SWSR (Sunway Sulfur Recovery)-7 technology and SWSR-7 device

A sulfur recovery and process technology, applied in the fields of sulfur compounds, chemical industry, sulfur preparation/purification, etc., can solve the problems that the sulfur recovery effect cannot meet the environmental protection requirements, high safety control requirements, and long process flow, etc., to meet the requirements of sustainable safety The effect of operation, process safety and reliability, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

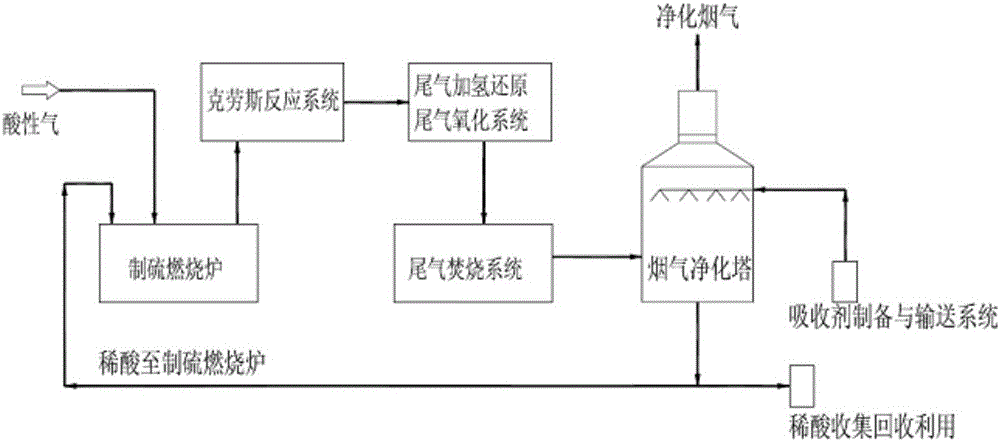

[0041] A SWSR-7 sulfur recovery process, comprising the following steps:

[0042] ① The acid gas containing hydrogen sulfide is generated through the sulfur combustion furnace and the Claus reaction system to generate sulfur and sulfur tail gas, and the sulfur is recovered and sent to the liquid sulfur storage facility;

[0043] ② The tail gas from sulfur production is mixed with air and sent to the tail gas incineration system for incineration, and all sulfur-containing media are converted into SO 2 , forming SO 2 Flue gas, the temperature of the flue gas is 180°C, and the content of sulfur dioxide is about 12000mg / Nm 3 , and then enter the flue gas purification tower through recovered heat energy;

[0044] ③ Contains SO2 The flue gas contacts with absorbent 3wt.% hydrogen peroxide solution in the flue gas purification tower, the SO in the flue gas 2 It is absorbed by the absorbent, and the recycled absorbent enters the bottom of the tower to remove SO 2 The purified flue...

Embodiment 2

[0053] A SWSR-7 sulfur recovery process, comprising the following steps:

[0054] ① The acid gas containing hydrogen sulfide is generated through the sulfur combustion furnace and the Claus reaction system to generate sulfur and sulfur tail gas, and the sulfur is recovered and sent to the liquid sulfur storage facility;

[0055] ② After the sulfur production tail gas passes through the tail gas hydrogenation reduction system, it is mixed with air and sent to the tail gas incineration system for incineration, and all sulfur-containing media are converted into SO 2 , forming SO 2 Flue gas, flue gas temperature 270°C, sulfur dioxide content 600mg / Nm 3 , and then enter the flue gas purification tower through recovered heat energy;

[0056] ③ Contains SO 2 The flue gas contacts with absorbent 2.5wt.% hydrogen peroxide solution in the flue gas purification tower, the SO in the flue gas 2 It is absorbed by the absorbent, and the recycled absorbent enters the bottom of the tower t...

Embodiment 3

[0065] A SWSR-7 sulfur recovery process, comprising the following steps:

[0066] ① The acid gas containing hydrogen sulfide is generated through the sulfur combustion furnace and the Claus reaction system to generate sulfur and sulfur tail gas, and the sulfur is recovered and sent to the liquid sulfur storage facility;

[0067] ② After the sulfur production tail gas passes through the oxidation system, it is mixed with air and sent to the tail gas incineration system for incineration, and all sulfur-containing media are converted into SO 2 , forming SO 2 Flue gas, flue gas temperature 270°C, sulfur dioxide content 410mg / Nm 3 , and then enter the flue gas purification tower through recovered heat energy;

[0068] ③ Contains SO 2 The flue gas contacts with absorbent 2.5wt.% hydrogen peroxide solution in the flue gas purification tower, the SO in the flue gas 2 It is absorbed by the absorbent, and the recycled absorbent enters the bottom of the tower to remove SO 2 The puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com