Preparation method of lead-free and bismuth-free conductive silver paste, silver grid wire and silicon solar cell

A technology of silicon solar cells and solar cells, applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve the problems of easy desorption of electrodes, inability to obtain large-scale industrial applications, and low efficiency of silver paste advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

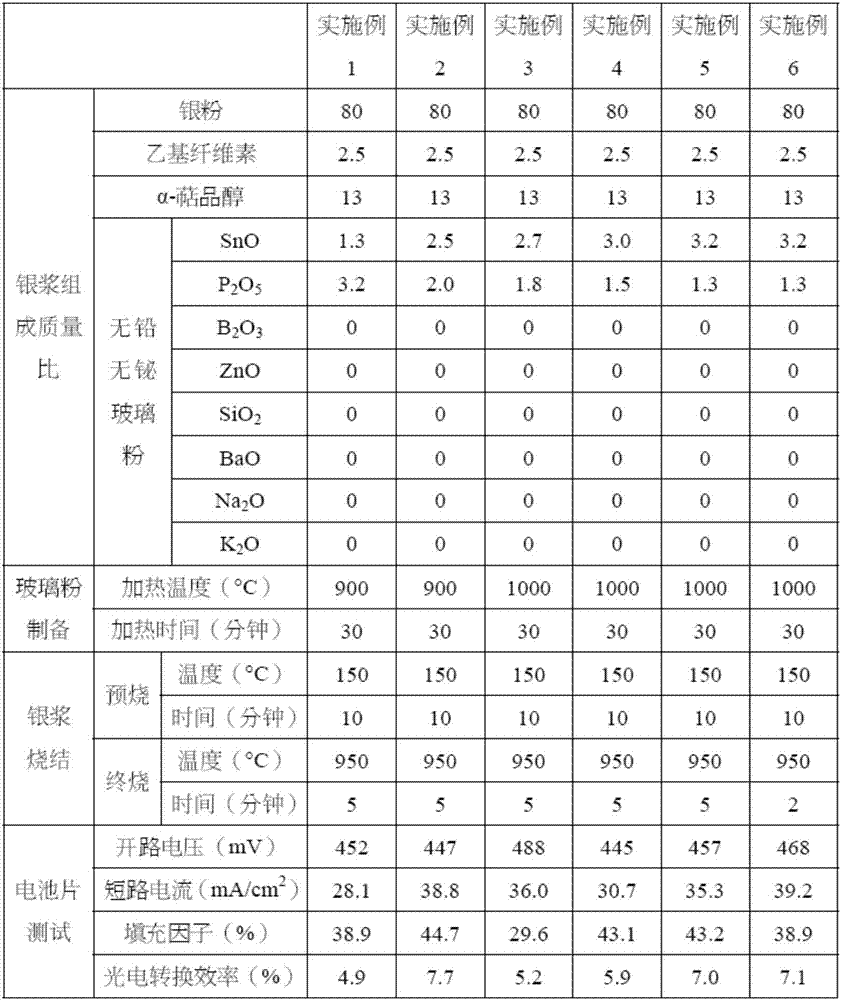

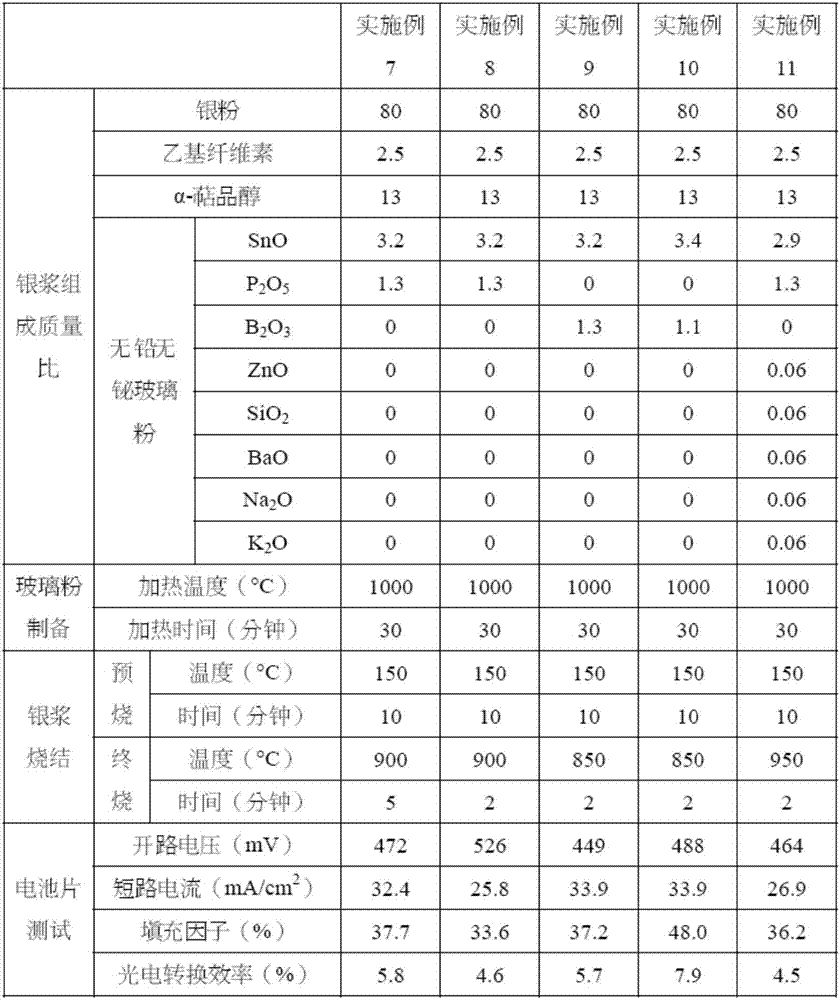

Embodiment 1

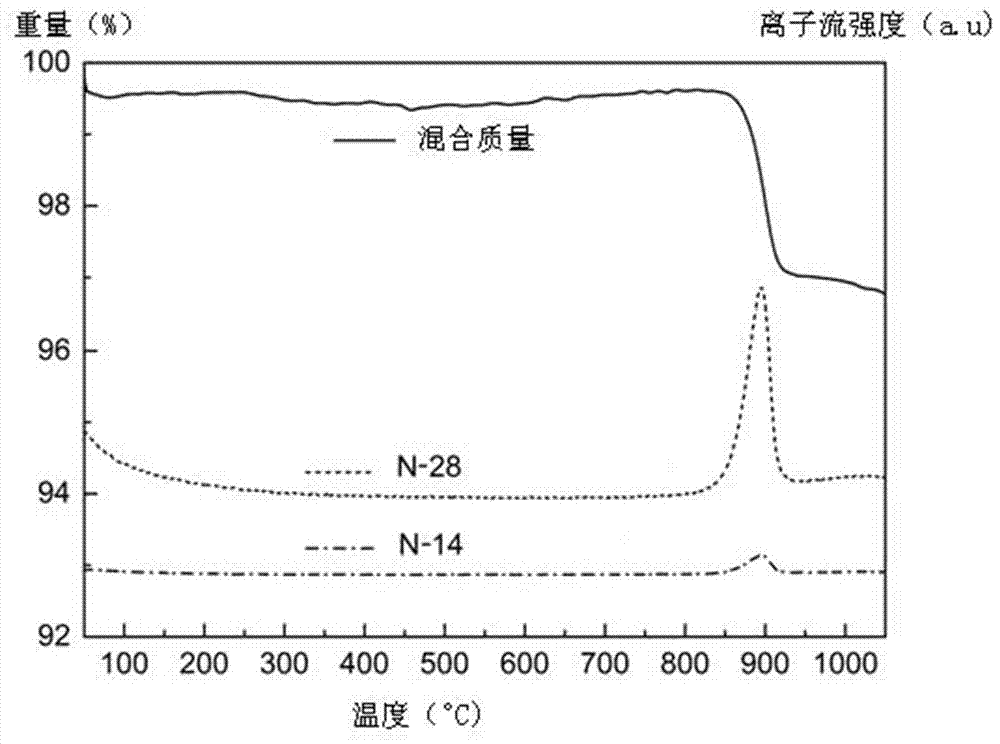

[0032] First, lead-free and bismuth-free glass powder is prepared. Take SnO powder 4.3g and P 2 o 5 Powder 10.7g, these solid powders were uniformly mixed in a glove box filled with nitrogen. Next, put the obtained solid mixture into a quartz tube and vacuumize, heat at 900°C for 30 minutes, and put the obtained molten mixture into ionized water to quench. Finally, the obtained solid was ball-milled at a speed of 350 rpm for 3 hours with a planetary ball mill, and the obtained glass powder was used for the preparation of silver paste.

[0033] Next, prepare lead-free and bismuth-free solar cell conductive silver paste. Silver powder, ethyl cellulose and the above-mentioned lead-free and bismuth-free glass powder were mixed in a mass ratio of 80:2.5:4.5, and then ball milled for 3 hours at a speed of 350 revolutions per minute using a planetary ball mill, and the mixture obtained by ball milling was 8.7 g and 1.3g of α-terpineol are uniformly mechanically mixed to obtain le...

Embodiment 2

[0037] First, lead-free and bismuth-free glass powder is prepared. Take SnO powder 8.4g and P 2 o 5 Powder 6.6g, these solid powders were uniformly mixed in a glove box filled with nitrogen. Next, put the obtained solid mixture into a quartz tube and vacuumize, heat at 900°C for 30 minutes, and put the obtained molten mixture into ionized water to quench. Finally, the obtained solid was ball-milled at a speed of 350 rpm for 3 hours with a planetary ball mill, and the obtained glass powder was used for the preparation of silver paste.

[0038] Next, prepare lead-free and bismuth-free solar cell conductive silver paste. Silver powder, ethyl cellulose and the above-mentioned lead-free and bismuth-free glass powder were mixed in a mass ratio of 80:2.5:4.5, and then ball milled for 3 hours at a speed of 350 revolutions per minute using a planetary ball mill, and the mixture obtained by ball milling was 8.7 g and 1.3g of α-terpineol are uniformly mechanically mixed to obtain lea...

Embodiment 3

[0042] First, lead-free and bismuth-free glass powder is prepared. Take SnO powder 9.1g and P 2 o 5 Powder 5.9g, these solid powders were uniformly mixed in a glove box filled with nitrogen. Next, put the obtained solid mixture into a quartz tube and vacuumize, heat at 1000°C for 30 minutes, and put the obtained molten mixture into ionized water to quench. Finally, the obtained solid was ball-milled at a speed of 350 rpm for 3 hours with a planetary ball mill, and the obtained glass powder was used for the preparation of silver paste.

[0043] Next, prepare lead-free and bismuth-free solar cell conductive silver paste. Silver powder, ethyl cellulose and the above-mentioned lead-free and bismuth-free glass powder were mixed in a mass ratio of 80:2.5:4.5, and then ball milled for 3 hours at a speed of 350 revolutions per minute using a planetary ball mill, and the mixture obtained by ball milling was 8.7 g and 1.3g of α-terpineol are uniformly mechanically mixed to obtain le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com