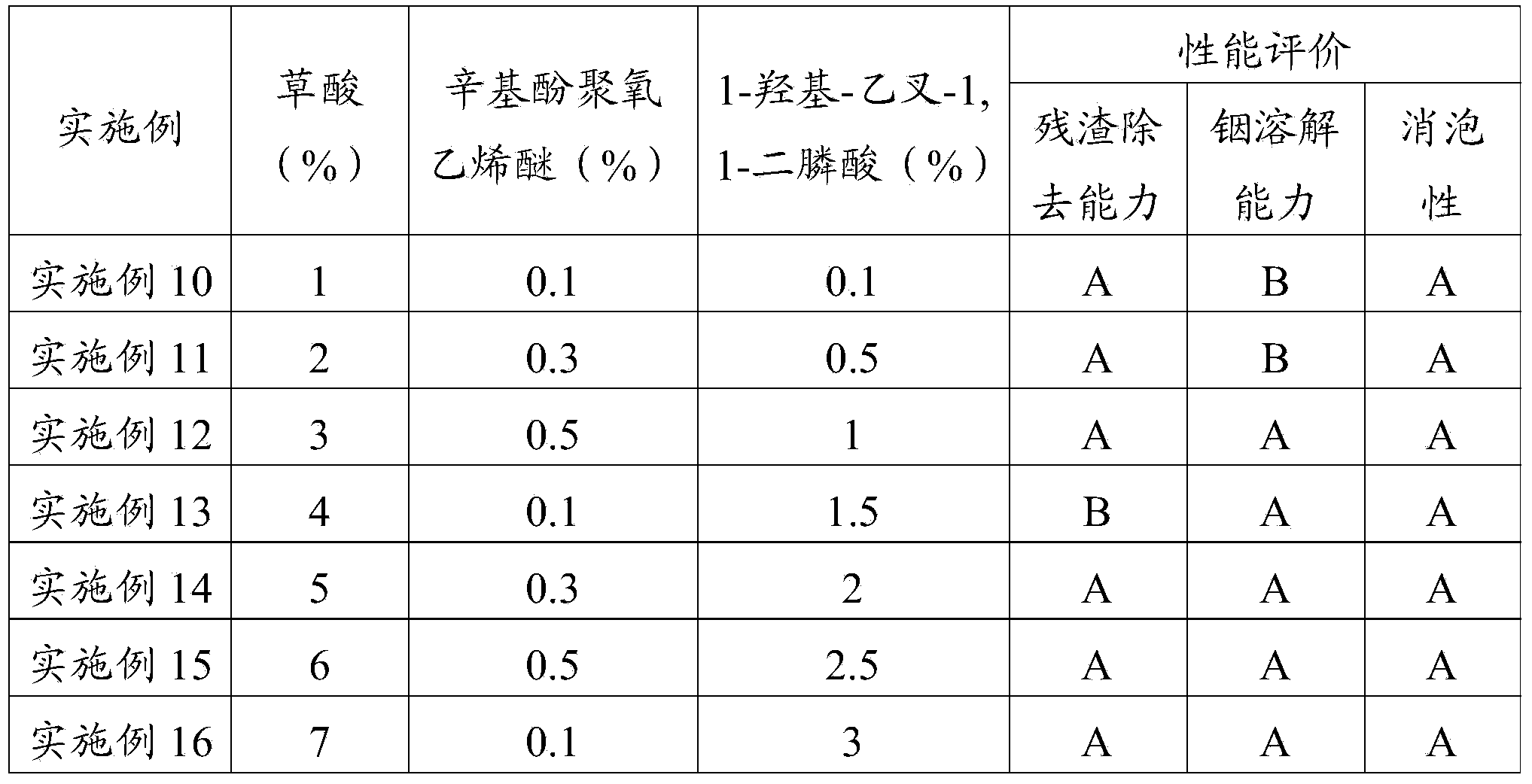

Oxalic acid-series ITO (Indium Tin Oxide) etching liquid, as well as preparation method and application thereof

ActiveCN104388090AInhibit effective foamingEfficient and etchedConductive layers on insulating-supportsCable/conductor manufacturePhenolsIndium tin oxide

The invention discloses an oxalic acid-series ITO (Indium Tin Oxide) etching liquid, as well as a preparation method and application thereof. The oxalic acid-series ITO etching liquid comprises the following raw materials in percent by weight: 0.5 to 10 percent of oxalic acid, 0.1 to 0.5 percent of an alkyl phenol polyoxyethylene ether-series surfactant, 0.1 to 5 percent of organic polybasic phosphonic acid, and the balance of water. The oxalic acid-series ITO etching liquid can be used for etching an ITO layer under a mild condition, while residue and a great amount of foam cannot be generated after etching.

Owner:SHENZHEN CAPCHEM TECH

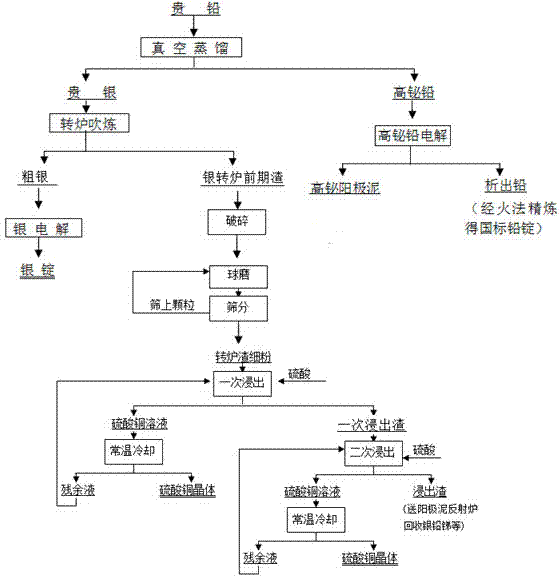

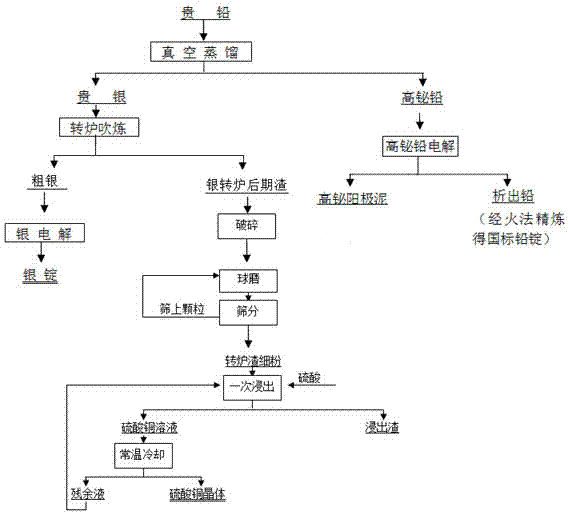

Method for recycling lead, sliver and copper by taking noble lead as raw material

The invention relates to a method for recycling lead, sliver and copper by taking noble lead as a raw material, and belongs to the technical field of combining a pyrogenic process with a wet process. The method comprises the following steps: firstly, carrying out vacuum distillation onto the noble lead for separating lead, stibium, bismuth and copper to produce high-bismuth lead and noble sliver; carrying out high-bismuth lead electrolysis onto the obtained high-bismuth lead to obtain separated-out lead, producing crude sliver by carrying out converter refining onto the obtained noble sliver, and refining noble lead byproducts obtained according to converter refining time length to obtain converter early-stage slag and converter later-stage slag; and electrolyzing the obtained crude sliver by crude sliver to obtain a sliver ingot, respectively crushing the obtained converter early-stage slag and converter later-stage slag until grain size is less than 6mm, then grinding to form powder with grain size being less than 100 meshes to obtain converter slag fine powder, and adding the converter slag fine powder into sulfuric acid liquor for leaching, and thus obtaining leaching slag and copper sulfate liquor after leaching is completed. The method disclosed by the invention improves treatment process flow of the noble lead material, and has the effects that process flow is refined and concise, energy is saved and consumption is lowered, and production environment is optimized.

Owner:蒙自矿冶有限责任公司

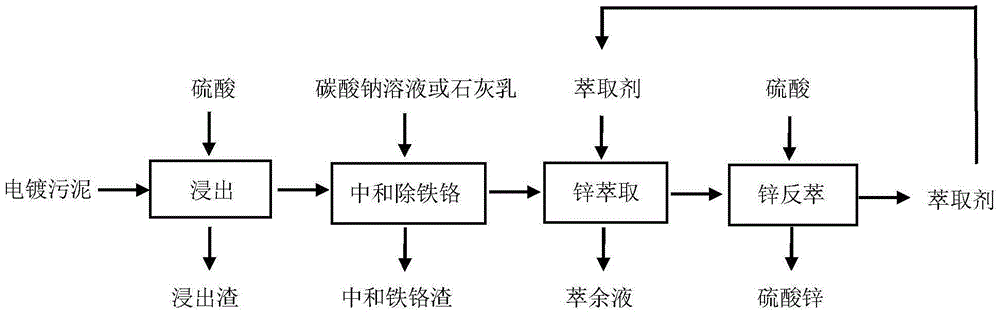

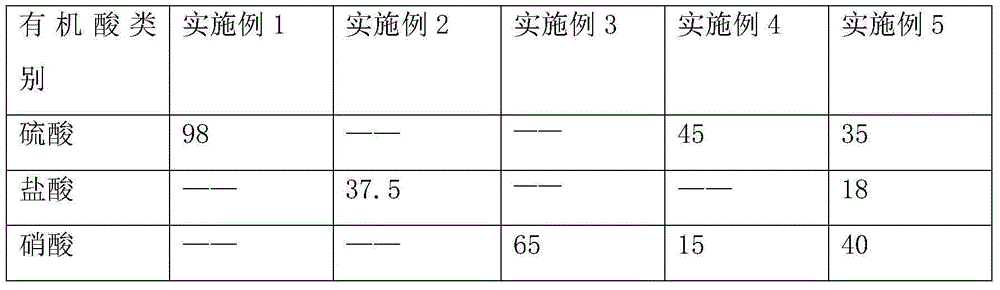

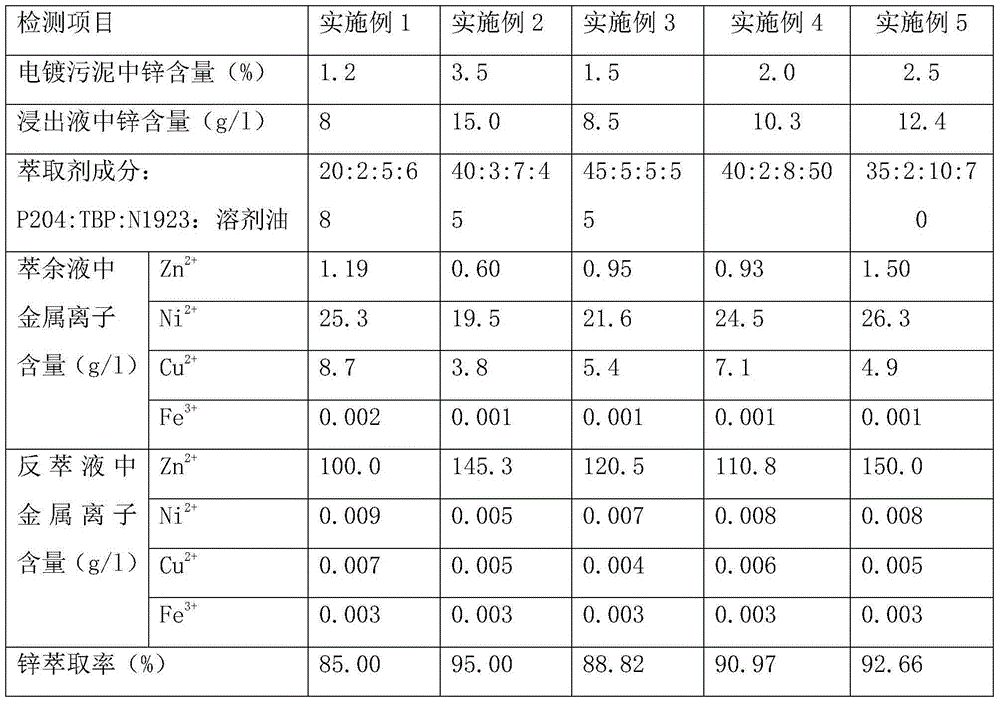

Method of separating and recovering zinc from electroplating sludge

InactiveCN105200239AShort processImprove extraction rateProcess efficiency improvementOrganic acidChromium(III) hydroxide

The invention belongs to the field of metallurgy and particularly relates to a method of separating and recovering zinc from electroplating sludge, comprising the steps of 1, performing leaching treatment: leaching the electroplating sludge with an organic acid, and carrying out solid-liquid separation to obtain leaching residue and leachate; 2, removing iron and chromium by neutralizing: adding a neutralizing agent into the leachate obtained in step 1, and carrying out solid-liquid separation to obtain ferric hydroxide precipitate, chromic hydroxide precipitate and leachate; 3, performing extracting: mixing P204, tributyl phosphate, an organic extracting agent N1923 and a solvent oil to obtain a mixed extracting agent, extracting the leachate generated in step 2, with the mixed extracting agent, and adding an organic acid to carry out re-extraction to obtain raffinate and zinc-containing re-extracted liquor, namely purified liquor containing zinc sulfate. The method has the advantages that the zinc may be extracted and separated from sulfuric acid leachate of the electroplating sludge so that the zinc is comprehensively recycled, an extracting process needs no caustic soda liquid for saponification, recycling cost is decreased, and economic benefit is increased.

Owner:广西银亿再生资源有限公司 +1

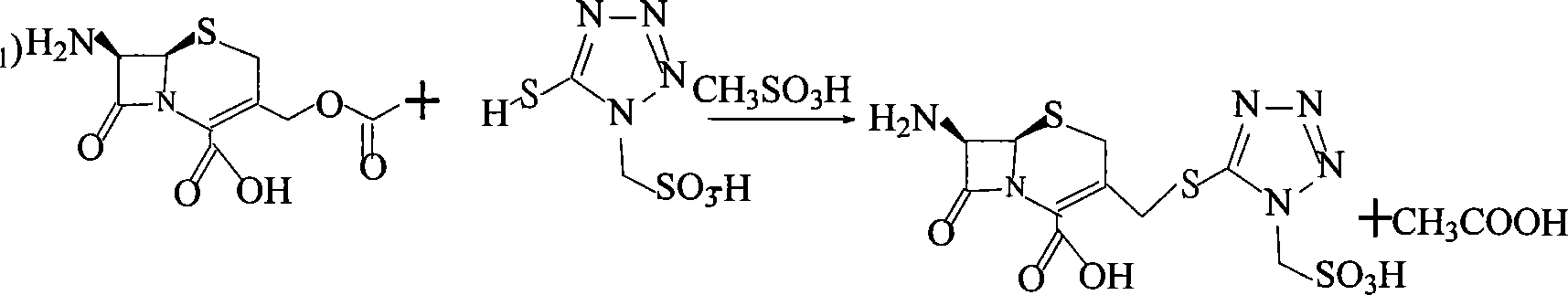

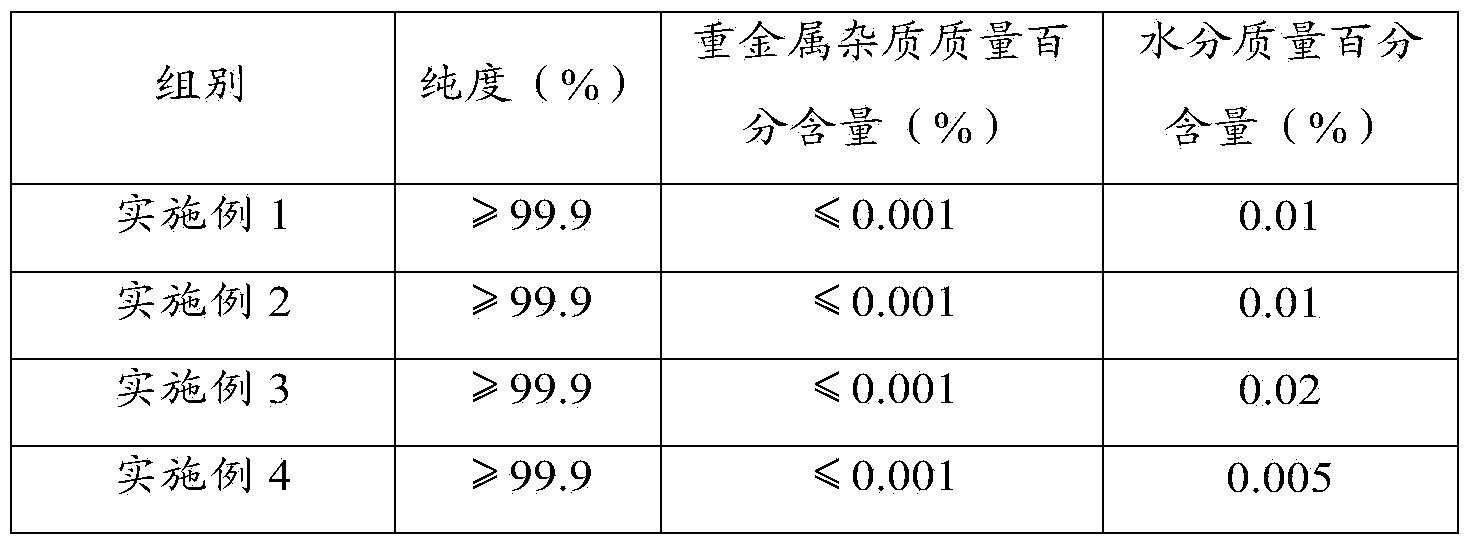

Method for preparing cefonicid or its medicinal salt and intermediate

ActiveCN101085781AProduced noHigh post-processing costOrganic chemistryDecreased energyEconomic benefits

The invention provides a method for preparing cephalosporin nixi or its salt and its intermediate. The invention employs alkyl sulfonic acid to replace BF3 used in curretn technique as catalyst for reaction of 1- methanesulfonic acid- 5- mercapto- 1, 2, 3, 4- tetrazole acid or its salt and 7-aminocephalosporanic acid or its salt. It is characterized by reduced cost, decreased energy consumption, less toxic waste gas discharge and apparent economic benefit.

Owner:SHANDONG SALUBRIS PHARMA +1

Method for preparing vanadium pentoxide

ActiveCN104261473AProduced noNo pollution in the processVanadium oxidesDecompositionAmmonium metavanadate

The invention relates to the field of production of vanadium pentoxide and in particular relates to a method for preparing vanadium pentoxide. The method comprises the following steps: (A) adding a sulfuric acid solution and an additive into stone coal, thereby obtaining a first mixture; (B) adding the first mixture into deionized water, stirring, and performing solid-liquid separation; (C) standing the liquid phase, thereby obtaining a first precipitate, separating the first precipitate, adding ammonium bicarbonate into the first supernatant, stirring to be uniform, continuously standing and separating a second precipitate, thereby obtaining the second supernatant; (D) adding calcium hydroxide and / or calcium oxide into the second supernatant, thus obtaining a third precipitate and the third supernatant; (E) saturating an ion exchange resin, eluting by using sodium hydroxide, thereby obtaining a vanadium solution; and (F) adding a pH regulator into the vanadium solution, adding hydrogen peroxide, finally adding ammonium chloride, performing centrifugal separation, obtaining a precipitate ammonium metavanadate, carrying out an ammonium metavanadate decomposition reaction, thereby obtaining the vanadium pentoxide. According to the preparation method disclosed by the invention, the cost is low, and three wastes are avoided.

Owner:江西钒业科技有限公司

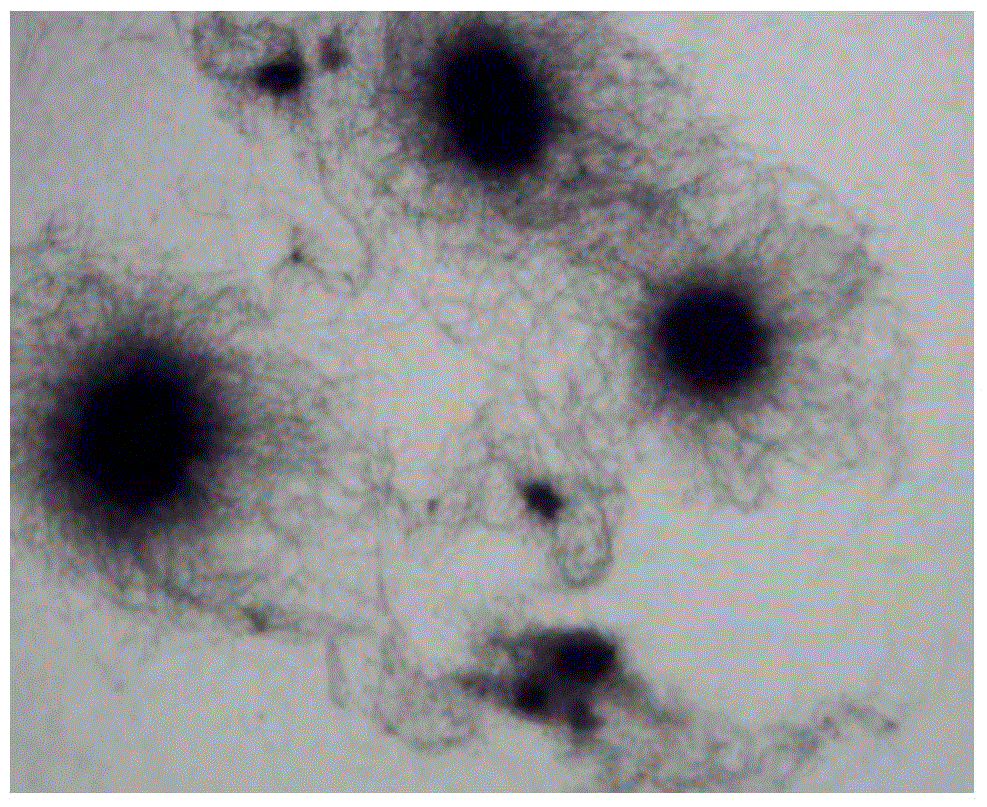

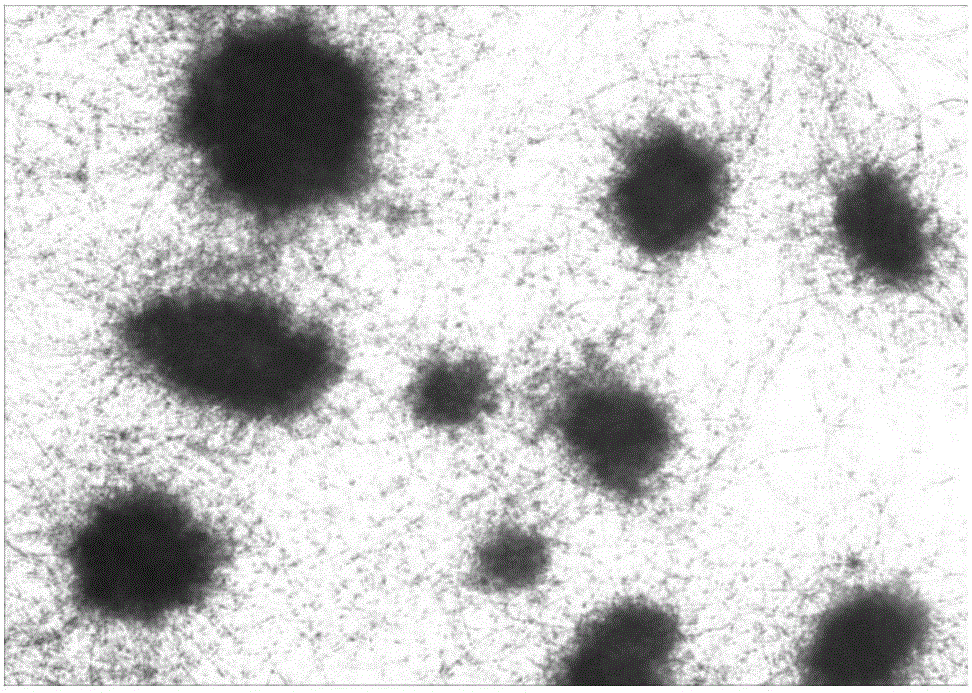

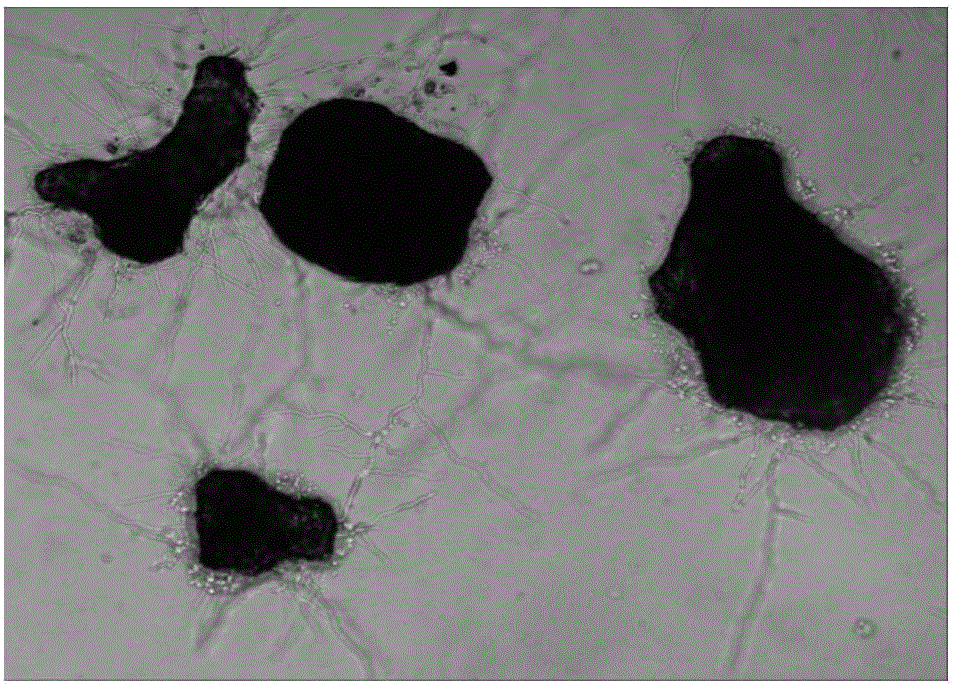

Fermentation method and applications of paecilomyce lilacinus microsclerotia

The invention discloses a fermentation method and applications of paecilomyce lilacinus microsclerotia. The fermentation method comprises the following steps: preparing paecilomyce lilacinus spore suspension; adding the paecilomyce lilacinu spore suspension into induction culture solution, and performing shake cultivation; and filtering the fermentation liquor to obtain microsclerotia precipitate. The generated microsclerotia can adapt to outside poor environments such as high temperature, drought, strong ultraviolet, and is stress-tolerant and storage-resistant, long in shelf life and capable of continuously controlling harm; the microsclerotia is short in fermentation period, low in production cost, and strong in technological controllability, and the raw materials can be easily available. The microsclerotia can be used as an active ingredient for preparing a novel insecticide fungus preparation.

Owner:CHONGQING UNIV

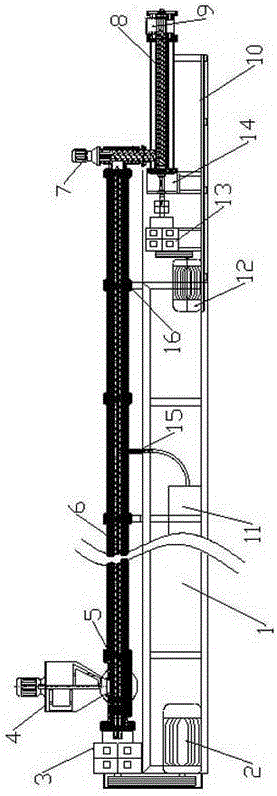

Environment-friendly desulfurization extruder of regenerated rubber

The invention discloses an environment-friendly desulfurization extruder of regenerated rubber. The environment-friendly desulfurization extruder comprises a base, an upper motor, an upper gearbox, a charging device, a double-screw feeding device, cylinder screws, a transitional conveying device, a double-screw cooling extruding device and a waste recovery device, wherein the upper motor and the upper gearbox are installed on the left side of the base, the double-screw feeding device is installed at the right end of the upper gearbox, the charging device is installed at the upper part of the double-screw feeding device, the multiple cylinder screws are installed on the right side of the double-screw feeding device, the transitional conveying device is installed at the right ends of the cylinder screws, the double-screw cooling extruding device is installed at the lower part of the transitional conveying device, and the waste recovery device is installed in the middle of the base and communicates with the interiors of the cylinder screws through pipelines. A distribution box, a lower gearbox and a lower motor are sequentially installed on the left side of the double-screw cooling extruding device, the distribution box, the lower gearbox, the lower motor and the double-screw cooling extruding device are installed on a sliding rail through supports, and the sliding rail is located on the base. According to the environment-friendly desulfurization extruder, dynamic installation is realized.

Owner:舟山富德斯机械有限公司

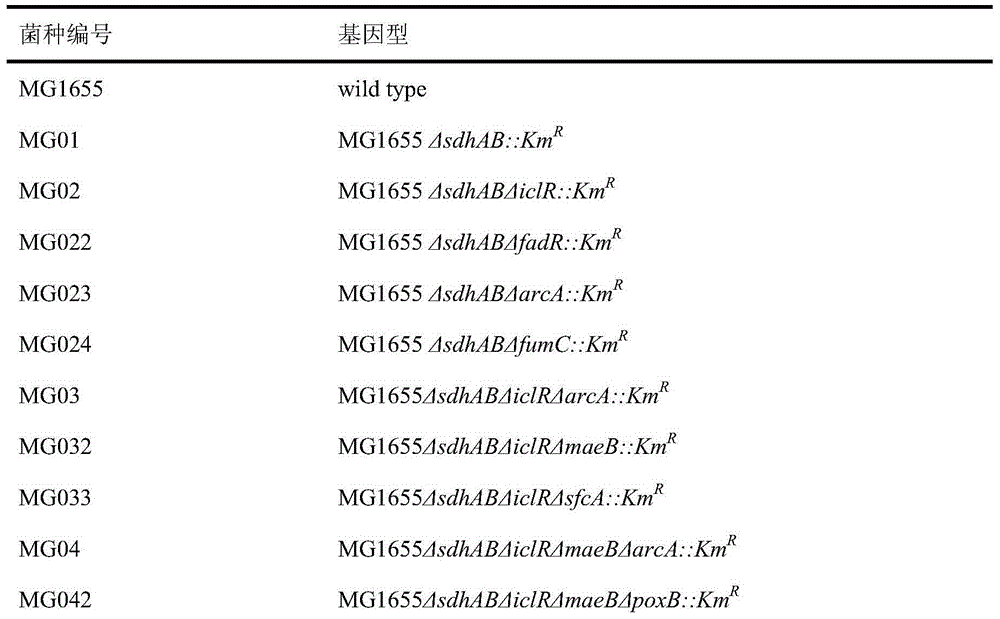

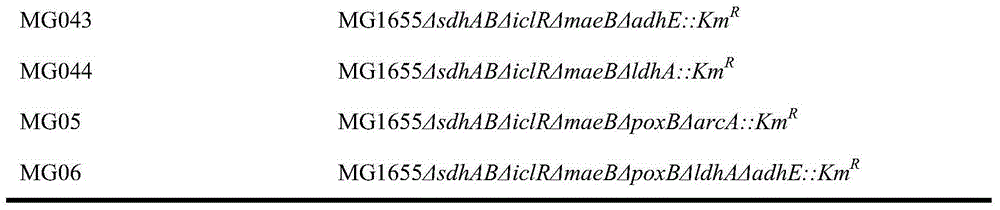

Construction method and applications of metabolic engineering escherichia coli strain for producing succinic acid by using acetic acid

The present invention discloses a construction method and applications of a metabolic engineering escherichia coli strain for producing succinic acid by using acetic acid, wherein escherichia coli transformed through metabolic engineering uses acetic acid as a raw material to perform fermented production of succinic acid, and the transformation pathway comprises: blocking TCA cycle, and / or blocking succinic acid utilization pathway, and / or enhancing acetic acid uptake and oxaloacetic acid supply, strengthening glyoxylic acid cycle, and / or deleting by-product generation pathway, and / or reducing futile cycle caused by acetic acid production using pyruvic acid decarboxylation, and / or dredging acetyl CoA node metabolic flow. According to the present invention, through the analysis on the metabolic pathway and the regulation, the escherichia coli is transformed by using the genetic engineering way, the obtained strain can produce succinic acid in the culture medium adopting acetic acid as the carbon source, and no by-product is generated.

Owner:EAST CHINA UNIV OF SCI & TECH

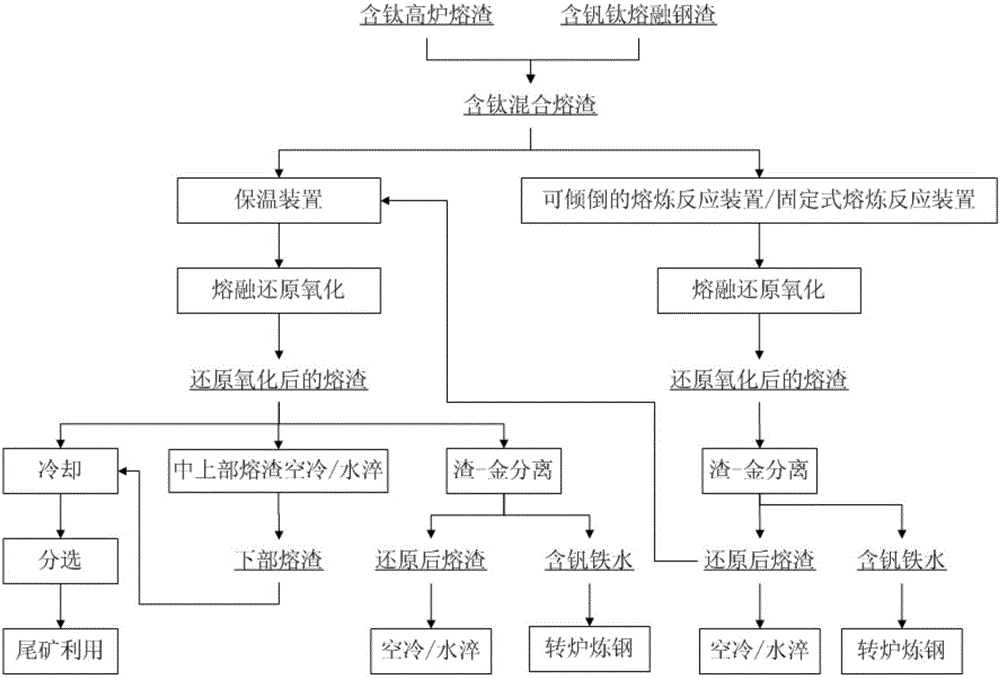

Method for smelting reduction, recycling and thermal refining of titaniferous mixed slag

ActiveCN106048108AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementThermal energySlag

The invention discloses a method for smelting reduction, recycling and thermal refining of titaniferous mixed slag. The method comprises the following steps: (1) mixing titaniferous blast furnace slag with vanadium-titanium-containing molten steel slag to form titaniferous mixed slag, and controlling the temperature of the titaniferous mixed slag within a set temperature range; (2) jetting oxidizing gas for smelting reduction and oxidization; during the process, the temperature of the titaniferous mixed slag is ensured to be within the set temperature range, and in the titaniferous mixed slag, low-valence titanium is oxidized into high-valence titanium, and iron oxide is reduced into metallic iron; and (3) carrying out separation and recycle according to different reaction devices. According to the invention, efficient recycle of the titanium component, iron component, vanadium component, phosphorus component and free calcium oxide component in the mixed slag is realized, and cold-state vanadium-titanium-iron-containing material can be treated to realize efficient comprehensive utilization of a resource; the reaction time is short, the metal recovery rate is high, the production cost is low, the raw material adaptability is high, the handing capacity is high, environment-friendliness is realized, the economic benefit is high, and the problem about efficient recycle of the metallurgy resource and thermal energy can be effectively solved.

Owner:NORTHEASTERN UNIV

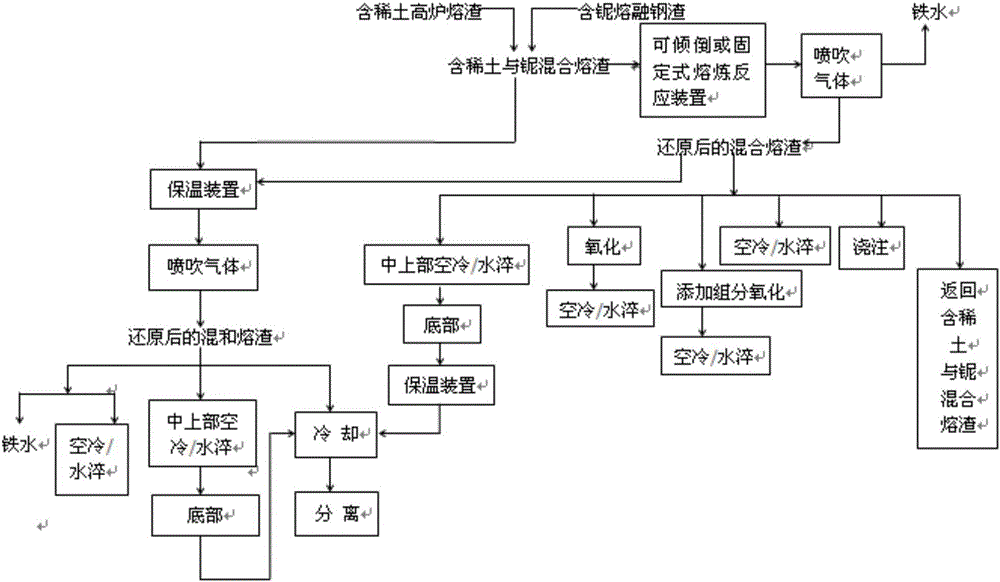

Smelting reduction recovery and thermal refining method for rare-earth-niobium-containing slag mixture

ActiveCN106048106AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementNiobiumSlag

The invention relates to a smelting reduction recovery and thermal refining method for a rare-earth-niobium-containing slag mixture and belongs to the field of non-blast furnace ironmaking and resource comprehensive utilization. The smelting reduction recovery and thermal refining method for the rare-earth-niobium-containing slag mixture comprises the following steps of (1) mixing rare-earth-containing blast furnace slag and niobium-containing molten steel slag to form the rare-earth-niobium-containing slag mixture and controlling the temperature of the rare-earth-niobium-containing slag mixture within a set temperature range; (2) injecting oxidative gas and conducting smelting reduction to reduce iron oxide into metallic iron fully; and (3) conducting separation and recovery according to different reaction devices. According to the method, the rare earth, the calcium component, the niobium component and the phosphorus component in the slag mixture can be efficiently recycled; cold-state niobium-rare-earth-iron-containing materials can be processed and at the same time thermal refining of the slag can be realized, so that the efficient resource comprehensive utilization can be achieved. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity, friendly with environment, high in economic income and capable of solving the problems of efficient recovery and utilization of metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

Environment-friendly slow-release polymer scale inhibitor and preparation method thereof

ActiveCN107304078ABiodegradableWon't happenWaste water treatment from quariesWater treatment compoundsOil fieldRelease time

The invention discloses an environment-friendly slow-release polymer scale inhibitor, which is good in scale inhibition and slow release effects. The dosage of the scale inhibitor which needs to be added within a maintenance cycle can be estimated in advance according to the actual production condition of an oil well; the scale inhibitor is put into a sieve tube at the lower end of an oil-well pump of the oil well in regular repair and maintenance processes of an oil-well pipeline and a gathering pipeline; scale inhibition components are slowly dissolved and released to achieve the long-term scale inhibition effect through one-off addition when a produced liquid flows through the sieve tube, so that the long-term effective concentration can be maintained, the scale inhibiting ratio within the effective service cycle (about 90-120d) is greater than 85%, the effective release time can reach 90d or over, the protection period on the pipeline is long, and the production and maintenance cost of an oil field can be effectively reduced. The environment-friendly slow-release polymer scale inhibitor is nontoxic, harmless and degradable, and does not harm the formation and surrounding environment, and is environmentally friendly and suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Method for extracting indium and tin from waste ITO targets through reduction and electrolysis

ActiveCN104711426AImprove conversion rateImprove overall recoveryPhotography auxillary processesIndiumElectrolysis

The invention provides a method for extracting indium and tin from waste ITO targets through reduction and electrolysis. According to the method, waste ITO targets having undergone crushing and ball milling are reduced in a reducing furnace through reducible substances, and indium oxide and tin oxide are respectively reduced into metallic indium and metallic tin; an indium tin alloy anode is casted under the protection of alkali; and electrolysis is carried out under alkaline conditions so as to realize electrodeposition of tin onto a cathode and recovery of refined tin, anode mud is indium hydroxide, and refined indium is extracted from indium hydroxide through leaching, purifying and electrodeposition. The method provided by the invention has simple process flow, a short cycling period and high recovery rates of indium and tin and overcomes the problem of difficult filtering of indium hydroxide at the same time, so the method has the obvious advantages of low recovery cost, energy conservation, environmental protection, etc. In industrial production, the recovery rate of tin reaches 98.5%, the recovery rate of indium is more than 99%, and the grades of refined indium and refined tin exceed 99.995%.

Owner:ZHUZHOU SMELTER GRP

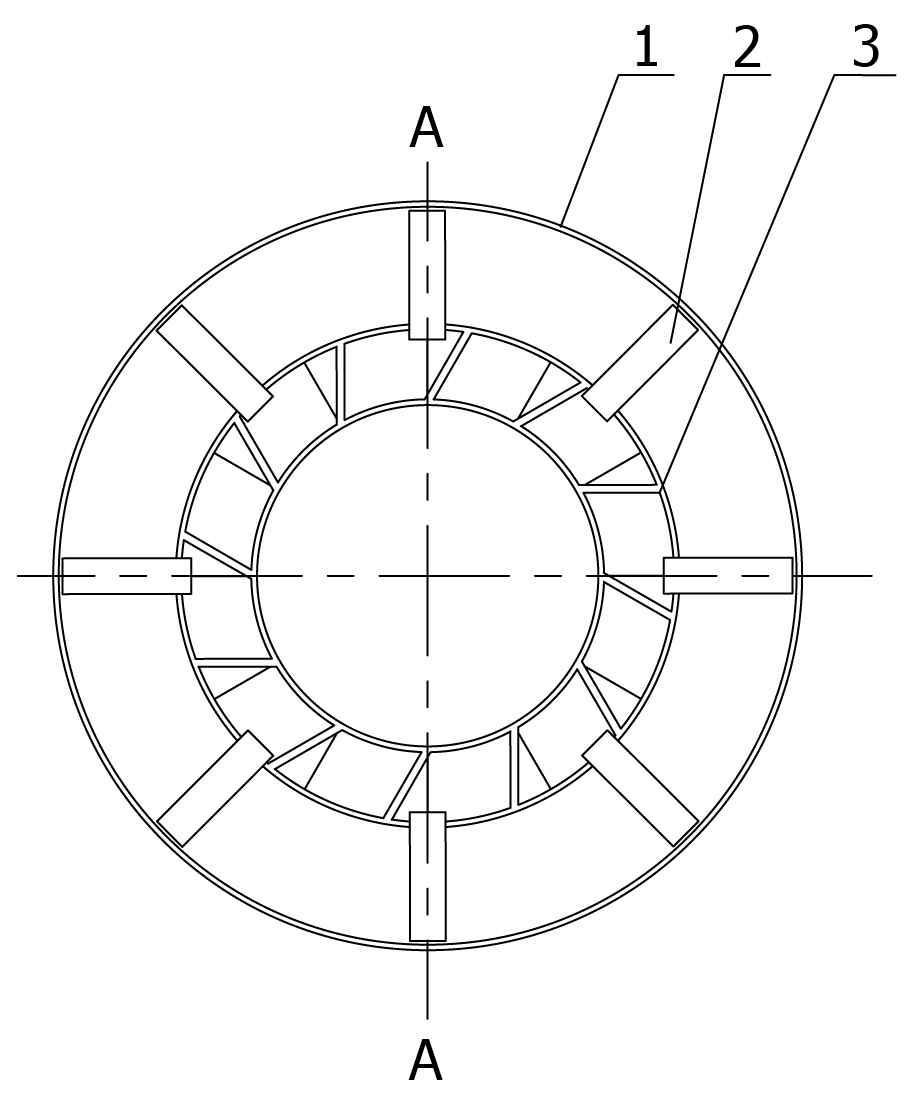

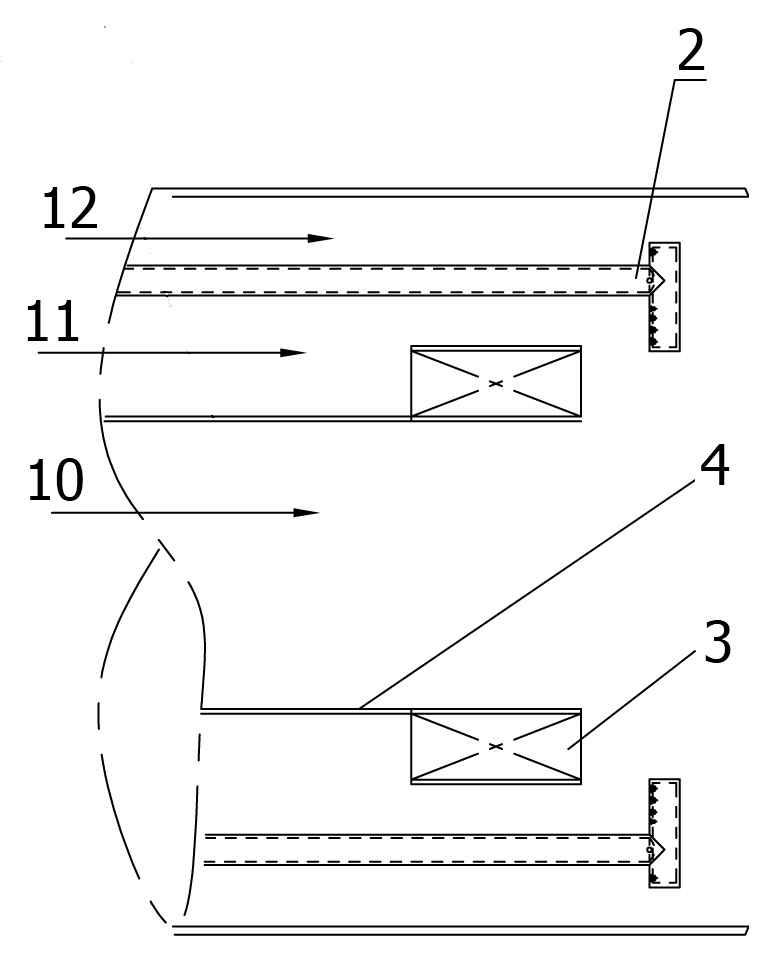

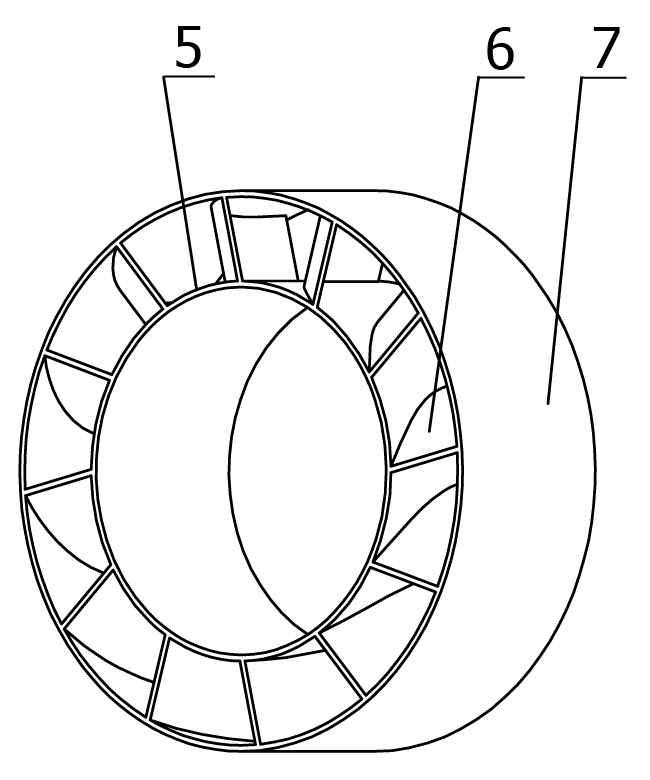

Gas back-jetting pre-mixing low-NOx combustion apparatus and combustion method of combustion apparatus

The invention discloses a gas back-jetting pre-mixing low-NOx combustion apparatus and a combustion method of the combustion apparatus, which belongs to the technical field of a high-power industrial combustor. The combustion apparatus is characterized in that: a centre cylinder is axially arranged at a throat opening centre; the end part of the centre cylinder is connected with a whirlcone which is coaxially arranged; an inner diameter and an outer diameter of the centre cylinder are consistent with the inner diameter and the outer diameter of an inner ring of the whirlcone; a peripheral axial wind channel is arranged between the periphery of the outer ring of the whirlcone and the inner wall of a throat opening; back-jetting hammer gas guns are radically distributed on the throat opening. The combustion method of the combustion apparatus is characterized in that: the gas is divided into two parts, namely the gas which is jet from a straight back-jetting hole, is backwards jet in an axial direction and rushes with axial wind at the periphery oppositely, and gas which is jet from an inclined back-jetting hole and rushes tangentially with swirl wind, after the gas enters the channel from a combustible gas hammer-type gas gun. The gas back-jetting pre-mixing low-NOx combustion apparatus disclosed by the invention has the beneficial effects that: the gas and the air are jet and oppositely rushed to be fully and uniformly mixed, so that a little of NOx smaller than 29ppm is generated without generation of CO (carbonic oxide). The combustion is stable and reliable, and the highest power of a single machine can be up to over 70MW.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

Process method for extracting indium and tin from indium tin oxide (ITO) waste target

InactiveCN109957655AImprove conversion rateImprove overall recoveryPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a process method for extracting indium and tin from an indium tin oxide (ITO) waste target. The ITO waste target is crushed and ball-milled using a reducing substance, indiumoxide and tin oxide are reduced to the indium and the tin in a reduction furnace correspondingly, the indium and tin are cast into an indium-tin alloy anode under the protective effect of alkali, electrolysis is conducted under alkaline conditions, the tin is electro-deposited to a cathode and purity tin is recycled, anode slime is indium hydroxide, and the indium hydroxide is extracted through the processes of leaching, purification and electrodeposition. The process method for extracting the indium and the tin from the ITO waste target has the advantages of simple technological process, short recycling cycle and high indium and tin recovery rate, meanwhile, the problem of difficult filtration of tin hydroxide is solved, and thus the obvious advantages of low recycling cost, energy savingand environmental protection, and the like are achieved; and in industrial production, the recovery rate of the tin reaches 98.5%, the recovery rate of the indium is 99% or above, and the grade of purity indium and the purity tin exceeds 99.995%.

Owner:ZHUZHOU SMELTER GRP +1

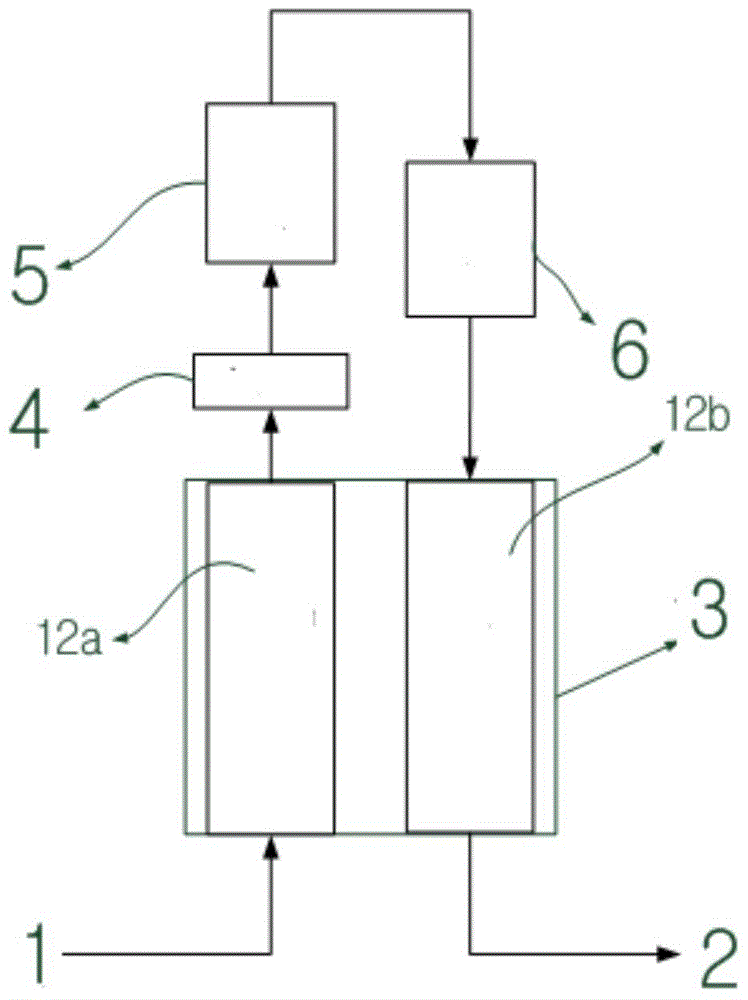

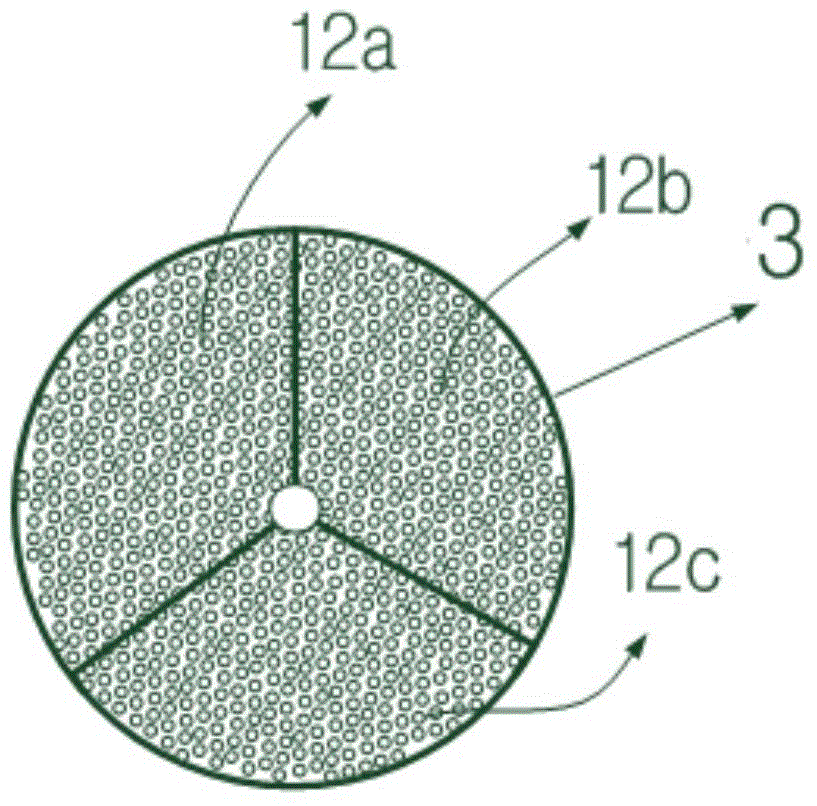

Heat exchange method for low-temperature heat accumulating type catalytic oxidation treatment device

ActiveCN105066149AHigh processing indexImprove securityIncinerator apparatusCatalytic oxidationEngineering

The invention relates to a heat exchange method for a low-temperature heat accumulating type catalytic oxidation treatment device. The problems that in the prior art, serious potential safety hazards exist, ignition temperature is high, and energy consumption is large are mainly solved. The heat exchange method for the low-temperature heat accumulating type catalytic oxidation treatment device is adopted, VOCs gas with the concentration lower than 25% of an explosion limit enters a cold stroke of a rotary type honeycomb ceramic heat accumulator, and then enters a heating chamber to be heated; heated gas enters a low-temperature catalytic oxidation bed to be in contact with nano-silver or nano-silver / manganese oxide / cerium oxide loaded honeycomb ceramic catalysts, and then gas enters a high-temperature catalytic oxidation bed to be in contact with a Pt or Pd loaded noble metal catalyst; and after heat is released, gas enters a hot stroke of the rotary type honeycomb ceramic heat accumulator to be subjected to further high-temperature combustion in the rotary type honeycomb ceramic heat accumulator, and the treatment efficiency of above 99% is achieved. According to the technical scheme, the problems are solved well, and the method can be used for the low-temperature heat accumulating type catalytic oxidation treatment device.

Owner:CHINA PETROLEUM & CHEM CORP +1

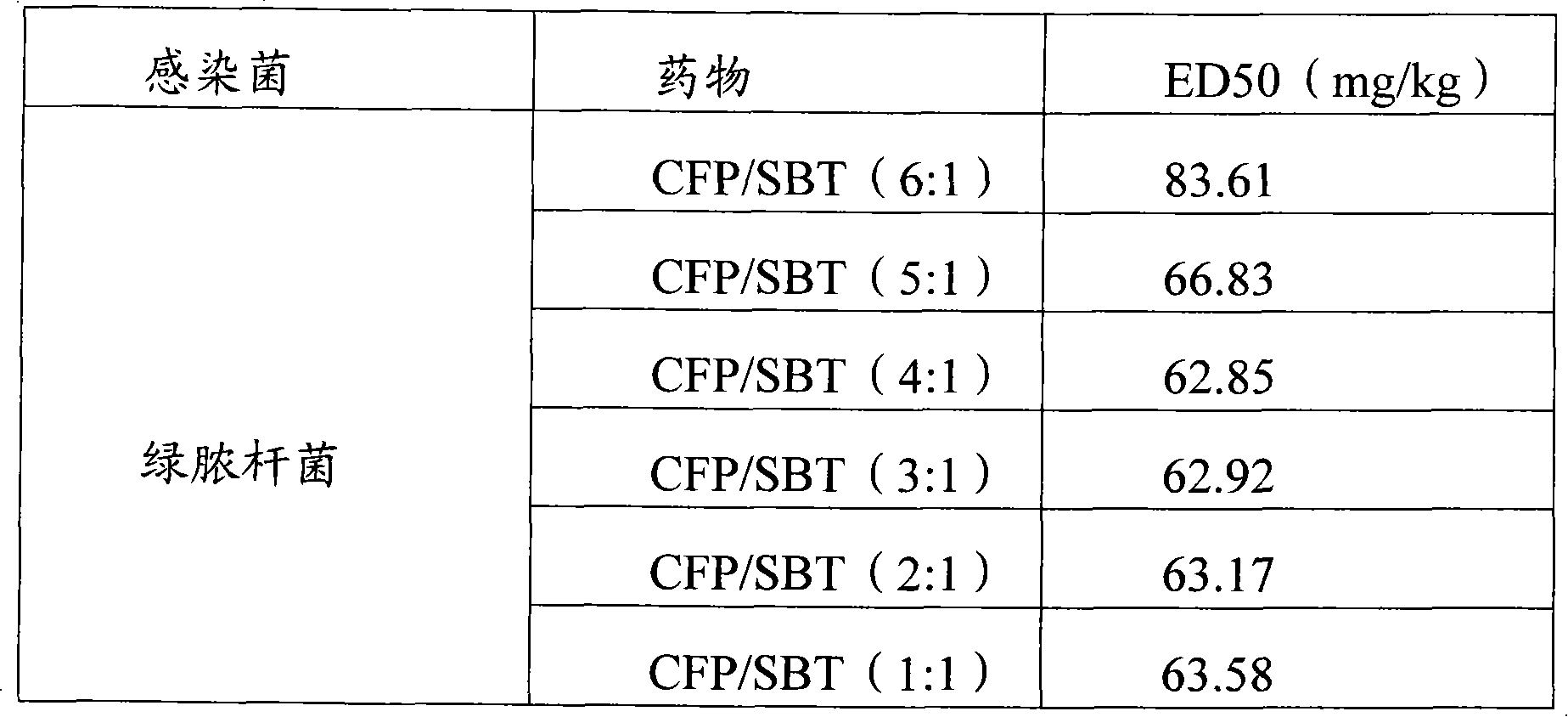

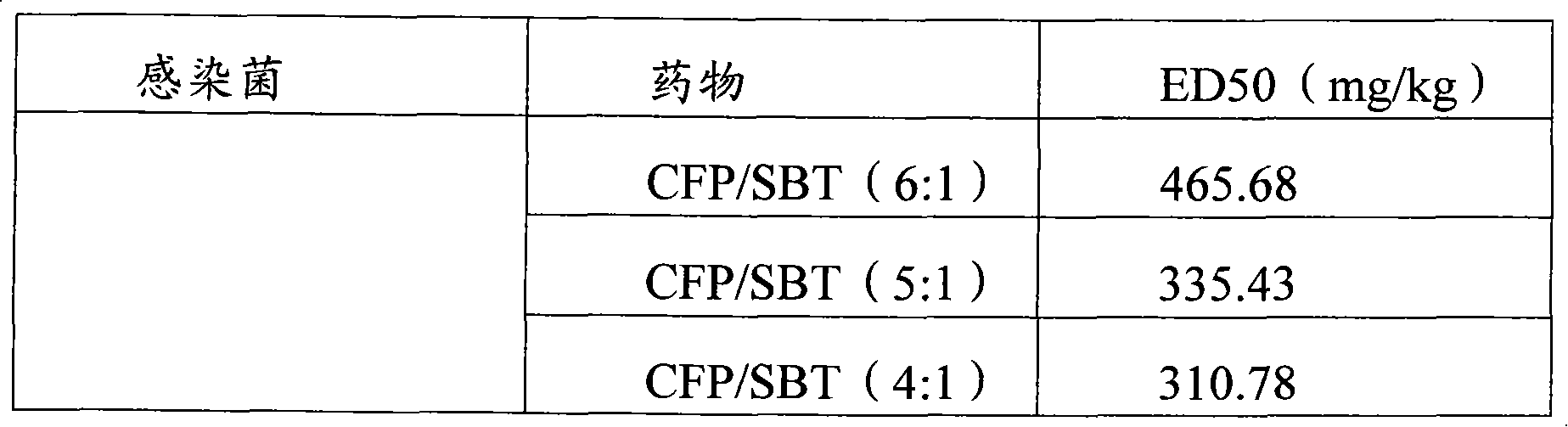

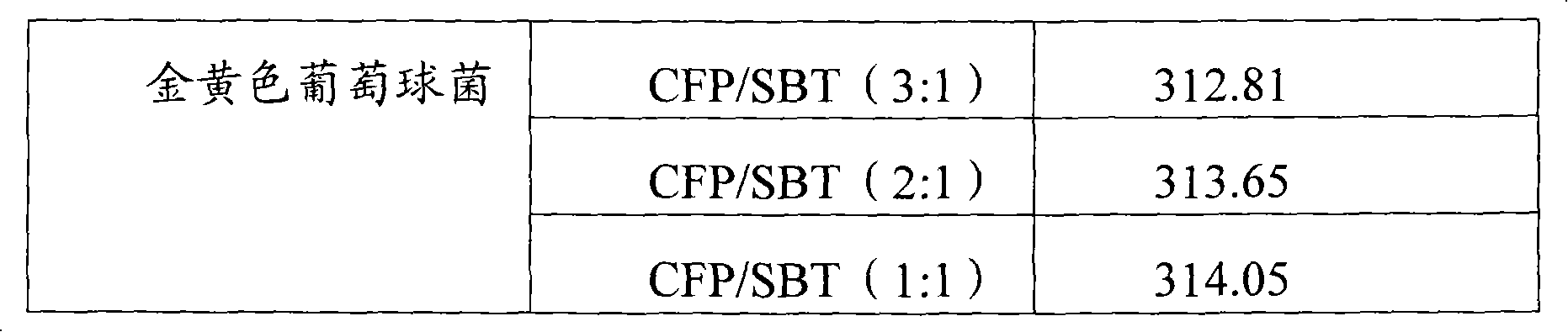

Infection contamination resistance pharmaceutical combination containing optimum proportioning cefoperazone natrium and sulbactam sodium and method of preparing the same

InactiveCN101249092AGuaranteed curative effectImprove securityAntiinfectivesHeterocyclic compound active ingredientsDrugSulbactam Sodium

The invention relates to an anti-infective pharmaceutical composition comprising cefoperazone sodium and sulbactam sodium in optimal proportion. In the pharmaceutical composition, the weight ratio of the cefoperazone sodium and the sulbactam sodium is (2-4):1, preferably 4:1. The pharmaceutical composition with the weight ratio is excellent in antibacterial activity to drugs containing equal amounts (1:1) of cefoperazone sodium and sulbactam sodium in clinic. The dosage of sulbactam sodium in the inventive pharmaceutical composition is reduced by more than two times than the existing similar drugs, which improves safety of kidney and reduces production cost. The raw materials used in the invention meet the standards of Chinese Pharmacopoeia. Therefore, the pharmaceutical composition has good quality, safety and stability.

Owner:黄芝芳

Culture method and application of isaria microsclerotia

ActiveCN105695344AGood insecticidal activityShort fermentation cycleBiocideFungiSclerotiumControllability

The invention discloses a culture method and application of isaria microsclerotia. A fermentation method comprises the steps of (1) preparing an isaria spore inoculant; (2) carrying out induction culture on microsclerotia: adding the isaria spore inoculant prepared in the step 1 into an induction culture solution, and carrying out shake cultivation for 6-8 days; (3) filtering fermentation liquor, removing supernatant to obtain microsclerotia precipitate, drying and storing. The invention also discloses the application of the isaria microsclerotia in control of whitefly pests and a biocontrol agent used for controlling the whitefly pests. The isaria microsclerotia produced by the invention is capable of adapting external bad environments such as high temperature, drought, strong ultraviolet and the like, and has the characteristics of stress tolerance, storage stability, long shelf life and continuous pest control; the isaria microsclerotia is short in fermentation period, low in production cost, high in technology controllability and easy in raw material obtaining. The isaria microsclerotia can be used for preparing active ingredients of a novel insecticidal fungus preparation.

Owner:CHONGQING UNIV

Comprehensive utilization method of hydrargillite-produced 4A zeolite waste residue

InactiveCN102167351AWell sourcedRealize comprehensive utilizationInorganic/elemental detergent compounding agentsAluminosilicate zeolite type-AAluminium chlorohydrateSynthesis methods

The invention provides a comprehensive utilization method of hydrargillite-produced 4A zeolite waste residue. The method comprises the steps of: separating the ferrosilicoaluminum component in the hydrargillite-produced 4A zeolite waste residue by means of acid leaching and filtering, wherein the obtained mixed liquor of filter liquor and filter residue washing liquor is used for preparing a polymeric aluminum ferric chloride water purifying agent; and removing iron from the wet slag obtained by washing the filter residue by means of alkali fusing, roasting and activating, and synthesizing the 4A zeolite by a hydrothermal method by means of adjusting and assembling. Triethanolamine is taken as a complexing agent of the microelement iron in the liquor during synthesizing the 4A zeolite, so that the produce of an iron precipitate is overcome, and the whiteness of a 4A zeolite product is guaranteed; sodium sulfide is reacted with a triethanolamine iron complex in the zeolite-synthesized mother liquor to reduce the triethanolamine and obtain an iron sulfide precipitate; and removing the mother liquor of the iron sulfide precipitate to realize the cycle utilization. The synthesis method of the 4A zeolite adopts a sealed cycle technology, thereby being stable in operation, and free of the generation of new waste liquor and new waste slag.

Owner:HEBEI UNIV OF TECH

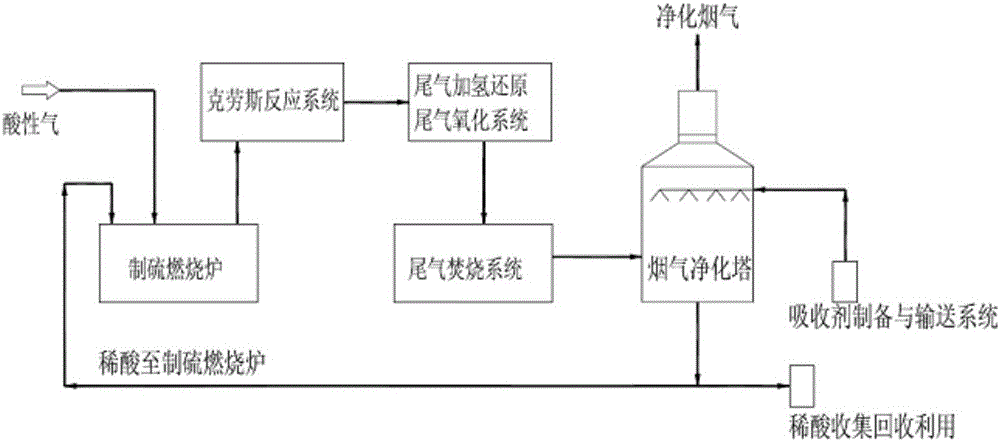

SWSR (Sunway Sulfur Recovery)-7 technology and SWSR-7 device

ActiveCN105692563AHigh recovery rateReduce sulfur dioxide contentChemical industrySulfur preparation/purificationCombustionFlue gas

The invention belongs to the technical field of sulfur recovery and tail gas treatment, in particular relates to an SWSR (Sunway Sulfur Recovery)-7 technology and an SWSR-7 device. The SWSR-7 technology comprises the following steps of (1) generating sulfur and sulfur-making tail gas through a sulfur-making combustion furnace and a Claus reaction system by an acid gas containing hydrogen sulfide, and recovering and feeding the sulfur into a liquid sulfur storage facility; (2) mixing the sulfur-making tail gas with air after enabling the sulfur-making tail gas to pass through or not pass through a tail gas hydrogenation reduction or oxidation system, feeding the mixed gas into a tail gas incineration system for being incinerated, converting all sulfur-containing media into SO2, forming SO2 flue gas, and then enabling heat energy to enter a flue gas purifying tower through recovery; (3) enabling SO2-containing flue gas to be in contact with an absorbent, i.e. hydrogen peroxide, in the flue gas purifying tower, absorbing the SO2 in the SO2-containing flue gas by the absorbent, circulating the absorbent, enabling the absorbent to enter the tower bottom, and feeding purified flue gas having no SO2 into a chimney for being discharged; (4) a system for preparing and conveying the absorbent. According to the SWSR-7 technology disclosed by the invention, the technological process is safe and reliable, and the content of the SO2 in discharged gas can be reduced to below 50 mg / Nm<3> and can meet the requirements regulated by the nation.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

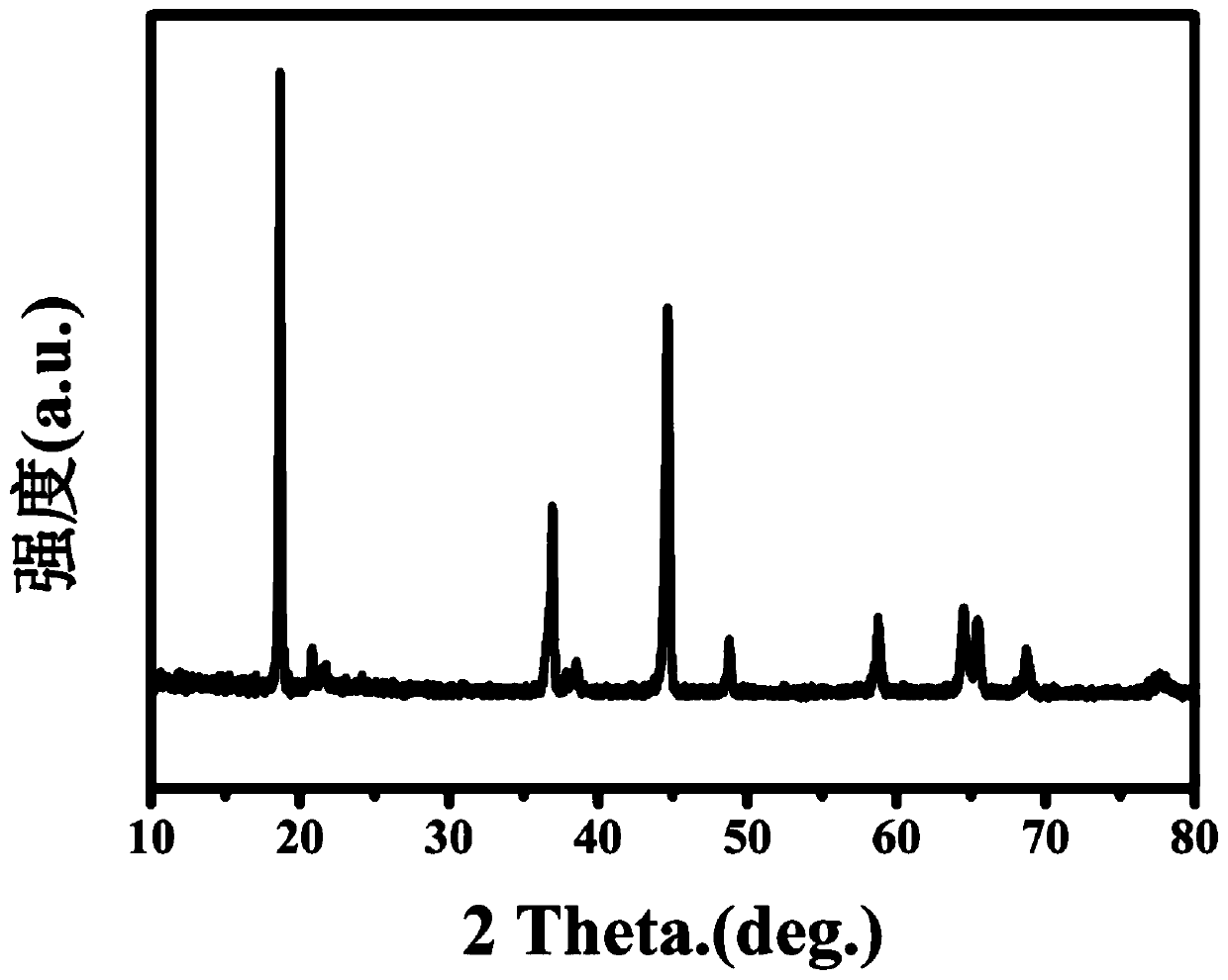

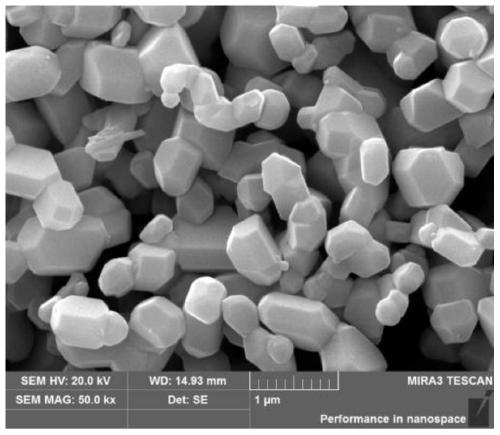

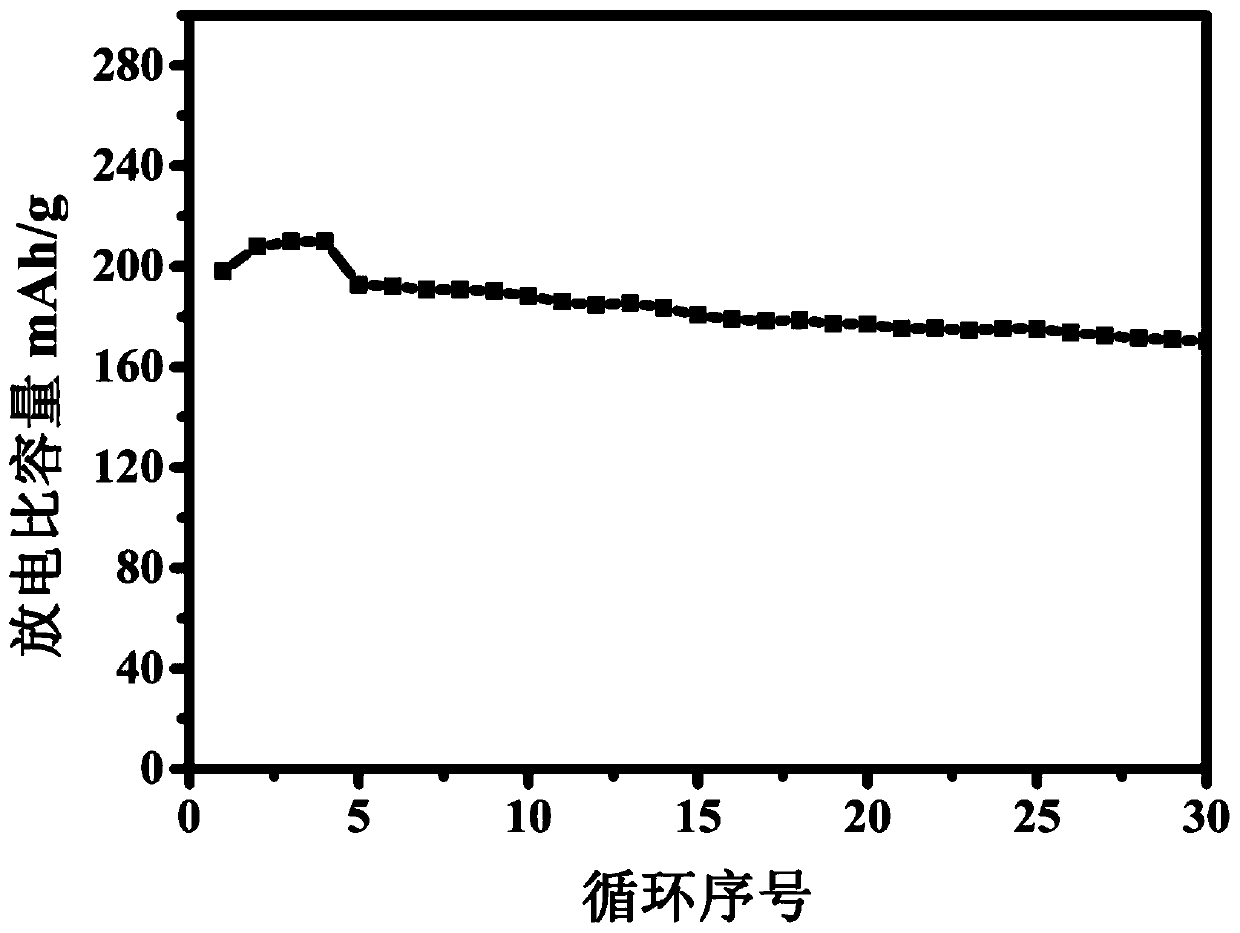

Method for regenerating lithium-rich manganese-based positive electrode material by utilizing waste lithium battery

ActiveCN111082178AAvoid stepwise separation and recyclingIncrease valueCell electrodesWaste accumulators reclaimingLithium carbonatePhysical chemistry

The invention discloses a method for regenerating a lithium-rich manganese-based positive electrode material from a waste lithium battery. The method comprises the steps of carrying out carbon thermalreduction on positive electrode material powder obtained by pretreatment, reducing the waste ternary nickel-cobalt-manganese positive electrode material into a mixture of nickel, cobalt, lithium carbonate and manganese oxide by carbon thermal reduction, carrying out ammonia leaching, then preparing a precursor by a one-step sol-gel method, and finally, calcining to obtain the lithium-rich manganese-based positive electrode material. According to the method, the valuable metal mixed powder is subjected to carbon thermal reduction, so that the process requirement that pressurization must be adopted in the leaching process is avoided, step-by-step separation and recovery of multiple metals are avoided, the technological process is shortened, the operation is easy, the cost is reduced, and the value of recovered and regenerated products is improved.

Owner:兰溪博观循环科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com