Gas back-jetting pre-mixing low-NOx combustion apparatus and combustion method of combustion apparatus

A combustion device, gas technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve problems such as explosion, burner backfire, hindering technology development and application, etc., achieve uniform temperature, improve boiler efficiency, and avoid flames The effect of the temperature peak region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

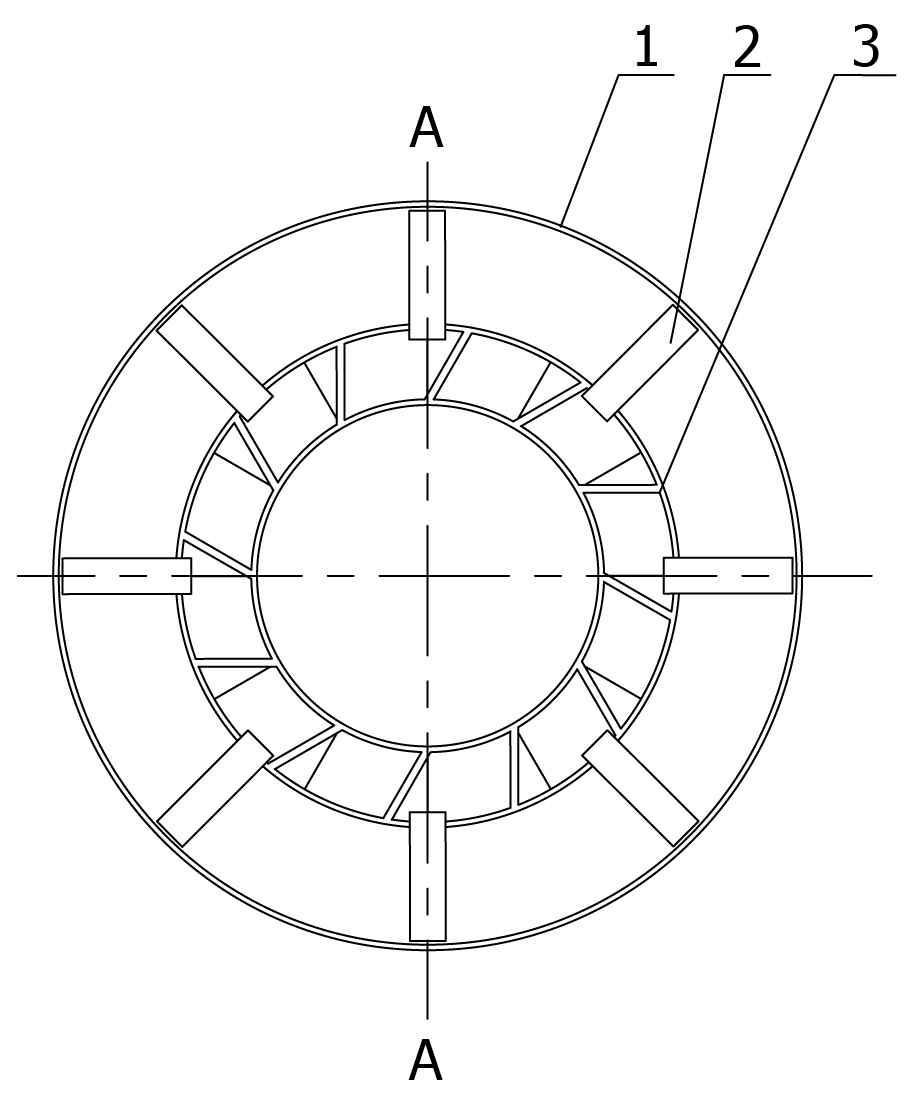

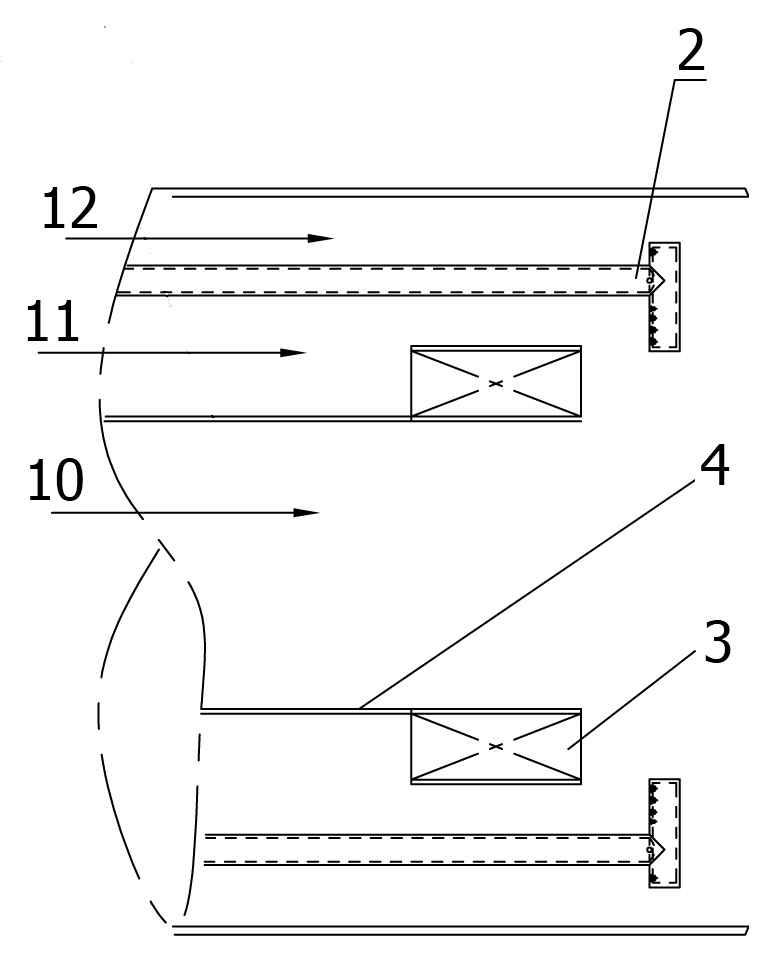

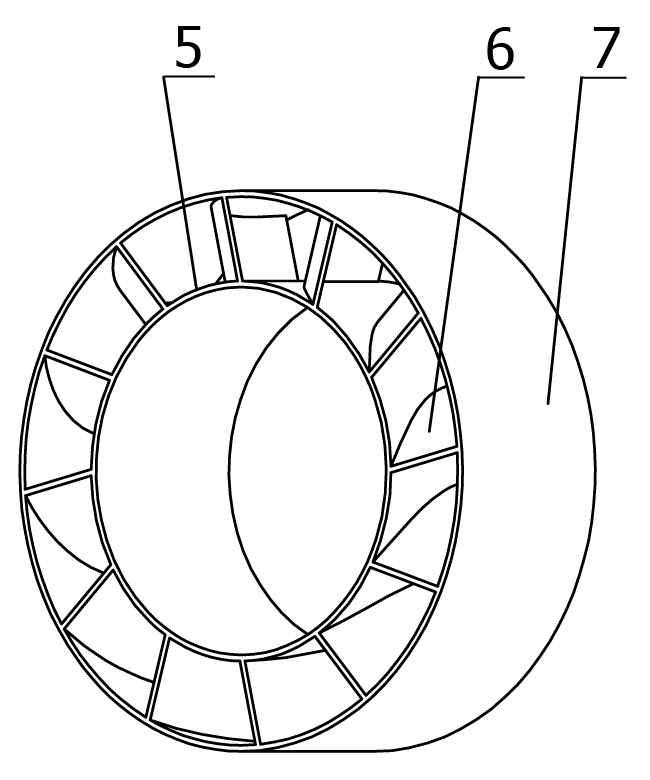

[0018] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A-A sectional structural schematic diagram of A-A, as shown in the figure, a gas back-injection premixed low NOx combustion device, including a swirler 3, a back-injection hammer gas gun 2, and a combustion device throat 1, is characterized in that In the center of the throat 1, a center tube 4 is arranged axially, the end of the center tube 4 is connected to the coaxial cyclone 3, and the inner and outer diameters of the center tube 4 are in line with the inner diameter of the cyclone. The inner and outer diameters of the ring 5 are consistent, and there is a peripheral axial flow air passage 12 between the periphery of the outer ring of the cyclone 3 and the inner wall of the throat 1, and the radial direction of the throat 1 is arranged with back-spray hammers. Type gas gun 2.

[0019] As shown in the figure, the middle cylinder 4 is in the middle of the burner, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com