Patents

Literature

36 results about "Bismuth lead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling bismuth in bullion lead

ActiveCN104141057AImprove direct yieldSave capacityPhotography auxillary processesProcess efficiency improvementElectrolysisAdditive ingredient

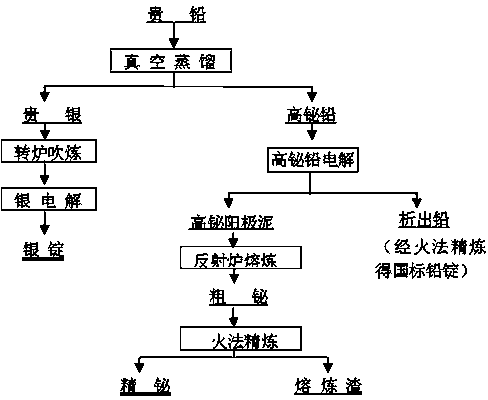

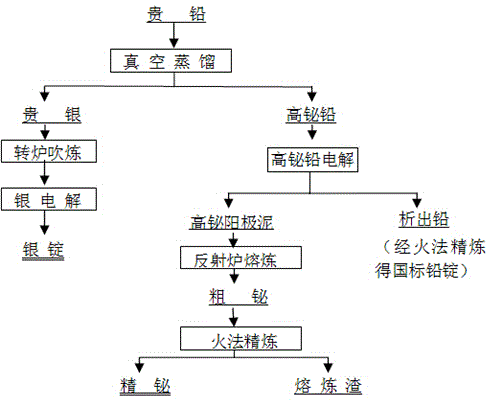

The invention relates to a method for recycling bismuth in bullion lead, and belongs to the field of the metallurgical technology combining a pyrogenic process with a wet process. The bullion lead is placed in a vacuum furnace first, vacuum distillation is carried out to separate lead, antimony, bismuth and copper, primary high bismuth lead and silver are produced, the produced primary high bismuth lead is placed in the vacuum furnace, vacuum distillation is conducted again to separate lead, antimony, bismuth and copper under control of the previous condition, and secondary high bismuth lead and residual silver are produced; the obtained secondary high bismuth lead and lead bullion ingredients are thrown into an anode pot to be cast into a bismuth anode plate, the bismuth anode plate is put into an electrolytic bath, mixed electrolytic refining is conducted on the bismuth anode plate together with the main process of lead electrolysis, and dissolved-out lead and washed high bismuth anode slime are obtained; the obtained high bismuth anode slime is subjected to reduction smelting and converting to produce crude bismuth; fire refining is carried out on the obtained crude bismuth, sulphur is added to the crude bismuth to remove copper, the crude bismuth is oxidized to remove arsenic and antimony, chlorine gas is led to the crude bismuth to remove lead, zinc is added to the crude bismuth to remove silver, finally caustic soda and saltpeter are added for refining, and a bismuth ingot product meeting national standards is produced. The technological process of the method is refined and simple.

Owner:蒙自矿冶有限责任公司

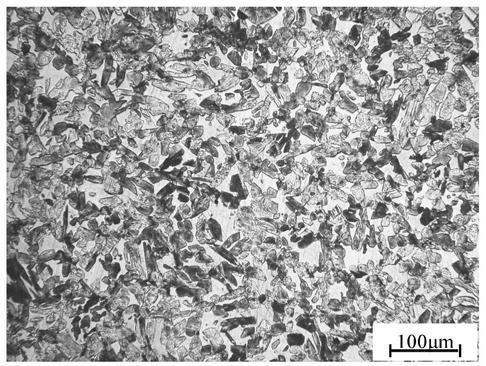

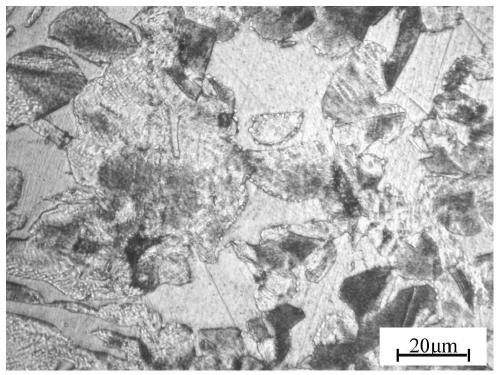

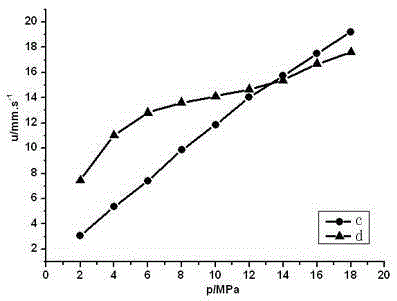

Magnesium titanate bismuth-lead titanate piezoelectric ceramics suitable for high-temperature field

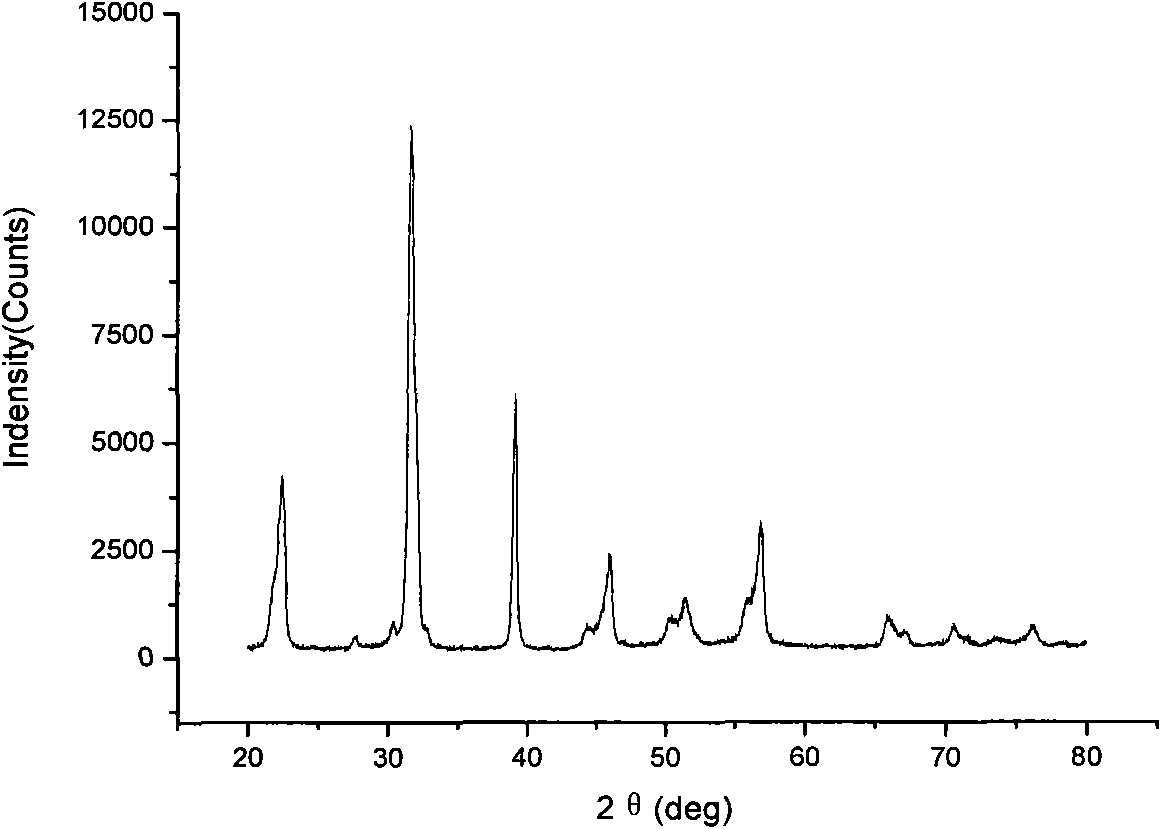

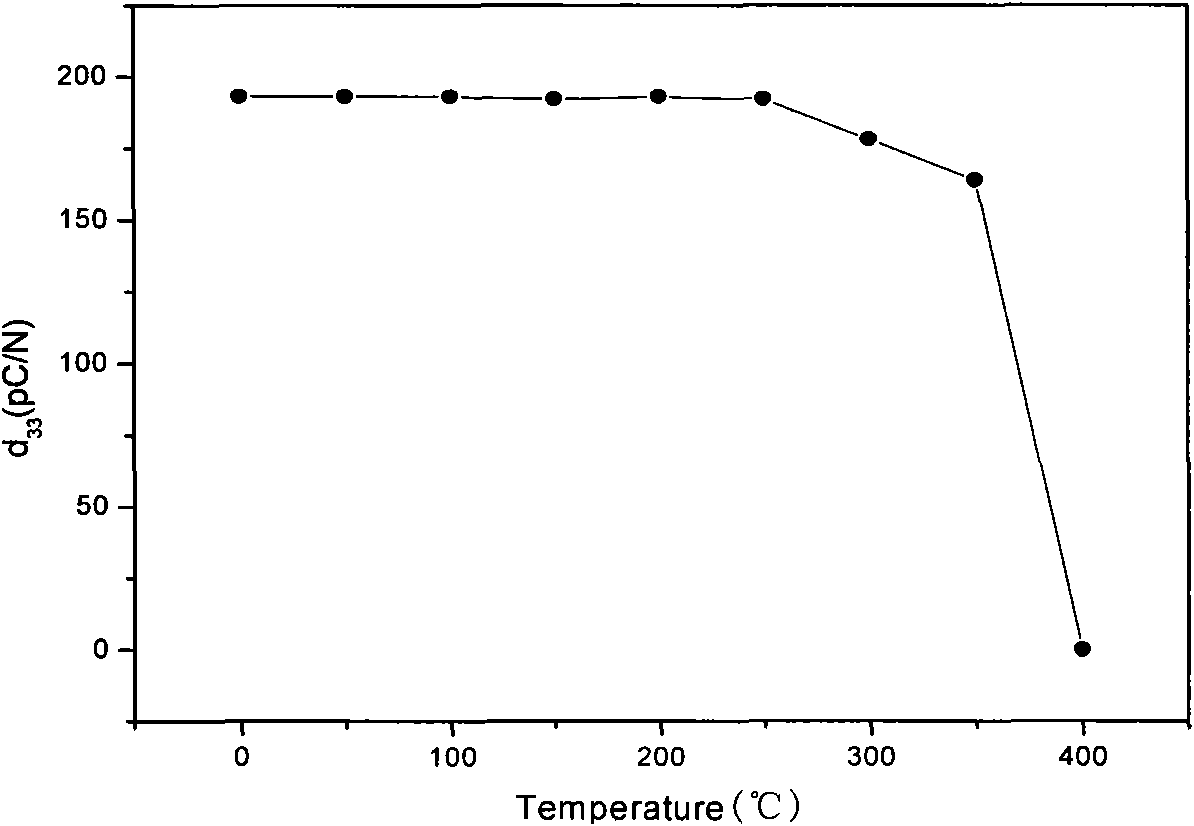

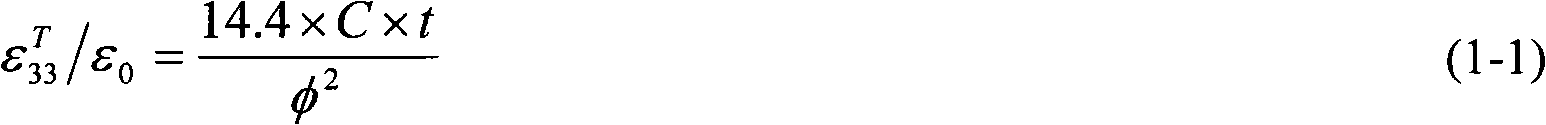

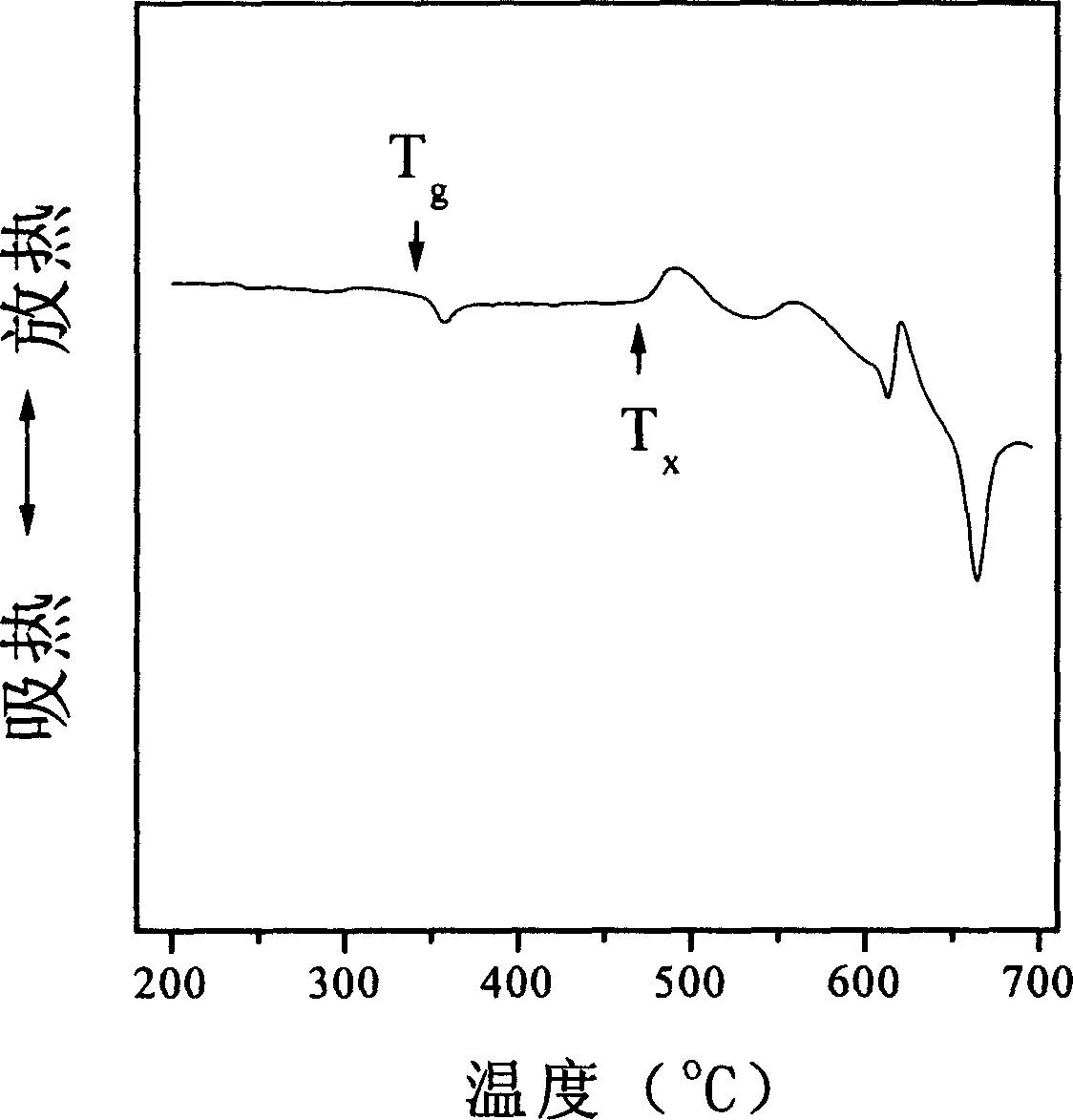

The invention discloses a magnesium titanate bismuth-lead titanate piezoelectric ceramics suitable for a high-temperature field, belonging to perovskite structure piezoelectric ceramics. The invention can be represented by the general formula: (1-x)Bi(Mg1 / 2Ti1 / 2)O3-xPbTiO3+alphaMnO2(mol%), wherein x=0.32-0.42, x represents the molar percent of PbTiO3, alpha=0-2 mol%, and the alpha is the molar percent for MnO2 to account for the raw material total amount; MnO2 is a doped metallic oxide and can lower the loss factor of the piezoelectric ceramics. The piezoelectric ceramics is prepared by the traditional piezoelectric ceramics preparation technology, lead tolerance is lower than 42 mol%; d33 can be kept at 170 pC / N at the temperature of 350 DEG C; and after MnO2 is doped, Curie temperature Tc can be 520 DEG C, d33 is 120 pC / N, and the loss factor tan delta is lowered to 0.018. The invention has huge high-temperature application potential and practical application value.

Owner:TIANJIN UNIV

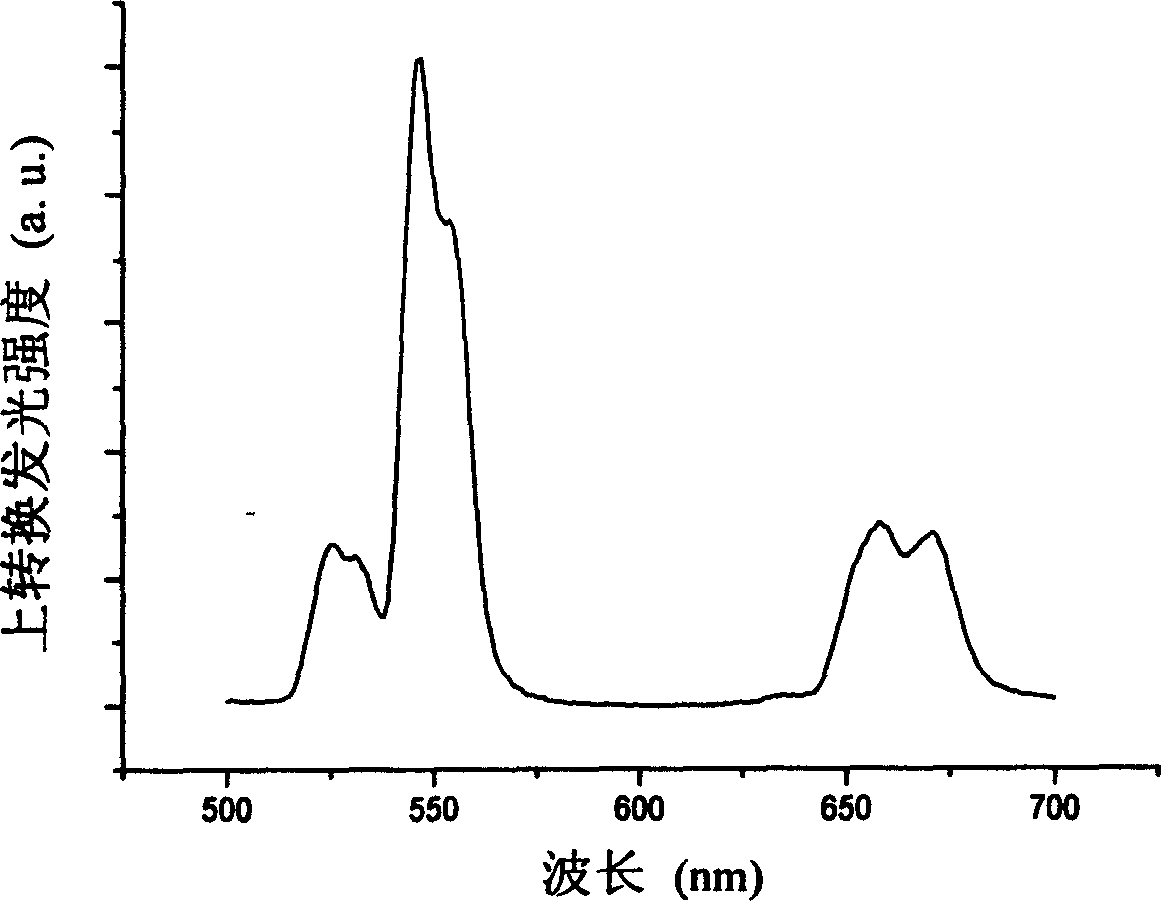

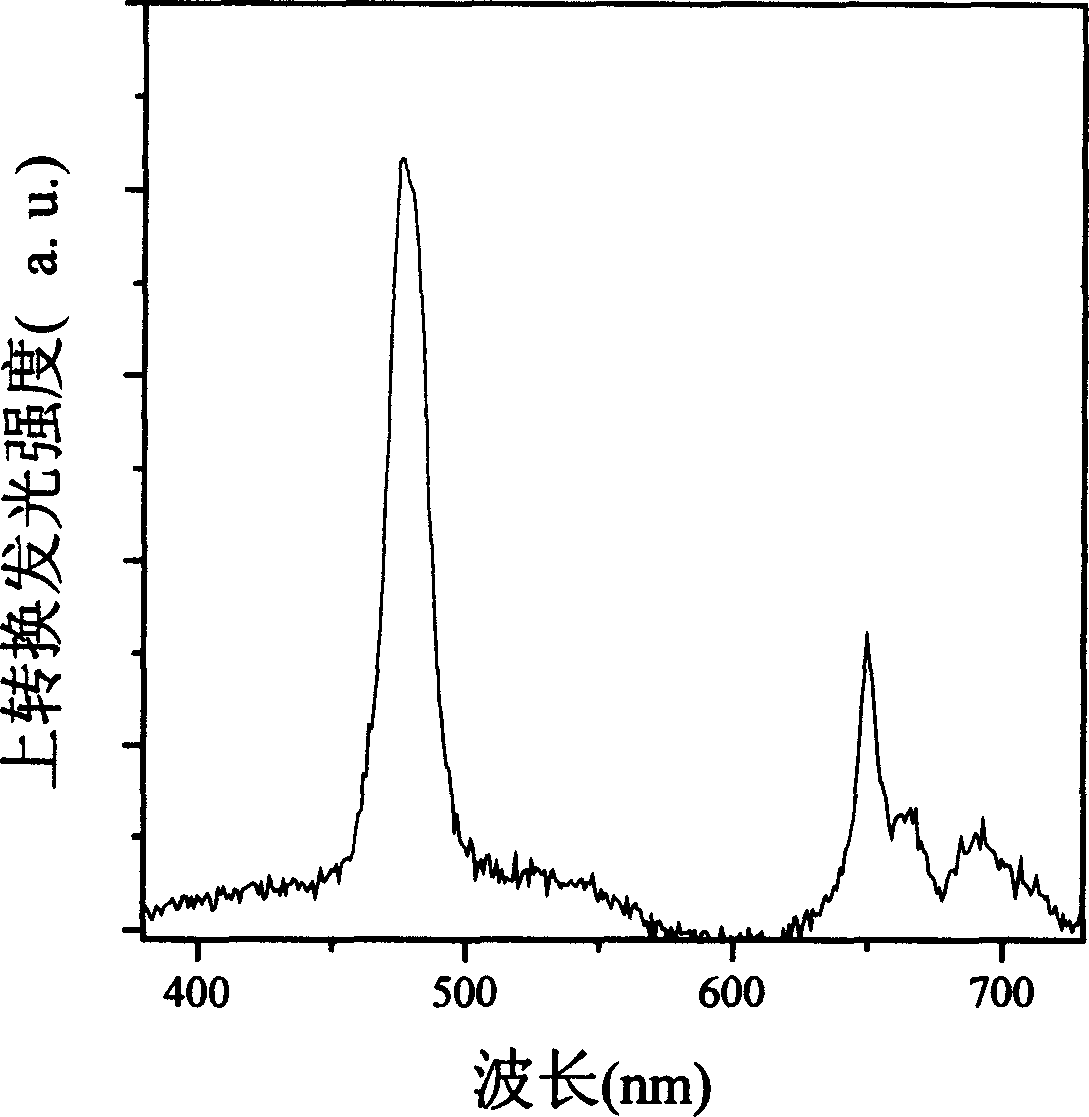

Rare earth doped gallium germanium bismuth lead luminous glass material and its preparation method and uses

InactiveCN1807310AWith integrationWith miniaturizationGlass furnace apparatusWaveguide lasersRare earth

The disclosed Ga-Ge-Bi-Pb fluorescent glass material doped with rare earth is prepared by: mixing and fusing the Ga2O3, Bi2O3, GeO2, lead-contained compound and rare earth compound to obtain the fused glass liquor; clearing and pouring the liquor into the mold to obtain the glass; putting the glass rapidly into a muffle furnace with temperature as the glass transformation temperature for heat preservation; finally, cooling to room temperature. This product can be manufactured into different shape, and has wide application as the gain medium.

Owner:SOUTH CHINA UNIV OF TECH

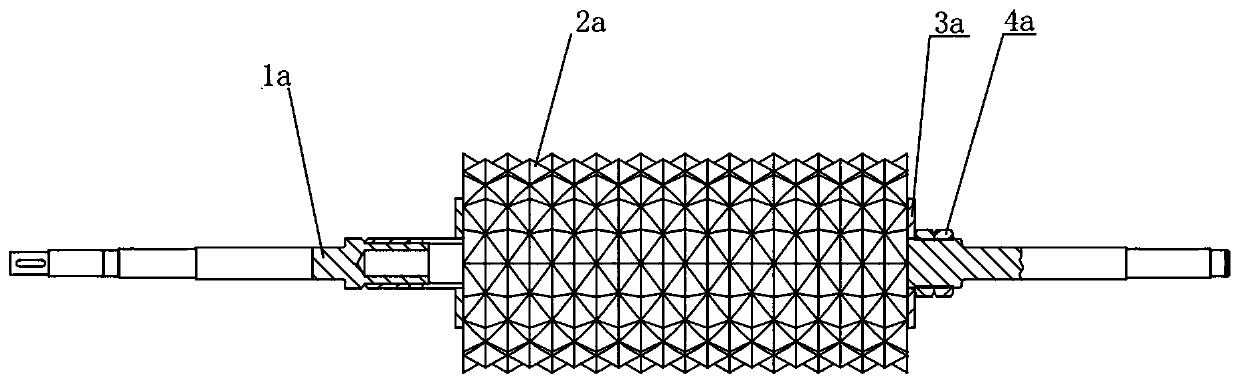

Control rod for liquid heavy metal cooling reactor

InactiveCN103236276ASimple structureStable structureNuclear energy generationNuclear reaction controlHigh densityNuclear reactor

The invention discloses a control rod for a liquid heavy metal cooling reactor, belonging to the field of nuclear reactors. The control rod is a part of a control rod assembly and is inserted into the core of the reactor together with a fuel assembly to control the reactivity. The control rod comprises a high-density neutron absorber (1), a gap (2) and an involucrum (3). The control rod provided by the invention is used for overcoming the problem that the traditional control rod cannot drop by virtue of gravity at an accident state due to small density in a bismuth-lead / lead cooling environment or stably stay in the reactor core when materials of the reactor are changed on the basis of meeting the reactivity control capability of a bismuth-lead / lead cooling reactor. The control rod provided by the invention is simple in structure and reliable and convenient to maintain.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

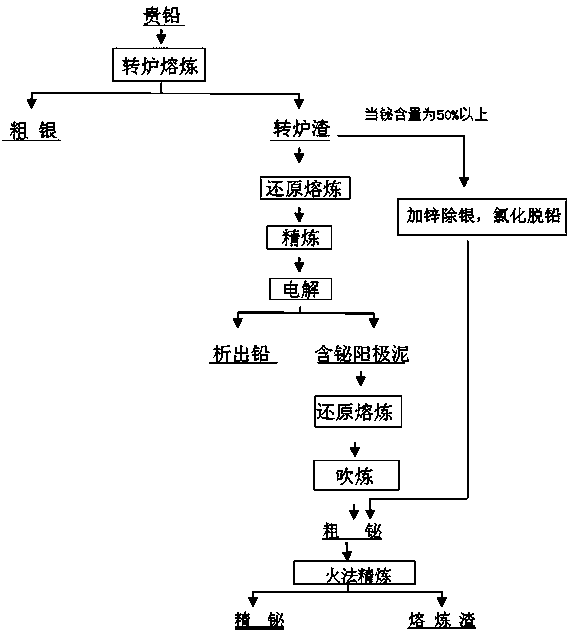

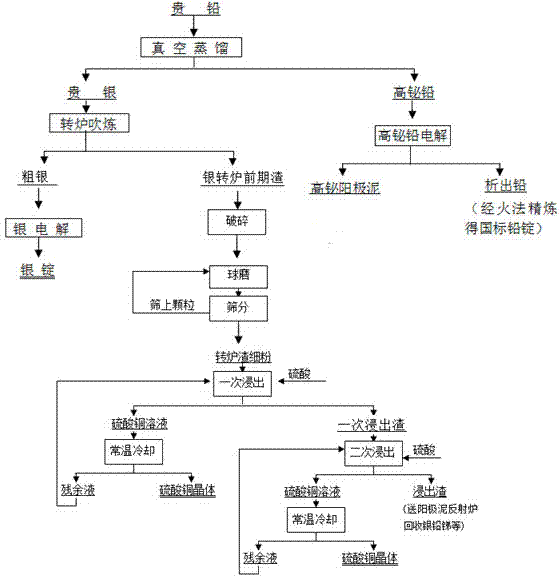

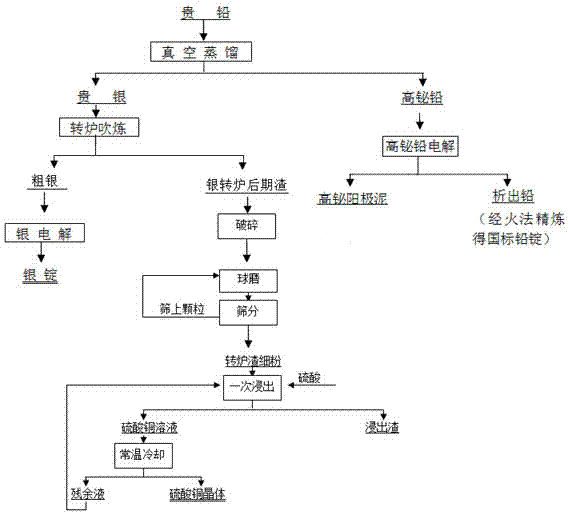

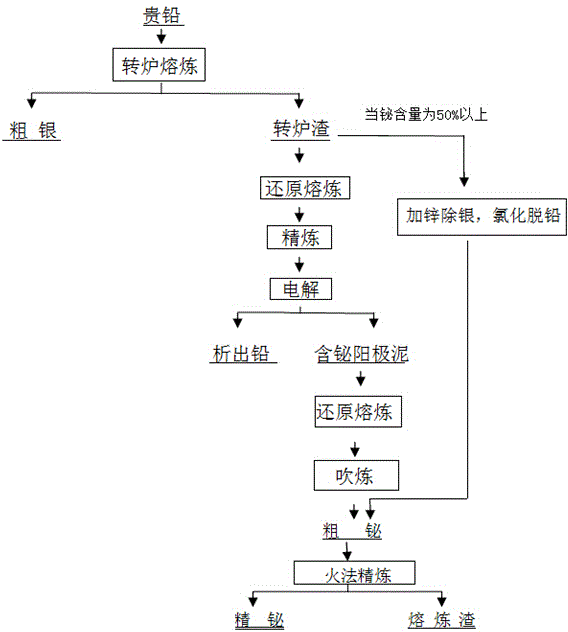

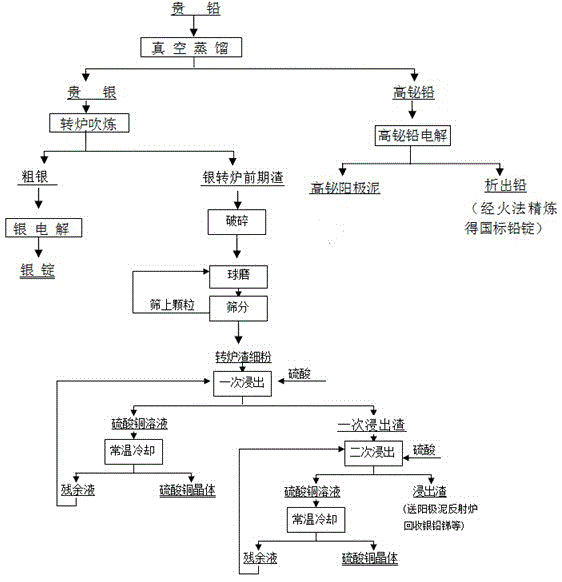

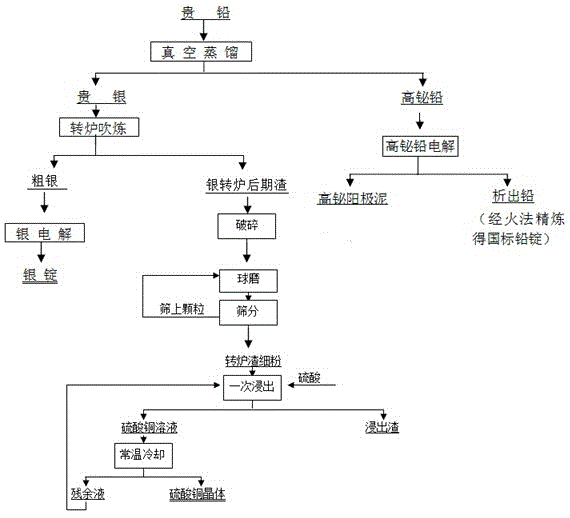

Method for recycling lead, sliver and copper by taking noble lead as raw material

The invention relates to a method for recycling lead, sliver and copper by taking noble lead as a raw material, and belongs to the technical field of combining a pyrogenic process with a wet process. The method comprises the following steps: firstly, carrying out vacuum distillation onto the noble lead for separating lead, stibium, bismuth and copper to produce high-bismuth lead and noble sliver; carrying out high-bismuth lead electrolysis onto the obtained high-bismuth lead to obtain separated-out lead, producing crude sliver by carrying out converter refining onto the obtained noble sliver, and refining noble lead byproducts obtained according to converter refining time length to obtain converter early-stage slag and converter later-stage slag; and electrolyzing the obtained crude sliver by crude sliver to obtain a sliver ingot, respectively crushing the obtained converter early-stage slag and converter later-stage slag until grain size is less than 6mm, then grinding to form powder with grain size being less than 100 meshes to obtain converter slag fine powder, and adding the converter slag fine powder into sulfuric acid liquor for leaching, and thus obtaining leaching slag and copper sulfate liquor after leaching is completed. The method disclosed by the invention improves treatment process flow of the noble lead material, and has the effects that process flow is refined and concise, energy is saved and consumption is lowered, and production environment is optimized.

Owner:蒙自矿冶有限责任公司

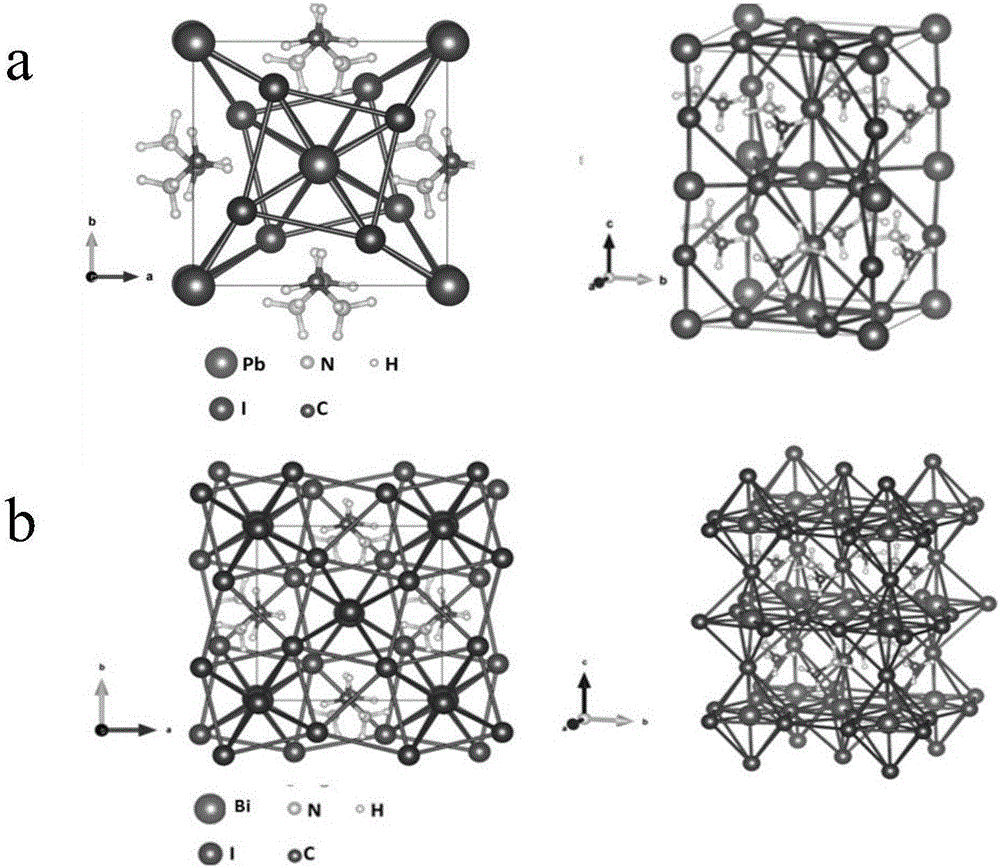

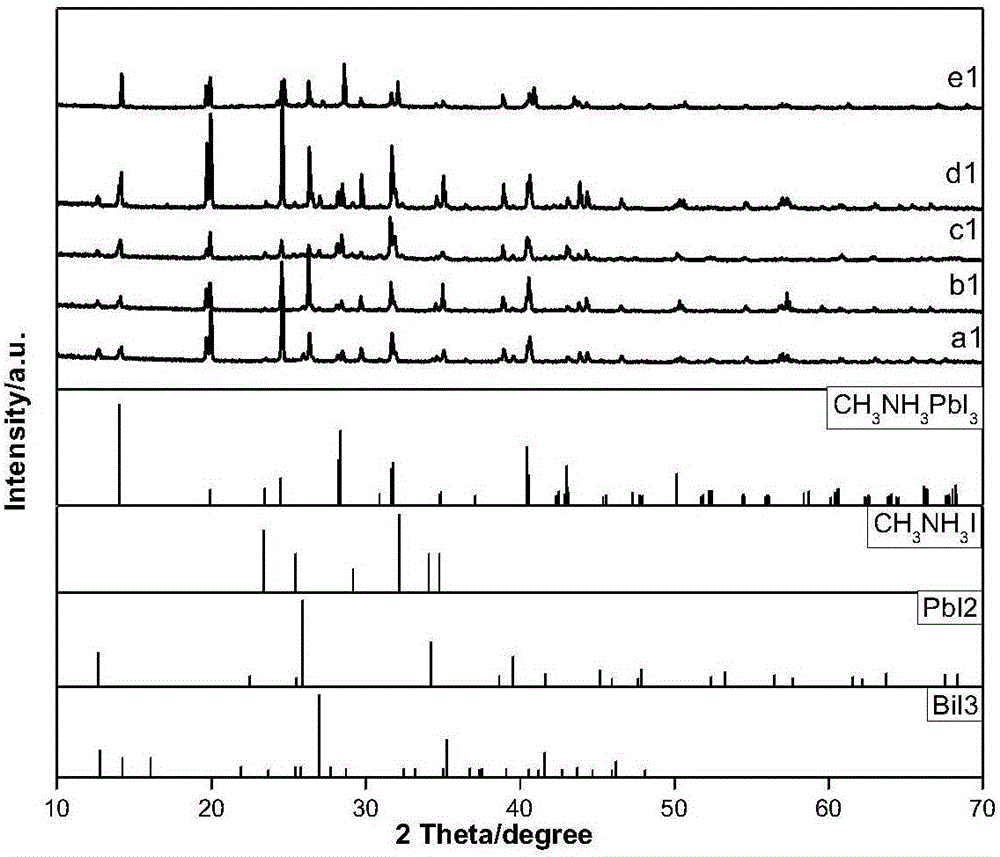

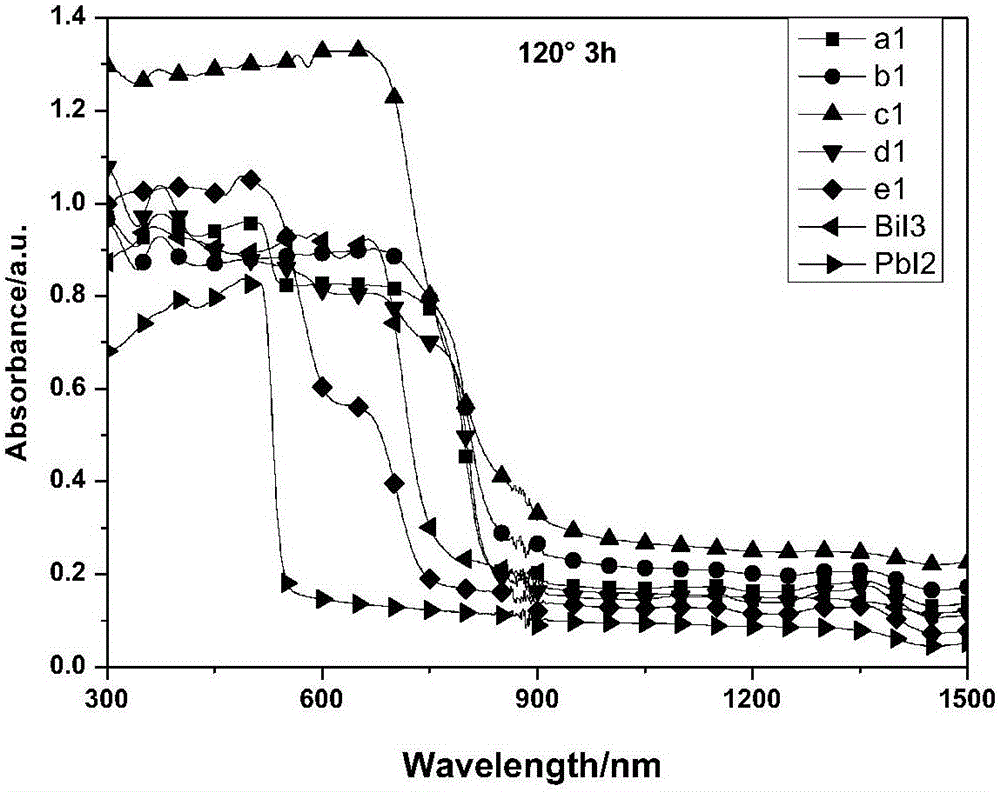

Methyl amino lead iodide bismuth perovskite crystal light absorption layer material and preparation method thereof

ActiveCN105820055AReduce contentImprove stabilityAmino compound purification/separationOrganic compound preparationPerovskite solar cellCrystal structure

The invention provides a light absorption material of perovskite crystal of methyl amino lead iodide bismuth (for short methylamine bismuth lead iodine) and a preparation method thereof. A general formula is CH3NH3BixPb1-xI3, wherein x is 0.01-1. The crystal of the perovskite crystal light absorption material formed calcining the material under the condition of water-insulation and oxygen-insulation has the same crystal structure and similar light absorption performance of methylamine iodine lead CH3NH3PbI3. The method uses bismuth atom to substitute lead atom in CH3NH3PbI3 effectively, and the crystal structure is not changed. The lead content is reduced effectively by means of controlling the raw material ratio of bismuth to lead. The crystal material with perovskite structure of methylamine bismuth lead iodine CH3NH3BixPb1-xI3 prepared by the invention can be used for substituting the crystal material of methylamine lead iodine CH3NH3PbI3 which is used as an absorbed layer of a perovskite solar cell. Moreover, the material stability can be improved effectively, the lead content can be reduced, and the material toxicity can be reduced.

Owner:XIAN POLYMER LIGHT TECH

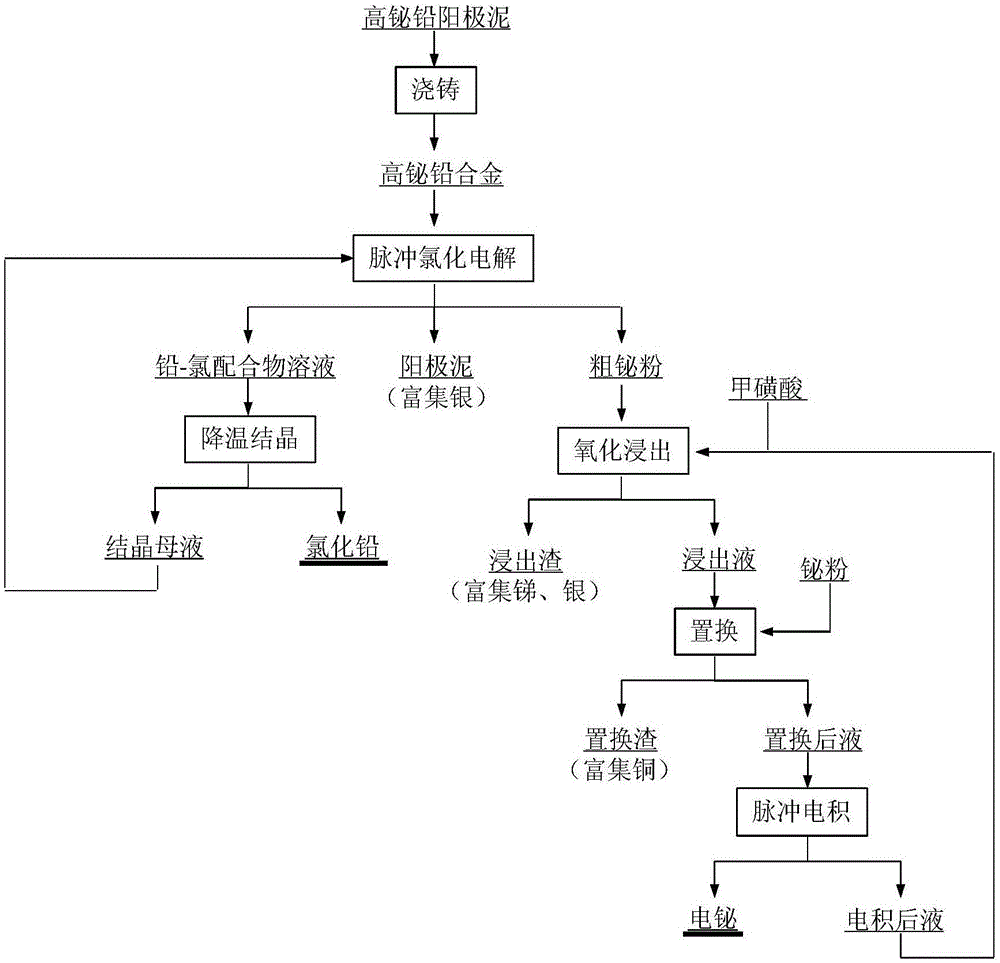

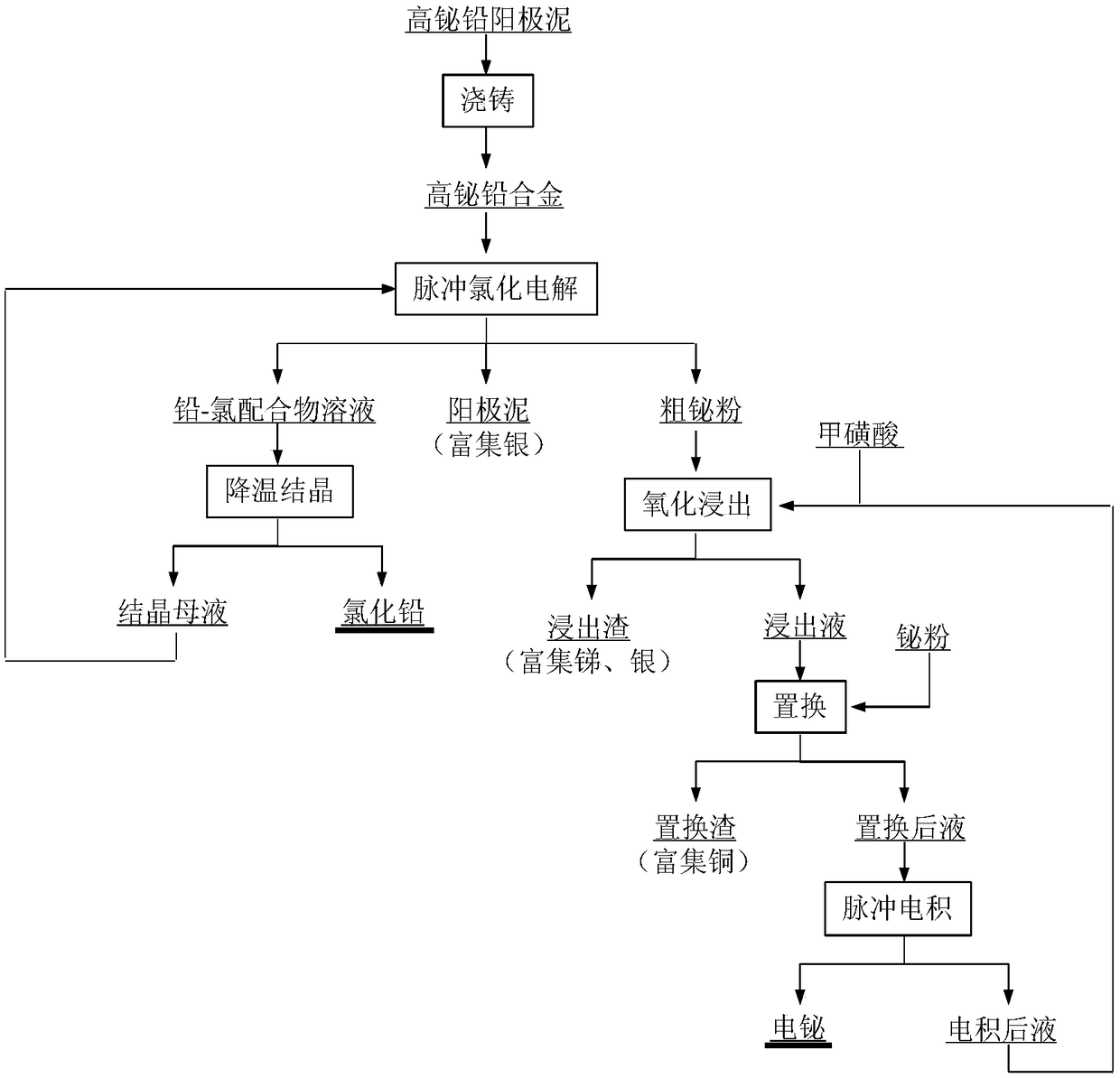

Process for separating lead and bismuth from high bismuth lead alloy

ActiveCN107177865ATo achieve full enrichmentElectrolysis componentsPhotography auxillary processesElectrolysisSlag

The invention discloses a process for separating lead and bismuth from a high bismuth lead alloy; and the process uses an alloy formed by casting high bismuth lead anode mud as an anode; and the alloy is fed in an anode bag for pulse chlorination electrolysis in a hydrochloric acid-chlorine salt system. Insoluble matters of the anode fall into the anode bag to form anode mud during electrolyzing; lead is dissolved in solution in a lead-chlorine complex form; and bismuth is separated out from a cathode in a rough bismuth powder form. The anode mud, lead chloride complex solution and rough bismuth powder are respectively obtained after electrolysis. The lead chloride solution is cooled for crystallization to obtain lead chloride; and crystallization mother liquor is returned to prepare electrolyte. The oxidation leaching is performed on the rough bismuth powder by adopting methane sulfonic acid to respectively obtain leaching liquid and leaching slag enriched with antimony and silver. The leaching liquid is replaced and purified for pulse electrodeposition to obtain electric bismuth; and electrodeposition back liquid is returned to leaching of the rough bismuth powder. The process can perform classified extraction on lead and bismuth in the high bismuth lead alloy; silver is enriched; the closed cycle of the technological process is realized; and the process has the advantages of simple technological process, high yield of valuable elements, cleanness and environmental protection.

Owner:YIYANG SHENGLI CHEM IND

Method for electrolyzing and recycling valuable metal from high-bismuth lead bullion

ActiveCN104947146ASolve the problem that cannot handle high bismuth crude leadImprove raw material adaptabilityPhotography auxillary processesElectrolysisBullion

The invention relates to a method for electrolyzing and recycling valuable metal from high-bismuth lead bullion, and belongs to the field of nonferrous metallurgy. The method comprises the steps that the lead bullion is rationally combined, and compositions of an anode plate are properly controlled; the current density is properly reduced, and the cell voltage is controlled; lead ions are supplemented in time, and compositions of electrolytes are ensured; a washing operation system of the anode plate is adjusted; final refining is carried out; and a qualified lead ingot is obtained. According to the method, the requirement for lead and bismuth contained in the lead bullion in an existing production technology is broken through, and the method allows the lead-contained range in a lead anode to be expanded to more than 85% and the bismuth-contained range to be expanded to smaller than or equal to 10%; and through electrolytic refining, the qualified lead ingot is produced, and the aim of rapidly recycling the valuable metal such as the bismuth, gold and silver is achieved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Treatment method for high-bismuth lead anode mud or bismuth slags

ActiveCN106978538AIncrease costLow recovery ratePhotography auxillary processesProcess efficiency improvementPurification methodsSlag

The invention discloses a treatment method for high-bismuth lead anode mud or bismuth slags. The method is characterized in that SnCl4 and HCl are used as a leaching agent; the high-bismuth lead anode mud or bismuth slags are directly leached through oxidization to obtain bismuth-containing lixivium and leaching residue enriched with gold and silver; then the bismuth-containing lixivium is subjected to bismuth powder reduction purification; and silver ions in the lixivium are substituted into the residue; a certain amount of a precipitant is added in the liquid subjected to substitution, and the acidity of the liquid is adjusted with H2SO4, so that As3+, Pb2+, Cu2+ and Sb3+ in the solution are precipitated in the residue; and Pb2+ and As3+ ions in the liquid subjected to precipitation are further removed with a double-salt purification method. The purified liquid is subjected to diaphragm electrodeposition for extracting bismuth; after the bismuth is extracted, cathode liquid and anode liquid are mixed, and the solution is subjected to substitution treatment by using tin powder as a purification agent; and the liquid subjected to substitution is subjected to acid adjustment and then returns to be used for leaching the high-bismuth lead anode mud as a leaching agent. By adopting the technique, bismuth, lead, stibium, arsenic and copper in the high-bismuth lead anode mud or bismuth slags are extracted in a classified manner; gold and silver and gathered; closed-loop circulation of a technique process is realized; and the treatment method has the distinctive advantages of being high in raw material adaptability, simple in technique process, high in valuable element recycle rate, clean and environment-friendly.

Owner:YIYANG SHENGLI CHEM IND

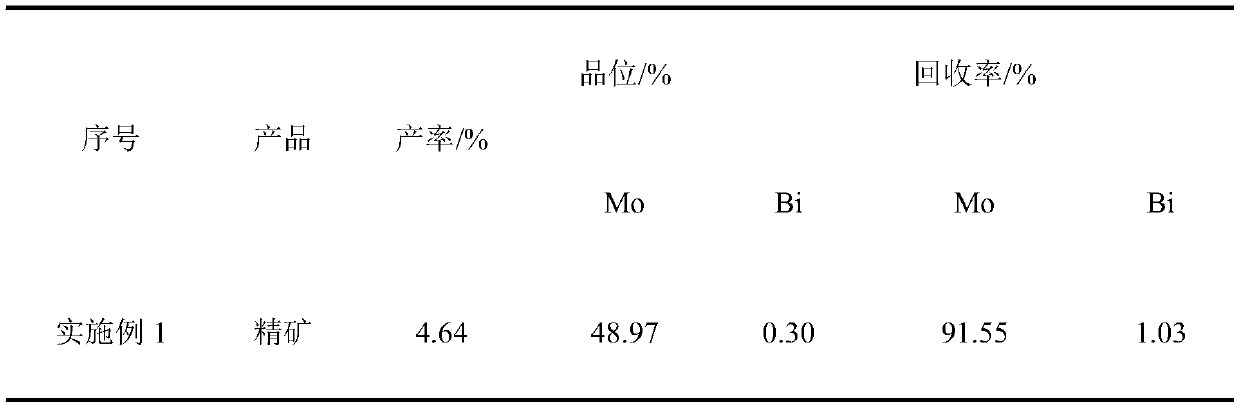

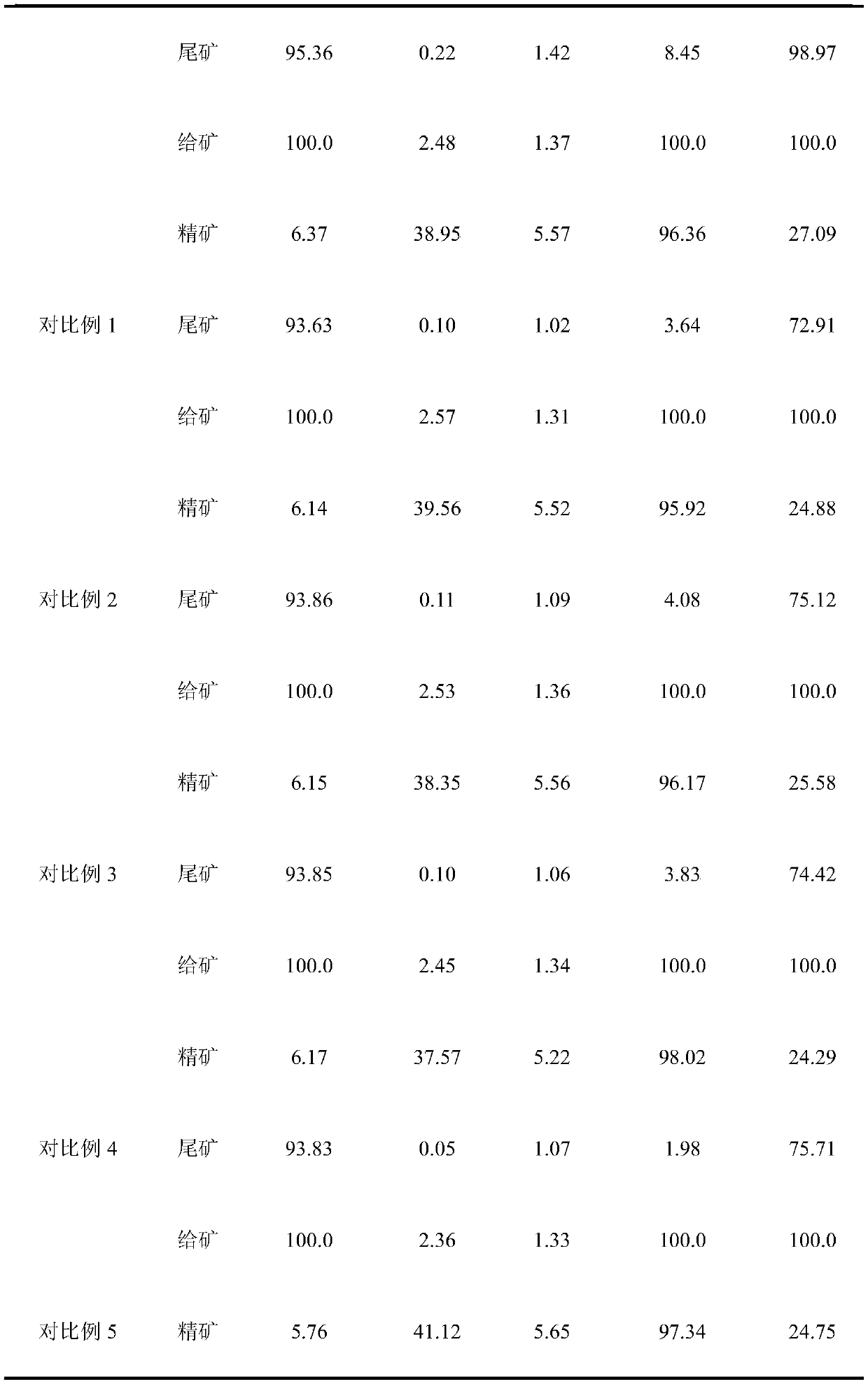

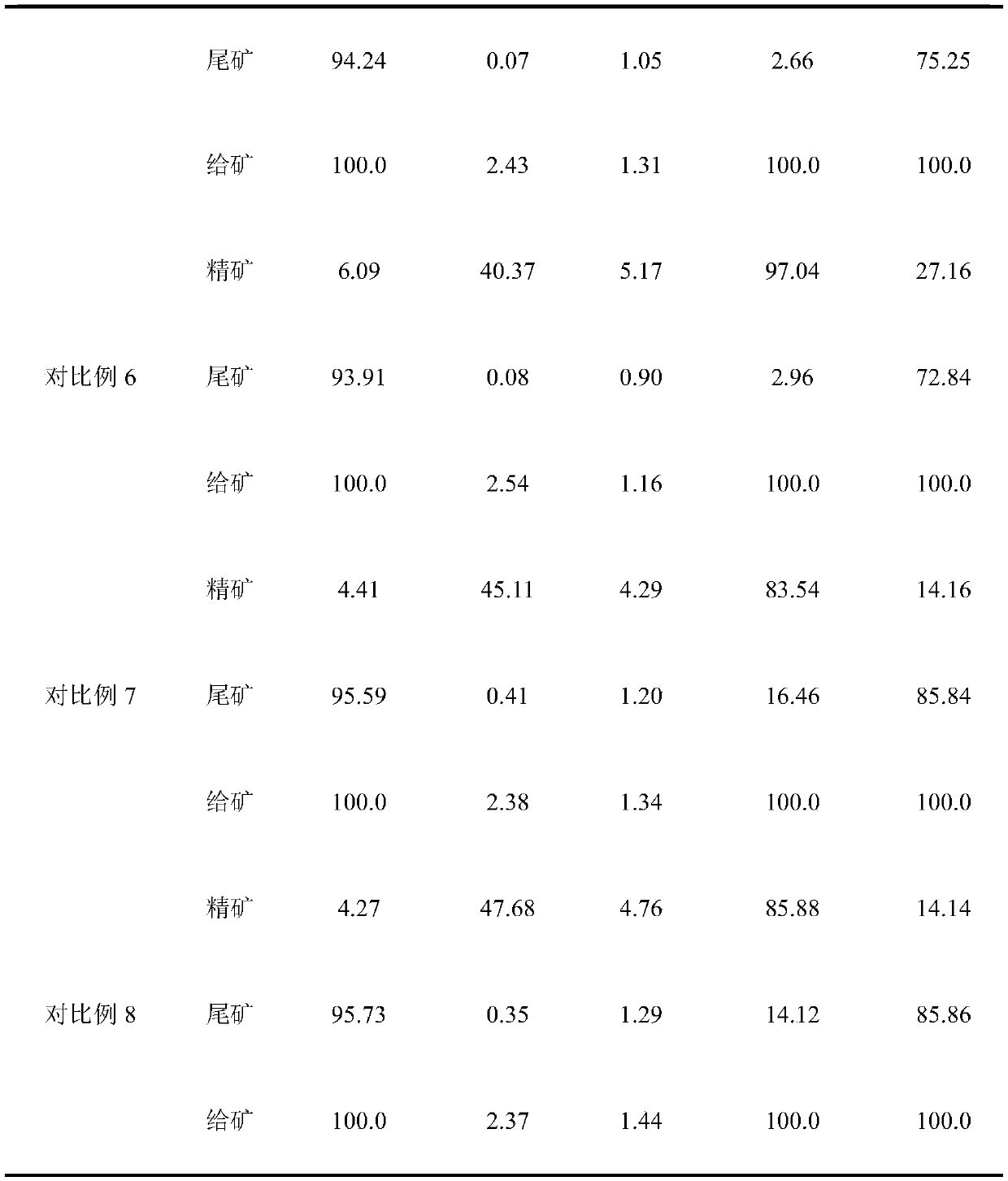

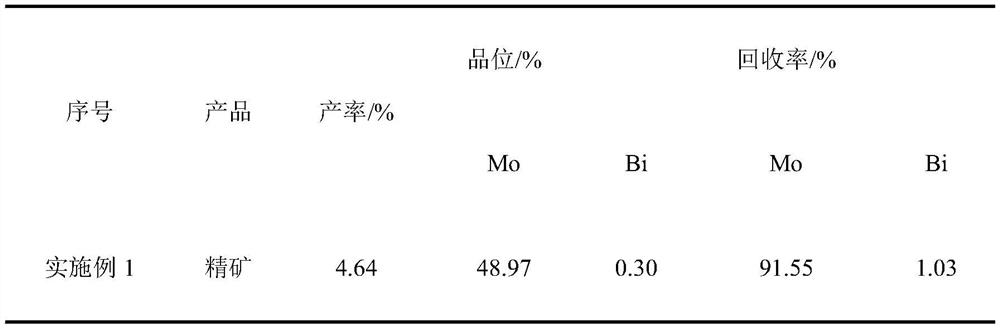

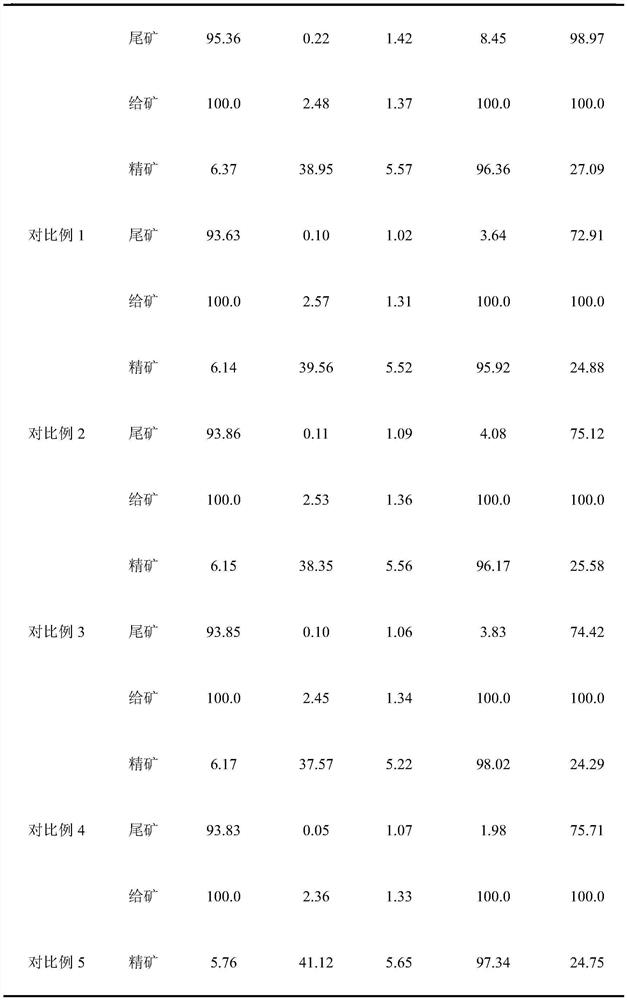

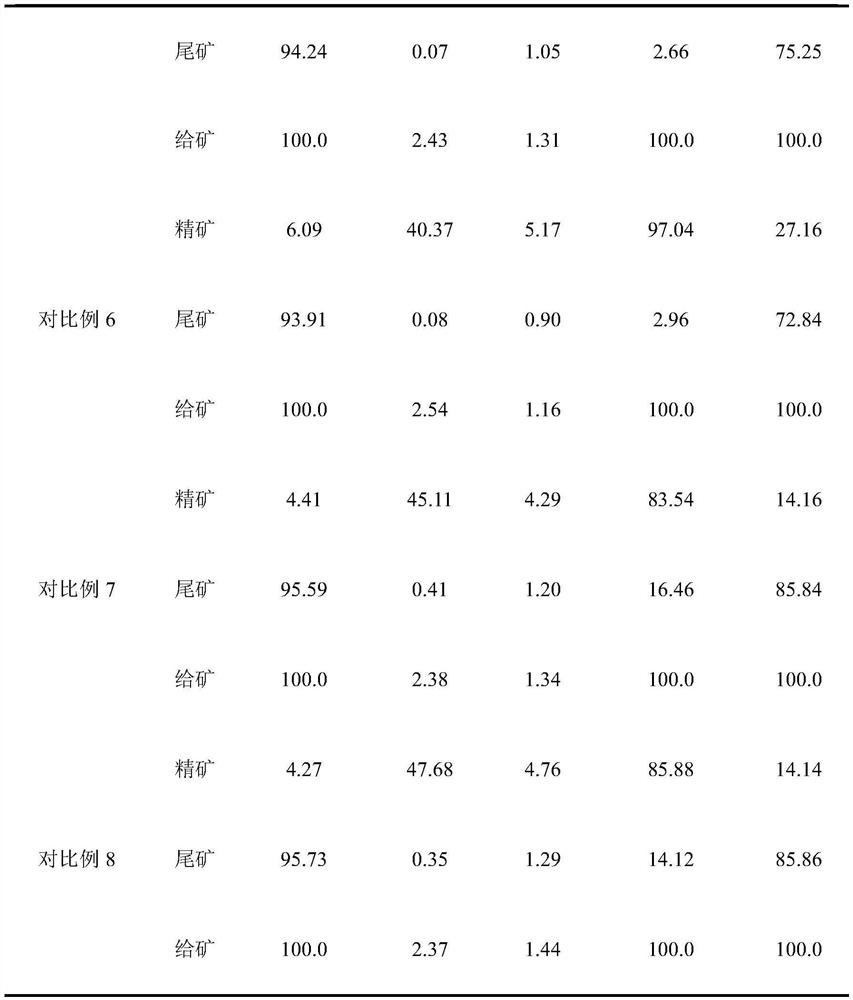

Preparation method of bismuth lead sulfide ore flotation inhibitor and use method of inhibitor

ActiveCN110013916AEnhanced inhibitory effectImprove separation efficiencyFlotationBismuth sulfideCarboxylic acid

The invention belongs to the technical field of sulfide ore beneficiation, and particularly relates to a preparation method of a bismuth lead sulfide ore flotation inhibitor and a use method thereof.The bismuth lead sulfide ore flotation inhibitor is prepared by the following steps: step 1, in parts by mass, preparing and getting 10 to 20 parts of halogenated carboxylic acid, 30 to 60 parts of imidazole, 30 to 60 parts of carbon disulfide, and 25 to 50 parts of organic solvent; and step 2, uniformly mixing the raw materials of the first step, conducting reacting on the mixture at 0 to 95 DEGC for 2-12 hours, so as to obtain the bismuth lead sulfide ore flotation inhibitor. The obtained product has inhibitory effects on primary and secondary sulfide ore of bismuth and lead, and can be applied to flotation separation of molybdenum bismuth ore, molybdenum lead ore, lead zinc ore, copper lead ore and the like, especially for bismuth-containing sulfide ore or non-bismuth sulfide ore. Thepreparation method of the flotation inhibitor is simple in operation, mild in process conditions, low in raw material cost, convenient in use and less in environmental pollution, and meets industrialproduction requirements.

Owner:CENT SOUTH UNIV

High-purity bismuth-lead alloy and preparation method thereof

The invention discloses a high-purity bismuth-lead alloy and a preparation method thereof. The preparation method comprises the steps that a compounding step is carried out, specifically, according tothe composition design of the bismuth-lead alloy, massive lead materials and bismuth materials are used as raw materials for compounding and mixing; a smelting step is carried out, specifically, themixed raw materials are smelted under vacuum; a cooling step is carried out, specifically, alloy melt obtained after smelting is subjected to cooling; a filtering step is carried out, specifically, the alloy melt after cooling is subjected to filtration treatment; and a casting step is carried out, specifically, the filtered alloy molt is casted into a mold under vacuum and cooled to obtain an alloy ingot. According to the high-purity bismuth-lead alloy and the preparation method thereof, through the combination of high-temperature vacuum melting and low-temperature vacuum casting, oxides andother metal impurities in the lead and bismuth raw materials can be efficiently and advantageously removed, so that the purity of the alloy reaches above 99.998%. And through timing electromagnetic stirring and controlling of the weight of a single alloy ingot, the overall composition of the alloy is uniform and controllable, and the problem of excessive composition segregation is avoided.

Owner:安泰天龙钨钼科技有限公司 +1

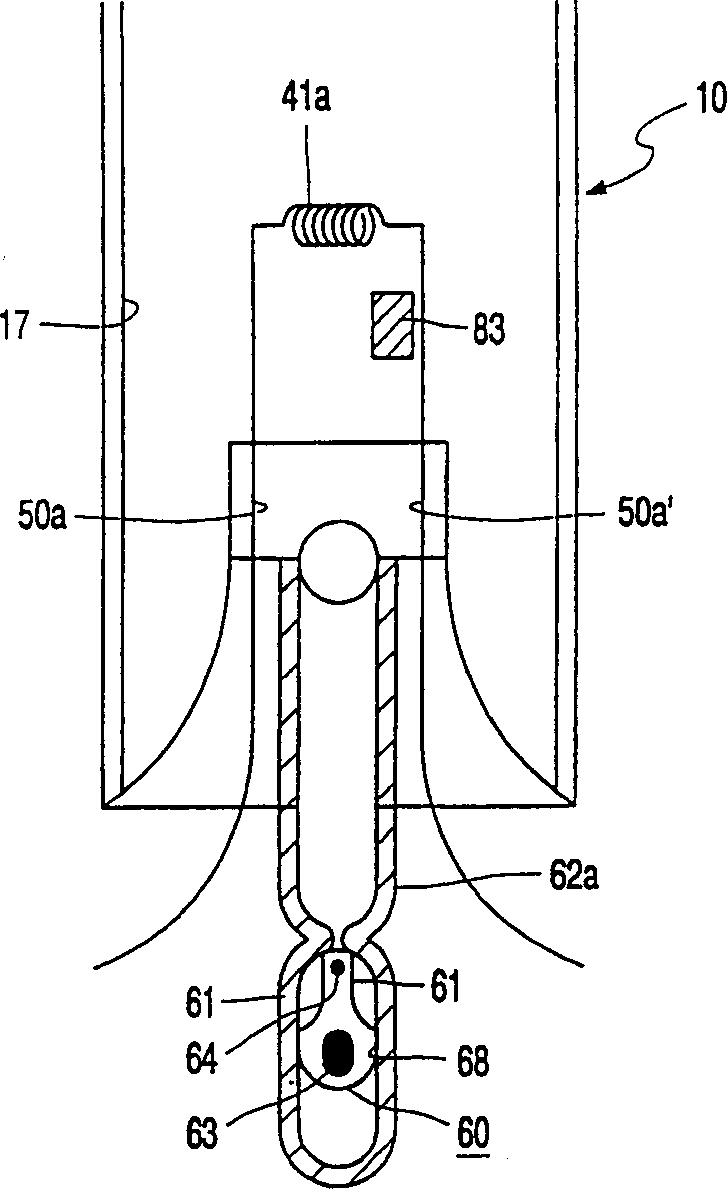

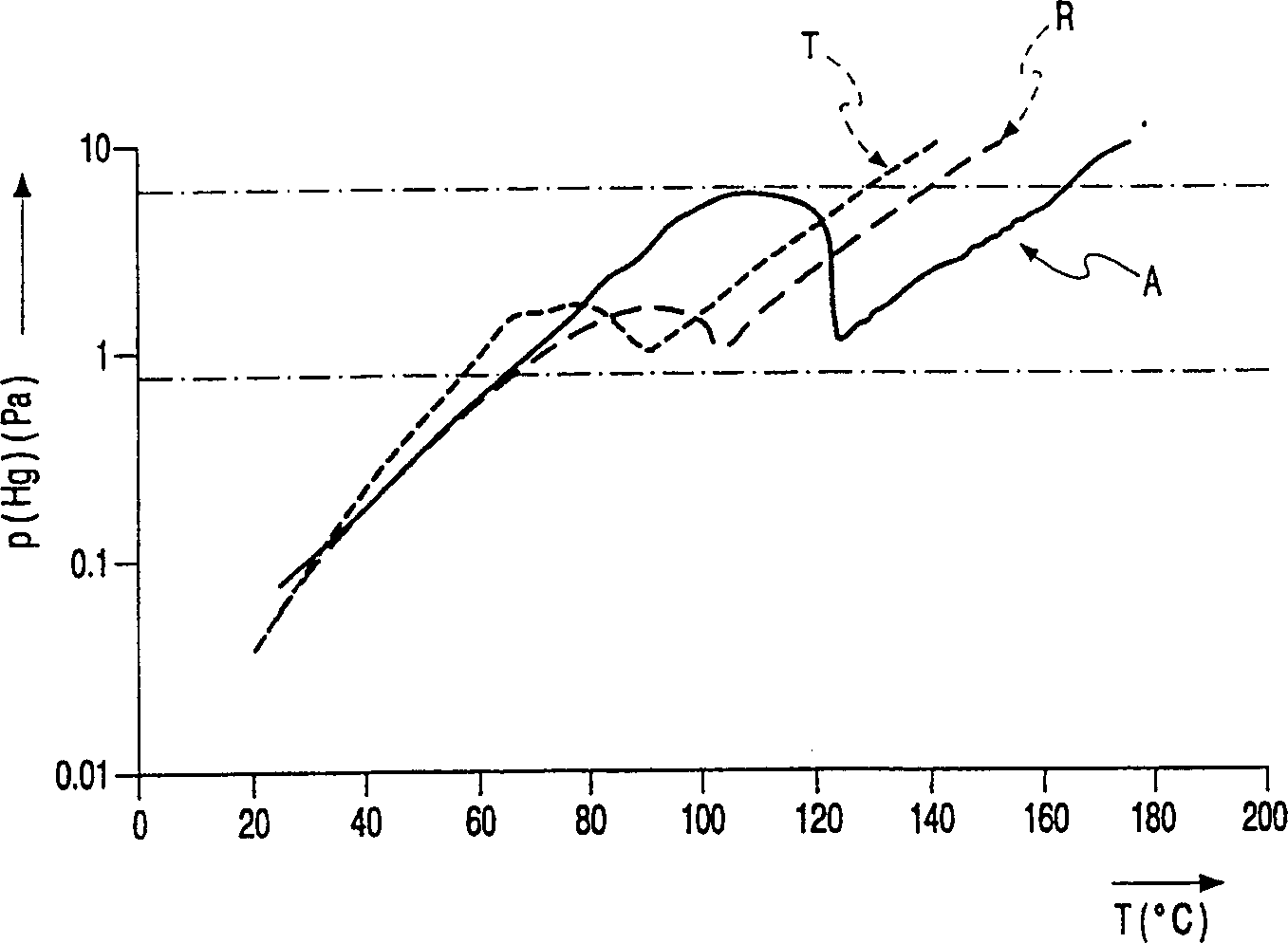

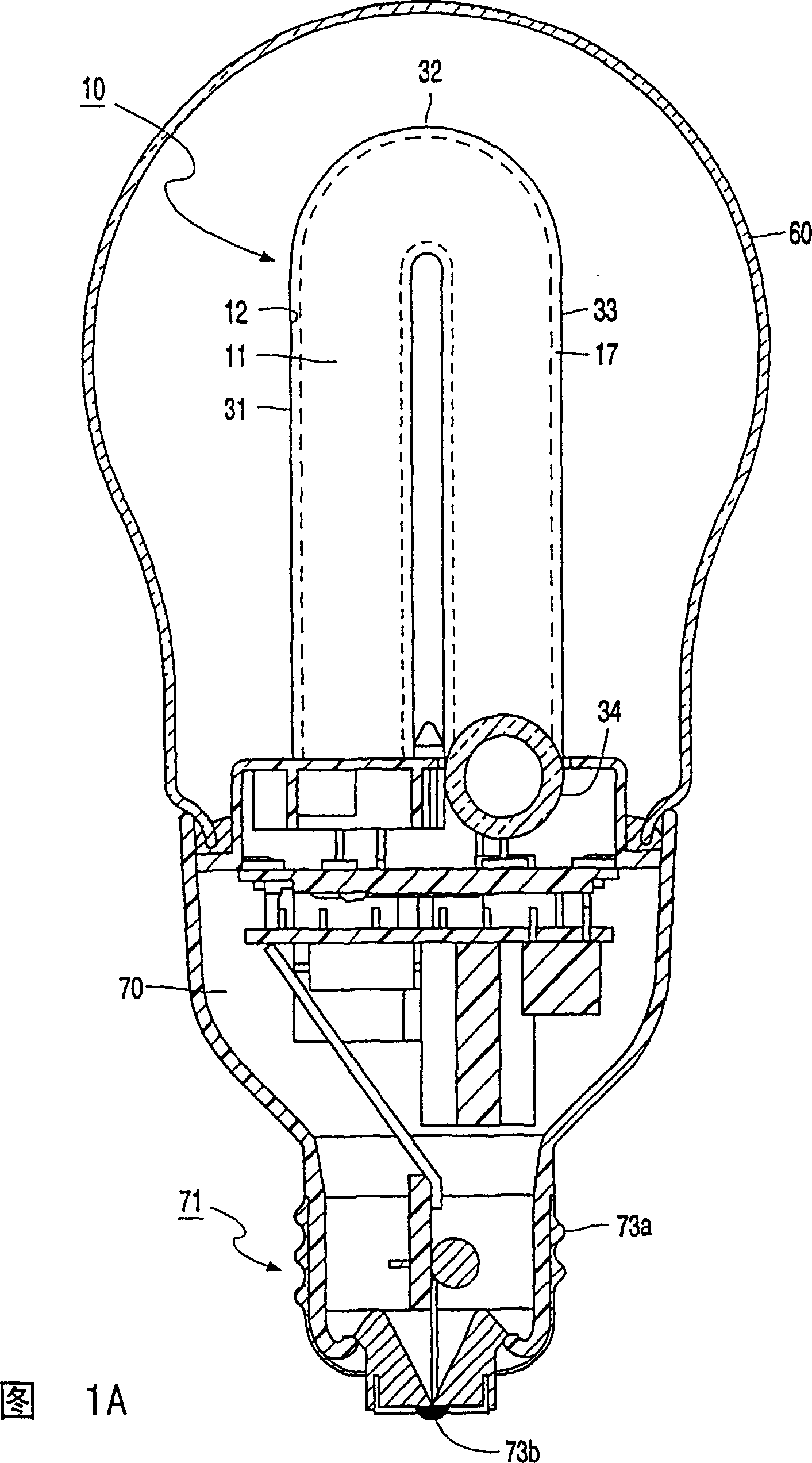

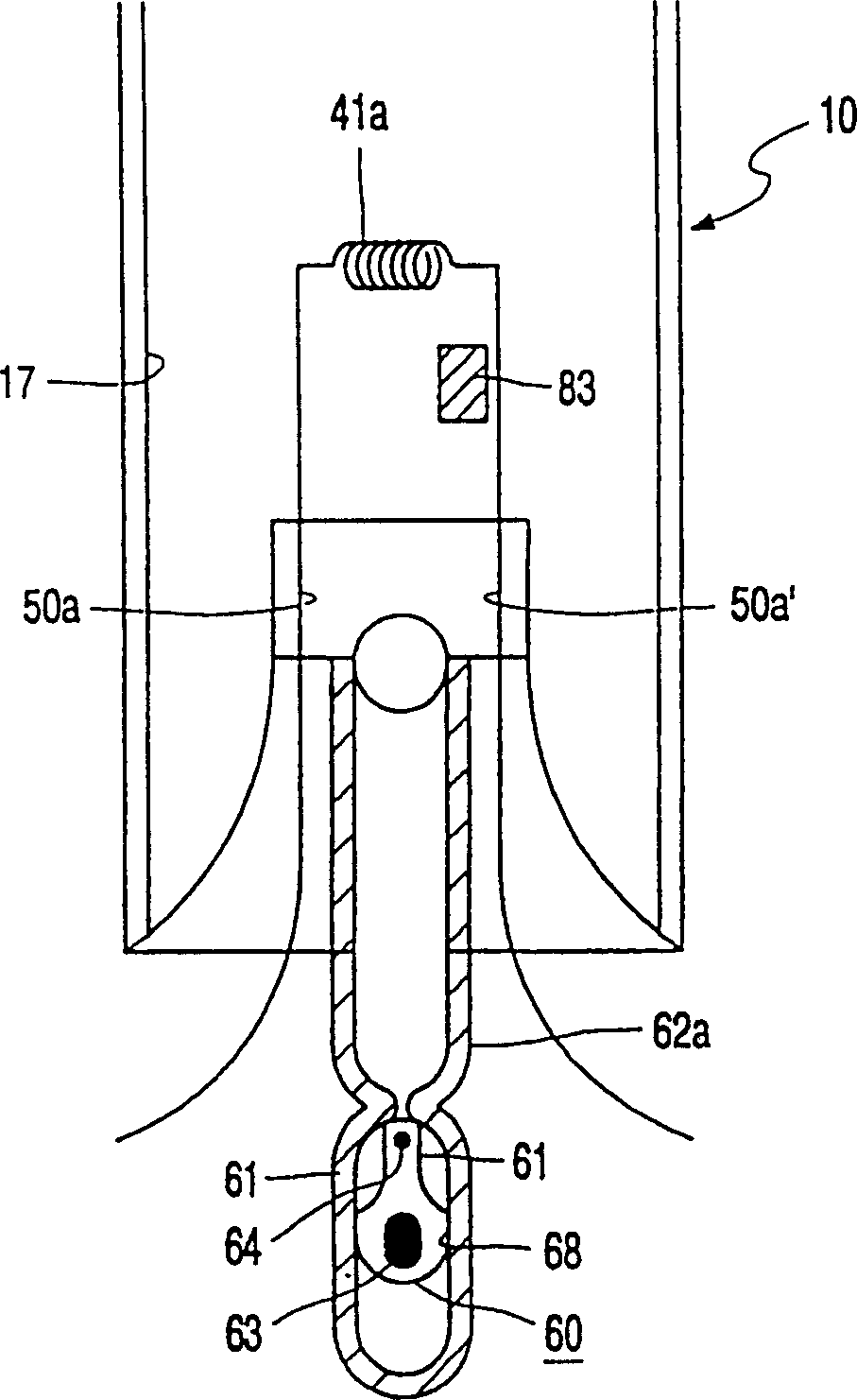

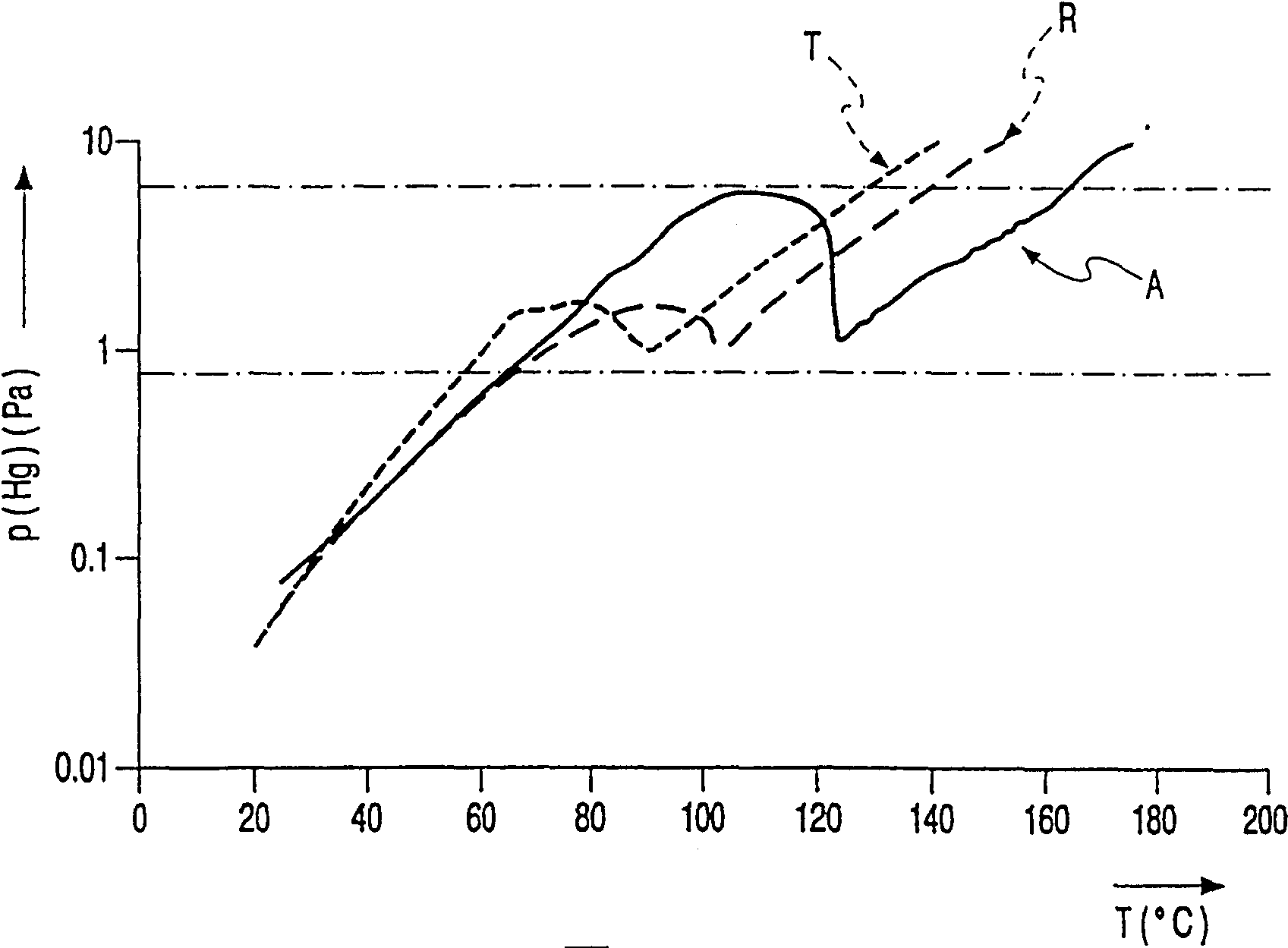

Low-pressure mercury-vapor discharge lamp and amalgam

InactiveCN1365509AGood initial radiation outputShorten start timeLow-pressure discharge lampsGas discharge lamp detailsGas-discharge lampGold content

A low-pressure mercury-vapor discharge lamp is provided with a discharge vessel (10). The discharge vessel (10) encloses a discharge space (11) provided with a filling of mercury and an inert gas in a gastight manner. The discharge vessel (10) is provided with an amalgam which communicates with the discharge space (11). The discharge lamp comprises means for maintaining an electric discharge in the discharge vessel (10). The discharge lamp is characterized in that the amalgam comprises a bismuth-lead amalgam having a lead content in the range from 35 <= Pb <= 60 at. %, a bismuth content in the range from 40 <= Bi <= 65 at. %, and a mercury content in the range from 0.05 <= Hg <= 1 at. %. Preferably, the amalgam additionally comprises gold with a gold content in the range from 0.1 <= Au <= 20 at. %. Preferably, the gold content is in the range from 8 <= Au <= 12 at. %. The lamp according to the invention exhibits a comparatively high initial radiation output and a short run-up time in combination with a relatively high radiation output at nominal lamp operation, which is achieved in a comparatively large temperature interval.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Silicon bismuth lead-free casting brass alloy and preparing method thereof

The invention relates to a silicon bismuth lead-free casting brass alloy and a preparing method thereof. The brass alloy comprises, by mass percent, 61 to 67% of Cu, 0.5 to 1.0% of Bi, 0.8 to 1.25% of Si, 0.3 to 0.7% of Al, 0.05 to 0.3% of Sn, smaller than 0.01% of Pb, not larger than 0.002% of B, not larger than 0.008% of Ti, not larger than 0.01% of a rare earth modifier (at least comprising three of Nd, Eu, Er, Y, Zr and the like) and the balance Zn and smaller than 0.3% of impurities. Bi / Si is larger than or equal to 0.4 and smaller than or equal to 1.1.

Owner:FUJIAN UNIV OF TECH

A process for separating lead and bismuth from a high-bismuth-lead alloy

ActiveCN107177865BTo achieve full enrichmentPhotography auxillary processesElectrolysis componentsElectrolysisSlag

The invention discloses a process for separating lead and bismuth from a high bismuth lead alloy; and the process uses an alloy formed by casting high bismuth lead anode mud as an anode; and the alloy is fed in an anode bag for pulse chlorination electrolysis in a hydrochloric acid-chlorine salt system. Insoluble matters of the anode fall into the anode bag to form anode mud during electrolyzing; lead is dissolved in solution in a lead-chlorine complex form; and bismuth is separated out from a cathode in a rough bismuth powder form. The anode mud, lead chloride complex solution and rough bismuth powder are respectively obtained after electrolysis. The lead chloride solution is cooled for crystallization to obtain lead chloride; and crystallization mother liquor is returned to prepare electrolyte. The oxidation leaching is performed on the rough bismuth powder by adopting methane sulfonic acid to respectively obtain leaching liquid and leaching slag enriched with antimony and silver. The leaching liquid is replaced and purified for pulse electrodeposition to obtain electric bismuth; and electrodeposition back liquid is returned to leaching of the rough bismuth powder. The process can perform classified extraction on lead and bismuth in the high bismuth lead alloy; silver is enriched; the closed cycle of the technological process is realized; and the process has the advantages of simple technological process, high yield of valuable elements, cleanness and environmental protection.

Owner:YIYANG SHENGLI CHEM IND

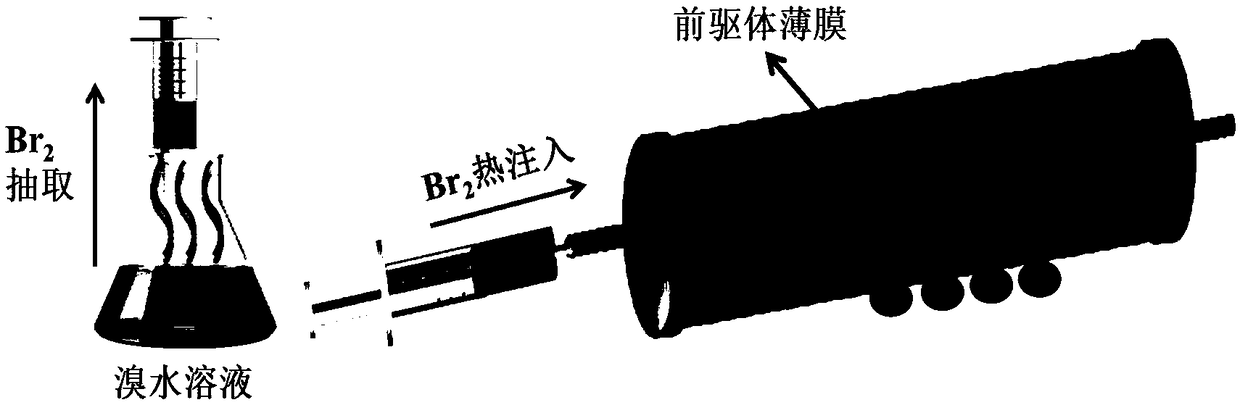

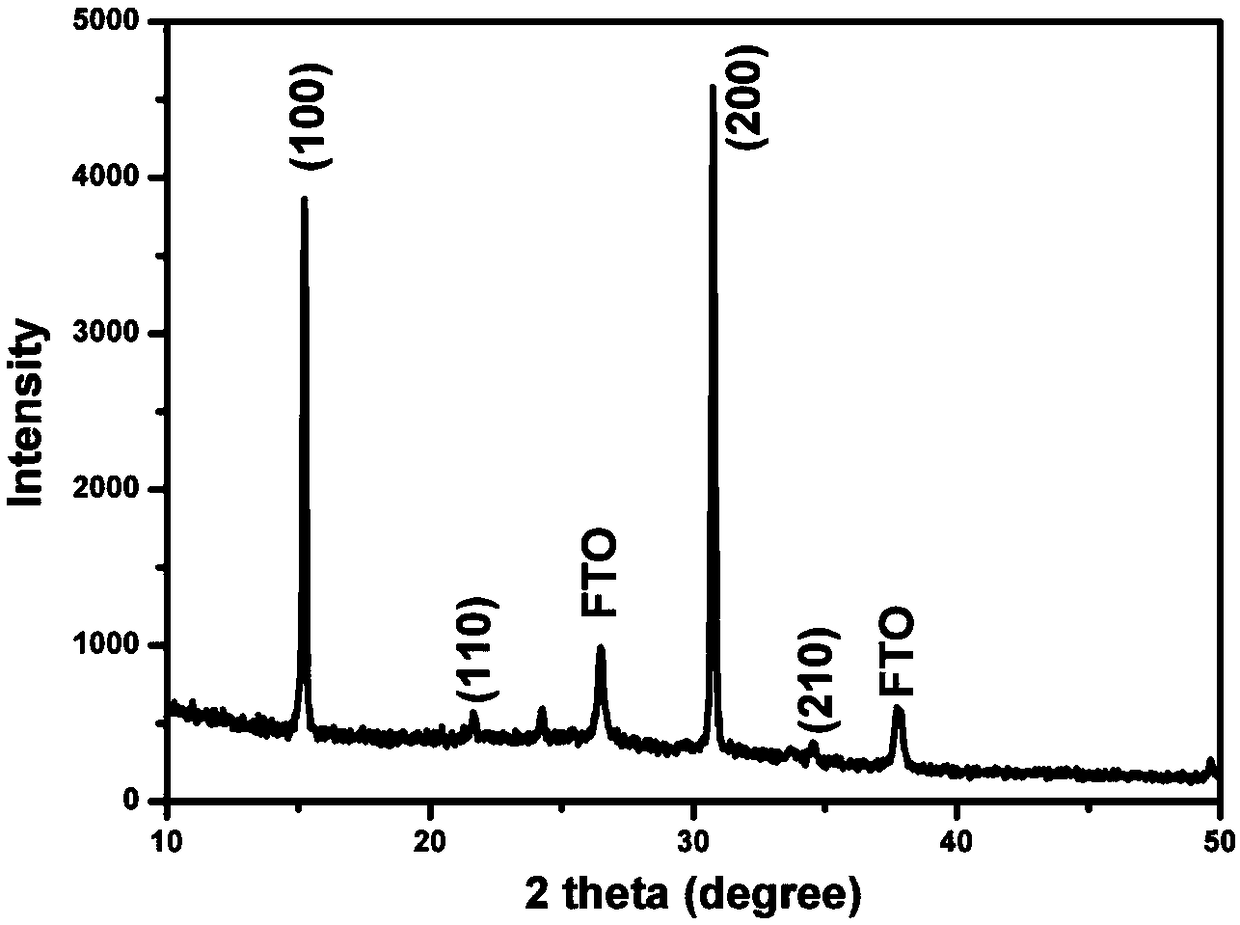

Preparation method of cesium lead bromine inorganic perovskite film and photovoltaic device based on it

ActiveCN107564978BImprove film qualityGood substrate coverageFinal product manufacturePhotovoltaic energy generationSolubilityGas phase

The invention discloses a preparation method for a cesium lead bromide inorganic perovskite thin film and a photovoltaic device based on the cesium lead bromide inorganic perovskite thin film. An unstable yellow oblique-phase CsPbI3 thin film is prepared by employing a one-step solution method and then is converted to a stable black cubic-phase CsPbBr3 thin film by employing a Br2 steam thermal injection gas-phase deposition method. Gas-phase exchange reaction of halide ions is utilized, I<-> in CsPbI3 is substituted by Br<-> with smaller radius, the purpose of lattice shrinkage, phase changesuppression and stability improvement are achieved, the bottleneck problem that Br solubility of a traditional one-step solution method is limited can be effectively solved, and the problems that thethin film is easy to fall during immersion of a two-step solution method also can be prevented; and meanwhile, the prepared CsPbBr3 thin film is also used as a light absorption layer to prepare an FTO / c-TiO2 / m-TiO2 / CsPbBr3 / C perovskite solar cell with an all-inorganic structure, the photoelectric efficiency of a battery in initial batch reaches 3.23%, and the battery shows favorable long-term stability.

Owner:HEFEI UNIV OF TECH

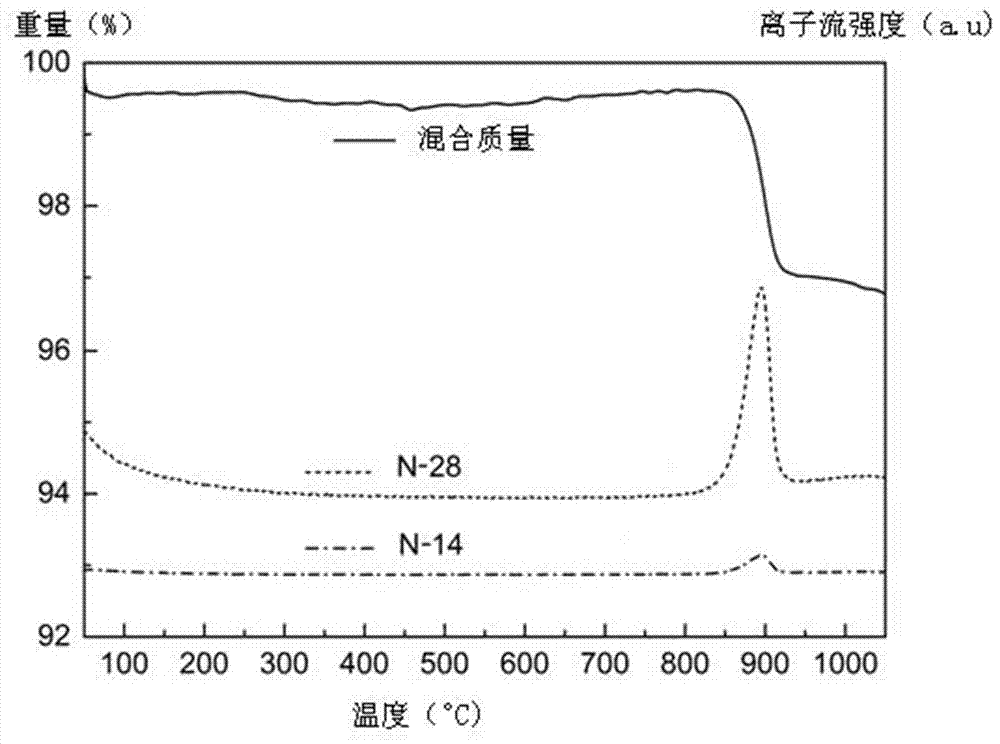

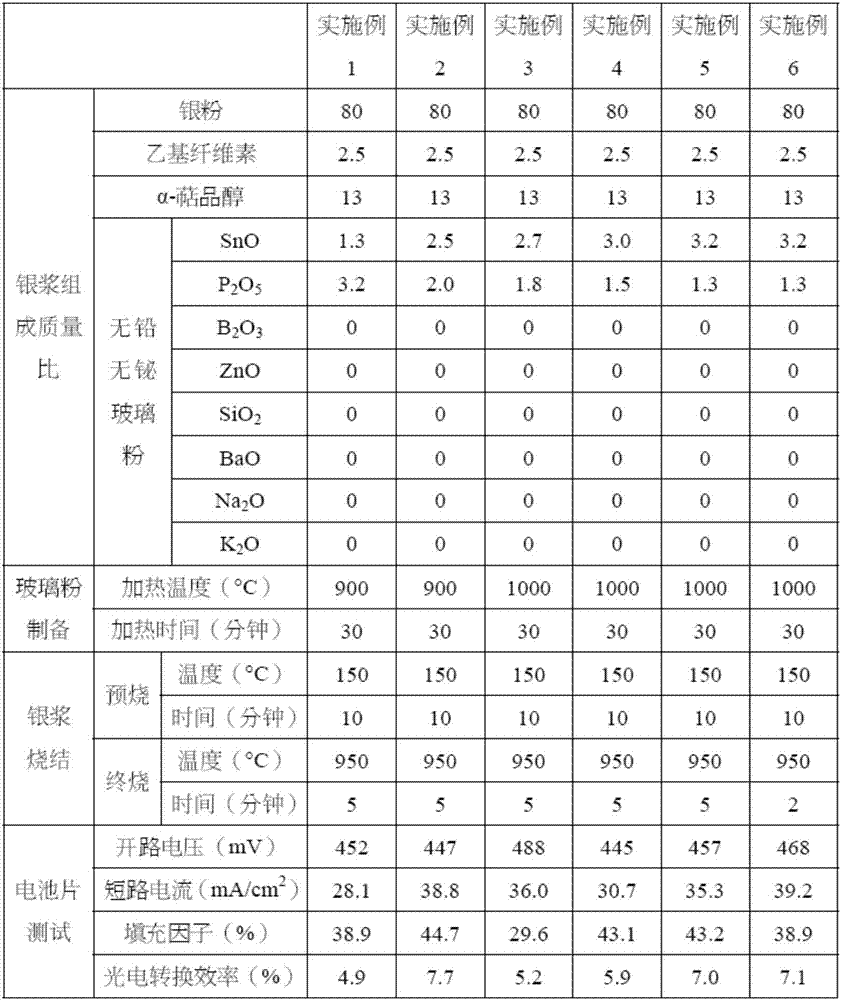

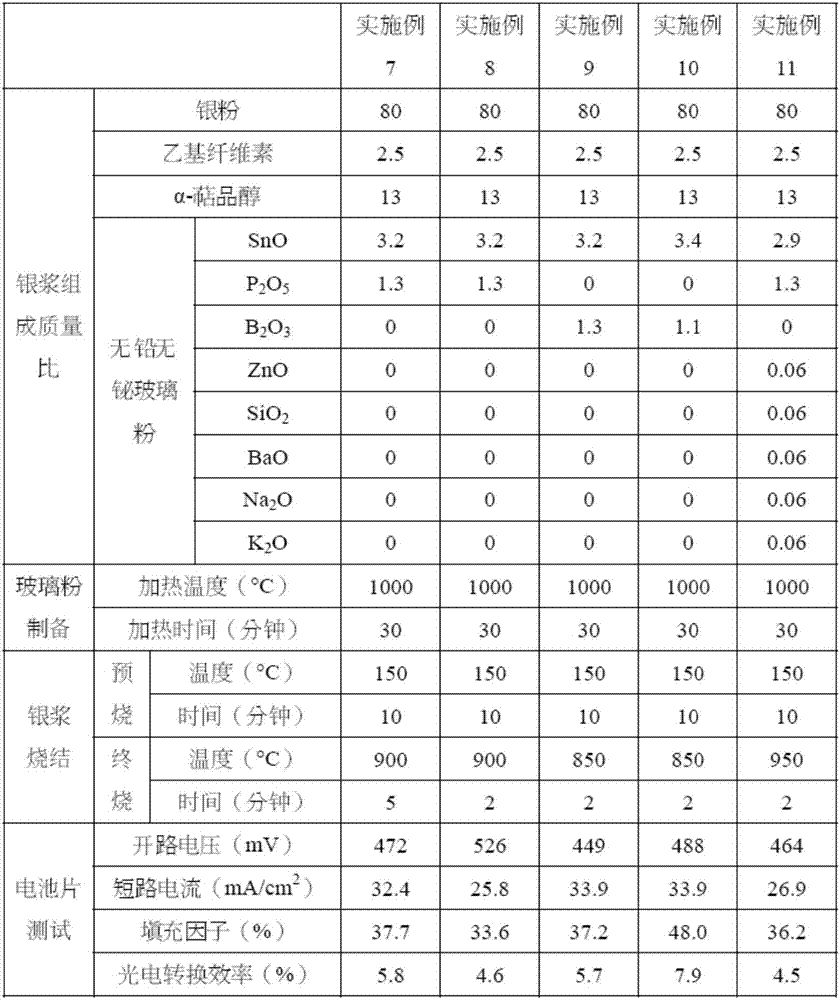

Preparation method of lead-free and bismuth-free conductive silver paste, silver grid wire and silicon solar cell

ActiveCN105590663BNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteOrganic solvent

Owner:TSINGHUA UNIV

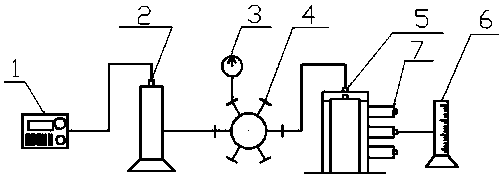

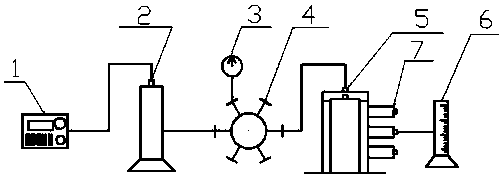

A device and method for studying the plugging law of oil well cement sheath channeling

The present invention relates to a device and method for studying the plugging law of oil well cement ring channeling, wherein the device for studying the plugging rule of oil well cement ring channeling includes a plugging agent injection device, an oil well model, multiple groups of bismuth-lead-tin alloy sheets, steel column; the intermediate container of the plugging agent injection device is connected to the oil well model, and the perforations of the oil well model are respectively connected to a core with different permeability; The shaft is screwed between the top cover and the base, and the steel column is used to seal the perforation; multiple sets of bismuth-lead-tin alloy sheets with a width of 25mm, and one group is multiple bismuth-lead-tin alloys with the same thickness, the same length, and different bending shapes one group of bismuth-lead-tin alloy sheets with the same length, same shape, and different thickness; one group of bismuth-lead-tin alloy sheets with the same thickness, same shape, and different length. The invention can observe the gelation status of various plugging agents in cracks of various shapes, and the migration rule of the plugging agents in the rock core and cement sheath in the pore space.

Owner:NORTHEAST GASOLINEEUM UNIV

A kind of processing method of high bismuth lead anode slime or bismuth slag

ActiveCN106978538BLow recovery ratePhotography auxillary processesProcess efficiency improvementPregnant leach solutionPurification methods

Owner:YIYANG SHENGLI CHEM IND

A kind of method that reclaims bismuth in precious lead

ActiveCN104141057BReduce manufacturing costReduce dosageMetal recyclingPhotography auxillary processesElectrolysisMaterials science

The invention relates to a method for recycling bismuth in bullion lead, and belongs to the field of the metallurgical technology combining a pyrogenic process with a wet process. The bullion lead is placed in a vacuum furnace first, vacuum distillation is carried out to separate lead, antimony, bismuth and copper, primary high bismuth lead and silver are produced, the produced primary high bismuth lead is placed in the vacuum furnace, vacuum distillation is conducted again to separate lead, antimony, bismuth and copper under control of the previous condition, and secondary high bismuth lead and residual silver are produced; the obtained secondary high bismuth lead and lead bullion ingredients are thrown into an anode pot to be cast into a bismuth anode plate, the bismuth anode plate is put into an electrolytic bath, mixed electrolytic refining is conducted on the bismuth anode plate together with the main process of lead electrolysis, and dissolved-out lead and washed high bismuth anode slime are obtained; the obtained high bismuth anode slime is subjected to reduction smelting and converting to produce crude bismuth; fire refining is carried out on the obtained crude bismuth, sulphur is added to the crude bismuth to remove copper, the crude bismuth is oxidized to remove arsenic and antimony, chlorine gas is led to the crude bismuth to remove lead, zinc is added to the crude bismuth to remove silver, finally caustic soda and saltpeter are added for refining, and a bismuth ingot product meeting national standards is produced. The technological process of the method is refined and simple.

Owner:蒙自矿冶有限责任公司

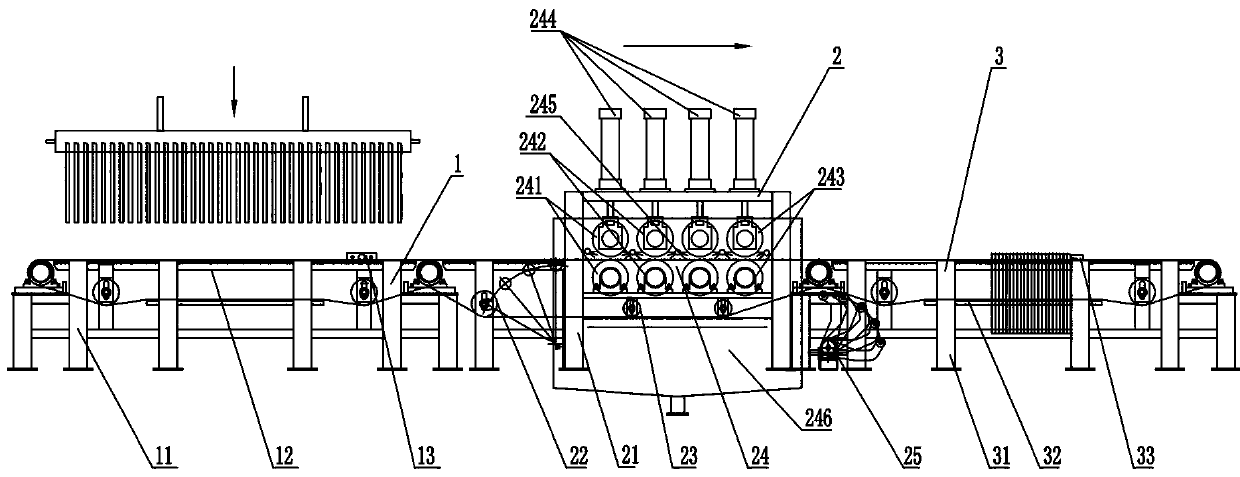

A kind of high antimony content lead electrolytic anode slime cleaning equipment and cleaning method thereof

ActiveCN108396339BAvoid the dangers of exposure to toxic heavy metalsHigh degree of automationPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

The invention relates to high antimony content lead electrolysis anode mud cleaning equipment and a cleaning method thereof. The cleaning equipment comprises an inlet receiver, a scrubbing machine anda collapsing conveying machine; the inlet receiver is connected with one end of the scrubbing machine; the other end of the scrubbing machine is connected with the collapsing conveying machine; and the scrubbing machine comprises a scrubbing rack, auxiliary flat laying devices, cleaning conveying devices, a scrubbing device and an auxiliary erecting device. For the high antimony content lead electrolysis anode mud cleaning equipment, by adopting a horizontal type scrubbing manner, an anode plate is horizontally placed; by using a manner of continuous roll scrubbing with crushing rolls, scraping rolls and scrubbing rolls, through an operation manner of rolling for crushing as well as simulating manual scraping and scrubbing, a high antimony content lead electrolysis anode plate can be cleanly cleared; and the equipment is high in automation degree, simple in structure, low in energy consumption and high in production efficiency and avoids a danger that a worker is exposed to toxic heavy metals.

Owner:云南南星科技开发有限公司

A kind of method for recovering lead, silver and copper with precious lead as raw material

The invention relates to a method for recovering lead, silver and copper by using precious lead as a raw material, and belongs to the technical field of combining fire method and wet method. Firstly, noble lead is separated from lead, antimony, bismuth and copper by vacuum distillation to produce high-bismuth lead and precious silver; the obtained high-bismuth lead is electrolyzed with high-bismuth lead to obtain precipitated lead, and the obtained precious silver is refined in a converter to produce Crude silver, and according to the length of converter refining time to obtain the early converter slag and converter late slag; the obtained coarse silver is electrolyzed with silver to obtain silver ingots, and the obtained converter early slag and converter late slag are respectively crushed to a particle size < 6mm, and then finely ground Converter slag fine powder is obtained by forming a powder with a particle size of less than 100 mesh, and then adding sulfuric acid solution to the converter slag fine powder for leaching, and obtaining leaching slag and copper sulfate solution after leaching is completed. The method improves the process flow for treating precious lead materials, and has the effects of refining and concise process flow, saving energy and reducing consumption, and optimizing the production environment.

Owner:蒙自矿冶有限责任公司

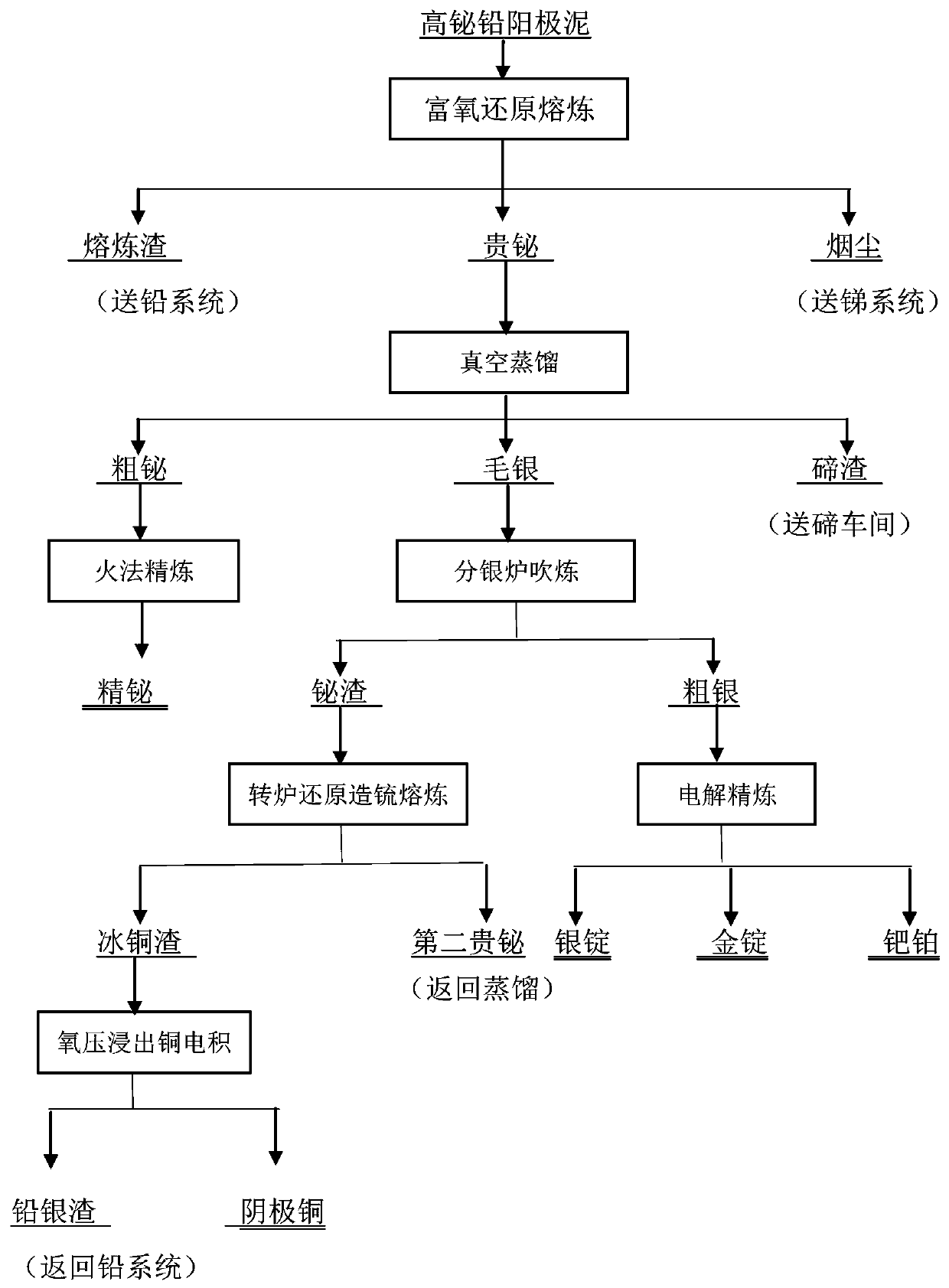

A kind of processing technology of high bismuth lead anode slime

ActiveCN108913898BHigh recovery rateSimple processPhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

A treatment technology for high-bismuth and high-lead anode slime comprises the following steps: carrying out oxygen-rich reduction smelting on the high-bismuth and high-lead anode slime to produce noble bismuth, slag (lead slag) and soot (crude antimony white); delivering the lead slag to a lead system, delivering the crude antimony white to a bismuth system, carrying out vacuum distillation on the noble bismuth to produce crude silver, crude bismuth and tellurium slag, pyro-refining the crude bismuth to produce refined bismuth, delivering the tellurium slag into a tellurium recovery workshopto produce refined tellurium, blowing the crude silver a silver-smelting furnace to produce crude silver and bismuth slag, delivering the crude silver into a silver electrolysis workshop to produce silver and gold, delivering the bismuth slag into a converter, carrying out reduction matte smelting to produce noble bismuth and matte slag, returning the noble bismuth to the vacuum distillation process, and delivering the matte slag to an oxygen-pressure leaching copper electrodeposition process to produce cathode copper and lead-silver slag respectively, wherein the cathode copper is sold as aproduct, and the lead-silver slag is returned to the lead smelting system. The technology has the characteristics of simple process, high production efficiency, short cycle, high recovery rate of valuable metals, and low production cost.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Low-pressure mercury-vapor discharge lamp and amalgam

InactiveCN1221009CGood initial radiation outputShorten start timeLow-pressure discharge lampsGas discharge lamp detailsGas-discharge lampGold content

A low-pressure mercury-vapor discharge lamp is provided with a discharge vessel (10). The discharge vessel (10) encloses a discharge space (11) provided with a filling of mercury and an inert gas in a gastight manner. The discharge vessel (10) is provided with an amalgam which communicates with the discharge space (11). The discharge lamp comprises means for maintaining an electric discharge in the discharge vessel (10). The discharge lamp is characterized in that the amalgam comprises a bismuth-lead amalgam having a lead content in the range from 35 <= Pb <= 60 at. %, a bismuth content in the range from 40 <= Bi <= 65 at. %, and a mercury content in the range from 0.05 <= Hg <= 1 at. %. Preferably, the amalgam additionally comprises gold with a gold content in the range from 0.1 <= Au <= 20 at. %. Preferably, the gold content is in the range from 8 <= Au <= 12 at. %. The lamp according to the invention exhibits a comparatively high initial radiation output and a short run-up time in combination with a relatively high radiation output at nominal lamp operation, which is achieved in a comparatively large temperature interval.

Owner:KONINK PHILIPS ELECTRONICS NV

A kind of preparation method and application method of bismuth lead sulfide ore flotation inhibitor

ActiveCN110013916BEnhanced inhibitory effectImprove separation efficiencyFlotationBismuth sulfideOrganosolv

Owner:CENT SOUTH UNIV

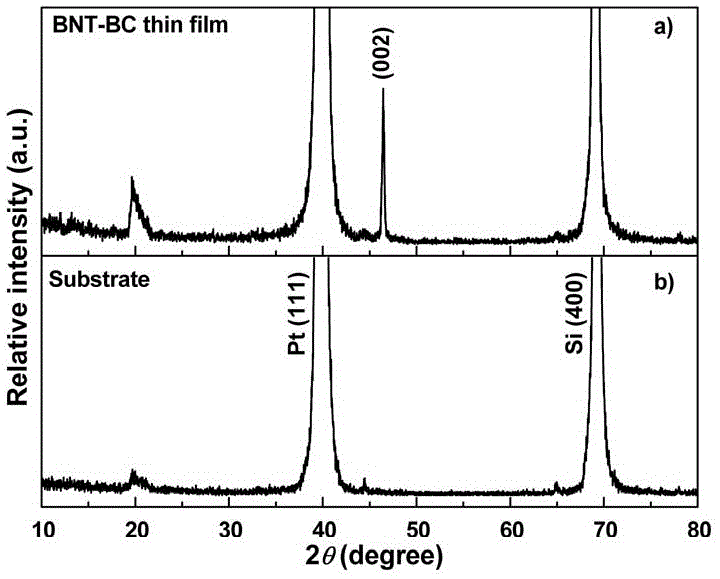

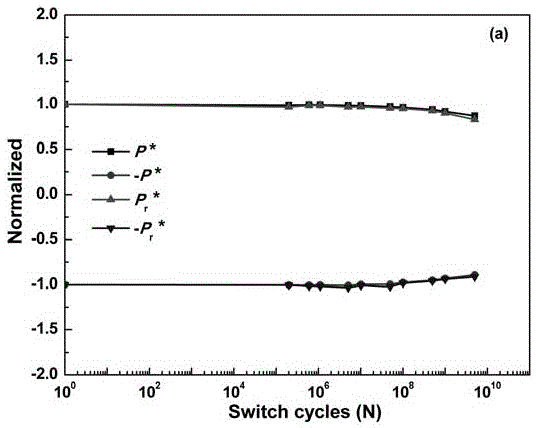

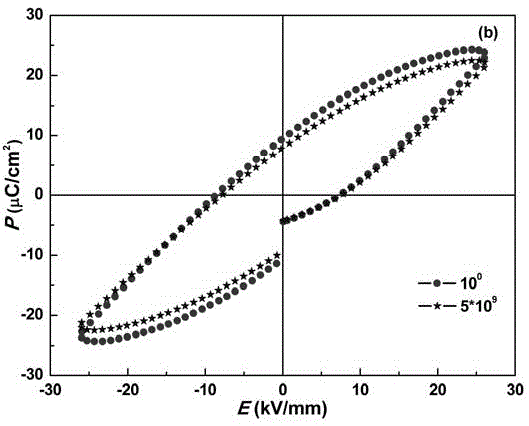

Lead-free piezoelectric thin film material and preparing method thereof

InactiveCN106119777ASimple componentsAbundant raw materialsVacuum evaporation coatingSputtering coatingElectricitySocial benefits

The invention relates to a lead-free piezoelectric thin film material and a preparing method thereof. The problem of harms caused in the preparation, using and abandoning processes of a lead-based thin film material to the ecological environment and the human health is solved. According to the technical scheme, the lead-free piezoelectric thin film material is a sodium bismuth titanate-cobalt acid bismuth lead-free piezoelectric thin film material (1-(i)x( / i))Bi0.5Na0.5TiO3-(i)x( / i))BiCoO3(BNT-BC), wherein (i)x( / i) indicates the mole number, and the (i)x( / i) is larger than 0 and smaller than or equal to 0.06. According to the preparing method, PLD is adopted for preparing a sodium bismuth titanate-cobalt acid bismuth lead-free piezoelectric thin film. The lead-free piezoelectric thin film material is simple in component, abundant in raw material, easy to prepare, good in product quality and stable and excellent in performance, is an innovation on the lead-free piezoelectric thin film material, and has the good economical and social benefits.

Owner:ANYANG HUASEN PAPER

Device and method for researching cement sheath channeling plugging law of oil well

ActiveCN108825209AIncrease profitImprove the blocking effectConstructionsRock coreRate of penetration

The invention relates to a device and method for researching a cement sheath channel plugging law of an oil well. The device for researching the cement sheath channel plugging law of the oil well comprises a plugging agent injecting device, an oil well model, a plurality of sets of bismuth-lead-tin alloy sheets and a steel column. A middle container of the plugging agent injecting device is connected with the oil well model, and perforation holes of the oil well model are connected with rock cores with different permeability. An outer tube of the oil well model is formed by two semicircular tubes in a covered mode, an inner tube and the outer tube are coaxially screwed and fixed between a top cover and a base, and steel columns are used for plugging the perforation holes. The multiple setsof bismuth-lead-tin alloy sheets with the width being 25 mm comprise a set of multiple bismuth-lead-thin alloy sheets with the same thickness and length and in different bent shapes. According to thedevice and method, the gel forming conditions of all plugging agents in various types of cracks can be observed, and the migration law of the plugging agents in the rock cores and a cement sheath ina pore space is observed.

Owner:NORTHEAST GASOLINEEUM UNIV

1,8-dihydroxyanthraquinone lead compound and its preparation method and application

ActiveCN103626646BIncrease burn rateGood catalyticOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCombustionCatalytic effect

The invention discloses a 1,8-dihydroxy anthraquinone lead compound which is shown as the structural formula (I). The 1,8-dihydroxy anthraquinone lead compound can be used as a combustion catalyst, has a good catalytic effect on a biradical solid propellant or a modified biradical solid propellant, and can significantly increase the burning rate of the biradical solid propellant or the modified biradical solid propellant and reduce the pressure index.

Owner:XIAN MODERN CHEM RES INST

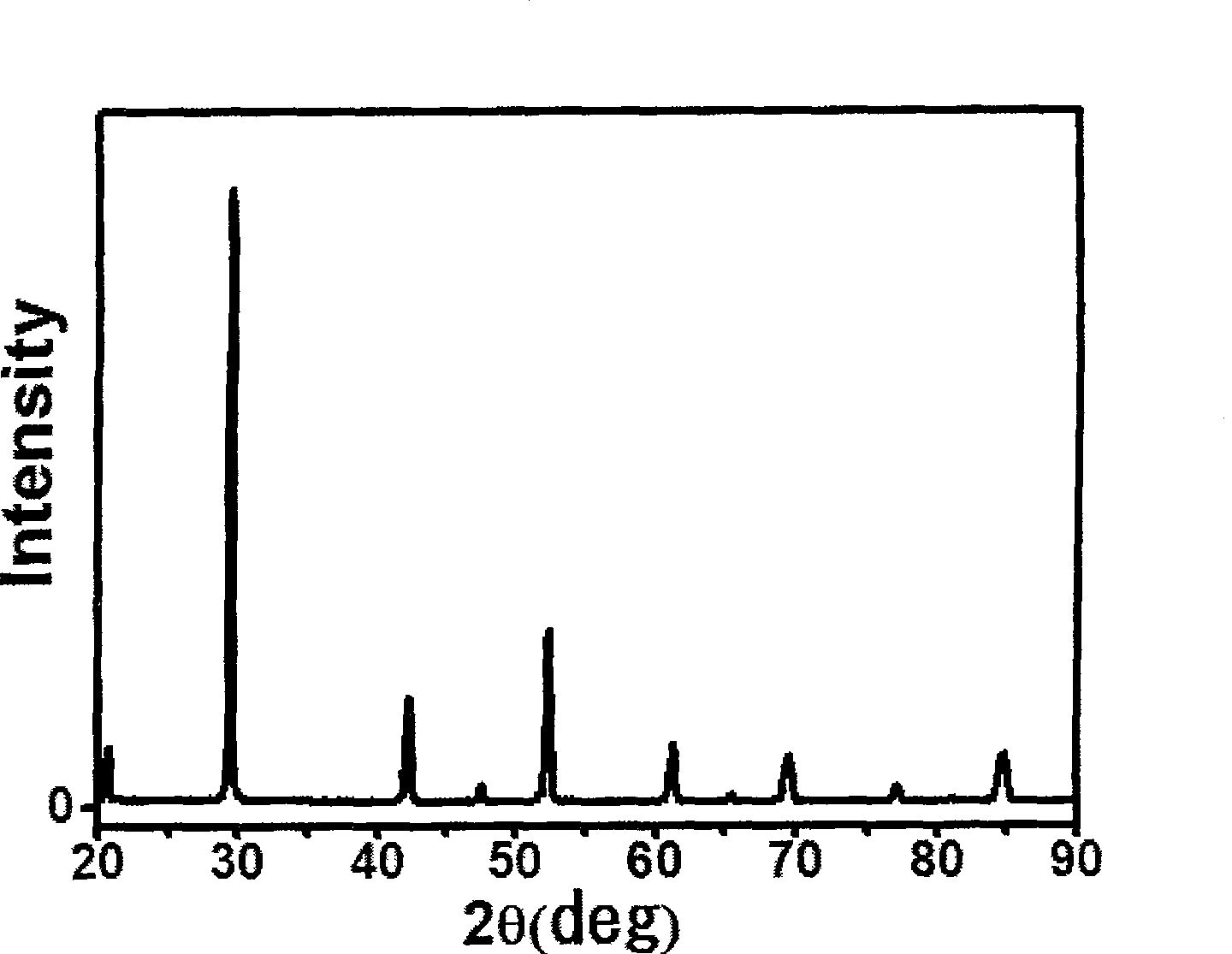

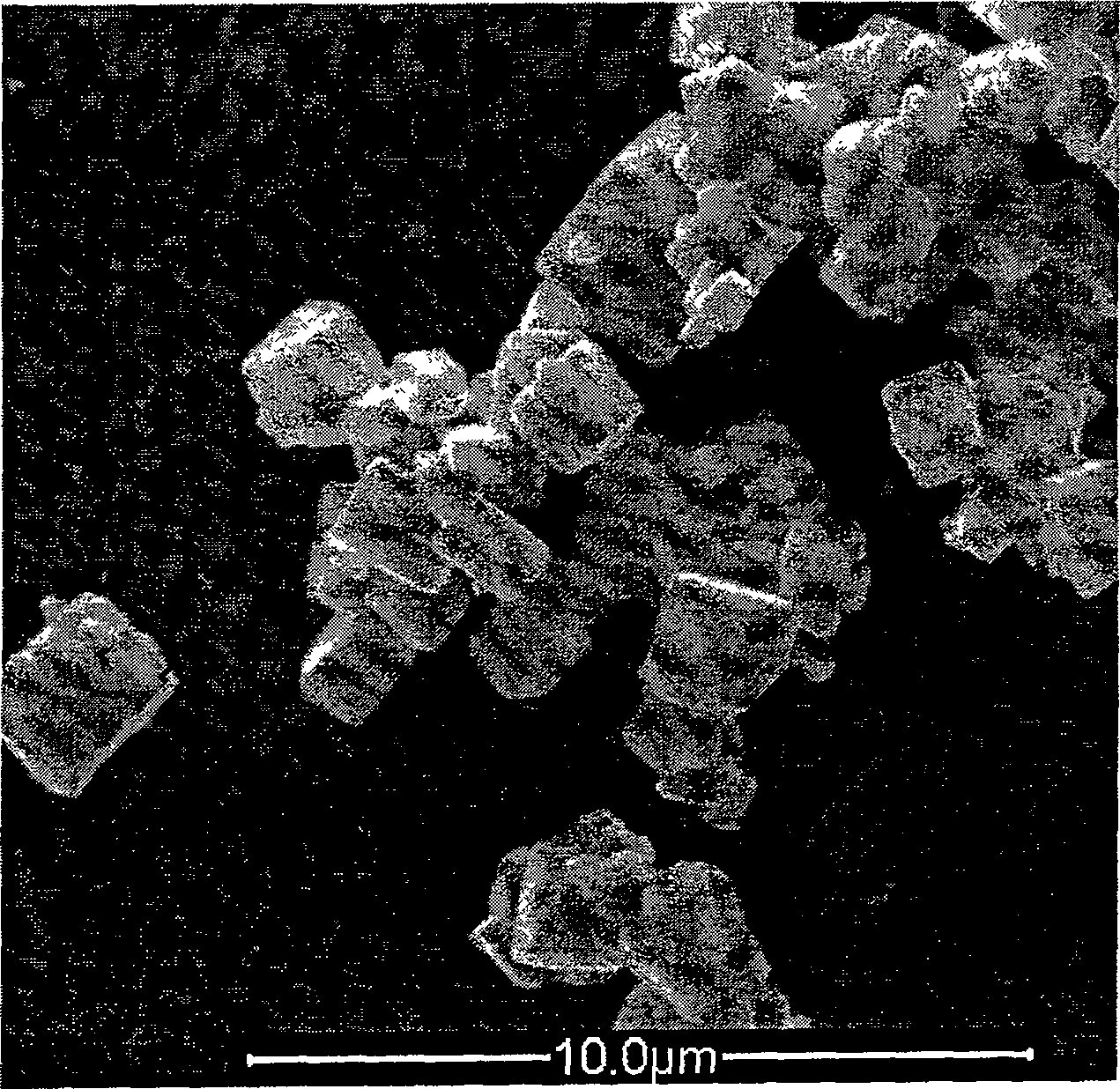

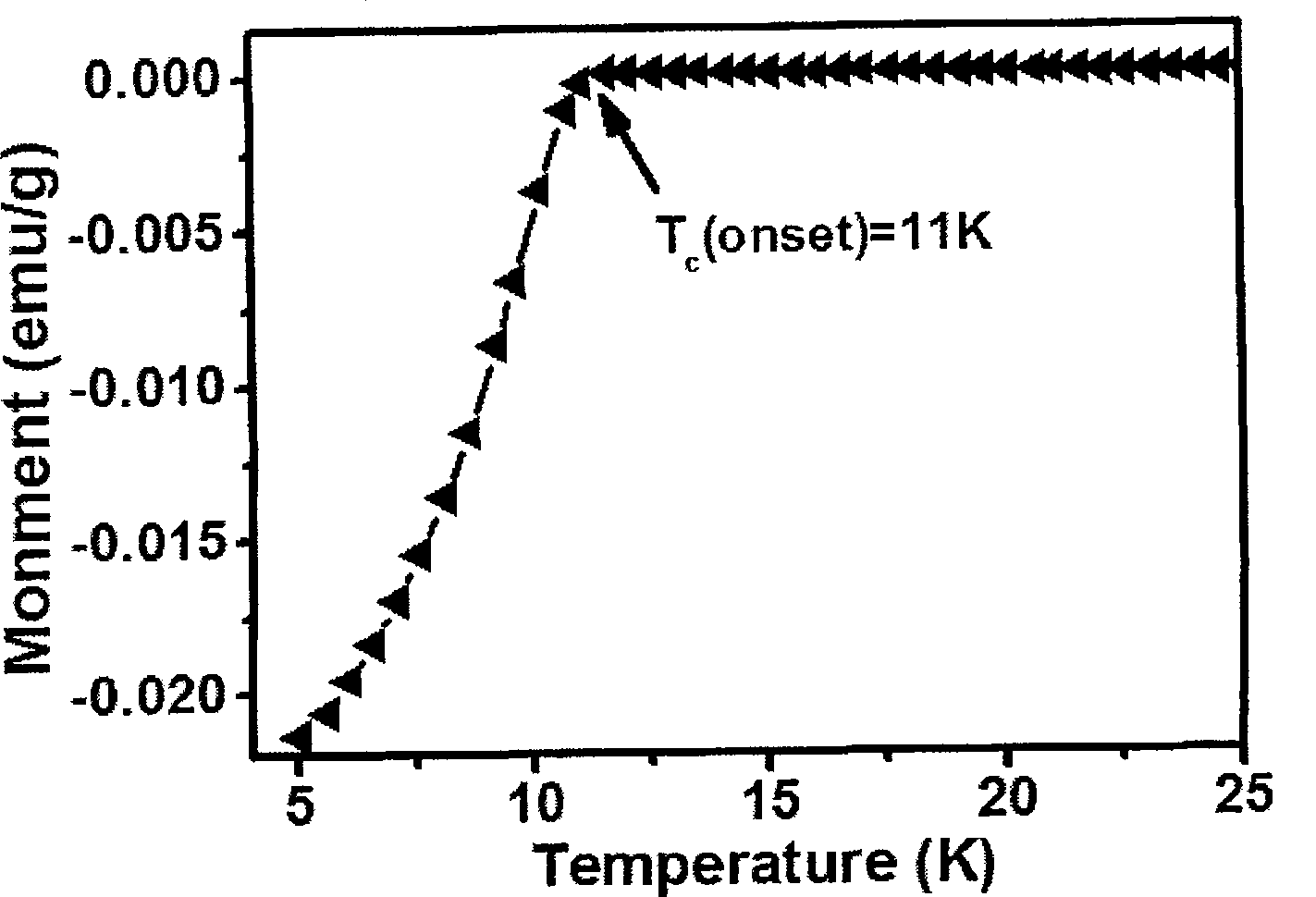

Method for preparing barium - plumbum - bismuth - oxygen superconduct, and electronic material

InactiveCN100519471CImprove solubilitySmall granularityCable/conductor manufactureSemiconductor materialsElectrical conductor

A method for preparing barium-lead-bismuth-oxygen superconducting and electronic materials, the steps are: a. according to the stoichiometric ratio of preparing barium-lead-bismuth-oxygen BaPb1-xBixO3, 0≤x≤1.0, weighing raw material Ba(OH)2 8H2O , Pb3O4, NaBiO3 2H2O and Bi2O3, wherein the molar ratio of NaBiO3 2H2O and Bi2O3 is 0.5 to 2.5:1; the raw materials are ground into powder and mixed evenly as mixed raw materials; another potassium nitrate and sodium nitrate with a molar ratio of 1:1 are selected The mixture is used as a molten salt, and the molar ratio of the molten salt to the prepared BaPb1-xBixO3 is 10 to 30:1; b. mix the mixed raw materials and the molten salt evenly, heat at 100 to 200°C for 2 to 3 hours, and then heat the mixture at 400 to 200°C. 600°C, keep warm for 10-20 hours, and cool; c. Rinse and dry. The prepared barium lead bismuth oxide BaPb1-xBixO3, x=0 is a metal conductor electronic material; 0.05≤x≤0.30 is a superconducting material; 0.30<x≤1.0 is a semiconductor material. The method has low preparation temperature, short cycle, simple process and is convenient for industrialized production; the chemical composition of the obtained product is easy to control, the composition is stable, the particle size is small and uniform, and the performance is stable.

Owner:SOUTHWEST JIAOTONG UNIV

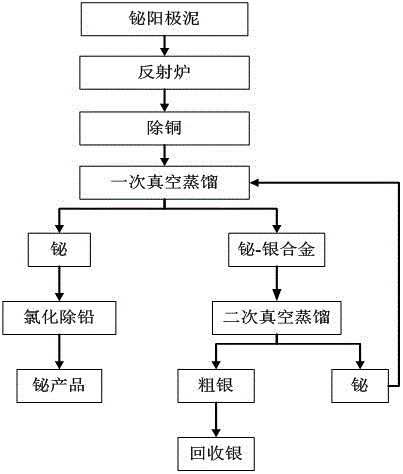

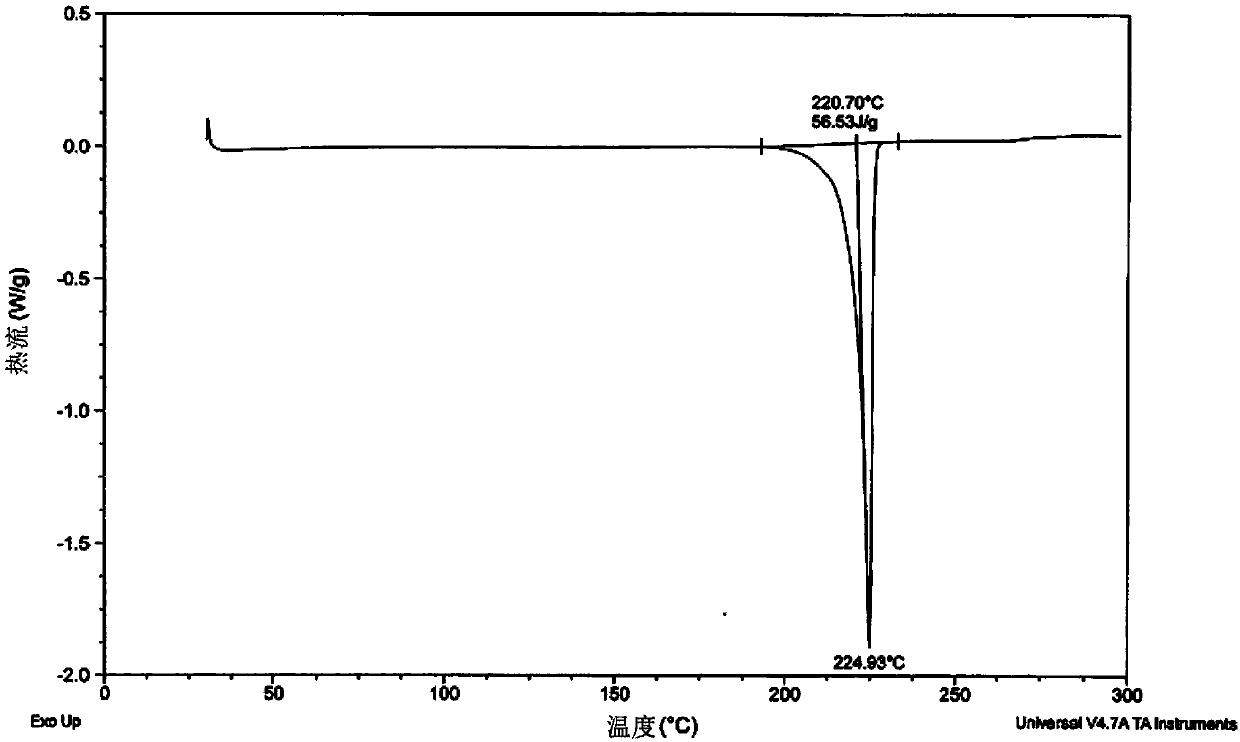

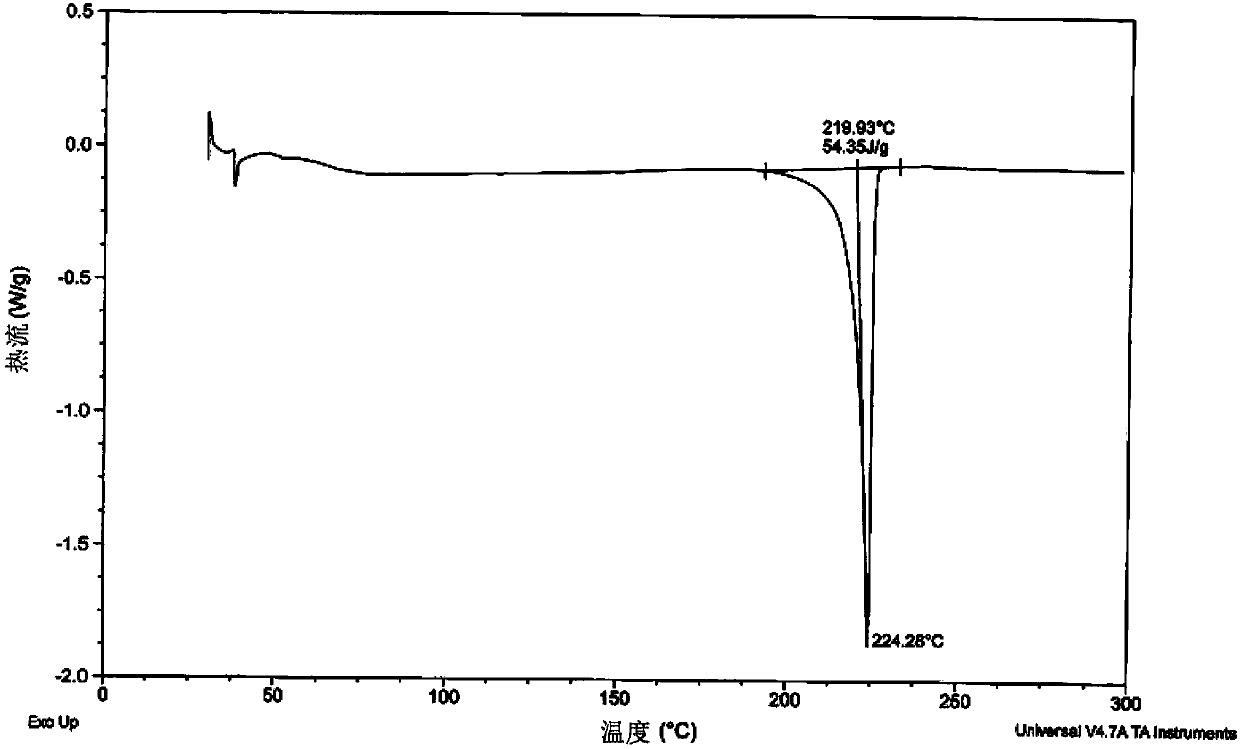

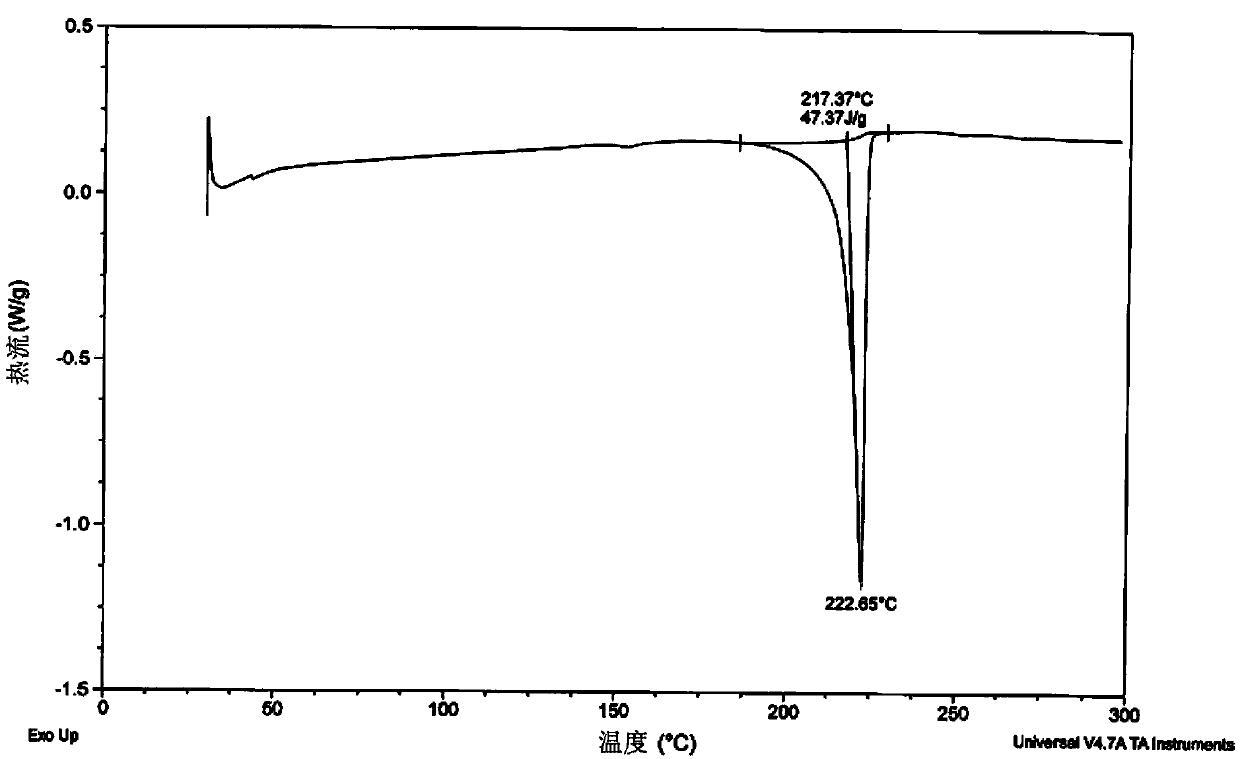

Treatment method for bismuth anode slime

InactiveCN106191449ANo pollution in the processGuaranteed direct yieldProcess efficiency improvementSulfurLiquid state

The invention discloses a treatment method for bismuth anode slime. The treatment method comprises the following steps that a, antimony white and crude bismuth are separated through a reverberating furnace, specifically, the bismuth anode slime is input into the reverberating furnace to be refined for four days, the antimony white component containing 70% or above of Sb2O3 is separated out, and a bottom solution is discharged to be cast into the crude bismuth; b, copper is removed from the crude bismuth, specifically, the obtained crude bismuth is placed into a boiler for conducting liguation and sulfdization decoppering, noble bismuth is obtained, and copper slag is delivered to be treated with a wet method; c, primary vacuum distillation is conducted, specifically, the obtained noble bismuth is placed into a vacuum smelting furnace to be distilled with the pressure being -10Pa and the temperature being 900 DEG C, a gaseous state bismuth-lead alloy is separated out, and a liquid state substance is a bismuth-silver alloy; d, chlorination de-leading is conducted, specifically, the gaseous state bismuth-lead alloy obtained in primary vacuum distillation is condensed into a liquid state and subjected to chlorination de-leading, so that refined bismuth with the purity being 99% or above is obtained; and e, secondary distillation is conducted, specifically, the liquid state bismuth-silver alloy obtained in primary vacuum distillation is placed in to the vacuum smelting furnace to be subjected to secondary distillation, and crude silver with the purity being 90% or above and a bismuth alloy containing 69% or above of bismuth are separated out from the bismuth-silver alloy.

Owner:永兴县亿翔环保科技有限公司

Tin-bismuth-lead ternary alloy solder composition using electroplating

InactiveCN107779664AAvoid breakingWelding/cutting media/materialsMetal working apparatusElectroplatingHeating temperature

The present invention relates to a Sn-Pb-Bi ternary alloy solder composition. In the present invention, since an amount of Bi is 5 wt% or less, and a melting point of the composition is determined in146-225 degree centigrade, soldering at a lower heating temperature than a common temperature is possible. Breaking phenomenon due to the inclusion of bismuth is not found.

Owner:HOJIN PLATECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com